Page 1

User's

Manual

Models AE100D, AE200D, and AE300D

Magnetic Flow Tube

[Style:S2]

IM 1E7D0-01E

IM 1E7D0-01E

11th Edition

Page 2

CONTENTS

CONTENTS

1. INTRODUCTION..........................................................................................1-1

2. HANDLING PRECAUTIONS ....................................................................... 2-1

2.1 Checking Model and Specifications.................................................... 2-1

2.2 Accessories ......................................................................................... 2-1

2.3 Storage Precautions............................................................................ 2-1

2.4 Installation Location Precautions ........................................................ 2-1

2.5 Terminal Box Reorientation Precautions ............................................ 2-1

3. INSTALLATION ........................................................................................... 3-1

3.1 Piping Design Precautions.................................................................. 3-1

3.2 Handling Precautions .......................................................................... 3-3

3.2.1 General Precautions ..................................................................... 3-3

3.2.2 Flow Tube Piping ......................................................................... 3-4

3.3 Mounting.............................................................................................. 3-5

3.3.1 Nominal Diameter 2.5 mm (0.1in.) to 10 mm (0.4in.)

Union Joint Type .......................................................................... 3-5

3.3.2 Nominal Diameter 2.5mm (0.1in.) to 40mm (1.5in.)

Wafer Type................................................................................... 3-6

3.3.3 Nominal Diameter 50 mm(2in.) to 300 mm(12in.) Wafer Type ... 3-9

3.3.4 Nominal Diameter 15 mm (0.5in.) to 400 mm (16in.)

Flange Type ............................................................................... 3-12

3.3.5 Mounting Procedure for Sanitary Type ...................................... 3-14

3.4 Wiring Precautions ............................................................................ 3-14

3.4.1 Protective Grounding.................................................................. 3-14

3.4.2 General Precautions ................................................................... 3-14

3.4.3 Cable Types ............................................................................... 3-15

3.4.4 Connnection to AE14 Magnetic Flow Converter ........................ 3-16

3.4.5 Wiring Ports................................................................................ 3-16

4. MAINTENANCE...........................................................................................4-1

4.1 Regular Inspection Items .................................................................... 4-1

4.2 Trouble Shooting................................................................................. 4-1

5. OUTLINE......................................................................................................5-1

6. EXPLOSION PROTECTED TYPE INSTRUMENT...................................... 6-1

6.1 ATEX Directive.................................................................................... 6-1

6.2 FM ....................................................................................................... 6-2

6.3 CSA ..................................................................................................... 6-2

6.4 SAA ..................................................................................................... 6-3

7. PRESSURE EQUIPMENT DIRECTIVE.......................................................7-1

FD No. IM 1E7D0-01E

11th Edition: Dec., 2003 (YG)

All Rights Reserved, Copyright © 1994, Yokogawa Electric Corporation

i

Page 3

1. INTRODUCTION

NOTE

1. INTRODUCTION

This instrument has been already adjusted at the

factory before shipment.

To ensure correct use of the instrument, please read

this manual thoroughly and fully understand how to

operate the instrument before operating it.

Regarding This Manual

•This manual should be passed on to the end user.

• Before use, read this manual thoroughly to comprehend its contents.

• The contents of this manual may be changed

without prior notice.

• All rights reserved. No part of this manual may be

reproduced in any form without Yokogawa’s written

permission.

•Yokogawa makes no warranty of any kind with

regard to this material, including, but not limited to,

implied warranties of merchantability and suitability

for a particular purpose.

• All reasonable effort has been made to ensure the

accuracy of the contents of this manual. However, if

any errors are found, please inform Yokogawa.

• Yokogawa assumes no responsibilities for this

product except as stated in the warranty.

• If the customer or any third party is harmed by the

use of this product, Yokogawa assumes no responsibility for any such harm owing to any defects in the

product which were not predictable, or for any

indirect damages.

The following safety symbol marks are used in

this manual and instrument;

WARNING

A WARNING sign denotes a hazard. It calls

attention to procedure, practice, condition or the

like, which, if not correctly performed or adhered

to, could result in injury or death of personnel.

CAUTION

A CAUTION sign denotes a hazard. It calls

attention to procedure, practice, condition or the

like, which, if not correctly performed or adhered

to, could result in damage to or destruction of

part or all of the product.

IMPORTANT

A IMPORTANT sign denotes an attention to

avoid leading to damage to instrument or system

failure.

Safety Precautions

• The following general safety precautions must be

observed during all phases of operation, service, and

repair of this instrument. Failure to comply with

these precautions or with specific WARNINGS

given elsewhere in this manual violates safety

standards of design, manufacture, and intended use

of the instrument. YOKOGAWA Electric Corporation assumes no liability for the customer’s failure to

comply with these requirements. If this instrument is

used in a manner not specified in this manual, the

protection provided by this instrument may be

impaired.

A NOTE sign denotes a information for essential

understanding of the operation and features.

Protective grounding terminal.

Function grounding terminal. This terminal

should not be used as a “Protective grounding

terminal”.

Alternating current.

Direct current.

1-1

IM 1E7D0-01E

Page 4

1. INTRODUCTION

Warranty

• The guaranteed term of this instrument is described

in the quotation. We repair the damages that

occurred during the guaranteed term for free.

• Please contact with our sales office when this

instrument is damaged.

• If the instrument has trouble, please inform us

model code, serial number, and concrete substances

or situations. It is preferable to be attached a outline

or data.

• We decide after the examination if free repair is

available or not.

• Please consent to the followings for causes of

damages that are not available as free repair, even if

it occured during the guaranteed term.

A:Unsuitable or insufficient maintenance by the

customer.

B: The handling, using, or storage that ignore the

design and specifications of the instrument.

C: Unsuitable location that ignore the description in

this manual.

D:Remaking or repair by a person except whom we

entrust.

E: Unsuitable removing after delivered.

F: A natural disaster (ex. a fire, earthquake, storm and

flood, thunderbolt) and external causes.

For Safety Using

For safety using the instrument, please give attention

mentioned below.

WARNING

(1) Installation

• The instrument must be installed by expert

engineer or skilled personnel. The procedures

described about INSTALLATION are not

permitted for operators.

• The Magnetic Flow Tube is a heavy instrument.

Please give attention to prevent that persons

are injured by carrying or installing. It is preferable for carrying the instrument to use a cart

and be done by two or more persons.

•In case of high process temperature, care

should be taken not to burn yourself because

the surface of body and case reach a high

temperature.

•When removing the instrument from hazardous

processes, avoid contact with the fluid and the

interior of the flow tube.

• All installation shall comply with local installation requirement and local electrical code.

(2) Wiring

• The instrument must be installed by expert

engineer or skilled personnel. The procedures

described about WIRING are not permitted for

operators.

•Please confirm voltages between the power

supply and the instrument before connecting

the power cables. And also, please confirm

that the cables are not powered before connecting.

• The protective grounding must be connected to

the terminal in order to avoid personal shock

hazard.

(3) Operation

• Wait 10 min. after power is turned off, before

opening the covers.

(4) Maintenance

•Please do not carry out except being written to

a maintenance descriptions. When these

procedures are needed, please contact to

nearest YOKOGAWA office.

• Care should be taken to prevent the build up of

drift, dust or other material on the display glass

and data plate. In case of its maintenance, soft

and dry cloth is used.

(5) Explosion Protected Type Instrument

• For explosion proof type instrument, the description in Chapter 6 “EXPLOSION PROTECTED TYPE INSTRUMENT” is prior to the

other description in this user's manual.

• Only trained persons use this instrument in the

industiral location.

• The protective grounding must be connected

to a suitable IS grounding system.

• Take care not to generate mechanical spark

when access to the instrument and peripheral

devices in hazardous locations.

(6) The Instrument in Compliance with PED

• For the instrument in compliance with PED, the

description in Chapter 7 “PRESSURE EQUIPMENT DIRECTIVE” is prior to the other description in this User’s Manual.

1-2

IM 1E7D0-01E

Page 5

1. INTRODUCTION

■ ATEX Documentation

This procedure is only applicable to the countries in

European Union.

GB

All instruction manuals for ATEX Ex related products

are available in English, German and French. Should

you require Ex related instructions in your local

language, you are to contact your nearest Yokogawa

office or representative.

DK

Alle brugervejledninger for produkter relateret til

ATEX Ex er tilgængelige på engelsk, tysk og fransk.

Skulle De ønske yderligere oplysninger om håndtering

af Ex produkter på eget sprog, kan De rette

henvendelse herom til den nærmeste Yokogawa

afdeling eller forhandler.

I

Tutti i manuali operativi di prodotti ATEX

contrassegnati con Ex sono disponibili in inglese,

tedesco e francese. Se si desidera ricevere i manuali

operativi di prodotti Ex in lingua locale, mettersi in

contatto con l’ufficio Yokogawa più vicino o con un

rappresentante.

E

Todos los manuales de instrucciones para los productos

antiexplosivos de ATEX están disponibles en inglés,

alemán y francés. Si desea solicitar las instrucciones de

estos artículos antiexplosivos en su idioma local,

deberá ponerse en contacto con la oficina o el

representante de Yokogawa más cercano.

NL

SF

Kaikkien ATEX Ex -tyyppisten tuotteiden käyttöhjeet

ovat saatavilla englannin-, saksan- ja ranskankielisinä.

Mikäli tarvitsette Ex -tyyppisten tuotteiden ohjeita

omalla paikallisella kielellännne, ottakaa yhteyttä

lähimpään Yokogawa-toimistoon tai -edustajaan.

P

Todos os manuais de instruções referentes aos produtos

Ex da ATEX estão disponíveis em Inglês, Alemão e

Francês. Se necessitar de instruções na sua língua

relacionadas com produtos Ex, deverá entrar em

contacto com a delegação mais próxima ou com um

representante da Yokogawa.

F

Tous les manuels d’instruction des produits ATEX Ex

sont disponibles en langue anglaise, allemande et

française. Si vous nécessitez des instructions relatives

aux produits Ex dans votre langue, veuillez bien

contacter votre représentant Yokogawa le plus proche.

D

Alle Betriebsanleitungen für ATEX Ex bezogene

Produkte stehen in den Sprachen Englisch, Deutsch

und Französisch zur Verfügung. Sollten Sie die

Betriebsanleitungen für Ex-Produkte in Ihrer

Landessprache benötigen, setzen Sie sich bitte mit

Ihrem örtlichen Yokogawa-Vertreter in Verbindung.

S

Alla instruktionsböcker för ATEX Ex (explosionssäkra)

produkter är tillgängliga på engelska, tyska och

franska. Om Ni behöver instruktioner för dessa

explosionssäkra produkter på annat språk, skall Ni

kontakta närmaste Yokogawakontor eller representant.

Alle handleidingen voor producten die te maken

hebben met ATEX explosiebeveiliging (Ex) zijn

verkrijgbaar in het Engels, Duits en Frans. Neem,

indien u aanwijzingen op het gebied van

explosiebeveiliging nodig hebt in uw eigen taal, contact

op met de dichtstbijzijnde vestiging van Yokogawa of

met een vertegenwoordiger.

GR

ATEX Ex

, .

Ex

Yokogawa .

1-3

IM 1E7D0-01E

Page 6

2. HANDLING PRECAUTIONS

2. HANDLING PRECAUTIONS

This instrument has been already tested thoroughly at

the factory. When the instrument is delivered, please

check externals and make sure that no damage

occurred during transportation.

In this chapter, handling precautions are described.

Please read this chapter thoroughly at first. And please

refer to the relative matter about other ones.

If you have any problems or questions, please make

contact with Yokogawa sales office.

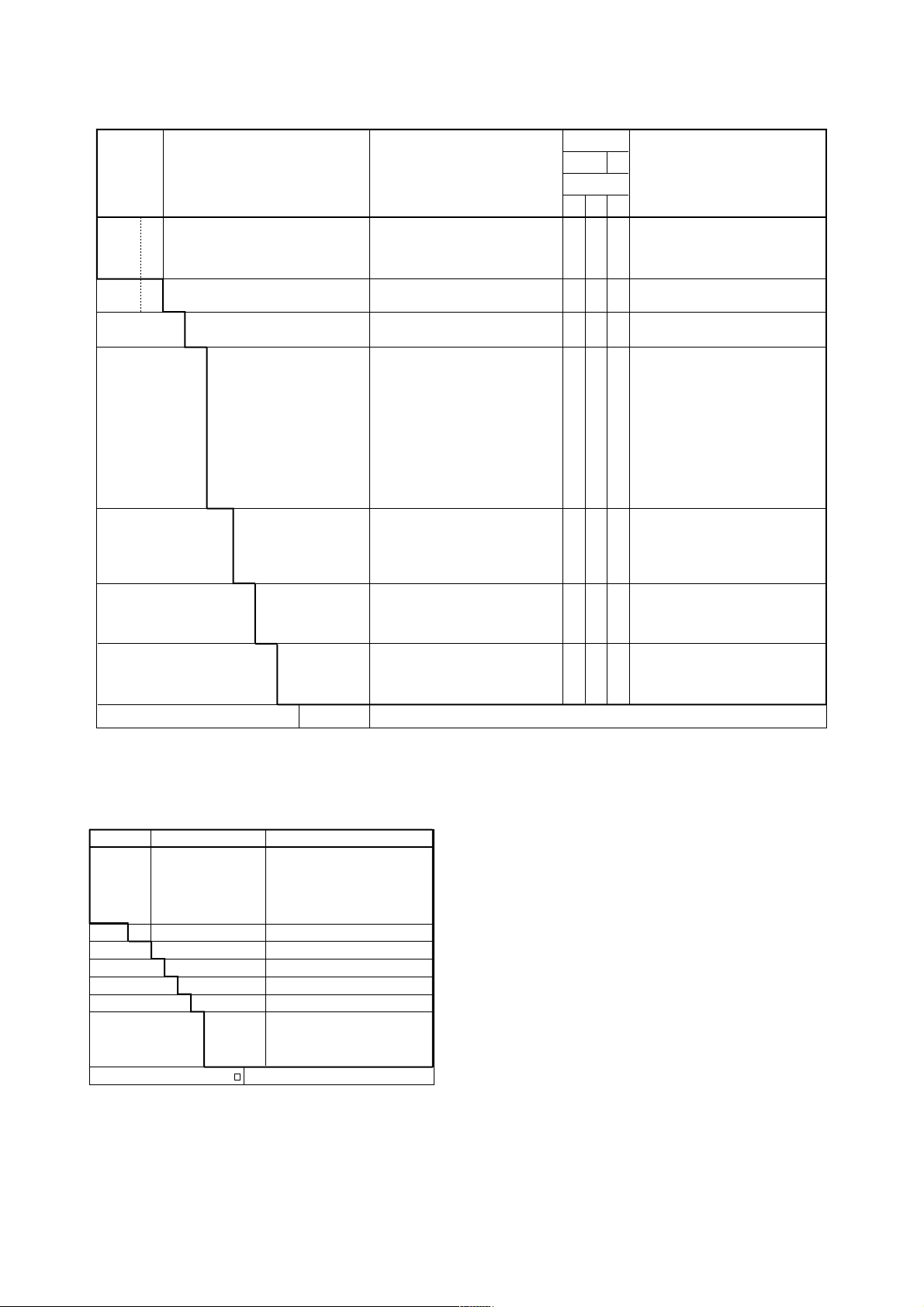

2.1 Checking Model and Specifications

The model and specifications are shown on the Data

Plate. Please confirm the specifications between the

instrument that was delivered and the purchase order

(refer to the chapter 5. Outline).

Please let us know Model and Serial No. when making

contact with Yokogawa sales office.

MODEL

SUFFIX

STYLE

SIZE

METER

FACTOR

NO.

Figure 2.1 Data Plate

MAGNETIC FLOW DETECTOR

mm

L

H

Made in Japan

LINING

MATERIAL

ELECTRODE

MATERIAL

FLUID TEMP.

FLUID PRESS.

AMB. TEMP.

IM: User’s Manual

°C MAX. (SEE IM)

-0.1 MPa MIN. (SEE IM)

+60 °C MAX. (SEE IM)

0038

N200

F0201.EPS

2.2 Accessories

2.3 Storage Precautions

In case the instrument is expected to be stored over a

long term, please give attention to the followings;

• The instrument should be stored in its original

packing condition.

• The storage location should be selected according to

the following conditions:

1) The location where it is not exposed to rain or

water.

2) The location where there is few vibration or

shock.

3) Temperature and humidity should be:

Temperature: –20 to 60˚C (–4 to 140˚F)

Humidity: 5 to 80% RH (no condensation)

Preferable ambient temperature and humidity

are 25˚C(77˚F) and about 65% RH.

2.4 Installation Location

Precautions

Please select the installation location considering the

following items to ensure long term stable operation of

the flow tube.

• Ambient Temperature:

Please avoid to install the instrument at the location

where temperature changes continuously. If the

location receives radiant heat from the plant, provide

heat insulation or improve ventilation.

•Atmospheric Condition:

Please avoid to install the instrument in an corrosive

atmosphere. In case of installing in the corrosive

atmosphere, please keep ventilating sufficiently and

prevent rain from entering the conduit.

•Vibration or shock:

Please avoid to install the instrument at the location

where there is heavy vibration or shock.

When the instrument is delivered, please make sure

that the following accessories are in the package.

• Centering device 1-set (for wafer type)

• Hexagonal wrench 1-piece (for hazardous duty type)

2.5 Terminal Box Reori-

entation Precautions

Please do not change the terminal box orientation at

the customer’s site. If the terminal box reorientation is

required, please contact Yokogawa office or service

center.

2-1

IM 1E7D0-01E

Page 7

3. INSTALLATION

NOTE

3. INSTALLATION

WARNING

This instrument must be installed by expert

engineer or skilled personnel. The procedures

described in this chapter are not permitted for

operators.

3.1 Piping Design Precautions

IMPORTANT

Please design the correct piping referring to the

followings to prevent damage for flow tube and

to keep correct measuring.

(1) Location

Gate valve

fully open

5 D or more 2 D or more 2 D or more

Tee

Figure 3.1.1 Minimum Length of Required Straight Run

Reducer pipe Expander pipe

Do not care to 0 D Do not care to 0 D

90° degrees bent

D: Nominal diameter of flow tube

10 D or more

Various types of valves

10 D or more5 D or more5 D or more Do not care to 0 D Do not care to 0 D

1. Nothing must be inserted or installed in the

metering pipe than may interfere with the

magnetic field, induced signal voltages, and

flow velocity distribution.

2. These straight runs may not be required on

the downstream side flowmeter. However, if

the downstream valve or other fittings cause

channeling on the upstream side, provide a

straight run of 2 D to 3 D on the downstream

side.

2 D or more

F030101.EPS

IMPORTANT

Please install the flow tube to the location where

it is not exposed to direct sunlight and ambient

temperature is –20 to + 60°C (–4 to 140°F).

* The minimum temperature is –10°C (14°F) in case

of the 40mm or larger size with the carbon steel

flange connection or wafer connection.

(2) Noise Rejection

IMPORTANT

The instrument should be installed away from

large electrical motors, transformers and other

power sources in order to avoid interference with

the measurement.

(3) Length of Straight Run

To keep accurate measuring, JIS B7554 “Electro

Magnetic Flow Tubes” explains about upstream piping

condition of Magnetic Flow Tubes.

(4) Liquid Conductivity

IMPORTANT

Please avoid to install the flow tube at location

where liquid conductivity is likely to be nonuniform. Because it is possible to have bad

influences to the flow indication by non-uniform

conductivity when a chemical liquid is injected

from upstream side close to the flow tube. When

this occurs, it is recommended that chemical

application ports are installed on the downstream

side of the flow tube. In case chemicals must be

added upstream side, please keep the pipe

length enough so that liquid is properly mixed.

(BAD)

Upstream side

(GOOD)

Downstream side

F030102.EPS

We recommend to our customers about the piping

conditions shown in Figure 3.1.1 based on JIS B7554

and our piping condition test data.

Figure 3.1.2 Chemical Insertion

3-1

IM 1E7D0-01E

Page 8

3. INSTALLATION

(5) Liquid Sealing Compound

IMPORTANT

Please give attention in using Liquid Sealing

Compound to the piping, because it brings bad

influences to measurement by flowing out and

cover the surfaces of electrode and earth-ring.

(6) Service Area

Please select the location where there is enough area to

service installing, wiring, overhaul, etc.

(7) Bypass Line

It is recommended to install the Bypass Line to

facilitate maintenance and zero adjustment.

Bypass valve

Block

valve

Block valve

F030103.EPS

Please design the piping that a fluid is always filled in

the pipes. The Vertical Mounting is effective for fluids

that is easily separate or slurry settles within pipes.

In this case, please flow a fluid from bottom to up.

(GOOD)

h

h>0

Horizontal mounting Vertical mounting

Figure 3.1.4 Filling the Pipe with Liquid

(BAD)

(GOOD)

h>0

(BAD)

h

F030104.EPS

(10) No Air Bubbles

IMPORTANT

Please give attention to prevent bad influences

or measuring errors from air bubbles that gathers inside measuring pipes.

In case the fluid includes air bubbles, please design the

piping that prevent to gather air bubbles. In case valves

are installed upstream of the flow tube, it is possible

that a valve causes air bubbles, please install the flow

tube upstream side of a valve.

Figure 3.1.3 Bypass Line

(8) Supporting the Flow Tube

CAUTION

Please avoid to support only the flow tube, but

fix pipes at first and support the flow tube by

pipes to protect the flow tube from forces caused

by vibration, shock, expansion and contraction

through piping.

For small sized flow tubes, please provide a

mounting base so thet the tubes are fixed in the

piping. See the section 3.3 Mounting.

(9) Piping Condition

IMPORTANT

The piping should be designed so that a full pipe

is maintained at all times to prevent loss of

signal and erroneous readings.

(GOOD)

(BAD)

Figure 3.1.5 Avoiding Air Bubbles

(GOOD)

(11) Mounting Direction

IMPORTANT

When the electrodes are vertical to ground, the

electrode is covered with air bubbles at upper

side or slurry at downside, and it may cause the

measuring errors.

Please be sure to mount the terminal box upper

side of piping to prevent water penetration into

terminal box.

(Good)

(No good)

Electrodes

Figure 3.1.6 Mounting Direction

Electrodes

Air Bubbles

Slurry

(No good)

3-2

(BAD)

F030105.EPS

Water slowly

percolates

downward into

terminal box.

F030106.EPS

IM 1E7D0-01E

Page 9

3. INSTALLATION

(12) Grounding

IMPORTANT

Improper grounding can have an adverse affect

on the flow measurement. Please ensure that

the instrument is properly grounded.

The electromotive force of the magnetic flow tube is

minute and it is easy to be affected by noise. And also

that reference electric potential is the same as the

measuring fluid potential. Therefore, the reference

electric potential (terminal potential) of the Flow Tube

and the Converter/Amplifier also need to be the same

as the measuring fluid. And moreover, that the potential must be the same with ground.

Please be sure to ground according to Figure 3.1.7.

600 V vinyl insulated

electric cable

2

(2 mm

or larger)

3.2 Handling Precautions

WARNING

The Magnetic Flow tube is a heavy instrument.

Please be careful to prevent persons from

injuring when it is handled.

3.2.1 General Precautions

(1) Precaution for Carrying

The Magnetic Flow Tube is packed tightly. When it is

unpacked, please give attention to prevent damages to

the flow tube. And to prevent the accident during carry

to the installing location, please carry it near the

location keeping packed as it delivered.

CAUTION

Earth ring

Grounding resistance 100 Ω or less

In case earth rings are used.

Note; See "3.4.1 Protective Grounding" for information on

protective grounding.

Figure 3.1.7 Grounding

In case earth rings are not used.

(Available only for metal piping)

F030107.EPS

In case the Magnetic Flow Tube lifts up, please

refer to Figure 3.2.1. Please never lift up by

using a bar through the flow tube. It damages

liner severely.

Horizontal Lifting

Figure 3.2.1 Lifting Flow Tubes

Vertical Lifting Sling

Rigging Method

F030201.EPS

3-3

IM 1E7D0-01E

Page 10

3. INSTALLATION

(2) Precaution for Shock

CAUTION

Care should be taken not to drop the flow tube

or subject it to excessive shock. This may lead

to liner damage which will cause inaccurate

readings.

(3) Flange Protection Covers

IMPORTANT

Please keep the protection cover (ex. corrugated

paper or anything possible to protect) attached

with flange except when mounting to the pipe.

(4) Terminal Box Cover

IMPORTANT

3.2.2 Flow Tube Piping

CAUTION

Mis-aligned or slanted piping can lead to leakage

and damage to flanges.

•Please correct mis-alignment or slanted piping and

improper distance between mounting flanges before

install the flow tube. (Please refer to Figure 3.2.2)

• Inside a pipeline which is newly installed, some

foreign substances (such as welding scrap or wood

chips) may exist. Please remove them by flushing

piping before mounting the flow tube.

Slant

Mis-alignment

F030202.EPS

Please never leave the terminal box cover open

until wiring to prevent insulation deterioration.

(5) Long-term Non-use

IMPORTANT

It is not preferable to leave the flow tube for long

term non-use after installation.

In case the flow tube is compelled to do that,

please take care of the flow tube by the followings.

• Confirmation of Sealing Condition for the Flow

Tube

Please confirm the sealing conditions of the terminal

box screw and wiring ports.

In case of the Conduit Piping, please provide the

drain plugs or waterproof glands to it to prevent that

moisture or water penetrates into the flow tube

through the conduit.

• Regular Inspections

Please inspect the sealing condition (as above

mentioned) and inside of the terminal box. And

when it is suspect that water penetration into the

inside flow tube (ex. rain fall), please inspect when

it happened.

Figure 3.2.2 Slant and Mis-alignment of Flow Tube Piping

3-4

IM 1E7D0-01E

Page 11

3. INSTALLATION

3.3 Mounting

3.3.1 Nominal Diameter 2.5 mm

(0.1in.) to 10 mm (0.4in.) Union

Joint Type

NOTE

Please ensure to use the attached connecting

fittings.

Ceramic linings with a diameter of 2.5, 5 or 10 mm are

connected using union joints.

Use the connecting fittings according to the table

below. Depending on whether the fitting is to be

welded to or screwed on to the piping.

Table 3.3.1 Fitting Dimensions

Unit: mm (inch)

Screw joint (Code: U2, U3)

D

(1) Mounting Direction

Please mount the Magnetic Flow Tube matching the

flow direction of the fluid to be measured with the

direction of the arrow mark on the flow tube.

IMPORTANT

If it is impossible to match the direction, please

never remodel by changing direction of the

terminal box. In case the measuring fluid flows

against the arrow direction, please refer to the

section “Reversing Flow Direction” in the Instruction Manual of AE14 Magnetic Flow Converter.

(2) Connecting Process Piping

Weld or screw the connecting fittings to the process

piping.

IMPORTANT

(0.16)

Size

mm(inch)

2.5(0.1)

5(0.2)

10(0.4)

ØAØBØB

(0.16)

Size

mm(inch)

2.5(0.1)

5(0.2)

10(0.4)

ØA

11.5(0.4)

4

30(1.2)

Code A B C D

22(0.87)

U2

22(0.87)

U3

22(0.87)

U2

22(0.87)

U3

25(0.98)

U2

25(0.98)

U3

Weld joint (Code: U1)

4

Code A B C D

22(0.87)

U1

22(0.87)

U1

25(0.98)

U1

8(0.31)

8(0.31)

8(0.31)

8(0.31)

10(0.39)

10(0.39)

35(1.38)

8(0.31)

8(0.31)

10(0.39)

18.5(0.73)

18.5(0.73)

18.5(0.73)

18.5(0.73)

22.5(0.89)

22.5(0.89)

10(0.39)

14.3(0.56)

14.3(0.56)

17.8(0.70)

ØC

ØC

0

–0.1

R1/4(PT1/4)

NPT1/4

R1/4(PT1/4)

NPT1/4

R3/8(PT3/8)

NPT3/8

0.3

0

0

–0.1

ØD

18.5(0.73)

18.5(0.73)

22.5(0.89)

T030301.EPS

• Please be sure to pass the connecting fittings

through the union joint nuts in advance. Then

connect the connecting fitting to the piping by

screwing or welding the connecting fitting to the

piping (see Figure 3.3.1).

• In case of weld joint type, please pay attention

the welding condition to avoid deforming piping

or making the stagnant portion of the fluid;

joint preparation, level defference in butt joint,

welding current.

(3) Positioning the Flow Tube

Install the magnetic flow tube on a mounting base and

position it so that the center axis of the flow tube is

aligned with that of the piping. Then mount the flow

tube to union joint nuts by screwing the nuts to the

connecting ports of the flow tube.

CAUTION

The ceramic pipe will be damaged if they are

tightened when they are not properly aligned.

3-5

IM 1E7D0-01E

Page 12

3. INSTALLATION

(4) Tightening Nuts

CAUTION

Tighten the union joint nuts according to Torque

Values in Table 3.3.1 using a torque wrench. As

the gasket material is Fluorocarbon PTFE, it is

possible that nuts may loose by it’s character as

time passes. Please tighten the nuts regularly.

The table below shows the tightening torque

values. Be sure to use gasket : t=1.5 attached.

Gasket

Connecting fitting

Union joint nut

Piping*

Mounting base*

*: user's scope

Table 3.3.2

Size: mm(inch) Tightening Torque N-m {kgf-cm} [in-lbf]

2.5(0.1)

5(0.2)

10(0.4)

Max.12{122}[106]

Max.12{122}[106]

Max.18{183}[160]

T030302.EPS

3.3.2 Nominal Diameter 2.5mm (0.1in.) to 40mm (1.5in.) Wafer Type

IMPORTANT

Please use appropriate bolts and nuts according

to process connection. In case stud type of

through bolts are used, be sure outside diameter

of a shank is smaller than a thread ridge’s one.

Please use compressed non-asbestos fiber

gasket, PTFE gasket or the gasket which has

equal elasticity. In case of optional code/FRG,

please use rubber gasket or others which has

equal elasticity. Be sure the inner diameter of

the gasket does not protrude to inner piping.

(Refer to Table 3.3.8)

Horizontal Mounting

(1) Mounting Direction

Please mount the Magnetic Flow Tube matching the

flow direction of the fluid to be measured with the

direction of the arrow mark on the flow tube.

IMPORTANT

If it is impossible to match the direction, please

never remodel by changing direction of the

terminal box. In case the measuring fluid flows

against the arrow direction, please refer to the

section “Reversing Flow Direction” in the Instruction Manual of AE14 Magnetic Flow Converter.

(2) Mounting Centering Devices

To keep concentricity of the Flow Tube with pipes,

please mount centering devices on the Mini-Flanges of

the Flow Tube.

Please give attention to the nominal diameter and

flange ratings of the centering devices.

Vertical Mounting

Figure 3.3.1 Mounting Procedure (Size: 2.5 mm(0.1in.) to

10 mm(0.4in.))

F030301.EPS

3-6

IM 1E7D0-01E

Page 13

3. INSTALLATION

(3) Positioning Flow Tube

Please pass two through-bolts to adjacent holes of both

flanges and mount the Flow Tube, and pass other

through-bolts to other holes. (Refer to Figure 3.3.2/

3.3.3) In case stud type of through-bolts are used,

position them coming in contact centering devices with

thread of bolts.

(4) Tightening Nuts

Please tighten the bolts according to Torque Values in

Table 3.3.3. In case of PVC piping, please select

optional code /FRG, use rubber gasket and tighten with

the torque value in Table 3.3.4.

Through-bolts (four)

Nuts

Please use appropriate bolts and

nuts according to process

connection.

CAUTION

In case of PFA lining type, as the lining material

is Fluorocarbon PFA, it is possible that nuts may

loose by its character as time passes. Please

tighten the nuts regularly.

Please be sure to tighten the bolts following

prescribed torque values. Please tighten the

flange bolts diagonally with the same torque

values, step by step up to the prescribed torque

value.

Gasket (two)

Mini-flange

Centering devices (two)

Flange

Nuts (eight)

Horizontal Mounting Vertical Mounting

Figure 3.3.2 Mounting Procedure (Size: 2.5 mm(0.1in.) to 15 mm(0.5in.))

Through-bolts (four)

Gasket (two)

Mini-flange

Nuts (eight)

Please use appropriate

bolts and nuts according

to process connection.

Centering devices (two)

F030302.EPS

Flange

Horizontal Mounting Vertical Mounting

Figure 3.3.3 Mounting Procedure (Size: 25 mm(1in.), 40 mm(1.5in.))

F030303.EPS

3-7

IM 1E7D0-01E

Page 14

Table 3.3.3 Tightening Torque Values for Metal Piping

Tightening Torque Values for PFA lining / Polyurethane lining Type N-m {kgf-cm} [in-lbf]

Size

mm(inch)

2.5(0.1), 5(0.2)

10(0.4), 15(0.5)

25(1)

40(1.5)

Flange

Rating

10K

6 to 9

{61 to 92}

[53 to 80]

15 to 22

{153 to 224}

[133 to 195]

21 to 32

{214 to 327}

[186 to 283]

JIS ANSI DIN

20K

6 to 9

{61 to 92}

[53 to 80]

15 to 22

{153 to 224}

[133 to 195]

21 to 32

{214 to 327}

[186 to 283]

150

6 to 9

{61 to 92}

[53 to 80]

12 to 18

{122 to 184}

[106 to 159]

17 to 26

{173 to 265}

[150 to 230]

300

6 to 9

{61 to 92}

[53 to 80]

15 to 22

{153 to 224}

[133 to 195]

25 to 38

{255 to 388}

[221 to 336]

{112 to 173}

{214 to 327}

[186 to 283]

Maximum Tightening Torque Values for Ceramic lining Type N-m {kgf-cm} [in-lbf]

Size

mm(inch)

15(0.5)

40(1.5)

25(1)

Flange

Rating

10K

{143}

[124]

{306}

[265]

{449}

[389]

14

30

44

JIS

20K

14

{143}

[124]

30

{306}

[265]

44

{449}

[389]

150

14

{143}

[124]

22

{224}

[195]

33

{337}

[292]

ANSI

300

14

{143}

[124]

30

{306}

[265]

51

{520}

[451]

3. INSTALLATION

PN10/16

6 to 9

{61 to 92}

[53 to 80]

11 to 17

[97 to 150]

21 to 32

DIN

PN10/16

14

{143}

[124]

25

{255}

[221]

50

{510}

[442]

*Please use compressed non-asbestos fiber gasket, PTFE gasket or the gasket which has equal elasticity.

T030303.EPS

Table 3.3.4 Tightening Torque Values for PVC Piping

Tightening Torque Values for PFA lining / Polyurethane lining Type N-m {kgf-cm} [in-lbf]

Size

mm(inch)

2.5(0.1), 5(0.2)

10(0.4), 15(0.5)

25(1)

40(1.5)

Flange

Rating

10K

2.0

{20}

[18]

5.2

{53}

[46]

7.4

{76}

[65]

JIS

20K

—

—

—

150

2.1

{21}

[19]

4.2

{43}

[37]

6.0

{61}

[53]

ANSI

300

—

—

—

DIN

PN10/16

2.0

{20}

[18]

4.0

{41}

[35]

7.4

{76}

[65]

Maximum Tightening Torque Values for Ceramic Type N-m {kgf-cm} [in-lbf]

Size

mm(inch)

15(0.5)

40(1.5)

25(1)

Flange

Rating

10K

1.3

{13}

[12]

3.5

{36}

[31]

5.7

{58}

[50]

JIS

20K

—

—

—

150

1.3

{13}

[12]

2.8

{29}

[25]

4.6

{47}

[41]

ANSI

300

—

—

—

DIN

PN10/16

1.3

{13}

[12]

2.7

{28}

[24]

5.7

{58}

[50]

*Please select optional code/FRG and use rubber gasket or others which has equal elasticity.

T030304.EPS

3-8

IM 1E7D0-01E

Page 15

3.3.3 Nominal Diameter 50 mm(2in.)

NOTE

Centering devices (four)

Nuts

Through bolts

Flanges

Gaskets (two)

Please use appropriate

bolts and nuts

according to Process

connection.

Mini-Flange

Housing

Horizontal Mounting Vertical Mounting

F030304.EPS

to 300 mm(12in.) Wafer Type

IMPORTANT

Please use appropriate bolts and nuts according

to process connection. In case stud type of

through bolts are used, be sure outside diameter

of a shank is smaller than a thread ridge’s one.

Please use compressed non-asbestos fiber

gasket, PTFE gasket or the gasket which has

equal elasticity. In case of optional code/FRG,

please use rubber gasket or others which has

equal elasticity. Be sure the inner diameter of

the gasket does not protrude to inner piping.

(Refer to Table 3.3.8)

(1) Mounting Direction

Please mount the Magnetic Flow Tube matching the

flow direction of the fluid to be measured with the

direction of the arrow mark on the flow tube.

IMPORTANT

3. INSTALLATION

When installing a size 150mm with JIS F12

(JIS75M) flange, please displace in circumferential direction slightly because the cover of

electrode chamber will interfere against the bolts.

(4) Tightening Nuts

Please tighten the bolts according to Torque Values in

Table 3.3.5. In case of PVC piping, please select

optional code/FRG, use rubber gasket and tighten with

the torque value in Table 3.3.6.

CAUTION

In case of PFA lining type as the lining material

is Fluorocarbon PFA, it is possible that nuts

loose by its character as time passes. Please

tighten the nuts regularly.

Please be sure to tighten the bolts following

prescribed torque values. Please tighten the

flange bolts diagonally with the same torque

values, step by step up to the prescribed torque

value.

If it is impossible to match the direction, please

never remodel to change direction of the terminal box. In case the measuring fluid flows

against the arrow direction, please refer to the

section “Reversing Flow Direction” in the Instruction Manual of AE14 Magnetic Flow Converter.

(2) Mounting Centering Devices

To keep concentricity between the Flow Tube and

pipes, centering devices must be used. Pass two

through-bolts through the four centering devices (two

for each) and lower adjacent holes of both flanges.

(Refer to Figure 3.3.4)

Please give attention to the nominal size and flange

ratings of the centering devices. (Refer to Table 3.3.7)

(3) Positioning Flow Tube

Position the Flow Tube coming in contact four centering devices with Mini-Flanges. At this time, pay

attention to avoid four centering devices come in

contact with Housing. In case stud type of throughbolts are used, position them coming in contact four

centering devices with thread of the bolts. (Refer to

Figure 3.3.4) After positioning the Flow Tube, pass

remaining through-bolts to remaining holes.

Figure 3.3.4 Mounting Procedure

3-9

IM 1E7D0-01E

Page 16

Table 3.3.5 Tightening Torque Values for Metal Piping

Tightening Torque Values for PFA lining / Polyurethane lining Type N-m {kgf-cm} [in-lbf]

Size

mm(inch)

Maximum Tightening Torque Values for Ceramic lining Type N-m {kgf-cm} [in-lbf]

Size

mm(inch)

*Please use compressed non-asbestos fiber gasket, PTFE gasket or the gasket which has equal elasticity.

Flange

Rating

50(2)

65(2.5)

80(3)

100(4)

125(5)

150(6)

200(8)

250(10)

300(12)

50(2)

80(3)

100(4)

150(6) —

200(8)

Flange

Rating

{286 to 429}

[248 to 372]

{530 to 610}

[460 to 531]

{214 to 316}

[186 to 274]

{357 to 520}

[310 to 451]

{630 to 760}

[549 to 664]

{663 to 959}

[575 to 832]

{582 to 857}

[504 to 743]

{996 to 1307}

[867 to 1133]

{871 to 1098}

[752 to 956]

JIS ANSI DIN

10K 20K 150 300 PN10

28 to 42

52 to 60

21 to 31

35 to 51

62 to 75

65 to 94

57 to 84

98 to 128

85 to 108

10K 20K

50

{510}

[442]

36

{367}

[319]

48

{490}

[425]

79

{806}

[699]

70

{714}

[619]

{143 to 214}

[124 to 186]

{265 to 398}

[230 to 345]

{439 to 653}

[381 to 566]

{439 to 694}

[381 to 602]

{622 to 939}

[540 to 814]

JIS

14 to 21

—

26 to 39

43 to 64

—

43 to 68

61 to 92

—

—

27

{276}

[239]

44

{449}

[389]

58

{592}

[513]

55

{561}

[487]

76

{776}

[673]

28 to 42

{286 to 429}

[248 to 372]

52 to 60

{530 to 610}

[460 to 531]

41 to 61

{418 to 622}

[363 to 540]

35 to 51

{357 to 520}

[310 to 451]

60 to 72

{610 to 730}

[531 to 637]

63 to 89

{643 to 908}

[558 to 788]

93 to 120

{949 to 1224}

[823 to 1062]

89 to 130

{909 to 1329}

[788 to 1150]

106 to 146

{1083 to 1489}

[938 to 1292]

150 300

50

{510}

[442]

75

{765}

[664]

49

{500}

[434]

66

{673}

[584]

102

{1041}

[903]

ANSI

14 to 21

{143 to 214}

[124 to 186]

—

25 to 37

{255 to 378}

[221 to 327]

41 to 61

{418 to 622}

[363 to 540]

—

41 to 60

{418 to 612}

[363 to 531]

65 to 93

{663 to 949}

[575 to 823]

—

—

27

{276}

[239]

44

{449}

[389]

56

{571}

[496]

43

{439}

[381]

76

{776}

[673]

{663 to 959}

[575 to 832]

{959 to 1276}

[832 to 1106]

{924 to 1195}

[805 to 1035]

{1103 to 1339}

[956 to 1159]

65 to 94

94 to 125

91 to 117

108 to 131

{1051}

—

—

—

—

—

PN10 PN16

—

—

—

103

[911]

DIN PN

PN16

28 to 42

{286 to 429}

[248 to 372]

52 to 60

{530 to 610}

[460 to 531]

21 to 31

{214 to 316}

[186 to 274]

35 to 52

{357 to 531}

[310 to 460]

52 to 60

{530 to 610}

[460 to 531]

65 to 94

{663 to 959}

[575 to 832]

58 to 84

{592 to 857}

[513 to 743]

—

—

63

{643}

[558]

36

{367}

[319]

48

{490}

[425]

76

{776}

[673]

67

{684}

[593]

JIS G3451

F12

—

—

41 to 62

{418 to 633}

[363 to 549]

68 to 102

{694 to 1041}

[602 to 903]

71 to 80

{720 to 810}

[628 to 708]

68 to 100

{694 to 1020}

[602 to 885]

69 to 101

{704 to 1031}

[611 to 894]

139 to 176

{1416 to 1792}

[1230 to 1558]

131 to 158

{1337 to 1606}

[1159 to 1398]

JIS G3451

F12

—

80

{816}

[708]

105

{1071}

[929]

84

{857}

[743]

102

{1041}

[903]

T030305.EPS

3. INSTALLATION

Table 3.3.6 Tightening Torque Values for PVC Piping

Tightening Torque Values for PFA lining / Polyurethane lining Type N-m {kgf-cm} [in-lbf]

Size

mm(inch)

Flange

Rating

50(2) — — —

80(3)

100(4)

150(6)

200(8)

Maximum Tightening Torque Values for Ceramic lining Type N-m {kgf-cm} [in-lbf]

Size

mm(inch)

Flange

Rating

50(2)

80(3)

100(4)

150(6)

200(8)

*Please select optional code/FRG and use rubber gasket or others which has equal elasticity.

JIS ANSI DIN

10K 20K 150 300 PN10

9.8

{100}

[87]

7.2

{73}

[64]

12.2

{124}

[108]

21.4

{218}

[189]

19.3

{197}

[171]

JIS

10K 20K

8.2

{84}

[73]

6.2

{63}

[55]

8.0

{82}

[71]

19.8

{202}

[175]

17.5

{179}

[155]

———

——

——

——

————

———

———

——

——

9.8

{100}

[87]

14.4

{147}

[127]

12.2

{124}

[108]

20.5

{209}

[181]

27.6

{282}

[244]

ANSI

150 300

8.2

{84}

[73]

12.4

{127}

[110]

8.1

{83}

[72]

18.9

{193}

[167]

25.1

{256}

[222]

—

21.4

{218}

[189]

28.9

{295}

[256]

DIN

PN10 PN16

19.8

{202}

[175]

26.2

{267}

[232]

3-10

PN16

9.8

{100}

[87]

7.2

{73}

[64]

12.2

{124}

[108]

21.4

{218}

[189]

19.3

{197}

[171]

8.2

{84}

[73]

6.2

{63}

[55]

8.0

{82}

[71]

19.8

{202}

[175]

17.5

{179}

[155]

JIS G3451

F12(75M)

—

14.4

{147}

[127]

24.4

{249}

[216]

23.4

{239}

[207]

31.6

{322}

[280]

JIS G3451

F12(75M)

12.3

{126}

[109]

16.1

{164}

[142]

21.6

{220}

[191]

28.7

{293}

[254]

T030306.EPS

IM 1E7D0-01E

Page 17

Table 3.3.7 Centering Device Identification

Flange Rating

Lining mm(inch)

PFA,

Polyurethane

Ceramics

65(2.5)

100(4)

125(5)

150(6)

200(8)

250(10)

300(12)

100(4)

150(6)

200(8)

50(2)

80(3)

50(2)

80(3)

JIS 10K

B

B

B

B

G

C

C

C

C

B

B

B

B

B

*Each Centering Devices is engraved a character as identifidation.

JIS 20K

B

—

F

F

—

D

D

—

—

B

F

F

C

C

JIS G3451

F12

—

—

H

H

H

D

D

D

D

—

H

H

G

C

ANSI 150 ANSI 300

B

B

F

C

C

C

D

K

L

B

F

C

B

G

F

—

C

H

—

E

E

—

—

F

C

H

D

J

DIN PN

10/16

F

F

G

F

G

C

C

C

C

F

G

F

B

B

T030307.EPS

Table 3.3.8 Earth Ring inside diameter

Unit: mm(inch)

Size

2.5(0.1)

5(0.2)

10(1.4)

15(0.5)

25(1)

40(1.5)

50(2)

65(2.5)

80(3)

100(4)

125(5)

150(6)

200(8)

250(10)

300(12)

350(14)

400(16)

PFA/Polyurethane lining Ceramic lining

φ15(0.6)

φ15(0.6)

φ15(0.6)

φ15(0.6)

φ27(1.1)

φ40(1.6)

φ52(2.1)

φ63.5(2.5)

φ81(3.2)

φ98(3.9)

φ118.6(4.7)

φ140.7(5.6)

φ188.9(7.5)

Wafer; φ243.7(9.6), Flange; φ239.1(9.5)

Wafer; φ294.7(11.6), Flange; φ291.3(11.5)

φ323.4(12.8)

φ373.5(14.8)

—

—

—

φ15(0.6)

φ27(1.1)

φ40(1.6)

φ52(2.1)

—

φ81(3.2)

φ98(3.9)

—

φ144(5.7)

φ192(7.6)

—

—

—

—

T030308.EPS

*Please ensure that the I.D. of the gasket does not protrude into the I.D. of the Earth Ring.

(This dimension is also applied when no earth ring is used)

3. INSTALLATION

3-11

IM 1E7D0-01E

Page 18

3. INSTALLATION

3.3.4 Nominal Diameter 15 mm (0.5in.) to 400 mm (16in.) Flange Type

IMPORTANT

Please use appropriate bolts and nuts according

to process connection. Please use compressed

non-asbestos fiber gasket, PTFE gasket or the

gasket which has equal elasticity. In case of

optional code/FRG, please use rubber gasket or

others which has equal elasticity. Be sure the

inner diameter of the gasket does not protrude to

inner piping.(Refer to Table 3.3.8)

(1) Mounting Direction

Please mount the Magnetic Flow Tube matching the

flow direction of the fluid to be measured with the

direction of the arrow mark on the flow tube.

(2) Tightening Nuts

Please tighten the bolts according to Torque Values in

Table 3.3.9. In case of PVC piping, please select

optional code/FRG, use rubber gasket and tighten with

the torque value in Table 3.3.10.

CAUTION

In case of PFA lining type as the lining material

is Fluorocarbon PFA, it is possible that bolts

loose by its character as time passes. Please

tighten the nuts regularly.

Please be sure to tighten the bolts following

prescribed torque values. Please tighten the

flange bolts diagonally with the same torque

values, step by step up to the prescribed torque

value.

IMPORTANT

If it is impossible to match the direction, please

never remodel to change direction of the terminal box. In case the measuring fluid flows

against the arrow direction, please refer to the

section “Reversing Flow Direction” in the Instruction Manual of AE14 Magnetic Flow Converter.

Gasket (two)

Flange (Flow tube)

Bolts

Please use appropriate bolts and

nuts according to process

conneciton.

Figure 3.3.5 Mounting Procedure (Size: 15 mm (0.5in.) to 400 mm (16in.))

Nuts

Flange

(Piping side)

3-12

F030305.EPS

IM 1E7D0-01E

Page 19

Table 3.3.9 Tightening Torque Values for Metal Piping in N-m{kgf-cm} [in-lbf]

15(0.5mm)

25(1mm)

40(1.5mm)

50(2mm)

80(3mm)

100(4mm)

150(6mm)

200(8mm)

250(10mm)

300(12mm)

350(14mm)

400(16mm)

Flange

Rating

{31 to 51}

[27 to 44]

{82 to 133}

[71 to 115]

{184 to 265}

[159 to 230]

{224 to 316}

[195 to 274]

{153 to 224}

[133 to 195]

{214 to 357}

[186 to 310]

{663 to 959}

[575 to 832]

{582 to 857}

[504 to 743]

142 to 174

{1449 to 1776}

[1257 to 1540]

114 to 138

{1163 to 1408}

[1009 to 1221]

158 to 183

{1612 to 1867}

[1398 to 1619]

243 to 261

{2480 to 2663}

[2150 to 2310]

Size

mm(inch)

*Please use compressed non-asbestos fiber gasket, PTFE gasket or the gasket which has equal elasticity.

JIS ANSI DIN

10K 20K 150 300 PN10

3 to 5

8 to 13

18 to 26

22 to 31

15 to 22

21 to 35

65 to 94

57 to 84

3 to 5

{31 to 51}

[27 to 44]

8 to 13

{82 to 133}

[71 to 115]

18 to 26

{184 to 265}

[159 to 230]

11 to16

{112 to 163}

[97 to 142]

18 to 27

{184 to 276}

[159 to 239]

25 to 44

{255 to 449}

[221 to 389]

43 to 68

{439 to 694}

[381 to 602]

61 to 92

{622 to 939}

[540 to 814]

154 to 182

{1571 to 1857}

[1363 to 1611]

125 to 145

{1276 to 1480}

[1106 to 1283]

—

—

3 to 5

{31 to 51}

[27 to 44]

6 to 10

{61 to 102}

[53 to 88]

15 to 21

{153 to 214}

[133 to 186]

23 to 31

{235 to 316}

[204 to 274]

35 to 43

{357 to 439}

[310 to 381]

22 to 35

{224 to 357}

[195 to 310]

63 to 89

{643 to 908}

[558 to 788]

93 to 120

{949 to 1224}

[823 to 1062]

145 to 177

{1480 to 1806}

[1283 to 1566]

164 to 187

{1673 to 1908}

[1451 to 1655]

245 to 284

{2500 to 2898}

[2168 to 2513]

253 to 275

{2582 to 2806}

[2239 to 2434]

3 to 5

{31 to 51}

[27 to 44]

8 to 13

{82 to 133}

[71 to 115]

21 to 31

{214 to 316}

[186 to 274]

11 to 16

{112 to 163}

[97 to 142]

18 to 26

{184 to 265}

[159 to 230]

25 to 42

{255 to 429}

[221 to 372]

41 to 59

{418 to 602}

[363 to 522]

65 to 93

{663 to 949}

[575 to 823]

126 to 151

{1286 to 1541}

[1115 to 1336]

154 to 180

{1571 to 1837}

[1363 to 1593]

—

—

65 to 94

{663 to 959}

[575 to 832]

94 to 125

{959 to 1276}

[832 to 1106]

136 to 164

{1388 to 1673}

[1204 to 1451]

155 to 199

{1582 to 2031}

[1372 to 1761]

152 to 192

{1551 to 1959}

[1345 to 1699]

248 to 331

{2531 to 3378}

[2195 to 2929]

—

—

—

—

—

—

PN16

3 to 5

{31 to 51}

[27 to 44]

6 to 10

{61 to 102}

[53 to 88]

18 to 26

{184 to 265}

[159 to 230]

23 to 31

{235 to 316}

[204 to 274]

16 to 22

{163 to 224}

[142 to 195]

21 to 35

{214 to 357}

[186 to 310]

65 to 94

{663 to 959}

[575 to 832]

58 to 84

{592 to 857}

[513 to 743]

154 to 175

{1571 to 1786}

[1363 to 1549]

175 to 213

{1786 to 2173}

[1549 to 1885]

—

—

JIS G3451

F12(75M)

—

—

—

—

33 to 47

{337 to 480}

[292 to 416]

47 to 75

{480 to 765}

[416 to 664]

65 to 100

{663 to 1020}

[575 to 885]

69 to 101

{704 to 1031}

[611 to 894]

215 to 270

{2194 to 2755}

[1903 to 2389]

190 to 249

{1939 to 2541}

[1681 to 2204]

274 to 325

{2796 to 3316}

[2425 to 2876]

313 to 395

{3194 to 4031}

[2770 to 3496]

T030309.EPS

3. INSTALLATION

Table 3.3.10 Tightening Torque Values for PVC Piping in N-m{kgf-cm} [in-lbf]

Flange

mm(inch)

*Please select optional code/FRG and use rubber gasket or others which has equal elasticity.

RatingSize

15(0.5)

25(1)

40(1.5)

50(2)

80(3)

100(4)

150(6)

200(8)

JIS

10K 20K

1.1

{11}

[10]

2.9

{30}

[26]

5.9

{60}

[52]

7.2

{73}

[64]

4.9

{50}

[43]

8.1

{83}

[72]

29.8

{304}

[264]

26.3

{268}

[233]

ANSI

150 300

—

—

—

—

—

—

—

—

1.1

{11}

[10]

2.3

{23}

[20]

4.7

{48}

[42]

7.2

{73}

[64]

9.9

{101}

[88]

8.2

{84}

[73]

28.5

{291}

[252]

37.7

{385}

[334]

—

—

—

—

—

—

—

—

DIN

PN10 PN16

—

—

—

—

—

—

29.8

{304}

[264]

39.4

{4,2}

[349]

1.1

{11}

[10]

2.2

{22}

[19]

5.9

{60}

[52]

7.2

{73}

[64]

4.9

{50}

[43]

8.1

{83}

[72]

29.8

{304}

[264]

26.3

{268}

[233]

JIS G3451

F12(75M)

—

—

—

—

9.9

{101}

[88]

16.3

{166}

[144]

32.6

{33}

[288]

43.1

{440}

[381]

T030310.EPS

3-13

IM 1E7D0-01E

Page 20

3. INSTALLATION

3.3.5 Mounting Procedure for Sanitary Type

The sanitary type is mounted using ISO(IDF) clamps.

(1) Mounting Direction

Please mount the Magnetic Flow Tube matching the

flow direction of the fluid to be measured with the

direction of the arrow mark on the flow tube.

IMPORTANT

If it is impossible to macth the direction, please

never remodel to change direction of the terminal box. In case the measuring fluid flows

against the arrow direction, please refer to the

section “Reversing Flow Direction” in the Instruction Manual of AE14 Magnetic Converter.

(2) Welding of Mating Ferrule to Piping

3.4 Wiring Precautions

This section is described wiring only for flow tube

side. Please see "Wiring" in AE14 Magnetic Flow

Converter Instruction Manual for converter side.

3.4.1 Protective Grounding

CAUTION

Please be sure to connect protective grounding

of ADMAG AE with cable of 2mm2 or larger

cross section in order to avoid the electrical

shock to the operators and maintenance

engineers and prevent the influence of external

noise. And further connect the grounding wire to

the mark (100Ω or less).

3.4.2 General Precautions

Please give attention to the followings in wiring.

IMPORTANT

Weld the attached ferrules to the piping. Please

pay attention to the welding condition to avoid

deforming piping or making the stagnant portion

of the fluid; joint preparation, level difference in

butt joint, welding current.

(3) Mounting Gasket

Mount the attached gasket so it fits into the groove on

the ferrule.

(4) Positioning Flow Tube

Position the flow tube between the mating ferrule.

(5) Tightening Clamp

Mount the clamp so they cover the flow tube and

mating ferrule tapered part.

Clamp

Ferrule

Pipe

Welding

F030308.EPS

CAUTION

•Please pay attention to avoid the cable is

bended excessively.

• Please do not connect cables outdoors in case

of rain to prevent damages from dew formation

and to keep insulation inside the terminal box

of the flow tube.

• Please do not splice the cable between a flow

tube and a converter if it is too short. Please

replace the short cable with the cable which is

appropriate length wholly.

• The all cable ends are to be provided with

round crimp-on terminal.

• The signal cables must be routed in separate

steel conduit tubes or flexible tubes.

•Please keep conduit or flexible tube water-tight

using sealing tape.

•Please ground each of a flow tube and a

converter separately.

• Please cover each shield of the signal cable

with PVC tube or PVC tape to avoid contacting

between two shields; shield and case.

•When waterproof glands or union equipped

waterproof glands are used, the glands must be

properly tightened to keep the box watertight.

• Please be sure to fully tighten the terminal box

cover before the power is turned on.

• Please be sure to turn off the power before

opening the terminal box cover.

Figure 3.3.8 Mounting Procedure

3-14

IM 1E7D0-01E

Page 21

3. INSTALLATION

NOTE

3.4.3 Cable Types

(1) Dedicated Signal Cable(AM011)

The flow signal is transmitted via this dedicated cable.

The cable is constructed with double shielding over the

two conductors, and used heat-resistant vinyl as the

outer jacket material.

Finished diameter: 10.5 mm (0.413in.)

Maximum length: 30 m (98 ft)

Maximum temperature: 80°C (176°F)

Figure 3.4.1 Dedicated Signal Cable AM011

IMPORTANT

If the cable is longer than required, cut off any

extra length, rather coiling it up, and terminate

the conductors as shown in Figure 3.4.2. Avoid

using intermediate terminal boards to extend the

cable length, or this will interrupt the shielding.

CAUTION

Since A, B, SA, SB, and C all operate at different electrical potentials, securely insulate them

from each other so they do not touch.

The shields must not be allowed to touch each

other or to touch the case.

Cover each shield with vinyl tube or wrap in vinyl

tape.

Conductors A and B carry the signal from the

electrodes, and C is at the potentials of the liquid

it self (signal common) . Shields SA and SB are

kept at the same potentials as the individual

electrodes (these are actively driven shields).

This is done to reduce the effect of the distributed capacitance of the cable at long cable

length. Note that, since the signals from the

individual electrodes are impedance converted

inside the converter, errors will result if they

come in contact with any other component.

Great care must be taken in the cable end

treatment.

(2) Excitation Cable

Please use Polyvinyl chloride insulated and sheathed

control cables (JIS C3401) or Polyvinyl chloride

insulated and sheathed portable power cables (JIS

C3312) or equivalents.

ACB

SA

On the converter

25 (0.98)

(WHITE) (BLACK) (RED)

side

150

(5.9)

SB

50 (1.97)

70 (2.76)

80 (3.15)

8 (0.3) Max.

L (SPECIFIED LENGTH)

20 (0.8)

AM011*A

ACB

90 (3.5)

(WHITE) (BLACK) (RED)

8 (0.3) Max.

150

(5.9)

ø10.5 (0.4)

Figure 3.4.2 Treatment of Dedicated Signal Cable

55 (2.2)

On the flow tube

side

F030402.EPS

90 (3.5)

Outer Diameter

• 6.5 to 12mm in diameter (10.5 to 11.5 mm for

waterproof gland / ECG, /ECU)

Nominal Cross Section

•Single wire; 0.5 to 2.5mm2 , Stranded wire; 0.5 to

2

2.5mm

(3.3)

EX1

85

EX2

EX1

60

(2.4)

On the converter side On the flow tube side

Figure 3.4.3 End Treatment of Excitation Cable

3-15

Unit: mm (inch)

EX2

F030403.EPS

IM 1E7D0-01E

Page 22

3. INSTALLATION

3.4.4 Connnection to AE14 Magnetic Flow Converter

Flow Tube Model AE100D, AE200D and AE300D

Connect the flow tube and converter in the following

method.

Magnetic Flow Converter

Excitation Cable

Dedicated Cable

AM011-4

A

B

C

Magnetic Flow Tube

AE100D, AE200D and AE300D

Figure 3.4.4 Connection

EX2

EX1

AE14

E

X

1

Y

L

P

E

!

P

X

/-

U

S

2

R

E

C

W

O

P

S

T

A

U

O

R

U

A

C

T

U

B

O

M

L

S

A

/

- P+ I- I+ L/+ N

S

B

L

P

P

Connected Terminals

Converter

Terminals

Note: Terminate those shielding wire

Flowtube AE100D,

AE200D and AE300D

SA (See Note below)

A

B

SB (See Note below)

C

EX1

EX2

terminals using insulating tape.

A

B

C

EX1

EX2

F030405.EPS

3.4.5 Wiring Ports

Please select the most suitable standard of wiring

procedure for the wiring ports by customer’s own.

B : Insulation Check

After wiring is completed, check insulation of the

following terminals together with the wiring under the

condition of the converter side wiring terminals

disconnected.

Between terminal EX1 and terminal A, B, C

Between terminal C and terminal A, B

Between terminal A and terminal B

Between terminal EX1 and ground

Between terminal EX2 and ground

All insulation measurements must be performed with a

500V megger. Insulation resistances must be 100MΩ

or more each.

IMPORTANT

Be sure to disconnect the cables at the terminal

of the converter when checking insulation.

C : Conduit Wiring

In case of conduit wiring, please use the waterproof

gland to prevent water flowing through the conduit

pipe into the wiring connection.

A : Using the Waterproof Gland

IMPORTANT

To prevent water or condensate from entering

the converter housing, waterproof glands are

recommended. Do not over-tighten the glands or

damage to the cables may result. Tightness of

the gland can be checked by confirming that the

cable is held firmly in place.

Waterproof gland

Optional code : /ECG

Gasket

Tightening

gland

Waterproof gland with union joint

Optional code : /ECU

G1/2 female

Gasket

Tightening gland

G1/2 female

F030406.EPS

Please slope the conduit pipe down, and install a drain

valve at the low end of the vertical pipe.

Please open the drain valve regularly.

Drain valve

F030407.EPS

Figure 3.4.6 Conduit Wiring

Figure 3.4.5 Waterproof Gland

3-16

IM 1E7D0-01E

Page 23

4. MAINTENANCE

4. MAINTENANCE

WARNING

This instrument must be repaired or maintenance-serviced by expert engineer or skilled

personnel. The procedures described in this

chapter are not permitted for operators.

Regular maintenance and inspection should be carried

out to fully utilize all functions and to obtain maximum

performance from the magnetic flowmeter.

4.1 Regular Inspection Items

(1)Inspection of moisture-proofing inside the

terminal box: Once/year

(2)Refastening of piping joint screws: About

twice/year

(3)Inspection of electrodes and lining (in case

of adhesive and/or abrasive fluid, etc.)

Determine the period of regular inspection as

necessary.

(2) Insulation Resistance Check

Check the insulation resistances in accordance with the

tables below. If one of them falls below the value in

the tables, replacement or repair of the flow tube is

needed.

Coil Circuit

Checking is possible even if the pipe is filled with

fluid.

Test T erminals

Between Terminals EX1 and C

Test V oltage Specification

500 V DC 1MΩ or more

T0401.EPS

Signal Circuit

Be sure to empty and dry the pipe inside, and release

wiring connection of converter side before checking.

Test T erminals

Between Terminals A and C

Between Terminals B and C

Test V oltage

500 V DC 100MΩ or more for each

Specification

T0402.EPS

4.2 Trouble Shooting

Since the ADMAG AE magnetic flowmeter has “self

diagnostic functions”, if a failure occurs, it is displayed

on the AE14 magnetic flow converter. Please refer to

Instruction Manual of AE14 magnetic flow converter.

IMPORTANT

Be sure to disconnect the cables at the terminals

of the flow tube when checking.

(1) Excitation Coil Check

Check that the resistance between terminals EX1 and

EX2 in the terminal box is 150 Ω or less with a

multimeter. If it is not, coils may be broken down, and

replacement or repair of the flow tube is needed.

4-1

IM 1E7D0-01E

Page 24

5. OUTLINE

5. OUTLINE

STANDARD SPECIFICATIONS

Protection: IP67, NEMA4X, JISC0920 water tight type

Size:

• General Purpose Type

Lining PFA Ceramic Polyurethane

Size in mm

(inch)

2.5(0.1), 5(0.2),

10(0.4), 15(0.5),

25(1), 40(1.5),

50(2), 65(2.5),

80(3), 100(4),

125(5), 150(6),

200(8), 250(10),

300(12), 350(14),

400(16)

• Explosion Proof Type

Lining PFA Ceramic

Size in mm

(inch)

*250 to 400mm with flange connection are only for ATEX or SAA.

250 and 300mm with wafer connection are only for general

purpose use.

*65 and 125mm are only for ATEX.

2.5(0.1), 5(0.2), 10(0.4),

15(0.5), 25(1), 40(1.5),

50(2), 65(2.5), 80(3),

100(4), 125(5), 150(6),

200(8), 250(10)*,

300(12)*, 350(14)*,

400(16)*

• Sanitary Type

Lining PFA

Size in mm(inch)

* 15 and 125mm flow tubes are available on request.

25(1), 40(1.5), 50(2), 65(2.5), 80(3), 100(4)

Coating:

Terminal box:

Polyurethane corrosion-resistant coating

Cover; Deep sea moss green(Munsell 0.6GY3.1/2.0)

Case; Frosty white (Munsell 2.5Y8.4/1.2)

Body:

Size 2.5 to 100 mm(0.1 to 4 in.)

No coating(Stailess steel surface)

Size 125 to 400 mm(5 to 16 in.)

Polyurethane corrosion-resistant coating

Frosty white (Munsell 2.5Y8.4/1.2)

Flow Tube Material:

Size 2.5 to 15 mm(0.1 to 0.5 in.)

Housing: Stainless steel (SCS11)

Mini-flange for wafer conn.: Stainless steel (SUS430)

Flange (15 mm(0.5 in.) only): Stainless steel

(SUS304)

Pipe: Stainless steel (SCS13) or Alumina

ceramic (99.9%)

Terminal box : Aluminum alloy

Size 25 to 100 mm(1 to 4 in.)

Housing: Stainless steel (SUS304)

Mini-flange for wafer conn.: Stainless steel (SUS430)

Flange: Stainless steel (SUS304)

Pipe: Stainless steel (SUS304)* or Alumina

ceramic (99.9%)

Terminal box : Aluminum alloy

2.5(0.1), 5(0.2),

10(0.4), 15(0.5),

25(1), 40(1.5),

50(2), 80(3),

100(4), 150(6),

200(8)

2.5(0.1), 5(0.2), 10(0.4),

15(0.5), 25(1), 40(1.5),

50(2), 80(3), 100(4),

150(6), 200(8)

25(1), 40(1.5),

50(2), 80(3),

100(4), 150(6),

200(8), 250(10),

300(12),

350(14), 400(16)

T01.EPS

T02.EPS

T03.EPS

Size 125 to 400 mm(6 to 16 in.)

Housing: Carbon steel (SS400)

Mini-flange for wafer conn.: Carbon steel (SS400)

Flange: Carbon steel (SS400)

Pipe: Stainless steel (SUS304)* or Alumina

ceramic (99.9% — Sizes 150 and 200

mm only)

Terminal box : Aluminum alloy

* For PF A or Polyurethane lining

Wetted Part Material:

Lining: Fluorocarbon PFA, Alumina ceramic,

Polyurethane.

Electrode: Stainless steel (SUS316L), Hastelloy C

(equivalent to Hastelloy C-276), Titanium,

Tantalum, Platinum-Iridium,

Platinum-alumina cermet only for ceramic

lining.

* For sanitary type, SUS316L only

Earth Ring/Earth Electrode: Stainless steel

(SUS316), Hastelloy C (equivalent to

Hastelloy C-276), Titanium, PFA lining +

Earth electrodes (Tantalum, PlatinumIridium)

Gasket: • VALQUA#7020 : Fluoro resin with filler

(between flow tube body and earth ring;

for ceramic lining)

• VALQUA#4010 : Fluoro rubber, viton

(between flow tube body and earth ring;

for optional code /FRG)

• Non-asbestos joint sheet sheathed with

fluoro resin (between earth ring and

process flange; for optional code /BCF or

/BSF)

• Chloroprene rubber (between earth ring

and process flange; for optional code /

BCC or /BSC)

• EPDM, ethylene propylene rubber (for

sanitary type)

* Other gaskets between flow tube body and earth ring;

• VALQUA#7026 : corrosion resistance

gasket (Fluoro resin with carbon)

• VALQUA#4010 (Mixing#RCD970) :Alkali

resistance gasket for PVC piping (Fluoro

rubber)

• VALQUA#4010 (Mixing#RCD470) :

Acid

resistance gasket for PVC piping (Fluoro

rubber)

Contact Yokogawa office. (Refer to TI 1E6A0-06E.)

Union Joint: Stainless steel (SUS316L) for ceramic

lining size 10 mm(0.4in.) or less.*

* Contact Yokogawa office if PVC union joints are

required.

Ferrule (for sanitary type): SCS13

Electrode Construction:

• General Purpose/Ex-proof Type

PFA, Polyurethane Lining: External insertion type.

Ceramic Lining: Integral type.

• Sanitary Type

Internal insertion type

* Only PFA lining is available for sanitary type.

Electrical Connection:

ANSI 1/2NPT female, DIN Pg 13.5 female, ISO

M201.5 female, JIS G1/2 female.

Note: Hastelloy is a registered trademark of Haynes

International Inc.

5-1

IM 1E7D0-01E

Page 25

5. OUTLINE

Accuracy:

PFA and Ceramic Lining

Size in mm

2.5 to 15

(0.1 to 0.5)

25 or larger

(1)

(inch)

Span in m/s

(ft/s)

0.3 to 1

(1 to 3)

1 to 10

(3 to 33)

0.3 to 1

(1 to 3)

1 to 10

(3 to 33)

Accuracy

0.5% of span

0.25% of span

(at indications below 50% of span)

0.5% of flowrate

(at indications 50% of span or more)

0.25% of span

(at indications below 50% of span)

0.5% of flowrate

(at indications 50% of span or more)

0.1% of span

(at indications below 20% of span)

0.5% of flowrate

(at indications 20% of span or more)

T04.EPS

Polyurethane Lining

Size in mm

25 or larger

(1)

(inch)

Span in m/s

(ft/s)

0.3 to 1

(1 to 3)

1 to 10

(3 to 33)

Accuracy

0.5% of span

0.25% of span

(at indications below 50% of span)

0.5% of flowrate

(at indications 50% of span or more)

T05.EPS

Repeatability: 0.1% of flowrate (minimum 1 mm/s)

Maximum Power Consumption: 12.5W

Insulation Resistance:

• 100MΩ between excitation terminal and each

signal terminal at 500 V DC.

• 100MΩ among signal terminals at 500V DC.

Withstand Voltage :

• 1500 V AC between excitation terminal and

ground terminal for 1minute. (for ex-proof

type).

• 500 V AC between signal terminal and

ground terminal for 1minute for ex-proof type

except CENELEC ATEX , in case of

CENELEC ATEX 1500 V AC for 1minute is

applied.

• 1760 V AC between each signal terminal and