Page 1

User’s

Manual

AXW

Magnetic Flowmeter

Remote Flowtube

IM 01E25D11-01EN

IM 01E25D11-01EN

2nd Edition

Page 2

AXW

Magnetic Flowmeter

Remote Flowtube

IM 01E25D11-01EN 2nd Edition

Contents

1. INTRODUCTION ........................................................................................ 1-1

1.1 Using the Magnetic Flowmeter Safely ............................................................ 1-2

1.2 Warranty .............................................................................................................1-3

1.3 Combination Remote Converters ...................................................................1-3

2. HANDLING PRECAUTIONS ..................................................................... 2-1

2.1 Checking Model and Specications ...............................................................2-1

2.2 Storage Precautions .........................................................................................2-1

2.3 Installation Location Precautions ...................................................................2-1

i

3. INSTALLATION ......................................................................................... 3-1

3.1 Piping Design Precautions ..............................................................................3-1

3.2 Handling Precautions .......................................................................................3-3

3.2.1 General Precautions ..........................................................................3-3

3.2.2 Flowmeter Piping ...............................................................................3-4

3.3 Mounting Procedures .......................................................................................3-4

4. WIRING ...................................................................................................... 4-1

4.1 Wiring the Remote Flowtube ...........................................................................4-1

4.1.1 Wiring Precautions ............................................................................. 4-1

4.1.2 Cables ................................................................................................ 4-2

4.1.3 Wiring Ports .......................................................................................4-3

4.1.4 Wiring Connections ............................................................................4-4

5. MAINTENANCE ......................................................................................... 5-1

5.1 Changing Direction of Electrical Connection ................................................5-1

5.2 Regular Inspection Items ................................................................................. 5-2

5.3 Excitation Coil and Insulation Resistance Check ........................................5-2

5.4 Troubleshooting ................................................................................................5-3

5.4.1 No Indication ......................................................................................5-3

5.4.2 Unstable Zero .................................................................................... 5-4

5.4.3 Disagreement Between Indication and Actual Flow .......................... 5-5

6. OUTLINE .................................................................................................... 6-1

n STANDARD SPECIFICATIONS ........................................................................ 6-1

n STANDARD PERFORMANCE .......................................................................... 6-1

n NORMAL OPERATING CONDITIONS .............................................................. 6-2

n MODEL AND SUFFIX CODE .............................................................................6-3

2nd Edition: Sep. 2013 (KP)

All Rights Reserved, Copyright © 2012, Yokogawa Electric Corporation

IM 01E25D11-01EN

Page 3

n OPTIONAL SPECIFICATIONS .........................................................................6-5

n OPTIONAL SPECIFICATIONS (continued) .....................................................6-6

n DIMENSIONAL DRAWINGS .............................................................................6-7

n SIZING DATA ....................................................................................................6-19

Revision Information ...............................................................................................i

ii

IM 01E25D11-01EN

Page 4

<1. INTRODUCTION>

1. INTRODUCTION

1-1

This instrument has been adjusted at the factory

before shipment.

To ensure correct use of the instrument, please

read this manual thoroughly and fully understand

how to operate the instrument before operating it.

NOTE

The ADMAG AXW remote owtube is used in

combination with the AXFA11 remote converter.

This manual describes the hardware

conguration of the ADMAG AXW remote

owtube. For details of the AXFA11 remote

converter, see IM 01E20C01-01E instruction

manual.

When setting the parameter “C30” in the remote

converter, select “ADMAG AXF” for ADMAG

AXW remote owtube.

n Regarding This User’s Manual

• This manual should be provided to the end

user.

• Before use, read this manual thoroughly to

comprehend its contents.

• The contents of this manual may be changed

without prior notice.

• All rights are reserved. No part of this manual

may be reproduced in any form without

Yokogawa’s written permission.

• Yokogawa makes no warranty of any kind with

regard to this material, including, but not limited

to, implied warranties of merchantability and

suitability for a particular purpose.

• All reasonable effort has been made to ensure

the accuracy of the contents of this manual.

However, if any errors or omissions are found,

please inform Yokogawa.

• Yokogawa assumes no responsibilities for this

product except as stated in the warranty.

• Please note that this user’s manual may not

be revised for any specication changes,

construction changes or operating part changes

that are not considered to affect function or

performance.

• If the customer or any third party is harmed by

the use of this product, Yokogawa assumes

no responsibility for any such harm owing to

any defects in the product which were not

predictable, or for any indirect damages.

n Safety and Modication Precautions

• The following general safety precautions must

be observed during all phases of operation,

service, and repair of this instrument. Failure

to comply with these precautions or with

specic WARNINGS given elsewhere in

this manual violates safety standards of

design, manufacture, and intended use of the

instrument. Yokogawa assumes no liability for

the customer’s failure to comply with these

requirements. If this instrument is used in

a manner not specied in this manual, the

protection provided by this instrument may be

impaired.

• Yokogawa will not be liable for malfunctions or

damage resulting from any modication made

to this instrument by the customer.

• The following safety symbol marks are used in

this user’s manual and instrument.

WARNING

A WARNING sign denotes a hazard. It calls

attention to procedure, practice, condition or the

like, which, if not correctly performed or adhered

to, could result in injury or death of personnel.

CAUTION

A CAUTION sign denotes a hazard. It calls

attention to procedure, practice, condition or the

like, which, if not correctly performed or adhered

to, could result in damage to or destruction of

part or all of the product.

IMPORTANT

An IMPORTANT sign denotes that attention is

required to avoid damage to the instrument or

system failure.

NOTE

A NOTE sign denotes information necessary

for essential understanding of operation and

features.

IM 01E25D11-01EN

Page 5

<1. INTRODUCTION>

1-2

Protective grounding terminal

Functional grounding terminal

(This terminal should not be used as a

protective grounding terminal.)

Alternating current

Direct current

1.1 Using the Magnetic Flowmeter Safely

(1) Installation

WARNING

• Installation of the magnetic owmeter must

be performed by expert engineer or skilled

personnel. No operator shall be permitted to

perform procedures relating to installation.

• The magnetic owmeter must be installed

within the specication conditions.

• The magnetic owmeter is a heavy instrument.

Be careful that no damage is caused to

personnel through accidentally dropping it, or

by exerting excessive force on the magnetic

owmeter. When moving the magnetic

owmeter, always use a trolley, forklift, or crane

and have at least two people carry it.

• When the magnetic owmeter is processing

hot uids, the instrument itself may become

extremely hot. Take sufcient care not to get

burnt.

• Where the uid being processed is a toxic

substance, avoid contact with the uid and

avoid inhaling any residual gas, even after the

instrument has been taken off the piping line for

maintenance and so forth.

• Do not apply excessive weight, for example, a

person stepping on the magnetic owmeter.

• All procedures relating to installation must

comply with the electrical code of the country

where it is used.

(2) Wiring

WARNING

• The wiring of the magnetic owmeter must

be performed by expert engineer or skilled

personnel. No operator shall be permitted to

perform procedures relating to wiring.

• When connecting the wiring, check that

the supply voltage to the converter is within

the range of the voltage specied for this

instrument before connecting the power cable.

In addition, check that no voltage is applied to

the power cable before connecting the wiring.

• The protective grounding must be connected

securely at the terminal with the mark to

avoid danger to personnel.

(3) Operation

WARNING

• When opening the cover, wait for more than 10

minutes after turning off the power. Only expert

engineer or skilled personnel are permitted to

open the cover.

• Do not open the cover in wet weather or humid

environment. When the cover is open, stated

enclosure protection is not applicable.

• Be sure to set parameters as “Protect” on the

write protect function after nish of parameter

setting work.

Under extremely rare case, the infra-red

switches may respond unexpectedly in

such conditions as sticking ball of water or

extraneous substances on the surface of

display panel glass according to the principle of

infra-red switch operation.

Its probability rises in such cases as sticking

rain water by storm or other similar situation

and washing up work near owmeter

installation place.

Either to illuminate or stop illuminating the infra-

red switches by the ashlight may cause the

mis-reaction.

Refer to the manual for converter on how to

use the write protect function in detail.

IM 01E25D11-01EN

Page 6

<1. INTRODUCTION>

1-3

(4) Maintenance

WARNING

• Maintenance of the magnetic owmeter should

be performed by the trained personnel having

knowledge of safety standard. No operator

shall be permitted to perform any operations

relating to maintenance.

• When opening the cover, wait for more than 10

minutes after turning off the power.

• Do not open the cover in wet weather or humid

environment. When the cover is open, stated

enclosure protection is not applicable.

• Always conform to maintenance procedures

outlined in this manual. If necessary, contact

Yokogawa.

• Care should be taken to prevent the build up

of dirt, dust or other substances on the display

panel glass or data plate. If these surfaces do

get dirty, wipe them clean with a soft dry cloth.

1.2 Warranty

• The terms of this instrument that are

guaranteed are described in the quotation.

We will make any repairs that may become

necessary during the guaranteed term free of

charge.

• Please contact our sales ofce if this instrument

requires repair.

• If the instrument is faulty, contact us with

concrete details about the problem and the

length of time it has been faulty, and state the

model and serial number. We would appreciate

the inclusion of drawings or additional

information.

• The results of our examination will determine

whether the meter will be repaired free of

charge or on an at-cost basis.

n The guarantee will not apply in the

following cases:

• Damage due to negligence or insufcient

maintenance on the part of the customer.

• Problems or damage resulting from handling,

operation or storage that violates the intended

use and specications.

• Problems that result from using or performing

maintenance on the instrument in a location

that does not comply with the installation

location specied by Yokogawa.

• Problems or damage resulting from repairs or

modications not performed by Yokogawa or

someone authorized by Yokogawa.

• Problems or damage resulting from

inappropriate reinstallation after delivery.

• Problems or damage resulting from disasters

such as res, earthquakes, storms, oods, or

lightning strikes and external causes.

n Trademarks:

ADMAG and AXW are registered trademarks of

Yokogawa Electric Corporation.

Company names and product names used

in this material are registered trademarks or

trademarks of their respective owners.

1.3 Combination Remote Converters

IMPORTANT

• The AXW remote owtube (size 500 (20

in.) to 1800 mm (72 in.)) should be used in

combination with AXFA11 remote converter.

Contact Yokogawa before using it in

combination with converters other than

AXFA11.

IM 01E25D11-01EN

Page 7

Blank Page

Page 8

<2. HANDLING PRECAUTIONS>

2. HANDLING PRECAUTIONS

2-1

This instrument has been inspected carefully at

the factory before shipment. When the instrument

is delivered, visually check that no damage has

occurred during transportation.

Read this section carefully as it contains important

information on handling this instrument. Refer to

the relevant sections for information not contained

in this section. If you have any problems or

questions, please contact Yokogawa sales ofce.

2.1 Checking Model and

Specications

The model code and specications are found on

the data plate located on the outside of the case.

Check that the model code and specications

match what you have ordered.

Be sure you have your model number and serial

number available when contacting Yokogawa.

KCCREMYHQEEN

165

2.2 Storage Precautions

If the instrument is to be stored for a long period of

time after delivery, observe the following points.

The instrument should be stored in its original

packing condition in the storage location.

Select a storage location that fulls the following

conditions:

• A place where it will not be exposed to rain or

water

• A place subject to minimal vibrations or

shocks

• Temperature and humidity levels should be

as follows:

Temperature: -10 to 70°C

Humidity: 5 to 80% RH (no condensation)

The preferred ambient temperature

and humidity levels are 25°C and

approximately 65% RH.

If the magnetic owmeter is transferred to

the installation site and stored without being

installed, its performance may be impaired due

to the inltration of rainwater and so forth. Be

sure to install and wire the magnetic owmeter

as soon as possible after transferring it to the

installation location.

Figure 2.1.1 Data Plate

F0201.ai

2.3 Installation Location Precautions

Select the installation location with consideration

to the following items to ensure long-term stable

operation of the instrument.

n Ambient Temperature:

Avoid installing the instrument in locations

with constantly uctuating temperatures. If the

location is subject to radiant heat from the plant,

provide heat insulation or improve ventilation.

n Atmospheric Condition:

Avoid installing the instrument in a corrosive

atmosphere. In situations where this is

unavoidable, consider ways to improve

ventilation and to prevent rainwater from

entering and being retained in the conduit

pipes.

n Vibrations or Shocks:

Avoid installing the instrument in a place subject

to shocks or vibrations.

IM 01E25D11-01EN

Page 9

Blank Page

Page 10

<3. INSTALLATION>

(Incorrect)

(Correct)

3. INSTALLATION

gures.

WARNING

Installation of the magnetic owmeter must

be performed by expert engineer or skilled

personnel. No operator shall be permitted to

perform procedures relating to installation.

When installing two or more magnetic owmeters

on a single pipe, provide a run of at least 10D

between them.

Gate valve

fully open

Reducer

pipe

Expander

pipe

3-1

D: Flowtube Size

3.1 Piping Design Precautions

IMPORTANT

Design piping correctly, referring to the following

to prevent damage to owtubes and to assure

accurate measuring.

(1) Location

IMPORTANT

Install the owmeter in a location where it is

not exposed to direct sunlight. The minimum

ambient temperature is limited by the minimum

uid temperature of the owtube (the lining). For

more information, refer to Chapter 6 “OUTLINE”.

The owmeter may be used in an ambient

humidity where the relative humidity ranges from

0 to 100%. However, avoid long-term continuous

operation at relative humidity above 95%.

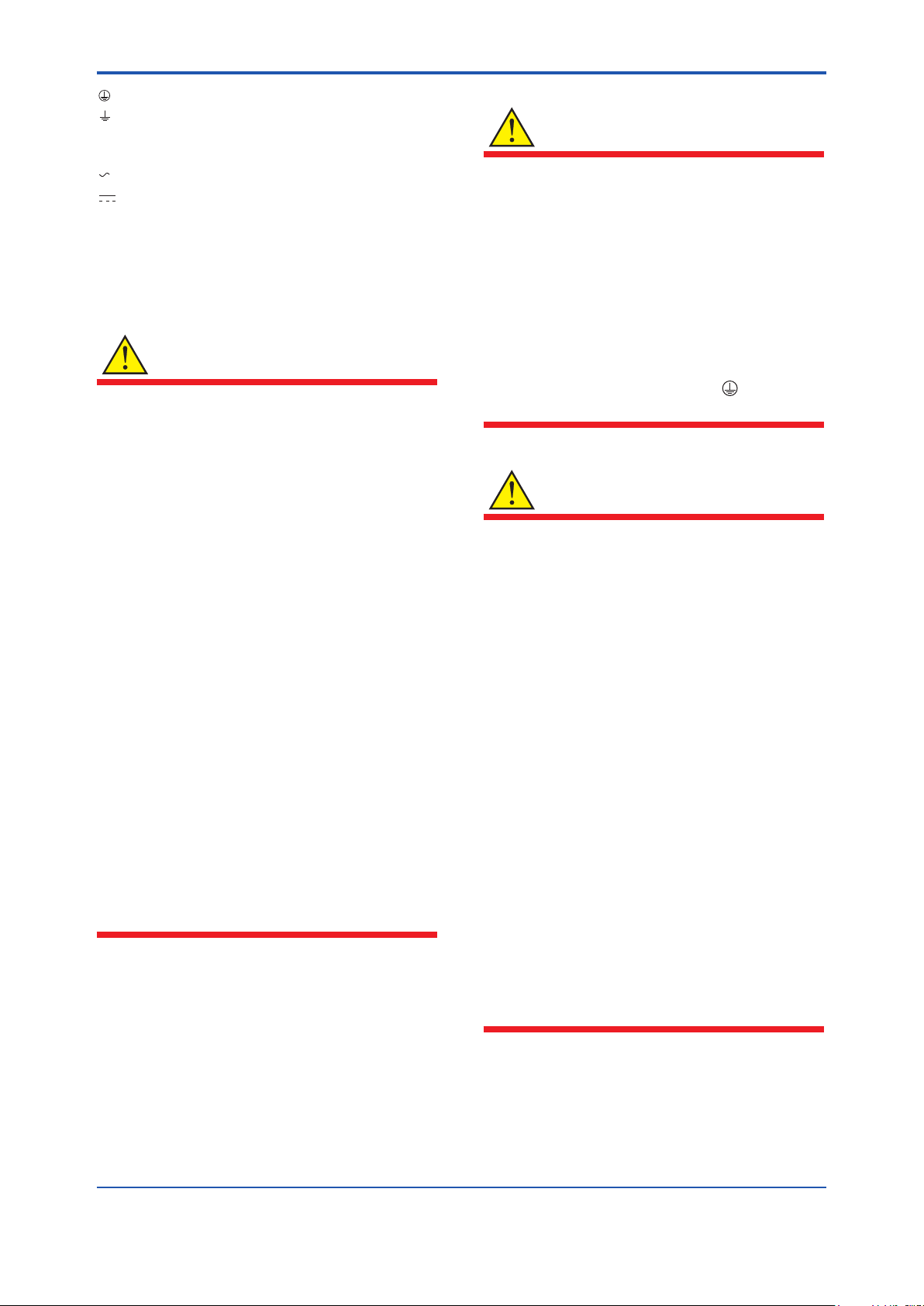

5D or more2Dor more

Tee

0 is allowable.5D or more 0 is allowable.5D or more

Figure 3.1.1 Required Lengths of Straight Runs

0 is allowable. 0 is allowable.

90-degree bent

10D or more

Various valves

10D or more

or more

or more

*1: Do not install anything in the vicinity that may

interfere with the magnetic eld, induced signal

voltages, or ow velocity distributions of the

owmeter.

*2: A straight run may not be required on the

downstream side of the owmeter. However,

if a downstream valve or other tting causes

irregularity or deviation in ows, provide a

straight run of 2D to 3D on the downstream

side.

*3: The valves shall be mounted on the

downstream side so that deviated ows do not

occur in the owtube and to avoid startup from

an empty condition.

(4) Maintaining Stable Fluid Conductivity

2D

2D

F0301.ai

(2) Noise Avoidance

IMPORTANT

The owmeter should be installed away from

electrical motors, transformers, and other power

sources in order to avoid interference with

measurement.

(3) Required Lengths of Straight Runss

To maintain accurate measurement, see JIS B7554

“Electro Magnetic Flowmeters” which explains the

requirements for upstream piping conditions of

magnetic owmeters.

Based on JIS B7554 “Electro Magnetic Flowmeters”

and our piping condition test data, we recommend

the piping conditions as shown in the following

IMPORTANT

Do not install the owmeter where uid

conductivity tends to become uneven. If

chemicals are fed near the upstream side of a

magnetic owmeter, they may affect the ow

rate’s indications. To avoid this situation, it is

recommended that the chemical feed ports be

located on the downstream side of the owmeter.

If it is unavoidable that chemicals must be fed on

the upstream side, provide a sufcient length of

straight run (approximately 50D) to ensure the

proper mixture of uids.

Upstream side

Figure 3.1.2 Chemical Injection

Downstream side

F0302.ai

IM 01E25D11-01EN

Page 11

<3. INSTALLATION>

Bypass valve

3-2

(5) Precautions for Use of Liquid Sealing

Compounds

IMPORTANT

Care must be taken in using liquid sealing

compounds on the piping, as it may have a

negative inuence on the ow indications by

owing out and covering the surfaces of an

electrode or grounding ring. In particular, care

must be taken if a liquid sealing compound is

used in the case of vertical piping.

(6) Service Area

Select locations where there is adequate space to

service installing, wiring, overhauling, etc

(7) Bypass Line

It is recommended to install a bypass line to facilitate

maintenance and zero adjustment.

Block valve

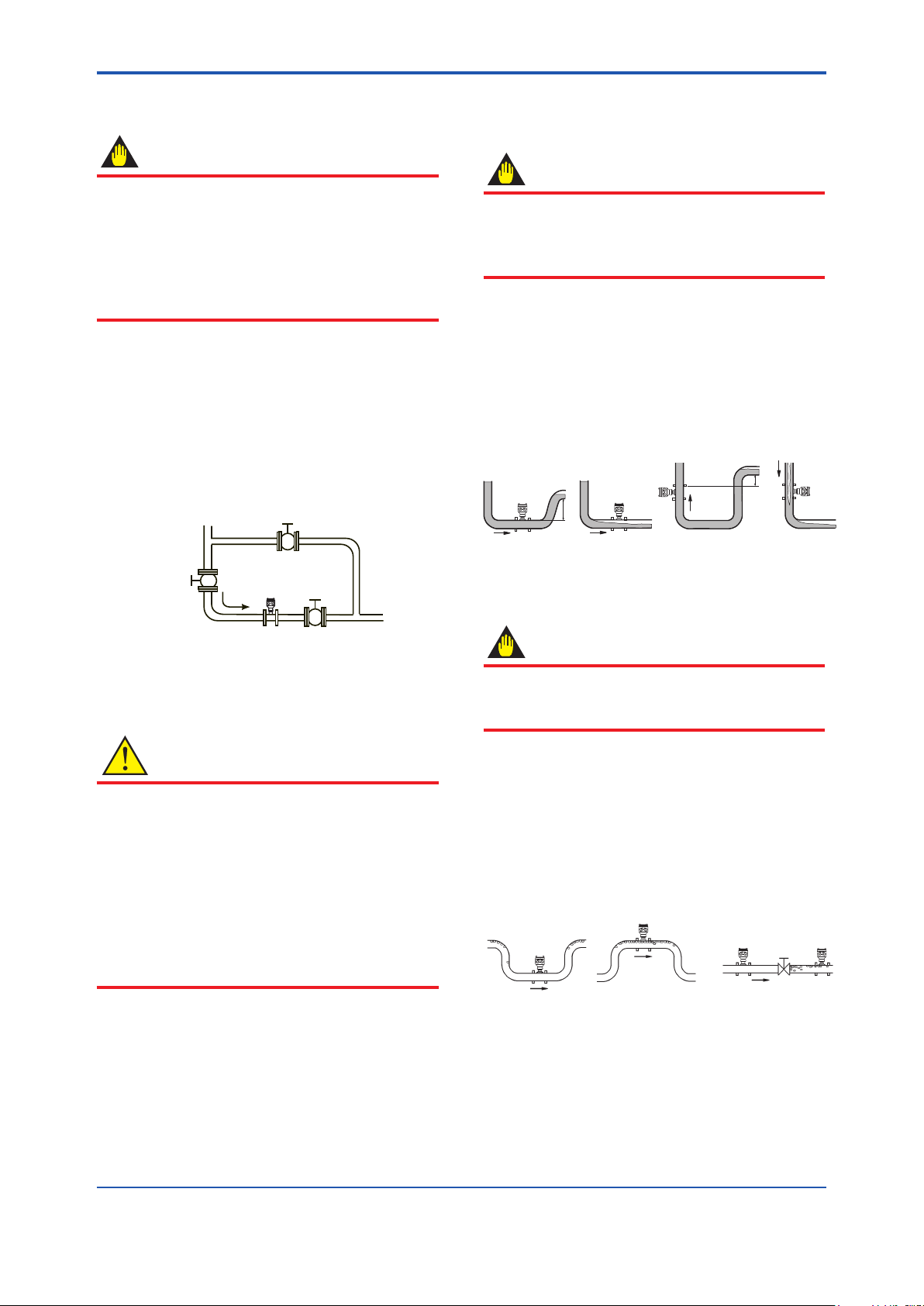

(9) Mounting Positions

• Pipes must be fully lled with liquids.

IMPORTANT

It is essential that pipes remain fully lled at

all times, otherwise ow rate indications may

be affected and measurement errors may be

caused.

Piping shall be designed so as to maintain the

interior of the owtube lled with uids.

Vertical mounting is effective in such cases as

when uids tend to separate or solid matter may be

precipitated. When employing vertical mounting,

direct the uids from the bottom to the top to ensure

that the pipes remain fully lled.

(Correct)

Figure 3.1.4 Mounting Positions

(Incorrect)

h

h>0

(Correct)

h>0

(Incorrect)

h

F0304.ai

Block valve

Figure 3.1.3 Bypass Line

F0303.ai

(8) Supporting the Flowmeter

CAUTION

Do not secure the owmeter separately to

prevent the vibrations, shocks, and expansion

and contraction forces of the piping from

affecting it. Fix the pipeline or its anges rst,

then let them support the owmeter.

For vertical, mounting, make sure that the weight

of piping does not weigh on the owmeter.

To release the load from tightening the owmeter

to the pipeline, set a expansive pipe in the

downstream side.

• Avoid air bubbles.

IMPORTANT

If air bubbles enter a measurement pipe,

ow rate indications may be affected and

measurement errors may be caused.

In cases where uids contain air bubbles, piping must

be designed to prevent them from accumulating in

the measurement pipe of a owtube.

If a valve exists near the owmeter, try to mount the

owmeter on the valve’s upstream side in order to

prevent a possible reduction of pressure inside the

pipe, thereby avoiding the possibility of air bubbles.

(Correct)

(Incorrect)

Figure 3.1.5 Avoiding Air Bubbles

(Correct)

(Incorrect)

Valve

F0305.ai

IM 01E25D11-01EN

Page 12

<3. INSTALLATION>

Correct

• Mounting orientation

3-3

IMPORTANT

If electrodes are perpendicular to the ground, air

bubbles near the top or precipitates at the bottom

may cause measurement errors. Ensure that the

terminal box of a remote owtube is mounted

above the piping to prevent water from entering

them.

Incorrect

Air bubble

Electrode

Figure 3.1.6 Mounting Orientation

Electrode

Precipitate

Incorrect

Water can

seep into

the terminal

box.

3.2 Handling Precautions

F0306.ai

90 degrees or less

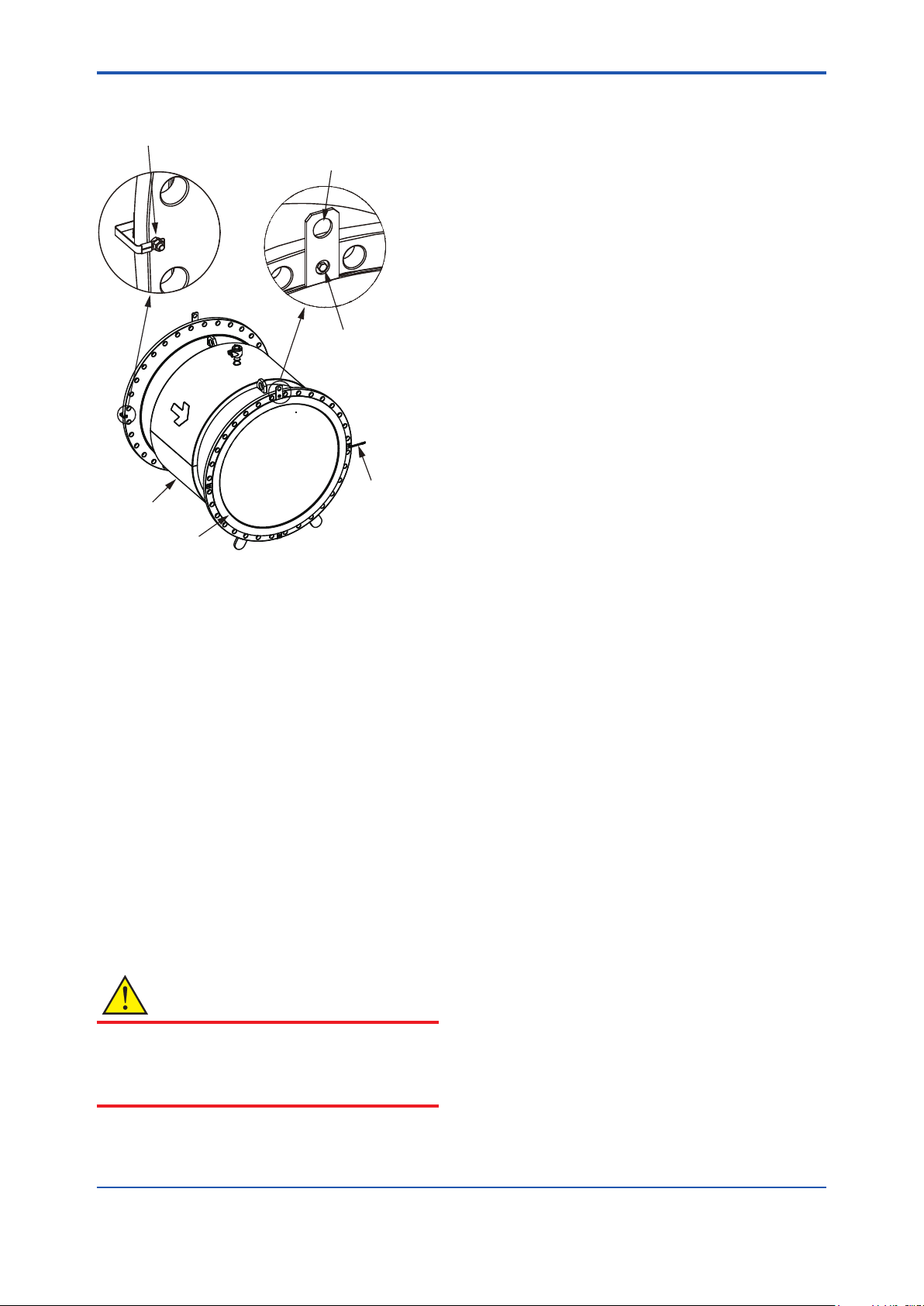

Eye bolt Eye plate

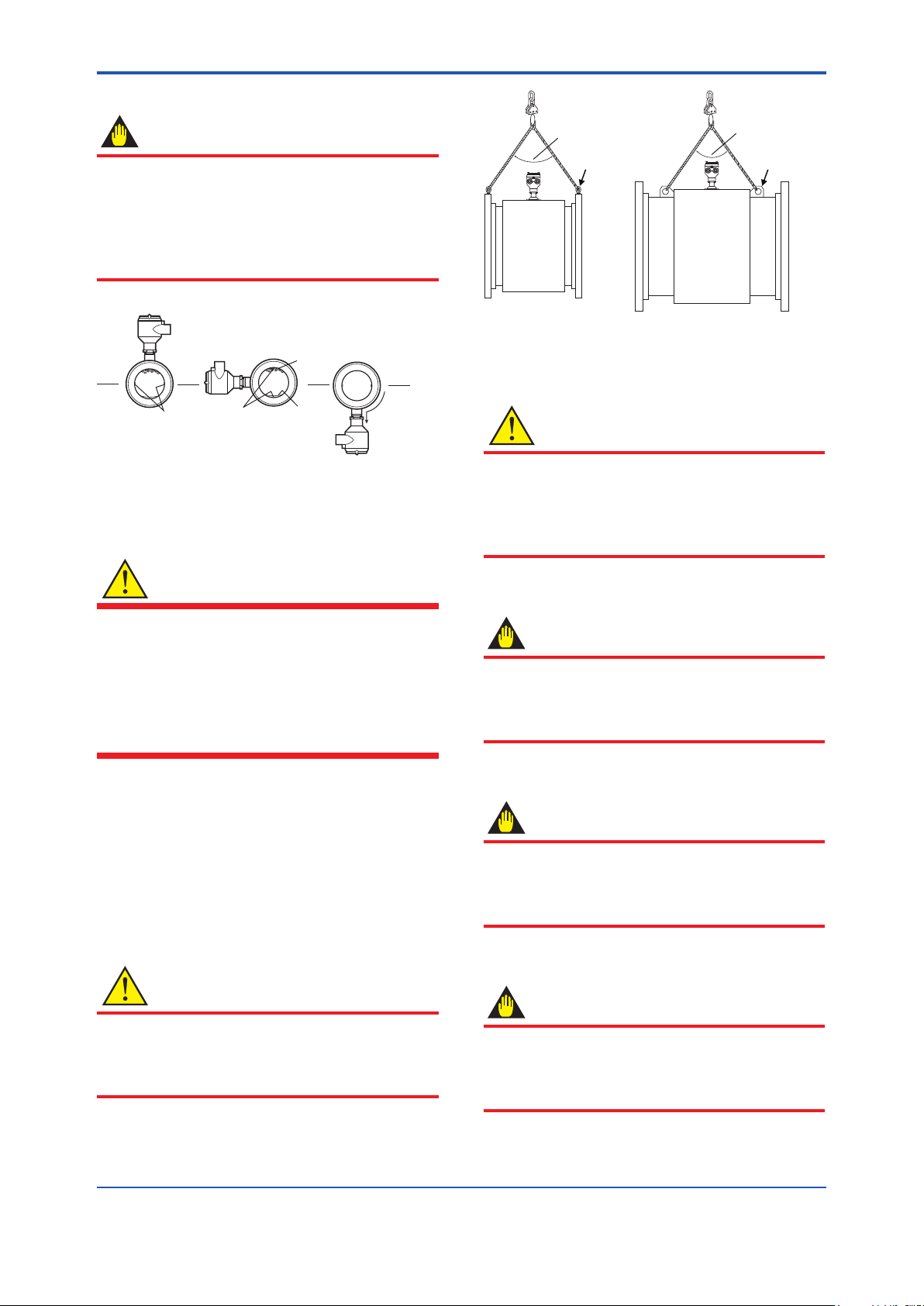

Figure 3.2.1 Lifting Flowtube

90 degrees or less

F0307.ai

(2) Avoiding Shocks from Impact

CAUTION

Care should be taken not to drop the owmeter

or expose it to excessive shock. In particular, be

careful not to subject the ange surface to shock.

This may lead to liner damage which will result in

inaccurate readings.

WARNING

The magnetic owmeter is a heavy instrument.

Be careful that no damage is caused to

personnel through accidentally dropping it, or

by exerting excessive force on the magnetic

owmeter. When moving the magnetic

owmeter, always use a trolley, forklift, or crane

and have at least two people carry it.

3.2.1 General Precautions

(1) Precaution during Transportation

The magnetic owmeter is packed tightly. When

it is unpacked, pay attention to prevent damaging

the owmeter. To prevent accidents while it is being

transported to the installing location, transport it to

the site in its original packing.

CAUTION

When lifting the owtube, use the lifting rings

(eye bolts or eye plates) as in Figure 3.2.1.

Never lift it using a bar passed through the

owtube as this damages the liner severely.

(3) Flange Protection Covers

IMPORTANT

Keep the protective covering (i.e. the corrugated

cardboard or other cushioning material) in place

over the ange except when mounting the

owmeter to the pipe.

(4) Terminal Box Cover

IMPORTANT

As it is possible that the insulation will

deteriorate, do not remove the wrapping of the

terminal box nor open the terminal box cover

until it is time to wire it.

(5) Long-term Non-use

IMPORTANT

It is not desirable to leave the owmeter unused

for a long term after installation. If this situation

is unavoidable, take care of the owmeter by

observing the following.

IM 01E25D11-01EN

Page 13

<3.INSTALLATION>

3-4

• Conrmationofsealingconditionsforthe

owmeter

Conrm that the terminal box screw and wiring ports

are well sealed. Equip the conduit piping with drain

plugs or waterproof glands to prevent moisture or

water from penetrating into the owmeter through

the conduit.

• Regularinspections

Inspect the sealing conditions as mentioned above,

and the inside of the terminal box at least once a

year. Also, due to rain, etc. when it is suspected

that water may have penetrated into the inside

owmeter perform supplementary inspections.

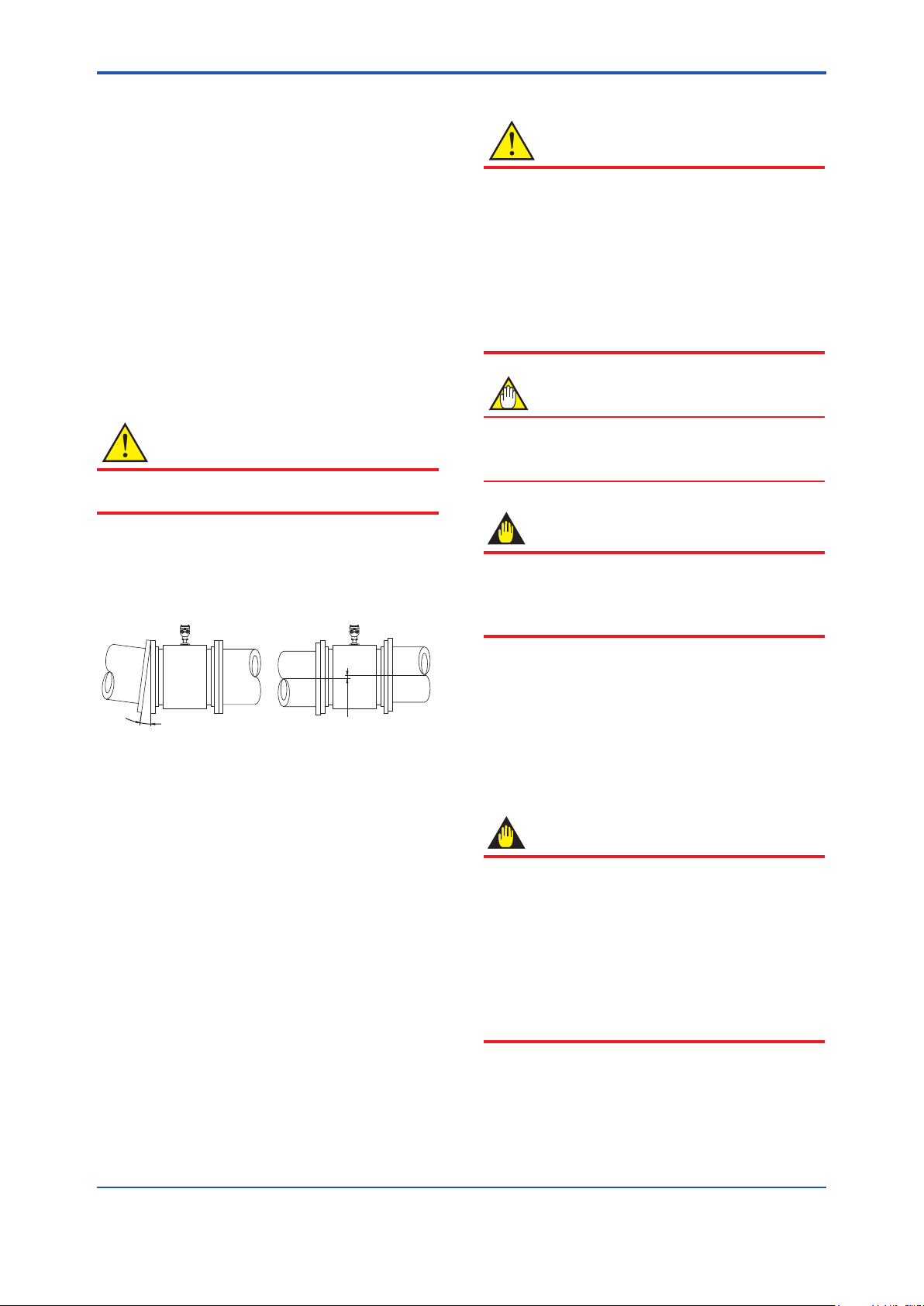

3.2.2 FlowmeterPiping

CAUTION

Misaligned or slanted piping can lead to leakage

and damage to the anges.

(1) Correct any misaligned or slanted piping, and

any gaps that may exist between mounting

anges before installing the owmeter (refer to

Figure 3.2.2).

3.3 MountingProcedures

CAUTION

When attaching optional grounding rings to

the owtube with lining material natural hard

rubber or uorocarbon PTFE, gaskets must be

placed between each grounding ring and the

owtube. Fluid leakage will happen without these

gaskets. These gaskets are to be supplied by

customer. Do not forget those gaskets also when

ordering and attaching the grounding rings later

additionally.

NOTE

The tightening torque value varies depending

on the type of lining and gasket as shown in the

tables in this section.

IMPORTANT

Use bolts and nuts in compliance with the ange

ratings. When choosing the gaskets, be sure to

choose sheet gaskets designed to t for ange

standard.

Slanted

Figure3.2.2 SlantedandMisalignedFlowmeter

Piping

(2) Inside a newly installed pipeline, there may

be some foreign substances such as residue

from welding or wood chips. Remove them

by ushing the piping before mounting the

owmeter. This prevents the lining from

being damaged, as well as the occurrence

of erroneous measured signals resulting

from foreign substances passing through the

owtube during measurement.

Misaligned

F0308.ai

(1) MountingDirection

Mount the owmeter so that the ow direction of

the uid to be measured is in line with the direction

of the arrow mark on the owmeter. It may be

especially difcult to move large size owtubes after

bringing them into the pit. Check directions before

bringing.

IMPORTANT

If it is impossible to match the direction of

the arrow mark, the direction of the electrical

connection can be changed. Refer to Section 5.1

to do this properly.

In case the uid being measured ows against

the arrow direction, refer to the parameter J20:

FlowDirection in the user’s manual of the

AXFA11 Magnetic Flowmeter Remote Converter

(IM 01E20C01-01E).

IM 01E25D11-01EN

Page 14

<3. INSTALLATION>

A

A

3-5

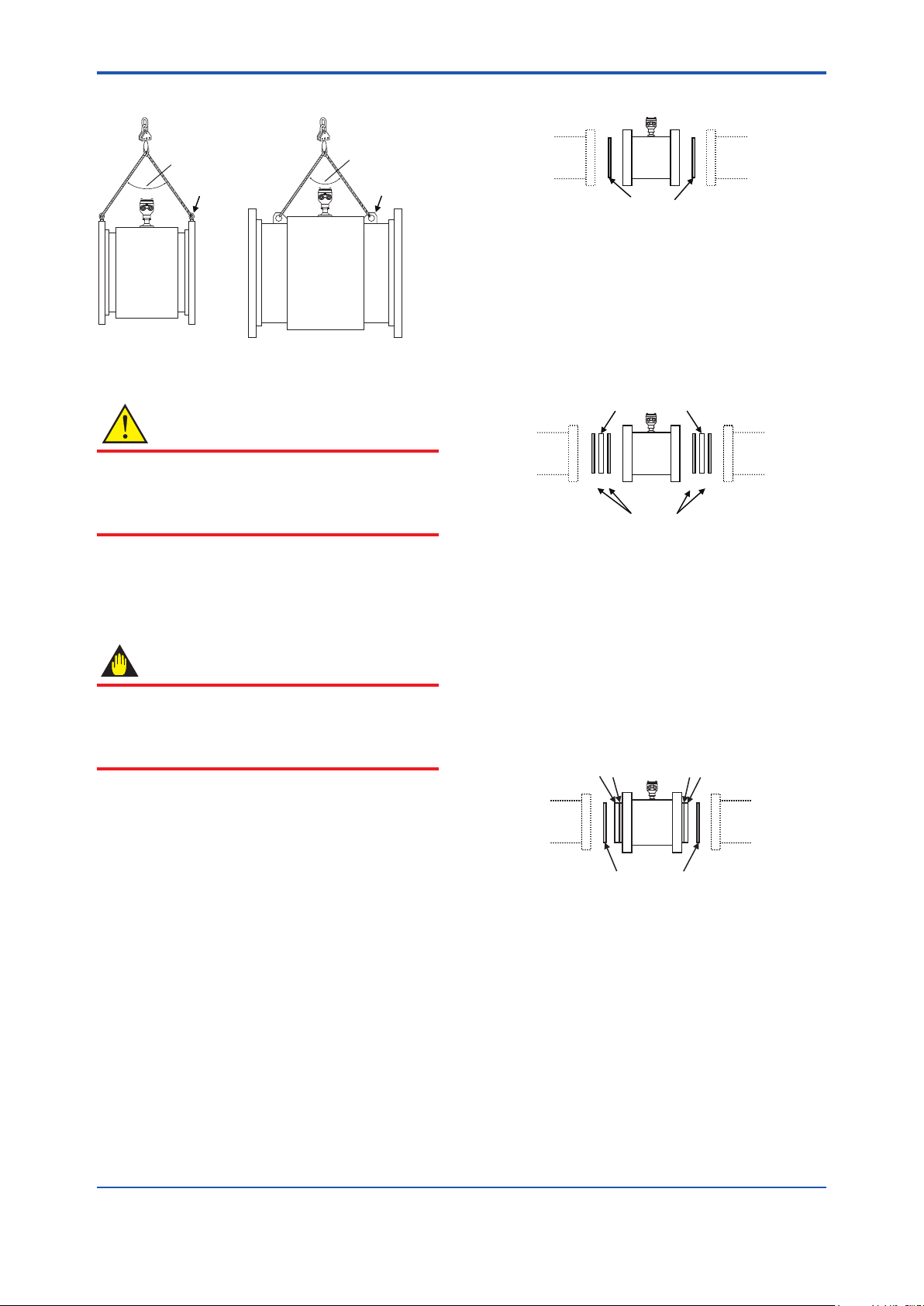

(2) Carrying Flowtube

90 degrees or less

Eye bolt

Figure 3.3.1 Carrying Flowtube

90 degrees or less

Eye plate

CAUTION

• When carrying the owtube, use the lifting

rings (eye bolts or eye plates).

• To assure safety, keep lifting angle less than

90 degrees as shown in Figure 3.3.1

(3) Positioning Flowtube

F0309.ai

1. Standard (no grounding rings)

Customer

pipe

A A

Gaskets A supplied by customer

Figure 3.3.2 Installation without Grounding

Rings

Customer

pipe

F0310.ai

When using the GF type-1 gaskets, the

gasket groove is required as mentioned

above.

2. With optional grounding rings (code GR1)

Optional grounding rings

Customer

pipe

B

Gaskets A and B supplied by customer

B

Figure 3.3.3 Installation with Grounding Rings

GR1

Customer

pipe

F0311.ai

Bring in the owtube, place it and use a jack to

adjust its position.

IMPORTANT

Apply the jack to the anges of the owtube.

In addition, adjust any misalignment when the

owtube is brought in, as the jack can adjust

vertical position, but not horizontal one.

(4) Applying Gasket and optional Grounding

Rings

Gasket:

Necessary gaskets for piping connection are

as below depending on the choice of grounding

rings.

Use sheet gaskets designed to t for ange

standard. The GF type-1 gaskets by JIS G

3443-2 should be used for the JIS F12 ange

models in sizes 1100 mm (44 in.) and above. In

this case, the gasket groove is required on the

customer pipe anges.

The thickness of gasket should be 2mm

(0.08in.) to 5mm (0.2in.) for sizes up to 1000

mm (40 in.), and 5 mm (0.2 in.) or more

for larger sizes. The type of gasket should

be a kind of soft rubber, or its equivalent in

hardness.

It is recommended to use the same gasket

for A and B. Both gaskets A and B are to be

supplied by customer.

When polyurethane or natural soft rubber

lining, the gaskets B are not necessary.

3. With optional grounding rings (code GR2)

Optional grounding rings

with integrated gaskets B included

B

Customer

pipe

A A

Gaskets A supplied by customer

B

Customer

pipe

F0312.ai

Figure 3.3.4 Installation with Grounding Rings

GR2

This is available for the models with

process connection JIS F12 (JIS 75M) in

sizes 1100 mm (44 in.) and above. Only

gaskets A are to be supplied by customer.

The grounding rings are installed and

locked onto the owtube with gaskets B

when shipped from factory.

Mounting Procedure (no Grounding Rings):

Connect the owtube’s ange and the

customer’s pipe which contact process uid by

some wire supplied by customer.

IM 01E25D11-01EN

Page 15

<3. INSTALLATION>

3-6

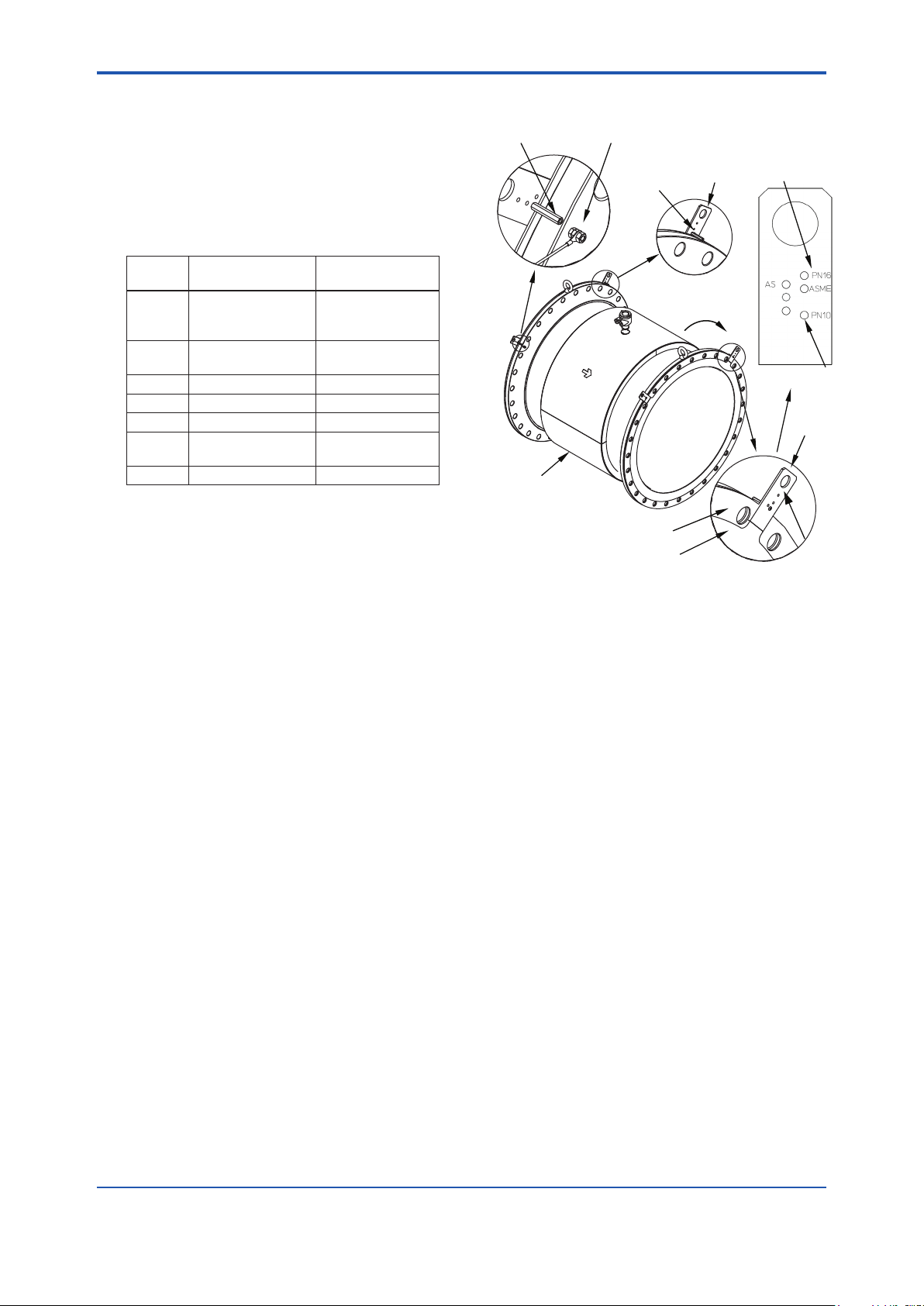

Mounting Procedure (with optional

Grounding Rings GR1 for sizes up to

1000 mm (40 in.)):

1. Handles of the grounding ring have some

holes which correspond to outer diameter

of each ange type. There are printings

near each hole. The printings show types

of ange. See the table below.

Printing

Process

Connection Code

ASME -CA1

AWWA -CB1

PN10 -CE1 EN1092-1 PN10

PN16 -CE2 EN1092-1 PN16

10K -CJ1 JIS B2220 10K

AS -CS1, -CS2, -CT1

F12 -CG1 JIS F12 (JIS 75M)

Flange Standard

ASME B16.5

Class 150, ASME

B16.47 Class 150

AWWA C207

Class D

AS2129 table D, E

AS4087 PN16

2. Conrm the centering pin is xed to the

hole corresponding to ange or x the

centering pin to the correct hole.

3. Hang the grounding rings with their

ange type printings outer side of the

owtube. Set the angle of both handles

symmetrically to be 45 degree from top. If

there are any bolt-holes under the handles,

turn the grounding rings clockwise in order

to locate handles between bolt-holes.

Center the grounding ring to the center of

the owtube.

4. Connect the wire from the grounding ring

to the screw of the owtube’s ange and x

the wire by the nut. This procedure (item 1

to 4) must be done for the both sides of the

owtube.

5. Install the owtube into the customer’s pipe

with the gaskets A.

Centering Pin

Flowtube

Note : Gasket A and B are also placed concentrically with

Figure 3.3.5 Mounting Procedure with Grounding

Screw & Nut : Connect the wire from the

grounding ring or the customer’s pipe

Centering Pin

Gasket B

Grounding Ring

the owtube.

Handle

Clockwise

Rings GR1 for sizes up to 1000 mm

(40 in.)

Printing of

Flange Type

F12

10K

Handle

Mounting Procedure (with optional

Grounding Rings GR1 for sizes 1100mm (44

in.)) and above :

1. The grounding ring is temporarily xed

onto the owtube by four bolts. Hang the

grounding ring up using a crane or a hoist

so that it would not fall down from the

owtube while setting the gasket B.

2. Unfasten the bolts and remove the

grounding ring off from the owtube.

3. Place the gasket B to the owtube. Cut out

holes on the gasket B if necessary, so that

the bolts can go through. Fix the grounding

ring to the owtube by the four bolts again.

4. Connect the wire from the grounding ring

to the screw at the owtube ange and x

the wire by the nut. This procedure (item 1

to 4) must be done for the both sides of the

owtube.

Hole

Printed

Surface

F0313.ai

IM 01E25D11-01EN

Page 16

<3. INSTALLATION>

5. Install the owtube into the customer’s pipe

with the gaskets A.

Screw & Nut : Connect the wire from the

grounding ring or the customer’s pipe.

Flowtube

Hang the grounding

ring up with this point.

Unfasten the bolts and

remove the grounding rings.

Cut out some holes on the

gasket B when necessary.

Wire

3-7

Grounding Ring

F0314.ai

Note : Gasket A and B should be placed concentrically with

the owtube.

Figure 3.3.6 Mounting Procedure with Grounding

Rings GR1 for sizes 1100 mm (44 in.)

and above

Mounting Procedure (with optional

Grounding Rings GR2):

The grounding rings are installed and locked

onto the owtube with gaskets B when shipped

from factory. Install the owtube into the

customer’s pipe with gaskets A supplied by

customer.

(5) Tightening Nuts

Pass the bolts from pipe line side, not owtube side,

and tighten the bolts according to the torque values

for the metal piping in Table 3.3.1 or 3.3.2

CAUTION

• Be sure to tighten the nuts according to the

prescribed toeque values. Tighten them

diagonally with the same torque values, step

by up to the prescribed torque value.

IM 01E25D11-01EN

Page 17

<3. INSTALLATION>

Table 3.3.1 Tightening Torque Values for Metal Piping (N-m)

Lining type

Gasket type Soft rubber gasket, or the equivalent in hardness (supplied by customer)

Process

connection

Size

mm (inch)

500 (20) 99 to 166 85 to 140 143 to 238 151 to 233

600 (24) 144 to 240 108 to 175 218 to 363 239 to 331

700 (28) 168 to 281 176 to 266 180 to 300 176 to 293 240 to 333

800 (32) 259 to 432 212 to 302 236 to 393 246 to 410 400 to 612

900 (36) 274 to 457 206 to 338 224 to 373 258 to 430 399 to 604

1000 (40) 274 to 457 277 to 422 307 to 512 286 to 477 422 to 587

Lining type Polyurethane rubber

Gasket type Soft rubber gasket, or the equivalent in hardness (supplied by customer)

Process

connection

Size

mm (inch)

500 (20) 71 to 118 60 to 99 74 to 123 76 to 123 131 to 218

600 (24) 97 to 162 82 to 126 101 to 168 118 to 171 124 to 206

700 (28) 125 to 208 135 to 202 146 to 244 120 to 200 167 to 242 202 to 337

800 (32) 176 to 294 160 to 229 190 to 316 169 to 281 218 to 348 197 to 328

900 (36) 170 to 283 151 to 251 178 to 296 161 to 268 200 to 317 221 to 369

1000 (40) 175 to 291 206 to 314 220 to 367 165 to 275 253 to 370 218 to 363

B16.5 (500, 600)

B16.47 (700-1000)

ASME

B16.5 (500, 600)

B16.47 (700-1000)

Class 150

ASME

EN1092-1 PN10

JIS B2220 10K

Class 150

PTFE / Natural hard rubber / Natural soft rubber

EN1092-1 PN10

JIS B2220 10K

EN 1092-1

EN 1092-1 PN16

PN16

AWWA C207

Class D

AWWA C207

Class D

AS2129 Table

D, E

AS4087 PN16

AS2129 Table D, E

AS4087 PN16

(JIS 75M)

3-8

Unit: N-m

Unit: N-m

JIS F12

Lining type Natural hard rubber

Gasket type Soft rubber gasket, or the equivalent in hardness (supplied by customer)

Process

connection

Size

mm (inch)

1100 (44) 285 to 476

1200 (48) 180 to 300 327 to 546 298 to 497 400 to 582 281 to 468

1350 (54) 397 to 662

1400 (56) 233 to 388 379 to 632

1500 (60) 421 to 702

1600 (64) 238 to 397 532 to 886 532 to 887

1800 (72) 291 to 485 552 to 919 468 to 779

EN1092-1 PN6 EN1092-1 PN10

AWWA C207

Class D

AS2129 Table D, E

AS4087 PN16

Polyurethane

Unit: N-m

rubber

JIS F12

(JIS 75M)

IM 01E25D11-01EN

Page 18

<3. INSTALLATION>

Table 3.3.2 Tightening Torque Values for Metal Piping (lbf-in)

Lining type

Gasket type Soft rubber gasket, or the equivalent in hardness (supplied by customer)

Process

connection

Size

mm (inch)

500 (20) 880 to 1467 748 to 1239 1266 to 2110 1332 to 2062

600 (24) 1275 to 2125 955 to 1546 1928 to 3214 2113 to 2932

700 (28) 1490 to 2483 1561 to 2357 1594 to 2657 1558 to 2596 2123 to 2943

800 (32) 2292 to 3820 1880 to 2671 2085 to 3475 2176 to 3627 3538 to 5413

900 (36) 2426 to 4043 1821 to 2991 1980 to 3301 2285 to 3809 3535 to 5346

1000 (40) 2426 to 4043 2450 to 3739 2717 to 4528 2534 to 4224 3734 to 5265

Lining type Polyurethane rubber

Gasket type Soft rubber gasket, or the equivalent in hardness (supplied by customer)

Process

connection

Size

mm (inch)

500 (20) 626 to 1044 527 to 876 652 to 1087 674 to 1089 1159 to 1931

600 (24) 862 to 1436 727 to 1113 894 to 1490 1043 to 1512 1095 to 1825

700 (28) 1106 to 1843 1193 to 1791 1295 to 2159 1061 to 1769 1478 to 2142 1788 to 2980

800 (32) 1562 to 2603 1420 to 2024 1680 to 2800 1494 to 2491 1926 to 3076 1739 to 2899

900 (36) 1505 to 2508 1340 to 2218 1571 to 2619 1422 to 2370 1773 to 2808 1958 to 3263

1000 (40) 1546 to 2577 1824 to 2781 1951 to 3251 1459 to 2432 2239 to 3274 1928 to 3213

B16.5 (500, 600)

B16.47 (700-1000)

ASME

B16.5 (500, 600)

B16.47 (700-1000)

Class 150

ASME

EN1092-1 PN10

JIS B2220 10K

Class 150

PTFE / Natural hard rubber / Natural soft rubber

EN1092-1 PN10

JIS B2220 10K

EN 1092-1

EN 1092-1 PN16

PN16

AWWA C207

Class D

AWWA C207

Class D

AS2129 Table

D, E

AS4087 PN16

AS2129 Table D, E

AS4087 PN16

JIS F12

(JIS 75M)

3-9

Unit: lbf-in

Unit: lbf-in

Lining type Natural hard rubber

Gasket type Soft rubber gasket, or the equivalent in hardness (supplied by customer)

Process

connection

Size

mm (inch)

1100 (44) 2527 to 4211

1200 (48) 1594 to 2657 2898 to 4830 2639 to 4398 3539 to 5149 2484 to 4139

1350 (54) 3517 to 5862

1400 (56) 2060 to 3434 3358 to 5597

1500 (60) 3729 to 6215

1600 (64) 2109 to 3515 4705 to 7842 4713 to 7854

1800 (72) 2576 to 4293 4883 to 8138 4138 to 6897

EN1092-1 PN6 EN1092-1 PN10

AWWA C207

Class D

AS2129 Table D, E

AS4087 PN16

Polyurethane

(JIS 75M)

Unit: lbf-in

rubber

JIS F12

IM 01E25D11-01EN

Page 19

Blank Page

Page 20

<4. WIRING>

4. WIRING

4-1

4.1 Wiring the Remote Flowtube

This section describes the wiring of the remote

owtube only. For information relating to the wiring

of the converter, refer to the user’s manual of the

AXFA11 Magnetic Flowmeter Remote Converter

(IM 01E20C01-01E).

WARNING

The wiring of the magnetic owmeter must

be performed by expert engineer or skilled

personnel. No operator shall be permitted to

perform procedures relating to wiring.

CAUTION

Once all wiring is complete, check the

connections before applying power to the

instrument. Improper arrangements or wiring

may cause a unit malfunction or damage.

4.1.1 Wiring Precautions

Be sure to observe the following precautions when

wiring:

CAUTION

• In cases where the ambient temperature

exceeds 50°C (122°F), use external heatresistant wiring with a maximum allowable

temperature of 70°C (158°F) or above.

• Do not connect cables outdoors in wet

weather in order to prevent damage from

condensation and to protect the insulation,

e.g. inside the terminal box of the owtube.

• Do not splice the cable between the owtube

terminal and the converter if it is too short.

Replace the short cable with a cable that is the

appropriate length.

• All the cable ends must be provided with

round crimp-on terminals and be securely

wired.

• The signal cables must be routed in separate

steel conduit tubes 16 (JIS C 8305) or exible

conduit tubes 15 (JIS C 8309).

• Keep conduits or exible tubes watertight

using sealing tape.

• Ground the remote owtube and the converter

separately.

• Cover each shield of the signal cable with vinyl

tube or vinyl tape to avoid contact between

two shields or between a shield and a case.

• When waterproof glands or union equipped

waterproof glands are used, avoid tightening

the glands with an excessive torque.

• Be sure to turn the power off before opening

the terminal box cover.

• Before turning the power on, tighten the

terminal box cover securely.

• When opening the terminal box cover, use a

hexagonal wrench (nominal size 3 mm). For

handling the locking screw, refer to Figure

4.1.7.

• Be sure to lock the cover using a hexagonal

wrench (nominal size 3 mm) after installing the

cover. For handling the locking screw, refer to

Figure 4.1.11.

• When submersible type or optional code DHC

is selected, waterproof glands, signal and

excitation cables are attached.

In order to preserve the effectiveness of

waterproof features, the terminal box cover

and waterproof glands must not be detached

from owmeter.

IMPORTANT

Prepare the signal cable and the excitation cable

almost the same length. It is recommended to lay

them together closely.

IM 01E25D11-01EN

Page 21

<4. WIRING>

4.1.2 Cables

CAUTION

(1) Dedicated Signal Cable (AXFC)

Conductors (A and B)

Shields (SA and SB)

Tape

Outer jacket

Shield (C)

Insulation

Insulation

10.5 (0.413")

F0401.ai

Figure 4.1.1 Dedicated Signal Cable AXFC

The ow signal is transmitted via this dedicated

cable. The cable is constructed with double

shielding over the two conductors, and heatresistant vinyl is used for the outer jacket material.

Finished diameter: 10.5 mm (0.413”)

Maximum length:

Combination with the AXFA11 converter:

200 m (660 ft)

Maximum temperature: 80°C (176°F)

• As crimp terminals A, B, SA, SB and C have

their own electrical potentials, securely

insulate them so as not to come in contact

with one another.

• To prevent a shield from coming in contact

with another shield or the case, cover each

shield with a vinyl tube or wrap it in vinyl tape.

NOTE

Conductors A and B carry the signal from the

electrodes, and C is at the potential of the liquid

(signal common). Shields SA and SB are kept at

the same potentials as the individual electrodes

(these are actively driven shields.) This is done

to reduce the effect of the distributed capacitance

of the cable at long cable length. Note that, since

the signals from the individual electrodes are

impedance converted inside the converter, errors

will result if they come in contact with any other

component. Great care must be taken in the

cable nish treatment.

4-2

IMPORTANT

If the cable is longer than required, cut off

any extra length rather than coiling it up, and

terminate the conductors as shown in Figure

4.1.2. Avoid using junction terminal boards to

extend the cable length, as this will interrupt the

shielding.

Unit : mm

(approx. inch)

ACB

SA

On the

converter

side

25 (0.98)

White Black

±5

150

8(0.3) max.

(5.9)

SB

50 (1.97)

20 (0.8)

70 (2.76)

Red

L (Specified Dimensions)

AXFC

60 (2.36)

Figure 4.1.2 Treatment of Dedicated Signal Cables

ACB

55 (2.17)

90 (3.54)

White Black Red

8 (0.3) max.

±5

(5.9)

150

On the

flowtube

side

ø10.5 (0.4)

F0402.ai

90 (3.54)

(2) Excitation Cable

JIS C 3401 control cable equivalent

JIS C 3312 power cable equivalent

14 AWG Belden 8720 equivalent

Outer Diameter: 6.5 to 12 mm (0.26 to 0.47 in.)

10.5 or 11.5 mm (0.41 to 0.45 in.) for optional

code EG, EU and EW.

Nominal Cross Section:

Single wire: 0.5 to 2.5 mm

Stranded wire: 0.5 to 1.5 mm

2

2

IM 01E25D11-01EN

Page 22

<4. WIRING>

4-3

Unit : mm

(approx. inch)

Crimp terminal

EX2

EX1

85 (3.35)

On the converter side

Figure 4.1.3 Finish Treatment of Excitation Cable

85 (3.35)

On the flowtube side

EX1

EX2

F0403.ai

NOTE

• For excitation cables, always use a crimp

terminal with an insulation cover.

• Use crimp tools from the manufacturer of the

crimp terminal you want to use to connect the

crimp terminal and cable.

• Use crimp tools that are appropriate for the

diameter of the cable to be connected.

4.1.3 Wiring Ports

This instrument is of watertight construction as

stipulated in JIS C0920. It is shipped with a wiring

bracket (waterproof gland or waterproof gland

with union), only in cases where an optional

specication is selected for the wiring port.

When submersible type or option code DHC is

selected, waterproof glands and a 30-meter (or

customer designated) length cable are attached

with resin lled in the terminal box. In this case,

wiring at this terminal box is not necessary and do

not open it.

IMPORTANT

The wiring port is sealed with a cap (not waterproof). Do not remove the cap from the wiring

port until wiring a cable. If waterproof property is

necessary, please use waterproof glands.

(1) When waterproof property is unnecessary

(When there are no particular optional

specications)

The wiring port is sealed with a cap (not waterproof) that must be removed before wiring. When

wiring, handle the wiring with proper procedures for

necessary protection.

(2) When waterproof property is necessary

(Wiring using waterproof glands)

IMPORTANT

To prevent water or condensation from entering

the terminal box, waterproof glands are

recommended. Do not over-tighten the glands

or damage to the cables may result. Tightness of

the gland can be checked by conrming that the

cable is held rmly in place.

For working on the electric wire tubes or the exible

tubes (G1/2), remove the waterproof gland and

attach them directly to the wiring port.

Be sure to use the washers and gaskets as shown

in the drawings. Check and see that the cable is

rmly xed realizing waterproofness.

IM 01E25D11-01EN

Page 23

<4. WIRING>

4.1.4 Wiring Connections

4-4

Washer

Gasket

Waterproof gland

Cable

F0404.ai

Figure 4.1.4 Waterproof Gland (Optional code EG)

Gasket

PF1/2

Washer

Tightening gland

Cable

When working on conduit pipes or flexible pipes (G1/2 only)

Figure 4.1.5 Waterproof Gland with Union Joint

(Optional code EU)

F0405.ai

WARNING

Before wiring, be sure that the power supply for

AXFA11 converter has been turned off to prevent

an electrical shock.

(1) Removing Cover

Loosen the cover locking screw clockwise using a

hexagonal wrench (nominal size 3 mm) to unlock

the cover. (Upon shipment from the manufacturing

plant, the cover is unlocked.) Remove the cover

by turning it in the direction of the arrow as shown

below.

(3) Conduit Wiring

When wiring the conduits, pass the conduit through

the wiring connection port, and utilize the waterproof

gland to prevent water from flowing in. Place the

conduit pipe on an angle as shown in Figure 4.1.6.

Install a drain valve at the low end of the vertical

pipe, and open the valve regularly.

Drain valve

F0406.ai

Figure 4.1.6 Conduit Wiring

F0407.ai

Figure 4.1.7 Removing the Terminal Box Cover

(2) Terminal Conguration

When the cover is removed, the connection

terminals will be visible.

Terminal

Symbols

A

B

C

EX1

EX2

Figure 4.1.8 Terminal Conguration

Description

Flow signal output

Excitation current input

Protective grounding

(Outside of the terminal)

F0408.ai

IM 01E25D11-01EN

Page 24

<4.WIRING>

4-5

(3) WiringtheRemoteFlowtubewithAXFA11

Converters

Connect wiring as shown in the gure below.

SO1+ COMSO2+

FUSE

2.5A 250V

Shortbar

I+

CURRENT OUT

4-20mA out

N/– L/+

POWER SUPPLY

I–

AL+ AL– C SA A B SB

STATUS OUT

ALARM OUT

EX2EX1

P– SI1+ SI2+ COMP+

EXCIT ATION

PULSE OUT STATUS IN

SIGNAL

AXFA11 converter

AXFC dedicated

Excitation

cable

A

EX2

B

EX1

C

Remote flowtube

signal cable

Converter

SA

A

B

SB

C

EX1

EX2

* Individually tape and insulate

the shields corresponding to

SA and SB on the remote

flowtube side.

Remote

flowtube

Taping*

A

B

Taping*

C

EX1

EX2

F0409.ai

Figure4.1.9 WiringDiagram

(4) Grounding

600 V vinyl insulated

electric cable

(2 mm2 or larger)

• Class D requirements (ground resistance.

100 Ω or less).

CAUTION

Be sure to connect the protective grounding of

the remote owtube with a cable of 2 mm2 or

larger cross section in order to avoid electrical

shock to the operators and maintenance

engineers and to prevent the inuence of

external noise.

Connect the grounding wire to the mark.

The grounding should satisfy Class D

requirements (ground resistance, 100 Ω or less).

IMPORTANT

Improper grounding can have an adverse affect

on the ow measurement. Ensure that the

instrument is properly grounded.

The electromotive force of the magnetic owmeter

is minute and it is easy to be affected by noise. And

also that reference electric potential is the same

as the measuring uid potential. Therefore, the

reference electric potential (terminal potential) of

the owtube and the converter also need to be the

same as the measuring uid. Moreover, that the

potential must be the same with ground.

Be sure to ground according to Figure 4.1.10.

Refer to Figure 3.3.5 or 3.3.6 for wiring to the

anges of remote owtube when optional grounding

rings are not used.

Without optional grounding rings.

(Available only for metal piping)

With optional grounding

rings.

F0410.ai

Figure4.1.10ProtectiveGroundingTerminalLocation

(5)InstallingtheCover

Install the cover to the owtube by turning it in the

direction of the arrow as shown below. Tighten

the cover locking screw counterclockwise using a

hexagonal wrench (nominal size 3 mm) to lock the

cover.

F0411.ai

Figure4.1.11 InstallingtheTerminalBoxCover

IM 01E25D11-01EN

Page 25

Blank Page

Page 26

<5. MAINTENANCE>

5. MAINTENANCE

5-1

WARNING

• Maintenance work must be carried out by the

trained personnel having knowledge of safety

standard and not by operators.

• When opening the cover, wait for more

than 10 minutes after turning off the power.

Furthermore, opening of the cover must also

be carried out by the trained personnel having

knowledge of safety standard.

CAUTION

• When opening the cover, use a hexagonal

wrench (nominal size 3 mm).

• Be sure to lock the cover using a hexagonal

wrench (nominal size 3 mm) after installing the

cover.

5.1 Changing Direction of

F0501.ai

(4) Using the hexagonal wrench, loosen the screw

in the neck.

(5) Turn the terminal box in the desired direction.

NOTE

The terminal box can be turned –140 degree to

+180 degree from the arrow mark indicating the

ow direction. Do not exceed these angle.

(6) Using the hexagonal wrench, retighten the neck

screw.

+180º-140º

Electrical Connection

IMPORTANT

The following types can not be changed direction

of electrical connection after delivery.

• Submersible Type.

• Optional code DHC (for district heating and

cooling or condensation-proof).

(1) The following tools are required to change the

direction of the electrical connection:

• Hexagonal wrench (nominal size 1.5 mm)

• Wrench

(2) Turn off the power to the owmeter.

(3) Using the wrench, loosen the hexagonal nut at

the neck of the instrument.

F0502.ai

(7) Using the wrench, retighten the hexagonal nut

at the neck. After that, check that the terminal

box is xed.

IM 01E25D11-01EN

Page 27

<5. MAINTENANCE>

5-2

5.2 Regular Inspection Items

(1) Inspection of moisture-proong inside the

terminal box: Once/year

(2) Retightening of piping joint screws: About

twice/year

(3) Inspection of electrodes and lining (in case

of adhesive and/or abrasive uids, etc.)

Determine the period of regular inspection as

necessary.

5.3 Excitation Coil and Insulation Resistance Check

WARNING

• Before checking of the excitation coil and the

insulation resistance, be sure that the power

supply for AXFA11 converter has been turned

off.

• Before checking, be sure to disconnect the

cables from the terminals of the remote

owtube.

Coil Circuit

Checking is possible even if the pipe is lled with

uid.

Test Terminals Test Voltage Specication

Between

terminals

EX1 and C

500 V DC (Use an

insulation

tester or the

equivalent.)

1 MΩ or more

Signal Circuit

Before testing, be sure to empty and dry the interior

of the pipe, checking that there is no adhesive

material. Also undo the wiring connection on the

converter side before testing.

Test Terminals Test Voltage Specication

Between

terminals

A and C

Between

terminals

B and C

500 V DC (Use an

insulation

tester or the

equivalent.)

100 MΩ or

more for each

(1) Excitation Coil Check

Check that there is continuity between terminals

EX1 and EX2 in the terminal box. If there is no

continuity, the coils may be broken and replacement

or repair of the owtube is necessary. The coil

resistance is designed to be 150 Ω or less. If it is

not, this may be an abnormal condition. Consult

Yokogawa’s sales or service ofces.

(2) Insulation Resistance Check

Check the insulation resistances in the terminal

box in accordance with the tables below. If any

of them falls below the values listed in the tables,

consult Yokogawa’s sales or service ofces for

investigation. If the insulation resistance cannot be

restored, replacement or repair of the owtube is

needed. In case of submersible type owmeters,

undo the wiring connection on the converter side

and measure resistance at the cable terminals.

IM 01E25D11-01EN

Page 28

<5. MAINTENANCE>

5.4 Troubleshooting

Although magnetic owmeters rarely require maintenance, failures may occur when the instrument is not

operated correctly. This section describes troubleshooting procedures where the cause of the breakdown is

identied through receiver indication.

5.4.1 No Indication

START

Is an error being displayed? Check the converter display.

5-3

Is an error being

displayed?

NO

Is anything else

being displayed?

YES

Does the

arrow on the tube match the

flow direction?

YES

Check whether the flowtube

is filled with fluid.

Is the flowtube

full of fluid?

YES

Check the resistance between

the flowtube’s A, B, and C

terminals using a circuit tester.

YES

NO

NO

NO

Refer to the “Alarm Functions” in

the AXFA11.

Perform either of the following:

a. Reinstall the flowtube in

order to make the arrow and

flow direction match.

b. Reverse the setting for the

flow direction.

Change the piping or the

mounting condition so that

the tube fills with the fluid.

resistance between A-C or B-C

Remove the tube and

inspect the inside of the pipe.

Remove the foreign matter.

Is the

100 MΩ or more?

YES

Is foreign

matter adhering to

the walls?

YES

NO

NO

Contact a service center.

F0503.ai

IM 01E25D11-01EN

Page 29

<5. MAINTENANCE>

5.4.2 Unstable Zero

START

Investigate whether or not the flowtube

is filled with fluid and that it is free of

bubbles.

*1

Is the flowtube

completely full of fluid?

YES

NO

*1: When checking for bubbles, it is

convenient if there is a gas vent hole

on the flowtube’s downstream side.

Particular care must be taken in the case

of horizontal mounting. In order to ensure

complete filling of the tube, either adjust

the mounting position or switch to vertical

mounting.

5-4

Are there bubbles

in the fluid?

NO

Check for the presence of valve

leakage.

Are valves leaking?

NO

●

Confirm the flowmeter grounding.

●

Confirm whether or not the

grounding wire is disconnected

from the earth flange.

Is the flowmeter properly

grounded?

YES

Recheck the fluid to be measured.

● Does the fluid’s

conductivity vary?

● Is the fluid conductivity

within the limits?

NO

Is the fluid likely to

contain deposits?

NO

YES

YES

NO

YES

YES

Install a defoaming device on the

flowtube’s upstream side.

Replace the valve(s).

Completely ground the converter and

flowtube (Refer to the section on

grounding in the relevant user's manual.)

●

Ensure that the fluid’s conductivity

changes as little as possible.

●

Do not use the meter when fluid

conductivity is out of limits.

●

Whenever possible, reduce the flow

velocity to being in the vicinity of the

lower conductivity limit.

●

Remove dirt and scale of and near

electrodes.

●

Use a soft brush or cloth to perform

scale removal, and make sure that

the lining is not damaged.

Is the flowmeter

located near motors, transformers,

or electric equipment?

NO

Contact a service center.

YES

Provide the meter with sufficient

shielding or move it away from the

electrical equipment

F0504.ai

IM 01E25D11-01EN

Page 30

<5. MAINTENANCE>

5.4.3 Disagreement Between Indication and Actual Flow

START

5-5

Are parameters

set correctly?

YES

Examine the condition of the fluid in the

flowtube, of bubbles, and of grounding.

Was zero

adjustment carried out

correctly?

YES

Is the tube

filled completely with

fluid?

YES

Does the fluid

contain bubbles?

NO

Is the

flowmeter completely

grounded?

YES

Is the

signal cable terminal

treatment of

complete?

YES

Does the

conductivity stay within the

specified range?

YES

Is the

fluid likely to contain

deposits?

NO

Confirm that a valve is located

immediately upstream of the flowtube

(i.e., on the upstream side).

Is a valve

located immediately upstream

of the flowtube?

NO

Remove the flowtube and examine the

insulation resistance.

NO

NO

NO

YES

NO

NO

NO

YES

YES

Set the parameters correctly.

Execute zero adjustment when the

flowtube is filled completely with fluid and

when the fluid is not moving.

● Change the mounting position or piping

so that the flowtube is

completely filled with fluid.

● Switch to vertical mounting.

Install a defoaming device on the

flowtube’s upstream side.

Completely ground the converter and

flowtube (Refer to the section on

grounding in the relevant user's manual.)

Fully terminate the signal cable using

PVC tubing or insulation tape, thus

insuring that conductors, inner shields,

and outer shields do not make contact

with each other or with the case.

Use within the specified conductivity range.

● Remove scales. Especially clean the

electrodes and their vincinity.

● Use a soft brush or cloth to perform

scale removal, and make sure that the

lining is not damaged.

● If any valve located immediately

upstream of the flowtube is used in a

half-open condition, the indication may

be affected by turbulence in the flow.

● Relocate the valve to the downstream

side.

● If the valve must be located on the

upstream side, ensure that the minimum

distance to the flowmeter is 10 times

the flow-tube diameter; alternatively,

use the valve fully open.

Signal terminals A-C and B-C:

100 MΩ or more

Excitation terminals EX1-C:

1 MΩ or more

YES

?

1

?

*

Examine the operation of the converter

using an AM012 calibrator in order to

determine whether the fault lies in the

converter or in the flowtube.

Contact a service center.

NO

Dry the tube fully to restore insulation

resistance.

*1: Refer to Section 5.3 for how to check

the resistance of the flowtube.

F0505.ai

IM 01E25D11-01EN

Page 31

Blank Page

Page 32

<6. OUTLINE>

6. OUTLINE

6-1

n STANDARD SPECIFICATIONS

Protection:

General-purpose type: IP66, IP67

Submersible type: IP68 (conforms to continuous

immersion under the following

test condition)

Test Condition: 50 m below the surface of the water, equivalent to

0.5 MPa hydraulic pressure, for one month.Cable

should be protected at customer site.

Material (non-wetted parts):

Flowtube:

Housing: Carbon steel

Flange: Carbon steel

Pipe: Stainless steel

Terminal box: Aluminum alloy

Material (wetted parts):

Lining:

Fluorocarbon PTFE

Natural hard rubber (plus EPDM for sealing)

Natural soft rubber

Polyurethane rubber

Contact Yokogawa ofce for others.

Electrode:

JIS SUS316L(AISI 316L SS Equivalent)

Hastelloy C276 Equivalent

Grounding ring (option):

JIS SUS304 or SUSF304 (AISI 304 SS

Equivalent)

Gasket (for option GR2):

Mixture of SBR and NR

Coating:

General-purpose type:

Pipe, Housing, Flange, Terminal Box:

Corrosion-resistant coating

Coating color: Mint green

Submersible type:

Pipe, Housing, Flange, Terminal Box:

Non-tar epoxy coating (black)

Wiring:

Electrical connection:

ANSI 1/2 NPT female

ISO M20 x 1.5 female

JIS G1/2 (PF1/2) female

Direction of Electrical Connection:

The direction can be changed even after

delivery except for submersible type and DHC

option type.

Wiring Terminal:

M4 screw

Grounding:

Grounding resistance 100 Ω or less

Combined Converter:

AXFA11 converter

Signal Cable:

AXFC, Maximum cable length to AXFA11

converter up to 200m (660 ft)

n STANDARD PERFORMANCE

Accuracy (Pulse Output):

0.35% of rate for sizes 500 mm (20 in.) to 1000

mm (40 in.)

0.5% of rate for sizes 1100 mm (44 in.) to 1800

mm (72 in.)

Size

mm(in.)

500(20)

to 1000(40)

1100(44)

to 1800(72)

For sizes 500mm (20 in.) to 1000mm (40 in.)

% of rate

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0 1 2 3 4 5 6 7 8 9 10

For sizes 1100mm (44 in.) to 1800mm (72 in.)

% of rate

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0 1 2 3 4 5 6 7 8 9 10

Flow Velocity

V m/s (ft/s)

V < 0.3 (1.0) ±2.0mm/s

0.3 ≤ V ≤ 10

(1.0) (33)

V < 0.3 (1.0) ±3.0mm/s

0.3 ≤ V < 1

(1.0) (3.3)

1 ≤ V ≤ 10

(3.3) (33)

Pulse Output Accuracy

Pulse Output Accuracy

±0.35% of rate ±1.0mm/s

±0.4% of rate ±1.8mm/s

±0.5% of rate ±1.0mm/s

V [m/s]

V [m/s]

Accuracy

F0601.ai

F0602.ai

IM 01E25D11-01EN

Page 33

<6. OUTLINE>

6-2

Note: The accuracy of a product before shipment is dened

as totalized value at the result of calibration test in

our water actual ow test facility.

Calibrated conditions in our water actual test facility

are as follows:

Fluid temperature: 20 ± 10°C

Ambient temperature: 20 ± 5°C

Length of straight runs:

10 D or more on the upstream side

5 D or more on the downstream side

Reference conditions:

Similar to BS EN29104, ISO 9104

Accuracy (Current Output):

Accuracy (Pulse Output) plus ±0.05% of span

Repeatability:

±0.2% of rate (V ≥ 1m/s (3.3ft/s))

±0.1% of rate ± 1mm/s (V < 1m/s (3.3ft/s))

Maximum Power Consumption:

Combined with AXFA11: 20W

Insulation Resistance:

Between excitation current terminal and signal

/ common terminals : 100MΩ at 500V DC

Between signal terminals : 100MΩ at 500V DC

Between signal terminals and common terminal (C) : 100MΩ at 500V DC

CAUTION

*1: When performing the Insulation Resistance

Test, please obey the following caution.

• Following the relevant test, wait for more

than 10 seconds after the power supply has

been turned off before removing the cover.

• Remove all wires from terminals before

testing.

• After testing, be sure to discharge by using

a resistance and return all wires to its

correct position.

• Screws must be tightened to a torque of

1.18 N-m or more.

• After closing the cover, the power supply

can be restored.

EMC Conformity Standards:

EN61326-1 Class A, Table2 (For use in industrial locations)

EN61326-2-3

EN61000-3-2 Class A

EN61000-3-3

CAUTION

This instrument is a class A product, and it is

designed for use in the industrial environment.

Please use this instrument in the industrial

environment only.

n NORMAL OPERATING CONDITIONS

Ambient Temperature:

–10 to +60°C (+14 to +140°F)

Note: Minimum temperature should also be limited accord-

ing to minimum uid temperature of ow tube’s specication. Refer to description of “Fluid Temperature

and Pressure”. Contact Yokogawa ofce for lower

temperature.

Ambient Humidity:

0 to 100%

Note: Lengthy continuous operation at 95% or more is not

recommended.

Fluid Conductivity:

20 µS /cm or larger for sizes 1000 mm and

below

50 µS /cm or larger for sizes 1100 mm and

above

Measurable Flow Rate Range:

Size

mm (in.)

500 (20)

600 (24)

700 (28)

800 (32)

900 (36)

1000 (40)

Size

mm (in.)

1100 (44)

1200 (48)

1350 (54)

1400 (56)

1500 (60)

1600 (64)

1800 (72)

Fluid Temperature and Pressure:

Note: The following values show maximum allowable uid

pressure for the owtube. Further uid pressure

should also be limited according to ange rating.

Lining Material Fluid Temperature Fluid Pressure

Fluorocarbon PTFE -10 to 120°C

Natural

hard rubber

Natural

soft rubber

Polyurethane

rubber

Min. Span

0.1m/s (0.33ft/s)

0 to 70.69 m

(0 to 311.3 GPM)

0 to 101.79

(0 to 448.2)

0 to 138.55

(0 to 610.0)

0 to 180.96

(0 to 796.8)

0 to 229.03

(0 to 1,009)

0 to 282.75

(0 to 1,245)

Min. Span

0.3 m/s (1 ft/s)

0 to 1,026.4 m

(0 to 4,519 GPM)

0 to 1,221.5

(0 to 5,378)

0 to 1,545.9

(0 to 6,807)

0 to 1,662.5

(0 to 7,320)

0 to 1,908.6

(0 to 8,403)

0 to 2,171.5

(0 to 9,561)

0 to 2,748.3

(0 to 12,101)

(14 to 248°F)

-5 to 80°C

(23 to 175°F)

-10 to 70°C

(14 to 158°F)

-10 to 40°C

(14 to 104°F)

3

/h

3

(0 to 31,122 GPM)

/h

(0 to 150,630 GPM)

Max. Span

10m/s (33ft/s)

0 to 7,068 m3/h

0 to 10,178

(0 to 44,815)

0 to 13,854

(0 to 60,999)

0 to 18,095

(0 to 79,672)

0 to 22,902

(0 to 100,835)

0 to 28,274

(0 to 124,488)

Max. Span

10 m/s (33 ft/s)

0 to 34,211 m3/h

0 to 40,715

(0 to 179,262)

0 to 51,529

(0 to 226,879)

0 to 55,418

(0 to 243,997)

0 to 63,617

(0 to 280,098)

0 to 72,382

(0 to 318,689)

0 to 91,608

(0 to 403,341)

0 to 1 MPa

(0 to 145 psi)

0 to 1 MPa

(0 to 145 psi)

0 to 1 MPa

(0 to 145 psi)

-0.1 to 1 MPa

(-14.5 to 145 psi)

IM 01E25D11-01EN

Page 34

<6. OUTLINE>

6-3

n MODEL AND SUFFIX CODE

For Process Connections other than JIS F12 (JIS 75M)

Model Sufx Code Description Available Size / Model

AXW500 Size 500 mm (20 in.) Remote Flowtube

AXW600 Size 600 mm (24 in.) Remote Flowtube

AXW700 Size 700 mm (28 in.) Remote Flowtube

AXW800 Size 800 mm (32 in.) Remote Flowtube

AXW900 Size 900 mm (36 in.) Remote Flowtube

AXW10L Size 1000 mm (40 in.) Remote Flowtube

AXW12L Size 1200 mm (48 in.) Remote Flowtube

AXW14L Size 1400 mm (56 in.) Remote Flowtube

AXW16L Size 1600 mm (64 in.) Remote Flowtube

AXW18L Size 1800 mm (72 in.) Remote Flowtube

Use G General-purpose type

W Submersible type

Converter -N

Power Supply

Lining (*1) F Fluorocarbon PTFE

Electrode Material (*1) L JIS SUS316L (AISI 316L SS Equivalent)

Electrode Structure 1 Non-replaceable

Grounding Structure (*2) N None (*3), available as optional feature (GR1)

Process Connection

(*4)

Lay Length N Standard

Electrical Connection -0 JIS G1/2 female

Indicator N None

Calibration B Standard

Optional Specications

*1:

Users must consider the characteristics of selected wetted parts material and inuence of process uids. The use of inappropriate materials

can result in the leakage of corrosive process uids and cause injury to personnel and/or damage to plant facilities. It is also possible that the

instrument itself can be damaged and that fragments from the instrument can contaminate the user’s process uids.

Be very careful with highly corrosive process uids such as hydrochloric acid, sulfuric acid, hydrogen sulde, sodium hypochlorite, and high-

temperature steam (150°C [302°F] or above). Contact Yokogawa for detailed information of the wetted parts material.

*2: Select optional grounding rings (code GR1) if necessary. For example, grounding rings are necessary for plastic piping.

*3: “None” is applicable only for metal piping and wiring for grounding will be necessary so that the electric potentials between owtube and piping

ange should be the same.

*4: Contact Yokogawa ofce for ISO ange connection.

N Remote Flowtube

H Natuarl Hard Rubber

D Natuarl Soft Rubber

U Polyurethane Rubber

H Hastelloy C276 Equivalent

-CA1

-CB1 AWWA C207 Class D (Carbon Steel)

-CEJ

-CEK

-CE1

-CE2

-CJ1 JIS B2220 10K Flange (Carbon Steel)

-CS1 AS2129 Table D (Carbon Steel)

-CS2 AS2129 Table E (Carbon Steel)

-CT1 AS4087 PN16 (Carbon Steel)

-2

-4

Remote Flowtube for Combined Use with AXFA11

See “Proces Connection”.

See “Proces Connection”.

See “Proces Connection”.

See “Proces Connection”.

ASME B16.5 Class 150 Flange (Carbon Steel)

ASME B16.47 Series A Class 150 Flange

(Carbon Steel)

500 mm (20 in.) and 600 mm (24 in.)

for lining code F/H/D/U

700 mm (28 in.) to 1000 mm (40 in.)

for lining code F/H/D/U

700 mm (28 in.) to 1000 mm (40 in.)

for lining code F/H/D/U

1200 mm (48 in.) for lining code H

EN1092-1 PN6 Flange (Carbon Steel)

EN1092-1 PN10 Flange (Carbon Steel)

(uid pressure up to 0.6 MPa)

1200 mm (48 in.) to 1800 mm (72 in.)

for lining code H

500 mm (20 in.) to 1000 mm (40 in.)

EN1092-1 PN10 Flange (Carbon Steel)

(uid pressure up to 1 MPa)

for lining code F/H/D/U

1200 mm (48 in.) to 1800 mm (72 in.)

for lining code H

EN1092-1 PN16 Flange (Carbon Steel)

(uid pressure up to 1 MPa)

500 mm (20 in.) to 1000 mm (40 in.)