Page 1

Technical

Information

Combining ADMAG AXF

with Existing Remote Type

Magnetic Flowmeters

TI 01E20A02-01E

Company Confidential

Contents

Introduction .................................................................................................................. 2

1. Combining AXF Flowtubes with Existing Converters ...................................... 3

1.1 Combination between AM11 and AXF Flowtubes............................................. 3

1.2 Combination between AE14 and AXF Flowtubes ............................................. 3

1.3 Combination between YMA11 and AXF Flowtubes........................................... 4

2. Combining AXFA Converters with Existing Flowtubes .................................... 7

2.1 Combination between AM Flowtubes and AXFA11........................................... 8

(Combination between AM Flowtubes and AXFA14)

2.2 Combination between AE Flowtubes and AXFA14 ........................................... 9

(Combination between AE Flowtubes and AXFA11)

2.3 Combination between SE Flowtubes and AXFA11 ......................................... 10

2.4 Combination between YM Flowtubes and AXFA11......................................... 11

2.5 Combination between Flowtubes of Other Manufacturers and AXFA11 ......... 13

3. How to Check the Performance of Existing Flowtubes.................................. 16

4. How to Obtain Meter Factor using the Customer's Flow Line ....................... 17

4.1 How to Perform Flow Calibration in Combination with AXFA11 using the

Customer's Facilities ....................................................................................... 17

4.2 How to Obtain Meter Factor by Incorporating the Indicated Flow Rate of the

Existing Converter. .......................................................................................... 18

4.3 How to Obtain Meter Factor According to the Inferred Flow Rates Such as

Valve Openings or Pump Rpm ........................................................................ 19

5. Compatibility with AXFA11 and AXFA14 ....................................................... 20

Appendix. 1 Electrical Connection............................................................................ 21

(1)Combination AXFA11 and FOXBORO 1800 Series ........................................ 22

(2) Combination AXFA11 and FOXBORO 2800 Series ........................................ 24

(3) Combination AXFA11 and F&P 10D1418 Series ............................................ 26

(4) Combination AXFA11 and F&P 10D1419 Series ............................................ 28

(5) Combination AXFA11 and F&P 10D1430 Series ............................................ 29

(6) Combination AXFA11 and F&P 10D1435 (MAGX) Series (6” to 48”).............. 31

(7) Combination AXFA11 and F&P 10D1475 (MINI MAGX) Series...................... 32

(8) Combination AXFA11 and BROOKS 7000 Series .......................................... 33

(9) Combination AXFA11 and BROOKS 7100 Series .......................................... 34

(10) Combination AXFA11 and BROOKS 7400 Series .......................................... 35

(11) Combination AXFA11 and BROOKS 7500 Series .......................................... 36

(12) Combination AXFA11 and KROHNE ALTFLUX X-1000, M900 Series ........... 37

(13) Combination AXFA11 and ROSEMOUNT 8701.............................................. 39

(14) Combination AXFA11 and TAYLOR 1100 Series ............................................ 40

Yokogawa Electric Corporation

2-9-32 Nakacho, Musashino-shi, Tokyo 180, Japan

Tel.: 81-422-52-4443 Fax.: 81-422-52-2018

TI 01E20A02-01E

©Copyright Aug. 2004

1st Edition Aug. 2004

Page 2

<T oc> <Ind>

Introduction

This technical information describes how to combine ADMAG AXF magnetic flowmeters with

existing remote type flowtubes or con verters. A magnetic flo wmeter is used by obtaining a meter

factor , which is a calibration coefficient unique to a flo wtube, according to flo w calibration and then

by setting the meter factor to a conv erter. Values of meter factors depend on the models of

converters to be combined. Therefore, in order to measure flow rates with high accuracy, flow

calibration must be re-performed at the factory. If this is not possible, refer to additional errors and

meter factor conversion coefficients described in this technical inf ormation.

There are various precautions for combinations with e xisting instruments. In some cases , such

instruments cannot be combined or require settings by Yokogaw a's service personnel. Read this

technical information carefully and take appropriate measures.

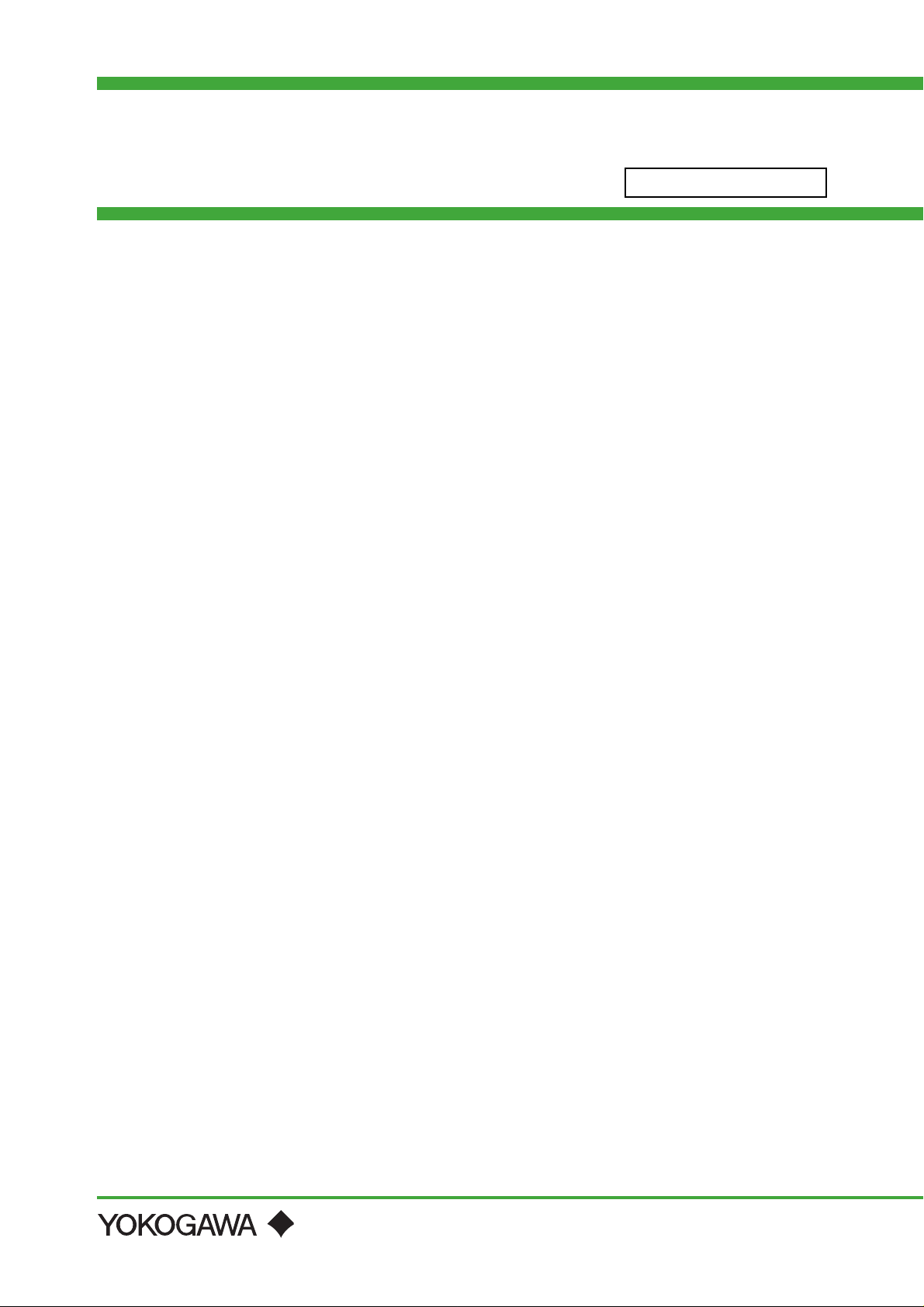

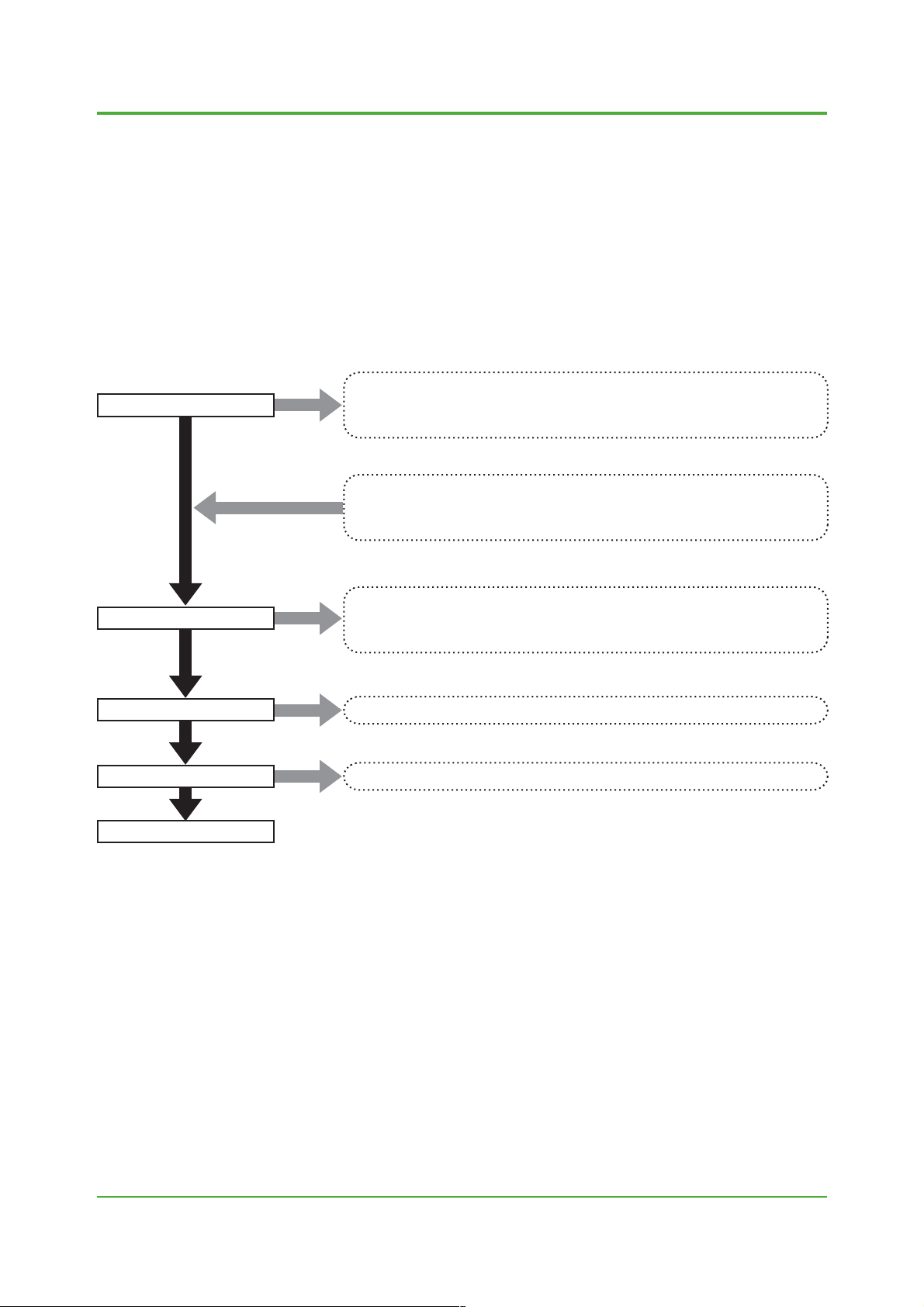

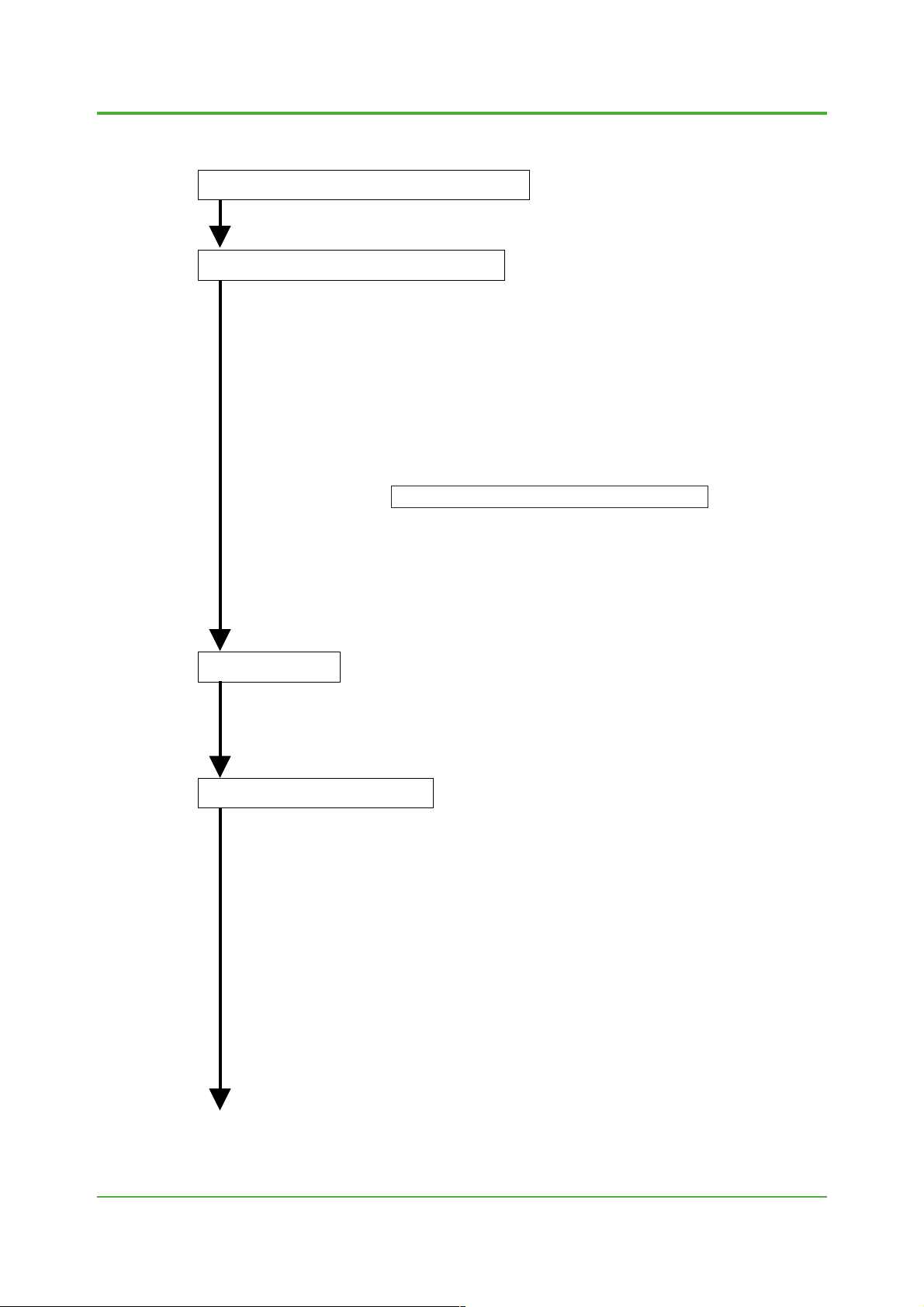

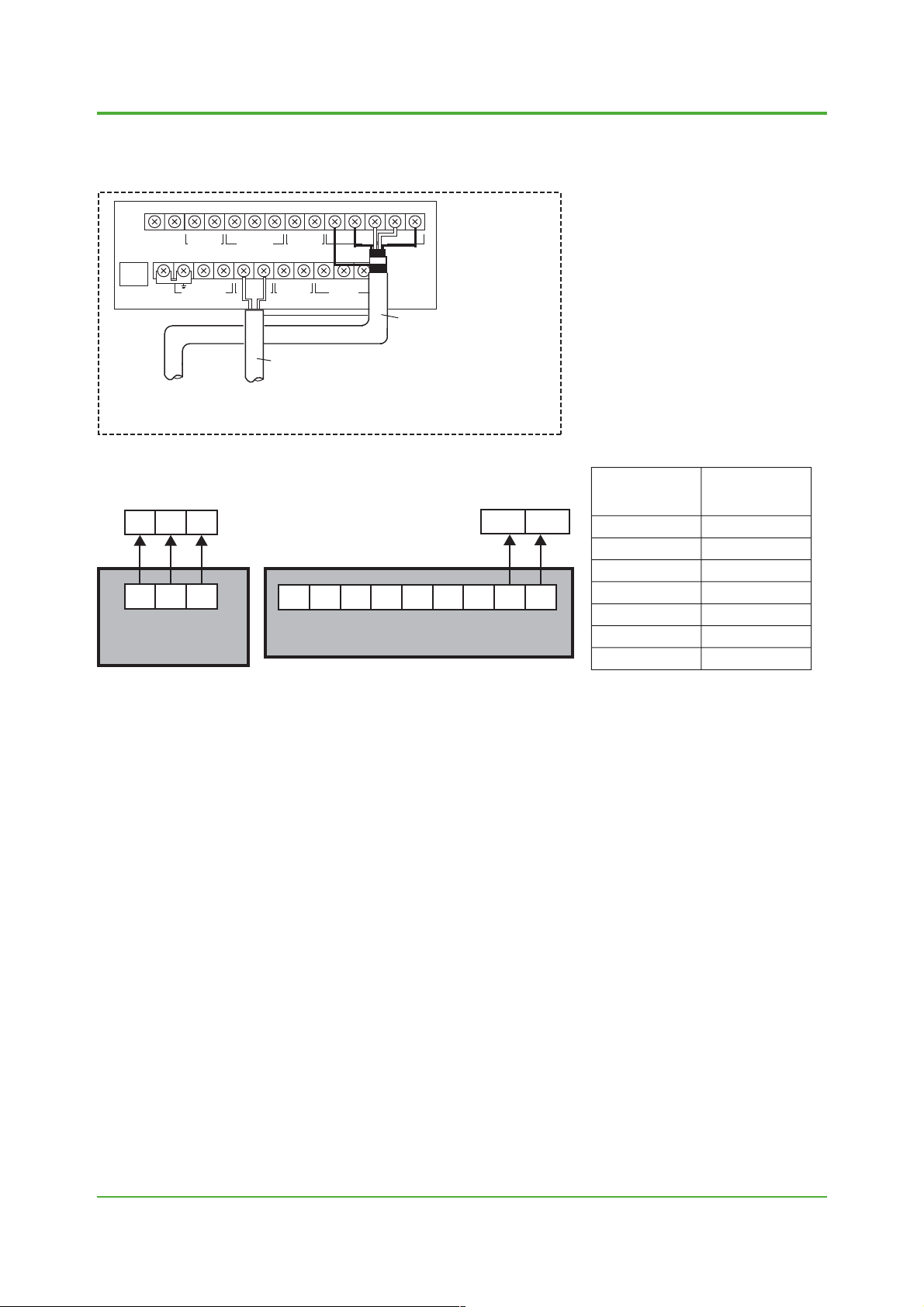

Possible Combinations between Existing Remote Type Flowtubes/Con verters and ADMAG AXF

Series

Converters

Flowtubes

2

AXFA14 AM11AXFA11

Section 1.1

AE14 YMA11SE14

Section 1.2—

Not possible

Section 1.3 Not possibleAXF Flowtube

Converters of Other

Manufacturers

AM Flowtube

AE Flowtube

SE Flowtube

YM Flowtube

Flowtubes of Other

Manufacturers

Section 2.1

See Note in

Section 2.2

Section 2.3

Section 2.4 Not possible

Note: Even if a flowtube is an e xplosion-proof type, the e xplosion-proof capability is not satisfied if the flo wtube is

combined with a different model. If the explosion-proof capability is required, the flowtube must be used in the

combination specified for the same model.

See Note in

Section 2.1

Section 2.2

Not possible

Not possibleSection 2.5

T01.EPS

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

TI 01E20A02-01E 2004-00

Page 3

<T oc> <Ind>

1. Combining AXF Flowtubes with Existing Con verters

Note 1: For combinations between an existing converter and an AXF flowtube, only AM11, AE14 and YMA11 can be

used. Other conv erters (SE14 and converters of other companies) cannot be combined with AXF flowtubes.

Note 2: Even if flow calibration is redone, functions and capabilities are equivalent to those of existing instruments. The

functions unique to AXF such as enhanced dual frequency excitation cannot be used.

1.1 Combination between AM11 and AXF Flowtubes

1.1.1 When newly pur chasing AXF flowtubes

• Issue a Tokuchu request for purchasing AXF flowtubes. In this case, the enhanced dual

frequency excitation function (option codes /HF1 and /HF2) cannot be selected. In the

Tokuchu request, be sure to enter a model name of an existing converter (a full model

and suffix code) and indicate clearly that an AXF flowtube will be combined with this

converter.

• In addition to the regular flow calibration with AXFA converters, flow calibration in

combination with AM11 is performed and then both meter factors are inscribed on the

data plate. Set the meter factor for AM11 to AM11 before operation. The accuracy in this

case will be the same as AM.

Note: Meter factors for combinations diff er , depending on whether an e xisting con v erter is AM11-AS/DH/DB

or AM11-DL. Theref ore, be sure to state a full model and suffix code clearly in a Tokuchu request.

3

1.1.2 When using existing or stock AXF flo wtubes

Combination with AM11-AS, DH or DB

• It is recommended that flow calibration be redone for the AXF flowtubes at Yokogawa's

factory. The accuracy in this case will be the same as AM.

• If flow calibration cannot be redone at Yokogawa's factory, set the meter factors (both

the low MF value and the high MF value) inscribed on AXF flowtubes to AM11 as they

are. The accuracy for reference in this case will be approximately AM accuracy ⫾additional 0.5% for flowtubes for AXFA11 (model name: AXFxxxx-N) and approximately AM

accuracy ⫾additional 1.5% for flowtubes for AXFA14 (model name: AXFxxxx-P).

Combination with AM11-DL

• Flow calibration must be redone for the AXF flowtubes at Yokogawa's factory. The

accuracy in this case will be the same as AM.

• If flow calibration cannot be redone at Yokogawa's factory, contact Yokogawa. Since

meter factors differ substantially for combination with the DL-type, meter factors inscribed on the AXF flowtubes cannot be set for use as they are.

1.2 Combination between AE14 and AXF Flowtubes

Note: Sizes of the flowtubes which can be combined with AE14 are 2.5 mm (0.1 in.) to 400 mm (16 in.) only.

1.2.1 When newly pur chasing AXF flowtubes

• Issue a Tokuchu request for purchasing AXF flowtubes. In this case, the enhanced dual

frequency excitation function (option codes /HF1 and /HF2) cannot be selected. In the

Tokuchu request, be sure to indicate clearly that AXF flowtubes will be combined with

AE14.

• In addition to the regular flow calibration with AXFA converters, flow calibration in

combination with AE14 is performed and then both meter factors are inscribed on the

data plate. Set the meter factor for AE14 to AE14 before operation. The accuracy in this

case will be the same as AE.

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation TI 01E20A02-01E

2004-00

Page 4

<T oc> <Ind>

1.2.2 When using existing or stock AXF flo wtubes

• It is recommended that flow calibration be redone for the AXF flowtubes at Yokogawa's

factory. The accuracy in this case will be the same as AE.

• If flow calibration cannot be redone at Yokogawa's factory, set the meter factors (both

the low MF value and the high MF value) inscribed on AXF flowtubes to AE14 as they

are. The accuracy for reference in this case will be approximately AE accuracy ⫾addi-

tional 0.5% for flowtubes for AXFA14 (model name: AXFxxxx-P) and approximately AE

accuracy ⫾additional 1.5% for flowtubes for AXFA11 (model name: AXFxxxx-N).

1.3 Combination between YMA11 and AXF Flowtubes

1.3.1 When newly pur chasing AXF flowtubes

• Issue a Tokuchu request for purchasing AXF flowtubes. In this case, the enhanced dual

frequency excitation function (option codes /HF1 and /HF2) cannot be selected. In the

Tokuchu request, be sure to indicate clearly that AXF flowtubes will be combined with

existing YMA11 converters.

• In addition to the regular flow calibration with AXFA converters, flow calibration in

combination with YMA11 is performed and then both meter factors are inscribed on the

data plate. Set the meter factor for YMA11 and an excitation current value to YMA11

before operation. Obtain a relevant excitation current value from Tables 1.3.1 to 1.3.3.

The accuracy in this case will be the same as YM.

4

1.3.2 When using existing or stock AXF flo wtubes

• It is recommended that flow calibration be redone for the AXF flowtubes at Yokogawa's

factory. The accuracy in this case will be the same as YM.

• If flow calibration cannot be redone at Yokogawa's factory and if a flowtube for AXFA11

(AXFxxxx-N) is used, obtain a necessary excitation current value and an approximate

meter factor value from Tables 1.3.1 to 1.3.3, and combine the flowtube with YMA11.

The meter factor for YMA11 is obtained by multiplying the low meter factor (the meter

factor inscribed on the "METER FACTOR L" section of the data plate) of the AXF

flowtube with a coefficient in Tables 1.3.1 to 1.3.3. Although the accuracy in this case is

not guaranteed, it will be approximately YM accuracy ⫾additional 2% as a reference.

Also, the excitation current value needs to be set to YMA11.

• Flowtubes for AXFA14 (AXFxxxx-P) cannot be combined with YMA11 without redoing

flow calibration.

• AXF flowtubes with the size of 32 mm (1.25 in.), 65 mm (2.5 in.) or 125 mm (5 in.) cannot

be combined with YMA11.

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

TI 01E20A02-01E 2004-00

Page 5

<T oc> <Ind>

5

Table 1.3.1 Combination between AXF Ceramic Lining Flowtubes and YMA11

Meter factor for YMA11 = Low meter factor for AXF flowtube ⫻ coefficient in the table below

Size of AXF

Flowtube

[mm (in.)]

2.5 (0.1)

5 (0.2)

10 (0.4)

15 (0.5)

25 (1.0)

40 (1.5)

50 (2.0)

80 (3.0)

100 (4.0)

150 (6.0)

200 (8.0)

YMA11 Excitation

Current Setting

Value (A)

0.12

0.13

0.22

0.22

0.14

0.13

0.12

0.16

0.14

0.11

0.12

Coefficient in 1/8 Mode Excitation Coefficient in 1/2 Mode Excitation

60 Hz Area 50 Hz Area50 Hz Area 60 Hz Area

1.0304

0.9771

0.6542

0.9589

0.9756

0.9723

0.9697

0.9701

0.9619

0.9672

0.9666

1.0313

0.9757

0.9542

0.9584

0.976

0.9724

0.9691

0.9688

0.9602

0.9661

0.9661

1.0232

0.9760

0.95

0.9589

0.9748

0.9732

0.9683

0.9673

0.9567

0.9639

0.9596

Table 1.3.2 Combination between AXF PF A Lining Flowtubes and YMA11

Meter factor for YMA11 = Low meter factor for AXF flowtube ⫻ coefficient in the table below

Size of AXF

Flowtube

[mm (in.)]

2.5 (0.1)

5 (0.2)

10 (0.4)

15 (0.5)

25 (1.0)

40 (1.5)

50 (2.0)

80 (3.0)

100 (4.0)

150 (6.0)

200 (8.0)

250 (10.0)

300 (12.0)

350 (14.0)

400 (16.0)

For " * " sections in the table, contact Yok ogaw a.

YMA11 Excitation

Current Setting

Value (A)

0.12

0.14

0.23

0.23

0.15

0.13

0.13

0.17

0.14

0.11

0.12

0.5

0.5

0.5

0.5

Coefficient in 1/8 Mode Excitation Coefficient in 1/2 Mode Excitation

60 Hz Area 50 Hz Area50 Hz Area 60 Hz Area

1.0127

0.9786

0.94

0.9423

0.9755

0.9727

0.9728

0.9741

0.9635

0.9796

0.9767

0.9924

0.9864

*

0.9844

1.0162

0.9788

0.9403

0.9419

0.976

0.9719

0.9725

0.9726

0.9625

0.9779

0.9759

0.9925

0.9855

*

0.9841

1.0092

0.9763

0.9351

0.9398

0.9746

0.9716

0.9715

0.9701

0.9562

0.9679

0.9756

0.9595

0.9435

*

0.9367

1.0205

0.9730

0.9487

0.9583

0.9746

0.9717

0.9675

0.9658

0.9546

0.9603

0.9550

T02.EPS

1.006

0.975

0.9335

0.9399

0.9747

0.9708

0.9705

0.9674

0.9526

0.9613

0.9468

0.9483

0.9265

*

0.9193

T03.EPS

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation TI 01E20A02-01E

2004-00

Page 6

<T oc> <Ind>

6

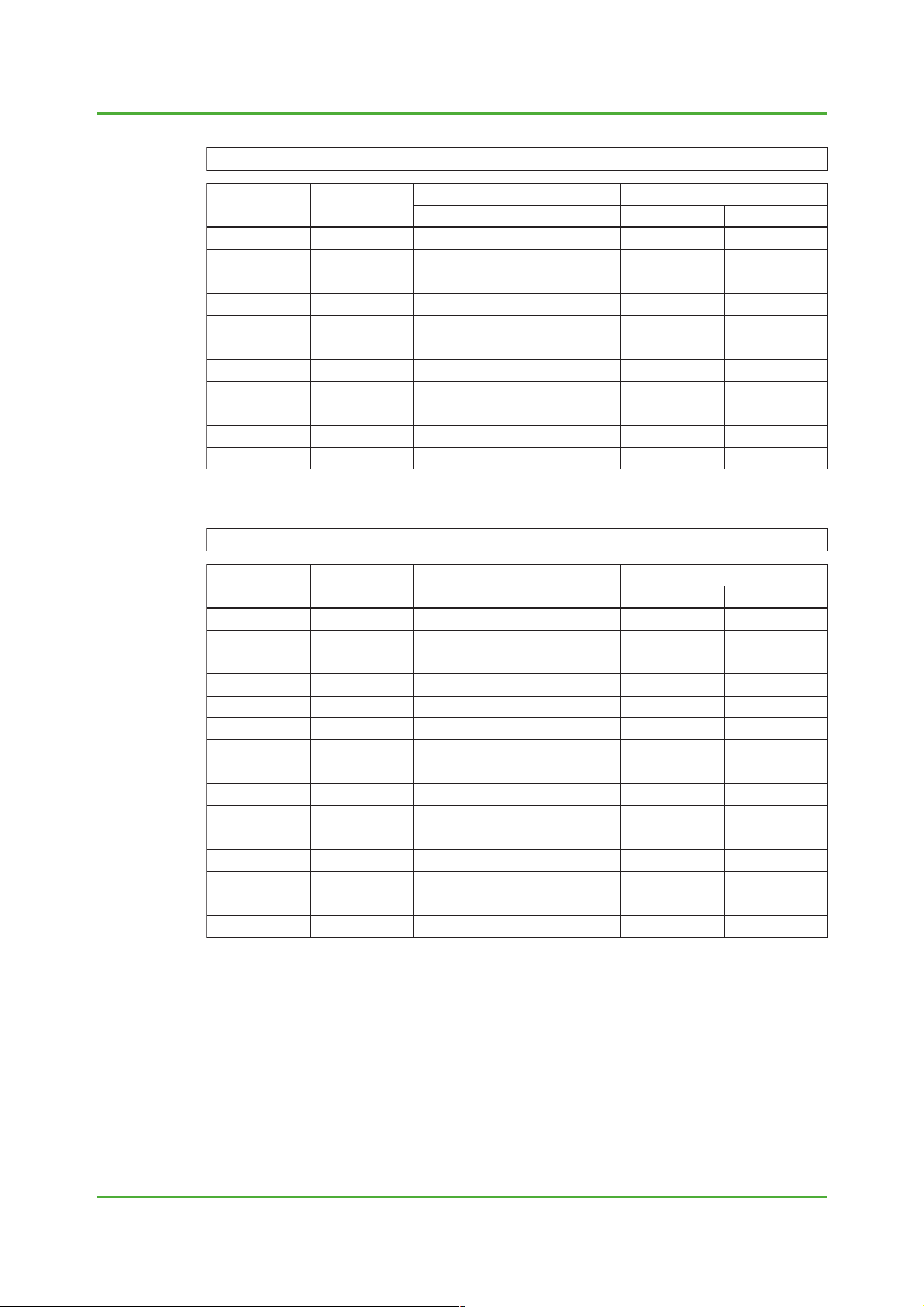

Table 1.3.3 Combination between AXF P ol yurethane Lining Flowtubes and YMA11

Meter factor for YMA11 = Low meter factor for AXF flowtube ⫻ coefficient in the table below

Size of AXF

Flowtube

[mm (in.)]

25 (1.0)

40 (1.5)

50 (2.0)

80 (3.0)

100 (4.0)

150 (6.0)

200 (8.0)

For " * " sections in the table, contact Yok ogawa.

YMA11 Excitation

Current Setting

Value (A)

0.2

*

*

0.23

0.2

0.15

0.17

Coefficient in 1/8 Mode Excitation Coefficient in 1/2 Mode Excitation

0.9841

*

*

0.9836

0.9562

0.9845

0.9818

60 Hz Area 50 Hz Area50 Hz Area 60 Hz Area

0.9835

*

*

0.9821

0.9553

0.9827

0.9802

0.9840

*

*

0.972

0.9491

0.9742

0.9621

0.9838

*

*

0.9701

0.9452

0.9684

0.9519

T04.EPS

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

TI 01E20A02-01E 2004-00

Page 7

<T oc> <Ind>

2. Combining AXF A Con verters with Existing Flowtubes

Note: In some cases, these instruments cannot be combined. Ev en if they can be combined, it is strongly recommended

to redo flow calibration if existing flowtubes are Yokoga w a's products. The accuracy in this case will be the

standard accuracy of the existing flowtubes. If flow calibration cannot be redone or if AXFA conv erters need to be

combined with flowtubes of other manufacturers, meter f actors based on calculations or on-site actual flow tests

shall be incorporated. Note that the accuracy is not guaranteed in this case. It may also not be possible to provide

additional errors for reference.

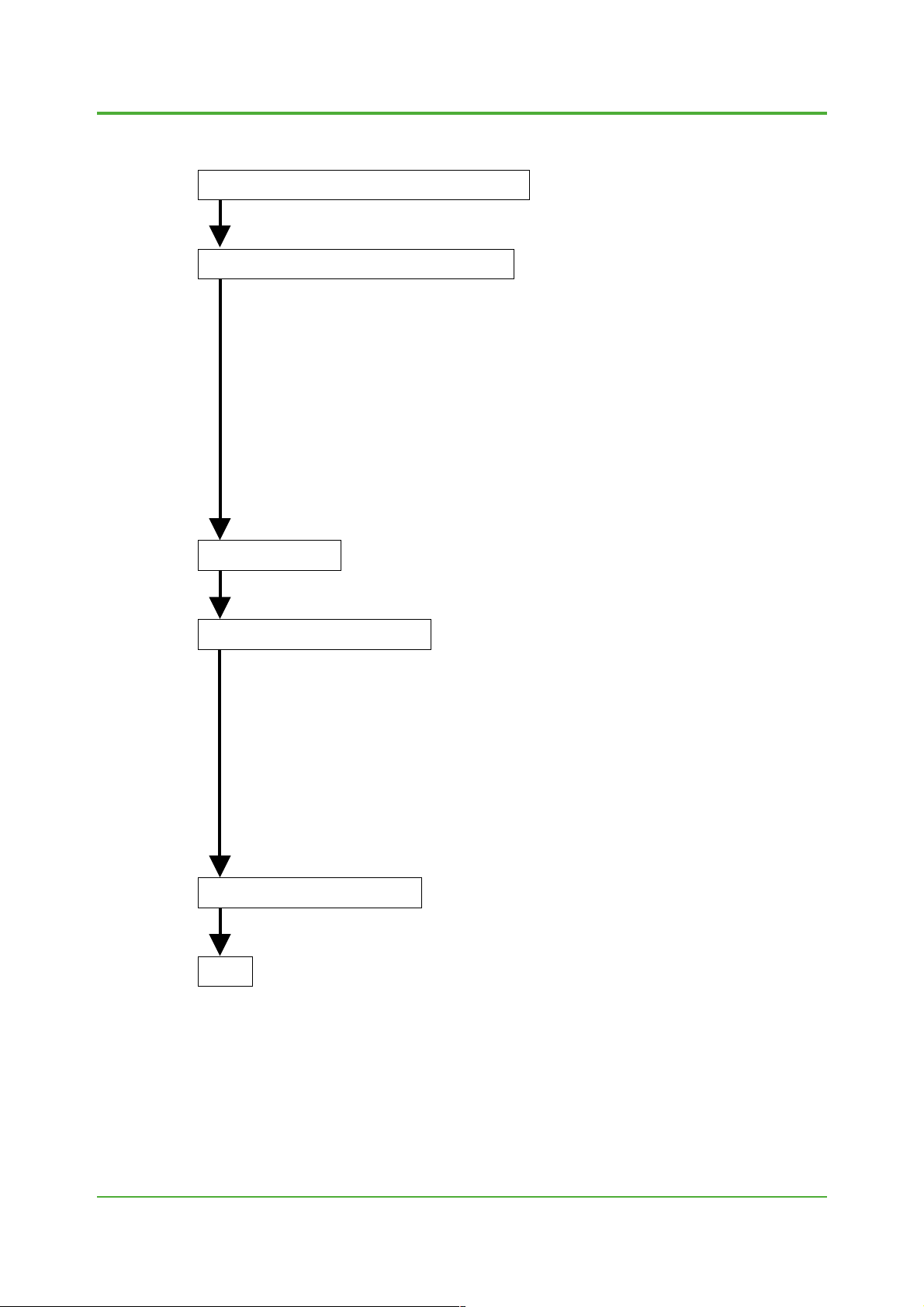

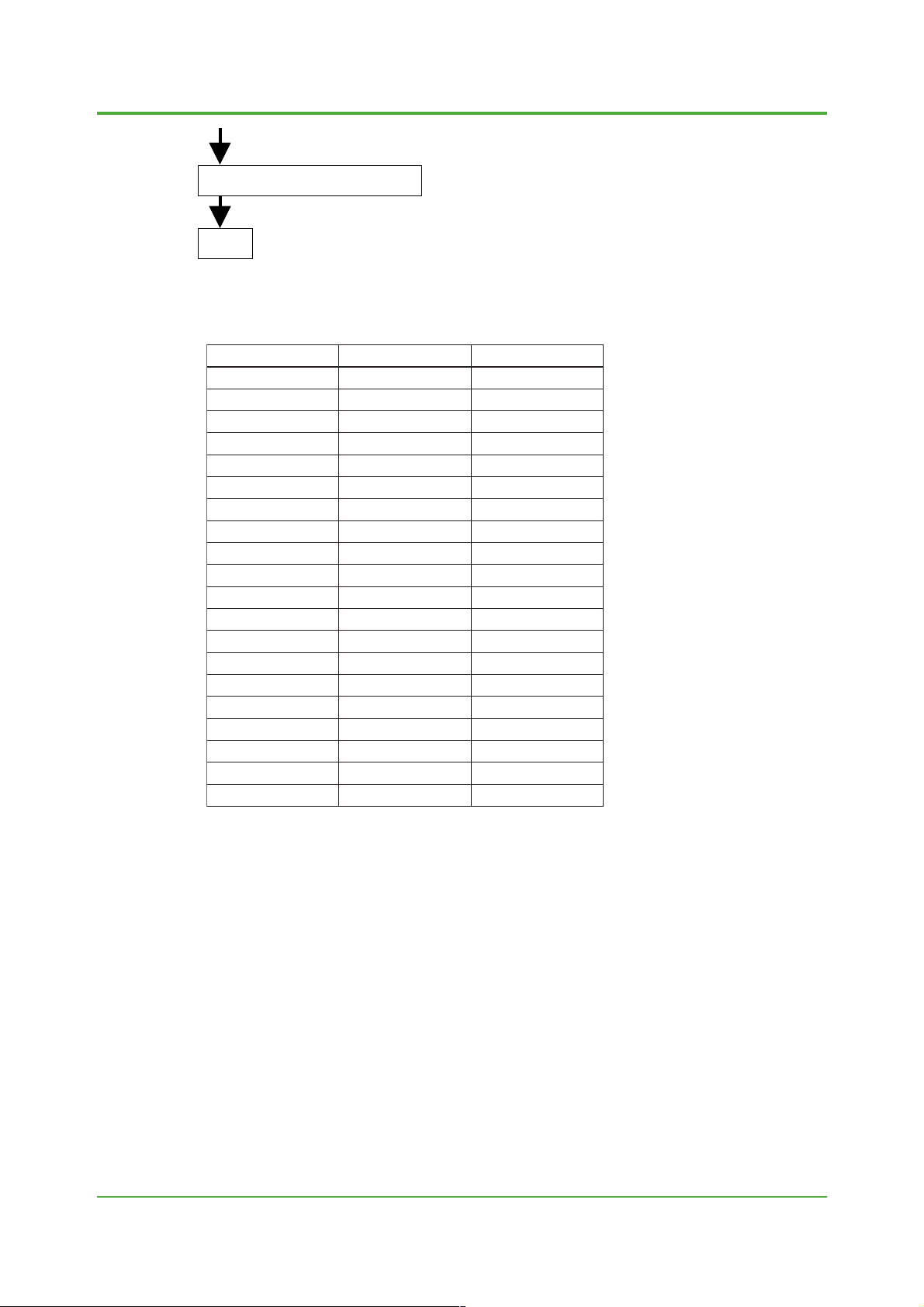

Outline of procedures

• For details, see Sections 2.1 to 2.5.

(1) Continuity and insulation check of excitation coils

Flowtube performance check

(2) Continuity and insulation check of signal lines

(See Chapter 3 "How to Check the Performance of Existing Flowtubes.")

Obtain a meter factor:

(1) Obtain a meter factor by referring to Sections 2.1 to 2.5 and Chapter 4.

(2) For redoing flow calibration at the factory, request Yokogawa.

7

Wiring

AXFA parameter setting

Automatic zero adjustment

End

(1) For signal cables, use dedicated signal cable AXFC. Note that AM011 cable

and YM011 cable can be used if insulation and continuity are not deteriorated.

(2) Connect flowtubes and converters.

(1) For parameter setting, see Sections 2.1 to 2.5 and the user's manual for AXFA.

Perform the automatic zero adjustment by referring to the user's manual for AXFA.

F01.EPS

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation TI 01E20A02-01E

2004-00

Page 8

<T oc> <Ind>

2.1 Combination between AM Flowtubes and AXFA11

2.1.1 Flowtube performance c heck

Based on Chapter 3 "How to Check the Performance of Existing Flowtubes," check

that an existing flowtube is not damaged.

2.1.2 Obtaining the meter factors

Obtain the meter factors by either of the following two methods a) or b) depending on

the situation:

a) By obtaining the meter factors by redoing flow calibration at Yokogawa's

factory

The accuracy in this case will be the same as AM.

b) By using the meter factors of AM

• For the sizes from 2.5 mm (0.1 in.) to 1000 mm (40 in.) and the sizes from 1100

mm (44 in.) to 2600 mm (104 in.) style A or style B (model code: AM5xxx.....*A

or *B), the meter factors inscribed on AM flowtubes can be set to AXFA11 as

they are. The accuracy for reference in this case will be approximately AM

accuracy ⫾additional 0.5%.

• If the existing flowtube is 1100 mm (44 in.) to 2600 mm (104 in.) style C (model

code: AM5xxx.....*C), the AM's meter factor cannot be set to AXFA11 as it is,

because the meter factor in combination with AXFA11 differs substantially.

Contact Yokogawa for how to deal with such situations.

8

2.1.3 Wiring

Connect the AM flowtube with AXFA11.

The wiring is the same as in the case of connecting AXF flowtubes with AXFA11.

2.1.4 Parameter setting

Set the following parameters to AXFA11:

• Select "ADMAG" in the parameter "C30: Select Flow Tube." Flowtubes with the

size of 400 mm (16 in.) or smaller are driven with dual frequency excitation,

while those with the size of 500 mm (20 in.) or larger are driven with pulsed DC

calculation. The enhanced dual frequency excitation function cannot be used.

• Set both "C21: Low MF" and "C22: High MF" as meter factors for flowtubes with

the sizes from 2.5 mm (0.1 in.) to 400 mm (16 in.). Set "C21: Low MF" as the

meter factor for flowtubes with the sizes from 500 mm (20 in.) to 2600 (104 in.)

mm, and set 1.0000 to "C22: High MF."

• For the sizes from 1100 mm (44 in.) to 2600 mm (104 in.), select "No" in the

parameter "J30: Power Synch" and set "49.00" to "J31: Power Frequency."

• For details on setting parameters other than the above, follow the user's

manual for AXFA11.

2.1.5 Zero adjustment

Perform the automatic zero adjustment according to the user's manual for AXFA11.

End

Note: Combinations between AM flo wtubes and AXFA14 can also be operated using the same

procedure. How ev er, in "b) By using the meter factors of AM" of Section 2.1.2 "Obtaining the

meter factors," the accuracy f or ref erence will be appro ximately AM accuracy ⫾additional 1.5%.

Moreover , in the case of the siz es from 250 mm (10 in.) to 400 mm (16 in.), output fluctuations

may become larger than in the case of operations using AXFA11 due to EMF differences.

Note that combinations between AM flowtubes and AXFA14 are only possible for the sizes from

2.5 mm (0.1 in.) to 400 mm (16 in.).

There is no need to set the parameter "C30: Select Flo w Tube" (there is no parameter "C30" in

AXFA14).

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

TI 01E20A02-01E 2004-00

Page 9

<T oc> <Ind>

2.2 Combination between AE Flowtubes and AXFA14

2.2.1 Flowtube performance chec k

Based on Chapter 3 "How to Check the Performance of Existing Flowtubes," check

that an existing flowtube is not damaged.

2.2.2 Obtaining the meter factors

Obtain the meter factors by either of the following two methods a) or b) depending on

the situation:

a) By obtaining the meter factors by redoing flow calibration at Yokogawa's

factory

The accuracy in this case will be the same as AE.

b) By using the meter factors of AE

The meter factors inscribed on AE flowtubes can be set to AXFA14 as they are.

The accuracy for reference in this case will be approximately AE accuracy

⫾additional 0.5%.

2.2.3 Wiring

Connect the AE flowtube with AXFA14.

The wiring is the same as in the case of connecting AXF flowtubes with AXFA14.

2.2.4 Parameter setting

Set the following parameters to AXFA14:

• Set both "C21: Low MF" and "C22: High MF" as meter factors.

• For details on setting parameters other than the above, follow the user's

manual for AXFA14.

Note: AE flowtubes are driv en with dual frequency e xcitation. The enhanced dual frequency e xcitation

function cannot be used.

9

2.2.5 Zero adjustment

Perform the automatic zero adjustment according to the user's manual for AXFA14.

End

Note: Combinations between AE flo wtubes and AXFA11 can also be operated using the same

procedure. Ho we v er , in "b) By using the meter factors of AE" of Section 2.2.2 "Obtaining the

meter factors," the accuracy f or ref erence will be approximately AE accur acy ⫾additional 1.5%.

Select "ADMAG AE" in the parameter "C30: Select Flo w Tube" for AXF A11.

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation TI 01E20A02-01E

2004-00

Page 10

<T oc> <Ind>

2.3 Combination between SE Flowtubes and AXFA11

2.3.1 Flowtube performance c heck

Based on Chapter 3 "How to Check the Performance of Existing Flowtubes," check

that an existing flowtube is not damaged.

2.3.2 Obtaining the meter factor

Obtain the meter factor by either of the following two methods a) or b) depending on

the situation:

a) By obtaining the meter factor by redoing flow calibration at Yokogawa's

factory

The accuracy in this case will be the same as SE.

b) By obtaining meter factor using the customer's flow line according to

Chapter 4

Follow Section 2.3.3 "Wiring" and Section 2.3.4 "Parameter setting" before

obtaining meter factor according to the actual flow test.

2.3.3 Wiring

Connect the SE flowtube with AXFA11.

The wiring is the same as in the case of connecting AXF flowtubes with AXFA11.

2.3.4 Parameter setting

Set the following parameters to AXFA11:

• Select "ADMAG SE" in the parameter "C30: Select Flow Tube." SE Flowtubes

are driven with pulsed DC calculation.

• Set the obtained meter factor to "C21: Low MF." Set 1.0000 to "C22: High MF."

• For details on setting parameters other than the above, follow the user's

manual for AXFA11.

10

2.3.5 Zero adjustment

Perform the automatic zero adjustment according to the user's manual for AXFA11.

End

Note 1: Meter factors of SE flowtubes cannot be used for setting as they are, as meter factors diff er substantially in the

combinations between SE flowtubes and AXF A11.

Note 2: AXFA14 cannot be combined with SE flowtubes, as it cannot drive the SE flowtubes .

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

TI 01E20A02-01E 2004-00

Page 11

<T oc> <Ind>

2.4 Combination between YM Flowtubes and AXFA11

2.4.1 Flowtube performance chec k

Based on Chapter 3 "How to Check the Performance of Existing Flowtubes," check

that an existing flowtube is not damaged.

2.4.2 Obtaining the meter factor

Obtain the meter factor by either one of the following three methods a), b) and c),

depending on the situation:

a) By obtaining the meter factor by redoing flow calibration at Yokogawa's

factory

The accuracy in this case will be the same as YM.

b) By calculating from the meter factor of YM

The accuracy for reference will be approximately YM accuracy

(1) Read the meter factor in 1/8 mode (standard mode) and 50 Hz from the data

plate of a YEWMAG flowtube.

(2) The meter factor is obtained by multiplying the YM meter factor in 1/8 mode

and 50 Hz by a coefficient determined for each size shown in Table 2.4

"Meter Factor Calculation Coefficient Table".

Example:

c) By obtaining meter factor using the customer's flow line according to

Chapter 4

Follow Section 2.4.3 "Wiring" and Section 2.4.4 "Parameter setting" before

obtaining meter factor according to the actual flow test.

YM102 1/8 mode, 50 Hz Meter factor: 0.2800

50 Hz area:

Meter factor: 0.2800 ⫻ 1.0825 = 0.3031

60 Hz area:

Meter factor: 0.2800 ⫻ 1.0820 = 0.3030

11

⫾additional 1%.

2.4.3 Wiring

Connect the YM flowtube with AXFA11.

The wiring is the same as in the case of connecting AXF flowtubes with AXFA11.

Note that, if BARD is used for a YM explosion-proof type flowtube, remove the BARD

and use the flowtube as a non-explosion-proof type product. This combination

cannot satisfy the requirements of explosion-proof capabilities.

2.4.4 Parameter setting

Set the following parameters to AXFA11:

• Select "YEWMAG" in the parameter "C30: Select Flow Tube."

• Check the software revision number of AXFA11 which is indicated in the

parameter "J50: Software Rev No."

If the revision number is "R1.05" or "R1.08":

Select "Low" in the service parameter (not disclosed) "U15: 4-20mA Sel."

Be sure to contact Yokogawa for the service parameter setting. Pulsed DC

calculations apply to all sizes.

If the revision number is other than "R1.05" or "R1.08":

There is no need to set "U15: 4-20mA Sel." Pulsed DC calculations automatically apply to all sizes by selecting "YEWMAG" in the parameter "C30:

Select Flow Tube" as above.

• Set the obtained meter factor to "C21: Low MF." Set 1.0000 to "C22: High MF."

• For the sizes from 1100 mm (44 in.) to 2600 mm (104 in.), select "No" in the

parameter "J30: Power Synch" and set "49.00" to "J31: Power Frequency."

• For details on setting parameters other than the above, follow the user's

manual for AXFA11.

(To the next page)

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation TI 01E20A02-01E

2004-00

Page 12

<T oc> <Ind>

2.4.5 Zero adjustment

Perform the automatic zero adjustment according to the AXFA11 user's manual.

End

Note: AXFA14 cannot be combined with YM flowtubes , as it cannot oper ate the YM flowtubes.

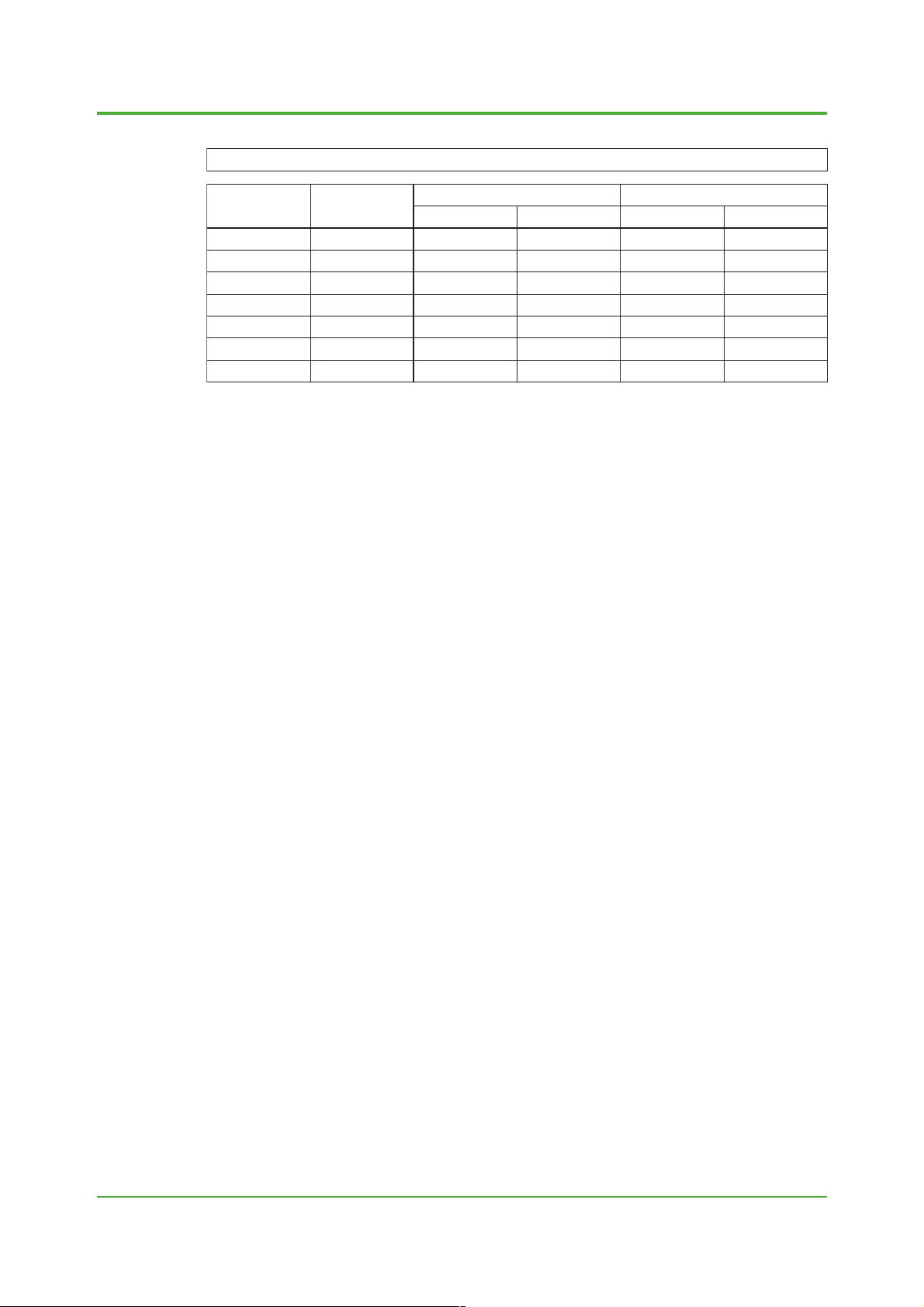

Table 2.4 List of Meter Factor Calculation Coefficients

50 Hz Area 60 Hz Area

YM102

YM104

YM106

YM115

YM202

YM204

YM205

YM208

YM210

YM315

YM320

YM325

YM330

YM335

YM340

YM405

YM406

YM407

YM408

YM409

1.0825

1.0541

1.0417

1.1184

1.0633

1.0181

1.0124

1.0120

1.0124

1.0095

1.0053

1.0185

1.0251

1.0250

1.0506

1.0180

1.0195

1.0224

1.0252

1.0198

1.0820

1.0545

1.0448

1.1185

1.0633

1.0170

1.0123

1.0122

1.0152

1.0098

1.0065

1.0170

1.0249

1.0263

1.0537

1.0179

1.0201

1.0217

1.0254

1.0206

T05.EPS

12

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

TI 01E20A02-01E

2004-00

Page 13

<T oc> <Ind>

2.5 Combination between Flowtubes of Other Manufacturer s and AXFA11

Note: It may not be possible to operate some flowtubes of other manuf acturers due to the diff erence in magnetic circuits .

Although the coil resistance of a flowtube must be 240 ⍀ or less, it ma y not be possib le to operate the flowtube

even if the resistance is 240 ⍀ or less. Especially, if the excitation current of an existing model is designed to be

0.26 mA or less, it is more likely that the flowtube cannot be driven by AXFA11.

2.5.1 Flowtube performance chec k

Based on Chapter 3 "How to Check the Performance of Existing Flowtubes," check

that an existing flowtube is not damaged.

2.5.2 Obtaining the meter factor

Obtain the meter factor by one of the following three methods a), b) and c), depending on the situation:

a) By obtaining meter factor using the customer's flow line according to

Chapter 4

Follow Section 2.5.3 "wiring" and Section 2.5.4 "Parameter setting" before

obtaining meter factor according to the actual flow test.

b) By obtaining meter factor through calculation

The calculated meter factor is an approximation. Calculations must be performed

when it is difficult to obtain a meter factor according to the actual flow test.

Accuracy for reference cannot be provided.

13

Driving methods of existing flowtubes

(Known) Model Name

FOXBORO 1800 and 2800 series

Reference voltage method

Flowtube inscribed with C/F/P

Flowtube inscribed with

generated EMF

Method

* FOXBORO 1800 and 2800 series have two types: C/F/P is inscribed on one

type, while the generated EMF is inscribed on the other. Check the types

shown in the data plate. Both C/F/P and the generated EMF may be inscribed

on some models. In this case, use C/F/P for calculation.

b.1) Reference voltage method

Reference voltage ("Reference.v") is inscribed on the data plate or CP unit

(open the terminal box cover). Calculate the meter factor using the reference

voltage:

Meter factor for FOXBORO 1800 and 2800 series =

Reference voltage (v)

5 ⫻ excitation current

Relevant

Section

b.1)

b.2)

b.3)

T06.EPS

(To the next page)

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation TI 01E20A02-01E

2004-00

Page 14

<T oc> <Ind>

b.2) Flowtube inscribed with C/F/P

If C/F/P is inscribed on the data plate, calculate the meter factor as follows:

Meter factor =

10 ⫻ span flow velocity (m/s)

C ⫻ F

b.3) Flowtube inscribed with generated EMF

If the generated EMF is inscribed on the data plate and if the excitation

current value is already known, calculate the meter factor as follows.

Meter factor =

Excitation current value of an existing instrument

Generated EMF per 1 m/s

How to obtain the generated EMF per 1 m/s:

14

Example)

The generated EMF of 0.0540 mV (m3/h) means that "the EMF to

The flow velocity for size 25 mm (1 in.) when the flow rate is 1 m

where,

D: Nominal size (to be set in units of m)

Q: Flow rate (to be set in m

Since the generated EMF for 1 m

If the size is 25 mm (1 in.) and the generated EMF is 0.0540 mV (m3/h):

be generated when the flow rate is 1 m

Flow velocity V(m/s) = ⫻Q(m3/s)

= ⫻ (m

generated EMF for 1 m/s will be:

0.0540 mV⫻ = 0.0954 mV

c) By using an already-known approximate meter factor

Approximate meter factors of the FOXBORO 1800 and 2800 series are already

known. They are shown in Appendix 1 "Wiring". Since these values are approximations, they shall be used when it is difficult to obtain meter factors using actual

flow tests or through calculations. Accuracy for reference cannot be provided.

2.5.3 Wiring

Connect the flowtubes of other manufacturers with AXFA11. For reference, see

Appendix 1 "Wiring" which contains known and available information.

2.5.4 Parameter setting

Set the following parameters to AXFA11:

• Check the software revision number of AXFA11 which is indicated in the

parameter "J50: Software Rev No."

If the revision number is "R1.05" or "R1.08":

(1) Select "YEWMAG" or "Calibrator" in the parameter "C30: Select Flow Tube":

"YEWMAG" if the flowtube's coil resistance is 60 ⍀ or less.

"Calibrator" if the flowtube's coil resistance is 61 ⍀ to 240 ⍀.

(2) Select "Low" in the service parameter (not disclosed) "U15: 4-20mA Sel." Be

sure to contact Yokogawa for the service parameter setting. Pulsed DC

calculations apply to all sizes.

If the revision number is other than "R1.05" or "R1.08":

(1) Select "YEWMAG" or "Other" in the parameter "C30: Select Flow Tube":

"YEWMAG" if the flowtube's coil resistance is 60 ⍀ or less.

"Other" if the flowtube's coil resistance is 61 ⍀ to 240 ⍀.

There is no need to set "U15: 4-20mA Sel." Pulsed DC calculations automatically apply to all sizes by selecting "YEWMAG" or "Other" in the parameter

"C30: Select Flow Tube."

1

0.566

4

2

π

(m)

D

4

3.14⫻(0.025(m))

3

/h (= 0.566 m/s) is 0.054 mV, the

3

/h is 0.0540 mV."

1

3

2

3600

/s)=0.566(m/s)

3

/s)

3

/h:

(To the next page)

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

TI 01E20A02-01E

2004-00

Page 15

<T oc> <Ind>

15

• Set the obtained meter factor to "C21: Low MF." Set 1.0000 to "C22: High MF."

• For details on setting parameters other than the above, follow the user's

manual for AXFA11.

2.5.5 Zero adjustment

Perform the automatic zero adjustment according to the user's manual for AXFA11.

End

Note: AXFA14 cannot be combined with flowtubes of other manufacturers .

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation TI 01E20A02-01E

2004-00

Page 16

<T oc> <Ind>

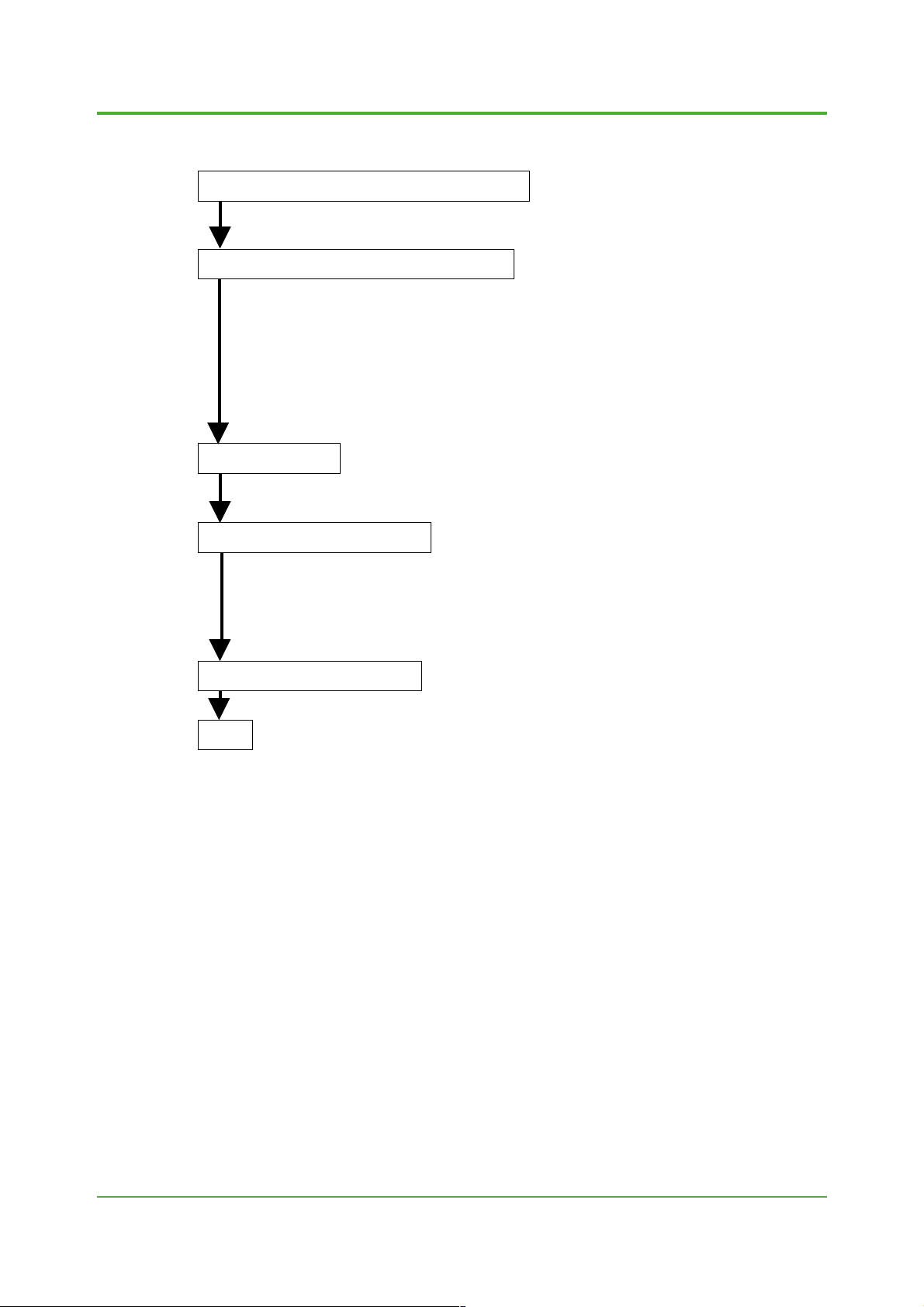

3. How to Chec k the Performance of Existing Flowtubes

(1) Repair any abnormality in the external appearance.

(2) Open the terminal box and repair any abnormality (for example, contamination

External appearance check

Continuity and insulation

check of the flowtube's

excitation coil

Continuity and insulation

check of signal lines

due to liquid infiltration or abnormal seal surface).

* If the flowtube is a Yokogawa product, contact Yokogawa when repair is

required. Otherwise, contact the relevant manufacturer.

(1) If the flowtube is a Yokogawa product, the coil resistance is between several ⍀

to approximately 100 ⍀. Check if the coil resistance is between these values

using a multimeter. In case of other manufacturer's product, it may be possible

to drive the flowtube using the AXFA11 converter as long as the coil resistance

is 240 ⍀ or less.

(2) Check if the coil insulation is 1 M⍀ or more using a 500 V DC megohmmeter.

(1) If the flowtube cannot be taken out from the pipeleine:

It is not possible to know the exact status of a signal line. On the assumption

that the existing flowmeter is operating properly in flow measurement, check

the status of the flowtube as follows:

• If the pipe is filled with the fluid, the resistance between A/B signal terminals

and the grounding is several hundred ⍀ to several dozen k⍀ respectively (to

be measured by a multimeter).

• If the resistance between the A signal terminal and the grounding is

substantially different from the resistance between the B signal terminal and

the grounding (more than double), it is necessary to take out the flowtube

from the pipeline and check the flowtube (using the multimeter) as there

may be an electrode insulation failure or adhesion on the surface of an

electrode.

(2) If the flowtube can be taken out from a pipeline:

• Check the lining surface and remove adhesions, if any.

• Confirm that there is no abnormality on the lining .

• Check the signal line continuity between the electrode surface and the

terminals.

• Use a multimeter or a megohmmeter to check if the insulation between the

signal terminals and the grounding is more than 100 times the wetted

electrode resistance (between A and C or between B and C, whichever is

greater). For example, 1 M⍀ or more when the wetted electrode resistance

is 10 k⍀.

16

End

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

F03.EPS

TI 01E20A02-01E 2004-00

Page 17

<T oc> <Ind>

4. How to Obtain Meter F actor using the Customer's Flow Line

This chapter describes the following three methods to obtain meter f actor using the customer's

flow line by means of AXFA11 and an existing flowtube:

• Flow calibration in combination with AXFA11 using the customer's facilities

• Obtaining meter factor by incorporating the indicated flow rate of the existing con v erter.

• Using inferred flow rate such as valve openings or pump rpm

4.1 How to P erform Flow Calibration in Combination with AXFA11 using the Customer's Facilities

This method can be used if there is a tank or other vessel which can serve as a volumetric

standard, or if another flow meter can be used as a master meter . The accur acy f or ref erence in

this case will be more than three times the accuracy of the volumetric standard or the reference

meter, or the nominal accuracy of the flo wtube, whiche v er is greater . As a rule, calibration should

be performed by Y okoga wa's service personnel.

17

4.1.1 Parameter setting

Set the size and span to AXFA11. The span shall be 1.5 to 2 times the flow rate (the

same span as the one for the master meter if the master meter method is used). In

addition, set the parameters according to any combination with relevant models in

Chapter 2. For "C21: Low MF," set 1.0000 at first temporarily.

4.1.2 Zero adjustment

Before allowing the fluid to flow, see the user's manual for AXFA11 and perform the

automatic zero adjustment.

4.1.3 Measuring flow and calculating the meter factor

Allow the fluid to flow and calculate the new meter factor as follows:

New meter factor = old meter factor ⫻

Use 1.0000, which was temporarily set to the old meter factor, to calculate the new

meter factor. After setting the new meter factor, confirm that the flow indication is

correct. If the flow indication is not correct, repeat the above procedure and incorporate the new meter factor.

Indicated value of AXFA11

(or indicated value of the master meter)

Volumetric standard

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation TI 01E20A02-01E

2004-00

Page 18

<T oc> <Ind>

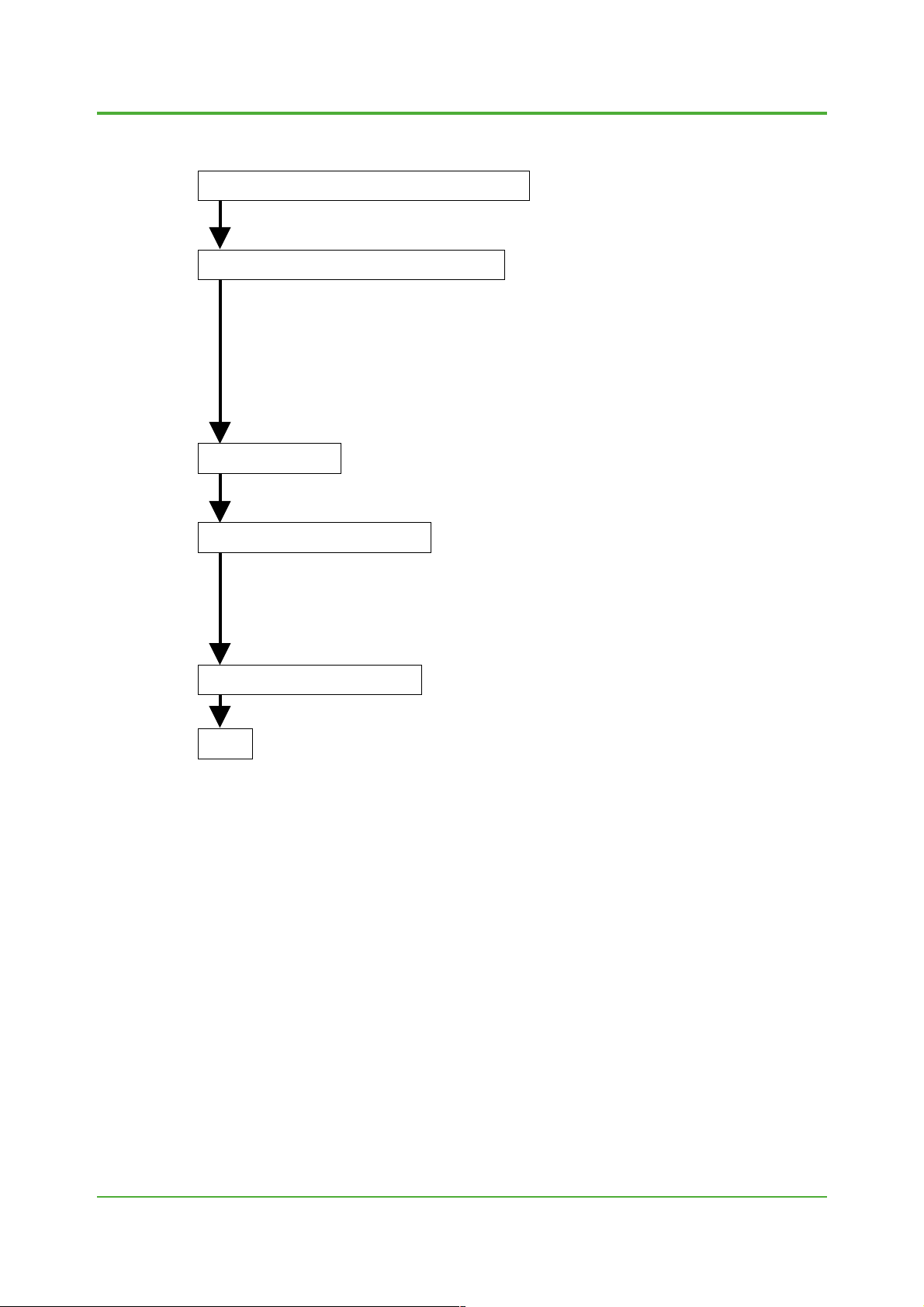

4.2 How to Obtain Meter Factor b y Incorporating the Indicated Flow Rate of the Existing Con verter .

This method can be used if an existing flowtube operates properly. In addition, the method

requires that the flow rate is constant and stable. In case of this method, the accuracy for reference cannot be provided as it depends on the accuracy of the measuring flow system. As a rule,

calibration should be performed by Y okoga wa service personnel.

Electrical connection:

Connect an existing flowtube and an e xisting conv erter as shown in the figure below:

18

Existing converter

Excitation cable

Change electrical connections

Signal cable

AXFA11

Flowtube

4.2.1 Parameter setting

Set the size and span to AXFA11. The span shall be the same as the one for the

existing converter. In addition, set the parameters according to any combination with

relevant models in Chapter 2. For "C21: Low MF," set 1.0000 at first temporarily.

4.2.2 Zero adjustment

Before allowing the fluid to flow, see the user's manual for AXFA11 and perform the

automatic zero adjustment. Also apply the zero adjustment to the existing converter.

4.2.3 Measuring flow with existing con verter

Measure an instantaneous flow rate in the combination with the existing converter

and record the 4 to 20 mA output. Since the indication of AXFA11 at the same flow

rate is checked in the next step, do not change the flow rate.

4 to 20 mA

Recorder

4 to 20 mA

F04.EPS

4.2.4 Measuring flow with AXFA11 converter

Change the connections of the existing flowtube to AXFA11 and record the 4 to w20

mA output in the same manner.

4.2.5 Calculating the meter factor

Use the indicated value of the existing converter and the indicated value of AXFA11,

which were recorded in the above step, and calculate the new meter factor as

follows:

New meter factor = old meter factor ⫻

Use 1.0000, which was temporarily set to the old meter factor, to calculate the new

meter factor. After setting the new meter factor, confirm that the flow indication is

correct. If the flow indication is not correct, repeat the above procedure and incorporate the new meter factor.

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

Indicated value of AXFA11 (%)

Indicated value of the existing converter (%)

TI 01E20A02-01E 2004-00

Page 19

<T oc> <Ind>

4.3 How to Obtain Meter Factor Accor ding to the Inferred Flow Rates Such as Valve Openings or Pump Rpm

The accuracy for ref erence in this case cannot be provided as it depends on the accur acy of the

inferred flow rate . As a rule, calibr ation should be performed by Yokogawa's service personnel.

4.3.1 Parameter setting

Set the size and span to AXFA11. The span shall be 1.5 to 2 times the flow rate. In

addition, set necessary parameters according to any combination with relevant

models in Chapter 2. For "C21: Low MF," set 1.0000 at first temporarily.

4.3.2 Zero adjustment

Before allowing the fluid to flow, see the user's manual for AXFA11 and perform the

automatic zero adjustment.

4.3.3 Measuring flow and calculating the meter factor

Allow the fluid to flow and calculate the new meter factor as follows:

19

New meter factor = old meter factor ⫻

Use 1.0000, which was temporarily set to the old meter factor, to calculate the new

meter factor. After setting the new meter factor, confirm that the flow indication is

correct. If the flow indication is not correct, repeat the above procedure and incorporate the new meter factor.

Indicated value of AXFA11

Inferred flow rate

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation TI 01E20A02-01E

2004-00

Page 20

<T oc> <Ind>

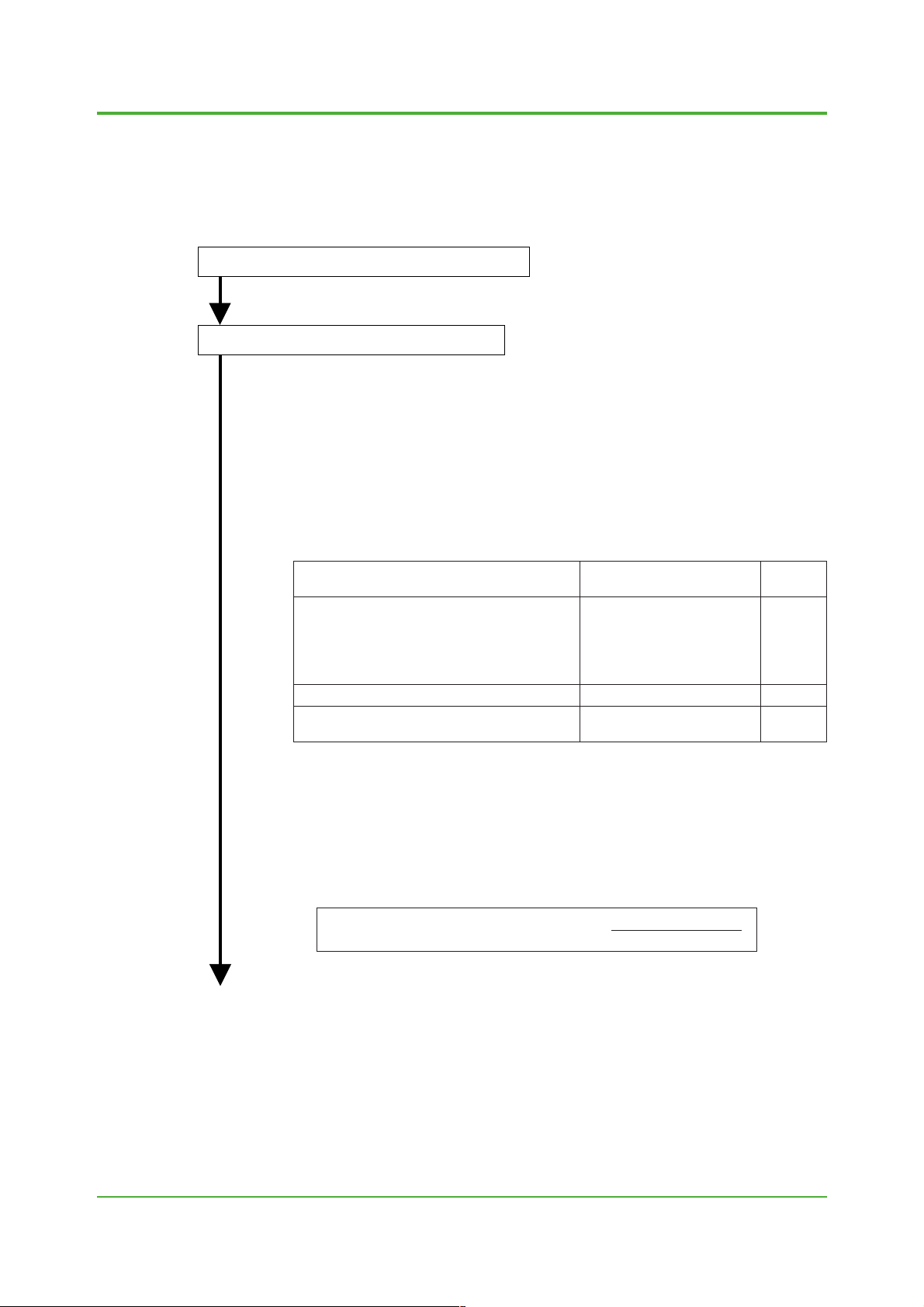

5. Compatibility with AXF A11 and AXFA14

If the same AXF flowtube is combined with AXF A11 or AXFA14, meter factors will differ due to

differences between the excitation circuit of AXFA11 and that of AXFA14. Therefore, wrong

combinations will cause a span error. A span error for reference is approximately 1.5%. Select the

correct converter for combination using the flowtube's model and suffix code when ordering.

Since AXF A14 does not hav e a parameter f or setting the e xcitation current v alue or s witching to

the pulsed DC calculation, AXF A14 cannot operate SE, YM and flowtubes of other manufactures.

AXF A14 can only operate AXF, AM and AE flowtubes.

On the other hanwd, as AXF A11 has a parameter “C30:Select Flo w tube” for setting the e xcitation

current value or switching to the pulsed DC calculation, AXFA11 can operate other flowtubes

including SE and YM.

Compatibility errors for AXFA11 and AXFA14 if flow calibration is not redone (v alues for

reference)

Converter

Flowtube

AXF flowtube

for AXFA11

(AXFxxxx-N)

AXF flowtube

for AXFA14

(AXFxxxx-P)

AM flowtube

AE flowtube

SE flowtube

AXFA11

AXF std.

performance

accuracy

AXF std. accuracy

⫾1.5%

AM std. accuracy

⫾0.5%

AE std. accuracy

⫾1.5%

not available

unless redoing

flow calibration

YM std. accuracy

⫾1% when

calculated MF is

used

AXFA14

AXF std. accuracy

⫾1.5%

AXF std.

performance

accuracy

AM std. accuracy

⫾1.5%

AE std. accuracy

⫾0.5%

not available

AM11

AM std. accuracy

⫾0.5%

AM std. accuracy

⫾1.5%

AM std.

performance

accuracy

AE std. accuracy

⫾1.5%

not available

See TI 1E6C1-01E not availablenot available not availableYM flowtube

AE std. accuracy

⫾1.5%

AE std. accuracy

⫾0.5%

AE std. accuracy

⫾1.5%

(in principle, not

available)

AE std.

performance

accuracy

not available

not available

not available

not available

not available

performance

accuracy

20

YMA11AE14 SE14

YM std. accuracy

⫾2% when

calculated MF is

used.

not available

unless redoing

flow calibration

See TI 1E6C1-01E

not available

SE std.

not available

YM std.

performance

accuracy

T07.EPS

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

TI 01E20A02-01E 2004-00

Page 21

<T oc> <Ind>

Appendix. 1 Electrical Connection

CAUTION

1. Disconnect ac power the magmeter flowtube.

Flowtube will be powered by the Yokogawa converter.

2. Follow the proper Y okoga wa wiring procedure f or the make and model of magnetic flo wtube

being converted. f ailure to f ollow the proper wiring procedure will result in damage to the

Yokogawa converter .

21

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation TI 01E20A02-01E

2004-00

Page 22

<T oc> <Ind>

(1) Combination AXFA11 and FO XBOR O 1800 Series

22

AXFA11 Wiring Connections

FUSE

2.5A 250V

I+ I–

CURRENT OUT

N/– L/+

POWER SUPPLY

SO1+ COMSO2+

STATUS OUT

EXCIT ATION

AL+ AL– C SA A B SB

ALARM OUT

EX2EX1

PULSE OUT STATUS IN

Excitation cable

AM011 or YM011 Dedicated signal cable

can be used unless those cables are

deteriorated.

FOXBORO 1800 Wiring

Sample A

To AXFA11 Excitation Terminals

Terminal correspondences

Converter

AXFA11

SIGNAL

P– SI1+ SI2+ COMP+

AXFA11 Converter

SA *

SB *

A

1

1

B

AXFC Dedicated signal

cable

C

EX1 *

EX2 *

2

2

Flowtube

1800 Series

Taped

Taped

B

W

SH

L1

L2

*1 When a shield drive is not caried out,

SA and SB marked are not used.

*2 If we read negative output, exchange

EX1 and EX2 at AXFA11 terminal.

*3 Exciting power coils must be isolated

from ground and other all terminals.

Excitation Power Coil Wiring

Excitation Power Terminals

Sample B

To AXFA11 Excitation Terminals

Excitation Power Terminals

WB

W

G

To AXFA11 Signal Terminals

Signal T erminals

To AXFA11 Signal Terminals

OUT

Signal T erminals

BG

B

SH

Series Wiring Parallel Wiring

Excitation Power Coil Wiring

SH

Series Wiring Parallel Wiring

AF02.EPS

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

TI 01E20A02-01E

2004-00

Page 23

<T oc> <Ind>

23

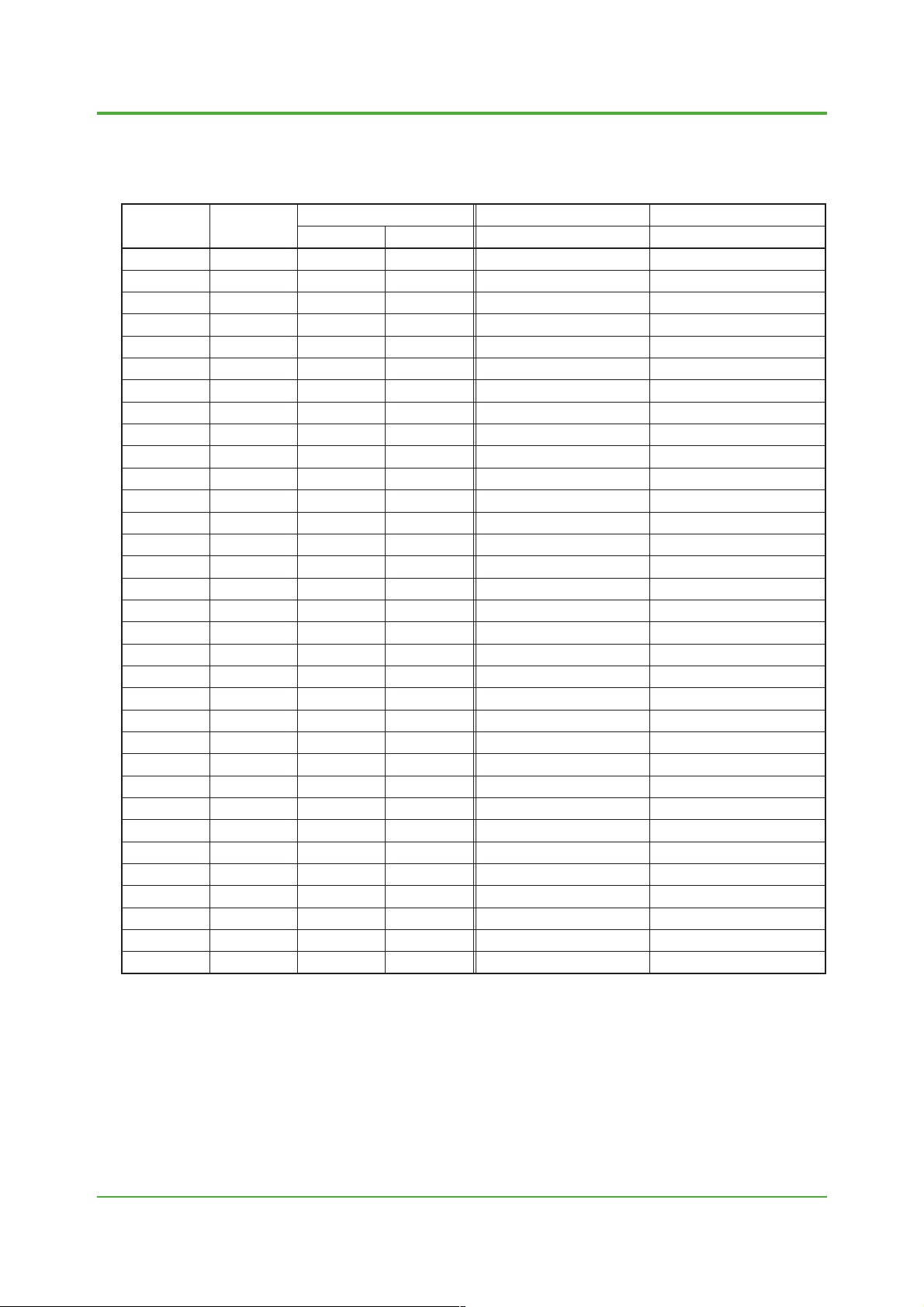

FOXBOR O 1800 Series Meter Factor List

Following are model numbers , Exciting current values and appro ximate meter f actors f or

flowtubes where the coils are wired either in series or parallel.

Nominal Size Series Connection

LOW MF (C21)

15

25

40

50

80

100

150

200

250

300

350

400

0.5

1

1.5

2

3

4

6

8

10

12

14

16

0.4483

0.4852

0.5852

0.5518

0.6150

0.4609

0.4167

0.3500

0.3990

0.2727

0.3274

0.6373

Parallel Connection

LOW MF (C21)mm inch

0.2241

0.2426

0.2926

0.2765

0.3075

0.2304

0.2083

0.1705

0.1995

0.1363

0.1316

0.3183

For FOXBORO 1800 Series

AF03.EPS

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation TI 01E20A02-01E

2004-00

Page 24

<T oc> <Ind>

(2) Combination AXFA11 and FO XBOR O 2800 Series

24

AXFA11 Wiring Connections

FUSE

2.5A 250V

I+ I–

CURRENT OUT

N/– L/+

POWER SUPPLY

SO1+ COMSO2+

STATU S OU T

EXCIT ATION

AL+ AL– C SA A B SB

ALARM OUT

EX2EX1

PULSE OUT STATUS IN

Excitation cable

AM011 or YM011 Dedicated signal cable

can be used unless those cables are

deteriorated.

FOXBORO 2800 Wiring

Terminal correspondences

Converter

AXFA11

SIGNAL

AXFA11 Converter

SA

SB

P– SI1+ SI2+ COMP+

A

B

AXFC Dedicated signal

cable

C

EX1 *

EX2 *

Flowmeter

2800 Series

BG

WG

B

W

SH

L1

L2

* If we read negative output, exchange

EX1 and EX2 at AXFA11 terminals.

Excitation Power Coil Wiring

WG

Excitation Power Terminals

W

BG

B

SH

G

Signal T erminals

To AXFA11 Signal Terminals

To AXFA11 Excitation Terminals

Series Wiring

Parallel Wiring

AF04.EPS

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

TI 01E20A02-01E

2004-00

Page 25

<T oc> <Ind>

25

FOXBOR O 2800 Series Meter Factor List

Following are model numbers , Excitation current values and appro ximate meter f actors f or

flowtubes where the coils are wired either in series or parallel.

Model

2891

2893

2893

280H

2801

2801

281H

281H

2802

2802

2802

2802

2803

2803

2803

2803

2804

2804

2804

2804

2806

2806

2806

2806

2808

2808

2808

2810

2810

2810

2812

2812

2812

Liner

TF

TF

TF

TF

TF

TT

TF

TT

TF

TT

CR

UL

TF

TT

CR

UL

TF

TT

CR

UL

TF

TT

CR

UL

TF

CR

UL

TF

CR

UL

TF

CR

UL

Nominal Size Series Connection

LOW MF (C21)

2.5

5.1

9.5

15

25

25

40

40

50

50

50

50

80

80

80

80

100

100

100

100

150

150

150

150

200

200

200

250

250

250

300

300

300

0.1

0.2

0.375

0.5

1

1

1.5

1.5

2

2

2

2

3

3

3

3

4

4

4

4

6

6

6

6

8

8

8

10

10

10

12

12

12

0.2229

0.2922

0.4280

0.4854

0.5767

0.9939

0.7500

1.0690

0.7630

0.9852

0.8593

1.0370

0.8992

1.0310

0.9612

1.1630

0.7823

0.8686

0.7823

0.9921

0.5139

0.5421

0.5275

0.6045

0.4269

0.4267

0.4731

0.6316

0.6322

0.6704

0.5018

0.5023

0.5272

Parallel Connection

LOW MF (C21)mm inch

—

—

—

0.2426

0.2883

0.4649

0.3750

0.5374

0.3814

0.4925

0.4296

0.5185

0.4496

0.5115

0.4806

0.5813

0.3911

0.4342

0.3911

0.4960

0.2569

0.2710

0.2637

0.3022

0.2134

0.2138

0.2365

0.3158

0.3158

0.3352

0.2509

0.2511

0.2635

AF05.EPS

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation TI 01E20A02-01E

2004-00

Page 26

<T oc> <Ind>

(3) Combination AXFA11 and F&P 10D1418 Series

AXFA11 Wiring Connections

26

AXFA11 Converter

FUSE

2.5A 250V

I+ I–

CURRENT OUT

N/– L/+

POWER SUPPLY

SO1+ COMSO2+

STATU S OU T

EXCIT ATION

AL+ AL– C SA A B SB

ALARM OUT

EX2EX1

P– SI1+ SI2+ COMP+

PULSE OUT STATUS IN

SIGNAL

AXFC Dedicated signal

cable

Excitation cable

AM011 or YM011 Dedicated signal cable

can be used unless those cables are

deteriorated.

F&P 10D1418 (Internal Phase) Wiring (1/10” to 4”)

To AXFA11 Signal Terminals

ABC

Phasing TB

123

Meter

Pipe

8L2L1 567

Signal Compartment

Terminal correspondences

(Integral phase)

Converter

AXFA11

1

SA *

2

SB *

A

B

C

2

EX1 *

2

EX2 *

F&P 10D1418

AC-MAG

Taped

Taped

1

2

3

L1

L2

*1 When a shield drive is not caried out,

SA and SB marked are not used.

*2 If we read negative output, exchange

EX1 and EX2 at AXFA11 terminal.

*3 Exciting power coils must be isolated

from ground and other all terminals.

Disconnection

L1 L2G5876

Power Compartment

EX1 EX2

To AXFA11 Excitation Terminals

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

Phasing Network (No Use)

TI 01E20A02-01E

AF06.EPS

2004-00

Page 27

<T oc> <Ind>

F&P 10D1418 (Remote Phase) Wiring (1/10” to 4”)

To AXFA11 Signal Terminals

ABC

123

Meter

Pipe

Signal Compartment

Terminal correspondences

(Remote phase)

Converter

AXFA11

1

SA *

2

SB *

A

B

C

2

EX1 *

2

EX2 *

*1 When a shield drive is not caried out,

SA and SB marked are not used.

*2 If we read negative output, exchange

EX1 and EX2 at AXFA11 terminal.

*3 Exciting power coils must be isolated

from ground and other all terminals.

F&P 10D1418

AC-MAG

Taped

Taped

1

2

3

L1

8

27

U2 5L1U1 G 76L2 8

Power Compartment

EX1 EX2

To AXFA11 Excitation Terminals

MODIFICATION

1) Disconnect AC-Power Supply from flowtube, and connect Excitation Cable from AXFA11 to flowtube Terminal

(Power Compartment T B L1, 8)

2) Connect Signal Cable from AXFA11 to flowtube. Be sure that No. 3 Terminal of Signal Compartment is definitely

grounded to the Mag Body.

AF07.EPS

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation TI 01E20A02-01E

2004-00

Page 28

<T oc> <Ind>

(4) Combination AXFA11 and F&P 10D1419 Series

AXFA11 Wiring Connections

28

FUSE

2.5A 250V

I+ I–

CURRENT OUT

N/– L/+

POWER SUPPLY

SO1+ COMSO2+

STATUS OUT

EXCIT ATION

AL+ AL– C SA A B SB

ALARM OUT

EX2EX1

P– SI1+ SI2+ COMP+

PULSE OUT STATUS IN

SIGNAL

AXFC Dedicated signal

cable

Excitation cable

AM011 or YM011 Dedicated signal cable

can be used unless those cables are

deteriorated.

F&P 10D1419 (Integral) Wiring (1/10” to 4”)

To AXFA11 Signal TerminalsTo AXFA11 Excitation Terminals

EX1 EX2

BA C

18L1 17L2 1 3216

TB

MODIFICATION

Disconnect L1, L2, M1, M2 of magnet driver ass’y. Connect L1

and M1 at air, also connect L2 and M2 at air. (Do not Connect

these wires at terminals)

AXFA11 Converter

Terminal correspondences

Converter

AXFA11

1

SA *

1

SB *

A

B

C

2

EX1 *

2

EX2 *

F&P 10D1419

AC-MAG

Taped

Taped

1

2

3

L1

L2

*1 When a shield drive is not caried out,

SA and SB marked are not used.

*2 If we read negative output, exchange

EX1 and EX2 at AXFA11 terminal.

*3 Exciting power coils must be isolated

from ground and other all terminals.

F&P 10D1419 (Remote Type) Wiring

To AXFA11 Excitation Terminals

EX1 EX2

To AXFA11 Signal Terminals

BA C

M1L1 M2L2 1 325

TB

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

Terminal correspondences

Converter

AXFA11

1

SA *

1

SB *

A

B

C

2

EX1 *

2

EX2 *

F&P 10D1419

AC-MAG

Taped

Taped

1

2

3

M1

M2

*1 When a shield drive is not caried out,

SA and SB marked are not used.

*2 If we read negative output, exchange

EX1 and EX2 at AXFA11 terminal.

*3 Exciting power coils must be isolated

from ground and other all terminals.

AF08.EPS

TI 01E20A02-01E

2004-00

Page 29

<T oc> <Ind>

(5) Combination AXFA11 and F&P 10D1430 Series

AXFA11 Wiring Connections

29

FUSE

2.5A 250V

I+ I–

CURRENT OUT

N/– L/+

POWER SUPPLY

SO1+ COMSO2+

STATU S OU T

EXCIT ATION

AL+ AL– C SA A B SB

ALARM OUT

EX2EX1

P– SI1+ SI2+ COMP+

PULSE OUT STATUS IN

SIGNAL

AXFC Dedicated signal

cable

Excitation cable

AM011 or YM011 Dedicated signal cable

can be used unless those cables are

deteriorated.

F&P 10D1430 (Integral Phasing Type) Wiring

To AXFA11 Signal Terminals

BA C

TB1

TB2

37216U1L1 U2L2

To AXFA11 Excitation Terminals

EX1 EX2

7G2613 U2U1L2

L1

8

Disconnection

AXFA11 Converter

Interconnection

Terminal correspondences

Converter

AXFA11

1

SA *

1

SB *

A

B

C

2

EX1 *

2

EX2 *

F&P 10D1430

Taped

Taped

1

2

3

L1

L2

*1 When a shield drive is not caried out,

SA and SB marked are not used.

*2 If we read negative output, exchange

EX1 and EX2 at AXFA11 terminal.

*3 Exciting power coils must be isolated

from ground and other all terminals.

Calibration components

MODIFICATION

1) Remove L2 at TB2 (FM TB) and connect No. 8 terminal of TB2.

2) Disconnect No. 8 terminal of TB2 (Wire from calibration components) and tape it.

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation TI 01E20A02-01E

AF09.EPS

2004-00

Page 30

<T oc> <Ind>

F&P 10D1430 (Remote Cali. Type) Wiring

To AXFA11 Signal Terminals

BA C

Signal Junction Box

1) Disconnect power wires L1, 8 at Power junction box, and

connect AXFA11's excitation cable to these L1, 8 terminal.

Disconnect power

wires from calib.

MODIFICATION

To AXFA11 Excitation Terminals

EX2 EX1

Power Junction Box

30

Terminal correspondences

Converter

AXFA11

1

SA *

1

SB *

A

8G L1123

*1 When a shield drive is not caried out,

*2 If we read negative output, exchange

*3 Exciting power coils must be isolated

B

C

2

EX1 *

2

EX2 *

SA and SB marked are not used.

EX1 and EX2 at AXFA11 terminal.

from ground and other all terminals.

F&P 10D1430

Taped

Taped

1

2

3

L1

8

F&P 10D1430 (Submersible Type) Wiring

To AXFA11 Signal Terminals

BA C

213T1T3T2 T4

8L2 6L1 7 U2 GU1

Remote Phasing Box

Disconnection

EX1 EX2

To AXFA11 Excitation Terminals

Meter

Pipe

Terminal correspondences

Converter

AXFA11

1

SA *

1

SB *

A

B

C

2

EX1 *

2

EX2 *

*1 When a shield drive is not caried out,

SA and SB marked are not used.

*2 If we read negative output, exchange

EX1 and EX2 at AXFA11 terminal.

*3 Exciting power coils must be isolated

from ground and other all terminals.

F&P 10D1430

Taped

Taped

1

2

3

L1

8

MODIFICATION

1) Disconnect power wires L1, 8 at remote box, and connect

AXFA11's excitation cable to L1, 8 air.

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

TI 01E20A02-01E

AF10.EPS

2004-00

Page 31

<T oc> <Ind>

(6) Combination AXFA11 and F&P 10D1435 (MAGX) Series (6” to 48”)

AXFA11 Wiring Connections

31

FUSE

2.5A 250V

I+ I–

CURRENT OUT

N/– L/+

POWER SUPPLY

SO1+ COMSO2+

STATU S OU T

EXCIT ATION

AL+ AL– C SA A B SB

ALARM OUT

EX2EX1

P– SI1+ SI2+ COMP+

PULSE OUT STATUS IN

SIGNAL

AXFC Dedicated signal

cable

Excitation cable

AM011 or YM011 Dedicated signal cable

can be used unless those cables are

deteriorated.

F&P 10D1435 (Integral Magnet Driver) Wiring

To AXFA11 Signal Terminals

BA C

TB1

18 17316 M2 L1GM1

163G12 17 U118 GU2L1

TB2

L2

L2

TB3

Ex. Coil

EX1 EX2

To AXFA11 Excitation Terminals

AXFA11 Converter

Terminal correspondences

Converter

AXFA11

1

SA *

1

SB *

A

B

C

2

EX1 *

2

EX2 *

F&P 10D1435

MAGX

Taped

Taped

1

2

3

Ex. Coil

Ex. Coil

*1 When a shield drive is not caried out,

SA and SB marked are not used.

*2 If we read negative output, exchange

EX1 and EX2 at AXFA11 terminal.

*3 Exciting power coils must be isolated

from ground and other all terminals.

MODIFICATION

Disconnect Ex. Coil Wires from M1, M2 and Connect Ex1 and

Ex2 cable from AXFA11 at air.

Terminal correspondences

F&P 10D1435 (Remote Magnet Driver) Wiring

To AXFA11 Excitation Terminals

EX1 EX2

Mgnet Driver

Converter

AXFA11

1

SA *

1

SB *

A

F&P 10D1435

B

L2 M2L1GM117163

3L2L1G12T2T1T3T4

18

C

2

EX1 *

2

EX2 *

*1 When a shield drive is not caried out,

SA and SB marked are not used.

Remote Driver

BC A

To AXFA11 Signal Terminals

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation TI 01E20A02-01E

*2 If we read negative output, exchange

EX1 and EX2 at AXFA11 terminal.

*3 Exciting power coils must be isolated

from ground and other all terminals.

MAGX

Taped

Taped

1

2

3

M1

M2

AF11.EPS

2004-00

Page 32

<T oc> <Ind>

(7) Combination AXFA11 and F&P 10D1475 (MINI MAGX) Series

AXFA11 Wiring Connections

32

FUSE

2.5A 250V

I+ I–

CURRENT OUT

N/– L/+

POWER SUPPLY

SO1+ COMSO2+

STATU S OU T

EXCIT ATION

AL+ AL– C SA A B SB

ALARM OUT

EX2EX1

P– SI1+ SI2+ COMP+

PULSE OUT STATUS IN

SIGNAL

AXFC Dedicated signal

cable

Excitation cable

AM011 or YM011 Dedicated signal cable

can be used unless those cables are

deteriorated.

F&P 10D1475 (Integral Type) Wiring

To AXFA11 Signal Terminals

AB C

To AXFA11 Excitation Terminals

EX1 EX2

2A 12MR536M1M2CT

(Ground Terminal)

MODIFICATION

1) Disconnect all wires from this terminal except signal and

exciting wires as shown.

AXFA11 Converter

Terminal correspondences

Converter

AXFA11

1

SA *

1

SB *

A

B

C

2

EX1 *

2

EX2 *

F&P 10D1475

MINI-MAG

Taped

Taped

1

2

Ground

M1

MR

*1 When a shield drive is not caried out,

SA and SB marked are not used.

*2 If we read negative output, exchange

EX1 and EX2 at AXFA11 terminal.

*3 Exciting power coils must be isolated

from ground and other all terminals.

F&P 10D1475C (Remote Type) Wiring

To AXFA11 Signal Terminals

BA C

To AXFA11 Excitation Terminals

EX1 EX2

M1 M2V⫺V⫹ 11632

CT MRMRM2 M1 M1

MODIFICATION

1) Disconnect M1, M2 of primary board and connect another

M1, MR.

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

Terminal correspondences

Converter

AXFA11

1

SA *

1

SB *

A

B

C

2

EX1 *

2

EX2 *

F&P 10D1475

MINI-MAG

Taped

Taped

1

2

3

M1

M2

*1 When a shield drive is not caried out,

SA and SB marked are not used.

*2 If we read negative output, exchange

EX1 and EX2 at AXFA11 terminal.

*3 Exciting power coils must be isolated

from ground and other all terminals.

AF12.EPS

TI 01E20A02-01E

2004-00

Page 33

<T oc> <Ind>

(8) Combination AXFA11 and BR OOKS 7000 Series

AXFA11 Wiring Connections

33

SO1+ COMSO2+

I+ I–

FUSE

2.5A 250V

CURRENT OUT

POWER SUPPLY

N/– L/+

STATU S OU T

EXCIT ATION

BROOKS 7000 Wiring

To AXFA11 Signal Terminals

A B C

E1 E3

To Mag Flowtube

E2

AL+ AL– C SA A B SB

ALARM OUT

EX2EX1

P– SI1+ SI2+ COMP+

PULSE OUT STATUS IN

SIGNAL

AXFC Dedicated signal

cable

Excitation cable

AM011 or YM011 Dedicated signal cable

can be used unless those cables are

deteriorated.

To AXFA11 Excitation Terminals

EX1 EX2

11 12

Amplifier board

To Mag Flowtube

Do not leave the wires (black,

white, No.11, 12) inthe terminal

AXFA11 Converter

TB-02

Terminal correspondences

Converter

AXFA11

1

SA *

1

SB *

A

B

C

2

EX1 *

2

EX2 *

BROOKS

7000 Series

Taped

Taped

E1 of AMP.

E3 of AMP.

E2 of AMP.

11 of TB-02.

12 of TB-02.

*1 When a shield drive is not caried out,

SA and SB marked are not used.

*2 If we read negative output, exchange

EX1 and EX2 at AXFA11 terminal.

*3 Exciting power coils must be isolated

from ground and other all terminals.

MODIFICATION

1) Disconnect power supply at L1 DG TB4-AC power and J2, J5 in Mag flowtube. (No power supply needs to Brooks Mag)

2) Remove wires of TB-11 and 12 in power supply board and connect EX1, EX2 (AXFA11) to these wires as follows:

EX1 EX2=Excitation Power from AXFA11

AXFA11

EX1

EX2

7000 TB-02

11

12

Do not connect these wires at

terminals, connect at air

3) Remove E1, E2, E3 of amplifier board and connect A, B and C

AXFA11

EX1 EX2=Signal terminal from AXFA11

A

B

C

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation TI 01E20A02-01E

7000 TB-02

E1

E3

E2

Do not connect these wires at

terminals, connect at air

AF13.EPS

2004-00

Page 34

<T oc> <Ind>

(9) Combination AXFA11 and BR OOKS 7100 Series

AXFA11 Wiring Connections

34

SO1+ COMSO2+

I+ I–

FUSE

2.5A 250V

CURRENT OUT

POWER SUPPLY

N/– L/+

STATUS OUT

EXCIT ATION

BROOKS 7100 Wiring

To AXFA11 Signal Terminals

C

BA

ACB

To Pre Amp. Area

AL+ AL– C SA A B SB

ALARM OUT

EX2EX1

P– SI1+ SI2+ COMP+

PULSE OUT STATUS IN

SIGNAL

AXFC Dedicated signal

cable

Excitation cable

AM011 or YM011 Dedicated signal cable

can be used unless those cables are

deteriorated.

To AXFA11 Excitation Terminals

EX1 EX2

L

LG

TB-2

Junction box on top of flowtube

AXFA11 Converter

TB-4

Terminal correspondences

Converter

AXFA11

1

SA *

1

SB *

A

B

C

2

EX1 *

2

EX2 *

BROOKS

7100 Series

AC-MAG

Taped

Taped

A (TB2)

C (TB2)

B (TB2)

L (TB4)

LG (TB4)

*1 When a shield drive is not caried out,

SA and SB marked are not used.

*2 If we read negative output, exchange

EX1 and EX2 at AXFA11 terminal.

*3 Exciting power coils must be isolated

from ground and other all terminals.

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

TI 01E20A02-01E

AF14.EPS

2004-00

Page 35

<T oc> <Ind>

(10) Combination AXF A11 and BROOKS 7400 Series

AXFA11 Wiring Connections

35

I+ I–

SO1+ COMSO2+

FUSE

2.5A 250V

CURRENT OUT

POWER SUPPLY

N/– L/+

STATU S OU T

EXCIT ATION

BROOKS 7400 Wiring

To AXFA11 Signal Terminals

CA

B

123

TB-1

AL+ AL– C SA A B SB

ALARM OUT

EX2EX1

P– SI1+ SI2+ COMP+

PULSE OUT STATUS IN

SIGNAL

AXFC Dedicated signal

cable

Excitation cable

AM011 or YM011 Dedicated signal cable

can be used unless those cables are

deteriorated.

To AXFA11 Excitation Terminals

324168957

TB-4

AXFA11 Converter

EX1 EX2

Terminal correspondences

Converter

AXFA11

1

SA *

1

SB *

A

B

C

2

EX1 *

2

EX2 *

BROOKS

7400 Series

Wafer-MAG

Taped

Taped

2 (TB1)

3 (TB1)

1 (TB1)

8 (TB2)

9 (TB2)

*1 When a shield drive is not caried out,

SA and SB marked are not used.

*2 If we read negative output, exchange

EX1 and EX2 at AXFA11 terminal.

*3 Exciting power coils must be isolated

from ground and other all terminals.

Brooks 7400 Wafer Mag

It is necessary to modify following terminal and connectors.

1) Signal Cable Connector J1

2) Field Coil Connector J3

3) Customer Hook-up TB1, TB2

How to Modify BROOKS 7400 Wafer Mag

1) Open Electronic Box Cover.

2) Remove whole electronics from electronics box.

3) Disconnect all wires from TB1, TB2, except No. One Terminal of TB1.

4) Modification of J3 (Field Coil)

Connect No.2, No.5 wires of J3 Connector (Field Coil Connector) to Terminal 8, 9 of TB2.

Connect No.1, No.6 wires of J3 at air. (To make a closed loop of an excitation circuit)

5) J1 (Signal Cable)

Connect No.2, No.3 wires at air.

Also connect No.4, No.1 wires to No.2 and No.3 Terminal of TB1.

6) Connect cables from AXFA11 to Wafer-Mag customer hook-up.

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation TI 01E20A02-01E

AF15.EPS

2004-00

Page 36

<T oc> <Ind>

(11) Combination AXF A11 and BROOKS 7500 Series

AXFA11 Wiring Connections

36

I+ I–

SO1+ COMSO2+

FUSE

2.5A 250V

CURRENT OUT

POWER SUPPLY

N/– L/+

STATUS OUT

EXCIT ATION

BROOKS 7500 Wiring

To AXFA11

Excitation

Terminals

EX2

EX1

5

2

J3

AL+ AL– C SA A B SB

ALARM OUT

EX2EX1

P– SI1+ SI2+ COMP+

PULSE OUT STATUS IN

SIGNAL

AXFC Dedicated signal

cable

Excitation cable

AM011 or YM011 Dedicated signal cable

can be used unless those cables are

deteriorated.

4

J4

Left

Electrode

J1

Top Coil

Right Electrode

Bottom Coil

AXFA11 Converter

To AXFA11

Signal

Terminals

1

B

A

Terminal correspondences

Converter

AXFA11

1

SA *

1

SB *

A

B

C

2

EX1 *

2

EX2 *

BROOKS

7500 Series

Taped

Taped

1 of J1

4 of J1

System Com

2 of J3

5 of J3

*1 When a shield drive is not caried out,

SA and SB marked are not used.

*2 If we read negative output, exchange

EX1 and EX2 at AXFA11 terminal.

*3 Exciting power coils must be isolated

from ground and other all terminals.

How to Combination AXFA11 and BROOKS 7500

1) Power disconnection of flowtube

Disconnect power supply (L, N) at TB1 in customer hook-up. (No power supply needs to BROOKS 7500 Mag.)

2) Excitation power from AXFA11 to flowtube.

Cut wires of connector J3 (Female side) on power supply coil drive.

Connect EX1, EX2 (From AXFA11) to these wires as follows:

AXFA11

EX1

EX2

7500 J3/Power

Coil Drive

2

5

Do not connect these wires at

terminals, connect at air

3) Signal wiring to AXFA11

Cut wires of connecter (J1, Female) on signal conditioner.

Connect A, B and C to these wires as follows:

AXFA11

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

7500 J3/Power Coil Drive

A

B

C

System Com. at signal

Cond. (2, 3) Maile side

1

4

Do not connect these wires at

terminals, connect at air

TI 01E20A02-01E

AF16.EPS

2004-00

Page 37

<T oc> <Ind>

(12) Combination AXF A11 and KROHNE ALTFLUX X-1000, M900 Series

AXFA11 Wiring Connections

37

AXFA11 Converter

FUSE

2.5A 250V

I+ I–

CURRENT OUT

N/– L/+

POWER SUPPLY

SO1+ COMSO2+

STATU S OU T

EXCIT ATION

AL+ AL– C SA A B SB

ALARM OUT

EX2EX1

P– SI1+ SI2+ COMP+

PULSE OUT STATUS IN

SIGNAL

AXFC Dedicated signal

cable

Excitation cable

AM011 or YM011 Dedicated signal cable

can be used unless those cables are

deteriorated.

X-1000, M900 Series (Using Signal Cable Type A) Wiring

To AXFA11 Signal Terminals To AXFA11 Excitation Terminals

C

AB

EX1 EX2

32120 30 1112789

T900

21 3

M900, X-1000

7

8

Disconnection

Terminal correspondences

Converter

AXFA11

1

SA *

1

SB *

A

B

C

2

EX1 *

2

EX2 *

L1

N

*1 When a shield drive is not caried out,