Page 1

User's

Manual

ADMAG AE

Magnetic Flowmeter

Fieldbus Communication Type

IM 1E7F1-01E

IM 1E7F1-01E

5th Edition

Page 2

CONTENTS

Contents

1. INTRODUCTION............................................................................................1-1

■ Regarding This Manual............................................................................ 1-1

■ Warranty................................................................................................... 1-1

■ Safety Precautions................................................................................... 1-2

2. AMPLIFIER FOR FIELDBUS COMMUNICATION ....................................... 2-1

3. ABOUT FIELDBUS .......................................................................................3-1

3.1 Outline ................................................................................................. 3-1

3.2 Internal Structure of ADMAG AE ........................................................ 3-1

3.2.1 System/network Management VFD ............................................. 3-1

3.2.2 Function Block VFD ..................................................................... 3-1

3.3 Logical Structure of Each Block.......................................................... 3-1

3.4 Wiring System Configuration .............................................................. 3-1

4. GETTING STARTED..................................................................................... 4-1

4.1 Connection of Devices ........................................................................ 4-1

4.2 Host Setting......................................................................................... 4-2

4.3 Bus and ADMAG AE Power ON......................................................... 4-2

4.4 Integration of DD................................................................................. 4-3

4.5 Reading the Parameters ..................................................................... 4-3

4.6 Continuous Record of Values ............................................................. 4-3

4.7 Generation of Alarm............................................................................ 4-3

5. CONFIGURATION.........................................................................................5-1

5.1 Network Design................................................................................... 5-1

5.2 Network Definition ............................................................................... 5-1

5.3 Definition of Combining Function Blocks ............................................ 5-2

5.4 Setting of Tags and Addresses .......................................................... 5-3

5.5 Communication Setting ....................................................................... 5-4

5.5.1 VCR Setting .................................................................................. 5-4

5.5.2 Function Block Execution Control ................................................ 5-5

5.6 Block Setting ....................................................................................... 5-5

5.6.1 Link Object ................................................................................... 5-5

5.6.2 Trend Object ................................................................................. 5-6

5.6.3 View Object .................................................................................. 5-6

5.6.4 AI Function Block Parameters ..................................................... 5-8

5.6.5 Transducer Block Parameters ...................................................... 5-9

6. IN-PROCESS OPERATION ..........................................................................6-1

6.1 Mode Transition .................................................................................. 6-1

6.2 Generation of Alarm............................................................................ 6-1

6.2.1 Indication of Alarm ....................................................................... 6-1

6.2.2 Alarms and Events ....................................................................... 6-1

6.3 Simulation Function............................................................................. 6-2

FD No. IM 1E7F1-01E

5th Edition: Aug. 2004(KP)

All Rights Reserved, Copyright © 2000, Yokogawa Electric Corporation

i

Page 3

CONTENTS

7. DEVICE STATUS ..........................................................................................7-1

8. GENERAL SPECIFICATIONS ......................................................................8-1

APPENDIX 1. LIST OF PARAMETERS FOR EACH BLOCK OF THE

ADMAG AE .................................................................. A-1

A1.1 Resource Block.................................................................................A-1

A1.2 Al Function Block..............................................................................A-3

A1.3 Transducer Block..............................................................................A-5

APPENDIX 2. APPLICATION, SETTING AND CHANGE OF BASIC

PARAMETERS ............................................................. A-7

A2.1 Applications and Selection of Basic Parameters ..............................A-7

A2.2 Setting and Change of Basic Parameters........................................A-8

A2.3 Setting the AI Function Block ........................................................... A-8

A2.4 Setting the Transducer Block ...........................................................A-9

APPENDIX 3. OPERATION OF EACH PARAMETER IN FAILURE MODE. A-10

APPENDIX 4. PID Block ................................................................................. A-12

A4.1 Function Diagram ............................................................................A-12

A4.2 Functions of PID Block ................................................................... A-12

A4.3 Parameters of PID Block ................................................................ A-13

A4.4 PID Computation Details ................................................................A-15

A4.4.1 PV-proportional and -derivative Type PID (I-PD)

Control Algorithm ....................................................................A-15

A4.4.2 PID Control Parameters ......................................................... A-15

A4.5 Control Output .................................................................................A-15

A4.5.1 Velocity Type Output Action ...................................................A-15

A4.6 Direction of Control Action..............................................................A-15

A4.7 Control Action Bypass ....................................................................A-15

A4.8 Feed-forward...................................................................................A-16

A4.9 Block Modes ...................................................................................A-16

A4.9.1 Mode Transitions ....................................................................A-16

A4.10 Bumpless Transfer.......................................................................... A-16

A4.11 Setpoint Limiters ............................................................................. A-17

A4.11.1 When PID Block Is in AUTO Mode ........................................ A-17

A4.11.2 When PID Block Is in CAS or RCAS Mode ........................... A-17

A4.12 External-output Tracking................................................................. A-17

A4.13 Measured-value Tracking ...............................................................A-17

A4.14 Initialization and Manual Fallback (IMAN) ......................................A-18

A4.15 Manual Fallback.............................................................................. A-18

A4.16 Auto Fallback .................................................................................. A-18

A4.17 Mode Shedding upon Computer Failure ........................................A-18

A4.17.1 SHED_OPT.............................................................................A-18

A4.18 Alarms .............................................................................................A-19

A4.18.1 Block Alarm (BLOCK_ALM) ...................................................A-19

A4.18.2 Process Alarms.......................................................................A-19

A4.19 Example of Block Connections....................................................... A-20

A4.19.1 View Object for PID Function Block ....................................... A-20

ii

IM 1E7F1-01E

Page 4

CONTENTS

APPENDIX 5. LINK MASTER FUNCTIONS .................................................. A-22

A5.1 Link Active Scheduler ..................................................................... A-22

A5.2 Link Master .....................................................................................A-22

A5.3 Transfer of LAS ...............................................................................A-23

A5.4 LM Functions ..................................................................................A-24

A5.5 LM Parameters ...............................................................................A-25

A5.5.1 LM Parameter List .................................................................. A-25

A5.5.2 Descriptions for LM Parameters............................................. A-27

A5.6 FAQs...............................................................................................A-29

iii

IM 1E7F1-01E

Page 5

1. INTRODUCTION

1. INTRODUCTION

This manual contains a description of the ADMAG AE

Magnetic Flowmeter FOUNDATION Fieldbus

Communication Type. The FOUNDATION Fieldbus

communication type is similar to the BRAIN

communication type in terms of basic performance and

operation. This manual describes only those topics that

are required for operation of the FOUNDATION

Fieldbus communication type and that are not

contained in the BRAIN communication type

instruction manual. Refer to ADMAG AE Magnetic

Flowmeter instruction manual IM1E7B0-02E or

1E7C1-E for topics common to the BRAIN

communication and FOUNDATION Fieldbus communication types.

■ Regarding This Manual

•This manual should be passed on to the end user.

• The contents of this manual are subject to change

without prior notice.

• All rights reserved. No part of this manual may be

reproduced in any form without Yokogawa’s written

permission.

• Yokogawa makes no warranty of any kind with

regard to this manual, including, but not limited to,

implied warranty of merchantability and fitness for a

particular purpose.

• If any question arises or errors are found, or if any

information is missing from this manual, please

inform the nearest Yokogawa sales office.

• The specifications covered by this manual are

limited to those for the standard type under the

specified model number break-down and do not

cover custom-made instrument.

• Please note that changes in the specifications,

construction, or component parts of the instrument

may not immediately be reflected in this manual at

the time of change, provided that postponement of

revisions will not cause difficulty to the user from a

functional or performance standpoint.

■ Warranty

•The warranty shall cover the period noted on the

quotation presented to the purchaser at the time of

purchase. Problems occurred during the warranty

period shall basically be repaired free of charge.

• In case of problems, the customer should contact the

Yokogawa representative from which the instrument

was purchased, or the nearest Yokogawa office.

• If a problem arises with this instrument, please

inform us of the nature of the problem and the

circumstances under which it developed, including

the model specification and serial number. Any

diagrams, data and other information you can

include in your communication will also be helpful.

• Responsible party for repair cost for the problems

shall be determined by Yokogawa based on our

investigation.

• The Purchaser shall bear the responsibility for repair

costs, even during the warranty period, if the

malfunction is due to:

- Improper and/or inadequate maintenance by the

purchaser.

- Failure or damage due to improper handling, use

or storage which is out of design conditions.

- Use of the product in question in a location not

conforming to the standards specified by

Yokogawa, or due to improper maintenance of

the installation location.

- Failure or damage due to modification or repair

by any party except Yokogawa or an approved

representative of Yokogawa.

- Malfunction or damage from improper relocation

of the product in question after delivery.

- Reason of force majeure such as fires, earthquakes, storms/floods, thunder/lightening, or

other natural disasters, or disturbances, riots,

warfare, or radioactive contamination.

FOUNDATION is a registered trademark of Fieldbus

FOUNDATION .

1-1

IM 1E7F1-01E

Page 6

1. INTRODUCTION

WARNING

• The Magnetic Flowmeter is a heavy

instrument. Please give attention to prevent

that persons are injured by carrying or

installing. It is preferable for carrying the

instrument to use a cart and be done by two

or more persons.

• In wiring, please confirm voltages between

the power supply and the instrumet before

connecting the power cables. And also,

please confirm that the cables are not

powered before connecting.

• If the accumulated process fluid may be toxic

or otherwise harmful, take appropriate care

to avoid contact with the body, or inhalation

of vapors even after dismounting the instrument from process line for maintenance.

■ Safety Precautions

• For the protection and safety of the operator and the

instrument or the system including the instrument,

please be sure to follow the instructions on safety

described in this manual when handling this instrument. In case the instrument is handled in contradiction to these instructions, Yokogawa does not

guarantee safety.

• The following safety symbol marks are used in this

Manual:

IMPORTANT

Indicates that operating the hardware or software

in this manner may damage it or lead to system

failure.

NOTE

Draws attention to information essential for

understanding the operation and features.

WARNING

Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious

injury.

CAUTION

Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate

injury. It may also be used to alert against

unsafe practices.

1-2

IM 1E7F1-01E

Page 7

1. INTRODUCTION

■ ATEX Documentation

This procedure is only applicable to the countries in

European Union.

GB

All instruction manuals for ATEX Ex related products

are available in English, German and French. Should

you require Ex related instructions in your local

language, you are to contact your nearest Yokogawa

office or representative.

DK

Alle brugervejledninger for produkter relateret til

ATEX Ex er tilgængelige på engelsk, tysk og fransk.

Skulle De ønske yderligere oplysninger om håndtering

af Ex produkter på eget sprog, kan De rette

henvendelse herom til den nærmeste Yokogawa

afdeling eller forhandler.

I

Tutti i manuali operativi di prodotti ATEX

contrassegnati con Ex sono disponibili in inglese,

tedesco e francese. Se si desidera ricevere i manuali

operativi di prodotti Ex in lingua locale, mettersi in

contatto con l’ufficio Yokogawa più vicino o con un

rappresentante.

E

Todos los manuales de instrucciones para los productos

antiexplosivos de ATEX están disponibles en inglés,

alemán y francés. Si desea solicitar las instrucciones de

estos artículos antiexplosivos en su idioma local,

deberá ponerse en contacto con la oficina o el

representante de Yokogawa más cercano.

NL

SF

Kaikkien ATEX Ex -tyyppisten tuotteiden käyttöhjeet

ovat saatavilla englannin-, saksan- ja ranskankielisinä.

Mikäli tarvitsette Ex -tyyppisten tuotteiden ohjeita

omalla paikallisella kielellännne, ottakaa yhteyttä

lähimpään Yokogawa-toimistoon tai -edustajaan.

P

Todos os manuais de instruções referentes aos produtos

Ex da ATEX estão disponíveis em Inglês, Alemão e

Francês. Se necessitar de instruções na sua língua

relacionadas com produtos Ex, deverá entrar em

contacto com a delegação mais próxima ou com um

representante da Yokogawa.

F

Tous les manuels d’instruction des produits ATEX Ex

sont disponibles en langue anglaise, allemande et

française. Si vous nécessitez des instructions relatives

aux produits Ex dans votre langue, veuillez bien

contacter votre représentant Yokogawa le plus proche.

D

Alle Betriebsanleitungen für ATEX Ex bezogene

Produkte stehen in den Sprachen Englisch, Deutsch

und Französisch zur Verfügung. Sollten Sie die

Betriebsanleitungen für Ex-Produkte in Ihrer

Landessprache benötigen, setzen Sie sich bitte mit

Ihrem örtlichen Yokogawa-Vertreter in Verbindung.

S

Alla instruktionsböcker för ATEX Ex (explosionssäkra)

produkter är tillgängliga på engelska, tyska och

franska. Om Ni behöver instruktioner för dessa

explosionssäkra produkter på annat språk, skall Ni

kontakta närmaste Yokogawakontor eller representant.

Alle handleidingen voor producten die te maken

hebben met ATEX explosiebeveiliging (Ex) zijn

verkrijgbaar in het Engels, Duits en Frans. Neem,

indien u aanwijzingen op het gebied van

explosiebeveiliging nodig hebt in uw eigen taal, contact

op met de dichtstbijzijnde vestiging van Yokogawa of

met een vertegenwoordiger.

GR

ATEX Ex

, .

Ex

Yokogawa .

1-3

IM 1E7F1-01E

Page 8

2. AMPLIFIER FOR FIELDBUS COMMUNICATION

2. AMPLIFIER FOR FIELDBUS

COMMUNICATION

Refer to the instruction manual for detailed

descriptions of the parts. This section describes the

topics applicable to the Fieldbus communication type.

(1) In the Fieldbus communication type, there are no

local key access function.

(2) The Fieldbus communication type has no BRAIN

terminal connection pin.

(3) The Fieldbus communication type has no

Instantaneous/Totalizer rate alternate display

function.

(4) The Fieldbus communication type has a simulation

function. A SIMULATE-ENABLE jumper switch

is mounted in the ADMAG AE amplifier. Refer to

Section 6.3, “Simulation Function” for details of

the simulation function.

(5) ADMAG AE adjusting using AM012 calibrator

must be done on off-line.

SIMU

SIMULATE_ENABLE jumper

Figure 2.1 Amplifier for Fieldbus communication

2-1

IM 1E7F1-01E

Page 9

3. ABOUT FIELDBUS

3. ABOUT FIELDBUS

3.1 Outline

Fieldbus is a bi-directional digital communication

protocol for field devices, which offers an advancement

in implementation technologies for process control

systems and is widely employed by numerous field

devices.

ADMAG AE Fieldbus communication type employs

the specification standardized by The Fieldbus

Foundation, and provides interoperability between

Yokogawa devices and those produced by other

manufacturers. Fieldbus comes with software

consisting of AI function block, providing the means to

implement a flexible instrumentation system.

For information on other features, engineering, design,

construction work, startup and maintenance of

Fieldbus, refer to “Fieldbus Technical Information” (TI

38K3A01-01E).

3.2 Internal Structure of ADMAG

AE

ADMAG AE contains two Virtual Field Devices

(VFD) that share the following functions.

3.2.1 System/network Management VFD

(4)PID function block(option)

• Performs the PID control computation based on the

deviation of the measured value from the set point.

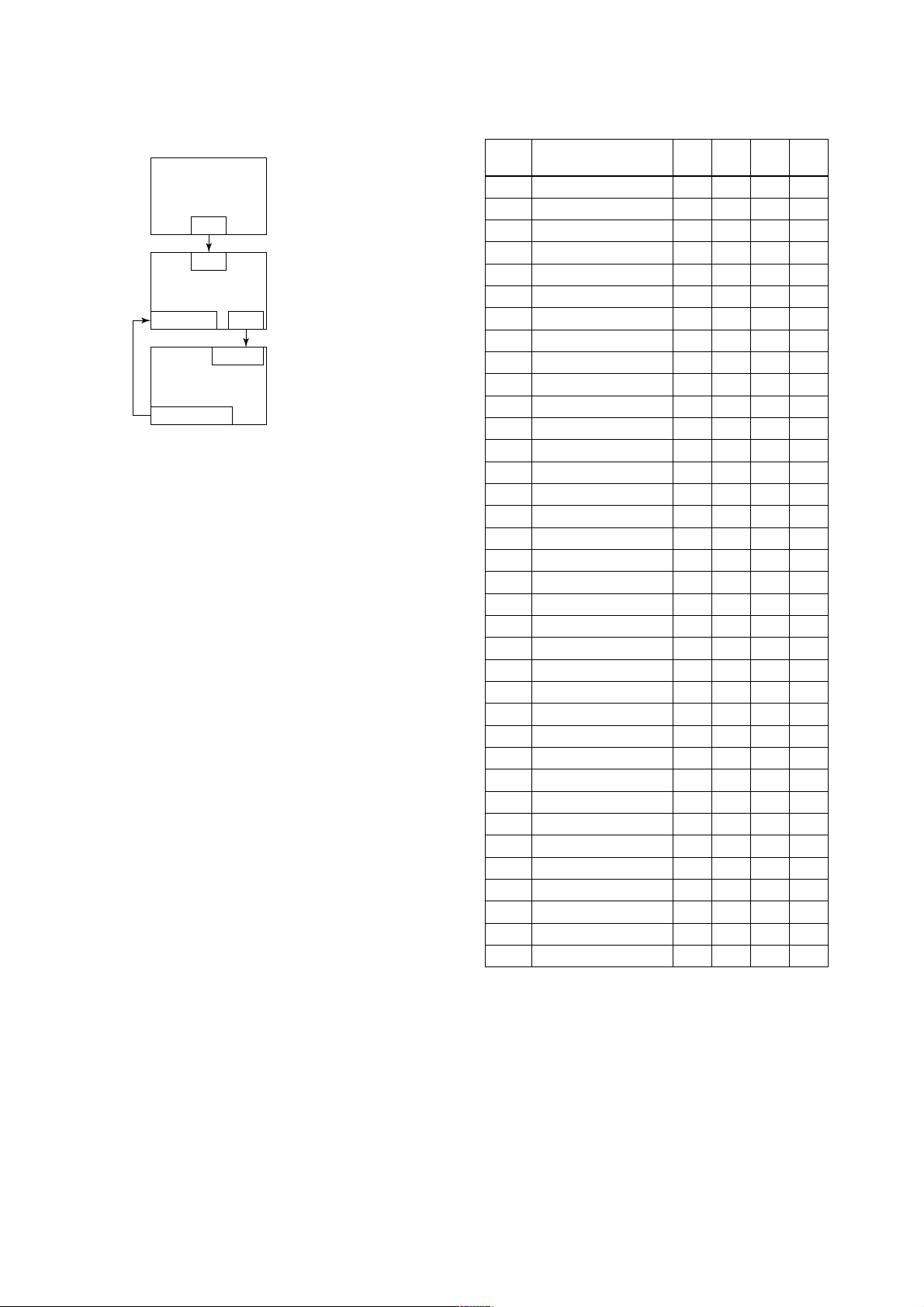

3.3 Logical Structure of Each

Block

ADMAG AE

Fieldbus

Sensor

input

Sensor

System/network management VFD

PD Tag

Node address

Link master(Option)

Function block VFD

Transducer

block

Block tag

Parameters

Communication

parameters

VCR

Function block

execution schedule

PID function

block(Option)

AI function

block

Block tag

Parameters

OUT

Output

•Sets node addresses and Physical Device tags (PD

Tag) necessary for communication.

• Controls the execution of function blocks.

•Manages operation parameters and communication

resources (Virtual Communication Relationship:

VCR).

3.2.2 Function Block VFD

(1)Resource block

• Manages the status of ADMAG AE hardware.

•Automatically informs the host of any detected

faults or other problems.

(2)Transducer block

•Converts sensor output to flow rate signal and

transfers to AI function block.

(3)AI function block

• Conditions raw data from the Transducer block.

• Outputs flow rate signals.

• Carries out scaling extraction.

Resource block

Block tag

Parameters

F0301.EPS

Figure 3.1 Logical Structure of Each Block

Setting of various parameters, node addresses, and PD

Tags shown in Figure 3.1 is required before starting

operation.

3.4 Wiring System Configuration

The number of devices that can be connected to a

single bus and the cable length vary depending on

system design. When constructing systems, both the

basic and overall design must be carefully considered

to allow device performance to be fully exhibited.

3-1

IM 1E7F1-01E

Page 10

4. GETTING STARTED

4. GETTING STARTED

Fieldbus is fully dependent upon digital communication protocol and differs in operation from conventional 4 to 20 mA transmission and the BRAIN

communication protocol. It is recommended that

novice users use fieldbus devices in accordance with

the procedures described in this section. The

procedures assume that fieldbus devices will be set up

on a bench of an instrument shop.

4.1 Connection of Devices

The following instruments are required for use with

Fieldbus devices:

• Power supply:

Fieldbus requires a dedicated power supply. It is

recommended that current capacity be well over the

total value of the maximum current consumed by all

devices (including the host). Conventional DC

current cannot be used as is. For ADMAG AE,

power supply is required separately. ADMAG AE

current consumption does not concern the dedicated

power supply for Fieldbus.

• Terminator:

Fieldbus requires two terminators. Refer to the

supplier for details of terminators that are attached

to the host.

• Host:

Used for accessing field devices. A dedicated host

(such as DCS) is used for an instrumentation line

while dedicated communication tools are used for

experimental purposes. For operation of the host,

refer to the instruction manual for each host. No

details of the host are explained in the rest of this

material.

•Cable:

Used for connecting devices. Refer to “Fieldbus

Technical Information” (TI 38K3A01-01E) for

details of instrumentation cabling. If the total length

of the cable is in a range of 2 to 3 meters for

laboratory or other experimental use, the following

simplified cable (a twisted pair wire with a cross

section of 0.9 mm2 or more and cycle period of

within 5 cm (2 inches) may be used.) Termination

processing depends on the type of device being

deployed. For ADMAG AE, use an M4 screw

terminal. Some hosts require a connector.

Refer to Yokogawa when making arrangements to

purchase the recommended equipment.

Connect the devices as shown in Figure 4.2. Connect

the terminators at both ends of the trunk, with a

minimum length of the spur laid for connection.

The polarity of signal and power must be maintained.

•Field devices:

Connect Fieldbus communication type ADMAG

AE. Two or more ADMAG AE devices or other

devices can be connected. Refer to Figure 4.1

Terminal Connection for ADMAG AE.

Integral Type Flowmeter:

Terminal Symbols Description

P+

P–

I+

I–

L/+

N/–

Remote Type Converter (AE14):

Terminal Symbols

SA

A

B

SB

C

EX1

EX2

P+

P–

I+

I–

L/+

N/–

Figure 4.1 Terminal connection for ADMAG AE

Not used

Fieldbus communication signal

Power supply

Protective grounding

Description

A shield

Flow signal input

B shield

Common

Excitation current output

Not used

Fieldbus communication signal

Power supply

Protective grounding

T03.EPS

Fieldbus power

supply

FIELDBUS

Terminator

Figure 4.2 Device Connection

ADMAG AE

I

IFIELDBUS

HOST

Terminator

Before using a Fieldbus configuration tool other than

the existing host, confirm it does not affect the loop

functionality in which all devices are already installed

in operation. Disconnect the relevant control loop from

the bus if necessary.

4-1

IM 1E7F1-01E

F0401.EPS

Page 11

4. GETTING STARTED

IMPORTANT

Connecting a Fieldbus configuration tool to a

loop with its existing host may cause communication data scrambles resulting in a functional

disorder or a system failure.

4.2 Host Setting

To activate Fieldbus, the following settings are

required for the host.

IMPORTANT

Do not turn off the power immediately after

setting. When the parameters are saved to the

EEPROM, the redundant processing is executed

for the improvement of reliability. If the power is

turned off within 60 seconds after setting is

made, the modified parameters are not saved

and the settings may return to the original

values.

Table 4.1 Operation Parameters

Symbol Parameter Description and Settings

V (ST) Slot-Time

V (MID)

V (MRD)

V (FUN) First-Unpolled-Node

V (NUN) Number-of-

Minimum-Inter-PDUDelay

Maximum-ReplyDelay

consecutiveUnpolled-Node

Set 4 or greater value.

Set 4 or greater value.

Set so that V (MRD) V

(ST) is 12 or greater

Indicate the address next

to the address range used

by the host. Set 0x15 or

greater.

Unused address range.

ADMAG AE address is

factory-set to 0xF4. Set this

address to be within the

range of the BASIC device

in Figure 4.3.

T0401.EPS

0x00

0x10

V(FUN)

V(FUN)V(NUN)

ADMAG AE(0xF4)

Note 1: LM device: with bus control function (Link Master function)

Note 2: BASIC device: without bus control function

Figure 4.3 Available Address Range

0xF7

0xF8

0xFB

0xFC

0xFF

Not used

LM device

Unused V(NUN)

BASIC device

Default address

Portable device address

F0402.EPS

4.3 Bus and ADMAG AE Power ON

Turn on the power of the host, the bus and ADMAG

AE. Where the ADMAG AE is equipped with an LCD

indicator(option), first all segments are lit, then the

segments for a right-most digit are blinking till

communication starting. If the indicator is not lit, check

the voltage of the power supply for ADMAG AE.

Using the host device display function, check that the

ADMAG AE is in operation on the bus. Unless

otherwise specified, the following settings are in effect

when shipped from the factory.

PD tag: FT1002

Node address: 244 (hexadecimal F4)

Device ID: 5945430004xxxxxxxx (xxxxxxxx = a total

of 8 alphanumeric characters)

If no ADMAG AE is detected, check the available

address range. If the node address and PD Tag are not

specified when ordering, default value is factory set. If

two or more ADMAG AEs are connected at a time

with default value, only one ADMAG AE will be

detected from host as ADMAG AEs have the same

initial address. Separately connect each ADMAG AE

and set a different address for each.

4-2

IM 1E7F1-01E

Page 12

4. GETTING STARTED

4.4 Integration of DD

If the host supports DD (Device Description), the DD

of the ADMAG AE needs to be installed. Check if host

has the following directory under its default DD

directory.

594543\0004

(594543 is the manufacturer number of Yokogawa

Electric Corporation, and 0004 is the ADMAG AE

device number, respectively.)

If this directory is not found, DD of ADMAG AE has

not been included. Create the above directory and copy

the DD file "0m0n.ffo,0m0n.sym" (m, n is a numeral)

into the directory.

If you do not have the DD file, you can download it

from our web site.

Visit the following web site.

http://www.yokogawa.com/fi/fieldbus/download.htm

Once the DD is installed in the directory, the name and

attribute of all parameters of the ADMAG AE are

displayed.

Off-line configuration is possible using Capability

file(CFF).

NOTE

Ensure to use the suitable file for the device.

ADMAG AE has two types, /FB-with a AI

function block, and /FB/LC1-with PID/LM

function. If the different type CFF is used, some

errors occur at downloading to the device.

4.7 Generation of Alarm

If the host is allowed to receive alarms, generation of

an alarm can be attempted from ADMAG AE. In this

case, set the reception of alarms on the host side.

ADMAG AE’s VCR-7 is factory-set for this purpose.

For practical purposes, all alarms are placed in a

disabled status; for this reason, it is recommended that

you first use one of these alarms on a trial basis. Set

the value of link object-3 (index 30002) as “0, 299, 0,

6, 0”. Refer to section 5.6.1 Link Object for details.

Since the LO_PRI parameter (index 4029) of the AI

block is set to “0”, try setting this value to “3”. Select

the Write function from the host in operation, specify

an index or variable name, and write “3” to it.

The LO_LIM parameter (index 4030) of the AI block

determines the limit at which the lower bound alarm

for the process value is given. In usual cases, a very

small value is set to this limit. Set 1 (the unit is same

as XD_SCALE unit) to the limit. Since the flow rate is

almost 0, a lower bound alarm is raised. Check that the

alarm can be received at the host. When the alarm is

confirmed, transmission of the alarm is suspended.

The above-mentioned items are a description of the

simple procedure to be carried out until ADMAG AE

is connected to Fieldbus. In order to take full advantage of the performance and functionality of the device,

it is recommended that it be read together with Chapter

5, where describes how to use the ADMAG AE.

4.5 Reading the Parameters

To read ADMAG AE parameters, select the AI block

of the ADMAG AE from the host screen and read the

OUT parameter. The current flow rate is displayed.

Check that MODE_BLOCK of the function block and

resource block is set to AUTO.

4.6 Continuous Record of Values

If the host has a function of continuously recording the

indications, use this function to list the indications

(values). Depending on the host being used, it may be

necessary to set the schedule of Publish (the function

that transmits the indication on a periodic basis).

4-3

IM 1E7F1-01E

Page 13

5. CONFIGURATION

5. CONFIGURATION

This chapter contains information on how to adapt the

function and performance of the ADMAG AE to suit

specific applications. Because two or more devices are

connected to Fieldbus, settings including the

requirements of all devices need to be determined.

Practically, the following steps must be taken.

(1)Network design

Determines the devices to be connected to Fieldbus

and checks the capacity of the power supply.

(2)Network definition

Determines the PD tag and node addresses for all

devices.

(3)Definition of combining function blocks

Determines the method for combination between

each function block.

(4)Setting tags and addresses

Sets the PD Tag and node addresses one by one for

each device.

(5)Communication setting

Sets the link between communication parameters

and function blocks.

(6)Block setting

Sets the parameters for function blocks.

The following section describes each step of the

procedure in the order given. Using a dedicated

configuration tool allows the procedure to be significantly simplified. This section describes the procedure

to be assigned for a host which has relatively simple

functions. Refer to Appendix 5 when the ADMAG AE

is used as Link Master (option).

5.1 Network Design

Select the devices to be connected to the Fieldbus

network. The following instruments are necessary for

operation of Fieldbus.

• Power supply

Fieldbus requires a dedicated power supply. It is

recommended that current capacity be well over the

total value of the maximum current consumed by all

devices (including the host). For ADMAG AE,

separate power supply is required. Therefore,

ADMAG AE current consumption does not affect

the dedicated power supply for Fieldbus.

• Terminator

Fieldbus requires two terminators. Refer to the

supplier for details of terminators that are attached

to the host.

•Field devices

Connect the field devices necessary for instrumentation. ADMAG AE has passed the interoperability

test conducted by The Fieldbus Foundation. In order

to properly start Fieldbus, it is recommended that

the devices used satisfy the requirements of the

above test.

• Host

Used for accessing field devices. A minimum of one

device with bus control function is needed.

• Cable

Used for connecting devices. Refer to “Fieldbus

Technical Information” for details of instrumentation cabling. Provide a cable sufficiently long to

connect all devices. For field branch cabling, use

terminal boards or a connection box as required.

First, check the capacity of the power supply. The

power supply capacity must be greater than the sum of

the maximum current consumed by all devices to be

connected to Fieldbus. For ADMAG AE, separate

power supply is required. Thus, ADMAG AE current

consumption does not concern the dedicated power

supply for Fieldbus. The cable must have the spur in a

minimum length with terminators installed at both ends

of the trunk.

5.2 Network Definition

Before connection of devices with Fieldbus, define the

Fieldbus network. Allocate PD Tag and node addresses

to all devices (excluding such passive devices as

terminators).

The PD Tag is the same as the conventional one used

for the device. Up to 32 alphanumeric characters may

be used for definition. Use a hyphen as a delimiter as

required.

5-1

IM 1E7F1-01E

Page 14

5. CONFIGURATION

The node address is used to specify devices for

communication purposes. Because data is too long for

a PD Tag, the host uses the node address in place of

the PD Tag for communication. A range of 16 to 247

(or hexadecimal 10 to F7) can be set. The device (LM

device) with bus control function (Link Master

function) is allocated from a smaller address number

(16) side, and other devices (BASIC device) without

bus control function allocated from a larger address

number (247) side respectively. Place ADMAG AE in

the range of the BASIC device. When the ADMAG

AE is used as Link Master (option), place ADMAG

AE in the range of LM device. Set the range of

addresses to be used to the LM device. Set the

following parameters.

Table 5.1 Parameters for Setting Address Range

Symbol

V (FUN) First-Unpolled-Node

V (NUN) Number-of-

Parameters Description

Indicates the address next

to the address range used

for the host or other LM

device.

Unused address range

consecutiveUnpolled-Node

T0501.EPS

The devices within the address range written as

“Unused” in Figure 5.1 cannot be used on a Fieldbus.

For other address ranges, the range is periodically

checked to identify when a new device is mounted.

Care must be taken not to allow the address range to

become wider, which can lead to exhaustive consumption of Fieldbus communication performance.

0x00

Not used

0x10

V(FUN)

V(FUN)V(NUN)

0xF7

0xF8

0xFB

0xFC

0xFF

Figure 5.1 Available Range of Node Addresses

LM device

Unused V(NUN)

BASIC device

Default address

Portable device address

F0501.EPS

To ensure stable operation of Fieldbus, determine the

operation parameters and set them to the LM devices.

While the parameters in Table 5.2 are to be set, the

worst-case value of all the devices to be connected to

the same Fieldbus must be used. Refer to the specification of each device for details. Table 5.2 lists ADMAG

AE specification values.

Table 5.2 Operation Parameter Values of the ADMAG AE

to be Set to LM Devices

Symbol Parameters Description and Settings

V (ST) Slot-Time

V (MID) Minimum-Inter-PDU-

Delay

V (MRD) Maximum-Reply-Delay

Indicates the time

necessary for immediate

reply of the device. Unit of

time is in octets (256 µs).

Set maximum specification

for all devices. For

ADMAG AE, set a value of

4 or greater.

Minimum value of

communication data

intervals. Unit of time is in

octets (256 µs). Set the

maximum specification for

all devices. For ADMAG

AE, set a value of 4 or

greater.

The worst case time

elapsed until a reply is

recorded. The unit is Slottime; set the value so that

V (MRD) V (ST) is the

maximum value of the

specification for all

devices. For ADMAG AE,

value of V(MRD)V (ST)

must be 12 or greater.

T0502.EPS

5.3 Definition of Combining Function Blocks

The input/output parameters for function blocks are

combined. For the ADMAG AE, AI block output

parameter (OUT) and PID block (option) is subject to

combination. They are combined with the input of the

control block as necessary. Practically, setting is

written to the ADMAG AE link object with reference

to “Block setting” in Section 5.6 for details. It is also

possible to read values from the host at proper intervals

instead of connecting the ADMAG AE block output to

other blocks.

The combined blocks need to be executed synchronously with other blocks on the communications

schedule. In this case, change the ADMAG AE

schedule according to the following table. Enclosed

values in the table are factory-settings.

5-2

IM 1E7F1-01E

Page 15

5. CONFIGURATION

Table 5.3 Execution Schedule of the ADMAG AE Function

Blocks

Index Parameters

269

MACROCYCLE_

(SM)

DURATION

276

FB_START_ENTRY.1

(SM)

277

FB_START_ENTRY.2

(SM)

278

FB_START_ENTRY.3

(SM)

279

FB_START_ENTRY.4

(SM)

Setting (Enclosed is

factory-setting)

Cycle (MACROCYCLE)

period of control or

measurement. Unit is 1/32

ms. (32000 = 1 s)

AI block startup time.

Elapsed time from the start

of MACROCYCLE specified

in 1/32 ms. (0 = 0 s)

9600=0.3s for PID block

(option)

Not factory-set.

Not factory-set.

T0503.EPS

A maximum of 100 ms is taken for execution of AI

block. For scheduling of communications for combination with the next function block, the execution is so

arranged as to start after a lapse of longer than 100 ms.

Figure 5.3 shows an example of schedule based on the

loop shown in Figure 5.2.

FIC100

When the control period (macrocycle) is set to more

than 4 seconds, set the following interval to be

more than 1% of the control period.

- Interval between "end of block execution" and

"start of sending CD from LAS"

- Interval between "end of block execution" and

"starrt of the next block execution"

5.4 Setting of Tags and Addresses

This section describes the steps in the procedure to set

PD Tags and node addresses in the ADMAG AE.

There are three states of Fieldbus devices as shown in

Figure 5.4, and if the state is other than the lowest

SM_OPERATIONAL state, no function block is

executed. ADMAG AE must be transferred to this state

when an ADMAG AE tag or address is changed.

UNINITIALIZED

(No tag nor address is set)

Tag clear Tag setting

ADMAG AE

#1

FI100

ADMAG AE

#2

FI200

Figure 5.2 Example of Loop Connecting Function Block of

Two ADMAG AE with Other Instruments

Macrocycle (Control Period)

Function

Block

Schedule

Commu-

nication

Schedule

Figure 5.3 Functionn Block Schedule and Communication

FI100

OUT

BKCAL_IN

FI200

Schedule

IN

FIC100

OUT

FIC200

CAS_IN

FIC200

IN

BKCAL_IN

Unscheduled

Communication

FC100

F0502.EPS

BKCAL_OUT

FC100

BKCAL_OUT

Scheduled

Communication

F0503.EPS

INITIALIZED

(Only tag is set)

Address clear

SM_OPERATIONAL

(Tag and address are retained, and

the function block can be executed.)

Figure 5.4 Status Transition by Setting PD Tag and Node

Address

Address setting

F0504.EPS

ADMAG AE has a PD Tag (FT1002) and node address

(244, or hexadecimal F4) that are set upon shipment

from the factory unless otherwise specified. To change

only the node address, clear the address once and then

set a new node address. To set the PD Tag, first clear

the node address and clear the PD Tag, then set the PD

Tag and node address again.

Devices whose node address was cleared will await the

default address (randomly chosen from a range of 248

to 251, or from hexadecimal F8 to FB). At the same

time, it is necessary to specify the device ID in order to

correctly specify the device. The device ID of the

ADMAG AE is 5945430004xxxxxxxx. (The xxxxxxxx

at the end of the above device ID is a total of 8

alphanumeric characters.)

5-3

IM 1E7F1-01E

Page 16

5. CONFIGURATION

5.5 Communication Setting

To set the communication function, it is necessary to

change the database residing in SM-VFD.

5.5.1 VCR Setting

Set VCR (Virtual Communication Relationship), which

specifies the called party for communication and

resources. ADMAG AE has 16 VCRs whose application can be changed, except for the first VCR, which is

used for management.

ADMAG AE has VCRs of four types:

Server(QUB) VCR

A Server responds to requests from a host. This

communication needs data exchange. This type of

communication is called QUB (Queued Usertriggered Bidirectional) VCR.

Source (QUU) VCR

A Source multicasts alarms or trends to other

devices. This type of communication is called QUU

(Queued User-triggered Unidirectional) VCR.

Publisher (BNU) VCR

A Publisher multicasts AI block output to another

function block(s). This type of communication is

called BNU (Buffered Network-triggered Unidirectional) VCR.

Subscriber (BNU) VCR

A Subscriber receives output of another function

block(s) by PID block.

A Server VCR is capable to respond to requests from a

Client (QUB) VCR after the Client initiates connection

to the Server successfully. A Source VCR transmits

data without established connection. A Sink (QUU)

VCR on another device can receive it if the Sink is

configured so. A Publisher VCR transmits data when

LAS requests so. An explicit connection is established

from Subscriber (BNU) VCR(s) so that a Subscriber

knows the format of published data.

Each VCR has the parameters listed in Table 5.4.

Parameters must be changed together for each VCR

because modification for each parameter may cause

inconsistent operation.

Table 5.4 VCR Static Entry

Sub-

index

1 FasArTypeAndRole

2 FasDllLocalAddr

3 FasDllConfigured

4 FasDllSDAP

5 FasDllMaxConfirm

6 FasDllMaxConfirm

7 FasDllMaxDlsduSize

8 FasDllResidual

9 FasDllTimelinessClass

10 FasDllPublisherTime

11 FasDllPublisher

Parameter Description

RemoteAddr

DelayOnConnect

DelayOnData

ActivitySupported

WindowSize

SynchronizaingDlcep

Indicates the type and role of

communication (VCR). The

following 4 types are used

for ADMAG AE.

0x32: Server (Responds to

requests from host.)

0x44: Source (Transmits

alarm or trend.)

0x66: Publisher (Sends AI

block output to other

blocks.)

0x76: Subscriber (Receives

output of other blocks

by PID block.)

Sets the local address to

specify VCR in ADMAG AE.

A range of 20 to F7 in

hexadecimal.

Sets the node address of the

called party for

communication and the

address (DLSAP or DLCEP)

used to specify VCR in that

address. For DLSAP or

DLCEP, a range of 20 to F7

in hexadecimal is used.

Addresses in Subindex 2

and 3 need to be set to the

same contents of the VCR

as the called party (local and

remote are reversed).

Specifies the quality of

communication. Usually, one

of the following types is set.

0x2B: Server

0x01: Source (Alert)

0x03: Source (Trend)

0x91: Publisher/Subscriber

To establish connection for

communication, a maximum

wait time for the called

party's response is set in

ms. Typical value is 60

secounds (60000).

For request of data, a

maximum wait time for the

called party's response is

set in ms. Typical value is

60 secounds (60000).

Specifies maximum DL

Service Data unit Size

(DLSDU). Set 256 for Server

and Trend VCR, and 64 for

other VCRs.

Specifies whether

connection is monitored. Set

TRUE (0xff) for Server. This

parameter is not used for

other communication.

Not used for ADMAG AE.

Not used for ADMAG AE.

Not used for ADMAG AE.

T0504-1.EPS

5-4

IM 1E7F1-01E

Page 17

5. CONFIGURATION

Sub-

index

12 FasDllSubscriberTime

13 FasDllSubscriber

14 FmsVfdId

15 FmsMaxOutstanding

16 FmsMaxOutstanding

17 FmsFeatures

Parameter

WindowSize

SynchronizationDlcep

ServiceCalling

ServiceCalled

Supported

Description

Not used for ADMAG AE.

Not used for ADMAG AE.

Sets VFD for ADMAG AE to

be used.

0x1: System/network

management VFD

0x1234: Function block

VFD

Set 0 to Server. It is not

used for other applications.

Set 1 to Server. It is not

used for other applications.

Indicates the type of

services in the application

layer. In the ADMAG AE, it is

automatically set according

to specific applications.

T0504-2.EPS

16 VCRs are factory-set as shown in Table 5.5.

Table 5.5 VCR List

Index

(SM)

293 For system management (Fixed)1

294 Server (LocalAddr = 0xF3)2

295 Server (LocalAddr = 0xF4)3

296 Server (LocalAddr = 0xF7)4

297 Trend Source (LocalAddr = 0x07,

298 Publisher (LocalAddr = 0x20)6

299

300 Server (LocalAddr = 0xF9)8

301

302

303

304

305

306

307

308

VCR

Number

5

7

9

10

11

12

13

14

15

16

Factory Setting

Remote Address=0x111)

Alert Source (LocalAddr = 0x07,

Remote Address=0x110)

Not factory-set.

Not factory-set.

Not factory-set.

Not factory-set.

Not factory-set.

Not factory-set.

Not factory-set.

Not factory-set.

T0505.EPS

5.5.2 Function Block Execution Control

According to the instructions given in Section 5.3, set

the execution cycle of the function blocks and schedule

of execution.

5.6 Block Setting

Set the parameter for function block VFD.

5.6.1 Link Object

Link object combines the data voluntarily sent by the

function block with VCR. ADMAG AE has 11 link

objects. A single link object specifies one combination.

Each link object has the parameters listed in Table 5.6.

Parameters must be changed together for each VCR

because the modifications made to each parameter may

cause inconsistent operation.

Table 5.6 Link Object Parameters

Sub-

index

1 LocalIndex

2VcrNumber

3RemoteIndex

4ServiceOperation

5StaleCountLimit

Link objects are not factory-set. Set link objects as

shown in Table 5.7.

Table 5.7 Settings of Link Objects (example)

Index Link Object #

30000

30001 2

30002 3

30003 No used4

30004 No used5

30005 No used6

30006 No used7

30007 No used8

30008 No used9

30009 No used10

30010 No used11

Parameters Description

Sets the index of function

block parameters to be

combined; set “0” for Trend

and Alert.

Sets the index of VCR to

be combined. If set to “0”,

this link object is not used.

Not used in ADMAG AE.

Set to “0”.

Set one of the following.

Set only one each for link

object for Alert or Trend.

0: Undefined

2: Publisher

3: Subscriber

6: Alert

7: Trend

Set the maximum number

of consecutive stale input

values which may be

received before the input

status is set to BAD. To

avoid the unnecessary

mode transition caused

when the data is not

correctly received by

subscriber, set this

parameter to "2" or more.

Settings(example)

1

AI. OUT VCR#6

Trend VCR#5

Alert VCR#7

T0506.EPS

T0507.EPS

5-5

IM 1E7F1-01E

Page 18

5. CONFIGURATION

5.6.2 Trend Object

It is possible to set the parameter so that the function

block automatically transmits Trend. ADMAG AE has

four Trend objects, three of which are used for Trend

in analog mode parameters and one is used for Trend

in discrete mode parameter. A single Trend object

specifies the trend of one parameter of Resource block.

Each Trend object has the parameters listed in Table

5.8. The first four parameters are the items to be set.

Before writing to a Trend object, it is necessary to

release the WRITE_LOCK parameter of Resource

block.

Table 5.8 Parameters for Trend Objects

Sub-

index

Parameters

1Block Index

2 Parameter Relative

Index

3 Sample Type

4 Sample Interval

5 Last Update

6 to 21 List of Status

21 to 37 List of Samples

Five trend objects are not factory-set.

Description

Sets the leading index of

the function block that

takes a trend.

Sets the index of

parameters taking a trend

by a value relative to the

beginning of the function

block. In the ADMAG AE

AI block, the following

three types of trends are

possible.

7: PV

8: OUT

19: FIELD_VAL

Specifies how trends are

taken. Choose one of the

following 2 types:

1: Sampled upon

execution of a function

block.

2: The average value is

sampled.

Specifies sampling

intervals in units of 1/32

ms. Set the integer

multiple of the function

block execution cycle.

The last sampling time.

Status part of a sampled

parameter.

Data part of a sampled

parameter.

T0508.EPS

SMIB

ADMAG

AE

(System

Management

Information

Base)

NMIB

(Network

Management

Information

Base)

Link

object

VCR

DLSAP

0xF8 0xF3 0xF4 0xF7

DLCEP

Fieldbus Cable

Resource

block

#1

Host 1

#2

FBOD

#3 #4

Host 2

Transducer

block

#1 #2

#8

0xF9

Device

AI OUT

#6

0x20

#3

#7

Alert

Trend

#5

0x07

F0505.EPS

Figure 5.5 Examle of Default Configuration

5.6.3 View Object

This is the object to form groups of parameters in a

block. One of advantage brought by forming groups of

parameters is the reduction of load for data transaction.

ADMAG AE has four View Objects for each Resource

block, Transducer block, and AI function block, and

each View Object has the parameters listed in Table

5.11 to 5.14.

Table 5.10 Purpose of Each View Object

Description

VIEW_1

VIEW_2

VIEW_3

VIEW_4

Set of dynamic parameters required by operator

for plant operation. (PV, SV, OUT, Mode etc.)

Set of static parameters which need to be

shown to plant operator at once. (Range etc.)

Set of all the dynamic parameters.

Set of static parameters for configuration or

maintenance.

T0510.EPS

Table 5.9 Trend Objects

Index Trend Object # Factory Settings

32000 Not factory-set.TREND_FLT.1

32001 Not factory-set.TREND_FLT.2

32002 Not factory-set.TREND_FLT.3

32003 Not factory-set.TREND_FLT.4

32004 Not factory-set.

TREND_DIS.1

(only with PID function)

T0509.EPS

5-6

IM 1E7F1-01E

Page 19

5. CONFIGURATION

Table 5.11 View Object for Resource Block

Relative

Parameter Mnemonic

Index

1 ST_REV 2

2 TAG_DESC

3 STRATEGY

4 ALERT_KEY

5 MODE_BLK 4

6 BLOCK_ERR 2

7 RS_STATE

8 TEST_RW

9 DD_RESOURCE

10 MANUFAC_ID

11 DEV_TYPE

12 DEV_REV

13 DD_REV

14 GRANT_DENY

15 HARD_TYPES

16 RESTART

17 FEATURES

18 FEATURE_SEL

19 CYCLE_TYPE

20 CYCLE_SEL

21 MIN_CYCLE_T

22 MEMORY_SIZE

23 NV_CYCLE_T

24 FREE_SPACE

26 SHED_RCAS

27 SHED_ROUT

29 SET_FSTATE

30 CLR_FSTATE

31 MAX_NOTIFY

32 LIM_NOTIFY

33 CONFIRM_TIME

34 WRITE_LOCK

35 UPDATE_EVT

36 BLOCK_ALM

38 ACK_OPTION 2

39 WRITE_PRI 1

40 WRITE_ALM

41 ITK_VER

42 SOFT_REV

43 SOFT_DESC

44 SIM_ENABLE_MSG

45 DEVICE_STATUS_1

46 DEVICE_STATUS_2

47 DEVICE_STATUS_3

48 DEVICE_STATUS_4

49 DEVICE_STATUS_5

50 DEVICE_STATUS_6

51 DEVICE_STATUS_7

52 DEVICE_STATUS_8

VIEW1VIEW2VIEW

2

11

2

2

2

4

4

425 FREE_TIME

4

4

128 FAULT_STATE

1

4

1

837 ALARM_SUM

Table 5.12 View Object for Transducer Block

VIEW

VIEW

3

4

2

2

2

1

4

2

4

2

1

1

2

2

2

4

2

4

1

1

8

2

4

4

4

4

4

4

4

4

Relative

Parameter Mnemonic

Index

1 ST_REV 2

2 TAG_DESC

3 STRATEGY

4 ALERT_KEY

5 MODE_BLK 4

6 BLOCK_ERR 2

7 UPDATE_EVT

8 BLOCK_ALM

9 TRANSDUCER_

DIRECTORY

12 COLLECTION_

DIRECTORY

13 PRIMARY_VALUE_

TYPE

15 PRIMARY_VALUE_

RANGE

16 CAL_POINT_HI

17 CAL_POINT_LO

18 CAL_MIN_SPAN

19 CAL_UNIT

20 SENSOR_TYPE

21 SENSOR_RANGE

22 SENSOR_SN

23 SENSOR_CAL_

METHOD

24 SENSOR_CAL_LOC

25 SENSOR_CAL_DATE

26 SENSOR_CAL_WHO

27

LIN_TYPE

28

SECONDARY_VALUE

SECONDARY_

29

VALUE_UNIT

30

PRIMARY_VALUE_FTIME

PRIMARY_VALUE_LOWCUT

31

LINE_SIZE

32

SIZE_UNIT

33

LOW_MF

34

HIGH_MF

35

ZERO_TUNING

36

AUTO_ZERO

37

FLOW_DIRECTION

38

RATE_LMT

39

DEAD_TIME

40

POWER_SYNCH

41

POWER_FREQ

42

PULSATING_FLOW

43

EMPTY_PIPE

44

45

MODEL

DISPLAY_MODE

46

DISPLAY_CYCLE

47

ALARM_SUM

48

VIEW

1

2

2

2

210 TRANSDUCER_TYPE

111 XD_ERROR

2

514 PRIMARY_VALUE

4

4

4

2

4

2

4

4

1

8

VIEW

3

2

4

2

2

1

5

5

8

VIEW

4

2

2

1

2

11

4

2

2

11

4

2

32

7

32

1

2

1

4

2

2

1

4

1

1

1

1

Totals (# bytes)

22 30 54 31

T0511.EPS

5-7

Totals (# bytes)

24 35 29 135

T0512.EPS

IM 1E7F1-01E

Page 20

5. CONFIGURATION

Table 5.13 View Object for AI Function Block

Relative

Parameter Mnemonic

Index

1 ST_REV 2

2 TAG_DESC

3 STRATEGY

4 ALERT_KEY

5 MODE_BLK 4

6 BLOCK_ERR 2

7PV

8 OUT 5

9SIMULATE

10 XD_SCALE

11 OUT_SCALE

12 GRANT_DENY

13 IO_OPTS

14 STATUS_OPTS

15 CHANNEL

16 L_TYPE

17 LOW_CUT

18 PV_FTIME

20 UPDATE_EVT

21 BLOCK_ALM

23 ACK_OPTION

24 ALARM_HYS

25 HI_HI_PRI

26 HI_HI_LIM

HI_PRI

27

28 HI_LIM

29 LO_PRI

LO_LIM

30

31 LO_LO_PRI

32 LO_LO_LIM

33 HI_HI_ALM

34 HI_ALM

35 LO_ALM

36 LO_LO_ALM

37 TOTAL

38

TOTAL_UNIT

39 TOTAL_SCALE

40 TOTAL_LIM

41 TOTAL_LOWCUT

42 TOTAL_SET_VALUE

43 REVERSE_TOTAL

44 DIFF_TOTAL

45

TOTAL_OPTS

46 VELOCITY_CHECK

Totals (# bytes)

VIEW1VIEW

2

2

55

11

11

2

519 FIELD_VAL

822 ALARM_SUM

31 26 46 55

VIEW

3

2

4

2

5

5

8

5

5

5

VIEW

4

2

2

1

2

2

2

1

4

4

2

4

1

4

1

4

1

4

1

4

1

4

2

1

1

T0513.EPS

Table 5.14 Indexes of View for Each Block

Resourse Block

Transducer Block

AI Function Block

(PID Function Block)

VIEW_1

40100

40200

40400

40800

VIEW_2

40101

40201

40401

40801

VIEW_3

40102

40202

40402

40802

5.6.4 AI Function Block Parameters

AI Function block parameters can be read or set from

the host. For a list of the parameters of blocks held by

the ADMAG AE, refer to "List of parameters for each

block of the ADMAG AE" in Appendix 1. The

following is a list of important parameters with a guide

to how to set them. For PID/LM function option, refer

to Appendix 4 and 5.

MODE_BLK:

Indicates the three types of function block modes;

Out_Of_Service, Manual, and Auto. In

Out_Of_Service mode, the AI block does not

operate. The Manual mode does not allow values to

be updated. The Auto mode causes the measured

value to be updated. Under normal circumstances,

set the Auto mode to take effect. The Auto mode is

the factory default.

CHANNEL:

This is the parameter of the transducer block to be

input to the AI block. AI block is assigned flow

rate. Do not change this setting.

XD_SCALE:

Scale of input from the transducer block. "0"(0%),

"10"(100%), and "m/s" for the unit are factory-set

unless otherwise specified. Changing the unit (can

be set only in flow rate) also causes the unit within

the transducer block to be automatically changed.

(The unit is automatically changed according to the

unit selected by AI.) Units which can be set by

XD_SCALE are shown below.

m/s(1061), ft/s(1067), m

m3/min(1348), m3/h(1349), m3/d(1350),

L/s(1351), L/min(1352), L/h(1353), L/d(1354),

cm3/s(1511), cm3/min(1512), cm3/h(1513),

cm3/d(1514), Mgal/s(1451), Mgal/min(1455),

Mgal/h(1459), Mgal/d(1366), kgal/s(1450),

kgal/min(1454), kgal/h(1458), kgal/d(1462),

gal/s(1362), GPM(1363), gal/h(1364),

gal/d(1365), mgal/s(1449), mgal/min(1453),

mgal/h(1457), mgal/d(1461), kbbl/s(1481),

kbbl/min(1485), kbbl/h(1489), kbbl/d(1493),

bbl/s(1371), bbl/min(1372), bbl/h(1373),

bbl/d(1374), mbbl/s(1480), mbbl/min(1484),

mbbl/h(1488), mbbl/d(1492), ubbl/s(1479),

ubbl/min(1483), ubbl/h(1487), ubbl/d(1491)

5-8

3

/s(1347),

IM 1E7F1-01E

VIEW_4

40103

40203

40403

40803

T0514.EPS

Page 21

5. CONFIGURATION

OUT_SCALE:

Sets the range of output (from 0% to 100%).

Available units for OUT_SCALE are the above

units for XD_SCALE and the units shown below.

%(1342), CFS(1356), CFM(1357), CFH(1358),

ft3/d(1359), t/s(1326), t/min(1327), t/h(1328),

t/d(1329), kg/s(1322), kg/min(1323),

kg/h(1324), kg/d(1325), g/s(1318), g/min(1319),

g/h(1320), g/d(1321), lb/s(1330), lb/min(1331),

lb/h(1332), lb/d(1333), STON/s(1334),

STON/min(1335), STON/h(1336),

STON/d(1337), LTON/s(1338),

LTON/min(1339), LTON/h(1340),

LTON/d(1341), MImpGal/s(1466),

MImpGal/min(1470), MImpGal/h(1474),

MImpGal/d(1478), kImpGal/s(1465),

kImpGal/min(1469), kImpGal/h(1474),

kImpGal/d(1477), ImpGal/s(1367),

ImpGal/min(1368), ImpGal/h(1369),

ImpGal/d(1370), mImpGal/s(1464),

mImpGal/min(1468), mImpGal/h(1472),

mImpGal/d(1476)

L_TYPE:

Specifies the operation function of the AI block. If

set to “Direct”, the input delivered to CHANNEL is

directly reflected on OUT. If set to “Indirect”,

scaling by XD_SCALE and OUT_SCALE is carried

out and is reflected on OUT. “Indirect SQRT” is

not used for ADMAG AE.

PV_FTIME:

Sets the time constant of the damping function

within AI block (primary delay) in seconds.

Alarm Priority:

Indicates the priority of the process alarm. If a value

of 3 or greater is set, an alarm is transmitted. The

factory default is 0. Four types of alarm can be set:

HI_PRI, HI_HI_PRI, LO_PRI, and LO_LO_PRI.

Alarm Threshold:

Sets the threshold at which a process alarm is

generated. The factory default setting is a value that

does not generate an alarm. Four types of alarm can

be set: HI_LIM, HI_HI_LIM, LO_LIM, and

LO_LO_LIM.

5.6.5 Transducer Block Parameters

The transducer block sets functions specific to the flow

rate measurement of the ADMAG AE. For a list of the

parameters of each block of the ADMAG AE, refer to

“List of parameters for each block of the ADMAG

AE” in Appendix 1. The following is a list of important parameters with a guide to how to set them.

LINE_SIZE:

Sets the size of the flow tube.

SIZE_UNIT:

Sets the unit of the flow tube size.

LOW_MF:

Sets the meter factor of low frequency side.

HIGH_MF:

Sets the meter factor of high frequency side.

For integral type ADMAG AE, these above parameters

are set when shipping. Please confirm with data plate.

For remote type AE14 converter, please set the above

parameters which are shown in the data plate on the

combined flow tube.

PRIMARY_VALUE_FTIME:

Sets output time constants. Setting range is 0.1 to

200sec. “ 3sec.” is factory set.

PRIMARY_VALUE_LOWCUT:

Sets low cut range for output. Setting range is 0 to

10%. “ 0%” is factory set. The larger absolute value

from EU at 100% or EU at 0% is used for the scale.

DISPLAY_MODE:

Sets the unit to be used for LCD display.

1=Out value

2=%

3=Totalized value

4=Reverse totalized value

5=Diff. totalized value

The factory default setting is 2.

DISPLAY_CYCLE:

Sets the cycle of LCD display. The display cycle is

500ms x (setting). The factory default setting is 1,

but if a low temperature environment makes it

difficult to view the display, it is recommended that

you set a longer display cycle.

5-9

IM 1E7F1-01E

Page 22

6. IN-PROCESS OPERATION

6. IN-PROCESS OPERATION

This chapter describes the procedure performed when

changing the operation of the function block of the

ADMAG AE in process.

6.1 Mode T ransition

When the function block mode is changed to

Out_Of_Service, the function block pauses and a block

alarm is issued.

When the function block mode is changed to Manual,

the function block suspends updating of output values.

In this case alone, it is possible to write a value to the

OUT parameter of the block for output. Note that no

parameter status can be changed.

6.2 Generation of Alarm

6.2.1 Indication of Alarm

When the self-diagnostics function indicates that a

device is faulty, an alarm (device alarm) is issued from

the resource block. When an error (block error) is

detected in each function block or an error in the

process value (process alarm) is detected, an alarm is

issued from each block. If an LCD indicator is installed, the error number is displayed as AL-XX. If two

or more alarms are issued, multiple error numbers are

displayed in 2-second intervals. (when "1" is set to

DISPLAY_CYCLE). An alarm lamp(LED) flashes

during alarming.

Alarm lamp(LED)

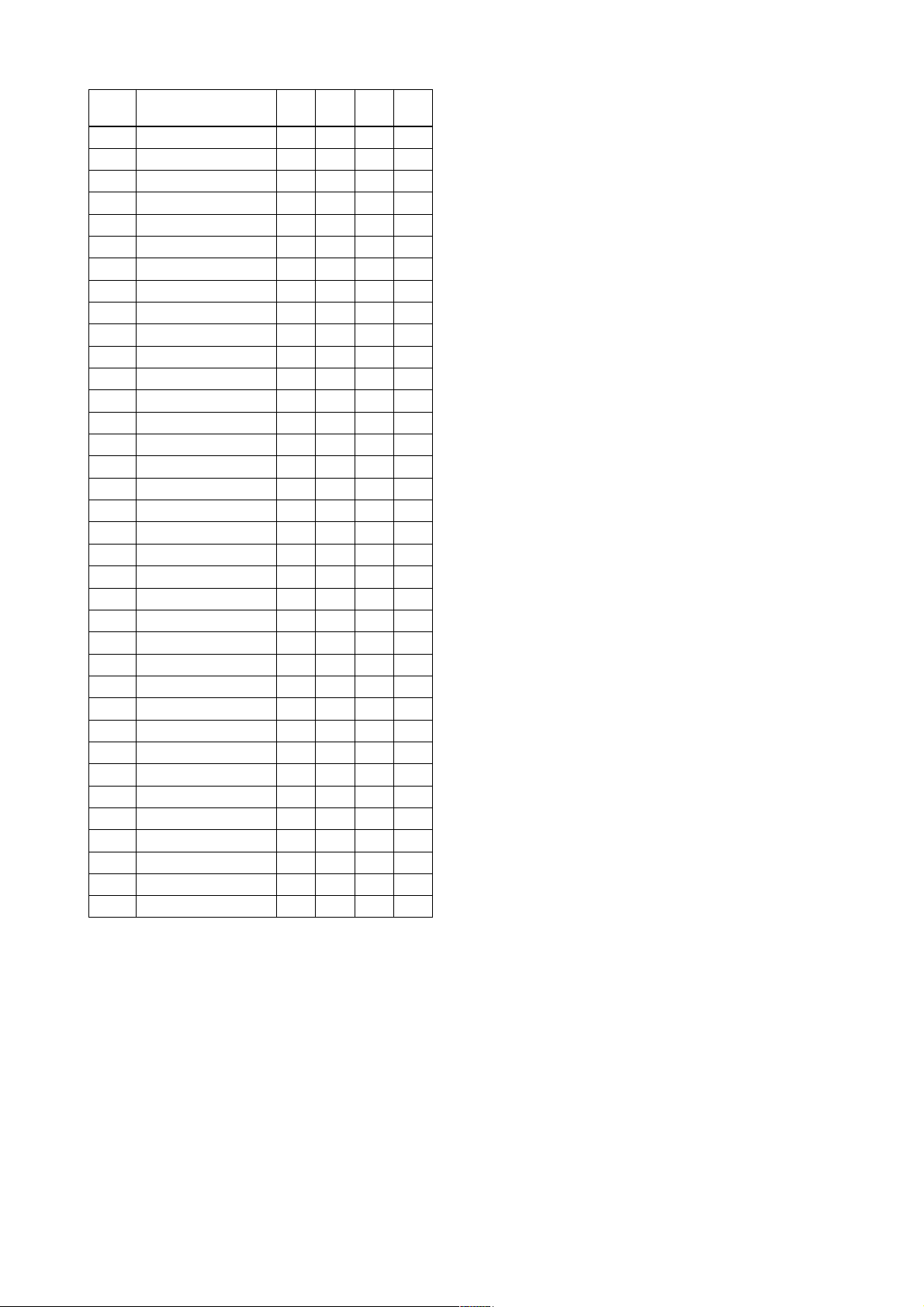

Table 6.1 List of Error Messages

LCD

AL_01

AL_02

AL_03

AL_04

AL_05

AL_06

AL_07

AL_20

AL_21

AL_22

AL_23

AL_41

AL_42

AL_43

AL_44

AL_45

AL_46

AL_47

AL_61

AL_62

AL_63

AL_64

✽

Microprocessor failure.

Amplifier or hardware failure.

EEPROM failure.

A/D converter(high frequency side) failure.

A/D converter(low frequency side) failure.

Excessive input signal.

Flow tube coil open-circuit.

AI block is not scheduled.

The resource block is in O/S mode.

The transducer block is in O/S mode.

AI function block is in O/S mode.

The flow rate is out of the measurement

range. Measurement flow velocity exceed

108% of forward flow direction span setting.

The flow rate is out of the measurement

range. Measurement flow velocity exceed

-108% of reverse flow direction span setting.

Setting for flow velocity span exceeds 11m/s.

Setting for flow velocity span is 0.2m/s or

under.

Totalization rate exceeds 1100pps.

Totalization rate is 0.00005pps or less.

Empty pipe detection. Flow tube is not filled

with fluid.

Out of the range of the indicator

display.

AI function block is in Simulate mode.

AI function block is in Man mode.

Zero-point adjustment is abnormal.

ADMAG AE is not participating in Fieldbus

network.

Content of Alarms

✽ The segments for a right-most digit are blinking.

T0601.EPS

Figure 6.1 Error Identification on Indicator

F0601.EPS

6.2.2 Alarms and Events

Following alarm or event can be reported by ADMAG

AE as an alert.

Analog Alerts (Generated when a process value

exceeds threshold)

By AI Block: Hi-Hi Alarm, Hi Alarm, Low

Alarm, Low-Low Alarm

Discrets Alerts (Generated when an abnormal

condition is detected)

By Resource Block: Block Alarm, Write Alarm

By Transducer Block:Block Alarm

By AI Block: Block Alarm

6-1

IM 1E7F1-01E

Page 23

6. IN-PROCESS OPERATION

Update Alerts (Generated when a important

(restorable) parameter is updated)

By Resource Block: Update Event

By Transducer Block:Update Event

By AI Block: Update Event

An alert has following structure:

Table 6.2 Alert Object

Subindex

Alert

Alert

Analog

11 1

22 2

33 3

44 4

55 5

66

77

88

99

10 10

Update

Discrete

6

7

8

911 11

Parameter

Name

Alert

Block Index

Alert Key

Standard

Type

Mft Type

Message

Type

Priority

Time Stamp

Subcode

Value

Relative

Index

Static

Revision

Unit Index

Explanation

Index of block from which

alert is generated

Alert Key copied from the

block

Type of the alert

Alert Name identified by

manufacturer specific DD

Reason of alert

notification

Priority of the alarm

Time when this alert is first

detected

Enumerated cause of this

alert

Value of referenced data

Relative Index of

referenced data

Value of static revision

(ST_REV) of the block

Unit code of referenced

data

T0602.EPS

The SIMULATE parameter of AI block consists of the

elements listed in Table 6.3 below.

Table 6.3 SIMULATE Parameter

Sub-

index

1Simulate Status

2Simulate Value

3 Transducer Status

4 Transducer Value

5Simulate En/Disable

Parameters Description

Sets the data status to be

simulated.

Sets the value of the data

to be simulated.

Displays the data status

from the transducer block.

It cannot be changed.

Displays the data value

from the transducer block.

It cannot be changed.

Controls the simulation

function of this block.

1: Disabled (standard)

2: Active(simulation)

T0603.EPS

When Simulate En/Disable in Table 6.3 above is set to

"Active", the applicable function block uses the

simulation value set in this parameter instead of the

data from the transducer block. This setting can be

used for propagation of the status to the trailing blocks,

generation of a process alarm, and as an operation test

for trailing blocks.

SIMU

6.3 Simulation Function

The simulation function simulates the input of a

function block and lets it operate as if the data was

received from the transducer block. It is possible to

conduct testing for the downstream function blocks or

alarm processes.

A SIMULATE_ENABLE jumper switch is mounted in

the ADMAG AE amplifier. This is to prevent the

accidental operation of this function. When jumper is

shortcircuited with a pin, simulation is enabled. (See

Figure 6.2.) To initiate the same action from a remote

terminal, if REMOTE LOOP TEST SWITCH is

written to SIM_ENABLE_MSG (index 1044 )

parameter of the resource block, the resulting action is

the same as is taken when the above switch is on. Note

that this parameter value is lost when the power is

turned OFF. In simulation enabled status, an alarm is

generated from the resource block, and other device

alarms will be masked; for this reason the simulation

must be disabled immediately after using this function.

STD

SIMU

OFF

ON

Figure 6.2 SIMULATE_ENABLE Switch Position

IMPORTANT

This display board connector is released before

simulation jumper switching. Do not pull the

amplifier out of the case. After jumper switching,

please confirm that the display board connector

is not loose.

6-2

IM 1E7F1-01E

Page 24

7. DEVICE STATUS

7. DEVICE STATUS

Device status and failures of ADMAG AE are indicated

by using parameter DEVICE_STATUS_1,

DEVICE_STATUS_2 and DEVICE_STATUS_3 (index

1045, 1046 and 1047) in Resource Block.

Table 7.1 Contents of DEVICE_STATUS__1 (index 1045)

Hexadecimal

030000000

040000000

020000000

010000000

008000000

004000000

002000000

001000000

000800000

000400000

000200000

000100000

000080000

000040000

000020000

000010000

000008000

000004000

000002000

000001000

000000800

000000400

000000200

000000100

000000080

000000040

000000020

000000010

000000008

000000004

000000002

000000001

Display through DD

Sim.enable Jmpr On

RB in O/S mode(AL.21)

AMP Module Failure 2(AL.03)

LINK OBJ. 1/17 not open Link object 1 is not open.

LINK OBJ. 2 not open

LINK OBJ. 3 not open

LINK OBJ. 4 not open

LINK OBJ. 5 not open

LINK OBJ. 6 not open

LINK OBJ. 7 not open

LINK OBJ. 8 not open

LINK OBJ. 9 not open

LINK OBJ. 10 not open Link object 10 is not open.

LINK OBJ. 11 not open

LINK OBJ. 12 not open

LINK OBJ. 13 not open

LINK OBJ. 14 not open

LINK OBJ. 15 not open

LINK OBJ. 16 not open

Description

SIMULATE_ENABLE Switch

is ON.

Resource Block is in O/S mode.

AMP module failure.

Link object 2 is not open.

Link object 3 is not open.

Link object 4 is not open.

Link object 5 is not open.

Link object 6 is not open.

Link object 7 is not open.

Link object 8 is not open.

Link object 9 is not open.

Link object 11 is not open.

Not used for ADMAG AE.

Not used for ADMAG AE.

Not used for ADMAG AE.

Not used for ADMAG AE.

Not used for ADMAG AE.

T0701.EPS

Table 7.2 Contents of DEVICE_STATUS__2 (index 1046)

Hexadecimal

080000000

040000000

020000000

010000000

008000000

004000000

002000000

001000000

000800000

000400000

000200000

000100000

000080000

000040000

000020000

000010000

000008000

000004000

000002000

000001000

000000800

000000400

000000200

000000100

000000080

000000040

000000020

000000010

000000008

000000004

000000002

000000001

Display through DD

Zero adjustment error(AL-64)

Data is out of LCD display

range(AL-61)