Page 1

Technical

Information

TI 30A30A10-01EN

Installation Guidance

for N-IO eld enclosure

Yokogawa Electric Corporation

2-9-32, Nakacho, Musashino-shi, Tokyo, 180-8750 Japan

TI 30A30A10-01EN

©Copyright Feb. 2018 (YK)

1st Edition Feb. 2018 (YK)

Page 2

Blank Page

Page 3

Introduction

The N-IO eld enclosure is a standardized remote I/O enclosure for outdoor use, which

include N-IO node. There are two types of N-IO eld enclosure, one is for CENTUM VP and

the other is for ProSafe-RS.

This document provides guidance that allows users to consider how to accumulate

the power capacity and install devices at a planning stage of deploying the N-IO eld

enclosures for CENTUM VP and ProSafe-RS.

Chapter 1 System installation requirements

This chapter describes specications covering N-IO eld enclosure installation and

environmental specications, inrush current, power consumption, noise prevention, and

grounding necessary for designing a power supply system.

Chapter 2 Transportation, storage and installation

This chapter describes general cautions for transporting and carrying the N-IO eld enclosure

which is a precision device, precautions for temperature and humidity changes when unpacking

or storing it temporarily, space necessary for maintenance (servicing area), and how to install

devices.

i

Chapter 3 Cabling

This chapter describes how to connect power, grounding, signal and communication cables to

the installed devices, and how to connect optical ber cables.

Chapter 4 Installation specications

This chapter covers power consumption and power dissipation, in-rush current, circuit protector

and breaker ratings, and parts that need replacement within 10 years. Read this section when

deciding power supply capacity.

Chapter 5 Post-installation inspection and environmental preservation

This chapter describes items that must be checked before applying power and the precautions to

be taken to safeguard the environment after installing the system.

All Rights Reserved Copyright © 2018, Yokogawa Electric Corporation

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 4

Safety Precautions

n Safety, Protection, and Modication of the Product

• In order to protect the system controlled by the product and the product itself and ensure

safe operation, observe the safety precautions described in this Technical Information. We

assume no liability for safety if users fail to observe these instructions when operating the

product.

• If this product is used in a manner not specied in this Technical Information, the protection

provided by this product may be impaired.

• If any protection or safety circuit is required for the system controlled by the product or for

the product itself, prepare it separately.

• Be sure to use the spare parts approved by Yokogawa Electric Corporation (hereafter

simply referred to as YOKOGAWA) when replacing parts or consumables.

• Do not use the accessories (Power supply cord set, etc.) that came with the product for any

other products.

• Modication of the product is strictly prohibited.

• The following symbols are used in the product and instruction manual to indicate that there

are precautions for safety:

ii

Indicates that caution is required when handling the equipment. This symbol is labeled

on the Product to indicate the possibility of dangers such as electric shock on personnel

and equipment, and also indicate that the user must refer to the User’s Manuals for

necessary actions. In the User’s Manuals, this symbol is used together with a signal word

“WARNING” or “CAUTION” at the locations where precautions for avoiding dangers are

described.

Indicates that caution is required for hot surface. Note that the devices with this symbol

become hot. The risk of burn injury or some damages exists if the devices are touched or

contacted.

Identies a protective conductor terminal. Ensure to ground the protective conductor

terminal to avoid electric shock before using the product.

Identies a functional grounding terminal. A term “FG” is also used. This terminal is

equipped with the same function and used for purposes other than the protective

grounding. Before using the product, ground the terminal.

Indicates an AC supply.

Indicates a DC supply.

Indicates that the main switch is ON

Indicates that the main switch is OFF

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 5

n Symbol Marks of Installation Guidance

CAUTION

Throughout this Technical Information, you will nd several dierent types of symbols are used to

identify dierent sections of text. This section describes these icons.

WARNING

Identies important information required to understand operations or functions.

Identies instructions that must be observed in order to avoid physical injury and electric

shock or death to the operator.

IMPORTANT

Identies important information required to understand operations or functions.

TIP

iii

Identies additional information.

SEE

ALSO

Identies a source to be referred to.

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 6

n Cautions for Safely Applying the Device

l Wiring Power Cable

WARNING

Connect the power cables according to the procedure in this document.

Power cables must conform to the safety standards of the country where the device is installed.

SEE

For wiring power cable, refer to 3.2, “Connecting power cable.”

ALSO

l Earth Wiring

WARNING

This equipment requires a protective grounding dened by the safety standard.

Ground the device following the procedure in this document to prevent from electric shock and to

minimize the noise.

iv

SEE

For earth wiring, refer to 3.3, “Connecting grounding cable.”

ALSO

l Tightening Torque of Screws

IMPORTANT

The tightening torque that the product recommends is showed in the following table. However,

if the tightening torque of the screw is specied in the User’s Manuals, follow the instructions

described in the User’s Manuals.

Table Recommended tightening torque

Nominal diameter of a screw M2.6 M3 M3.5 M4 M5 M6 M8 M10

Recommended tightening torque

(N•m)

0.35 0.6 0.8 1.2 2.8 3.0 12.0 24.0

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 7

l Wiring I/O Cables

CAUTION

Wiring I/O cables must follow the procedure in this document.

SEE

For wiring I/O cables, refer to 3.4, “Connecting signal cable.”

ALSO

l Connecting Devices

IMPORTANT

To ensure this system compliance with the CSA safety standards, all devices connected to this

system shall be CSA certied devices.

l Exchanging Fuse

v

WARNING

• The fuses for exchange must be the Yokogawa designated fuses.

l Maintenance

CAUTION

• The maintenance work for the devices described in this manual should be performed only

by the educated experts.

• When the device becomes dusty, use a vacuum cleaner or a soft cloth to clean it.

• During maintenance, put up wrist strap, and take other ESD (Electrostatic Discharge)

measures.

• If the existing caution label is dirty and illegible, prepare a new label (part number:T9029BX)

to replace it.

SEE

For maintenance, refer to 1.4.2, “Countermeasures against static electricity.”

ALSO

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 8

l Field Power Supply

IMPORTANT

Do not use output voltage potentiometer.

n Drawing Conventions

Some drawings may be partially emphasized, simplied, or omitted, for the convenience of

description.

vi

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 9

Trademark

n Trademark

• CENTUM, ProSafe, and Vnet/IP are registered trademarks of Yokogawa Electric

Corporation.

• All other company and product names mentioned in this manual are trademarks or

registered trademarks of their respective companies.

• We do not use TM or ® mark to indicate those trademarks or registered trademarks in this

manual.

• We do not use logos and logo marks in this manual.

vii

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 10

Blank Page

Page 11

Installation Guidance

for N-IO eld enclosure

TI 30A30A10-01EN 1st Edition

CONTENTS

1. System installation requirements .......................................................... 1-1

1.1 Installation environment .................................................................................. 1-1

1.2 Power supply system ....................................................................................... 1-5

1.3 Grounding ..........................................................................................................1-8

1.4 Noise countermeasures .................................................................................1-12

1.4.1 Noise sources and noise countermeasures .................................... 1-12

1.4.2 Countermeasures against static electricity ...................................... 1-15

1.5 Cabling requirements .....................................................................................1-16

Toc-1

2. Transportation, storage and installation ............................................... 2-1

2.1 Precautions for transportation ........................................................................ 2-1

2.2 Unpacking .......................................................................................................... 2-4

2.3 Storage ............................................................................................................... 2-5

2.4 Servicing area ....................................................................................................2-6

2.5 Installing equipment ......................................................................................... 2-7

3. Cabling....................................................................................................... 3-1

3.1 Connecting cables to the cable entry ............................................................. 3-1

3.2 Connecting power cable .................................................................................. 3-2

3.3 Connecting grounding cable ........................................................................... 3-5

3.3.1 Connecting grounding cable for the enclosure .................................. 3-5

3.3.2 Connecting grounding cable to grounding bar for shield lines .......... 3-6

3.4 Connecting signal cable ..................................................................................3-7

3.4.1 Connecting signal cable (for CENTUM VP) ...................................... 3-7

3.4.2 Connecting signal cable (for ProSafe-RS)......................................... 3-7

3.4.3 Connecting shield lines of the signal cable ........................................ 3-9

3.5 Connecting communication cable ................................................................3-10

4. Installation specications ....................................................................... 4-1

5. Post-installation inspection and environmental preservation ............ 5-1

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 12

Blank Page

Page 13

1. System installation requirements

1. System installation requirements

This section describes installation requirements such as environmental conditions,

required space and layout considerations, power consumption, cabling and grounding.

1.1 Installation environment

The system must be installed in an appropriate environment to operate it safely and stably over

a long period of time. This section describes an overview of environmental specications. It is

recommended that the user makes an assessment to see whether the installation environment

requirements are met. For the installation environment assessment, consult with Yokogawa or

the Service of Yokogawa.

n Temperatures and humidity

When equipment is brought from the place out of operational temperature range to the place in

operational temperature range, bring it without a package, keep it within temperature change rate

and avoid condensation. Keep ambient temperature within operational temperature range and

leave it for more than three hours before starting operation.

Under normal operation, the rate of change of ambient temperatures should be within 10 °C/h.

All the equipment should be kept out of the rain and direct sunlight by installing a sun shield or

canopy.

1-1

SEE

See “Table of equipment installation specications” in this section, for the temperatures and humidity limits for

ALSO

operating and storing this equipment.

n Condensation

Prevent condensation. If condensation occurs, or its trace is found on the equipment, contact

Yokogawa.

SEE

See “Section 2.3 Storage” for more information.

ALSO

n Magnetic eld

Do not install a magnetic disk, or the like near cables with large current owing or in the magnetic

eld of a power supply. If installed in such locations, the storage medium data may be corrupted

by the magnetic elds.

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 14

1. System installation requirements

n Electric eld strength (Electric wave condition)

For stable operation, the system equipment should be used while the doors are closed. The

electric eld strength of the location for the enclosure housing the equipment should be kept

below the following values.

10 V/m or less (80 MHz to 1.0 GHz)

3 V/m or less (1.4 to 2.0 GHz)

1 V/m or less (2.0 to 2.7 GHz)

In case of the usage of wireless equipment such as transceiver nearby this system, note as

following:

• The door of this system should be closed.

• In case of the usage of transceiver with 3 W or less, the distance from this system should be

kept 1 m or more, with 10 W or less, 2 m or more.

• As for the usage of wireless equipment with 1 W or less such as mobile-telephone, PHS,

wireless telephone or LAN equipment, the distance should be kept 1 m or more. Attention

should be paid to the micro wave radiated from mobile-telephone or PHS even out of usage.

n Installation specication

1-2

Installation height: Altitude of up to 2000 m

Installation category based on IEC 61010-1 (*1):

Category I

• For YOKOGAWA products, category I applies to the device that receives the electric power

not more than 33 V AC, 70 V DC.

Category II

• For YOKOGAWA products, category II applies to the device that receives the electric power

exceeding 33 V AC or 70 V DC.

Pollution degree based on IEC 61010-1: 2 (Environment inside the enclosure) (*2) (*3)

Indoor/Outdoor use

*1: The installation category, also referred to as an overvoltage category, denes the standard for impulse voltage. The category

number from I to IV applies the devices to determine the clearance required by this standard.

Category I applies to the device intended to be connected to a power supply with impulse voltage reduced to the safe level.

Category II applies to the device intended to be supplied from the building wiring.

*2: Pollution degree indicates the adhesion level of foreign matter in a solid, liquid, or gaseous state that can reduce dielectric

strength. Degree 2 refers to a pollution level equivalent to the general indoor environment.

*3: Do not submerge the enclosure in water.

SEE

See “Installation environment specications” at the end of this chapter.

ALSO

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 15

1. System installation requirements

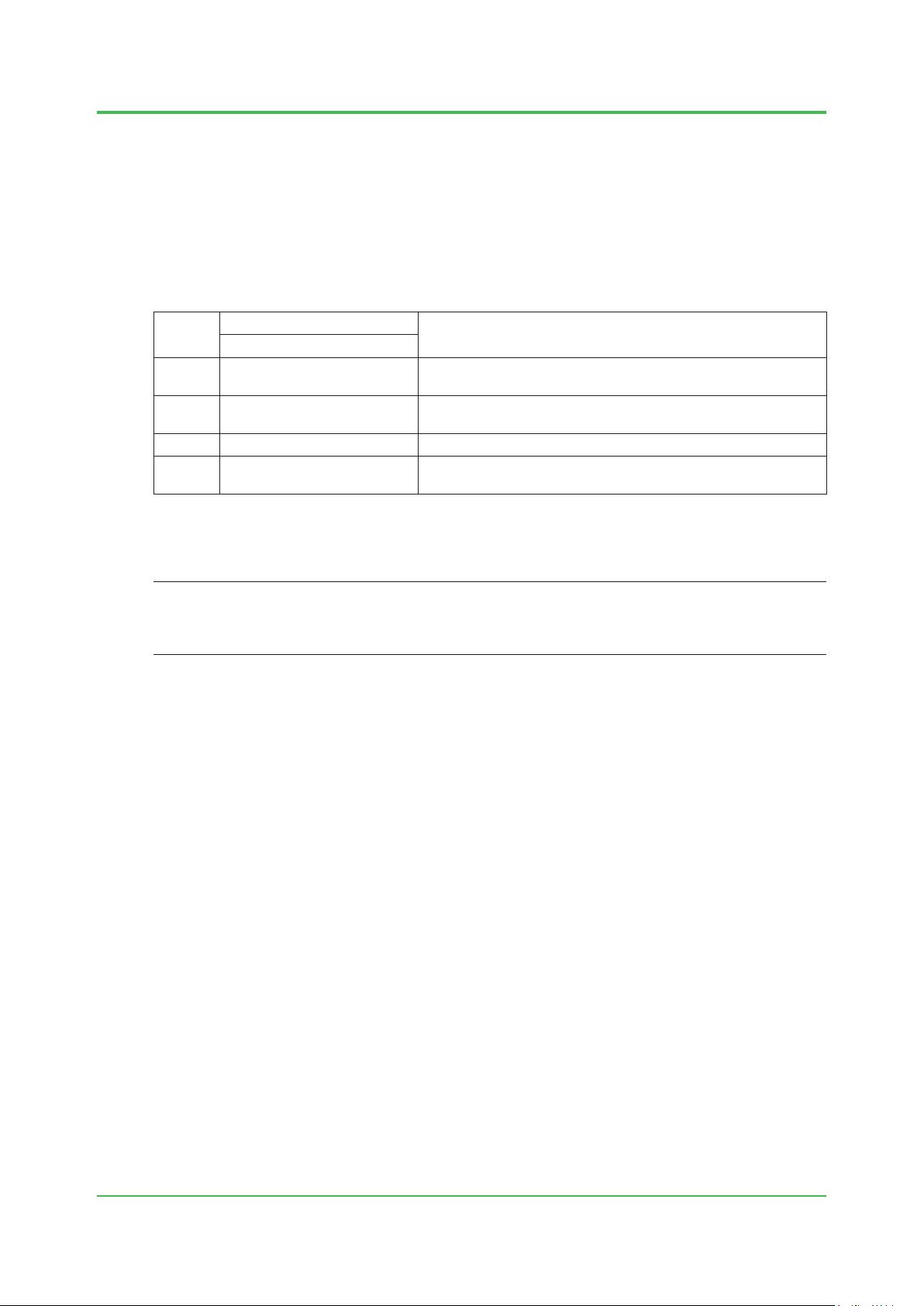

n Measurement categories

Regarding the measurement inputs, the following requirements must be satised to meet the

specications for the device:

The category of the equipment applies to No.1 in the following table.

The rated transient overvoltage is 1500 V.

Note: Do not use the equipment for measurements within measurement categories II, III and IV.

Table Measurement category

1-3

No.

No. 1 O (Other)

No. 2 Measurement category II

No. 3 Measurement category III For measurements performed in the building installation.

No. 4 Measurement category IV

Applicable standard

IEC/EN/CSA 61010-2-030

n Applied standards

SEE

For the applicable standards for the N-IO eld enclosure, refer to the following GS.

ALSO

For CENTUM VP, “N-IO eld enclosure” (GS 33J62R10-01EN)

For ProSafe-RS, “ N-IO eld enclosure” (GS 32P06Q10-01EN)

Description

For measurements performed on circuits not directly connected to

MAINS.

For measurements performed on circuits directly connected to the

low voltage installation.

For measurements performed at the source of the low-voltage

installation.

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 16

1. System installation requirements

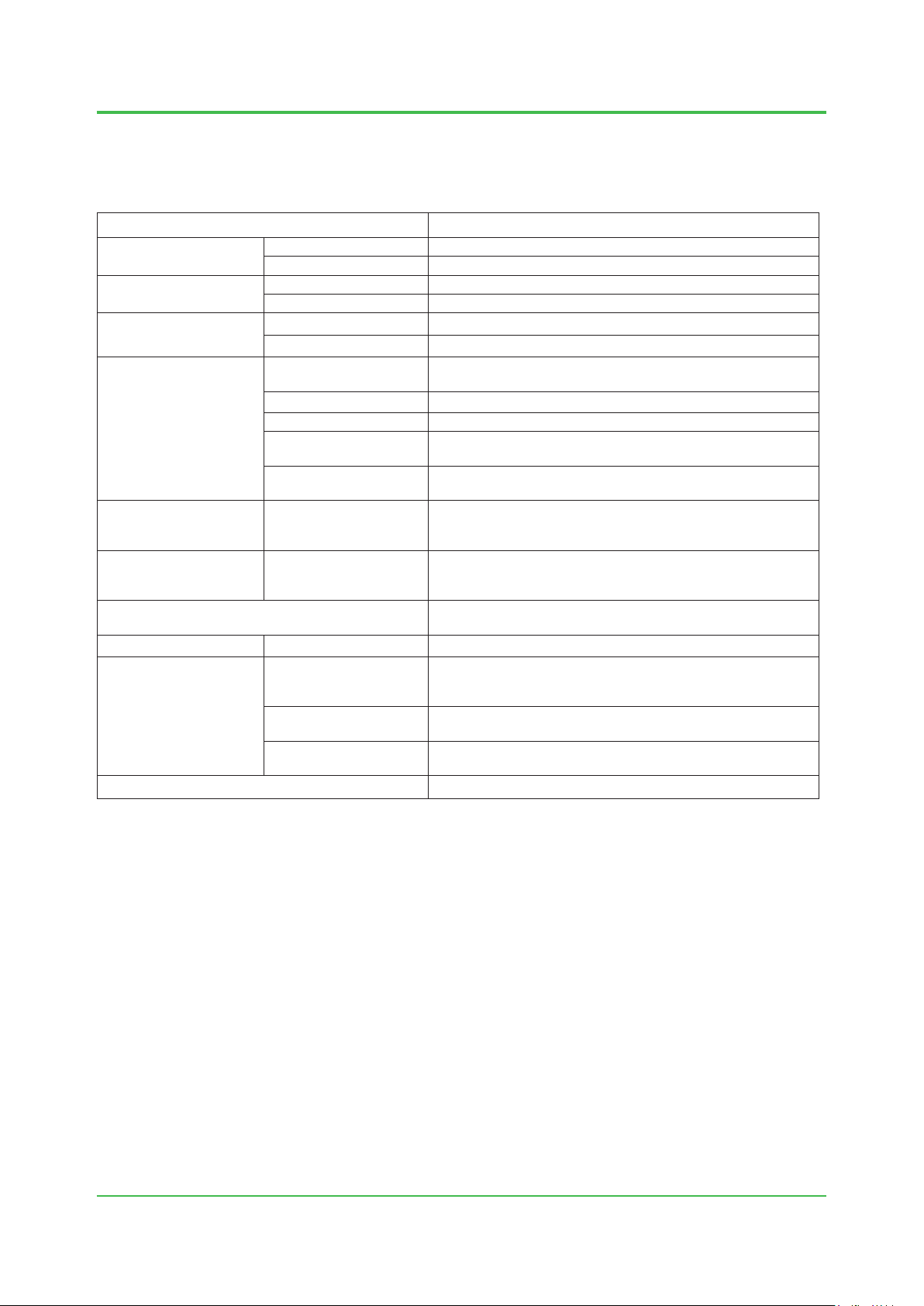

n Installation environment specications

The following table shows the installation environment specications of the N-IO eld enclosure.

Table Equipment installation specications

1-4

Ambient temperature (*1)

Ambient humidity

Ambient temperature

change rate

Item

Normal operation –40 to 55 ºC (Base unit: –40 to 70 ºC)

In transport/storage –40 to 85 ºC

Normal operation 5 to 100 %RH (no condensation)

In transport/storage 5 to 95 %RH (no condensation)

Normal operation Within ±10 ºC/h

In transport/storage Within ±20 ºC/h

Voltage range

100 to 120 V AC ±10 %

220 to 240 VAC ±10 %

Specications

Frequency 50/60 ±3 Hz

Power supply

Distortion factor 10 % or less

Peak value

Instantaneous power

failure

128 V or larger (100 V system)

258 V or larger (220 V system)

20 ms or lower (when receiving rated AC voltage)

Between power input

Withstanding voltage

terminal and protective

1500 V AC for 1 minute

conductor terminal

Between power input

Insulation resistance

terminal and protective

20 MΩ/ 500 VDC

conductor terminal

Grounding

Shock (*2) Transport shock Horizontal 48 m/s

Apply the grounding system which is dened by the rules and

standards of the country or the region.

2

or less

10 V/m or less (80 MHz to 1.0 GHz)

Electric eld

3 V/m or less (1.4 to 2.0 GHz)

1 V/m or less (2.0 to 2.7 GHz)

Noise

Magnetic eld

Static electricity

30 A/m or less (AC)

400 A/m or less (DC)

4 kV or less (contact discharge)

8 kV or less (aerial discharge)

Altitude 2000 m or less

*1: Avoid direct sunlight. For outdoor installation, protect the enclosure against direct sunlight with a sun shield.

*2: When transporting the enclosure in a truck, use a truck equipped with an air cushion between the truck bed and body. Also, when loading,

load the enclosure horizontally and keep it in a horizontal position.

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 17

1. System installation requirements

1.2 Power supply system

To stable system operation, the following conditions should be met:

• Voltage and frequency uctuations are within the limits specied for each system

component.

• Relationship between the waveform’s eective values and peak value is within the specied

range.

• High-frequency noise is not at a level that aects system operation.

• Use an UPS (uninterruptible power supply) if necessary.

n AC Power specication

AC power used for the system must satised rated voltage and the peak value must be greater

than the minimum specied (see below).

IMPORTANT

If the power unit has high output impedance or high wiring impedance, the resulting voltage drop

attens the input voltage wave, forming a distorted waveform with a low peak value (“B” in the

chart below).

1-5

Even if the eective value of the distorted input voltage wave is the same as that specied for a

non-distorted input voltage wave, the voltage across the terminals of the smoothing capacitor

in the power circuit may be so low that the system detects power failure. If input voltage waves

A and B shown below, have the same eective value of 100 V AC, wave B will have a lower

smoothing capacitor terminal voltage.

A: Ideal, non-distorted input voltage wave

B: Distorted input voltage wave

Peak A

Peak B

F010201.ai

Figure Distorted input voltage waveform

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 18

1. System installation requirements

V

Effective

F010202.ai

V

V

The system operating voltage range is shown below based on the relationship between eective

and peak values at the power input terminal of each system. Apply AC power within these ranges

to operate the system.

TIP

Average rectied measuring meters such as testers cannot measure eective values accurately. Use Yokogawa’s

WT series power meter or an meter, which enables eective values, peak values, and waveform distortion to be

measured with one unit.

132

value

(V rms)

120

110

100

90

System operating

voltage range

Effective

value

(V rms)

V op= 2 V rms V op= 2 V rms

264

240

220

200

198

System operating

voltage range

1-6

125 127

130 140 150 160 170

120

Peak value (V op)

Figure System operating voltage range

n Selecting a power system

N-IO eld enclosure system requires a power supply that satises power requirements in

accordance with EMC regulations. For selection of the power supply unit, consult with a power

unit manufacturer taking the following points into consideration.

lSource output capacity

Take the following items into consideration when consulting with a power unit manufacturer to

determine the output capacity.

Power consumption: Both volt-ampere and watt data should be studied

(refer to Chapter 4).

Device in-rush current: See Chapter 4 Table “System equipment power-on

In-Rush current” The method of turning on the power

should also be studied.

180

187

274

V

280 310 340 370

Peak value (V op)

374

Backup ready time after failure: Time period required to backup the devices when power

fails.

Reserve capacity: An extra power capacity should be determined as

reserve to meet any device additions.

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 19

1. System installation requirements

lIn-Rush current

When the equipment is turned on, a large in-rush current ows as the capacitor is

instantaneously charged and the transformer is excited. When any equipment is turned on, this

should not cause any voltage uctuation that could adversely aect other equipment. Do not turn

on all equipment at the same time. Start equipment one by one.

Power may be switched to backup or AC line power if in-rush current activates the overload

protection circuit on power-up. After such an overload, select an uninterruptible power unit, with

automatic-recovery.

n Cabling

Observe the following when cabling the power unit to the system equipment:

• Protect signal cables from induced noise.

• Protect signal cables from induced noise from high-voltage power lines.

• Separate the system power supply from other equipment power supplies using a power

distribution board.

• Provide a dedicated breaker for each power supply.

• Label the breakers with the name of the connected equipment.

1-7

• Install the breakers where they can be easily operated.

• The breaker, must not interrupt connection by wiring to protective grounding system.

• Install power supply cables and high-voltage power lines in metallic conduits as much as

possible.

• Use shielded cables if metallic conduits cannot be provided.

TI 30A30A10-01EN

June 30, 2016-00

Page 20

1. System installation requirements

1.3 Grounding

To avoid electric shocks and minimize the inuences of external noise, the installed devices must

be grounded to the protective grounding system which complies with the safety standards, the

electrical installations standard, and the power distribution system of the country or the region.

As for the protective grounding systems, the meshed grounding systems described in IEC 60364,

IEC 62305 and IEC 61000-5-2 can be applied. A protective device is to be installed in compliance

with the rules and regulations, in order to prevent electric shocks caused by a ground fault.

n Grounding of enclosure

Connect the protective conductor terminal outside N-IO eld enclosure to the protective

grounding system. Apply the grounding system which is dened by the rules and standards of the

country or the region.

SEE

See “Section 3.3.1 Connecting grounding cable for the enclosure”, for the cables and terminals.

ALSO

1-8

Figure Grounding of enclosure

Protective conductor terminal

Protective grounding system

F010301.ai

TI 30A30A10-01EN

June 30, 2016-00

Page 21

1. System installation requirements

As shown below gure, it is also possible to connect the grounding bar inside the enclosure to the

protective grounding system via cable entry.

Protective conductor

terminal: M10 bolt

Grounding bar

Protective grounding

system

1-9

Power input terminal

Grounding

cable

Protective grounding system

Figure Grounding of enclosure

Cable entry

F010302.ai

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 22

1. System installation requirements

n Grounding of grounding bar for shield lines

The N-IO eld enclosure has a grounding bar for shield lines to connect shield lines of signal

cables in an enclosure. At the time of delivery, this grounding bar for shield lines is internally

connected to a grounding bar in the enclosure.It is possible to separate the protective grounding

system of the grounding bar for shield lines from the one of the enclosure system by changing

the grounding connection as shown in the gure below.

SEE

See “Section 3.3.2 Connecting grounding cable to grounding bar for shield lines”, for the cables and terminals.

ALSO

1-10

Grounding bar for sheild lines

Grounding bar

Protective conductor terminal

Cable entry

Protective grounding system Protective grounding system

Figure Grounding of grounding bar for shield lines

Grounding cableGrounding cable

F010303.ai

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 23

1. System installation requirements

n Grounding circuit

An enclosure must be grounded according to the grounding network topology of the building or

plant for installation. In order to connect an enclosure with a protective grounding system, the

grounding topology shown in the gures “Grounding connected to single grounding bus inlet” or

“Grounding connected to each grounding bus inlet” can be used. A grounding cable with a cross

section of at least 5.5 mm

should be used between each enclosure and grounding bus inlet.

When providing lightning arresters on power and signal lines, those arresters need to be

grounded to the same bus. For details, see Section 1.4, “Noise countermeasures.”

Enclosure Enclosure Enclosure Enclosure

G G G G

2

or more that complies with the standards in each country and region

1-11

Graunding bus inlet

G: Protective conductor terminal

Protective grounding system

Figure Grounding connected to a single grounding bus inlet

Enclosure Enclosure Enclosure Enclosure

G

Protective

grounding

system

Graunding bus inlet

G: Protective conductor terminal

G G G

Protective

grounding

system

Protective

grounding

system

Figure Grounding connected to each grounding bus inlet

F010304.ai

Protective

grounding

system

F010305.ai

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 24

1. System installation requirements

1.4 Noise countermeasures

Noise may be induced by electromagnetic induction, electrostatic induction, or from radio waves,

lightning, inductive loads, static electricity and ground potential dierences. It can be picked up

by power, signal and grounding cables, and devices. With computerized control systems, noiseinduced errors in A/D conversion or in an instruction word may lead to malfunction.

To prevent noise and electrostatic buildup, take the measures described in this section in

deciding cable type, cable routing, and grounding.

1.4.1 Noise sources and noise countermeasures

It is not easy to identify the cause of any noise-triggered errors or failures due to their lack of

reproducibility. If noise problems occur, take the following countermeasures.

The following table lists typical noise sources, symptoms of noise problems, and preventive

countermeasures.

Table Noise sources & countermeasures

Noise sources Eects Countermeasures

• Maintain separation from magnetic-eld source.

Electromagnetic induction

(magnetic eld)

Electrostatic induction

Lightning

Electrostatic discharge

Inductive load open/close

Radio (electric eld)

Ground potential dierence

• Destroys magnetic disk data.

• Equipment maloperation.

• Interference with signals.

• Interference with signals.

• Equipment maloperation.

• Component damage.

• Equipment maloperation.

• Electronic component deterioration,

damage.

• Paper jam.

• Spike noise interference to power

and signal lines.

• Equipment maloperation.

• Interference with signals.

• Equipment Maloperation

(noise imposed on signal lines)

• Shield power cables with metallic conduits.

• Shield magnetic eld using ferromagnetic

substance (e.g. Permalloy).

• Use twisted-pair cables.

• Use shielded signal cables.

• Electrically separate power and signal cables

using metallic conduits and separators.

• Lay power and signal cables which intersect at

right angles.

• Lay cables underground.

• Use optical ber cables.

• Lay cables as close to ground as possible if the

cables cannot be laid underground.

• Install and ground arresters on eld and system.

• Discharge static electricity from operators.

• Provide proper humidity.

• Ground equipment properly.

• Use antistatic oor material and clothing.

• Add spark-killer to noise source.

• Separate laying of cables.

• Use devices (transceivers, mobile phones,

smartphones, etc.) that transmit radio waves

away from the system so as not to exceed the

electric eld specications.

• Avoid multipoint grounding of signal cable.

1-12

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 25

1. System installation requirements

n Grounding with lightning arresters

Connect the protective grounding terminals of arresters and the N-IO eld enclosure to the

grounding pole as shown in the diagram below. The grounding method must comply with the

grounding system dened by rules and standards of the country or the region.

Concatenation grounding a lightning arrester and other equipment may cause high-tension in

each equipment by the product of lightning current from arrester and grounding resistance. To

prevent from electrication, overall connection should be equipotential including the oor and the

case of other equipment.

Grounding bar for sheild lines

Terminal block

Grounding bar

Protective conductor terminal

1-13

Signal cable

Arrester

Signal cable

Protective grounding system

Figure Grounding with lightning arresters

grounding cable

F010401.ai

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 26

1. System installation requirements

lExamples of arrester

The following shows how to install an arrester as a countermeasure against lightning-induced

noise:

: Induced lightning strike point AR: Arrester

1-14

2-wire transmitter/analyzer

+

2-wire

transmitter

Resistance temperature detector

A

B

B

AR AR

-

Field wiring

AR AR

Field wiring

System side

System side

I/O

module

GND

I/O

module

GND

Figure Examples of arrester installation

n Examples of spark-killer installation

Thermocouple

+

-

Field wiring

Power supply

Field wiring

AR

AR

I/O

module

GND

System side

System

GND

F010402.ai

The following shows how to install a spark-killer as a countermeasure against inductive load-

caused noise:

Relay contact

The diode protects the output transistor

from noise occurring during on-to-off

transitions of the relay.

The spark killer protects the output

relay contact.

Power supply

The spark killer prevents noisecaused equipment failure when

a fluorescent lamp or fan is

turned on or off.

Example

Figure Examples of spark-killer installation

Example

R: 120 Ω

C: 0.1 to 0.3 μF

R: 120 Ω

C: 0.1 μF

Spark

killer

Fluorescent

lamp or fan

24 V DC

Relay

Spark

killer

Diode

100 V AC

Controller

control signal

Tr

N-IO field

enclosure

F010403.ai

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 27

1. System installation requirements

1.4.2 Countermeasures against static electricity

Take countermeasures against electrostatic damage when handling cards with semi-conductor

IC components, for maintenance or to change settings.

Observe the following to prevent electrostatic damage:

• When storing or carrying maintenance parts, be sure to enclose them in an antistatic bag.

(For shipment these parts are enclosed in an antistatic bag labeled with precautions against

electrostatic charge.)

• During maintenance work use a wrist strap with a ground wire via a grounding resistance of

1 MΩ. Be sure to ground the wrist strap.

• When performing maintenance work on a desk or a table, place a conductivity sheet

grounded via a grounding resistance of 1 MΩ. The maintenance person must wear a wrist

strap while performing maintenance work. Take any plastic and other materials that can

easily be charged away from the work area.

• Exercise caution so as not to touch any of the maintenance parts while the wrist strap and a

conductivity sheet are not being used.

1-15

Wrist strap

1 MΩ

Protective grounding bar

F010404.ai

Figure Example of using a wrist strap

Wrist straps and conductive sheets are available from Yokogawa.

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 28

1. System installation requirements

1.5 Cabling requirements

The following requirements must be fullled when laying power and signal cables (These

are shielded cables unless specied).

Any signal cable used for high-voltage, high-frequency signals (inductive load ON/ OFF)

must be separated from other signal cables.

n Separator

Provide a separator between power and signal cables as illustrated below:

Separator (steel plate)

1-16

Signal

cables

Figure Separator used in duct/pit

Power

cables

Protective grounding system

(different from the system grounding for the enclosure)

n Distance between cables

If a separator cannot be used, keep a distance between signal cables and power cables.

The distances between cables due to operating voltages and currents are shown below.

Table Required distance between Power & Shielded signal cables

Operating voltage Operating current Distance

240 V AC max. 10 A max. 150 mm min.

240 V AC max. 10 A min. 600 mm min.

240 V AC min. 10 A max. 600 mm min.

240 V AC min. 10 A min. Cannot be laid together.

F010501.ai

Power cables

Signal cables

150 mm

or more

Figure Distance between cables under pit/free-access oor

Signal cables Power cables

150 mm

or more

F010502.ai

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 29

1. System installation requirements

Signal cables

Steel plate (1.6 mm or thicker, grounded)

F010503.ai

n Intersecting cables

With unshielded power cables, place a grounded steel plate with a thickness of at least 1.6 mm

over the cables where they intersect with signal cables.

1-17

Protective grounding system

Figure Intersecting cables under pit/free-access oor

n Ambient temperature

The ambient temperature where signal and bus cables are laid must be within the range

–40 to 55 °C.

n Measures against EMI

As a rule, avoid laying the cables on the oor. However, lay them on the oor when there are no

ducts and no pits. In that case, it is required to take measures such as covering them with shield

plates or using the shielded cables to suit the EMC Directive.

Unshielded power cables

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 30

2. Transportation, storage and installation

2. Transportation, storage and installation

This chapter describes the precautions in transporting, storing, and installing the N-IO eld

enclosure.

SEE

See “Section 1.1 Installation environment” for the environmental requirement for each piece of equipment.

ALSO

2.1 Precautions for transportation

This section describes the precautions required to transport the N-IO eld enclosure. It is

intended to prevent accidents caused by transportation.

These precautions apply when the equipment is contained in our original packing.

n Transportation

2-1

SEE

See “Table Equipment installation specications” in Section 1.1 Installation environment for ambient temperature,

ALSO

humidity and impact.

lLoading

• Load crates horizontally.

• When loading crates on top of others, up to the following number of stacking stages is

allowable.

Table Allowable total number of stacking stages

Model Allowable total number of stacking stages

A2NN70D, S2NN70D Total 3 stages

A2NN60D, S2NN60D Total 4 stages

A2CB60, S2CB60 Total 3 stages

• Keep all crates upright.

• Secure loaded crates using ropes, and cover them completely with waterproof coverings.

• Do not load crates outdoors when it is raining.

lDon’t stack outdoors

Be sure to store cargoes inside a warehouse if they must be stored for some time.

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 31

2. Transportation, storage and installation

lTransportation

The N-IO eld enclosure is a precision device. Select a company specializing in the

transportation of computers and precision instruments.

Keep all products horizontally during air transport, freightage, or truck transport. When

transporting by track, drive at low speed to avoid vibration and impact. Also, slow down to the

limit on a bad road.

lOthers

Do not transport equipment through areas where there may be corrosive gas, intense electric or

magnetic elds.

n Unloading

Prepare special equipment for unloading. Avoid unloading outdoor in case of rain.

lLocation for unloading

To select a location for safe unloading, check that:

• There is ample space for crane and forklift maneuvering.

2-2

• Ground is solid.

• The handrails of scaold can be removed.

• There is enough working space for unpacking (at least 2500 mm by 4000 mm). Provide a

platform if necessary.

• Outdoor-indoor temperature dierence should be less than 10 °C to avoid condensation.

lKeep upright

Keep crates upright when unloading.

lAvoid physical shock

Avoid physical shock. Be careful not to lose balance or swing when lifting or placing cargoes on

the ground or platform. Also check scaold strength.

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 32

2. Transportation, storage and installation

lLifting an N-IO eld enclosure

When lifting an N-IO eld enclosure by a crane, follow the instructions below.

• The N-IO field enclosure has two pad eyes on the top surface of the enclosure to lift it by

a crane. Use a wire rope for each pad eye.

• Keep the lifting angle of about 60 degrees.

• The wire or the crane must have enough strength against the product weights.

60°

Pad eye

2-3

Figure How to lift of an enclosure

n Carrying

This section describes how to carry enclosures.

lCarrying space, passage

Carry enclosures into the location of installation without unpacking.

Determine the passage according to the product’s packing size and weight and carrier’s size and

weight.

Table Packing size and packing weight of the product

Model Packing size (mm) Packing weight (kg)

A2NN70D, S2NN70D 1020 (D) x 1510 (W) x 560 (H) Product weight + 11.2

A2NN60D, S2NN60D 863 (D) x 1225 (W) x 490 (H) Product weight + 10.0

A2CB60, S2CB60 1020 (D) x 1510 (W) x 560 (H) roduct weight + 11.2

F020101.ai

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 33

2. Transportation, storage and installation

2.2 Unpacking

In unpacking the received cargoes and equipment, inspect them according to inspection list

below. It is recommended to unpack by Yokogawa engineers or in their presence.

Table Inspection list

Inspection Items Result Measures Required

Exterior

Interior

• Environment of unpacking location

(temperature, humidity, dust)

• Rapid temperature uctuation

(should be within ±10 °C/h)

• Damage to equipment exterior

• Condensation or its trace on

equipment exterior.

• Loose parts inside equipment.

• Damage to equipment interior.

• Condensation or its trace on

equipment interior.

CAUTION

Condensation in the enclosure may cause critical trouble in the system. Be sure to unpack

the equipment indoor under the specied environmental conditions. Strictly observe the

allowable temperature uctuation range of ±10 °C/h. Do not bring the equipment into a heated

room straight from the outside in winter. Our warranty does not cover any damage caused by

condensation. Proper treatment may be able to minimize the damage caused by condensation,

however. Contact Yokogawa in case of condensation.

Suitable Unsuitable If unsuitable, select proper location according to

No Yes If yes, do not unpack and wait until the

No Yes

No Yes If yes, inform Yokogawa.

No Yes

No Yes

No Yes If yes, inform Yokogawa.

specied environmental requirements.

uctuation remains within ±10 °C/h.

If damaged badly, inform Yokogawa.

If yes, remove them and check the surrounding.

If damaged badly, inform Yokogawa.

2-4

CAUTION

Be careful not to let the products fall when you handle them.

When they are hit hard, the interior of them can be damaged, although there is no damage in the

exterior.

If you accidentally drop an product, stop using it immediately and report it to YOKOGAWA or

YOKOGAWA’s service department.

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 34

2. Transportation, storage and installation

2.3 Storage

The delivery date should be determined in accordance with your installation schedule. Avoid

storing products more than three months. If long-term storage more than three months cannot be

avoided, consult us in advance because it is necessary to provide waterproong, condensation

prevention, and dustproong measures as well as periodical inspections.

n Storage condition

Store products without unpacking. Be sure to conrm that the crate is not damaged. To store

them after unpacking, be sure to take the precautions described below.

n Location of storage

Store products in a warehouse or indoor facilities - never in an open-air location.

n Storage environment

• Ambient Temperature for storage: -40 to 85 °C

• Avoid direct sunlight.

2-5

• Prevent wet with water.

• Prevent condensation.

• Do not store products where corrosive gas or salty air may be present.

SEE

See “Section 1.1 Installation environment” for permissible temperature, humidity and temperature uctuation of

ALSO

storage area.

n Storage of packed equipment

• Store crates horizontally.

• When loading crates on top of others, up to the following number of stacking stages is

allowable.

Table Allowable total number of stacking stages

Model Allowable total number of stacking stages

A2NN70D, S2NN70D Total 3 stages

A2NN60D, S2NN60D Total 4 stages

A2CB60, S2CB60 Total 3 stages

• Make sure to provide good air circulation in the storage area and periodically inspect the

crates to keep them under proper conditions.

n Storage of unpacked equipment

To store unpacked products without power connection, follow the specied environmental

requirements. If stored in a non-air-conditioned room, cover them with polyethylene or other

sheets for protection against dust and moisture. For moisture-proong, place a sucient amount

of Silica gel or other desiccating agent inside the covering and inspect replace from time to time.

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 35

2. Transportation, storage and installation

2.4 Servicing area

Take enough space around equipment for its operation and maintenance service. This servicing

area is indicated for each equipment.

This servicing area should be considered when determining the installation location.

When installing the product on the side of a corridor, provide enough space for people to pass by

in addition to the space below.

2-6

Top view

800

R800

Figure N-IO eld enclosure servicing area

Unit: mm

F020401.ai

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 36

2. Transportation, storage and installation

2.5 Installing equipment

This section describes the precautions required to install the N-IO eld enclosure.

n Precautions for installing the enclosure

• The mounting surface shall be at and vertical and the mounting support shall be capable of

withstanding a load of approx. 4 times the product weight or more.

• When installing the enclosure on concrete, use proper concrete anchor screws.

• When installing the enclosure on a steel plate, drill holes and use M10 lock washers and

nuts to secure it.

• Provide a heat dissipation space (g) of at least 100 mm over the top of the enclosure.

In addition, provide a space (h) under the enclosure, which includes a cable bending radius

space for cables passed through the cable entry at the bottom (provide the proper space to

suit the cables used).

• Do not put any object on the top surface of the enclosure.

2-7

g

Front view

h

Figure Space over and under the enclosure

F020501.ai

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 37

3. Cabling

3. Cabling

This section describes how to cable the installed system equipment.

Connecting terminals for power, grounding, signal, and communication cables are shown

in gures.

3.1 Connecting cables to the cable entry

Cables should be connected with the enclosure through the cable entry at the bottom of the

enclosure. In order to prevent dust and water entry from outside the enclosure, cables should be

connected to the enclosure through cable glands or sealing modules.

3-1

Figure Cable entry at the enclosure’s bottom

F030102.ai

Figure Insertion of power cable into the cable entry

n Installation of Roxtec’s sealing module

When installing the sealing module into the sealing system frame, the specialized tool provided

by Roxtec enables the quick and safe on site installation. For details, refer to the Roxtec website.

Table Roxtec tools

F030101.ai

Part names Part numbers

PRE-COMP ECCENTRIC TOOL COMPACT ICT0001000316

PRE-COMPRESSION WEDGE 40/60 5ICT000003691

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 38

3. Cabling

F030201.ai

Insulation covering

Hole diameter

3.2 Connecting power cable

n Power cables

Nominal conductor cross-section area: AWG10 (5.5 mm2 equivalent) or more

Temperature rating of cables: Enclosure ambient temperature + 35 ºC or more

Note: Use cables capable of supplying current required by respective pieces of equipment with low voltage drop.

Note: Ensure to secure the minimum bending radius of the cable. The minimum bending radius is either the value shown in the cable

manufacturer’s specications or six-fold of the cable conductor diameter, whichever is bigger should be applied.

n Power cable termination

lSolderless (crimp-on) lug terminal processing

Use solderless lugs for power cables (see Figure). Use solderless (crimp-on) terminals with

insulating cover, which have low contact resistance little aging.

inside diameter

3-2

Lug outside

diameter

Figure Solderless (crimp-on) lug

Lug length

lSolderless (crimp-on) lug specications

The solderless lug to use must have the dimensions given in table according to the nominal cross

sectional area of the power cable for which the lug is to be used.

Crimping terminal: For round crimping terminal M5

Table Solderless lug dimensions

Nominal cross

sectional area

*1: Recommended tightening torque: 2.5 Nm to 3.0 Nm

2

(mm

)

5.5 5 (*1) 5.3 or more 9.7 or less approx.29 5.9 or more

Screw used

(mm)

Hole diameter

(mm)

Lug outside

diameter

(mm)

Lug length

(mm)

Insulation

covering inside

diameter

(mm)

CAUTION

• Always use solderless lugs with insulating covering.

• Always use solderless lugs and crimp-on tool manufactured by the same manufacturer.

• The crimp-on tool must be matched to the wire thickness.

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 39

3. Cabling

CAUTION

• Power cables must be laid 1 cm or further away from signal cables.

• Power and grounding cable are use power and grounding cables which are in conformance

with the safety standard of each country.

n Type and maximum length of power cables

Formulas are given below for determining the type and the maximum length (m) of branch cables

from an indoor low-voltage main line.

• The standard type of cable used (nominal cross sectional area) is equivalent to JIS C 3312.

• Calculate the maximum power cable length from the following conditions in Figure.

However, the power cable must meet the conditions described in Section “1.2 Power supply

system”, “AC Power specication”.

AC wiring (100 V AC, 220 V AC)

L (m)

3-3

High-voltage

wiring

Equivalent voltage drop (referred to 100 V

supply) of 2 V or less in the main line, viewed

from the indoor power distribution board

Low-voltage

wiring

Power distribution

board

Equipment

Voltage drop of 2 V or less

across this section of wiring

F030202.ai

Figure Maximum cable length calculation conditions

[Maximum power cable length calculation conditions]

Use the following formula to calculate the maximum power cable length:

• 100 V AC and 220 V AC supply voltages

L (m)=

Note: In the formulas above, the voltage drop across wiring is assumed to be 2 V for AC power supplies ; the number of cores is two;

Conductor resistance (Ω/km)×(Number of cores)×Equipment current consumption

and the conductor resistance is as specied in the table below.

Table Wire nominal cross sectional areas and resistances

Wire nominal cross sectional area 5.5 mm2 8 mm2 14 mm2 22 mm2

Wire conductor resistance 3.37 Ω/km 2.39 Ω/km 1.36 Ω/km 0.82 Ω/km

Voltage drop across wiring

× 1000

F030203.ai

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 40

3. Cabling

n Power distribution boards

Power distribution boards are normally provided by the customer. Figures show examples of AC

distribution boards.

lAC Power distribution board

The power cables are branched to each unit by way of a circuit breaker.

Each power system uses three terminals (AC and ground: ISO M4 to M6 screws).

Power distribution board

3-4

100-120 V AC or

220-240 V AC

Figure AC Power distribution board

Enclosure

Enclosure

Enclosure

F030204.ai

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 41

3. Cabling

CAUTION

CAUTION

3.3 Connecting grounding cable

3.3.1 Connecting grounding cable for the enclosure

SEE

See “Section 1.3 Grounding n Grounding of enclosure” for grounding of enclosure.

ALSO

The protective conductor terminal of the N-IO eld enclosure should be connected to the

protective grounding system.

n Grounding cables

Nominal conductor cross-section area: AWG6 (14 mm2) or more

Temperature rating of cables: Enclosure ambient temperature + 35 ºC or more

Note: The cable used should be determined according to the standards in each country and region.

Note: Ensure to secure the minimum bending radius of the cable. The minimum bending radius is either the value shown in the cable

manufacturer’s specications or six-fold of the cable conductor diameter, whichever is bigger should be applied.

3-5

n Grounding cable termination

Use solderless lugs for power cables.

The solderless lug to use must have the dimensions given in table according to the nominal cross

sectional area of the cable for which the lug is to be used.

Crimping terminal: For round crimping terminal M10

Table Solderless lug dimensions

Nominal cross sectional area

• Always use solderless lugs and crimp-on tool manufactured by the same manufacturer.

• The crimp-on tool must be matched to the wire thickness.

2

(mm

)

22.0 10.3 or more

Hole diameter

(mm)

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 42

3. Cabling

3.3.2 Connecting grounding cable to grounding bar for shield lines

SEE

See “Section 1.3 Grounding n Grounding of grounding bar for shield lines” for more information.

ALSO

n Grounding cables

Nominal conductor cross-sectional area: 0.5 to 6.0 mm2 (Solid)

0.5 to 4.0 mm

Temperature rating of cables: Enclosure ambient temperature + 35 ºC or more

n Grounding cable termination

Connect the cable with the cable coating stripped (without a sleeve).

The peel-o length should be 16 mm.

2

(Flexible)

3-6

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 43

3. Cabling

CAUTION

3.4 Connecting signal cable

3.4.1 Connecting signal cable (for CENTUM VP)

For CENTUM VP, the A2BN3D terminal block in the N-IO eld enclosure interfaces with the eld

devices.

SEE

For signal cable connection for CENTUM VP, refer to the “CENTUM VP Installation Guidance” (TI 33J01J10-

ALSO

01EN).

3.4.2 Connecting signal cable (for ProSafe-RS)

For ProSafe-RS, the eld wiring terminal block in the enclosure interfaces with the eld devices.

n Process I/O signal connection

• Power, control bus, and signal cables must be separately laid. Avoid laying them in parallel.

• In case of using multicore cables for eld wiring, do not share one multicore cable with I/O

modules of dierent voltage types (i.e. 24 V DC).

3-7

• Use group-shielded twisted-pair cables specically for noise countermeasures. A twisted-

pair cable pitch of 50 mm or less should be used and the shielded cables must be grounded.

• The use of twisted-pair cables is also recommended for digital signals.

• The twisted-pair cable has the following advantages over a solid wire:

- More exible for easy curving and cabling in limited spaces.

• Signal cables must be clamped so that their weight does not aect terminals.

• Be careful not to apply excessive force to the cable when laying it.

n When mixing AI and DO in the same multi-core cable (N-IO I/O Unit)

When mixing analog input (AI) signal and digital output (DO) signal in the same multi-core cable,

take the following inuence from DO pulse diagnostics or ON/OFF operation into consideration.

• The accuracy for Analog input function may be worse by several tens of μA depending on

the type, length of a cable and DO load current.

• A delay may occur in updating the HART event.

lSpring clamp terminal, Push-in terminal

• The N-IO eld enclosure for ProSafe-RS uses a spring clamp terminal and push-in terminal

for signal connection.

• For cable connection with a sleeve attached, use a sleeve and a clamp tool from the same

manufacturer.

• Use a clamp tool which suits the cable thickness.

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 44

3. Cabling

n Signal cables

Nominal conductor cross-sectional area: 0.5 to 2.5 mm2 (AWG 20 to 14)

Temperature rating of cables: Enclosure ambient temperature + 35 ºC or more

Note: Ensure to secure the minimum bending radius of the cable. The minimum bending radius is either the value shown in the cable

manufacturer’s specications or six-fold of the cable conductor diameter, whichever is bigger should be applied.

n Signal cable termination

Connect the cable either with the cable coating stripped (without a sleeve) or with a sleeve

attached.

When using a sleeve

At the cable end, peel o the coating and attach a sleeve. The specications of the sleeve dier,

depending on the cable thickness. Provide cable termination according to the following gure and

tables:

3-8

Peel-off length

Core Cable

Figure Cable termination

Table When sleeves with insulating cover are used

Nominal cross

sectional area (mm

0.5 10 14 8 H0.5/14

0.75 10 14 8 H0.75/14

1.0 10 14 8 H1.0/14

1.5 10 14 8 H1.5/14

2.5 11 14 8 H2.5/14D

Table When sleeves without insulating cover are used

Nominal cross

sectional area (mm

0.5 6 6 H0.5/6

0.75 6 6 H0.75/6

1.0 6 6 H1.0/6

1.5 7 7 H1.5/7

2.5 7 7 H2.5/7

Peel-o length

2

)

Peel-o length

2

)

Sleeve with insulating cover

L2

L1

(mm)

(mm)

Sleeve dimensions (mm)

L1 L2

Sleeve dimensions (mm)

Sleeve (without insulating cover)

L1

F030501.ai

Weidmuller model

Weidmuller model

L1

No.

No.

When not using a sleeve

The peel-o length should be 7 mm.

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 45

3. Cabling

3.4.3 Connecting shield lines of the signal cable

For a signal cable with a shield line, connect the shield line to the grounding bar for a shield line in

the enclosure.

n Shield lines

Nominal conductor cross-sectional area: 0.5 to 6.0 mm2 (Solid)

0.5 to 4.0 mm

Temperature rating of cables: Enclosure ambient temperature + 35 ºC or more

n Shield lines termination

Connect the cable with the cable coating stripped (without a sleeve).

The peel-o length should be 16 mm.

2

(Flexible)

3-9

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 46

3. Cabling

3.5 Connecting communication cable

n Communication cables

lOptical ESB bus (for CENTUM VP and ProSafe-RS)

Temperature rating of cables: 60 ºC or more

Enclosure ambient temperature + 20 ºC or more

(When the enclosure ambient temperature exceeds 40 ºC)

Table Specications of ber-optic cables

Optical ber specications

Optical connector type LC (compliant with IEC 61754-20), or Fusion splicing

Max. permissible optical loss

Optical ber

5 km 0 to 10 dB@1.3 μm

5-50 km 3 to 16 dB@1.55 μm (*1)

Type Quartz single-mode optical ber (*2)

Required

number of cores

Max. length 50 km

2

3-10

*1: If attenuation of light in the optical ESB bus (5 to 50 km) connection is less than 3 dB, attenuate to 3 dB by using an attenuator.

*2: JIS C 6835 SSMA -9.3/125 or IEC 607932-50B1.1 type

Lay ber-optic cables according to the manufacturer’s cable handling precautions such as

allowable bending radius.

lN-ESB bus (for CENTUM VP)

Transmission cable:

• UTP straight cable of CAT5e or better (ANSI Standard TIA/EIA-568-B compliant)

• STP straight cable of CAT5e or better (ANSI Standard TIA/EIA-568-B compliant)

Connector:

RJ45 connector (ISO/IEC 8877 compliant)

Lay cables according to the manufacturer’s cable handling precautions such as allowable

bending radius.

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 47

4.Installationspecications

4. Installation specications

This section summarizes power consumption, in-rush current, circuit protector ratings,

parts durability and other data for the installation.

n Electrical specications

The table shows the power consumption and heating value of the N-IO eld enclosure.

Table Electrical specications

Input-voltage range

Model Name

A2NN70D N-IO eld enclosure

S2NN70D N-IO eld enclosure

*1: Power consumption in steady operation is indicated in VA (AC). When power consumption varies according to the installed

number of equipment, power consumption by the maximum number of units installed is listed.

*2: Heating value in steady operation is indicated in Joule/hour. When heating value varies according to the installed number of

equipment, heating value by the maximum number of units installed is listed.

Voltage (V AC) Frequency (Hz)

100-120

50/60±3

220-240 1180

100-120

50/60±3

220-240 1360

Max. power

consumption

(VA) (*1)

980

1190

4-1

Heating value

(J/h) (*2)

3492 × 10

(970 W)

3420 × 10

(950 W)

4248 × 10

(1180 W)

4140 × 10

(1150 W)

3

3

3

3

n Actual power-on In-Rush current of each component

The following shows an example of actual in-rush current measurement data.

Table System equipment power-on In-Rush current

Model Name

A2NN70D N-IO eld enclosure 70 92

S2NN70D N-IO eld enclosure 70 92

100-120 V AC 220-240 V AC

Input current peak values and waveforms, inuenced by input impedance, varies with system

congurations, line sharing with other systems, and other factors. The rush current data shown

above were measured under predetermined conditions (see below). Please note that the values

are subject to change.

lMeasurement conditions

Input voltage: 132/264 V AC, 50 Hz

Turn-on timing: At 50 Hz, 90° or 5 ms after the AC zero-crossing point

(60 Hz data are almost identical to the 50 Hz data shown above.)

lNote

In-Rush current (A)

• The restart in-rush current after a momentary power failure exceeds the above data and its

timing is also dierent.

• For a system composed of multiple pieces of equipment, the in-rush current is normally

smaller than the total of the in-rush currents by individual pieces of equipment.

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 48

4.Installationspecications

n Circuit protector specications

The table lists the circuit protector ratings used in the N-IO eld enclosure.

4-2

Model Name

A2NN70D N-IO eld enclosure 30/250 40/250

S2NN70D N-IO eld enclosure 30/250 40/250

n Parts durability

Some parts require periodical replacements. For preventative maintenance, the recommended

intervals to replace parts with life span of less than 10 years are shown in the table below.

Users can replace parts indicated by “Yes” in the “user replacement”. For other parts, contact

Yokogawa for replacement.

The average ambient temperature shown in the table is the average temperature surrounding the

corresponding parts.

When the parts are installed in an enclosure, though varies with actual installations, in general,

the temperature inside of the enclosure is about 10 °C higher than the temperature outside the

enclosure.

Note: Random failures within the recommended replacement intervals may occur in some parts.

IMPORTANT

The reliability and life span of electronic equipment greatly depend on the operating environment.

It is essential for ensuring reliable operation and prolonged life span that the equipment is used

not only within the range of environment resistance standards but also in a more satisfactory

environment. For instance, if a piece of equipment is always used at 35 °C when its operating

temperature ranges from 5 to 40 °C, generally its estimated failure rate almost doubles compared

with operation at 25 °C.

Built-in circuit protector rating

(A/V)

External breaker rating (A/V)

(*1)

If corrosive gas is present in the environment, the corrosion of the equipment’s contacts and

printed circuit boards is accelerated more than in a cleaner environment, resulting in a reduced

life span. Moreover, if dust can be easily generated in the environment, lters must be cleaned

and replaced more often.

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 49

4.Installationspecications

4-3

lLimited-life parts of the N-IO eld enclosure for CENTUM VP

Table Periodic replacement parts having dened life spans

Part names Part numbers

replacement

cycle

Field power supply S9201UD 8 years Yes

Recommended

Power supply unit

(100-240 V AC)

A2PW503-S030/NCBL

8 years Yes

Replacement

by user

Remarks

Average ambient temperature 40

°C

or less (*1)

Average ambient temperature 40 °C

or less (*2)

A2EN501-S13

N-ESB bus module

A2EN501-S23

A2EN501-S13

4 years Yes —

A2EN501-S23

*1: This ambient temperature means the temperature inside the enclosure. Estimate the ambient temperature around the eld power supply by

roughly 20 ° C higher than the outside of the enclosure.

*2: This ambient temperature means the temperature inside the enclosure. Estimate the ambient temperature around the power supply unit by

roughly 10 ° C higher than the outside of the enclosure.

lLimited-life parts of the N-IO eld enclosure for ProSafe-RS

Table Periodic replacement parts having dened life spans

Part names Part numbers

replacement

cycle

Field power supply S9201UD 8 years Yes

Recommended

Power supply unit

(100-240 V AC)

S2PW503-S030

8 years Yes

S2EN501-S13

N-ESB bus module

S2EN501-S23

S2EN501-S13

4 years Yes —

S2EN501-S23

*1: This ambient temperature means the temperature inside the enclosure. Estimate the ambient temperature around the eld power supply by

roughly 20 ° C higher than the outside of the enclosure.

*2: This ambient temperature means the temperature inside the enclosure. Estimate the ambient temperature around the power supply unit by

roughly 10 ° C higher than the outside of the enclosure.

Replacement

by user

Remarks

Average ambient temperature 40

°C

or less (*1)

Average ambient temperature 40 °C

or less (*2)

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 50

5. Post-installation inspection and environmental preservation

5. Post-installation inspection and environmental preservation

lPost-installation inspection

Upon the completion of installation of instrumentation, before turning on the power inspect the

following items in the list below to avoid system contamination by dust and moisture dust and

condensation.

Table Inspection before power on

Inspection items (daily inspection/maintenance items)

No water intrusion from cable ducts.

No wind/rain blow-in

Enclosure bottoms covered to prevent entry of wind, dust, moisture

Environment

Equipment

Enclosures and surroundings cleaned

No dust entering

Free of salty, ferrous, corrosive gas

No direct sunlight on equipment

No condensation or traces on enclosure interior/exterior

No discoloration or rust on enclosure interior/exterior

No condensation or traces on cards (disconnect cards on the upper, middle, and lower

stands, and left and right sides of the enclosure to check that there is no condensation on

the cards or defects anywhere in the enclosure.)

No dust remaining inside cabinet

5-1

It is recommended that you turn on the power in the presence of Yokogawa when turning it on

rst.

lPost-installation environment preservation

The following precautions should be taken to preserve the proper operating environment after the

system has been installed:

• Monitor and record ambient temperature and humidity. To maintain the reliability of the

equipment be sure to remove the cause if they uctuate violently.

• Note that leaving the door of the enclosure open during installation, or leaving open cable

ducts whiles pulling cables, may result in condensation.

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 51

Revision Information

l Title : Installation Guidance for N-IO eld enclosure

l Manual No. : TI 30A30A10-01EN

Feb. 2018/1st Edition

Newly published

i

TI 30A30A10-01EN

Feb. 26, 2018-00

Page 52

Written by Yokogawa Electric Corporation

Published by Yokogawa Electric Corporation

2-9-32 Nakacho, Musashino-shi, Tokyo 180-8750, JAPAN

Subject to change without notice.

Loading...

Loading...