Yaskawa Sigma Mini Servo System Product Catalog Supplement

Sigma Mini Servo System Product Catalog Supplement

Sigma Mini Servo System

Product Catalog Supplement

Table of Contents

SGMM Sigma Mini Servo System

SGMM Ratings & Specifications......................................................................5 - 6

SGMM Speed/Torque Curves...............................................................................7

SGMM Dimensions..........................................................................................8 - 9

SGMM Selection/Ordering Information........................................................10 - 14

SGDF Sigma Mini Servo Amplifier

SGDF Ratings & Specifications...................................................................15 - 17

SGDF Dimensions ..............................................................................................18

SGDF Internal Connection Diagrams..........................................................19 - 22

Overload Characteristics.....................................................................................23

Cable Specifications and Peripheral Devices..............................................24 - 26

3

Table of Contents

NOTES:

Super High Power Rate Series

SGMM Sigma Mini Servo System

SGMM Servomotors

Design Features

1. Compact

Small sized motor

!

Two frame sizes: up to 27.1oz-in. peak torque.

Smaller installation space for more compact machine designs.

High torque to inertia ratio.

2. High Speed and Power

High power rating

!

High power is achieved by minimizing the inertia of the motor.

This increases the acceleration/deceleration rate and reduces positioning time.

Maximum rotation speed of 5000rpm

!

Increases maximum rotation speed and shortens positioning time.

Rated speed of 3000rpm

!

3. Encoder

2048 PPR incremental encoder (standard)

!

4. Enclosure

Totally enclosed, self-cooled IP55 (not including shaft).

!

Vibration resistance: 5G.

!

5. Application Emphasis

Semiconductor equipment

!

Chip mounters

!

Robots

!

Packaging

!

6. Certified International Standards

CE compliance.

!

- With Incremental Encoder

Rated Output: 10W, 20W

For Additional Information Page(s)

SGMM Ratings & Specifications

SGMM Speed/Torque Curves

SGMM Dimensions

SGMM Selection/Ordering Information

SGDF Ratings & Specifications

6

7

8 - 9

10 - 14

15 - 17

SGMM

5

SGMM Sigma Mini Servo System

Servomotor Ratings and Specifications

Time Rating: Continuous

Insulation: Class B

Vibration: 15µm or less

Withstand Voltage: 1000VAC

Insulation Resistance: 500VDC

SGMM

10MΩ

minimum

Enclosure: Totally-enclosed, self-cooled

Ambient Temperature: 0 to 40ºC

Ambient Humidity: 20 to 80%

(non-condensing)

Rated Rotation Speed: 3000rpm

Max. Rotation Speed: 5000rpm

Excitation: Permanent magnet

Drive Method: Direct drive

Mounting: Flange-mounted

Applicable Encoder:

Incremental encoder 2048PPR

Applied

Voltage

24VDC

Applied

Voltage

24VDC

M O T O R :

SGMM-

"

A1

"

A2

Rate

Output

W (hp)

10 (0.013) 4.5 (0.0318) 13.5 (0.0955) 2.1 6.0 90000 2.9

20 (0.027)

Rated

Torque

oz • in (N • m)

9.02

(0.0637)

Instantaneous

Peak Torque

oz • in (N • m)

27.1 (0.191) 2.0 5.7 120000 7.4

Continuous

Rated Current

A

rms

*Values when se rvomotor is combined with SGDF servo amplifier

MOTOR

SGMM-

"

A1

"

A2

Moment of Inertia (JM)

Motor without Brake Motor with Brake

2

oz • in • s

(kgf • m

0.0501

(0.00354)

0.0776

(0.00548)

-3

)

oz • in • s

(kgf • m

×

10

2

-4

×

10

2

× 10

2

× 10

0.069

(0.00487)

0.0967

(0.00683)

-4

Capacity Torque

-3

)

Holding Brake (at 20°C)

kg

W

2 0.325 320 0.075

2.6 0.65 221.5 0.108

• m

f

*

.

Maximum

Peak

.Current

A

rms

Coil

Resis-

tance

Ω

*

Rated

Angular

Acceleration

rad/s

Rated

Current

A

2

Allowable Load

Inertia (J

oz • in • s

(kg • m

(0.1064)

Rated

Power Rating

KW/s

)

L

2

-3

×

10

2

-4

)

×

10

1.5072

2.4832

(0.164)

6

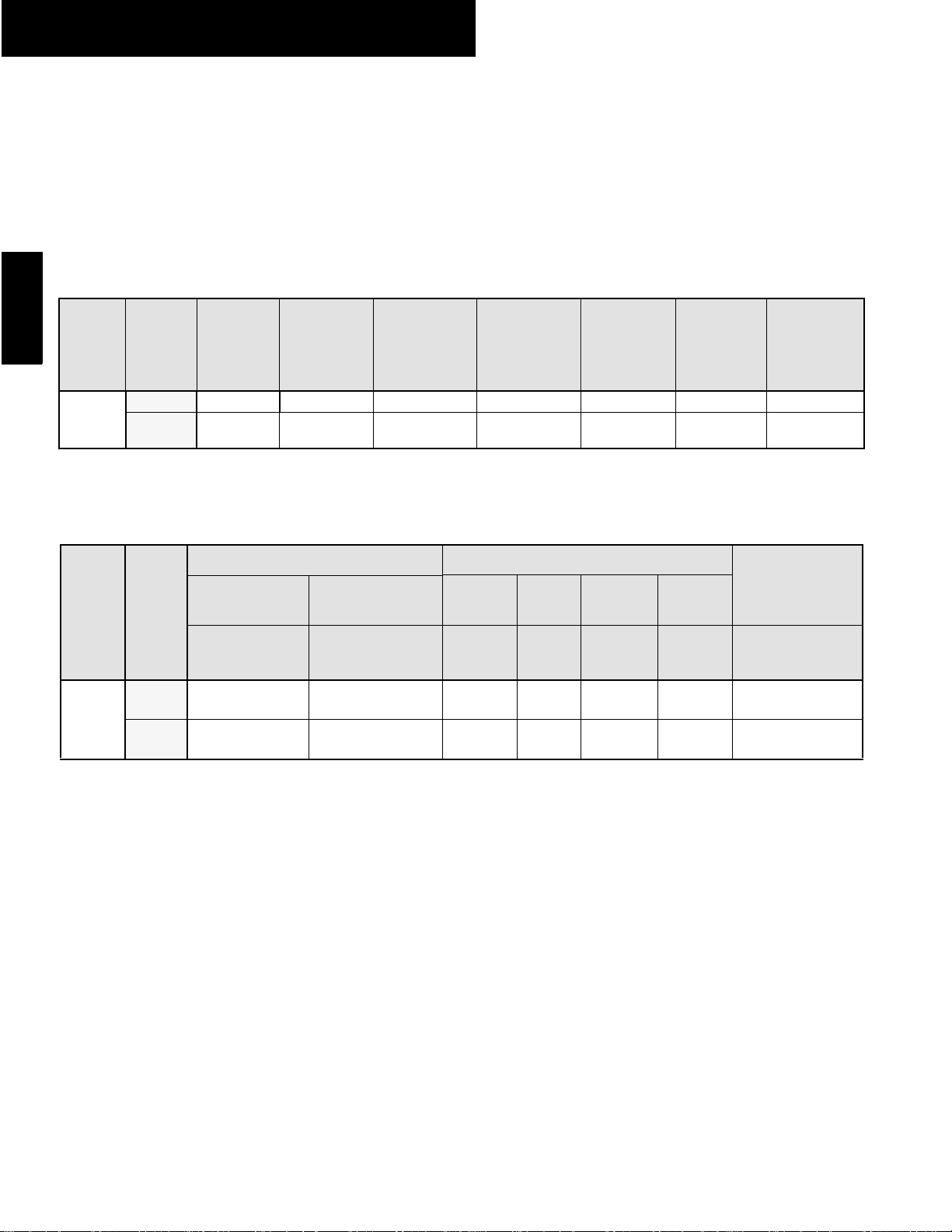

SGMM Sigma Mini Servo System

Speed / Torque Curves

24V Servomotors

SGMM - A1S

5000

4000

3000

2000

SPEED (rpm)

1000

A

0

0 0.02 0.04 0.06 0.08 0.10

TORQUE (N · m)

0 0.2 0.4 0.6 0.8

TORQUE (lb · in)

SGMM - A2S

5000

4000

3000

B

2000

SPEED (rpm)

1000

0

0 0.05 0.1 0.15 0.2

B

A

TORQUE (N · m)

0 0.5 1.0 1.5

TORQUE (oz · in)

SGMM

7

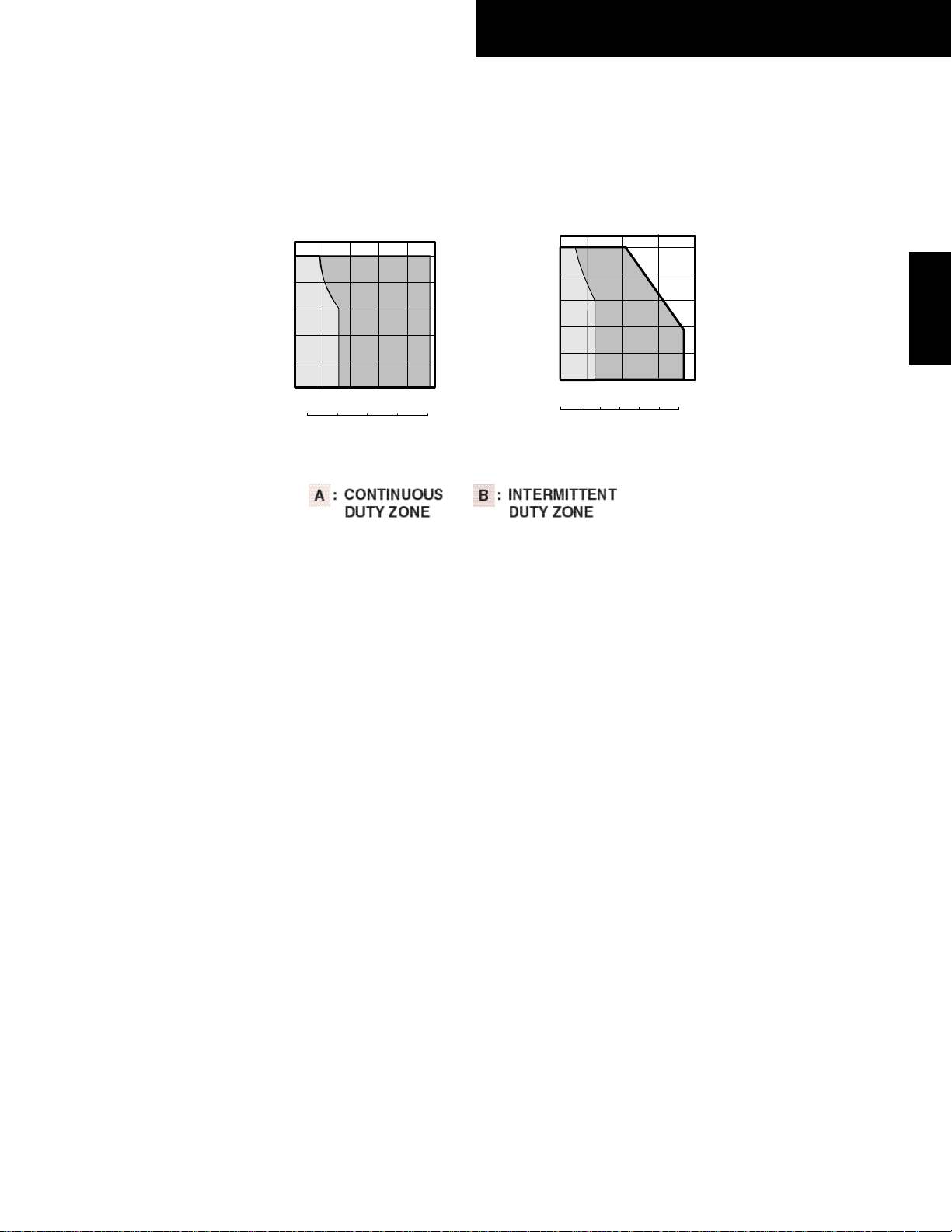

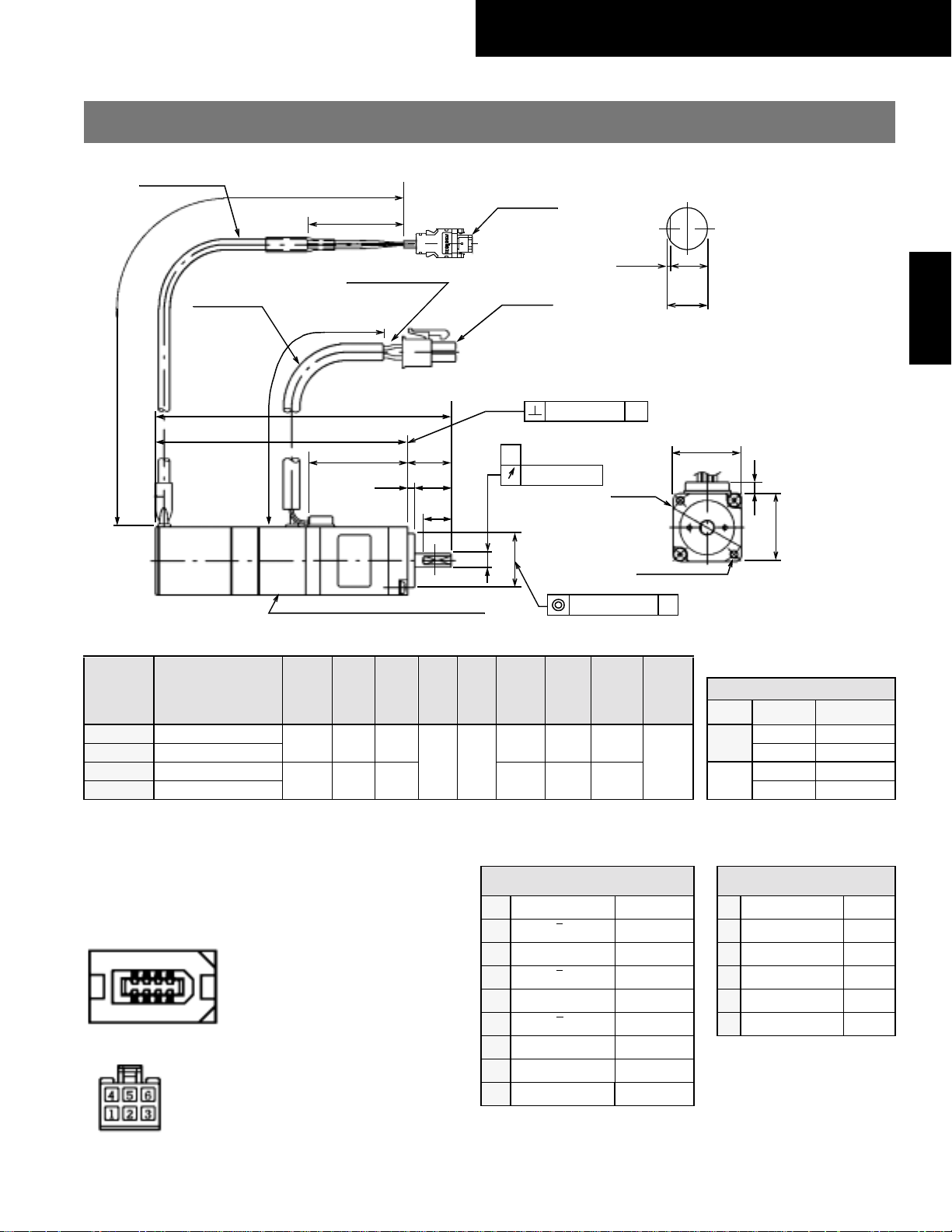

SGMM Sigma Mini Servo System

Dimensions in inches (mm)

(1) 2048PPR Increm ental E ncoder, without Brake

•10W (0.013hp), 20W (0.027hp)

Encoder Cable

UL20276

SGMM

11.81 (300) ±1.18 (30)

1.38 (35)

Encoder Plug

Protective Tube

0.20 (Φ5)

Φ

(black)

11.81 (300) ±1.18 (30)

Motor Leads, AWG24

UL10095

L

LL

1.04

1.44

0.63 (16)

0.197

(5)

Type

SGMM-

A1S312

A1S313

A2S312

A2S313

Without Flat Seat

With Flat Seat

Without Flat Seat

With Flat Seat

LM

0.10 (2.5)

L LL LM *ΦS

2.76

2.13

(70)

(54)

(26.5)

3.15

2.52

(80)

(64)

(36.5)

Note: The detector uses a 2048PPR incremental encoder.

The allowable load is applied to the shaft end.

Connector Specifications

Encoder Plug

1 7

2 8

Motor Plug

Plug 55101-0800 (Molex Japan)

Connected to:

Socket: 54280-0600

Receptacle: 5557-04R (Molex)

Terminal: 5556T

Connected to:

Socket: 5559-04P

Terminal: 5558T

Motor Plug

0.02 (0.5)

Cross-section Y - Y

(with flat seat)

0.0016 (0.04) A

A

0.53 (13.5)

0.39 (10)

Y

Y

ΦLB

0.0133

0.787

(20)

0.0266

1 Chan nel A Outp ut Blue 1 Phase U Red

2 Channel A Ouput Blue/Black 2 Phase V White

3 Chan nel B Outp ut Yellow 3Phase W Blue

4 Channel B Output Yellow/Black 4 FG (Frame Ground) Green

5 Chan nel C Outp ut G ree n

6 Channel C Output Green/Black

7 0V (Power Supply) Grey

8 +5V (Power Supply) Red

9 FG (Frame Ground) Orange

0.0008 (0.002)

1.10 (Φ28)

Φ

LB

S

Φ

Φ

*

**

Output

Approx

W

(hp)

(10)

(120)

(20)

(160)

Incremental Encoder Connection Motor Connection

Mass

0z (g)

4.23

5.64

0.0016 (Φ0.04)

Φ

Allowable

Allowable

Radial

Load

lb (N)

7.7

(34.3)

9.9

(44.1)

A

2 × M3 tap screws

depth: 0.20 (5)

Thrust

Load

lb (N)

3.3

(14.7)

0.18 (4.5)

S

Φ

0.98 (25)

0.63 (16)

0.14 (4)

Specified Tolerances

Diameter Tolerance

0.197in

*ΦS

5.000mm

**ΦLB

0.787in

20mm

0.98 (25)

-0.0001 -0.0005

+0.000 -0.008

+0.0004 -0.0001

+0.000 -0.013

8

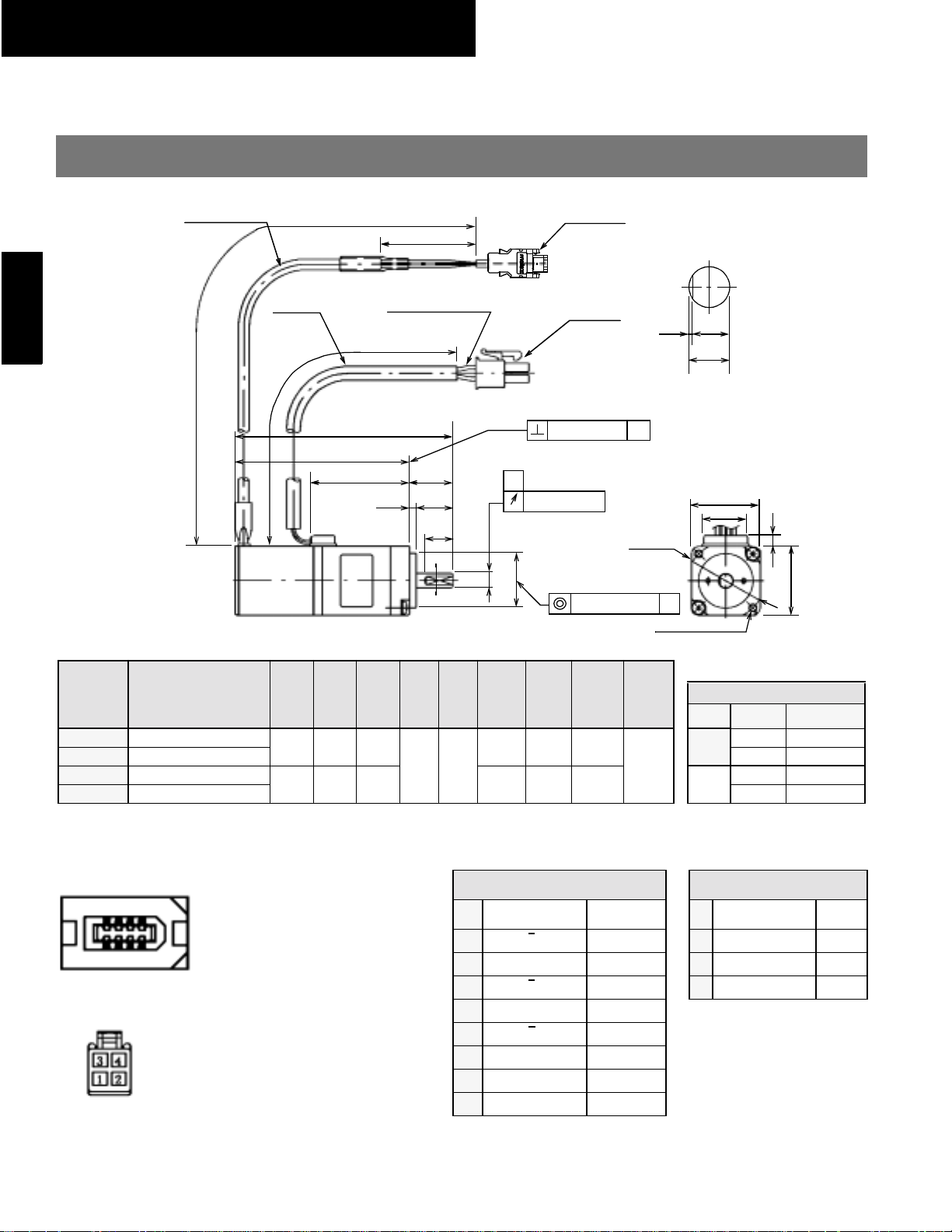

SGMM Sigma Mini Servo System

(2) 2048PPR Incremental Encoder, with Brake

•10W (0.013hp), 20W (0.027hp)

Encoder Cable

UL20276

11.81 (300) ±1.18 (30)

1.38 (35)

Encoder Plug

Motor Leads, AWG24

Protective Tube

0.20 (Φ5)

Φ

(black)

11.81 (300) ±1.18 (30)

UL10095

L

LL

1.04

(26.5)

1.44

(36.5)

0.63 (16)

0.53 (13.5)

0.39 (10)

Y

Y

0.197

(5)

Type

SGMM-

A1S312C

A1S313C

A2S312C

A2S313C

QK L LL LM *ΦS

Without Flat Seat

With Flat Seat

Without Flat Seat

With Flat Seat

LM

0.10 (2.5)

Magnetic brake Non-excitation operaton

DC power supply: 24V

Maximu m ca pacity: 3W

3.72

4.27

3.09

(78.5)

3.64

(92.5)

(94.5)

(108.5)

Note: The detector uses a 2048PPR incremental encoder.

The allowable load is applied to the shaft end.

Connector Specifications

ΦLB

0.787

(20)

Motor Plug

S

Φ

*

Output

0.0133

0.0266

0.0016 (0.04) A

A

0.0008 (0.02)

LB

Φ

**

W

(hp)

(10)

(20)

0.0016 (Φ0.04)

Φ

Approx

Mass

0z (g)

7.23

(205)

9.17

(260)

0.02 (0.5)

Cross-section Y - Y

(with flat seat)

1.10 (Φ28)

Φ

2 × M3 tap screws

depth: 0.20 (5)

A

Allowable

Radial

Load

lb (N)

Allowable

Thrust

Load

lb (N)

7.7

(34.3)

9.9

3.3

(14.7)

(44.1)

0.18

(4.5)

S

Φ

0.98 (25)

0.14 (4)

0.98 (25)

Specified Tolerances

Diameter Tolerance

0.197in

*ΦS

5.000mm

**ΦLB

0.787in

20mm

SGMM

-0.0001 -0.000 5

+0.000 -0.008

+0.0004 -0.000 1

+0.000 -0.013

Encoder Plug

1 7

2 8

Motor Plug

Plug 55101-0800 (Molex Japan)

Connected to:

Socket: 54280-0800

Receptacle: 5557-06R (Molex)

Terminal: 5556T

Connected to:

Socket: 5559-06P

Terminal: 5558T

Incremental Encoder Connection Motor Connection

1 Channel A Ouput Blue 1 Phase U Red

2 Channel A Ouput Blue/Black 2 Phase V White

3 Channel B Output Yellow 3Phase W Blue

4 Channel B Output Yellow/Black 4 FG (Frame Ground) Green

5 Channel C Output Green 5 Brake Terminal Black

6 Channel C Output Green/Blac k 6 Brake Terminal Black

7 0V (Power Supply) Grey

8 +5V (Power Supply) Red

9 FG (Frame Ground) Orange

9

Loading...

Loading...