Page 1

Electronic Lineshaft

With Alignment

F7 Drive Software

Technical Manual

Software Number: VSF11005X, Drive Models: CIMR-F7UXXXXXX-064, CIMR-F7UXXXXXX-065

Document Number: TM.F7SW.064, Date: 02/25/2010, Rev: 10-02

Page 2

This document is intended to provide proper installation and use of the Yaskawa drive with custom software. This

document is a supplement to the standard drive technical manual. It describes the effects on the drive parameters

and functions with the software installed. Read and understand this document and the standard drive technical

manuals before attempting to install, adjust, operate, inspect, or maintain the drive.

warnings in this document and the standard drive technical manuals.

Custom software is written to add

Observe all cautions and

functionality to a standard AC drive to enhance or enable use in a specific application. The software is loaded to

the flash ROM area of the control board, and replaces the standard drive software. Custom software can add new

functions, modify standard functions, or even inhibit standard functions. It can be used to modify display text or

parameter names. Custom software is usually loaded to the drive before delivery. The control board and drive

nameplate are assigned unique part numbers and the software is registered, archived, and retrievable.

When seeking support for a drive with custom software, it is imperative to provide the unique part number shown

on the drive nameplate. The software has been flashed to the control board memory and the operation of

parameters, functions, and monitors are different than the standard drive software, as described herein.

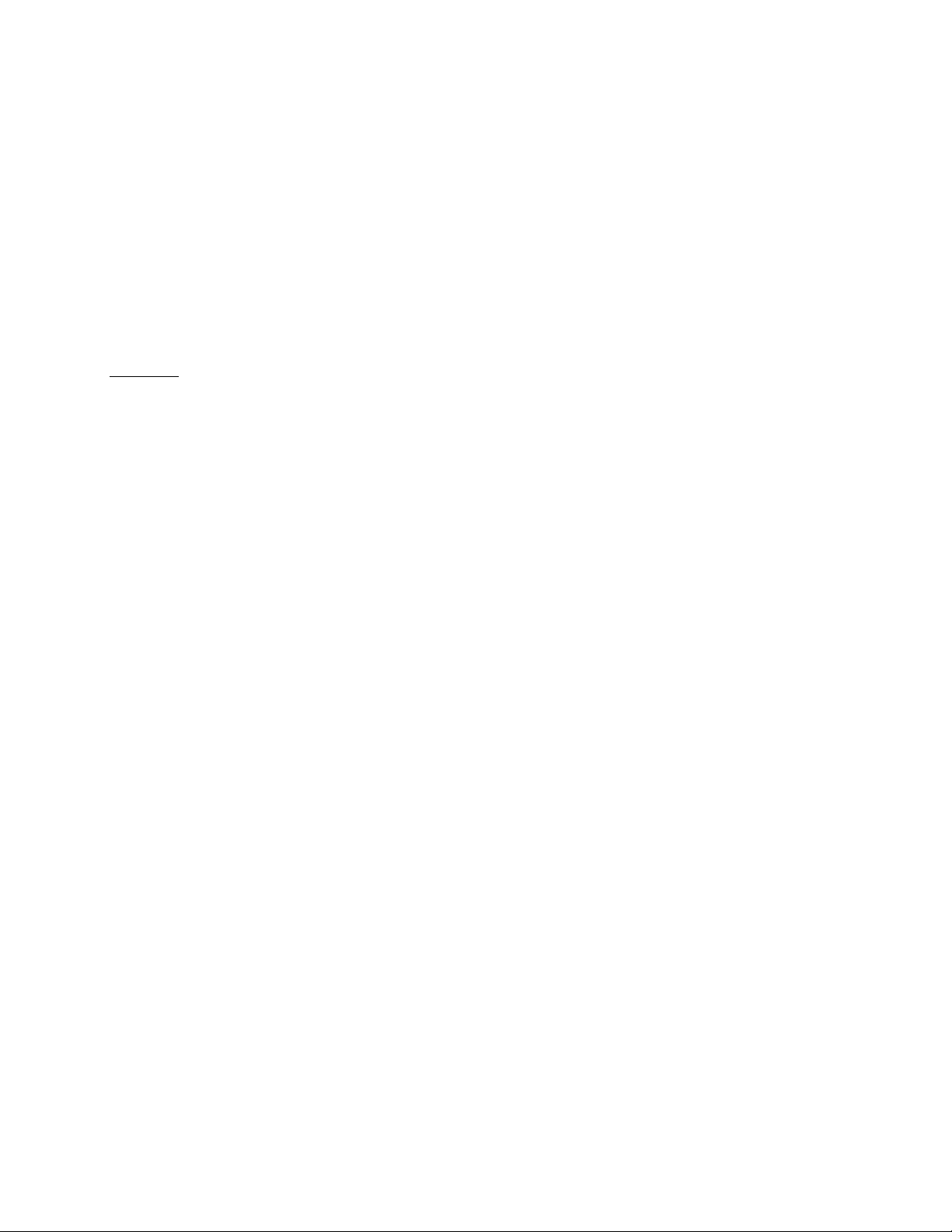

1.0 Overview

The Electronic Lineshaft (ELS) function allows a drive to precisely follow a master encoder (PG) signal in

speed, direction, and phase. The follower can match its position (phase angle) to the master within several

quadrature encoder counts. The function is used in applications where the machinery being driven requires

two mechanically isolated, moving parts to maintain a constant position relationship. The gear ratio between

the master and the follower is infinitely adjustable. In addition, a gear ratio adjustment (“draw”) can be added

to the speed reference via parameter, analog input, multi-function input, MOP, or network communication.

The drive can also be run in a pure speed follower mode for applications that do not require matched position,

only velocity following.

Both the master and follower encoder signals are fed into the follower drive’s dual encoder (PG) option card.

The master encoder speed is multiplied by the programmed gear ratio to determine the speed reference. The

error between the master and follower position is determined. This is fed into a PI controller, which is in turn

added to the previously calculated speed reference. When the drive is configured as a speed follower, the

position regulator is disabled.

A signed-run mode is also available in ELS. When P1-01 = 5 (Electronic Line Shaft - Sign Run), ELS

functions identically to standard ELS (P1-01 = 4), with the following difference:

When a reverse run command is given through the terminal S2 digital input, the follower will match the

When a forward run command is present through terminal S1, the follower will run in the same direction is

With revision VSF110052, the software adds an automatic alignment feature to the base electronic line shaft

software. This is accomplished by using two proximity switches connected to the trigger inputs on the follower

drive. One switch is used to indicate the position of the master, and the other switch is used to indicate the

position of the follower. When the alignment feature is activated and the machine is running, the distance

between the trigger switches is measured and then compensated for by either advancing or retarding the

follower motor.

velocity and phase of the master, but in the opposite direction. If the master runs in the forward direction,

the follower will run in reverse direction. If the master runs in the reverse direction, the follower will run in

the forward direction.

the master.

Date: 02/25/2010, Rev: 10-02 Page 2 of 34 TM.F7SW.064

Page 3

Speed Calculation

ELS – Sign Mode Enabled

AND Reverse Run Command

Master Encoder

Master Encoder

Pulse Count

Speed

Position Regulator

ELS – Sign Mode Enabled

AND Reverse Run Command

Follower Encoder

Pulse Count

Gear

Calculation

Gear

Calculation

ELS Mode Enabled OR

ELS – Sign Mode

Enabled

+

-

Position Error

Accumulator

PI

Controller

+

+

Simplified Block Diagram of the Electronic Lineshaft Function

Gear

Follower

Box

d

e

n

g

i

l

A

Master

Motor

Master Motor

Master Encoder

Master Trigger Switch

Follower Trigger Switch

PG-X2

Motor

Follower Motor

Follower Encoder

F 7

Simplified Application Example of Electronic Lineshaft with Alignment Function

Frequency

Reference

PG-W2

F 7

Date: 02/25/2010, Rev: 10-02 Page 3 of 34 TM.F7SW.064

Page 4

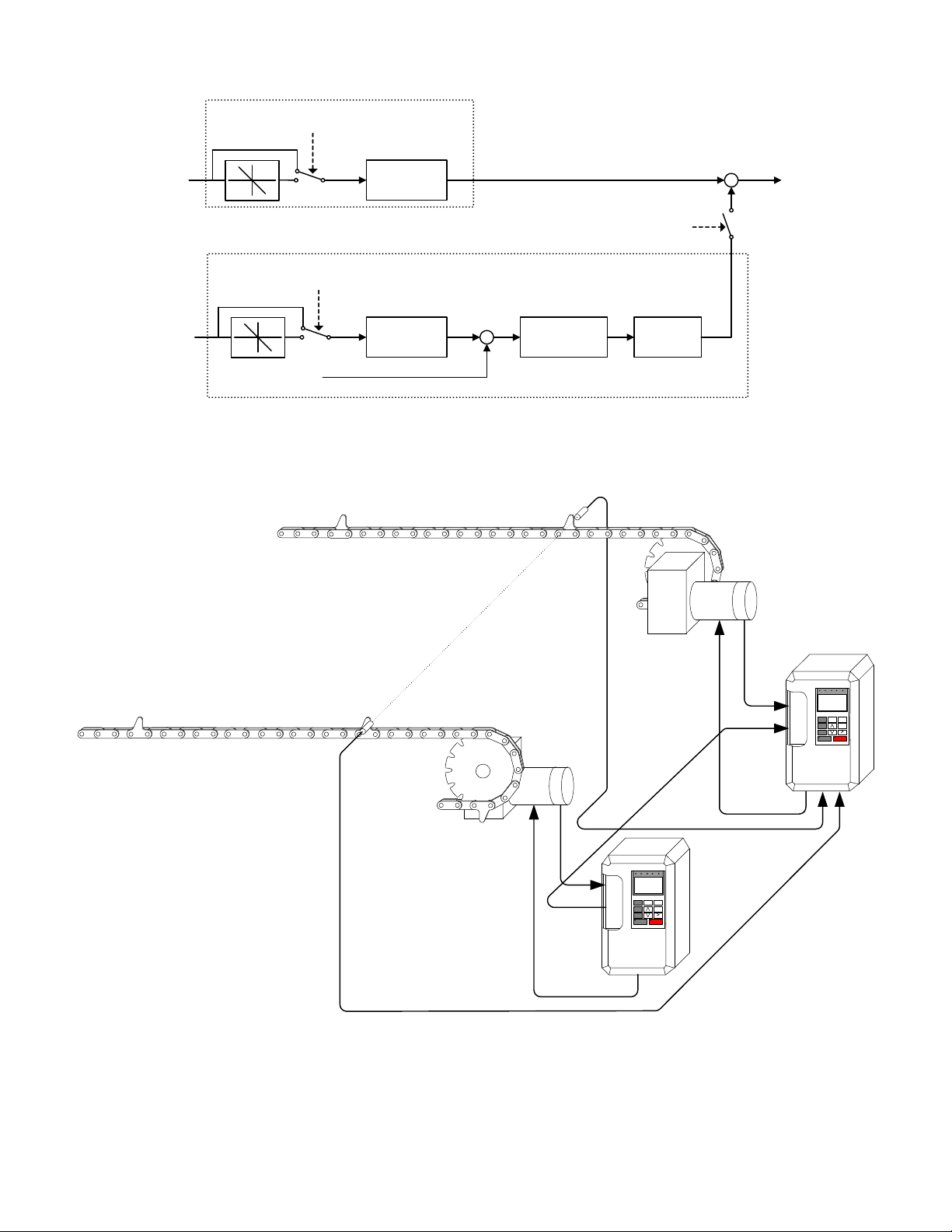

Input Channel

Monitor Output

Channel 1 Input

Channel 2 Input

Monitor Output

.

.

.

Channel 1 Input

Channel 2 Input

PG-X2

Pulse

Master Drive

PG-W2

Pulse

Follower Drive 1

PG-W2

Follower Drive n

F7

F7

.

.

.

F7

PG

M

PG

M

PG

M

Typical Connection Diagram for Electronic Lineshaft

Date: 02/25/2010, Rev: 10-02 Page 4 of 34 TM.F7SW.064

Page 5

2.0 Changes from Standard Product

a. The Motor 2 Selection (H1-0X = 16) multi-function digital input function is deleted (only Motor 1 can be

used).

b. The kWh monitors (U1-29 and U1-30) are deleted.

c. Parameter E2-04 (Motor Poles) is available in all control modes (Advanced access level only for V/f and

Open Loop Vector).

d. T he follower drive uses acceleration and deceleration times of zero during standard Electronic Line Shaft

(P1-01 = 4, 5).

e. All “A2” parameters along with the entire user access level have been deleted from this software.

3.0 Limitations

a. For ELS modes (P1-01 = 4, 5), Flux Vector control mode is highly recommended (A1-02 = 3).

b. For ELS modes (P1-01 = 4, 5), the gear ratio must be exactly expressed, including remainder, to prevent

phase drift (error). See section 5.0.

c. The proper encoder (PG) option card must be used based on the control mode and follower mode

selection. The table below shows the supported option cards for each configuration.

d. If the “Clear Position Error” digital input is activated when an alignment is being performed, the drive could

possibly experience a step-change in frequency reference.

e. Alignment accuracy will be lessened at higher speeds. This is due to latency in the trigger

switches themselves and the drive’s digital inputs and internal scan rate.

Encoder (PG) Option Card Selection

Control Mode P1-01 = 1, 2, 3 (Speed Follower) P1-01 = 4, 5 (ELS)

V/f w/ PG PG-W2, PG-Y2, PG-Z2

Open Loop Vector PG-B2, PG-T2, PG-X2, PG-W2, PG-Y2, PG-Z2

Flux Vector PG-W2, PG-Y2, PG-Z2

V/f PG-B2, PG-T2, PG-X2, PG-W2, PG-Y2, PG-Z2

PG-W2, PG-Y2, PG-Z2

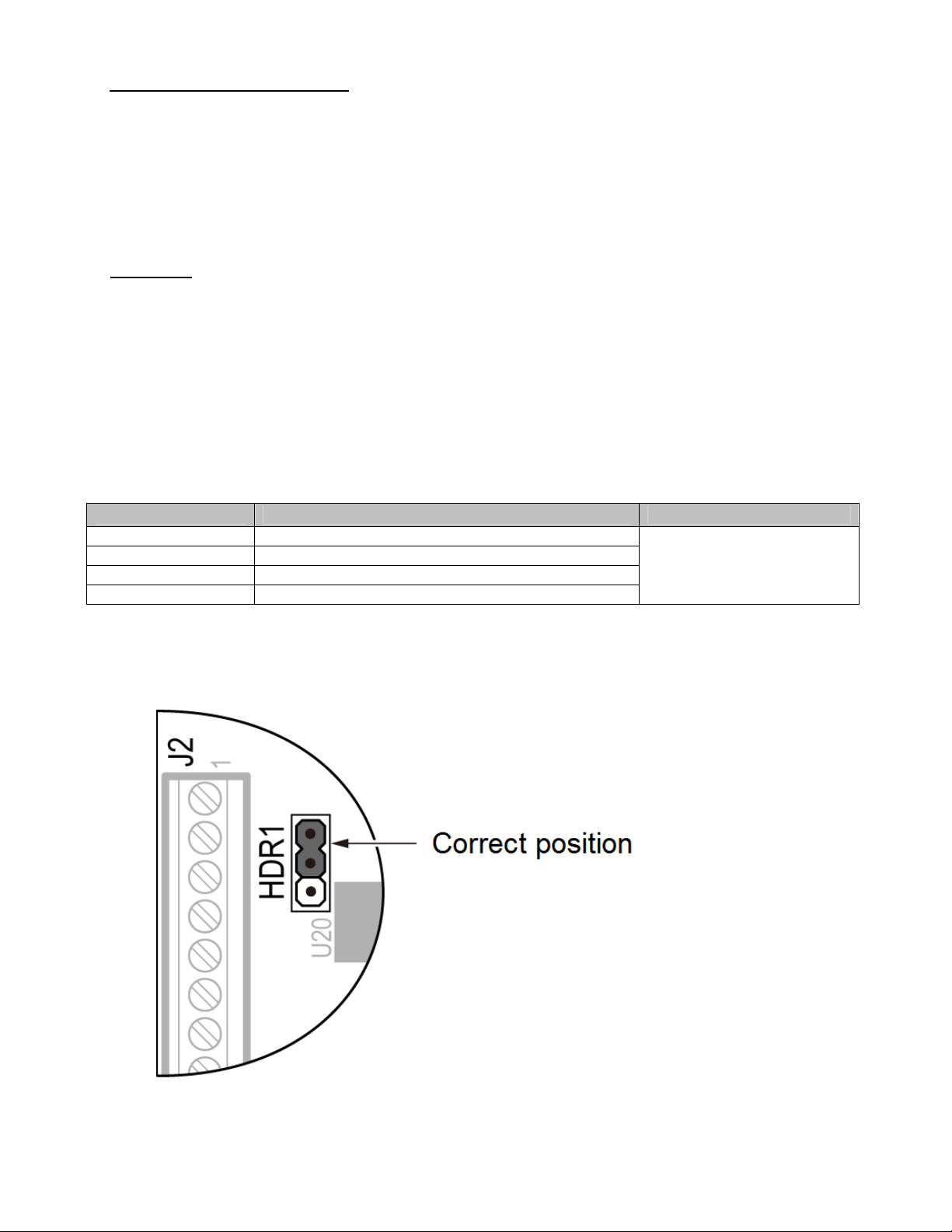

Note: If the PG-W2 option is used, jumper HDR1 must be set to the correct position

according to the figure below.

Date: 02/25/2010, Rev: 10-02 Page 5 of 34 TM.F7SW.064

Page 6

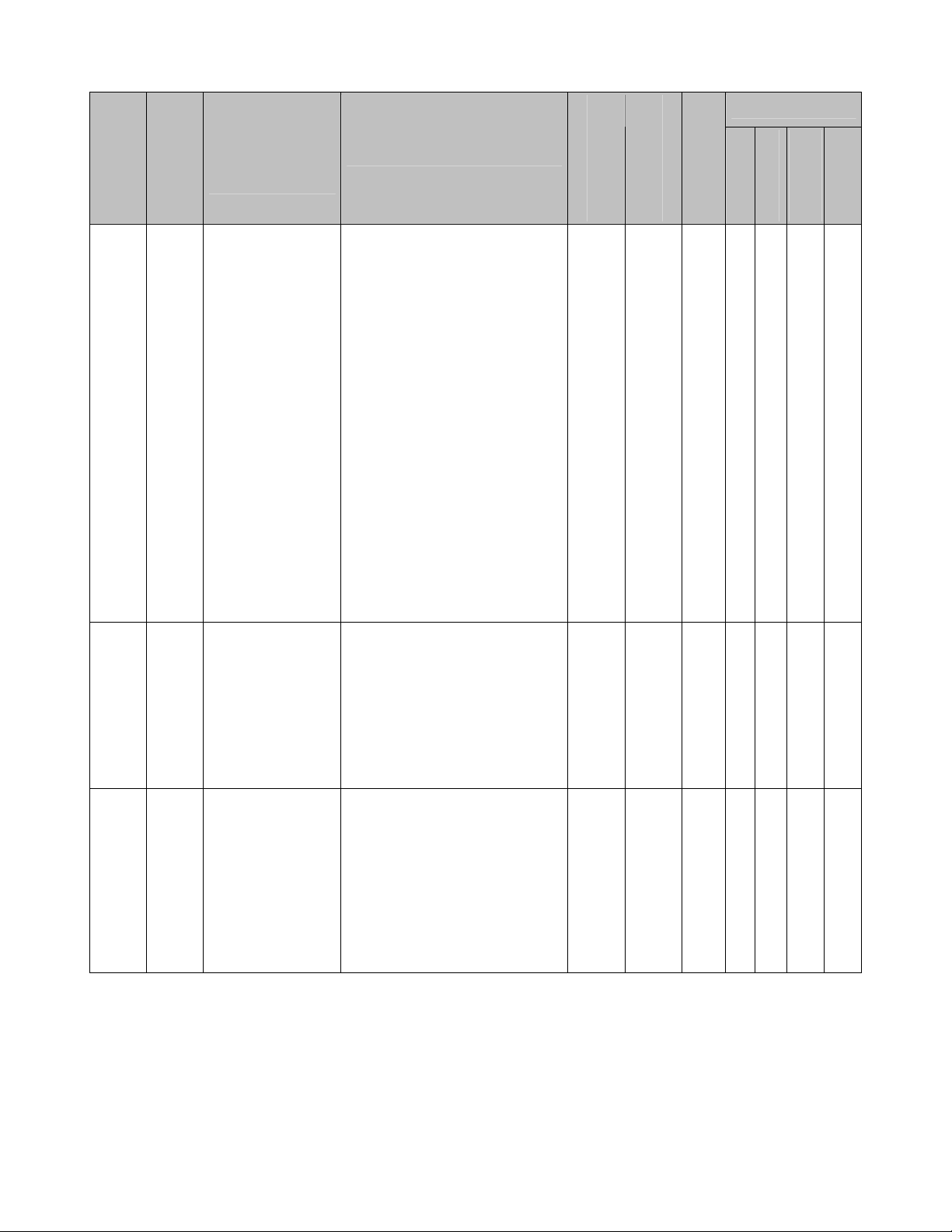

4.0 Related Parameters and Functions

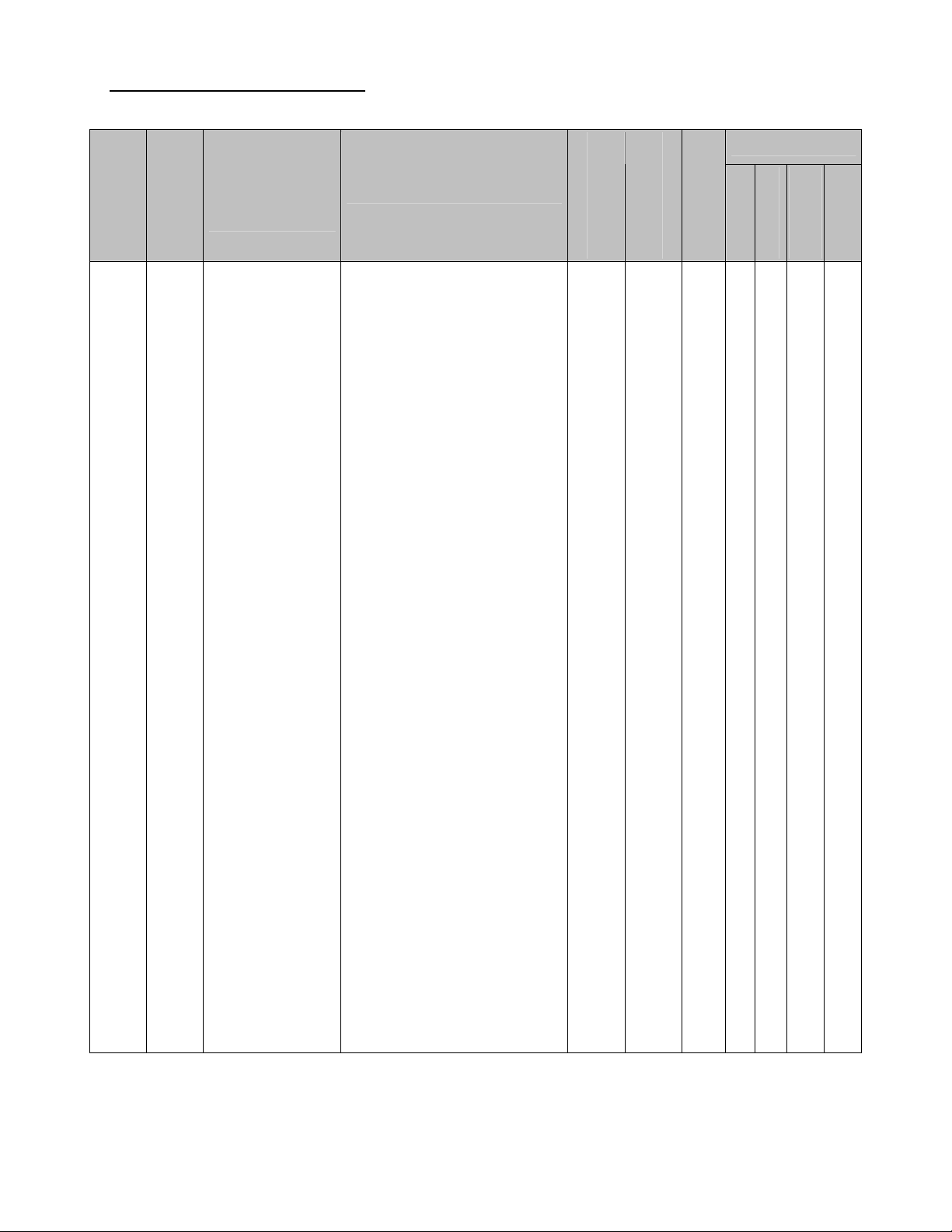

4.1 Parameters

Parameter

Address

Number

Modbus

Parameter Name

Digital Operator

Range

Description

Display

Selects the follower mode.

0: Disabled

Follower mode is disabled

and the follower drive runs

from the normal frequency

reference (B1-01).

1: Speed – Both Dir

The follower drive follows

the master encoder speed

in both directions.

2: Speed – One Dir

The follower drive follows

the master encoder speed

in the direction of the run

command only.

3: Speed – Abs Val

The follower drive follows

the master encoder speed

but ignores the master

P1-01 600H

Follower Mode

Selection

Follower Mode

encoder direction (motion is

always in the direction of

the run command).

4: Elec Line Shaft

0 ~ 5 0 No Q Q Q Q

The follower drive follows

the master encoder speed

and position (both

directions). Terminals S1 or

S2 can be used to issue the

run command. There is no

directional effect.

5: ELS – Sign Run

The follower drive follows

the master encoder speed

and position (both

directions). When a forward

run command is present

(terminal S1), the drive

follows the master in the

same direction. When a

reverse run command is

present (terminal S2), the

drive follows in the opposite

direction of the master.

*1: Access Level (A1-01): Q = “Quick Start”, A = “Advanced”, F = “Factory”.

Default

Change During

Run

Control Mode *1

Open Loop

V/f w/ PG

V/f

Vector

Flux Vector

Date: 02/25/2010, Rev: 10-02 Page 6 of 34 TM.F7SW.064

Page 7

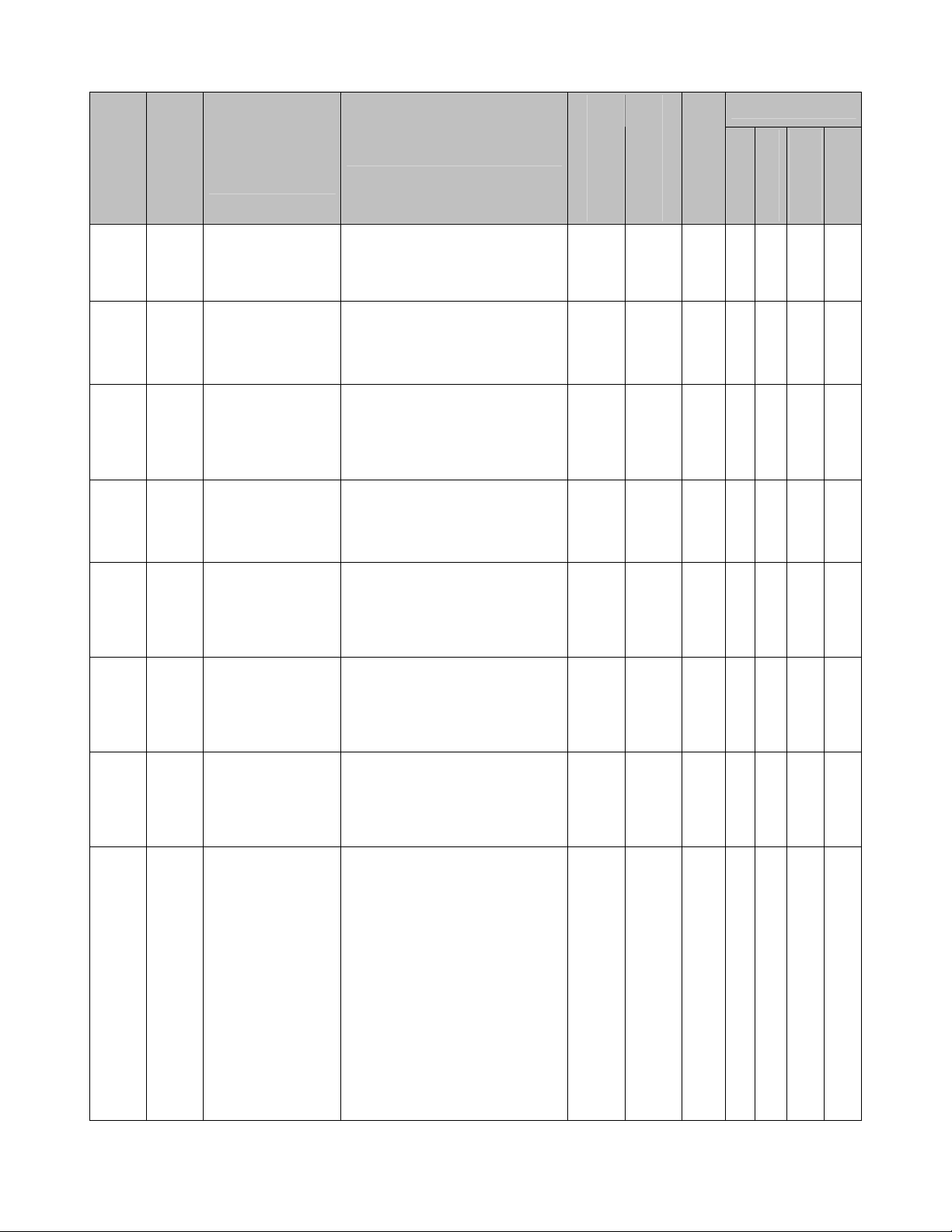

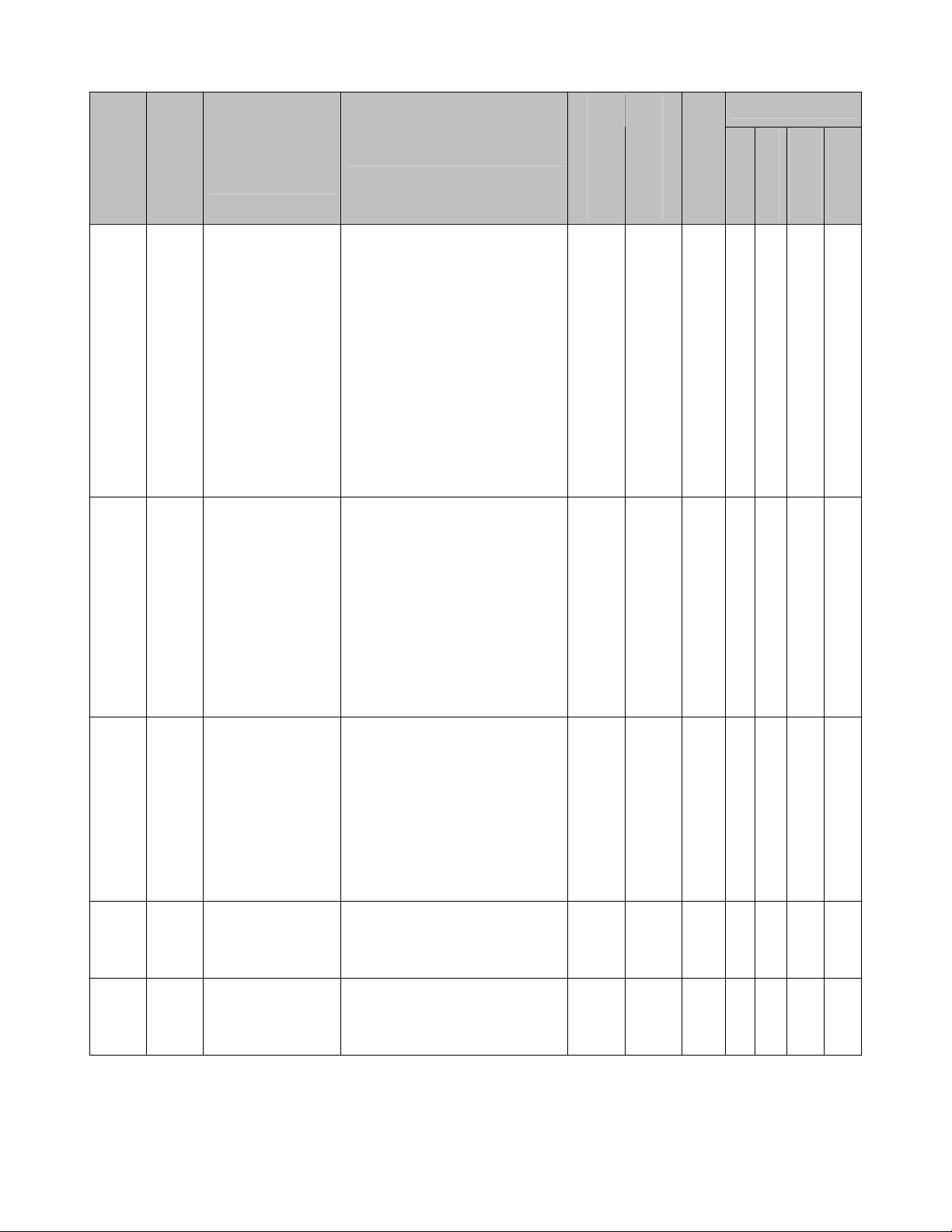

4.1 Parameters (continued)

Parameter

Address

Number

Modbus

Parameter Name

Digital Operator

Display

Description

Range

Default

Change During

Run

Control Mode *1

Open Loop

V/f w/ PG

V/f

Vector

Flux Vector

P1-02 601H

P1-03 602H

Master Encoder

PPR

Master PG PPR

Ratio Numerator

(Upper 4 Digits)

Ratio Num High

Sets the pulses per revolution

(PPR) of the master encoder

(PG).

Sets the upper 4 digits of the

primary gear ratio numerator.

See section 5.1.

20 ~

60,000

Pulses

0 ~

9999

Ratio

P1-04 603H

Denominator

(Upper 4 Digits)

Sets the upper 4 digits of the

primary gear ratio

denominator. See section 5.1.

0 ~

9999

Ratio Den High

P1-05 604H

Ratio Numerator

(Lower 4 Digits)

Ratio Num Low

Sets the lower 4 digits of the

primary gear ratio numerator.

See section 5.1.

0 ~

9999

Ratio

Sets the lower 4 digits of the

primary gear ratio

denominator. See section 5.1.

0 ~

9999

P1-06 605H

Denominator

(Lower 4 Digits)

Ratio Den Low

Sets the numerator of the

secondary gear ratio. Active

when a multi-function digital

input is set to 81 (Ratio 2

Select) and the input is closed.

Sets the denominator of the

secondary gear ratio. Active

when a multi-function digital

input is set to 81 (Ratio 2

Select) and the input is closed.

1 ~

65,535

1 ~

65,535

P1-07 606H

P1-08 607H

Ratio 2

Numerator

Ratio 2 Num

Ratio 2

Denominator

Ratio 2 Den

Sets when the position error

accumulator is enabled in the

follower drive.

0: Only During Run

Position error is only

calculated when the

follower drive is running

during High Slip Braking)

1: Always

Position error is calculated

0 ~ 1 0 No A A A A

(not

.

P1-09 608H

Position Error

Accumulation

Selection

Pos Accum

Select

whenever power is applied

to the follower drive.

Note: ELS modes only.

*1: Access Level (A1-01): Q = “Quick Start”, A = “Advanced”, F = “Factory”.

1024 No Q Q Q Q

1000 Yes Q Q Q Q

1000 Yes Q Q Q Q

0 Yes A A A A

0 Yes A A A A

1 Yes A A A A

1 Yes A A A A

Date: 02/25/2010, Rev: 10-02 Page 7 of 34 TM.F7SW.064

Page 8

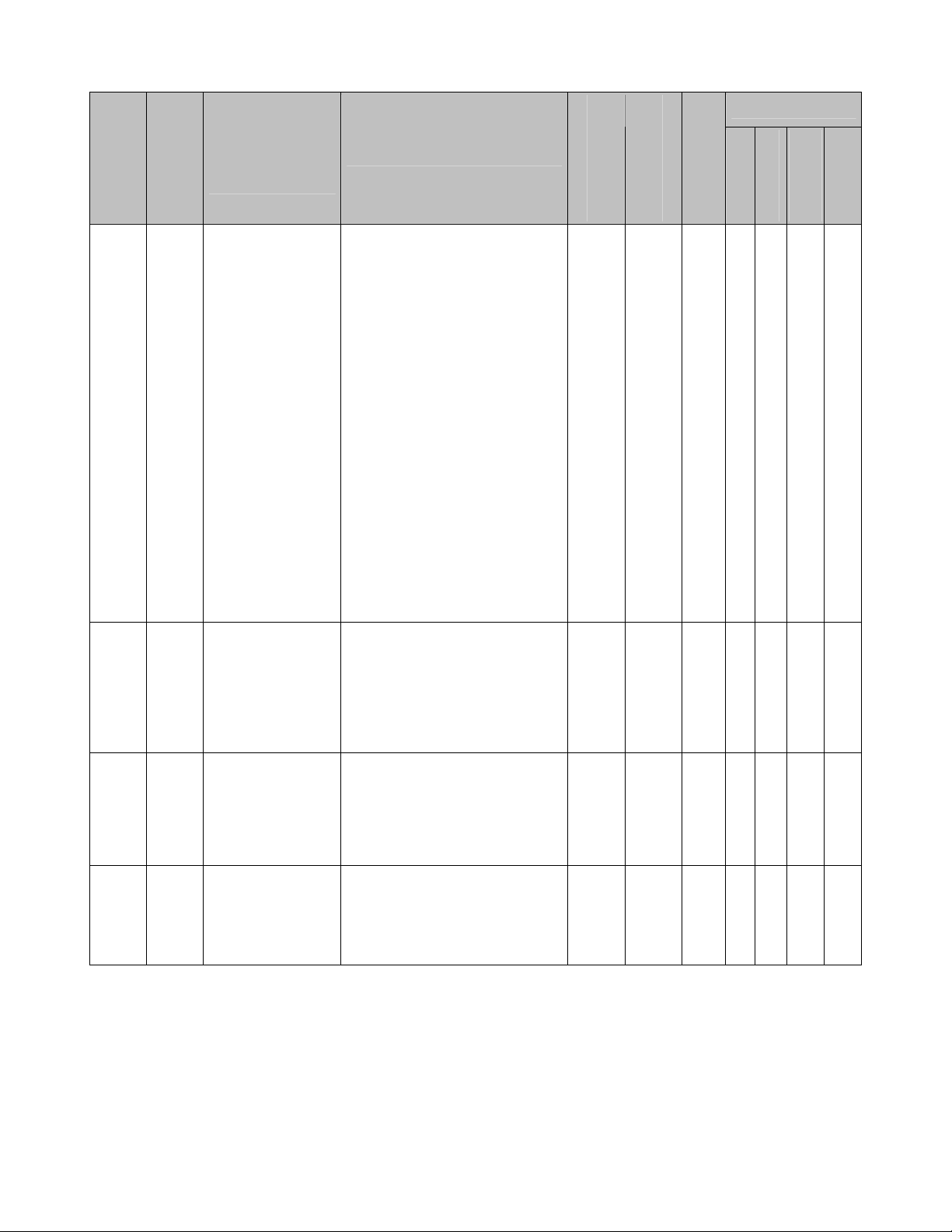

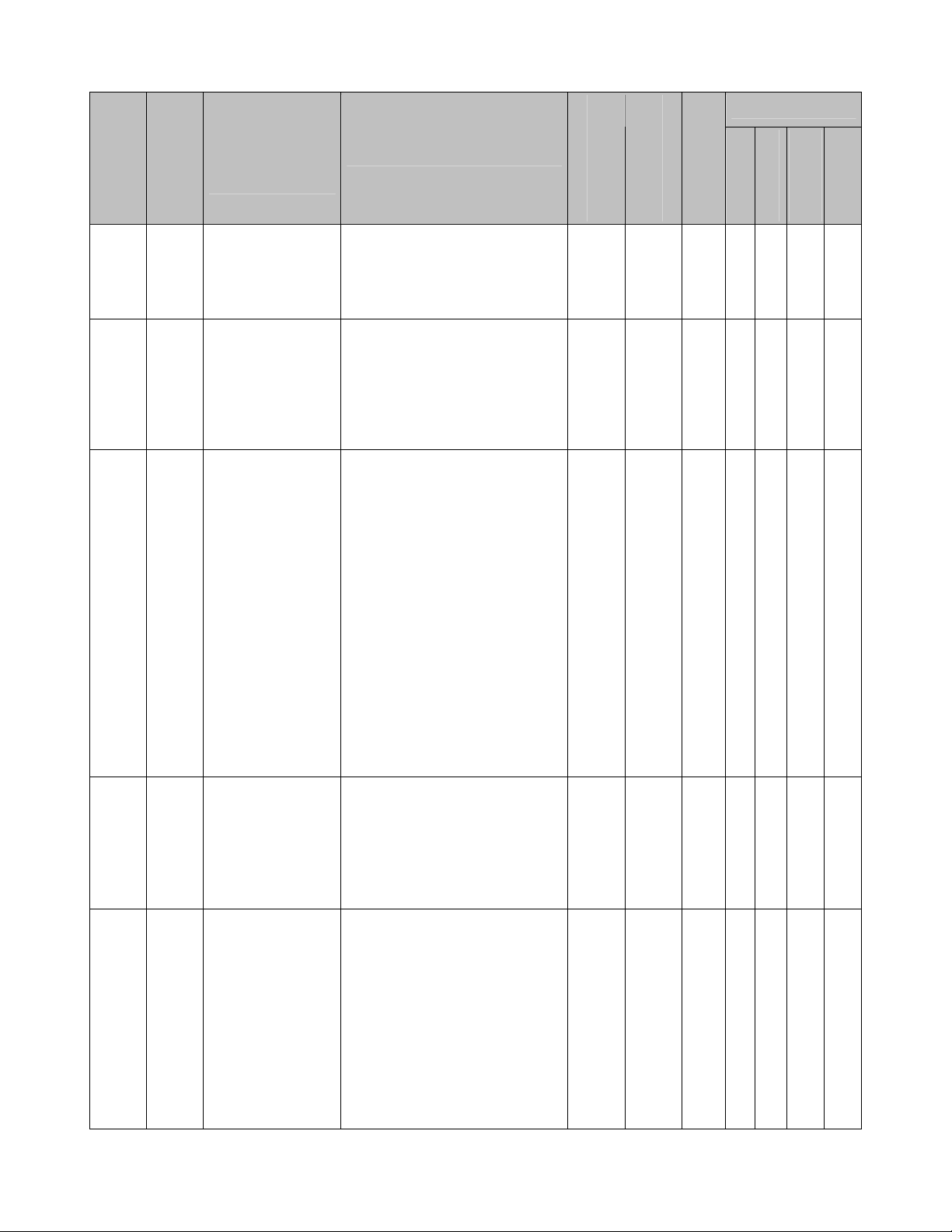

4.1 Parameters (continued)

Parameter

Address

Number

Modbus

Parameter Name

Digital Operator

Range

Description

Display

Selects the units used for the

follower drive Position Error

Monitor (U1-96).

0: Encoder Counts

Position error is displayed in

quadrature follower encoder

counts (cts).

1: Motor Revs

P1-10 609H

Position Units

Selection

Position Units

Position error is displayed in

follower motor revolutions

(0.001rev).

2: Motor Degrees

0 ~ 3 0 Yes A A A A

Position error is displayed in

follower motor degrees

(0.1°).

3: Motor Radians

Position error is displayed in

follower motor radians

(0.001rad).

Note: ELS modes only.

Sets the digital gear ratio

adjustment of the follower

drive. The gear ratio

adjustment is also influenced

by the analog, MOP and

communication gear ratio

-99.99

~

+99.99

%

P2-01 60AH

Digital Ratio

Adjustment

Digital RatioAdj

adjustments.

Sets the time for the MOP ratio

P2-02 60BH

MOP Adjust Time

MOP Adjust

Time

adjustment to change by

100.00% when the MOP

Adjust Increase or MOP Adjust

Decrease multi-function input

0.0 ~

6000.0

sec

is closed.

P2-03 60CH

Gear Ratio

Adjustment Ramp

Time

Ratio Adj Ramp

Sets the time for the composite

gear ratio adjustment of the

follower drive to change by

100.00%.

0.0 ~

6000.0

sec

*1: Access Level (A1-01): Q = “Quick Start”, A = “Advanced”, F = “Factory”.

Change During

Control Mode *1

Default

Run

V/f

V/f w/ PG

Open Loop

Flux Vector

Vector

0.00 Yes A A A A

50.0 Yes A A A A

10.0 Yes A A A A

Date: 02/25/2010, Rev: 10-02 Page 8 of 34 TM.F7SW.064

Page 9

4.1 Parameters (continued)

Parameter

Address

Number

Modbus

Parameter Name

Digital Operator

Range

Description

Display

Selects the advance/retard

functionality of the follower

drive.

0: Continuous

The follower will advance or

retard continuously while

the Advance Follower or

Retard Follower multifunction input is closed. P205 sets amount of

advance/retard encoder

counts per second.

1: Step

0 ~ 1 0 No A A A A

P2-04 60DH

Advance/Retard

Mode Selection

Adv/Ret Mode

Sel

The follower will advance or

retard by the amount set in

parameter P2-05 each time

the Advance Follower or

Retard Follower multifunction input is closed.

Note: ELS modes only.

Sets the number of quadrature

follower encoder counts the

follower will advance/retard per

second when P2-04 = 0. Sets

the step amount of the

advance/retard function when

P2-04 = 1.

0 ~

65,535

Counts

P2-05 60EH

Advance/Retard

Amount

Adv/Ret Amount

Note: ELS modes only.

Sets the amount of position

error in quadrature follower

encoder counts that will

P2-06 60FH

Follower

Deviation Level

Follower Dev Lvl

activate the follower deviation

detection. Also sets the

scaling for the Position Error

analog output selection (H3-

0 ~

65,535

Counts

05, H3-09 = 94).

Note: ELS modes only.

*1: Access Level (A1-01): Q = “Quick Start”, A = “Advanced”, F = “Factory”.

Change During

Control Mode *1

Default

Run

V/f

V/f w/ PG

Open Loop

Flux Vector

Vector

2048 Yes A A A A

4096 No A A A A

Date: 02/25/2010, Rev: 10-02 Page 9 of 34 TM.F7SW.064

Page 10

4.1 Parameters (continued)

Parameter

Address

Number

Modbus

Parameter Name

Digital Operator

Range

Description

Display

Selects the follower drive

action when the position error

exceeds the P2-06 setting.

0: No Detection

P2-07 610H

Follower

Deviation

Selection

Follower Dev Sel

The drive continues to run.

1: Alarm

The drive continues to run

and an FDEV alarm flashes

on the digital operator.

0 ~ 2 2 No A A A A

2: Fault (Coast to Stop)

The FDEV fault is

displayed, the drive fault

contact is activated, and the

motor coasts to a stop.

Selects which input encoder

signal is sent to the PG

monitor output when using a

P2-08 611H

Encoder (PG)

Monitor Channel

Selection

PG Mon Ch

Select

dual channel PG option card

(PG-W2, PG-Y2, or PG-Z2).

0: Channel 1

Encoder 1 is sent to the

monitor output.

0 ~ 1 1 Yes A A A A

1: Channel 2

Encoder 2 is sent to the

monitor output.

Determines if the MOP gear

adjustment is memorized when

P2-09 612H

MOP Adjustment

Memorization at

Power Off

MOP Mem @Pwr

Off

the drive loses power.

0: Disabled

MOP adjustment is not

memorized at power down.

1: Enabled

0 ~ 1 0 No A A A A

MOP adjustment is

memorized at power down.

Sets the proportional gain of

the position regulator PI loop.

Note: ELS modes only.

Sets the integral time of the

position regulator PI loop.

Note: ELS modes only.

0.00 ~

100.00

0.00 ~

50.00

sec

P3-01 614H

P3-02 615H

Position P Gain

Position P Gain

Position I Time

Position I Time

*1: Access Level (A1-01): Q = “Quick Start”, A = “Advanced”, F = “Factory”.

Change During

Control Mode *1

Default

Run

V/f

V/f w/ PG

Open Loop

Flux Vector

Vector

5.00 Yes A A A A

0.00 Yes A A A A

Date: 02/25/2010, Rev: 10-02 Page 10 of 34 TM.F7SW.064

Page 11

4.1 Parameters (continued)

Parameter

Address

Number

Modbus

Parameter Name

Digital Operator

Display

Description

Range

Default

Change During

Run

Control Mode *1

Open Loop

V/f w/ PG

V/f

Vector

Flux Vector

P3-03 616H

Position

Regulator Filter

Time

Pos Filter Time

Sets the filter time of the

position regulator output. This

is a first order lag filter.

Note: ELS modes only.

0.00 ~

1.50

sec

Sets the limit (+/-) of the

position regulator output. Set

P3-04 617H

Position PI Limit

Pos PI Limit

as a percentage of the

maximum output frequency

E1-04.

0.00 ~

10.00

%

Note: ELS modes only.

Selects how the position

regulator output is used to trim

the follower drive speed

reference (master encoder

frequency).

0: Constant

The position regulator

output is independent of the

master encoder speed

reference.

1: Speed Prop

0 ~ 1 0 Yes A A A A

P3-05 618H

Position

Regulator Trim

Mode

Pos Trim Mode

The position regulator

output is proportional to the

master encoder speed

reference.

Note: ELS modes only.

Speed

Proportional

P3-06 619H

Position Trim

Lower Limit

Sets the lower limit of the

position regulator trim when

P3-05 = 1.

0.00 ~

100.00% 10.00 Yes A A A A

SpdProp

LowerLim

Sets the frequency width used

to determine “Speed Agree”

when the drive is accelerating

P3-07 61AH

Ratio Change

Speed Agree

Width

RatioChg

SpdAgrF

or decelerating due to one of

the following:

Gear ratio change

Change in state of the

Follower Disable multi-

0.0 ~

20.0

Hz

function input

Change in state of the run

command

*1: Access Level (A1-01): Q = “Quick Start”, A = “Advanced”, F = “Factory”.

0.00 Yes A A A A

8.00 Yes A A A A

0.5 Yes A A A A

Date: 02/25/2010, Rev: 10-02 Page 11 of 34 TM.F7SW.064

Page 12

4.1 Parameters (continued)

Change During

Number

Parameter

Address

Modbus

Parameter Name

Digital Operator

Description

Range

Default

Run

Control Mode *1

Open Loop

V/f w/ PG

V/f

Vector

Flux Vector

Display

Enables and disables the

alignment feature.

0: Alignment Disabled

1: Manual Align

2: Auto Align at Start

0 ~ 3 0 N A A A A

P4-01 106H

Alignment Select

Alignment Sel

3: Continuous Align

P4-02 107H

Alignment Trim

Rate

Align Trim Rate

Sets the amount of speed

added or subtracted from the

follower drive during an

alignment procedure. *2

0.1 ~

30.0

Hz

6.0 Y A A A A

Sets an offset value to correct

P4-03 108H

Alignment Offset

Align Offset

for the physical misalignment

of the trigger inputs. A positive

value moves follower

alignment forward. A negative

value moves the follower

-99.99

~

99.99

rev

0.00 N A A A A

alignment in reverse.

Used in conjunction with a

digital output to detect if the

master and the follower trigger

pulses are within a preset

window. When the number of

follower quadrature encoder

counts between the two trigger

inputs is less than this value,

0 ~

65535

Cts

100 Y A A A A

P4-04 109H

Alignment Check

Alignment

Check

the “Alignment Check” digital

output will activate. (H2-0X =

42)

Sets the normal (not activated)

state of the Master and

Follower trigger switches

0: Both NO

1: Mstr NO Folwr NC

2: Mstr NC Folwr NO

0 ~ 3 0 N A A A A

P4-05 10AH

Trigger Switch

Type

Trigger Sw Type

3: Both NC

Sets the reaction of the drive

when the distance (follower

motor revolutions) between the

two trigger inputs exceeds the

P4-07 setting.

0: Disabled

0 ~ 2 0 N A A A A

P4-06 10BH

Align Fault Select

Align Fault Sel

1: Ignore First Trigger

2: Fault

*1: Access Level (A1-01): Q = “Quick Start”, A = “Advanced”, F = “Factory”.

*2: The software will add speed in terms of (whole number) encoder counts / 5ms. Therefore the trim rate may not

be exact. Also, the minimum amount of trim is 1 encoder count / 5ms, which could result in a faster than expected

rate, especially for low resolution encoders (less than 1024PPR).

Date: 02/25/2010, Rev: 10-02 Page 12 of 34 TM.F7SW.064

Page 13

4.1 Parameters (continued)

Open

Parameter

Address

Number

Modbus

Parameter Name

Digital Operator

Display

Description

Range

Default

Change During

Run

Control Mode *1

Open Loop

V/f w/ PG

V/f

Vector

Flux Vector

P4-07 10CH

Maximum

Alignment

Distance

Max Align Dist

Sets the maximum number of

follower motor revolutions

between the trigger inputs

before an Alignment Fault will

occur (P4-06).

1 ~

5000

rev

Sets the maximum follower

speed that will be allowed for

P4-08 10DH

Maximum

Alignment Speed

Max Align Speed

an alignment to occur. This

can be used to prevent

alignment at high speeds

where accuracy is diminished.

0.0 ~

400.0

Hz

A setting of 0.0 Hz disables

this function.

*1: Access Level (A1-01): Q = “Quick Start”, A = “Advanced”, F = “Factory”.

4.2 Monitors (U1-XX)

Monitor Number

Modbus Address

Scaling for

Monitor Name

Digital Operator

Display

Description

Multi-function

Analog Output

Terminals

FM and AM

(H4-01, H4-04)

1000 N A A A A

0.0 Y A A A A

Control Mode *1

Unit

V/f w/ PG

V/f

Flux Vector

Loop

U1-90 720H

U1-91 721H

U1-92 722H

Master Encoder

Reference

Master PG Fref

Follower

Reference After

Gear Ratio

Fref After Gear

Gear Ratio

Adjustment

Gear Ratio Adj

Displays the frequency

of the master encoder

before gear ratios and

MOP gains are

applied.

Displays the frequency

of the master encoder

after the active gear

ratio (P1-03 ~ P1-08)

is applied.

Displays the total gear

ration adjustment (sum

of digital, analog, MOP

and communication

adjustments).

100% =

Maximum

Output

Frequency

(E1-04)

100% =

Maximum

Output

Frequency

(E1-04)

100% =

100.00%

0.1

Hz

0.1

Hz

Q Q Q Q

Q Q Q Q

0.01% Q Q Q Q

*1: Access Level (A1-01): Q = “Quick Start”, A = “Advanced”, F = “Factory”.

Date: 02/25/2010, Rev: 10-02 Page 13 of 34 TM.F7SW.064

Page 14

4.2 Monitors (U1-XX) (continued)

Open

Monitor Number

U1-93 723H

U1-94 724H

Modbus Address

Monitor Name

Digital Operator

Display

Follower

Reference After

Gear Ratio

Adjustment

Fref After Adj

Master

Counts/5ms

Master Cts/5ms

Description

Displays the frequency

from the master

encoder after the

digital, analog, MOP

and network

communication gear

ratio adjustments are

applied.

Displays the number of

quadrature encoder

counts per 5ms scan

from the master drive.

Note: ELS modes only.

Note: This monitor is

representative only

and should be used

Scaling for

Multi-function

Analog

Output

Terminals

FM and AM

(H4-01, H4-

04)

100% =

Maximum

Output

Frequency

(E1-04)

100% =

Counts/5ms

at Maximum

Output

Frequency

(E1-04)

Control Mode *1

Unit

V/f w/ PG

V/f

0.1

Hz

Counts Q Q Q Q

Q Q Q Q

Flux Vector

Loop

only to confirm that

encoder counts are

U1-95 725H

Follower

Counts/5ms

Follower Cts/5ms

being received.

Displays the number of

quadrature encoder

counts per 5ms scan

from the follower drive.

Note: ELS modes only.

Note: This monitor is

representative only

and should be used

100% =

Counts/5ms

at Maximum

Output

Frequency

(E1-04)

Counts Q Q Q Q

only to confirm that

encoder counts are

being received.

Displays the position

error between the

master and follower

encoders in quadrature

follower encoder

counts.

U1-96 726H

Position Error

Position Error

Note: ELS modes only.

*1: Access Level (A1-01): Q = “Quick Start”, A = “Advanced”, F = “Factory”.

*2: Unit is dependent on the setting of the Position Units Selection (P1-10). When the position error is greater

than the maximum value that can be displayed, the digital operator will flash “OVER” in place of the U1-96 data.

When reading by network communication (register 726H), the unit is fixed at quadrature encoder counts.

100% =

Maximum

Output

Frequency

(E1-04)

1

Count

*2

Q Q Q Q

Date: 02/25/2010, Rev: 10-02 Page 14 of 34 TM.F7SW.064

Page 15

4.2 Monitors (U1-XX) (continued)

Open

Monitor Number

Modbus Address

Scaling for

Multi-function

Monitor Name

Digital Operator

Display

Description

Analog

Output

Terminals

FM and AM

(H4-01, H4-

04)

U1-97 727H

U1-98 728H

U1-99 729H

Position Regulator

P Output

Position P Out

Position Regulator

I Output

Position I Out

Position Regulator

PI Output

Position PI Out

Displays the

proportional gain

contribution of the

position PI regulator.

Note: ELS modes only.

Displays the output of

the integrator of the

position PI regulator.

Note: ELS modes only.

Displays the output of

the position PI

regulator.

Note: ELS modes only.

Maximum

Frequency

Maximum

Frequency

Maximum

Frequency

100% =

Output

(E1-04)

100% =

Output

(E1-04)

100% =

Output

(E1-04)

*1: Access Level (A1-01): Q = “Quick Start”, A = “Advanced”, F = “Factory”.

Control Mode *1

Unit

V/f w/ PG

V/f

Flux Vector

Loop

0.01% Q Q Q Q

0.01% Q Q Q Q

0.01% Q Q Q Q

Date: 02/25/2010, Rev: 10-02 Page 15 of 34 TM.F7SW.064

Page 16

4.3 Multi-function Digital Input Settings (H1-0X)

Setting

Name

Description

Follower Disable

80

Closed: Follower mode (P1-01) is disabled and the follower drive will follow

the normal frequency reference (based on B1-01 setting) and use the

selected Accel/Decel times.

Ratio 2 Select

Closed: Gear Ratio 2 (P1-07 and P1-08) is selected. When in either ELS

81

mode (P1-01 = 4 or 5), the follower drive will clear its position error and

follow the C1-03 and C1-04 Accel/Decel times to ramp to the new ratio.

Upon reaching speed agree, the position loop will re-enable.

Advance Follower

Closed: Follower position is advanced relative to the master encoder. No

82

position error is accumulated. See P2-04 and P2-05.

Note: ELS modes only.

Retard Follower

Closed: Follower position is retarded relative to the master encoder. No

83

position error is accumulated. See P2-04 and P2-05.

84

85

86

Note: ELS modes only.

MOP Adjust Increase

Closed: The MOP ratio adjustment is increased. See P2-02 and P2-09.

MOP Adju st Decrease

Closed: The MOP ratio adjustment is decreased. See P2-02 and P2-09.

MOP Adju st Reset

Closed: The MOP ratio adjustment is reset to zero. See P2-02 and P2-09.

Position Error Reset

87

Closed: Position error is reset to zero.

Note: ELS modes only.

Position Regulator Integral Reset

88

Closed: Position regulator integral is reset to zero.

Note: ELS modes only.

Follower Trigger

89

This input is connected to a switch which detects the position of the

follower machine. Configurable using parameter P4-05.

Master Trigger

8A

This input is connected to a switch which detects the position of the master

machine. Configurable using parameter P4-05.

Align Fol Cmd

8B

Commands the align function to begin when parameter P4-01 = 1 or 2.

This input is edge triggered (open to closed transition).

*1: = Available, – = Not Available.

Control Mode *1

Open Loop

Flux Vector

V/f

V/f w/ PG

Vector

Date: 02/25/2010, Rev: 10-02 Page 16 of 34 TM.F7SW.064

Page 17

4.4 Multi-function Digital Output Settings (H2-0X)

Setting

Name

Description

Follower Position Deviation

Closed: The position error has exceeded the Follower Deviation Level

40

(P2-06).

Note: ELS modes only.

Align Complete – Closed after a successful alignment operation

41

completes. Opens when the follower is stopped, faulted, or electronic line

shaft position error is cleared or disabled. Also opens when an

advance/retard command is given.

In Alignment – Closed after both trigger inputs are received AND the

distance between them is less than the P4-04 value.

Open after:

• The first trigger has been received, and the accumulated

42

distance exceeds the sum of the |P4-03| and P4-04

distances.

• When the follower is stopped, faulted, or electronic line

shaft position error is cleared or disabled.

• An advance/retard command is given.

*1: = Available, – = Not Available.

4.5 Multi-function Analog Input Settings (H3-0X)

Setting

Name

Description

Scaling

Control Mode *1

Open Loop

Flux Vector

V/f

V/f w/ PG

Vector

Control Mode *1

Open Loop

Flux Vector

V/f

V/f w/ PG

Vector

Analog Ratio Adjustment

20

Input value is added to the digital, MOP and

network communication ratio adjustment to form

100% = 100.00%

the total gear ratio adjustment.

*1: = Available, – = Not Available.

Date: 02/25/2010, Rev: 10-02 Page 17 of 34 TM.F7SW.064

Page 18

4.6 Network Communication Functions

Modbus

Address

61CH

61DH

Network Communication Gear Ratio Adjustment

Allows gear ratio adjustment via network communication. The total gear ratio

adjustment is the sum of the analog, digital, MOP and network communication

ratio adjustments. Data is interpreted as signed, so the adjustment can be set

from –327.68% ~ 327.67%.

Note: The ENTER command is not required when writing to this register.

Network Communication Advance/Retard Counts

Allows for advancement/retardment of the follower drive via network

communication. Data is interpreted as signed, so the advance/retard counts

can be set from –32768 ~ 32767. This is set in quadrature follower encoder

counts. After this register is set, its data returns to zero automatically.

Name

Description

encoder count

Note: ELS modes only.

Note: The ENTER command is not required when writing to this register.

4.7 Faults

Fault Display Description Causes Countermeasures

Scaling

1 = 0.01%

1 = 1

quadrature

OPE12

Follower Sel Err

There is a problem with the

configuration of the

Follower function.

P1-01 = 4, 5 (ELS

modes) and the PG-W2,

PG-Y2, or PG-Z2 is not

installed.

P1-01 = 1, 2, 3 (Speed

Follower modes), the

control mode is V/f w/

PG or Flux Vector and

the PG-W2, PG-Y2, or

PG-Z2 is not installed.

P1-01 = 1, 2, 3 (Speed

Follower modes), the

control mode is V/f or

Open Loop Vector and

one of the following

option cards is not

installed: PG-B2, PGT2, PG-X2, PG-W2, PGY2, or PG-Z2.

Install the appropriate

encoder (PG) option card

for the control mode and

follower mode selection.

Date: 02/25/2010, Rev: 10-02 Page 18 of 34 TM.F7SW.064

Page 19

4.7 Faults (continued)

Fault Display Description Causes Countermeasures

FDEV

Follower Pos

Dev

PL

Loss of Position

AF

Alignment Fault

The position error has

exceeded the Follower

Deviation Level (P2-06)

and the Follower Deviation

Selection (P2-07) is set to

2 (Coast to Stop).

The follower drive has lost

its position information.

This has occurred because

one of the following

conditions exist:

The position error has

exceeded 268,435,456

counts.

The pulse frequency

after the gear ratio is

so high that the

follower cannot run at

this speed without

exceeding the encoder

option card hardware

limitation (300kHz).

Too much distance

(follower motor

revolutions) was

counted between the

two trigger inputs

during an alignment

routine.

The distance

measured between the

two trigger pulses

(during alignment) has

exceeded 268,435,456

encoder counts.

(Regardless of the

P4-07 setting).

Mechanical binding of

the follower motor.

The Follower Deviation

Level (P2-06) is too low.

The master encoder is

rotating, the follower is

stopped, and the

Position Error

Accumulation Selection

(P1-09) is set to 1 (error

is always accumulated).

The master input

frequency is greater than

the follower maximum

frequency (E1-04).

Mechanical binding of

the follower motor.

The master encoder is

rotating, the follower

drive is stopped, and the

Position Error

Accumulation Selection

(P1-09) is set to 1

(position error is always

accumulated).

The desired follower

speed is too high for the

PPR of the installed

encoder.

The distance between

the master and the

follower exceeded the

allowable amount

(P4-07).

Malfunctioning or mis-

wired trigger switches.

Confirm the machinery

is operating correctly

and the follower motor

is not binding.

Increase P2-06.

If the application

requires that the master

encoder rotate while the

follower is stopped, set

P1-09 = 0 (position

error only during run).

Set E1-04 to 10% faster

than the maximum

master input frequency.

Confirm the machinery

is operating correctly

and the follower motor

is not binding.

If the application

requires that the master

encoder rotate while the

follower is stopped, set

P1-09 = 0 (position

error only during run).

Replace the follower

motor’s encoder with a

lower PPR model.

Check the machine

integrity.

Check the trigger

switches for proper

wiring and operation.

Date: 02/25/2010, Rev: 10-02 Page 19 of 34 TM.F7SW.064

Page 20

4.8 Alarms

Alarm Display Description Cause Countermeasures

FDEV

Follower Pos

Dev

The position error has

exceeded the Follower

Deviation Level (P2-06)

and the Follower Deviation

Selection (P2-07) is set to

1 (Alarm Only).

Mechanical binding of

the follower motor.

The Follower Deviation

Level (P2-06) is too low.

The master encoder is

rotating, the follower

drive is stopped, and the

Position Error

Accumulation Selection

(P1-09) is set to 1 (error

is always accumulated).

The master input

frequency is greater than

the follower maximum

frequency (E1-04).

Confirm the machinery

is operating correctly

and the follower motor

is not binding.

Increase P2-06.

If the application

requires that the master

encode rotate while the

follower is stopped, set

P1-09 = 0 (position

error only during run).

Set E1-04 to 10% faster

than the maximum

master input frequency.

Date: 02/25/2010, Rev: 10-02 Page 20 of 34 TM.F7SW.064

Page 21

5.0 Function Description

5.1 Basic Electronic Lineshaft

When the Follower Mode Selection P1-01 = 1 ~ 3 (speed follower mode), the follower drive will follow the

speed of the master encoder signal. Using the gear ratio parameters P1-03 ~ P1-06, the follower drive

can be made to run at a ratio of the master speed. The alternate gear ratio (P1-07 & P1-08) can be

selected using the Ratio 2 Select multi-function digital input (H1-0X = 81). The basic gear ratio formula is:

Follower Frequency Reference = Master Encoder Frequency Reference x (Numerator / Denominator)

For the primary gear ratio, the formula is:

The pairs of numerator and denominator parameters are used together to form an 8-digit number divided

by an 8-digit number. For ratio’s that can be expressed using 4-digit numbers or less, simply use P103/P1-04. Gear ratio 2 can only be expressed as a 4-digit number divided by a 4-digit number.

The gear ratio needed for the application must be able to be exactly expressed by the above formula.

This includes the complete remainder. If the ratio cannot be exactly expressed, the follower will drift in

phase over time.

The gear ratio can be further adjusted using the Digital Ratio Adjustment P2-01), the Analog Ratio

Adjustment (H3-05/09 = 20), the MOP Adjust multi-function inputs (H1-0X = 84 ~ 86), and the Network

Communication Ratio Adjustment (Modbus register 61CH). These adjustments are summed and then

added to 100% to produce the total gear ratio adjustment, which is multiplied by the master encoder

frequency (after gear ratio calculation). See Figure 8 at the end of the document.

When Follower Mode Selection P1-01 = 4 or 5 (ELS modes), the drive will track follower position relative

to the master encoder. A PI regulator is applied to the position error. The output of the position PI

regulator is used to trim the speed reference calculated from the master encoder signal, gear ratio

parameters, and gear ratio adjustment. In this manner, the position of the follower motor will be

synchronized with the position of the master encoder. The Advance Follower (H1-0X = 82) and Retard

Follower (H1-0X = 83) multi-function inputs can be used to change the position of the follower relative to

the master. See Figure 7 at the end of the document.

When the gear ratio of the drive is changed instantaneously in ELS mode (either due to the gear ratio

parameters being changed during run or because of a change of state of the Ratio 2 Select multi-function

input), the drive will ramp to the new ratio using Accel/Decel Time 2 (C1-03/C1-04). The position error will

be held to zero during the ratio change until the drive re-enters Speed Agree (based on the Ratio Change

Speed Agree Width P3-07).

Master

Encoder

Frequency

Reference

(U1-90)

P1-03

P1-05

Follower

X X X X X X X X

X

X X X X X X X X

Frequency

=

Reference

(U1-91)

P1-04

P1-06

Date: 02/25/2010, Rev: 10-02 Page 21 of 34 TM.F7SW.064

Page 22

Notes:

In speed follower mode (P1-01 = 1, 2, 3), the follower motor direction is determined based on the run

command direction, the master encoder direction, and the exact P1-01 setting.

In standard ELS mode (P1-01 = 4), the follower motor direction is always the same as the master

encoder direction. Forward (terminal S1) and reverse (terminal S2) run commands are treated

identically.

Parameter F1-05 (PG Rotation) only affects the encoder 1 input (follower encoder) when the dual PG

feedback option (PG-W2, PG-Y2, or PG-Z2) is used. It does not affect the encoder 2 input or pulse

monitor output.

In either ELS mode, the Position P Gain setting (P3-01) is scaled in relation to the drive’s Max

Frequency (E1-04), so if the E1-04 setting is changed the proportional contribution of the position

regulator will be influenced.

The follower drive’s Maximum Output Frequency (E1-04) must be set higher than the

maximum input frequency from the master source for proper position control. As a general

rule, set E1-04 in the follower to be 10% (or at least equal to P3-04 Position PI Limit) greater

than the maximum input frequency of the master source. Failure to do so can result in large

continuous amounts of Position Error (U1-96).

The exact gear ratio (including remainder) must be known and able to be expressed using the

gear ratio parameters. Any error in the gear ratio settings will result in follower motor drift.

5.2 Electronic Lineshaft with Sign

When Follower Mode Selection P1-01 = 5 (ELS – Sign Run mode), the drive behaves identically to when

P1-01 = 4 (Standard ELS mode), except when a reverse run command (terminal S2) is given. A reverse

run command will cause the follower drive to match speed and position in the opposite direction of the

master.

In the Standard ELS mode, when an Advance Follower input (H1-0X = 82) is active, the follower drive

moves in the absolute positive direction with respect to the master and in the absolute negative direction

when the Retard Follower input is active. These functions behave the same way in ELS – Sign Run mode

when a forward run command (terminal S1) is given. When a reverse run command (terminal S2) is given

during ELS – Sign Run mode, the Advance Follower input will move the follower drive in the absolute

negative direction while the Retard Follower input will move the follower drive in the absolute positive

direction.

Date: 02/25/2010, Rev: 10-02 Page 22 of 34 TM.F7SW.064

Page 23

For the ELS – Sign Run mode (P1-01 = 5), the functionality of the Communication Advance/Retard

Counts Register is adjusted in the same way. With a forward run command, a positive value in the

register will move the follower drive in the absolute positive direction and a negative value will move the

follower drive in the absolute negative direction, while with a reverse run command these directions are

switched. The direction the follower is moved by the Advance/Retard command is always with respect to

the run command direction. The functionality of Advance/Retard for both P1-01 = 4 (Standard ELS) and

P1-01 = 5 (ELS - Sign Run) is shown on the following page.

When the drive is put into local mode (digital input or keypad button) or when the drive is given a forward

or reverse jog command, the frequency reference is switched back to standard frequency reference and

the selected Accel / Decel times are used.

The table below shows the direction of the Follower depending on the direction of the Master, P1-01

setting, B1-04 (reverse operation prohibit selection) setting, and the forward run / reverse run digital input

signal.

Follower Rotation Direction for Various Settings and Master Direction

B1-04

(Reverse

Operation)

B1-04 = 0

Enabled

B1-04 = 1

Disabled

Digital

Input

Signal

FWD FWD REV FWD NONE FWD FWD FWD REV FWD REV

REV REV FWD NONE REV REV REV FWD REV REV FWD

FWD FWD NONE FWD NONE FWD FWD FWD NONE FWD NONE

REV NONE NONE NONE NONE NONE NONE NONE NONE NONE NONE

P1-01 = 1 P1-01 = 2 P1-01 = 3 P1-01 = 4 P1-01 = 5

Master:

FWD

Master:

REV

Master:

FWD

Master:

REV

Master:

FWD

Master:

REV

Master:

FWD

Master:

REV

Master:

FWD

The diagrams below outline the Follower direction and Advance/Retard behavior for P1-04 settings and

forward / reverse run command selections.

FWD Run Command REV Run Command

Master Follower Master Follower

P1-01 = 4

FWD FWD

Adv

REVREV

Ret

FWD

REV

Adv

FWD

Ret

REV

Master:

REV

P1-01 = 5

Adv

FWD FWD

Adv

REVREV

Adv

Ret

FWD

Ret

REV FWD

Ret

Adv

Adv

Adv

Ret

REV

Ret

Ret

Follower Direction and Advance/Retard Behavior

Date: 02/25/2010, Rev: 10-02 Page 23 of 34 TM.F7SW.064

Page 24

5.3 Wiring the Encoders for Electronic Lineshaft

The master signal (encoder) and the follower encoder must be wired to a dual input encoder card (ex.

PG-W2). All signals need to be a line driver type circuit. Wire the master signal (encoder) input into

terminals 10 ~ 13 of the PG-W2. Wire the follower encoder input into terminals 3 ~ 6 of the PG-W2. For

other dual input encoder cards, consult their installation guide for exact terminals. The marker (Z) pulse is

not required for this Electronic Lineshaft software. The figure below details the wiring of the PG-W2 option

card.

F7 Drive

T1

T2

T3

Follower

Encoder

IM

Motor

with ELS

GND

10

11

12

13

14

15

16

17

PG-W2 Option Card

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

12VDC Supply

Common

A+

AB+

B-

A+

AB+

B-

Note: The master encoder may be

powered by the PG-W2 if the combined

current draw of both encoders does not

exceed the 200mA power supply rating of

the PG-W2. If the combined current draw

is more than 200mA, power the master

encoder using an external power supply.

Master

Encoder

Wiring Example of PG-W2 Option Card

Date: 02/25/2010, Rev: 10-02 Page 24 of 34 TM.F7SW.064

Page 25

5.4 Alignment Function

5.4.1 Alignment Enable

In order for the alignment function to be enabled, both the master and the follower trigger multi-function

digital input functions need to be programmed into the H1-0X parameters, and parameter P4-01 needs to

be set to a non-zero value.

The alignment function will NOT operate under the following conditions:

• Drive is faulted

• Drive is not running

• Follower is ramping between forward & reverse run commands

• Electronic Lineshaft is disabled via a multi-function input (H1-0X = 80)

• Electronic Lineshaft is disabled via parameter (P1-01 < 4)

• Drive is in “Local” mode

• A “Jog” is being commanded of the follower drive

• Drive is ramping to speed due to a gear ratio change or Lineshaft being re-enabled

• Position error is being cleared via a multi-function input (H1-0X = 87)

5.4.2 Alignment Select

The alignment select parameter (P4-01) enables / disables the alignment feature. When P4-01 = 0, the

drive will not do an alignment and the two digital outputs associated with alignment (H2-0X = 41 & H2-0X

= 42) will remain de-energized.

• P4-01 = 0 – Disabled. The drive will NOT perform an alignment.

• P4-01 = 1 – Manual Alignment. The drive must see the rising edge of the align command (H1-

0X = 8B) in order to start the alignment process. The drive will not attempt another alignment until

there is another rising edge on the align command.

• P4-01 = 2 – Auto Align at Start. The drive will attempt to complete the alignment process once

as soon as the run command is applied. The drive will then respond to the align command as

stated above (P4-01 = 1).

• P4-01 = 3 – Continuous Alignment. The drive will attempt to complete the alignment process as

soon as the run command is applied. Each time two valid trigger inputs are received, the drive

will automatically re-start the alignment process. Trigger pulses will be ignored if the drive has not

completed the previous alignment attempt.

5.4.3 Alignment Process

The alignment function can be used to align the follower to the master using fixed trigger positions. This

process does not control the master drive. All correction is made by the follower drive. The amount of the

correction is controlled by the quadrature counts that are accumulated from the time when the first

(leading) trigger starts the process and continues until the second (trailing) trigger stops it. The speed of

the correction is controlled by parameter P4-02. The correction will be made as soon as the trailing

trigger input becomes active. The rate at which the drive accelerates or decelerates during the alignment

procedure is fixed. For a 1024 PPR encoder, the ramp rate will be about 20 Hz/ 1 sec. The alignment

process is intended to be performed at low speed, but will function as long as the triggers provide at least

a 15 millisecond signal so that the follower drive can see the trigger inputs.

Maximum alignment speed:

up” to the master, it will only be allowed to compensate at a rate of up to 95% of the follower’s maximum

frequency setting. If the follower is already running at or above the 95% speed level, the alignment

function will not complete.

Minimum alignment speed:

the master to “catch up”, the follower drive

04 = 1), the follower drive will only be allowed to run at a minimum of zero speed (no reverse).

If an alignment is in process and the follower needs to run faster to “catch

If an alignment is in process, and the follower needs to slow down in order for

could

run in reverse. If reverse on the follower is disabled (b1-

Date: 02/25/2010, Rev: 10-02 Page 25 of 34 TM.F7SW.064

Page 26

5.4.4 Align ment Fault Select

When the Alignment Fault Selection parameter is set to “disabled” (P4-06 = 0), there is no settable limit to

the number of follower motor revolutions that can elapse between master and follower trigger inputs.

Note: To prevent internal overflow, the maximum number of encoder counts allowed between the two

trigger inputs is 268,435,456. (65,536 motor revolutions with a 1024 PPR encoder)

When the Alignment Fault Select parameter is set to “Ignore 1

first trigger input (regardless of master or follower) once the P4-07 distance (either direction) has elapsed.

As shown in the timing diagrams below in Section 6, if the align command is asserted between the time

that the master and follower trigger inputs are read, and then the P4-07 distance elapses, the drive will

then disregard the first input and wait for two valid trigger inputs. When using this mode, it is useful to

program the P4-07 distance to 50% to 90% the total trigger-to-trigger distance.

When the Alignment Fault Select parameter is set to “Fault” (P4-06 = 2), the drive will fault out on an “AF

– Alignment Fault” and coast to stop after the P4-07 distance (follower motor revolutions) has elapsed

after the first trigger input (regardless of master or follower). When this mode is used, it is useful to set the

P4-07 parameter greater than the normal trigger-to-trigger distance. This fault is only active while the

alignment function is being commanded.

5.4.5 Align Complete / In Alignment Multi-function Digital Outputs

The Align Complete” digital output (H2-0X = 41) will close whenever a successful align procedure has

been completed. The Align Complete digital output will de-energize whenever the rising edge of an Align

Follower Command is detected. If the drive is set to reset position error at stop (P1-09 = 0), the Align

Complete digital output will also de-energize when the run command is removed or if electronic line shaft

is disabled (H1-0X = 80). If the drive is set to accumulate position error at all times (P1-09 = 1), the Align

Complete will de-energize only if electronic line shaft is disabled, or another align command is received.

The “In Alignment” digital output (H2-0X = 42) is provided to indicate whether the trigger inputs are

activated within a settable quadrature encoder count range. An Alignment Check output will energize

when the triggers are within the P4-07 setting and will de-energize when the P4-07 setting is exceeded.

This output will only change state after the trailing trigger has activated.

5.4.6 Alignment Function Diagrams

The following several pages detail the alignment function using detailed diagrams.

st

Pulse” (P4-06 = 1), it will disregard the

Date: 02/25/2010, Rev: 10-02 Page 26 of 34 TM.F7SW.064

Page 27

Forward Run - Alignment - Master Before Follower

Master Run Input

Follower Run Input

Align Input

Master Trig Input

Follower Trig Input

Master Motor Speed

Follower Motor Speed

Align Trim Rate (P4-02)

Align Complete Output

In Alignment Output

Master Run Input

Follower Run Input

Align Input

Master Trig Input

Follower Trig Input

Forward Run - Alignment - Follower Before Master

Master Motor Speed

Follower Motor Speed

Align Trim Rate (P4-02)

Align Complete Output

In Alignment Output

Note: The “Align Input” is edge triggered. It doesn’t matter whether the input is maintained or momentary.

Date: 02/25/2010, Rev: 10-02 Page 27 of 34 TM.F7SW.064

Page 28

Master Run Input

Follower Run Input

Align Input

Master Trig Input

Follower Trig Input

Master Motor Speed

Reverse Run - Alignment - Master Before Follower

Follower Motor Speed

Align Trim Rate (P4-02)

Align Complete Output

In Alignment Output

Master Run Input

Follower Run Input

Align Input

Master Trig Input

Follower Trig Input

Master Motor Speed

Reverse Run - Alignment - Follower Before Master

Follower Motor Speed

Align Trim Rate (P4-02)

Align Complete Output

In Alignment Output

Note: The “Align Input” is edge triggered. It doesn’t matter whether the input is maintained or momentary.

Date: 02/25/2010, Rev: 10-02 Page 28 of 34 TM.F7SW.064

Page 29

Follower Run Input

Master Trig Input

Follower Trig Input

In Alignment Digital Output

Follower Run Input

Master Trig Input

Follower Trig Input

In Alignment Digital Output

In Alignment (Digital Output) Function , no offset (P4-03 = 0.00 revs)

(P4-04 = 4096 cts)

P4-04 P4-04 P4-04 P4-04 P4-04

In Alignment (Digital Output) Function , w/offset (P4-03 = +3.00 revs)

(P4-04 = 4096 cts)

P4-03

P4-04

P4-03

P4-04

P4-03

P4-04

P4-03

P4-04

Date: 02/25/2010, Rev: 10-02 Page 29 of 34 TM.F7SW.064

Page 30

Master Run Input

Follower Run Input

Align Input

Master Trig Input

Follower Trig Input

Master Motor Speed

Follower Motor Speed

Align Complete Output

Master Run Input

Follower Run Input

Align Input

Master Trig Input

Follower Trig Input

Master Motor Speed

Follower Motor Speed

Align Complete Output

Master Run Input

Follower Run Input

Align Input

Master Trig Input

Follower Trig Input

Master Motor Speed

Follower Motor Speed

Align Complete Output

AL - Alignment Fault

Alignment Fault Select = Disabled (P4-06 = 0)

Follower slows down for a long period

while the master catches up.

Align Trim Rate (P4-02)

P4-07

Max Align Dist

Alignment Fault Select = Ignore 1st Pulse (P4-06 = 1)

The first follower trigger pulse is

ignored after the P4-07 distance has

Max Align Dist

elapsed.

P4-07

Align Trim Rate (P4-02)

Alignment Fault Select = Fault (P4-06 = 2)

Coast

P4-07

Max Align Dist

To

Stop

Drive faults once the distance set into

P4-07 as passed.

Date: 02/25/2010, Rev: 10-02 Page 30 of 34 TM.F7SW.064

Page 31

Master Run Input

Follower Run Input

Align Input

Master Trig Input

Follower Trig Input

Master Motor Speed

Follower Motor Speed

Align Complete Output

Master Run Input

Follower Run Input

Align Input

Master Trig Input

Follower Trig Input

Master Motor Speed

Follower Motor Speed

Align Complete Output

In Alignment Output

Master Run Input

Follower Run Input

Align Input

Master Trig Input

Follower Trig Input

Master Motor Speed

Follower Motor Speed

Align Complete Output

In Alignment Output

(P4-02)

Continuous Alignment (P4-01 = 3)

(P4-02)

Normally Open Trigger Inputs (P4-05 = 0)

Align Trim Rate (P4-02)

Normally Closed Trigger Inputs (P4-05 = 3)

Align Trim Rate (P4-02)

(P4-02)

Date: 02/25/2010, Rev: 10-02 Page 31 of 34 TM.F7SW.064

Page 32

Two conveyor belts shown aligned but with different trigger switch positioning

(corrected with the Align Offset parameter P4-03).

Master Conveyor Belt

Forward

Forward

Master

Trigger

Flags

Follower Conveyor Belt

Switch

P4-03 Align Offset

+3.00 rev

Forward

Follower

Trigger

Switch

Forward

Date: 02/25/2010, Rev: 10-02 Page 32 of 34 TM.F7SW.064

Page 33

Reference

Frequency

Follower Mode

Selection (P1-01)

1,2,3

+

(U1-93)

Gear Ratio Adjustment

Follower Reference After

Gear Ratio

Adjustment

Mode (P3-05)

4

Position Regulator Trim

01

+

Output

Position

(U1-99)

Regulator PI

Input

Multi-function

Position Error

Integral Reset

(U1-98)

Trim Lower Limit (P3-06)

Speed Proportional Position

Time (P3-03)

Position Error

Reset Multi-

function Input

Position PI Regulator

Position Regulator I Output

(U1-97)

Position Regulator P Output

6.0 Block Diagrams

(U1-96)

Position I Time (P3-02)

Position P Gain (P3-01)

Position Regulator Filter

(U1-91)

After Gear Ratio

Follower Reference

Gear

Ratio

Calculation

(U1-90)

Master Encoder

Frequency Reference

Speed

Master

Encoder

Master Encoder Speed

Master Encoder PPR (P1-02)

Ratio 2 Select

Multi-function Input

Reference

Calculation

Primary Ratio

P1-03 ~ P1-06

Follower Encoder PPR (F1-01)

Position PI Limit (P3-04)

P1-07 ~ P1-08

Secondary Ratio

Position Error

(U1-95)

Follower

Counts/5ms

Calculation

Position Error

Master

(U1-94)

Counts/5ms

Master Pulse Count

Follower Pulse Count

Master Encoder PPR (P1-02)

Encoder PPR (F1-01)

Gear Ratio Adjustment

Advance/Retard Multi-function Inputs

Clear Position Error Multi-function Input

Communication Advance/Retard Counts

Software Overview Diagram

Date: 02/25/2010, Rev: 10-02 Page 33 of 34 TM.F7SW.064

Page 34

Follower

Reference After

(U1-92)

Gear Ratio

Adjustment

Gear Ratio

Adjustment

Analog Ratio

H3-05/09 = 20

(U1-93)

Gear Ratio

Adjustment

Follower

(P2-03)

Adjustment

Ramp Time

100%

(U1-91)

Gear Ratio

Reference After

+

+

(P2-01)

Adjustment

Digital Ratio

+

+

+

Ratio Adjustment

Network Communication

(Modbus Register 61CH)

Composite Gear Ratio Diagram

MOP

Adjustment

MOP Reset (H1-XX = 86)

MOP Increase (H1-XX = 84)

MOP Decrease (H1-XX = 85)

6.0 Block Diagrams (continued)

Date: 02/25/2010, Rev: 10-02 Page 34 of 34 TM.F7SW.064

Loading...

Loading...