Page 1

E7 Drive

User Manual

Model: E7U Document Number: TM.E7.01

Page 2

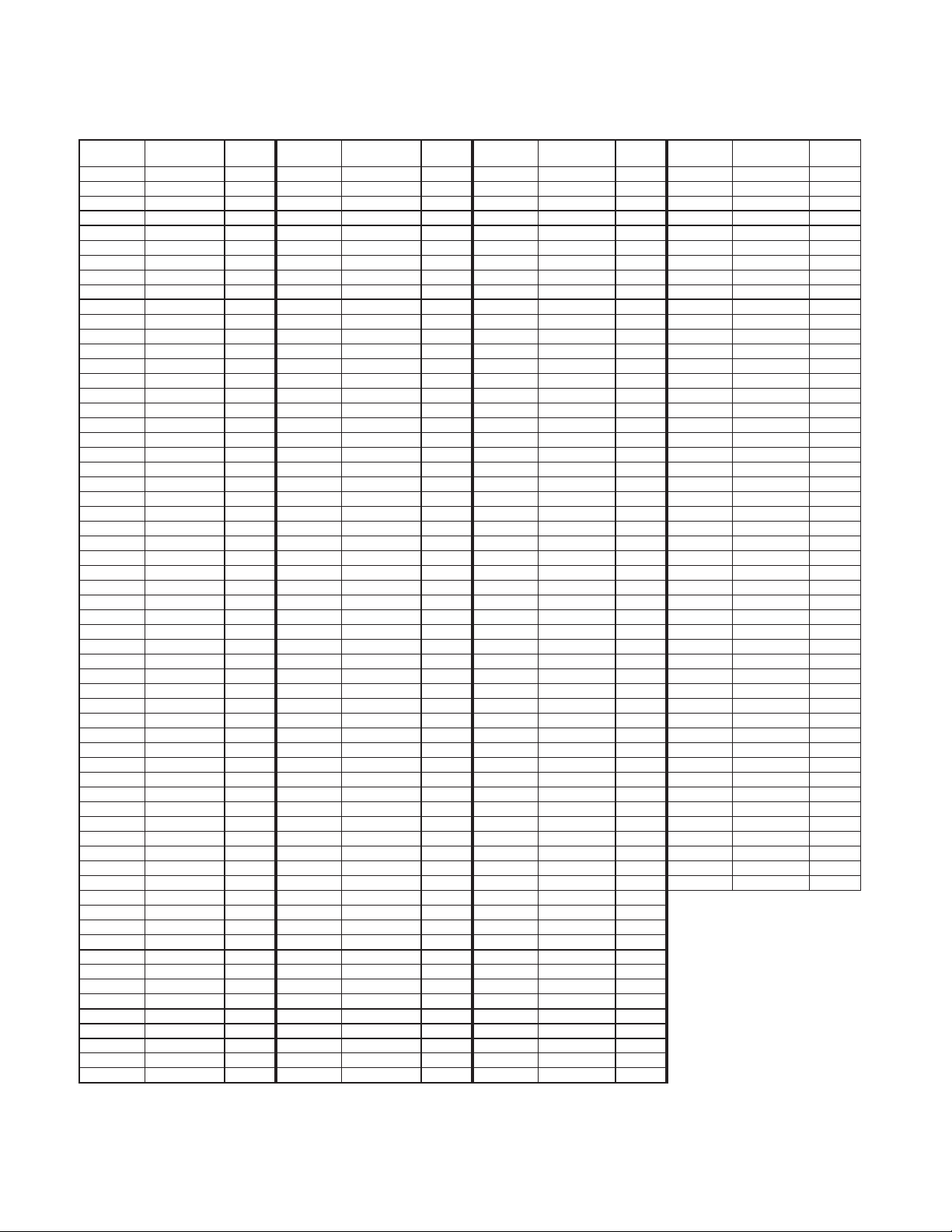

Quick Reference for E7 Parameters

Parameter

Number

A1-000 b5-07 0E1-07 3L4-02 2

A1-012 b5-08 0E1-08 18 L4-05 1

A1-030 b5-09 0E1-09 1.5L4-06 80

A1-040 b5-10 1E1-10 10.8L5-01 0

A1-050 b5-110 E1-110 L5-02 0

A2-01b5-12 0E1-12 0L5-03 180

A2-02b5-13 0E1-13 0L6-01 6

A2-03b5-14 1E2-01 kVA Dep. L6-02 15

A2-04b5-15 0E2-03 kVA Dep. L6-03 10

A2-05b5-16 0E2-05 kVA Dep. L8-01 0

A2-06b5-17 0F6-01 1L8-02 kVA Dep.

A2-07b5-18 0F6-02 0L8-03 4

A2-08b5-19 0F6-03 1L8-06

A2-09b5-20 1F6-05 0L8-09 1

A2-10b5-21 1H1-01 24 L8-100

A2-11b5-22 0H1-02 14 L8-11 300

A2-12b5-23 0H1-033 L8-12 45

A2-13b5-24 0H1-044 L8-15 1

A2-14b5-25 0H1-056 L8-18 1

A2-15b5-26 0H2-010 L8-19 20

A2-16b5-27 60 H2-02A n1-01 1

A2-17b5-28 0H3-02 100n1-02 1

A2-18b5-29 1H3-030 n3-01 5

A2-19b5-30 0H3-082 n3-02 150

A2-20b8-01 0H3-092 n3-03 1

A2-21b8-04 kVA D

A2-22b8-05 20 H3-110 o1-01 6

A2-23b8-06 0H3-120.3o1-02 1

A2-24C1-01 30 H3-130 o1-03 0

A2-25C1-02 30 H4-012 o1-05 3

A2-26C1-03 30 H4-02100 o1-06 0

A2-27C1-04 30 H4-030 o1-07 2

A2-28C1-09 10 H4-048 o1-08 3

A2-29C1-11 0H4-05 50 o2-011

A2-30C2-01 0.2H4-060 o2-02 1

A2-31C2-02 0.2H4-070 o2-03 0

A2-32C4-01 1H4-080 o2-04 kVA Dep.

b1-011 C4-02200 H5-011Fo2-05 1

b1-02 1C6-01 2H5-023 o2-06 1

b1-030 C6-02kVA Dep. H5-030 o2-070

b1-041 C6-03kVA Dep. H5-043 o2-081

b1-070 C6-04kVA Dep. H5-051

b1-08 0C6-05 0H5-065

b1-110 d1-01 0H5-071

b1-12 0d1-02 0H5-080

b2-01 0.5d1-03 0H5-092

b2-02 50 d1-04 0 L1-011

b2-03 0d1-17 6 L1-028

b2-04 0d2-01 100 L1-033

b2-09 0d2-02 0 L1-041

b3-01 2d2-03 0 L1-050.2

b3-02 120 d3-01 0 L2-012

b3-03 2d3-02 0 L2-02kVA Dep.

b3-05 0.2d3-03 0 L2-03

b3-14 1d3-04 1 L2-04

b4-01 0d4-01 0 L2-05

b4-02 0d4-02 10 L3-011

b5-01 0E1-01 240V or 480V L3-02120

b5-02 2E1-03 F L3-041

b5-03 5E1-04 60 L3-051

b5-04 100 E1-05 240V or 480V L3-06120

b5-06 100 E1-06 60 L4-0

Factory

Setting

User

Setting

Parameter

Number

Factory

Setting

ep. H3-10100 n3-04 40

User

Setting

Parameter

Number

10

Factory

Setting

kVA Dep.

kVA Dep.

Voltage Dep.

User

Setting

Parameter

Number

o2-10 0

o2-12 0

o2-14 0

o2-15 1

o3-01 0

o3-02 0

T1-02kVA Dep.

T1-04kVA Dep.

Factory

Setting

kVA Dep.

User

Setting

Page 3

Warnings and Cautions

WARNING

WARNING

This Section provides warnings and cautions pertinent to this product, that if not

heeded, may result in personal injury, fatality, or equipment damage. Yaskawa is

not responsible for consequences of ignoring these instructions.

YASKAWA manufactures component parts that can be used in a wide variety of industrial applications. The selection and

application of YASKAWA products remain the responsibility of the equipment designer or end user. YASKAWA accepts no

responsibility for the way its products are incorporated into the final system design. Under no circumstances should any

YASKAWA product be incorporated into any product or design as the exclusive or sole safety control. Without exception, all

controls should be designed to detect faults dynamically and fail safely under all circumstances. All products designed to

incorporate a component part manufactured by YASKAWA must be supplied to the end user with appropriate warnings and

instructions as to that part’s safe use and operation. Any warnings provided by YASKAWA must be promptly provided to the

end user. YASKAWA offers an express warranty only as to the quality of its products in conforming to standards and

specifications published in the YASKAWA manual. NO OTHER WARRANTY, EXPRESS OR IMPLIED, IS OFFERED.

YASKAWA assumes no liability for any personal injury, property damage, losses, or claims arising from misapplication of its

products.

• Read and understand this manual before installing, operating, or servicing this Drive. All warnings, cautions, and

instructions must be followed. All activity must be performed by qualified personnel. The Drive must be installed according

to this manual and local codes.

• Do not connect or disconnect wiring while the power is on. Do not remove covers or touch circuit boards while the power is

on. Do not remove or insert the digital operator while power is on.

• Before servicing, disconnect all power to the equipment. The internal capacitor remains charged even after the power supply

is turned off. Status indicator LEDs and Digital Operator display will be extinguished when the DC bus voltage is below

50 VDC. To prevent electric shock, wait at least five minutes after all indicators are OFF and measure DC bus voltage level

to confirm safe level.

• Do not perform a withstand voltage test on any part of the unit. This equipment uses sensitive devices and may be damaged

by high voltage.

• The Drive is not suitable for circuits capable of delivering more than the specified RMS symmetrical amperes. Install

adequate branch short circuit protection per applicable codes. Refer to the specification. Failure to do so may result in

equipment damage and/or personal injury.

• Do not connect unapproved LC or RC interference suppression filters, capacitors, or overvoltage protection devices to the

output of the Drive. These devices may generate peak currents that exceed Drive specifications.

• To avoid unnecessary fault displays caused by contactors or output switches placed between Drive and motor, auxiliary

contacts must be properly integrated into the control logic circuit.

• YASKAWA is not responsible for any modification of the product made by the user; doing so will void the warranty. This

product must not be modified.

• Verify that the rated voltage of the Drive matches the voltage of the incoming power supply before applying power.

• To meet CE directives, proper line filters and proper installation are required.

Warnings i

Page 4

WARNING

• Some drawings in this manual may be shown with protective covers or shields removed, to describe details. These must be

replaced before operation.

• Observe electrostatic discharge procedures when handling circuit cards to prevent ESD damage.

• The equipment may start unexpectedly upon application of power. Clear all personnel from the drive, motor, and machine

area before applying power. Secure covers, couplings, shaft keys, and machine loads before energizing the Drive.

• Please do not connect or operate any equipment with visible damage or missing parts. The operating company is responsible

for any injuries or equipment damage resulting from failure to heed the warnings in this manual.

Intended Use

Drives are intended for installation in electrical systems or machinery.

For use in the European Union, the installation in machinery and systems must conform to the following product standards of

the Low Voltage Directive:

EN 50178, 1997-10, Equipping of Power Systems with Electronic Devices

EN 60201-1, 1997-12 Machine Safety and Equipping with Electrical Devices

Part 1: General Requirements (IEC 60204-1:1997)/

EN 61010, 1997-11Safety Requirements for Information Technology Equipment

(IEC 950:1991 + A1:1992 + A2:1993 + A3:1995 + A4:1996, modified)

CE certification per EN 50178 can be achieved using the line filters specified in this manual and following the appropriate

installation instructions.

Other

The E7 Drive is suitable for use on a circuit capable of delivering not more than 100,000 RMS symmetrical amperes, 240Vac

maximum (240V Class) and 480Vac maximum (480V Class).

Warnings ii

Page 5

Introduction

This Section describes the applicability of the Manual

The E7 Drive is a Pulse Width Modulated Drive for 3-Phase AC induction motors. This type of Drive is also known as an

Adjustable Frequency Drive, Variable Frequency Drive, AC Drive, AFD, ASD, VFD, and Inverter. In this manual, the E7

Drive will be referred to as the “Drive”.

The E7 Drive is a variable torque AC drive, designed specifically for HVAC applications in building automation, including

fans, blowers and pumps. A new benchmark for size, cost, performance, benefits, and quality, the E7 includes numerous

built-in features such as network communications, H/O/A, PI, parameter storage and copy functions.

®

The E7 has embedded communications for the popular building automation protocols, Johnson Controls Metasys

TM

Siemens APOGEE

The LCD keypad/operator is equipped with Hand/Off/Auto functions, copy feature, 7 language choices, and 5 lines of display

with 16 characters per line. User parameter settings can be recovered at any time via “user initialization”. Optional software

allows upload/download, as well as graphing and monitoring of drive parameters from a PC for ease of drive management.

Built-in PI control eliminates the need for closed loop output signals from a building automation system. It includes feedback

display, inverse, square root and differential control functions, and maintains setpoint for closed loop control of fans and

pumps for pressure, flow, or temperature regulation.

FLN, as well as Modbus®. An optional LONWORKS® interface card is also available.

and

This manual is applicable to E7 Drives defined by model numbers CIMR-E7U_ _ _ _ . This manual reflects the Software Version 4010.

This manual is subject to change as product improvements occur. The latest version of the manual can be obtained from the

Yaskawa website www.drives.com

. The date shown on the rear cover is changed when revisions are made.

Introduction iii

Page 6

This manual may describe trademarked equipment, which is the property of other companies. These trademarks are the

property of the registered owner companies and may include the following:

APOGEE

Metasys

Modbus

L

ONWORKS

TM

FLN, trademark of Siemens Building Technologies, Inc.

®

, trademark of Johnson Controls Inc.

®

, trademark of Schneider Automation, Inc.

®

, trademark of Echelon Corporation

Other Documents and Manuals are available to support special use or installation of this product. These documents may be

provided with the product or upon request. Contact Yaskawa Electric America, Inc. as required. Documents may include the

following:

TM.E7.02.Programming… Manual included on CD ROM with product

TM.E7.11.Modbus… Manual included on CD ROM with product

TM.E7.20.L

TM.E7.21.APOGEE

ONWORKS… Manual included on CD ROM with product

… Manual included on CD ROM with product

TM. E7.22. Metasys… Manual included on CD ROM with product

TM.E7B.01. Bypass… This manual should be used when the E7 Drive is packaged with Bypass Control

DriveWizard... Software and Manual…Included on CD ROM with product

Option Instructions… Included on CD ROM with product

Introduction iv

Page 7

Table of Contents

Quick Reference Parameter List ....................................................... Inside front cover

Warnings and Cautions............................................................................................... i

Introduction................................................................................................................. iii

Chapter 1 - Physical Installation .................................................................... 1-1

E7 Model Number and Enclosure Style .................................................................. 1-2

Confirmations upon Delivery ................................................................................... 1-3

Component Names ................................................................................................. 1-5

Exterior and Mounting Dimensions ......................................................................... 1-7

Heat Loss Data...................................................................................................... 1-11

Checking and Controlling the Installation Site....................................................... 1-13

Installation Orientation and Clearances ................................................................ 1-14

Removing and Attaching the Terminal Cover........................................................ 1-15

Removing/Attaching the Digital Operator and Front Cover ................................... 1-16

Chapter 2 - Electrical Installation ................................................................... 2-1

Terminal Block Configuration .................................................................................. 2-2

Wiring Main Circuit Terminals ................................................................................. 2-3

Control Wiring........................................................................................................ 2-12

Chapter 3 - Digital Operator............................................................................ 3-1

Digital Operator Display .......................................................................................... 3-2

Digital Operator Keys .............................................................................................. 3-3

Drive Mode Indicators ............................................................................................. 3-5

Drive Main Menu ..................................................................................................... 3-7

Quick Setting Menu (-QUICK-).............................................................................. 3-12

Programming Menu (-ADV-).................................................................................. 3-13

Example of Changing a Parameter ....................................................................... 3-15

Table of Contents v

Page 8

Chapter 4 - Start Up......................................................................................... 4-1

Drive Start Up Preparation ...................................................................................... 4-2

Drive Start Up Procedures ...................................................................................... 4-5

Chapter 5 - Basic Programming..................................................................... 5-1

A1 Initialization ........................................................................................................ 5-2

b1 Sequence ........................................................................................................... 5-4

b2 DC Braking ....................................................................................................... 5-10

b3 Speed Search................................................................................................... 5-12

b5 PI Function ....................................................................................................... 5-16

b8 Energy Savings ................................................................................................ 5-25

C1 Accel/Decel...................................................................................................... 5-26

d2 Reference (Speed Command) Limits ............................................................... 5-27

d3 Jump Frequencies............................................................................................ 5-28

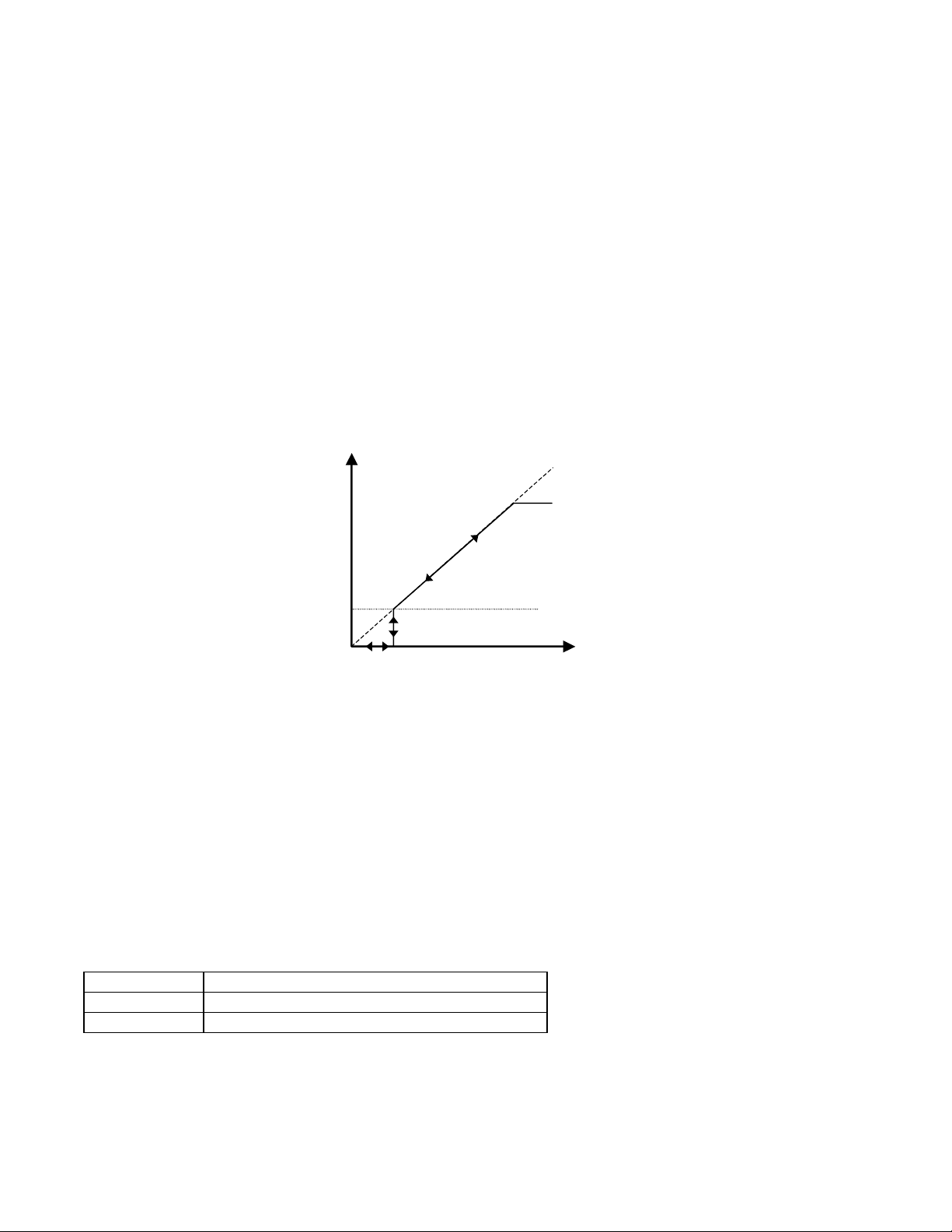

E1 V/f Pattern ........................................................................................................ 5-29

E2 Motor Setup ..................................................................................................... 5-32

F6 Com OPT Setup (applies only to the LonWorks option) .................................. 5-33

H3 Analog Inputs................................................................................................... 5-34

L2 Momentary Power Loss Ride-thru Function..................................................... 5-40

L3 Stall Prevention ................................................................................................ 5-41

L4 Speed Command Loss Detection..................................................................... 5-45

L5 Fault Restart..................................................................................................... 5-46

L6 Torque Detection.............................................................................................. 5-48

L8 Hardware Protection......................................................................................... 5-50

o1 Monitor Configuration ....................................................................................... 5-52

o2 Key Selections.................................................................................................. 5-56

o3 Digital Operator Copy Function ........................................................................ 5-58

T1 Auto-Tuning...................................................................................................... 5-61

Chapter 6 - Diagnostics & Troubleshooting ................................................ 6-1

Fault Detection ........................................................................................................ 6-2

Alarm Detection....................................................................................................... 6-9

Operator Programming Errors (OPE) .................................................................... 6-12

Auto-Tuning Faults................................................................................................ 6-13

Table of Contents vi

Page 9

Digital Operator COPY Function Faults ................................................................ 6-14

Troubleshooting..................................................................................................... 6-15

Main Circuit Test Procedure.................................................................................. 6-21

Drive Date Stamp Information ............................................................................... 6-25

Chapter 7 - Maintenance ................................................................................. 7-1

Periodic Inspection .................................................................................................. 7-2

Preventive Maintenance.......................................................................................... 7-3

Heatsink Cooling Fan Replacement........................................................................ 7-4

Removing and Mounting the Terminal Card............................................................ 7-6

Appendix A - Parameters ............................................................................... A-1

Parameter List ......................................................................................................... A-2

Monitor List ............................................................................................................ A-26

Fault Trace List...................................................................................................... A-28

Fault History List.................................................................................................... A-29

Decimal to Hex Conversion: .................................................................................. A-30

Appendix B - Capacity Related Parameters ................................................. B-1

Drive Capacity......................................................................................................... B-2

Appendix C - Specifications .......................................................................... C-1

Standard Drive Specifications ................................................................................ C-2

Appendix D - Communication ....................................................................... D-1

Using Modbus Communication .............................................................................. D-2

Modbus Function Code Details .............................................................................. D-7

Modbus Data Tables .............................................................................................. D-9

Modbus Self-Diagnosis ........................................................................................ D-14

Table of Contents vii

Page 10

Appendix E - Peripheral Devices .................................................................. E-1

Branch Circuit Short Circuit Protection.................................................................... E-2

Branch Circuit Overload Protection......................................................................... E-5

Peripheral Devices .................................................................................................. E-6

Appendix F - EMC Compatibility .................................................................... F-1

EMC Compatibility................................................................................................... F-2

Electromagnetic Compatibility (EMC)...................................................................... F-3

Index .............................................................................................................................................. Index-1

Support Services ............................................................................................................. Inside rear cover

Table of Contents viii

Page 11

Chapter 1

Physical Installation

This chapter describes the requirements for receiving and installing the E7 Drive.

E7 Model Number and Enclosure Style..................................... 1-2

Confirmations upon Delivery...................................................... 1-3

Component Names .................................................................... 1-5

Exterior and Mounting Dimensions ............................................ 1-7

Heat Loss Data ........................................................................ 1-11

Checking and Controlling the Installation Site ......................... 1-13

Installation Orientation and Clearances................................... 1-14

Removing and Attaching the Terminal Cover .......................... 1-15

Removing/Attaching the Digital Operator and Front Cover...... 1-16

Physical Installation 1 - 1

Page 12

E7 Model Number and Enclosure Style

Table 1.1 E7 Model Numbers and Enclosure Style

Input

Voltage

3-Phase

208-240Vac

208-230Vac

480 Vac

E7

Model-Number

CIMR-E7U20P4 NEMA Type 1 (IP20) 3.6 0.5/0.75

CIMR-E7U20P7 NEMA Type 1 (IP20) 4.6 1

CIMR-E7U21P5 NEMA Type 1 (IP20) 7.8 1.5/2

CIMR-E7U22P2 NEMA Type 1 (IP20) 10.8 3

CIMR-E7U23P7 NEMA Type 1 (IP20) 16.8 5

CIMR-E7U25P5 NEMA Type 1 (IP20) 23.0 7.5

CIMR-E7U27P5 NEMA Type 1 (IP20) 31.0 7.5/10

CIMR-E7U2011 NEMA Type 1 (IP20 ) 46.2 15

CIMR-E7U2015 NEMA Type 1 (IP20) 59.4 20

CIMR-E7U2018 NEMA Type 1 (IP20) 74.8 25

CIMR-E7U2022 NEMA Type 1 (IP20) 88.0 30

CIMR-E7U2030 NEMA Type 1 (IP20) 115.0 40

CIMR-E7U2037 Open Chassis (IP00) 162.0 50/60

CIMR-E7U2045 Open Chassis (IP00) 192.0 60/75

CIMR-E7U2055 Open Chassis (IP00) 215.0 75

CIMR-E7U2075 Open Chassis (IP00) 312.0 100/125

CIMR-E7U2090 Open Chassis (IP00) 360.0 125/150

CIMR-E7U2110 Open Cha ssis (IP00 ) 415.0 150

CIMR-E7U40P4 NEMA Type 1 (IP20) 1.8 0.5/0.75

CIMR-E7U40P7 NEMA Type 1 (IP20) 2.1 1

CIMR-E7U41P5 NEMA Type 1 (IP20) 3.7 1.5/2

CIMR-E7U42P2 NEMA Type 1 (IP20) 5.3 3

CIMR-E7U43P7 NEMA Type 1 (IP20) 7.6 5

CIMR-E7U45P5 NEMA Type 1 (IP20) 12.5 7.5

CIMR-E7U47P5 NEMA Type 1 (IP20) 17.0 10

CIMR-E7U49P0 NEMA Type 1 (IP20) 21.0 15

CIMR-E7U4011 NEMA Type 1 (IP20 ) 27.0 20

CIMR-E7U4015 NEMA Type 1 (IP20) 34.0 25

CIMR-E7U4018 NEMA Type 1 (IP20) 40.0 30

CIMR-E7U4024 NEMA Type 1 (IP20) 52.0 40

CIMR-E7U4030 NEMA Type 1 (IP20) 67.2 50

CIMR-E7U4037 NEMA Type 1 (IP20) 77.0 60

CIMR-E7U4045 NEMA Type 1 (IP20) 96.0 75

CIMR-E7U4055 NEMA Type 1 (IP20) 125.0 100

CIMR-E7U4075 Open Cha ssis (IP00) 156.0 125

CIMR-E7U4090 Open Cha ssis (IP00) 180.0 150

CIMR-E7U4110 Open Cha ssis (IP00 ) 240.0 200

CIMR-E7U4160 Open Cha ssis (IP00) 304.0 250

CIMR-E7U4185 Open Chassis (IP00) 414.0 300/350

CIMR-E7U4220 Open Chassis (IP00) 515.0 400/450

CIMR-E7U4300 Open Cha ssis (IP00) 675.0 500+

Enclosure Style

Rated

Output

Current

Nominal

Hp

Physical Installation 1 - 2

Page 13

Confirmations upon Delivery

Input Power Specifications

Output Power Specifications

Drive Model Number

Drive Enclosure and

Weight

Serial Number

UL File Number

Drive Spec Number

Output Power Rating

Input Power Rating

Note: The Drive Model Number and Drive Spec Number are required to completely identify a Drive.

Receiving Checks

Check the following items as soon as the Drive is received.

Table 1.2 Receiving Checks

Item Method

Has the correct model of Drive been

delivered?

Check the model number on the nameplate on the right side of the Drive.

Reconcile with packing slip and/or order information.

Is the Drive damaged in any way?

Are any screws or other components

loose?

If there are any irregularities in the above items, contact the shipping company, the distributor or representative who sold the

Drive, or a Yaskawa office immediately.

The E7 is thoroughly tested at the factory. Any damages or shortages evident when the equipment is received must be reported

immediately to the commercial carrier that transported the material. Shipping damage is not covered by the Yaskawa warranty.

After unpacking and inspecting for damage, verify that internal wire connections have not come loose during shipment by spot

checking wire terminations with a screwdriver or the appropriate tool.

E7 Drive storage must be in a clean and dry location. Maintain the factory packaging and provide covering as needed to

protect the E7 from construction site dirt, water, debris and traffic prior to and during construction.

Inspect the entire exterior of the Drive to see if there are any dents, scratches or

other damage resulting from shipping.

Use a screwdriver or other tool to check for tightness.

Nameplate Information

A nameplate is attached to the right side of each Drive. The following nameplate is an example for a standard Drive.

Fig 1.1 E7 Drive Nameplate

Physical Installation 1 - 3

Revision Code

Page 14

Drive Model Numbers

No.

Spec

UL Specification

CIMR – E7 U 2 0 11

AC Drive

U

No.

Voltage

2

4

3-phase, 208-240Vac

3-phase, 480Vac

Rating

E7 Family

2 011 1 A

No.

2

4

Voltage

3-phase, 208 - 240Vac

3-phase, 480Vac

No.

Enclosure Type

0 Open chassis (IEC IP00)

1

NEMA Type 1 (IEC IP20)

Hardware Revision

Rating

The model number on the nameplate indicates the design specification, voltage, and rating of the Drive in alphanumeric codes.

Fig 1.2 Drive Model Number Structure

Drive Enclosure and Revision Code

The Drive SPEC number on the nameplate indicates the voltage, Drive rating, enclosure type, and the revision code of the

Drive in alphanumeric codes.

Fig 1.3 SPEC Number Structure

Open Chassis Type (IEC IP00)

Protected so that parts of the human body cannot reach electrically charged parts from the front when the

Drive is mounted in a control panel, also called (protected chassis).

NEMA Type 1 (IEC IP20)

The Drive is shielded from the exterior, and can thus be mounted to the interior wall of a building

(not necessarily enclosed in a control panel). The protective structure conforms to the standards of NEMA

Type 1 in the USA. All protective covers (Fig 1.4) must be installed to conform with IEC IP20 and NEMA Type

1 requirements.

Physical Installation 1 - 4

TERMS

Page 15

Component Names

Models CIMR-E7U20P4 thru 2018 (25HP @ 208V/240V) and 40P4 thru 4018

(30HP @ 480V)

The external appearance, component names, and terminal arrangement of the Drive are shown in Fig 1.4. and 1.5.

Top protective cover

Front cover

Digital Operator

Terminal cover

Mounting hole

Diecast Heat Sink

Nameplate

Bottom protective cover

Fig 1.4 Drive Appearance

Fig 1.5 Terminal Arrangement (Terminal Cover Removed)

Physical Installation 1 - 5

Page 16

Models CIMR-E7U2022 thru 2110 (30HP and above @ 208V/240V) and 4030 thru

Mounting holes

Cooling fan

Nameplate

Drive cover

Front cover

Digital Operator

Terminal cover

Mounting holes

Cooling fan

Nameplate

Drive cover

Front cover

Digital Operator

Terminal cover

Charge indicator

Control circuit

terminals

Main circuit

terminals

Ground terminal

Ground terminal

4300 (40HP and above @ 480V)

The external appearance, component names, and terminal arrangement of the Drive are shown in Fig 1.6 and 1.7.

Fig 1.6 Drive Appearance

Fig 1.7 Terminal Arrangement (Terminal Cover Removed)

Physical Installation 1 - 6

Page 17

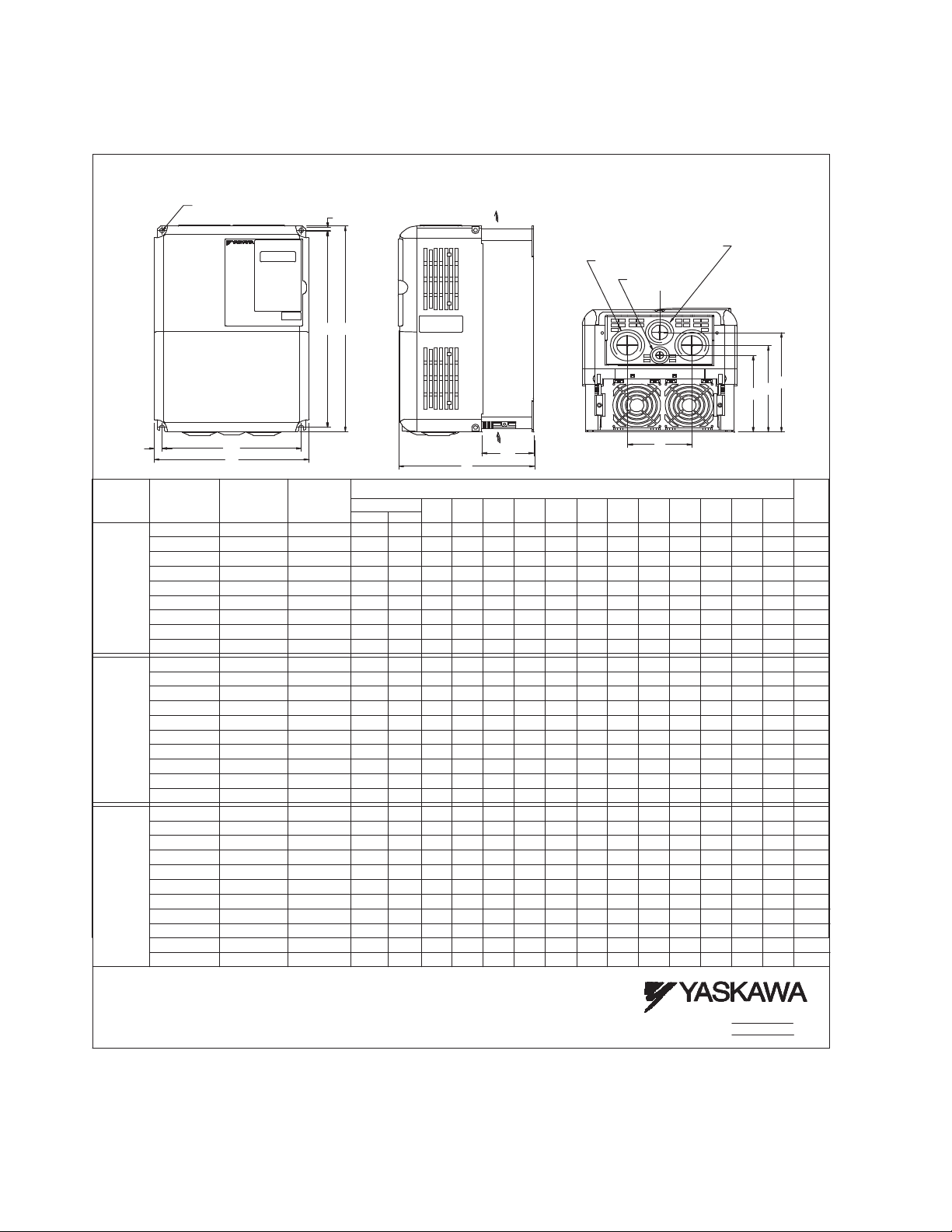

Exterior and Mounting Dimensions

DIMENSIONS: E7 (NEMA 1)

208/240V (3.6-74.8 AMPS) 480V (1.8- 40.0 AMPS)

FRONT VIEW

MOUNTING HO LES

RATED

INPUT

208V

240V

480V

W2

CIMR-E7U

20P41

20P71

22P21

23P71

27P51

20P41

20P71

22P21

23P71

25P51

27P51

40P41

40P71 2.1

42P21

43P71

45P51

FOR "A" SIZE SCREW

MODEL

21P51

20111

20151

20181

21P51

20111

20151

20181

41P51

49P01

40111

40151

W1

W

RATED

OUTPUT

CURRENT

(AMPS)

3.6

4.6

7.8

10.8

31.0

46.2

59.4

74.8 13.19

3.6

4.6

7.8

10.8

16.8

23.0

31.0

46.2

59.4

74.8

1.8

3.7

5.3

7.6

12.5

21.0

27.0

34.0

40.0 40181

NOMINAL

1/2 3/4

7.5-10

1/2 3/4

1/2 3/4 -

H2

H1

H

HP

-

1

2

3

5

15

20

25

-

1

2

3

5

7.5

10

15

20

25

1

2

3

5

7.5

10 17.0 47P51

15

20

25

30

FOR REFERENCE ONLY UNLESS PROPERLY ENDORSED.

IN ORDER TO ACHIEVE ADEQUATE COOL ING

THE DRIVE MUST BE POSITIONED TO ALLOW A MINIMUM

OF FREE AIR SPACE OF 1.2 INCHES ON SIDES AND

5 INCHES TOP AND BOTTOM

SIDE VIEW

AIR

AIR

D1

D

DIMENSIONS IN INCHES

MOUNTING

H1 W1

4.96

10.47

4.96

10.47

4.96

10.47

4.96

10.47

4.96 10.47

7.32

11.22

7.32

11.22

8.50

13.19

8.50 14.96 9.45 .30

10.47

4.96

4.96

10.47

4.96

10.47

10.47

4.96

10.47

4.96

10.47

4.96

11.22

7.32

11.22

7.32

13.19

8.50

13.19 8.50 14.96 9.45 .301/4 .47 8.27

10.47

4.96

10.47

4.96

10.47

4.96

10.47

4.96

4.96

10.47

4.96

10.47

11.22 7.327.87 11.81.28

7.32

11.22

13.19

8.50 9.45

13.19 8.50

11.02 5.51

11.02 5.51

11.02

11.02

7.87

11.81

7.87

12.20

9.45

13.78

11.02

11.02

11.02

11.02

11.02

5.51

11.02

7.87

11.81

7.87

12.20

9.45

13.78

11.02

11.02 5.51

11.02

11.02

11.02

11.02

5.51

11.817.87

13.78

9.45 13.78

W HH2

5.51

5.51

5.51

5.51

5.51

5.51

5.51

5.51

5.51

5.51

5.51

W2

.28

.28

.28

.28

.28

.28

.28

.30

.28

.28

.28

.28

.28

.28

.28

.28

.30

.28

.28

.28

.28

.28

.28

.28

.30

.30

6.30

.28

6.30

.28

6.30

.28

6.30

.28 .28 5.51 11.02 16.8

.28

7.87

.28

7.87

.47

8.27

.28

6.30

.28

6.30

.28

6.30

.28

6.30

.28

7.09

.28

7.09

.28

7.87

.28

7.87

.47

8.27

.28

6.30

.28

6.30

.28

6.30

.28

7.09

.28

7.09

.28

7.09

.28 7.87 1/44.63 6.21 3.07 1.

.28 7.871/44.63

.28

7.87

.47

8.27

.47

8.27

1.38 DIA.

(2) HOLES SIZE "J"

.87 DIA.

C

L

E

C

B

F

BOTTOM VIEW

APPROX.

WEIGHT

J

1.10

1.10

1.10

1.10

1.38

1.38

1.73

1.73 24.2

1.10

1.10

1.10

1.10

1.10

1.10

1.38

1.38

1.73

1.73

1.10

1.10 6.6

1.10

1.10

1.10

1.10

38 13.2

1.38 13.2

1.73

1.73

9.29.04

(LBS.)

6.6

6.6

6.6

6.6

13.2

15.4

24.2

6.6

6.6

6.6

6.6

8.8

8.8

13.2

15.4

24.2

24.2

6.6

6.6

8.8

8.8

8

.8

22

22

D1 B A DCE

1.54

1.54

1.54

1.54

2.32

2.58

2.58

3.07

3.07

1.54

1.54

1.54

1.54

2.32

2.32

2.58

2.58

3.07

3.07

1.54

1.54

1.54

2.32

2.32

2.32

2.58

2.58

2.58

3.07

3.07

1/4

1/4

1/4

#10

#10

#10

#10

4.63

1/4

1/4

1/4

#10

#10

#10

#10

#10

#10

4.63

1/4

1/4

#10

#10

#10

#10

#10

#10

1/4

1/4

---

3.35

---

3.35

---

3.35

---

3.35

---

5.11

4.63

5.11

5.79

5.12

5.12 .47 3.94 5.79 8.27

3.35

---

3.35

---

3.35

---

---

3.35

---

4.14

---

4.14

5.11

4.63

5.11

5.12

5.79

5.12

5.79

3.35

---

3.35

---

3.35

---

4.14

---

4.14

---

4.14

---

5.11

5.11 11.22 7.327.87 11.81.28

4.63

5.11

5.79

5.12 6.65

5.79

5.12

DR BY

APPVL.

F

1.97

4.73

1.97

4.73

1.97

4.73

1.97

4.73

5.52 #10 1.10 4.14 1.97 7.09 8.8

6.21

3.07

6.21

3.07

6.65

3.94

6.65

4.73

1.97

4.73

1.97

4.73

1.97

4.73

1.97

5.52

1.97

5.52

1.97

6.21

3.07

6.21

3.07

6.65

3.94

6.65

3.94

4.73

1.97

4.73

1.97

4.73

1.97

5.52

1.97

5.52

1.97

5.52

1.97

6.21

3.07 1.38 13.2

6.21

3.07

3.94

6.65

3.94

RIP 9.29.04

TA

Physical Installation 1 - 7

Page 18

DIMENSIONS: E7 (NEMA 1)

CURRENT

(LBS.)

APPROX.

WEIGHT

208/240V (88.0-115 AMPS) 480V (52.0-125 AMPS)

Physical Installation 1 - 8

Page 19

DIMENSIONS: E7 (PROTECTED CHASSIS)

FRONT VIEW

MOUNTING HO LES

FOR "A" SIZE SCREW

208-230V (162-415 AMPS)

480V (156-304 AMPS)

H2

H1

H

AIR

W2

W1

W

FOR REFERENCE ONLY UNLESS PROPERLY ENDORSED.

IN ORDER TO ACHIEVE ADEQUATE COOLING

THE DRIVE MUST BE POSITIONED TO ALLOW A MINIMUM

OF FREE AIR SPACE OF 1.2 I NCHES ON SIDE S AND

5 INCHES TOP AND BOTTOM

RATED

INPUT

208V

230V

480V

MODEL

CIMR-E7U

20370

20450

20550

20750

20900

21100

20370

20450

20750

20900

40900

41100

41600

RATED

OUTPUT

CURRENT

(AMPS)

162

215

312

360

415

162

192

360

156 40750

180

240

304

AIR

D1

D

NOM.

MOUNTING

HP

H1 W1

22.64

50

22.64 60

27.56

75

32.28

125

33.66

150

22.64 23.62 9.84 14.76 .49 125 3.94 11. 81 2.46 3/8

50-60

22.64 23.62 9.84 14.76 .49 139 5.12 12.99 2.46 3/8

75

27.56 28.54 12.80 17.72 .49 191 5.12 13.78 2.46 3/8

100-125 312

32.2833.46 14.57 19.69 .59 238 5.12 14.17 2.56 3/

150

125

27.56

150

27.56

200

32.28

250

33.66

DIMENSIONS IN INCHES

HWH2W2D

9.84

9.84

12.80

14.57

17.52

12.80

12.80

14.57

17.52

23.62

23.62

28.54

33.46

34.84

28.54

28.54

33.46

36.06

14.76

.49

14.76

.49

17.72

.49

19.69

.59 2.56

22.64 . 59

.49

17.72

.49 196

17.72

.59

19.69

.59

22.64

2.46

11.81

2.46

12.99 192

2.46

13.78

2.46 17.72 .49 12.80 27.56 28.54 100

13.78

14.17

2.56

14.96

13.78

2.46

2.46 3/8

13.78

14.17

2.56

14.96

2.56

DR BY

APPVL.

D1 A

3.94

3/8

5.12

3/8

5.12

3/8

5.12

3/8

5.12

3/8

5.51

3/8

8

5.12

3/8

5.12

5.12

3/8

5.51

3/8

RIP 9.29.04

TA 9.29.04

APPROX.

WEIGHT

(LBS.)

125

139

189

191

238

330

194

224

352

Physical Installation 1 - 9

Page 20

16.34

16.34

16.34 515

675

414 41850

42200

43000 58.07

51.38

51.38

56.70

50.00

50.00 400-450

500

300-350

14.37

10.63

10.63

36.06

27.95

27.95

.79

.79

.79

3.66

3.35

3.35

4.94

4.94

4.94

3/8

3/8

3/8

572

891

616

W

W1

W1

W2

H

H1

H2

AIR

D1

D

AIR

RIP 8-02

TBS 9.5.02

IN ORDER TO ACHIEVE ADEQUATE COOLING

THE DRIVE MUST BE POSITIONED TO ALLOW A MINIMUM

OF FREE AIR OF 1.2 INCHES ON SIDES AND

5 INCHES TOP AND BOTTOM

DIMENSIONS IN INCHES

OUTPUT

CURRENT

RATED

(AMPS)

INPUT

RATED

480V

MODEL

MOUNTING

HP

NOM.

H1 W 1

HWH2W2D

CIMR-E7U

D1 A

APPROX.

WEIGHT

(LBS.)

MOUNTING HOLES

FOR "A" SIZE SCREWS

DIMENSIONS: E7 (PROTECTED CHASSIS)

FOR REFERENCE ONLY UNLESS PROPERLY ENDORSED.

APPVL.

DR BY

Physical Installation 1 - 10

Page 21

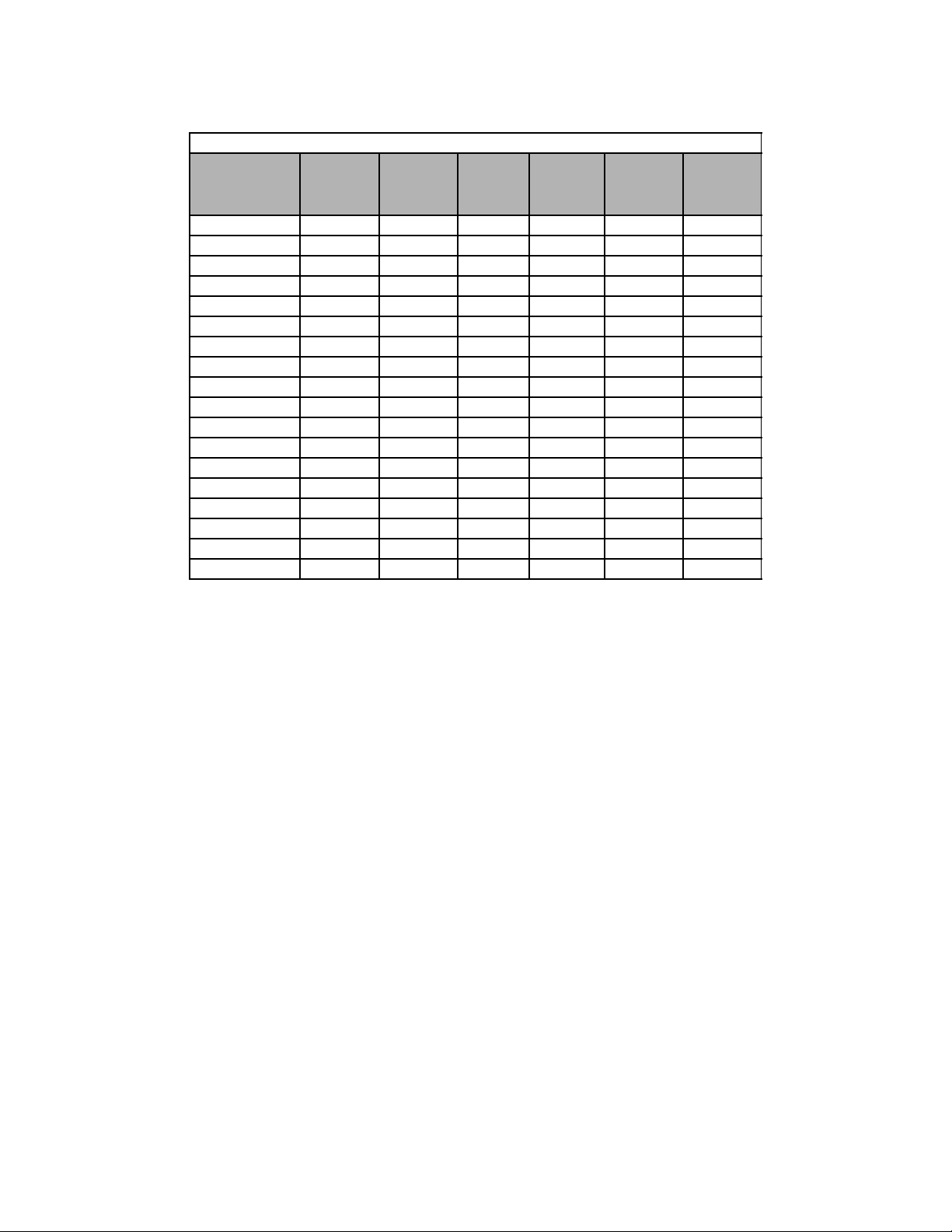

Heat Loss Data

TYPE

CIMR-E7U

20P4 1.4 3.6 19 39 58 Self

20P7 1.8 4.6 26 42 68 Self

21P5 3.0 7.8 48 50 98 Self

22P2 4.1 10.8 68 59 127 Self

23P7 6.4 16.8 110 74 184 Fan

25P5 8.8 23 164 84 248 Fan

27P5 12 31 219 113 332 Fan

2011 18 46.2 357 168 524 Fan

2015 23 59.4 416 182 597 Fan

2018 29 74.8 472 208 680 Fan

2022 34 88 583 252 835 Fan

2030 44 115 883 333 1217 Fan

2037 62 162 1010 421 1430 Fan

2045 73 192 1228 499 1727 Fan

2055 82 215 1588 619 2206 Fan

2075 120 312 1956 844 2800 Fan

2090 140 360 2194 964 3157 Fan

2110 160 415 2733 1234 3967 Fan

Table 1.3 200V Class Heat Loss Data

Drive

(Inverter)

Capacity

(kVA)

Rated

Output

Current

(A)

Cooling

Fin Side

(W)

Internal

Unit Side

(W)

Total

Watt

Loss

(W)

Cooling

Method

Physical Installation 1 - 11

Page 22

Table 1.4 400V Class Heat Loss Data

TYPE

CIMR-E7U

40P4 1.4 1.8 14 39 53 Self

40P7 1.6 2.1 17 41 58 Self

41P5 2.8 3.7 36 48 84 Self

42P2 4.0 5.3 59 56 115 Fan

43P7 5.8 7.6 80 68 140 Fan

44P0 6.6 8.7 90 70 160 Fan

45P5 9.5 12.5 127 81 209 Fan

47P5 13 17 193 114 307 Fan

49P0 16 21 232 158 390 Fan

4011 21 27 232 158 390 Fan

4015 26 34 296 169 465 Fan

4018 30 40 389 201 590 Fan

4022 38 50.4 420 233 653 Fan

4024 40 52 691 297 989 Fan

4030 51 67.2 691 297 989 Fan

4037 59 77 801 332 1133 Fan

4045 73 96 901 386 1287 Fan

4055 95 125 1204 478 1682 Fan

4075 120 156 1285 562 1847 Fan

4090 140 180 1614 673 2287 Fan

4110 180 240 1889 847 2736 Fan

4132 200 260 2388 1005 3393 Fan

4160 230 304 2636 1144 3936 Fan

4185 315 414 2791 1328 3964 Fan

4220 390 515 3797 1712 5509 Fan

4300 510 675 5838 2482 8319 Fan

Drive

(Inverter)

Capacity

(kVA)

Rated

Output

Current

(A)

Cooling

Fin Side

(W)

Internal

Unit Side

(W)

Total

Watt

Loss

(W)

Cooling

Method

Physical Installation 1 - 12

Page 23

Checking and Controlling the Installation Site

Install the Drive as described below and maintain optimum conditions.

WARNING

The Drive heatsink temperature may exceed 158°F (70°C). Therefore, mount the Drive to a surface suitable

for high temperature.

Installation Site

Locate the E7 Drive as close as possible to the motor. Install the Drive under the following conditions in UL Pollution Degree

1 & 2 environments. This excludes wet locations where surfaces may become conductive due to moisture and contaminant

loading.

Table 1.5 Installation Site Specifications

Type Ambient Operating Temperature Humidity Plenum Rated

NEMA Type 1 14° F -to- 104°F ( - 1 0 -to- + 40 °C) 95%-RH-or-less-(no-condensation) Yes

Open Chassis 14° F -to- 113°F ( - 1 0 - to -+ 45 °C ) 9 5 % -RH-or-less-(no-condensation) No

Protective covers are attached to the top and bottom of the Drive. It is recommended to remove the protective covers before

operating a CIMR-E7U2030/4055 Drive and smaller in a panel to obtain the 113°F (45°C) ambient operating temperature.

Observe the following precautions when installing the Drive:

• in a clean location which is free from oil mist and dust.

• in an environment where metal shavings, oil, water, or other foreign materials will not get into the Drive enclosure.

• in a location free from radioactive materials.

• in a location free from harmful gasses and liquids.

• in a location free from excessive vibration.

• in a location free from chlorides.

• in a location away from direct sunlight.

• on a non-combustible surface.

Controlling the Ambient Temperature

To enhance the reliability of operation, the Drive should be installed in an environment free from extreme temperature

variations. If the Drive is installed in an enclosure, use a cooling fan or air conditioner to maintain the internal air temperature

below 113°

F (45°C).

Protecting the Drive from Foreign Matter

During Drive installation and project construction it is possible to have foreign matter, such as metal shavings or wire

clippings, fall inside the Drive. To prevent foreign matter from falling into the Drive, place a temporary cover over the Drive.

Always remove the temporary cover from the Drive before Start-Up. Otherwise, ventilation will be reduced, causing the Drive

to overheat.

Physical Installation 1 - 13

Page 24

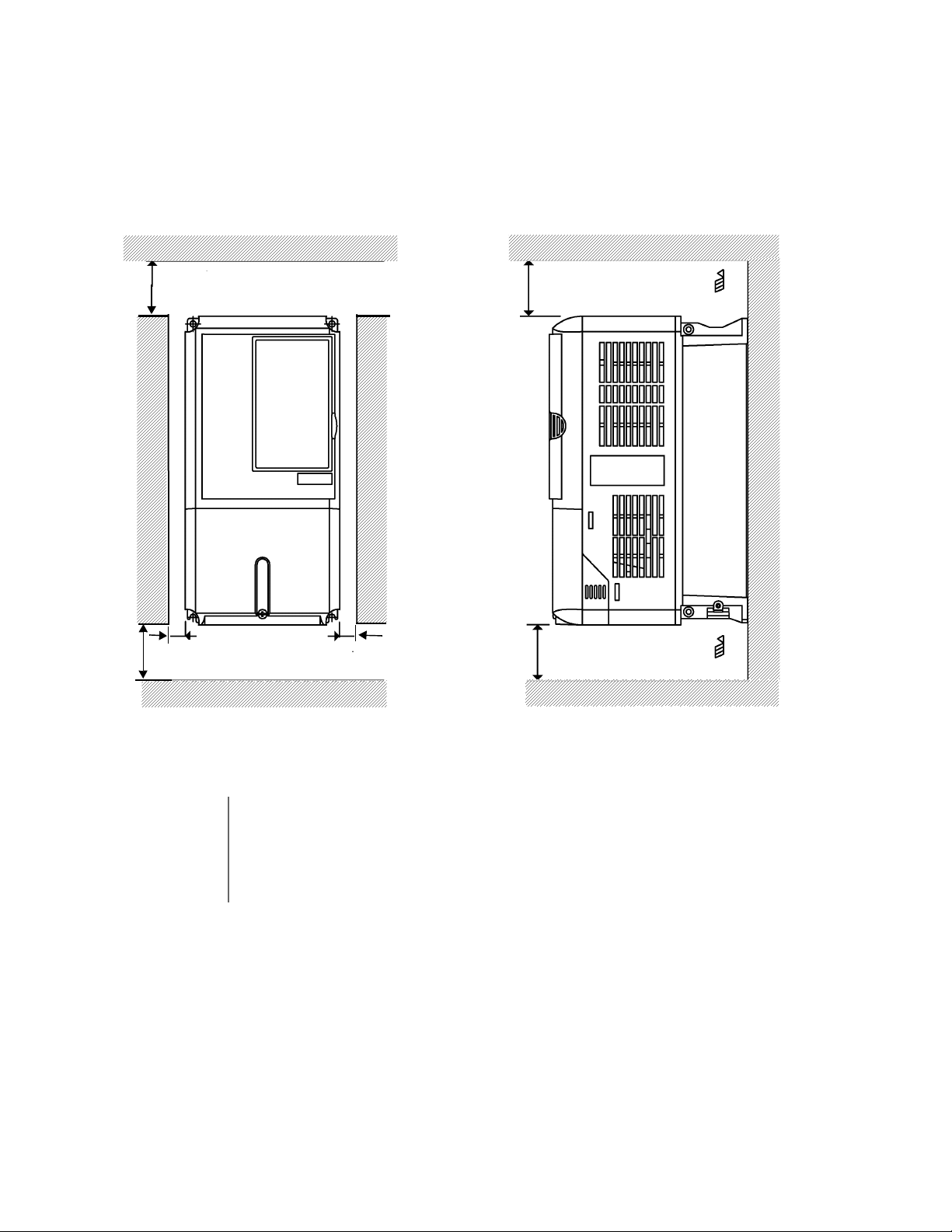

Installation Orientation and Clearances

4.75 in (120 mm. minimum)

4.75 in (120 mm. minimum)

Air

Air

Vertical ClearanceHorizontal Clearance

1.2 in

(30.5 MM.) min.

1.2 in

(30.5 mm. minimum)

1.2 in

(30.5 mm. minimum)

4.75 in (50 mm. minimum)

4.75 in (120 mm. minimum)

Install the Drive vertically so as not to reduce the cooling efficiency. When installing the Drive, always provide the following

installation clearances to allow normal heat dissipation. For 3HP, 208V/240V (CIMR-E7U22P2 and below) or 2HP, 480V

(CIMR-E7U41P5 and below), ensure that the heatsink is against a closed surface to avoid diverting cooling air around the

heatsink.

IMPORTANT

Fig 1.8 Drive Installation Orientation and Clearance

1. The same clearance is required horizontally and vertically for both Open Chassis (IP00) and NEMA

Type 1 Drives.

2. Always remove the top and bottom protection covers before installing a CIMR-E7U2018/4018 and

smaller Drive in a panel.

Always provide enough clearance for lifting eye bolts and the main circuit wiring when installing a

CIMR-E7U2022/4030 and larger Drive in a panel.

Physical Installation 1 - 14

Page 25

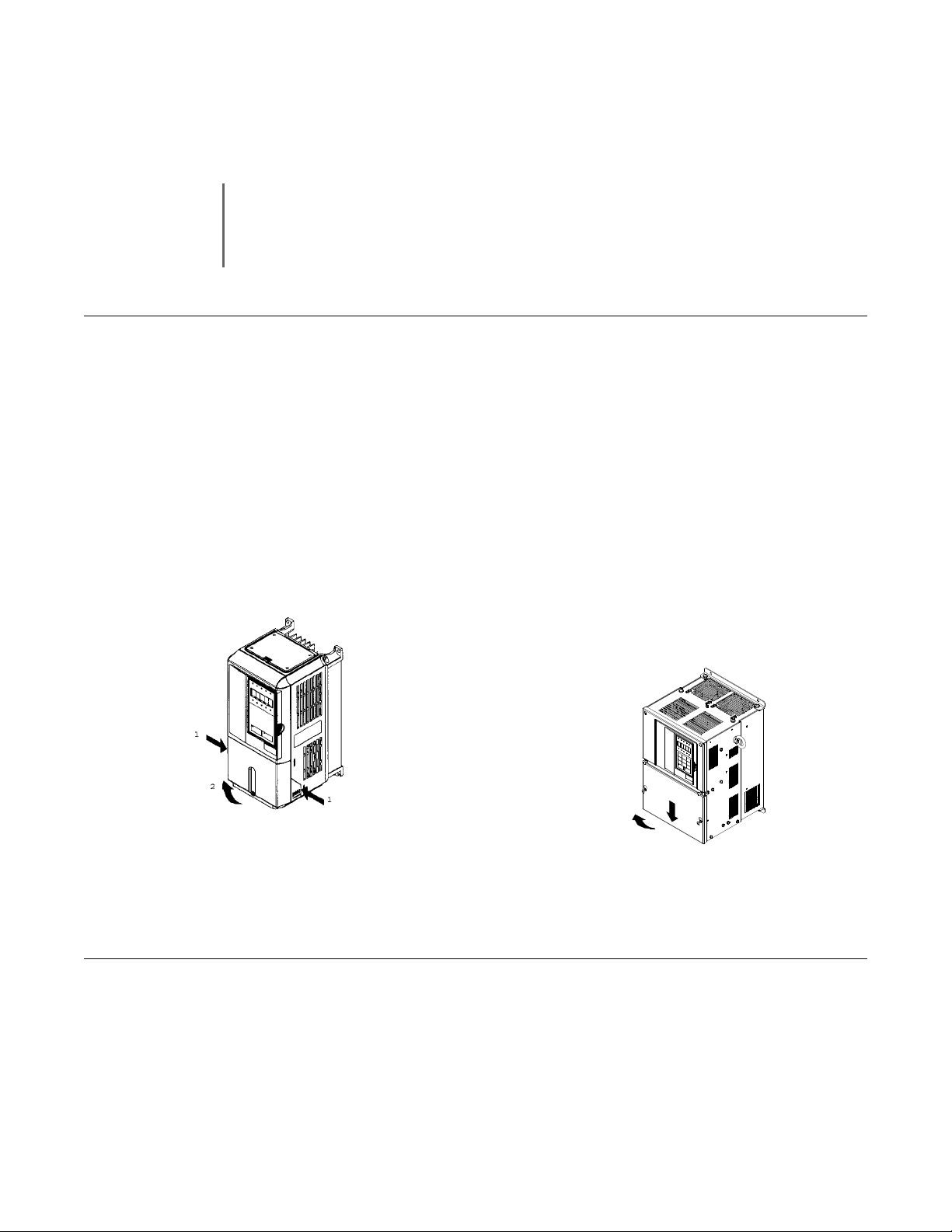

Removing and Attaching the Terminal Cover

1

2

Remove the terminal cover to connect cables to the control circuit and main circuit terminals.

Prior to removing any protective cover or wiring any part of the Drive, remove all power sources, including

main input power and control circuit power. Wait a minimum of 5 minutes after power removal, before

WARNING

Removing the Terminal Cover

Models CIMR-E7U20P4 thru 2018 (0.5HP to 25HP @ 208V/240V) and 40P4 thru 4018

(0.5HP to 30HP @ 480V)

Loosen the screw at the bottom of the terminal cover, press in on the sides of the terminal cover in the directions of arrows 1,

and then lift up on the terminal in the direction of arrow 2. Refer to Fig 1.9

Models CIMR-E7U2022 thru 2110 (30HP to 150HP @ 208V/240V) and 4030 thru 4300

(40HP to 500HP @ 480V)

removing any cover. The charge lamp located within the Drive should be off prior to working inside. Even if

the charge lamp is off, one must measure the AC input, output, and DC Bus potential to insure safe levels

prior to resuming work. Failure to adhere to this warning may result in personal injury or death.

Loosen the screws on the left and right at the top of the terminal cover, pull down the terminal cover in the direction of arrow

1 and then lift up on the terminal cover in the direction of arrow 2. Refer to Fig 1.10

Fig 1.9 Removing the Terminal Cover

Fig 1.10 Removing the Terminal Cover

Attaching the Terminal Cover

After wiring the terminal block, attach the terminal cover by reversing the removal procedure.

For Models CIMR-E7U2018/4018 and smaller, insert the tab on the top of the terminal cover into the groove on the Drive and

press in on the bottom of the terminal cover until it snaps into place.

For Drives CIMR-E7U2022/4030 and larger, insert the tab on the top of the terminal cover into the groove on the Drive, and

secure the terminal cover by lifting it up toward the top of the Drive.

Physical Installation 1 - 15

Page 26

Removing/Attaching the Digital Operator and Front Cover

2

1

1

2

Models CIMR-E7U20P4 thru 2018 (0.5HP to 25HP @ 208V/240V) and 40P4 thru

4018 (0.5HP to 30HP @ 480V)

For Models CIMR-E7U2018/4018 and smaller, remove the terminal cover and then use the following procedures to remove

the Digital Operator and front cover.

Removing the Digital Operator

Press on the side of the Digital Operator in the direction of arrow 1 to unlock, then lift the Digital Operator in the direction of

arrow 2 to remove it as shown in Fig 1.11.

Fig 1.11 Removing the Digital Operator

Removing the Front Cover

Press the left and right sides of the front cover in the direction of arrows 1 and lift the bottom of cover in the direction of arrow

2 to remove it as shown in Fig 1.12.

Fig 1.12 Removing the Front Cover

Attaching the Front Cover

Mount the front cover to the Drive by performing the steps to remove the front cover in reverse order.

1. Do not mount the front cover with the Digital Operator attached to the front cover; this may cause the Digital Operator to

malfunction due to imperfect contact.

2. Insert the tab of the upper part of the front cover into the groove of the Drive and press the lower part of the front cover

onto the Drive until the front cover snaps into place.

Physical Installation 1 - 16

Page 27

Models CIMR-E7U2022 thru 2110 (30HP to 150HP @ 208V/240V) and 4030 thru

1

2

4300 (40HP to 500HP @ 480V)

For Models CIMR-E7U2022/4030 and larger, remove the terminal cover and then use the following procedures to remove the

Digital Operator and front cover.

Removing the Digital Operator

Use the same procedure for Models CIMR-E7U2018/4018 and smaller.

Removing the Front Cover

Loosen all screws on the front cover. Lift up at the location labeled 1 at the top of the control circuit terminal card and move in

the direction of arrow 2.

Fig 1.13 Removing the Front Cover

Attaching the Front Cover

Attach the front cover by reversing the procedure to remove it.

1. Confirm that the Digital Operator is not mounted on the front cover. Contact faults can occur if the cover is attached while

the Digital Operator is mounted to it.

2. Insert the tab on the top of the front cover into the slot on the Drive and press in on the cover until it snaps into place on

the Drive.

Physical Installation 1 - 17

Page 28

Attaching the Digital Operator

A

B

1

2

After attaching the front cover, mount the Digital Operator onto the Drive using the following procedure.

1. Hook the Digital Operator at A (two locations) on the front cover by moving in the direction of arrow 1 as shown in the

following illustration.

2. Press the Digital Operator in the direction of arrow 2 until it snaps in place at B (two locations).

Fig 1.14 Mounting the Digital Operator

1. Do not remove or attach the Digital Operator or mount or remove the front cover using methods other

than those described above, damage to the Digital Operator or Drive may occur.

IMPORTANT

2. Never attach the front cover to the Drive with the Digital Operator attached to the front cover. Damage to

the Digital Operator may occur. Always attach the front cover to the Drive first, and then attach the Digital

Operator to the front cover.

Physical Installation 1 - 18

Page 29

Chapter 2

Electrical Installation

This chapter describes wiring terminals, main circuit terminal connections, main

circuit terminal wiring specifications, control circuit terminals, and control circuit

wiring specifications.

Terminal Block Configuration ..................................................... 2-2

Wiring Main Circuit Terminals ................................................... 2-3

Control Wiring........................................................................... 2-12

Electrical Installation 2 - 1

Page 30

Terminal Block Configuration

Models CIMR-_ _ _ 2022 (30 HP, 208V)/

4030 (40 HP, 480V) and larger

AC MP

AMS6

-V

IG

R- M5

FM

R+RP

S1

S4SPS7 M4

+V

S3

SCS+A2

M2

SN M6

AC

A1

E(G) E(G)

MCMB

S5

M1

AC MA

M3S2 S-

AC MP

AMS6

-VIGR- M5FMR+RP

S1

S4SPS7 M4

+V

S3

SCS+A2M2SN M6

AC

A1

E(G) E(G)

MCMB

S5

M1

AC MA

M3S2 S-

Models CIMR-_ _ _ 2018 (25 HP, 208V)/

4018 (30 HP, 480V) and smaller

Ground terminal

Ground terminal

Ground terminal

Ground terminal

Charge indicator

Main circuit terminals

Main circuit terminals

Control circuit terminals

Control circuit terminals

Charge indicator

The wiring terminals are shown in Fig 2.1.

Fig 2.1 Drive Terminal Configuration

Electrical Installation 2 - 2

Page 31

Wiring Main Circuit Terminals

Applicable Wire Sizes and Closed-loop Connectors

Select the appropriate wires and crimp terminals from Table 2.1 to Table 2.2.

Table 2.1 208-240Vac Wire Sizes and Connector Specifications

Drive Model

CIMR-E7U

20P4 0.5/0.75

20P7 2

21P5 1.5/2

22P2 3

23P7 5

25P5 7.5

27P5 10

2011 15

Nominal

Hp

Terminal Symbol

R/L1, S/L2, T/L3, , 1, 2,

B1, B2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

B1, B2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

B1, B2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

B1, B2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

B1, B2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

B1, B2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

B1, B2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

B1, B2, U/T1, V/T2, W/T3

Te rm i na l

Screws

M4

M4

M4

M4

M4

M4

M5

M5

Clamping

Torque

lb. in.

(N•m)

13.3

(1.5)

13.3

(1.5)

13.3

(1.5)

13.3

(1.5)

13.3

(1.5)

13.3

(1.5)

22.1

(2.5)

22.1

(2.5)

Recommended

Wire Size

AWG

2

)

(mm

14

(2.1)

14

(2.1)

14

(2.1)

12

(3.3)

10

(5.3)

10

(5.3)

8

(8)

6

(13.3)

Wire

Type

600Vac

UL Approved

vinyl-sheathed

or equivalent

2015 20

2018 25

2022 30

2030 40

R/L1, S/L2, T/L3, , 1, 2, U/T1, V/T2, W/T3

B1, B2 M5

R/L1, S/L2, T/L3, , 1, 2, U/T1, V/T2, W/T3

B1, B2 M5

R/L1, S/L2, T/L3, , 1, U/T1, V/T2,

W/T3, R1/L11, S1/L21, T1/L31

3

R/L1, S/L2, T/L3, , 1 U/T1,

V/T2, W/T3, R1/L11, S1/L21, T1/L31

3

Electrical Installation 2 - 3

M6

M6

M8

M6

M8

M6

M8

M8

M6

M8

44.3

(5.0)

22.1

(2.5)

44.3

(5.0)

88.5

(10.0)

22.1

(2.5)

44.3

(5.0)

88.5

(10.0)

45.1

(5.1)

88.5

(10.0)

88.5

(10.0)

45.1

(5.1)

88.5

(10.0)

4

(21.2)

6

(13.3)

6

(13.3)

2

(33.6)

6

(13.3)

4

(21.2)

1

(42.4)

4

(21.2)

4

(21.2)

1/0

(53.5)

4

(21.2)

2

(38)

Page 32

Table 2.1 208-240Vac Wire Sizes and Connector Specifications

Drive Model

CIMR-E7U

2037 50

2045 60

2055 75

2075 75/100

2090 125

2110 150

*Use 75°C copper wire or equivalent

Nominal

Hp

Terminal Symbol

R/L1, S/L2, T/L3, , 1 U/T1,

V/T2, W/T3, R1/L11, S1/L21, T1/L31

3

l1, s/l2

r/

R/L1, S/L2, T/L3, , 1 U/T1,

V/T2, W/T3, R1/L11, S1/L21, T1/L31

3

l1, s/l2

r/

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L31 M10

3

l1, s/l2

r/

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L31 M10

3

l1, s/l2

r/

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L31 M12

3

l1, s/l2

r/

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L31 M12

3

l1, s/l2

r/

Terminal

Screws

M10

M8

M10

M4

M10

M8

M10

M4

M10

M8

M10

M4

M10

M8

M10

M4

M12

M8

M12

M4

M12

M8

M12

M4

Clamping

To rq u e

lb. in.

(N•m)

199

(22.5)

88.5

(10.0)

203.6

(23)

12.4

(1.4)

199

(22.5)

88.5

(10.0)

199

(22.5)

12.4

(1.4)

199

(22.5)

199

(22.5)

88.5

(10.0)

199

(22.5)

12.4

(1.4)

199

(22.5)

199

(22.5)

88.5

(10.0)

199

(22.5)

12.4

(1.4)

347

(39.2)

347

(39.2)

88.5

(10.0)

347

(39.2)

12.4

(1.4)

347

(39.2)

347

(39.2)

88.5

(10.0)

347

(39.2)

12.4

(1.4)

Recommended

Wire Size

AWG

2

)

(mm

4/0

(100)

4

(22)

2/0

(67.4)

14

(2.1)

300

(152)

4

(21.2)

3/0

(85)

14

(2.1)

1/0 X 2P

(53.5 X 2P)

1/0 X 2P

(53.5 X 2P)

2/0

(67.4)

4/0

(107.2)

14

(2.1)

4/0 X 2P

(80 X 2P)

3/0 X 2P

(85 X 2P)

2/0

(67.4)

2/0 X 2P

(67.4 X 2P)

14

(2.1)

250 x2P

(127 x2P)

4/0 X 2P

(107.2 X 2P)

2/0

(67.4)

2/0 X 2P

(67.4 X 2P)

14

(2.1)

300 X 2P

(152 X 2P)

300 X 2P

152 X 2P

2/0

(67.4)

4/0 X 2P

(107.2 X 2P)

16

(1.25)

Wire

Typ e

600Vac

UL Approved

vinyl-sheathed

or equivalent

Electrical Installation 2 - 4

Page 33

Table 2.2 480Vac Wire Sizes and Connector Specifications

Drive Model

CIMR-E7U

40P4 0.5/0.75

40P7 1

41P5 1.5/2

42P2 3

43P7 5

45P5 7.5

47P5 10

49P0/4011 15/20

4015 25

Nominal

Hp

Termin al S y m b o l

R/L1, S/L2, T/L3, , 1, 2,

B1, B2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

B1, B2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

B1, B2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

B1, B2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

B1, B2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

B1, B2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

B1, B2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

B1, B2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2,

B1, B2, U/T1, V/T2, W/T3

Terminal

Screws

M4

M4

M4

M4

M4

M4

M4

M5

M5

Clamping

To rq u e

lb. in.

(N•m)

13.3

(1.5)

13.3

(1.5)

13.3

(1.5)

13.3

(1.5)

13.3

(1.5)

13.3

(1.5)

13.3

(1.5)

22.1

(2.5)

22.1

(2.5)

Recommended

Wire Size AWG

2)

(mm

14

(2.1)

14

(2.1)

14

(2.1)

14

(2)

14

(2.1)

14

(2.1)

12

(3.5)

14

(2)

10

(5.5)

12

(3.5)

8

(8)

10

(5.5)

8

(8)

Wire Type

600Vac

UL Approved

vinyl-sheathed

or equivalent

4018 30

4024/4030 40/50

4037 60

4045 75

R/L1, S/L2, T/L3, , 1, 3, U/T1, V/T2, W/T3,

B1, B2 M5

R/L1, S/L2, T/L3, , 1, 3, U/T1, V/T2, W/T3,

R/L1, S/L2, T/L3, , 1, U/T1, V/T2, W/T3, R1/L11,

R/L1, S/L2, T/L3, , 1, U/T1, V/T2, W/T3, R1/L11,

R1/L11, S1/L21, T1/L31

S1/L21, T1/L31

3

S1/L21, T1/L31

3

Electrical Installation 2 - 5

M6

M6

M6

M8

M8

M6

M8

M8

M6

M8

44.3

(5.0)

21.1

(2.5)

44.3

(5.0)

44.3

(5.0)

88.5

(10.0)

88.5

(10.0)

44.3

(5.0)

88.5

(10.0)

88.5

(10.0)

44.3

(5.0)

88.5

(10.0)

6

(13.3)

8

(8)

6

(13.3)

3

(26.7)

6

(13.3)

2

(33.6)

4

(21.2)

4

(21.2)

2

(33.6)

4

(21.2)

4

(21.2)

Page 34

Table 2.2 480Vac Wire Sizes and Connector Specifications

Drive Model

CIMR-E7U

4055 100

4075 125

4090 150

4110 200

4160 250

Nominal

Hp

Terminal Symbol

R/L1, S/L2, T/L3, , 1, U/T1, V/T2,

W/T3, R1/L11, S1/L21, T1/L31

3

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L31 M10

3

l1, s200/l

r/

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L31 M10

r/

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L31 M10

r/

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L31 M12

r/

200, s400/l2400 M4

2

3

l1, s200/l

200, s400/l2400 M4

2

3

l1, s200/l

200, s400/l2400 M4

2

3

l1, s200/l

200, s400/l2400 M4

2

Te rm i na l

Screws

M8

M6

M8

M10

M8

M12

M10

M8

M12

M10

M8

M12

M12

M8

M12

Clamping

Torque

lb. in.

(N•m)

88.5

(10.0)

44.3

(5.0)

88.5

(10.0)

199

(22.5)

199

(22.5)

88.5

(10.0)

347

(39.2)

12.4

(1.4)

199

(22.5)

199

(22.5)

88.5

(10.0)

347

(39.2)

12.4

(1.4)

199

(22.5)

199

(22.5)

88.5

(10.0)

347

(39.2)

12.4

(1.4)

347

(39.2)

347

(39.2)

88.5

(10.0)

347

(39.2)

12.4

(1.4)

Recommended

Wire Size AWG

2)

(mm

2/0

(33.6)

4

(21.2)

1

(42.4)

4/0

(107.2)

3/0

(85)

4/0

(107.2)

1/0

(53.5)

14

(2.1)

250

(127)

4/0

(107.2)

4/0

(107.2)

2/0

(67.4)

14

(2.1)

2/0 X 2P

(67.4 X 2P)

1/0 X 2P

(53.5 X 2P)

2/0

(67.4)

4/0

(107.2)

14

(2.1)

4/0 X 2P

(107.2 X 2P)

3/0 X 2P

(85 X 2P)

2/0

(67.4)

1/0 X 2P

(53.5 X 2P)

14

(2.1)

Wire Type

600Vac

UL Approved

vinyl-sheathed

or equivalent

Electrical Installation 2 - 6

Page 35

Table 2.2 480Vac Wire Sizes and Connector Specifications

3

Drive Model

CIMR-E7U

4185 300/350

4220 400/450

4300 500+

*Use 75°C copper wire or equivalent.

Nominal

Hp

Terminal Symbol

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L33 M8

3

l1, s200/l

r/

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L33 M8

r/

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L33 M8

r/

200, s400/l2400 M4

2

3

l1, s200/l

200, s400/l2400 M4

2

3

l1, s200/l

200, s400/l2400

2

Te rm i na l

Screws

M8

M8

M16

M8

M8

M16

M8

M8

M8

M16

Clamping

Torque

lb. in.

(N•m)

88.5

(10.0)

88.5

(10.0)

88.5

(10.0)

867.4

(98.0)

12.4

(1.4)

88.5

(10.0)

88.5

(10.0)

88.5

(10.0)

867.4

(98.0)

12.4

(1.4)

88.5

(10.0)

88.5

(10.0)

88.5

(10.0)

867.4

(98.0)

12.4

(1.4)

Recommended

Wire Size AWG

2)

(mm

300 X 2P

(152 X 2P)

300 X 2P

(152 X 2P)

2/0

(67.4)

3/0 X 2P

(85 X 2P)

14

(2.1)

500 X 2P

(253 X 2P)

400 X 2P

(203 X 2P)

2/0

(67.4)

250 X 2P

(127 X 2P)

14

(2.1)

700 X 2P

(355 X 2P)

600 X 2P

(304 X 2P)

2/0

(67.4)

400 X 2P

(203 X 2P)

14

(2.1)

Wire Type

600Vac

UL Approved

vinyl-sheathed

or equivalent

IMPORTANT

WARNING

Determine the wire size for the main circuit so that line voltage drop is within 2% of the rated voltage. Line

voltage drop is calculated as follows:

Line voltage drop (V) =

Prior to removing any protective cover or wiring any part of the Drive, remove all power sources, including

main input power and control circuit power. Wait a minimum of 5 minutes after power removal, before

x wire resistance (Ω/km) x wire length (m) x current (A) x 10

-3

removing any cover. The charge lamp located within the Drive should be off prior to working inside. Even if

the charge lamp is off, one must measure the AC input, output, and DC Bus potential to insure safe levels

prior to resuming work. Failure to adhere to this warning may result in personal injury or death.

Electrical Installation 2 - 7

Page 36

Main Circuit Terminal Functions

Main circuit terminal functions are summarized according to terminal symbols in Table 2.3. Wire the terminals correctly for

the desired purpose.

Table 2.3 Main Circuit Terminal Functions (208-240Vac and 480Vac)

Purpose Terminal Designation

R/L1, S/L2, T/L3 20P4 to 2110 40P4 to 4300

Main circuit power input

R1/L11, S1/L21, T1/L31 2022 to 2110 4030 to 4300

Drive outputs U/T1, V/T2, W/T3 20P4 to 2110 40P4 to 4300

Model: CIMR-E7U_ _ _ _

208-240Vac 480Vac

DC power input

DC reactor connection

Ground 20P4 to 2110 40P4 to 4300

1,

1, 2

20P4 to 2110 40P4 to 4300

20P4 to 2018 40P4 to 4018

Electrical Installation 2 - 8

Page 37

Main Circuit Configurations 208-240Vac

Power

supply

Control

circuits

{

1

Note

CIMR-_ _ _ 20P4 to 2018

(1/2 Hp to 25 Hp)

Power

supply

Control

circuits

{

Notes

1 & 3

CIMR-_ _ _ 2037 to 2110

(50 Hp to 150 Hp)

Power

supply

Control

circuits

{

Notes

1 & 3

The 208-240Vac main circuit configurations of the Drive are shown in Table 2.4.

Table 2.4 Drive Main Circuit Configurations

208-240 VAC

CIMR-_ _ _ 2022 and 2030

(30 Hp to 40 Hp)

Note1. Input fuses or molded case circuit breakers are required for proper branch circuit protection for all Drives. Failure

2. Control power is supplied internally from the main circuit DC power supply for all Drives.

3. Consult your Yaskawa representative before using 12-pulse rectification.

---

to use recommended fuses/circuit breakers (See Appendix E) may result in damage to the wiring, Drive and/or

personal injury.

Electrical Installation 2 - 9

Page 38

Main Circuit Configurations 480Vac

Power

supply

Control

circuits

{

Note

1

CIMR-_ _ _ 4024 to 4055

(40 Hp to 100 Hp)

Power

supply

Control

circuits

{

Notes

1 & 3

Power

supply

Control

circuits

{

Notes

1 & 3

3

CIMR-_ _ _ 4075 to 4160 and CIMR-_ _ _ 4185 to 4300

(125 Hp to 500 Hp)

The 480Vac main circuit configurations of the Drive are shown in Table 2.5.

Table 2.5 Drive Main Circuit Configurations

480 VAC

CIMR-_ _ _ 40P4 to 4018

(1/2 Hp to 30 Hp)

Note1. Input fuses or molded case circuit breakers are required for proper branch circuit protection for all Drives. Failure

to use recommended fuses/circuit breakers (See Appendix E) may result in damage to the wiring, Drive and/or

personal injury.

2. Control power is supplied internally from the main circuit DC power supply for all Drives.

3. Consult your Yaskawa representative before using 12-pulse rectification.

---

Electrical Installation 2 - 10

Page 39

Cable Length between Drive and Motor

NO

OK

OK

NOT OK

The E7 should be installed as close as possible to the motor to minimize the length of load side power cable needed between

the Drive and the motor.

If the cable between the Drive and the motor is long, the high-frequency leakage current will increase, causing the Drive

output current to increase as well. This may affect peripheral devices. To prevent this, reduce the cable length whenever

possible, or if necessary, adjust the carrier frequency (set in C6-02) as shown in Table 2.6.

The line side power cables, load side power cables and the control wiring should all be run in a separate conduit. Careful attention to this recommended design practice will avoid many potential motor and Drive related problems.

Table 2.6 Motor Cable Length vs. Carrier Frequency (C6-02)

Motor Cable Length 164 ft. (50m) maximum 328 ft. (100m) maximum More than 328 ft.(100m)

Carrier Frequency 15kHz maximum 10kHz maximum 5kHz maximum

(See the limitations on carrier frequency, based on Drive capacity and model number in Appendix B).

Ground Wiring

Observe the following precautions when connecting the ground wire:

1. 208-240Vac Drives should have a ground connection with resistance of less than 100Ω.

2. 480Vac Drives should have a ground connection with resistance of less than 10Ω.

3. Do not share the ground wire with other devices, such as motors or large-current electrical equipment.

4. Always use a ground wire that complies with technical standards on electrical equipment and minimize the length of the

ground wire. Leakage current flows through the Drive. Therefore, if the distance between the ground rod and the ground

terminal is too long, potential on the ground terminal of the Drive will become unstable.

5. When using more than one Drive, be careful not to loop the ground wire. See Fig 2.2.

Fig 2.2 Ground Wiring Examples

Control Circuit Ground Terminals

The removable Drive control terminal card provides two ground terminals (marked TB3 and TB4) to accept the control wire

shield connection. The control wire shield should be connected on this end only, the opposite end should be isolated with

electrical tape.

IMPORTANT

Grounding of the E7 enclosure and motor is required for proper system operation.

Electrical Installation 2 - 11

Page 40

Control Wiring

Signal Terminal Connections

0-10Vdc A1 to AC

4-20mA

or

0-10Vdc

A2 to AC

E(G)

+ V + 1 5 V D C , 20 m A

A 1 0- 1 0 V D C (2 0K )

A 2 H 3 - 0 8

4 - 20 m A (2 50 K )

[0 to + 10 V (2 0 K )]

AC

E7

4 to 20m A

PP

External

Frequency

R eference

2k

2k

(P=Pair)

External

Frequency

Reference

E (G)

2kΩ

2k

P P

4 to 20m A

+V +15VDC, 20mA

A1 0-10VDC (20k Ω)

A2 H3-08

4-20m A (250K Ω)

[0 to +10V (20K Ω)]

AC

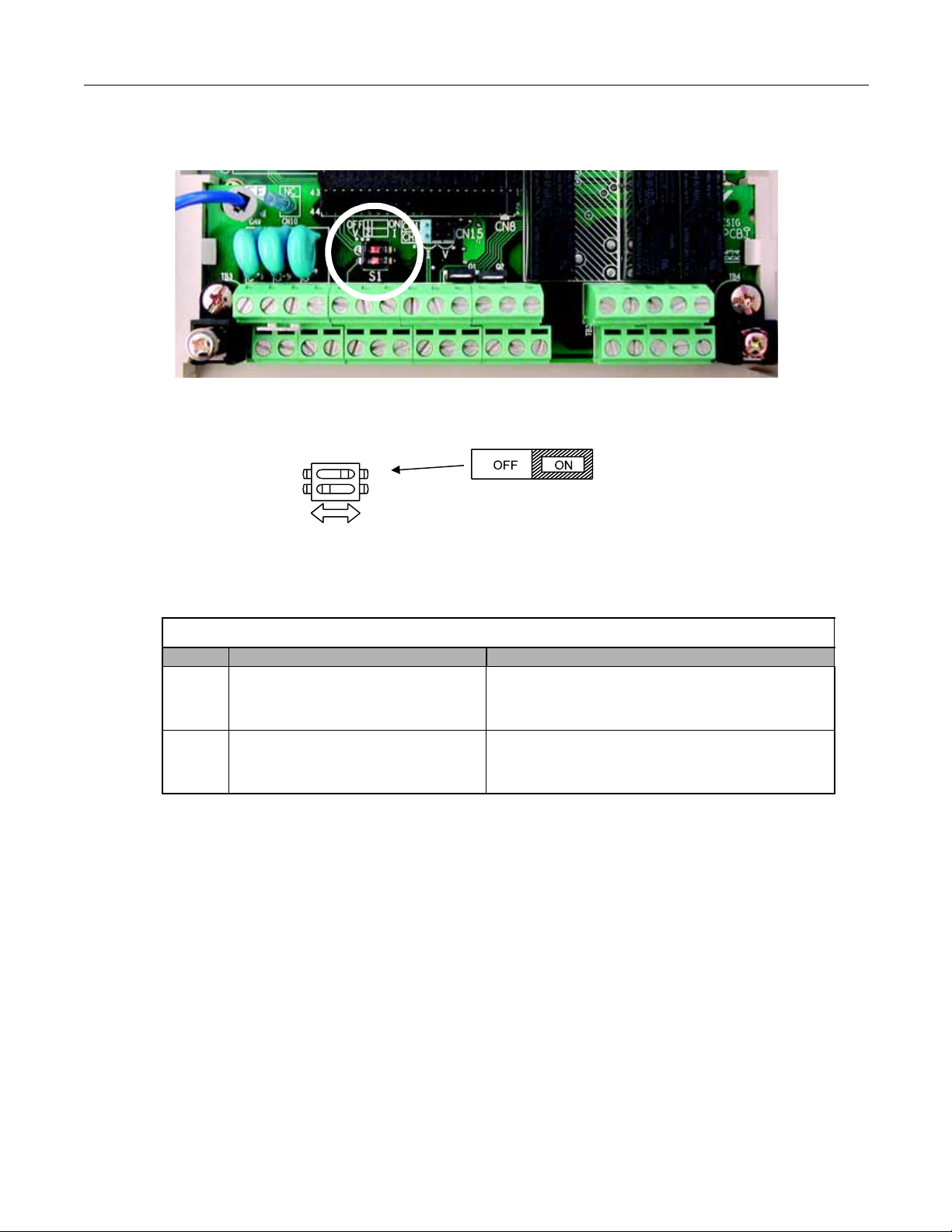

Control Circuit Wire Sizes

The auto mode speed reference (speed command) field wiring connection is made to E7 Drive terminals A1 or A2 (signal

positive), AC (signal common) and G (shield). Keep this lead length as short as possible to maintain signal quality. Insulated

twisted shielded pair wire (2 conductor # 18 ga, Belden 8760 or equivalent) is required. Do not run these wires in the same

conduit as other AC power or control wires. The shield must be connected on this end only, stub and isolate the other end. The

A2 signal employed is 4 to 20 mA with parameter H3-08 set for “2: 4 - 20 mA”. For 0 to 10 VDC, parameter H3-08 is set for

“0: 0 - 10 VDC” and the E7 control board DIP switch S1-2 must be in the OFF position. (See Fig 2.4).

For remote operation, keep the length of the control wiring to 50m or less. Separate the control wiring from high-power lines

(input power, motor leads or relay sequence circuits) to reduce noise induction from peripheral devices.

When setting speed commands (frequency references) from an external speed potentiometer (and not from the Digital Operator), use shielded twisted-pair wires and ground the shield to terminal E(G), as shown in Fig 2.3. Terminal numbers and wire

sizes are shown in Table 2.7.

Ω

Ω

Ω

Ω

Fig 2.3 Analog Input Terminal Configuration

Table 2.7 Terminal Numbers and Wire Sizes (Same for all Drives)

Tightening

Terminals

Te rm in a l

Screws

Torque

lb-in

(N•m)

S1, S2, S3, S4, S5, S6, S7

SN, SC, SP, +V, A1, A2,

AC, MI, M2, M3, M4,

MA, MB, MC, FM, AC,

Phoenix

*3

type

4.2 to 5.3

(0.5 to 0.6)

AM, R+, R-, S+, S-, IG

E(G) M3.5

*1. Use shielded twisted-pair cables to input an external speed command.

*2. Yaskawa recommends using straight solderless terminals on digital inputs to simplify wiring and improve reliability.

*3. Yaskawa recommends using a thin-slot screwdriver with a 3.5 mm blade width.

7.0 to 8.8

(0.8 to 1.0)

Possible

Wire Sizes

AWG (mm2)

Stranded

wire:

26 to 16

(0.14 to 1.5)

20 to 14

(0.5 to 2*2)

Recommended

Wire Size AWG

(mm2)

18

(0.75)

12

(1.25)

• Shielded, twisted-pair wire

• Shielded, polyethylene-covered,

Wire Type

*1

vinyl sheath cable

Electrical Installation 2 - 12

Page 41

Wiring Checks

After all wiring is completed, perform the following checks:

1. Is all wiring correct?

2. Have all wire clippings, screws or other foreign material been removed from the Drive enclosure?

3. Are all terminal screws tight?

Electrical Installation 2 - 13

Page 42

Control Circuit Terminal Functions

The factory default functions of the control circuit terminals for 2-wire control are shown in Table 2.8.

Table 2.8 Control Circuit Terminals

Typ e No. Signal Name Description Signal Level

S1 Forward run/stop command Forward run when CLOSED; stopped when OPEN.

S2 Reverse run/stop command Reverse run when CLOSED; stopped when OPEN.

S3 External fault input Fault when CLOSED.

Digital

input

signals

Analog

input

signals

Digital

output

signals

Analog

output

signals

RS-485/

422

S4 Fault reset Reset when CLOSED

Multi-step speed reference 1

S5

S6 Multi-step speed reference 2

S7 Jog frequency reference Jog frequency when CLOSED.

SN

SC

SP