Page 1

DX200 OPTIONS

1/54

INSTRUCTIONS

FOR ARC SENSOR COMARC FUNCTION

Upon receipt of the product and prior to initial operation, read these instructions thoroughly, and retain

for future reference.

MOTOMAN INSTRU CTIONS

MOTOMAN-- INSTRUCTIONS

DX200 INSTRUCTIONS

DX200 OPERA TOR’S MANUAL

DX200 MAINTENANCE MANUAL

The DX200 Operator’s manual above corresponds to specific usage.

Be sure to use the appropriate manual.

Part Number: 165557-1CD

Revision: 0

MANUAL NO.

HW1482187

0

Page 2

Arc Sensor Comarc

MANDATORY

CAUTION

2/54

165557-1CD

• This manual explains the arc sensor COMARC function of the

DX200 system and general operations. Read this manual carefully

and be sure to understand its contents before handling the DX200.

• General items related to safety are listed in Chapter 1: Safety of the

DX200 Instructions. To ensure correct and safe operation, carefully

read the DX200 Instructions before reading this manual.

• Some drawings in this manual are shown with the protective covers

or shields remov ed for clarity. Be sure all covers and shields are

replaced before operating this product.

• The drawings and photos in this manual are representative

examples and differences may exist between them and the

delivered product.

• YASKAWA may modify this model without notice when necessary

due to product improvements, modifications, or changes in

specifications.

• If such modification is made, the manual number will also be

revised.

• If your copy of the manual is damaged or lost, contact a YASKAWA

representative to order a new copy. The representatives are listed

on the back cover. Be sure to tell the representative the manual

number listed on the front cover.

• YASKA WA is not responsible for incidents arising from unauthorized

modification of its products. Unauthorized modification voids your

product's warranty.

ii

HW1482187

Page 3

165557-1CD

WARNING

CAUTION

MANDATORY

PROHIBITED

NOTE

3/54

Arc Sensor Comarc

Notes for Safe Operation

Read this manual carefully before installation, operation, maintenance, or

inspection of the DX200.

In this manual, the Notes for Safe Operation are classified as

“WARNING”, “CAUTION”, “MANDATORY”, or “PROHIBITED”.

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury to

personnel.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury to

personnel and damage to equipment.

It may also be used to alert against

unsafe practices.

Always be sure to follow explicitly the

items listed under this heading.

Must never be performed.

Even items described as “CAUTION” may result in a serious accident in

some situations.

At any rate, be sure to follow these important items

To ensure safe and efficient operation at all times, be sure to

follow all instructions, even if not designated as "CAUTION"

and "WARNING".

iii

HW1482187

Page 4

Arc Sensor Comarc

WARNING

TURN

4/54

165557-1CD

• Before operating the manipulator, check that servo power is turned

OFF pressing the emergency stop buttons on the front door of the

DX200 and the programming pendant.

When the servo power is turned OFF, the SERVO ON LED on the

programming pendant is turned OFF.

Injury or damage to machinery may result if the emergency stop circuit

cannot stop the manipulator during an emergency. The manipulator

should not be used if the emergency stop buttons do not function.

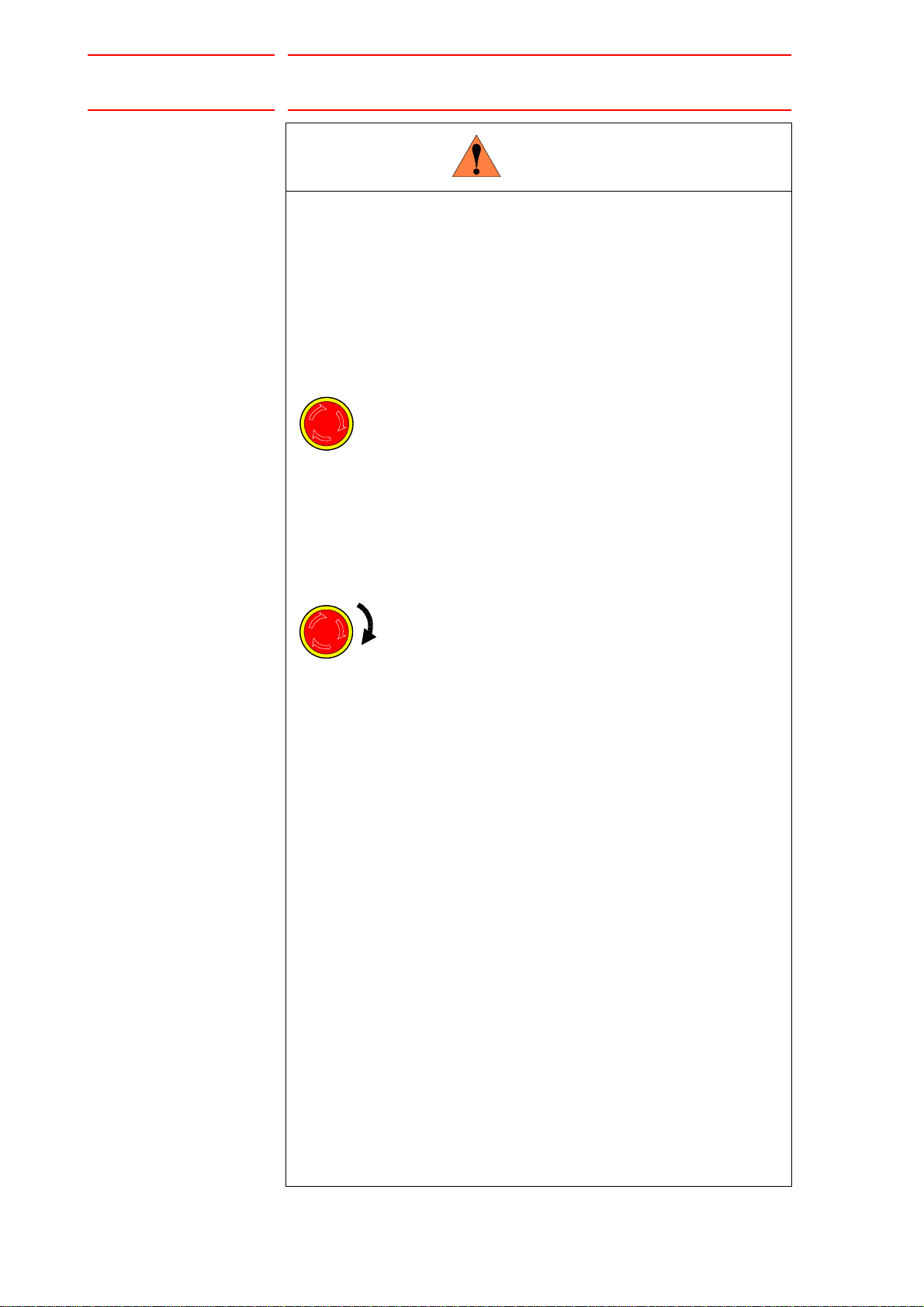

Figure 1: Emergency Stop Button

• Once the emergency stop button is released, clear the cell of all

items which could interfere with the operation of the manipulator.

Then turn the servo power ON.

Injury may r esult from unintentional or u nexpected manipulator motion.

Figure 2: Release of Emergency Stop

• Observe the following precautions when performing teaching

operations within the P-point maximum envelope of the

manipulator:

– View the manipulator from the front whenever possible.

– Always follow the predetermined operating procedure.

– Keep in mind the emergency response measures against the

manipulator’s unexpected motion toward you.

– Ensure that you have a safe place to retreat in case of

emergency.

Improper or unintended manipulator operation may result in injury.

• Confirm that no person is present in the P-point maximum envelope

of the manipulator and that you are in a safe location before:

– Turning ON the power for the DX200.

– Moving the manipulator with the programming pendant.

– Running the system in the check mode.

– Performing automatic operatio ns .

• Injury may result if anyone enters the P-point maximum envelope of

the manipulator during operation. Always press an emergency stop

button immediately if there is a problem.

The emergency stop buttons are located on the right of front door of

the DX200 and the programming pendant.

iv

HW1482187

Page 5

165557-1CD

CAUTION

5/54

Arc Sensor Comarc

• Perform the following inspection procedures prior to conducting

manipulator teaching. If problems are found, repair them

immediately, and be sure that all other necessary processing has

been performed.

– Check for problems in manipulator movement.

– Check for damage to insulation and sheath ing of external wires.

• Always return the programming pendant to the hook on the cabinet

of the DX200 after use.

The programming pendant can be damaged if it is left in the

manipulator's work area, on the floor, or near fixtures.

• Read and understand the Explanation of Warning Labels in the

DX200 Instructions before operating the manipulator.

Definition of Terms Used Often in This Manual

The MOTOMAN is the YASKAWA industrial robot product.

The MOTOMAN usually consists of the manipulator, the controller, the

programming penda nt, and su pply cab le s.

In this manual, the equipment is designated as follows.

Equipment Manual Designation

DX200 controller DX200

DX200 programming pendant Programming pendant

Cable between the ma nipulator and th e

controller

Manipulator cable

v

HW1482187

Page 6

Arc Sensor Comarc

6/54

Descriptions of the programming pendant keys, buttons, and displays are

shown as follows:

Equipment Manual Designation

Programming

Pendant

Character Keys

/Symbol Keys

Axis Keys

/Numeric Keys

Keys pressed

simultaneously

Displays The menu displayed in the programming

The keys which have characters or its

symbol printed on them are denote d with [ ].

ex. [ENTER]

[Axis Key] and [Numeric Key] are generic

names for the keys for axis operation and

number input.

When two keys are to be pressed

simultaneously, the keys are shown with a

“+” sign between them ,

ex. [SHIFT]+[COORD]

pendant is denoted with { }.

ex. {JOB}

Description of the Operation Procedure

165557-1CD

In the explanation of the operation procedure, the expression "Select • • • "

means that the cursor is moved to the object item and the SELECT key is

pressed, or that the item is directly selected by touching the screen.

Registered Trademark

In this manual, names of companies, corporations, or products are

trademarks, registered trademarks, or brand names for each company or

corporation. The indications of (R) and

TM

are omitted.

vi

HW1482187

Page 7

165557-1CD

7/54

Arc Sensor Comarc

1 Installation....................................................................................................................................... 1-1

1.1 Starting Point Detecting Unit..............................................................................................1-2

1.2 Current Detecting Unit ....................................................................................................... 1-3

2 DX200 Wiring.................................................................................................................................. 2-1

2.1 Connection Diagnosis........................................................................................................2-4

3 Arc Sensor Function ....................................................................................................................... 3-1

3.1 Basic Understanding of the Arc Sensor............................................................................. 3-1

3.1.1 Left and Right Path Correction............................................................................. 3-1

3.1.2 Up and Down Path Correction..............................................................................3-2

3.1.3 Applicable Range of the Arc Sensor..................................................................... 3-2

3.2 Main Operations for the Arc Sensor Function.................................................................... 3-3

Table of Contents

3.2.1 Job Preparation for Welding and Adjustment of Welding Conditions................... 3-3

3.2.1.1 Registration of Arc Sensing Instructions .................................................3-4

3.3 Arc Sensor Function and Weaving Condition.................................................................... 3-5

3.3.1 Path Correction Direction and Weaving Basis Coordinate System...................... 3-5

3.3.2 Cases that Require the Registration of Reference Points....................................3-7

4 Registration of Instructions ............................................................................................................. 4-1

4.1 COMARCON (Sensing Start Instruction)...........................................................................4-1

4.2 COMARCOF (Sensing End Instruction) ............................................................................4-4

4.3 COMARCSET (Sensing Condition Change)...................................................................... 4-5

4.4 REFP (Reference Point Registration)................................................................................ 4-7

5 Phase Compensation Value ...........................................................................................................5-1

5.1 Job Preparation for Measurement of Phase Compensation Value....................................5-1

5.2 Measurement and Registration of a Phase Compensation Value.....................................5-3

6 Measurement and Registration of Sensing Conditions................................................................... 6-1

6.1 Job for Measuring Sensing Conditions..............................................................................6-1

6.2 Measurement of Sensing Conditions................................................................................. 6-3

6.3 Registration of Sensing Conditions.................................................................................... 6-4

6.4 Adjustment of Sensing Conditions..................................................................................... 6-5

6.5 Results of Arc Sensing ......................................................................................................6-6

vii

HW1482187

Page 8

165557-1CD

8/54

Arc Sensor Comarc

7 COMARC Condition File .................................................................................................................7-1

7.1 COMARC Condition File....................................................................................................7-1

7.2 File Operation ....................................................................................................................7-3

7.2.1 Display of a File ....................................................................................................7-3

7.2.2 Editing of a File.....................................................................................................7-3

7.2.2.1 Editing of “CORRECTION SELECT” and “CONDITION” ........................7-3

7.2.2.2 Editing of Other Items..............................................................................7-3

7.2.3 Initialization of the File..........................................................................................7-4

8 Modification of the Settings in COMARC Function .........................................................................8-1

9 Instruction List.................................................................................................................................9-1

10 Parameter List.............................................................................................................................10-1

Table of C ontents

11 Alarm Message List.....................................................................................................................11-1

viii

HW1482187

Page 9

165557-1CD

WARNING

9/54

Arc Sensor Comarc

1 Installation

1 Installation

• Since detected voltage (200 V), welding current, and welding

voltage are applied to the starting point detecting unit, install the unit

securely so that it does not fall.

Failure to observe this warning may result in an electric shock or

damage to the unit.

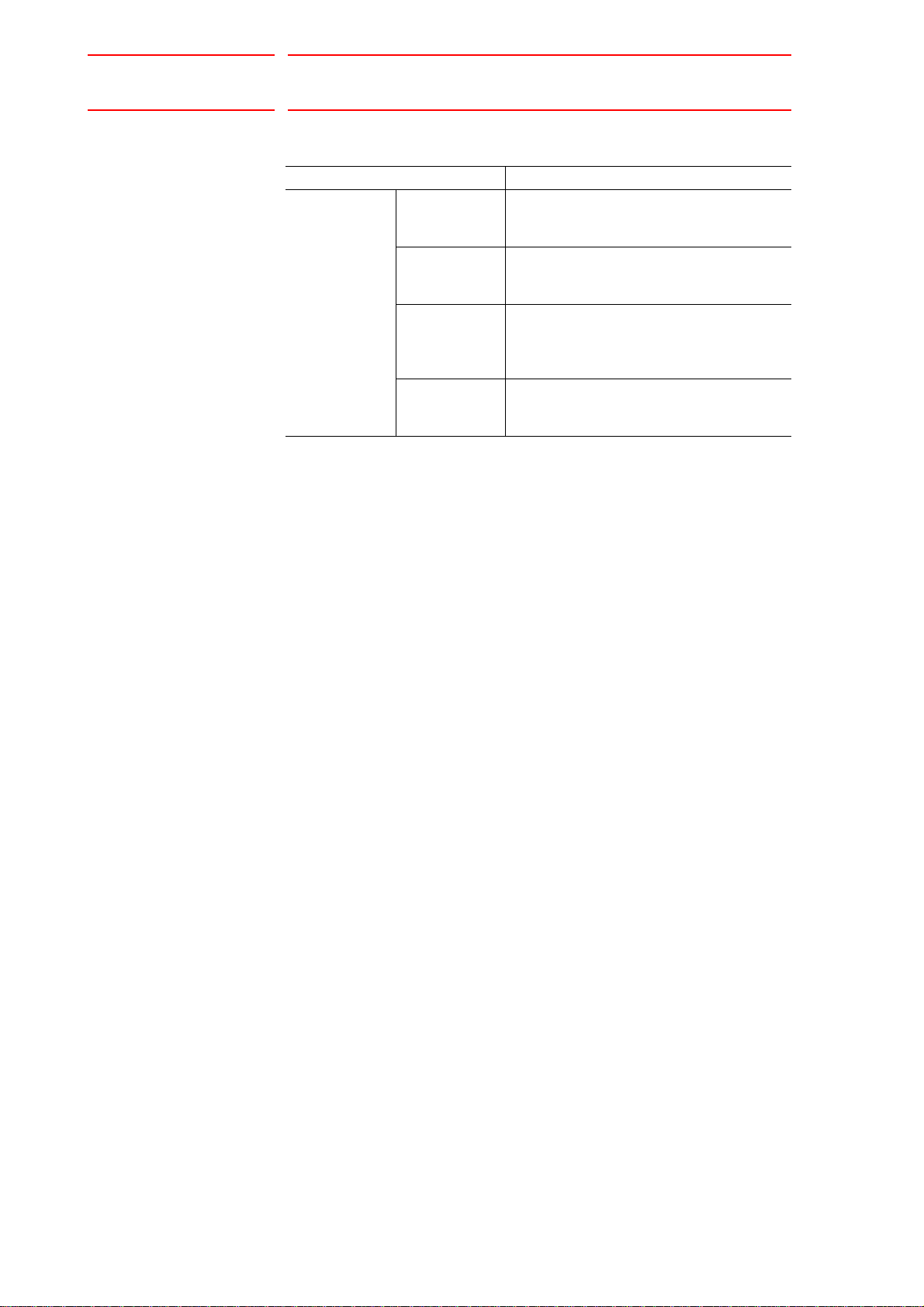

For installation methods of a starting point detecting unit and a current

detecting unit, refer to Fig.1-1 Installation of Starting Point Detecting Unit

and Fig.1-2 Installation of Current Detecting Unit.

The starting point detecting unit should be installed outside of the

manipulator interference area.

1-1

HW1482187

Page 10

Arc Sensor Comarc

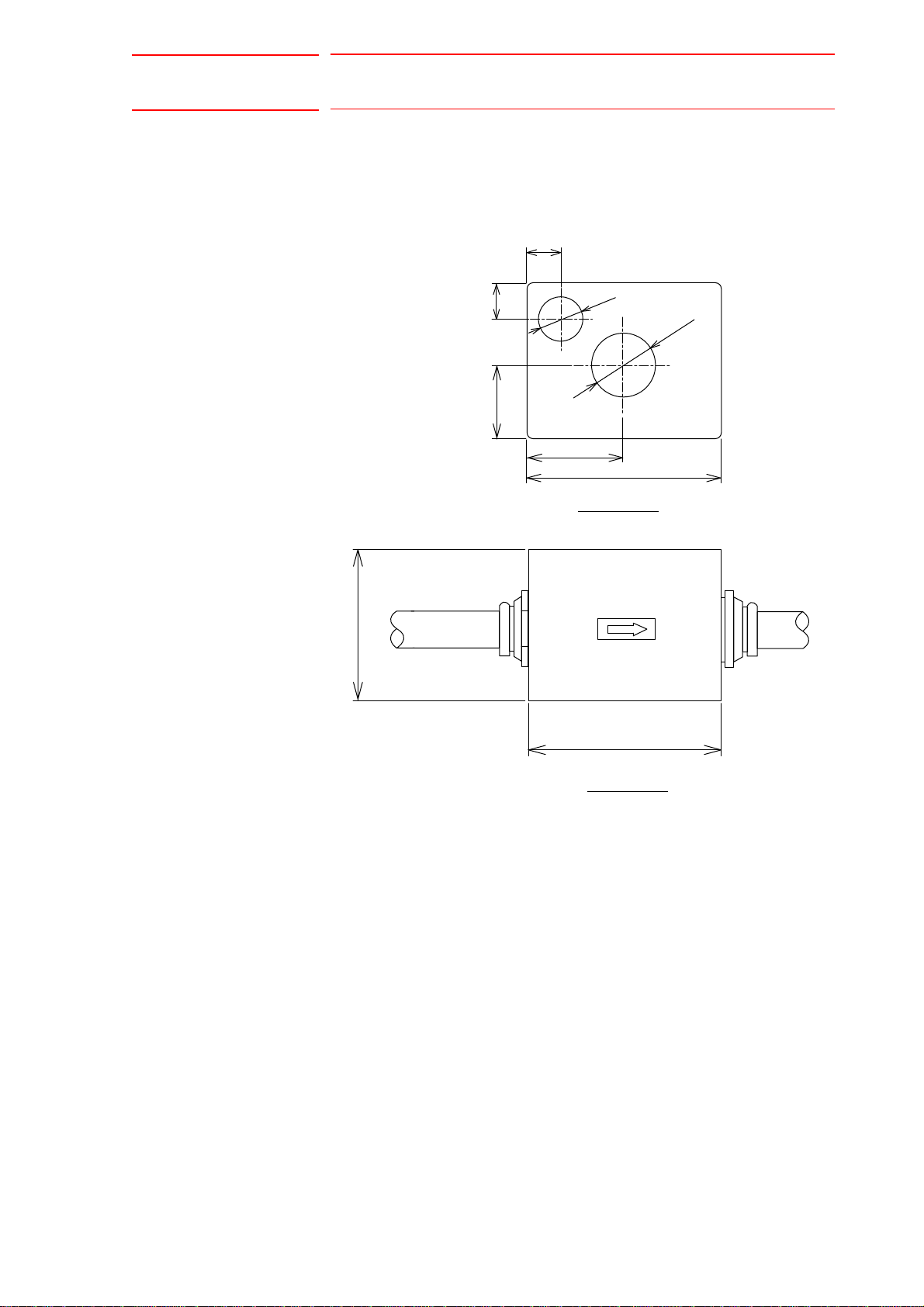

400

400

345

1NL 1LED 1PEI

3

1SW

ON

OFF

1FU

1A

2

1

Air vent

Front View

Eyebolt M8 (2 eyebolts)

500

(38)

150

Air vent

Side View

Units: mm

10/54

165557-1CD

1 Installation

1.1 Starting Point Detecting Unit

1.1 Starting Point Detecting Unit

The starting point detecting unit should be installed on the side of the

welder.

When installing the unit on a welder or other devices, use a fixture to fix

the unit with the mounting holes located on both sides of the unit in order

to prevent the unit from falling.

Fig. 1-1: Installation of Starting Point Detecting Unit

1-2

HW1482187

Page 11

165557-1CD

11/54

Arc Sensor Comarc

1 Installation

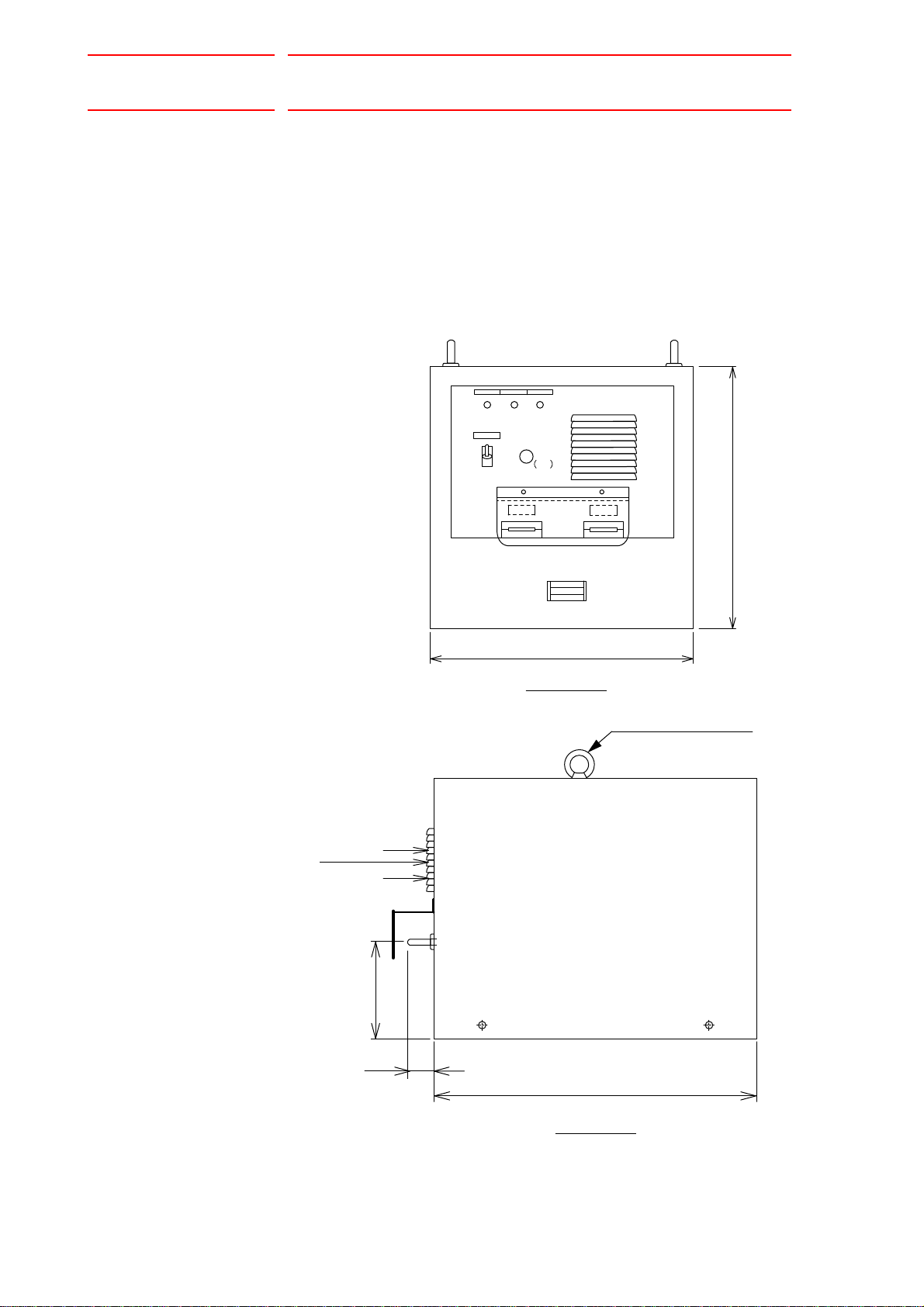

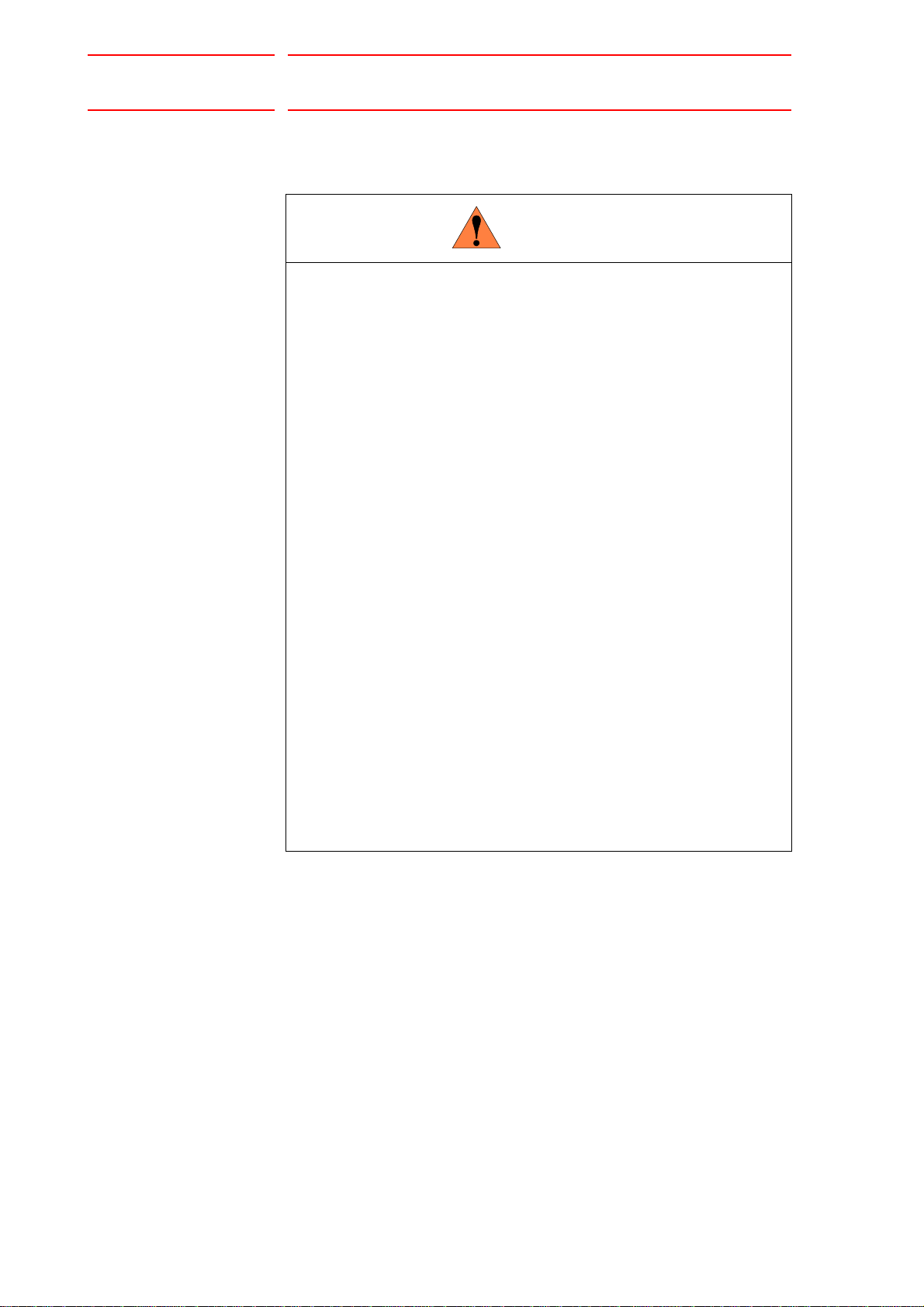

1.2 Current Detecting Unit

1.2 Current Detecting Unit

Fig. 1-2: Installation of Current Detecting Unit

18

18

80

18

Ǿ21

Ǿ33.5

38

50

100

Front View

100

Units: mm

Side View

1-3

HW1482187

Page 12

Arc Sensor Comarc

WARNING

12/54

2 DX200 Wiring

165557-1CD

2 DX200 Wiring

• Before connecting the inter-unit cables and the welding cables, be

sure to turn OFF the power supply to the DX200 and the welder.

Failure to observe this warning may result in an electric shock.

• Special attention should be paid during starting point detection,

since 200 VDC is applied across the wire and the workpiece

(welding jig).

Failure to observe this warning may result in an electric shock.

• Do not place any object directly on the cable of the starting point

detecting unit.

Failure to observe this warning may result in an injury or damage

caused by the disconnection of the cable.

• Attach the cable of the starting point detecting unit for the wire

feeder with the wire stand, to protect it from robot movement.

If interference between the cable and the peripheral devices cannot

be avoided, cover the cable with a rubber plate or spiral tube, etc.

Failure to observe this warning may result in an electric shock caused

by damage to the cable, or an injury or damage caused by malfunction.

• Do not lay the cable of the starting point detecting unit directly on

the floor, but install them in a pit or duct, or attach the cable with a

protective co ve r.

Failure to observe this warning may result in an injury or damage to the

cable.

• Since a high current flows through the welding cable, separate it

from the cables of the control circuit system. If the cables cannot be

separated, take preventative measures such as using metallic ducts

or tubes on the cables of the control circuit system.

2-1

HW1482187

Page 13

165557-1CD

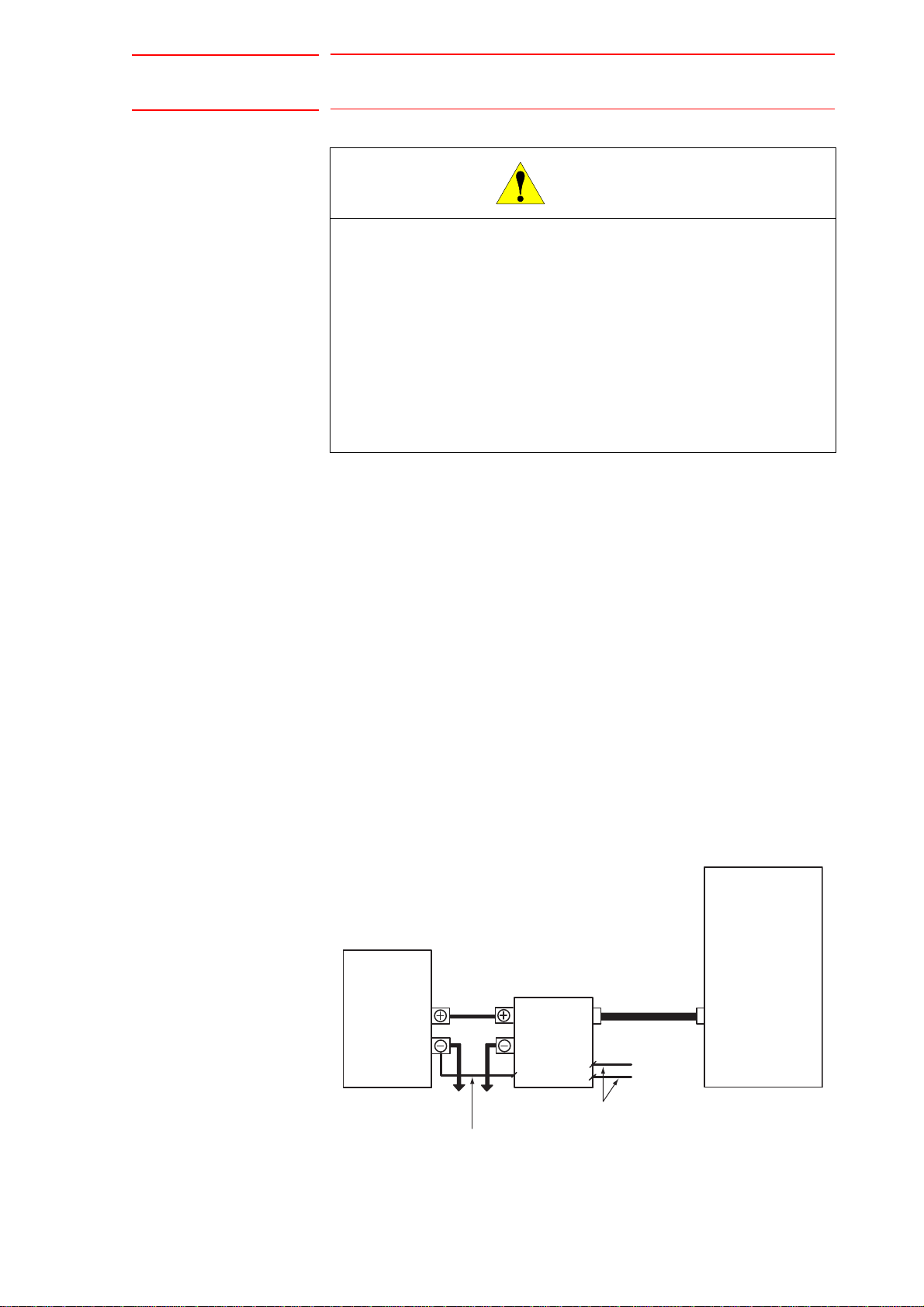

CAUTION

1CN

SE1

SE2

DX200

E

Welder

Welding cable

Starting point

detecting unit

Ground cable

To the workpiece To the wire feeder

Cable for welding voltage detection

To the torch

To the welder

Inter-unit cable

YCP02 board

13/54

Arc Sensor Comarc

2 DX200 Wiring

• Insert the inter-unit cable on the starting point detecting unit side,

firmly to the connector, and fix it securely by tightening the coupling

nut.

• Fix the other cables connected to the terminal stand securely by

tightening the terminal screws.

Failure to observe these cautions may result in an electric shock, an

injury, or damage caused by malfunctioning.

• After connected, be sure to reinstall the terminal covers of starting

point detecting unit and welder.

Failure to observe this caution may result in an electric shock.

Wire the unit in the following manner, referring to Fig.2-1 Configuration

Diagram of Starting Point Detecting Unit and Fig.2-2 Configuration

Diagram of Current Detecting Unit.

Starting Point Detecting U nit

1. Connect the starting point detecting unit to the DX200.

2. Connect the plus terminal of the starting point detecting unit to the plus

terminal of the welder.

3. Connect the minus terminal of the starting point detecting unit to the

torch power supply unit on the wire feeder.

4. Connect the front terminal of the stand of the starting point detecting

unit to the welding voltage detecting terminal on the wire feeder in the

case of a floor-standing type, and to the terminal stand in the welder in

the case of a welder-side hung type, respectively.

Fig. 2-1: Configuration Diagram of Starting Point Detecting Unit

2-2

HW1482187

Page 14

Arc Sensor Comarc

14/54

165557-1CD

2 DX200 Wiring

Current Detecting Unit

1. Connect the connection cable of current detecting unit to the DX200.

2. Connect the plus cable of the current detecting unit to the + terminal of

the welder.

Connect the other cable to the welding cable from the torch power

supply unit on the wire feeder, and tape it with an insulating tape.

Fig. 2-2: Configuration Diagram of Current Detecting Unit

DX200

Welder

Current detecting unit

YCP02 board

To the workpiece To the wire feeder

2-3

HW1482187

Page 15

165557-1CD

NOTE

15/54

Arc Sensor Comarc

2 DX200 Wiring

2.1 Connection Diagnosis

2.1 Connection Diagnosis

To confirm a connection, perform a diagnosis of the input status to the

YCP02 board.

(The YCP02 board is a board for the COMARC.)

Use the following procedure to call the YCP 02 I/O status display.

1. Select {IN/OUT} from the main menu.

2. Select {YCP02 I/O}.

– The YCP02 I/O STATUS window appears.

– In this display, confirm the values read-by the YCP02 board’s A/D

converter and the general I/O status.

– Eight channels are provided for the A/D converter.

– Four points for input and output respectively are provided for general

I/O.

– Use the YCP02 I/O STATUS window for the following purposes;

• Check whether the A/D converter is correctly operating.

• Check whether the cables for the current detecting unit are correctly connected.

For an incorrect

connection

For normal status When welding is performed by

• The YCP02 I/O STATUS window can be called only in

"MANAGEMENT MODE".

• When the icon {YCP02 I/O} does not appear, switch the

security mode to "MANAGEMENT MODE".

When welding is performed, the A/D

data shows a negative value (-).

executing the normal ARCON/ARCOF,

the A/D data show a positive value (+).

(Execute a job without using

COMARCON/COMARCOF.)

2-4

HW1482187

Page 16

Arc Sensor Comarc

Welding current: = , (When the distance

between the tip and the base metal is the same on

both sides.)

1 2

1 2

Welding current > (shifted to the left) Welding current < (shifted to the right)

Direction of path

correction

Direction of path

correction

1

21 2

1 2 1 2

16/54

3 Arc Sensor Function

3.1 Basic Understanding of the Arc Sensor

3 Arc Sensor Function

3.1 Basic Understanding of the Arc Sensor

For welding with a power supply that has constant voltage characteristics,

the welding current fluctuates as the distance L changes as shown below.

Distance L is the distance between the tip and the base metal. The arc

sensor function uses these characteristics.

Consumable

electrode (wire)

Arc

165557-1CD

Welding current

High Low

Tip

L

Base

metal

3.1.1 Left and Right Path Corre ction

During welding with the torch weaving from side to side, an equal amount

welding current flows on points and if the distance L is the same on

both sides (points and ) due to the aforementioned characteristics.

If the distances L are different at points and , different currents flow at

these two points as shown below.

The arc sensor checks the welding currents at points and and

corrects the path to equalize the values.

3-1

HW1482187

Page 17

165557-1CD

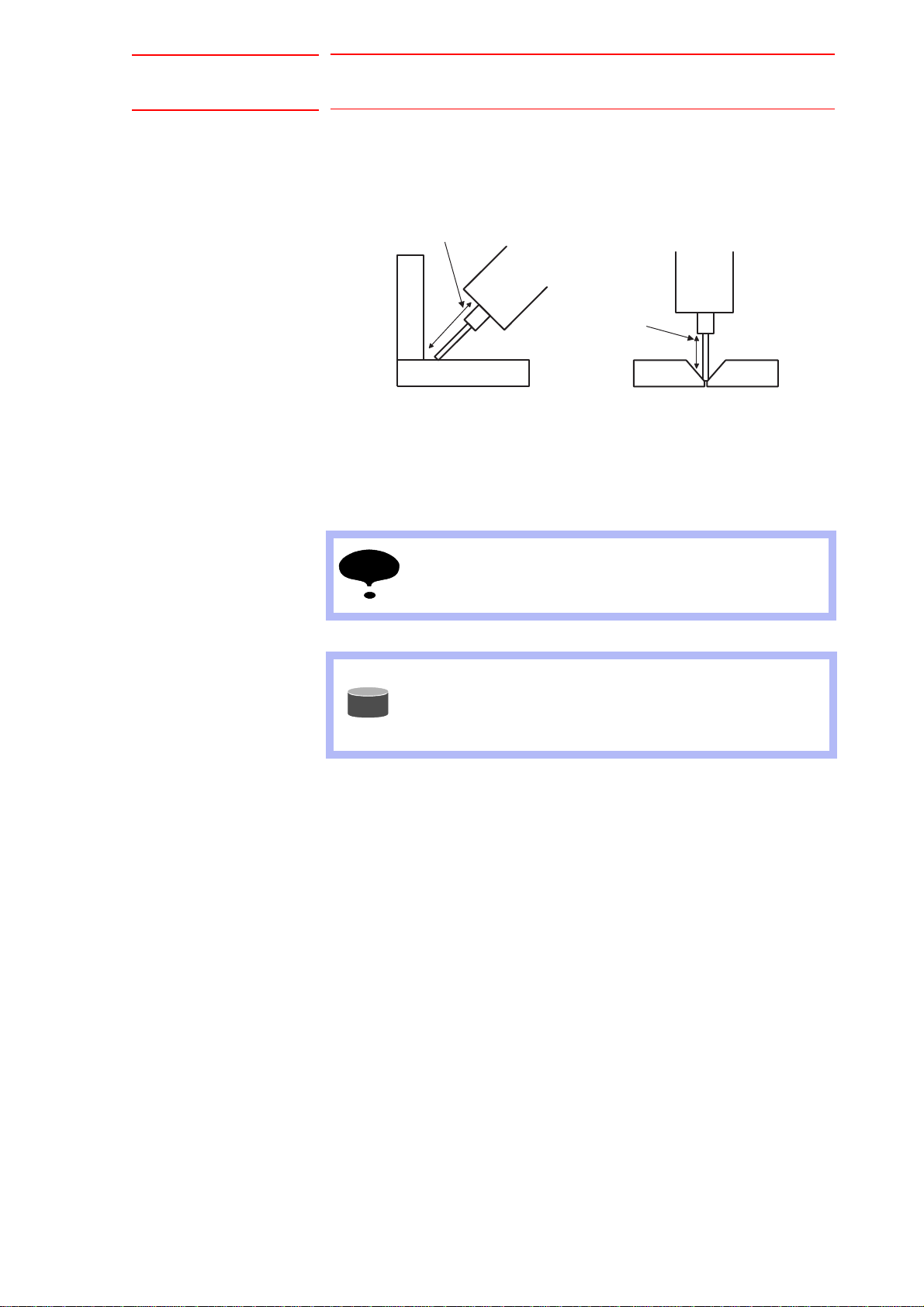

Up and down path

correction

Up and down path

correction

NOTE

SUPPLE-

MENT

17/54

Arc Sensor Comarc

3 Arc Sensor Function

3.1 Basic Understanding of the Arc Sensor

3.1.2 Up and Down Path Correction

During welding with the torch moving up and down, the arc sensor checks

the welding currents at any 2 points, an upper point and a lower point, and

corrects the path to equalize the values.

3.1.3 Applicable Range of the Arc Sensor

The applicable metal thickness and joint are as follows.

Metal thickness: 3.2 mm or more

Joint: T joint, Lap joint

Speed: 1 m/min or less

The arc sensor function can be used except that the droplet

transfer status is a spray transfer.

• The droplet transfer means that the welded tip of wire

(droplet) transfers to the base metal.

• For the status of droplet transfer, there are dip transfer,

spray transfer, and etc.

3-2

HW1482187

Page 18

Arc Sensor Comarc

Prepare a job for welding.

Set and adjust the welding

conditions.

18/54

165557-1CD

3 Arc Sensor Function

3.2 Main Operations for the Arc Sensor Function

3.2 Main Operations for the Arc Sensor Function

3.2.1 Job Preparation for Welding and Adjustment of Welding Conditions

Prepare a job for welding and adjust the welding conditions.

3-3

HW1482187

Page 19

165557-1CD

NOTE

Register a COMARCON/

COMARCOF instruction in

the arc sensing section.

19/54

Arc Sensor Comarc

3.2.1.1 Registration of Arc Sensing Instructions

3 Arc Sensor Function

3.2 Main Operations for the Arc Sensor Function

Register a COMARCON/COMARCOF instructions in the section where

arc sensing is to be performed.

Set the UP/DOWN correction condition (U/D) to the same values as the

value of the current setting in the ARCON instruction.

Set the LEFT/RIGHT co rrecti on con di tion to "0".

When adjustment of the targeted position is required after seeing the

results of the welding done with the arc sensor, adjust the UP/DOWN

correction conditions (U/D) or the LEFT/RIGHT correction conditions (L/

R).

For details on how to adjust the UP/DOWN and LEFT/RIGHT correction

conditions, refer to Section 6.4 “Adjustment of Sensing Conditions” on

page 6-5.

Depending on the welding current range to be used, the

current value set with ARCON instruction may differ from

the current value actually output from the welder.

In this case, measure the sensing conditions when

registering the COMARCON instruction.

For details on how to measure a sensing condition, refer to

Chapter 6 "Measurement and Registration of Sensing

Conditions" on page 6-1.

When an actual workpiece cannot be used to measure a

sensing condition, use a test pie ce .

Then, for the UP/DOWN and LEFT/RIGH T correc ti on

conditions ( U/D a n d L /R) for the COMARCON instruction in

the actual work job, enter the values based on those

measurements using the numeric keys.

3-4

HW1482187

Page 20

Arc Sensor Comarc

SUPPLE-

MENT

NOTE

Horizontal direction

Weaving Basis Coordinate System

Advance direction

Wall direction

Wall direction

Z direction

Horizontal

direction

Approach point

20/54

165557-1CD

3 Arc Sensor Function

3.3 Arc Sensor Function and Weaving Condition

3.3 Arc Sensor Function and Weaving Condition

3.3.1 Path Correction Direction and Weaving Basis Coordinate System

As described in Section 3.1 “Basic Understanding of the Arc Sensor” on

page 3-1 , the path correcting direction and weaving action are closely

related.

Weaving is performed based on the following coordinate system. This

coordinate system is generated automatically when weaving is executed.

Wall Direction: Z direction of the robot axis

Horizontal Direction: The direction of approach point from the wall

Advance Direction: The direction that the torch moves from the weaving

start point to the end poin

t

The approach point is a point indicated by a step

immediately before the step where weaving starts.

Depending on the mouthing and shape of the workpiece, a

definition of the above coordinate system may not be

sufficient to generate a weaving pattern. In that case,

register the reference point REFP 1 or REFP 2.

For details, refer to Section 3.3.2 “Cases that Require the

Registration of Reference Points” on page 3-7

.

3-5

HW1482187

Page 21

165557-1CD

21/54

Arc Sensor Comarc

3 Arc Sensor Function

3.3 Arc Sensor Function and Weaving Condition

The weaving coordination and the path correcting direction are as follows.

Wall direction

Up and Down

Up and Down

Left and Right

Horizontal

direction

Wall direction

Left and Right

Horizontal

direction

Left and Right path correction is same as the amplitude direction of a

weaving, and Up and Down path correction is same as perpendicular

direction against the amplitude of a weaving.

3-6

HW1482187

Page 22

Arc Sensor Comarc

SUPPLE-

MENT

REFP1 REFP2

On the wall surface or

its expansion plane

On the right or left side of the wall

Horizontal

direction

Advance

direction

Wall direction

WallWall

REFP1REFP1REFP1

REFP1

REFP2

REFP2

Advance

direction

Wall direction

22/54

165557-1CD

3 Arc Sensor Function

3.3 Arc Sensor Function and Weaving Condition

3.3.2 Cases that Require the Registration of Reference Points

The registration of the reference point REFP1 or REFP2 is not usually

required. They are required only with a special workpiece condition, etc.

The REFP1, that defines the wall direction, is a point on the wall surface

or its expansion plane. The REFP2, which defines the horizontal

direction, is a point on the right or left side of the wall.

< Example 1 >

REFP1 is registered because the wall direction is not parallel to the Z

direction of the robot axis.

Also, register REFP1 when a robot is hanging from the ceiling. In such

case, the Z direction of the robot axis differs from wall direction.

For information on registering REFP, refer to Section 4.4

“REFP (Reference Point Registration)” on page 4-7.

Z direction

Wall direction

REFP1

0003

0004

0005

0006

0007

Example

MOVL V=120

REFP 1

WVON WEV#(1)

MOVL V=50

WVOF

3-7

HW1482187

Page 23

165557-1CD

A

23/54

Arc Sensor Comarc

3 Arc Sensor Function

3.3 Arc Sensor Function and Weaving Condition

< Example 2 >

REFP2 is registered because the approach point is on another side of

the wall.

Example

Wall

pproach point

REFP2

Approach point

0009 MOVJ VJ=25.00

0010

MOVL V=120

0011

REFP 2

0012

WVON WEV#(1)

0013

MOVL V=50

0014

WVOF

3-8

HW1482187

Page 24

Arc Sensor Comarc

24/54

4 Registration of Instructions

4.1 COMARCON (Sensing Start Instruction)

4 Registration of Instructions

4.1 COMARCON (Sensing Start Instruction)

The COMARCON instruction starts the arc sensing and weaving.

correction conditions (UP/DOWN correction condition, RIGHT/LEFT

correction condition), and the COMARC condition file No. specifications.

< > indicates numerical or alphabetical data.

COMARCON Function Starts arc sensing and weaving.

165557-1CD

Instructio

n items

Examples COMARCON AMP=2.0 FREQ=3.0 U/D=200 L/R=0.0

Settings Data input range Unit

Weaving conditions

AMP = <Weaving amplitude>

FREQ = <Weaving frequency>

ANGL=<Weaving angle>

WEV# (<Weaving file No.>)

DIR=<Weaving direction>

Correction conditions

U/D = <Correcting the up and down

path)

L/R = <Correcting the left and right

path>

COMARC condition file No.

CAF# (<COMARC condition file No.>) 1 to 128 -

COMARCON WEV#(1) U/D=200 L/R=0.0

COMARCON AMP=2.0 FREQ=3.0 U/D=200 L/R=0.0 CAF#(1)

COMARCON WEV#(1) U/D=200 L/R=0.0 CAF#(1)

1)

AMP: 0.1 to 99.9

FREQ: 0.1 to 5.0

ANGL: 0.0 to 180.0

1 to 255

0 or 1

U/D: 1 to 999

L/R: -255.0 to 255.0

0.1 mm

0.1 Hz

0.1 deg.

-

-

1 A

0.1 A

1 Two setting methods are available: setting by AMP and FREQ or setting by WEV#. When

weaving condition s are set by AMP and FRE Q, the weavin g mod e is “sin gle oscil latio n”. When

ANGL is set to UNUSED, weaving angle is set to 45 deg.

Do not use DIR normally. DIR specifies the weaving direction changing. DIR=0 equals to

UNUSED.

4-1

HW1482187

Page 25

165557-1CD

NOTE

25/54

Arc Sensor Comarc

4 Registration of Instructions

4.1 COMARCON (Sensing Start Instruction)

• Be sure to register the COMARCON instruction after the

ARCON instruction.

Register the COMARCON/COMARCOF instruction and

the ARCON/ARCOF instruction in the same job.

• For setting and adjusting sensor correction conditions,

refer to Chapter 6 "Measurement and Registration of

Sensing Conditions" on page 6-1.

• When a COMARC condition file is not specified for the

COMARCON instruction, perform sensing under the

following conditions in the COMARC condition file display.

• “CORRECTION SELECT” (direction of path correction):

U/D & L/R (all directions)

• “CONDITION” (operation after pass-over): NOT

MONITOR

For details on the COMARC condition file, refer to Chapter

7 "COMARC Condition File" on page 7-1.

1. Move the cursor to the address area.

2. Press [I NFORM LIST].

3. Select "SENSOR".

4. Select "COMARCON".

– The instruction appears with the previously registered additional

items in the input buffer line.

5. Press [SELECT], and set the conditions in the detail edit window.

(1) Move the cursor to the item to be set, and press [SELECT].

(2) Enter each condition using the numeric keys, and then press

[ENTER].

4-2

HW1482187

Page 26

Arc Sensor Comarc

26/54

165557-1CD

4 Registration of Instructions

4.1 COMARCON (Sensing Start Instruction)

– The following two methods are available to set weaving conditions.

• When a weaving condition is set by additional items

• When a weaving condition is specified by the file

6. Press [ENTER] twice.

– Press [ENTER] in the detail edit window to display the setting details

in the input buffer line.

Press [ENTER] again to register the setting details in the job.

4-3

HW1482187

Page 27

165557-1CD

NOTE

27/54

Arc Sensor Comarc

4 Registration of Instructions

4.2 COMARCOF (Sensing End Instruction)

4.2 COMARCOF (Sensing End Instruction)

The COMARCOF instruction ends arc sensing and weaving.

COMARCOF Function End s arc sen si ng and weav in g.

Instruction

item

Example COMARCOF

Be sure to register the COMARCOF instruction before the

ARCOF instruction.

Register the COMARCON/COMARCOF instruction and the

ARCON/ARCOF instruction in the same job.

1. Move the cursor to the address area.

2. Press [I NFORM LIST].

-

3. Select "SENSOR".

4. Select "COMARCOF".

– The instruction appears in the input buffer line.

5. Press [ENTER].

4-4

HW1482187

Page 28

Arc Sensor Comarc

NO TE

28/54

165557-1CD

4 Registration of Instructions

4.3 COMARCSET (Sensing Condition Change)

4.3 COMARCSET (Sensing Condition Change)

The COMARCSET instruction changes the arc sensing conditions and the

weaving conditions.

There are three types of settings for the COMARCSET instruction:

weaving conditions (weaving amplitude, weaving angle), sensor

correction conditions (UP/DOWN correction condition, RIGHT/LEFT

correction direction), and the COMARC condition file No. specifications.

<> indicates numerical or alphabetical data.

COMARCSET

1)

Function Changes the sensing conditions and the weaving condition.

Instruction

items

Examples COMARCSET AMP=2.5 U/D=210 L/R=0.0 CAF#(2)

Settings Data input range Unit

Weaving conditions

AMP = <Weaving amplitude>

ANGL=<Weaving angle>

Correction conditions

U/D = <correcting the up and down path>

L/R = <correcting the left and right path>

COMARC condition file No.

CAF# (<COMARC condition file No.>) 1 to 128 -

COMARCSET AMP=2.5

COMARCSET U/D=210

COMARCSET L/R=1.0

COMARCSET CAF#(2)

AMP: 0.1 to 99.9

ANGL: 0.0 to 180.0

U/D: 1 to 999

L/R: -255.0 to 255.0

1 For the COMARCSET instruction, only the items to be changed can be set.

• The conditions registered with the COMARCSET

instruction are validated when executing the move

instruction after the COMARCSET instruction.

0.1 mm

0.1 deg.

1 A

0.1 A

• For setting and adjusting sensor correction conditions,

refer to Chapter 6 "Measurement and Registration of

Sensing Conditions" on page 6-1.

• For details on the COMARC condition file, refer to Chapter

7 "COMARC Condition File" on page 7-1.

4-5

HW1482187

Page 29

165557-1CD

29/54

Arc Sensor Comarc

4 Registration of Instructions

4.3 COMARCSET (Sensing Condition Change)

1. Move the cursor to the address area.

2. Press [I NFORM LIST].

3. Select "SENSOR".

4. Select "COMARCSET".

– The instruction appears with the previously registered additional

items in the input buffer line.

5. Press [SELECT], and set the conditions in the detail edit window.

(1) Move the cursor to the item to be set, and press [SELECT].

(2) Enter each condition using the numeric keys, and then press

[ENTER].

6. Press [ENTER] twice.

4-6

HW1482187

Page 30

Arc Sensor Comarc

Place before where

reference point is to

be registered

Reference point

is registered.

30/54

165557-1CD

4 Registration of Instructions

4.4 REFP (Reference Point Registration)

4.4 REFP (Reference Point Registration)

Reference point instructions (REFP) set an auxiliary point such as a wall

point for weaving.

Reference points No.1 to 8 are assigned for each application. Follow the

procedure below to register reference point instructions.

1. Select {JOB} under the main menu.

2. Select {JOB}.

3. Move the cursor.

– Move the cursor to the line immediately before the position where

the reference point to be registered.

4. Squeeze the Enable switch.

– The servo power is turned ON.

5. Press the axis key.

– Use the axis key to move the manipulator to the position to be

registered as a reference point.

6. Press [REFP].

– The reference point instruction is displayed in the input buffer line.

7. Change the reference point number.

– Move the cursor to the reference point number, and press [SHIFT] +

the cursor key to change the reference point number.

– If you use the numeric keys to input the reference point number,

press [SELECT] when the cursor is on the reference point number

("Ref-point_no.=").

The data input line is displayed. Input number and press [ENTER].

8. Press [INSERT].

– The [INSERT] key lamp lights.

– When registering before the END instruction, [INSERT] is not

needed.

9. Press [ENTER].

– The REFP instruction is registe r ed.

4-7

HW1482187

Page 31

165557-1CD

A

31/54

Arc Sensor Comarc

5 Phase Compensation Value

5.1 Job Preparation for Measurement of Phase Compensation Value

5 Ph ase Compensation Value

As explained in Section 3.1 “Basic Understanding of the Arc Sensor” on

page 3-1, the arc sensing corrects the manipulator path by measuring the

welding current values at the peak and bottom of the waves of weaving

motion.

However, in the actual welding, a discrepancy between the weaving cycle

and the peak value of the current variation cycle is generated as shown in

the following figure.

The phase compensation value compensates for this discrepancy.

Since the phase compensation value differs depending on the welding

circumstances, measure and register a value for each welder.

Welding current peak value

Welding current wave form

Both ends of weaving motion

discrepancy between the weaving motion and the welding current peak value is generated.

5.1 Job Preparation for Meas ureme n t of Phas e

Compensa tion Value

Prepare a job to measure a phase compensation value.

Refer to the following job example to prepare a job for measurement of a

phase compensatio n val ue.

Table 5-1: Job Example for Measurement of Phase Compensation Value

NOP

MOVJ VJ=50.00

MOVJ VJ=50.00

ARCON AC=200 AVP=100

COMARCON AMP=2.0 FREQ=3.0 U/D=200 L/R=0.0

MOVL V=80

COMARCOF

ARCOF

MOVL V=800

MOVJ VJ=50.00

END

Weaving motion

5-1

HW1482187

Page 32

Arc Sensor Comarc

NO TE

32/54

165557-1CD

5 Phase Compensation Value

5.1 Job Preparation for Measurement of Phase Compensation Value

For measurement of a phase

compensation value, teach the

torch positions as if there is a top

plate. (Steps 2 and 3).

Step 4

Step 3

Step 2

Steps 1

and 5

• Execute a job for measurement of phase compensation

value under the same welding condition (current value,

voltage value, torch positions) as a job with an actual

workpiece.

• For the weaving conditions, measure the phase

compensation values for all the weaving frequencies used

in the actual welding.

• For measurement of a phase compensation va lue , teach

the torch positions as if there is a top plate. (Steps 2 and

3).

5-2

HW1482187

Page 33

165557-1CD

NO TE

33/54

Arc Sensor Comarc

5 Phase Compensation Value

5.2 Measurement and Registration of a Phase Compensation Value

5.2 Measurement and Registration of a Phase Compensation

Value

• Measuring and registering a phase compensation value is

only possible in “MANAGEMENT MODE”. Change the

security mode to “MANAGEMENT MODE”.

• The phase compensation value is registered in the

parameter SxE. To measure and register phase

compensation value, set the parameter SxE197 to “1” first,

then proceed the following operations.

• After the registration of phase compensation value, be

sure to reset the parameter SxE197 to “0”.

1. Select the job for measurement of a phase compensation value.

2. Select {U TILITY} in the JOB CONTENT window in pl ay mode.

3. Select {SETUP SPECIAL RUN} from the selection dialog box.

– The SPECIAL PLAY window appears.

4. Set the "COMARC MEASURE MODE" to "VALID".

(1) Move the cursor to "COMARC MEASURE MODE", and press

[SELECT] to set the mode to "VALID".

(2) The message "COMARC MEASURE MODE" appears in the mes-

sage line.

5. Execute the job.

6. Select {UTILITY} in t he teach mode.

5-3

HW1482187

Page 34

Arc Sensor Comarc

NO TE

34/54

165557-1CD

5 Phase Compensation Value

5.2 Measurement and Registration of a Phase Compensation Value

7. Select {COMARC COND. MODIFY}.

– The COMARC PHASE COMP window appears.

8. Select {PARAMETER} from the main menu.

9. Select {SxE}.

10.Display the parameter No. to be changed.

11. Register the measured value.

– Register the phase compensation value confirmed in the COMARC

PHASE COMP window appears.

• After measuring the phase compensation value, be sure to

reset the "COMARC MEASURE MODE" to “INVALID”.

• When the shielding gas is changed, measure and register

the phase compensation value.

If the type of shielding gas is different, the parameter No.

is different.

Measure and register phase compensation values for all the

frequencies used in the actual welding.

Depending on the frequency for which a phase

compensation value is measured, the values may be

registered in same parameter No.. In this case, register the

average value of several measured phase compensation

values.

<Example>

The phase compensation values for the weaving frequencies 4.0 Hz and 5.0 Hz are registered in SxE060.

In this case, the average value of the phase compensation values for the weaving frequencies 4.0 Hz and 5.0 Hz

is registered in SxE060.

5-4

HW1482187

Page 35

165557-1CD

1

6

3

2

4

5

1 to 6: Taught steps

35/54

Arc Sensor Comarc

6 Measurement and Registration of Sensing Conditions

6.1 Job for Measuring Sensing Conditions

6 M easurement and Registration of Sensing Cond itio ns

6.1 Job for Measuring Sensing Conditions

Play back the measuring job in the sensing condition measurement mode

to automatically measure the data of the sensing conditions (correction

conditions in the up/ down/left/right directions).

The following shows an example of a measuring job.

<Example>

Job for measuring sensing conditions

0000 NOP

0001 MOVJ VJ=50.00

0002 MOVJ VJ=50.00

0003 MOVJ VJ=30.00

0004 ARCON AC=200 AVP=100

0005 COMARCON AMP=2.0 FREQ=3.0 U/D=200 L/R=0.0

0006 MOVL V=80

0007 COMARCOF

0008 ARCOF

0009 MOVJ VJ=30.00

0010 MOVJ VJ=50.00

0011 END

Stand-by position

Welding star t posi tio n

Sensing starts

(measures a conditio n)

Welding end position

Sensing completed

Stand-by position

6-1

HW1482187

Page 36

Arc Sensor Comarc

NO TE

36/54

165557-1CD

6 Measurement and Registration of Sensing Conditions

6.1 Job for Measuring Sensing Conditions

Before measuring a condition, make sure that the

workpiece is not dislocated.

If the workpiece is dislocated, correct the dislocation or

correct the taught position for the measuring job.

Measure the sensing conditions in a single section within

the same job.

Do not set more than one sensing section in the same job.

<Wrong Setting Example>

MOVJ VJ=30.00

ARCON AC=200 AVP=100

COMARCON AMP=2.0 FREQ=3.0 U/D=200 L/R=0.0

MOVL V=80

COMARCOF

COMARCON AMP=2.0 FREQ=3.0 U/D=200 L/R=0.0

MOVL V=80

COMARCOF

ARCOF

MOVJ VJ=30.00

6-2

HW1482187

Page 37

165557-1CD

NO TE

37/54

Arc Sensor Comarc

6 Measurement and Registration of Sensing Conditions

6.2 Measurement of Sensing Conditions

6.2 Measurement of Sensing Conditions

1. Select {UTILITY} in the JOB CONTENT window in the play mode.

2. Select {SPECIAL PLAY} from the selection dialog box.

– The SPECIAL PLAY window appears.

3. Set "COMARC MEASURE MODE" to "VALID".

(1) Move the cursor to "COMARC MEASURE MODE", and press

[SELECT} to set the mode to "VALID".

(2) "COMARC MEASURE MODE" appears in the message line.

4. Execute the job.

Be sure to reset the “COMARC MEASURE MODE” to

"INVALID" after measuring the sensing conditions.

6-3

HW1482187

Page 38

Arc Sensor Comarc

38/54

165557-1CD

6 Measurement and Registration of Sensing Conditions

6.3 Registration of Sensing Conditions

6.3 Registration of Sensing Conditions

1. Select {UTILITY} in the JOB CONTENT window in the teach mode.

2. Select {COMARC COND. MODIFY}.

– The COMARC COND. MODIFY window appears.

3. Select "MODIFY COMARC COND" from the {DATA} selection box.

– The sensing conditions are registered in the job.

– When registration is complete, the JOB CONTENT window

reappears.

6-4

HW1482187

Page 39

165557-1CD

NO TE

39/54

Arc Sensor Comarc

6 Measurement and Registration of Sensing Conditions

6.4 Adjustment of Sensing Conditions

6.4 Adjustment of Sensing Conditions

1. Move the curso r t o th e inst ru ctio n ar ea of t h e COM ARC ON inst ru cti on

or the COMARCSET instr uct ion.

2. Press [SELECT] twice.

3. Select either "UP/DOWN" or "LEFT/RIGHT" in the DET AIL EDIT

window.

– Enter a value using the numeric keys.

The following is the relation between the settings of the

correction conditions and the correction direction.

To define the direction along the wall and horizontally, refer

to Section 3.3 “Arc Sensor Function and Weaving

Condition” on page 3-5.

• To lengthen a wire extension, decrease the UP/DOWN (U/

D) correction condition in units of 10 A.

• T o shorten a wire extension, increase the UP/DOWN (U/D)

correction condition in units of 10 A.

• To move the targeted position toward the wall, decrease

the LEFT/RIGHT (L/R) correction condition in units of 5 A.

• To move the targeted position toward the horizontal

direction, increase the LEFT/RIGHT (L/R) correction

condition in units of 5 A.

Wall

direction

LEFT

DOWN

UP

RIGHT

Horizontal

direction

6-5

HW1482187

Page 40

Arc Sensor Comarc

NO TE

40/54

165557-1CD

6 Measurement and Registration of Sensing Conditions

6.5 Results of Arc Sensing

6.5 Results of Arc Sensing

After arc sensing has been performed, the history of the correction

amount in each step can be viewed.

1. Select {ARC WELDING} from the main menu.

2. Select {COMARC CORRECT}.

– The correction amount in each step appears.

The CORRECTING LIST window only appears when

sensing has been performed.

Therefore, the icon “COMARC CORRECT” does not appear

when turning the power ON or before performing sensing.

6-6

HW1482187

Page 41

165557-1CD

41/54

Arc Sensor Comarc

7 COMARC Condition File

7.1 COMARC Condition File

7 COMARC Condition File

Set the following two items in the COMARC co nditi on file s.

• Direction of path correction by sensing

• Pass-over monitoring condition

7.1 COMARC Condition File

1

2

3

4

5

6

COND NO. (1 to 128)

Displays the file No.

CORRECTION SELECT (direction of path correction) (U/D & L/R,

U/D, L/R, NO CORRECTION)

Specifies the direction to be corrected. When “NO CORRECTION” is

selected, a correction by sensing is not performed.

U/D & /L/R Corrects the path in the up, down, left, and right directions.

L/R Corrects the path in the left and right directions

(the up and down directions are not co rrec ted) .

U/D Corrects the path in the up and down directions

(the left and right directions are not corrected).

CONDITION (operation after pass-over) (ALARM, TEACHING

POSITION, CORRECTION RETAIN, NOT MONITOR)

Specifies the operation to be done when a pass-over occurs.

ALARM An alarm occurs, and the manipulator stops.

Pass-over occurred,

and the manipulator

stops.

Pass-over

monitor value

Actual welding line

7-1

Taught line

: Taught

position

HW1482187

Page 42

Arc Sensor Comarc

Pass-over occurred

Sensing stops, and the manipulator returns to the taught

position.

Restarts sensing from the taught position

Pass-over

occurred

Sensing restarts at a new, adjusted position.

The distance between this new position and the

taught position is equal to the amount of shift

from the taught position just before the pass-over.

Amount of shift from

the taught position

Taught position just before

the occurrence of pass-over

Taught position just after

the occurrence of pass-over

SUPPLE-

MENT

42/54

165557-1CD

7 COMARC Condition File

7.1 COMARC Condition File

TEACHING

POSITION

CORRECTION

RETAIN

Sensing stops, and the manipulator returns to the taught position and continues welding.

The taught position just after the occurrence of pas s-over. The manipulator restarts

welding from a pos ition ad justed fo r the amo unt of s hift from the t aught positio n just be fore

the occurrence of the pass-over.

NOT

MONITOR

The pass-over is not monit ored .

VERTICAL MONITOR (the pass-over monitor value in the up and

down directions)(0.0 to 25.5 mm)

Sets the pass-over monitor value in the up and down directions.

When set to 0.0, the up and down directions are not monitored.

HORIZONTAL MONITOR (the pass-over monitor value in the left

and right directions) (0.0 to 25.5 mm)

Sets the pass-over monitor value in the left and right directions.

When set to 0.0, the left and right directions are not monitored.

NO. (the number of pass-overs) (1 to 10)

When the number of pass-over exceeds this set value, the manipulator

moves as described in

The pass-over monitor function monitors whether the

manipulator is in the rectangular range specified by the

vertical monitor value and horizontal monitor value with the

taught path as its center line.

When the manipulator moves out of the specified range

more than the set number of times, the manipulator moves

as described in .

7-2

HW1482187

Page 43

165557-1CD

43/54

Arc Sensor Comarc

7 COMARC Condition File

7.2 File Operation

7.2 File Operation

7.2.1 Display of a File

1. Select {ARC WELDING} from the main menu.

2. Select {COMARC COND}.

3. Display a desired file No.

– Press the [PAGE] to call the next file No.

– Press [SHIFT] + [PAGE] to call back the previous file No.

7.2.2 Editing of a File

7.2.2.1 Editing of “CORRECTION SELECT” and “CONDITION”

1. Move the cursor to "CORRECTION SELECT" or "CONDITION", and

press [SELECT].

2. Select the item to be set from the selection dialog box.

7.2.2.2 Editing of Other Items

1. Move the cursor to the item to be set, and press [SELECT].

2. Enter a value to be set using the numerical keys.

3. Press [ENTER].

7-3

HW1482187

Page 44

Arc Sensor Comarc

NO TE

44/54

165557-1CD

7 COMARC Condition File

7.2 File Operation

7.2.3 Initialization of the File

The COMARC condition file can be initialized in the maintenance mode.

To initialize the COMARC condition file, set the security

mode to “MANAGEMENT MODE”.

(When the security mode is set to “OPERATION MODE” or

“EDITING MODE”, a file cannot be initialized.)

1. While pressing [MAIN MENU], turn ON the power.

2. Change the security mode ("SECURITY") to "MANAGEMENT MODE".

3. Select {FILE} from the main menu.

4. Select {INITIALIZE}.

5. Select "FILE/GENERAL DATA".

– The selection window of condition file/general data appears.

6. Select "COMARC COND FILE".

–A star "

7. Press [ENTER].

– The confirmation dialog box appea rs.

" appears on the left of the "COMARC COND FILE".

7-4

HW1482187

Page 45

165557-1CD

45/54

Arc Sensor Comarc

7 COMARC Condition File

7.2 File Operation

8. Select "YES".

– The COMARC condition file is initialized.

9. Turn ON the power again.

7-5

HW1482187

Page 46

Arc Sensor Comarc

NO TE

SUPPLE-

MENT

46/54

8 Modification of the Settings in COMARC Function

8 M odification of the Settings in COMARC Function

To validate the COMARC function, mount the JANCD-YCP02 board in the

CPU rack (JZNC-YRK21) with the power OFF.

To invalidate the COMARC function, remove the JANCD-YCP02 board

from the CPU rack (JZNC-YRK21) with the power OFF.

The COMARC function has been set before shipment.

• Do not change the settings for the COMARC function

unless it is required to invalidate the COMARC function.

• To validate/invalidate the COMARC function, change the

security mode to “MANAGEMENT MODE”.

• When the security mode is set to “OPERATION MODE” or

“EDITING MODE”, the setting status can be only

referenced.

165557-1CD

1. While pressing [MAIN MENU], turn ON the power.

2. Change the security mode ("SECURITY") to "MANAGEMENT MODE".

3. Select {SYSTEM} from the main menu.

4. Select {SETUP}.

– The SETUP window appears.

8-1

HW1482187

Page 47

165557-1CD

47/54

Arc Sensor Comarc

8 Modification of the Settings in COMARC Function

5. Select {OPTION BOARD}.

(1) The setting status appears.

– When the YCP02 board is mounted, the following window appears.

Fig. 8-1: When the YCP02 board is Mounted

(2) Press [SEL ECT], and the YCP02 win dow appe ar s.

(3) Set the “YCP02” to “USED”.

(4) To change the ROBOT SENSOR OPTION, Select “DETAIL” of

“ROBOT SENSOR OPTION”.

8-2

HW1482187

Page 48

Arc Sensor Comarc

48/54

165557-1CD

8 Modification of the Settings in COMARC Function

– When the YCP02 board is not mounted, the following window

appears.

Fig. 8 -2: When the YCP 02 boa rd is not Mounte d

6. Press [ENTER].

– The confirmation dialog box appea rs.

7. Select "YES".

8. Turn ON the power again.

8-3

HW1482187

Page 49

165557-1CD

49/54

Arc Sensor Comarc

9 Instruction List

9 Instruction List

< > indicates numerical or alphabetical data.

COMARCON Function Starts arc sensing and weaving.

Instruction

item

Settings Data input range Unit

Weaving conditions

AMP = <Weaving amplitude>

FREQ = <Weaving frequency>

ANGL=<Weaving angle>

WEV# (<Weaving file No.>)

DIR=<Weaving direction>

Correction conditions

U/D = <Correcting the up and down

path)

L/R = <Correcting the left and right

path>

COMARC cond ition file No.

CAF# (<COMARC condition file No.>) 1 to 128 -

1)

AMP: 0.1 to 99.9

FREQ: 0.1 to 5.0

ANGLE: 0.0 to 180.0

1 to 255

0 or 1

U/D: 1 to 999

L/R: -255.0 to 255.0

0.1 mm

0.1 Hz

0.1 deg.

-

-

1A

0.1A

Examples COMARCON AMP=2.0 FREQ=3.0 U/D=200 L/R=0.0

COMARCON WEV#(1) U/D=200 L/R=0.0

COMARCON AMP=2.0 FREQ=3.0 U/D=200 L/R=0.0 CAF#(1)

COMARCON WEV#(1) U/D=200 L/R=0.0 CAF#(1)

COMARCOF Function Ends arc sensing and weaving.

COMARCSET

Instructtion

item

Example COMARCOF

2)

Function Changes sensing condition and weaving condition.

Instructtion

item

Example COMARCSET AMP=2.5 U/D=210 L/R=5.0 CAF#(2)

-

Settings Data input range Unit

Weaving condition

AMP = <Weaving amplitude>

ANGL=<Weaving angle>

Correction condition

U/D = <Correcting the up and down

path>

L/R = <Correcting the left and right

path>

COMARC cond ition file No.

CAF# (<COMARC condition file No.>) 1 to 128 -

COMARCSET AMP=2.5

COMARCSET U/D=210

COMARCSET L/R=5.0

COMARCSET CAF#(2)

AMP: 0.1 to 99.9

ANGL: 0.0 to 180.0

U/D: 1 to 999

L/R: -255.0 to 255.0

0.1 mm

0.1d eg

1A

0.1A

1 Two setting methods are available: setting by AMP and FREQ, or setting by WEV#.

When weaving conditions are set by AMP and FREQ, the weaving mode is “single oscillation”.

When ANGL is set to UNUSED, weaving angle is set to 45 deg.

Do not use DIR normally. DIR specifies the weaving direction changing.

DIR=0 equals to UNUSED; the weaving directions are identical.

2 For the COMARCSET instruction, only the items to be changed can be set.

9-1

HW1482187

Page 50

Arc Sensor Comarc

NO TE

50/54

165557-1CD

9 Instruction List

The data in < > can be set by using constants or user

variables.

To use user variables, pay attention to the unit of set data.

<Example>

COMARCSET AMP=B000

The unit for the weaving amplitude settings is “0.1 mm”. To

set 2.5 mm as the amplitude, set the B000 to “25”.

9-2

HW1482187

Page 51

165557-1CD

51/54

Arc Sensor Comarc

10 Parameter List

Table 10-1: SxE Parameters

10 Parameter List

Parameter

No.

0 Application designation - - -

1 to 19 Not used - - -

20 Analog signal input channel - SL1: 1

21 Compensation value for conversion of an AD

22 Number of times that correction was prohibited at

23 Number of times that correction was prohibited at

24 Correction prohibited minimum current [0.1A] 500 0 to 10000

25 Correction prohibited maximum current [0.1A] 10000 0 to 10000

Contents Unit Initial

Value

SL2: 2

SL3: 3

SL4: 4

SL5: 5

SL6: 6

SL7: 7

SL8: 8

[%] 100 0 to 100

value to a current value

- 4 0 to 10000

COMARCON

-0-

MIN: correction prohibited current

Setting Range

1 to 8

26 Not used - - -

27 Dead zone U/D [0.1A] 50 0 to 10000

28 Dead zone L/R [0.1A] 50 0 to 10000

29 Not used - - -

30 Correction amount Y+

(Weaving frequency less than 2.0 [Hz])

31 Correction amount Y-

(Weaving frequency less than 2.0 [Hz])

32 Correction amount Z+

(Weaving frequency less than 2.0 [Hz])

33 Correction amount Z-

(Weaving frequency less than 2.0 [Hz])

34 Correction amount Y+

(Weaving frequency 2.0 [Hz] or more, less than

3.0 [Hz])

35 Correction amount Y-

(Weaving frequency 2.0 [Hz] or more, less than

3.0 [Hz])

[m] 150 0 to 10000

[m] 150 0 to 10000

[m] 150 0 to 10000

[m] 150 0 to 10000

[m] 150 0 to 10000

[m] 150 0 to 10000

36 Correction amount Z+

(Weaving frequency 2.0 [Hz] or more, less than

3.0 [Hz])

[m] 150 0 to 10000

10-1

HW1482187

Page 52

Arc Sensor Comarc

52/54

Table 10-1: Sx E Par am ete rs

165557-1CD

10 Parameter List

Parameter

No.

37 Correction amount Z-

38 Correction amount Y+

39 Correction amount Y-

40 Correction amount Z+

41 Correction amount Z-

42 Correction amount Y+

43 Correction amount Y-

Contents Unit Initial

(Weaving frequency 2.0 [Hz] or more, less than

3.0 [Hz])

(Weaving frequency 3.0 [Hz] or more, less than

4.0 [Hz])

(Weaving frequency 3.0 [Hz] or more, less than

4.0 [Hz])

(Weaving frequency 3.0 [Hz] or more, less than

4.0 [Hz])

(Weaving frequency 3.0 [Hz] or more, less than

4.0 [Hz])

(Weaving frequency 4.0 [Hz] or more)

(Weaving frequency 4.0 [Hz] or more)

Setting Range

Value

[m] 150 0 to 10000

[m] 100 0 to 10000

[m] 100 0 to 10000

[m] 100 0 to 10000

[m] 100 0 to 10000

[m] 100 0 to 10000

[m] 100 0 to 10000

44 Correction amount Z+

(Weaving frequency 4.0 [Hz] or more)

45 Correction amount Z-

(Weaving frequency 4.0 [Hz] or more)

46 to 49 Not used - - -

50 Sampling interval [msec] 2 1 to 10

51 to 59 Not used - - -

60 to 179 Phase compensation value [msec] - -

180 to 196 Not used - - -

197 Measurement mode (1: Phase compensation

value measurement)

198,199 Not used - - -

[m] 100 0 to 10000

[m] 100 0 to 10000

-00,1

10-2

HW1482187

Page 53

165557-1CD

53/54

Arc Sensor Comarc

11 Alarm Message List

11 Alarm Message List

Alarm

Number

4410 TWO STEPS SAME

4486 PASS OVER

4494 DEFECTIVE TAUGHT

1003 ROM ERROR

Message Cause Remedy

POSITION (WEAV)

[Decimal data]

POINT (WEAV)

[Decimal data]

(YCP02)

The weaving base point was the same

as the wall point.

The path went outside the designated

pass-over monitoring area.

1: Weaving start point and end point

were the same.

If not using hover weaving, the

weaving sta rt point and end point will

be the same point, or the weaving

start point and the reference point

will be the same point.

If using hover weaving, the weaving

start point and the reference point

will be the same point.

2: Weaving targeted point outer

product error

Checksum error in the ROM (memory)

of the sensor program.

Reset the alarm. Reteach the 3

different points.

Remove the cause of the passover.

Set the pass-over radius inside

the permitted range.

Check the s tart point, th e end

point, and the reference point.

Teach again.

Replace the YCP02 board.

5010 ANALOG INPUT

ERROR

(YCP02)

[Decimal data]

5012 SYSTEM ERROR

(COMARC)

[Decimal data]

5013 COMARC ERROR

[Decimal data]

The analog input value of YCP02

board cannot be read properly.

The decimal dat a ind icates the ch annel

where an input fault occurs.

An error occurs in the system of the

sensor in the COMARC function.

The decimal data indicates the

contents of error.

An error occurs when processing the

sensor in the COMARC function.

The decimal data indicates the

contents of error.

Check the cable connection.

Replace the YCP02 board.

Needs investigation. Contact

your Yaskawa representative.

State any observations, the

alarm No. and data displayed.

Needs investigation. Contact

your Yaskawa representative.

State any observations, the

alarm No. and data displayed.

11-1

HW1482187

Page 54

DX200 OPTIONS

54/54

INSTRUCTIONS

FOR ARC SENSOR COMARC FUNCTION

Specifications are subject to change without notice

for ongoing product modifications and improvements.

MANUAL NO.

HW1482187

0

Loading...

Loading...