Page 1

DX200 OPTIONS

1 of 48

INSTRUCTIONS

FOR PENDANT OSCILLOSCOPE FUNCTION

Upon receipt of the product and prior to initial operation, read these instructions thoroughly, and retain

for future reference.

MOTOMAN INSTRUCTIONS

MOTOMAN- INSTRUCTIONS

DX200 INSTRUCTIONS

DX200 OPERATOR’S MANUAL (for each purpose)

DX200 MAINTENANCE MANUAL

The DX200 Operator’s manual above corresponds to specific usage.

Be sure to use the appropriate manual.

Part Number: 165467-1CD

Revision: 1

MANUAL NO.

HW1481803

1

Page 2

Pendant Oscilloscope

2 of 48

Function

165467-1CD

Copyright © 2015, Yaskawa America, Inc.

Terms of Use and Copyright Notice

All rights reserved. This manual is freely available as a service to Yaskawa

customers to assist in the operation of Motoman robots, related equipment

and software This manual is copyrighted property of Yaskawa and may

not be sold or redistributed in any way. You are welcome to copy this

document to your computer or mobile device for easy access but you may

not copy the PDF files to another website, blog, cloud storage site or any

other means of storing or distributing online content.

Printed in the United States of America

First Printing, 2015

Yaskawa America, Inc.

Motoman Robotics Division

100 Automation Way

Miamisburg, OH 45342

Phone: 937-847-6200

www.motoman.com

ii

HW1481803

Page 3

165467-1CD

MANDATORY

CAUTION

3 of 48

Pendant Oscilloscope

Function

• This manual explains the Pendant Oscilloscope Function of the

DX200 system and general operations. Read this manual carefully

and be sure to understand its contents before handling the DX200.

• General items related to safety are listed in Chapter 1: Safety of the

DX200 Instructions. To ensure correct and safe operation, carefully

read the DX200 Instructions before reading this manual.

• Some drawings in this manual are shown with the protective covers

or shields removed for clarity. Be sure all covers and shields are

replaced before operating this product.

• The drawings and photos in this manual are representative

examples and differences may exist between them and the

delivered product.

• YASKAWA may modify this model without notice when necessary

due to product improvements, modifications, or changes in

specifications.

• If such modification is made, the manual number will also be

revised.

• If your copy of the manual is damaged or lost, contact a YASKAWA

representative to order a new copy. The representatives are listed

on the back cover. Be sure to tell the representative the manual

number listed on the front cover.

• YASKAWA is not responsible for incidents arising from unauthorized

modification of its products. Unauthorized modification voids your

product's warranty.

iii

HW1481803

Page 4

Pendant Oscilloscope

4 of 48

Function

165467-1CD

We suggest that you obtain and review a copy of the ANSI/RIA National

Safety Standard for Industrial Robots and Robot Systems (ANSI/RIA

R15.06-2012). You can obtain this document from the Robotic Industries

Association (RIA) at the following address:

Robotic Industries Association

900 Victors Way

P.O. Box 3724

Ann Arbor, Michigan 48106

TEL: (734) 994-6088

FAX: (734) 994-3338

www.roboticsonline.com

Ultimately, well-trained personnel are the best safeguard against

accidents and damage that can result from improper operation of the

equipment. The customer is responsible for providing adequately trained

personnel to operate, program, and maintain the equipment. NEVER

ALLOW UNTRAINED PERSONNEL TO OPERATE, PROGRAM, OR

REPAIR THE EQUIPMENT!

We recommend approved Yaskawa training courses for all personnel

involved with the operation, programming, or repair of the equipment.

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC rules. These limits

are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications.

iv

HW1481803

Page 5

165467-1CD

CAUTION

MANDATORY

PROHIBITED

NOTE

5 of 48

Pendant Oscilloscope

Function

Notes for Safe Operation

Read this manual carefully before installation, operation, maintenance, or

inspection of the DX200.

In this manual, the Notes for Safe Operation are classified as “DANGER”,

“WARNING”, “CAUTION”, “MANDATORY”, or “PROHIBITED”.

DANGER

WARNING

Indicates an imminent hazardous

situation which, if not avoided, could

result in death or serious injury to

personnel.

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury to

personnel.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury to

personnel and damage to equipment.

It may also be used to alert against

unsafe practices.

Always be sure to follow explicitly the

items listed under this heading.

Must never be performed.

Even items described as “CAUTION” may result in a serious accident in

some situations.

At any rate, be sure to follow these important items

To ensure safe and efficient operation at all times, be sure to

follow all instructions, even if not designated as “DANGER”,

“WARNING” and “CAUTION”.

v

HW1481803

Page 6

Pendant Oscilloscope

WARNING

TURN

6 of 48

Function

165467-1CD

• Before operating the manipulator, check that servo power is turned

OFF pressing the emergency stop buttons on the front door of the

DX200 and the programming pendant.

When the servo power is turned OFF, the SERVO ON LED on the

programming pendant is turned OFF.

Injury or damage to machinery may result if the emergency stop circuit

cannot stop the manipulator during an emergency. The manipulator

should not be used if the emergency stop buttons do not function.

Figure 1: Emergency Stop Button

• Once the emergency stop button is released, clear the cell of all

items which could interfere with the operation of the manipulator.

Then turn the servo power ON.

Injury may result from unintentional or unexpected manipulator motion.

Figure 2: Release of Emergency Stop

• Observe the following precautions when performing teaching

operations within the P-point maximum envelope of the

manipulator:

– Be sure to use a lockout device to the safeguarding when going

inside. Also, display the sign that the operation is being

performed inside the safeguarding and make sure no one closes

the safeguarding.

– View the manipulator from the front whenever possible.

– Always follow the predetermined operating procedure.

– Keep in mind the emergency response measures against the

manipulator’s unexpected motion toward you.

– Ensure that you have a safe place to retreat in case of

emergency.

Improper or unintended manipulator operation may result in injury.

• Confirm that no person is present in the P-point maximum envelope

of the manipulator and that you are in a safe location before:

– Turning ON the power for the DX200.

– Moving the manipulator with the programming pendant.

– Running the system in the check mode.

– Performing automatic operations.

Injury may result if anyone enters the P-point maximum envelope of the

manipulator during operation. Always press an emergency stop button

immediately if there is a problem.

The emergency stop buttons are located on the right of front door of the

DX200 and the programming pendant.

vi

HW1481803

Page 7

165467-1CD

CAUTION

7 of 48

Pendant Oscilloscope

Function

• Perform the following inspection procedures prior to conducting

manipulator teaching. If problems are found, repair them

immediately, and be sure that all other necessary processing has

been performed.

– Check for problems in manipulator movement.

– Check for damage to insulation and sheathing of external wires.

• Always return the programming pendant to the hook on the cabinet

of the DX200 after use.

The programming pendant can be damaged if it is left in the

manipulator's work area, on the floor, or near fixtures.

• Read and understand the Explanation of Warning Labels in the

DX200 Instructions before operating the manipulator:

Definition of Terms Used Often in This Manual

The MOTOMAN is the YASKAWA industrial robot product.

The MOTOMAN usually consists of the manipulator, the controller, the

programming pendant, and the manipulator cables.

In this manual, the equipment is designated as follows:

Equipment Manual Designation

DX200 controller DX200

DX200 programming pendant Programming pendant

Cable between the manipulator and the

controller

Descriptions of the programming pendant, buttons, and displays are

shown as follows:

Equipment Manual Designation

Programming

Pendant

Character

ys

Ke

Symbol Keys

Axis Keys

Number Keys

The keys which have characters printed on

them are denoted with [ ].

ex. [ENTER]

“Axis Keys” and “Number Keys” are generic

names for the keys for axis operation and

number input.

Manipulator cable

Keys pressed

simultaneously

Displays The menu displayed in the programming

When two keys are to be pressed

simultaneously, the keys are shown with a “+”

sign between them, ex. [SHIFT]+[COORD]

pendant is denoted with { }.

ex. {JOB}

vii

HW1481803

Page 8

Pendant Oscilloscope

NOTE

(937) 847-3200

8 of 48

Function

Description of the Operation Procedure

In the explanation of the operation procedure, the expression “Select • • •”

means that the cursor is moved to the object item and the SELECT key is

pressed, or that the item is directly selected by touching the screen.

Registered Trademark

In this manual, names of companies, corporations, or products are

trademarks, registered trademarks, or brand names for each company or

corporation. The indications of (R) and TM are omitted.

Customer Support Information

If you need assistance with any aspect of your Pendant Oscilloscope

Function system, please contact Motoman Customer Support at the

following 24-hour telephone number:

165467-1CD

For routine technical inquiries, you can also contact Motoman Customer

Support at the following e-mail address:

techsupport@motoman.com

When using e-mail to contact Motoman Customer Support, please provide

a detailed description of your issue, along with complete contact

information. Please allow approximately 24 to 36 hours for a response to

your inquiry.

Please use e-mail for routine inquiries only. If you have an

urgent or emergency need for service, replacement parts,

or information, you must contact Motoman Customer

Support at the telephone number shown above.

Please have the following information ready before you call:

• System Pendant Oscilloscope Function

• Robot

• Primary Application

• Controller DX200

• Software Version Access information on the

Programming Pendant’s LCD

display screen by selecting {MAIN

MENU} - {SYSTEM INFO} {VERSION}

• Robot Serial Number Located on the robot data plate

• Robot Sales Order Number Located on the DX200 controller

data plate

viii

HW1481803

Page 9

165467-1CD

9 of 48

Pendant Oscilloscope

Function

Table of Contents

Table of Contents

1 Overview ......................................................................................................................................... 1-1

1.1 Pendant Oscilloscope Function ......................................................................................... 1-1

1.2 Specification ...................................................................................................................... 1-2

1.3 Setup ................................................................................................................................. 1-2

2 Setting and Operation for Data Measurement ................................................................................ 2-1

2.1 Startup of Pendant Oscilloscope Function......................................................................... 2-1

2.2 Main Screen Configuration ................................................................................................ 2-2

2.2.1 Main Screen (Not In-measurement Mode) ........................................................... 2-2

2.2.2 Main Screen (In-measurement Mode).................................................................. 2-3

2.3 Setting Measurement Conditions....................................................................................... 2-4

2.3.1 Channel Setting Window ...................................................................................... 2-4

2.3.2 CH Display Setting Panel ..................................................................................... 2-8

2.3.3 TimeScale Setting Panel .................................................................................... 2-10

2.3.4 Trigger Setting Panel.......................................................................................... 2-11

2.4 Starting and Ending Measurement .................................................................................. 2-15

2.4.1 Continuous Mode ............................................................................................... 2-15

2.4.2 Trigger Mode ...................................................................................................... 2-16

2.5 Termination and Minimization of Pendant Oscilloscope Function ................................... 2-17

2.5.1 Termination of PP Oscilloscope ......................................................................... 2-17

2.5.2 Minimizing PP Oscilloscope Application............................................................. 2-17

3 Saving and Loading the Measurement Data................................................................................... 3-1

3.1 SaveMode Setting Panel ................................................................................................... 3-1

3.1.1 Data File Name and Save Destination ................................................................. 3-1

3.1.2 CSV File ............................................................................................................... 3-2

3.2 Load Panel ........................................................................................................................ 3-3

4 Other Functions .............................................................................................................................. 4-1

4.1 Zoom Function................................................................................................................... 4-1

4.1.1 During Execution of Zoom Function ..................................................................... 4-2

4.2 Cursor Measurement Function .......................................................................................... 4-3

4.2.1 Cursor Measurement Parameters ........................................................................ 4-5

ix

HW1481803

Page 10

165467-1CD

10 of 48

Pendant Oscilloscope

Function

4.3 Job Step No. Saving Function ........................................................................................... 4-6

4.3.1 Channel Setting .................................................................................................... 4-7

4.3.2 Adjustment of Acquisition Time of Job Name and Step No.................................. 4-7

4.4 Operation Function by Dedicated Input ............................................................................. 4-8

4.4.1 Dedicated Input Signal.......................................................................................... 4-8

4.4.2 Dedicated Output Signal..................................................................................... 4-10

5 Supplementary Explanation ............................................................................................................ 5-1

5.1 Division [div]: Unit for Measurement Screen Position ........................................................ 5-1

5.2 Reference Unit ................................................................................................................... 5-2

6 Error Messages............................................................................................................................... 6-1

Table of Contents

x

HW1481803

Page 11

165467-1CD

11 of 48

Pendant Oscilloscope

Function

1Overview

1.1 Pendant Oscilloscope Function

1 Overview

1.1 Pendant Oscilloscope Function

Pendant Oscilloscope Function (hereinafter referred to as “PP

oscilloscope”) is the monitoring function of speed reference, torque

reference, as well as of concurrent I/O signals of each robot axis on the

Programming Pendant. The PP oscilloscope is configured by the

software, which requires no special hardware equipment. By carrying out

the PP oscilloscope function, the pendant oscilloscope application

(hereinafter referred to as “PP oscilloscope application”) starts on the

Programming Pendant.

Equipped with an integral display screen containing the waveform display

window and the condition setting panel, the PP oscilloscope application

enables to perform several processes from condition setting to

measurement at a time. Other available functions include Trigger function

that stops the data acquisition at a given condition, Measure and display

function of maximum/minimum values after data acquisition, Zoom

function that displays the waveform data in a magnified view, and data

output function in a format available on the computer. Fig. 1-1 shows a

typical display of PP oscilloscope.

Fig. 1-1: Display of PP Oscilloscope

START HOLD

TEACH

REMOTE

PLAY

Programming

pendant

Waveform display area

Condition setting panel

1-1

HW1481803

Page 12

Pendant Oscilloscope

NOTE

12 of 48

Function

1 Overview

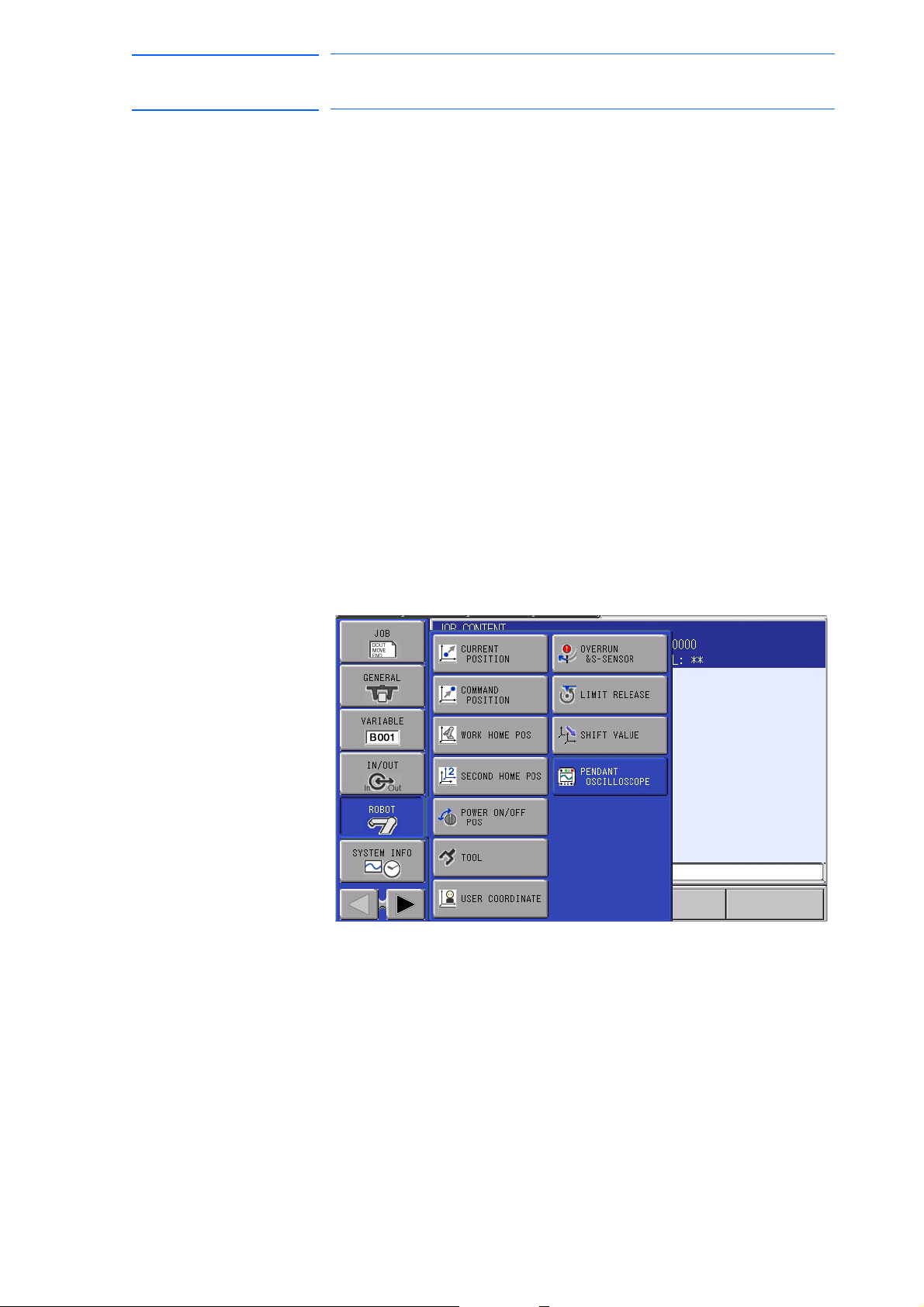

1.2 Specification

1.2 Specification

Main specification of the PP oscilloscope is listed in Table 1-1 below:

Table 1-1: Main Specifications of PP Oscilloscope

Parameter Specification Description

Measurement data

type

Maximum channel

number

Sampling time 4.0, 8.0, 16.0, 32.0, 64.0

Maximum data length 50 [s] to 100 [s] Indicates data length that can be recorded at a

Waveform acquisition

mode

Trigger condition ○Trigger for measurement

Data saving format CSV

Speed reference, Speed

FB, Torque reference,

Concurrent I/O signal,

Register value

10 channels Number of channels that can be measured at the same

[ms]

Continuous mode

Trigger mode

waveform

- Up trigger

- Down trigger

- Up&Down trigger

○Alarm trigger

JPG

Number of channels that can be measured at the same

time.

time.

Indicates time interval for data sampling.

Smaller values enable more detailed measurement data,

but shorten the data record time due to much data volume.

measurement. Some setting of sampling time can limit the

maximum data length available.

Selects the mode according to the Trigger state

(valid/invalid):

○Trigger Invalid: Continuous

The Continuous mode displays the acquired data in a timeseries order.

○Trigger Valid: Trigger

The Trigger mode automatically stops the measurement and

displays waveform when the trigger conditions are satisfied.

Other than normal waveform triggers, alarm trigger is also

included.

Saves the acquired data in CF or USB memory with the

CSV (Comma Separated Value) format.

Saves the displayed data on the screen in CF or USB

memory with the JPG (Joint Photographic Experts Group)

format.

165467-1CD

1.3 Setup

The register value output function is applicable from version

DN1.61.00A(--)-00.

To activate the function, the optional parameters of the pendant

oscilloscope function need to be effective (note that the user cannot

change the parameter setting).

For the parameter setting other than specified above, contact a Yaskawa

sales representative.

1-2

HW1481803

Page 13

165467-1CD

13 of 48

Pendant Oscilloscope

Function

2 Setting and Operation for Data Measurement

2.1 Startup of Pendant Oscilloscope Function

2 Setting and Operation for Data Measurement

This chapter describes setting and operation required for the

measurement.

Basically the PP oscilloscope is operated by touching on the screen; for

pull-down selection box or entry box,

however, the Cursor Keys enable the cursor operation, and [SELECT],

[ENTER] or [CANCEL] key enables selection, determination, or cancel,

just as the normal operation on the pendant screens.

In performing numerical input using an entry box, first activate the

parameter to a selective state by [SELECT] key, input numerical values by

the Number Keys of the pendant, and press [ENTER] key to determine it.

To cancel the input numerical values, press [CANCEL] key in the selective

state.

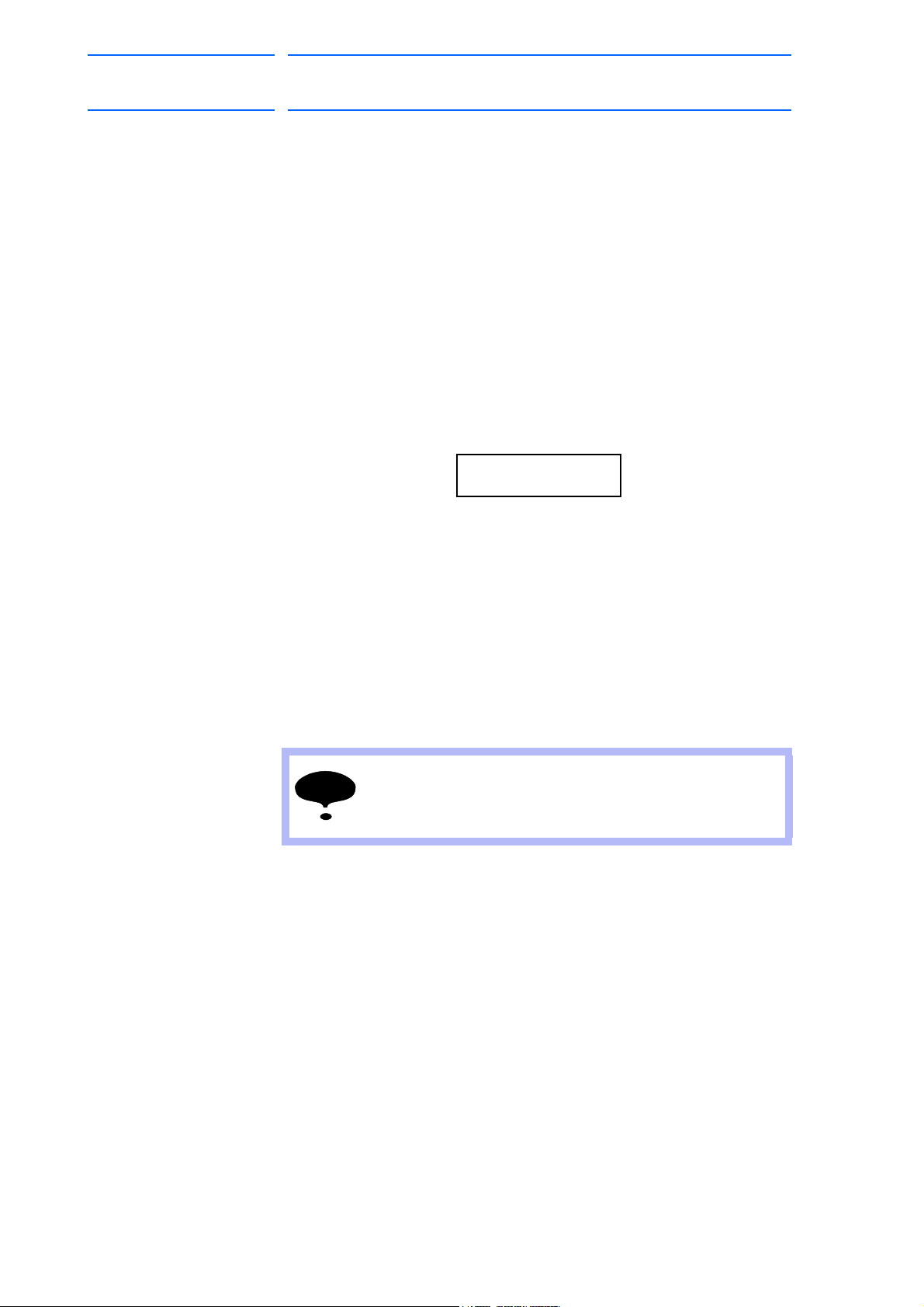

2.1 Startup of Pendant Oscilloscope Function

The PP oscilloscope can be started up by the following step:

1. Select {ROBOT} from the menu in the left of screen.

2. Select {PENDANT OSCILLOSCOPE} from the expanded menu (see

Fig. 2-1).

Fig. 2-1: PP Oscilloscope Startup Menu

2-1

HW1481803

Page 14

Pendant Oscilloscope

14 of 48

Function

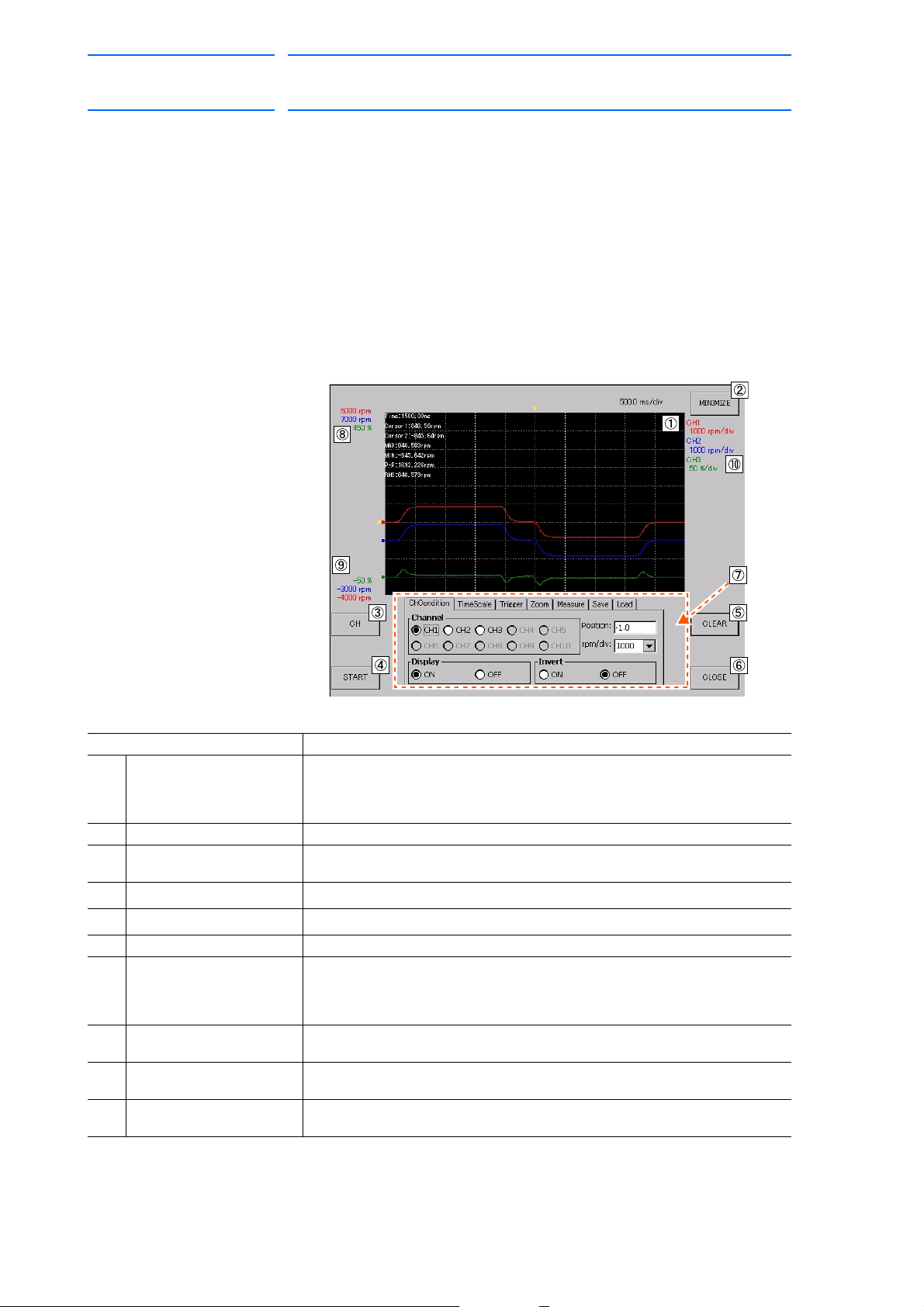

2.2.1 Main Screen (Not In-measurement Mode)

165467-1CD

2 Setting and Operation for Data Measurement

2.2 Main Screen Configuration

2.2 Main Screen Configuration

Here explains the configuration of the Main screen.

The PP oscilloscope is displayed on the entire screen of Programming

Pendant. The main screen has two types of modes; in-measurement and

without not in-measurement (Waiting), in which functions or availability of

some buttons are changed.

Condition setting is only available in not in-measurement mode (Waiting).

Main screen of not in-measurement mode (Waiting) is shown in Fig. 2-2

below with description.

Fig. 2-2: Main Screen (Not In-measurement Mode)

Name Function

Waveform display area Displays measured data waveform. When the data is not yet acquired soon

after the startup or when the data is cleared, nothing is shown here.

At the upper left of the area, measurement value obtained by the cursor

measurement function is displayed.

{MINIMIZE} button Minimizes the PP oscilloscope application.

{CH} button Opens the Channel Setting window. (For details of the Channel Setting

{START} button Starts the data measurement.

{CLEAR} button Deletes the displayed data waveform.

window, refer to section 2.3.1 “Channel Setting Window” on page 2-4)

{CLOSE} button Terminates the PP oscilloscope.

Condition setting panel Enables to set various conditions. Touching the upper tab enables to open

the setting screen corresponding to each parameter. (For details of each

condition setting, refer to section 2.3.2 “CH Display Setting Panel” on page 2-

8 to section 2.3.4 “Trigger Setting Panel” on page 2-11.)

Maximum display value Displays values and units at the uppermost of waveform display area by each

channel.

Minimum display value Displays values and units at the lowermost of waveform display area by each

channel.

Reference unit Displays the reference unit by each channel. For details of the reference unit,

refer to section 5.2 “Reference Unit” on page 5-2.

On the Main screen, information by channels is displayed in each specific

color; for example in Fig. 2-2, information on CH3 is displayed in green,

where the reference unit is 50%/div, the maximum display value is 450%,

and the minimum display value is -50%.

2-2

HW1481803

Page 15

165467-1CD

NOTE

15 of 48

Pendant Oscilloscope

Function

2 Setting and Operation for Data Measurement

2.2 Main Screen Configuration

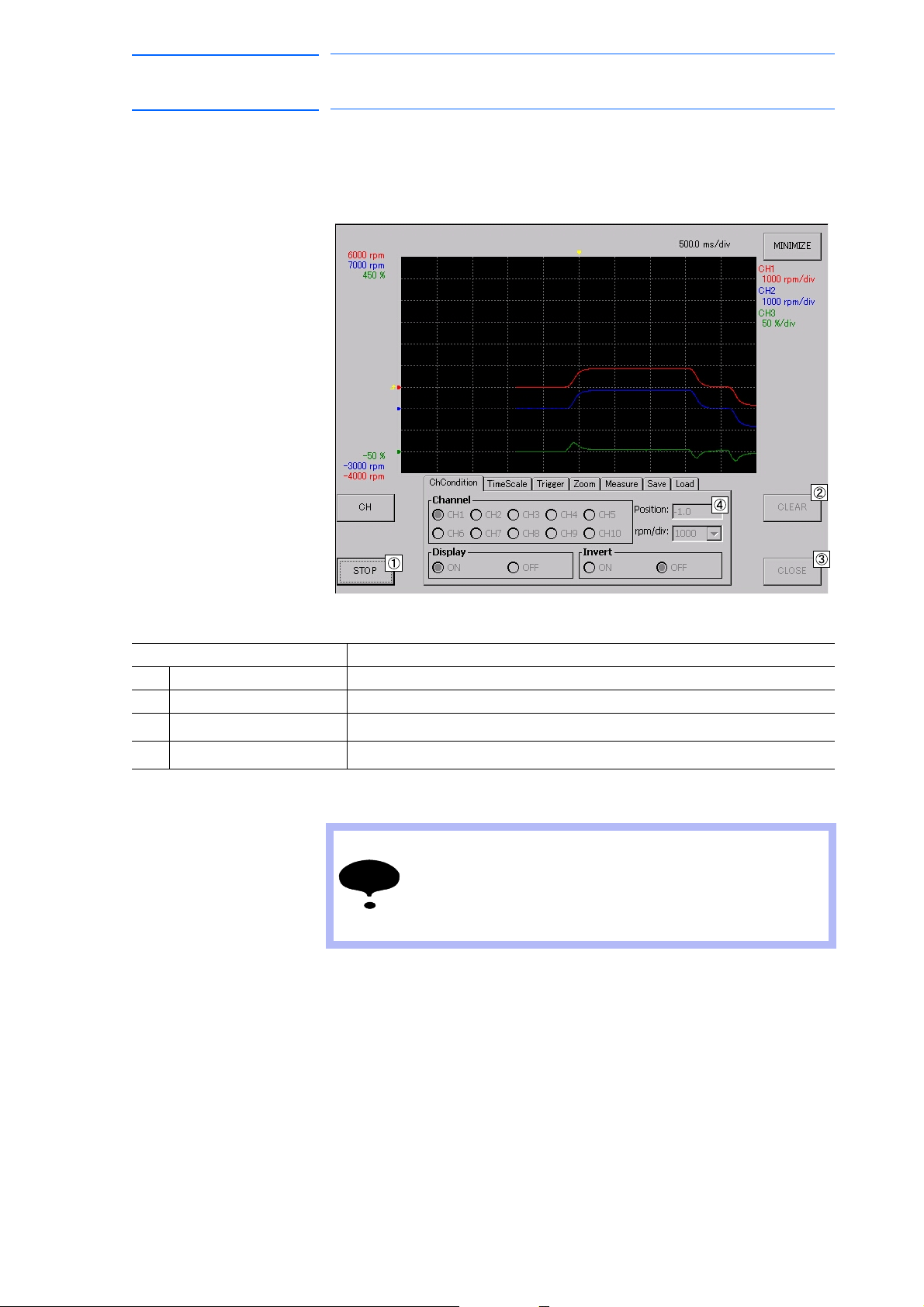

2.2.2 Main Screen (In-measurement Mode)

Main screen of In-measurement mode is shown in Fig. 2-3. In this mode,

the states of some buttons are changed. Here describes such buttons;

Fig. 2-3: Main Screen (In-measurement Mode)

Name Function

{STOP} button Switched from the {START} button, stops the data measurement.

{CLEAR} button In measurement mode, the button operation is disabled.

{CLOSE} button In measurement mode, the button operation is disabled.

Condition setting panel In measurement mode, the operation on tab is disabled.

Soon after switching the buttons {START} / {STOP}, button

operation is not available for a certain period of time to

avoid continuous pressing of the buttons.

When the buttons {START} / {STOP} are disabled, wait until

the operation becomes available.

2-3

HW1481803

Page 16

Pendant Oscilloscope

NOTE

16 of 48

Function

2.3.1 Channel Setting Window

165467-1CD

2 Setting and Operation for Data Measurement

2.3 Setting Measurement Conditions

2.3 Setting Measurement Conditions

Here describes how to set the measurement conditions on the channel

setting window and the condition setting panel.

Pressing the {CH} button on the Main screen opens the channel setting

window. Fig. 2-4 shows the typical display example of the channel setting

window. On this window, data type for measurement at each channel,

measurement target axis, and measurement interval of each data can be

set.

Fig. 2-4: Channel Setting Window

Sampling time

Sets the sampling interval of the data to be acquired. Settable options

are 4.0, 8.0, 16.0, 32.0, and 64.0 [ms], each of which corresponds to

the sampling frequencies of 250, 125, 62.5, 31.25, and 15.625 [Hz],

respectively.

Measurement valid/invalid check box

Requires setting for each channel, where the channel with a check

mark becomes valid for measurement.

When the multiple channels are to be valid, the channel numbers are

not necessarily to be sequential.

The more the channels are available, the more the process

is overloaded, and it affect the data updating speed in the

waveform display area; it is recommended that

unnecessary channels, if any, should be set to invalid.

2-4

HW1481803

Page 17

165467-1CD

NOTE

17 of 48

Pendant Oscilloscope

Function

2 Setting and Operation for Data Measurement

2.3 Setting Measurement Conditions

Tar get

Requires setting for each channel, where the setting of output signal

type is available.

Servo: Enables to select the servo CPU signals at the option .

I/O signal: Enables to input the concurrent I/O signal at the option .

Register: Enables to input the register number at the option .

Signal selection

Requires setting for each channel.

When {Servo} is selected at the option : Select speed reference,

speed feedback, or torque reference.

When {I/O signal} is selected at the option : Input signal number of

concurrent I/O. For the details of concurrent I/O, refer to “DX200

Concurrent I/O Instruction Manual (165294-1CD).”

Requirements on Concurrent I/O Signal

The concurrent I/O signal is updated in every 4.0 [ms].

Whereas when the PP oscilloscope allows the setting of

sampling time as 8.0 [ms] or more, the measurement data

has a delay time up to as long as that of the sampling time.

Even when the sampling time is 4.0 [ms], the signal turning

ON/OFF only for 4.0 [ms] may have data skipped; ensure to

keep the time interval of 20 [ms] or more between the signal

ON and OFF for the measurement target of concurrent I/O

signal.

When {Register} is selected at the option : Input register number.

Input the numerical value between M000 and M999.

Axis selection

Set the target axis for data acquisition. (Only when Servo is selected at

option Tar ge t )

One servo board (SRDA-EAXA21A) can connect up to 9 motors.

Furthermore, up to 8 servo boards can be connected to a system. This

means that the maximum axis configuration on a system allows

simultaneous connection of 72 axes of motors.

The PP oscilloscope specifies the measurement target axis by the

unique number of physical connection among these 72 axes. This is

called as “physical axis connection”.

Under the basic system configuration of a servo board, the physical

axes 1 to 6 are occupied by robot axis, and external axes are

connected to the physical axes 7, 8, and 9. When every servo board is

added, the number of physical axis is represented by offsetting each

+9. This relationship is shown in the following table Table 2-1:

Table 2-1: Relationship between the number of servo board and the

physical axis number (Sheet 1 of 2)

No. of servo board Physical axis number of the board

SV#1 1 to 9

SV#2 10 to 18

SV#3 19 to 27

2-5

HW1481803

Page 18

Pendant Oscilloscope

18 of 48

Function

165467-1CD

2 Setting and Operation for Data Measurement

2.3 Setting Measurement Conditions

Table 2-1: Relationship between the number of servo board and the

physical axis number (Sheet 2 of 2)

No. of servo board Physical axis number of the board

SV#4 28 to 36

SV#5 37 to 45

SV#6 46 to 54

SV#7 55 to 63

SV#8 64 to 72

The following example shows the typical specification of physical axis

number in the main system configuration.

Example:

○Normal 6-axis robot, R1 to R8

Target axis SL URBT

Axis selection

No. (R1)

Axis selection

No. (R2)

Axis selection

No. (R3)

Axis selection

No. (R4)

Axis selection

No. (R5)

Axis selection

No. (R6)

Axis selection

No. (R7)

Axis selection

No. (R8)

123456

10 11 12 13 14 15

19 20 21 22 23 24

28 29 30 31 32 33

37 38 39 40 41 42

46 47 48 49 50 51

55 56 57 58 59 60

64 65 66 67 68 69

○7-axis single-arm robot (such as SIA), R1 to R8

Target axis S L URBTE

Axis selection

No. (R1)

Axis selection

No. (R2)

Axis selection

No. (R3)

Axis selection

No. (R4)

Axis selection

No. (R5)

Axis selection

No. (R6)

Axis selection

No. (R7)

Axis selection

No. (R8)

1234567

10 11 12 13 14 15 16

19 20 21 22 23 24 25

28 29 30 31 32 33 34

37 38 39 40 41 42 43

46 47 48 49 50 51 52

55 56 57 58 59 60 61

64 65 66 67 68 69 70

2-6

HW1481803

Page 19

165467-1CD

19 of 48

Pendant Oscilloscope

Function

2 Setting and Operation for Data Measurement

2.3 Setting Measurement Conditions

○7-axis dual-arm robot (such as SDA)

Target axis SL URBT E

Axis selection

No. (R1)

Axis selection

No. (R2)

Target axis

1234567

10 11 12 13 14 15 16

EX1

Axis selection

No. (S1)

8

EX1 in this table corresponds to the waist axis (external axis) of dual-arm

robot.

○Normal 6-axis robot + external axis, R1 to R8 (R1 + S1 [3-axis] setting)

Target axis SL URBT

Axis selection

No. (R1)

Target axis

Axis selection

No. (S1)

123456

EX1 EX2 EX3

789

○7-axis robot + external axis (R1 + S1 [1-axis] + S2 [1-axis] setting)

Target axis SL URBT E

Axis selection

No. (R1)

Target axis

Axis selection

No. (S1)

Axis selection

No. (S2)

1234567

EX1

8

9

{OK} button

Closes the window with the change given on the channel setting

window reflected. When there is a measured waveform at the

waveform display area, the waveform data is cleared.

When no change has been given after the channel setting window is

opened, this button acts just as the {CANCEL} button.

{CANCEL} button

Closes the window without reflecting the change given on the channel

setting window. The waveforms data is not cleared.

2-7

HW1481803

Page 20

Pendant Oscilloscope

20 of 48

Function

2.3.2 CH Display Setting Panel

165467-1CD

2 Setting and Operation for Data Measurement

2.3 Setting Measurement Conditions

With the data measurement stopped, select (touch) the {ChCondition} tab

on the condition setting panel. Fig. 2-5 shows the typical display example

of the CH display setting panel.

Fig. 2-5: ChCondition Setting Panel

This panel allows the setting of panel display targeted to the channels

validated in the channel setting window.

Channel

Select the target channel for setting operation. Upon the channels set

here, the setting change given to the following options to is

reflected.

Note that the invalid channels are disabled (in which the radio button is

inoperable), and cannot be selected.

Display

Enables to select either to display {ON} or hide {OFF} the waveform

data of target channel. The data is internally stored even when the data

is measured with the Display {OFF}, and the corresponding waveform

data is displayed when Display {ON} is selected.

Invert

Enables to select either to invert the waveform data of target channel or

not. Selecting Invert {ON} inverts the display of waveform data in a

waveform display area between positive and negative. Selecting Invert

{OFF} returns to the original state.

2-8

HW1481803

Page 21

165467-1CD

21 of 48

Pendant Oscilloscope

Function

2 Setting and Operation for Data Measurement

2.3 Setting Measurement Conditions

Position

Sets the zero position of target channel. Specify the zero point within

the range of -5.0 to 5.0 [div] in the vertical axis of waveform display

area.

On the extreme left of waveform display area, a marker is provided

showing a zero point for each channel in which the current zero point

can be confirmed (see Fig. 2-6).

Fig. 2-6: Zero Point Marker

Zero point

maker

Unit (rpm/div, %/div, U/div)

Selects the reference unit of target channel in the vertical axis scale.

(For description of the unit, refer to section 5.2 “Reference Unit” on

page 5-2.)

Displayed unit and its selection depend on the signal output by the

target channel.

Speed reference, Speed FB:

Unit [rpm/div]: selectable among 250, 500, 1000, and 2000

Torque reference:

Unit [%/div]: selectable among 33, 50, 66, and 100

Concurrent I/O signal:

Unit [U/div]: selectable among 0.2, 0.5, 1.0, 2.0, 5.0, and 10.0

Register:

Unit [-/div]: selectable among 1, 2, 5, 10, 20, 50, 100, 200, 500, 1000,

2000, 3277, 5000, 6554, 10000, 13107, 20000, 32768, 50000 and

65535.

2-9

HW1481803

Page 22

Pendant Oscilloscope

22 of 48

Function

2.3.3 TimeScale Setting Panel

165467-1CD

2 Setting and Operation for Data Measurement

2.3 Setting Measurement Conditions

With the data measurement stopped, touch {TimeScale} tab on the

condition setting panel. Fig. 2-7 shows the typical display example of

TimeScale setting panel.

Fig. 2-7: TimeScale Setting Panel

ms/div

Sets the time for the horizontal axis of the waveform display area. The

value selected here should be the time width [ms] per division of

horizontal axis. Since there are 10 divisions in the entire horizontal

axis, the eventual data length is 10 times of the specified value.

Selectable range of ms/div depends on the combination of sampling

time set on the Channel Setting window:

With the sampling time of 4 [ms]:

Up to 5000 [ms/div] (data length: 50 [s])

With the sampling time of 8 [ms] or more:

Up to 10000 [ms/div] (data length: 100 [s])

2-10

HW1481803

Page 23

165467-1CD

Data before Trigger 3[s]

Data length

Pre-trigger

Data after Trigger 7[s]

Trigger level

Zero point of

waveform display

Zero point of

channel

Horizontal axis

23 of 48

Pendant Oscilloscope

Function

2 Setting and Operation for Data Measurement

2.3 Setting Measurement Conditions

2.3.4 Trigger Setting Panel

With the data measurement stopped, select (touch) {Trigger} tab on the

condition setting panel. Fig. 2-8 shows the typical display example of

Trigger setting panel.

This panel allows the setting of trigger function.

Fig. 2-8: Trigger Setting Panel

The trigger function is the function to automatically stop the measurement

and display the waveform at the point where a certain condition is satisfied

during the data measurement.

As trigger conditions, three options are available: when the target channel

data exceeds or falls below the specified value (trigger level), or when any

alarm occurs.

The data stop position is determined by Pre-trigger. The measurement

result is displayed so that the position satisfying the trigger conditions

becomes the Pre-trigger position. For example in Fig. 2-9, the data length

is 10 [s] and the specified Pre-trigger is 3 [div] in horizontal axis. This

allows the setting where the data before the trigger is acquired for 3

seconds, and the data after the trigger is acquired for 7 seconds.

Fig. 2-9: Outline of Trigger Function

CH

Select the channel as trigger target. Only the valid channel is

selectable.

2-11

HW1481803

Page 24

Pendant Oscilloscope

Pre-trigger

maeker

24 of 48

Function

165467-1CD

2 Setting and Operation for Data Measurement

2.3 Setting Measurement Conditions

TrgType (Trigger type)

Select the trigger type to use. Selectable options are Up, Down,

Up&Down, and Alarm.

When selecting Alarm, some of the setting parameters of Trigger

Conditions are changed.

Table 2-2: Characteristics of Trigger Type

Trigger type Trigger condition

Up When the trigger target channel data exceeds the trigger level

Down When the trigger target channel data falls below the trigger level

Up&Down When the trigger target channel data is either over or below the

trigger level

Alarm When the alarm assigned to alarm number occurs

PreTrg (Pre-trigger)

Specify the pre-trigger position by the horizontal axis division

(0 to 10.0).

Current pre-trigger position is shown by a marker on the upper part of

the waveform display area (see Fig. 2-10).

Fig. 2-10: Pre-trigger Marker

2-12

HW1481803

Page 25

165467-1CD

NOTE

Trigger level

marker

25 of 48

Pendant Oscilloscope

Function

2 Setting and Operation for Data Measurement

2.3 Setting Measurement Conditions

Level

Specify the trigger level by the vertical division (-10.0 to +10.0).

The current trigger level is shown by a marker on the left of the

waveform display area (see Fig. 2-11).

The marker shape depends on the selected trigger type.

Fig. 2-11: Trigger Level Marker

The value specified here is regarded as a position with the

zero point of trigger target channel as reference. When the

trigger level is specified as 2.5 [div] with the channel zero

position of -2.0 [div] (in vertical axis), the displayed position

of trigger level on the waveform display area is 0.5 [div] (in

vertical axis). (See the example of Fig. 2-9.)

TriggerMode

Switches the valid/invalid state of trigger. According to this setting, the

waveform data acquisition mode is switched.

• Invalid: Continuous mode

When the waveform data measurement is started, the acquired data is

continuously displayed in a time-series order.

• Valid: Trigger mode

The measurement is automatically stopped when the trigger conditions

are satisfied, and the waveform is displayed.

○When {Alarm} is selected as TrigType:

When {Alarm} is selected as the trigger type, the only condition for the

trigger is when the target alarm specified

here by the number occurs. The alarm trigger does not depend on the

channel setting, so the settings of {CH} or {Level} are not referred.

2-13

HW1481803

Page 26

Pendant Oscilloscope

NOTE

26 of 48

Function

165467-1CD

2 Setting and Operation for Data Measurement

2.3 Setting Measurement Conditions

Fig. 2-12 shows the typical display example when the option {Alarm} is

selected as TrigType.

Fig. 2-12: Trigger Setting Panel (Alarm Trigger)

AlarmNo

Selecting {Alarm} as the trigger type switches {Level} turns to an entry

box of {AlarmNo}. Input a valid alarm number here. When a nonexistent alarm number is specified, an error occurs when the

measurement starts.

For details of alarm number, refer to “DX200 Maintenance manual

(165293-1CD)”.

Major alarms, when occur, may contain abnormal data

transmission between the controller hardware, and a

normal operation of pendant oscilloscope cannot be

guaranteed.

It is recommended that the target alarm number as the

alarm trigger should be Minor or User alarms rather than

Major alarms.

2-14

HW1481803

Page 27

165467-1CD

SUPPLE-

MENT

27 of 48

Pendant Oscilloscope

Function

2 Setting and Operation for Data Measurement

2.4 Starting and Ending Measurement

2.4 Starting and Ending Measurement

Here describes the step of actual data measurement. Ensure to start the

measurement after completing the condition setting described in section

2.3 “Setting Measurement Conditions” on page 2-4.

2.4.1 Continuous Mode

The Continuous mode is the mode in which the measurement data is

always displayed and updated in the time-series order. Follow the step

below:

1. Select OFF for {TriggerMode} on the Trigger setting panel.

2. Start the measurement by the {START} button. The data

measurement starts, and the data is displayed in the time-series order

on the waveform display area, and updated in series.

3. When the time passes longer than the specified data length from the

asurement start, the data is discarded from the oldest one, and the

me

new data is updated in series (see Fig. 2-13).

4. When the target waveform data is displayed on the waveform display

ea, press the {STOP} button to stop the measurement.

ar

Fig. 2-13: Continuous Mode

Flow of data update

Old data Latest data

Continuous mode enables to display the measurement data

in time-series order, but it does not necessarily assure the

real-time display. The data contain a delay to a certain

extent, and the delay can be extended as the measured data

is large in volume.

The following setting changes help for the challenging of

real-time display:

- Trying smaller number of available channels

- Trying longer sampling time

- Trying shorter data length

2-15

HW1481803

Page 28

Pendant Oscilloscope

28 of 48

Function

2.4.2 Trigger Mode

165467-1CD

2 Setting and Operation for Data Measurement

2.4 Starting and Ending Measurement

The Trigger mode automatically stops the measurement when the trigger

condition is satisfied, and displays the waveform on the screen. Follow

the step below:

1. Set the trigger conditions on the Trigger setting panel.

2. Select ON for {TriggerMode}.

3. Start the measurement by the {START} button. This starts the data

asurement, and the waveform display area is turned to the waiting

me

state, and holds the state until the trigger condition is satisfied. On the

screen, a message “Waiting for trigger...” is displayed (see Fig. 2-14).

To cancel the measurement during this st

Fig. 2-14: Display of Trigger Mode “Waiting for trigger”

ate, press the {STOP} button.

4. When the trigger condition is satisfied, “Triggered” is displayed on the

screen (s

trigger position, the condition is held for as long as 100 seconds

ccording to the setting of data length and pre-trigger. To cancel the

a

measurement during this state, press the {STOP} button.

Fig. 2-15: Display of Trigger Mode “Triggered”

ee Fig. 2-15). To collect the waveform data later than the

5. When all the waveform data for an entire window is acquired, the

m

easurement automatically ends and the waveform is displayed.

2-16

HW1481803

Page 29

165467-1CD

29 of 48

Pendant Oscilloscope

Function

2 Setting and Operation for Data Measurement

2.5 Termination and Minimization of Pendant Oscilloscope Function

2.5 Termination and Minimization of Pendant Oscilloscope

Function

2.5.1 Termination of PP Oscilloscope

Pressing the {CLOSE} button on the Main screen terminates the PP

oscilloscope. Each condition setting parameter is automatically saved,

and the setting at the termination will be reflected at the next startup.

2.5.2 Minimizing PP Oscilloscope Application

Pressing the {MINIMIZE} button on the Main screen can minimize the PP

oscilloscope application. Minimizing means the PP oscilloscope changes

to the background process with running. When minimized PP

oscilloscope disappears just as the system termination does, but the

waveform measurement process is continued. This is useful when the

operations on the other system screens are necessary with the waveform

data measurement continued.

When an alarm or an error occurs on the controller, the PP oscilloscope

application is forcefully minimized to display the alarm preferentially.

When the PP oscilloscope application is minimized during the data

measurement, the following message is displayed on the message area of

the Pendant System screen: “Measuring the pendant oscilloscope data.”

(See Fig. 2-16).

Fig. 2-16: Message Display during the data measurement

Minimized PP oscilloscope application can be returned to the original state

by selecting {Pendant Oscilloscope} from the menu as in the startup

operation.

2-17

HW1481803

Page 30

Pendant Oscilloscope

NOTE

30 of 48

Function

3 Saving and Loading the Measurement Data

3.1 SaveMode Setting Panel

3 Saving and Loading the Measurement Data

This chapter describes the saving and loading of the measurement data.

3.1 SaveMode Setting Panel

With the data measurement stopped, select (touch) {Save} tab in the

condition setting panel. Fig. 3-1 shows the typical example of SaveMode

setting on the panel.

Fig. 3-1: SaveMode Setting Panel

165467-1CD

SaveMode

Enables to select Manual/Auto of the saving mode. In selecting the

automatic saving mode {Auto}, ensure to perform the setting with the

external CF or USB memory inserted to the Programming Pendant.

Automatic save mode

The automatic save function works only when the trigger

mode is valid.

The data is saved when the trigger conditions are satisfied

and the measurement is completed.

{HardCopy} button

Pressing the button enables to save the hard copy of the screen in CF

or USB memory.

{SaveCSV} button

It is available only when {Manual} is selected for the SaveMode option.

Pressing the button enables saving the measurement data into CF or

USB memory.

3.1.1 Data File Name and Save Destination

The measurement data is saved in the CSV (Comma Separated Value)

file format.

The file is automatically given a file name consisting of the time, date and

the year when the save operation starts (yyyymmdd_hhmmss.csv).

As the CSV file destination, a folder of the following address is

automatically created in the external CF or USB memory of the pendant,

and the data is saved in the folder:

¥PP_OSCILLOSCOPE¥csv¥user¥

The hard copy data of the screen is saved in the JPG (Joint Photographic

Experts Group) format.

3-1

HW1481803

Page 31

165467-1CD

NOTE

31 of 48

Pendant Oscilloscope

Function

3 Saving and Loading the Measurement Data

3.1 SaveMode Setting Panel

The file is automatically given a file name consisting of the time, date and

the year when the save operation starts (yyymmdd_hhmmss.jpg).

The JPG file is saved in the root folder in the external CF or USB memory

of the pendant.

When both CF and USB memory are inserted, USB memory is given

priority for the data storage destination.

3.1.2 CSV File

The CSV file contains the setting parameters shown in Table 3-1.

The CSV file can be used for file output of waveform data, as well as for

backup of the current setting status.

The setting parameters of TP oscilloscope are automatically

saved to the pendant when {OK} is pressed on the Channel

Setting window or {CLOSE} on the Main screen.

However, at system software version-up, these parameters

are initialized. Use the CSV file for backup as necessary.

Table 3-1: Parameters to Save for CSV Files

Parameter Description

Sampling time As left

Timescale setting

(data length)

Channel setting Valid/Invalid

Channel display setting Zero point position

Trigger setting Target channel

Waveform data Waveform data of available channel(s)

As left

Target

Signal

Target axis

Reference unit

Display ON/OFF

Invert ON/OFF

Trigger type

Trigger level

Pre-trigger

Alarm number

Valid/Invalid

3-2

HW1481803

Page 32

Pendant Oscilloscope

32 of 48

Function

165467-1CD

3 Saving and Loading the Measurement Data

3.2 Load Panel

3.2 Load Panel

With the data measurement stopped, select (touch) {Load} tab on the

condition setting panel. Fig. 3-2 shows the typical example of the Load

panel.

Fig. 3-2: Load Panel

The Load panel loads the CSV file previously saved to recreate the

waveform and setting parameters (those in Table 3-1) at that time.

The current setting parameters are overwritten by the loaded CSV file

data when the data is loaded.

Pull-down box for file selection

Select the file to load. The pull-down menu displays the file name

stored in the folder of the following address in the external CF or USB

memory of the Programming Pendant:

¥PP_OSCILLOSCOPE¥csv¥user¥

When both CF and USB memory are inserted, USB memory is given

priority.

When a file other than that saved in the PP oscilloscope is included in

the above folder, it may appear on the list, but it will cause an error

when it is loaded.

{LoadCSV} button

After selecting the file to load, touch the {LoadCSV} button.

A message, “Overwrite current setting. OK?” appears. Selecting {OK}

starts the data loading.

3-3

HW1481803

Page 33

165467-1CD

33 of 48

Pendant Oscilloscope

Function

4 Other Functions

4.1 Zoom Function

4 Other Functions

4.1 Zoom Function

With the data measurement stopped, select (touch) {Zoom} tab on the

condition setting panel. Fig. 4-1 shows the typical example of the Zoom

function setting panel.

This panel enables to set and perform the zoom function.

Fig. 4-1: Zoom Function Setting Panel

The Zoom function is the function to enlarge the specified range within the

waveform display area to the timescale direction.

Set the range to enlarge as in Fig. 4-2, to perform the Zoom function.

Fig. 4-2: Outline of Zoom Function

Center

Width

Waveform display area

Range to be zoomed

Center

Specify the center position in the zoom range by the division (0 to 10.0) in

the horizontal axis. The center position is not shown in the actual screen.

It is the center between two width lines.

When pressing [SHIFT] key + Cursor with {Zoom} tab opened, the center

position may move to right and left at 0.05[div]. And when keep pressing

[SHIFT] key + Cursor, the center position may move at high speed.

4-1

HW1481803

Page 34

Pendant Oscilloscope

NOTE

34 of 48

Function

4.1.1 During Execution of Zoom Function

165467-1CD

4 Other Functions

4.1 Zoom Function

Width

Specify the size of zoom range by width, with the center position specified

in the Center. The width is shown in the waveform display area by a white

line.

In case the width of the range to be zoomed extended outside the

waveform display area, the center position is automatically adjusted so

that the width fits inside the range.

{Zoom} button

Touching this button after setting of Center and Width zooms the specified

range.

When the Zoom function is performed, the currently displayed waveform

disappears, and the data in the zoom range is enlarged and displayed on

the waveform display area. Although the waveform before zoomed

temporarily disappears, it is retained inside the system; once canceling

the zoom function returns to the original state.

While the zoom function is performed, the {Zoom} button is switched to

the {ZoomCancel} button.

While the zoom function is performed, operations of the

{START} button and the {CH} button, and of the panels as

tab switch setting become unavailable. To enable these

operations, touch the {ZoomCancel} button.

4-2

HW1481803

Page 35

165467-1CD

35 of 48

Pendant Oscilloscope

Function

4 Other Functions

4.2 Cursor Measurement Function

4.2 Cursor Measurement Function

With the data measurement stopped, select (touch) the {Measure} tab on

the condition setting panel. Fig. 4-3 shows the typical example of the

Measure panel.

Fig. 4-3: Measure Panel and Cursor Display (with Vertical Cursor)

Measurement

parameters

Cursor

4

The cursor measurement function is the function to read the data within

the range selected by two cursors, calculate the values corresponding to

the specified measurement parameters, and display the result.

CursorType

Select the cursor type either from Horizontal or Vertical. Select the type

according to the usage. The {OFF} option makes the function

unavailable.

CH

Specify the channel to which the cursor measurement is targeted. The

channel specified as unavailable in the Channel Setting window cannot

be selected.

Cursor1, Cursor2

When the vertical cursor is selected in , specify the cursor position in

the horizontal division (0 to 10.0).

When the horizontal cursor is selected in , specify it in the vertical

division (-5.0 to 5.0).

The area enclosed by Cursor1 and Cursor2 becomes the target area of

cursor measurement. Even when the positions of Cursor1 and Cursor2

are switched, the target area is always the area inside these two lines.

4-3

HW1481803

Page 36

Pendant Oscilloscope

36 of 48

Function

165467-1CD

4 Other Functions

4.2 Cursor Measurement Function

The cursor is displayed by a white broken line on the waveform display

area.

When there is no target channel data within the specified cursor range,

a part of the measurement parameters is not calculated. When this

happens, the result is shown in hyphens (“-”).

CursorMode

When pressing [SHIFT] key + Cursor with {Zoom} tab opened, the

center position may move 0.05[div] to right and left. And when keep

pressing [SHIFT] key + Cursor, the position may move at high

speed.

When Horizontal cursor type is selected at

moves horizontally, and it moves vertically when Vertical cursor type is

selected.

Only the cursor 1 moves along the key input when “Cursor 1” is selected

and only cursor 2 moves when “Cursor 2” is selected. Also, both cursor

1 and 2 moves when “1 and 2” is selected.

on the display, the cursor

4-4

HW1481803

Page 37

165467-1CD

37 of 48

Pendant Oscilloscope

Function

4 Other Functions

4.2 Cursor Measurement Function

4.2.1 Cursor Measurement Parameters

○For horizontal cursor

With the cursor measurement valid, the measurement parameters and the

calculation result are automatically displayed at the upper left of waveform

display area. The type of measurement parameters in the horizontal

cursor is shown in Table 4-1.

Table 4-1: Measurement Parameters of Horizontal Cursors

Parameter Description

Cursor1 Value of measurement target channel at the Cursor1

Cursor2 Value of measurement target channel at the Cursor2

MAX Maximum value of measurement target channel between

Cursor1 and Cursor2

MIN Minimum value of measurement target channel between

Cursor1 and Cursor2

P-P (Peak to Peak: difference of MAX and MIN)

Absolute value of the result obtained by: MAX-MIN

○For vertical cursor

With the cursor measurement valid, the measurement parameters and the

calculation result are automatically displayed at the upper left of waveform

display area. The type of measurement parameters in the vertical cursor

is shown in Table 4-2.

Table 4-2: Measurement Parameters of Vertical Cursors

Parameter Description

Time Time width between Cursor1 and Cursor2

Cursor1 Value of measurement target channel at the Cursor1

Cursor2 Value of measurement target channel at the Cursor2

MAX Maximum value of measurement target channel between

Cursor1 and Cursor2

MIN Minimum value of measurement target channel between

Cursor1 and Cursor2

P-P (Peak to Peak: difference of MAX and MIN)

Absolute value of the result obtained by: MAX-MIN

RMS (RMS: Root Mean Square)

Data between Cursor1 and Cursor2; calculated actual value of

the measurement target channel

4-5

HW1481803

Page 38

Pendant Oscilloscope

NOTE

NOTE

38 of 48

Function

165467-1CD

4 Other Functions

4.3 Job Step No. Saving Function

4.3 Job Step No. Saving Function

When “1” is set to S2C1242, the job step No. saving function is enabled.

In this function, the job name and the step No. which are under execution

at the time are added to the waveform data of the CSV file, and the

waveform data and the job step No. are related and saved.

The job step No. saving function is available in the version

DN1.61.00A(--)-00 and the later.

Fig. 4-4: Example for Adding Items to Be Saved in CSV File (Job Name

and Step No.)

The job name and the step No. are saved only when the play mode

executes a job and when the teach mode executes a trial run or a NEXT

operation. In a JOG operation or an IO jog operation, the job name and

the step No. are not saved.

Table 4-3: Conditions that Job Name and Step No. Are Saved

Operation Saved/not

Playback Saved

Trial run Saved

Interlock + NEXT Saved

NEXT Saved

NEXT for P variable Not

IO jog Not

Jog operation Not

The job name and the step No. are assigned to the position

instruction. On the other hand, the waveform data interprets

the position instruction and acquires data when the motor

operates actually. Therefore, deviations of acquisition timing

for a certain time occurs between both data.

Be careful when referring to the data which is close to the

switching point of the step No.

4-6

HW1481803

Page 39

165467-1CD

39 of 48

Pendant Oscilloscope

Function

4 Other Functions

4.3 Job Step No. Saving Function

4.3.1 Channel Setting

Only one control group can be specified at one measurement time as the

control group which is targeted to acquire the job name and the step No.

The setting can be performed in Channel Setting screen of the PP

oscilloscope (Fig. 4-5).

When the job including a control group which is set in this item works, the

job name and the step No. are saved.

Fig. 4-5: Adding Items to "ControlGroup" of Channel Setting Screen

4.3.2 Adjustment of Acquisition Time of Job Name and Step No.

When the job cursor reaches END or when the other job is called (when

the assignment of the job name and the step No. to the targeted control

group are stopped), the job name and the step No. which are output lastly

can be kept recording for a certain time.

This can be performed when assignment of the job name and the step No.

are interrupted because of the deviation of the waveform against the

instruction.

S4C1039 can adjust this addition time (unit: msec, default value: 500 msec).

Fig. 4-6: Example for Acquisition Time of Job Name and Step No.

Range that job names and step Nos. are generally added

Additional time for acquiring

job names and step Nos.

CH1, Signal for indicating

"under running"

CH2, Speed FB CH3, Torque instruction

4-7

HW1481803

Page 40

Pendant Oscilloscope

NOTE

NOTE

NOTE

Rising

40 of 48

Function

165467-1CD

4 Other Functions

4.4 Operation Function by Dedicated Input

4.4 Operation Function by Dedicated Input

When “1” is set to S2C1244, the signal operation function is enabled.

This function makes the following operations performed on the

programming pendant executable externally by the dedicated input

signals.

• Starting PP oscilloscope

• Starting measurement

• Saving CSV file

Also, the PP oscilloscope status is output to the dedicated output signal,

and it can be externally referred.

The operation function by dedicated input is available in the

version DN1.61.00A(--)-00 and the later.

This function aims to start measurement externally without

operating and referring to the programming pendant.

Therefore, it has no dedicated input signal to stop

measurement.

For stopping measurement, use the trigger mode.

4.4.1 Dedicated Input Signal

40767 40766 40765 40764 40763 40762 40761 40760

SIN#608 SIN#607 SIN#606 SIN#605 SIN#604 SIN#603 SIN#602 SIN#601

OSC

SAVE START

40760: Starting Pendant Oscilloscope

Starts PP oscilloscope.

When PP oscilloscope is in minimized status, it is released.

This signal performs the same operation as the operation when

pressing {Robot}

When it is in one of the following status, pendant

oscilloscope cannot be started even if this signal is turned

ON.

After releasing the status, turn ON this signal.

→ {Pendant oscilloscope} from the main menu.

OSC

MEAS.START

OSC

STARTUP

• An error exists.

• Other external application is running.

4-8

HW1481803

Page 41

165467-1CD

Rising

NOTE

Rising

㻝㻌㼟㼑㼏㻚㻌㼛㼞㻌

㼘㼛㼚㼓㼑㼞

㻝㻌㼟㼑㼏㻚㻌㼛㼞㻌

㼘㼛㼚㼓㼑㼞

㻿㼕㼓㼚㼍㼘㻌㼍㼏㼏㼑㼜㼠㼍㼚㼏㼑㻌㼞㼑㼍㼐㼥

㻔㻡㻝㻝㻣㻞㻕

㻹㼑㼍㼟㼡㼞㼑㼙㼑㼚㼠㻌㼟㼠㼍㼞㼠㻌㼞㼑㼝㼡㼑㼟㼠

㻔㻠㻜㻣㻢㻝㻕

41 of 48

Pendant Oscilloscope

Function

4 Other Functions

4.4 Operation Function by Dedicated Input

40761: Pendant Oscilloscope Starting Measurement

Starts measurement.

This signal performs the same operation as the operation when

pressing [START] of PP oscilloscope.

40762: Pendant Oscilloscope Saving CSV File

Saves the measured data to the CSV file.

This signal performs the same operation as the operation when

pressing [Save CSV] of PP oscilloscope.

The measurement start requesting signal (40761) and the

CSV file saving requesting signal (40762) are monitored

only when the signal acceptance ready (51172) is ON.

In order to accept the request surely, put a requesting signal

with the following procedure.

• After the signal acceptance ready (51172) is turned ON,

wait for 1 second, and then put the signal.

• After putting the signal, ON status should be maintained for

1 second or longer.

4-9

HW1481803

Page 42

165467-1CD

State

State

SUPPLE-

MENT

State

42 of 48

Pendant Oscilloscope

Function

4 Other Functions

4.4 Operation Function by Dedicated Input

4.4.2 Dedicated Output Signal

Displays PP oscilloscope operation status. When PP oscilloscope is not

running, all signals are OFF.

50907 50906 50905 50904 50903 50902 50901 50900

SOUT#720 SOUT#719 SOUT#718 SOUT#717 SOUT#716 SOUT#715 SOUT#714 SOUT#713

MEASURING

PP-OSC

51177 51176 51175 51174 51173 51172 51171 51170

SOUT#936 SOUT#935 SOUT#934 SOUT#933 SOUT#932 SOUT#931 SOUT#930 SOUT#929

OSC

SAVE ERROR

OSC

SAVING

OSC

MEAS.ERROR

OSC I/O

READY

OSC

MINIMIZE

OSC

RUNNING

50903: Pendant Oscilloscope Under Measurement

Notifies that measurement is currently performed.

Only this signal varies regardless of S2C1244 setting.

51170: Pendant Oscilloscope Running

Notifies that PP oscilloscope is running.

This signal is turned ON even if PP oscilloscope is in minimized

status.

51171: Pendant Oscilloscope Minimized

Notifies that PP oscilloscope is in minimized status.

PP oscilloscope is minimized by the following factors:

• The {MINIMIZE} button is pressed.

• An alarm or an error occurs.

The minimized status can be cancelled by selecting {Pendant

oscilloscope} from the main menu or using the start

requesting signal (40760).

4-10

HW1481803

Page 43

165467-1CD

SUPPLE-

MENT

State

State

State

State

43 of 48

Pendant Oscilloscope

Function

4 Other Functions

4.4 Operation Function by Dedicated Input

51172: Pendant Oscilloscope IO Acceptance Ready

Notifies that PP oscilloscope is monitoring the start request

(40761) and the CSV file saving request (40762).

Only when the following conditions are satisfied, this signal is

turned ON.

• Measurement CH settings are completed.

• Not under measurement.

• Not under saving the CSV file.

• Not in the minimized status.

• Not under zooming (section 4.1.1 “During Execution of

Zoom Function” on page 4-2).

51173: Pendant Oscilloscope Measurement Error

Notifies that the measurement failed to start when the {START}

button or the start requesting signal (40761) tried to start

measurement.

Check that there are no errors in the measurement conditions.

This signal is turned OFF when newly starting measurement.

51174: Pendant Oscilloscope CSV File Under Saving

Notifies that the CSV file is under saving.

51175: Pendant Oscilloscope CSV File Error in Saving

Notifies that saving is failed when starting saving with the {Save

CSV} button or the CSV file saving requesting signal (40762).

Check the condition of the external storage device.

This signal is turned OFF when newly starting saving.

When requesting saving in the condition that the measurement

is never performed after starting PP oscilloscope, saving is not

performed but this signal is not turned ON.

4-11

HW1481803

Page 44

Pendant Oscilloscope

44 of 48

Function

5 Supplementary Explanation

5.1 Division [div]: Unit for Measurement Screen Position

5 Supplementary Explanation

Here explains some of the terms used in this manual.

5.1 Division [div]: Unit for Measurement Screen Position

The PP oscilloscope includes the operation that specifies the various

positions (or range) in the waveform display area, such as specifying zero

point of measurement channel, specifying cursor range, or zoom range.

To specify these positions, unit of “division [div]” is used. Here describes

the details.

The waveform display area is represented in a range of 10 vertical grids

and 10 horizontal grids. The cell consisted of a vertical grid and a

horizontal grid is called as Division [div], both for vertical axis and

horizontal axis. The vertical axis is divided into 10 cells, 5 for the upper

part and 5 for the lower part. The center is regarded as 0 [div], and the

maximum value in the upmost position is 5 [div], whereas the minimum

value in the bottom position is -5 [div]. For the horizontal axis, the left end

position is regarded as 0 [div], and the right end position is 10 [div]. The

outline is shown in Fig. 5-1.

165467-1CD

For example, in specifying 3 [div], if it is given to the vertical axis, it shows

the location

shows the location

Fig. 5-1: Illustration of Division in Waveform Display Area

Vertical direction

in Fig. 5-1,whereas if it is given to the horizontal axis, it

.

Horizontal direction

5-1

HW1481803

Page 45

165467-1CD

45 of 48

Pendant Oscilloscope

Function

5 Supplementary Explanation

5.2 Reference Unit

5.2 Reference Unit

Here describes the reference unit.

The data of measurement target has each unit, as shown in Table 5-1.

Table 5-1: Unit of Data

Data type Unit

Speed

reference

Speed

feedback

To rq u e

reference

Concurrent I/O No unit, for it is just an ON/OFF signal.

Register No unit, for it is just an register value.

[rpm]

Rotating speed of target axis motor in a minute

[rpm]

Actual rotating speed of target axis motor in one minute

[%]

Current torque reference value when the target axis motor rated

torque is converted as 100%.

To differentiate from other signal data, [U] (unit) is used for

expediency.

OFF: 0 U is output

ON: 1.0 U is output

Register value is output without changed.

Example: When the vertical scale is 100[-/div] and the target

register value is 200, the output of 2 divisions is given

.

When the speed reference is selected as a measurement signal of the

target channel, the initial value of the reference unit is 1000 [rpm/div].

This means that the speed is 1000 [rpm] when the output of vertical 1 [div]

is given from the target channel zero position. From this relationship, the

outline of waveform data output on the waveform display area can be

grasped.

Example: with the setting of 1000 [rpm/div]:

Output of 2.0 [div]: 2000 [rpm]

Output of -3.3 [div]: -3300 [rpm]

Since the reference unit can be changed in the {ChCondition} tab, the

waveform display scale in the vertical direction can be changed

accordingly.

Example: with the actual output of 1000 [rpm]:

Setting of 1000 [rpm/div]: Output of 1 division

Setting of 500 [rpm/div]: Output of 2 divisions

5-2

HW1481803

Page 46

Pendant Oscilloscope

46 of 48

Function

6 Error Messages

165467-1CD

6 Error Messages

The pendant oscilloscope can output the messages for confirming the

operation or notifying the process completion. Especially when the data

acquisition error or abnormal setting should occur, the application outputs

error messages such as shown in Fig. 6-1 to notify the problem.

When any error message is displayed, first check the content, touch {OK}

to clear the message, and follow necessary countermeasures.

Fig. 6-1: Example of Error Message

Table 6-1 shows the list of error messages and the countermeasure.

Table 6-1: Error Messages and Countermeasures of PP Oscilloscope

(Sheet 1 of 2)

Error messages Countermeasures

Input the value between ** and **.

The value to ** decimal places can be

input.

Input the numeric value.

(**: numerical value)

The specified number for the alarm

trigger is not correct.

Review the setting.

Any trigger can be detected with this

setting.

Review the trigger level setting.

The axis number which doesn't exist

in the system has been specified.

Review the channel setting.

Input correct I/O number. The concurrent I/O number which does

Processing time insufficient.

Set slower sampling time or decrease

the number of available channels.

The input value is out of the limitation of

input box.

Retry inputting a correct value according

to the error message.

This error can occur in all of the input

boxes.

A non-existent number is specified as the

alarm number of alarm trigger. Retry

setting a correct number.

The trigger level is out of the waveform

display area due to excessively large

trigger level or channels zero position.

Check the trigger level setting.

The axis number which does not exist in

the system is specified to either of axes

in the channel setting window.

Set the correct number.

not exist is specified.

Set the correct number.

Process time for data acquisition is not

enough for the volume of measurement

data.

Set a slower sampling time, or decrease

the available channel number.

6-1

HW1481803

Page 47

165467-1CD

47 of 48

Pendant Oscilloscope

Function

6 Error Messages

Table 6-1: Error Messages and Countermeasures of PP Oscilloscope

(Sheet 2 of 2)

Error messages Countermeasures

The acceptable delaying range of

graph drawing exceeded. Implement

any of the following countermeasures.

- Set slower sampling time.

- Decrease the number of available

channels.

- Set shorter value for Time Scale

setting. (Shorten the data length.)

No corresponding data exists within

the zoom range.

Cannot recognize Flash Memory.

Setting for SaveMode is switched

from Auto to Manual.

Cannot recognize Flash Memory.

SaveMode is switched from Auto to

Manual.

Perform manual saving if necessary.

Failed in saving CSV file.

Perform manual saving if necessary.

Not enough disk space.

Make room for the file to perform

manual saving.

File format is not correct. The file to load has not been matched

Failed in loading CSV file. The file to load has been found not to be

File not specified. Specify the file to load.

Specified file not exist. The specified file does not exist on the