YAMAHA YFM660FP SERVICE MANUAL

YFM660FP

SERVICE MANUAL

LIT-11616-15-01 5KM-28197-E0

EB001000

NOTICE

This manual was produced by the Yamaha Motor Company primarily for use by Yamaha dealers

and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one

manual, so it is assumed that anyone who uses this book to perform maintenance and repairs on

Yamaha machine has a basic understanding of the mechanical ideas and the procedures of

machine repair. Repairs attempted by anyone without this knowledge are likely to render the

machine unsafe and unfit for use.

Yamaha Motor Company, Ltd. is continually striving to improve all its models. Modifications and significant changes in specifications or procedures will be forwarded to all authorized Yamaha dealers

and will appear in future editions of this manual where applicable.

OTE:

Designs and specifications are subject to change without notice.

IMPORTANT INFORMATION

Particularly important information is distinguished in this manual by the following notations.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED!

WARNING

CAUTION:

NOTE:

Failure to follow WARNING instructions could result in severe injury or death

to the machine operator, a bystander or a person inspecting or repairing the

machine.

A CAUTION indicates special precautions that must be taken to avoid damage to the machine.

A NOTE provides key information to make procedures easier or clearer.

EB002000

HOW TO USE THIS MANUAL

MANUAL ORGANIZATION

This manual consists of chapters for the main categories of subjects. (See “Illustrated symbols”)

1st title 1: This is the title of the chapter with its symbol in the upper right corner of each page.

2nd title 2: This title indicates the section of the chapter and only appears on the first page of each

section. It is located in the upper left corner of the page.

3rd title 3: This title indicates a sub-section that is followed by step-by-step procedures accompanied by corresponding illustrations.

EXPLODED DIAGRAMS

To help identify parts and clarify procedure steps, there are exploded diagrams at the start of each

removal and disassembly section.

1. An easy-to-see exploded diagram 4 is provided for removal and disassembly jobs.

2. Numbers 5 are given in the order of the jobs in the exploded diagram. A number that is enclosed

by a circle indicates a disassembly step.

3. An explanation of jobs and notes is presented in an easy-to-read way by the use of symbol marks

6. The meanings of the symbol marks are given on the next page.

4. A job instruction chart 7 accompanies the exploded diagram, providing the order of jobs, names

of parts, notes in jobs, etc.

5. For jobs requiring more information, the step-by-step format supplements 8 are given in addition

to the exploded diagram and the job instruction chart.

12

GEN

INFO

34

SPEC

CHK

ENG

ADJ

56

COOL

78

CARB

EB003000

ILLUSTRATED SYMBOLS

Illustrated symbols 1 to 0 are printed on the

top right of each page and indicate the subject

of each chapter.

1 General information

2 Specifications

3 Periodic checks and adjustments

4 Engine

5 Cooling system

6 Carburetion

7 Drive train

8 Chassis

9 Electrical

0 Troubleshooting

DRIV

90

–+

ELEC

AB

CD

EF

T

.

R

.

GH

CHAS

TRBL

SHTG

Illustrated symbols A to H are used to identify

the specifications appearing in the text.

A Can be serviced with engine mounted

B Filling fluid

C Lubricant

D Special tool

E Torque

F Wear limit, clearance

G Engine speed

Ω, V, A

H

IJK

LS

G

M

M

New

E

LMN

B

OP

LT

Illustrated symbols I to N in the exploded

diagrams indicate the types of lubricants and

lubrication points.

I Apply engine oil

J Apply gear oil

K Apply molybdenum disulfide oil

L Apply wheel bearing grease

M Apply lightweight lithium-soap base grease

N Apply molybdenum disulfide grease

Illustrated symbols O to P in the exploded

diagrams indicate where to apply a locking

agent O and when to install a new part P.

O Apply the locking agent (LOCTITE

P Replace

)

TABLE OF CONTENTS

GENERAL INFORMATION

SPECIFICATIONS

PERIODIC CHECKS AND

ADJUSTMENTS

ENGINE

COOLING SYSTEM

GEN

INFO

SPEC

CHK

ADJ

ENG

COOL

1

2

3

4

5

CARBURETION

DRIVE TRAIN

CHASSIS

ELECTRICAL

TROUBLESHOOTING

CARB

DRIV

CHAS

–+

ELEC

TRBL

SHTG

6

7

8

9

10

CONTENTS

CHAPTER 1.

GENERAL INFORMATION

MACHINE IDENTIFICATION

VEHICLE IDENTIFICATION NUMBER ................................................. 1-1

MODEL LABEL ...................................................................................... 1-1

FEATURES

FRONT DIFFERENTIAL ........................................................................ 1-2

TRANSMISSION ...................................................................................1-9

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL PROCEDURES .............................1-10

REPLACEMENT PARTS ..................................................................... 1-10

GASKETS, OIL SEALS AND O-RINGS ..............................................1-10

LOCK WASHERS/PLATES AND COTTER PINS ............................... 1-11

BEARINGS AND OIL SEALS .............................................................. 1-11

CIRCLIPS ............................................................................................1-11

CHECKING OF CONNECTIONS

SPECIAL TOOLS

...................................................................................................1-2

........................................................................................1-13

........................................................................1-1

.....................................................................1-10

................................................................ 1-12

CHAPTER 2.

SPECIFICATIONS

GENERAL SPECIFICATIONS

MAINTENANCE SPECIFICATIONS

ENGINE .................................................................................................2-4

CHASSIS ............................................................................................. 2-14

ELECTRICAL ......................................................................................2-18

HOW TO USE THE CONVERSION TABLE

GENERAL TORQUE SPECIFICATIONS

......................................................................2-1

............................................................. 2-4

............................................... 2-20

................................................... 2-20

LUBRICATION POINTS AND LUBRICANT TYPES .................................. 2-21

ENGINE ...............................................................................................2-21

COOLANT FLOW DIAGRAMS ................................................................... 2-22

OIL FLOW DIAGRAMS .............................................................................. 2-24

CABLE ROUTING ....................................................................................... 2-27

CHAPTER 3.

PERIODIC CHECKS AND ADJUSTMENTS

INTRODUCTION ...........................................................................................3-1

PERIODIC MAINTENANCE/LUBRICATION INTERVALS ..........................3-1

SEAT, CARRIERS, FENDERS AND FUEL TANK .......................................3-3

SEAT AND SIDE PANELS .................................................................... 3-3

FRONT CARRIER, FRONT BUMPER AND FRONT GRILL ................. 3-4

HANDLEBAR COVER, FUEL TANK COVER AND FRONT FENDER . 3-5

REAR CARRIER AND REAR FENDER ................................................ 3-7

ENGINE SKID PLATE (CENTER) AND ENGINE SKID PLATE

(REAR) ..............................................................................................3-9

FUEL TANK ......................................................................................... 3-10

FOOTREST BOARDS ................................................................................ 3-12

ENGINE ....................................................................................................... 3-13

ADJUSTING THE VALVE CLEARANCE ............................................ 3-13

ADJUSTING THE TIMING CHAIN ...................................................... 3-16

ADJUSTING THE IDLING SPEED ......................................................3-16

ADJUSTING THE THROTTLE LEVER FREE PLAY .......................... 3-17

ADJUSTING THE SPEED LIMITER .................................................... 3-19

ADJUSTING THE STARTER CABLE ................................................. 3-21

CHECKING THE SPARK PLUG ......................................................... 3-22

CHECKING THE IGNITION TIMING ................................................... 3-23

MEASURING THE COMPRESSION PRESSURE .............................. 3-24

CHECKING THE ENGINE OIL LEVEL ................................................ 3-26

CHANGING THE ENGINE OIL ...........................................................3-27

CLEANING THE AIR FILTER .............................................................. 3-29

CHECKING THE COOLANT LEVEL ...................................................3-31

CHANGING THE COOLANT ............................................................... 3-32

CHECKING THE COOLANT TEMPERATURE WARNING LIGHT ..... 3-36

CHECKING THE V-BELT ....................................................................3-36

CLEANING THE SPARK ARRESTER ................................................3-37

CHASSIS ....................................................................................................3-39

ADJUSTING THE REAR BRAKE ........................................................ 3-39

CHECKING THE BRAKE FLUID LEVEL ............................................. 3-41

CHECKING THE FRONT BRAKE PAD .............................................. 3-43

CHECKING THE REAR BRAKE PAD ................................................. 3-43

CHECKING THE BRAKE HOSE ......................................................... 3-43

BLEEDING THE HYDRAULIC BRAKE SYSTEM ............................... 3-44

ADJUSTING THE SELECT LEVER CONTROL CABLE

AND SHIFT ROD ............................................................................. 3-46

ADJUSTING THE REAR BRAKE LIGHT SWITCH ............................. 3-47

CHECKING THE FINAL GEAR OIL LEVEL ........................................ 3-48

CHANGING THE FINAL GEAR OIL ....................................................3-48

CHECKING THE DIFFERENTIAL GEAR OIL .....................................3-49

CHANGING THE DIFFERENTIAL GEAR OIL .................................... 3-50

CHECKING THE CONSTANT VELOCITY JOINT DUST BOOT ........ 3-51

CHECKING THE STEERING SYSTEM .............................................. 3-51

ADJUSTING THE TOE-IN ...................................................................3-51

ADJUSTING THE FRONT SHOCK ABSORBER ................................3-53

ADJUSTING THE REAR SHOCK ABSORBER .................................. 3-54

CHECKING THE TIRE ........................................................................ 3-54

CHECKING THE WHEEL .................................................................... 3-56

CHECKING AND LUBRICATING THE CABLE ................................... 3-57

LUBRICATING THE LEVERS, PEDAL, ETC. ..................................... 3-57

ELECTRICAL .............................................................................................. 3-58

CHECKING THE BATTERY ................................................................ 3-58

CHECKING THE FUSE .......................................................................3-63

ADJUSTING THE HEADLIGHT BEAM ............................................... 3-65

CHANGING THE HEADLIGHT BULB ................................................. 3-65

CHAPTER 4.

ENGINE

ENGINE REMOVAL ...................................................................................... 4-1

AIR DUCTS, MUFFLER AND EXHAUST PIPE .................................... 4-1

SELECT LEVER UNIT AND COOLANT RESERVOIR ......................... 4-3

HOSES AND LEADS ............................................................................. 4-4

ENGINE MOUNTING BOLTS ...............................................................4-5

INSTALLING THE ENGINE ................................................................... 4-7

CYLINDER HEAD COVER ........................................................................... 4-8

REMOVING THE CYLINDER HEAD COVER .....................................4-10

CHECKING THE CYLINDER HEAD COVER ..................................... 4-10

CHECKING THE TAPPET COVER ..................................................... 4-11

INSTALLING THE CYLINDER HEAD COVER ................................... 4-11

ROCKER ARMS ......................................................................................... 4-12

REMOVING THE ROCKER ARM .......................................................4-14

CHECKING THE ROCKER ARM ........................................................ 4-14

INSTALLING THE ROCKER ARM ...................................................... 4-15

CAMSHAFT AND CYLINDER HEAD ......................................................... 4-16

REMOVING THE CAMSHAFT AND CYLINDER HEAD .....................4-18

CHECKING THE CAMSHAFT ............................................................. 4-19

CHECKING THE CAMSHAFT SPROCKET ........................................ 4-19

CHECKING THE DECOMPRESSION SYSTEM ................................. 4-19

CHECKING THE TIMING CHAIN GUIDE ........................................... 4-20

CHECKING THE TIMING CHAIN TENSIONER .................................. 4-20

CHECKING THE CYLINDER HEAD ................................................... 4-20

INSTALLING THE CAMSHAFT AND CYLINDER HEAD .................... 4-21

VALVES AND VALVE SPRINGS ............................................................... 4-24

REMOVING THE VALVE AND VALVE SPRING ................................4-25

CHECKING THE VALVE AND VALVE SPRING ................................. 4-26

INSTALLING THE VALVE AND VALVE SPRING ............................... 4-30

CYLINDER AND PISTON ........................................................................... 4-32

REMOVING THE PISTON ..................................................................4-33

CHECKING THE CYLINDER AND PISTON ....................................... 4-33

CHECKING THE PISTON RING ......................................................... 4-35

CHECKING THE PISTON PIN ............................................................ 4-36

INSTALLING THE PISTON ................................................................. 4-36

INSTALLING THE CYLINDER ............................................................ 4-37

RECOIL STARTER AND AC MAGNETO ................................................... 4-38

REMOVING THE AC MAGNETO ........................................................ 4-41

DISASSEMBLING THE RECOIL STARTER .......................................4-41

CHECKING THE AC MAGNETO ........................................................ 4-41

CHECKING THE STARTER CLUTCH ................................................ 4-42

CHECKING THE STARTER PULLEY ................................................. 4-43

CHECKING THE RECOIL STARTER ................................................. 4-43

ASSEMBLEING THE RECOIL STARTER ..........................................4-43

INSTALLING THE AC MAGNETO ...................................................... 4-44

BALANCER GEARS AND OIL PUMP GEARS .......................................... 4-47

REMOVING THE BALANCER DRIVE GEAR

AND BALANCER DRIVEN GEAR ................................................... 4-48

REMOVING THE BALANCER DRIVE GEAR

AND BUFFER BOSS ....................................................................... 4-48

CHECKING THE OIL PUMP DRIVE ................................................... 4-48

CHECKING THE BALANCER DRIVE ................................................. 4-49

INSTALLING THE BALANCER DRIVE GEAR

AND BALANCER DRIVEN GEAR ................................................... 4-49

PRIMARY AND SECONDARY SHEAVES ................................................. 4-51

PRIMARY SHEAVE ............................................................................. 4-53

SECONDARY SHEAVE ...................................................................... 4-54

REMOVING THE PRIMARY AND SECONDARY SHEAVES ............. 4-55

DISASSEMBLING THE SECONDARY SHEAVE ................................4-55

CHEKING THE PRIMARY SHEAVE ................................................... 4-56

CHECKING THE SECONDARY SHEAVE .......................................... 4-56

ASSEMBLING THE PRIMARY SHEAVE ............................................ 4-57

ASSEMBLING THE SECONDARY SHEAVE ......................................4-57

INSTALLING THE PRIMARY AND SECONDARY SHEAVES ............ 4-59

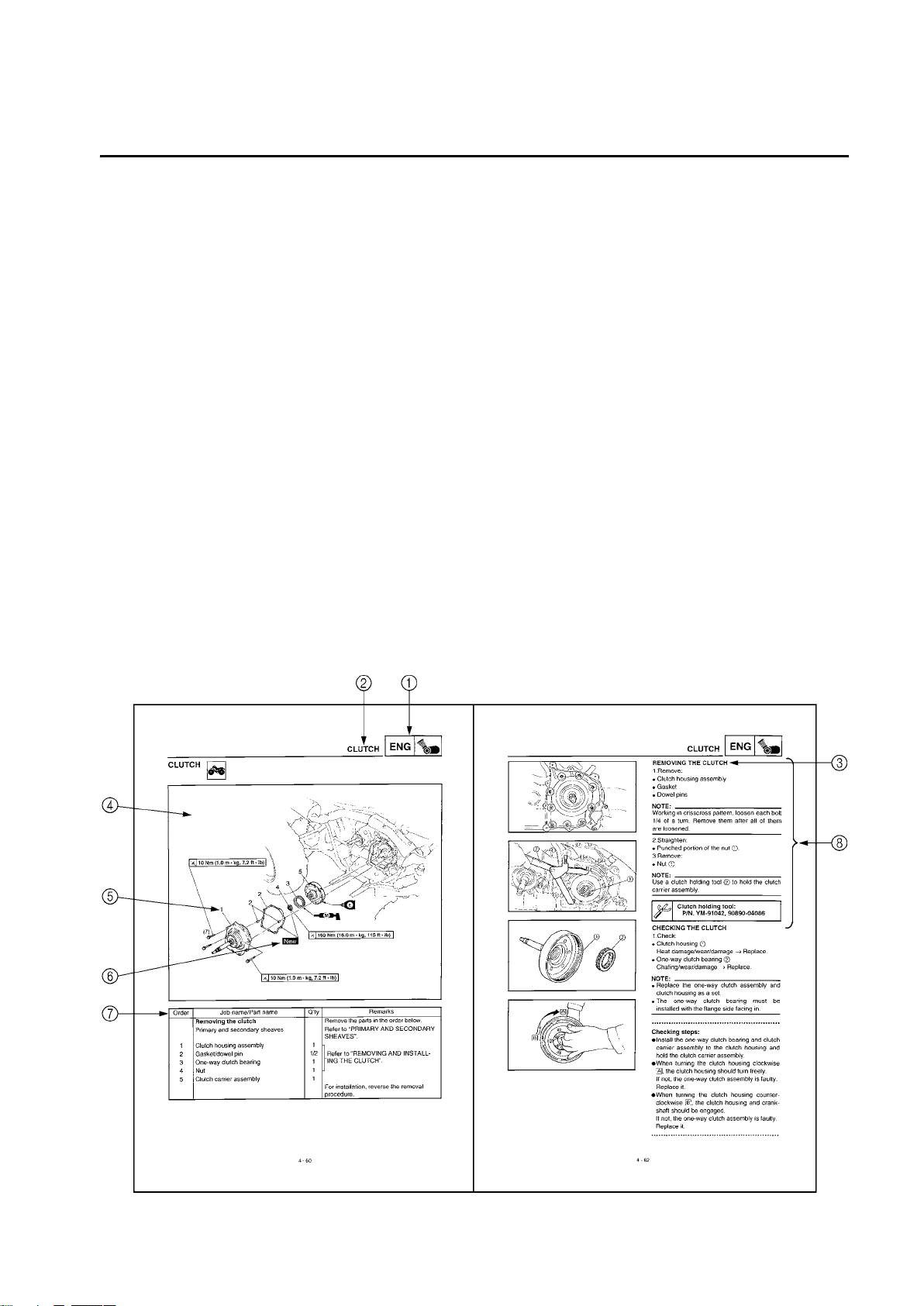

CLUTCH ...................................................................................................... 4-60

REMOVING THE CLUTCH ................................................................. 4-62

CHECKING THE CLUTCH ..................................................................4-62

INSTALLING THE CLUTCH ................................................................4-63

CRANKCASE ..............................................................................................4-65

STARTER MOTOR, TIMING CHAIN AND OIL FILTER ...................... 4-65

CRANKCASE ......................................................................................4-67

CRANKCASE BEARING ..................................................................... 4-68

SEPARATING THE CRANKCASE ...................................................... 4-69

CHECKING THE TIMING CHAIN AND GUIDE ................................... 4-69

CHECKING THE OIL DELIVERY PIPE ............................................... 4-69

CHECKING THE CRANKCASE .......................................................... 4-70

CHECKING THE BEARINGS .............................................................. 4-70

ASSEMBLING THE CRANKCASE ...................................................... 4-70

INSTALLATING THE SHIFT LEVER ................................................... 4-71

CRANKSHAFT AND OIL PUMP ................................................................ 4-72

OIL PUMP ........................................................................................... 4-73

REMOVING THE CRANKSHAFT .......................................................4-74

CHECKING THE OIL PUMP ............................................................... 4-74

CHECKING THE RELIEF VALVE ....................................................... 4-75

CHECKING THE OIL STRAINER .......................................................4-75

ASSEMBLING THE OIL PUMP ...........................................................4-75

CHECKING THE CRANKSHAFT ........................................................ 4-76

INSTALLING THE CRANKSHAFT AND BALANCER ......................... 4-77

TRANSMISSION .........................................................................................4-78

REMOVING THE TRANSMISSION ....................................................4-81

CHECKING THE SHIFT FORK ........................................................... 4-81

CHECKING THE SHIFT CAM ............................................................. 4-82

CHECKING THE DRIVE AXLE ...........................................................4-82

CHECKING THE HIGH WHEEL GEAR

AND MIDDLE DRIVE GEAR ........................................................... 4-82

CHECKING THE SECONDARY SHAFT

AND DRIVEN SPROCKET .............................................................. 4-83

CHECKING THE CHAIN ..................................................................... 4-83

CHECKING THE STOPPER LEVER

AND STOPPER WHEEL ................................................................. 4-83

ASSEMBLING THE SHIFT FORK ASSEMBLY ..................................4-84

INSTALLING THE TRANSMISSION .................................................... 4-84

MIDDLE GEAR ...........................................................................................4-85

MIDDLE DRIVE SHAFT ...................................................................... 4-85

MIDDLE DRIVEN SHAFT .................................................................... 4-86

REMOVING THE MIDDLE DRIVE SHAFT ......................................... 4-88

REMOVING THE MIDDLE DRIVEN SHAFT ....................................... 4-88

CHECKING THE PINION GEAR ......................................................... 4-91

MIDDLE DRIVE AND DRIVEN GEAR SHIM SELECTION ................. 4-91

INSTALLING THE MIDDLE DRIVEN SHAFT ..................................... 4-94

INSTALLING THE MIDDLE DRIVE SHAFT ........................................ 4-96

MEASURING THE MIDDLE GEAR BACKLASH ................................. 4-97

CHAPTER 5.

COOLING SYSTEM

RADIATOR .................................................................................................... 5-1

CHECKING THE RADIATOR ................................................................5-3

INSTALLING THE RADIATOR ..............................................................5-4

THERMOSTAT ..............................................................................................5-5

CHECKING THE THERMOSTAT .......................................................... 5-6

INSTALLING THE THERMOSTAT ........................................................ 5-6

WATER PUMP ..............................................................................................5-7

DISASSEMBLING THE WATER PUMP ................................................ 5-9

CHECKING THE WATER PUMP .......................................................... 5-9

ASSEMBLING THE WATER PUMP .................................................... 5-10

CHAPTER 6.

CARBURETION

CARBURETOR

DISASSEMBLING THE CARBURETOR ...............................................6-4

CHECKING THE CARBURETOR ......................................................... 6-4

ASSEMBLING THE CARBURETOR .....................................................6-6

ADJUSTING THE FUEL LEVEL ............................................................ 6-7

.............................................................................................6-1

CHAPTER 7.

DRIVE TRAIN

TROUBLESHOOTING

FRONT CONSTANT VELOCITY JOINTS

AND DIFFERENTIAL GEAR

DISASSEMBLING THE UNIVERSAL JOINT ........................................ 7-9

REMOVING THE RING GEAR ............................................................ 7-10

CHECKING THE CONSTANT VELOCITY JOINT .............................. 7-10

CHECKING THE DIFFERENTIAL GEAR ............................................ 7-10

CHECKING THE GEAR MOTOR ........................................................7-11

ASSEMBLING THE FRONT CONSTANT VELOCITY JOINT ............. 7-11

ASSEMBLING THE DIFFERENTIAL GEAR ....................................... 7-12

INSTALLING THE UNIVERSAL JOINT ............................................... 7-14

MEASURING AND ADJUSTING

THE DIFFERENTIAL GEAR LASH ................................................. 7-15

CHECKING THE DIFFERENTIAL GEAR OPERATION ..................... 7-17

..................................................................................7-1

.................................................................... 7-4

REAR CONSTANT VELOCITY JOINT/FINAL DRIVE GEAR

AND DRIVE SHAFT

ASSEMBLING THE REAR CONSTANT VELOCITY JOINT ............... 7-22

REMOVING AND DISASSEMBLING

THE FINAL DRIVE ROLLER BEARING ..........................................7-23

POSITIONING THE FINAL DRIVE PINION GEAR

AND RING GEAR ............................................................................ 7-24

CHECKING THE DRIVE SHAFT ......................................................... 7-29

CHECKING THE FINAL DRIVE GEAR ............................................... 7-29

MEASUREMENT AND ADJUSTING THE FINAL GEAR LASH ..........7-30

ASSEMBLING THE FINAL DRIVE GEAR ........................................... 7-32

INSTALLING THE FINAL DRIVE GEAR ............................................. 7-32

................................................................................7-18

CHAPTER 8.

CHASSIS

FRONT WHEELS AND BRAKE DISCS

FRONT WHEELS .................................................................................. 8-1

CHECKING THE FRONT WHEEL ........................................................ 8-3

CHECKING THE FRONT WHEEL HUB ................................................ 8-3

CHECKING THE FRONT BRAKE DISC ............................................... 8-4

INSTALLING THE FRONT WHEEL HUB .............................................. 8-4

INSTALLING THE FRONT WHEEL ...................................................... 8-4

REAR WHEELS AND BRAKE DISC

REAR WHEELS ....................................................................................8-6

REAR BRAKE DISC .............................................................................. 8-7

CHECKING THE REAR WHEEL ........................................................... 8-8

CHECKING THE REAR WHEEL HUB .................................................. 8-8

CHECKING THE REAR BRAKE DISC .................................................. 8-8

INSTALLING THE REAR WHEEL HUB ................................................ 8-9

INSTALLING THE REAR WHEEL ......................................................... 8-9

FRONT AND REAR BRAKES

FRONT BRAKE PADS ........................................................................ 8-10

REAR BRAKE PADS ........................................................................... 8-11

REPLACING THE FRONT BRAKE PAD .............................................8-12

REPLACING THE REAR BRAKE PAD ............................................... 8-14

FRONT BRAKE MASTER CYLINDER ................................................ 8-16

REAR BRAKE MASTER CYLINDER ..................................................8-18

CHECKING THE MASTER CYLINDER .............................................. 8-21

ASSEMBLING THE FRONT BRAKE MASTER CYLINDER ............... 8-22

ASSEMBLING THE REAR BRAKE MASTER CYLINDER ..................8-22

INSTALLING THE FRONT BRAKE MASTER CYLINDER .................. 8-23

INSTALLING THE REAR BRAKE MASTER CYLINDER .................... 8-24

FRONT BRAKE CALIPER ................................................................... 8-26

REAR BRAKE CALIPER ..................................................................... 8-28

DISASSEMBLING THE BRAKE CALIPER ......................................... 8-30

DISASSEMBLING THE REAR BRAKE CALIPER .............................. 8-30

CHECKING THE FRONT AND REAR BRAKE CALIPER ................... 8-31

ASSEMBLING THE FRONT BRAKE CALIPER .................................. 8-32

INSTALLING THE FRONT BRAKE CALIPER .................................... 8-32

ASSEMBLING THE REAR BRAKE CALIPER .................................... 8-34

INSTALLING THE REAR BRAKE CALIPER ....................................... 8-35

....................................................................8-10

....................................................... 8-1

............................................................ 8-6

STEERING SYSTEM .................................................................................. 8-36

HANDLEBAR ....................................................................................... 8-36

REMOVING THE REAR BRAKE SWITCH ......................................... 8-37

CHECKING THE HANDLEBAR ..........................................................8-37

INSTALLING THE HANDLEBAR ........................................................8-37

INSTALLING THE REAR BRAKE LEVER .......................................... 8-37

INSTALLING THE MASTER CYLINDER ASSEMBLY ........................ 8-38

STEERING STEM ............................................................................... 8-39

REMOVING THE BEARING RETAINER ............................................ 8-41

CHECKING THE STEERING STEM ................................................... 8-41

INSTALLING THE BEARING RETAINER ........................................... 8-41

INSTALLING THE STEERING STEM ................................................. 8-41

INSTALLING THE CABLE GUIDE ...................................................... 8-42

TIE ROD AND STEERING KNUCKLE ................................................ 8-43

REMOVING THE STEERING KNUCKLE ........................................... 8-44

CHECKING THE TIE ROD ..................................................................8-44

CHECKING THE STEERING KNUCKLE ............................................ 8-44

CHECKING THE BALL JOINT ............................................................ 8-45

CHECKING THE TIE ROD ..................................................................8-45

FRONT ARMS AND FRONT SHOCK ABSORBER ................................... 8-46

REMOVING THE FRONT ARMS ........................................................ 8-48

CHECKING THE FRONT ARM ........................................................... 8-48

CHECKING THE FRONT SHOCK ABSORBER ................................. 8-48

INSTALLING THE FRONT ARMS

AND FRONT SHOCK ABSORBER .................................................8-49

REAR KNUCKLE AND STABILIZER ......................................................... 8-50

CHECKING THE REAR KNUCKLE .................................................... 8-51

CHECKING THE STABILIZER ............................................................8-51

REAR ARMS AND REAR SHOCK ABSORBER ....................................... 8-52

CHECKING THE REAR ARM .............................................................8-53

CHECKING THE REAR SHOCK ABSORBER .................................... 8-53

CHECKING THE REAR ARMS

AND REAR SHOCK ABSORBER ................................................... 8-53

CHAPTER 9.

ELECTRICAL

ELECTRICAL COMPONENTS

CHECKING THE SWITCH

CHECKING THE SWITCH .................................................................... 9-2

CHECKING A SWITCH SHOWN IN THE MANUAL ............................. 9-2

CHECKING THE SWITCH CONTINUITY ............................................. 9-4

CHECKING THE BULBS AND BULB SOCKETS

TYPES OF BULBS ................................................................................ 9-6

CHECKING THE CONDITION OF THE BULBS ................................... 9-6

CHECKING THE CONDITION OF THE BULB SOCKETS ................... 9-8

CHECKING THE LEDs .......................................................................... 9-8

IGNITION SYSTEM

CIRCUIT DIAGRAM .............................................................................. 9-9

TROUBLESHOOTING ........................................................................9-10

ELECTRIC STARTING SYSTEM

CIRCUIT DIAGRAM ............................................................................ 9-15

STARTING CIRCUIT OPERATION ..................................................... 9-16

TROUBLESHOOTING ........................................................................9-17

.......................................................................................9-9

..................................................................... 9-1

............................................................................9-2

........................................ 9-6

............................................................... 9-15

STARTER MOTOR ............................................................................. 9-21

CHECKING THE STARTER MOTOR ................................................. 9-22

ASSEMBLING THE STARTER MOTOR .............................................9-23

CHARGING SYSTEM

CIRCUIT DIAGRAM ............................................................................ 9-24

TROUBLESHOOTING ........................................................................9-25

LIGHTING SYSTEM

CIRCUIT DIAGRAM ............................................................................ 9-27

TROUBLESHOOTING ........................................................................9-28

CHECKING THE LIGHTING SYSTEM ................................................ 9-30

SIGNAL SYSTEM

CIRCUIT DIAGRAM ............................................................................ 9-32

TROUBLESHOOTING ........................................................................9-34

CHECKING THE SIGNAL SYSTEM ...................................................9-36

.................................................................................9-24

....................................................................................9-27

.......................................................................................9-32

9-21

COOLING SYSTEM ....................................................................................9-47

CIRCUIT DIAGRAM ............................................................................ 9-47

TROUBLESHOOTING ....................................................................... 9-48

2WD/4WD SELECTING SYSTEM .............................................................. 9-52

CIRCUIT DIAGRAM ............................................................................ 9-52

TROUBLESHOOTING ........................................................................9-53

CHAPTER 10.

TROUBLESHOOTING

STARTING FAILURE/HARD STARTING ................................................... 10-1

FUEL SYSTEM .................................................................................... 10-1

ELECTRICAL SYSTEM ....................................................................... 10-1

COMPRESSION SYSTEM .................................................................. 10-2

POOR IDLE SPEED PERFORMANCE ......................................................10-2

POOR IDLE SPEED PERFORMANCE ............................................... 10-2

POOR MEDIUM AND HIGH-SPEED PERFORMANCE ............................. 10-2

POOR MEDIUM AND HIGH-SPEED PERFORMANCE ..................... 10-2

FAULTY DRIVE TRAIN .............................................................................. 10-3

FAULTY GEAR SHIFTING ......................................................................... 10-4

HARD SHIFTING ................................................................................. 10-4

SHIFT LEVER DOES NOT MOVE ...................................................... 10-4

JUMPS OUT OF GEAR ....................................................................... 10-4

FAULTY CLUTCH PERFORMANCE .........................................................10-4

ENGINE OPERATES BUT MACHINE WILL NOT MOVE ...................10-4

CLUTCH SLIPPING ............................................................................ 10-4

POOR STARTING PERFORMANCE ..................................................10-4

POOR SPEED PERFORMANCE ........................................................10-5

OVERHEATING .......................................................................................... 10-5

OVERHEATING ..................................................................................10-5

FAULTY BRAKE .........................................................................................10-5

POOR BRAKING EFFECT ..................................................................10-5

SHOCK ABSORBER MALFUNCTION ....................................................... 10-6

MALFUNCTION ...................................................................................10-6

UNSTABLE HANDLING ............................................................................. 10-6

UNSTABLE HANDLING ...................................................................... 10-6

LIGHTING SYSTEM ....................................................................................10-6

HEADLIGHT DARK ............................................................................. 10-6

BULB BURNT OUT ............................................................................. 10-6

MACHINE IDENTIFICATION

GENERAL INFORMATION

MACHINE IDENTIFICATION

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number 1 is

stamped into the left side of the frame.

MODEL LABEL

The model label 1 is affixed to the frame. This

information will be needed to order spare

parts.

GEN

INFO

1 - 1

FEATURES

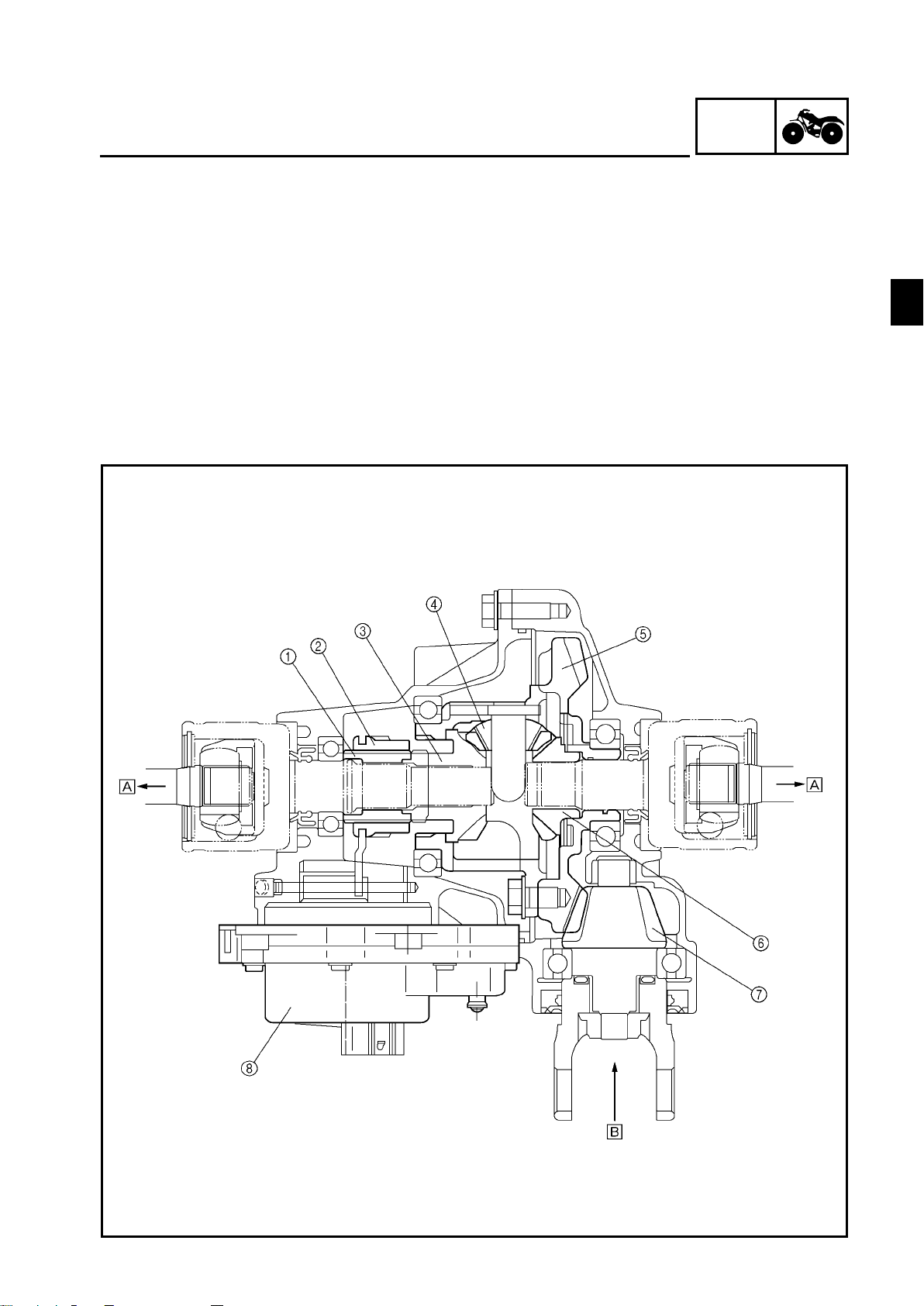

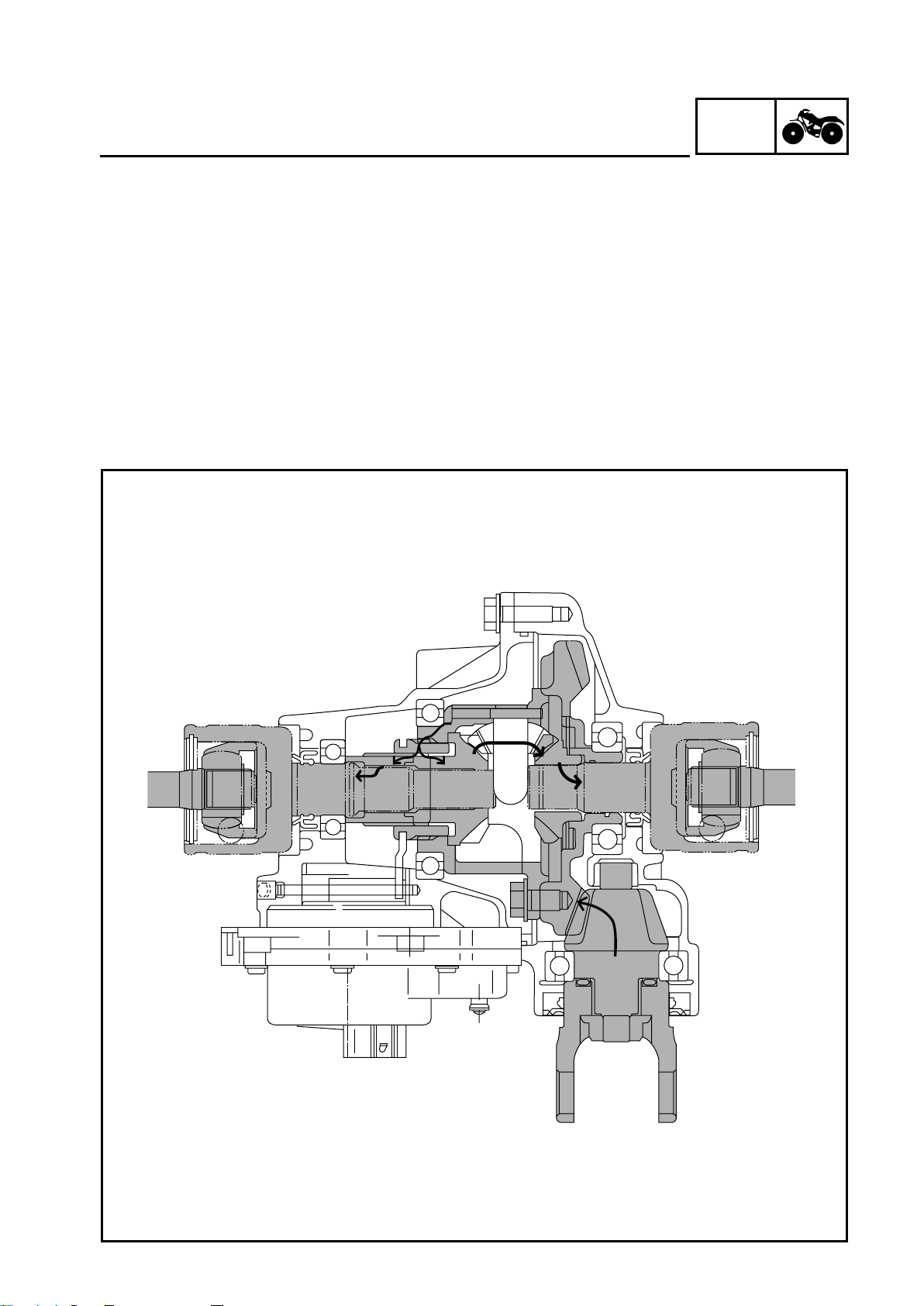

FRONT DIFFERENTIAL

1 Adapter

2 Drive clutch

3 Differential side gear (left)

4 Differential pinion gear

5 Ring gear

6 Differential side gear (right)

FEATURES

7 Drive pinion gear

8 Gear motor

È To front wheel

É From the middle gear

GEN

INFO

1

1 - 2

GEN

FEATURES

2WD

Power is transmitted as follows: middle gear → front drive shaft → drive pinion gear 7 → ring gear

5 → differential pinion gear 4. In the 2WD mode, the left differential side gear 3 and the drive

clutch 2 are not engaged, therefore, the left side gear runs idle and does not transmit power to the

left front constant velocity joint.

INFO

1 - 3

GEN

FEATURES

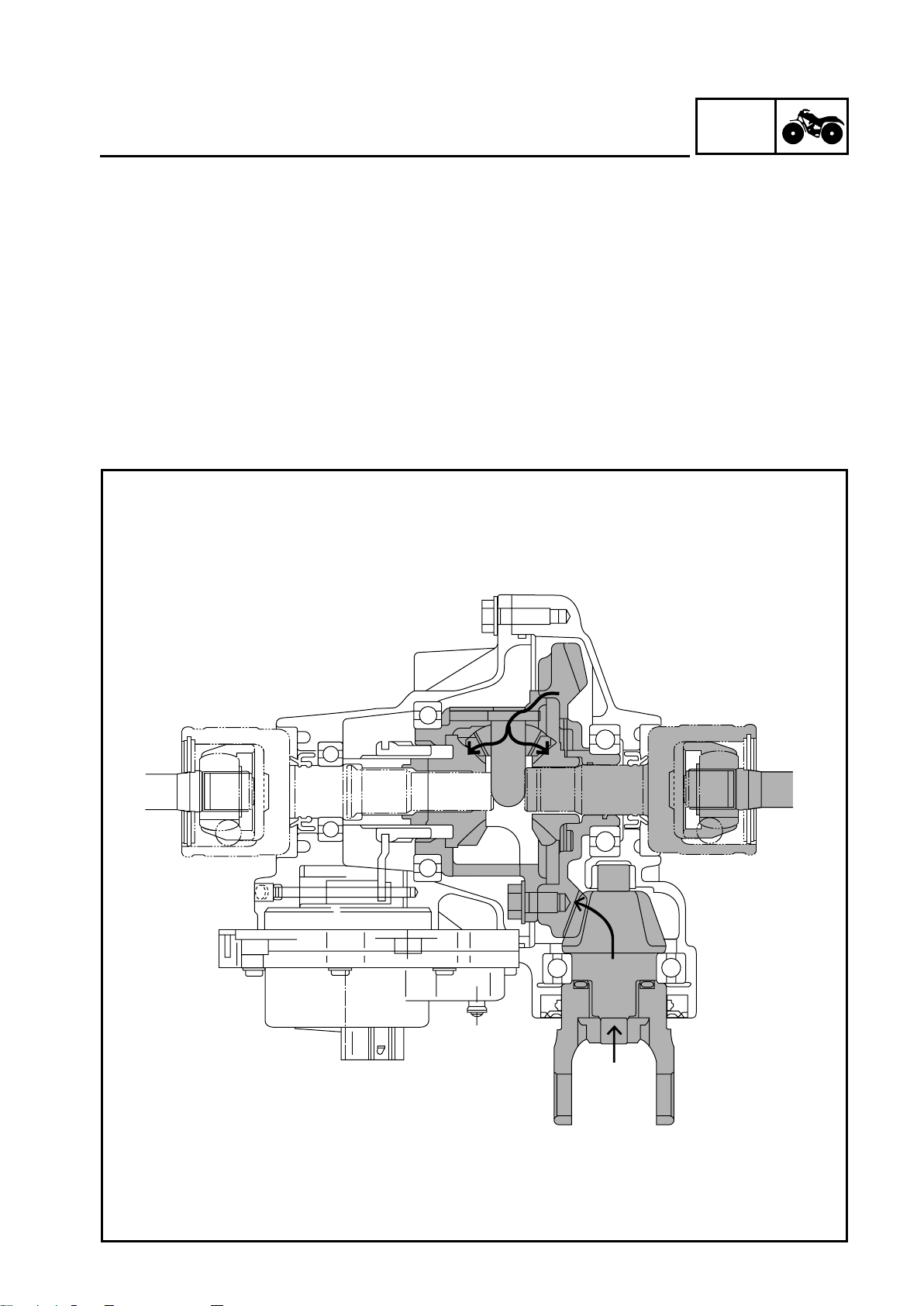

4WD

When the 4WD mode is selected, the gear motor is operated, and the drive clutch 2 moves to the

right and engages with the left differential side gear 3. Accordingly, power is transmitted as follows:

ring gear 5 → differential pinion gear 4 → left differential side gear 3 → drive clutch 2 → adapter

1 → left front constant velocity joint.

Meanwhile, power from the differential pinion gear 4 is transmitted to the right front constant velocity joint via the right differential side gear 6.

The ring gear 5 and the drive clutch 2 are not engaged at this time. Therefore, the rotational difference that occurs between the right and left wheels, while the handlebar is being turned, is absorbed

by the difference in the rotational speeds of the ring gear 5 and the left differential side gear 3.

INFO

1 - 4

GEN

FEATURES

4WD (Diff-Lock)

When the 4WD (Diff-Lock) mode is selected, the gear motor moves the drive clutch 2 further to the

right, which causes the ring gear 5 and the drive clutch 2 to engage. As a result, power is transmitted directly from the ring gear 5 to the drive clutch 2, then to the left front constant velocity joint via

the adapter 1.

Meanwhile, because the ring gear 5 and the drive clutch 2 are engaged, the ring gear 5, the drive

clutch 2, and the right differential side gear 6 become locked coaxially. Thus, power is transmitted

as follows: differential pinion gear 4 → right differential pinion gear 6 → right front constant velocity joint.

When the ATV is in the 4WD (Diff-Lock) mode, the right and left wheels rotate constantly at the

same speed, which affects the maneuverability of the ATV (e.g., making it difficult to steer). Therefore, the maximum traveling speed is limited to 35 km/h (22 mph).

INFO

1 - 5

GEN

FEATURES

In addition, the 4WD (Diff-Lock) mode can be engaged only when the ATV is stopped. Even if an

attempt is made to select this mode when the ATV is traveling, it will only result in a standby condition (i.e., when the differential lock select switch and the differential gear are not matched).

(1) When the ATV is traveling

Even if the 4WD (Diff-Lock) mode is selected, the gear motor will stand by, instead of operating.

Therefore, the ATV can be driven in the normal 4WD mode. When this occurs, the differential gear

lock indicator light “ ” in the speedometer unit will flash to alert the driver that the control is on

standby. When the ATV is stopped, the control transfers to the condition described in (2).

(2) When the ATV is stopped

The gear motor operates to connect the drive clutch to the differential case, thus resulting in the

differential lock condition. When this occurs, the differential gear lock indicator light “ ” in the

speedometer unit changes to a constant illumination.

* Until the drive clutch and the differential case mesh together (i.e., the splines are unmeshed) the

engine misfires to control the engine speed. During this time, the differential gear lock indicator light

in the speedometer unit continues to flash.

DIFF.

LOCK

INFO

DIFF.

LOCK

1 - 6

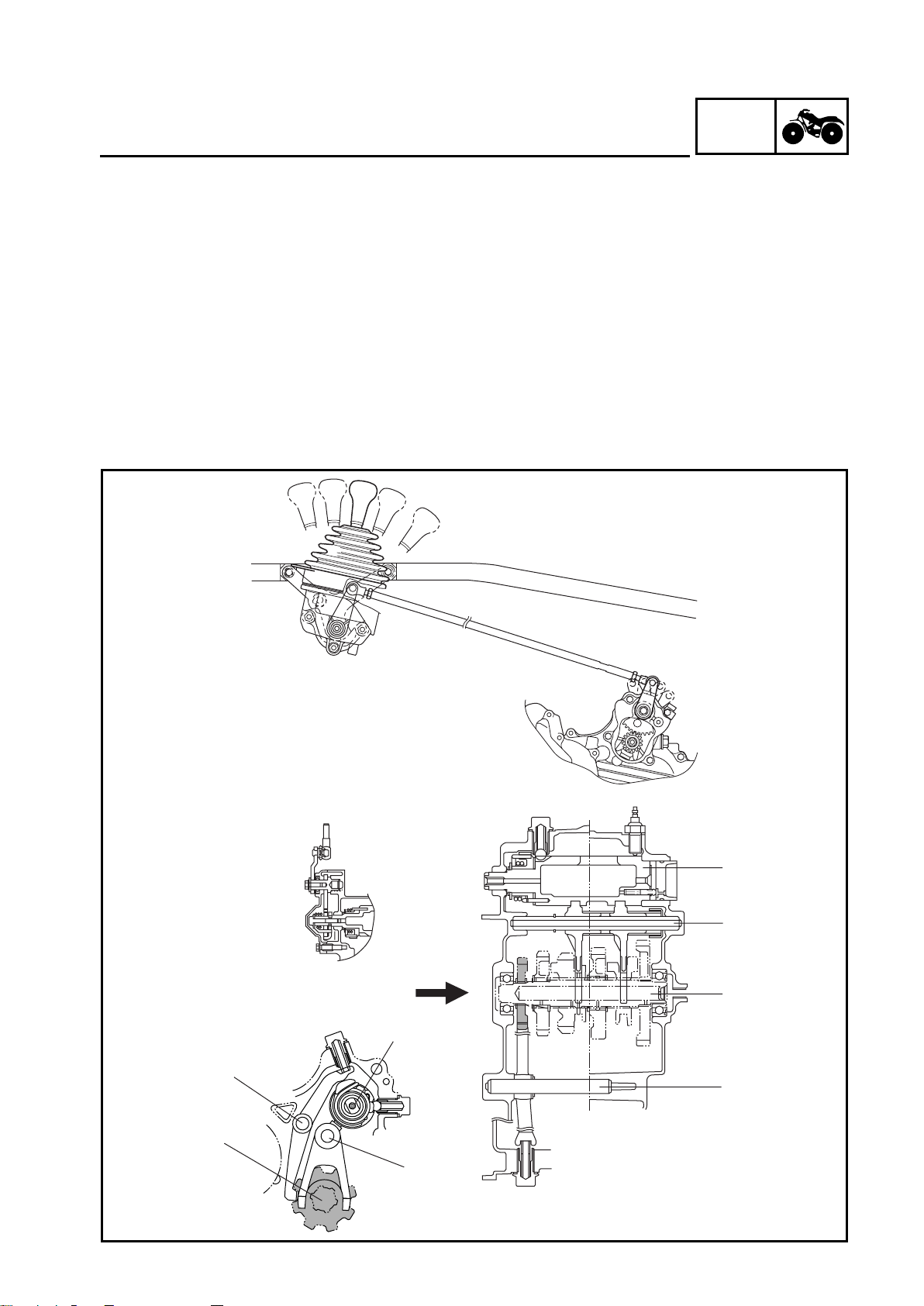

FEATURES

Shift mechanism

A new shift mechanism with a parking position has been added to the YFM660F.

1.Shift cam

2.Shift fork guide bar

3.Drive axle

4.Stopper lever shaft

H

L

N

R

P

GEN

INFO

H

N

L

R

P

1

2

3

1

4

4

3

2

1 - 7

GEN

FEATURES

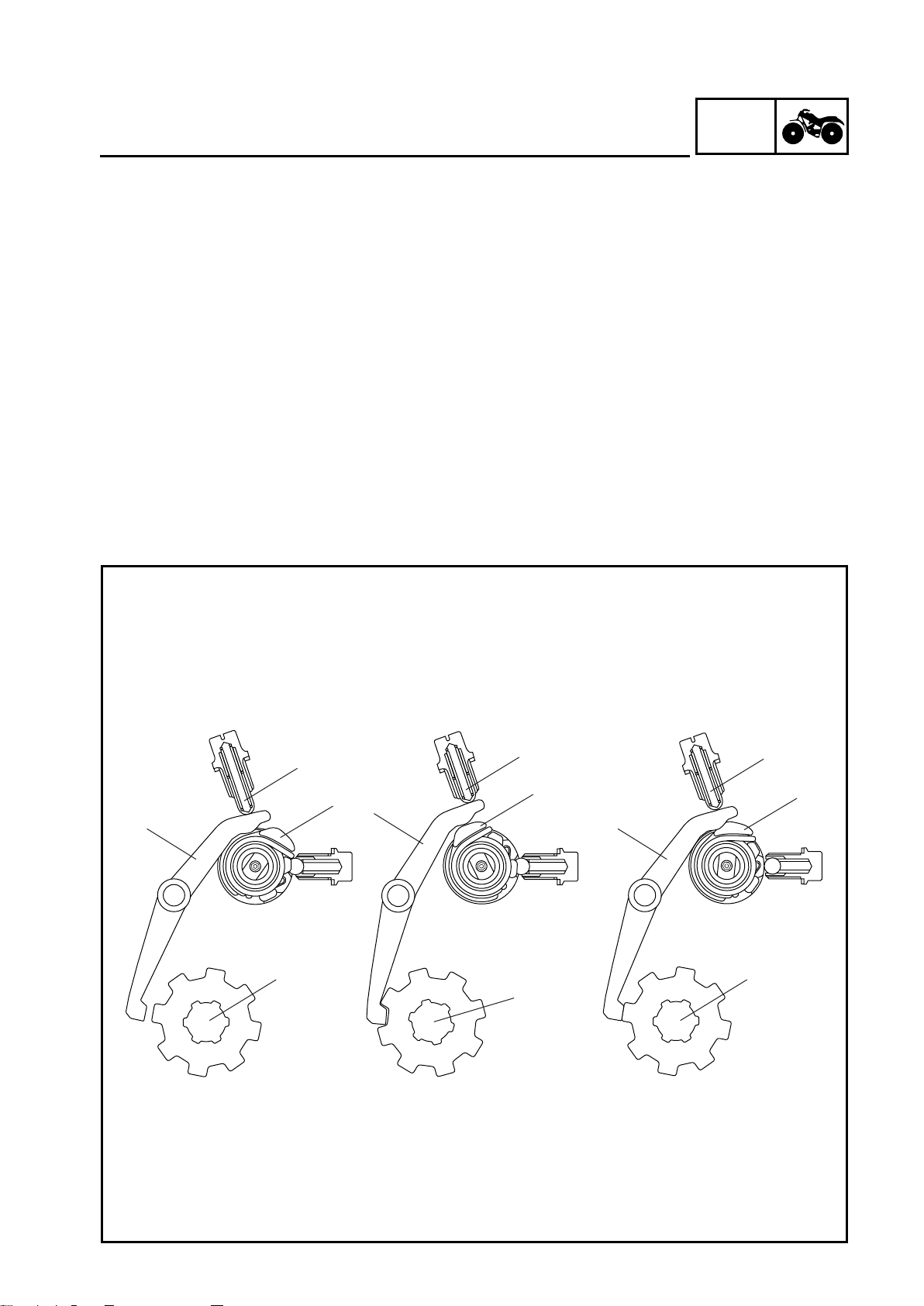

Parking

(1) L (Low), H (High), N (Neutral), and R (Reverse) positions

The end of the stopper lever is held by the return spring 1. Then, the stopper lever tab is sepa-

rated from the drive axle stopper to free the drive axle.

(2) P (Park) position

When the drive select lever is shifted to the “P” position, the cam lever of the shift cam pushes

up on the end of the stopper lever. Then, the stopper lever tab pushes against the drive axle

stopper to lock the drive axle.

(3) Not synchronized

If the stopper lever tab and the drive axle stopper are not synchronized, the torsion spring is

compressed. As a result, the spring pushes the stopper lever tab against the drive axle stopper

and waits until the synchronization is completed. When the stop lever tab and the drive axle are

synchronized, the stop lever tab pushes against the drive axle stopper in order to lock the drive

axle.

1 Stopper lever

2 Return spring

3Shift cam

4Drive axle

INFO

2

3

1

4

(1) (2) (3)

1

2

3

1

4

2

3

4

1 - 8

GEN

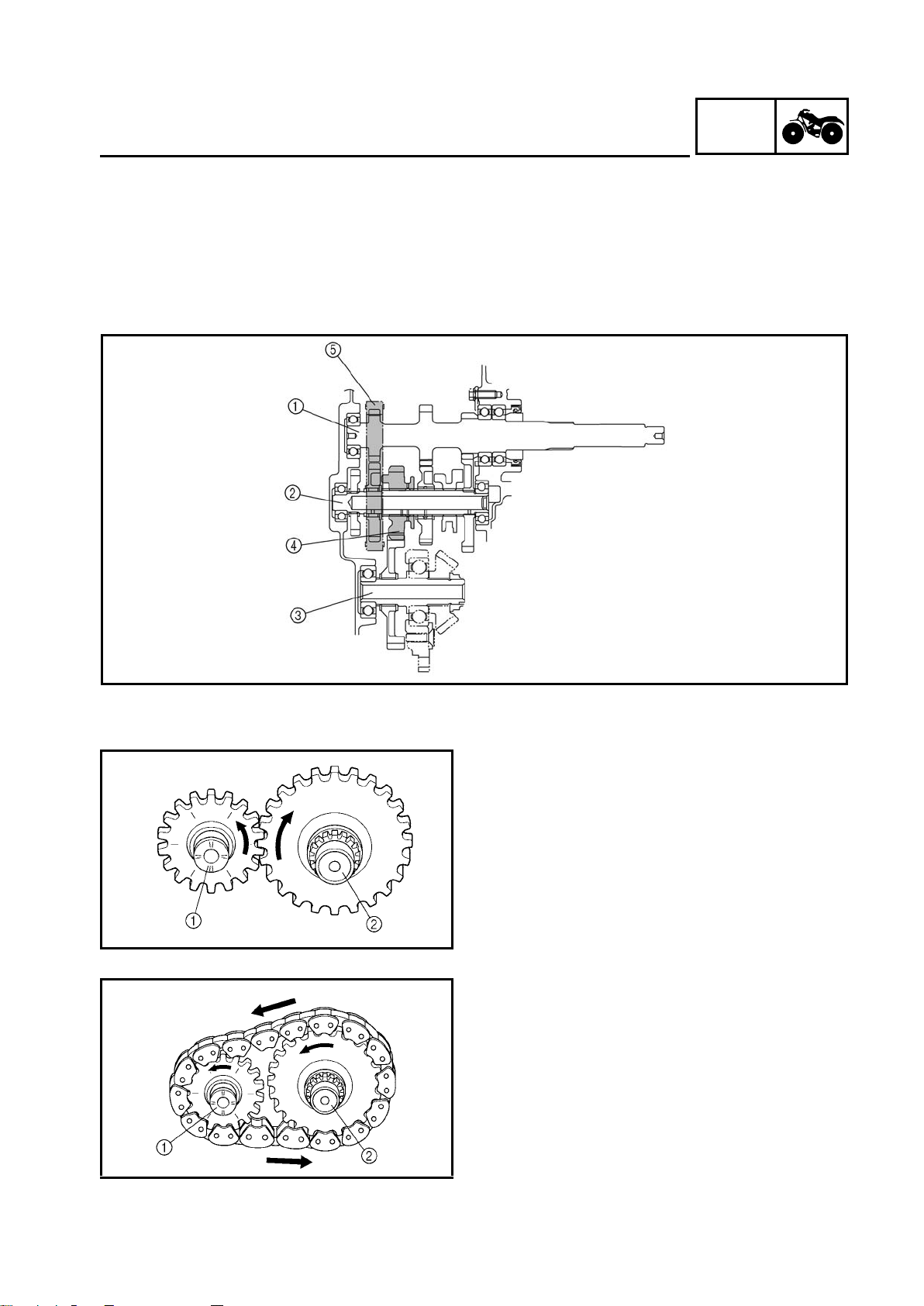

FEATURES

TRANSMISSION

To create a compact, 3-axle transmission, a chain drive has been adopted for the reverse transmission.

1 Secondary shaft

2 Drive axle

3 Middle drive shaft

4 Low wheel gear

5 Chain

INFO

1 Secondary shaft

2 Drive axle

L (Low) or H (High) mode

When the transmission is in either the low or

high mode, the drive axle is driven via the secondary shaft and gear. Therefore, the rotation

of the drive axle is the opposite of the secondary shaft.

R (Reverse) mode

When the transmission is in the reverse mode,

the drive axle is driven via the drive chain.

Therefore, the rotation of the drive axle is the

same as the secondary shaft. (As a result, the

rotation of the drive axle is opposite to that of

the low and high modes.)

1 - 9

IMPORTANT INFORMATION

EB101000

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL

PROCEDURES

1.Remove all dirt, mud, dust and foreign material before removal and disassembly.

2.Use proper tools and cleaning equipment.

Refer to the “SPECIAL TOOLS” section.

3.When disassembling the machine, always

keep mated parts together. This includes

gears, cylinder, piston and other parts that

have been “mated” through normal wear.

Mated parts must always be reused or

replaced as an assembly.

4.During machine disassembly, clean all parts

and place them in trays in the order of disassembly. This will speed up assembly and

allow for the correct installation of all parts.

5.Keep all parts away from any source of fire.

GEN

INFO

EB101010

REPLACEMENT PARTS

1.Use only genuine Yamaha parts for all

replacements. Use oil and grease recommended by Yamaha for all lubrication jobs.

Other brands may be similar in function and

appearance, but inferior in quality.

EB101020

GASKETS, OIL SEALS AND O-RINGS

1.Replace all gaskets, seals and O-rings when

overhauling the engine. All gasket surfaces,

oil seal lips and O-rings must be cleaned.

2.Properly oil all mating parts and bearings

during reassembly. Apply grease to the oil

seal lips.

1 - 10

IMPORTANT INFORMATION

EB101030

LOCK WASHERS/PLATES AND COTTER

PINS

1.Replace all lock washers/plates 1 and cotter

pins after removal. Bend lock tabs along the

bolt or nut flats after the bolt or nut has been

tightened to specification.

EB101040

BEARINGS AND OIL SEALS

1.Install bearings and oil seals so that the

manufacturer’s marks or numbers are visible.

When installing oil seals, apply a light coating of lightweight lithium base grease to the

seal lips. Oil bearings liberally when installing, if appropriate.

1 Oil seal

GEN

INFO

CAUTION:

Do not use compressed air to spin the

bearings dry. This will damage the bearing

surfaces.

1 Bearing

EB101050

CIRCLIPS

1.Check all circlips carefully before reassembly. Always replace piston pin clips after one

use. Replace distorted circlips. When installing a circlip 1, make sure that the sharpedged corner 2 is positioned opposite the

thrust 3 it receives. See sectional view.

4 Shaft

1 - 11

CHECKING OF CONNECTIONS

EB801000

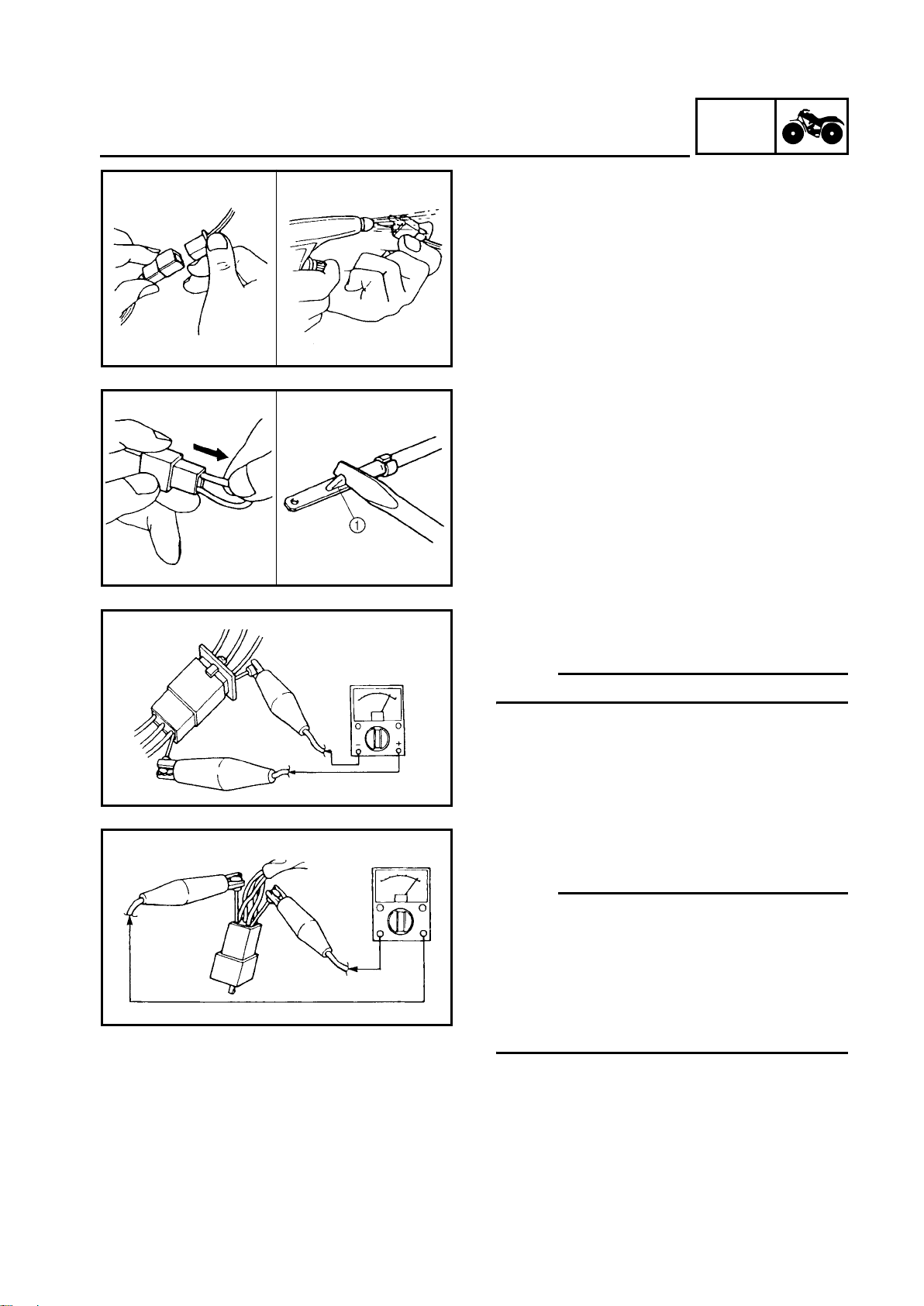

CHECKING OF CONNECTIONS

Check the connectors for stains, rust, moisture, etc.

1.Disconnect:

Connector

●

2.Check:

Connector

●

Moisture → Dry each terminal with an air

blower.

Stains/rust → Connect and disconnect the

terminals several times.

3.Check:

Connector leads

●

Looseness → Bend up the pin 1 and connect the terminals.

GEN

INFO

4.Connect:

Connector terminals

●

OTE:

The two terminals “click” together.

5.Check:

Continuity (using a pocket tester)

●

OTE:

If there is no continuity, clean the terminals.

●

When checking the wire harness be sure to

●

perform steps 1 to 3.

As a quick remedy, use a contact revitalizer

●

available at most part stores.

Check the connector with a pocket tester as

●

shown.

1 - 12

Loading...

Loading...