Page 1

2000

YFM40FPM

YFM400FW

(

M

)

4GB-AE4

SUPPLEMENTARY

SERVICE MANUAL

Page 2

FOREWORD

This Supplementary Service Manual has been prepared to introduce new service and new data for

the YFM40FPM/YFM400FW(M) 2000. For complete information on service procedures, it is necessary to use this Supplementary Service Manual together with the following manual.

YFM400FW ’93 SERVICE MANUAL: 4GB-ME1

YFM400FW ’93 SUPPLEMENTARY SERVICE MANUAL: 4GB-AE1

YFM400FW(H) ’96 SUPPLEMENTARY SERVICE MANUAL: 4GB-AE2

YFM40FPM/YFM400FW(M) 2000

SUPPLEMENTARY

SERVICE MANUAL

1999 by Yamaha Motor Co., Ltd.

1st Edition, December 1999

All rights reserved. Any reproduction

or unauthorized use without the written

permission of Yamaha Motor Co., Ltd.

is expressly prohibited.

Page 3

NOTICE

This manual was written by the Yamaha Motor Company, Ltd. primarily for use by Yamaha dealers

and qualified mechanics. It is not possible to put an entire mechanic’s education into one manual,

so persons using this book to perform maintenance and repairs on Yamaha machines should have

a basic understanding of the mechanical concepts and the procedures inherent in machine repair

technology. Without such knowledge, attempted repairs or service to the machine may render it

unfit to use and/or unsafe.

Yamaha Motor Company, Ltd. is continually striving to improve all models manufactured by

Yamaha. Modifications and significant changes in specifications or procedures will be forwarded to

all Authorized Yamaha dealers and will, where applicable, appear in future editions of this manual.

NOTE:

Designs and specifications are subject to change without notice.

PARTICULARLY IMPORTANT INFORMATION

This material is distinguished by the following notation.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED!

WARNING

CAUTION:

TE:

Failure to follow WARNING instructions could result in severe injury or

death to the machine operator, a bystander, or a person inspecting or

repairing the machine.

A CAUTION indicates special precautions that must be taken to avoid damage to the machine.

A NOTE provides key information to make procedures easier or clearer.

Page 4

”.

HOW TO USE THIS MANUAL

CONSTRUCTION OF THIS MANUAL

This manual consists of chapters for the main categories of subjects. (See “Illustrated symbols”)

1st title

2nd title

1

: This is a chapter with its symbol on the upper right of each page.

2

: This title appears on the upper of each page on the left of the chapter sym-

bol. (For the chapter “Periodic inspection and adjustment” the 3rd title

appears.)

3rd title

3

: This is a final title.

MANUAL FORMAT

All of the procedures in this manual are organized in a sequential, step-by-step format. The information has been compiled to provide the mechanic with an easy to read, handy reference that contains

comprehensive explanations of all disassembly, repair, assembly, and inspections.

A set of particularly important procedure 4 is placed between a line of asterisks “

cedure preceded by “

●

” with each pro-

*

IMPORTANT FEATURES

Data and a special tool are framed in a box preceded by a relevant symbol

●

●

An encircled numeral

alignment mark

●

A condition of a faulty component will precede an arrow symbol

7

6

indicates a part name, and an encircled alphabetical letter data or an

, the others being indicated by an alphabetical letter in a box

9

and the course of action will

5

.

8

.

follow it.

EXPLODED DIAGRAM

Each chapter provides exploded diagrams before each disassembly section for ease in identifying

correct disassembly and assembly procedures.

Page 5

12

GEN

SPEC

INFO

34

INSP

ENG

ADJ

56

CARB

78

CHAS

90

DRIV

–+

ELEC

TRBL

SHTG

AB

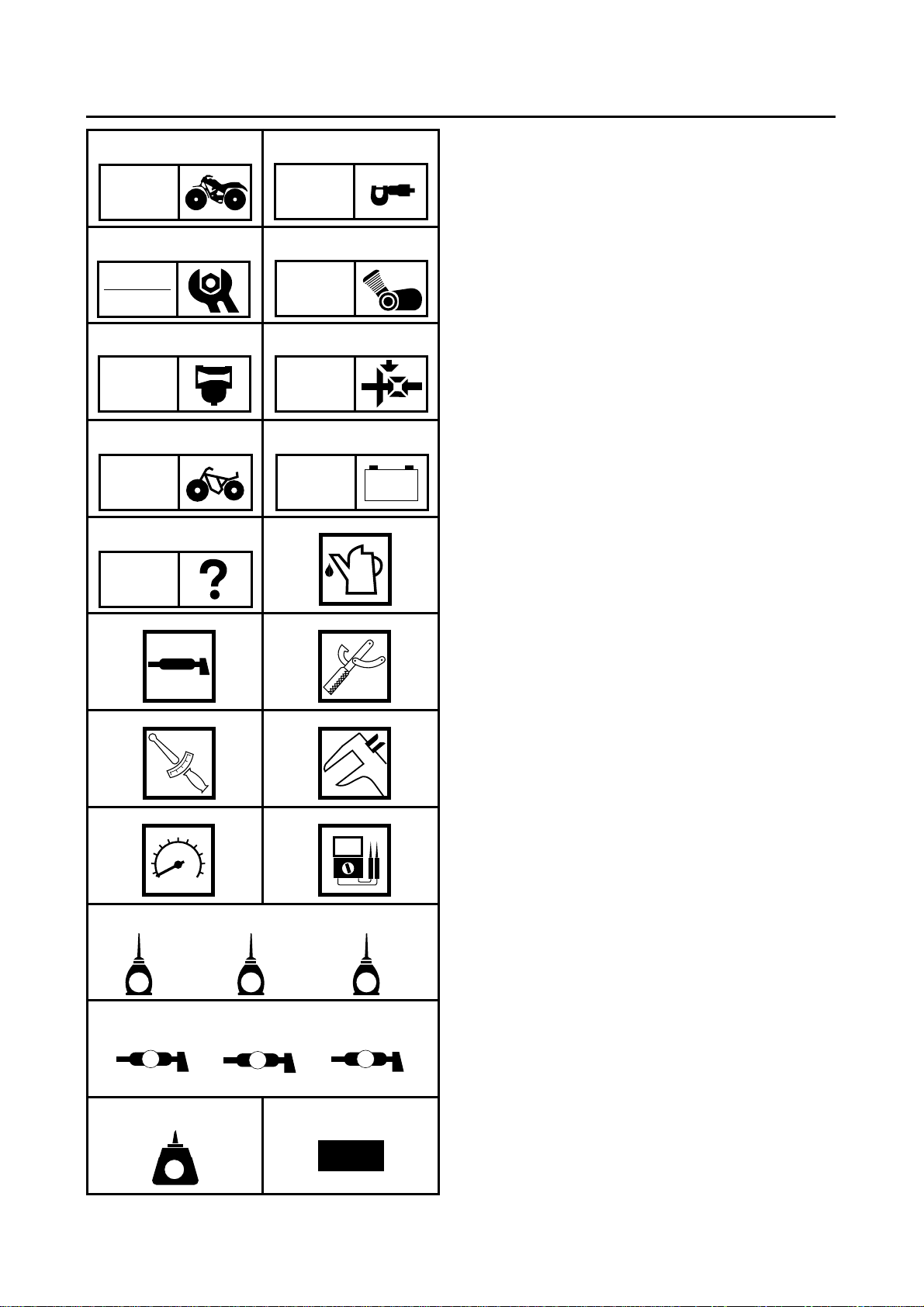

ILLUSTRATED SYMBOLS

(Refer to the illustration)

Illustrated symbols

thumb tabs to indicate the chapter’s number

and content.

1

General information

2

Specifications

3

Periodic inspections and adjustments

4

Engine overhaul

5

Carburetion

6

Drive train

7

Chassis

8

Electrical

9

Troubleshooting

Illustrated symbols

the specifications appearing in the text.

0

Filling fluid

A

Lubricant

B

Special tool

C

Tightening

D

Wear limit, clearance

E

Engine speed

F

, V, A

Ω

0

1

to

9

are designed as

to

F

are used to identify

CD

T

.

R

.

EF

GHI

E

JKL

B

M N

LT

G

LS

M

M

New

Illustrated symbols

G

to

N

in the exploded

diagrams indicate grade of lubricant and location of lubrication point.

G

Apply engine oil

H

Apply gear oil

I

Apply molybdenum disulfide oil

J

Apply wheel bearing grease

K

Apply lightweight lithium-soap base grease

L Apply molybdenum disulfide grease

M Apply the locking agent (LOCTITE®)

N Use new one

Page 6

CONTENTS

GENERAL INFORMATION ..............................................................................1

MACHINE IDENTIFICATION .................................................................... 1

VEHICLE IDENTIFICATION NUMBER................................................. 1

MODEL LABEL.....................................................................................1

SPECIFICATIONS

GENERAL SPECIFICATIONS..................................................................2

MAINTENANCE SPECIFICATIONS ......................................................... 4

ENGINE ................................................................................................ 4

CHASSIS .............................................................................................. 5

ELECTRICAL........................................................................................6

CABLE ROUTING.....................................................................................8

PERIODIC INSPECTIONS AND ADJUSTMENTS

INTRODUCTION.....................................................................................15

PERIODIC MAINTENANCE/LUBRICATION .......................................... 15

SEAT, CARRIERS, FENDERS AND FUEL TANK..................................17

REMOVAL........................................................................................... 17

INSTALLATION................................................................................... 20

ENGINE................................................................................................... 22

STARTER LEVER FREE PLAY ADJUSTMENT................................. 22

CHASSIS................................................................................................. 23

FRONT BRAKE PAD INSPECTION...................................................23

AIR BLEEDING (HYDRAULIC BRAKE SYSTEM)..............................23

REAR SHOCK ABSORBER ADJUSTMENT......................................24

TIRE INSPECTION............................................................................. 25

ELECTRICAL..........................................................................................27

BATTERY INSPECTION..................................................................... 27

FUSE INSPECTION............................................................................ 32

............................................................................................2

.........................................15

ENGINE OVERHAUL

ENGINE ASSEMBLY AND ADJUSTMENT ............................................34

VALVE, CAMSHAFT AND ROCKER ARM.........................................34

.....................................................................................34

Page 7

CHASSIS ........................................................................................................35

FRONT AND REAR WHEELS................................................................35

REMOVAL........................................................................................... 36

FRONT BRAKE.......................................................................................38

BRAKE PAD REPLACEMENT............................................................ 39

CALIPER DISASSEMBLY .................................................................. 41

MASTER CYLINDER DISASSEMBLY................................................ 42

INSPECTION AND REPAIR...............................................................43

CALIPER ASSEMBLY ........................................................................ 46

MASTER CYLINDER ASSEMBLY...................................................... 49

FRONT SHOCK ABSORBER AND FRONT ARM .................................. 52

INSTALLATION................................................................................... 53

ELECTRICAL

ELECTRICAL COMPONENTS ...............................................................54

YFM40FP/YFM400FW WIRING DIAGRAM

..................................................................................................54

Page 8

GEN

MACHINE IDENTIFICATION

GENERAL INFORMATION

MACHINE IDENTIFICATION

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number

stamped into the left side of the frame.

MODEL LABEL

The model label

information will be needed to order spare

parts.

1

is affixed to the frame. This

INFO

1

is

– 1 –

Page 9

GENERAL SPECIFICATIONS

SPEC

SPECIFICATIONS

GENERAL SPECIFICATIONS

Model YFM40FP/YFM400FW

Model code: 4SHK (for CDN)

4SHL (for Europe)

4SHM (for Oceania)

Dimensions:

Overall length 1,956 mm (77.0 in)

Overall width 1,155 mm (45.5 in)

Overall height 1,144 mm (45.0 in)

Seat height 835 mm (32.9 in)

Wheelbase 1,210 mm (47.6 in)

Minimum ground clearance 215 mm (8.46 in)

Minimum turning radius 3,500 mm (137.8 in)

Basic weight:

With oil and full fuel tank 286 kg (631 lb)

Spark plug:

Type DR8EA

Manufacturer NGK

Spark plug gap 0.6 ~ 0.7 mm (0.024 ~ 0.028 in)

Transmission:

Primary reduction system Spur gear

Primary reduction ratio 76/24(3.167)

Secondary reduction system Shaft drive

Secondary reduction ratio 24/18 × 33/09 (4.889)

Transmission type Constant mesh 5-speed forward, 1-speed

reverse

Operation Left foot operation

Gear ratio 1st 38/13 (2.923)

2nd 34/18 (1.889)

3rd 30/22 (1.364)

4th 26/25 (1.040)

5th 24/29 (0.828)

Sub transmission low 20/24 × 27/15 (1.500)

high 20/24 × 22/20 (0.916)

Reverse gear 36/13 × 27/16 (4.673)

Chassis:

Frame type Steel tube frame

Caster angle 2.5˚

Trail 15 mm (0.59 in)

Tread (STD) front 850 mm (33.46 in)

Tread (STD) rear 820 mm (32.28 in)

Toe-in 5 ~ 15 mm (0.20 ~ 0.59 in)

– 2 –

Page 10

GENERAL SPECIFICATIONS

Model YFM40FP/YFM400FW

Tire:

Type Tubeless

Size front AT25 × 8-12

rear AT25 × 10-12

Manufacturer front DUNLOP (for CDN and Europe)

CHENG SHIN (for Oceania)

rear DUNLOP (for CDN and Europe)

CHENG SHIN (for Oceania)

Type front KT402 (for CDN and Europe)

C-828 (for Oceania)

rear KT406 (for CDN and Europe)

C-828 (for Oceania)

Tire pressure (cold tire):

Off-road riding

front 22 ~ 28 kPa (0.22 ~ 0.28 kg/cm

rear 22 ~ 28 kPa (0.22 ~ 0.28 kg/cm

Brake:

Front brake type Single disc brake

operation Right hand operation

Rear brake type Drum brake

operation Left hand and right foot operation

Electrical:

Ignition system C.D.I.

Generator system A.C. magneto

Battery type YTX20L-BS

Battery capacity 12 V 18 AH

Bulb wattage × quantity:

Headlight 12 V 30 W/30 W × 2

Taillight 12 V 7.5 W × 1

Meter light 12 V 3 W × 1

Neutral indicator light 12 V 1.7 W × 1

Reverse indicator light 12 V 1.7 W × 1

Oil temperature indicator light 12 V 1.7 W × 1

SPEC

2

, 3.2 ~ 4.0 psi)

2

, 3.2 ~ 4.0 psi)

– 3 –

Page 11

MAINTENANCE SPECIFICATIONS

SPEC

MAINTENANCE SPECIFICATIONS

ENGINE

Model YFM40FP/YFM400FW

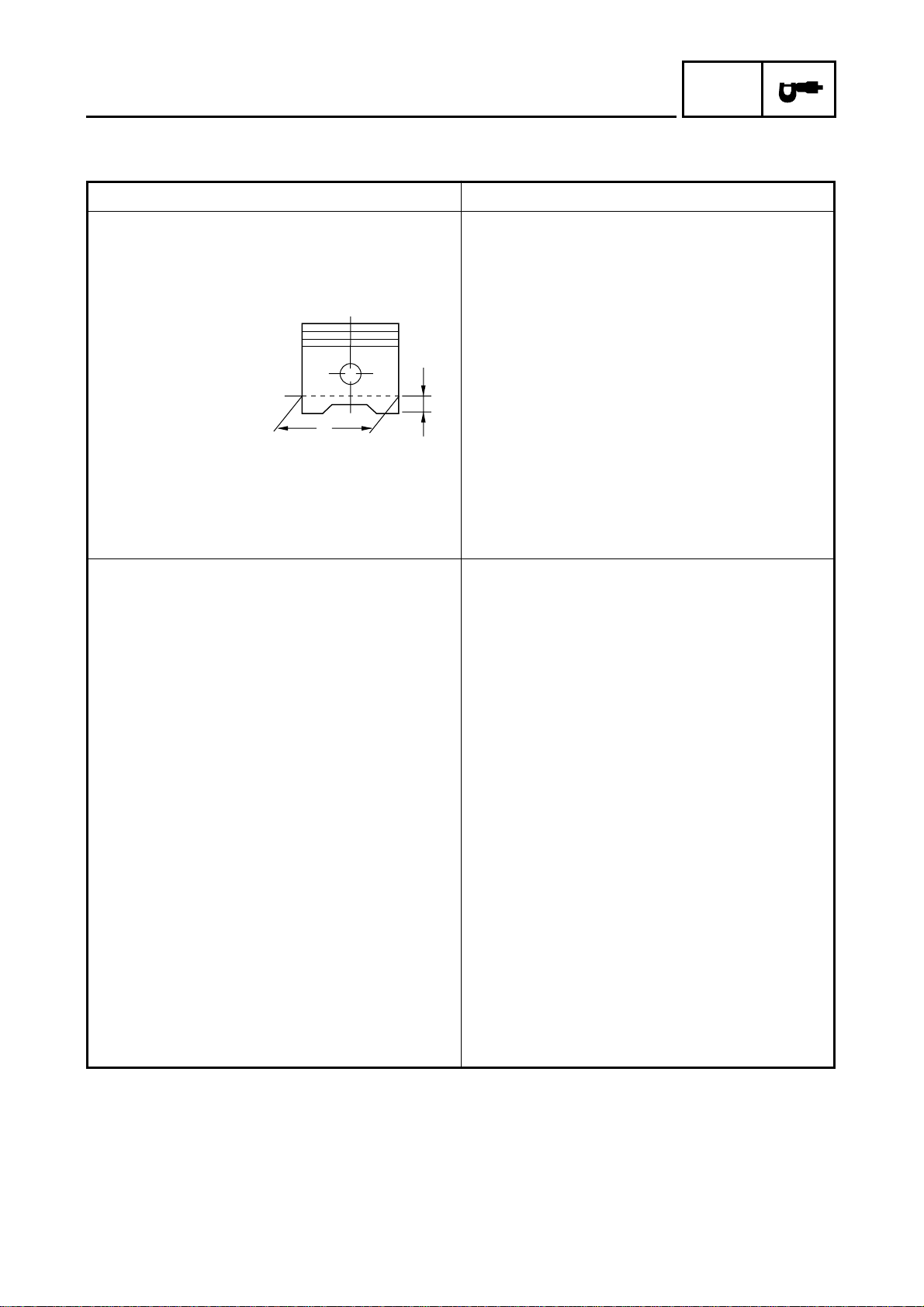

Piston:

Piston to cylinder clearance 0.04 ~ 0.06 mm (0.0016 ~ 0.0024 in)

<Limit> <0.15 mm (0.0059 in)>

Piston size “D” 82.92 ~ 82.97 mm (3.265 ~ 3.267 in)

H

D

Measuring point “H” 5.5 mm (0.217 in)

Piston off-set 0.5 mm (0.02 in)

Piston off-set direction Intake side

Piston pin bore inside diameter 19.004 ~ 19.015 mm (0.7482 ~ 0.7486 in)

Piston pin outside diameter 18.990 ~ 18.995 mm (0.7476 ~ 0.7478 in)

Carburetor:

I. D. mark 4SHK 20 (for CDN)

4SHL 30 (for Europe and Oceania)

Main jet (M.J.) #105

Main air jet (M.A.J.) 0.7

Jet needle (J.N.) 5H26-2

Needle jet (N.J.) N-8 (#786)

Pilot air jet (P.A.J.1) 1.0

Pilot air jet (P.A.J.2) 0.9

Pilot outlet (P.O.) 0.75

Pilot jet (P.J.) #45

Pilot screw (P.S.) 2 turns out

Bypass 1 (B.P.1) 0.8

Bypass 2 (B.P.2) 0.8

Bypass 3 (B.P.3) 1.0

Valve seat size (V.S.) 2.5

Starter jet (G.S.1) #60

Throttle valve size (Th.V.) #130

Float height (F.H.) 11.4 ~ 13.4 mm (0.45 ~ 0.53 in)

Fuel level (F.L.) 1 ~ 2 mm (0.04 ~ 0.08 in)

Engine idle speed 1,350 ~ 1,450 r/min

Intake vacuum 33.3 kPa (250 mmHg, 10 inHg)

– 4 –

Page 12

MAINTENANCE SPECIFICATIONS

CHASSIS

Model YFM40FP/YFM400FW

Front suspension:

Shock absorber travel 67.5 mm (2.66 in)

Fork spring free length 229.5 mm (9.04 in)

Spring rate (K1) 19.6 N/mm (1.96 kg/mm, 111 lb/in)

Stroke (K1) 0 ~ 67.5 mm (0 ~ 2.66 in)

Optional spring No

Rear suspension:

Shock absorber travel 75 mm (2.95 in)

Spring free length 264.3 mm (10.4 in)

Fitting length 221.3 mm (8.71 in)

Spring rate (K1) 32.4 N/mm (3.24 kg/mm, 185 lb/in)

Stroke (K1) 0 ~ 75 mm (0 ~ 2.95 in)

Optional spring No

Front wheel:

Type Disc wheel

Rim size 12 × 6.0AT

Rim material Steel

Rim runout limit radial 2 mm (0.08 in)

lateral 2 mm (0.08 in)

Rear wheel:

Type Disc wheel

Rim size 12 × 7.5AT

Rim material Steel

Rim runout limit radial 2 mm (0.08 in)

lateral 2 mm (0.08 in)

Front disc brake:

Type Single

Disc outside diameter × thickness 180 × 3.5 mm (7.09 × 0.14 in)

Pad thickness 4.5 mm (0.18 in)

<Limit> <1.0 mm (0.04 in)>

Master cylinder inside diameter 15.87 mm (0.62 in)

Caliper cylinder inside diameter 32 mm (1.26 in)

Brake fluid type DOT 4

Brake lever & brake pedal:

Brake lever free play (left) 4 ~ 7 mm (0.16 ~ 0.28 in)

Brake pedal position 5 mm (0.2 in)

Brake pedal free play 20 ~ 30 mm (0.8 ~ 1.2 in)

Throttle lever free play 3 ~ 5 mm (0.1 ~ 0.2 in)

SPEC

– 5 –

Page 13

MAINTENANCE SPECIFICATIONS

Tightening torques

Tightening torque

Part to be tightened Thread size

Nm m·kg ft·lb

Steering shaft and frame M10 35 3.5 25

Tie-rod and locknut M10 30 3.0 22

Fuel tank and fuel cock M6 4 0.4 2.9

Front wheel and wheel hub M10 64 6.4 46

Front axle and wheel hub M16 150 15 110

Front brake caliper and steering knuckle M8 30 3.0 22

Front brake disc and wheel hub M8 30 3.0 22

Brake disc guard and steering knuckle M6 7 0.7 5.1

Front brake pipe nut M10 19 1.9 13

Master cylinder and handlebar M6 7 0.7 5.1

Footrest and frame M10 64 6.4 46

Front carrier and frame M8 31 3.1 22

Front carrier and front bumper M6 10 1.0 7.2

Front bumper and frame M8 31 3.1 22

Rear carrier and frame M8 33 3.3 24

SPEC

Remarks

ELECTRICAL

Model YFM40FP/YFM400FW

C.D.I.:

Magneto model/manufacturer F4T466/MITSUBISHI

Pickup coil resistance/color 459 ~ 561 Ω at 20 ˚C (68 ˚F)/White/Green –

White/Red

C.D.I. unit model/manufacturer F8T36471/MITSUBISHI

Ignition coil:

Model/manufacturer 2JN/YAMAHA

Minimum spark gap 6 mm (0.24 in)

Primary winding resistance 0.18 ~ 0.28 Ω at 20 ˚C (68 ˚F)

Secondary winding resistance 6.32 ~ 9.48 kΩ at 20 ˚C (68 ˚F)

Charging system:

Type A.C. magneto

Model/manufacturer F4T466/MITSUBISHI

Nominal output 14 V 15 A at 5,000 r/min

Charging coil resistance/color 0.70 ~ 0.86 Ω at 20 ˚C (68 ˚F)/White – White

Rectifier/regulator:

Model/manufacturer SH640E-11/SHINDENGEN

Capacity 14 A

Withstand voltage 200 V

– 6 –

Page 14

MAINTENANCE SPECIFICATIONS

Model YFM40FP/YFM400FW

Electric starter system:

Type Constant mesh type

Starter motor

Model/manufacturer DBEDU/DENSO

Output 0.7 kW

Armature coil resistance 0.011 ~ 0.013 Ω at 20 ˚C (68 ˚F)

Brush overall length 12 mm (0.47 in)

<Limit> <8.5 mm (0.33 in)>

Spring force 6.37 ~ 9.32 N (637 ~ 932 g, 22.5 ~ 32.9 oz)

Commutator diameter 28 mm (1.10 in)

<Wear limit> <27 mm (1.06 in)>

Mica undercut 0.6 mm (0.02 in)

Starter relay

Model/manufacturer MS5E-691/JIDECO

Amperage rating 180 A

Coil winding resistance 4.18 ~ 4.62 Ω at 20 ˚C (68 ˚F)

Fan motor relay:

Model/manufacturer 29U/MATSUSHITA

Coil winding resistance 72 ~ 88

Thermo unit:

Model/manufacturer 4SH/DENSO

Horn: (Europe and Oceania only)

Type Plane

Model/manufacturer MF-12/NIKKO

Circuit breaker:

Type Fuse

Amperage for individual circuit

Main fuse 30 A × 1

Headlight fuse 15 A × 1

Signaling system fuse 10 A × 1

Ignition fuse 10 A × 1

Auxiliary DC jack fuse 10 A × 1

Reserve fuse 30 A × 1

15 A × 1

10 A × 1

Ω

SPEC

– 7 –

Page 15

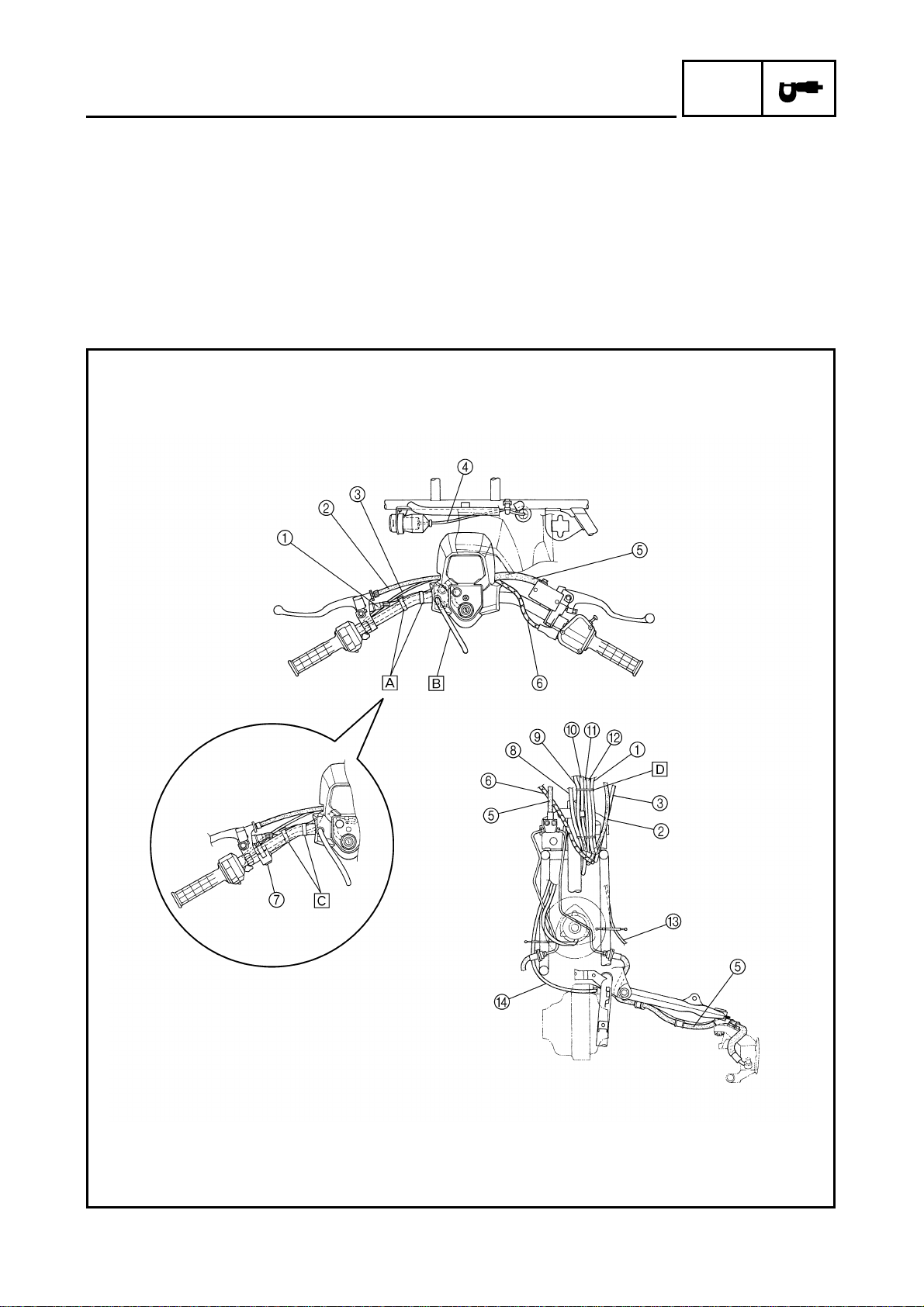

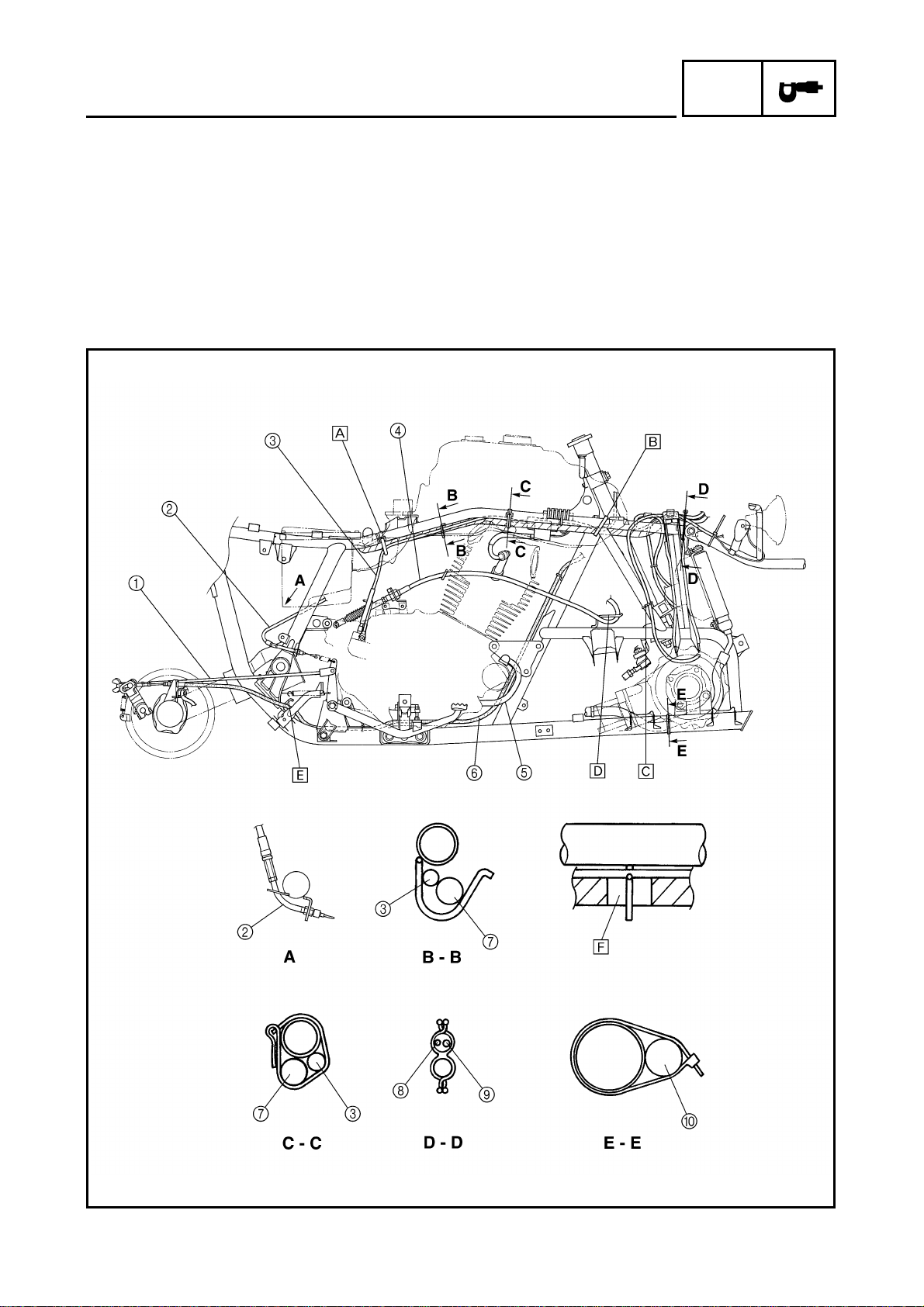

CABLE ROUTING

1

Rear brake switch

2

Rear brake cable

3

Starter cable

4

Auxiliary DC jack lead

5

Front brake hose

6

Throttle cable

7

Horn (for Europe and Oceania)

8

Speedometer cable

CABLE ROUTING

9

Speedometer lead

0

Main switch lead

A

Oil temperature indicator light lead

B

Handlebar switch lead

C

Reverse control cable 2

D Differential gear case breather hose

SPEC

– 8 –

Page 16

CABLE ROUTING

Å Fasten the handlebar switch lead and rear brake switch lead to the handlebar with the plastic band.

ı Route the fuel tank breather hose through the hole in the handlebar cover.

Ç Fasten the handlebar switch lead, rear brake switch lead and horn lead to the handlebar with the plastic

band. (for Europe and Oceania)

Î Fasten the speedometer lead, main switch lead, oil temperature indicator light lead, handlebar switch lead,

rear brake switch lead and horn lead with a plastic locking tie.

SPEC

– 9 –

Page 17

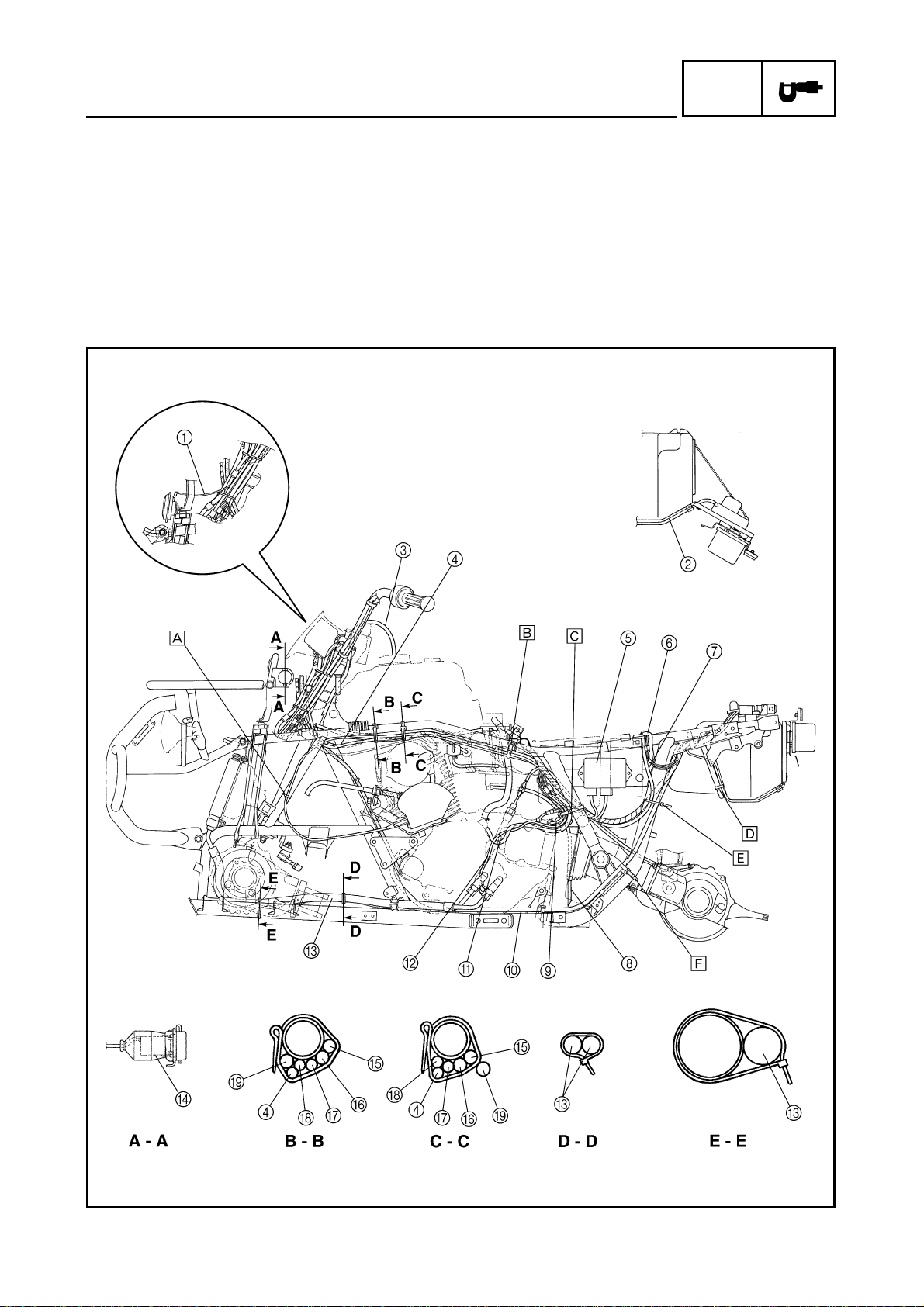

CABLE ROUTING

SPEC

1 Horn lead (for Europe and Oceania)

2 Taillight lead

3 Fuel tank breather hose

4 Starter cable

5 CDI unit

6 Positive battery lead

7 Negative battery lead

8 Carburetor overflow hose

9 Reverse switch lead

0 Starter motor lead

A CDI magneto lead

B Ground lead

C Oil hose

D Auxiliary DC jack

E Rear brake breather hose

6 Final gear case breather hose

7 Carburetor air vent hose

8 Reverse control cable 2

9 Throttle cable

– 10 –

Page 18

CABLE ROUTING

SPEC

Å Fasten the reverse control cable 2 to the frame

with the plastic clip.

ı Fasten the reverse control cable 2, rear brake

breather hose and final gear case breather hose

to the frame with the plastic band.

Ç Fasten the neutral switch lead, CDI magneto

lead, reverse switch lead and negative battery

lead to the frame with the plastic band.

Î Fasten the taillight lead to the frame with the

plastic band.

‰ Fasten the wire harness, negative battery lead

and starter motor lead to the frame with a plastic

locking tie.

Ï Fasten the starter motor lead to the frame with

the plastic band.

– 11 –

Page 19

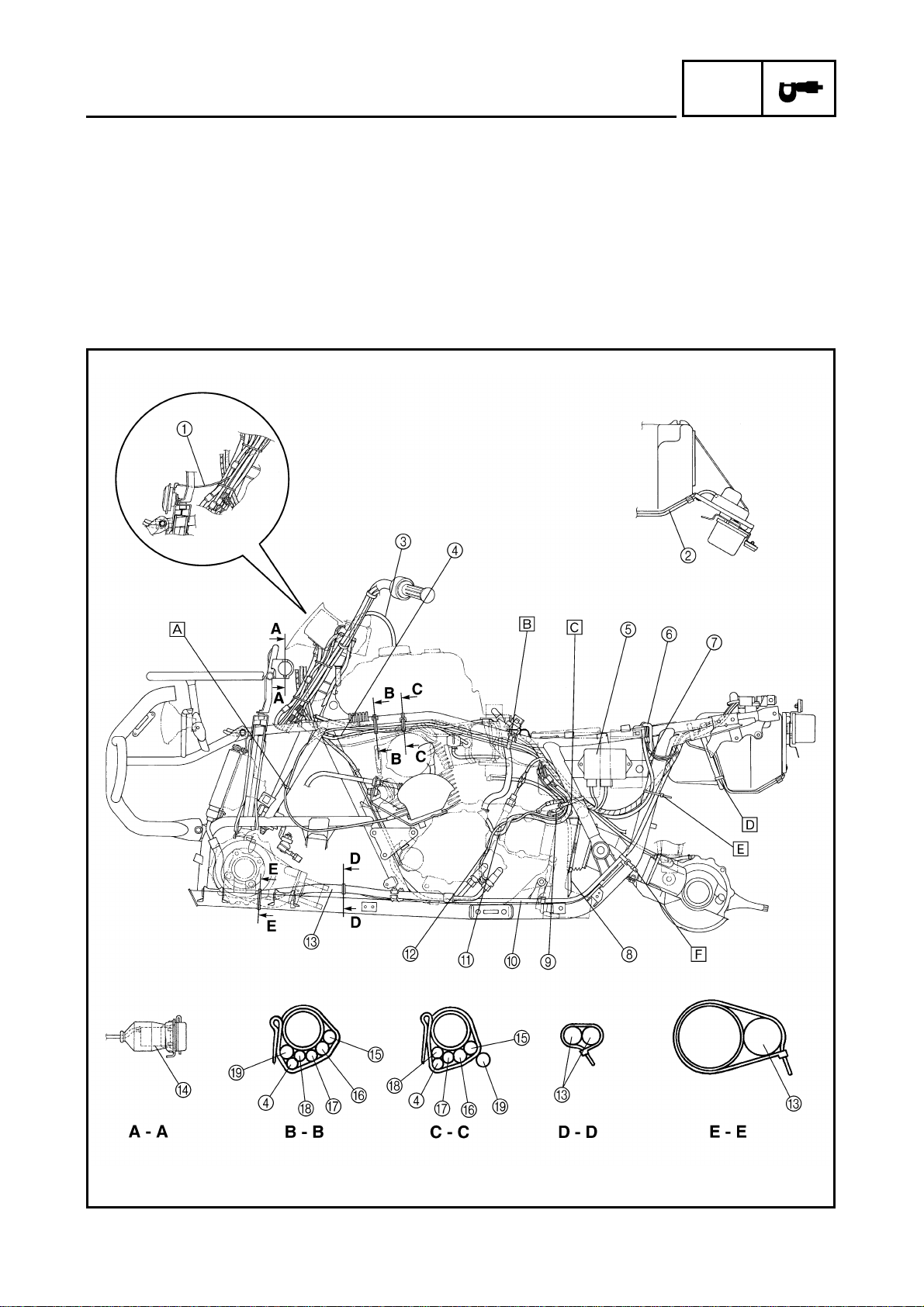

CABLE ROUTING

SPEC

1 Rear brake rod

2 Reverse control cable 2

3 Speedometer cable

4 Reverse control cable 1

5 Starter motor lead

6 Rear brake cable

7 Wire harness

8 Differential gear case breather

hose

9 Fan motor breather hose

0 Oil hose

Å Fasten the wire harness and speedometer cable to the frame

with the metal band.

ı Fasten the wire harness to the frame with the plastic band.

Ç Fasten the differential gear case breather hose to the frame

with the plastic clip.

Î Pass the reverse control cable 1 through the cable guide.

‰ Pass the rear brake cable through the cable guide.

Ï Align the portion of the wire harness marked with white tape

with the guide.

– 12 –

Page 20

CABLE ROUTING

SPEC

1 Fan motor breather hose

2 Differential gear case breather hose

3 Auxiliary DC jack lead

4 Reverse control cable 2

5 Battery

6 Main fuse

7 Positive battery lead

8 Neutral relay

9 Rectifier/regulator

0 Fan motor relay

A Starting circuit cut-off relay

B Starter relay

C Reverse relay

D Fan motor control unit

E Negative battery lead

F Fuse box

G Speedometer cable

H Starter motor lead

I Wire harness

J Taillight lead

K Fan motor control unit lead

L Neutral relay lead

– 13 –

Page 21

CABLE ROUTING

SPEC

M Starter relay lead

N Starting circuit cut-off relay lead

O Rectifier/regulator lead

P Reverse relay lead

Q Final gear case breather hose

R Rear brake breather hose

.

Å Fasten the wire harness to the frame with a plas-

tic locking tie.

ı Align the portion of the wire harness marked with

white tape with the guide.

– 14 –

Page 22

INTRODUCTION/

PERIODIC MAINTENANCE/LUBRICATION

INSP

ADJ

PERIODIC INSPECTIONS AND ADJUSTMENTS

INTRODUCTION

This chapter includes all information necessary to perform recommended inspections and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable machine

operation and a longer service life. In addition, the need for costly overhaul work will be greatly

reduced. This information applies to machines already in service as well as new machines that are

being prepared for sale. All service technicians should be familiar with this entire chapter.

PERIODIC MAINTENANCE/LUBRICATION

ITEM ROUTINE

Valves*

Spark plug

Air filter

Carburetor*

Fuel line*

Engine oil

Transfer gear oil

Engine oil filter • Replace.

Engine oil strainer • Clean.

Final gear oil

Differential gear oil

Front brake*

Rear brake*

Clutch*

Drive select lever

safety system*

Wheels*

Wheel bearings*

Steering system*

• Check valve clearance.

• Adjust if necessary.

• Check condition.

• Adjust gap and clean.

• Replace if necessary.

• Clean.

• Replace if necessary.

• Check idle speed/starter operation.

• Adjust if necessary.

• Check fuel hose for cracks or damage.

• Replace if necessary.

• Replace (Warm engine before draining).

• Check oil level/oil leakage.

• Replace every 12 months.

• Check operation/fluid leakage/see NOTE.

• Correct if necessary.

• Check operation.

• Adjust if necessary.

• Check operation.

• Adjust if necessary.

• Check operation.

• Adjust if necessary.

• Check balance/damage/runout.

• Repair if necessary.

• Check bearing assemblies for looseness/

damage.

• Replace if damaged.

• Check operation.

• Replace if damaged.

• Check toe-in.

• Adjust if necessary.

INITIAL EVERY

1 month 3 months 6 months 6 months 1 year

Every 20 ~ 40 hours

(More often in wet or dusty areas.)

– 15 –

Page 23

PERIODIC MAINTENANCE/LUBRICATION

INSP

ADJ

ITEM ROUTINE

Front axle boots*

Fittings and Fas-

teners*

*It is recommended that these items be serviced by a Yamaha dealer.

• Check operation.

• Replace if damaged.

• Check all chassis fittings and fasteners.

• Correct if necessary.

1 month 3 months 6 months 6 months 1 year

INITIAL EVERY

NOTE:

● Recommended brake fluid: DOT 4 (If DOT 4 is not available, DOT 3 can be used.)

● Brake fluid replacement:

1.When disassembling the master cylinder or caliper cylinder, replace the brake fluid. Normally

check the brake fluid level and add fluid as required.

2.On the inner parts of the master cylinder and caliper cylinder, replace the oil seals every two

years.

3.Replace the brake hoses every four years, or if cracked or damaged.

WARNING

Indicates a potential hazard that could result in serious injury or death.

– 16 –

Page 24

SEAT, CARRIERS, FENDERS AND FUEL TANK

SEAT, CARRIERS, FENDERS AND

FUEL TANK

REMOVAL

1.Place the machine on a level place.

2.Remove:

● Seat

NOTE:

Pull up the seat lock lever 1, then remove by

pulling up on the rear of the seat.

3.Disconnect:

● Auxiliary DC jack coupler 1

● Headlight couplers 2

4.Remove:

● Plastic locking tie 3

INSP

ADJ

5.Remove:

● Front carrier 1

(with the auxiliary DC jack 2)

6.Remove:

● Front bumper 1

– 17 –

Page 25

SEAT, CARRIERS, FENDERS AND FUEL TANK

7.Remove:

● Front fender 1

INSP

ADJ

8.Turn the fuel cock lever to “OFF”.

9.Disconnect:

● Fuel hose 1

NOTE:

Place a rag on the engine to absorb spilled

fuel.

WARNING

Gasoline is highly flammable.

Avoid spilling fuel on the hot engine.

10.Remove:

● Fuel tank 1

NOTE:

Remove the air duct 2 from fuel tank.

– 18 –

Page 26

SEAT, CARRIERS, FENDERS AND FUEL TANK

11.Remove:

● Main fuse 1

(from the battery holding bracket)

● Battery holding bracket 2

12.Disconnect:

● Battery leads

CAUTION:

Disconnect the negative lead first and then

disconnect the positive lead.

13.Remove:

● Battery 3

14.Remove:

● Rear carrier 1

INSP

ADJ

15.Remove:

● Rear fender 1

– 19 –

Page 27

SEAT, CARRIERS, FENDERS AND FUEL TANK

INSTALLATION

Reverse the “REMOVAL” procedure.

Note the following points.

1.Install:

● Fuel tank 1

NOTE:

● Insert the fuel tank air duct into the fuel tank

hole a. Refer to “CABLE ROUTING”.

● Insert the fuel tank breather hose 2 into the

handlebar protector hole b. Refer to

“CABLE ROUTING”.

INSP

ADJ

2.Install:

● Rear fender

● Battery 1

● Battery holding bracket 2

● Main fuse 3

3.Connect:

● Battery leads

CAUTION:

Connect the positive lead first and then

connect the negative lead.

NOTE:

Pass the positive lead through the lead holders

4. Refer to “CABLE ROUTING”.

4.Install:

● Rear carrier 1

– 20 –

Bolt (rear carrier and frame):

T

33 Nm (3.3 m • kg, 24 ft • lb)

.

R

.

Bolt (rear carrier and rear

bumper):

9 Nm (0.9 m • kg, 6.5 ft • lb)

Page 28

SEAT, CARRIERS, FENDERS AND FUEL TANK

5.Install:

● Front fender

● Front bumper 1

Bolt (front bumper):

T

31 Nm (3.1 m • kg, 22 ft • lb)

.

R

.

6.Install:

● Front carrier 1

(with the auxiliary DC jack 2)

Bolt (front carrier and frame):

T

31 Nm (3.1 m • kg, 22 ft • lb)

.

R

.

Nut (front carrier and front

bumper):

10 Nm (1.0 m • kg, 7.2 ft • lb)

INSP

ADJ

7.Install:

● Plastic locking tie 1

8.Connect:

● Headlight couplers 2

● Auxiliary DC jack coupler 3

9.Install:

● Seat

NOTE:

Insert the lobes 1 on the seat front into the

receptacles 2 on the frame, then push down

the seat at the rear.

– 21 –

Page 29

STARTER LEVER FREE PLAY ADJUSTMENT

ENGINE

STARTER LEVER FREE PLAY

ADJUSTMENT

1.Check:

● Starter lever free play a

Out of specification → Adjust.

Starter lever free play:

5.5 ~ 14.2 mm (0.22 ~ 0.56 in)

2.Adjust:

● Starter lever free play

*********************************************

Adjustment steps:

●Pull back the adjuster cover 1.

●Loosen the locknut 2.

●Turn the adjuster 3 in or out until the correct

free play is obtained.

INSP

ADJ

Turning in Free play is increased.

Turning out Free play is decreased.

●Tighten the locknut 2.

●Push in the adjuster cover 1.

WARNING

After adjusting the free play, turn the handlebar to right and left, and make sure that

the engine idling speed does not increase.

*********************************************

– 22 –

Page 30

FRONT BRAKE PAD INSPECTION/

AIR BLEEDING (HYDRAULIC BRAKE SYSTEM)

CHASSIS

FRONT BRAKE PAD INSPECTION

1.Remove:

● Front wheels

2.Inspect:

● Brake pad

Wear indicators 1 almost touch the brake

disc → Replace the brake pads as a set.

Refer to “FRONT BRAKE”.

3.Operate the brake lever.

4.Install:

● Front wheels

INSP

ADJ

AIR BLEEDING (HYDRAULIC BRAKE

SYSTEM)

WARNING

Bleed the brake system if:

● The system has been disassembled.

● A brake hose or brake pipe have been

loosened or removed.

● The brake fluid has been very low.

● The brake operation has been faulty.

A loss of braking performance may occur if

the brake system is not properly bled.

1.Bleed:

● Brake system

*********************************************

Air bleeding steps:

a. Add the proper brake fluid to the reservoir.

b. Install the diaphragm. Be careful not to spill

any fluid or allow the reservoir to overflow.

c. Connect the clear plastic hose 1 tightly to

the caliper bleed screw 2.

d. Place the other end of the hose into a con-

tainer.

e. Slowly apply the brake lever several times.

f. Pull the lever in and hold it.

– 23 –

Page 31

AIR BLEEDING (HYDRAULIC BRAKE SYSTEM)/

REAR SHOCK ABSORBER ADJUSTMENT

g. Loosen the bleed screw and allow the lever

to travel towards its limit.

h. Tighten the bleed screw when the lever limit

has been reached, then release the lever.

i. Repeat steps (e) to (h) until all the air bub-

bles have disappeared from the fluid.

j. Tighten the bleed screw.

Bleed screw:

T

6 Nm (0.6 m • kg, 4.3 ft • lb)

.

R

.

NOTE:

If bleeding is difficult, it may be necessary to

let the brake fluid settle for a few hours.

Repeat the bleeding procedure when the tiny

bubbles in the system have disappeared.

k. Add brake fluid to the proper level.

Refer to “BRAKE FLUID LEVEL INSPEC-

TION”.

INSP

ADJ

WARNING

Check the operation of the brake after

bleeding the brake system.

*********************************************

REAR SHOCK ABSORBER ADJUSTMENT

1.Adjust:

● Spring preload

Turn the adjuster to increase or decrease the

spring preload.

NOTE:

The spring preload of the rear shock absorber

can be adjusted to suit the rider’s preference,

weight, and the riding conditions.

– 24 –

Standard position: B

Softest position: A

Stiffest position: E

Page 32

INSP

TIRE INSPECTION

TIRE INSPECTION

WARNING

This model is equipped with low pressure

tires. It is important that they be inflated

correctly and maintained at the proper

pressures.

● TIRE CHARACTERISTICS

1)Tire characteristics influence the han-

dling of ATV’s. The tires listed below

have been approved by Yamaha Motor

Co., Ltd. for this model. If other tire combinations are used, they can adversely

affect your machine’s handling characteristics and are therefore not recommended.

For CDN and Europe

Manufacturer Size Type

ADJ

Front DUNLOP AT25 × 8-12 KT402

Rear DUNLOP AT25 × 10-12 KT406

For Oceania

Manufacturer Size Type

Front CHENG SHIN AT25 × 8-12 C-828

Rear CHENG SHIN AT25 × 10-12 C-828

● TIRE PRESSURE

1)Recommended tire pressure

Front 25 kPa (0.25 kg/cm

Rear 25 kPa (0.25 kg/cm

2

, 3.6 psi)

2

, 3.6 psi)

2)Tire pressure below the minimum speci-

fied could cause the tire to dislodge from

the rim under severe riding conditions.

The following are minimums:

Front 22 kPa (0.22 kg/cm

Rear 22 kPa (0.22 kg/cm

2

, 3.2 psi)

2

, 3.2 psi)

3)Use no more than

Front 250 kPa (2.5 kg/cm

Rear 250 kPa (2.5 kg/cm

2

, 36 psi)

2

, 36 psi)

when seating the tire beads. Higher pres-

sures may cause the tire to burst.

Inflate the tires very slowly and carefully.

Fast inflation could cause the tire to

burst.

● MAXIMUM LOADING LIMIT

1)Vehicle load limits: 220 kg (485 lb)*

* Total weight of cargo, trailer hitch verti-

cal load, rider, and accessories.

2)Storage box: 2 kg (4.4 lb)

– 25 –

Page 33

INSP

TIRE INSPECTION

3)Trailer hitch:

Horizontal load:

500 kg (1,102 lb) (for CDN)

410 kg (904 lb) (for Europe and Oceania)

Total weight of trailer and cargo.

Vertical load: 15 kg (33 lb)

Vertical weight on trailer hitch joint.

Be extra careful of the machine balance

and stability when towing a trailer.

1.Measure:

● Tire pressure (cold tire pressure)

Out of specification → Adjust.

NOTE:

● The low-pressure tire gauge 1 is included in

the standard equipment.

● If dust or the like is stuck to this gauge, it does

not provide correct readings. Therefore, make

two measurements on the tire pressure and

get the second reading.

ADJ

Cold tire

pressure

Standard

Minimum

Maximum

Front Rear

25 kPa

(0.25 kg/cm

3.6 psi)

22 kPa

(0.22 kg/cm

3.2 psi)

28 kPa

(0.28 kg/cm

4.0 psi)

2

,

2

,

2

,

25 kPa

(0.25 kg/cm2,

3.6 psi)

22 kPa

(0.22 kg/cm2,

3.2 psi)

28 kPa

(0.28 kg/cm2,

4.0 psi)

WARNING

Uneven or improper tire pressure may

adversely affect the handling of this

machine and may cause loss of control.

● Maintain proper tire pressures.

● Set tire pressures when the tires are cold.

● Tire pressures must be equal in both

front tires and equal in both rear tires.

2.Inspect:

● Tire surfaces

Wear/damage → Replace.

Tire wear limit a:

Front and rear: 3.0 mm (0.12 in)

WARNING

It is dangerous to ride with a worn-out tire.

When tire wear is out of specification,

replace the tire immediately.

– 26 –

Page 34

BATTERY INSPECTION

EB305000

ELECTRICAL

BATTERY INSPECTION

NOTE:

Since the MF battery is a sealed type battery, it

is not possible to measure the specific gravity

of the electrolyte in order to check the charge

state of the battery. Therefore the charge of

the battery has to be checked by measuring

the voltage at the battery terminals.

CAUTION:

CHARGING METHOD

● This is a sealed type battery. Never

remove the sealing caps. If the sealing

caps have been removed, the balance will

not be maintained and battery performance will deteriorate.

● Charging time, charging current and

charging voltage for the MF battery are

different from those of general type batteries. The MF battery should be charged

as explained in “CHARGING METHOD”. If

the battery is overcharged, the electrolyte

level will drop considerably. Therefore,

take special care when charging the battery.

INSP

ADJ

WARNING

Battery electrolyte is dangerous; it contains sulfuric acid which is poisonous and

highly caustic.

Always follow these preventive measures:

● Avoid bodily contact with electrolyte as it

can cause severe burns or permanent eye

injury.

● Wear protective eye gear when handling

or working near batteries.

Antidote (EXTERNAL):

● SKIN - Wash with water.

● EYES - Flush with water for 15 minutes

and get immediate medical attention.

Antidote (INTERNAL):

● Drink large quantities of water or milk fol-

lowed with milk of magnesia, beaten egg

or vegetable oil. Get immediate medical

attention.

– 27 –

Page 35

BATTERY INSPECTION

Batteries generate explosive hydrogen gas.

Always follow these preventive measures:

● Charge batteries in a well-ventilated area.

● Keep batteries away from fire, sparks or

open flames (e.g., welding equipment,

lighted cigarettes, etc.)

● DO NOT SMOKE when charging or han-

dling batteries.

KEEP BATTERIES AND ELECTROLYTE

OUT OF REACH OF CHILDREN.

1.Remove:

● Seat

Refer to “SEAT, CARRIERS, FENDERS

AND FUEL TANK”.

INSP

ADJ

2.Disconnect:

● Battery leads

CAUTION:

First disconnect the negative lead 1, then

disconnect the positive lead 2.

3.Remove:

● Main fuse 3

(from the battery holding bracket)

● Battery holding bracket

● Battery

4.Check:

● Battery condition

*********************************************

Battery condition checking steps:

●Connect a digital voltmeter to the battery ter-

minals.

Tester (+) lead → battery (+) terminal

Tester (–) lead → battery (–) terminal

– 28 –

Page 36

BATTERY INSPECTION

NOTE:

The charge state of an MF battery can be

checked by measuring the open-circuit voltage

(i.e. the voltage when the positive terminal is

disconnected).

INSP

ADJ

Open-circuit

voltage

12.8 V or higher

●Check the condition of the battery using the

Charging time

No charging is

necessary.

following charts.

Example:

●Open-circuit voltage = 12.0 V

●Charging time = 6.5 hours

●Charge condition of the battery = 20 ~ 30%

●Charging method for MF batteries

CAUTION:

● If it is impossible to set the standard

charging current, be careful not to overcharge.

● When charging the battery, be sure to

remove it from the motorcycle. (If charg-

ing has to be done with the battery

mounted on the motorcycle, be sure to

disconnect the wire at the negative termi-

nal.)

● Never remove the sealing caps of an MF

battery.

● Make sure that the charging clips are in

full contact with the terminal and that

they are not shorted together. (A cor-

roded clip on the charger may cause the

battery to generate heat in the contact

area. A weak clip spring may cause

sparks.)

● Before removing the clips from the bat-

tery terminals, be sure to turn off the

charger’s power switch.

● The open-circuit voltage variation for the

MF battery, after charging, is shown

below. As shown in the figure, the open-

circuit voltage stabilizes about 30 min-

utes after charging has been completed.

Therefore, wait 30 minutes after charging

is completed before measuring the open-

circuit voltage.

– 29 –

Page 37

BATTERY INSPECTION

Charging method using a variable voltage charger

INSP

ADJ

– 30 –

Page 38

BATTERY INSPECTION

Charging method using a constant voltage charger

INSP

ADJ

– 31 –

Page 39

BATTERY INSPECTION/

FUSE INSPECTION

5.Inspect:

● Battery terminals

Dirty → Clean with a wire brush.

Poor connection → Correct.

NOTE:

After cleaning the terminals, apply a light coat

of grease.

6.Install:

● Battery

● Battery holding bracket

● Main fuse

7.Connect:

● Battery leads

CAUTION:

First, connect the positive lead 1, then

connect the negative lead 2.

INSP

ADJ

NOTE:

Connect the positive lead pass the lead holders 3. Refer to “CABLE ROUTING”.

8.Install:

● Seat

Refer to “SEAT, CARRIERS, FENDERS

AND FUEL TANK”.

FUSE INSPECTION

CAUTION:

Always turn off the main switch when

checking or replacing a fuse. Otherwise, a

short circuit may occur.

1.Remove:

● Seat

Refer to “SEAT, CARRIERS, FENDERS

AND FUEL TANK”.

2.Inspect:

● Fuses

*********************************************

Inspection steps:

●Connect the pocket tester to the fuse and

check it for continuity.

– 32 –

Page 40

INSP

FUSE INSPECTION

NOTE:

Set the tester to the “Ω × 1” position.

Pocket tester:

P/N. YU-03112, 90890-03112

● If the tester indicates “0”, replace the fuse.

*********************************************

3.Replace:

● Blown fuse

*********************************************

Replacement steps:

●Turn off the ignition.

●Install a new fuse of the proper amperage.

●Turn on switches to verify operation of the

related electrical devices.

●If the fuse immediately blows again, check

the electrical circuit.

ADJ

*********************************************

Description Current rating Quantity

Main 30 A 1

Headlight 15 A 1

Ignition 10 A 1

Terminal

(Auxiliary

10 A 1

DC jack)

Signal 10 A 1

Reserve 30 A 1

Reserve 15 A 1

Reserve 10 A 1

WARNING

Never use a fuse with a rating other than

that specified. Never use other materials in

place of a fuse. An improper fuse may

cause extensive damage to the electrical

system, a malfunction of the lighting and

ignition systems and could possibly cause

a fire.

– 33 –

4.Install:

● Seat

Refer to “SEAT, CARRIERS, FENDERS

AND FUEL TANK”.

Page 41

ENGINE ASSEMBLY AND ADJUSTMENT

ENGINE OVERHAUL

ENGINE ASSEMBLY AND ADJUSTMENT

VALVE, CAMSHAFT AND ROCKER ARM

1 Locknut (valve adjusting)

2 Adjuster (valve adjusting)

3 Wave washer

4 Rocker arm

5 Rocker arm shaft

6 O-ring

7 Valve cotter

8 Valve spring retainer

9 Oil seal

0 Valve spring

A Valve spring seat

B Valve

C Bearing retainer

D Lock washer

ENG

E Bearing

F Camshaft

G Bearing

H Circlip

I Valve guide

VALVE CLEARANCE (COLD):

Intake: 0.06 ~ 0.10 mm (0.002 ~ 0.004 in)

A

Exhaust: 0.16 ~ 0.20 mm

(0.006 ~ 0.008 in)

VALVE SPRING TILT LIMIT:

Inner spring:

B

2.5˚ or 1.6 mm (0.06 in)

Outer spring:

2.5˚ or 1.6 mm (0.06 in)

VALVE SPRING LENGTH LIMIT (FREE):

C

Inner spring: 37.9 mm (1.49 in)

Outer spring: 41.27 mm (1.62 in)

STEM RUNOUT LIMIT:

D

0.02 mm (0.0008 in)

VALVE SEAT WIDTH LIMIT:

E

1.6 mm (0.06 in)

FWD

– 34 –

Page 42

FRONT AND REAR WHEELS

CHASSIS

FRONT AND REAR WHEELS

1 Wheel cap

2 Cotter pin

3 Axle nut

4 Plain washer

5 Wheel nut

6 Front wheel

7 Front wheel hub

‰ Tapered wheel nuts are used for both the front

and rear wheels. Install the nut with its tapered

side towards the wheel.

8 O-ring

9 Rear wheel

0 Rear brake drum

A Rear wheel hub

CHAS

TIRE AIR PRESSURE

Cold Tire Pressure Front Rear

Standard

Minimum

Maximum

A

B

25 kPa

(0.25 kg/cm2,

3.6 psi)

22 kPa

(0.22 kg/cm2,

3.2 psi)

28 kPa

(0.28 kg/cm2,

4.0 psi)

TIRE SIZE:

FRONT: AT25 × 8-12

REAR: AT25 × 10-12

RIM SIZE:

FRONT: 12 × 6.0AT

REAR: 12 × 7.5AT

25 kPa

(0.25 kg/cm2,

3.6 psi)

22 kPa

(0.22 kg/cm2,

3.2 psi)

28 kPa

(0.28 kg/cm2,

4.0 psi)

WHEEL RUNOUT LIMIT:

C

RADIAL: 2 mm (0.08 in)

LATERAL: 2 mm (0.08 in)

D TIRE WEAR LIMIT: 3 mm (0.12 in)

FWD

– 35 –

Page 43

FRONT AND REAR WHEELS

REMOVAL

Front wheels

1.Place the machine on a level surface.

2.Loosen:

● Nuts (front wheel)

Apply the front brake.

3.Block the rear wheels, and elevate the front

wheels by placing the suitable stand under

the frame.

4.Remove:

● Nuts (front wheel)

● Front wheel

CHAS

5.Remove:

● Wheel cap

● Cotter pin 1

● Nut (wheel hub) 2

● Washer 3

6.Remove:

● Front brake caliper 1

OTE:

Do not depress the brake lever when the

wheel is off the machine otherwise the brake

pads will be forced shut.

7.Remove:

● Front wheel hub 1

(with brake disc)

– 36 –

Page 44

FRONT AND REAR WHEELS

8.Remove:

● Front brake disc 1

CHAS

– 37 –

Page 45

FRONT BRAKE

1 Brake master cylinder reservoir cap

2 Brake master cylinder reservoir dia-

phragm

3 Brake master cylinder

4 Brake master cylinder kit

5 Copper washer

6 Union bolt

7 Brake hose

8 Brake pipe

9 Brake disc

BRAKE FLUID TYPE:

A

DOT 4

BRAKE PAD WEAR LIMIT:

B

1.0 mm (0.04 in)

BRAKE DISC WEAR LIMIT:

C

3.0 mm (0.12 in)

FRONT BRAKE

0 Bleed screw

A Retaining bolt

B Brake caliper

C Pad shim

D Brake pad

E Piston

F Piston seal

G Brake disc guard

CHAS

FWD

– 38 –

Page 46

FRONT BRAKE

CHAS

CAUTION:

Disc brake components rarely require disassembly. DO NOT:

● Disassemble components unless abso-

lutely necessary.

● Use solvents on internal brake components.

● Use contaminated brake fluid for clean-

ing. Use only clean brake fluid.

● Allow brake fluid to come in contact with

the eyes, otherwise eye injury may occur.

● Allow brake fluid to contact painted sur-

faces or plastic parts otherwise damage

may occur.

● Disconnect any hydraulic connection oth-

erwise the entire system must be disassembled, drained, cleaned, and then

properly filled and bled after reassembly.

BRAKE PAD REPLACEMENT

OTE:

It is not necessary to disassemble the brake

caliper and brake hose to replace the brake

pads.

1.Remove:

● Front wheel

2.Loosen:

● Retaining bolts 1

3.Remove:

● Front brake caliper 2

4.Remove:

● Retaining bolts 1

– 39 –

Page 47

FRONT BRAKE

CHAS

5.Remove:

● Brake pads 1

(with pad shim 2)

● Pad spring 3

OTE:

● When pad replacement is required, also

replace the pad spring and shim.

● Replace the pads as a set if either is found to

be worn to the wear limit a.

Wear limit a:

1.0 mm (0.04 in)

6.Install:

● Pad shim

(onto inside brake pad)

● Pad spring

● Brake pads

*********************************************

Installation steps:

●Connect a suitable hose 1 tightly to the cali-

per bleed screw 2. Then, place the other

end of this hose into an open container.

●Loosen the caliper bleed screw and push the

pistons into the caliper with the finger.

●Tighten the caliper bleed screw 2.

Caliper bleed screw:

6 Nm (0.6 m • kg, 4.3 ft • lb)

T

.

R

.

●Install the pad shim 3 (new) onto the brake

pad (new).

OTE:

The arrow mark a on the pad shim must point

in the direction of the disc rotation.

●Install the pad spring (new) and brake pads

(new).

*********************************************

– 40 –

Page 48

FRONT BRAKE

CHAS

7.Install:

● Retaining bolts

● Front brake caliper

Retaining bolt:

18 Nm (1.8 m • kg, 13 ft • lb)

T

.

R

.

Bolt (front brake caliper):

30 Nm (3.0 m • kg, 22 ft • lb)

8.Install:

● Front wheel

9.Inspect:

● Brake fluid level

Refer to “FRONT BRAKE FLUID LEVEL

INSPECTION”.

a “LOWER” level line

10.Check:

● Brake lever operation

A soft or spongy feeling → Bleed brake system.

Refer to “AIR BLEEDING (HYDRAULIC

BRAKE SYSTEM)”.

CALIPER DISASSEMBLY

OTE:

Before disassembling the front brake caliper,

drain the brake hose, master cylinder, brake

caliper and reservoir tank of their brake fluid.

1.Remove:

● Front wheel

2.Loosen:

● Union bolt

● Retaining bolts

● Retaining bolt (caliper bracket)

3.Remove:

● Front brake caliper

● Retaining bolts

● Brake pads

(with pad shim)

● Pad spring

Refer to “BRAKE PAD REPLACEMENT”.

– 41 –

Page 49

FRONT BRAKE

CHAS

4.Remove:

● Union bolt 1

● Copper washers 2

● Brake hose 3

OTE:

Place the open end of the hose into a container and pump the oil fluid out carefully.

5.Remove:

● Caliper body 1

● Caliper bracket 2

OTE:

Before removing the caliper body from the

bracket, disconnect the dust boot from the

guide shaft on the bracket.

6.Remove:

● Piston

● Piston seals 1

*********************************************

Removal steps:

●Blow compressed air into the hose joint

opening to force out the caliper piston from

the caliper body.

●Remove the piston seals.

WARNING

Never try to pry out the piston.

*********************************************

MASTER CYLINDER DISASSEMBLY

OTE:

Before disassembling the front brake master

cylinder, drain the brake hose, master cylinder,

brake caliper and reservoir tank of their brake

fluid.

– 42 –

Page 50

FRONT BRAKE

CHAS

1.Remove:

● Brake lever 1

● Spring

● Union bolt 2

● Copper washers 3

● Brake hose 4

OTE:

Hold a container under the master cylinder and

under the hose end to collect any remaining

brake fluid.

2.Remove:

● Brake master cylinder reservoir cap 1

● Brake master cylinder reservoir diaphragm

holder

● Brake master cylinder reservoir diaphragm

● Brake master cylinder 2

3.Remove:

● Dust boot 1

● Circlip 2

● Brake master cylinder kit 3

Drain the excess fluid.

INSPECTION AND REPAIR

Recommended brake component

replacement schedule:

Brake pads As required

Piston seal Every two years

Brake hoses Every four years

Brake fluid Replace only when

brakes are disassembled.

WARNING

All internal parts should be cleaned in new

brake fluid only. Do not use solvents as

they will cause seals to swell and distort.

– 43 –

Page 51

FRONT BRAKE

CHAS

1.Inspect:

● Caliper piston 1

Scratches/rust/wear → Replace caliper

assembly.

● Caliper cylinder 2

Wear/scratches → Replace caliper assembly.

● Caliper body 3

Cracks/damage → Replace.

● Oil delivery passage (caliper body)

Blow out with compressed air.

WARNING

Replace the piston seal whenever the caliper is disassembled.

2.Inspect:

● Brake master cylinder

Wear/scratches → Replace the brake master

cylinder assembly.

● Brake master cylinder body

Cracks/damage → Replace.

● Oil delivery passage (master cylinder body)

Blow out with compressed air.

3.Inspect:

● Brake master cylinder kit

Scratches/wear/damage → Replace as a

set.

4.Inspect:

● Brake master cylinder reservoir diaphragm

Wear/damage → Replace.

5.Inspect:

● Brake hose

Cracks/wear/damage → Replace.

– 44 –

Page 52

FRONT BRAKE

CHAS

6.Measure:

● Brake pads (thickness) a

Out of specification → Replace.

OTE:

● When pad replacement is required, also

replace the pad spring and shim.

● Replace the pads as a set if either is found to

be worn to the wear limit a.

Wear limit a:

1.0 mm (0.04 in)

7.Inspect:

● Brake disc

Galling/damage → Replace.

8.Measure:

● Brake disc deflection

Out of specification → Inspect wheel runout.

If wheel runout is in good condition, replace

the brake disc(s).

Maximum deflection:

0.15 mm (0.006 in)

● Brake disc thickness a

Out of specification → Replace.

– 45 –

Minimum thickness:

3.0 mm (0.12 in)

1 Dial gauge

Page 53

FRONT BRAKE

CHAS

OTE:

Tighten the bolts (brake disc) in stage using a

crisscross pattern.

Bolt (brake disc):

30 Nm (3.0 m • kg, 22 ft • lb)

T

.

R

.

CALIPER ASSEMBLY

WARNING

● All internal parts should be cleaned in

new brake fluid only.

● Internal parts should be lubricated with

brake fluid when installed.

Recommended brake fluid:

DOT 4

● Replace the piston seals whenever a cali-

per is disassembled.

1.Install:

● Piston seals 1

● Piston 2

New

WARNING

Always use new piston seals.

2.Install:

● Caliper bracket 1

● Caliper body 2

OTE:

Apply lithium soap base grease onto the caliper guide shaft and retaining bolt.

– 46 –

Page 54

FRONT BRAKE

CHAS

3.Install:

● Brake caliper 1

(temporarily)

● Copper washers 2

● Brake hose 3

● Union bolt 4

New

Union bolt:

27 Nm (2.7 m • kg, 19 ft • lb)

T

.

R

.

CAUTION:

When installing the brake hose on the caliper, make sure that the brake pipe touches

the projection a on the brake caliper.

WARNING

● Proper hose routing is essential to insure

safe machine operation. Refer to “CABLE

ROUTING”.

● Always use new copper washers.

4.Remove:

● Brake caliper

5.Install:

● Pad spring

● Brake pads

(with pad shim)

● Retaining bolts

● Front brake caliper

Refer to “BRAKE PAD REPLACEMENT”.

T

.

R

.

– 47 –

Retaining bolt (caliper bracket):

28 Nm (2.8 m • kg, 20 ft • lb)

Retaining bolt:

18 Nm (1.8 m • kg, 13 ft • lb)

Bolt (front brake caliper):

30 Nm (3.0 m • kg, 22 ft • lb)

Page 55

FRONT BRAKE

CHAS

6.Fill:

● Reservoir tank

Recommended brake fluid:

DOT 4

OTE:

If DOT 4 is not available, 3 can be used.

CAUTION:

Brake fluid may erode painted surfaces or

plastic parts. Always clean up spilled fluid

immediately.

WARNING

● Use only the designated quality brake

fluid: otherwise, the rubber seals may

deteriorate, causing leakage and poor

brake performance.

● Refill with the same type of brake fluid:

mixing fluids may result in a harmful

chemical reaction and lead to poor performance.

● Be careful that water does not enter the

master cylinder when refilling. Water will

significantly lower the boiling point of the

fluid and may result in vapor lock.

7.Air bleed:

● Brake system

Refer to “AIR BLEEDING (HYDRAULIC

BRAKE SYSTEM)”.

8.Inspect:

● Brake fluid level

Fluid level is under “LOWER” level line →

Replenish.

Refer to “FRONT BRAKE FLUID LEVEL

INSPECTION”.

a “LOWER” level line

– 48 –

Page 56

FRONT BRAKE

CHAS

MASTER CYLINDER ASSEMBLY

WARNING

● All internal parts should be cleaned in

new brake fluid only.

● Internal parts should be lubricated with

brake fluid when installed.

Recommended brake fluid:

DOT 4

● Replace the piston seals and dust seals

whenever a brake master cylinder is disassembled.

1.Install:

● Brake master cylinder kit 1

● Circlip 2

● Dust boot 3

2.Install:

● Brake master cylinder 1

CAUTION:

● Install the brake master cylinder holder

with the “UP” mark facing upward.

● Align the end of the brake master cylinder

holder with the punch mark a in the handlebar.

● Tighten first the upper bolt, then the

lower bolt.

– 49 –

Bolt (brake master cylinder

holder):

T

.

R

.

7 Nm (0.7 m • kg, 5.1 ft • lb)

Page 57

FRONT BRAKE

CHAS

3.Install:

● Copper washers

● Brake hose

● Union bolt

Union bolt:

27 Nm (2.7 m • kg, 19 ft • lb)

T

.

R

.

OTE:

● Tighten the union bolt while holding the

brake hose as shown.

● Check that the brake hose does not touch

other parts (throttle cable, wire harness,

leads, etc.) by turning the handlebar left and

right, and correct if necessary.

WARNING

● Proper hose routing is essential to insure

safe machine operation. Refer to “CABLE

ROUTING”.

● Always use new copper washers.

4.Install:

● Brake lever

5.Fill:

● Brake master cylinder reservoir

Recommended brake fluid:

DOT 4

OTE:

If DOT 4 is not available, 3 can be used.

CAUTION:

Brake fluid may erode painted surfaces or

plastic parts. Always clean up spilled fluid

immediately.

WARNING

● Use only the designated quality brake

fluid: otherwise, the rubber seals may

deteriorate, causing leakage and poor

brake performance.

– 50 –

Page 58

FRONT BRAKE

● Refill with the same type of brake fluid:

CHAS

mixing fluids may result in a harmful

chemical reaction and lead to poor performance.

● Be careful that water does not enter the

master cylinder when refilling. Water will

significantly lower the boiling point of the

fluid and may result in vapor lock.

6.Air bleed:

● Brake system

Refer to “AIR BLEEDING (HYDRAULIC

BRAKE SYSTEM)”.

7.Inspect:

● Brake fluid level

Fluid level is under “LOWER” level line →

Replenish.

Refer to “FRONT BRAKE FLUID LEVEL

INSPECTION”.

a “LOWER” level line

– 51 –

Page 59

FRONT SHOCK ABSORBER AND FRONT ARM

FRONT SHOCK ABSORBER AND FRONT ARM

1 Bushing

2 Front shock absorber

3 Upper arm

4 Lower arm

5 Protector

FRONT SHOCK

A

ABSORBER:

B STANDARD POSITION: B

C STIFFEST POSITION: E

CHAS

FWD

– 52 –

Page 60

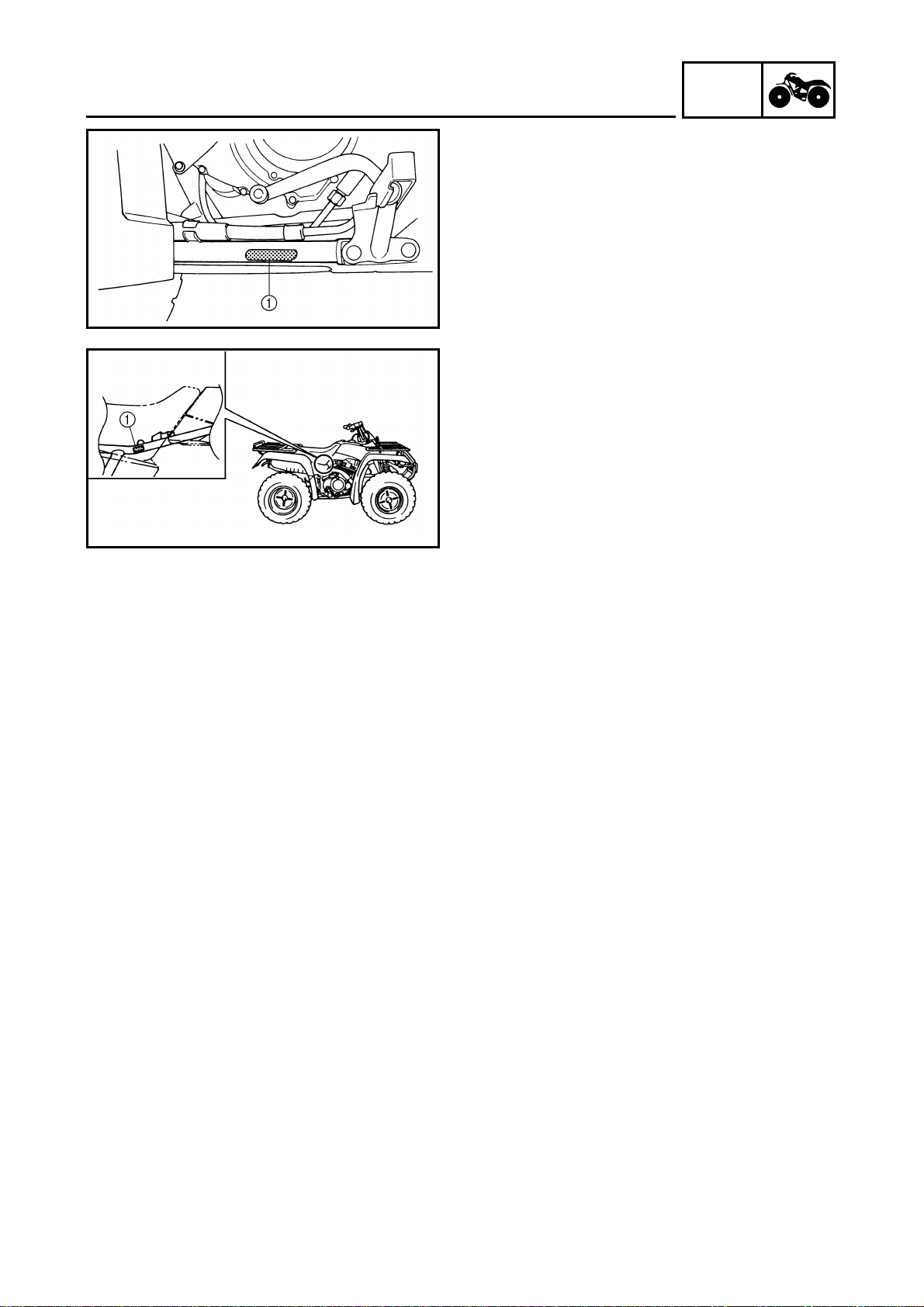

FRONT SHOCK ABSORBER AND FRONT ARM

INSTALLATION

Reverse the “REMOVAL” procedure.

Note the following points.

1.Lubricate:

● Pivot bolts (front arm)

Lithium-soap base grease

2.Install:

● Front upper arm 1

● Front lower arm 2

● Bolts

● Nuts

● Protector 3

OTE:

● Be sure to position the bolts (upper and lower)

so that the bolt head faces outward.

● Temporarily tighten the nuts (front arm).

CHAS

a

3.Install:

● Front shock absorber 1

Nut (front shock absorber):

45 Nm (4.5 m • kg, 32 ft • lb)

T

.

R

.

4.Install:

● Steering knuckle

Refer to “STEERING SYSTEM”.

5.Tighten:

● Nuts (front arm)

OTE:

Before tightening the nuts, adjust the length a

to 295 mm (11.6 in).

Nut (front arm):

45 Nm (4.5 m • kg, 32 ft • lb)

T

.

R

.

6.Install:

● Engine guard (front)

7.Install:

● Front wheel hubs

● Front wheels

Refer to “FRONT AND REAR WHEELS”.

8.Adjust:

● Toe-in

Refer to “TOE-IN ADJUSTMENT”.

– 53 –

Page 61

ELECTRICAL COMPONENTS

ELECTRICAL COMPONENTS

1 Meter assembly

2 Oil temperature indi-

cator light

3 Main switch

4 Diode

5 Rear brake switch

6 Handlebar switch

7 Fan motor relay

8 Rectifier/regulator

9 Neutral relay

0 Starter relay

A Starter circuit cut-

off relay

B Reverse relay

C Fan motor control

unit

D Taillight

E Main fuse

F Battery

G CDI unit

ELECTRICAL

H Fuse box

I Reverse switch

J Thermo unit

K Neutral switch

L Ignition coil

M Auxiliary DC jack

N Fan

O Headlight

P Circuit breaker

(fan motor)

ELEC

–+

SPECIFICATIONS RESISTANCE

IGNITION COIL:

PRIMARY 0.18 ~ 0.28 Ω

SECONDARY 6.32 ~ 9.48 kΩ

PICKUP COIL 459 ~ 561 Ω

STATOR COIL 0.70 ~ 0.86 Ω

A BATTERY:

CAPACITY:

B

12 V, 18 AH

– 54 –

Page 62

YFM40FP/YFM400FW WIRING DIAGRAM

W

WWWWW

R

W/G

R

W/LW/R

W/RW/L

A

]

B

`

OFF

ON

W/G

1

W/G W/L

W/R

R B

W/L

W/R

W/G

R

R

W/L

W/R

W/G

Y/B O O

4

W

W

W

W

W

Br/L

W

2

BR

WWW

(BLACK)

R R R R

B

R

3

ON

OFF

Br/L B/W

B

Br/L

B

B/W

RBr

B/W

B

Br/L

R

Br/L

5

B

RRR

6

B

B

B

7

R

B

B

Br/L

L/WL/BL/WR/W

(BLACK)

(BLACK)

L/B

Y/B

L/WL/W

8

Y/BL/W

R/WR/W

R/W

R/W

B/W

9

R/WSbB

Y/B

G/Y

R/WB/WSbO

(BLACK)(BLACK)

G/Y

G/Y

B

B

Br/L

BB

(BLACK)

G/YB

(BLACK)

C

1 CDI magneto

2 Rectifier/regulator

3 Main switch

4 Main fuse

5 Battery

B

0

A

6 Starter relay

7 Starter motor

8 Starting circuit cut-off relay

9 CDI unit

0 Ignition coil

A Spark plug

B Rear brake switch

C Circuit breaker (fan motor)

D Fan motor relay

E Fan motor

F Fan motor control unit

G Diode

H Oil temperature indicator light

I Thermo unit

R/B

J Neutral relay

K Neutral switch

L Reverse switch

M Reverse relay

N Meter assembly

\

Br

Br

Br

Br

B B

T

Br

Br

B

B

P

B

B

P B

R/Y

L/B

G

Y

B

L

[

R/Y

PB

R/Y

UVW

OFF

Br

R/W

LO

YLG

HI

B

LLY G

a

L

Y G Y G

RSR

YG

GY

B

B

B B

B

Y

P

X

R/W

Z

G

W/B

B/W

YG

B

B

OFF

ON

GY

B

L/B

R/WR/W L/B

GH

W/L

W/G

L/B

W/L

Br

R/W

W/L

W/L

W/G

W/G

W/L

WB

WB

F

W/G

W

I

B

W...........White

Y............Yellow

B/W .......Black/White

Br/L........Brown/Blue

G/L ........Green/Blue

G/Y........Green/Yellow

L/B.........Blue/Black

L/W........Blue/White

OFF

PUSH

B

R/W

R/W

W/L

(GREEN)

R/W

W/L

(GREEN)

W/L

N

LSbBr

L

OPQ

B

G/L

G/L

Br

B

G/Y

(BLUE)

B

(BLACK)

Sb

MJ

R/W

G/L

G/L

B

Sb B

(BLACK)

W/B

Br

G/Y

Br

G/Y

G/Y

G/YBrSb

W/B

Sb

W/G

B

(BLACK)

COLOR CODE

B............Black

Br...........Brown

L

Sb

G............Green

L ............Blue

O............Orange

Sb

K

P............Pink

R............Red

Sb..........Sky blue

D

R/W

R/B

W L

E

R/WWLR/B

L

BL

(BLACK) (BLACK)

BB

LB

O Meter light

P Reverse indicator light

Q Neutral indicator light

R Headlight

S Taillight

T Handlebar switch (left)

U Lights switch

V Engine stop switch

W Start switch

X Ignition fuse

Y Auxiliary DC jack fuse

Z Auxiliary DC jack

[ Headlight fuse

\ Signaling system fuse

] Clock

^ Horn switch

a Horn

Å Option

ı for Europe and Oceania

R/B........ Red/Black

R/W....... Red/White

R/Y........ Red/Yellow

W/B....... White/Black

W/G....... White/Green

W/L ....... White/Blue

W/R....... White/Red

Y/B........ Yellow/Black

Loading...

Loading...