Page 1

OWNER'S MANUAL

Page 2

Page 3

CONTENTS

CHAPTER 1 Using the Robot Safely

1 Safety Information ..................................................................1-1

2 Essential Caution Items ..........................................................1-2

3 Special Training for Industrial Robot Operation ......................1-9

4 Robot Safety Functions ........................................................1-10

5 Safety Measures for the System .......................................... 1-11

6 Trial Run ...............................................................................1-12

7 Work Within the Safeguard Enclosure .................................. 1-13

8 Automatic Operation .............................................................1-14

9 Adjustment and Inspection ...................................................1-14

10 Repair and Modification ........................................................1-14

11 Warranty ...............................................................................1-15

12 CE Marking ...........................................................................1-16

CHAPTER 2 Product Outline

1 Robot ......................................................................................2-1

2 Names of each part ................................................................2-2

3 Robot Controller .....................................................................2-7

CHAPTER 3 Preparing the Robot

1 Robot Installation Environment ............................................... 3-1

2 Unpacking the Robot ..............................................................3-2

3 Checking the Product .............................................................3-3

4 Transporting the Robot ...........................................................3-5

5 Installation ..............................................................................3-7

5-1 Installation base ............................................................................... 3-7

5-2 Installing the Robot .......................................................................... 3-8

6 Protective connections ...........................................................3-9

7 Connecting the Robot Cables ............................................... 3-10

7-1 Connecting with the DRCX controller ............................................ 3-12

7-2 Connecting with the TRCX controller ............................................. 3-14

7-2-1 3-axis model .................................................................................. 3-14

7-2-2 4-axis model .................................................................................. 3-16

7-3 Connecting to the QRCX or RCX40 controller ............................... 3-18

8 Installing the Tool ..................................................................3-20

9 User Wiring and User Piping ................................................3-21

Page 4

10 Setting the Robot ..................................................................3-22

10-1 Setting the payload ........................................................................ 3-22

10-2 Setting the maximum speed .......................................................... 3-23

10-3 Setting the acceleration ................................................................. 3-24

11 Absolute Reset .....................................................................3-25

CHAPTER 4 Periodic Inspections

1 Outline ....................................................................................4-1

2 Precautions ............................................................................. 4-1

3 Daily inspection ......................................................................4-2

4 Three-month inspection ..........................................................4-2

5 Six-month inspection ..............................................................4-3

6 Three-year inspection .............................................................4-4

7 Replenishing the grease .........................................................4-5

8 Maintenance and inspection of harmonic drives ....................4-6

8-1 Harmonic grease replacement period .............................................. 4-7

CHAPTER 5 Specifications

1 Specifications .........................................................................5-1

1-1 Robot cable ...................................................................................... 5-1

1-2 User I/O cable .................................................................................. 5-5

CHAPTER 6 PXYX

1 Installation ..............................................................................6-1

1-1 Installation bolt types ....................................................................... 6-1

1-2 Installation bolt nominal length......................................................... 6-1

1-3 Tightening torque ............................................................................. 6-1

1-4 Installation methods ......................................................................... 6-2

2 Protective Connections ........................................................... 6-3

2-1 Ground terminal ............................................................................... 6-3

2-2 Ground wire ..................................................................................... 6-4

2-3 Wiring method .................................................................................. 6-4

3 Installing the Tool ....................................................................6-5

4 User Wiring and User Piping ..................................................6-6

5 Periodic Inspections ...............................................................6-8

5-1 Replenishing grease to the linear guide........................................... 6-8

5-2 Replenishing grease to the ball screw ............................................. 6-9

Page 5

CHAPTER 7 FXYX

1 Installation ..............................................................................7-1

1-1 Installation bolt types ....................................................................... 7-1

1-2 Installation bolt nominal length......................................................... 7-1

1-3 Tightening torque ............................................................................. 7-1

1-4 Installation methods ......................................................................... 7-2

2 Protective Connections ........................................................... 7-3

2-1 Ground terminal ............................................................................... 7-3

2-2 Ground wire ..................................................................................... 7-4

2-3 Wiring method .................................................................................. 7-4

3 Installing the Tool ....................................................................7-5

3-1 Arm type 2-axis model ..................................................................... 7-5

3-2 ZS (3rd-axis option) ......................................................................... 7-7

4 User Wiring and User Piping ..................................................7-8

4-1 Cable carrier type............................................................................. 7-8

4-1-1 Example of wiring and piping methods using cable carrier ............. 7-8

4-1-2 Cable carrier specifications ........................................................... 7-11

4-1-3 User I/O cable specifications .........................................................7-12

5 Periodic Inspections .............................................................7-13

5-1 Replenishing grease to the linear guide......................................... 7-13

5-2 Replenishing grease to the ball screw ........................................... 7-14

CHAPTER 8 SXYX

1 Installation ..............................................................................8-1

1-1 Installation bolt types ....................................................................... 8-1

1-2 Installation bolt nominal length......................................................... 8-1

1-3 Tightening torque ............................................................................. 8-2

1-4 Installation methods ......................................................................... 8-2

2 Protective Connections ........................................................... 8-5

2-1 Ground terminal ............................................................................... 8-5

2-2 Ground wire ..................................................................................... 8-6

2-3 Wiring methods ................................................................................ 8-6

3 Installing the Tool .................................................................. 8-11

3-1 Arm type, pole type 2-axis model.................................................... 8-11

3-2 Moving arm type 2-axis model ....................................................... 8-13

3-3 ZF

3-4 RF

3-5 ZS/ZRS (Arm type 3/4-axis option, XZ type 2/3-axis model) ......... 8-16

2-3-1 Arm type with cable carrier ..............................................................8-7

2-3-2 Arm type with whipover cable, moving arm type, pole type ............ 8-9

2-3-3 XZ type .......................................................................................... 8-10

(Arm type, moving arm type, 3rd-axis option/XZ type 2-axis model) .........

(Arm type, moving arm type, 4th-axis option/XZ type 3rd-axis option) .....

8-14

8-15

Page 6

3-6 ZFH (Arm type, gantry type, moving arm type 3rd-axis option)

3-7 ZFL

4 User Wiring and User Piping ................................................8-19

4-1 Cable carrier type........................................................................... 8-19

4-2 Whipover cable type ...................................................................... 8-24

5 Periodic inspections .............................................................. 8-26

5-1 Replenishing grease to the linear guide......................................... 8-26

5-2 Replenishing grease to the ball screw ........................................... 8-27

5-3 Periodic inspection of the ZS/ZRS unit .......................................... 8-29

CHAPTER 9 MXYX

XZ 2nd-axis option ......................................................................... 8-17

(Arm type, moving arm type, 3rd-axis option/XZ type 2-axis model) ...

4-1-1 Example of wiring and piping methods using cable carrier ........... 8-19

4-1-2 Cable carrier specifications ........................................................... 8-22

4-1-3 User I/O cable specifications .........................................................8-23

4-2-1 Examples of wiring and piping with whipover cable ...................... 8-24

5-3-1 Replenishing grease to the Z-axis ball screw and ball spline ........8-29

5-3-2 Adjusting the R-axis belt tension (ZRS) ........................................ 8-30

5-3-3 Replacing the R-axis harmonic drive (ZRS) .................................. 8-31

8-18

1 Installation ..............................................................................9-1

1-1 Installation bolt types ....................................................................... 9-1

1-2 Installation bolt nominal length......................................................... 9-1

1-3 Tightening torque ............................................................................. 9-1

1-4 Installation methods

(Arm type, moving arm type, pole type, gantry type X-axis) ............ 9-2

1-5 Installation methods (Gantry type support axis)............................... 9-4

2 Protective Connections ........................................................... 9-5

2-1 Ground terminal ............................................................................... 9-5

2-2 Ground wire ..................................................................................... 9-5

2-3 Wiring methods ................................................................................ 9-6

3 Installing the Tool ....................................................................9-7

3-1 Arm type, pole type 2-axis model..................................................... 9-7

3-2 Moving arm type 2-axis model ......................................................... 9-9

3-3 ZF

(Arm type, moving arm type, gantry type 3rd-axis option) ............. 9-10

3-4 RF

(Arm type, moving arm type, 4th-axis option/XZ type 3rd-axis option) ...

3-5 ZFH (Arm type, gantry type, moving arm type 3rd-axis option)

XZ 2nd-axis option ......................................................................... 9-12

3-6 ZFL

(Arm type, moving arm type, 3rd-axis option/XZ type 2-axis model) ...

9-11

9-13

Page 7

4 User Wiring and User Piping ................................................9-14

4-1 Cable carrier type........................................................................... 9-14

4-2 Whipover cable type ...................................................................... 9-19

5 Periodic Inspections .............................................................9-21

5-1 Replenishing grease to the linear guide......................................... 9-21

5-2 Replenishing grease to the ball screw ........................................... 9-22

CHAPTER 10 HXYX

1 Installation ............................................................................10-1

1-1 Installation method 1

1-2 Installation method 2 (XZ type) ...................................................... 10-4

1-3 Installation method 3 (Gantry type support axis) ........................... 10-6

4-1-1 Example of wiring and piping methods using cable carrier ........... 9-14

4-1-2 Cable carrier specifications ........................................................... 9-17

4-1-3 User I/O cable specifications .........................................................9-18

4-2-1 Examples of wiring and piping with Whipover cable ..................... 9-19

(Arm type, moving arm type, pole type, gantry type X-axis) .......... 10-1

1-1-1 Installation bolt types .....................................................................10-1

1-1-2 Installation bolt nominal length ...................................................... 10-1

1-1-3 Tightening torque........................................................................... 10-2

1-1-4 Installation methods ...................................................................... 10-2

1-2-1 Installation bolt .............................................................................. 10-4

1-2-2 Installation bolt nominal length ...................................................... 10-4

1-2-3 Tightening torque........................................................................... 10-5

1-2-4 Installation methods ...................................................................... 10-5

2 Protective Connections ......................................................... 10-7

2-1 Ground terminal ............................................................................. 10-7

2-2 Ground wire ................................................................................... 10-8

2-3 Wiring methods .............................................................................. 10-8

3 Installing the Tool ................................................................10-10

3-1 Arm type, gantry type 2-axis model .............................................. 10-11

3-2 Moving arm type 2-axis model ..................................................... 10-12

3-3 Pole type 2-axis model................................................................. 10-13

3-4 ZH

(Arm type, gantry type, moving arm type 3rd-axis option/XZ type 2-axis model) ....

3-5 ZL

(Arm type, gantry type, moving arm type 3rd-axis option/XZ type 2-axis model) ....

3-6 ZPH (Pole type 3rd-axis option) ................................................... 10-16

3-7 RH

(Arm type, moving arm type, gantry type 4th-axis option/XZ type 3rd-axis option) .....

10-14

10-15

10-17

4 User Wiring and User Piping ..............................................10-18

4-1 Cable carrier type......................................................................... 10-18

4-1-1 Example of wiring and piping methods using cable carrier ......... 10-18

4-1-2 Cable carrier specifications ......................................................... 10-20

4-1-3 User I/O cable specifications .......................................................10-21

4-2 Whipover cable type .................................................................... 10-22

4-2-1 Examples of wiring and piping with Whipover cable ................... 10-22

Page 8

5 Periodic Inspections ...........................................................10-24

5-1 Replenishing grease to the linear guide....................................... 10-24

5-2 Replenishing grease to the ball screw ......................................... 10-25

CHAPTER 11 FXYBX/SXYBX

1 Installation ............................................................................ 11-1

1-1 Installation bolt types ...................................................................... 11-1

1-2 Installation bolt nominal length........................................................ 11-1

1-3 Tightening torque ............................................................................ 11-2

1-4 Installation methods ........................................................................11-2

2 Protective connections ......................................................... 11-3

2-1 Ground terminal .............................................................................. 11-3

2-2 Ground wire .................................................................................... 11-4

2-3 Wiring methods (Cable carrier type) ............................................... 11-4

2-4 Wiring methods (Whipover cable type) ...........................................11-6

3 Installing the Tool .................................................................. 11-7

3-1 FXYBX arm type 2-axis model ........................................................ 11-7

3-2 SXYBX arm type 2-axis model........................................................ 11-8

3-3 SXYBX-ZF (XZ type 2-axis, arm type 3rd-axis option) ................... 11-9

3-4 ZS/ZRS (FXYBX, SXYBX 3/4-axis option).................................... 11-10

3-5 ZFH (Arm type, gantry type, moving arm type 3rd-axis option)

XZ 2nd-axis option ........................................................................ 11-11

3-6 ZFL

(Arm type, moving arm type, 3rd-axis option/XZ type 2-axis model) ...

11-12

4 User Wiring and User Piping .............................................. 11-13

4-1 Cable carrier type.......................................................................... 11-13

4-1-1 Example of wiring and piping methods using cable carrier ......... 11-13

4-1-2 Cable carrier specifications ......................................................... 11-15

4-1-3 User I/O cable specifications ....................................................... 11-16

4-2 Whipover cable type ..................................................................... 11-16

4-2-1 Examples of wiring and piping with Whipover cable ................... 11-17

5 Changing the Motor Installation Position ............................ 11-19

5-1 Changing the motor installation position .......................................11-19

6 Installing the Cover ............................................................. 11-21

7 Adjusting the Timing Belt Tension ....................................... 11-22

7-1 Adjusting the drive belt tension .....................................................11-23

7-2 Adjusting the speed reduction belt tension ................................... 11-25

8 Periodic inspections ............................................................ 11-27

8-1 Replacing the motor ...................................................................... 11-27

8-2 Replacing the drive belt ................................................................ 11-28

8-3 Replacing the speed reduction belt............................................... 11-31

8-4 Replacing the slider ...................................................................... 11-32

8-5 Replenishing the grease ............................................................... 11-33

8-5-1 Replenishing grease to the linear guide ...................................... 11-33

8-5-2 Replenishing grease to the ball screw (ZF) ................................. 11-35

Page 9

8-6 Periodic inspection of the ZS/ZRS unit ......................................... 11-36

CHAPTER 12 HXYLX

1 Installation ............................................................................12-1

1-1 Installation method 1

1-2 Installation method 3 (Gantry type support axis) ........................... 12-5

2 Protective Connections ......................................................... 12-6

2-1 Ground terminal ............................................................................. 12-6

2-2 Ground wire ................................................................................... 12-7

2-3 Wiring methods .............................................................................. 12-7

3 Installing the Tool ..................................................................12-8

3-1 Arm type, gantry type 2-axis model ............................................... 12-8

3-2 Moving arm type 2-axis model ....................................................... 12-9

3-3 Pole type 2-axis model................................................................. 12-10

3-4 ZH

3-5 ZL (Arm type, gantry type) ........................................................... 12-12

3-6 ZPH (Pole type 3rd-axis option) ................................................... 12-13

3-7 RH (Arm type, gantry type 4th-axis option) .................................. 12-14

8-6-1 Replenishing grease to the Z-axis ball screw and ball spline ...... 11-36

8-6-2 Adjusting the R-axis belt tension (ZRS) ...................................... 11-37

8-6-3 Replacing the R-axis harmonic drive (ZRS) ................................ 11-38

(Arm type, moving arm type, pole type, gantry type X-axis) .......... 12-1

1-1-1 Installation bolt types .....................................................................12-1

1-1-2 Installation bolt nominal length ...................................................... 12-1

1-1-3 Tightening torque........................................................................... 12-2

1-1-4 Installation methods ...................................................................... 12-2

(Arm type, gantry type, moving arm type 3rd-axis option) ............ 12-11

4 User Wiring and User Piping ..............................................12-15

4-1 Cable carrier type......................................................................... 12-15

4-1-1 Example of wiring and piping methods using cable carrier ......... 12-15

4-1-2 Cable carrier specifications ......................................................... 12-17

4-1-3 User I/O cable specifications .......................................................12-18

4-2 Whipover cable type (moving arm type/pole type 3-axis) ............ 12-19

4-2-1 Examples of wiring and piping with Whipover cable ................... 12-19

5 Periodic Inspections ...........................................................12-21

5-1 Replenishing grease to the linear guide....................................... 12-21

5-2 Replenishing grease to the ball screw ......................................... 12-22

5-3 Adjusting the timing belt tension (X-axis) ..................................... 12-24

5-4 Replacing the motor (X-axis) ....................................................... 12-25

5-5 Installing and removing the cover ................................................ 12-27

5-5-1 Stroke cover ................................................................................ 12-27

5-5-2 Belt cover .................................................................................... 12-28

5-5-3 Motor cover ................................................................................. 12-29

Page 10

MEMO

Page 11

CHAPTER 1

Using the Robot Safely

1 Safety Information ..................................................................1-1

2 Essential Caution Items ..........................................................1-2

3 Special Training for Industrial Robot Operation ......................1-9

4 Robot Safety Functions ........................................................1-10

5 Safety Measures for the System .......................................... 1-11

6 Trial Run ...............................................................................1-12

7 Work Within the Safeguard Enclosure .................................. 1-13

8 Automatic Operation .............................................................1-14

9 Adjustment and Inspection ...................................................1-14

10 Repair and Modification ........................................................1-14

11 Warranty ...............................................................................1-15

12 CE Marking ...........................................................................1-16

Page 12

MEMO

Page 13

1 Safety Information

Industrial robots are highly programmable machines that provide a large degree

of freedom in movement. To ensure correct and safe use of YAMAHA robots,

carefully read this manual to make yourself well acquainted with the contents.

FOLLOW THE WARNINGS, CAUTIONS AND INSTRUCTIONS INCLUDED

IN THIS MANUAL. Failure to take necessary safety measures or mishandling

due to not observing the instructions in this manual may result in trouble or damage to the robot and injury to personnel (robot installer, operator or service personnel) including fatal accidents.

Warning information in this manual is classified into the following items.

DANGER

Failure to follow DANGER instructions will result in severe injury or death

to the robot operator, bystanders or persons servicing the robot.

Chapter 1 Using the Robot Safely

WARNING

Failure to follow WARNING instructions could result in severe injury or

death to the robot operator, bystanders or persons servicing the robot.

!

CAUTION

Failure to follow CAUTION instructions may result in injury to the robot operator, bystanders or persons servicing the robot, or damage to the robot and/or

robot controller.

NOTE

Explains the keypoint in the operation in a simple and clear manner.

Refer to the instruction manual by any of the following methods to operate or

adjust the robot safely and correctly.

1. Operate or adjust the robot while referring to the printed version of the instruction manual (available for an additional fee).

2. Operate or adjust the robot while viewing the CD-ROM version of the instruction manual on your computer screen.

3. Operate or adjust the robot while referring to a printout of the necessary

pages from the CD-ROM version of the instruction manual.

It is not possible to list all safety items in detail within the limited space of this

manual. Thus, it is essential that the user have full knowledge of basic safety

rules and that the operator makes correct judgments on safety procedures during

operation.

When exporting this robot, the warning labels and instruction manuals must be

changed to export specifications.

1-1

Page 14

Chapter 1 Using the Robot Safely

2 Essential Caution Items

Particularly important cautions for handling or operating the robot are described

below. In addition, safety information about installation, operation, inspection

and maintenance is provided in each chapter. Be sure to comply with these instructions to ensure safe use of the robot.

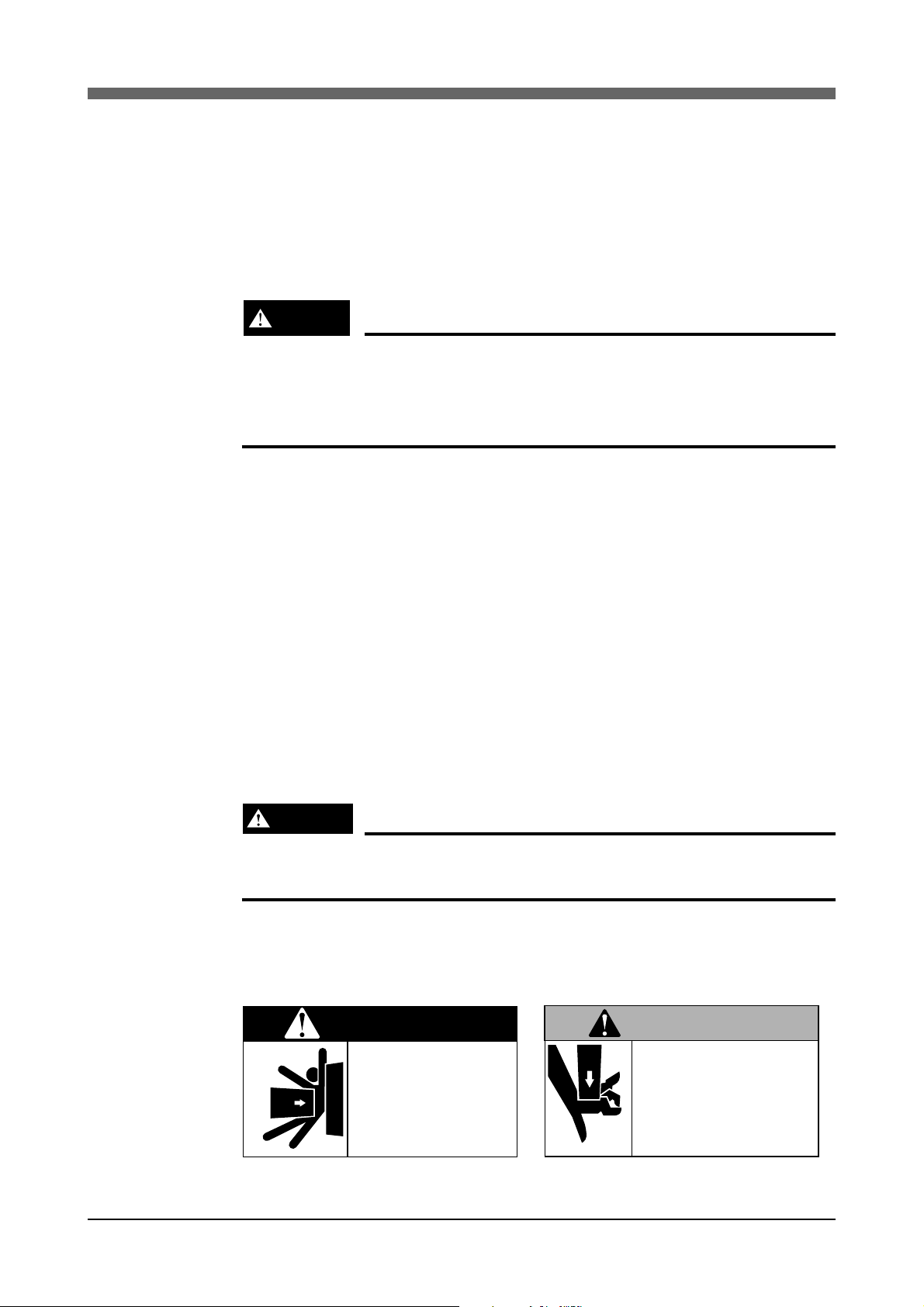

(1) Observe the following cautions during automatic operation

DANGER

Serious injury will result from impact with moving robot.

• Keep outside safeguard enclosure during automatic operation.

• Press the emergency stop button before entering the safeguard enclosure.

The warning label 1 (Fig. 1-1) is attached to the robot.

• Install a safeguard enclosure to keep all personnel from entering within the

movable range of the robot and suffering injury due to being struck by

moving parts.

• Install a safety interlock that triggers emergency stop when the door or

panel is opened.

• Install safeguards so that no one can enter inside except from doors or

panels equipped with safety interlocks.

• The warning label 1 (Fig. 1-1) are supplied with the robot and should be

affixed to conspicuous places on doors or panels equipped with safety interlocks.

(2) Use caution to prevent hands or fingers from being pinched or

crushed.

WARNING

Moving parts can pinch or crush.

Keep hands always from robot arms.

Warning label 2 (Fig. 1-2) is affixed to the robot.

Use caution to prevent hands or fingers from being pinched or crushed in the

robot’s moving parts during transporting the robot or teaching, etc.

DANGER

Serious injury or death

will result from impact

with moving robot.

• Keep outside of guard

during operation.

• Lock out power before

approaching robot.

WARNING

Moving parts can

pinch or crush.

Keep hands away

from robot arms.

Fig. 1-1 Warning label 1 Fig. 1-2 Warning label 2

1-2

Page 15

Chapter 1 Using the Robot Safely

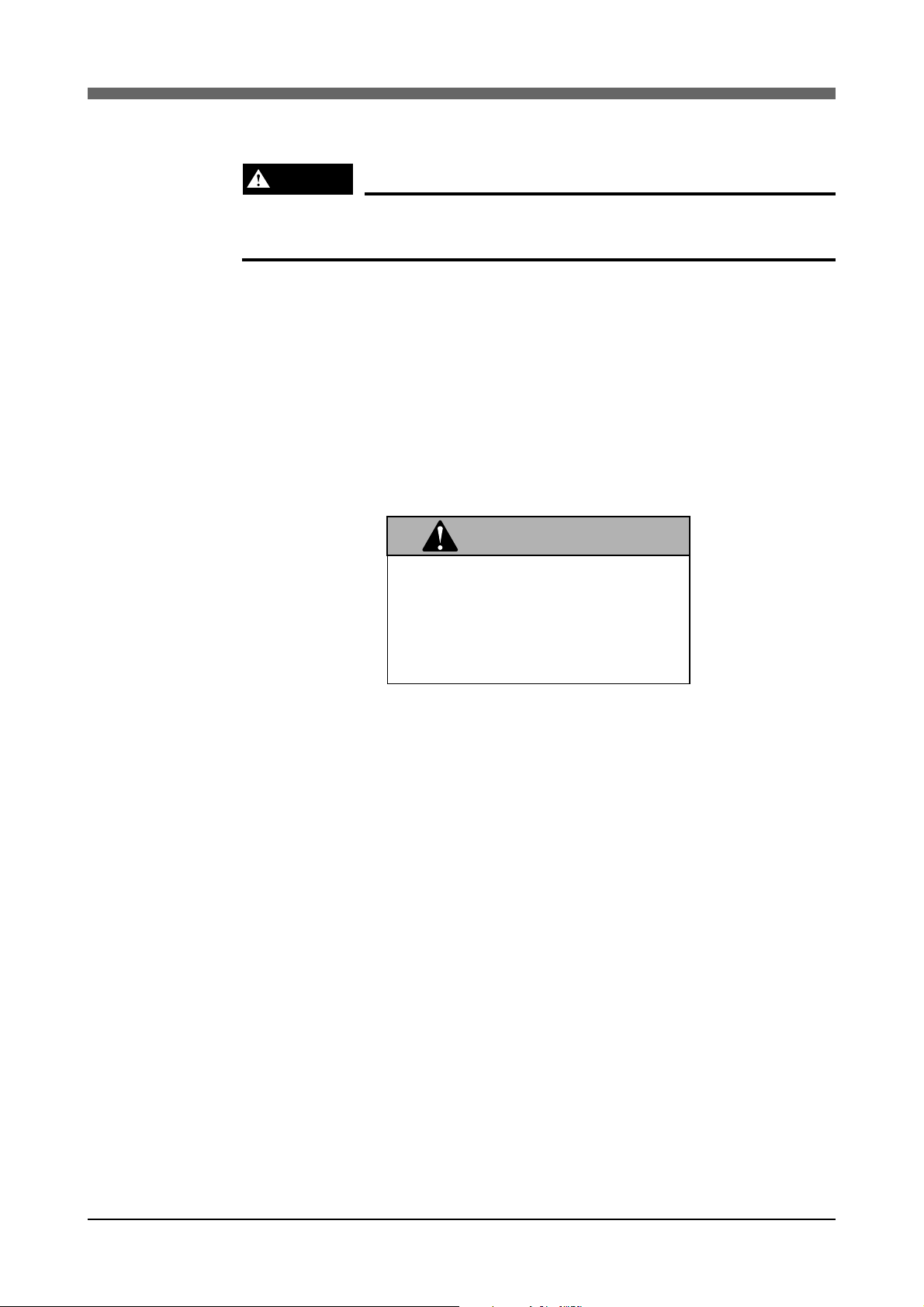

(3) Follow the instructions listed on warning labels and in this

manual.

WARNING

Improper installation or operation can result in serious injury. Read the

Instruction Manual and all warning labels before operation.

The warning label 3 (Fig. 1-3) is attached to the robot.

• Be sure to read the warning labels and this manual carefully and make sure

to thoroughly understand the contents before attempting installation and

operation of the robot.

• Before starting robot operation, be sure to reread the procedures and cautions related to the work as well as the descriptions in this chapter (Chapter

1. “Using the Robot Safely”).

• Never install, adjust, inspect, service or operate the robot in any manner

that does not comply with the instructions in this manual.

WARNING

Improper Installation or operation

can result in serious injury or

death.

Read owner's manual and all

warning labels before operation.

Fig. 1-3 Warning label 3

1-3

Page 16

Chapter 1 Using the Robot Safely

(4) Do not use the robot in environments containing inflammable

gas, etc.

WARNING

• This robot is not designed for operation in environments where inflammable of explosive substances are present.

• Do not use the robot in environments containing inflammable gas,

dust or liquids.

Explosions or fire might otherwise result.

(5) Do not use the robot in locations possible subject to electro-

magnetic interference, etc.

WARNING

Avoid using the robot in locations subject to electromagnetic interference, electrostatic discharge or radio frequency interference.

Malfunctions might otherwise occur.

(6) Use caution when releasing the brake for the Z-axis (vertical axis).

WARNING

The Z-axis will drop when the brake is released, creating a hazardous

situation.

• Press the emergency stop button and prop up the Z-axis with a support

stand, etc., before releasing the brake.

• Be careful not to let your body get caught between the Z-axis and installation base, etc., when releasing the brake to perform direct teaching.

(7) Provide safety measures for end effector (gripper, etc.)

WARNING

• End effectors must be designed and manufactured so that they create

no hazards (for example, a workpiece that comes loose) even if power

(electricity, air pressure, etc.) is shut off or a power fluctuation occurs.

• If there is a possible danger that the object gripped by the end effector

may fly off or drop, then provide appropriate safety protection taking

into account the object size, weight, temperature and chemical properties.

1-4

Page 17

Chapter 1 Using the Robot Safely

(8) Movement of Z-axis at controller power shut off and emergency

stop (for ZAS)

WARNING

The Z-axis will start to rise when the controller power is shut off, the PLC

power is shut off, the program is reset, emergency stop is applied, and

when the supply of air to the Z-axis air cylinder’s solenoid valve is started.

• Take care not to pinch or crush hands, etc., in the Z-axis moving sections.

• If there are any interferences in the Z-axis' upward travel path, reevaluate

the robot position, except for emergencies.

(9) Pay attention to interference of Z-axis with peripheral devices

(for ZAS)

WARNING

If the Z-axis interferes with a peripheral device and stops, there is a risk of

pinching hands, etc., when the interfering object is removed as the Z-axis

will suddenly move.

• Turn the controller power OFF and stop the air supply before removing

the interfering object.

• The Z-axis will naturally drop, so prop it up with a support stand, etc.,

before stopping the air supply.

(10)Z-axis movement when air supply is stopped

WARNING

The Z-axis will drop when the air supply is stopped, creating a hazardous

situation.

Prop up the Z-axis with a support stand, etc., before turning the controller

power OFF and stopping the air supply.

(11) Use caution when disassembling and replacing the pneumatic

devices

WARNING

If the pneumatic devices are disassembled or replaced while the air is

supplied, the parts or air could scatter.

• Turn the controller power OFF, stop the air supply and release all residual pressure from the pneumatic devices before starting work.

• The Z-axis will naturally drop, so prop it up with a support stand, etc.,

before stopping the air supply.

1-5

Page 18

Chapter 1 Using the Robot Safely

(12)Use caution when disassembling and replacing the motor

WARNING

When disassembling or assembling the motor for a ball-screw drive type

robot, a strong magnetic attraction force will be present between the motor

stator (fixed coil) and rotor (rotating magnet), causing a risk of pinching

hands, etc.

A YAMAHA-trained operator must carry out this work using the YAMAHArecommended jigs.

(13)Use caution when removing the Z-axis brake

WARNING

The Z-axis will naturally drop when the brake is removed, causing a hazardous situation.

• Prop up the Z-axis with a support stand, etc., before turning the control

power OFF and removing the brake.

• Be careful not to let your body get caught between the Z-axis drive

section and Z-axis installation base, etc.

(14)Take the following safety precautions during inspection of the

controller

WARNING

• If the terminals or connectors on the outside of the controller must be

touched during inspection, etc., always first turn the controller power

OFF and the power source to prevent possible electrical shock.

• Refer to the "YAMAHA Robot Controller Instruction Manual" for precautions on handling the controller. Never touch any internal parts of

the controller.

(15)Consult YAMAHA for corrective action when the robot is dam-

aged or malfunctions occur.

WARNING

If any part of the robot is damaged or any malfunction occurs, continuing

the operation may be very dangerous. Please consult your YAMAHA sales

office or dealer for corrective action.

Damage or Trouble Possible Danger

Damage to machine harness or robot cable Electrical shock, malfunction of robot

Damage to exterior of robot Flying outward of damaged parts during

robot operation

Abnormal operation of robot (positioning error,

excessive vibration, etc.)

Z-axis brake trouble

1-6

Malfunction of robot

Dropping of load

Page 19

Chapter 1 Using the Robot Safely

(16)Use caution not to touch the controller rear panel cooling fan

WARNING

• Injury may occur from coming into contact with the cooling fan while it

is rotating.

• When removing the fan cover for inspection, first turn OFF the controller and make sure that the fan has stopped.

(17)Be careful not to touch the motor or speed reduction gear cas-

ing when hot.

WARNING

The motor and speed reduction gear casing are extremely hot after automatic operation, so burns may occur if these are touched.

• Before handling these parts during inspection or servicing, turn the

controller power OFF, wait for a while and check that the part has cooled.

(18)Do not remove, alter or stain the warning labels

WARNING

If the warning labels are removed or difficult to see, then essential precautions might not be taken resulting in accidents.

• Do not remove, alter or stain the warning labels on the robot.

• Do not allow the warning labels to be hidden by devices installed onto

the robot by the user.

• Provide proper lighting so that the symbols and instructions on the

warning labels can be clearly seen even from outside the safeguard

enclosure.

(19)Protective connections

WARNING

Be sure to ground the robot and controller to prevent electrical shock.

(20)Be sure to make correct parameter settings - Part 1

!

CAUTION

Always input the correct parameters matching the payload and stroke (working

envelope) before operating the robot.

1-7

Page 20

Chapter 1 Using the Robot Safely

(21)Be sure to make correct parameter settings - Part 2

!

CAUTION

When using a rotary axis (RF, RH, etc.) the robot must be operated with the

tolerable moment of inertia and correct acceleration coefficients according to

the tip mass and moment of inertia. If these are not correct, the drive unit service life may end prematurely, and damage to robot parts or residual vibration

during positioning may result.

(22) Do not use the robot for tasks requiring motor thrust.

!

CAUTION

Avoid using the belt-driven type robots for tasks that utilize motor thrust (press

fitting, burr removal, etc.).

These tasks may cause malfunctions in the robot.

1-8

Page 21

Chapter 1 Using the Robot Safely

3

Special Training for Industrial Robot Operation

Companies or factories using industrial robots must make sure that every person,

who handles the robot such as for teaching, programming, movement check, inspection, adjustment and repair, has received appropriate training and also has

the skills needed to perform the job correctly and safely.

Since YAMAHA Cartesian Robot XY Series falls under the industrial robot category, the user must observe local regulations and safety standards for industrial

robots, and provide special training for every person involved in robot-related

tasks (teaching, programming, movement check, inspection, adjustment, repair,

etc.).

1-9

Page 22

Chapter 1 Using the Robot Safely

4 Robot Safety Functions

(1) Overload detection

This function detects an overload applied to the motor and shuts off the servo

power.

(2) Overheat detection

This detects an abnormal rise in the controller driver temperature and shuts

off the servo power.

If an overload or overheat error occurs, take the following measuring.

1. Insert a timer in the program.

2. Reduce the acceleration coefficient.

(3) Soft limits

Soft limits can be set on each axis to limit the working envelope in manual

operation after return-to-origin and during automatic operation. Note that

the working envelope is the area limited by soft limits.

(4) Mechanical stoppers

If the servo power is suddenly shut off during high-speed operation by emergency stop or safety functions, these mechanical stoppers prevent the axis

from exceeding the movable range.

No mechanical stopper is provided on the R-axis.

Note that the movable range is the area limited by the mechanical stoppers.

(5) Z-axis (vertical axis) brake

An electromagnetic brake is installed on the Z-axis to prevent the Z-axis

from dropping when the servo power is shut off. This brake is working when

the controller power is OFF or if the Z-axis servo is OFF even when the

controller power is ON.

The Z-axis brake can be released by means of the programming unit or by a

command in the program when the controller power is ON.

WARNING

The Z-axis will drop when the brakes are released, creating a hazardous

situation.

• Press the emergency stop button and prop up the Z-axis with a support

stand, etc., before releasing the brake.

• Be careful not to let your body get caught between the Z-axis and installation base, etc., when releasing the brake to perform direct teaching.

1-10

Page 23

Chapter 1 Using the Robot Safely

5 Safety Measures for the System

When the robot is commonly used in conjunction with an automated system,

dangerous situations are more likely to occur from the automated system than

from the robot itself. Appropriate safety measures must be taken on the part of

the system manufacturer according to the individual system.

The system manufacture should provide a proper instruction manual for safe,

correct operation and servicing of the system.

1-11

Page 24

Chapter 1 Using the Robot Safely

6 Trial Run

After making installations, adjustments, inspections, maintenance or repairs to

the robot, carry out trial run using the following procedures.

(1) If a safeguard enclosure has not yet been provided right after installa-

tion of the robot, rope off or chain off the movable range in place of

the safeguard enclosure, and observe the following points.

1. Use sturdy, stable posts that will not fall over easily.

2. The rope or chain should be easily visible by everyone around the robot.

3. Place a sign to keep the operator or other personnel from entering the

movable range.

(2) Check the following points before turning the controller ON.

1. Is the robot securely and correctly installed?

2. Are the electrical connections to the robot correct?

3. Are items such as air pressure correctly supplied?

4. Is the robot correctly connected to peripheral devices?

5. Have safety measures (safeguard enclosure, etc.) been taken?

6. Does the installation environment meet the specified standards?

(3) After the controller power is turned ON, check the following points

from outside the safeguard enclosure.

1. Does the robot start and stop as intended? Can the operation mode be

selected correctly?

2. Does each axis move as intended within the soft limits?

3. Does the end effector move as intended?

4. Are the signal transmissions to the end effector and peripheral devices

correct?

5. Does emergency stop work?

6. Are the teaching and playback functions normal?

7. Are the safeguard enclosure and interlock working as intended?

8. Does the robot move correctly during automatic operation?

1-12

Page 25

Chapter 1 Using the Robot Safely

7 Work Within the Safeguard Enclosure

(1) When work is required in the safeguard enclosure, always turn the

controller power OFF and place a sign indicating that the robot is

being adjusted or serviced in order to keep any other personnel from

touching the controller power switch or operation panel, except for

the following cases.

1) Soft limit settings

2) Teaching

For item 1), follow the precautions and procedure for each section.

To perform item 2), refer to the description in (2) below.

(2) Teaching

When performing teaching within the safeguard enclosure, comply with the

instructions listed below.

1) Check or perform the following points from outside the safeguard enclosure.

1. Make sure that no hazards are present within the safeguard enclosure

by a visual check.

2. Check that the programming unit MPB or TPB operates correctly.

3. Check that no failures are found in the robot.

4. Check that emergency stop works correctly.

5. Select teaching mode and prohibit automatic operation.

2) Never enter the movable range of the robot while within the safeguard

enclosure.

1-13

Page 26

Chapter 1 Using the Robot Safely

8 Automatic Operation

(1) Check the following before starting automatic operation.

1. No one is within the safeguard enclosure.

2. The programming unit or tools, etc., are in their specified location.

3. The alarm or error lamps, etc., on the robot and peripheral devices do not

flash.

4. The safeguard enclosure is securely installed with safety interlocks, etc.,

actuated.

(2) Observe the following during automatic operation or in cases where

an error occurs.

1) After automatic operation has started, check the operation status and warning lamps to ensure that the robot is in automatic operation.

2) Never enter the safeguard enclosure during automatic operation.

3) If an error occurs in the robot or peripheral devices, observe the following

procedures before entering the safeguard enclosure.

1. Press the emergency stop button to set the robot to emergency stop.

2. Place a sign on the start switch indicating that the robot is being in-

spected in order to keep any other person from touching the start switch

and restarting the robot.

9 Adjustment and Inspection

WARNING

Do not attempt any installation, adjustment, inspection or maintenance

unless described in this manual. Unexpected accidents or troubles may

otherwise result.

10 Repair and Modification

WARNING

Do not attempt any repair, part replacement or modification unless described in this manual. These matters require technical knowledge and

skills, and may also involve work hazards.

1-14

Page 27

11 Warranty

The YAMAHA robot and/or related product you have purchased are warranted

against the defects or malfunctions as described below.

Warranty description : If a failure or breakdown occurs due to defects

Warranty Period :The warranty period ends when any of the fol-

Chapter 1 Using the Robot Safely

in materials or workmanship in the genuine parts

constituting this YAMAHA robot and/or related

product within the warranty period, then

YAMAHA will repair or replace those parts free

of charge (hereafter called "warranty repair").

lowing applies:

1) After 18 months (one and a half year) have

elapsed from the date of shipment

2) After one year has elapsed from the date of

installation

3) After 2,400 hours of operation

Exceptions to the Warranty

Failures resulting from the following causes are not covered by warranty repair.

1) Damage due to earthquakes, storms, floods, thunderbolt, fire or any other

natural or man-made disasters.

2) Troubles caused by procedures prohibited in this manual.

: This warranty will not apply in the following

cases

1) Fatigue arising due to the passage of time,

natural wear and tear occurring during operation (natural fading of painted or plated

surfaces, deterioration of parts subject to

wear, etc.)

2) Minor natural phenomena that do not affect

the capabilities of the robot and/or related

product (noise from computers, motors, etc.).

3) Programs, point data and other internal data

that were changed or created by the user.

3) Modifications to the robot and/or related product not approved by

YAMAHA or YAMAHA sales representatives.

4) Use of any other than genuine parts and specified grease and lubricants.

5) Incorrect or inadequate maintenance and inspection.

6) Repairs by other than authorized dealers.

1-15

Page 28

Chapter 1 Using the Robot Safely

YAMAHA MOTOR CO., LTD. MAKES NO OTHER EXPRESS OR IMPLIED

WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

THE WARRANTY SET FORTH ABOVE IS EXCLUSIVE AND IS IN LIEU

OF ALL EXPRESSED OR IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE,

OR WARRANTIES ARISING FROM A COURSE OF DEALING OR USAGE

OF TRADE.

YAMAHA MOTOR CO., LTD. SOLE LIABILITY SHALL BE FOR THE DELIVERY OF THE EQUIPMENT AND YAMAHA MOTOR CO., LTD. SHALL

NOT BE LIABLE FOR ANY CONSEQUENTIAL DAMAGES (WHETHER

ARISING FROM CONTRACT, WARRANTY, NEGLIGENCE OR STRICT

LIABILITY). YAMAHA MOTOR CO., LTD. MAKES NO WARRANTY WHATSOEVER WITH REGARD TO ACCESSORIES OR PARTS NOT SUPPLIED

BY YAMAHA MOTOR CO., LTD.

12 CE Marking

Refer to the following YAMAHA Robot Controller Instruction Manuals for details on the related CE Marking for export to or use in EU regions.

• QRCX-E Instruction Manual

• ERCX/SRCX/DRCX compatible with CE marking supplement manual

1-16

Page 29

CHAPTER 2

Product Outline

1 Robot ......................................................................................2-1

2 Names of each part ................................................................2-2

3 Robot Controller .....................................................................2-7

Page 30

MEMO

Page 31

1 Robot

The robot is configured of the standard function X/Y axes (horizontal cartesian

slide) and optional function Z-axis (vertical slide) and R-axis (rotation).

These configuration axes can move in the following manner. High-accuracy and

high-speed work can be carried out over a wide range by installing work tools.

(+) and (-) indicate the jog key movement directions. (Default settings)

Chapter 2 Product Outline

Y-axis arm movement

Z-axis (vertical)

(-)

(-)

(+)

(+)

R-axis (rotation)

(-)

(+)

(+)

(-)

X-axis arm movement

Robot movements (with ZR axes)

2-1

Page 32

Chapter 2 Product Outline

2 Names of each part

■ Arm type with cable carrier

Y-axis

Y-axis stroke cover

Frame bracket

X-axis motor

Robot cable

Y-axis wiring box

Y-axis motor

Cable carrier between XY

(The machine harness between XY

is wired inside)

X-axis slider

X-axis wiring box

■ Arm type with whipover cable

Y-axis

Y-axis stroke cover

X-axis stroke cover

X-axis

Y-axis slider (tool installation section)

Frame bracket

X-axis motor

Robot cable

X-axis wiring box

Y-axis motor

whipover cable between XY

X-axis slider

X-axis stroke cover

X-axis

Y-axis wiring box

Y-axis slider

(tool installation section)

2-2

Page 33

■ Gantry type

Chapter 2 Product Outline

Support axis

installation bracket

X-axis motor

Robot cable

Y-axis wiring box

Frame bracket

Support axis

Y-axis

Y-axis stroke cover

Y-axis motor

Cable carrier between XY

(The machine harness between XY

is wired inside)

X-axis stroke cover

X-axis

Y-axis slider (tool installation section)

X-axis wiring box

X-axis slider

2-3

Page 34

Chapter 2 Product Outline

■ Moving arm type (with cable carrier)

Y-axis wiring box

Y-axis wiring box

Cable carrier between XY

(The machine harness between XY is wired inside)

X-axis stroke cover

X-axis

X-axis slider

X-axis wiring box

X-axis motor

■ Moving arm type (with whipover cable)

Y-axis whipover cable

Y-axis bracket

(tool installation section)

Y-axis

Y-axis stroke cover

Y-axis motor

Y-axis wiring box

X-axis wiring box

X-axis motor

X-axis slider

X-axis stroke cover

X-axis

Y-axis motor

whipover cable

between XY

Y-axis bracket

(tool installation section)

Y-axis stroke cover

Y-axis

2-4

Page 35

■

Pole

-type with cable carrier

Chapter 2 Product Outline

Y-axis motor

Y-axis slider

(tool installation section)

Y-axis stroke cover

■

Y-axis

Robot cable

Pole

-type with whipover cable

Y-axis relay harness

Y-axis wiring box

Cable carrier between XY

(The machine harness between XY is wired inside)

X-axis stroke cover

X-axis

X-axis slider

X-axis wiring box

X-axis motor

Independent cable

between XY

Robot cable

X-axis wiring box

X-axis motor

X-axis slider

Y-axis slider

(tool installation section)

X-axis stroke cover

Y-axis motor

Y-axis

X-axis

2-5

Page 36

Chapter 2 Product Outline

■ XZ-type with cable carrier

Cable carrier between XY

(The machine harness between XZ

is wired inside)

Z-axis

Z-axis wiring box

Z-axis motor

X-axis wiring box

Robot cable

X-axis

X-axis motor

■ XZ-type with whipover cable

Z-axis slider

Z-axis cover stroke

X-axis stroke cover

whipover cable between XY

X-axis wiring box

Robot cable

X-axis

X-axis motor

Z-axis

Z-axis motor

Z-axis slider

X-axis stroke cover

2-6

Page 37

3 Robot Controller

A RCX40, QRCX, TRCX or DRCX Series robot controller is enclosed with the

XY-X Series according to the user’s order.

Refer to the separate “YAMAHA Robot Controller Instruction Manual” for details on the robot controller.

Chapter 2 Product Outline

DRCX

P

O

W

E

R

C

P

U

O

K

S

E

R

V

O

A

L

A

R

M

QRCX

TRCX

MOTOR

PWR

SRV

XM

ERR

ROB

I/O

XY

YM

ROB

I/O

ZR

ZM

SAFETY

RM

MPB

COM

STD.DIO

OP.1 OP.3

OP.2 OP.4

RCX40

BATT

X

Y

Z

R

RGEN

P

N

ACIN

L

N

RCX40

Robot Controller

2-7

Page 38

MEMO

2-8

Page 39

CHAPTER 3

Preparing the Robot

1 Robot Installation Environment ............................................... 3-1

2 Unpacking the Robot ..............................................................3-2

3 Checking the Product .............................................................3-3

4 Transporting the Robot ...........................................................3-5

5 Installation ..............................................................................3-7

5-1 Installation base ............................................................................... 3-7

5-2 Installing the Robot .......................................................................... 3-8

6 Protective connections ...........................................................3-9

7 Connecting the Robot Cables ............................................... 3-10

7-1 Connecting with the DRCX controller ............................................ 3-12

7-2 Connecting with the TRCX controller ............................................. 3-14

7-2-1 3-axis model .................................................................................. 3-14

7-2-2 4-axis model .................................................................................. 3-16

7-3 Connecting to the QRCX or RCX40 controller ............................... 3-18

8 Installing the Tool ..................................................................3-20

9 User Wiring and User Piping ................................................3-21

10 Setting the Robot ..................................................................3-22

10-1 Setting the payload ........................................................................ 3-22

10-2 Setting the maximum speed .......................................................... 3-23

10-3 Setting the acceleration ................................................................. 3-24

11 Absolute Reset .....................................................................3-25

Page 40

MEMO

Page 41

Chapter 3 Preparing the Robot

1 Robot Installation Environment

WARNING

Avoid installing the robot in locations where the ambient conditions may

exceed the allowable ambient temperature or relative humidity, or in environments where excessive moisture, corrosive gas, metallic powder or

dust is generated.

Malfunctions, failures or short circuits may otherwise result.

WARNING

• This robot is not designed for operation in environments where inflammable of explosive substances are present.

• Do not use the robot in environments containing inflammable gas, dust

or liquids.

Explosions or fire might otherwise result.

WARNING

Do not use the robot in locations subject to excessive vibration. Robot

installation bolts may otherwise become loose causing the robot to fall

over.

!

CAUTION

Avoid using the robot in locations subject to electromagnetic interference, electrostatic discharge or radio frequency interference.

Malfunctions might otherwise occur.

Always install the robot in the following type of environment.

Item Specifications

Allowable ambient temperature 0 to 40°C

Allowable ambient relative humidity

Altitude 0 to 1000m above mean sea level

Ambient environment

Vibration

Air supply pressure, etc.

Working space

35 to 80%RH (with no dew condensation)

Avoid installing near water, cutting water, oil, dust,

metallic chips or organic solvent.

Avoid installing near corrosive gas or corrosive materials.

Avoid installing in

dust or fluid.

Avoid installing near objects causing electromagnetic

interference, electrostatic discharge or radio frequency

interference.

Do not subject robot to impact or vibration.

Supply clean dry air, that does not contain deteriorated

compressor oil, etc., at a pressure within 0.58MPa

(6.0kgf/cm2).

The air filter filtering degree must be 40µm or less.

Allow sufficient space so that work (teaching, inspection,

repairs, etc.) can be carried out safely.

atmosphere containing inflammable gas,

Refer to the “YAMAHA Robot Controller Instruction Manual” for details on the

controller installation conditions.

3-1

Page 42

Chapter 3 Preparing the Robot

2 Unpacking the Robot

WARNING

The robot and robot controller are heavy. Take care not to drop these

parts or damage the devices while unpacking the packages.

The packages are divided into the robot (XY-X Series), robot controller (RCX40,

QRCX, TRCX or DRCX Series) and accessories according to the items ordered

by the user.

Carefully unpack the packages while taking care not to damage the devices.

Robot (XY-X Series)

Robot controller

(RCX40, QRCX, TRCX or DRCX Series)

Example of packaging state

3-2

Accessories

Page 43

3 Checking the Product

!

CAUTION

Contact your YAMAHA dealer immediately if any parts are missing or have

been damaged during transportation.

After unpacking, check the state of the components and the product.

An example of the common combination of components is shown below. Check

the products according to the actual order.

Example of combination with RCX40 controller

Chapter 3 Preparing the Robot

ZR-axis unit (option)

I/O connector set for user

OWNER'S MANUAL

RCX40 controller

Robot (XY-X Series)

Robot cable

Controller power connector

Terminator

STD I/O connector

OP DI, OP DO connector

(option)

MPB programming unit (option)

3-3

Warning labels

Page 44

Chapter 3 Preparing the Robot

OWNER'S MANUAL

Example of combination with TRCX controller

Z-axis unit (option)

Robot (XY-X Series)

I/O connector set for user

Robot cable

TRCX controller

TPB programming unit

(option)

Example of combination with DRCX controller

OWNER'S MANUAL

Y

A

M

A

H

A

Y

A

M

A

H

A

M

O

T

O

R

C

O

.

,

L

T

D

I/O connector set for user

Controller power

connector

Terminator

Warning labels

STD I/O connector

OP DI, OP DO connector

(option)

Robot (XY-X Series)

DRCX connector

TPB programming unit

(option)

Robot cable

Controller power

connector

Y

A

M

A

H

A

Y

A

M

A

H

A

M

O

T

O

R

C

O

., L

T

D

I/O connector

Warning labels

3-4

Page 45

4 Transporting the Robot

WARNING

Serious injury may occur if the robot being transported falls and pins

someone under it.

• Use a hoist and rope with transporting capacity strong enough to support the robot weight.

• Make sure the rope stays securely on the hoist hook.

• Remove all loads attached to the robot end. If any load is still attached,

the robot balance may shift while being transported, and the robot may

topple over causing accidents.

• Always wear a safety helmet, safety shoes and gloves during this work.

• When transporting the robot by equipment such as a forklift, which

requires a license, only properly qualified personnel may operate such

equipment. The equipment and tools used for transporting the robot

should be serviced daily.

Chapter 3 Preparing the Robot

WARNING

Hands and fingers could get caught and serious injury could result if the

slider moves while transporting the robot.

Accidents could also result if the weight balance shifts and the robot drops,

etc.

• Fix the slider with a rope, etc., to prevent movement during transportation.

• Do not place fingers between frame and cover during transportation.

• Do not tilt the robot during transportation.

WARNING

Observe the following precautions when temporarily installing the robot.

Failure to observe these could cause injuries to hands or fingers if the

robot tilts over.

• Always fix the robots with bolts even when only temporarily installing

the robot.

• When temporarily installing the arm type without using bolts, set a

spacer under the arm, etc., to prevent the robot from tilting over. Make

sure that the spacer has sufficient strength and stability.

• The

pole

-type robot’s stability is especially poor, so take special care

to prevent tilting during temporary installation.

3-5

Page 46

Chapter 3 Preparing the Robot

Use of a hoist, dolly or forklift is recommended for transporting the robot or

controller. Use sufficient caution when transporting robots with a long stroke or

large payload as they are heavy.

3-6

Page 47

5 Installation

5-1 Installation base

WARNING

If the installation base is not sufficiently rigid and stable, vibration (resonance) may occur during operation and adversely affect the robot work.

In worst cases the robot might even fall over causing a serious accident.

!

CAUTION

If the installation surface accuracy is insufficient, the robot positioning accuracy

and machine life may drop, and noise may be generated.

1) Select an installation base that has sufficient rigidity and stability to withstand the robot (including tool) and workpiece weight and the reaction generated during operation.

Chapter 3 Preparing the Robot

2) The installation base surface must be machined to a flatness within ±0.05mm/

500mm.

3) If there is a clearance between the installation base and robot frame when the

robot is set on the base, insert suitably thick shims in the clearance to prevent

stress from being applied on the robot frame.

4) Avoid fixing the robot onto the installation base with less than the specified

number of bolts, or installing only one end of the robot. Failure to observe

this could lead to an increase in robot vibration and decrease in positioning

accuracy.

3-7

Page 48

Chapter 3 Preparing the Robot

5-2 Installing the Robot

Always observe the safety precautions and the following procedures to ensure

that the robot is correctly and safety installed.

WARNING

• Take care not to pinch hands, etc., when removing the hoist belt from

the X-axis.

• The robot could tilt over if the hoist belt comes undone and if the balance is lost. Prevent tilting by suspending the tilting section with a

hoist or by using spacers, etc.

1) Tap or hole is machined into the installation base where the robot is to

be secured.

Refer to the XY-X Series catalog for the machining dimensions and positions.

2) Fix the installation base at the specified position.

Securely fix the installation base so that it will not sway during robot operation. (Depending on the installation place or installation base shape, this step

may be carried out after the robot is fixed onto the installation base.)

3) Using a hoist, carefully place the robot onto the installation base.

4) Remove the hoist belt from the Robot.

5) Install the robot referring the explanation for each robot in Chapter 6

and following.

3-8

Page 49

6 Protective connections

WARNING

Be sure to ground the robot and controller to prevent electrical shock.

WARNING

Turn the controller power OFF before starting connecting the ground.

The ground terminal position differs for each robot. Refer to the explanation for

each robot in Chapter 6 and following for details.

1) Provide a terminal marked “PE” as the protective conductor for the entire

system, and connect to an external protective conductor. Also securely connect the ground terminal on the robot base to the protective conductor.

(Symbol 417-IEC-5019)

Chapter 3 Preparing the Robot

2) When the end effector uses an electrical device which, if it malfunctions,

might make contact with the power supply, the user must provide proper

grounding on his own responsibility. The XY-X series robots do not have a

ground terminal for this purpose.

3) For details on protective bonding on the robot body to comply with CE marking, follow the instructions on protective bonding explained in the "YAMAHA

QRCX-E robot controller owner's manual".

3-9

Page 50

Chapter 3 Preparing the Robot

7 Connecting the Robot Cables

WARNING

1. The robot cable is the most important cable for controlling the robot. If

the connector is insufficiently connected and there are pin contact

faults, the robot could malfunction. Confirm that each connector is

securely connected before turning the controller power ON.

2. Arrange the connected cables so that they will not get in the way of

robot movements or the operator’s operations. Make sure that excessive load is not applied on the connector due to pulling of the cables.

WARNING

• Before connecting the cables, check that there are no bends or breaks

in the robot cable connector pins and that the cables are not damaged.

Bent or broken pins or cable damage may cause robot malfunctions.

• Turn the controller power OFF before connecting the controller and

robot cable.

WARNING

With the RCX40, QRCX and TRCX4 controllers, the motor connectors XM

and ZM, YM and RM and Robot I/O connectors XY and ZR have the same

shape. Take special care when connecting as incorrect connections could

cause malfunctions.

WARNING

With the TRCX3 controller, the motor connectors XM and ZM have the

same shape. Take special care when connecting as incorrect connections

could cause malfunctions.

WARNING

• If the connector is insufficiently connected and there are pin contact

faults, the robot could malfunction. Confirm that each connector is securely connected before turning the controller power ON.

• Before turning on the controller, check that the robot I/O connector is

securely attached.

• Make sure that excessive load is not applied on the connector due to

pulling of the robot cables.

WARNING

Arrange the robot cable so that it will not get in the way of robot movements. Do not set the area where the robot cable interferes with the load

on the robot tip as the working envelope. If the robot’s moving sections

interfere with the cable, the robot cable could be damaged and malfunctions could occur.

3-10

Page 51

Chapter 3 Preparing the Robot

WARNING

Arrange the connected robot cable so that it will not get in the way of

operator’s operations. The operator could trip on the robot cable and be

injured.

WARNING

When connecting the robot cable, insert the robot cable connector straight

into the mating connector on the controller. Inserting the connector while

tilted might cause the pins to make poor contact, causing robot malfunction and the connector itself might even break.

!

CAUTION

These connectors all work in only one direction. Take a good look at the connector shape before trying to attach it. Connecting the wrong way may damage

the connectors.

The robot cable is connected beforehand to the XY Series robot side.

Correctly install the other end of the robot cable to the robot controller. For details on connections to the robot controller, refer to 7-1 to 7-4.

3-11

Page 52

Chapter 3 Preparing the Robot

7-1 Connecting with the DRCX controller

WARNING

When connecting the robot cable, insert the robot cable connector straight

into the mating connector on the controller. Inserting the connector while

tilted might cause the pins to make poor contact, causing robot malfunction and the connector itself might even break.

!

CAUTION

These connectors all work in only one direction. Take a good look at the connector shape before trying to attach it. Connecting the wrong way may damage

the connectors.

1) Prepare the required tools.

Precision phillips-head screwdriver.

2) While referring to Table 3-1 and Fig.3-1, securely insert the motor connector

into the correct position on the controller unitl a click is heard.

3) While referring to Table 3-1 and Fig.3-1, insert the robot I/O cable into the

correct position on the controller.

4) Use the precision phillips-head screwdriver to tighten the robot I/O connector screws.

Table 3-1

Robot cable DRCX

XM MOTOR X

YM MOTOR Y

XY ROB I/O

3-12

Page 53

Robot cable

MOTOR connector

XM

YM

Chapter 3 Preparing the Robot

XY

ROBOT

I/O connector

DRCX controller

Fig. 3-1 Connection to DRCX controller

To robot

3-13

Page 54

Chapter 3 Preparing the Robot

7-2 Connecting with the TRCX controller

7-2-1 3-axis model

WARNING

When connecting the robot cable, insert the robot cable connector straight

into the mating connector on the controller. Inserting the connector while

tilted might cause the pins to make poor contact, causing robot malfunction and the connector itself might even break.

!

CAUTION

These connectors all work in only one direction. Take a good look at the connector shape before trying to attach it. Connecting the wrong way may damage

the connectors.

!

CAUTION

With the TRCX3 controller, the MOTOR connectors XM and ZM have the same

shape. Take care not to reverse the robot cable XM and ZM when connecting.

1) Prepare the required tools.

Precision phillips-head screwdriver.

2) While referring to Table 3-2 and Fig.3-2, securely insert the motor connector

into the correct position on the controller unitl a click is heard.

3) While referring to Table 3-2 and Fig.3-2, insert the robot I/O cable into the

correct position on the controller.

4) Use the precision phillips-head screwdriver to tighten the robot I/O connector screws.

Table 3-2

Robot cable TRCX

XM MOTOR X

YM MOTOR Y

XY ROB I/O

ZM MOTOR Z

Z ROB I/O

Main side unit

Sub-side unit

3-14

Page 55

ROBOT

I/O connector

MOTOR

connector

Chapter 3 Preparing the Robot

Z

M

Z

MOTOR

connector

XM

YM

X

Y

ROBOT

I/O connector

Robot cable

Fig. 3-2 Connection to TRCX controller (3-axis model)

To robot

3-15

Page 56

Chapter 3 Preparing the Robot

7-2-2 4-axis model

WARNING

When connecting the robot cable, insert the robot cable connector straight

into the mating connector on the controller. Inserting the connector while

tilted might cause the pins to make poor contact, causing robot malfunction and the connector itself might even break.

!

CAUTION

These connectors all work in only one direction. Take a good look at the connector shape before trying to attach it. Connecting the wrong way may damage

the connectors.

!

CAUTION

With the TRCX4 controller, the MOTOR connector and PI connector shapes

are the same for the XY-axis and ZR-axis. Take care not to reverse the robot

cables XY and ZR when connecting.

1) Prepare the required tools.

Precision phillips-head screwdriver.

2) While referring to Table 3-3 and Fig.3-3, securely insert the motor connector

into the correct position on the controller unitl a click is heard.

3) While referring to Table 3-3 and Fig.3-3, insert the robot I/O cable into the

correct position on the controller.

4) Use the precision phillips-head screwdriver to tighten the robot I/O connector screws.

Table 3-3

Robot cable TRCX

XM MOTOR X

YM MOTOR Y

XY ROB I/O

ZM MOTOR X

RM MOTOR Y

ZR ROB I/O

Main side unit

Sub-side unit

3-16

Page 57

ROBOT

I/O connector

MOTOR

connector

Chapter 3 Preparing the Robot

ZM

RM

Z

R

MOTOR

connector

XM

YM

X

Y

ROBOT

I/O connector

Robot cable

Fig. 3-3 Connection to TRCX controller (4-axis model)

To robot

3-17

Page 58

Chapter 3 Preparing the Robot

7-3

Connecting to the QRCX or RCX40 controller

WARNING

When connecting the robot cable, insert the robot cable connector straight