Yamaha XS650 1974-1980 Service Manual 11 ergaenzung sf2f

FOREWORD

This Supplementary Service Manual for XS650SF/XS650-2F has been

published to supplement the Service Manual for the XS650E (LIT-1 1616-00-

76), and provides updated information for the XS650E model as well as new

data concerning the XS650SF/XS650-2F. For complete information on

service procedures, it is necessary to use this Supplementary Service Manual

together with the Service Manual for the XS650E (LIT-1 1616-00-76).

NOTE:

This Supplementary Manual contains special information regarding periodic

maintenance to the emissions control system for the XS650SE. Please read

this material carefully.

SERVICE DEPT.

INTERNATIONAL DIVISION

YAMAHA MOTOR CO., LTD.

-136-

Page numbers shown in brackets correspond

to page numbers of the XS650E Service

Manual (LIT-11616-00-76).

NOTE:

In the XS650E Service Manual there are a few

pages that are not arranged in order. These are

pages 7, 8 and 9. They should be read in the

(PAGE 4

-

5)

reverse order,

i.e. 9,

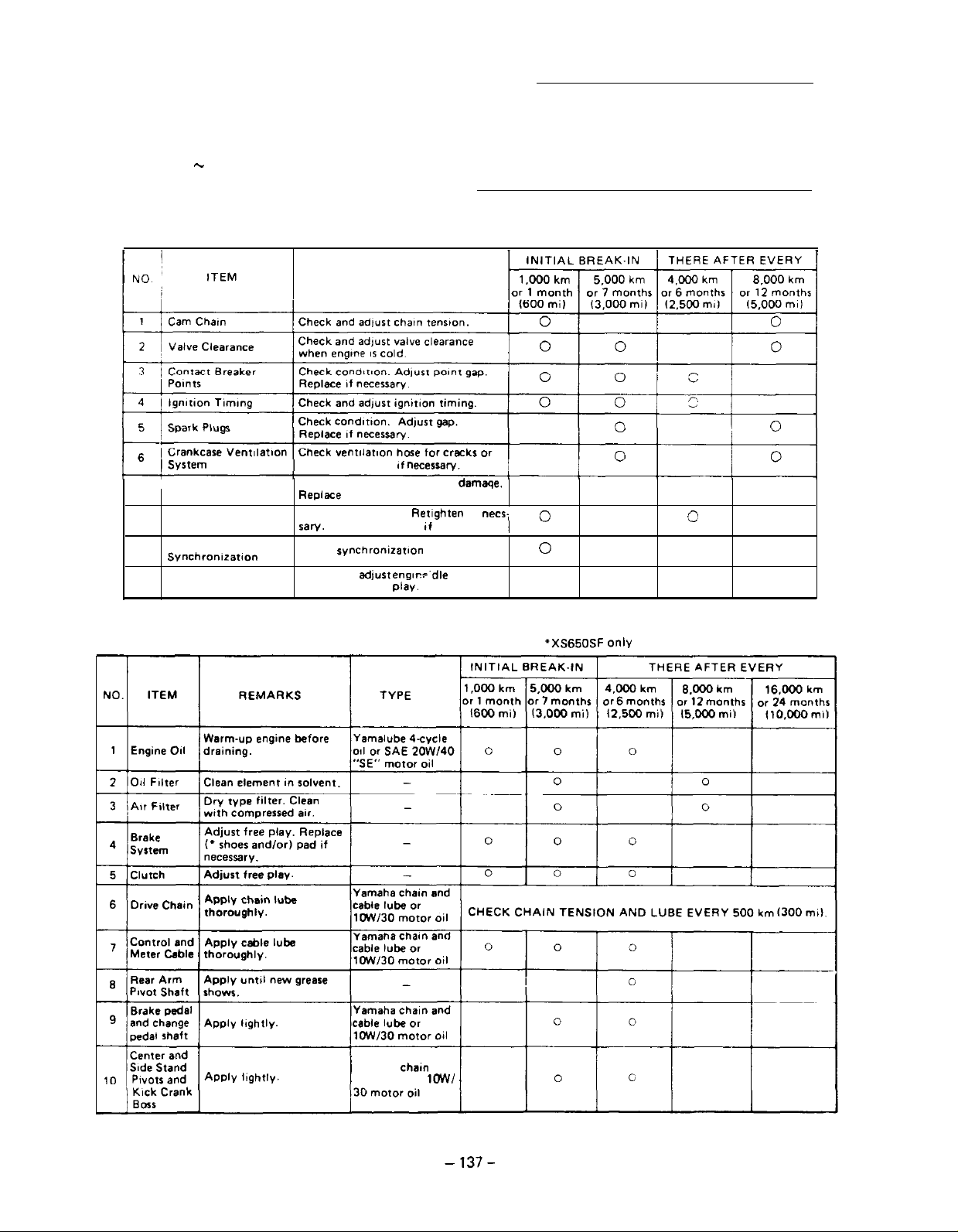

2-2. MAINTENANCE INTERVALS CHARTS

A. PERIODIC MAINTENANCE EMISSION CONTROL SYSTEM

REMARKS

8 and 7.

damage.

7

Fuel Hose

8

Exhaust System

Carburetor

9

Svnchronlzataon

10

Idle Speed

GENERAL MAINTENANCE/LUBRICATION

B.

Check

Replace If necessary

Check for leakage.

saw.

Adjust

Check and

Adjust cable free play.

Replace If

fuel

Replace gasket(s) tf necessary.

svnchronizaf~on

n

hose for cracks or

Retlghten as

of carburetors.

ad,ust engnr+ .dle

damaqe.

speed.

necr-

0 0

0

)

0

C

0 0

0 0 0

‘XS65OSF

onlv

z

Yamaha

cham

cable lube or

and

lCWV/

NO.

Front Fork

” 011

Steerung Ball

,2 Beanng

RKH

,3

Wheel

Bearings

14

l8attew

,5

A.C.

Generator

ITEM

Check bearings assembly

and for looseness. Moderately wheel bearing

REMARKS TYPE

Drawn

completely.

Refill to specification.

repack every 16,000 km

(10.000 mi).

Check bearings for smooth

rotation. Moderaltelv

repsk eVeV 16,ooO

(10,000

Check specific

1

Check breather

proper

Replace generator brushes.

Replace at initial 9,000

km (5.500 mi)

mil.

operatio;l:

gravitv.

D~DC

km

for

Yamaha fork oil

1OWt

or equivalent

Medwm weight

gre.%e.

Medium weight

wheel bearing

gresre.

i

INITIAL BREAK-IN

1,000 km 5.000 km 4,000 km 8,000 km

or 1 month or 7 months or 6 months or 12 months

1600 mil

-

_

K3,OOOmil

IO

j

(2.500 mi) (5,000 mil

0 3

0

IO

THEREAFTEREVERY

G

I

0

16,000 km

or24month

~10,000 mi

0

Repack

Repack

(PAGE 7 - 8)

2-3. ENGINE

B. Air filters

2. Cleaning method

c. The air filter element should be cleaned

specified intervals. It should be cleaned

more often if the machine is operated in

extremely dusty areas.

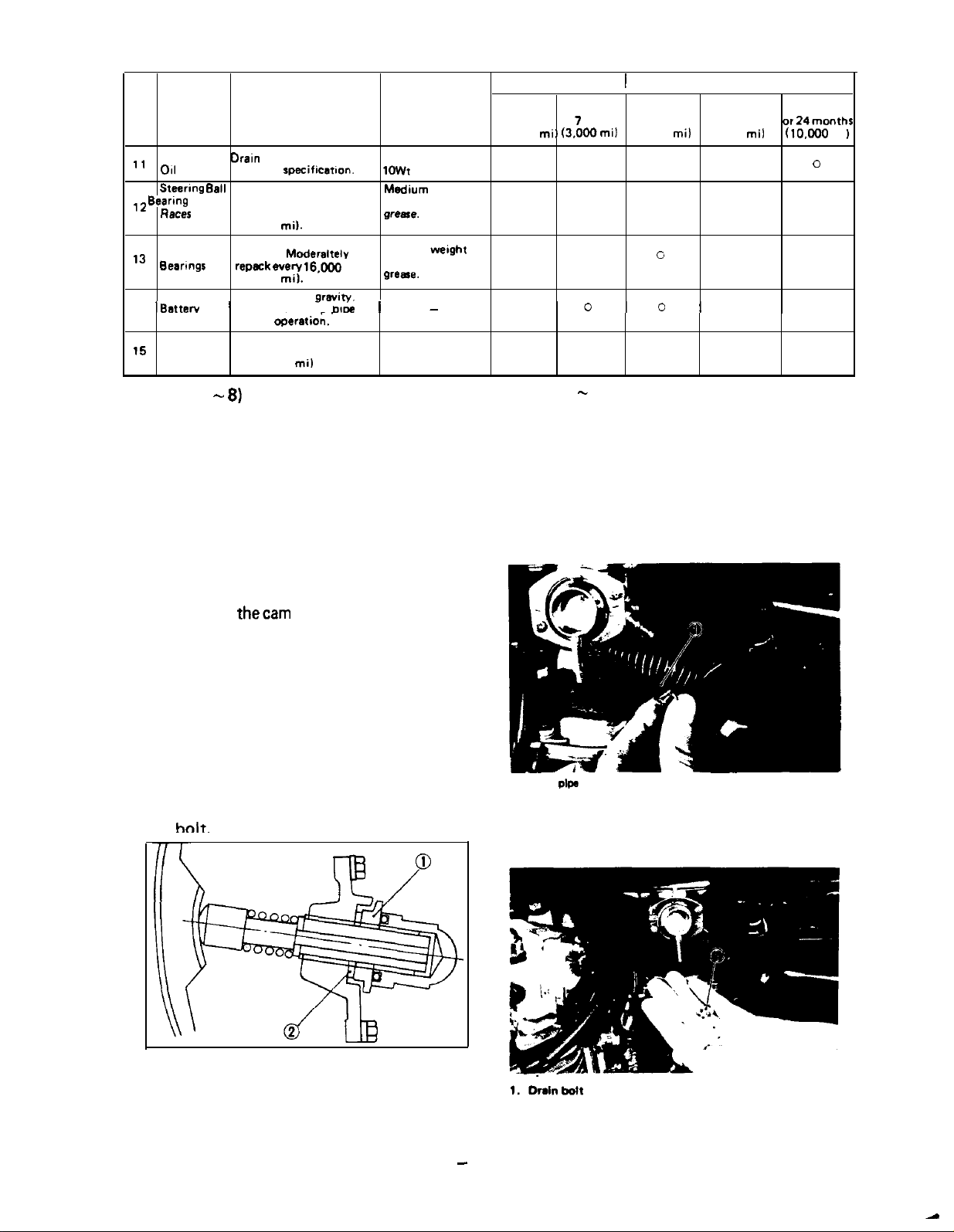

E. Cam chain adjustment

Check/adjust thecam chain tension as follows:

1.

Remove the cap nut and loosen the lock

nut.

2. Turn the left end of the crankshaft

counterclockwise. As the crankshaft is

turning, check to see that the cam chain

adjuster push rod is flush with the end of

the bolt. If not, turn the adjuster bolt

until the push rod is flush.

3. Secure the lock nut and tighten the cap

hnlt.

(PAGE 9 - 13)

2-4. CHASSIS

A. Fuel petcock cleaning

1. Open the seat and remove the fuel tank

securing bolt.

2. Turn the petcock lever to the “ON” or

“RES” position. Raise the fuel tank to

remove the fuel pipe.

1. Fuel

PIP

3. Remove the drain bolt and clean with

solvent If gasket is damaged, replace.

1. Locknut

2. Gasket

-

138-

E. Rear brake

(XS650SF

only)

The rear brake pedal should be so adjusted

that it has a free play of 13

-

0.59 in) from when the brake pedal is first

-

15 mm (0.51

moved to when the brake begins to be

effected .

1. Loosen the adjuster lock nut (for pedal

height).

2.

By turning the adjuster bolt clockwise or

counterclockwise, adjust the brake pedal

position so that its top end is approx. 12

-

18 mm (0.47 - 0.71 in) below the

footrest top end.

3. Secure the adjuster lock nut.

4. Loosen the brake rod adjuster lock nut

and screw brake rod downward until

there is noticeable free play between rod

and master cylinder.

5. Turn in the brake rod until it lightly

touches the master cylinder, then turn it

out by approx.

l-1/5

turns (for proper

free play).

6.

Tighten the brake rod adjuster lock nut.

NOTE:

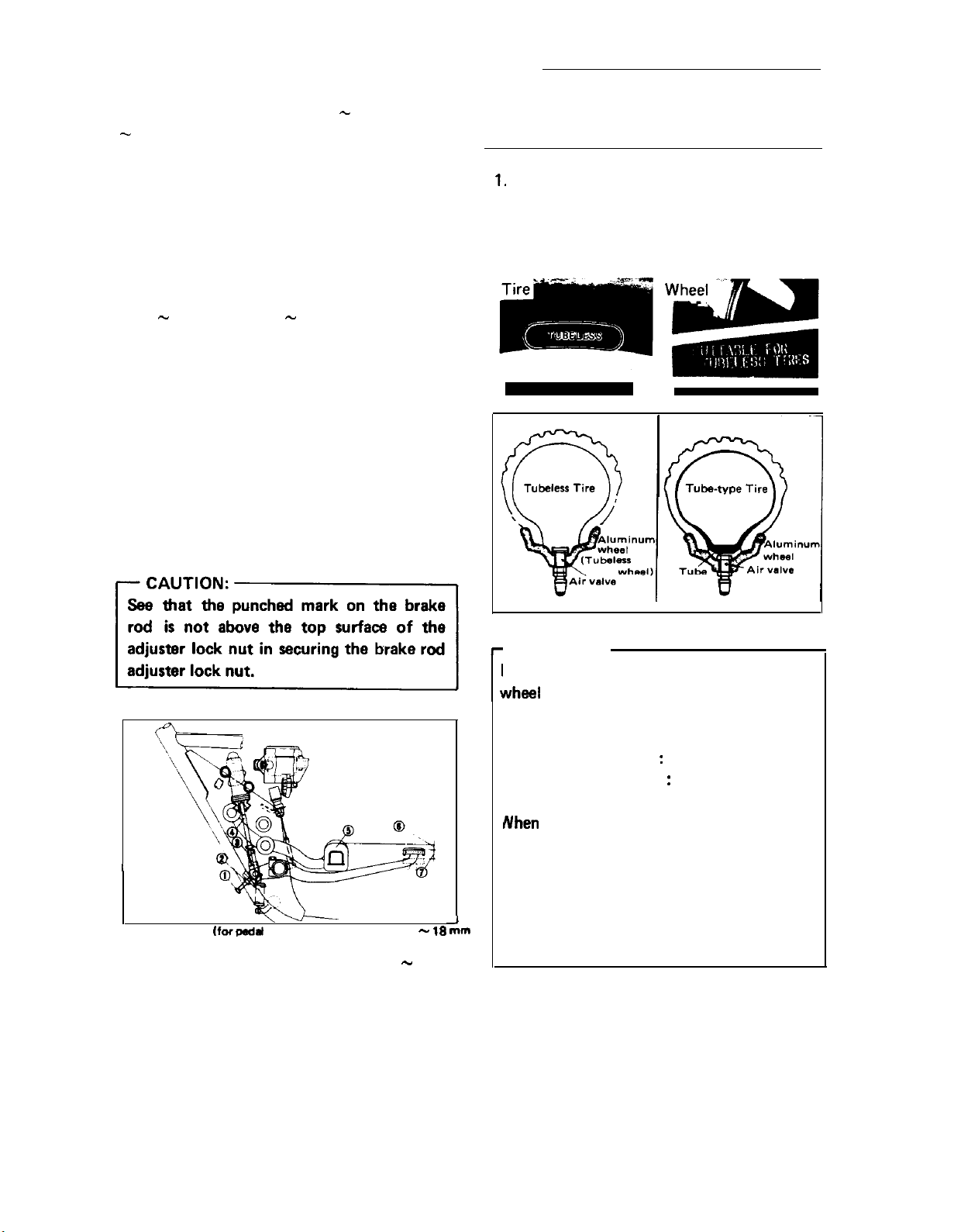

This model is available in two types, tubeless

tire and tube-type tires. Before servicing tires,

please note the following instructions.

1.

Tubeless tire

a. The identification marks are fitted on

the tire sidewall and wheel spoke for

tubeless tires as shown.

I

6.

Pedal

(for

pedal

1.

Adjuster bolt

2.Lock nut

3. Lock nut

4. Brake rod

5. Footrest

height)

7. Free play 13

height

-0.71

(0.47

(0.51 -0.59 in)

F. Wheels and tires

Tubeless tires and aluminium wheels

(XS650SF only)

12 -18

in)

-

15 mm

-WARNING:

I-

Do not attempt to use tubeless tires on a

wheel

designed for use only with tube-type

tires. Tire failure and personal injury may

result from sudden deflation.

‘Tube-type wheel

:

Tube-type Only

“Tubeless-type wheel : Tube-type or Tube

less tires

When

using tube-type tires, be sure to

install the proper tube also.

After installing a tire, ride conservatively to

allow the tire to seat itself on the properly.

i

ml-

Failure to allow proper seating may cause

”

tire failure resulting in serious injury to the

machine and rider.

After repairing or replacing a tire, check

b.

to be sure the valve stem lock nut is

securely fastened. If not, torque it as

specified.

-139-

Tightening torque:

1.5 m-kg (1.1 ft-lb)

Aluminium wheels

2.

Always inspect the aluminium wheels

a.

before riding. Place the machine on the

center stand and check for cracks, bends

or warapage of the wheels. Do not attempt even small repairs to the wheel. It

must be replaced.

Tires and wheels should be balanced

b.

whenever either one is changed or re

placed. Failure to have a wheel assembly

balanced can result in poor perfo-

rmance, adverse handling character-

istics,

and shortened tire life.

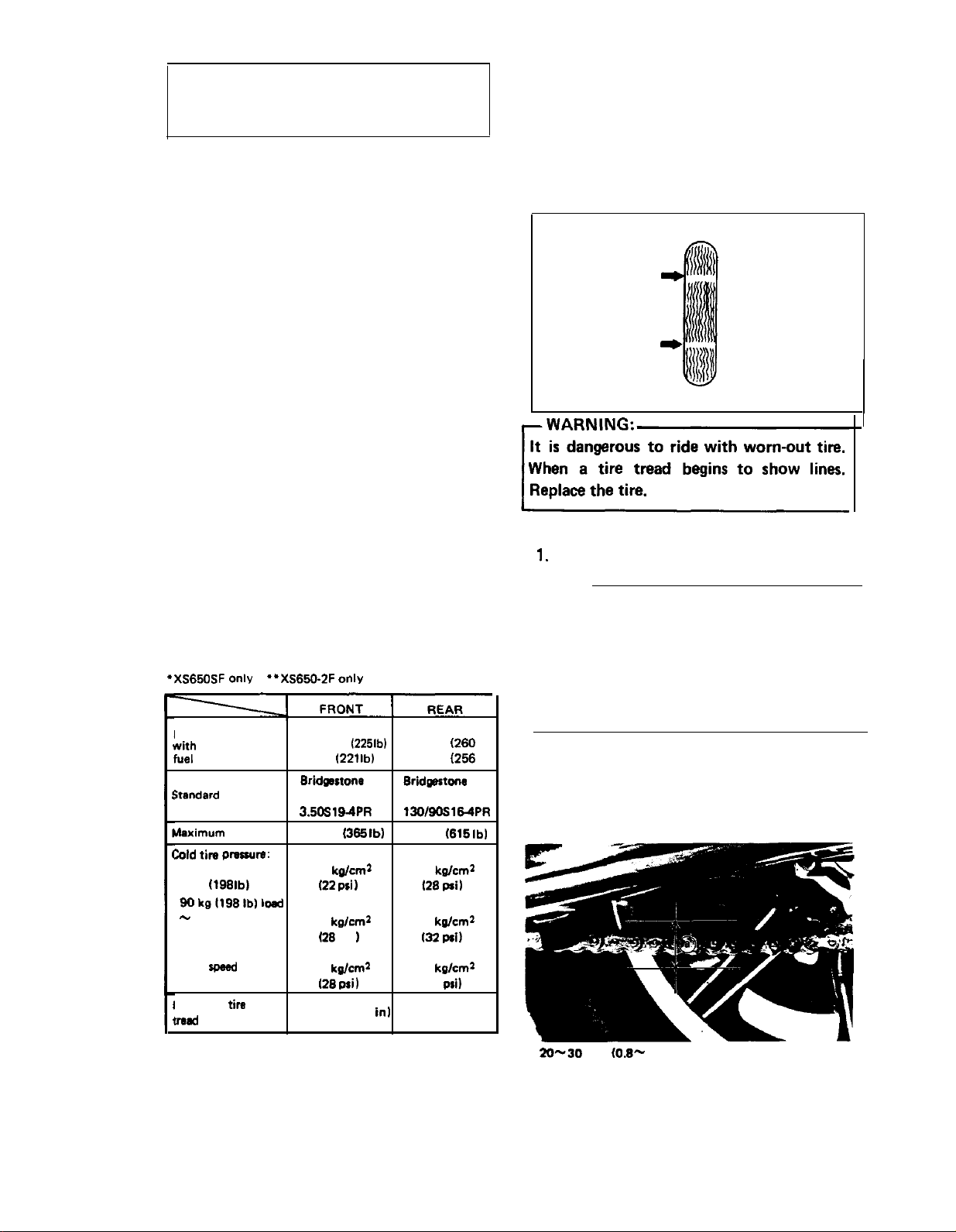

2. Before operation, always check the tire

surfaces for wear and/or damage; for

example: cracks, glass, nails, metal

fragments, stones, etc. Correct any such

hazard before riding. If a tire tread

shows crosswise lines, it means that the

tire is worn to its limit. Reolace the tire.

Tire pressure

(XS650SF/XS650-2F)

To insure maximum performance and long

service, note the following:

1. Always maintain proper air pressure as

described in the chart. Check tire pressure daily, before riding, and adjust as

necessary.

‘XS65OSF Only

BASIC WEIGHT

Nith

oil and full

fuel

tank “100 kg

standard

tire

vlsximum

Zold tire presswe:

UP to 90 kg

(198

9Okg1198Ib)load

5

206 kg (453 lb)

load (Maximum

load)

High

speed

Minimum

wad

depth

“XS650-2F only

load limit

lb)

load

riding

tire

l

102 kg (226

Bridgestone

Yokohama

3.5OS194PR

166 kg I365

1.6

(22

2.0

(28

2.0

(28 psi)

0.8 mm (0.03

lb)

(221 lb)

l

or

lb)

kg/cm2

psi 1

kg/cm2

psi

I

kg/cm2

in)

‘118 kg (260 lb

*116 kg (256 lb

Bridgestone

Yokohama

13OBOS184PR

279 kg

2.0

2.3

or

(615 lb1

kg/cm=

(28 psi1

kg/cm2

132 Psi)

2.3

kg/cm2

132

psi)

0.8 mm (0.03 in)

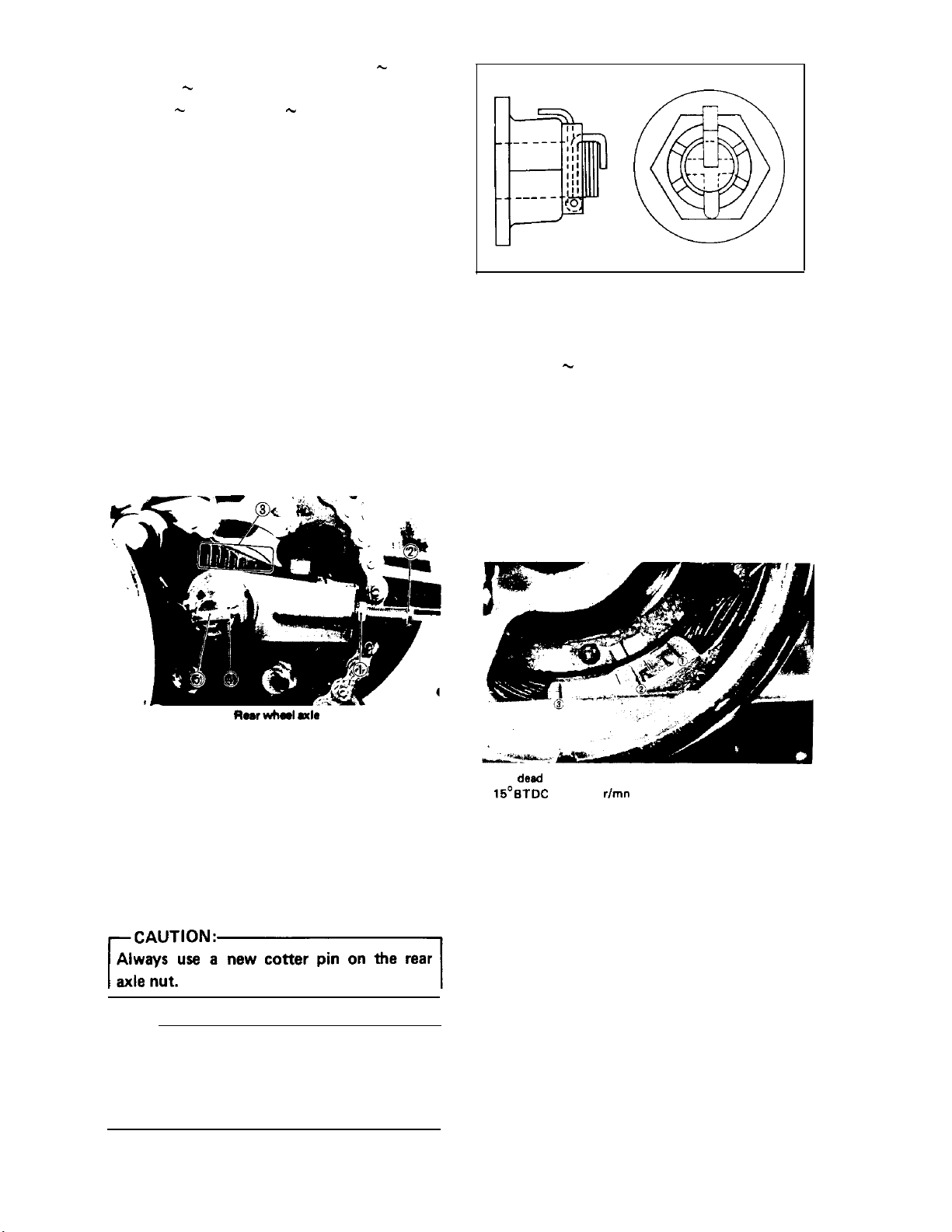

G. Drive chain

1.

Tension check

NOTE:

Before checking and/or adjusting, rotate

rear

wheel

through several revolutions and

check tension several times to find the

tightest point.

Check and/or adjust chain

tension with rear wheel in this “tight chain”

position.

Inspect the drive chain with both tires

touching the ground and without rider.

Check the tension at the position shown

in the illustration, The normal vertical

- 140-

. .

20-30

mm

(0.8-

1.2 in)

deflection is approximately 20 - 30 mm

(0.8

-

1.2

in). If the deflection exceeds

20- 30 mm (0.8 - 1.2 in) adjust the

chain tension.

Tension adjustment

2.

a.

Loosen the rear brake adjusting nut

(XS650-2F only).

Remove the cotter pin of the rear wheel

b.

axle nut with pliers.

C.

Loosen the rear wheel axle nut.

d.

Loosen the lock nuts on each side. To

tighten chain,turn chain puller adjusters

clockwise. To loosen chain, turn adjusters

counterclockwise and push wheel forward. Turn each adjuster exactly the

same amount to maintain correct axle

alignment. (There are marks on each side

of rear arm and on each chain puller; use

them to check for proper alignment.)

g. In the final step, adjust the play in the

brake pedal (XS650-2F only).

(PAGE 14

-

15)

2-5. ELECTRICAL

C. Ignition timing

1. Point gap must be set before setting

timing.

2. Ignition timing is checked with a

timing

light by observing the position of the

stationary marks stamped on the

stator

and the pointer on the generator rotor.

Roar whal ale

1. Locknut

2. Adjuster 5. Cotter pin

3. Marks for

4.

alignment

nut

e. After adjusting, be sure to tighten the

lock nuts and the rear wheel axle nut.

f. Inset-t the cotter pin into the rear wheel

axle nut and bend the end of the cotter

pin as shown in the illustration (if the

nut notch and the cotter pin hole do not

match, tighten the nut slightly to match).

NOTE:

Excessive chain tension will overload the engine and other vital parts, keep the tension

within the specified limits. Also, replace the

rear axle cotter pin with a new one.

-141-

1. Top

dead

canter

2. 15’

ETDC

at 1,200

Connect timing light to right (left)

3.

3. Advanced mark

rlmn

cylinder spark plug lead wire. Ignition

timing of right cylinder must be set first.

Start the engine and keep the engine

4.

speed as specified on the label. Use a

tachometer for checking.

5.

The rotor pointer should line up the “F”

stamped timing mark on the

specified engine speed. If it does not

align, loosen the two breaker backing

plate screws (breaker assembly holding

screws for left cylinder) and move the

complete backing plate (breaker assembly for left cylinder) until the point

marks align.

stator

at a

6. Retighten screws. Check timing again

for right cylinder.

7. Repeat procedure (steps 2

-

6) for left

cylinder.

1. Right cylinder timing adjustment

2. Left cylinder timing adjustment

F. Spark plug

Check electrode condition and wear, insulator

color, and electrode gap. Use a wire gauge for

adjusting the plug gap.

If the electrodes

become too worn, replace it.

When installing the plug, always clean the

gasket surface, wipe off any grime that might

be present on the surface of the spark plug,

and torque the spark plug properly.

Standard spark plug:

N-7Y (CHAMPION) or

BP7ES

(NGK)

Spark plug gap:

0.7 - 0.8 mm (0.028 - 0.031 in)

Spark plug tightening torque:

2.0 m-kg (14.5 ft-lb)

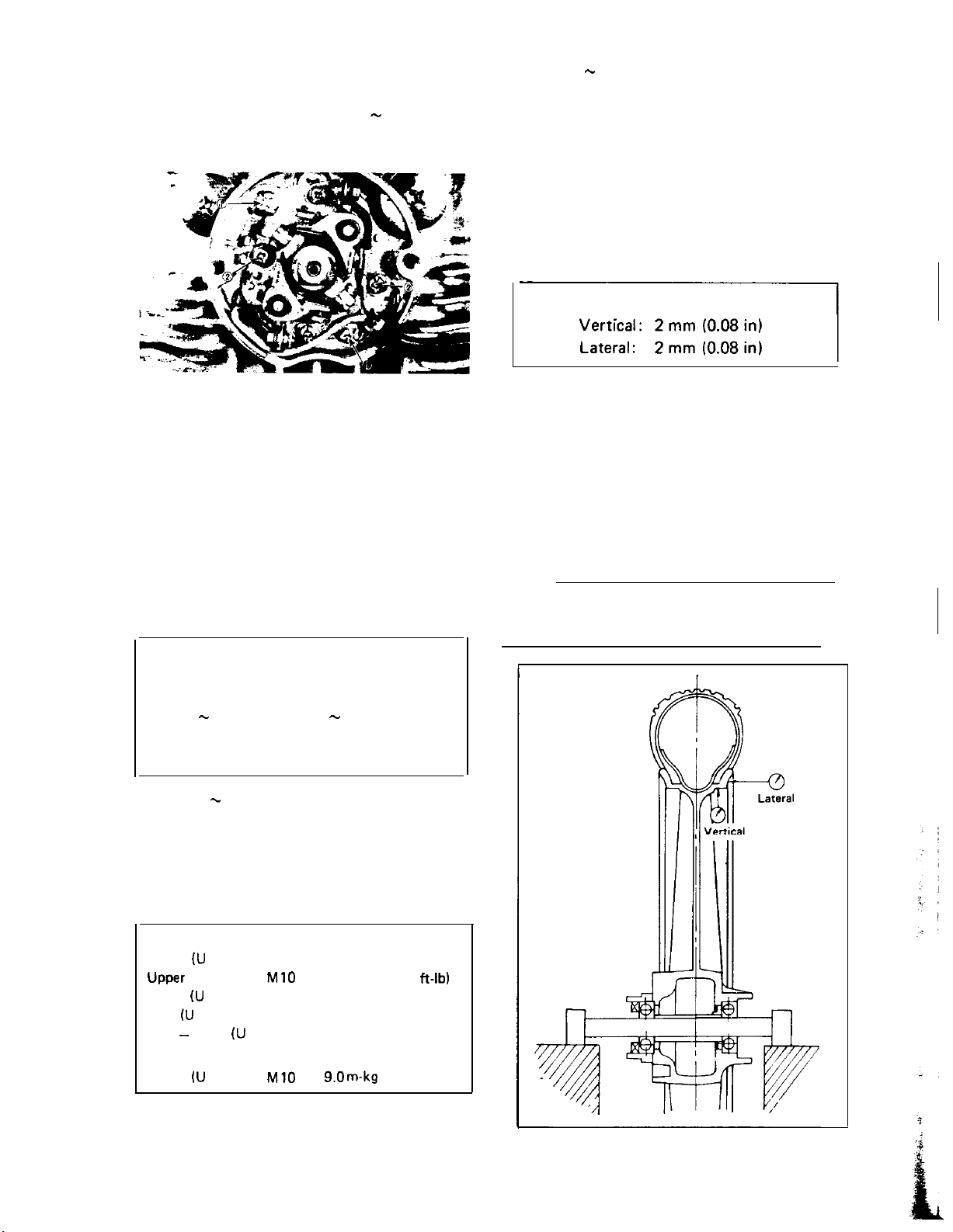

(PAGE 39 - 40)

5-1. FRONT WHEEL

C. Front wheel inspection

1. Check for cracks,

(XS650SF

only)

bends, or warpage

of

wheels. If a wheel is deformed or cracked, it must be replaced.

2. Check wheel run-out

If deflection exceeds tolerance, check

wheel bearing or replace wheel as required.

Rim run-out limits (XS650SF/XS650-2F):

Check wheel balance

3.

Rotate wheel lightly several times and

observe resting position.

If wheels is not statically balanced,

wheel will come to rest at the same position. install balance weight at lighter

position (at top) as illustrated.

NOTE:

The wheel should be balanced with brake disc

installed.

(PAGE 29

3-4.

ENGINE ASSEMBLY AND ADJUSTMENT

-

33)

0. Engine

Specifications should be changed as

follows:

Engine mounting bolt torque:

Upper (U Nut)

Upper

Front

(U

Nut)

Rear

(U

Nut)

Rear - under

Under

(U

Nut)

(U

Nut)

M8

Ml0

Ml0

Ml0

Ml0

Ml0

1.8 m-kg (13.0 ft-lb)

3.0 m-kg (215

ft-lbl

4.6 m-kg (33.5 ft-lb)

4.1 m-kg (29.5 ft-lb)

4.6 m-kg (33.5 h-lb)

9.0

m-kg

(65.0 ft-lb)

-142-

Loading...

Loading...