Yamaha XP-7000 Service manual

POWER AMPLIFIER

/

SERVICE MANUAL

XP7000

このサービスマニュアルはエコパルプ

(ECF:無塩素系漂白パルプ)を使用しています。

This document is printed on chlorine free (ECF) paper.

XP5000

■ CONTENTS (目次)

SPECIFICATIONS (総合仕様)............................................... 3/5

MONITOR/REMOTE PIN LAYOUT

(MONITOR/REMOTEピンレイアウト)................................. 4/6

DIMENSIONS (寸法図)........................................................... 7

PERFOMANCE GRAPHS (特性図).......................................... 7

PANEL LAYOUT (パネルレイアウト)...................................... 8

CIRCUIT BOARD LAYOUT & WIRING

(ユニットレイアウト&結線図).............................................. 10

DISASSEMBLY PROCEDURES (分解手順).......................... 16

IC BLOCK DIAGRAM (ICブロック図)................................... 23

CIRCUIT BOARDS (シート基板図)........................................ 24

INSPECTIONS (検査)....................................................... 36/42

PS CIRCUIT BOARD REPAIR GUIDE

(PSシート故障修理ガイド)............................................... 48/56

PARTS LIST

IC & DIODE OUTSIDE FIGURE (外形図)

BLOCK DIAGRAM (ブロックダイアグラム)

WIRING DIAGRAM (基板結線図)

CIRCUIT DIAGRAM (回路図)

PA 011812

XP7000: 200512-281400

XP5000: 200512-239400

HAMAMATSU, JAPAN

Copyright (c) Yamaha Corporation. All rights reserved. 06.01

XP7000/XP5000

IMPORTANT NOTICE

This manual has been provided for the use of authorized Yamaha Retailers and their service personnel. It has been assumed that basic service

procedures inherent to the industry, and more specifically Yamaha Products, are already known and under stood by the users, and have

therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in per-sonal injury, destruc-

tion of expensive components and failure of the product to perform as specified. For these reasons, we advise all Yamaha

product owners that all service required should be performed by an authorized Yamaha Retailer or the appointed service

representative.

IMPORTANT: This presentation or sale of this manual to any individual or firm does not constitute authorization, certification, recognition of

any applicable technical capabilities, or establish a principal-agent relationship of any form.

The data provided is believed to be accurate and applicable to the unit (s) indicated on the cover. The research engineering, and service

departments of Yamaha are continually striving to improve Yamaha products. Modifications are, therefore, inevitable and changes in specification are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist, please contact the distributor’s Service

Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity your body may have accumulated by

IMPORTANT: Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power to the unit.

grounding yourself to the ground bus in the unit (heavy gauge black wiresonnect to this bus).

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and/or plastic (Where applicable)

components may also contain traces of chemicals found by the California Health and Welfare Agency (and possibly other entities) to cause

cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON WHAT SO

EVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or expose eyes to solder/flux

vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before handling food.

IMPORTANT NOTICE FOR THE UNITED KINGDOM

Connecting the Plug and Cord

WARNING: THIS APPARATUS MUST BE EARTHED

IMPORTANT. The wires in this mains lead are coloured in accordance with the following code:

As the colours of the wires in the mains lead of this apparatus may not correspond with the coloured markings identifying the terminals in your

plug proceed as follows:

The wire which is coloured GREEN-and-YELLOW must be connected to the terminal in the plug which is marked by the letter E or by the safety

earth symbol or colored GREEN or GREEN-and-YELLOW.

The wire which is coloured BLUE must be connected to the terminal which is marked with the letter N or coloured BLACK.

The wire which is coloured BROWN must be connected to the terminal which is marked with the letter L or coloured RED.

GREEN-AND-YELLOW: EARTH

BLUE: NEUTRAL

BROWN: LIVE

• This applies only to products distributed by Yamaha-Kemble Music (U.K.) Ltd. (3 wires)

■ WARNING

Components having special characteristics are marked and must be replaced with parts having specification equal to those originally

installed.

印の部品は、安全を維持するために重要な部品です。交換する場合は、安全のために必ず指定の部品をご使用ください。

2

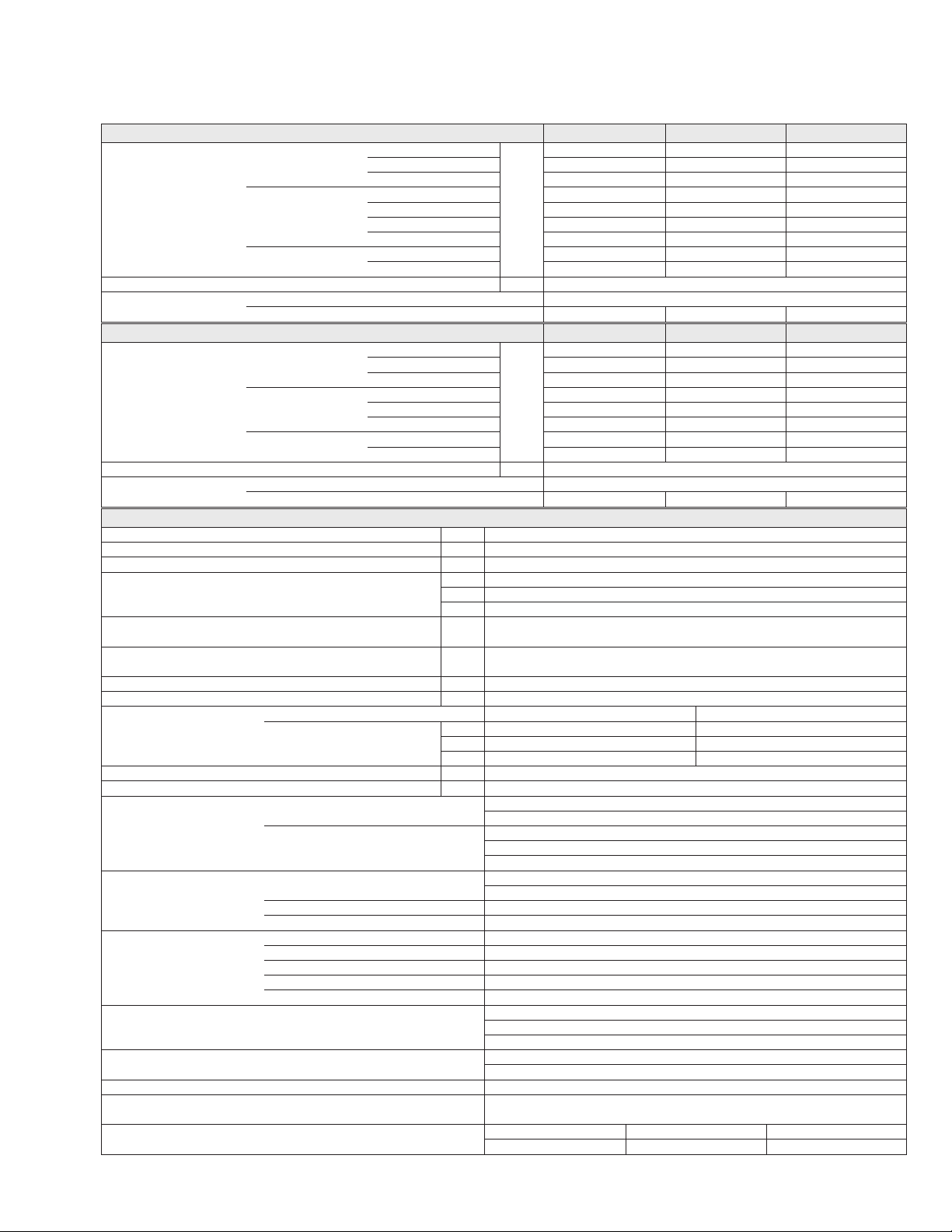

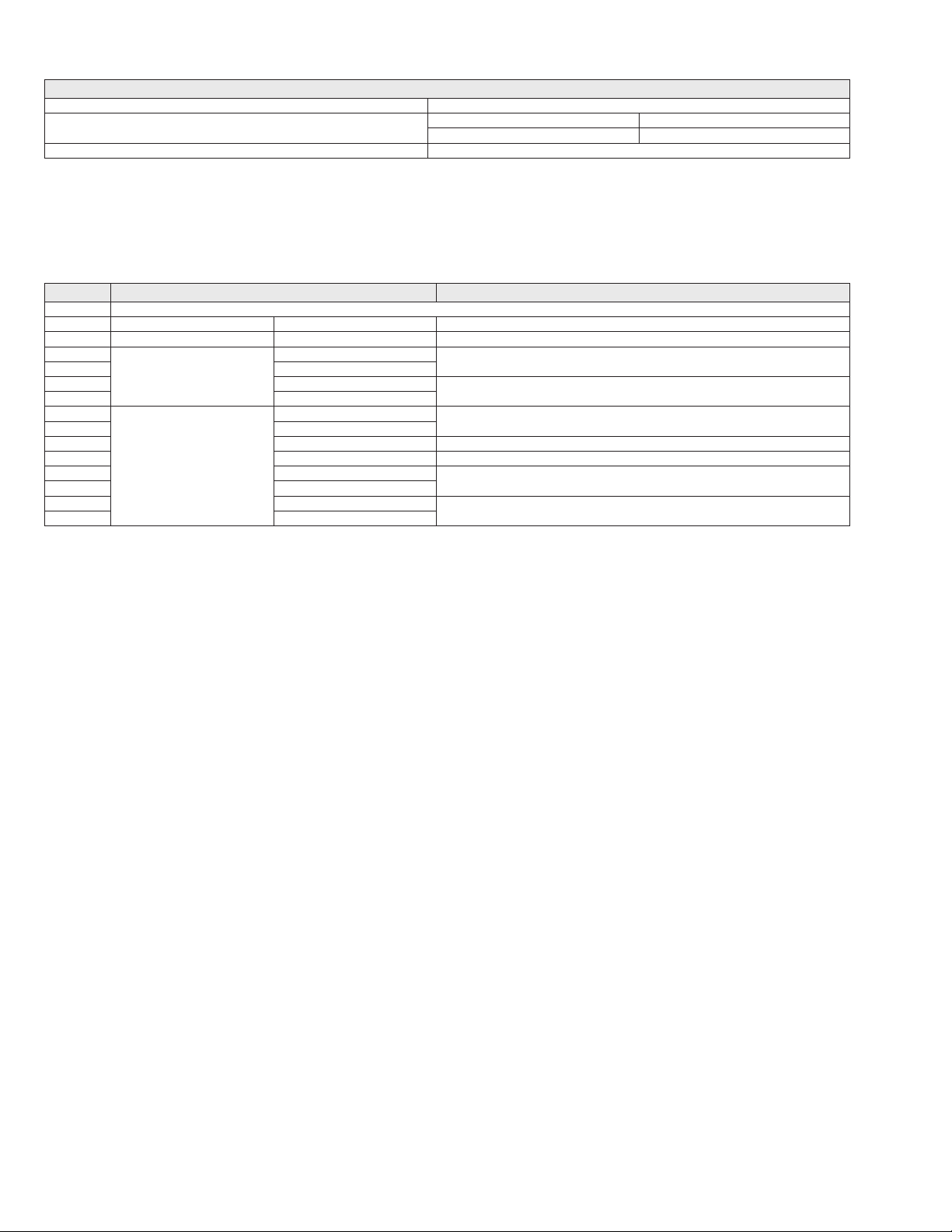

■ SPECIFICATIONS

XP7000 120V (U/T) 230V (H/B/K/O) 240V (A)

Output Power

SN Ratio

Power Consumption

Output Power

SN Ratio

Power Consumption

Power Bandwidth

THD+N

Intermoduration Distortion

Frequency Response

Channel Separation

Residual Noise

Damping Factor

Voltage Gain

Input Sensitivity (dBu)

Maximum Input Voltage

Input Impedance

Controls

Connectors

Indicators

Load Protection

Amplifier Protection

Power Supply Protection

Cooling

Power Requirements

1kHz

THD+N=1%

20Hz - 20kHz

THD+N=1%

1kHz

20mS nonclip

20Hz - 20kHz

Standby/Idle

1/8 (4ohms/Pink noise)

XP5000 120V (U/T) 230V (H/B/K/O) 240V (A)

1kHz

THD+N=1%

20Hz - 20kHz

THD+N=1%

1kHz

20mS nonclip

20Hz - 20kHz

Standby/Idle

1/8 (4ohms/Pink noise)

All Models

Half Power, THD+N=0.5%

20Hz - 20kHz, Half Power

60Hz:7kHz, 4:1, Half Power

RL=8ohms, Po=1W, HPF=OFF

20Hz - 50kHz

Half Power, RL=8ohms, 1kHz,

Att. Max, input 600ohms shunt

20Hz - 20kHz, Att. Min,

(DIN AUDIO)

RL=8ohms, 1kHz

Att. Max

Switch Position

Front Panel

Rear Panel

Input

Output

MONITOR/REMOTE

POWER/STANDBY

SIGNAL

CLIP

PROTECTION

TEMP

8ohms/STEREO

4ohms/STEREO

8ohms/BRIDGE

8ohms/STEREO

4ohms/STEREO

70 V/STEREO RL=8ohms

8ohms/BRIDGE

2ohms/STEREO

4ohms/BRIDGE

(DIN AUDIO)

8ohms/STEREO

4ohms/STEREO

8ohms/BRIDGE

8ohms/STEREO

4ohms/STEREO

8ohms/BRIDGE

2ohms/STEREO

4ohms/BRIDGE

(DIN AUDIO)

MIN

MAX

MAX

MAX

TYP

MIN

MIN

MAX

MIN

TYP

+4dBu

26dB

36dB

MIN

TYP

XP7000/XP5000

750W + 750W

1100W + 1100W

2200W

700W + 700W

MIN

MIN

MIN

MIN

10Hz - 40kHz

0.1%

0.1%

0dB

0dB

-1dB

70dB

-70dBu

350

Selectable from 32dB or 26dB (or +4dBu input sensitivity) by GAIN switch

+22dBu

20kohms (balanced), 10kohms (unbalanced)

POWER switch (push on/push off)

Attenuator (31-position) x 2

MODE switch (STEREO/BRIDGE/PARALLEL) x 1

HPF switch (20Hz/55Hz/OFF 12dB/oct) x 2

GAIN switch (32dB/26dB/+4dBu) x 1

XLR-3-31 type/ch

Euroblock connector (balanced) /ch

SPEAKON /ch, 5 way binding post x 1

D-Sub 15 pin x 1

x 1 (Green/Orange)

x 2 (Green)

x 2 (Red)

x 1 (Red)

x 1 (Red) heatsink temp ≥ 85°C

POWER switch on/off mute

DC-fault: power supply shutdown

Clip limiting: THD ≥ 0.5%

Thermal: cuts the output (heatsink temp ≥ 90°C)

VI limiter (RL ≤ 1ohm)

Thermal: power supply shutdown (heatsink temp ≥ 100°C)

Variable-speed fan x 2

Fan stops at heatsink temp ≤ 55°C

950W + 950W

625W + 625W

1900W

1600W + 1600W

3200W

650W

525W + 525W

750W + 750W

1500W

500W + 500W

700W + 700W

1400W

1300W + 1300W

2600W

500W

XP7000 XP5000

+4 +4

+13.7 +12.2

+7.7 +6.2

U/T H/B/K/O A

120V, 60Hz 230V, 50Hz 240V, 50Hz

750W + 750W

1100W + 1100W

2200W

650W + 650W

950W + 950W

625W + 625W

1900W

1600W + 1600W

3200W

104dB

5W/35W

650W

525W + 525W

750W + 750W

1500W

500W + 500W

700W + 700W

1400W

1300W + 1300W

2600W

103dB

5W/35W

500W

750W + 750W

1100W + 1100W

2200W

700W + 700W

950W + 950W

625W + 625W

1900W

1600W + 1600W

3200W

650W

525W + 525W

750W + 750W

1500W

500W + 500W

700W + 700W

1400W

1300W + 1300W

2600W

500W

3

XP7000/XP5000

All Models

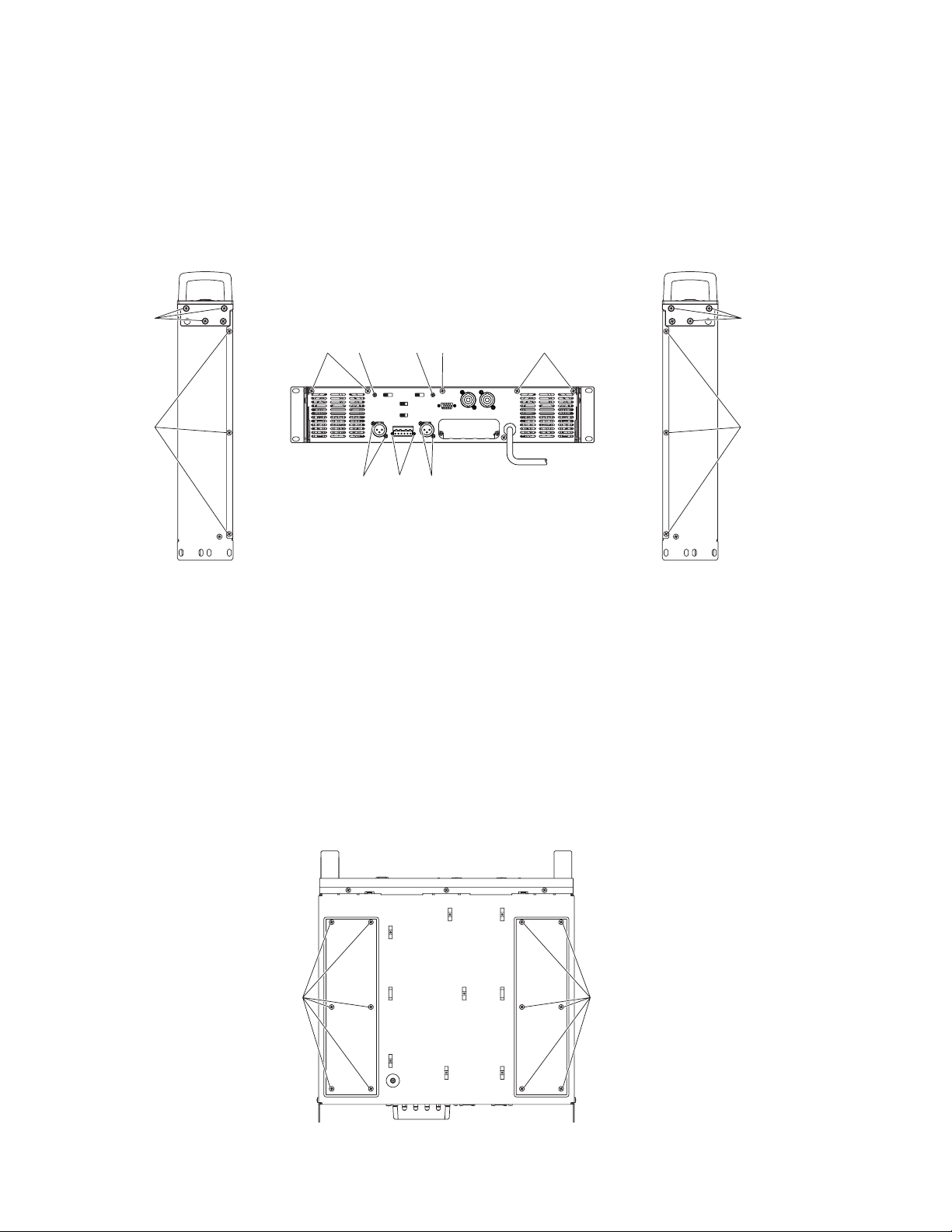

Dimensions (W x H x D)

Weight

Accessories

0dBu=0.775Vrms, Half Power=1/2 Output Power (3dB below rated power)

■ MONITOR/REMOTE PIN LAYOUT

480 x 88 x 456 mm

XP7000 XP5000

14 kg 14 kg

Security cover (with a hex wrench), Owner’s Manual

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

GND

REMOTE CONTROL

MONITOR

REMOTE CONTROL

MONITOR

Signal

STANDBY

MODEL ID

NC

NC

MUTE CH B

MUTE CH A

NC

NC

PROTECT STATUS CH B

PROTECT STATUS CH A

NC

NC

OUTPUT LEVEL CH B

OUTPUT LEVEL CH A

Description

STANDBY Control: Supply 5VDC, 5mADC

1.0kohms (Impedance to GND)

MUTE Control: Connected to GND, +5V, 1mA

PROTECTION Off/Output On: +5VDC, Zo=270ohms

PROTECTION On/Output Off: 0VDC, Zo=High

+4dBu (-27.2dB of Speaker Output Level) at 100W/8ohms, RL=7.5kohms,

Zo=300ohms

4

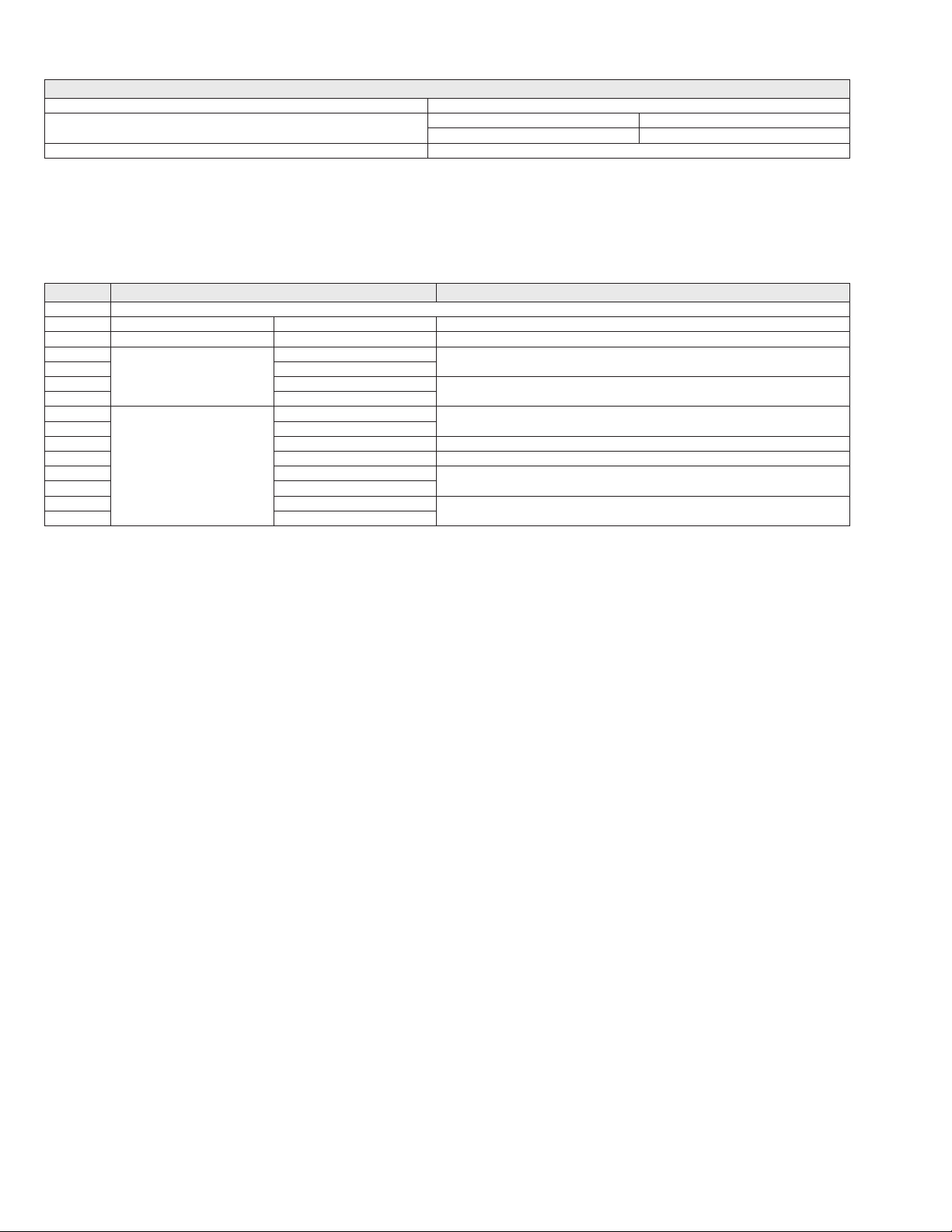

■ 総合仕様

XP7000/XP5000

出力レベル

SN比

消費電力

出力レベル

SN比

消費電力

出力帯域幅

THD+N

混変調歪率

周波数特性

チャンネル間セパレーション

残留ノイズ

ダンピングファクター

ボルテージゲイン

入力感度(dBu)

最大電圧入力

入力インピーダンス

コントロール

コネクター

インジケーター

ロードプロテクション

アンププロテクション

パワーサプライプロテクション

クーリング

電源

XP7000

1kHz

THD+N=1%

20Hz〜20kHz

THD+N=1%

1kHz

20mSnonclip

20Hz〜20kHz

Standby/Idle

1/8(4Ω/ピンクノイズ)

XP5000 100V(J)

1kHz

THD+N=1%

20Hz〜20kHz

THD+N=1%

1kHz

20mSnonclip

20Hz〜20kHz

Standby/Idle

1/8(4Ω/ピンクノイズ)

All Models

HalfPower、THD+N=0.5%

20Hz〜20kHz、HalfPower

60Hz:7kHz、4:1、HalfPower

RL=8Ω、Po=1W、HPF=OFF

20Hz〜50kHz

HalfPower、RL=8Ω、1kHz、

ボリューム最大、入力600Ωシャント

20Hz〜20kHz、ボリューム最小、

(DINAUDIO)

RL=8Ω、1kHz

ボリューム最大

スイッチポジション

フロントパネル

リアパネル

入力

出力

MONITOR/REMOTE

POWER/STANDBY

SIGNAL

CLIP

PROTECTION

TEMP

8Ω/STEREO

4Ω/STEREO

8Ω/BRIDGE

8Ω/STEREO

4Ω/STEREO

70V/STEREORL=8Ω

8Ω/BRIDGE

2Ω/STEREO

4Ω/BRIDGE

(DINAUDIO)

8Ω/STEREO

4Ω/STEREO

8Ω/BRIDGE

8Ω/STEREO

4Ω/STEREO

8Ω/BRIDGE

2Ω/STEREO

4Ω/BRIDGE

(DINAUDIO)

100V(J)

750W + 750W

1100W + 1100W

2200W

700W + 700W

MIN

MIN

MIN

MIN

10Hz〜40kHz

MIN

0.1%

MAX

0.1%

MAX

0dB

MAX

0dB

TYP

-1dB

MIN

70dB

MIN

-70dBu

MAX

350

MIN

32dBまたは26dB(または入力感度+4dBu)、GAINスイッチにより選択可

TYP

+4dBu

26dB

36dB

+22dBu

MIN

20kΩ(バランス)、10kΩ(アンバランス)

TYP

POWERスイッチ(プッシュオン/プッシュオフ)

ボリューム(31ポジション)x2

MODEスイッチ(STEREO/BRIDGE/PARALLEL)x1

HPFスイッチ(20Hz/55Hz/OFF12dB/oct)x2

GAINスイッチ(32dB/26dB/+4dBu)x1

XLR-3-31端子(各チャンネル)

ユーロブロックコネクター(バランス型)(各チャンネル)

スピコン(各チャンネル)、5ウェイバインディングポストx1

D-Sub15ピンx1

x1(緑/橙)

x2(緑)

x2(赤)

x1(赤)

x1(赤)ヒートシンク温度≧85℃

POWERスイッチオン/オフ、ミュート

DC検出:シャットダウン

クリップリミット:THD≧0.5%

温度検出:ヒートシンク温度≧90℃で出力カット

VIリミッター(RL≦1Ω)

温度検出:ヒートシンク温度≧100℃でシャットダウン

連続可変ファンx2

ヒートシンク温度≦55℃で停止

100V、50/60Hz

XP7000 XP5000

+4 +4

+13.7 +12.2

+7.7 +6.2

930W + 930W

625W + 625W

1860W

1400W + 1400W

2800W

104dB

5W/35W

650W

525W + 525W

750W + 750W

1500W

500W + 500W

700W + 700W

1400W

1050W + 1050W

2100W

103dB

5W/35W

500W

5

XP7000/XP5000

All Models

最大外形寸法(WxHxD)

質量

付属品

0dBu=0.775Vrms, Half Power=1/2 Output Power (3dB below rated power)

■ MONITOR/REMOTEピンレイアウト

480x88x456mm

XP7000 XP5000

14kg 14kg

セキュリティーカバー(6角レンチを含む)、取扱説明書

ピン番号

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

GND

REMOTECONTROL

MONITOR

REMOTECONTROL

MONITOR

機能名称

STANDBY

MODELID

NC

NC

MUTECHB

MUTECHA

NC

NC

PROTECTSTATUSCHB

PROTECTSTATUSCHA

NC

NC

OUTPUTLEVELCHB

OUTPUTLEVELCHA

仕様

STANDBYControl:Supply5VDC、5mADC

1.0kΩ(ImpedancetoGND)

MUTEControl:ConnectedtoGND、+5V、1mA

PROTECTIONOff/OutputOn:+5VDC、Zo=270Ω

PROTECTIONOn/OutputOff:0VDC、Zo=High

+4dBu(-27.2dBofSpeakerOutputLevel)at100W/8Ω、RL=7.5kΩ、

Zo=300Ω

6

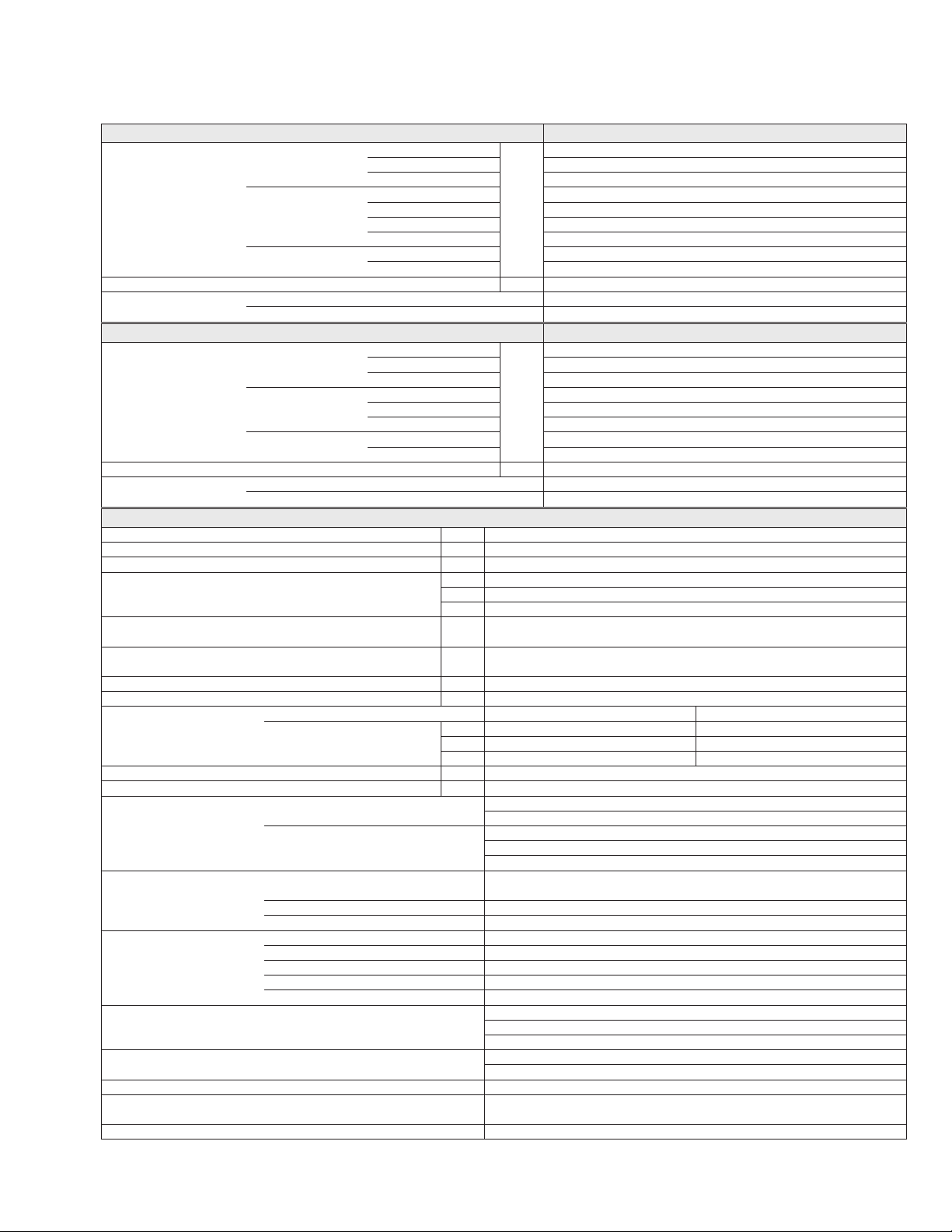

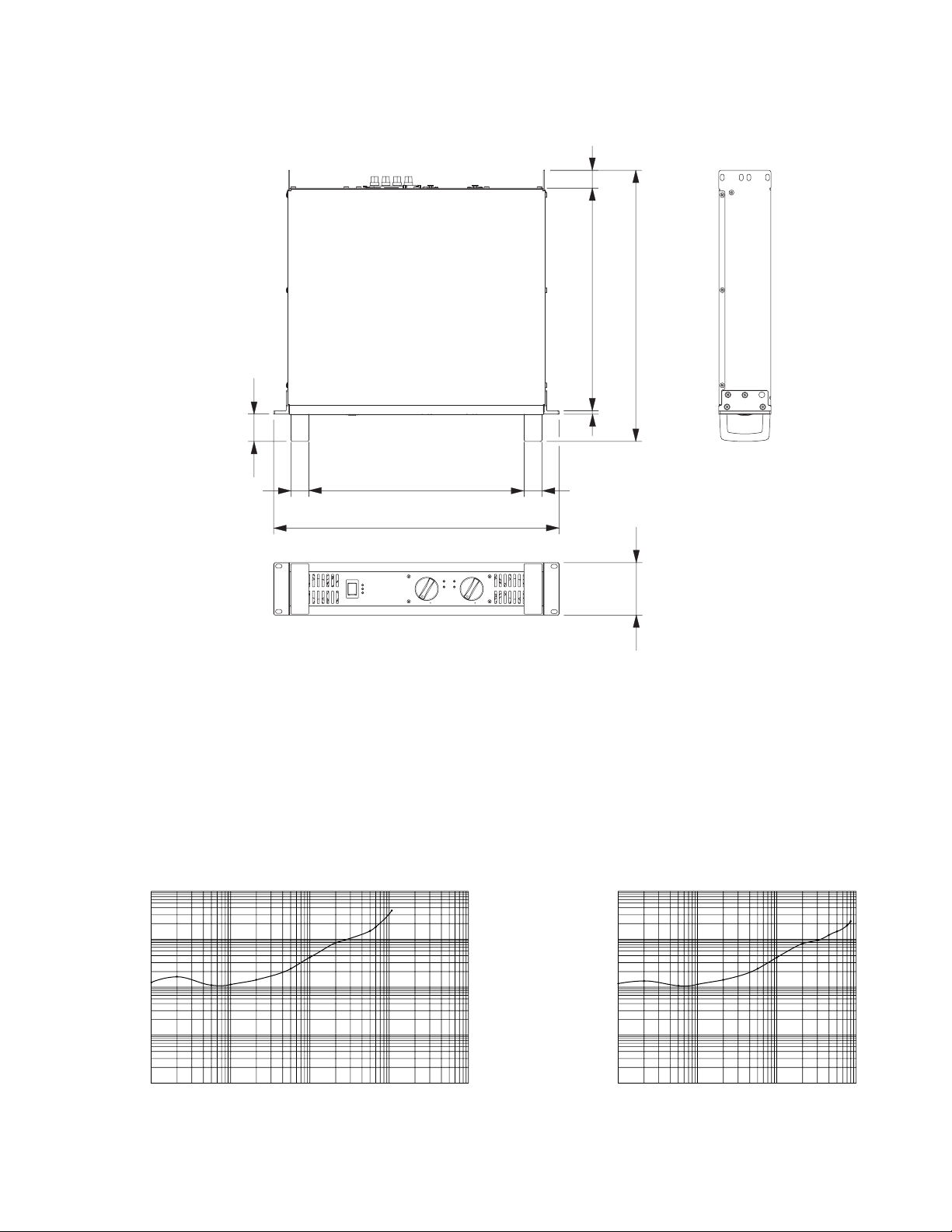

■ DIMENSIONS (寸法図)

• XP7000 • XP5000

Mode:STEREO

Both ch Driven

RL=4 Ω, f=1 kHz

Power Consumption [W]

Output Power [W]

1

10

100

10000

1000

1 10 100 1000 10000

Mode:STEREO

Both ch Driven

RL=4 Ω, f=1 kHz

Power Consumption [W]

Output Power [W]

1

10

100

10000

1000

1 10 100 1000

30

374.5

XP7000/XP5000

456

46

480

■ PERFOMANCE GRAPHS (特性図)

5.5

3030 362

88

Unit: mm

単位:mm

7

XP7000/XP5000

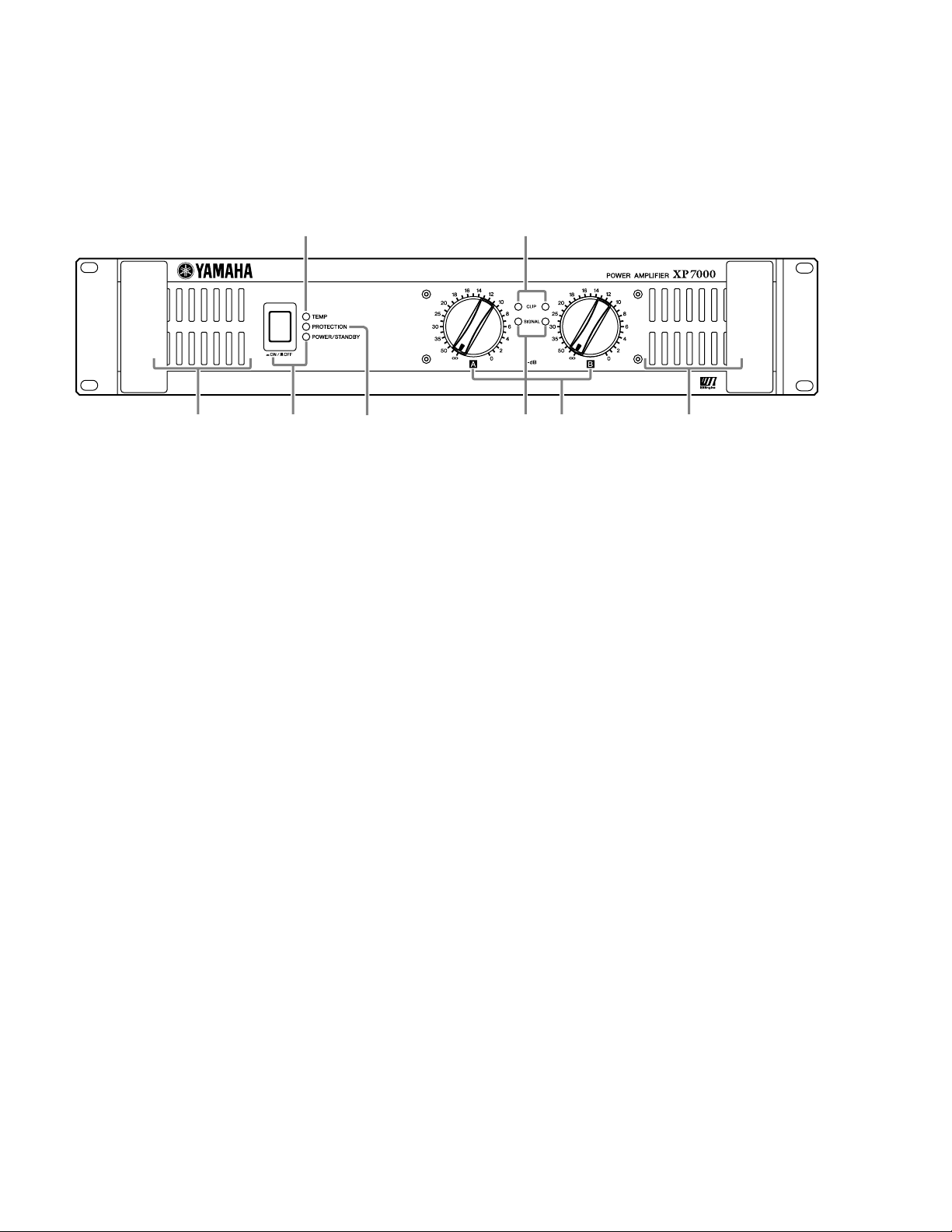

■ PANEL LAYOUT (パネルレイアウト)

• Front Panel (フロントパネル)

713 6 75

42

1 [POWER] switch and indicator

2 [TEMP] indicator

3 [PROTECTION] indicator

4 [CLIP] indicator

5 [SIGNAL] indicator

6 Volume control knobs

7 Air intakes

1

[POWER]スイッチ/インジケーター

2

[TEMP]インジケーター

3

[PROTECTION]インジケーター

4

[CLIP]インジケーター

5

[SIGNAL]インジケーター

6

ボリューム

7

吸気口

8

8

53

4

7

7

6

1

2

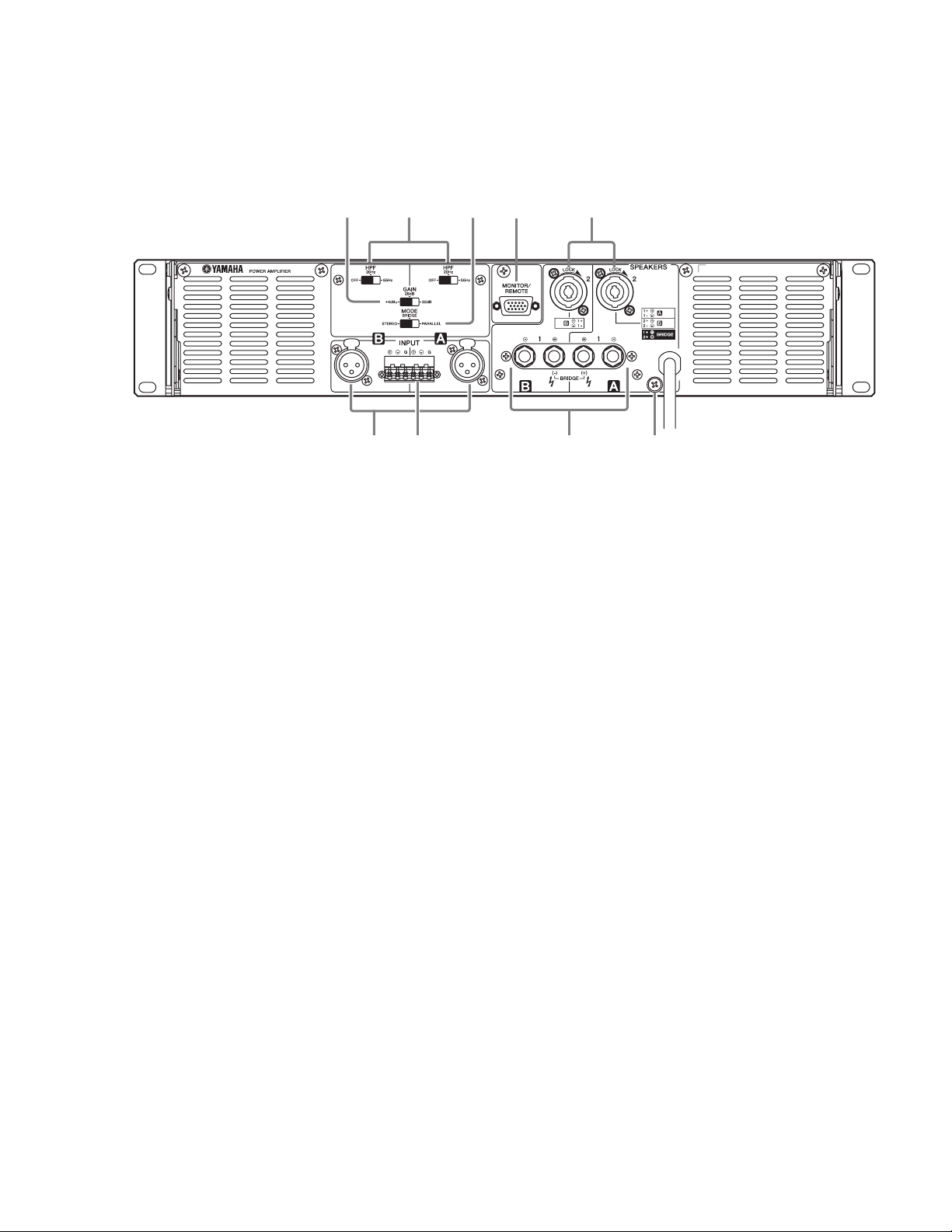

• Rear Panel (リアパネル)

XP7000/XP5000

1 XLR inputs connectors (One pair for each channel)

2 Euroblock inputs connector

3 [HPF] switches (One pair for each channel)

4 [GAIN] switch

5 [MODE] switch

6 [MONITOR/REMOTE] terminal

7 [SPEAKERS] terminals

8 GND terminal

1

XLR入力端子(チャンネルA、B)

2

ユーロブロックコネクター

3

[HPF]スイッチ(チャンネルA、B)

4

[GAIN]スイッチ

5

[MODE]スイッチ

6

[MONITOR/REMOTE]端子

7

[SPEAKERS]端子

8

GND端子

9

XP7000/XP5000

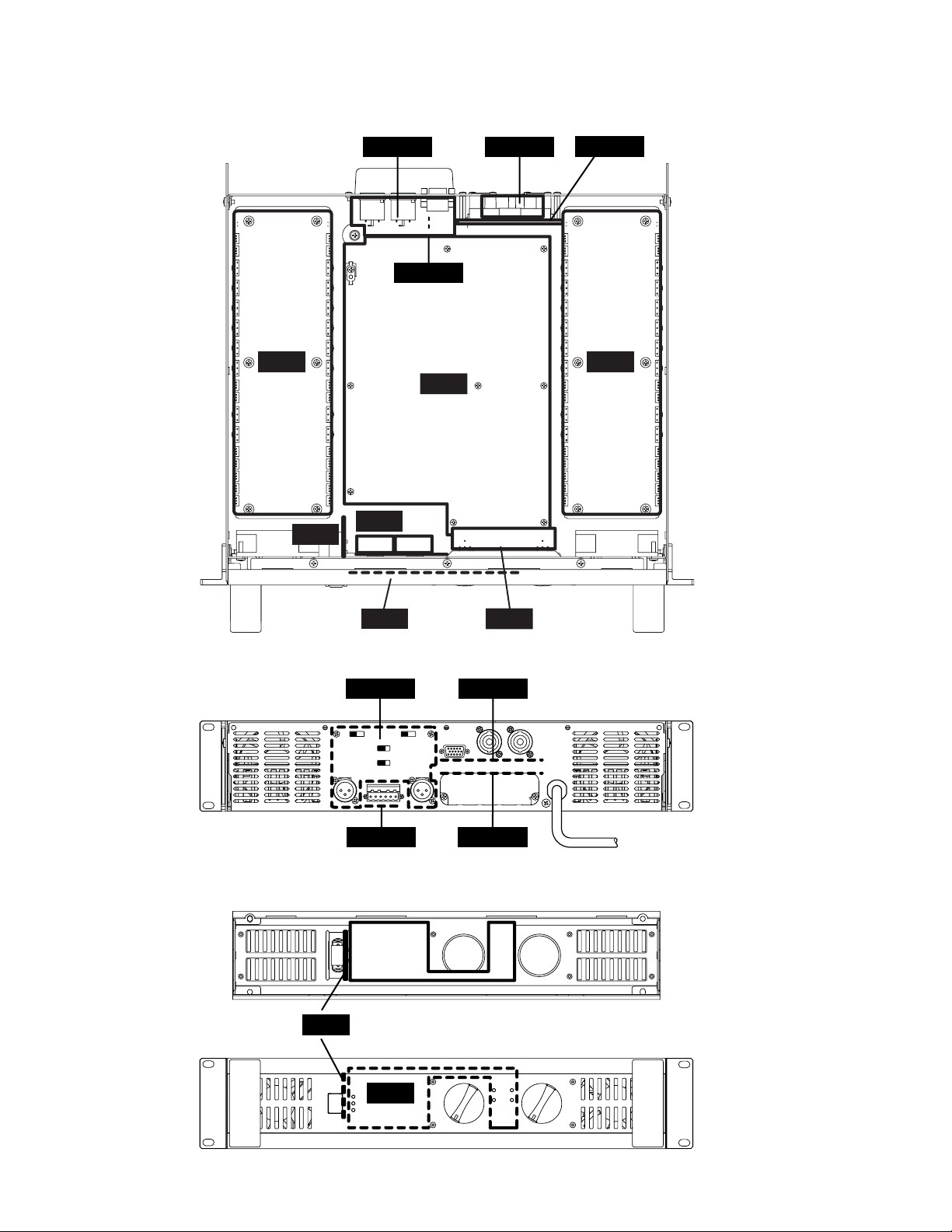

■ CIRCUIT BOARD LAYOUT&WIRING (ユニットレイアウト&結線図)

PAH

PSW

IO 3/4

COIL

IO 4/4

PS

*

IO 2/4

IO 1/4

PAH

* J/H/B/K/O destinations

only.

VRLED

Rear Panel

(リアパネル)

IO 1/4

IO 3/4

IO 2/4 IO 4/4

The figure which looked at the front panel from the inner side

(フロントパネルを内側から見た図)

LED

Front Panel

(フロントパネル)

PSW

↑ Bottom(下側)

↓ Top(上側)

↑ Top(上側)

10

LED

↓ Bottom(下側)

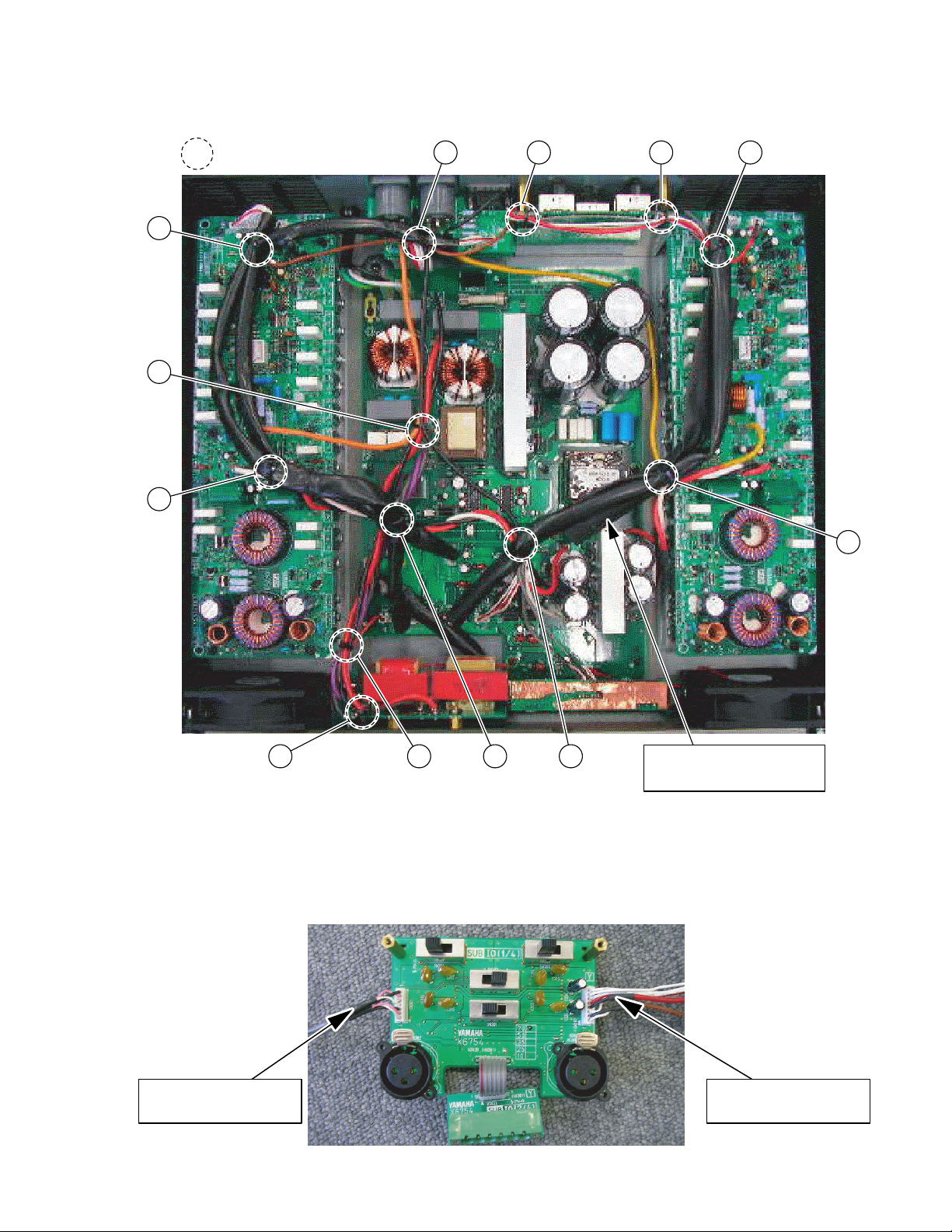

• Whole wiring drawing (全体の結線図)

1291011

8

7

1

2

See page 12 See page 13 See page 13 See page 13

See page

13

See page

14, 15

See page

14, 15

See page

14, 15

See page

14, 15

* Not available as service parts.

サービスパーツではありません

3 4 5

See page

12

See page

13

See page

13

6

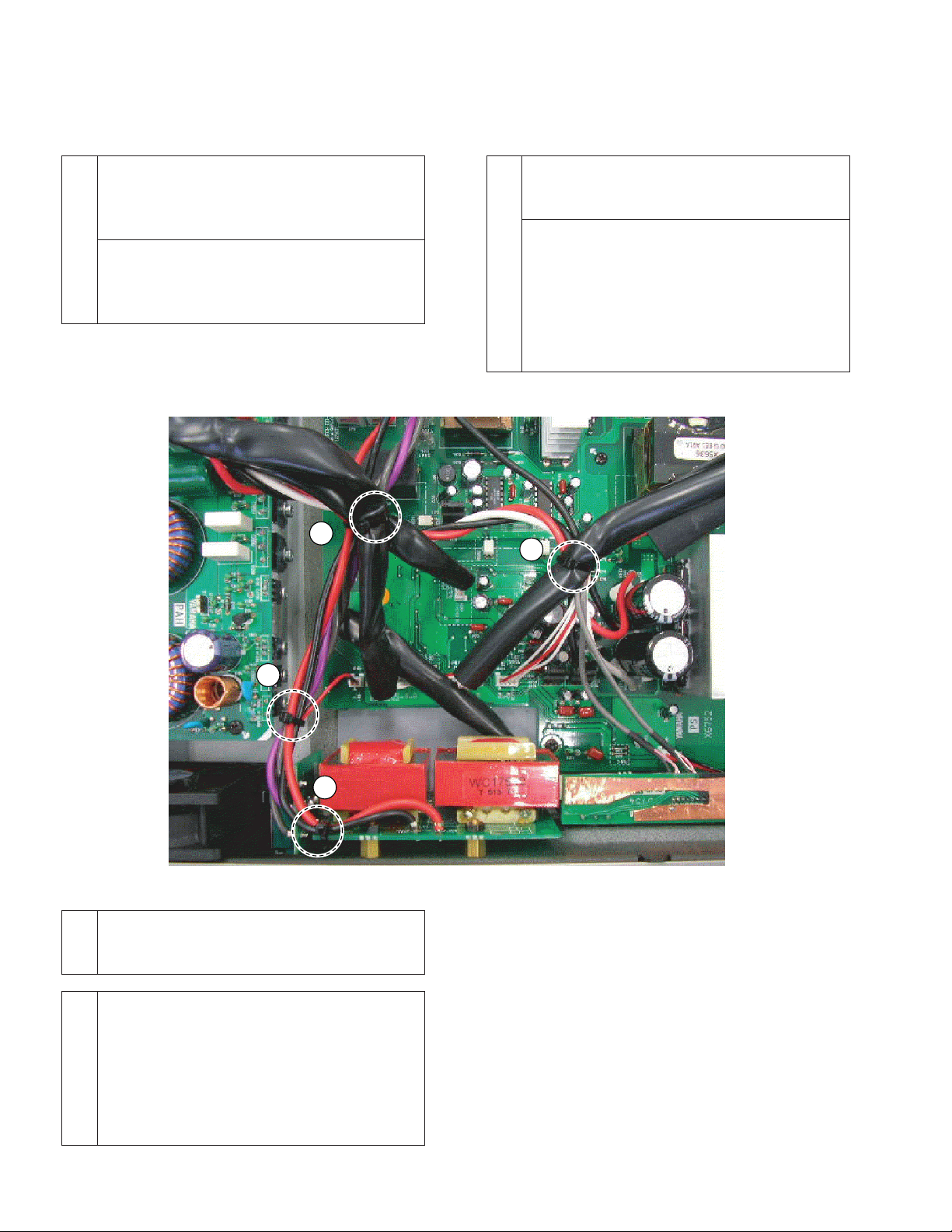

This point has a wire harness tie.

インシュロックタイで束ねます

Tube 18: BLACK (CH00440)

XP7000/XP5000

• Detail drawing IO 1/4 (IO1/4シートの詳細図)

* Attach connector assembly ATT (WD359600) and connector assembly SIG (WF442900) as follows before attaching IO 1/4

circuit board to main chassis.

IO1/4シートをメインシャーシに取り付ける前に、下図の通り束線ATT(WD359600)と束線SIG(WF442900)を取り付けます

Connector assembly ATT

(WD359600)

Connector assembly SIG

(WF442900)

11

XP7000/XP5000

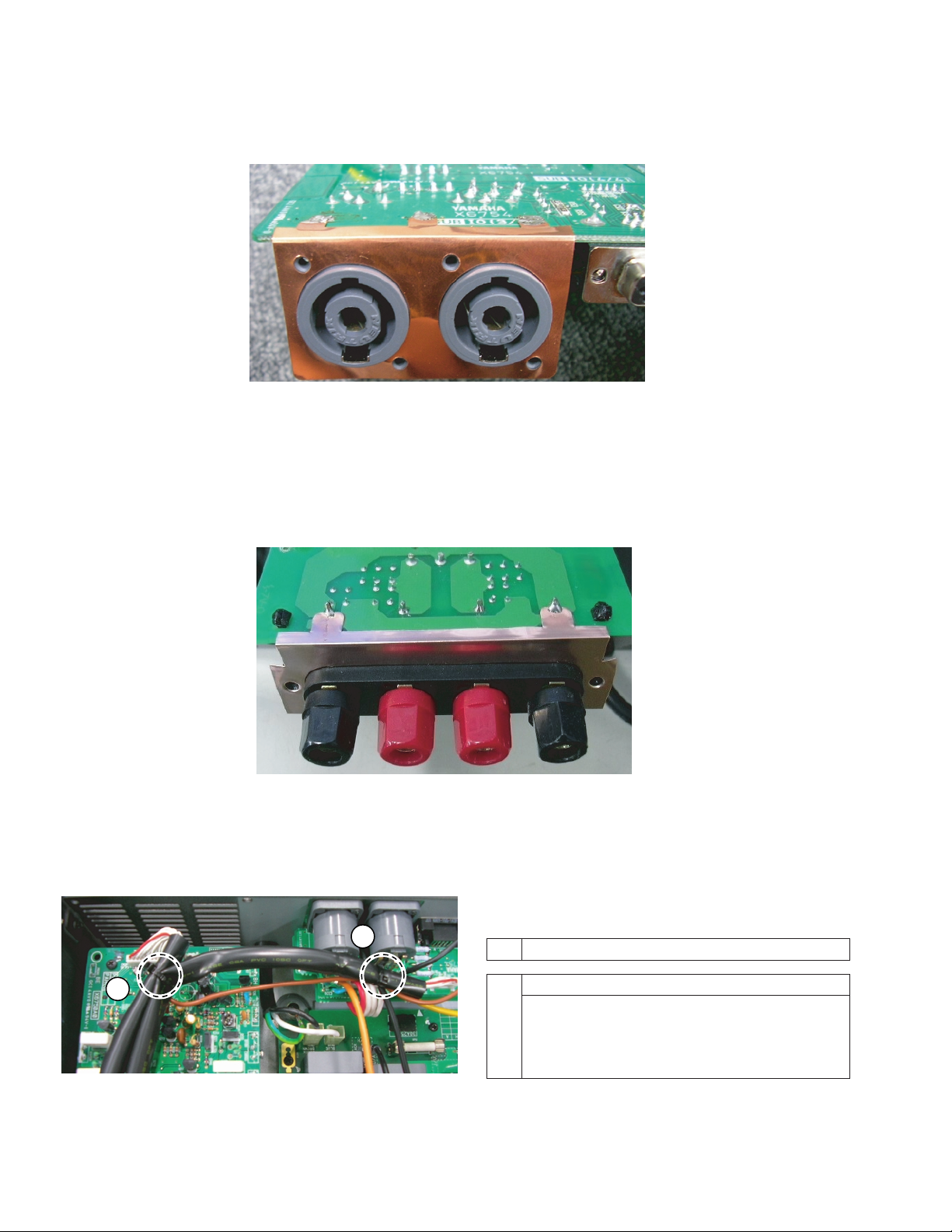

• Detail drawing IO 3/4 (IO3/4シートの詳細図)

* Attach earth film (WG463400) to speaker terminal SP301 and SP302 as follows.

アースフィルム(WG463400)は下図のとおりスピーカー端子SP301およびSP302に装着します

• Detail drawing IO 4/4 (IO4/4シートの詳細図)

* Attach earth film (WD494300) as follows and attached it to speaker terminal SP303.

アースフィルム(WD494300)は下図のとおり折り曲げて、スピーカー端子SP303に装着します

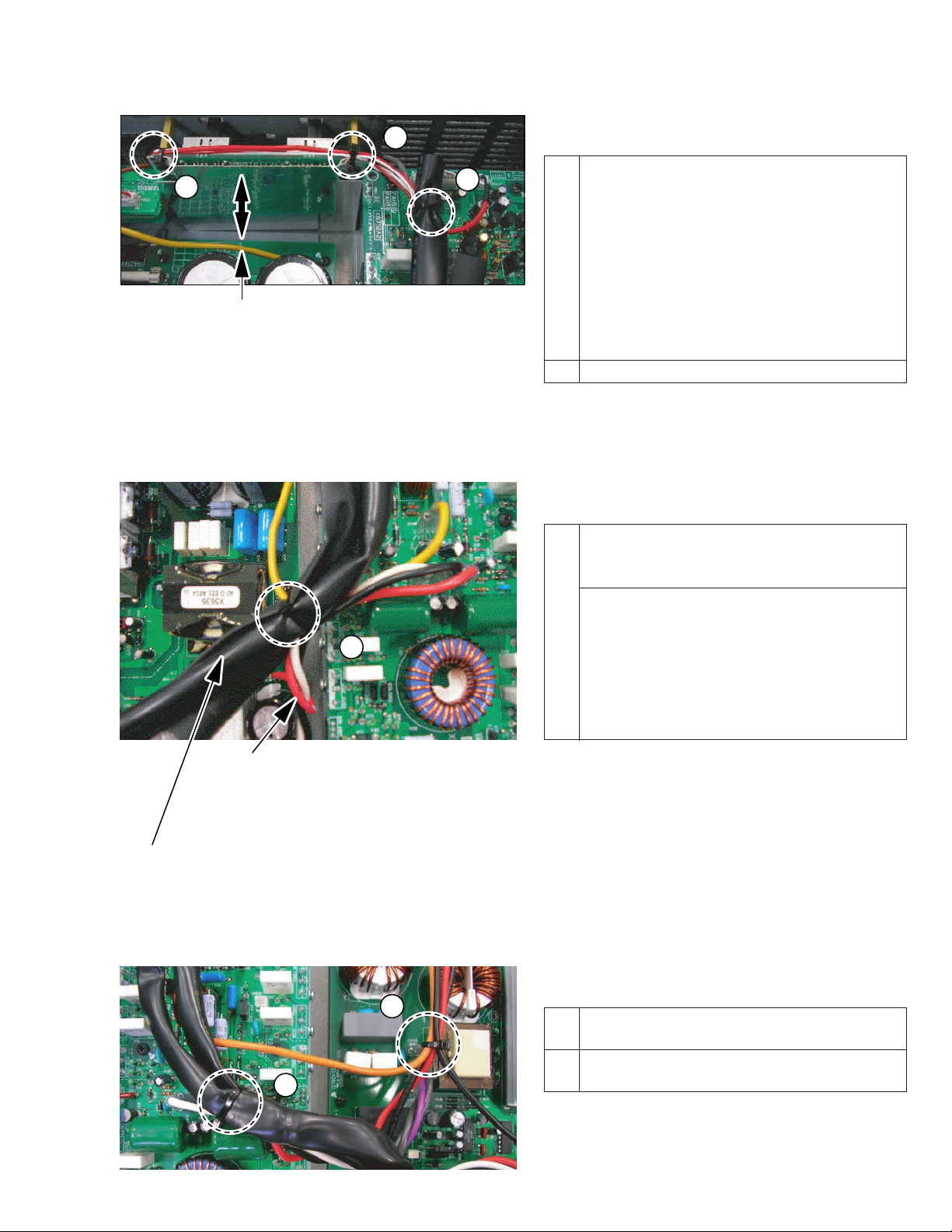

• Detail drawing

1

12

11

1

11

22

2 (

22

11

1

11

22

2

22

部詳細図)

* Tie the following connector assemblies.

下記束線を束ねます

2

1 WF442700, WF442800, WF442900

WF442800, WF442900, WD360100 (W305)

WD360100 (W305) should be crossed under the

others.

2

WD360100(W305)は他の束線の下を交差させてく

ださい

• Detail drawing

33

3

33

44

4

44

55

5 (

55

33

3

33

44

4

44

55

5

55

部詳細図)

4

XP7000/XP5000

* Tie the following connector assemblies.

下記束線を束ねます

3

Keep connector assembly WD360900 (W306) as far away from

IO 1/4 circuit board as possible.

束線WD360900(W306)はできるだけIO1/4シートから離してく

ださい

66

6

66

• Detail drawing

66

6 (

66

部詳細図)

6

5

Connector assembly WF442900 is tied to IO 1/4

circuit board with cord holder.

Connector assembly is placed on a compornent

side of the circuit board.

Each tie is laced through the hole on the circuit

3

board and shield paper (WG46350).

4

束線WF442900はインシュロックタイを用いてIO

1/4シートに固定します

束線はシートの部品面側に固定します

インシュロックタイは基板およびシールドペー

パー(WG46350)にある穴を通します

5 WD359600, WF442700, WF442900

* WG46350 is not available as service par ts.

WG46350はサービスパーツではありません

* Tie the following connector assemblies.

下記束線を束ねます

WD359600, WF442900, WF442700, WD360900

(W306), WD360300 (W406), WD360400 (W407),

WD360500 (W408)

WD359600 and WF442900 are laced through tube

(CH00440).

6

WD359600とWF442900はスミチューブ(CH00440)

をとおしてください

WD360900 (W306) should be crossed under the

others.

WD360900(W306)は他の束線の下を交差させてく

ださい

Connector assemblies WD360300 (W406), WD360400

(W407) and WD360500 (W408) are twisted more than

two rotations.

束線WD360300(W306)、WD360400(W407)、

WD360500(W408)は2回以上ツイストしてください

Keep three connector assemblies (WD359600, WF442900,

WF442700) as far away from transformer (T402) as possible.

3つの束線(WD359600、WF442900、WF442700)はできるだけト

ランス(T402)から離してください

77

88

7

8

77

• Detail drawing

77

7

77

88

8 (

88

88

部詳細図)

8

7

* CH00440 is not available as service parts.

CH00440はサービスパーツではありません

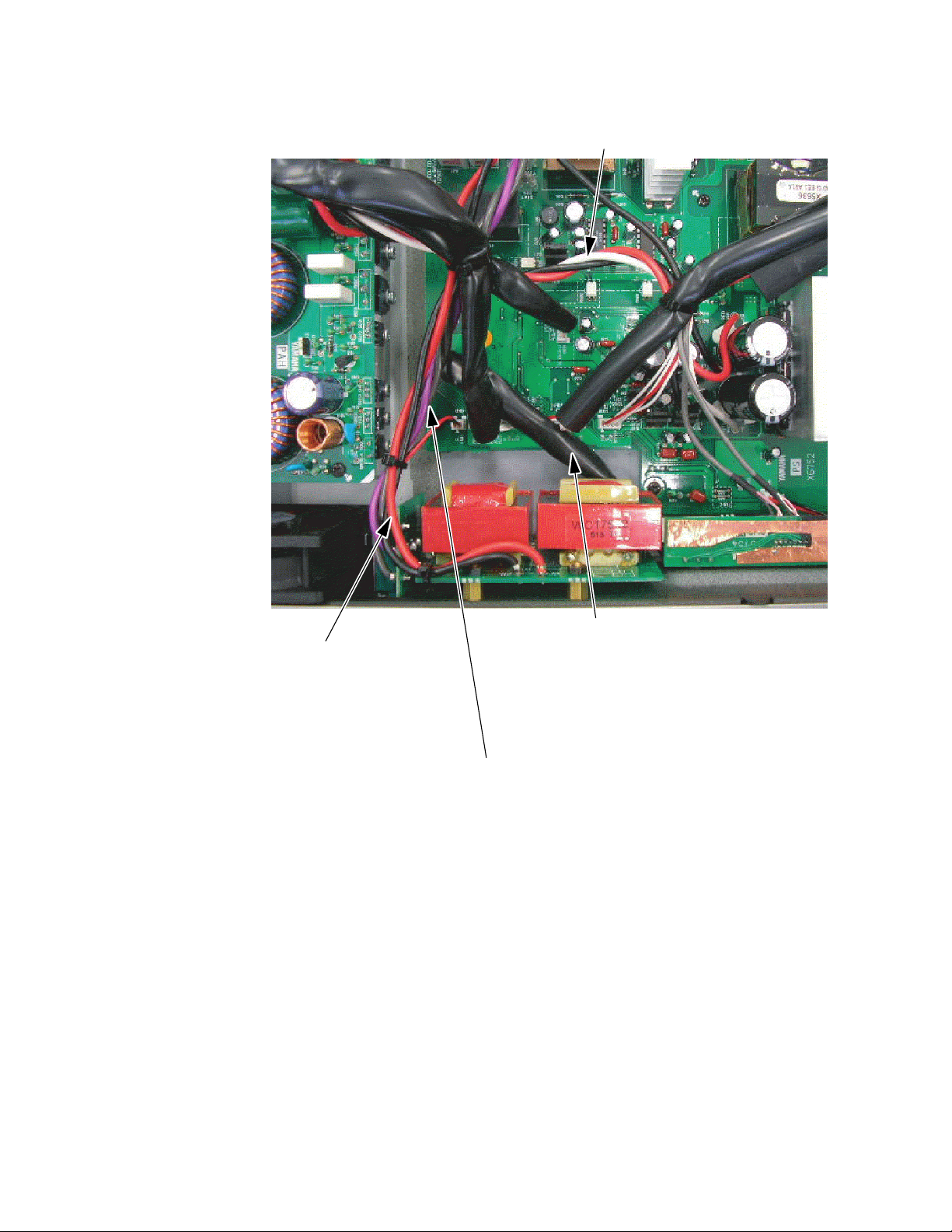

* Tie the following connector assemblies.

下記束線を束ねます

WD361000 (W701), WD361100 (W702), WF444300

7

(W304), WD360100 (W305)

WD360000 (W401), WD360100(W402),

8

WD360200 (W403), WF442700, WF442800

13

XP7000/XP5000

99

00

AA

• Detail drawing

* Tie the following connector assemblies.

下記束線を束ねます

9

99

0

00

A

AA

BB

B (

BB

99

9

99

00

0

00

AA

A

AA

BB

B

BB

部詳細図)

WD360000 (W401), WD360100 (W402), WD360200

(W403), WF443200 (W309), WD361000 (W701),

WD361100 (W702), WF443100 x 2 (W307, W308),

WF442700, WF442800

9

WF443100 x 2 (W307, W308) and WF443200

(W309) should be crossed under the others.

WF443100x2(W307、W308)およびWF443200

(W309)は他の束線の下を交差させてください

9

WD359600, WF442900, WF442700, WD360000

(W401), WD360200 (W403), WD360100 x 2 (W305,

W402)

WD359600, WF442900 and WF442700 shoud be

crossed over the others.

B

WD359600、WF442900、WF442700は他の束線

の上を交差させてください

WD360100 (W305) should be crossed under the

others.

WD360100(W305)は他の束線の下を交差させてく

ださい

12

10

11

WF443100 x 2 (W307, W308), WF443200 (W309),

0

WD361000 (W701), WD361100 (W702), FAN Lead

Wiring

Connector assemblies WD361000 (W701) and

WD361100 (W702) are tied to COIL circuit board

with cord holder (J/H/B/K/O destinations). The cord

holder is laced through the hole on the circuit board.

A

束線WD361000(W701)とWD361100(W702)はイ

ンシュロックタイ(J/H/B/K/O仕向)を用いてCOIL

シートに固定します。インシュロックタイは基板

にある穴を通します

14

XP7000/XP5000

Connector assemblies WD360000 (W401), WD360100 (W402), and WD360200 (W403)

are twisted more than two rotations.

束線WD360000(W401)、WD360100(W402)、WD360200(W403)は2回以上ツイスト

してください

Connector assemblies WD361000 (W701)

and WD361100 (W702) are twisted more than

two rotations.

束線WD361000(W701)とWD361100(W702)

は3回以上ツイストしてください

Connector assemblies WD361000 (W701) and WD361100 (W702) are tied to COIL

circuit board with cord holder. The cord holder is laced through the hole on the circuit

board.

束線WD361000(W701)とWD361100(W702)はインシュロックタイを用いてCOILシー

トに固定します。インシュロックタイは基板にある穴を通します

Connector assembly WF872900 (W310) is located on

the left side of WF442700 connected to CN411 and

crossed under WF442700 connected to CN412.

束線WF872900(W310)はCN411に接続される

WF442700の左側を通し、CN412に接続される

WF442700の下を通してください

15

XP7000/XP5000

■ DISASSEMBLY PROCEDURES (分解手順)

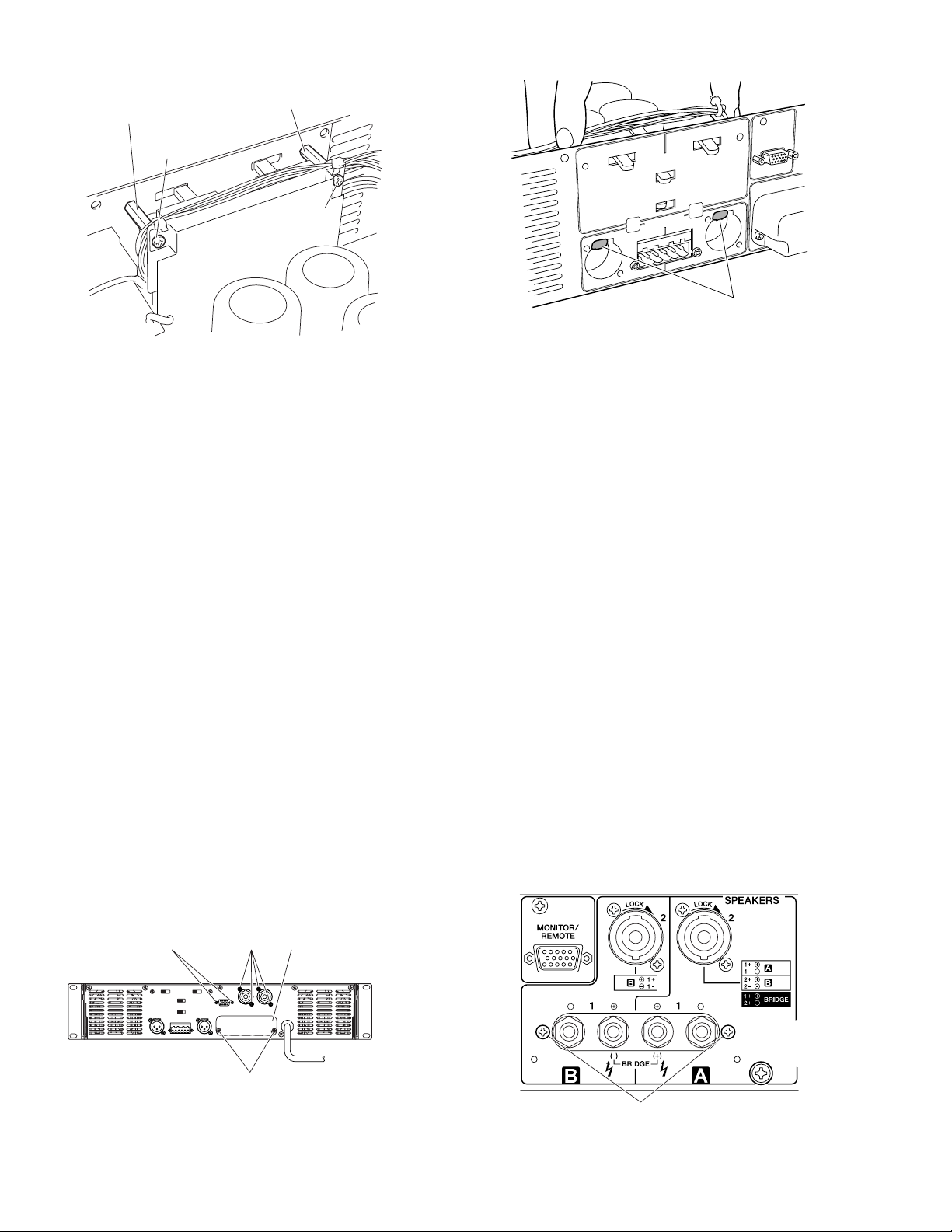

1. Rack Angle (Time required: about 1 min.)

1-1 Remove the three (3) screws marked [470] for each side.

The rack angle can then be removed. (Fig. 1)

2. Top Cover (Time required: about 2 min.)

2-1 Remove the eleven (11) screws marked [530].

The top cover can then be removed. (Fig. 1)

[470] [470]

[530] [345]

[530]

[320] [320][310]

[310]: Pan Head Screw 2.6X6 MFZN2B3 (WE986400) 小ネジ+PAN

[320]: Bonding Tapping Screw-B 3.0X10 MFZN2B3 (WE878000) Bタイト+BOND

[345]: Bind Head Tapping Screw-S 3.0X6 MFZN2B3 (WE877800) Sタイト+BIND

[470]: Bind Head Screw 4.0X10 MFZN2B3 (WE980400) 小ネジ+BIND

[530]: Bind Head Screw 4.0X8 MFZN2B3 (WE962000) Bタイト+BIND

[345]

1. ラックアングル(所要時間:約1分)

1-1 [470]のネジを左右3本ずつ外し、ラックアングルを外

します。(Fig.1)

2. トップカバー(所要時間:約2分)

2-1 [530]のネジ11本を外し、トップカバーを外します。

(Fig.1)

[530][530]

[530]

(Fig. 1)

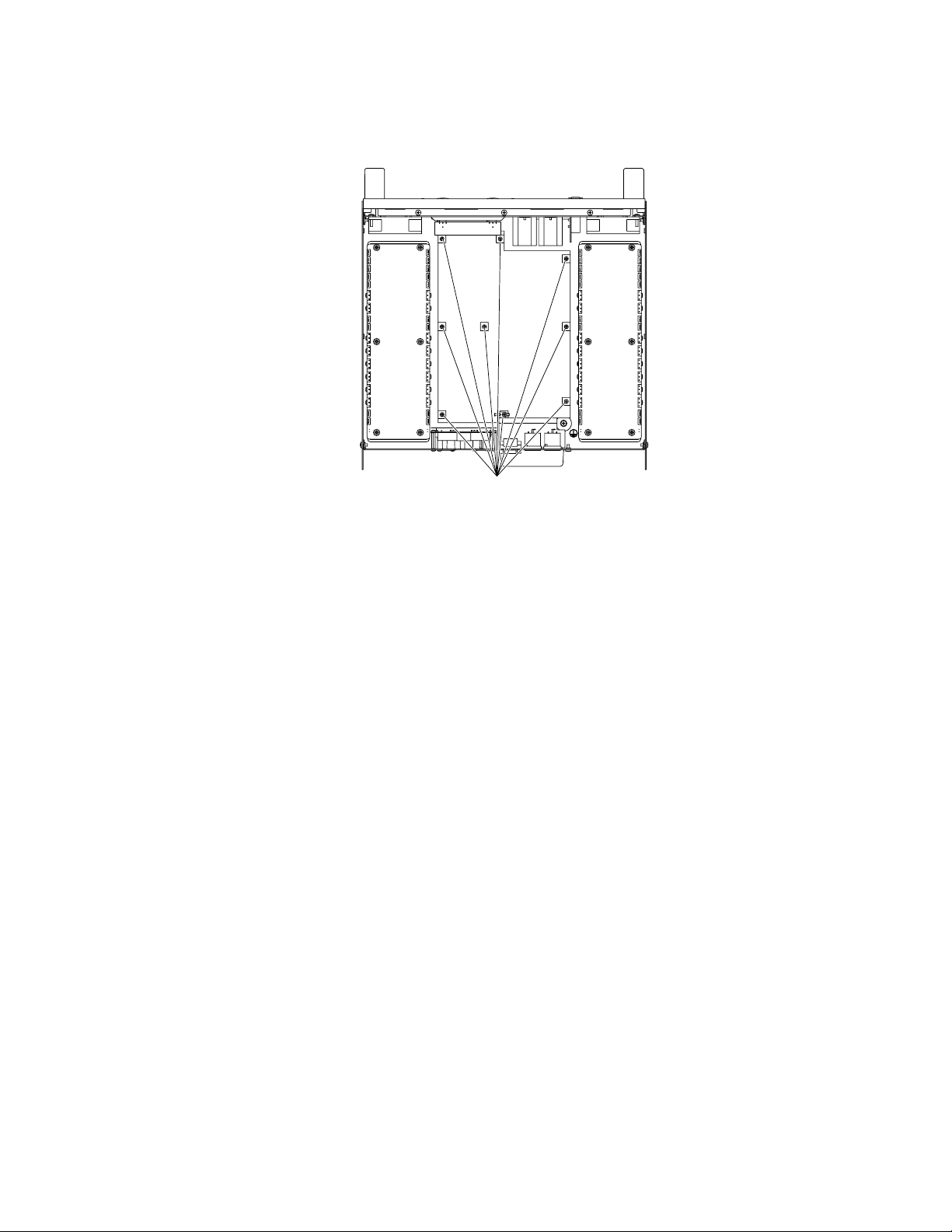

3. PA Unit (Time required: about 5 min.)

3-1 Remove the top cover. (See procedure 2.)

3-2 Remove the six (6) screws marked [200] for each side

from the bottom. The PA units can then be removed.

(Fig. 2)

* Flat washers are attached between the main chassis

and PA unit. Take care not to lose flat washers when

removing screw marked [200].

[200] [200]

[200]: Bind Head Screw 4.0X8 MFZN2B3 (WE962000) Bタイト+BIND

16

3. PAユニット(所要時間:約5分)

3-1 トップカバーを外します。(2項参照)

3-2 本体の底面より[200]のネジを左右6本ずつ外し、各PA

ユニットを外します。(Fig.2)

* PAユニットとメインシャーシの間には平座金があり

ます。[200]のネジを外すときは、平座金を紛失しな

いように注意してください。

<Bottom View>

(Fig. 2)

XP7000/XP5000

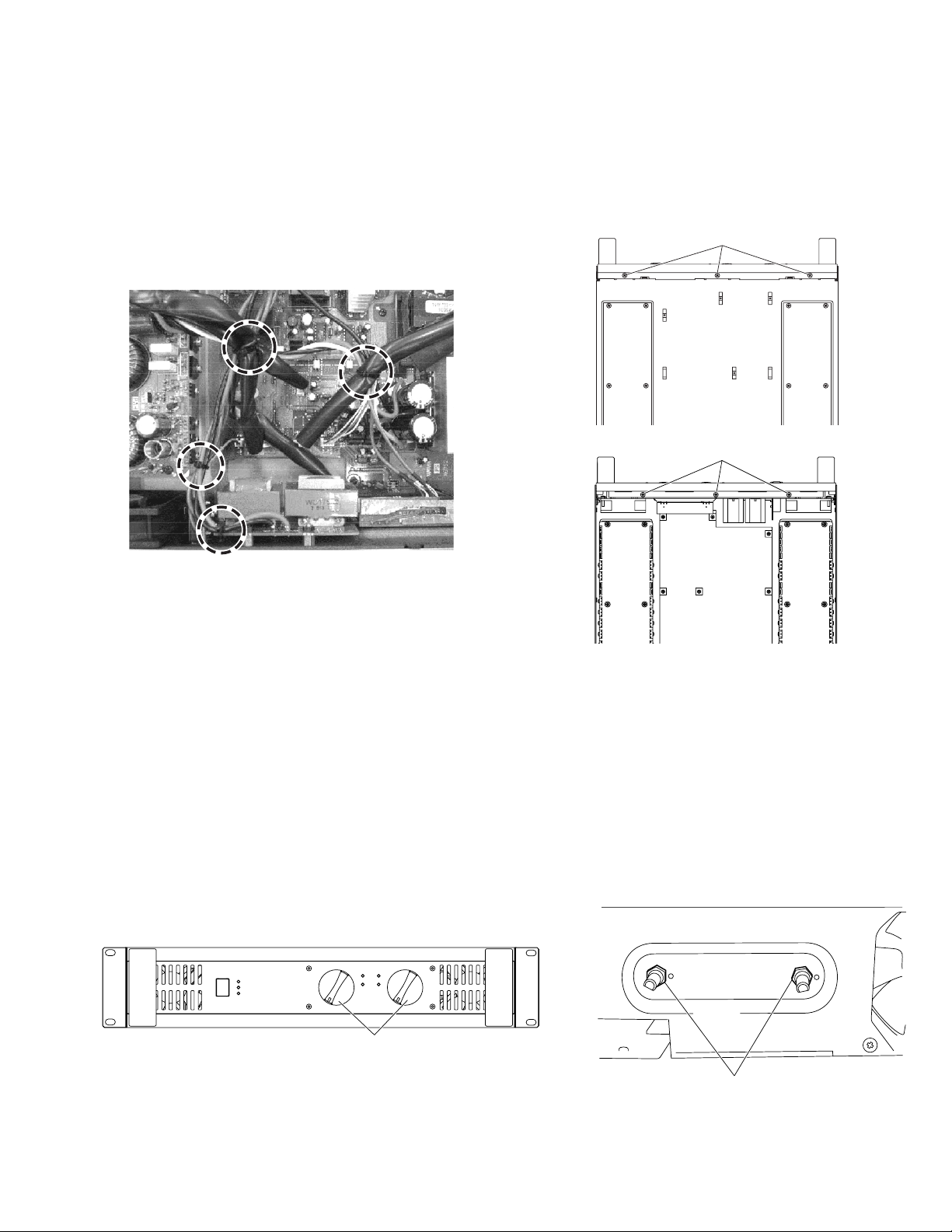

4. PS Circuit Board (Time required: about 5 min.)

4-1 Remove the top cover. (See procedure 2.)

4-2 Remove the nine (9) screws marked [230]. The PS cir-

cuit board can then be removed. (Fig. 3)

[230]: Bind Head Tapping Screw-S 3.0X6 MFZN2W3 (WE877900) Sタイト+BIND

4. PSシート(所要時間:約5分)

4-1 トップカバーを外します。(2項参照)

4-2 [230]のネジ9本を外し、PSシートを外します。(Fig.3)

<Top View>

[230]

(Fig. 3)

5. IO 1/4 Circuit Board (Time required: about 6 min.)

5-1 Remove the top cover. (See procedure 2.)

5-2 Remove the two (2) screws marked [310], the four (4)

screws marked [320] and the two (2) screws marked

[345]. (Fig. 1)

5-3 Remove the two (2) screws marked [340] to remove the

two hexagonal spacers. (Fig. 4)

5-4 Remove the solder of W302B on the IO 1/4 circuit board,

or W302A on the IO 2/4 circuit board since the IO 1/4

circuit board and the IO 2/4 circuit board are connected

with connector assembly W302. Also remove the solder

of W301A on the IO 1/4 circuit board, or W301B on the

IO 3/4 circuit board since the IO 1/4 circuit board and

the IO 3/4 circuit board are connected with connector

assembly W301. The IO 1/4 circuit board can then be

removed.

* When reinstalling the IO 1/4 circuit board, let the

hooks of the XLR connectors out of the chassis at

first, and inserts the jacks or switches into the holes

on the chassis. (Fig. 5)

* The IO 1/4 circuit board is not available as service

parts individually.

6. IO 2/4 Circuit Board (Time required: about 6 min.)

6-1 Remove the top cover. (See procedure 2.)

6-2 Remove the IO 1/4 circuit board. (See procedure 5.)

6-3 Remove the solder of W302A on the IO 2/4 circuit board,

or W302B on the IO 1/4 circuit board since the IO 2/4

circuit board and the IO 1/4 circuit board are connected

with connector assembly W302. The IO 2/4 circuit board

can then be removed.

* The IO 2/4 circuit board is not available as service

parts individually.

5. IO1/4シート(所要時間:約6分)

5-1 トップカバーを外します。(2項参照)

5-2 [310]のネジ2本、[320]のネジ4本と[345]のネジ2本を

外します。(Fig.1)

5-3 [340]のネジ2本を外し、6角スペーサーを外します。

(Fig.4)

5-4 IO1/4シートとIO2/4シートは束線W302で接続されて

いますので、IO1/4シート側端子W302B、またはIO2/

4シート側端子W302Aのハンダを外します。またIO3/

4シートと束線W301で接続されていますので、IO1/4

シート側端子W301A、またはIO 3/4シート側端子

W301Bのハンダを外します。IO 1/4シートを外せま

す。

* IO1/4シートを再度取り付けるときは、キャノンタ

イプコネクタのツメをシャーシの外側に出した後、

ジャックやスイッチをシャーシの穴に通します。

(Fig.5)

* IO1/4シート単体はサービスパーツではありません。

6. IO2/4シート(所要時間:約6分)

6-1 トップカバーを外します。(2項参照)

6-2 IO1/4シートを外します。(5項参照)

6-3 IO2/4シートとIO1/4シートは束線W302で接続されて

いますので、IO2/4シート側端子W302A、またはIO1/

4シート側端子W302Bのハンダを外します。IO2/4シー

トを外せます。

* IO2/4シート単体はサービスパーツではありません。

17

XP7000/XP5000

Hexagonal Spacer

Hexagonal Spacer

6角スペーサー

[340]

[340]: Bind Head Tapping Screw-S 3.0X6 MFZN2W3 (WE877900)

Sタイト+BIND

(Fig. 4)

6角スペーサー

[340]

Hooks

ツメ

(Fig. 5)

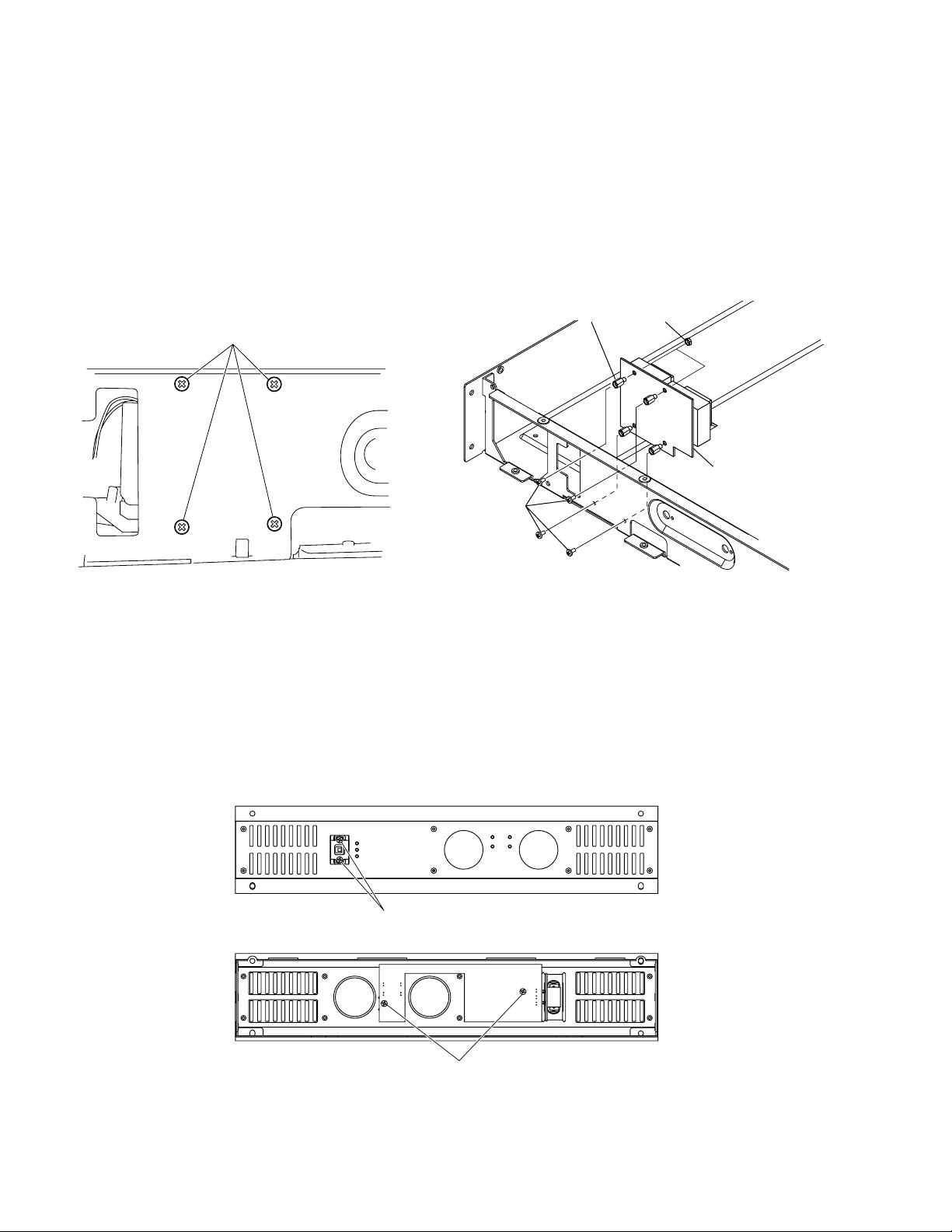

7. IO 3/4 Circuit Board (Time required: about 4min.)

7-1 Remove the top cover. (See procedure 2.)

7-2 Remove the two (2) hexagonal locked spacers. (Fig. 6)

7-3 Remove the four (4) screws marked [360]. (Fig. 6)

7-4 Remove the solder of W301B on the IO 3/4 circuit board,

or W301A on the IO 1/4 circuit board since the IO 3/4

circuit board and the IO 1/4 circuit board are connected

with connector assembly W301. Also remove the solder

of W303A on the IO 3/4 circuit board, or W303B on the

IO 4/4 circuit board since the IO 3/4 circuit board and

the IO 4/4 circuit board are connected with connector

assembly W303. The IO 3/4 circuit board can then be

removed.

* The IO 3/4 circuit board is not available as service

parts individually.

8. IO 4/4 Circuit Board (Time required: about 5 min.)

8-1 Remove the top cover. (See procedure 2.)

8-2 Remove the IO 3/4 circuit board. (See procedure 6.)

8-3 Remove the two (2) screws marked [550].

Remove the speaker terminal cover. (Fig. 6)

8-4 Remove the two (2) screws marked [350]. (Fig. 7)

8-5 Remove the solder of W303B on the IO 4/4 circuit board,

or W303A on the IO 3/4 circuit board since the IO 4/4

circuit board and the IO 3/4 circuit board are connected

with connector assembly W303. The IO 4/4 circuit board

can then be removed.

* The IO 4/4 circuit board is not available as service

parts individually.

Hexagonal Locked Spacer

6角ロックネジ

Speaker Terminal Cover

[360]

SPターミナルカバー

7. IO3/4シート(所要時間:約4分)

7-1 トップカバーを外します。(2項参照)

7-2 6角ロックネジ2本を外します。(Fig.6)

7-3 [360]のネジ4本を外します。(Fig.6)

7-4 IO3/4シートとIO1/4シートは束線W301で接続されて

いますので、IO3/4シート側端子W301B、またはIO1/

4シート側端子W301Aのハンダを外します。またIO4/

4シートと束線W303で接続されていますので、IO3/4

シート側端子W303A、またはIO 4/4シート側端子

W303Bのハンダを外します。IO 3/4シートを外せま

す。

* IO3/4シート単体はサービスパーツではありません。

8. IO4/4シート(所要時間:約5分)

8-1 トップカバーを外します。(2項参照)

8-2 IO3/4シートを外します。(7項参照)

8-3 [550]のネジ2本を外し、SPターミナルカバーを外しま

す。(Fig.6)

8-4 [350]のネジ2本を外します。(Fig.7)

8-5 IO4/4シートとIO3/4シートは束線W303で接続されて

いますので、IO4/4シート側端子W303B、またはIO3/

4シート側端子W303Aのハンダを外します。IO4/4シー

トを外せます。

* IO4/4シート単体はサービスパーツではありません。

[550]

[360]: Flat Head Tapping Screw-B 3.0X8 MFZN2B3 (WF266800)

Bタイト+FLAT

[550]: Bind Head Tapping Screw-S 3.0X6 MFZN2B3 (WE877800)

Sタイト+BIND

18

[350]

[350]: Bonding Tapping Screw-B 3.0X10 MFZN2B3 (WE878000)

Bタイト+BOND

(Fig. 7)(Fig. 6)

XP7000/XP5000

9. Front Panel Unit (Time required: about 5 min.)

9-1 Remove the rack angle. (See procedure 1.)

9-2 Remove the top cover. (See procedure 2.)

9-3 Cut cord holder (4 point) of the connector assembly. (Fig.

8)

9-4 Remove the six (6) screws marked [450]. (Fig. 9)

9-5 Draws out the front panel unit.

9. フロントパネル部(所要時間:約5分)

9-1 ラックアングルを外します。(1項参照)

9-2 トップカバーを外します。(2項参照)

9-3 束線のインシュロックタイ(4箇所)を切断します。

(Fig.8)

9-4 [450]のネジ6本を外します。(Fig.9)

9-5 フロントパネル部を前方へ引き出します。

<Bottom View>

<Top View>

[450]

[450]

Front Panel side

(フロントパネル側)

(Fig. 8)

10. VR Circuit Board (Time required: about 6 min.)

10-1 Remove the front panel unit. (See procedure 9.)

10-2 Remove the attenuation knobs. (Fig. 10)

10-3 Remove the two (2) hexagonal nuts.

The VR circuit board can then be removed. (Fig. 11)

[450]: Bind Head Screw 4X8 MFZN2B3 (WE962000)

Bタイト+BIND

(Fig. 9)

10. VRシート(所要時間:約6分)

10-1 フロントパネル部を外します。(9項参照)

10-2 アッテネーターノブを外します。(Fig.10)

10-3 6角ナット2個を外し、VRシートを外します。(Fig.11)

(Fig. 10)

Attenuation Knob

アッテネーターノブ

Hexagonal Nut

6角ナット

(Fig. 11)

19

XP7000/XP5000

11. COIL Circuit Board (Time required: about 7 min.)

<J/H/B/K/O destinations only>

11-1 Remove the front panel unit. (See procedure 9.)

11-2 Remove the PS circuit board. (See procedure 4.)

11-3 Remove the four (4) screws marked [70].

The COIL circuit board can then be removed. (Fig. 12)

11-4 Remove the four (4) hexagonal nuts.

The four (4) hexagonal spacers can then removed.

(Fig. 13)

* When reinstalling the COIL circuit board, connect the

red wire to PS-CN406 and the black wire to PS-CN415.

[70]

11. COILシート(所要時間:約7分)

〈J/H/B/K/O仕向のみ〉

11-1 フロントパネル部を外します。(9項参照)

11-2 PSシートを外します。(4項参照)

11-3 [70]のネジ4本を外し、COILシートを外します。

(Fig.12)

11-4 6角ナット4個を外し、6角スペーサ4本を外します。

(Fig.13)

* コイルを再度取り付けるとき、コイルシートのワイ

ヤー赤はPS-CN406、黒はPS-CN415へ接続して

ください。

Hexagonal Spacer

6角スペーサー

[70]

Hexagonal Nut

6角ナット

COIL Circuit Board

COILシート

[70]: Bind Head Tapping Screw-S 3.0X6 MFZN2W3 (WE877900)

Sタイト+BIND

(Fig. 12)

12. LED Circuit Board (Time required: about 5min.)

12-1 Remove the front panel unit. (See procedure 9.)

12-2 Remove the two (2) screws marked [180].

The LED circuit board can then be removed. (Fig. 14)

[140]

To p(上側) ↑

Bottom(下側) ↓

[70]: Bind Head Tapping Screw-S 3.0X6 MFZN2W3 (WE877900)

Sタイト+BIND

(Fig. 13)

12. LEDシート(所要時間:約5分)

12-1 フロントパネル部を外します。(9項参照)

12-2 [180]のネジ2本を外してLEDシートを外します。

(Fig.14)

<Front View>

<Back View>

20

[180]

[140]: Bind Head Tapping Screw-S 3.0X6 MFZN2W3 (WE877900) Sタイト+BIND

[180]: Bind Head Tapping Screw-S 3.0X6 MFZN2W3 (WE877900) Sタイト+BIND

(Fig. 14)

XP7000/XP5000

Power Switch Knob

PSWノブ

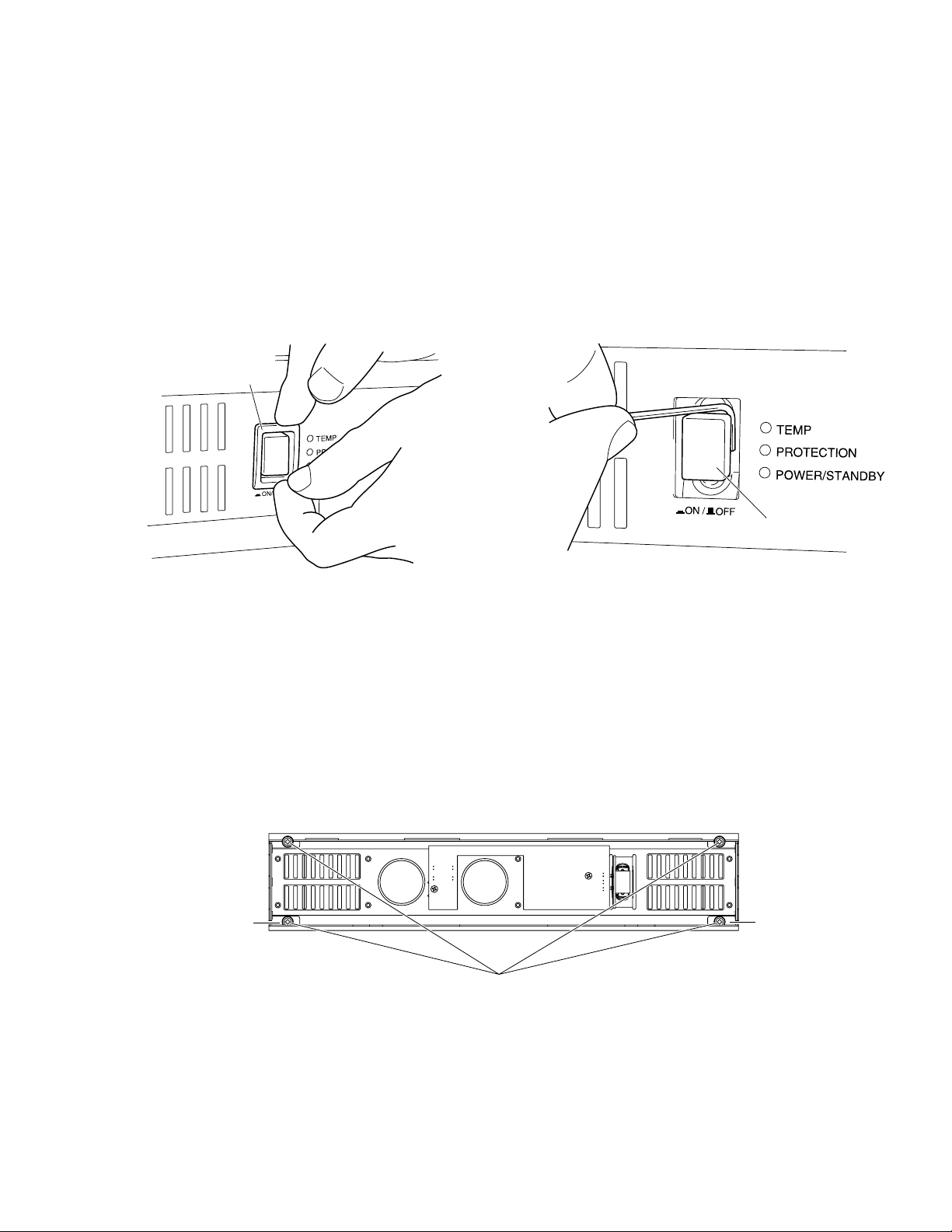

13. PSW Circuit Board (Time required: about 10 min.)

13-1 Remove the front panel unit. (See procedure 9.)

13-2 Remove the power switch escutcheon. (Fig. 15)

13-3 Press lightly from the panel back and remove the power

switch knob.

* When it is hard to remove the power switch knob, in-

sert an L-shaped rod into the gap and pull out the

knob as shown the illustration. (Fig. 16) Take care not

to scratch to bruise a panel and a knob at this time.

13-4 Remove the two (2) screws marked [140].

The PSW circuit board can then be removed. (Fig. 14)

* The PSW circuit board can be removed easily if you re-

move the front panel (2) beforehand. (See procedure 15.)

Power Switch Escutcheon

PSWエスカッション

13. PSWシート(所要時間:約10分)

13-1 フロントパネル部を外します。(9項参照)

13-2 PSWエスカッションを外します。(Fig.15)

13-3 パネル裏面から軽く押し出してPSWノブを外します。

* 外しにくいときは、図で示すように隙間からL型の

棒などを挿入し、PSWノブを引き出して外します。

(Fig.16)このときパネルやノブへ傷をつけない様に

注意してください。

13-4 [140]のネジ2本を外し、PSWシートを外します。

(Fig.14)

* フロントパネル2印刷を外しておくと、簡単に取り外

し作業が行えます。(15項参照)

(Fig. 15) (Fig. 16)

14. Handle (Time required: about 6 min.)

14-1 Remove the front panel unit. (See procedure 9.)

14-2 Remove the two (2) screws marked [430] for each side.

The handles can then be removed. (Fig. 17)

* The handle angle is removed simultaneously, at this

time.

Handle Angle

ハンドルアングル

[430]: Bind Head Screw 5.0X16 MFZN2W3 SP (WG168300) 小ネジ+BIND

14. ハンドル(所要時間:約6分)

14-1 フロントパネル部を外します。(9項参照)

14-2 [430]のネジを左右2本ずつ外し、ハンドルを外しま

す。(Fig.17)

* この時、ハンドルアングルも同時に外れます。

<Back View>

Handle Angle

ハンドルアングル

[430]

(Fig. 17)

21

XP7000/XP5000

15. Front Panel (Time required: about 8 min.)

15-1 Remove the front panel unit. (See procedure 9.)

15-2 Remove the handles. (See procedure 14.)

15-3 Remove the eight (8) screws marked [400].

The front panels can then be removed. (Fig. 18)

[400]: Hex Socket Set Screw-S 3.0X10 MFZN2B3 (WF419400) Sタイト6角孔付き

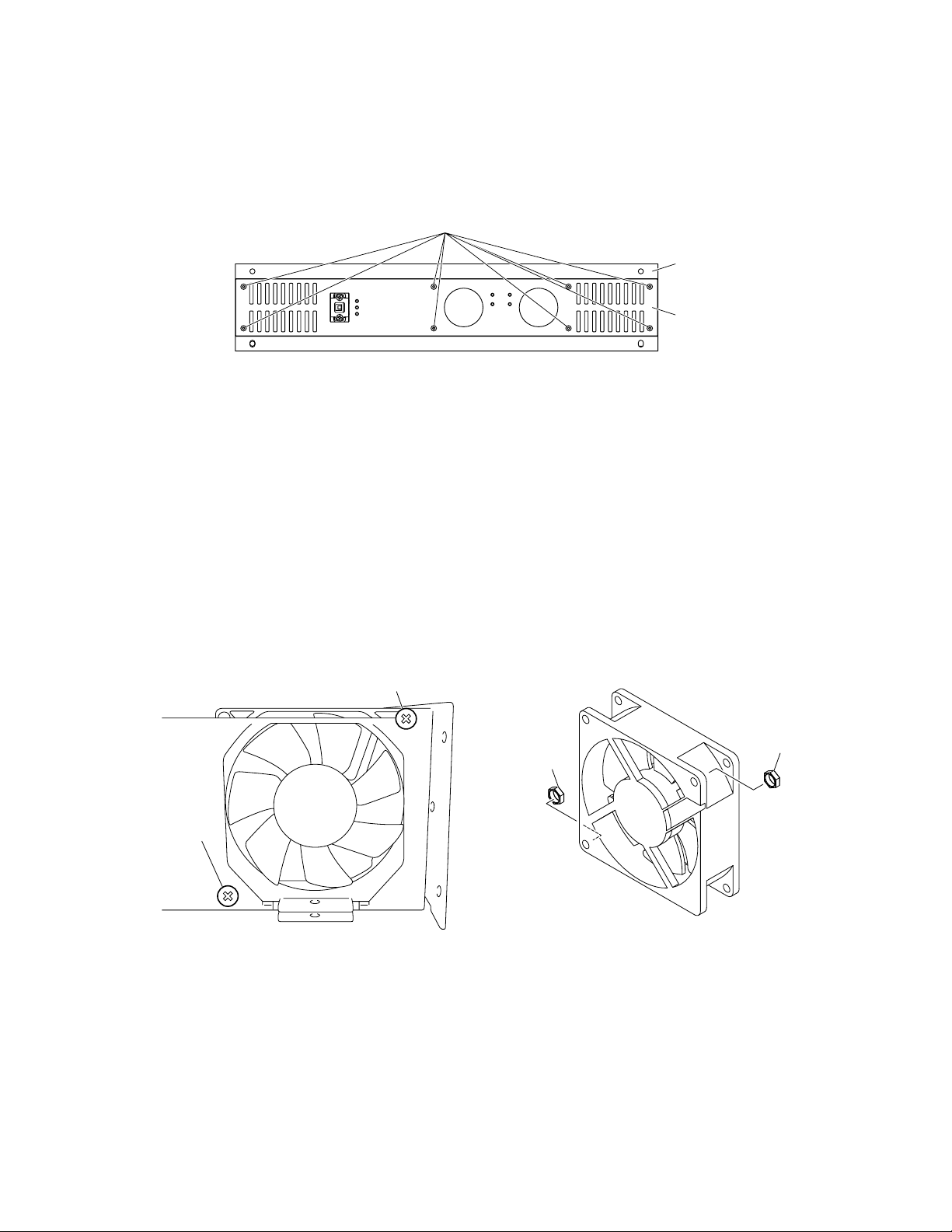

16. Fan (Time required: about 12 min.)

16-1 Remove the front panel unit. (See procedure 9.)

16-2 Remove the PA unit located on the same side as the fan

to remove. (See procedure 3.)

16-3 Remove the two (2) screws marked [40] and the two (2)

hexagonal nuts for each side. Fans can then be removed.

(Fig. 19)

15. フロントパネル1印刷、フロントパネル2印刷

(所要時間:約8分)

15-1 フロントパネル部を外します。(9項参照)

15-2 ハンドルを外します。(14項参照)

15-3 [400]のネジ8本を外し、フロントパネル1印刷とフロン

トパネル2印刷を外します。(Fig.18)

[400]

Front Panel (1)

フロントパネル1印刷

Front Panel (2)

フロントパネル2印刷

(Fig. 18)

16. DCファン(所要時間:約12分)

16-1 フロントパネル部を外します。(9項参照)

16-2 外すDCファンと同じ側のPAユニットを外します。

(3項参照)

16-3 [40]のネジを左右2本ずつと6角ナットを左右2個ずつ外

し、DCファンを外します。(Fig.19)

[40]

Hexagonal Nut

6角ナット

[40]

[40]: Bind Head Screw 4.0X16 MFZN2W3 SP (WE984000) 小ネジ+BIND

(Fig. 19)

Hexagonal Nut

6角ナット

22

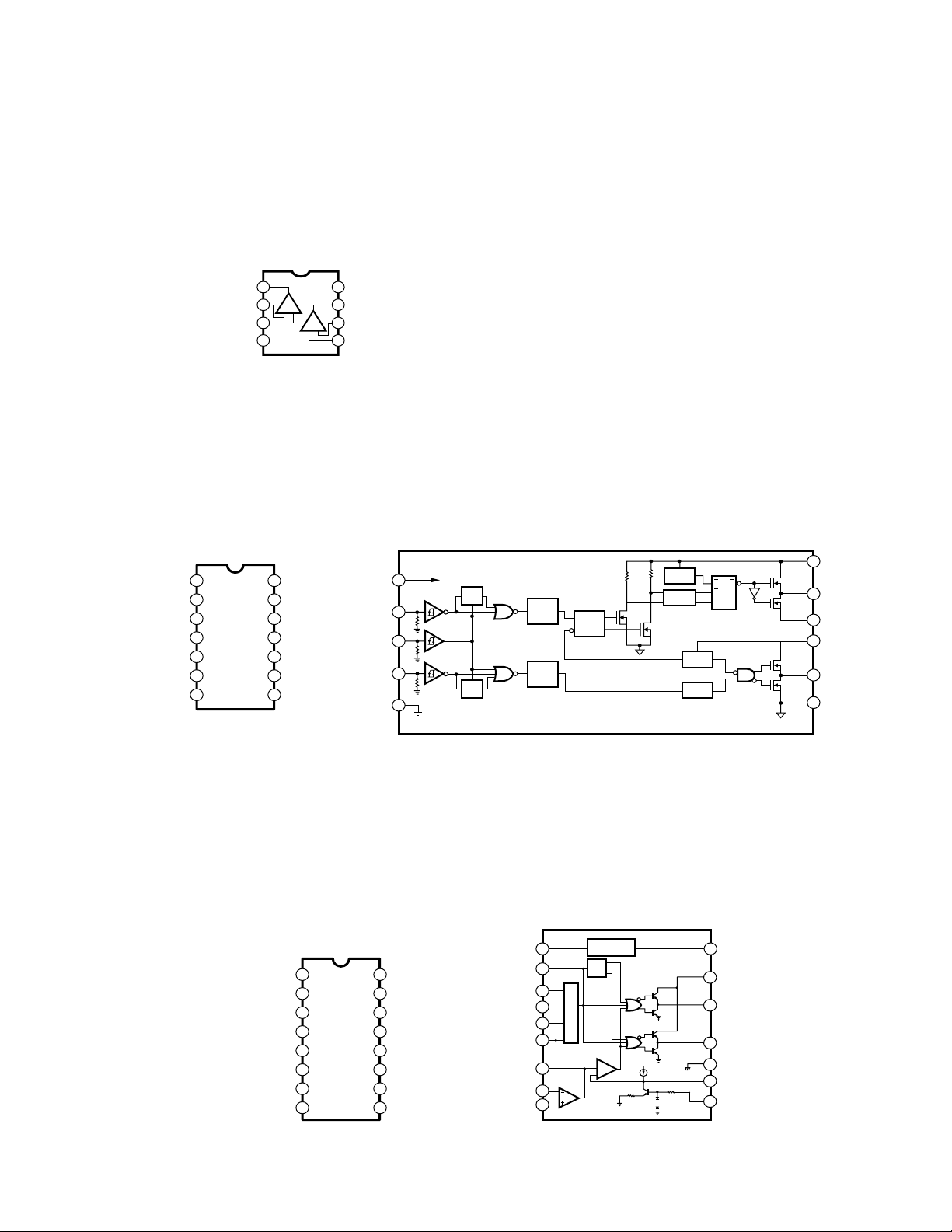

■ IC BLOCK DIAGRAM (ICブロック図)

• NJM2068MD-TE2 (X3505A00)

Dual Operational Amplifier

XP7000 SUB: IC301, IC302, IC303, IC304, IC305

PAH: IC201

XP5000 SUB: IC301, IC302, IC303, IC304, IC305

PAH: IC201

XP7000/XP5000

Output A +V

Inverting

Input A

Non-Inverting

Input A

-DC Voltage Supply

• IR2110 (X2382A00)

Driver

XP7000 PS: IC402

XP5000 PS: IC402

1

LO

2

COM

VCC

3

4

5

VS

6

VB

HO

7

1

2

3

4-V

14

13

12

11

10

+DC Voltage

8

Supply

Output B

7

+-

VSS

LIN

SD

HIN

9

VDD

8

+-

6

5

Inverting

Input B

Non-Inverting

Input B

V

B

HV

UV

GEN

GEN

LEVEL

SHIFT

DETECT

PULSE

FILTER

UV

DETECT

DELAY

R

Q

R

S

9

V

DD

10

HIN

11

SD

LIN

12

V

SS

13

Q

R

S

S

Q

R

VDD/V

LEVEL

SHIFT

VDD/V

LEVEL

SHIFT

CC

PULSE

PULSE

CC

6

7

HO

5

V

S

3

CC

V

LO

1

2

COM

• SG3525AN (X2383A00)

Regulating Pulse Width Modulator

XP7000 PS: IC401

XP5000 PS: IC401

1

INV. INPUTN

N.I. INPUT

2

3

SYNC

DISCHARGE

4

C

5

T

R

6

T

7

8

OSC. OUTPUT

SOFT-START

REF

V

16

+V

15

14

OUTPUT B

13

V

C

12

GROUND

11

OUTPUT A

SHUTDOWN

10

9

COMPENSATION

OSCILLATOR

E/A

REFERENCE

REGULATOR

FLIP/

FLOP

PWM

50 A

15

+V

IN

13

V

C

A

B

5K

11

OUTPUT A

14

OUTPUT B

GROUND

12

8

10

SOFT-START

SHUTDOWN

5K

REF

V

16

OSC. OUTPUT

IN

COMPENSATION

SYNC

DISCHARGE

INV. INPUTN

N.I. INPUT

4

3

6

R

T

7

C

5

T

9

1

2

23

XP7000/XP5000

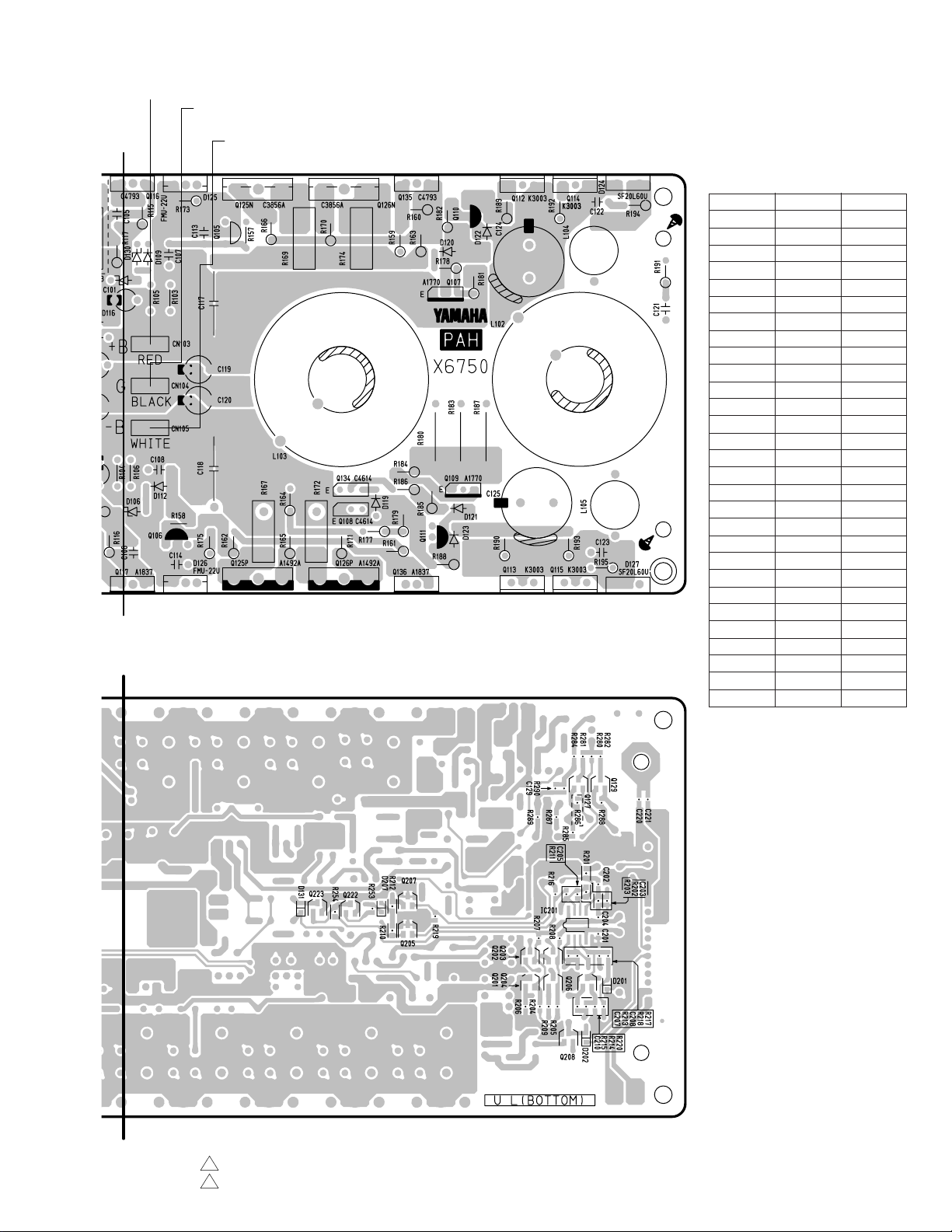

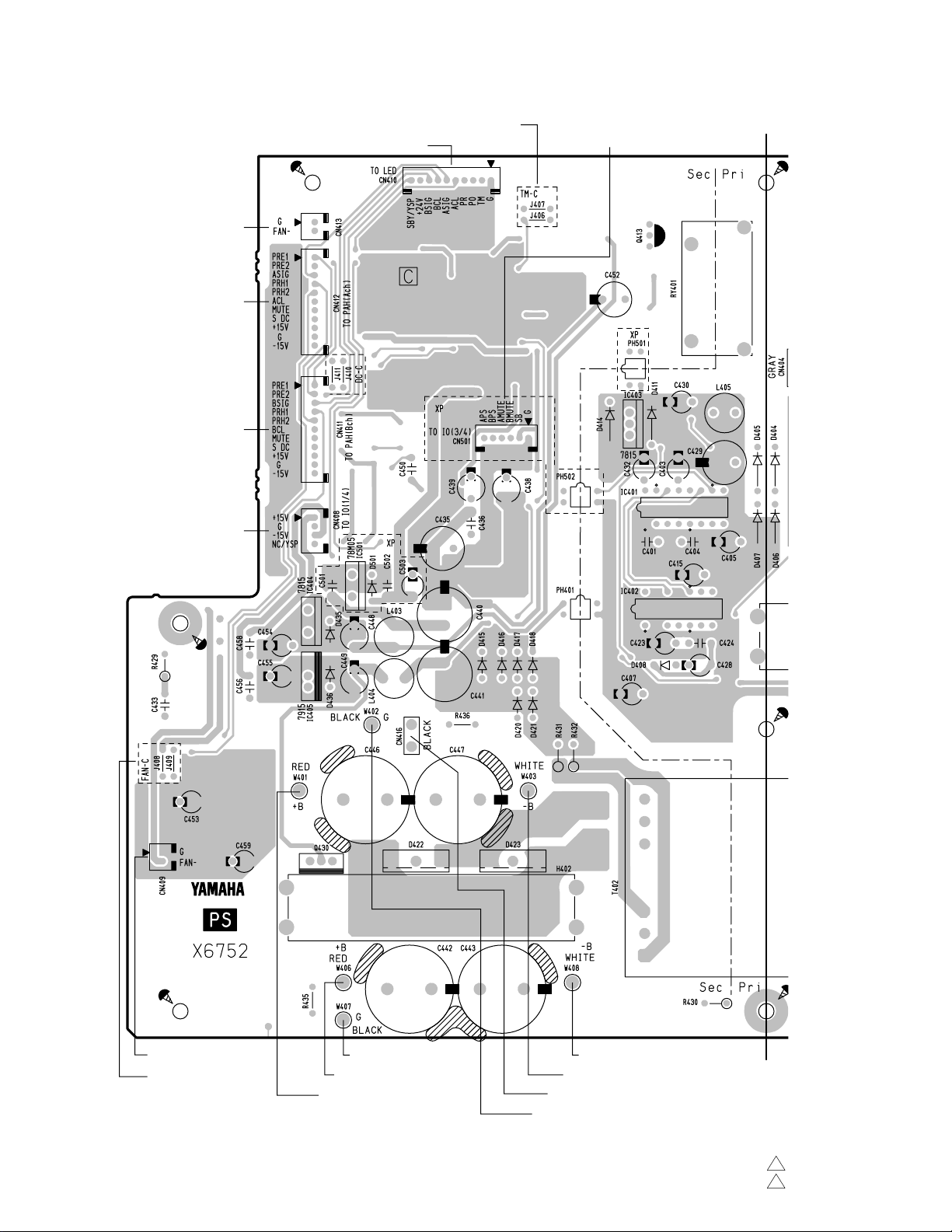

■ CIRCUIT BOARDS (シート基板図)

CONTENTS (目次)

• COIL Circuit Board (X6755B0) ............................................................. 24

• LED Circuit Board (X6754D0) ............................................................ 25

• PAH Circuit Board (X6750B0) ............................................................. 26

• PS Circuit Board (X6752C0) ............................................................ 28

• IO 1/4 Circuit Board (X6754D0) ............................................................ 32

• IO 2/4 Circuit Board (X6754D0) ............................................................ 33

• IO 3/4 Circuit Board (X6754D0) ............................................................ 33

• IO 4/4 Circuit Board (X6754D0) ............................................................ 34

• PSW Circuit Board (X6754D0) ............................................................ 35

• VR Circuit Board (X6754D0) ............................................................ 35

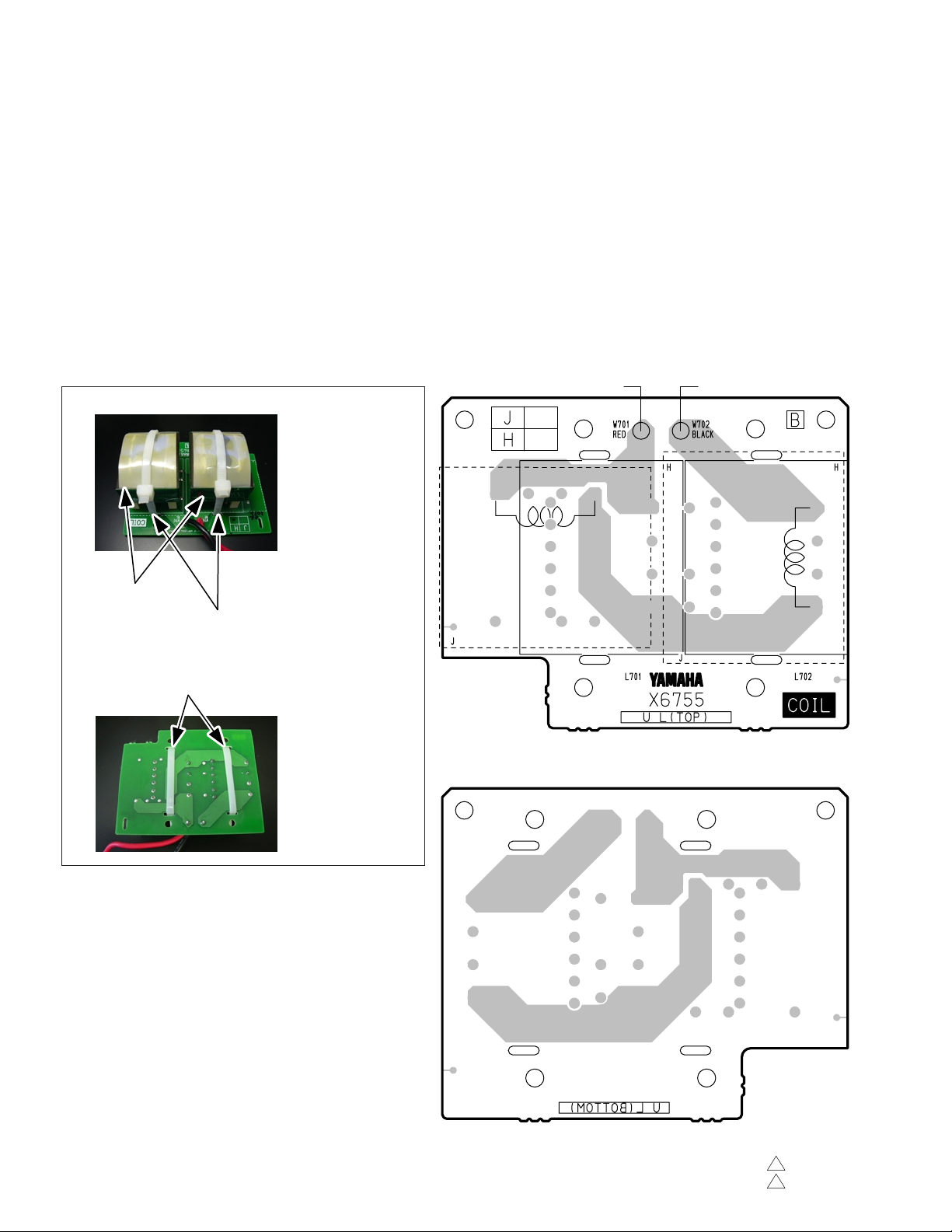

• COIL Circuit Board

H/B/K/O destinations

Component side

to PS-CN415to PS-CN406

L701, L702

Cord holder

Put cord holder through the holes of circuit board.

(インシュロックタイを基板 の 穴に通してコイルを固定します)

Pattern side

Component side (部品側)

24

Pattern side (パターン側)

2NA-WF40160 1 (XP7000)

2NA-WF40160 1 (XP5000)

2NA-WF39910

2NA-WF39910

3

3

(XP7000)

(XP5000)

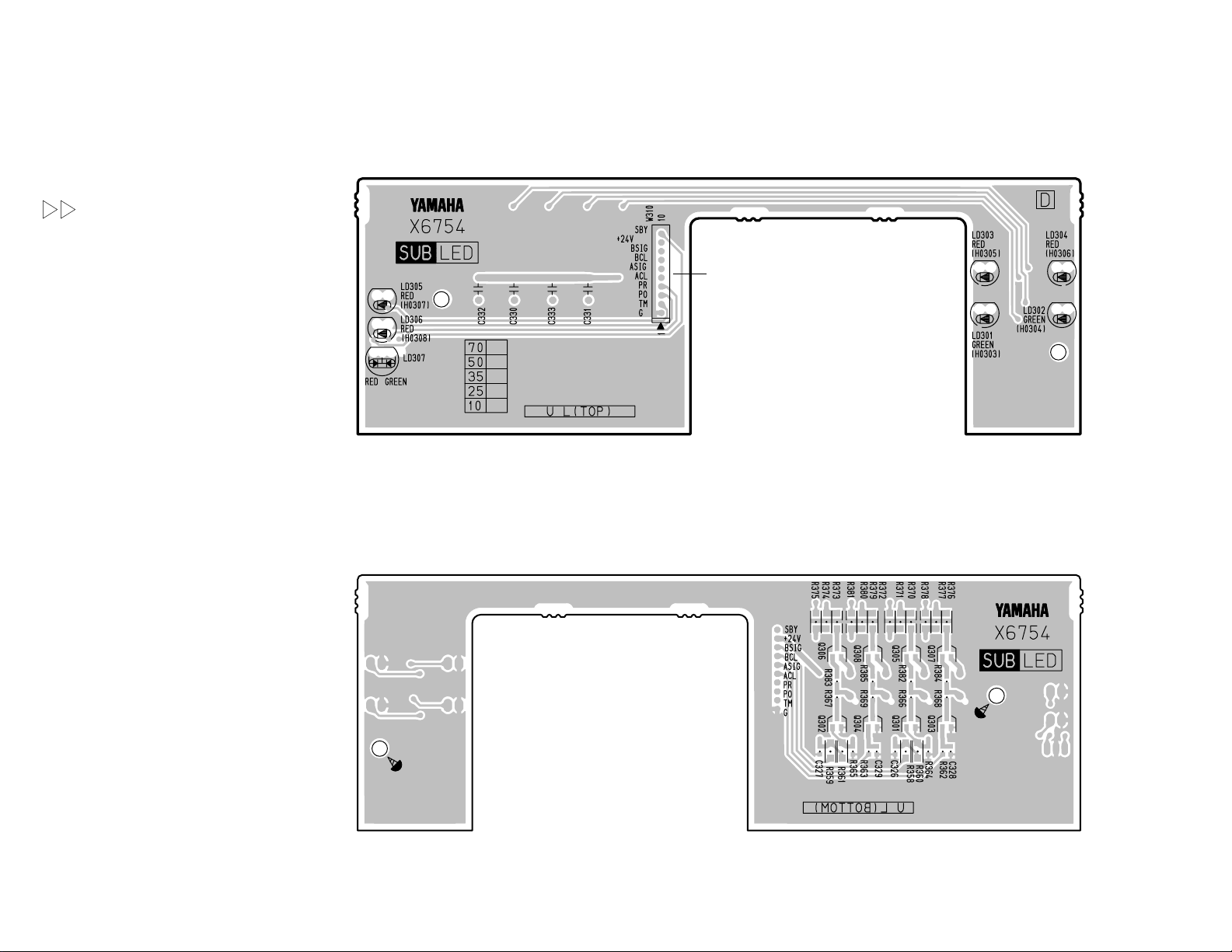

• LED Circuit Board

Component side (部品側) Pattern side (パターン側)

PROTECTION

POWER/STANDBY

TEMP

to PS-CN410

CLIP

SIGNAL

25

XP7000/XP5000

XP7000/XP5000

• PAH Circuit Board

to PS-CN412 (Ach)

to PS-CN411 (Bch)

to IO 1/4-CN302 (Ach, Bch)

to IO 3/4-W304 (Ach)

to IO 3/4-W306 (Bch)

A

Component side (部品側)

A'

B

26

Pattern side (パターン側)

B'

2NA-WF39660 1 (XP7000)

2NA-WF39660 1 (XP5000)

to PS-W401 (Ach)

to PS-W406 (Bch)

A

to PS-W402 (Ach)

to PS-W407 (Bch)

to PS-W403 (Ach)

to PS-W408 (Bch)

XP7000/XP5000

Following semi-conductors are

installed for the PA unit.

(下記半導体はPAユニットで取

付けされます)

A'

Ref.

XP7000

D124

D125

D126

D127

Q112

-115

Q116

Q117

Q135

Q136

Q218

Q118N

Q118P

Q119N

Q119P

Q120N

Q120P

Q121N

Q121P

Q122N

Q122P

Q123N

Q123P

Component side (部品側)

Q125N

Q125P

Q126N

B

Q126P

PR201

PR202

O:Installed

– :Not installed

XP5000

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

–

–

O

O

O

O

O

O

B'

1

2NA-WF39660

(XP7000)

2NA-WF39660 1 (XP5000)

Pattern side (パターン側)

27

XP7000/XP5000

• PS Circuit Board

to FAN (Ach)

to PAH-CN201 (Ach)

to PAH-CN201 (Bch)

to IO 1/4-CN302

TEMP LED TEST POINT

to LED-W310

to IO 3/4-CN304

A

28

to FAN (Bch)

FAN TEST POINT

Component side (部品側)

to PAH-CN104 (Bch)

to PAH-CN103 (Bch)

to PAH-CN103 (Ach)

to PAH-CN105 (Bch)

to PAH-CN105 (Ach)

to IO 3/4-W305

to PAH-CN104 (Ach)

A'

2NA-WF39710 2 (XP7000)

2NA-WF39710 2 (XP5000)

Loading...

Loading...