Yamaha WR450F 2-TRAC, WR450FS 2-TRAC Supplementary Owner's Service Manual

WR450F(S) 2-TRAC

SUPPLEMENTARY

OWNER’S SERVICE MANUAL

5TJ-F8199-E0

WR450F(S) 2-TRAC

SUPPLEMENTARY

OWNER’S SERVICE MANUAL

© 2004 by Yamaha Motor Italia S.p.A.

First edition, March 2004

All rights reserved. Any reproduction or

unauthorized use without the written

permission of Yamaha Motor Italia S.p.A.

is expressly prohibited.

Printed in Italy

1

CONTENTS

HYDROSTATIC TRANSMISSION .......................................................................................... 2

WHEN DRIVING.............................................................................................................. 2

FUNCTION ...................................................................................................................... 2

ADJUSTMENTS .............................................................................................................. 3

ALTERNATE RATIOS (OPTIONS) .................................................................................. 3

TOOLS ............................................................................................................................ 3

SPECIAL TOOLS .................................................................................................................. 4

SPECIFICATIONS .................................................................................................................. 6

GENERAL SPECIFICATIONS ........................................................................................ 6

MAINTENANCE SPECIFICATIONS ...................................................................................... 7

CHASSIS ........................................................................................................................ 7

TIGHTENING TORQUES ................................................................................................ 8

CABLE ROUTING DIAGRAM.......................................................................................... 9

REGULAR INSPECTION AND ADJUSTMENTS..................................................................17

MAINTENANCE INTERVALS ........................................................................................ 17

SUPPLEMENT ARY INSPECTION AND ADJUSTMENTS ............................................ 17

HYDROSTATIC TRANSMISSION.................................................................................. 17

STEERING DAMPER ADJUSTMENT .......................................................................... 18

FRONT FORK REBOUND DAMPING FORCE ADJUSTMENT.................................... 21

FRONT FORK COMPRESSION DAMPING FORCE ADJUSTMENT .......................... 22

REAR SHOCK ABSORBER SPRING PRELOAD ADJUSTMENT................................ 23

REAR SHOCK ABSORBER REBOUND DAMPING FORCE ADJUSTMENT .............. 24

REAR SHOCK ABSORBER LOW COMPRESSION DAMPING FORCE

ADJUSTMENT .............................................................................................................. 25

REAR SHOCK ABSORBER HIGH COMPRESSION DAMPING FORCE

ADJUSTMENT .............................................................................................................. 26

CARBURETOR DISASSEMBLY .......................................................................................... 27

TRANSMISSION .................................................................................................................. 28

DRIVE UNIT – TRANSMISSION ASSY ........................................................................ 28

HYDROSTATIC TRANSMISSION.................................................................................. 30

INSPECTION ................................................................................................................ 30

CHANGE OIL IN THE HYDRAULIC MOTOR REDUCTION GEAR HOUSING............ 30

CHANGE OIL IN THE PUMP TRANSMISSION HOUSING .......................................... 31

CHECK THE WEAR IN THE PUMP TRANSMISSION.................................................. 32

CHANGING THE RATIOS FOR THE PUMP TRANSMISSION .................................... 33

FRONT WHEEL .................................................................................................................... 35

FRONT WHEEL REMOVAL .......................................................................................... 35

FRONT FORK ...................................................................................................................... 36

FRONT FORK DISASSEMBLY...................................................................................... 36

FRONT FORK SPECIFICATION CARD – ÖHLINS®.................................................... 38

OIL LEVEL ADJUSTMENT ............................................................................................ 39

CHANGING SPRINGS .................................................................................................. 40

DISMANTLING .............................................................................................................. 42

ASSEMBLING................................................................................................................ 45

REAR SHOCK ABSORBER ................................................................................................ 48

REAR SHOCK ABSORBER DISASSEMBLY................................................................ 48

INSPECTION AND MAINTENANCE.............................................................................. 49

STEERING DAMPER .......................................................................................................... 50

DISASSEMBLY AND INSPECTION .............................................................................. 51

2

HYDROSTATIC TRANSMISSION

WHEN DRIVING

Driving a two wheel driven motorcycle is different from driving a conventional motorcycle. The front wheel

drive system, during certain conditions, affects the feeling of the handlebar. In sand, mud and snow the

traction is greatly improved. However in conditions with deep ruts and slippery surfaces the two wheel

drive system might contribute to that the motorcycle feels heavier and more brutal.

WARNING

It is of absolute necessity that the two wheel drive motorcycle has a steering damper. If driven

without steering damper the front wheel, when hitting a root or a stone, can give unduly high

reaction forces to the handlebar.

Before racing, practise as much as possible on different tracks and under different conditions to

get used to the different behaviour of the two wheel drive system.

On rough road surfaces the front wheel drive can make the steering harder. This is noticeable,

especially when driving aggressively.

When landing after jumps the two wheel drive system will make the front fork feel stiffer due to

that the driving force tries to extend the front fork, especially if the throttle is applied before

touchdown.

NOTE:

This 2-Trac system has been tested extensively on both test tracks and in races. Imperative for the durability and function is high quality material in all components. The high quality materials used are not

always the best suited to provide beautiful surface treatment. As a result we can sometimes see shades

and/or mis-colouring on the anodised aluminium surfaces.

FUNCTION

With the motorcycle free rolling, the pump rotates roughly with the same speed as the

motor.

When throttle is applied the rear wheel and thereby the pump, due to deformation of the

rear tire, starts to rotate a little bit faster even if the driving force is just large enough to

maintain constant speed.

The increased volume stream from the pump causes the speed of the motor to increase,

but to a lesser extent than the pump, thereby creating a driving torque from the front

wheel. Thus the amount of front wheel driving force varies with speed and ground condition and comes in gradually depending on throttle position.

The system has a maximum pressure relieve valve installed to prevent dangerously high

pressure in the system, when for instance on slippery surfaces, where excessive rear

wheel spin can occur.

The oil in the transmission can sometimes get very hot. For instance in sandy, slow

speed conditions or when trying to escape from a mud pit. In order to prevent damage to

the transmission a built in thermostat valve shortcuts the hydraulic circuit, thereby disconnecting the front wheel drive. When this occur a couple of minutes cooling time is needed

to get the system back into function again.

CAUTION:

3

ADJUSTMENTS

The pulling force, at a given circumstance, can be varied by changing the rear wheel

sprocket up or down one tooth. If we increase the no by one tooth the pump rotates

faster in relation to the hydraulic motor, thereby increasing the pressure in the system

and increasing the pulling force of the front wheel. It must be understood that even the

reaction forces in the handlebar increases. From experience the gain is negligible.

When decreasing with one/two/three teeth the pulling force is reduced. The advantage is

that the steering feels lighter and, on most ground conditions, there is no increased lap

times, but can be preferable during long endurance races.

WARNING

Changing the number of teeth of the sprockets more than one tooth up causes unduly high reaction forces in the handlebar. It can also give permanent damages to the hydraulic transmission

because of raised oil temperature in the transmission and increased wear.

Changing the number of teeth in the pump transmission without changing the rear-wheel

ratio also can cause permanent damage to the hydraulic transmission.

ALTERNATE RATIOS (OPTIONS)

There are alternate ratios for the pump transmission.

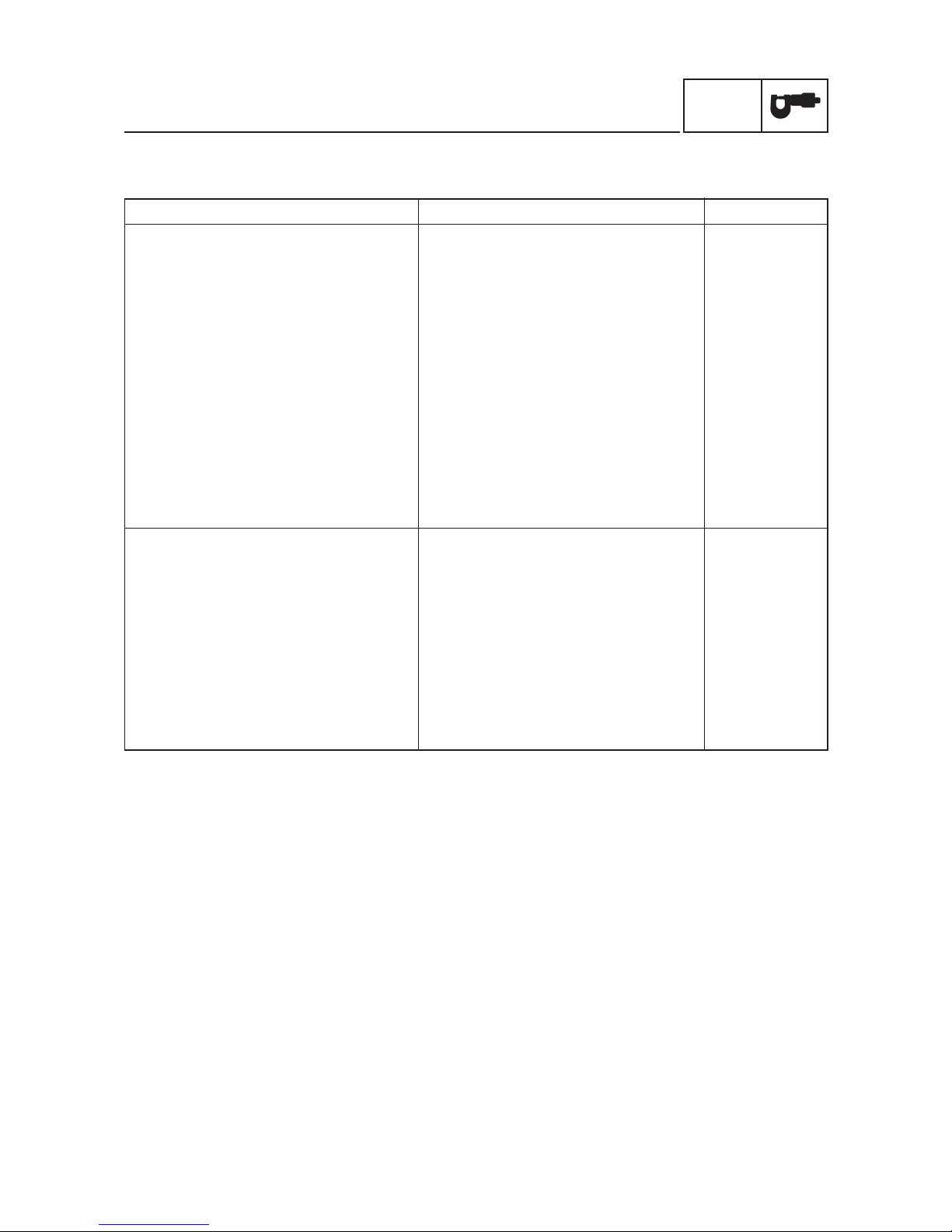

Alternate ratios kit Pump transmission ratio Rear wheel ratio

GTYA E00 15/22 standard 14/50

GTYA E01 12/20 P-D 15/47

The kit contains:

– Chain-sprocket pump

– Chain-wheel pump

– Chain

– Chain guide

– Collar

– Screw chain-sprocket

NOTE:

More ratios will be available later.

TOOLS

A specially designed puller tool is demanded to remove the pump sprocket. Refer to

“SPECIAL TOOLS”.

4

GEN

INFO

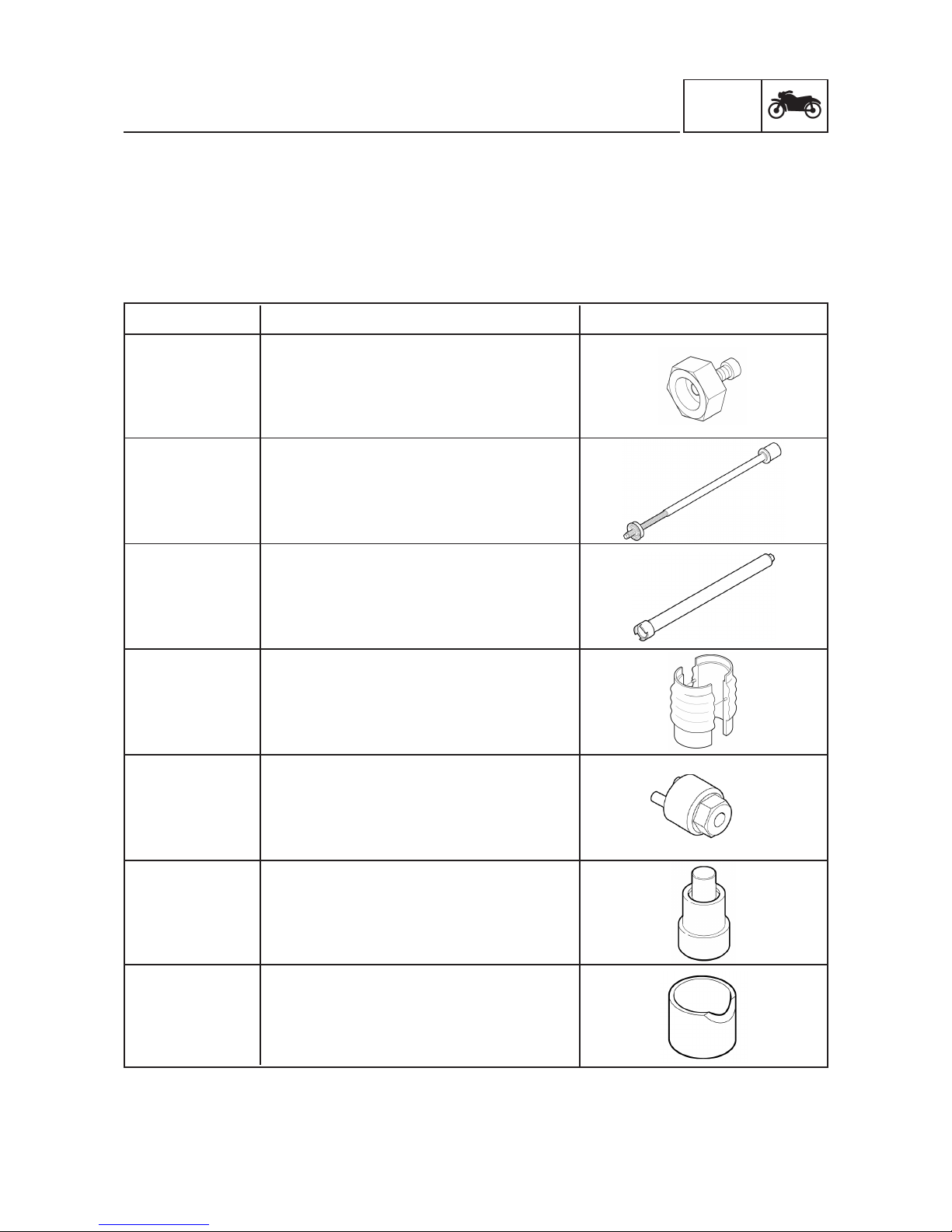

SPECIAL TOOLS

SPECIAL TOOLS

The following special tools are necessary for complete and accurate tune-up and assembly . Use only the

appropriate special tools; this will help prevent damage caused by the use of inappropriate tools or

improvised techniques. Special tools may differ by shape and part number from country to country. In

such a case, two types are provided.

When placing an order, refer to the list provided below to avoid any mistakes.

Tool No.

90890-XXXXX

(1702-02)

Bushing remover

Use this tool to remove the front forks bushing.

90890-XXXXX

(1797-01)

Tool cartridge top cap

Use this tool to remove and install the front

forks damper rod.

Tool name/How to use Illustration

90890-XXXXX

(1874-01)

Puller

Use this tool to remove the pump sprocket

(hydraulic transmission).

90890-XXXXX

(1799-02)

Mounting sleeve

Use this tool to install the front forks bushing

and seals.

90890-XXXXX

(1860-01)

Tool compression adjuster (Bob)

Use this tool to unscrew and screw the front

forks top cap.

90890-XXXXX

(0721-01)

Mandrel ball joints (26 mm)

This tool is needed to remove and install the

ball joints.

90890-XXXXX

(0723-01)

Sleeve (26 mm)

This tool is needed to remove and install the

ball joints with the mandrel.

5

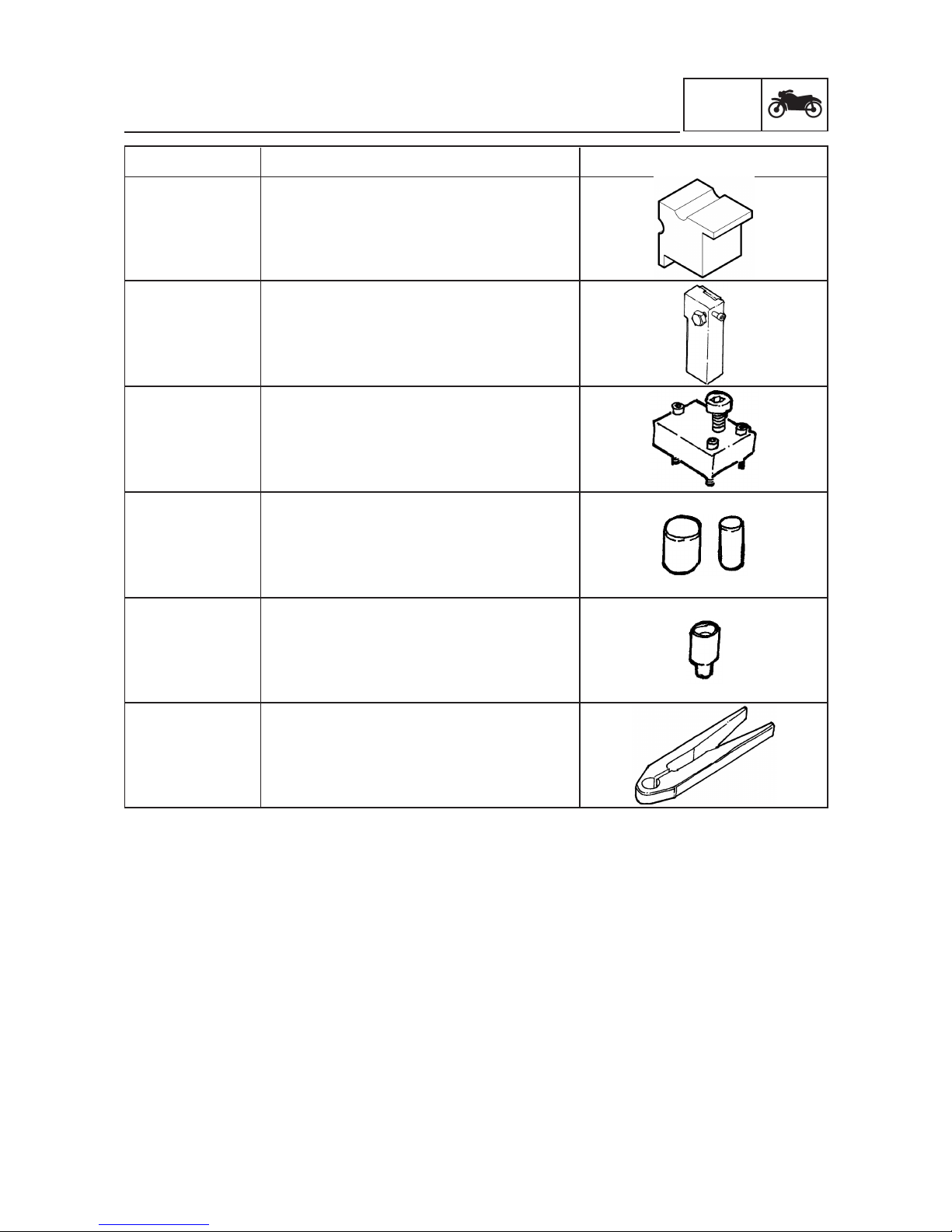

Tool No.

90890-XXXXX

(0727-03)

Soft jaws

Use this tool for piston shafts 14-16 mm.

Tool name/How to use Illustration

90890-XXXXX

(04957-01)

Steering damper holder

Use this tool for holding the steering damper

unit with or without link arm.

90890-XXXXX

(04954-01)

Puller

Use this tool for demounting the steering

damper linkarm.

90890-XXXXX

(04955-01)

90890-XXXXX

(04956-01)

Sockets

Use this tools for mounting the steering

damper linkarm.

90890-XXXXX

(04951-01)

Mandrel

Use this tool to install the steering damper

X-ring seal.

90890-XXXXX

(04960-01)

Holder

This tool is used for gripping the steering

damper high speed adjuster.

GEN

INFO

SPECIAL TOOLS

GENERAL SPECIFICATIONS

6

SPEC

SPECIFICATIONS

GENERAL SPECIFICATIONS

Item Standard

Model name: WR450F ’04 – 2-TRAC (EUROPE)

Model code number: 5TJ6 (EUROPE)

Dimensions:

Overall length 2,171 mm (85.5 in)

Overall width 827 mm (32.6 in)

Overall height 1,303 mm (51.3 in)

Seat height 998 mm (39.3 in)

Wheelbase 1,485 mm (58.5 in)

Minimum ground clearance 371 mm (14.6 in)

Dry weight:

Without oil and fuel 128.0 kg (282 lb)

Tire:

Type With tube

Size (front) 90/90-21 54R (EUROPE, AUS, NZ)

Size (rear) 130/90-18 69R (EUROPE, AUS, NZ)

Tire pressure (front) 100~120 kpa (1.0~1.2 kgf/cm

2

, 15~17 psi)

(depending on the track condition)

Tire pressure (rear) 100 kPa (1.0 kgf/cm2, 15 psi)

Suspension:

Front suspension Telescopic fork

Rear suspension Swingarm (link type monocross suspension)

Shock absorber:

Front shock absorber Coil spring/oil damper

Rear shock absorber Coil spring/gas, oil damper

Wheel travel:

Front wheel travel 300 mm (11.8 in)

Rear wheel travel 315 mm (12.4 in)

Hydrostatic transmission:

Pump/Motor:

Displacement of pump/motor 5 cm

3

per revolution

Max speed 8,000 rpm

Max torque 25 Nm

Max pressure 320 bar

Typical pressure 50-200 bar

Transmission:

Transmitted power, maximum 21 kW

Weight 6.7 kg

Efficiency 92 %

Oil volume 0.6 L

Ratio hydraulic motor/front wheel 5.36 : 1

Torque distribution 0-15 % on front wheel – depending

on ground condition and throttle position

Max pulling force on front wheel 382 N

Oil capacity:

Pump transmission housing 0.07-0.08 L

Hydraulic motor reduction gear housing 0.075 L

Oil type:

Pump transmission housing Castrol SLX030

Hydraulic motor reduction gear housing Castrol SLX030

SPEC

MAINTENANCE SPECIFICATIONS

7

MAINTENANCE SPECIFICATIONS

CHASSIS

Item Standard Limit

Front suspension:

Shock absorber travel 300 mm •••

Fork spring free length 467 mm 460 mm

Installed length 463 mm (4 mm preload) •••

Collar length – •••

Spring rate (K1) 4.5 N/mm (Left leg), 4.1 N/mm (Right leg) •••

Spring rate (K2) 10 N/mm (Top out spring) •••

Spring stroke (K1) 300 mm •••

Spring stroke (K2) 25 mm (approximately) •••

Optional spring available Yes •••

Quantity 625 cm

2

(approximately) •••

Level 105 mm •••

Recommended oil Öhlins part no: 1305-01 (SAE 5W) •••

Inner tube outer diameter 46 mm •••

Rear suspension:

Rear shock absorber assembly travel 132 mm •••

Rear wheel travel 315 mm •••

Spring free length 270 mm •••

Installed length 251.5 mm (18.5 mm preload) ± 5 mm

Spring rate (K1) 52 N/mm •••

Spring stroke (K1) 0~132 mm •••

Optional spring available Yes •••

Enclosed gas/air pressure (STD) 10 bar •••

Recommended oil Öhlins part no: 1306-01 •••

Loading...

Loading...