Yamaha WR450F, WR450FG Owner's Service Manual

2016

q Read this manual carefully before operating this vehicle.

q Il convient de lire attentivement ce manuel avant la première utilisation du véhicule.

OWNER’S SERVICE MANUAL

MANUEL D’ATELIER DU

PROPRIETAIRE

WR450F

WR450FG

2GC-28199-70

Q

Read this manual carefully before operating this vehicle. This manual should stay with this vehicle if it is sold.

Q

Il convient de lire attentivement ce manuel avant la première utilisation du véhicule. Le manuel doit

être remis avec le véhicule en cas de vente de ce dernier.

Read this manual carefully before operating this vehicle.Read this manual carefully before operating this vehicle.

20152016

OWNER’S SERVICE MANUALOWNER’S SERVICE MANUAL

WR450F

WR450FG

2GC-28199-70-E0

EAS2GC1002

WR450F

WR450FG

OWNER’S SERVICE MANUAL

©2015 by Yamaha Motor Co., Ltd.

First edition, August 2015

All rights reserved.

Any reproduction or unauthorized use

without the written permission of

Yamaha Motor Co., Ltd.

is expressly prohibited.

Printed in Japan.

EAS2GC1003

TIP

WARNING

WARNING

NOTICE

TIP

INTRODUCTION

Congratulations on your purchase of a Yamaha WR series. This model is the culmination of Yamaha's vast experience in the production of pacesetting racing machines. It represents the highest

grade of craftsmanship and reliability that have made Yamaha a leader.

This manual explains operation, inspection, basic maintenance and tuning of your machine. If you

have any questions about this manual or your machine, please contact your Yamaha dealer.

The design and manufacture of this Yamaha machine fully comply with the emissions standards for

clean air applicable at the date of manufacture. Yamaha has met these standards without reducing

the performance or economy of operation of the machine. To maintain these high standards, it is important that you and your Yamaha dealer pay close attention to the recommended maintenance

schedules and operating instructions contained within this manual.

Yamaha continually seeks advancements in product design and quality. Therefore, while this manual

contains the most current product information available at the time of printing, there may be minor

discrepancies between your machine and this manual. If you have any questions concerning this

manual, please consult your Yamaha dealer.

EWA

PLEASE READ THIS MANUAL CAREFULLY AND COMPLETELY BEFORE OPERATING THIS

MACHINE. DO NOT ATTEMPT TO OPERATE THIS MACHINE UNTIL YOU HAVE ATTAINED A

SATISFACTORY KNOWLEDGE OF ITS CONTROLS AND OPERATING FEATURES AND UNTIL

YOU HAVE BEEN TRAINED IN SAFE AND PROPER RIDING TECHNIQUES. REGULAR INSPECTIONS AND CAREFUL MAINTENANCE, ALONG WITH GOOD RIDING SKILLS, WILL ENSURE

THAT YOU SAFETY ENJOY THE CAPABILITIES AND THE RELIABILITY OF THIS MACHINE.

EAS2GC1004

IMPORTANT MANUAL INFORMATION

Particularly important information is distinguished in this manual by the following notations.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

A WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

A NOTICE indicates special precautions that must be taken to avoid

damage to the vehicle or other property.

A TIP provides key information to make procedures easier or clearer.

EAS2GC1005

SAFETY INFORMATION

THIS MACHINE IS DESIGNED STRICTLY FOR COMPETITION USE, ONLY ON A CLOSED

COURSE. It is illegal for this machine to be operated on any public street, road, or highway. Off-road

use on public lands may also be illegal. Please check local regulations before riding.

• THIS MACHINE IS TO BE OPERATED BY AN EXPERIENCED RIDER ONLY.

Do not attempt to operate this machine at maximum power until you are totally familiar with its characteristics.

• THIS MACHINE IS DESIGNED TO BE RIDDEN BY THE OPERATOR ONLY.

Do not carry passengers on this machine.

• ALWAYS WEAR PROTECTIVE APPAREL.

When operating this machine, always wear an approved helmet with goggles or a face shield. Also

wear heavy boots, gloves, and protective clothing. Always wear proper fitting clothing that will not

be caught in any of the moving parts or controls of the machine.

• ALWAYS MAINTAIN YOUR MACHINE IN PROPER WORKING ORDER.

For safety and reliability, the machine must be properly maintained. Always perform the pre-operation checks indicated in this manual.

Correcting a mechanical problem before you ride may prevent an accident.

• GASOLINE IS HIGHLY FLAMMABLE.

Always turn off the engine while refueling. Take care to not spill any gasoline on the engine or exhaust system. Never refuel in the vicinity of an open flame, or while smoking.

• GASOLINE CAN CAUSE INJURY.

If you should swallow some gasoline, inhale excess gasoline vapors, or allow any gasoline to get

into your eyes, contact a doctor immediately. If any gasoline spills onto your skin or clothing, immediately wash skin areas with soap and water, and change your clothes.

• ONLY OPERATE THE MACHINE IN AN AREA WITH ADEQUATE VENTILATION.

Never start the engine or let it run for any length of time in an enclosed area. Exhaust fumes are

poisonous. These fumes contain carbon monoxide, which by itself is odorless and colorless. Carbon monoxide is a dangerous gas which can cause unconsciousness or can be lethal.

• PARK THE MACHINE CAREFULLY; TURN OFF THE ENGINE.

Always turn off the engine if you are going to leave the machine. Do not park the machine on a slope

or soft ground as it may fall over.

• THE ENGINE, EXHAUST PIPE AND MUFFLER WILL BE VERY HOT AFTER THE ENGINE HAS

BEEN RUN.

Be careful not to touch them or to allow any clothing item to contact them during inspection or repair.

• PROPERLY SECURE THE MACHINE BEFORE TRANSPORTING IT.

For safety, drain the gasoline from the fuel tank before transporting the vehicle.

EAS2GC1006

1

7

3

4

6

2

5

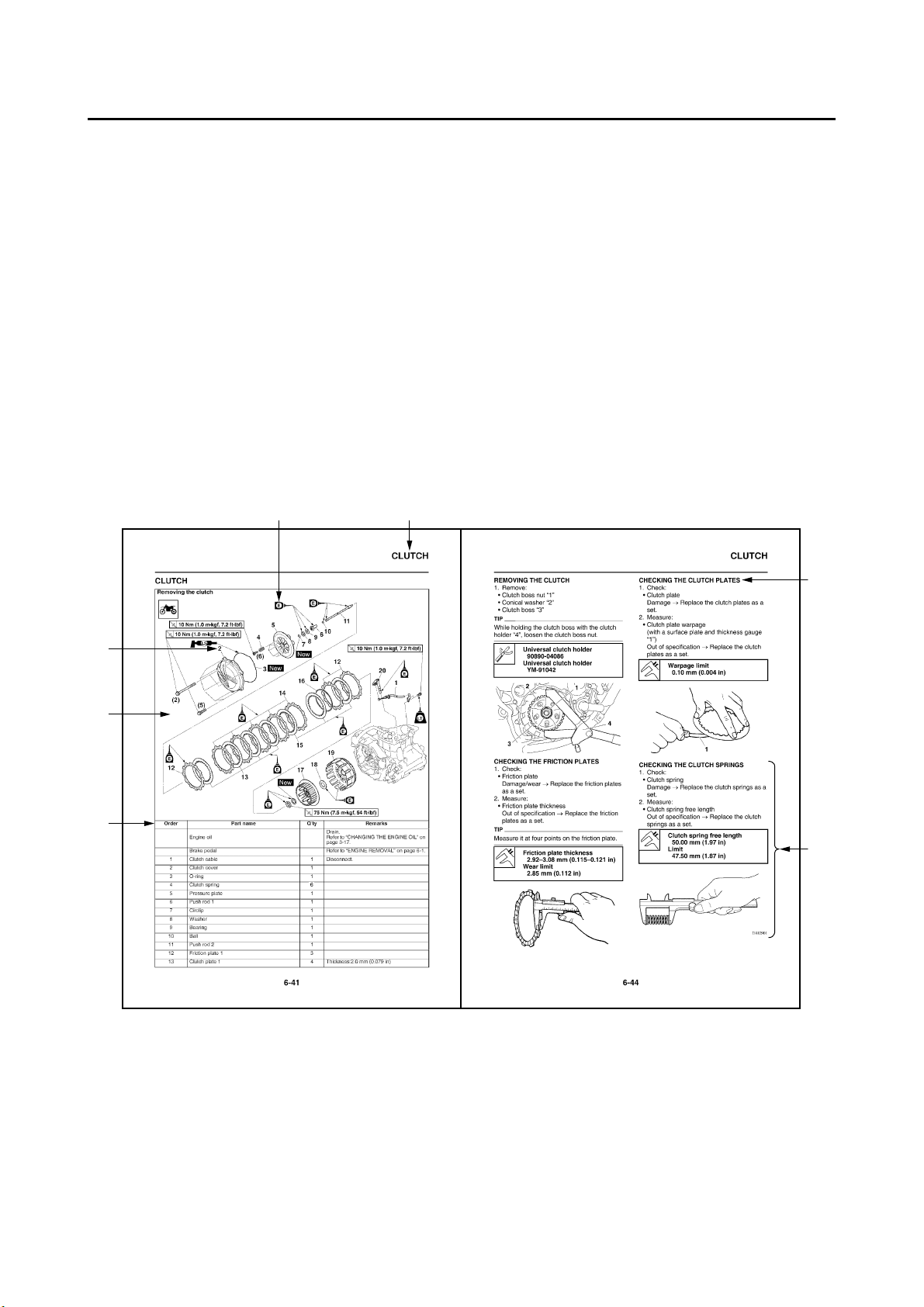

HOW TO USE THIS MANUAL

In this manual, descriptions of installation, removal, disassembly, assembly, check, and adjustment

procedures are laid out with the individual steps in sequential order.

• The manual is divided into chapters and each chapter is divided into sections. The current section

title “1” is shown at the top of each page.

• Sub-section titles “2” appear in smaller print than the section title.

• To help identify parts and clarify procedure steps, there are exploded diagrams “3” at the start of

each removal and disassembly section.

• Numbers “4” are given in the order of the jobs in the exploded diagram. A number indicates a removal or a disassembly step.

• Symbols “5” indicate parts to be lubricated or replaced.

Refer to “SYMBOLS”.

• A job instruction chart “6” accompanies the exploded diagram, providing the order of jobs, the

names of parts, the notes in jobs, etc.

• Jobs “7” requiring more information (such as special tools and technical data) are described sequentially.

EAS2GC1007

TIP

G

M

BF

B

T

R

.

.

LS

M

S

LT

E

New

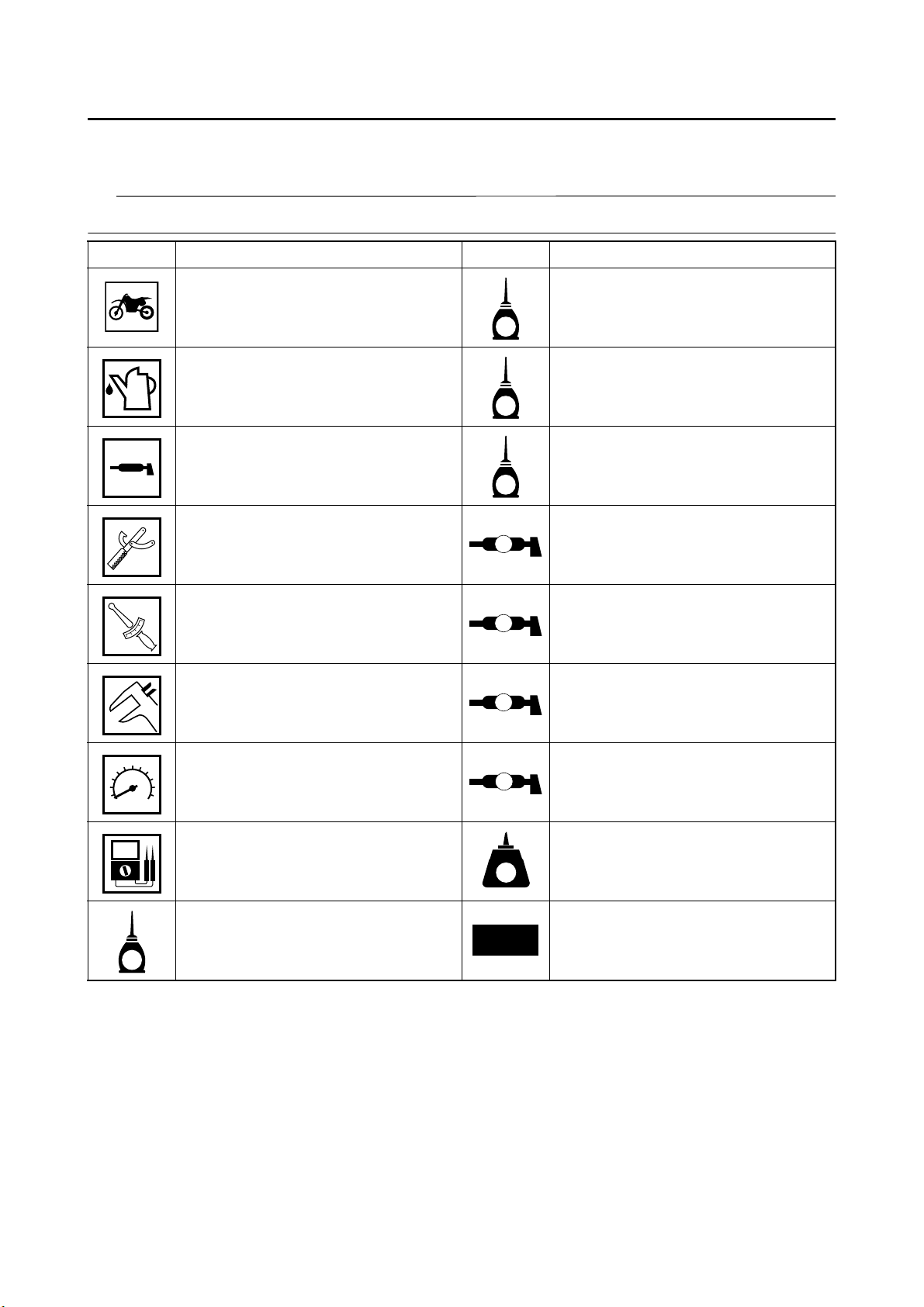

SYMBOLS

The following symbols are used in this manual for easier understanding.

The following symbols are not relevant to every vehicle.

SYMBOL DEFINITION SYMBOL DEFINITION

Serviceable with engine mounted Gear oil

Filling fluid Molybdenum disulfide oil

Lubricant Brake fluid

Special tool Wheel bearing grease

Tightening torque Lithium-soap-based grease

Wear limit, clearance Molybdenum disulfide grease

Engine speed Silicone grease

Electrical data Locking agent (LOCTITE®)

Engine oil Replace the part with a new one.

TABLE OF CONTENS

GENERAL INFORMATION

SPECIFICATIONS

PERIODIC CHECKS AND

ADJUSTMENTS

TUNING

CHASSIS

1

2

3

4

5

ENGINE

COOLING SYSTEM

FUEL SYSTEM

ELECTRICAL SYSTEM

TROUBLESHOOTING

6

7

8

9

10

GENERAL INFORMATION

LOCATION OF IMPORTANT LABELS............................................................1-1

DESCRIPTION..................................................................................................1-4

IDENTIFICATION .............................................................................................1-5

VEHICLE IDENTIFICATION NUMBER ......................................................1-5

ENGINE SERIAL NUMBER .......................................................................1-5

VEHICLE EMISSION CONTROL INFORMATION LABEL.........................1-5

INCLUDED PARTS ..........................................................................................1-6

SPARK PLUG WRENCH ...........................................................................1-6

NIPPLE WRENCH......................................................................................1-6

HANDLEBAR PROTECTOR ......................................................................1-6

FUEL HOSE JOINT COVER ......................................................................1-6

COUPLER FOR CONNECTING OPTIONAL PART...................................1-6

IMPORTANT INFORMATION ..........................................................................1-7

PREPARATION FOR REMOVAL AND DISASSEMBLY............................ 1-7

REPLACEMENT PARTS............................................................................1-7

GASKETS, OIL SEALS AND O-RINGS ..................................................... 1-8

LOCK WASHERS/PLATES AND COTTER PINS ......................................1-8

BEARINGS AND OIL SEALS .....................................................................1-8

CIRCLIPS ...................................................................................................1-8

1

BASIC SERVICE INFORMATION....................................................................1-9

ELECTRICAL SYSTEM..............................................................................1-9

SPECIAL TOOLS ...........................................................................................1-13

CONTROL FUNCTIONS ................................................................................1-18

INDICATOR LIGHTS AND WARNING LIGHTS.......................................1-18

ENGINE STOP SWITCH..........................................................................1-18

START SWITCH.......................................................................................1-18

CLUTCH LEVER ......................................................................................1-18

SHIFT PEDAL ..........................................................................................1-19

KICKSTARTER LEVER............................................................................1-19

THROTTLE GRIP.....................................................................................1-19

FRONT BRAKE LEVER ...........................................................................1-19

REAR BRAKE PEDAL..............................................................................1-19

SIDESTAND .............................................................................................1-20

STARTER KNOB/IDLE SCREW ..............................................................1-20

FUEL TANK CAP .....................................................................................1-20

MULTI-FUNCTION DISPLAY.........................................................................1-21

DESCRIPTION .........................................................................................1-21

BASIC MODE ...........................................................................................1-21

CHANGEOVER TO BASIC MODE/RACE MODE.................................... 1-22

RACE MODE............................................................................................1-23

FUNCTION DIAGRAM .............................................................................1-26

STARTING AND BREAK-IN ..........................................................................1-28

FUEL ........................................................................................................1-28

HANDLING NOTE ....................................................................................1-28

AIR FILTER MAINTENANCE ...................................................................1-28

STARTING A COLD ENGINE ..................................................................1-28

STARTING A WARM ENGINE.................................................................1-30

BREAK-IN PROCEDURES ...................................................................... 1-30

MAINTENANCE AFTER BREAK-IN ..............................................................1-31

MAJOR MAINTENANCE..........................................................................1-31

TORQUE-CHECK POINTS ............................................................................1-32

MOTORCYCLE CARE AND STORAGE........................................................1-34

CARE........................................................................................................1-34

STORAGE ................................................................................................1-35

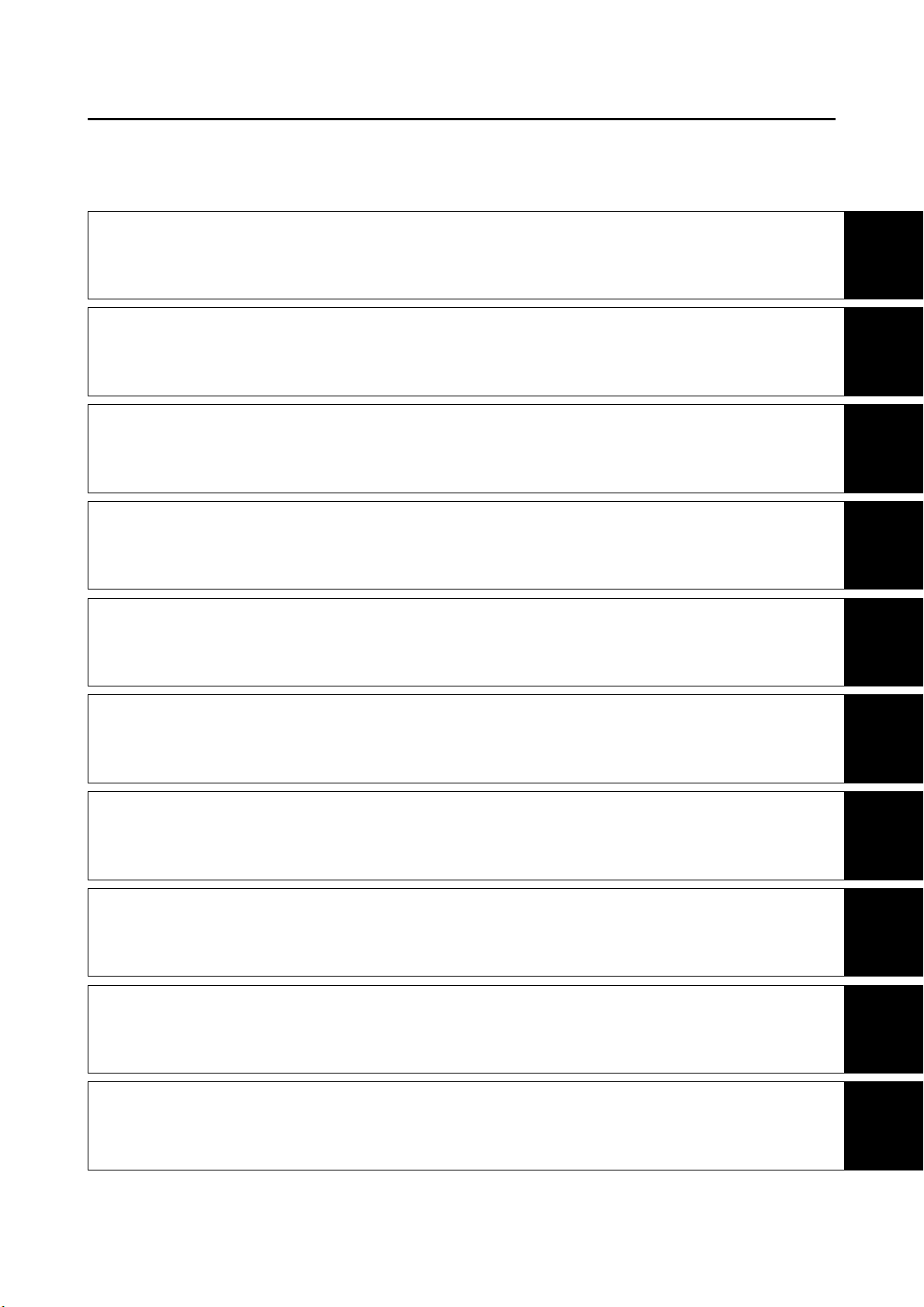

LOCATION OF IMPORTANT LABELS

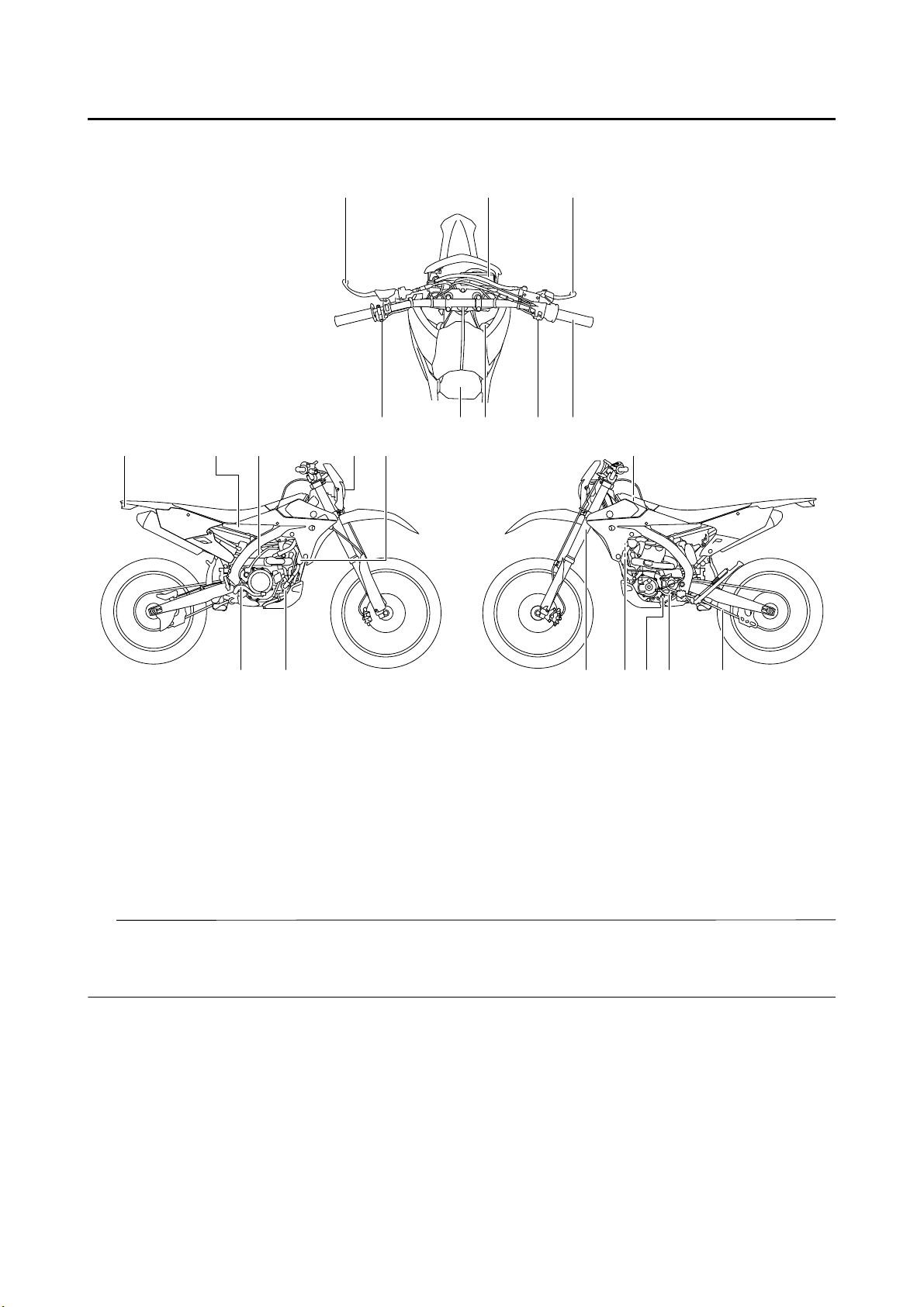

9,10,117,8

13

12

1,2,3 4,5,6

EAS2GC1008

LOCATION OF IMPORTANT LABELS

Please read the following important labels carefully before operating this vehicle.

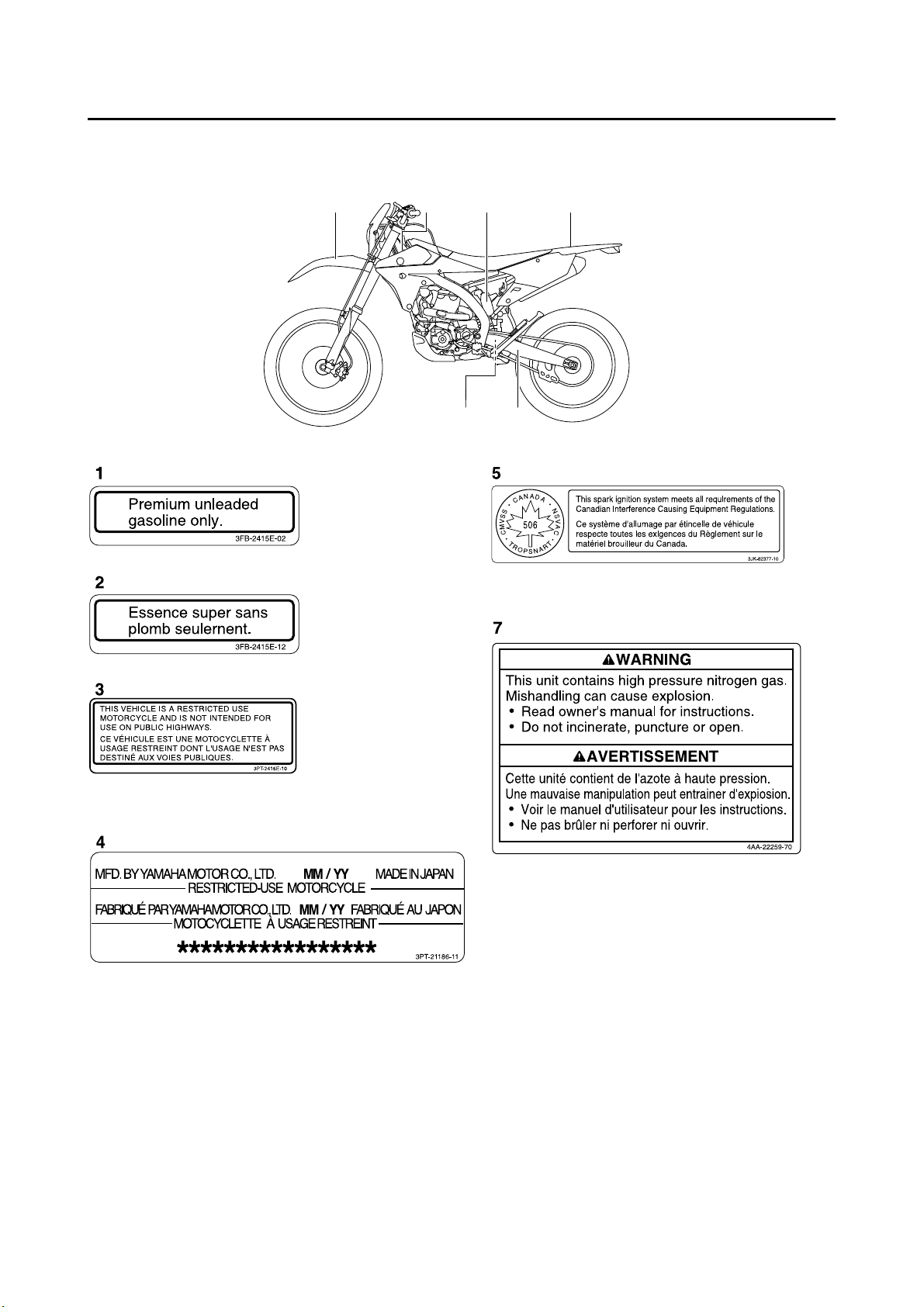

CAN

1-1

LOCATION OF IMPORTANT LABELS

EUR

1-2

AUS, NZL, ZAF

LOCATION OF IMPORTANT LABELS

1-3

EAS2GC1009

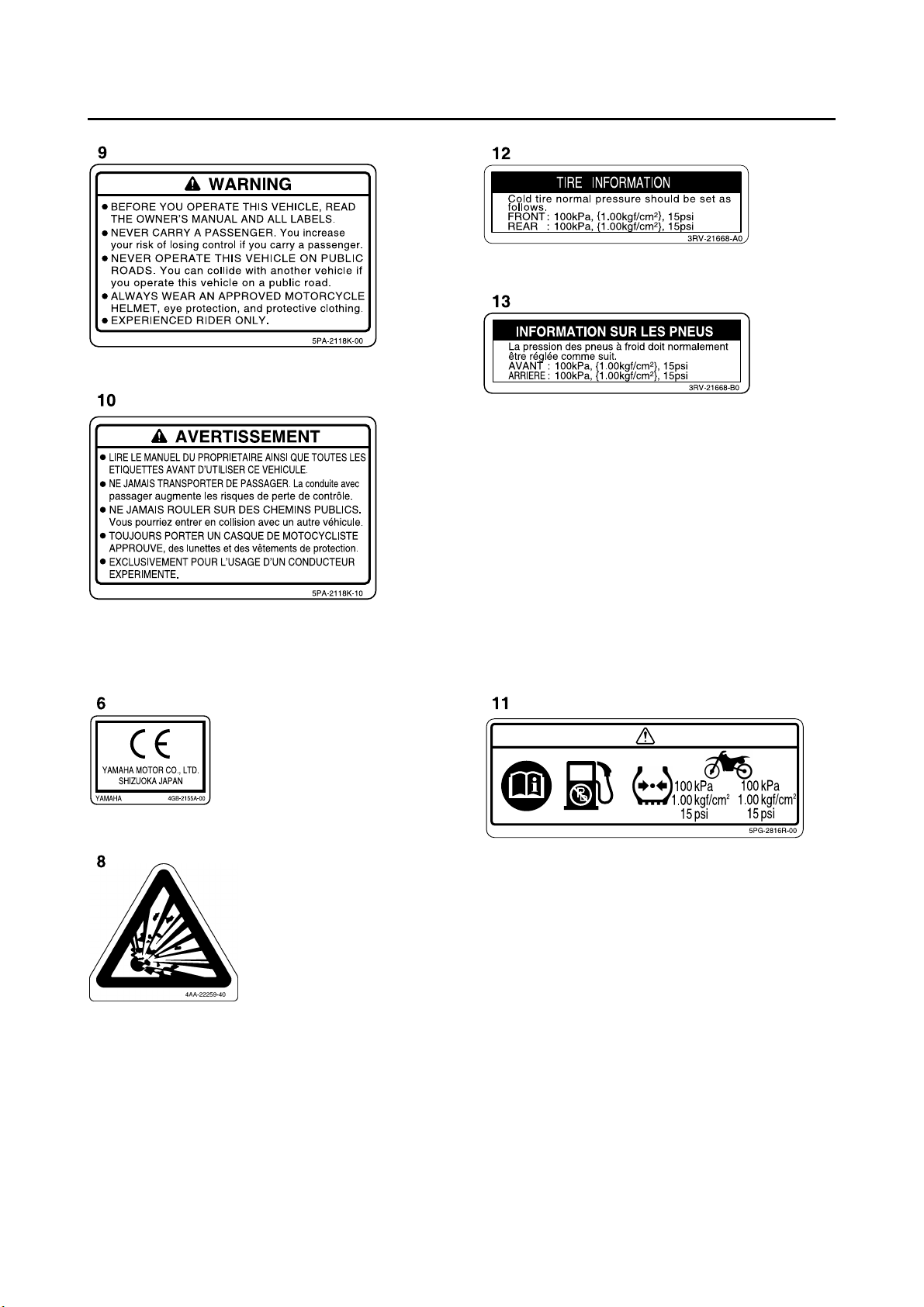

TIP

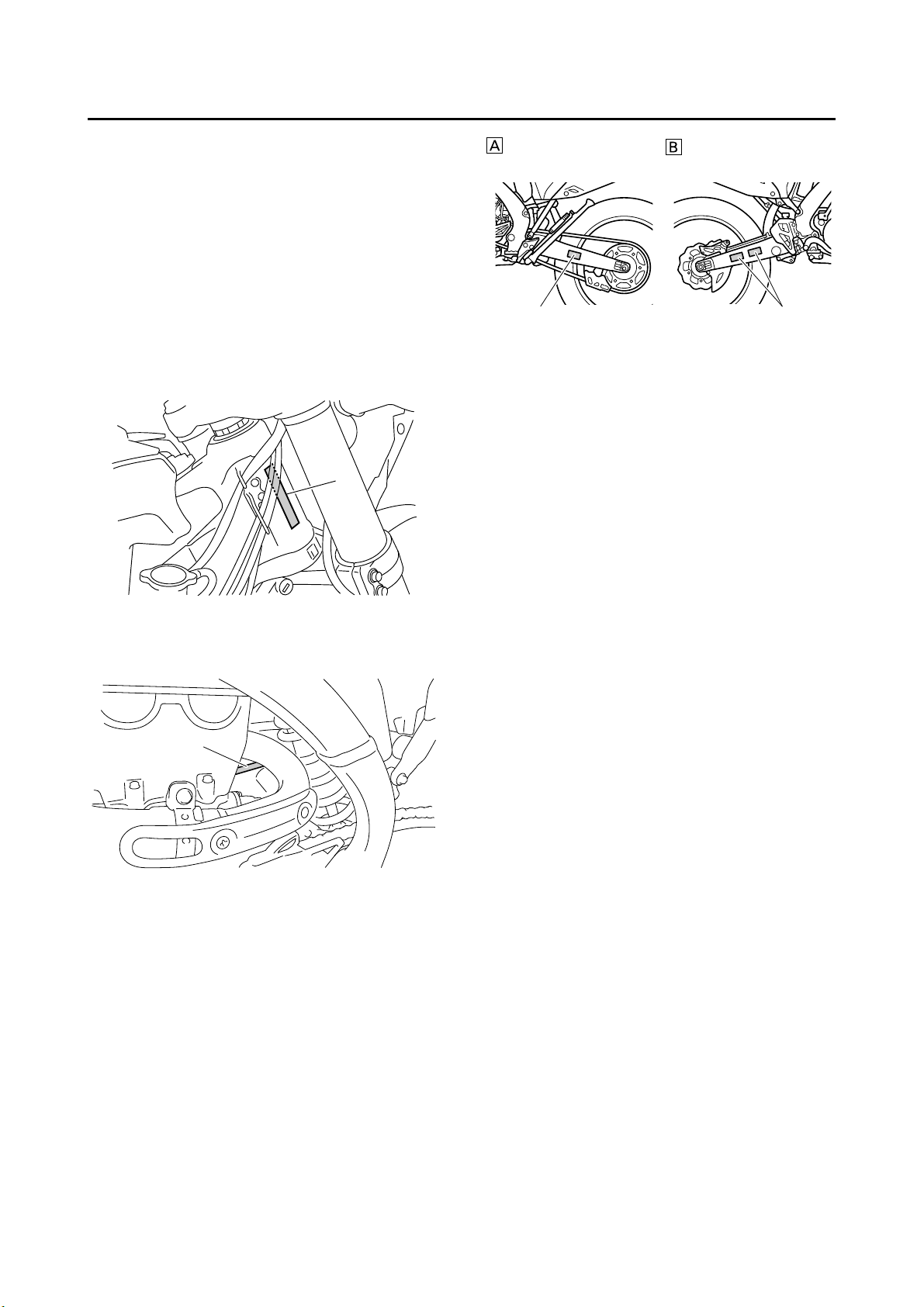

321

8

10

91112 13

76

54

15 14 21 20 19 18 17

16

DESCRIPTION

DESCRIPTION

1. Clutch lever 12. Headlight

2. Multi-function display 13. Radiator

3. Front brake lever 14. Coolant drain bolt

4. Throttle grip 15. Rear brake pedal

5. Start switch 16. Air filter

6. Radiator cap 17. Drive chain

7. Fuel tank cap 18. Shift pedal

8. Engine stop switch 19. Oil level check window

9. Taillight 20. Starter knob/idle screw

10. Fuel tank 21. Front fork

11. Kickstarter lever

Designs and specifications of the vehicle are subject to change without notice. Therefore, please

note that the descriptions in this manual may be different from those for the vehicle you have purchased.

1-4

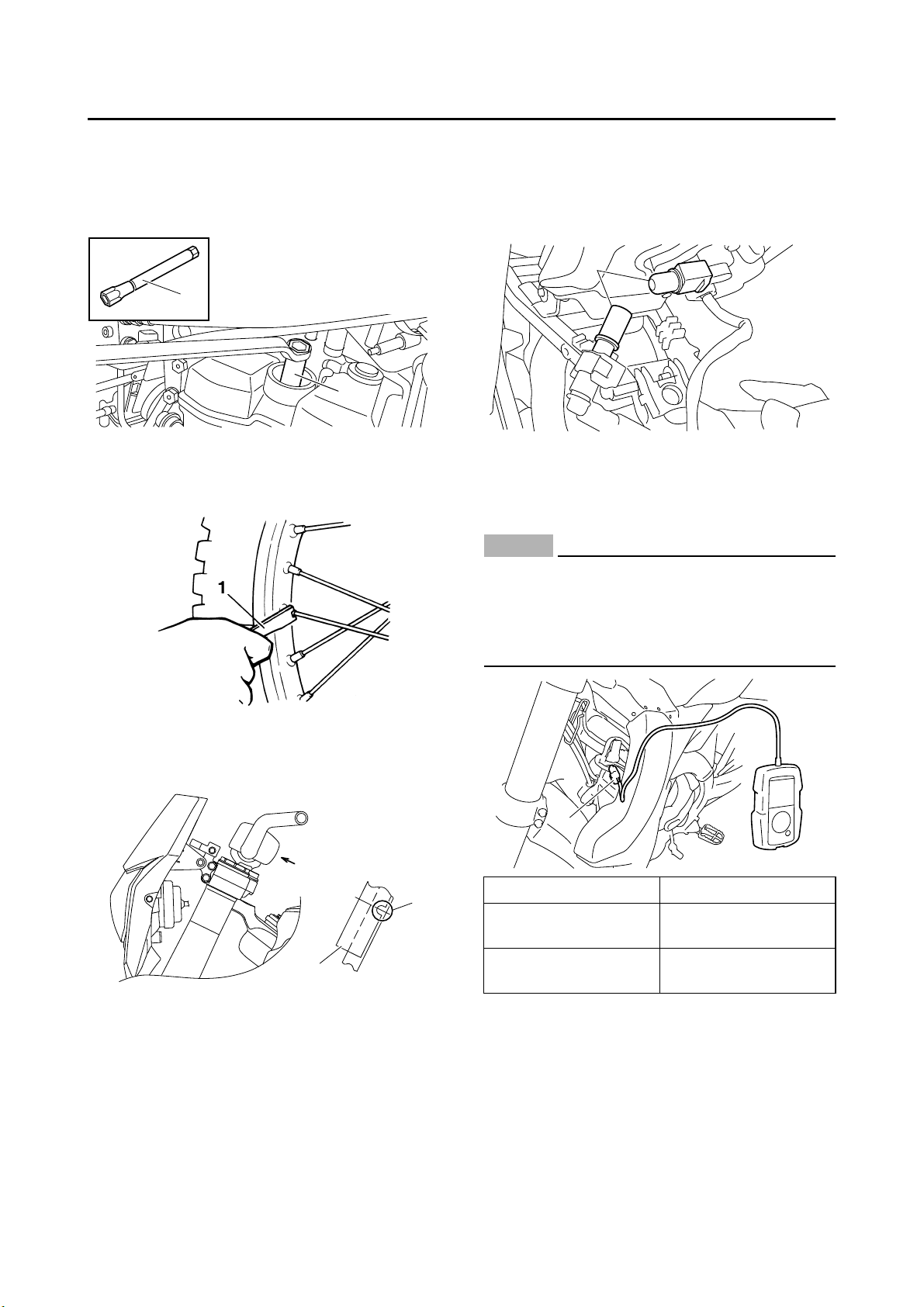

EAS2GC1010

1

1

1

1

IDENTIFICATION

There are two significant reasons for knowing

the serial number of your vehicle:

1. When ordering parts, you can give the num-

ber to your Yamaha dealer for positive identification of the model you own.

2. If your vehicle is stolen, the authorities will

need the number to search for and identify

your vehicle.

EAS2GC1011

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number “1” is

stamped into the right side of the frame.

IDENTIFICATION

A: For Canada

B: For USA and Canada

EAS2GC1012

ENGINE SERIAL NUMBER

The engine serial number “1” is stamped into

the elevated part of the right-side of the engine.

EAS2GC1013

VEHICLE EMISSION CONTROL INFORMATION LABEL

The Vehicle Emission Control Information label

“1” is affixed at the location in the illustration.

This label shows specifications related to exhaust emissions as required by federal law,

state law and Environment Canada.

1-5

INCLUDED PARTS

NOTICE

1

1

A

a

1

A

1

1

EAS2GC1014

INCLUDED PARTS

EAS2GC1015

SPARK PLUG WRENCH

The spark plug wrench “1” is used to remove or

install the spark plug.

EAS2GC1016

NIPPLE WRENCH

The nipple wrench “1” is used to tighten the

spoke.

EAS2GC1018

FUEL HOSE JOINT COVER

The fuel hose joint covers “1” are used to prevent mud, dust, and other foreign materials

from entering the inside when the fuel hose is

disconnected.

EAS2GC1019

COUPLER FOR CONNECTING OPTIONAL

PART

The coupler “1” is used for connecting the optional Power Tuner and so on.

ECA

When no optional parts, etc. are connected,

connect the connection terminal to the original coupler.

Before disconnecting the coupler, thoroughly wipe off any mud or water stuck to it.

EAS2GC1017

HANDLEBAR PROTECTOR

Install the handlebar protector “1” so that the

notch “a” face backward.

Part name Part number

GYTR Power Tuner

33D-H59C0-V2

(For USA)

YZ Power Tuner

33D-859C0-11

(Except for USA)

The Power Tuner is an optional part.

1-6

EAS20180

WARNING

IMPORTANT INFORMATION

EAS2GC1020

PREPARATION FOR REMOVAL AND DISASSEMBLY

1. Before the jobs, completely remove mud,

dust, and the like in order to prevent the entry of them into the inside during the jobs.

• Before cleaning with high-pressure water of

washers, cover the following parts.

Air duct

Silencer exhaust port

Drain hole on the cylinder head (right side)

Hole under the water pump housing

IMPORTANT INFORMATION

4. During disassembly, clean each of the parts,

and store them in trays for each section.

5. Flammable. Keep servicing areas away

from any source of fire.

6. During servicing, take special care not to receive an injury or a burn on the engine, the

exhaust pipe, the silencer, or the like.

7. If coolant is left adhered to the chassis, paint

and plating will be damaged. Therefore,

rinse it out with water in good time.

EWA

Coolant is potentially harmful and should

be handled with special care.

• If it enters your eyes, wash it away with wa-

ter enough and then get medical attention

• If it splashes on your skin or clothes,

quickly wash it away with water and then

with soapy water.

• If it is swallowed, immediately induce vom-

iting and get medical attention.

2. Use proper special tools and equipment.

See “SPECIAL TOOLS”.

3. During disassembly, check and measure the

required parts, and make a record of them

so that you may refer to the record when installing them. Moreover, arrange gears, cylinders, pistons, and other parts for each

section so as not to confuse or lose them.

EAS2GC1021

REPLACEMENT PARTS

Make sure that the parts and grease or oil to be

used for repair of the vehicle, including periodic

replacement parts, are new YAMAHA genuine

parts and recommended parts.

Do not use any used parts, because these may

not be genuine though they have similar appearances or because the quality may be

changed by aging.

1-7

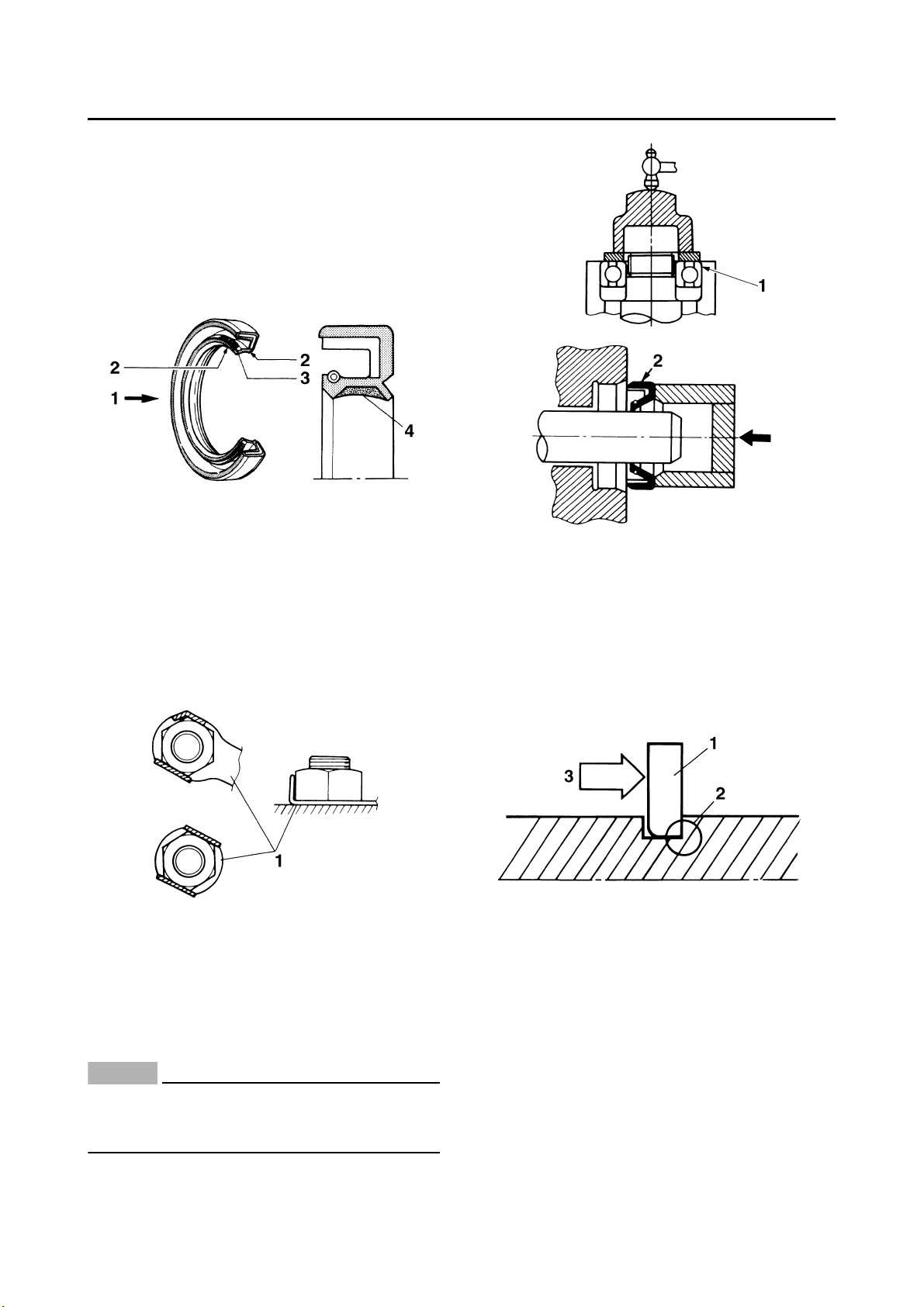

EAS2GC1022

NOTICE

GASKETS, OIL SEALS AND O-RINGS

1. When overhauling the engine, replace all

gaskets and O-rings. All gasket surfaces, oil

seal lips, and O-rings must be cleaned so

that there may be no dust on them.

2. During assembly, always apply proper oil to

bearings and proper grease to oil seal lips

before installation.

1. Oil

2. Lip

3. Spring

4. Grease

EAS2GC1023

LOCK WASHERS/PLATES AND COTTER

PINS

After removal, replace lock washers/plates “1”

and cotter pins with new ones. After the bolt or

nut has been tightened to specification, firmly

bend the lock tabs along a flat of the bolt or nut.

IMPORTANT INFORMATION

EAS2GC1025

CIRCLIPS

When assembling parts, always use new circlips. During installation of a circlip, make sure

that the edge “2” of the circlip “1” is positioned

opposite to the force “3” that the circlip receives. Install the circlip with its end aligned

with the center of the spline, without opening

the circlip more than necessary.

EAS2GC1024

BEARINGS AND OIL SEALS

Install bearings “1” and oil seals “2” with their

manufacturer’s marks or size symbols facing

outward. During installation of an oil seal, make

sure that its main lip faces the oil chamber (the

target to be sealed). Before installation, always

apply a light coat of grease to the oil seal lip.

ECA

Do not spin the bearing with compressed air

because this will damage the bearing surfaces.

1-8

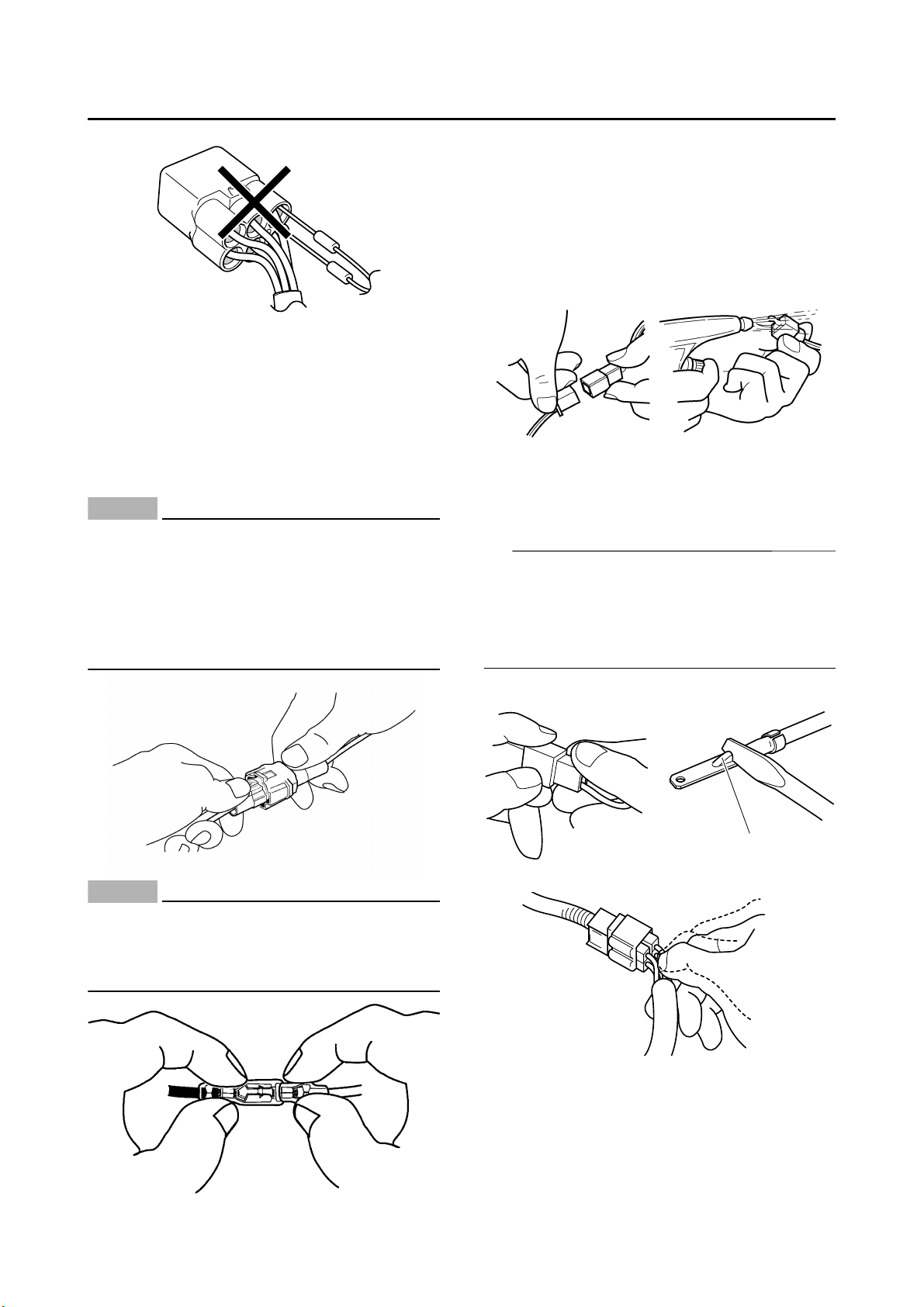

EAS2GC1026

NOTICE

NOTICE

TIP

NOTICE

NOTICE

NOTICE

BASIC SERVICE INFORMATION

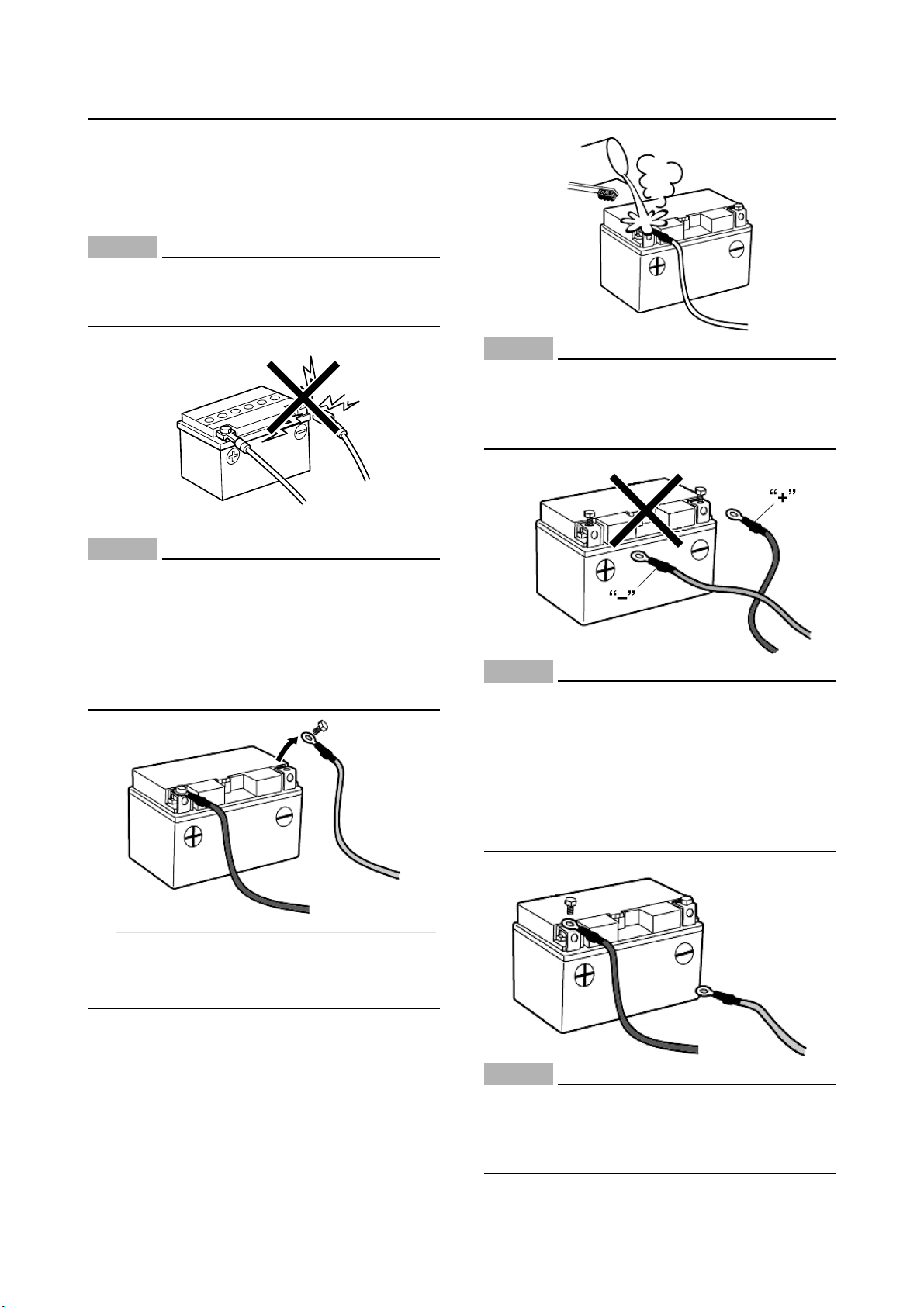

EAS2GC1027

ELECTRICAL SYSTEM

Electrical parts handling

ECA

Never disconnect a battery lead while the

engine is running; otherwise, the electrical

components could be damaged.

BASIC SERVICE INFORMATION

ECA

Be sure to connect the battery leads to the

correct battery terminals. Reversing the

battery lead connections could damage the

electrical components.

ECA

When disconnecting the battery leads from

the battery, be sure to disconnect the negative battery lead first, then the positive battery lead. If the positive battery lead is

disconnected first and a tool or similar item

contacts the vehicle, a spark could be generated, which is extremely dangerous.

If a battery lead is difficult to disconnect due to

rust on the battery terminal, remove the rust using hot water.

ECA

When connecting the battery leads to the

battery, be sure to connect the positive battery lead first, then the negative battery

lead. If the negative battery lead is connected first and a tool or similar item contacts

the vehicle while the positive battery lead is

being connected, a spark could be generated, which is extremely dangerous.

ECA

Make sure that the multi-function display

goes off after pushing and holding the engine stop switch before disconnecting or

connecting any electrical components.

1-9

BASIC SERVICE INFORMATION

NOTICE

NOTICE

TIP

TIP

NOTICE

NOTICE

a

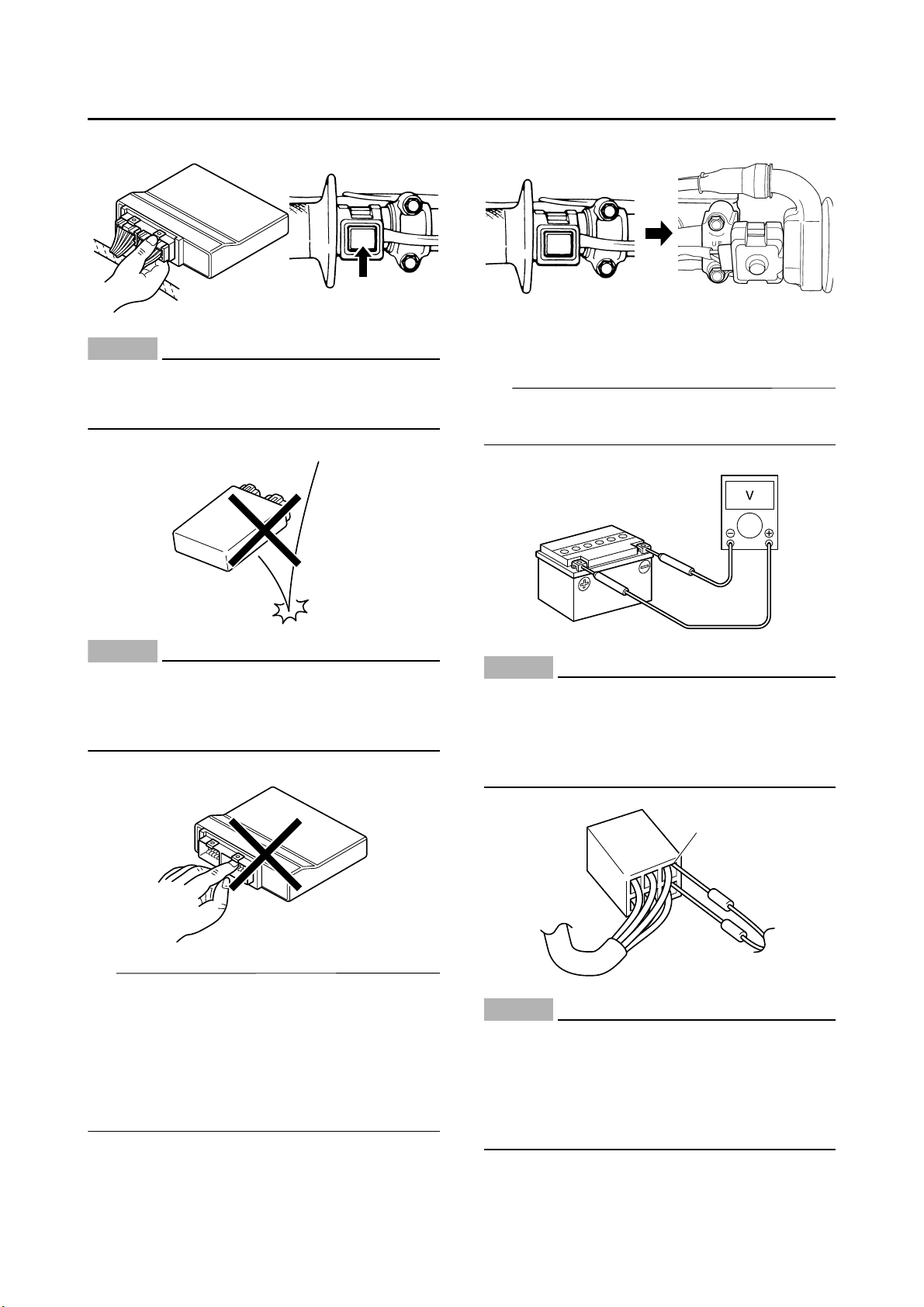

ECA

Handle electrical components with special

care, and do not subject them to strong

shocks.

ECA

Electrical components are very sensitive to

and can be damaged by static electricity.

Therefore, never touch the terminals and be

sure to keep the contacts clean.

Checking the electrical system

Before checking the electrical system, make

sure that the battery voltage is at least 12 V.

ECA

Never insert the tester probes into the coupler terminal slots. Always insert the probes

from the opposite end “a” of the coupler,

taking care not to loosen or damage the

leads.

Push and hold the engine stop switch to turn off

the multi-function display when resetting the

ECU (Electronic Control Unit). Disconnect the

starter motor lead of the starter relay, and then

push the starter switch. Be sure to wait for five

seconds or longer before pushing the start

switch after the multi-function display goes off.

ECA

For waterproof couplers, never insert the

tester probes directly into the coupler.

When performing any checks using a waterproof coupler, use the specified test harness or a suitable commercially available

test harness.

1-10

Checking the connections

NOTICE

NOTICE

TIP

1

Check the leads, couplers, and connectors for

stains, rust, moisture, etc.

1. Disconnect:

• Lead

• Coupler

• Connector

ECA

• When disconnecting a coupler, release the

coupler lock, hold both sections of the

coupler, and then disconnect the coupler.

• There are many types of coupler locks;

therefore, be sure to check the type of coupler lock before disconnecting the coupler.

BASIC SERVICE INFORMATION

2. Check:

• Lead

• Coupler

• Connector

Moisture Dry with compressed air.

Rust/stains Connect and disconnect several times.

3. Check:

• All connections

Loose connection Connect properly.

• If the pin “1” on the terminal is flattened, bend

it up.

• After disassembling or assembling a coupler,

pull on the leads to make sure that they are installed securely.

ECA

When disconnecting a connector, do not

pull the leads. Hold both sections of the

connector, and then disconnect the connector.

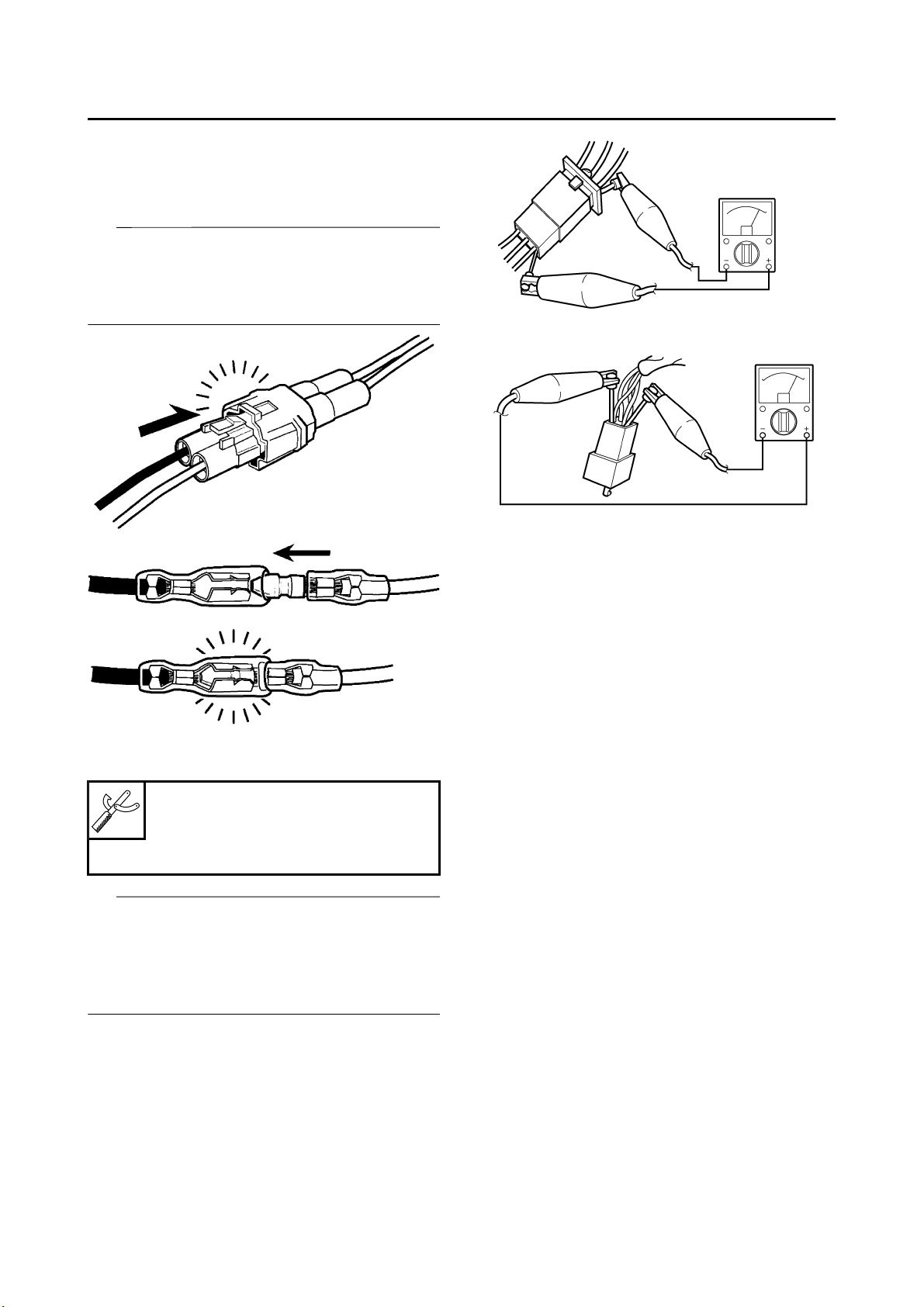

1-11

4. Connect:

TIP

TIP

• Lead

• Coupler

• Connector

• When connecting a coupler or connector,

make sure that both terminals are connected

securely.

• Make sure all connections are tight.

BASIC SERVICE INFORMATION

5. Check:

• No continuity

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• If there is no continuity, clean the terminals.

• When checking the wire harness, perform

steps (1) to (4).

• As a quick remedy, use a contact revitalizer

available at most part stores.

1-12

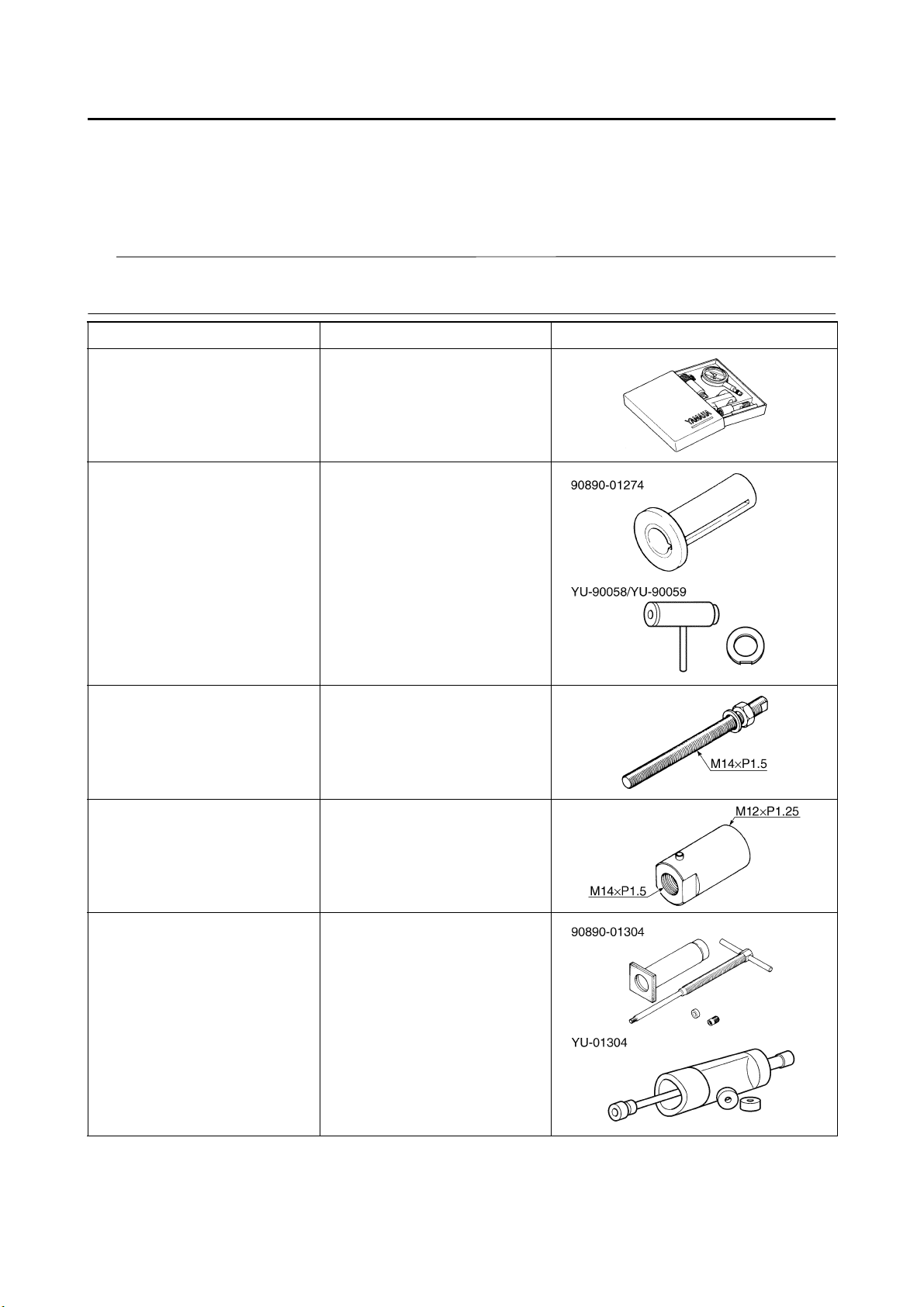

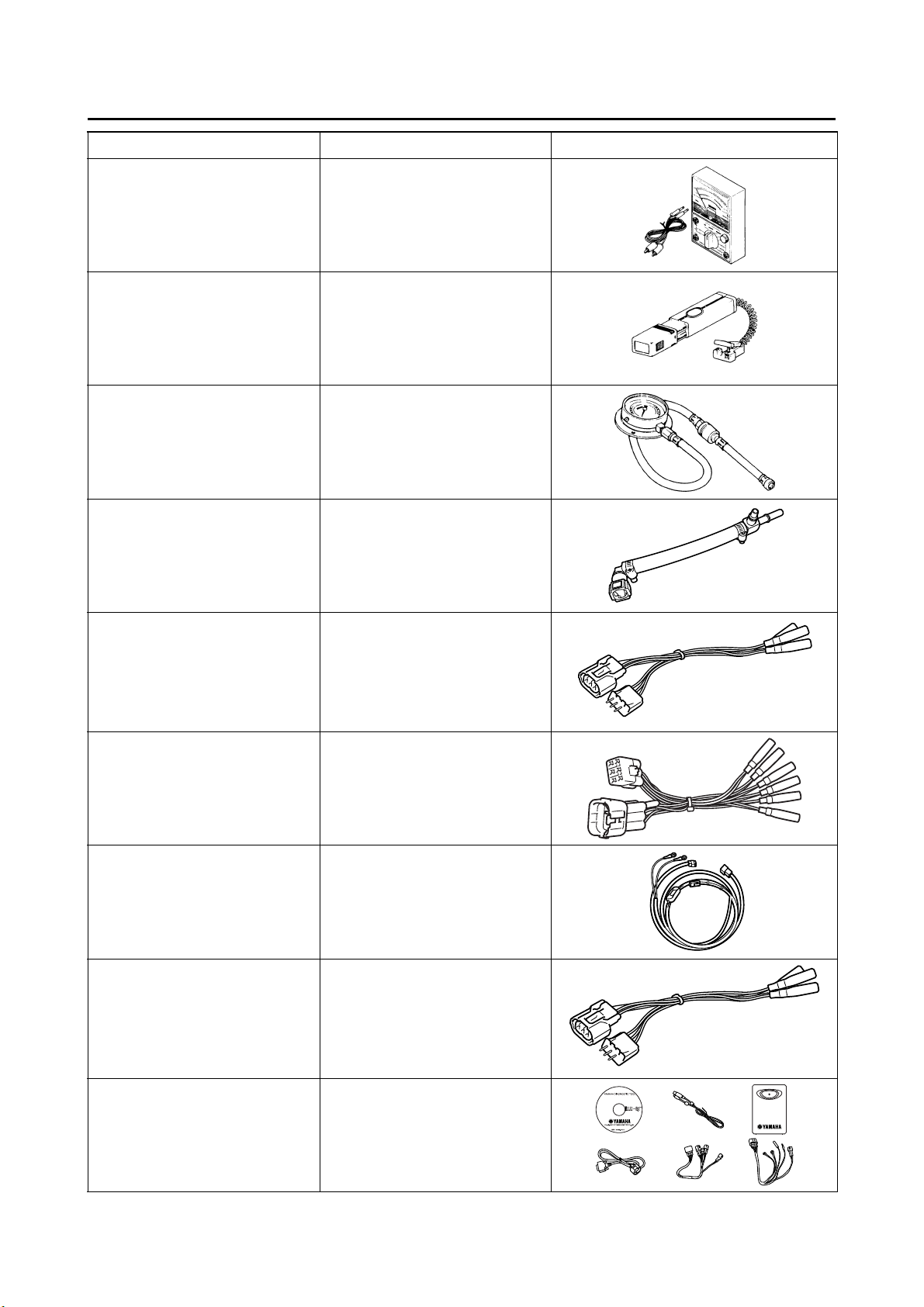

SPECIAL TOOLS

TIP

EAS2GC1028

SPECIAL TOOLS

The following special tools are required for accurate and complete adjustment and assembly. Using

the correct special tool will help prevent damage caused by the use of improper tools or improvised

techniques. The shape and tool number used for the special tool differ by country, so two types are

provided. Refer to the list provided to avoid errors when placing an order.

• For U.S.A. and Canada, use tool number starting with “YM-”, “YU-”, or “ACC-”.

• For others, use tool number starting with “90890-”.

Tool name/Part number How to use Illustration

Dial gauge & stand set

90890-01252

Dial gauge set

YU-03097-B

This tool is used to check

parts for runout or bend.

Crankshaft installer pot

90890-01274

Installing pot

YU-90058

Crankshaft installer bolt

90890-01275

Bolt

YU-90060

Adapter (M12)

90890-01278

Adapter #3

YU-90063

This tool is used to install the

crankshaft.

This tool is used to install the

crankshaft.

This tool is used to install the

crankshaft.

Piston pin puller set

90890-01304

Piston pin puller

YU-01304

This tool is used to remove

the piston pin.

1-13

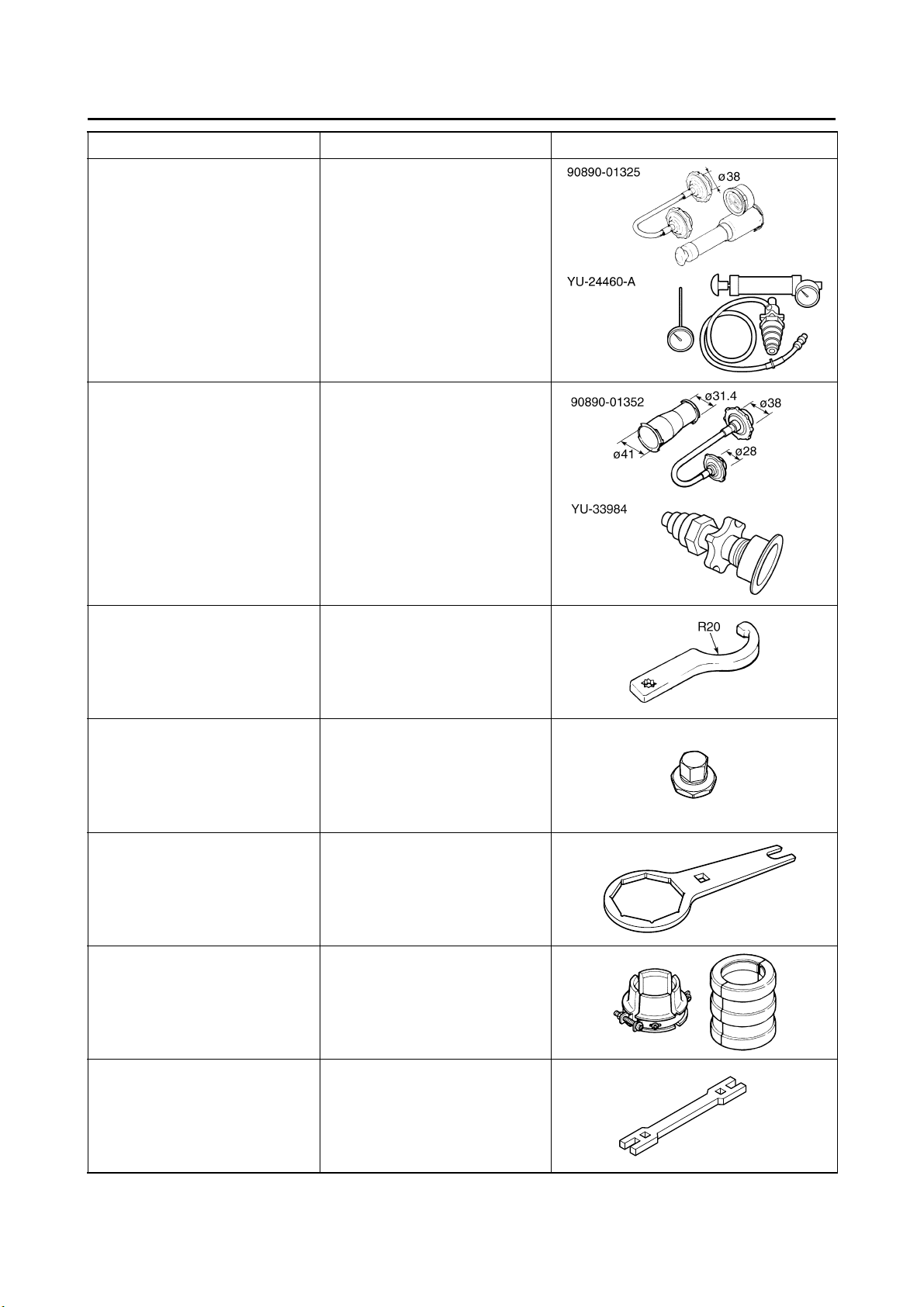

SPECIAL TOOLS

Tool name/Part number How to use Illustration

Radiator cap tester

90890-01325

Mityvac cooling system tester

kit

YU-24460-A

Radiator cap tester adapter

90890-01352

Pressure tester adapter

YU-33984

Steering nut wrench

90890-01403

Exhaust flange nut wrench

YU-A9472

This tool is used to check the

radiator and the radiator cap.

This tool is used to check the

radiator and the radiator cap.

This tool is used to remove or

tighten the steering nut.

Cap bolt wrench

90890-01500

Cap bolt wrench

YM-01500

Cap bolt ring wrench

90890-01501

Cap bolt ring wrench

YM-01501

Fork seal driver

90890-01502

Fork seal driver (48)

YM-A0948

Spoke nipple wrench (6–7)

90890-01521

Spoke nipple wrench (6–7)

YM-01521

This tool is used to remove or

tighten the base valve.

This tool is used to loosen or

tighten the damper assembly.

This tool is used to install the

oil seal of the front fork.

This tool is used to tighten the

spoke.

1-14

SPECIAL TOOLS

Tool name/Part number How to use Illustration

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

Timing light

90890-03141

Timing light

YU-03141

Pressure gauge

90890-03153

Pressure gauge

YU-03153

Fuel pressure adapter

90890-03186

Fuel pressure adapter

YM-03186

This tool is used to measure

the voltage, current, and resistance of electrical components.

This tool is used to measure

the ignition timing.

This tool is used to measure

the fuel pressure.

This tool is used to mount the

pressure gauge.

Test harness S– pressure

sensor (3P)

90890-03207

Test harness S– pressure

sensor (3P)

YU-03207

Test harness– lean angle

sensor (6P)

90890-03209

Test harness– lean angle

sensor (6P)

FI diagnostic tool sub–lead

90890-03212

FI diagnostic tool sub–lead

YU-03212

Test harness– speed sensor

5TJ (3P)

90890-03228

Test harness– speed sensor

5TJ (3P)

YU-03228

This tool is used to check the

throttle position sensor input

voltage.

This tool is used to check the

lean angle sensor output voltage.

This tool is used to connect

the Yamaha diagnostic tool

to a battery.

This tool is used to check the

speed sensor output voltage.

Yamaha diagnostic tool

90890-03231

Yamaha diagnostic tool (US)

90890-03234

This tool is used to check error codes or carry out self-diagnosis.

1-15

SPECIAL TOOLS

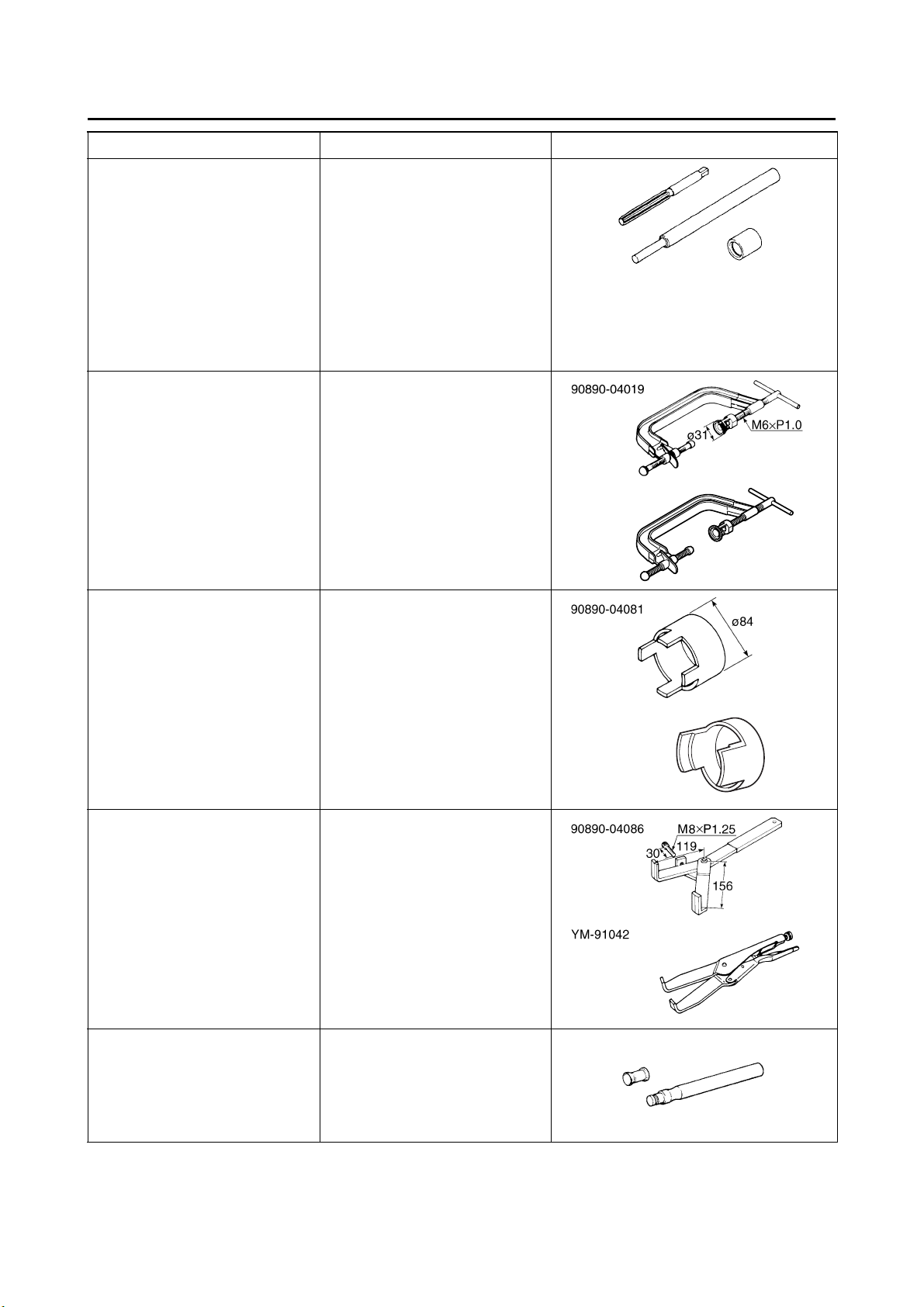

YM-04019

YM-91044

Tool name/Part number How to use Illustration

Valve guide remover & installer set (ø5.5)

90890-04016

Valve guide remover (5.5

mm)

YM-01122

Valve guide installer (5.5

mm)

YM-04015

Valve guide reamer (5.5 mm)

90890-01196

Valve spring compressor

90890-04019

Valve spring compressor

YM-04019

Spacer (crankshaft installer)

90890-04081

Pot spacer

YM-91044

This tool is used to replace

the valve guide.

This tool is used to disconnect or connect the valve and

the valve spring.

This tool is used to install the

crankshaft.

Universal clutch holder

90890-04086

Universal clutch holder

YM-91042

Valve lapper

90890-04101

Valve lapping tool

YM-A8998

This tool is used to hold the

clutch when removing or installing the clutch boss securing nut.

This tool is used to remove

the valve lifter or lap the

valve.

1-16

Loading...

Loading...