Page 1

Page 2

Page 3

SPECIAL SERVICE TOOL LIST

©2004 Yamaha Motor Co.,Ltd.

1st Edition, August 2004

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Co.,Ltd.

is expressly prohibited.

Printed in Japan

LISTE DES OUTILS D’ENTRETIEN SPÉCIAUX

©2004 Yamaha Motor Co., Ltd.

1ère Edition, Août 2004

Tous droits réservés.

Toute réimpression ou utilisation

sans la permission écrite de la

Ya maha Motor Co., Ltd.

est formellement interdite.

Imprimé en Japon

LISTA DE HERRAMIENTAS ESPECIALES DE

SERVICIO

©2004 Yamaha Motor Co., Ltd.

1ª edición, Agosto 2004

Reservados todos los derechos.

Se prohíbe expresamente toda reimpresión

o utilización no autorizada de este manual

sin el consentimiento por escrito de

Yamaha Motor Co., Ltd.

Impreso en Japón

Page 4

E

NOTICE

This list of special service tools has been prepared for quick and easy reference, to enable you to

find the appropriate service tool(s) for each model.

The special service tools have been improved and upgraded for each new model. However, your

existing service manual does not include the latest information. Also, the list does not cover the

models of which information could not be obtained at the time of preparation of the manual. The

information will be provided through the next issue of the special service tool list.

Outboard motor models : All models to be released only in this fiscal year (except those of

which information can not be obtained )

Watercraft models : All models including those released in several years ago to the lat-

est models (The new models of this fiscal year may be excluded

because the development period of watercrafts is different from that

of the outboard motors.)

The special service tools mentioned in the service manual of each model are listed here.

Tool numbers in round brackets indicate current tool numbers, and will be replaced with the replacement tool numbers (not in brackets) when stock runs out.

In addition, the tool names always appear in English in this manual.

MANUAL FORMAT

APPLICATION CHARTS

Tool numbers and the outboard motor/watercraft models to which they apply are shown in the

charts.

Tools, which are to be supplied in an assembly, are listed with a dot (

) :Dots in round brackets indicate that the particular tool is not absolutely necessary and which

(

•

can be substituted by another tool.

] :Square brackets indicate that the tool applies only to models in square brackets in the corre-

[

sponding column header.

) in front of the tool name.

•

TOOL DESCRIPTIONS

The tool number, name, illustration, and description of its use are shown. The required tool size is

also given to assist in the identification of the correct tool.

The construction and meaning of each section are as follows:

Measuring tool : Mechanical or electrical precision tools (Some measuring tools may

be listed in one of the following sections instead.)

Engine servicing : Special tool for engine servicing

Lower unit/jet pump servicing

Shim selection, PTT tool : Special tool for shim selection and power trim and tilt unit servicing

: Special tool for lower unit/jet pump servicing

REPAIR KITS (RECONDITION TOOL)

The following kits can be used for repairing/replacing damaged parts, avoiding the need to replace

the whole unit. Some skill is required to use these.

“Heli-sert” kit : For reconditioning damaged bolt threads

Marine terminal kit : For repairing conventional marine round plug/socket and eye termi-

nals This water-resistant and rust-resistant connector type, although

similar, is different from that on a motorcycle.

Coupler kit : For repairing water-resistant multiple pole couplers

NOTE:

Identify the correct coupler and do not try to use a coupler of the incorrect type.

INDEX

Find the desired tool through its number (part number) in order to determine the page in the APPLICATION CHARTS and TOOL DESCRIPTIONS, where a more detailed explanation of the tool can

be found.

Page 5

F

NOTE

Cette liste d'outils spéciaux a été préparée afin que les mécaniciens puissent trouver rapidement et aisément le ou les outils spéciaux requis selon les modèles.

Yamaha a modifié et amélioré certains outils d'entretien spéciaux pour les nouveaux modèles. Toutefois, votre manuel

d'atelier existant ne comprend pas ces nouvelles informations. De même, la liste ne concerne pas les modèles dont on ne

disposait pas d'informations au moment de la préparation du manuel. Les informations seront présentées dans la prochaine

publication de la liste d'outils spéciaux.

Modèles de moteur hors-bord : Tous les modèles à sortir cette année fiscale

(à l’exception de ceux à propos desquels on ne peut pas obtenir d’informations)

Modèles de scooters nautiques : Tous les modèles de ceux sortis il y a plusieurs années aux modèles les plus récents

(Les nouveaux modèles de cette année fiscale peuvent être exclus car la période

dedéveloppement des scooters nautiques est différente de celle des moteurs hors-

bord)

Les outils d'entretien spéciaux mentionnés dans le manuel d'atelier pour chaque modèle sont mentionnés ici.

Les numéros d’outils entre parenthèses indiquent les numéros des outils actuels et seront remplacés par les numéros des

outils de rechange (pas entre parenthèses) à l’épuisement du stock.

Le nom des outils figure en anglais.

ORGANISATION DU MANUEL

TABLEAUX D'APPLICATION (APPLICATION CHARTS)

Le numéro des outils spéciaux ainsi que les modèles de moteur hors-bord/de scooter nautique auxquels les outils spéciaux

s'appliquent sont indiqués dans des tableaux.

Dans ce catalogue, les outils qui sont fournis dans un ensemble sont précédés d'un point (•).

(•): Les points entre parenthèses indique que l’outil n’est pas absolument nécessaire et qu’il peut être remplacé par un

autre outil.

[ ]: Les crochets indiquent que l’outil ne s’appliquent qu’aux modèles qui sont entre crochets dans l’en-tête de colonne

correspondante.

FONCTION DES OUTILS (TOOL DESCRIPTIONS)

Les informations données pour chacun de ces outils comprennent leur numéro, leur nom, une représentation graphique

et leur fonction.

Pour plus de commodité d'identification des outils, la taille requise pour l'outil est également indiquée.

Les outils spéciaux sont répartis dans les sections suivantes :

Outil de mesure : Outil de précision mécanique ou électronique (Tous les outils de mesure ne figurent

pas nécessairement dans cette section. Contrôler la liste des sections suiantes.)

Entretien du moteur : Outil spécial requis pour l'entretien du moteur

Entretien du boîtier d'hélice/ : Outil spécial requis pour l'entretien du boîtier d'hélice/pompe de propulsion

pompe de propulsion

Sélection de cales, outil pour PTT : Outil spécial requis pour la sélection de cales et l'entretien du système d'assiette et

d'inclinaison assistées pour PTT

KITS DE REPARATION (OUTIL DE RECONDITIONNEMENT)

Les kits suivants permettent de réparer/remplacer des pièces endommagées et d'ainsi éviter de devoir remplacer les

assemblages.

L'emploi de ces kits de réparation requiert certaines compétences.

Kit de taraudage : Pour le reconditionnement des filetages de boulon endommagés

Kit de bornes marines : Pour la réparation des fiches/prise rondes marines classiques et les cosses. Ce type

de connecteur résistant à l'eau et à la corrosion est différent de celui d'une motocy-

clettes, bien qu'il soit similaire.

Kit de coupleur : Pour la réparation de coupleurs à multipôles étanches

N.B.:

Identifiez le coupleur correct et n'essayez pas d'utiliser un coupleur d'un type incorrect.

INDEX

Les outils sont classés d'après leur numéro. Se servir de ce numéro pour trouver la page des sections Tableaux d'application (APPLICATION CHARTS) et Fonction des outils (TOOL DESCRIPTIONS) contenant les renseignements détaillés de l'outil recherché.

Page 6

ES

AVISO

Esta lista de herramientas de servicio especiales ha sido preparada para encontrar rápida y fácilmente la(s)

herramienta(s) de servicio necesarias para cada modelo respectivo.

Las herramientas de servicio especiales han sido mejoradas para ser utilizadas en los nuevos modelos.

Sin embargo, su manual de servicio existente no cubre la información más reciente. Además, la lista no

incluye los modelos sobre los cuales no pudo obtenerse información en el momento de preparación del manual. Esta información se facilitará en la próxima publicación de la lista de herramientas especiales de servicio.

Modelos de motores fueraborda : Sólo todos los modelos que se lancen en este año fiscal (excepto

aquellos sobre los cuales no puede obtenerse información)

Modelos de embarcaciones : Todos los modelos, incluidos los lanzados, desde hace varios años

hasta los últimos modelos (los modelos nuevos de este año fiscal

pueden ser excluidos porque el período de desarrollo de las embarcaciones es distinto del de los motores fueraborda).

Aquí se enumeran las herramientas especiales de servicio mencionadas en el manual de servicio de cada

modelo.

Los números de herramientas entre paréntesis indican los números de las herramientas nuevas y deben

sustituirse por los números de las herramientas de repuesto (no entre paréntesis) cuando se agoten las existencias.

Además, los nombres de las herramientas siempre aparecen en inglés en este manual.

FORMATO DEL MANUAL

TABLAS DE APLICACIÓN

En las tablas se muestran los números de herramienta y los modelos aplicables de motores fueraborda y

moto de agua.

Las herramientas suministradas como conjunto se señalan con un punto (•) que precede al nombre de la herramienta.

(•): Los puntos entre paréntesis indican que no es absolutamente necesaria la herramienta específica y que

puede sustituirse por otra herramienta.

[ ]: Los corchetes indican que la herramienta se aplica sólo a los modelos entre corchetes en el encabezado

de columna correspondiente.

DESCRIPCION DE LAS HERRAMIENTAS

Se muestran el número, el nombre, y la ilustración de las herramientas, y la descripción de su utilización.

Se indica también el tamaño de la herramienta necesaria para ayudarle a identificarla con más facilidad.

La construcción y el significado de los elementos son los siguientes:

Herramienta de medición : Herramientas de precisión mecánicas o eléctricas (Algunas herramientas

de medición pueden estar enumeradas en una las secciones siguientes.)

Servicio del motor : Herramienta especial para el servicio del motor

Servicio de la unidad inferior/ : Herramienta especial para el servicio de la unidad inferior/bomba de inyecbomba de inyección ción

Selección de laminillas, : Herramienta especial para la selección de laminillas y el servicio de la unherramienta PTT idad de estibado e inclinación motorizados

JUEGOS DE REPARACION (HERRAMIENTA DE REACONDICIONAMIENTO)

Los juegos siguientes pueden utilizarse para la reparación/reemplazo de las partes dañadas para evitar el

reemplazo de toda la unidad. Para emplear estos juegos se necesita experiencia práctica.

Juego “Heli-sert” : Para reacondicionar las roscas de los pernos dañadas

Juego de terminales marinos : Para reparar los terminales de ojal y acopladores redondos convencionales

de uso marino. Este tipo de conector resistente al agua e inoxidable,

aunque similar, es diferente del de una motocicleta.

Juego de acoplador : Para reparar los acopladores multipolares resistentes al agua

NOTA:

Identifique el acoplador correcto y no trate de utilizar un acoplador del tipo incorrecto.

ÍNDICE

Podrá encontrar las herramientas que busca empleando su número (numero de parte) para poder determinar la página de las TABLAS DE APLICACIÓN y de la DESCRIPCIÓN DE LAS HERRAMIENTAS, donde se

da una explicación más detallada de las herramientas.

Page 7

CONTENTS

1.APPLICATION CHART

OUTBOARDS MOTOR TOOL ........................................................................................ 1-1

MEASURING TOOL/PEAK VOLTAGE MEASUREMENT (2 stroke model) .................. 1-1

MEASURING TOOL/PEAK VOLTAGE MEASUREMENT

(Enduro/Kerosene model, 4 stroke model) ................................................................. 1-3

ENGINE SERVICE (2 stroke model) ............................................................................. 1-5

ENGINE SERVICE (Enduro/Kerosine nodel, 4-stroke model) ...................................... 1-7

ENGINE SERVICE (4 stroke model) ............................................................................. 1-9

VALVE SEAT CUTTER (Refering) ........................................................................ 1-10

ENGINE SERVICE (Test propeller) ............................................................................... 1-11

ENGINE SERVICE (Crankshaft disassembly and reassembly) .................................... 1-13

LOWER UNIT SERVICE (2 stroke model) .................................................................... 1-15

LOWER UNIT SERVICE (Enduro/Kerosine nodel, 4-stroke model) ............................. 1-19

SHIM SELECTION/PTT TOOL (2 stroke model) ........................................................... 1-23

SHIM SELECTION/PTT TOOL (Enduro/Kerosine nodel, 4-stroke model) .................... 1-25

WATERCRAFT TOOL ............................................................................................. 1-27

MEASURING TOOL/PEAK VOLTAGE MEASUREMENT ............................................. 1-27

ENGINE SERVICE ........................................................................................................ 1-27

ENGINE SERVICE/JET PUMP SERVICE ..................................................................... 1-29

E

2.TOOL DESCRIPTION

MEASURING TOOL....................................................................................................... 2-1

PEAK VOLTAGE MEASUREMENT ............................................................................... 2-7

ENGINE SERVICE ........................................................................................................ 2-8

4 stroke ................................................................................................................. 2-13

Watercraft.............................................................................................................. 2-16

Crankshaft disassembly and reassembly ............................................................. 2-17

Test propeller ........................................................................................................ 2-18

LOWER UNIT SERVICE/JET PUMP SERVICE ............................................................ 2-19

SHIM SELECTION......................................................................................................... 2-29

PTT TOOL...................................................................................................................... 2-31

3.RECONDITION TOOL

HELI-SERT KIT (90890-05155) ..................................................................................... 3-1

MARINE TERMINAL KIT (90890-05354)....................................................................... 3-2

COUPLER KIT A (61A) (90890-05353) ......................................................................... 3-3

OPTIONAL PARTS ........................................................................................................ 3-4

4.INDEX

INDEX ............................................................................................................................ 4-1

Page 8

TABLE DES MATIERES

1.TABLEAUXD’APPLICATION (APPLICATION CHART)

OUTILS POUR LES MOTEURS HORS-BORD .......................................................................... 1-1

OUTIL DE MESURE/MESURE DE CRÊTES DE TENSION (modèle 2 temps)...................... 1-1

OUTIL DE MESURE/MESURE DE CRÊTES DE TENSION

(modèle enduro/kérosène model, modèle 4 temps) ................................................................... 1-3

D’ENTRETIEN MOTEUR (modèle 2 temps) ............................................................................. 1-5

D’ENTRETIEN MOTEUR (modèle enduro/kérosène model, modèle 4 temps)......................... 1-7

D’ENTRETIEN MOTEUR (modèle 4 temps) ............................................................................. 1-9

FRAISE A SIEGE DE SOUPAPE (référence) .................................................................... 1-10

D’ENTRETIEN MOTEUR (Hélices d’essai) .............................................................................. 1-11

D’ENTRETIEN MOTEUR (Depose et le remontage du vilebreguin) ........................................ 1-13

D’ENTRETIEN BOÎTIER D’HÉLICE (modèle 2 temps) ........................................................... 1-15

D’ENTRETIEN BOÎTIER D’HÉLICE (modèle enduro/kérosène model, modèle 4 temps) ...... 1-19

SÉLECTION DE CALES/OUTIL POUR PTT (modèle 2 temps) ............................................... 1-23

SÉLECTION DE CALES/OUTIL POUR PTT

(modèle enduro/kérosène model, modèle 4 temps) ................................................................... 1-25

F

OUTILS POUR LES SCOOTER NAUTIQUES .................................................................... 1-27

OUTIL DE MESURE/MESURE DE CRÊTES DE TENSION ................................................... 1-27

D’ENTRETIEN MOTEUR .......................................................................................................... 1-27

D’ENTRETIEN MOTEUR/D’ENTRETIEN POMPE DE PROPULSION ................................ 1-29

2.FONCTION DES OUTILS (TOOL DESCRIPTION)

OUTIL DE MESURE ................................................................................................................... 2-1

MESURE DE CRÊTES DE TENSION........................................................................................ 2-7

D’ENTRETIEN MOTEUR .......................................................................................................... 2-8

4 temps ................................................................................................................................ 2-13

Scooter Nautiques ............................................................................................................... 2-16

Depose et le remontage du vilebreguin............................................................................... 2-17

Hélices d’essai..................................................................................................................... 2-18

D’ENTRETIEN BOÎTIER D’HÉLICE/D’ENTRETIEN POMPE DE PROPULSION .............. 2-19

SÉLECTION DE CALES ............................................................................................................. 2-29

OUTIL POUR PTT ....................................................................................................................... 2-31

3.OUTIL DE REVISION (RECONDITION TOOL)

KIT DE TARAUDAGE (90890-05155) ....................................................................................... 3-1

KIT DE BORNES (90890-05354) ................................................................................................ 3-2

KIT DE COUPLEURS A (61A) (90890-05353) .......................................................................... 3-3

PIÈCES EN OPTION ................................................................................................................... 3-4

4.INDEX (INDEX)

INDEX .......................................................................................................................................... 4-1

Page 9

CONTENIDO

1.GRÁFICAS DE APLICACIÓN (APPLICATION CHART)

HERRAMIENTAS PARA MOTORES DE FUERA DE BORDA.................................. 1-1

HERRAMIENTA DE MEDICIÓN/MEDICIÓN DE LA TENSIÓN PICO

(modelo de 2 tiempos) ................................................................................................ 1-1

HERRAMIENTA DE MEDICIÓN/MEDICIÓN DE LA TENSIÓN PICO

(modelo Enduro/Keroseno, modelo de 4 tiempos) ..................................................... 1-3

SERVICIO DEL MOTOR (modelo de 2 tiempos) .......................................................... 1-5

SERVICIO DEL MOTOR (modelo Enduro/Keroseno, modelo de 4 tiempos) ............... 1-7

SERVICIO DEL MOTOR (modelo de 4 tiempos) .......................................................... 1-9

CORTADOR DE ASIENTO DE VÁLVULA (referencia) ......................................... 1-10

SERVICIO DEL MOTOR (Hélices de prueba) . ............................................................. 1-11

SERVICIO DEL MOTOR (Desmontage yel montage delcigüeñal)................................ 1-13

SERVICIO DE UNIDAD IN FERIOR/BOMBA DEINYECCIÓN

SERVICIO DE UNIDAD IN FERIOR/BOMBA DEINYECCIÓN

(modelo Enduro/Keroseno, modelo de 4 tiempos) ..................................................... 1-19

SELECCIÓN DE LAMINILLAS/HERRAMIENTA PTT (modelo 2 tiempos).................... 1-23

SELECCIÓN DE LAMINILLAS/HERRAMIENTA PTT

(modelo Enduro/Keroseno, modelo de 4 tiempos) ..................................................... 1-25

(modelo de 2 tiempos)

ES

... 1-15

HERRAMIENTAS PARA MOTO DE AGUA .................................................................. 1-27

HERRAMIENTA DE MEDICIÓN/MEDICIÓN DE LA TENSIÓN PICO ........................... 1-27

SERVICIO DEL MOTOR................................................................................................ 1-27

SERVICIO DEL MOTOR/ESERVICIO DE BOMBA DE INYECCIÓN............................ 1-29

2.DESCRIPCION DE LAS HERRAMIENTA (TOOL DESCRIPTION)

HERRAMIENTA DE MEDICIÓN .................................................................................... 2-1

MEDICIÓN DE LA TENSIÓN PICO............................................................................... 2-7

SERVICIO DEL MOTOR................................................................................................ 2-8

4 tiempos............................................................................................................... 2-13

Moto de agua ........................................................................................................ 2-16

Desmontage yel montage del cigüeñal................................................................. 2-17

Hélices de prueba ................................................................................................. 2-18

SERVICIO DE UNIDAD IN FERIOR/BOMBA DE INYECCIÓN ..................................... 2-19

SELECCIÓN DE LAMINILLAS ...................................................................................... 2-29

HERRAMIENTA PTT ..................................................................................................... 2-31

3.HERRAMIENTAS REACONDICION (RECONDITION TOOL)

JUEGO HELI-SERT (90890-05155) .............................................................................. 3-1

JUEGO DE TERMINALES MARINOS (90890-05354).................................................. 3-2

JUEGO DE ACOPLADOR A (61A) (90890-05353)

PA RTE DE OPTIONAL .................................................................................................. 3-4

................................................... 3-3

4.ÍNDICE (INDEX)

ÍNDICE ........................................................................................................................... 4-1

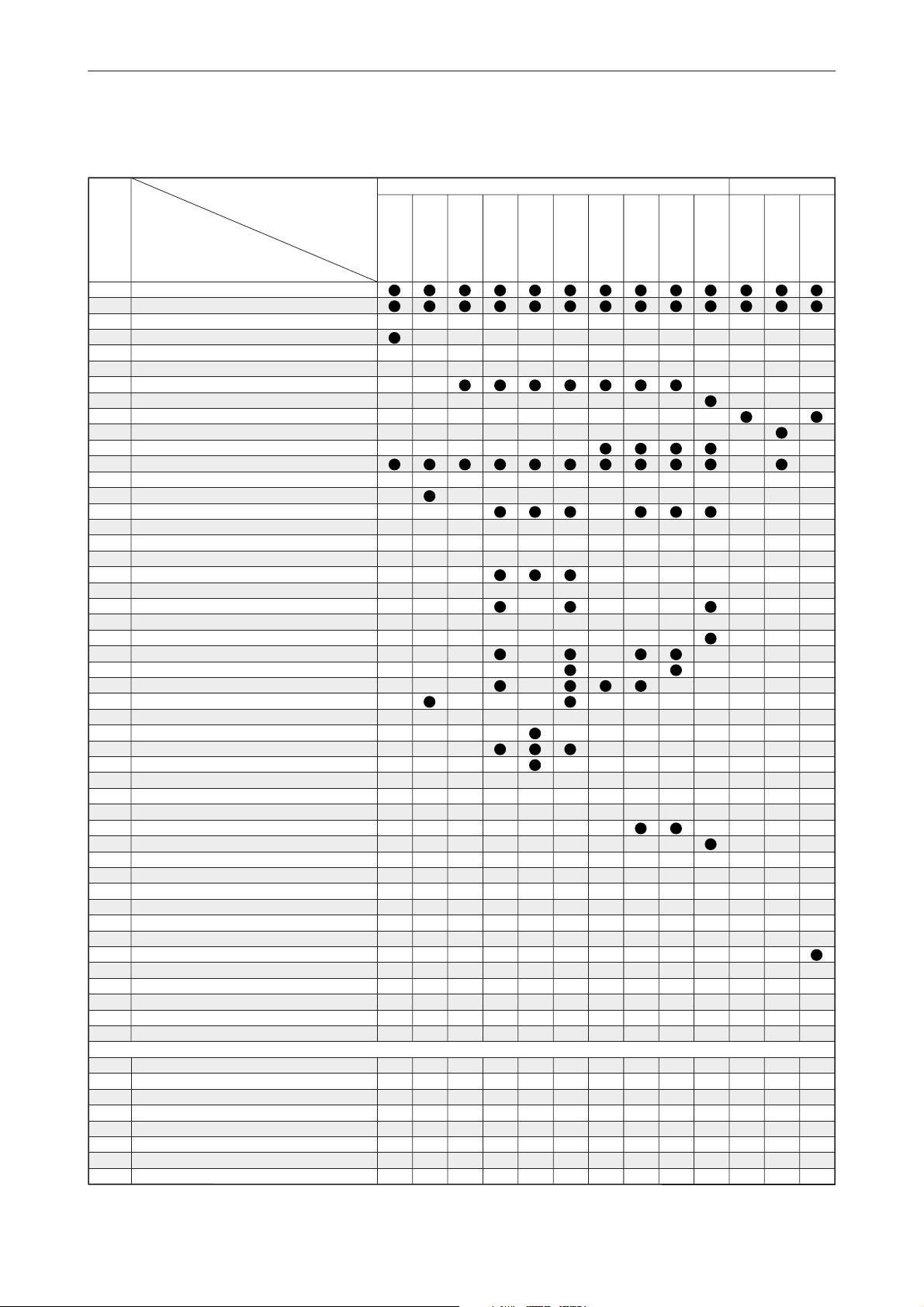

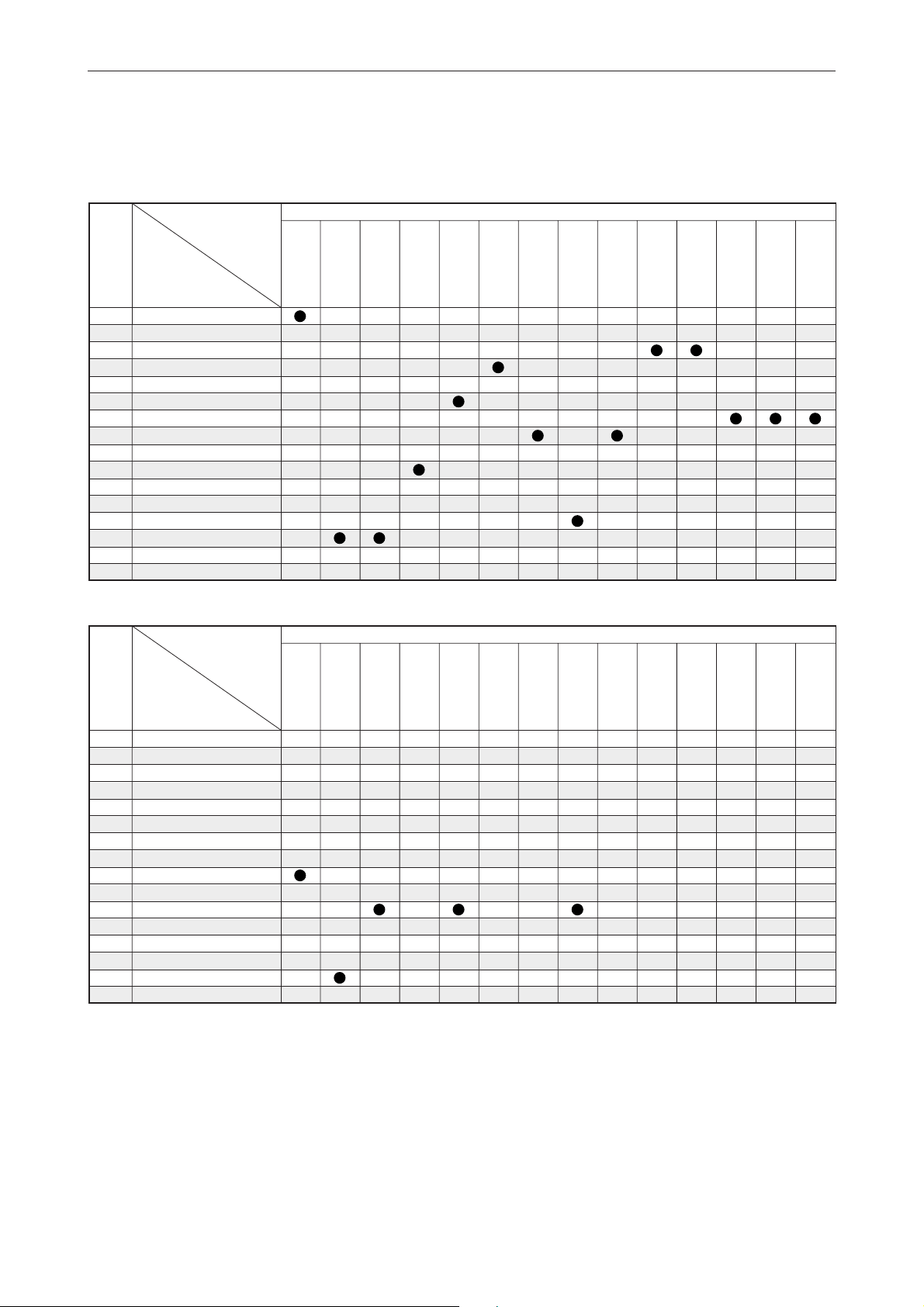

Page 10

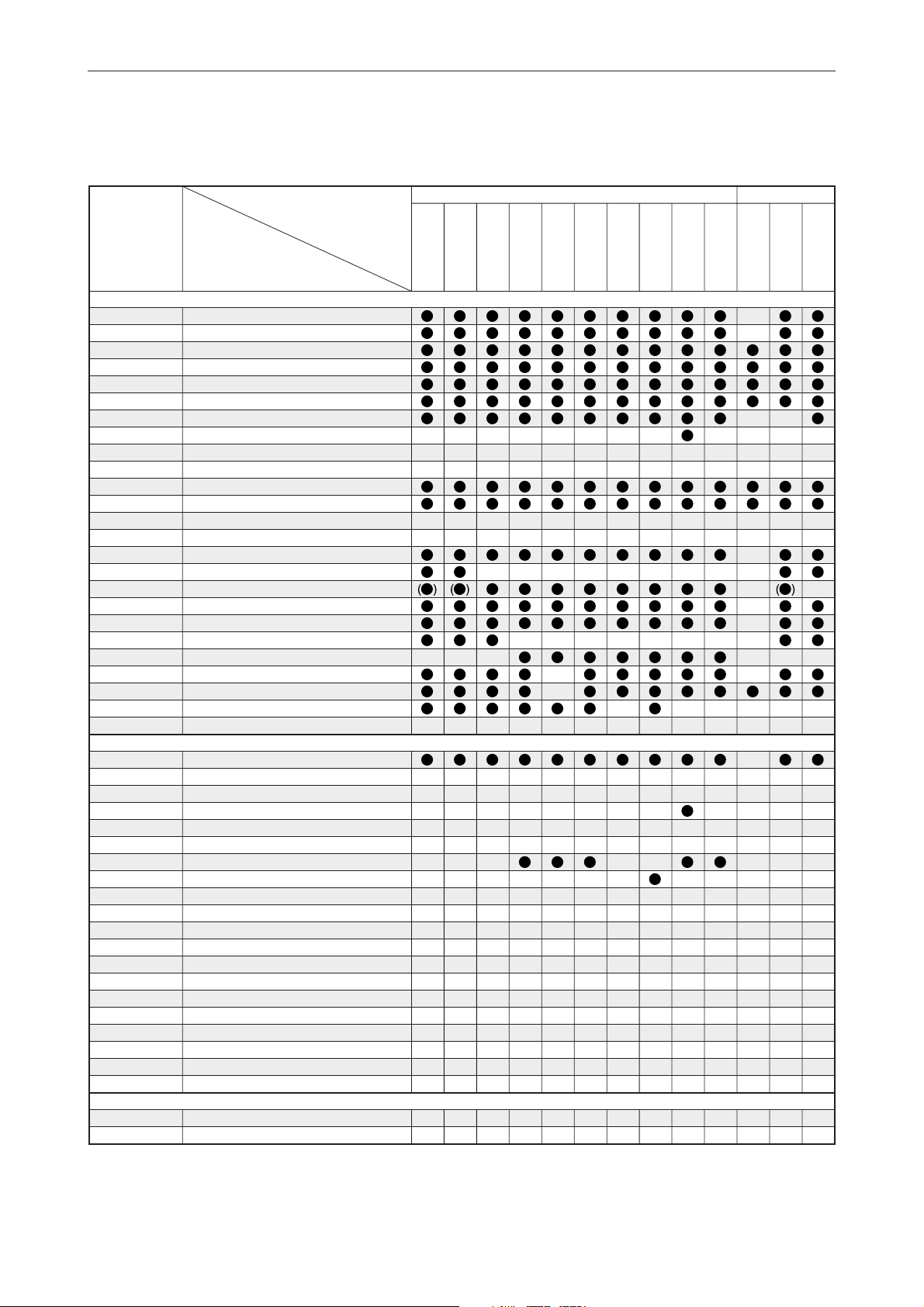

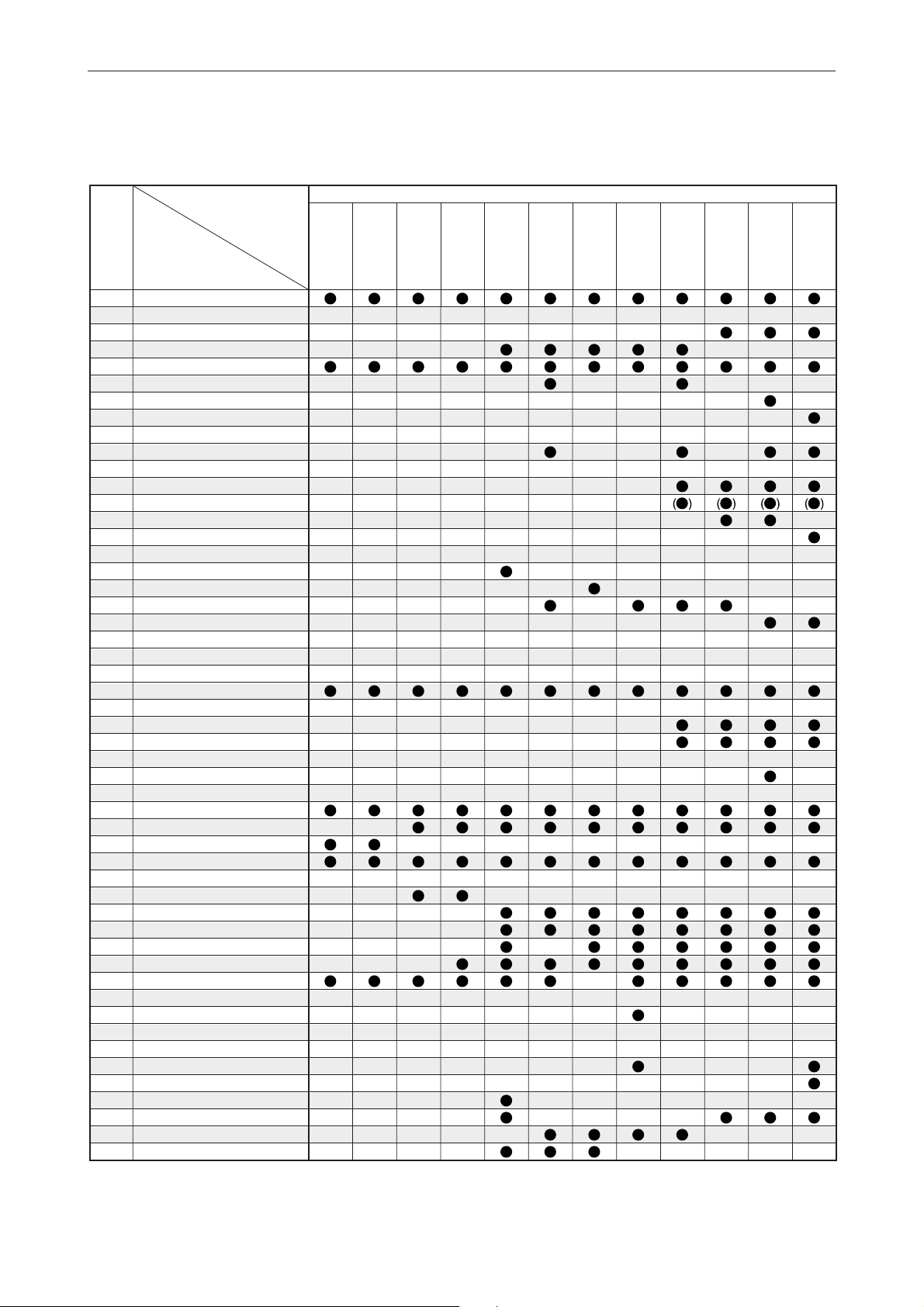

OUTBOARDS MOTOR TOOL

MEASURING TOOL/PEAK VOLTAGE MEASUREMENT

(2 stroke model)

APPLICATION CHART

Tool

No.

90890-

MEASURING TOOL

01252

03112

03141

03160

03174

06754

06756

06757

06865

06864

06760

06840

06786

06942

06704

03016

06759

03006

03007

03008

03009

03010

03180

03107

06563

PEAK VOLTAGE MEASUREMENT

03172

06867 (06767)

06868 (06768)

06857 (06757)

06869 (06769)

06870 (06770)

06871 (06771)

06875 (06775)

06872 (06772)

06879 (06779)

06887 (06787)

06888 (06788)

06790

06791

06792

06793

06861

06846

06847

06848

YAMAHA DIAGNOSTIC SYSTEM

60V-85300-02

60V-WS853-02

Dial gauge set

Pocket tester

Timing light

Compression gauge

Digital circuit tester

Ignition tester

Vacuum/pressure pump gauge set

Throttle sensor adjusting lead FWY-3

Diagnostic flash indicator B

Diagnostic flash adapter 4

Digital tachometer

Leakage tester

Fuel pressure gauge

Fuel pressure gauge adapter B

Digital caliper

Cylinder gauge 35 - 60

Cylinder gauge 50 - 100

Outside micrometer 0 - 25

Outside micrometer 25 - 50

Outside micrometer 50 - 75

Outside micrometer 75 - 100

Inside micrometer 5 - 25

Thickness gauge

Crankshaft aligner

Compression gauge extension M14

Peak voltage adapter B

Test harness FWY-2

Test harness EJ-II-2

Throttle sensor adjusting lead FWY-3

Test harness EJ-II-3

Test harness SMT250-3

Test harness FWY-4

Test harness AMP-4

Test harness FWY-6

Test harness FWY-8

Test harness FW13613-2

Test harness FW13613-1

Test harness FSW-6

Test harness FWY-3-L

Test harness SMHW090-2

Test harness SMHW099-3

Test harness SM6195043

Test harness QLW-3

Test harness QLWD-3

Test harness FSW-6A

Yamaha Diagnostic System (KIT)

Yamaha Diagnostic System(CD-ROM) *5

MODEL

2B

2C

3A

4AC

4AS

5C

5CS

6C

8C

9.9F

13.5A

15F

2 Stroke model

20D

20C

25N

25B

25X

30H

30D

40V

40Y

50H

55B

50G

60F

70B

*1 V4 :115B, 115C, 130B, 140B, 140C

2

V6 :150F, 150G, 150J, 150L, 175D, 200F, 200G,

*

200H, 200J, 225D, 225G

3

*

Electronic fuel injectioned model only

4

2 stroke model

*

5

Up-date CD-ROM only

*

1-1

Page 11

01252

03112

03141

03160

03174

06754

06756

06757

06865

06864

06760

06840

06786

06942

06704

03016

06759

03006

03007

03008

03009

03010

03180

03107

06563

Tool

No.

90890-

55D

75A

75B

85A

75C

80A

90A

V4*

1

L130B

V6*2D150N

150A

175A

200A

2 Stroke model

L150F

L150J

L150A

L200F

L200A

L200J

225C

250A

225F

250B

APPLICATION CHART

Z150P

L225C

L250A

L225F

L250B

Z150Q

Z175G

Z175H

Z200N

Z200P

LZ150P

LZ200N

Z225H

Z250F

Z250D

Z300A

Z300B

LZ250D

LZ300A

03172

06867 (06767)

06868 (06768)

06857 (06757)

06869 (06769)

06870 (06770)

06871 (06771)

06875 (06775)

06872 (06772)

06879 (06779)

06887 (06787)

06888 (06788)

06790

06791

06792

06793

06861

06846

06847

06848

60V-85300-02

60V-WS853-02

1-2

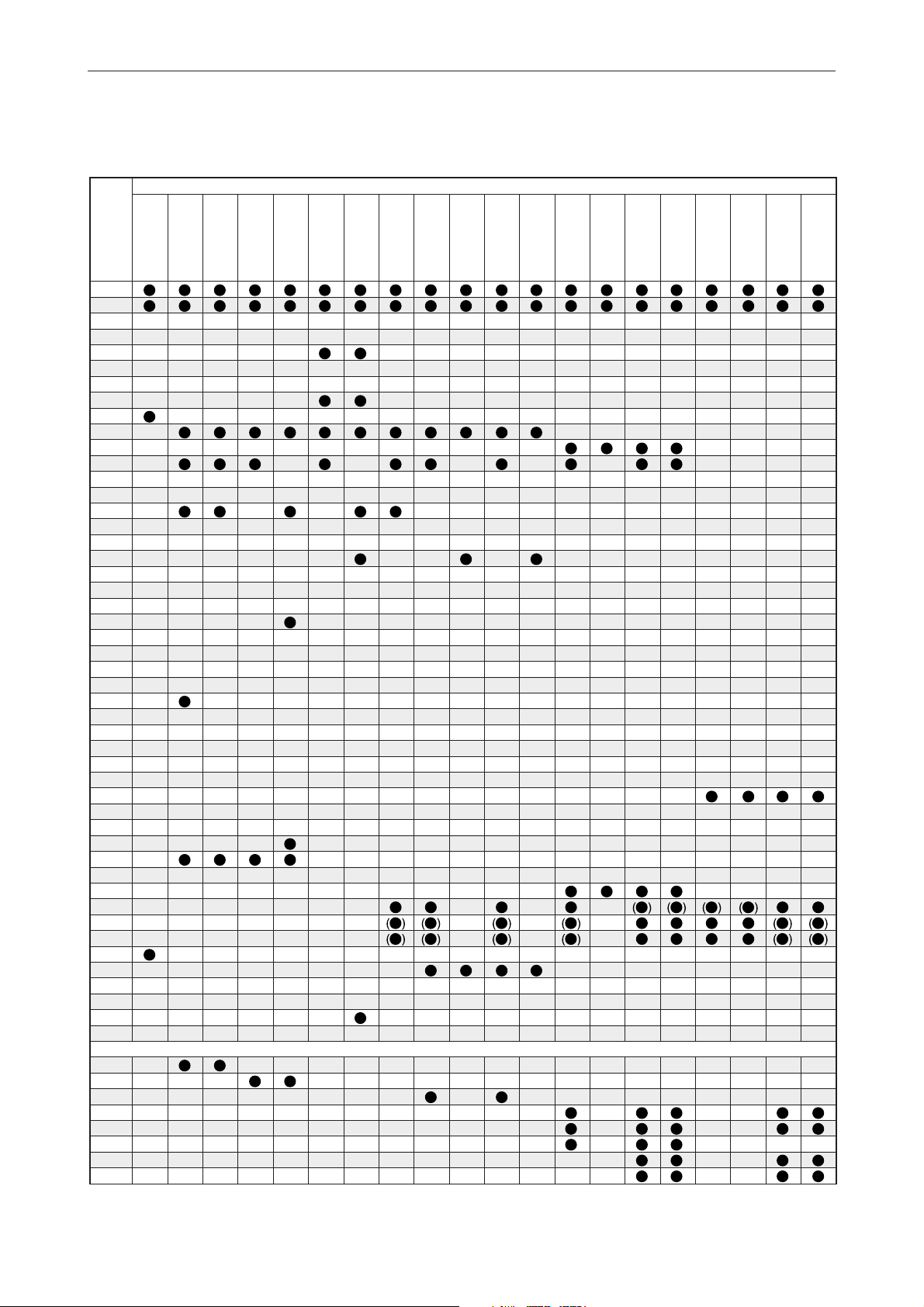

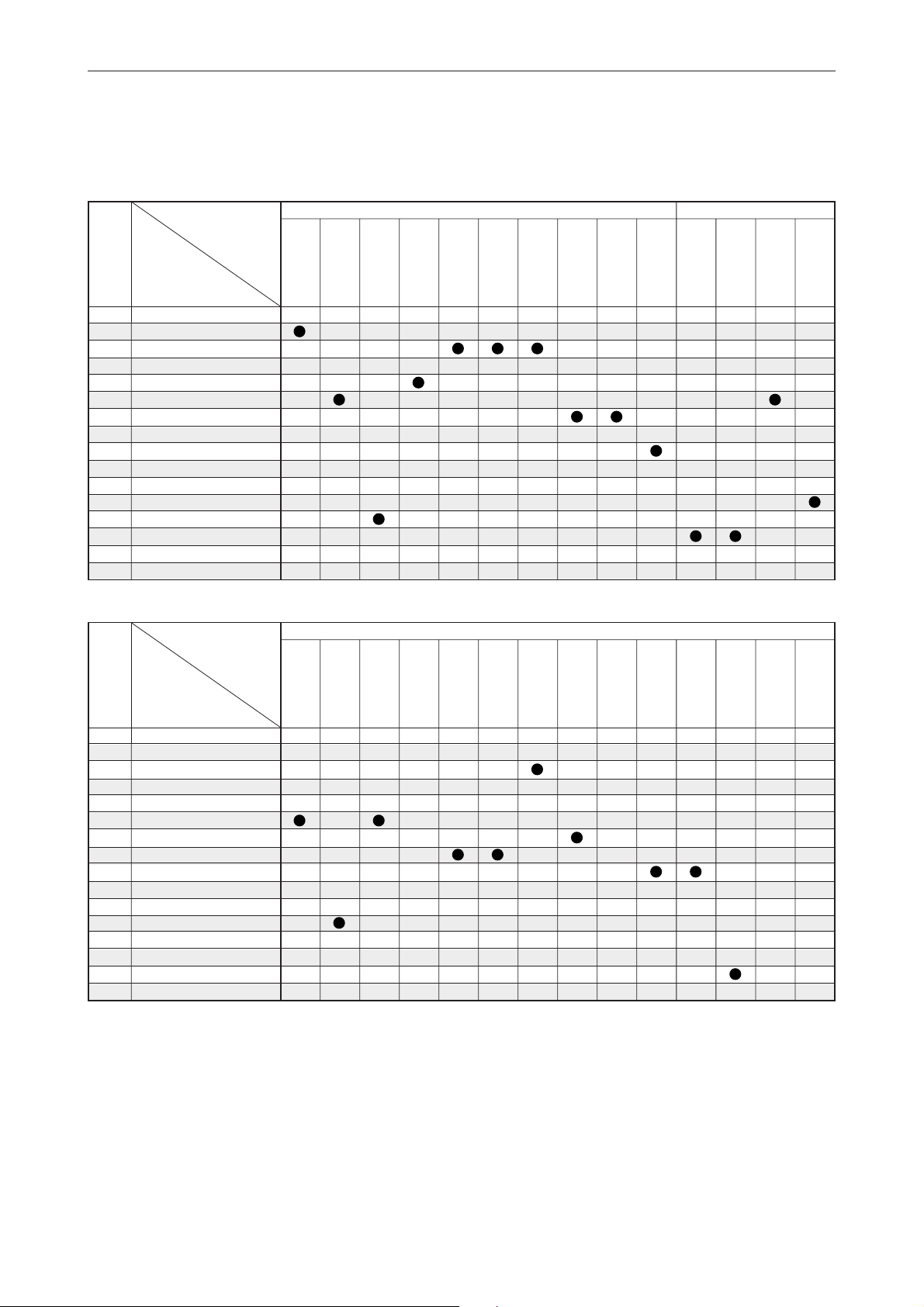

Page 12

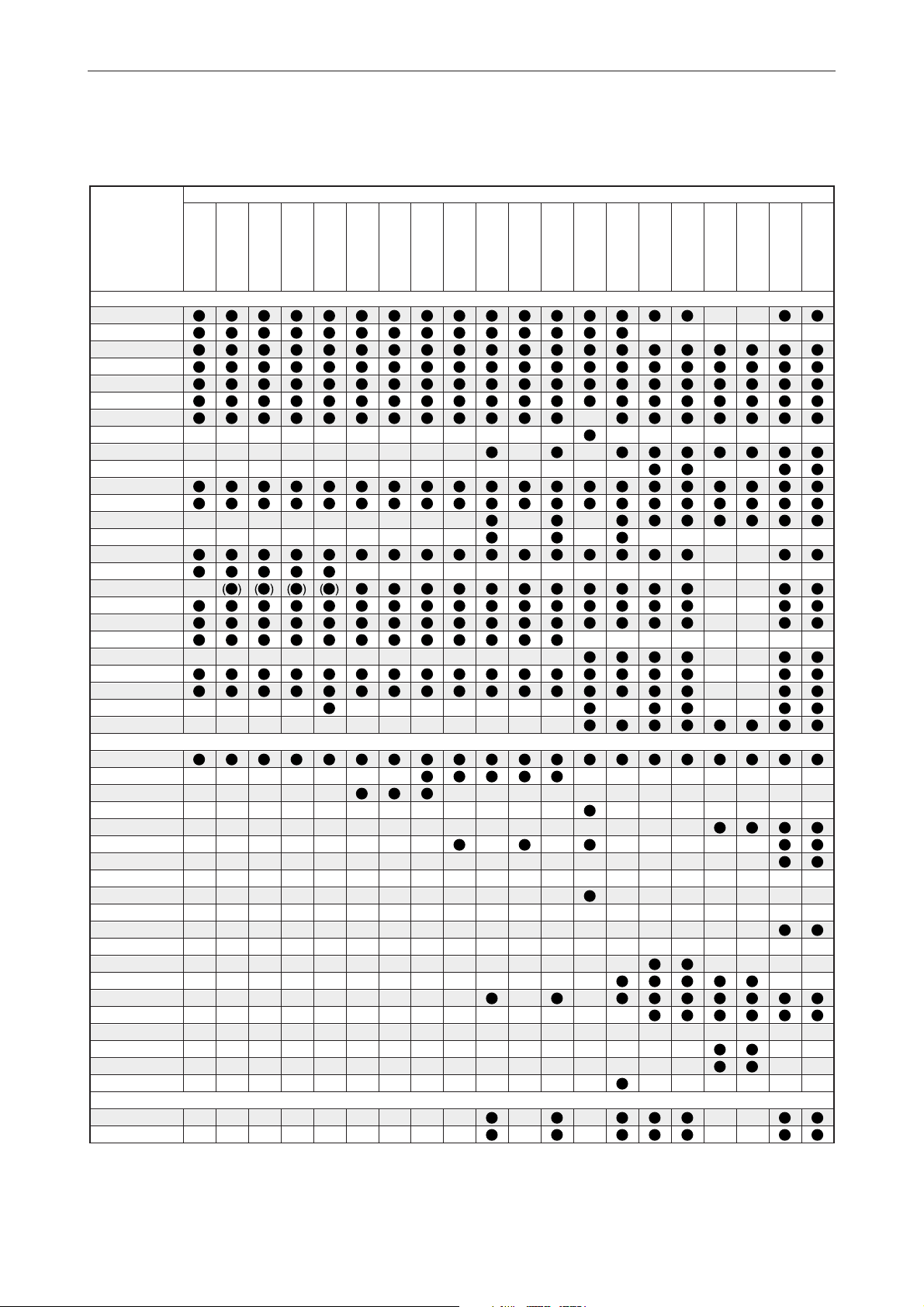

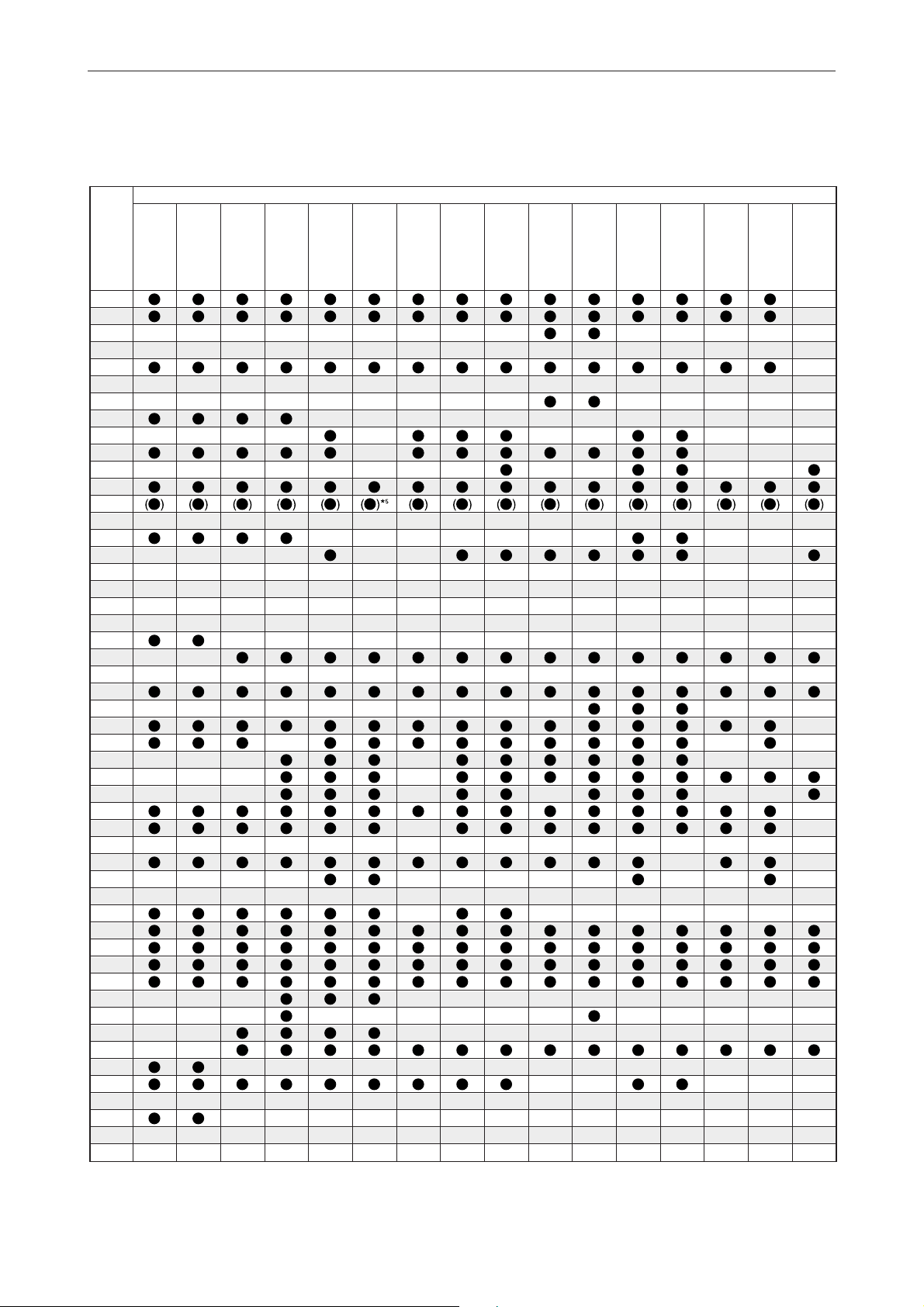

MEASURING TOOL/PEAK VOLTAGE MEASUREMENT

(Enduro/Kerosene model, 4 stroke model)

APPLICATION CHART

Tool

No.

90890-

MEASURING TOOL

01252

03112

03141

03160

03174

06754

06756

06757

06865

06864

06760

06840

06786

06942

06704

03016

06759

03006

03007

03008

03009

03010

03180

03107

06563

PEAK VOLTAGE MEASUREMENT

03172

06867 (06767)

06868 (06768)

06857 (06757)

06869 (06769)

06870 (06770)

06871 (06771)

06875 (06775)

06872 (06772)

06879 (06779)

06887 (06787)

06888 (06788)

06790

06791

06792

06793

06861

06846

06847

06848

YAMAHA DIAGNOSTIC SYSTEM

60V-85300-02

60V-WS853-02

Dial gauge set

Pocket tester

Timing light

Compression gauge

Digital circuit tester

Ignition tester

Vacuum/pressure pump gauge set

Throttle sensor adjusting lead FWY-3

Diagnostic flash indicator B

Diagnostic flash adapter 4

Digital tachometer

Leakage tester

Fuel pressure gauge

Fuel pressure gauge adapter B

Digital caliper

Cylinder gauge 35 - 60

Cylinder gauge 50 - 100

Outside micrometer 0 - 25

Outside micrometer 25 - 50

Outside micrometer 50 - 75

Outside micrometer 75 - 100

Inside micrometer 5 - 25

Thickness gauge

Crankshaft aligner

Compression gauge extension M14

Peak voltage adapter B

Test harness FWY-2

Test harness EJ-II-2

Throttle sensor adjusting lead FWY-3

Test harness EJ-II-3

Test harness SMT250-3

Test harness FWY-4

Test harness AMP-4

Test harness FWY-6

Test harness FWY-8

Test harness FW13613-2

Test harness FW13613-1

Test harness FSW-6

Test harness FWY-3-L

Test harness SMHW090-2

Test harness SMHW099-3

Test harness SM6195043

Test harness QLW-3

Test harness QLWD-3

Test harness FSW-6A

Yamaha Diagnostic System (KIT)

Yamaha Diagnostic System(CD-ROM) *5

MODEL

E8D

EK8D

E9.9D

E15D

EK9.9D

EK15D

EK9.9J

EK15P

EK9.9H

EK15N

Enduro/Kerosene model 4 Stroke model

E25B

EK25B

E30H

4

40G*

E40G

EK40G

E40X

40X*

40J*

4

K40J

4

E48C

E55C

E60H

K50E

E60J

E65A

E75B

E115A

F2.5A

F4A

F6A

F6B

F8C

*1 V4 :115B, 115C, 130B, 140B, 140C

2

V6 :150F, 150G, 150J, 150L, 175D, 200F, 200G,

*

200H, 200J, 225D, 225G

3

*

Electronic fuel injectioned model only

4

2 stroke model

*

5

Up-date CD-ROM only

*

1-3

Page 13

01252

03112

03141

03160

03174

06754

06756

06757

06865

06864

06760

06840

06786

06942

06704

03016

06759

03006

03007

03008

03009

03010

03180

03107

06563

Tool

No.

90890-

FT8D

F9.9B

FT9.9A

F9.9C

FT9.9D

F15B F25C

F13.5A

F15A

F20A

F25A

FT25B

F30A

F40B

4 Stroke model

F50A

F50F

F50D

F60C

F60A

FT50B

FT50C

FT60B

FT50G

FT60D

APPLICATION CHART

F75A

F80A

F75B

F90A

F100A

F100B

F100C

F90B

F115A

FL115A

F150A

FL150A

F200A

F225A

FL200A

FL225A

03172

06867 (06767)

06868 (06768)

06857 (06757)

06869 (06769)

06870 (06770)

06871 (06771)

06875 (06775)

06872 (06772)

06879 (06779)

06887 (06787)

06888 (06788)

06790

06791

06792

06793

06861

06846

06847

06848

60V-85300-02

60V-WS853-02

1-4

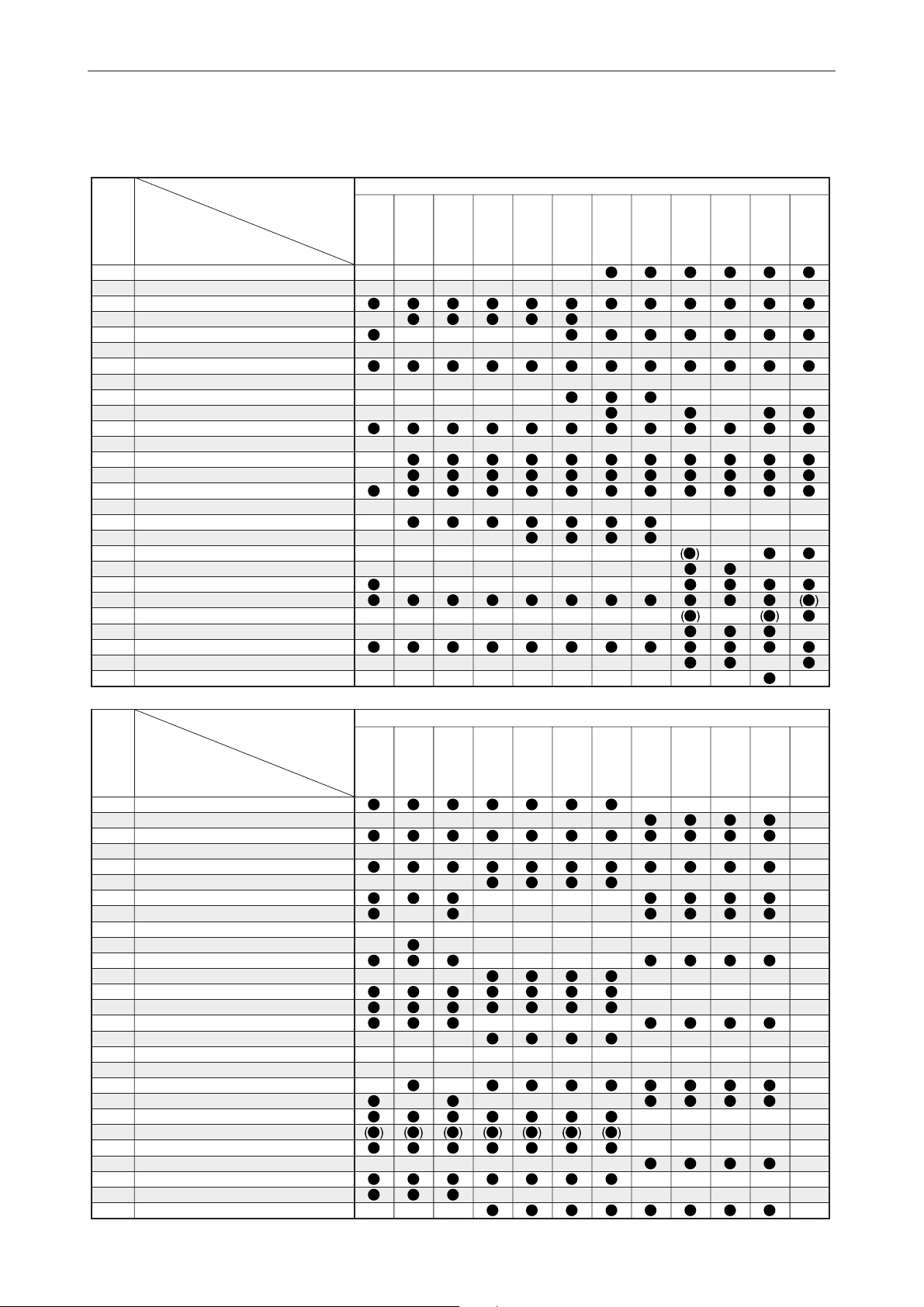

Page 14

ENGINE SERVICE

(2 stroke model)

APPLICATION CHART

Tool

No.

90890-

06521

06522

06523

06524

06525

06526

06527

06528

06843

06529

06530

06534

06540

06543

06606

06623

06624

06626

06652

06630

06631

06635

06637

06639

06640

06641

06644

06645

06613

06654

06655

06660

05158

06661

06662

06663

06069

06355

06552

03159

03094

03060

06561

06562

01235

01701

04086

06991

GENERAL TOOL

Flywheel puller

Flywheel holder

Bearing outer race puller Assy

Small end bearing installer

Small end bearing installer

Small end bearing installer

Small end bearing installer

Small end bearing installer

Piston slider ø58

Piston slider ø70

Piston slider ø85

Bearing separator

Gear puller

Small end bearing installer

Driver rod LS

Bearing outer race attachment

Bearing outer race attachment

Bearing outer race attachment

Driver rod L3

Ball bearing attachment

Ball bearing attachment

Ball bearing attachment

Ball bearing attachment

Bearing inner race attachment

Bearing inner race attachment

Bearing inner race attachment

Bearing inner race attachment

Bearing inner race attachment

Needle bearing attachment

Needle bearing attachment

Ball bearing attachment

Bearing inner race attachment

Piston ring compressor

Bearing inner race attachment

Bearing inner race attachment

Ball bearing attachment

Shaft holder

Crankshaft holder 16

Crankshaft holder 20

Vacuum gauge

Vacuum gauge [Selector type]

• Attachment

Crankshaft holder 12

Crankshaft holder 18

Rotor holder

Sheave holder

Universal clutch holder

Injector grease

G1

Deep socket 1 (30

Deep socket 2 (36

G2

Deep socket 3 (41

G3

Deep socket 4 (46

G4

T-type TORX socket T55

G5

E-type TORX socket E10

G6

TORX tamper resistant driver T20

G7

TORX tamper resistant driver T25

G8

MODEL

X

100)

X

100)

X

100)

X

100)

2B

2C

3A

4AC

4AS

5C

5CS

6C

8C

9.9F

13.5A

15F

2 Stroke model

20D

20C

25N

25B

25X

30H

30D

40V

40Y

50H

55B

50G

60F

70B

*1 V4 :115B, 115C, 130B, 140B, 140C

2

V6 :150F, 150G, 150J, 150L, 175D, 200F, 200G,

*

200H, 200J, 225D, 225G

3

*

Electronic fuel injectioned model only

4

2 stroke model

*

1-5

Page 15

Tool

No.

90890-

06521

06522

06523

06524

06525

06526

06527

06528

06843

06529

06530

06534

06540

06543

06606

06623

06624

06626

06652

06630

06631

06635

06637

06639

06640

06641

06644

06645

06613

06654

06655

06660

05158

06661

06662

06663

06069

06355

06552

03159

03094

03060

06561

06562

01235

01701

04086

06991

55D

75A

75B

85A

75C

80A

90A

1

L130B V6*2D150N

V4*

150A

175A

200A

2 Stroke model

L150J

L150A

L200F

L200A

L200J

225C

250A

225F

250B

APPLICATION CHART

Z150P

L225C

L250A

L225F

L250B

Z150Q

Z175G

Z175H

Z200N

Z200P

LZ150P

LZ200N

Z225H

Z250F

Z250D

Z300A

Z300B

LZ250D

LZ300A

G1

G2

G3

G4

G5

G6

G7

G8

1-6

Page 16

ENGINE SERVICE

(Enduro/Kerosene model, 4 stroke model)

APPLICATION CHART

Tool

No.

90890-

Flywheel puller

06521

Flywheel holder

06522

Bearing outer race puller Assy

06523

Small end bearing installer

06524

Small end bearing installer

06525

Small end bearing installer

06526

Small end bearing installer

06527

Small end bearing installer

06528

Piston slider ø58

06843

Piston slider ø70

06529

Piston slider ø85

06530

Bearing separator

06534

Gear puller

06540

Small end bearing installer

06543

Driver rod LS

06606

Bearing outer race attachment

06623

Bearing outer race attachment

06624

Bearing outer race attachment

06626

Driver rod L3

06652

Ball bearing attachment

06630

Ball bearing attachment

06631

Ball bearing attachment

06635

Ball bearing attachment

06637

Bearing inner race attachment

06639

Bearing inner race attachment

06640

Bearing inner race attachment

06641

Bearing inner race attachment

06644

Bearing inner race attachment

06645

Needle bearing attachment

06613

Needle bearing attachment

06654

Ball bearing attachment

06655

Bearing inner race attachment

06660

Piston ring compressor

05158

Bearing inner race attachment

06661

Bearing inner race attachment

06662

Ball bearing attachment

06663

Shaft holder

06069

Crankshaft holder 16

06355

Crankshaft holder 20

06552

Vacuum gauge

03159

Vacuum gauge [Selector type]

03094

• Attachment

03060

Crankshaft holder 12

06561

Crankshaft holder 18

06562

Rotor holder

01235

Sheave holder

01701

Universal clutch holder

04086

Injector grease

06991

GENERAL TOOL

G1

Deep socket 1 (30

G2

Deep socket 2 (36 X 100)

G3

Deep socket 3 (41 X 100)

G4

Deep socket 4 (46 X 100)

G5

T-type TORX socket T55

G6

E-type TORX socket E10

G7

TORX tamper resistant driver T20

G8

TORX tamper resistant driver T25

X

100)

MODEL

E8D

EK8D

E9.9D

E15D

EK9.9D

EK15D

EK9.9J

EK15P

EK9.9H

EK15N

Enduro/Kerosene model

E25B

EK25B

E30H

4

40G*

E40G

EK40G

E40X

40X*

4

40J*

K40J

4

E48C

E55C

E60H

K50E

E60J

E65A

E75B

E115A

4 Stroke model

F2.5A

F4A

F6A

F6B

F8C

*1 V4 :115B, 115C, 130B, 140B, 140C

2

V6 :150F, 150G, 150J, 150L, 175D, 200F, 200G,

*

200H, 200J, 225D, 225G

3

*

Electronic fuel injectioned model only

4

2 stroke model

*

1-7

Page 17

Tool

No.

90890-

06521

06522

06523

06524

06525

06526

06527

06528

06843

06529

06530

06534

06540

06543

06606

06623

06624

06626

06652

06630

06631

06635

06637

06639

06640

06641

06644

06645

06613

06654

06655

06660

05158

06661

06662

06663

06069

06355

06552

03159

03094

03060

06561

06562

01235

01701

04086

06991

FT8D

F9.9B

FT9.9A

F9.9C

FT9.9D

F15B F25C

F13.5A

F15A

F20A

F25A

FT25B

F30A

F40B

F50A

F50D

F60A

4 Stroke model

FT50B

F50F

FT50C

F60C

FT60B

FT50G

FT60D

F75A

F80A

F90A

F100A

F100B

F100C

APPLICATION CHART

F75B

F90B

F115A

FL115A

F150A

FL150A

F200A

F225A

FL200A

FL225A

G1

G2

G3

G4

G5

G6

G7

G8

1-8

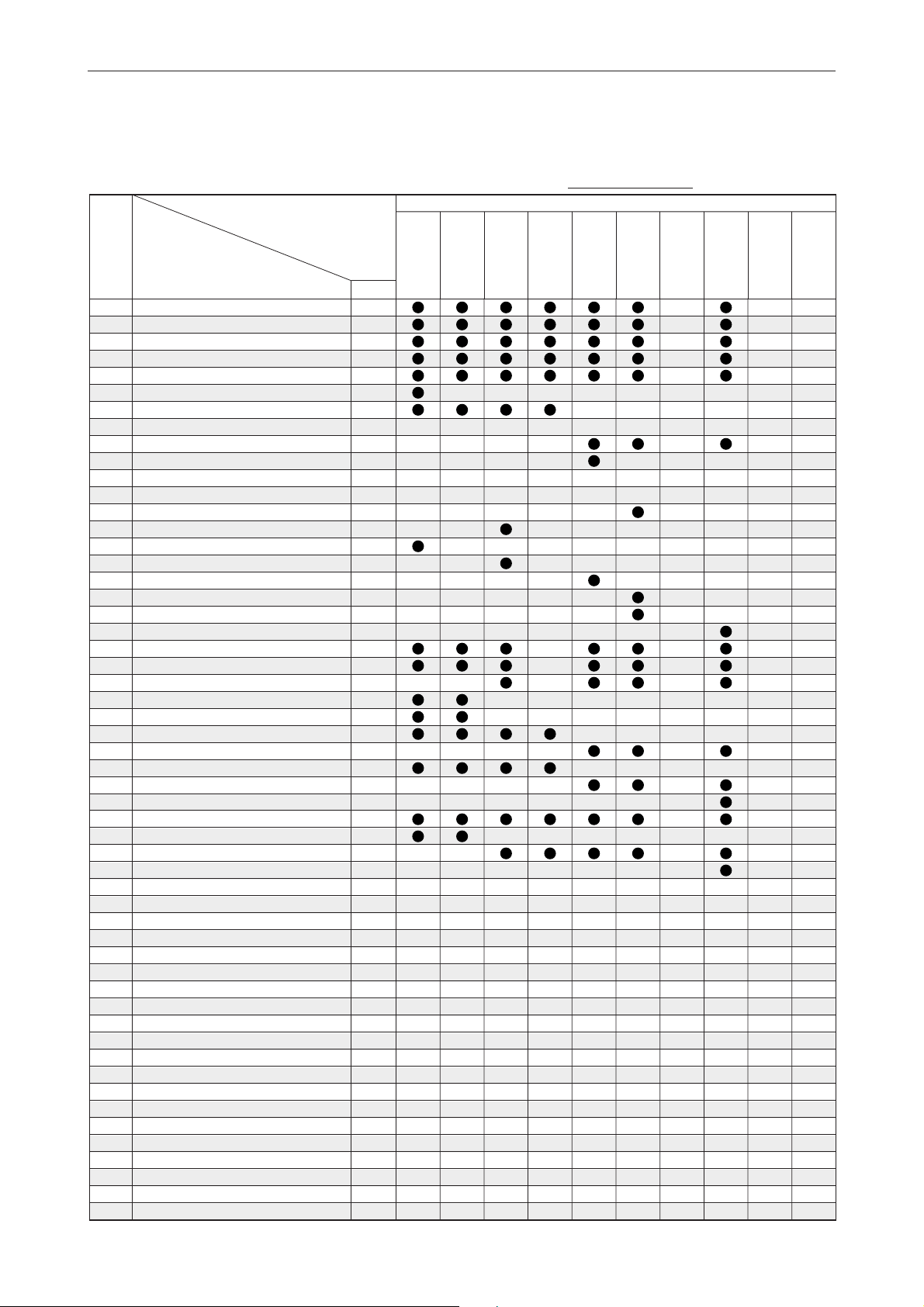

Page 18

ENGINE SERVICE

(4 stroke model)

APPLICATION CHART

Tool

No.

90890-

01426

06830

04019

04108

06320

04064

06801

06810

06802

04015

06804

04066

05041

04101

06316

06553

06313

06314

06326

06327

06328

06312

06555

06325

06315

06323

06324

MODEL

Oil filter wrench 64

Oil filter wrench 72.5

Valve spring compressor

Valve spring compressor attachment

Valve spring compressor attachment

Valve guide remover/installer 5.9

Valve guide remover/installer 5.4

Valve guide installer 5.5

Valve guide installer 5.4

Valve guide installer 5.6

Valve guide reamer 5.5

Valve guide reamer 6.02

Tap handle (5–6)

Valve lapper

Valve seat cutter holder ø5.5

Valve seat cutter holder ø6.0

Valve seat cutter 5°-25

Valve seat cutter 5°-29

Valve seat cutter 30°-32.5

Valve seat cutter 30°-35

Valve seat cutter 30°-27

Valve seat cutter 45°-27.5

Valve seat cutter 45°-30

Valve seat cutter 45°-35

Valve seat cutter 60°-26

Valve seat cutter 60°-31

Valve seat cutter 60°-36

F2.5A

F4A

F6A

F6B

F8C

4 Stroke model

F9.9C

FT8D

F9.9B F15B F25C

FT9.9A

FT9.9D

F13.5A

F15A

F20A

F25A

FT25B

F30A

F40B

F50A

F50D

F60A

Tool

No.

90890-

01426

06830

04019

04108

06320

04064

06801

06810

06802

04015

06804

04066

05041

04101

06316

06553

06313

06314

06326

06327

06328

06312

06555

06325

06315

06323

06324

MODEL

Oil filter wrench 64

Oil filter wrench 72.5

Valve spring compressor

Valve spring compressor attachment

Valve spring compressor attachment

Valve guide remover/installer 5.9

Valve guide remover/installer 5.4

Valve guide installer 5.5

Valve guide installer 5.4

Valve guide installer 5.6

Valve guide reamer 5.5

Valve guide reamer 6.02

Tap handle (5–6)

Valve lapper

Valve seat cutter holder ø5.5

Valve seat cutter holder ø6.0

Valve seat cutter 5°-25

Valve seat cutter 5°-29

Valve seat cutter 30°-32.5

Valve seat cutter 30°-35

Valve seat cutter 30°-27

Valve seat cutter 45°-27.5

Valve seat cutter 45°-30

Valve seat cutter 45°-35

Valve seat cutter 60°-26

Valve seat cutter 60°-31

Valve seat cutter 60°-36

F50F

F60C

FT50B

FT50C

FT60B

FT50G

FT60D

F75A

F80A

F90A

F100A

F100B

F100C

F75B

F90B

4 Stroke model

F115A

FL115A

F150A

FL150A

F200A

F225A

FL200A

FL225A

1-9

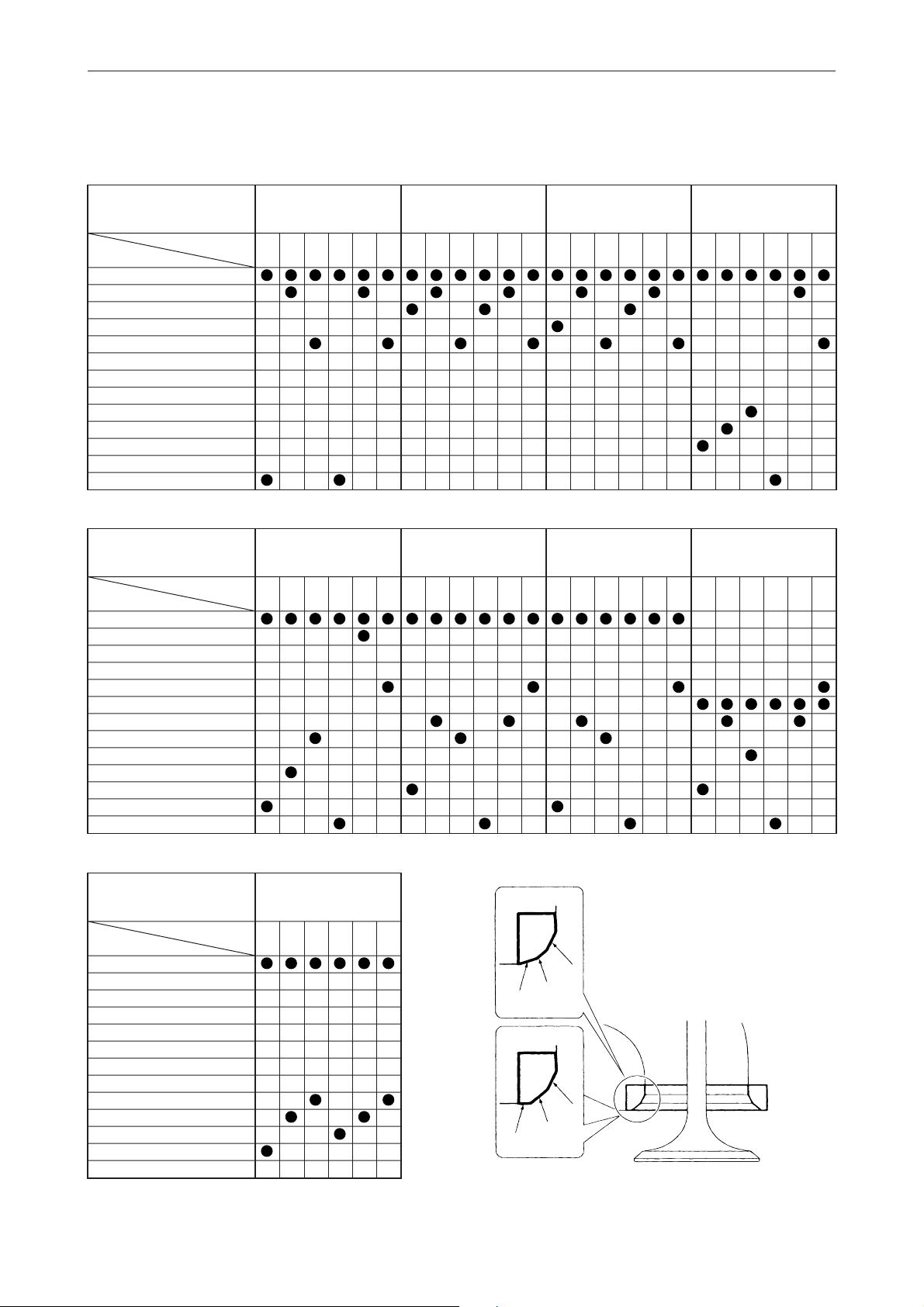

Page 19

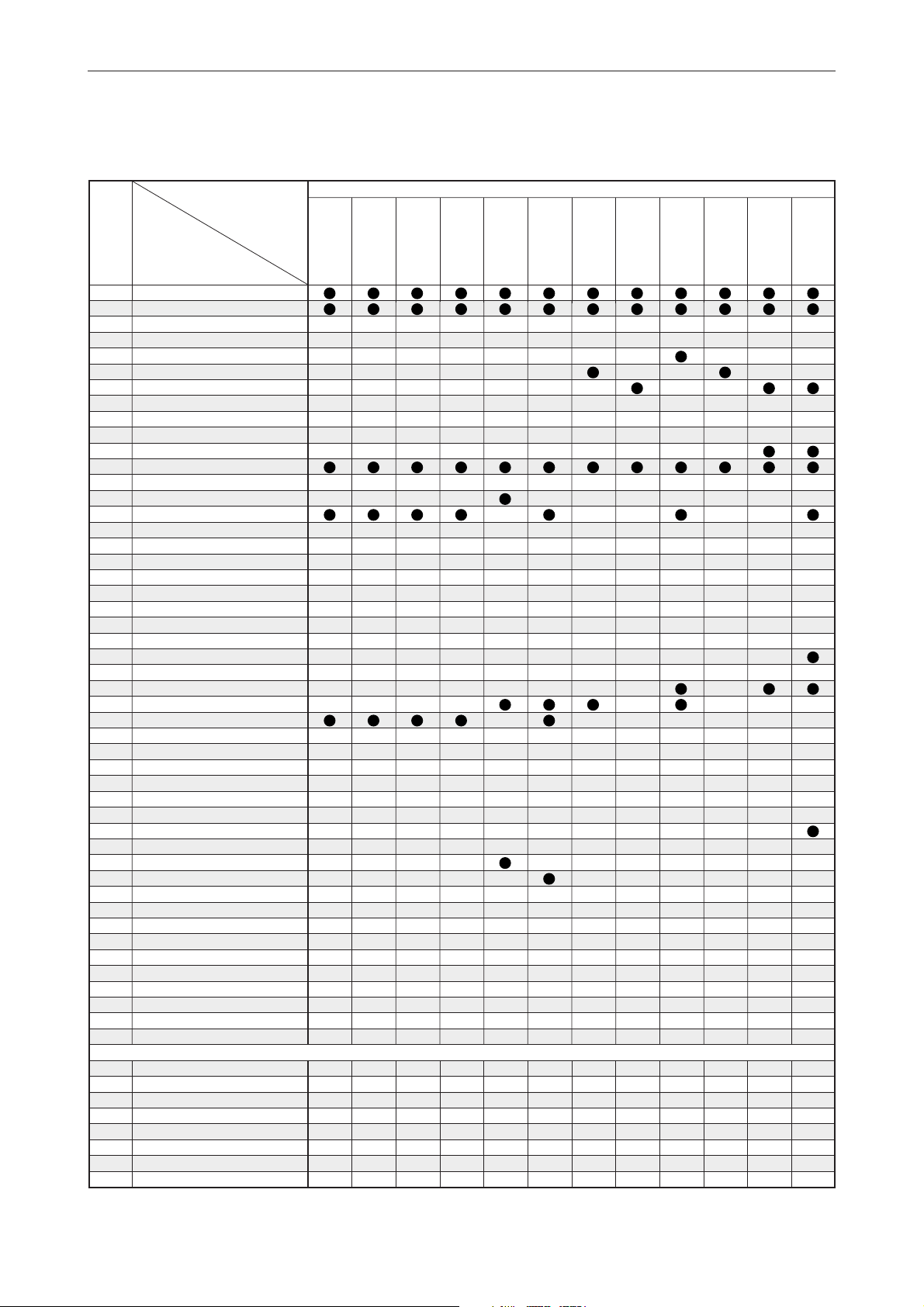

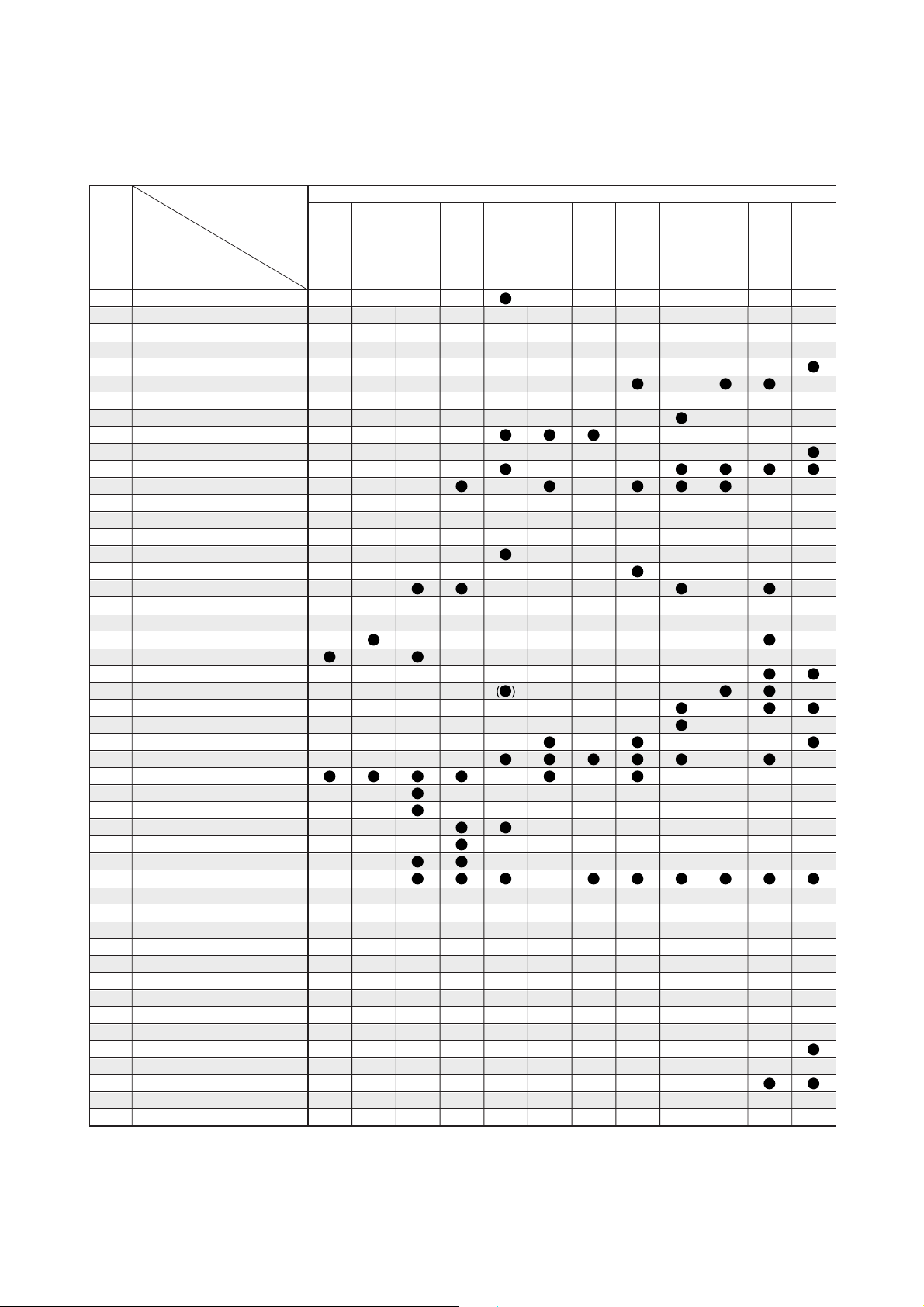

VALVE SEAT CUTTER (Refering)

APPLICATION CHART

MODEL

Part of port

TOOL No.9089006316 (ø5.5 mm holder)

06312 (45°, ø27.5 mm)

06313 (5°, ø25 mm)

06314 (5°, ø29 mm)

06315 (60°, ø26 mm)

06553 (ø6.0 mm holder)

06555 (45°, ø30 mm)

06323 (60°, ø31 mm)

06324 (60°, ø36 mm)

06325 (45°, ø35 mm)

06326 (30°, ø32.5 mm)

06327 (30°, ø35 mm) New

06328 (30°, ø27 mm)

MODEL

Part of port

TOOL No.9089006316 (ø5.5 mm holder)

06312 (45°, ø27.5 mm)

06313 (5°, ø25 mm)

06314 (5°, ø29 mm)

06315 (60°, ø26 mm)

06553 (ø6.0 mm holder)

06555 (45°, ø30 mm)

06323 (60°, ø31 mm)

06324 (60°, ø36 mm)

06325 (45°, ø35 mm)

06326 (30°, ø32.5 mm)

06327 (30°, ø35 mm) New

06328 (30°, ø27 mm)

F2.5A

In. A In. B In. C Ex. A Ex. B Ex. C In. A In. B In. C Ex. A Ex. B Ex. C In. A In. B In. C Ex. A Ex. B Ex. C In. A In. B In. C Ex. A Ex. B Ex. C

F25C

In. A In. B In. C Ex. A Ex. B Ex. C In. A In. B In. C Ex. A Ex. B Ex. C In. A In. B In. C Ex. A Ex. B Ex. C In. A In. B In. C Ex. A Ex. B Ex. C

F4A/F6A

F6B

F8C/FT8D

F50A/F60A/FT60B

FT50B/FT50C/F50D

F9.9A/F9.9B

F9.9C/F9.9D

F13.5A/F15A/F15B

F50F/FT50G/F60C/FT60D

F20A/F25A/FT25B

F30A/F40B

F75A/F75B/F80A/F90A

F90B/F100A/F100B

F100C/F115A/FL115A

MODEL

Part of port

TOOL No.9089006316 (ø5.5 mm holder)

06312 (45°, ø27.5 mm)

06313 (5°, ø25 mm)

06314 (5°, ø29 mm)

06315 (60°, ø26 mm)

06553 (ø6.0 mm holder)

06555 (45°, ø30 mm)

06323 (60°, ø31 mm)

06324 (60°, ø36 mm)

06325 (45°, ø35 mm)

06326 (30°, ø32.5 mm)

06327 (30°, ø35 mm) New

06328 (30°, ø27 mm)

F150A/F200A/FL200A

FL150A/F225A/FL225A

In. A In. B In. C Ex. A Ex. B Ex. C

1-10

C

B

A

C

B

A

Page 20

ENGINE SERVICE

(Test propeller)

(2 stroke model)

APPLICATION CHART

Tool

No.

90890-

01601

Test propeller (646)

01609

Test propeller (647)

01611

Test propeller (663)

01613

Test propeller (664)

01618

Test propeller (676)

01619

Test propeller (683)

01620

Test propeller (688)

01621

Test propeller (689)

01624

Test propeller (6E5)

01625

Test propeller (6G1)

01626

Test propeller (6G5)

01627

Test propeller (6G8)

01629

Test propeller (61N)

01630

Test propeller (6L5)

01631

Test propeller (6L6)

Tool

No.

90890-

01601

Test propeller (646)

01609

Test propeller (647)

01611

Test propeller (663)

01613

Test propeller (664)

01618

Test propeller (676)

01619

Test propeller (683)

01620

Test propeller (688)

01621

Test propeller (689)

01624

Test propeller (6E5)

01625

Test propeller (6G1)

01626

Test propeller (6G5)

01627

Test propeller (6G8)

01629

Test propeller (61N)

01630

Test propeller (6L5)

01631

Test propeller (6L6)

MODEL

MODEL

2B

3A

2C

1

L130B V6*2D150N

V4*

2 Stroke model

4AS

5C

5CS

9.9F

6C

8C

L200A

NA NA NA NA NA NA NA NA NA

13.5A

15F

150A

175A

200A

20C

2 Stroke model

L150F

L150J

L200F

L200J

20D

25N

L150A

L200A

25B

25X

30H

225C

250A

225F

250B

30D

L225C

L250A

L225F

L250B

40V

40Y

50H

Z150P

Z150Q

Z175G

Z175H

Z200N

Z200P

55B

LZ150P

LZ200N

50G

60F

70B

Z225H

Z250F

55D

75A

75B

85A

Z250D

Z300A

Z300B

75C

80A

90A

LZ250D

LZ300A

*1 V4 :115B, 115C, 130B, 140B, 140C

2

V6 :150F, 150G, 150J, 150L, 175D, 200F, 200G, 200H, 200J, 225D, 225G

*

3

Electronic fuel injectioned model only

*

4

2 stroke model

*

NA : Not availables

1-11

Page 21

(Test propeller)

(Enduro/Kerosene model, 4 stroke model)

Enduro/Kerosene model 4 Stroke model

4

40G*

E25B

E30H

E40G

EK40G

E40X

40X*

Tool

No.

90890-

01601

Test propeller (646)

01609

Test propeller (647)

01611

Test propeller (663)

01613

Test propeller (664)

01618

Test propeller (676)

01619

Test propeller (683)

01620

Test propeller (688)

01621

Test propeller (689)

01624

Test propeller (6E5)

01625

Test propeller (6G1)

01626

Test propeller (6G5)

01627

Test propeller (6G8)

01629

Test propeller (61N)

01630

Test propeller (6L5)

01631

Test propeller (6L6)

MODEL

E8D

EK8D

E9.9D

E15D

EK9.9D

EK15D

EK9.9J

EK15P

EK9.9H

EK15N

EK25B

4

40J*

K40J

4

E48C

E55C

APPLICATION CHART

E60J

E60H

K50E

E65A

E75B

E115A

F2.5A F4A

F6A

F6B

F8C

FT8D

Tool

No.

90890-

01601

Test propeller (646)

01609

Test propeller (647)

01611

Test propeller (663)

01613

Test propeller (664)

01618

Test propeller (676)

01619

Test propeller (683)

01620

Test propeller (688)

01621

Test propeller (689)

01624

Test propeller (6E5)

01625

Test propeller (6G1)

01626

Test propeller (6G5)

01627

Test propeller (6G8)

01629

Test propeller (61N)

01630

Test propeller (6L5)

01631

Test propeller (6L6)

MODEL

F9.9B FT9.9A

F9.9C

FT9.9D

F13.5A

F15A

F15B

F25C

NA

F20A

F25A

FT25B

4 Stroke model

F50A

F30A

F50D

F40B

F60A

FT50B

FT50C

FT60B

F50F

FT50G

F60C

FT60D

F75B

F90B

NA

F75A

F80A

F90A

F100A

F100B

F100C

F115A

FL115A

F150A

FL150A

NA NA

F200A

FL200A

F225A

FL225A

1-12

Page 22

ENGINE SERVICE

(Crankshaft disassembly and reassembly)

(2 stroke model)

MODEL

Tool

No.

90890-

02422

02351

02352

02353

02354

02355

02357

02358

02359

02361

02363

02365

02366

02399

02367

02369

02371

02376

02377

02379

02384

02385

02386

02387

02388

02389

02390

02391

02392

02393

02394

02395

02396

02419

02401

02402

02403

02404

06590

Q’ty

Crank shaft jig set

• Flange

• Body

• Bolt

• Washer

• Bushing-1 (D15)

• Bushing-3 (D20)

• Bushing-4 (D22)

• Bushing-5 (D25)

• Bushing-7 (D29)

• Bushing-9 (D30)

• Bushing-1 (B11)

• Bushing-12 (D35)

• Bushing-13 (D20)

• Height ring-1 (H28)

• Height-ring-3 (H40)

• Height ring-5 (H47)

• Height ring-10 (H53)

• Height ring-5 (H54)

• Height ring-13 (H57)

• Pressure plate

• Press body

• Plate A

• Plate B

• Bolt

• Pressure pin A

• Pressure pin B

• Bearing pressure A

• Bearing pressure B

• Bearing pressure C

• Support

• Spacer A

• Spacer B

• Bushing 14 (E25A/25V)

• Height ring (E40G/J)

• Plate C

• Pressure pin C

• Spacer C

• Height ring 640 (H-19)

2B

2C

1

1

1

4

4

1

2

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

2

1

1

1

1

2

1

1

1

3A

APPLICATION CHART

The tools on these pages (1-13 and 1-14) can be ordered from

the Marine Service Division of Yamaha Motor Co., Ltd.

2 stroke model

4AC

4AS

5C

5CS

6C

8C

9.9F

13.5A

15F

20C

20D

25N

25B

25X

30H

02416

02407

02408

02409

02410

02411

02417

02412

02413

02414

02415

02418

Q’ty : The figure for this part indicates the quantity of the parts ordered in a set or a kit.

Disassembling kit

• Nut

• Pressure plate

• Pole

• Plate A

• Plate B

Assembling kit

• Guide

• Guide plate

• Guide pole

• Base

Crank separater kit (set 02416 + 02417)

1

6

1

3

1

1

1

3

1

1

1

–

1-13

Page 23

(Crankshaft disassembly and reassembly)

(Enduro/Kerosene model)

MODEL

Tool

No.

90890-

02422

02351

02352

02353

02354

02355

02357

02358

02359

02361

02363

02365

02366

02399

02367

02369

02371

02376

02377

02379

02384

02385

02386

02387

02388

02389

02390

02391

02392

02393

02394

02395

02396

02419

02401

02402

02403

02404

06590

Crank shaft jig set

• Flange

• Body

• Bolt

• Washer

• Bushing-1 (D15)

• Bushing-3 (D20)

• Bushing-4 (D22)

• Bushing-5 (D25)

• Bushing-7 (D29)

• Bushing-9 (D30)

• Bushing-1 (B11)

• Bushing-12 (D35)

• Bushing-13 (D20)

• Height ring-1 (H28)

• Height-ring-3 (H40)

• Height ring-5 (H47)

• Height ring-10 (H53)

• Height ring-5 (H54)

• Height ring-13 (H57)

• Pressure plate

• Press body

• Plate A

• Plate B

• Bolt

• Pressure pin A

• Pressure pin B

• Bearing pressure A

• Bearing pressure B

• Bearing pressure C

• Support

• Spacer A

• Spacer B

• Bushing 14 (E25A/25V)

• Height ring (E40G/J)

• Plate C

• Pressure pin C

• Spacer C

• Height ring 640 (H-19)

Q’ty

1

1

1

4

4

1

2

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

2

1

1

1

1

2

1

1

1

E8D

EK8D

EK9.9D

EK15D

EK9.9J

EK15P

EK9.9H

EK15N

E9.9D

E15D

E25B

EK25B

E30H

APPLICATION CHART

Enduro/Kerosene model

1

40G*

E40X

40X*

40J*

1

K40J

E40G

EK40G

1

E48C

E55C

E60H

K50E

02416

02407

02408

02409

02410

02411

02417

02412

02413

02414

02415

02418

*

Disassembling kit

• Nut

• Pressure plate

• Pole

• Plate A

• Plate B

Assembling kit

• Guide

• Guide plate

• Guide pole

• Base

Crank separater kit (set 02416 + 02417)

1

2 stroke model

1

6

1

3

1

1

1

3

1

1

1

–

1-14

Page 24

LOWER UNIT SERVICE

(2 stroke model)

APPLICATION CHART

Tool

No.

90890-

06501

06502

06503

06564

06504

06509

06510

06511

06512

06513

06578

06715

06505

06506

06507

06508

06515

06516

06517

06518

06519

06520

06565

06534

06521

06523

06532

06533

06531

06514

06535

06536

06537

06538

06540

06601

06602

06603

06604

06605

06606

06607

06608

06609

06610

06611

06612

06613

06614

06615

06616

MODEL

Stopper guide plate

Bearing housing puller claw L

Bearing housing puller claw M

Bearing housing puller claw S

Center bolt

Ring nut wrench 1

Ring nut wrench 2

Ring nut wrench 3

Ring nut wrench 4

Ring nut wrench extension

Ring nut wrench

Pinion nut holder

Pinion nut holder

• Socket adapter 1

• Socket adapter 2

• Socket adapter 3

Drive shaft holder 1

Drive shaft holder 2

Drive shaft holder 3

Drive shaft holder 4

Drive shaft holder 5

Drive shaft holder 6

Drive shaft holder 7

Bearing separator

Flywheel puller

Bearing outer race puller assembly

• Outer race puller claw A

Outer race puller claw B

Slide hammer handle

Puller head

Bearing puller assembly

• Bearing puller claw 1

• Bearing puller claw 2

Stopper guide stand

Gear puller

Bushing installer center bolt

Driver rod SL

Bearing depth plate

Driver rod SS

Driver rod LL

Driver rod LS

Needle bearing attachment

Needle bearing attachment

Needle bearing attachment

Needle bearing attachment

Needle bearing attachment

Needle bearing attachment

Needle bearing attachment

Needle bearing attachment

Needle bearing attachment

Needle bearing attachment

2B

2C

3A

4AC

4AS

5C

5CS

6C

8C

9.9F

13.5A

15F

2 Stroke model

20D

20C

25N

25B

25X

30H

30D

40V

40Y

50H

55B

50G

60F

70B

1

*

V4 :115B, 115C, 130B, 140B, 140C

2

*

V6 :150F, 150G, 150J, 150L, 175D, 200F,

200G, 200H, 200J, 225D, 225G

1-15

3

Electronic fuel injectioned model only

*

4

*

2 stroke model

5

Apply pressure to outer propeller shaft

*

Page 25

55D

75A

75B

85A

75C

80A

90A

V4*

1

L130B

V6*2D150N

150A

175A

200A

L150F

L150J

L200F

L200J

225C

250A

225F

250B

L225C

L250A

L225F

L250B

Z150P

Z150Q

Z175G

Z175H

Z200N

Z200P

LZ150P

LZ200N

Z225H

Z250F

Z250D

Z300A

Z300B

LZ250D

LZ300A

L150A

L200A

2 Stroke model

Tool

No.

90890-

06501

06502

06503

06564

06504

06509

06510

06511

06512

06513

06578

06715

06505

06506

06507

06508

06515

06516

06517

06518

06519

06520

06565

06534

06521

06523

06532

06533

06531

06514

06535

06536

06537

06538

06540

06601

06602

06603

06604

06605

06606

06607

06608

06609

06610

06611

06612

06613

06614

06615

06616

1-16

APPLICATION CHART

Page 26

APPLICATION CHART

Tool

No.

90890-

06617

Needle bearing attachment

06618

Needle bearing attachment

06619

Bearing outer race attachment

06620

Bearing outer race attachment

06621

Bearing outer race attachment

06622

Bearing outer race attachment

06623

Bearing outer race attachment

06624

Bearing outer race attachment

06625

Bearing outer race attachment

06626

Bearing outer race attachment

06627

Bearing outer race attachment

06628

Bearing outer race attachment

06629

Ball bearing attachment

06630

Ball bearing attachment

06631

Ball bearing attachment

06632

Ball bearing attachment

06633

Ball bearing attachment

06634

Ball bearing attachment

06635

Ball bearing attachment

06636

Ball bearing attachment

06637

Ball bearing attachment

06638

Ball bearing attachment

06639

Bearing inner race attachment

06640

Bearing inner race attachment

06641

Bearing inner race attachment

06642

Bearing inner race attachment

06643

Bearing inner race attachment

06644

Bearing inner race attachment

06645

Bearing inner race attachment

06646

Bushing puller center bolt

06648

Bushing puller spacer

06649

Bushing attachment

06650

Bushing attachment

06651

Bushing attachment

06652

Driver rod L3

06653

Needle bearing attachment

06654

Needle bearing attachment

06655

Ball bearing attachment

06656

Ball bearing attachment

06657

Ball bearing attachment

06658

Bearing outer race attachment

06659

Bearing inner race attachment

06660

Bearing inner race attachment

06661

Bearing inner race attachment

06662

Bearing inner race attachment

MODEL

2B

2C

3A

4AC

4AS

5C

5CS

6C

8C

9.9F

13.5A

15F

2 Stroke model

20D

20C

25N

25B

25X

30H

30D

40V

40Y

50H

55B

50G

60F

70B

06052

Shift rod push arm

YB-42223

Gland nut wrench

YB-42224

Pinion nut wrench

1

*

V4 :115B, 115C, 130B, 140B, 140C

2

*

V6 :150F, 150G, 150J, 150L, 175D, 200F, 200G, 200H, 200J, 225D, 225G

3

*

Electronic fuel injectioned model only

4

*

2 stroke model

5

*

Apply pressure to outer propeller shaft

1-17

Page 27

Tool

No.

90890-

06617

06618

06619

06620

06621

06622

06623

06624

06625

06626

06627

06628

06629

06630

06631

06632

06633

06634

06635

06636

06637

06638

06639

06640

06641

06642

06643

06644

06645

06646

06648

06649

06650

06651

06652

06653

06654

06655

06656

06657

06658

06659

06660

06661

06662

55D

75A

75B

85A

75C

80A

90A

V4*

1

L130B

V6*2D150N

150A

175A

200A

2 Stroke model

L150F

L150J

L150A

L200F

L200A

L200J

225C

250A

225F

250B

APPLICATION CHART

Z150P

L225C

L250A

L225F

L250B

Z150Q

Z175G

Z175H

Z200N

Z200P

LZ150P

LZ200N

Z250F

Z225H

Z250D

Z300A

Z300B

LZ250D

LZ300A

06052

YB-42223

YB-42224

1-18

Page 28

LOWER UNIT SERVICE

(Enduro/Kerosene model, 4 stroke model)

APPLICATION CHART

Tool

No.

90890-

06501

Stopper guide plate

06502

Bearing housing puller claw L

06503

Bearing housing puller claw M

06564

Bearing housing puller claw S

06504

Center bolt

06509

Ring nut wrench 1

06510

Ring nut wrench 2

06511

Ring nut wrench 3

06512

Ring nut wrench 4

06513

Ring nut wrench extension

06578

Ring nut wrench

06715

Pinion nut holder

06505

Pinion nut holder

06506

• Socket adapter 1

06507

• Socket adapter 2

06508

• Socket adapter 3

06515

Drive shaft holder 1

06516

Drive shaft holder 2

06517

Drive shaft holder 3

06518

Drive shaft holder 4

06519

Drive shaft holder 5

06520

Drive shaft holder 6

06565

Drive shaft holder 7

06534

Bearing separator

06521

Flywheel puller

06523

Bearing outer race puller assembly

06532

• Outer race puller claw A

06533

Outer race puller claw B

06531

Slide hammer handle

06514

Puller head

06535

Bearing puller assembly

06536

• Bearing puller claw 1

06537

• Bearing puller claw 2

06538

Stopper guide stand

06540

Gear puller

06601

Bushing installer center bolt

06602

Driver rod SL

06603

Bearing depth plate

06604

Driver rod SS

06605

Driver rod LL

06606

Driver rod LS

06607

Needle bearing attachment

06608

Needle bearing attachment

06609

Needle bearing attachment

06610

Needle bearing attachment

06611

Needle bearing attachment

06612

Needle bearing attachment

06613

Needle bearing attachment

06614

Needle bearing attachment

06615

Needle bearing attachment

06616

Needle bearing attachment

MODEL

E8D

E8DK

E9.9D

E15D

EK9.9D

EK15D

EK9.9J

EK15P

EK9.9H

EK15N

Enduro/Kerosene model 4 Stroke model

4

E25B

EK25B

E30H

40G*

E40G

EK40G

E40X

40X*

4

40J*

K40J

4

E48C

E55C

E60H

K50E

E60J

E65A

E75B

E115A

F2.5A

F4A

F6A

F6B

F8C

1

*

V4 :115B, 115C, 130B, 140B, 140C

2

*

V6 :150F, 150G, 150J, 150L, 175D, 200F,

200G, 200H, 200J, 225D, 225G

1-19

3

*

Electronic fuel injectioned model only

4

*

2 stroke model

5

*

Apply pressure to outer propeller shaft

Page 29

Tool

No.

FT8D F9.9B F15B F25C

90890-

06501

06502

06503

06564

06504

06509

06510

06511

06512

06513

06578

06715

06505

06506

06507

06508

06515

06516

06517

06518

06519

06520

06565

06534

06521

06523

06532

06533

06531

06514

06535

06536

06537

06538

06540

06601

06602

06603

06604

06605

06606

06607

06608

06609

06610

06611

06612

06613

06614

06615

06616

FT9.9A

F9.9C

FT9.9D

F13.5A

F15A

F20A

F25A

[FT25B]

F30A

F40B

4 Stroke model

F50A

F50F

F50D

F60C

F60A

FT50B

FT50C

[FT60B]

FT50G

[FT60D]

F75A

F80A

F90A

F100A

F100B

F100C

APPLICATION CHART

F75B

F90B

F115A

FL115A

F150A

FL150A

F200A

F225A

FL200A

FL225A

1-20

Page 30

APPLICATION CHART

Tool

No.

90890-

06617

Needle bearing attachment

06618

Needle bearing attachment

06619

Bearing outer race attachment

06620

Bearing outer race attachment

06621

Bearing outer race attachment

06622

Bearing outer race attachment

06623

Bearing outer race attachment

06624

Bearing outer race attachment

06625

Bearing outer race attachment

06626

Bearing outer race attachment

06627

Bearing outer race attachment

06628

Bearing outer race attachment

06629

Ball bearing attachment

06630

Ball bearing attachment

06631

Ball bearing attachment

06632

Ball bearing attachment

06633

Ball bearing attachment

06634

Ball bearing attachment

06635

Ball bearing attachment

06636

Ball bearing attachment

06637

Ball bearing attachment

06638

Ball bearing attachment

06639

Bearing inner race attachment

06640

Bearing inner race attachment

06641

Bearing inner race attachment

06642

Bearing inner race attachment

06643

Bearing inner race attachment

06644

Bearing inner race attachment

06645

Bearing inner race attachment

06646

Bushing puller center bolt

06648

Bushing puller spacer

06649

Bushing attachment

06650

Bushing attachment

06651

Bushing attachment

06652

Driver rod L3

06653

Needle bearing attachment

06654

Needle bearing attachment

06655

Ball bearing attachment

06656

Ball bearing attachment

06657

Ball bearing attachment

06658

Bearing outer race attachment

06659

Bearing inner race attachment

06660

Bearing inner race attachment

06661

Bearing inner race attachment

06662

Bearing inner race attachment

MODEL

E8D

E8DK

E9.9D

E15D

EK9.9D

EK15D

EK9.9J

EK15P

EK9.9H

EK15N

Enduro/Kerosene model 4 Stroke model

4

40G*

E25B

EK25B

E30H

E40G

EK40G

E40X

40X*

4

40J*

K40J

4

E48C

E55C

E60H

K50E

E60J

E65A

E75B

E115A

F2.5A

F4A

F6A

F6B

F8C

06052

Shift rod push arm

Gland nut wrench

YB-42223

Pinion nut wrench

YB-42224

1

*

V4 :115B, 115C, 130B, 140B, 140C

2

*

V6 :150F, 150G, 150J, 150L, 175D, 200F, 200G, 200H, 200J, 225D, 225G

3

Electronic fuel injectioned model only

*

4

2 stroke model

*

5

*

Apply pressure to outer propeller shaft

1-21

Page 31

4 Stroke model

Tool

No.

90890-

FT8D F15B F25CF9.9B

FT9.9A

F9.9C

FT9.9D

F13.5A

F15A

F20A

F25A

F50F

F60C

F75B

F90B

FT50G

FT60D

F50A

F50D

F60A

FT50B

FT50C

FT60B

F75A

F80A

F90A

F100A

F100B

F100C

F115A

FL115A

F150A

FL150A

FT25B

F30A

F40B

F200A

F225A

FL200A

FL225A

06617

06618

06619

06620

06621

06622

06623

06624

06625

06626

06627

06628

06629

06630

06631

06632

06633

06634

06635

06636

06637

06638

06639

06640

06641

06642

06643

06644

06645

06646

06648

06649

06650

06651

06652

06653

06654

06655

06656

06657

06658

06659

06660

06661

06662

06052

YB-42223

YB-42224

APPLICATION CHART

1-22

Page 32

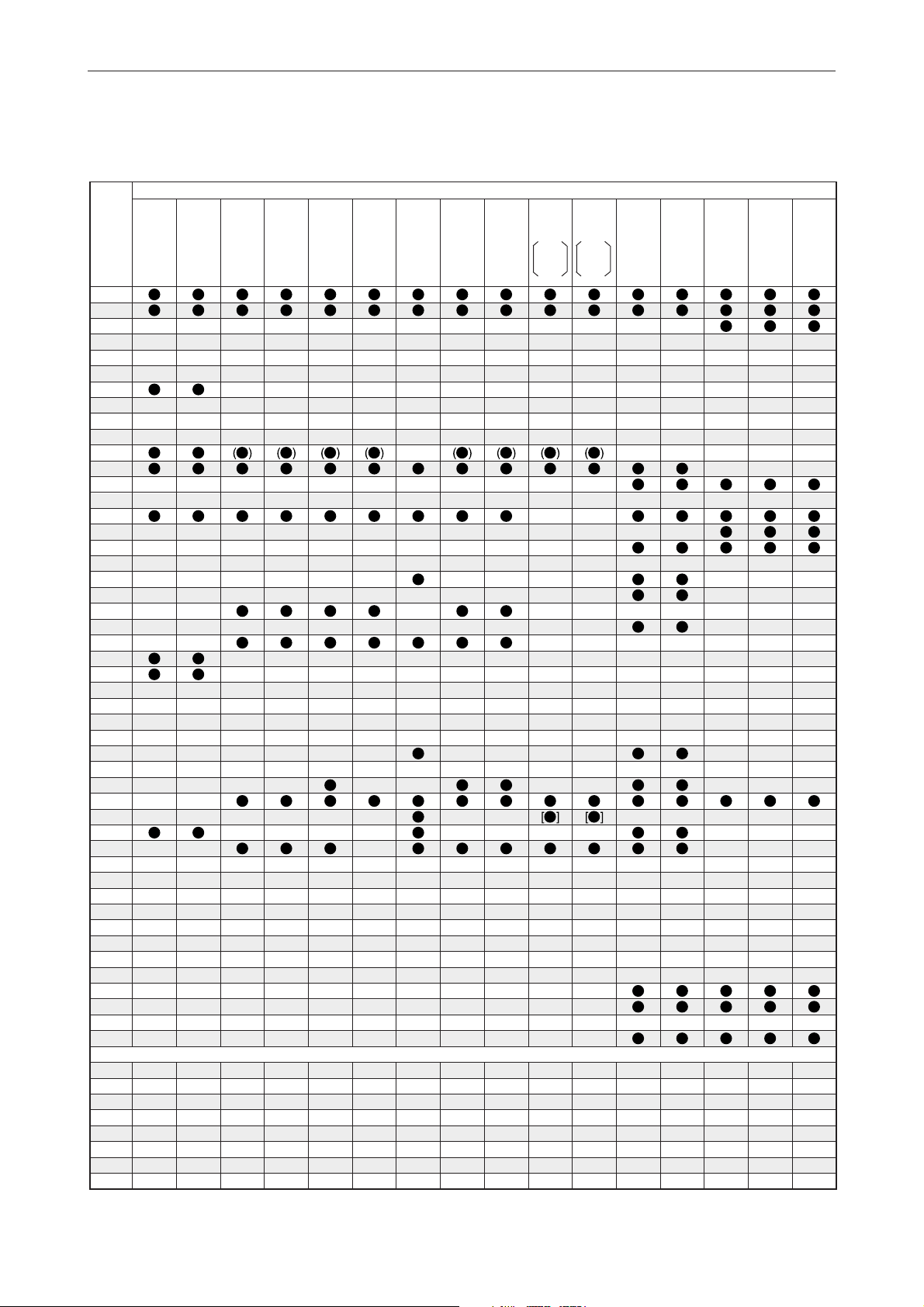

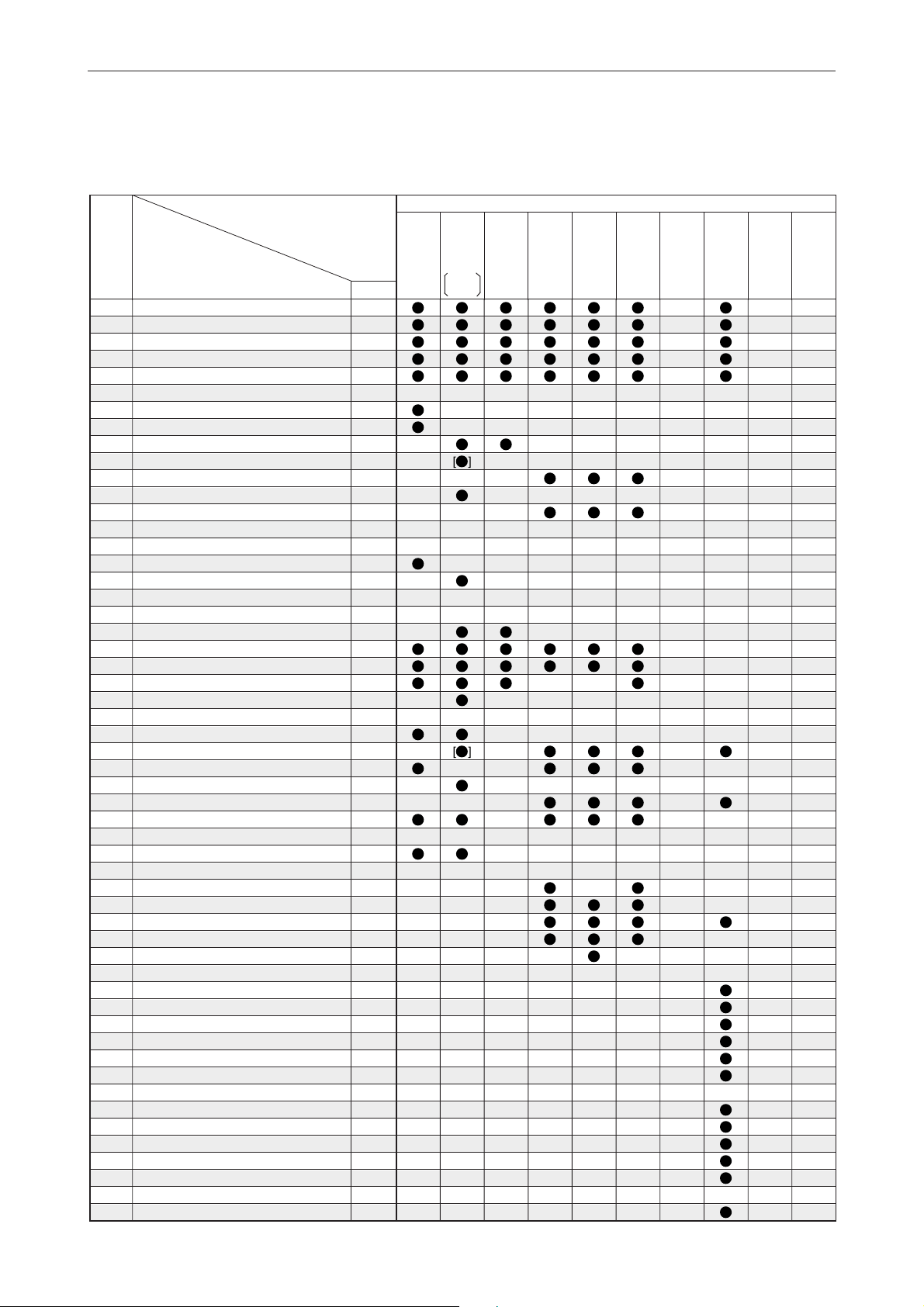

SHIM SELECTION / PTT TOOL

(2 stroke model)

APPLICATION CHART

Tool

No.

90890-

SHIM SELECTION

06701

06710

06711

06712

06703

06704

06844

06706

07003

01252

PTT TOOL

06568

(06544)

06587

(06548)

06588

06773

06774

06776

06560

06580

06581

06569

06572

Shimming plate

Pinion height gauge

• Pinion height gauge plate A

Pinion height gauge plate B

Pinion height plate

Digital caliper

Magnet base

Backlash indicator

Magnet base plate

Dial gauge set

Cylinder-end screw wrench

Cylinder-end screw wrench

Trim & tilt wrench

Trim & tilt wrench

PTT wrench 46

Up relief fitting

Down relief fitting

Hydraulic pressure gauge

Power tilt wrench

PTT oil pressure gauge assembly

PTT oil pressure gauge adapter

Title rod wrench

PTT piston vice attachment

MODEL

2B

2C

3A

4AC

4AS

5C

5CS

6C

8C

9.9F

13.5A

15F

2 Stroke model

20D

20C

25N

25B

25X

30H

30D

40V

40Y

50H

55B

50G

60F

70B

1

*

V4 :115B, 115C, 130B, 140B, 140C

2

V6 :150F, 150G, 150J, 150L, 175D, 200F, 200G, 200H, 200J, 225D, 225G

*

1-23

Page 33

Tool

No.

90890-

06701

06710

06711

06712

06703

06704

06844

06706

07003

01252

06568

(06544)

06587

(06548)

06588

06773

06774

06776

06560

06580

06581

06569

06572

55D

75A

75B

85A

75C

80A

90A

V4*

1

L130B

V6*2D150N

150A

175A

200A

2 Stroke model

L150F

L150A

L150J

L200A

L200F

L200J

225C

250A

225F

250B

APPLICATION CHART

Z150P

L225C

L250A

L225F

L250B

Z150Q

Z175G

Z175H

Z200N

Z200P

LZ150P

LZ200N

Z225H

Z250F

Z250D

Z300A

Z300B

LZ250D

LZ300A

1-24

Page 34

SHIM SELECTION / PTT TOOL

(Enduro/Kerosene model, 4 stroke model)

APPLICATION CHART

Tool

No.

90890-

SHIM SELECTION

06701

06710

06711

06712

06703

06704

06844

06706

07003

01252

Shimming plate

Pinion height gauge

• Pinion height gauge plate A

Pinion height gauge plate B

Pinion height plate

Digital caliper

Magnet base

Backlash indicator

Magnet base plate

Dial gauge set

PTT TOOL

06568

(06544)

06587

(06548)

06588

06773

06774

06776

06560

06580

06581

06569

06572

Cylinder-end screw wrench

Cylinder-end screw wrench

Trim & tilt wrench

Trim & tilt wrench

PTT wrench 46

Up relief fitting

Down relief fitting

Hydraulic pressure gauge

Power tilt wrench

PTT oil pressure gauge assembly

PTT oil pressure gauge adapter

Title rod wrench

PTT piston vice attachment

MODEL

E8D

E8DK

E9.9D

E15D

EK9.9D

EK15D

EK9.9J

EK15P

EK9.9H

EK15N

Enduro/Kerosene model 4 Stroke model

1

40G*

E25B

EK25B

E30H

E40G

EK40G

E40X

40X*

1

40J*

K40J

1

E48C

E55C

E60H

K50E

E60J

E65A

E75B

E115A

F2.5A

F4A

F6A

F6B

F8C

1

*

2 stroke model

1-25

Page 35

Tool

No.

90890-

06701

06710

06711

06712

06703

06704