Page 1

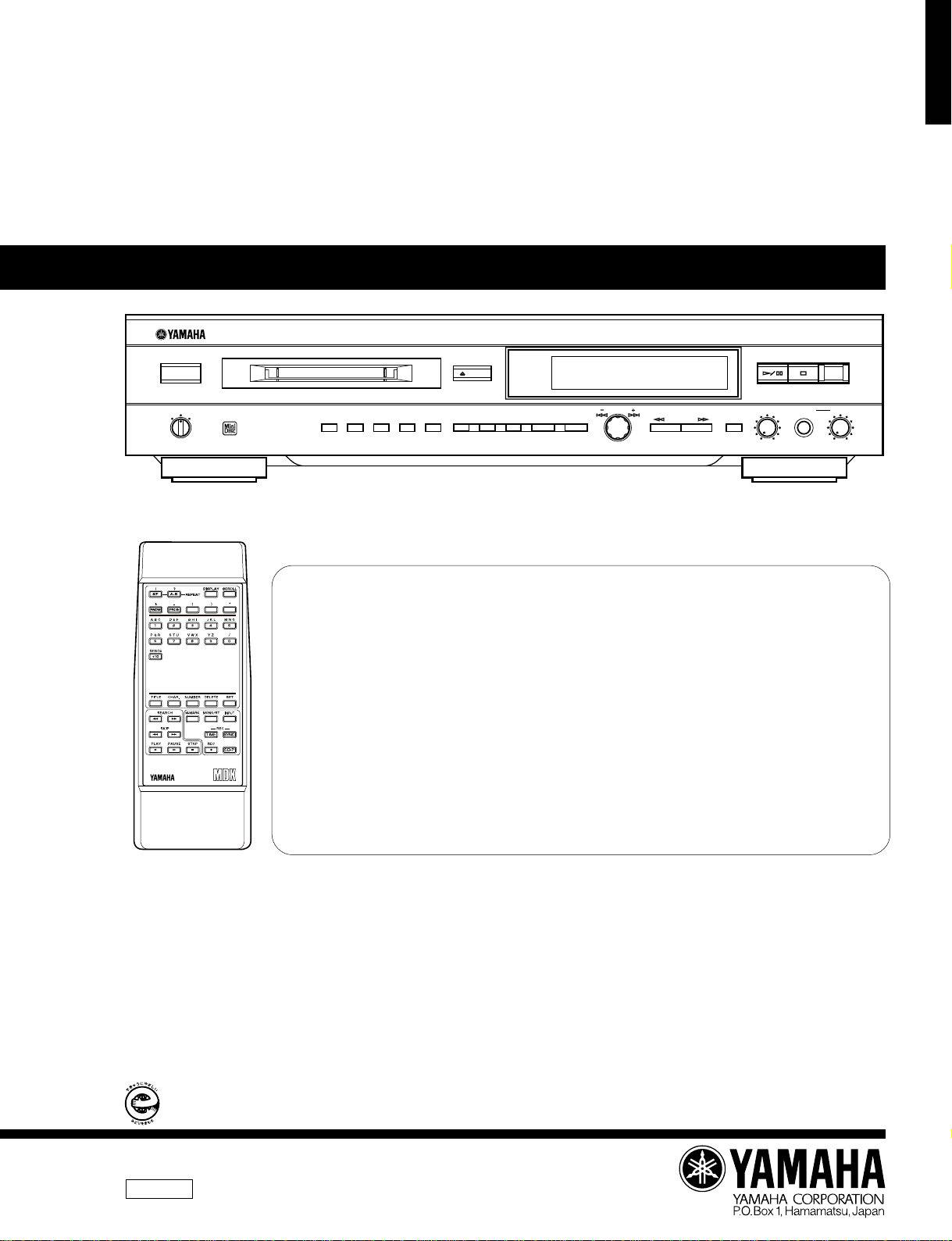

NATURAL SOUND MINIDISC RECORDER MDX-595

MDX-595

MINIDISC RECORDER

MDX-595

SERVICE MANUAL

MDX-595

POWER

PHONES

REC

LEVEL

0 10

EJECT

TIMER

OFF

PLAYREC

S/F REPEAT A-B

DELETE

CHARA.TITLESCROLLDISPLAYRANDOM

CANCEL

DIGITAL

REC LEVEL

SETEDIT

ENTER

SEARCH

ANALOG

REC LEVEL

INPUT

0 10

IMPORTANT NOTICE

This manual has been provided for the use of authorized YAMAHA Retailers and their service personnel.

It has been assumed that basic service procedures inherant to the industry, and more specifically YAMAHA Products, are already

known and understood by the users, and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in personal

IMPORTANT: The presentation or sale of this manual to any individual or firm does not constitute authorization, certification or

The data provided is be lieved to be accurate and applicable to the unit(s) indica ted on the cove r. The rese arch, engineerin g, and

service departments of YAMAHA are continually striving to improve YAMAHA products. Modifications are, therefore, inevitable

and specifications are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist, plea se contact

the distributor's Service Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity your body may have accumu-

IMPORTANT: Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power to the unit.

injury, destruction of expensive components and failure of the product to perform as specified. For these reasons,

we advise all YAMAHA product owners that all service required should be performed by an authorized

YAMAHA Retailer or the appointed service representative.

recognition of any applicable technical capabilities, or establish a principle-agent relationship of any form.

lated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this buss).

■ CONTENTS

TO SERVICE PERSONNEL . . . . . . . . . . . . . . . . . .1~2

REAR PANELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

INTERNAL VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DISASSEMBLY PROCEDURES . . . . . . . . . . . . . . .4~8

ADJUSTMENT & TEST MODE . . . . . . . . . . . . . . . 9~16

SPECIAL TEST MODE . . . . . . . . . . . . . . . . . . . . . . . 17

ERROR DISPLAY . . . . . . . . . . . . . . . . . . . . . . . .18~19

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . .20~24

このサービスマニュアルは、エコマーク認定の再生紙を使用しています。

This Service Manual uses recycled paper.

100671

IC DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25~34

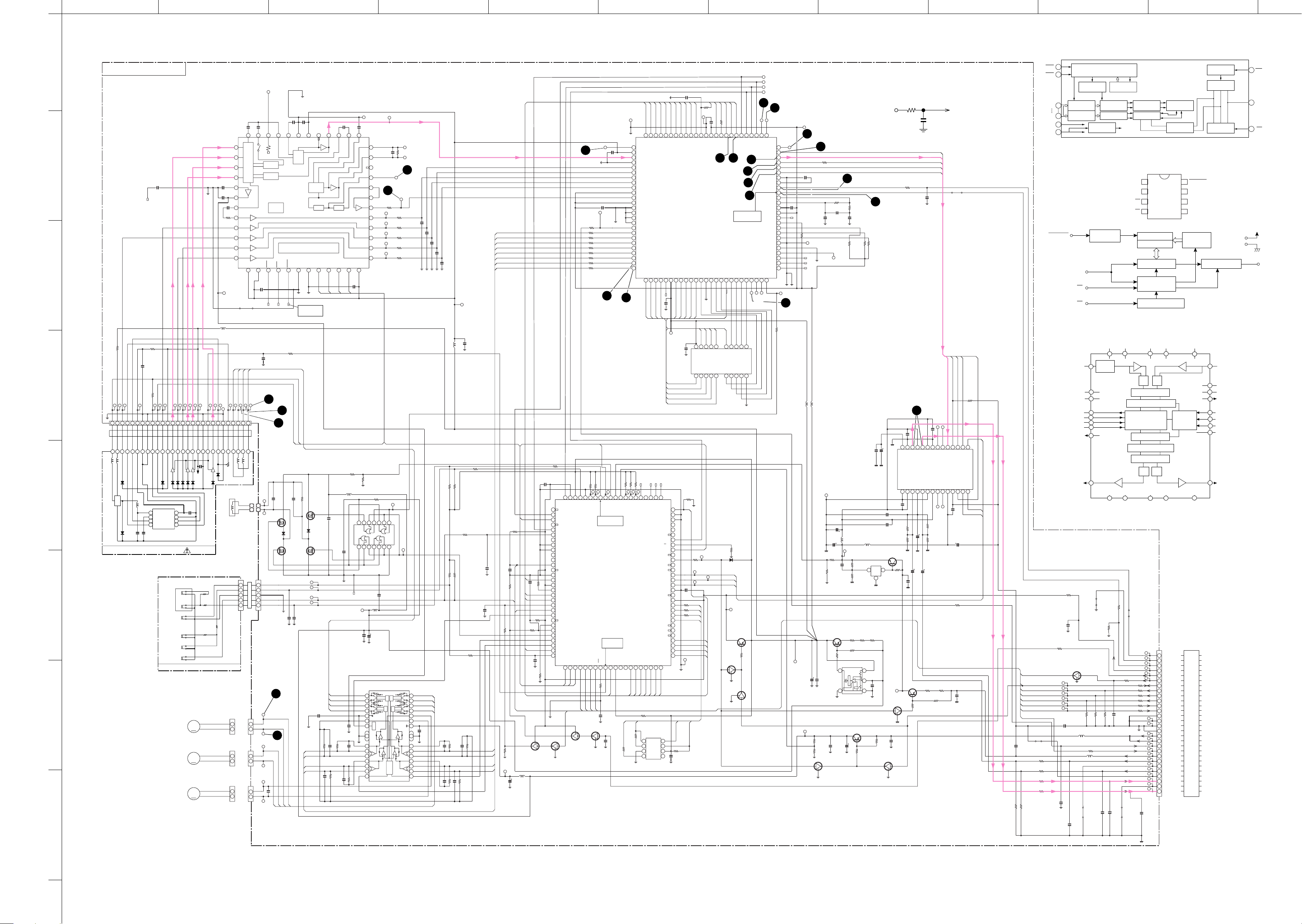

BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . .35~37

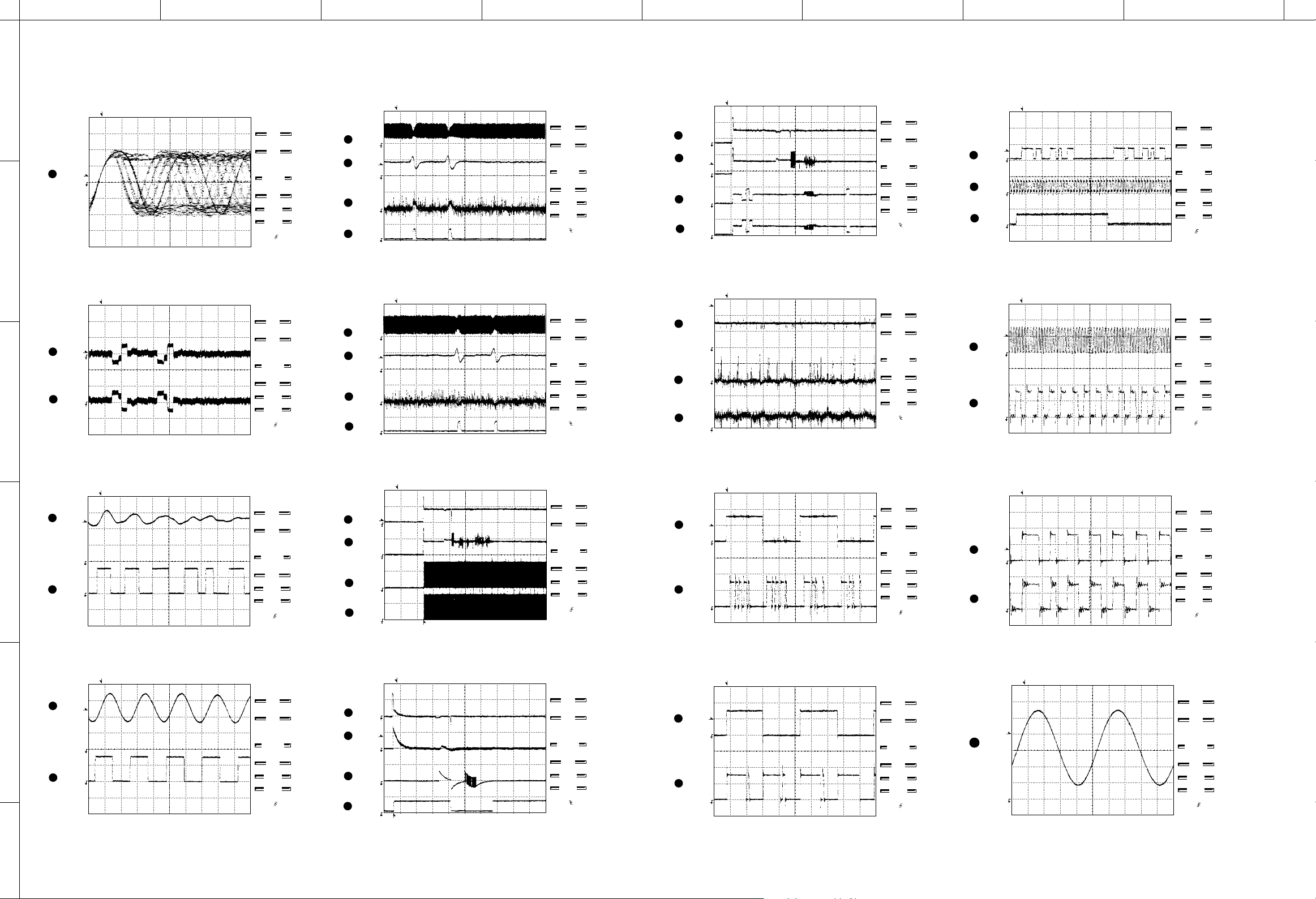

TEST POINT WAVEFORMS . . . . . . . . . . . . . . . . 38~39

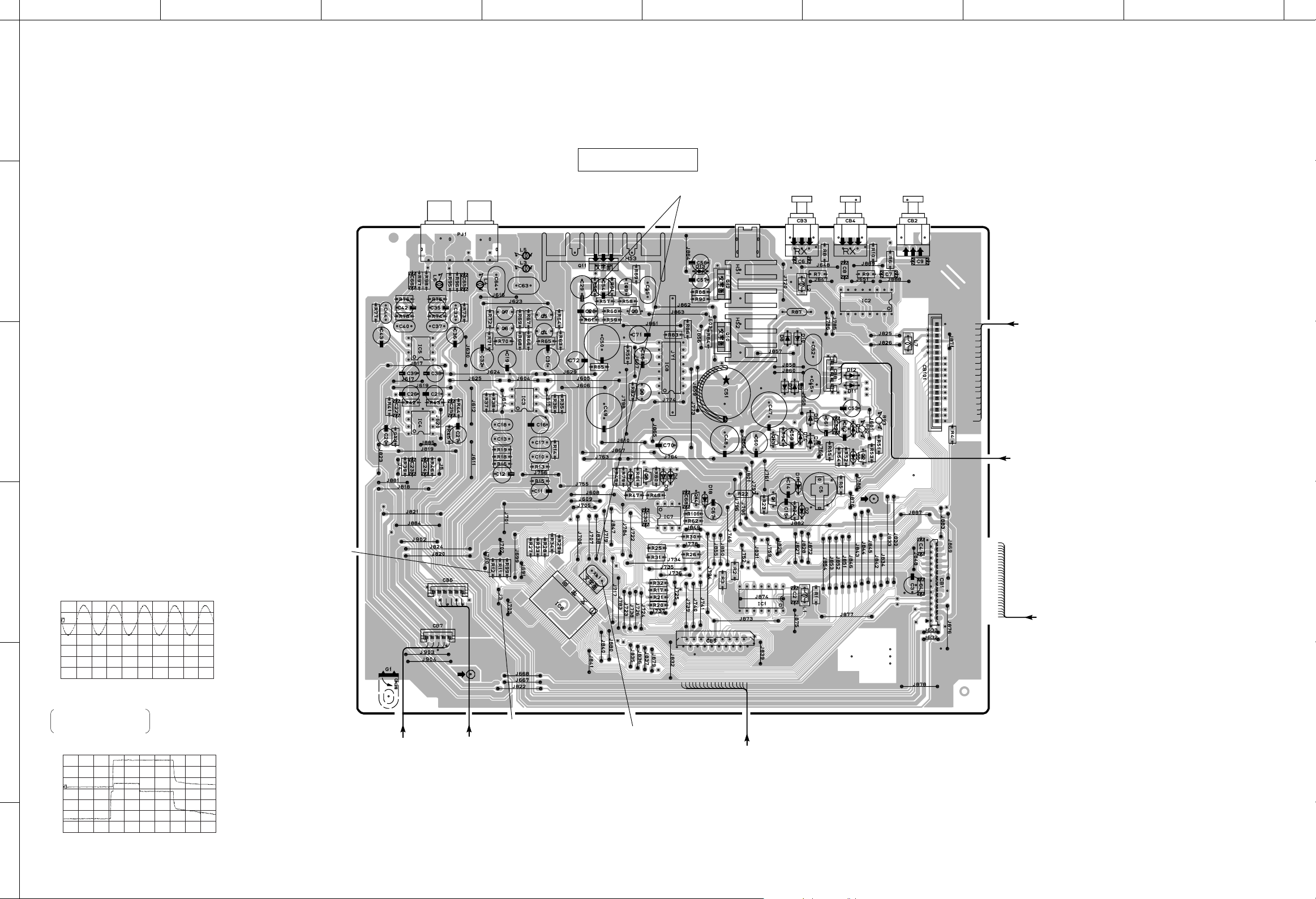

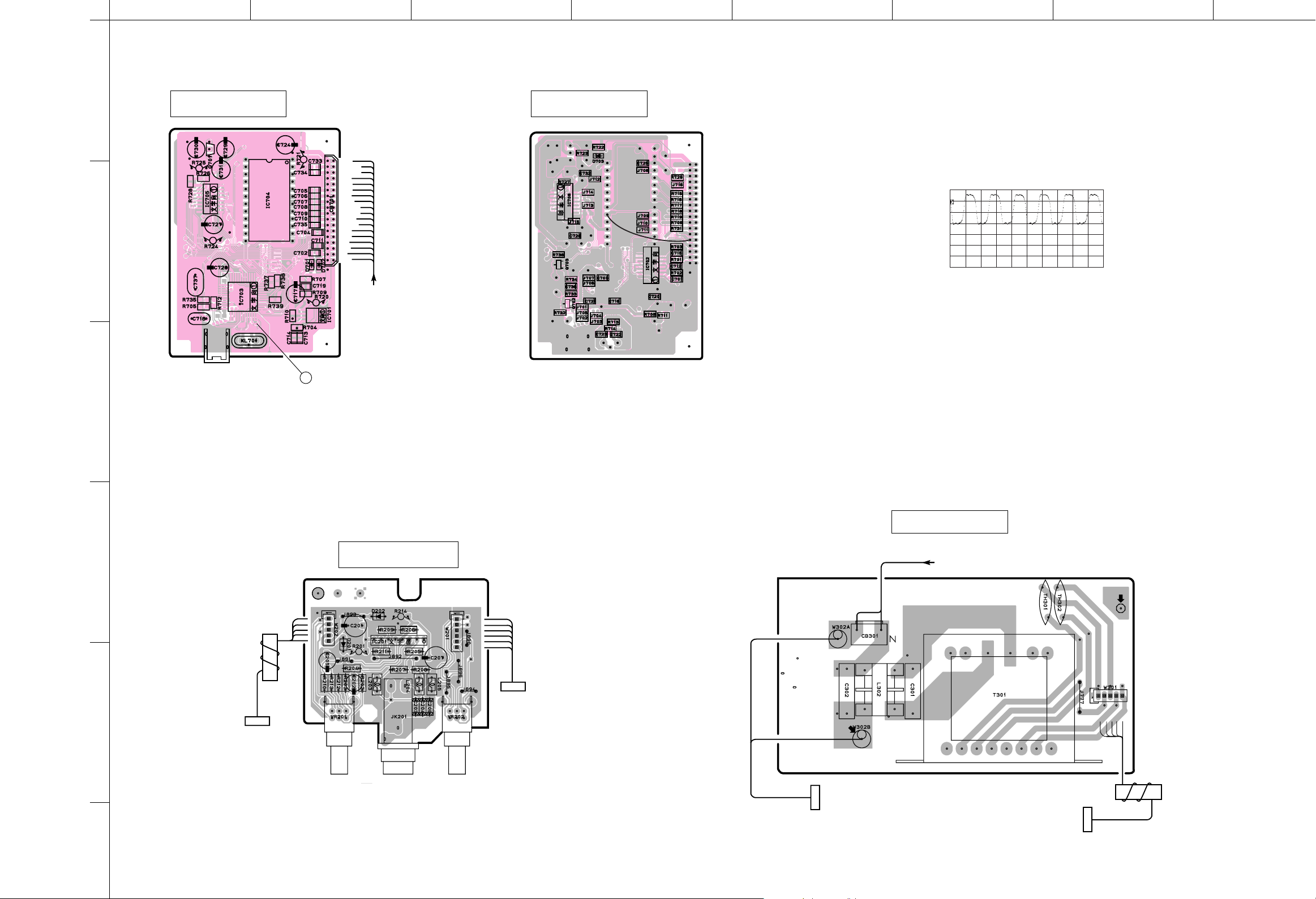

PRINTED CIRCUIT BOARD . . . . . . . . . . . . . . . .40~47

SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . .48~51

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52~64

GREASE APPLICATION DIAGRAM . . . . . . . . . . . . 65

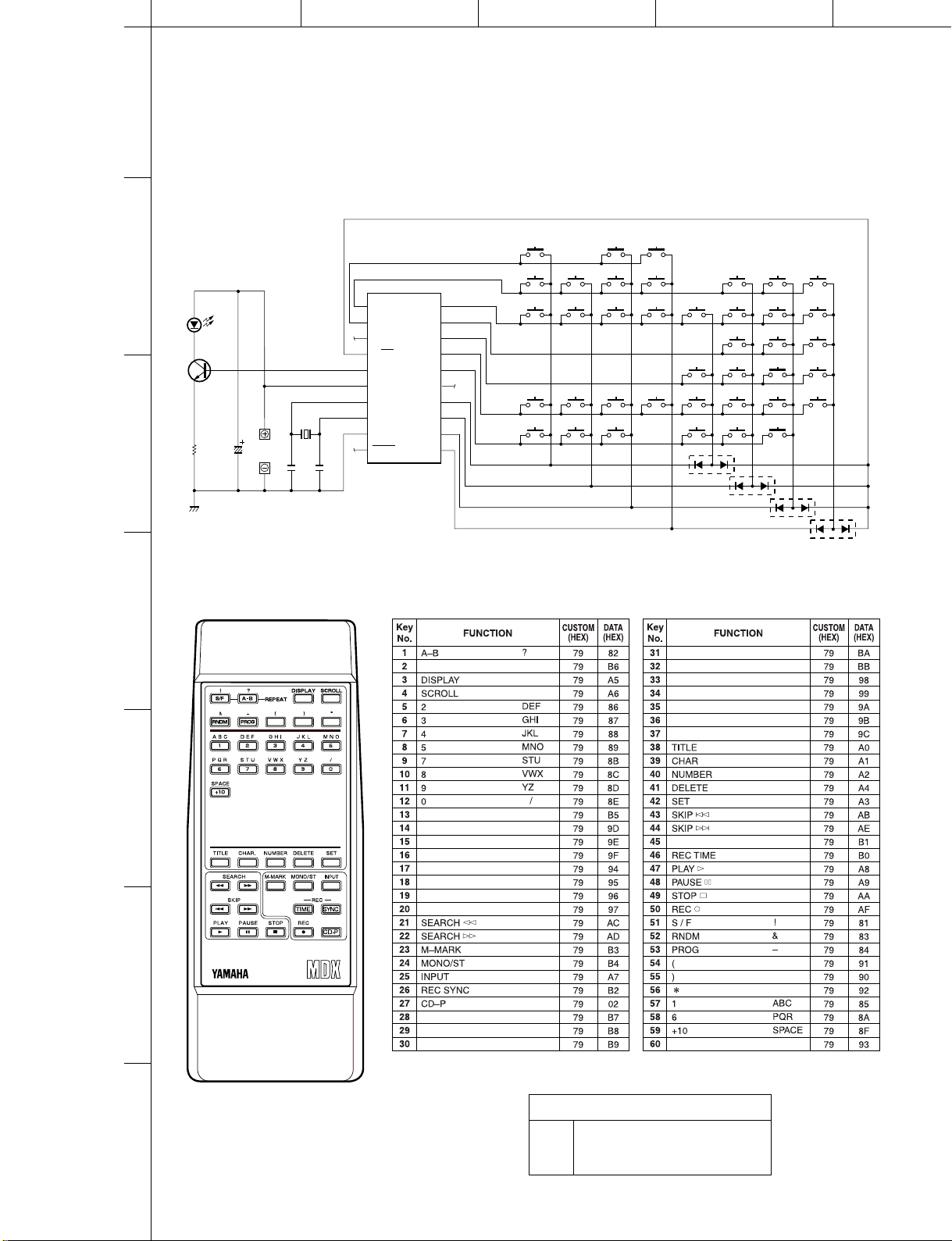

REMOTE CONTROL TRANSMITTER . . . . . . . . . . . 66

Page 2

MDX-595

■ TO SERVICE PERSONNEL

MDX-595

1. Critical Components Information.

Components having special characteristics are marked Z

and must be replaced with parts having specifications equal

to those originally installed.

2. Leakage Current Measurement (For 120V Models Only).

When service has been completed, it is imperative to verify

that all exposed conductive surfaces are properly insulated

from supply circuits.

● Meter impedance should be equivalent to 1500 ohm shunted

by 0.15µF.

● Leakage current must not exceed 0.5mA.

● Be sure to test for leakage with the AC plug in both

polarities.

CAUTION: USE OF CONTROLS OR ADJUSTMENTS

OR PERFORMANCE OF PROCEDURES

OTHER THAN THOSE SPECIFIED

HEREIN MAY RESULT IN HAZARDOUS

RADIATION EXPOSURE.

WALL

OUTLET

EQUIPMENT

UNDER TEST

INSULATING

TABLE

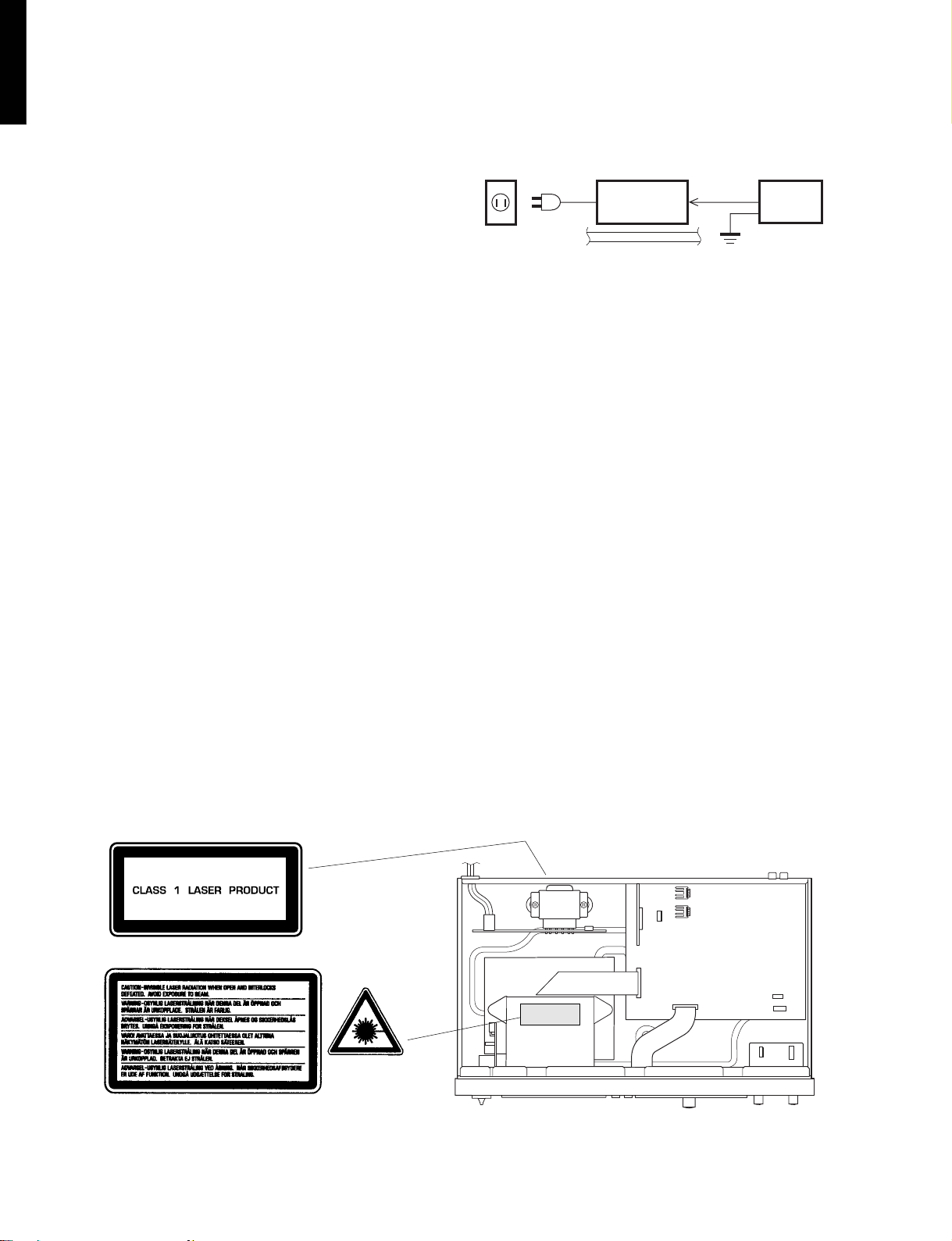

Laser Diode Properties

Material: GaAIAs

Wavelength: 785 nm

Pulse time: Read mode ...0.8 mW Continuous

AC LEAKAGE

TESTER OR

EQUIVALENT

Write mode ...max 10 mW 0.5S

THE MINI DISC RECORDER SHOULD NOT BE

ADJUSTED OR REPAIRED BY ANYONE EXCEPT

PROPERLY QUALIFIED SERVICE PERSONNEL.

min cycle 1.5S

Repetition

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and/or

plastic (where applicable) components may also contain traces of chemicals found by the California Health and

Welfare Agency (and possibly other entities) to cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR

ANY REASON WHATSOEVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes

or expose eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands

before handling food.

G, B models

➀

G, B models

➁

1

Page 3

MDX-595

English

➀ THIS PRINTING (SEE POSITION SHOWN IN THE ILLUSTRATION) INFORMS THE USER THAT THE APPARATUS

CONTAINS A LASER COMPONENT.

➁ THIS LABEL (SEE POSITION SHOWN IN THE ILLUSTRATION) WARNS THAT ANY FURTHER PROCEDURE WILL

BRING THE USER INTO EXPOSURE WITH THE LASER BEAM.

CAUTION : USE OF CONTROLS, ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE

SPECIFIED HEREIN, MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

Swedish

➀ DENNA MÄRKNING (SE FIGUR) UPPLYSER OM ATT DET I APPARATEN INGÅR EN LASERKOMPONENT AV

TYP KLASS 1.

➁ VARNINGSMÄRKNING (SE FIGUR) FÖR STRÅLNING. INGREPP I APPARATEN BÖR ENDAST FÖRETAGAS AV

FACKMAN MED KÅNNEDOM OM LASER. APPARATEN INNEHÄLLER EN LASERKOMPONENT SOM AVGER

STRÅLNING ÖVERSTIGANDE GRÄNSEN FÖR LASERKLASS 1.

VARNING : OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRREN ÄR URKOPPLAD.

STIRRA EJ I STRÅLEN OCH BETRAKTA EJ STRÅLEN GENOM OPTISKT INSTRUMENT.

Danish

➀ DETTE MÆRKAT ER ANBRAGT SOM VIST I ILLUSTRATIONEN FOR AT ADVARE BRUGEREN OM AT AP-

PARATET INDEHOLDER EN LASERKOMPONENT.

MDX-595

➁ DETTE MÆRKAT OM LASEREN ER ANBRAGT PÅ APPARATET SOM EN OPLYSNING OM AT APPARATET

INDEHOLDER ET LASERKOMPONENT.

ADVARSEL : USYNLIG LASERSTRÅLING VED ÅBNING, NÅR SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION.

SE IKKE IND I STRÅLEN-HELLER IKKE MED OPTISKE INSTRUMENTER.

ADVARSEL : USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG SIKKERHEDSLÄS BRYTES. STIRR IKKE INN

I STRÅLEN ELLER SE DIREKTE MED OPTISKE INSTRUMENTER.

Finnish

VARO! :

AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA NÄKYMÄTTÖMÄLLE LASER-SÄTEILYLLE.

ÄLÄ TUIJOTA SÄTEESEEN ÄLÄKÄ KATSO SITÄ OPTISEN LAITTEEN LÄPI.

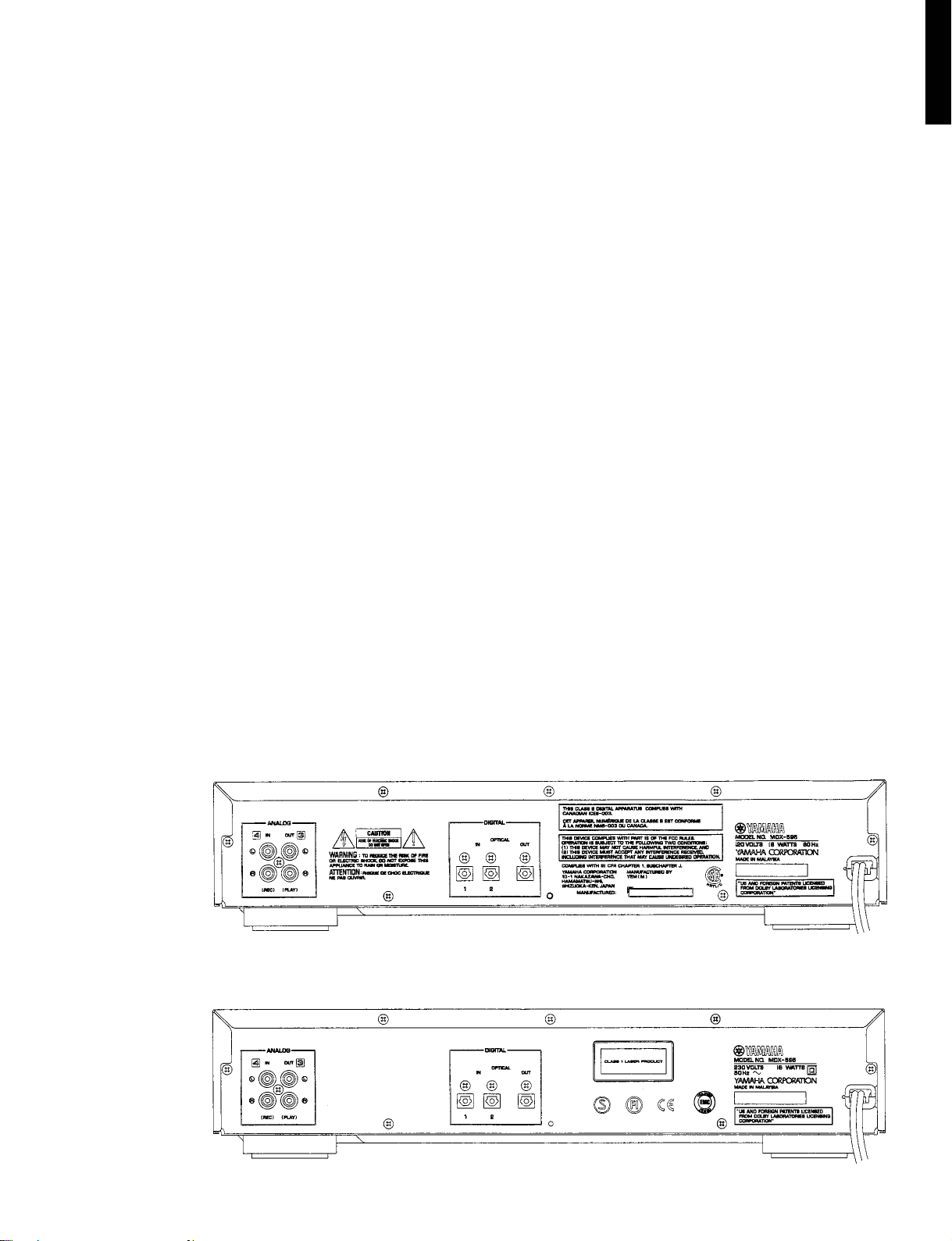

■ REAR PANELS

▼ U model

▼ G, B models

2

Page 4

MDX-595

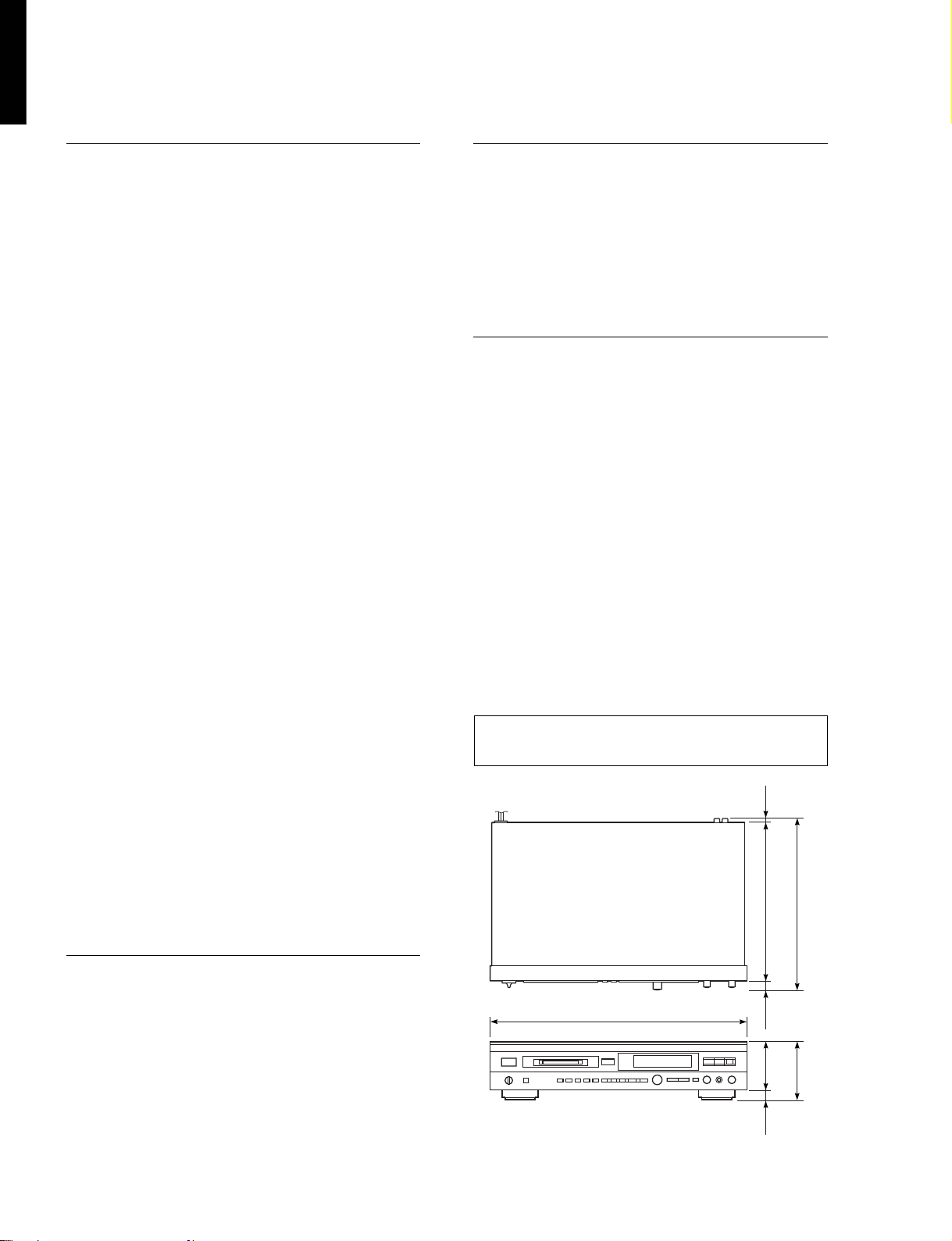

■ SPECIFICATIONS

MDX-595

Digital audio system

System

MiniDisc digital audio system

Disc

MiniDisc

Recording method

Magnetic field variation overwrite

Reading method

Non-contact optical pickup (using semiconductor laser)

Laser

Semiconductor laser

Laser Diode Properties

Material: GaAIAs

Wavelength: 785 nm

Pulse time:

Read mode ... 0.8 mW Continuous

Write mode ... max 10 mW 0.5S

min cycle 1.5S

Repetition

Record/playback time

Max. 80 minutes

80 minutes (stereo)

160 minutes (mono)

Revolutions

Approx. 400~900 rpm (CLV)

Error Correction

ACIRC (Advanced Cross Interleave Reed-solomon Code)

Sampling frequency

44.1 kHz (32 kHz and 48 kHz signals converted to 44.1 kHz

for recording)

Coding

ATRAC (Adaptive TRansform Acoustic Coding)

Modulation system

EFM (Eight-to-Fourteen Modulation)

Number of channels

2 (stereo) or 1 (mono, for extended recording)

Frequency Response

5 ~ 20,000 Hz ±0.5 dB

Signal-to-Noise Ratio

More than 99 dB during playback

Wow and Flutter

Below measurable limit

Outputs

LINE OUT (PLAY)

Type: pin jack

Standard output level: 2.0 ± 0.5 Vrms

DIGITAL OUT (OPTICAL)

Type: square optical connector jack

PHONES

Standard output level

(Input 150 ohms shorted, – 20 dB): 300 ± 60 mV

GENERAL

Power Supplies

U model 120 V, 60 Hz

G, B models 230 V, 50 Hz

Power Consumption

20 W

Dimensions (W x H x D)

435 x 96 x 288 mm (17-1/8" x 3-3/4" x 11-5/16")

Weight

4.1 kg (9 lbs. 1 oz.)

Accessories

Remote Control.... 1

Audio cord... 2

Optical cord... 1

Batteries (size AA, R6, UM-3).... 2

Specifications subject to change without notice.

U : USA model

B : British model

G : European model

* US and foreign patents licensed from Dolby Laboratories

Licensing Corporation.

6.5

(1/4")

Inputs

LINE IN (REC)

Type: pin jack

Input impedance: greater than 56 k-ohms

Standard input level: 300 mV

DIGITAL IN (OPTICAL) 1/2

Type: square optical connector jack

3

435(17–1/8")

288(11–5/16")

266.5(10–1/2")

15

(9/16")

80

96

(3–1/8")

(3–3/4")

16

(5/8")

Units : mm (inch)

Page 5

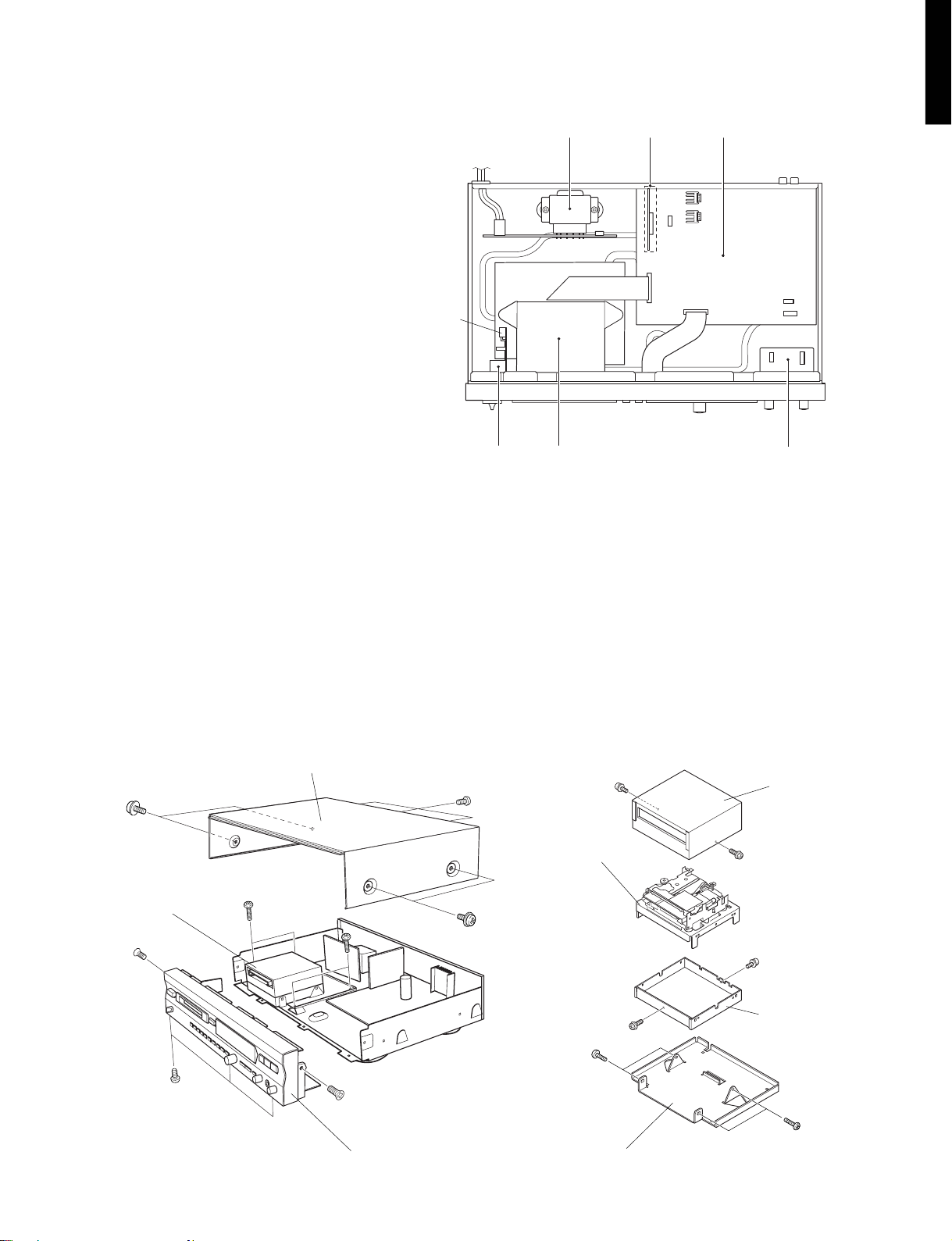

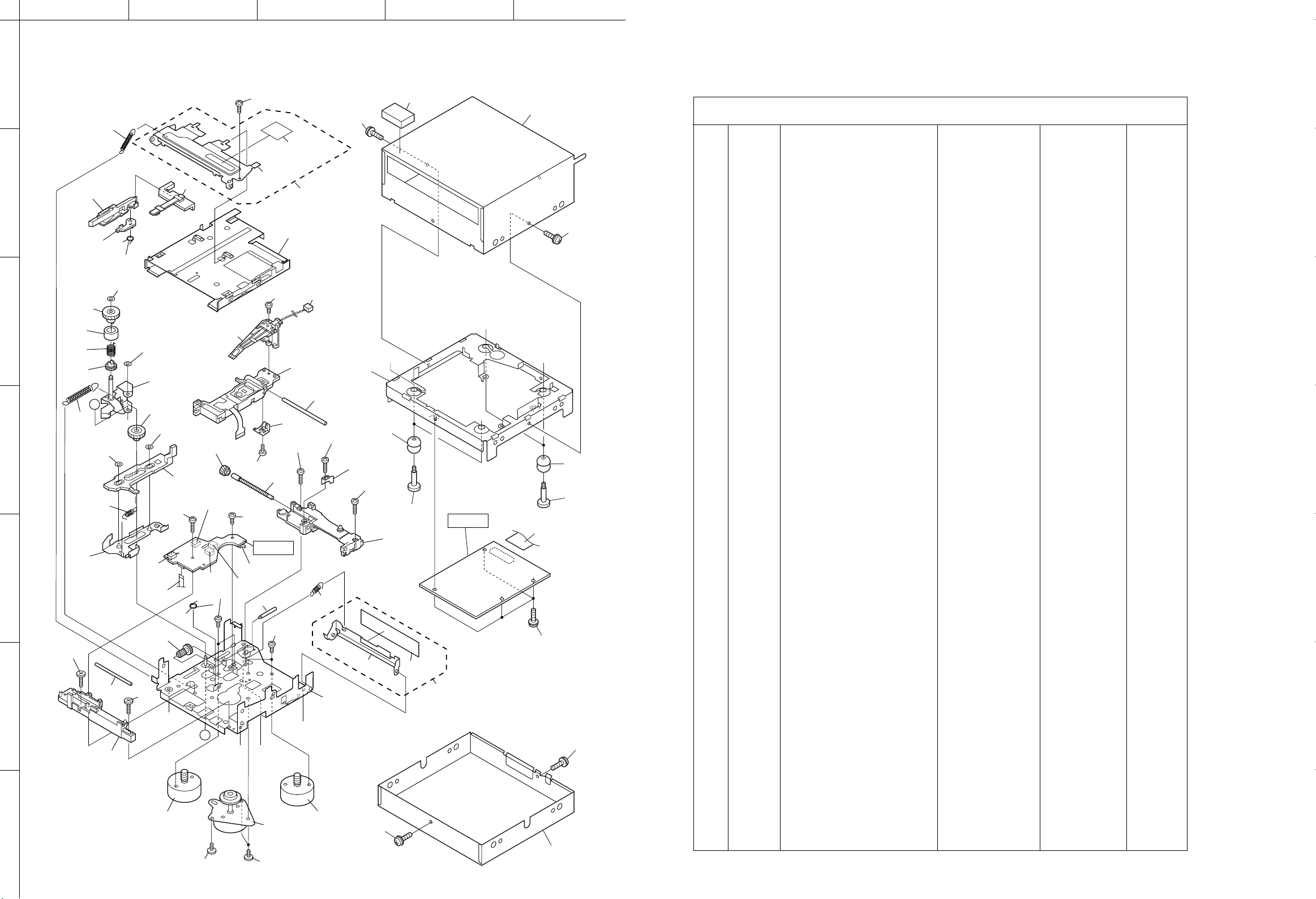

■ INTERNAL VIEW

MDX-595

MDX-595

q POWER TRANSFORMER

w P.C.B. DIGITAL

e P.C.B. MAIN (1)

r POWER SWITCH

t MD MECHANISM UNIT

y P.C.B. MAIN (2)

CB401

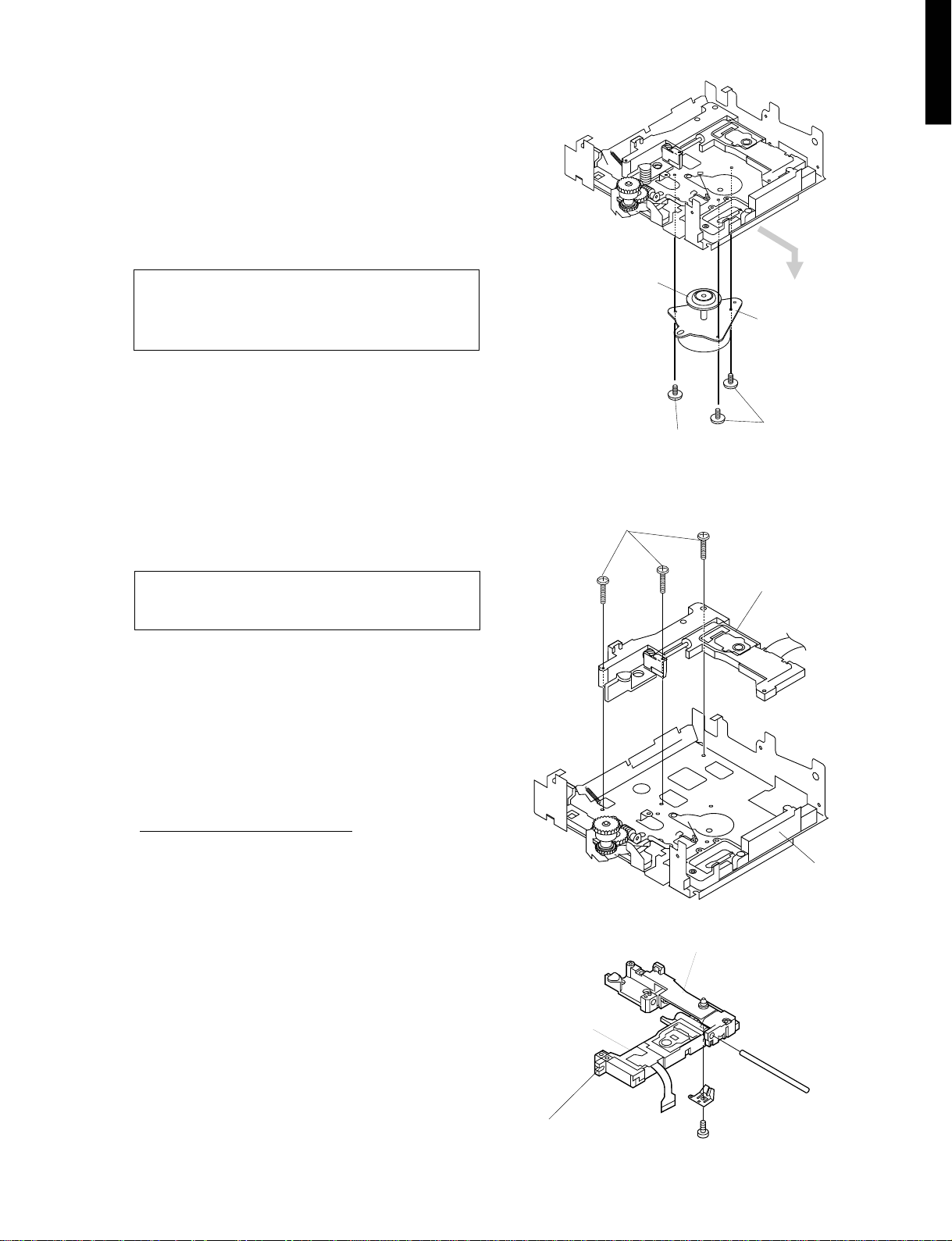

■ DISASSEMBLY PROCEDURES

(Remove parts in disassembly order as numbered.)

q w e

CB1

CB5

CB6

CB7

r t y

1. Removal of Top Cover

a. Remove 4 screws ( q ) and 3 screw

2. Removal of Front Panel

a. Remove 4 connectors.

CB5, CB6, CB7, CB401

( e )

b. Remove 3 screws

q

MD Mechanism Unit

r

t

and 2 screws

Top Cover

t

( w )

( r )

in Fig. 1.

in Fig. 1

w

3. Removal of MD Mechanism Unit

a. Remove 1 connector.

CB1

b. Remove 4 screws ( t ) in Fig. 1.

c. Remove 4 screws ( y ) in Fig. 2.

.

q

d. Remove 2 screws ( u ) in Fig. 2.

e. Remove 2 screws ( i ) in Fig. 2.

i

MD Mechanism Unit

u

y

i

Shield Case (Top)

u

Shield Case (Bottom)

e

r

Front Panel

Fig. 1

y

Support (Mechanism)

Fig. 2

4

Page 6

MDX-595

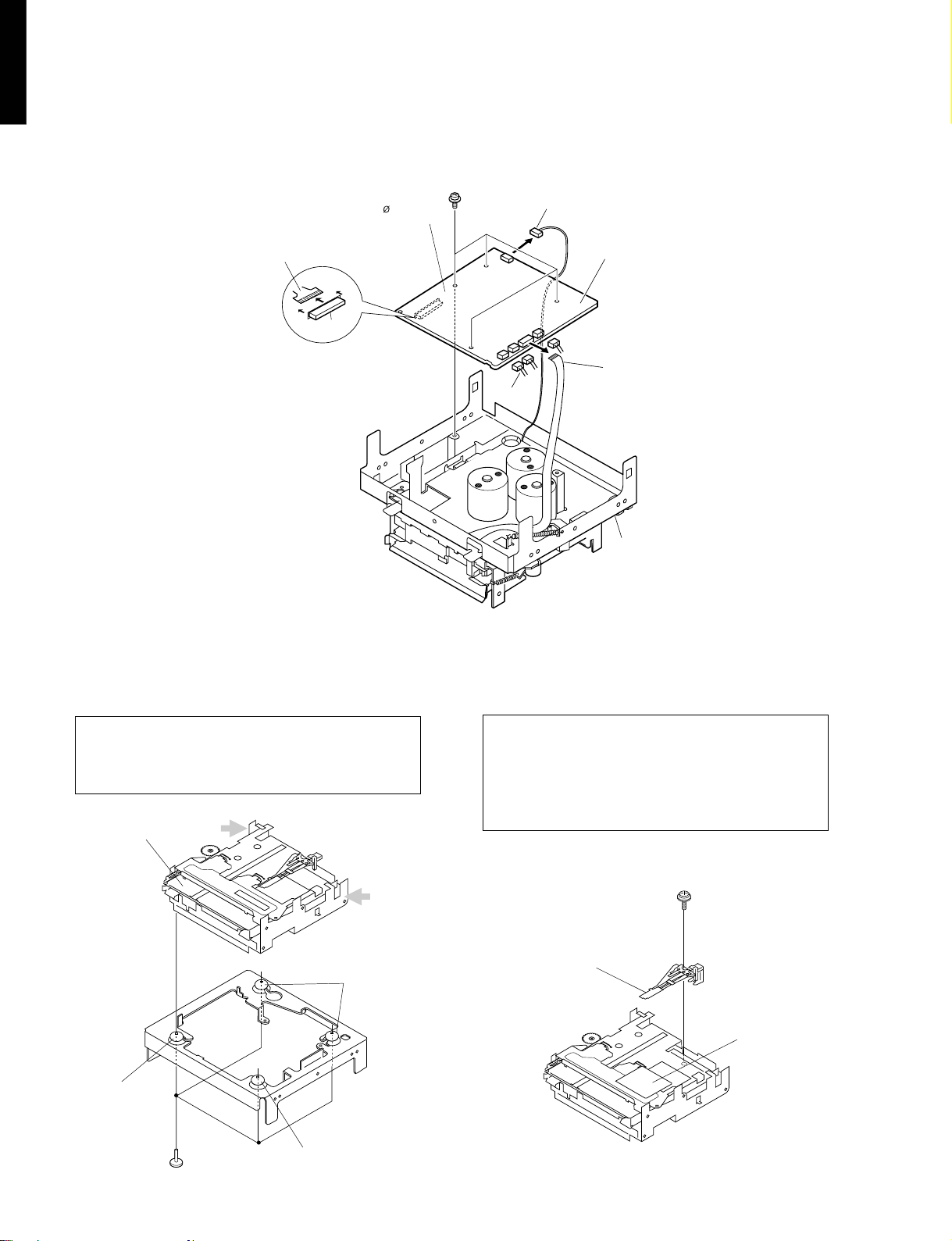

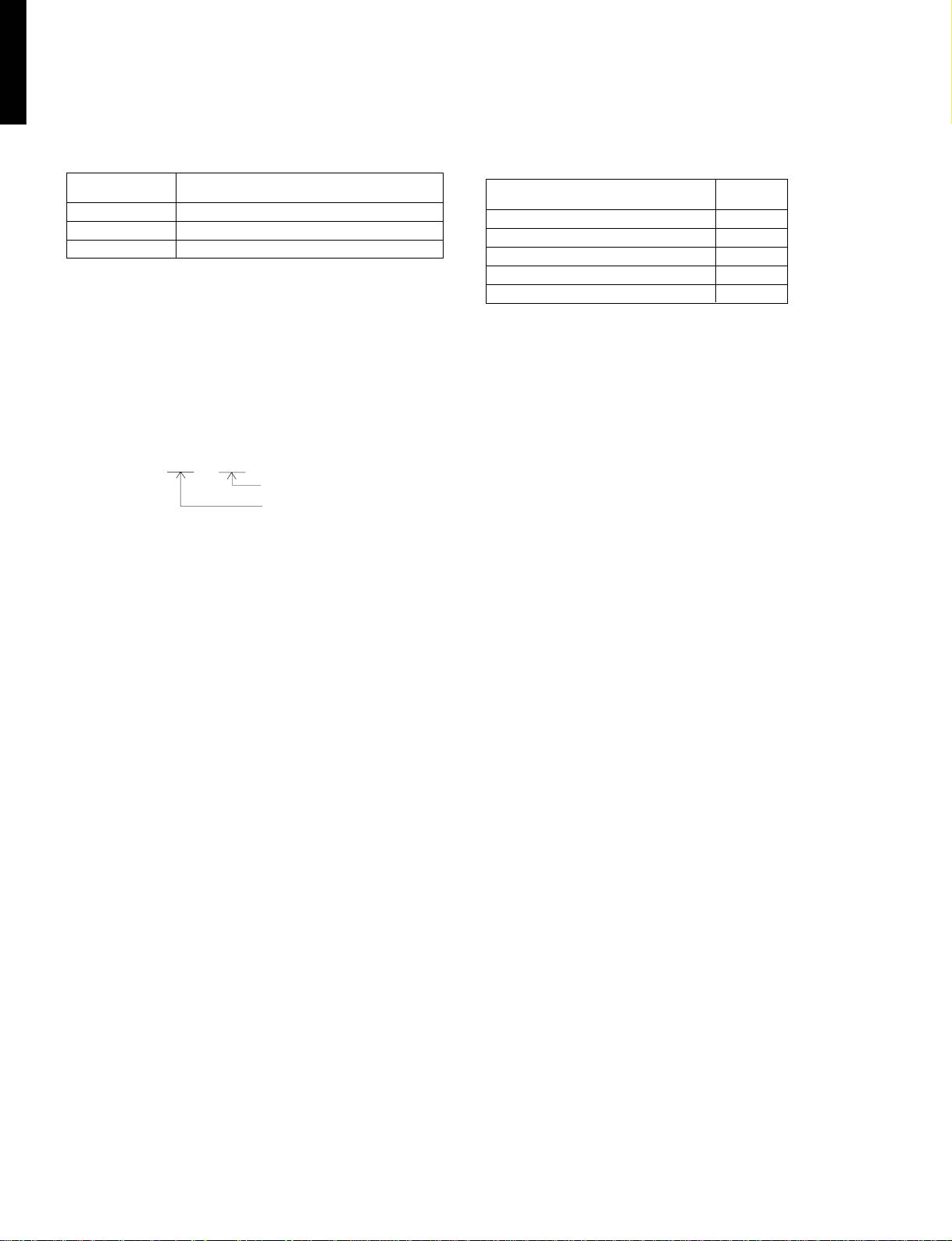

Disassembly of MD Mechanical Unit

MDX-595

Remove the MD mechanical unit according to Steps 1 ~ 3 of the disassembly procedure (page 4).

Removal of MD Main P.C.B. (Fig. 3)

1. Remove 4 screws (Q1).

2. Remove 6 connectors (Q2).

( Q1 ) x 4

1.7 x 3mm

( Q2 ) x 1

Flexible P.C.B. for

optical pickup (*1)

(Q2)x1

(*1) After pulling off the flexible P.C.B.

for the optical pickup from the

connector, cover its end with

aluminum foil or the like which is

electrically conductive so as to prevent

the optical pickup from being

damaged by static electricity.

Removal of MD Mechanism (Fig.4)

1. Remove 4 screws (R1).

Caution

Almost the entire surface of the cartridge holder is

coated with oil. When removing the mechanism, hold it

at the rear end (where marked with arrows in the figure)

and avoid touching the oiled surface.

Cartridge Holder

MD Mechanism

MD Main P.C.B.

( Q2 ) x 1

( Q2 ) x 3

Frame

Fig. 3

Removal of Magnetic Head (Fig.5)

1. Remove a screw (A1).

Caution

a. When removing the magnetic head, hold its base and

do not touch the magnetic head itself or the leaf

spring.

b. Place the magnetic head upside down.

c. Use special care so as not to cause any damage to

the magnetic head when installing it.

(A1)x1

ø1.7x5mm

Gray

(R1)x4

ø1.7x8.9mm

Gray

Black

Leaf Spring

MD Mechanism

Fig. 4

Magnetic Head

Sheet, Head

Fig. 5

5

Page 7

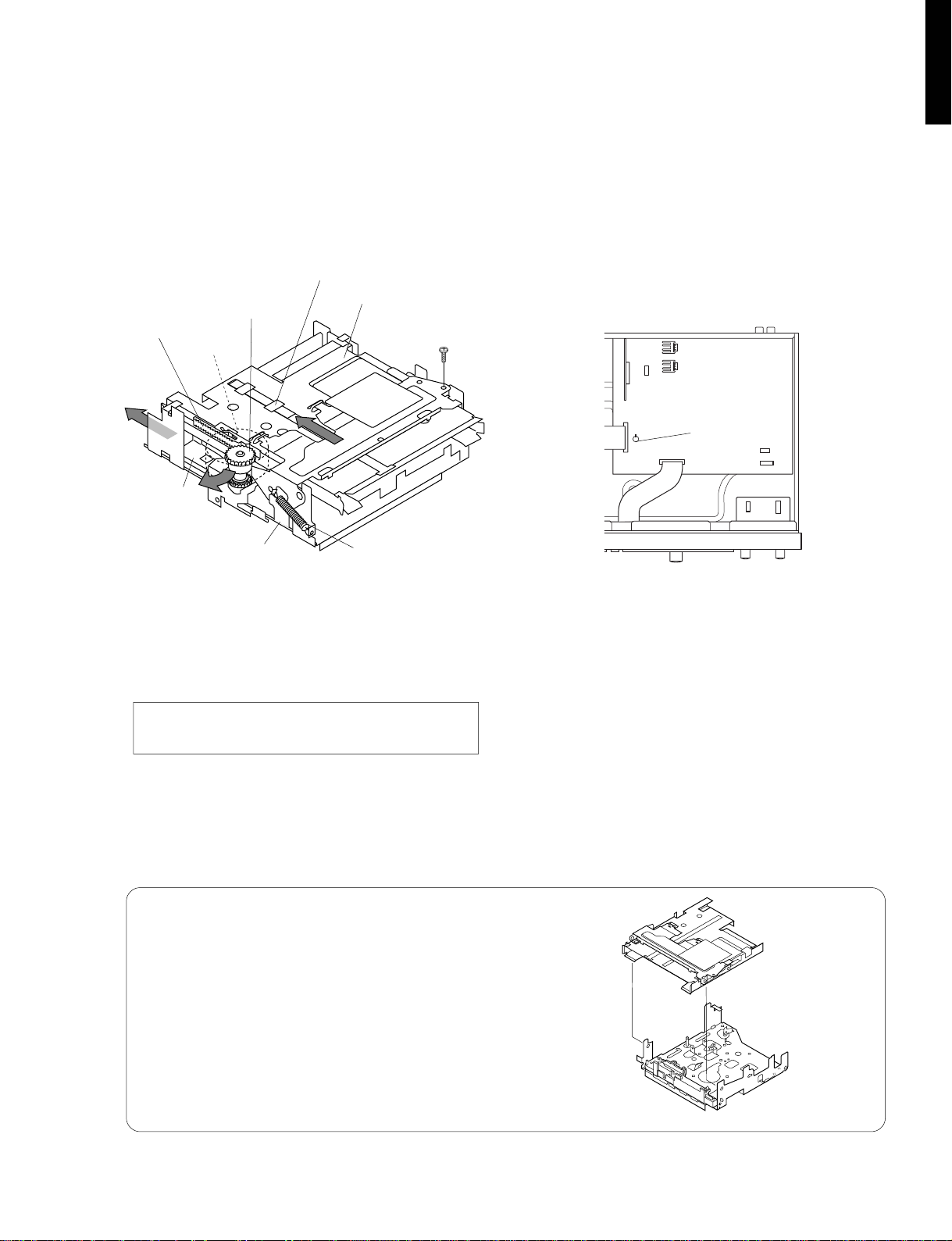

Removal of Cartridge Holder (Fig.6)

1. Open the roller arm lever in the arrow direction and move the clamper lever to the rear.

2. With a +5V voltage (*2) applied to the red line side of the blue connector of the loading

motor, push the rack gear in the arrow direction until the cam plate lever clicks.

(*2) A +5V voltage can be obtained from the pluspol (D6.5/5V) of C3 and the ground

terminal of the Main P.C.B.

3. Remove a screw (B1 and B2, 1 each) from the holder arm and remove the cartridge

holder by moving it to the left.

Slider Lever

Cartridge Holder

(B1) x1

Ø1.7x5mm

Clamper

Lever

Loading

Motor

Roller Arm Lever

MDX-595

MDX-595

Rack Gear

Cam Plate

Lever

(B2) x1

Fig.6

Caution

Be careful so that oil does not get on the clamper lever

which contacts the roller of the roller arm lever.

C3

Pluspol (D6.5/5V)

Installation of Cartridge Holder

• To install the cartridge holder, the rack of the mechanism must be

lowered toward the rear.

• While pushing the roller arm lever outward, push in the slider lever.

• Apply a +5V voltage to the loading motor (until clicking sound is

heard) and push in the rack gear.

• With the slider lever and the rack gear installed as described above,

fit the cartridge holder as shown in the figure and tighten screws.

6

Page 8

MDX-595

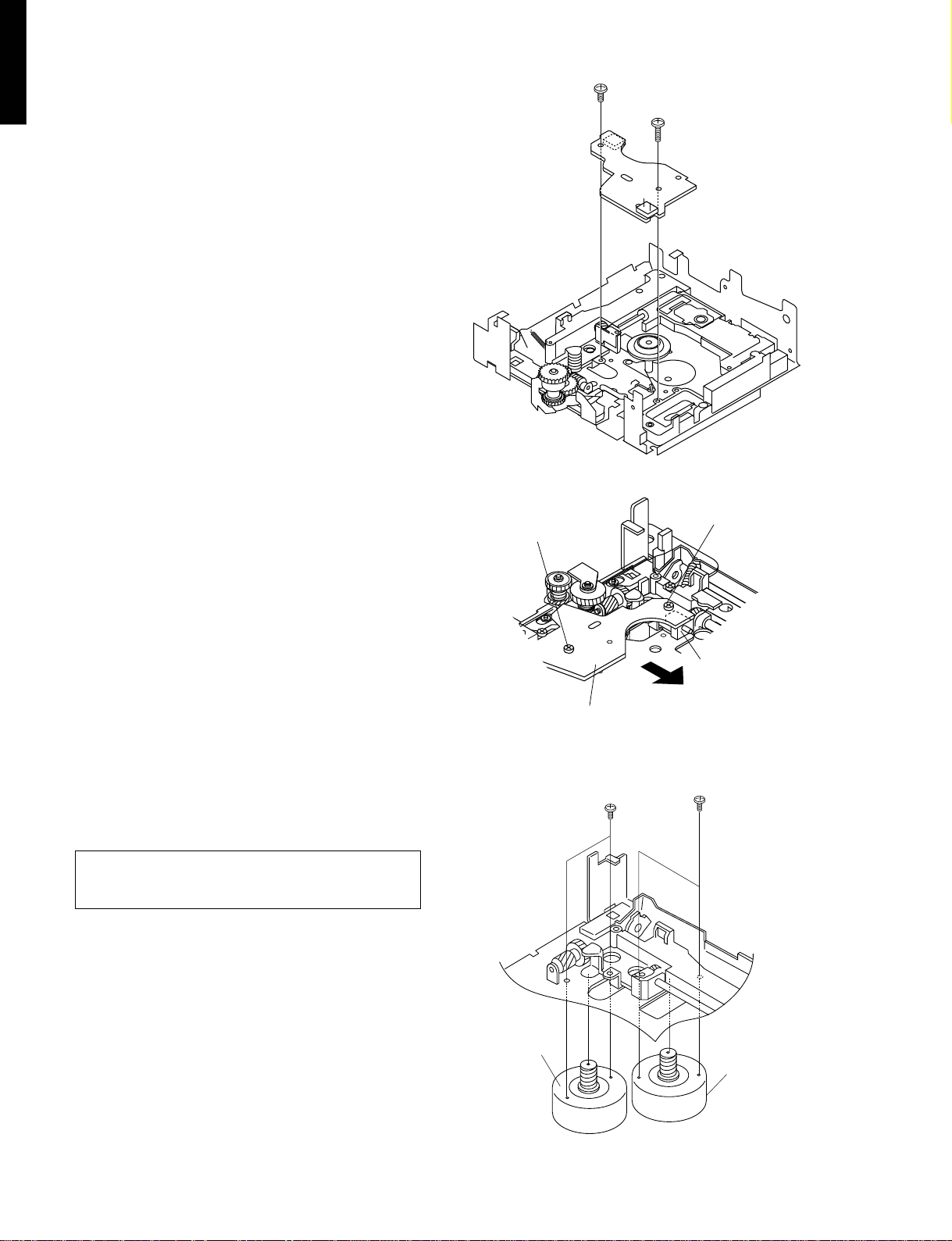

Removal of Mechanism SW P.C.B. (Fig.7)

MDX-595

• Once the mechanism switch P.C.B. is removed, it will

be necessary to perform “Adjustment of Lead-in Switch

Position”. (See page 13.)

1. Remove 2 screws (E1) and then remove the Mechanism SW P.C.B.

Installation of Mechanism SW P.C.B.

• Set the mechanism to the eject mode by applying -5V

to the loading motor.

• Install the mechanism SW P.C.B. so that the boss fits

in the hole in it.

• Push the lead switch on the mechanism SW P.C.B.

toward the optical pickup side (so that looseness in the

boss hole is eliminated).

• Tighten screws and apply thread lock.

• Measure the lead-in switch position. (See page 13.)

(Enter the result in EEPROM.)

(E1)x1

Ø1.7x9.5mm

(E1)x1

Ø1.7x3mm

(E1)x1

Ø1.7x9.5mm

Mechanism SW P.C.B.

(E1)x1

Ø1.7x3mm

Lead-in switch

Fig.7

Removal of Sled Motor/Loading Motor (Fig.8)

1. Remove 4 screws (D1) and then remove the sled

motor/loading motor.

Caution

Use care so as not to cause any damage to the gear.

(The damaged gear will cause abnormal noise to occur

while searching.)

Loading Motor

Mechanism SW P.C.B.

(D1)x2

Ø1.7x2mm

(D1)x2

Ø1.7x2mm

Sled motor

Fig. 8

7

Page 9

Removal of Spindle Motor (Fig.9)

• Once the spindle motor is removed, it will be neces-

sary to perform “Pickup Rating”. (See page 14.)

1. Remove 3 screws (C1).

2. Remove the spindle motor by moving it in the arrow

direction.

Caution

a. Be careful not to scratch the gear.

(Scratched gear will produce noises during searching.)

b. As the turn-table is magnetized, keep foreign objects

from being attracted.

Turn Table

(C1)x1

Ø1.7x2.1mm

MDX-595

Spindle Motor

(C1)x3

Ø1.7x2.5mm

MDX-595

Removal of Optical Pickup Head (Fig.10 and Fig.11)

1. Remove 3 screws (F1).

Caution

Use care so as not to cause any damage to the gear.

(The damaged gear will cause abnormal noise to occur

while searching.)

2. Remove a screw (F2).

The leaf spring (A) attached to the P.U. will be reused

when replacing the pickup. It is not supplied with the

optical pickup.

3. Using tweezers or the like, pull the PU shaft from the

base a little. Pull only enough to allow the pickup to

come off. If it is pulled off completely, the oil on the

shaft will be scraped off.

Be sure to keep oil on the shaft!

(F1)x3

Ø1.7x9.5mm

Fig.9

Optical Pickup Head

MD Guide (B)

Fig. 10

Assembly of Optical Pickup

• When installing the pickup to the MD guide (A), be

sure to tighten the leaf spring (A) with it.

• When installing the pickup to the MD mechanism, fit

the pickup into the MD guide (B) first, match the boss

of the MD guide (A) and its hole in the chassis and

tighten them with a screw.

Optical Pickup

Fit the pickup into the MD guide (B) first

MD Guide (A)

Leaf Spring (A)

(F2)x1

Ø1.4x2.2mm

PU Shaft

Fig. 11

8

Page 10

MDX-595

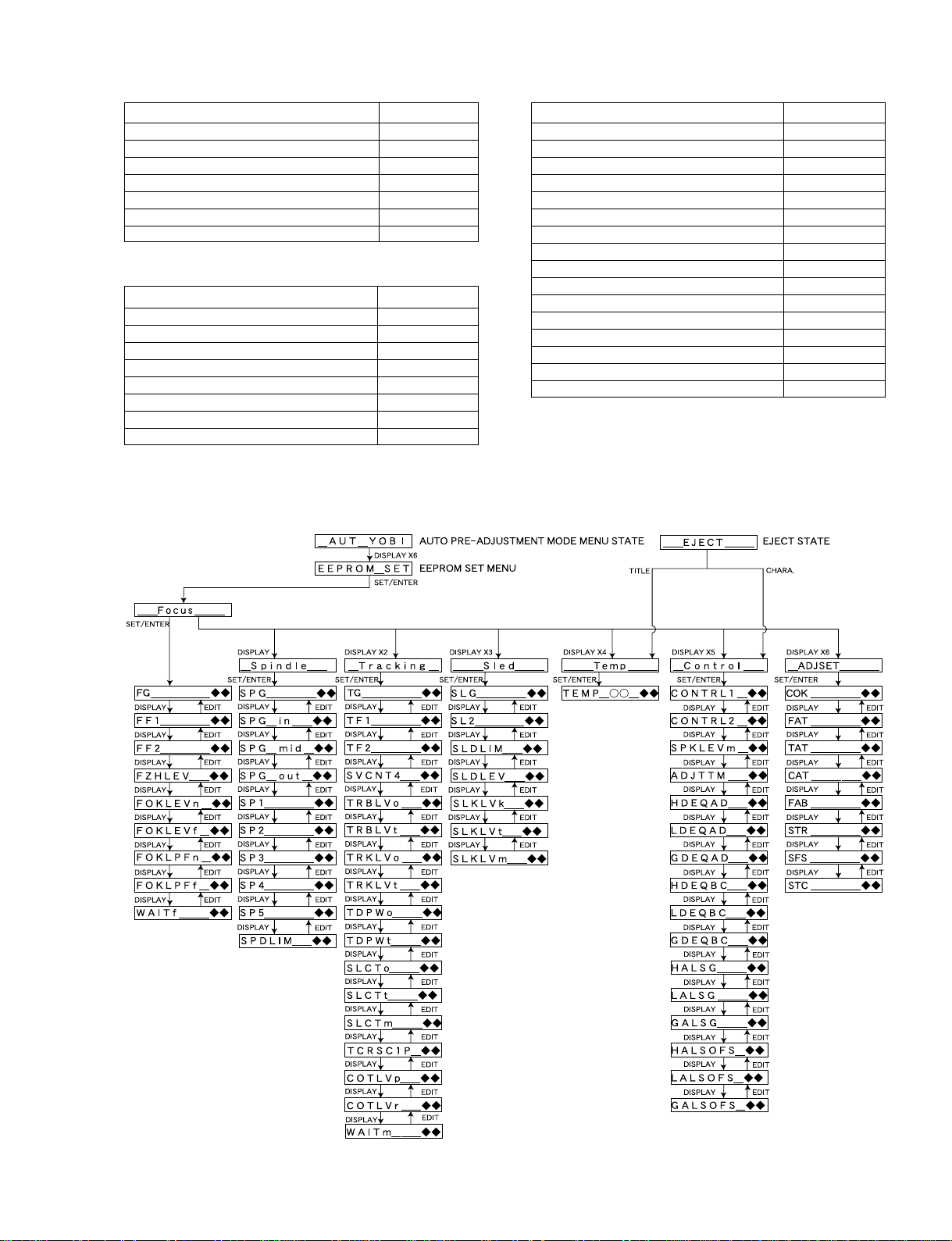

■ ADJUSTMENT & TEST MODE

MDX-595

Preparation before Adjustment

● Test disc

● Extension cable

(see connection diagram on page 14.)

Type Test disc

High reflecting disc TDYS1 (SONY) [for reproduction] (P/No. TX945850)

Low reflecting disc Commercially available mini disc for recording

Low reflecting disc MMD-318 [for pre-adjustment] (P/No. AAX04890)

1. Extension P.C.B. for servicing TX946230

2. 2-pin extension connector for servicing TX946200

3. 6-pin extension connector for servicing TX946210

4. 5-pin flat cable for servicing TX946190

5. 28-pin flat cable for servicing TX946220

Type Part No.

TEST MODE

1. How to set to the test mode

1) Press the POWER button while pressing the SET/ENTER button and the PLAY/PAUSE button.

Version of microprocessor on display (about 1 second)

t s m 1 3 * * e * *

Version of EEPROM protect data (from 01)

Version of microprocessor ROM (from 01)

“EJECT” on display

2) Load either a disc for reproduction or a disc for recording.

“AUT YOBI” on display

This completes setting to the test mode.

2. How to set to each mode

Every time the DISPLAY button is pressed, the mode changes. (For operation of each mode, refer to the section

describing each mode.)

->AUTO pre-adjustment -> AUTO adjustment -> RESULT preparation -> RESULT -> MANUAL pre-adjustment ->

MANUAL adjustment -> EEPROM setting

Caution) The AUTO pre-adjustment and AUTO adjustment modes are used for adjustment during servicing. Other modes

are used when checking the specific measured values and adjusted values or when changing the set value and the

adjusted value. Note that use of other modes will rewrite RAM and EEPROM.

3. How to cancel test mode

1) Finish the AUTO pre-adjustment and AUTO adjustment. ( “COMPLETE” appears on the display)

2) Press the REC button. ( “TEST END” appears on the display)

3) Eject the disc by pressing the EJECT button.

4) Turn off the power.

● When using a new combination of a mechanical pickup and an MD P.C.B. after a repair or for some other

reason, make sure to set to the TEST mode and perform AUTO pre-adjustment and AUTO adjustment according to the following procedure.

1) Set to the TEST mode and perform AUTO pre-adjustment and AUTO adjustment.

2) Cancel the TEST mode by pressing the REC button. (Writing into EEPROM starts from here.)

3) Eject the disc by pressing the EJECT button.

4) Turn off the power.

9

Page 11

MDX-595

Description of TEST modes

1. AUTO pre-adjustment mode Automatic pre-adjustment is performed. (Grating adjustment mode after this adjustment.)

[ _ AUT _ YOBI _ ] Adjusted values are output by using the interface.

2. AUTO adjustment mode Automatic adjustment is performed.

[ AUTO _ AJST _ ] Adjusted values are output by using the interface.

Continuous reproduction is performed. (Error rate on display, jump test)

3. RESULT preparation mode Not used (Do not use this function as it is not for servicing)

[ _ RST _ YOBI _ ]

4. RESULT mode (main adjustment) Not used (Do not use this function as it is not for servicing)

[ _ RESULT _ _ _ ]

5. MANUAL pre-adjustment mode Not used (Do not use this function as it is not for servicing)

[ _ MNU _ YOBI _ ]

6. MANUAL adjustment mode Not used (Do not use this function as it is not for servicing)

[ _ MNU _ AJST _ ]

7. EEPROM setting mode Various factors of the digital servo function are changed manually.

[ EEPROM _ SET ] Each servo function is turned on independently.

The voltage is measured at the temperature detect terminal and the standard value is set.

8. TEST-PLAY mode Continuous reproduction from the specified address is performed.

[ TEST _ PLAY _ ] C1 error rate is measured and ADIP error rate is measured.

9. TEST-REC mode Continuous recording from the specified address is performed.

[ TEST _ REC _ _ ]

10. INNER mode The position where the INNER switch is turned ON is measured.

[ _ _ INNER _ _ _ ]

11. EJECT mode To TEMP setting (of EEPROM setting)

[ _ _ EJECT _ _ _ ] To CONTROL setting (of EEPROM setting)

Laser power setting (record/reproduction power) is performed.

MDX-595

1. AUTO pre-adjustment mode Low reflecting disc (MMD-318) only

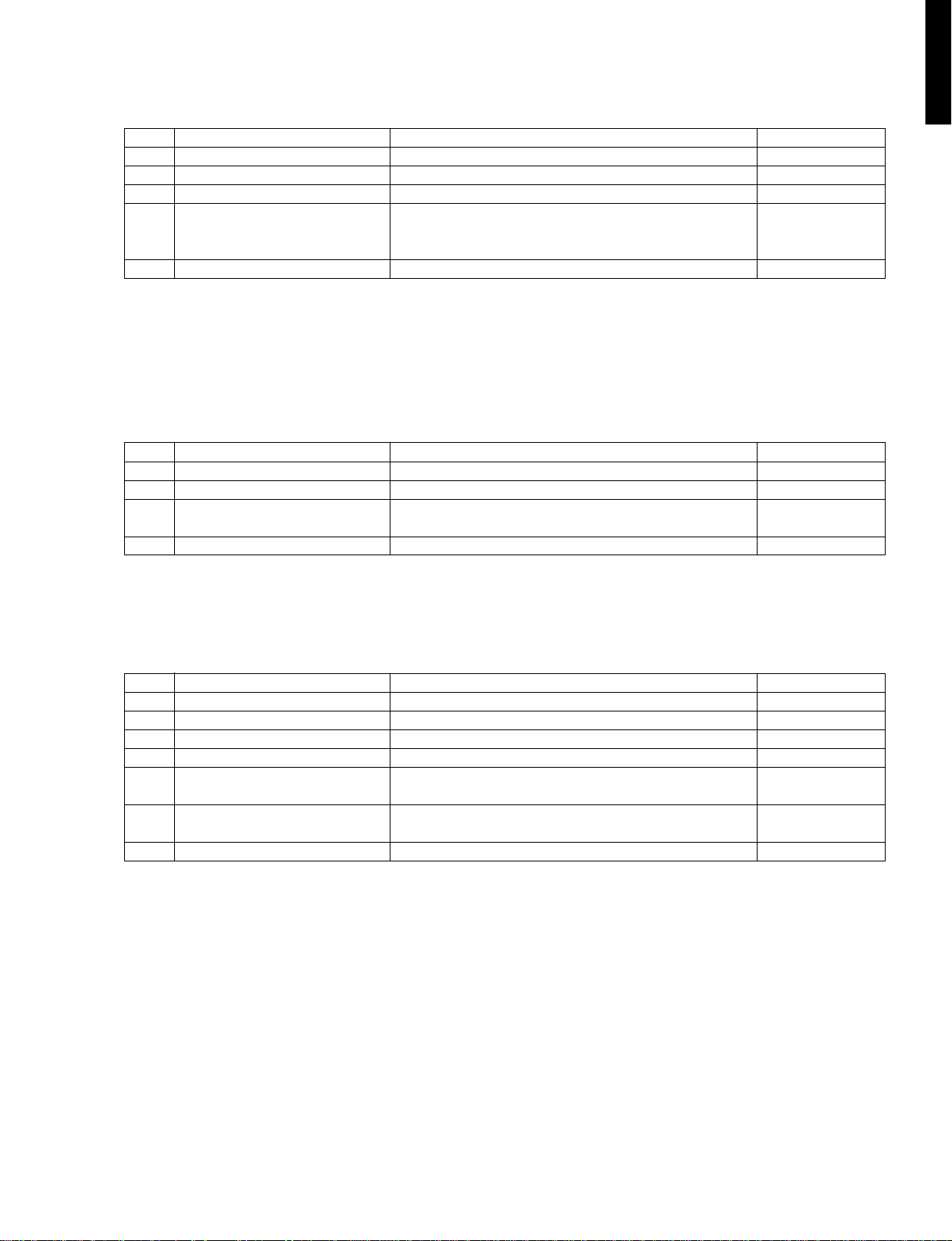

Step Setting method Remark Display

1

Set the Test mode to STOP.

2

Load a disc.

3

Press the SET/ENTER button once.

Grating adjustment is performed and

adjusted values are output.

Adjustment is completed.

4

When adjustment is OK, press the

DELETE/CANCEL button.

5

When adjustment is NG, press the

DELETE/CANCEL button.

No disc is loaded.

Auto pre-adjustment menu

Auto pre-adjustment is started after sliding to the innermost

track.

“ *** ” changes in the following order during automatic

adjustment.

HAo -> RFg -> SAg -> SBg -> PTG -> PCH -> GTG -> GCH ->

RCG -> SEG -> RFG -> SAG -> HAO -> HEO -> TCO -> LAO

Proceed to Step 4 when adjustment is OK.

Proceed to Step 5 when adjustment is NG.

The display returns to the AUTO pre-adjustment menu.

There is an abnormality at the adjusted point such as HAo.

Refer to “Troubleshooting”. (page 20)

[ EJECT ]

[ LOADING ]

[ _ AUT _ YOBI _ ]

[ *** : _ _ _ _ _ _ ]

[ _ COMPLETE _ ]

[ Can't _ ADJ. ]

[ _ AUT _ YOBI _ ]

[ Can't _ ADJ. ]

10

Page 12

MDX-595

2. AUTO adjustment mode

MDX-595

Step Setting method Remark Display

1

Set the TEST mode to STOP.

2

Load a disc.

Press the DISPLAY button once.

3

Press the SET/ENTER button once.

Adjusted values are output.

Adjustment is completed.

4

When adjustment is OK, press the

SET/ENTER button.

5

Press the INPUT button.

Press the DELETE/CANCEL button.

6

When adjustment is NG, press the

DELETE/CANCEL button.

No disc is loaded.

AUTO pre-adjustment menu

AUTO adjustment menu

Automatic pre-adjustment is started after sliding to the innermost

track.

“ *** ” changes in the following order when a high reflecting disc

(disc for reproduction) is used.

PEG -> HAG

“ *** ” changes in the following order when a low reflecting disc

(disc for recording) is used.

PEG -> LAG -> GCG -> GEG -> LAG

Proceed to Step 4 when adjustment is OK.

Proceed to Step 5 when adjustment is NG.

Continuous reproduction (bit section)

(Address + C1 error display)

Continuous reproduction (group section)

(Address + C1 error display)

Continuous reproduction (group section)

(Address + ADIP error display)

Display returns to the AUTO adjustment menu display.

There is an abnormality at the adjusted point such as PEG.

Refer to “Troubleshooting”. (page 20)

[ EJECT ]

[ LOADING ]

[ _ AUT _ YOBI _ ]

[ AUTO _ AJST _ ]

[ *** : _ _ _ _ _ _ ]

[ _ COMPLETE _ ]

[ Can't _ ADJ. ]

[ s XXXX c YYYY ]

[ a XXXX c YYYY ]

[ a XXXX a YYYY ]

[ AUTO _ AJST _ ]

[ Can't _ ADJ. ]

Note) *** : Adjustment name, XXXX: Address, YYYY: Measured value

8. TEST-PLAY mode

(Use this mode to check that the playback function is provided at the specified address.)

Step Setting method Remark Display

1

Load a disc.

2

Press the TITLE button.

3

Press the INPUT button.

Press the SET/ENTER button.

4

Continuous reproduction (bit section)

Continuous reproduction (group section)

5

Press the INPUT button.

Continuous reproduction (group section)

6

Press the DELETE/CANCEL button.

• Every time the TITLE button is pressed in the address setting mode, the address changes in the order of 0050-> 03C0 -> 0700 -> 08A0

-> 0050 -> —

• Pressing the DISPLAY button in the TEST-PLAY menu changes to the AUTO pre-adjustment menu.

AUTO pre-adjustment menu

TEST-PLAY menu

ADDRESS setting (The initial value of the target address is displayed.)

Set the search output to “H” while searching and back to “L” when

continuous reproduction is started.

(Address + C1 error display)

(Address + C1 error display)

(Address + ADIP error display)

TEST-PLAY menu

[ _ AUT _ YOBI _ ]

[ TEST _ PLAY _ ]

[ ADRES _ 0050 ]

[ s XXXX c YYYY ]

[ a XXXX c YYYY ]

[ a XXXX a YYYY ]

[ TEST _ PLAY _ ]

11

Page 13

MDX-595

9. TEST-REC mode

Use a disc for confirmation of recording function. (It is used to check the REC function at the specified address.)

Step Setting method Remark Display

1

Load a disc.

2

Press the TITLE button twice.

3

Press the SET/ENTER button.

4

Press the SET/ENTER button.

5

Press the DELETE/CANCEL button.

• Every time the TITLE button is pressed in the address setting mode, the address changes in the order of 0050-> 03C0 -> 0700 -> 08A0

-> 0050 -> —

• Pressing the DISPLAY button in the TEST-REC menu changes to the AUTO pre-adjustment menu.

AUTO pre-adjustment menu

TEST-REC menu

ADDRESS setting (The initial value of the address is displayed.)

Set the search output to “H” while searching and back to “L” when

continuous reproduction is started.

Continuous recording

TEST-REC menu

[ _ AUT _ YOBI _ ]

[ TEST _ REC _ _ ]

[ a0050 _ pw ZZ ]

[ a XXXX _ pw ZZ ]

[ TEST _ REC _ _ ]

10. INNER mode

Step Setting method Remark Display

1

Load a disc.

2

Press the CHARA. button.

3

Press the SET/ENTER button.

4

Press the DELETE/CANCEL button.

• Pressing the DISPLAY button in the INNER menu changes to the AUTO pre-adjustment menu.

AUTO pre-adjustment menu

INNER menu

INNER switch position is measured.

(Both SUBQ address and C1 error are displayed.)

INNER menu

[ _ AUT _ YOBI _ ]

[ _ _ INNER _ _ _ ]

[ s XXXX c YYYY ]

[ _ _ INNER _ _ _ ]

MDX-595

11. EJECT mode

Step Setting method Remark Display

1

EJECT status in the TEST mode

2

Press the INPUT button.

3

Press the INPUT button.

4

Press the INPUT button.

5

Press the TITLE edit button.

6

Press the CHARA. button.

7

Press the DELETE/CANCEL button.

EJECT menu (No disc is loaded.)

Maximum power output status

Recording power output status

Reproduction power output status

To TEMP setting of EEPROM setting

(Refer to TEMP setting of EEPROM.)

To CONTROL setting of EEPROM setting

(Refer to CONTROL setting of EEPROM.)

EJECT menu

[ _ _ EJECT _ _ _ ]

[ xpw _ _ _ _ _ _ _ ]

[ rpw _ _ _ _ _ _ _ ]

[ ppw _ _ _ _ _ _ _ ]

[ _ _ EJECT _ _ _ ]

● Confirmation of pick-up laser power

Recording and reproduction can be checked by using the laser power meter. However it should be used for checking only

because there is variation in its measurement.

When the measured value is excessively deviated from the reference value, replace the pick-up.

Reference value (measured at room temperature of 25 °C)

During reproduction (ppw) : 0.72 ± 0.1 mW

During recording : 5.5 ± 0.5 mW

Note : Be very careful when using the laser power meter. The laser beam would cause damage to your eye if exposed to it

directly.

12

Page 14

MDX-595

●

MDX-595

Lead-in switch position measurement mode

Load a TDYS1 disc for reproduction (high reflecting disc).

Note) Adjust the position of the lead-in switch to FF85 ~ FFD2.

1. Loosen 2 screws (A) fixing the mechanism switch P.C.B.

2. Retighten screws while pushing the mechanism switch P.C.B. in the arrow (<-) direction and then measure the

position of the lead-in switch again. After adjusting the position, tighten 2 screws (A) securely. (Fig.12)

Loosen 2 screws (A)

Note) Apply thread lock to 2 screws on the

P.C.B. after tightening them.

Lead-in switch

Mechanism SW P.C.B.

Fig.12

● Forced rotation of loading motor

It is possible to force the loading motor to rotate by turning the jog dial when the microprocessor version (tsm13**e**)

of the test mode or EJECT appears on display. (This is used when the disc cannot be ejected.)

* To obtain the microprocessor version on display When a disc is loaded, “ _ AUT _ YOBI _ ” appears on display. Press

the DELETE/CANCEL key in this state, and the microprocessor version will appear.

● Confirmation of magnetic head installation position

• After replacing the magnetic head and the optical pick-up, be

sure to confirm their installation positions.

• To facilitate adjustment of their installation positions, bring the

optical pick-up to the center position and follow the procedure

described below.

Objective lens

Magnetic head

Radial direction

Circumferentical direction

Push down with a finger.

1.Push down the up-shift arm of the magnetic head with a finger to

raise the magnetic head.

2.Looking at the unit from above, check if the magnetic head

matches with the optical pick-up objective lens.

3.Check to ensure that the magnetic head moves up and down

smoothly.

13

Magnetic head

Page 15

MDX-595

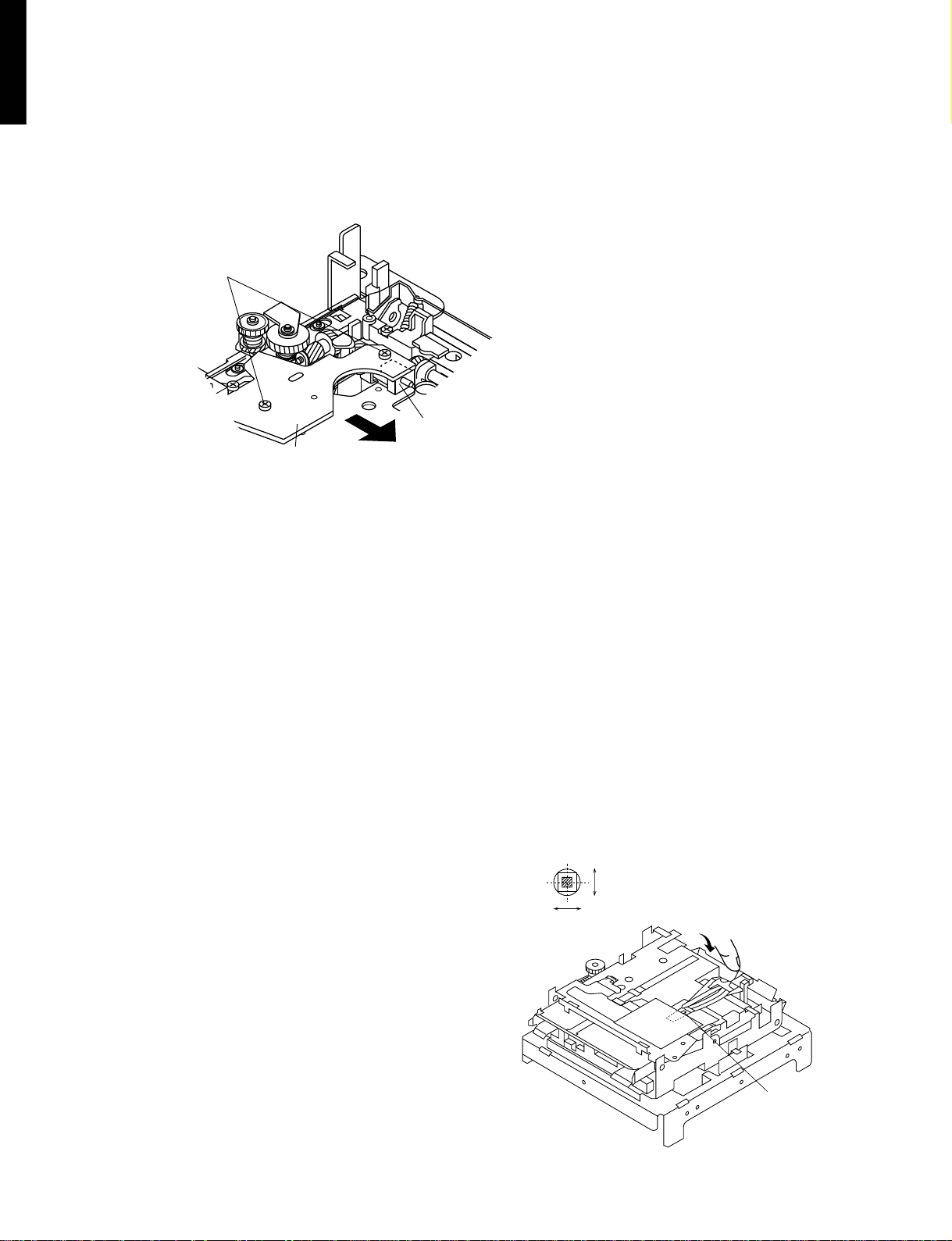

MECHANISM ADJUSTMENT

When making adjustment, be sure to connect an extension cable for servicing and an expansion P.C.B. as shown in

Fig.16.

1. Optical pickup rating inspection method

GND (TP1125)

IC1101 No.43 pin

EOUT (TP1129)

IC1101 No.26 pin

FOUT (TP1130)

IC1101 No.25 pin

(See page E41/J39)

(Externally attached)

100K

470p

470p

100K

Oscilloscope

GND CH1 CH2

XY

Lissajous waveform

a:b = Within 4:1

Fig. 13

a

b

Spindle motor

1

3

2

MDX-595

After performing automatic adjustment in the AUTO mode

selected from the test mode by using a high reflecting MD

disc (COMPLETE status on display), adjust the EOUT to

FOUT Lissajous waveform (x-y).

1. Loosen 3 screws of the spindle motor a little and make

adjustment while watching the Lissajous waveform.

2. After adjustment, tighten screws in the order of (q), (w)

and (e).

2. Jitter verification method

After performing automatic adjustment in the AUTO mode

selected from the test mode by using a low reflecting MD

disc, confirm the jitter in the pit continuous reproduction

mode and the groove continuous reproduction mode.

FFC for 5P extension

TX946190

Connector for 2P extension

TX946200

Adjustment hole

3

Spindle motor

1

2

IC1201 No.1 pin (TP1201)

EFMMON

GND

(TP1125)

(See page E41/J39)

From magnetic head

Adjustment hole

Fig. 14

Check the Lissajous waveform while adjusting the

installation position by using a

screwdriver in the adjustment

hole in the spindle motor.

Jitter meter

Fig. 15

CN1300(Rear face)

CN1602(Rear face)

CN1601(Rear face)

CN1603(Rear face)

CN1604(Rear face)

MD Main P.C.B.

Connector for 6P-2P extension

TX946210

CN1101

From motor

Mechanism

SW P.C.B.

FFC for 28P extension

TX946220

From optical pickup

Extension P.C.B. for servicing

(TX946230)

Install an Extension P.C.B. for servicing

to the mechanism.

Fig. 16

14

Page 16

PROCEDURE TO WRITE DATA INTO EE-PROM (IC1402)

1. Procedure to change the EE-PROM and write the

initial value of the microprocessor into EE-PROM

(1) Replace the EE-PROM.

(2) Refer to the latest “List of EE-PROM contents”.

(3) Press the POWER button while pressing the SET/

ENTER button and the PLAY/PAUSE button to start

the test mode.

(4) Version on display

Version of EEPROM protect data (from 01)

t s m 1 3 * * e * *

Version of microprocessor ROM (from 01)

(5) Load a disc.

[ AUT YOBI ]

(6) Press the DISPLAY button 6 times.

[ EEPROM SET ]

(7) Perform the procedure to have “EE-PROM setting

mode transition diagram” displayed, compare it with

“List of EE-PROM contents” and set to “List of EEPROM contents” by using the jog dial.

(8) Set the temperature standard value.

(Refer to “Procedure to set the temperature standard

value”.)

(9) Use the same settings as “List of EE-PROM con-

tents” for all.

10)Set to the TEST mode and perform AUTO pre-

adjustment and AUTO adjustment.

11)Cancel the TEST mode by pressing the REC button.

(Writing into EEPROM starts from here.)

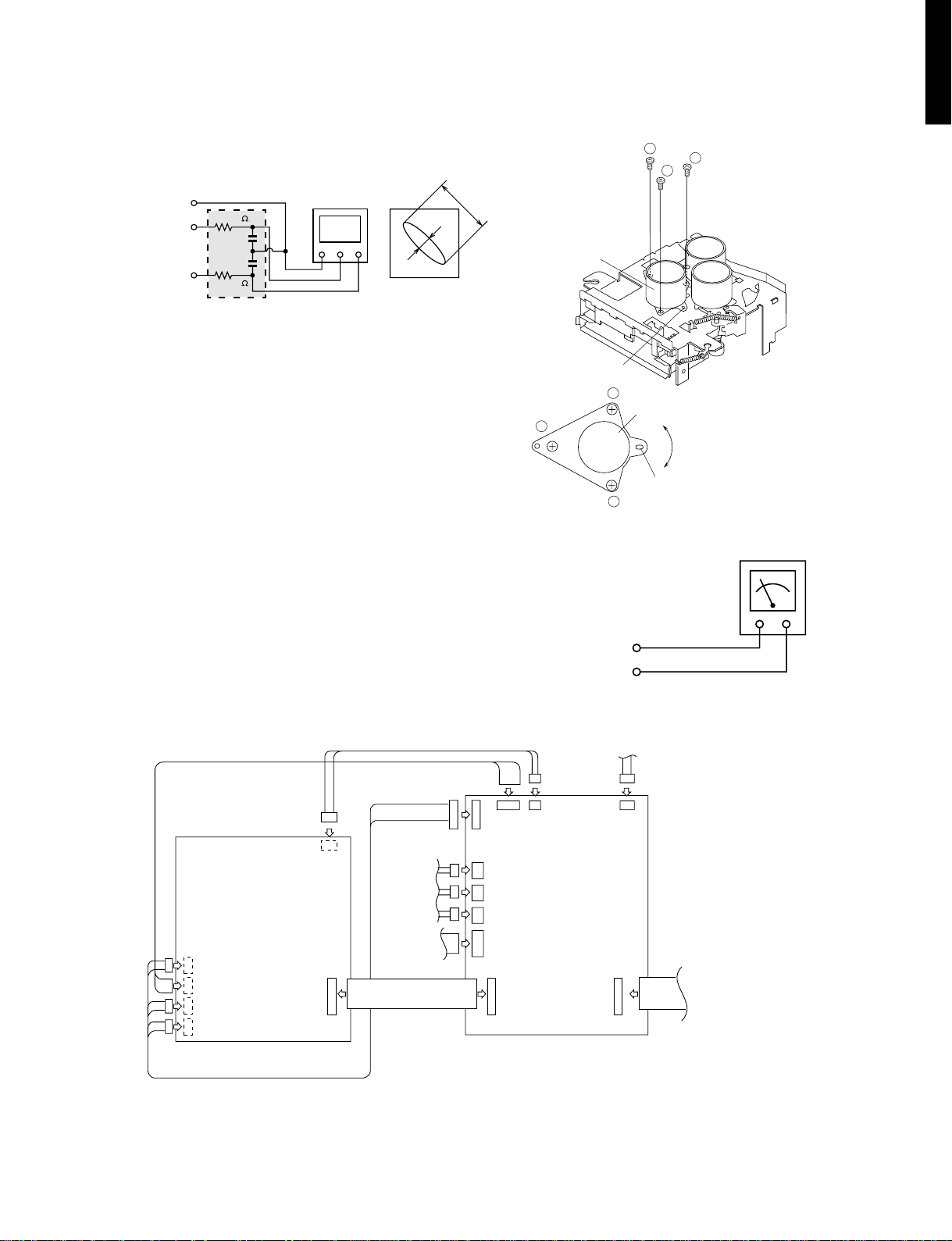

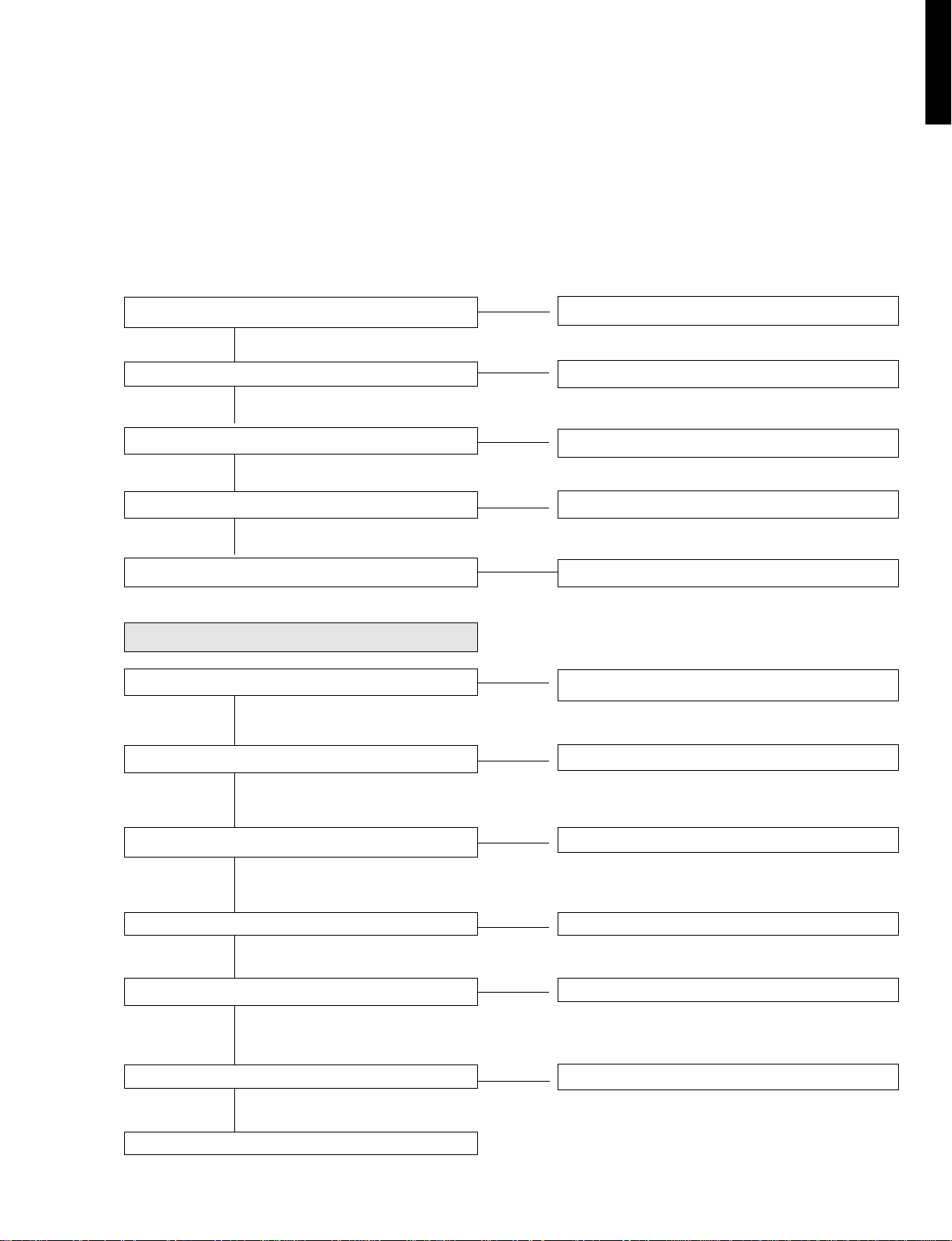

2. Procedure to set the temperature standard value

(This setting should be performed within the room

temperature range of 21 ˚C ~ 29 ˚C.)

(1) Have the AUTO pre-adjustment mode menu dis-

played.

[ AUT YOBI ]

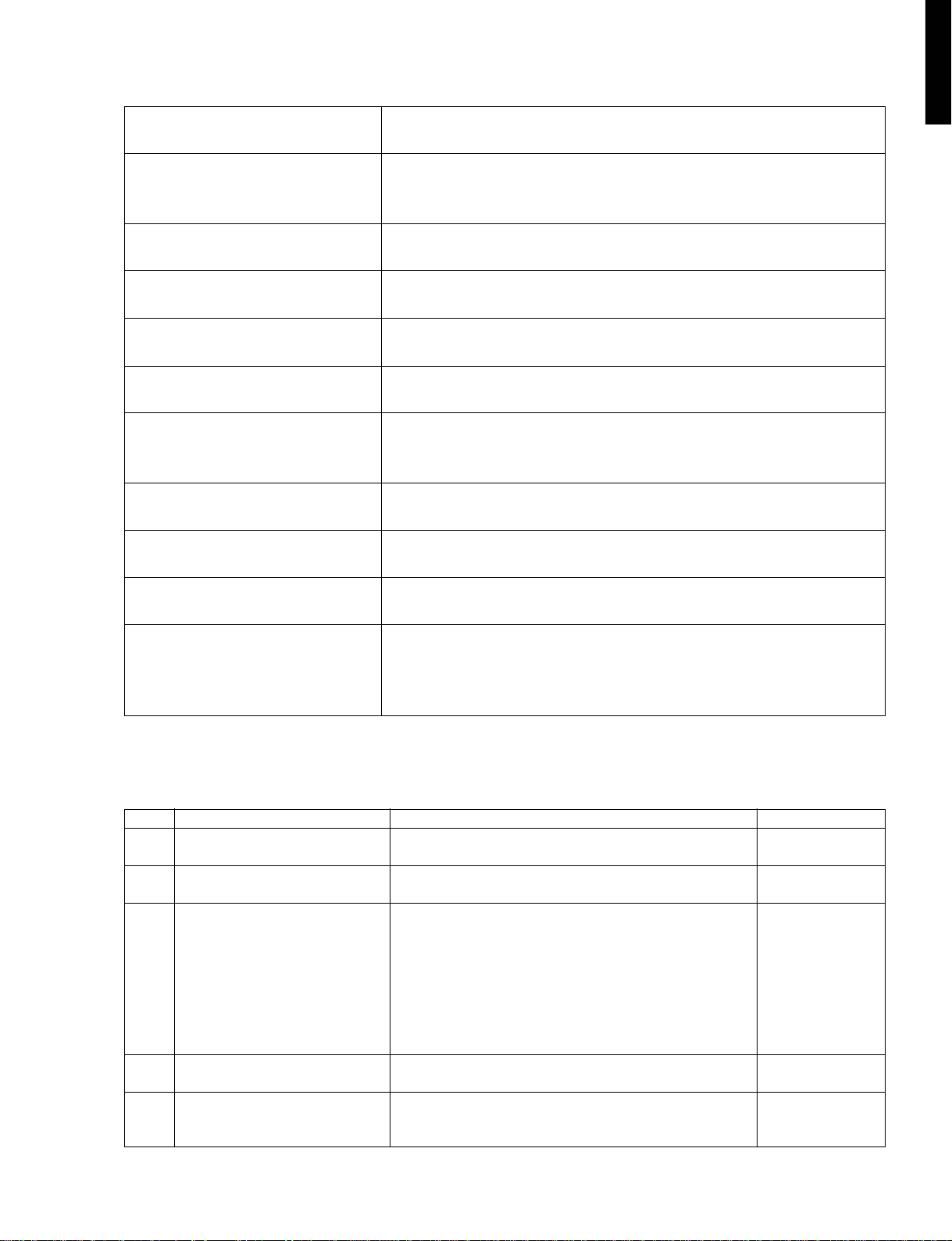

(2) Compensate the temperature to be suitable for the

ambient temperature, referring to the table below.

Ambient temperature Compensation value

˚C ~ + 23.2 ˚C

+ 21.0

+ 23.3

+ 26.9

˚C ~ + 26.8 ˚C

˚C ~ + 23.7 ˚C

– 01H

± 0H

+ 01H

Example : When the ambient temperature is 22 ˚C

and the temperature measured value is 7A

H

Temperature set value = 7AH – 01H

= 79H

* When the measured temperature deflects between 2

values, use the smaller one as the measured value

(79

H if measured values are 7AH and 79H).

(3) Press the DISPLAY button 6 times.

[ EEPROM SET ]

(4) Press the SET/ENTER button 7 times.

[ Focus ]

(5) Press the DISPLAY button 4 times.

[ Temp ]

(6) Press the SET/ENTER button.

[ TEMP ❍ ❍ ◆ ◆ ]

❍ ❍ : Temperature measured value

◆ ◆ : Temperature set value

(7) Adjust the temperature set value to the value ob-

tained as described above by using the jog dial.

(8) Press the DELETE/CANCEL button.

[ EEPROM SET ]

LIST OF EE-PROM CONTENTS

● Focus setting

Item on display Set value

FG ❍ ❍ DA H

FF1 ❍ ❍ 70 H

FF2 ❍ ❍ E0 H

FZHLEV ❍ ❍ ED H

FOKLEVn ❍ ❍ 08 H

FOKLEVf ❍ ❍ 08 H

FOKLPFn ❍ ❍ 00 H

FOKPFVf ❍ ❍ 88 H

WAITf ❍ ❍ 90 H

● Spin setting

Item on display Set value

SPG ❍ ❍ 20 H

SPG-in ❍ ❍ B8 H

SPG-mid ❍ ❍ 95 H

SPG-out ❍ ❍ 79 H

SP1 ❍ ❍ 10 H

SP2 ❍ ❍ 87 H

SP3 ❍ ❍ E3 H

SP4 ❍ ❍ E3 H

SP5 ❍ ❍ 10 H

SPDLIM ❍ ❍ 7F H

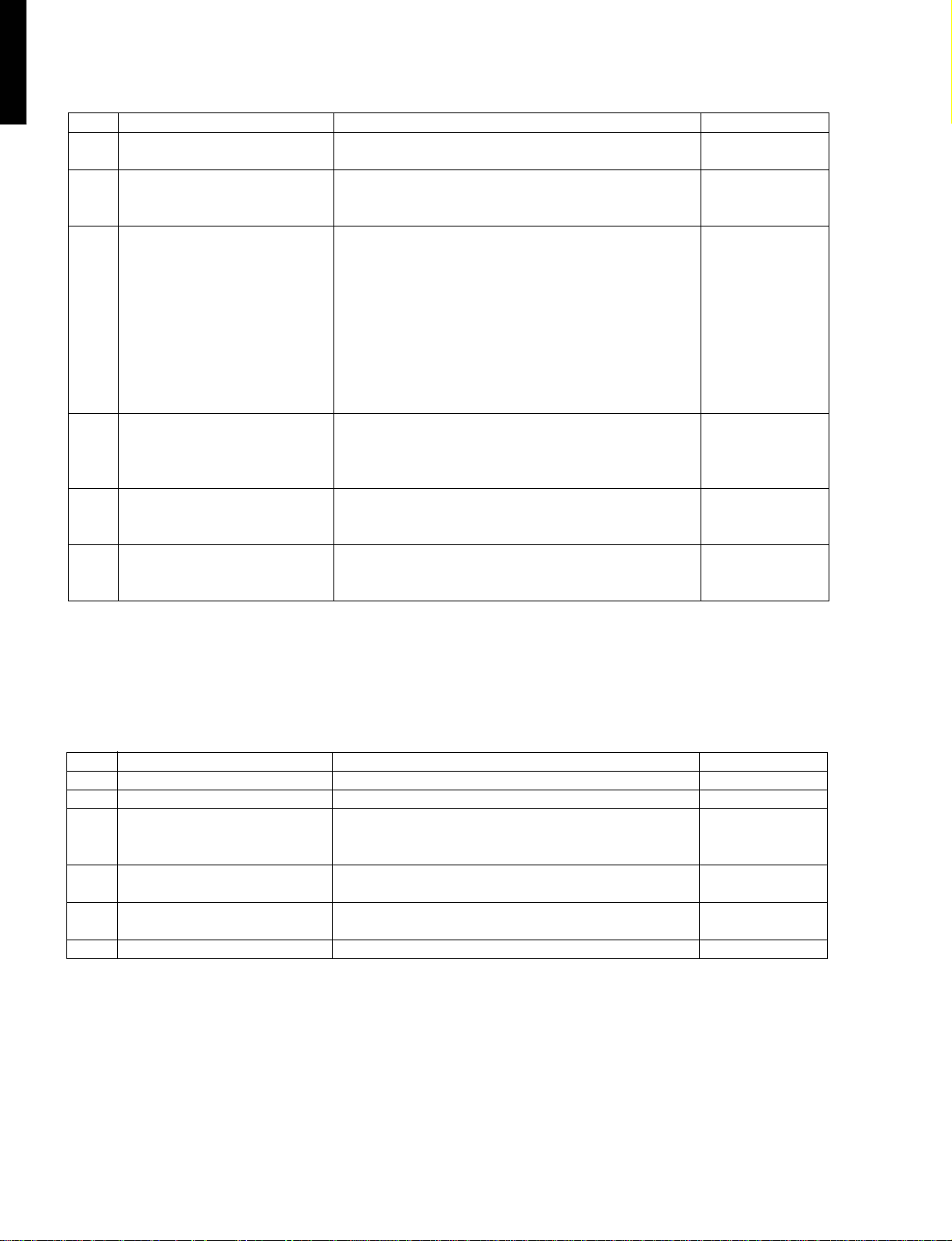

● Tracking setting

Item on display Set value

TG ❍ ❍ 6B H

TF1 ❍ ❍ 6B H

TF2 ❍ ❍ E0 H

SVCNT4 ❍ ❍ 00 H

TRBLVo ❍ ❍ 50 H

TRBLVt ❍ ❍ 54 H

TRkLVo ❍ ❍ 50 H

TRkLVt ❍ ❍ 2E H

TDPWo ❍ ❍ 89 H

TDPWt ❍ ❍ 1A H

SLCTo ❍ ❍ 00 H

SLCTt ❍ ❍ 40 H

SLCTm ❍ ❍ 53 H

TCRSCIP ❍ ❍ 16 H

COTLVP ❍ ❍ 0A H

COTLVr ❍ ❍ 1C H

WAITm ❍ ❍ FF H

15

Page 17

● Slide setting

Item on display Set value

SLG ❍ ❍ 3B H

SL2 ❍ ❍ 18 H

SLDLIM ❍ ❍ 7F H

SLDLEV ❍ ❍ 12 H

SLKLVk ❍ ❍ 50 H

SLKLVt ❍ ❍ 3A H

SLKLVm ❍ ❍ 50 H

● Adjust setting

Item on display Set value

COK ❍ ❍ A0 H

FAT ❍ ❍ C0 H

TAT ❍ ❍ 3E H

CAT ❍ ❍ 20 H

FAB ❍ ❍ 64 H

STR ❍ ❍ 0A H

SFS ❍ ❍ 0D H

STC ❍ ❍ 0D H

EE-PROM SETTING MODE TRANSITION DIAGRAM

● Control setting

Item on display Set value

CONTROL1 ❍ ❍ 80 H

CONTROL2 ❍ ❍ 02 H

SPKLEVm ❍ ❍ 26 H

ADJTTM ❍ ❍ 14 H

HDEQAD ❍ ❍ 92 H

LDEQAD ❍ ❍ 8F H

GDEQAD ❍ ❍ 8D H

HDEQBC ❍ ❍ 8C H

LDEQBC ❍ ❍ 8F H

GDEQBC ❍ ❍ 8D H

HALSG ❍ ❍ 21 H

LALSG ❍ ❍ 21 H

GALSG ❍ ❍ 11 H

HALSOFS ❍ ❍ FF H

LALSOFS ❍ ❍ 00 H

GALSOFS ❍ ❍ 00 H

Note) To return to the SUB MENU or MAIN MENU display of the test mode, press the DELETE/CANCEL button.

16

Page 18

MDX-595

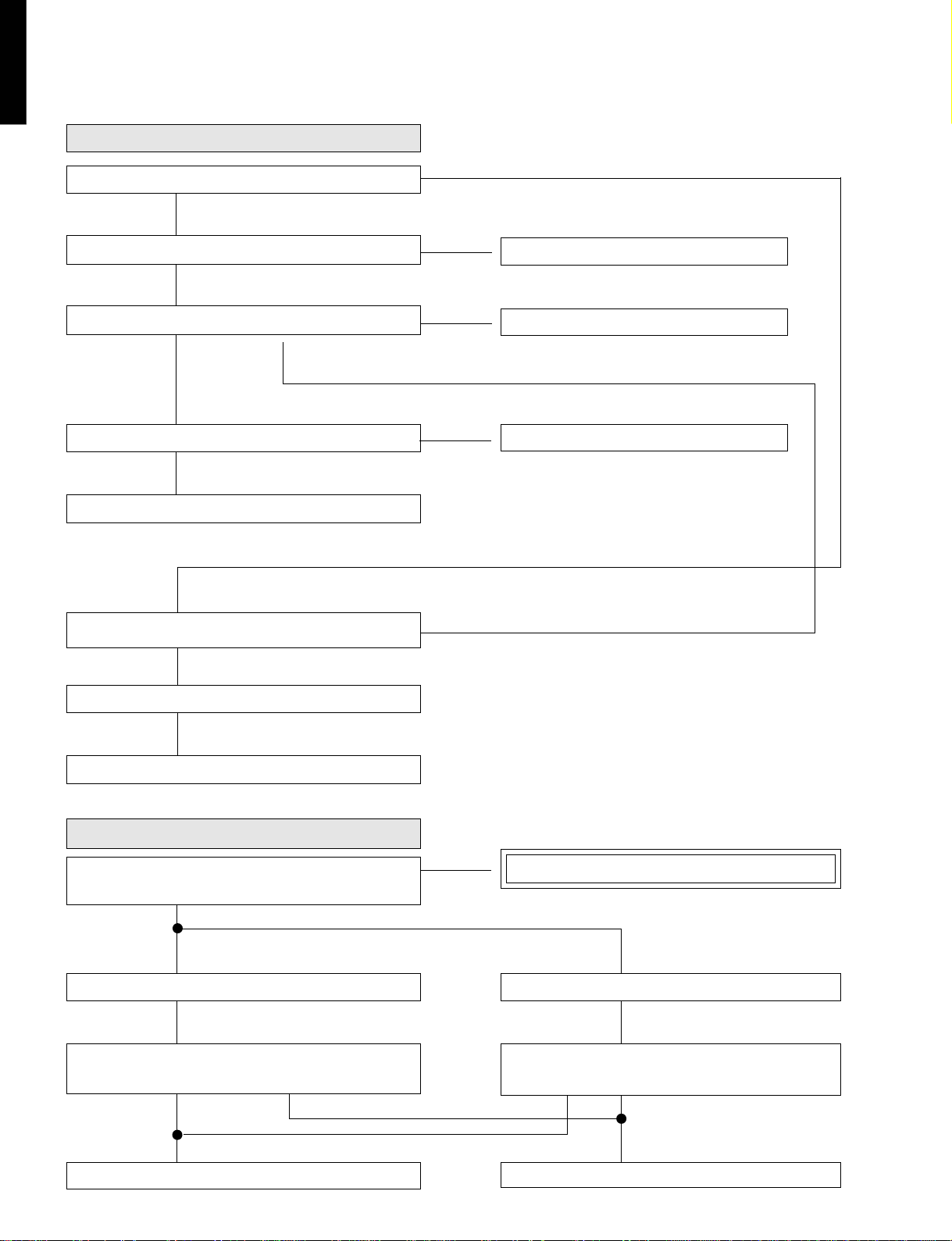

■ SPECIAL TEST MODE

MDX-595

● How to set to the special test mode

Press the POWER button while pressing the SET/ENTER button and the STOP button. Then all the indicators will light up.

● Operation procedure

Every time the SET/ENTER button is pressed, lighting of indicators and items on the display change as follows.

1) All indicators light up.

2) All indicators turn off.

3) Segments not sharing the border light up.

4) Above segments turn off and other segments light up.

5) The date when the software was entered appears on the display.

6) The version of the micro processor appears on the display. [ CPU Ver:TP01 ]

7) The time of auto-marking appears on the display. [ AM Time :C8h ]

8) The analog level of auto-marking appears on the display. [ AM Lv1_A:24h ]

9) The digital level of auto-marking appears on the display. [ AM Lv1_D:1Ah ]

10) Write/read check for EEPROM appears on the display [ EE W/R Check ]

When the INPUT button is pressed at this point, whether the micro processor executed data write/read function into

EEPROM or not is checked.

If [OK] appears on the display and the pin 6 of IC6 is at “H”, the check result is satisfactory.

[NG] is displayed when there is an error while writing or reading the data.

In such a case, check EEPROM (IC7).

● How to cancel the special mode

Press the STOP button, and the mode will change from the special test mode to the product mode and the data in RAM will

be cleared.

Note : Turning off the power will cancel the special test mode but will not clear the data in RAM.

Data to write in EEPROM (IC7) Initial settings

INPUT mode ANALOG

REPEAT mode OFF

RANDOM mode OFF

PROGRAM mode OFF

REC mode (STEREO/MONO) STEREO

AUTO MARK/MANUAL AUTO (“MANUAL” does not light up.)

DISPLAY mode DISC TITLE

17

Page 19

■ ERROR DISPLAY

Error on display Description Countermeasure

Can't REC

• DEFECT occurred 10 times continuously during REC-

PLAY.

• Recordable cluster became “0” due to occurrence of

DEFECT during REC-PLAY.

• REC mode cannot be set for 20 seconds even after

repeated try of reading the read disabled address.

• Check that the disc is free from scratch, dust,

finger print, black spot, etc. and that

decentering, face deflection, etc. are not

excessive.

MDX-595

MDX-793

MDX-595

Can't Copy

DIGin Unlock

TOC Full

UTOC ERR R

• One of the following judgments has been made

depending on the channel status of the digital signal

inputted from D-IN during REC-PAUSE or REC-PLAY.

(1) Other than audio

(2) Other than civil purpose

(3) Copy NG due to reversed COPY bit of CD

• Either of the following symptoms occurred for the digital

signal inputted from D-IN during REC-PAUSE or REC-

PLAY.

(1) Digital IN PLL is unlocked.

(2) Locked under conditions other than FS=44.1kHz.

• No space is left to register music No and character data

(song name, disc name, etc.) while the REC-PLAY

function is used.

• No recordable space is left when trying to activate the

REC-PAUSE function.

• “FTNO > LTNO” occurred.

• “FTNO = 0 or 1” occurred.

• UTOC recorded in the disc could not be read.

• Check if the CD is a copy inhibited on (e.g., CD-

R, etc.)

• Check that the D-IN signal line is free from

abnormality.

• Use a disc for recording and reproduction with a

space left to register UTOC.

• As an abnormality exists in the UTOC data, use

another disc.

UTOC ERR A

UTOC ERR L0 ~ 4

Not Audio

Disc Full

Playback MD

Protected

• “Start address > end address” occurred.

• Any one of the UTOC0 ~ 4 data was looped.

• Data not for audio purpose is recorded in the track mode

of TNO which is currently selected.

• No recordable space is left when trying to activate the

REC-PAUSE function.

• The loaded disc was for reproduction only when trying to

activate the REC-PAUSE function or trying to edit.

• Recording of editing was attempted while the data

protector of the disc for recording and reproduction is

set to the data protected state.

• Editing the track subject to write protect function was

attempted by using the data written in UTOC.

• Select another TNO or use another disc.

• Use another disc for recording with a recordable

space left.

• As the loaded disc is for reproduction only, use

a disc for recording.

• Try again with the data protector set to the

original position.

• As the track to be edited is write protected, try

again with another track.

18

Page 20

MDX-595

MDX-595

Can' t Edit

Error on display Description Countermeasure

• Editing conditions were not satisfied with respect to

each editing function.

• Wrong operation procedure was used. Try

again by using the correct procedure.

TMP Over!!

DISC ERR R

DISC ERR S

DISC ERR W

TOC ERR S

TOC ERR R

U TOC W ERR

FOCUS ERR

BLANK DISC

• The temperature in the set (MD unit) went up exces-

sively high due to occurrence of some abnormality.

• The data was not correct or it was not possible to read it

correctly.

• Recording the music data failed as an abnormality

occurred while recording it.

• The TOC data was not correct.

• It was not possible to read the TOC data.

• It was not possible to rewrite UTOC correctly and an

abnormality occurred while rewriting it.

• The disc was loaded but it was not possible to draw in

FOCUS.

• The total number of TNO and NAME characters was “0”

as a result of reading UTOC.

• Check according to troubleshooting.

• Check the temperature of the area where the

unit is used.

• Use another disc as there is an abnormality in

TOC or UTOC data or the disc has a scratch or

other faulty condition.

• The TOC data recorded in the disc is not in

compliance with the MD standard.

• Use another disc as the disc has a scratch or

other faulty condition.

• Use another disc as the disc has a scratch or

other faulty condition.

• Check that the disc is free from scratch, dust,

finger print, black spot, etc. and that

decentering, face deflection, etc. are not

excessive.

• Check if the disc is recordable by actually

recording.

TOC W ERROR

EEPROM ERROR

• UTOC can be read but cannot be rewritten.

• The EEPROM data is not correct

Mechanism Error

Error on display Description

MECHA_ERR2_* The head fails to move up.

MECHA_ERR3_* The head fails to move down.

HINF (IC1401 No.97 pin)

* = E Eject completed position < 1.3 V

* = M Horizontal midway position > 3.06 V

* = L Load completed position 1.853 ~ 2.48 V

* = D Head down position 1.3 ~ 1.853 V

• Check if the recording head contacts properly

and if wiring from the circuit board to the

recording head is free from breakage.

• Try again after resetting and if still NG, replace

EEPROM.

19

Page 21

MDX-595

■ TROUBLESHOOTING

When MD fails to operate

When the objective lens of the optical pickup becomes dirty, MD may fail to operate. Clean the objective lens first and

check MD for reproduction function. If it still fails to operate, check according to the following flow charts.

Contaminant on the pickup lens such as dust and a foreign matter may cause the pickup to skip or the TOC (content of the

selection) not to be displayed. Check if the lens is clean before making adjustments. If the lens is dirty, clean it as follows.

● Turn off the power. Dampen the lens cleaning paper with a small amount of isopropyl alcohol and wipe the lens with it,

using care not to cause any damage to the lens. Be sure not to touch the lens with your hand directly.

MDX-595

Does the power turn on when the POWER button of the main unit is pressed?

YES

▼

Does the disc loading function work properly?

YES

▼

Is the play mode available when the PLAY/PAUSE button is pressed?

YES

▼

Is appropriate audio output provided?

YES

▼

Does recording/reproduction function work properly? Check the trouble item “Recording/reproduction function”.

Power fails to turn on.

Does the unit operate properly when its STOP button of is pressed?

NO

▼

Is +5V ~ +6V voltage applied to No.17 and 18 pins of CN1501?

NO

NO

NO

NO

NO

YES

NO

▲

Check the trouble item “Power fails to turn on”.

▲

Check the trouble item “Disc cannot be loaded properly.”.

▲

Check the trouble item “Play mode is not available.”.

▲ ▲

Check the trouble item “Audio reproduction circuit”.

▲

Check the display section.

Check the power supply section and CN1501.

YES

Is a pulse applied to No.6 pin of CN1501 when the reset power is turned on?

▼

YES

▼

Is the voltage at No.62 pin of IC1401 +3.2V? Check IC1401.

NO

▼

Is a 8.4672MHz pulse applied to No.15 pin of IC1401? Check IC1201.

YES

▼

Is a pulse output from No.34 pin of IC1401? Check IC1401.

YES

NO

YES

NO

NO

▲▲

Check IC6 and CN1501.

▲

▲

▲

▼

Check CN1501 and IC6.

20

Page 22

MDX-595

MDX-595

Disc cannot be loaded properly.

Does the loading function work properly when a disc is inserted?

NO

▼

Does No.4 pin of CN1901 become “L”?

YES

▼

Does a change occur at either No.1 or 28 pin of IC1601?

YES

▼

▼

Does a change occur at either No.9 or 10 pin of IC1601?

YES

▼

Check M1953 and CN1604.

YES

▼

Does eject function work when the MD eject button is pressed?

YES

NO

NO

NO

NO

▲ ▲

Check CN1901 and SW1956.

Check IC1401.

▲

Check CN1604 and IC1601.

YES

▼

Is the disc drawn in again immediately after it is ejected?

YES

▼

Check CN1901 and SW1956.

Play mode is not available.

Is the play mode unavailable with either high reflecting disc

or low reflecting disc?

NO

▼

Is the play mode unavailable only with the high reflecting disc?

YES

▼

Is the voltage at No.93 pin of IC1401 1.02 ± 0.3V in the test

mode state with a high reflecting disc loaded?

NO

YES

▼

▼

After readjustment, proceed to the check item “Normal reproduction”.

YES

▲

Proceed to the check item “Checking by using the test mode”.

NO

▼

The play mode unavailable only with the low reflecting disc.

YES

▼

Is the voltage at No.93 pin of IC1401 with a low reflecting disc loaded

3.2V ± 0.3V (recordable) or 2.06V ± 0.3V (recording inhibited)?

▼

YES

NO

▼

Check SW1952A/B, mechanical unit switch circuit board and CN1901.

21

Page 23

Normal reproduction

Applicable when the E2-PROM value has been confirmed as normal in the test mode

MDX-595

MDX-595

Is initialization done properly for reproduction of a high reflecting disc?

YES

NO

▼

Is the disc turning properly?

NO

YES

▼

Is reading function attempted repeatedly to read the TOC section of

the low reflecting disc?

NO

YES

▼

Check the position of the lead-in switch by selecting the lead-in

switch position measurement mode from the adjustment items for

the high reflecting disc.

▲

Does the play time display count up properly?

NO

▼

Check IC1201.

▲

Does the lead-in switch turn on with the pickup at the

innermost track in the test mode?

(Is No.6 pin of IC1401 at “L”?)

NO

▼

Check SW1953, soldered points in the mechanical switch

circuit board and around No.1 pin of CNP1901.

▲

A new disc has no recording in the TOC section.

Replace it with a recorded low reflecting disc.

Audio reproduction circuit

Applicable when no sound is produced although the play time display counts up properly during reproduction in the normal mode

Is the audio output waveform obtained at No.24 and 26 pins of IC1701?

NO

YES

▼

Is the audio output waveform obtained at No.1 and 7 pins of IC7?

NO

▲

Check No.70 ~ 72, 74 pins of IC1201 and No.12, 16,

17, 19 pins of IC1701.

▲

Check IC7.

YES

▼

Check the muting section of IC6.

22

Page 24

MDX-595

MDX-595

Recording/reproduction function

Load a low reflection disc and after confirming the audio output in the normal reproduction mode, execute recording/reproduction.

Does the recording function fail from the starting address?

Is an RF waveform available at No.1 pin of PT1201 or IC1201

during reproduction after recording?

Does the level of No.3, 26 and 39 pins of IC1401 and No.9 and 19 pins of

CN1101 change between during recording and during reproduction?

Is an RF pattern provided at No.50 pin of IC1201?

▼

▼

▼

YES

NO

YES

NO

YES

NO

NO

▲

Check that the disc is not in the recording inhibited status.

▲

Check around IC1401 and CN1101.

▲

Check IC1201 for proper soldering.

YES

▼

Check IC1300, Q1300 ~ 1303 and CN1300.

▼

I

s an output waveform available at No. 1 and 7 pins of IC4 and No. 1

and 7 pins of IC5 while recording the LINE input in the normal mode?

YES

▼

Is an input waveform applied to No.3 and 5 pins of IC1701?

YES

▼

Check between CN1701 and No.70 ~ 73 pins of IC1201.

Focus servo function does not work.

Is a correct waveform provided at No.27 and 28 pins of IC1101

during the focus gain rough adjustment step in the test mode?

YES

▼

Has No.81 pin of IC120 fall from “H” to “L”? Is a pulse

waveform provided at No.82 pin of IC1201?

YES

▼

Does the pulse waveform duty of No.18 and 19 pins of IC1201 change?

YES

▼

Does the waveform change at No.15, 16, 26, 27 pins of IC1601?

NO

NO

NO

NO

NO

NO

▲

Check around IC4 and IC5 and also check the REC

LEVEL volume.

▲

Check around IC1701 and CN1501.

▲

Check the waveform and soldering of No.9 and 10 pins of

IC1101.

▲ ▲

Check the waveform and soldering of No.8 and 9 pins of

IC1201.

▲

Check soldering and parts of IC1201

Check soldering and parts of IC1601.

YES

▼

Does the waveform change at No.2 and 4 pins of CN1101?

YES

▼

OK

23

NO

▲

Check CN1101 and the pickup.

Page 25

Disc motor does not run.

Is a correct waveform provided at No.24 and 25 pins of IC1201

during the focus gain rough adjustment step in the test mode?

YES

▼

Is a waveform provided at No.11 and 12 pins of IC1601 as

well as at No.1 and 2 pins of CN1603?

YES

▼

Replace the disc motor as a complete unit.

Tracking servo function does not work.

Is a correct waveform provided at No.17 and 18 pins of IC1601

well as at No.1 and 3 pins of CN1101

adjustment step in the test mode?

during the tracking gain

as

NO

NO

NO

MDX-595

▲

Check No.24 and 25 pins of IC1201 as well as soldering

and parts of the peripheral circuit.

▲

Check the circuit boards of IC1601 and the complete disc

motor of CN1601 for soldering.

▲

Check No.20 and 21 pins of IC1201, IC1601 and CN1101

for soldering.

MDX-595

YES

▼

Replace the pickup head

Slide servo function does not work.

Does the pickup move outward and inward when the R and

E button is pressed respectively in the test mode?

NO

NO

▼

Does a change occur at No.22 and 23 pins of IC1201 when

R and E buttons are pressed?

NO

YES

▼

Does a change occur at No.13 and 14 pins of IC1601 and No.1 and

2 pins of CN1602 when the R and E buttons are pressed?

NO

YES

▼

Does a voltage change occur at the + and - terminals of the

slide motor when the R and E buttons are pressed?

NO

▲

Check the waveform at No.22 and 23 pins of IC1201,

peripheral parts and soldering.

▲

Check the waveform at No.22 and 23 pins of IC1201,

peripheral parts and soldering.

▲

Check IC1601 and 1602 for soldering.

▲

Check the connection section to the slide motor for

soldering and broken wire.

YES

▼

Replace the slide motor.

24

Page 26

MDX-595

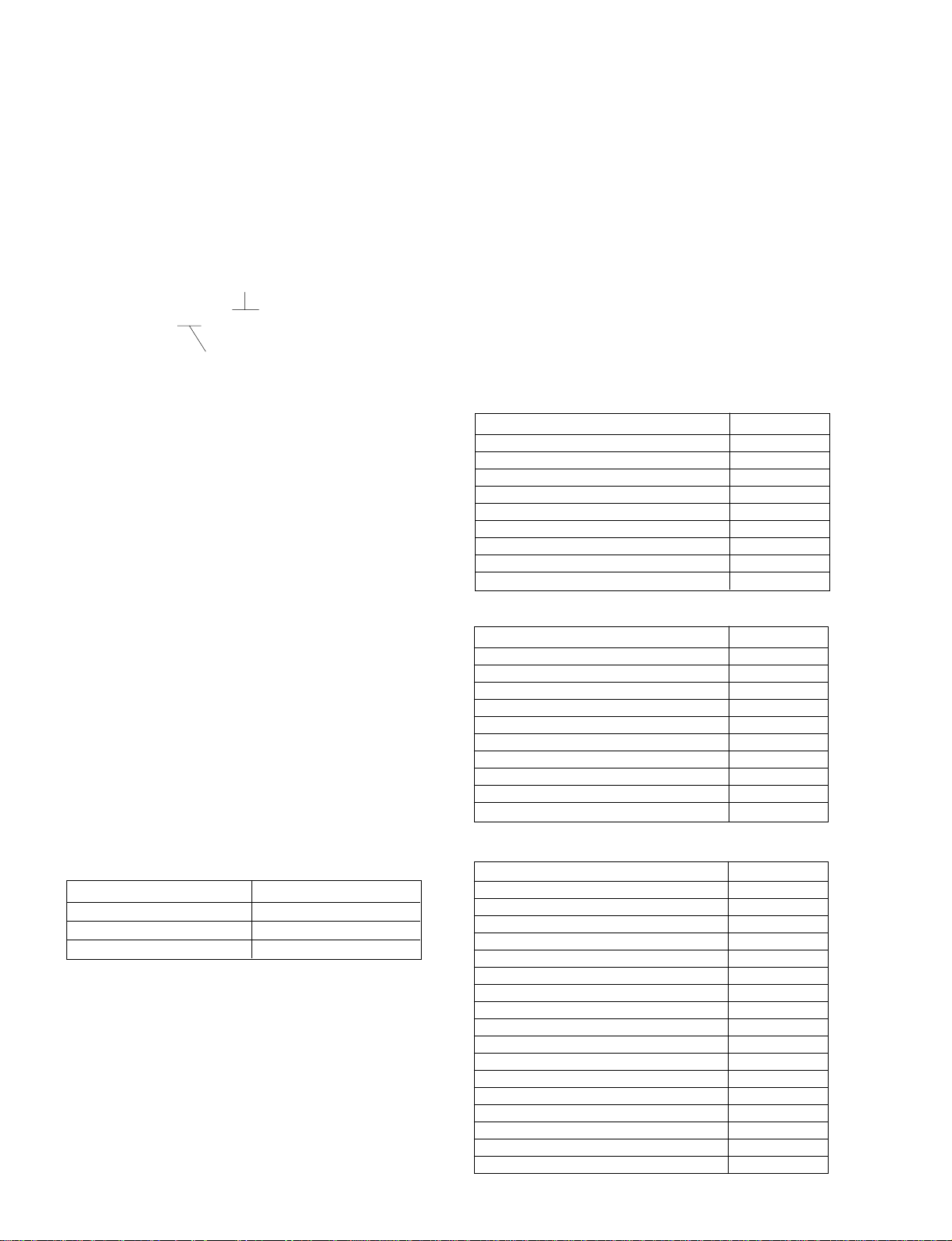

■ IC DATA

MDX-595

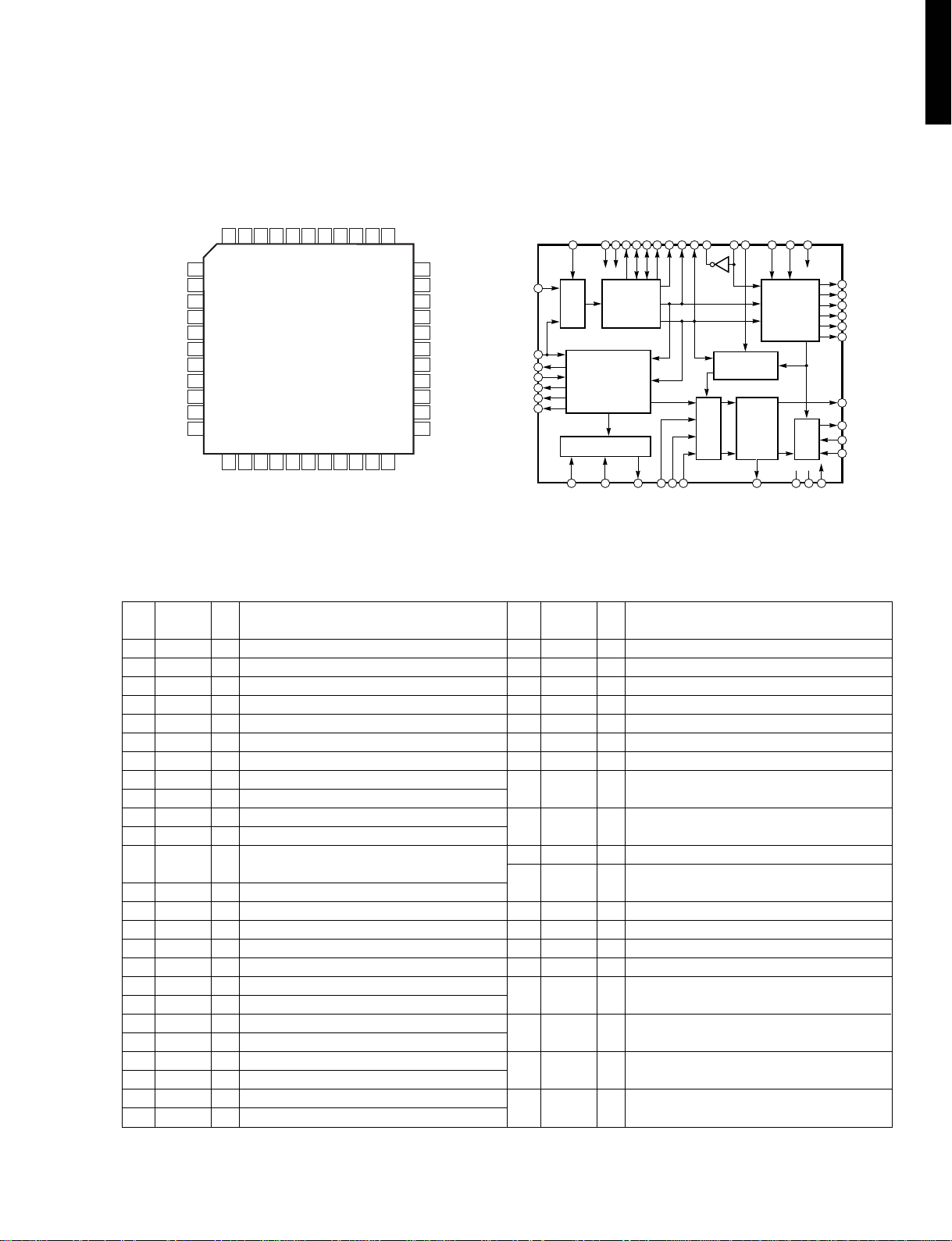

IC1101 : IR3R55

RF Signal Processing

25

POUT

GOUT

ATTR

EFMAGI

EFMAGC

AGND

AVCC

EFMI

EFMO

RF2-1

ADAGI

CLOCK

DATA

ADAGC

36

35

34

33

32

31

30

29

28

27

26

25

DVCC

ADIPI

ADIPO

NC

ADLPFO

22KO

22KI

WBO

TCGO

AOUT

BOUT

EOUT

FOUT

No. Pin Name

1 RF1

2 RF2

3 RF3

4 RF4

5 REFI

6 REFO

7 RFADD

8 TCGI

9 AIN

10 BIN

11 EIN

12 FIN

13 BIAS

14 AVCC

15* VSTBY

16* XDISC

17* XSGAIN

18 AGND

19 DGND

20 DTEMP

21 LATCH

22 CLOCK

23 DATA

24 DVCC

25 FOUT

26 EOUT

27 BOUT

28 AOUT

29 TCGO

30 WBO

31 22KI

32 22KO

33* ADLPFO

34* NC

35 ADIPO

36 ADIPI

37 ADAGC

38 ADAGI

39 RF2-1

40 EFMO

41* EFMI

42 AVCC

43 AGND

44 EFMAGC

45 EFMAGI

46* ATTR

47 GOUT

48 POUT

48 47 46 45 44 43 42 41 40 39 38 37

RF1

RF2

RF3

RF4

REFI

REFO

RFADD

TCGI

1

2

3

4

5

6

7

8

9

AIN

10

BIN

11

EIN

12

FIN

13 14 15 16 17 18 19 20 21 22 23 24

EFM

AGC

DIFF

DIFF

RESISTOR & SW

BIAS

BAIS

AVCC

XSTBY

XDISC

XSGAIN

ADIP

AGC

LPF

LOGIC

AGND

DGND

DTEMP

HPF

LATCH

Function

RF signal input terminal 1 to input RF signal output from pickup

RF signal input terminal 2 to input RF signal output from pickup

RF signal input terminal 3 to input RF signal output from pickup

RF signal input terminal 4 to input RF signal output from pickup

Amplifier input terminal for reference voltage

Amplifier output terminal for reference voltage

Output terminal for added resistance of RF1 ~ 4

Amplifier input terminal for track cross detect signal when in groove section

Amplifier (focus servo system) reverse input terminal for servo signal

Amplifier (focus servo system) reverse input terminal for servo signal

Amplifier (tracking servo system) reverse input terminal for servo signal

Amplifier (tracking servo system) reverse input terminal for servo signal

Bias input terminal

Power supply terminal for analog section

Output terminal for logic signal (Inverse STBY signal is output.)

Output terminal for logic signal (Inverse DISC signal is output.)

Output terminal for logic signal (Inverse SGAIN signal is output.)

Ground terminal for analog section

Ground terminal for digital section

Chip temperature detect terminal

Input terminal for latch signal

Input terminal for clock signal

Input terminal for serial data

Power supply terminal for digital section

Amplifier (tracking servo system) output terminal for servo signal

Amplifier (tracking servo system) output terminal for servo signal

Amplifier (focus servo system) output terminal for servo signal

Amplifier (focus servo system) output terminal for servo signal

Amplifier output terminal for track cross detect signal when in groove section

Comparator output terminal to make ADIP signal into binary value

Comparator input terminal to make ADIP signal into binary value

HPF amplifier output terminal for ADIP signal

LPF amplifier output terminal for ADIP signal

NC

Pre-amplifier output terminal for ADIP signal

AGC amplifier output terminal for ADIP signal

AGC smooth capacitor connecting terminal for ADIP signal

AGC amplifier input terminal for ADIP signal

RF1, RF2 differential signal

Pre-amplifier output terminal for RF signal

AGC amplifier output terminal for RF signal

Power supply terminal for analog section

Ground terminal for analog section

AGC smooth capacitor connecting terminal for EFM signal

AGC amplifier input terminal for EFM signal

Terminal to attenuate 47, 48 pin output signal

Output terminal for RF1+RF2-RF3-RF4 signal when in groove section

Output terminal for added resistance of RF1 ~ 4 when in pit section

The * marked terminal is a terminal which is not connected externally (open terminal).

Page 27

IC1201 : LR376484

ATRAC Encoder/Decoder

TOTMON

TEMON

SBCK

SBO

SBSY

SFSY

FOK

SENSE

COUT

MCCK

DINTX

VDD1

DGND

RSTX

SYD0

SYD1

SYD2

SYD3

SYD4

SYD5

SYD6

SYD7

SYWRX

SYRDX

SYRS

FEMON

DADATA

ADDATA

DFCK

BCLK

LRCK

DGND

VDD3

DOUT

DINXOXI

DGND

VDD1

7574737271706968676665646362616059 5857565554535251

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

VPO

LR376484

VXI

CDBCLK

CDLRCK

CDDATA

TEST4

TEST3

TESO1

EXPORT1

EXPORT0

X700KO

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

EFMO

PLCK

ACRCER

TCRS

RAD0

RAD1

RAWEX

RARASX

RAA9

RAD3

RAD2

RACASX

DGND

RAOEX

RAA8

RAA7

RAA6

RAA5

RAA4

VDD2

RAA10

RAA0

RAA1

RAA2

RAA3

MDX-595

MDX-595

1 2 3 4 5 6 7 8 9 10111213141516 1718192021222324 25

FIN

AIN

EIN

BIN

WBI

TCG

EFMI

AVCC

EFMMON

AGND

VBAT

VDD1

DGND

TEST0

TEST1

TEST2

X176KO

No. Pin Name I/O

1* EFMMON O

2 AVCC

3 EFMI I

4 AGND

5 AIN I

6 EIN I

7 TCG I

8 BIN I

9 FIN I

10 VBAT I

11 WBI I

12 VDD1

13 DGND

14,15 TEST0,TEST1 I

16 TEST2 I

EFM monitor output

Power supply terminal for analog section

Input terminal for EFM signal from RF amplifier

Ground terminal for analog section

Focus error signal A

Tracking error signal E

Tracking cross signal

Focus error signal B

Tracking error signal F

Power supply voltage detect signal for constant voltage servo

ADIP wobble signal

Power supply terminal for digital section

Digital ground terminal

Test input terminal, connected to GND when in normal use

Test input terminal, to select encode/decode/servo mode or ATRAC mode.

Connected to GND in normal use

17 X176KO O

18 FODRF O

19 FODRR O

20 TRDRF O

21 TRDRR O

22 SLDRF O

23 SLDRR O

24 SPDRF O

25 SPDRR O

26 RAA3 O

27 RAA2 O

28 RAA1 O

29 RAA0 O

30* RAA10 O

31 VDD2

32 RAA4 O

33 RAA5 O

34 RAA6 O

Clock output. f=176.4KHz (4fs)

Focus servo forward output. PWM

Focus servo reverse output. PWM

Tracking servo forward output. PWM

Tracking servo reverse output. PWM

Slide servo forward output. PWM

Slide servo reverse output. PWM

Spindle servo forward output or spindle serve output. PWM

Spindle servo reverse output or switching of spindle rotation forward/reverse

Address output to external D-RAM. ADR3

Address output to external D-RAM. ADR2

Address output to external D-RAM. ADR1

Address output to external D-RAM. ADR0 (LSB)

Address output to external D-RAM. ADR10 (MSB)

Power supply terminal for DRAM interface

Address output to external D-RAM. ADR4

Address output to external D-RAM. ADR5

Address output to external D-RAM. ADR6

The * marked terminal is a terminal which is not connected externally (open terminal).

FODRF

FODRR

Function

TRDRF

TRDRR

SLDRF

SLDRR

SPDRF

SPDRR

26

Page 28

MDX-595

IC1201 : LR376484

MDX-595

ATRAC Encoder/Decoder

No. Pin Name I/O

35 RAA7 O

36 RAA8 O

37 RAOEX O

38 DGND

39 RACASX O

40 RAD2 I/O

41 RAD3 I/O

42 RAA9 O

43 RARASX O

44 RAWEX O

45 RAD1 I/O

46 RAD0 I/O

47* TCRS O

48* ACRCER O

49* PLCK O

50 EFM0 O

51* X700KO O

52* EXPORT0 O

53* EXPORT1 O

54* TESO1 O

55 TEST3 I/O

56 TEST4 I/O

57 CDDATA I/O

58 CDLRCK I/O

59 CDBCLK I/O

60 VXI I

61* VPO O

62 VDD1

63 DGND

64 XI I

65 XO O

66 DIN I

67 DOUT O

68 VDD3

69 DGND

70 LRCK O

71 BCLK O

72 DFCK O

73 ADDATA I

74 DADATA O

75* FEMON O

76* TOTMON O

77* TEMON O

78 SBCK I

79 SBO O

80 SBSY O

81 SFSY O

82 FOK O

83 SENSE O

84 COUT O

85 MCCK O

86 DINTX O

87 VDD1

88 DGND

89 RSTX I

90 SYD0 I/O

91 ~ 96 SYD1 ~ SYD6 I/O

97 SYD7 I/O

98 SYWRX I

99 SYRDX I

100 SYRS I

The * marked terminal is a terminal which is not connected externally (open terminal).

(Note) Set RSTX to "L" when or after turning on the power supply.

Address output to external D-RAM. ADR7

Address output to external D-RAM. ADR8

Data output enable signal output to external D-RAM

Ground terminal for digital section

Column address strobe signal output to external D-RAM

Data input/output with external D-RAM. D2

Data input/output with external D-RAM. D3 (MSB)

Address output to external D-RAM. ADR9

Low address strobe signal output to external D-RAM

Data write enable signal output to external D-RAM

Data input/output with external D-RAM. D1

Data input/output with external D-RAM. D0 (LSB)

Track cross signal

CRC error flag monitor output of ADIP

EFM PLL clock output during reproduction

EFM signal output during recording and C1F (C1 error flag) monitor output during reproduction

Clock output. f=705.6KHz. No clock output when RSTX=0.

Microporcessor expansion output port 0

Microprocessor expansion output port 1

Microprocessor expansion output port 2 when switching PLLLR.

Microprocessor expansion output port 3 when switching PLLOSC.

Microprocessor expansion output port 4 when switching EXTCLK.

CD data input for high speed dubbing. Microprocessor expansion output port 5 when switching.

CD LR clock input for high speed dubbing. Microprocessor expansion output port 6 when switching.

CD bit clock input for high speed dubbing. Microprocessor expansion output port 7 when switching.

PLL clock input for variable pitch.

PLL phase error output for variable pitch.

Power supply terminal for digital section

Ground terminal for digital section

Oscillation circuit input. 33.8688MHz

Oscillation circuit output. 33.8688MHz

Digital input signal

Digital output signal

Power supply terminal for internal PLL

Ground terminal for digital section

Output terminal for switching music data to Lch, Rch

Shift clock for music data

Clock for AD/DA converter digital filter. 256Fs

Voice data input

Voice data output

Focus error signal monitor output

Total signal monitor output

Tracking error signal monitor output

DIN sub-code reading clock. EIAJ CP-309 format

DIN sub-code serial data. EIAJ CP-309 format.

DIN sub-code block synchronous signal. EIAJ CP-309 format.

DIN sub-code frame synchronous signal. EIAJ CP-309 format.

Focus OK detect signal. "0": focus OK

Servo state detect signal. "1": Auto move, auto jump, auto focus being drawn in

Track cross signal output

Clock output for microprocessor. Clock output also when RSTX=0

Output terminal used to request interrupt into system control interface.

Power supply terminal for digital section

Ground terminal for digital section

Chip reset input. Reset at "L" (Note)

Data bus terminal of system control interface (LSB)

Data bus terminal of system control interface.

Data bus terminal of system control interface. (MSB)

Input terminal for register write pulse of system control interface

Input terminal for register read pulse of system control interface

Input terminal for register selection of system control interface

Function

27

Page 29

IC1401 : iX0290AW

MD System Microprocessor

No. Pin Name I/O

1* NX O

2 SBCK O

3 LDVAR O

4* ADIS O

5 SFSY O

6 LOADIN I

7 ERROR I

8 BYTE I

9 CNVss I

10 STID OUT O

11 SEACH OUT O

12 RESET I

13* NC

14 Vss

15 MCCK I

16 Vcc

17 P85 I

18 DINT I

19 DSENSE I

20 ST-ID I

21 SERCH I

22 MDRSW O

23* FSW I

24 VARI-PSW O

25 P-DOWN I

26 HD ON O

27 LD+ O

28 LD- O

29 CIN I

30 INNER I

31 DATA O

32 LATCH O

33 CLOCK O

34 DSTB O

35 MD DATA O

36 K DATA I

37 DSCK I

38 4M/16M I

39 R/P O

40 FOK I

41 PLL SEL O

42 S2 O

43 S1 O

44 SYRS O

45 SYRD O

46 SYWR O

47 SYS D7 I/O

48 SYS D6 I/O

49 SYS D5 I/O

50 SYS D4 I/O

51 SYS D3 I/O

52 SYS D2 I/O

53 SYS D1 I/O

54 SYS D0 I/O

Input/output port P96

Function

Input/output port P95

LDVAR (Laser power adjustment output)

ADJS (for automatic adjustment step check)

Input/output port P92

LD SW CK input (interrupt input only when used individually)

ERR input (UNLOCK of monitor PLL)

GND

GND

ST-ID output

MD search output

RESET input

Clock output

GND

EXTAL (8.4672MHz)

+3.15V

Input/output port P85

DINT (interrupt input from MD•LSI)

DSENSE (servo sense input from MD•LSI)

ST-ID input (MD-ON)

CD search input (Synchro REC interrupt input)

MD RSW output

FSW1 (SW for power frequency switching)

Corresponding measure to variable pitch, provided (H)/ not provided (L)

P-DOWN (power failure detect)

HDON (Magnetic head current ON/OFF output)

LD+ (Loading motor + control output)

LD- (Loading motor - control output)

CIN (Track count signal input)

INN SW (Inner SW detect input)

R-DATA

R-LATCH

R-CLK

DSTB (System control communication possible and communication being executed)

MD DATA (MD data output)

K DATA (System control data input)

DSCK (System control communication clock input)

4M/16M DRAM select input

R/P output (REC/PLAY switching)

FOK (Focus servo state monitor input)

Input/output port P55

S2 output

S1 output

SYRS (MD-LSI register select signal output)

SYRD (MD-LSI read signal output)

SYWR (MD-LSI write signal output)

SYS D7 (Data bus 7)

SYS D6 (Data bus 6)

SYS D5 (Data bus 5)

SYS D4 (Data bus 4)

SYS D3 (Data bus 3)

SYS D2 (Data bus 2)

SYS D1 (Data bus 1)

SYS D0 (Data bus 0)

MDX-595

MDX-595

The * marked terminal is a terminal which is not connected externally (open terminal).

28

Page 30

MDX-595

IC1401 : iX0290AW

MDX-595

MD System Microprocessor

No. Pin Name I/O

55* P37/A15 O

56* P36 O

57* P35 O

58 EEPRO O

59 EPCS O

60 EEPD I/O

61 EEPK O

62 Vcc I

63* P30 O

64 GND

65 L3 DATA O

66 L3 MODE O

67 L3 CLK O

68* P24 O

69* P23 O

70 PCNT0 O

71* PCNT1 O

72 LD ON O

73 A/B O

74 SBSY O

75* DAP ON O

76* DFS0 O

77* DFS1 O

78 DIG EX O

79 DIG CD O

80 XRST O

81* AD MUTE O

82* EMPH O

83* DAMUT O

84 MUTE O

85 DOUTM O

86 TEST2 I

87 TEST1 I

88 TEST0 I

89 AVCK3 I

90 AVCK2 I

91 AVCK1 I

92 DTEMP I

93 MINF I

94 TEST K1 I

95 TEST K2 I

96 GND

97 HINF I

98 VREF

99 AVcc

100 S80 I

Input/output port P37

Function

Input/output port P36

Input/output port P35

EEPRO (E2PROM protect cancel)

EPCS (E2PROM chip selector output)

EEPD (E2PROM serial data output)

EEPK (E2PROM serial clock output)

+3.15V

Input/output port P30

GND

L3 DATA (soft serial communication, 2 modes provided, LSB first)

L3 MODE (soft serial communication, 2 modes provided, LSB first)

L3 CLK (soft serial communication, 2 modes provided, LSB first)

Input/output port P24

Input/output port P23

PCNT0 output

Input/output port

LDON output (H: ON)

ANLPTR output

ADPON output (for CK)

DAPON output (for CK)

DFS0 output

DFS1 output

DIG EX output (for CK)

DIG CD OUTPUT (for CK)

XRST (system reset output)

ADMUTE output (for CK)

EMPHA output (for CK)

DAMUTE output (for CK)

MUTE output

DOUTM output (for CK)

TEST2 (special mode select 2)

TEST1 (special mode select 1)

TEST0 (special mode select 0)

AVCK3 (special mode monitor input)

AVCK2 (AD/DA section 3.1V monitor input)

AVCK1 (DOUT section 5V monitor input)

DTEMP (temperature detect input)

MINF (for each disc type/REC input)

TEST K1 (test key input 1)

TEST K2 (test key input 2)

GND

HINF (mechanical unit position/head position)

+3.15V

+3.15V

Input/output port

The * marked terminal is a terminal which is not connected externally (open terminal).

29

Page 31

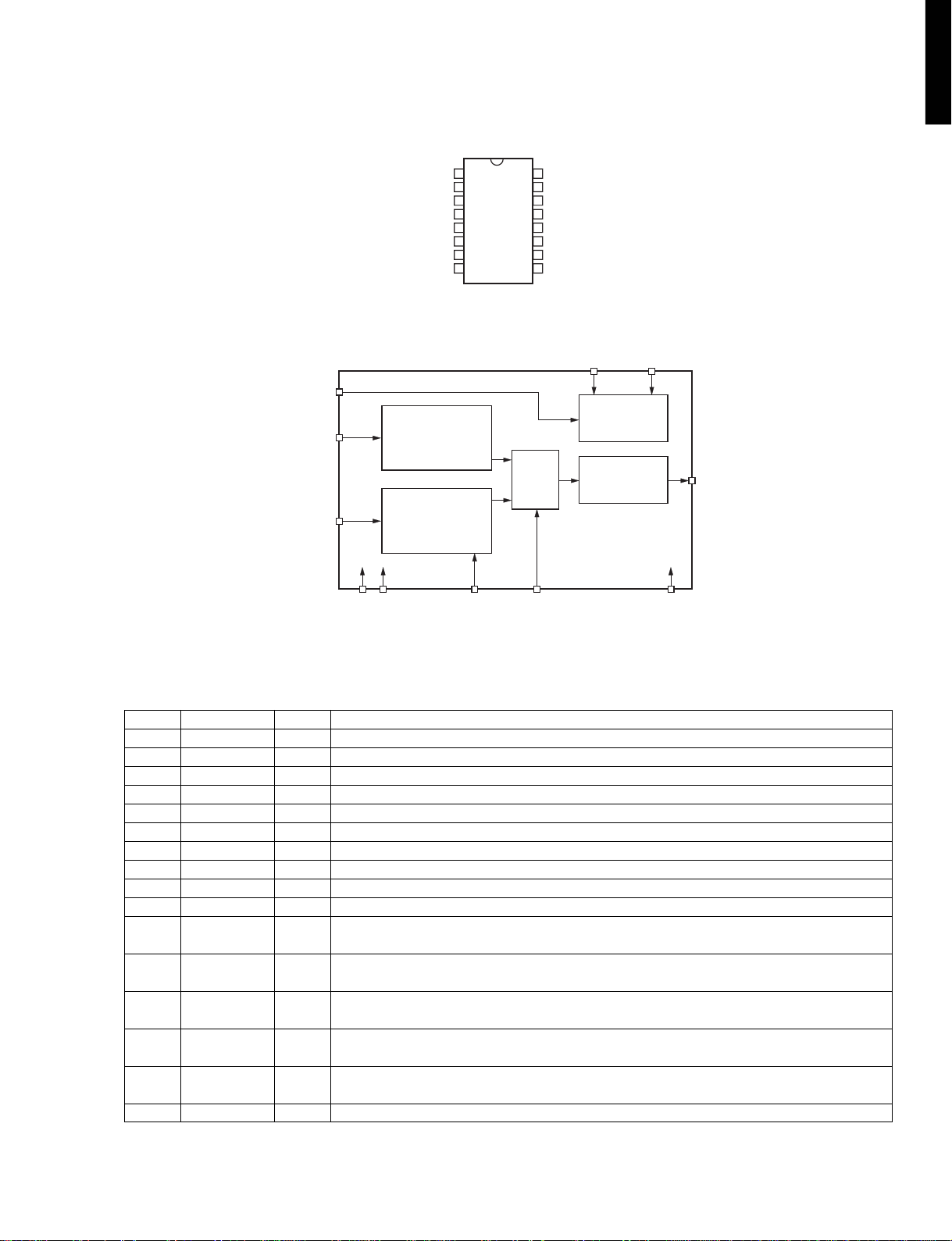

IC6 : M30622M8-xxxFP

Main System Microprocessor

MDX-595

MDX-595

P07/D7

P06/D6

P05/D5

P04/D4

P03/D3

P02/D2

P01/D1

P00/D0

P107/AN7/K13

P106/AN6/K12

P105/AN5/K11

P104/AN4/K10

P103/AN3

P102/AN2

P101/AN1

AVSS

P100/AN0

VREF

AVCC

P97/ADTRG

P10/D8

P11/D9

P12/D10

P13/D11

P14/D12

P15/D13

8079787776757473727170696867666564636261605958575655545352

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

1234567891011121314151617181920212223242526272829

4/DA1

P93/DA0

P9

5/ANEX0

P92/TB2IN

P96/ANEX1

P91/TB1IN

P9

P16/D14

P17/D15

BYTE

P90/TB0IN

1/A1/(/D1/D0)P22/A2/(/D2/D1)P23/A3/(/D3/D2)P24/A4/(/D4/D3)P25/A5/(/D5/D4)P26/A6/(/D6/D5)P27/A7/(/D7/D6)

P20/A0/(/D0/-)

P2

SS

OUT

X

CNV

RESET

P87/XCIN

P86/XCOUT

SS

CC

P30/A8(/-/D7)

P31/A9

P32/A10

P33/A11

P34/A12

P35/A13

P36/A14

V

V

XIN

VSS

VCC

4/INT2

P85/NMI

P83/INT1

P82/INT0

P8

P81/TA4IN

P80/TA4OUT

P37/A15

P77/TA3IN

P75/TA2IN

P76/TA3OUT

P74/TA2OUT

P40/A16

P41/A17

P42/A18

P43/A19

51

50

P44/CS0

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

P71/RXD2/TA0IN

P72/CLK2/TA1OUT

P70/TXD2/TA0OUT

P73/CTS2/RTS2/TA1IN

5/CS1

P4

6/CS2

P4

7/CS3

P4

0/WRL/WR

P5

1/WRH/BHE

P5

2/RD

P5

3/BCLK

P5

4/HLDA

P5

5/HOLD

P5

6/ALE

P5

7/RDY/CLKOUT

P5

P60/CTS0/RTS0

P61/CLK0

P62/RXD0

P63/TXD0

P64/CTS1/RTS1/CTS0/CLKS1

P65/CLK1

P66/RXD1

P67/TXD1

No. Port I/O Name

1 P96/ANEX1 O CDI

2 P95/ANEX0 O XCLK

3 P94/DA1 I LDCKN

4 P93/DA0 O DSELB

5 P92/TB2in O DSELA

6 P91/TB1in O /MUTE

7 P90/TB0in

8 BYTE I GND

9 CNVss I GND

10 P87/Xcin I/O

11 P86/Xcout I/O

12 /RESET I /RES

13 Xout O XOUT

14 Vss I GND

15 Xin I XIN

16 Vcc I VCC

17 P85//NMI I PU

18 P84//INT2 I DSTB

19 P83//INT1 I /PDN

20 P82//INT0 I REM

21 P81/TA4in I/O

22 P80/TA4out I/O

23 P77/TA3in I/O

24 P76/TA3out I/O

25 P75/TA2in I/O

26 P74/TA2out O 6.5/5V

27 P73/TA1in O

28 P72/TA1out O SCL

29 P71/TA0in I SDI

30 P70/TA0out O SDO

31 P67/TxD1 O FLDAT

32 P66/RxD1 O /FLCE

33 P65/CLK1 O FLCLK

34 P64//CTS O /FLRES

Function

Data to DEQ

Clock to DEQ

Lock flag input for DIR

Digital input switching

Digital input switching

LINE MUTE