Yamaha RX-V385, HTR-372 Service Manual

AV RECEIVER

RX-V385/HTR-3072

SERVICE MANUAL

Notes: When the DIGITAL P.C.B. or IC23 on DIGITAL P.C.B. is replaced, this unit will display “Internal Error” and

will not operate properly. The model name, destination and serial number MUST be written to the backup IC

(EEPROM: IC23 on DIGITAL P.C.B.) to have proper operation.

(For detailed procedure, refer to related Service News or Service Bulletin. Or contact your local Yamaha

representative.)

注意: DIGITALP.C.B. または DIGITALP.C.B. の IC23 を交換すると、“InternalError” が表示されて本機が正常に動作し

なくなります。正常に動作させるために、モデル名、仕向け先、シリアル番号をバックアップ IC(EEPROM:

DIGITALP.C.B. の IC23)へ書き込む必要があります。

(詳しい手順は、関連するサービスニュース、または技術報告を参照してください。もしくはヤマハのサービ

スセンターまでご連絡ください。)

This manual has been provided for the use of authorized Yamaha Retailers and their service personnel.

It has been assumed that basic service procedures inherent to the industry, and more specifi cally Yamaha Products, are already known

and understood by the users, and have therefore not been restated.

WARNING:

IMPORTANT:

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research, engineering, and service

departments of Yamaha are continually striving to improve Yamaha products. Modifi cations are, therefore, inevitable and specifi cations

are subject to change without notice or obligation to retrofi t. Should any discrepancy appear to exist, please contact the distributor's

Service Division.

WARNING:

IMPORTANT:

Failure to follow appropriate service and safety procedures when servicing this product may result in personal injury,

destruction of expensive components, and failure of the product to perform as specifi ed. For these reasons, we advise

all Yamaha product owners that any service required should be performed by an authorized Yamaha Retailer or the

appointed service representative.

The presentation or sale of this manual to any individual or fi rm does not constitute authorization, certifi cation or

recognition of any applicable technical capabilities, or establish a principle-agent relationship of any form.

Static discharges can destroy expensive components. Discharge any static electricity your body may have

accumulated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this buss).

Turn the unit OFF during disassembly and part replacement. Recheck all work before you apply power to the unit.

■ CONTENTS

TO SERVICE PERSONNEL ............................................2

FRONT PANELS ............................................................. 3

REAR PANELS ...............................................................5

REMOTE CONTROL PANEL ........................................ 10

SPECIFICATIONS /

INTERNAL VIEW .......................................................... 15

SERVICE PRECAUTIONS /

DISASSEMBLY PROCEDURES /

UPDATING FIRMWARE /

ファームウェアのアップデート

SELF-DIAGNOSTIC FUNCTION /

ダイアグ(自己診断機能)

参考仕様

....................................... 11

サービス時の注意事項

分解手順

.................................. 20

........................................... 24

.................16

.....15

IMPORTANT NOTICE

POWER AMPLIFIER ADJUSTMENT /

パワーアンプ調整

DISPLAY DATA .............................................................63

IC DATA .........................................................................65

BLOCK DIAGRAMS ......................................................79

WIRING DIAGRAMS .....................................................81

PRINTED CIRCUIT BOARDS .......................................84

PIN CONNECTION DIAGRAMS ...................................96

CIRCUIT DIAGRAMS ....................................................97

REPLACEMENT PARTS LIST .................................... 109

REMOTE CONTROL ................................................... 132

.......................................................62

RX-V385/HTR-3072

101407

Copyright (c) Yamaha Corporation All rights reserved.

This manual is copyrighted by Yamaha and may not be copied or

redistributed either in print or electronically without permission.

P.O.Box 1, Hamamatsu, Japan

'18.03

RX-V385/HTR-3072

■ TO SERVICE PERSONNEL

1. Critical Components Information

Components having special characteristics are marked ⚠ and

must be replaced with parts having specifications equal to those

originally installed.

2. Leakage Current Measurement (For 120V Models Only)

When service has been completed, it is imperative to verify

that all exposed conductive surfaces are properly insulated

from supply circuits.

• Meter impedance should be equivalent to 1500 ohms shunted

by 0.15 μF.

“CAUTION”

“F5401: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE 1.25A,

250V FUSE.”

“F5402: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE 6A,

125V FUSE.”

“F5405: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE 2A, 63V

CHIP FUSE.”

For C model

CAUTION

F5401: REPLACE WITH SAME TYPE 1.25A, 250V FUSE.

F5402: REPLACE WITH SAME TYPE 6A, 125V FUSE.

F5405: REPLACE WITH SAME TYPE 2A, 63V CHIP FUSE.

ATTENTION

F5401: UTILISER UN FUSIBLE DE RECHANGE DE MÉME TYPE DE 1.25A, 250V.

F5402: UTILISER UN FUSIBLE DE RECHANGE DE MÉME TYPE DE 6A, 125V.

F5405: UTILISER UN FUSIBLE À PUCE DE RECHANGE DE MÉME TYPE DE 2A, 63V.

WALL

OUTLET

• Leakage current must not exceed 0.5mA.

• Be sure to test for leakage with the AC plug in both polarities.

EQUIPMENT

UNDER TEST

INSULATING

TABLE

AC LEAKAGE

TESTER OR

EQUIVALENT

About lead free solder /

All of the P.C.B.s installed in this unit and solder joints are

soldered using the lead free solder.

Among some types of lead free solder currently available,

RX-V385/HTR-3072

it is recommended to use one of the following types for

the repair work.

• Sn + Ag + Cu (tin + silver + copper)

• Sn + Cu (tin + copper)

• Sn + Zn + Bi (tin + zinc + bismuth)

Caution:

As the melting point temperature of the lead free solder

is about 30°C to 40°C (50°F to 70°F) higher than that of

the lead solder, be sure to use a soldering iron suitable

to each solder.

2

無鉛ハンダについて

本機に搭載されているすべての基板およびハンダ付けに

よる接合部は無鉛ハンダでハンダ付けされています。

無鉛ハンダにはいくつかの種類がありますが、修理時に

は下記のような無鉛ハンダの使用を推奨します。

Sn+Ag+Cu(錫+銀+銅)

Sn+Cu(錫 + 銅)

Sn+Zn+Bi(錫 + 亜鉛 + ビスマス)

注意:

無鉛ハンダの融点温度は通常の鉛入りハンダに比べ 30 〜

40℃程度高くなっていますので、それぞれのハンダに合っ

たハンダごてをご使用ください。

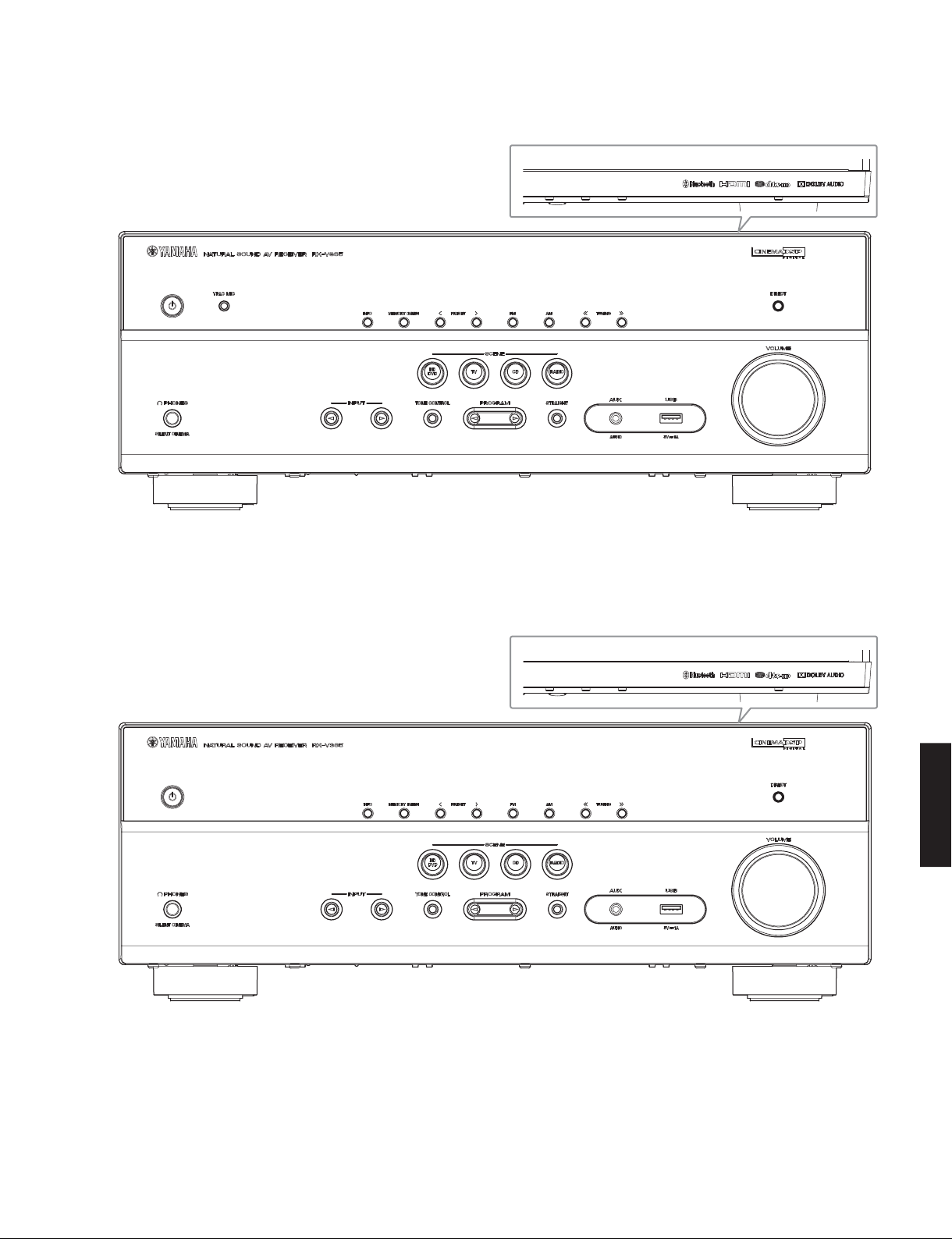

■ FRONT PANELS

RX-V385 (U, C, K, A, B, G, F, L, V, P, S, J models)

RX-V385/HTR-3072

RX-V385 (T model)

RX-V385/HTR-3072

3

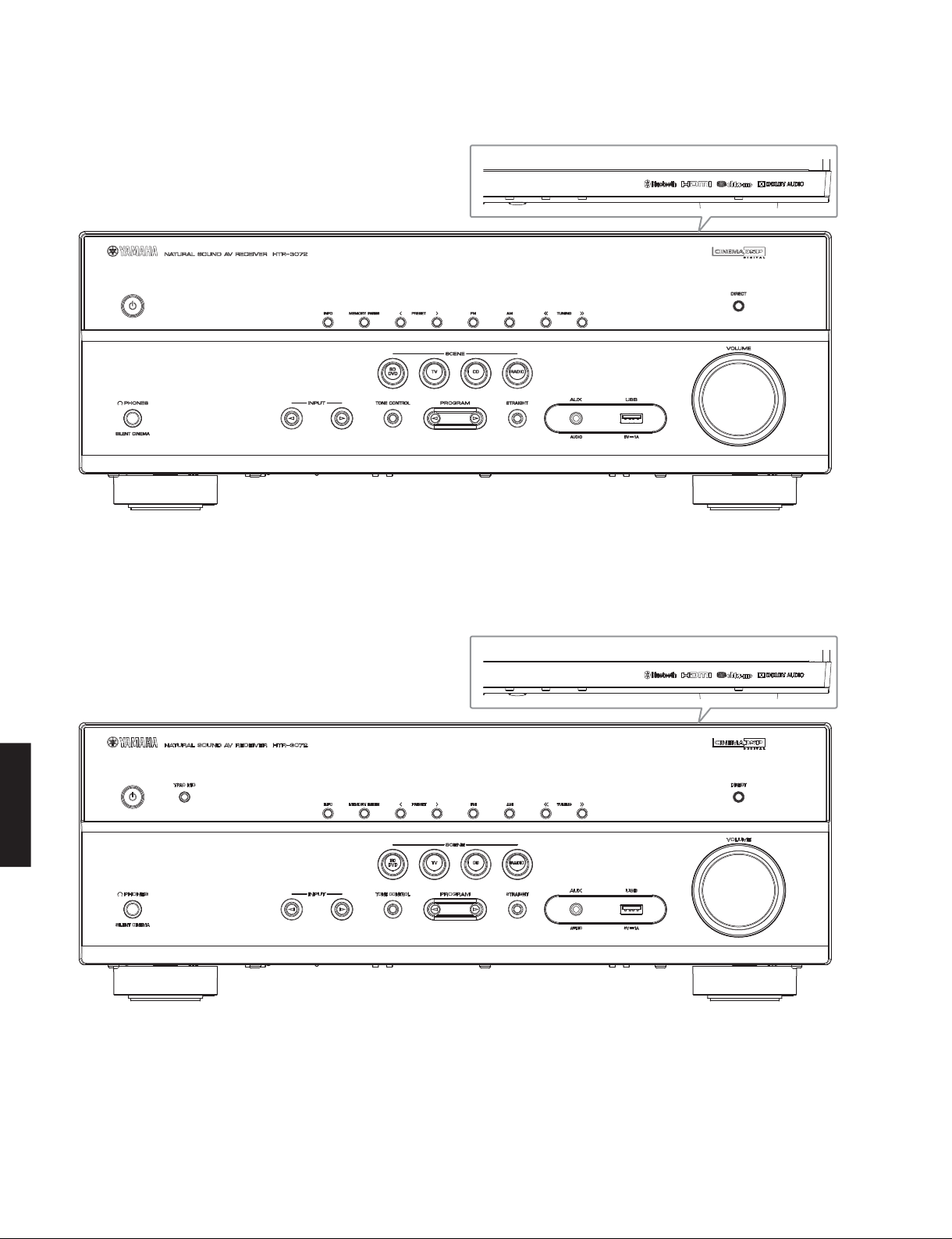

RX-V385/HTR-3072

HTR-3072 (T model)

HTR-3072 (K, B, G, F, L models)

RX-V385/HTR-3072

4

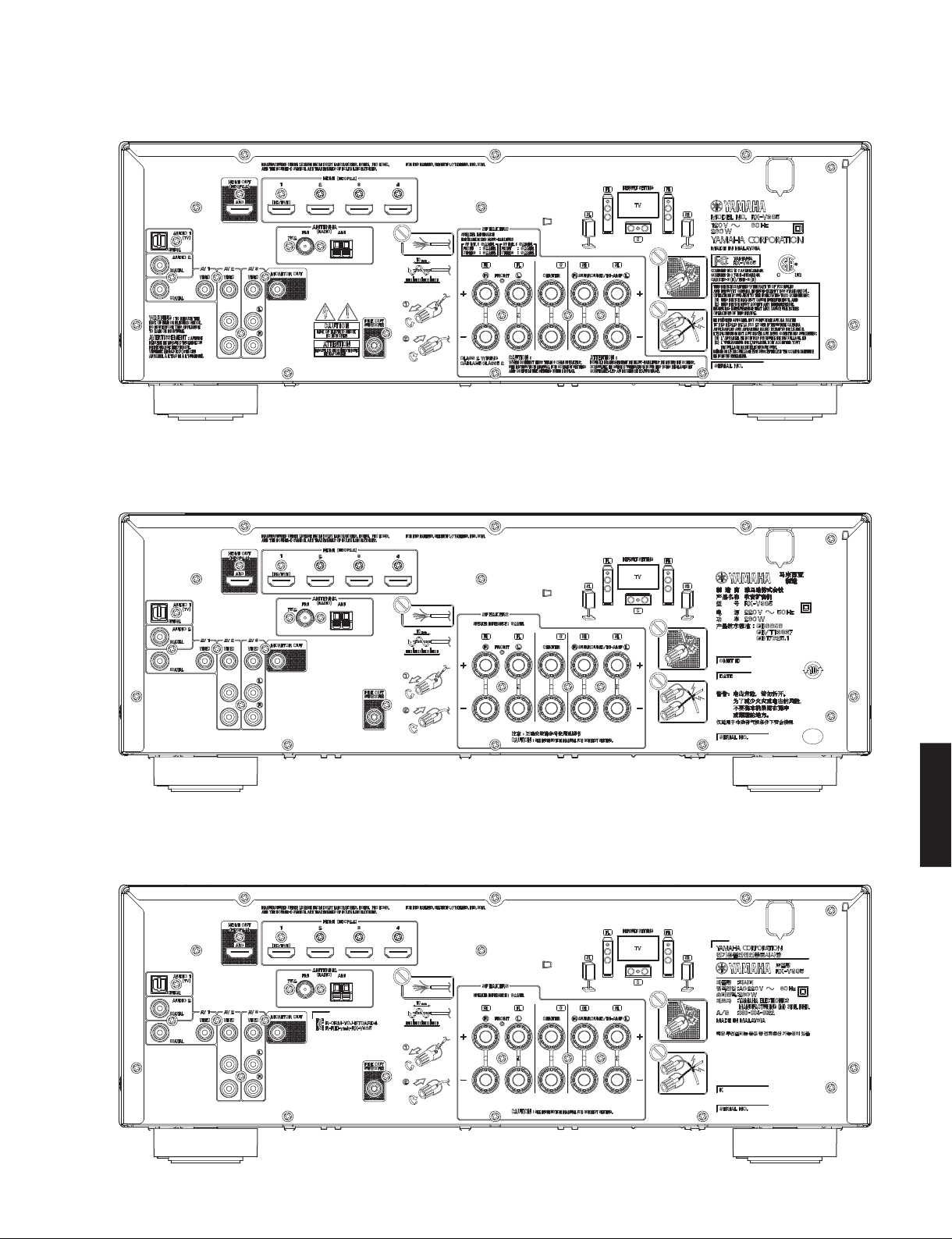

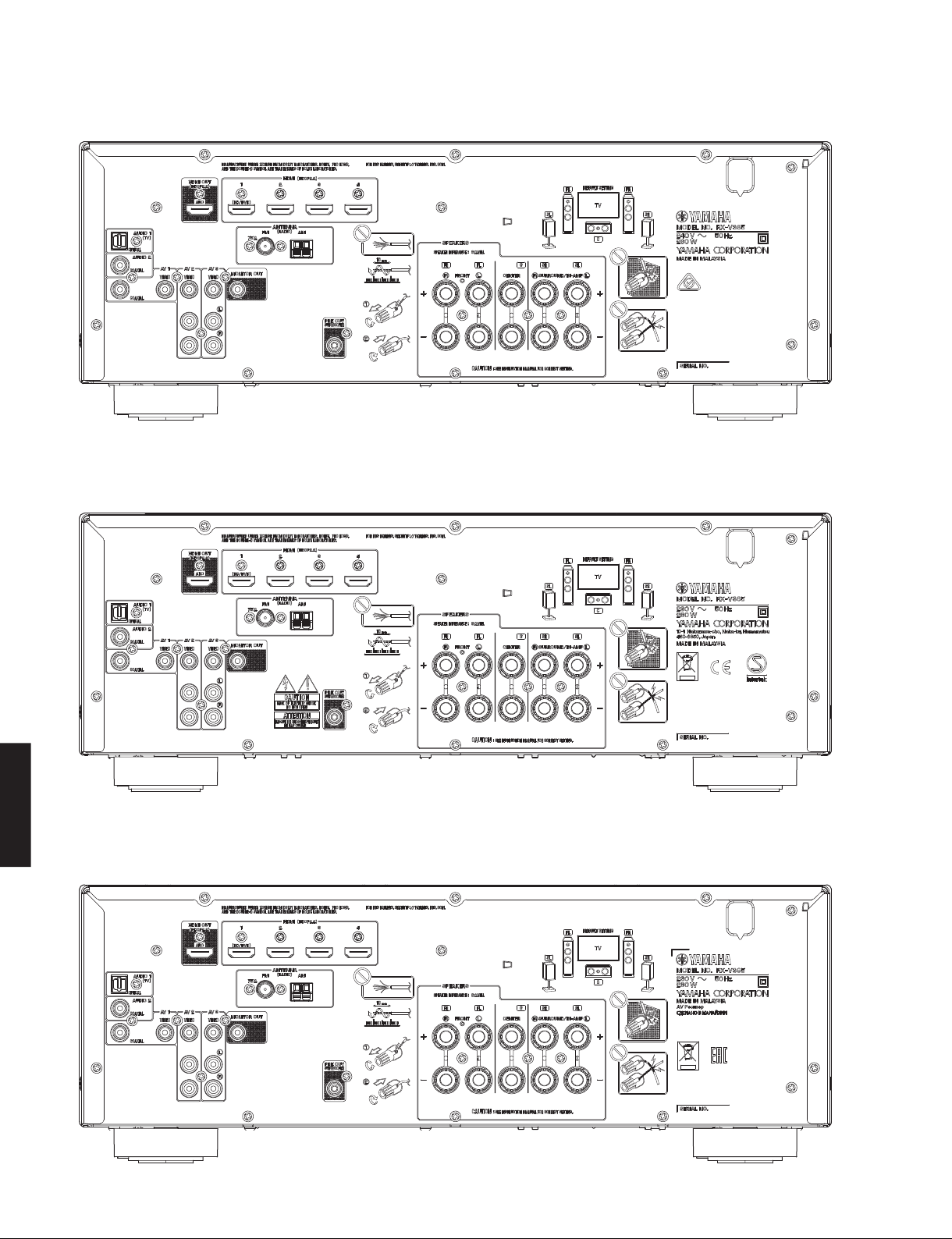

■ REAR PANELS

RX-V385 (U, C models)

RX-V385 (T model)

RX-V385/HTR-3072

RX-V385 (K model)

RX-V385/HTR-3072

5

RX-V385/HTR-3072

RX-V385 (A model)

RX-V385 (B, G models)

RX-V385/HTR-3072

RX-V385 (F model)

6

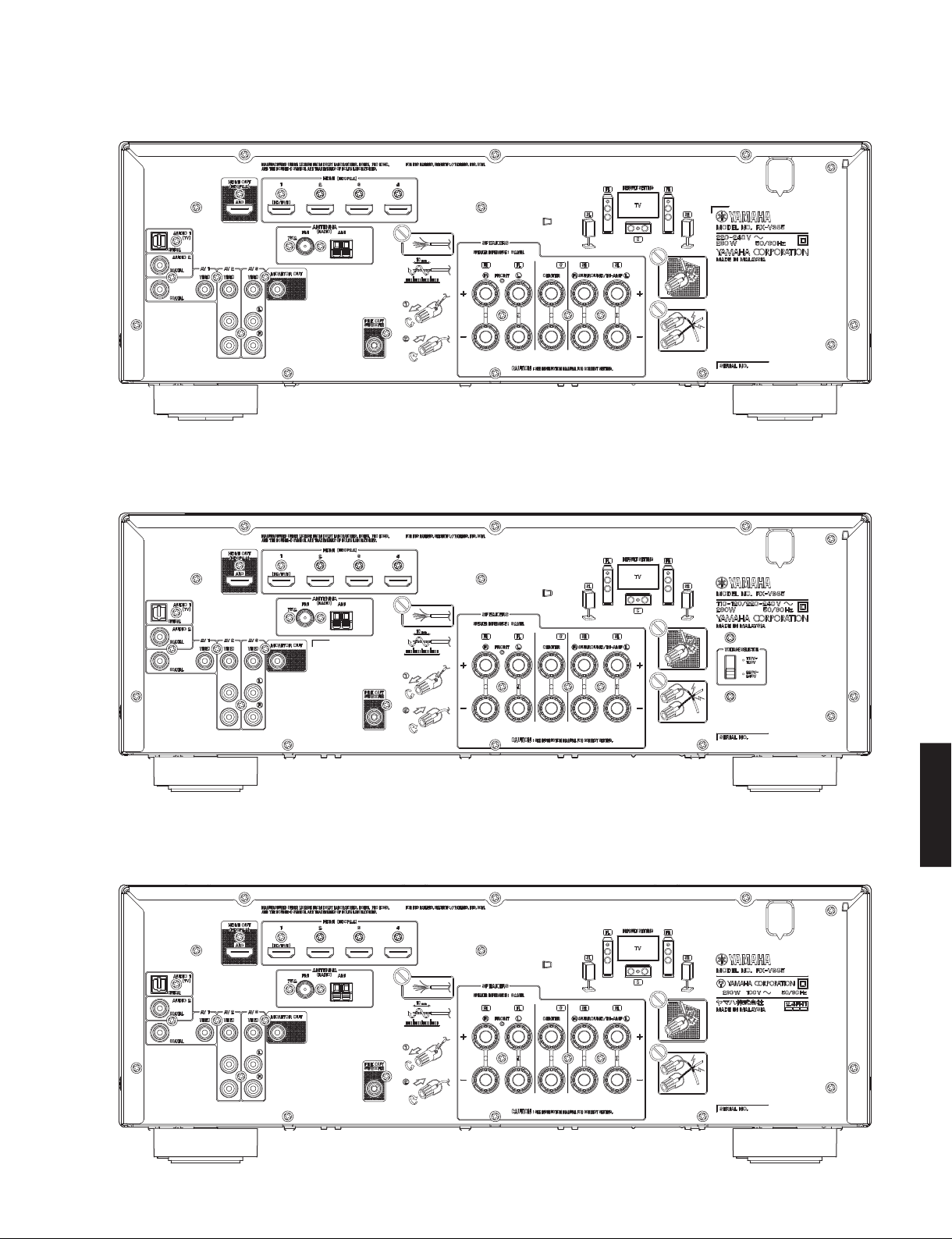

RX-V385 (L model)

RX-V385 (V, P, S models)

RX-V385/HTR-3072

RX-V385 (J model)

RX-V385/HTR-3072

7

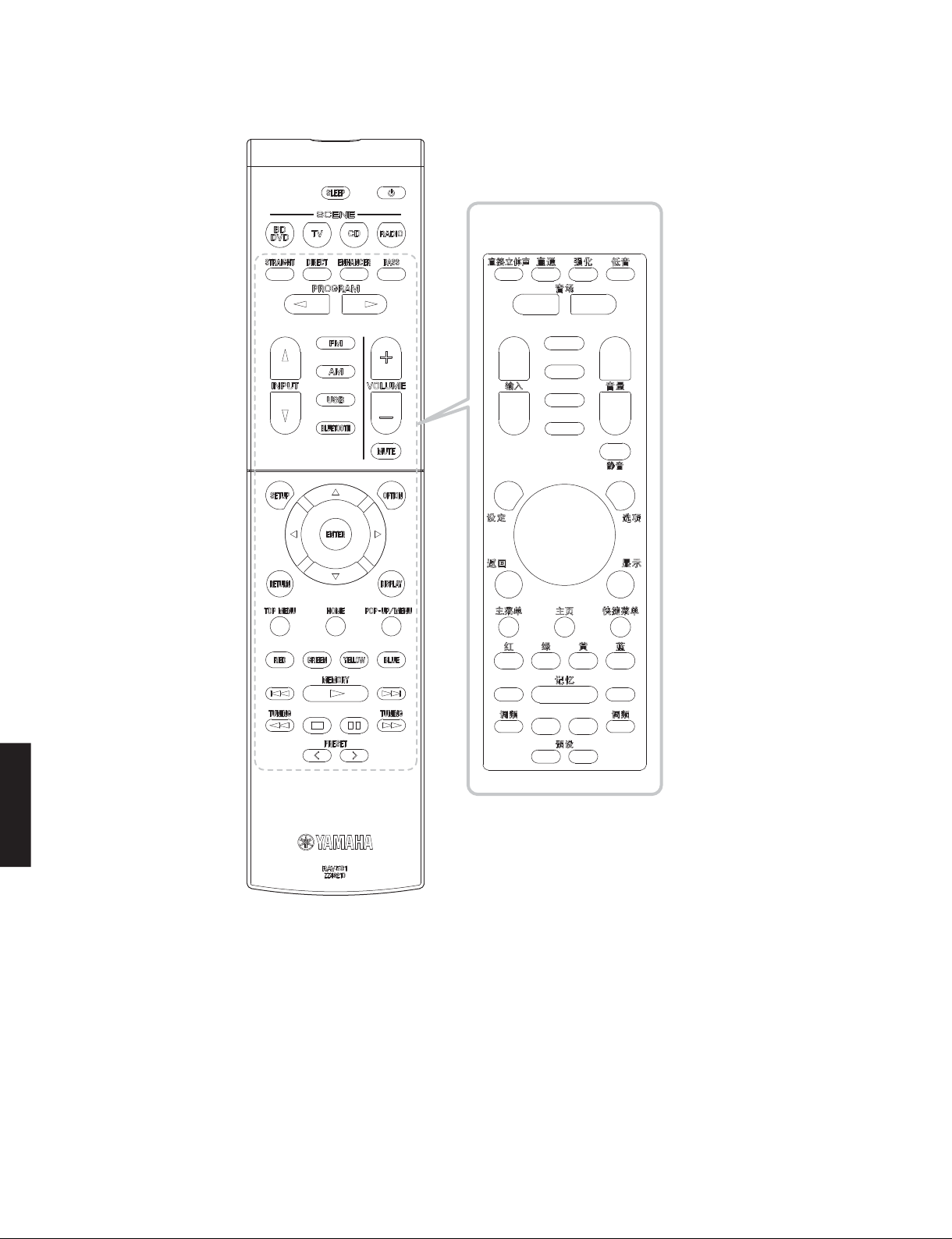

RX-V385/HTR-3072

HTR-3072 (T model)

HTR-3072 (K model)

RX-V385/HTR-3072

HTR-3072 (B, G models)

8

HTR-3072 (F model)

HTR-3072 (L model)

RX-V385/HTR-3072

RX-V385/HTR-3072

9

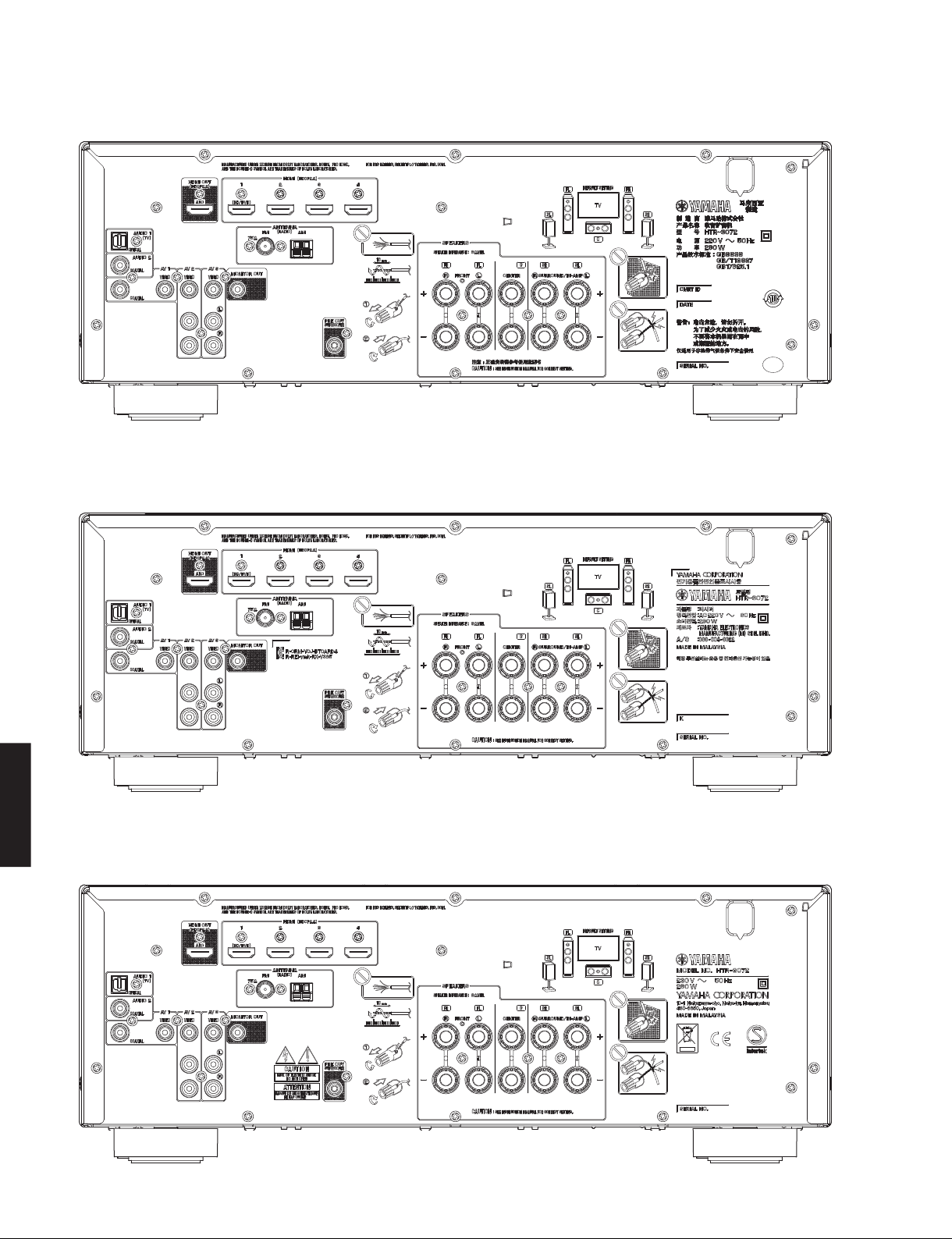

RX-V385/HTR-3072

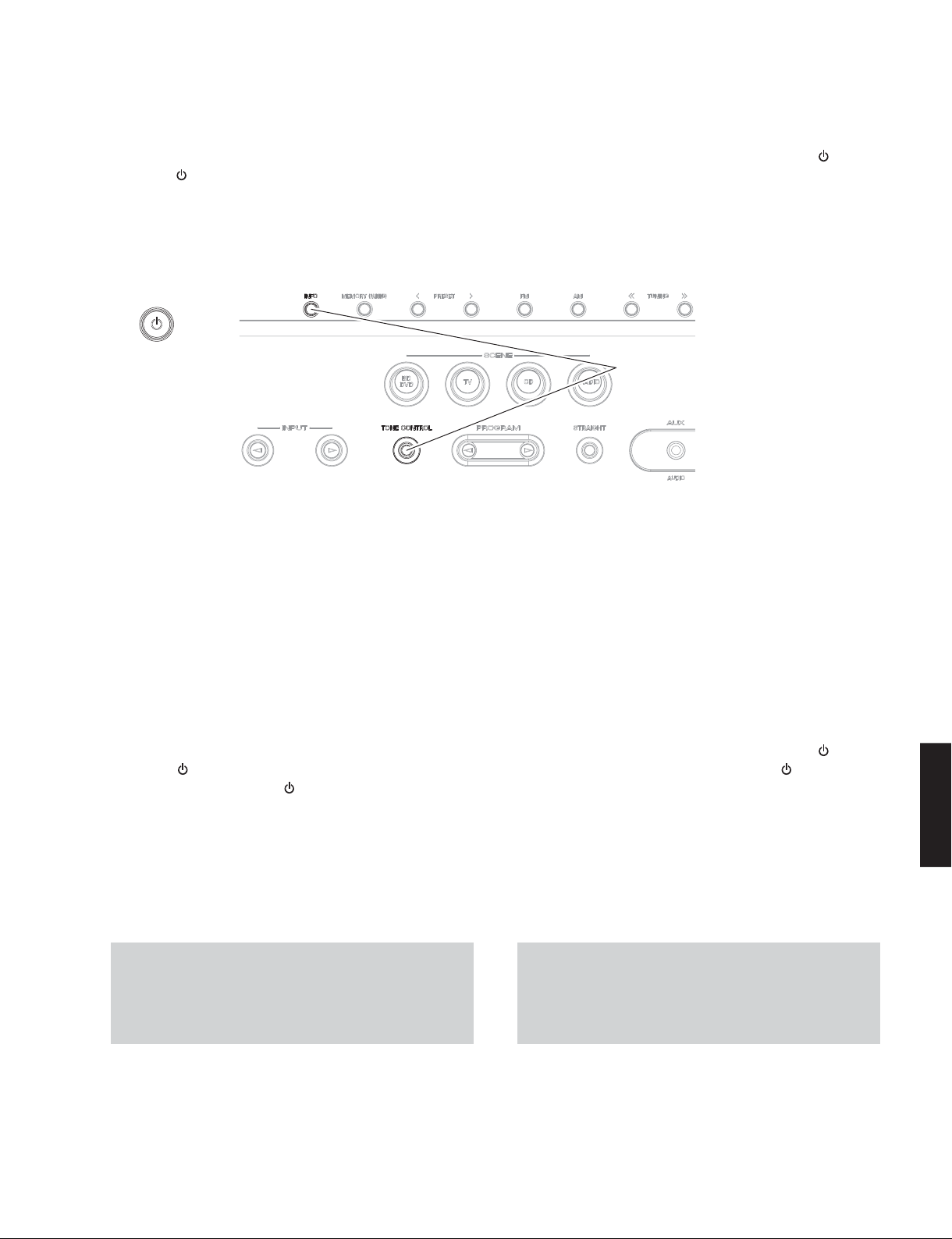

■ REMOTE CONTROL PANEL

RAV561

T model

Remote control sheet

RX-V385/HTR-3072

10

RX-V385/HTR-3072

■ SPECIFICATIONS /

■ Audio Section /

Rated Output Power (Power Amplifier Section) /

定格出力(パワーアンプ部)

(1 kHz, 0.9 % THD)

– 1 channel driven –

U, C models (8 ohms)

FRONT L/R ................................................................ 100 W/ch

CENTER .......................................................................... 100 W

SURROUND L/R ........................................................ 100 W/ch

T, K, A, B, G, F, L, V, P, S, J models (6 ohms)

FRONT L/R ................................................................ 100 W/ch

CENTER .......................................................................... 100 W

SURROUND L/R ........................................................ 100 W/ch

– 2 channels driven simultaneously –

U, C models (8 ohms)

FRONT L/R ...........................................................85 W + 85 W

CENTER ............................................................................ 85 W

SURROUND L/R ...................................................85 W + 85 W

(20 Hz to 20 kHz, 0.09 % THD)

– 2 channels driven simultaneously –

U, C models (8 ohms)

FRONT L/R ...........................................................70 W + 70 W

T, K, A, B, G, F, L, V, P, S, J models (6 ohms)

FRONT L/R ...........................................................70 W + 70 W

Maximum Effective Output Power /

(1 channel driven / 1 kHz, 10 % THD)

U, C models (8 ohms)

FRONT L/R ...................................................................... 130 W/ch

CENTER ............................................................................... 130 W

SURROUND L/R .............................................................. 130 W/ch

(6 ohms)

FRONT L/R ...................................................................... 145 W/ch

CENTER ............................................................................... 145 W

SURROUND L/R .............................................................. 145 W/ch

T, K, A, B, G, F, L, V, P, S, J models (6 ohms)

FRONT L/R ...................................................................... 135 W/ch

CENTER ............................................................................... 135 W

SURROUND L/R .............................................................. 135 W/ch

Dynamic Power Per Channel /

FRONT L/R drive / 1 channel driven

U, C models

(8 / 6 / 4 / 2 ohms) .................................. 110 / 130 / 160 / 180 W

T, K, A, B, G, F, L, V, P, S, J models

(6 / 4 / 2 ohms) ................................................ 110 / 130 / 150 W

Damping Factor /

FRONT L/R .....................................................................100 or more

Input Sensitivity/Input Impedance /

(1 kHz, 100 W/6 ohms)

AV2 etc. ............................................................200 mV / 47 k-ohms

Maximum Input Signal /

AV2 etc. (EFFECT ON) .............................................................. 2.3 V

Output Impedance /

SUBWOOFER (2 ch stereo and FRONT SP: small)

............................................................................. 1 V / 1.2 k-ohms

Headphone Jack Rated Output/Output Impedance /

ヘッドホン出力/出力インピーダンス

AV2 etc. input .....................................................100 mV / 470 ohms

Frequency Response /

AV2 etc., FRONT ..................................................................0 / -3 dB

Signal to Noise Ratio /

AV2 etc. to SP OUT (Input 1 k-ohm shorted)

.............................................................................. 110 dB or more

オーディオ部

ダイナミックパワー

ダンピングファクター

最大許容入力

出力インピーダンス

再生周波数帯域

信号対雑音比

参考仕様

実用最大出力

(20 Hz to 20 kHz, 8 ohms)

入力感度/入力インピーダンス

(1 kHz, 0.5 % THD)

(1 kHz, 50 mV, 8 ohms)

(10 Hz to 100 kHz)

(IHF-A network)

(JEITA)

(IHF)

Residual Noise /

FRONT L/R to SP OUT ................................................150 μV or less

Channel Separation /

AV2 etc. (Input 1 k-ohm shorted)

1 kHz / 10 kHz ............................... 70 dB or more / 50 dB or more

Volume Control/Step /

......................................... MUTE / -80 dB to +16.5 dB / 0.5 dB step

Tone Control Characteristics /

Bass

Boost/Cut ........................................ ±6 dB / 0.5 dB step, at 50 Hz

Turnover frequency .............................................................350 Hz

Treble

Boost/Cut .......................................±6 dB / 0.5 dB step, at 20 kHz

Turnover frequency ............................................................ 3.5 kHz

Filter Characteristics /

FRONT, CENTER, SURROUND small (H.P.F.)

....................fc=40/60/80/90/100/110/120/160/200 Hz, 12 dB/oct.

SUBWOOFER small (L.P.F.)

....................fc=40/60/80/90/100/110/120/160/200 Hz, 24 dB/oct.

Optical Jack, Coaxial Jack Support Frequencies /

Optical 端子、Coaxial 端子対応 fs

............................................................................... 32 kHz to 96 kHz

■ Video Section /

Video Signal Type /

U, C, K, V, P, S, J models ......................................................... NTSC

T, A, B, G, F, L models ................................................................PAL

Composite Video Signal Level /

...............................................................................1 Vp-p / 75 ohms

Video Maximum Input Level /

(VIDEO Conversion Off)

............................................................................... 1.5 Vp-p or more

Video Signal to Noise Ratio /

................................................................................... 50 dB or more

Monitor Out Frequency Response /

(VIDEO Conversion Off)

.......................................................................5 Hz to 60 MHz, -3 dB

■ FM Section /

Tuning Range /

U, C models ......................................................... 87.5 to 107.9 MHz

T, K, A, B, G, F models ....................................87.50 to 108.00 MHz

L, V, P, S models ..............87.5 to 108.0 MHz / 87.50 to 108.00 MHz

J model ..................................................................76.0 to 94.9 MHz

50 dB Quieting Sensitivity /

(1 kHz, 100 % MOD.)

Mono ......................................................................... 3 μV (20.8 dBf)

Signal to Noise Ratio /

Mono ........................................................................................65 dB

Stereo ......................................................................................64 dB

Harmonic Distortion / 歪率 (1 kHz)

Mono ...................................................................................... 0.50 %

Stereo ....................................................................................0.60 %

Antenna Input /

....................................................................... 75 ohms unbalanced

残留ノイズ

ビデオ部

FM部

受信周波数範囲

アンテナ入力

(IHF-A Network)

チャンネルセパレーション

可変範囲/ステップ

トーンコントロール特性

フィルタ特性

ビデオ信号方式

信号対雑音比

コンポジットビデオ信号

ビデオ最大許容入力

ビデオ信号対雑音比

モニター出力周波数帯域

50dBSN 感度

(IHF)

(IHF)

RX-V385/HTR-3072

11

RX-V385/HTR-3072

■ AM Section /

Tuning Range /

U, C models ........................................................... 530 to 1,710 kHz

T, K, A, B, G, F, J models ....................................... 531 to 1,611 kHz

L, V, P, S models ......................530 to 1,710 kHz / 531 to 1,611 kHz

Antenna /

..................................................................................... Loop antenna

■ General /

Power Supply /

U, C models ............................................................ AC 120 V, 60 Hz

T model ................................................................... AC 220 V, 50 Hz

K model .................................................................. AC 220 V, 60 Hz

A model .................................................................. AC 240 V, 50 Hz

B, G, F models ........................................................ AC 230 V, 50 Hz

L model ...................................................... AC 220–240 V, 50/60 Hz

V, P, S models ..............................AC 110–120/220–240 V, 50/60 Hz

J model .............................................................. AC 100 V, 50/60 Hz

Power Consumption /

................................................................................................ 260 W

Standby Power Consumption (reference data) /

待機時消費電力(参考値)

Standby through: OFF / Bluetooth standby: OFF

.............................................................................................. 0.2 W

Bluetooth standby: OFF

HDMI control: ON / Standby through: AUTO

INPUT: HDMI1 (HDMI no signal) ........................................1.2 W

Standby through: ON

INPUT: HDMI1 (HDMI no signal) ........................................1.2 W

Bluetooth standby: ON

HDMI control: OFF / Standby through: OFF

...........................................................................................0.2 W

HDMI control: ON / Standby through: AUTO

INPUT: HDMI1 (HDMI no signal) ........................................1.2 W

Standby through: ON

INPUT: HDMI1 (HDMI no signal) ........................................1.2 W

Maximum Power Consumption /

................................................................................................ 600 W

Dimensions (W x H x D) /

RX-V385/HTR-3072

............................... 435 x 161 x 315 mm (17-1/8" x 6-3/8" x 12-3/8")

Weight / 質量

............................................................................... 7.7 kg (17.0 lbs.)

Finish /

仕上げ

[RX-V385]

U, C, T, K, A, B, G, F, L, V, P, S, J models ..................... Black color

K, B, G, F, L models .................................................Titanium color

T, L models .....................................................................Gold color

[HTR-3072]

T, K, B, G, F, L models .................................................. Black color

T, L models .....................................................................Gold color

AM部

受信周波数範囲

アンテナ

総合

電源電圧

消費電力

最大消費電力

寸法(幅×高さ×奥行き)

Accessories /

Remote control ..............................................................................x 1

Battery (R03, AAA, UM-4) .............................................................x 2

FM antenna (1.4 m) ......................................................................x 1

AM antenna (1 m) .........................................................................x 1

YPAO microphone (6 m)

(U, C, K, A, B, G, F, L, V, P, S, J models) .....................................x 1

Antenna isolator (T model) ...........................................................x 1

Remote control sheet (T model) ...................................................x 1

* Specifications are subject to change without notice.

※ 参考仕様および外観は、製品の改良のため予告なく変更すること

があります。

U .......................U.S.A. model

C .................Canadian model

T .................... Chinese model

K .....................Korean model

A ................Australian model

B ......................British model

G .................European model

付属品

F .................... Russian model

L .................Singapore model

V ..................... Taiwan model

P ........Latin American model

S ..................Brazilian model

J .................. Japanese model

12

Manufactured under license from Dolby Laboratories. Dolby, Dolby Audio,

Dolby Vision, Pro Logic, and the double-D symbol are trademarks of Dolby

Laboratories.

ドルビーラボラトリーズからの実施権に基づき製造されています。

Dolby、ドルビー、DolbyAudio、ProLogic、Dolby Vision、AAC ロゴ及びダブ

ル D 記号はドルビーラボラトリーズの商標です。

Manufactured under license from DTS Licensing Limited. DTS, DTS-HD,

the Symbol, & DTS and the Symbol together are registered trademarks of

DTS, Inc. © DTS, Inc. All Rights Reserved.

本製品は DTSLicensingLimited のライセンスに基づき製造しています。DTS、

DTS-HD、それらのシンボルマークおよび DTS とそのシンボルマークの組み合せ

は、DTS 社の登録商標です。

©DTS,Inc.AllRightsReserved.

RX-V385/HTR-3072

Google Noto Fonts

This product uses the following fonts.

Copyright © June 2015, Google

(https://www.google.com/get/noto/#sans-lgc), with Reserved Font Name

Noto Sans Version 1.004.

Copyright © June 2015, Google

(https://www.google.com/get/noto/help/cjk/), with Reserved Font Name

Noto Sans CJK Version 1.004.

This Font Software is licensed under the SIL Open Font License,

Version1.1.

This license is available with a FAQ at: http://scripts.sil.org/OFL

この製品には Apache バージョン 2.0 ライセンスで配布されている製作物が含

まれています。

Copyright©2012GoogleInc.Allrightsreserved.

Licensedunderthe ApacheLicense, Version2.0(the“License” );youmaynot

usethisfileexceptincompliancewiththeLicense.

Youmay obtainacopy oftheLicenseat http://www.apache.org/licenses/

LICENSE-2.0

Unlessrequiredbyapplicablelaworagreedtoinwriting,softwaredistributed

underthe Licenseisdistributed on an“ASIS” BASIS,WITHOUTWARRANTIES

ORCONDITIONSOFANYKIND,eitherexpressorimplied.

Seethe Licenseforthe specific languagegoverningpermissions and

limitationsundertheLicense.

The terms HDMI, the HDMI Logo, and High-Definition Multimedia Interface

are trademarks or registered trademarks of HDMI Licensing LLC in the

United States and other countries.

HDMI、HDMI ロゴ、および High-DefinitionMultimediaInterface は、米国およ

びその他の国々における HDMILicensingLLC の商標または登録商標です。

x.v.Color™

“x.v.Color” is a trademark of Sony Corporation.

「x.v.Color」は、ソニー株式会社の商標です。

The Bluetooth® word mark and logos are registered trademarks owned by

Bluetooth SIG, Inc. and any use of such marks by Yamaha Corporation is

under license.

Bluetooth® のワードマークおよびロゴは、BluetoothSIG,Inc. が所有する登録商

標であり、ヤマハ株式会社はこれらのマークをライセンスに基づいて使用して

います。その他の商標およびトレードネームは、それぞれの所有者に帰属します。

App Store is a service mark of Apple Inc.

AppStore は AppleInc. のサービスマークです。

Android™ is a trademark of Google Inc.

AAC ロゴマーク(マーク)はドルビーラボラトリーズの商標です。

Android™ Google Play™

Android、GooglePlay は、GoogleInc. の商標または登録商標です。

Bluetooth プロトコルスタック (BlueSDK)

Ⓒ1999-2014OpenSynergyGmbH

Allrightsreserved.Allunpublishedrightsreserved.

RX-V385/HTR-3072

“SILENT CINEMA” is a trademark of Yamaha Corporation.

「サイレントシネマ™SILENTCINEMA ™」はヤマハ株式会社の登録商標です。

13

RX-V385/HTR-3072

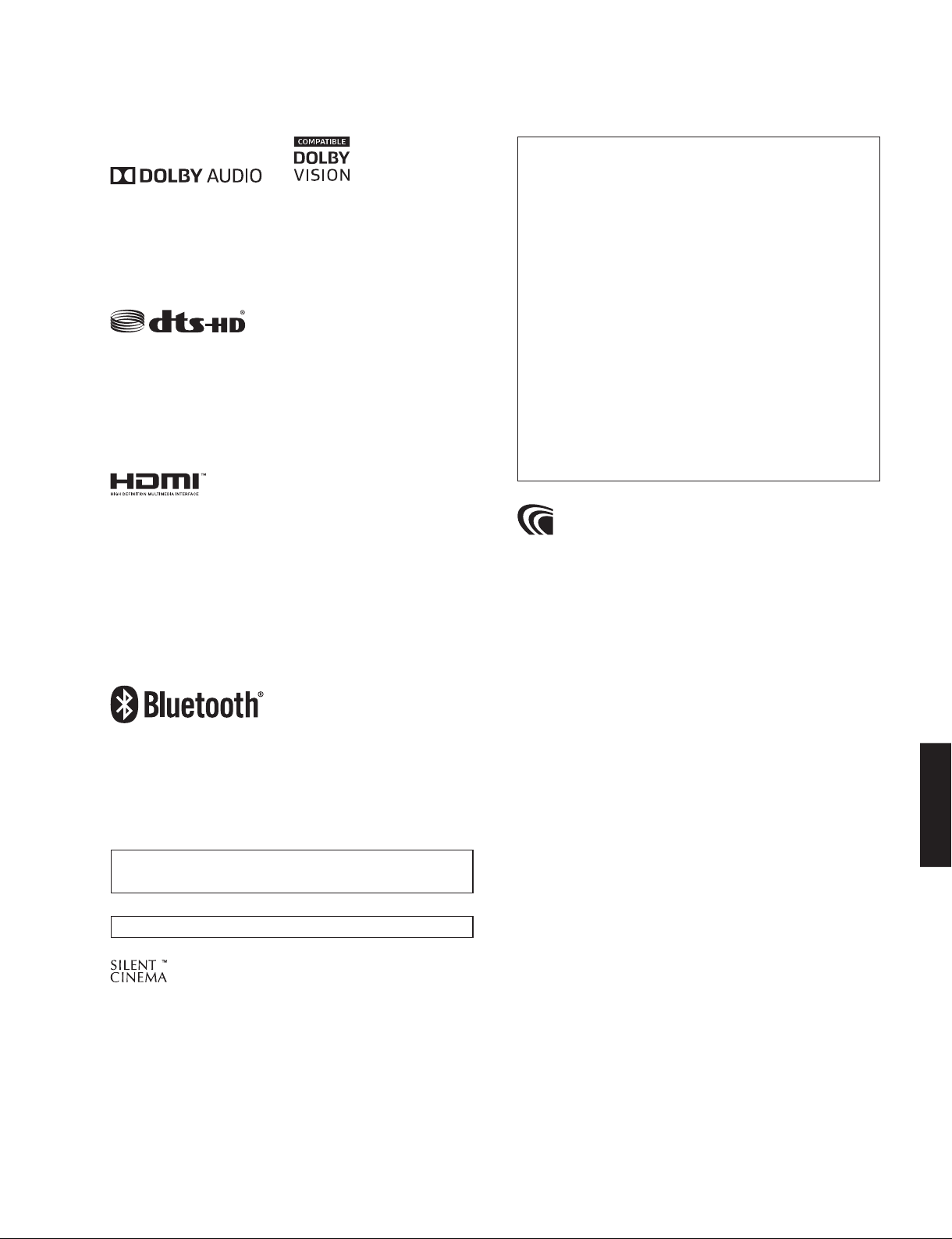

• DIMENSIONS /

寸法図

47

170 (6-5/8")58

(1-7/8")

(2-1/4")

Top view

(2")

Front view

ø 60

23

(7/8")

315 (12-3/8")

274 (10-3/4")

335 (13-1/4")50

50

(2")

18

(3/4")

130 (5-1/8")

151 (5-7/8")

RX-V385/HTR-3072

435 (17-1/8")

21

(7/8")

Unit: mm (inch)

単位:mm(インチ)

14

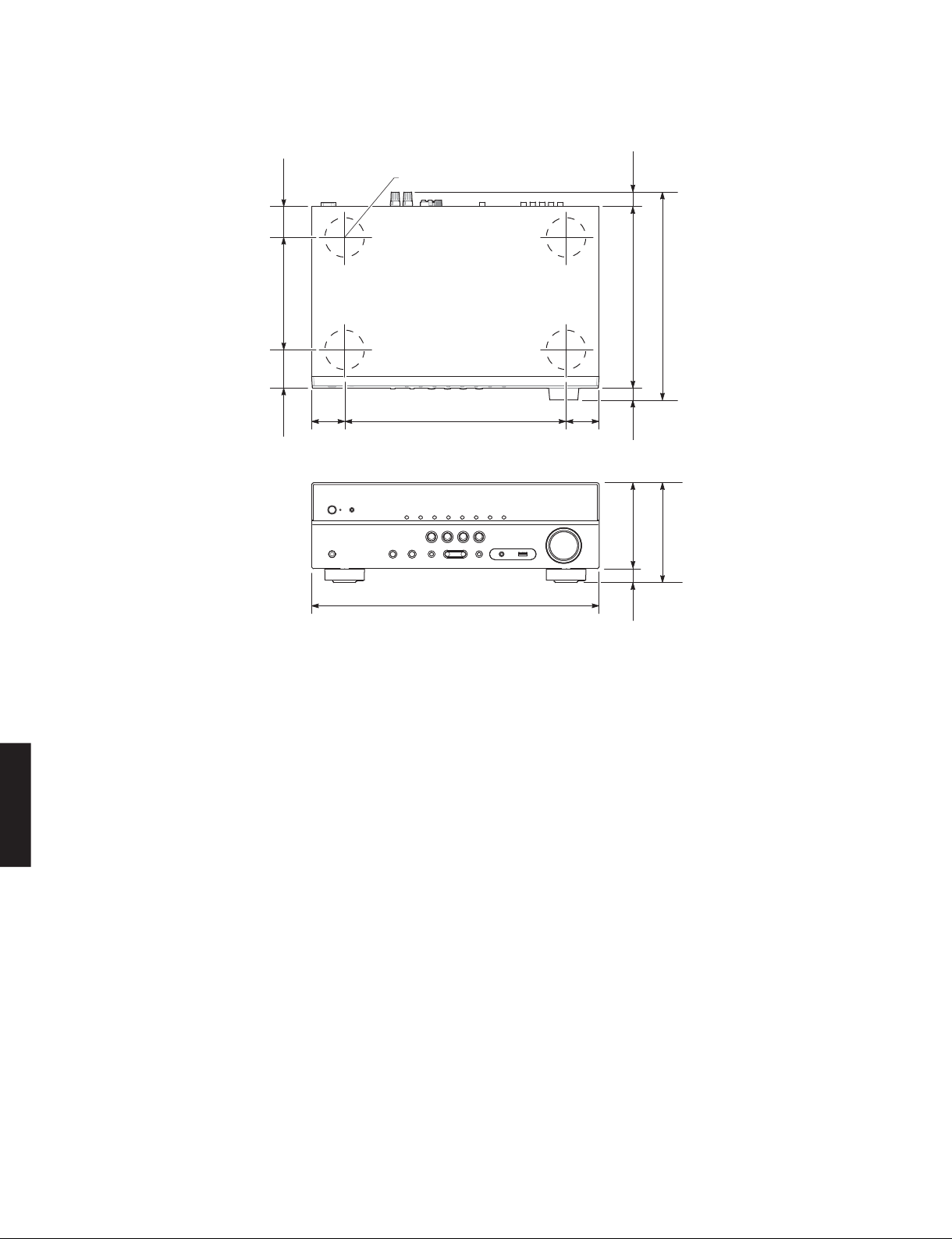

■ INTERNAL VIEW

Top view

23 456 71 8

12 1011 9

Front view

1413 1615

RX-V385/HTR-3072

1

OPERATION (2) P.C.B.

2

OPERATION (13) P.C.B. (V, P, S models)

3

MAIN (1) P.C.B.

4

DIGITAL P.C.B.

5

TUNER MODULE

6

OPERATION (3) P.C.B.

7

MAIN (3) P.C.B.

8

MAIN (2) P.C.B.

9

OPERATION (8) P.C.B.

OPERATION (10) P.C.B.

10

OPERATION (4) P.C.B.

11

MAIN (5) P.C.B.

12

POWER TRANSFORMER

13

OPERATION (5) P.C.B.

14

OPERATION (1) P.C.B.

15

BLUETOOTH MODULE

16

OPERATION (11) P.C.B.

17

OPERATION (6) P.C.B.

18

OPERATION (12) P.C.B.

19

OPERATION (7) P.C.B.

171819

■ SERVICE PRECAUTIONS /

サービス時の注意事項

Safety measures

• Some internal parts in this product contain high voltages

and are dangerous.

Be sure to take safety measures during servicing, such

as wearing insulating gloves.

• Note that the capacitors indicated below are dangerous

even after the power is turned off because an electric

charge remains and a high voltage continues to exist

there.

Before starting any repair work, connect a discharging

resistor (5 k-ohms/10 W) to the terminals of each

capacitor indicated below to discharge electricity.

The time required for discharging is about 30 seconds

per each.

C5419 and C5422 on OPERATION (2) P.C.B.

C5219 and C5220 on OPERATION (4) P.C.B.

C2185 and C2186 on MAIN (1) P.C.B.

RX-V385/HTR-3072

安全対策

・ この製品の内部には高電圧部分があり危険です。修理

の際は、絶縁性の手袋を使用するなどの安全対策を

行ってください。

・ 下記のコンデンサには電源を OFF にした後も電荷が残

り、高電圧が維持されており危険です。

修理作業前に放電用抵抗(5k Ω /10W)を下記の各

コンデンサの端子間に接続して放電してください。

放電所用時間は各々約 30 秒間です。

OPERATION(2)P.C.B. の C5419、C5422

OPERATION(4)P.C.B. の C5219、C5220

MAIN(1)P.C.B. の C2185、C2186

詳しくは “PRINTEDCIRCUITBOARDS” を参照してくだ

さい。

For details, refer to “PRINTED CIRCUIT BOARDS”.

15

RX-V385/HTR-3072

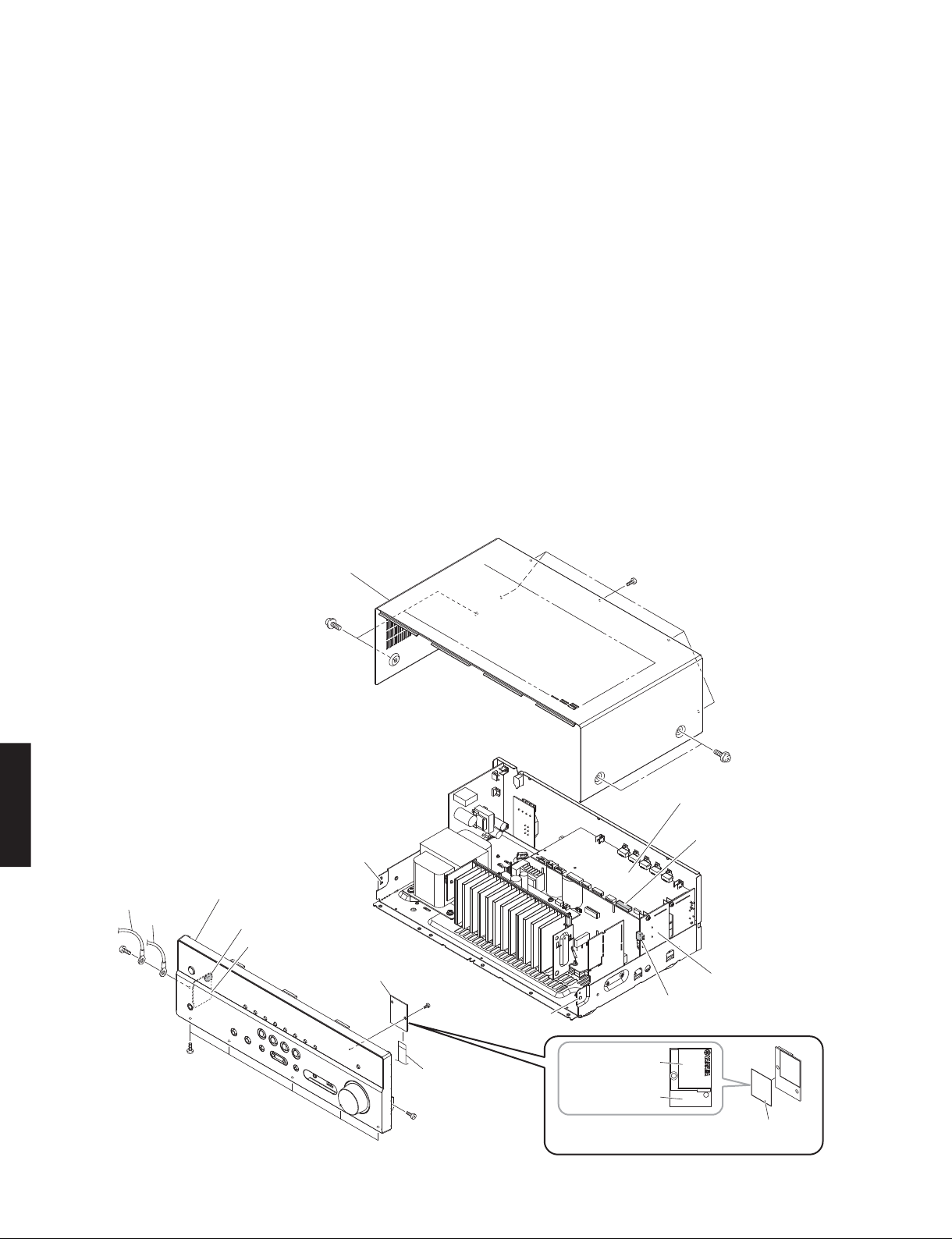

■ DISASSEMBLY PROCEDURES /

(Remove parts in the order as numbered.)

Disconnect the power cable from the AC outlet.

1. Removal of Top Cover (Fig. 1)

a. Remove 5 screws (①) and 4 screws (②).

b. Lift the rear side of the top cover to remove it.

2. Removal of Front Panel Unit (Fig. 1)

a. Remove 7 screws (③), W4501 and W4761.

b. Remove CB21, CB253 and CB477.

c. Release 2 hooks, and then remove the front panel

unit.

3. Removal of Bluetooth Module (Fig. 1)

a. Remove screw (④).

b. Remove the flexible flat cable.

c. Remove the Bluetooth module.

* When replacing the Bluetooth module with a new

one, remove the label attached on the pattern

face of the old Bluetooth module and reuse it by

attaching it to the new Bluetooth module.

分解手順

(番号順に部品を外してください。)

AC 電源コンセントから、電源コードを抜いてください。

1. トップカバーの外し方(Fig.1)

a. ①のネジ 5 本、②のネジ 4 本を外します。

b. トップカバーの後部を持ち上げ、外します。

2. フロントパネルユニットの外し方(Fig.1)

a. ③のネジ 7 本、W4501、W4761 を外します。

b. CB21、CB253、CB477 を外します。

c. フック 2 箇所を外し、フロントパネルユニットを外し

ます。

3. Bluetooth モジュールの外し方(Fig.1)

a. ④のネジ 1 本を外します。

b. カード電線を外します。

c. Bluetooth モジュールを外します。

※ 新しい Bluetooth モジュールへ交換する場合、古

い Bluetooth モジュールのパターン面に貼ってあ

るラベルを剥がし、新しい Bluetooth モジュール

に貼り直してください。

RX-V385/HTR-3072

W4761

③

W4501

トップカバー

Front panel unit

フロントパネルユニット

CB477

OPERATION (7) P.C.B.

③

Top cover

②

Hook

フック

Bluetooth module

Bluetoothモジュール

⑤

Flexible flat cable

カード電線

③

Hook

フック

①

②

DIGITAL P.C.B.

CB21

MAIN (2) P.C.B.

CB253

Label

ラベル

P.C.B. pattern side

P.C.B. パターン面

* Attaching detached label

※ ラベルの貼り直し

16

Fig. 1

RX-V385/HTR-3072

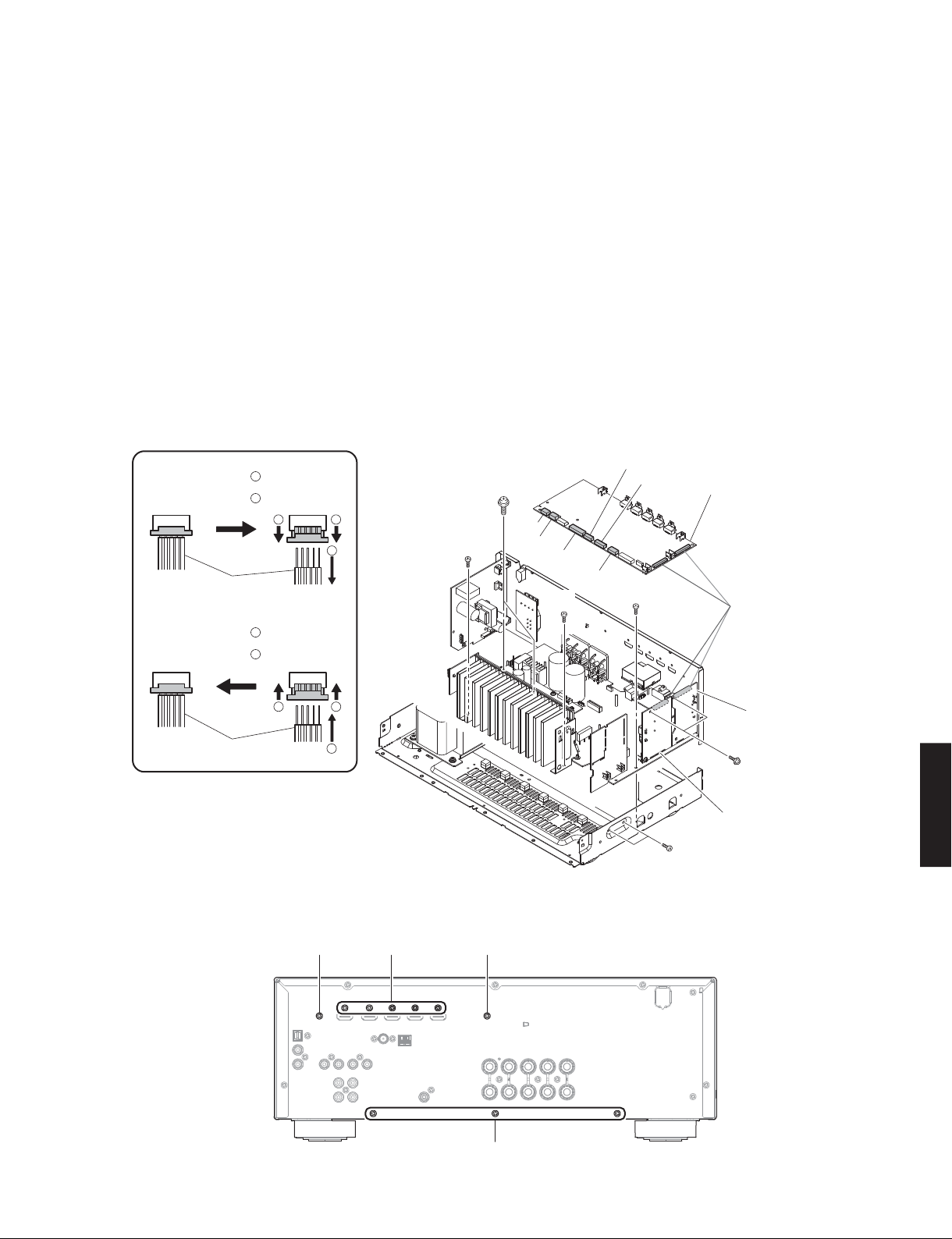

4. Removal of DIGITAL P.C.B.

a. Remove 2 screws (⑤) and 5 screws (⑥). (Fig. 3)

b. Remove 2 screws (⑦). (Fig. 2)

c. Remove CB22, CB24, CB26 and CB81. (Fig. 2)

d. Unlock and remove CB25 and CB27. (Fig. 2)

e. Remove the DIGITAL P.C.B. which is connected directly

to the MAIN (2) P.C.B. and MAIN (3) P.C.B. with boardto-board connectors. (Fig. 2)

5. Removal of AMP Unit

a. Remove 2 screws (⑧), 2 screws (⑨) and 3 screws (⑩).

(Fig. 2)

b. Remove 3 screws (⑪). (Fig. 3)

c. Remove the amp unit. (Fig. 2)

Remove CB25 and CB27

Connected

接続

ケーブル

Connect CB25 and CB27

Connected

接続

Cable

Unlock the connector

1

コネクターロック解除

Remove the cable

2

ケーブルを外す

11

2

Lock the connector

1

コネクターロック

Insert the cable

2

ケーブルを差し込む

⑧

4. DIGITALP.C.B. の外し方

a. ⑤のネジ 2 本、⑥のネジ 5 本を外します。(Fig.3)

b. ⑦のネジ 2 本を外します。(Fig.2)

c. CB22、CB24、CB26、CB81 を外します。(Fig.2)

d. ロックを外し、CB25、CB27 を外します。(Fig.2)

e. DIGITALP.C.B. を外します。ただし、DIGITALP.C.B. は

MAIN(2)P.C.B.、MAIN(3)P.C.B.に基板対基板コネクター

で直接接続されています。(Fig.2)

5. アンプユニットの外し方

a. ⑧のネジ 2 本、⑨のネジ 2 本、⑩のネジ 3 本を外し

ます。(Fig.2)

b. ⑪のネジ 3本を外します。(Fig.3)

c. アンプユニットを外します。(Fig.2)

CB27

⑨

CB24

CB81

CB22

⑧

CB25

CB26

⑩

DIGITAL P.C.B.

Board-to-board

connectors

基板対基板コネクター

Cable

ケーブル

11

2

MAIN (3) P.C.B.

RX-V385/HTR-3072

⑦

MAIN (2) P.C.B.

⑩

Fig. 2

⑥⑤ ⑤

⑪

Fig. 3

17

RX-V385/HTR-3072

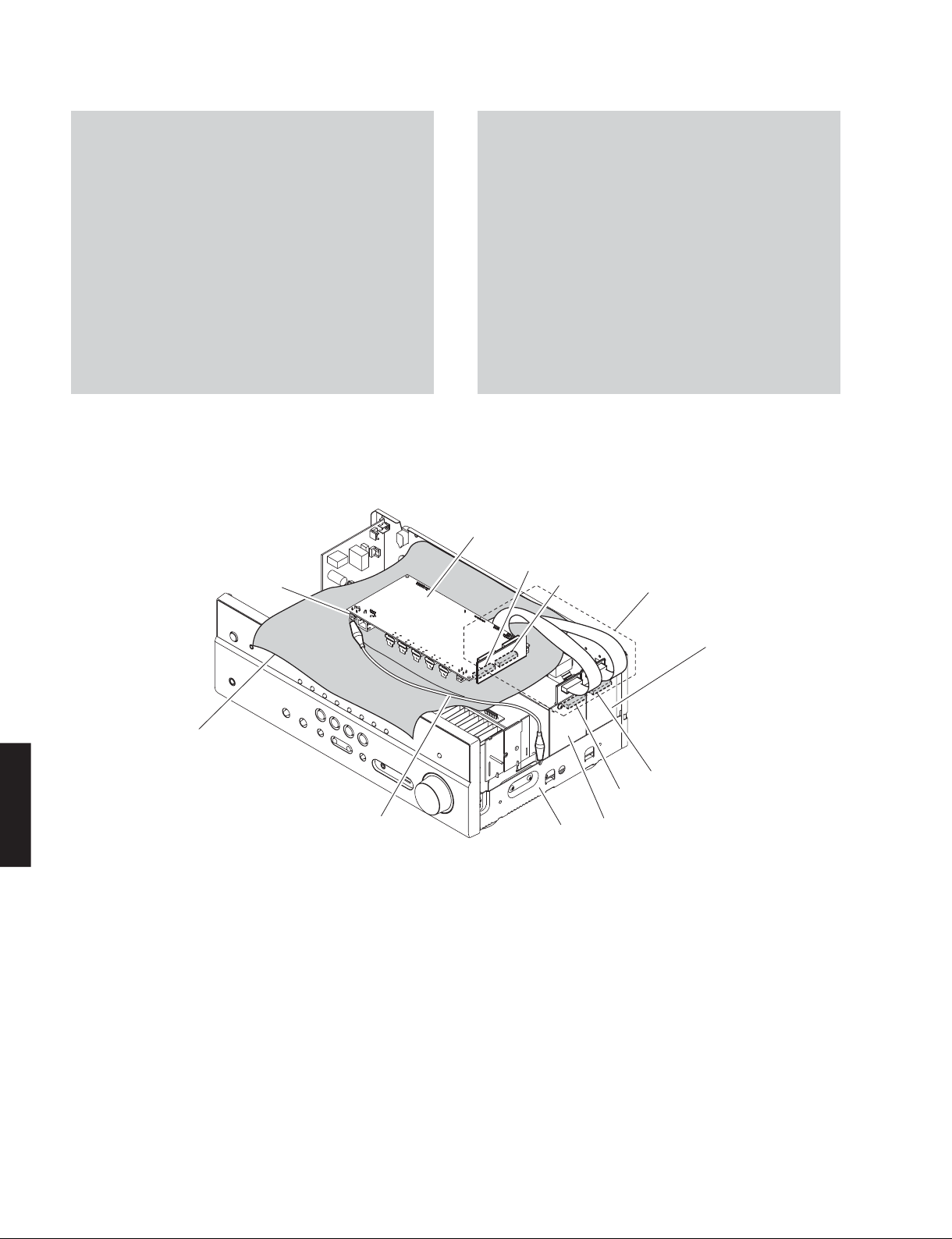

When checking the DIGITAL P.C.B.:

• Put the rubber sheet and cloth over this unit, and

place the DIGITAL P.C.B. on them. (Fig. 4)

• Connect ST952 on DIGITAL P.C.B. to the chassis

with a ground lead. (Fig. 4)

• Reconnect all cables (connectors) that have been

disconnected. Be sure to use the P.C.B. CHECKING

JIG (Part No.: ZG780000) to connect between the

following connectors.

CB61 on DIGITAL P.C.B. – CB271 on MAIN (3) P.C.B.

CB62 on DIGITAL P.C.B. – CB251 on MAIN (2) P.C.B.

• When connecting the flexible flat cable, be careful

with polarity.

ST952

DIGITALP.C.B. をチェックする場合には:

・ 本機の上にゴムシートと布を敷き、その上に

DIGITALP.C.B. を置きます。(Fig.4)

・ DIGITALP.C.B. の ST952 のアースをリード線でシャー

シに接続してください。(Fig.4)

・ 外したケーブル(コネクター)をすべて接続しま

す。ただし下記のコネクター間を接続するには

P.C.B. チェック用ジグ(部品番号:ZG780000)を使

用してください。

DIGITALP.C.B. の CB61 − MAIN(3)P.C.B. の CB271

DIGITALP.C.B. の CB62 − MAIN(2)P.C.B. の CB251

・ カード電線を接続する際、極性に注意してください。

DIGITAL P.C.B.

CB61

CB62

P.C.B. CHECKING JIG

P.C.B. チェック用ジグ

RX-V385/HTR-3072

Rubber sheet and cloth

ゴムシートと布

Ground lead

アース線

Fig. 4

Chassis

シャーシ

MAIN (3) P.C.B.

CB271

CB251

MAIN (2) P.C.B.

18

RX-V385/HTR-3072

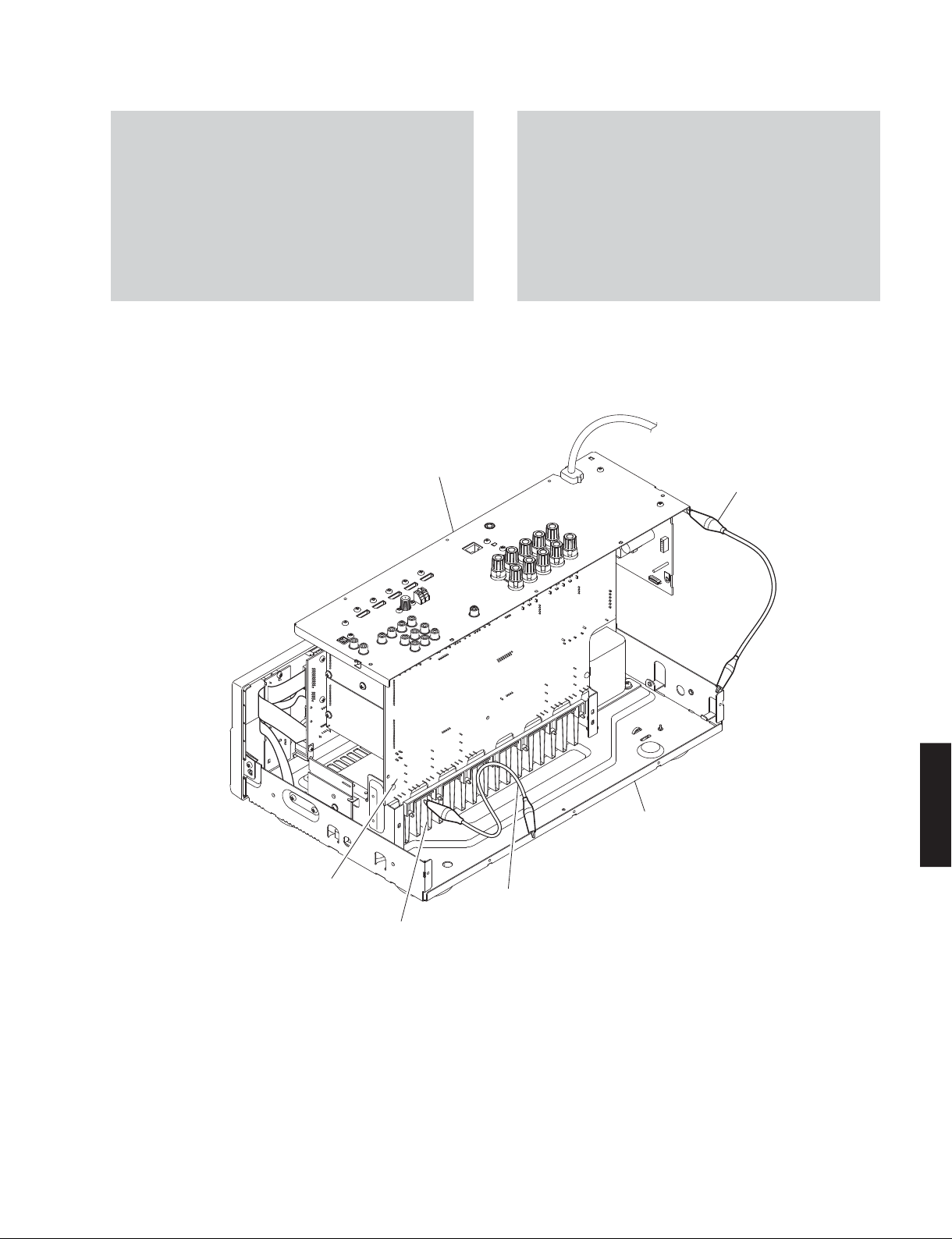

When checking the MAIN (1) P.C.B.:

• Place the P.C.B.s (with rear panel) upright. (Fig. 5)

• Connect the heatsink and rear panel to the chassis

with a ground lead or the like. (Fig. 5)

• Reconnect all cables (connectors) that have been

disconnected.

• When connecting the flexible flat cable, be careful

with polarity.

Rear panel

リアパネル

MAIN(1)P.C.B. をチェックする場合には:

• リアパネルと一緒に P.C.B. を立ち上げて置きます。

(Fig.5)

• ヒートシンク、リアパネルをリード線等でシャーシ

に接続してください。(Fig.5)

• 外したケーブル(コネクター)をすべて接続します。

• フラットケーブルを接続する際、極性に注意してく

ださい。

Ground lead

アース線

MAIN (1) P.C.B.

RX-V385/HTR-3072

Chassis

シャーシ

Ground lead

アース線

Heatsink

ヒートシンク

Fig. 5

19

RX-V385/HTR-3072

■ UPDATING FIRMWARE /

When the following parts are replaced, the firmware must

be updated to the latest version.

DIGITAL P.C.B.

IC21 and IC44 on DIGITAL P.C.B.

ファームウェアのアップデート

● Confirmation of firmware version and checksum

Before and after updating the firmware, check the

firmware version and checksum by using the selfdiagnostic function menu.

Start up the self-diagnostic function and select “S4.

ROM VERSION/CHECKSUM” menu.

Using the sub-menu, have the firmware version and

checksum displayed, and note them down.

(For details, refer to “SELF-DIAGNOSTIC FUNCTION”.)

* When the firmware version is different from

written one after updating, perform the updating

procedure again from the beginning again.

下記の部品を交換した場合、ファームウェアを最新バー

ジョンにアップデートする必要があります。

DIGITALP.C.B.

DIGITALP.C.B. の IC21、IC44

● ファームウェアのバージョンとチェックサムの

確認

ファームウェアのアップデートの前後に、ファーム

ウェアのバージョンとチェックサムをダイアグで確

認します。

ダイアグを起動し、“S4.ROM VERSION/CHECKSUM”

メニューを選択します。

サブメニューでファームウェアのバージョンと

チェックサムを表示し、それらを書きとめます。

(詳細は “ダイアグ” を参照してください。)

※ アップデート後、ファームウェアのバージョンが

書き込まれたものと異なる場合、アップデートの

操作を最初からやり直してください。

● Initializing the back-up IC

After updating the firmware, the back-up IC MUST

be initialized by the following procedure to store the

setting information (soundfield parameters, system

memory and tuner presetting, etc.) properly.

Start up the self-diagnostic function and select “S3.

FACTORY PRESET” menu.

(For details, refer to “SELF-DIAGNOSTIC FUNCTION”.)

Select “PRESET:RSRV”, press the “

turn off the power once and turn on the power again.

Then the back-up IC is initialized.

RX-V385/HTR-3072

● Required Tools

• USB storage device

• Latest firmware

● Preparation

1. Download the latest firmware from the specified

download source to the folder of the PC.

(EEPROM: IC23 on DIGITAL P.C.B.)

” (power) key to

● バックアップ IC の初期化

(EEPROM:DIGITALP.C.B. の IC23)

ファームウェアのアップデート後、設定情報(音

場プログラムのパラメーターやシステムメモリー、

チューナープリセット等)を正常に保存するために、

下記の方法でバックアップ IC を初期化する必要が

あります。

本機のダイアグを起動し、“S3.FACTORYPRESET” メ

ニューを選択します。

(詳細は “ダイアグ” を参照してください。)

“PRESET:RSRV” を選択し、“

て電源を一度きってから、もう一度電源を入れると

バックアップ IC が初期化されます。

”(電源)キーを押し

● 必要なツール

・ USB フラッシュメモリー

・ 最新のファームウェア

● 準備

1. 指定のダウンロード先から、最新のファームウェ

アを PC のフォルダへダウンロードしてください。

20

2. Copy the latest firmware from the PC to the root

folder of the USB storage device.

Note) When the latest firmware is copied to a sub-

folder of the USB storage device, the update

will not proceed.

2. PC から USB フラッシュメモリーのルートフォル

ダへ最新のファームウェアをコピーします。

注意)最新のファームウェアをサブフォルダにコピー

した場合、書き込みはできません。

RX-V385/HTR-3072

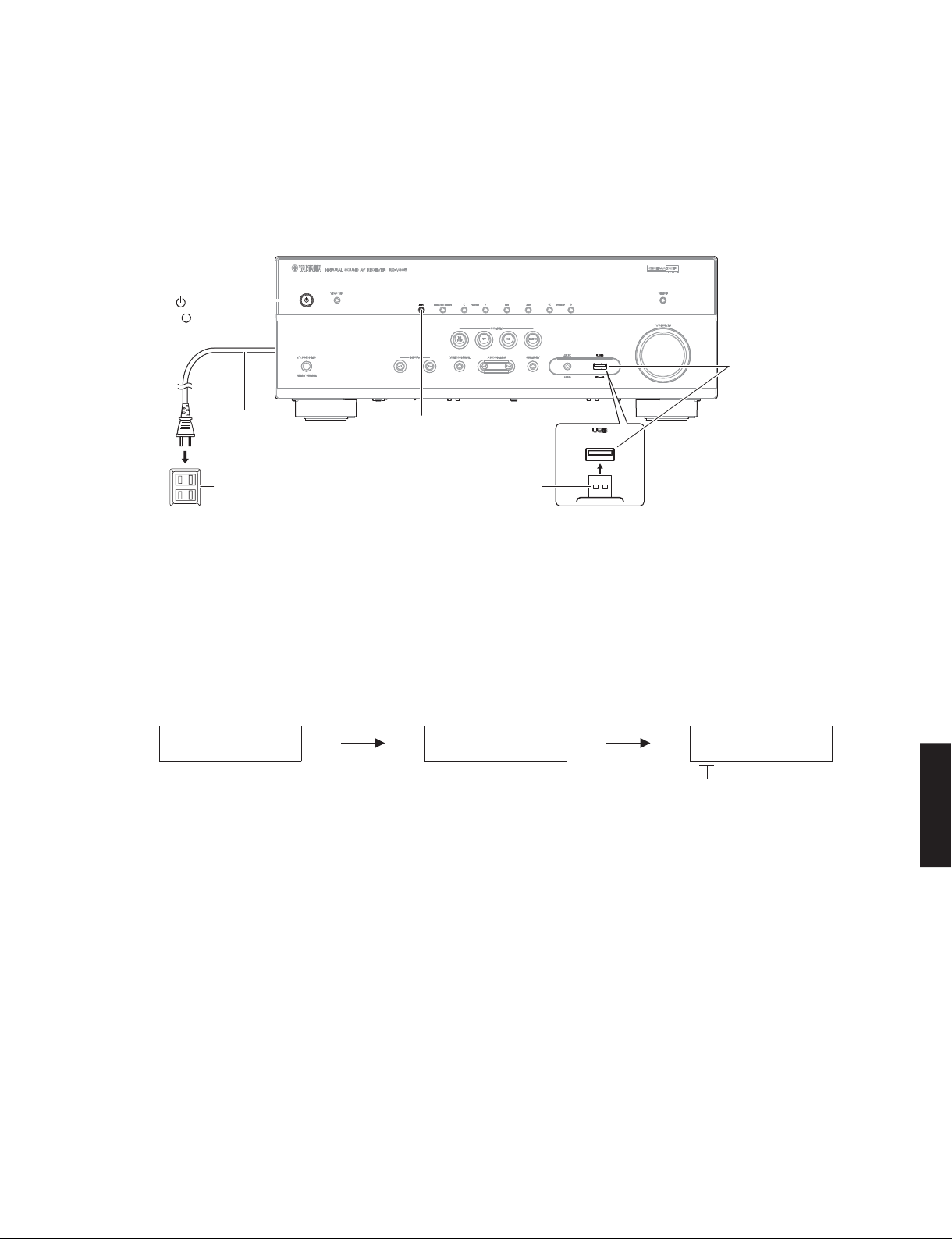

● Operation Procedures

1. Insert the USB storage device to the USB jack.

(Fig. 1)

2. While pressing the “INFO” key, connect the power

cable to the AC outlet. (Fig. 1)

" " (power) key

""(電源)キー

Power cable

電源コード

AC outlet

AC コンセント

"INFO" key

“INFO” キー

USB フラッシュメモリー

● 操作手順

1. USB 端子に USB フラッシュメモリーを差し込みま

す。(Fig.1)

2. “INFO” キーを押しながら、電源コードを AC コン

セントに接続します。(Fig.1)

USB jack

USB 端子

USB storage device

Fig. 1

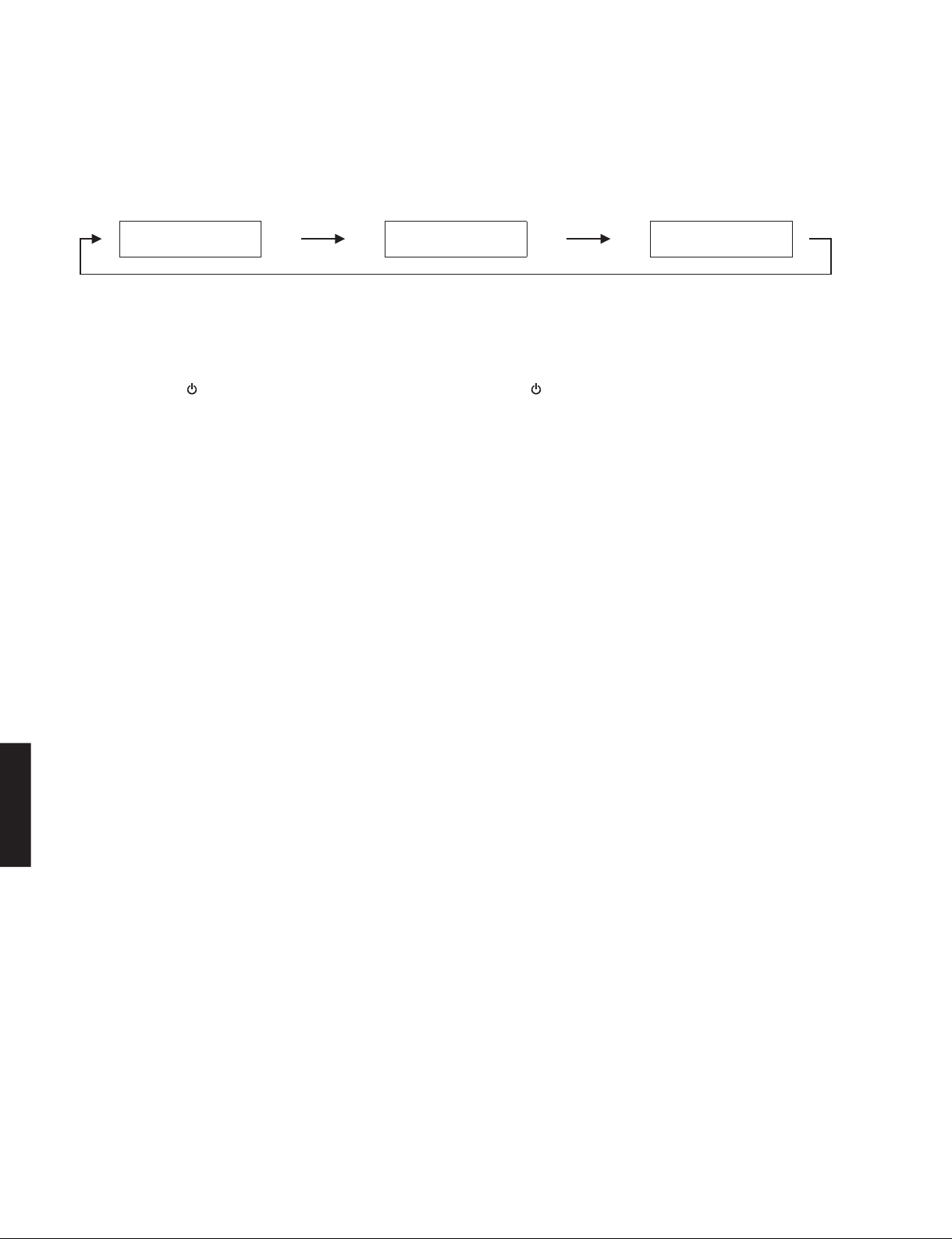

3. The USB UPDATE mode is activated and “USB

Update” is displayed. Writing of the firmware

starts automatically. (Fig. 2)

Writing is started. /

USBUPDATE VERIFYING... Sx-x:xx%

書き込み開始

3. USBUPDATE モードが起動し、“USBUpdate” が表

示されて、ファームウェアの書き込みが自動的に

開始されます。(Fig.2)

Writing being executed. /

S1: Not for service /

S2: MAIN (IC22 on DIGITAL P.C.B.) section

S3: DSP (IC44 on DIGITAL P.C.B.) section

S4: Not for service /

S5: OSD (IC21 on DIGITAL P.C.B.) section

書き込み中

Fig. 2

* If “ERROR! xxxxxx” is displayed during

writing of the firmware, refer to “List of Error

Messages” to determine the cause and

perform the updating procedure again from

※ ファームウェアの書き込みの途中で “ERROR!

xxxxxx” が表示された場合、“エラーメッセー

ジ一覧” で原因を参照し、アップデートの操

作を最初からやり直してください。

the beginning.

RX-V385/HTR-3072

サービスでは使用しません

サービスでは使用しません

21

RX-V385/HTR-3072

4. When writing of the firmware is completed,

“UPDATE SUCCESS”, “PLEASE ...” and “POWER

OFF!” are displayed repeatedly. (Fig. 3)

Writing is completed. /

UPDATESUCCESS PLEASE... POWEROFF!

書き込み完了

4. ファームウェアの書き込み完了後、“UPDATE

SUCCESS”、“PLEASE...”、“POWEROFF!” が繰り返

し表示されます。(Fig.3)

Fig. 3

5. Press the “ ” (power) key to turn off the power.

(Fig. 1)

6. Remove the USB storage device from the USB

jack. (Fig. 1)

7. Start up the self-diagnostic function and check

that the firmware version and checksum are the

same as written ones.

(For details, refer to “Confirmation of firmware

5. “

”(電源)キーを押して電源を切ります。(Fig.1)

6. USB 端子から USB フラッシュメモリーを抜きま

す。(Fig.1)

7. ダイアグを起動し、ファームウェアのバージョン

とチェックサムが、書き込まれたものと同じであ

ることを確認します。

(詳細は “ファームウェアのバージョンとチェック

サムの確認” を参照してください。)

version and checksum”.)

RX-V385/HTR-3072

22

RX-V385/HTR-3072

List of Error Messages

When firmware writing error, “ERROR! xxxxxx” is displayed.

* “xxxxxx” is a hexadecimal value, and each bit is

represented as follows.

エラーメッセージ一覧

ファームウェアの書き込みエラーが発生すると “ERROR!

xxxxxx” が表示されます。

※ “xxxxxx” は 16 進数値で、以下のように各ビットを表

しています。

Display /

ERROR!xxxxxx

Display Binary Error Message

表示

バイナリ

000001 0 bit 1: Main microprocessor preparation error /

000002 1 bit 1: Main microprocessor erase error /

000004 2 bit 1: Main microprocessor program error /

000008 3 bit 1: Main microprocessor checksum error /

000010 4 bit 1: DSP1 status port error /

000020 5 bit 1: DSP1 checksum error /

000040 6 bit 1: DSP1 data reception timeout /

000080 7 bit 1: DSP1 checksum calculation timeout /

000100 8 bit 1: DSP2 status port error /

000200 9 bit 1: DSP2 checksum error /

000400 10 bit 1: DSP2 data reception timeout /

000800 11 bit 1: DSP2 checksum calculation timeout /

001000 12 bit 1: DSP3 status port error /

002000 13 bit 1: DSP3 checksum error /

004000 14 bit 1: DSP3 data reception timeout /

008000 15 bit 1: DSP3 checksum calculation timeout /

010000 16 bit 1: OSD Flash ROM erase error /

020000 17 bit 1: OSD Flash ROM program error /

040000 18 bit 1: OSD Flash ROM checksum error /

080000 19 bit 1: Model determination error /

DSP1 ステータスポートエラー

DSP1 チェックサムエラー

DSP1 データ受信タイムアウト

DSP2 ステータスポートエラー

DSP2 チェックサムエラー

DSP2 データ受信タイムアウト

DSP3 ステータスポートエラー

DSP3 チェックサムエラー

DSP3 データ受信タイムアウト

OSDFlashROM 消去エラー

モデル判定エラー

メインマイコン準備エラー

メインマイコン消去エラー

メインマイコンプログラムエラー

メインマイコンチェックサムエラー

DSP1 チェックサム計算タイムアウト

DSP2 チェックサム計算タイムアウト

DSP3 チェックサム計算タイムアウト

OSDFlashROM プログラムエラー

OSDFlashROM チェックサムエラー

表示

エラーメッセージ

Error number /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

エラー番号

0: No error /

0: No error /

0: No error /

0: No error /

0: No error /

0: No error /

0: No error /

0: No error /

0: No error /

0: No error /

0: No error /

0: No error /

0: No error /

0: No error /

0: No error /

0: No error /

0: No error /

0: No error /

0: No error /

0: No error /

エラーなし

エラーなし

エラーなし

エラーなし

エラーなし

エラーなし

エラーなし

エラーなし

エラーなし

サービスでは使用しません

エラーなし

サービスでは使用しません

エラーなし

サービスでは使用しません

エラーなし

サービスでは使用しません

エラーなし

サービスでは使用しません

エラーなし

サービスでは使用しません

エラーなし

サービスでは使用しません

エラーなし

サービスでは使用しません

エラーなし

エラーなし

エラーなし

エラーなし

)

)

)

)

)

)

)

)

RX-V385/HTR-3072

* The error number is displayed in the 6-digit hexadecimal notation.

エラー番号は 6 桁の 16 進数で表示されます。

* The error numbers are added when a multiple number of errors occur at the same time.

エラー番号は同時に複数のエラーが発生すると、加算されます。

Example / 例 If errors by the error number “000002” and “000008” occur at the same time, the error number will be displayed as “00000A”.

エラー番号の000002と000008のエラーが同時に発生すると、エラー番号は00000Aと表示されます。

23

RX-V385/HTR-3072

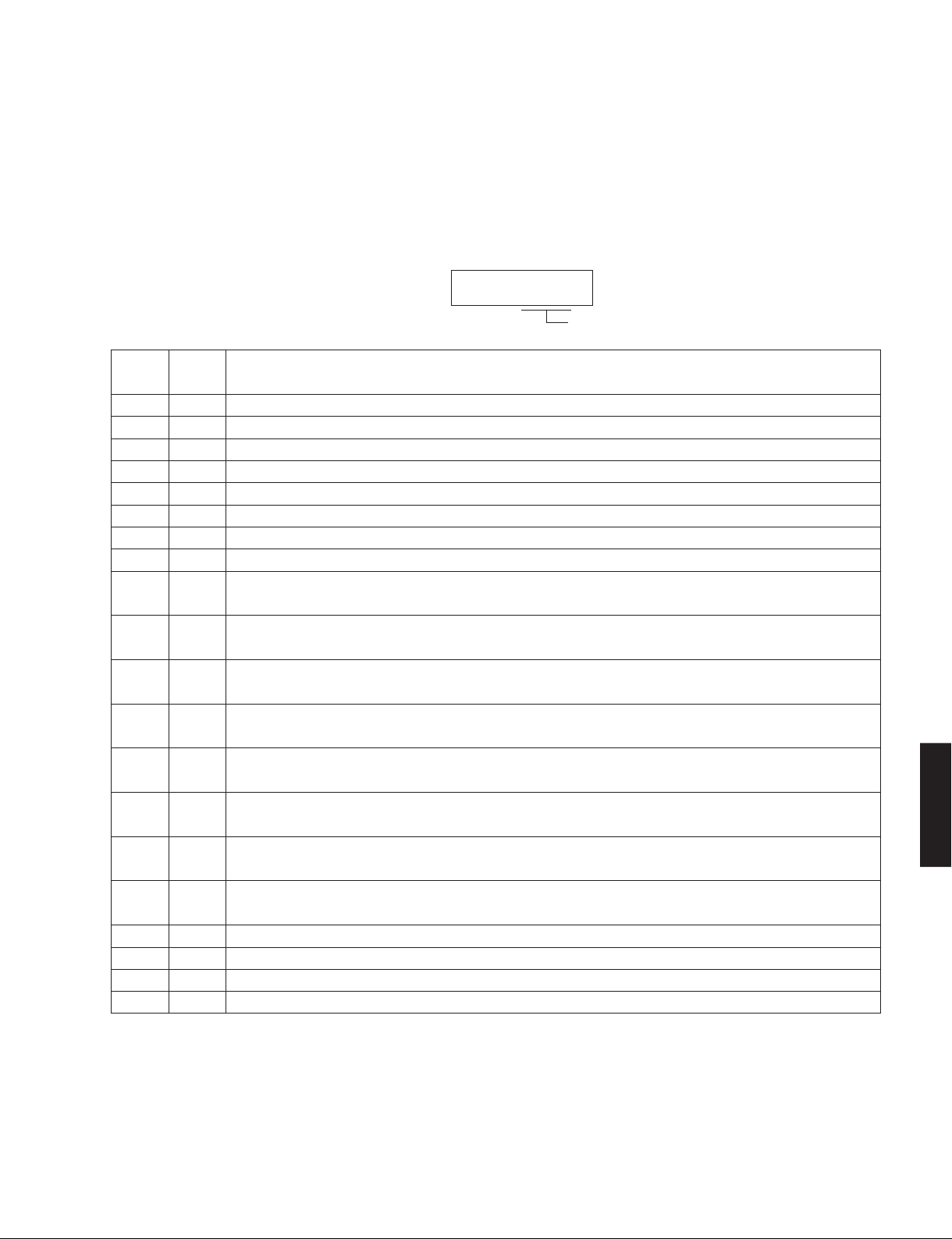

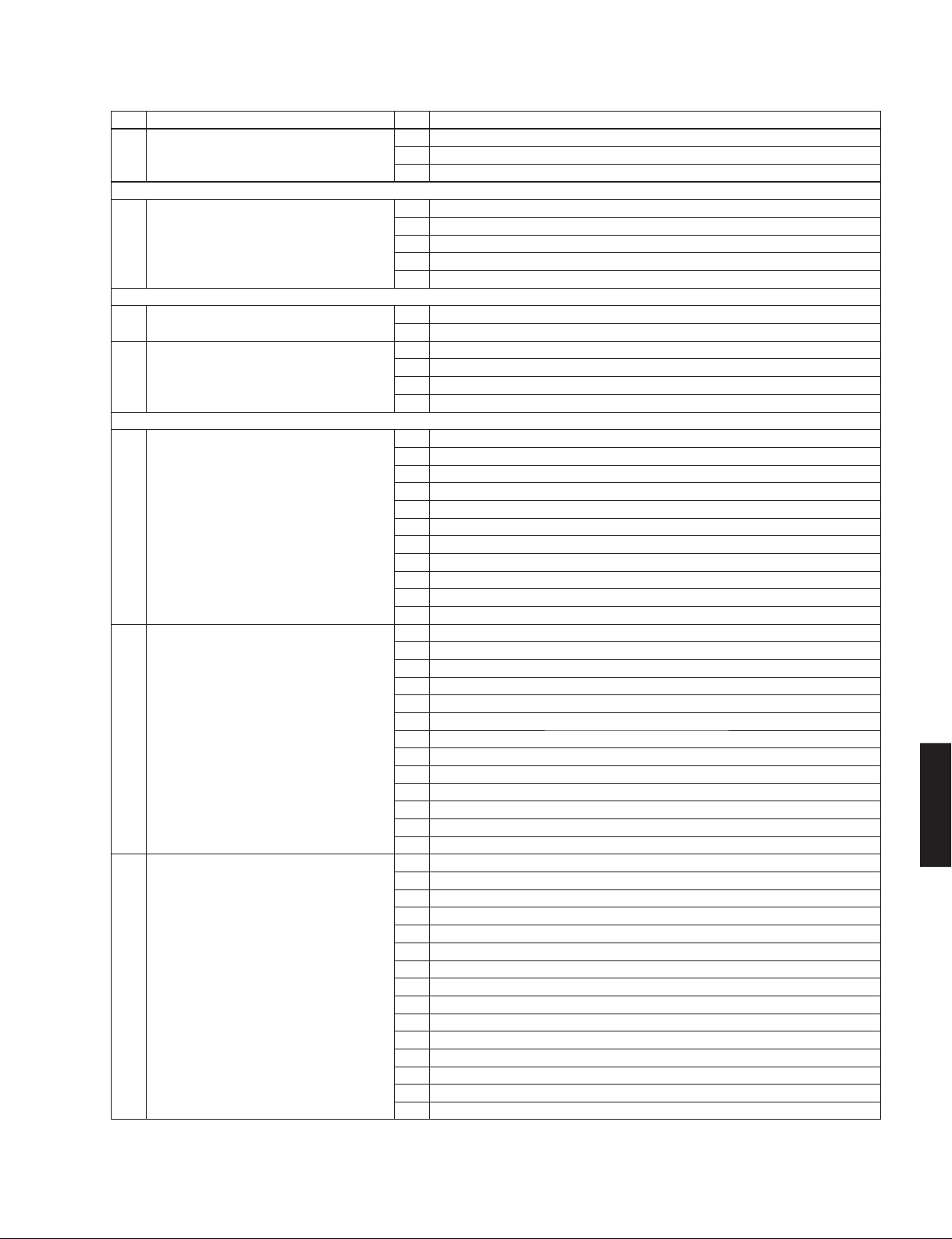

■ SELF-DIAGNOSTIC FUNCTION /

This unit has self-diagnostic functions that are intended

for inspection, measurement and location of faulty point.

Each item has a main menu, each of which has sub-menu

items.

Listed in the table below are main menu items and submenu items.

Note: Some of the menu items listed below may not apply

to the models covered in this service manual.

No. Main menu No. Sub-menu

A: Audio system /

A1 DSP AUDIO 1 DSP THROUGH

A2 CH AUDIO 1 CH AUDIO: VH

A3 HDMI AUDIO 1 HDMI AUTO

A4 AUDIO ROUTE CHECK 1 BI-AMP

RX-V385/HTR-3072

A5 IMPEDANCE TEST 1 INVALID ITEM

(Not for service /

A6 MIC CHECK 1 MIC ROUTE CHECK

A7 DIR PLL LOCK CHECK 1 DIR PLL

A8 MANUAL TEST 1 TEST ALL

24

オーディオ系

サービスでは使用しません

ダイアグ(自己診断機能)

2 INVALID ITEM

2 CH AUDIO: VL

3 CH AUDIO: CENTER

4 CH AUDIO: SURROUND

5 INVALID ITEM

6 CH AUDIO: SUBWOOFER

7 INVALID ITEM

2 INVALID ITEM

3 HDMI THROUGH

4 ARC 1

5 INVALID ITEM

6 eARC

2 INVALID ITEM

3 INVALID ITEM

4 FULL MUTE

5 INVALID ITEM

6 INVALID ITEM

7 INVALID ITEM

8 INVALID ITEM

9 INVALID ITEM

10 INVALID ITEM

11 INVALID ITEM

12 INVALID ITEM

13 INVALID ITEM

14 INVALID ITEM

15 INVALID ITEM

16 INVALID ITEM

)

2 INVALID ITEM

2 INVALID ITEM

3 INVALID ITEM

4 INVALID ITEM

5 INVALID ITEM

6 INVALID ITEM

7 INVALID ITEM

8 INVALID ITEM

9 INVALID ITEM

10 INVALID ITEM

11 INVALID ITEM

12 INVALID ITEM

13 INVALID ITEM

14 INVALID ITEM

本機には、検査、測定、不良個所の発見を目的にしたダ

イアグ(自己診断機能)があります。

ダイアグには項目別にメインメニューがあり、そのそれ

ぞれにサブメニューがあります。

下表はダイアグメニュー一覧です。

注意: 以下のメニュー項目の一部は、このサービスマニュ

アルに記載されているモデルに適用されない場合

があります。

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

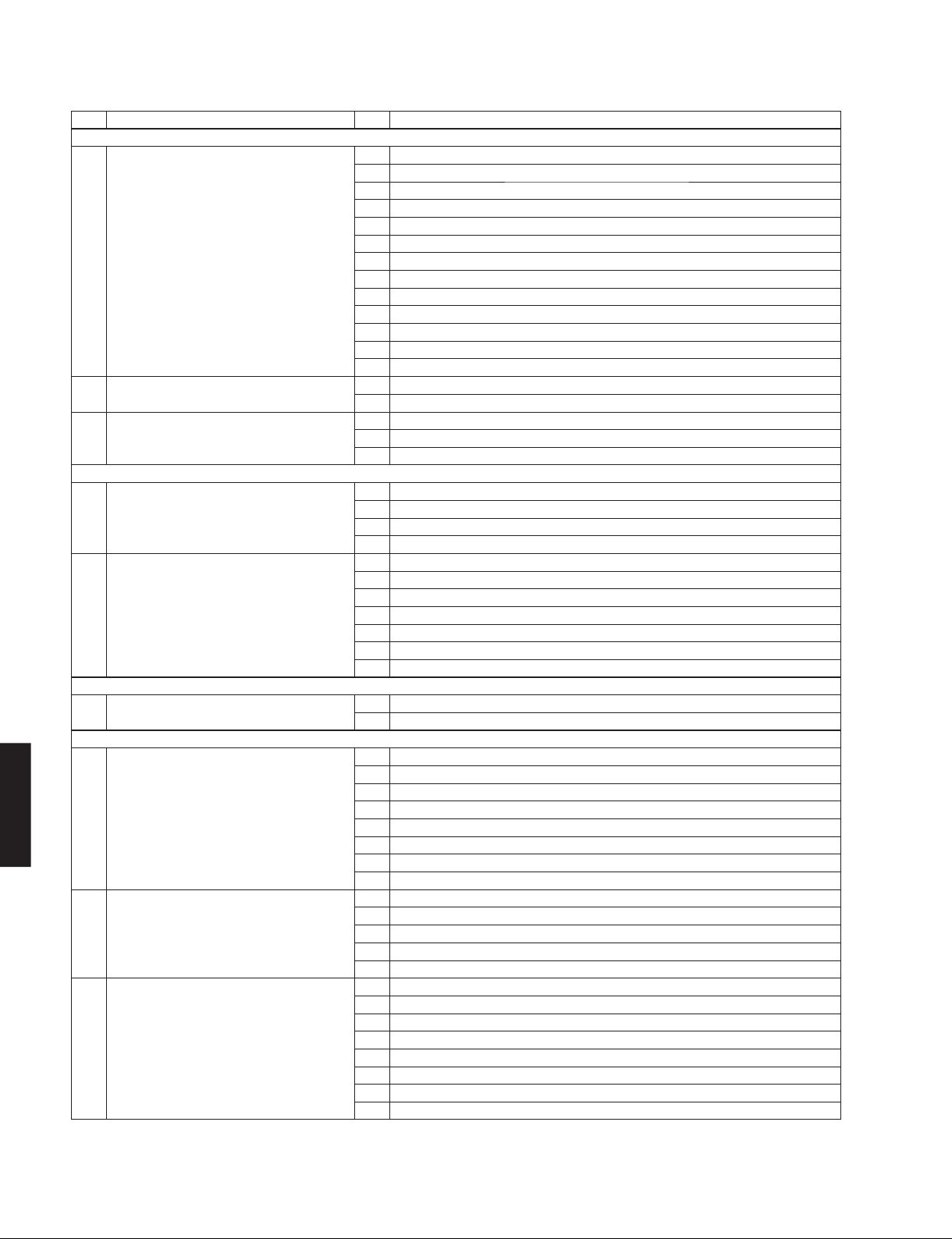

No. Main menu No. Sub-menu

A9 AUDIO LOOPBACK TEST 1 AUD LOOPBK0:

(Not for service /

サービスでは使用しません

)

2 AUD LOOPBK1:

3 AUD LOOPBK2:

D: Display system /

表示系

D1 FL CHECK 1 INITIAL DISPLAY

2 ALL SEGMENT OFF

3 ALL SEGMENT ON

4 CHECK PATTERN 1

5 CHECK PATTERN 2

U: Universal system /

特殊端子系

U1 USB 1 USB FRONT 1 TRACK

2 INVALID ITEM

(Not for service /

U2 USB COMPLIANCE TEST 1 TEST PACKET

(Not for service /

N: Network system /

サービスでは使用しません

ネットワーク系

N1 INVALID ITEM 1 INVALID ITEM

(Not for service /

サービスでは使用しません

N2 INVALID ITEM 1 INVALID ITEM

(Not for service /

サービスでは使用しません

)

2 INVALID ITEM

3 INVALID ITEM

4 INVALID ITEM

)

2 INVALID ITEM

3 INVALID ITEM

4 INVALID ITEM

5 INVALID ITEM

6 INVALID ITEM

7 INVALID ITEM

8 INVALID ITEM

9 INVALID ITEM

10 INVALID ITEM

11 INVALID ITEM

)

2 INVALID ITEM

3 INVALID ITEM

4 INVALID ITEM

5 INVALID ITEM

6 INVALID ITEM

7 INVALID ITEM

8 INVALID ITEM

9 INVALID ITEM

10 INVALID ITEM

11 INVALID ITEM

12 INVALID ITEM

13 INVALID ITEM

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

N3 BLUETOOTH 1 Bluetooth MODULE VERSION

2 Bluetooth MODULE ADDRESS

3 INVALID ITEM

4 Bluetooth AUDIO LOOPBACK

5 LINE: N/A

6 LINE: L1

7 LINE: L2

8 LINE: L3

9 LINE: L4

10 LINE: L5

11 LINE: L6

12 LINE: L7

13 LINE: L8

14 LINE: L9

15 LINE: L10

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

RX-V385/HTR-3072

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

RX-V385/HTR-3072

25

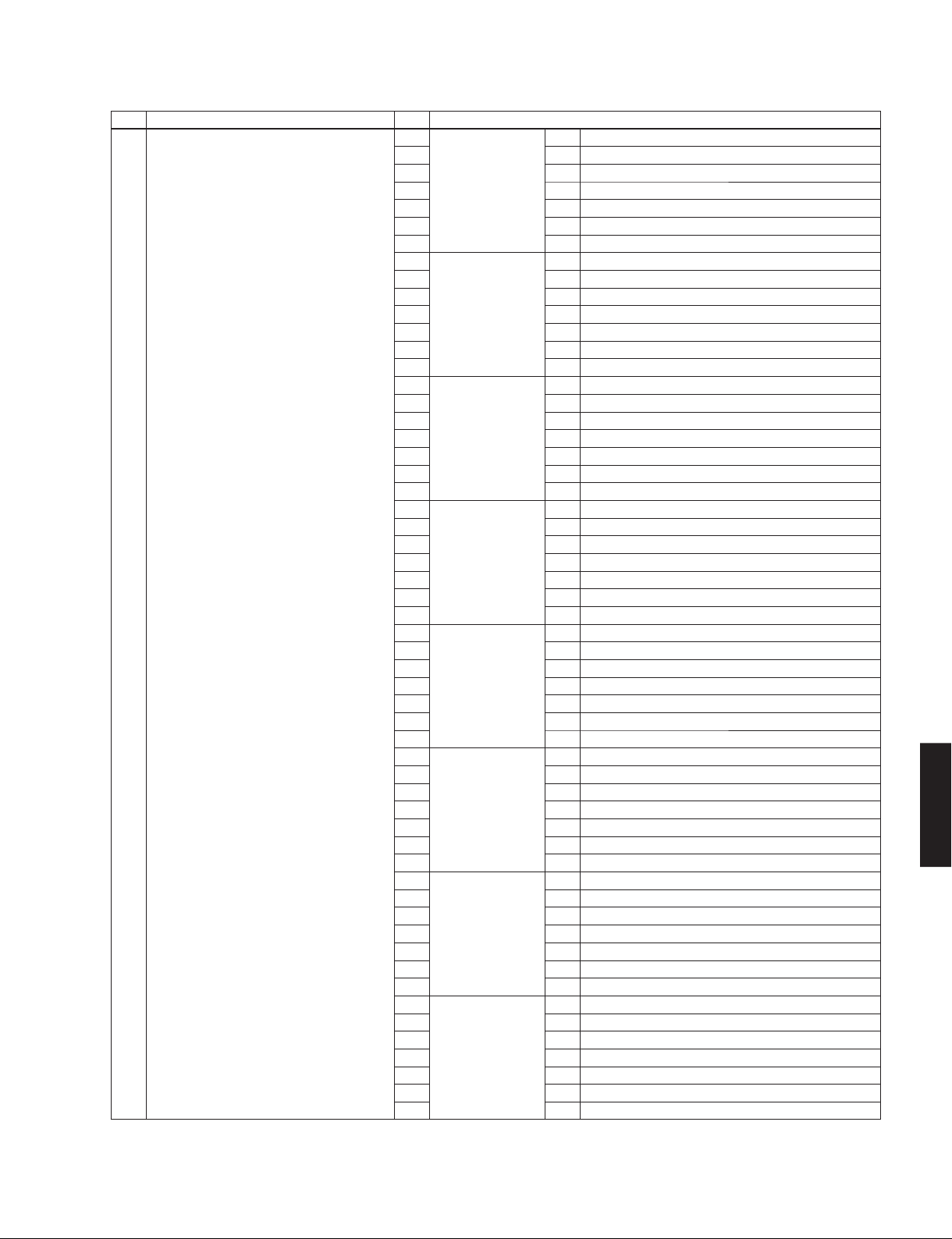

RX-V385/HTR-3072

No. Main menu No. Sub-menu

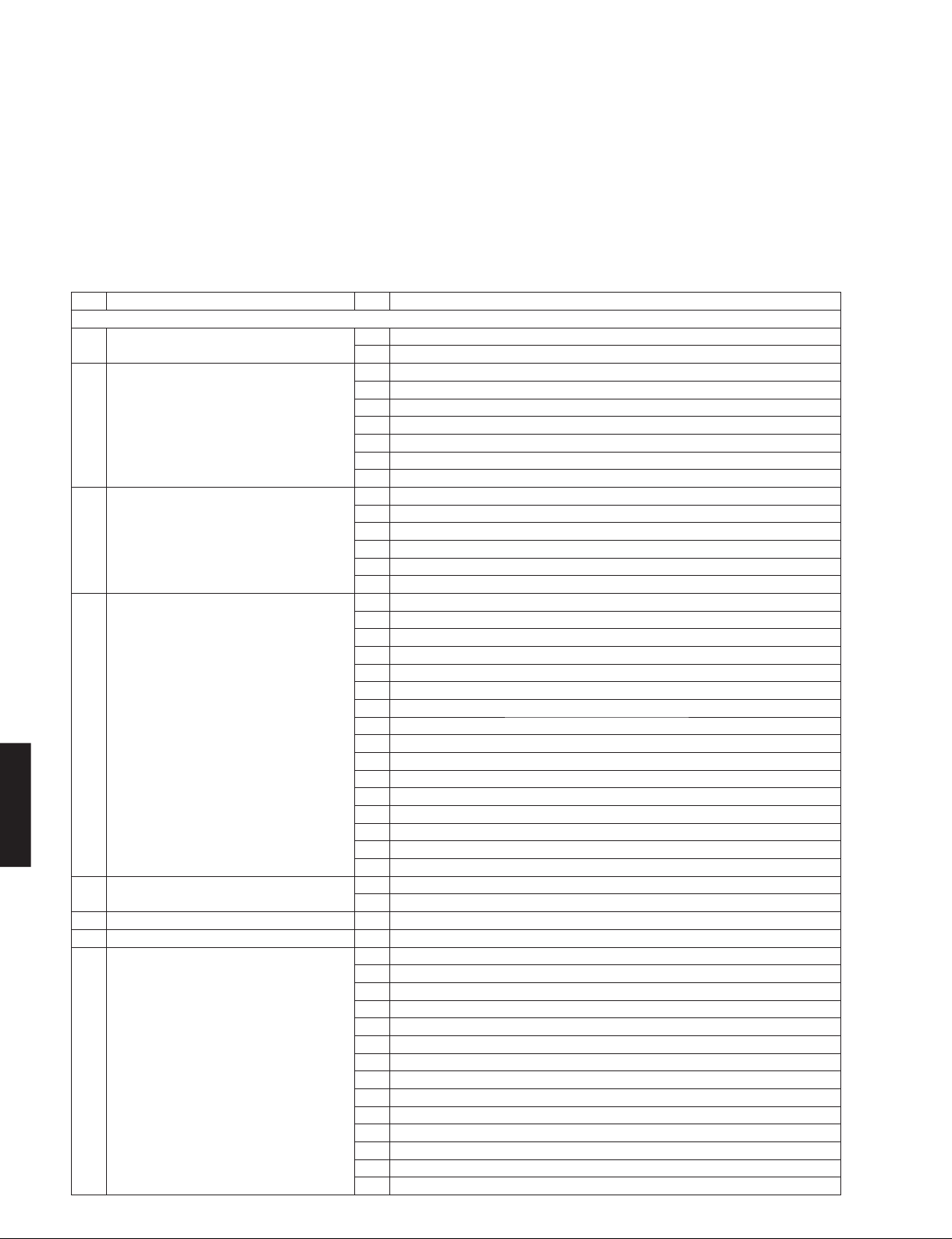

C: Communication system /

C1 ACCESS CHECK 1 ALL

C2 INVALID ITEM 1 INVALID ITEM

(Not for service /

C3 INVALID ITEM 1 INVALID ITEM

(Not for service /

V: Video system /

V1 ANALOG VIDEO CHECK 1 ANALOG BYPASS

V2 DIGITAL VIDEO CHECK 1 HDMI REPEAT

R: Radio system /

R1 INVALID ITEM 1 INVALID ITEM

(Not for service /

T: Troubleshooting Information /

T1 TROUBLE SHOOTING INFORMATION 1 OPERATING TIME

RX-V385/HTR-3072

T2 USAGE ENVIRONMENT 1 MAIN ZONE HIGHEST VOLUME

T3 EXTERNAL EVENT 1 HISTORY 1

通信・バスライン系

サービスでは使用しません

サービスでは使用しません

ビデオ系

TUNER・衛星放送系

サービスでは使用しません

サービス・設計用故障解析情報

2 MCPU OSD

3 INVALID ITEM

4 INVALID ITEM

5 I2C

6 INVALID ITEM

7 DIR BUS

8 DSP BUS

9 EEPROM

10 INVALID ITEM

11 INVALID ITEM

12 CEC CHECK

13 Bluetooth CHECK

)

2 INVALID ITEM

)

2 INVALID ITEM

3 INVALID ITEM

2 INVALID ITEM

3 MUTE CHECK

4 INVALID ITEM

2 OSD-VIDEO OUT

3 INVALID ITEM

4 INVALID ITEM

5 INVALID ITEM

6 INVALID ITEM

7 INVALID ITEM

)

2 INVALID ITEM

2 POWER-RELAY ON

3 POWER AMP B

4 OUTPUT LEVEL

5 POWER OFF TIME-OUT

6 MICROPROCESSOR OPERATION TIME

7 MICROPROCESSOR RESET START NUMBER

8 PROTECTION LOCK NUMBER

2 INVALID ITEM

3 INVALID ITEM

4 THM HIGHEST TEMPREATURE

5 EEPROM ERROR

2 HISTORY 2

3 HISTORY 3

4 HISTORY 4

5 HISTORY 5

6 HISTORY 6

7 HISTORY 7

8 HISTORY 8

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

26

No. Main menu No. Sub-menu

T4 PROTECTION DETECTION 1 HISTORY 1 1. HISTORY 1

2 1. LAST INPUT

3 1. LAST VOLUME

4 1. POWER RELAY ON TIME

5 1. POWER RELAY OPERATION TIME

6 1. MICROPROCESSOR OPERATION TIME

7 1. MICROPROCESSOR RESET START NUMBER

8 HISTORY 2 2. HISTORY 2

9 2. LAST INPUT

10 2. LAST VOLUME

11 2. POWER RELAY ON TIME

12 2. POWER RELAY OPERATION TIME

13 2. MICROPROCESSOR OPERATION TIME

14 2. MICROPROCESSOR RESET START NUMBER

15 HISTORY 3 3. HISTORY 3

16 3. LAST INPUT

17 3. LAST VOLUME

18 3. POWER RELAY ON TIME

19 3. POWER RELAY OPERATION TIME

20 3. MICROPROCESSOR OPERATION TIME

21 3. MICROPROCESSOR RESET START NUMBER

22 HISTORY 4 4. HISTORY 4

23 4. LAST INPUT

24 4. LAST VOLUME

25 4. POWER RELAY ON TIME

26 4. POWER RELAY OPERATION TIME

27 4. MICROPROCESSOR OPERATION TIME

28 4. MICROPROCESSOR RESET START NUMBER

29 HISTORY 5 5. HISTORY 5

30 5. LAST INPUT

31 5. LAST VOLUME

32 5. POWER RELAY ON TIME

33 5. POWER RELAY OPERATION TIME

34 5. MICROPROCESSOR OPERATION TIME

35 5. MICROPROCESSOR RESET START NUMBER

36 HISTORY 6 6. HISTORY 6

37 6. LAST INPUT

38 6. LAST VOLUME

39 6. POWER RELAY ON TIME

40 6. POWER RELAY OPERATION TIME

41 6. MICROPROCESSOR OPERATION TIME

42 6. MICROPROCESSOR RESET START NUMBER

43 HISTORY 7 7. HISTORY 7

44 7. LAST INPUT

45 7. LAST VOLUME

46 7. POWER RELAY ON TIME

47 7. POWER RELAY OPERATION TIME

48 7. MICROPROCESSOR OPERATION TIME

49 7. MICROPROCESSOR RESET START NUMBER

50 HISTORY 8 8. HISTORY 8

51 8. LAST INPUT

52 8. LAST VOLUME

53 8. POWER RELAY ON TIME

54 8. POWER RELAY OPERATION TIME

55 8. MICROPROCESSOR OPERATION TIME

56 8. MICROPROCESSOR RESET START NUMBER

RX-V385/HTR-3072

RX-V385/HTR-3072

27

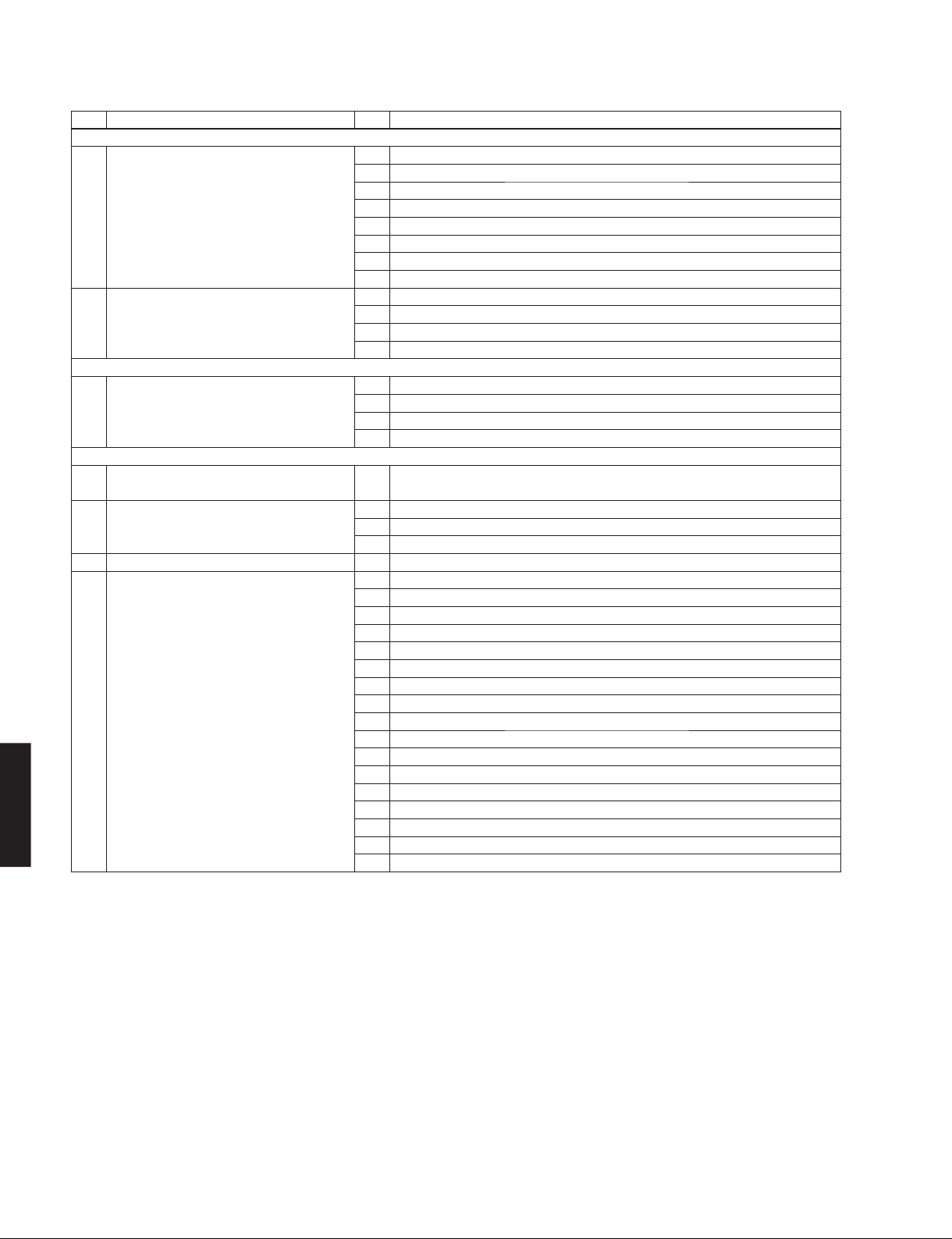

RX-V385/HTR-3072

No. Main menu No. Sub-menu

P: Power supply and protection system /

P1 AD DATA CHECK 1 DC

P2 PROTECTION HISTORY 1 HISTORY 1

E: Etc /

E1 INVALID ITEM 1 INVALID ITEM

(Not for service /

S: System and version system /

S1 INVALID ITEM 1 INVALID ITEM

(Not for service /

S2 SET INFORMATION 1 MODEL

S3 FACTORY PRESET 1 PRESET INHIBIT/RESERVED

S4 ROM VERSION/CHECKSUM 1 SYSTEM VERSION

RX-V385/HTR-3072

その他

サービスでは使用しません

システム・バージョン系

サービスでは使用しません

電源・プロテクション系

2PS

3 THM

4 OUTPUT LEVEL

5 LIMITER CONTROL

6 USB

7 INVALID ITEM

8 KEY

2 HISTORY 2

3 HISTORY 3

4 HISTORY 4

)

2 INVALID ITEM

3 INVALID ITEM

4 INVALID ITEM

)

2 DESTINATION

3 SERIAL NUMBER

2 FACTORY VERSION

3 MICROPROCESSOR VERSION

4 MICROPROCESSOR CHECKSUM

5 FLASH ROM VERSION

6 FLASH ROM CHECKSUM

7 DSP1 VERSION

8 DSP1 CHECKSUM

9 INVALID ITEM

10 INVALID ITEM

11 INVALID ITEM

12 INVALID ITEM

13 INVALID ITEM

14 INVALID ITEM

15 INVALID ITEM

16 INVALID ITEM

17 INVALID ITEM

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

(Not for service /

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

サービスでは使用しません

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

28

RX-V385/HTR-3072

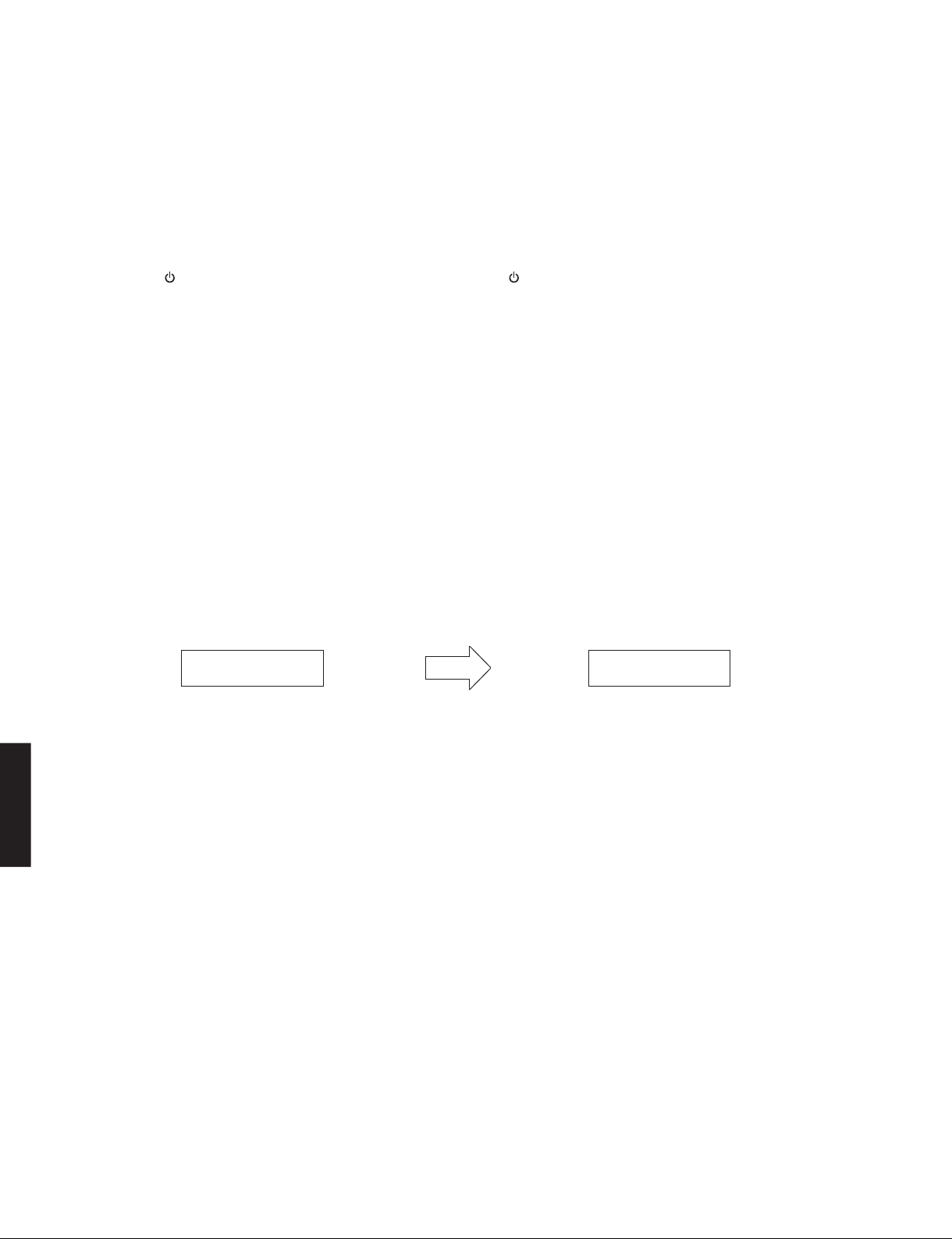

● Starting Self-Diagnostic Function

While pressing the “TONE CONTROL” and “INFO” keys,

press the “

those 2 keys.

The self-diagnostic function mode is activated.

(power / 電源)

” (power) key to turn on the power, and release

Keys of this unit /

● ダイアグの起動

“TONECONTROL” と “INFO” キーを押しながら “ ”(電源)

キーを押して電源を入れた後、2 つのキーを放します。

ダイアグが起動します。

本機キー

While pressing these keys, turn on the power.

これらのキーを押しながら、電源を入れます。

● Starting Self-Diagnostic Function in the protection cancel mode

If the protection function works and causes hindrance

to troubleshooting, cancel the protection function by the

procedure below, and it will be possible to enter the selfdiagnostic function mode. (The protection functions other

than the excess current detect function will be disabled.)

While pressing the “TONE CONTROL” and “INFO” keys,

press the “

pressing those 2 keys and “

or longer.

The self-diagnostic function mode is activated with the

protection functions disabled.

In this mode, the “SLEEP” segment of the FL display flashes

to indicate that the mode is self-diagnostic function mode

with the protection functions disabled.

CAUTION!

Using this unit with the protection function disabled may

cause further damage to this unit. Use special care for

this point when using this mode.

” (power) key to turn on the power and keep

” (power) key for 3 seconds

●プロテクション解除モードでの起動

プロテクションが動作することにより、故障箇所の診断

に支障をきたすような場合は、次の方法によりプロテク

ションを解除した状態でダイアグモードに入ることがで

きます。(過電流検出以外のプロテクション動作を解除す

る)

“TONECONTROL” と “INFO” キーを押しながら “

キーを押して電源を入れ、2つのキーと “

を 3 秒以上押し続けます。

プロテクション解除モードでダイアグが起動します。

このモードでは FL の “SLEEP” セグメントが点滅し、プロ

テクションを解除した状態でのダイアグモードであるこ

とを知らせます。

注意!

プロテクションを解除した状態でのダイアグモードは、

危険な状態でもプロテクションが作動しないため、動作

させると、本機を破壊することがあります。このモード

を使用する場合は十分注意してください。

”(電源)

”(電源)キー

RX-V385/HTR-3072

29

RX-V385/HTR-3072

● Canceling Self-Diagnostic Function

1. Before canceling self-diagnostic function, execute

setting for “S3. FACTORY PRESET” menu. (Memory

initialization inhibited or Memory initialized).

* In order to keep the user memory preserved, be

sure to select PRESET INHIBIT (Memory initialization

inhibited).

2. Press the “

” (power) key to turn off the power.

● Display provided when Self-Diagnostic Function started

The display is as described below depending on the

situation when the power to this unit is turned off.

1. When the power is turned off by usual operation:

“NO PROTECT” is displayed. Then “A1-1. DSP

THROUGH” is displayed in a few seconds.

● ダイアグの解除

1. ダイアグを解除する前に、“S3.FACTORYPRESET” メ

ニュー(メモリーの初期化禁止/またはメモリーの

初期化)の設定をします。

※ ユーザーメモリーを保持したい場合は、必ず

PRESETINHIBIT(メモリー初期化禁止)を選択し

てください。

2. “

”(電源)キーを押して電源を切ります。

● ダイアグ起動時の表示

本機の電源が切れたときの状況により、下記のように表

示されます。

1. 通常の操作で電源を切った場合:

“NOPROTECT” が表示されます。数秒後、“A1-1. DSP

THROUGH” が表示されます。

RX-V385/HTR-3072

Opening message /

NOPROTECT

オープニング表示

After a few seconds /

Main menu display /

数秒後

メインメニュー表示

A1-1

DSPTHROUGH

30

Loading...

Loading...