Page 1

WaveRunner

GP800R

SERVICE MANUAL

*LIT186160226*

F0W-28197-1A-11LIT-18616-02-26

Page 2

E

NOTICE

This manual has been prepared by Yamaha primarily for use by Yamaha dealers and their

trained mechanics when performing maintenance procedures and repairs to Yamaha equipment. It has been written to suit the needs of persons who have a basic understanding of the

mechanical and electrical concepts and procedures inherent in the work, for without such

knowledge attempted repairs or service to the equipment could render it unsafe or unfit for

use.

Because Yamaha has a policy of continuously improving its products, models may differ in

detail from the descriptions and illustrations given in this publication. Use only the latest edition of this manual. Authorized Yamaha dealers are notified periodically of modifications and

significant changes in specifications and procedures, and these are incorporated in successive editions of this manual.

A10001-0*

WaveRunner GP800R

SERVICE MANUAL

©2000 by Yamaha Motor Corporation, USA

1st Edition, November 2000

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Corporation, USA

is expressly prohibited.

Printed in USA

LIT-18616-02-26

Page 3

E

HOW TO USE THIS MANUAL

MANUAL FORMAT

All of the procedures in this manual are organized in a sequential, step-by-step format. The

information has been compiled to provide the mechanic with an easy to read, handy reference that contains comprehensive explanations of all disassembly, repair, assembly, and

inspection operations.

In this revised format, the condition of a faulty component will precede an arrow symbol and

the course of action required will follow the symbol, e.g.,

●

Bearings

Pitting/scratches

To assist you in finding your way through this manual, the section title and major heading is

given at the top of every page.

ILLUSTRATIONS

The illustrations within this service manual represent all of the designated models.

→

Replace.

CROSS REFERENCES

The cross references have been kept to a minimum. Cross references will direct you to the

appropriate section or chapter.

Page 4

E

IMPORTANT INFORMATION

In this Service Manual particularly important information is distinguished in the following

ways.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED!

WARNING

Failure to follow WARNING instructions could result in severe injury or death

operator, a bystander, or a person inspecting or repairing the watercraft.

to the machine

CAUTION:

A CAUTION indicates special precautions that must be taken to avoid damage to the watercraft.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

IMPORTANT:

This part has been subjected to change of specification during production.

Page 5

1

2

3

4

5

6

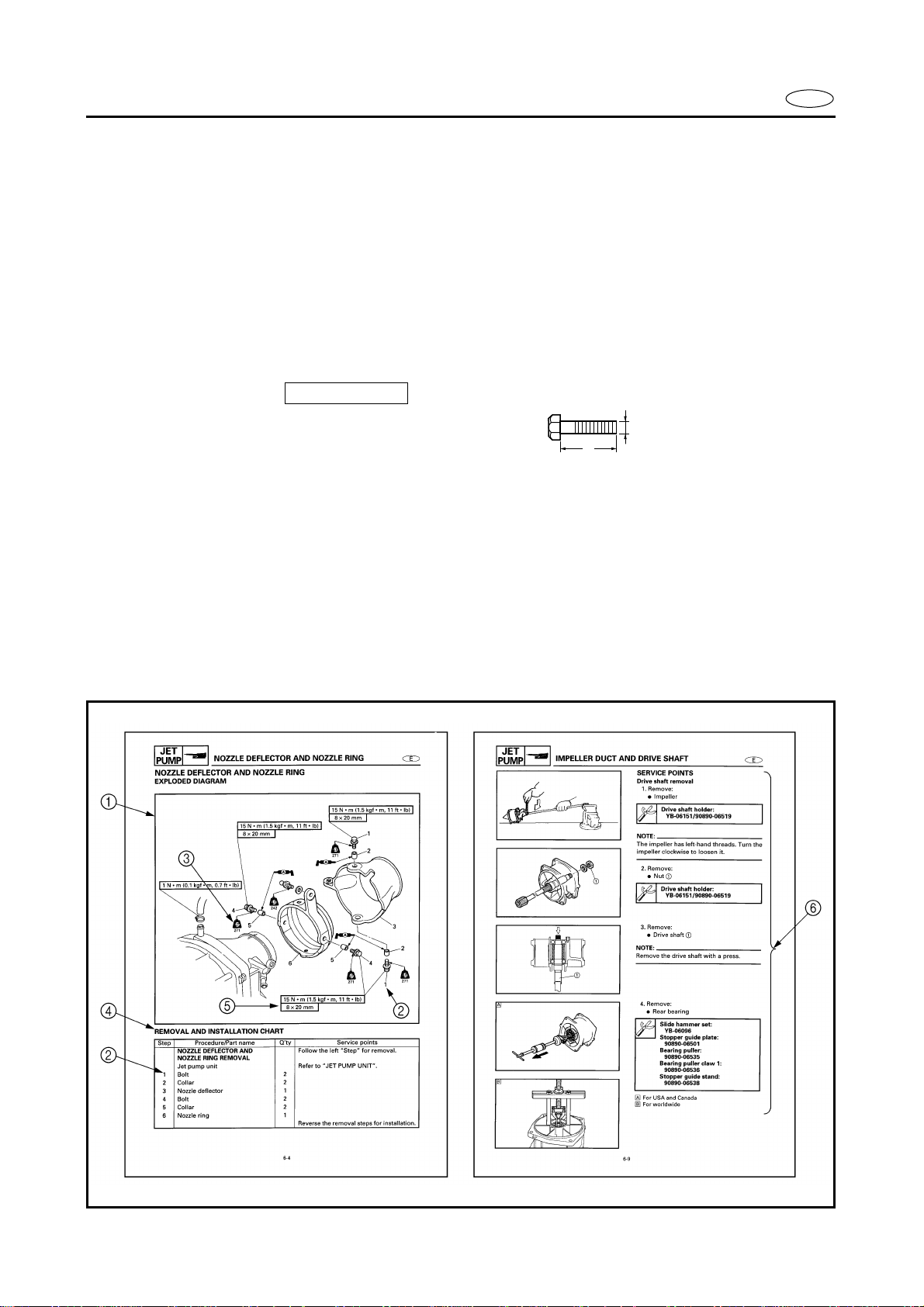

HOW TO USE THIS MANUAL

To help identify parts and clarify procedure steps, there are exploded diagrams at the start

of each removal and disassembly section.

Numbers are given in the order of the jobs in the exploded diagram.

Symbols indicate parts to be lubricated or replaced (see “SYMBOLS”).

A job instruction chart accompanies the exploded diagram, providing the order of jobs,

names of parts, notes in jobs, etc.

Dimension figures and the number of parts, are provided for fasteners that require a tightening torque.

Example:

Bolt or screw size : M10 (D)

10 × 25 mm

Jobs requiring more information (such as special tools and technical data) are described

sequentially.

×

25 mm (L)

D

L

E

Page 6

1

2

3

4

5

6

7

8

9

0

A

B

C

D

E

F

G

H

I

E

12

GEN

INFO

34

SPEC

INSP

FUEL

ADJ

56

JET

POWR

PUMP

78

–+

HULL

ELEC

HOOD

90

TRBL

ANLS

AB

A50001-1-4

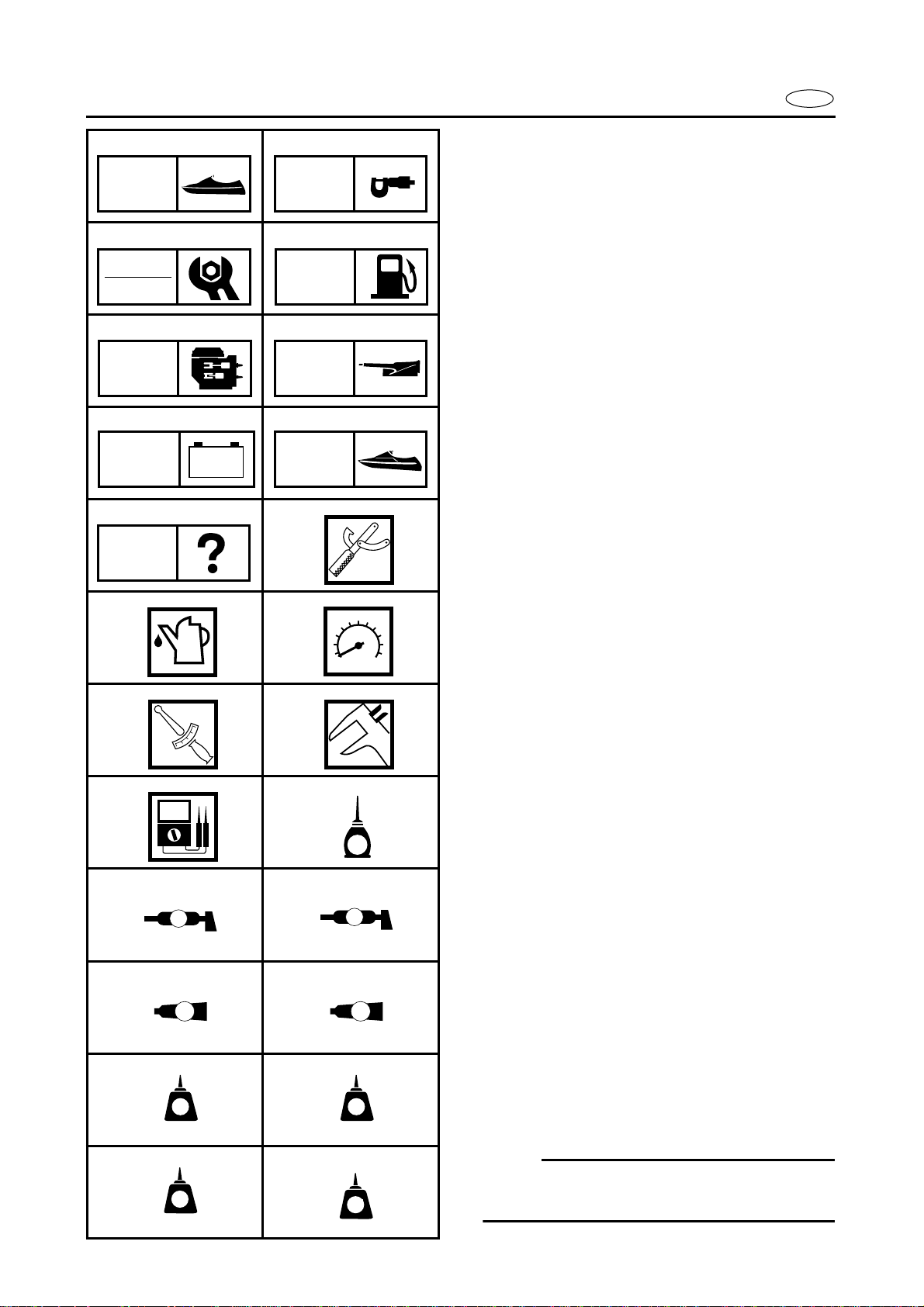

SYMBOLS

Symbols 1 to 9 are designed as thumbtabs to indicate the content of a chapter.

General Information

Specifications

Periodic Inspection and Adjustment

Fuel System

Power Unit

Jet Pump Unit

Electrical System

Hull and Hood

Trouble analysis

Symbols 0 to E indicate specific data:

Special tool

Specified liquid

Specified engine speed

Specified torque

Specified measurement

Specified electrical value

[Resistance (

(A)]

Ω

), Voltage (V), Electric current

CD

T

.

R

.

EF

E

GH

A

IJ

GM

KL

LT

271

M

4

LT

242

Symbol F to H in an exploded diagram

indicate the grade of lubricant and the location of lubrication point:

Apply YAMALUBE 2-W oil or TC-W3 cirtified

outboard oil

Apply water resistant grease

(Yamaha grease A, Yamaha marine grease)

Apply molybdenum disulfide grease

Symbols I to N in an exploded diagram

indicate the grade of the sealing or locking

agent, and the location of the application

point:

Apply Gasket Maker

J Apply Yamabond #4

(Yamaha bond number 4)

K Apply LOCTITE® No. 271 (Red LOCTITE)

L Apply LOCTITE® No. 242 (Blue LOCTITE)

M Apply LOCTITE® No. 572

N Apply silicone sealant

®

MN

LT

572

SS

LT

NOTE:

In this manual, the above symbols may not

be used in every case.

Page 7

A30000-0

E

INDEX

GENERAL INFORMATION

SPECIFICATIONS

PERIODIC INSPECTION AND

ADJUSTMENT

FUEL SYSTEM

GEN

INFO

SPEC

INSP

ADJ

FUEL

1

2

3

4

POWER UNIT

JET PUMP UNIT

ELECTRICAL SYSTEM

HULL AND HOOD

POWR

JET

PUMP

–+

ELEC

HULL

HOOD

5

6

7

8

TROUBLE ANALYSIS

TRBL

ANLS

9

Page 8

Page 9

GEN

INFO

CHAPTER 1

GENERAL INFORMATION

IDENTIFICATION NUMBERS......................................................................... 1-1

PRIMARY l.D. NUMBER........................................................................... 1-1

ENGINE SERIAL NUMBER ...................................................................... 1-1

JET PUMP UNIT SERIAL NUMBER ........................................................ 1-1

HULL IDENTIFICATION NUMBER (H.l.N.).............................................. 1-1

E

1

SAFETY WHILE WORKING ...................................................................... 1-2

FIRE PREVENTION................................................................................... 1-2

VENTILATION........................................................................................... 1-2

SELF-PROTECTION.................................................................................. 1-2

OILS, GREASES AND SEALING FLUIDS................................................ 1-2

GOOD WORKING PRACTICES................................................................ 1-3

DISASSEMBLY AND ASSEMBLY........................................................... 1-4

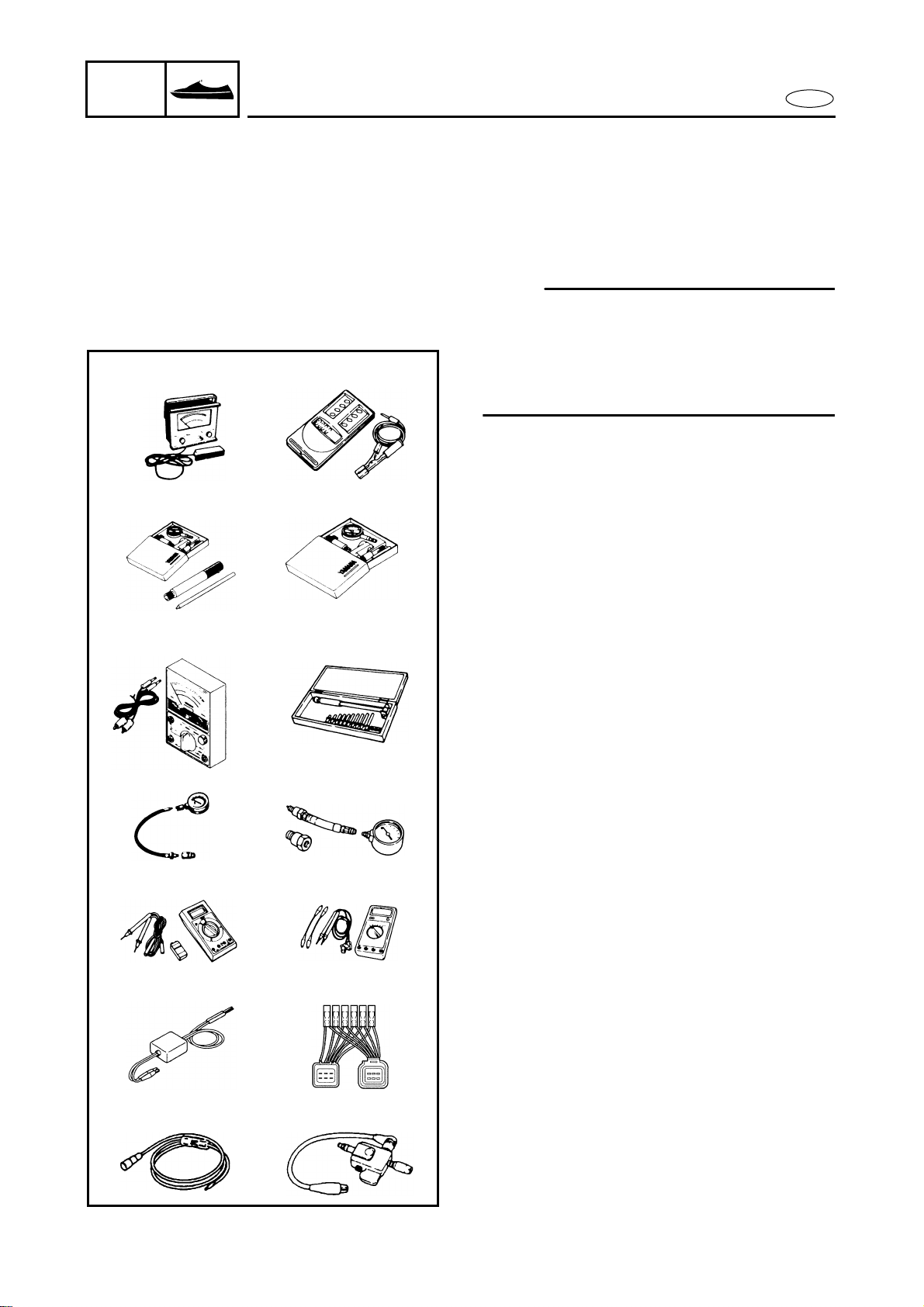

SPECIAL TOOLS............................................................................................. 1-5

MEASURING ............................................................................................ 1-5

REMOVAL AND INSTALLATION ............................................................ 1-6

2

3

4

5

6

7

8

9

Page 10

GEN

INFO

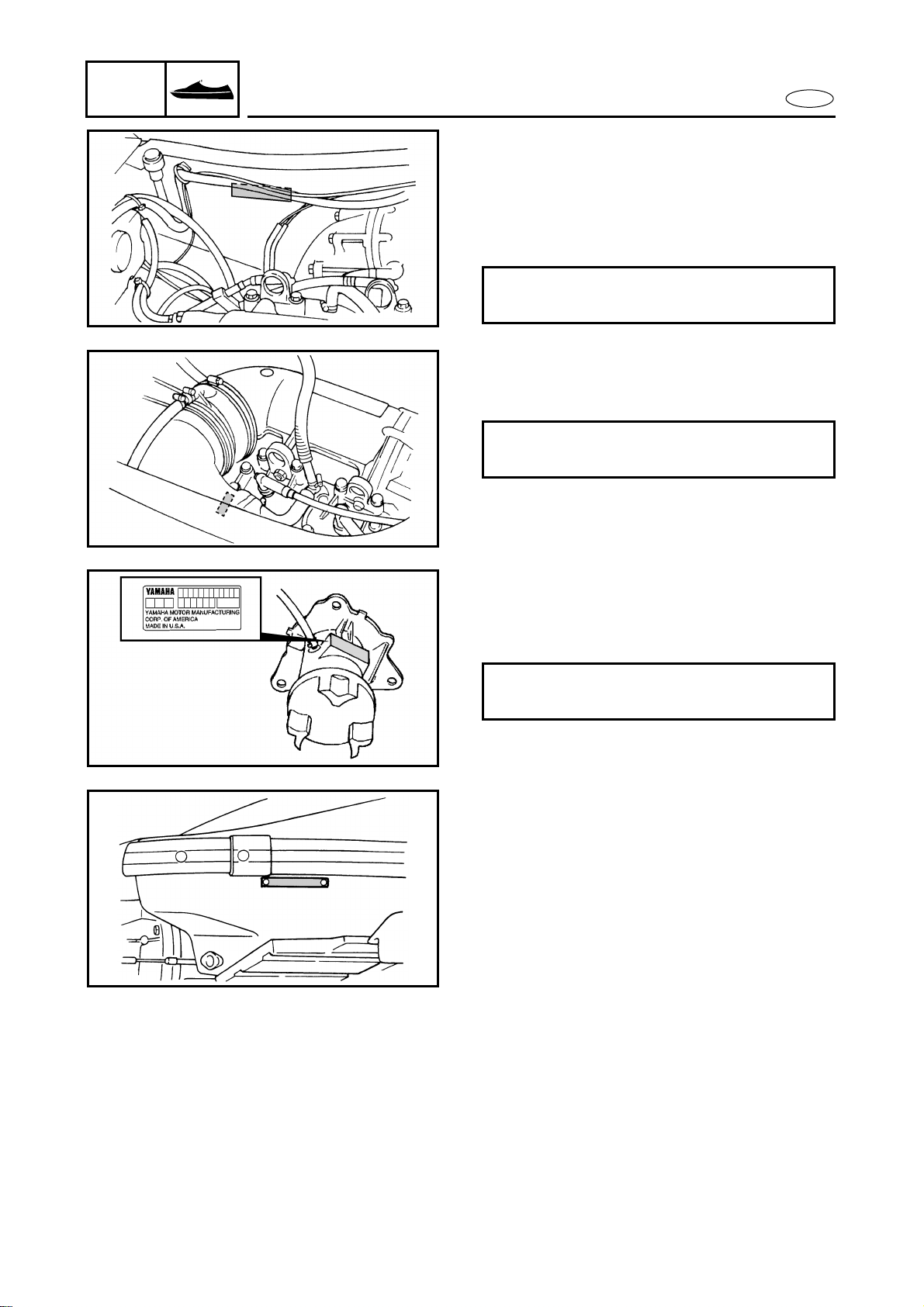

IDENTIFICATION NUMBERS

A60700-0*

IDENTIFICATION NUMBERS

PRIMARY l.D. NUMBER

The primary l.D. number is stamped on a

label attached to the inside of the engine

compartment.

Starting primary l.D. number:

F0W: 800101–

ENGINE SERIAL NUMBER

The engine serial number is stamped on a

label attached to the cylinder head.

Starting serial number:

68A: 000101–

E

JET PUMP UNIT SERIAL NUMBER

The jet pump unit serial number is stamped

on a label attached to the intermediate

housing.

Starting serial number:

68A: 800101–

HULL IDENTIFICATION NUMBER

(H.l.N.)

The H.l.N. is stamped on a plate attached to

the aft deck.

1-1

Page 11

GEN

INFO

SAFETY WHILE WORKING

SAFETY WHILE WORKING

The procedures given in this manual are

those recommended by Yamaha to be followed by Yamaha dealers and their

mechanics.

FIRE PREVENTION

Gasoline (petrol) is highly flammable.

Gasoline vapor is explosive if ignited.

Do not smoke while handling gasoline

(petrol) and keep it away from heat, sparks,

and open flames.

E

VENTILATION

Gasoline vapor is heavier than air and is

deadly if inhaled in large quantities. Engine

exhaust gases are harmful to breathe.

When test-running an engine indoors,

maintain good ventilation.

SELF-PROTECTION

Protect your eyes with suitable safety spectacles or safety goggles when grinding or

doing any operation which may cause particles to fly off.

Protect hands and feet by wearing safety

gloves or protective shoes if appropriate to

the work you are doing.

OILS, GREASES AND SEALING

FLUIDS

Use only genuine Yamaha oils, greases,

and sealing fluids or those recommended

by Yamaha.

1-2

Page 12

GEN

INFO

SAFETY WHILE WORKING

Under normal conditions of use there

should be no hazards from the use of the

lubricants mentioned in this manual, but

safety is all-important, and by adopting

good safety practises any risk is minimized.

A summary of the most important precautions is as follows:

1. While working, maintain good standards of personal and industrial

hygiene.

2. Clothing which has become contaminated with lubricants should be

changed as soon as practicable and

laundered before further use.

3. Avoid skin contact with lubricants (e.g.,

do not place a soiled rag in your

pocket).

4. Hands and any other part of the body

which have been in contact with lubricants or lubricant-contaminated clothing should be thoroughly washed with

hot water and soap as soon as practicable.

5. To protect the skin, the application of a

suitable barrier cream to the hands

before working is recommended.

6. A supply of clean lint-free cloths should

be available for wiping purposes.

E

GOOD WORKING PRACTICES

1. The right tools

Use the recommended special tools to

protect parts from damage. Use the

right tool in the right manner – do not

improvise.

2. Tightening torque

Follow the tightening torque instructions. When tightening bolts, nuts and

screws, tighten the larger sizes first and

tighten inner-positioned fixings before

outer-positioned ones.

1-3

Page 13

GEN

INFO

SAFETY WHILE WORKING

3. Non-reusable items

Always use new gaskets, packings, Orings, oil seals, split-pins, circlips, etc.,

on reassembly.

DISASSEMBLY AND ASSEMBLY

1. Clean parts with compressed air when

disassembling.

2. Oil the contact surfaces of moving parts

during assembly.

E

3. After assembly, check that moving parts

operate normally.

4. Install bearings with the manufacturer’s

markings on the side exposed to view

and liberally oil the bearings.

CAUTION:

Do not spin bearings with compressed air

because this will damage their surfaces.

5. When installing oil seals, apply a light

coat of water-resistant grease to the

outside diameter.

1-4

Page 14

GEN

INFO

YU-8036-A 90890-06760

1

YU-03097

2

YU-01256

YU-03112

90890-03112

YU-33223 90890-03160

5

J-39299 90890-06752

6

YU-39991

90890-03169

SPECIAL TOOLS

43

87

90890-01252

YU-03017

90890-06759

YW-06779

90890-06779

E

SPECIAL TOOLS

Using the correct special tools recommended by Yamaha, will aid the work and

enable accurate assembly and tune-up.

Improvisations and using improper tools

can damage the equipment.

NOTE:

● For U.S.A. and Canada, use part numbers

starting with “J-”, “YB-”, “YM-”, “YU-” or

“YW-”.

● For other countries, use part numbers

starting with “90890-”.

MEASURING

1 Engine tachometer

P/N. YU-8036-A

90890-06760

2 Dial gauge and stand

P/N. YU-03097, YU-01256

90890-01252

3 Pocket tester

P/N. YU-03112

90890-03112

4 Cylinder gauge set

P/N. YU-03017

90890-06759

5 Compression gauge

P/N. YU-33223

90890-03160

6 Digital tester

P/N. J-39299

90890-06752

7 Peak voltage adapter

P/N. YU-39991

90890-03169

8 Peak voltage test harness

P/N. YW-06779

90890-06779

9 Spark gap tester

P/N. YM-34487

90890-06754

YM-34487 90890-06754

9

1-5

Page 15

GEN

INFO

SPECIAL TOOLS

E

YW-06551

90890-06551

3

YB-06117 90890-06521

YB-06151 90890-06519

90890-06501 90890-06535

90890-06536 90890-06538

90890-06652 YB-06112

YB-06156 90890-06634

B

YB-06071 90890-06606 YB-34474

YB-06552 YB-06016 90890-06626

E

90890-06552

YW-06550 90890-06550

21

YB-06096

54

76

98

A0

YB-06196

DC

F

90890-06614

90890-06653

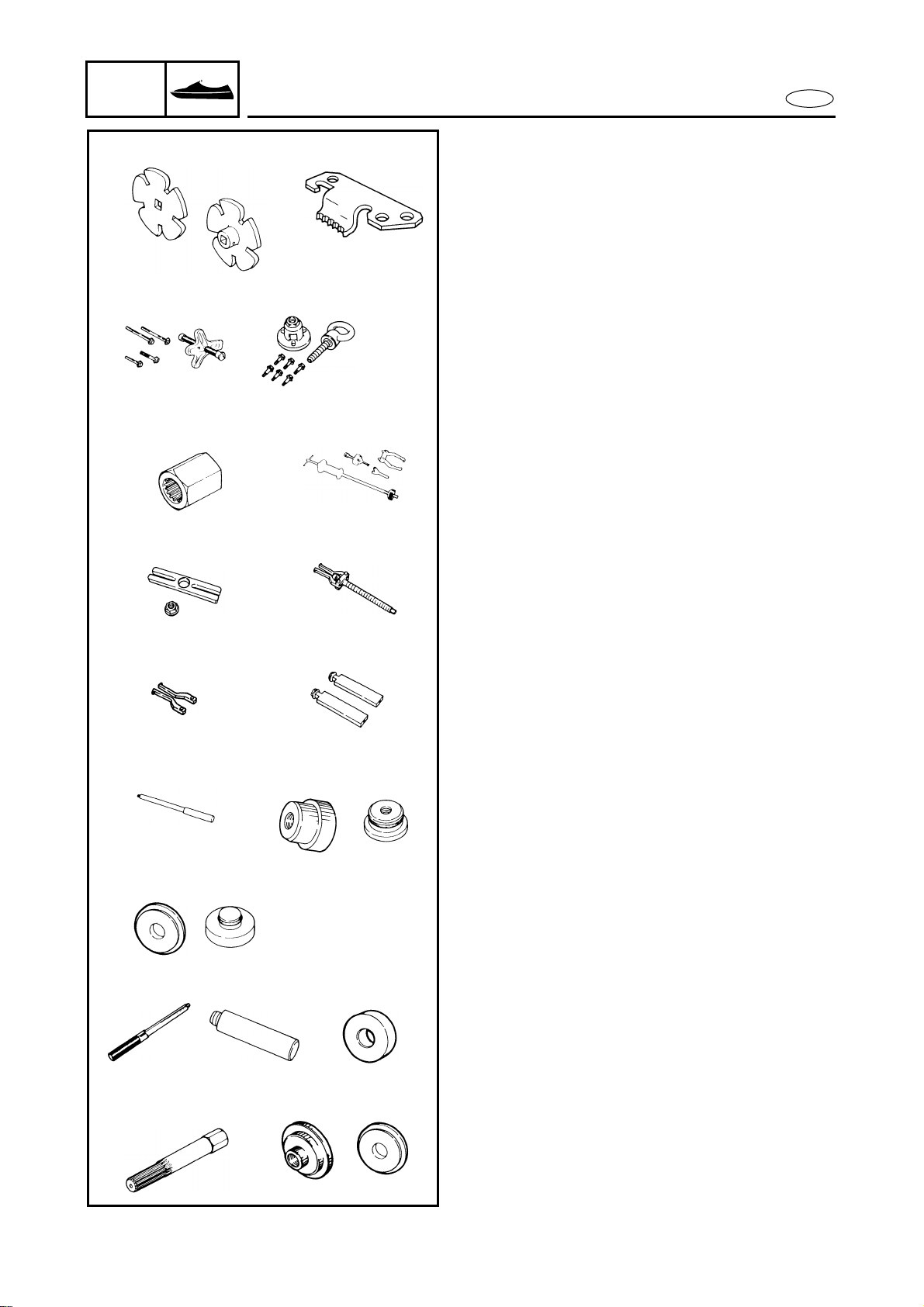

REMOVAL AND INSTALLATION

1 Coupler wrench

P/N. YW-06551

90890-06551

2 Flywheel holder

P/N. YW-06550

90890-06550

3 Flywheel puller

P/N. YB-06117

90890-06521

4 Drive shaft holder (impeller)

P/N. YB-06151

90890-06519

5 Slide hammer set (jet pump bearing)

P/N. YB-06096

6 Stopper guide plate (jet pump bearing)

P/N. 90890-06501

7 Bearing puller (jet pump bearing)

P/N. 90890-06535

8 Bearing puller claw 1 (jet pump bearing)

P/N. 90890-06536

9 Stopper guide stand (jet pump bearing)

P/N. 90890-06538

0 Drive rod L3 (jet pump bearing)

P/N. 90890-06652

A Needle bearing attachment

(jet pump bearing and oil seal)

P/N. YB-06112, YB-06196

90890-06614, 90890-06653

B Ball bearing attachment

(jet pump oil seal)

P/N. YB-06156

90890-06634

C Driver rod

(intermediate shaft and jet pump)

P/N. YB-06071

90890-06606

D Bearing inner/outer race attachment

(jet pump bearing)

P/N. YB-34474

E Shaft holder (intermediate shaft)

P/N. YB-06552

90890-06552

F Bearing outer race attachment

(intermediate shaft)

P/N. YB-06016

90890-06626

1-6

Page 16

Page 17

SPEC

E

CHAPTER 2

SPECIFICATIONS

GENERAL SPECIFICATIONS.......................................................................... 2-1

1

MAINTENANCE SPECIFICATIONS................................................................ 2-3

ENGINE..................................................................................................... 2-3

JET PUMP UNIT....................................................................................... 2-4

HULL AND HOOD .................................................................................... 2-4

ELECTRICAL ............................................................................................. 2-5

2

TIGHTENING TORQUES................................................................................ 2-7

SPECIFIED TORQUES.............................................................................. 2-7

GENERAL TORQUE ............................................................................... 2-10

CABLE AND HOSE ROUTING...................................................................... 2-11

3

4

5

6

7

8

9

Page 18

SPEC

GENERAL SPECIFICATIONS

GENERAL SPECIFICATIONS

E

Item Unit

MODEL CODE

Hull F0W

Engine 68A

DIMENSIONS

Length mm (in) 2,930 (115.4)

Width mm (in) 1,150 (45.3)

Height mm (in) 1,020 (40.2)

Dry weight kg (lb) 268 (591)

Watercraft capacity 2

PERFORMANCE

Maximum output kW (PS) @ r/min 88.2 (120) @ 7,000

Maximum fuel consumption R/h (US gal/h,

lmp gal/h)

Cruising range h 1.2

ENGINE

Engine type 2-stroke

Number of cylinders 2

3

Displacement cm

Bore × stroke mm (in) 80.0 × 78.0 (3.15 × 3.07)

Compression ratio 6.6:1

Intake system Reed valve

Carburetor model

(manufacturer) × quantity

Enrichment control Choke valve

Scavenging system Loop charge

Lubrication system Oil injection

Cooling system Water

Starting system Electric

Ignition system Digital CDI

Ignition timing Degree 15 BTDC–20 BTDC

Spark plug model

(manufacturer)

Battery capacity V/Ah (kC) 12/19 (68.4)

Lighting coil max. A @ r/min 8 @ 6,000

Propulsion system Jet pump

DRIVE UNIT

Jet pump type Axial flow, single stage

Impeller rotation (from rear) Counterclockwise

Transmission Direct drive from engine

Nozzle angle (horizontal) Degree 23 + 23

Nozzle angle (vertical) Degree –5, 0, 5, 10, 15

Trim system Manual 5 positions

(cu. in) 784 (47.8)

Model

GP800R

49 (12.9, 10.8)

BN44 (Mikuni) × 2

BR8ES (NGK)

2-1

Page 19

SPEC

GENERAL SPECIFICATIONS

E

Item Unit

FUEL AND OIL

Fuel Regular unleaded gasoline

Fuel rating PON* 86

RON* 90

Oil YAMALUBE 2-W or an equivalent TC-W3

certified outboard oil

Fuel/oil mixing ratio

(wide open throttle)

Fuel tank capacity R(US gal,

Imp gal)

Fuel tank reserve capacity R(US gal,

Imp gal)

Oil tank capacity R(US gal,

Imp gal)

PON*: Pump Octane Number = (Motor Octane Number + Research Octane Number)/2

RON*: Research Octane Number

Model

GP800R

30:1

60 (15.9, 13.2)

10 (2.6, 2.2)

5.5 (1.45, 1.21)

2-2

Page 20

SPEC

MAINTENANCE SPECIFICATIONS

MAINTENANCE SPECIFICATIONS

ENGINE

E

Item Unit

CYLINDER HEAD

Warpage limit mm (in) 0.1 (0.004)

Compression pressure

CYLINDERS

Bore size mm (in) 80.000–80.018 (3.1496–3.1503)

Taper limit mm (in) 0.08 (0.003)

Out-of-round limit mm (in) 0.05 (0.002)

Wear limit mm (in) Original cylinder bore + 0.04 (0.0016)

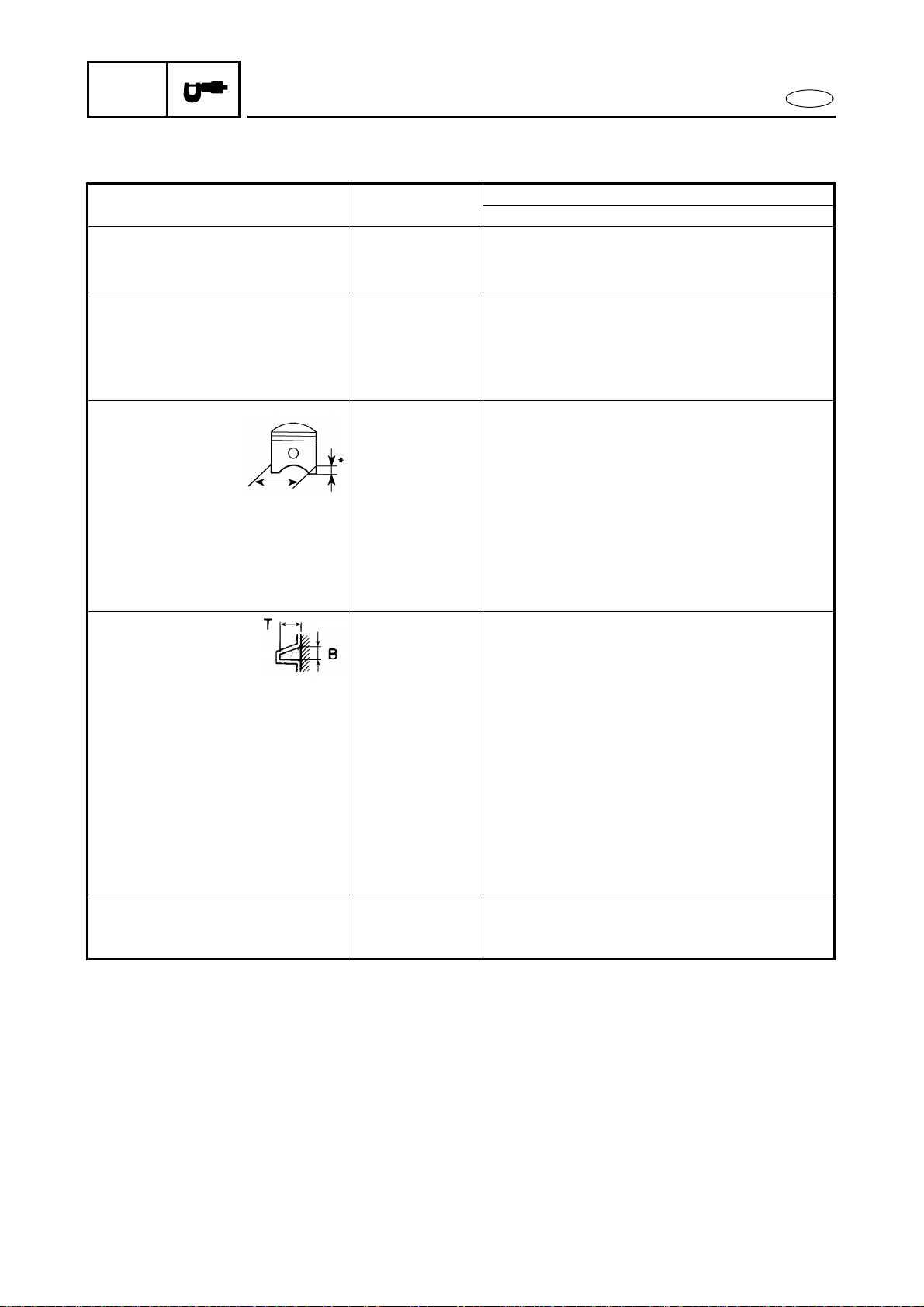

PISTONS

Diameter mm (in) Red: 79.899–79.902 (3.1456–3.1457)

Measuring point* mm (in) 22 (0.87)

Piston-to-cylinder clearance mm (in) 0.100–0.105 (0.0039–0.0041)

Wear limit mm (in) Cylinder bore – 0.105 (0.0041)

Piston pin bore inside

diameter

PISTON RINGS

Top

Type Keystone

Dimensions (B) mm (in) 1.2 (0.05)

Dimensions (T) mm (in) 2.85 (0.112)

End gap mm (in) 0.30–0.45 (0.012–0.018)

Ring groove clearance mm (in) 0.03–0.05 (0.001–0.002)

*2

2nd

Type Keystone

Dimensions (B) mm (in) 1.2 (0.05)

Dimensions (T) mm (in) 2.85 (0.112)

End gap mm (in) 0.30–0.45 (0.012–0.018)

Ring groove clearance mm (in) 0.03–0.05 (0.001–0.002)

PISTON PINS

Diameter mm (in) 21.995–22.000 (0.8659–0.8661)

Wear limit mm (in) 21.990 (0.8657)

*1

kPa (kg/cm2) 560 (5.6)

Orange: 79.903–79.906 (3.1458–3.1459)

Green: 79.907–79.910 (3.1459–3.1461)

Purple: 79.911–79.914 (3.1461–3.1462)

mm (in) 22.004–22.025 (0.8663–0.8671)

Model

GP800R

*1: At 760 mmHg and 20 ˚C (68 ˚F)

*2: The top ring and 2nd ring are of the same type.

2-3

Page 21

SPEC

MAINTENANCE SPECIFICATIONS

E

Item Unit

CRANKSHAFT ASSEMBLY

Crank width A mm (in) 72.95–73.00 (2.872–2.874)

Deflection limit B mm (in) 0.05 (0.002)

Big end side clearance C mm (in) 0.25–0.75 (0.010–0.030)

Maximum small end axial

play D

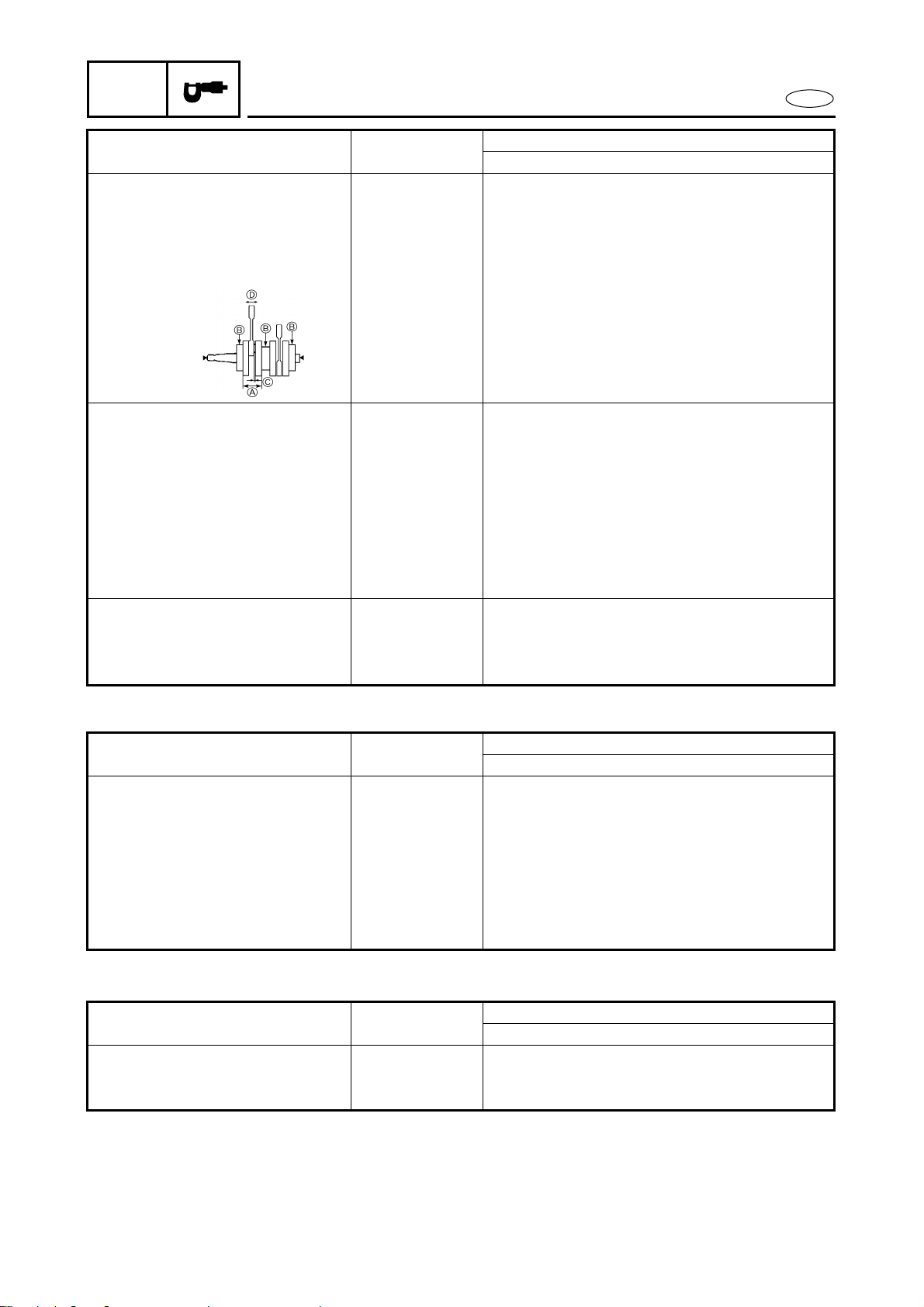

CARBURETORS

Type Floatless

Identification mark #1: 68A-01, #2: 68A-02

Main nozzle mm (in) 3.0 (0.12)

Main jet 150

Pilot jet 90

Throttle valve 120

Valve seat size mm (in) 1.2 (0.05)

Trolling speed r/min 1,300 ± 50

REED VALVES

Thickness mm (in) 0.52 (0.020)

Reed valve stopper height mm (in) 10.8–11.4 (0.43–0.45)

Reed valve warpage limit mm (in) 0.2 (0.01)

mm (in) 2.0 (0.08)

Model

GP800R

JET PUMP UNIT

Item Unit

JET PUMP

Impeller material Stainless steel

Number of impeller blades 3

Impeller pitch angle Degree 13.2

Impeller clearance mm (in) 0.35–0.45 (0.014–0.018)

Impeller clearance limit mm (in) 0.6 (0.024)

Drive shaft runout limit mm (in) 0.3 (0.012)

Nozzle diameter mm (in) 86.8 (3.42)

Model

GP800R

HULL AND HOOD

Item Unit

FREE PLAY

YPVS cable slack mm (in) 0.5–1.5 (0.02–0.06)

Throttle lever free play mm (in) 4–7 (0.16–0.28)

Model

GP800R

2-4

Page 22

SPEC

ELECTRICAL

MAINTENANCE SPECIFICATIONS

E

Item Unit

BATTERY

Type Fluid

Capacity V/Ah (kC) 12/19 (68.4)

CDI UNIT (O – B)

Output peak voltage lower

limit

@cranking 1 V 85

@cranking 2 V 110

@2,000 r/min V 205

@3,500 r/min V 200

STATOR

Charge coil (Br – L)

Output peak voltage

lower limit

@cranking 1 V 90

@cranking 2 V 120

@2,000 r/min V 220

@3,500 r/min V 210

Pickup coil (W/R – W/B)

Output peak voltage

lower limit

@cranking 1 V 5

@cranking 2 V 3

@2,000 r/min V 7

@3,500 r/min V 11

Lighting coil (G – G)

Output peak voltage

lower limit

@cranking 1 V 8.5

@cranking 2 V 8.5

@2,000 r/min V 13

@3,500 r/min V 13

Charge coil resistance Ω (color) 299–365 (Br – L)

Pickup coil resistance Ω (color) 446–545 (W/R – W/B)

Lighting coil resistance Ω (color) 0.86–1.06 (G – G)

Minimum charging current A @ r/min 9 @ 6,000

IGNITION COIL

Minimum spark gap mm (in) 10 (0.39)

Primary coil resistance Ω (color) 0.078–0.106 (O – B)

Secondary coil resistance kΩ 14.3–30.5

(#1 Spark plug cap – #2 Spark plug cap)

Model

GP800R

Cranking 1: unloaded

Cranking 2: loaded

2-5

Page 23

SPEC

MAINTENANCE SPECIFICATIONS

E

Item Unit

RECTIFIER/REGULATOR

(R – B)

Output peak voltage lower

limit (unloaded)

@cranking V 7.5

@2,000 r/min V 12.5

@3,500 r/min V 12.5

THERMO SWITCH

On temperature ˚C (˚F) 80 (177)

Off temperature ˚C (˚F) 70 (159)

STARTER MOTOR

Brush length mm (in) 12.5 (0.49)

Wear limit mm (in) 6.5 (0.26)

Commutator undercut mm (in) 0.7 (0.03)

Limit mm (in) 0.2 (0.01)

Commutator diameter mm (in) 28.0 (1.10)

Limit mm (in) 27.0 (1.06)

FUSE

Rating V/A 12/10

Model

GP800R

2-6

Page 24

SPEC

TIGHTENING TORQUES

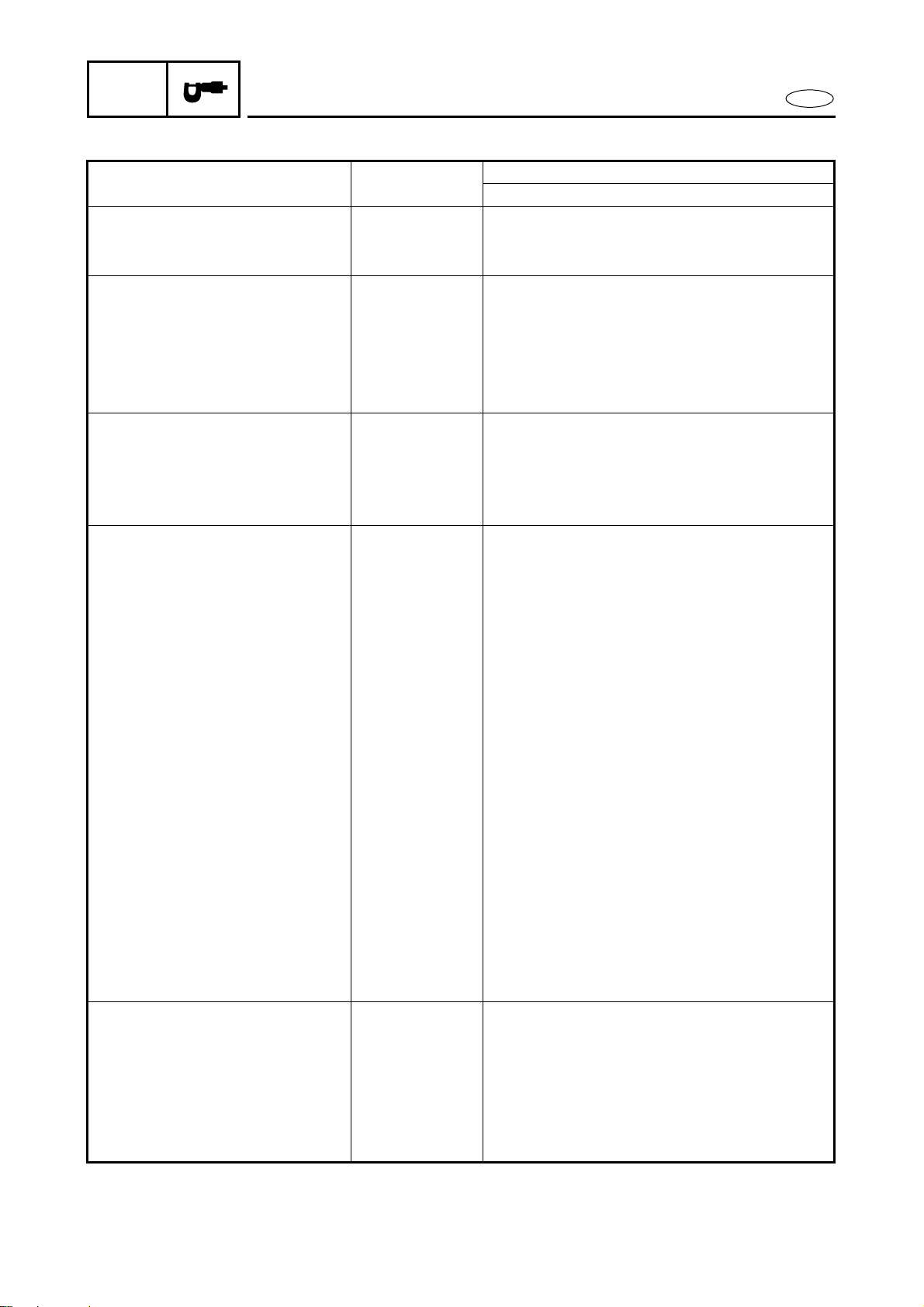

TIGHTENING TORQUES

SPECIFIED TORQUES

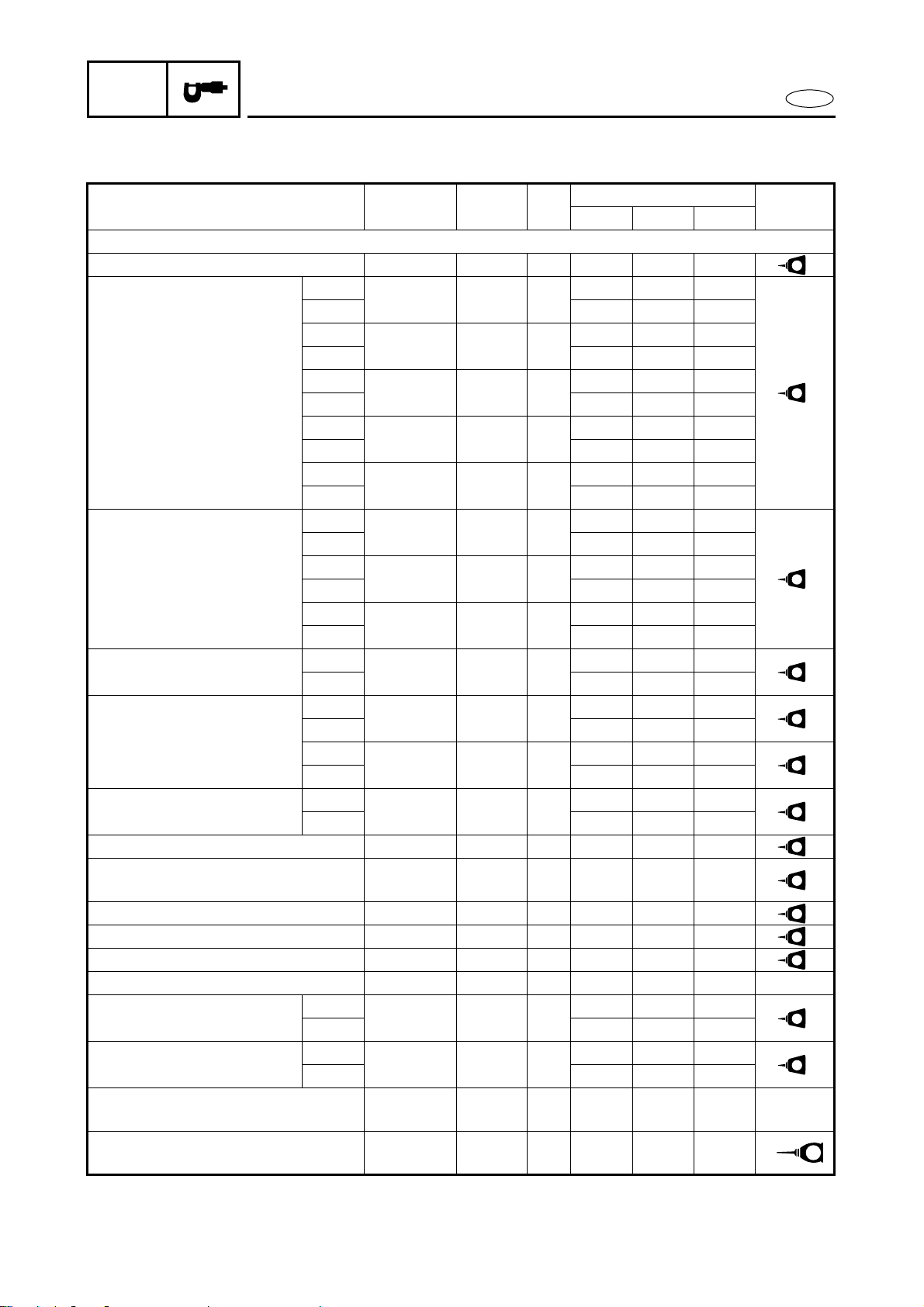

E

Part to tightened Part name

Thread

size

Q’ty

Tightening torque

N•m kgf•m ft•lb

ENGINE UNIT

Engine unit – engine mount Bolt M8 4 17 1.7 12

Exhaust chamber

assembly – muffler stay 1

– muffler stay 3

Exhaust chamber –

muffler

Exhaust chamber joint –

exhaust manifold

Exhaust chamber joint –

muffler stay

Exhaust manifold –

cylinder

1st

4th 51 5.1 37

2nd

6th 39 3.9 28

3rd

5th 51 5.1 37

7th

9th 49 4.9 35

8th

10th 49 4.9 35

1st

2nd 39 3.9 28

1st

2nd 33 3.3 24

1st

2nd 51 5.1 37

1st

2nd 34 3.4 24

1st

3rd 49 4.9 35

2nd

4th 37 3.7 27

1st

2nd 51 5.1 37

Bolt M10 2

Bolt M10 4

Nut M10 2

Bolt M10 1

Bolt M10 1

Nut M8 2

Bolt M8 3

Nut M10 1

Bolt M8 5

Bolt M10 1

Bolt M8 2

Bolt M10 8

2 0.2 1.4

2 0.2 1.4

2 0.2 1.4

2 0.2 1.4

2 0.2 1.4

15 1.5 11

15 1.5 11

15 1.5 11

17 1.7 12

2 0.2 1.4

2 0.2 1.4

23 2.3 17

Reed valve – reed valve seat Screw M3 16 0.8 0.08 0.58

YPVS cable bracket – YPVS cover

– cylinder

Bolt M6 2 10 1.0 7.2

YPVS cover – cylinder Bolt M6 6 10 1.0 7.2

YPVS valve assembly – cylinder Bolt M5 2 4 0.4 2.9

YPVS valve lever – shaft Bolt M4 2 3 0.3 2.2

Spark plug – cylinder head Spark plug M14 2 25 2.5 18

Cylinder head – cylinder

Cylinder – crankcase

1st

2nd 37 3.7 27

1st

2nd 39 3.9 28

Starter motor lead – starter

motor

Flywheel magneto – crankshaft

assembly

Bolt M8 10

Bolt M10 8

Nut M6 1 5 0.5 3.6

Bolt M10 1 74 7.4 53

15 1.5 11

22 2.2 16

Remarks

LT

572

LT

271

LT

271

LT

271

LT

271

LT

271

LT

271

LT

242

LT

572

LT

572

LT

271

LT

242

LT

572

LT

572

E

2-7

Page 25

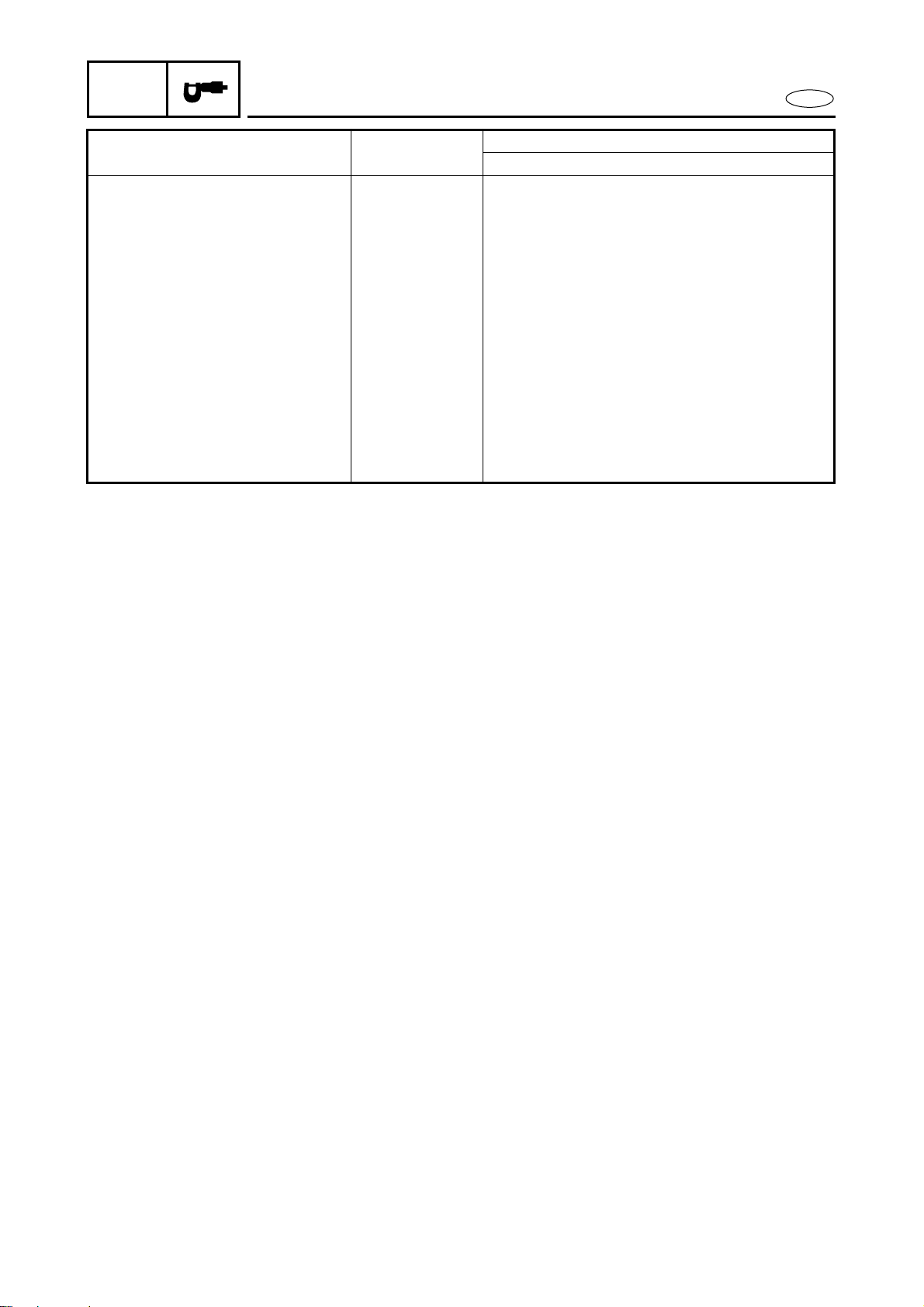

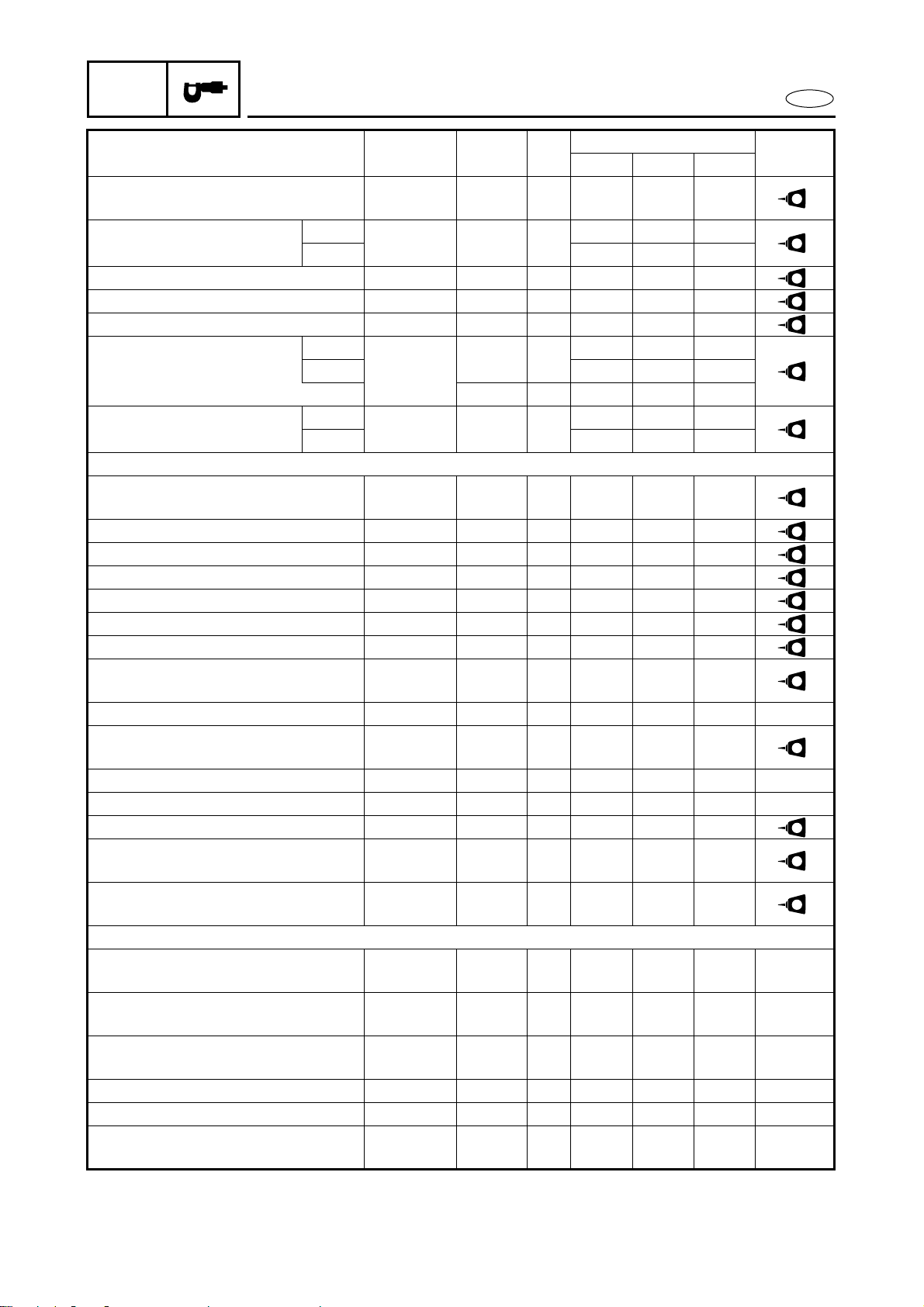

SPEC

TIGHTENING TORQUES

E

Part to tightened Part name

Drive coupling – crankshaft

assembly

Generator cover –

crankcase

Thread

size

Drive

coupling

1st

2nd 27 2.7 19

Bolt M8 8

M27 1 36 3.6 25

Q’ty

Tightening torque

N•m kgf•m ft•lb

15 1.5 11

Pickup coil – generator cover Bolt M5 2 5 0.5 3.6

Cable holder – generator cover Bolt M6 2 14 1.4 10

Stator coil – generator cover Bolt M6 3 14 1.4 10

Lower crankcase – upper

crankcase

1st

2nd 27 2.7 19

Bolt

M8 13

15 1.5 11

M6 7 11 1.1 8.0

Mount bracket –

crankcase

1st

2nd 27 2.7 19

Bolt M8 6

15 1.5 11

JET PUMP UNIT

Steering cable joint – nozzle

deflector

Nut M6 1 7 0.7 5.1

Ride plate – hull Bolt M8 4 17 1.7 12

Intake duct – hull Bolt M8 4 17 1.7 12

Intake grate – hull Bolt M6 4 7 0.7 5.1

Speed sensor – ride plate Screw M5 4 4 0.4 2.9

Nozzle ring – nozzle Bolt M8 2 15 1.5 11

Nozzle deflector – nozzle ring Bolt M8 2 15 1.5 11

Water inlet cover – water inlet

strainer – impeller duct

Bolt M6 4 7 0.7 5.1

Drive shaft nut – drive shaft Nut M16 1 74 7.4 53

Impeller (left-hand threads) –

drive shaft

Impeller M22 1 18 1.8 13

Transom plate – hull Nut M10 4 26 2.6 19

Bilge strainer holder – bulkhead Screw M5 1 4 0.4 2.9

Intermediate housing – bulkhead Bolt M8 3 17 1.7 12

Driven coupling – shaft

Grease nipple – intermediate

housing

Driven

coupling

M27 1 36 3.6 25

Nipple — 1 5 0.5 3.6

HULL AND HOOD

Handlebar cover – handlebar

cover stay

Handlebar cover stay – steering

column

Upper handlebar holder/lower

handle holder – steering column

Screw M6 4 1.1 0.11 0.8

Screw M6 4 2.9 0.29 2.1

Bolt M8 4 16 1.6 11

QSTS converter – hull Nut M6 2 5 0.5 3.6

QSTS cable 1, 2 locknut Nut M8 2 16 1.6 11

Throttle lever assembly –

handlebar

Screw M5 2 3 0.3 2.2

Remarks

LT

572

LT

271

LT

242

LT

242

LT

242

LT

572

LT

271

LT

242

LT

572

LT

572

LT

572

LT

242

LT

271

LT

271

LT

572

LT

572

LT

572

LT

572

LT

572

2-8

Page 26

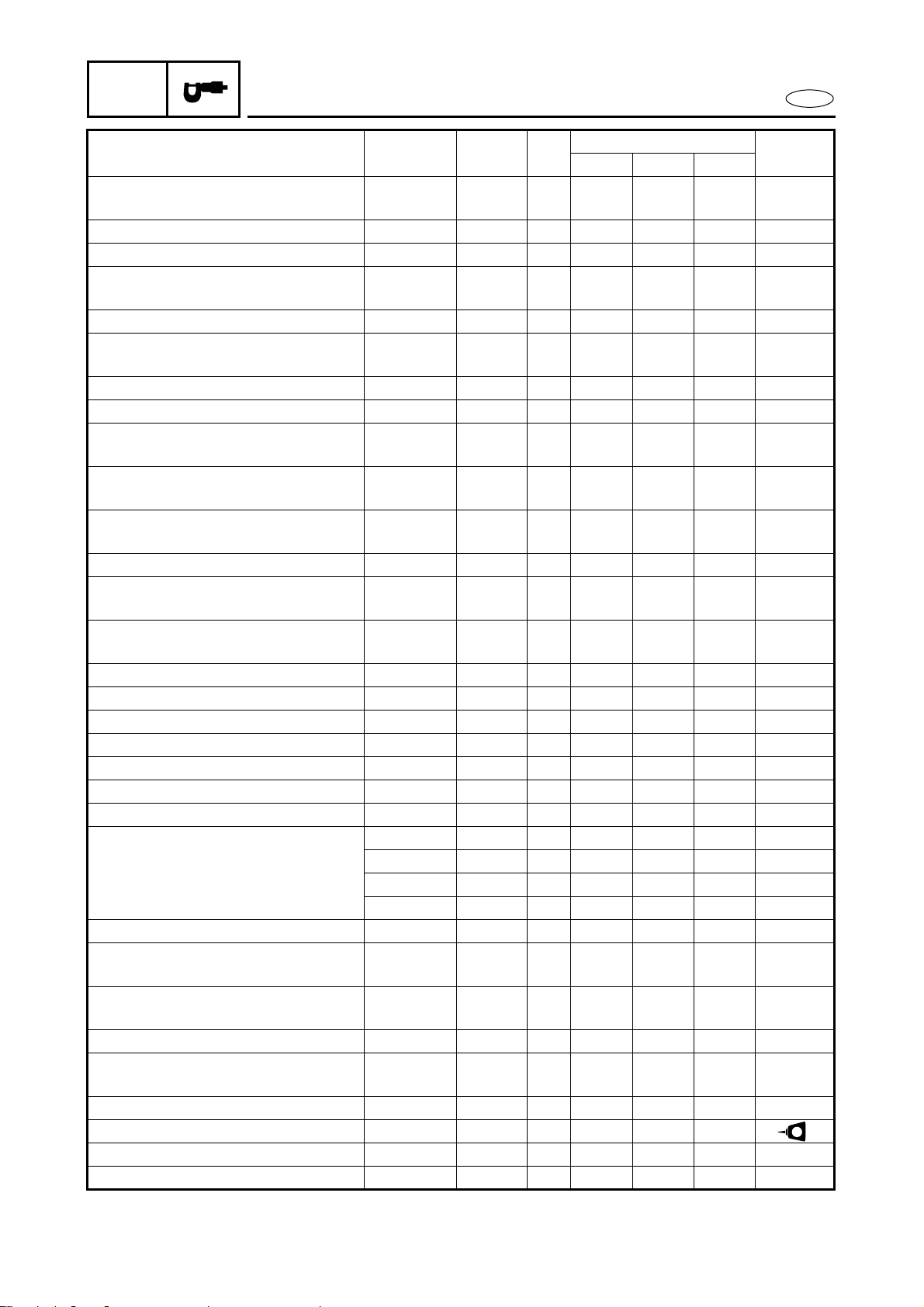

SPEC

TIGHTENING TORQUES

E

Part to tightened Part name

Handlebar switch assembly –

handlebar

Thread

size

Q’ty

Screw M5 2 3 0.3 2.2

Tightening torque

N•m kgf•m ft•lb

QSTS grip assembly – handlebar Screw M6 1 3 0.3 2.2

Grip end – handlebar Bolt M5 2 1 0.1 0.7

Choke lever assembly –

handlebar

Screw M5 2 3 0.3 2.2

QSTS cable housing – cover Screw M4 1 1 0.1 0.7

Plate/steering column assembly

– deck

Nut M8 2 16 1.6 11

Steering column assembly – deck Nut M8 2 16 1.6 11

Steering arm – steering column Nut M8 1 16 1.6 11

Steering cable ball joint –

steering arm

Handlebar stopper – steering

column housing

QSTS cable locknut

(nozzle ring side)

Nut M6 1 5 0.5 3.6

Nut M10 1 26 2.6 19

Nut M5 1 3 0.3 2.2

QSTS cable – hull Nut — 1 6 0.6 4.3

QSTS cable end – pin – QSTS

converter

Steering cable locknut

(nozzle deflector side)

Nut M6 1 4 0.4 2.9

Nut M6 1 6 0.6 4.3

Steering cable – hull Nut — 1 6 0.6 4.3

Steering cable holder – bracket Bolt M6 1 6 0.6 4.3

Speed sensor lead – hull Nut — 1 6 0.6 4.3

Hinge assembly – front hood Bolt M6 2 12 1.2 8.7

Wind shield – front hood Screw M5 8 1 0.1 0.7

Hood lock – front hood Bolt M6 2 5 0.5 3.6

Hinge assembly – deck Nut M8 2 16 1.6 11

Nut M6 2 5 0.5 3.6

Steering console cover assembly

– deck

Bolt M6 4 3 0.3 2.2

Screw M5 2 2 0.2 1.4

Nut M8 2 16 1.6 11

Multifunction meter – holder Nut M5 2 2 0.2 1.4

Steering console cover – side

cover

Steering console cover – glove

compartment

Screw M6 4 3 0.3 2.2

Screw M5 4 1 0.1 0.7

Steering cable bracket – deck Bolt M6 1 6 0.6 4.3

Buzzer bracket – deck – steering

cable bracket

Bolt M6 2 6 0.6 4.3

Hood lock assembly – deck Nut M6 2 6 0.6 4.3

Seat lock assembly – seat Bolt M6 2 6 0.6 4.3

Bracket/deck – notch Nut M10 1 26 2.6 19

Bracket/deck – hand grip Bolt M8 2 5 0.5 3.6

Remarks

LT

572

2-9

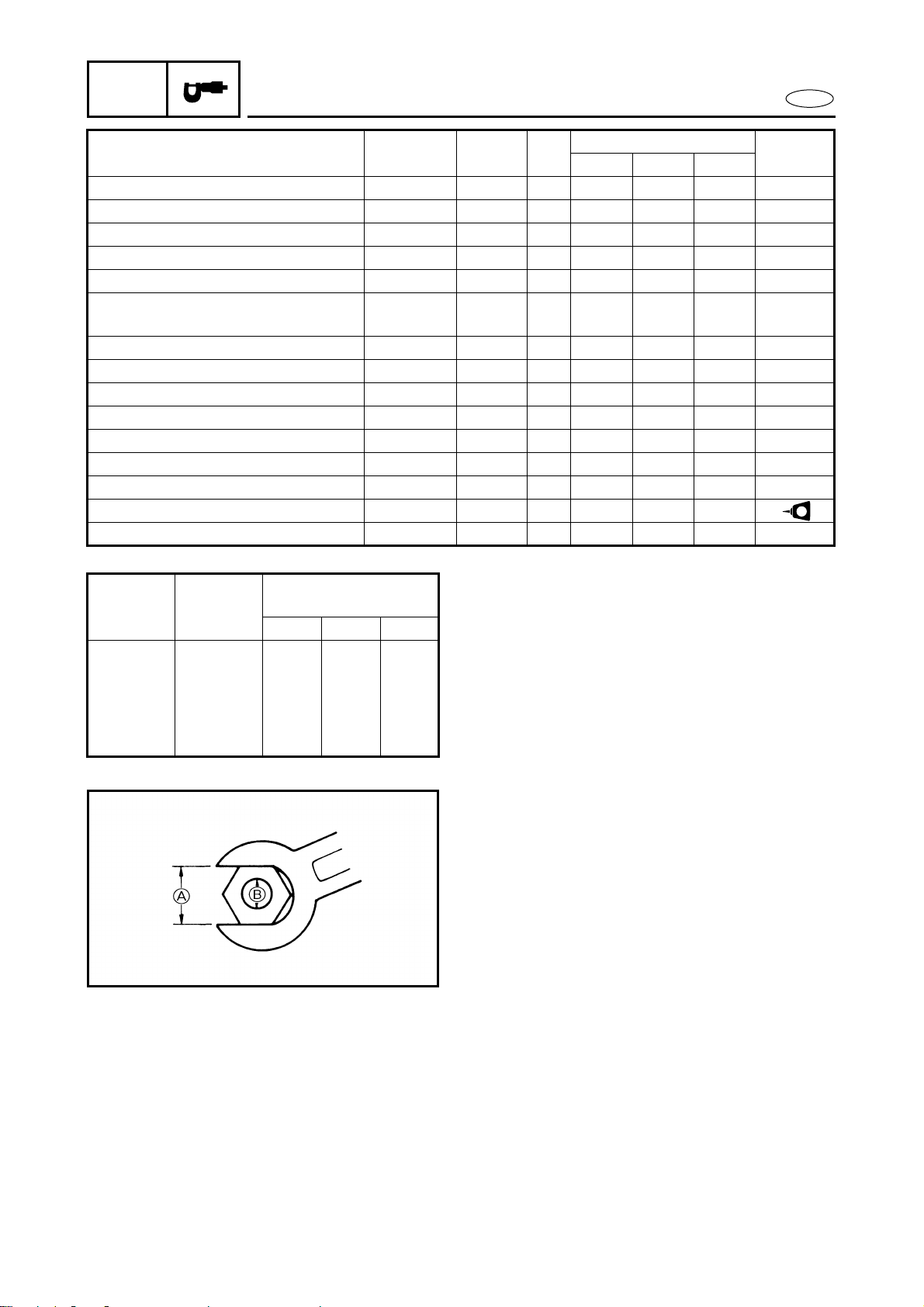

Page 27

SPEC

TIGHTENING TORQUES

E

Part to tightened Part name

Thread

size

Q’ty

Tightening torque

N•m kgf•m ft•lb

Hand grip – deck Nut M8 2 5 0.5 3.6

Seat bracket – deck Nut M8 2 15 1.5 11

Battery box/stay – holder Nut M6 2 9 0.9 6.5

Battery box – bracket/deck Nut M8 2 13 1.3 9.4

Battery box – electrical box Bolt M8 3 15 1.5 11

Extension bolt – battery negative

terminal

Bolt M6 1 6 0.6 4.3

Exhaust outlet – hull Bolt M6 3 6 0.6 4.3

Sponson – hull Bolt M8 6 18 1.8 13

Spout – hull Nut M24 1 5 0.5 3.6

Rope hole – hull Nut M24 2 5 0.5 3.6

Bow eye – hull Bolt M6 2 13 1.3 9.4

Flap – hull Bolt M6 8 6 0.6 4.3

Drain plug/packing – hull Nut M5 4 2 0.2 1.4

Engine mount – hull Bolt M8 8 17 1.7 12

Engine damper – hull Bolt M6 2 6 0.6 4.3

General torque

Nut A Bolt B

specifications

N•m kgf•m ft•lb

8 mm M5 5.0 0.5 3.6

10 mm M6 8.0 0.8 5.8

12 mm M8 18 1.8 13

14 mm M10 36 3.6 25

17 mm M12 43 4.3 31

GENERAL TORQUE

This chart specifies tightening torques for

standard fasteners with a standard ISO

thread pitch. Tightening torque specifications for special components or assemblies

are provided in applicable sections of this

manual. To avoid warpage, tighten multifastener assemblies in a crisscross fashion

and progressive stages until the specified

tightening torque is reached. Unless otherwise specified, tightening torque specifications require clean, dry threads.

Components should be at room temperature.

Remarks

LT

572

2-10

Page 28

SPEC

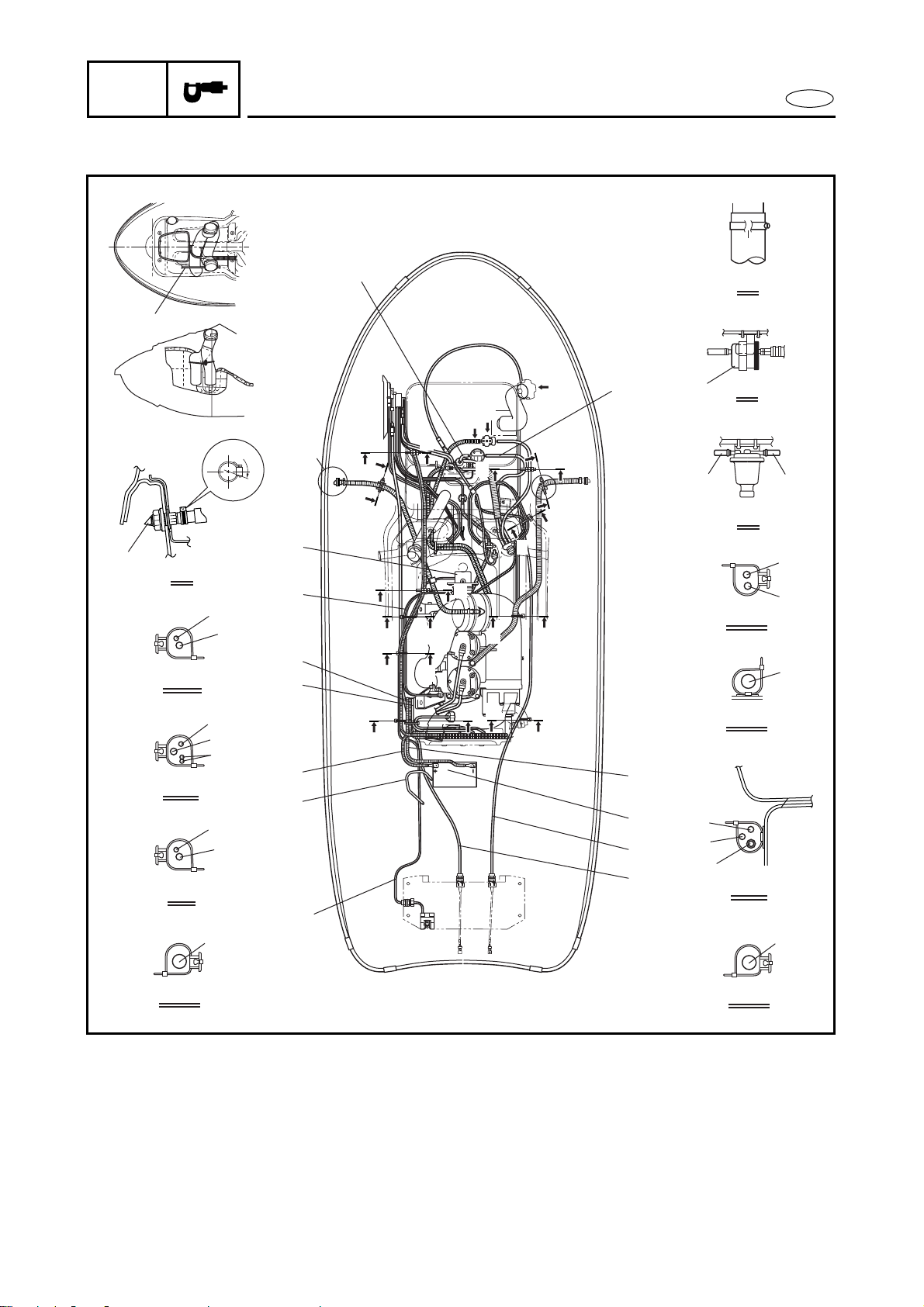

CABLE AND HOSE ROUTING

CABLE AND HOSE ROUTING

E

B

F

L

K-K

J-J

I-I

9

9

9

8

0

A

0

0

20˚

K

A

J

I

H

G

9

2

A

B

C

L

K

E

E

K

E

D

E

F

F

2

D

1

2

A

B

2

C

2

K

K

3

D-D

J

J

J J

I I

GG

H H

4

E-E

C

D

E

F

5

6

7

F-F

4

H-H

1 Fuel filter

2 Fuel tank breather hose

3 Fuel hose

4 Cooling water hose

5 Choke cable

6 Throttle cable

7 Oil return hose

8 Bilge hose

9 Speed sensor lead

0 Electrical box lead

A YPVS cables

B Cooling water pilot outlet

C Battery negative lead

D Battery

E Steering cable

F QSTS cable

2-11

G-G

G Battery breather hose

H Battery positive lead

I Starter motor lead

J Generator lead

K YPVS servomotor

Page 29

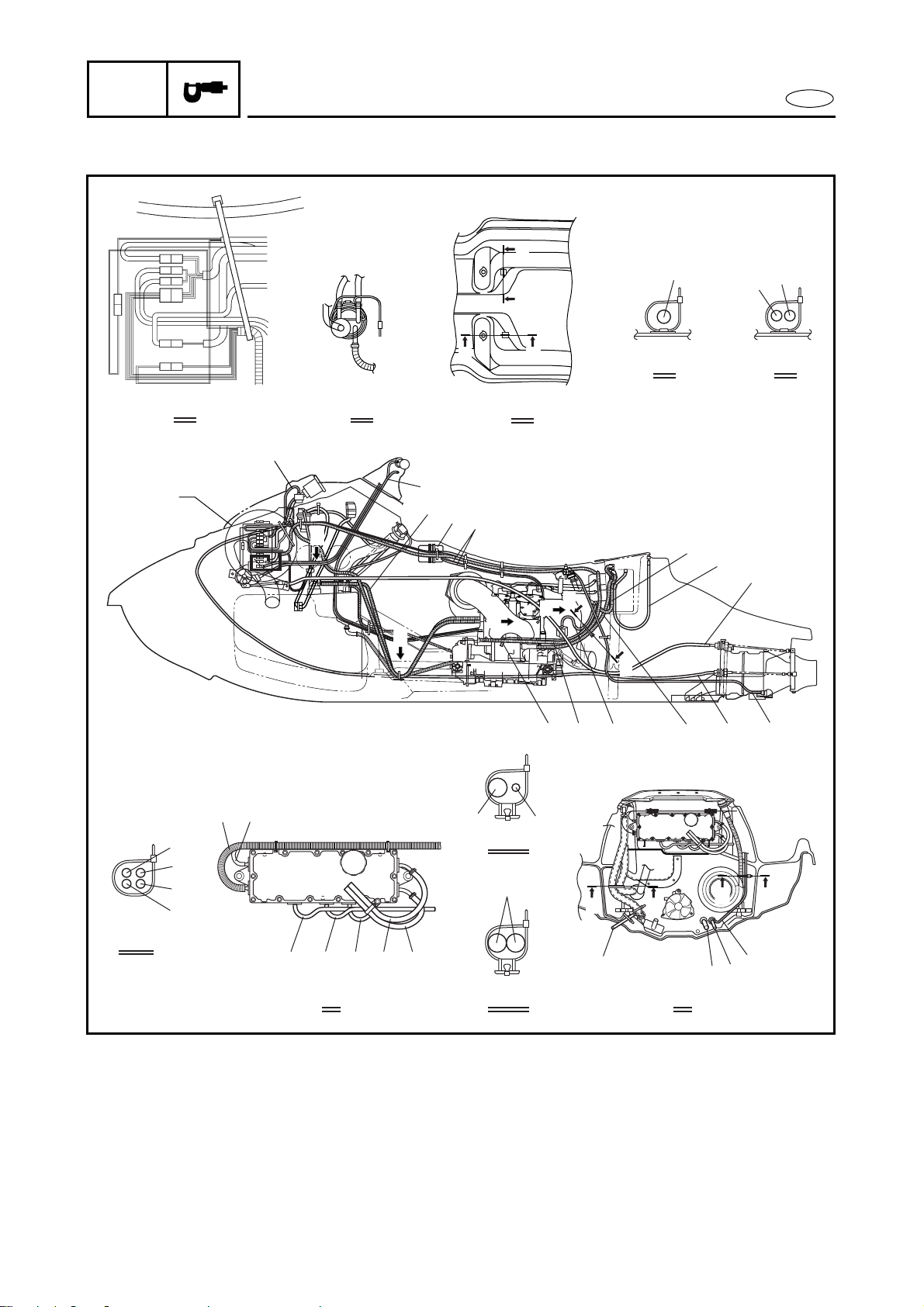

SPEC

CABLE AND HOSE ROUTING

D

D

1

2

E

3

E

A

B

E

D E

C

H

A

B

I

2

J

K

L

M

5

J

F

C

I

E

A

F

J

7

4

G

0

E

A

F

G

J-J

1 Oil delivery hose

2 Fuel return hose

3 Fuel suction hose

4 Speed sensor lead

5 QSTS cable

6 Cooling water hose

7 Steering cable

8 Flushing hose

A

F

8

G-G

D

E

I

9 Bilge hoses

0 To multifunction meter

A To stator assembly

B To cylinder #1

C To cylinder #2

D To battery positive terminal

E To starter motor positive

B

C

terminal

H-H

2-12

9

4

6

G

5

H

H

7

F

F To thermoswitch

G Battery negative lead

H Buzzer lead

I Choke cable

J YPVS servomotor

K YPVS cables

L Battery positive lead

M Battery breather hose

G

4

Page 30

Page 31

INSP

ADJ

CHAPTER 3

PERIODIC INSPECTION AND ADJUSTMENT

MAINTENANCE INTERVAL CHART.............................................................. 3-1

PERIODIC SERVICE ........................................................................................ 3-2

CONTROL SYSTEM ................................................................................. 3-2

Steering column inspection ............................................................. 3-2

Steering cable inspection and adjustment ..................................... 3-2

Throttle cable inspection and adjustment ...................................... 3-3

Choke cable inspection and adjustment ......................................... 3-4

QSTS cable inspection and adjustment .......................................... 3-5

YPVS cable adjustment .................................................................... 3-6

FUEL SYSTEM.......................................................................................... 3-7

Fuel line inspection ........................................................................... 3-7

Trolling speed check and adjustment ............................................. 3-8

OIL INJECTION SYSTEM......................................................................... 3-9

Oil line inspection ............................................................................. 3-9

POWER UNIT............................................................................................ 3-9

Spark plug inspection ....................................................................... 3-9

ELECTRICAL ........................................................................................... 3-10

Battery inspection ........................................................................... 3-10

JET PUMP UNIT..................................................................................... 3-13

Impeller inspection ......................................................................... 3-13

Water inlet strainer inspection....................................................... 3-14

Bilge strainer inspection................................................................. 3-14

GENERAL................................................................................................ 3-14

Drain plug inspection...................................................................... 3-14

Lubrication points ........................................................................... 3-15

E

1

2

3

4

5

6

7

8

9

Page 32

INSP

ADJ

MAINTENANCE INTERVAL CHART

MAINTENANCE INTERVAL CHART

The following chart should be considered strictly as a guide to general maintenance intervals.

Depending on operating conditions, the intervals of maintenance should be changed.

E

Item Remarks

Initial Every

10 hours

(Break-in)

50 hours

(3 months)

100 hours

(6 months)

200 hours

(1 year)

Refer to

page

CONTROL SYSTEM

Steering cable Inspect/adjust 3-2

Steering column Inspect 3-2

Throttle cable Inspect/adjust 3-3

Carburetor throttle shaft Inspect/adjust —

Choke cable Inspect/adjust 3-4

QSTS cable Inspect/adjust 3-5

YPVS cable Inspect/adjust 3-6

FUEL SYSTEM

Fuel tank Clean 4-9

Fuel filter Clean/replace 3-7

Fuel line Inspect 3-7

Trolling speed Check/adjust 3-8

Carburetor setting Inspect/adjust 4-18

OIL INJECTION SYSTEM

Oil injection system Check/clean 3-9

Oil pump cable Inspect/adjust 4-30

POWER UNIT

Spark plugs Inspect/clean/adjust 3-9

Cooling water passage Inspect/clean

*1

—

Rubber coupling Inspect —

ELECTRICAL

Battery Inspect

*2

3-10

JET PUMP UNIT

Impeller Inspect 3-13

Water inlet strainer Clean 3-14

Bilge strainer Clean 3-14

GENERAL

Bolts and nuts Retighten —

Drain plugs Inspect/replace 3-14

Lubrication points Grease 3-15

Intermediate housing Grease

*3

*4

3-17

*1: After every ride

*2: Inspect fluid level before every ride

*3: Grease capacity 33.0–35.0 cm

*4: Grease capacity 6.0–8.0 cm

3

(1.11–1.18 oz)

3

(0.20–0.27 oz)

3-1

Page 33

INSP

ADJ

CONTROL SYSTEM

E

PERIODIC SERVICE

CONTROL SYSTEM

Steering column inspection

1. Inspect:

● Steering column

Excessive play → Replace the steer-

ing column.

Refer to “STEERING COLUMN” in

chapter 8.

Inspection steps:

● Move the handlebar up and down and

back and forth.

● Check the excessive play of the han-

dlebar.

Steering cable inspection and adjustment

1. Inspect:

● Distance a, b (between the nozzle

and nozzle deflector)

Out of specification → Adjust.

2

Inspection steps:

● Set the control grip in the neutral posi-

tion.

● Turn the handlebar from lock to lock.

● Measure distances a and b.

● If the difference is not within specifica-

tion, adjust the cable joint.

Difference of distances a and b:

Maximum 5 mm (0.2 in)

2. Adjust:

● Steering cable joint

(steering column side)

Adjustment steps:

● Loosen the locknut 1.

● Disconnect the steering cable joint 2

from the ball joint 3.

● Turn the cable joint in or out for adjust-

ing the distances a and b.

Turn in Distance a is increased.

1

Turn out Distance b is increased.

3

3-2

Page 34

INSP

ADJ

CONTROL SYSTEM

E

WARNING

The cable joint must be screwed in more

than 8 mm (0.31 in).

● Connect the cable joint and tighten the

locknut.

Locknut:

T

6 N • m (0.6 kgf • m, 4.3 ft • lb)

.

R

.

NOTE:

If the steering cable cannot be properly

adjusted at the steering column side, make

sure the steering cable at the jet pump side

is set to the specified length. Refer to

“REMOTE CONTROL CABLES AND SPEED

SENSOR LEAD” in chapter 8.

Throttle cable inspection and adjustment

NOTE:

Before adjusting the throttle lever free play,

adjust the trolling speed.

1. Measure:

● Throttle lever free play a

Out of specification → Adjust.

Throttle lever free play:

4–7 mm (0.16–0.28 in)

2. Adjust:

● Throttle lever free play

Adjustment steps:

● Loosen the locknut 1.

● Turn the adjuster 2 in or out until the

specified free play is obtained.

Turn in Free play is increased.

Turn out Free play is decreased.

● Tighten the locknut.

3-3

Page 35

INSP

ADJ

CONTROL SYSTEM

E

WARNING

After adjusting the free play, turn the handlebar to the right and left and make sure

that the trolling speed does not increase.

Choke cable inspection and adjustment

1. Check:

● Choke lever operation

Incorrect operation → Adjust.

Checking steps:

● Check that the choke lever moves back

slightly when it is fully opened.

● Check that the inner cable has some

slack when the choke lever is completely closed.

2. Adjust:

● Choke lever operation

Adjustment steps:

● Loosen the locknut 1.

● Screw the adjuster 2 fully into the

bracket.

● Align the choke lever end a within the

line marks b.

● Turn out the adjuster 2 until the inner

cable is taut.

NOTE:

If the inner cable is difficult to make taut

using the adjuster 2, adjust the choke

lever so that the cable is taut. The cable

must be taut when the choke lever end

a is positioned within the line marks b.

Reset the adjuster if necessary.

● Tighten the locknut 1.

3-4

Page 36

INSP

ADJ

CONTROL SYSTEM

E

QSTS cable inspection and adjustment

1. Measure:

● Nozzle deflector set length a, b

Difference → Adjust.

Measurement steps:

● Set the control grip in the neutral posi-

tion.

● Measure the nozzle deflector set

length a and b.

● If a and b length are not even, adjust

the cable joint.

2. Adjust:

● QSTS cable

Adjustment steps:

● Set the control grip in the neutral posi-

tion.

● Loosen the locknut 1.

● Remove the nut 2 and pivot pin 3.

● Set the nozzle deflector in the center

position.

● Turn the cable joint 4 for adjusting.

Turn in Length b is increased.

Turn out Length a is increased.

WARNING

The cable joint must be screwed in more

than 8 mm (0.31 in).

● Connect the cable joint 4 and pivot

pin 3 and tighten the nut 2.

Nut:

T

4 N • m (0.4 kgf • m, 2.9 ft • lb)

.

R

.

● Tighten the locknut 1.

Locknut:

T

4 N • m (0.4 kgf • m, 2.9 ft • lb)

.

R

.

3-5

Page 37

INSP

ADJ

CONTROL SYSTEM

E

NOTE:

If the QSTS cable cannot be properly

adjusted at the QSTS converter side, make

sure the QSTS cable at the jet pump side is

set to the specified length.

Refer to “REMOTE CONTROL CABLES AND

SPEED SENSOR LEAD” in chapter 8.

YPVS cable adjustment

1. Check:

● YPVS valve position

Incorrect position → Adjust the YPVS

cable.

Checking steps:

● Start the engine and then stop it.

NOTE:

When the engine has been stopped for 3

seconds, the YPVS valve assembly will

retract and extend one time.

● Check that the hole a in the pulley is

aligned with the hole in the cylinder

when the YPVS valve is fully closed.

2. Measure:

● YPVS cable slack a

Out of specification → Adjust.

YPVS cable slack:

0.5–1.5 mm (0.02–0.06 in)

3-6

Page 38

INSP

ADJ

41

3

2

CONTROL SYSTEM/FUEL SYSTEM

3. Adjust:

● YPVS cables 1 and 2

Adjustment steps:

● Loosen locknuts 1 and 2.

● Turn in adjusters 3 and 4 until there

is slack in the cables.

● Align the hole a in the pulley with the

hole in the cylinder.

● Insert a 4-mm-diameter pin through

the holes in the pulley and cylinder.

● Turn adjusters 3 and 4 in or out until

the specified slack is obtained.

Turn in Slack is increased.

Turn out Slack is decreased.

● Finger tighten locknuts 1 and 2.

● Remove the pin.

● Start and stop the engine.

● Recheck the hole alignment.

● If the hole alignment is correctly,

tighten the locknuts.

● If the hole alignment is incorrect,

repeat the above steps.

E

FUEL SYSTEM

WARNING

● Stop the engine, set the fuel cock to

“OFF” before servicing the fuel system.

● When removing fuel system parts, wrap

them in a cloth and take care that no fuel

spills into the engine compartment.

Fuel line inspection

1. Inspect:

● Fuel filter 1

Contaminants → Replace.

Cracks/damage → Replace.

Water contamination → Replace and

check the fuel tank.

● Fuel hoses

● Fuel tank

● Fuel hoses through part

● Fuel filler cap

Cracks/damage → Replace.

3-7

Page 39

INSP

ADJ

FUEL SYSTEM

E

2. Inspect:

● Water separator 1

Water accumulation → Drain.

NOTE:

If need the water draining, remove the drain

plug 2.

Trolling speed check and adjustment

1. Check:

● Trolling speed

Out of specification → Adjust.

Trolling speed:

1,300 ± 50 r/min

Checking steps (with the watercraft in

the water):

● Start the engine and allow it to warm

up for several minutes.

● Attach the engine tachometer to the

spark plug lead.

1

Engine tachometer:

YU-8036-A/90890-06760

● Measure the engine trolling speed.

2. Adjust:

● Trolling speed

Adjustment steps:

● Start the engine and allow it to warm

up for several minutes.

● Attach the engine tachometer to the

spark plug lead.

Engine tachometer:

YU-8036-A/90890-06760

● Turn the throttle stop screw 1 in or

out until the specified trolling speed is

obtain.

3-8

Page 40

INSP

ADJ

OIL INJECTION SYSTEM/POWER UNIT

OIL INJECTION SYSTEM

Oil line inspection

1. Inspect:

● Oil filter

Contaminants → Clean.

Frays/tears → Replace.

● Rubber seal

Cracks/wear → Replace.

● Oil hoses

● Oil tank

● Oil filler cap

Cracks/damage → Replace.

● Check valve

Malfunction → Replace.

CAUTION:

Do not allow the oil tank to become completely empty. If the oil tank becomes

empty the oil injection pump must be bled

to ensure proper oil flow, otherwise engine

damage may occur. Refer to “OIL PUMP” in

chapter 4.

E

POWER UNIT

Spark plug inspection

1. Inspect:

● Electrodes 1

Damage/wear → Replace.

● Insulator color 2

Distinctly different color → Check the

engine condition.

Color guide:

Medium to light tan color:

Normal

Whitish color:

Lean fuel mixture

Air leak

Incorrect settings

Blackish color:

Overly rich mixture

Electrical malfunction

Excessive oil use

Defective spark plug

2. Clean:

● Spark plug

(with a spark plug cleaner or wire

brush)

3-9

Page 41

INSP

ADJ

POWER UNIT/ELECTRICAL

3. Measure:

● Spark plug gap a

4. Tighten:

● Spark plug

NOTE:

● Before installing the spark plug, clean the

gasket surface and spark plug surface.

Also, it is suggested to apply a thin film of

anti-seize compound to the spark plug

threads to prevent thread seizure.

● If a torque wrench is not available, a good

estimate of the correct tightening torque

for a new spark plug is to finger tighten a

the spark plug and then tighten it another

1/4 to 1/2 of a turn b.

Out of specification → Regap.

Spark plug gap:

0.7–0.8 mm (0.028–0.031 in)

Spark plug:

T

25 N • m (2.5 kgf • m, 18 ft • lb)

.

R

.

E

ELECTRICAL

Battery inspection

WARNING

Battery electrolyte is dangerous; it contains

sulfuric acid which is poisonous and highly

caustic.

Always follow these preventive measures:

● Avoid bodily contact with electrolyte as it

can cause severe burns or permanent eye

injury.

● Wear protective eye gear when handling

or working near batteries.

Antidote (EXTERNAL):

● SKIN - Wash with water.

● EYES - Flush with water for 15 minutes

and get immediate medical attention.

3-10

Page 42

INSP

ADJ

ELECTRICAL

E

Antidote (INTERNAL):

● Drink large quantities of water or milk fol-

lowed with milk of magnesia, beaten egg

or vegetable oil. Get immediate medical

attention.

Batteries generate explosive, hydrogen

gas. Always follow these preventive measures:

● Charge batteries in a well-ventilated area.

● Keep batteries away from fire, sparks or

open flames (e.g., welding equipment,

lighted cigarettes).

● DO NOT SMOKE when charging or han-

dling batteries.

KEEP BATTERIES AND ELECTROLYTE OUT

OF REACH OF CHILDREN.

CAUTION:

● Do not place the battery on its side.

● Before adding electrolyte or recharging,

be sure to remove the battery from the

battery box.

● Make sure that the battery breather hose

is properly connected and is not pinched

or damaged.

1. Remove:

● Band

● Battery negative lead 1

● Battery positive lead 2

● Battery

● Battery breather hose 3

WARNING

● When removing the battery, disconnect

the negative lead first.

● Remove the battery to prevent acid loss

during turning the machine on its side for

the impeller service.

3-11

Page 43

INSP

ADJ

ELECTRICAL

E

2. Inspect:

● Electrolyte level

Low → Add distilled water.

The electrolyte level should be

between the upper a and lower b

level marks.

Filling steps:

● Remove each filler cap.

● Add distilled water.

● When the electrolyte level reaches the

upper level mark, allow the cell to

stand for 20 minutes. If the electrolyte

level drops, add more distilled water

so the level reaches the upper level

mark.

CAUTION:

Use only distilled water. Other types of

water contain minerals which are harmful

to batteries.

3. Inspect:

● Specific gravity

Out of specification → Charge.

Specific gravity at 20 ˚C (68 ˚F):

1.28

Charging current:

1.9 amps × 10 hrs (68.4 kC)

4. Install:

● Filler caps

CAUTION:

Before installation, rinse off any fluid from

the battery box and battery and make sure

that the battery is dry before installing it.

3-12

Page 44

INSP

ADJ

ELECTRICAL/JET PUMP UNIT

5. Install:

● Battery breather hose 1

● Battery

● Battery positive lead 2

● Battery negative lead 3 (with termi-

nal extension at battery negative terminal)

● Band

CAUTION:

● Connect the positive lead to the battery

terminal first.

● Make sure the battery leads are con-

nected properly. Reversing the leads can

seriously damage the electrical system.

● Make sure that the battery breather hose is

properly connected and is not obstructed.

● Coat the terminals with a water resistant

grease to minimize terminal corrosion.

E

JET PUMP UNIT

Impeller inspection

1. Check:

● Impeller 1

Damage/wear → Replace.

Nicks/scratches → File or grind.

2. Measure:

● Impeller-to-housing clearance a

Out of specification → Replace.

Max. impeller-to-housing

clearance:

0.6 mm (0.02 in)

Measurement steps:

● Remove the battery leads.

● Remove the intake grate 1 and intake

duct 2.

● Measure the clearance at each impel-

ler blade as shown (a total of three

measurements).

● Install the intake grate and intake duct.

3-13

Bolt:

T

M6: 7 N • m

.

R

.

(0.7 kgf • m, 5.1 ft • lb)

M8: 17 N • m

(1.7 kgf • m, 12 ft • lb)

● Install the battery leads.

Page 45

INSP

ADJ

1

JET PUMP UNIT/GENERAL

a

E

Water inlet strainer inspection

1. Inspect:

● Water inlet strainer

Contaminants → Clean.

Cracks/damage → Replace.

Inspection steps:

● Remove the water inlet cover 1.

● Inspect the water inlet strainer mesh

a.

● Install the water inlet cover.

1

Bilge strainer inspection

1. Inspect:

● Bilge strainer

Contaminants → Clean.

Cracks/damage → Replace.

Inspection steps:

● Disconnect the bilge strainer 1 from

the bilge strainer holder.

● Inspect the bilge strainer.

GENERAL

Drain plug inspection

1. Inspect:

● Drain plugs

Cracks/damage → Replace.

● O-rings

Cracks/wear → Replace.

● Screw threads

Contaminants → Clean.

3-14

Page 46

INSP

ADJ

GENERAL

E

Lubrication points

1. Lubricate:

● Throttle cable (handlebar side)

Recommended lubricant:

Rust inhibitor

NOTE:

Before lubricating the throttle cable,

squeeze the throttle lever and remove the

rubber seal 1.

2. Lubricate:

● QSTS control cables (handlebar side)

Recommended lubricant:

Yamaha marine grease,

Yamaha grease A

(Water resistant grease)

NOTE:

Before lubricating the QSTS control cables,

remove the QSTS cable housing cover.

Spray the rust inhibitor into the outer

cables, and apply grease to the inner

cables.

3. Lubricate:

● Choke cable (handlebar side)

3-15

Recommended lubricant:

Rust inhibitor

Page 47

INSP

ADJ

GENERAL

E

4. Lubricate:

● Throttle cable (carburetor side)

● Oil pump cable

● QSTS cables (pulley side)

● YPVS cables

Recommended grease:

Yamaha marine grease,

Yamaha grease A

(Water resistant grease)

3-16

5. Lubricate:

● Nozzle pivot shaft

● Steering cable (nozzle side)

● QSTS cable (nozzle side)

Recommended grease:

Yamaha marine grease,

Yamaha grease A

(Water resistant grease)

Page 48

INSP

ADJ

GENERAL

E

6. Lubricate:

● Steering cable

● Steering cable joint

NOTE:

Disconnect the joints and apply a small

amount of grease.

Recommended grease:

Yamaha marine grease,

Yamaha grease A

(Water resistant grease)

7. Fill:

● Intermediate housing

Recommended grease:

Yamaha marine grease,

Yamaha grease A

(Water resistant grease)

NOTE:

Fill the intermediate housing with the recommended grease through the grease nipples.

3-17

Page 49

Page 50

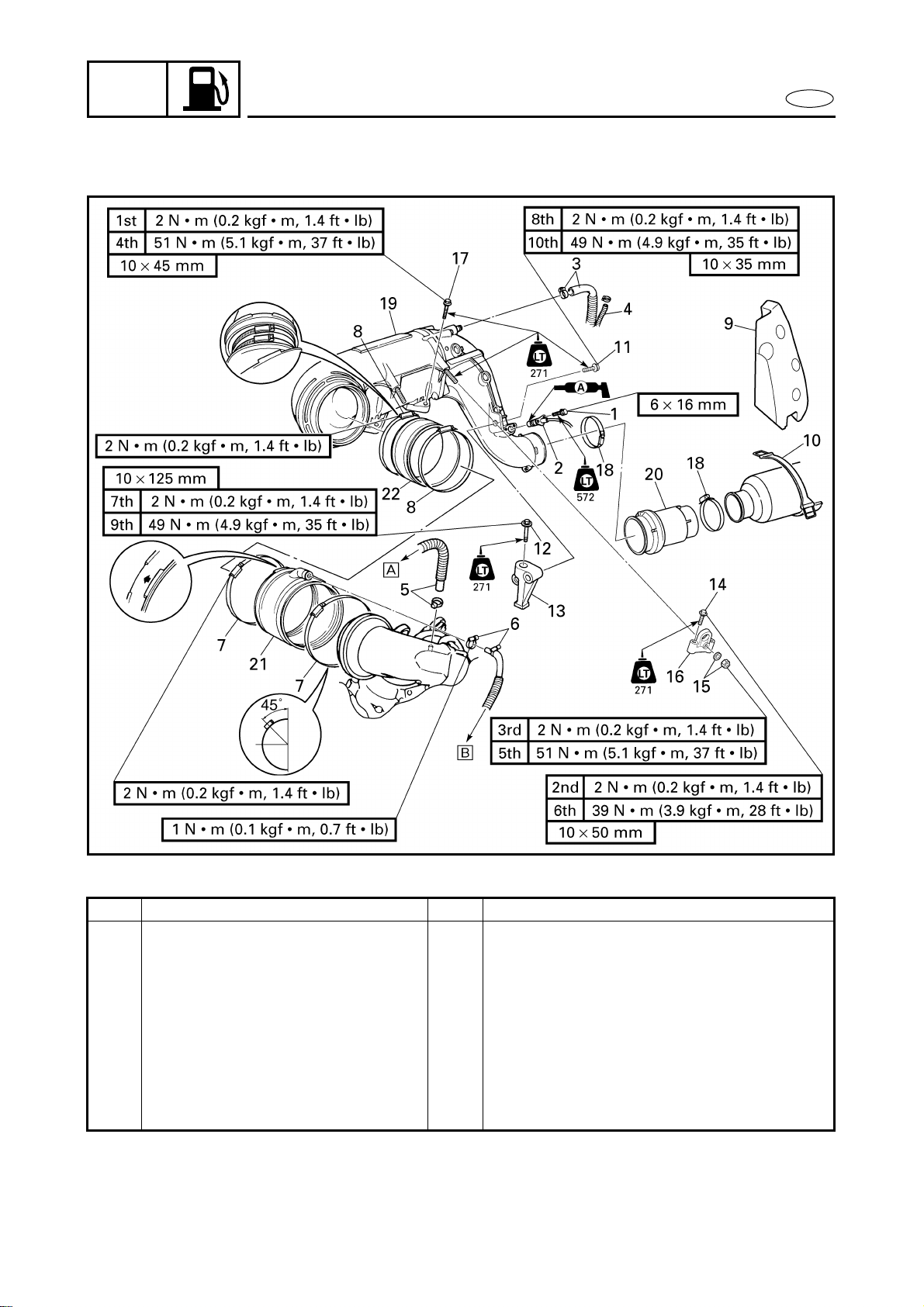

FUEL

E

CHAPTER 4

FUEL SYSTEM

FUEL COCK AND FUEL FILTER ..................................................................... 4-1

EXPLODED DIAGRAM............................................................................. 4-1

REMOVAL AND INSTALLATION CHART ............................................... 4-1

SERVICE POINTS ..................................................................................... 4-2

Fuel filter inspection ......................................................................... 4-2

Fuel cock inspection.......................................................................... 4-2

OIL TANK ........................................................................................................ 4-3

EXPLODED DIAGRAM............................................................................. 4-3

REMOVAL AND INSTALLATION CHART ............................................... 4-3

SERVICE POINTS ..................................................................................... 4-5

Oil line inspection ............................................................................. 4-5

Oil level sensor inspection ............................................................... 4-5

Oil tank inspection ............................................................................ 4-5

FUEL TANK ..................................................................................................... 4-6

EXPLODED DIAGRAM............................................................................. 4-6

REMOVAL AND INSTALLATION CHART ............................................... 4-6

SERVICE POINTS ..................................................................................... 4-9

Check valve inspection ..................................................................... 4-9

Fuel level sensor inspection............................................................. 4-9

Fuel tank inspection .......................................................................... 4-9

Pipe joint inspection ......................................................................... 4-9

INTAKE SILENCER ....................................................................................... 4-10

EXPLODED DIAGRAM........................................................................... 4-10

REMOVAL AND INSTALLATION CHART ............................................. 4-10

CARBURETOR UNIT..................................................................................... 4-11

EXPLODED DIAGRAM........................................................................... 4-11

REMOVAL AND INSTALLATION CHART ............................................. 4-11

SERVICE POINTS ................................................................................... 4-18

Throttle valve synchronization inspection and adjustment ........ 4-18

Choke cable and throttle cable installation................................... 4-19

Oil pump cable installation ............................................................ 4-19

Carburetor assembly ...................................................................... 4-19

Page 51

FUEL

CARBURETOR .............................................................................................. 4-20

EXPLODED DIAGRAM........................................................................... 4-20

REMOVAL AND INSTALLATION CHART ............................................. 4-20

SERVICE POINTS ................................................................................... 4-23

Diaphragm inspection .................................................................... 4-23

Accelerator pump body inspection ............................................... 4-23

Arm inspection ................................................................................ 4-23

Regulator body inspection ............................................................. 4-24

Needle valve inspection ................................................................. 4-24

Jet and carburetor body inspection .............................................. 4-24

Carburetor assembly ...................................................................... 4-24

E

1

FUEL PUMP .................................................................................................. 4-25

EXPLODED DIAGRAM........................................................................... 4-25

REMOVAL AND INSTALLATION CHART ............................................. 4-25

SERVICE POINTS ................................................................................... 4-27

Fuel pump inspection ..................................................................... 4-27

Fuel filter inspection ....................................................................... 4-27

OIL PUMP...................................................................................................... 4-28

EXPLODED DIAGRAM........................................................................... 4-28

REMOVAL AND INSTALLATION CHART ............................................. 4-28

SERVICE POINTS ................................................................................... 4-30

Oil pump inspection........................................................................ 4-30

Oil hose inspection ......................................................................... 4-30

Check valve inspection ................................................................... 4-30

Oil pump cable adjustment ............................................................ 4-30

Oil injection pump air bleeding ..................................................... 4-31

2

3

4

5

6

7

8

9

Page 52

FUEL

FUEL COCK AND FUEL FILTER

FUEL COCK AND FUEL FILTER

EXPLODED DIAGRAM

E

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

FUEL COCK AND FUEL FILTER

REMOVAL

1 Screw 1

2 Knob 1

3 Nut 1

4 Fuel cock assembly 1

5 Fuel hose 3

6 Holder 1

7 Fuel filter 1

8 Fuel hose 1

Follow the left “Step” for removal.

Reverse the removal steps for installation.

4-1

Page 53

FUEL

FUEL COCK AND FUEL FILTER

SERVICE POINTS

Fuel filter inspection

Refer to “FUEL SYSTEM” in chapter 3.

Fuel cock inspection

1. Check:

● Fuel cock

Contaminants → Clean.

Rough movement → Replace.

E

4-2

Page 54

FUEL

OIL TANK

OIL TANK

EXPLODED DIAGRAM

E

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

OIL TANK REMOVAL Follow the left “Step” for removal.

Engine unit Refer to “ENGINE UNIT” in chapter 5.

Steering console cover assembly Refer to “STEERING CONSOLE COVER”

in chapter 8.

1 Oil level sensor coupler 1

2 Band 1

3 Nut 1

4 Oil filler neck 1

5 Rubber seal 1

Not reusable

Disconnect the oil filler hose from the oil

filler neck.

4-3

Page 55

FUEL

OIL TANK

EXPLODED DIAGRAM

E

Step Procedure/Part name Q’ty Service points

6 Breather hose 1

7 Oil hose 1

8 Bolt 2

9 Tank belt 2

10 Oil tank assembly 1

11 Hose clamp 1

12 Oil filler hose 1

13 Oil level sensor 1

Reverse the removal steps for installation.

4-4

Page 56

FUEL

OIL TANK

E

SERVICE POINTS

Oil line inspection

1. Inspect:

● Oil filter

Contaminants → Clean.

Frays/tears → Replace.

● Rubber seal

Cracks/wear → Replace.

● Oil hoses

● Oil tank

● Oil filler cap

Cracks/damage → Replace.

● Check valve

Malfunction → Replace.

Oil level sensor inspection

Refer to “INDICATION SYSTEM” in

chapter 7.

Oil tank inspection

1. Inspect:

● Oil tank

Cracks/damage → Replace.

4-5

Page 57

FUEL

FUEL TANK

FUEL TANK

EXPLODED DIAGRAM

E

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

FUEL TANK REMOVAL Follow the left “Step” for removal.

Oil tank Refer to “OIL TANK”.

1 Fuel level sensor coupler 1

2 Hose clamp 1 Disconnect the fuel filler hose from the

fuel filler neck.

3 Nut 1

4 Fuel filler neck 1

5 Rubber seal 1

6 Fuel reserve hose 1

4-6

Page 58

FUEL

FUEL TANK

EXPLODED DIAGRAM

E

Step Procedure/Part name Q’ty Service points

7 Fuel hose 1

8 Fuel return hose 1

9 Fuel tank breather hose 1

10 Fuel tank assembly 1

11 Hose clamp 1

12 Fuel filler hose 1

13 Hose clamp 1

14 Fuel sensor assembly 1

4-7

Page 59

FUEL

FUEL TANK

EXPLODED DIAGRAM

E

Step Procedure/Part name Q’ty Service points

15 One way valve 1

16 Screw/washer 1/1

17 Filter 1

18 Screw/washer 1/1

19 Sleeve 1

20 Floatation 1

21 Bolt 2

22 Tank belt 2

Reverse the removal steps for installation.

4-8

Page 60

FUEL

FUEL TANK

E

SERVICE POINTS

A

A

B

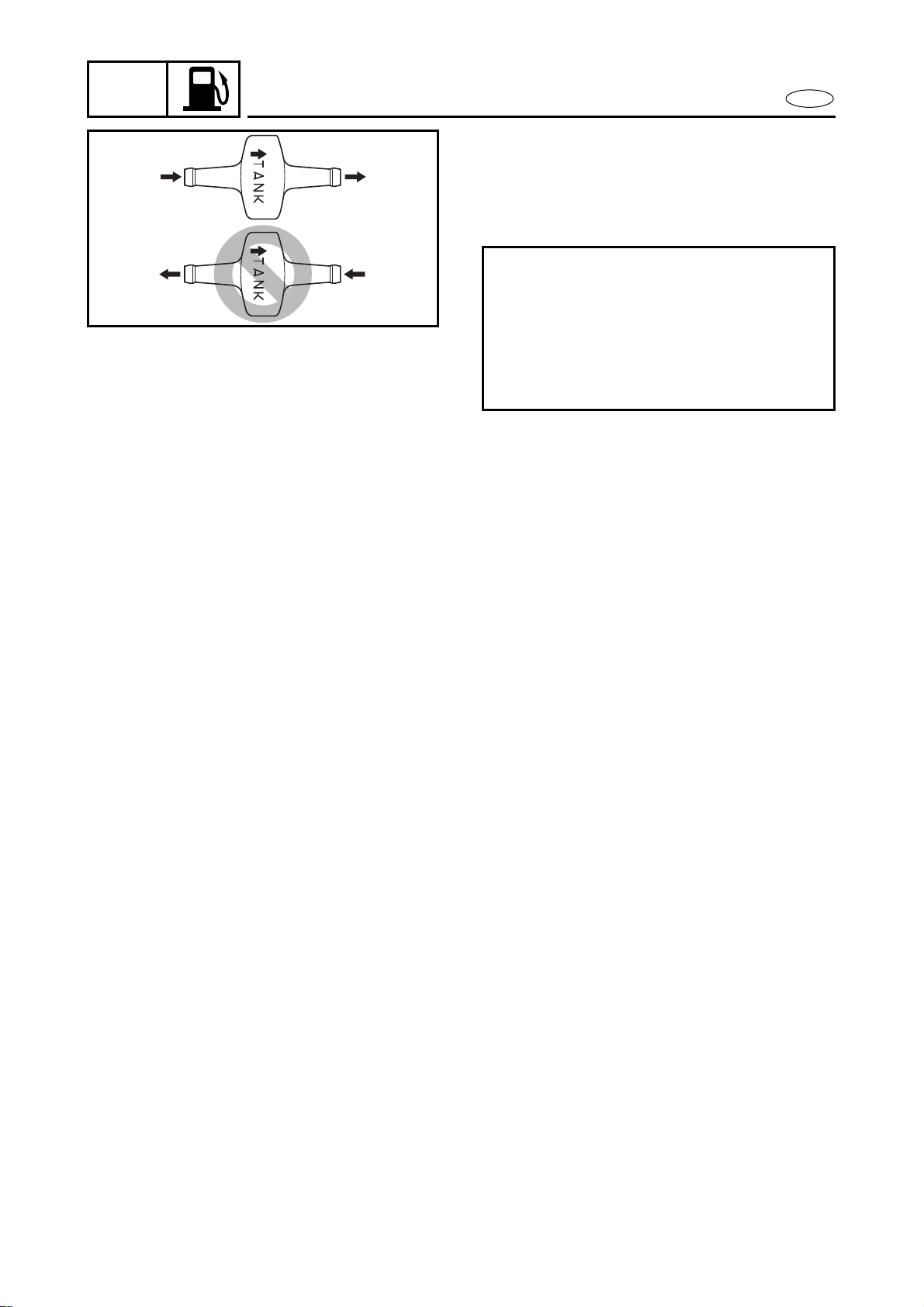

Check valve inspection

1. Check:

● Check valve

Faulty → Replace.

B

Checking steps:

● Connect a hose to the end of check

valve “A” and blow into it.

Air should come out from end “B”.

● Connect the hose to the end of check

valve “B” and blow into it.

Air should not come out from end “A”.

Fuel level sensor inspection

Refer to “INDICATION SYSTEM” in

chapter 7.

Fuel tank inspection

1. Inspect:

● Fuel tank

Cracks/damage → Replace.

Pipe joint inspection

1. Inspect:

● Pipe

Contaminants → Clean.

Bends/damage → Replace.

4-9

Page 61

FUEL

INTAKE SILENCER

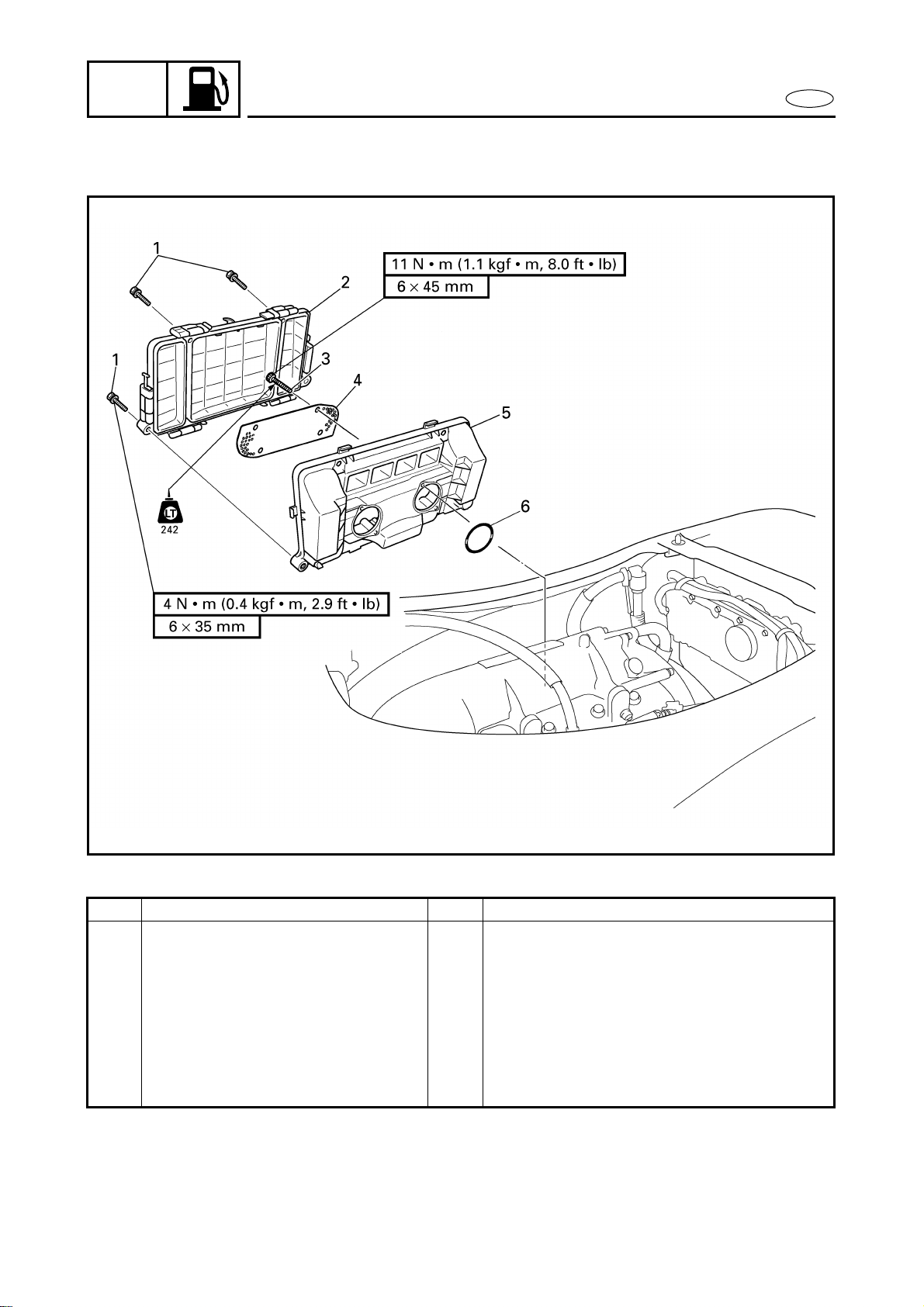

INTAKE SILENCER

EXPLODED DIAGRAM

E

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

INTAKE SILENCER REMOVAL Follow the left “Step” for removal.

1 Bolt 3

2 Intake silencer cover 1

3 Bolt 4

4 Spark arrester 1

5 Intake silencer 1

6 O-ring 2

Reverse the removal steps for installation.

4-10

Page 62

FUEL

CARBURETOR UNIT

CARBURETOR UNIT

EXPLODED DIAGRAM

E

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

CARBURETOR REMOVAL Follow the left “Step” for removal.

Battery box Refer to “BATTERY BOX” in chapter 8.

Intake silencer Refer to “INTAKE SILENCER”.

1 Bolt 2

2 Thermoswitch 1

3 Clamp/cooling water hose 1/1

4 Grease hose 1

5 Clamp/cooling water hose 1/1 Å For cooling water pilot outlet on

6 Clamp/cooling water hose 1/1 ı For cooling water pilot outlet on port

NOTE:

When removing the carburetor, the

exhaust chamber assembly does not

need to be removed if the engine unit has

already been removed.

starboard side

side

4-11

Page 63

FUEL

CARBURETOR UNIT

EXPLODED DIAGRAM

E

Step Procedure/Part name Q’ty Service points

7 Hose clamp 2 Slide the outer exhaust joint.

8 Hose clamp 2

9 Floatation 1

10 Water lock band 1

11 Bolt 1

12 Bolt 1

13 Muffler stay 3 1

14 Bolt 4

15 Nut/washer 2/2

4-12

Page 64

FUEL

CARBURETOR UNIT

EXPLODED DIAGRAM

E

Step Procedure/Part name Q’ty Service points

16 Muffler stay 1 2

17 Bolt 2

18 Hose clamp 2

19 Exhaust chamber assembly 1

20 Rubber joint 1 Slide the water lock to back

21 Outer exhaust joint 1

22 Inner exhaust joint 1

NOTE:

Make sure to remove spark plugs before

removing the muffler stay 1.

4-13

Page 65

FUEL

CARBURETOR UNIT

EXPLODED DIAGRAM

E

Step Procedure/Part name Q’ty Service points

23 Fuel hose 2 Å suction

ı return

NOTE:

Use the white marks a on the fuel hoses

to distinguish the hose ends.

24 Oil feed hose 2

25 Choke cable 1

26 Throttle cable 1

27 Oil pump cable 1

4-14

Page 66

FUEL

CARBURETOR UNIT

EXPLODED DIAGRAM

E

Step Procedure/Part name Q’ty Service points

28 Pulse hose 2

29 Bolt 2

30 Bolt 4

31 Carburetor unit 1

32 Gasket 1

33 Dowel pin 2

4-15

Not reusable

Reverse the removal steps for installation.

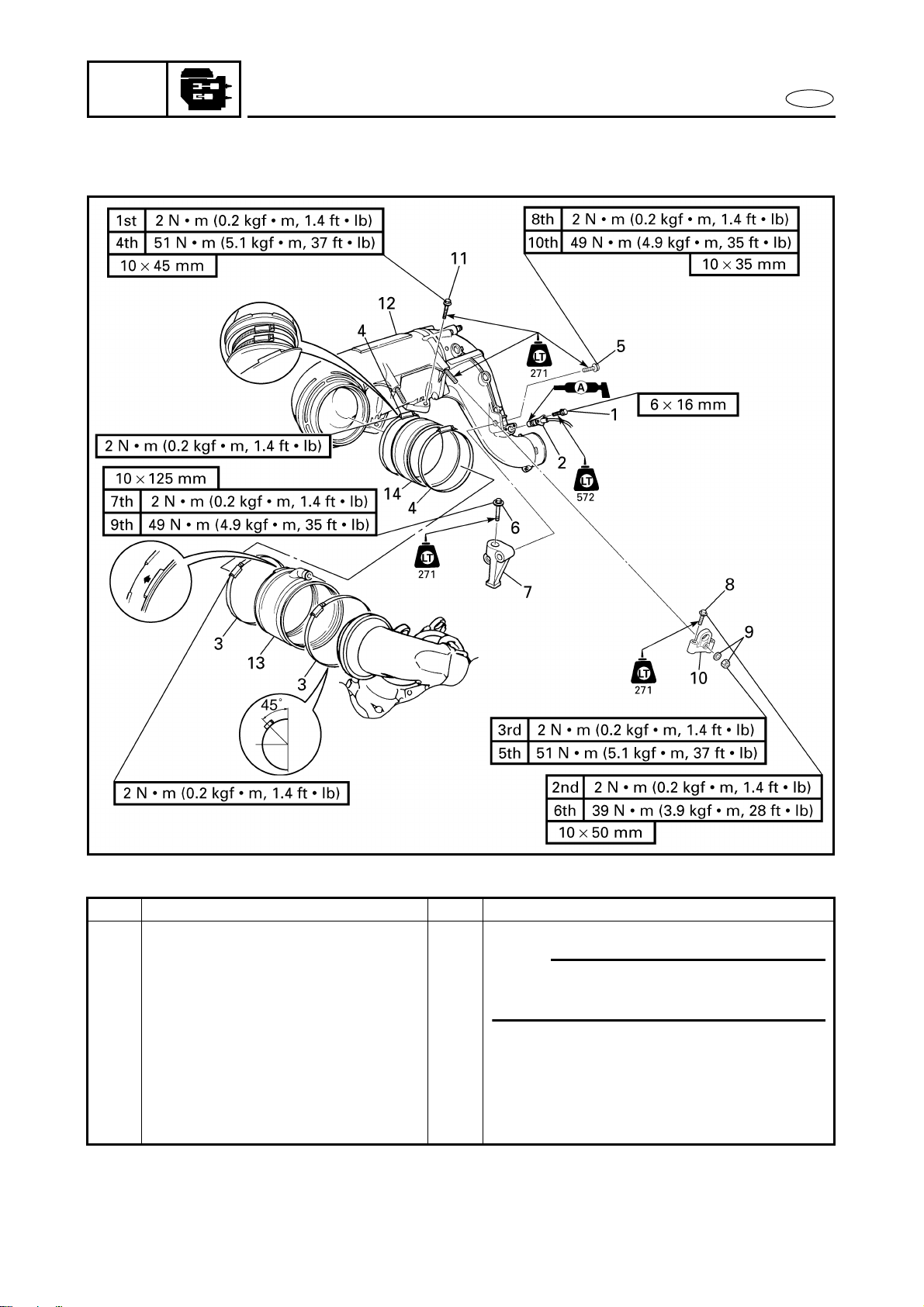

Page 67

FUEL

CARBURETOR UNIT

EXPLODED DIAGRAM

E

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

CARBURETOR UNIT

SEPARATION

1 Pulse hose 2

2 Fuel hose 4 Å suction

3 Oil feed hose 2

4 Accelerator pump fuel hose 3

5 Throttle link 1

6 Choke link 1

Follow the left “Step” for removal.

ı return

4-16

Page 68

FUEL

CARBURETOR UNIT

EXPLODED DIAGRAM

E

Step Procedure/Part name Q’ty Service points

7 Bolt 3

8 Cable bracket 1

9 Bolt 4

10 Carburetor 2

11 Gasket 2

12 Carburetor joint 1

13 Bolt/washer 2/2

14 Fuel hose guide 1

4-17

Not reusable

Reverse the removal steps for installation.

Page 69

FUEL

CARBURETOR UNIT

aa

E

SERVICE POINTS

Throttle valve synchronization inspection

and adjustment

1. Check:

● Throttle valve synchronization

Different clearances → Adjust.

Checking steps:

● Loosen the throttle stop screw 1 until

untouched the screw end from the

throttle lever.

● Check the each throttle valve is fully

closed a.

2. Adjust:

● Throttle valve synchronization

Adjustment steps:

● Loosen the throttle stop screw 1 until

untouched the screw end from the

throttle lever.

● Loosen the screws 2.

NOTE:

Make sure that the throttle valves are in

the fully closed position.

● Tighten the screws 2.

Screw:

2 N • m (0.2 kgf • m, 1.4 ft • lb)

T

.

R

.

● Turn in the throttle stop screw to the

original position.

4-18

Page 70

FUEL

CARBURETOR UNIT

E

Choke cable and throttle cable installation

1. Install:

● Choke cable 1

● Throttle cable 2

Choke cable guide installation

position a:

13–15 mm (0.51–0.59 in)

Throttle cable guide installation

position a:

18–20 mm (0.71–0.79 in)

2. Adjust:

● Throttle lever free play

● Choke lever operation

Refer to “CONTROL SYSTEM” in

chapter 3.

Oil pump cable installation

1. Adjust:

● Oil pump cable

Refer to “OIL PUMP”.

Carburetor assembly

1. Adjust:

● Trolling speed

Refer to “FUEL SYSTEM” in chapter 3.

4-19

Page 71

FUEL

CARBURETOR

CARBURETOR

EXPLODED DIAGRAM

E

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

CARBURETOR DISASSEMBLY Follow the left “Step” for disassembly.

1 Accelerator pump fuel hose 1 Carburetor #1

2 Screw 4

3 Accelerator pump/carburetor

cover

4 Diaphragm 1

5 Screw 2

6 Regulator body 1

7 Gasket 1

8 Main jet 1

9 Pilot jet 1

1/1 Carburetor #1/carburetor #2

4-20

Page 72

FUEL

CARBURETOR

EXPLODED DIAGRAM

E

Step Procedure/Part name Q’ty Service points

10 Screw 1

11 Arm 1

12 Arm pin 1

13 Spring 1

14 Screw 1

15 Needle valve seat holder 1

16 Needle valve 1

17 Needle valve seat 1

18 O-ring 1

Reverse the disassembly steps for

assembly.

4-21

Page 73

FUEL

CARBURETOR

EXPLODED DIAGRAM

E

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

ACCELERATOR PUMP

DISASSEMBLY

1 Screw 1

2 Stay 1

3 Spring 1

4 Spring seat 1

5 Screw 4

6 Accelerator pump cover 1

7 Spring 1

8 Diaphragm 1

9 Accelerator pump body 1

Follow the left “Step” for disassembly.

Reverse the disassembly steps for

assembly.

4-22

Page 74

FUEL

CARBURETOR

E

SERVICE POINTS

NOTE:

Before disassembling the carburetor, make

sure to note the number of times the pilot

screw is turned in from its set position to

the seated position.

CAUTION:

Do not use steel wire for cleaning the jets.

This may enlarge the jet diameters and

seriously affect performance.

Diaphragm inspection

1. Inspect:

● Diaphragm

Damage → Replace.

Accelerator pump body inspection

1. Inspect:

● One way valve

Crack/damage → Replace the acceler-

ator pump body.

● Fuel passage

Clog → Clean or replace.

Arm inspection

1. Inspect:

● Arm 1

Bends/damage → Repair or replace.

2. Measure:

● Arm height a

Arm height:

0–0.2 mm (0–0.008 in)

NOTE:

● Measure the distance between the surface

of the carburetor body b and the top surface of the arm.

● The arm should be resting on the needle

valve, but not compressing it.

4-23

Page 75

FUEL

CARBURETOR

E

Regulator body inspection

1. Inspect:

● Regulator body

Contaminants → Clean.

Damage → Replace.

● Valve (clear film) 1

Damage → Replace.

Needle valve inspection

1. Inspect:

● Needle valve

● Needle valve seat

Contaminants a → Clean.

Wear b → Replace.

NOTE:

Always replace the needle valve and needle

valve seat as a set.

Jet and carburetor body inspection

1. Inspect:

● Main jet

● Pilot jet

● Carburetor body

Clog/contaminants → Clean.

Damage/wear → Replace.

CAUTION:

Do not use a steel wire to clean the jets.

This may enlarge the jet diameters and

seriously affect performance.

Carburetor assembly

NOTE:

Before assembling the carburetor, make

sure to turn out the pilot screw the same

number of times, as noted before disassembly, from the seated position to the set position.

4-24

1. Adjust:

● Trolling speed

Refer to “FUEL SYSTEM” in chapter 3.

Page 76

FUEL

FUEL PUMP

FUEL PUMP

EXPLODED DIAGRAM

E

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

FUEL PUMP DISASSEMBLY Follow the left “Step” for disassembly.

Carburetors Refer to “CARBURETOR UNIT”.

1 Screw 4

2 Fuel pump cover 1

3 Gasket 1

4 Diaphragm 1

5 O-ring 1

6 Diaphragm body 1

4-25

Not reusable

Page 77

FUEL

FUEL PUMP

EXPLODED DIAGRAM

E

Step Procedure/Part name Q’ty Service points

7 Rubber diaphragm 1

8 Diaphragm 1

9 Packing 1

10 Fuel filter 1

Reverse the disassembly steps for

assembly.

4-26

Page 78

FUEL

FUEL PUMP

E

SERVICE POINTS

Fuel pump inspection

1. Inspect:

● Diaphragm

● Rubber diaphragm

● Diaphragm body

Damage → Replace.

Fuel filter inspection

1. Inspect:

● Fuel filter

Clog/contaminants → Clean.

Damage → Replace.

4-27

Page 79

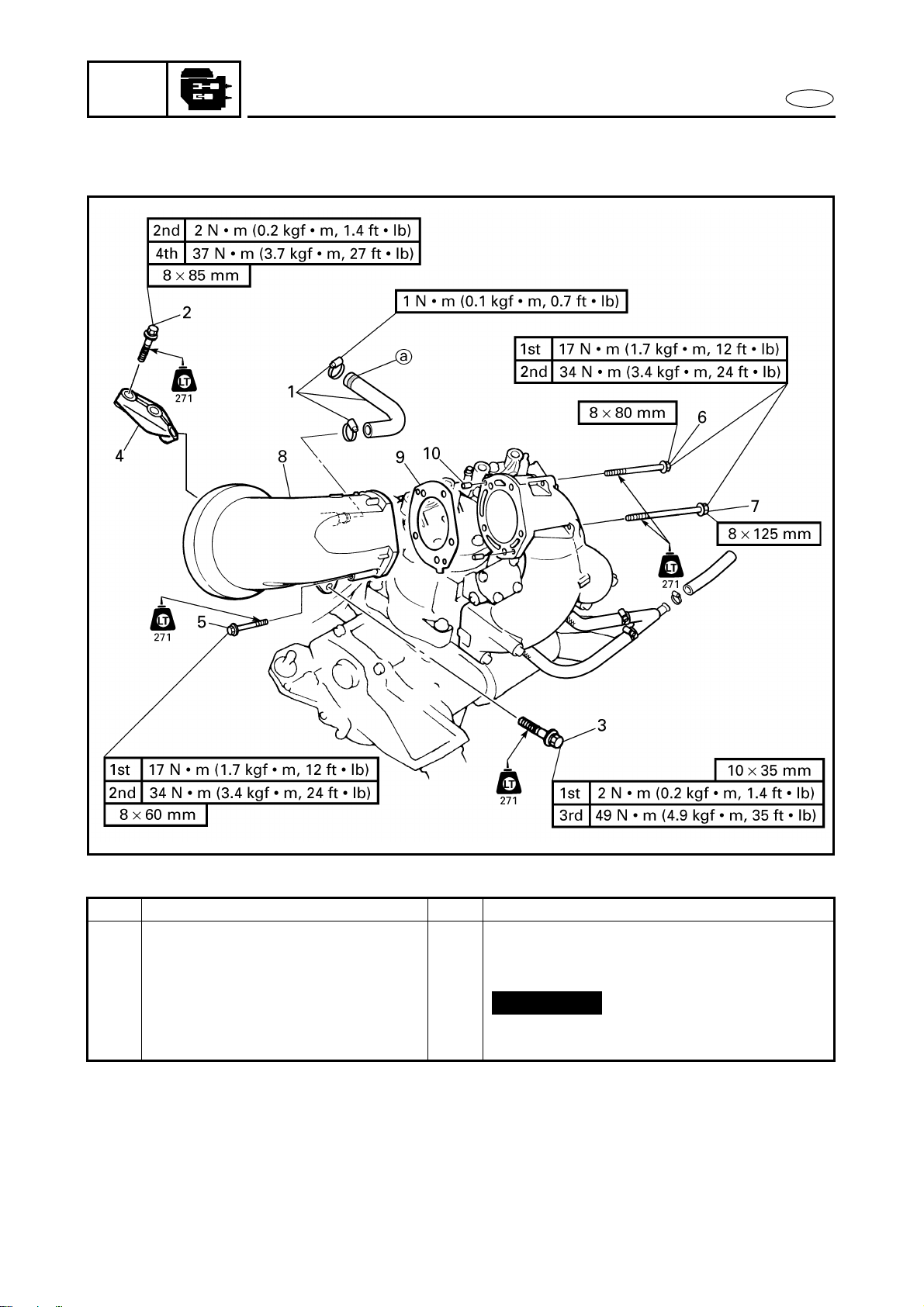

FUEL

OIL PUMP

OIL PUMP

EXPLODED DIAGRAM

1