Yamaha FZS 600 Fazer 1999 Service manual

0-12 Daily or (pre-ride) checks

Note: The daily (pre-ride) checks outlined in the owner's manual covers those items which should be inspected on a daily basis.

1 Engine/transmission oil level check

Before you start

• On YZF models, support the motorcycle

in an upright position, using an auxiliary stand

if required. On FZS models, put the

motorcycle on its centrestand. Make sure it is

on level ground.

• Start the engine and let it idle for several

minutes to allow it to reach normal operating

temperature.

Caution: Do not run the engine in an

enclosed space such as a garage or

workshop.

• Stop the engine. Leave the motorcycle

undisturbed for a few minutes to allow the oil

level to stabilise.

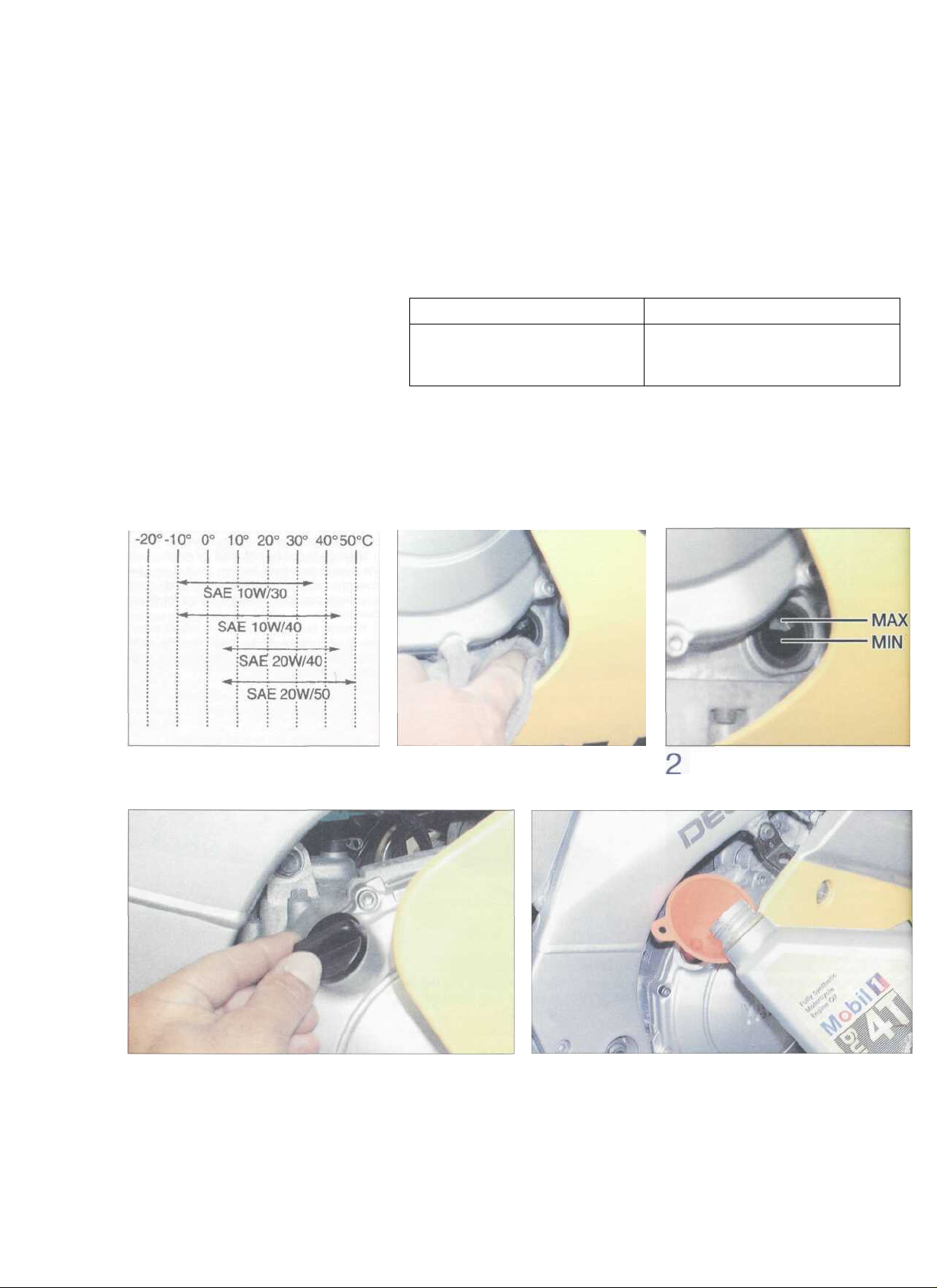

The correct oil

• Modern, high-revving engines place great demands on their oil. It is very important that

the correct oil for your bike is used.

• Always top up with a good quality oil of the specified type and viscosity and do not overfill

the engine.

Caution: Do not use chemical additives or oils with a grade of CD or higher, or use oils

labelled "ENERGY CONSERVING II". Such additives or oils could cause clutch slip.

Oil type

Oil viscosity*

UK models

US models

"Refer to the viscosity table to select the oil best suited to your conditions.

API grade SE, SF or SG (min)

SAE 10W30or10W40

SAE10W30or20W50

Bike care

• If you have to add oil frequently, you should check whether you have any oil leaks. If there is no sign of oil leakage from the joints and gaskets |

the engine could be burning oil (see Fault Finding).

Oil viscosity table; select the oil best suited

If the level is below the minimum line, remove the filler cap from

3

the top of the clutch cover.

to the conditions

Wipe the oil level inspection window,

I

located on the right-hand side of the

engine, so that it is clean.

With the motorcycle vertical, the oil level

should lie between the maximum and

minimum levels on the window.

Top the engine up with the recommended grade and type of oil, to

4

bring the level up to the maximum level on the window.

2 Coolant level check

Daily or (pre-ride) checks 0-13

Warning: DO NOT remove the radiator pressure cap to add coolant. Topping

up is done via the coolant reservoir tank filler. DO NOT leave open containers

of coolant about, as it is poisonous.

Before you start

• Make sure you have a supply of coolant

available - a mixture of 50% distilled water

and 50% corrosion inhibited ethylene glycol

anti-freeze is needed. Note: Yamaha specify

that soft tap water can be used, but NOT hard

water. If in doubt, boil the water first or use

only distilled water.

• Always check the coolant level when the

engine is cold.

• On YZF models, support the motorcycle

in an upright position, using an auxiliary stand

if required. On FZS models, put the

motorcycle on its centrestand. Make sure it is

on level ground.

Bike care

• Use only the specified coolant mixture. It

is important that anti-freeze is used in the

system all year round, and not just in the

winter. Do not top the system up using only

water, as the system will become too diluted.

• Do not overfill the reservoir. If the coolant

is significantly above the "FULL" level line at

any time, the surplus should be siphoned or

drained off to prevent the possibility of it

being expelled out of the overflow hose.

• If the coolant level falls steadily, check the

system for leaks (see Chapter 1). If no leaks

are found and the level continues to fall, it is

recommended that the machine is taken to a

Yamaha dealer for a pressure test.

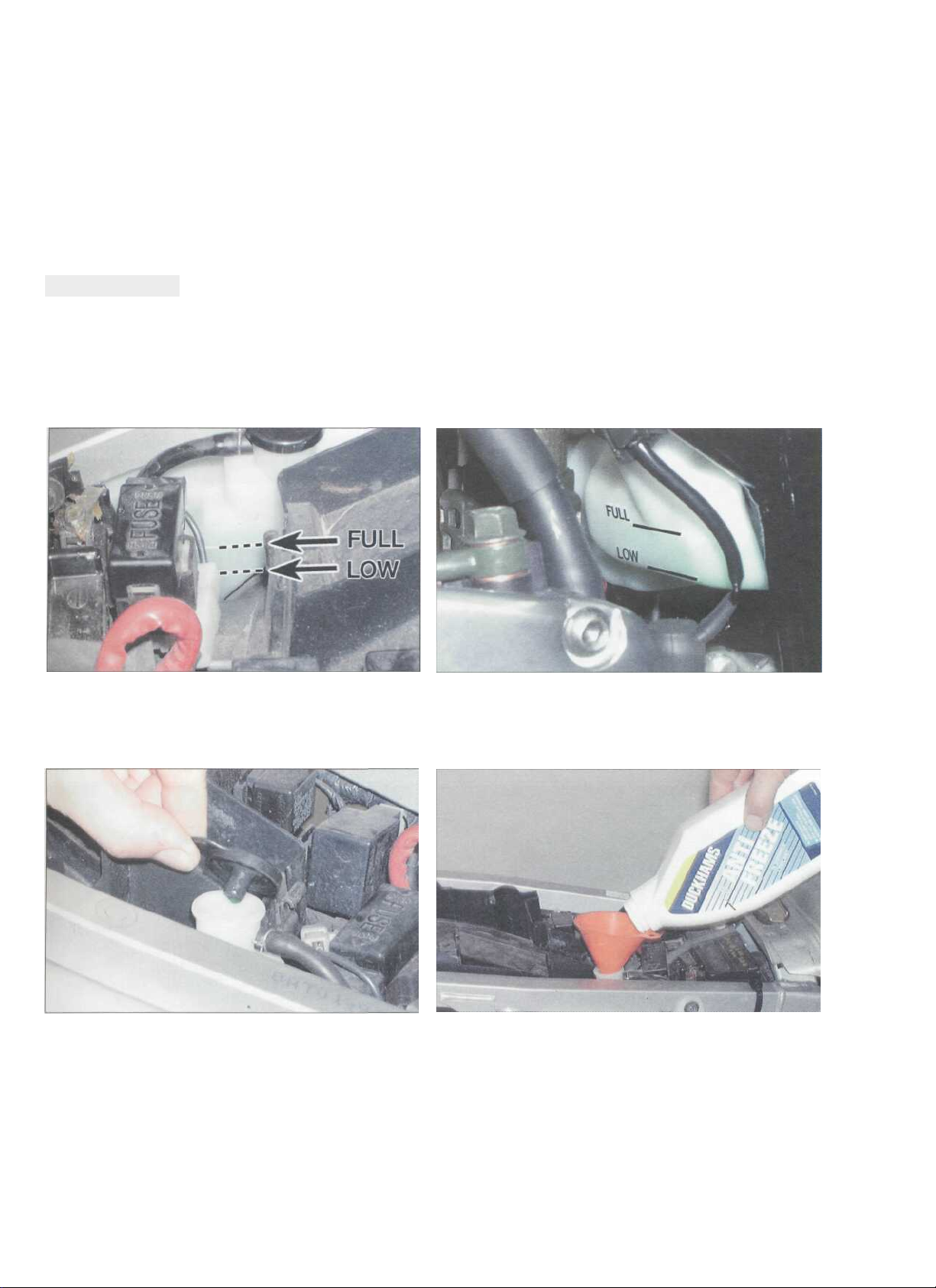

On YZF models, remove the seat to access the coolant reservoir

I

(see Chapter 8). The coolant "FULL" and "LOW" level lines are

marked on the reservoir.

If the coolant level is not in between the "FULL" and "LOW" level

3

lines, on FZS models remove the right-hand side cover (see

Chapter 8, Section 3), then on all models remove the reservoir filler

cap.

On FZS models, the coolant "FULL and "LOW" level lines are

marked on the back of the reservoir and are visible below the

right-hand side panel.

Top the coolant level up with the recommended coolant mixture.

4

Fit the cap securely, then install the side cover (see Chapter 8).

o-i4 Daily or (pre-ride) checks

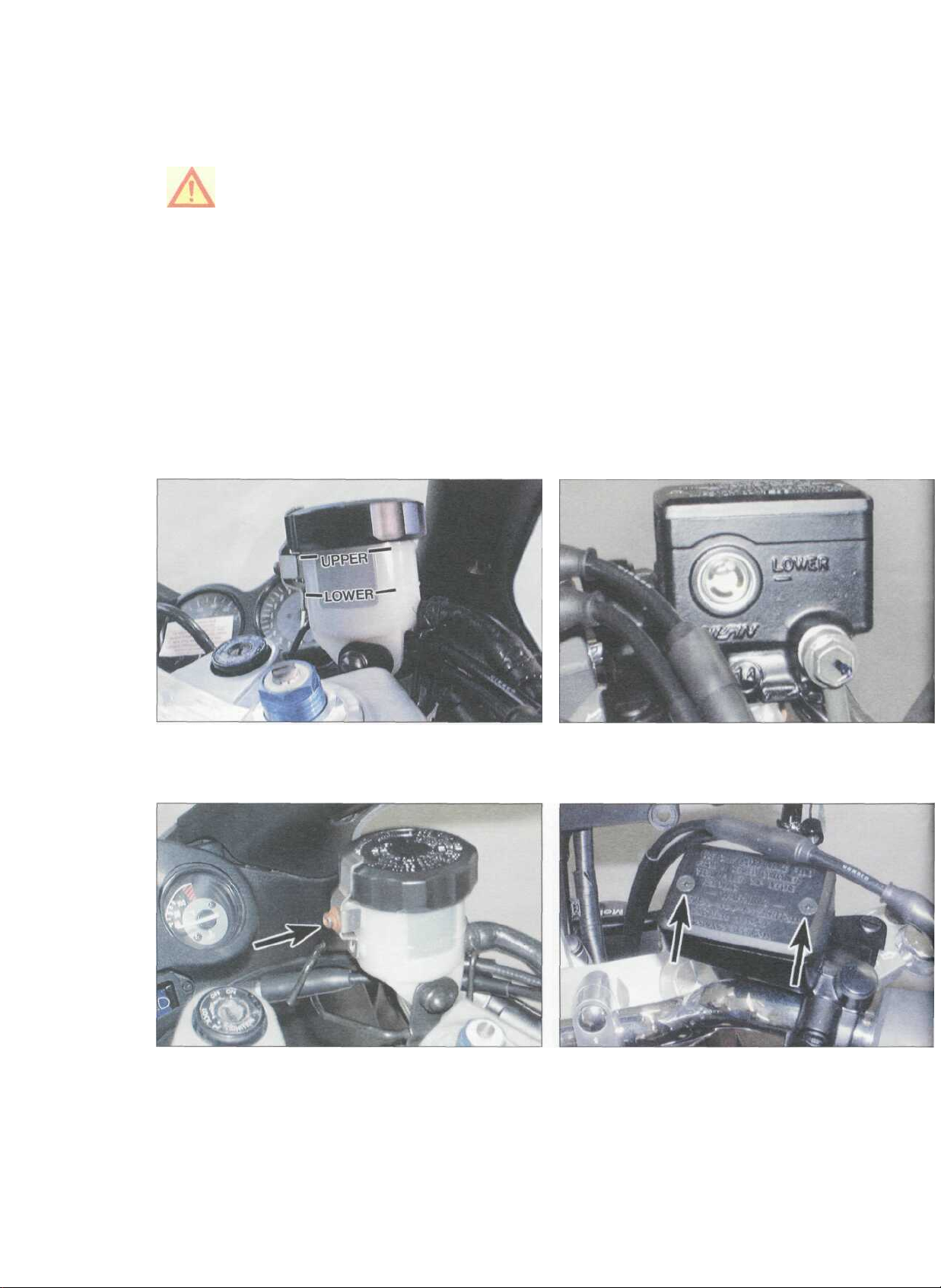

3 Brake fluid level checks

Warning: Brake hydraulic fluid can harm your eyes and damage painted surfaces, so use extreme caution when handling

and pouring it and cover surrounding surfaces with rag. Do not use fluid that has been standing open for some time, as it

absorbs moisture from the air which can cause a dangerous loss of braking effectiveness.

Before you start

• On YZF models, support the motorcycle

in an upright position, using an auxiliary stand

if required. On FZS models, put the

motorcycle on its centrestand. Turn the

handlebars until the top of the front master

cylinder is as level as possible. If necessary,

tilt the motorcycle to make it level. The rear

master cylinder reservoir is located behind the

right-hand side cover.

FRONT BRAKE FLUID LEVEL

• Make sure you have the correct hydraulic

fluid. DOT 4 is recommended.

• Wrap a rag around the reservoir being

worked on to ensure that any spillage does

not come into contact with painted surfaces.

Bike care

• The fluid in the front and rear brake

master cylinder reservoirs will drop slightly as

the brake pads wear down.

• If any fluid reservoir requires repeated

topping-up this is an indication of a hydraulic

leak somewhere in the system, which should

be investigated immediately.

• Check for signs of fluid leakage from the

hydraulic hoses and components - if found

rectify immediately.

• Check the operation of both brakes

before taking the machine on the road; if there

is evidence of air in the system (spongy feel to

lever or pedal), it must be bled as described in

Chapter 7.

On YZF models, the front brake fluid level is visible through the

I

reservoir body - it must be between the "UPPER" and "LOWER"

level lines.

On YZF models, if the level is below the "LOWER" level line,

3

remove the reservoir cap clamp screw (arrowed), then unscrew

the cap and remove the diaphragm plate and the diaphragm.

On FZS models, the front brake fluid level is visible through thJ

window in the reservoir body - it must be above the "LOWER

level line.

On FZS

models,

remove the two reservoir cover screws (arrowed) and remove th>

cover, the diaphragm plate and the diaphragm.

if the

level

is

below

the

"LOWER" level

line

Daily or (pre-ride) checks 0-15

Top up with new clean hydraulic fluid of the recommended type,

5

until the level is above the "LOWER" level line. Take care to avoid

spills (see Warning above).

REAR BRAKE FLUID LEVEL

On YZF models, the rear brake fluid level

7

is visible through the cutout in the righthand side cover - it must be above "LOWER"

level line.

On FZS models, remove the right-hand

8

side cover (see Chapter 8, Section 3) the rear brake fluid level is visible through the

reservoir body - it must be above "LOWER"

level line.

Ensure that the diaphragm is correctly seated before installing the

6

plate and cover or cap. On YZF models, secure the cap with its

clamp.

If the level is below the "LOWER" level

9

line, on YZF models remove the righthand side cover (see Chapter 8, Section 3),

then slacken the reservoir cap (A) and remove

the mounting screw (B), and displace the

reservoir so that it is clear of the clamp (C).

•4 A To replenish the fluid, unscrew the reservoir cap and remove the

I vy diaphragm plate and diaphragm. Top up with new clean

hydraulic fluid of the recommended type, until the level is above the

lower

mark.

Take care

to

avoid spills (see

Warning

above).

H Ensure that the diaphragm is correctly seated before installing

1

I the plate and cap. Tighten the cap securely. On YZF models,

locate the reservoir and tighten its screw securely. Install the side

cover (see Chapter 8).

o-i6 Daily or (pre-ride) checks

4 Tyre checks

The correct pressures

• The tyres must be checked when cold,

not immediately after riding. Note that low tyre

pressures may cause the tyre to slip on the

rim or come off. High tyre pressures will cause

abnormal tread wear and unsafe handling.

• Use an accurate pressure gauge.

• Proper air pressure will increase tyre life

and provide maximum stability and ride

comfort.

YZF models

Loading/speed

Rider only

Rider and passenger, or high speed riding

FZS models

Loading/speed

Rider only

Rider and passenger, or high speed riding

Tyre care

• Check the tyres carefully for cuts, tears,

embedded nails or other sharp objects and

excessive wear. Operation of the motorcycle

with excessively worn tyres is extremely

hazardous, as traction and handling are

directly affected.

• Check the condition of the tyre valve and

ensure the dust cap is in place.

Front

32 psi

36 psi

Front

32 psi

32 psi

(2.2

Bar)

(2.5 Bar)

(2.2

Bar)

(2.2

Bar)

Rear

36 psi

41 psi

Rear

36 psi

40 psi

(2.5 Bar)

(2.8 Bar)

(2.5 Bar)

(2.8

Bar)

• Pick out any stones or nails which may

have become embedded in the tyre tread. If

left, they will eventually penetrate through the

casing and cause a puncture.

• If tyre damage is apparent, or

unexplained loss of pressure is experienced,

seek the advice of a tyre fitting specialist

without delay.

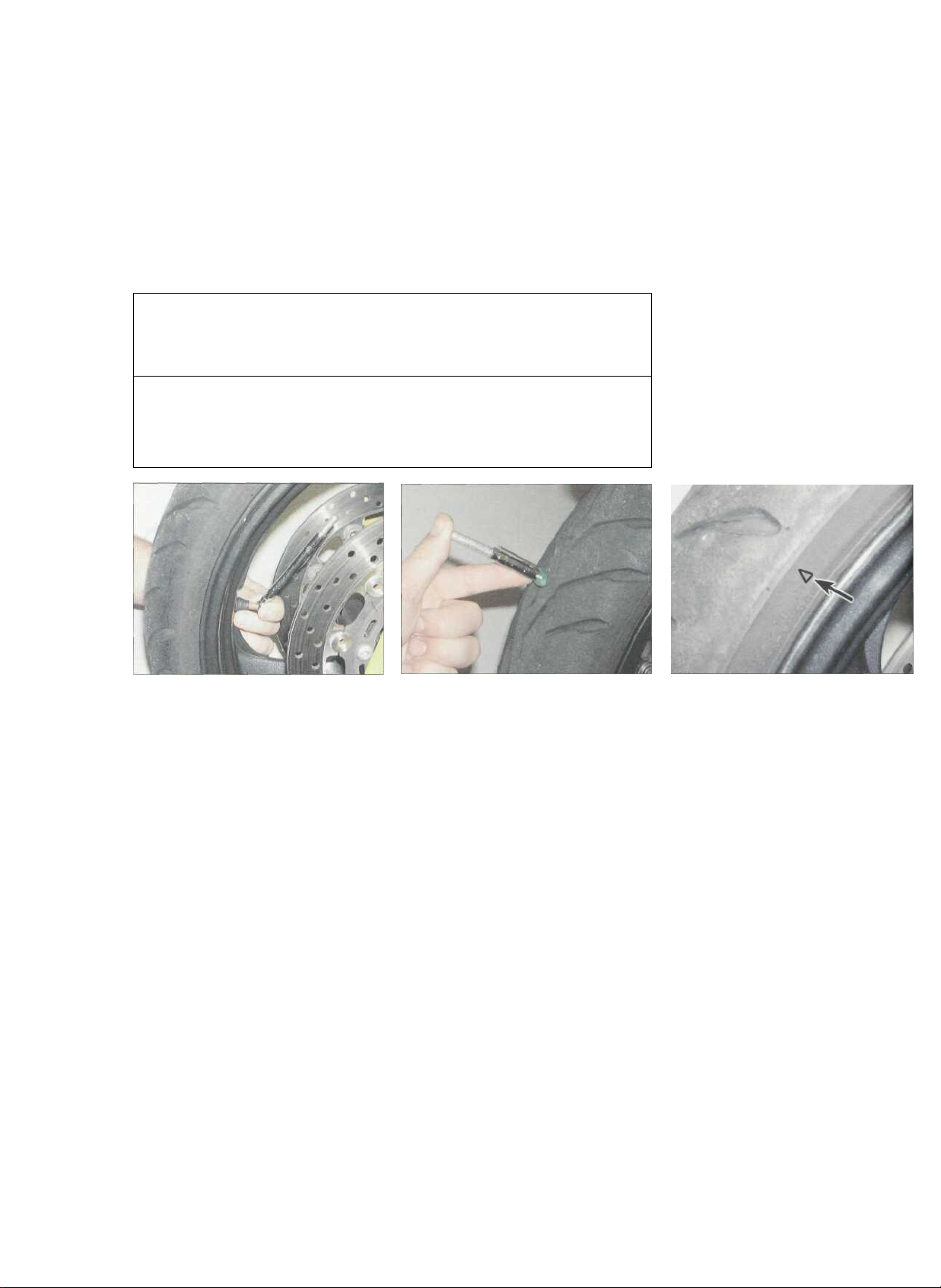

Tyre tread depth

• At the time of writing, UK law requires that

tread depth must be at least 1 mm over 3/4 ot

the tread breadth all the way around the tyre,

with no bald patches. Many riders, however,

consider 2 mm tread depth minimum to be a

safer limit. Yamaha recommend a minimum of

1.6 mm.

• Many tyres now incorporate wear

indicators in the tread. Identify the triangular

pointer or "TWI" mark on the tyre sidewall to

locate the indicator bar and replace the tyre if

the tread has worn down to the bar.

Check the tyre pressures when the tyres

1

are cold and keep them properly inflated.

Measure tread depth at the centre of the

2

tyre using a tread depth gauge.

Tyre tread wear indicator bar and its

location marking (usually either an arrow,

a triangle or the letters TWI) on the sidewall

(arrowed).

5 Suspension, steering and final drive checks

Suspension and Steering Final drive

• Check that the front and rear suspension

operates smoothly without binding.

• Check that the suspension is adjusted as

required.

• Check that the steering moves smoothly

from lock-to-lock.

• Check that the drive chain slack isn't

excessive, and adjust if necessary (see

Chapter 1).

• If the chain looks dry, lubricate it (see

Chapter 1).

6 Legal and safety checks

Lighting and signalling

• Take a minute to check that the headlight,

taillight, brake light, instrument lights and turn

signals all work correctly.

• Check that the horn sounds when the

switch is operated.

• A working speedometer graduated in mph

is a statutory requirement in the UK.

Safety

• Check that the throttle grip rotates

smoothly, and snaps shut when released, in

all steering positions. Also check for the

correct amount of freeplay (see Chapter 1).

• Check that the engine shuts off when the

kill switch is operated.

• Check that sidestand and centrestand

(where fitted) return springs hold the stand

securely up when retracted.

Fuel

• This may seem obvious, but check that

you have enough fuel to complete your

journey. If you notice signs of fuel leakage rectify the cause immediately.

• Ensure you use the correct grade fuel see Chapter 4 Specifications.

Chapter 1

Routine maintenance and Servicing

Contents

Air filter-cleaning and replacement

Battery - charging see Chapter 9

Battery - check 11

Battery- removal, installation, inspection and

maintenance see Chapter 9

Brake caliper and master cylinder seals - replacement 26

Brake hoses - replacement 28

Brake pads - wear check 8

Brake system - check 9

Brakes - fluid change 25

Carburettor synchronisation 4

Clutch - check and adjustment 10

Cooling system - check 16

Cooling system - draining, flushing and refilling 22

Cylinder compression - check 30

Drive chain and sprockets - check, adjustment and lubrication .... 1

Engine oil and oil filter change 21

Engine oil change 7

Degrees of difficulty

5

Engine oil pressure - check 31

Front forks - oil change 33

Fuel hoses - replacement 32

Fuel system - check 6

Headlight aim - check and adjustment 29

Idle speed - check and adjustment 3

Nuts and bolts - tightness check 15

Sidestand and centrestand (where fitted) - check 14

Spark plug gaps - check and adjustment 2

Stand, lever pivots and cables - lubrication 18

Steering head bearings - freeplay check and adjustment 20

Steering head bearings - lubrication 24

Suspension - check 19

Swingarm and suspension linkage bearings - re-greasing 23

Throttle and choke cables - check 17

Valve clearances - check and adjustment 27

Wheel bearings - check 13

Wheels and tyres - general check 12

1-1

Easy, suitable for

novice with little

experience

Fairly easy, suitable

for beginner with

some experience

Fairly difficult,

suitable for competent

DIY mechanic

Difficult, suitable for

experienced DIY

mechanic

Specifications

Engine

Spark plugs

Type NGK CR9E or Nippondenso U27ESR-N

Electrode gap 0.7 to 0.8 mm

Engine idle speed

YZF models 1200 to 1300 rpm

FZS models 1150 to 1250 rpm

Carburettor synchronisation - intake vacuum

YZF models

FZS models

Carburettor synchronisation - max. difference between carburettors

YZF models

FZS models

Valve clearances (COLD engine)

Intake valves 0.11 to 0.20 mm

Exhaust valves 0.21 to 0.30 mm

Cylinder compression

YZF

Standard 220 psi (15.2 Bar)

Maximum 235 psi (16.2 Bar)

Minimum 185 psi (12.8 Bar)

Max. difference between cylinders 14.5 psi (1.0 Bar)

FZS models

Standard 213 psi (14.7 Bar)

Maximum 225 psi (15.5 Bar)

Minimum 170 psi (11.7 Bar)

Max. difference between cylinders 14.5 psi (1.0 Bar)

Engine oil pressure

YZF models

FZS models

225 mmHg

230 to 250 mmHg

10 mmHg

10 mmHg

models

50 to 64 psi (3.5 to 4.4 Bar)

64 psi (4.4 Bar)

Very difficult,

suitable for expert DIY

or professional

Specifications

Miscellaneous

Drive chain slack

YZF models 20 to 30 mm

FZS models

1998

and

1999

2000 models 30 to 45 mm

Chain stretch limit (see text)

YZF models 151mm

FZS models 150 mm

Rear brake pedal height (see text)

YZF models 42 mm

FZS models 36.6 mm

Clutch cable freeplay 10 to 15 mm at lever end

Throttle cable freeplay

YZF models 3 to 7 mm

FZS models 3 to 5 mm

Tyre pressures (cold) see Daily (pre-ride) checks

Recommended lubricants and fluids

Engine/transmission oil type see Daily (pre-ride) checks

Engine/transmission oil capacity

YZF models

Oil change 2.6 litres

Oil and filter change 2.9 litres

Following engine overhaul - dry engine, new filter 3.5 litres

FZS models

Oil change 2.5 litres

Oil and filter change 2.7 litres

Following engine overhaul - dry engine, new filter 3.5 litres

Coolant type 50% corrosion inhibited ethylene glycol anti-freeze, 50% distilled

Coolant capacity 1.95 litres

Brake fluid DOT 4

Drive chain SAE 30 to 50 W engine oil or chain lubricant suitable for O-ring chains

30 to 40 mm

water. Note: Yamaha specify that soft tap water can be used, but NOT

hard water. If in doubt, boil the water first or use only distilled water.

Miscellaneous

Steering head bearings Lithium-based multi-purpose grease

Swingarm pivot and bearings Molybdenum disulphide grease

Suspension linkage bearings Molybdenum disulphide grease

Bearing seal lips Lithium-based multi-purpose grease

Gearchange lever/clutch lever/front brake lever/

rear brake pedal/sidestand/centrestand pivots Lithium-based multi-purpose grease

Cables 10W30 motor oil

Throttle grip Multi-purpose grease or dry film lubricant

Torque settings

Alternator cover bolts 12 Mm

Cooling system drain plug(s) 10 Nm

Fork clamp bolts (top yoke) 30 Nm

Main oil gallery plug 8 Nm

Oil drain plug 43 Nm

Oil filter 17 Nm

Rear axle nut 117 Nm

Spark plugs

YZF models 12.5 Nm

FZS models 13 Nm

Steering head bearing adjuster nut (using Yamaha service tool)

YZF models

Initial setting 52 Nm

Final setting 3 Nm

FZS models

Initial setting 52 Nm

Final setting 18Nm

Steering stem nut 110 Nm

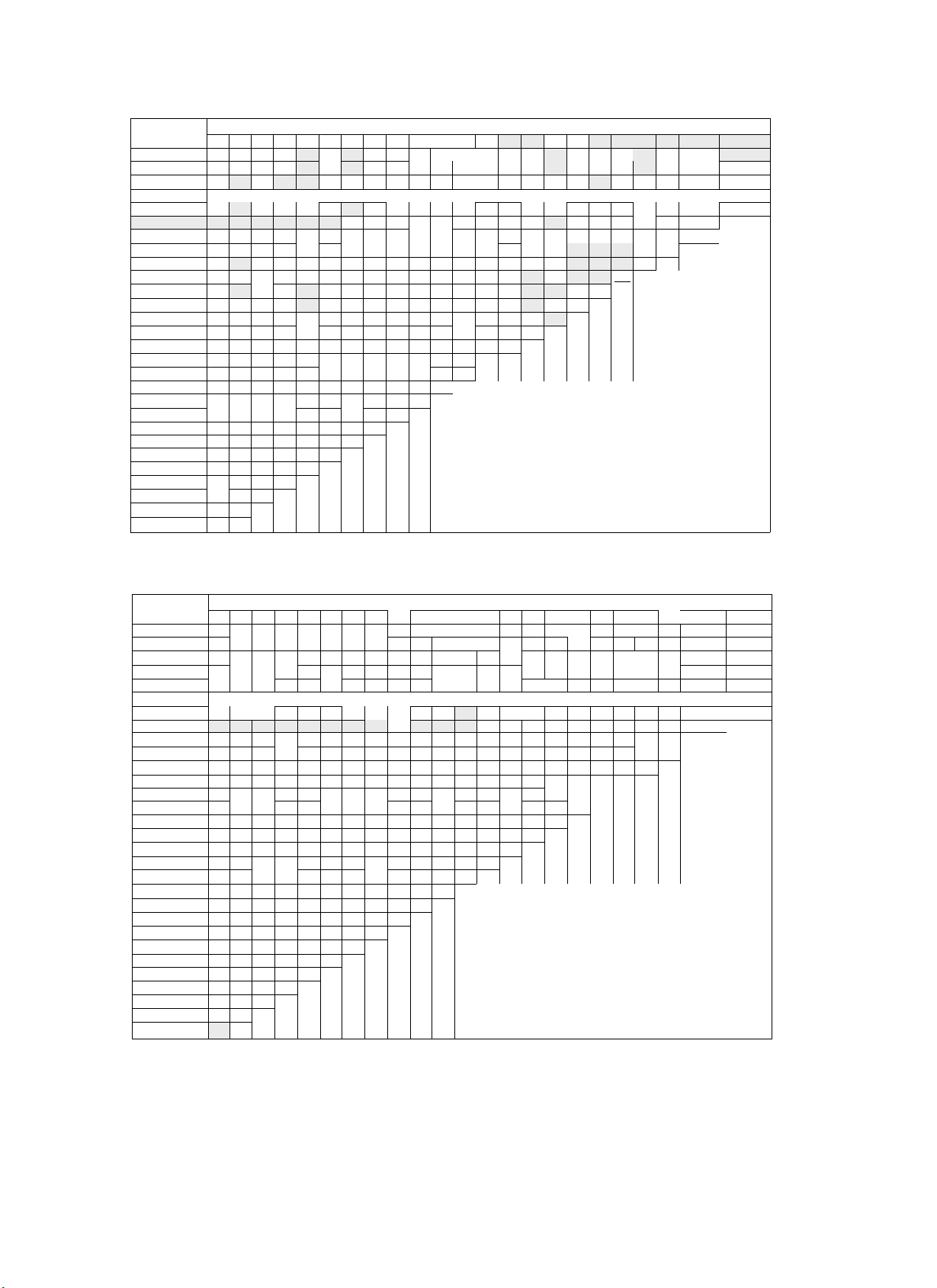

Maintenance schedule K

Note: The daily (pre-ride) checks outlined in

the owner's manual covers those items which

should

be

perform

inspected

the

on a

daily

pre-ride inspection

basis. Always

at

every

maintenance interval (in addition to the

procedures listed). The intervals listed below

are the intervals recommended by the

manufacturer for each particular operation

Daily (pre-ride)

See 'Daily (pre-ride) checks' at the beginning of this

manual.

After

the

initial

Note: This check is usually performed by a Yamaha dealer after the

first

600

miles

out

according

(1000

carried

600

miles (1000

km)

from new. Thereafter, maintenance

to the

following

intervals

of the

km)

schedule.

Every 600 miles (1000 km)

D Check, adjust, clean and lubricate the drive chain

(Section 1)

Every 4000 miles (6000 km) or

6 months (whichever comes sooner)

H Check the spark plug gaps (Section 2)

I] Check and adjust the idle speed (Section 3)

D Check/adjust the carburettor synchronisation

(Section 4)

D Clean and check the air filter element (Section 5)

I Check the fuel system and hoses (Section 6)

D Change the engine oil (Section 7)

j Check the brake pads (Section 8)

L Check the brake system and brake light switch

operation (Section 9)

D Check and adjust the clutch (Section 10)

C Check the battery (Section 11)

M Check the condition of the wheels and tyres

(Section 12)

H Check the wheel bearings (Section 13)

C Check the sidestand and centrestand (where fitted)

(Section 14)

I! Check the tightness of all nuts, bolts and fasteners

(Section 15)

Check the cooling system (Section 16)

n

Check and adjust the throttle and choke cables

(Section 17)

3 Lubricate the clutch/gearshift/brake lever/brake

pedal/sidestand/centrestand pivots and the

throttle/choke/clutch cables (Section 18)

^ Check the suspension (Section 19)

H Check and adjust the steering head bearings

(Section 20)

during the model years covered in this

manual. Your owner's manual may have

different intervals for your model.

Every 8000 miles (12,000 km) or

12 months (whichever comes sooner)

Carry out all the items under the 4000 mile (6000 km) check, plus the

following

D Change the engine oil and filter (Section 21)

D Replace the spark plugs (US models) (Section 12)

is

Every 16,000 miles (24,000 km) or

two years (whichever comes

sooner)

Carry out all the items under the 8000 mile (12000 km) check, plus

the following

D Replace the coolant (Section 22)

D Re-grease the swingarm and suspension linkage

bearings (Section 23).

D Re-grease the steering head bearings (Section 24).

D Change the brake fluid (see Section 25)

n Replace the brake master cylinder and caliper

seals (Section 26)

Every 28,000 miles (42,000 km) or

42 months (whichever comes

sooner)

Carry out all the items under the 4000 mile (6000 km) check, plus the

following

D Check and adjust the valve clearances (Section 27)

Every four years

D Replace the brake hoses (Section 28)

Non-scheduled maintenance

D Check and adjust the headlight aim (Section 29)

D Check the cylinder compression (Section 30)

D Check the engine oil pressure (see Section 31)

n Replace the fuel hoses (Section 32)

D Change the front fork oil (Section 33)

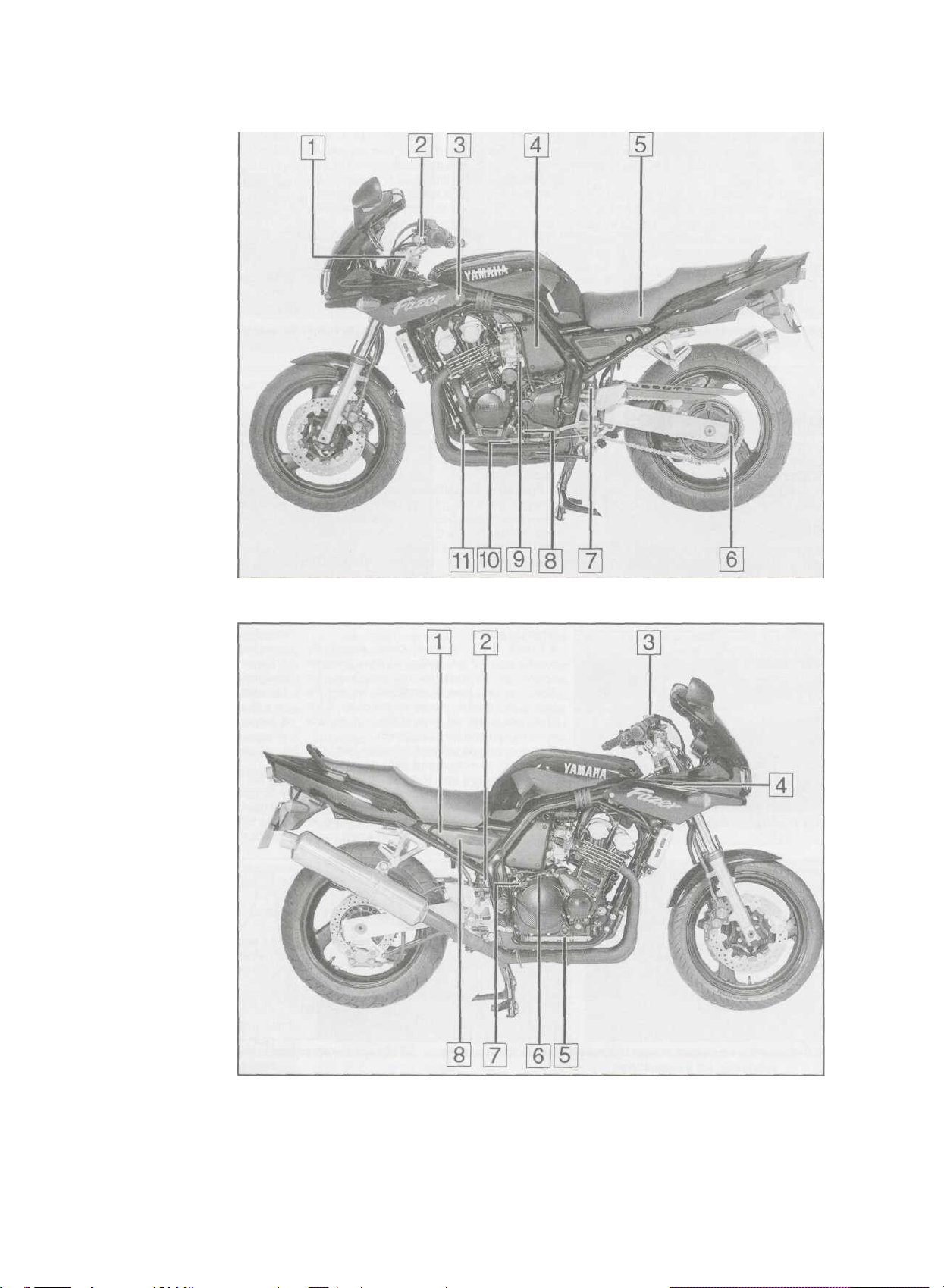

1-4 Component location - YZF600R Thundercat

Component locations on left-hand side

1 Clutch cable adjuster

2 Steering head bearings

3 Air filter housing

4 Model code label

5 Fuse box

6 Drive chain adjuster

7 Rear suspension pre-load

8 Coolant drain plug

9 Engine oil drain plug

10 Carburettor vent hose

11 Engine oil filter

12 Speedometer cable

adjuster

11 10 9 87

Component locations on right-hand side

1 Coolant reservoir

2 Idle speed adjuster

3 Front brake fluid reservoir

4 Frame number

5 Cooling system pressure

cap

6 Engine oil level inspection

window

7 Engine number

8 Engine oil filler plug

9 Rear brake fluid reservoir

1 Steering head bearings

2 Clutch cable adjuster

3 Cooling system pressure

cap

4 Air filter housing

5 Model code label

6 Drive chain adjuster

7 Rear suspension pre-load

adjuster

8 Coolant drain plug

9 Idle speed adjuster

10 Engine oil drain plug

11 Engine oil filter

Component location - FZS600 Fazer 1-5

Component locations on left-hand side

1 Fuse box

2 Coolant reservoir

3 Front brake fluid reservoir

4 Frame number

5 Engine oil level inspection

window

6 Engine number

7 Engine oil filler plug

8 Rear brake fluid reservoir

Component locations on right-hand side

•6 Maintenance procedures

Introduction

1 This Chapter is designed to help the home

mechanic maintain his/her motorcycle for

safety, economy, long life and peak

performance.

2 Deciding where to start or plug into the

routine maintenance schedule depends on

several factors. If the warranty period on your

motorcycle has just expired, and if it has been

maintained according to the warranty

standards, you may want to pick up routine

maintenance as it coincides with the next

mileage or calendar interval. If you have

owned the machine for some time but have

never performed any maintenance on it, then

you may want to start at the nearest interval

and include some additional procedures to

ensure that nothing important is overlooked. If

you have just had a major engine overhaul,

then you may want to start the maintenance

routine from the beginning. If you have a used

machine and have no knowledge of its history

or maintenance record, you may desire to

combine all the checks into one large service

initially and then settle into the maintenance

schedule prescribed.

3 Before beginning any maintenance or

Every 600 miles (1000 km)

2 To check the chain, place the bike on its

1 Drive chain and sprockets -

check, adjustment and ^

lubrication 2^

Check

1 A neglected drive chain won't last long and

can quickly damage the sprockets. Routine

chain adjustment and lubrication isn't difficult

and will ensure maximum chain and sprocket

life.

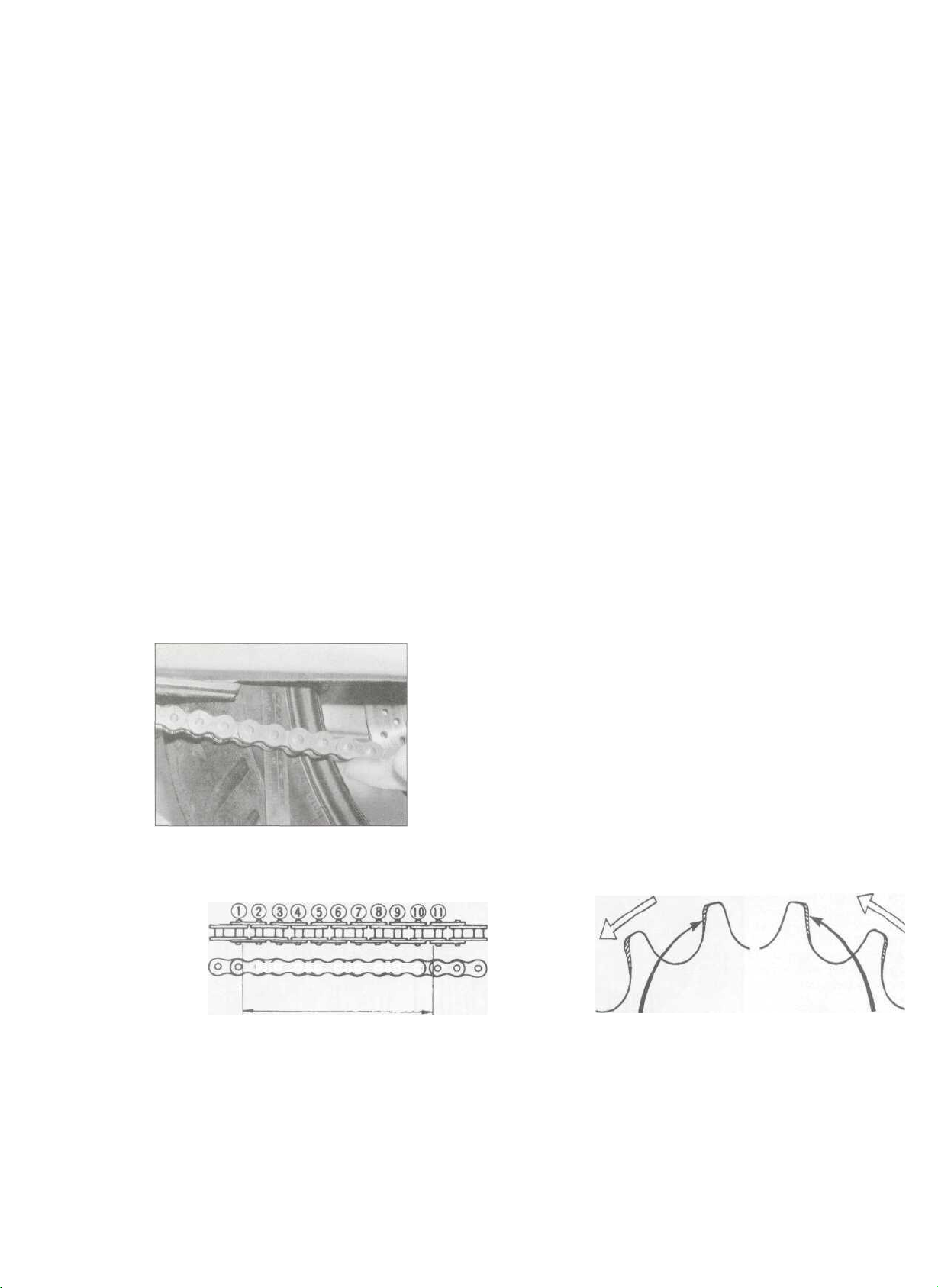

1.3 Push up on the chain and measure the

slack

sidestand and shift the transmission into

neutral.

3 Push up on the bottom run of the chain and

measure the slack midway between the two

sprockets, then compare your measurement

to that listed in this Chapter's Specifications

(see illustration). As the chain stretches with

wear, adjustment will periodically be

necessary (see below). Since the chain will

rarely wear evenly, roll the bike forwards so

that another section of chain can be checked;

do this several times to check the entire

length of chain.

4 Check the amount of chain stretch by

measuring a 10-link section of clean chain as

shown and comparing the length to the

Specifications (see illustration). Repeat the

test at 2 or 3 other places on the chain. If the

chain has stretched beyond the limit, replace

it with a new one (see Chapter 6).

5 In some cases where lubrication has been

neglected, corrosion and galling may cause

the links to bind and kink, which effectively

shortens the chain's length. Such links should

be thoroughly cleaned and worked free. If the

chain is tight between the sprockets, rusty or

kinked, it's time to replace it with a new one. If

repair, the machine should be cleanec

thoroughly, especially around the oil filter

spark plugs, valve cover, side panels

carburettors, etc. Cleaning will help ensure

that dirt does not contaminate the engine anc

will allow you to detect wear and damage thai

could otherwise easily go unnoticed.

4 Certain maintenance information i;

sometimes printed on decals attached to the

motorcycle. If the information on the decal;

differs from that included here, use the

information on the decal.

you find a tight area, mark it with felt pen oi

paint, and repeat the measurement after the

bike has been ridden. If the chain's still tight ir

the same area, it may be damaged or worn

Because a tight or kinked chain can damage

the transmission output shaft bearing, it's i

good idea to replace it with a new one (see

Chapter 6).

6 Check the entire length of the chain fo

damaged rollers, loose links and pins, anc

missing O-rings and replace it if damage is

found. Note: Never install a new chain on ok

sprockets, and never use the old chain if yot

install new sprockets - renew the chain anc

sprockets as a set.

7 Remove the front sprocket cover (sef

Chapter 6). Check the teeth on the engin!

sprocket and the rear wheel sprocket for wea

(see illustration).

8 Inspect the drive chain slider on thi

swingarm for excessive wear and renew it i

worn (see Chapter 6).

Adjustment

9 Rotate the rear wheel until the chain ii

positioned with the tightest point at the centri

of its bottom run, then place the machine oi

its sidestand.

OHO

0)(0

OHO

0)(0

O

1.4 Check the amount of stretch by measuring a 10-link length as

shown

DIRECTION OF ROTATION

ENGINE SPROCKET

WORN TOOTH

1.7 Check the sprockets in the areas indicated to see if they are

worn excessively

REAR SPROCKET

WORN TOOTH

061SH

Every 600 miles (1000 km)

1.10 Slacken the rear axle nut (arrowed)

1.11b On YZF models, check the relative position of the notch (A)

10 Slacken the axle nut (see illustration).

11 Slacken the adjuster locknut on each side

of the swingarm, then turn the adjusters

evenly until the amount of freeplay specified

at the beginning of the Chapter is obtained at

the centre of the bottom run of the chain (see

illustration). Following chain adjustment,

check that each chain adjustment marker is in

the same position in relation to the marks on

the swingarm (see illustrations). It is

important each adjuster aligns with the same

notch; if not, the rear wheel will be out of

alignment with the front. Also check that there

is no clearance between the adjuster and the

end of the swingarm - push the wheel

forwards to eliminate any.

12 If there is a discrepancy in the chain

adjuster positions, adjust one of them so that

its position is exactly the same as the other.

Check the chain freeplay as described above

and readjust if necessary.

13 Tighten the axle nut to the torque setting

specified at the beginning of the Chapter, then

tighten the adjuster locknuts securely (see

illustration).

with the lines (B) on each side

the machine and allowed to soak in the

paraffin (see Chapter 6).

Caution: Don't use petrol, solvent or other

cleaning fluids which might damage the

internal sealing properties of the chain.

Don't use high-pressure water. The entire

process shouldn't take longer than ten

minutes - if it does, the O-rings in the

chain rollers could be damaged.

15 For routine lubrication, the best time to

lubricate the chain is after the motorcycle has

been ridden. When the chain is warm, the

lubricant will penetrate the joints between the

side plates better than when cold. Note:

Yamaha specifies SAE 30 to 50 W engine oil;

Lubrication

14 If required, wash the chain in paraffin

(kerosene), then wipe it off and allow it to dry,

using compressed air if available. If the chain

is excessively dirty it should be removed from

1.13 Tighten the axle nut to the specified

1.11 a Slacken the locknut (A) and turn the adjuster (B) as required

1.11 c On FZS models, check the relative position of the washer

torque

(A) with the lines (B) on each side

do not use chain lube, which may contain

solvents that could damage the O-rings,

unless it is specified for O-ring chains. Apply

the lubricant to the area where the side plates

overlap - not the middle of the rollers (see

illustration).

Apply the lubricant to the

top of the lower chain run,

so centrifugal force will work

it into the chain when the

bike is moving. After applying the

lubricant, let it soak in a few minutes

before wiping off any excess.

1.15 Apply the lubricant to the overlap

between the sideplates

•8 Maintenance procedures

Every 4000 miles (6000 km) or 6 months

Check the threads, the washer and the

2 Spark plug gaps -

check and adjustment

1 Make sure your spark plug socket is the

correct size before attempting to remove the

plugs - a suitable one is supplied in the

motorcycle's tool kit which is stored under the

seat.

2 Using compressed air if available, clean the

area around the base of the spark plugs to

prevent any dirt falling into the engine when

the plugs are removed.

3 Check that the cylinder location is marked

on each plug lead, then pull the spark plug

cap off each spark plug (see illustration).

Using either the plug removing tool supplied

in the bike's toolkit or a deep socket type

wrench, unscrew the plugs from the cylinder

head (see illustration). Lay each plug out in

relation to its cylinder; if any plug shows up a

problem it will then be easy to identify the

troublesome cylinder.

4 Inspect the electrodes for wear. Both the

centre and side electrodes should have

square edges and the side electrodes should

be of uniform thickness. Look for excessive

deposits and evidence of a cracked or

chipped insulator around the centre electrode.

Compare your spark plugs to the colour spark

plug reading chart at the end of this manual.

ceramic insulator body for cracks and other

damage.

5 If the electrodes are not excessively worn,

and if the deposits can be easily removed with

a wire brush, the plugs can be re-gapped and

re-used (if no cracks or chips are visible in the

insulator). If in doubt concerning the condition

of the plugs, replace them with new ones, as

the expense is minimal. On UK models,

Yamaha do not specify a replacement

interval, but leave it to the discretion of the

owner. On US models, Yamaha specify that

the spark plugs should be renewed at every

second service interval.

6 Cleaning spark plugs by sandblasting is

permitted, provided you clean the plugs with a

high flash-point solvent afterwards.

7 Before installing the plugs, make sure they

are the correct type and heat range and check

the gap between the electrodes (see

illustrations). Compare the gap to that

specified and adjust as necessary. If the gap

must be adjusted, bend the side electrodes

only and be very careful not to chip or crack

the insulator nose (see illustration). Make

sure the washer is in place on the plug before

installing it.

8 Since the cylinder head is made of

aluminium, which is soft and easily damaged,

thread the plugs into the heads turning the

tool by hand (see illustration). Once the

plugs are finger-tight, the job can be finished

with a spanner on the tool supplied or a

socket drive (see illustration 2.3b). If a torque

wrench can be applied, tighten the spark

plugs to the specified torque setting.

Otherwise tighten them according the

instructions on the box, or by 1/4 to 1/2 turn ;

after they have been fully hand tightened and

have seated. Do not over-tighten them.

As the plugs are quite

, , recessed, you can slip a

HllUT

tool to thread it into place. The hose will

grip the plug well enough to turn it, but

will start to slip if the plug begins to

cross-thread in the hole - this will

prevent damaged threads.

9 Reconnect the spark plug caps, making

sure they are securely connected to the

correct cylinder. Install all other components

previously removed.

HllUT

Workshop Tips' in the

section.

short

length

of

end of the plug to use as a

Stripped plug threads in the

I cylinder head can be

9

repaired

insert - see

hose over

with a Heli-Coil

Tools and

Reference

the

-am

It

J

2.3a Remove the spark plug cap ,

A

2.7b Using a feeler gauge to measure the 2.7c Adjust the electrode gap by bending 2.8 Thread the plug as far as possible

spark plug electrode gap the side electrode only turning the tool by hand

2.3b ... then unscrew the spark plug 2.7a Using a wire type gauge to measure

the spark plug electrode gap

Every 4000 miles (6000 km) or 6 months 1-9

3.3a Idle speed adjuster screw (arrowed) YZF models

3 Idle speed -

check and adjustment

1

I

1 The idle speed should be checked and

adjusted before and after the carburettors are

synchronised (balanced) and when it is

obviously too high or too low. Before

adjusting the idle speed, make sure the valve

clearances and spark plug gaps are correct,

and the air filter is clean. Also, turn the

handlebars back-and-forth and see if the idle

speed changes as this is done. If it does, the

throttle cable may not be adjusted or routed

correctly, or may be worn out. This is a

dangerous condition that can cause loss of

control of the bike. Be sure to correct this

problem before proceeding.

2 The engine should be at normal operating

temperature, which is usually reached after 10

to 15 minutes of stop-and-go riding. Make

sure the transmission is in neutral, and place

the motorcycle on its stand.

3 The idle speed adjuster is located on the

right-hand side of the engine on YZF models,

and on the left-hand side on FZS models (see

illustrations). With the engine idling, adjust

the idle speed by turning the adjuster screw

until

the

idle speed listed

Specifications is obtained. Turn the screw

clockwise to increase idle speed, and anticlockwise to decrease it.

4 Snap the throttle open and shut a few

times, then recheck the idle speed. If

necessary, repeat the adjustment procedure.

5 If a smooth, steady idle can't be achieved,

the fuel/air mixture may be incorrect (check

the pilot screw settings - see Chapter 4,

Section 5) or the carburettors may need

synchronising (see Section 4). Also check the

intake manifold rubbers for cracks which will

cause an air leak, resulting in a weak mixture.

in

this Chapter's

3.3b Idle speed adjuster screw (arrowed) •

4 Carburettor synchronisation

Warning: Petrol (gasoline) is

extremely flammable, so take

on any part of the fuel system. Don't smoke

or allow open flames or bare light bulbs

near the work area, and don't work in a

garage where a natural gas-type appliance

is present. If you spill any fuel on your skin,

rinse it off immediately with soap and

water. When you perform any kind of work

on the fuel system, wear safety glasses and

have a fire extinguisher suitable for a Class

B type fire (flammable liquids) on hand.

A

take-off points on the intake manifolds. Do

not allow exhaust gases to build up in the

work area; either perform the check outside

or use an exhaust gas extraction system.

1 Carburettor synchronisation is simply the

process of adjusting the carburettors so they

pass the same amount of fuel/air mixture to

each cylinder. This is done by measuring the

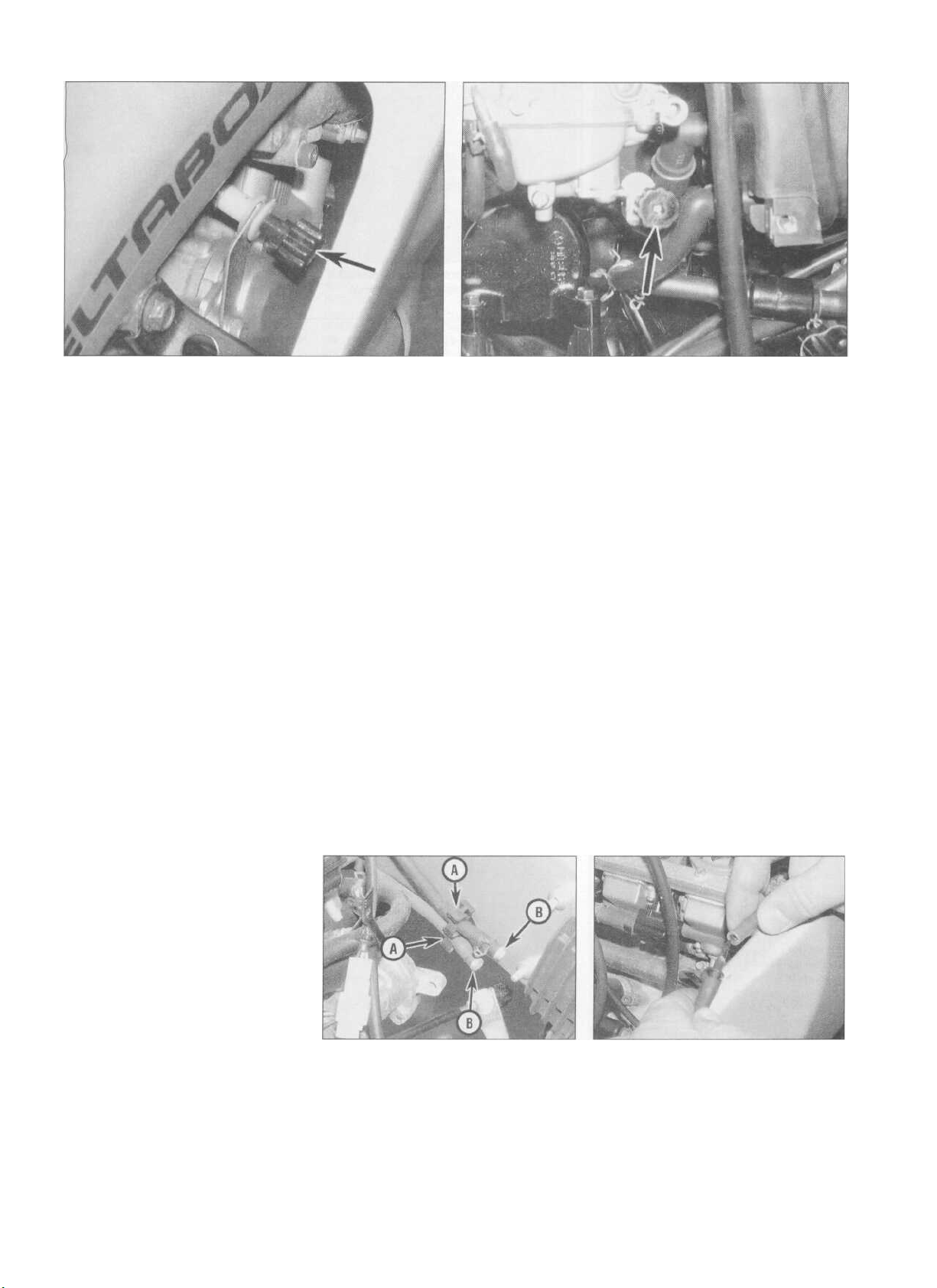

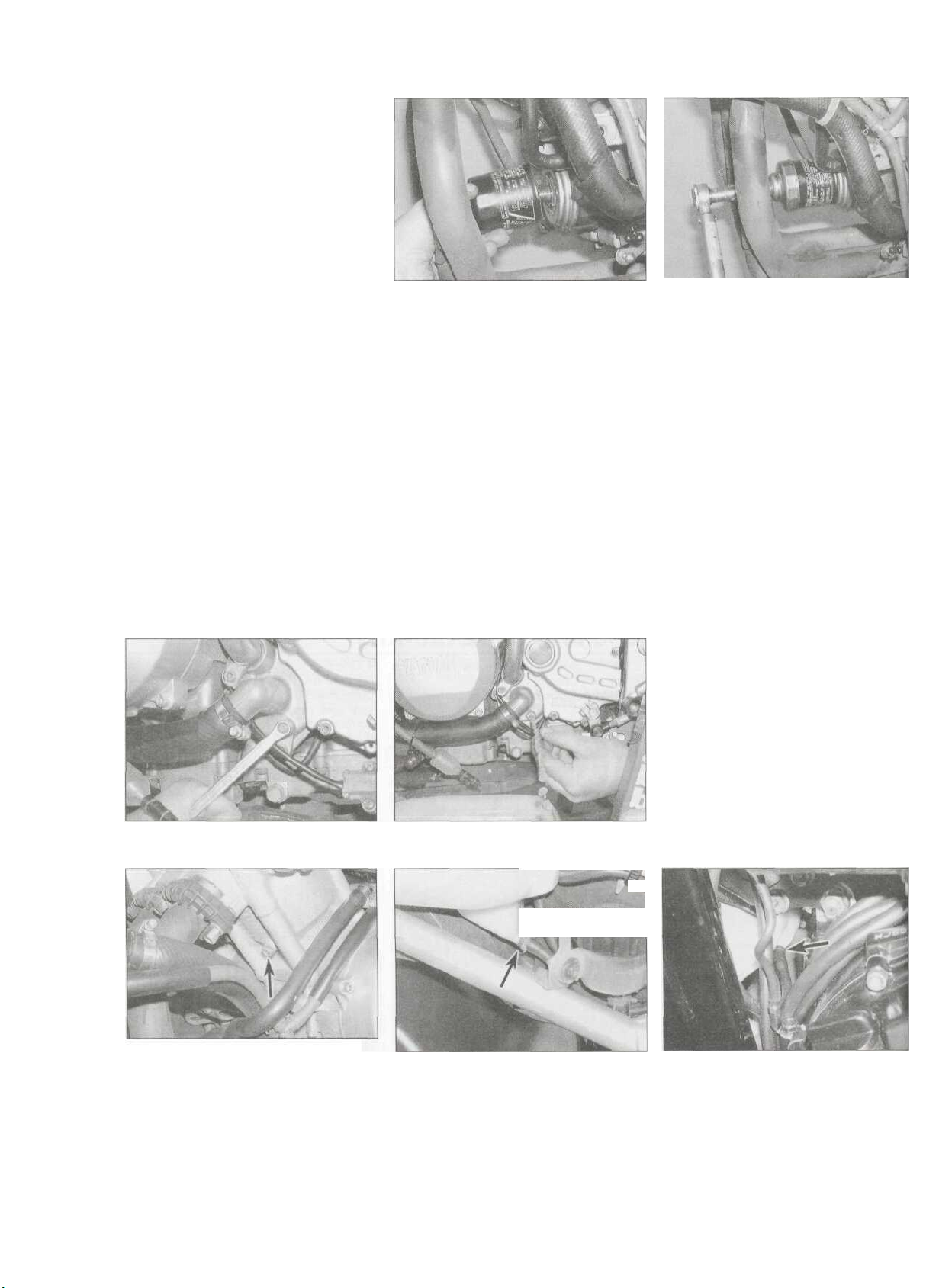

4.4a Detach the hoses from their clips (A),

extra precautions when you work

Warning: Take great care not to

burn your hand on the hot engine

unit when accessing the gauge

then remove the blanking plugs (B)

FZS models

vacuum produced in each cylinder.

Carburettors that are out of synchronisation

will result in decreased fuel mileage,

increased engine temperature, less than ideal

throttle response and higher vibration levels.

Before synchronising the carburettors, make

sure the valve clearances and idle speed are

properly set.

2 To properly synchronise the carburettors

you will need a set of vacuum gauges or a

manometer. These instruments measure

engine vacuum, and can be obtained from

motorcycle dealers or mail order parts

suppliers. The equipment used should be

suitable for a four cylinder engine and come

complete with the necessary adapters and

hoses to fit the take off points. Note: Because

of the nature of the synchronisation procedure

and the need for special instruments, most

owners leave the task to a Yamaha dealer.

3 Start the engine and let it run until it reaches

normal operating temperature, then shut it off.

4 On YZF models, remove the fuel tank (see

Chapter 4). Detach the vacuum hoses from

their clips on each frame beam (there are two

hoses on each side), then pull the blanking

plug out of the end of each hose in turn and

attach the gauge or manometer hoses to them

using a suitable union (see illustrations).

4.4b Connect the gauge hoses using

suitable unions

Every 4000 miles (6000 km) or 6 months

4.4c Connect the remote fuel supply to the

fuel pump union

4.8a Carburettor synchronisation screws (arrowed) YZF models

On California models, only three of the hoses

will have blanking plugs, while the other one

will be attached to a union on one of the EVAP

system components. Make sure the No. 1

gauge is attached to the hose from the No. 1

(left-hand) carburettor, and so on. Arrange a

temporary fuel supply, either by using a small

temporary tank with its hose attached to the

fuel pump (see illustration), or by using an

extra long fuel pipe to the now remote fuel

tank. Alternatively, position the tank on a

suitable base on the motorcycle, taking care

not to scratch any paintwork, and making sure

that the tank is safely and securely supported,

and that access to the synchronising screws

is not restricted.

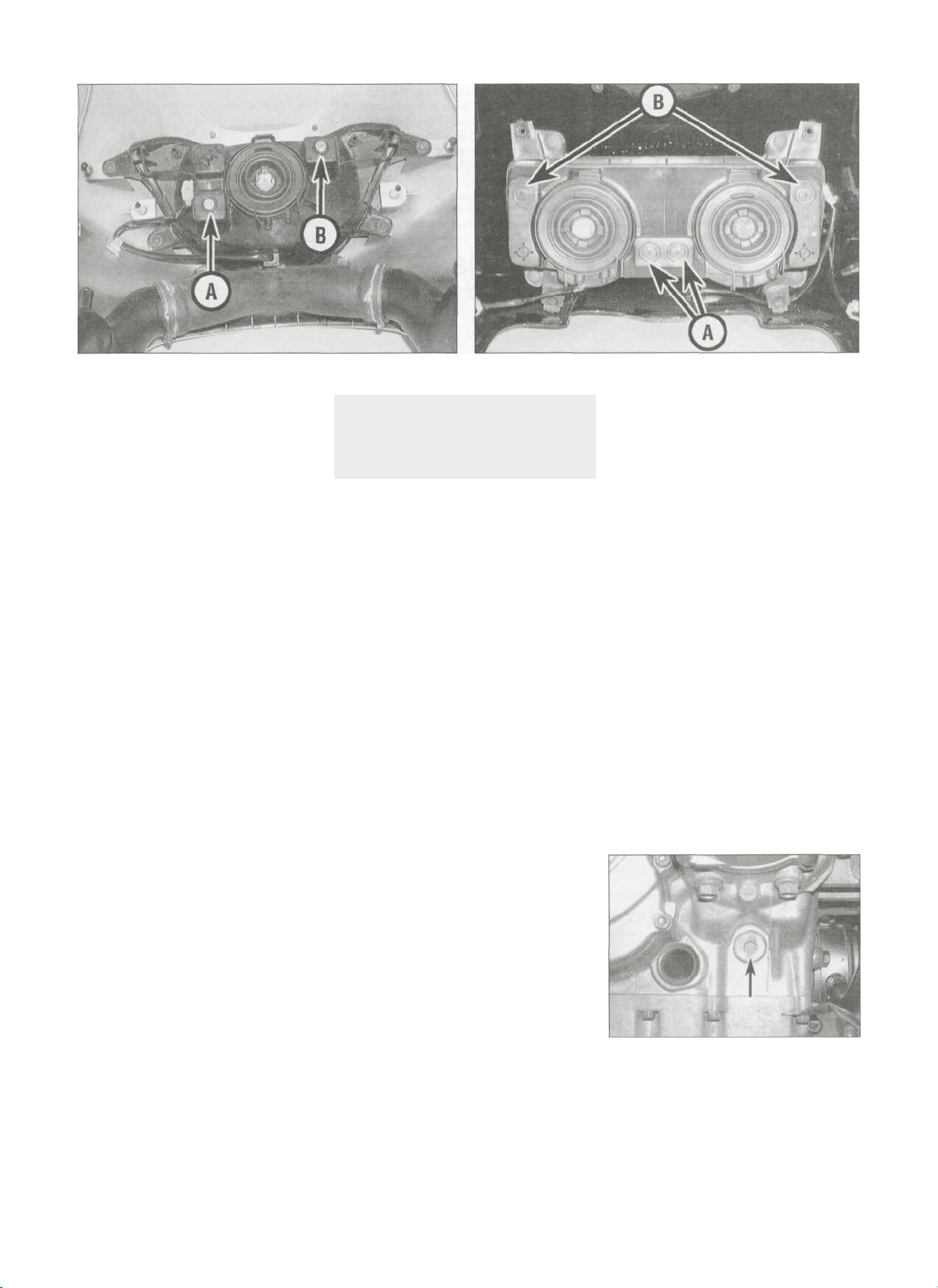

5 On FZS models, remove the blanking plugs

from the take-off stubs on the intake

manifolds between each carburettor and the

cylinder head and attach the gauge or

manometer hoses to them using a suitable

union (see illustration). Make sure the No. 1

gauge is attached to the hose from the No. 1

(left-hand) carburettor, and so on.

6 Start the engine and let it idle. If the gauges

are fitted with damping adjustment, set this so

that the needle flutter is just eliminated but so

that they can still respond to small changes in

pressure.

4.5 Remove the blanking cap (arrowed)

from each intake manifold

4.8b Carburettor synchronisation screws (arrowed) •

7 The vacuum readings for all cylinders

should be the same (see illustration). If the

vacuum readings differ, proceed as follows.

8 The carburettors are balanced by turning

the synchronising screws situated in-between

each carburettor, in the throttle linkage (see

illustrations). Note: Do not press on the

screws whilst adjusting them, otherwise a

false reading will be obtained. First

synchronise No. 1 carburettor to No. 2 using

the left-hand synchronising screw until the

readings are the same. Then synchronise No.

3 carburettor to No. 4 using the right-hand

screw. Finally synchronise Nos. 1 and 2

carburettors to Nos. 3 and 4 using the centre

screw. When all the carburettors are

synchronised, open and close the throttle

quickly to settle the linkage, and recheck the

gauge readings, readjusting if necessary.

9 When the adjustment is complete, recheck

the vacuum readings, then adjust the idle speed

(see Section 3) until the speed listed in this

Chapter's Specifications is obtained. Remove

the gauges and refit the blanking plugs or caps

as required by your model (see Steps 4 and 5).

On California models, do not forget to attach

the vacuum hose to the EVAP system. On YZF

models, detach the temporary fuel supply and

install the fuel tank (see Chapter 4).

4.7 Carburettor sychronisation set-up

FZS models

5 Air filter-

cleaning and replacement

I

I

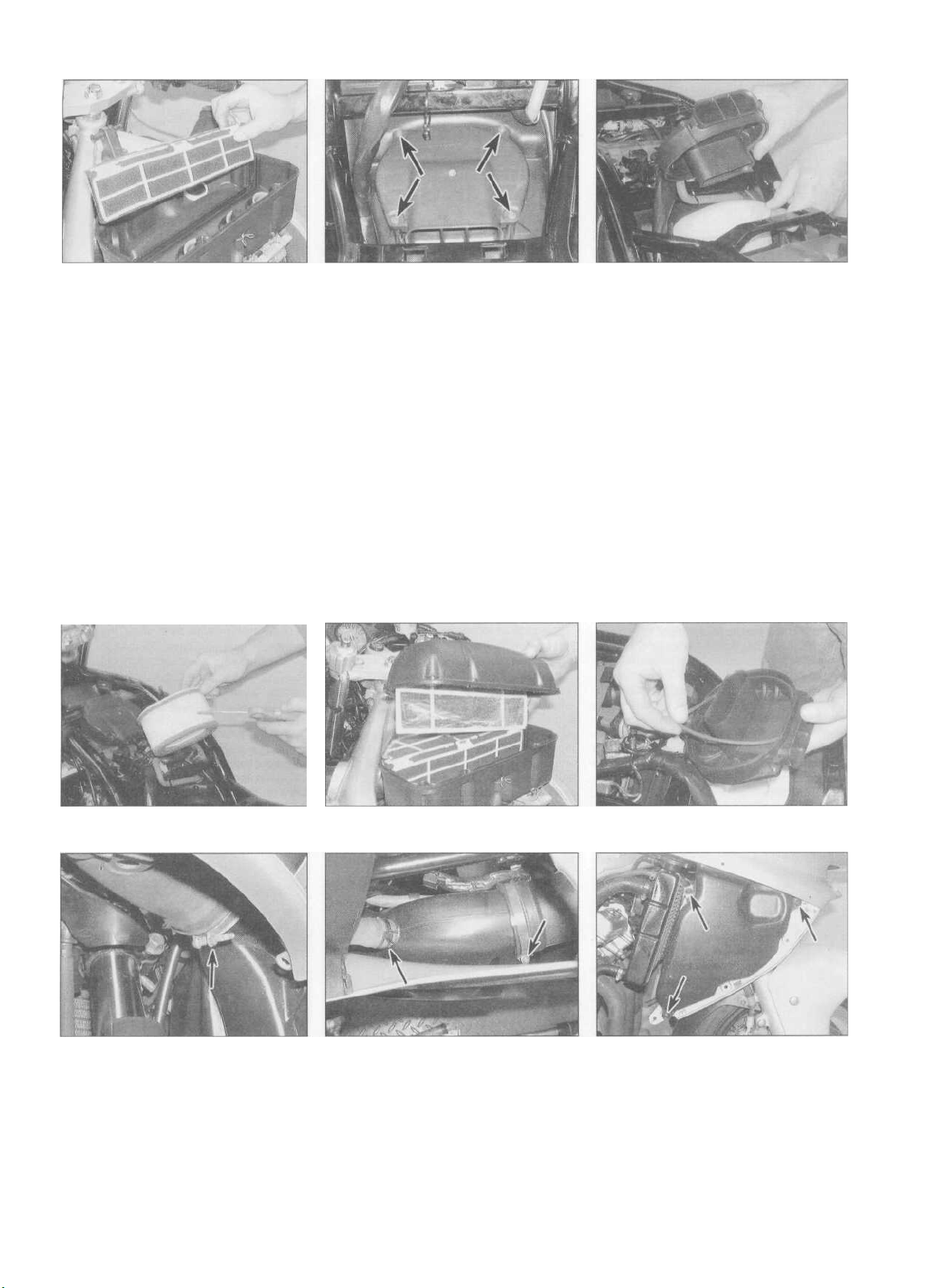

1 Remove the fuel tank (see Chapter 4). On

FZS models, remove the rubber trim cover,

which is secured by two lugs.

2 Remove the screws securing the air filter

cover to the filter housing, then remove the

cover and withdraw the filter element from the

housing (see illustrations).

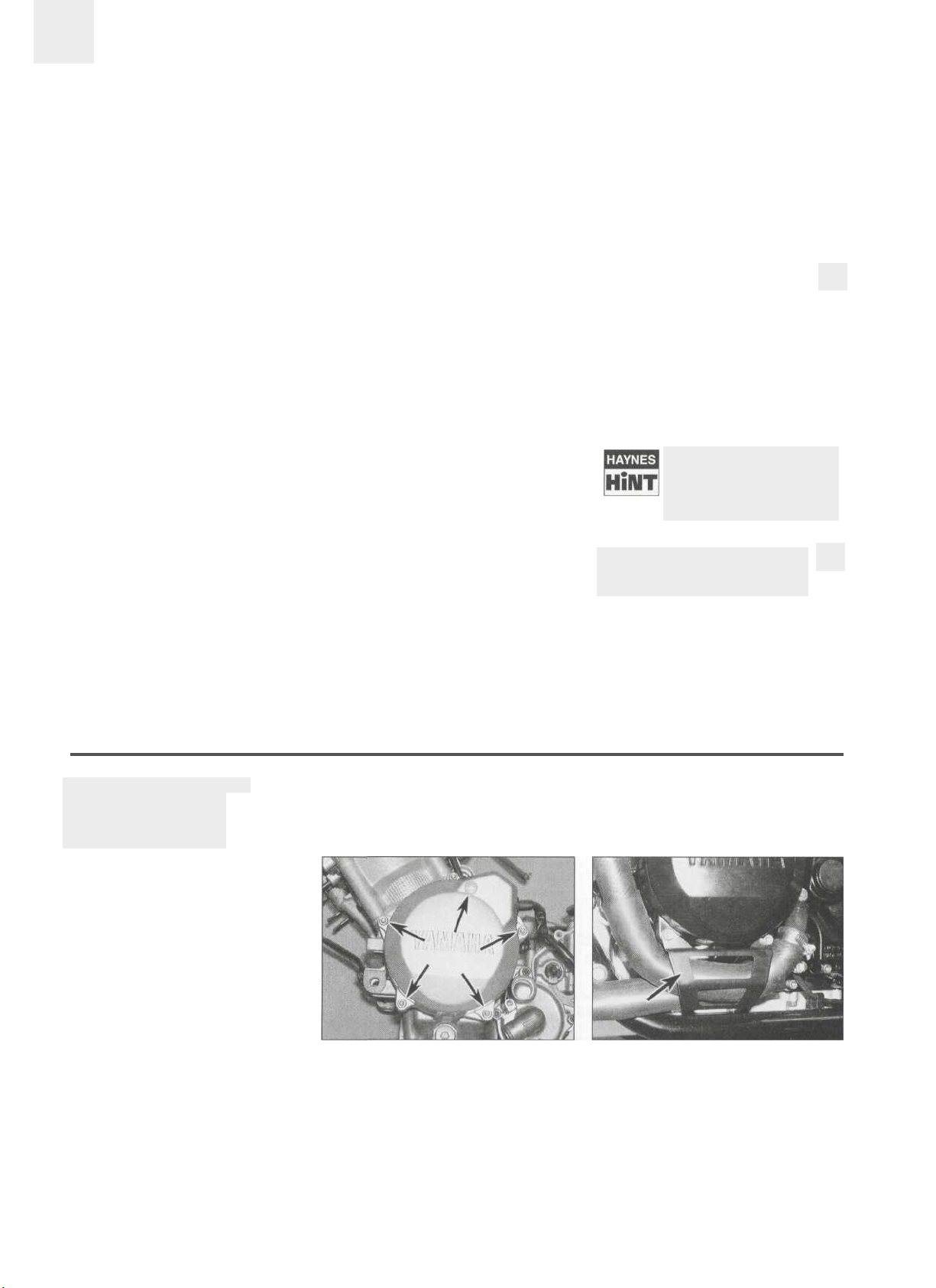

5.2a On YZF models, remove the four

screws on each side (arrowed) and lift off

the cover..

Every 4000 miles (6000 km) or 6 months 1-11

5.2b ... then withdraw the element 5.2c On FZS models, remove the screws

3 On YZF models, clean the element using a

high flash-point solvent, then remove the

solvent by patting the element dry. If

available, use compressed air to dry the

element. Smear the entire surface of the

element with clean engine oil and allow it to

soak in. Again pat the element to soak up any

excess oil - the element should be wet with oil

but none should be dripping off it.

4 On FZS models, tap the element on a hard

surface to dislodge any large particles of dirt,

then if compressed air is available, use it to

clean the element, directing the air from the

outside in (see illustration).

5 Check the element for signs of damage. If

the element is torn or cannot be cleaned, or is

obviously beyond further use, replace it with a

new

one.

6 Install the filter element, making sure it is

(arrowed) and lift off the cover ...

properly seated - on YZF models the element

fits into the large slots in the housing (see

illustration 5.2b). Fit the air filter cover,

making sure the rubber seal is in place, and

on YZF models making sure the gauze screen

fits into the small slots behind the filter

element (see illustrations). On FZS models,

fit the rubber trim cover. Install the fuel tank

(see Chapter 4).

7 Check that the collector in the air filter

housing drain hose has not become blocked,

and drain it if necessary - on YZF models the

hose comes out of the rear left side of the

housing, and on FZS it comes out of the front

left side of the housing.

8 Check the crankcase breather hose between

the engine and the air filter housing for loose

connections, cracks and deterioration and

replace it with a new one if necessary.

5.2d ... then withdraw the element

9 On YZF models, the surge tanks in the air

intake system must also be drained and

cleaned. Remove the fairing side panels to

access them (see Chapter 8, Section 3).

Release the clamps securing each tank to the

intake in the fairing, to the air duct, to the filter

housing, and to the hose on the top (see

illustrations). Access to the front clamp

screws is best achieved by turning the

handlebars onto full lock. Remove the screws

securing each tank and remove the tanks,

noting how they fit. Flush the tanks out with

clean water then allow them to drain. Repeat

until all debris is removed, then allow them to

dry before refitting them.

Caution: If the machine is continually

ridden in dusty conditions, the filter should

be cleaned more frequently.

5.4 Clean the element using compressed

air if available

5.9a Slacken the front clamp (arrowed)...

5.6a Installing the cover on YZF models 5.6b Make sure the rubber seal is in place

5.9b . . . and the rear clamps (arrowed)

and detach the top hose ...

5.9c . .. then remove the screws (arrowed)

- FZS shown

and detach the surge tank

Every 4000 miles (6000 km) or 6 months

6.5 On YZF models, drain the carburettor

vent hose collector (arrowed)

Fuel system check

Warning: Petrol (gasoline) is

extremely flammable, so take extra

precautions when you work on any

part of the fuel system. Don't smoke or

allow open flames or bare light bulbs near

the work area, and don't work in a garage

where a natural gas-type appliance is

present. If you spill any fuel on your skin,

rinse it off immediately with soap and water.

When you perform any kind of work on the

fuel system, wear safety glasses and have a

fire extinguisher suitable for a Class B type

fire (flammable liquids) on hand.

Check

1 Remove the fuel tank (see Chapter 4) and

check the tank, the fuel tap, the filter, the fuel

pump and the fuel hoses for signs of leakage,

deterioration or damage; in particular check that

there is no leakage from the fuel hoses. Replace

any hoses which are cracked or deteriorated.

2 If the fuel tap is leaking, tighten the

assembly screws and mounting bolts (see

Chapter 4). If leakage persists remove the tap

and disassemble it, noting how the

components fit. Inspect all components and

replace any that are worn or damaged. Some

components are available individually, though

it may be necessary to replace the whole tap,

depending on the fault.

3 If the carburettor gaskets are leaking, the

carburettors should be disassembled and rebuilt

6.8a In-line fuel filter (arrowed) YZF models

using new gaskets and seals (see Chapter 4).

4 On California models, check the EVAP

system hoses for loose connections, cracks

and deterioration and replace them with new

ones if necessary.

5 On YZF models, remove the left-hand

fairing side panel (see Chapter 8, Section 3),

then remove the plug from the end of the

carburettor vent hose on the left-hand side of

the engine and allow any residue that has

accumulated in the collector to completely

drain (see illustration). Install the plug on

completion.

Filter cleaning

6 Replacement of the fuel filter is advised

after a particularly high mileage has been

covered. It is also necessary if fuel starvation

is suspected.

7 A fuel strainer is mounted in the tank and is

integral with the fuel tap. Remove the fuel tank

and the fuel tap (see Chapter 4). Clean the

gauze strainer to remove all traces of dirt and

fuel sediment. Check the gauze for holes. If

any are found, a new tap should be fitted - the

strainer is not available separately.

8 An in-line fuel filter is fitted in the hose from

the fuel tap to the fuel pump - on YZF models,

it is on the underside of the fuel tank, on FZS

models it is next to the fuel pump (see

illustrations). Remove the fuel tank for

access (see Chapter 4). If the filter is dirty or

clogged or otherwise needs replacing, have a

rag handy to soak up any residual fuel, then

release the clamps and disconnect the hoses

from the filter. Release the filter from its holder

and install the new filter so that its arrow

6.8b In-line fuel filter (arrowed) FZS models

points in the direction of fuel flow (i.e. towards!

the pump). Fit the hoses to unions on the filter!

and secure them with the clamps. Install the!

fuel tank (see Chapter 4). Start the engine and!

check that there are no leaks.

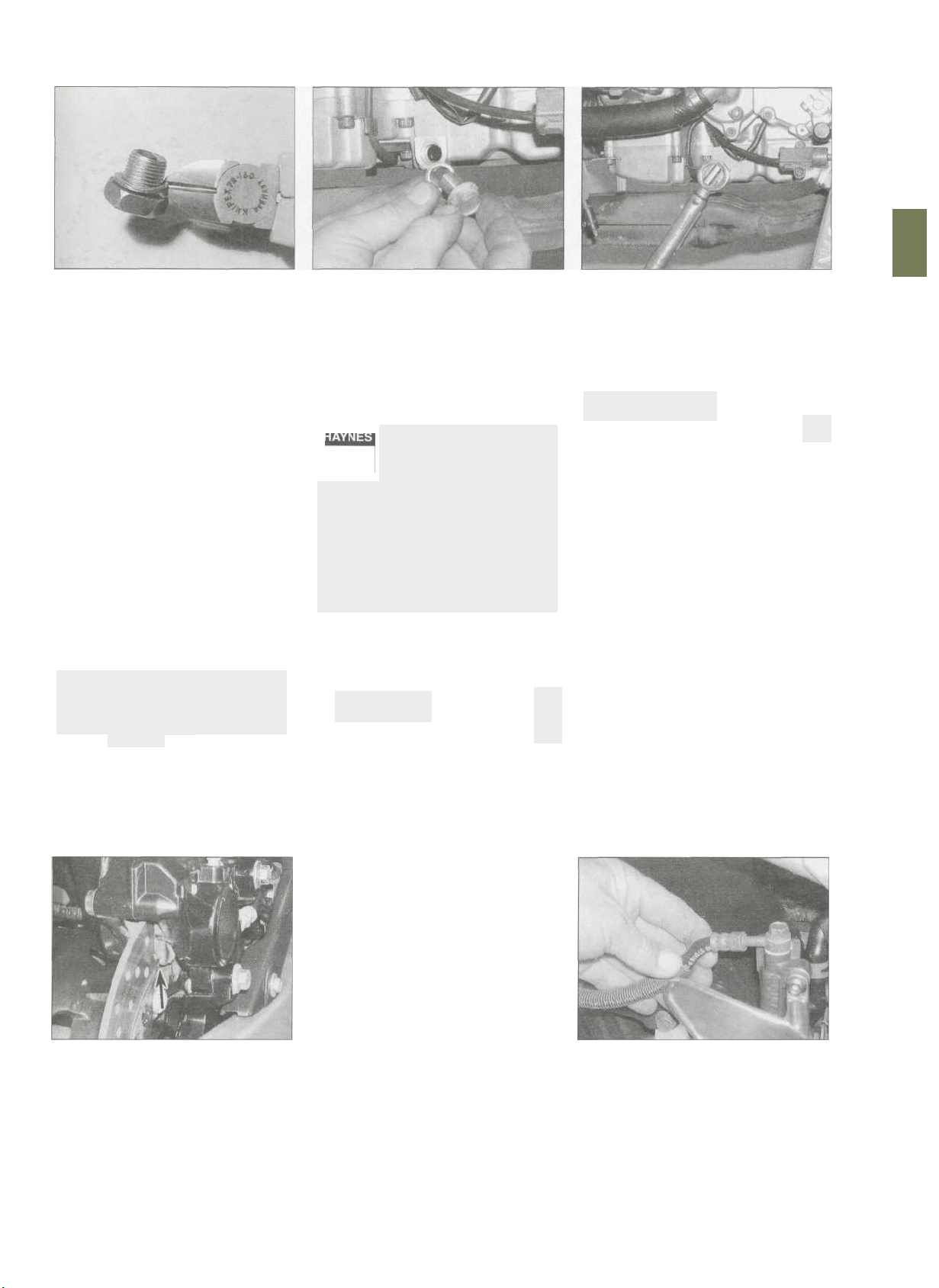

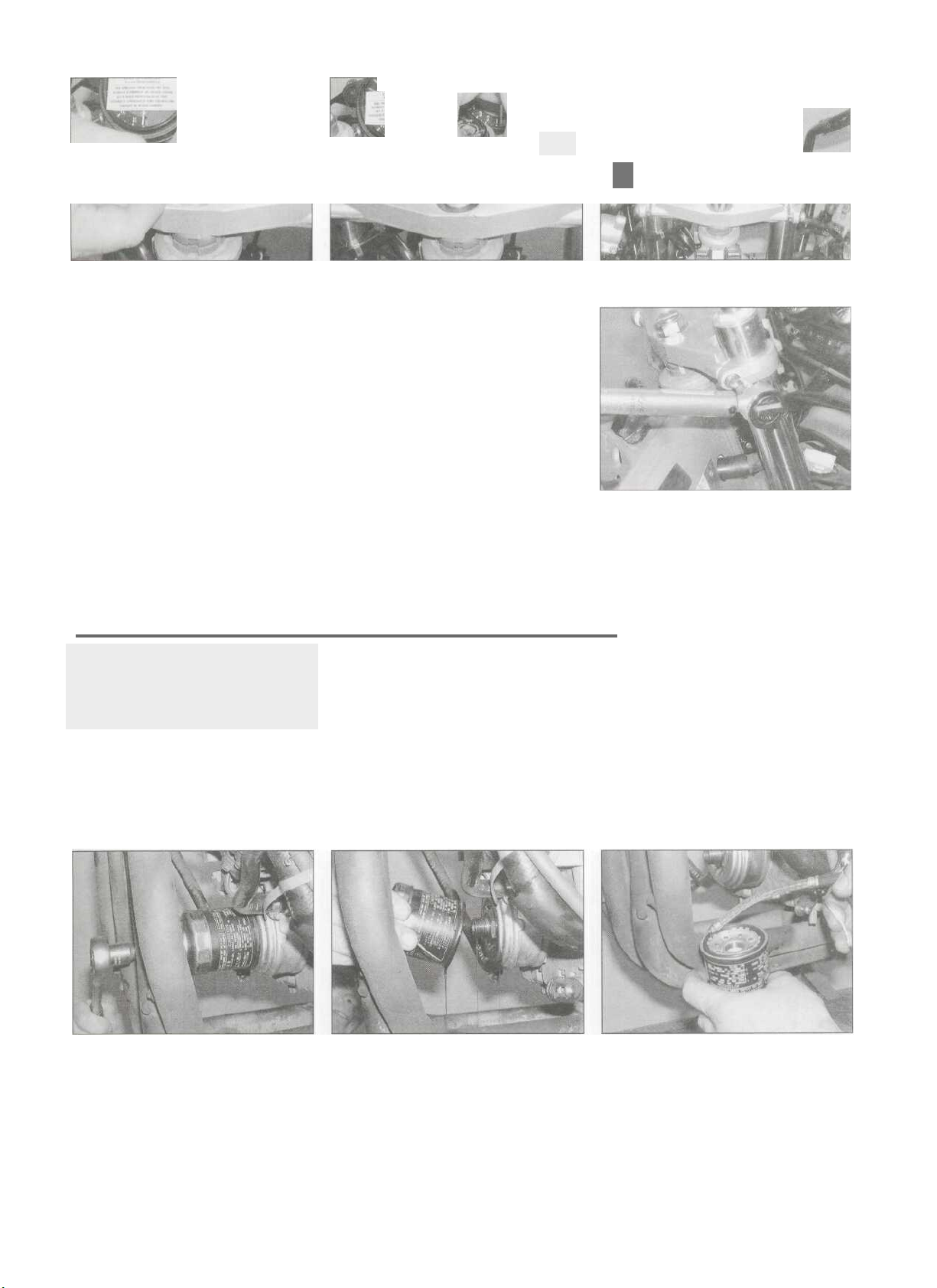

7 Engine oil change

Warning: Be careful whenl

draining the oil, as the exhaust!

pipes, the engine, and the oil itsen

can cause severe burns.

1 Consistent routine oil and filter changes arel

the single most important maintenance pro-J

cedure you can perform on a motorcycle. The!

oil not only lubricates the internal parts of thj

engine, transmission and clutch, but it alsJ

acts as a coolant, a cleaner, a sealant, and a

protectant. Because of these demands, the oil

takes a terrific amount of abuse and should bel

replaced often with new oil of the recomJ

mended grade and type. The oil filter should

be changed with every second oil change.

2 Before changing the oil, warm up the

engine so the oil will drain easily. On YZF

models, remove the left-hand fairing side

panel (see Chapter 8, Section 3).

3 Put the motorcycle on its sidestand, and

position a clean drain tray below the engine.

Unscrew the oil filler cap from the clutch covei

to vent it and to act as a reminder that there is

no oil in the engine (see illustration).

4 Unscrew the oil drain plug from the lefthand side of the crankcase and allow the oil to

flow into the drain tray (see illustrations).

::

7.3 Remove the oil filler cap from the

clutch cover

7.4a Unscrew the crankcase oil drain

plug ...

7.4b ... and allow the oil to drain

Every 4000 miles (6000 km) or 6 months 1-13

7.4c To remove the old sealing washer,

Check

the

the drain plug and discard it if it is damaged or

worn

- it

will

old one off using cutters (see illustration).

5 When the oil has completely drained, fit the

plug

into

the

washer

if

required,

setting specified at the beginning of the

Chapter (see illustrations). Avoid

overtightening, as damage to the crankcase

will result.

6 Refill the engine to the proper level using

the recommended type and amount of oil (see

Daily

(pre-ride)

vertical,

the oil

maximum and minimum level lines on the

inspection window (see Daily (pre-ride)

checks). Install the filler cap. Start the engine

and let it run for two or three minutes. Stop

the engine, wait a few minutes, then check the

oil level. If necessary, add more oil to bring the

level

up to the

window. Check around the drain plug for

leaks.

UTOJI35 Saving a little money on the

VUUISl (jiff

\IM mU^f\

HINT

7

Every

so

do not fit an oil pressure switch and warning

light (the system fitted uses an oil level

sensor), it is advisable to perform an oil

pressure check (see Section 31).

8.2 Brake pad wear indicator (arrowed) -

cut it off

condition

and

often,

of the

probably

crankcase, using

if the engine is damaged asif the engine

a result.

be

and

tighten

checks).

level should

With

maximum level line

between good

erence

cheap

oils

and

especially

YZF shown

sealing

necessary

a new

it to the

the

lie

between

won't

as

washer

on

to cut the

sealing

torque

motorcycle

the

on the

pay off

Yamaha

7.5a Install the drain plug, using a new

sealing washer if necessary ...

8 The old oil drained from the engine cannot

be re-used and should be disposed of

properly. Check with your local refuse

disposal company, disposal facility or

environmental agency to see whether they will

accept the used oil for recycling. Don't pour

used oil into drains or onto the ground.

Check the old oil carefully if it is very metallic coloured,

HilUT

break-in (new engine) or from

insufficient lubrication. If there are

flakes or chips of metal in the oil, then

something is drastically wrong

internally and the engine will have to be

disassembled for inspection and repair.

If there are pieces of fibre-like material

in the oil, the clutch is experiencing

excessive wear and should be checked.

9 On YZF models, install the left-hand fairing

side panel (see Chapter 8).

then the engine is

experiencing wear from

Brake pads -

wear check

I

I

1 Each brake pad has wear indicators that

can be viewed without removing the pads

from the caliper.

2 The turned in corners of the brake pad

backing material form the wear indicators when they are almost contacting the disc itself

the pads must be replaced. The indicators are

visible by looking at the bottom corner of the

pads (see illustration). Note: Some after-

market pads may use different indicators,

such as a groove cut into the friction material,

to those on the original equipment as shown.

The pad is worn when the groove is no longer

visible.

Caution: Do not allow the pads to wear to

the extent that the indicators contact the

disc itself as the disc will be damaged.

3 If the pads are worn to the indicators, new

ones must be installed. If the pads are dirty or

if you are in doubt as to the amount of friction

material remaining, remove them for

inspection (see Chapter 7). If required,

7.5b ... and tighten it to the specified

torque

measure the amount of friction material

remaining - the minimum is 0.5 mm.

4 Refer to Chapter 7 for details of pad

replacement.

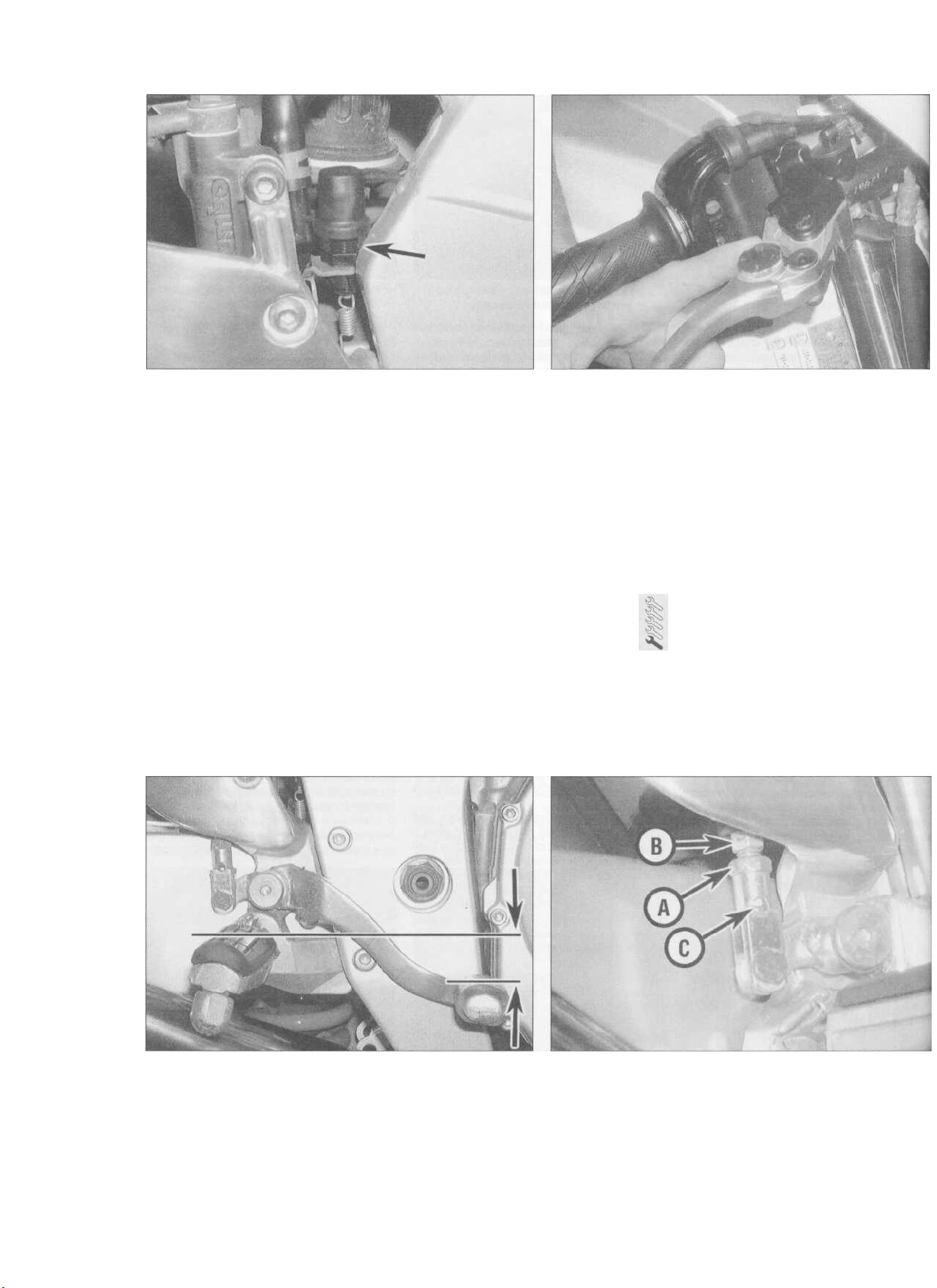

9 Brake system -

check

1 A routine general check of the brake system

will ensure that any problems are discovered

and remedied before the rider's safety is

jeopardised.

2 Check the brake lever and pedal for

looseness, improper or rough action,

excessive play, bends, and other damage.

Replace any damaged parts with new ones

(see Chapter 7). Clean and lubricate the lever

and pedal pivots if their action is stiff or rough

(see Section 18).

3 Make sure all brake fasteners are tight.

Check the brake pads for wear (see Section 8)

and make sure the fluid level in the reservoirs

is correct (see Daily (pre-ride) checks). Look

for leaks at the hose connections and check

for cracks in the hoses themselves (see

illustration). If the lever or pedal is spongy,

bleed the brakes (see Chapter 7).

4 Make sure the brake light operates when the

front brake lever is pulled in. The front brake

light switch, mounted on the underside of the

master cylinder, is not adjustable. If it fails to

operate properly, check it (see Chapter 9).

5 Make sure the brake light is activated just

before the rear brake takes effect. If adjustment

is necessary, hold the switch and turn the

9.3 Flex the brake hose and check for

cracks, bulges and leaking fluid

:

Every 4000 miles (6000 km) or 6 months

9.5 Rear brake light switch (arrowed) YZF shown

adjuster nut on the switch body until the brake

light is activated when required (see

illustration). If the brake light comes on too

late, turn the nut clockwise. If the brake light

comes on too soon or is permanently on, turn

the nut anti-clockwise. If the switch doesn't

operate the brake light, check it (see Chapter 9).

6 The front brake lever has a span adjuster

which alters the distance of the lever from the

handlebar (see illustration). Each setting is

identified by a number on the adjuster which

aligns with the arrow on the lever bracket. Pull

the lever away from the handlebar and turn

the adjuster ring until the setting which best

suits the rider is obtained. There are four

settings - setting one gives the largest span,

and setting 4 the smallest. Make sure that the

pin on the brake lever holder is firmly seated

in the hole in the adjuster.

7 Check the position of the brake pedal.

Yamaha recommend the distance between

the top of the end of the brake pedal and the

top of the rider's footpeg should be as

specified at the beginning of the Chapter (see

9.6 Front brake lever span adjuster

illustration). If the pedal height is incorrect, or

if the rider's preference is different, slacken

the clevis locknut on the master cylinder

pushrod, then turn the pushrod using a

spanner on the hex on the rod until the pedal

is at the correct or desired height (see

illustration). After adjustment check that the

pushrod end is visible in the hole in the clevis.

On completion tighten the locknut securely.

Adjust the rear brake light switch after

adjusting the pedal height (see Step 5).

10 Clutch-

check and adjustment

1 Check that the clutch lever operates

smoothly and easily.

2 If the clutch lever operation is heavy or stiff,

remove the cable (see Chapter 2) and

lubricate it (see Section 18). If the cable is still

stiff, fit a new one. Install the lubricated or new

cable (see Chapter 2).

3 With the cable operating smoothly, checkl

that the clutch lever is correctly adjusted.!

Periodic adjustment is necessary to com-l

pensate for wear in the clutch plates and!

stretch of the cable. Check that the amount of

freeplay at the clutch lever end is within thel

specifications listed at the beginning of the!

Chapter (see illustration).

4 If adjustment is required, loosen thel

lockring on the adjuster at the top of the cable!

and turn the adjuster in or out until thel

required amount of freeplay is obtained (seel

illustration). To increase freeplay, turn thel

adjuster in. To reduce freeplay, turn thel

adjuster out. Tighten the locking ring securely.!

5 If all the adjustment has been taken up all

the lever, reset the adjuster to give thai

maximum amount of freeplay, then set thel

release mechanism adjuster in the front|

sprocket cover as described below:

6 On YZF models, remove the left-hand

fairing side panel (see Chapter 8, Section 3).

7 Remove the rubber cover from the clutch

release mechanism set in the engine sprocket

9.7a Measure the distance between the top of the footpeg and

the top of the brake pedal as shown

9.7b Slacken the locknut (A) and turn the pushrod using the hex

(B) making sure the rod end is still visible in the hole (C)

Every 4000 miles (6000 km) or 6 months 1-15

10.3 Measuring clutch cable freeplay 10.4 Slacken the lockring (A) and turn the adjuster (B) as required

cover (see illustration). Slacken the locknut on

the release mechanism adjuster screw, then

turn

the

adjuster screw

then back it off 1/4 turn (see illustration). When

doing this, counter-hold the locknut as shown

to prevent it from tightening and locking the

adjuster. Now counter-hold the adjuster screw

to prevent it turning and tighten the locknut.

Replace the rubber cover (see illustration).

8 Now adjust the freeplay using the adjuster

at the lever end of the cable as described in

Step 4 until

9 On YZF models, install the left-hand fairing

side panel (see Chapter 8).

the

freeplay

in

until

is

resistance

correct.

is

felt,

11 Battery-

check

1 All models are fitted with a sealed battery

which

requires

attempt to remove the battery caps to check

the electrolyte level or battery specific gravity.

Removal will damage the caps, resulting in

electrolyte leakage and battery damage.

2 All that should be done is to check that the

terminals are clean and tight and that the

casing is not damaged or leaking. See

Chapter 9 for further details.

no

maintenance.

Note:

Do not

Caution: Be extremely careful when

handling or working around the battery.

The electrolyte is very caustic and an

explosive gas (hydrogen) is given off when

the battery is charging.

3 If the machine is not in regular use, discon-

nect the battery and give it a refresher charge

every four to six weeks (see Chapter 9).

12 Wheels and tyres -

general check

Tyres

1 Check the tyre condition and tread depth

thoroughly - see Daily (pre-ride) checks.

Wheels

2 Cast wheels as fitted on all models are

virtually maintenance free, but they should be

kept clean and checked periodically for

cracks and other damage. Also check the

wheel runout and alignment (see Chapter 7).

Never attempt to repair damaged cast wheels;

they must be replaced with new ones. Check

the valve rubber for signs of damage or

deterioration and have it replaced if

necessary. Also, make sure the valve cap is in

place and tight.

10.7a Remove the rubber cover ...

13 Wheel bearings-

check

1 Wheel bearings will wear over a period of

time and result in handling problems.

2 Support the motorcycle upright using an

auxiliary stand on YZF models or the

centrestand on FZS models. Check for any

play in the bearings by pushing and pulling

the wheel against the hub (see illustration).

Also rotate the wheel and check that it rotates

smoothly.

10.7b ... then slacken the locknut using a

ring spanner and turn the adjuster using a

screwdriver as described

10.7c On completion, replace the rubber

cover

13.2 Checking for play in the wheel

bearings

Every 4000 miles (6000 km) or 6 months

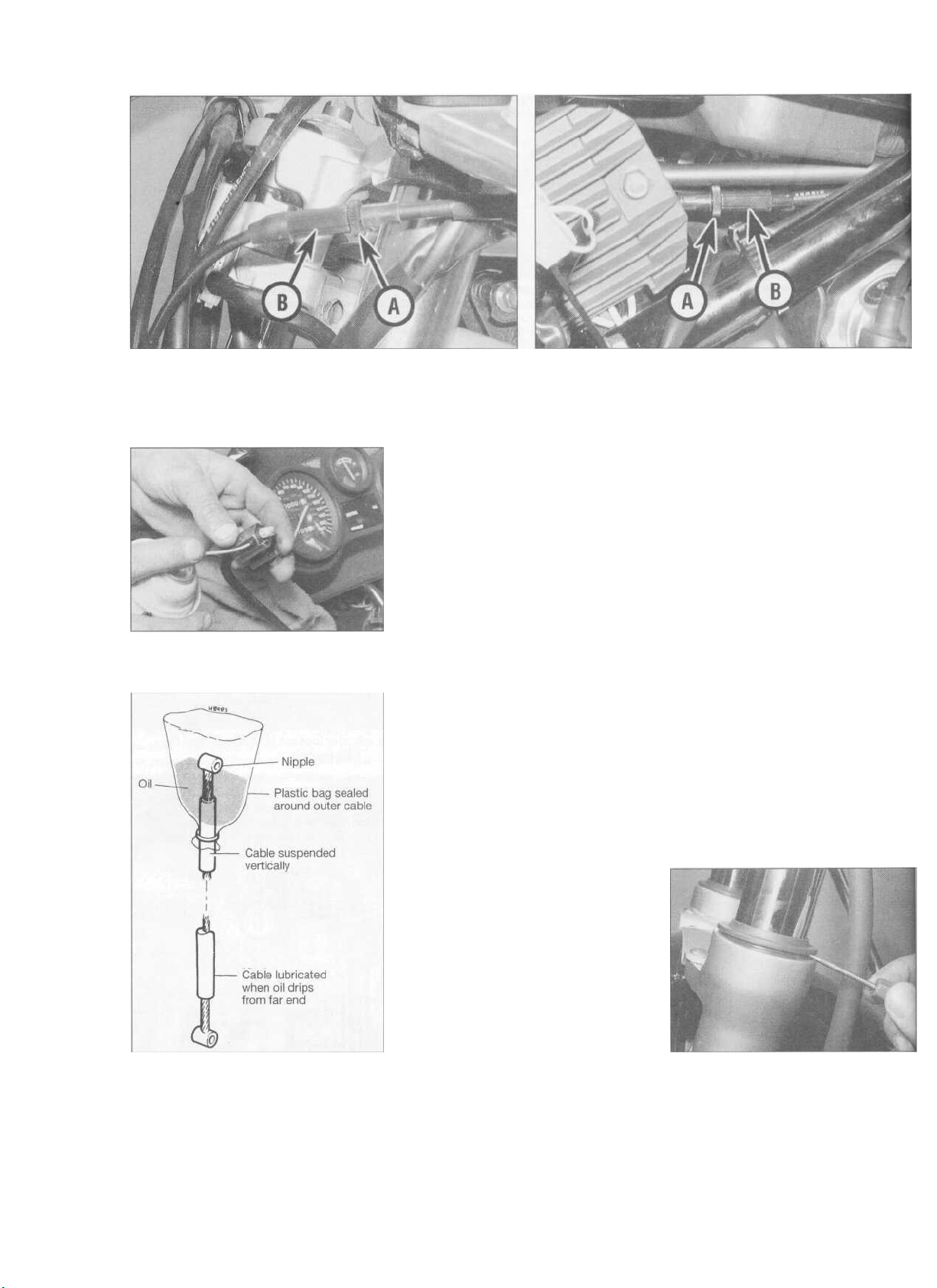

17.9a Choke cable adjuster lockring (A) and adjuster (B) -

8 If this fails to improve the operation of the

choke, a new cable must be installed. Note that

in very rare cases the fault could lie in the

YZF models

carburettors rather than the cable, necessitating

the removal of the carburettors and inspection

of the choke plungers (see Chapter 4).

9 Make sure there is a small amount of

freeplay in the cable before the plungers

move. If there isn't, check that the cable is

seating correctly at the carburettor end. If it is,

slacken the lockring on the cable adjuster and

turn the adjuster as required until there is

some freeplay (see illustrations) - on FZS

models, remove the fairing for improved

access to the adjuster (see Chapter 8).

Otherwise, renew the cable.

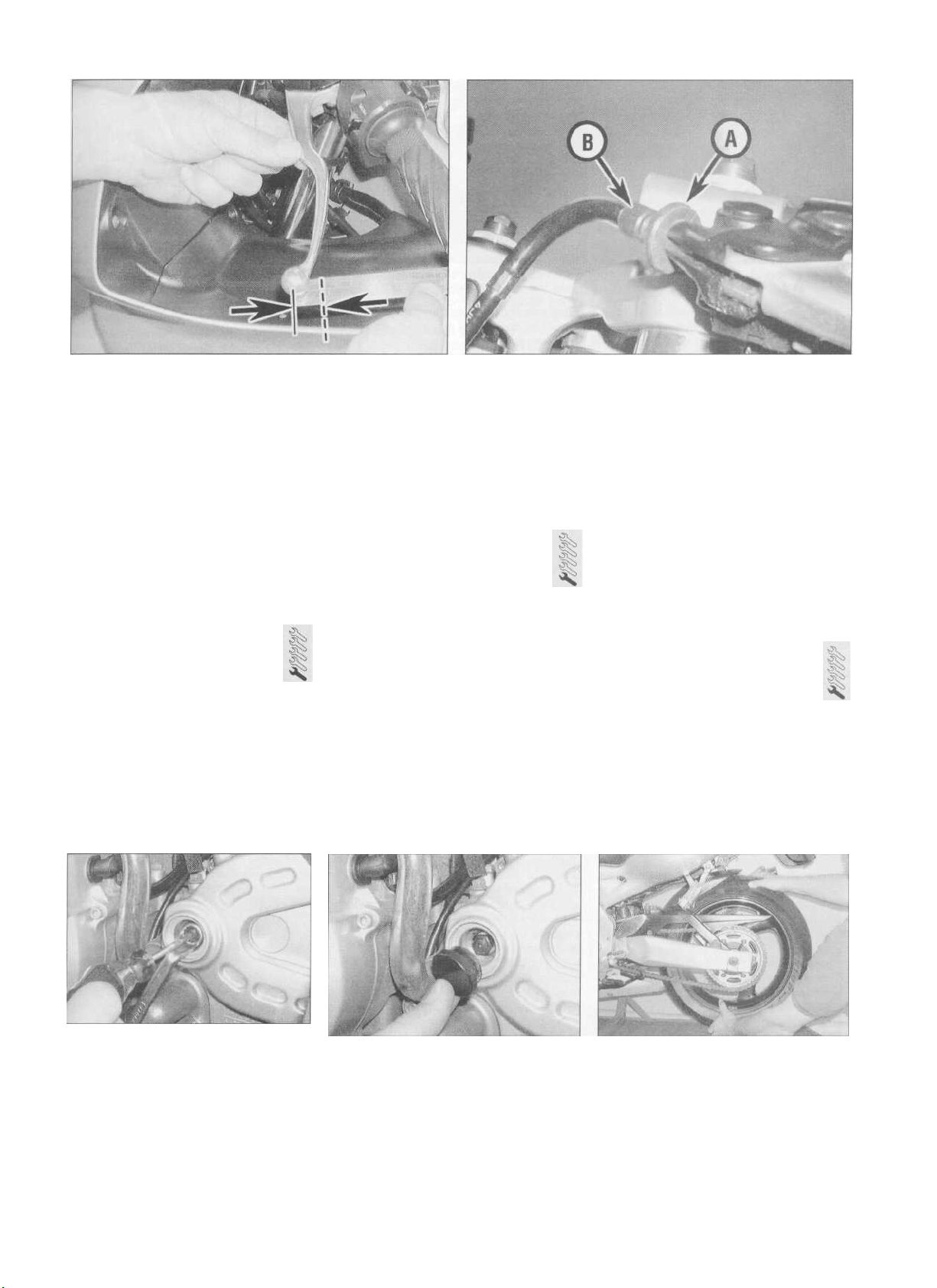

18 Stand, lever pivots

18.3a Lubricating a cable with a pressure

lubricator. Make sure the tool seals around

18.3b Lubricating a cable with a makeshift

the Inner cable

funnel and motor oil

1 Since the controls, cables and various other

components of a motorcycle are exposed to

the elements, they should be lubricated

periodically to ensure safe and trouble-free

operation.

2 The footrests, clutch and brake levers, brake

pedal, gearshift lever linkage and

sidestand/centrestand pivots should be

lubricated frequently. In order for the lubricant

to be applied where it will do the most good,

the component should be disassembled.

However, if chain and cable lubricant is being

used, it can be applied to the pivot joint gaps

and will usually work its way into the areas

where friction occurs. If motor oil or light

grease is being used, apply it sparingly as it

may attract dirt (which could cause the controls

to bind or wear at an accelerated rate). Note:

One of the best lubricants for the control lever

pivots is a dry-film lubricant (available from

many sources by different names).

3 To lubricate the cables, disconnect the

relevant cable at its upper end, then lubricate

the cable with a pressure adapter, or if one is

not available, using the set-up shown (see

illustrations). See Chapter 4 for the throttle

and choke cable removal procedures, and

Chapter 2 for the clutch cable.

and cables lubrication

17.9b Choke cable adjuster lockring (A) and adjuster (B) FZS models

4 The speedometer cable should be removed

(see Chapter 9, Section 15) and the innel

cable withdrawn from the outer cable and

lubricated with motor oil or cable lubricant. Da

not lubricate the upper few inches of the cable

as the lubricant may travel up into the

instrument head.

19 Suspension -

check

1 The suspension components must be

maintained in top operating condition to

ensure rider safety. Loose, worn or damaged

suspension parts decrease the motorcycle's

stability and control.

Front suspension

2 While standing alongside the motorcycle,

apply the front brake and push on the

handlebars to compress the forks several

times. See if they move up-and-down

smoothly without binding. If binding is felt, the

forks should be disassembled and inspected

(see Chapter 6).

3 Inspect the area around the dust seal for

signs of oil leakage, then carefully lever off the

dust seal using a flat-bladed screwdriver and

inspect the area around the fork seal (see

illustrations). If leakage is evident, new seals

19.3a Lever off the dust seal...

Every 4000 miles (6000 km) or 6 months 1-19

19.3b ... and check underneath it for

must

tubes for scratches, corrosion and pitting as

these will cause premature seal failure. If the

damage is excessive new tubes should be

installed (see Chapter 6).

4 Check the tightness of all suspension nuts

and bolts to be sure none have worked loose,

referring to the torque settings specified at the

beginning of Chapter 6.

signs of oil leakage

be

fitted

(see Chapter

6).

Check

the

fork

Rear suspension

5 Inspect the rear shock for fluid leakage and

tightness of its mountings. If leakage is found, a

new shock should be installed (see Chapter 6).

6

With

the aid of an

bike, compress the rear suspension several

times. It should move up and down freely

without binding. If any binding is felt, the worn

or faulty component must be identified and

renewed. The problem could be due to either

the shock absorber, the suspension linkage

components or the swingarm components.

7 Support the motorcycle using an auxiliary

stand

(YZF models)

models) so that the rear wheel is off the ground.

Grab the swingarm and rock it from side to side

-there should be no discernible movement at

the rear (Yamaha specify a maximum of 1 mm)

(see illustration). If there's a little movement or

a slight clicking can be heard, inspect the

tightness of all the rear suspension mounting

bolts and nuts, referring to the torque settings

specified at the beginning of Chapter 6, and recheck for movement. Next, grasp the top of the

rear

wheel

and

no discernible freeplay before the shock

absorber begins to compress (see illustration).

assistant

or the

centrestand (FZS

pull

it

upwards - there should

to

support

the

be

19.7a Checking for play in the swingarm

bearings

Any freeplay felt in either check indicates worn

bearings in the suspension linkage or swingarm,

or worn shock absorber mountings. The worn

components must be renewed (see Chapter 6).

8 To make an accurate assessment of the

swingarm bearings, remove the rear wheel

(see Chapter 7) and the bolt securing the

suspension linkage rods to the swingarm (see

Chapter 6). Grasp the rear of the swingarm

with one hand and place your other hand at

the junction of the swingarm and the frame.

Try to move the rear of the swingarm from

side-to-side. Any wear (play) in the bearings

should be felt as movement between the

swingarm and the frame at the front. If there is

any play the swingarm will be felt to move

forward and backward at the front (not from

side-to-side). Alternatively, measure the

amount of freeplay at the swingarm end Yamaha specify a maximum of 1 mm. Next,

move the swingarm up and down through its

full travel. It should move freely, without any

binding or rough spots. If any play in the

swingarm is noted or if the swingarm does not

move freely, the bearings must be removed

for inspection or renewal (see Chapter 6).

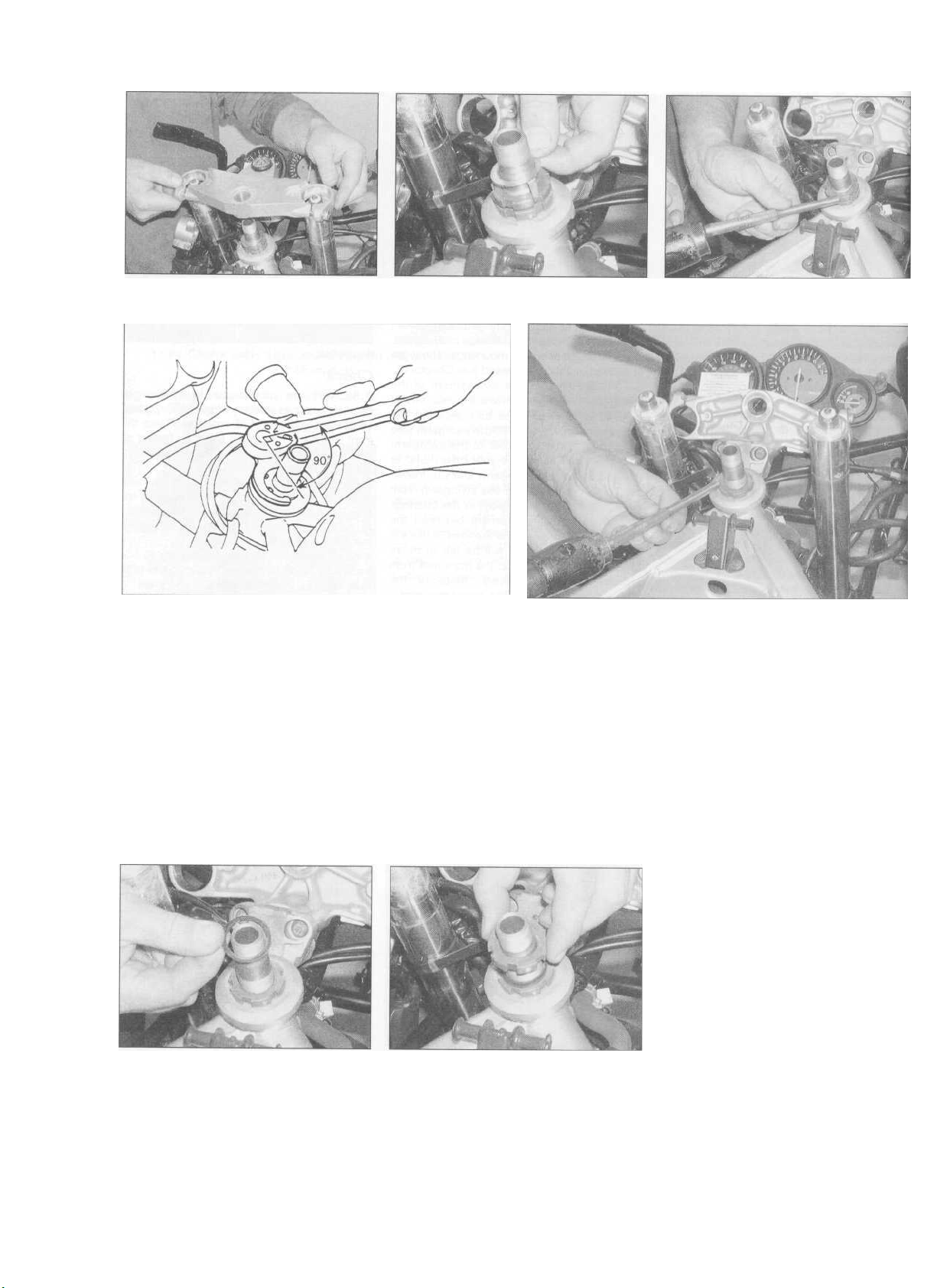

20 Steering head bearings - ft^

freeplay check and adjustment

1 This motorcycle is equipped with caged ball

steering head bearings which can become

dented, rough or loose during normal use of

the machine. In extreme cases, worn or loose

19.7b Checking for play in the suspension

linkage bearings

steering head bearings can cause steering

wobble - a condition that is potentially

dangerous.

Check

2 Support the motorcycle in an upright

position using an auxiliary stand (YZF models)

or the centrestand (FZS models). Raise the

front wheel off the ground either by having an

assistant push down on the rear or by placing

a support under the engine.

3 Point the front wheel straight-ahead and

slowly move the handlebars from side-toside. Any dents or roughness in the bearing

races will be felt and the bars will not move

smoothly and freely.

4 Next, grasp the fork sliders and try to pull

and push them forward and backward (see

illustration). Any looseness in the steering

head bearings will be felt as front-to-rear

movement of the forks. If play is felt in the

bearings, adjust the steering head as follows.

Freeplay in the fork due to

worn fork bushes can be

misinterpreted for steering

head bearing play - do not

confuse the two.

Adjustment

5 Displace the handlebars from the top yoke

(see Chapter 6).

6 Slacken the fork clamp bolts in the top yoke

(see illustration). Unscrew the steering stem

nut and remove it along with its washer (see

illustration).

20.4 Checking for play in the steering

head bearings

20.6a Slacken the fork clamp bolt

(arrowed) on each side ...

20.6b ... and unscrew the steering stem

nut (arrowed)

i-2o Every 4000 miles (6000 km) or 6 months

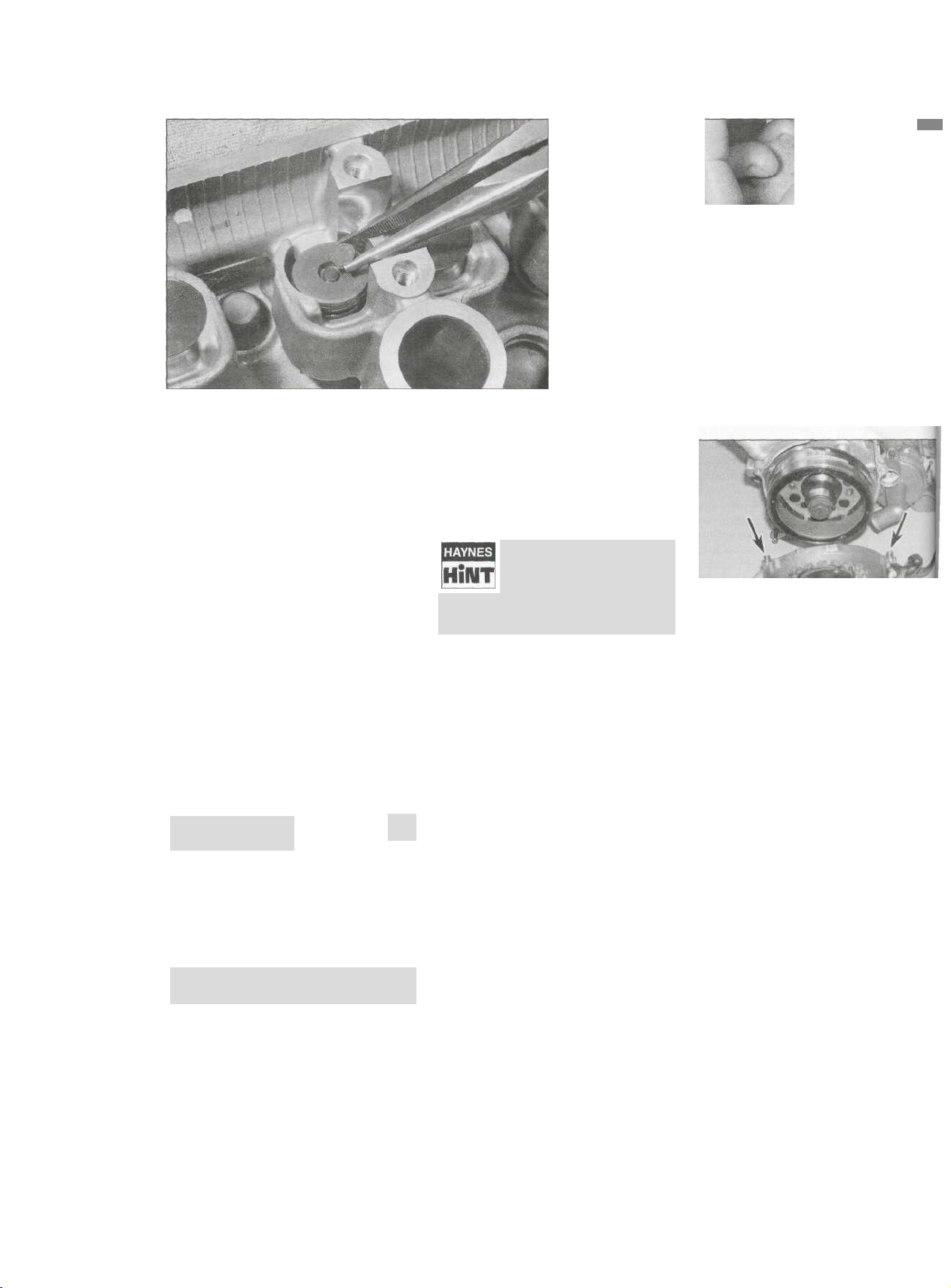

20.7 Ease the top yoke up off the steering 20.8a Remove the tabbed lockwasher.

20.9 Make sure the torque wrench arm is at right angles (90°) to

7 Gently ease the top yoke upwards off the

fork tubes and position it clear, using a rag to

protect the tank or other components (see

illustration).

8 Remove the tabbed lockwasher, noting

how it fits, then unscrew and remove the

locknut using either a C-spanner, a peg

spanner or a drift located in one of the

notches (see illustrations). Remove the

washer (see illustration 20.11a).

9 To adjust the bearings as specified by

Yamaha, a special service tool (part No.

90890-01403) and a torque wrench are

required. If the tool is available, first slacken

stem and forks

20.11 a Fit the washer .

the tool

20.10 If the tool is not available, adjust the bearings as described

the adjuster nut, then tighten it to the initial

torque setting specified at the beginning of

the Chapter, making sure the torque wrench

handle is at right angles (90°) to the line

between the adjuster nut and the wrench

socket in the special tool (see illustration).

Now slacken the nut so that it is loose, then

tighten it to the final torque setting specified.

Check that the steering is still able to move

freely from side to side, but that all freeplay is

eliminated.

10 If the Yamaha tool is not available, using

either a C-spanner, a peg spanner or a drift

located in one of the notches, slacken the

20.11b ... and the locknut

20.8b . .. then unscrew the locknut

adjuster nut slightly until pressure is justl

released, then tighten it until all freeplay is;

removed, then tighten it a little more (see

illustration). This pre-loads the bearings. Now]

slacken the nut, then tighten it again, setting it

so that all freeplay is just removed yet the!

steering is able to move freely from side to

side. To do this tighten the nut only a little at a

time, and after each tightening repeat the!

checks outlined above (Steps 2 to 4) until the

bearings are correctly set. The object is to set j

the adjuster nut so that the bearings are under,

a very light loading, just enough to remove any i

freeplay.

Caution: Take great care not to apply

excessive pressure because this will cause

premature failure of the bearings.

11 With the bearings correctly adjusted,

install the washer and the locknut (see

illustrations). Tighten the locknut finger-tight,

then tighten it further until its notches align

with those in the adjuster nut. If necessary,

counter-hold the adjuster nut and tighten the

locknut using a C-spanner or drift until the

notches align, but make sure the adjuster nut

does not turn as well. Install the tabbed

lockwasher so that the tabs fit into the

notches in both the locknut and adjuster nut

(see illustration 20.8a)

Every 4000 miles (6000 km) or 6 months 1-21

C

20.12a Fit the washer ...

12 Fit the top yoke onto the steering stem