OWNER’S MANUAL

LIT-11626-16-33

FZS1000R

FZS1000RC

FZS1000SR

FZS1000SRC

5LV-28199-12

EAU03438

U5LV12.book Page 1 Thursday, June 27, 2002 5:49 PM

EAU00002

INTRODUCTION

Congratulations on your purchase of the Yamaha FZS1000/FZS1000S. This model

is the result of Yamaha’s vast experience in the production of fine sporting, touring,

and pacesetting racing machines. It represents the high degree of craftsmanship and

reliability that have made Yamaha a leader in these fields.

This manual will give you an understanding of the operation, inspection, and basic

maintenance of this motorcycle. If you have any questions concerning the operation

or maintenance of your motorcycle, please consult a Yamaha dealer.

The design and manufacture of this Yamaha motorcycle fully comply with the emissions standards for clean air applicable at the date of manufacture. Yamaha has met

these standards without reducing the performance or economy of operation of the

motorcycle. To maintain these high standards, it is important that you and your

Yamaha dealer pay close attention to the recommended maintenance schedules and

operating instructions contained within this manual.

U5LV12.book Page 1 Thursday, June 27, 2002 5:49 PM

IMPORTANT MANUAL INFORMATION

Particularly important information is distinguished in this manual by the following notations:

EAU00003

NOTE:

●

This manual should be considered a permanent part of this motorcycle and should remain

with it even if the motorcycle is subsequently sold.

●

Yamaha continually seeks advancements in product design and quality. Therefore, while

this manual contains the most current product information available at the time of printing,

there may be minor discrepancies between your motorcycle and this manual. If you have

any questions concerning this manual, please consult your Yamaha dealer.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED!

Failure to follow WARNING instructions could result in severe injury or death to the

motorcycle operator, a bystander or a person inspecting or repairing the motorcycle.

A CAUTION indicates special precautions that must be taken to avoid damage to the

motorcycle.

CAUTION:

NOTE: A NOTE provides key information to make procedures easier or clearer.

U5LV12.book Page 2 Thursday, June 27, 2002 5:49 PM

IMPORTANT MANUAL INFORMATION

EW000000

_

PLEASE READ THIS MANUAL AND THE “YOU AND YOUR MOTORCYCLE: RIDING

TIPS” BOOKLET CAREFULLY AND COMPLETELY BEFORE OPERATING THIS MOTOR-

CYCLE. DO NOT ATTEMPT TO OPERATE THIS MOTORCYCLE UNTIL YOU HAVE ATTAINED ADEQUATE KNOWLEDGE OF ITS CONTROLS AND OPERATING FEATURES

AND UNTIL YOU HAVE BEEN TRAINED IN SAFE AND PROPER RIDING TECHNIQUES.

REGULAR INSPECTIONS AND CAREFUL MAINTENANCE, ALONG WITH GOOD RIDING

SKILLS, WILL ENSURE THAT YOU SAFELY ENJOY THE CAPABILITIES AND THE RELIABILITY OF THIS MOTORCYCLE.

_

WARNING

U5LV12.book Page 3 Thursday, June 27, 2002 5:49 PM

IMPORTANT MANUAL INFORMATION

AFFIX DEALER

LABEL HERE

EAU04247

FZS1000R/FZS1000RC/FZS1000SR/FZS1000SRC

OWNER’S MANUAL

©2002 by Yamaha Motor Corporation, U.S.A.

1st edition, May 2002

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Corporation, U.S.A.

is expressly prohibited.

Printed in Japan.

P/N LIT-11626-16-33

U5LV12.book Page 1 Thursday, June 27, 2002 5:49 PM

EAU00009

TABLE OF CONTENTS

1 SAFETY INFORMATION

1

2 DESCRIPTION

2

3 INSTRUMENT AND CONTROL FUNCTIONS

3

4 PRE-OPERATION CHECKS

4

5 OPERATION AND IMPORTANT RIDING POINTS

5

6 PERIODIC MAINTENANCE AND MINOR REPAIR

6

7 MOTORCYCLE CARE AND STORAGE

7

8 SPECIFICATIONS

8

9 CONSUMER INFORMATION

9

INDEX

U5LV12.book Page 1 Thursday, June 27, 2002 5:49 PM

SAFETY INFORMATION

1

Safe riding........................................................................................1-1

Protective apparel ............................................................................1-3

Modifications ....................................................................................1-3

Loading and accessories ..................................................................1-3

Gasoline and exhaust gas ................................................................1-5

Location of important labels ..............................................................1-7

U5LV12.book Page 1 Thursday, June 27, 2002 5:49 PM

MOTORCYCLES ARE SINGLE TRACK VEHICLES. THEIR SAFE USE AND OPERATION ARE

DEPENDENT UPON THE USE OF PROPER RIDING TECHNIQUES AS WELL AS THE EXPERTISE

OF THE OPERATOR. EVERY OPERATOR SHOULD KNOW THE FOLLOWING REQUIREMENTS

BEFORE RIDING THIS MOTORCYCLE.

HE OR SHE SHOULD:

1.

OBTAIN THOROUGH INSTRUCTIONS FROM A COMPETENT SOURCE ON ALL ASPECTS OF

MOTORCYCLE OPERATION.

2.

OBSERVE THE WARNINGS AND MAINTENANCE REQUIREMENTS IN THE OWNER’S

MANUAL.

3.

OBTAIN QUALIFIED TRAINING IN SAFE AND PROPER RIDING TECHNIQUES.

4.

OBTAIN PROFESSIONAL TECHNICAL SERVICE AS INDICATED BY THE OWNER’S MANUAL

AND/OR WHEN MADE NECESSARY BY MECHANICAL CONDITIONS.

Safe riding

1.

Always make pre-operation checks. Careful checks may help prevent an accident.

2.

This motorcycle is designed to carry the operator and a passenger.

3.

The failure of motorists to detect and recognize motorcycles in traffic is the predominating cause of

automobile/motorcycle accidents. Many accidents have been caused by an automobile driver who

did not see the motorcycle. Making yourself conspicuous appears to be very effective in reducing the

chance of this type of accident.

Therefore:

a.

Wear a brightly colored jacket.

b.

Use extra caution when you are approaching and passing through intersections, since intersections are the most likely places for motorcycle accidents to occur.

c.

Ride where other motorists can see you. Avoid riding in another motorist’s blind spot.

1-1

SAFETY INFORMATION

EAU00014

U5LV12.book Page 2 Thursday, June 27, 2002 5:49 PM

SAFETY INFORMATION

4.

Many accidents involve inexperienced operators. In fact, many operators who have been involved in

accidents do not even have a current motorcycle license.

a.

Make sure that you are qualified and that you only lend your motorcycle to other qualified

operators.

b.

Know your skills and limits. Staying within your limits may help you to avoid an accident.

c.

We recommend that you practice riding your motorcycle where there is no traffic until you have

become thoroughly familiar with the motorcycle and all of its controls.

5.

Many accidents have been caused by error of the motorcycle operator. A typical error made by the

operator is veering wide on a turn due to EXCESSIVE SPEED or undercornering (insufficient lean

angle for the speed).

a.

Always obey the speed limit and never travel faster than warranted by road and traffic conditions.

b.

Always signal before turning or changing lanes. Make sure that other motorists can see you.

6.

The posture of the operator and passenger is important for proper control.

a.

The operator should keep both hands on the handlebar and both feet on the operator footrests

during operation to maintain control of the motorcycle.

b.

The passenger should always hold onto the operator, the seat strap or grab bar, if equipped, with

both hands and keep both feet on the passenger footrests.

c.

Never carry a passenger unless he or she can firmly place both feet on the passenger footrests.

7.

Never ride under the influence of alcohol or other drugs.

8.

This motorcycle is designed for on-road use only. It is not suitable for off-road use.

1-2

U5LV12.book Page 3 Thursday, June 27, 2002 5:49 PM

SAFETY INFORMATION

Protective apparel

The majority of fatalities from motorcycle accidents are the result of head injuries. The use of a safety

helmet is the single most critical factor in the prevention or reduction of head injuries.

1.

Always wear an approved helmet.

2.

Wear a face shield or goggles. Wind in your unprotected eyes could contribute to an impairment of vision that could delay seeing a hazard.

3.

The use of a jacket, heavy boots, trousers, gloves, etc., is effective in preventing or reducing abrasions or lacerations.

4.

Never wear loose-fitting clothes, otherwise they could catch on the control levers, footrests, or wheels

and cause injury or an accident.

5.

Never touch the engine or exhaust system during or after operation. They become very hot and can

cause burns. Always wear protective clothing that covers your legs, ankles, and feet.

6.

A passenger should also observe the above precautions.

Modifications

Modifications made to this motorcycle not approved by Yamaha, or the removal of original equipment,

may render the motorcycle unsafe for use and may cause severe personal injury. Modifications may

also make your motorcycle illegal to use.

Loading and accessories

Adding accessories or cargo to your motorcycle can adversely affect stability and handling if the weight

distribution of the motorcycle is changed. To avoid the possibility of an accident, use extreme caution

when adding cargo or accessories to your motorcycle. Use extra care when riding a motorcycle that

has added cargo or accessories. Here are some general guidelines to follow if loading cargo or adding

accessories to your motorcycle:

1-3

U5LV12.book Page 4 Thursday, June 27, 2002 5:49 PM

SAFETY INFORMATION

Loading

The total weight of the operator, passenger, accessories and cargo must not exceed the maximum

load limit of FZS1000, FZS1000S: 189 kg (417 lb) / FZS1000C, FZS1000SC: 188 kg (415 lb). When

loading within this weight limit, keep the following in mind:

1.

Cargo and accessory weight should be kept as low and close to the motorcycle as possible. Make

sure to distribute the weight as evenly as possible on both sides of the motorcycle to minimize imbalance or instability.

2.

Shifting weights can create a sudden imbalance. Make sure that accessories and cargo are securely

attached to the motorcycle before riding. Check accessory mounts and cargo restraints frequently.

3.

Never attach any large or heavy items to the handlebar, front fork, or front fender. These items, including such items as sleeping bags, duffel bags, or tents, can create unstable handling or a slow

steering response.

Accessories

Genuine Yamaha accessories have been specifically designed for use on this motorcycle. Since

Yamaha cannot test all other accessories that may be available, you must personally be responsible

for the proper selection, installation and use of non-Yamaha accessories. Use extreme caution when

selecting and installing any accessories.

Keep the following guidelines in mind, as well as those provided under “Loading” when mounting acces-

sories.

1.

Never install accessories or carry cargo that would impair the performance of your motorcycle. Carefully inspect the accessory before using it to make sure that it does not in any way reduce ground

clearance or cornering clearance, limit suspension travel, steering travel or control operation, or obscure lights or reflectors.

1-4

U5LV12.book Page 5 Thursday, June 27, 2002 5:49 PM

SAFETY INFORMATION

a.

Accessories fitted to the handlebar or the front fork area can create instability due to improper

weight distribution or aerodynamic changes. If accessories are added to the handlebar or front

fork area, they must be as lightweight as possible and should be kept to a minimum.

b.

Bulky or large accessories may seriously affect the stability of the motorcycle due to aerodynamic

effects. Wind may attempt to lift the motorcycle, or the motorcycle may become unstable in cross

winds. These accessories may also cause instability when passing or being passed by large

vehicles.

c.

Certain accessories can displace the operator from his or her normal riding position. This improper position limits the freedom of movement of the operator and may limit control ability, therefore,

such accessories are not recommended.

2.

Use caution when adding electrical accessories. If electrical accessories exceed the capacity of the

motorcycle’s electrical system, an electric failure could result, which could cause a dangerous loss of

lights or engine power.

Gasoline and exhaust gas

1.

GASOLINE IS HIGHLY FLAMMABLE:

a.

Always turn the engine off when refueling.

b.

Take care not to spill any gasoline on the engine or exhaust system when refueling.

c.

Never refuel while smoking or in the vicinity of an open flame.

2.

Never start the engine or let it run for any length of time in a closed area. The exhaust fumes are poisonous and may cause loss of consciousness and death within a short time. Always operate your

motorcycle in an area that has adequate ventilation.

3.

Always turn the engine off before leaving the motorcycle unattended and remove the key from the

main switch. When parking the motorcycle, note the following:

1-5

U5LV12.book Page 6 Thursday, June 27, 2002 5:49 PM

SAFETY INFORMATION

a.

The engine and exhaust system may be hot, therefore, park the motorcycle in a place where pedestrians or children are not likely to touch these hot areas.

b.

Do not park the motorcycle on a slope or soft ground, otherwise it may fall over.

c.

Do not park the motorcycle near a flammable source (e.g., a kerosene heater, or near an open

flame), otherwise it could catch fire.

4.

When transporting the motorcycle in another vehicle, make sure that it is kept upright. If the motorcycle should lean over, gasoline may leak out of the carburetor or fuel tank.

5.

If you should swallow any gasoline, inhale a lot of gasoline vapor, or allow gasoline to get into your

eyes, see your doctor immediately. If any gasoline spills on your skin or clothing, immediately wash

the affected area with soap and water and change your clothes.

1-6

U5LV12.book Page 7 Thursday, June 27, 2002 5:49 PM

SAFETY INFORMATION

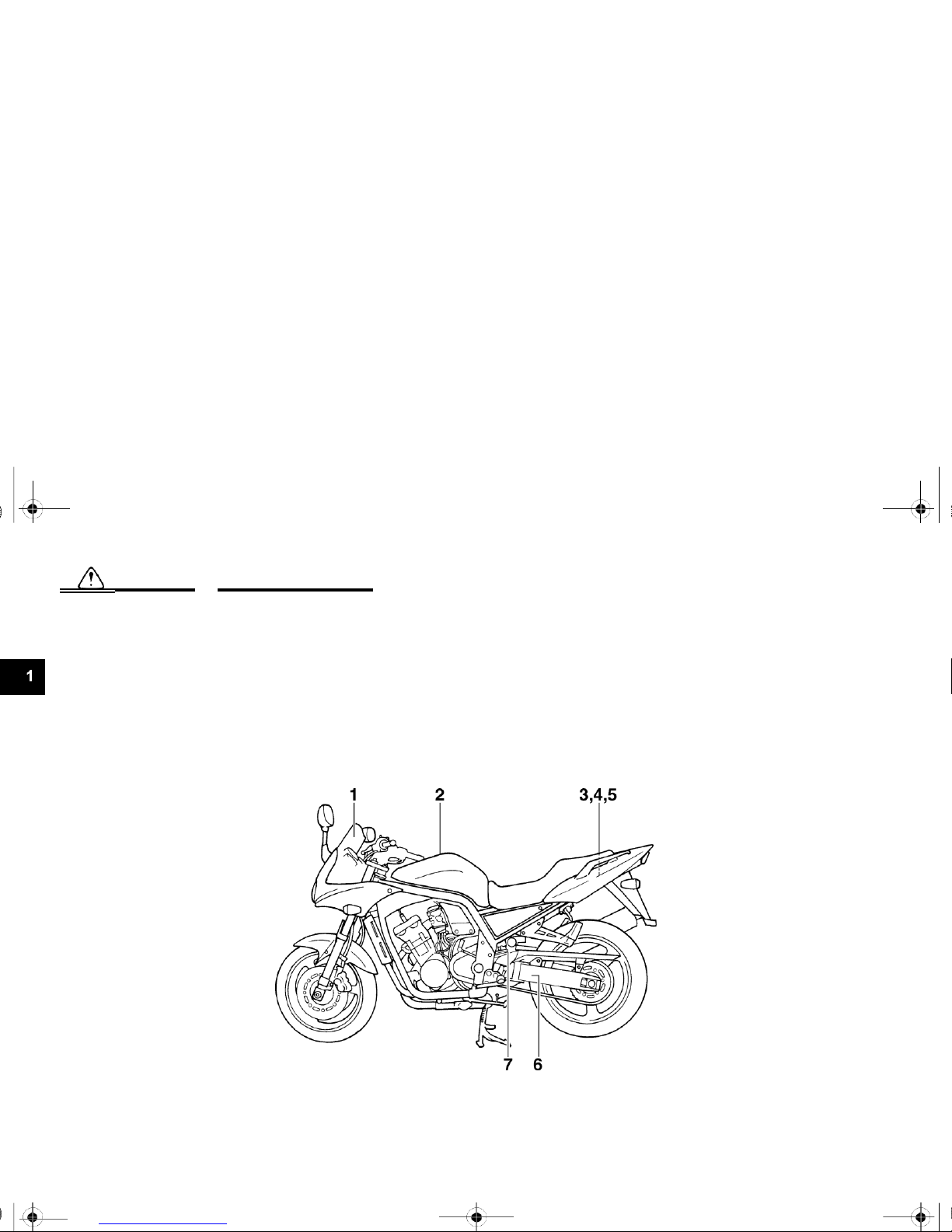

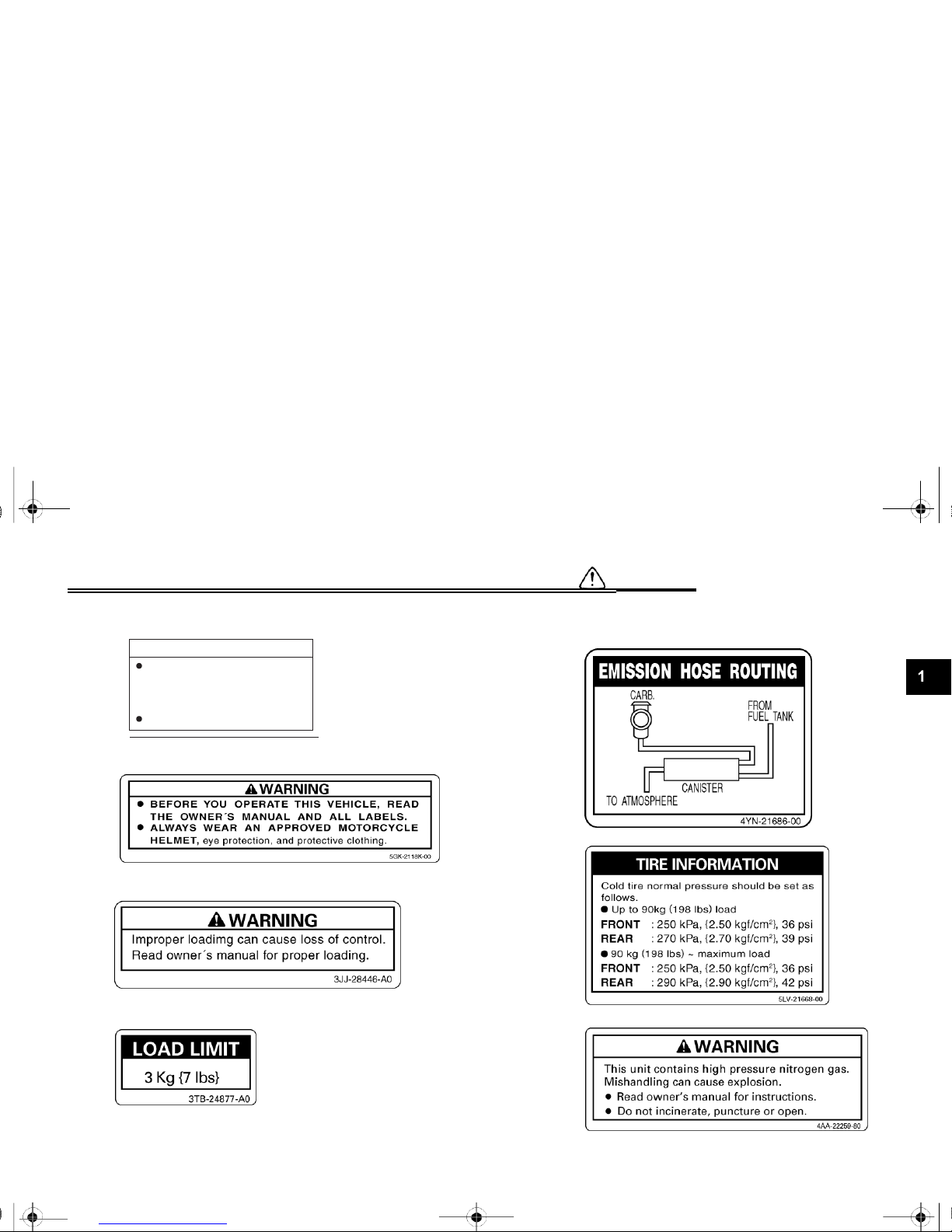

Location of important labels

Please read the following important labels carefully before operating this motorcycle.

EAU02977

1-7

U5LV12.book Page 8 Thursday, June 27, 2002 5:49 PM

SAFETY INFORMATION

1

5JW-00

(5JW-2835Y-00)

2

3

4

1-8

5

California only

6

7

Cleaning with alkaline or

acid cleaner, gasoline or

solvent will damage

windshield.

Use neutral detergent.

CAUTION

U5LV12.book Page 1 Thursday, June 27, 2002 5:49 PM

DESCRIPTION

2

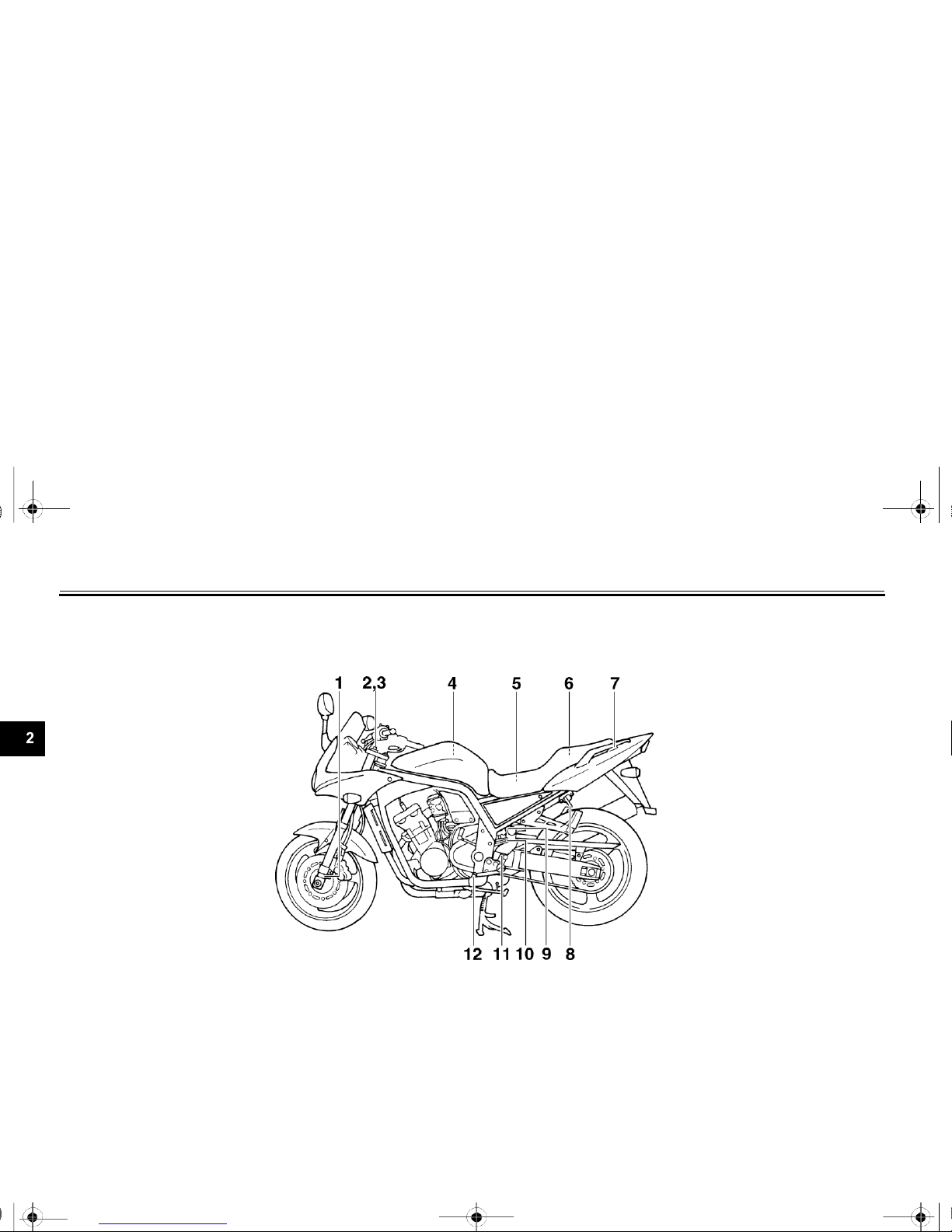

Left view ..........................................................................................2-1

Right view ........................................................................................2-2

Controls and instruments..................................................................2-3

U5LV12.book Page 1 Thursday, June 27, 2002 5:49 PM

DESCRIPTION

Left view

EAU00026

1. Front fork compression damping

8. Seat lock/helmet holder

(page 3-11)

force adjusting screw

(page 3-14)

9. Shock absorber assembly

2. Front fork rebound damping force

compression damping force

adjusting screw

(page 3-13)

adjusting screw

(page 3-16)

3. Front fork spring preload adjusting

10. Shock absorber assembly spring

bolt

(page 3-13)

preload adjusting ring

(page 3-15)

4. Air filter element

(page 6-19)

11. Shock absorber assembly rebound

5. Fuses

(page 6-38)

damping force adjusting knob

(page 3-15)

6.

Storage compartment (page 3-12)

7.

Grab bar

2-1

12.

Shift pedal (page 3-7)

U5LV12.book Page 2 Thursday, June 27, 2002 5:49 PM

DESCRIPTION

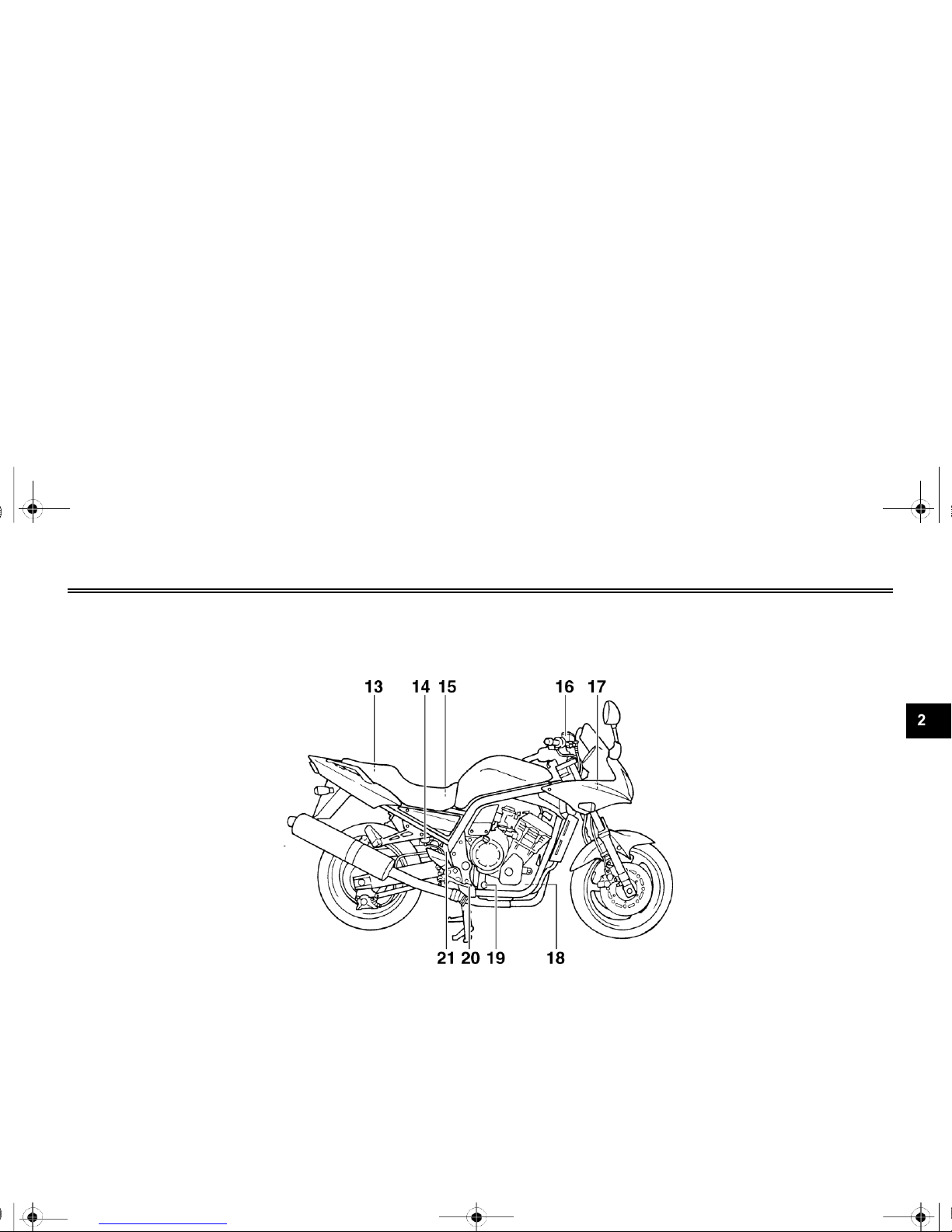

Right view

13.

Owner’s tool kit (page 6-1)

14.

Rear brake fluid reservoir (page 6-30)

15.

Battery (page 6-37)

16.

Front brake fluid reservoir (page 6-29)

17.

Radiator cap (page 6-17)

18.

Engine oil filter cartridge (page 6-13)

19.

Engine oil level check window (page 6-12)

20.

Brake pedal (page 3-8)

21.

Coolant reservoir (page 6-15)

2-2

U5LV12.book Page 3 Thursday, June 27, 2002 5:49 PM

DESCRIPTION

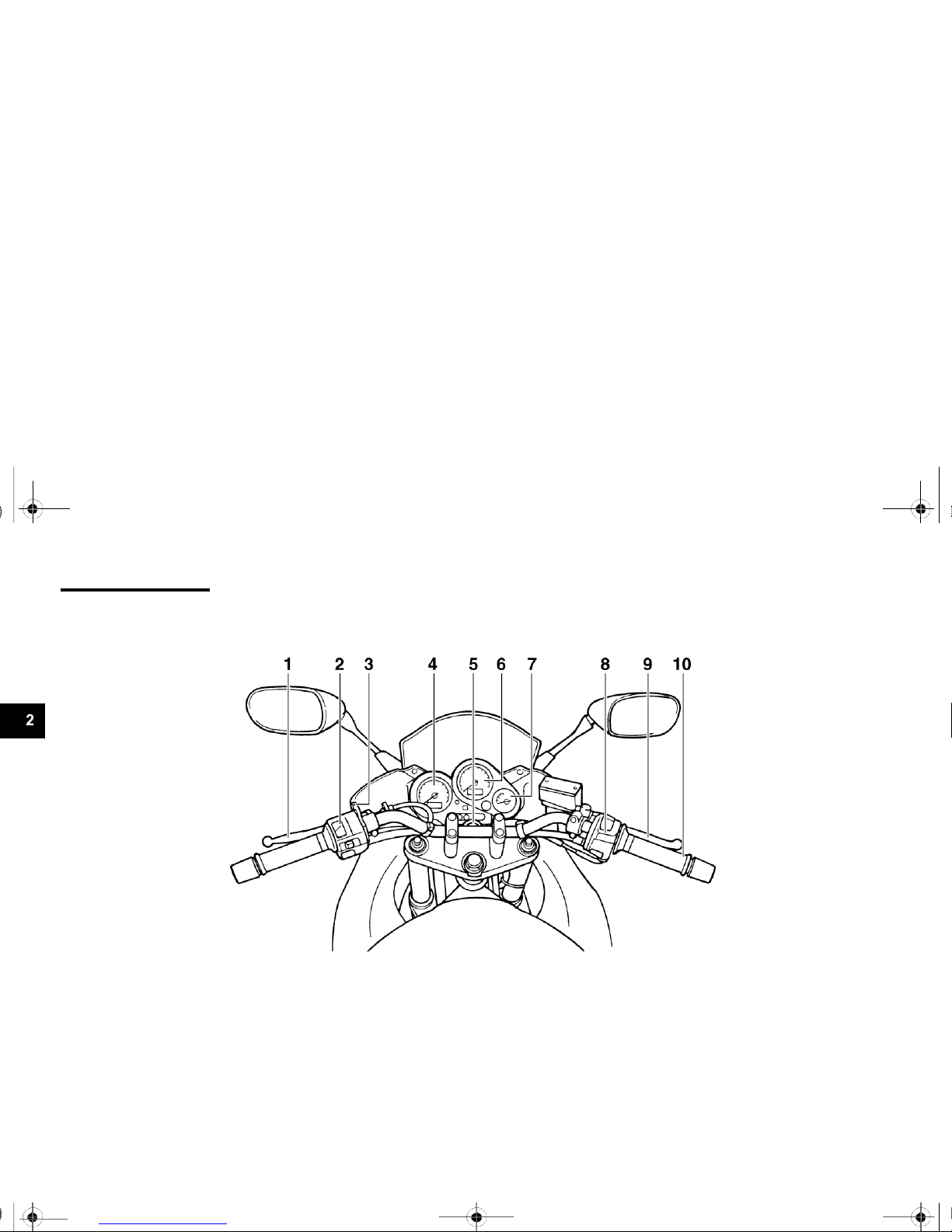

Controls and instruments

1.

Clutch lever (page 3-7)

2.

Left handlebar switches (page 3-6)

3.

Starter (choke) lever (page 3-10)

4.

Speedometer unit (page 3-3)

5.

Main switch/steering lock (page 3-1)

6.

Tachometer unit (page 3-4)

7.

Fuel gauge (page 3-5)

8.

Right handlebar switches (page 3-6)

9.

Brake lever (page 3-7)

10.

Throttle grip (page 6-22)

2-3

U5LV12.book Page 1 Thursday, June 27, 2002 5:49 PM

INSTRUMENT AND CONTROL FUNCTIONS

3

Main switch/steering lock..................................................................3-1

Indicator and warning lights ..............................................................3-2

Speedometer unit .............................................................................3-3

Tachometer unit................................................................................3-4

Self-diagnosis devices ......................................................................3-5

Fuel gauge .......................................................................................3-5

Handlebar switches ..........................................................................3-6

Clutch lever .............................................................................................. 3-7

Shift pedal ........................................................................................3-7

Brake lever ............................................................................................... 3-7

Brake pedal ......................................................................................3-8

Fuel tank cap ...................................................................................3-8

Fuel .................................................................................................3-9

Starter (choke) lever..............................................................................3-10

Seat ................................................................ ............................... 3-11

Helmet holder................................................................................. 3-11

Storage compartment ..................................................................... 3-12

Adjusting the front fork ................................................................... 3-12

Adjusting the shock absorber assembly .......................................... 3-14

EXUP system ................................................................................. 3-17

Sidestand ....................................................................................... 3-17

Ignition circuit cut-off system .......................................................... 3-18

WARNING

U5LV12.book Page 1 Thursday, June 27, 2002 5:49 PM

INSTRUMENT AND CONTROL FUNCTIONS

EAU00027

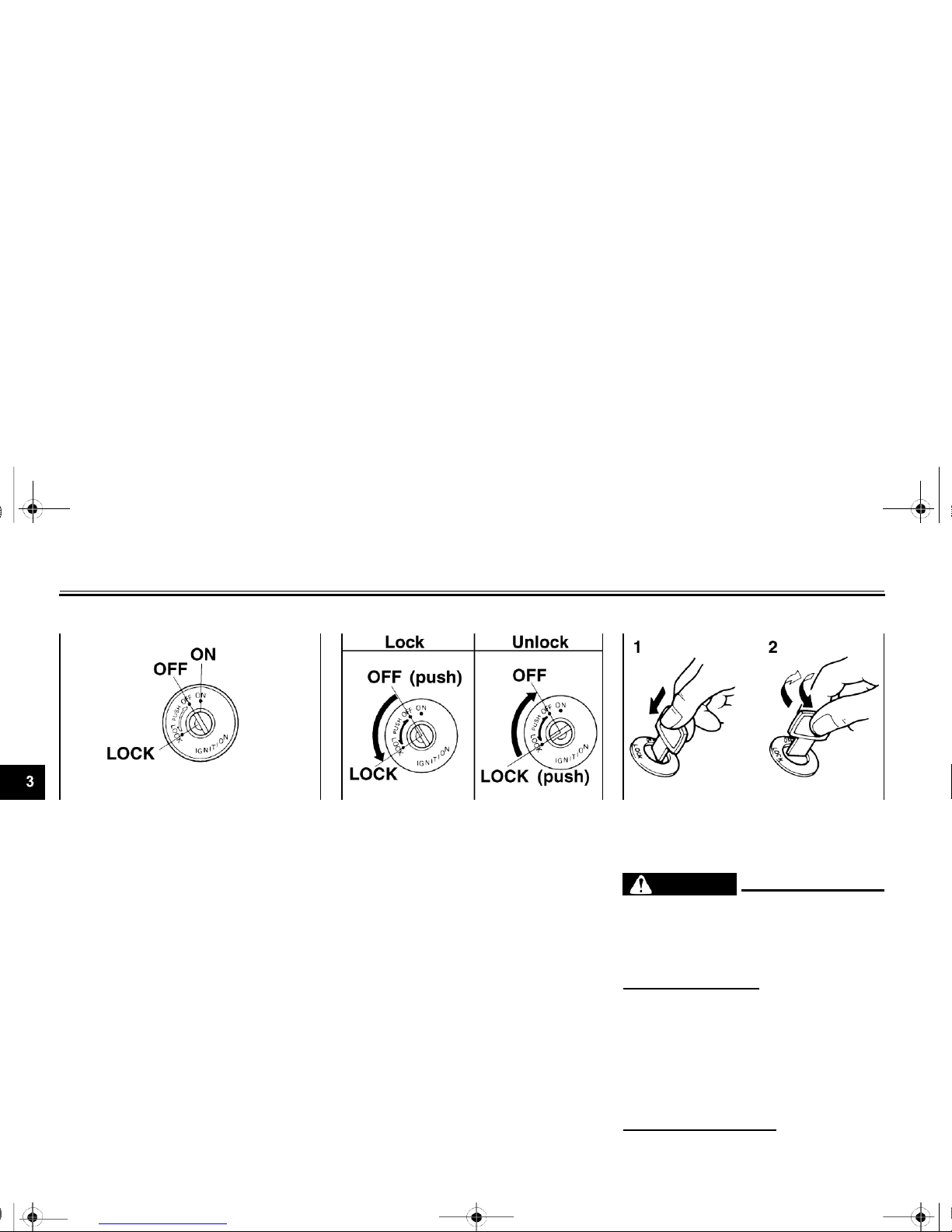

Main switch/steering lock

EAU00029

LOCK

EAU00040

1.

Push.

2.

Turn.

EW000016

The main switch/steering lock controls

the ignition and lighting systems, and is

The steering is locked, and all electrical

systems are off. The key can be

_

used to lock the steering. The various

positions are described below.

EAU00032

ON

All electrical systems are supplied with

power, and the headlight, meter lighting, taillight and position lights come

on, and the engine can be started. The

key cannot be removed.

EAU00038

OFF

All electrical systems are off. The key

can be removed.

removed.

To lock the steering

1.

Turn the handlebars all the way to the left.

2.

Push the key in from the “OFF” po- sition,

and then turn it to “LOCK” while still pushing

it.

3.

Remove the key.

To unlock the steering

Push the key in, and then turn it to “OFF” while

still pushing it.

3-1

Never turn the key to “OFF” or

“LOCK” while the motorcycle is

moving, otherwise the electrical

systems will be switched off,

which may result in loss of

control or an accident. Make

sure that the motor- cycle is

stopped before turning the key

to “OFF” or “LOCK”.

_

U5LV12.book Page 2 Thursday, June 27, 2002 5:49 PM

INSTRUMENT AND CONTROL FUNCTIONS

EAU00063

High beam indicator light “ ”

This indicator light comes on when the

high beam of the headlight is switched

on.

EAU04881

Coolant temperature warning light

“

”

This warning light comes on when the

engine overheats. When this occurs,

stop the engine immediately and allow

Oil level warning light “ ”

EAU04877

the engine to cool.

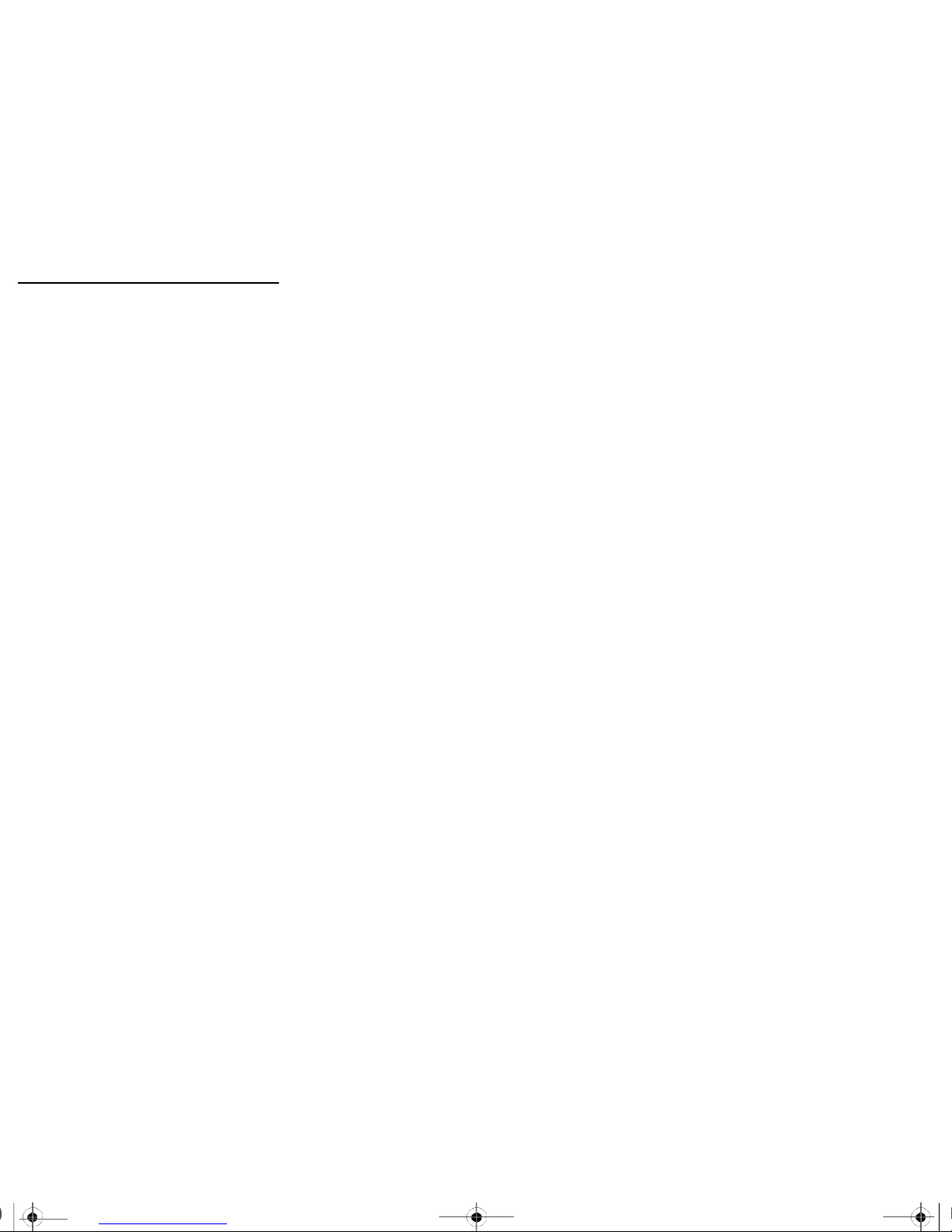

1.

Left turn signal indicator light “ ”

2.

Neutral indicator light “ ”

3.

High beam indicator light “ ”

4.

Oil level warning light “ ”

5.

Right turn signal indicator light “ ”

6.

Coolant temperature warning light “ ”

7.

Fuel level warning light “ ”

EAU03034

Indicator and warning lights

EAU04121

Turn signal indicator lights

“

” and “ ”

The corresponding indicator light flashes when the turn signal switch is

pushed to the left or right.

This warning light comes on when the

engine oil level is low.

The electrical circuit of the warning light

can be checked by turning the key to

“ON”.

If the warning light does not come on

for a few seconds, then go off, have a

Yamaha dealer check the electrical circuit.

NOTE:

Even if the oil level is sufficient, the

warning light may flicker when riding on

a slope or during sudden acceleration

or deceleration, but this is not a malfunction.

The electrical circuit of the warning light

can be checked by turning the key to

“ON”.

If the warning light does not come on

for a few seconds, then go off, have a

Yamaha dealer check the electrical circuit.

EC000002

CAUTION:

_

Do not operate the engine if it is overheated.

Neutral indicator light “ ”

EAU00061

This indicator light comes on when the

transmission is in the neutral position.

3-2

U5LV12.book Page 3 Thursday, June 27, 2002 5:49 PM

INSTRUMENT AND CONTROL FUNCTIONS

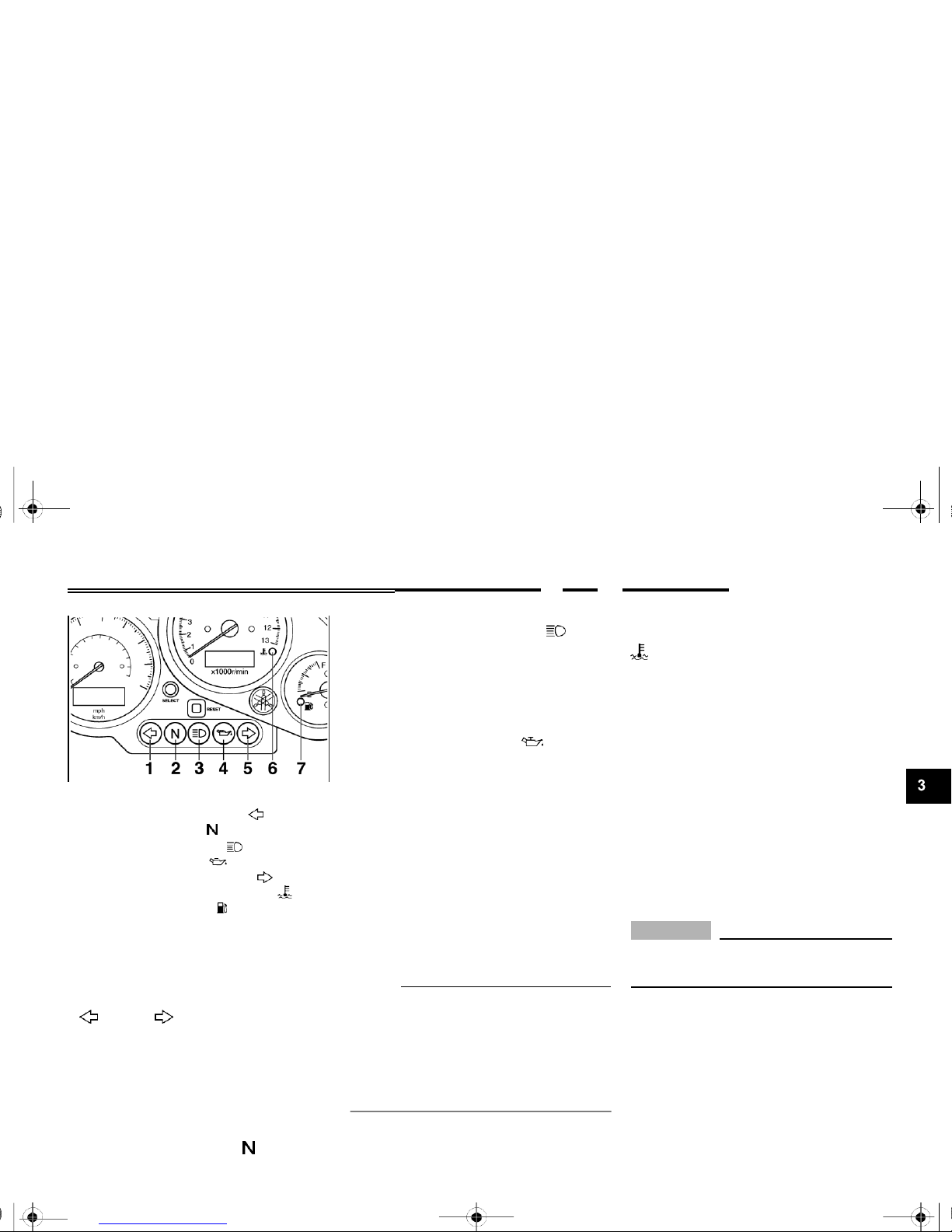

This information will enable you to plan

future fuel stops.

1.

Left turn signal indicator light “ ”

2.

Neutral indicator light “ ”

3.

High beam indicator light “ ”

4.

Oil level warning light “ ”

5.

Right turn signal indicator light “ ”

6.

Coolant temperature warning light “ ”

7.

Fuel level warning light “ ”

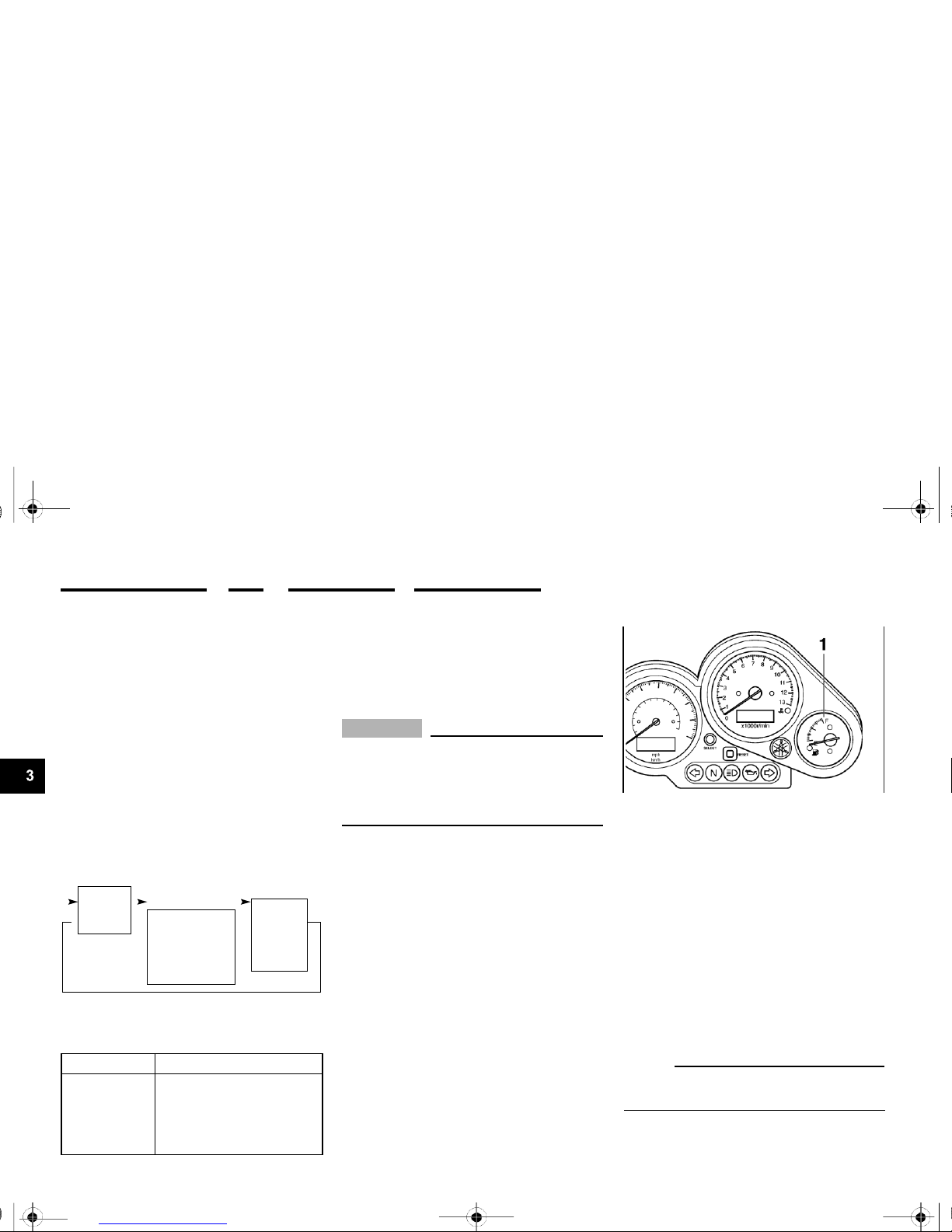

1.

Speedometer

2.

Odometer/tripmeter

3.

“SELECT” button

4.

“RESET” button

Speedometer unit

EAU04289

To set a mode

Push the “SELECT” button to change

between the odometer mode “ODO”,

and the tripmeter modes “TRIP 1” and

“TRIP 2” in the following order:

ODO TRIP 1 TRIP 2 ODO

To reset a meter

To reset either tripmeter 1 or 2 to 0.0,

select either by pushing the “SELECT”

button, and then push the “RESET”

Fuel level warning light “ ”

EAU04878

The speedometer unit is equipped with

the following:

button for at least one second.

This warning light comes on when the

fuel level drops below approximately 4

L (0.9 Imp gal, 1.1 US gal). When this

occurs, refuel as soon as possible.

The electrical circuit of the warning light

can be checked by turning the key to

“ON”.

If the warning light does not come on

for a few seconds, then go off, have a

Yamaha dealer check the electrical circuit.

●

an odometer

●

two tripmeters

When set to “ODO”, the motorcycle’s

total mileage is indicated.

When set to “TRIP 1” or “TRIP 2”, the

motorcycle’s mileage since the tripme-

ter was last reset is indicated. The tripmeters can be used together with the

fuel gauge to estimate the distance that

can be traveled on a full tank of fuel.

3-3

U5LV12.book Page 4 Thursday, June 27, 2002 5:49 PM

INSTRUMENT AND CONTROL FUNCTIONS

To set the clock:

1.

Push both the “SELECT” and

“RESET” buttons for at least two

seconds.

2.

When the hour digits start flashing,

push the “RESET” button to set

the hours.

3.

Push the “SELECT” button to

change the minutes.

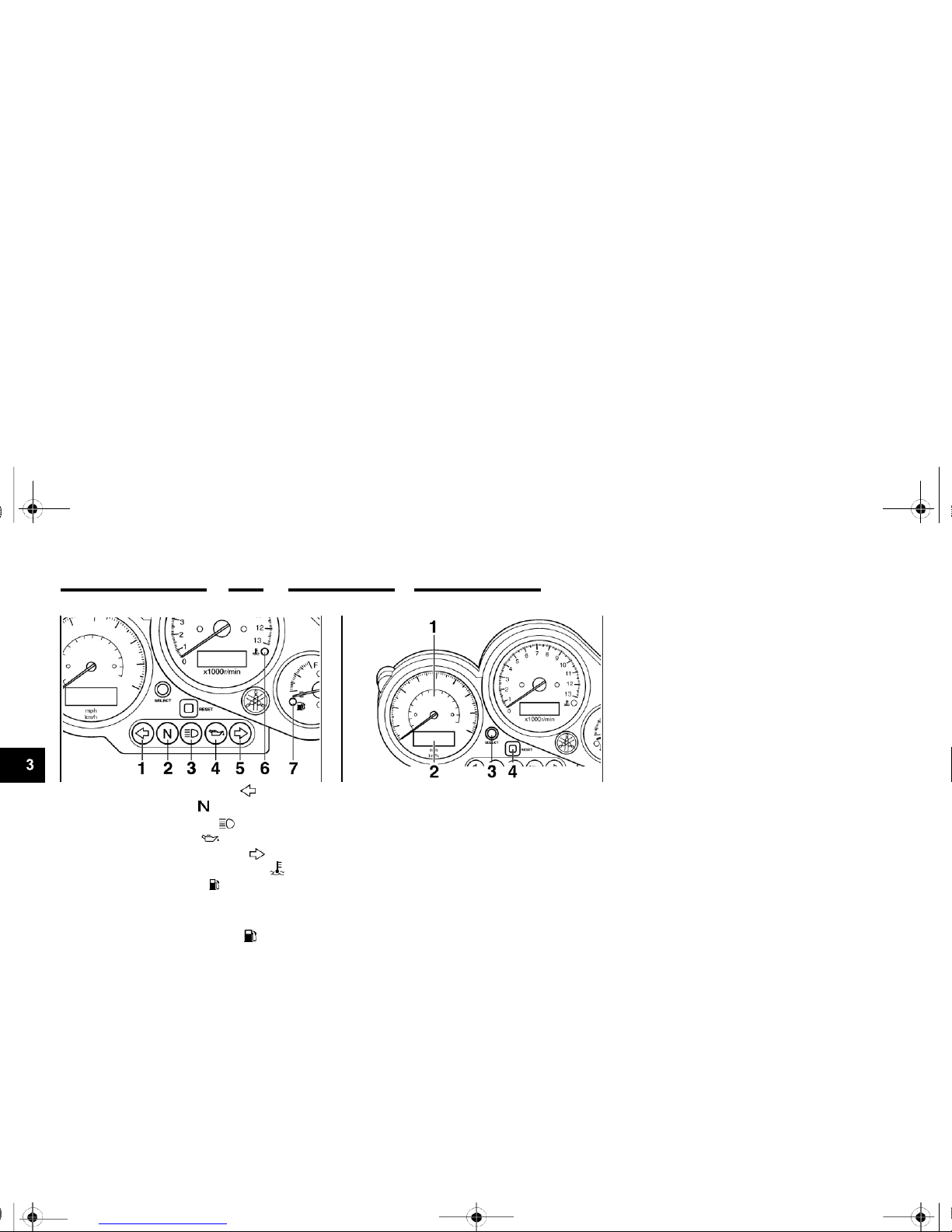

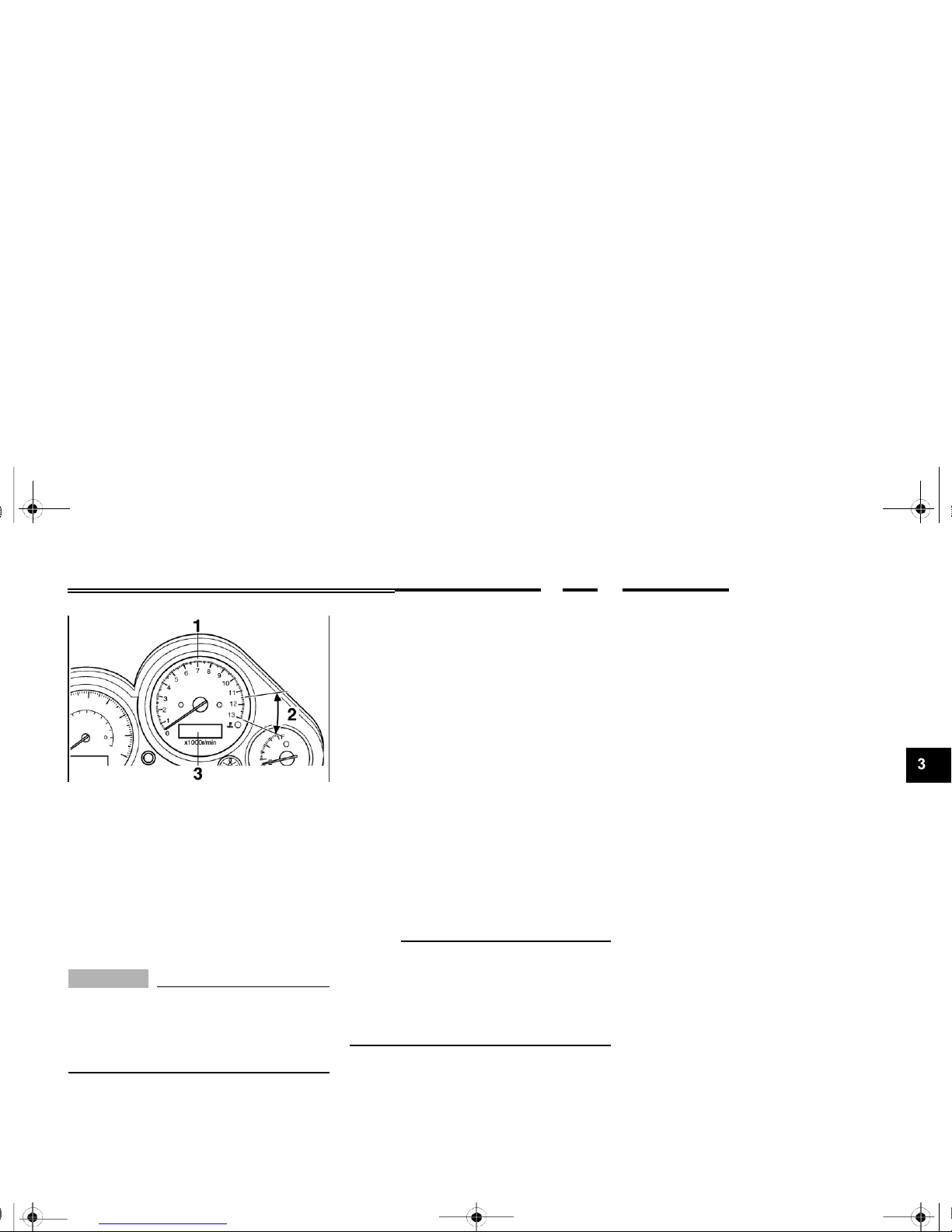

1.

Tachometer

2.

Tachometer red zone

3.

Clock

Tachometer unit

EAU03954

4.

When the minute digits start flash-

ing, push the “RESET” button to

set the minutes.

5.

Push the “SELECT” button to start

The electric tachometer allows the rider

to monitor the engine speed and keep it

within the ideal power range.

EC000003

CAUTION:

_

Do not operate the engine in the ta-

the clock.

NOTE:

After setting the clock, be sure to push

the “SELECT” button before turning the

key to “OFF”, otherwise the clock will

not be set.

chometer red zone. Red zone: 11,500 r/min and above

This tachometer unit is equipped with a

clock.

3-4

0 r/min for

Circuit-specific

number of r/min

U5LV12.book Page 5 Thursday, June 27, 2002 5:49 PM

INSTRUMENT AND CONTROL FUNCTIONS

Self-diagnosis devices

EAU04290

If the tachometer displays such an error code, note the circuit-specific num-

This model is equipped with a self-diagnosis device for the following electrical circuits:

●

throttle position sensor

●

speed sensor

●

EXUP system

●

overturn switch

If any of those circuits are defective,

the tachometer will repeatedly display

the following error code:

ber of r/min, and then have a Yamaha

dealer check the motorcycle.

EC000004

CAUTION:

_

When the tachometer displays an error code, the motorcycle should be checked as soon as possible in order to avoid engine damage.

1.

Fuel gauge

Fuel gauge

EAU00110

Current

engine

3 seconds

for 2.5 seconds

(See the table

speed for

3 seconds

below.)

Use the chart below to identify the

faulty electrical circuit.

Specific r/min

Faulty electrical circuit

3,000 r/min

Throttle position sensor

4,000 r/min

Speed sensor

7,000 r/min

EXUP system

9,000 r/min

Overturn switch

3-5

The fuel gauge indicates the amount of

fuel in the fuel tank. The needle moves

towards “E” (Empty) as the fuel level

decreases. When the needle reaches

“E”, approximately 4 L (0.9 Imp gal,

1.1

US gal) of fuel remain in the fuel

tank. If this occurs, refuel as soon as

possible.

NOTE:

Do not allow the fuel tank to empty itself completely.

U5LV12.book Page 6 Thursday, June 27, 2002 5:49 PM

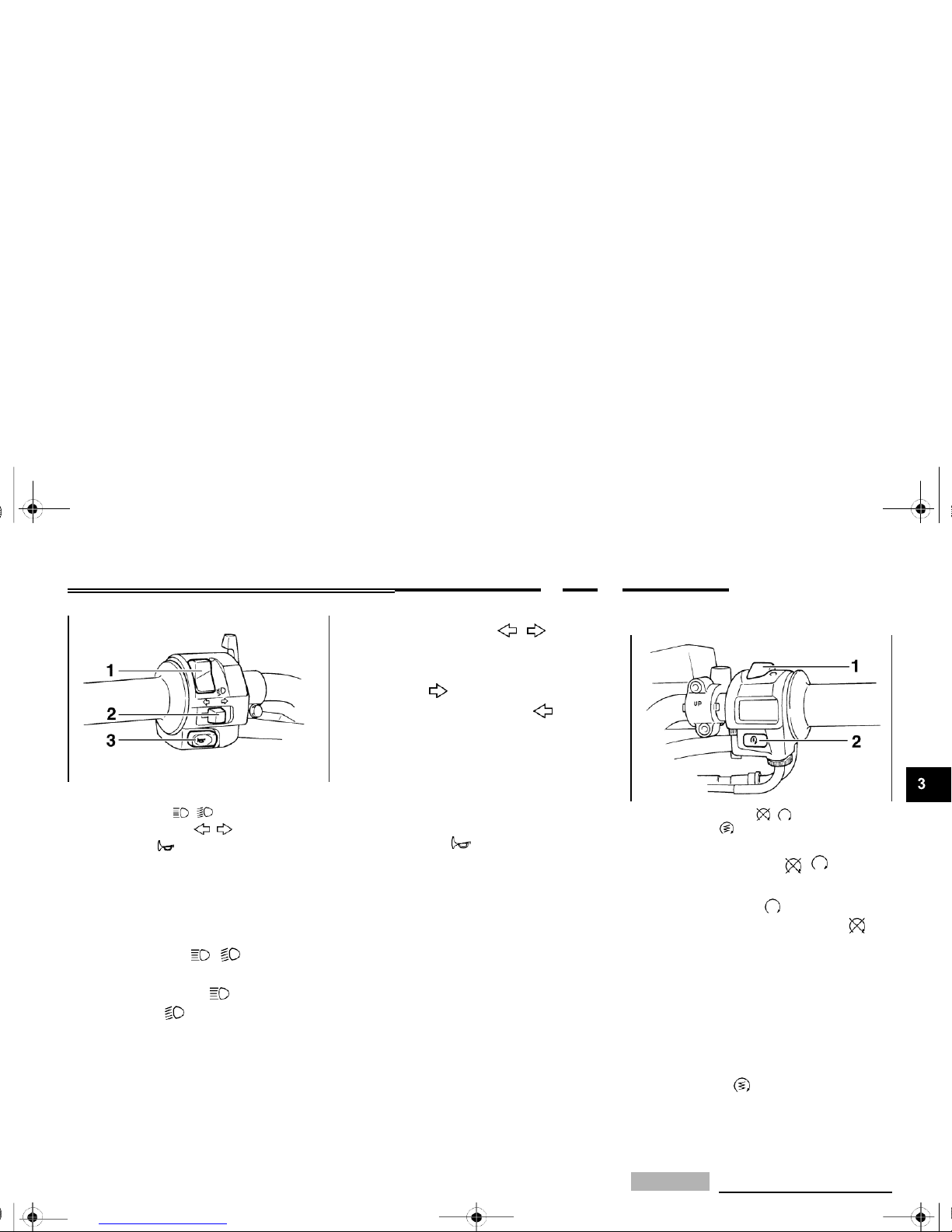

INSTRUMENT AND CONTROL FUNCTIONS

Turn signal switch “ / ”

EAU03889

1.

Dimmer switch “

/

”

2.

Turn signal switch “ / ”

3.

Horn switch “ ”

EAU00118

To signal a right-hand turn, push this

switch to “ ”. To signal a left-hand

turn, push this switch to “ ”. When

released, the switch returns to the center position. To cancel the turn signal

lights, push the switch in after it has returned to the center position.

EAU00129

Horn switch “ ”

Press this switch to sound the horn.

1.

Engine stop switch “ / ”

2.

Start switch “ ”

Engine stop switch “

/

”

EAU03890

Handlebar switches

Dimmer switch “ / ”

EAU03888

Set this switch to “ ” before starting

the engine. Set this switch to “ ” to

stop the engine in case of an emergen-

Set this switch to “ ” for the high

beam and to “ ” for the low beam.

cy, such as when the motorcycle overturns or when the throttle cable is

stuck.

Start switch “ ”

EAU00143

Push this switch to crank the engine

with the starter.

CAUTION:

_

EC000005

See page 5-1 for starting instructions prior to starting the engine.

3-6

U5LV12.book Page 7 Thursday, June 27, 2002 5:49 PM

INSTRUMENT AND CONTROL FUNCTIONS

1.

Clutch lever 1. Shift pedal 1. Brake lever

2.

Brake lever position adjusting dial

Clutch lever

EAU00152

Shift pedal

EAU00157

3.

Arrow mark

a. Distance between brake lever and handlebar

The clutch lever is located at the left

handlebar grip. To disengage the

clutch, pull the lever toward the handle-

The shift pedal is located on the left

side of the engine and is used in combination with the clutch lever when

grip

Brake lever

EAU00161

bar grip. To engage the clutch, release

the lever. The lever should be pulled

rapidly and released slowly for smooth

clutch operation.

The clutch lever is equipped with a

clutch switch, which is part of the ignition

circuit cut-off system. (See page 3-18

for an explanation of the ignition circuit

cut-off system.)

shifting the gears of the 6-speed constant-mesh transmission equipped on

this motorcycle.

3-7

The brake lever is located at the right

handlebar grip. To apply the front brake,

pull the lever toward the handlebar grip.

The brake lever is equipped with a position adjusting dial. To adjust the distance between the brake lever and the

handlebar grip, turn the adjusting dial

while holding the lever pushed away

from the handlebar grip. Make sure that

the appropriate setting on the adjusting

dial is aligned with the arrow mark on

the brake lever.

U5LV12.book Page 8 Thursday, June 27, 2002 5:49 PM

INSTRUMENT AND CONTROL FUNCTIONS

2. Turn the key counterclockwise to

the original position, remove it,

and then close the lock cover.

NOTE:

The fuel tank cap cannot be closed unless the key is in the lock. In addition,

the key cannot be removed if the cap is

not properly closed and locked.

1.

Brake pedal 1. Fuel tank cap lock cover

2.

Unlock.

EAU00162

Brake pedal

EAU02935

_

EWA00025

The brake pedal is on the right side of

the motorcycle. To apply the rear

brake, press down on the brake pedal.

Fuel tank cap

To open the fuel tank cap

Open the fuel tank cap lock cover, insert the key into the lock, and then turn

it 1/4 turn clockwise. The lock will be released and the fuel tank cap can be

opened.

To close the fuel tank cap

1.

Push the fuel tank cap into position with the key inserted in the

lock.

Make sure that the fuel tank cap is properly closed before riding.

_

WARNING

3-8

U5LV12.book Page 9 Thursday, June 27, 2002 5:49 PM

INSTRUMENT AND CONTROL FUNCTIONS

CAUTION:

_

EAU00185 EAU04265

Immediately wipe off spilled fuel

with a clean, dry, soft cloth, since

fuel may deteriorate painted surfaces or plastic parts.

1.

Fuel tank filler tube

2.

Fuel level

EAU03753

CAUTION:

_

ECA00104

Fuel

Make sure that there is sufficient fuel in

the tank. Fill the fuel tank to the bottom

of the filler tube as shown.

EW000130

Use only unleaded gasoline. The

use of leaded gasoline will cause severe damage to internal engine

parts, such as the valves and piston

rings, as well as to the exhaust system.

_

●

Do not overfill the fuel tank, otherwise it may overflow when the

fuel warms up and expands.

●

Avoid spilling fuel on the hot

engine.

_

3-9

WARNING

Recommended fuel:

UNLEADED GASOLINE ONLY

Fuel tank capacity:

Total amount:

21 L (4.6 Imp gal, 5.5 US gal)

Reserve amount:

4 L (0.9 Imp gal, 1.1 US gal)

U5LV12.book Page 10 Thursday, June 27, 2002 5:49 PM

INSTRUMENT AND CONTROL FUNCTIONS

Your Yamaha engine has been designed to use regular unleaded gasoline with a pump octane number

[(R+M)/2] of 86 or higher, or a research

octane number of 91 or higher. If

knocking (or pinging) occurs, use a

gasoline of a different brand or premium unleaded fuel. Use of unleaded fuel

will extend spark plug life and reduce

maintenance costs.

Gasohol

There are two types of gasohol: gasohol containing ethanol and that containing methanol. Gasohol containing

ethanol can be used if the ethanol content does not exceed 10%. Gasohol

containing methanol is not recommended by Yamaha because it can

cause damage to the fuel system or vehicle performance problems.

EAU03839

Starter (choke) lever “ ”

Starting a cold engine requires a richer

air-fuel mixture, which is supplied by

the starter (choke).

Move the lever in direction a to turn on

the starter (choke).

Move the lever in direction b to turn off

the starter (choke).

3-10

1. Starter (choke) lever “ ”

U5LV12.book Page 11 Thursday, June 27, 2002 5:49 PM

INSTRUMENT AND CONTROL FUNCTIONS

1.

Seat lock

2.

Unlock.

Seat

EAU03956

1.

Projection

2.

Seat holder

To install the seat

1.

Insert the projection on the front of

1.

Helmet holder

2.

Unlock.

Helmet holder

EAU04291

To remove the seat

1.

Insert the key into the seat lock,

and then turn it clockwise.

2.

While holding the key in that position, lift the rear of the seat, and

then pull the seat off.

the seat into the seat holder as

shown.

2.

Push the rear of the seat down to

lock it in place.

3.

Remove the key.

NOTE:

Make sure that the seat is properly secured before riding.

To open the helmet holder, insert the

key into the seat lock, and then turn the

key as shown.

To lock the helmet holder, turn the key

to the original position, and then remove it.

EW000030

_

Never ride with a helmet attached to the helmet holder, since the helmet may hit objects, causing loss of control and possibly an accident.

_

3-11

WARNING

U5LV12.book Page 12 Thursday, June 27, 2002 5:49 PM

INSTRUMENT AND CONTROL FUNCTIONS

When storing the owner’s manual or

other documents in the storage com-

Adjusting the front fork

EAU04293

partment, be sure to wrap them in a

plastic bag so that they will not get wet.

When washing the motorcycle, be

careful not to let any water enter the

storage compartment.

This front fork is equipped with spring

preload adjusting bolts, rebound damping force adjusting screws and compression damping force adjusting

screws.

EW000035

_

1.

Storage compartment

Storage compartment

EAU04101

Always adjust both fork legs equally, otherwise poor handling and loss

of stability may result.

The storage compartment is located

_

under the seat. (See page 3-11 for seat

removal and installation procedures.)

EWA00005

_

●

Do not exceed the load limit of

3 kg (7 lb) for the storage compartment.

●

Do not exceed the maximum

load of FZS1000, FZS1000S:

189 kg (417 lb) / FZS1000C,

FZS1000SC: 188 kg (415 lb) for

the vehicle.

_

WARNING

WARNING

3-12

U5LV12.book Page 13 Thursday, June 27, 2002 5:49 PM

INSTRUMENT AND CONTROL FUNCTIONS

1.

Spring preload adjusting bolt 1. Current setting 1. Rebound damping force adjusting screw

Spring preload

To increase the spring preload and

thereby harden the suspension, turn

the adjusting bolt on each fork leg in direction

a.

To decrease the spring preload and thereby soften the

suspension, turn the adjusting bolt on

each fork leg in direction b.

2.

Front fork cap bolt

NOTE:

Align the appropriate groove on the adjusting mechanism with the top of the

front fork cap bolt.

Setting

Minimum (soft)

5*

Standard 2

Maximum (hard)

1

* fully turned out position

Rebound damping force

To increase the rebound damping

force and thereby harden the rebound

damping, turn the adjusting screw on

each fork leg in direction

a.

To decrease the rebound damping force and

thereby soften the rebound damping,

turn the adjusting screw on each fork

leg in direction b.

Minimum (soft)

17 clicks in direction b*

Standard

7 clicks in direction b*

Maximum (hard)

1 click in direction b*

*

With the adjusting screw fully turned in direction a

3-13

U5LV12.book Page 14 Thursday, June 27, 2002 5:49 PM

INSTRUMENT AND CONTROL FUNCTIONS

1.

Compression damping force adjusting screw

Compression damping force

To increase the compression damping

force and thereby harden the compression damping, turn the adjusting screw

on each fork leg in direction

a.

To decrease the compression damping force

and thereby soften the compression

damping, turn the adjusting screw on

each fork leg in direction b.

Minimum (soft)

21 clicks in direction b*

Standard

6 clicks in direction b*

Maximum (hard)

1 click in direction b*

*

With the adjusting screw fully turned in direction a

EC000015

CAUTION:

_

Never attempt to turn an adjusting mechanism beyond the maximum or minimum settings.

NOTE:

Although the total number of clicks of a

damping force adjusting mechanism

may not exactly match the above specifications due to small differences in

production, the actual number of clicks

always represents the entire adjusting

range. To obtain a precise adjustment,

it would be advisable to check the number of clicks of each damping force adjusting mechanism and to modify the

specifications as necessary.

EAU04295*

Adjusting the shock absorber

assembly

This shock absorber assembly is

equipped with a spring preload adjusting ring, a rebound damping force adjusting knob and a compression

damping force adjusting screw.

EC000015

CAUTION:

_

Never attempt to turn an adjusting

mechanism beyond the maximum

or minimum settings.

3-14

U5LV12.book Page 15 Thursday, June 27, 2002 5:49 PM

INSTRUMENT AND CONTROL FUNCTIONS

NOTE:

●

Align the appropriate notch in the

adjusting ring with the position indicator on the shock absorber.

●

Use the special wrench included in

the owner’s tool kit to make the ad-

justment.

1.

Spring preload adjusting ring

2.

Special wrench

3.

Position indicator

Spring preload

To increase the spring preload and

thereby harden the suspension, turn

the adjusting ring in direction

a.

To decrease the spring preload and thereby

soften the suspension, turn the adjusting ring in direction b.

1.

Rebound damping force adjusting knob

Rebound damping force

To increase the rebound damping

force and thereby harden the rebound

damping, turn the adjusting knob in direction

a.

To decrease the rebound

damping force and thereby soften the

rebound damping, turn the adjusting

knob in direction b.

Minimum (soft)

20 clicks in direction b*

Standard

10 clicks in direction b*

Maximum (hard)

3 clicks in direction b*

* With the adjusting knob fully turned in direction a

3-15

Setting

Minimum (soft)

1 Standard 6

Maximum (hard)

11

U5LV12.book Page 16 Thursday, June 27, 2002 5:49 PM

INSTRUMENT AND CONTROL FUNCTIONS

NOTE:

Although the total number of clicks of a

_

EAU00315

1.

Compression damping force adjusting screw

Compression damping force

To increase the compression damping

force and thereby harden the compression damping, turn the adjusting screw

in direction

a.

To decrease the compression damping force and thereby

soften the compression damping, turn

the adjusting screw in direction b.

Minimum (soft)

1 click in direction a*

Standard

7 clicks in direction a*

Maximum (hard)

12 clicks in direction a*

* With the adjusting screw fully turned in direction b

damping force adjusting mechanism

may not exactly match the above specifications due to small differences in

production, the actual number of clicks

always represents the entire adjusting

range. To obtain a precise adjustment,

it would be advisable to check the number of clicks of each damping force adjusting mechanism and to modify the

specifications as necessary.

This shock absorber contains highly pressurized nitrogen gas. For

proper handling, read and understand the following information before handling the shock absorber.

The manufacturer cannot be held responsible for property damage or

personal injury that may result from

improper handling.

●

Do not tamper with or attempt to

open the gas cylinder.

●

Do not subject the shock absorber to an open flame or other

high heat sources, otherwise it

may explode due to excessive

gas pressure.

●

Do not deform or damage the

gas cylinder in any way, as this

will result in poor damping performance.

●

Always have a Yamaha dealer

service the shock absorber.

_

3-16

WARNING

U5LV12.book Page 17 Thursday, June 27, 2002 5:49 PM

INSTRUMENT AND CONTROL FUNCTIONS

EXUP system

EAU01571

Sidestand

EAU00330 EW000044

This motorcycle is equipped with

Yamaha’s EXUP (EXhaust Ultimate

Power valve) system. This system

boosts engine power by means of a

valve that regulates the diameter of the

exhaust pipe. The EXUP system valve

is constantly adjusted in accordance

with the engine speed by a computercontrolled servomotor.

EC000027

_

●

The EXUP system has been set

and extensively tested at the

Yamaha factory. Changing

these settings without sufficient

technical knowledge may result

in poor performance of or damage to the engine.

●

If the EXUP system does not operate, have a Yamaha dealer

check it.

The sidestand is located on the left side

of the frame. Raise the sidestand or

lower it with your foot while holding the

motorcycle upright.

NOTE:

The built-in sidestand switch is part of

the ignition circuit cut-off system, which

cuts the ignition in certain situations.

(See further down for an explanation of

the ignition circuit cut-off system.)

_

The motorcycle must not be ridden

with the sidestand down, or if the

sidestand cannot be properly

moved up (or does not stay up), otherwise the sidestand could contact

the ground and distract the operator, resulting in a possible loss of

control. Yamaha’s ignition circuit

cut-off system has been designed to

assist the operator in fulfilling the

responsibility of raising the sidestand before starting off. Therefore,

check this system regularly as described below and have a Yamaha

dealer repair it if it does not function

properly.

_

WARNING

CAUTION:

3-17

U5LV12.book Page 18 Thursday, June 27, 2002 5:49 PM

INSTRUMENT AND CONTROL FUNCTIONS

EAU03741

Ignition circuit cut-off system

The ignition circuit cut-off system (comprising the sidestand switch, clutch

switch and neutral switch) has the following functions.

●

It prevents starting when the transmission is in gear and the sidestand is up, but the clutch lever is

not pulled.

●

It prevents starting when the transmission is in gear and the clutch

lever is pulled, but the sidestand is

still down.

●

It cuts the running engine when

the transmission is in gear and the

sidestand is moved down.

Periodically check the operation of the

ignition circuit cut-off system according

to the following procedure.

EW000046

_

●

The vehicle must be placed on

the centerstand during this inspection.

●

If a malfunction is noted, have a

Yamaha dealer check the system before riding.

_

3-18

WARNING

U5LV12.book Page 19 Thursday, June 27, 2002 5:49 PM

INSTRUMENT AND CONTROL FUNCTIONS

NOTE:

This check is most reliable if performed with

a warmed-up engine.

3-19

The system is OK. The motorcycle can be ridden.

The clutch switch may be defective.

The motorcycle should not be ridden until

checked by a Yamaha dealer.

The sidestand switch may be defective.

The motorcycle should not be ridden until

checked by a Yamaha dealer.

The neutral switch may be defective.

The motorcycle should not be ridden until

checked by a Yamaha dealer.

With the engine turned off:

1.

Move the sidestand down.

2.

Make sure that the engine stop switch is set to “ ”.

3.

Turn the key to “ON”.

4.

Shift the transmission into the neutral position.

5.

Push the start switch.

Does the engine start?

YES NO

With the engine still running:

6.

Move the sidestand up.

7.

Keep the clutch lever pulled.

8.

Shift the transmission into gear.

9.

Move the sidestand down.

Does the engine stall?

YES NO

After the engine has stalled:

10.

Move the sidestand up.

11.

Keep the clutch lever pulled.

12.

Push the start switch.

Does the engine start?

YES NO

U5LV12.book Page 1 Thursday, June 27, 2002 5:49 PM

PRE-OPERATION CHECKS

4

Pre-operation check list ....................................................................4-1

U5LV12.book Page 1 Thursday, June 27, 2002 5:49 PM

PRE-OPERATION CHECKS

EAU01114

The condition of a vehicle is the owner’s responsibility. Vital components can start to deteriorate quickly and unexpectedly,

even if the vehicle remains unused (for example, as a result of exposure to the elements). Any damage, fluid leakage or loss

of tire air pressure could have serious consequences. Therefore, it is very important, in addition to a thorough visual inspection, to check the following points before each ride.

Pre-operation check list

EAU03439

ITEM

CHECKS

PAGE

Fuel

•

Check fuel level in fuel tank.

•

Refuel if necessary.

•

Check fuel line for leakage.

3-9–3-10

Engine oil

•

Check oil level in engine.

•

If necessary, add recommended oil to specified level.

•

Check vehicle for oil leakage.

6-12

Coolant

•

Check coolant level in reservoir.

•

If necessary, add recommended coolant to specified level.

•

Check cooling system for leakage.

6-15–6-16

Front brake

•

Check operation.

•

If soft or spongy, have Yamaha dealer bleed hydraulic system.

•

Check fluid level in reservoir.

•

If necessary, add recommended brake fluid to specified level.

•

Check hydraulic system for leakage.

6-29–6-30

Rear brake

•

Check operation.

•

If soft or spongy, have Yamaha dealer bleed hydraulic system.

•

Check fluid level in reservoir.

•

If necessary, add recommended brake fluid to specified level.

•

Check hydraulic system for leakage.

6-27–6-30

Clutch

•

Check operation.

•

Lubricate cable if necessary.

•

Check lever free play.

•

Adjust if necessary.

6-27,

6-34

4-1

U5LV12.book Page 2 Thursday, June 27, 2002 5:49 PM

PRE-OPERATION CHECKS

ITEM

CHECKS

PAGE

Throttle grip

•

Make sure that operation is smooth.

•

Check cable free play.

•

If necessary, have Yamaha dealer adjust cable free play and lubricate cable and

grip housing.

6-22,

6-33

Control cables

•

Make sure that operation is smooth.

•

Lubricate if necessary.

6-33

Drive chain

•

Check chain slack.

•

Adjust if necessary.

•

Check chain condition.

•

Lubricate if necessary.

6-31–6-32

Wheels and tires

•

Check for damage.

•

Check tire condition and tread depth.

•

Check air pressure.

•

Correct if necessary.

6-23–6-26

Brake and shift pedals

•

Make sure that operation is smooth.

•

Lubricate pedal pivoting points if necessary.

6-33

Brake and clutch levers

•

Make sure that operation is smooth.

•

Lubricate lever pivoting points if necessary.

6-34

Centerstand, sidestand

•

Make sure that operation is smooth.

•

Lubricate pivots if necessary.

6-34

Chassis fasteners

•

Make sure that all nuts, bolts and screws are properly tightened.

•

Tighten if necessary.

—

Instruments, lights, signals

and switches

•

Check operation.

•

Correct if necessary.

—

Sidestand switch

•

Check operation of ignition circuit cut-off system.

•

If system is defective, have Yamaha dealer check vehicle.

3-17

4-2

U5LV12.book Page 3 Thursday, June 27, 2002 5:49 PM

PRE-OPERATION CHECKS

NOTE:

Pre-operation checks should be made each time the motorcycle is used. Such an inspection can be accomplished in a very

short time; and the added safety it assures is more than worth the time involved.

EWA00033

_

If any item in the Pre-operation check list is not working properly, have it inspected and repaired before operating the motorcycle.

_

4-3

WARNING

U5LV12.book Page 1 Thursday, June 27, 2002 5:49 PM

OPERATION AND IMPORTANT RIDING POINTS

5

Starting and warming up a cold engine .............................................5-1

Starting a warm engine ....................................................................5-3

Shifting.............................................................................................5-4

Engine break-in ................................................................................5-5

Parking ............................................................................................5-6

U5LV12.book Page 1 Thursday, June 27, 2002 5:49 PM

OPERATION AND IMPORTANT RIDING POINTS

EAU00372

EAU00373

_

●

Become thoroughly familiar

with all operating controls and

their functions before riding.

Consult a Yamaha dealer regarding any control or function

that you do not thoroughly

understand.

●

Never start the engine or operate it in a closed area for any

length of time. Exhaust fumes

are poisonous, and inhaling

them can cause loss of consciousness and death within a

short time. Always make sure

that there is adequate ventilation.

●

Before starting out, make sure

that the sidestand is up. If the

sidestand is not raised completely, it could contact the

ground and distract the operator, resulting in a possible loss

of control.

EAU00376

CAUTION:

_

●

Make sure not to store personal

items near the air cleaner intake, otherwise air intake will be

blocked and performance will

suffer.

●

Make sure not to put anything

near the battery and its terminals, otherwise electrical failure

and acid corrosion may result.

EAU04827

Starting and warming up a

cold engine

In order for the ignition circuit cut-off

system to enable starting, one of the

following conditions must be met:

●

The transmission is in the neutral

position.

●

The transmission is in gear with

the clutch lever pulled and the

sidestand up.

EW000054

_

●

Before starting the engine,

check the function of the ignition circuit cut-off system according to the procedure

described on page 3-19.

●

Never ride with the sidestand

down.

_

_

WARNING

WARNING

5-1

U5LV12.book Page 2 Thursday, June 27, 2002 5:49 PM

OPERATION AND IMPORTANT RIDING POINTS

1.

Turn the key to “ON” and make

sure that the engine stop switch is

set to “ ”.

ECA00108

CAUTION:

_

The oil level warning light, coolant temperature warning light and fuel level warning light should come on for a few seconds, then go off. If a warning light does not go off, have a

4.

Start the engine by pushing the

start switch.

NOTE:

If the engine fails to start, release the

start switch, wait a few seconds, and

then try again. Each starting attempt

should be as short as possible to preserve the battery. Do not crank the engine more than 10 seconds on any one

attempt.

with sufficient engine oil, have a

Yamaha dealer check the electrical circuit.

●

If the coolant temperature warn-

ing light flickers or remains on

after starting, immediately stop

the engine, and then check the

coolant level and the vehicle for

coolant leakage. If necessary,

add coolant, and then check the

Yamaha dealer check the electrical

warning light again. If, when the

circuit.

2.

Shift the transmission into the neutral position.

NOTE:

When the transmission is in the neutral

position, the neutral indicator light

should be on, otherwise have a

Yamaha dealer check the electrical circuit.

3.

Turn the starter (choke) on and

completely close the throttle. (See

page 3-10 for starter (choke) operation.)

ECA00116

CAUTION:

_

●

If the oil level warning light flickers or remains on after starting,

immediately stop the engine,

and then check the engine oil

level and the vehicle for oil leakage. If necessary, add engine

oil, and then check the warning

light again. If, when the key is

turned to “ON”, the warning

light does not come on for a few

seconds, then go off, or if it

does not go off after starting

key is turned to “ON”, the warn-

ing light does not come on for a

few seconds, then go off, or if it

does not go off after starting

with sufficient coolant, have a

Yamaha dealer check the elec-

trical circuit.

●

If the fuel level warning light re -

mains on after starting, stop the

engine, and then check the fuel

level. If necessary, refuel as

soon as possible, and then

check the warning light again.

If, when the key is turned to

“ON”, the warning light does

5-2

U5LV12.book Page 3 Thursday, June 27, 2002 5:49 PM

OPERATION AND IMPORTANT RIDING POINTS

not come on for a few seconds, then go off, or if it does not go

NOTE:

The engine is warm when it responds

Starting a warm engine

EAU01258

off after starting with sufficient fuel, have a Yamaha dealer check the electrical circuit.

_

5.

After starting the engine, move the

starter (choke) back halfway.

ECA00055

normally to the throttle with the starter

(choke) turned off. To avoid the possibility of excessive exhaust emissions,

never leave the starter (choke) on longer than necessary. The time necessary

for starter (choke) use depends upon

Follow the same procedure as for starting a cold engine with the exception

that the starter (choke) is not required

when the engine is warm.

CAUTION:

_

For maximum engine life, always warm the engine up before starting off. Never accelerate hard when the engine is cold!

_

the ambient temperature. Temperatures above 10 °C (50 °F) require about

10 seconds of starter (choke) use and

temperatures below 10 °C (50 °F) require about 35 seconds with the starter

(choke) turned on, then about 2.5 min-

6.

When the engine is warm, turn the

starter (choke) off.

utes with the starter (choke) in the halfway position.

5-3

U5LV12.book Page 4 Thursday, June 27, 2002 5:49 PM

OPERATION AND IMPORTANT RIDING POINTS

EC000048

CAUTION:

To start out and accelerate

EAU02988

1. Shift pedal

N. Neutral position

Shifting

EAU00423

_

●

Even with the transmission in

the neutral position, do not

coast for long periods of time

with the engine off, and do not

tow the motorcycle for long distances. The transmission is

properly lubricated only when

the engine is running. Inadequate lubrication may damage

the transmission.

1.

Pull the clutch lever to disengage

the clutch.

2.

Shift the transmission into first

gear. The neutral indicator light

should go out.

3.

Open the throttle gradually, and at

the same time, release the clutch

lever slowly.

4.

At the recommended shift points

shown in the table on page 5-5,

Shifting gears lets you control the

amount of engine power available for

starting off, accelerating, climbing hills,

etc.

The gear positions are shown in the

illustration.

NOTE:

To shift the transmission into the neutral position, press the shift pedal down

repeatedly until it reaches the end of its

travel, and then slightly raise it.

●

Always use the clutch while

changing gears to avoid damaging the engine, transmission,

and drive train, which are not

designed to withstand the

shock of forced shifting.

close the throttle, and at the same

time, quickly pull the clutch lever

in.

5.

Shift the transmission into second

gear. (Make sure not to shift the

transmission into the neutral posi-

tion.)

6.

Open the throttle part way and

gradually release the clutch lever.

7.

Follow the same procedure when

shifting to the next higher gear.

NOTE:

Always shift gears at the recommended shift points.

5-4

U5LV12.book Page 5 Thursday, June 27, 2002 5:49 PM

OPERATION AND IMPORTANT RIDING POINTS

To decelerate

EAU00427

Recommended shift points

EAU02989

Engine break-in

EAU01128

1.

Apply both the front and the rear

brakes to slow the motorcycle.

2.

Shift the transmission into first

gear when the motorcycle reaches

25 km/h (15.5 mi/h). If the engine

is about to stall or runs very roughly, pull the clutch lever in and use

the brakes to stop the motorcycle.

3.

Shift the transmission into the neutral position when the motorcycle

is almost completely stopped. The

neutral indicator light should come

on.

The recommended shift points during

acceleration and deceleration are

shown in the table below.

Acceleration

shift point

km/h (mi/h)

Deceleration

shift point

km/h (mi/h)

1st 2nd

16 (9.9) –

2nd 3rd

24 (14.9)

25 (15.5)

3rd 4th

32 (19.9)

25 (15.5)

4th 5th

40 (24.9)

25 (15.5)

5th 6th

48 (29.8)

25 (15.5)

There is never a more important period

in the life of your engine than the period

between 0 and 1,600 km (1,000 mi).

For this reason, you should read the

following material carefully.

Since the engine is brand new, do not

put an excessive load on it for the first

1,600 km (1,000 mi). The various parts

in the engine wear and polish themselves to the correct operating clearances. During this period, prolonged

full-throttle operation or any condition

that might result in engine overheating

must be avoided.

5-5

U5LV12.book Page 6 Thursday, June 27, 2002 5:49 PM

OPERATION AND IMPORTANT RIDING POINTS

0–1,000 km (0–600 mi)

EAU03749*

Parking

EAU00460

Avoid prolonged operation above

5,000 r/min.

1,000–1,600 km (600–1,000 mi)

Avoid prolonged operation above

6,000 r/min.

EC000052*

CAUTION:

_

After 1,000 km (600 mi) of operation, the engine oil must be changed and the oil filter cartridge replaced.

1,600 km (1,000 mi) and beyond

The vehicle can now be operated

normally.

When parking, stop the engine, and

then remove the key from the main

switch.

EW000058

_

●

Since the engine and exhaust

system can become very hot,

park in a place where pedestrians or children are not likely to

touch them.

●

Do not park on a slope or on

soft ground, otherwise the

motorcycle may overturn.

_

CAUTION:

_

EC000053

●

Keep the engine speed out of

the tachometer red zone.

●

If any engine trouble should occur during the engine break-in

period, immediately have a

Yamaha dealer check the vehicle.

WARNING

5-6

U5LV12.book Page 1 Thursday, June 27, 2002 5:49 PM

PERIODIC MAINTENANCE AND MINOR REPAIR

Periodic maintenance ..........................................6-1

Owner’s tool kit ....................................................6-1

Periodic maintenance chart for the emission

control system .................................................. 6-3

General maintenance and lubrication chart ..........6-5

Removing and installing panels .......................... 6-8

Checking the spark plugs .................................. 6-10

Canister (for California only) .............................. 6-11

Engine oil and oil filter cartridge ......................... 6-12

Coolant ............................................................. 6-15

Cleaning the air filter element ............................ 6-19

Adjusting the carburetors ................................... 6-21

Adjusting the throttle cable free play.................... 6-22

Adjusting the valve clearance ............................ 6-22

Tires.................................................................. 6-23

Cast wheels ...................................................... 6-26

Accessories and replacement parts ................... 6-26

Adjusting the clutch lever free play ...................... 6-27

Adjusting the brake pedal position ..................... 6-27

Adjusting the rear brake light switch ................... 6-28

Checking the front and rear brake pads ............. 6-29

Checking the brake fluid level .............................. 6-29

Changing the brake fluid .................................... 6-30

Drive chain slack ............................................... 6-31

Lubricating the drive chain ................................. 6-32

Checking and lubricating the cables................... 6-33

Checking and lubricating the throttle grip and

cable ............................................................... 6-33

Checking and lubricating the brake and

shift pedals...................................................... 6-33

Checking and lubricating the brake and

clutch levers ......................................................... 6-34

Checking and lubricating the centerstand and

idestand .......................................................... 6-34

Lubricating the rear suspension ......................... 6-35

Checking the front fork ...................................... 6-35

Checking the steering ....................................... 6-36

6

Checking the wheel bearings ............................. 6-36

Battery .............................................................. 6-37

Replacing the fuses ........................................... 6-38

Replacing a headlight bulb ................................ 6-39

Replacing a tail/brake light bulb ......................... 6-41

Replacing a turn signal light bulb ....................... 6-41

Front wheel ....................................................... 6-42

Rear wheel........................................................ 6-43

Troubleshooting ..................................................... 6-45

Troubleshooting charts ...................................... 6-46

U5LV12.book Page 1 Thursday, June 27, 2002 5:49 PM

PERIODIC MAINTENANCE AND MINOR REPAIR

EAU00462

EAU01790

Safety is an obligation of the owner.

Periodic inspection, adjustment and lubrication will keep your vehicle in the

safest and most efficient condition possible. The most important points of

motorcycle inspection, adjustment, and

lubrication are explained on the following pages.

Maintenance, replacement, or repair of the emission control devices and systems may be performed by any

EAU00467

PERIODIC MAINTENANCE

PROPER PERIODIC MAINTENANCE

OF YOUR MOTORCYCLE IS IMPORTANT IN ORDER TO ENJOY LONG,

PLEASURABLE SERVICE. ESPECIALLY IMPORTANT ARE THE

MAINTENANCE SERVICES RELATED TO EMISSIONS CONTROL.

THESE CONTROLS NOT ONLY

FUNCTION TO ENSURE CLEANER

AIR, BUT ARE ALSO VITAL TO

1.

Owner’s tool kit

Owner’s tool kit

EAU04479

repair establishment or individual

that is certified (if applicable).

EW000060

_

If you are not familiar with motorcycle maintenance work, have a

Yamaha dealer do it for you.

_

PROPER ENGINE OPERATION AND

MAXIMUM PERFORMANCE. IN THE

FOLLOWING PERIODIC MAINTENANCE CHARTS, THE SERVICES

RELATED TO EMISSIONS CONTROL ARE GROUPED SEPARATELY. THESE SERVICES REQUIRE

SPECIALIZED DATA, KNOWLEDGE,

AND EQUIPMENT. YAMAHA DEALERS ARE TRAINED AND EQUIPPED

TO PERFORM THESE PARTICULAR

SERVICES.

The owner’s tool kit is located inside

the storage compartment under the

seat. (See page 3-11 for seat removal

and installation procedures.)

The service information included in this

manual and the tools provided in the

owner’s tool kit are intended to assist

you in the performance of preventive

maintenance and minor repairs. However, additional tools such as a torque

wrench may be necessary to perform

certain maintenance work correctly.

WARNING

6-1

U5LV12.book Page 2 Thursday, June 27, 2002 5:49 PM

PERIODIC MAINTENANCE AND MINOR REPAIR

NOTE:

If you do not have the tools or experience required for a particular job, have

a Yamaha dealer perform it for you.

EW000062

_

Modifications not approved by

Yamaha may cause loss of performance, excessive emissions, and

render the vehicle unsafe for use.

Consult a Yamaha dealer before attempting any changes.

_

6-2

WARNING

U5LV12.book Page 3 Thursday, June 27, 2002 5:49 PM

PERIODIC MAINTENANCE AND MINOR REPAIR

Periodic maintenance chart for the emission control system

EAU00471

6-3

No.

ITEM

ROUTINE

INITIAL

ODOMETER READINGS

600 mi

(1,000 km)

or

1 month

4,000 mi

(7,000 km)

or

6 months

8,000 mi

(13,000 km)

or

12 months

12,000 mi

(19,000 km)

or

18 months

16,000 mi

(25,000 km)

or

24 months

20,000 mi

(31,000 km)

or

30 months

1

*

Valve clearance

•

Check and adjust valve clearance

when engine is cold.

Every 26,600 mi (42,000 km)

2

Spark plugs

•

Check condition.

•

Adjust gap and clean.

•

Replace every 8,000 mi (13,000 km) or

12 months.

Replace.

Replace.

3

*

Crankcase

ventilation system

•

Check ventilation hose for cracks or

damage.

•

Replace if necessary.

4

*

Fuel line

•

Check fuel hoses and vacuum hose

for cracks or damage.

•

Replace if necessary.

5

*

Fuel filter

•

Replace every 20,000 mi (31,000 km)

or 30 months.

Replace.

6

*

Exhaust system

•

Check for leakage.

•

Retighten if necessary.

•

Replace gasket(s) if necessary.

7

*

Carburetor

synchronization

•

Adjust synchronization of carburetors.

8

*

Idle speed

•

Check and adjust engine idle speed.

•

Adjust cable free play.

U5LV12.book Page 4 Thursday, June 27, 2002 5:49 PM

PERIODIC MAINTENANCE AND MINOR REPAIR

No.

ITEM

ROUTINE

INITIAL

ODOMETER READINGS

600 mi

(1,000 km)

or

1 month

4,000 mi

(7,000 km)

or

6 months

8,000 mi

(13,000 km)

or

12 months

12,000 mi

(19,000 km)

or

18 months

16,000 mi

(25,000 km)

or

24 months

20,000 mi

(31,000 km)

or

30 months

9

*

Evaporative

emission control

system (For

California only)

•

Check control system for damage.

•

Replace if necessary.

10

*

Air induction

system

•

Check the air cut valve and reed valve

for damage.

•

Replace the entire air induction

system if necessary.

* Since these items require special tools, data and technical skills, have a Yamaha dealer perform the service.

6-4

U5LV12.book Page 5 Thursday, June 27, 2002 5:49 PM

PERIODIC MAINTENANCE AND MINOR REPAIR

General maintenance and lubrication chart

EAU00472

6-5

No.

ITEM

ROUTINE

INITIAL

ODOMETER READINGS

600 mi

(1,000 km)

or

1 month

4,000 mi

(7,000 km)

or

6 months

8,000 mi

(13,000 km)

or

12 months

12,000 mi

(19,000 km)

or

18 months

16,000 mi

(25,000 km)

or

24 months

20,000 mi

(31,000 km)

or

30 months

1

Engine oil

•

Replace (warm engine before

draining). (See NOTE on page 6-7.)

2

Engine oil filter

cartridge

•

Replace at initial 600 mi (1,000 km) or

1 month, and thereafter every

8,000 mi (13,000 km) or 12 months.

3

*

Air filter element

•

Clean with compressed air.

•

Replace if necessary.

4

*

Cooling system

•

Check hose for cracks or damage.

•

Replace if necessary.

•

Replace coolant every 24 months. #3

Replace.

5

*

Brake system

•

Check operation, pad wear, and fluid

leakage. (See NOTE on page 6-7.)

•

Correct if necessary.

6

*

Clutch

•

Check operation.

•

Adjust or replace cable.

7

*

Control cable

•

Apply chain lube thoroughly. #1

8

*

Throttle grip

housing and

cable

•

Check operation and free play.

•

Adjust the throttle cable free play if

necessary.

•

Lubricate the throttle grip housing and

cable.

U5LV12.book Page 6 Thursday, June 27, 2002 5:49 PM

PERIODIC MAINTENANCE AND MINOR REPAIR

No.

ITEM

ROUTINE

INITIAL

ODOMETER READINGS

600 mi

(1,000 km)

or

1 month

4,000 mi

(7,000 km)

or

6 months

8,000 mi

(13,000 km)

or

12 months

12,000 mi

(19,000 km)

or

18 months

16,000 mi

(25,000 km)

or

24 months

20,000 mi

(31,000 km)

or

30 months

9

*

Swingarm pivot

bearing

•

Check bearing assembly for

looseness.

•

Moderately repack every 16,000 mi

(25,000 km) or 24 months. #2

Repack.

10

*

Rear suspension

link pivots

•

Check operation.

•

Moderately repack every 16,000 mi

(25,000 km) or 24 months. #2

Repack.

11

*

Shock absorber

assembly

•

Check operation and for oil leakage.

•

Replace if necessary.

12

*

Front fork

•

Check operation and for oil leakage.

•

Repair if necessary.

13

*

Steering bearings

•

Check bearing assembly for

looseness.

•

Moderately repack every 16,000 mi

(25,000 km) or 24 months. #2

Repack.

14

Brake and clutch

lever pivot shafts

•

Lubricate. #2

15

Brake and shift

pedal pivot shafts

•

Lubricate. #2

16

*

Drive chain

•

Check chain slack/alignment

condition.

•

Adjust and lubricate chain thoroughly.

#1

Every 600 mi (1,000 km) or after washing the motorcycle

or riding in the rain.

17

*

Wheel bearings

•

Check bearings for smooth operation.

18

*

Sidestand and

centerstand

pivots

•

Check operation.

•

Lubricate. #2

6-6

U5LV12.book Page 7 Thursday, June 27, 2002 5:49 PM

PERIODIC MAINTENANCE AND MINOR REPAIR

*

Since these items require special tools, data and technical skills, have a Yamaha dealer perform the service.

#1 : Yamaha chain lube

#2 : Lithium-soap-based grease (all-purpose grease)

#3 : Ethylene glycol anti-freeze coolant

EAU03907

NOTE:

From 24,000 mi (37,000 km) or 36 months, repeat the maintenance intervals starting from 4,000 mi (7,000 km) or 6 months.

EAU03234*

NOTE:

●

The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

●

Hydraulic brake service

•