Page 1

Page 2

FOREWORD

This Assembly Manual contains the information required for the correct reassembly of this Y amaha motorcycle prior to delivery to the customer. Since some external parts of the motorcycle have been removed at the

Y amaha factory for the convenience of packing, assembly by the Y amaha dealer is required. It should be noted

that the reassembled motorcycle should be throughly

cleaned, inspected, and adjusted prior to delivery to the

customer.

NOTICE

The service specifications given in this assembly manual are based on the model as manufactured. Modifications and significant changes in specifications and / or

procedures will be forwarded to Authorized Yamaha

Dealers. The procedures below are described in the order that the procedures are carried out correctly and

completely.Failure to do so can result in poor performance and possible harm to the motorcycle and/or rider.

Particularly important information is distinguished in this

manual by the following notations.

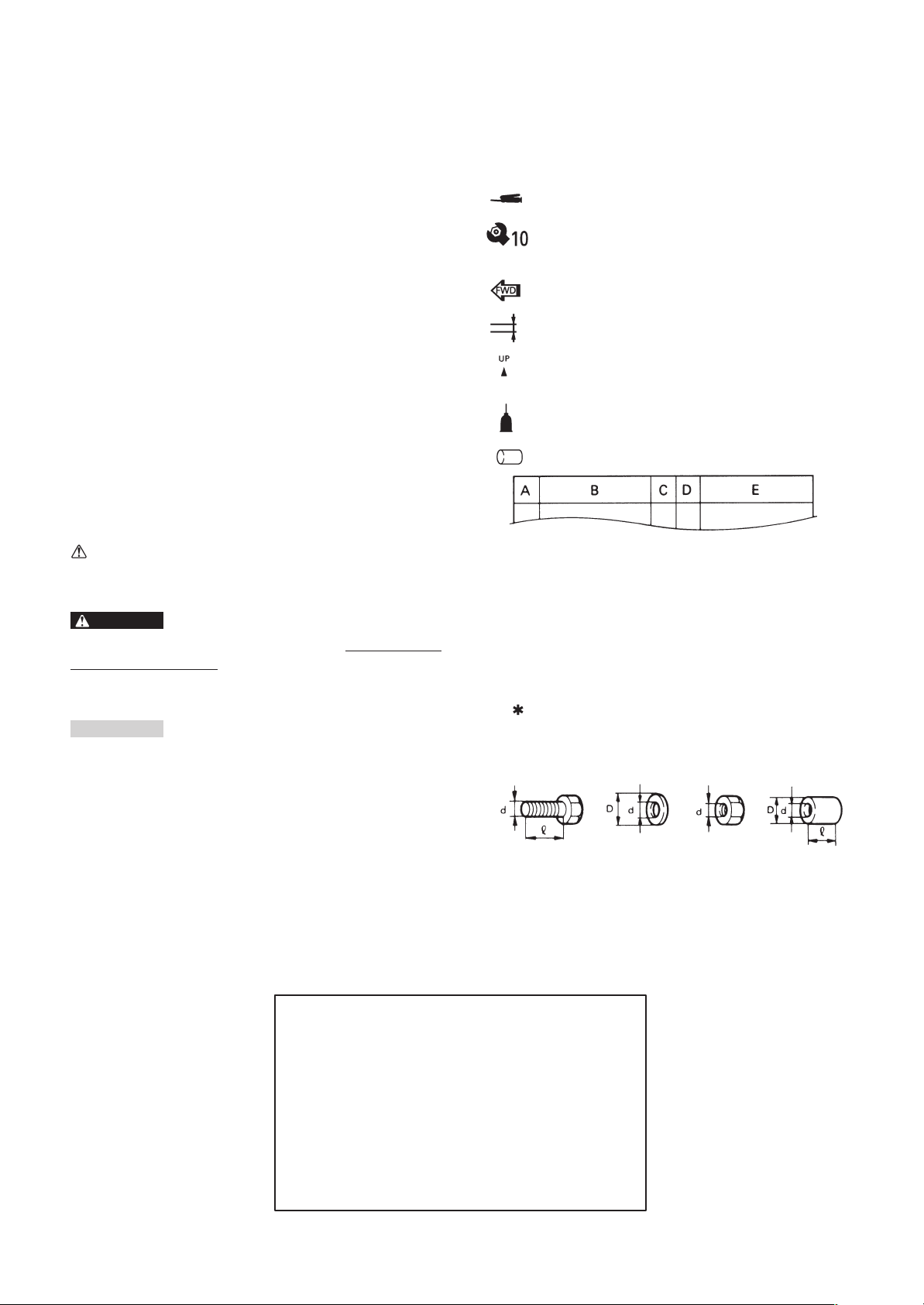

SYMBOLS USED IN

ASSEMBLY MANUAL

In order to simplify descriptions in assembly manuals,

the following symbols are used:

: Coat with lithium soap base grease.

: Tighten to 10 Nm.

: (10 Nm = 1.0 mkg)

: Front ward of the motorcycle.

: Provide a clearance.

: Install so that the arrow mark faces

: upward.

: Apply a motor oil.

: Made of rubber or plastics.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

WARNING

Failure to follow WARNING instructions could result in

severe injury or death to the motorcycle operator, a bystander, or a person inspecting or repairing the motorcycle.

CAUTION:

A CAUTION indicates special precautions that must be

taken to avoid damage to the motorcycle.

NOTE:

A NOTE provides key information to make procedures

easier or clearer.

A: Ref No. (indicating the order or operations.)

B: Part name

C: Quantity of parts per motorcycle.

D: Place where parts are held.

V: Stored in vinyl bag.

C: Stored in carton box.

S: Fixed inside the steel frame and/or contained

in the styrofoam tray (upper or lower).

: Temporarily installed or secured.

E: Size or material of parts.

d/D:Diameter of part.

: Length of part.

ex, 5 = 5 mm

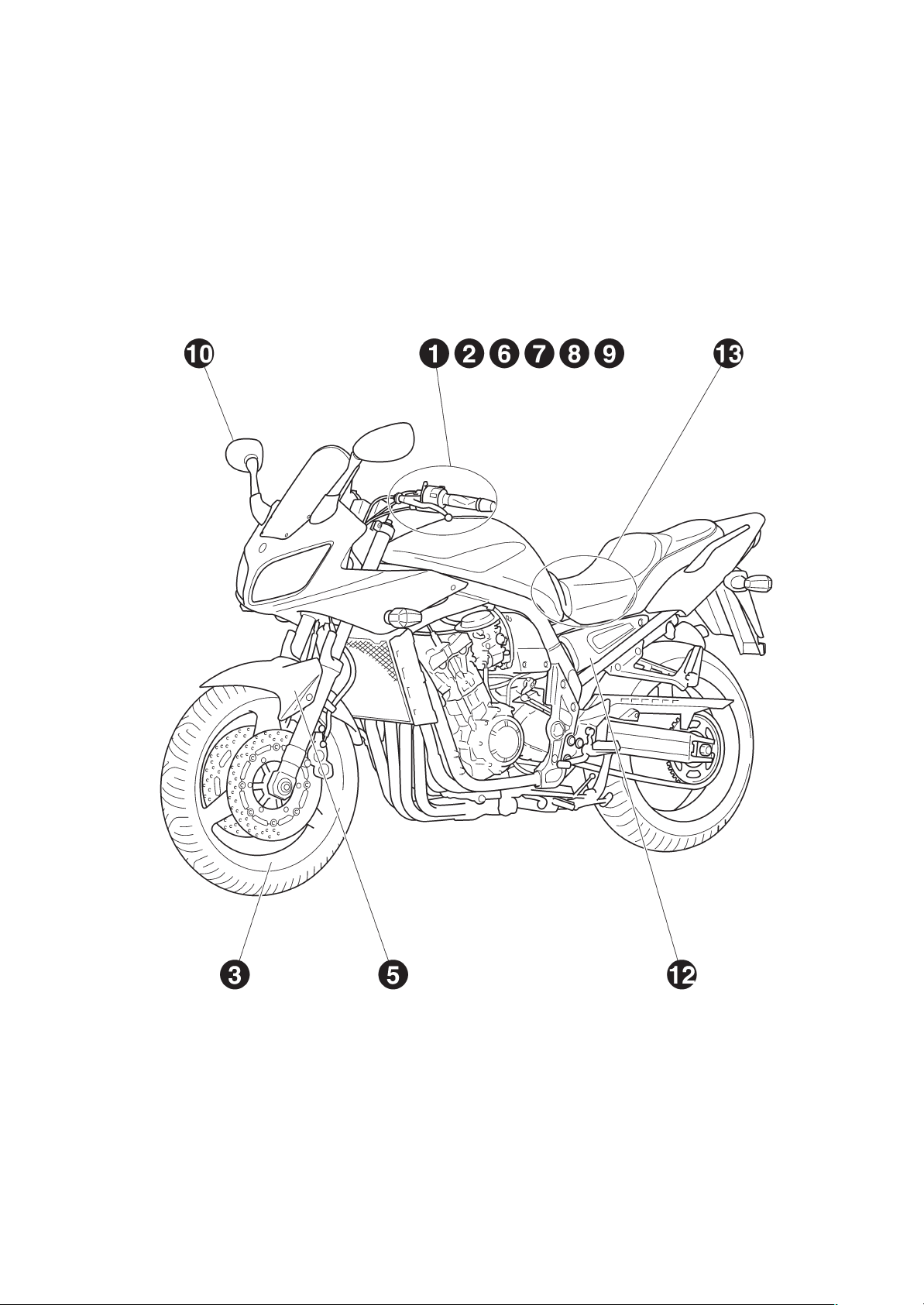

FZS1000 (N) 2001

ASSEMBLY MANUAL

2000 by Yamaha Motor Co., Ltd.

First Edition, December 2000

All rights reserved. Any reproduction or

unauthorized use without the written

permission of Yamaha Motor Co., Ltd.

is expressly prohibited.

Printed in BELGIUM

Page 3

FZS1000 (N) 2001

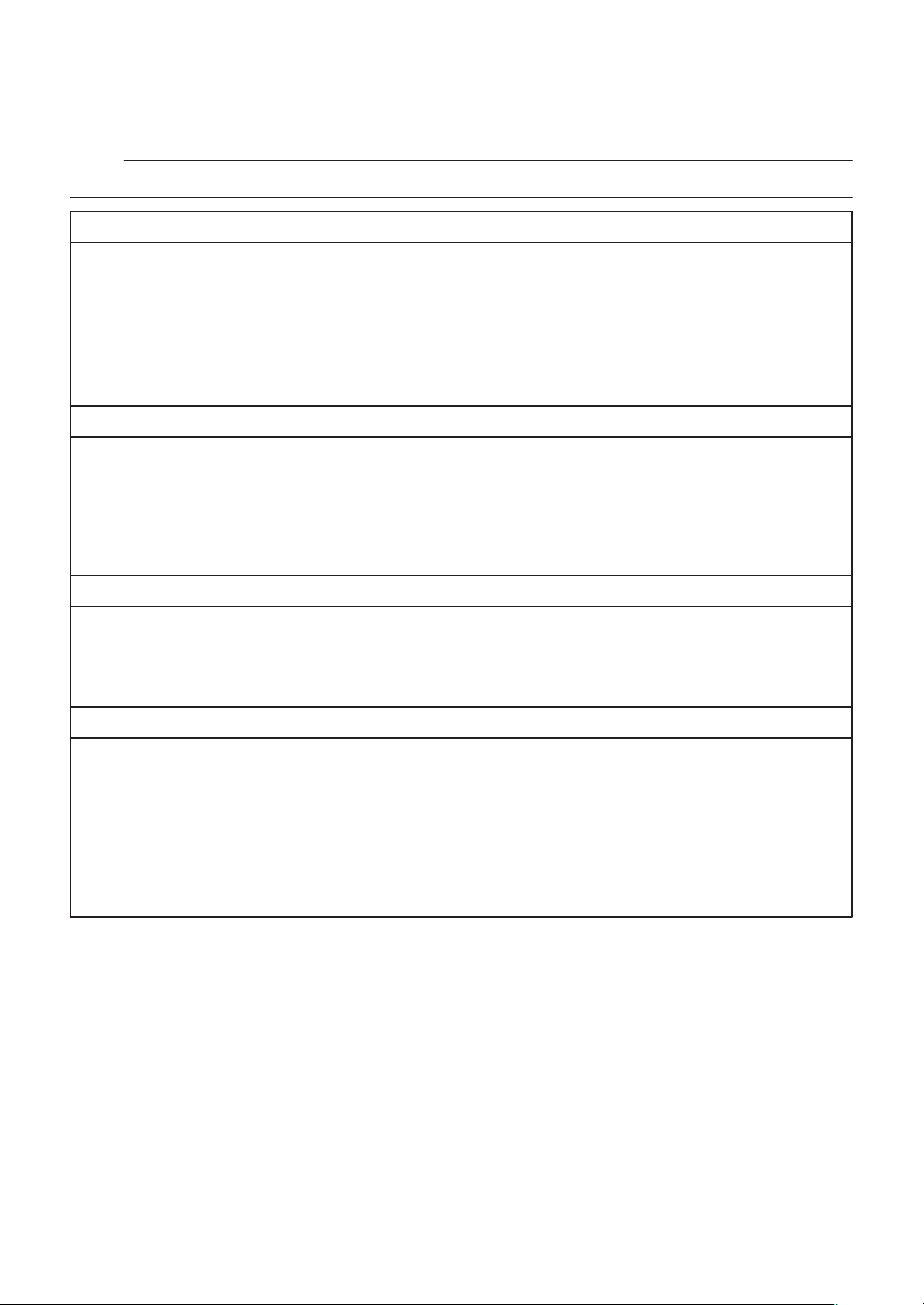

SET-UP AND PREDELIVERY CHECKLIST

NOTE:

Check the following items again when set up and predelivery service are completed.

A: INSTALLATION OF THE PARTS INCLUDED IN THE CRATE

Handlebar

Throttle grip

Front wheel

Front fender

Front brake hose clamp

Front brake master cylinder

Handlebar switch (left)

B: TIGHTENING TORQUE OF EACH PART

Handlebar holder (upper) 28 Nm (2.8 mkg)

Front fender and outer tube 10 Nm (1.0 mkg)

Front wheel axle 59 Nm (5.9 mkg)

Front wheel axle pinch bolt 20 Nm (2.0 mkg)

Master cylinder and bracket 10 Nm (1.0 mkg)

Side cover 4 Nm (0.4 mkg)

C: ROUTING OF WIRE, CABLES, ETC.

Throttle cables

Brake hose

Clutch cable

Left handlebar switch lead

Clutch cable

Band

Rear view mirror

Windscreen

Inner panel

Side cover (left)

Battery

Right handlebar switch lead

Battery positive lead

Battery negative lead

Starter cable

D: ADJUSTMENTS

Checking and charging the battery

Drain the fuel

Checking the tire pressure

Checking the engine oil level

Checking the coolant level

Adjusting the engine idling speed

Adjusting the throttle cable free play

Adjusting the front brake

Adjusting the rear brake

Checking the brake fluid level

Breeding the hydraulic brake system

Adjusting the clutch cable free play

Adjusting the front fork legs

Adjusting the rear shock absorber assembly

Adjusting the drive chian slack

Adjusting the rear brake light switch

Adjusting the headlight beams

Adjusting the digital clock

Page 4

E: FUNCTION AND PERFORMANCE

Check for the function of headlight, meter light and tail light

Check for the funciton of brake light

Check for the function of flasher light and indicator light

Check for the tone quality of the horn

Check for the function of the indicator on the speedometer

Check for brake feeling

Check for engine noise (Yes/No)

Check for exhaust leak (Yes/No)

F: ACCESSORIES, ETC. FOR DELIVERY

Owner’s manual

Owner’s tool kit

Page 5

SETUP PROCEDURES

–1–

Page 6

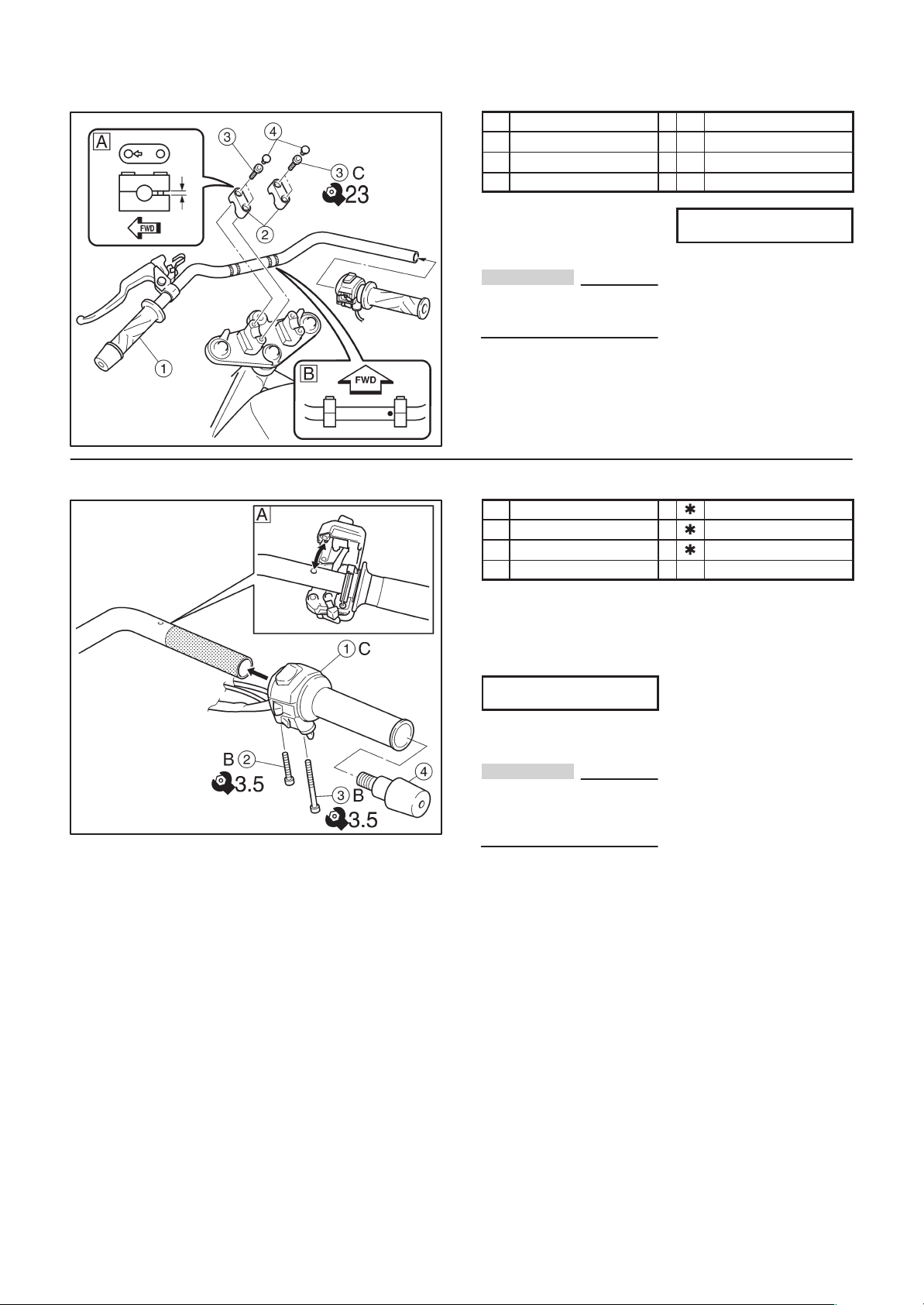

1. Handlebar

1 Handlebar 1 C

2 Handlebar holder 2 V

3 Hexagon socket bolt 4 V d = 8, = 30

4 Plug 4 V

2. Throttle grip

A: The handlebar holder should be

installed with the arrow mark

forward.

Tightening torque:

23 Nm (2.3 mkg)

CAUTION:

First tighten the bolts on the

front side, and then tighten the

bolts on the rear side.

B: Align the punch mark on the

handlebar with the top of the

lower handlebar holder.

C: Tighten the bolts to specified

torque.

1 Throttle grip 1

2 Screw 1 d = 5, = 30

3 Screw 1 d = 5, = 50

4 Grip end 1 V

A: Align the projection on the han-

dlebar switch with the hole in

the handlebar.

B: Tighten the bolt to specified

torque.

Tightening torque

3.5 Nm (0.4 mkg)

C: Check the throttle grip for

smooth action.

CAUTION:

Proper cable routing is essential

to assure safe motorcycle operation.

Refer to “CABLE ROUTING”.

–2–

Page 7

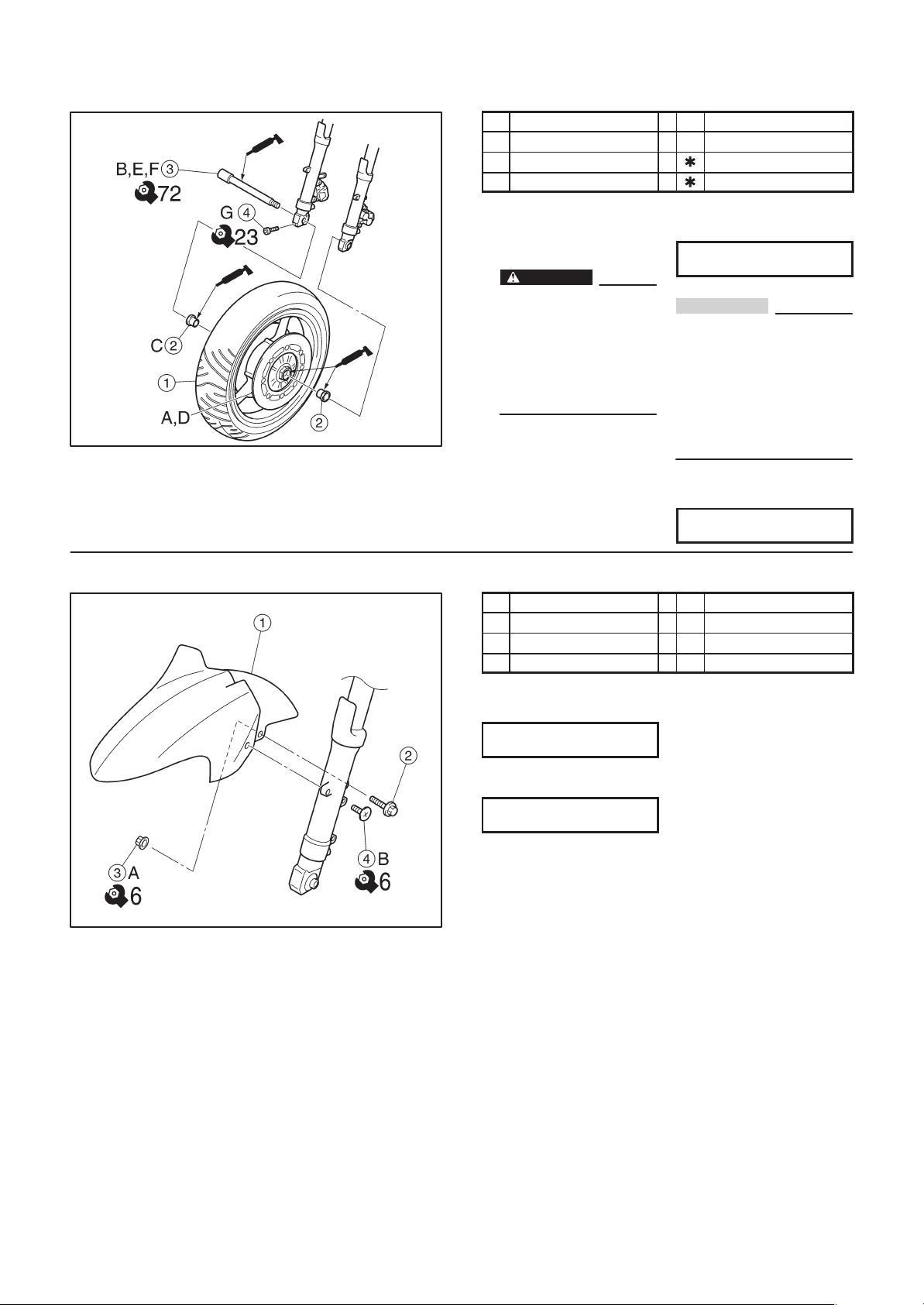

3. Front wheel

1 Front wheel 1 S

2 Collar 2 V

3 Front wheel axle 1

4 Axle pinch bolt 1 d = 8, = 45

4. Front fender

A: Clean the brake disc.

B: Clean the front wheel axle.

C: Clean the collar .

D:

WARNING

Take care not to put grease

on the brake disc or inner

surface of the brake pads. If

you do so, clean using a rag

dampened with a solvent.

Foreign material on braking

surface can cause impaired

braking action.

E: Lift the front wheel and install

the front wheel axle.

1 Front fender 1 C

2 Flange bolt 2 V d = 6, = 9

3 Nut 2 V d = 6

4 Screw 2 V d = 6, = 61

F: Tighten the front wheel axle to

specified torque.

Tightening torque:

72 Nm (7.2 mkg)

CAUTION:

Before tightening the pinch bolt,

stroke the front forks several

times to make sure of proper fork

operation. With the pinch bolt

loose, work the left fork leg back

and forth until the proper clearance between the disc and caliper bracket on the front fork are

obtained.

G: Tighten the axle pinch bolt to

specified torque.

Tightening torque:

23 Nm (2.3 mkg)

A: Tighten the nuts to specified

torque.

Tightening torque:

6 Nm (0.6 mkg)

B: Tighten the screw to specified

torque.

Tightening torque:

6 Nm (0.6 mkg)

–3–

Page 8

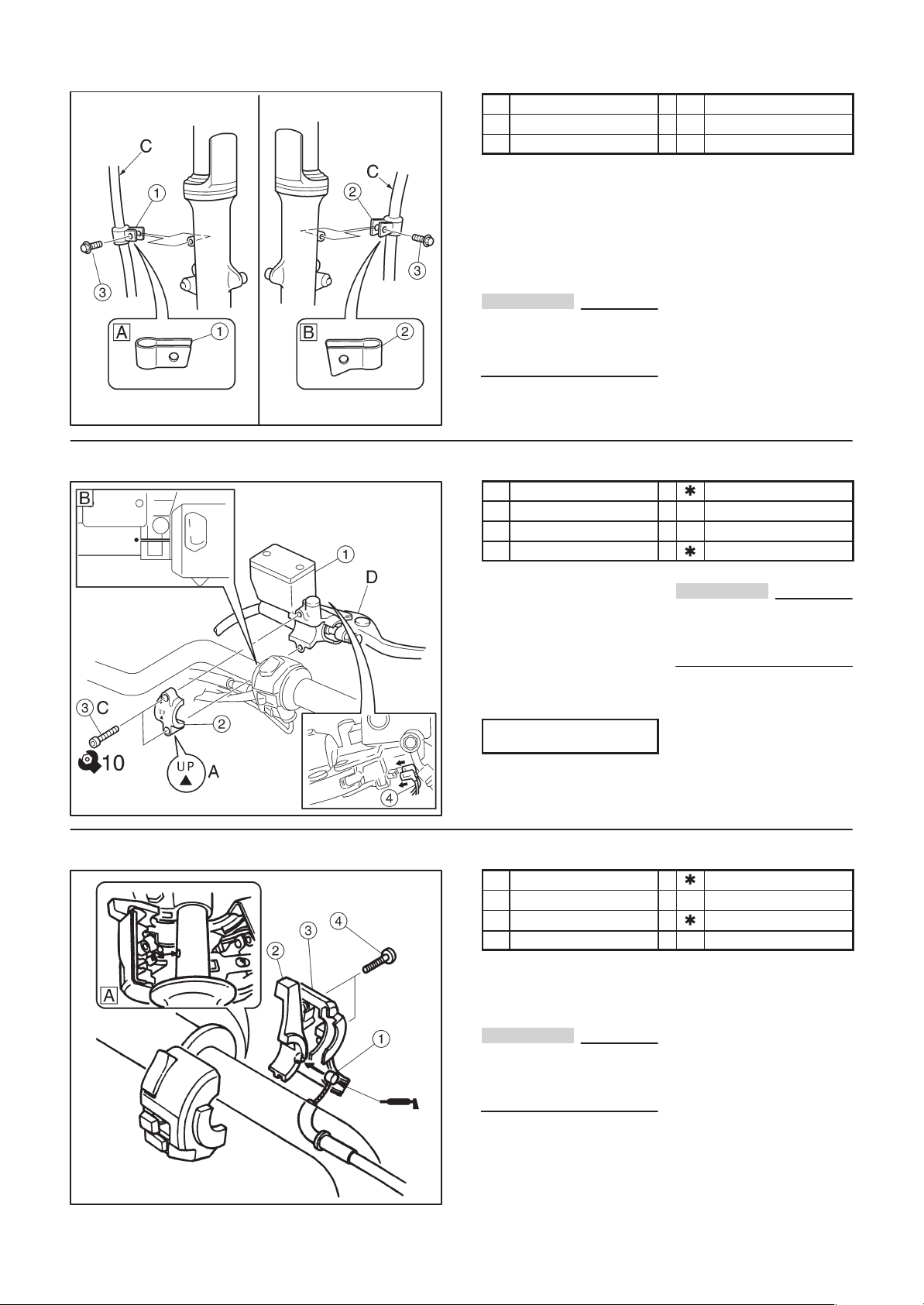

5. Front brake hose clamp

6. Front brake master cylinder

1 Brake hose clamp (right) 1 V

2 Brake hose clamp (left) 1 V

3 Flange bolt 2 V d = 6, = 25

A: Install the brake hose clamp on

the right side brake hose.

B: Install the brake hose clamp on

the left side brake hose.

C: Pass the brake hose through

the brake hose holder and secure the holder to the front fork.

CAUTION:

Proper hose routing is essential

to assure safe motorcycle operation.

Refer to “CABLE ROUTING”.

1

Master cylinder 1

2 Bracket 1 V

3 Hexagon socket bolt 2 V d = 6, = 10

4 Brake switch lead 2

7. Handlebar switch (left)

A: Make sure that the “UP” mark

with the bracket is pointed upward.

B: Align the punch mark on the

handlebar with the gap of the

master cylinder bracket.

C: Tighten the bolts in stages and

maintain an equal gap on each

side of the bracket.

Tightening torque:

10 Nm (1.0 mkg)

D: Check the brake lever for

smooth action.

1

Starter cable 1

2 Starter lever 1 V

3 handlebar switch (left) 1

4 Panhead screw 2 C d = 5, = 25

A: Align the projection on the han-

dlebar switch (left) with the hole

in the handlebar.

CAUTION:

Proper cable and hose routing is

essential to assure safe motorcycle operation. Refer to

“CABLE ROUTING”.

CAUTION:

Proper cable routing is essential

to assure safe motorcycle operation.

Refer to “CABLE ROUTING”.

–4–

Page 9

8. Clutch cable

9. Band

1 Clutch cable 1

2 Clutch switch coupler 1

A: Check the clutch lever for

smooth action.

CAUTION:

Proper cable routing is essential

to assure safe motorcycle operation.

Refer to “CABLE ROUTING”.

1 Band 2 V

A: Clamp the left handlebar switch

lead.

B: Clamp the right handlebar

switch lead.

10. Rear view mirror

NOTE:

Refer to “CABLE ROUTING”.

Rear view mirror

1

(left and right)

2 Cap nut 4 V d = 6

2 C

–5–

Page 10

11. Windscreen

12. Inner panel

1 Windscreen 1 C

2 Special nut 6 V d = 5

3 Screw 6 V d = 5, = 23

CAUTION:

The windscreen is made of an

acrylate resin. Take care so that

it is not scratched.

A: Tighten the screw to specified

torque.

Tightening torque:

0.4 Nm (0.04 mkg)

1 Inner panel (left and right) 2 C

2 Button head screw 4 V d = 5, = 13

3 Button head screw 2 V d = 6, = 16

4 Plastic washer 2 V d = 6

13. Side cover (left)

A: Tighten the screw to specified

torque.

Tightening torque

1.5 Nm (0.2 mkg)

B: Tighten the screw to specified

torque.

Tightening torque

4.5 Nm (0.5 mkg)

1 Side cover (left) 1 C

2 Button head screw 1 V d = 6, = 16

A: Tighten the screw to specified

torque.

Tightening torque:

3.8 Nm (0.4 mkg)

–6–

Page 11

14. Battery

1 Battery 1

2 Bolt 2 d = 6, = 10

3 Band 1

4 Seat 1

A: Installing the battery.

NOTE:

Refer to “ADJUSTMENTS AND

PREDELIVERY SERVICE”.

B: First, connect the positive lead

(Red color lead) to the positive

terminal.

C: Connect the negative lead

(Black color lead) to the negative terminal.

NOTE:

Refer to “CABLE ROUTING”.

–7–

Page 12

CABLE ROUTING

WARNING

Proper cable and lead routing is essential to insure

safe motorcycle operation.

1

Handlebar switch lead (right)

2

Throttle cable 1

3

Throttle cable 2

4

Clutch cable

5

Starter cable

6

Handlebar switch lead (left)

7

Main switch lead

8

Battery negative lead

9

Battery positive lead

10

Battery

A

Fasten the handlebar switch lead (right) and handlebar with a plastic band.

B

Route the handlebar switch lead (right) backward

the throttle cable and right side the brake hose guide.

C

Fasten the handlebar switch lead (left) and handlebar with a plastic band.

D

Route the throttle cable 1 and 2 backward the brake

hose, and left side the brake hose guide.

E

Fasten the battery negative lead with a battery band.

F

Insert the ground lead coupler in the battery band.

–8–

Page 13

ADJUSTMENTS AND PREDELIVERY SERVICE

–9–

Page 14

A. CHECKING AND CHARGING THE BAT-

TERY

NOTE:

The battery used in this motorcycls is a new version maintenance free “Valve Regulated Lead

Acid Battery”, it has been pre-filled with electrolyte

at the factory so there is no need for you to add any

fluid at any time.

1. Check:

Using a digital volt meter, the state of a discharged MF battery can be chacked by measuring open-circuit voltage (the voltage measured with the positive and negative terminals

being disconnected).

Open-circuit

voltage

12.8 V or

higher

Charging time

Charging is not necessary

WARNING

Do not attempt boost charging under any

circumstances.

Battery electrolyte is poisonous and danger-

ous, causing severe burns, etc. Contains

sulfric acid. Avoid contact with skin, eyes or

clothing.

Antidote: External – Flush with water. Internal – Drink large quantities of water or milk.

Follow with milk of magnesia, beaten egg, or

vegetable oil. Call physician immediately .

Eyes: Flush with water for 15 minutes and

get prompt medical attention. Batteries produce explosive gases. Keep sparks, flame,

cigarettes, etc., away . V entilate when charging or using in enclosed space. Always

shield eyes when working near batteries.

KEEP OUT OT REACH OF CHILDREN.

CAUTION:

If the voltage is lower than 12.8 V the battery

must be charged. If this is not done, the life

of the battery will be shortened drastically.

Since the procedure for charging the battery

is not explained in the assembly manual, refer to the service manual for more datails.

Never remove the strip of caps, nor add any

water or electrolyte.

B. DRAIN THE FUEL

1. Put a rag under the carburetor drain hose so

fuel does not contact the crankcase.

2. Loosen the four drain screws

standing fuel.

and drain the

1

WARNING

FUEL IS HIGHLY FLAMMBLE:

Always turn off the engine when draining.

Take care not to spill any fuel on the engine

or exhaust pipe(s)/muffler(s) when draining.

Never drain fuel while smoking or in the vi-

cinity of an open flame.

3. Retighten the four drain screws securely.

–10–

Page 15

EAA00128

C. CHECKING THE TIRE PRESSURE

1. Measure:

tire pressure

Out of specification Adjust.

WARNING

Tire inflation pressure should be checked

and adjusted when the temperature of the

tire equals the ambient air temperature. Tire

inflation pressure must be adjusted according to total weight of cargo, rider, and accessories (fairing, saddlebags, etc. if approved

for this model), and vehicle speed.

Proper loading of your motorcycle is impor-

tant for the handling, braking, and other performance and safety characteristics of your

motorcycle. Do not carry loosely packed

items that can shift.

Securely pack your heaviest items close to

the center of the motorcycle, and distribute

the weight evenly from side to side. Properly

adjust the suspension for your load, and

check the condition and pressure of your

tires.

NEVER OVERLOAD YOUR MOTORCYCLE.

Make sure the total weight of the cargo, rider,

and accessories (fairing, saddlebags, etc. if

approved for this model) does not exceed the

maximum load of the motorcycle. Operation of

an overload motorcycle could cause tire damage, an accident, or even injury.

Basic weight

with oil and a

231 kg

full fuel tank

Maximum

load*

Cold tire

pressure

Up to 90 kg

load*

90 kg

maximum load*

High

speed riding

(2.5 kgf/cm2)

(2.5 kgf/cm2)

(2.5 kgf/cm2)

189 kg

Front Rear

250 kPa

270 kPa

2.7 kgf/cm2)

250 kPa

290 kPa

(2.9 kgf/cm2)

250 kPa

290 kPa

(2.9 kgf/cm2)

*: total of cargo, rider, passenger and accessories

EAA00129

D. CHECKING THE ENGINE OIL LEVEL

1. Stand the motorcycle on a level surface.

NOTE:

Place the motorcycle on a suitable stand.

Make sure that the motorcycle is upright.

2. Let the engine idle for a few minutes.

3. Check:

engine oil level

The engine oil level should be between the

a

minimum level marks

marks

.

b

and maximum level

Below the minimum level mark Add the recommended engine oil to the proper level.

Recommended engine oil

Refer to the chart for the engine oil grade

which is best suited for certain atmospheric

temperatures.

API standard

SE or higher grade

ACEA standard

G4 or G5

Quantity

With oil filter element replacement

3.0 L

CAUTION:

Engine oil also lubricates the clutch and the

wrong oil types or additives could cause

clutch slippage. Therefore, do not add any

chemical additives or use engine oils with a

grade of CD

labeled “ENERGY CONSERVING II”

a

or higher and do not use oils

or

b

higher.

Do not allow foreign materials to enter the

crankcase.

4. Start the engine, warm it up for several minutes, and then turn it off.

5. Check the engine oil level again.

NOTE:

Before checking the engine oil level, wait a few

minutes until the oil has settled.

–11–

Page 16

EAA00136

E. CHECKING THE COOLANT LEVEL

1. Stand the motorcycle on a level surface.

NOTE:

Place the motorcycle on a suitable stand.

Make sure that the motorcycle is upright.

2. Check:

coolant level

The coolant level should be between the maximum level mark

.

b

a

and minimum level marks

Below the minimum level mark Add the recommended coolant to the proper level.

CAUTION:

Adding water instead of coolant lowers the

antifreeze content of the coolant. If water is

used instead of coolant, check and correct

the antifreeze concentration of the coolant.

Use only distilled water. Soft water may be

used if distilled water is not available.

3. Start the engine, warm it up for several minutes, and then turn it off.

4. Check:

coolant level

NOTE:

Before checking the coolant level, wait a few minutes until it settles.

EAA00140

F. ADJUSTING THE ENGINE IDLING SPEED

NOTE:

Prior to adjusting the engine idling speed, the carburetor synchronization should be adjusted properly, the air filter should be clean, and the engine

should have adequate compression.

1. Start the engine and let it warm up for several

minutes.

2. Attach:

engine tachometer

(to the spark plug lead of cylinder #1)

Engine tachometer

90890-031 13

3. Measure:

engine idling speed

Out of specification Adjust.

Engine idling speed

1,050 1,150 r/min

EAA00141

G. ADJUSTING THE THROTTLE CABLE FREE

PLA Y

NOTE:

Prior to adjusting the throttle cable free play, the

engine idling speed should be adjusted.

1. Measure:

throttle cable free play

a

Out of specification Adjust.

Throttle cable free play (at the

flange of the throttle grip)

3 5 mm

4. Adjust:

engine idling speed

a. Turn the pilot screw

in or out until it is lightly

1

seated.

b. Turn the pilot screw out the specified number of

turns.

Pilot screw

2 turns out

c. Turn the throttle stop screw

or

until the specified engine idling speed is

b

in direction

2

obtained.

Engine idling speed is

Direction

Direction

a

increased.

Engine idling speed is

b

decreased.

2. Adjust:

a. Loosen the locknut

b. Turn the adjusting nut 2 in direction

.

1

a

or

until the specified throttle cable free play is obtained.

Throttle cable free play is

Direction

Direction

a

increased.

Throttle cable free play is

b

decreased.

c. Tighten the locknut.

WARNING

After adjusting the throttle cable free play, turn

the handlebar to the right and to the left to ensure that this does not cause the engine idling

speed to change.

a

b

–12–

Page 17

EAA00142

H. ADJUSTING THE FRONT BRAKE

1. Adjust:

D brake lever position

(distance

lever)

a. While pushing the brake lever forward, turn the

adjusting dial

desired position.

NOTE:

Be sure to align the setting on the adjusting dial

with the arrow mark

Position #1 Distance is the largest.

Position #4 Distance is the smallest.

a

from the throttle grip to the brake

until the brake lever is in the

1

on the brake lever holder.

2

a

a

WARNING

After adjusting the brake lever position, make

sure that the pin on the brake lever holder is

firmly inserted in the hole in the adjusting dial.

CAUTION:

After adjusting the brake lever position, make

sure that there is no brake drag.

WARNING

A soft or spongy feeling in the brake lever can

indicate the presence of air in the brake system. Before the vehicle is operated, the air

must be removed by bleeding the brake system. Air in the brake system will considerably

reduce braking performance and could result

in loss of control and possibly an accident.

Therefore, check and, if necessary, bleed the

brake system.

EAA00146

I. ADJUSTING THE REAR BRAKE

1. Measure:

D brake pedal position

(distance

the top of the brake pedal)

Out of specification Adjust.

Brake pedal position (below the top of the

rider footrest)

40 mm

2. Adjust:

D brake pedal position

a. Loosen the locknut

b. Turn the adjusting bolt 2 in direction

until the specified brake pedal position is obtained.

Direction Brake pedal is raised.

Direction Brake pedal is lowered.

a

from the top of the rider footrest to

.

1

a

b

a

or

WARNING

After adjusting the brake pedal position, check

that the end of the adjusting bolt

through the hole

c

.

is visible

2

c. Tighten the locknut

Locknut

18 Nm (1.8 mSkg)

to specification.

1

WARNING

A soft or spongy feeling in the brake pedal can

indicate the presence of air in the brake system. Before the vehicle is operated, the air

must be removed by bleeding the brake system. Air in the brake system will considerably

reduce braking performance and could result

in loss of control and possibly an accident.

Therefore, check and, if necessary, bleed the

brake system.

b

CAUTION:

After adjusting the brake pedal position, make

sure that there is no brake drag.

–13–

Page 18

A

B

EAA00151

J. CHECKING THE BRAKE FLUID LEVEL

1. Stand the motorcycle on a level surface.

NOTE:

D Place the motorcycle on a suitable stand.

D Make sure that the motorcycle is upright.

2. Check:

D brake fluid level

Below the minimum level mark

a

Add the

recommended brake fluid to the proper level.

Recommended brake fluid

DOT 4

WARNING

D Use only the designated brake fluid. Other

brake fluids may cause the rubber seals to

deteriorate, causing leakage and poor brake

performance.

D Refill with the same type of brake fluid that is

already in the system. Mixing brake fluids

may result in a harmful chemical reaction,

leading to poor brake performance.

D When refilling, be careful that water does not

enter the reservoir. Water will significantly

lower the boiling point of the brake fluid and

could cause vapor lock.

Front brake

A

Rear brake

B

EAA00154

K. BLEEDING THE HYDRAULIC BRAKE SYS-

TEM

WARNING

Bleed the hydraulic brake system whenever:

D the system was disassembled,

D a brake hose was loosened or removed,

D the brake fluid level is very low,

D brake operation is faulty.

1. Remove:

D reservoir cap

D diaphragm

1

2

NOTE:

D Be careful not to spill any brake fluid or allow the

brake fluid reservoir to overflow.

D When bleeding the hydraulic brake system,

make sure that there is always enough brake

fluid before applying the brake. Ignoring this precaution could allow air to enter the hydraulic

brake system, considerably lengthening the

bleeding procedure.

D If bleeding is difficult, it may be necessary to let

the brake fluid settle for a few hours. Repeat the

bleeding procedure when the tiny bubbles in the

hose have disappeared.

2. Bleed:

D hydraulic brake system

CAUTION:

Brake fluid may damage painted surfaces and

plastic parts. Therefore, always clean up any

spilt brake fluid immediately.

NOTE:

In order to ensure a correct reading of the brake

fluid level, make sure that the top of the reservoir is

horizontal.

c. Connect a clear plastic hose

tightly to the

1

bleed screw 2.

Front

A

Rear

B

d. Place the other end of the hose into a contain-

er.

e. Slowly apply the brake several times.

f. Fully squeeze the brake lever or fully depress

the brake pedal and hold it in position.

g. Loosen the bleed screw.

This will release the tension and cause the

brake lever to contact the throttle grip or the

brake pedal to fully extend.

h. Tighten the bleed screw and then release the

brake lever or brake pedal.

i. Repeat steps (e) to (h) until all of the air

bubbles have disappeared from the brake fluid

in the plastic hose.

j. Tighten the bleed screw to specification.

Bleed screw

6 Nm (0.6 mSkg)

k. Fill the reservoir to the proper level.

Refer to “CHECKING THE BRAKE FLUID

LEVEL”.

WARNING

After bleeding the hydraulic brake system,

check the brake operation.

a. Add the recommended brake fluid to the prop-

er level.

b. Install the brake fluid resorvoir diaphragm.

–14–

Page 19

L. ADJUSTING THE CLUTCH CABLE FREE

PLAY

1. Check:

clutch cable free play

Out of specification Adjust.

Clutch cable free play (at the end of the clutch

lever)

10 15 mm

2. Adjust:

clutch cable free play

a

Clutch cable free play is

Direction

Direction

c. Tighten the locknut.

NOTE:

If the specified clutch cable free play cannot be obtained on the handlebar side of the cable, use the

adjusting nut on the engine side.

a

increased.

Clutch cable free play is

b

decreased

a. Loosen the locknut

b. Turn the adjusting bolt 2 in direction

until the specified clutch cable free play is obtained.

.

1

a

or

b

–15–

Page 20

EAA00159

M. ADJUSTING THE FRONT FORK LEGS

The following procedure applies to both of the front

fork legs.

WARNING

Always adjust both front fork legs evenly.

Uneven adjustment can result in poor handling and loss of stability.

Securely support the motorcycle so that

there is no danger of it falling over.

Rebound damping

CAUTION:

Never go beyond the maximum or minimum

adjustment positions.

1. Adjust:

rebound damping

a. Turn the adjusting screw

.

b

in direction

2

a

or

Spring preload

CAUTION:

Grooves are provided to indicate the adjust-

ment position.

Never go beyond the maximum or minimum

adjustment positions.

1. Adjust:

spring preload

a. Turn the adjusting bolt

Spring preload is

Direction

Direction

Adjusting positions

Standard: 4

Minimum: 8

Maximum: 1

increased (suspension is

a

harder).

Spring preload is

decreased (suspension is

b

softer).

in direction

1

a

or

b

Rebound damping is

Direction

Direction

Adjusting positions

Standard: 7 clicks out*

.

Minimum: 17 clicks out*

Maximum: 1 clicks out*

*: from the fully turned-in position

Compression damping

increased (suspension is

a

harder).

Rebound damping is

decreased (suspension is

b

softer).

CAUTION:

Never go beyond the maximum or minimum

adjustment positions.

1. Adjust:

compression damping

a. Turn the adjusting screw

.

b

Compression damping is

Direction

Direction

increased (suspension is

a

harder).

Compression damping is

decreased (suspension is

b

softer).

in direction

3

a

or

–16–

Adjusting positions

Standard: 6 clicks out*

Minimum: 21 clicks out*

Maximum: 1 clicks out*

*: from the fully turned-in position

Page 21

EAA00169

N. ADJUSTING THE REAR SHOCK ABSORB-

ER ASSEMBL Y

WARNING

Securely support the motorcycle so that there

is no danger of it falling over.

Spring preload

CAUTION:

Never go beyond the maximum or minimum

adjustment positions.

1. Adjust:

spring preload

NOTE:

Adjust the spring preload with the special wrench

and extension bar included in the owner’s tool kit.

a. Turn the adjusting ring

b. Align the desired position on the adjusting ring

with the stopper

Direction

Direction

a

b

in direction

1

.

2

Spring preload is

increased (suspension

is harder).

Spring preload is

decreased (suspension

is softer).

a

or

b

Rebound damping

CAUTION:

Never go beyond the maximum or minimum

adjustment positions.

1. Adjust:

rebound damping

a. Turn the adjusting knob

.

b

Direction

Direction

Adjusting positions

.

Standard: 20 clicks out*

Minimum: 10 clicks out*

Maximum: 3 clicks out*

*: from the fully turned-in position

Compression damping

a

b

Rebound damping is

increased (suspension

is harder).

Rebound damping is

decreased (suspension

is softer).

in direction

2

CAUTION:

Never go beyond the maximum or minimum

adjustment positions.

a

or

Adjusting positions

Standard: 6

Minimum: 1

Maximum: 11

1. Adjust:

compression damping

a. Turn the adjusting screw

.

b

Compression damping is

a

Direction

Direction

Adjusting positions

Standard: 7 clicks in*

Minimum: 1 clicks in*

Maximum: 12 clicks in*

*: from the fully turned-out position

increased (suspension

is harder).

Compression damping is

decreased (suspension

b

is softer).

in direction

3

a

or

–17–

Page 22

EAA00178

O. ADJUSTING THE DRIVE CHAIN SLACK

NOTE:

The drive chain slack must be checked at the tightest point on the chain.

CAUTION:

A drive chain that is too tight will overload the

engine and other vital parts, and one that is too

loose can skip and damage the swingarm or

cause an accident. Therefore, keep the drive

chain slack within the specified limits.

1. Stand the motorcycle on a level surface.

WARNING

Securely support the motorcycle so that there

is no danger of it falling over.

4. Loosen:

D wheel axle nut

1

5. Adjust:

D drive chain slack

a. Loosen both locknuts 2.

b. Turn both adjusting bolts 3 in direction

until the specified drive chain slack is ob-

b

a

or

tained.

Direction Drive chain is tightened.

Direction Drive chain is loosened.

a

b

NOTE:

D To maintain the proper wheel alignment, adjust

both sides evenly.

D Push the rear wheel forward to make sure that

there is no clearance between the wheel axle

plates and the end of the adjusting bolts.

NOTE:

Both wheels should be on the ground without a rider on the motorcycle.

2. Rotate the rear wheel several times and check

the drive chain to locate its tightest point.

3. Measure:

D drive chain slack

a

Out of specification Adjust.

Drive chain slack

40 50 mm

EAA00181

P. ADJUSTING THE REAR BRAKE LIGHT

SWITCH

NOTE:

The rear brake light switch is operated by movement of the brake pedal.

The rear brake light switch is properly adjusted

when the brake light comes on just before the braking effect starts.

1. Check:

D rear brake light operation timing

Incorrect Adjust.

c. Tighten the wheel axle nut to specification.

Wheel axle nut

150 Nm (15 mSkg)

d. Tighten the locknuts to specification.

Locknut

16 Nm (1.6 mSkg)

2. Adjust:

D rear brake light operation timing

a. Hold the main body

of the rear brake light

1

switch so that it does not rotate and turn the ad-

a

justing nut

in direction

2

or

b

until the rear

brake light comes on at the proper time.

Direction

Direction

a

b

Brake light comes on

sooner.

Brake light comes on

later.

EAA00184

Q. ADJUSTING THE HEADLIGHT BEAMS

The following procedure applies to both of the

headlights.

1. Adjust:

D headlight beam (vertically)

a. Turn the adjusting screw

.

b

Direction Headlight beam is raised.

Direction Headlight beam is lowered.

a

b

in direction

1

a

or

–18–

2. Adjust:

D headlight beam (horizontally)

a. Turn the adjusting knob

.

b

2

Left headlight

Direction

Direction

a

b

Headlight beam moves to

the right.

Headlight beam moves to

the left.

Right headlight

Direction

Direction

a

b

Headlight beam moves to

the left.

Headlight beam moves to

the right.

in direction

a

or

Page 23

EAA00185

R. ADJUSTING THE DIGITAL CLOCK

NOTE:

This digital clock constantly displays the time.

1. Adjust:

digital clock

a. Hold down the “RESET” button 2 and “SE-

LECT” button

b. Push the “RESET” button 2 to set the hour.

And push the “SELECT” button.

c. Push the “RESET” button 2 to set the min-

utes. And push the “SELECT” button.

NOTE:

When setting the time (e.g., after reconnecting the

battery), first set the clock to 1:00 AM, then set it to

the correct time.

1

.

3

–19–

Page 24

APPENDICES

SERVICE DAT A

FZS1000 (N) 2001

Engine idling speed: 1,050 1,150 r/min

Spark plug:

Type

Gap

Fuel:

Recommended fuel

Fuel tank capacity Total:

Valve clearance (cold): IN

EX

Maximum load * 201 kg

Up to 90 kg load *

Tire pressure

90 kg Maximum load *

High speed riding

CR9E (NGK), U27ESR-N (DENSO)

0.7 0.8 mm

Regular unleaded gasoline

21 L

0.11 0.20 mm

0.21 0.25 mm

Front Rear

250 kPa

(2.5 kgf/cm

2

, 2.5 bar)

250 kPa

(2.5 kgf/cm2, 2.5 bar)

250 kPa

(2.5 kgf/cm2, 2.5 bar)

270 kPa

(2.7 kgf/cm

2

, 2.7 bar)

290 kPa

(2.9 kgf/cm2, 2.9 bar)

290 kPa

(2.9 kgf/cm2, 2.9 bar)

* Load is the total weight of cargo, rider, passenger, and accessories.

ST ANDARD EQUIPMENT

No.

Part name Q’ty

1 Owner’s manual 1

2 Owner’s tool kit 1

OWNER’S TOOL KIT

No. Part name Q’ty

1 Owner’s tool bag 1

2 Pliers 1

3 Wrench (10 – 12) 1

4 Wrench (12 – 14) 1

5 Wrench (14 – 17) 1

6 Wrench (32) 1

7 Special wrench 1

8 Extension bar 1

9 Spark plug wrench 1

10 Screwdriver grip 1

11 Screwdriver bit (phillips-slotted) 1

12 Screwdriver bit (phillips) 1

13 Hexagon wrench (3) 1

14 Hexagon wrench (4) 1

15 Hexagon wrench (5) 1

–20–

Page 25

TIGHTENING TORQUE

Part to be tightened

Thread size

Engine:

Spark plug

Engine oil drain bolt

Chassis

Upper bracket pinch bolt

Upper bracket cap nut

Upper bracket and handlebar holder

Handlebar holder

Lower bracket pinch bolt

Lower bracket ring nut

Front brake master cylinder

Front brake hose union bolt

Engine mounting

Engine mounting bolt/nut

Engine mounting bolt/nut

Frame and down tube

Clutch cable lock nut

Ignition coil and stay

Pivot shaft

Rear shock absorber (upper)

Rear shock absorber and relay arm

Relay arm and frame

Relay arm and connecting arm

Connecting arm and swing arm

Drive chain guard

Drive chain case

Fuel cock

Fuel sender

Side cover

Coolant reservoir tank

Front wheel axle

Front wheel axle pinch bolt

Front brake caliper

Front brake disk

Front brake bleed screw

Rear brake torque rod

Rear wheel sprocket

Drive chain adjusting nut

Rear brake caliper

Rear wheel axle

Rear brake hose union bolt

Rear brake bleed screw

Rear brake disk

Rider footrest bracket and frame

Rear brake reservoir tank

Rear brake master cylinder

Rider footrest and bracket

Passenger footrest bracket and frame

Passenger footrest bracket and muffler

M10

M14

M8

M22

M10

M8

–

M25

M6

M10

M10

M8

M10

M8

M6

M18

M10

M10

M10

M12

M12

M6

M6

M6

M5

M6

M6

M16

M8

M10

M6

M8

M8

M10

M8

M10

M24

M10

M8

M8

M8

M6

M8

M10

M8

M10

Tightening torque

Nm mkg

13

43

30

110

32

23

23

See note

10

30

55

33

89

7

7

125

40

40

40

48

48

7

7

7

4

4

4

72

23

40

18

6

23

69

16

40

150

30

6

23

30

4

23

55

28

48

1.3

4.3

3.0

11

3.2

2.3

2.3

10

3.0

5.5

3.3

8.9

0.7

0.7

12.5

4.0

4.0

4.0

4.8

4.8

0.7

0.7

0.7

0.4

0.4

0.4

7.2

2.3

4.0

1.8

0.6

2.3

6.9

1.6

4.0

15

3.0

0.6

2.3

3.0

0.4

2.3

5.5

2.8

4.8

NOTE:

1. First, tighten the ring nut approximately 52 Nm (5.2 mkg) by using the torque wrench, then loosen the ring nut

2. Retighten the ring nut 18 Nm (1.8 mkg).

completely .

–21–

Page 26

HOW TO USE THE CONVERSION TABLE

Torque

Weight

Distance

Mi

neous

All specification date in this manual is listed

in SI and METRIC UNITS.

Use this table to convert METRIC unit data

to IMP unit data.

Ex.

METRIC MULTIPLIER IMP

**mm 0.03937 = **in

2 mm 0.03937 = 0.08in

Volume/

Capacity

scella-

CONVERSION TABLE

METRIC TO IMP

Known Multiplier Result

mSkg 7.233 ftSlb

mSkg 86.794 inSlb

cmSkg 0.0723 ftSlb

cmSkg 0.8679 inSlb

kg 2.205 lb

g 0.03527 oz

km/hr 0.6214 mph

km 0.6214 mi

m 3.281 ft

m 1.094 yd

cm 0.3937 in

mm 0.03937 in

cc (cm3) 0.03527 oz (IMP liq.)

cc (cm3) 0.06102 cu. in

lit (liter) 0.8799 qt (IMP liq.)

lit (liter) 0.2199 gal (IMP liq.)

kg/mm 55.997 lb/in

2

kg/cm

Centigrade 9/5 (_C) +32 Fahrenheit (_F)

14.2234 psi (lb/in2)

–22–

Page 27

Page 28

PRINTED ON RECYCLED PAPER

PRINTED IN BELGIUM

2000 12 - 1.4 1

I

Loading...

Loading...