Page 1

F90D

SERVICE MANUAL

*LIT186160286*

6D8-28197-1G-11LIT-18616-02-86

Page 2

NOTICE

This manual has been prepared by Yamaha primarily for use by Yamaha dealers and their trained

mechanics when performing maintenance procedures and repairs to Yamaha equipment. It has

been written to suit the needs of persons who have a basic understanding of the mechanical and

electrical concepts and procedures inherent in the work, for without such knowledge attempted

repairs or service to the equipment could render it unsafe or unfit for use.

Because Yamaha has a policy of continuously improving its products, models may differ in detail

from the descriptions and illustrations given in this publication. Use only the latest edition of this

manual. Authorized Yamaha dealers are notified periodically of modifications and significant

changes in specifications and procedures, and these are incorporated in successive editions of this

manual.

Important information

Particularly important information is distinguished in this manual by the following notations:

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED!

WARNING

Failure to follow WARNING instructions could result in severe injury or death to the machine

operator, a bystander, or a person inspecting or repairing the outboard motor.

CAUTION:

A CAUTION indicates special precautions that must be taken to avoid damage to the outboard motor.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

1

F90D

SERVICE MANUAL

©2004 by Yamaha Motor Corporation, USA

1st Edition, June 2004

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Corporation, USA

is expressly prohibited.

Printed in USA

LIT-18616-02-86

Page 3

Contents

General information

Specifications

Periodic checks and adjustments

Fuel system

Power unit

GEN

INFO

SPEC

CHK

ADJ

FUEL

POWR

1

2

3

4

5

Lower unit

Bracket unit

Electrical systems

Troubleshooting

Index

LOWR

BRKT

–+

ELEC

TRBL

SHTG

6

7

8

9

Page 4

GEN

INFO

General information

How to use this manual.................................................................................1-1

Manual format............................................................................................1-1

Symbols.....................................................................................................1-2

Safety while working......................................................................................1-3

Fire prevention...........................................................................................1-3

Ventilation..................................................................................................1-3

Self-protection ...........................................................................................1-3

Parts, lubricants, and sealants ..................................................................1-3

Good working practices .............................................................................1-4

Disassembly and assembly .......................................................................1-4

1

2

Identification...................................................................................................1-5

Applicable model .......................................................................................1-5

Serial number ............................................................................................1-5

Propeller selection.........................................................................................1-5

Propeller size.............................................................................................1-5

Selection....................................................................................................1-6

Predelivery checks ........................................................................................1-6

Checking the fuel system ..........................................................................1-6

Checking the engine oil level.....................................................................1-6

Checking the gear oil level ........................................................................1-7

Checking the battery..................................................................................1-7

Checking the outboard motor mounting height..........................................1-7

Checking the remote control cables ..........................................................1-7

Checking the steering system ...................................................................1-8

Checking the gear shift and throttle operation...........................................1-8

Checking the power trim and tilt system....................................................1-8

Checking the engine start switch and engine stop lanyard switch ............1-8

Checking the cooling water pilot hole ........................................................1-9

Test run .....................................................................................................1-9

Break-in .....................................................................................................1-9

After test run ..............................................................................................1-9

3

4

5

6

7

6D81G11

8

9

Page 5

GEN

INFO

General information

How to use this manual

Manual format

The format of this manual has been designed to make service procedures clear and easy to understand. Use the information below as a guide for effective and quality service.

1

Parts are shown and detailed in an exploded diagram and are listed in the components list.

2

Tightening torque specifications are provided in the exploded diagrams and after a numbered

step with tightening instructions.

3

Symbols are used to indicate important aspects of a procedure, such as the grade of lubricant

and lubrication point.

4

The components list consists of part names and part quantities, as well as bolt and screw dimensions.

5

Service points regarding removal, checking, and installation are shown in individual illustrations

to explain the relevant procedure.

NOTE:

For troubleshooting procedures, see Chapter 9, “Troubleshooting.”

1

40 mm

10 45 mm

60 mm

3

LOWR

Lower unit

No. Part name Q’ty Remarks

1 Lower unit 1

2 Plastic tie 1

3Hose 1

4 Check screw 1

5 Gasket 2

6 Dowel pin 2

7 Bolt 4 M10

8 Drain screw 1

9Grommet 1

10 Bolt 1 M

11 Bolt 1 M8

12 Thrust washer 1

13 Propeller 1

14 Washer 1

15 Washer 1

16 Cotter pin 1

17 Propeller nut 1

18 Trim tab 1

6-5

Lower unit

Not reusable

Not reusable

Not reusable

4

2

62Y5A11

1

LOWR

Removing the drive shaft

1. Remove the drive shaft assembly and

pinion, and then pull out the forward

gear.

Disassembling the drive shaft

1. Install the pinion nut 1, tighten it finger

tight, and then remove the drive shaft

bearing 2 using a press.

CAUTION:

• Do not press the drive shaft threads

directly.

• Do not reuse the bearing, always

replace it with a new one.

Disassembling the forward gear

1. Remove the taper roller bearing from the

forward gear using a press.

Lower unit

S62Y6850K

Drive shaft holder 4 1: 90890-06518

Pinion nut holder 2: 90890-06505

Socket adapter 2 3: 90890-06507

Bearing inner race attachment 3:

90890-06639

CAUTION:

Do not reuse the bearing, always replace

it with a new one.

Bearing separator 1: 90890-06534

2. Remove the needle bearing from the forward gear.

CAUTION:

Do not reuse the bearing, always replace

it with a new one.

a

Stopper guide plate 2: 90890-06501

Stopper guide stand 3:

90890-06538

Bearing puller 4: 90890-06535

Bearing puller claw 1 5:

90890-06536

S62Y6740K

1-1

5

6-19

62Y5A11

6D81G11

Page 6

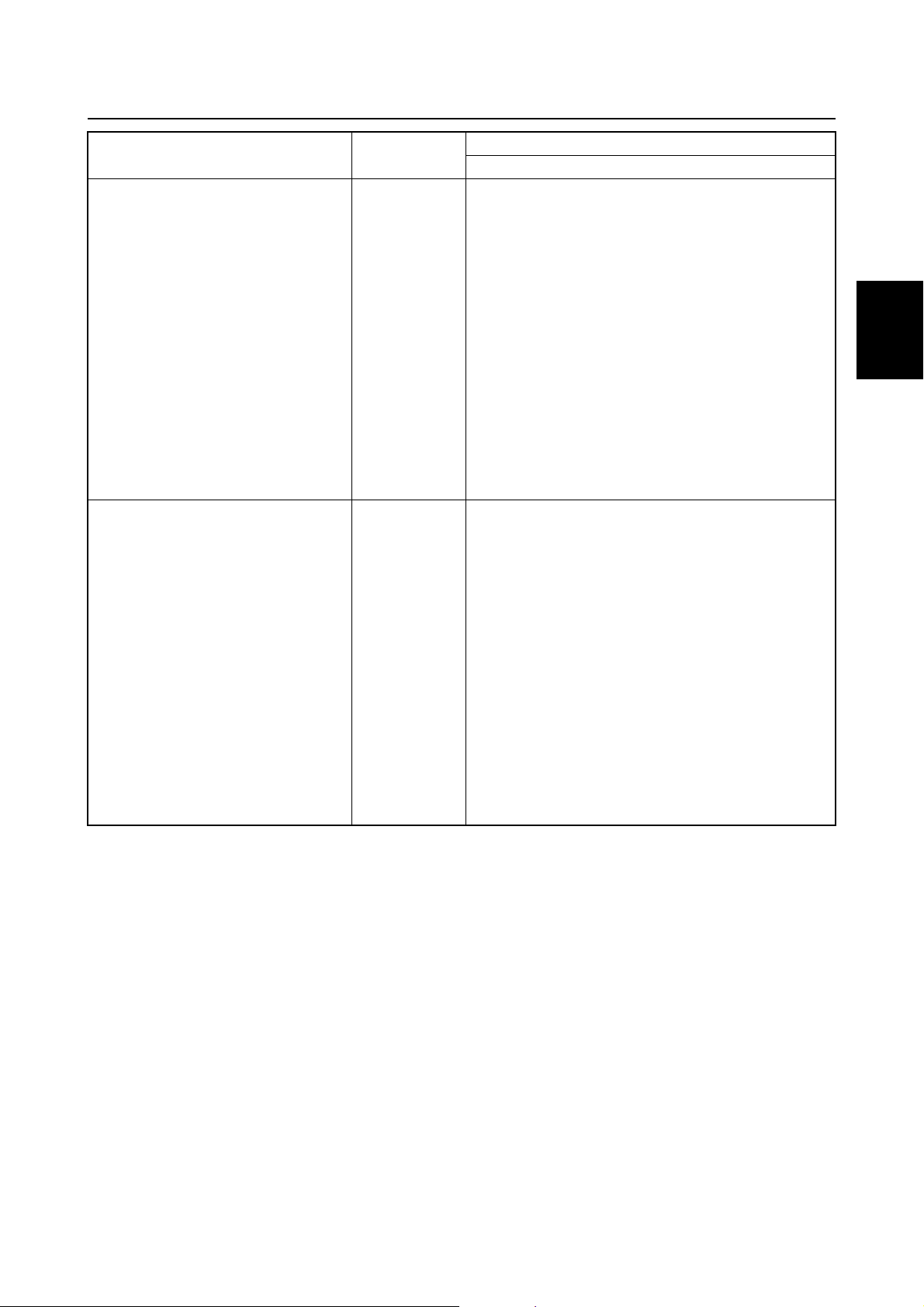

Symbols

T

R

.

.

D

The symbols below are designed to indicate the content of a chapter.

How to use this manual

General information

GEN

INFO

Specifications

SPEC

Periodic checks and adjustments

CHK

ADJ

Symbols 1 to 6 indicate specific data.

123456

Fuel system

FUEL

Power unit

POWR

Lower unit

LOWR

Bracket unit

BRKT

Electrical systems

ELEC

Troubleshooting

– +

TRBL

SHTG

1

2

3

4

Special tool

1

Specified oil or fluid

2

Specified engine speed

3

Specified tightening torque

4

Symbols 7 to C in an exploded diagram indicate the grade of lubricant and the lubrication point.

7890ABC

A M

E G

Apply Yamaha 4-stroke motor oil

7

Apply gear oil

8

Apply water resistant grease (Yamaha grease A)

9

Apply molybdenum disulfide grease

0

Symbols D to H in an exploded diagram indicate the type of sealant or locking agent and the application point.

DEFGH

GM

LT

271

Specified measurement

5

Specified electrical value

6

(resistance, voltage, electric current)

C I

Apply corrosion resistant grease

A

(Yamaha grease D)

Apply low temperature resistant grease

B

(Yamaha grease C)

Apply injector grease

C

LT

242

LT

572

SS

5

6

7

8

9

Apply Gasket Maker

D

Apply LOCTITE 271 (red)

E

Apply LOCTITE 242 (blue)

F

6D81G11

Apply LOCTITE 572

G

Apply silicon sealant

H

1-2

Page 7

GEN

INFO

General information

Safety while working

To prevent an accident or injury and to

ensure quality service, follow the safety procedures provided below.

Fire prevention

Gasoline is highly flammable.

Keep gasoline and all flammable products

away from heat, sparks, and open flames.

Ventilation

Gasoline vapor and exhaust gas are heavier

than air and extremely poisonous. If inhaled

in large quantities they may cause loss of

consciousness and death within a short time.

When test running an engine indoors (e.g., in

a water tank) be sure to do so where adequate ventilation can be maintained.

1

Parts, lubricants, and sealants

Use only genuine Yamaha parts, lubricants,

and sealants or those recommended by

Yamaha, when servicing or repairing the outboard motor.

Under normal conditions, the lubricants mentioned in this manual should not harm or be

hazardous to your skin. However, you should

follow these precautions to minimize any risk

when working with lubricants.

Self-protection

Protect your eyes by wearing safety glasses

or safety goggles during all operations involving drilling and grinding, or when using an air

compressor.

Protect your hands and feet by wearing protective gloves and safety shoes when necessary.

1-3

1. Maintain good standards of personal and

industrial hygiene.

2. Change and wash clothing as soon as

possible if soiled with lubricants.

3. Avoid contact with skin. Do not, for

example, place a soiled rag in your

pocket.

4. Wash hands and any other part of the

body thoroughly with soap and hot water

after contact with a lubricant or lubricant

soiled clothing has been made.

5. To protect your skin, apply a protective

cream to your hands before working on

the outboard motor.

6D81G11

Page 8

Safety while working

6. Keep a supply of clean, lint-free cloths for

wiping up spills, etc.

Good working practices

Special service tools

Use the recommended special service tools

to protect parts from damage. Use the right

tool in the right manner—do not improvise.

Tightening torques

Follow the tightening torque specifications

provided throughout the manual. When tightening nuts, bolts, and screws, tighten the

large sizes first, and tighten fasteners starting

in the center and moving outward.

Non-reusable parts

Always use new gaskets, seals, O-rings, cotter pins, circlips, etc., when installing or

assembling parts.

Disassembly and assembly

1. Use compressed air to remove dust and

dirt during disassembly.

2. Apply engine oil to the contact surfaces

of moving parts before assembly.

3. Install bearings with the manufacture

identification mark in the direction indicated in the installation procedure. In

addition, be sure to lubricate the bearings

liberally.

4. Apply a thin coat of water-resistant

grease to the lip and periphery of an oil

seal before installation.

5. Check that moving parts operate normally after assembly.

1

2

3

4

5

6

7

8

9

6D81G11

1-4

Page 9

GEN

INFO

General information

Identification

Applicable model

This manual covers the following model.

Applicable model

F90TR

Serial number

The outboard motor serial number is

stamped on a label attached to the port

clamp bracket.

S6D81010

1

Propeller selection

1

The performance of a boat and outboard

motor will be critically affected by the size

and type of propeller you choose. Propellers

greatly affect boat speed, acceleration,

engine life, fuel economy, and even boating

and steering capabilities. An incorrect choice

could adversely affect performance and

could also seriously damage the engine.

Use the following information as a guide for

selecting a propeller that meets the operating

conditions of the boat and the outboard

motor.

Propeller size

The size of the propeller is indicated on the

propeller boss end, on the side of the propeller boss.

Model name

1

Approved model code

2

Transom height

3

Serial number

4

Model name

Approved

model code

F90TR 61P 1007790–

Starting

serial No.

× -

abc

Propeller diameter (in inches)

a

Propeller pitch (in inches)

b

Propeller type (propeller mark)

c

× -

abc

S69J1100

S60C1120

1-5

6D81G11

Page 10

Identification / Propeller selection / Predelivery checks

Selection

When the engine speed is at the full throttle

operating range (5,000–6,000 r/min), the

ideal propeller for the boat is one that provides maximum performance in relation to

boat speed and fuel consumption.

Propeller size (in) Material

12 5/8 × 21 - K

13 × 19 - K

13 × 23 - K

13 × 25 - K

Aluminum

13 1/4 × 17 - K

13 1/2 × 15 - K

13 5/8 × 13 - K

1

2

3

14 × 11 - K

13 × 17 - K

13 × 19 - K

13 × 21 - K

13 × 23 - K

13 × 25 - K

13 1/2 × 14 - K

13 1/2 × 16 - K

Predelivery checks

To make the delivery process smooth and

efficient, the predelivery checks should be

completed as explained below.

Checking the fuel system

1. Check that the fuel hoses are securely

connected and that the fuel tank is full

with fuel.

Stainless

S6D81020

CAUTION:

This is a 4-stroke engine. Never use premixed fuel.

Checking the engine oil level

1. Check the engine oil level.

1

a

4

5

6

b

S60C1150

NOTE:

If the engine oil is below the minimum level

mark b, add sufficient oil until the level is

between a and b.

7

8

6D81G11

Recommended engine oil:

4-stroke motor oil

API: SE, SF, SG, SH, or SJ

SAE: 10W-30 or 10W-40

Engine oil quantity:

Without oil filter replacement:

4.3 L (4.55 US qt, 3.78 Imp qt)

9

1-6

Page 11

GEN

INFO

General information

Checking the gear oil level

1. Check the gear oil level.

S60C1140

Checking the battery

1. Check the capacity, electrolyte level, and

specified gravity of the battery.

Recommended battery capacity:

CCA/SAE: 380 A

MCA/ABYC: 502 A

RC/SAE: 124 Minute

Electrolyte specified gravity:

1.280 at 20 °C (68 °F)

NOTE:

The optimum mounting height is affected by

the combination of the boat and the outboard

motor. To determine the optimum mounting

height, test run the outboard motor at different heights.

2. Check that the clamp brackets are

secured with the clamp bolts.

Checking the remote control cables

1. Set the remote control lever to the neutral position and fully close the throttle

lever.

2. Check that the stopper 1 on the throttle

cam contacts the fully closed stopper

on the cylinder block.

2

2

2. Check that the positive and negative battery leads are securely connected.

Checking the outboard motor

mounting height

1. Check that the anti-cavitation plate is

aligned with the bottom of the boat. If the

mounting height is too high, cavitation

will occur and propulsion will be reduced.

Also, the engine speed will increase

abnormally and cause the engine to

overheat. If the mounting height is too

low, water resistance will increase and

reduce engine efficiency.

1

S6D81030

3. Check that the alignment mark a on the

bushing is aligned with the alignment

mark b on the bracket.

a

b

S6D81040

1-7

6D81G11

Page 12

Predelivery checks

N

F

R

c

WARNING

The shift/throttle cable joint must be

screwed in a minimum of 8.0 mm (0.31 in)

.

c

Checking the steering system

1. Check the steering friction for proper

adjustment.

2. Check that the steering operates

smoothly.

S69J3370

a

a

S69J1210

Checking the power trim and tilt

system

1. Check that the outboard motor tilts up

and down smoothly when operating the

power trim and tilt unit.

2. Check that there is no abnormal noise

produced when the outboard motor is

tilted up or down.

3. Check that there is no interference with

wires or hoses when the tilted-up outboard motor is steered.

4. Check that the trim meter points down

when the outboard motor is tilted all the

way down.

1

2

3

4

5

S60C1200

3. Check that there is no interference with

wires or hoses when the outboard motor

is steered.

Checking the gear shift and throttle

operation

1. Check that the gear shift operates

smoothly when the remote control lever

is shifted from neutral to forward or

reverse.

2. Check that the throttle operates smoothly

when the remote control lever is shifted

from forward or reverse to the fully open

position a.

Checking the engine start switch and

engine stop lanyard switch

1. Check that the engine starts when the

engine start switch is turned to START.

2. Check that the engine turns off when the

engine start switch is turned to OFF.

S60V1070

6

7

8

9

6D81G11

1-8

Page 13

GEN

INFO

General information

3. Check that the engine turns off when the

engine stop lanyard is pulled from the

engine stop lanyard switch.

Checking the cooling water pilot

hole

1. Check that cooling water is discharged

from the cooling water pilot hole.

Break-in

During the test run, perform the break-in

operation in the following three stages.

1. One hour a at 2,000 r/min or at approximately half throttle

2. One hour b at 3,000 r/min or 3/4 throttle

and 1 minute out of every 10 at full throttle

3. Eight hours c at any speed, however,

avoid running at full speed for more than

5 minutes

È

ab

0

1

210

c

Test run

1. Start the engine, and then check that the

gear shift operates smoothly.

2. Check the engine idle speed after the

engine has been warmed up.

3. Operate at trolling speed.

4. Run the outboard motor for 1 hour at

2,000 r/min or at half throttle, then for

another hour at 3,000 r/min or at 3/4

throttle.

5. Check that the outboard motor does not

tilt up when shifting into reverse and that

water does not flow in over the transom.

S69J1240

Hour

È

After test run

1. Check for water in the gear oil.

2. Check for fuel leakage in the cowling.

3. Flush the cooling water passage with

fresh water using the flushing kit and with

the engine running at idle.

NOTE:

The test run is part of the break-in operation.

1-9

6D81G11

Page 14

SPEC

Specifications

General specifications...................................................................................2-1

Maintenance specification ............................................................................2-3

Power unit..................................................................................................2-3

Lower unit ..................................................................................................2-6

Electrical ....................................................................................................2-6

Dimensions................................................................................................2-9

Tightening torques.......................................................................................2-11

Specified torques.....................................................................................2-11

General torques.......................................................................................2-13

1

2

3

4

5

6

7

8

9

6D81G11

Page 15

SPEC

Specifications

General specifications

Item Unit

Dimension

Overall length mm (in) 817 (32.2)

Overall width mm (in) 479 (18.9)

Overall height

(L) mm (in) 1,582 (62.3)

(X) mm (in) 1,710 (67.3)

Boat transom height

(L) mm (in) 508 (20.0)

(X) mm (in) 635 (25.0)

Weight

(without propeller)

(L) kg (lb) 168 (370)

(X) kg (lb) 172 (379)

Performance

Maximum output kW (hp) 66.2 (90) at 5,500 r/min

Full throttle operating range r/min 5,000–6,000

Maximum fuel consumption L (US gal,

33.0 (8.72, 7.26) at 6,000 r/min

Imp gal)/hr

Engine idle speed r/min 700 ± 50

Power unit

Type In-line, 4-stroke, DOHC, 16 valves

Cylinder quantity 4

Total displacement cm

3

(cu. in) 1,596 (97.39)

Bore × stroke mm (in) 79.0 × 81.4 (3.11 × 3.20)

Compression ratio 9.6

Control system Remote control

Starting system Electric

Fuel system Fuel injection

Ignition control system TCI

Advance type Micro computer

Maximum generator output V, A 12, 25

Spark plug LFR5A-11 (NGK)

Cooling system Water

Exhaust system Propeller boss

Lubrication system Wet sump

Model

F90TR

2

2-1

6D81G11

Page 16

General specifications

Item Unit

Fuel and oil

Fuel type Regular unleaded gasoline

Fuel minimum rating RON

Engine oil 4-stroke motor oil

Engine oil grade API

Engine oil quantity

(without oil filter replacement) L (US qt,

(with oil filter replacement) L (US qt,

Gear oil type GEAR CASE LUBE

Gear oil grade SAE 90

Gear oil quantity cm

Bracket unit

Trim angle

(at 12° boat transom)

Tilt-up angle Degree 70

Steering angle Degree 35 + 35

Drive unit

Gear shift positions F-N-R

Gear ratio 2.31 (30/13)

Reduction gear type Spiral bevel gear

Clutch type Dog clutch

Propeller shaft type Spline

Propeller direction (rear view) Clockwise

Propeller mark K

Electrical

Battery minimum capacity

CCA/SAE A 380

MCA/ABYC A 502

RC/SAE Minute 124

(*1)

RON: Research Octane Number

PON: Pump Octane Number =

(RON + Motor Octane Number)/2

(*2)

CCA: Cold Cranking Ampere

MCA: Marine Cranking Ampere

ABYC: American Boat and Yacht Council

SAE: Society of Automotive Engineers

RC: Reserve Capacity

(*2)

(*1)

PON

SE, SF, SG, SH, or SJ

SAE

Imp qt)

Imp qt)

3

(US oz,

Imp oz)

Degree –4 to 16

10W-30 or 10W-40

Model

F90TR

91

86

4.3 (4.55, 3.78)

4.5 (4.76, 3.96)

670 (22.7, 23.6)

1

2

3

4

5

6

7

8

9

6D81G11

2-2

Page 17

SPEC

Specifications

Maintenance specification

Power unit

Item Unit

Power unit

Minimum compression

pressure

Oil pressure

(*1)

(*2)

kPa

kPa

(kgf/cm2, psi)

(kgf/cm

2

, psi)

510 (5.1, 74.0) at engine idle speed

Cylinder head

Warpage limit mm (in) 0.1 (0.0039)

(lines indicate straightedge

position)

Camshaft cap inside diameter mm (in) 25.000–25.021 (0.9843–0.9851)

Cylinders

Bore size mm (in) 79.000–79.020 (3.1102–3.1110)

Taper limit mm (in) 0.08 (0.0032)

Out-of-round limit mm (in) 0.05 (0.0020)

Pistons

Piston diameter (D) mm (in) 78.928–78.949 (3.1074–3.1082)

Measuring point (H) mm (in) 13.0 (0.51)

Piston clearance mm (in) 0.070–0.080 (0.0028–0.0031)

Over size piston diameter mm (in) 79.178–79.199 (3.1172–3.1181)

Piston rings

Top ring

Dimension B mm (in) 1.17–1.19 (0.0461–0.0469)

Dimension T mm (in) 2.80–3.00 (0.1102–0.1181)

End gap mm (in) 0.15–0.30 (0.0059–0.0118)

Side clearance mm (in) 0.04–0.08 (0.0016–0.0031)

2nd piston ring

Dimension B mm (in) 1.47–1.49 (0.0579–0.0587)

Dimension T mm (in) 3.00–3.20 (0.1181–0.1260)

End gap mm (in) 0.70–0.90 (0.0276–0.0354)

Side clearance mm (in) 0.03–0.07 (0.0012–0.0028)

(*1)

Measuring conditions:

Ambient temperature 20 °C (68 °F), wide open throttle, with spark plugs removed from all cylinders.

The figures are for reference only.

(*2)

The figures are for reference only.

Model

F90TR

860 (8.6, 124.7)

2

2-3

6D81G11

Page 18

Maintenance specification

Item Unit

Oil ring

Dimension B mm (in) 2.38–2.48 (0.0937–0.0976)

Dimension T

End gap mm (in) 0.20–0.70 (0.0079–0.0276)

Side clearance mm (in) 0.03–0.15 (0.0012–0.0059)

Camshafts

Intake (A) mm (in) 36.48–36.58 (1.4362–1.4402)

Exhaust (A) mm (in) 36.90–37.06 (1.4528–1.4591)

Intake (B) mm (in) 29.95–30.05 (1.1791–1.1831)

Exhaust (B) mm (in) 29.92–30.08 (1.1780–1.1842)

Camshaft journal diameter mm (in) 24.960–24.980 (0.9827–0.9835)

Camshaft runout limit mm (in) 0.03 (0.0012)

Valves

Valve clearance (cold)

Intake mm (in) 0.20 ± 0.03 (0.008 ± 0.001)

Exhaust mm (in) 0.34 ± 0.03 (0.013 ± 0.001)

Head diameter (A)

Intake mm (in) 29.0–29.2 (1.14–1.15)

Exhaust mm (in) 24.0–24.2 (0.94–0.95)

Face width (B)

Intake mm (in) 1.99–2.44 (0.0783–0.0961)

Exhaust mm (in) 2.27–2.72 (0.0894–0.1071)

Seat contact width (C)

Intake mm (in) 1.20–1.60 (0.0472–0.0630)

Exhaust mm (in) 1.20–1.60 (0.0472–0.0630)

Margin thickness (D)

Intake mm (in) 0.80–1.20 (0.0315–0.0472)

Exhaust mm (in) 1.00–1.40 (0.0394–0.0551)

Stem diameter

Intake mm (in) 5.975–5.990 (0.2352–0.2358)

Exhaust mm (in) 5.960–5.975 (0.2346–0.2352)

Guide inside diameter

Intake and exhaust mm (in) 6.000–6.018 (0.2362–0.2369)

Stem-to-guide clearance

Intake mm (in) 0.010–0.043 (0.0004–0.0017)

Exhaust mm (in) 0.025–0.058 (0.0010–0.0023)

Stem runout limit mm (in) 0.01 (0.0004)

Valve springs

Free length mm (in) 53.20 (2.0945)

Tilt limit mm (in) 2.6 (0.10)

(*)

mm (in) 2.40 (0.0945)

Model

F90TR

1

2

3

4

5

6

7

8

9

(*)

The figure is for reference only.

6D81G11

2-4

Page 19

SPEC

Specifications

Item Unit

Valve lifters

Valve lifter outside diameter mm (in) 27.965–27.980 (1.1010–1.1016)

Valve lifter-to-cylinder head

clearance

Valve shims

Valve shim thickness

(in 0.025 mm increments)

Connecting rods

Big end inside diameter mm (in) 47.025–47.045 (1.8514–1.8522)

Big end side clearance mm (in) 0.14–0.28 (0.0055–0.0110)

Crankpin oil clearance mm (in) 0.024–0.044 (0.0009–0.0017)

Big-end bearing thickness

Yellow mm (in) 1.499–1.506 (0.0590–0.0593)

Green mm (in) 1.506–1.513 (0.0593–0.0596)

Blue mm (in) 1.513–1.520 (0.0596–0.0598)

Red mm (in) 1.520–1.527 (0.0598–0.0601)

Crankshaft

Crankshaft journal diameter mm (in) 47.985–48.000 (1.8892–1.8898)

Crankpin diameter mm (in) 43.982–44.000 (1.7316–1.7323)

Crankpin width mm (in) 21.00–21.07 (0.8268–0.8295)

Runout limit mm (in) 0.03 (0.0012)

Crankcase

Crankshaft journal oil

clearance

Upper crankcase main bearing

thickness

Green mm (in) 2.992–2.999 (0.1178–0.1181)

Blue mm (in) 2.999–3.006 (0.1181–0.1183)

Red mm (in) 3.006–3.013 (0.1183–0.1186)

Upper crankcase main bearing

#3 thickness

Green mm (in) 2.992–2.999 (0.1178–0.1181)

Blue mm (in) 2.999–3.006 (0.1181–0.1183)

Red mm (in) 3.006–3.013 (0.1183–0.1186)

Lower crankcase main bearing

thickness

Yellow mm (in) 3.010–3.017 (0.1185–0.1188)

Green mm (in) 3.017–3.024 (0.1188–0.1191)

Blue mm (in) 3.024–3.031 (0.1191–0.1193)

Red mm (in) 3.031–3.038 (0.1193–0.1196)

mm (in) 0.020–0.056 (0.0008–0.0022)

mm (in) 2.0–3.3 (0.08–0.13)

mm (in) 0.024–0.044 (0.0009–0.0017)

Model

F90TR

2-5

6D81G11

Page 20

Maintenance specification

Item Unit

Oil pump

Discharge

at 97–103 °C (207–217 °F)

with 10W-30 engine oil

Pressure

at 97–103 °C (207–217 °F)

with 10W-30 engine oil

Relief valve opening pressure kPa

Thermostat

Opening temperature °C (°F) 58–62 (136–144)

Fully open temperature °C (°F) 70 (158)

Valve open lower limit mm (in) 4.3 (0.17)

Lower unit

Item Unit

Gear backlash

Pinion-to-forward gear mm (in) 0.28–0.63 (0.0110–0.0248)

Pinion shims mm 0.10, 0.12, 0.15, 0.18, 0.30, 0.40, 0.50

Forward gear shims mm 0.10, 0.12, 0.15, 0.18, 0.30, 0.40, 0.50

Electrical

L (US gal,

Imp gal)/min

kPa

(kgf/cm

(kgf/cm

2

, psi)

2

, psi)

5.9 (1.559, 1.298) at 1,000 r/min

118.0 (1.18, 17.1) at 1,000 r/min

441–539 (4.41–5.39, 63.9–78.2)

Model

F90TR

Model

F90TR

1

2

3

4

5

Item Unit

Ignition and ignition control

system

Spark plug gap mm (in) 1.0–1.1 (0.039–0.043)

Ignition coil resistance

at 20 °C (68 °F)

Primary coil (R – B/W)

Secondary coil kΩ 12.495–16.905

Spark plug wire resistance

#1 kΩ 4.5–10.7

#2 kΩ 3.3–8.0

#3 kΩ 3.7–8.9

#4 kΩ 4.3–10.2

Ω

1.53–2.07

Model

F90TR

6

7

8

9

6D81G11

2-6

Page 21

SPEC

Specifications

Item Unit

Model

F90TR

ECM output peak voltage

(B/R, B/W – Ground)

at cranking (loaded) V 210

at 1,500 r/min (loaded) V 290

at 3,500 r/min (loaded) V 290

Pulser coil output peak voltage

(W/R, W/B – B)

at cranking (unloaded) V 3.6

at cranking (loaded) V 3.4

at 1,500 r/min (loaded) V 18.2

at 3,500 r/min (loaded) V 34.3

Pulser coil resistance

(*)

Ω

459–561

(W/R, W/B – B)

Throttle position sensor

Output voltage (P – B) V 0.8–1.2 at engine idle speed

Cooling water temperature

sensor resistance

at 0 °C (32 °F) kΩ 5.21–6.37

at 80 °C (176 °F) kΩ 0.290–0.354

Oil pressure switch

Operating pressure kPa

(kgf/cm

2

, psi)

127.5–166.7 (1.28–1.67, 18.49–24.17)

Fuel control system

(*)

Fuel injector resistance

at 21 °C (70 °F)

Ω

12.0

Starter motor

Type Sliding gear

Output kW 1.40

Cranking time limit Second 30

Brushes

Standard length mm (in) 15.5 (0.61)

Wear limit mm (in) 9.5 (0.37)

Commutator

Standard diameter mm (in) 29.0 (1.14)

Wear limit mm (in) 28.0 (1.10)

Mica

Standard undercut mm (in) 0.8 (0.03)

Wear limit mm (in) 0.2 (0.01)

(*)

The figures are for reference only.

2-7

6D81G11

Page 22

Maintenance specification

Item Unit

Charging system

Fuse A 20

Stator coil output peak voltage

(W – W)

at cranking (unloaded) V 12.4

at 1,500 r/min (unloaded) V 45.3

at 3,500 r/min (unloaded) V 98.3

Stator coil resistance

at 20 °C (68 °F)

Rectifier Regulator output

peak voltage (R–Ground)

at 1,500 r/min (unloaded) V 13.0

at 3,500 r/min (unloaded) V 13.0

Power trim and tilt system

Trim sensor

Setting resistance (P – B)

Resistance (P – B)

Fluid type ATF Dexron II

Brushes

Standard length mm (in) 10.0 (0.39)

Wear limit mm (in) 3.5 (0.14)

Commutator

Standard diameter mm (in) 22.0 (0.87)

Wear limit mm (in) 21.0 (0.83)

Mica

Standard undercut mm (in) 1.5 (0.06)

Wear limit mm (in) 1.0 (0.04)

(*)

The figure is for reference only.

(*)

(W – W)

Ω

0.24–0.36

Ω

10

Ω

9–378.8

Model

F90TR

±

1

1

2

3

4

5

6

6D81G11

7

8

9

2-8

Page 23

SPEC

Dimensions

Exterior

Specifications

mm (in)

35˚

204 (9.4)

405 (15.9)

857 (33.7)

666 (26.2)

L : 536 (21.1)

X: 663 (26.1)

171 (6.73)

366 (14.4)

49 (1.9)

527 (20.7)

164 (6.5)

27 (1.1)

L: 998 (39.3)

X: 1,115 (43.9)

651 (25.6)

62 (2.4)

2-9

L: 917 (36.1)

X: 1,044 (41.1)

191 (7.5)

L : 25 (1.0)

X: 24 (0.9)

63 (2.5)

12˚

66˚

4˚

574 (22.6)28 (1.1)

L: 766 (30.2)

X: 842 (33.1)

S6D82010

6D81G11

Page 24

Clamp bracket

180 (7.1)

Maintenance specification

mm (in)

1

2

180 (7.1)

163.5 (6.4)163.5 (6.4)

3

50.8 (2.0)

348.5 (13.7)

125.4 (4.9)125.4 (4.9)

13 (0.5)

13 (0.5)

254 (10.0)

18.5 (0.7)

55.5 (2.2)

80 (3.1)

4

5

6

7

8

6D81G11

9

S6D82020

2-10

Page 25

SPEC

Specifications

Tightening torques

2

Specified torques

Part to be tightened Thread size

Fuel system

Fuel filter cup — 30.32.2

Fuel pump mounting bolt M6 10 1.0 7.4

Fuel pump screw M6 4 0.4 3.0

Sensor assembly screw M5 3.7 0.37 2.7

Idle speed control screw M5 3.7 0.37 2.7

Fuel rail mounting bolt M6 8 0.8 5.9

Throttle body mounting bolt M6 8 0.8 5.9

Fuel cooler screw M6 3 0.3 2.2

Float chamber screw M5 3 0.3 2.2

Vapor separator drain screw — 1.5 0.15 1.1

Pressure regulator bolt M6 5 0.5 3.7

Fuel hose joint — 40.43.0

Plate screw M4 2 0.2 1.5

Wiring harness holder screw M4 2 0.2 1.5

Pressure check valve — 10 1.0 7.4

Power unit

Power unit mounting bolt

1st

2nd 42 4.2 31.0

M10

Apron screw M6 4 0.4 3.0

Flywheel magnet nut M24 215 21.5 158.6

Starter motor bolt M8 29 2.9 21.4

Spark plug wire cover screw M6 4 0.4 3.0

Starter relay lead bolt M6 4 0.4 3.0

Starter relay holder screw M6 3 0.3 2.2

Main and fuel pump relay screw M6 3 0.3 2.2

Oil pressure switch — 80.85.9

Oil pressure switch lead bolt M4 2 0.2 1.5

PTT relay lead nut M6 4 0.4 3.0

PTT motor lead bolt M6 4 0.4 3.0

Positive battery lead nut M8 9 0.9 6.6

Timing belt tensioner bolt M10 39 3.9 28.8

Drive sprocket nut M40 265 26.5 195.5

Driven sprocket bolt M10 60 6.0 44.3

Camshaft cap bolt

1st

2nd 17 1.7 12.5

M7

Cylinder head cover plate screw M4 2 0.2 1.5

Cylinder head cover bolt

1st

2nd 8 0.8 5.9

M6

Tightening torques

N·mkgf·mft·lb

42 4.2 31.0

80.85.9

80.85.9

2-11

6D81G11

Page 26

Tightening torques

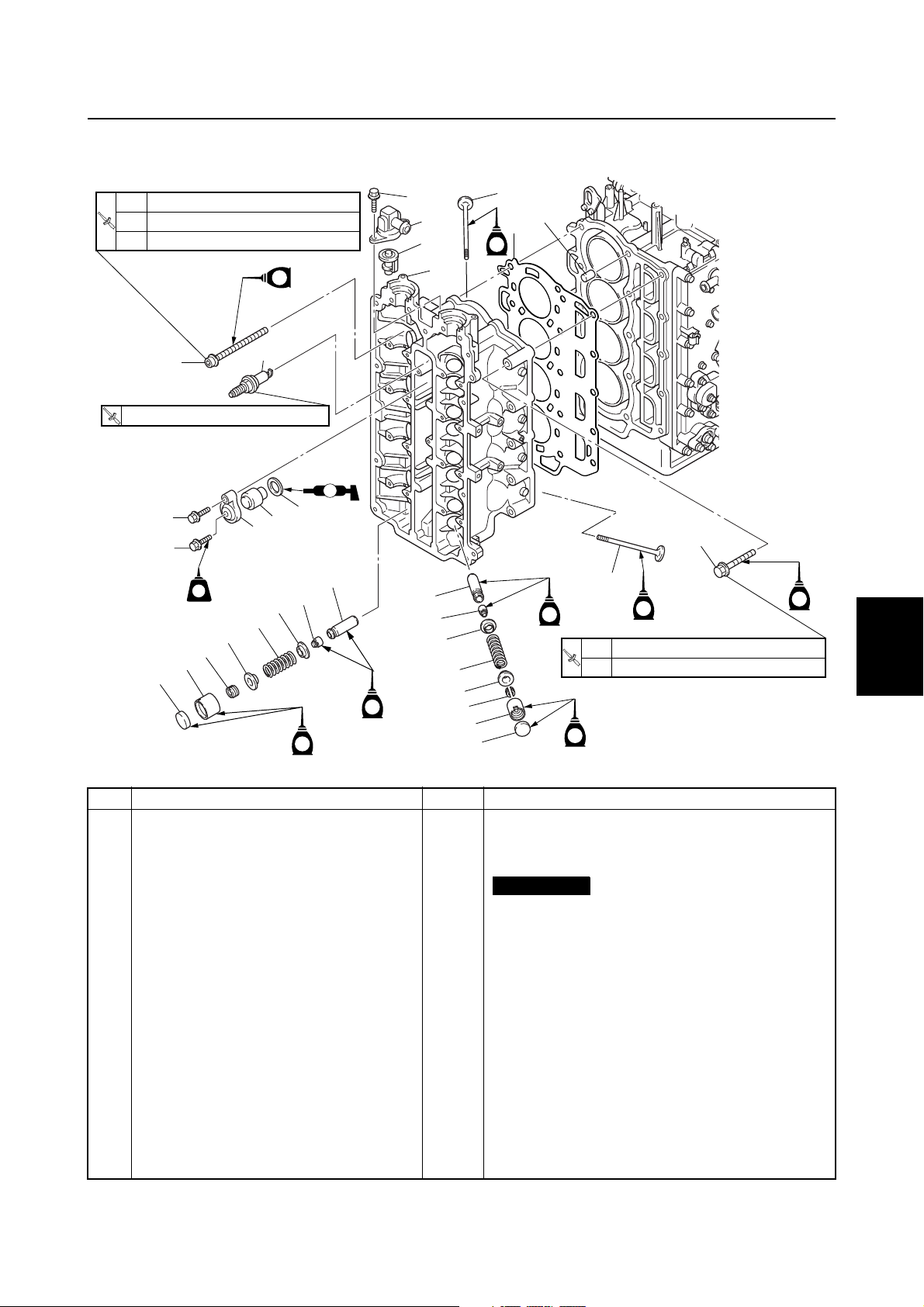

Part to be tightened Thread size

1st

2nd 28 2.8 20.7

Cylinder head bolt

Spark plug — 25 2.5 18.4

Cylinder block plug M14 23 2.3 17.0

Oil filter joint — 49 4.9 36.1

Oil filter — 18 1.8 13.3

Exhaust cover bolt

Anode screw M4 2 0.2 1.5

Exhaust cover plug M18 55 5.5 40.6

Crankcase bolt

Connecting rod cap bolt

Lower unit

Gear oil drain screw — 90.96.6

Gear oil check screw — 90.96.6

Lower case mounting bolt (L-transom model) M10 39 3.9 28.8

Lower case mounting nut (X-transom model) — 39 3.9 28.8

Propeller nut M16 34 3.4 25.1

Ring nut — 103 10.3 76.0

Cooling water inlet cover screw — 50.53.7

Pinion nut M16 93 9.3 68.6

Bracket unit

Shift rod detent bolt — 18 1.8 13.3

Shift position switch screw M4 1 0.1 0.7

Flushing hose adapter screw M6 2 0.2 1.5

Oil pump bolt M6 10 1.0 7.4

Upper mounting nut — 51 5.1 37.6

Lower mounting nut — 51 5.1 37.6

Grease nipple — 30.32.2

Oil pump cover screw M6 4 0.4 3.0

Oil seal housing screw M6 4 0.4 3.0

Upper mount bolt M8 28 2.8 20.7

Muffler assembly bolt M8 20 2.0 14.8

Engine oil drain bolt M14 27 2.7 20.0

Oil strainer bolt M6 10 1.0 7.4

Oil pan bolt M6 11 1.1 8.1

Exhaust manifold bolt M6 11 1.1 8.1

1st

2nd 30 3.0 22.1

3rd 90°

1st

2nd 12 1.2 8.9

1st

2nd 28 2.8 20.7

1st

2nd 60°

1st

2nd 80°

M8

M10

M6

M8

M10

M8

Tightening torques

N·mkgf·mft·lb

14 1.4 10.3

15 1.5 11.1

60.64.4

14 1.4 10.3

19 1.9 14.0

18 1.8 13.3

1

2

3

4

5

6

7

8

9

6D81G11

2-12

Page 27

SPEC

Specifications

Part to be tightened Thread size

Steering arm stud bolt M10 20 2.0 14.8

Self-locking nut — 15 1.5 11.1

Trim sensor cam screw M6 2 0.2 1.5

Power trim and tilt unit

Reservoir cap — 70.75.2

PTT motor bolt M6 4 0.4 3.0

Gear pump bolt M5 5 0.5 3.7

Gear pump housing bolt M5 5 0.5 3.7

Relief valve cap bolt

Lever bolt M3 2 0.2 1.5

Manual valve — 20.21.5

Gear pump bracket bolt

Trim cylinder end screw — 90 9.0 66.4

Tilt cylinder end screw — 80 8.0 59.0

Tilt piston bolt M12 85 8.5 62.7

M4 4 0.4 3.0

M5 5 0.5 3.7

M3 2 0.2 1.5

M5 4 0.4 3.0

Tightening torques

N·mkgf·mft·lb

General torques

This chart specifies tightening torques for

standard fasteners with a standard ISO

thread pitch. Tightening torque specifications

for special components or assemblies are

provided in applicable sections of this manual. To avoid warpage, tighten multi-fastener

assemblies in a crisscross fashion and progressive stages until the specified torque is

reached. Unless otherwise specified, torque

specifications require clean, dry threads.

Components should be at room temperature.

General torque

Nut (A) Bolt (B)

8 mm M5 5 0.5 3.6

10 mm M6 8 0.8 5.8

12 mm M8 18 1.8 13

14 mm M10 36 3.6 25

17 mm M12 43 4.3 31

specifications

N·mkgf·mft·lb

2-13

6D81G11

Page 28

CHK

ADJ

Periodic checks and adjustments

Special service tools .....................................................................................3-1

Maintenance interval chart............................................................................3-2

Top cowling ....................................................................................................3-3

Checking the top cowling...........................................................................3-3

Fuel system ....................................................................................................3-3

Checking the fuel joint and fuel hoses (fuel joint-to-fuel injector) ..............3-3

Checking the fuel filter ...............................................................................3-3

Power unit.......................................................................................................3-4

Checking the engine oil .............................................................................3-4

Changing the engine oil using an oil changer............................................3-4

Changing the engine oil by draining it .......................................................3-4

Replacing the oil filter ................................................................................3-5

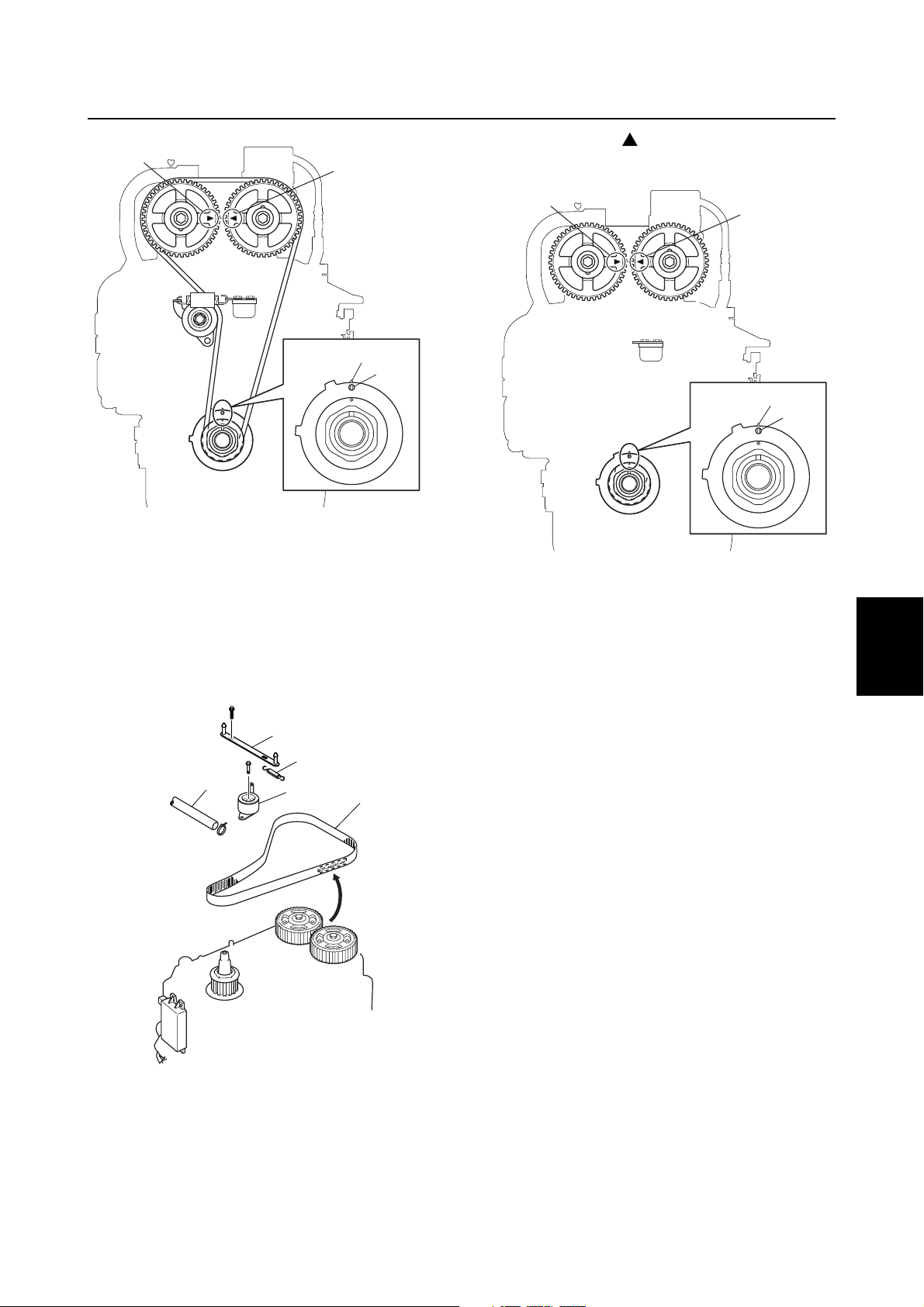

Checking the timing belt ............................................................................3-6

Checking the spark plugs ..........................................................................3-6

Checking the thermostat............................................................................3-7

Checking the cooling water passage.........................................................3-8

Control system...............................................................................................3-8

Checking the engine idle speed ................................................................3-8

Adjusting the throttle link and throttle cable...............................................3-8

Checking the gear shift operation............................................................3-10

1

2

3

4

5

Bracket unit ..................................................................................................3-11

Checking the power trim and tilt operation .............................................. 3-11

Checking the power trim and tilt fluid level ..............................................3-11

Lower unit.....................................................................................................3-12

Checking the gear oil level ......................................................................3-12

Changing the gear oil ..............................................................................3-12

Checking the lower unit for air leakage ...................................................3-13

Checking the propeller.............................................................................3-13

General..........................................................................................................3-14

Checking the anodes...............................................................................3-14

Checking the battery................................................................................3-14

Lubricating the outboard motor................................................................3-15

6

7

8

9

6D81G11

Page 29

CHK

ADJ

Periodic checks and adjustments

Special service tools

Digital tachometer

YU-39951-B

Battery powered timing light

YM-33277-A

3

Pressure/vacuum tester

YB-35956-A

Oil filter wrench

YU-38411

3-1

6D81G11

Page 30

Special service tools / Maintenance interval chart

Maintenance interval chart

Use the following chart as a guideline for general maintenance.

Adjust the maintenance intervals according to the operating conditions of the outboard motor.

Initial Every

Item Remarks

Anodes (external) Check/replace 3-14

Anodes (internal) Check/replace 3-14

Battery Check/charge 3-14

Cooling water passages Clean 3-8

Top cowling Check 3-3

Fuel filter

(can be disassembled)

Fuel system Check 3-3

Gear oil Change 3-12

Lubrication points Lubricate 3-15

Engine idle speed

(EFI models)

PCV (Pressure Control Valve) Check 5-38

Power trim and tilt unit Check 3-11

Propeller and cotter pin Check/replace 3-13

Shift link/shift cable Check/adjust 3-10

Thermostat Check 3-7

Throttle link/throttle cable/

throttle pick-up timing

Water pump Check 6-9

Engine oil Check/change 3-4

Oil filter Change 3-5

Spark plugs Clean/adjust/

Timing belt Check/replace 3-6

Check/replace 3-3

Check/adjust 3-8

Check/adjust 3-8

replace

10 hours

(1 month)

50 hours

(3 months)

100 hours

(6 months)

200 hours

(1 year)

Refer to

page

3-6

3

1

2

3

4

5

6

NOTE:

When operating in salt water, turbid or muddy water, the engine should be flushed with clean water

after each use.

Every

Item Remarks

Timing belt Replace 5-13

Valve clearance (DOHC) Check/adjust 5-10

NOTE:

When using lead or high-sulfur gasoline, checking valve clearance may be required more frequently

than every 500 hours.

6D81G11

500 hours

(2.5 years)

1,000 hours

(5 years)

Refer to

page

3-2

7

8

9

Page 31

CHK

ADJ

Periodic checks and adjustments

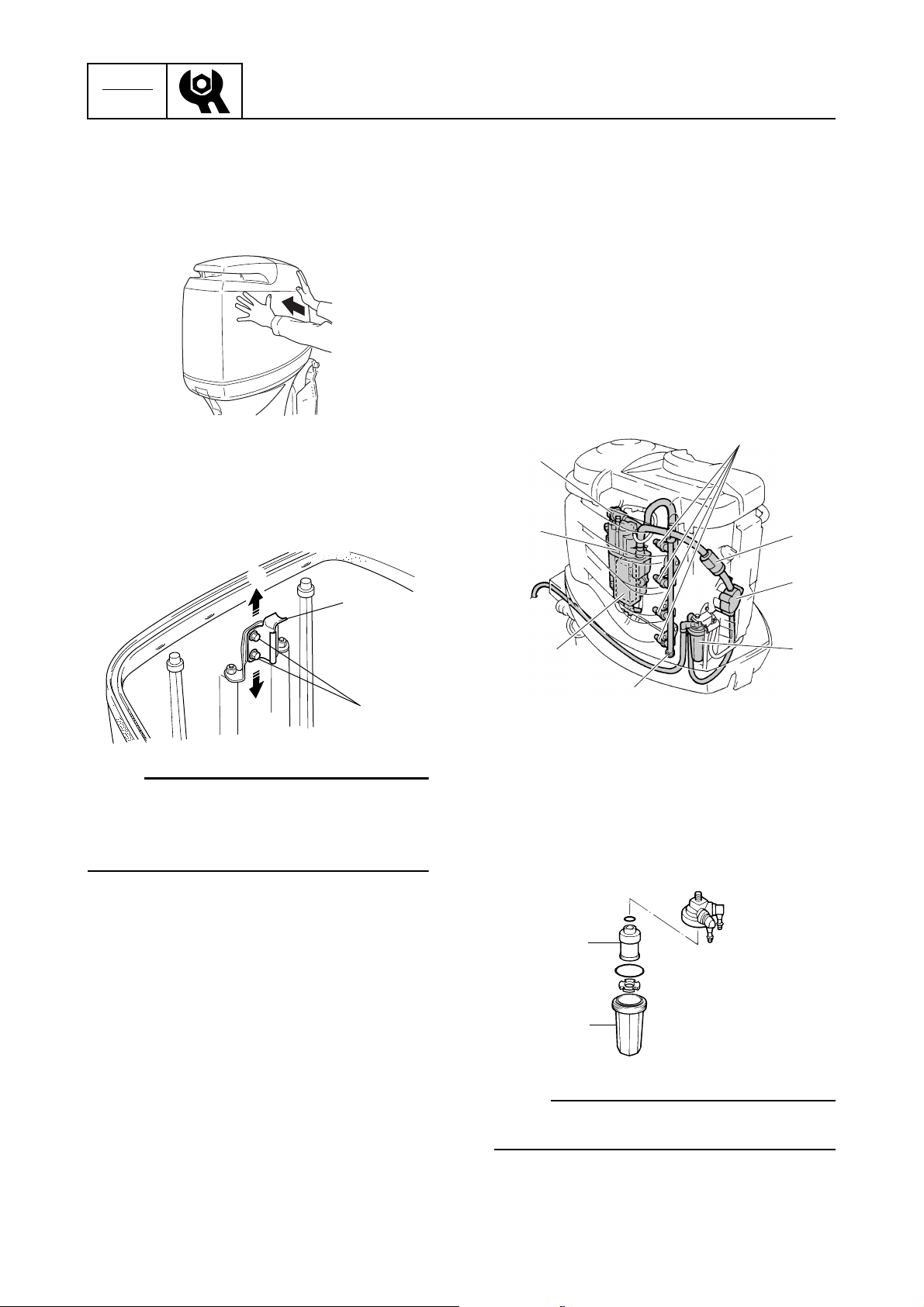

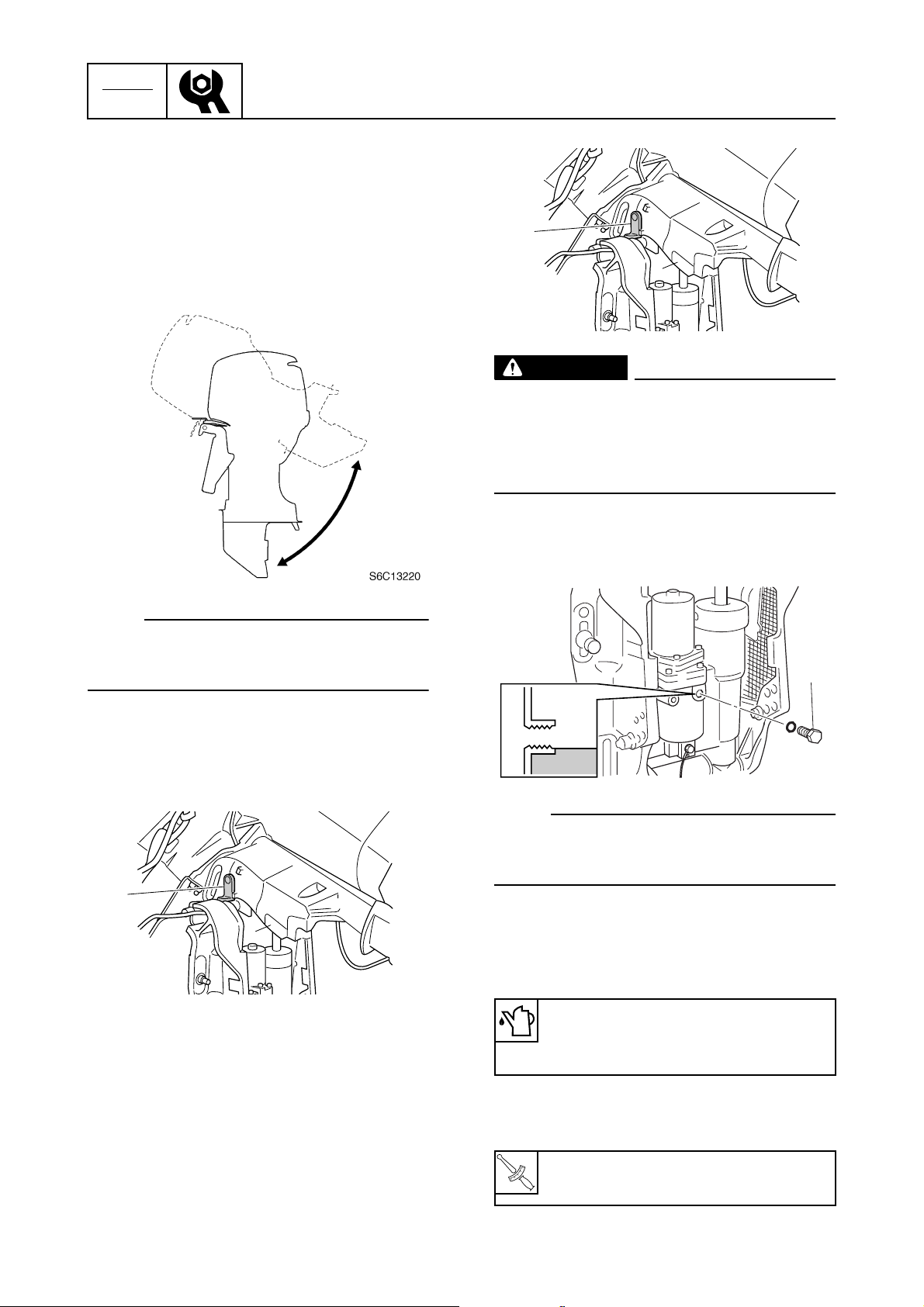

Top cowling

Checking the top cowling

1. Check the fitting by pushing the cowling

with both hands. Adjust if necessary.

S60C3010

2. Loosen the bolts 1.

3. Move the hook 2 up or down slightly to

adjust its position.

a

2

3

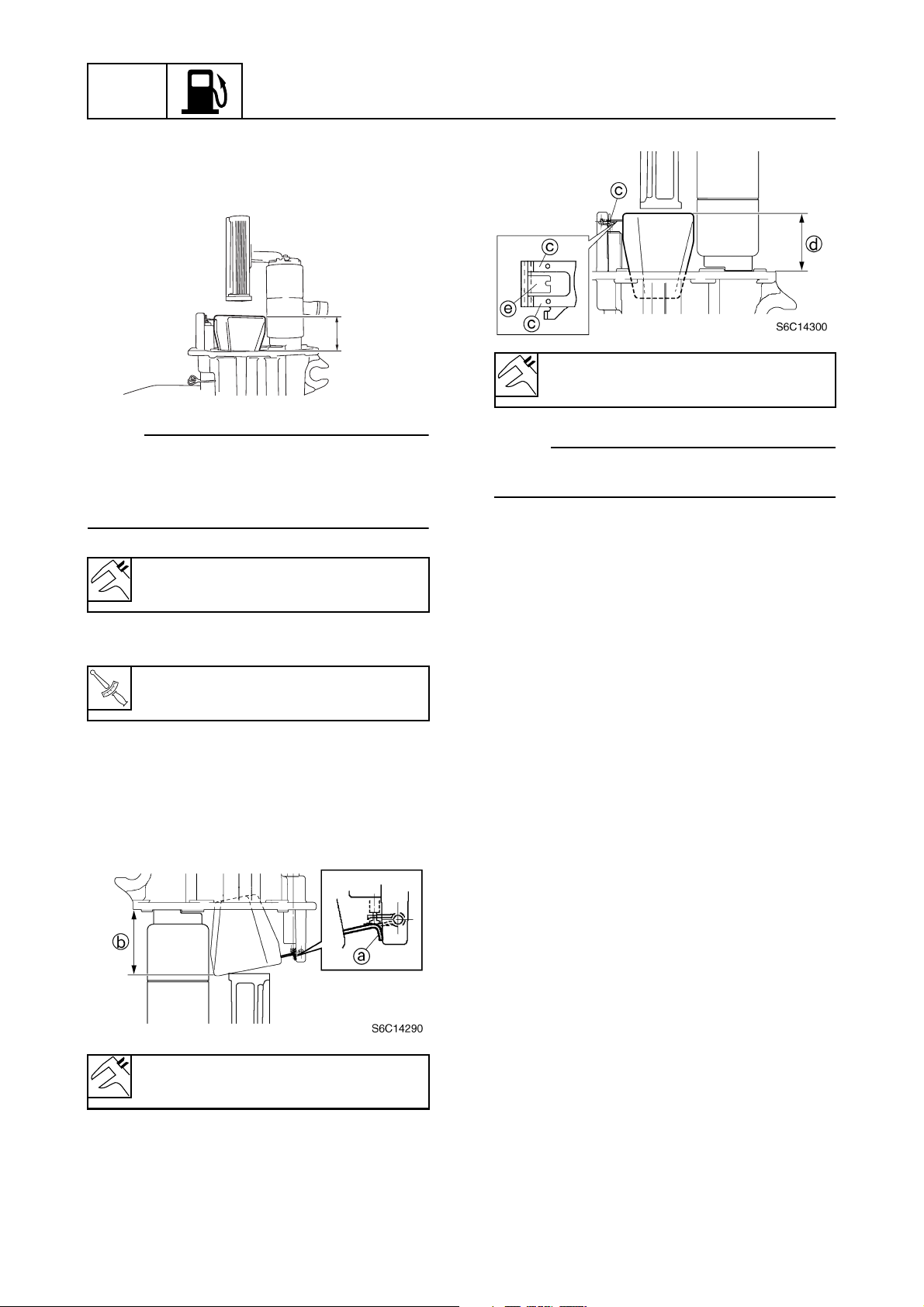

2. Check the low-pressure fuel hose connections and fuel joint for leaks. Replace

if necessary. Also, check the fuel filter 1,

fuel pump 2, strainer 3, and fuel cooler

4

for leaks or deterioration. Replace if

necessary.

3. Check the high-pressure fuel hose connections for leaks. Replace if necessary.

Also, check the vapor separator 5, fuel

rail 6, fuel injectors 7, and pressure

regulator 8 for leaks or deterioration.

Replace if necessary.

7

8

5

3

2

b

1

S6D83010

NOTE:

• To loosen the fitting, move the hook in

direction a.

• To tighten the fitting, move the hook in

direction b.

4. Tighten the bolts.

5. Check the fitting again and, if necessary,

repeat steps 2–4.

Fuel system

Checking the fuel joint and fuel

hoses (fuel joint-to-fuel injector)

1. Remove the flywheel magnet cover.

4

6

1

S6D83020

Checking the fuel filter

1. Check the fuel filter element 1 for dirt

and residue and check the fuel filter cup

2

for foreign substances and cracks.

Clean the cup with straight gasoline and

replace the element if necessary.

1

3

NOTE:

Be sure not to spill any fuel when removing

the fuel filter cup.

2

S6D83030

3-3

6D81G11

Page 32

Top cowling / Fuel system / Power unit

Power unit

Checking the engine oil

1. Place the outboard motor in an upright

position.

2. Remove the oil dipstick, wipe it clean,

and then insert it back into the dipstick

hole.

3. Remove the oil dipstick again to check

the oil level and to check the oil for discoloration and its viscosity.

a

b

S60C1150

3

1

2

4. Operate the oil changer to extract the oil.

NOTE:

Be sure to clean up any oil spills.

5. Pour the specified amount of the recommended engine oil into the oil filler hole.

3

4

NOTE:

• Change the oil if it appears milky or dirty.

• If the engine oil is below the minimum level

mark b, add sufficient oil until the level is

between a and b.

Changing the engine oil using an oil

changer

1. Start the engine, warm it up, and then

turn it off.

2. Remove the oil dipstick and oil filler cap

1

.

1

Recommended engine oil:

4-stroke motor oil

API: SE, SF, SG, SH, or SJ

SAE: 10W-30 or 10W-40

Engine oil quantity:

Without oil filter replacement:

4.3 L (4.55 US qt, 3.78 Imp qt)

6. Install the oil filler cap and oil dipstick,

and then start the engine and warm it up

for 5 minutes.

7. Turn the engine off, and then check the

oil level and correct it if necessary.

Changing the engine oil by draining

it

1. Start the engine, warm it up, and then

turn it off.

5

6

7

8

S60C3060

3. Insert the tube of the oil changer 2 into

the dipstick hole 3.

6D81G11

9

3-4

Page 33

CHK

ADJ

Periodic checks and adjustments

2. Remove the oil dipstick and oil filler cap

1

.

1

S60C3060

3. Place a drain pan under the drain hole,

and then remove the drain bolt 2 and let

the oil drain completely.

7. Turn the engine off, and then check the

oil level and correct it if necessary.

Replacing the oil filter

1. Extract the engine oil with an oil changer

or drain it.

2. Place a rag under the oil filter, and then

remove the oil filter using the oil filter

wrench.

S6D83050

NOTE:

• Wait more than 5 minutes after turning the

engine off to replace the oil filter.

• Be sure to clean up any oil spills.

NOTE:

Be sure to clean up any oil spills.

4. Install the drain bolt, and then tighten it to

the specified torque.

Engine oil drain bolt:

T

.

R

.

27 N·m (2.7 kgf·m, 20.0 ft·lb)

5. Pour the specified amount of the recommended engine oil into the oil filler hole.

Recommended engine oil:

4-stroke motor oil

API: SE, SF, SG, SH, or SJ

SAE: 10W-30 or 10W-40

Engine oil quantity:

Without oil filter replacement:

4.3 L (4.55 US qt, 3.78 Imp qt)

6. Install the oil filler cap and oil dipstick,

and then start the engine and warm it up

for 5 minutes.

Oil filter wrench: YU-38411

3. Apply a thin coat of engine oil to the Oring of the new oil filter.

4. Install the oil filter, and then tighten it to

the specified torque using the oil filter

wrench.

3-5

6D81G11

Page 34

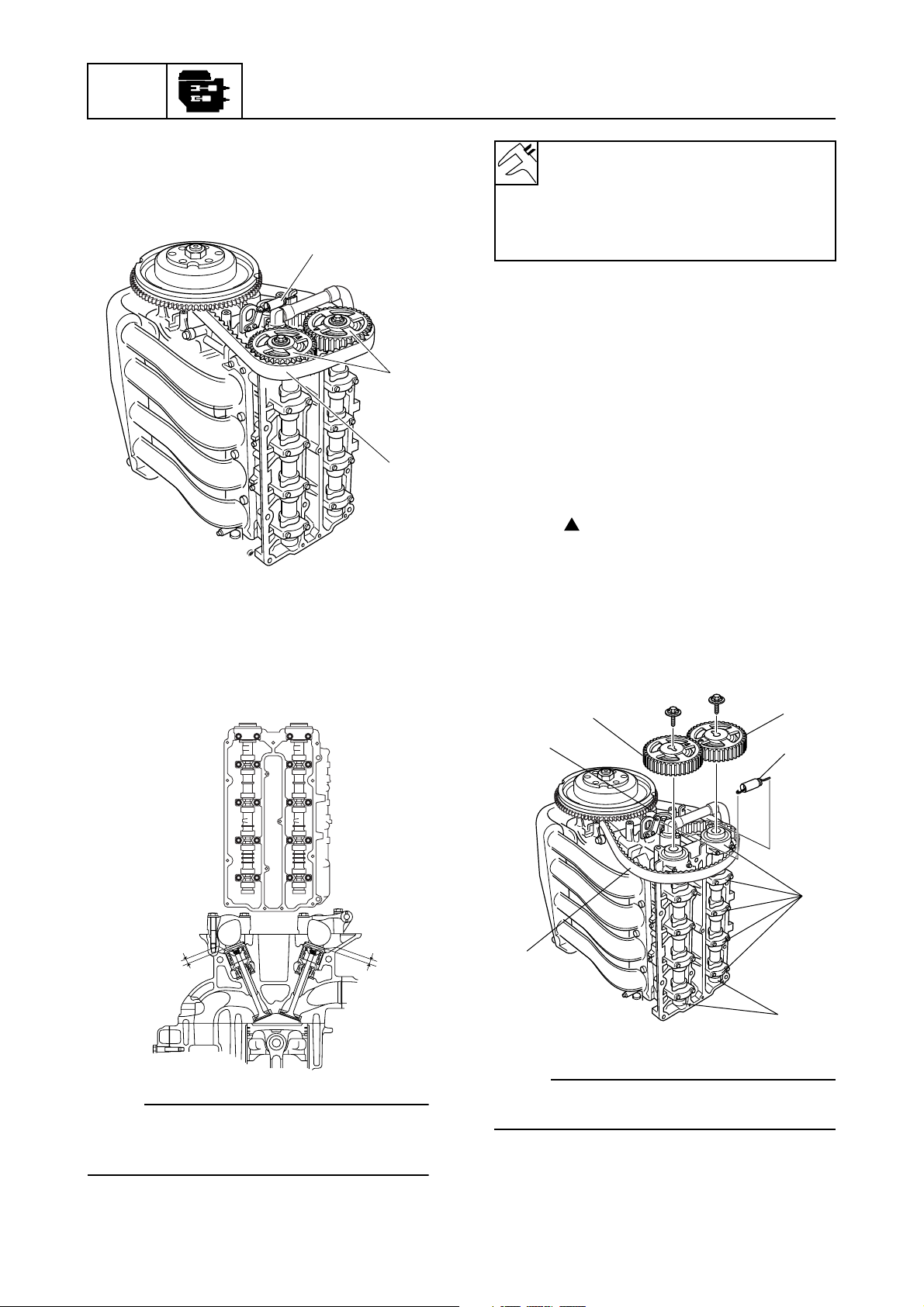

Power unit

2. While turning the flywheel magnet clockwise, check the interior a and the exterior b of the timing belt for cracks,

damage, or wear. Replace if necessary.

E

S6D83060

Oil filter:

T

.

R

.

18 N·m (1.8 kgf·m, 13.3 ft·lb)

5. Pour the specified amount of the recommended engine oil into the oil filler hole.

Recommended engine oil:

4-stroke motor oil

API: SE, SF, SG, SH, or SJ

SAE: 10W-30 or 10W-40

Engine oil quantity:

With oil filter replacement:

4.5 L (4.76 US qt, 3.96 Imp qt)

a

b

NOTE:

For replacement procedures, see Chapter 5,

“Replacing the timing belt.”

Checking the spark plugs

1. Remove the spark plug wire cover.

2. Disconnect the spark plug wires, and

then remove the spark plugs.

3. Clean the electrodes 1 with a spark plug

cleaner or wire brush. Replace the spark

plug if necessary.

S6D83070

1

2

3

4

5

6

6. Install the oil filler cap and oil dipstick,

and then start the engine and warm it up

for 5 minutes.

7. Turn the engine off, and then check the

oil level and correct it if necessary.

Checking the timing belt

CAUTION:

Do not turn the flywheel magnet counterclockwise, otherwise the valve system

may be damaged.

1. Remove the flywheel magnet cover.

6D81G11

4. Check the electrodes for erosion and

excessive carbon or other deposits, and

the gasket for damage. Replace the

spark plug if necessary.

3-6

7

8

9

Page 35

CHK

ADJ

5. Check the spark plug gap a. Adjust if out

of specification.

Periodic checks and adjustments

Specified spark plug:

LFR5A-11 (NGK)

Spark plug gap a:

1.0–1.1 mm (0.039–0.043 in)

6. Install the spark plugs, tighten them finger tight, then to the specified torque

using a spark plug wrench.

Spark plug:

T

.

R

.

25 N·m (2.5 kgf·m, 18.4 ft·lb)

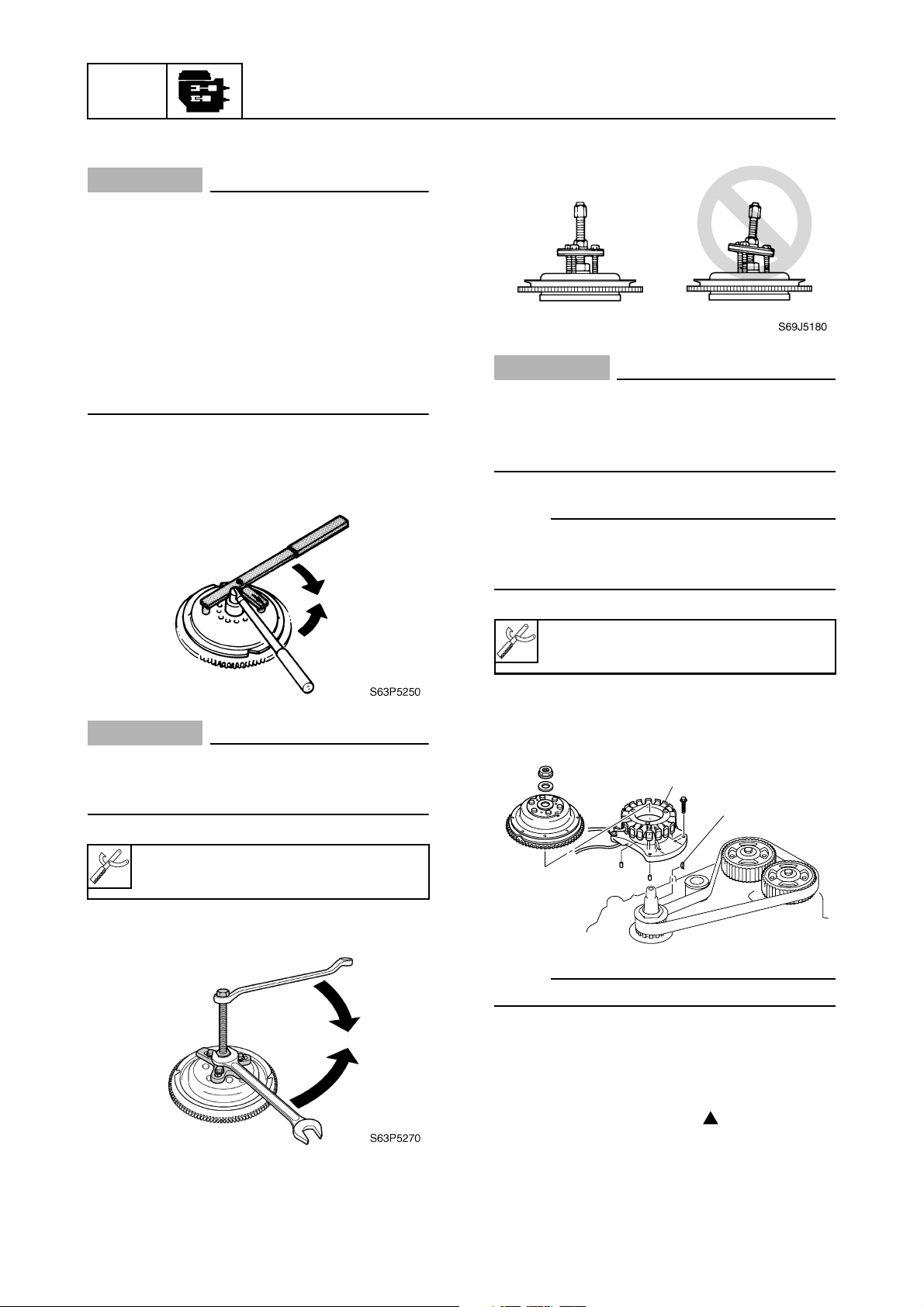

2

1

3

S6D83080

3. Suspend the thermostat in a container of

water.

4. Place a thermometer in the water and

slowly heat the water.

7. Install the spark plug wire cover.

Spark plug wire cover screw:

T

.

R

.

4 N·m (0.4 kgf·m, 3.0 ft·lb)

Checking the thermostat

1. Remove the flywheel magnet cover.

2. Disconnect the cooling water hose 1,

and then remove the thermostat cover

and thermostat 3.

2

S69J5E40

5. Check the thermostat valve opening at

the specified water temperatures.

Replace if out of specification.

3-7

6D81G11

Page 36

Power unit / Control system

Water

temperature

58–62 °C

(136–144 °F)

above

70 °C (158 °F)

6. Install the thermostat and cover.

7. Connect the cooling water hose, and

then install the flywheel magnet cover.

Checking the cooling water passage

1. Check the cooling water inlet cover

and cooling water inlet for clogs. Clean if

necessary.

Valve lift a

0.05 mm

(0.0020 in)

(valve begins to lift)

more than

4.3 mm (0.17 in)

1

Control system

Checking the engine idle speed

1. Start the engine and warm it up for 5 minutes.

2. Attach the special service tool to spark

plug wire #1 1, and then check the

engine idle speed.

1

1

2

3

3

4

1

1

S62Y3320

2. Place the lower unit in water, and then

start the engine.

3. Check for water flow at the cooling water

pilot hole. If there is no water flow, check

the cooling water passage inside the outboard motor.

5

S60C3450

6

Digital tachometer: YU-39951-B

Engine idle speed: 700 ± 50 r/min

7

Adjusting the throttle link and

throttle cable

1. Remove the intake silencer.

8

2. Set the remote control lever to the neutral position and fully close the throttle

lever.

9

6D81G11

3-8

Page 37

CHK

ADJ

3. Loosen the locknut 1, remove the clip

2

, and then disconnect the throttle cable

joint 3.

4. Loosen the locknut 4, and then disconnect the throttle link rod joint 5 from the

ball joint of the throttle body.

Periodic checks and adjustments

a

9

8

S6D83110

8. Adjust the throttle link rod joint to align its

hole with the ball joint 0 on the throttle

body.

5

4

1

3

2

S6D83090

5. Check that the stopper 6 on the throttle

cam contacts the fully closed stopper

7

on the cylinder block.

7

6

S6D83100

6. Check that the throttle valve fully close.

NOTE:

Do not turn the throttle stop screw.

0

S6D83120

9. Connect the throttle link rod joint, and

then tighten the locknut.

10. Operate the throttle cam to check that

the throttle valve fully closes and fully

opens, and check that the gap

b

between the stopper A on the throttle

lever and fully open stopper B on the

throttle body is less than 5 mm (0.20 in)

when the throttle cam is in the fully open

position.

B

A

7. Push the throttle link rod 8 toward the

cylinder head and check that the throttle

cam roller 9 contacts the side a of the

throttle cam.

3-9

b

S6D83130

11. Adjust the position of the throttle cable

joint until its hole is aligned with the set

pin on the throttle cam.

6D81G11

Page 38

Control system

5. Align the alignment mark a on the bushing and alignment mark b on the

bracket.

c

WARNING

The throttle cable joint must be screwed

in a minimum of 8.0 mm (0.31 in) c.

12. Connect the throttle cable joint, install the

clip, and then tighten the locknut.

13. Check the throttle cable for smooth operation and, if necessary, repeat steps 2–

12.

14. Install the intake silencer.

Checking the gear shift operation

1. Check that the gear shift operates

smoothly when shifting it from neutral to

forward or reverse. Adjust the shift cable

length if necessary.

2. Set the gear shift to the neutral position.

S69J3370

a

b

S6D81040

6. Install the clip 4.

7. Adjust the position of the shift cable joint

until its hole is aligned with the set pin.

c

WARNING

The shift cable joint must be screwed in a

minimum of 8.0 mm (0.31 in) c.

S69J3370

1

2

3

4

5

6

3. Loosen the locknut 1, remove the clip

2

, and then disconnect the shift cable

joint 3.

4. Remove the clip 4.

2

4

3

1

6D81G11

S6D83140

8. Connect the cable joint, install the clip,

and then tighten the locknut.

9. Check the gear shift for smooth operation

and, if necessary, repeat steps 2–8.

3-10

7

8

9

Page 39

CHK

T

R

.

.

ADJ

Periodic checks and adjustments

Bracket unit

Checking the power trim and tilt

operation

1. Fully tilt the outboard motor up and down

a few times and check the entire trim and

tilt range for smooth operation. Check the

power trim and tilt fluid level if necessary.

3

1

S6D83150

WARNING

After tilting up the outboard motor, be

sure to support it with the tilt stop lever.

Otherwise, the outboard motor could suddenly lower if the power trim and tilt unit

should lose fluid pressure.

2. Remove the reservoir cap 2, and then

check the fluid level in the reservoir.

NOTE:

Be sure to listen to the winding sound of the

power trim and tilt motor for smooth operation.

2. Fully tilt the outboard motor up, and then

support it with the tilt stop lever 1 to

check the lock mechanism of the lever.

1

S6D83150

Checking the power trim and tilt fluid

level

1. Fully tilt the outboard motor up, and then

support it with the tilt stop lever 1.

2

S6D83160

NOTE:

If the fluid is at the correct level, the fluid

should overflow out of the filler hole when the

reservoir cap is removed.

3. If necessary, add sufficient fluid of the

recommended type until it overflows out

of the filler hole.

Recommended power trim and tilt

fluid:

ATF Dexron II

4. Install the reservoir cap, and then tighten

it to the specified torque.

Reservoir cap:

7 N·m (0.7 kgf·m, 5.2 ft·lb)

3-11

6D81G11

Page 40

Bracket unit / Lower unit

Lower unit

Checking the gear oil level

1. Fully tilt the outboard motor down.

2. Remove the check screw 1, and then

check the gear oil level in the lower case.

1

S60C3540

NOTE:

If the oil is at the correct level, the oil should

overflow out of the check hole when the

check screw is removed.

3

1

2

3. Check the oil for metal and discoloration,

and its viscosity. Check the internal parts

of the lower case if necessary.

3

4

3. If necessary, add sufficient gear oil of the

recommended type until it overflows out

of the check hole.

Recommended gear oil:

GEAR CASE LUBE

SAE: 90

4. Install the check screw, and then tighten

it to the specified torque.

Gear oil check screw:

T

.

R

.

9 N·m (0.9 kgf·m, 6.6 ft·lb)

Changing the gear oil

1. Tilt the outboard motor up slightly.

2. Place a drain pan under the drain screw

1

, remove the drain screw, then the

check screw 2 and let the oil drain completely.

5

6

7

8

6D81G11

9

3-12

Page 41

CHK

ADJ

4. Insert a gear oil tube or gear oil pump

into the drain hole and slowly fill the gear

oil until oil flows out of the check hole and

no air bubbles are visible.

Periodic checks and adjustments

Pressure/vacuum tester:

YB-35956-A

2. Apply the specified pressure to check

that the pressure is maintained in the

lower unit for at least 10 seconds.

CAUTION:

Do not over pressurize the lower unit, otherwise the oil seals can be damaged.

Recommended gear oil:

GEAR CASE LUBE

SAE: 90

Gear oil quantity:

670 cm

3

(22.7 US oz, 23.6 Imp oz)

5. Install the check screw and quickly install

the drain screw, and then tighten them to

the specified torque.

Gear oil check screw and drain

T

.

R

.

screw:

9 N·m (0.9 kgf·m, 6.6 ft·lb)

Checking the lower unit for air

leakage

1. Remove the check screw 1, and then

install the special service tool.

NOTE:

Cover the check hole with a rag when removing the tester from the lower unit.

Lower unit holding pressure:

2

100 kPa (1.0 kgf/cm

, 14.5 psi)

3. If pressure drops below specification,

check the drive shaft and propeller shaft

oil seals for damage.

Checking the propeller

1. Check the propeller blades and splines

for cracks, damage, or wear. Replace if

necessary.

3-13

6D81G11

Page 42

Lower unit / General

General

Checking the anodes

1. Check the anodes and trim tab for

scales, grease, or oil. Clean if necessary.

3

NOTE:

If it is necessary to disassemble the outboard

motor to check an anode, refer to the applicable disassembly procedure in this manual.

1

2. Replace the anodes or trim tab if excessively eroded.

Checking the battery

1. Check the battery electrolyte level. If the

level is at or below the minimum level

mark a, add distilled water until the level

is between the maximum and minimum

level marks.

a

2

3

4

S6D83170

S6D83210

S62Y3640

S69J3620

5

6

7

8

CAUTION:

Do not oil, grease, or paint the anodes or

the trim tab, otherwise they will be ineffective.

6D81G11

9

3-14

Page 43

CHK

ADJ

Periodic checks and adjustments

2. Check the specific gravity of the electrolyte. Fully charge the battery if out of

specification.

WARNING

Battery electrolyte is dangerous; it contains sulfuric acid which is poisonous and

highly caustic.

Always follow these preventive measures:

• Avoid bodily contact with electrolyte as

it can cause severe burns or permanent

eye injury.

• Wear protective eye gear when handling

or working near batteries.

Antidote (EXTERNAL):

• SKIN – Wash with water.

• EYES – Flush with water for 15 minutes

and get immediate medical attention.

Antidote (INTERNAL):

• Drink large quantities of water or milk

followed with milk of magnesia, beaten

egg, or vegetable oil. Get immediate

medical attention.

Batteries generate explosive, hydrogen

gas. Always follow these preventive measures:

• Charge batteries in a well-ventilated

area.

• Keep batteries away from fire, sparks or

open flames (e.g., welding equipment,

lighted cigarettes).

• DO NOT SMOKE when charging or han-

dling batteries.

KEEP BATTERIES AND ELECTROLYTE

OUT OF REACH OF CHILDREN.

Lubricating the outboard motor

1. Apply water resistant grease to the areas

shown.

AA

S60C3660

AA

S60C3670

AA

S6D83180

a

a

NOTE:

• Batteries vary per manufacturer. The procedures mentioned in this manual may not

always apply, therefore, consult the instruction manual of the battery.

• Disconnect the negative battery lead first,

then the positive battery lead.

Electrolyte specific gravity:

1.280 at 20 °C (68 °F)

3-15

AA

a

S60C3695

6D81G11

Page 44

a

General

1

a

AA

S60C3710

NOTE:

Apply grease to the grease nipple until it

flows from the bushings a.

2. Apply low temperature resistant grease

to the area shown.

C

2

3

4

5

6

S6D83190

3. Apply corrosion resistant grease to the

area shown.

6D81G11

7

8

9

3-16

Page 45

FUEL

Fuel system

Special service tools .....................................................................................4-1

Hose routing...................................................................................................4-2

Fuel and blowby hoses..............................................................................4-2

Fuel filter and fuel pump ...............................................................................4-3

Checking the fuel pump.............................................................................4-5

Disassembling the fuel pump ....................................................................4-5

Checking the diaphragm and valves .........................................................4-6

Assembling the fuel pump .........................................................................4-6

Intake manifold...............................................................................................4-7

Checking the throttle position sensor ........................................................4-9

Installing the throttle position sensor .........................................................4-9

Checking the idle speed control ................................................................4-9

Vapor separator............................................................................................4-10

Reducing the fuel pressure......................................................................4-13

Disconnecting the quick connector..........................................................4-13

Measuring the fuel pressure ....................................................................4-13

Checking the pressure regulator .............................................................4-14

Draining the fuel ......................................................................................4-15

Removing the fuel hose clamp ................................................................4-15

Installing the fuel hose clamp ..................................................................4-15

Disassembling the vapor separator .........................................................4-15

Checking the vapor separator .................................................................4-16

Assembling the vapor separator..............................................................4-16

Adjusting the float ....................................................................................4-17

1

2

3

4

5

6

6D81G11

Canister.........................................................................................................4-18

Checking the canister ..............................................................................4-19

7

8

9

Page 46

FUEL

Fuel system

Special service tools

Pressure/vacuum tester

YB-35956-A

Fuel pressure gauge

YB-06766

4

Fuel pressure gauge adapter B

YB-06942

4-1

6D81G11

Page 47

Special service tools / Hose routing

Hose routing

Fuel and blowby hoses

4

1

2

3

4

Blowby hose

1

Fuel hose (primary pump-to-fuel filter)

2

Fuel hose (fuel filter-to-fuel pump)

3

Fuel hose (fuel pump-to-strainer)

4

Fuel hose (strainer-to-vapor separator)

5

High-pressure fuel hose (vapor separator-to-fuel rail)

6

Fuel hose (pressure regulator-to-fuel cooler)

7

Fuel hose (fuel cooler-to-vapor separator)

8

Canister hose (vapor separator-to-canister)

9

Canister hose (canister-to-idle speed control)

0

Canister hose (canister-to-filter)

A

Canister hose (filter-to-bottom cowling)

B

5

6

7

8

9

6D81G11

4-2

Page 48

FUEL

Fuel system

Fuel filter and fuel pump

1

15

4

T

.

R

.

10 N

m (1.0 kgf

·

m, 7.4 ft

·

·

Ib)

14

13

9

10

12

10

3

11

4

5

6

2

7

T

3 N

m (0.3 kgf

.

·

R

.

No. Part name Q’ty Remarks

1Nut 1

2 Fuel filter assembly 1

3O-ring 1

4 Fuel filter element 1

5O-ring 1

6Float 1

7Cup 1

8 Fuel hose 1

9 Fuel pump 1

10 Bolt 2 M6 × 30 mm

11 Fuel hose 1

12 Strainer 1

13 Bolt 1 M6 × 12 mm

14 Bracket 1

15 O-ring 1

m, 2.2 ft

·

·

Ib)

Not reusable

Not reusable

Not reusable

8

S6D84020

4-3

6D81G11

Page 49

Fuel filter and fuel pump

4

T

.

R

.

4 N

m (0.4 kgf

·

m, 3.0 ft

·

·

Ib)

1

1

4

2

3

5

2

3

8

4

6

10

9

7

11

No. Part name Q’ty Remarks

1Screw 3 ø6 × 35 mm

2 Cover 1

3Gasket 1

4 Fuel pump body 2 assembly 1

5 Diaphragm 1

6Pin 1

7Spring 1

8 Fuel pump body 1 1

9Spring 1

10 Plunger 1

11 Nut 3

Not reusable

5

S6D84030

6

7

8

9

6D81G11

4-4

Page 50

FUEL

Fuel system

Checking the fuel pump

1. Place a drain pan under the fuel hose

connections, and then disconnect the

fuel hoses from the fuel pump.

2. Connect the special service tool to the

fuel pump inlet.

3. Cover the fuel pump outlet with a finger,

and then apply the specified positive

pressure. Check that there is no air leakage.

S63P4090

6. Apply the specified positive pressure and

check that there is no air leakage. Disassemble the fuel pump if necessary.

S63P4110

NOTE:

Assemble the fuel pump valve to the fuel

pump body, and moisten the inside of the fuel

pump with gasoline to ensure a good seal.

Specified pressure:

2

50 kPa (0.5 kgf/cm

, 7.3 psi)

Pressure/vacuum tester:

YB-35956-A

Specified pressure:

50 kPa (0.5 kgf/cm

2

, 7.3 psi)

4. Apply the specified negative pressure

and check that there is no air leakage.

S63P4100

Specified pressure:

30 kPa (0.3 kgf/cm

2

, 4.4 psi)

Disassembling the fuel pump

1. Disassemble the fuel pump.

2. Push down on the plunger and the diaphragm, turn fuel pump body 1

approximately 90° to a position where the

pin 2 can be removed easily, and then

remove the pin.

1

5. Connect the special service tool to the

fuel pump outlet.

4-5

6D81G11

Page 51

3. Slowly let up on the plunger and diaphragm, and then remove them.

Checking the diaphragm and valves

1. Check the diaphragm for tears and the

valves for cracks. Replace if necessary.

Assembling the fuel pump

NOTE:

Clean the parts and soak the valves and the

diaphragm in gasoline before assembly to

obtain prompt operation of the fuel pump

when starting the engine.

Fuel filter and fuel pump

1

2

1. Align the plunger and diaphragm installation holes a, and then install the plunger

into the diaphragm.

2. Push down on the plunger and the diaphragm, and then install the pin 1.

3. Turn fuel pump body 1 2 approximately

90°, and then push down on the plunger

several times to make sure that the pin

does not come out.

3

4

5

6

7

NOTE:

Make sure that the gasket and diaphragm are

kept in place through the assembly process.

6D81G11

8

9

4-6

Page 52

FUEL

Fuel system

Intake manifold

2

3

1

4

3

4

14

15

13

12

7

6

9

5

No. Part name Q’ty Remarks

1 Intake silencer 1

2Bolt 2 M6 × 80 mm

3 Bushing 4

4 Collar 2

5 Intake manifold assembly 1

6Bolt 4 M8 × 30 mm

7 Collar 5

8Bolt 1 M8 × 100 mm

9Spacer 1

10 Bolt 3 M6 × 45 mm

11 Collar 3

12 Holder 1

13 Gasket 1

14 Pin 2

15 Joint 1

Not reusable

11

10

8

S6D84040

4-7

6D81G11

Page 53

Intake manifold

4

3.7 N

m (0.37 kgf

·

T

.

R

.

3

5

m, 2.7 ft

·

6

lb)

·

3

2

T

m (0.8 kgf

8 N

.

·

R

.

4

13

m, 5.9 ft

·

15

·

Ib)

1

2

3

11

10

12

7

9

14

8

1

16

4

16

5

T

8 N

m (0.8 kgf

.

·

R

.

No. Part name Q’ty Remarks

1 Intake manifold 1

2 Sensor assembly 1

3Screw 4 ø5 × 13 mm

4O-ring 1

5 Idle speed control 1

6O-ring 1

7 Throttle body assembly 1

8Bolt 3 M6 × 16 mm

9Gasket 1

10 Throttle position sensor 1

11 Screw 2

12 O-ring 1

13 Fuel injector 4