Yamaha F70A, F40GET, F75BET, F70A w/6X4 tiller handle, F75A Rigging Manual

...

90894-62983-01Worldwide Edition

RIGGING GUIDE

2014

PREFACE

WARNING

NOTICE

The information in this guide is based on 2014 model specification information available at the time

when the guide has been issued.

Throughout this guide, Worldwide model names are given first followed by US and Canada model

names in parentheses for descriptive purpose.

For Australia and New Zealand, US and Canada model names are used for 4-stroke 150HP and

larger models.

In this guide, particularly important information is distinguished in the following ways.

A WARNING indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

A NOTICE indicates special precautions that must be taken to avoid damage to the products

or other property.

Specifications and descriptions are subject to change without notice.

The PDF file is available from the service portal site maintained by Yamaha Motor Co., Ltd.

The following contracted terms are expediently used in this guide.

ASSY: assembly

DEC: Digital Electronic Remote Control

ECM: Electronic Control Module

EXT: extension

GND: ground, (–)

IG: ignition

LED: light emitting diode

MGT: management

NA: not applicable, not available

OP: optional

P/N: part number

PTT: power trim & tilt

PWR: power

RC: remote control

STD: standard

STR: steering

SW: switch

TBD: to be determined

© Yamaha Motor Co., Ltd.

All rights reserved.

Mar. 2014

Produced by

Technical Publication Division

After Sales Section

CS Center

CONTENTS

INSTALLATION............................................................................................1-1

TOP COVER PICTOGRAPH DESCRIPTION...............................................................1-2

ENGINE OIL REMINDER TAG (4-STROKE ENGINES)...............................................1-2

UNCRATING PROCEDURE

(FOR TYPICAL STEEL FRAME) .............................................................................. 1-3

MOUNTING THE OUTBOARD MOTOR....................................................................... 1-5

MOUNTING THE REMOTE OIL TANK.......................................................................1-11

OUTBOARD MOTOR DIMENSIONS..........................................................................1-12

PROPELLERS..............................................................................................2-1

PROPELLER SPECIFICATIONS.................................................................................. 2-2

PROPELLER SELECTION ...........................................................................................2-6

2014 PROPELLER APPLICATIONS ............................................................................2-6

WOT OPERATION RANGE TABLE ...........................................................................2-23

REMOTE CONTROLS .................................................................................3-1

REMOTE CONTROL TYPES AND APPLICATIONS....................................................3-2

REMOTE SWITCH TYPES AND APPLICATIONS .....................................................3-18

REMOTE CONTROL CABLES ...................................................................................3-33

REMOTE CONTROL ATTACHMENT KIT ..................................................................3-35

STEERING HOOK ......................................................................................................3-39

STEERING GUIDE ATTACHMENT KIT .....................................................................3-42

TIE-BAR KIT ...............................................................................................................3-44

CONVENTIONAL WIRE HARNESS ...........................................................................3-45

DIGITAL ELECTRONIC REMOTE CONTROL WIRE HARNESS ..............................3-46

TILLER HANDLES .......................................................................................4-1

6X4 MULTI-FUNCTION TILLER HANDLE ...................................................................4-2

STEERING FRICTION CONTENTS ...........................................................................4-24

To be continued.

CONTENTS

CONVENTIONAL GAUGE (6Y5 & 6Y7) ......................................................5-1

MOUNTING THE METERS ..........................................................................................5-4

ANALOG TACHOMETER .............................................................................................5-5

DIGITAL TACHOMETER ..............................................................................................5-7

SPEEDOMETER...........................................................................................................5-9

FUEL MANAGEMENT GAUGE ..................................................................................5-12

ANALOG TRIM METER..............................................................................................5-18

COOLANT PRESSURE METER ................................................................................5-19

COOLANT TEMP. METER .........................................................................................5-20

HOUR METER ............................................................................................................5-27

VOLTAGE METER......................................................................................................5-29

FUEL METER .............................................................................................................5-30

CHARGE WARNING UNIT .........................................................................................5-31

WIRE HARNESSES....................................................................................................5-32

WIRING DIAGRAMS...................................................................................................5-36

RIGGING GROMMET DESCRIPTION .......................................................................5-47

DIGITAL NETWORK GAUGE (6Y8) ............................................................6-1

DIGITAL NETWORK GAUGE COMPATIBLE MODELS ..............................................6-2

DIGITAL NETWORK GAUGE APPLICATION ..............................................................6-2

DIGITAL NETWORK GAUGE DIMENSIONS ...............................................................6-3

OPTIONAL EQUIPMENT..............................................................................................6-5

WIRE HARNESS ..........................................................................................................6-8

NETWORK HUB ...........................................................................................................6-9

OPTIONAL EQUIPMENT............................................................................................6-10

IMMOBILIZER UNIT ...................................................................................................6-11

NETWORK WIRING DIAGRAMS ...............................................................................6-12

INITIAL GAUGE SETUP .............................................................................................6-16

TROUBLESHOOTING ................................................................................................6-17

BASIC REQUIREMENTS ...........................................................................................6-18

NMEA0183 COMPATIBLE EQUIPMENT CONNECTION ..........................................6-18

DIGITAL NETWORK GAUGE (6Y8) FUNCTION TABLE ...........................................6-19

DIGITAL NETWORK PREMIUM GAUGE (6Y9) ..........................................7-1

DIGITAL NETWORK PREMIUM GAUGE COMPATIBLE MODELS............................. 7-3

DIGITAL NETWORK PREMIUM GAUGE APPLICATION ............................................7-3

DIGITAL NETWORK PREMIUM GAUGE DIMENSIONS .............................................7-4

OPTIONAL EQUIPMENT..............................................................................................7-5

NETWORK HUB ...........................................................................................................7-8

WIRE HARNESS ..........................................................................................................7-9

NETWORK WIRING DIAGRAMS ...............................................................................7-14

To be continued.

CONTENTS

BATTERY .....................................................................................................8-1

RECOMMENDED BATTERY........................................................................................8-2

BATTERY CABLE LENGTH .........................................................................................8-4

BATTERY WIRING .......................................................................................................8-6

APPENDIX....................................................................................................9-1

MODEL NAME DESIGNATION ....................................................................................9-3

FUEL SYSTEM VACUUM PRESSURE STANDARD ...................................................9-5

PORTABLE FUEL TANKS (TYPICAL) .........................................................................9-7

FUEL PIPES (TYPICAL) ...............................................................................................9-8

PRIMARY PUMP (TYPICAL) ........................................................................................9-8

PRE-DELIVERY INSPECTION (PDI) ...........................................................................9-9

CONVENTIONAL RIGGING KIT CONTENTS............................................................9-10

DIGITAL NETWORK GAUGE RIGGING KIT CONTENTS .........................................9-13

IMMOBILIZER RIGGING KIT CONTENTS.................................................................9-22

DIGITAL NETWORK PREMIUM GAUGE RIGGING KIT CONTENTS .......................9-24

OTHER RIGGING KIT CONTENTS............................................................................9-27

2014 YEAR MODELS MANUFACTURE STARTING SERIAL NUMBERS................. 9-30

INSTALLATION

TOP COVER PICTOGRAPH DESCRIPTION........................................... 1-2

ENGINE OIL REMINDER TAG (4-STROKE ENGINES) .......................... 1-2

UNCRATING PROCEDURE

(FOR TYPICAL STEEL FRAME) ......................................................... 1-3

MOUNTING THE OUTBOARD MOTOR .................................................. 1-5

WATER LEVEL GUIDELINE (4-STROKE ENGINES).......................... 1-9

ADJUSTING TWIN ENGINES ............................................................ 1-10

MAX. BOAT SPEED ESTIMATION .................................................... 1-10

MOUNTING THE REMOTE OIL TANK ..................................................1-11

REMOTE OIL TANK DIMENSIONS ................................................... 1-11

NOTICE FOR MOUNTING THE REMOTE OIL TANK ....................... 1-11

OUTBOARD MOTOR DIMENSIONS ..................................................... 1-12

OVERALL DIMENSION ITEMS..........................................................1-12

OVERALL DIMENSIONS (4-STROKE) .............................................. 1-14

OVERALL DIMENSIONS (2-STROKE) .............................................. 1-23

CLAMP BRACKET DIMENSION ITEMS ............................................ 1-29

CLAMP BRACKET DIMENSIONS...................................................... 1-30

1-1

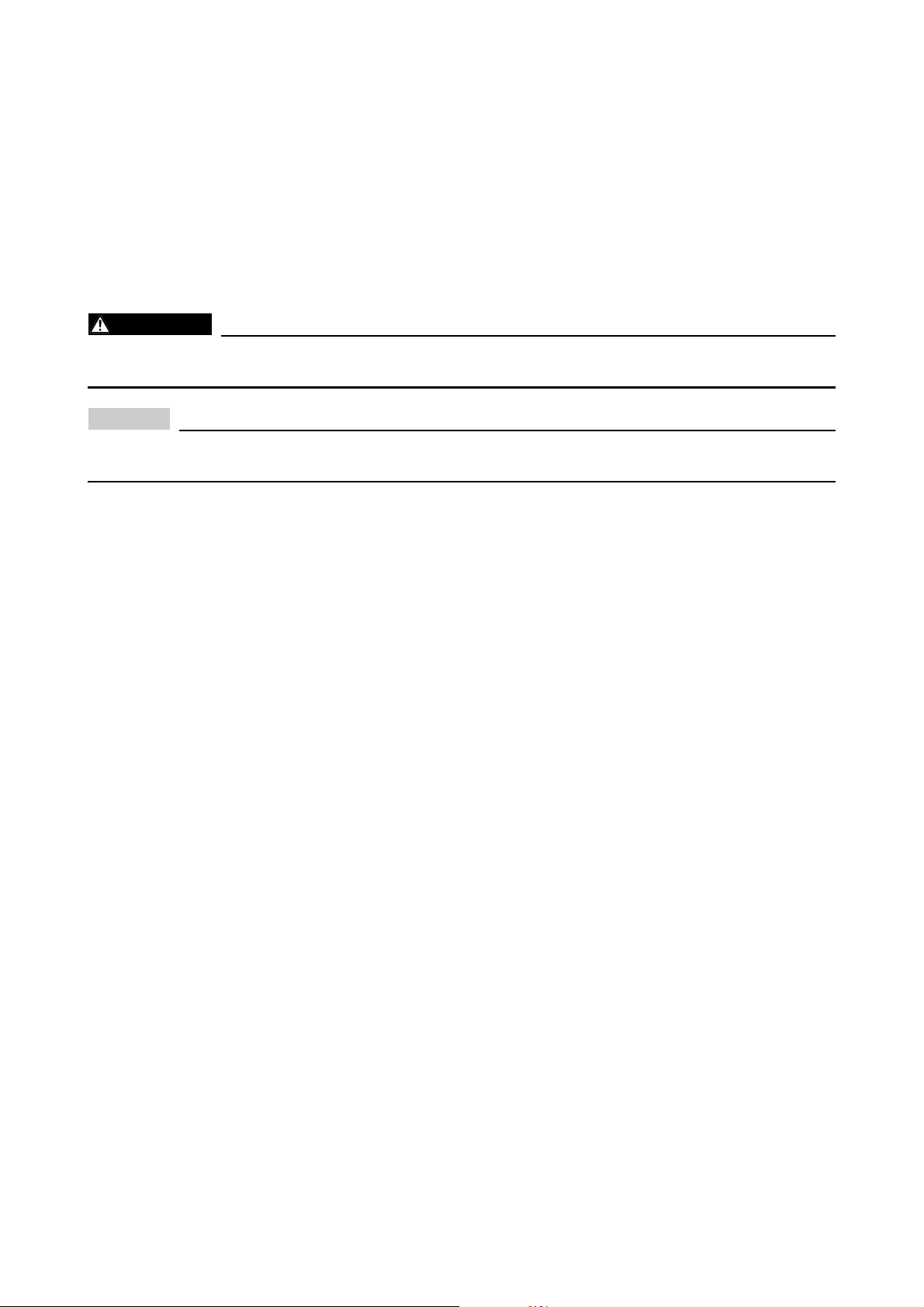

TOP COVER PICTOGRAPH DESCRIPTION

Product barycentric position

Lifting fork insert position

Stack limit: Max. 4 units for storage

Upward indication

Care handling indication

Water avoidance indication

The following pictographs are important sign to handle the crate.

Read the NOTICE and understand what pictographs mean to avoid a damage to the product when

handling, transporting and/or keeping the crate.

* Photo shows F350.

ENGINE OIL REMINDER TAG (4-STROKE ENGINES)

This tag is hung around the bottom cowling or the bracket to indicate that there is no engine oil in

the oil pan when the outboard motor is uncrated.

1-2

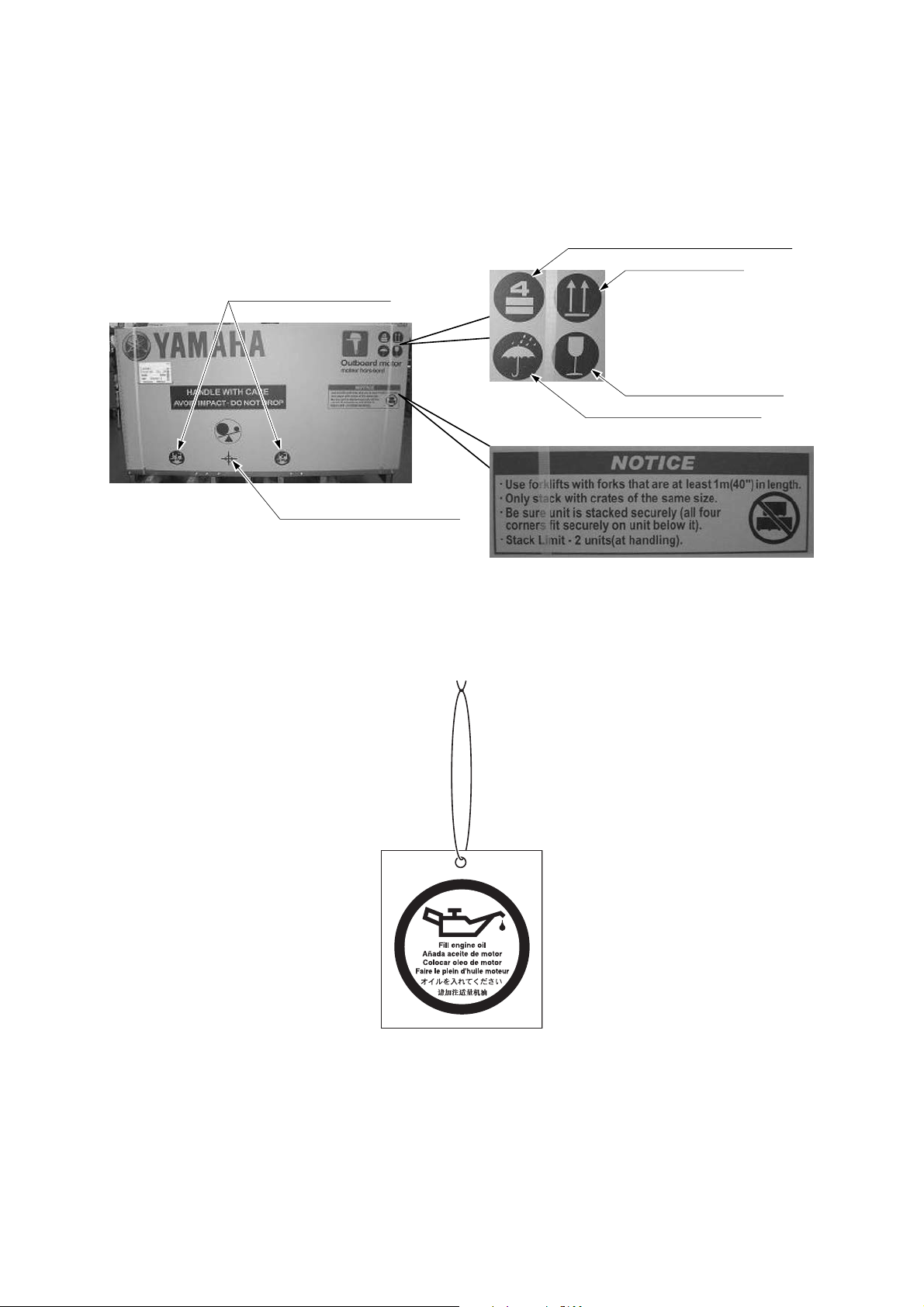

UNCRATING PROCEDURE

WARNING

(1)

(2)

(3)

(4)

(5)

(FOR TYPICAL STEEL FRAME)

Wear gloves to avoid injury by sharp steel

edges while uncrating.

This is an example of the steel crate for V6

models.

For other steel crate models, refer to this procedure for uncrating the steel frame.

1. Inspect the crate for shipping damage. If

any damage has been found, consult your

Yamaha dealer.

2. Cut the strap (1).

4. Remove the bottom bolts (3).

5. Lift the top frame (4) straight up.

3. Lift the top cover (2) straight up to remove.

6. Remove the wrapping (5), and inspect the

outboard motor for concealed damage. If

any damage is found, consult your Yamaha

dealer.

To be continued.

1-3

UNCRATING PROCEDURE

(6)

(7)

(8)

(7)

(8)

(A)(A)

(D)(D)

(B)(B)

(C)(C)

Eye bolt (C)Eye bolt (C)

Attachment (A)Attachment (A)

Eye bolt (C)

M10 bolt (B) M10 bolt (B)

90890-06821 (3 pcs)90890-06821 (3 pcs)

M10 bolt (B)

90890-06821 (3 pcs)

Attachment (A)

(FOR TYPICAL STEEL FRAME)

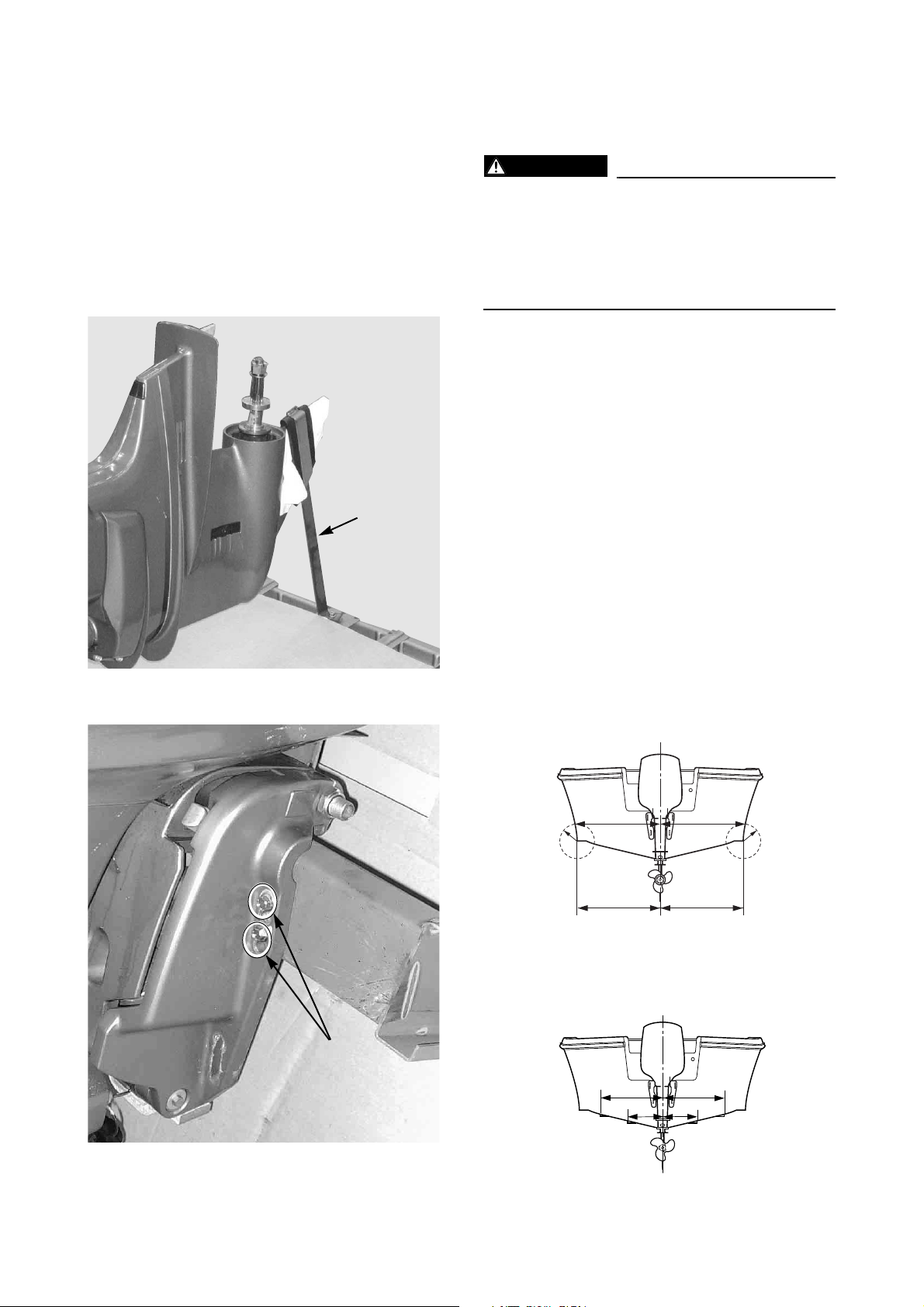

7. Remove the top cowling (6).

8. If the lifting points are covered by the flywheel cover, remove it.

9. Attach a lifting harness (7) securely to the

lifting points (8), and tighten the harness.

For 4-stroke V8, V6 (4.2L) and L4 (2.8L,

1.8L) engines, install the lifting attachment

(A) to the flywheel using the exclusive 3

bolts (B), insert the eye bolt (C) to the

attachment, attach a lifting harness (D) to

the eye bolt, and tension the harness.

M10 bolt (B) torque:

36 Nm, 3.6 kgf•m, 27 ft•lb

* Special service tool for 4-stroke V8, V6 (4.2L)

and L4 (2.8L) engines: Lifting eye kit (P/N:

90890-06820)

Lifting eye kit contents:

To be continued.

1-4

UNCRATING PROCEDURE

WARNING

(9)

(10)

*C/L: Centerline of the transom.

C/L

(a)

(b)

(c)

(d)

To be continued.

MOUNTING THE OUTBOARD

(FOR TYPICAL STEEL FRAME)

10. Carefully lift up the motor with the bottom

crate so that the lifting-harness does not

contact the engine components.

Have a helper hold the frame to avoid injury

while lifting.

11. Remove the skeg holder (9) if it is attached.

MOTOR

Overpowering a boat may cause severe

instability. Never install an outboard motor

that exceeds the maximum boat horsepower rating capacity. If a boat does not

have the capacity plate, ask to the boat

manufacturer.

Proper mount of outboard motor will obtain

better engine performance, product reliability,

fuel economy, customer satisfaction, etc.

This chapter describes the brief summary of

outboard motor mount.

For the first requirement, make sure the outboard motor has clearance for full movement,

from port to starboard, as well as during tilt

operation.

For the motor dimensions, see the later pages.

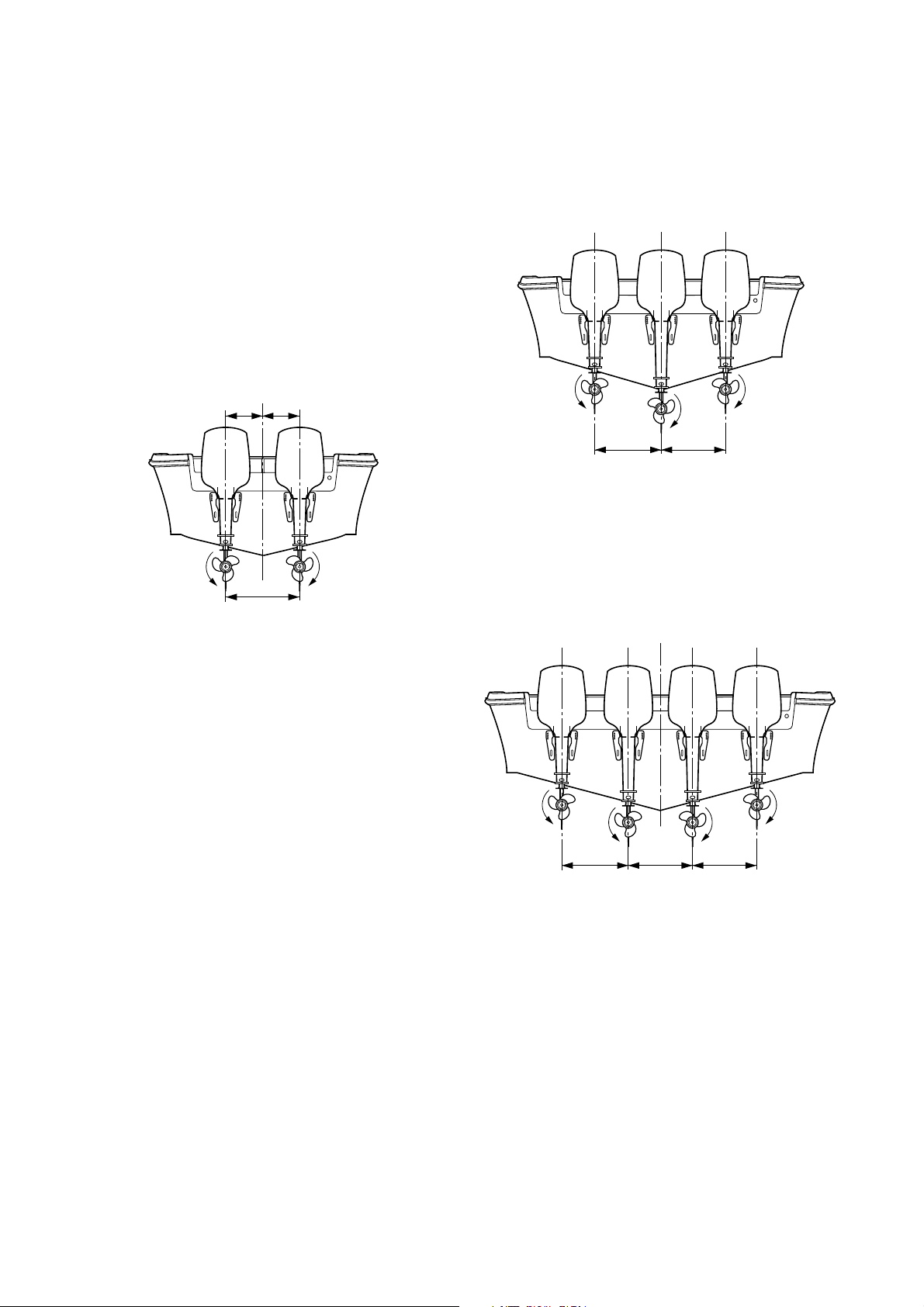

1. Set an outboard motor on the vertical center

line of boat transom.

Measurement points are shown in the illustration.

12. Remove the bracket bolts (10).

No strakes hull

Make a same radius (R) at both sides of hull,

and have another measurement points.

C/L

RR

(a)

(c)

(b)

(d)

Strakes hull

Make measurements between port and starboard strakes.

1-5

MOUNTING THE OUTBOARD

(T1)

C/L

(e)

(f)

(T1) (T1)

C/L

(T1) (T1)

C/L

(T1)

MOTOR

Recheck the measurements, and verify the

boat transom vertical centerline is straight.

Measurements (a) and (b) should be the

same, and measurement (c) and (d) should be

the same.

For twin engine application, set the engines

so that the distance between the boat transom

center line and the motor center line should be

equal for the both engines.

For triple engine application, set the engines

as shown below.

If a boat has V-hull, the center motor should

use longer transom motor than outside

engines.

For quad engine application, set the engines

as shown below.

If a boat has V-hull, inner twin engine should

use longer transom motor than outside

engines.

Measurements (e) and (f) should be the same.

Maintain a minimum distance (T1) that is the

measurement between both vertical centerlines of outboard motor.

Minimum distance (T1) is recommended on

each model, and its data is put on the dimension item.

To be continued.

1-6

MOUNTING THE OUTBOARD

0~25 mm (1 in.)

(a)

C/L

0~25 mm

(1 in.)

(a)

0~25 mm

(1 in.)

Twin engine application

Quad engine application

0~25 mm

(1 in.)

(a): Anti-cavitation plate

C/L

0~25 mm

(1 in.)

0~25 mm

(1 in.)

0~25 mm

(1 in.)

(a)

90

13 mm

(0.5 in.)

C/L

(H)

13 mm (0.5 in.)

(H)

(H): Motor transom height

Height position of

anti-cavitation plate

MOTOR

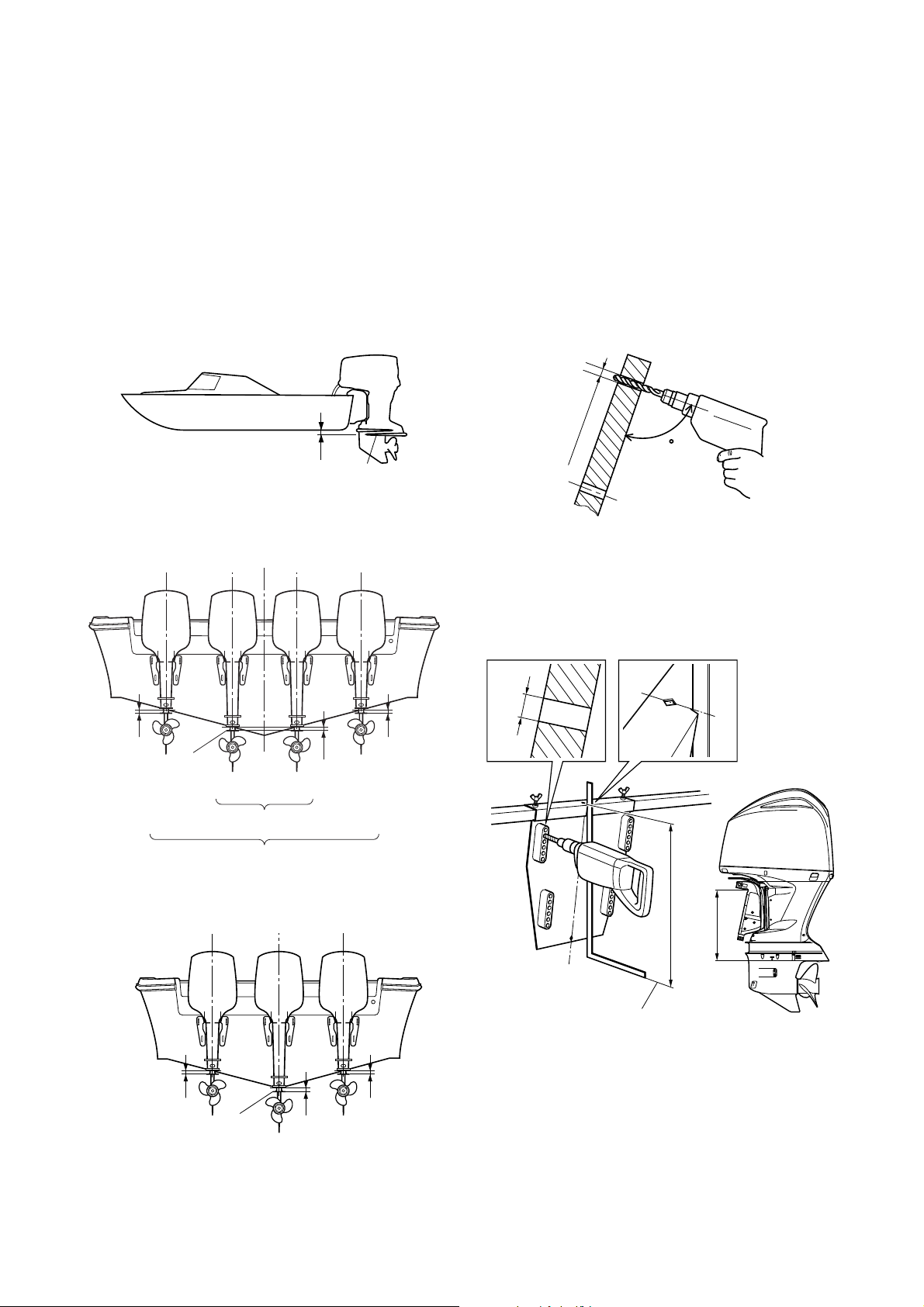

2. Adjust the height of outboard motor so that

the anti-cavitation plate is positioned to the

boat transom bottom, or lowered within 25

mm (1 in.).

For planing boats, the anti-cavitation plate

should be positioned to the boat transom

bottom or slightly higher.

Single engine application

Twin engine application/Quad engine application

* Due to combination of a boat type and an engine

type, the mount height of outboard motor varies.

Therefore, the complete information is impossible

to describe here.

For further information, see the instructions

issued by boat manufacturer, or ask to the manufacturer.

3. When the outboard motor mount position

has been determined, mark the 4 symmetrical mount hole positions onto the boat transom. Make the mount holes of 13 mm (0.5

in.) vertically on the marking points.

* To make the mounting holes easier, use the drill-

ing plate (P/N: 90890-06783 or YB-34465 for US).

Triple engine application

Ex: Drilling plate (90890-06783)

To be continued.

1-7

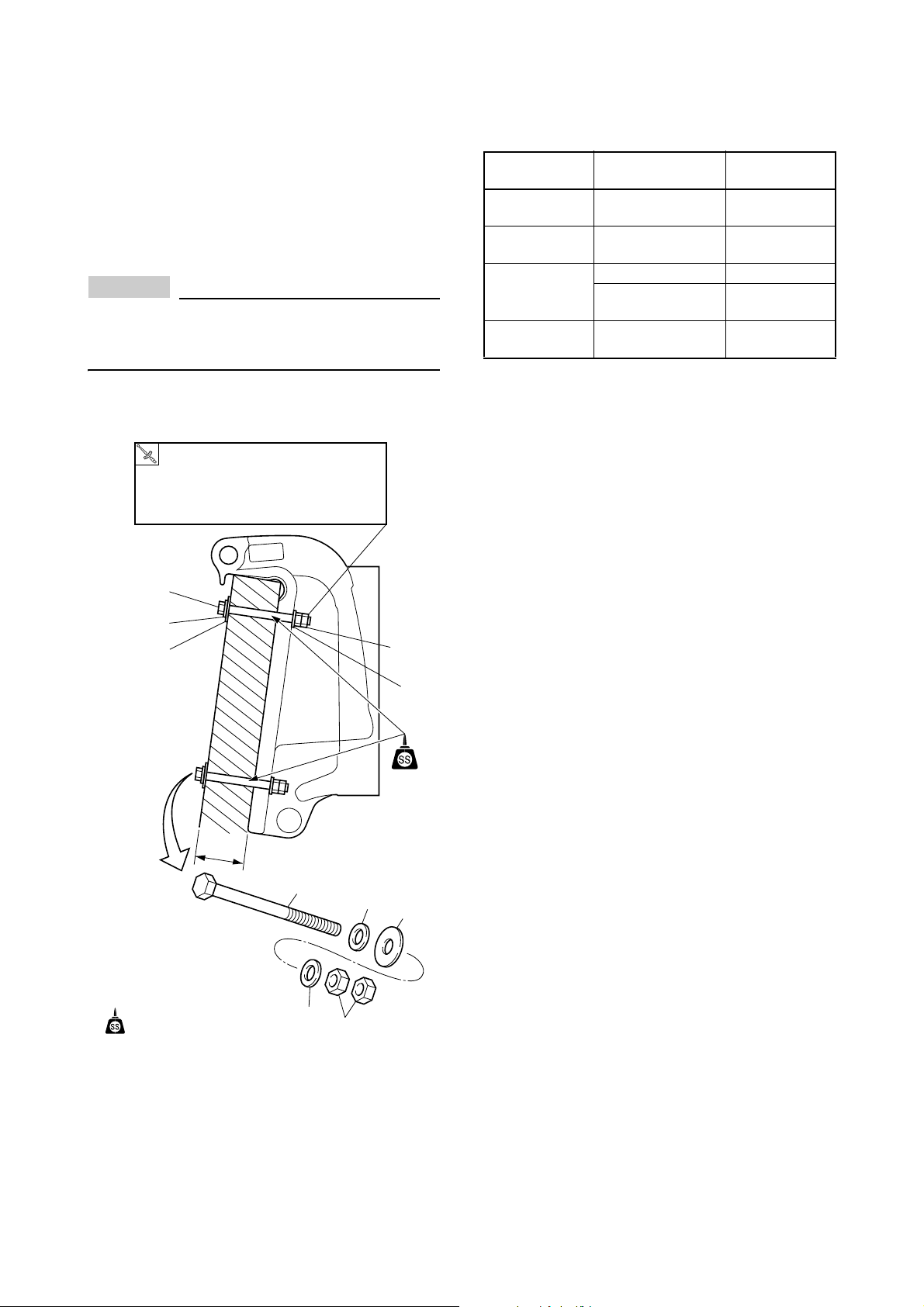

MOUNTING THE OUTBOARD

NOTICE

(a)

For reference:

(a)

(b)

(b)

(d)

(d)

(b)

(b)

(c)

(c)

(a) Mounting bolt

(b) Small washer

(c) Large washer

(d) Nut

: Sealant

T

M8: 18 Nm, 1.8 kgf•m, 13 lb•ft

M10: 36 Nm, 3.6 kgf•m, 27 lb•ft

M12: 52 Nm, 5.2 kgf•m, 38 lb•ft

MOTOR

For above 115 (V4) and F75, select the tran-

som mount bolt depending on the boat transom thickness.

4. Apply sealant to the mount holes, and secure the motor with supplied mount hardware.

For tightening procedure, first tighten the inside nut, then the double nuts each other.

Make sure there is no clearance between

boat transom and motor clamp bracket.

Otherwise, the clamp bracket could break.

* The upper mount bolt is usually installed to

the 2nd hole from top.

Boat transom

thickness (T)

55 – 65 mm

(2.17 – 2.56 in.)

65 – 75 mm

(2.56 – 2.95 in.)

75 – 95 mm

(2.95 – 3.74 in.)

95 – 115 mm

(3.74 – 4.53 in.)

* High tension bolt is recommended for F350.

Mount bolt size Bolt P/N

M12 ×115 mm 90101-12M03

M12 ×130 mm 90101-12M05

M12 ×150 mm 90101-12M77

M12 ×150 mm

[High tension bolt]

M12 ×170 mm

[High tension bolt]

90101-12031

90101-12036

* Tighten the mounting bolts/nuts to suitable torque

depending on the boat transom structure, material, design, etc.

1-8

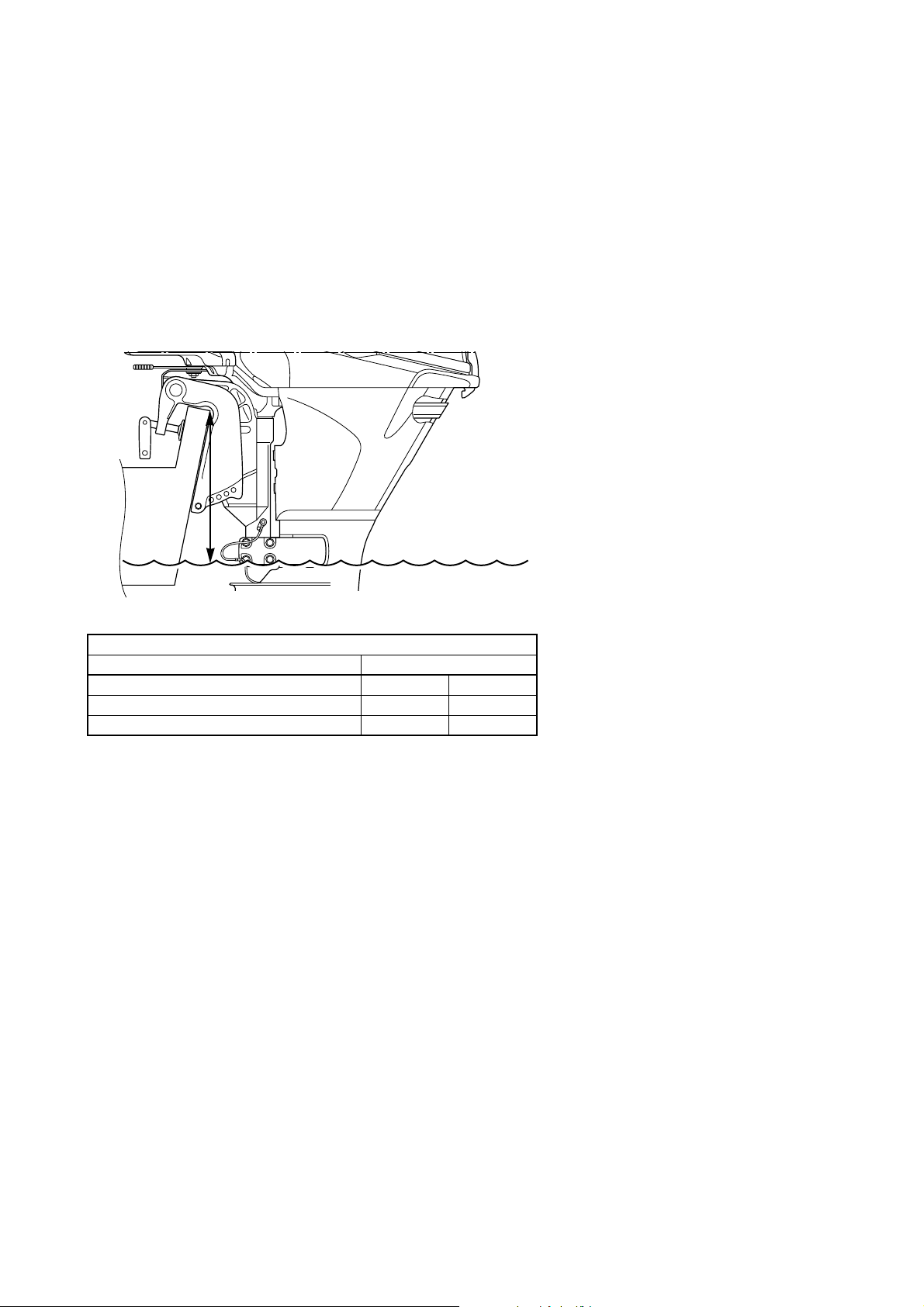

MOUNTING THE OUTBOARD MOTOR

Water surface

(H)

WATER LEVEL GUIDELINE (4-STROKE ENGINES)

If you replaced 2-stroke engine to 4-stroke engine which has the same horse power, a boat tends to

become “stern heavy” because of heavier engine weight.

As a result, water line will rise and get close to the power head.

This causes poor engine performance, and water could easily enter into the cylinder(s) and damage

the engine.

Therefore, you should consider the water level guideline when installing a 4-stroke outboard motor.

When mooring a boat with a maximum boat load, maintain the minimum height (H) shown in the

illustration between the water surface and the clamp bracket seating point.

Minimum height between water surface and bracket seating point

Model Min. height (H)

Carbureted F2 – F60 150 mm 5.9 in

Fuel injected F40 (4-cyl) – F70 100 mm 3.9 in

F75 and above 100 mm 3.9 in

1-9

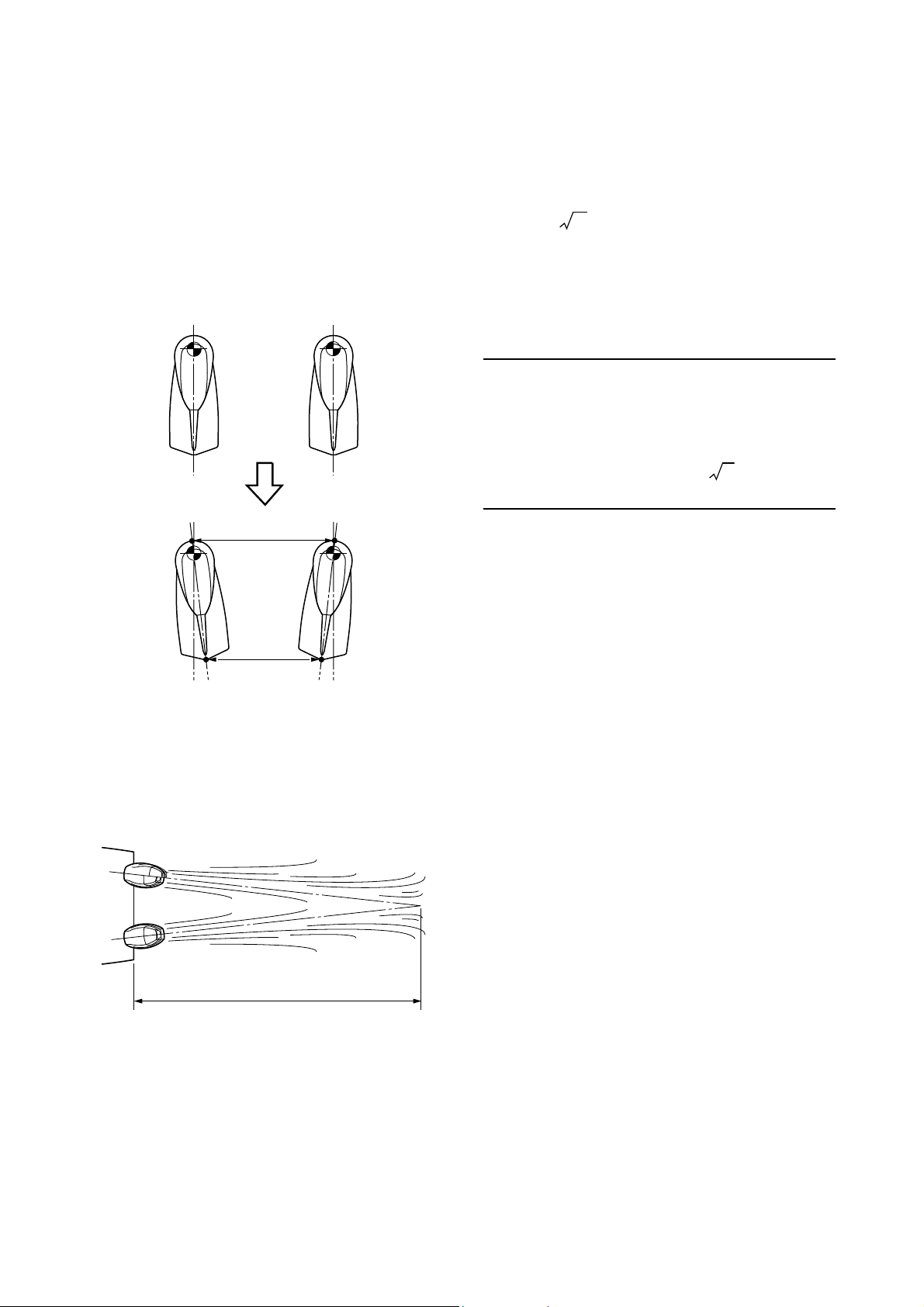

MOUNTING THE OUTBOARD

(b)

(a)

7.5 – 15 m (25 – 50 ft)

MOTOR

ADJUSTING TWIN ENGINES

Set the engines in the toe-out position, and

measure the distances between the two

engines at the center point of the rear (a) and

front (b) of the lower casing. The difference

between measurement (a) and measurement

(b) should not exceed 25 mm (1 in.).

MAX. BOAT SPEED ESTIMATION

Depending on the engine power, boat length

and boat weight, the maximum boat speed can

be generally estimated with the calculation formula as below.

V = 1.398 L (PS/)

V = Estimated maximum boat speed (km/h)

L = Boat length (m)

PS = Prop shaft output power

= Displacement volume (ton)

For example:

Boat length = 8 m (27 ft)

Engine power = 250 ps

Displacement volume = 3 ton (3000 kg)

0.623

*water line

*water line

* Adjustment: (b) – (a) = Within 25 mm (1 in)

For best result, your toe-out distance should

be set so that the twin engines wake meets

approximately 7.5 – 15 m (25 – 50 ft) past the

stern of the boat.

Max. boat speed [V] = 1.398 8 (250/3)

0.623

= 62.2 km/h (38.6 mph)

* This should be only used as a reference.

The maximum boat speed varies depending on

the hull design, rigging state, passengers weight,

engine weight, engine position, etc.

Confirm the actual boat speed by test run.

1-10

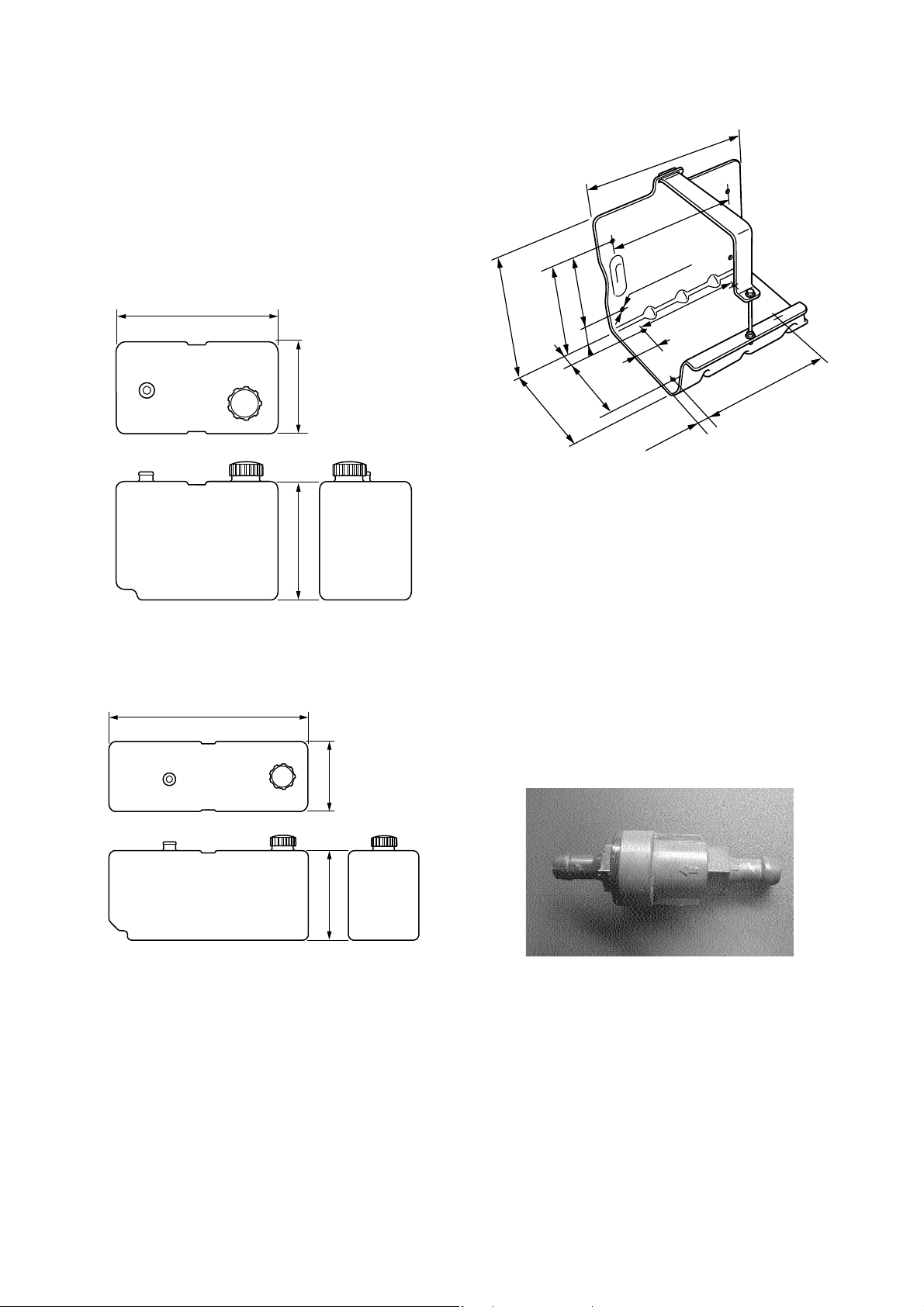

MOUNTING THE REMOTE OIL

320 (12.6)

180 (7.1)230 (9.1)

mm (in.)

180 (7.1)

508 (20)

235 (9.3)

mm (in.)

250 (9.8)

200 (7.9)

170 (6.7)

6.5 (0.26)

40 (1.6)

200 (7.9)

25 (1.0)

112

(4.4)

30

(1.2)

173

(6.8)

210 (8.3)

160 (6.3)

130 (5.1)

30

(1.2)

mm (in.)

TANK

The remote oil tank is required for 2-stroke V4

and V6 oil injection engines.

REMOTE OIL TANK DIMENSIONS

10.5 liter (2.8 US gallons) tank P/N: 6E5-21733-20

18 liter (4.8 US gallons) tank P/N: 6E5-21733-30

Oil tank holder

NOTICE FOR MOUNTING THE REMOTE OIL TANK

Follow the notifications below, for the remote

oil tank installation.

• Mount the oil tank in as dry as possible location to avoid water entering into the oil tank.

• Mount in a location that will allow service to

the filter located on the remote oil tank.

• Mount the remote oil tank lower than the

engine oil tank.

If the remote oil tank is mounted higher than

the top of the engine because of the boat

type, an optional check valve (P/N: 6R524408-00) shown below is required.

Install the check valve on the oil hose

between the engine and remote oil tank to

prevent siphoning of oil to the engine and

spillage.

• Route the oil hose between the engine and

the remote oil tank without pinching and

kinking.

1-11

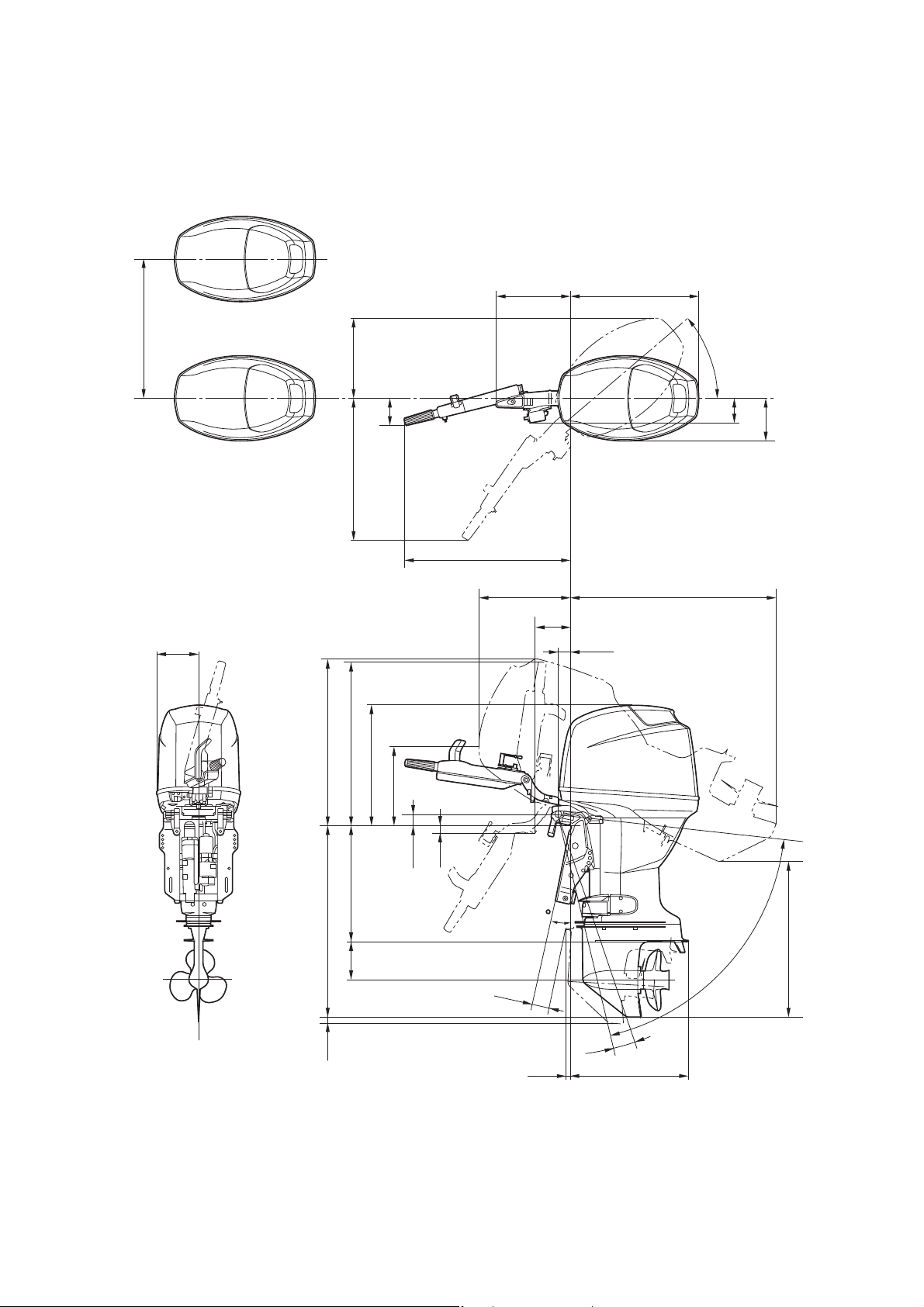

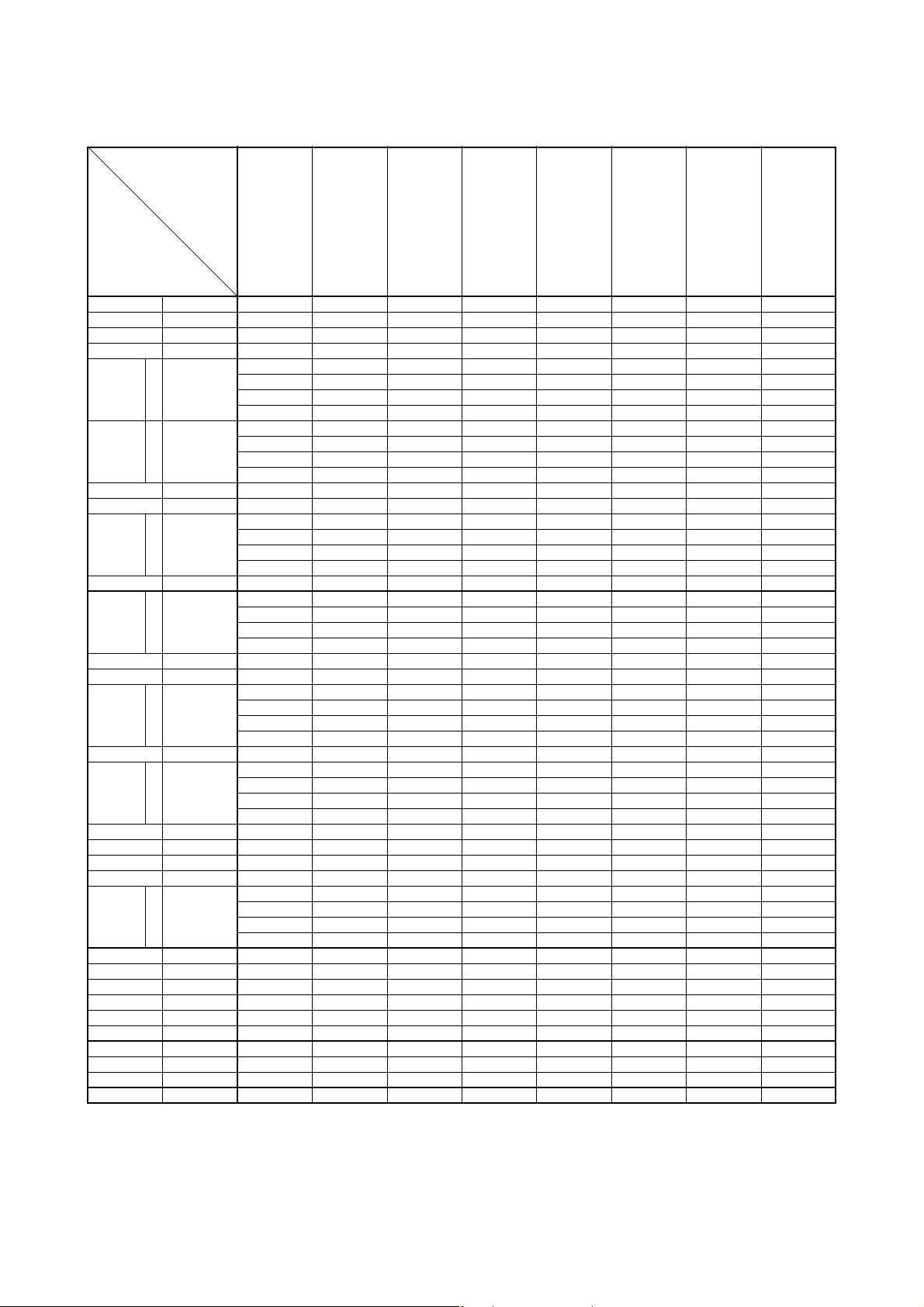

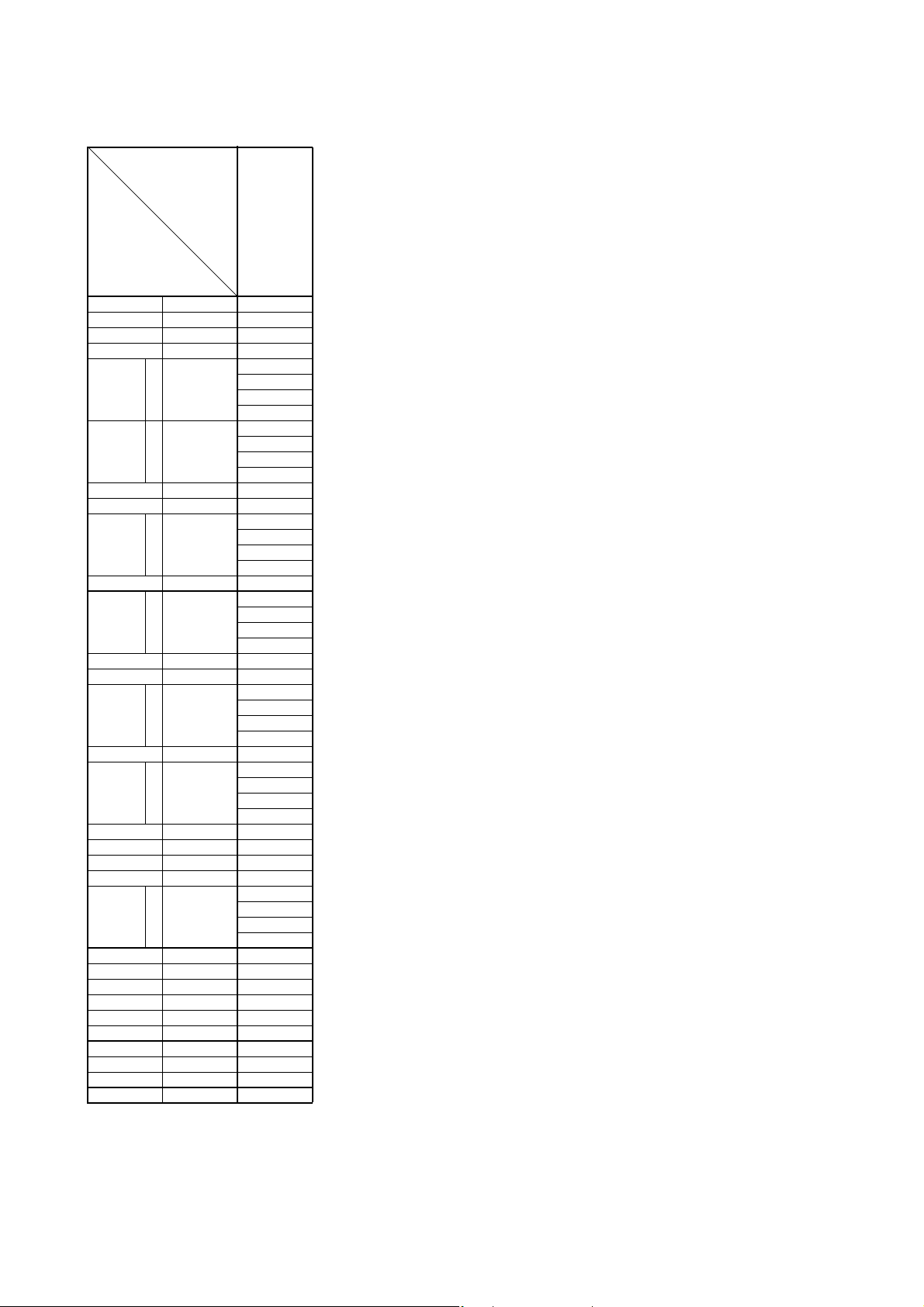

OUTBOARD MOTOR DIMENSIONS

OVERALL DIMENSION ITEMS

Symbol Definition and Description

L1 Horizontal distance from datum point to rearmost point of power unit

L2 Horizontal distance from datum point to forefront (depends on the model) of power unit

L3

L4 Horizontal distance from datum point to rearmost point of the lower case

L5

L6

L7

L8

L9 Horizontal forward protrusion of lower case from the datum line when PTT is fully trimmed down

L10 Horizontal distance from datum point to bracket shaft (bolt) center

H1 Vertical distance from datum point to lowest point of motor

H2 Vertical distance from datum point to highest point of power head

H3 Vertical distance from anti-cavitation plate undersurface to the center of propeller shaft

H4 Vertical distance from datum point to anti-cavitation plate undersurface

H5 Vertical distance from datum point to tiller handle tip when the handle is in vertical position

H6

H7 Vertical distance from datum line to protruded forefront when motor is tilted up (over-tilt position)

H8

H9 Vertical distance to the highest point of the motor when it is tilted up (over-tilt position)

H10 Vertical distance from datum point to bracket shaft (bolt) center

H11

W1 Leftward protrusion from center line of motor body when looking at the front face

W2 Distance from tiller handle tip to centerline of motor body when looking at the front face

W3 Distance from centerline to left or right edge of motor body, except for levers and handles

W4

W5 Distance from centerline to the farthest point on the body when steered to the maximum angle

W6

A1 Maximum steering angle each way (symmetrical), from centerline of motor body

A2 Tilt up angle (whole rotating range to over-tilt angle including negative trim angle)

A3 Maximum negative trim angle from the vertical line through the datum point

T1 Centerline-to-centerline minimum distance of the engines in case of twin installation

Distance from datum point to farthest point on tiller handle, when the handle is in horizontal position (in use)

Minimum distance from transom board or its extension to forefront of the lower case, with motor

fully trimmed down and steered to the full

Horizontal distance from datum point to rearmost point of protrusion when motor is tilted up (overtilt position)

Horizontal distance from datum point to protruded forefront when motor is tilted up (over-tilt position)

Horizontal distance from datum point to lowest point of protrusion when motor is tilted up (over-tilt

position)

Vertical distance from skeg tip at H1 to the lowest point of lower unit when motor is tilted up (overtilt position)

Vertical distance from datum line to lowest point of protrusion when motor is tilted up (over-tilt

position)

Difference in the height of lower unit lowest point comparing to the height in the standard position

and with PTT in the fully trimmed down position.

Distance from centerline to left or right end of motor body protrusion, except for levers and handles

Distance from centerline to the farthest point on the tiller handle when steered to the maximum

angle

1-12

OUTBOARD MOTOR DIMENSIONS

L

4

A

3

H

6

L

6

L

7

L

3

L

2

L

1

W

3

W

4

A

1

W

5

W

6

W

2

W

1

H

10

H

8

H

7

H

2

H

5

H

4

H

3

H

11

H

9

H

1

L

10

L

8

L

5

12

A

2

T

1

L

9

OVERALL DIMENSION ITEMS

1-13

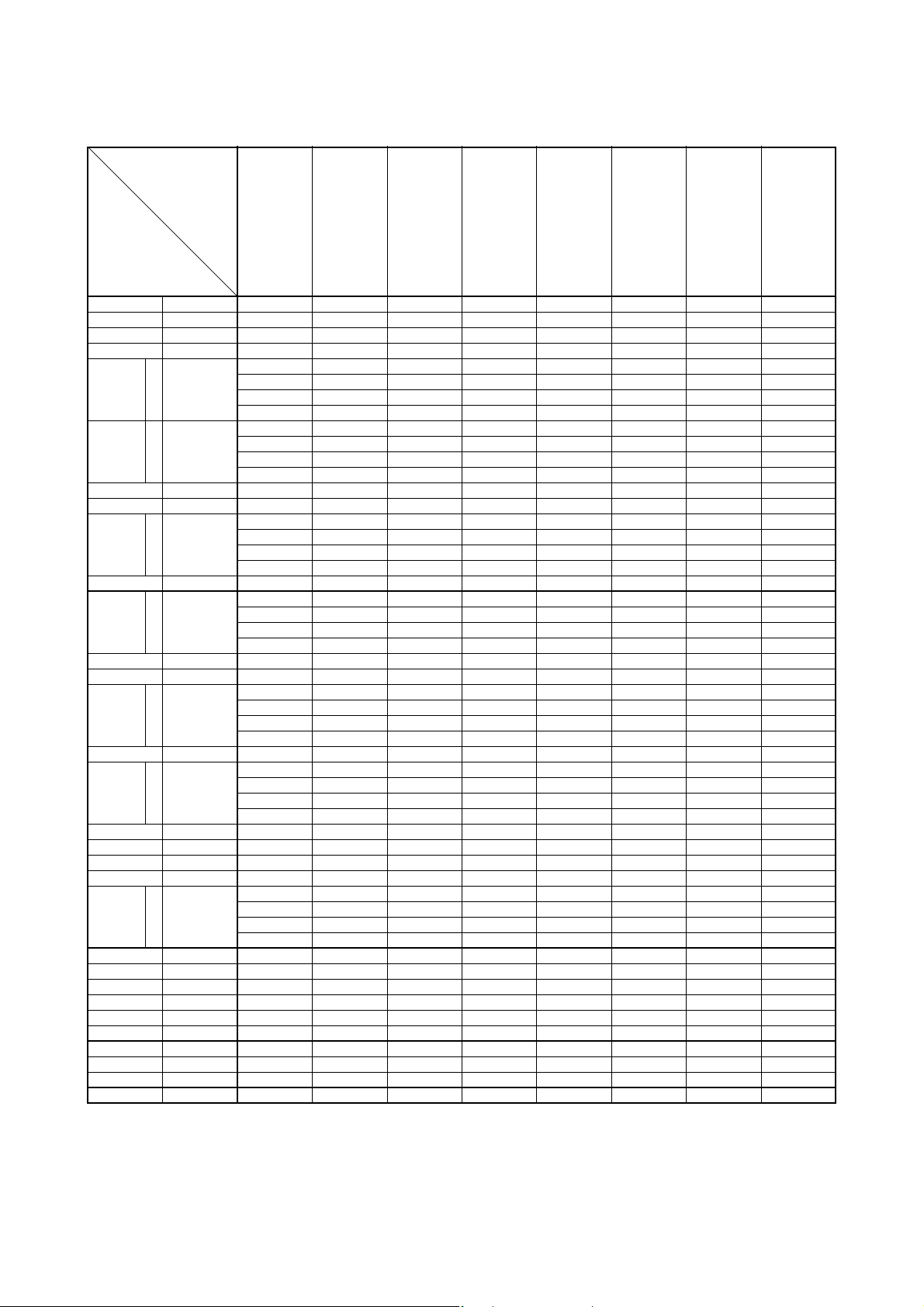

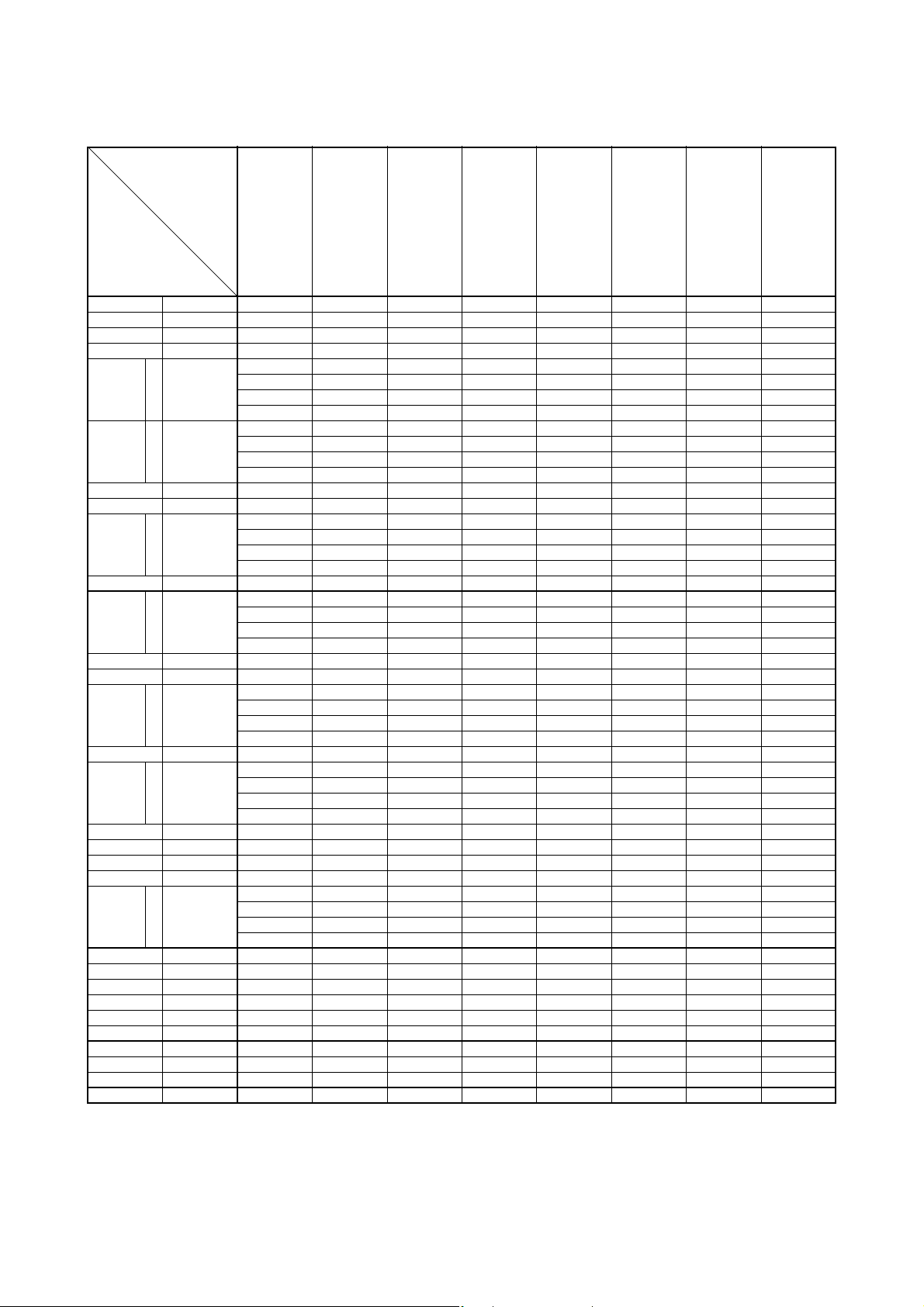

OUTBOARD MOTOR DIMENSIONS

OVERALL DIMENSIONS (4-STROKE)

Global model

(US, CA model)

F2AMH

F2.5AMH

Symbol

L1 mm (in) 315 (12.4) 315 (12.4) 409 (16.1) 430 (16.9) 430 (16.9) 430 (16.9) 430 (16.9) 430 (16.9)

L2 mm (in) 93 (3.7) 93 (3.7) 130 (5.1) 122 (4.8) 122 (4.8) 122 (4.8) 122 (4.8) 122 (4.8)

L3 mm (in) 309 (12.2) 309 (12.2) 341 (13.4) 608 (23.9) 498 (19.6) 608 (23.9) — —

L4 mm (in) 215 (8.5) 215 (8.5) 259 (10.2) 355 (14.0) 355 (14.0) 367 (14.4) 367 (14.4) 367 (14.4)

S

L 57 (2.2) 57 (2.2) 93 (3.7) 99 (3.9) 99 (3.9) 99 (3.9) 99 (3.9) 99 (3.9)

L5

L6

L7 mm (in) 366 (14.4) 388 (15.3) 383 (15.1) 271 (10.7) 271 (10.7) 271 (10.7) 271 (10.7) 271 (10.7)

L8 mm (in) 167 (6.6) 167 (6.6) 134 (5.3) 139 (5.5) 139 (5.5) 139 (5.5) 139 (5.5) 225 (8.9)

L9

L10 mm (in) 75 (3.0) 57 (2.2) 63 (2.5) 67 (2.6) 67 (2.6) 67 (2.6) 67 (2.6) 67 (2.6)

H1

H2 mm (in) 376 (14.8) 397 (15.6) 395 (15.6) 318 (12.5) 318 (12.5) 318 (12.5) 318 (12.5) 318 (12.5)

H3 mm (in) 103 (4.1) 103 (4.1) 104 (4.1) 123 (4.8) 123 (4.8) 157 (6.2) 157 (6.2) 157 (6.2)

H4

H5 mm (in) 470 (18.5) 470 (18.5) 430 (16.9) 673 (26.5) 563 (22.2) 673 (26.5) — —

H6

H7 mm (in) 264 (10.4) 255 (10.0) 191 (7.5) 203 (8.0) 203 (8.0) 203 (8.0) 203 (8.0) 203 (8.0)

H8 mm (in) 15 (0.6) 15 (0.6) 0.6 (0.02) 5 (0.2) 5 (0.2) 5 (0.2) 5 (0.2) 5 (0.2)

H9 mm (in) 406 (16.0) 406 (16.0) 503 (19.8) 529 (20.8) 529 (20.8) 529 (20.8) 529 (20.8) 529 (20.8)

H10 mm (in) 32 (1.3) 32 (1.3) 39 (1.5) 32 (1.3) 32 (1.3) 32 (1.3) 32 (1.3) 32 (1.3)

H11

W1 mm (in) 140 (5.5) 140 (5.5) 181 (7.1) 159 (6.3) 169 (6.7) 172 (6.8) 177 (7.0) 177 (7.0)

W2 mm (in) 205 (8.1) 205 (8.1) 222 (8.7) 199 (7.8) 206 (8.1) 199 (7.8) — 135 (5.3)

W3 mm (in) 139 (5.5) 139 (5.5) — 159 (6.3) 159 (6.3) 159 (6.3) 159 (6.3) 159 (6.3)

W4 mm (in) 135 (5.3) 135 (5.3) 153 (6.0) 159 (6.3) 159 (6.3) 159 (6.3) 159 (6.3) 159 (6.3)

W5 mm (in) — — 325 (12.8) 286 (11.3) 286 (11.3) 286 (11.3) 286 (11.3) 271 (10.7)

W6 mm (in) — — 425 (16.7) 619 (24.4) 536 (21.1) 619 (24.4) — 271 (10.7)

A1 degree 360 360 90 45 45 45 45 40

A2 degree 80 80 69 66 66 66 66 66

A3degree————————

T1mm (in)————————

mm (in)

X —————99 (3.9)99 (3.9)99 (3.9)

U ————————

S

L 761 (30.0) 761 (30.0) 753 (29.6) 822 (32.4) 822 (32.4) 879 (34.6) 879 (34.6) 879 (34.6)

mm (in)

X —————941 (37.0)941 (37.0) 941 (37.0)

U ————————

S

L ————————

mm (in)

X ————————

U ————————

S

L 772 (30.4) 772 (30.4) 771 (30.4) 809 (31.9) 809 (31.9) 869 (34.2) 869 (34.2) 869 (34.2)

mm (in)

X —————937 (36.9)937 (36.9) 937 (36.9)

U ————————

S

L 559 (22.0) 559 (22.0) 562 (22.1) 563 (22.2) 563 (22.2) 557 (21.9) 557 (21.9) 557 (21.9)

mm (in)

X —————625 (24.6)625 (24.6) 625 (24.6)

U ————————

S

L 746 (29.4) 746 (29.4) 637 (25.1) 669 (26.3) 669 (26.3) 717 (28.2) 717 (28.2) 717 (28.2)

mm (in)

X —————757 (29.8)757 (29.8) 757 (29.8)

U ————————

S

L ————————

mm (in)

X ————————

U ————————

57 (2.2) 57 (2.2) 71 (2.8) 72 (2.8) 72 (2.8) — — —

636 (25.0) 636 (25.0) 635 (25.0) 706 (27.8) 706 (27.8) — — —

————————

645 (25.4) 645 (25.4) 644 (25.4) 682 (26.9) 682 (26.9) — — —

432 (17.0) 432 (17.0) 435 (17.1) 436 (17.2) 436 (17.2) — — —

642 (25.3) 642 (25.3) 555 (21.9) 594 (23.4) 594 (23.4) — — —

————————

(F2.5MHA)

w/ EPA cap

F4BMH

(F4MHA)

F5AMH

F6CMH

(F6MHA)

F8CMH

(F8MHA)

Long handle

F8CMH

F8CWH

Short handle

FT8DMH

Long handle

FT8DE FT8DEP

1-14

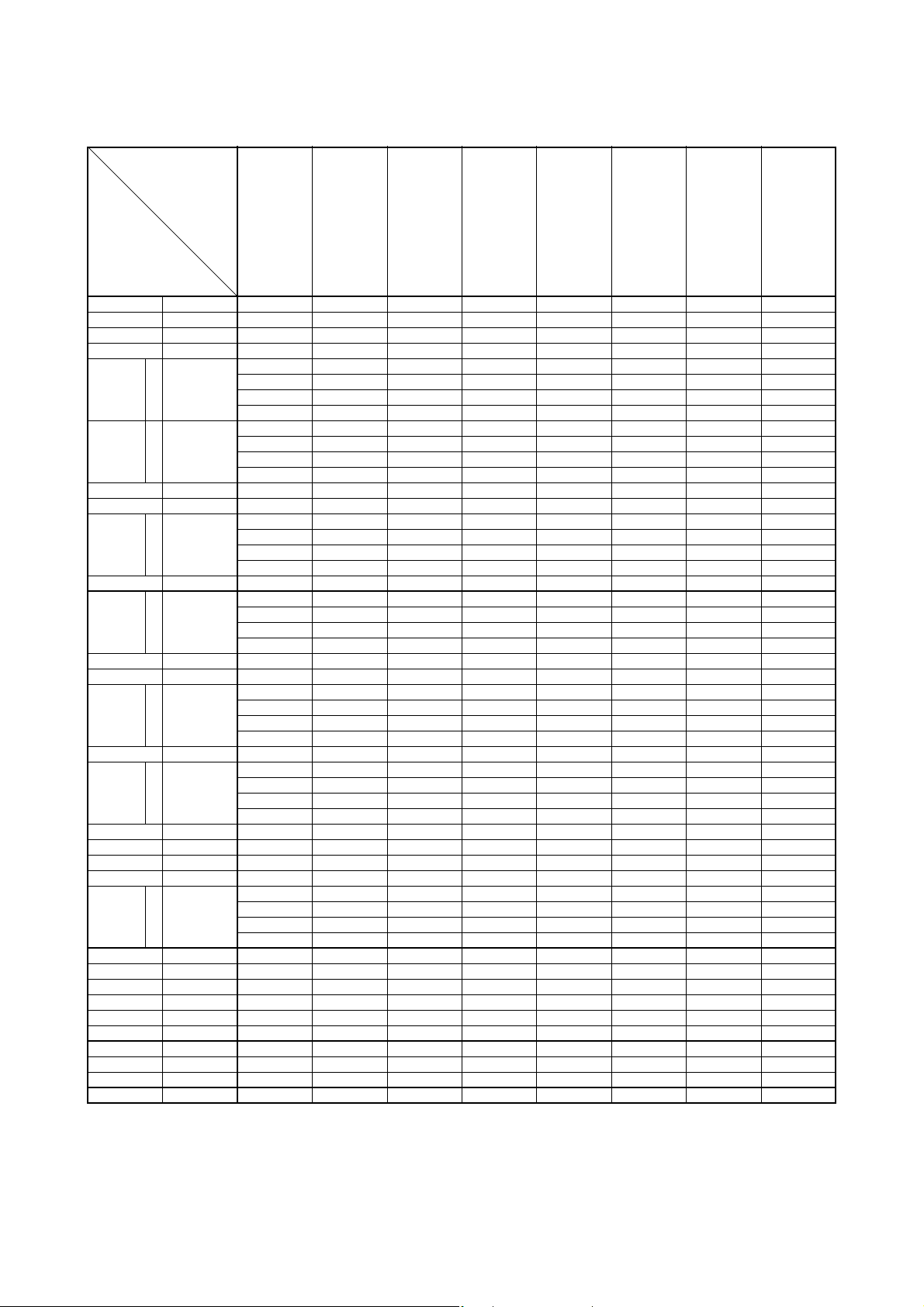

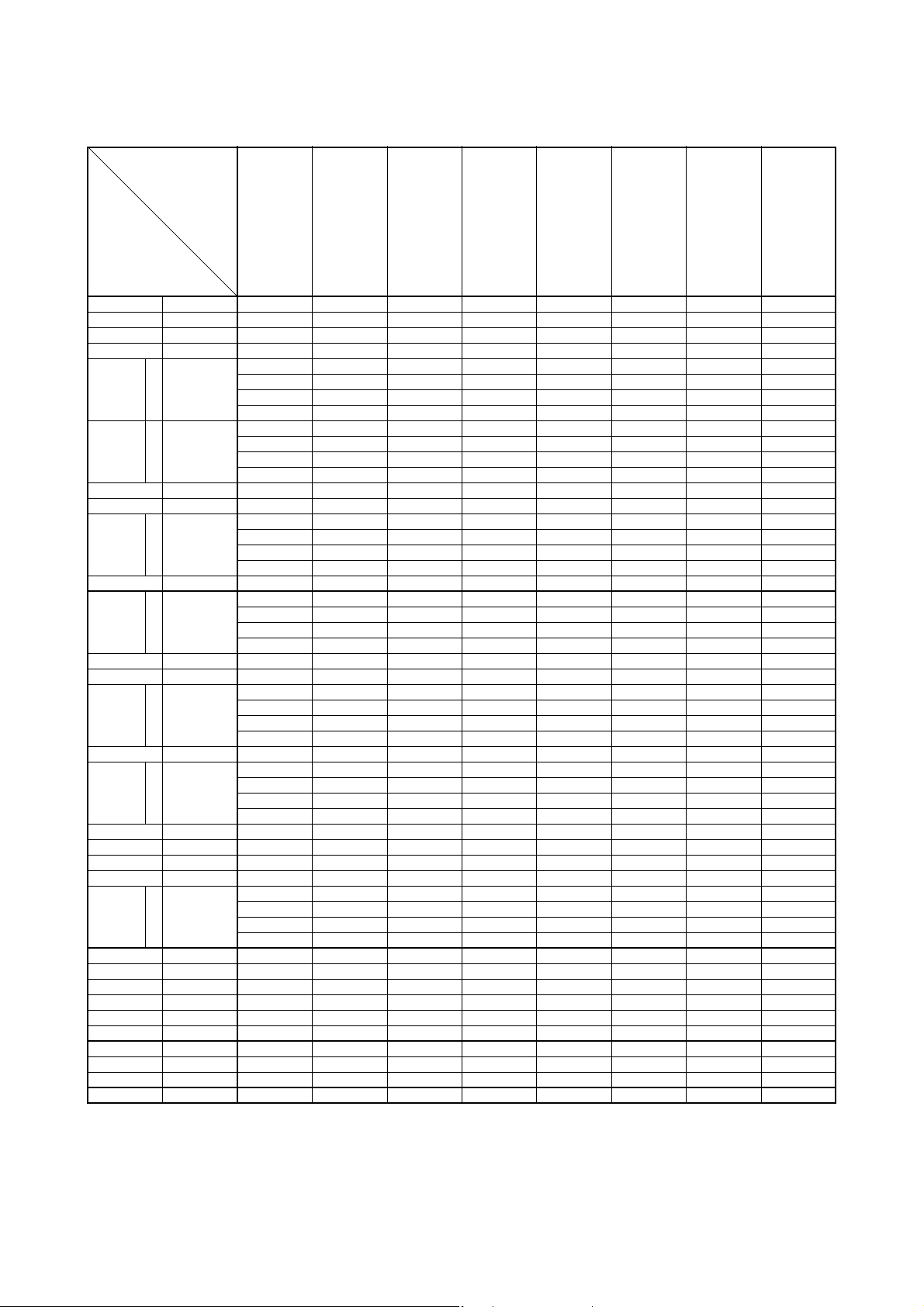

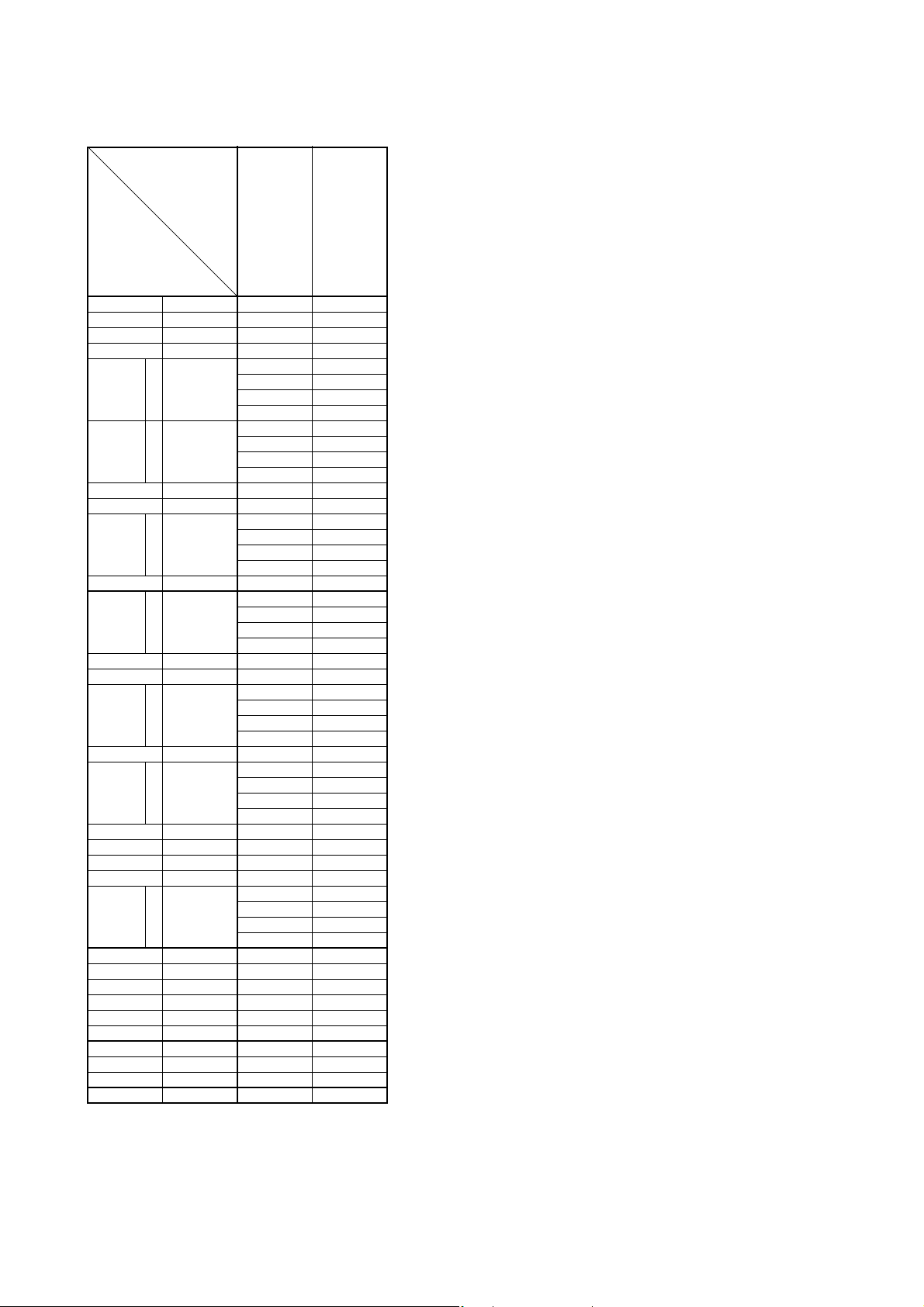

OUTBOARD MOTOR DIMENSIONS

OVERALL DIMENSIONS (4-STROKE)

F9.9HMH

Global model

(US, CA model)

Symbol

L1 mm (in) 436 (17.2) 436 (17.2) 436 (17.2) 435 (17.1) 436 (17.2) 435 (17.1) 489 (19.3) 488 (19.2)

L2 mm (in) 124 (4.9) 121 (4.8) 121 (4.8) 122 (4.8) 121 (4.8) 122 (4.8) 219 (8.6) 220 (8.7)

L3 mm (in) 547 (21.5) — 607 (23.9) 608 (23.9) — — 559 (22.0) 559 (22.0)

L4 mm (in) 356 (14.0) 356 (14.0) 367 (14.4) 367 (14.4) 367 (14.4) 367 (14.4) 387 (15.2) 386 (15.2)

S

L 67 (2.6) 67 (2.6) 67 (2.6) 35 (1.4) 67 (2.6) 35 (1.4) 82 (3.2) 82 (3.2)

L5

L6

L7 mm (in) 276 (10.9) 276 (10.9) 276 (10.9) 273 (10.7) 276 (10.9) 273 (10.7) 381 (15.0) 356 (14.0)

L8 mm (in) 141 (5.6) 138 (5.4) 138 (5.4) 139 (5.5) 138 (5.4) 139 (5.5) 237 (9.3) 176 (6.9)

L9

L10 mm (in) 66 (2.6) 66 (2.6) 66 (2.6) 67 (2.6) 66 (2.6) 67 (2.6) 66 (2.6) 67 (2.6)

H1

H2 mm (in) 331 (13.0) 331 (13.0) 331 (13.0) 326 (12.8) 331 (13.0) 326 (12.8) 377 (14.8) 372 (14.6)

H3 mm (in) 123 (4.8) 123 (4.8) 157 (6.2) 157 (6.2) 157 (6.2) 157 (6.2) 133 (5.2) 133 (5.2)

H4

H5 mm (in) 614 (24.2) — 678 (26.7) 673 (26.5) — — 570 (22.4) 566 (22.3)

H6

H7 mm (in) 216 (8.5) 216 (8.5) 216 (8.5) 213 (8.4) 216 (8.5) 273 (10.7) 399 (15.7) 414 (16.3)

H8 mm (in) 7 (0.3) 8 (0.3) 8 (0.3) 5 (0.2) 8 (0.3) 5 (0.2) 44 (1.7) 37 (1.5)

H9 mm (in) 527 (20.8) 527 (20.7) 609 (24.0) 604 (23.8) 527 (20.7) 522 (20.6) 580 (22.8) 575 (22.6)

H10 mm (in) 37 (1.5) 37 (1.5) 37 (1.5) 32 (1.3) 37 (1.5) 32 (1.3) 37 (1.5) 32 (1.3)

H11

W1 mm (in) 156 (6.1) 177 (7.0) 172 (6.8) 172 (6.8) 177 (7.0) 177 (7.0) 210 (8.3) 210 (8.3)

W2 mm (in) 188 (7.4) — 189 (7.4) 189 (7.4) — — 210 (8.3) 210 (8.3)

W3 mm (in) 156 (6.1) 156 (6.1) 156 (6.1) 156 (6.1) 156 (6.1) 156 (6.1) 176 (6.9) 176 (6.9)

W4 mm (in) 156 (6.1) 156 (6.1) 156 (6.1) 156 (6.1) 156 (6.1) 156 (6.1) — —

W5 mm (in) 284 (11.2) 284 (11.2) 284 (11.2) 265 (10.4) 284 (11.2) 265 (10.4) 341 (13.4) 320 (12.6)

W6 mm (in) 562 (22.1) — 603 (23.7) 567 (22.3) — — 598 (23.5) 568 (22.4)

A1degree4343433843384540

A2degree7171717471747167

3degree

A

T1mm (in)————————

mm (in)

X — — 67 (2.6) 35 (1.4) 67 (2.6) 35 (1.4) — —

U ————————

S

L 823 (32.4) 823 (32.4) 880 (34.6) 879 (34.6) 880 (34.6) 879 (34.6) 847 (33.3) 840 (33.1)

mm (in)

X — — 943 (37.1) 941 (37.0) 943 (37.1) 941 (37.0) — —

U ————————

S

L 27 (1.1) 27 (1.1) 27 (1.1) 62 (2.4) 27 (1.1) 62 (2.4) 18 (0.7) 18 (0.7)

mm (in)

X — — 27 (1.1) 62 (2.4) 27 (1.1) — — —

U ————————

S

L 804 (31.7) 804 (31.7) 864 (34.0) 869 (34.2) 864 (34.0) 869 (34.2) 828 (32.6) 833 (32.8)

mm (in)

X — — 932 (36.7) 937 (36.9) 932 (36.7) 937 (36.9) — —

U ————————

S

L 558 (22.0) 558 (22.0) 552 (21.7) 557 (21.9) 552 (21.7) 557 (21.9) 565 (22.2) 570 (22.4)

mm (in)

X — — 620 (24.4) 625 (24.6) 620 (24.4) 625 (24.6) — —

U ————————

S

L 682 (26.9) 682 (26.9) 730 (28.7) 717 (28.2) 730 (28.7) 717 (28.2) 694 (27.3) 643 (25.3)

mm (in)

X — — 771 (30.4) 757 (29.8) 771 (30.4) 757 (29.8) — —

U ————————

S

L 19 (0.7) 19 (0.7) 19 (0.7) 33 (1.3) 19 (0.7) 33 (1.3) 19 (0.7) 19 (0.7)

mm (in)

X — — 19 (0.7) 33 (1.3) 19 (0.7) 33 (1.3) — —

U ————————

F9.9JMH

(F9.9MHB)

F9.9JEH

(F9.9EHB)

F9.9JWH

49 (1.9) 49 (1.9) — — — — 64 (2.5) —

707 (27.8) 707 (27.8) — — — — 730 (28.7) —

18 (0.7) 18 (0.7) — — — — 9 (0.4) —

677 (26.7) 677 (26.7) — — — — 701 (27.6) —

431 (17.0) 431 (17.0) — — — — 438 (17.2) —

604 (23.8) 604 (23.8) — — — — 616 (24.3) —

19 (0.7) 19 (0.7) — — — — 19 (0.7) —

44484844

F9.9JE

(F9.9EB)

FT9.9LMH

(T9.9MHB)

FT9.9LWH

(T9.9EHB)

FT9.9LEHP

(T9.9PHB)

FT9.9LE

(T9.9EB)

FT9.9LEP

(T9.9PB)

F15CMH

(F15MHA)

F15CEH

(F15EHA)

F15CWH

F20BMH

(F20MHA)

F20BEH

(F20EHA)

F20BWH

F20CMH

F15CEHP

(F15PHA)

F20BEHP

(F20PHA)

1-15

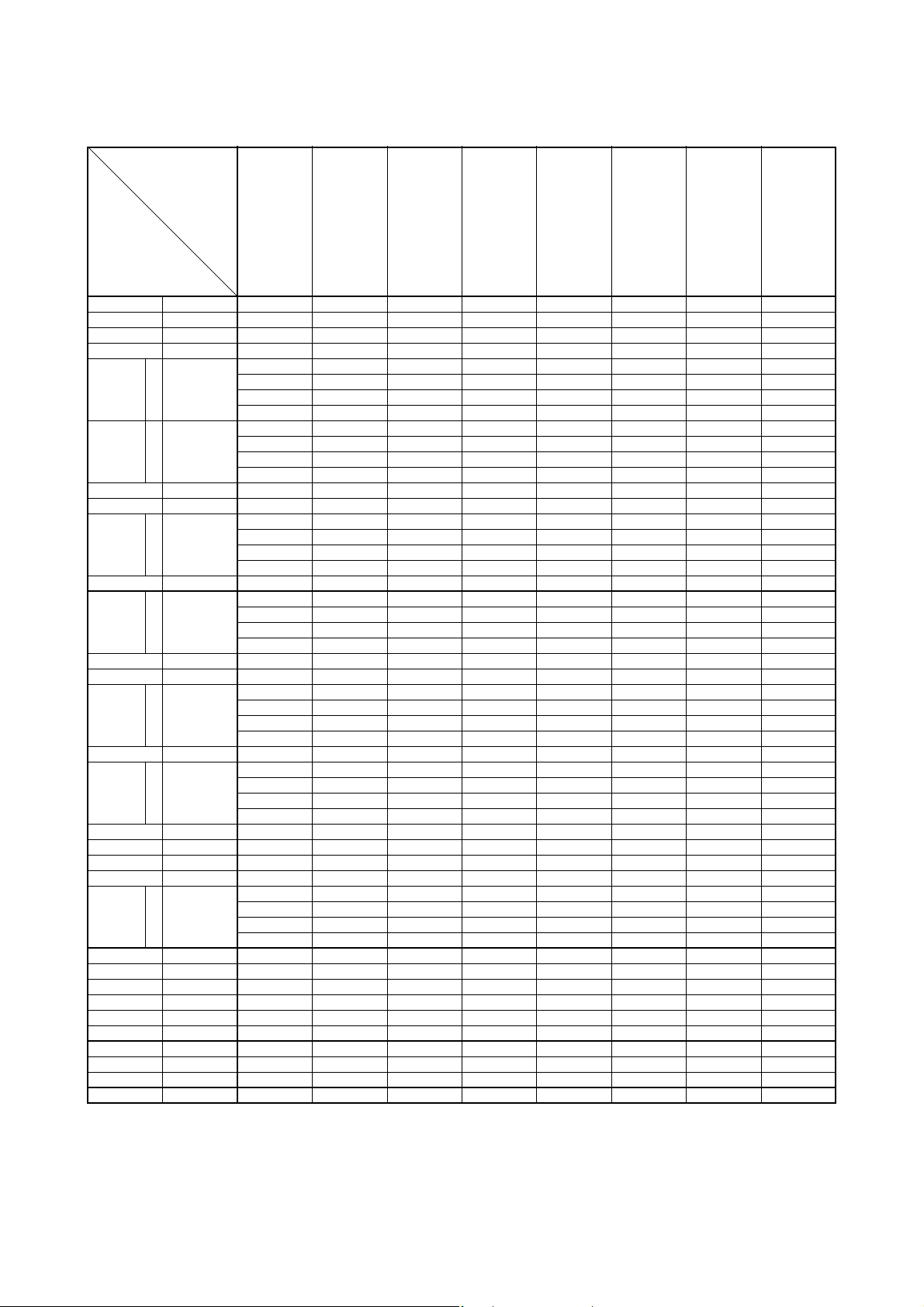

OUTBOARD MOTOR DIMENSIONS

OVERALL DIMENSIONS (4-STROKE)

Global model

(US, CA model)

Symbol

L1 mm (in) 489 (19.3) 488 (19.2) 601 (23.7) 601 (23.7) 601 (23.7) 601 (23.7) 601 (23.7) 601 (23.7)

L2 mm (in) 176 (6.9) 176 (6.9) — — — 255 (10.0) 123 (4.8) 123 (4.8)

L3 mm (in) — — 580 (22.8) 580 (22.8) 580 (22.8) 769 (30.3) — —

L4 mm (in) 387 (15.2) 386 (15.2) 433 (17.0) 433 (17.0) 433 (17.0) 433 (17.0) 433 (17.0) 433 (17.0)

S

L 82 (3.2) 82 (3.2) 103 (4.1) 111 (4.4) 111 (4.4) 103 (4.1) 103 (4.1) 111 (4.4)

L5

L6

L7 mm (in) 321 (12.6) 309 (12.2) 378 (14.9) 353 (13.9) 353 (13.9) 378 (14.9) 378 (14.9) 353 (13.9)

L8 mm (in) 184 (7.2) 188 (7.4) 189 (7.4) 197 (7.8) 197 (7.8) 159 (6.3) 147 (5.8) 150 (5.9)

L9

L10 mm (in) 66 (2.6) 67 (2.6) 65 (2.6) 65 (2.6) 65 (2.6) 65 (2.6) 65 (2.6) 65 (2.6)

H1

H2 mm (in) 377 (14.8) 372 (14.6) 450 (17.7) 450 (17.7) 450 (17.7) 450 (17.7) 450 (17.7) 450 (17.7)

H3 mm (in) 133 (5.2) 133 (5.2) 144 (5.7) 144 (5.7) 144 (5.7) 144 (5.7) 144 (5.7) 144 (5.7)

H4

H5mm (in)—————766 (30.2)——

H6

H7 mm (in) 218 (8.6) 230 (9.1) 258 (10.2) 282 (11.1) 282 (11.1) 258 (10.2) 258 (10.2) 282 (11.1)

H8 mm (in) 32 (1.3) 28 (1.1) 41 (1.6) 26 (1.0) 26 (1.0) 47 (1.9) 12 (0.5) 22 (0.9)

H9 mm (in) 580 (22.8) 575 (22.6) 705 (27.8) 706 (27.8) 706 (27.8) 705 (27.8) 705 (27.8) 706 (27.8)

H10 mm (in) 37 (1.5) 32 (1.3) 43 (1.7) 43 (1.7) 43 (1.7) 43 (1.7) 43 (1.7) 43 (1.7)

H11

W1 mm (in) 210 (8.3) 210 (8.3) 199 (7.8) 199 (7.8) 199 (7.8) 199 (7.8) 199 (7.8) 199 (7.8)

W2 mm (in) — — 213 (8.4) 213 (8.4) 213 (8.4) 128 (5.0) — 213 (8.4)

W3mm (in)180 (7.1)180 (7.1)——————

W4mm (in)————————

W5 mm (in) 341 (13.4) 320 (12.6) 387 (15.2) 387 (15.2) 387 (15.2) 387 (15.2) 387 (15.2) 387 (15.2)

W6 mm (in) — — 604 (23.8) 604 (23.8) 604 (23.8) 665 (26.2) — 604 (23.8)

A1 degree 45 40 42 42 42 42 42 42

A2 degree 71 S:63 / L:67 73 66 66 73 73 66

A3 degree 4 S:0 / L:4 4 3 3 4 4 3

T1mm (in)————————

mm (in)

X — — 115 (4.5) 124 (4.9) 124 (4.9) — — —

U ————————

S

L 847 (33.3) 840 (33.1) 880 (34.6) 875 (34.4) 875 (34.4) 880 (34.6) 880 (34.6) 875 (34.4)

mm (in)

X — — 960 (37.8) 951 (37.4) 951 (37.4) — —

U ————————

S

L 18 (0.7) 18 (0.7) 6 (0.2) 14 (0.6) 14 (0.6) — 6 (0.2) 14 (0.6)

mm (in)

X — — 1 (0.05) 10 (0.4) 10 (0.4) — — —

U ————————

S

L 828 (32.6) 833 (32.8) 834 (32.8) 834 (32.8) 834 (32.8) 834 (32.8) 834 (32.8) 834 (32.8)

mm (in)

X — — 920 (36.2) 920 (36.2) 920 (36.2) — — —

U ————————

S

L 565 (22.2) 570 (22.4) 550 (21.7) 550 (21.7) 550 (21.7) 550 (21.7) 550 (21.7) 550 (21.7)

mm (in)

X — — 635 (25.0) 636 (25.0) 636 (25.0) — — —

U ————————

S

L 694 (27.3) 643 (25.3) 748 (29.4) 665 (26.2) 665 (26.2) 748 (29.4) 748 (29.4) 665 (26.2)

mm (in)

X — — 803 (31.6) 711 (28.0) 711 (28.0) — — —

U ————————

S

L 19 (0.7) 19 (0.7) 22 (0.9) 18 (0.7) 18 (0.7) 22 (0.9) 22 (0.9) 18 (0.7)

mm (in)

X — — 22 (0.9) 17 (0.7) 17 (0.7) — — —

U ————————

F9.9HE

F15CE

F20BE

(F20EA)

F20CE

64 (2.5) 89 (3.5) 85 (3.3) — — — 103 (4.1) —

730 (28.7) 727 (28.6) 761 (30.0) — — — 880 (34.6) —

9 (0.4) 18 (0.7) 15 (0.6) — — — 6 (0.2) —

701 (27.6) 706 (27.8) 707 (27.8) — — — 834 (32.8) —

438 (17.2) 443 (17.4) 423 (16.7) — — — 550 (21.7) —

616 (24.3) 574 (22.6) 667 (26.3) — — — 748 (29.4) —

19 (0.7) 19 (0.7) 23 (0.9) — — — 22 (0.9) —

F15CEP

F20BEP

(F20PA)

F25DMH

(F25MHA)

F25DEH

(F25EHA)

F25DWH

F25DMHD

(F25MHB)

F25DEHD

(F25EHB)

F25DWHD

F25DEHT

F25DEH

w/6X4 tiller

handle

F25DE

(F25EA)

F25DET

(F25A)

F20DET

1-16

OUTBOARD MOTOR DIMENSIONS

OVERALL DIMENSIONS (4-STROKE)

Global model

(US, CA model)

FT25FET

(T25A)

Symbol

L1 mm (in) 601 (23.7) 583 (23.0) 583 (23.0) 583 (23.0) 583 (23.0) 591 (23.3) 584 (23.0) 584 (23.0)

L2 mm (in) 134 (5.3) 235 (9.3) 235 (9.3) 134 (5.3) 134 (5.3) 122 (4.8) 122 (4.8) 122 (4.8)

L3 mm (in) — 779 (30.7) 779 (30.7) — ————

L4 mm (in) 522 (20.6) 522 (20.6) 522 (20.6) 522 (20.6) 522 (20.6) 582 (22.9) 533 (21.0) 533 (21.0)

S

L 66 (2.6) 66 (2.6) 66 (2.6) 66 (2.6) 66 (2.6) 67 (2.6) 97 (3.8) 97 (3.8)

L5

L6

L7 mm (in) 338 (13.3) 345 (13.6) 342 (13.5) 345 (13.6) 342 (13.5) 421 (16.6) 417 (16.4) 406 (16.0)

L8 mm (in) 158 (6.2) 177 (7.0) 178 (7.0) 158 (6.2) 158 (6.2) 152 (6.0) 147 (5.8) 148 (5.8)

L9

L10 mm (in) 65 (2.6) 65 (2.6) 65 (2.6) 65 (2.6) 65 (2.6) 62 (2.4) 62 (2.4) 62 (2.4)

H1

H2 mm (in) 433 (17.0) 471 (18.5) 471 (18.5) 471 (18.5) 471 (18.5) 561 (22.1) 545 (21.5) 545 (21.5)

H3 mm (in) 175 (6.9) 175 (6.9) 175 (6.9) 175 (6.9) 175 (6.9) 191 (7.5) 175 (6.9) 175 (6.9)

H4

H5 mm (in) — 770 (30.3) 770 (30.3) — ————

H6

H7 mm (in) 274 (10.8) 306 (12.0) 304 (12.0) 306 (12.0) 304 (12.0) 371 (14.6) 354 (13.9) 354 (13.9)

H8 mm (in) 14 (0.6) 44 (1.7) 43 (1.7) 14 (0.6) 15 (0.6) 26 (1.0) 22 (0.9) 25 (1.0)

H9 mm (in) 698 (27.5) 695 (27.4) 695 (27.4) 695 (27.4) 695 (27.4) 741 (29.2) 759 (29.9) 762 (30.0)

H10 mm (in) 43 (1.7) 43 (1.7) 43 (1.7) 43 (1.7) 43 (1.7) 49 (1.9) 49 (1.9) 49 (1.9)

H11

W1 mm (in) 199 (7.8) 192 (7.6) 192 (7.6) 192 (7.6) 192 (7.6) 193 (7.6) 192 (7.6) 192 (7.6)

W2mm (in)—128 (5.0)128 (5.0)—————

W3mm (in)————————

W4mm (in)————————

W5 mm (in) 376 (14.8) 364 (14.3) 364 (14.3) 364 (14.3) 364 (14.3) 363 (14.3) 360 (14.2) 360 (14.2)

W6 mm (in) — 654 (25.7) 654 (25.7) — ————

A1 degree 40 40 40 40 40 40 40 40

A2 degree 66 66 65 66 65 65 69 67

A3degree33333444

T1mm (in)——————560 (22.0) 560 (22.0)

mm (in)

X 66 (2.6) — 66 (2.6) 66 (2.6) — — 121 (4.8) —

U ————————

S

L 924 (36.4) 925 (36.4) 923 (36.3) 924 (36.4) 923 (36.3) 1000 (39.4) 932 (36.7) 930 (36.6)

mm (in)

X 1025 (40.4) — 1024 (40.3) 1025 (40.4) — — 1036 (40.8) —

U ————————

S

L 29 (1.1) 29 (1.1) 29 (1.1) 29 (1.1) 29 (1.1) 26 (1.0) 0 (0.0) 0 (0.0)

mm (in)

X 29 (1.1) — 29 (1.1) 29 (1.1) — — 0 (0.0) —

U ————————

S

L 879 (34.6) 879 (34.6) 879 (34.6) 879 (34.6) 879 (34.6) 915 (36.0) 870 (34.3) 870 (34.3)

mm (in)

X 993 (39.1) — 993 (39.1) 993 (39.1) — — 984 (38.7) —

U ————————

S

L 536 (21.1) 536 (21.1) 536 (21.1) 536 (21.1) 536 (21.1) 534 (21.0) 527 (20.7) 527 (20.7)

mm (in)

X 650 (25.6) — 650 (25.6) 650 (25.6) — — 641 (25.2) —

U ————————

S

L 667 (26.3) 667 (26.3) 660 (26.0) 667 (26.3) 660 (26.0) 749 (29.5) 708 (27.9) 682 (26.9)

mm (in)

X 728 (28.7) — 720 (28.3) 728 (28.7) — — 774 (30.5) —

U ————————

S

L 19 (0.7) 19 (0.7) 19 (0.7) 19 (0.7) 19 (0.7) 29 (1.1) 24 (0.9) 24 (0.9)

mm (in)

X 19 (0.7) — 19 (0.7) 19 (0.7) — — 24 (0.9) —

U ————————

— — 77 (3.0) 77 (3.0) 77 (3.0) — — —

— — 816 (32.1) 817 (32.2) 816 (32.1) — — —

— — 29 (1.1) 29 (1.1) 29 (1.1) — — —

— — 757 (29.8) 757 (29.8) 757 (29.8) — — —

— — 414 (16.3) 414 (16.3) 414 (16.3) — — —

— — 594 (23.4) 606 (23.9) 594 (23.4) — — —

— — 19 (0.7) 19 (0.7) 19 (0.7) — — —

F30BEHT

F40FEHT

F30BEHD

(F30EHA)

F40FEHD

(F40EHA)

F30BET

(F30A)

F40FET

(F40A)

F40FED

(F40EA)

F40GET

F40HET

F50HET

(F50B)

F60FET

(F60B)

F50HED

1-17

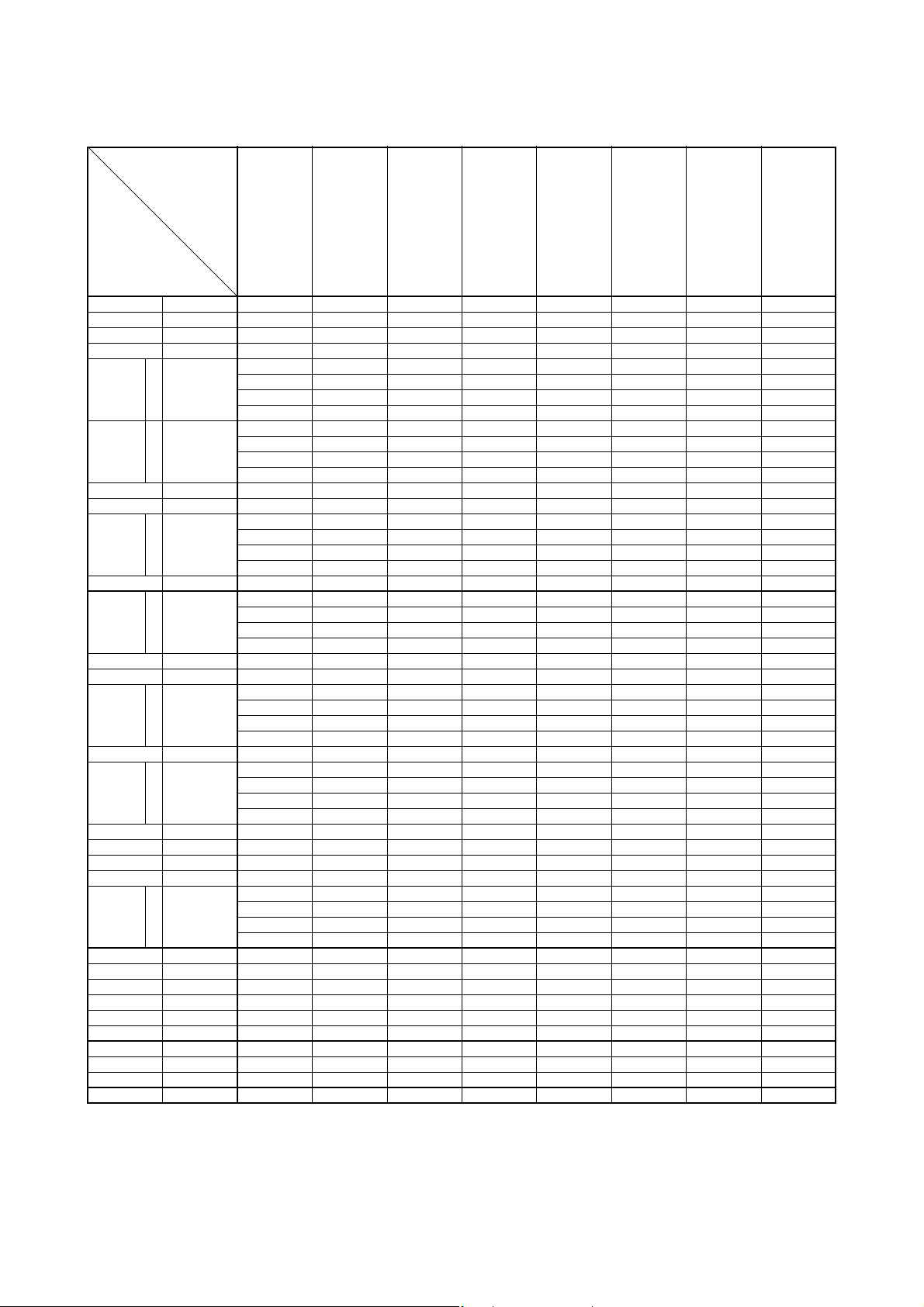

OUTBOARD MOTOR DIMENSIONS

OVERALL DIMENSIONS (4-STROKE)

Global model

(US, CA model)

F50DET F50HEHD

Symbol

L1 mm (in) 576 (22.7) 584 (23.0) 584 (23.0) 584 (23.0) 576 (22.7) 584 (23.0) 576 (22.7) 584 (23.0)

L2 mm (in) 142 (5.6) 225 (8.9) 225 (8.9) 122 (4.8) 142 (5.6) 225 (8.9) 272 (10.7) 225 (8.9)

L3 mm (in) — 788 (31.0) 788 (31.0) — — 788 (31.0) 797 (31.2) 778 (30.6)

L4 mm (in) 532 (20.9) 533 (21.0) 533 (21.0) 561 (22.1) 560 (22.1) 561 (22.1) 560 (22.1) 561 (22.1)

S

L 97 (3.8) 97 (3.8) 97 (3.8) 98 (3.9) 98 (3.9) 98 (3.9) 98 (3.9) 67 (2.6)

L5

L6

L7 mm (in) 407 (16.0) 406 (16.0) 417 (16.4) 417 (16.4) 407 (16.0) 417 (16.4) 397 (15.6) 407 (16.0)

L8 mm (in) 148 (5.8) 168 (6.6) 165 (6.5) 147 (5.8) 148 (5.8) 165 (6.5) 189 (7.2) 168 (6.6)

L9

L10 mm (in) 63 (2.5) 62 (2.4) 62 (2.4) 62 (2.4) 63 (2.5) 62 (2.4) 63 (2.5) 62 (2.4)

H1

H2 mm (in) 519 (20.4) 545 (21.5) 545 (21.5) 545 (21.5) 519 (20.4) 545 (21.5) 519 (20.4) 545 (21.5)

H3 mm (in) 175 (6.9) 175 (6.9) 175 (6.9) 191 (7.5) 194 (7.6) 191 (7.5) 194 (7.6) 191 (7.5)

H4

H5 mm (in) — 790 (31.1) 790 (31.1) — — 790 (31.1) 680 (26.8) 790 (31.1)

H6

H7 mm (in) 327 (12.9) 354 (13.9) 354 (13.9) 354 (13.9) 327 (12.9) 354 (13.9) 330 (13.0) 354 (13.9)

H8 mm (in) 3.5 (0.14) 33 (1.3) 37 (1.5) 22 (0.9) 3.5 (0.14) 37 (1.5) 110 (4.3) 34 (1.3)

H9 mm (in) 733 (28.9) 713 (28.1) 759 (29.9) 759 (29.9) 733 (28.9) 759 (29.9) 738 (29.1) 763 (30.0)

H10 mm (in) 44 (1.7) 49 (1.9) 49 (1.9) 49 (1.9) 44 (1.7) 49 (1.9) 44 (1.7) 49 (1.9)

H11

W1 mm (in) 181 (7.1) 192 (7.6) 192 (7.6) 192 (7.6) 181 (7.1) 192 (7.6) 181 (7.1) 192 (7.6)

W2 mm (in) — 137 (5.4) 137 (5.4) — — 137 (5.4) 213 (8.4) 137 (5.4)

W3 mm (in) 181 (7.1) — — — 181 (7.1) — 181 (7.13) —

W4mm (in)— ———— —— —

W5 mm (in) 345 (13.6) 360 (14.2) 360 (14.2) 360 (14.2) 345 (13.6) 360 (14.2) 345 (13.6) 360 (14.2)

W6 mm (in) — 672 (26.5) 672 (26.5) — — 672 (26.5) 738 (29.1) 672 (26.5)

A1 degree 40 40 40 40 40 40 40 40

A2 degree 65 67 69 69 65 69 63 67

A3degree44444444

T1 mm (in) 560 (22.0) — — 560 (22.0) 560 (22.0) 560 (22.0) 560 (22.0) —

mm (in)

X — — — 114 (4.5) 85 (3.4) — 85.0 (3.35) 98 (3.9)

U ————————

S

L 933 (36.7) 930 (36.6) 932 (36.7) 996 (39.2) 991 (39.0) 996 (39.2) 989 (38.9) 995 (39.2)

mm (in)

X — — — 1099 (43.3) 1095 (43.1) — 1092 (43.0) 1097 (43.2)

U ————————

S

L 0.6 (0.02) 0 (0.0) 0 (0.0) 0 (0.0) 1.0 (0.04) 0 (0.0) 0.8 (0.03) 0 (0.0)

mm (in)

X — — 0 (0.0) 0 (0.0) 16.0 (0.63) 0 (0.0) 16 (0.63) 0 (0.0)

U ————————

S

L 876 (34.5) 870 (34.3) 870 (34.3) 910 (35.8) 917 (36.1) 910 (35.8) 917 (36.1) 910 (35.8)

mm (in)

X — — — 1024 (40.3) 1026 (40.4) — 1026 (40.4) 1025 (40.4)

U ————————

S

L 533 (21.0) 527 (20.7) 527 (20.7) 530 (20.9) 536 (21.1) 530 (20.9) 533 (21.0) 530 (20.9)

mm (in)

X — — — 644 (25.4) 645 (25.4) — 645 (25.4) 644 (25.4)

U ————————

S

L 711 (28.0) 682 (26.9) 708 (27.9) 746 (29.4) 750 (29.5) 746 (29.4) 723 (28.5) 720 (28.3)

mm (in)

X — — — 812 (32.0) 813 (32.0) — 783 (30.8) 782 (30.8)

U ————————

S

L 24 (0.9) 24 (0.9) 24 (0.9) 24 (0.9) 28 (1.1) 24 (0.9) 28 (1.1) 29 (1.1)

mm (in)

X — — — 24 (0.9) 27 (1.0) — 27 (1.0) 24 (0.9)

U ————————

————————

————————

————————

————————

————————

————————

————————

F50HEHT

(F50HB)

F60FEHT

(F60HB)

FT50JET

(T50B)

FT60GET

(T60B)

FT50CET FT60GEHT FT50CEHD FT60GEHD

1-18

OUTBOARD MOTOR DIMENSIONS

OVERALL DIMENSIONS (4-STROKE)

Global model

(US, CA model)

F70AET

(F70A)

F40GET

Symbol

L1 mm (in) 591 (23.3) 591 (23.3) 651 (25.6) 651 (25.6) 664 (26.1) 664 (26.1) 664 (26.1) 665 (26.2)

L2 mm (in) 122 (4.8) 225 (8.9) 171 (6.7) 247 (9.7) 161 (6.3) 324 (12.8) 161 (6.3) 161 (6.3)

L3 mm (in) — 788 (31.0) — 822 (32.4) — 844 (33.2) — —

L4 mm (in) 582 (22.9) 582 (22.9) 574 (22.6) 574 (22.6) 631 (24.8) 631 (24.8) 631 (24.8) 631 (24.8)

S

L 67 (2.6) 67 (2.6) 63 (2.5) 63 (2.5) 79 (3.1) 79 (3.1) 69 (2.7) 69 (2.7)

L5

L6

L7 mm (in) 421 (16.6) 421 (16.6) 527 (20.7) 527 (20.7) 504 (19.8) 504 (19.8) 536 (21.9) 555 (21.9)

L8 mm (in) 152 (6.0) 165 (6.5) 164 (6.5) 108 (4.3) 168 (6.6) 208 (8.2) 158 (6.2) 158 (6.2)

L9

L10 mm (in) 62 (2.4) 62 (2.4) 62 (2.4) 62 (2.4) 75 (3.0) 75 (3.0) 75 (3.0) 75 (3.0)

H1

H2 mm (in) 561 (22.1) 561 (22.1) 666 (26.2) 666 (26.2) 667 (26.3) 667 (26.3) 666 (26.2) 681 (26.8)

H3 mm (in) 191 (7.5) 191 (7.5) 191 (7.5) 191 (7.5) 191 (7.5) 191 (7.5) 191 (7.5) 191 (7.5)

H4

H5 mm (in) — 790 (31.1) — 784 (30.9) — 764 (30.1) — —

H6

H7 mm (in) 371 (14.6) 371 (14.6) 366 (14.4) 366 (14.4) 401 (15.8) 401 (15.8) 388 (15.3) 406 (16.0)

H8 mm (in) 26 (1.0) 37 (1.5) 27 (1.1) 49 (1.9) 4 (0.2) 93 (3.7) 14 (0.6) 14 (0.6)

H9 mm (in) 741 (29.2) 741 (29.2) 857 (33.7) 857 (33.7) 892 (35.1) 892 (35.1) 877 (34.5) 879 (34.6)

H10 mm (in) 49 (1.9) 49 (1.9) 49 (1.9) 49 (1.9) 44 (1.7) 44 (1.7) 44 (1.7) 44 (1.7)

H11

W1 mm (in) 193 (7.6) 193 (7.6) 240 (9.4) 240 (9.4) 243 (9.6) 243 (9.6) 243 (9.6) 249 (9.8)

W2 mm (in) — 137 (5.4) — 137 (5.4) — 96 (3.8) — —

W3mm (in)————————

W4mm (in)————————

W5 mm (in) 363 (14.3) 363 (14.3) 405 (15.9) 405 (15.9) 384 (15.1) 384 (15.1) 384 (15.1) 392 (15.4)

W6 mm (in) — 676 (26.6) — 633 (24.9) — 578 (22.8) — —

A1 degree 40 40 35 35 30 30 30 30

A2 degree 65 65 70 70 64 64 70 70

A3degree44443344

T1 mm (in) 560 (22.0) — 660 (26.0) 660 (26.0) 660 (26.0) — 660 (26.0) 660 (26.0)

mm (in)

X 67 (2.6) 67 (2.6) 63 (2.5) 63 (2.5) 87 (3.4) 87 (3.4) 76 (3.0) 89 (3.5)

U ————————

S

L 1000 (39.4) 1000 (39.4) 998 (39.3) 998 (39.3) 1005 (39.6) 1005 (39.6) 1005 (39.6) 1005 (39.6)

mm (in)

X 1103 (43.4) 1103 (43.4) 1115 (43.9) 1115 (43.9) 1118 (44.0) 1118 (44.0) 1122 (44.2) 1122 (44.2)

U ————————

S

L 26 (1.0) 26 (1.0) 28 (1.1) 28 (1.1) 19 (0.7) 19 (0.7) 25 (1.0) 25 (1.0)

mm (in)

X 26 (1.0) 26 (1.0) 28 (1.1) 28 (1.1) 15 (0.6) 15 (0.6) 25 (1.0) 33 (1.3)

U ————————

S

L 915 (36.0) 915 (36.0) 917 (36.1) 917 (36.1) 929 (36.6) 929 (36.6) 929 (36.6) 929 (36.6)

mm (in)

X 1029 (40.5) 1029 (40.5) 1044 (41.1) 1044 (41.1) 1056 (41.6) 1056 (41.6) 1056 (41.6) 1056 (41.6)

U ————————

S

L 534 (21.0) 534 (21.0) 536 (21.1) 536 (21.1) 516 (20.3) 516 (20.3) 516 (20.3) 516 (20.3)

mm (in)

X 648 (25.5) 648 (25.5) 663 (26.1) 663 (26.1) 643 (25.3) 643 (25.3) 643 (25.3) 643 (25.3)

U ————————

S

L 749 (29.5) 749 (29.5) 766 (30.2) 766 (30.2) 709 (27.9) 709 (27.9) 776 (30.6) 773 (30.4)

mm (in)

X 815 (32.1) 815 (32.1) 842 (33.1) 842 (33.1) 776 (30.6) 776 (30.6) 854 (33.6) 850 (33.5)

U ————————

S

L 29 (1.1) 29 (1.1) 25 (1.0) 25 (1.0) 17 (0.7) 17 (0.7) 25 (1.0) 25 (1.0)

mm (in)

X 29 (1.1) 29 (1.1) 24 (0.9) 24 (0.9) 17 (0.7) 17 (0.7) 25 (1.0) 25 (1.0)

U ————————

————————

————————

————————

————————

————————

————————

————————

F70AET

(F70A)

w/6X4 tiller

handle

F75BET

(F75A)

F80BET

F90BET

(F90A)

F100DET

F75BET

(F75A)

F80BET

F90BET

(F90A)

F100DET

w/6X4 tiller

handle

F75CED

F75CEHD

F100BEHT

F100BEHD

F95AET

F100BET

F/FL115AET

(F/LF115A)

1-19

OUTBOARD MOTOR DIMENSIONS

OVERALL DIMENSIONS (4-STROKE)

Global model

(US, CA model)

F115AEHT

Symbol

L1 mm (in) 662 (26.1)

L2 mm (in) —

L3 mm (in) —

L4 mm (in) 631 (24.8)

S

L—

L5

L6

L7 mm (in) 555 (21.9)

L8 mm (in) —

L9

L10 mm (in) 75 (3.0)

H1

H2 mm (in) 681 (26.8)

H3 mm (in) 191 (7.5)

H4

H5 mm (in) —

H6

H7 mm (in) 404 (15.9)

H8 mm (in) —

H9 mm (in) 879 (34.6)

H10 mm (in) 45 (1.8)

H11

W1 mm (in) 246 (9.7)

W2 mm (in) —

W3 mm (in) —

W4 mm (in) —

W5 mm (in) 388 (15.3)

W6 mm (in) —

A1 degree 30

A2 degree 68

A3 degree 2

T1 mm (in) —

mm (in)

X 104 (4.1)

U—

S

L—

mm (in)

X 1122 (44.2)

U—

S

L—

mm (in)

X16 (0.6)

U—

S

L—

mm (in)

X 1056 (41.6)

U—

S

L—

mm (in)

X 643 (25.3)

U—

S

L—

mm (in)

X 850 (33.5)

U—

S

L—

mm (in)

X14 (0.6)

U—

—

—

—

—

—

—

—

1-20

OUTBOARD MOTOR DIMENSIONS

OVERALL DIMENSIONS (4-STROKE)

Global model

(US, CA,

ANZ model)

Symbol

L1 mm (in) 690 (27.2) 690 (27.2) 698 (27.5) 722 (28.4) 722 (28.4) 651 (25.6) 664 (26.1) 741 (29.2)

L2 mm (in) 127 (5.0) 300 (11.8) 164 (6.5) 198 (7.8) 198 (7.8) 219 (8.6) 206 (8.1) 218 (8.6)

L3mm (in)————————

L4 mm (in) 631 (24.8) 631 (24.8) 646 (25.4) 646 (25.4) 646 (25.4) 673 (26.5) 685 (27.0) 688 (27.1)

S

L 63 (2.5) 63 (2.5) 60 (2.5) 53 (2.1) 53 (2.1) — 62 (2.4) 54 (2.1)

L5

L6

L7 mm (in) 561 (22.1) 561 (22.1) 629 (24.8) 639 (25.2) 639 (25.2) 619 (24.4) 615 (24.2) 651 (25.6)

L8 mm (in) 135 (5.3) 121 (4.8) 162 (6.4) 163 (6.4) 163 (6.4) 230 (9.1) 226 (8.9) 237 (9.3)

L9

L10 mm (in) 75 (3.0) 75 (3.0) 75 (3.0) 75 (3.0) 75 (3.0) 75 (3.0) 75 (3.0) 75 (3.0)

H1

H2 mm (in) 700 (27.6) 700 (27.6) 769 (31.3) 796 (31.3) 796 (31.3) 752 (29.6) 754 (29.7) 817 (32.2)

H3 mm (in) 191 (7.5) 191 (7.5) 210 (8.3) 210 (8.3) 210 (8.3) 216 (8.5) 216 (8.5) 216 (8.5)

H4

H5 mm (in) — 782 (30.8) — — ————

H6

H7 mm (in) 429 (16.9) 429 (16.9) 455 (18.0) 501 (19.7) 501 (19.7) 387 (15.2) 399 (15.7) 507 (20.0)

H8 mm (in) 15 (0.6) 53 (2.1) 16 (0.6) 14 (0.6) 14 (0.6) 39 (1.5) 26 (1.0) 33 (1.3)

H9 mm (in) 877 (34.5) 877 (34.5) 915 (36.2) 928 (36.5) 928 (36.5) 902 (35.5) 915 (36.0) 1008 (39.7)

H10 mm (in) 45 (1.8) 45 (1.8) 45 (1.8) 45 (1.8) 45 (1.8) 45 (1.8) 45 (1.8) 45 (1.8)

H11

W1 mm (in) 262 (10.3) 262 (10.3) 256 (10.1) 274 (10.8) 274 (10.8) 317 (12.5) 318 (12.5) 332 (13.1)

W2mm (in)—137 (5.4)——————

W3mm (in)————————

W4mm (in)————————

W5 mm (in) 422 (16.6) 422 (16.6) 433 (17.1) 425 (16.7) 425 (16.7) 453 (17.8) 464 (18.3) 496 (19.5)

W6 mm (in) — 665 (26.2) — — ————

A1 degree 35 35 35 32 32 32 35 35

A2 degree 70 70 70 66 66 70 67 66

A3degree44444344

T1 mm (in) 660 (26.0) 660 (26.0) 660 (26.0) — 660 (26.0) 724 (28.5) — —

mm (in)

X 81 (3.2) 81 (3.2) 80 (3.2) — 63 (2.5) 59 (2.3) — —

U —————59 (2.3)——

S

L 1006 (39.6) 1006 (39.6) 1032 (40.6) 1033 (40.7) 1033 (40.7) — 1043 (41.1) 1033 (40.7)

mm (in)

X 1122 (44.2) 1122 (44.2) 1148 (45.2) — 1149 (45.2) 1115 (45.5) — —

U —————1272 (50.1) — —

S

L 32 (1.3) 32 (1.3) 35 (1.4) 42 (1.7) 42 (1.7) — 18 (0.7) 81 (3.2)

mm (in)

X 41 (1.6) 41 (1.6) 43 (1.8) — 51 (2.0) 52 (2.0) — —

U —————59 (2.3)——

S

L 929 (36.6) 929 (36.6) 946 (37.2) 946 (37.2) 946 (37.2) — 951 (37.4) 932 (36.7)

mm (in)

X 1056 (41.6) 1056 (41.6) 1073 (42.2) — 1073 (42.2) 1078 (42.4) — —

U —————1205 (47.4) — —

S

L 516 (20.3) 516 (20.3) 516 (20.3) 516 (20.3) 516 (20.3) — 516 (20.3) 493 (19.4)

mm (in)

X 643 (25.3) 643 (25.3) 643 (25.3) — 643 (25.3) 643 (25.3) — —

U —————770 (30.3)——

S

L 764 (30.1) 764 (30.1) 787 (31.0) 774 (30.5) 774 (30.5) — 779 (30.7) 715 (28.1)

mm (in)

X 840 (33.1) 840 (33.1) 864 (34.0) — 849 (33.4) 847 (33.3) — —

U —————924 (36.4)——

S

L

mm (in)

X 31 (1.2) 31 (1.2) 27 (1.1) — 32(1.3) 25 (1.0) — —

U —————25 (1.0)——

F/FL115BET

(F/LF115B)

————————

————————

————————

————————

————————

————————

————————

(1.2) 31 (1.2) 27 (1.1) 33 (1.3) 33 (1.3) — 26 (1.0) 35 (1.4)

31

F115BEHT

F/FL150AET

(F/LF150A)

F/FL150BET

F150CET

(VF150A)

F165AET

L-transom

F175AET

(F175A)

F/FL200FET

(F/LF200B)

F/FL200GET

(F/LF200CA)

F/FL200CET

(F/LF200A)

F/FL225BET

(F/LF225A)

F/FL250AET

(F/LF250A)

F/FL200BET

F/FL250GET

F225CET

L-transom

F200DET

(VF200LA)

F225DET

(VF225LA)

F250CET

(VF250LA)

F225GET

F250FET

F275AET

L-transom

1-21

OUTBOARD MOTOR DIMENSIONS

OVERALL DIMENSIONS (4-STROKE)

Global model

(US, CA,

ANZ model)

Symbol

L1 mm (in) 728 (28.7) 776 (30.6)

L2 mm (in) 230 (9.1) 255 (10.0)

L3 mm (in) — —

L4 mm (in) 673 (26.5) 732 (28.8)

S

L——

L5

L6

L7 mm (in) 639 (25.2) 712 (28.0)

L8 mm (in) 240 (9.4) 258 (10.2)

L9

L10 mm (in) 75 (3.0) 73 (2.9)

H1

H2 mm (in) 812 (32.0) 909 (35.8)

H3 mm (in) 216 (8.5) 229 (9.0)

H4

H5 mm (in) — —

H6

H7 mm (in) 510 (20.1) 588 (23.1)

H8 mm (in) 48 (1.9) 65 (2.6)

H9 mm (in) 951 (37.4) 1041 (41.0)

H10 mm (in) 45 (1.8) 49 (1.9)

H11

W1 mm (in) 317 (12.5) 317 (12.5)

W2 mm (in) — —

W3 mm (in) — —

W4 mm (in) — —

W5 mm (in) 454 (17.9) 475.6 (18.7)

W6 mm (in) — —

A1 degree 32 32

A2 degree 67 70

A3 degree 3 3

T1 mm (in) 724 (28.5) 723.9 (28.5)

mm (in)

X 59 (2.3) 48.4 (1.9)

U 59 (2.3) 48.4 (1.9)

S

L——

mm (in)

X 1155 (45.5) 1193 (47.0)

U 1272 (50.1) 1310 (51.6)

S

L——

mm (in)

X 53 (2.1) 56 (2.2)

U 59 (2.3) 62 (2.4)

S

L——

mm (in)

X 1078 (42.4) 1098 (43.2)

U 1205 (47.4) 1225 (48.2)

S

L——

mm (in)

X 643 (25.3) 637 (25.1)

U 770 (30.3) 764 (30.1)

S

L——

mm (in)

X 847 (33.3) 864 (34.0)

U 924 (36.4) 941 (37.0)

S

L——

mm (in)

X 25 (1.0) 26 (1.0)

U 25 (1.0) 26 (1.0)

F/FL225FET

(F/LF225CA)

F/FL250DET

(F/LF250CA)

F/FL300BET

(F/LF300CA)

——

——

——

——

——

——

——

F/FL350AET

(F/LF350CB)

1-22

Loading...

Loading...