F100B

F100C

SERVICE MANUAL

290429

60C-28197-5D-11

NOTICE

This manual has been prepared by Yamaha primarily for use by Yamaha dealers and their trained

mechanics when performing maintenance procedures and repairs to Yamaha equipment. It has

been written to suit the needs of persons who have a basic understanding of the mechanical and

electrical concepts and procedures inherent in the work, for without such knowledge attempted

repairs or service to the equipment could render it unsafe or unfit for use.

Because Yamaha has a policy of continuously improving its products, models may differ in detail

from the descriptions and illustrations given in this publication. Use only the latest edition of this

manual. Authorized Yamaha dealers are notified periodically of modifications and significant

changes in specifications and procedures, and these are incorporated in successive editions of this

manual.

Important information

Particularly important information is distinguished in this manual by the following notations:

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED!

WARNING

Failure to follow WARNING instructions could result in severe injury or death to the machine

operator, a bystander, or a person inspecting or repairing the outboard motor.

CAUTION:

A CAUTION indicates special precautions that must be taken to avoid damage to the outboard motor.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

1

F100B, F100C

SERVICE MANUAL

©2001 by Yamaha Motor Co., Ltd.

1st Edition, June 2001

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Co., Ltd.

is expressly prohibited.

Printed in the Netherlands

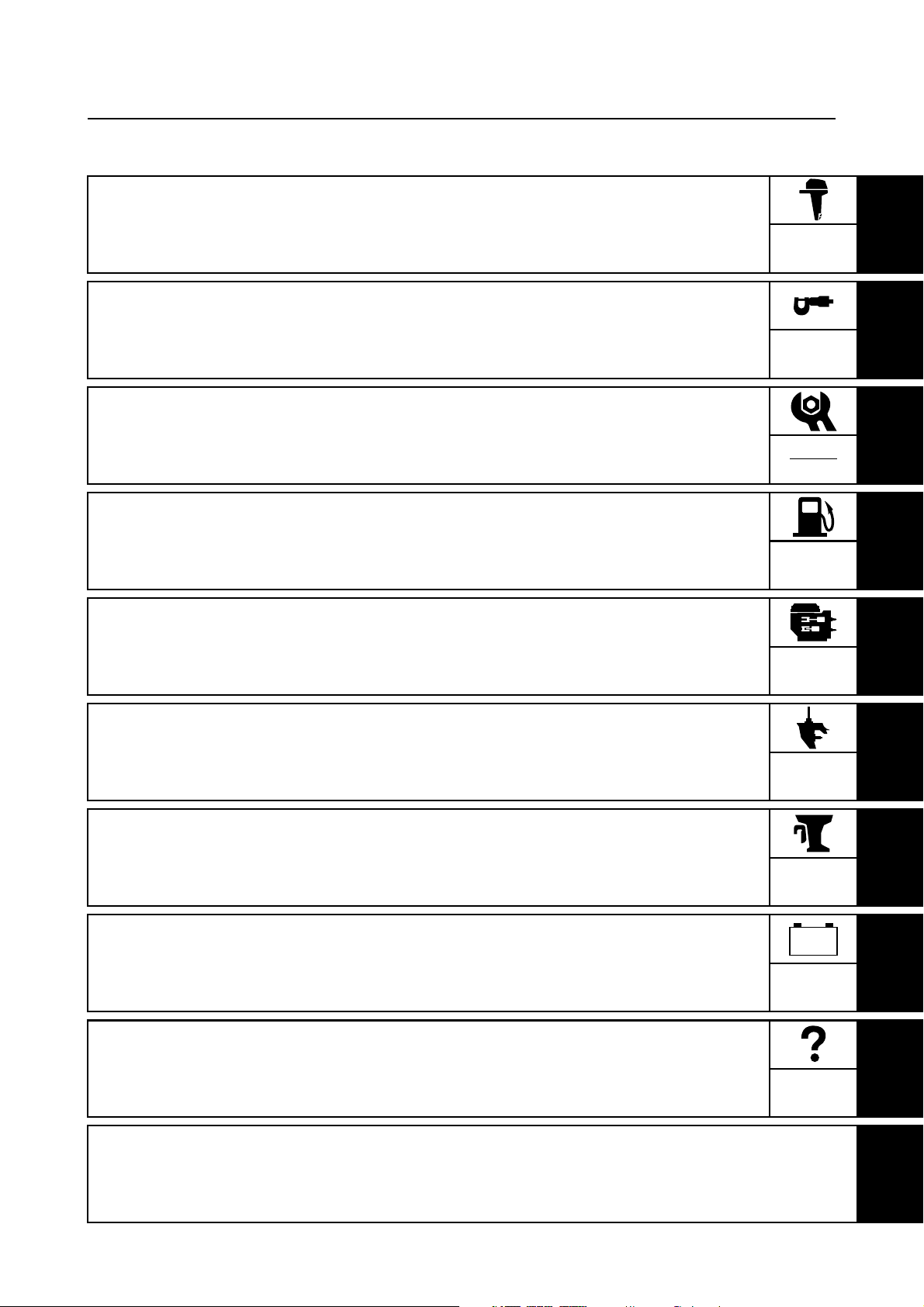

Contents

General information

Specifications

Periodic checks and adjustments

Fuel system

Power unit

GEN

INFO

SPEC

CHK

ADJ

FUEL

POWR

1

2

3

4

5

Lower unit

Bracket unit

Electrical systems

Troubleshooting

Index

LOWR

BRKT

–+

ELEC

TRBL

SHTG

6

7

8

9

GEN

INFO

General information

How to use this manual.................................................................................1-1

Manual format............................................................................................1-1

Symbols.....................................................................................................1-2

Safety while working......................................................................................1-3

Fire prevention...........................................................................................1-3

Ventilation..................................................................................................1-3

Self-protection ...........................................................................................1-3

Parts, lubricants, and sealants ..................................................................1-3

Good working practices .............................................................................1-4

Disassembly and assembly .......................................................................1-4

Identification...................................................................................................1-5

Applicable models .....................................................................................1-5

Serial number ............................................................................................1-5

Features and benefits....................................................................................1-6

Power unit..................................................................................................1-6

Ignition system.........................................................................................1-11

Bracket unit and the PTT unit ..................................................................1-13

Cooling system ........................................................................................1-14

Lower unit ................................................................................................1-15

Technical tips ...............................................................................................1-16

Carburetor ...............................................................................................1-16

Acceleration pump...................................................................................1-17

Ignition system.........................................................................................1-18

Ignition timing control...............................................................................1-18

Lubrication system...................................................................................1-20

Cooling system ........................................................................................1-21

PTT (power trim and tilt) unit (F100B) .....................................................1-22

PTT (power trim and tilt) unit (F100C) .....................................................1-24

Propeller selection.......................................................................................1-25

Propeller size...........................................................................................1-25

Selection..................................................................................................1-25

60C5D11

Predelivery checks ......................................................................................1-25

Checking the fuel system ........................................................................1-25

Checking the gear oil...............................................................................1-26

Checking the engine oil ...........................................................................1-26

Checking the battery................................................................................1-26

Checking the outboard motor mounting position.....................................1-26

Checking the remote control cables ........................................................1-27

Checking the steering system .................................................................1-27

Checking the gearshift and throttle operation..........................................1-27

Checking the tilt system...........................................................................1-28

Checking the engine start switch and engine stop switch/

engine shut-off switch ............................................................................1-28

Checking the pilot water outlet ................................................................1-28

Test run ...................................................................................................1-28

Break-in ...................................................................................................1-29

After test run ............................................................................................1-29

1

2

3

4

5

6

7

8

9

60C5D11

GEN

INFO

General information

How to use this manual

Manual format

The format of this manual has been designed to make service procedures clear and easy to understand. Use the information below as a guide for effective and quality service.

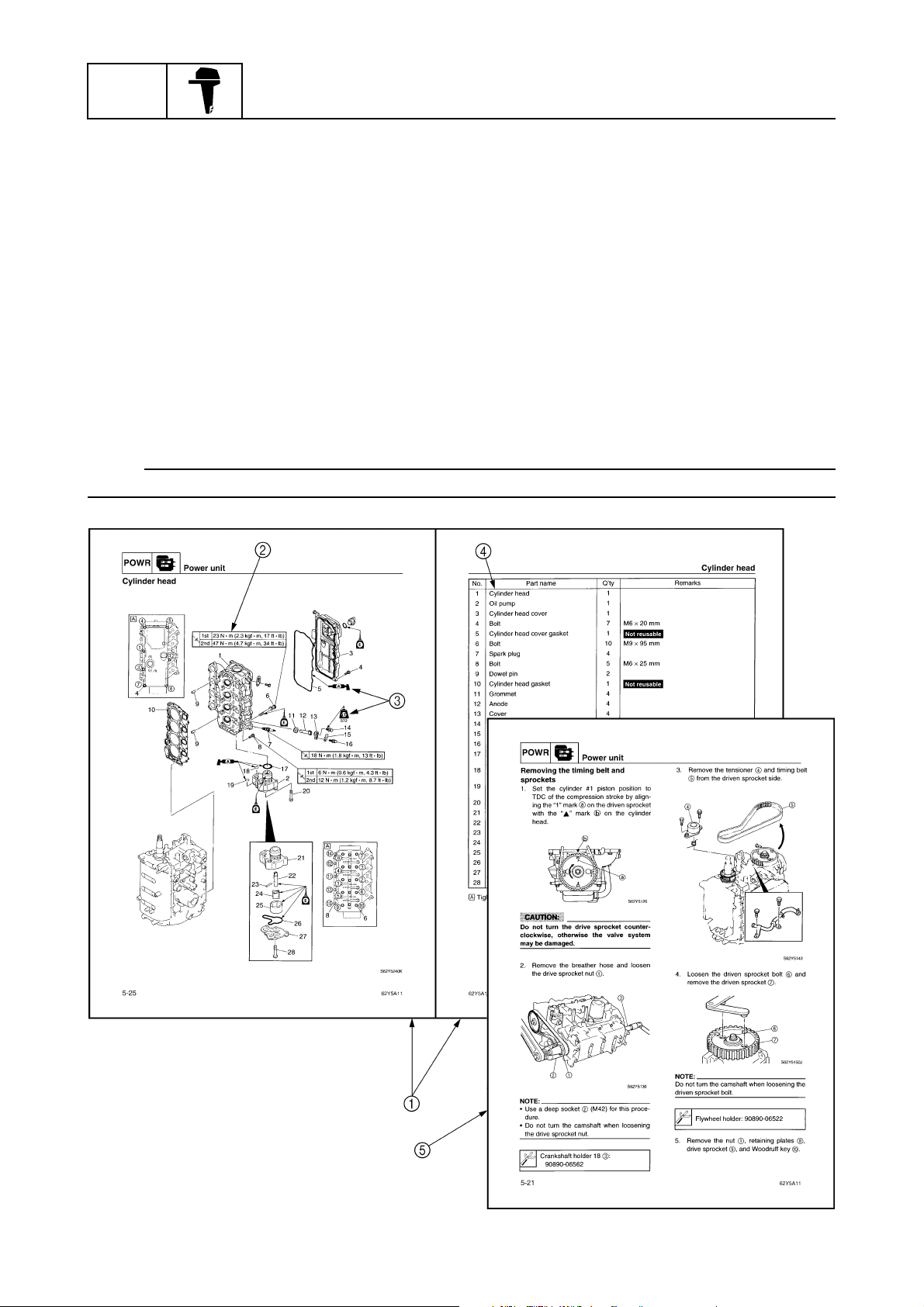

1

Parts are shown and detailed in an exploded diagram and are listed in the components list.

2

Tightening torque specifications are provided in the exploded diagrams and after a numbered

step with tightening instructions.

3

Symbols are used to indicate important aspects of a procedure, such as the grade of lubricant

and lubrication point.

4

The components list consist of parts and part quantities, as well as bolt, screw, O-ring, and hose

dimensions.

5

Service points regarding removal, checking, and installation are shown in individual illustrations

to explain the relevant procedure.

NOTE:

For troubleshooting procedures, see Chapter 9, “Troubleshooting.”

1

1-1

60C5D11

T

R

.

.

How to use this manual

Symbols

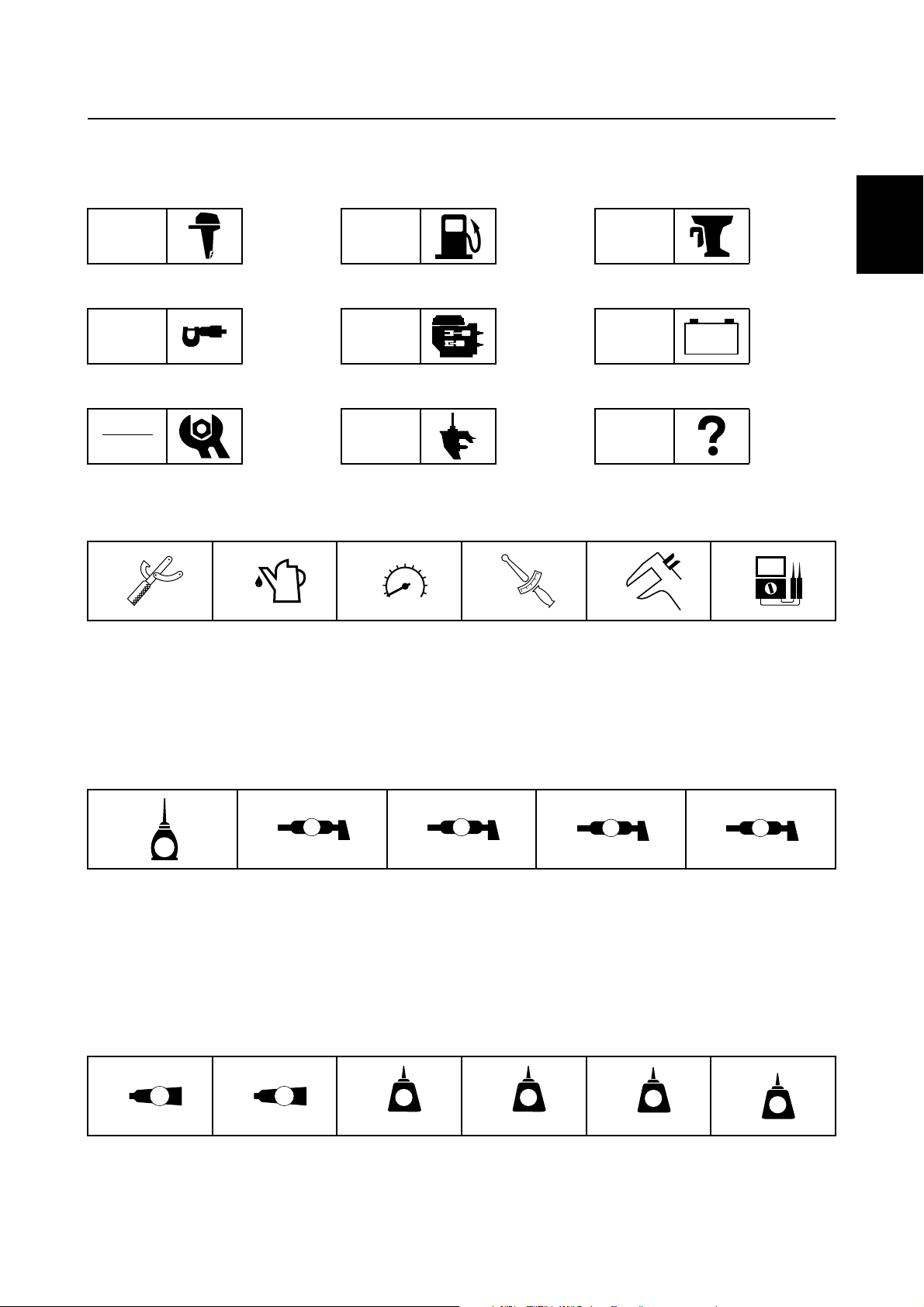

The symbols below are designed to indicate the content of a chapter.

General information

GEN

INFO

Specifications

SPEC

Periodic checks and adjustments

CHK

ADJ

Symbols 1 to 6 indicate specific data.

123456

Fuel system

FUEL

Power unit

POWR

Lower unit

LOWR

Bracket unit

BRKT

Electrical systems

ELEC

Troubleshooting

– +

TRBL

SHTG

1

2

3

4

Special tool

1

Specified oil or fluid

2

Specified engine speed

3

Specified tightening torque

4

Symbols 7 to A in an exploded diagram indicate the grade of lubricant and the lubrication point.

7890A

A M

E

Apply Yamaha 4-stroke motor oil

7

Apply water resistant grease (Yamaha grease A)

8

Apply molybdenum disulfide grease

9

Symbols B to G in an exploded diagram indicate the type of sealant or locking agent and the application point.

BCDEFG

GM

4

LT

271

Specified measurement

5

Specified electrical value

6

(Resistance, Voltage, Electric current)

D C

Apply corrosion resistant grease

0

(Yamaha grease D)

Apply low temperature resistant grease

A

(Yamaha grease C)

LT

242

LT

572

SS

5

6

7

8

9

®

Apply Gasket Maker

B

Apply Yamabond No. 4

C

Apply LOCTITE

D

60C5D11

®

No. 271 (Red)

Apply LOCTITE

E

Apply LOCTITE

F

Apply silicon sealant

G

®

No. 242 (Blue)

®

No. 572

1-2

GEN

INFO

General information

Safety while working

To prevent an accident or injury and to

ensure quality service, follow the safety procedures provided below.

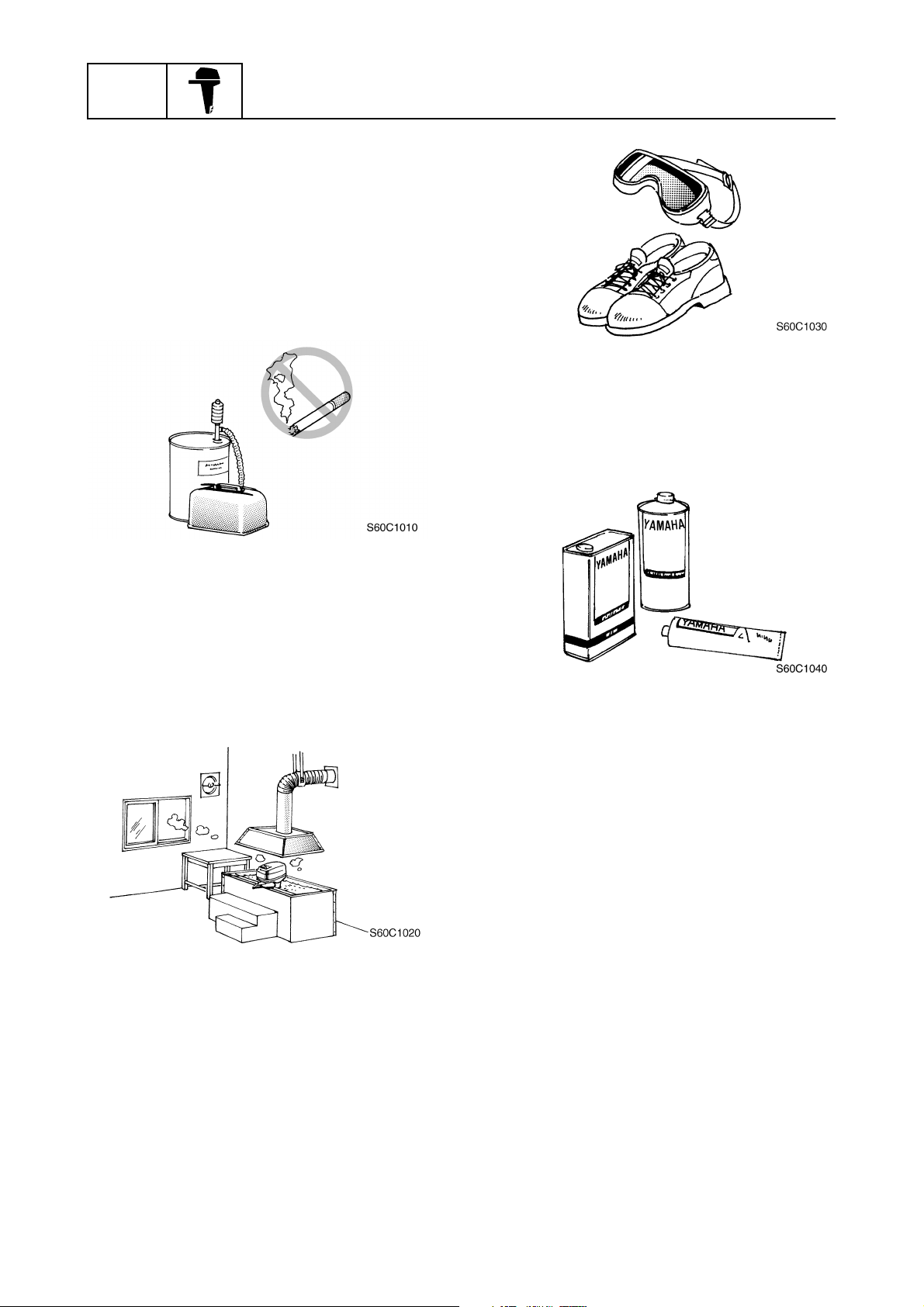

Fire prevention

Gasoline is highly flammable.

Keep gasoline and all flammable products

away from heat, sparks, and open flames.

Ventilation

Gasoline vapor and exhaust gas are heavier

than air and extremely poisonous. If inhaled

in large quantities they may cause loss of

consciousness and death within a short time.

When test running an engine indoors (e.g., in

a water tank) be sure to do so where adequate ventilation can be maintained.

1

Parts, lubricants, and sealants

Use only genuine Yamaha parts, lubricants,

and sealants or those recommended by

Yamaha, when servicing or repairing the outboard motor.

Under normal conditions, the lubricants mentioned in this manual should not harm or be

hazardous to your skin. However, you should

follow these precautions to minimize any risk

when working with lubricants.

Self-protection

Protect your eyes by wearing safety glasses

or safety goggles during all operations involving drilling and grinding, or when using an air

compressor.

Protect your hands and feet by wearing protective gloves and safety shoes when necessary.

1-3

1. Maintain good standards of personal and

industrial hygiene.

2. Change and wash clothing as soon as

possible if soiled with lubricants.

3. Avoid contact with skin. Do not, for

example, place a soiled rag in your

pocket.

4. Wash hands and any other part of the

body thoroughly with soap and hot water

after contact with a lubricant or lubricant

soiled clothing has been made.

5. To protect your skin, apply a protective

cream to your hands before working on

the outboard motor.

60C5D11

6. Keep a supply of clean, lint-free cloths for

wiping up spills, etc.

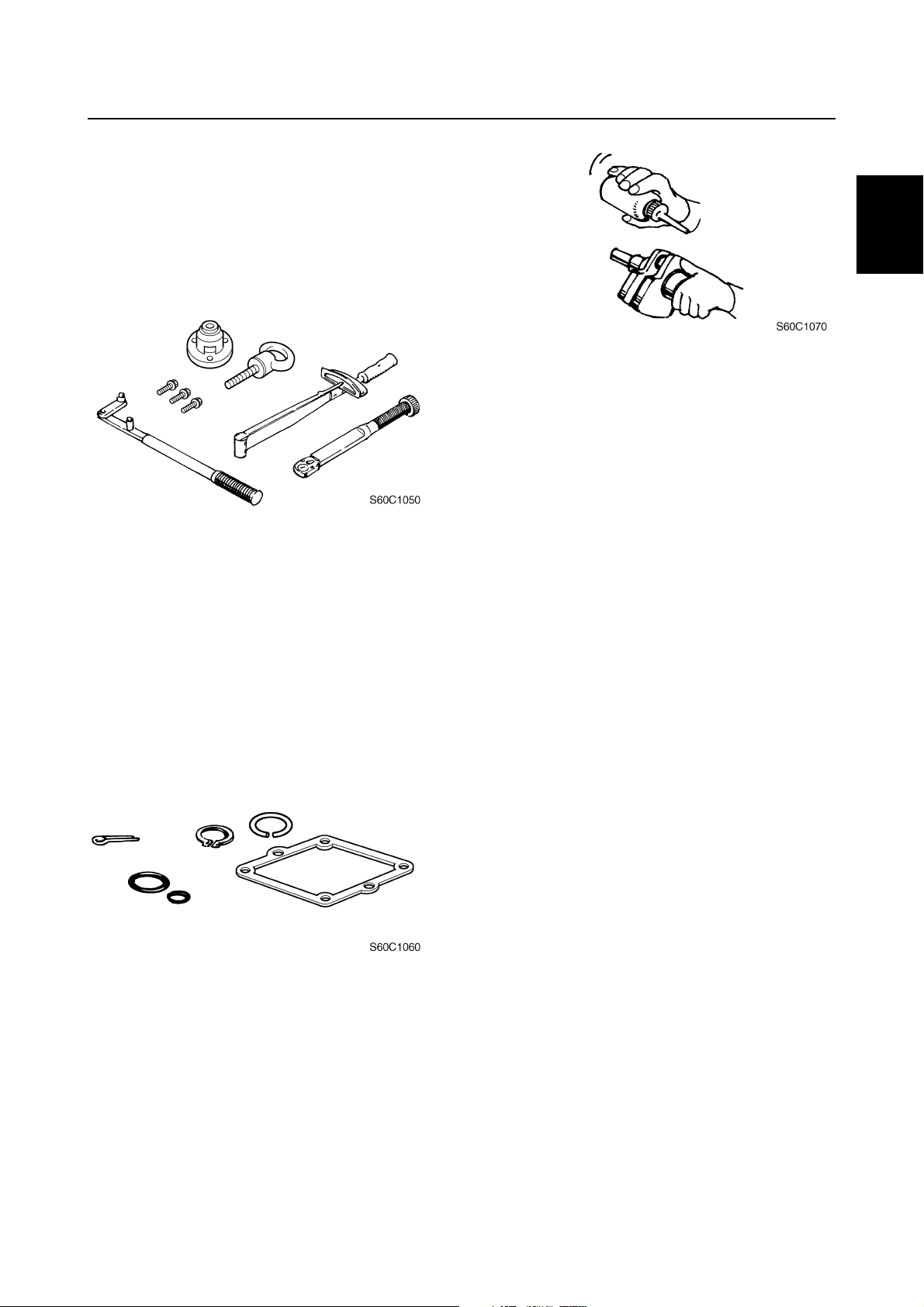

Good working practices

Special tools

Use the recommended special tools to protect parts from damage. Use the right tool in

the right manner—do not improvise.

Tightening torques

Follow the tightening torque specifications

provided throughout the manual. When tightening nuts, bolts, and screws, tighten the

large sizes first, and tighten fasteners starting

in the center and moving outward.

Non-reusable parts

Always use new gaskets, seals, O-rings, cotter pins, circlips, etc., when installing or

assembling parts.

Safety while working

3. Install bearings with the manufacture

identification mark in the direction indicated in the installation procedure. In

addition, be sure to lubricate the bearings

liberally.

4. Apply a thin coat of water-resistant

grease to the lip and periphery of an oil

seal before installation.

5. Check that moving parts operate normally after assembly.

1

2

3

4

5

Disassembly and assembly

1. Use compressed air to remove dust and

dirt during disassembly.

2. Apply engine oil to the contact surfaces

of moving parts before assembly.

6

7

8

9

60C5D11

1-4

GEN

INFO

General information

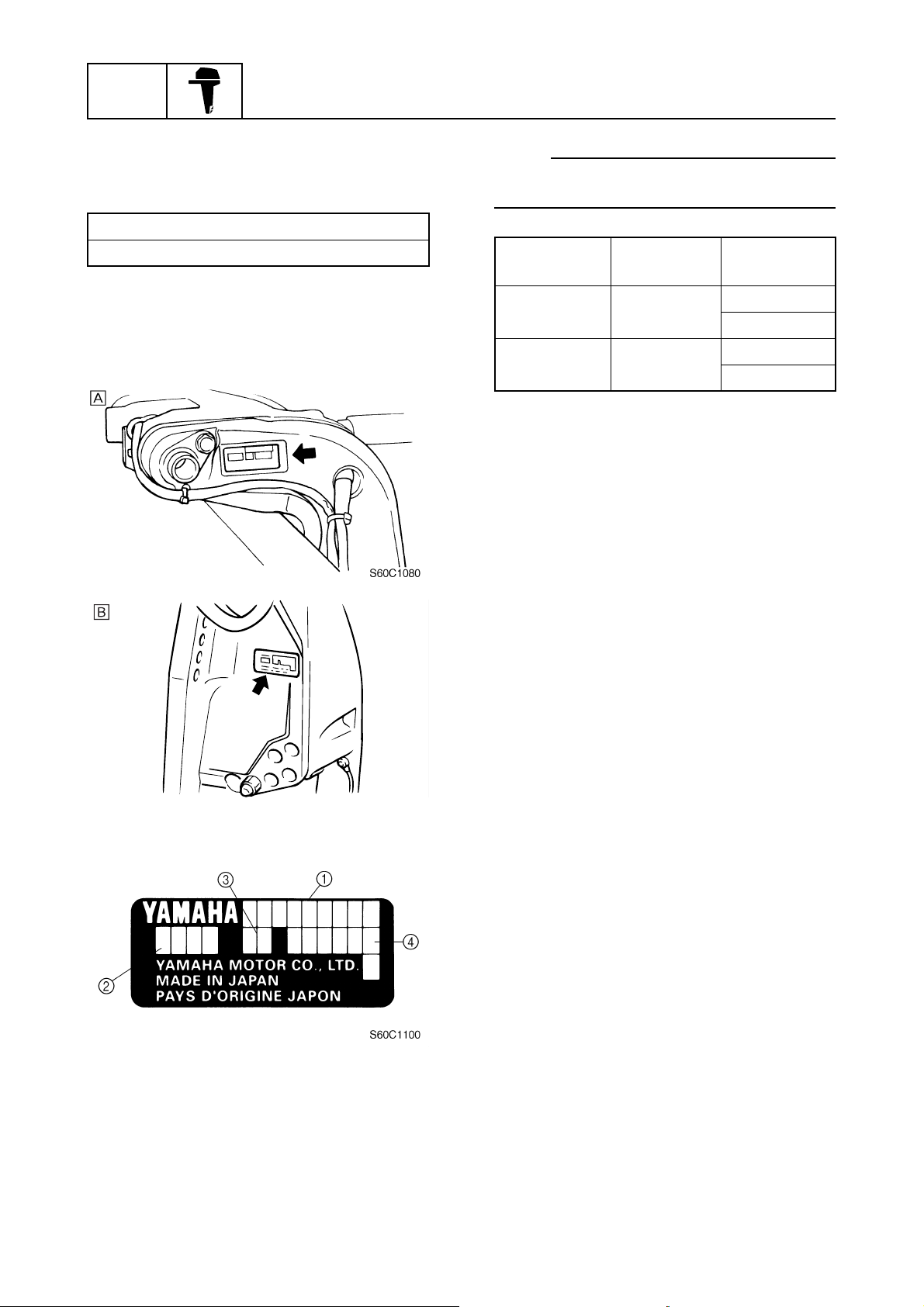

Identification

Applicable models

This manual covers the following models.

Applicable models

F100BET, F100CET

Serial number

The outboard motor serial number is

stamped on a label attached to the port

clamp bracket.

1

NOTE:

If the serial number label is removed, VOID

marks will appear on the label.

Model name

Approved

model code

Starting

serial No.

L: 000101–

F100BET 60C

X: 200101–

L: 000101–

F100CET 60D

X: 200101–

F100B

È

F100C

É

Model name

1

Approved model code

2

Transom height

3

Serial number

4

S60C1090

1-5

60C5D11

Identification / Features and benefits

Features and benefits

Power unit

The F100B and F100C have been developed on the bases of the F100A, which has been recognized as being environmentally friendly, with established emission control, and which has received

high marks as an efficiently superior model with a high fuel economy.

Blowby gas, which is discharged from the engine, is returned to the intake silencer and reburned to

purify the exhaust gas.

The intake passage and exhaust passage have been arranged around the engine to make the

entire engine compact. When compared to a small, 2-stroke, V4 engine it is compact like an in-line,

three cylinder engine.

1

1

2

3

4

Silencer

1

Carburetor

2

Intake

È

Exhaust gas

É

Blowby gas

Ê

5

6

7

:

:

:

S60C1250

8

9

60C5D11

1-6

GEN

INFO

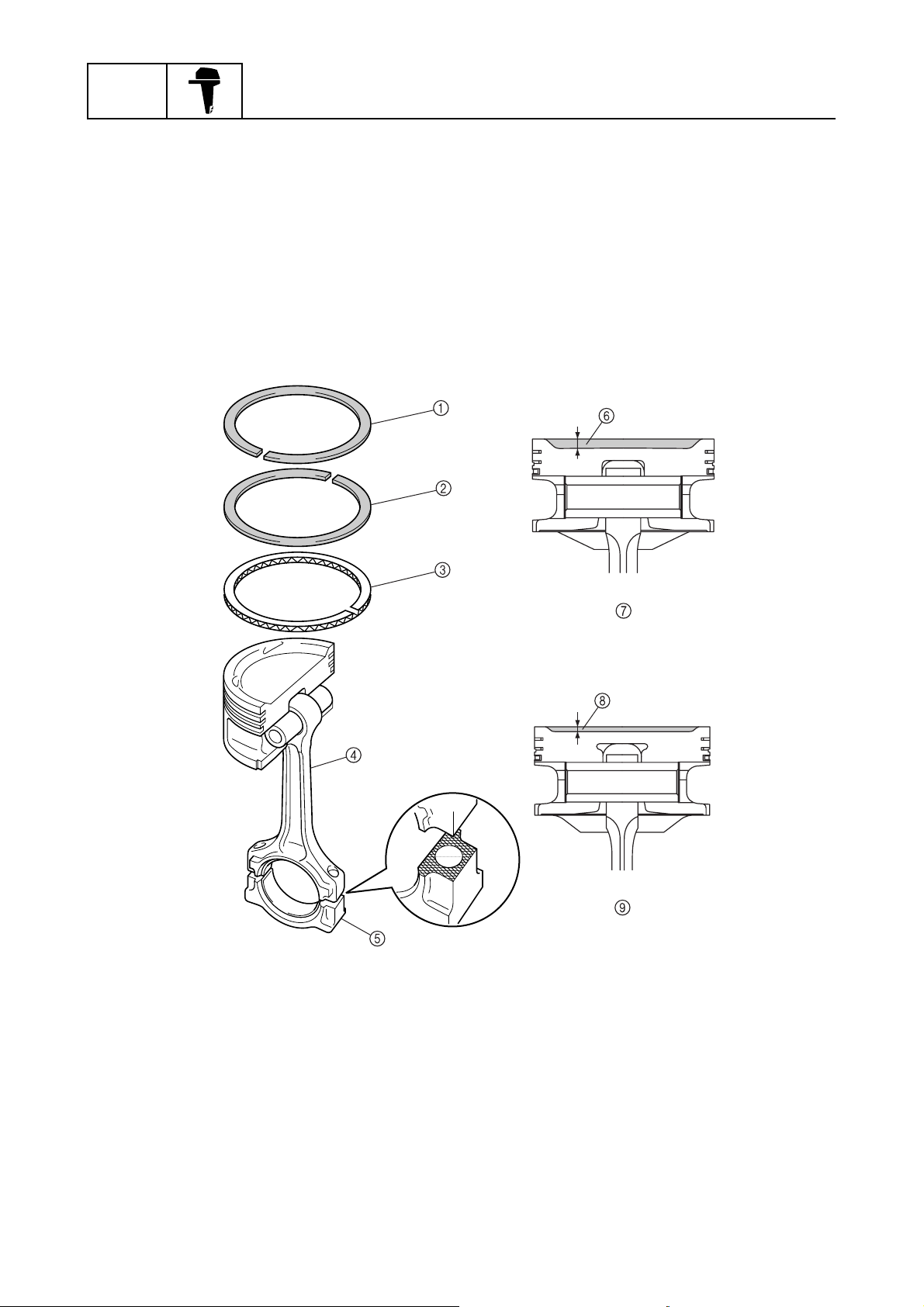

Piston and connecting rod

The piston pin has been installed by shrink fitting it to the small end of the connecting rod, as a

result, a circlip is not used to install the piston pin.

The top ring has been nitrided and the second ring has been chrome plated for use with leaded gasoline.

The connecting rod and end cap are processed as a single unit. After being heat treated, the single

unit is struck and the connecting rod and end cap are split apart as shown in the illustration. To

increase accuracy during installation, the connecting rod and end cap that were processed together

are always installed as a set.

The hollow volume at the top of the pistons has been made larger and the compression ration has

been lowered to increase reliability and durability.

General information

Top ring

1

Second ring

2

Oil ring

3

Connecting rod

4

Connecting rod end cap

5

F100B, F100C

F100A

Large hollow volume

6

Compression ratio (8.9)

7

Small hollow volume

8

Compression ratio (9.6)

9

S60C1270

1-7

60C5D11

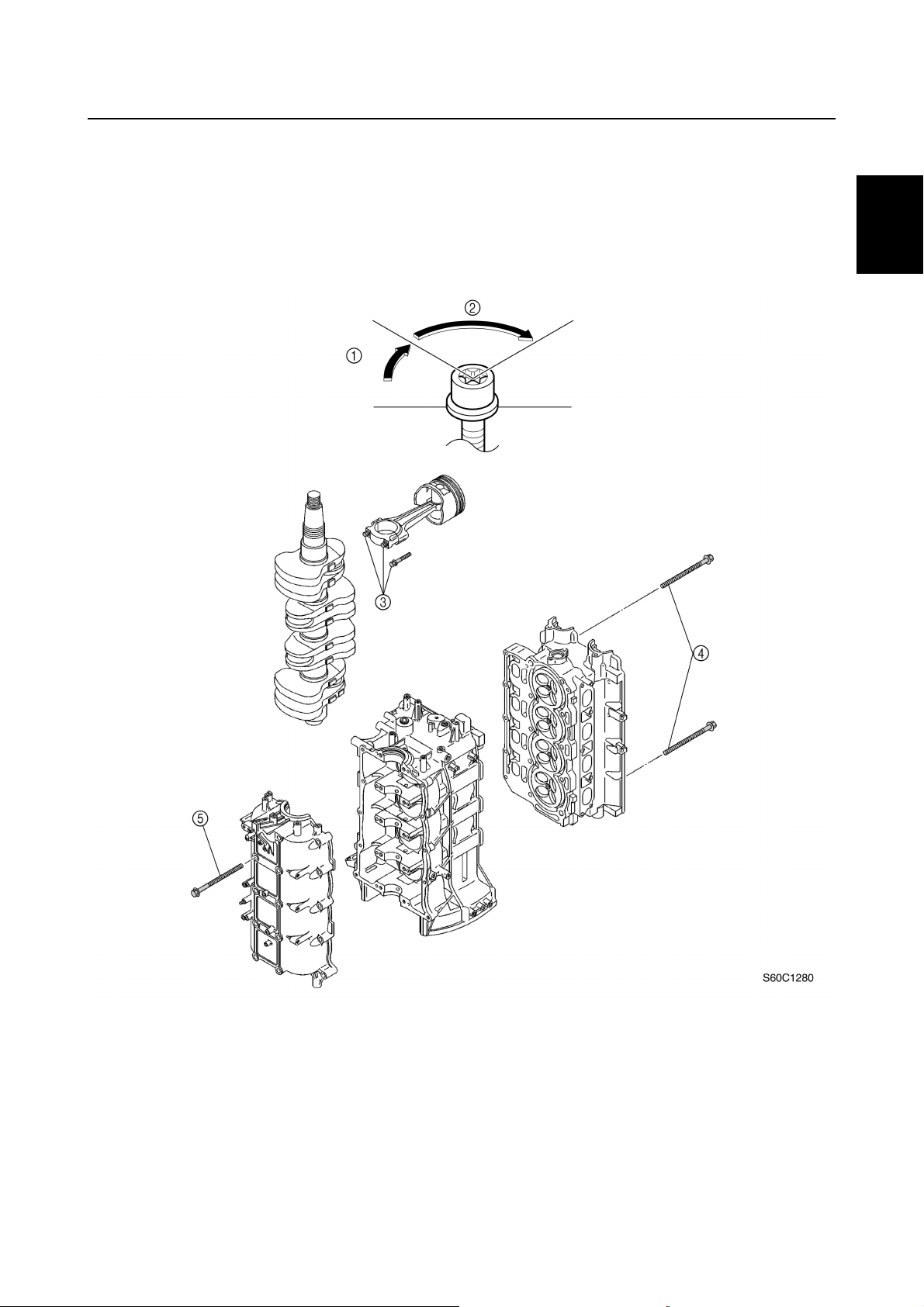

Features and benefits

New plastic-region tightening bolts

To tighten the plastic-region tightening bolts, tighten them to the specified torque, and then tighten

them to the specified angle. By tightening the bolts to the specified angle, they are contracted to a

more accurate torque, making periodic maintenance checks and adjustments to, as well as additional tightening of the bolt unnecessary.

The cylinder head bolts, connecting rod bolts, and crankcase bolts have adopted this method to

help better control torque accuracy.

1

2

3

4

5

6

7

8

Specified torque

1

Specified angle

2

Connecting rod bolt

3

60C5D11

Cylinder head bolt

4

Crankcase journal bolt

5

9

1-8

GEN

INFO

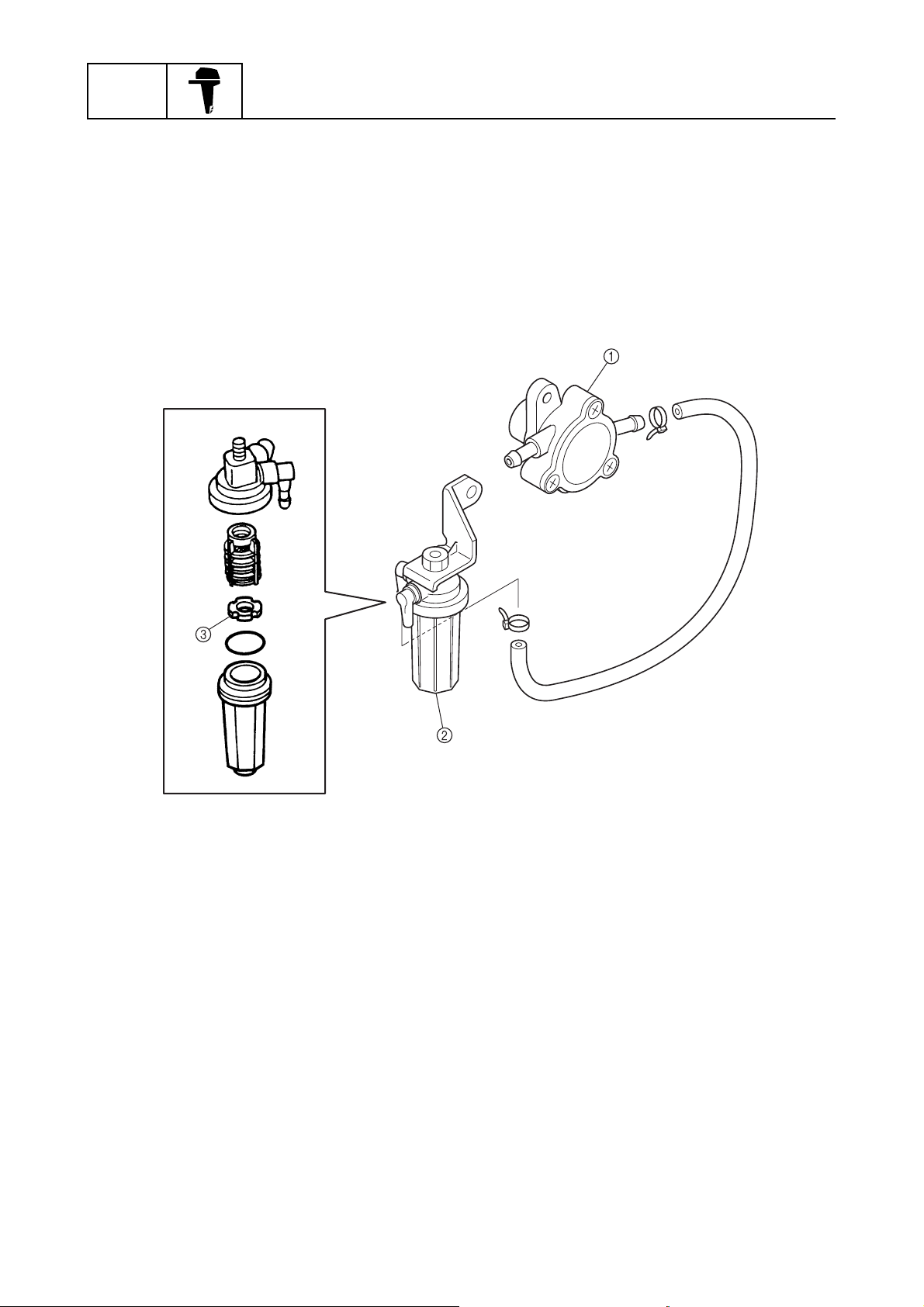

Fuel pump and fuel filter

The fuel pump found in the F115A has been adopted. Although the quantity of parts has been

reduced and the necessary servicing time has been decreased as well, the ability of the fuel pump

to supply sufficient fuel has been retained.

A water separation fuel filter has been adopted. When water is mixed with fuel, it is separated and

precipitated at the bottom of the filter to prevent it from flowing to the carburetors. As water gathers

in the fuel cup, the red float inside the cup begins to rise, indicating that the accumulation of water is

taking place. After water has gathered in the fuel cup, the fuel filter can be disassembled to dispose

of the water.

General information

Fuel pump

1

Fuel filter

2

Red float

3

1-9

S60C1290

60C5D11

Features and benefits

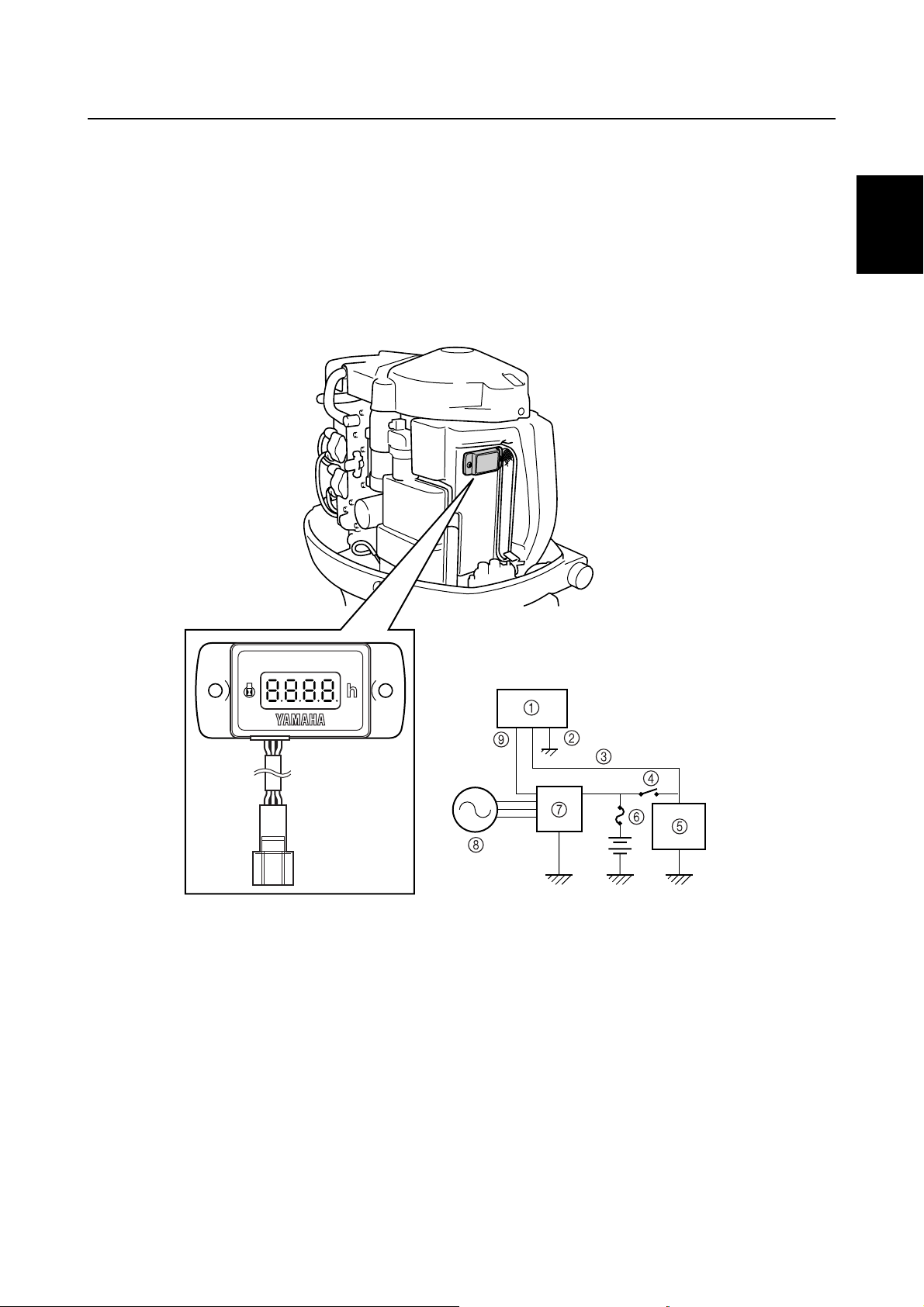

Hour meter

A newly developed hour meter is incorporated on the F100B and F100C. The hour meter makes it

possible to check the hours of operation of the outboard motor, which can be used to keep track of

periodic checks and adjustments.

When the engine switch is turned to ON, all LED on the display will illuminate for two seconds, and

then the hours of operation will be displayed.

A signal from the Rectifier Regulator, via the green and white (G/W) lead, is sent to the hour meter

as the hours of operation accumulation.

The hours of operation cannot be deleted.

1

2

3

Hour meter

1

Grand (B)

2

Battery (Y)

3

Engine start switch

4

Starter motor

5

Fuse

6

Rectifier Regulator

7

Flywheel magnet

8

Signal (G/W)

9

4

5

6

7

S60C1300

8

60C5D11

9

1-10

GEN

INFO

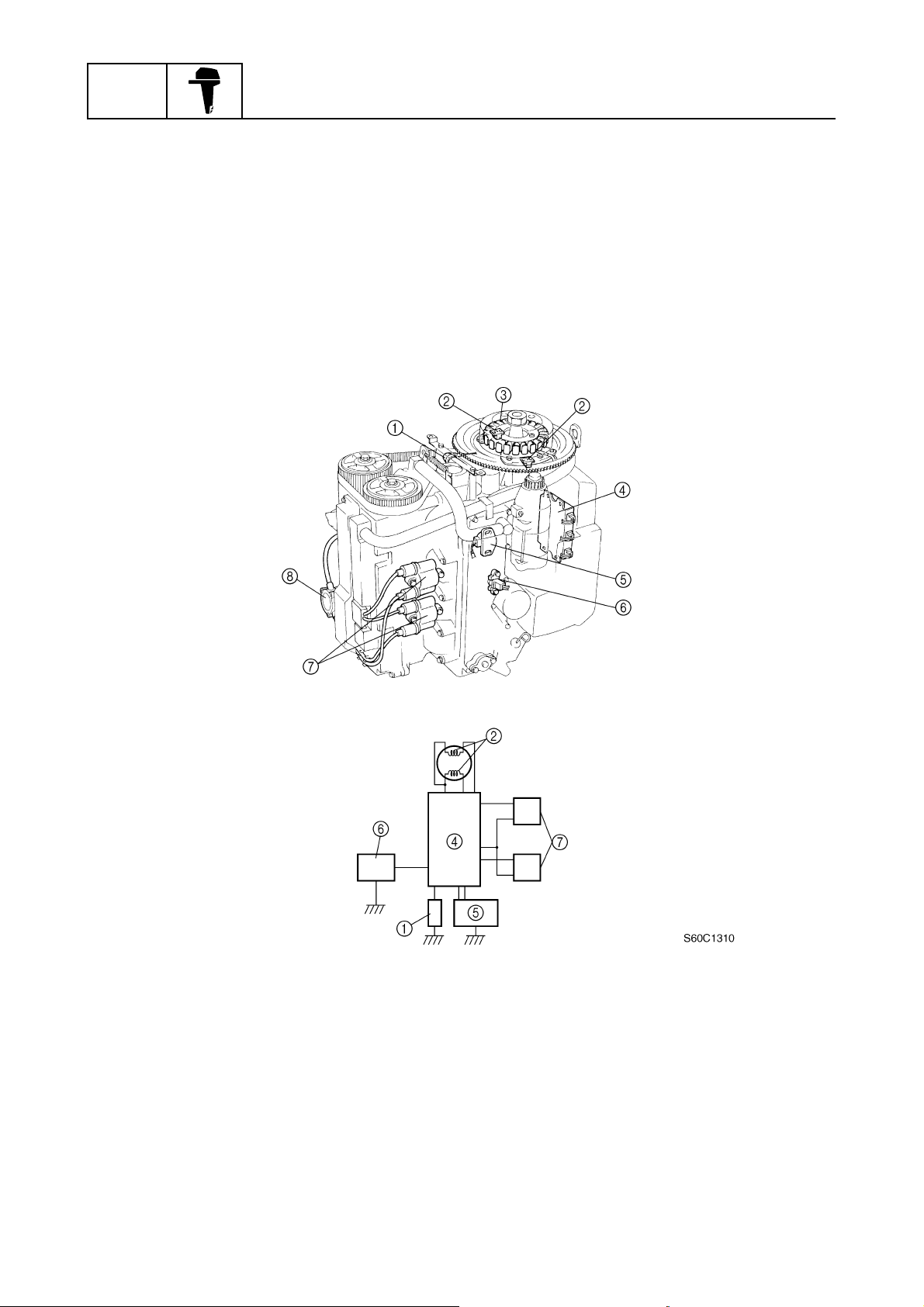

Ignition system

A CDI system has been incorporated. The CDI unit uses three signals (i.e., crankshaft position,

engine revolution, and throttle position) to determine the optimum ignition timing.

Engine speed is controlled by the CDI unit to prevent damage to the engine when the engine temperature sensor detects that the engine temperature (i.e., water temperature) is too high, or when

the oil pressure switch detects that the oil pressure is too low, or when the engine idle speed is too

high.

In addition, when the engine overheats or when there is low oil pressure, the warning lamp flashes

and the buzzer sounds.

If the throttle position sensor and engine temperature sensor malfunction, the engine ignition timing

is set by the CDI unit to prevent damage to the engine.

General information

Oil pressure switch

1

Puler coil

2

Lighting coil

3

CDI unit

4

1-11

Throttle position sensor

5

Engine temperature sensor

6

Ignition coils

7

Fuel pump

8

60C5D11

Features and benefits

At low speeds, the exhaust gas flows into the water wall through a hole on the side of the exhaust

guide.

:

1

2

3

:

Exhaust gas flow at low speeds

È

Exhaust gas flow at high speeds

É

An identification mark has been stamped on the exhaust manifold and exhaust chamber.

S60C1330

4

5

6

7

Identification mark “C”

1

Exhaust manifold

2

Exhaust chamber

3

Identification mark “D”

4

60C5D11

8

9

1-12

GEN

INFO

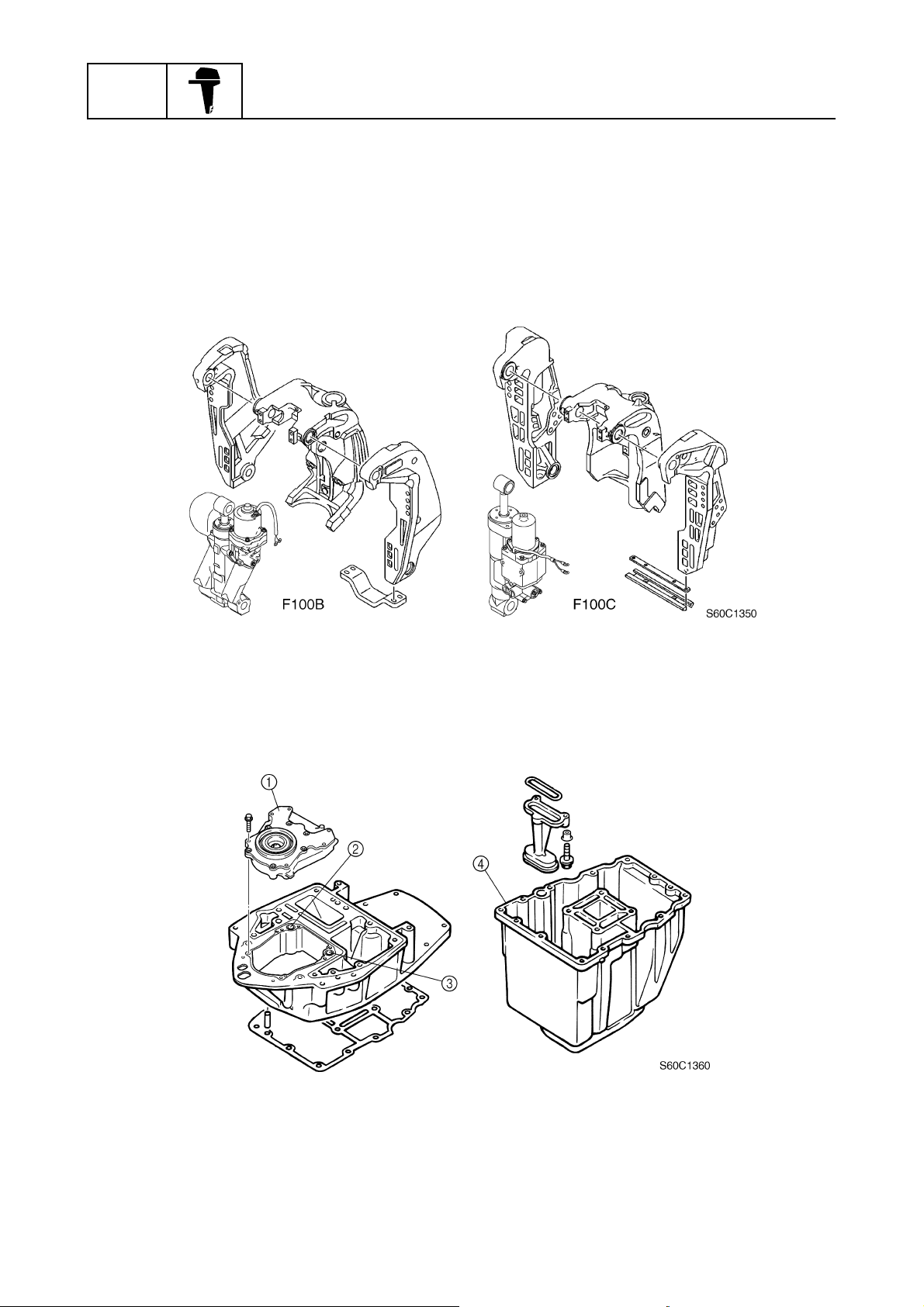

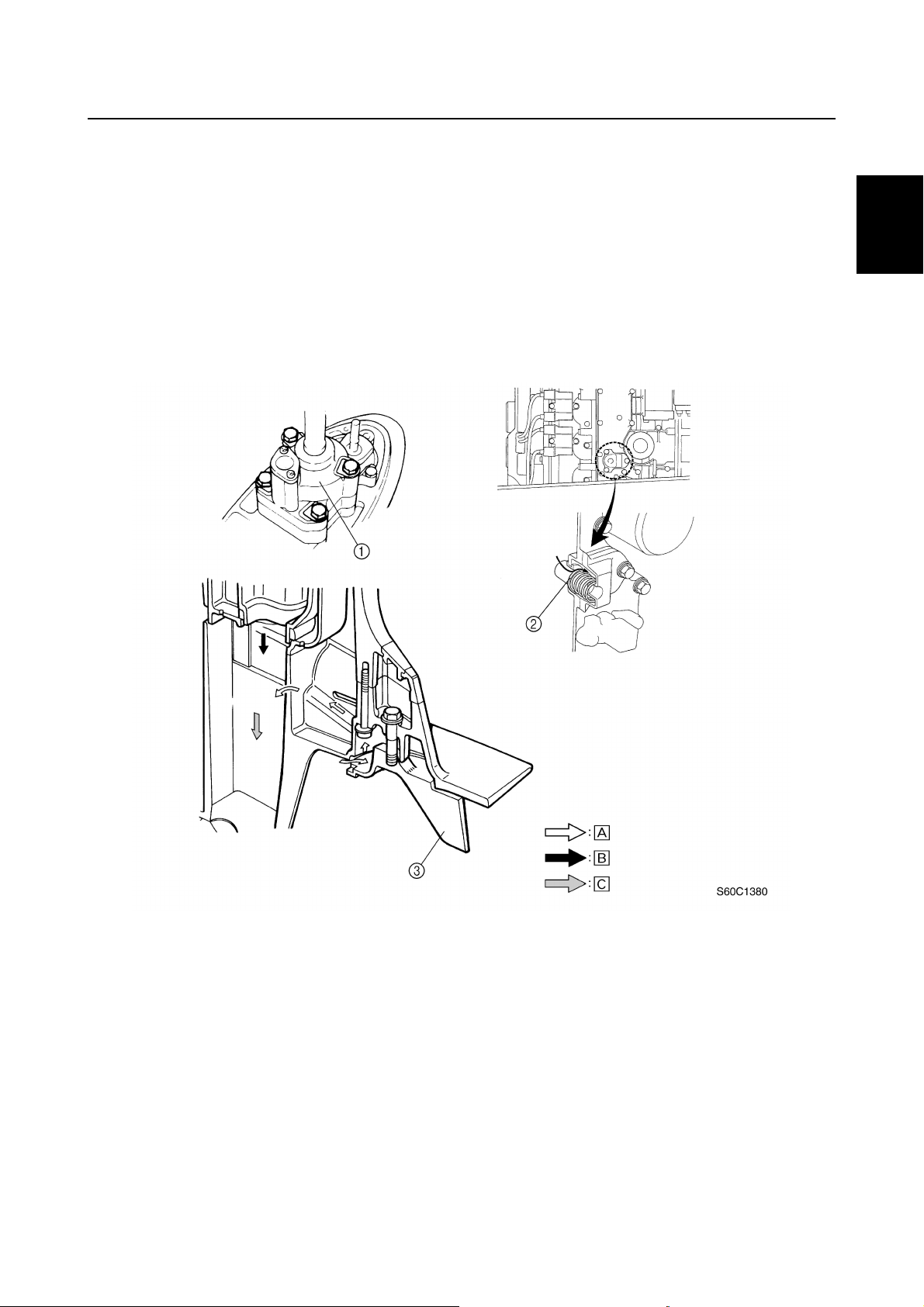

Bracket unit and the PTT unit

F100B uses the bracket unit of 2-stroke, V4 outboard motor and F100C uses that of F100A.

In addition, the PTT unit has been adopted from the F100A as well.

The F100B uses the one found on the proven 2-stroke, V4, and V6 outboard motors. This PTT unit

has been constructed to feature a single tilt cylinder and two trim cylinders.

The PTT unit of the F100C has been adopted from the proven F100A. This PTT unit consists of a

single cylinder for both tilt and trim functions, making the unit compact and lightweight.

General information

Oil pump

The oil pump has been installed directly above the oil pan and to the exhaust guide.

In addition, the oil pump is operated directly by the drive shaft, therefore proper oil delivery can be

achieved.

Oil pump

1

OUT

2

1-13

3

4

IN

Oil pan

60C5D11

Features and benefits

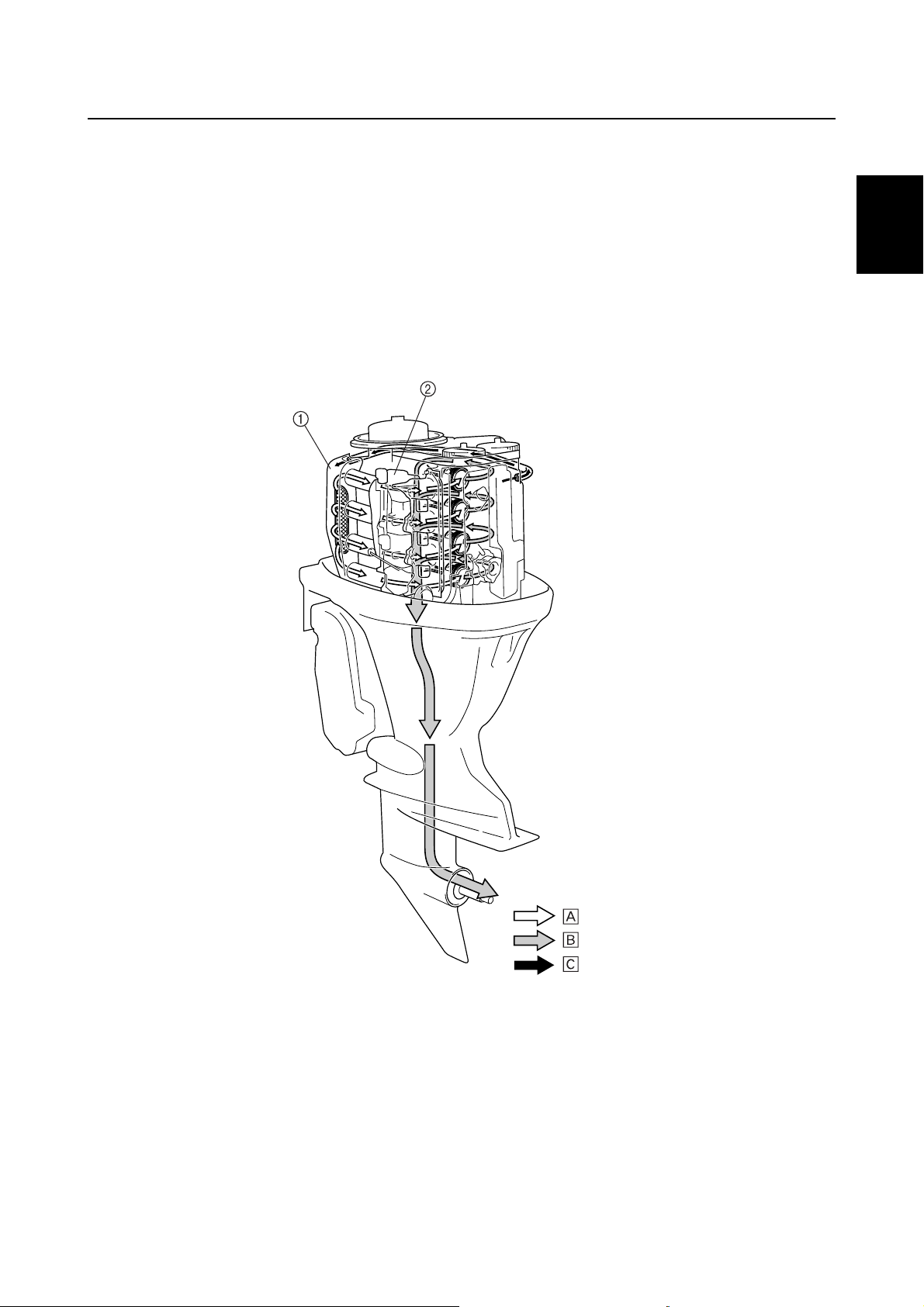

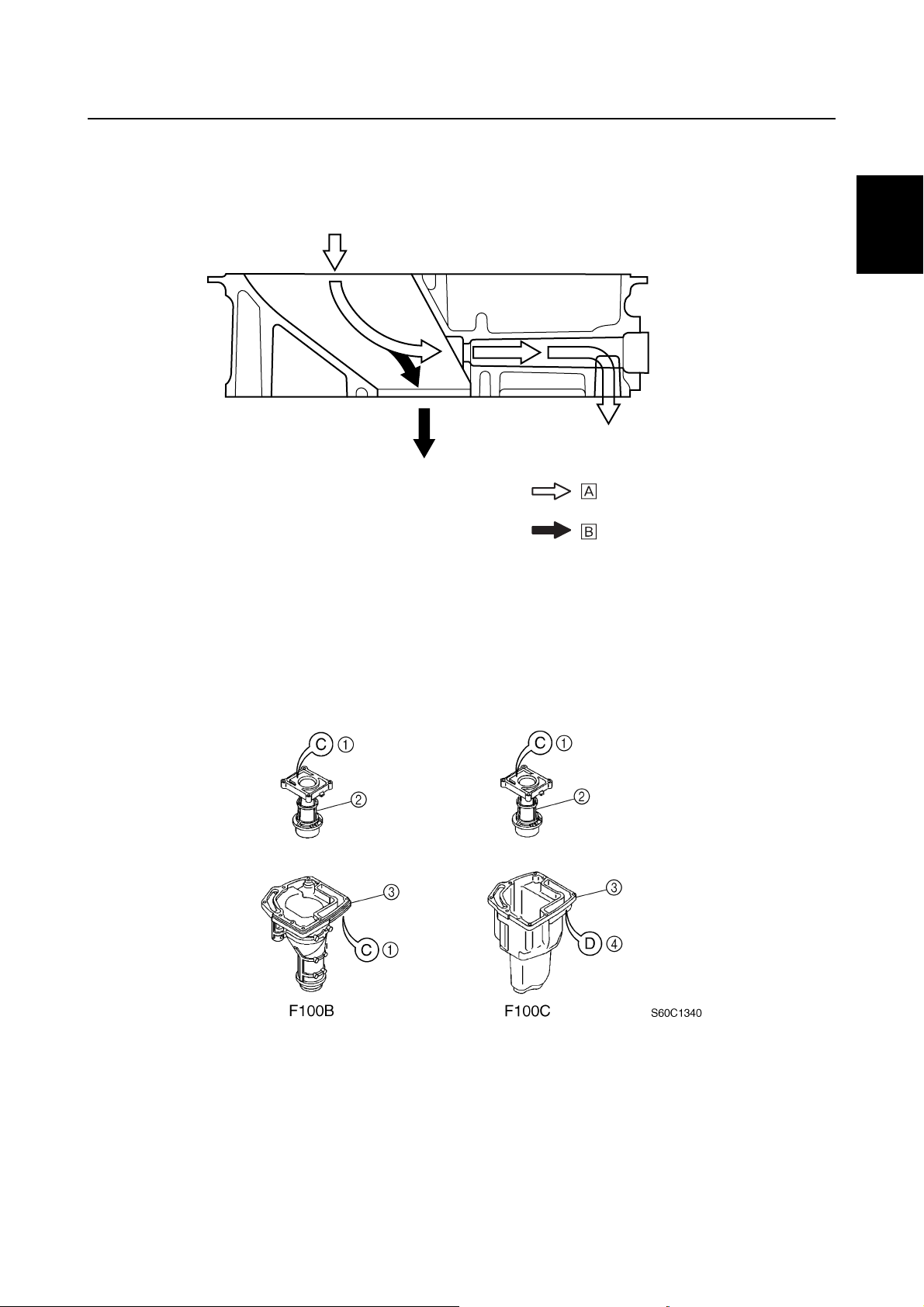

Cooling system

A high capacity water pump and a large cylinder head water jacket have been incorporated to

enable better cooling.

A pressure control valve (PCV) has also been incorporated to control the cooling water pressure,

which in turn helps prevent water leakage from the power unit. When the cooling water pressure

becomes too high, the PCV opens and the cooling water flows through a bypass passage to the

upper case.

An additional water inlet, located in front of the trim tab, allows cooling water to flow into the exhaust

passage in the lower unit during high-speed operation. This extra cooling water properly cools the

high-temperature exhaust gas before it exits through the propeller boss, helping to prevent the rubber parts in the propeller boss from being damaged by high gas temperatures.

1

2

3

Water pump

1

Pressure control valve (PCV)

2

Trim tab

3

Cooling water

È

Exhaust gas

É

Exhaust gas/Cooling water mixture

Ê

4

5

6

7

8

60C5D11

9

1-14

GEN

INFO

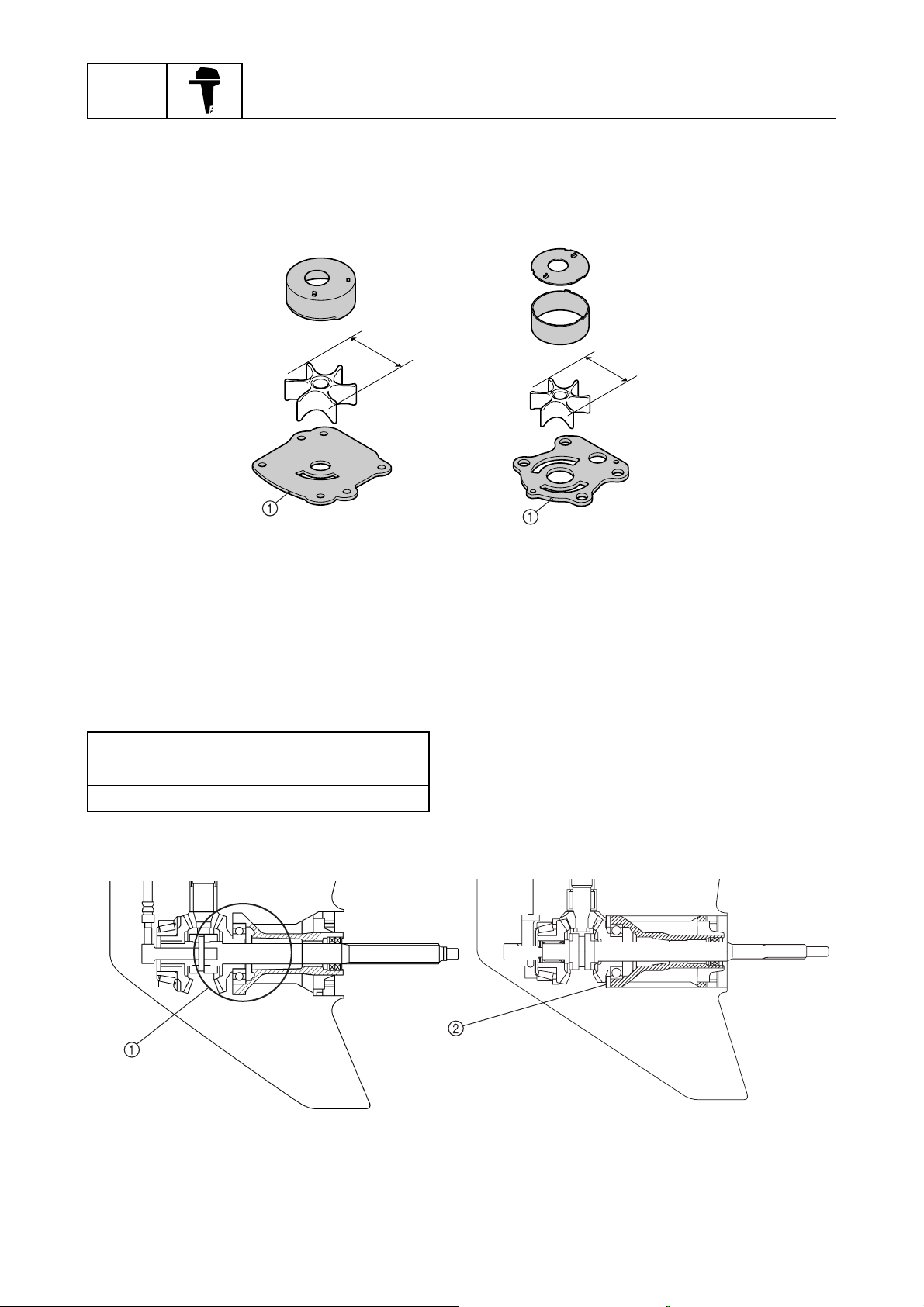

Water pump

The water pump has been hard chrome plated to prevent wear from muddy water. By hard chrome

plating the water pump, wear resistance has been enhanced, and as a result, the time necessary

between part changes or maintenance has been extended.

General information

89ø

58ø

S60C1390

Blue identification paint

1

F100B F100C

Lower unit

The lower unit of the F100C does not contain a reverse gear shim. Therefore, it is not necessary to

set the position of a shim for the reverse gear.

Gear ratio

F100A 2.31 (30/13)

F100B 2.15 (28/13)

F100C 2.31 (30/13)

No reverse gear shim

1

Reverse gear shim

2

1-15

F100C

F100B

S60C1410

60C5D11

Features and benefits

Technical tips

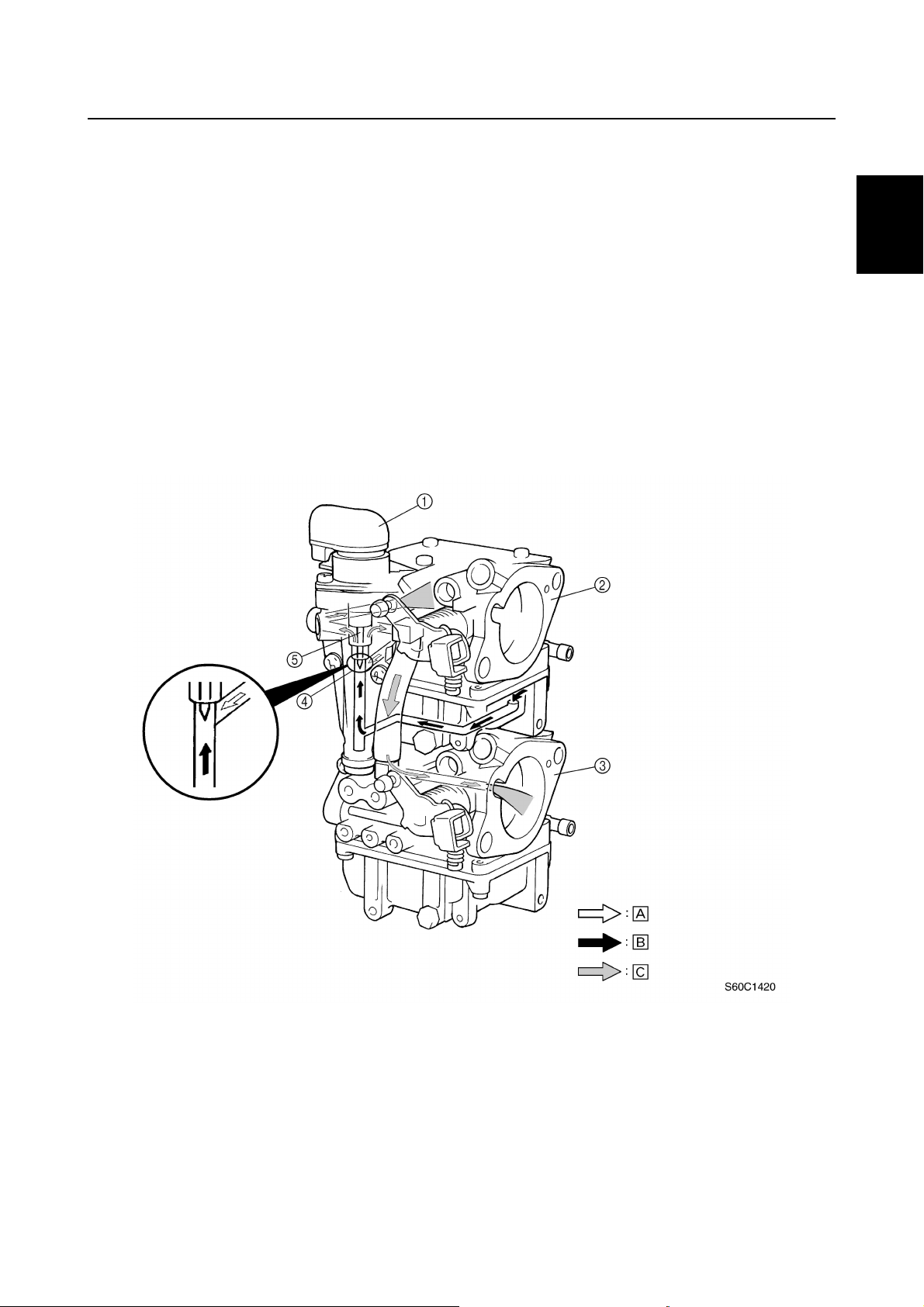

Carburetor

Prime start

To facilitate the starting of a cold engine, an air-fuel mixture that is richer than normal is required.

For this reason, the Prime Start system has been adopted in the F100B and F100C. In the Prime

Start system, the thermo heater plunger is in a position that fully opens the fuel enrichment valve

while the engine is being started. Thus, fuel enrichment is achieved during the starting of the

engine, and continues while the engine is being warmed up. Once the engine is started, a signal is

sent from the pulser coil to the CDI, and from the CDI to the Prime Start to allow the wax to expand.

The expanded wax moves the thermo heater plunger in the direction to close the enrichment valve.

As a result, the volume of fuel that passes through the fuel enrichment valve decreases. A few minutes after the engine has started, the thermo heater plunger completely closes the fuel enrichment

valve, thus ending the fuel enrichment by the Prime Start system.

1

1

2

3

4

Prime Start

1

Carburetor #1/#3

2

Carburetor #2/#4

3

Fuel enrichment valve

4

Thermo heater plunger

5

Air

È

Fuel

É

Air-fuel mixture

Ê

5

6

7

8

9

60C5D11

1-16

GEN

INFO

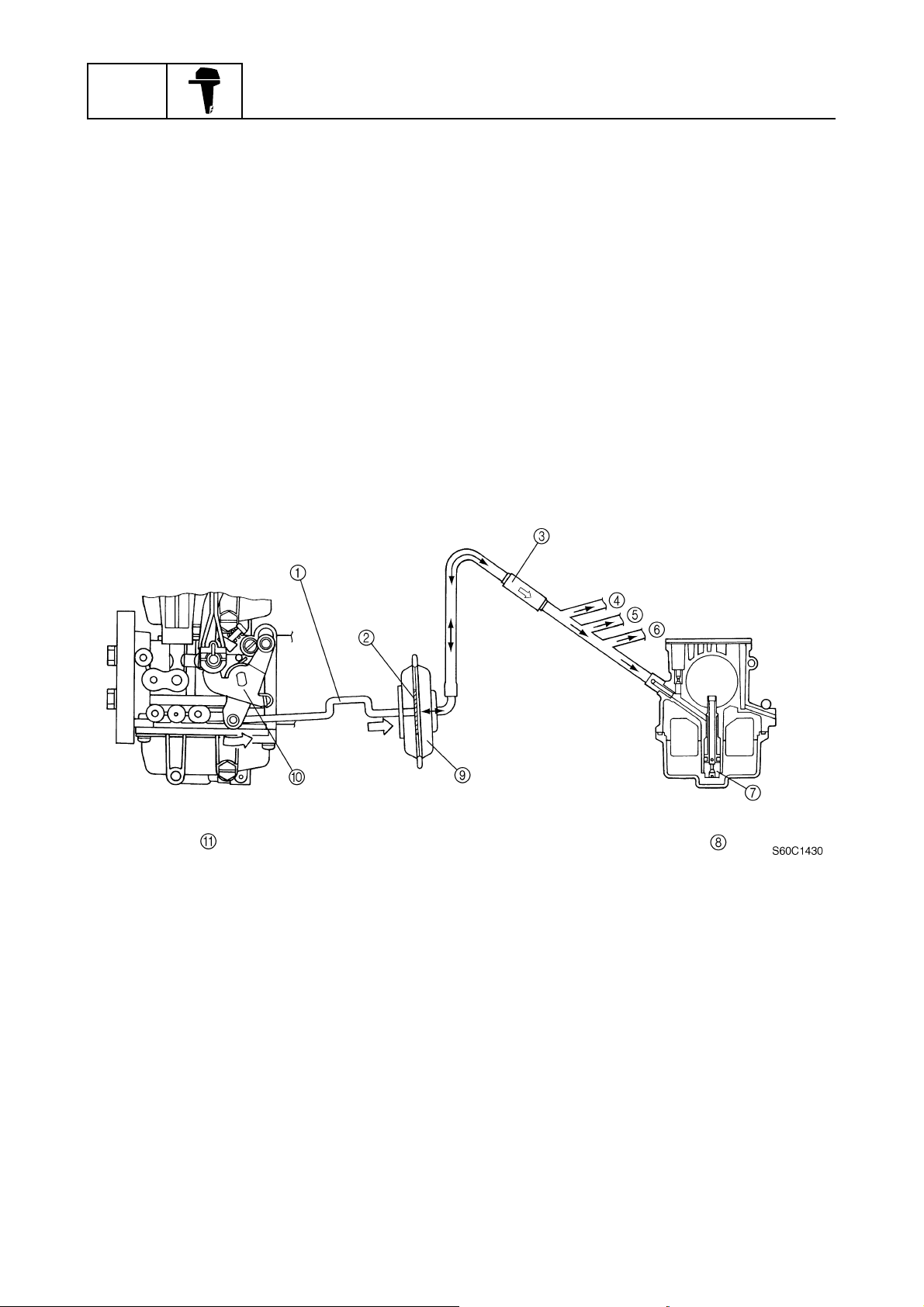

Acceleration pump

The function of the acceleration pump is to ensure a smooth acceleration by preventing the air-fuel

mixture from becoming temporarily lean in case the throttle valve is opened suddenly. When the

throttle valve is opened suddenly, a large volume of air is introduced into the engine. However,

because fuel is heavier than air, it is not possible to supply the volume of fuel that is necessary for

the large volume of air that has been introduced. Thus, because it is not possible to achieve the airfuel mixture that is required by the engine, bucking or hesitation results. For this reason, the acceleration pump temporarily increases the fuel volume in order to adjust the air-fuel mixture to a ratio that

is necessary for the engine in case the throttle valve is opened suddenly.

Operation

When the throttle is opened suddenly, diaphragm (via the link that is connected to the throttle lever)

operates to pressurize the air in the dashpot. The pressurized air distributed to the carburetors by

passing through the in-line, one-way valve that is connected to the carburetors. The pressurized

and distributed air then utilizes the passage of the main air jet to flow into the main nozzle. The pressure of the air helps suck fuel from the main jet, which increases the fuel in the main nozzle, and

thus achieves fuel enrichment.

General information

Throttle lever link rod

1

Diaphragm

2

In-line, one-way valve

3

To carburetor #1

4

To carburetor #2

5

To carburetor #3

6

1-17

Main jet

7

Carburetor #4 (cutaway view)

8

Dashpot

9

Throttle lever

0

Carburetor #4 (side view)

A

60C5D11

Technical tips

Ignition system

The computer controlled CDI system has three basic modes of operation: starting, warm-up, and

normal operation.

Ignition timing control

Starting mode

Ignition timing is fixed at 10° BTDC. The starting mode cuts off when the engine has been started

and the engine speed is over 600 r/min.

Warm-up mode

The engine speed is kept at approximately 1,100 r/min by the computer. The four main situations,

based on the cooling water temperature, that this mode operates in are as follows:

1. Below 0 °C (32 °F), this mode lasts approximately 300 seconds.

2. From 0 °C (32 °F)–20 °C (68 °F), this mode lasts approximately 180 seconds.

3. From 20 °C (68 °F)–40 °C (104 °F), this mode lasts approximately 120 seconds.

4. Over 40 °C (104 °F), this mode does not operate.

The warm-up mode will cut off if the engine speed exceeds 4,000 r/min.

1

2

3

Normal operation

This mode operates between 5° ATDC and 35° BTDC. The ignition timing is automatically adjusted

by the computer. The computer receives three signals (i.e, crankshaft position, engine revolution,

and throttle position) every five microseconds, and then adjusts the ignition timing accordingly.

Two pulser coils send signals to the computer which then determines the crankshaft position and

engine revolution.

The throttle position sensor also sends signals to the computer which then determines the throttle

position. The microcomputer uses these three signals to determine the proper ignition timing.

Fail-safe controls

When the engine start switch is turned on, both low oil pressure and overheat warning lights will turn

on. After the engine is started and the engine operates normally, the warning lights will turn off.

This ignition system incorporates three Fail-safe controls that are described below.

• Over-revolution control

Over 6,150 r/min, the ignition to either cylinder #1 or #4 is cut. At 6,175 r/min, the ignition to

both cylinders #1 and #4 is cut. Over 6,200 r/min, the ignition to both cylinders #1 and #4, and

either #2 or #3 is cut. Over 6,225 r/min, the ignition to cylinders #1, #2, #3, and #4 is cut.

• Overheating control

From 0–2,000 r/min (after starting the engine), this mode will not operate for 60 seconds.

From 2,000 r/min, it will not operate for 21 seconds.

When the cooling water temperature is 95 °C (203 °F) or above, this mode starts. The buzzer

will sound and the warning light will turn on. Ignition to cylinders #1 and #4 will cut off and the

engine speed will gradually lower to approximately 2,000 r/min.

This mode will stop when the cooling water temperature is 79 °C (174 °F) and the throttle is

fully closed. The buzzer will then stop and the warning light will turn off.

4

5

6

7

8

9

60C5D11

1-18

GEN

INFO

• Low oil pressure control

Three seconds after starting the engine this mode does not operate.

When the oil pressure switch turns on oil pressure is 150 kPa (1.5 kg/cm

this mode starts. The buzzer will sound and the warning light will turn on. Ignition to cylinders

#1 and #4 will cut off and the engine speed will gradually lower to approximately 2,000 r/min.

This mode will stop when the oil pressure is 150 kPa (1.5 kg/cm

throttle is fully closed. The buzzer will then stop and the warning light will turn off.

Throttle position sensor

If the throttle position sensor is faulty, the ignition timing will automatically be fixed at 10° BTDC.

Engine temperature sensor

If the engine temperature sensor is faulty, the ignition timing will automatically be fixed at 10° BTDC.

Dual engine control system

This control system is used when two outboard motors are installed, along with a dual switch panel.

If the overheating or low oil pressure protection control modes on one of the two outboard motors is

activated, the same protection control mode on the other engine will be activated as well. However,

on the other engine, the warning light will not light and the buzzer will not sound.

General information

2

, 21.3 psi) or below,

2

, 21.3 psi) or above and the

1-19

60C5D11

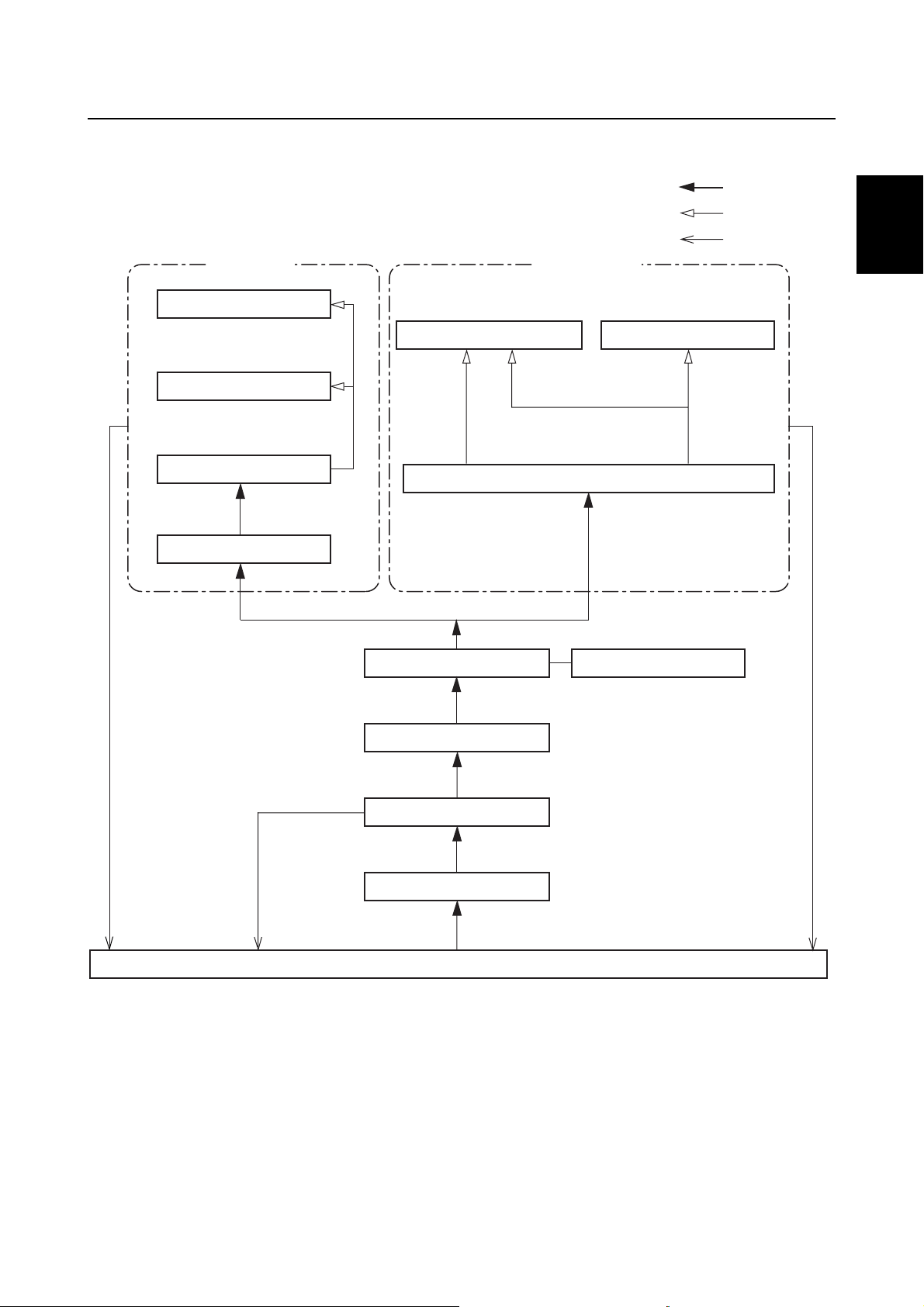

Lubrication system

Technical tips

Pressure fed

Splash

Crankcase

Sleeve

Piston

Crankshaft pin

Crankshaft journal

Cylinder head

Intake and exhaust valves

Camshaft journal

Main gallery

Return

Camshaft

Oil pressure switch

• Low oil pressure warning

1

2

3

4

5

Return route

• Oil pressure

regulation

Oil filter

Oil pump with relief valve

Oil strainer

Oil pan

• Oil sump

• Oil cooling

• Filtration of foreign objects

• Suction/pressure feeding

of oil

• Prevention of air suction

• Filtration of large foreign objects

S60C1450

Return route

6

7

8

9

60C5D11

1-20

GEN

INFO

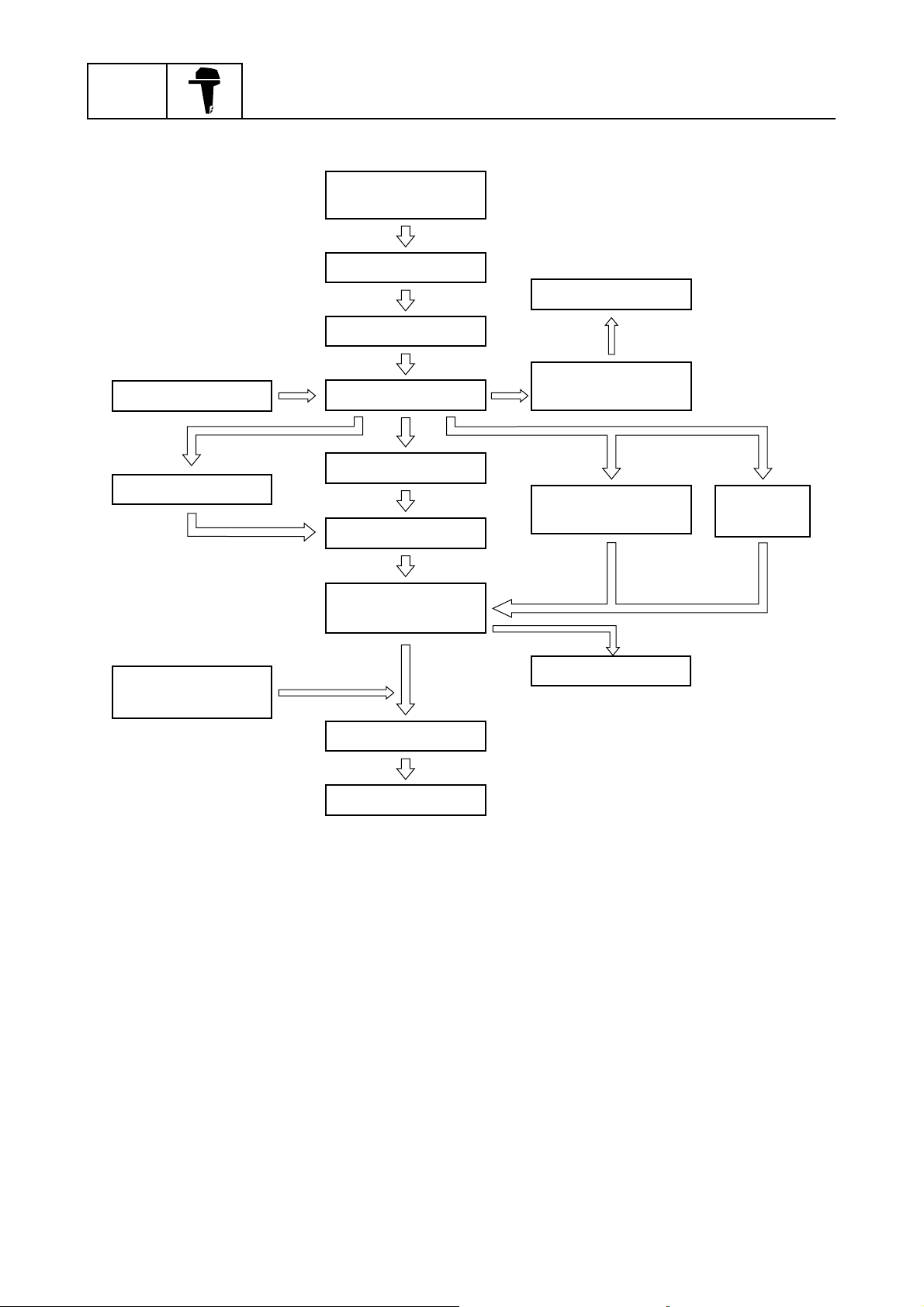

Cooling system

Flushing device

Cylinder head

General information

Cooling water

inlet

Water pump

Oil pan

Exhaust cover

Cylinder

Thermostat

Discharge

Pilot water

outlet

Pressure control

valve (PCV)

Exhaust

pipe

Trim tab

water inlet

Upper case

(water wall)

Propeller boss

Discharge

Discharge

S60C1460

1-21

60C5D11

Technical tips

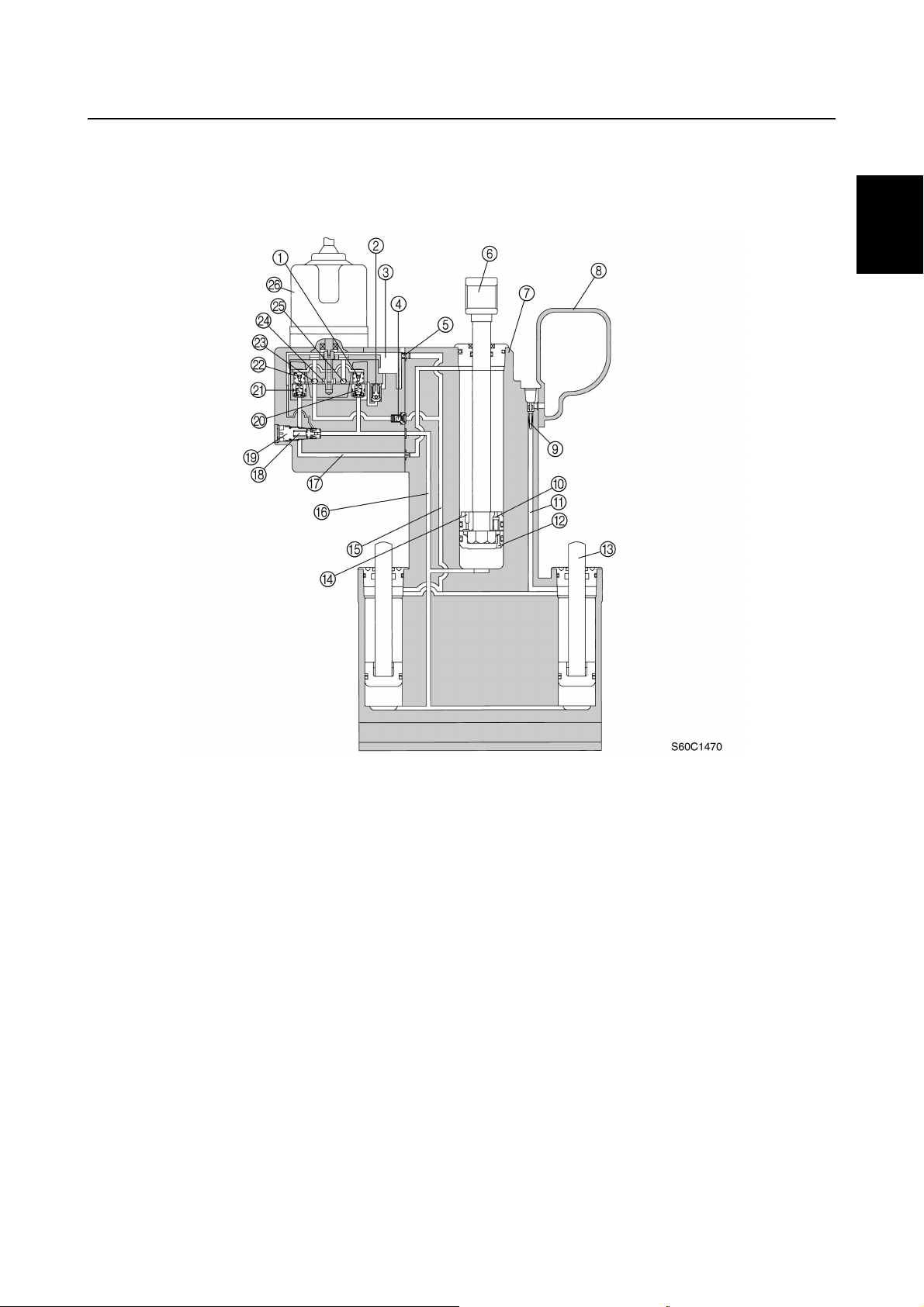

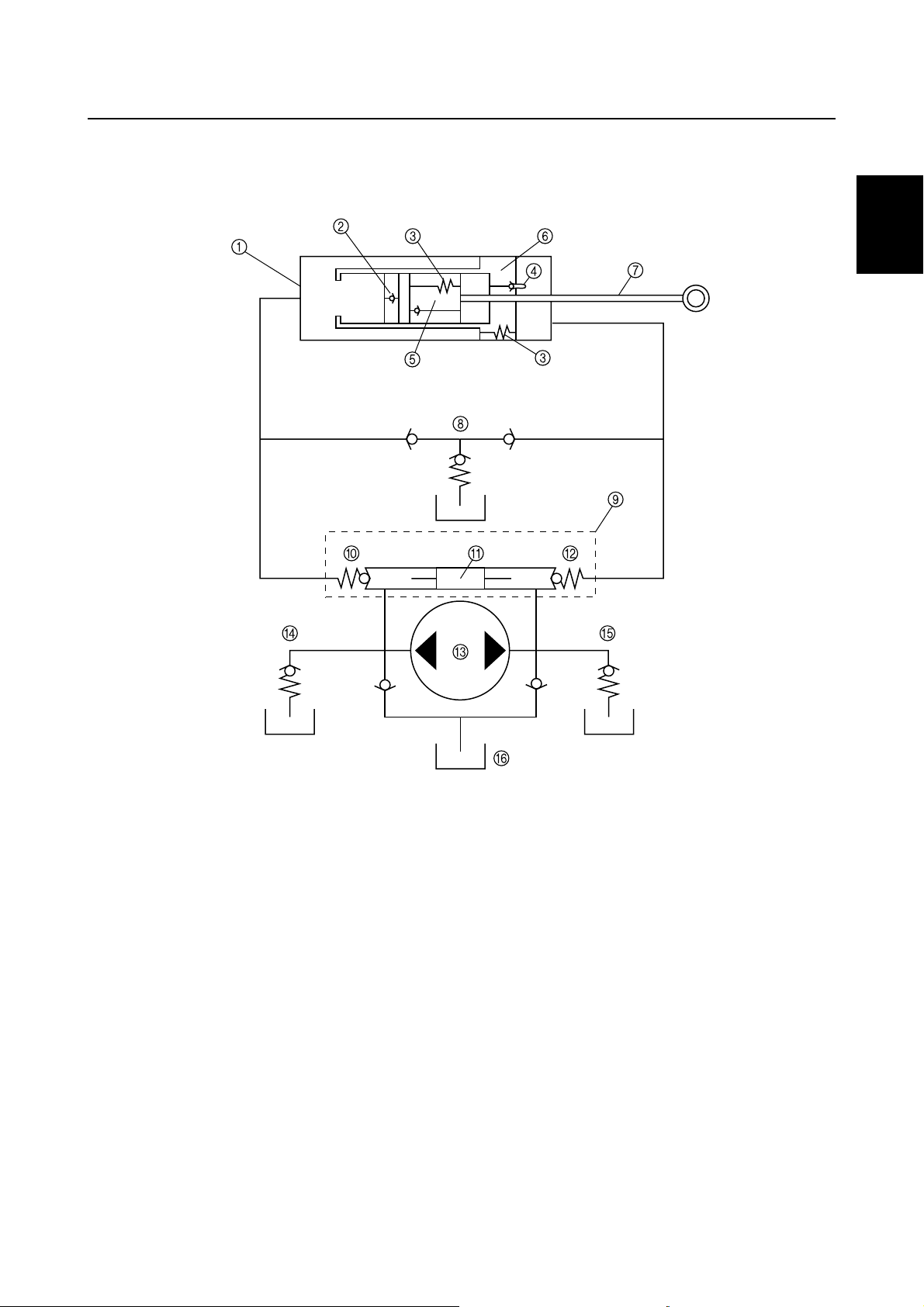

PTT (power trim and tilt) unit (F100B)

The circuit of the PTT unit and the location of its major components are shown in the illustration

below.

1

2

3

Lower chamber shuttle valve

1

Up-relief valve

2

Pump chamber

3

Down-check valve

4

Check valve

5

Tilt ram

6

Trim and tilt housing

7

Reservoir

8

Filter screen

9

Shock valve

0

Passage to reservoir

A

Free piston check valve

B

Trim ram

C

Shock return valve

D

Passage to upper chamber of trim cylinders

E

Passage to lower chambers of tilt cylinder and

F

trim cylinders

Passage to upper chamber of tilt cylinder

G

Thermal valve

H

Manual valve

I

Lower chamber check valve

J

Upper chamber check valve

K

Upper chamber shuttle valve

L

Up-intake valve

M

Pump

N

Down-intake valve

O

Motor

P

4

5

6

7

8

60C5D11

9

1-22

GEN

INFO

Component identification

Description Notes

Up-relief valve PTT fluid flows upward above 10.8 MPa (110 kg/cm

Down-check valve PTT fluid flows easily to the left while some fluid flows to

Lower chamber check valve PTT fluid flows easily downward.

Lower chamber shuttle valve PTT fluid flows easily upward, pressure on top causes

Upper chamber check valve PTT fluid flows easily downward.

Upper chamber shuttle valve PTT fluid flows easily upward, pressure on top causes

Manual valve Port side, clockwise to release

Free piston check valve PTT fluid flows easily downward.

Shock valve PTT fluid flows downward above 16.7 MPa (170 kg/cm

Shock return valve PTT fluid flows easily upward.

General information

1,500 psi).

the right through a small restriction.

valve to move down.

valve to move down.

2,420 psi).

2

,

2

,

Check valve PTT fluid flows easily to the right while a restriction allows

some flow to the left.

Thermal valve PTT fluid flows to the left above 18.6 MPa (190 kg/cm

2,700 psi).

Down-intake valve PTT fluid flows easily downward.

Up-intake valve PTT fluid flows easily downward.

2

,

1-23

60C5D11

Technical tips

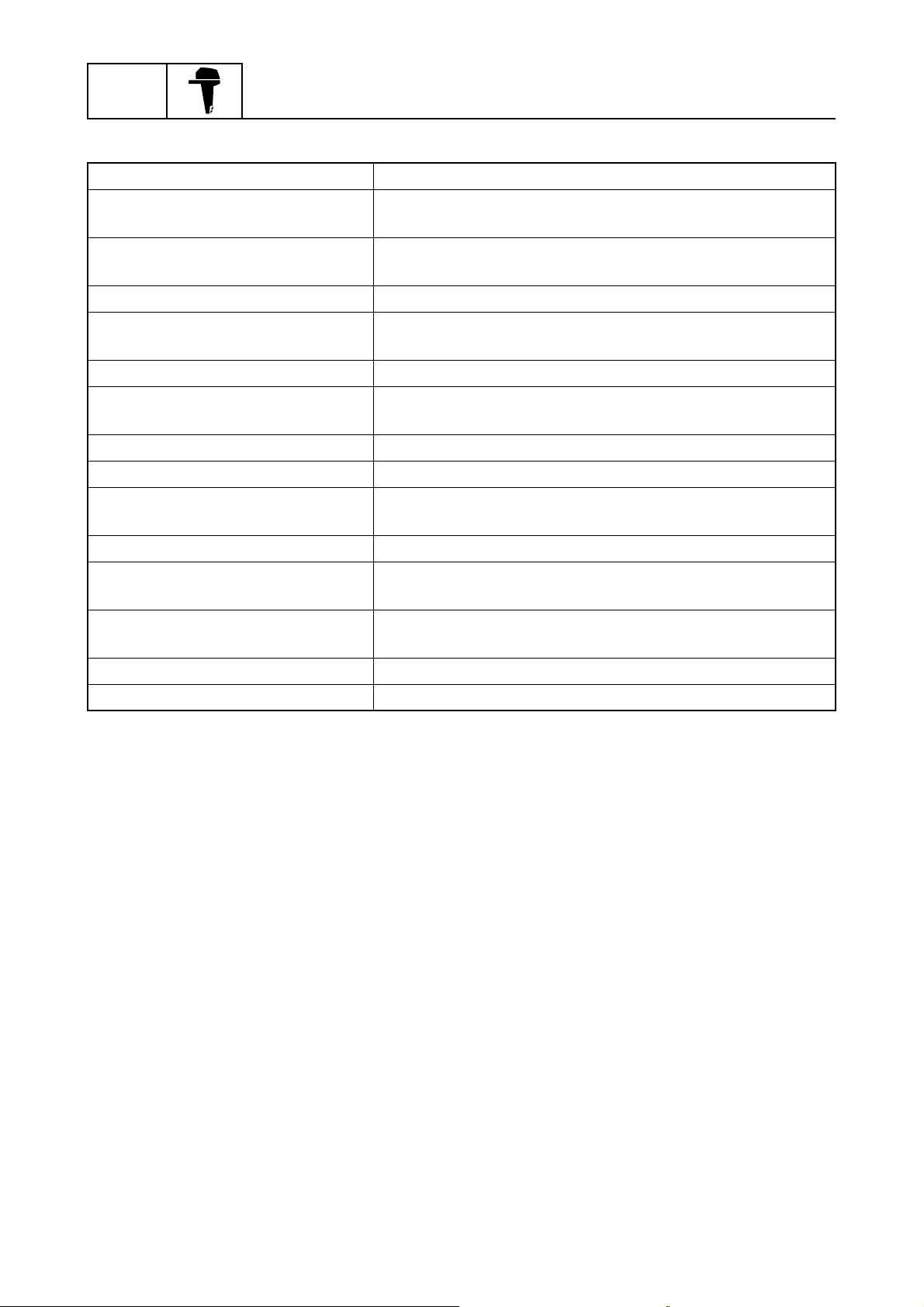

PTT (power trim and tilt) unit (F100C)

The circuit of the PTT unit and the location of its major components are shown in the illustration

below.

1

2

3

PTT cylinder

1

Free piston

2

Pressure-release valves

3

Check valve

4

Tilt piston

5

Trim piston

6

Ram

7

Manual valve

8

Main valve

9

Up-flow side

0

Shuttle piston

A

Down-flow side

B

Gear pump

C

Up-relief valve

D

Down-relief valve

E

Reservoir

F

4

5

S60C1480

6

7

8

60C5D11

9

1-24

GEN

INFO

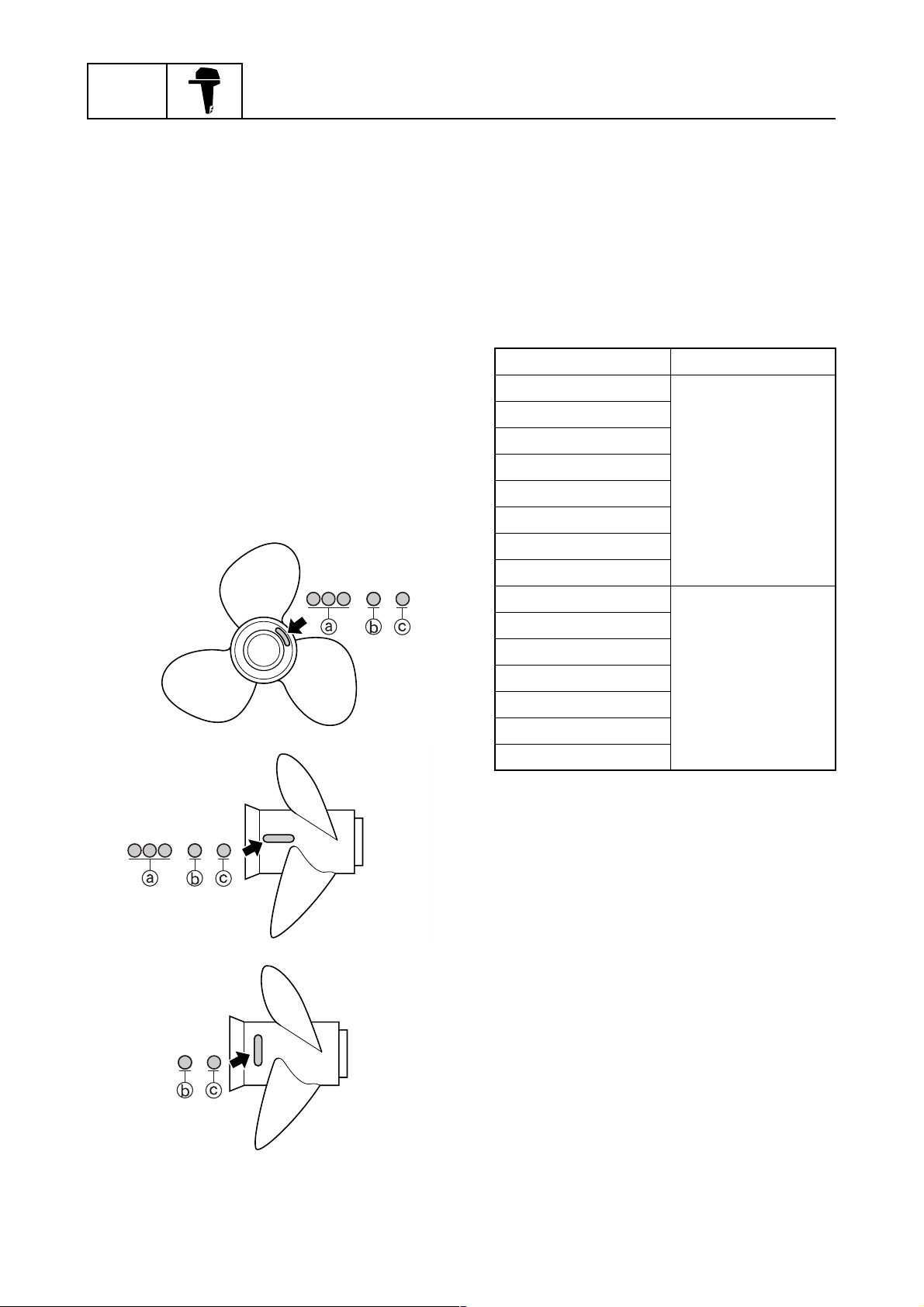

Propeller selection

The performance of a boat and outboard

motor will be critically affected by the size

and type of propeller you choose. Propellers

greatly affect boat speed, acceleration,

engine life, fuel economy, and even boating

and steering capabilities. An incorrect choice

could adversely affect performance and

could also seriously damage the motor.

Use the following information as a guide for

selecting a propeller that meets the operating

conditions of the boat and the outboard

motor.

Propeller size

The size of the propeller is indicated on the

propeller blade or outside of the propeller

boss.

General information

Propeller diameter (in inches)

1

a

Propeller pitch (in inches)

b

Propeller type (propeller mark)

c

Selection

When the engine speed is at the full throttle

operating range (5,000–6,000 r/min), the

ideal propeller for the boat is one that provides maximum performance in relation to

boat speed and fuel consumption.

Propeller size (in) Material

12 5/8 × 21 - K

13 × 19 - K

13 × 23 - K

13 × 25 - K

13 1/4 × 17 - K

13 1/2 × 15 - K

13 5/8 × 13 - K

Aluminum

× -

× -

S60C1110

S60C1120

14 × 11 - K

13 × 17 - K

13 × 19 - K

13 × 21 - K

13 × 23 - K

Stainless

13 × 25 - K

13 1/2 × 14 - K

13 1/2 × 16 - K

Predelivery checks

To make the delivery process smooth and

efficient, the predelivery checks should be

completed as explained below.

Checking the fuel system

1. Check that the fuel hoses are securely

connected and that the fuel tank is full

with fuel.

1

1-25

-

S60C1125

60C5D11

Loading...

Loading...