Yale ERP15-20VT Repair Manual

ERP15-20VT (G807)

SERVICE MANUAL CONTENTS

PART

SECTION

FRAME............................................................................................................................ 524295629 0100 YRM 1329 09/14

OPERATOR'S CAB........................................................................................................ 550025937 0100 YRM 1446 09/14

AC MOTOR REPAIR...................................................................................................... 524327049 0620 YRM 1385 09/14

TRANSAXLE................................................................................................................... 524295630 1300 YRM 1330 09/12

STEERING SYSTEM...................................................................................................... 524295631 1600 YRM 1331 09/14

BRAKE SYSTEM............................................................................................................ 524295632 1800 YRM 1332 12/10

HYDRAULIC SYSTEM.................................................................................................... 524295633 1900 YRM 1333 09/14

HYDRAULIC CLEANLINESS PROCEDURES............................................................... 550073240 1900 YRM 1620 12/14

MAIN CONTROL VALVES............................................................................................. 524319495 2000 YRM 1334 09/14

CYLINDER REPAIR (MAST S/N A270-72, A551, A555, A559, A626, A627, A751-52,

B551, B555, B586-91, B749-54, C661-63, C665, D507-09, D515, D562-64, E509,

E564).......................................................................................................................... 524319496 2100 YRM 1382 03/14

WIRE HARNESS REPAIR.............................................................................................. 524223769 2200 YRM 1128 12/14

USER INTERFACE SUPERVISOR................................................................................. 524319497 2200 YRM 1335 09/14

USER INTERFACE SERVICE TECHNICIAN................................................................. 524319498 2200 YRM 1336 09/14

ELECTRICAL SYSTEM.................................................................................................. 524320282 2200 YRM 1337 09/14

INDUSTRIAL BATTERY................................................................................................. 524158040 2240 YRM 0001 09/14

MAST REPAIR (S/N A270, A271, A272)........................................................................ 524327054 4000 YRM 1386 02/14

MAST REPAIR (S/N C661, C662, C663, C665)............................................................. 524333799 4000 YRM 1405 05/14

METRIC AND INCH (SAE) FASTENERS....................................................................... 524150797 8000 YRM 0231 10/13

PERIODIC MAINTENANCE............................................................................................ 524320290 8000 YRM 1339 09/14

CAPACITIES AND SPECIFICATIONS........................................................................... 524306565 8000 YRM 1340 09/14

DIAGRAMS..................................................................................................................... 524319503 8000 YRM 1341 09/14

DIAGNOSTIC TROUBLESHOOTING MANUAL............................................................ 524319504 9000 YRM 1377 10/14

NUMBER

YRM

NUMBER

REV

DATE

Service information for Cummins diesel engines can be ordered through the Hyster Literature Distribution Center.

PART NO. 524320408 (12/14)

SAFETY PRECAUTIONS

MAINTENANCE AND REPAIR

• When lifting parts or assemblies, make sure all slings, chains, or cables are correctly fastened, and

that the load being lifted is balanced. Make sure the crane, cables, and chains have the capacity to

support the weight of the load.

• Do not lift heavy parts by hand, use a lifting mechanism.

• Wear safety glasses.

• DISCONNECT THE BATTERY CONNECTOR before doing any maintenance or repair on electric lift

trucks. Disconnect the battery ground cable on internal combustion lift trucks.

• Always use correct blocks to prevent the unit from rolling or falling. See HOW TO PUT THE LIFT

TRUCK ON BLOCKS in the Operating Manual or the Periodic Maintenance section.

• Keep the unit clean and the working area clean and orderly.

• Use the correct tools for the job.

• Keep the tools clean and in good condition.

• Always use YALE APPROVED parts when making repairs. Replacement parts must meet or exceed

the specifications of the original equipment manufacturer.

• Make sure all nuts, bolts, snap rings, and other fastening devices are removed before using force to

remove parts.

• Always fasten a DO NOT OPERATE tag to the controls of the unit when making repairs, or if the unit

needs repairs.

• Be sure to follow the WARNING and CAUTION notes in the instructions.

• Gasoline, Liquid Petroleum Gas (LPG), Compressed Natural Gas (CNG), and Diesel fuel are

flammable. Be sure to follow the necessary safety precautions when handling these fuels and when

working on these fuel systems.

• Batteries generate flammable gas when they are being charged. Keep fire and sparks away from the

area. Make sure the area is well ventilated.

NOTE: The following symbols and words indicate safety information in this manual:

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could result in minor

or moderate injury and property damage.

On the lift truck, the WARNING symbol and word are on orange background.

The CAUTION symbol and word are on yellow background.

Transaxle Table of Contents

TABLE OF CONTENTS

General................................................................................................................................................................ 1

Discharging the Capacitors ............................................................................................................................. 2

Special Tools................................................................................................................................................... 2

Transaxle Assembly............................................................................................................................................. 3

Remove Transaxle From Frame...................................................................................................................... 3

Remove the Parking Brake and Traction Motor............................................................................................... 4

Install Parking Brake and Traction Motor......................................................................................................... 4

Install Transaxle to Frame ............................................................................................................................... 5

Maintenance and Repair ..................................................................................................................................... 6

Speed Sensor Repair...................................................................................................................................... 6

Trunnion Cap Repair ....................................................................................................................................... 6

Fluid Level Check............................................................................................................................................ 8

Fluid Change................................................................................................................................................... 8

Breather Repair............................................................................................................................................... 9

Stud Repair ..................................................................................................................................................... 10

Brake Cylinder Repair ..................................................................................................................................... 11

Input Seal Repair ............................................................................................................................................ 13

Cover to Housing Seal .................................................................................................................................... 13

During the Transaxle Warranty Period ........................................................................................................ 13

After the Transaxle Warranty Period ........................................................................................................... 14

Removing the Cover............................................................................................................................... 14

Installing the Cover................................................................................................................................. 15

Wet Brakes...................................................................................................................................................... 16

This section is for the following models:

ERP15-20VT (ERP030-040VT) [G807];

ERP16-20VF (ERP30-40VF) [A955]

©2012 Yale Materials Handling Corp. i

1300 YRM 1330 General

General

CAUTION

DO NOT remove the cover from the transaxle housing during the warranty period. Removing the cover

from the housing will void the transaxle warranty.

The transaxle warranty period may vary from truck

hours or other warranties. Contact Yale Company

Contact Management if you have questions about

warranty status.

CAUTION

Use only transmission fluid from approved vendors. Using fluid from unapproved vendors will

void the warranty. Contact Yale Company Contact

Management if you have questions about warranty

status.

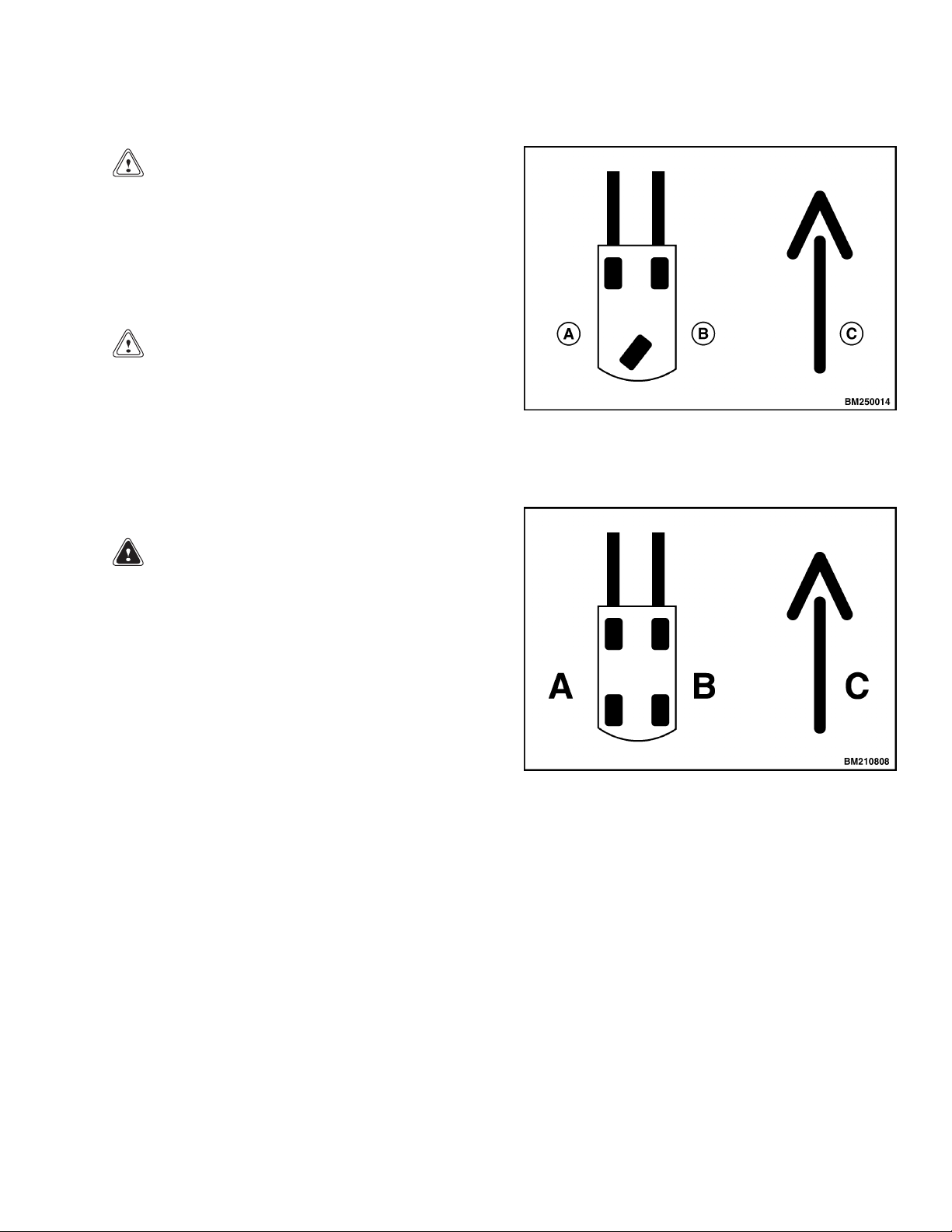

A. LEFT SIDE

B. RIGHT SIDE

C. FORWARD

TRAVEL

This section contains the removal, repair, inspection,

and installation instructions for the transaxle assembliesusedonthesemodels.

WARNING

DO NOT make repairs or adjustments unless you

have been properly trained and authorized to do so.

Improper repairs and adjustments can create dangerous operating conditions. DO NOT operate a lift

truck that needs repairs. Report the need for repairs

to your supervisor immediately. If repair is necessary, attach a DO NOT OPERATE tag on the steering

wheel and disconnect the battery.

Throughout this section, forward will refer to travel in

the direction of the forks and left and right will be determined by sitting in the seat facing forward. See Figure 1

or Figure 2.

Figure 1. Truck Orientation (Three-Wheel Trucks)

A. LEFT SIDE

B. RIGHT SIDE

Figure 2. Truck Orientation (Four-Wheel Trucks)

C. FORWARD

TRAVEL

1

General 1300 YRM 1330

DISCHARGING THE CAPACITORS

WARNING

DO NOT make repairs or adjustments unless you

have been properly trained and authorized to do so.

Improper repairs and adjustments can create dangerous operating conditions. DO NOT operate a lift

truck that needs repairs. Report the need for repairs

to your supervisor immediately. If repair is necessary, attach a DO NOT OPERATE tag on the steering

wheel and disconnect the battery.

Disconnect the battery and allow the capacitors to

discharge before opening any compartment covers or inspecting or repairing the electrical system.

DO NOT place tools on top of the battery. If a tool

causes a short circuit, the high current flow from

the battery can cause personal injury or property

damage.

Some checks and adjustments are performed with

the battery connected. DO NOT connect the battery

until the procedure instructs you to do so. Never

wear any metallic items on your fingers, arms, or

neck. Metal items can accidentally make an electrical connection and cause injury.

4. Blockdrivewheelstopreventlifttruckfrommoving.

5. Make sure Emergency Disconnect Switch HAS

NOT been activated. If Emergency Disconnect

Switch is activated, rotate switch to the right until it

pops up.

6. Press horn button. Wait 30 seconds to be sure

capacitors are fully discharged.

SPECIAL TOOLS

Special tools are necessary to properly perform some

repairs. These tools are available from your Yale

dealer. Warranty will not cover damage resulting from

work done using improper tools. Refer to Table 1.

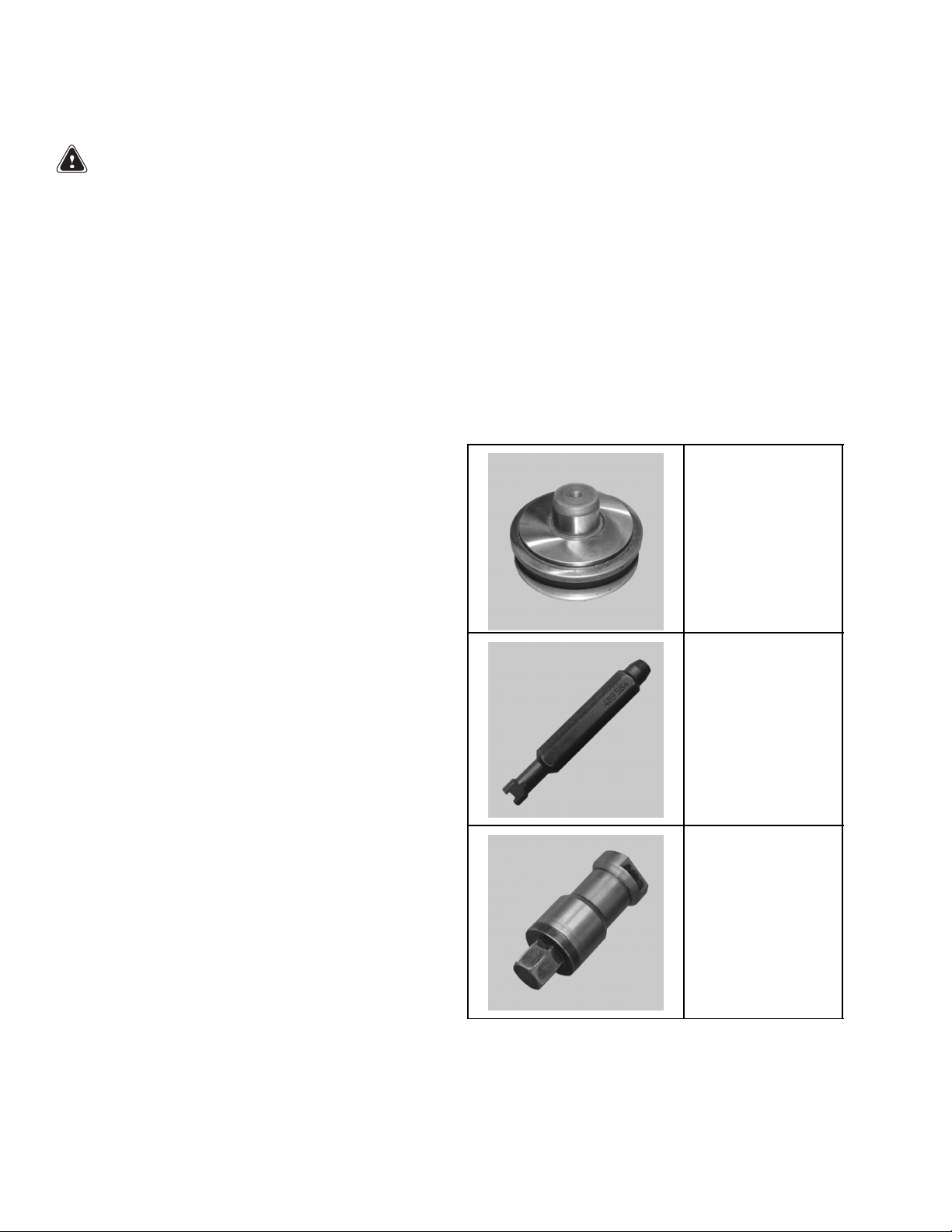

Table 1. Yale Special Tools

Input Seal Driver

Ya l e P a r t N o .

582000161

Before performing any tests or adjustments, block

the lift truck to prevent unexpected movement.

The capacitor in the transistor controller(s) can

hold an electrical charge for about 10 seconds

after the battery is disconnected. To prevent an

electrical shock and personal injury, discharge

the capacitor(s) before inspecting or repairing any

component in the drive unit compartment. Make

certain that the battery has been disconnected.

DO NOT short across the motor controller terminals

with a screwdriver or jumper wire.

Make certain the Emergency Disconnect Switch

has not been activated. This will isolate the controller and prevent the capacitors from discharging

properly. The proper way to disconnect the battery

is by separating the battery connectors.

1. Ensure capacitors are discharged by performing

Step 2 through Step 6 below.

2. Tu r n k ey o r k e yl es s sw it ch t o OFF position.

3. Disconnect battery by separating connectors.

Breather Set Tool

Ya l e P a r t N o .

582000187

Wheel Stud Tool

Ya l e P a r t N o .

582000162

2

1300 YRM 1330 Transaxle Assembly

Transaxle Assembly

REMOVE TRANSAXLE FROM FRAME

WARNING

The lift truck

of maintenan

of the batter

will cause la

Position add

lift truck is

over.

1. Remove mast

See Mast Rep

Masts 4000 Y

els

• ERP15-20VT

• ERP16-20VF

See Mast Rep

Masts 4000 Y

lift truck m

• ERP15-20VT

• ERP16-20VF

2. Tu r n k ey s wi

tery.

3. Position li

suspended o

must be put on blocks for some types

ce and transaxle repair. The removal

y, mast, transaxle, or the counterweight

rge changes in the center of gravity.

itional blocks under theframe when the

on blocks, so the lift truck cannot tip

assembly.

air, 2- and 3-Stage High Visibility

RM 1386 for European lift truck mod-

(G807)

(A955)

air, 2-, 3-, And 4-Stage Heavy Duty

RM 1405 for European and American

odels

(ERP030-040VT) (G807)

(ERP30-40VF) (A955)

tch to OFF position and disconnect bat-

ft truck frame on blocks so drive tires are

ff the floor.

8. Tag and disconnect power cables from traction mo-

tor studs.

9. Disconnect traction motor temperature sensor at

traction motor.

10. Disconnect service brake line from port on

transaxle. Cap brake line andplug port on transaxle

to reduce the possibility of contamination entering

brake system.

11. Loosen, but do not remove, five mounting cap-

screws and nuts that hold transaxle assembly on

lift truck.

WARNING

The transaxle and traction motor assemblies are

heavy. Be sure that all lifting devices are suitable

and of adequate capacity to lift the transaxle and

traction motor.

12. Position a floor jack under transaxle assembly.

Make sure assembly is properly balanced on floor

jack so it will not fall once mounting capscrews

have been removed.

CAUTION

Check that cables, hoses, and wires do not interfere

with the removal of the transaxle assembly.

See Period

truck mode

• ERP15-20V

See Period

truck mode

• ERP16-20V

4. Remove driv

assembly.

5. Disconnec

main wirin

6. Disconnec

wiring har

7. Disconnec

brakes.

t transaxle speed sensor connector from

g harness.

t parking brake connector from main

ness.

t manual override cable from parking

ic Maintenance 8000 YRM 1339 for lift

ls

T (ERP030-040VT) (G807)

ic Maintenance 8000 YRM 1373 for lift

ls

F (ERP30-40VF) (A955)

e tire lug nuts and drive tire and wheel

13. Remove five capscrews and washers holding

transaxle on lift truck frame. Carefully lower

transaxle assembly from lift truck frame using floor

jack.

WARNING

The transaxle and traction motor assemblies are

heavy. Be sure that all lifting devices are suitable

and of adequate capacity to lift the transaxle and

traction motor.

14. Transfer transaxle assembly from floor jack to a

clean workbench using an appropriate sling and

overhead lifting device.

3

Transaxle Assembly 1300 YRM 1330

REMOVE THE PARKING BRAKE AND

TRACTION MOTOR

WARNING

Cleaning solvents can be flammable and toxic and

can cause skin irritation. When using cleaning

solvents, always follow the solvent manufacturer’s

recommended safety procedures.

WARNING

The traction motor is heavy. Be sure that all lifting

devices are suitable and of adequate capacity to lift

the traction motor.

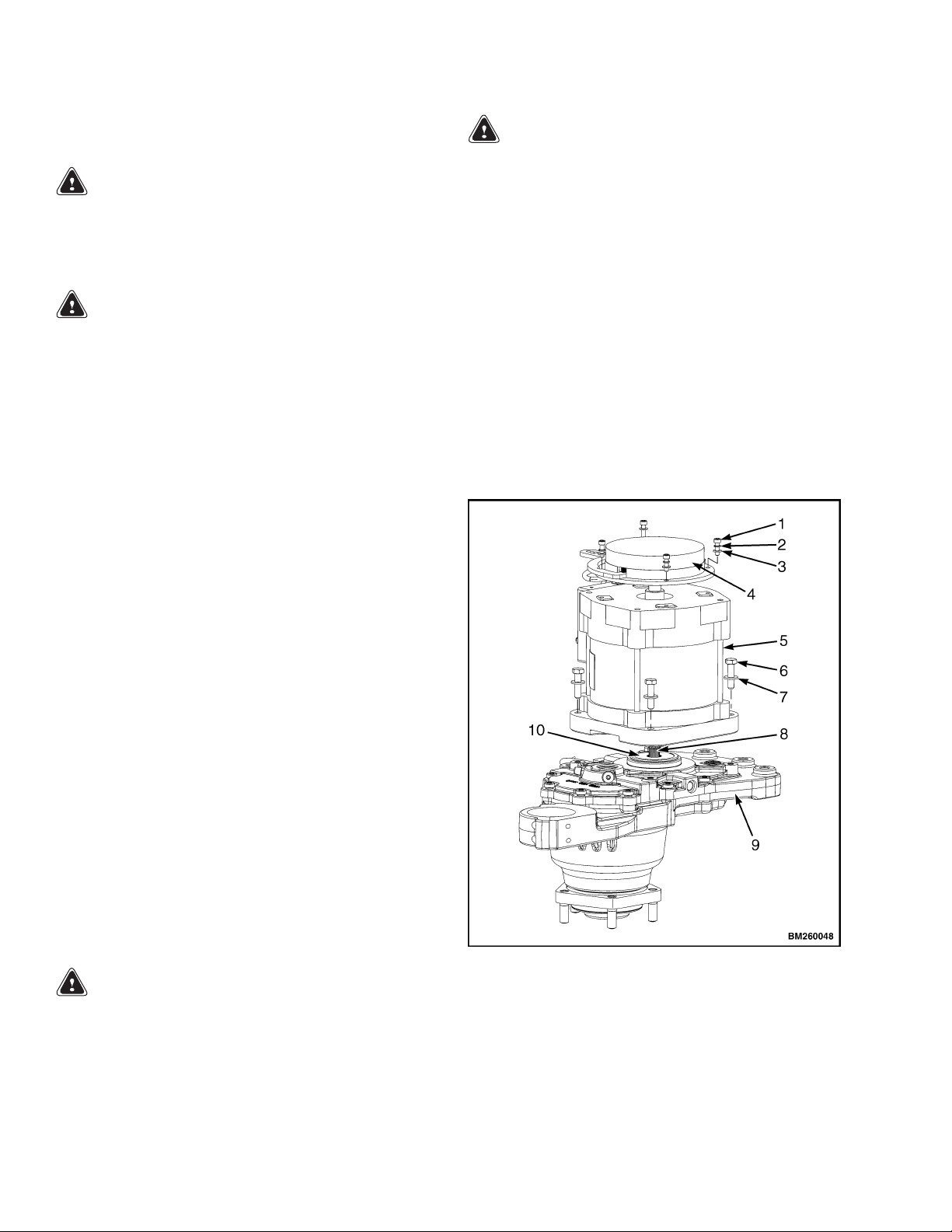

1. Position transaxle on blocks with studs down. Se-

curely support in this position.

2. Remove parking brake assembly from traction mo-

tor:

a. Remove four capscrews, lockwashers, and

washers holding brake assembly on traction

motor. See Figure 3.

WARNING

The traction mo

devices are sui

the traction m

1. Position tran

curely suppor

2. Install tract

a. Install an eye

attach an over

capacity to e

b. Lightly lubr

shaft with mu

seats proper

necessary to

it is lubrica

See Figure 4

otor.

ion motor on transaxle:

torisheavy.Besurethatalllifting

table and of adequate capacity to lift

saxle on blocks with studs down. Se-

t in this position.

bolt to traction motor shaft and

head lifting device of adequate

yebolt.

icate inside lip of transaxle input

ltipurpose grease to ensure seal

ly on traction motor shaft. It is not

lubricate traction motor shaft as

ted internally within the transaxle.

.

b. Pry evenly on opposite sides to remove brake

assembly from brake hub. Remove brake assembly by hand.

c. Remove snap ring holding brake hub on trac-

tion motor shaft. Slide hub from shaft. Remove

snap ring and woodruff key from beneath hub.

3. Remove traction motor from transaxle:

a. Install an eyebolt to traction motor shaft and

attach an overhead lifting device of adequate

capacity to eyebolt.

b. Remove four capscrews and washers mounting

traction motor to transaxle.

c. Lift traction motor from transaxle using over-

head lifting device.

INSTALL PARKING BRAKE AND

TRACTION MOTOR

WARNING

Cleaning solvents can be flammable and toxic and

can cause skin irritation. When using cleaning

solvents, always follow the solvent manufacturer’s

recommended safety procedures.

1. CAPSCREW

2. LOCKW

3. WASHER

4. PARKING BRAKE

ASSEMB

5. TRACTION MOTOR

ASHER

LY

6. CAPSCREW

7. WASHE

8. MOTOR SHAFT

9. TRANSAXLE

10. INPUT S

Figure 3. Traction Motor and Parking Brake

R

EAL

4

1300 YRM 1330 Transaxle Assembly

c. Lift traction motor and position it on transaxle

using overhead lifting device. Guide traction

motor shaft into transaxle through input seal.

Align motor with transaxle.

d. Install four capscrews and washers mounting

traction motor on transaxle. Tighten capscrews

to 48 N•m (35 lbf in).

e. Remove eyebolt from traction motor shaft.

3. Install parking brake assembly to traction motor:

a. Install lower snap ring and woodruff key on

traction motor shaft. Align groove in hub with

woodruff key and slide hub onto shaft. Install

upper snap ring holding brake hub onto traction motor shaft.

b. Position brake assembly onto brake hub. Align

splines and seat brake on traction motor end

head.

c. Install four capscrews, lockwashers, and wash-

ers to secure brake assembly. Tighten capscrews to 8 N•m (71 lbf in).

INSTALL TRANSAXLE TO FRAME

1. Check that dowels are installed in transaxle housing

and are in good condition. Replace as necessary.

WARNING

The transaxle and traction motor assembly are

heavy. Be sure that all lifting devices are suitable

and of adequate capacity to lift the transaxle and

traction motor.

2. Move transaxle assembly onto a floor jack using

an appropriate sling and lifting device. Make sure

assembly is balanced and properly supported so it

will not fall during installation.

3. Carefully position transaxle on frame using floor

jack. Align transaxle mounting dowels with their

mounting holes in frame.

4. Apply Loctite® 271 to five socket head capscrews

and washers. Install capscrews with washers

through transaxle and into mounting holes in

frame. Tighten capscrews to 220 N•m (162 lbf ft).

1. CAPSCREW

2. LOCKWASHER

3. WASHER

4. PARKING BRAKE

ASSEMBLY

5. TRACTION MOTOR

6. CAPSCREW

7. WASHER

8. MOTOR SHAFT

9. TRANSAXLE

10. INPUT SEAL

Figure 4. Traction Motor and Parking Brake

5. Remove cap and plug from service brake line and

service brake port. Install service brake line to service brake port. Tighten to 12 to 16 N•m (108 to

192 lbf in).

6. Connect power cables to traction motor studs as

tagged during removal. Tighten to 8 N•m (71 lbf in).

7. Connect traction motor temperature sensor con-

nectors to main wiring harness.

8. Connect parking brake connector to main wiring

harness.

9. Connect manual override cable to parking brakes.

10. Connect transaxle speed sensor connector to main

wiring harness.

5

Maintenance and Repair 1300 YRM 1330

CAUTION

Make sure the lift truck is blocked at the same

height as with the drive tire installed to ensure the

proper fluid level reading.

11. Bleed the service brakes. Refer Brake System

1800 YRM 1332 for procedures.

12. Check fluid level in transaxle. Fill as necessary.

See Fluid Level Check.

13. Install drive tire and wheel assembly on wheel hub.

Install lug nuts and tighten to 170 N•m (125 lbf ft).

14. Connect battery connector, turn key switch to ON

position, and test lift truck for proper operation.

15. Lower lift truck from the blocks.

See Periodic Maintenance 8000 YRM 1339 for lift

truck models

• ERP15-20VT (ERP030-040VT) (G807)

Maintenance and Repair

See Periodic Maintenance 8000 YRM 1373 for lift

truck models

• ERP16-20VF (ERP30-40VF) (A955)

16. Install mast on lift truck.

See Mast Repair, 2- and 3-Stage High Visibility

Masts 4000 YRM 1386 for European lift truck mod-

els

• ERP15-20VT (G807)

• ERP16-20VF (A955)

See Mast Repair, 2-, 3-, And 4-Stage Heavy Duty

Masts 4000 YRM 1405 for European and American

lift truck models

• ERP15-20VT (ERP030-040VT) (G807)

• ERP16-20VF (ERP30-40VF) (A955)

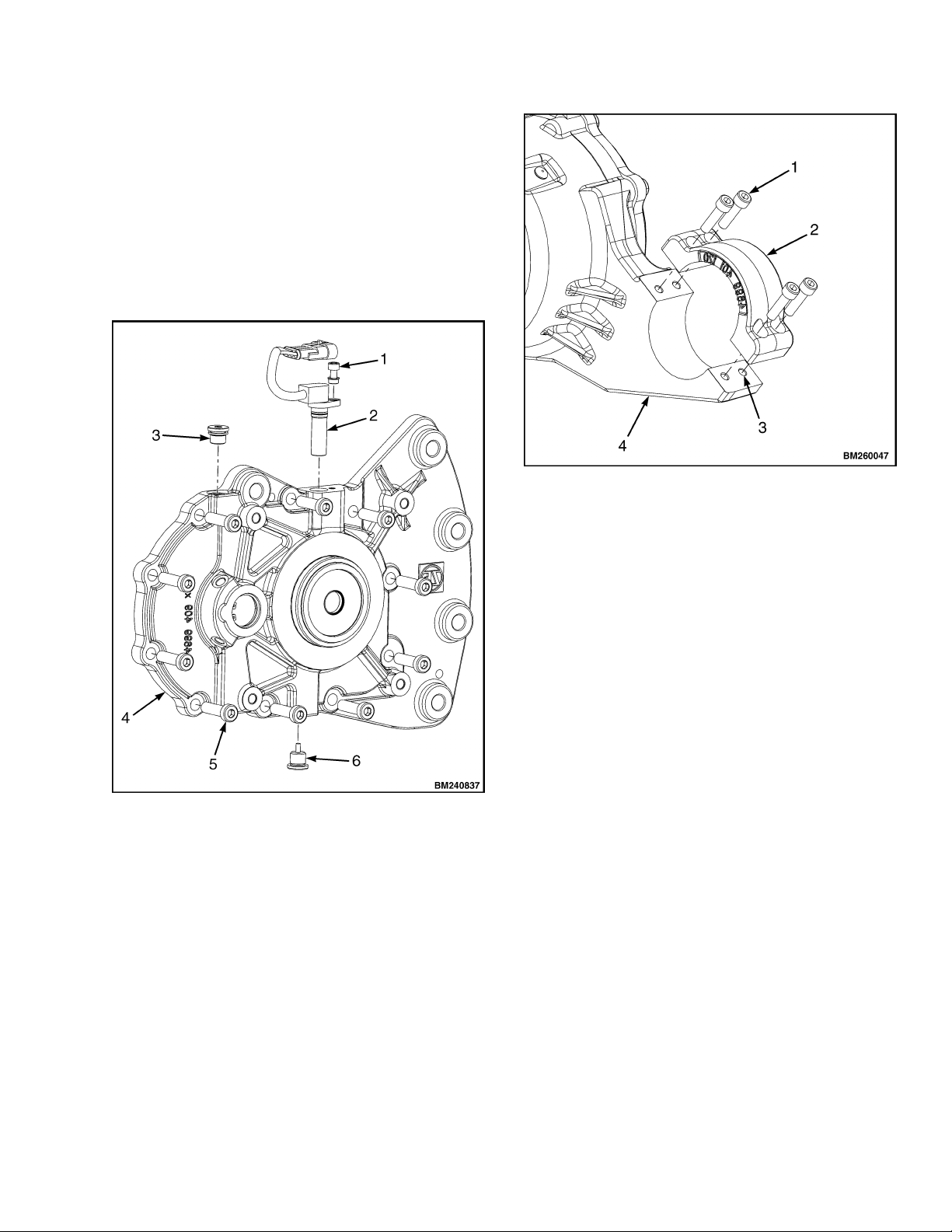

SPEED SENSOR REPAIR

The speed sensor monitors the speed of the transaxle

and relays the information to the controller. The speed

sensor can be replaced with the transaxle installed to

the lift truck.

1. Park lift truck on a level surface. Turn key switch to

OFF position and unplug battery connector.

2. Discharge capacitors. See section Discharging the

Capacitors.

3. Remove floor mat and floor plates from operator

compartment to access top of transaxle(s).

4. Disconnect sensor wiring harness from main wiring

harness.

CAUTION

Use a brush to clean around the sensor before removing to avoid contaminating the transaxle.

5. Remove capscrew holding sensor to transaxle us-

ing a 5mm Allen wrench. See Figure 5.

6. Pull sensor out of transaxle.

7. Insert new sensor into transaxle.

8. Align screw holes and install capscrew. Tighten

capscrew to 9.5 N•m (84.0 lbf in).

9. Connect sensor wiring harness to main wiring har-

ness.

10. Replace floor plates and floor mat in operator com-

partment.

11. Connect battery, turn key to ON position and test lift

truck for proper operation.

TRUNNION CAP REPAIR

To repair the trunnion cap:

1. Remove load from forks and park lift truck on a level

surface. Adjust mast to a vertical position, then turn

key switch to OFF position and separate battery

connectors.

2. Remove four capscrews holding trunnion cap on

transaxle housing. Remove trunnion cap. See Figure 6.

3. Wipe away any dirt or grease near mounting holes.

Clean holes with a proper sized tap and tap wrench

as necessary.

6

1300 YRM 1330 Maintenance and Repair

4. Position new cap over mast pin and onto transaxle.

5. Apply Loctite® 242 to threads and install four cap-

screws and tighten alternately in small increments.

Tighten capscrews to 24 N•m (216 lbf in).

6. Grease fitting in mast stub shaft to lubricate trun-

nion cap.

7. Connect battery, turn key to ON position and test lift

truck for proper operation.

1. CAPSCREWS

2. TRUNNION CAP

3. THREADED MOUNTING HOLES

4. TRANSAXLE HOUSING

1. CAPSCR

2. SPEED SENSOR

3. FILL PLUG

4. TRANSAX

5. COVER CAPSCREWS

6. DRAIN PLUG

EW

LE COVER

Figure 5. Speed Sensor

Figure 6. Trunnion Cap

7

Loading...

Loading...