Page 1

INSTRUCTION MANUAL

AC8652

REVISION C

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

2000 Series

Frame Mounted Pumps

Page 2

TABLE OF CONTENTS

DESCRIPTION......................................................3

PUMP APPLICATION...........................................3

SAFETY INSTRUCTIONS ....................................3

ELECTRICAL SAFETY: ................................3

THERMAL SAFETY: .....................................3

MECHANICAL SAFETY:...............................3

PUMP LOCATION ................................................5

INSTALLATION ....................................................6

LEVELING .....................................................6

GROUTING ...................................................7

SEE ANSI/OSHA COUPLER GUARD

REMOVAL/INSTALLATION ..................7

ALIGNMENT PROCEDURE .........................7

ANSI/OSHA COUPLER GUARD

REMOVAL/INSTALLATION ..................7

ROTATION ..................................................12

PIPING ................................................................12

PRIMING AND STARTING.................................13

LUBRICATION ............................................13

GENERAL INSTRUCTIONS .......................13

SERVICE INSTRUCTIONS ................................13

IMPELLER REMOVAL ................................14

DISMANTLING THE STUFFING BOX........14

FRAME DISASSEMBLY .............................14

CASING WEARING RING REMOVAL

(OPTIONAL) ........................................14

ASSEMBLY PROCEDURES..............................15

FRAME ASSEMBLY....................................15

STUFFING BOX ASSEMBLY .....................15

IMPELLER INSTALLATION...............................16

FINAL ASSEMBLY.............................................16

REPAIR PARTS LIST.........................................19

ORDERING PARTS............................................20

DEALER SERVICING.........................................20

NOTE

The information contained in this book is intended

to assist operating personnel by providing

information on the characteristics of the purchased

equipment.

It does not relieve the user of their responsibility of

using accepted engineering practices in the

installation, operation, and maintenance of this

equipment.

Any further questions, contact AC Fire Pump,

(847) 966-3700.

2

Page 3

DESCRIPTION

The Series 2000 Frame Mounted Centrifugal

Pump is an end suction centerline discharge

pump. The Series 2000 Pump’s rear pull out

construction makes servicing simpler and faster.

The hydraulically balanced impellers extend

bearing life and assure smoother, quieter

operation.

THERMAL SAFETY:

WARNING: Extreme Temperature

Hazard

If pump, motor, or piping is operating at extremely

high or low temperature, guarding or insulation is

required. Failure to follow these instructions could

result in serious personal injury or death, and

property damage.

PUMP APPLICATION

The Series 2000 Pump’s available constructions

and sizes make it ideal for applications in general

industry, water supply, water transfer, condenser,

and chilled and hot water circulation.

SAFETY INSTRUCTIONS

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual

and on the pump safety instruction decals to draw

attention to safety related instructions. When used

the safety alert symbol means ATTENTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THE INSTRUCTIONS

MAY RESULT IN A SAFETY HAZARD.

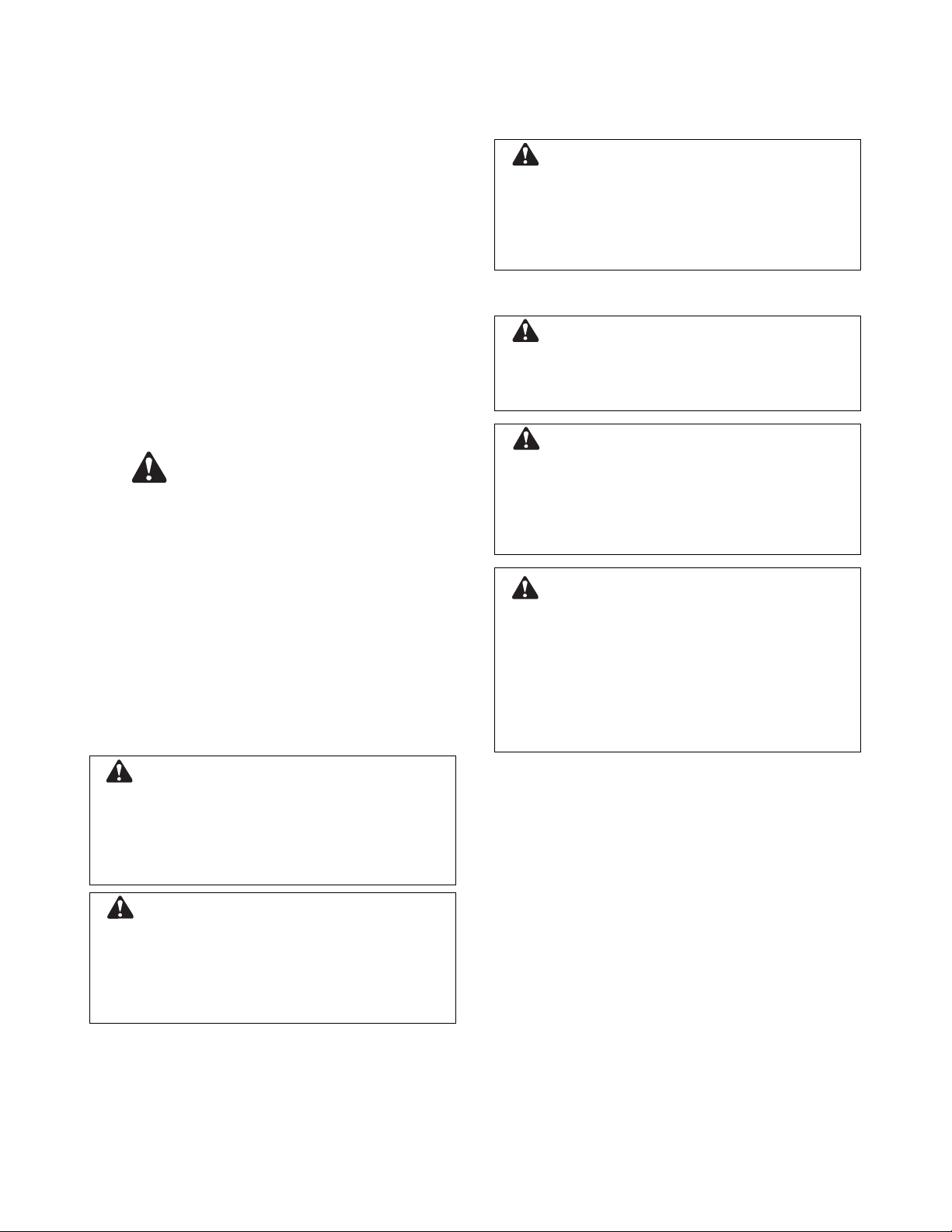

Your Series 2000 pump should have the following

safety instruction decals located approximately as

shown. If the decals are missing or are illegible

contact your local AC Fire Pump Systems

representative for a replacement. (Fig. 1)

ELECTRICAL SAFETY:

MECHANICAL SAFETY:

WARNING: Unexpected Startup Hazard

Disconnect and lockout power before

servicing. Failure to follow these instructions could

result in serious personal injury or death, and

property damage.

WARNING: Excessive System Pressure

Hazard

The maximum working pressure of the pump is

listed on the nameplate, do not exceed this

pressure. Failure to follow these instructions could

result in serious personal injury or death, and

property damage.

WARNING: Excessive Pressure Hazard

Volumetric Expansion

The heating of water and other fluids causes

volumetric expansion. The associated forces may

cause failure of system components and release

of high temperature fluids. Installing properly sized

and located compression tanks and pressure relief

valves will prevent this. Failure to follow these

instructions could result in serious personal injury

or death, and property damage.

WARNING: Electrical Shock Hazard

Electrical connections to be made by a

qualified electrician in accordance with all

applicable codes, ordinances, and good practices.

Failure to follow these instructions could result in

serious personal injury or death, and property

damage.

WARNING: Electrical Overload Hazard

Three phase motors must have properly

sized heaters to provide overload and under

voltage protection. Single-phase motors have

built-in overload protectors. Failure to follow these

instructions could result in serious personal injury

or death, and property damage.

3

Page 4

WARNING

ROTATING COMPONENTS

DISCONNECT AND LOCK OUT

POWER BEFORE SERVICING.

DO NOT OPERATE WITHOUT ALL

GUARDS IN PLACE.

CONSULT INSTALLATION AND

SERVICE INSTRUCTION SHEET

BEFORE OPERATING OR

SERVICING.

FAILURE TO FOLLOW

INSTRUCTIONS COULD RESULT

IN INJURY OR DEATH.

(2) REQUIRED

(1 EACH SIDE)

WARNING

EYEBOLTS OR LIFTING

LUGS IF PROVIDED ARE

FOR LIFTING ONLY THE

COMPONENTS TO WHICH

THEY ARE ATTACHED.

FAILURE TO FOLLOW

INSTRUCTIONS COULD

RESULT IN INJURY OR

DEATH.

FIG. 1

4

CAUTION

DO NOT RUN PUMP DRY, SEAL

DAMAGE MAY OCCUR.

INSPECT PUMP SEAL

REGULARY FOR LEAKS,

REPLACE AS REQUIRED.

FOR LUBRICATION

REQUIREMENTS, CONSULT

SERVICE INSTRUCTIONS.

FAILURE TO FOLLOW

INSTRUCTIONS COULD RESULT

IN INJURY OR PROPERTY

DAMAGE.

Page 5

PUMP LOCATION

Locate the pump so there is sufficient room for

inspection, maintenance, and service. If the use of

a hoist or tackle is needed, allow ample head

room.

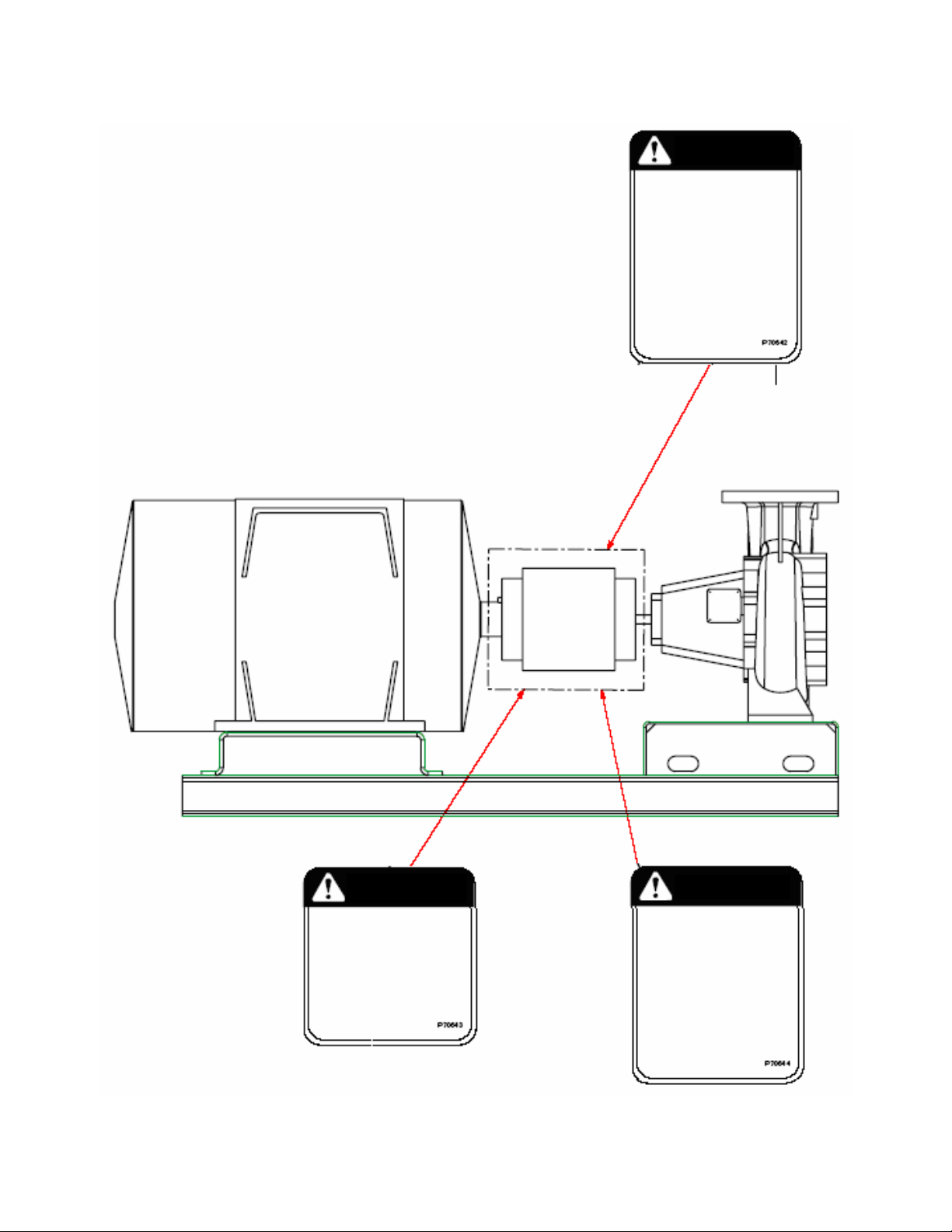

WARNING

Eyebolts or lifting lugs if provided are for

lifting only the components to which they are

attached. Failure to follow instructions could result

in injury or death.

If lifting of the entire pump is required, do so with

slings placed as shown. (Fig. 2 & 3)

The best pump location for sound and vibration

absorption is on a concrete floor with subsoil

underneath. If the pump location is overhead,

special precautions should be undertaken to

reduce possible sound transmission, consult a

sound specialist.

If the pump is not on a closed system, it should be

placed as near as possible to the source of the

liquid supply, and located to permit installation with

the fewest number of bends or elbows in the

suction pipe.

FIG. 2 – Bases with Lifting Holes

The installation must be evaluated to determine

that the Net Positive Suction Head Available

(NPSHA) meets or exceeds the Net Positive

Suction Head Required (NPSHR), as stated by the

pump performance curve.

IMPORTANT: Do not install and operate Series

2000 Pumps in closed systems unless the system

is constructed with properly sized safety devices

and control devices. Such devices include the use

of properly sized and located pressure relief

valves, compression tanks, pressure controls,

temperature controls, and flow controls as

appropriate. If the system does not include these

devices, consult the responsible engineer or

architect before making pumps operational.

“S” Hooks

FIG. 2A FIG. 2B

FIG. 3 – Bases without Lifting Holes

5

Page 6

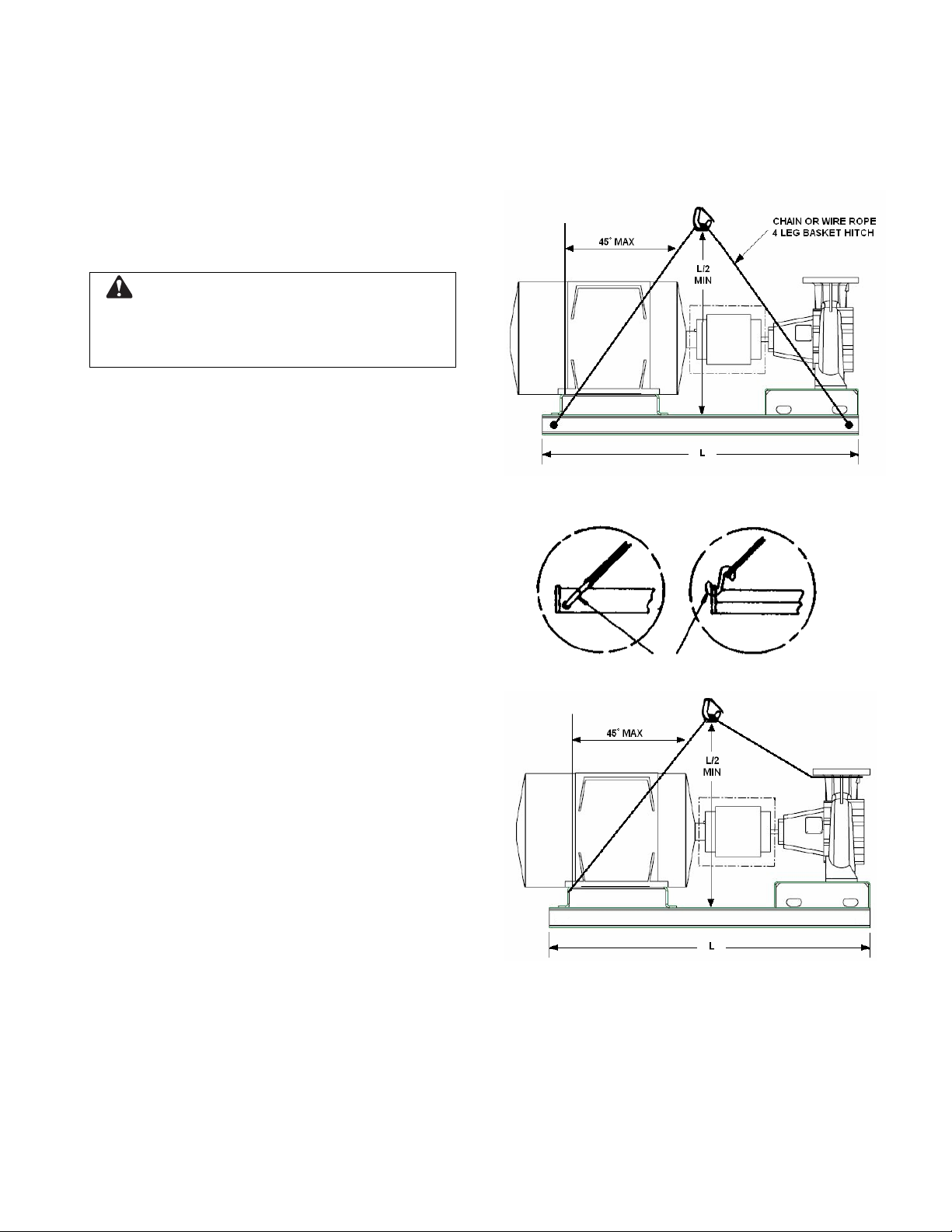

INSTALLATION

This pump is built to provide years of service if

installed properly and attached to a suitable

foundation. A base of concrete weighing 2-1/2

times the weight of the pump is recommended.

(Check the shipping ticket for pump weight.)

DRILL AND TAPER REAM

AFTER ALIGNMENT

SHIMS

ADJUST TO ALIGN

1/2" - 1-1/2"

8" - 12"

TUBE AT LEAST 4"

LONG

2 TIMES BOLT DIA.

OR 1/2" MIN.

SIDE CLEARANCE

TO PROVIDE

BOLT CLEARANCE

HOOK

If possible, tie the concrete pad in with the finished

floor. Use foundation bolts and larger pipe-sleeves

to give room for final bolt location. (Fig. 4)

MOTOR

TIGHTEN BOLTS BEFORE

CHECKING ALIGNMENT

BASEPLATE

ASSEMBLY

GROUT

12" - 18"

ALTERNATE BOLT

AND WASHER

FOUNDATION TO SUIT

LOCAL CONDITIONS

LEVELING

Place the pump on its concrete foundation

supporting it with steel wedges or shims

totaling 1" in thickness. These wedges or

shims should be put on both sides of each

anchor-bolt to provide a means of leveling the

base.

FIG. 4

IT IS VERY IMPORTANT THAT THE PUMPBASE BE SET LEVEL TO AVOID ANY

MECHANICAL DIFFICULTIES WITH THE

MOTOR OR PUMP. THIS PUMP WAS

PROPERLY ALIGNED (IF FURNISHED WITH

A MOTOR) AT THE FACTORY. HOWEVER,

SINCE ALL PUMP BASES ARE FLEXIBLE

THEY MAY SPRING AND TWIST DURING

SHIPMENT. DON’T PIPE THE PUMP UNTIL

IT IS REALIGNED. AFTER PIPING IS

COMPLETED AND AFTER THE PUMP IS

GROUTED-IN AND BOLTED-DOWN, ALIGN

IT AGAIN. IT MAY BE NECESSARY TO READJUST THE ALIGNMENT FROM TIME TO

TIME WHILE THE UNIT AND FOUNDATION

ARE NEW.

6

Page 7

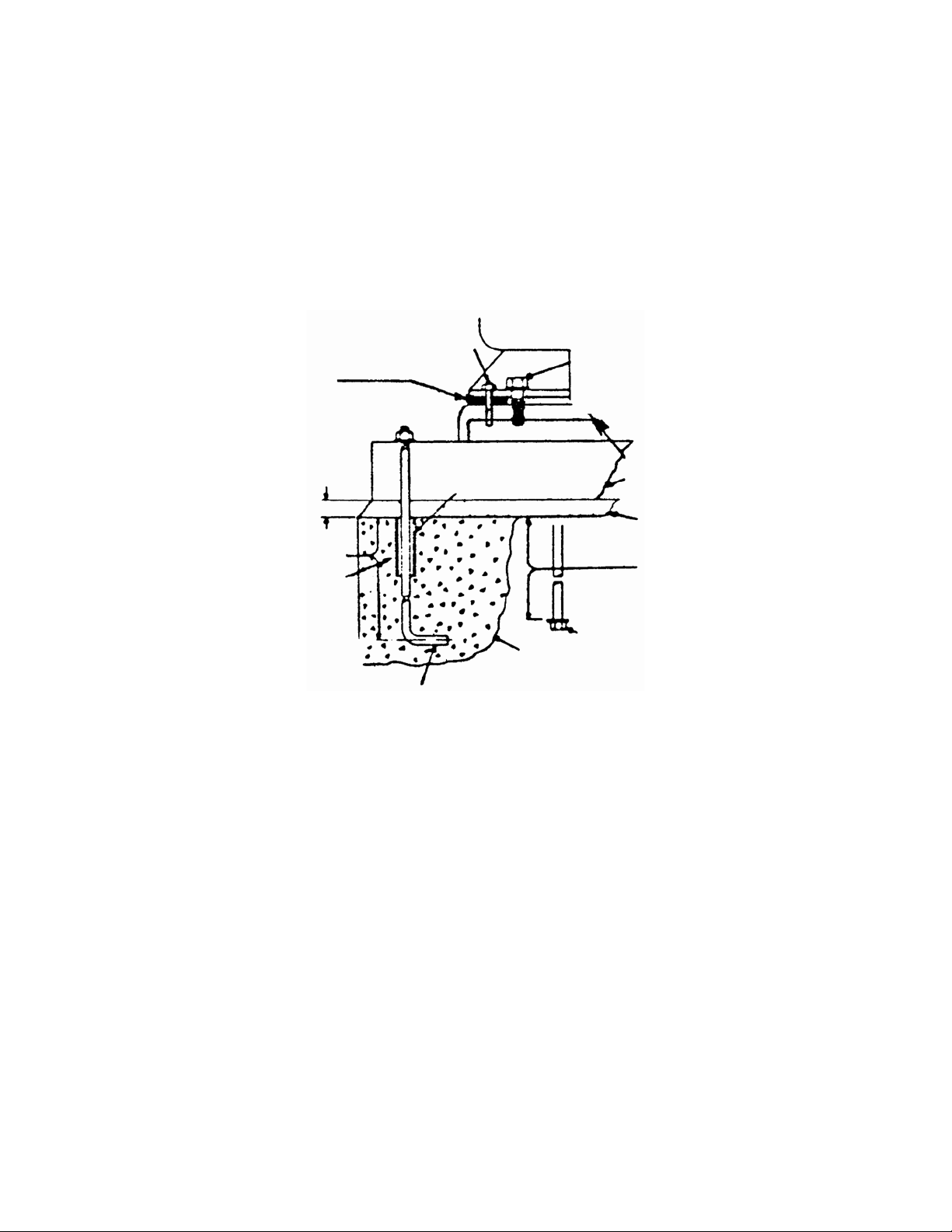

GROUTING

After the pump has been leveled, securely

bolted to the floor, and properly aligned, a

good grade of non-shrinking grout should be

poured inside the pump base. To hold

wedges or shims in place, allow the grout to

flow around them.

ANSI/OSHA COUPLER GUARD

REMOVAL/INSTALLATION

WARNING: Unexpected Start-up Hazard

Disconnect and lock out power before

servicing. Failure to follow these instructions could

result in serious personal injury or death and

property damage.

SEE ANSI/OSHA COUPLER GUARD

REMOVAL/INSTALLATION

(SEE BELOW)

ALIGNMENT PROCEDURE

NOTE: A flexible coupling will only

compensate for small amounts of

misalignment. Permissible misalignment will

vary with the make of coupling. Consult

coupling manufacturer’s data when in doubt.

Allowances are to be made for thermal

expansion during cold alignment, so that the

coupling will be aligned at operating

temperature. In all cases, a coupling must be

in alignment for continuous operation. Even

though the coupling may be lubricated,

misalignment causes excessive wear,

vibration, and bearing loads that result in

premature bearing failure and ultimate seizing

of the pump. Misalignment can be angular,

parallel, or a combination of these, and in the

horizontal and vertical planes. Final alignment

should be made by moving and shimming the

motor on the base plate, until the coupling

hubs are within the recommended tolerances

measured in total run-out. All measurements

should be taken with the pump and motor foot

bolts tightened. The shaft of sleeve bearing

motors should be in the center of its

mechanical float.

NOTE: Proper alignment is essential for

correct pump operation. This should be

performed after base plate has been properly

set and grout has dried thoroughly according

to instructions. Final alignment should be

made by shimming driver only. Alignment

should be made at operating temperatures.

WARNING: Unexpected Start-up Hazard

Disconnect and lock out power before

servicing. Failure to follow these instructions could

result in serious personal injury or death and

property damage.

NOTE: Do not spread the inner and outer

guards more than necessary for guard

removal or installation. Over spreading the

guards may alter their fit and appearance.

Removal

a. Remove the two capscrews that hold the

outer (motor side) coupler guard to the

support bracket(s).

b. Spread the outer guard and pull it off the

inner guard.

c. Remove the capscrew that holds the inner

guard to the support bracket.

d. Spread the inner guard and pull it over the

coupler.

Installation

a. Check coupler alignment before

proceeding. Correct if necessary.

b. Spread the inner guard and place it over

the coupler.

c. With the inner guard straddling the

support bracket, install a capscrew

through the hole (or slot) in the support

bracket and guard located closest to the

pump. Do not tighten the capscrew.

d. Spread the outer guard and place it over

the inner guard.

e. Install the outer guard capscrews by

following the step stated below which

pertains to your particular pump:

i. For pumps with a motor saddle support

bracket: Ensure the outer guard is

straddling the support arm, and install

but do not tighten the two remaining

capscrews.

ii. For pumps without a motor saddle

support bracket: Insert the spacer

washer between the holes located

closest to the motor in the outer guard,

and install, but do not tighten, the two

remaining capscrews.

7

Page 8

f. Position the outer guard so it is centered

around the shaft, and so there is less than

1/4" of the motor shaft exposed. On

guards that utilize a slotted support

bracket, the inner guard will have to be

ANSI/OSHA Coupling Guard Exploded View

For Typical 2000 Series Fire Pump Installation

OUTER GUARD

LOCATE SUPPORT ARM

BETWEEN OUTER GUARD ENDS.

ALIGN THE ARM WITH HOLES IN

THE OUTER GUARD AND HOLES

IN THE SADDLE BRACKET.

positioned so there is only 1/4" of the

pump shaft exposed.

g. Holding the guard in this position, tighten

the three capscrews.

INNER GUARD

ATTACH SUPPORT BRACKET

TO BEARING HOUSING

SUPPORT

BRACKET

NUT

LOCKWASHER

MOTOR SADDLE

BRACKET ATTACH

TO MOTOR SADDLE

CAPSCREW

FLAT WASHER

SPACER WASHER

THIS OPTION USED IN PLACE OF SPACER WHERE

OVERALL LENGTH OF GUARD EXCEEDS 12 INCHES

OR GUARD WITH IS OVER 10 INCHES ACROSS

THE FLATS.

Method 1 – Straight Edge Alignment for

Standard Sleeve Type Coupler with Black

Rubber Insert

(See Fig. 5A)

Proceed with this method only if satisfied that

face and outside diameters of the coupling

halves are square and concentric with the

coupling borers. If this condition does not

exist or elastomeric couplings do not make

this method convenient, use Method 2.

1. Check angular misalignment using a

micrometer or caliper. Measure from the

outside of one flange to the outside of the

opposite flange at four points 90° apart.

DO NOT ROTATE COUPLER.

Misalignment up to 1/64" per inch of

coupler radius is permissible.

FIG. 5

BRACKET SUPPORT

ATTACHED INSIDE HERE

IN LINE WITH BOLT

straight edge across one coupler half and

measuring the gap between the straight

edge and opposite coupler half. Up to a

1/64" gap is permissible.

ANGULAR ALIG PARALLEL ALIGNMENT NMENT

INCORRE IGNMENT

STRAIGHT EDGE

FEELER GAGE

BRACKET

SUPPORT

STRAIGHT EDGE

FEELER GAGE

CT AL

2. At four points 90° apart (DO NOT

ROTATE COUPLER), measure the

parallel coupler misalignment by laying a

CORRECT ALIGNMENT

FIG. 5A – CH ETHOD 1)

8

ECKING ALIGNMENT (M

Page 9

Method 2- For Orange Hytrel Insert, 3500

Operation, or All Other Coupler Types

Except as Noted Below

(See Fig. 5B)

a. Make sure each hub is secured to its

respective shaft and that all connecting

and/or spacing elements are removed at

this time.

b. The gap between the coupling hubs is set

by the manufacturer before the units are

shipped. However, this dimension should

be checked. (Refer to the coupling

manufacturer’s specifications supplied

with the unit.)

c. Scribe index lines on coupling halves as

shown in Fig. 5B.

d. Mount dial indicator on one hub as shown

for parallel alignment. Set dial to zero.

e. Turn both coupling halves so that index

lines remain matched. Observe dial

reading to see whether driver needs

adjustment (See paragraph i below).

f. Mount dial indicator on one hub as shown

for angular alignment. Set dial to zero.

g. Turn both coupling halves so that index

lines remain matched. Observe dial

reading to see whether driver needs

adjustment (See paragraph i below).

h. Assemble coupling. Tighten all bolts and

set screw(s). It may be necessary to

repeat steps c through f for a final check.

i. For single element couplings, a

satisfactory parallel misalignment is

0.004"T.I.R., while a satisfactory angular

misalignment is 0.004"T.I.R. per inch of

radius R (See Fig. 5B).

Grid Couplings

NOTE: The following procedure is intended

for mounting and alignment of Rexnord

Industries, LLC. and Clarke Fire Protection

Products, Inc., Tapered Grid Couplings.

Adequate lubrication is essential for

satisfactory operation. Grease supplied by

the coupling manufacturer is highly

recommended. Other greases to be used

should be approved by the coupling

manufacturer.

Alignment is shown using spacer bar and

straight edge. Rexnord Industries, LLC. and

Clarke Fire Protection Products, Inc. state

this practice has been proven for many

industrial applications. Superior alignment

can be achieved through the use of dial

indicators as shown above.

1. Clean all metal parts using non-flammable

solvent. Install keys and mount shaft hubs

with flange faces flush with shaft ends or

as otherwise specified. Unless otherwise

specified, BE (Shaft Gap) = 3.5” for

3x2x6.5F 2000 Series Firepump and 5.00”

for 4x3x9F 2000 Series Firepump. Tighten

setscrews.

FIG. 5C – SHAFT GAP

DIAL

PARALLEL

INDICATOR

ALIGNMENT

INDEX LINE

RESILIENT

SEPARATOR

ANGULAR

ALIGNMENT

DIAL

INDICATOR

FIG. 5B – CHECKING ALIGNMENT (METHOD 2)

2. Bring the pump and motor halves of the

coupler into approximate height alignment,

by placing equal amounts of shims under

all the motor feet. Tighten the motor bolts.

3. Lightly coat seals with coupling vendor

supplied grease and roll the seal over the

spacer hub teeth into place. Position each

half spacer hub on register of shaft hub

and fasten parts together. Torque

fasteners to specifications in Fig. 5J.

9

Page 10

. 5D – SHAFT HUB, SEAL, & SPACER HUB

FIG

ASSEMBLY

Use a spacer bar equal in thickness

4. to the

gap specified in Fig. 5J. Insert bar, as

shown below, t

o same depth at 90°

intervals and measure clearance between

bar and hub face with feeler gauges. The

difference in minim

um and maximum

measurements must not exceed the

ANGULAR installation limits shown in

Fig. 5J.

6. If adjustment is needed, loosen the motor

bolts and add (or remove) equal amounts

of shims unde

r each motor foot, to align

the height. To correct side misalignment,

strike the side of the motor foot with a

mallet. Tighten the motor bolts and check

again. If a correction is made, re-check

directions. Repeat this

alignment

in all

process until the desired result is

obtained.

7. Pack gap and grooves with coup

ling

vendor supplied grease before inserting

grid. When grids are furnished in t

more segme

nts, install them so that all cut

wo or

ends extend in the same direction as

shown below. This will ensure correct grid

contact with non-rotating pin in cover

halves. Spread the grid slightly to pass

over the coupling teeth and seat with a

soft mallet.

FIG. 5E– USING SPACER BAR

5. Align so that a straight edge rest

the limits shown in Fig. 5J on both hu

shown below and also at 90° intervals.

Check with feelers. The clearance must

not exceed the PARALLEL OFFSET

installation limits specified in Fig. 5J.

FIG. 5F – USING STRAIGHT

EDGE

FIG. 5G – SEATING THE GRID

s within

bs as

10

Page 11

8. Pack the spaces between and around the

grid with as much as coupling vendor

supplied grease as possible and wipe off

the excess until flush with the top of the

grid. Position seals on hubs to line-up with

grooves in cover. Position gaskets on

flange of lower cover half and assemble

covers so that the match marks are on the

same side.

9. Ensure lube plugs are installed in cover.

AUTION: Coupling Failure

C

Do not o .

Couplin

Failure

property ry.

perate coupling without proper lubrication

g failure may occur.

to follow these instructions could result in

damage and/or moderate personal inju

FIG. 5H – COVER INSTALLATION

Fastener Tightening

Installation Limits

End Float

Parallel

Offset

Size

1040T 0.006 0.003 0.125 0.211 100 120 3600 0.12

1050T 0.008 0.004 0.125 0.212 200 250 3600 0.15

1060T 0.008 0.005 0.125 0.258 200 440 3600 0.19

1070T 0.008 0.005 0.125 0.259 200 440 1800 0.25

80T 0.008 0.006 0.125 0.28

10

(P)

Max Inch Max Inch Inch Inch

Angular

(x-y)

Hub Gap

+/- 10%

Physical

Limit (Min)

Torque Values

Cover Fastener

Tightening Torque

2xF

8 200 825 1800 0.38

Values

In. Series

Fasteners

(lb*in)

Flange

Type

31 & 35

In. Series

Fasteners

(lb*in)

Maximum

Allowable

RPM

Lube Wt.

lb

FIG. 5J – MISALIGNMENT & FASTENER TORQUE VALUES

11

Page 12

Final Alignment

Fin

al alignment cannot be accomplished until

the

pump has been operated initially for a

suf

ficient length of time to attain operating

tem

perature. When normal operating

tem

perature has been attained, secure the

pu

mp to re-check alignment and compensate

for

temperature accordingly. See Alignment

Section.

WARNING: Rotating Components

Hazard

Do not operate pump without all guards in place.

Failure to follow these instructions could result in

serious personal injury or death and property

damage.

PIPING

WARNING: Coupling Failure

tt of

operate pump with coupling ouDo no

alignment. Ensure final coupling alignment is

within the values stated above or according to the

c

oupling manufacturer’s instr

pump, or driver failure may occur.

Failure to follow these instructions could result in

serious personal injury or death and property

dam

age.

Due to the different types of couplers

available for your Series 2000 pump, refer to

coupler manufacturer's instructions for

alignment values and additional instructions.

ROTATION

Pump rotation is clockwise when viewed from

back of the motor. An arrow is also located on

the pump to show the direction of rotation.

uctions. Coupling,

Always install a section of straight pipe

between the suction side of the pump and

first elbo

b

efore it enters the pump. The length should

be equal to ten times the diameter of the

pipe.

Be sure to eliminate any pipe-strain on the

pump. Support the suction and discharge

pipes independently by use of pipe hangers

near the pump. Line up the vertical and

horizontal piping so that the bolt-holes in the

pump flanges match the bolt-holes in the pipe

flanges. DO NOT ATTEMPT TO SPRING

THE SUCTION OR DISCHARGE LINES

INTO POSITION. Coupling and bearing wear

will result if suction or discharge lines are

forced into position. The code for Pressure

Piping (A.S.A.B. 31.1) lists many types of

supports available for various applications.

As a rule, ordinary wire or band hangers are

not adequate to maintain alignment. It is very

important to provide a strong, rigid support for

the suction and discharge lines.

Where considerable temperature changes

are anticipated, fittings for absorbing

w. This reduces turbulence of the

ction by straightening out the flow of lsu

iquid

expansion should be installed in the system

in such a way as to avoid strain on the pump.

On an open-system with a suction-lift, use a

foot-valve of equal or greater area than the

pump suction piping. Prevent clogging by

using a strainer at the suction inlet next to the

foot-valve. The strainer should have an area

three times that of the suction pipe with a

mesh hole diameter of no less than 1/4".

When using an isolation base, flexible piping

should be used on both the suction and

discharge sides of the pump.

A check valve installed in the discharge line

will serve to protect the pump from water

hammer. Also install an isolation valve for

servicing and for throttling.

NOTES:

1. The pipeline should have isolation valves

around the pump and have a drain valve

in the suction pipe.

2. When installing connections to a threaded

pump housing the use of PTFE tape

sealer or a high quality thread sealant is

recommended.

12

Page 13

PRIMING AND S R

TING TA

CAUTION: Seal Damage Hazard

Do not run pump dry, seal damage may

occu

r. Failure to follow these instructions could

resu

lt in property damage and/or moderate

pers

onal injury.

Before starting the pump, the pump body must be

ull of liquid. Manual priming may be required

f if the

system t automatically fill the pump body

with liquid.

The pump should be started with the discharge

valve closed and the suction valve fully open. After

th

v

IMPORTANT: The pump should never be

operated with suction valve closed or throttled.

This could result in cavitations.

does no

e pump

alve should be opened slowly.

is up to operating speed the discharge

SERVICE INSTRUCTIONS

WARNING

Disconnect and lock out power before

serv ld

icing. Failure to follow these instructions cou

resu

lt in injury or death.

1. Close valves on suction and discharge

sid

es of pump. (If no valves have been

installed, it will be necessary to drain the

system.)

CAUTION

Check surfaces for extreme temperatu

allow

pump temperature to reach acceptable level

befo

re proceeding. Open drain valve, do not

proc

eed until liquid stops coming out of drain

valv

e, if liquid does not stop flowing from drain

valv

e, isolation valves are not sealing and should

be re s

paired before proceeding. After liquid stop

flow

ing from drain valve, leave drain valve open

and

continue. Remove the drain plug located on

the b

ottom of the pump casing. Do not reinstall

or close drain valve until reassembly is

plug

pleted. Failure to follow these instructions

com

d result in injury or death.

coul

2. Remove coupler guard and loosen set

screws in both coupler halves and slide

each half back as far as possible o

shaft. Remove coupler sleeve. Where a

full diameter impeller is used, it may be

res,

n its

LUBRICATION

While pump is running, re-grease pump

bearings with #2 lithium base

grease after every 2500 hours of operation or

every 6 months, whichever occurs first.

Lubricate motor per motor manufacturer’s

instru

ctions.

ERAL INSTRUCTIONS

GEN

1. Keep this pump and motor properly

lubricated.

2. When there is a danger of freezing, drain

the p

ump.

3. Inspect pump regularly for leaky seals or

gaskets and loose or damaged

components. Replace or repair as

required.

necessary to remove the pump side

coupler half and to slide the motor back on

its base in order to gain sufficient

clearance to remove the pump assembly

from the casing.

3. Remove support foot capscrews. Loosen

casing capscrews (1-904-0), do not

remove them. Loosen only capscrews

holding stuff box cover to casing. Start

remove the pump assembly from the

casing (2-001-0).

CAUTION

Make certain the internal pressure is

ved before continuing. Failure to follow these

relie

uctions could result in injury or property

instr

age.

dam

R

emove seal flushing tube, if used.

Remove the casing capscrews and

remove the pump assembly from the

casing.

4. Pull the entire rotating assembly from the

casing leaving the casing connected to th

piping unless it is to be repaired, replaced

or if applicable, t

installed.

o have new wear rings

petroleum

to

e

,

13

Page 14

5. Remove the O-ring (2-914stuffing box cover and insp

0) from the

ect for damage.

Replace if necessary.

IMPEL

LER REMOVAL

1. Lock the coupling end of the shaft in a

padded vise.

2. Remove the impelle

r nut (4-023-0). To do

this, turn the impeller nut in the same

direction in which the impeller rotates

(counterclockwise viewing from the

suction inlet).

3. Pull the impeller (4-002-0) from the shaft

and remove the impeller key (4-911-0).

DISMANTLING THE STUFFING BOX

A. Pumps with Mechanical Seals

1. Remove spacer sleeve (1-154-0).

2. Remove the two nuts holdi

ng the gland

(6-014-0) to the stuffing box (2-036-0).

3. Pull the stuffing box cover o

ff the shaft

assembly.

: On the larg

NOTE er 2000 Series pumps, it

will be necessary to remov

e the capscrews

holding the stuffing box cover to the frame.

The mechanical seal (6-400-0) should now be

exposed on the shaf

t sleeve. (In some cases,

the shaft sleeve may come off the shaft with

the stuffing box cover. If this happens, gent

ss or pull the shaft sleeve and mechanic

pre al

l from the stuffing box toward frame side

sea

of the stuffing box cover.) This will expose the

mechani bove.

. Remove the seal from the shaft sleeve,

4

cal seal as a

examine for damage, and if necessary

replace.

5. Remove the gland (6-014-0), shaft slee

(1-009-0), and the deflector (1-136-0) from

the pump shaft. A puller may be used to

remove the shaft sleeve if it does not slid

off the pump shaft easily.

ve

packing rin

applicab

gs (6-924-0) and, where

le, the seal cage (6-013-0) from

the stuffing box. A standard packing hook

is recommended for removing the pack

and seal

cage.

4. Remove the packing base ring.

ME DISASSEMBLY

FRA

1. Remove bearing caps (5-018-3 and

5-018-4).

2. Remove snap ring (5-068-4) from the

outboard bearing hou

sing.

3. Press the shaft (5-007-0), outboard

bearing (5-0

26-4), and inboard bearing

(5-026-3) toward the motor side of the

frame until the outboard bearing clears the

frame’s out

board bearing housing.

4. Using a suitable pair of snap ring pliers,

remove snap ring (5-068-3) from th

outboard bearing housing. (Flat snap ri

located on

bearing h

the inside of the outboard

ousing.)

e

ng

5. Finish removing the shaft and outboard

bearing.

Remove the snap ring (5-086-0) from the

6.

outboard end (motor end) of the pu

mp

shaft.

Using a suitable bea

ly

7. ring press, remove

the inboard bearing (5-026-3) and the

outboard bearing (5-026-4) from the

pump

shaft (5-007-0).

CASING

(OPTIO

WEARING RING REMOVAL

NAL)

he optional w

T earing rings are removed from

e casing and stuffing box cover by the

th

following method:

1. Drill two axial holes into each wearin

ap

proximately 180° apart being careful not

e

to drill into casing or stuffing box cover.

g ring

2. Split the wearing rings using a chisel.

B. Pumps with Packed Stuffing Box

1. Loosen packing gland (6-014-0) by

loosening the two gland

retaining nuts.

2. Pull the stuffing box cover, gland, and

packing from the shaft.

Remove the two gland retaining nuts and

3.

remove the gland (6-014-0). Remove the

14

Remove the parts from the wearing rin

3. g

fit.

This completes the disassembly of the 2000

ries frame mounted pump.

Se

Page 15

ASSEMBLY PROCED

URES

FRAME ASSEMBLY

1. Press the outboard bearing (5-026-4) o

the motor side of the pump shaft

(5-007-0).

NOTE: When pressing bearings onto the

sha

ft, press only against the inner race.

2. p

Install snap ring (5-086-0) on the pum

shaft with the t

bearing (outboard side of outboard

bearing).

3. Place snap ring (5-068-3, flat snap ring)

over the pump shaft (5-007-0) p

the snap ring between the two be

shoulders.

NOTE: There are two snap rings that go into

the outboard bearing housing: snap rings

(5- is

068-3 and 5-068-4). Snap ring (5-068-3)

flat and goes into the inside snap ring groo

and snap ring (5-068-4) is tapered and goe

the outside

into snap ring groove.

4. Press inboard bearing (5-026-3) onto the

inboard side (pump side) of the pump

shaft.

5. Press the inboard end (pump end) of the

shaft-bearing assembly into the outboard

end (motor end) of the pump frame. Press

the unit toward the pump side of the frame

until the inboard bearing clears the

outboard bearing housing.

5-086-0 5086-4

apered edge away from the

nto

ositioning

aring

ve,

s

bearing (5-026-4) seats firmly against

snap ring (5-068

bearing housing.

8. Place snap ring (5-068-4) in the outside

snap ring groove o

housing (tapered edge away from

bearing).

9. Install bearing caps (5-018-3 and 5-018

onto both ends of the pump frame.

FFING BOX ASSEMBLY

STU

TE: There are two pipe taps on the

NO

ffing box; one closest to the gland, and

stu

furthest away from the gland.

one

If the pump is equipp

seals, the stuffing box cover should be

itioned with the pipe tap closest to the

pos

nd on top.

gla

e pump is equipped with packing, the

If th

stuffing box cover should be positioned so the

pipe tap furthest away from the gland is on

top.

For ease of assembly, install pipe fittings in

the stuffing box pipe taps before assembling

ffing box on the frame.

stu

A. Pumps with Mechanical Seals

Install the two gland retaining studs

1.

(6-908-0) into the stuffing box cover.

Install the rotating and

2. stationary elements

of the mechanical seal (6-400-0

shaft sleeve (1-009-0) being certain that

the two

Position the seal on the sleeve according

to the “G” dimension found in Fig. 7.

wearing surfaces face each other.

-3) inside the outboard

f the outboard bearing

ed with mechanical

-4)

) on the

FIG. 6 – Tapered Snap Rings

6.

Using a suitable pair of snap ring pliers,

place snap ring (5-068-3, located on th

pump shaft between the bearings) into

inside snap ring groove

bearing housing.

Continue pressing the shaft and bearing

7.

assembly into the frame until the outboard

of the outboard

e

the

15

3. Place seal spring retaine

4. Place seal spring into stuffing box.

Place sleeve and seal assembly into

5.

stuffing box with rotating half of seal

installed closest to the impeller.

6. Install the seal gland (6-014-0) (flat side

tow

ard stuffing box) on the stuffing box

using the gland studs (6-908-0) and gland

nuts (6-903-0). Tighten gland nuts evenly

until the gland is approxima

the stuffing box.

r into stuffing box.

tely 1/8" from

Page 16

STUFFING

BOX

IMPELLER

HUB

G

FIG. 7

“G” Setting Dimensions

Shaft Sleeve OD

(inches)

1.25 1.22

1.62 1.31

2.0 1.38

Slide the deflector ring (1-136-0) onto the

7.

motor shaft.

G

(inches)

B. Pumps w

1. Slide defle

shaft.

Slide the packing gland (6-014-0) onto th

2. e

pump shaft (flat side toward frame).

3. Slide the shaft sleeve (1-009-0) onto the

pump shaft. To prevent leakage, use

silicone sealant between the shaft and

shaft sleev

4. Place the packing base ring (6-152-0) into

the stuffing box. Slide the stuffing bo

cover over the pump shaft, and, if

applicable, bolt the stuf

frame using capscrews (1-904-0).

5. Install the packing (6-924-0) and, if

applicable, the seal cage (6-013

the stuffing box being sure to stagger t

joints.

ith Packed Stuffing Boxes

ctor (1-136-0) onto the pump

e.

x

fing box to the

-0) into

he

8. Slide the stuffing box cover, seal, and

sleeve assembly onto the frame shaft

being certain the stuffing box is closest to

the frame. To prevent any leakage, use

silicone sealant between the shaft and

shaft sleeve.

9. If applicable, bolt the frame to the stuffing

box using capscrews (1-904-0).

IMPELLER

1.

If the pump is equipped with mechanical

seals, slide the spacer sleeve (1-154-0)

over the shaft sleeve and into the st

box.

2. Install the impelle key into the keyway on

the impeller side of the pump shaft.

3. Slide the pump impeller (4-002-0) onto the

pump shaft.

r

uffing

FINAL ASSEMB

INSTAL

6. Tighten the packing gland nuts to seat t

packing. Lo

packing to expand then retighten finger

tight.

osen the nuts to permit the

LATION

4. Screw the impeller nut (4-023-0) onto

pump shaft until finger tight. Clamp th

coupling end of the pump shaft in a

padded vise, and tighten (clockwise as

viewed from the suction inlet) the impeller

nut to 25-30 ft. lbs.

5.

For pumps with mechanical seals, tighten

gland evenly against the stuffing box.

LY

he

the

e

1. Place the O-ring casing seal (2-914-0)

round the O-ring seat on the stu

a ing box

over.

c

2. Carefully slide the frame assembly into th

casing being sure not to pinch the O-ring.

Insert the capscrews (1-904-0) through

the frame and into the casing (the large

2000 Series pump

clamping lugs (2-937-0) to hold the frame

to the casing). Tighten opposite

s use capscrews and

ff

capscrews evenly around the fra

the stuffing box has been drawn evenly

into the casing. Then alternately torque

e

16

each capscrew to 25 lbs.

Secure frame foot to pump base.

3.

If necessary, con

4. nect the suction and

discharge piping to the pump.

5. Connect the flush line to the stuffing box.

me until

Page 17

6. Align the pump to the motor as instructed.

7. Connect the pump to the motor. Reinstall

the coupling guard and drain plugs. Close

drain valve.

8. Connect the power to the motor. CHECK

THE MOTOR ROTATION.

9. Open isolation valves, inspect pump for

leaks. If not le turn pump to

aking, re

service.

NOTE FOR PAC

adjustment of the

KED PUMPS:

gland nuts ne

with the pump running. Allow s

een a

betw djustments. Tightening the nuts too

ly can cause dam

quick age to the packing and

sleeve. A good adjustment sho w

Final

must be do

30 minute

uld allo

approximately one (1) drip per second.

This completes the assembly of the 2000

ries pump.

Se

NOTE: All pumps are shipped with couplin

ards. Coupling guards must be in place

gu

fore operating pump.

be

ARNING

W

o not operate

D without all guards in place.

re to follow these instructions could result in

Failu

injury or

death.

g

17

Page 18

ALTERNATE CLAMPING METHOD

INTERNAL OR EXTERNAL FLUSH

PUMP WITH PACKING

(PLUGGED)

PUMP WITH PACKING

OPTIONAL SEAL CAGE

(INTERNAL OR EXTERNAL)

18

Page 19

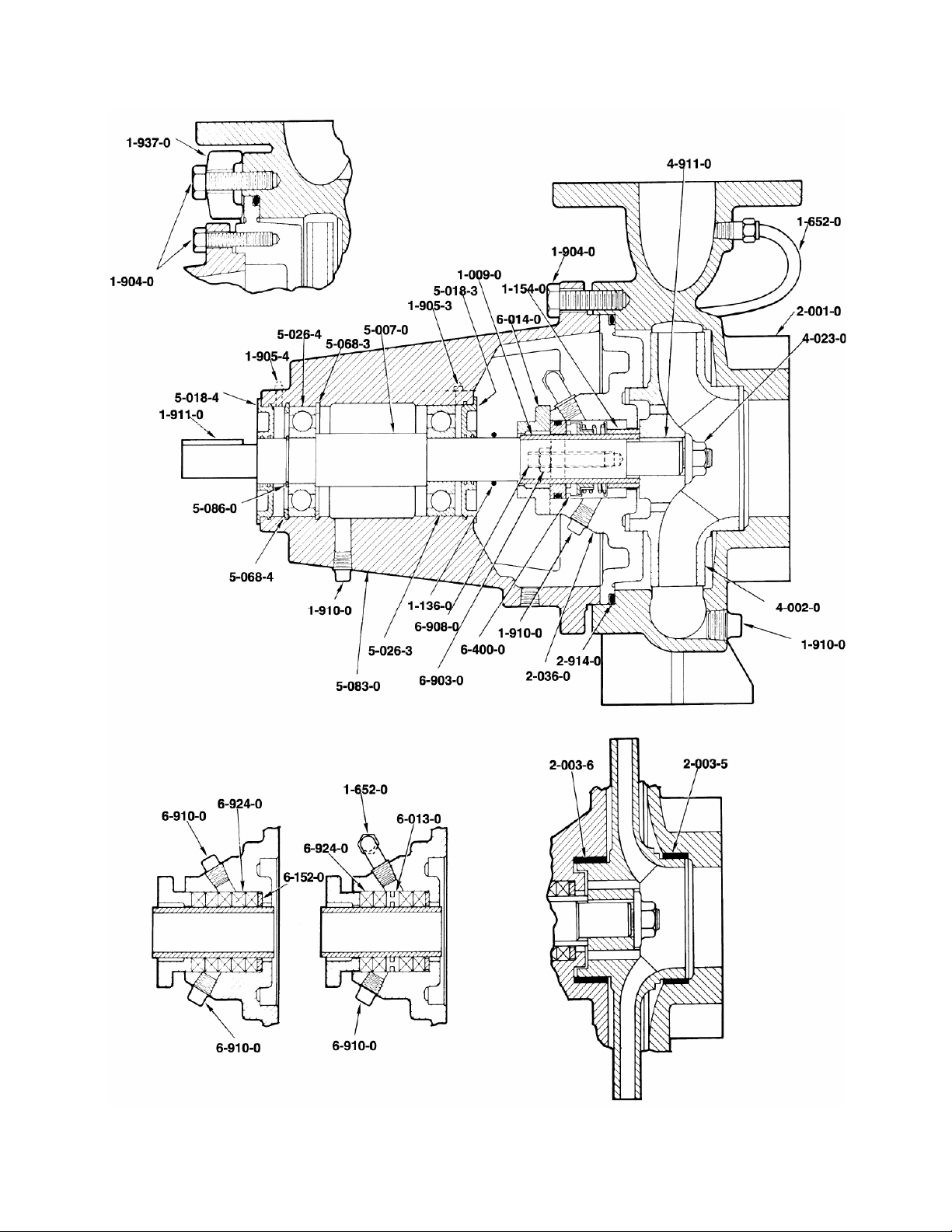

REPAIR PARTS LIST

Cat. No. Part Name Quantity Cat. No. Part Name Quantity

1-009-0 Shaft Sleeve 1 5-018-4 Bearing Cap, Outboard 1

1-136-0 Deflector 1 5-026-3 Bearing, Inboard 1

1-154-0 Spacer Sleeve 1 5-026-4 Bearing, Outboard 1

1-248-1 Frame Foot Assembly 1 5-068-3 Snap Ring, Inboard Bearing Housing 1

1-652-0 By-Pass Piping Kit 1 5-068-4 Snap Ring, Outboard Bearing Housing 1

Capscrews – Miscellaneous 81-904-0

With Lugs 5-086-0 Snap Ring, Shaft 1

1-905-3 Grease Fitting, Inboard 1 6-014-0 Gland 1

1-905-4 Grease Fitting Outboard 1 6-152-0 Ring Packing Base 1

Pipe Plugs 21-910-0

Without By-Pass 3

1-911-0 Key, Coupling 1 6-908-0 Gland Stud 2

2-001-0 Casing 1 Pipe Plug 16-910-0

2-036-0 Stuffing Box Cover 1

2-914-0 O-Ring, Casing Seal 1 Packing 5

2-937-0 Clamping Lug 8

4-002-0 Impeller 1

4-023-0 Impeller Nut 1

4-911-0 Key, Impeller 1

5-007-0 Shaft 1

5-018-3 Bearing Cap, Inboard 1

16

5-083-0 Frame 1

6-400-0 Mechanical Seal 1

6-903-0 Gland Nut 2

Without By-Pass 2

6-924-0

With Seal Cage 4

OPTIONAL COMPONENTS

1-652-0 By-Pass Piping Kit, Seal Cage 1

2-003-5 Wear Ring, Suction 1

2-003-6 Wear Ring, Stuffing Box 1

6-013-0 Seal Cage 1

19

Page 20

ORDERING PARTS

The pumps covered by this manual have

been designed and built with certain

rep storing parts. The st be manu

laceable wea

rec nventory of spa

ommended i re parts

dep

ends upon the installation and the

imp ontinued operatio

ortance of c n.

For rvice requiring a

critical se minimum of

“do e” a complete or “quick

wn tim change”

rotating element ended.

For service, with repairs

normal to be made in

the e following parts are

field, th

rec for stock.

ommended

x rings

1 set of bea

x g rings

1 set of wearin

x askets and O-rings

2 sets of g

x ical seals (complete)

2 mechan

Par

ts should be ordered as far in advance of

the sible since

ir use as pos circumstances

is recomm

DEAL R SER G

E VICIN

beyond the control of the company may

reduce existing stock. Not all parts are

cked and mu factured for

ord

er.

To pid handling of r

facilitate ra your order fo

spa parts, be sure to include the fol g

re lowin

info ation:

rm

1. r of the pump

Serial numbe .

2. h part.

Quantity of eac

3. mber of the pa

Catalog nu rt.

4. part.

Name of the

5. ed. (Parts d in

Material desir will be furnishe

original ma pecified as a

terials unless s

material change. All material substitutio

should be d the factory.)

iscussed with

each

ns

If trouble occurs that cannot be rectified,

contact your local AC Fire Pump

Systems representative. He will need the

following information in order to give you

assistance.

1. Complete nameplate data of pump and

motor.

2. Suction and discharge pipe pressure

gauge readings.

3. Ampere draw of the motor.

4. A sketch of the pump hook-up and piping.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/acfirepump

AC Fire Pump is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. AC8652C May 2013

Loading...

Loading...