Page 1

Guarantee

Xpelair

GB

UK: This fan is guaranteed against defects for 3 years from the date of purchase.

Xpelair reserve the right to repair or replace the fan.

Keep your purchase receipt.

Any problems, contact the address below.

Outside UK: See International section below.

Technical Advice & Service

UK - Xpelair have a comprehensive range of services including:

Free technical advice Help-Desk from Engineers on all aspects of ventilation.

Free design service, quotations and site surveys.

Outside UK: See International section below.

Please ask for details on:

Tel +44 (0) 8709 000430

Fax +44 (0) 8709 000530

Also at the address below

Head Office – UK Sales Office and Spares

Applied Energy Products Ltd, Morley Way, Peterborough, PE2 9JJ, England

Tel: +44 (0) 1733 456789

Fax: +44 (0) 1733 310606

Sales/Spares Hotline: +44 (0) 8709 000420

Sales/Spares Faxline: +44 (0) 8709 000520

Web: http://www.xpelair.co.uk

International

Condensation Control Fans

♦CF20 Pull Cord

♦CF20T Pull Cord/Timer

Remote Switched Centrifugal Ducted Fans

♦DX200 Remote Switch

♦DX200T Remote Switch/Timer

Installation and operating instructions

Please retain for end user’s future reference

F

D

NL

N

S

I

GR

a

ES

Guarantee – Contact your local distributor or Xpelair direct

Technical advice and Service - Contact your local Xpelair distributor.

567-2066-02

Revision A

Page 2

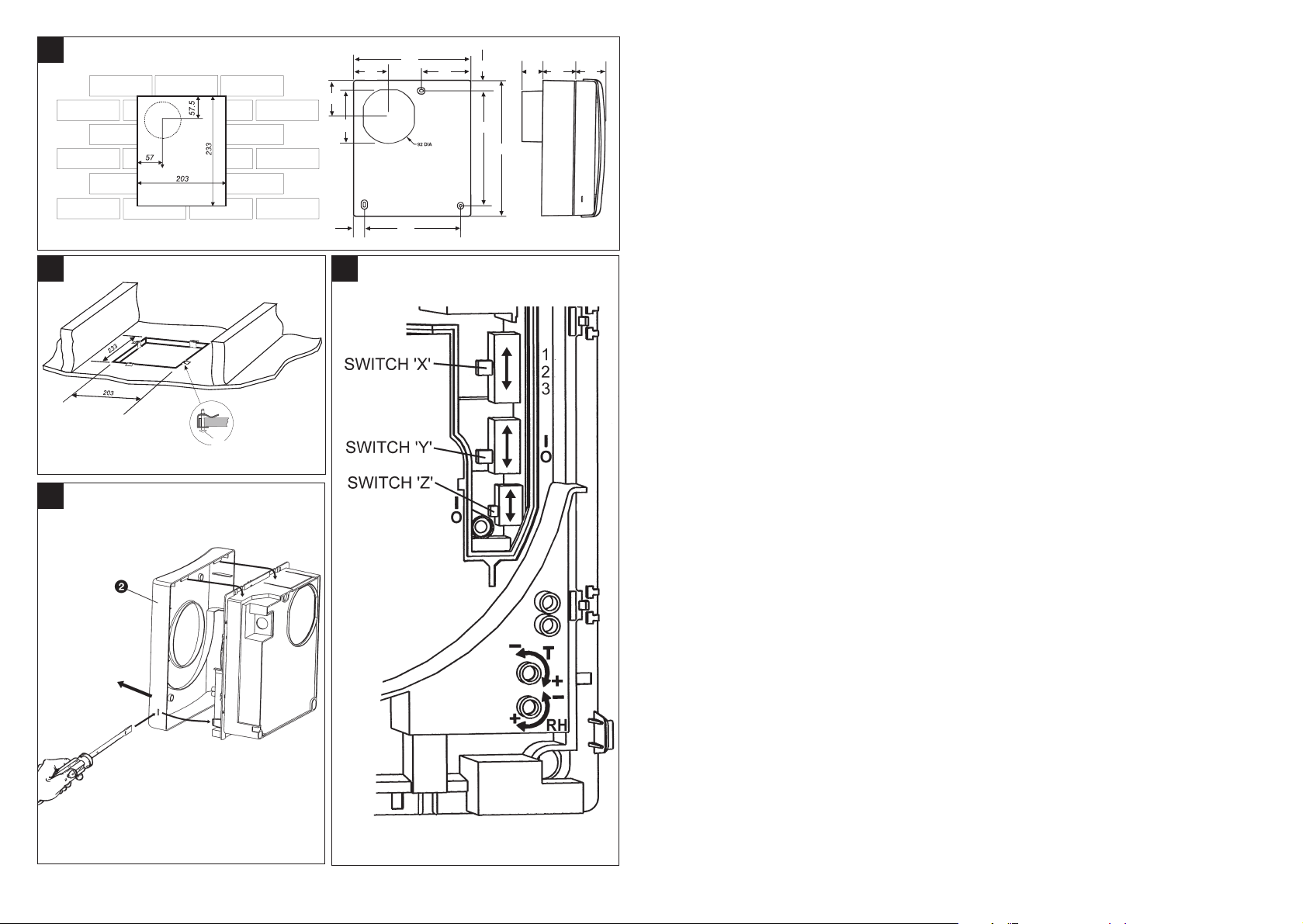

A

222

66

66

94

FIXING

HOLE

20

FIXING

FRONT VIEW

182

HOLE

93

FIXING

HOLE

20

213

40 62 56

252

B

C

D

!¡

Page 3

Page 4

DX200

CF20

CF20T / DX200T

G

F

ES

Opciones auxiliares

Para realizar la instalación rápida y fácilmente,

puede necesitar algunos de los accesorios

siguientes:

WD100 Conducto para pared

CFWG100 Rejilla para pared

FDA Juego de adaptador para

conducto plano

XCT100 Retenedor de condensación

DGW/B Rejilla para la puerta de

intercambio del aire

SP100 Placa del tubo

XAA Adaptador para ladrillo ventilador

VC10 Portezuela de ventilación

WT10 Kit de terminación del conducto

XF/FM Conducto plano (Plástico/Metal)

(Plástico 234 x 29mm Metal 230 x

25mm)

VK10 Kit de ventilación para pared

FD100 Conducto flexible

WDC5 Sujetadores de tornillo sin fin

XCMK Kit de montaje en techo

XBP Obturador de contratiro

EFT Kit de terminación de fácil

instalación

GMK Kit de montaje de cristal

PDXGF Filtro de grasa

A continuación se listan algunos de los

recambios disponibles. Remítase a la última

página de este folleto para los detalles de

pedido:

41520SK Kit de reparación (kit completo)

41528SK Tubo circular (gama completa)

41731SK Motor (DX200)

41733SK Motor (CF20/CF20T/

DX200T)

41782SK Conjunto PCB (DX200T)

41735SK Conjunto PCB (CF20)

41736SK Conjunto PCB (CF20T)

41737SK Cubierta delantera / Deflector

(DX200)

41738SK

Cubierta delantera / Deflector

(DX200T)

41739SK

Cubierta delantera / Deflector

(CF20/CF20T)

41740SK Moldura borde (gama completa)

41741SK Conjunto de cordón (CF20/CF20T)

41742SK Rotor (gama completa)

Page 5

N S I GR

Tilbehør

For å forenkle installasjonen og

spare tid, kan det være at din

installasjon krever noe av

tilbehøret som er listet opp

nedenfor:

WD100 Vegg-gjennomføring

CFWG100 Vegg-gitter

FDA Utstyrspakke med

plant kanaladapter

XCT100 Kondensavskiller

DGW/B Gitterluke for

luftutskiftning

SP100 Muffeplate

XAA Luftadapter for mur

VC10 Avtrekksdeksel

WT10 Kanalavslutnings-sett

XF/FM Plan rørkanal

(plast/metall)

(plast 234 x 29 mm

metall 230 x 25 mm)

VK10 Veggventil-sett

FD100 Fleksibel rørkanal

WDC5 Snekkeskrue-klips

XCMK Sett for montering i

himling

XBP In-line

tilbakeslippsklaff

EFT Lettmontert

avslutnings-sett

GMK Sett for montering i

vindu

PDXGF Fettfilter

Nedenfor er det listet opp enkelte

reservedeler som er tilgjengelige.

Se baksiden på denne trykksaken

for bestillingsinformasjon:

41520SK Monterings-sett

(komplett)

41528SK Rund muffe (komplett)

41731SK Motor (DX200)

41733SK Motor (CF20/CF20T/

DX200T)

41782SK Kretskort-komponent

(DX200T)

41735SK Kretskort-komponent

(CF20)

41736SK Kretskort-komponent

(CF20T)

41737SK Frontdeksel kompl.

med mottrykksplate

(DX200)

41738SK

Frontdeksel kompl. med

mottrykksplate (DX200T)

41739SK

Frontdeksel kompl. med

mottrykksplate

(CF20/CF20T)

41740SK Innfatningsprofil

(komplett)

41741SK

Snorbryter-komponent

(CF20/CF20T)

41742SK Viftehjul (komplett)

Tillbehör

I listan nedan hittar du hjälpmedel

som kan vara av nytta under

installationen:

WD100 Väggtrumma

CFWG100 Väggaller

FDA Adaptorsats för

planmontering

XCT100 Kondensavledare

DGW/B Luftregleringsgaller

SP100 Mufförbindningsplatta

XAA Adapter

VC10 Ventilhuv

WT10 Avspänningssats

XF/FM Planmontering

(plast/metall)

(plast 234 x 29 mm)

(metall 230 x 25 mm)

VK10 Väggventilsats

Accessori opzionali

Per un’installazione più facile e

veloce, potrebbero essere

necessari alcuni degli accessori

sottoelencati:

WD100 Condotto per parete

CFWG100 Grata per parete

FDA Kit adattatore per

XCT100

DGW/B Grata dello sportello di

SP100 Piastra di imbocco

XAA Adattatore per mattoni

VC10 Cappottatura di

WT10 Kit di terminazione

XF/FM Condotti piatti

FD100 Flexibel

ledningsdragning

WDC5 Skruvdriftsklämmor

XCMK Takmonteringssats

XBP Svart reglerventil

EFT Avspänningssats

GMK Glasmonteringssats

PDXGF Smörjningsfilter

I listan nedan hittar du

reservdelar. Du hittar

beställningsinformation på denna

bruksanvisnings baksida:

41520SK Fastsättningssats

(komplett)

41528SK Mufförbindning

(komplett sortiment)

41731SK Motor (DX200)

41733SK Motor (CF20/CF20T/

DX200T)

41782SK PCB-montering

(DX200T)

41735SK PCB-montering

(CF20)

41736SK PCB-montering

(CF20T)

41737SK Främre skydd med

skärm (DX200)

41738SK Främre skydd med

skärm (DX200T)

41739SK

Främre skydd med

skärm (CF20/CF20T)

41740SK Ramformning

(komplett sortiment)

41741SK Dragsnöresmontering

(CF20/CF20T)

41742SK Fläkthjul (komplett

sortiment)

VK10 Kit di ventilazione per

FD100 Condotti flessibili

WDC5 Fermagli a vite senza

XCMK Kit di montaggio al

XBP Otturatore in linea del

EFT Kit di terminazione di

GMK Kit per il montaggio su

PDXGF Filtro antigrasso

Qui di seguito sono elencati alcuni

dei ricambi disponibili. Per

informazioni su come ordinarli,

consultare la quarta di copertina:

41520SK Kit di fissaggio (kit

41528SK Imbocco a bicchiere

41731SK Motorino (DX200)

41733SK Motorino (CF20/

41782SK Gruppo PCB

41735SK Gruppo PCB (CF20)

41736SK Gruppo PCB (CF20T)

41737SK Coperchio anteriore

41738SK Coperchio anteriore

41739SK Coperchio anteriore

41740SK

41741SK

41742SK

condotto piatto

Pozzetto di

intercettazione della

condensa

ricambio aria

traforati

ventilazione

condotti

(plastica/metallo)

(plastica 234 x 29mm,

metallo 230 x 25mm)

parete

fine

soffitto

tiraggio di ritorno

facile montaggio

vetro

intero)

circolare (intera

gamma)

CF20T/DX200T)

(DX200T)

completo di

diaframma (DX200)

completo di

diaframma (DX200T)

completo di

diaframma

(CF20/CF20T)

Modanatura della

cornice

(intera gamma)

Gruppo cordicella

(CF20/CF20T)

Girante (intera

gamma)

Συµπληρωµατικές Επιλογές

Γι α γρήγορη και εύκολη

εγκατάσταση, η εγκατάσταση

σας µπορεί να χρειαστεί µερικά

απ τα Συµπληρωµατικά που

αναφέρονται πιο κάτω:

WD100 Αγωγς τοίχου

CFWG100 Κιγκλίδωµα τοίχου

FDA Προσαρµογέας

επίπεδου αγωγού

XCT100 Ατµοπαγίδα

DGW/B Κιγκλίδωµα πρτας

ανανέωσης αέρα

SP100 Πλάκα βύσµατος

XAA Προσαρµογέας

τούβλου αέρα

VC10

Κάλυµµα αεραγωγού

WT10 Σύνολο αγωγού

τερµατισµού

XF/FM Επίπεδος αγωγς

(πλαστικ/µέταλλο)

(Πλαστικ 234 χ 29 χλστ.

Μέταλλο 230 χ 25 χλστ.)

VK10 Σύνολο αεραγωγού

τοίχου

FD100 Εύκαµπτος αγωγς

WDC5 Κλιπ οφιοειδούς

κίνησης

XCMK

Σύνολο τοποθέτησης

σε ταβάνι

XBP Φράχτης

οπισθοδροµικού

ρεύµατος in-line

EFT Σύνολο

τερµατισµού

εύκολης εφαρµογής

GMK

Σύνολο τοποθέτησης

γυαλιού

PDXGF Φίλτρο γράσου

Πιο κάτω αναφέρονται µερικά

απ τα διαθέσιµα ανταλλακτικά.

Συµβουλευθείτε την πίσω ψη

του παρντος φυλλαδίου για

λεπτοµέρειες παραγγελίας:

41520SK Σύνολο στερέωσης

(ολκληρο σύνολο)

41528SK Κυκλικ βύσµα

41731SK Μοτέρ (DX200)

41733SK

Μοτέρ (CF20/CF20T/

DX200T)

41782SK

Σύνολο PCB (DX200T)

41735SK Σύνολο PCB (CF20)

41736SK

Σύνολο PCB (CF20T)

41737SK

Μπροστιν κάλυµµα

συνοδευµενο απ

εκτροπέα (DX200)

41738SK Μπροστιν

κάλυµµα

συνοδευµενο απ

εκτροπέα (DX200T)

41739SK

Μπροστιν κάλυµµα

συνοδευµενο απ

εκτροπέα (CF20/CF20T)

41740SK Χυτ πλαίσιο

(ολκληρη σειρά)

41741SK Σύνολο κορδονιού

τραβήγµατος

(CF20/CF20T)

41742SK Στροφείο

(ολκληρη σειρά)

GB

IMPORTANT

1. READ ALL THESE INSTRUCTIONS & WARNINGS FULLY BEFORE COMMENCING INSTALLATION.

2. INSTALLATIONS AND WIRING MUST CONFORM TO CURRENT IEE REGULATIONS (UK), LOCAL OR APPROPRIATE

REGULATIONS (OTHER COUNTRIES). IT IS THE INSTALLER’S RESPONSIBILITY TO ENSURE THAT THE APPROPRIATE

3. A QUALIFIED ELECTRICIAN MUST SUPERVISE ALL INSTALLATIONS.

4. THESE APPLIANCES ARE INTENDED FOR CONNECTION TO FIXED WIRING

5. CHECK THAT THE ELECTRICAL RATING SHOWN ON THE FAN MATCHES THE MAINS SUPPLY.

6.

7. SITE AWAY FROM DIRECT SOURCES OF HEAT (I.E.: GAS COOKERS OR EYE-LEVEL GRILLS) AND NOT WHERE

8. WHEN THE FAN IS INSTALLED IN A ROOM CONTAINING AFUEL BURNING APPLIANCE, PRECAUTIONS MUST BE TAKEN TO

9. ENSURE THAT ALL RELEVANT SAFETY PRECAUTIONS (CORRECT EYE PROTECTION AND PROTECTIVE CLOTHING

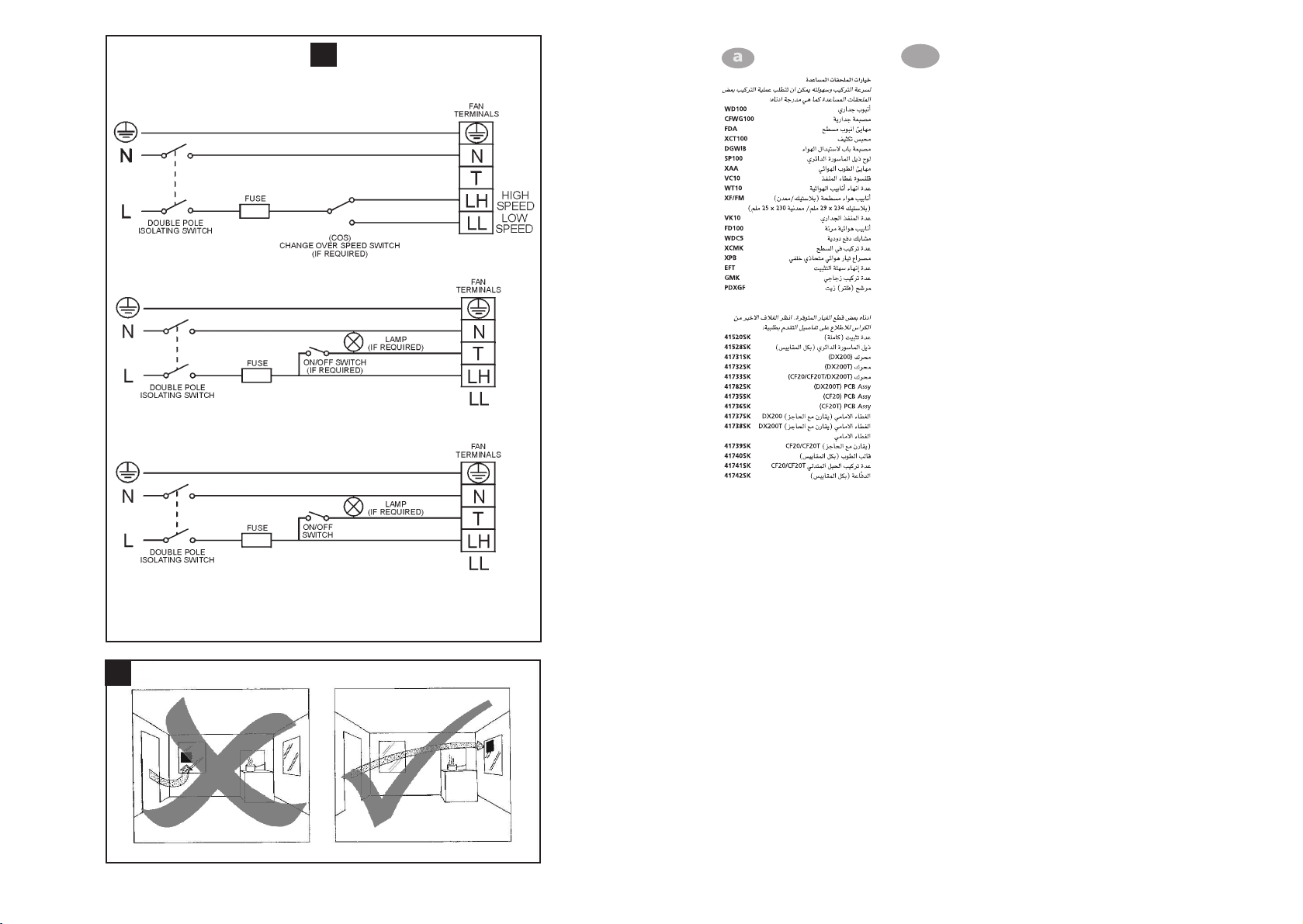

10. GENERAL GUIDANCE FOR SITING THE FAN SEE “FIG. G”. ALWAYS SITE FAN AS HIGH AS POSSIBLE

11. IF ANY SECTION OF THE DUCTWORK IS POSITIONED HIGHER THAN THE FAN A CONDENSATION TRAP (XCT100) MUST

For speed and ease of Installation, your installation may require some of the

Ancillaries indicated in “Ancillary Options”.

If installing on a wall (surface mounting)

1. Mark on the wall the centre of the duct hole A.

2. Use this centre to cut an opening through the wall 117mm dia, with a slight

fall to the exterior.

3. Fit the wall duct (WD100), not supplied, and mortar into place.

If installing on a wall (flush mounting)

1. Mark on the wall the centre of the duct hole A, and drill a pilot

hole through both walls at a slight downward angle.

2. Use the centre to mark a rectangular hole for the inner wall using the

dimensions

3. Cut the rectangular hole through the inner wall.

4. Go outside and cut a 117mm-diameter hole in the outer wall using the small

hole as the centre.

5. Measure the wall thickness.

Cut the wall duct (WD100), not supplied, so that it is 64mm less than the

wall thickness.

If installing in a ceiling (surface mounting)

This method requires a space above the ceiling, such as a loft or attic, to provide

access for 100mm internal diameter ducting.

1. Mark on the ceiling the centre of the duct hole A, avoiding ceiling joists and

buried cables etc.

2. Cut a 117mm-diameter hole using the marked centre.

If installing in a ceiling (flush mounting)

For 100mm diameter ducting:

1. Mark a rectangular hole using the dimensions

2. Cut the hole, avoiding ceiling joists and buried cables etc.

For flat ducting:

• This fan can be installed within a 47mm void without the circular spigot

(Fig.E). Flat ducting adapter kit (FDA) available.

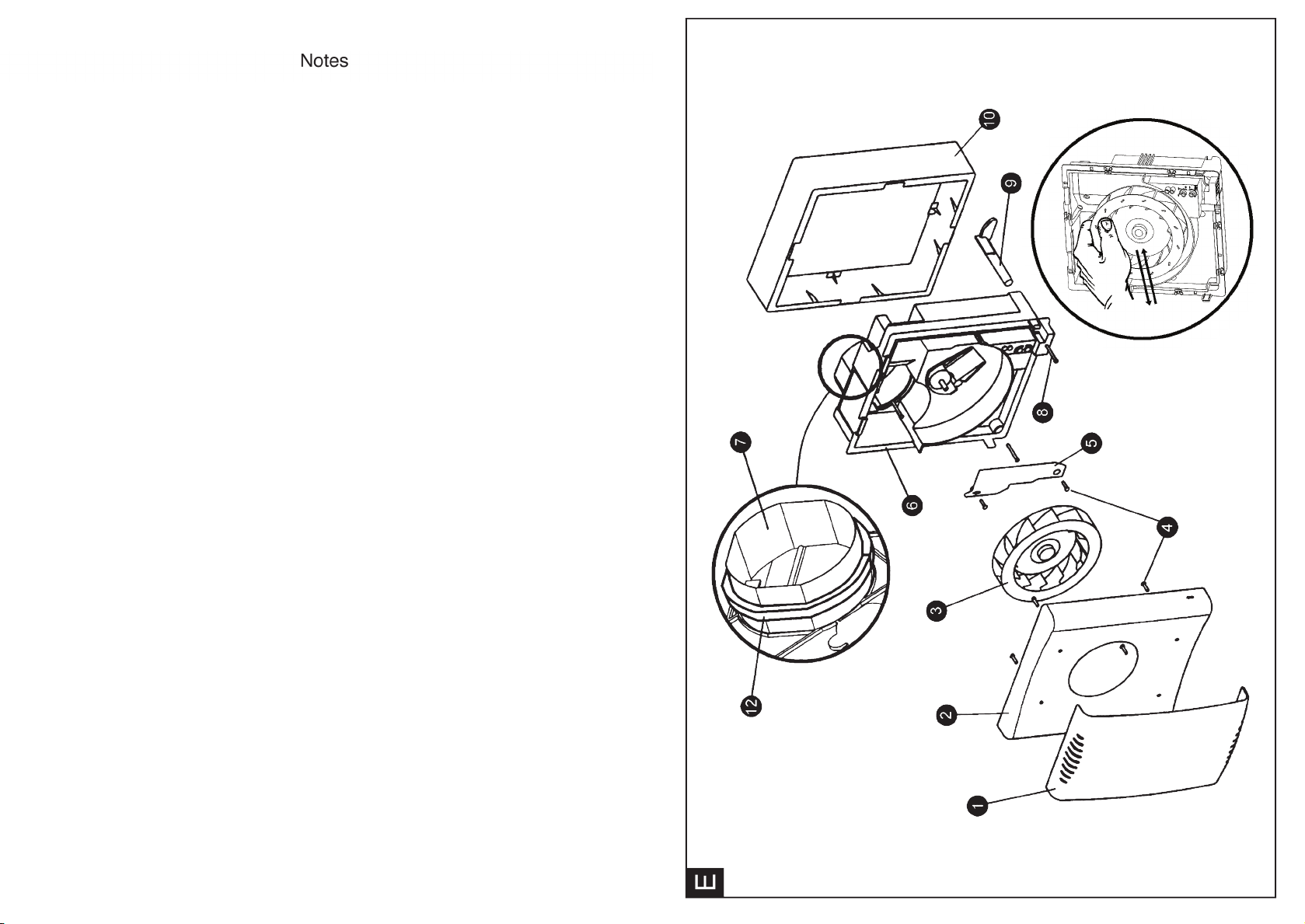

Preparing the fan for installation

1. Remove the front cover 2 (Fig.C)

2. Fit the foam tape

3. Remove the electrical cover

ease access (if required). This is a "push-on/pull-off" assembly.

Setting the fan speed

DX200T / CF20 / CF20T Only (Fig.D)

4. The correct condensation control speed (CF20/CF20T) or operating speed

(DX200T) should be selected to suit the room size in which the fan is to be

installed. Slide the switch

fan is factory set to “Position 2”.

5. Switch Position Size / Room Volume (m

1 Large (34 and above)

2 Medium (28 – 34)

3 Small (less than 28)

BUILDING CODES OF PRACTICE ARE ADHERED TO.

WARNING: THESE APPLIANCES MUST BE EARTHED.

AMBIENT TEMPERATURES ARE LIKELY TO EXCEED 50˚C.

AVOID THE BACKFLOW OF GASES INTO THE ROOM FROM THE OPEN FLUE OF THE FUEL BURNING APPLIANCE.

ETC) ARE TAKEN WHEN INSTALLING AND MAINTAINING THIS FAN.

BE FITTED AS CLOSE AS POSSIBLE TO THE FAN.

Setting the trickle speed

DX200T / CF20 / CF20T Only (Fig.D)

6. The fan can be set so that it provides constant trickle extraction. Slide the

Y to the required position. Please note that the fan is factory set to

switch

“Position 0”.

7. Switch Position Setting

0Trickle extraction OFF

ITrickle extraction ON

Setting the time delay start

DX200T / CF20T Only (Fig.D)

8. The fan can be set so that there is a 2-minute delayed start to its

A.

B.

!™ supplied around the circular spigot 7 (Fig.E).

5 (Fig.E). The impeller can be removed to

X to the required position. Please note that the

3

)

7

operation when used with an external on/off switch. Slide the

Z to the required position. Please note that the fan is

switch

factory set to “Position 0”.

Switch Position Setting

0Time delay start OFF

ITime delay start ON

Mounting the fan on a wall or ceiling (surface mounting)

1. Place the ducting into the hole and align to the required position. If wall

mounting, ensure that the ducting slopes down and away from the fan

2. Mark the positions of the three fixing holes

3. If wall mounting, drill three holes 5.5mm diameter for wall plugs (supplied).

If ceiling mounting

4. Cut out the cable inlet hole, if required, in the surround

grommet. Slide the surround

5. Pass the electrical cables into the fan box

hole and surround, and re-fit the cable grommet.

Ensure that cable grommet is in place and a tight fit.

6. Offer the fan box 6 up to the wall or ceiling. Ensure the circular spigot 7

enters the ducting.

7. Fix the fan box

appropriate fasteners (not supplied).

If mounting in a wall (flush mounting)

The surround 0 is not required. Fit the ducting to the circular spigot 7.

If the hole size is as recommended:

1. Assemble the three fan body clamps 9 to the fan box 6 using screws 8.

2. Slit the cable grommet. Pass the electrical cables into the fan box

through the cable inlet hole and cable grommet.

Ensure cable grommet is in place and a tight fit.

3. Offer the fan box 6 up to the wall.

4. Tighten up the three screws

The fan body clamps

OVERTIGHTEN

If the hole size is larger than recommended i.e.: larger than the flange on the

66

fan box

1. The fan body clamps ARE NOT suitable. Construct a wooden frame of

INTERNAL dimensions 203 x 233mm. Depth should be at least 50mm. Fit the

B , use appropriate fasteners (not supplied).

6 to the wall using screws 8 or to the ceiling using

8 until the fan is clamped to the inner wall.

9 will rotate to an automatic stop position. DO NOT

.

(Mostly relating to “retro-fit” installations):

A in Fan box 6 (Fig.E).

0 over the fan box 6.

6 through the rear cable inlet

0 and slit the cable

6

Page 6

wooden frame into the internal wall and make good the hole.

2. Offer the fan box

3. Screw the fan box

(screws not supplied).

If mounting in a ceiling (flush mounting)

1. The surround 0 is not required.

2. Insert the fan box

the flange

3. Remove the fan box

over the edge of the hole, so that the clips align with the marks on the ceiling

4. Drill 4 pilot holes into the ceiling through the hole of each clip, ensuring not to

damage the clip.

5. Fit the ducting to the circular spigot

6. Offer the fan box

7. Slit the cable grommet. Pass the electrical cable into the fan box

Ensure cable grommet is in place and a tight fit.

8. Using the screws !¡ (Fig.B), fix the fan box flange to the ceiling clips.

Terminating the ducting

Fit an outer grille (such as CFWG100, not supplied in the DX200/DX200T)

to the outer wall. For ceiling mounting, use appropriate ancillaries (not

supplied).

Wire the electrical connections

WARNING! THIS APPLIANCE MUST BE EARTHED

1. Isolate the electricity supply and remove all fuses.

The terminal block will accept cable up to 1.5mm

2. Use a double-pole isolating switch with a minimum contact gap of 3mm in

both poles.

3. Use suitably rated 3-core or 4-core cable dependant on application.

4. Remove the retaining screws of the terminal cover, if still in position.

5. Wire the fan as shown in

model to diagram.

DX200: “LH” =Live (High Speed)/ “LL” = Live(Low Speed)

6. Replace the terminal cover

7. See section on

those that have been factory set.

8. Refit the front cover(Fig.

Connect the cable from the isolating switch to electrical supply wiring, and

re-check installation.

10. Refit fuses before turning on electricity supply.

11. For fixed wiring circuits, the protective fuse for the appliance must not

exceed 5A.

For Australia Only

– Connection to the supply - flexible 3-core cable with 3 pin plug top for

CF20

insertion into an approved 10A wall mounted surface switch with at least 3mm

clearance between contacts.

ALL OTHERS – Permanently connected to the supply and a remote switch controls

operation. They should be directly wired to the supply through an approved 10A wall

mounted surface switch with at least 3mm clearance between contacts.

User adjustments

Before making any adjustments, isolate the fan completely from the mains

supply, check specification below to see which features apply to your fan.

1. Remove the front cover and replace after adjustment (Fig. C)

DX200

There are no user adjustments for this fan.

DX200T

1. The timer over-run period can be adjusted between approximately 30

seconds and 20 minutes. Use an electrician’s screwdriver and turn screw “T”

(Fig.

preset to approximately 10 minutes)

CF20

1. The humidity setting is adjustable between approximately 50% and 90%

relative humidity. Use an electrician’s screwdriver, and turn screw “RH”

(Fig.

to decrease. (Note: the fan is more sensitive at 50% RH than at 90% and is

factory preset to approximately 70%).

6 up to the wall.

6 to the wooden frame using the slots in the flange

6 into the hole and mark four positions using the slots in

B.

6 from ceiling and fit the four ceiling clips (supplied)

6 up to the ceiling.

the front cable inlet hole.

“User adjustments” if you wish to use settings other than

D), clockwise to increase time, anti-clockwise to decrease. (Factory

D), clockwise to increase the relative humidity setting and anti-clockwise

7.

6 through

2

F using the cable clamp provided. Check fan

5 and fasten the retaining screws.

C).

CF20T

1. The timer over-run period can be adjusted between approximately 30

seconds and 20 minutes. Use an electrician’s screwdriver and turn screw “T”

D), clockwise to increase time, anti-clockwise to decrease.

(Fig.

2. The humidity setting is adjustable between approximately 50% and 90%

relative humidity. Use an electrician’s screwdriver, and turn screw “RH”

D), clockwise to increase the relative humidity setting and anti-clockwise

(Fig.

to decrease. (Note: the fan is more sensitive at 50% RH than at 90%).

Using the fan

B.

DX200

Operate the fan using the external on/off switch. Repeat to switch off.

The fan speed is pre-set by the installer to either high or low speed. (If a change

over switch has been installed then the user can switch between high speed and

low speed.)

DX200T

Operate the fan using the external on/off switch. Repeat to switch off.

When the switch is turned off, the fan continues to operate for the selected overrun timer period. Top

The fan speed is pre-set by the installer to either high, medium or low speed.

Time delay start feature on or off

This is set by the installer to provide a 2-minute time delay start when the fan is

switched on using the external on/off switch.

CF20 / CF20T

Switched Operation

The fan can be wired with a separate on/off switch. Fan operates at condensation

speed when switched on. Top

switched on. When switched off, the fan will continue to operate if the humidity level

exceeds the set level.

at condensation speed for the adjustable timer over-run period.

Condensation Operation

The fan operates at condensation control speed, when the relative humidity

exceeds the set level, and turns off when the humidity drops.

Boost Operation

The integral pull cord switch switches the fan to run at high speed. Bottom “Light

is lit when the fan is operating at high speed.

II”

Note: If the separate on/off switch and integral pull cord are both on, then

will both be lit and the fan will run at high speed.

and “II”

CF20T only

Time delay start feature on or off

This is set by the installer to provide a 2-minute time delay start when the fan is

switched on using a separate on/off switch.

Cleaning

Before cleaning, isolate the fan completely from the mains supply

Only clean the external surface of the fan, using a damp lint free cloth.

Do not use strong detergents, solvents or chemical cleaners

Allow fan to dry thoroughly before use.

Apart from cleaning, no other maintenance is required.

Key See Diagram

1. Baffle Plate

2. Front Cover

3. Impeller

4. Fixing Screws

5. Terminal Cover

6. Fan Box

PLEASE LEAVE THIS LEAFLET WITH THE FAN FOR THE BENEFIT OF THE

USER

Light “I” is lit when the external on/off switch is switched on.

“Light I” is lit when the separate on/off switch is

CF20T only: When switched off, the fan continues to operate

Lights “I”

E

7. Circular Spigot

8. Clamp screws and wall plugs - 3 off

9. Fan Body Clamps – 3 off

10. Surround

11. Ceiling Screws 25mm long 4 off (Diagram

12. Foam Tape

B)

GB

Ancillary Options

For speed and ease of

Installation, your installation may

require some of the Ancillaries

listed below:

WD100 Wall Duct

CFWG100 Wall Grille

FDA Flat Duct Adaptor Kit

XCT100 Condensation Trap

DGW/B Air Replacement Door

Grille

SP100 Spigot Plate

XAA Air Brick Adaptor

VC10 Vent Cowl

WT10 Termination Ducting

Kit

XF/FM Flat Ducting

(Plastic/Metal)

(Plastic 234 x 29mm

Metal 230 x 25mm)

VK10 Wall Vent Kit

FD100 Flexible Ducting

WDC5 Worm Drive Clips

XCMK Ceiling Mounting Kit

XBP In-Line Back Draught

Shutter

EFT Easy Fit Termination

Kit

GMK Glass Mounting Kit

PDXGF Grease Filter

Listed below are some of the

spares available. See back page

of this booklet for ordering details:

41520SK Fixing kit (Entire kit)

41528SK Circular Spigot (Entire

Range)

41731SK Motor (DX200)

41733SK Motor (CF20/CF20T/

DX200T)

41782SK PCB Assy (DX200T)

41735SK PCB Assy (CF20)

41736SK PCB Assy (CF20T)

41737SK Front Cover c/w Baffle

(DX200)

41738SK Front Cover c/w Baffle

(DX200T)

41739SK Front Cover c/w Baffle

(CF20/CF20T)

41740SK Surround Moulding

(Entire Range)

41741SK Pull cord assembly

(CF20/CF20T)

41742SK Impeller (Entire

Range)

Accessoires en option

Pour une installation rapide et

facile, il est préconisé de se munir

des accessoires figurant sur la

liste ci-dessous :

WD100 Conduit mural

CFWG100 Grille murale

FDA Kit d'adapteur de

XCT100 Trappe de

DGW/B Grille de porte de

SP100 Plaquette pour ergot

XAA Adaptateur de brique

VC10 Capuchon d’évent

WT10 Kit de terminaison de

XF/FM Conduit plat

VK10 Kit pour évent mural

FD100 Conduit flexible

WDC5 Colliers à serrage par

XCMK Kit pour montage au

XBP Obturateur de

EFT Kit de terminaisons à

GMK Kit de pose sur une

PDXGF Filtre de graisse

Liste de quelques pièces de

rechange : Pour la commande,

prière de se reporter à la dernière

page de cette notice :

41520SK Kit de fixation (Kit

41528SK Ergot circulaire

41731SK Moteur (DX200)

41733SK Moteur (CF20/CF20T/

41782SK Carte imprimée

41735SK Carte imprimée

41736SK Carte imprimée

41737SK Couvercle avant avec

41738SK

41739SK

41740SK Moulure de cadre

41741SK

41742SK Hélice (gamme

F D NL

Zubehör

Die unten aufgeführten Produkte

unterstützen eine schnelle und

problemlose Installation:

WD100 Wandrohr

CFWG100 Wandgitter

FDA Flachrohr-Adapter

XCT100 Kondensationsfalle

conduit plat

condensation

remplacement d’air

perforée

conduit

(Plastique/Métallique)

(Plastique 234 x 29 mm

Métallique 230 x 25 mm)

DGW/B Luftaustauschtürgitter

SP100 Zapfenplatte

XAA Luftziegel-Adapter

VC10 Lüftungskappe

WT10 Bausatz für

XF/FM Flachrohr

VK10 Bausatz für

FD100 Flexibles Rohr

WDC5 Schneckenantriebs-

XCMK Bausatz für

vis sans fin

plafond

refoulement en

ligne

encliqueter

vitre

XBP In-Line-

EFT „Easy Fit" Bausatz für

GMK Bausatz für

PDXGF Fettfilter

Unten aufgeführt sind einige

Ersatzteile. Auf der Rückseite

dieses Hefts finden Sie

Einzelheiten über die Bestellung:

41520SK

41528SK Rundzapfen

complet)

(gamme complète)

DX200T)

(DX200T)

(CF20)

(CF20T)

chicane (DX200)

Couvercle avant avec

chicane (DX200T)

Couvercle avant avec

chicane (CF20/CF20T)

(gamme complète)

Ens. interrupteur à

cordon (CF20/CF20T)

41731SK Motor (DX200)

41733SK Motor (CF20/CF20T/

41782SK Flachbaugruppe

41735SK Flachbaugruppe

41736SK Flachbaugruppe

41737SK Frontabdeckung C/W

41738SK Frontabdeckung C/W

41739SK

41740SK Einfassungsform

41741SK Zugschnur

41742SK Gebläserad

complète)

Rohrabbruch/

Rohrabschluss

(Kunststoff/Metall)

Kunststoff 234 x 29 mm,

Metall 230 x 25 mm

Wandlüftungs

klemmen

Deckenmontage

Durchzugsklappe für

die Rückseite

Rohrabbruch/

Rohrabschluss

Glasmontage

Befestigungsbausatz

(gesamter Bausatz)

(gesamtes Sortiment)

DX200T)

(DX200T)

(CF20)

(CF20T)

Ablenkung (DX200)

Ablenkung (DX200T)

Frontabdeckung C/W

Ablenkung (CF20/CF20T)

(gesamtes Sortiment)

(CF20/CF20T)

(gesamtes Sortiment)

Accessoireopties

Voor snelheid en gemak van

installatie is het mogelijk dat u

sommige van de onderstaande

accessoires nodig heeft.

WD100 Muurdoorvoer

CFWG100 Muurrooster

FDA Adapterkit voor plat

XCT100 Condensaatvanger

DGW/B Deurrooster voor

SP100 Luchtinlaatplaat

XAA Adapter voor

VC10 Uitlaatkap

WT10 Muurdoorvoerset

XF/FM Plat kanaal

VK10 Muuruitlaatset

FD100 Flexibele slang

WDC5 Schroefdraadklemmen

XCMK Plafondmontagekit

XBP Gealigneerde

EFT

GMK Glasmontagekit

PDXGF Oliefilter

Hieronder vindt u een lijst van

verkrijgbare reserveonderdelen.

Verwijs naar de achterste pagina

voor het bestellen ervan.

41520SK Montageset (volledig

41528SK Ronde luchtinlaat

41731SK Motor (DX200) **

41732SK Motor (DX200T) **

41733SK Motor (CF20/CF20T/

41734SK PCB montage

41735SK PCB montage (CF20)

41736SK PCB montage

41737SK Bovendeel

41738SK Bovendeel

41739SK Bovendeel

41740SK Lijstwerk voor

41741SK Trekkoordmontage

41742SK Rotor (volledige

kanaal

luchtverversing

gaatsteen

(plastic/metaal)

(Plastic 234 x 29mm

Metaal 230 x 25mm)

achterste tochtklep

Gemakkelijk te

monteren aansluitingset

set)

(volledige reeks)

DX200T)

(DX200T)

(CF20T)

ventilatorhuis met

schermplaat (DX200)

ventilatorhuis met

schermplaat (DX200T)

ventilatorhuis met

schermplaat

(CF20/CF20T)

montageplaat

(volledige reeks)

(CF20/CF20T)

reeks)

Page 7

La profundidad deber ser de por lo menos 50 mm. Monte el marco de madera

en la pared interna y ajústelo en el agujero.

2. Sitúe la caja del ventilador

3. Atornille la caja del ventilador

saliente (los tornillos no se suministran).

Si se monta en el techo (montaje embutido)

1. No hace falta el borde 0.

2. Introduzca la caja del ventilador

con las ranuras en el saliente

3. Quite la caja del ventilador

(suministrados) por encima del borde del agujero, de forma que los sujetadores

queden alineados con las marcas del techo

4. Taladre

4 agujeros de referencia en el techo por el agujero de cada sujetador,

teniendo cuidado de no dañar el sujetador.

5. Monte el conducto en el tubo circular

6. Sitúe la caja del ventilador

7. Corte el ojal del cable. Pase el cable eléctrico hasta el interior de la caja del

ventilador

6 por el agujero de entrada del cable delantero.

Asegúrese de que el ojal del cable esté en su sitio y bien ajustado.

8. Con los tornillos !¡ (Fig. B), sujete el saliente de la caja del ventilador en los

sujetadores del techo.

Acabado del conducto

Monte la rejilla exterior (por ejemplo la CFWG100, no suministrada de los modelos

DX200/DX200T), en la pared exterior. Utilice los accesorios adecuados para el

montaje en el techo (no suministrados).

Conexiones eléctricas

¡ADVERTENCIA! ESTE APARATO NECESITA TOMA DE TIERRA

1. Aísle la toma de corriente y quite todos los fusibles. El bloque de

terminales acepta cable de hasta 1,5mm

2. Use un interruptor bipolar aislante con una separación de contacto mínima de

3mm en ambos polos.

3. Use un cable adecuado de 3 almas o 4 almas, según la aplicación.

4. Quite los tornillos de retención de la cubierta de terminales, si está todavía en

su sitio.

5. Ponga los cables del ventilador tal y como se indica en la figura

abrazadera del cable que se suministra. Compruebe el modelo del ventilador en

el diagrama.

DX200: "LH" =Activo (Alta velocidad)/ "LL" = Activo (Baja velocidad)

6. Vuelva a poner la cubierta de terminales

7. Vea la sección sobre "Ajustes del usuario" si quiere utilizar ajustes distintos a los

que vienen de fábrica.

8. Vuelva a poner la cubierta delantera (Fig.

9. Conecte el cable que va del interruptor aislante hasta el cable de alimentación,

y vuelva a comprobar la instalación.

10. Vuelva a poner los fusibles antes de conectar la alimentación eléctrica.

11. Para los circuitos de cableado fijo, el fusible protector del aparato no debe

superar los 5A.

Sólo para Australia

CF20 –

Conexión a la alimentación eléctrica – cable flexible de 3 almas con clavija de

3 pines para enchufe homologado de pared de 10A y por lo menos 3mm de

separación entre los contactos.

OTROS – Conexión permanente a la alimentación eléctrica y funcionamiento con

control remoto por conmutador. Conexión directa a la toma de corriente mediante

enchufe homologado de pared de 10A y por lo menos 3mm de separación entre los

contactos.

Ajustes del usuario

Antes de realizar cualquier ajuste, aíslese totalmente el ventilador de la toma de

corriente, comprobando las especificaciones que se indican más abajo para ver

las características del ventilador.

1. Quite la cubierta delantera y vuélvala a poner después de realizar el ajuste

(Fig.

C).

DX200

Este ventilador no admite ajustes.

DX200T

1. El periodo de rebase del temporizador se puede ajustar entre aproximadamente

30 segundos y 20 minutos. Use un destornillador de electricista para girar el

tornillo "T" (Fig.

para disminuirlo. (Viene ajustado de fábrica en aproximadamente 10 minutos).

CF20

1. El nivel de la humedad es ajustable entre aproximadamente 50% y 90% de

humedad relativa. Use un destornillador de electricista para girar el tornillo "RH"

(Fig.

D) hacia la derecha para aumentar la humedad relativa y hacia la

izquierda para disminuirla. (Nota: el ventilador es más sensible a 50% HR que a

90%, viniendo de fábrica ajustado a aproximadamente 70%).

6 contra la pared.

6 en el marco de madera usando las ranuras del

6 en el agujero y marque las cuatro posiciones

B.

6 del techo y ponga los cuatro sujetadores del techo

B.

7.

6 contra el techo.

2

.

F, usando la

5 y apriete los tornillos de retención.

C).

D) hacia la derecha para aumentar el tiempo, o hacia la izquierda

CF20T

1. El periodo de rebase del temporizador se puede ajustar entre aproximadamente

30 segundos y 20 minutos. Use un destornillador de electricista para girar el

tornillo "T" (Fig.

izquierda para disminuirlo.

2. El nivel de la humedad es ajustable entre aproximadamente 50% y 90% de

humedad relativa. Use un destornillador de electricista para girar el tornillo "RH"

(Fig.

D) hacia la derecha para aumentar la humedad relativa y hacia la

izquierda para disminuirla. (Nota: el ventilador es más sensible a 50% HR que a

90%).

Uso del ventilador

DX200

El ventilador se apaga y enciende con el interruptor externo. La velocidad del

ventilador es preajustada por el instalador en alta o baja. (El usuario puede cambiar

la velocidad si se ha instalado un interruptor a tal efecto).

DX200T

El ventilador se apaga y enciende con el interruptor externo. Cuando el interruptor se

apaga, el ventilador continúa funcionando durante el periodo de rebase

preseleccionado. El testigo superior Luz

externo correspondiente.

La velocidad del ventilador está preajustada por el instalador, bien a velocidad alta,

media o lenta.

Activación o desactivación del arrancador diferido

La función de arrancador diferido es ajustada por el instalador y retrasa en 2 minutos

el arranque del ventilador cuando se enciende con el interruptor externo.

CF20 / CF20T

Operación mediante conmutador

El ventilador se puede dotar de un interruptor aparte de encendido y apagado. El

ventilador funciona a la velocidad de condensación al encenderse. El testigo superior

"Luz I" se ilumina cuando se enciende el interruptor aparte. Cuando se apaga, el

ventilador continúa funcionando si el nivel de humedad supera el nivel previsto.

para el modelo CF20T:

velocidad de condensación durante el durante el periodo de rebase preseleccionado.

Funcionamiento por condensación

El ventilador funciona a la velocidad de control de condensación cuando la humedad

relativa supera el nivel previsto, apagándose cuando baja el nivel de humedad.

Funcionamiento de sobreempuje

El interruptor con cordón integrado permite el funcionamiento del ventilador a alta

velocidad. El testigo inferior

velocidad.

Nota: Si están encendidos el interruptor aparte de encendido / apagado y el

interruptor con cordón integrado, los testigos Luces

ventilador funciona a alta velocidad.

Sólo para el modelo CF20T

Activación o desactivación del arrancador diferido

La función de arrancador diferido es ajustada por el instalador y retrasa en 2 minutos

el arranque del ventilador cuando se enciende con el interruptor aparte.

Limpieza

Antes de limpiarlo, es necesario aislar completamente el ventilador de la fuente

de alimentación.

Límpiese sólo la superficie exterior del ventilador con un paño húmedo sin pelusa.

No utilice detergentes fuertes, disolventes ni productos de limpieza química.

Deje que el ventilador se seque completamente antes de utilizarlo.

Aparte de la limpieza, el ventilador no necesita ningún tipo de mantenimiento.

Llave Remítase al Diagrama

1. Placa deflectora

2. Cubierta delantera

3. Rotor

4. Tornillos de sujeción

5. Cubierta de terminales

6. Caja del ventilador

7. Tubo circular

POR FAVOR DEJE ESTE FOLLETO JUNTO AL VENTILADOR PARA

INFORMACIÓN DEL USUARIO

D) hacia la derecha para aumentar el tiempo, o hacia la

"I" se ilumina al encender el interruptor

Cuando se apaga, el ventilador continúa funcionando a la

"Luz II" se ilumina cuando se el ventilador funciona a alta

"I" y "II" se encienden y el

EE

8. Tornillos de abrazadera y tacos para la pared 3 unidades

9. Abrazaderas del cuerpo del ventilador – 3 unidades

10. Borde

11. Tornillos para el techo de 25 mm de longitud 4 unidades (Diagrama

12. Cinta de espuma

B)

Sólo

F

IMPORTANT

1. AVANT DE COMMENCER L’INSTALLATION, IL FAUT LIRE ATTENTIVEMENT ET JUSQU’À LA FIN CETTE NOTICE ET LES AVERTISSEMENTS.

2. L’INSTALLATION ET LE CBLAGE ÉLECTRIQUE DOIVENT ÊTRE CONFORMES AUX RÈGLEMENTS IEE (R.U.), AUX RÈGLEMENTS MUNICIPAUX OU AUTRES

RÈGLEMENTS APPLICABLES (AUTRES PAYS) EN VIGUEUR. - IL INCOMBE À L’INSTALLATION DE S’ASSURER QUE LES RÈGLES DE DÉONTOLOGIE

APPLICABLE À LA CONSTRUCTION SONT RESPECTÉES.

3. TOUTES LES INSTALLATIONS DOIVENT ÊTRE EFFECTUÉES SOUS LA SUPERVISION D’UN ÉLECTRICIEN QUALIFIÉ.

4. CES APPAREILS SONT CONÇUS POUR ÊTRE RACCORDÉS PAR CBLAGE FIXE.

5. VÉRIFIER QUE LA TENSION NOMINALE INDIQUÉE SUR L’APPAREIL CORRESPOND À CELLE DE L’ALIMENTATION SECTEUR.

AVERTISSEMENT : CES APPAREILS DOIVENT ÊTRE RACCORDÉS À LA TERRE.

6.

7. LES PLACER À L’ÉCART DE TOUTE SOURCE DIRECTE DE CHALEUR (EX : CUISINIÈRES À GAZ OU GRILS À HAUTEUR DES YEUX). NE PAS LES INSTALLER SI

LA TEMPÉRATURE AMBIANTE EST SUSCEPTIBLE DE DÉPASSER 50°C.

8. SI LE VENTILATEUR EST INSTALLÉ DANS UNE PIÈCE CONTENANT UN APPAREIL DE CHAUFFAGE AU MAZOUT, IL FAUT PRENDRE LES PRÉCAUTIONS

NÉCESSAIRES POUR ÉVITER L’ASPIRATION DES GAZ PROVENANT DU CONDUIT OUVERT DE L’APPAREIL DE CHAUFFAGE AU MAZOUT DANS LA PIÈCE.

9. LORS DE L’INSTALLATION ET DE L’ENTRETIEN DU VENTILATEUR, VÉRIFIER QUE TOUTES LES CONSIGNES DE SÉCURITÉ APPROPRIÉES (LUNETTES ET

VÊTEMENTS DE PROTECTION APPROPRIÉS, ETC.) SONT RESPECTÉES.

10. DIRECTIVES GÉN’ERALES POUR LE CHOIX DE L’EMPLACEMENT DU VENTILATEUR, VOIR "FIG. G". PLACER LE VENTILATEUR AUSSI HAUT QUE POSSIBLE

11. SI UNE SECTION DU CONDUIT EST PLACÉE À UNE HAUTEUR SUPÉRIEURE AU VENTILATEUR, IL FAUT MONTER UNE TRAPPE DE CONDENSATION (XCT100)

AUSSI PRÈS QUE POSSIBLE DU VENTILATEUR.

Pour une installation rapide et facile, il est préconisé de se munir des accessoires

mentionnés au paragraphe "Accessoires en option".

Pour un montage mural (en surface)

1. Marquer sur le mur le milieu de l’orifice A du conduit.

2. Utiliser ce milieu pour découper un orifice dans le mur de 117 mm de

diamètre, avec une légère inclinaison vers l’extérieur.

3. Poser le conduit mural (WD100) (non fourni), et le fixer en place au mortier.

Pour un montage mural (encastré)

1. Marquer sur le mur le milieu de l’orifice A du conduit, et percer un avanttrou dans les deux murs.

2. Utiliser le milieu pour marquer un trou rectangulaire dans le mur interne,

selon les dimensions

3. Découper le trou rectangulaire dans le mur interne.

4. Passer à l’extérieur, et découper un trou de 117 mm de diamètre dans le

mur extérieur, en se servant du petit trou comme milieu.

5. Mesurer l’épaisseur du mur.

Couper le conduit du mur (WD100) (non fourni) afin qu’il ait une longueur

de 64 mm de moins que l’épaisseur du mur.

Pour un montage au plafond (en surface)

Pour cette méthode, il faut disposer d’un espace au-dessus du plafond (ex. comble

ou grenier), afin de prévoir l’accès du conduit de 100 mm de diamètre interne.

1. Marquer le milieu du trou du conduit

solives de plafond et les câbles dissimulés, etc.

2. Découper un trou de 117 mm de diamètre autour du milieu marqué.

Pour un montage au plafond (encastré)

Pour un conduit de 100 mm de diamètre :

1. Marquer un trou rectangulaire selon les dimensions

2. Découper le trou en évitant les solives du plafond et les câbles enterrés, etc.

Pour un conduit plat :

• Ce ventilateur peut être installé dans un vide de 47 mm sans l’ergot circulaire

7 (Fig.E). Kit adaptateur pour conduit plat (FDA) disponible.

Préparation du ventilateur pour l’installation

1. Retirer le couvercle avant 2(Fig.C)

2. Enrouler l’isolant adhésif

3. Retirer le couvercle électrique

requis), on peut retirer l’hélice. Cet ensemble se met en place par

enfoncement et se retire par traction.

Règlage de la vitesse du ventilateur

DX200T / CF20 / CF20T seulement (Fig.D)

4. Il faut sélectionner la vitesse du régulateur de condensation (CF20/CF20T)

ou la vitesse de fonctionnement (DX200T) en tenant compte des dimensions

de la pièce où est installé le ventilateur. Glisser le curseur

requise. À noter que le ventilateur est réglé en usine sur la "Position 2".

5. Position du curseur Dimensions / Volume de la pièce (m

1 Grande (34 et plus)

2 Moyenne (28 – 34)

3 Petite (moins de 28)

A.

A dans le plafond, en évitant les

B.

!™ fournie autour de l’ergot circulaire 7 (Fig.E).

5 (Fig.E). Pour faciliter l’accès (si

X à la position

3

)

Réglage de vitesse d’extraction de maintien

DX200T / CF20 / CF20T seulement (Fig.D)

6. On peut régler le ventilateur de manière à ce qu’il assure une extraction de

maintien constante. Glisser le curseur

le ventilateur est réglé en usine sur la "Position 0".

7. Position du curseur Réglage

0 Extraction de maintien Arrêt

I Extraction de maintien Marche

Réglage du début du temporisateur

DX200T / CF20T seulement (Fig.D)

8. On peut régler le ventilateur de manière à obtenir un délai de 2 minutes

avant sa mise en route lorsqu’il est utilisé avec un commutateur

Marche/Arrêt externe. Glisser le curseur

que le ventilateur est réglé en usine sur la "Position 0".

Position du curseur Réglage

0 Début du temporisateur Arrêt

I Début du temporisateur Marche

Pour un montage du ventilateur sur un mur ou un plafond (en surface)

1. Placer le conduit dans le trou et l’aligner à la position requise. Pour un

montage sur un mur, vérifier que le conduit est incliné vers le bas et à l’écart

du ventilateur.

2. Marquer les positions des trois trous de fixation

ventilateur (Fig.

3. Pour un montage sur un mur, percer trois trous de 5,5 mm de diamètre pour

les chevilles (fournies). Pour un montage au plafond

appropriées (non fournies).

4. Découper le trou d’admission du câble, si requis, dans l’encadrement

fendre le passe-fils. Glisser l’encadrement

5. Faire passer le câble électrique dans le boîtier

trou d’admission arrière pour câble et à travers l’encadrement, puis remettre

le passe-fils en place.

Vérifier que le passe-fils est en place et bien ajusté serré.

6. Présenter le boîtier 6 du ventilateur dans le mur ou le plafond. Vérifier que

l’ergot circulaire

7. Fixer le boîtier

plafond à l’aide de fixations appropriées (non fournies).

Pour un montage dans un mur (encastré)

L’encadrement 0 n’est pas requis. Monter le conduit jusqu’à l’ergot circulaire 7.

Si les dimensions du trou sont celles recommandées :

1. À l’aide des vis 8, assembler les trois brides 9 de la carène dans le boîtier

6 du ventilateur.

2. Fendre le passe-fils. Faire passer le câble électrique dans le boîtier

ventilateur à travers le trou d’admission de câble par le passe-fils.

Vérifier que le passe-fils est en place et bien ajusté serré.

3. Présenter le boîtier 6 du ventilateur dans le mur.

4. Serrer les trois vis

interne. Les brides

position de butée automatique.

Si les dimensions du trou sont supérieures à celles recommandées, ex. :

supérieures à la bride sur le boîtier

généralement aux installations "de rattrapage") :

1. Les brides de la carène du ventilateur NE conviennent PAS. Fabriquer un

cadre en bois de dimensions INTERNES de 203 mm x 233 mm.

E).

7 pénètre dans le conduit.

6 du ventilateur dans le mur à l’aide des vis 8 ou dans le

8 jusqu’à ce que le ventilateur soit plaqué sur le mur

9 de la carène du ventilateur pivoteront jusqu’à une

Y à la position requise. À noter que

Z à la position requise. À noter

A dans le boîtier 6 du

B, utiliser des fixations

0 sur le boîtier 6 du ventilateur.

6 du ventilateur, à travers le

NE PAS TROP SERRER.

66

du ventilateur (ceci se rapporte

0 et

6 du

Page 8

Il doit avoir une profondeur d’au moins 50 mm. Poser le cadre en bois dans le

mur interne, et reboucher la partie autour du trou.

2. Présenter le boîtier

3. En utilisant les fentes prévues dans la bride, visser (vis non fournies) le boîtier

6 du ventilateur dans le cadre en bois.

Pour un montage dans un plafond (encastré)

1. L’encadrement 0 n’est pas requis.

2. Introduire le boîtier

en utilisant les fentes de la bride

3. Retirer le boîtier

par-dessus le bord du trou de manière à aligner les colliers avec les repères

marqués dans le plafond

4. Percer 4 avant-trous dans le plafond à travers le trou de chaque collier, en

veillant à ne pas endommager le collier.

5. Monter le conduit jusqu’à l’ergot circulaire

6. Présenter le boîtier

7. Fendre le passe-fils. Faire passer le câble électrique dans le boîtier

ventilateur à travers le trou d’admission de câble par le passe-fils.

Vérifier que le passe-fils est en place et bien ajusté serré.

8. À l’aide des vis !¡ (Fig. B), fixer la bride du boîtier de ventilateur dans les

colliers de plafond.

Terminaison du conduit

Monter une grille extérieure (de type CFWG100, par exemple, non fournie dans le

DX200/DX200T) sur le mur extérieur. Pour un montage au plafond, utiliser les

accessoires appropriés (non fournis).

Raccorder les câbles électriques

AVERTISSEMENT : CET APPAREIL DOIT ÊTRE RACCORDÉ À LA TERRE

1. Isoler l’alimentation électrique et retirer tous les fusibles.

La plaque à bornes peut recevoir un câble ayant un diamètre maximum de 1,5 mm

2. Utiliser un sectionneur bipolaire présentant un entrefer de contact minimum de

3 mm dans les deux pôles.

3. Utiliser un câble de tension nominale appropriée à 3 ou à 4 conducteurs selon

l’utilisation.

4. Si elles sont toujours en place, retirer les vis de retenue du couvercle du cachebornes.

5. Faire le raccordement du câble du ventilateur comme indiqué à la Fig.

utiliser le pince-câble fourni. Vérifier le modèle du ventilateur sur le schéma.

DX200: "LH" = Sous tension (Grande vitesse)/ "LL" = Sous tension

(Petite vitesse)

6. Remettre en place le cache-bornes

7. Pour utiliser des réglages autres que ceux fixés en usine, se reporter au

paragraphe "Réglages effectués par l’utilisateur".

8. Remettre le couvercle avant (Fig.

Raccorder le câble entre le sectionneur et le câble d’alimentation électrique, puis

vérifier à nouveau l’installation.

10. Avant de mettre l’ensemble sous tension, remettre les fusibles.

11. En ce qui concerne les circuits de câblage fixe, le pouvoir de coupure du fusible

de protection de l’appareil ne doit pas être supérieur à 5 A.

Pour l’Australie seulement

CF20 : Raccordement à l’alimentation électrique : utiliser un câble souple à 3

conducteurs avec une prise à 3 broches pour la brancher dans une douille murale

homologuée de 10 A présentant un entrefer d’au moins 3 mm entre les contacts.

TOUS LES AUTRES VENTILATEURS : un câble relié en permanence à l’alimentation

électrique et un commutateur à distance contrôlent le fonctionnement Ils doivent être

raccordés directement par un commutateur homologué 10 A monté en surface sur le

mur et présentant un entrefer d’au moins 3 mm entre les contacts.

Réglages effectués par l’utilisateur

Avant d’effectuer tout réglage, isoler complètement le ventilateur de l’alimentation

électrique. Vérifier les caractéristiques techniques indiquées ci-dessous pour

savoir quelles fonctions s’appliquent à ce ventilateur.

1. Retirer le couvercle avant, puis le remettre en place après le réglage (Fig. C).

DX200

Il n’y a pas de réglages utilisateur correspondant à ce ventilateur.

DX200T

1. L’utilisateur peut régler le délai de dépassement de fonctionnement du

temporisateur entre 30 secondes et 20 minutes environ. Utiliser un tournevis

d’électricien et tourner la vis "T" (Fig.

et en sens antihoraire pour la diminuer. (Préréglé en usine à 10 minutes environ)

CF20

1. Le réglage de l’humidité varie d’environ 50 à 90% d’humidité relative. Utiliser un

tournevis d’électricien et tourner la vis "RH" (Fig.

augmenter le réglage de l’humidité relative, et en sens antihoraire pour le diminuer.

(Nota : le ventilateur est plus sensible à 50% HR qu’à 90%. Il est préréglé en usine

sur une HR d’environ 70%).

6 du ventilateur dans le mur.

6 du ventilateur dans le trou et marquer les quatre positions

6 du plafond, et poser les quatre colliers de plafond (fournis)

B.

B.

6 du ventilateur dans le plafond.

7.

5 et fixer les vis de retenue.

C).

D) en sens horaire pour augmenter la durée,

D) en sens horaire pour

6 du

CF20T

1. L’utilisateur peut régler le délai de dépassement de fonctionnement du

temporisateur entre 30 secondes et 20 minutes environ. Utiliser un tournevis

d’électricien et tourner la vis "T" (Fig. D) en sens horaire pour augmenter la

durée, et en sens antihoraire pour la diminuer.

2. Le réglage de l’humidité varie d’environ 50 à 90% d’humidité relative. Utiliser un

tournevis d’électricien et tourner la vis "RH" (Fig.

augmenter le réglage de l’humidité relative, et en sens antihoraire pour le

diminuer. (Nota : le ventilateur est plus sensible à une HR de 50% qu’à 90%).

Utilisation du ventilateur

DX200

Pour faire fonctionner le ventilateur, utiliser le commutateur Marche/Arrêt externe.

L’utiliser à nouveau pour couper le ventilateur.

La vitesse du ventilateur est préréglée par l’installateur, soit sur grande vitesse, soit

sur petite vitesse. (Si un commutateur est installé, l’utilisateur peut basculer entre

grande et petite vitesse.)

DX200T

Pour faire fonctionner le ventilateur, utiliser le commutateur Marche/Arrêt externe.

L’utiliser à nouveau pour couper le ventilateur.

Lorsque le commutateur est sur arrêt, le ventilateur continue de fonctionner pendant

le délai de dépassement de fonctionnement préréglé. Le témoin supérieur

lorsque le commutateur Marche/Arrêt externe est mis sur Marche.

La vitesse du ventilateur est prérèglée par l'installateur, soit sur grande vitesse, soit

sur vitesse moyenne, soit sur petite vitesse.

Marche/Arrêt du temporisateur

Ce dispositif est réglé par l’installateur afin d’assurer un délai de 2 minutes avant le

fonctionnement du ventilateur lorsque celui-ci est mis en marche à l’aide du

2

commutateur Marche/Arrêt externe.

CF20 / CF20T

Fonctionnement commuté

On peut raccorder le ventilateur à un commutateur Marche/Arrêt séparé. Lorsque le

commutateur est mis sur Marche, le ventilateur fonctionne à la vitesse de

condensation. Le témoin supérieur

F et

séparé est mis sur Marche. Lorsque le commutateur est mis sur Arrêt, le ventilateur

continue de fonctionner si le niveau d’humidité dépasse le niveau préréglé.

seulement :

Lorsque le commutateur est mis sur Arrêt, le ventilateur continue de

fonctionner à la vitesse de condensation pendant la durée réglable du temporisateur.

Fonctionnement du régulateur de condensation

Le ventilateur fonctionne à la vitesse du régulateur de condensation lorsque l’humidité

relative dépasse le niveau préréglé. Il s’arrête lorsque le niveau d’humidité diminue.

Fonctionnement à grande vitesse

L’interrupteur à cordon incorporé met le ventilateur en marche à grande vitesse. Le

témoin inférieur

(Nota : Si le commutateur Marche/Arrêt séparé et l’interrupteur à cordon sont tous les

deux sur Marche, les deux témoins

fonctionne à grande vitesse.

CF20T seulement :

Marche ou Arrêt du temporisateur

Ce dispositif est réglé par l’installateur afin d’assurer un délai de 2 minutes avant le

fonctionnement du ventilateur lorsque celui-ci est mis en marche à l’aide du

commutateur Marche/Arrêt séparé.

Nettoyage

Avant de nettoyer le ventilateur, il faut l’isoler complètement de l’alimentation secteur

Ne nettoyer que la surface externe du ventilateur à l’aide d’un chiffon non pelucheux

humide.

Ne pas utiliser de détergents, solvants forts ou produits de nettoyage chimiques.

Attendre que le ventilateur soit complètement sec avant de l’utiliser.

À part le nettoyage, le ventilateur n’exige aucun autre entretien.

Légende Voir schéma

1. Séparateur à chicane

2. Couvercle avant

3. Hélice

4. Vis de fixation

5. Cache-bornes

6. Boîtier du ventilateur

PRIÈRE DE LAISSER CET IMPRIMÉ AVEC LE VENTILATEUR, À PORTÉE DE

L’UTILISATEUR

D) en sens horaire pour

"I" s’allume

"I" s’allume lorsque le commutateur Marche/Arrêt

CF20T

"II" s’allume lorsque le ventilateur fonctionne à grande vitesse.

"I" et "II" sont tous deux allumés, et le ventilateur

EE

7. Ergot circulaire

8. 3 Vis de serrage et chevilles murales

9. 3 Brides de carène de ventilateur

10. Cadre

11. 4 Vis de plafond 25 mm de long (Schéma

12. Isolant adhésif

B)

ES

IMPORTANTE

1. LEA TODAS LAS INSTRUCCIONES Y AVISOS ANTES DE EMPEZAR LA INSTALACIÓN.

2. LA INSTALACIÓN Y EL CABLEADO TIENEN QUE CUMPLIR LAS NORMAS ACTUALES IEE (UK), O LAS NORMAS LOCALES O APROPIADAS (OTROS PAÍSES).

LA PERSONA QUE REALIZA LA INSTALACIÓN ES RESPONSIBLE DE ASEGURARSE DE QUE SE RESPETEN LOS CÓDIGOS DE PRÁCTICA APROPIADOS.

3. LA INSTALACIÓN DEBE SER SUPERVISADA POR UN ELECTRICISTA CUALIFICADO.

4. ESTOS APARATOS HAN SIDO DISEÑADOS PARA SU CONEXIÓN A CABLEADO FIJO.

5. COMPRUEBE QUE LA CAPACIDAD ELÉCTRICA QUE SE INDICA EN EL VENTILADOR SEA LA MISMA QUE LA DE LA RED.

6. ADVERTENCIA: ESTOS APARATOS NECESITAN TOMA DE TIERRA.

7. NO REALIZAR LA INSTALACIÓN CERCA DE FUENTES DIRECTAS DE CALOR (POR EJEMPLO COCINAS DE GAS O PARRILLAS A NIVEL DE LOS OJOS),

ESPECIALMENTE DONDE LA TEMPERATURA SUPERE LOS 50°C.

8. SI EL VENTILADOR SE INSTALA EN UNA HABITACIÓN EN LA QUE HAYA UN APARATO QUE QUEME COMBUSTIBLE, SE DEBEN TOMAR PRECAUCIONES

PARA EVITAR EL RETORNO DE LOS GASES A LA HABITACIÓN DESDE POR EL CONDUCTO DE HUMOS DEL APARATO.

9. ASEGÚRESE DE QUE SE TOMEN TODAS LAS PRECAUCIONES DE SEGURIDAD RELEVANTES (PROTECCIÓN OCULAR Y ROPA CORRECTOS

ETC.). AL INSTALAR Y MANTENER ESTE VENTILADOR.

10. REMÍTASE A LA FIGURA "G" PARA INSTRUCCIONES GENERALES SOBRE LA SITUACIÓN DEL VENTILADOR. SITÚELO SIEMPRE A LA MAYOR ALTURA

POSIBLE.

11. SI CUALQUIER PARTE DE LOS CONDUCTOS SE SITÚA A MAYOR ALTURA QUE EL VENTILADOR, ES NECESARIO MONTAR DISPOSITIVO DE RETENCIÓN

DE CONDENSACIÓN (XCT100) LO MÁS CERCA POSIBLE DEL VENTILADOR.

Para rapidez y facilidad de instalación, puede necesitar algunos de los accesorios

auxiliares que se listan en "Opciones Auxiliares".

Si se instala en una pared (montaje de superficie)

1. Marque en la pared el centro del agujero del conducto

2. Use este centro para cortar una apertura en la pared de 117mm de

diámetro, con una ligera pendiente hacia el exterior.

3. Monte el conducto para la pared (WD100), que no se suministra, y la

argamasa.

Si se instala en una pared (montaje embutido)

1. Marque en la pared el centro del agujero del conducto

agujero guía que atraviese las dos paredes.

2. Use el centro para marcar un agujero rectangular para la pared interior

usando las dimensiones

3. Corte el agujero rectangular en la pared interior.

4. Salga al exterior y corte un agujero de 117mm de diámetro en la pared

exterior usando el agujero pequeño como centro.

5. Mida el grosor de la pared.

Corte el conducto de la pared (WD100), que no se suministra, de forma

que tenga una longitud 64mm inferior al grosor de la pared.

Si se monta en el techo (montaje de superficie)

Este método requiere un espacio por encima del techo, como por ejemplo un altillo o

un ático, con el fin de permitir el acceso al conducto interior de 100mm de diámetro.

1. Marque en el techo el centro del agujero del conducto

vigas y cables, etc.

2. Corte un agujero de 117mm de diámetro usando el centro marcado.

Si se monta en el techo (montaje embutido)

Para el conducto de 100mm de diámetro:

1. Marque un agujero rectangular usando las dimensiones

2. Corte el agujero, evitando las vigas y los cables, etc.

Para el conducto plano:

• Este ventilador se puede instalar dentro de un espacio de 47mm sin el tubo

circular 7(Fig. E). Juego de adaptador del conducto plano (FDA) disponible..

Preparación del ventilador para la instalación

1. Quite la cubierta delantera 2(Fig. C)

2.

Ponga la cinta de espuma !™ que se suministra alrededor del tubo circular 7 (Fig. E).

3. Quite la cubierta eléctrica 5(Fig. E). Se puede quitar el rotor facilitar el

acceso (si hace falta). Este es un conjunto de presión/estirar.

Ajuste de la velocidad del ventilador.

DX200T / CF20 / CF20T sólo (Fig. D)

4. La velocidad correcta de control de la condensación (CF20/CF20T) o la

velocidad de funcionamiento (DX200T) se debe seleccionar según el

tamaño de la habitación en la que se vaya a instalar el ventilador. Deslice el

interruptor

X

ventilador viene de fábrica ajustado en la "Posición 2".

5. Tamaño del interruptor – Posición / Volumen de la habitación (m

1 Grande (34 y superior)

2 Media (28 – 34)

3 Pequeño (menos de 28)

A

.

hasta la posición requerida. Por favor observe que el

A

.

A

, y taladre un

A

, evitando las

B

.

3

Ajuste de la velocidad lenta

DX200T / CF20 / CF20T Sólo (Fig.

6. El ventilador se puede ajustar para que realice una extracción lenta y

constante. Deslice el interruptor

observe que el ventilador viene de fábrica ajustado a la "Posición 0".

7. Ajuste de la posición del interruptor

0 Extracción lenta desactivada

I Extracción lenta activada

Ajuste del arrancador diferido

DX200T / CF20T Sólo (Fig. D)

8. El ventilador se puede ajustar de forma que arranque con un retraso de 2

minutos cuando se utilice con un interruptor externo. Deslice el interruptor

Z

hasta la posición requerida. Por favor observe que el ventilador viene de

fábrica ajustado a la "Posición 0".

Ajuste de la posición del interruptor

0 Arrancador diferido desactivado

I Arrancador diferido activado

Montaje del ventilador en pared o techo (montaje de superficie)

1. Ponga el conducto en el agujero y alinéelo hasta la posición requerida. Si lo

va a montar en la pared, asegúrese de que el conducto se incline hacia

abajo alejándose del ventilador.

2. Marque las posiciones de los tres agujeros de sujeción

3. Si lo va a montar en la pared, taladre tres agujeros de 5,5mm de diámetro

4. Corte el agujero de entrada del cable, si hace falta, en el

5. Pase los cables eléctricos hasta el interior de la caja del ventilador

6. Suba la caja del ventilador 6hasta la pared o techo. Asegúrese de que el

7. Sujete la caja del ventilador

Si se monta en pared (montaje embutido)

El borde 0no hace falta. Ponga el conducto en el tubo circular

Si el tamaño del agujero es como se recomienda:

1. Monte las tres abrazaderas del cuerpo del ventilador

2. Corte el ojal del cable. Pase los cables eléctricos a la caja del ventilador 6

3. Sitúe la caja del ventilador 6contra la pared.

4. Apriete los tres tornillos

Si el tamaño del agujero es mayor de lo recomendado, por ejemplo mayor

)

que el saliente de la caja del ventilador

que no necesitan instalación especial):

1. Las abrazaderas del cuerpo del ventilador NO SON adecuadas. Construya

6

(Fig. E).

ventilador

para los tacos de la pared (suministrados).

Si lo va a montar en el techo

suministrados).

el ojal del cable. Deslice el

entrada posterior de cables y borde, y vuelva a poner el ojal de los cables.

Asegúrese de que el ojal del cable esté en su sitio y que quede ajustado.

7

tubo circular

con los sujetadores correspondientes (no suministrados).

ventilador

por el agujero de entrada de cables y el ojal del cable.

Asegúrese de que el ojal del cable esté en su sitio y bien ajustado.

interior.

Las abrazaderas del cuerpo del ventilador

parada automática.

un marco de madera de dimensiones INTERNAS 203 x 233 mm.

entre en el conducto.

6

con los tornillos 8.

D)

Y

hasta la posición requerida. Por favor

A

en la caja del

B

, use los sujetadores apropiados (no

0

0

borde por la caja del ventilador 6.

6

en la pared con los tornillos 8o en el techo

8

hasta que el ventilador quede sujeto a la pared

9

NO LAS APRIETE DEMASIADO.

giran hasta la posición de

6

(sobre todo para los montajes

borde y corte

7

.

9

en la caja del

6

por la

Page 9

D

WICHTIG

1. LESEN SIE DIESE ANWEISUNGEN UND WARNUNGEN SORGFÄLTIG DURCH, BEVOR SIE MIT DER INSTALLATION BEGINNEN.

2. ALLE INSTALLATIONEN UND ELEKTRISCHEN ARBEITEN MÜSSEN DEN GEGENWÄRTIGEN IEE-BESTIMMUNGEN IN GROSSBRITANNIEN BZW. DEN

ENTSPRECHENDEN BESTIMMUNGEN IN ANDEREN LÄNDERN ENTSPRECHEN. DER INSTALLATEUR IST FÜR DIE EINHALTUNG ALLER BAU- UND SONSTIGEN

VORSCHRIFTEN VERANTWORTLICH.

3. ALLE INSTALLATIONSARBEITEN SIND VON EINEM QUALIFIZIERTEN ELEKTRIKER ZU BEAUFSICHTIGEN.

4. DIESE GERÄTE SIND FÜR DEN ANSCHLUSS AN EIN FEST VERKABELTES NETZ VORGESEHEN.

5. PRÜFEN SIE, DASS ALLE ELEKTRISCHEN WERTE AM ABZUG MIT DEM STROMNETZ KOMPATIBEL SIND.

6. WARNUNG: DIESE GERÄTE MÜSSEN GEERDET WERDEN.

7. WEDER IN DIREKTER UMGEBUNG VON HITZEQUELLEN (Z.B. GASHERDEN ODER GRILLÖFEN AUF AUGENHÖHE) NOCH IN EINER UMGEBUNG ANBRINGEN,

IN DER DIE RAUMTEMPERATUR 50°C ÜBERSTEIGT.

8. WENN DER ABZUG IN EINEM RAUM INSTALLIERT WERDEN SOLL, IN DEM BRENNSTOFF VERBRANNT WIRD, SIND BESONDERE VORSICHTSMASSNAHMEN

ERFORDERLICH, DAMIT GASE NICHT VON DER OFFENEN FLAMME DES BRENNERS IN DEN RAUM ZURÜCKFLIESSEN KÖNNEN.

9. ACHTEN SIE DARAUF, DASS ALLE ENTSPRECHENDEN SICHERHEITSMASSNAHMEN (DER RICHTIGE AUGENSCHUTZ SOWIE SCHUTZKLEIDUNG USW.) BEI

DER INSTALLATION UND WARTUNG DIESES ABZUGS GETROFFEN WERDEN.

10. ALLGEMEINE RICHTLINIEN FÜR GEEIGNETE STANDORTE ENTNEHMEN SIE BITTE DER „ABB.G". MONTIEREN SIE DEN ABZUG IMMER MÖGLICHST HOCH.

11. FALLS EIN TEIL DES ROHRWERKS HÖHER ALS DER ABZUG MONTIERT WIRD, IST DIE MONTAGE EINER KONDENSATIONSFALLE (XCT100) MÖGLICHST NAH

Die unter „Zubehör" aufgeführten Produkte unterstützen eine schnelle und

problemlose Installation.

Wandmontage (Aufsatz)

1. Markieren Sie die Mitte des Rohrloches Aan der Wand.

2. Schneiden Sie um diese Mitte ein Loch mit einem Durchmesser von

117 cm, dass sich nach außen leicht neigt.

3. Setzen Sie das nicht mitgelieferte Wandrohr (WD100) ein und befestigen

Sie es mit Mörtel.

Wandmontage (Einsatz)

1. Markieren Sie die Mitte des Rohrloches Aan der Wand und bohren Sie

ein Führungsloch durch beide Wände.

2. Markieren Sie mit Hilfe der markierten Mitte ein rechteckiges Loch mit den

Abmessungen

3. Schneiden Sie das rechteckige Loch durch die Innenwand.

4. Schneiden Sie von außen ein Loch mit einem Durchmesser von 117 cm in

die Außenwand; das kleine Loch dient als Mitte.

5. Messen Sie die Wandstärke. Schneiden Sie das nicht mitgelieferte

Wandrohr so zurecht, dass es 64 mm kürzer ist als die Wandstärke.

Deckenmontage (Aufsatz)

Für diese Methode braucht man einen Raum oberhalb der Decke, wie zum

Beispiel einen Dachboden, um das Rohr mit 100 mm Innendurchmesser

montieren zu können.

1. Markieren Sie die Mitte des Rohrloches

darauf, dass Sie keine Deckenbalken oder verlegte Leitungen beschädigen.

2. Schneiden Sie um diese Mitte ein Loch mit einem Durchmesser von 117 cm.

Deckenmontage (Einsatz)

Für das Rohr mit 100 mm Durchmesser:

1. Markieren Sie ein rechteckiges Loch mit den Abmessungen

2. Schneiden Sie das Loch; achten Sie darauf, dass Sie keine Deckenbalken

oder verlegte Leitungen beschädigen.

Für das Flachrohr:

• Dieser Abzug kann in einer Öffnung mit 47 mm Durchmesser ohne

Rundzapfen

Vorbereitung der Abzugsinstallation

1. Nehmen Sie die Frontabdeckung 2ab (Abb. C).

2. Montieren Sie das mitgelieferte Schaumband

(Abb.

3. Nehmen Sie die Elektroabdeckung

sich (falls nötig) entfernen, um den Zugang zu erleichtern. Dies ist eine

Druck-Ein/Zug-Aus-Montage.

Einstellung der Abzugsgeschwindigkeit

Nur für DX200T/CF20/CF20T (Abb. D)

4. Wählen Sie anhand der Zimmergröße die korrekte Geschwindigkeit zur

Regelung der Kondensation (CF20/CF20T) oder die Betriebsgeschwindigkeit (DX200T). Schieben Sie den Schalter

Stellung. Bitte beachten Sie, dass der Abzug im Werk auf „Stellung 2"

eingestellt wird.

5. Schalterstellung Größe / Zimmervolumen (m

1 groß (34 und mehr)

2 mittelgroß (28-34)

3 klein (weniger als 28)

AM ABZUG ERFORDERLICH.

A

für die Innenwand.

A

an der Decke, achten Sie

B

7

installiert werden (Abb. E). Ein Flachrohr-Adapter (FDA) ist

erhältlich.

E

).

!™ um den Rundzapfen 7.

5 ab. (Abb. E). Das Gebläserad lässt

X

in die gewünschte

3

)

Einstellung der Tropfextraktion

Nur für DX200T/CF20/CF20T (Abb. D)

6. Der Abzug lässt sich so einstellen, dass er ständig extrahiert. Schieben Sie

den Schalter

Y

Abzug im Werk auf „Stellung 0" eingestellt wird.

7. Schalterstellung Einstellung

0 Tropfenextraktion AUS

1 Tropfenextraktion EIN

Einstellung der Startverzögerung

Nur für DX200T/CF20T (Abb. D)

8. Der Abzug lässt sich so einstellen, dass er erst mit zweiminütiger

Verzögerung einsetzt, beispielsweise wenn der EIN/AUS-Schalter außen

montiert ist. Schieben Sie den Schalter

eingestellt wird.

Schalterstellung Einstellung

0 Verzögerung AUS

1Verzögerung EIN

Montage des Abzugs an der Wand oder an der Decke (Aufsatz)

1. Schieben Sie das Rohr in das Loch und passen Sie es entsprechend an.

Bei der Wandmontage müssen Sie darauf achten, dass das Rohr sich nach

unten und weg vom Abzug neigt.

2. Markieren Sie die Stellen für die drei Befestigungslöcher

Abzugskasten

3. Bei der Wandmontage bohren Sie drei Löcher mit jeweils 5,5 mm

Durchmesser für die Dübel (mitgeliefert). Bei der Deckenmontage

verwenden Sie bitte die entsprechende Befestigung (nicht mitgeliefert).

.

4. Schneiden Sie, falls nötig, das Loch für das Kabel in die Einfassung

und schlitzen Sie die Durchgangstülle auf. Schieben Sie die Einfassung

0

5. Schieben Sie nun die Elektrokabel in den Abzugskasten

hintere Kabelloch und die Einfassung und machen Sie die Durchgangstülle

wieder fest.

Achten Sie darauf, das die Durchgangstülle richtig sitzt und gut befestigt ist.

6. Halten Sie den Abzugskasten 6an die Wand bzw. Decke. Achten Sie

darauf, dass der Rundzapfen

7. Befestigen Sie den Abzugskasten mit Schrauben

der entsprechenden, nicht mitgelieferten Befestigung an der Decke.

Wandmontage (Einsatz)

Die Einfassung 0ist nicht erforderlich. Montieren Sie das Rohr am Rundzapfen

Wenn die Größe des Loches den Empfehlungen entspricht:

1. Befestigen Sie die drei Abzugskörperklemmen 9am Abzugskasten 6mit

Hilfe von Schrauben

2. Schlitzen Sie die Durchgangstülle auf. Schieben Sie nun die Kabel in den

Abzugskasten

darauf, das die Durchgangstülle richtig sitzt und gut befestigt ist.

3. Halten Sie den Abzugskasten 6an die Wand.

4. Ziehen Sie die drei Schrauben

festgeklemmt ist. Die Abzugskörperschrauben

automatischen Stop-Position.

Wenn das Loch größer als empfohlen ist, d.h. größer als der Flansch am

Abzugskasten

in die gewünschte Stellung. Bitte beachten Sie, dass der

Z

beachten Sie, dass der Abzug im Werk auf „Stellung 0"

6

(Abb. E).

über den Abzugskasten 6.

8

.

6

durch das Kabelloch und die Durchgangstülle. Achten Sie

6

(das ist meistens bei „Retro-Fit" Installationen der Fall):

in die gewünschte Stellung. Bitte

A

im

6

durch das

7

in das Rohr passt.

8

fest an, bis der Abzug auf der Innenwand

NICHT ZU FEST ANZIEHEN!

8

an der Wand bzw. mit

9

rotieren bis zur

B

0

7

.

Page 10

1. Die Abzugskörperklemmen SIND NICHT geeignet. Fertigen Sie einen

Holzrahmen mit den Innenmaßen 203 x 233 mm. Die Tiefe muss mindestens

50 mm betragen. Befestigen Sie den Holzrahmen in der Innenwand und

reparieren Sie das Loch.

2. Halten Sie den Abzugskasten

3. Schrauben Sie den Abzugskasten

Flansch fest (Schrauben sind nicht mitgeliefert).

6 an die Wand.

6 am Holzrahmen mit Hilfe der Schlitze im

Deckenmontage (Einsatz)

1. Die Einfassung 0 ist nicht erforderlich.

2. Setzen Sie den Abzugskasten

mit Hilfe der Schlitze im Flansch

3. Nehmen Sie den Abzugskasten

Deckenklammern (mitgeliefert) über dem Lochrand, so dass die Klammern der

Markierung an der Decke

4. Bohren Sie vier Führungslöcher in die Decke durch das Loch in jeder Klammer.

Achten Sie darauf, dass Sie die Klammer nicht beschädigen.

5. Befestigen Sie das Rohr am Rundzapfen

6. Halten Sie den Abzugskasten

7. Schlitzen Sie die Durchgangstülle auf. Schieben Sie nun die Kabel in den

Abzugskasten

Durchgangstülle richtig sitzt und gut befestigt ist.

8. Befestigen Sie mit Hilfe der Schrauben !¡(Abb. B) den Abzugskastenflansch

an den Deckenklammern.

6 durch das vordere Kabelloch. Achten Sie darauf, das die

6 in das Loch und markieren Sie die vier Stellen

B.

6 von der Decke ab und befestigen Sie die vier

B entsprechen.

7.

6 an die Decke.

Rohrabbruch/Rohrabschluss

Befestigen Sie ein Außengitter (z.B. CFWG100, bei DX200/DX200T nicht mitgeliefert)

an der Außenwand. Bei Deckenmontage verwenden Sie bitte das entsprechende

Zubehör (nicht mitgeliefert).

Elektrische Installation

WARNUNG! DIESES GERÄT MUSS GEERDET WERDEN

1. Unterbrechen Sie die Stromzufuhr und entfernen Sie alle Sicherungen. Der

Anschlussblock ist für Kabel bis zu 1,5 mm

2. Verwenden Sie einen zweipoligen Isolierschalter mit einem

Mindest kontakt abstand von 3 mm an beiden Polen.

3. Verwenden Sie je nach Anwendung das entsprechende Dreiader- bzw.

Vieraderkabel.

4. Entfernen Sie die Befestigungsschrauben an der Anschlussblockabdeckung,

falls noch in Position.

5. Verdrahten Sie den Abzug mit Hilfe der Kabelklemme wie in

Sie das Abzugsmodell und die Zeichnung.

DX200: „LH" = Live / stromführend (hohe Geschwindigkeit) / „LL" = Live/

stromführend (niedrige Geschwindigkeit).

6. Setzen Sie die Anschlussblockabdeckung

Schrauben an.

7. Falls Sie die im Werk vorgenommenen Einstellungen ändern möchten, lesen Sie

bitte den Abschnitt „Einstellung durch den Benutzer".

8. Setzen Sie die vordere Abdeckung wieder auf (Abb.

9. Schließen Sie das Kabel vom Isolierschalter an die elektrischen Stromkabel an

und prüfen Sie die Installation.

10. Setzen Sie die Sicherungen wieder ein, bevor Sie die Stromzufuhr einschalten.

11. Bei festen Kreisen darf die Schutzsicherung nicht über 5A liegen.

Nur für Australien

CF20 –

Der Anschluss an die Stromzufuhr erfolgt über flexible Dreiaderkabel mit

dreipoligem Stecker zum Einschub in zulässige Wandschalter mit 10A und

mindestens 3 mm Zwischenraum zwischen den Kontakten.

Alle anderen Länder – Permanenter Anschluss an das Netz und fernbedienter

Schalter. Die Verdrahtung zum Netz erfolgt über zulässige Wandschalter mit 10 A und

mindestens 3 mm Zwischenraum zwischen den Kontakten.

2

geeignet.

F gezeigt. Prüfen

5 wieder auf und ziehen Sie die

C).

Einstellungen durch den Benutzer

Bevor Sie irgend etwas verstellen, trennen Sie bitte den Abzug komplett von der

Stromzufuhr und prüfen Sie die nachstehenden Angaben, um zu sehen, was für

Sie zutrifft.

1. Nehmen Sie die Frontabdeckung ab und setzen Sie diese nach dem Verstellen

wieder auf (Abb.

C).

DX200

Für diesen Abzug gibt es keine Verstellmöglichkeiten.

DX200T

1. Die Überlaufzeit für den Timer lässt sich etwa von 30 Sekunden bis 20 Minuten

verstellen. Verwenden Sie einen Elektrikerschraubenzieher und drehen Sie die

Schraube „T" (Abb.

gegen den Uhrzeigersinn, wenn Sie diese senken möchten. (Werkseinstellung:

etwa 10 Minuten).

D) im Uhrzeigersinn, wenn Sie die Dauer erhöhen und

CF20

2. Die Einstellung der Feuchtigkeit variiert etwa zwischen 50% und 90% relativer

Feuchtigkeit. Verwenden Sie einen Elektrikerschraubenzieher und drehen Sie die

Schraube „RH" (Abb.

erhöhen und gegen den Uhrzeigersinn, wenn Sie diese senken möchten. (Bitte

beachten Sie: der Abzug reagiert bei 50% relativer Feuchtigkeit empfindlicher als