Page 1

Xerox® WorkCentre 5022/5024

Service Manual

Revised June 2014

702Pxxxxx

Page 2

WC 5022/5024

Service Documentation

WC 5022/5024 Service Documentation

702P02828

Version 1.0

06/2014

Published by Xerox. 800 Phillips Road, Webster, NY 14580

© 2014 by Xerox Co. All rights reserv ed. Xerox® and all identifying numbers used in connection with the Xerox products mentioned in this publication are trademarks of the Xerox Corporation.

***Xerox Private Data***

All service documentation is supplied to Xerox external customers for informational purposes

only. Xerox service documentation is intended for use by certified, product-trained service personnel only. Xerox does not warrant or represent that it will notify or provide to such customer

any future change to this documentation. Customer performed service of equipment, or m odules, components, or parts of such equipment may affect whether Xerox is responsible to fix

machine defects under the warranty offered by Xerox with respect to such equipment. You

should consult the applicable warranty for its terms regarding customer or third-party provided

service.

Xerox

While Xerox has tried to make the documentation accurate, Xerox will have no liability arising

out of any inaccuracies or omissions.

WARNING

This equipment generates, uses and can radiate radio frequency energy, and if not

installed and used in accordance with the instructions documentation, may cause interference to radio communications. It has be e n tested and found to com ply with the limits

for a Class A computing device pursuant to subpart J of part 15 of FCC rules, which are

designed to provide reasonable protection against such interference when operated in

a commercial environment. Operation of this equipment in a residential area i s likely to

cause interference in which case the user, at his own expense, w ill be required to correct the interference.

Versi on 1 .0

WC 5022/5024

06/2014

Preface

0-1

Page 3

Chapter 0 Introduction

Page 4

0.1 Getting to know this Service Manual........................................................................ 0-3

0.2 How to use the Service Manual ................................................. .... ..... .... .. .... .. .. ....... 0-3

0.3 Description for Terminol og y And Symbols............................... ........................... ..... 0-4

0 Introduction

Versi on 1 .0

WC 5022/5024

06/2014

0-1

Introduction

Page 5

0.1 Getting to know this Service Manual

This manual is used as the standard service manual for WorkCentre 5022/5024.

• Publication Comment Sheet

Enter any comments and/or corrections regarding this service manual into the Publication

Comment Sheet, and send it to the following department.

Solution Service & Operational Management CS Dept.

0.2 How to use the Service Manual

This manual describes the standard procedures for the servicing this product. Refer to Chapter 1 Service Call Procedure for efficient and effective servicing during maintenance calls.

For more information on the options, refer to the options manual.

0.2.1 Contents of Manual

This manual is divided into 10 chapters as described below.

• Chapter 1 Service Call Procedure

This chapter describes the general work and servicing procedures for the maintenance of

this product.

• Chapter 2 Troubleshooting

This chapter describes the troubleshooting procedures other than image quality trouble-

shooting for this product.

• Chapter 3 Image Quality Troubleshooting

This chapter describes the image quality troubleshooting procedures for this product.

• Chapter 4 Disassembly/Assembly and Adjustment

This chapter describes the disass embly, assembly, adjustment and replacement proce-

dures for components of this product.

• Chapter 5 Parts List

This chapter contains the spare parts information for this product.

• Chapter 6 General

This chapter contains the following information.

6.1 Specifications

6.2 Tools/Service Consumables/Consumables

6.3 Service Data

6.5 Service Mode

6.8 Fax-related Information

• Chapter 7 Wiring Data

This chapter contains the information about the Wiring Connector List/Locations, the Wir-

ing Data, and the BSD for this machine.

• Chapter 8 Accessories (not yet issued)

• Chapter 9 Installation/Removal

This chapter contains the installation and removal procedures for this product and the

options that are specific to it.

• Chapter 10 Mechanism & Functions Overview (not yet issued)

0.2.2 Information on Updating

This manual will be sent to each Service Center as specified below. Revisions must be incorporated correctly to keep the manual up-to-date.

Versi on 1 .0

WC 5022/5024

Updating Procedure:

• When the manual is updated, the issue number 'Ver. 1' will be changed to Ver. 1.1, Ver.

1.2, and so on.

06/2014

0-3

0.1 Getting to know this Service Manual

Introduction

Page 6

0.3 Description for Terminology And Symbols

The terms and symbols used throughout this manual are explained here.

• The terms and symbols used at the beginning of a text are defined as follows:

WARNING

Indicates an imminently hazardous situation, such as death or serious injury if op erators do not handle the machine correctly by disregarding the statement.

WARNING

Indicates a potentially hazardous situation, such as death or serious injury if operators do not handle the machine correctly by disregarding the statement.

CAUTION

Indicates a potentially hazardous situation, such as injury or property damage if operators do not handle the machine correctly by disregarding the statement.

Instruction: Used to alert you to a procedure which, if not strictly observed, could result in damage to the machine or equipment.

NOTE: Used when work procedures and rules are emphasized.

Used when other explanations are given.

Used to describe the purposes of Adjustment and Troubleshooting.

REP: Indicates the disassembly/assembly procedure for reference.

ADJ: Indicates the adjustment procedure for reference.

PL: Indicates the parts list for reference.

Terminology

Table 1 Terminology

Terminology Description

Assy Means Assembly. TEC Value Abbreviation of Typical Electricity Consumption, which means the stan-

dard power consumption. Read as 'tec'.

Installation of any part other than the ones designated by Xerox shall be strictly prohibited because it cannot be guaranteed in quality and safety.

Important Information Stored Component (ISC)

This component stores all the important customer information that is input after the installation.

When performing replacement, follow the procedures in 'Chapter 4 Disassembly/Assembly

and Adjustment' to replace/discard. Make absolutely sure that no customer information gets

leaked outside.

Introduction

06/2014

0.3 Description for Terminology And Symbols

0-4

Versi on 1 .0

WC 5022/5024

Page 7

Chapter 1 Service Call Procedures

Page 8

1.1 Before Starting th e Servicing .................................... ........................................ ....... 1-3

1.2 Service Call Procedure

1.2.2 Service Call Procedure ......................................................................................... 1-5

1.3 Detailed Contents of the Service Call ...................................................................... 1-5

1.4 TRIM Check List....................................................................................................... 1-6

1.5 Periodic Replacement Parts/Consumables List....................................................... 1-6

1 Service Call Proced ur es

Versi on 1 .0

WC 5022/5024

06/2014

1-1

Service Call Procedures

Page 9

1.1 Before Starting the Servicing

1.1.1 Safety

To prevent any accident that may occur during a maintenance service, any warning or any caution regarding the servicing must be strictly observed. Do not perform any haz ardous operation.

1. Power Supply To prevent electrical shocks, burns, or injury, etc., be sure to switch OFF the machine and

disconnect the plug before starting the maintenance service. If the machine has to be

switched ON, such as when measuring the voltage, take extra care not to get an electrical

shock.

2. Drive Area Never inspect, clear or lubricate the drive area such as chain belts, chain wheel or gears

during the machine operation.

3. Heavy Parts Position your hip lower when removing or installing heavy parts.

4. Safety Device See that safety devices for preventing mechanical accidents, such as fuses, circuit break-

ers, interlock switches, etc., and those for pr otecting customers from injury, such as panels and covers, function properly. Modifications that hinder the function of any safety

devices are strictly prohibited.

5. Installing and Removing Parts The edge of parts and covers may be sharp, take care not to touch them. Be careful not to

touch those parts, and wipe off any oil that may have adhered to your fingers or hands

before servicing. When removing parts, cables, and etc. do not pull them out by force but

remove them slowly.

6. CAUTION: RISK OF EXPLOSIO N IF BATTERY IS REPLACED BY AN INCORRECT TYPE . DIS-

POSE OF USED BATTERIE S ACCORDING TO THE INSTRUCTIONS.

7. Specified Tools Follow the instruction when a tool is specified.

8. Cleaning the Toner and Developer As the toner can be explosive, sweep or brush the spilled toner into a container for collect-

ing the sweepings.

Clean away the remaining toner with a damp cloth or use a standard vacuum cleaner that

is toner-tolerant. Never use the customer's vacuum cleaner.

Do the same when cleaning the Developer because it also contains some toner.

9. Organic Solvents When using an organic solvent such as the Drum Cleaner or Machine Cleaner, pay atten-

tion to the following:

• Ensure good ventilation in the room to prevent too much inhalation of solvent fumes.

• Do not use heated solvent.

• Keep it away from fire.

• Wash your hands thoroughly after use.

10. Modifications to the Machine Before altering the machine, submit the irregular use license application.

11. Harmful Laser The customer or service personnel would not be exposed to any harmful laser during the

usual copying or scanning of documents. However, if a customer finds that the lamp that

is used for exposing documents is too bright when performing platen copy or scan, it is

possible to block the light from the platen glass by covering the portion of the platen document area that is usually not used for copying or scanning documents.

Versi on 1 .0

WC 5022/5024

06/2014

1-3

Service Call Procedures

1.1 Before Starting the Servicing

Page 10

1.1.2 Things to Take Note When Handling Customer Information

1. Handling of customer's electronic information - samples of copy/print/received fax (paper data), log files (Activity Report), and etc.

Before you bring back any samples for the purpose of investigation/analysis, always

obtain permission from the customer. Make sure to assure them that the data will not be

used for any other purpose. When requesting for a retrieval application from the customer, either use the [Data Security Regulations: Annex 15 - Confidential Information/Personal Information Request Form (IS-019)] or use a letterhead that has been specified by

the customer after obtaining their agreement.

2. Handling of a PWB, etc. that contains customer information. Data such as Fax Address Numbers and URLs that are registered in the customer's

machine are all important customer information. These types of information are stored in

the PWB, etc. within the machine. Take extra care when handling them.

a. In case of replacements, transfer the data to the new PWB and make sure that all

data in the old parts is thoroughly erased before disposing it. Make sure that no

important customer information gets leaked. (For details, refer to the preface in

Chapters 4 and 5)

b. If a component was replaced and it was not found to be the cause of the malfunction,

return it to the machine it came from. (For components that were temporarily

installed/removed for troubleshooting, etc. clear the data using the CE Mode, etc.)

3. Security related NVM values that were changed during maintenance. If any security related NVM values, such as polling, were set for test purposes, make sure

you return them to their original values after the test. (E.g.: for the details on polling that is

common to all machine types, refer to FTO 2-202)

4. When connecting our company machine to the customer's network during maintenance, make sure that you have gone through the person-in-charge to obtain permission from the customer's systems administrator (or person-in-charge) before proceeding.

5. Follow the safety guidelines established within the OpCo and ens ure that customer data do not get leaked out when servicing.

1.1.3 Other Precautions

Pay attention to the following when performing maintenance service to avoid wrong or redundant servicing:

1. Reference Materials Before performing maintenance servicing, read all relevant technical materials such as

SB, FTI, or FTO to make a systematic approach.

2. Disassembling Make sure to check the assembled condition before removing parts or disassembling the

machine.

3. Installation/Adjustment After the installation or adjustment is complete, check that no parts or tools are left inside

or on the assemblies before using the machine.

4. Handling of replaced parts/consumables Make sure that the replaced parts or consumables as well as their packaging materials

are collected back to the Service Center.

For the separation and processing methods for the collected items, refer to the Common

Technical Information No. 2-027 for all machines.

• Drum Cleaner

WARNING

Never discard the Drum Cleaner into a fire. Always keep it away from open

flames to prevent it from catching and causing a fire. Always dispose of the

Drum Cleaner after it is completely used up. For recyclable parts, fill the necessary items in the [U-TAG] and perform collection.

5. General Precautions

• Take care not to disturb the customer's daily work.

• Place a drop cloth or paper on the floor of the service area to keep the site clean.

• Throw any trash generated during the maintenance service into a trash bag and

bring them back to the Service Center.

• Record clearly the service details and the consumables and parts replaced at visit in

the Machine Service Log.

Service Call Procedures

1.1 Before Starting the Servicing

06/2014

1-4

Versi on 1 .0

WC 5022/5024

Page 11

1.2.2 Service Call Procedure

1.2.2.1 Initial Actions

1. Ask the operator(s) about the machine condition.

2. Record the billing meter readings.

3. Inspect any error copies, then check the machine.

4. Check the Service Log.

1.2.2.2 When UM is requested, perform the following:

1. Check the problem status by performing the Level 1 Troubleshooting in [Chapter 2 Troubleshooting].

2. Perform the applicable Level 2 Troubleshooting FIP in [Chapter 2 Troubleshooting].

3. If there are no applicable items, troubleshoot by referring to [Chapter 7 BSD].

4. Check the copy quality. Make several sheets of copies using the Test Chart (499T 00247), then check the quality

of the copies for problems.

5. Output the following [Error History Report] and check the [System Fail History] and [Paper Jam History] in order to understand the machine status.

a. Press the <Machine Status> button.

b. Select [Print Report], then press the <OK> button.

c. Select the [Error History Report], then press the<OK> button.

NOTE: When replacing parts that will incur cost to the customer, obtain the customer's agreement before performing the replacement.

6. Repair all the secondary problems.

7. Perform TRIM Service.

1.2.2.3 When SM is requested, perform the following:

1. Check the copy quality. Make several sheets of copies using the Test Chart (499T 00247), then check the quality

of the copies for problems.

2. Output the [Error History Report] and check the [System Fail History] and [Paper Jam History] in order to understand the machine status.

• For how to output the [Error History Report], refer to [1.2.2.2 When UM is requested,

perform the following:].

NOTE: When replacing parts that will incur cost to the customer, obtain the customer's agreement before performing the replacement.

3. Perform TRIM Service.

1.2.2.4 Final Actions

1. Check overall operation/features.

2. Check the machine exterior and consumables.

3. Train the operator as required.

4. Complete the Service Log and Service Report.

5. Keep the copy samples with the Service Log.

1.3 Detailed Contents of the Service Call

1.3.1 Initial Actions

1. Ask the operator(s) about the machine condition.

• How often and where do paper jams have been occurring recently

• How is the copy quality

2. Record the copy meter readings.

3. Inspect any error copies, then check the machine.

4. Check the print samples from previous service calls and the Service Log.

1.3.2 Checking Reproducibility of Problem

1. Check the problem status by performing the Level 1 Troubleshooting in [Chapter 2 Troubleshooting].

2. Perform the applicable Level 2 Troubleshooting FIP in [Chapter 2 Troubleshooting].

3. If there are no applicable items, troubleshoot by referring to [Chapter 7 BSD].

1.3.3 Checking Copy Quality

1. Make several sheets of copies using the Test Chart (499T 00247), then check the quality of the copies.

1.3.4 TRIM Servicing

Perform TRIM servicing during a service call to maintain the machine performance.

1. Follow the TRIM Check List to perform the required TRIM items.

2. Check for parts that require periodical cleaning/replacement (consumables, parts) by

referring to the TRIM Chec List, the Periodic Replacement Parts/Consumables List, and

the Maintenance Report, and clean them if necessary. After a replacement, make sure

that you enter the CE Mode and use [HFSI Read / Clear] to clear the applicable

counter(s).

Versi on 1 .0

WC 5022/5024

06/2014

1-5

Service Call Procedures

1.2.2 Service Call Procedure

Page 12

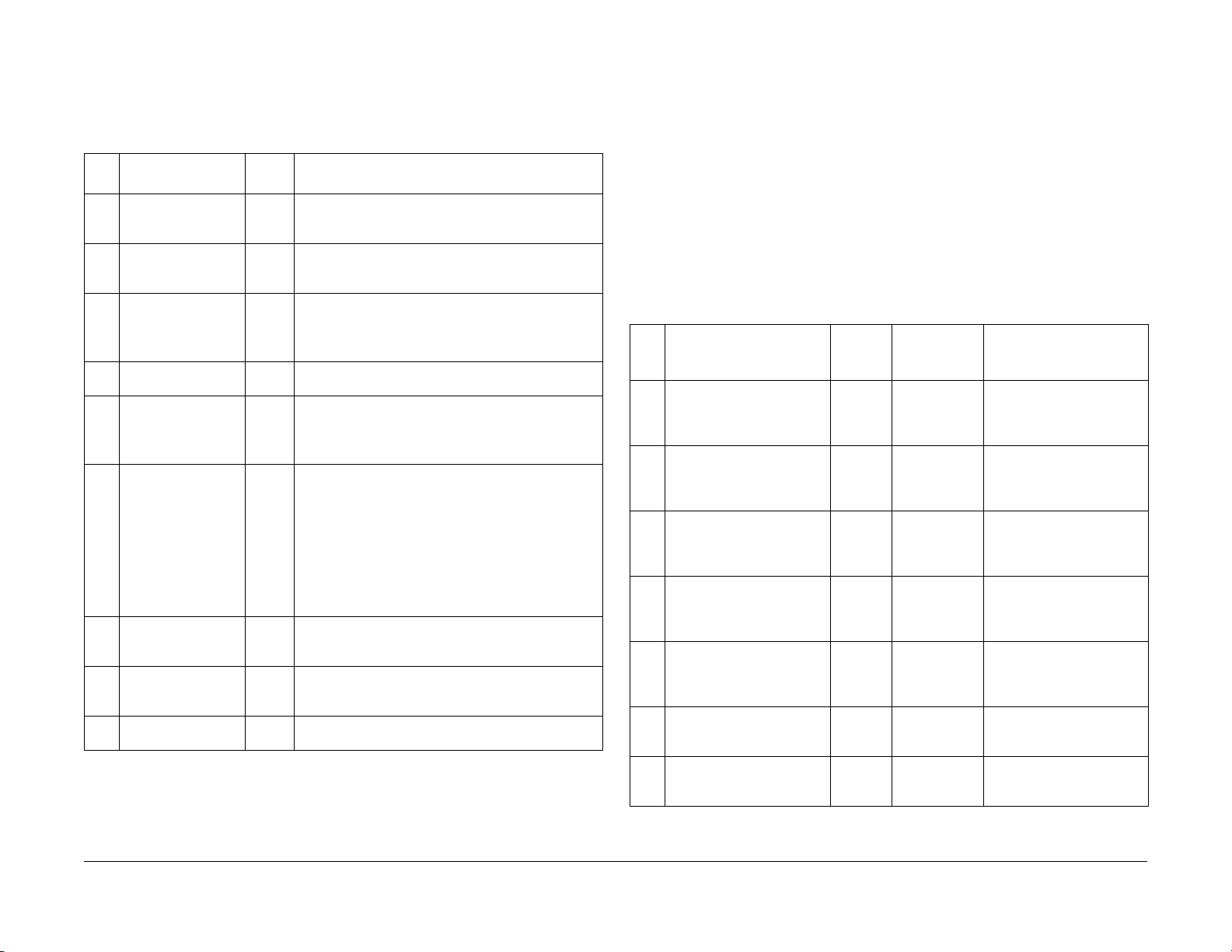

1.4 TRIM Check List

C: Perform checking. Clean, replace, or feed if necessary.

O: Always perform cleaning and checking.

*: Always perform replacement service at the specified interval.

T able 1

No. Servicing Items

1.1 Pre-servicing Check

(Check the machine

operation sound)

1.2 Pre-servicing Check

(Copy and print the

Test Chart)

2 Clean the interior of

the machine

(Clean the paper

transport system)

3 Cleaning the IIT C • Clean the Platen Glass surface and the Platen

4 Clean the DADF C • Clean the Feed Roll, Nudger Roll, and Retard Roll

5 S af ety Check O • Make sure that the power plug is plugged in prop-

6.1 Post-servicing check

(Copy Quality Check)

6.2 Post-servicing check

(Check the machine

operation)

6.3 Post-servicing check

(Check the meter)

Every time Service Details

C • Activate the machine and check that abnormal

noise is not heard.

C • Make several sheets of copies using the Test

Chart (499T 00247), then check the quality of the

copies.

C • Clean any paper dust and toner residue in the

paper path and on the jam sensor.

• Especially, clean the operation section of the

operator carefully.

Cushion with the optical cleaning cloth.

with a cloth that has been wrung dry.

• Clean the DADF Platen Glass with the optical

cleaning cloth.

erly.

• Make sure that the power cords are not cracked

and no wires are exposed.

• Make sure that no extension cord with insufficient

length or power cord outside the specification,

such as an off-the-shelf power strip, is being used.

• Make sure that a single socket does not have multiple power plugs plugged into it.

C • Make several sheets of copies using the Test

Chart (499T 00247), then check if the quality satisfies the specification.

C • Check the paper feed and abnormal noise.

C • Create the Service Log and Service Report.

1.5 Periodic Replacement Parts/Consumables List

When servicing, check the number of copies and number of fed sheets for the consumables

and parts that require periodical cleaning/replacement. Clean or replace them if necessary.

The history can be checked by printing the Maintenance Report or by checking the approriate

counter in [HFSI Read / Clear] in CE Mode (6.4.2.9 HFSI Read / Clear).

For the items that cannot be checked in CE Mode, clean or replace them according to the replacement intervals (standard PV).

CAUTION

Do not place the imaging materials, such as the Toner and the Drum, in the car for a long time. NOTE: Clean the Platen Glass with a Platen Wax Cleane r 499D 00194 (194D) every 10K

Feeds.

Table 1

Parts/Consumables Name/

No

PL No.

1 Tray 1 Feed No.

Tray 1 Feed Roll / Retard

Pad

(PL 9.2)

2 Tray 2 Feed No.

Tray 2 Feed Roll/Nudger

Roll/Retard Roll

(PL 10.3)

3 Tray 3 Feed No.

Tray 3 Feed Roll/Nudger

Roll/Retard Roll

(PL 11.3)

4 Tray 4 Feed No.

Tray 4 Feed Roll/Nudger

Roll/Retard Roll

(PL 11.3)

5 MS I Feed Count

MSI Feed Roll/MSI Nudger

Roll/MSI Retard Pad

(PL 13.3)

6 Fusing Unit

(PL 7.1)

7BTR Unit

(PL 6.1)

HFSI

[ChainLink]

950-803 50,000PV 1 Feed = 1 Count Up.

950-804 300,000PV 1 Feed = 1 Count Up.

950-808 300,000PV 1 Feed = 1 Count Up.

950-809 300,000PV 1 Feed = 1 Count Up.

950-802 50,000PV 1 Feed = 1 Count Up.

950-801 175,000PV 1 pass through the Fusing

950-800 100,000PV 1 pass through the Fusing

Replacement Interval Check the counter

Replace both at the same time.

Replace all 3 at the same time.

Replace all 3 at the same time.

Replace all 3 at the same time.

Replace all 3 at the same time.

Unit Exit Sensor = 1 Count

Up.

Unit Exit Sensor = 1 Count

Up.

Service Call Procedures

1.4 TRIM Check List

06/2014

1-6

Versi on 1 .0

WC 5022/5024

Page 13

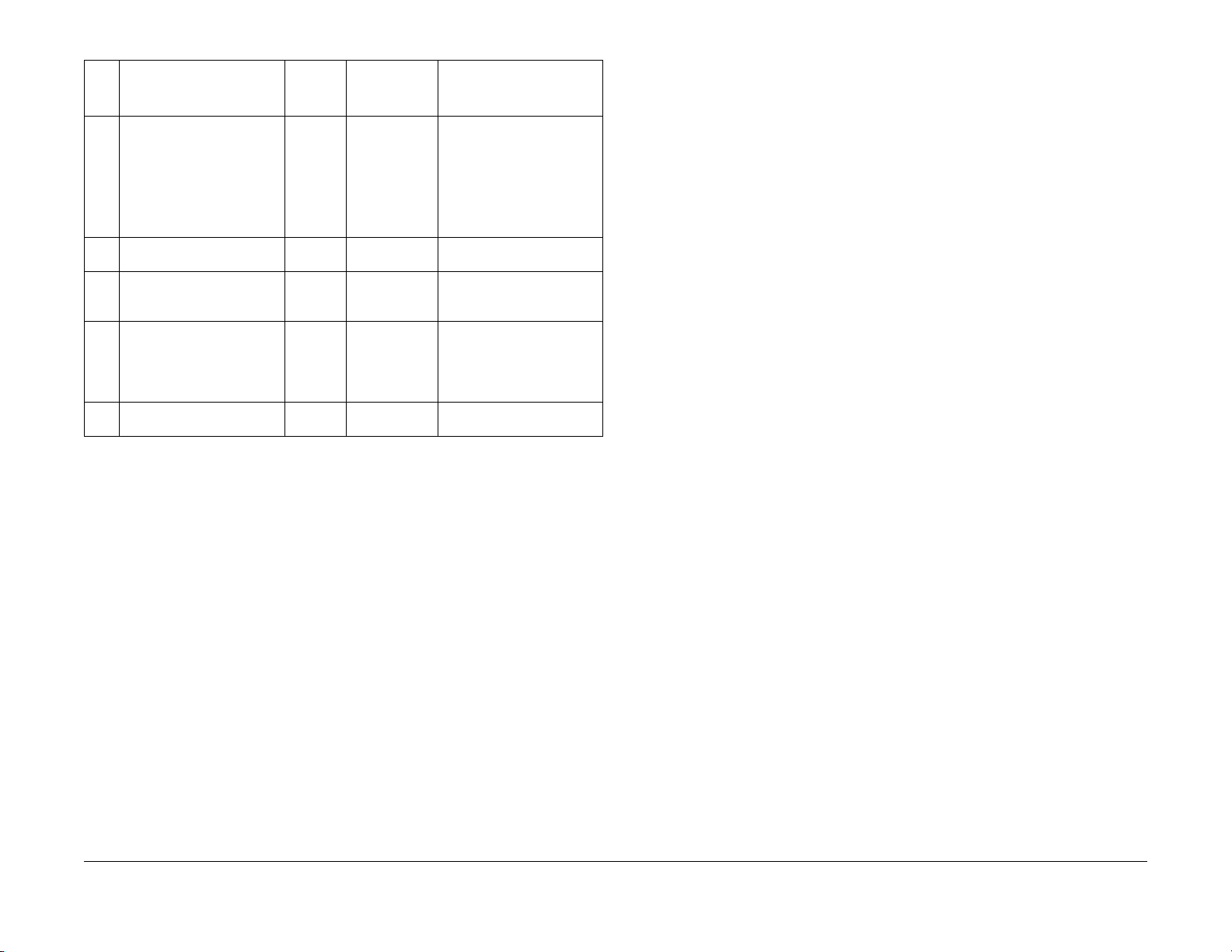

Table 1

Parts/Consumables Name/

No

PL No.

8 Docum ent Feed No.

DADF Feed Roll/Nudger Roll

(PL 56.5)

DADF Retard Pad

(PL 56.13)

9 Toner Cartridge

(PL 8.1)

10 Low Capacity Toner Car-

tridge

(PL 8.1)

13 Drum Cartridge *1

(PL 8.1)

15 Cartridge Guide

(PL 8.2)

*1 As the PV may differ greatly from the target value depending on the usage conditions, it should only be regarded as a reference value.

HFSI

[ChainLink]

955-806 200,000PV Replace the Feed Roll,

- 9,000PV

- 5,000PV

950-807 343k cycle

- 300,000PV

Replacement

Interval Check the counter

Nudger Roll, and Retard Pad

at the same time.

NOTE: Clean the Platen Glass with a Platen Wax Cleaner 499D 00914 (194D) every 10K Feeds.

66,000PV

(22PPM)

78,000PV

(24PPM)

Versi on 1 .0

WC 5022/5024

06/2014

1-7

Service Call Procedures

1.5 Periodic Replacement Parts/Consumables List

Page 14

Chapter 2 Troubleshooting

Page 15

2 Troubleshooting

2.1 Introduction

2.1.1 How to Troubleshoot............................................................................................. 2-5

2.1.3 Glossary........................................ ............................ ....................................... ..... 2-5

2.2 Product FIP

2.2.1 Leve l 1 FIP

2.2.1.1 Level 1 FIP..................................... ........................................ ............................ 2-7

2.2.2 Leve l 2 FIP

CHAIN 3

003-500 N-Up NG Out Of Range................................................................................... 2-9

003-754 IPS Overrun ...................................................................................... .... .... ....... 2-9

003-795 AMS NG Out Of Range.................................................................................... 2-10

003-942 Not-Supported Doc Size ................................................................... .... .. .... ..... 2-10

003-956 Not-Supported Doc Size ................................................................... .... .. .... ..... 2-11

003-963 APS NG Out Of Range.................................................................................... 2-11

003-972 1Job Max Page Over....................................................................................... 2-12

003-973 Auto Rotation NG Out Of Range...................................................................... 2-12

CHAIN 4

004-345 HVPS Communication Error ............................................................................ 2-13

CHAIN 5

005-122 DADF Simplex/Side 1 Pre Regi Sensor On Jam ............................................. 2-15

005-123 DADF Simplex/Side 1 Regi Sensor On Jam.................................................... 2-15

005-125/145 DADF Regi Sensor Off Jam/ DADF Regi Sensor Off Jam on Inverting.... 2-16

005-131/132 DADF Invert Sensor On Jam on Inverting/ DADF Invert Sensor On Jam. 2-16

005-134/139 DADF Invert Sensor Off Jam on Inverting/ DADF Invert Sensor Off Jam. 2-17

005-135 DADF Side 2 Pre Regi Sensor On Jam....................... .. .... .... ....... .... .. .... .... ..... 2-17

005-136 DADF Side 2 Regi Sensor On Jam.................................................................. 2-18

005-147 DADF Pre Regi Sensor Off Jam on Inverting .................................................. 2-18

005-196 Size Mismatch Jam on No Mix-Size ................................................................ 2-19

005-197 Prohibit Combine Size Jam.............................................................................. 2-19

005-198/199 Too Short Size Jam/ Too Long Size Jam ................................................. 2-20

005-210 DADF Download Fail ................................................................................ .. ..... 2-20

005-275/280 DADF RAM Test Fail/ DADF EEPROM Fail ............................................. 2-21

005-305 DADF Feeder Cover Interlock Open.......................... .. .... .... ......... .. .... .... .... ..... 2-21

005-500 DADF Download Flash Write Error ........................................ ....... .. .... .. .. .... ..... 2-22

005-907/908/913 DADF Pre Regi Sensor/DADF Regi Sensor/DADF Invert Sensor Static Jam

2-22

005-940 DADF No Original Fail ..................................................................................... 2-23

005-948 SS-Size Mismatch Jam on No Mix-size........................................................... 2-23

CHAIN 7

007-270 Tray 1 Paper Size Switch Broken .................................................................... 2-25

007-272 Tray 3 Paper Size Switch Broken .................................................................... 2-25

007-273 Tray 4 Paper Size Switch Broken .................................................................... 2-26

CHAIN 10

010-311 Fusing Unit Center Thermistor Defect.............................................................. 2-27

010-312 Fusing Unit Rear Thermistor Defect................................................................. 2-27

010-320 Over Heat Temperature Fail ............................................................................ 2-28

010-327 Fusing Unit On Time Fail ................................................................................. 2-28

010-379 Fusing Unit Hot Not Ready Return Time Fail................................................... 2-29

010-392 NOHAD Fan Defect.......................................................................................... 2-29

010-602 Over Temp Cooling Mode...................... ....... .... .. .... .... ....... .. .... .. .... ....... .... .. .... . 2-30

CHAIN 16

016-346 Fax Parameter Incorrect ............................................................... ....... ............ 2-31

016-372 File Access Error.............................................................................................. 2-31

016-500 Controller Download Flash Write Error ............................................................ 2-32

016-501 Controller Boot Flash Write Error..................................................................... 2-32

016-502 UI Panel Download Flash Write Error.............................................................. 2-33

016-504 UI panel Font Download Flash Write Error...................................................... 2-33

016-570 No Response from USB-Host for Scan Job..................................................... 2-34

016-571 No Response from USB-Host for Print Job...................................................... 2-34

016-598 E-mail Message Size Over............................................................................... 2-35

016-742/744 Download File Error/ Download File Check Sum Error............................. 2-35

016-749/799 HBPL or XPJL Syntax Error/ Print Instruction Fail .................................... 2-36

016-759 Copy Counter Full .............................................................. .... .... .... .. ......... .... ... 2-36

016-764 SMTP Server Connection Fail.......................................................................... 2-37

016-765 SMTP Server Disk Full. ............................ ........................................................ 2-37

016-766 SMTP Server Limit Over.................................................................................. 2-38

016-768 SMTP Sender Address Error ........................................................................... 2-38

016-776 Marker Code Detection Fail ............................................................................. 2-39

016-781 SMTP Server Refusal ...................................................................................... 2-39

016-981 EPC Memory Full............................................................................................. 2-40

016-982 SCAN Memory Full .......................................................................................... 2-40

016-985 Max Attachment Size Over .............................................................................. 2-41

CHAIN 17

017-745 SMB Size Over................................................................................................. 2-43

CHAIN 24

024-365 Image Output FIFO Error................................................................................. 2-45

024-910/911/915 Tray 1/Tray 2/MSI Paper Length Mismatch ....................................... 2-45

024-912 Tray 3 Paper Length Mismatch........................................................................ 2-46

024-913 Tray 4 Paper Length Mismatch........................................................................ 2-46

024-946 Tray 1 Unknown Paper Size ............................................................................ 2-47

024-947 Tray 2 Unknown Paper Size ............................................................................ 2-47

024-948 Tray 3 Unknown Paper Size ............................................................................ 2-48

024-949 Tray 4 Unknown Paper Size ............................................................................ 2-48

024-950 Tray 1 No Paper..................................................................... .. .... .. .. ....... .... .. .. . 2-49

024-951 Tray 2 No Paper..................................................................... .. .... .. .. ....... .... .. .. . 2-49

024-952 Tray 3 No Paper..................................................................... .. .... .. .. ....... .... .. .. . 2-50

024-953 Tray 4 No Paper..................................................................... .. .... .. .. ....... .... .. .. . 2-50

Versi on 1 .0

WC 5022/5024

06/2014

2-1

Status Indic a tor RAPs

Page 16

024-954 MSI No Paper .................................................................................................. 2-51

024-958/959/960 MSI/Tray 1/Tray 2 Paper Size Mismatch ........................................... 2-51

024-961 Tray 3 Paper Size Mismatch . ........................................................................... 2-52

024-962 Tray 4 Paper Size Mismatch . ........................................................................... 2-52

024-965 APS NG Unselected .............................................................. ......... .... .... .. ....... 2-53

024-966 APS NG Permission Denied............................................................................ 2-53

CHAIN 26

026-718 D-Fax Instruction Fail....................................................................................... 2-55

026-737 Network Error................................................................................................... 2-55

CHAIN 27

027-518 Forwarding Login Error .................................................................................... 2-57

027-520 SMB Forwarding Bad Volume.......................................................................... 2-57

027-522 Forwarding Access Error ................................................................................. 2-58

027-528 SMB Disk full.................................................................................................... 2-58

027-543 SMB Forwarding Bad Address......................................................................... 2-59

027-779 SMTP Server Login Error................................................................................. 2-59

CHAIN 33

033-313 Fax Board Communication Fail........................................................................ 2-61

033-316 Fax Box NVM Data Defect............................................................................... 2-61

033-325 Modem No Response...................................................................................... 2-62

033-326 Fax Controller File Broken ............................................................................... 2-62

033-503 Receive T1 Time Out ............................................... .... .. .... .... ....... .... .. .... .... ..... 2-63

033-504 T2 Time Out..................................................................................................... 2-63

033-505 T5 Time Out..................................................................................................... 2-64

033-506 DCN Receive .................................................. ....... .. .... .. .. .... .. ....... .. .. .... .. .. ....... 2-64

033-507 Unable to receive by remote............................................................................ 2-65

033-509 DIS DCS Illegal Command Receive ................................................................ 2-65

033-510 Fallback Error................................................................................................... 2-66

033-517 Timeout ECM Between Frame......................................................................... 2-66

033-526 ECM Send EOR-Q Send ................................................................................. 2-67

033-529 RTN Receive.................................................................................................... 2-67

033-531 DM Prevention Function Receive Refuse ................................................... ..... 2-68

033-532 Illegal Command Received.............................................................................. 2-68

033-541 No Destination Specified.................................................................................. 2-69

033-547 Cancel .. ............................................................................................................ 2-69

033-548 No Manual Send Line Job Cancel ................................................................... 2-70

033-549 Fax Service Disabled....................................................................................... 2-70

033-550 Phone Book Disabled ...................................................................................... 2-71

033-567 Fax AddressInfo Sum Check Fail .................................................................... 2-71

033-572 Fax Communication Management Report Full ................................................ 2-72

033-577 Control Channel Synchronization Error ........................................................... 2-72

033-578 Primary Channel Off Time Out......................................................................... 2-73

033-711 Fax File System Error ...................................................................................... 2-73

033-712 Fax Flash Full .................................................................................................. 2-74

033-725 In receive, memory full (under THRESH_MEMRX)......................................... 2-74

033-753 Fax Scan Page Full.......................................................................................... 2-75

CHAIN 34

034-522 No manual send Line....................................................................................... 2-77

034-550 Fax Board Loader Download Fail .................................................................... 2-77

034-711 Fax Send Count Limit....................................................................................... 2-78

034-726 Fax Calling Table Full ................................. ..................................................... 2-78

034-746 Line Connection Fail........................................................................................ 2-79

034-752 Dial Busy.......................................................................................................... 2-79

034-757 Fax Document Does Not Delete ...................................................................... 2-80

034-761 Fax Invalid Address book Data are Registered................................................ 2-80

034-765 Fax Report Disabled ........................................................................................ 2-81

CHAIN 35

035-550 FAX Board Download Flash Write Error .......................................................... 2-83

035-703 DCN Received at Phase B............................................................................... 2-83

035-704 Not Send Ability................................................................................................ 2-84

035-708 Post Message Resend Over ............................................................................ 2-84

035-728 G3 EOL Not Receive........................................................................................ 2-85

035-741 ECM Phase Timeout........................................................................................ 2-85

035-748 Fax Card Stopped............................................................................................ 2-86

035-758 Fax Document does not exist........................................................................... 2-86

035-759 Fax Unable to Cancel Operation...................................................................... 2-87

035-761 Fax File Open Error.......................................................................................... 2-87

CHAIN 36

036-506 V8 Error............................................................................................................ 2-89

036-550 FAX Board Loader Download Flash Write Error.............................................. 2-89

036-700 Fax Board Unable Communication.................................................................. 2-90

036-740 Fax Board Busy................................................................................................ 2-90

036-777 Control Channel Off Time Out.......................................................................... 2-91

036-796 Fax Document Mix Fail .................................................................................... 2-91

CHAIN 41

041-210/211 STM NVM Out-Of-Order/ STM NVM R/W Error........................................ 2-93

CHAIN 42

042-325/614 Main Motor Rotation Error/ Main Motor Rotation Warning........................ 2-95

042-400 Smell Life Over................................................................................................. 2-95

042-608 Voc Life Over ................................................................................................... 2-96

CHAIN 45

045-310 Image Ready Error........................................................................................ .. . 2-97

045-313 IOT Logic Fail................................................................................................... 2-97

CHAIN 47

047-218 MCU-2TM Communication Error...................................................................... 2-99

CHAIN 61

061-321 ROS Motor Fail ..................................................................................... .... .. .... . 2-101

061-325 No SOS Fail ......................................... ....... .... .. .... .. .... ....... .. .... .. .... .. ....... .... .. ... 2-101

CHAIN 62

062-277 DADF Communication Fail............................................................................... 2-103

062-300 Platen I/L Open................................................................................................ 2-103

062-311 IIT Software Logic Fail..................................................................................... 2-104

062-360 Carriage Position Fail....................................................................................... 2-104

062-371/380 Lamp Illumination Fail/ AGC Fail............................................................... 2-105

062-386 AOC Fail....................................................................................... .. ......... .. .... .. . 2-106

Status Indicator RAPs

06/2014

2-2

Versi on 1 .0

WC 5022/5024

Page 17

062-389 Carriage Over Run Fail (Scan End Side)......................................................... 2-106

062-396 CCD Cable Connection Fail............................................................................. 2-107

CHAIN 71

071-105 Regi Sensor On Jam (Tray 1).......................................................................... 2-109

CHAIN 72

072-102 Feed Out Sensor 2 On Jam............................................................................. 2-111

072-105 Regi Sensor On Jam (Tray 2).......................................................................... 2-111

072-210 Tray 2 Lift Up Fail..................................................... .. .. .... .. .... ..... .... .. .... .. .. ....... 2-112

072-212 Tray 2 Size Sensor Broken.............................................................................. 2-112

072-215 MCU-STM Communication Fail ....................................................................... 2-113

072-461 STM NVM Out-Of-Order .................................................................................. 2-113

072-470 STM NVM R/W Error ................................................................................ ....... 2-114

CHAIN 73

073-102 Feed Out Sensor 3 On Jam (Tray 3) ............................................................... 2-115

073-104 Feed Out Sensor 2 On Jam (Tray 3) ............................................................... 2-115

073-105 Regi Sensor On Jam (Tray 3).......................................................................... 2-116

073-210 Tray 3 Lift Up Fail..................................................... .. .. .... .. .... ..... .... .. .... .. .. ....... 2-116

CHAIN 74

074-101 Feed Out Sensor 4 On Jam (Tray 4) ............................................................... 2-117

074-102 Feed Out Sensor 3 On Jam (Tray 4) ............................................................... 2-117

074-104 Feed Out Sensor 2 On Jam (Tray 4) ............................................................... 2-118

074-105 Regi. Sensor On Jam (Tray 4)......................................................................... 2-118

074-210 Tray 4 Lift Up Fail..................................................... .. .. .... .. .... ..... .... .. .... .. .. ....... 2-119

CHAIN 75

075-135 Regi Sensor On Jam (MSI) . ............................................................................. 2-121

CHAIN 77

077-101 Regi Sensor Off Jam........................................................................................ 2-123

077-103 Fusing Unit Exit Sensor Off Jam (Long) .......................................................... 2-123

077-104 Fusing Unit Exit Sensor Off Jam (Short).......................................................... 2-124

077-106 Fusing Unit Exit Sensor On Jam . ..................................................................... 2-124

077-129 Regi Sensor On Jam (Duplex Wait)................................................................. 2-125

077-211 2TM Type Error . ................................................................................................ 2-125

077-212 Tray Module Reset Fail........................................................................... .. ....... 2-126

077-300 Front Cover Open ..................................................................................... ....... 2-126

077-301 Left Hand Cover Open..................................................................................... 2-127

077-305 2TM Cover Open ............................................................................................. 2-127

077-309 STM Cover Open................................................................. ........... .... ...... ....... 2-128

077-900/901/904 Regi Sensor/Fusing Unit Exit Sensor/Feed Out Sensor 2 Static Jam 2-128

077-905 Feed Out Sensor 3 Static Jam ......................................................................... 2-129

077-906 Feed Out Sensor 4 Static Jam ......................................................................... 2-129

CHAIN 91

091-401/402 Drum Cartridge Quality Life Over/ Drum Cartridge Life Over ................... 2-131

091-406/424 Drum Cartridge Normal Life Over/ D rum Cart ridge Abnorma l Life Over... 2-131

091-430 Drum Cartridge Life End .................................................................................. 2-132

091-440 Drum Cartridge Pre Near End.......................................................................... 2-132

091-441 Drum Cartridge Near End ................................................................................ 2-133

CHAIN 92

092-660/668 ATC Amplitude Fail/ ATC Average Fail..................................................... 2-135

092-661 Temperature Sensor Fail ................................................................................. 2-135

092-910 ATC Sensor Fail.............................................................................................. . 2-136

CHAIN 93

093-312 Toner Dispense Motor Rotation Fail ................................................................ 2-137

093-400 Toner Near Empty............................................................................................ 2-137

093-406 Toner Pre Near Empty .............................................................................. .. .... . 2-138

093-912 Toner Empty..................................................................................................... 2-138

093-956 Drum New CRU Installation Fail...................................................................... 2-139

093-959 Drum New CRU Installation Fail Exceeds Thresholding Times....................... 2-139

CHAIN 116

116-317 Configuration NG ..................................................................... .... .. ....... .... .. .. ... 2-141

116-321 Controller Logic Fail......................................................................................... 2-141

116-323 Controller NVM Data Defect............................................................................. 2-142

116-324 Exception Fail................................................................................................... 2-142

116-334 NVM Data Mismatch........................................................................................ 2-143

116-377 IIT Interrupt Timeout......................................................................................... 2-143

116-386 USB Host Terminal Unknown Device Connection Fail .................................... 2-144

116-747 Invalid Page Margin ......................................................................................... 2-144

CHAIN 117

117-327 Controller Extension Card NVM Data Defect................................................... 2-145

CHAIN 123

123-314 UI Panel Communication Fail........................................................................... 2-147

CHAIN 124

124-311 Serial Number Fail ............................................................................................ 2-149

CHAIN 127

127-396 E-mail Generate Fail........................................................................................ 2-151

CHAIN 133

133-226 Fax Country or Clock Not Set .......................................................................... 2-153

CHAIN 134

134-210 Fax Data Parameter Error ........................ ........................................................ 2-155

134-211 Fax Board Failure............................................................................................. 2-155

2.2.3 Other Failure FIP

2.2.3.1 AC Power FIP..................................................................................................... 2-157

2.2.3.2 +5VDC Power FIP.............................................................................................. 2-157

2.2.3.3 +24VDC Power FIP............................................................................................ 2-158

2.2.4 Generic FIP

2.2.4.1 Reflective Sensor Failure FIP............................................................................. 2-159

2.2.4.2 Permeable Sensor Failure FIP............................ .. .... .... ......... .. .... .... ......... .... .. ... 2-159

2.2.4.3 Switch (Normal/Open) Failure FIP ..................................................................... 2-160

2.2.4.4 Solenoid/Clutch Not Energized Failure FIP........................................................ 2-160

2.2.4.5 Solenoid/Clutch Left Energized Failure FIP....................................................... 2-161

2.2.4.6 Motor Does Not Rotate Failure FIP.................................................................... 2-161

Versi on 1 .0

WC 5022/5024

06/2014

2-3

Status Indic a tor RAPs

Page 18

2.2.4.7 Motor Left Running Failure FIP............................................ .... ......... .. .... .... .. ..... 2-162

2.2.4.8 NIP/RELEASE SOLENOID Not Energized Failure FIP...................................... 2-162

2.3 NET System Fault Check

2.3.1 Interface (Physical/Logical)................................................................................... 2-165

2.3.2 'Cannot connect to the network' or 'Print is not found from the PC' ...................... 2-165

2.3.3 No output is available, no data is printed.............................................................. 2-166

2.3.4 Printing can be performed but abnormally ............................................................ 2-167

2.3.5 Network-Related Details Check Flow.................................................................... 2-167

2.4 Software Download

2.4.1 Software Download.................................... ........................... ........................... ..... 2-169

Status Indicator RAPs

06/2014

2-4

Versi on 1 .0

WC 5022/5024

Page 19

2.1.1 How to Troubleshoot

Level 1 Troubleshooting:

• Level 1 Troubleshooting (Level 1 FIP) is the first step to diagnose a problem. Level 1 FIP

asks you whether any Fault Code and other problematic symptoms exist, guiding you to

Level 2 Troubleshooting or BSD to resolve the problem.

Level 2 Troubleshooting:

• Level 2 Troubleshooting is a diagnostic procedure of separating a problem by Fault Code,

document/paper jam and other problematic symptoms. Performing a FIP or an appropriate procedure in the Check Procedure enables you to discover causes of a problem in a

short period of time.

How to proceed with troubleshooting and Cautions:

• First, perform Level 1 FIP to categorize a problem. Second, proceed to an appropriate

Level 2 FIP or BSD to resolve the problem. To fi nd the causes of the problem using FIP or

Check Procedure etc., thoroughly read the instructions and follow the procedure properly.

Sometimes, when two or more causes exist, they cannot be identified at once, so the

same FIP should be repeated. In this case, pay attention to a different judgment made in

the process of the same FIP.

• For source voltage related problems, such as being unable to power up the machine,

refer to 'Other Failure FIP' to proceed with the troubleshooting.

• The Check Procedure for general electrical parts (Motor, Solenoid/Clutch, Switch, Sensor

etc.) may not be shown in each troubleshooting for some cases. In such cases, proceed

to troubleshoot by referring to 'Generic FIP'.

2.1.3 Glossary

The following terminology are used throughout the t roubleshooting section. The meaning of these terminology must be fully understood when performing problem analysis.

Common terms:

• Fault Code

This 6-digit code appears when the machine has found problems.

• Actuate (Deactuate)

To mechanically push (release) the Actuator of the switch or t he connected mechanical

linkage.

•Block

To place a sheet of document or paper on the photo sensor surface for detection.

• Check

To visually check for operation failure of parts such as relay or mechanical linkage, and

the failure status of the parts.

• Enter the CE Mode

To enter the CE Mode by following the procedure described in 'How to Enter/Exit the CE

Mode' of Chapter 6.

• Check the connection for short circuit

Turn the power OFF. Measure the resistance between the wire and the frame using the

ohm range of a tester.

• Check the connection for open circuit

Turn the power OFF. Measure the resistance between both ends of the wire using the

ohm range of a tester.

• Input Check [xxx-xxx]/Output Check [xxx-xxx]

To enter the Component Check by following the procedure described in 'How to Us e the

CE Mode' of Chapter 6.

• Analog Monitor [xxx-xxx]

To enter the Analog Monitor by following the procedure described in 'How to Use the CE

Mode' of Chapter 6.

• Check the voltage level

Versi on 1 .0

WC 5022/5024

Voltage Level Range

+3.3VDC (H)

(L)

+5VDC (H)

(L)

+24VDC (H)

(L)

• PL 4.2

Refer to PL 4.2 in Chapter 5 Parts List.

06/2014

2-5

Table 1

+3.2 to +3.6VDC

0.0 to +1.0VDC +4.8 to +5.4VDC

0.0 to +1.0VDC +23.3 to +25.7VDC

0.0 to +3.0VDC

Status Indic a tor RAPs

2.1.1 How to Troubleshoot

Page 20

• CH 6.2 Zone J4

Refer to Chain 6.2 Zone J4 in Chapter 7 BSD.

• REP 4.1.3

Refer to REP 4.1.3 in Chapter 4.

• ADJ 4.1.3

Refer to ADJ 4.1.3 in Chapter 4.

• Replace the parts in sequence

When it is impossible to analyze causes of a problem further, replace the parts in

sequence. The part with a higher replacement frequency or higher possibility of causing a

problem is listed first for replacement.

Status Indicator RAPs

2.1.3 Glossary

06/2014

2-6

Versi on 1 .0

WC 5022/5024

Page 21

2.2.1.1 Level 1 FIP

Procedure

Ask the operator about the problem. Did the operator operate the machine correctly?

YN

Explain the correct way to operate the machine to the operator.

Output all jobs that are stored in the memory. Turn the power OFF and ON. Is the UI display

normal?

YN

Refer to [BSD (CH2.1)] and [2.2.3 Other Failure FIP] to repair the malf unction in UI display.

Check the Shutdown History. Refer to [6.5.2.1 Shutdown History] to display the Fault Code on

the UI. Is the Fault Code displayed on the UI?

YN

Refer to [Troubleshooting] in the User Guide and repair the following errors.

• Problems With Hardware

• Problems With Image Quality

• Problems With Copy

• Problems W it h P rinter

• Problems With Scanner

• Problems With Network

• In Case of Paper Jam

• In Case of Document Jam

Proceed to Level 2 Troubleshooting and perform the applicable FIP.

Versi on 1 .0

WC 5022/5024

06/2014

2-7

Status Indic a tor RAPs

2.2.1.1 Level 1 FIP

Page 22

Status Indicator RAPs

2.2.1.1 Level 1 FIP

06/2014

2-8

Versi on 1 .0

WC 5022/5024

Page 23

003-500 N-Up NG Out O f Range

BSD-ON:-

003-754 IPS Overrun

BSD-ON:-

During 2-Up or 4-Up, the reduce/enlarge ration was not within the range of 25 to 400%.

Cause/Action

Press [Stop] on the UI Panel and change the settings.

The IPS processing has overtook the Scan processing.

Cause/Action

This might be avoided by setting the R/E ratio to 99% or 101%. If this occurs frequently, obtain the document from the User and contact the Support Department for assistance.

Versi on 1 .0

WC 5022/5024

06/2014

2-9

Status Indic a tor RAPs

003-500 N-Up NG Out O f Range

Page 24

003-795 AMS NG Out Of Range

BSD-ON:-

003-942 Not-Supported Doc Size

BSD-ON:-

When [Reduce/Enlarge] is set to [Auto], the reduce/enlarge ratio was not within the range of 50 to 200%.

Cause/Action

Press [Stop] on the UI Panel and change the settings.

NOTE: When performing the operation again, the same Fault will occur if the user had proceeded without changing the settings.

During DADF Scan of a Copy, Scan and Fax sending Job, an unsupported document size was detected.

Cause/Action

1. Press [Stop] on the UI Panel.

2. Check the setting of the document size group.

3. Check whether the document size is a supported size.

4. If the document size is a supported size, the DADF might have malfunctioned. Refer to following FIP to check the DADF.

• 005-196 (Size Mismatch Jam on No Mix-size)

• 005-948 (SS-Size Mismatch Jam on No Mix-size)

Status Indicator RAPs

003-795 AMS NG Out Of Range

06/2014

2-10

Versi on 1 .0

WC 5022/5024

Page 25

003-956 Not-Supported Doc Size

BSD-ON:-

003-963 APS NG Out Of Range

BSD-ON:-

During Platen Scan, an unsupported document size was detected.

Cause/Action

Press [Stop] on the UI Panel and change the document.

NOTE: When performing the operation again, the same Fault will occur if the user had proceeded without changing the document.

During Copy Job, when APS is selected, the image size obtained from document size x reduce/enlarge ratio was detected to be larger than the largest Standard Paper Size.

Cause/Action

Press [Stop] on the UI Panel and change the settings.

Versi on 1 .0

WC 5022/5024

06/2014

2-11

Status Indic a tor RAPs

003-956 Not-Supported Doc Size

Page 26

003-972 1Job Max Page Over

BSD-ON:-

003-973 Auto Rotation NG Out Of Range

BSD-ON:-

During Copy Job or Scan Job, the number of pages that can be scanned has been exceeded.

Cause/Action

Press [Stop] on the UI Panel and reduce the number of document pages.

During Copy Job, the following conditions were met.

• Rotation is required.

• The length of the image obtained by document x reduce/enlarge ratio is longer than 297

mm.

Cause/Action

Press [Stop] on the UI Panel and change the reduce/enlarge ratio.

Status Indicator RAPs

003-972 1Job Max Page Over

06/2014

2-12

Versi on 1 .0

WC 5022/5024

Page 27

004-345 HVPS Communication Error

BSD-ON: CH9.1

Communication failure between the ESS/MCU PWB and the HVPS was detected.

Cause/Action

1. Turn the power OFF and ON.

2. Turn OFF the power and check the connection between the HVPS J500 and the ESS/

MCU PWB J402 for open circuit, short circuit, and poor contact.

3. If no problem is found, replace the following parts in sequence:

• HVPS (PL 18.3)

• ESS/MCU PWB (PL 18.3)

Versi on 1 .0

WC 5022/5024

06/2014

2-13

Status Indic a tor RAPs

004-345 HVPS Communication Error

Page 28

Status Indicator RAPs

004-345 HVPS Communication Error

06/2014

2-14

Versi on 1 .0

WC 5022/5024

Page 29

005-122 DADF Simpl ex/Side 1 Pre Regi Sensor On Jam

BSD-ON: CH5.4

005-123 DADF Simplex/Side 1 Regi Sensor On Jam

BSD-ON: CH5.5, CH5.4

• After Pre-Feed started for the first sheet (DADF Feed M otor On (CW)) in Simplex and

Duplex, the DADF Pre Regi Sensor did not turn ON within the specified time.

• After Pre-Feed started for the second sheet onwards (DADF Feed Motor On (CW)) in

Duplex, the DADF Pre Regi Sensor did not turn ON within the specified time.

Cause/Action

Check the following:

• Transportation failure due to foreign substance on the document path.

• The surface of the Feed Roll and Nudger Roll for foreign substances.

• The surface of the Feed Roll and Nudger Roll for wear.

• The DADF Pre Regi Sensor (Input Check [005-206]) for operation failure. (PL 56.14)

• The DADF Feed Clutch (Output Check [005-062]) for operation failure. (PL 56.7)

• The DADF Feed Motor (Output Check [005-008]) for operation failure. (PL 56.6)

• The Drive Gear for wear and damage.

If no problem is found, replace the DADF PWB. (PL 56.2)

The DADF Regi Sensor does not turn ON within the specified time after the DADF Pre Regi Sensor On.

Cause/Action

Check the following:

• Transportation failure due to foreign substance on the document path.

• The surface of the Takeaway Roll and Regi Roll for foreign substances.

• The surface of the Takeaway Roll and Regi Roll for wear.

• The DADF Regi Sensor (Input Check [005-110]) for operation failure. (PL 56.14)

• The DADF Pre Regi Sensor (Input Check [005-206]) for operation failure. (PL 56.14)

• The DADF T/A Clutch (Output Check [005-098]) for operation failure. (PL 56.7)

• The DADF Feed Motor (Output Check [005-008]) for operation failure. (PL 56.6)

• The Drive Gear for wear and damage.

If no problem is found, replace the DADF PWB. (PL 56.2)

Versi on 1 .0

WC 5022/5024

06/2014

2-15

Status Indic a tor RAPs

005-122 DADF Simplex/Side 1 Pre Regi Sensor On

Page 30

005-125/145 DADF Regi Sensor Off Jam/ DADF Regi Sensor Off Jam on Inverting

BSD-ON: CH5.5, CH5.4

005-131/132 DADF Invert Sensor On Jam on Inverting/ DADF Invert Sensor On Jam

BSD-ON: CH5.5, CH5.4

[DADF Regi Sensor Off Jam]

After the DADF Pre Regi Sensor turned OFF at Scan operation, the DADF Regi Sensor did not turn OFF within the specified time.

[DADF Regi Sensor Off Jam on Inverting]

After the DADF Pre Regi Sensor turned OFF at Invert operation, the DADF Regi Sensor did not turn OFF within the specified time.

Cause/Action

Check the following:

• Transportation failure due to foreign substance on the document path.

• The surface of the Regi Roll, Out Roll, and Exit Roll for foreign substances.

• The surface of the Regi Roll, Out Roll, and Exit Roll for wear.

• The DADF Regi Sensor (Input Check [005-110]) for operation failure. (PL 56.14)

• The DADF Pre Regi Sensor (Input Check [005-206]) for operation failure. (PL 56.14)

• The DADF Feed Motor (Output Check [005-008]) for operation failure. (PL 56.6)

• The Drive Gear for wear and damage.

If no problem is found, replace the DADF PWB. (PL 56.2)

[DADF Invert Sensor On Jam on Inverting]

After the DADF Regi Sensor turned ON at Invert operation, the DADF Invert Sensor did not turn ON within the specified time.

[DADF Invert Sensor On Jam]

After the DADF Regi Sensor turned ON in the Scan operation, the DADF Invert Sensor did not turn ON within the specified time.

Cause/Action

Check the following:

• Transportation failure due to foreign substance on the document path.

• The surface of the Out Roll for foreign substances.

• The surface of the Out Roll for wear

• The DADF Invert Sensor (Input Check [005-211]) for operation failure. (PL 56.10)

• The DADF Regi Sensor (Input Check [005-110]) for operation failure. (PL 56.14)

• The DADF Feed Motor (Output Check [005-008]) for operation failure. (PL 56.6)

• The Drive Gear for wear and damage.

If no problem is found, replace the DADF PWB. (PL 56.2)

Status Indicator RAPs

005-125/145 DADF Regi Sensor Off Jam/ DADF Regi

06/2014

2-16

Versi on 1 .0

WC 5022/5024

Page 31

005-134/139 DADF Invert Sensor Off Jam on Inverting/ DADF Invert Sensor Off Jam

BSD-ON: CH5.5, CH5.4

[DADF Invert Sensor Off Jam on Inverting]

005-135 DADF Side 2 Pre Regi Sensor On Jam

BSD-ON: CH5.5, CH5.4

After the DADF Feed Motor started the reverse rotation at Invert operation, the DADF Pre Regi Sensor did not turn ON within the specified time.

During the Invert operation where there is a next document, after the DADF Regi Sensor turned OFF, the DADF Invert Sensor did not turn OFF within the specified time.

[DADF Invert Sensor Off Jam]

During the Simplex and Duplex Scan operation, after the DADF Regi Sensor turned OFF, the DADF Invert Sensor did not turn OFF within the specified time.

Cause/Action

Check the following:

• Transportation failure due to foreign substance on the document path.

• The surface of the Out Roll and Exit Roll for foreign substances.

• The surface of the Out Roll and Exit Roll for wear.

• The DADF Invert Sensor (Input Check [005-211]) for operation failure. (PL 56.10)

• The DADF Regi Sensor (Input Check [005-110]) for operation failure. (PL 56.14)

• The DADF Feed Motor (Output Check [005-008]) for operation failure. (PL 56.6)

• The Exit Pinch Roll for operation failure (including for the opera tion failure of the Exit Nip

Release Solenoid (Output Check [005-072])). (PL 56.7)

• The Drive Gear for wear and damage.

If no problem is found, replace the DADF PWB. (PL 56.2)

Cause/Action

Check the following:

• Transportation failure due to foreign substance on the document path.

• The surface of the Exit Roll for foreign substances.

• The surface of the Exit Roll for wear

• The DADF Pre Regi Sensor (Input Check [005-206]) for operation failure. (PL 56.14)

• The DADF Feed Motor (Output Check [005-048]) for operation failure. (PL 56.6)

• The Exit Pinch Roll for operation failure (including for the operation failure of the Exit Nip

Release Solenoid (Output Check [005-072])). (PL 56.7)

• The Drive Gear for wear and damage.

If no problem is found, replace the DADF PWB. (PL 56.2)

Versi on 1 .0

WC 5022/5024

06/2014

2-17

Status Indic a tor RAPs

005-134/139 DADF Invert Sensor Off Jam on Invert-

Page 32

005-136 DADF Side 2 Regi Sensor On Jam

BSD-ON: CH5.5, CH5.4

005-147 DADF Pre Regi Sensor Off Jam on Inverting

BSD-ON: CH5.5, CH5.4

After the DADF Pre Regi Sensor turned ON at Invert operation, the DADF Regi Sensor did not turn ON within the specified time.

Cause/Action

Check the following:

• Transportation failure due to foreign substance on the document path.

• The surface of the Exit Roll, Takeaway Roll, and Regi Roll for foreign substances.

• The surface of the Exit Roll, Takeaway Roll, and Regi Roll for wear.

• The DADF Regi Sensor (Input Check [005-110]) for operation failure. (PL 56.14)

• The DADF Pre Regi Sensor (Input Check [005-206]) for operation failure. (PL 56.14)

• The DADF Feed Motor (Output Check [005-008]) for operation failure. (PL 56.6)

• The DADF T/A Clutch (Output Check [005-098]) for operation failure. (PL 56.7)

• The Exit Pinch Roll for operation failure (including for the opera tion failure of the Exit Nip

Release Solenoid (Output Check [005-072])). (PL 56.7)

• The Drive Gear for wear and damage.

If no problem is found, replace the DADF PWB. (PL 56.2)

After the DADF Feed Motor started the reverse rotation at Invert operation, the DADF Pre Regi Sensor did not turn OFF within the specified time.

Cause/Action

Check the following:

• Transportation failure due to foreign substance on the document path.

• The surface of the Exit Roll, Takeaway Roll, Regi Roll, and Out Roll for foreign substances.

• The surface of the Exit Roll, Takeaway Roll, Regi Roll, and Out Roll for wear.

• The DADF Pre Regi Sensor (Input Check [005-206]) for operation failure. (PL 56.14)

• The DADF Feed Motor (Output Check [005-048/008] (CCW/CW)) for operation failure.

(PL 56.6)

• The Exit Pinch Roll for operation failure (including for the operation failure of the Exit Nip

Release Solenoid (Output Check [005-072])). (PL 56.7)

• The Drive Gear for wear and damage.

If no problem is found, replace the DADF PWB. (PL 56.2)

Status Indicator RAPs

005-136 DADF Side 2 Regi Sensor On Jam

06/2014

2-18

Versi on 1 .0

WC 5022/5024

Page 33

005-196 Size Mismatch Jam on No Mix-Size

BSD-ON: CH5.4, CH5.2

005-197 Prohibit Combine Size Jam

BSD-ON: CH5.4

The 2nd sheet or later of the document was detected to be of a different size conpared to the 1st sheet (the length of the document's 2nd sheet or later in SS direction is longer).

Cause/Action

1. Check the size of the document that was fed by the User.

2. If the error is not cleared, check the following:

• The DADF Pre Regi Sensor (Input Check [005-206]) for operation failure. (PL 56.14)

• The Document Tray Size Sensor 1/2 (Input Check [005-221/222]) for operation failure. (PL 56.11)

3. If no problem is found, replace the DADF PWB. (PL 56.2)

A Mixed Size document was detected.

Cause/Action

Explain to the User that Mixed Size is not supported.

Versi on 1 .0

WC 5022/5024

06/2014

2-19

Status Indic a tor RAPs

005-196 Size Mismatch Jam on No Mix-Size

Page 34

005-198/199 Too Short Size Jam/ Too Long Size Jam

BSD-ON: CH5.4, CH5.2

005-210 DADF Download Fail

BSD-ON: CH1.3

[Too Short Size Jam]

It was detected that the document length in Slow Scan direction is shorter than the specifications (Simpex: 85 mm, Duplex: 110 mm).

[Too Long Size Jam]

It was detected that the document length in Slow Scan direction is at the specifications (Sim pex: 1275 mm, Duplex: 480.1 mm) or longer.

Cause/Action

Check the size of the document that was fed by t he user. If it is within the permitted length for DADF transport, check the following:

• The DADF Pre Regi Sensor (Input Check [005-206]) for operation failure. (PL 56.14)

• The Document Tray Size Sensor 1/2 (Input Check [005-221/222]) for operation failure.

(PL 56.11)

If no problem is found, replace the DADF PWB. (PL 56.2)

When the IISS starts up (including at Power ON/Sleep recovery), it was detected that the DADF is in Download Mode.

Cause/Action

Perform the DADF software download.

Status Indicator RAPs

005-198/199 Too Short Size Jam/ Too Long Size Jam

06/2014

2-20

Versi on 1 .0

WC 5022/5024

Page 35

005-275/280 DADF RAM Test Fail/ DADF EEPROM Fail

BSD-ON: CH1.3

005-305 DADF Feeder Cover Interlock Open

BSD-ON: CH5.1

[DADF RAM Test Fail]

The DADF PWB RAM failed during the Read/Write operation. (At Power ON)

[DADF EEPROM Fail]

Write failure to DADF EEPROM or communication failure with EEPROM was detected.

Cause/Action

1. Turn the power OFF and ON.

2. If the problem persists, replace the DADF PWB. (PL 56.2)

The DADF Feeder Cover Interlock Switch was opened during DADF operation.

Cause/Action

1. Check the DADF Feeder Cover for mismatch.

2. Check the DADF Feeder Cover Interlock Switch (Input Check [005-212]) for operation

failure. (PL 56.6)

3. If no problem is found, replace the DADF PWB. (PL 56.2)

Versi on 1 .0

WC 5022/5024

06/2014

2-21

Status Indic a tor RAPs

005-275/280 DADF RAM Test Fail/ DADF EEPROM

Page 36

005-500 DADF Download Flash Write Error

BSD-ON: CH1.3

Failed to write into the Flash ROM during DAFD Download.

Cause/Action

1. Turn the power OFF and ON.

• If the device starts up normally

Check the FW Version of the DADF. If the FW Version is not the expected version,

turn OFF the power, start up the device in Download Mode, and then try to download

again. If the problem persists, replace the DADF PWB. (PL 56.2)

• If the device does not start up normally

Turn OFF the power and start up the device in Download Mode. If the device can

start up in Download Mode, try to download the FW again. If the problem persists,

replace the DADF PWB. (PL 56.2)

If it cannot start up in Download Mode, replace the DADF PWB. (PL 56.2)

005-907/908/913 DADF Pre Regi Sensor/DADF Regi Sensor/DADF Invert Sensor Static Jam

BSD-ON: CH5.5, CH5.4

Paper was detected by the applicable sensor at Power ON, Feeder Cover Interlock Close, or DADF Open Sensor Close.

Cause/Action

1. Check the applicable sensor for remaining paper, the Actuator for return failure, contamination on sensor, and etc.

2. Check the applicable sensor for operation failure.

• DADF Pre Regi Sensor (Input Check[005-206]) (PL 56.14)

• DADF Regi Sensor (Input Check[005-110]) (PL 56.14)

• DADF Invert Sensor (Input Check[005-211]) (PL 56.10)

3. If no problem is found, replace the DADF PWB. (PL 56.2)

Status Indicator RAPs

005-500 DADF Download Flash Write Error

06/2014

2-22

Versi on 1 .0

WC 5022/5024

Page 37

005-940 DADF No Ori ginal Fail

BSD-ON: CH5.1

005-948 SS-Size Mismatch Jam on No Mix-size

BSD-ON: CH5.4, CH5.2

It was detected that the document was pulled out during document feed.

Cause/Action

Reload the document.

In No Mix mode, it was detected that a document with a shorter size in Slow Scan (SS) direction was transported from the DADF.

Cause/Action

1. Check the size of the document that was fed by the User.

2. If the error is not cleared, check the following:

• The DADF Pre Regi Sensor (Input Check [005-206]) for operation failure. (PL 56.14)

• The Document Tray Size Sensor 1/2 (Input Check [005-221/222]) for operation fail-

ure. (PL 56.11)

3. If no problem is found, replace the DADF PWB. (PL 56.2)

Versi on 1 .0

WC 5022/5024

06/2014

2-23

Status Indic a tor RAPs

005-940 DADF No Original Fail

Page 38

Status Indicator RAPs

005-948 SS-Size Mismatch Jam on No Mix-size