Page 1

Phaser 8560MFP Multifunction Product

Service Documentation

701P01133

October 2006

Page 2

Phaser 8560MFP Multifunction Product

Service Documentation

Phaser 8560MFP Multifunction Product Service Manual

705P01133

Bus Updated November 1, 2006, Reissue

10/2006

Acrobat®, Adobe® Reader®, Adobe Type Manager®, ATM™, Illustrator® PageMaker®, Photoshop®, PostScript®, Adobe Brilliant® Screens, Adobe Garamond®, Adobe Jenson™,

Birch®, Carta®, IntelliSelect®, Mythos®, Quake®, and Tekton® are trademarks of Adobe Systems Incorporated in the United States and/or other countries.

Apple®, AppleTalk®, Bonjour®, EtherTalk®, LaserWriter®, LocalTalk®, Macintosh®, Mac

OS®, TrueType®, Apple Chancery®, Chicago®, Geneva®, Monaco®, New York® , and QuickDraw® are trademarks of Apple Computer, Inc. in the United States and/or other countries.

HP-GL®, HP-UX®, and PCL® are trademarks of Hewlett-Packard Corporation in the United

States and/or other countries.

Xerox Corporation

XOG Worldwide Product Training & Information

26600 Parkway - Bldg. 60

P.O. Box 1000, M/S 7060-776

Wilsonville, OR 97070-1000

NOTICE: All service documentation is supplied to Xerox external customers for informational

purposes only. Xerox service documentation is intended for use by certified, product trained

service personnel only. Xerox does not warrant or represent that such documentation is complete, nor does Xerox represent or warrant that it will notify or provide to such customer any

future changes to this documentation. Customer performed service of equipment, or modules,

components or parts of such equipment may affect the warranty offered by Xerox with respect

to such equipment. You should consult the applicable warranty for its terms regarding customer

or third party provided service. If the customer services such equipment, modules, components or parts thereof, the customer releases Xerox from any and all liability for the customer

actions, and the customer agrees to indemnify, defend and hold Xerox harmless from any third

party claims which arise directly or indirectly from such service.

Unpublished rights reserved under the copyright laws of the United States. Contents of this

publication may not be reproduced in any form without permission of Xerox Corporation.

Copyright protection claimed includes all forms of matters of copyrightable materials and information now allowed by statutory or judicial law or hereinafter granted, including without limitation, material generated from the software programs which are displayed on the screen such

as styles, templates, icons, screen displays, looks, etc.

IBM® and AIX® are trademarks of International Business Machines Corporation in the United

States and/or other countries.

Windows®, Vista™, Windows Server™, and Wingdings® are trademarks of Microsoft Corporation in the United States and/or other countries.

Novell®, NetWare®, NDPS®, NDS®, Novell Directory Services®, IPX™, and Novell Distributed Print Services™ are trademarks of Novell, Incorporated in the United States and/or other

countries.

SunSM, Sun Microsystems™, and Solaris™ are trademarks of Sun Microsystems, Incorporated in the United States and/or other countries.

SWOP® is a trademark of SWOP, Inc.

UNIX® is a trademark in the United States and other countries, licensed exclusively through X/

Open Company Limited.

PANTONE® Colors generated may not match PANTONE-identified standards. Consult current

PANTONE Publications for accurate color. PANTONE® and other Pantone, Inc. trademarks are

the property of Pantone, Inc. © Pantone, Inc., 2000.

Xerox technical training materials and service manuals are intended for use by authorized

Xerox service technicians and service partners only and are not for resale. These materials

may not be distributed, copied or otherwise reproduced without prior written consent from

Xerox Corporation.

XEROX®, The Document Company®, the digital X®, CentreWare®, infoSMART®, Made For

Each Other®, PagePack™, Phaser®, PhaserSMART®, and Walk-Up™ are trademarks of

Xerox Corporation in the United States and/or other countries.

Initial Issue

10/2006

Phaser 8510/8560MFP Multifunction Product

Introduction

ii

Page 3

About This Manual .......................................................................................................... iii

Organization....................................................................................................................iii

Power Safety................................................................................................................... iv

Service Safety Summary................................................................................................. iv

Moving the System.......................................................................................................... vi

Symbology and Nomenclature ........................................................................................ vii

Electrostatic Discharge Precautions ............................................................................... ix

Regulatory Specifications................................................................................................ ix

Phaser 8510/8560MFP Overview ................................................................................... x

System Configurations.................................................................................................... xi

Parts of the Product ........................................................................................................ xii

Control Panel Layout....................................................................................................... xiv

Specifications..................................................................................................................xvi

Introduction

Initial Issue

Phaser 8510/8560MFP Multifunction Product

10/2006

iii

Introduction

Page 4

About This Manual

The Phaser 8510/8560MFP Multifunction Product Service Manual is the primary document

used for diagnosing, repairing, maintaining, and troubleshooting the system. It is the controlling

publication for a service call. Information on its use is found in the Introduction of the Service

Documentation. To ensure understanding of this product, complete the Xerox Service Training

Program for this particular system.

For manual updates, Service Bulletins, knowledge base, and technical support, visit

www.xerox.com/office/support.

Service Manual Revision

Updates are issued as the system changes or as corrections are identified.

Organization

The titles of the sections and a description of the information contained in each section are

contained in the following paragraphs:

Introduction and General Information

This section contains documentation organization, symbology and nomenclature, translated

warnings, safety symbols, regulatory specifications, and general information about the printer.

Section 1 Service Call Procedures

This section contains procedures to be taken during a service call and in what sequence they

are to be completed. This is the entry level for all service calls.

Section 2 Status Indicator RAPs

This section contains descriptions of the diagnostic aids for troubleshooting that include Power

On Self Test (POST), Built-in Self Tests (BIST), and Fault Code error procedures.

Section 3 Image Quality

This section contains the diagnostic aids for troubleshooting image quality problems, as well as

image quality specifications and image defect samples.

Section 4 Repairs/Adjustments

This section contains all the removal, replacement, and adjustments procedures.

Repairs

Repairs include procedures for removal and replacement of spare parts listed in the Parts List.

Use the repair procedures for the correct order of removal and replacement, for warnings, cautions, and notes.

Initial Issue

Phaser 8510/8560MFP Multifunction Product

Adjustments

Adjustments include procedures for adjusting the parts that must be within specification for the

correct operation of the system. Use the adjustment procedures for the correct sequence of

operation for specifications, warnings, cautions and notes.

Section 5: Parts Lists

This section contains the illustrated Parts List.

Section 6: Diagnostic Information

This section contains details of the embedded Service Diagnostics test suite, as well as troubleshooting procedures for system problems not related to a specific fault code.

Section 7: Wiring Data

This section contains drawings, lists of plug/jack locations, and diagrams of the power distribution wire networks in the machine. Individual wire networks are shown in the Circuit Diagrams

contained in Section 2. This section also contains the Block Schematic Diagrams.

Section 8: Theory of Operation

This section contains detailed functional information on the print engine components.

10/2006

v

About This Manual, Organization

Introduction

Page 5

Power Safety

Power Source

For 115 VAC printers, do not apply more than 135 volts RMS between the supply conductors or

between either supply conductor and ground. For 230 VAC printers, do not apply more than

254 volts RMS between the supply conductors or between either supply conductor and ground.

Use only the specified power cord and connector. This manual assumes that the reader is a

qualified service technician.

Plug the three-wire power cord (with grounding prong) into a grounded AC outlet only. If necessary, contact a licensed electrician to install a properly grounded outlet. If the product loses its

ground connection, contact with conductive parts may cause an electrical shock. A protective

ground connection by way of the grounding conductor in the power cord is essential for safe

operation.

Disconnecting Power

WARNING

Turning the power off using the power switch does not completely de-energize the system. You must also disconnect the power cord from the system’s AC inlet. Disconnect

the power cord by pulling the plug, not the cord.

Disconnect the power cord in the following cases:

• if the power cord or plug is frayed or otherwise damaged,

• if any liquid or foreign material is spilled into the product,

• if the printer is exposed to any excess moisture,

• if the printer is dropped or damaged,

• if you suspect that the product needs servicing or repair,

• whenever you clean the product.

Service Safety Summary

General Safety

The system and recommended supplies have been designed and tested to meet strict safety

requirements. Attention to the following information will ensure the continued safe operation of

the system.

Electrical Safety

• Use the Power Cord supplied with the system.

• Plug the Power Cord directly into a properly grounded electrical outlet.

• Do not use a ground adapter plug to connect the system to an electrical outlet that does

not have a ground connection terminal.

• Do not use an extension cord or power strip.

• Do not place the system in an area where people might step on the power cord.

• Do not place objects on the power cord

• Do not block the ventilation openings. These openings are provided to prevent overheating of the system.

• Do not drop paper clips or staples into the system.

WARNING

Avoid the potential of electrical shock by ensuring that the system is properly grounded.

Electrical products may be hazardous if misused.

The power cord is attached to the system as a plug-in device on the side of the system. If it is

necessary to disconnect all electrical power from the system, disconnect the power cord from

the electrical outlet.

WARNING

Do not remove the covers or guards that are fastened with screws unless you are

installing optional equipment and are specifically instructed to do so. Power should be

OFF when performing these installations. Disconnect the power cord when removing

covers and guards for installing optional equipment. Except for user-installed options,

there are no parts that you can maintain or service behind these covers

WARNING

The following are hazards to your safety:

• Damaged or frayed Power Cord

• Liquid spilled into the system

• Exposure to water or excessive moisture

If any of these conditions occur, do the following:

1. Turn off the Power Switch

2. Disconnect the Power Cord from the electrical outlet.

3. Call an authorized service representative.

Maintenance Safety

• Do not attempt any maintenance procedure that is not specifically described in the documentation supplied with your system.

• Do not use aerosol cleaners. The use of supplies that are not approved may cause poor

performance and could create a hazardous condition.

Introduction

Power Safety, Service Safety Summary

10/2006

vi

Initial Issue

Phaser 8510/8560MFP Multifunction Product

Page 6

• Do not burn any consumables or routine maintenance items. For information on Xerox

supplies recycling programs, go to www.xerox.com/gwa.

Operational Safety

The system and supplies were designed and tested to meet strict safety requirements. These

include safety agency examination, approval, and compliance with established environmental

standards.

Pay attention to these safety guidelines to ensure the continued, safe operation of the system.

• Use the supplies specifically designed for your system. The use of unsuitable materials

may cause poor performance and a possible safety hazard.

• Follow all warnings and instructions marked on, or supplied with, the system, options and

supplies.

CAUTION

Use of other than Genuine Xerox Solid Ink may affect print and copy quality and system reliability. It is the only ink designed and manufactured under strict quality controls by Xerox for

specific use with this system. The Xerox Warranty, Service Agreements, and Total Satisfaction

Guarantee do not cover damage, malfunction, or degradation of performance caused by use of

non-Xerox supplies or consumables, or the use of Xerox supplies not specified for this system.

NOTE: The Total Satisfaction Guarantee is available in the United States and Canada. Coverage may vary outside these areas; please contact your local representative for details.

General Guidelines

For qualified service personnel only: Refer also to the preceding Power Safety Precautions.

Avoid servicing alone: Do not perform internal service or adjustment of this product unless

another person capable of rendering first aid or resuscitation is present.

Use care when servicing with power: Dangerous voltages may exist at several points in this

product. To avoid personal injury, do not touch exposed connections and components while

power is on. Disconnect power before removing the power supply shield or replacing components.

Servicing Electrical Components

Before starting any service procedure, switch off the printer power and unplug the power cord

from the wall outlet. If you must service the printer with power applied, be aware of the potential

for electrical shock.

WARNING

Do not touch any electrical component unless you are instructed to do so by a service

procedure.

Figure 1 Electrical Components Warning

Servicing Mechanical Components

WARNING

Do not try to manually rotate or manually stop the drive assemblies while any printer

motor is running.

Do not wear jewelry: Remove jewelry prior to servicing. Rings, necklaces and other metallic

objects could come into contact with dangerous voltages and currents.

Warning Labels

Read and obey all posted warning labels. Throughout the printer, warning labels are displayed

on potentially dangerous components. As you service the printer, check to make certain that all

warning labels remain in place.

Safety Interlocks

Make sure all covers are in place and all interlock switches are functioning correctly after you

have completed a printer service call. If you bypass an interlock switch during a service call,

use extreme caution when working on or around the printer.

Initial Issue

Phaser 8510/8560MFP Multifunction Product

10/2006

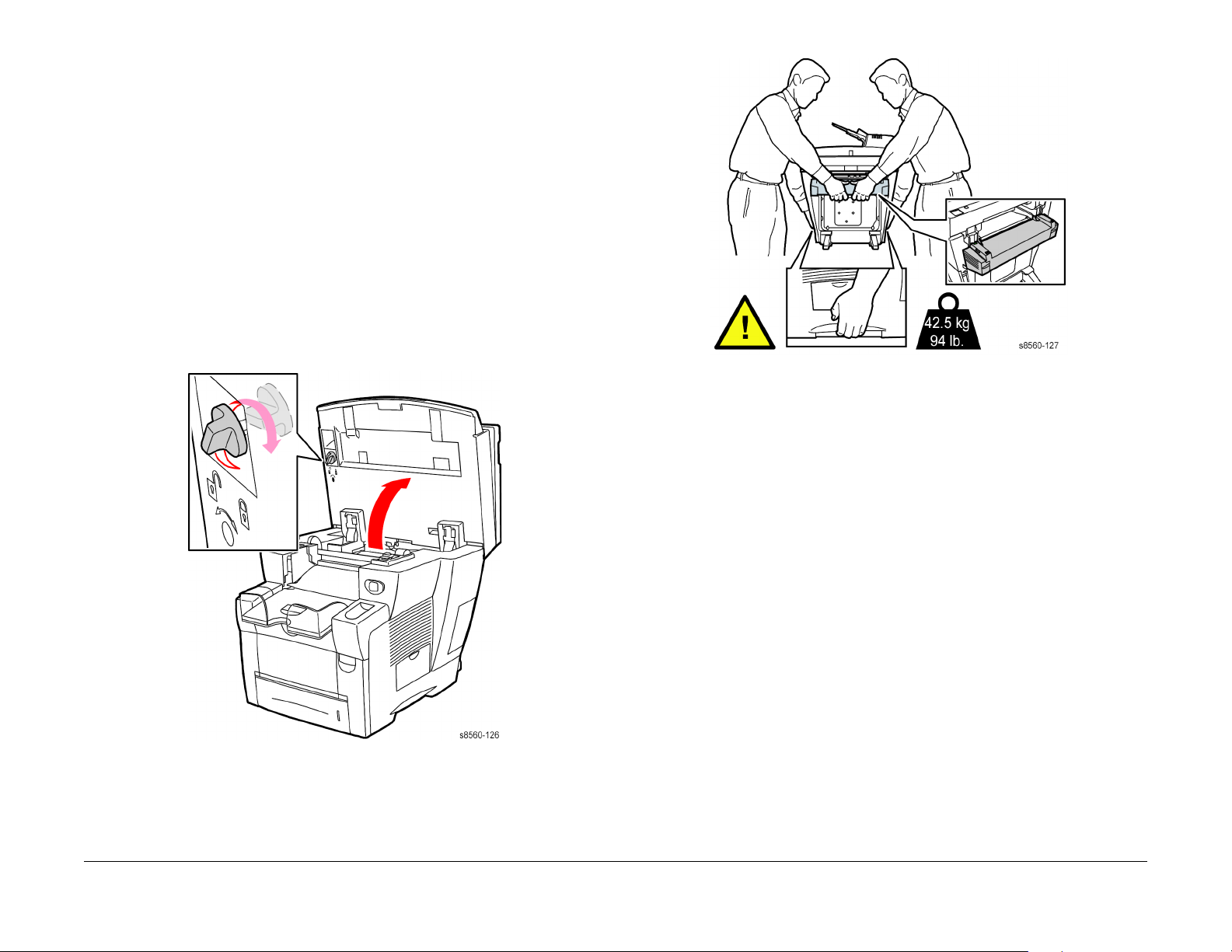

Figure 2 Mechanical Components Warning

Servicing Printhead Components

WARNING

This system uses heat to fuse the image to media. The Printhead is VERY HOT. Turn the

printer power off and wait at least 10 minutes for the Printhead to cool before you

attempt to service the Printhead or adjacent components.

Introduction

vii

Service Safety Summary

Page 7

Moving the System

WARNING

Parts of the system are hot. To avoid personal injury or damage to the system, allow the

ink to solidify. Run the shut-down procedure to cool the system quickly. Wait at least 30

minutes for the system to cool completely before moving or packing it.

• Allow the system to cool before it is moved to avoid ink spills which can damage the system.

• Use the shut-down procedure from the Control Panel before moving the system for best

results.

• Never move the system if you receive a Power Down Error-Head not Parked message at

the system’s control panel. This message means the system is not ready to be moved. If

the printhead is not locked, the system can be damaged during shipment.

• Always turn off the system using the power switch, located under the interface cover on

the right side of the system, and unplug all cables and cords. Do not turn off the system by

pulling the power cord or using a power-strip with an on/off switch.

• Always secure the scanhead shipping restraint on the left side of the scanner to lock the

scanhead before removing the scanner portion of the system. Shipping the scanner with

the scanhead unlocked can damage the scanner.

Figure 2 System Lifting Technique

• Always move the system separately from optional Trays 3 and 4.

When shipping the system, repack the system using the original packing material and boxes or

a Xerox repackaging kit. Additional instructions for repacking the system are provided in the

repackaging kit. If you do not have all the original packaging, or are unable to repackage the

system, contact your local Xerox service representative

CAUTION

Failure to repackage the system properly for shipment can result in damage to the system.

Damage to the system caused by improper moving is not covered by the Xerox warranty, service agreement, or Total Satisfaction Guarantee.

Figure 1 Locking the Scanhead

• Always remove the document feeder before shipping the system.

• Always remove the scanner before shipping the system.

• The system is heavy and must be lifted by two people. The illustration below shows the

proper technique for lifting the system.

Introduction

10/2006

Moving the System

viii

Initial Issue

Phaser 8510/8560MFP Multifunction Product

Page 8

Symbology and Nomenclature

The following reference symbols are used throughout the documentation.

Warnings, Cautions, and Notes

Warnings, Cautions, and Notes will be found throughout the Service Documentation. The

words WARNING or CAUTION may be listed on an illustration when the specific component

associated with the potential hazard is pointed out; however, the message of the WARNING or

CAUTION is always located in the text. Their definitions are as follows:

WARNING

A Warning is used whenever an operating or maintenance procedure, a practice, condition, or statement, if not strictly observed, could result in personal injury.

CAUTION

A Caution is used whenever an operating or maintenance procedure, a practice, condition, or

statement, if not strictly observed, could result in damage to the equipment.

NOTE: A Note is used whenever it is necessary to highlight an operating or maintenance procedure, practice, condition, or statement.

Table 2 Additional Warnings

REP 5.0.2 Scanner Power Supply

REP 5.0.19 Drum Heater Relay Board

WARNING

HIGH VOLTAGE!

DANGER: HAUTE TENSION!

Exercise care when making the voltage check in the following steps.

DANGER: Soyez extrêmement vigilant lorsque vous effectuez les tests de tension au

cours des étapes qui suivent.

WARNING

Personal injury may result from grasping hot areas of Printhead. If a hot Printhead must

be removed, grasp the Printhead by black plastic frame component.

DANGER: Des blessures peuvent résulter si les zones chaudes du module de four sont

touchées. Si un module de four chaud doit être enlevé, le saisir par l'élément en plastique noir du bâti.

Common Warnings and Safety Icons

The following common warnings are used throughout the documentation and the safety icons

are displayed on the machine. Additional specific warnings are included for the listed sections.

Common Warnings

WARNING

To avoid personal injury or shock, do not perform repair or adjustment activities with

the power switch on or electrical power applied to the machine.

DANGER: Afin d'éviter des blessures ou des chocs électriques, ne pas effectuer des

activités de maintenance ou de réglage avec l'équipement sur Marche ou avec le cordon

d'alimentation branché.

The following sections have additional specific warning information.

Table 1 Introduction and Section 4

Introduction - Symbology and Nomenclature

Section 4 - Repairs and Adjustments

WARNING

A Warning is used whenever an operating or maintenance procedure, a practice, conditioning, or statement, if not strictly observed, could result in personal injury.

DANGER: Une note DANGER est utilisée à chaque fois qu’une procédure de maintenance ou qu’une manipulation présente un risque de blessure si elle n’a pas été strictement observée.

The following sections have additional specific warning information.

Table 2 Additional Warnings

REP 2.0.2 Print head Assembly

REP 2.0.8 Left and Right Printhead Restraints

Machine Safety Icons

The following precautionary symbols may appear on the system.

This symbol indicates DANGER high voltage.

Figure 1 High Voltage Symbol

Protective ground (earth) symbol.

Figure 2 Protective Ground (earth) Symbol

These symbols indicate hot surface on or in the printer. Use caution to avoid personal injury.

Figure 3 Hot Surface Symbol

Initial Issue

Phaser 8510/8560MFP Multifunction Product

10/2006

ix

Introduction

Symbology and Nomenclature

Page 9

The surface is hot while the printer is running. After turning off the power, wait 30 minutes.

Figure 4 Wait 30 Minutes Symbol

Avoid pinching fingers in the printer. Use caution to avoid personal injury.

Figure 5 Pinch Injury Symbol

Voltage Measurement and Specifications

Measurements of DC voltage must be made with reference to the specified DC Common,

unless some other point is referenced in a diagnostic procedure. All measurements of AC voltage should be made with respect to the adjacent return or ACN wire.

Table 3 Voltage Measurement and Specifications

Voltage Specification

INPUT POWER 220 V 198 VAC TO 254 VAC

INPUT POWER 100 V 90 VAC TO 135 VAC

INPUT POWER 120 V 90 VAC TO 135 VAC

+5 VDC +4.75 VDC TO +5.25 VDC

+24 VDC +23.37 VDC TO +27.06 VDC

Logic Voltage Levels

Measurements of logic levels must be made with reference to the specified DC Common,

unless some other point is referenced in a diagnostic procedure.

Use caution (or draws attention to a particular component). Refer to the manual(s) for information.

Figure 6 Use Caution Symbol

Electrostatic Discharge (ESD) Field Service Kit

The purpose of the ESD Protection Program is to preserve the inherent reliability and quality of

electronic components that are handled by the Field Service Personnel. This program is being

implemented now as a direct result of advances in microcircuitry technology, as well as a new

acknowledgment of the magnitude of the ESD problem in the electronics industry today.

This program will reduce Field Service costs that are charged to PWB failures. Ninety percent

of all PWB failures that are ESD related do not occur immediately. Using the ESD Field Service

Kit will eliminate these delayed failures and intermittent problems caused by ESD. This will

improve product reliability and reduce callbacks.

The ESD Field Service Kit should be used whenever Printed Wiring Boards or ESD sensitive

components are being handled. This includes activities like replacing or reseating circuit

boards or connectors. The kit should also be used in order to prevent additional damage when

circuit boards are returned for repair.

The instructions for using the ESD Field Service Kit can be found in ESD Field Service Kit

Usage in the General Procedures section of the Service Documentation.

Table 4 Logic Levels

Voltage H/L Specification

+5 VDC H= +3.00 TO +5.25 VDC

L= 0.0 TO 0.8 VDC

+24 VDC H= +23.37 TO +27.06 VDC L= 0.0 TO 0.8 VDC

DC Voltage Measurements in RAPs

The RAPs have been designed so that when it is required to use the DMM to measure a DC

voltage, the first test point listed is the location for the red (+) meter lead and the second test

point is the location for the black meter lead. For example, the following statement may be

found in a RAP:

There is +5 VDC from TP7 to TP68.

In this example, the red meter lead would be placed on TP7 and the black meter lead on TP68.

If a second test point is not given, it is assumed that the black meter lead may be attached to

the copier frame.

Introduction

Symbology and Nomenclature

10/2006

x

Initial Issue

Phaser 8510/8560MFP Multifunction Product

Page 10

Electrostatic Discharge Precautions

Some semiconductor components, and the respective sub-assemblies that contain them, are

vulnerable to damage by Electrostatic discharge (ESD). These components include Integrated

Circuits (ICs), Large-Scale Integrated circuits (LSIs), field-effect transistors and other semiconductor chip components. The following techniques will reduce the occurrence of component

damage caused by static electricity.

Be sure the power is off to the chassis or circuit board, and observe all other safety precautions.

• Immediately before handling any semiconductor components assemblies, drain the electrostatic charge from your body. This can be accomplished by touching an earth ground

source or by wearing a wrist strap device connected to an earth ground source. Wearing a

wrist strap will also prevent accumulation of additional bodily static charges. Be sure to

remove the wrist strap before applying power to the unit under test to avoid potential

shock.

• After removing a static sensitive assembly from its anti-static bag, place it on a grounded

conductive surface. If the anti-static bag is conductive, you may ground the bag and use it

as a conductive surface.

• Do not use freon-propelled chemicals. These can generate electrical charges sufficient to

damage some devices.

• Do not remove a replacement component or electrical sub-assembly from its protective

package until you are ready to install it.

• Immediately before removing the protective material from the leads of a replacement

device, touch the protective material to the chassis or circuit assembly into which the

device will be installed.

• Minimize body motions when handling unpacked replacement devices. Motion such as

your clothes brushing together, or lifting a foot from a carpeted floor can generate enough

static electricity to damage an electro-statically sensitive device.

• Handle IC’s and EPROM’s carefully to avoid bending pins.

• Pay attention to the direction of parts when mounting or inserting them on Printed Circuit

Boards (PCB’s).

Regulatory Specifications

Xerox has tested this product to electromagnetic emission and immunity standards. These

standards are designed to mitigate interference caused or received by this product in a typical

office environment.

United States (FCC Regulations)

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy. If it is not

installed and used in accordance with these instructions, it may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his/her own

expense.

If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiver.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio/television technician for help.

Any changes or modifications not expressly approved by Xerox could void the user's authority

to operate the equipment. To ensure compliance with Part 15 of the FCC rules, use shielded

interface cables.

Canada (Regulations)

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme

à la norme NMB-003 du Canada.

Initial Issue

Phaser 8510/8560MFP Multifunction Product

European Union

This is a class A product. In a domestic environment this product may cause radio interference

in which case the user may be required to take adequate measures.

Xerox Corporation declares, under our sole responsibility, that the product to which this declaration relates is in conformity with the following standards and other normative documents:

10/2006

xi

Electrostatic Discharge Precautions, Regulatory

Introduction

Page 11

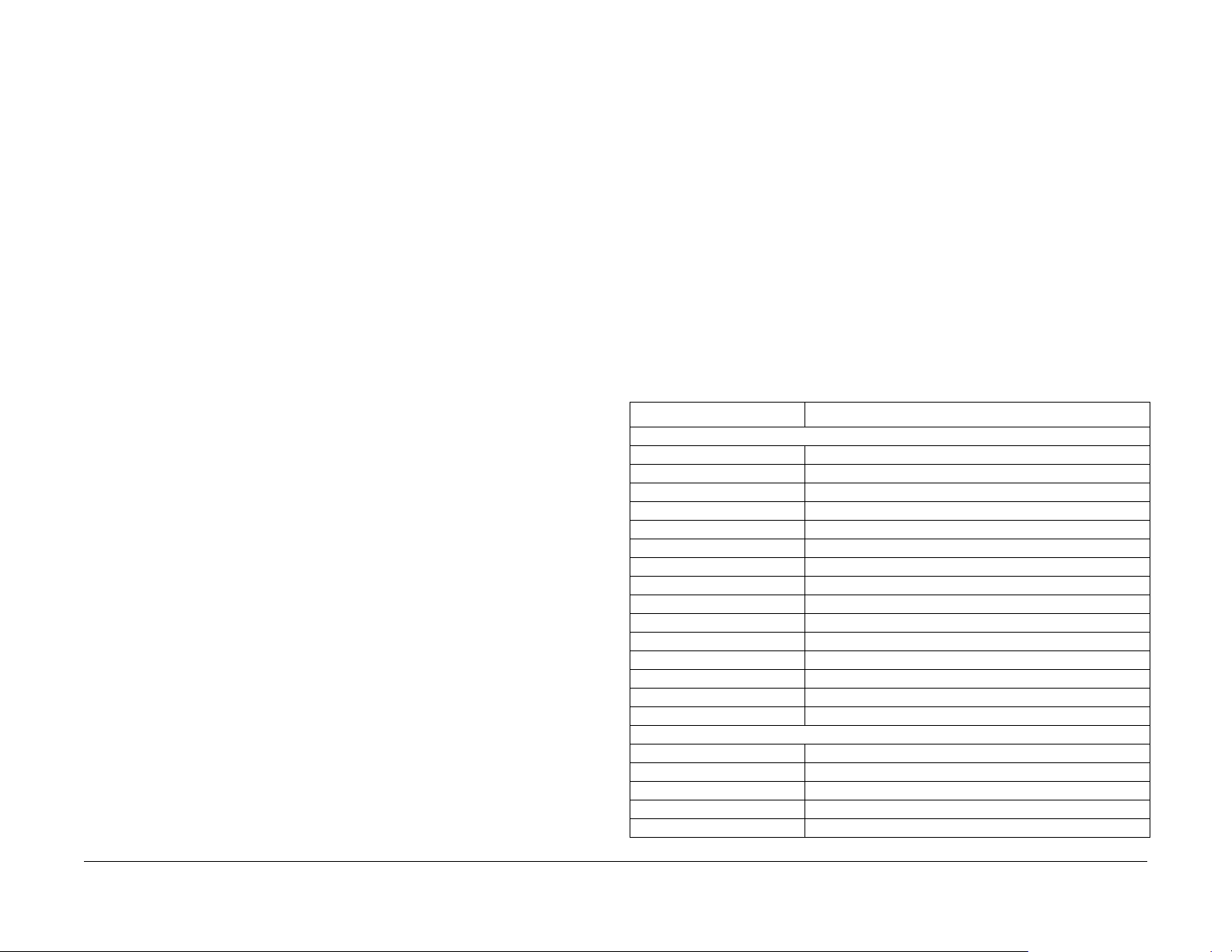

Table 1 Low Voltage Directive 73/23/EEC as amended

EN 60950-1:2001

Table 2 Electromagnetic Compatibility Directive 89/336/EEC as amended

EN 55022:1998 +A1:2000 +A2:2003

EN 55024:1998 +A1:2000 +A2:2003

EN 61000-3-2:2000

EN 61000-3-3:1994

IEC 61000-4-2:1995

IEC 61000-4-3:1995

IEC 61000-4-4:1995

IEC 61000-4-5:1995

IEC 61000-4-6:1996

IEC 61000-4-11:1994

This product, if used properly in accordance with the user’s instructions, is neither dangerous

for the consumer nor for the environment.

A signed copy of the Declaration of Conformity for this product can be obtained from Xerox.

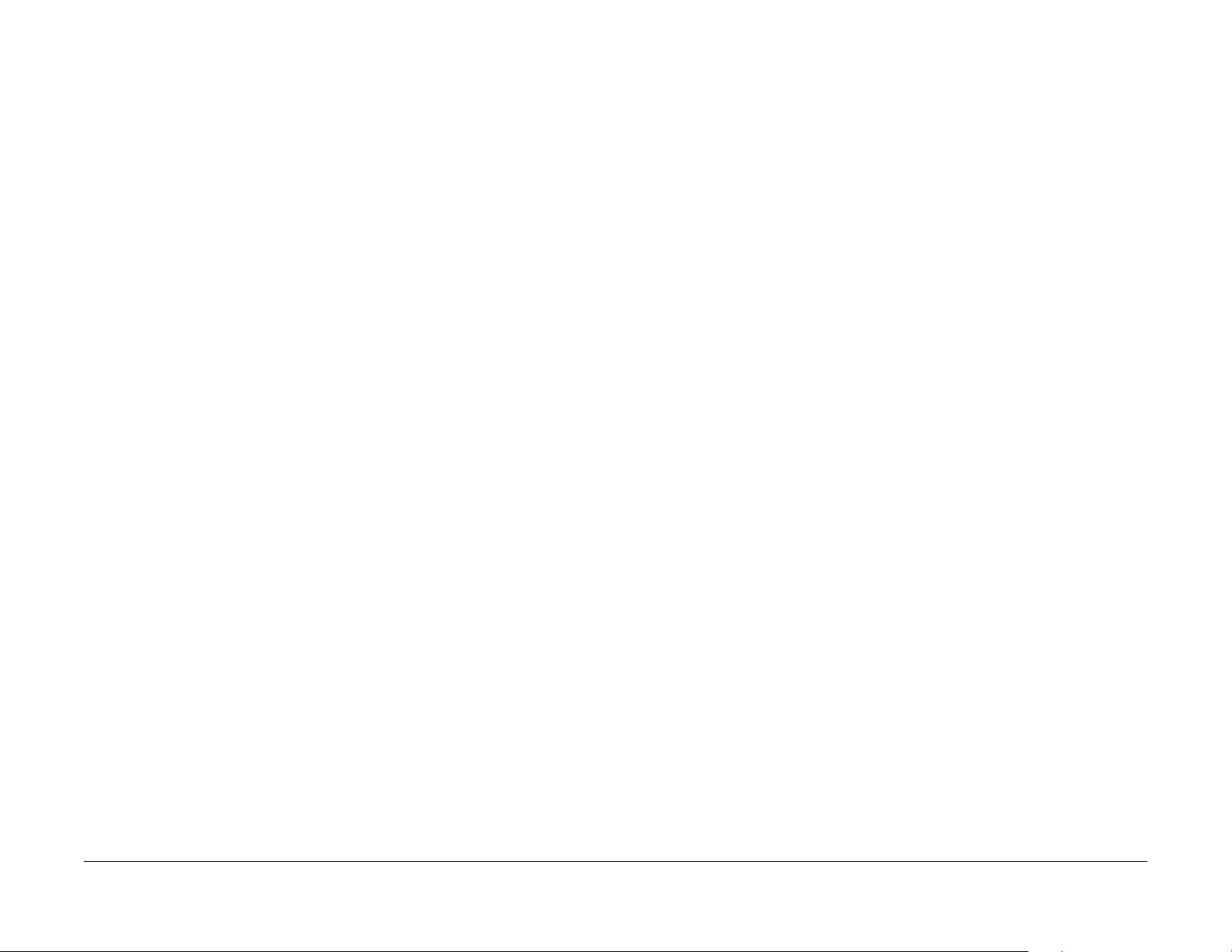

Phaser 8510/8560MFP Overview

The Phaser 8510/8560MFP uses a Printhead and four-color (YMCK) solid-ink sticks, with an

image processor supporting PostScript 3 and PCL5c page description languages. The system

is a high performance, Letter or A4, 24 (8510MFP) or 30 (8560MFP) page per minute (ppm)

multifunction product, supporting resolutions up to 525 x 1200 dots-per-inch (dpi). The product

features USB, Fax, and 10/100 base T Ethernet ports, with an optional Foreign Device Interface (FDI) for specialized installations. The 8510/8560MFP provides a 100-sheet Tray 1 from

which specialty media, card stock, and envelopes are fed. Tray 1 also supports manual feeding. Tray 2 provides 525 sheets of capacity. The Output Tray holds 250 sheets facedown. On

most configurations an Automatic Document Feeder (DADF) is installed providing enhanced

document handling functionality.

Phaser 8510/8560MFP options add memory, media capacity and functionality. RAM memory

upgrades are available to raise installed memory to the 1 GB maximum. A 525-Sheet Feeder is

also available. Two 525-Sheet Feeders may be installed to raise the maximum media input

storage capacity to 1675 sheets. A Configuration Card stores system model identity and configuration parameters.

After a predefined period of time since its last activity, the Phaser 8510/8560MFPP enters a

power saver standby mode. All communications interfaces remain active and have the ability to

wake the system up.

Introduction

Regulatory Specifications, Phaser 8510/8560MFP

10/2006

xii

Figure 1 Phaser 8510/8560MFP Multifunction Product with Optional Trays

Initial Issue

Phaser 8510/8560MFP Multifunction Product

Page 12

System Configurations

Standard Features

The Phaser 8510/8560MFP offers these standard features:

• Maximum print speed (pages per minute) based on letter-size plain paper:

NOTE: Print speeds for media fed from Tray 1 may be up to 50% slower.

Table 1 Phaser 8510/8560MFP Print Speeds

Phaser 8510MFP Multifunction Product Phaser 8560MFP Multifunction Product

PostScript Print Quality Modes:

– Fast Color: 24 ppm

– Enhanced: 12 ppm

PCL Print Quality Modes:

– 300 x 600 dpi: 13 ppm

– 600 x 600 dpi: 6 ppm

PostScript Print Quality Modes:

– Fast Color: 30 ppm

– Standard: 24 ppm

– Enhanced: 16 ppm

– High Resolution/Photo: 10 ppm

PCL Print Quality Modes:

– 300 x 600 dpi: 16 ppm

– 600 x 600 dpi: 8 ppm

Product Options

Phaser Multifunction Product options include:

• Additional Trays

• Memory

•System Cart

Additional Trays

Trays 1 and 2 are standard on all configurations. The following additional tray combinations are

supported:

• One 525-Sheet Feeder (Tray 3)

• Two 525-Sheet Feeders (Trays 3 and 4)

Memory

All configurations have two memory slots supporting 512 MB, and 1 GB SODIMM modules (up

to maximum of 1 GB DDR2).

System Cart

The System Cart supports a fully-optioned system and provides space for media storage.

• First-page-out: 8 seconds for color prints, 15 seconds for color copies

• Copy, Print, Scan, Fax capabilities (options vary according to configuration and memory)

• Connections: USB, Ethernet 10/100/1000 Base-Tx, RJ-11 Fax Modem, Foreign Device

Interface

Available Configurations

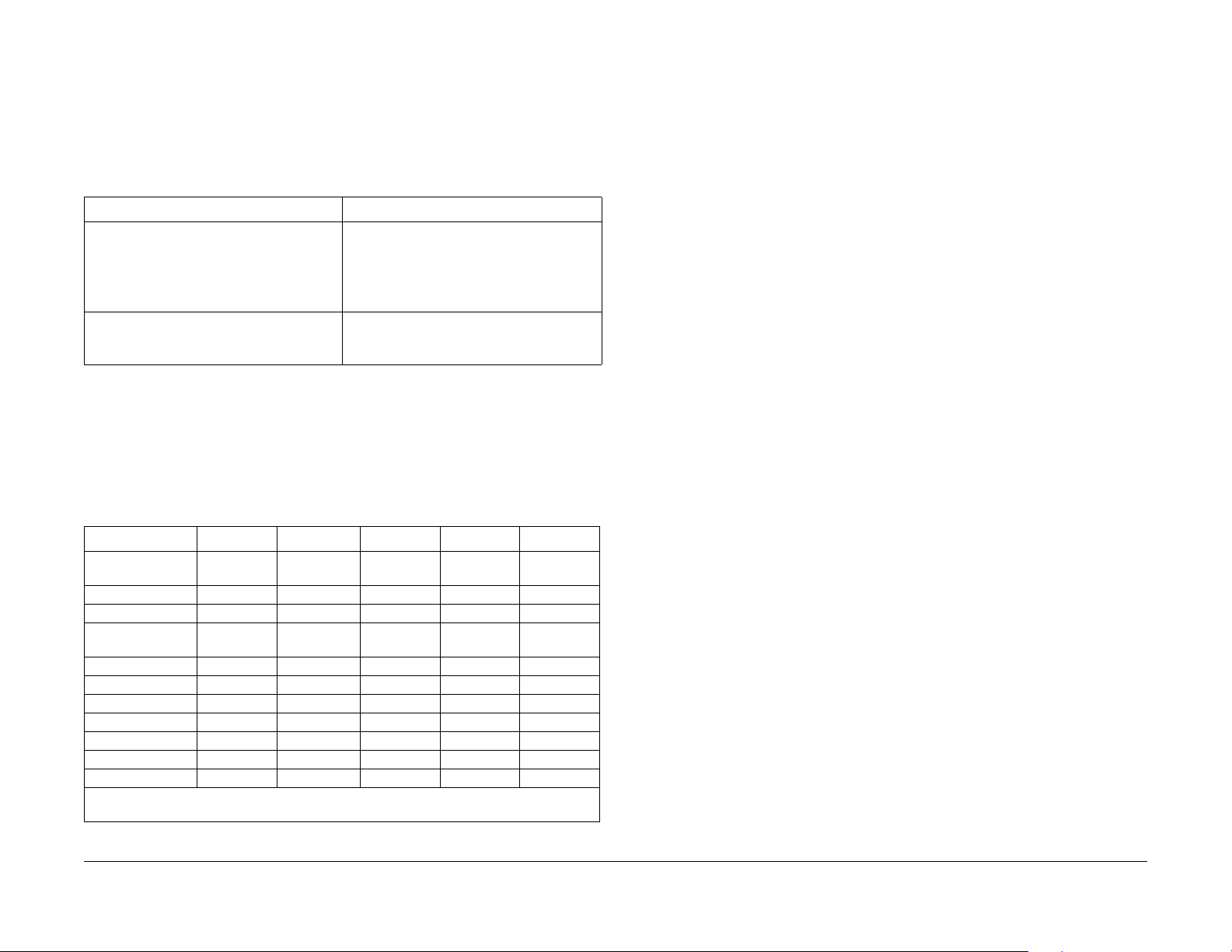

Table 2 lists the standard configurations.

Table 2 Phaser 8510/8560MFP Standard Configurations

Features 8510MFP/N 8510MFP/D 8560MFP/D 8560MFP/T 8560MFP/X

Memory 512 MB 512 MB

Hard Drive No No Yes Yes Yes

Flash Disk Yes Yes No No No

Automatic 2-sided

Printing (DADF)

525-Sheet Feeder No* No* No* Yes Yes

System Cart No* No* Yes Yes Yes

Copy Yes Yes Yes** Yes** Yes**

Scan to PC Yes Yes Yes Yes Yes

Scan to E-mail Yes Yes Yes Yes Yes

Scan to Hard Drive No No Yes Yes Yes

Fax Yes Yes Yes** Yes** Yes**

* This option can be purchased separately for this configuration.

** Hard Drive enables advanced features on this configuration.

No Yes Yes Yes Yes

(2x256)

512 MB 512 MB 512 MB

Metered Printing

Metered printing (PagePack), involves the combination of control software and specialized Ink

Sticks to meter system activity for billing purposes. The Configuration page lists Metered Ink as

Enabled when metering is enabled.

Metered Operation

When a metered printer is initialized at first power-up, the customer sets the printer to Metered

operation using a unique, factory-supplied, 4-digit PIN. Once set to Metered operation, the control software performs the following:

1. The Mode and PIN-entered values in Engine Control Board NVRAM are set.

2. The Control Panel momentarily displays “Metered Ink is now enabled”, then returns to

“Ready” (if no other errors).

3. The First Time Tips pages and the Configuration page are printed.

If an incorrect PIN is entered, “Incorrect numeric password” displays with a prompt “Retry” or

“Do not retry.” Retry returns to the enter prompt, “Do not retry” returns to the Replace Ink Stick

error message. The error persists until the correct PIN is entered.

NOTE: The Hidden Service menu provides an Enable Metered Ink option to restore the

Metered mode parameters to NVRAM should they become lost or corrupt.

Metered Ink

To support metered printing, metered Ink Sticks are available in all four colors. The shape of

the metered Ink Stick differs from the non-metered versions.

Initial Issue

Phaser 8510/8560MFP Multifunction Product

10/2006

xiii

Introduction

System Configurations

Page 13

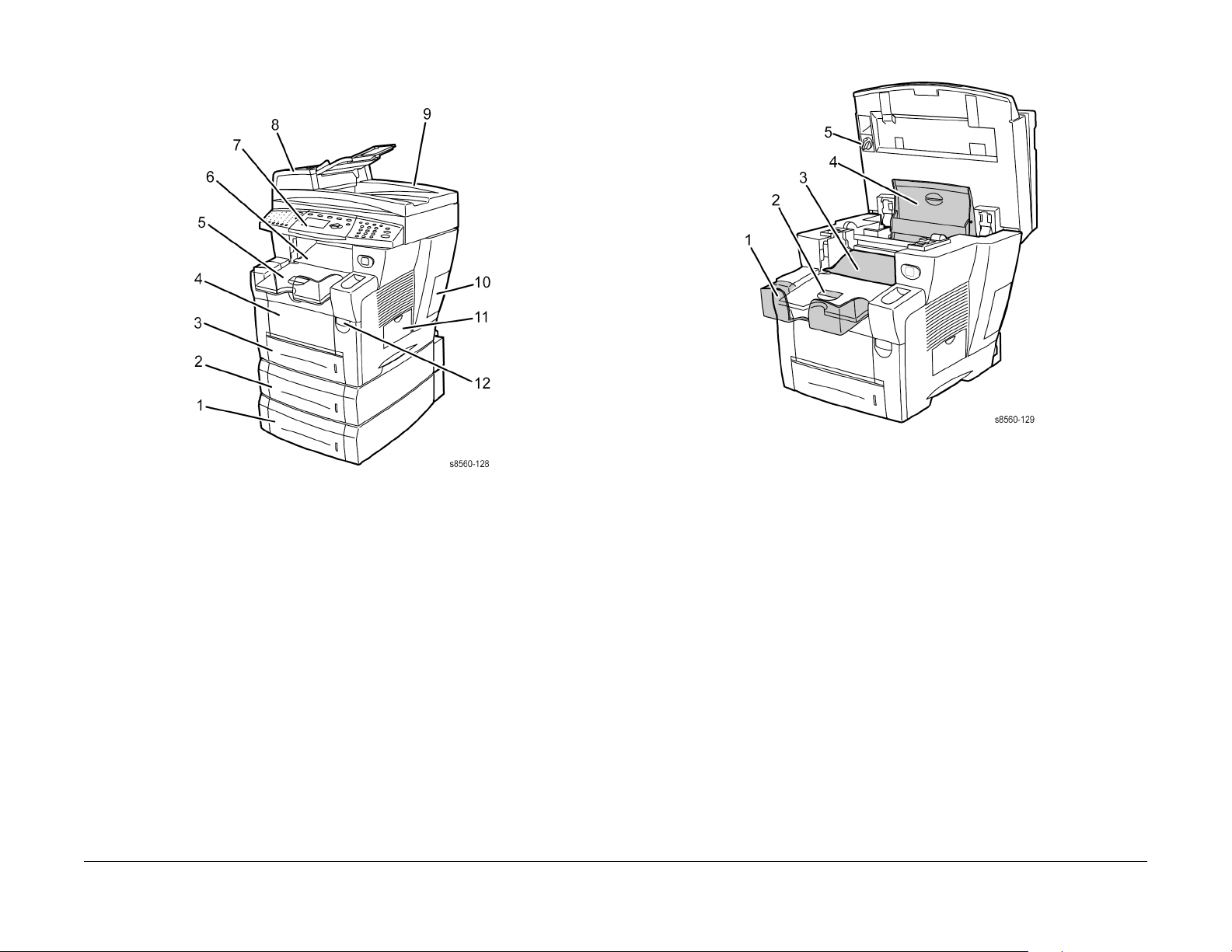

Parts of the Product

Front View

Figure 1 Front View

1. Tray 4 (optional)

2. Tray 3 (optional)

3. Tray 2

4. Tray 1 (MPT)

5. Output Tray

6. Exit Cover

7. Control Panel

8. Duplex Automatic Document Feeder (DADF) Front Cover

9. DADF

10. Interface Cover

11. Drum Maintenance Kit and Waste Tray access

12. Front Door Latch

Open View

Figure 2 Open View

1. Output Tray

2. Short Paper Stop

3. Exit Cover

4. Ink Loader Cover

5. Scan Head Lock

Introduction

Parts of the Product

10/2006

xiv

Initial Issue

Phaser 8510/8560MFP Multifunction Product

Page 14

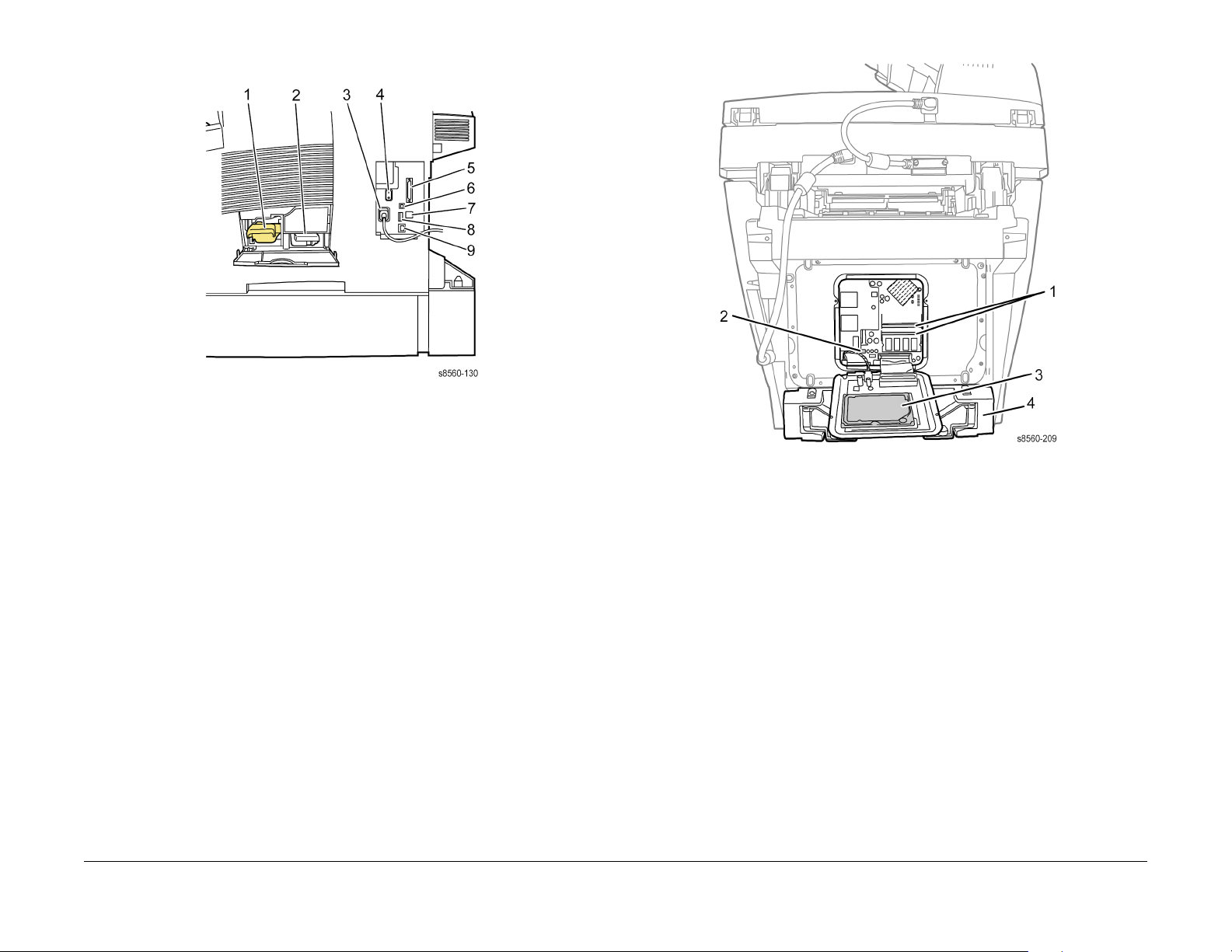

Side View with Interface Connections

Figure 3 Side View with Interface Connections

1. Drum Maintenance Kit

2. Waste Tray

3. AC Power Cord Connection

4. Power Switch

5. Scanner Cable Connection

6. USB Connection

7. Ethernet Connection

8. Configuration Card

9. RJ-11 Fax Modem Connection

Back View - Electronics Module

The system’s main electronics and power supply are enclosed in a metal case called the Electronics Module. The rear panel allows access to the electronics module, RAM, and NVRAM

chips. The system’s Hard Drive is mounted on the rear panel.

Figure 4 Back View

1. RAM Connectors

2. NVRAM Device

3. Hard Drive

4. Printer Stabilizer

NOTE: When replacing the electronics module, transfer these components to the new module.

•RAM

• Configuration Card

• NVRAM Device

• Hard Drive or Flash Disk

Initial Issue

Phaser 8510/8560MFP Multifunction Product

10/2006

xv

Introduction

Parts of the Product

Page 15

Routine Maintenance Items

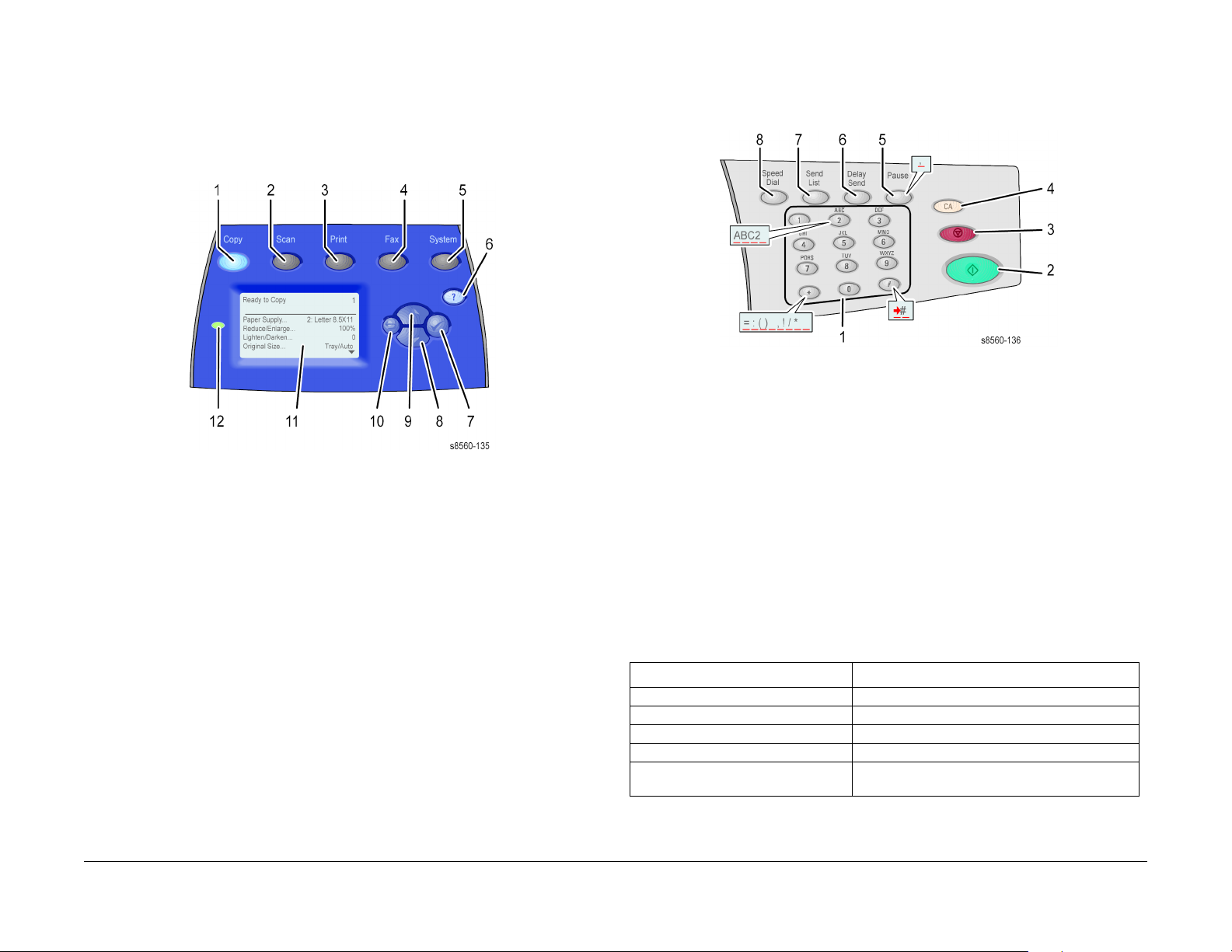

Control Panel Layout

The Control Panel functions are segregated into three areas.

Figure 1 Control Panel

Table 1 Control Panel Functional Areas

Left Side Center Right Side

Copy, Scan, and Fax functions

and indicator LEDs

Control Panel Left

The left side of the control panel contains the following copy, scan, and fax function buttons and

LEDs. A lighted LED indicates the current selection. Figure 2 shows each function’s location.

Display, Mode, Navigation buttons, and status LED’s

Numeric keypad, Stop, Start,

Clear, and Clear All buttons

Figure 5 Routine Maintenance Items and Consumables

Table 1 Routine Maintenance Life Expectancy

Routine Maintenance Items

Extended-Capacity Maintenance Kit 30,000 cycles (0-20% coverage)

20,000 cycles (20-100%) coverage.

Standard-Capacity Maintenance Kit 10,000 cycles

Waste Tray Empty every 7 Purges

DADF Pick Rollers and Separator Pad 50,000 scans

Introduction

Parts of the Product, Control Panel Layout

Figure 2 Left Side Control Panel

1. Color Mode selects black and white or color for copy or scan jobs.

2. Document Type selects the type of document (photo, graphic, mixed text and graphics, or

text only), for copy or scan jobs.

3. Output Quality selects the output quality mode for copies: fast color, standard, enhanced,

or high-resolution/photo.

4. 2-Sided selects either one or 2-sided for the original and one- or 2-sided for the output.

5. Lighten/Darken selects a setting for copy, scan, or fax jobs.

6. Reduce/Enlarge selects scale percentage for output: 25, 50, 100, 150, 200, 400.

10/2006

xvi

Phaser 8510/8560MFP Multifunction Product

Initial Issue

Page 16

7. The Down Arrow reduces the reduce/enlarge percentage in one percent increments.

8. The Up Arrow increases the reduce/enlarge percentage in one percent increments.

9. Reduce/Enlarge Percentage display indicates the current educe/enlarge setting.

Control Panel Center

The center of the Control Panel contains the display, mode and navigation buttons, as well as

the status LED. Figure 3 shows each function’s location.

Figure 3 Center Control Panel

1. Copy displays the Copy menu.

2. Scan displays the Scan menu.

3. Print displays the Print menu.

4. Fax displays the Fax menu.

5. System displays the System Setup menu.

6. Help(?) provides additional information about the menu or message displayed.

7. OK accepts the highlighted menu selection.

8. Down Arrow scrolls downward through menu selections.

9. Up Arrow scrolls upward through menu selections.

10. Back returns the previous menu to the display.

11. Control Panel display.

12. Status LED uses color to indicate these states of the current function:

• Green indicates the system is ready to print, copy, scan, or fax.

• Yellow indicates a warning condition. The system continues the operation.

• Red indicates a startup or operational error condition.

• Blinking indicates a warm-up or busy condition.

Control Panel Right

The right side of the Control Panel contains the numeric keypad, Start, Stop, and Clear buttons, as well as Fax control functions. Figure 4 shows each function’s location.

Figure 4 Right Side Control Panel

1. Numeric keypad for entering numbers for sending a fax, selecting a number of copies, or

entering a numeric password.

2. Start initiates the selected function (copy, scan. or fax).

3. Stop pauses a print, copy, scan, or fax job. To cancel the job, follow the instructions indicated on the display.

4. Clear All resets all job settings and returns to the top of the default function.

5. Pause enters a pause in a fax number.

6. Delayed Send stores a time for fax transmission.

7. Send List to view or add fax numbers to a list.

8. Speed Dial accesses directories of groups or individual fax numbers.

Control Panel Shortcuts

Table 2 Short Cuts

Mode Press this selection at Power On

Skip execution of POST diagnostics OK

Print Service Diagnostics Map INFO

Reset PostScript NVRAM BACK+ON

Password Bypass UP+DOWN

Enter Service Diagnostics BACK+? before the Xerox logo stops scrolling and

until Beginning Service Mode appears.

Initial Issue

Phaser 8510/8560MFP Multifunction Product

10/2006

xvii

Introduction

Control Panel Layout

Page 17

Specifications

Functional Specifications

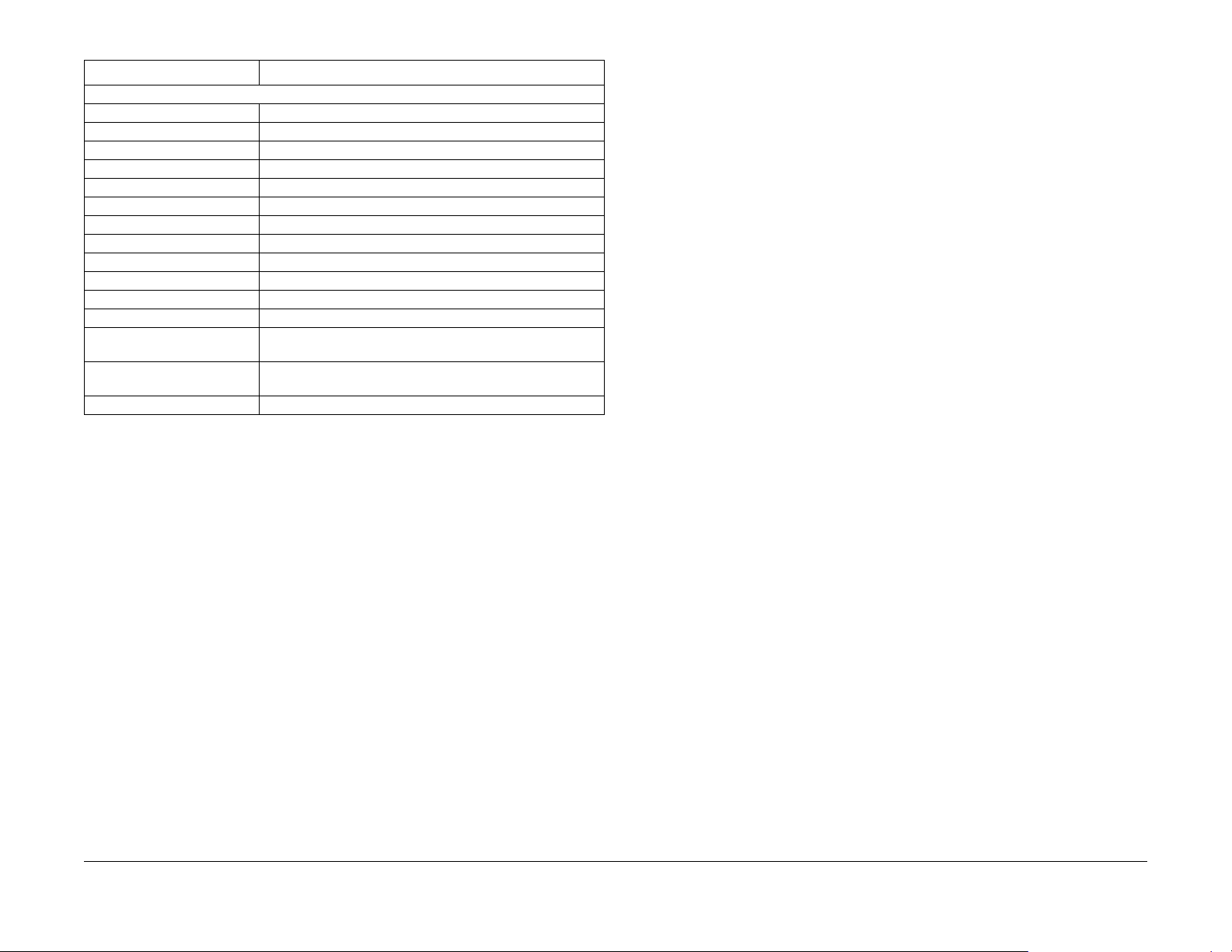

Table 1 Functional Specifications

Characteristic Specifications

Printing Process Four-color (CMYK) solid ink Printhead architecture.

Image System Transfix transfer from oil coated Drum

Color Medium Cyan, Magenta, Yellow, and Black Ink Sticks

Resolution Fast Color: 225 x 400 dpi

Standard: 300 x 450 dpi

Enhanced: 525 x 450 dpi

Photo: 525 x 2400 dpi

First Page-Out (from

Ready)

Warm-up Time Color and Monochrome: 12 minutes from Power On

Memory Specifications

Characteristic Specifications

Minimum RAM 512 MB

Maximum RAM 1 GB

Supported RAM Supports up to 1 GB of DDR2 memory using 2 slots

Flash Disk 256 MB NAND Flash Storage in 8510MFP

Color: 8 seconds

Monochrome: 8 seconds

Table 2 Memory Specifications

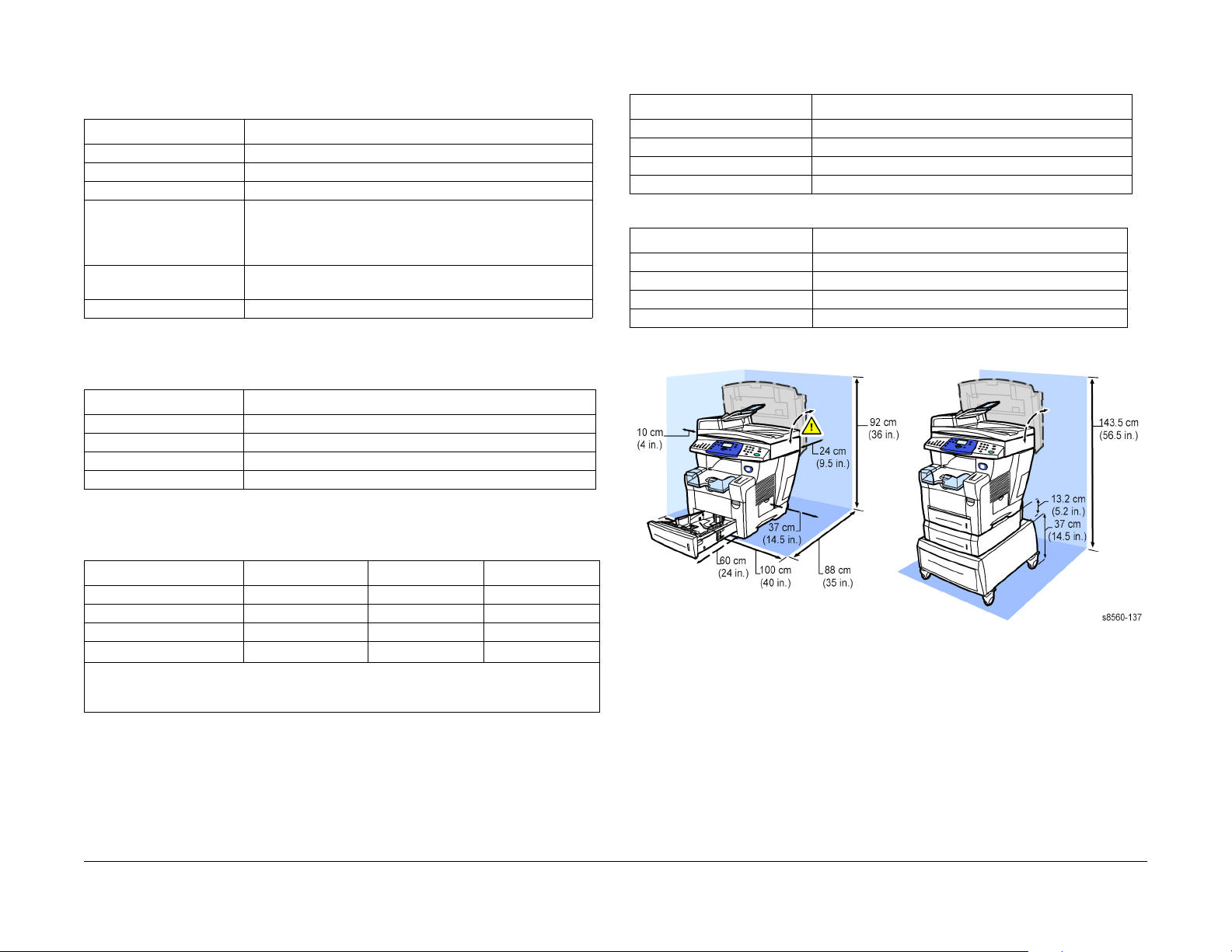

Physical Dimensions and Clearances

Table 4 Print Engine

Dimensions Value

Height 620 mm (24.4 in.)

Width 530 mm (20.9 in.)

Depth 660 mm (26.2 in.)

Weight 42 kg (93 lb.)

Table 5 525-Sheet Feeder

Dimensions Value

Height 132 mm (5.2 in.)

Width 422 mm (16.6 in.)

Depth 514 mm (20.24 in.

Weight 5.2 kg (11.5 lb.)

Media Tray Capacity

Table 3 Tray Capacity

Media and Weight Tray 1 Trays 2 and 3 DADF

Standard Paper 100 Sheets 525 Sheets 50 Sheets

Transparency 100 Sheets 50 Sheets

Envelopes 50

Weight

The DADF accommodates sizes from 114 x 140 mm (4.5 x 5.5 in.) to 216 x 356 mm (8.5 x

14.0 in.). The weight range includes 60-120 g/m2 (16-32 lb. Bond) (22-45 lb.

Cover).

Introduction

75-220 g/m

2

75-255* g/m

2

Specifications

10/2006

xviii

Figure 1 Minimum Clearances

Initial Issue

Phaser 8510/8560MFP Multifunction Product

Page 18

Print Engine Specifications

Table 6 Print Engine Functional Specifications

Characteristic Specification

Printing process Solid-ink

Controller 500 MHz processor

Color medium Yellow, cyan, magenta, and black ink sticks, each shape-

coded. The system uses the subtractive color system to

produce the colors red, green, and blue

Color Management Automatic, Black & White,

Office: sRGB, Vivid Color, None,

Press: Commercial, Euroscale, SWOP

FPOT, Color Copy < 15 seconds per page/1st copy

subsequent copies at printer speed.

Memory 2 slots; minimum 512 MB, maximum 1 GB, PC133 DRAM

Fonts 137 PostScript 3

81 PCL5c

Warm-up time From Off (cold start): 12 minutes

From power saver: 4 minutes

Table 7 Scanner/DADF Functional Specifications

Characteristic Specification

Noise Standby: < or equal to 45 dB

Scanning: < or equal to 50 dB

Electrical Specifications

Table 8 Electrical Specifications

Characteristic Specification

Primary Line Voltages 90-135 VAC

Primary Line Voltage Frequency Range

Power Consumption at Rated

Voltage Input

Energy Star 70 W

Scanner Power Supply 30 W

180-254 VAC

47 - 63 Hz

300 W (average during printing)

1500 W (peak) - 1000 typical

220 W (idle)

Scanner/DADF Specifications

Table 7 Scanner/DADF Functional Specifications

Characteristic Specification

Printing Process Print Engine

Scan to Capabilities Scan to Disk (mailbox) function

Scan/Copy Process Flatbed platen and C-shape ADF

Copies per Minute DADF: 20 ppm simplex, 10 ppm duplex

Memory 2 MB (1M x 16 SDRAM)

Image Buffer 32 MB SDRAM for Platen

Bit Depth Reading: 48 bits

Optical Resolution 600 x 300 to 600 x 2400 dpi (FS x SS)

Output Resolution from Scan-

ner

Calibration Time less than 2 seconds (performed prior to copier and scan

Power Saver Mode Scanner and DADF are switched OFF. Also, lamps automati-

Scan to PC

Charge Coupled Device scan head

RGB color pack

The scan controller provides 16 bit DMA interface for sending

image data through the scanner board to the image processor board in the electronics module.

128 MB SDRAM for DADF

Output: 24 bits

Always equals optical resolution

operations)

cally turn off after 20 minutes.

Environmental Specifications

Table 9 Environmental Specifications

Characteristic Specification

Operating Storage

Temperature

Humidity 10% - 80% RH Non-Condensing

Altitude 0 to 2,438 meters (8,000 ft.) 0 to 6,092 meters (20,000 ft.)

Acoustic Noise (db) Operating Mode Standby Mode

º

- 32º C / 50º - 90º F operating

10

operating

-30°C to 60°C (-22 F to 140 F)

30% to 95% RH, non-condensing

Initial Issue

Phaser 8510/8560MFP Multifunction Product

10/2006

xix

Introduction

Specifications

Page 19

Image Specifications

Table 10 Print Engine Only Skew Specifications

Characteristic Specification

Printed Left Side Margin 5.0 mm +

Leading Edge Margin 5.0 mm +

NOTE: To derive the skew specification for a particular media size, measure the width of the

leading edge in millimeters. Next, divide the measured length by 1000, then multiply by the

appropriate Image Area Tolerance specification in milli-radians. For example, A 5 in. by 7 in.

custom page would have a leading edge width, in millimeters, of 127mm (5 in.). Dividing the

127 by 1000 (127/1000), then multiplying the result by the 11 milli-radians specification results

in a maximum skew of 1.4 mm (127/1000) x 11 = 1.4 mm.

Table 11 System Skew Specifications Scan, Copy, Print

Characteristic Specification

Printed Left Side Margin 5.0 mm +

Leading Edge Margin 5.0 mm +

Image Area Tolerance Zone

Image Skew, Envelopes 15.5 milli-radians max across the width of the leading edge.

Image Skew, Index Card 18.0 milli-radians max across the width of the leading edge.

Image Skew, All other sizes 11.0 milli-radians max across the width of the leading edge.

Characteristic Specification

Maximum Print Area 302 mm x 1194 mm

Guaranteed Image Area 297 mm x 1194 mm

Resolution/Gradation Fast Color: 300 x 300 dpi

Standard: 300 x 450 dpi

Enhanced: 563 x 400 dpi

Photo/Hi Res: 525 x 1200 dpi

2.0 mm (0.197 in. + .080 in.)

1.3 mm (0.197 in. + .050 in.)

4.0 mm (0.197 in. + .157 in.)

3.3 mm (0.197 in. + .130 in.)

Table 12 Image Specifications

Media and Tray Specifications

The media trays accommodate most sizes and types of paper, transparencies, or other specialty media. Print the Paper Tips page for a list of supported media.

Media that May Damage the System

The system can use a variety of media for print and copy jobs. However, some media can

cause poor output quality, increased jams, or damage. Unacceptable media includes:

• Rough, plastic, or porous media

• Paper that has been stapled, folded, photocopied, or wrinkled

• Envelopes with windows, metal clasps, padding, or adhesives with release strips

• CD labels

• Media that is less than 60 g/m2 or more than 220 g/m2

Media Storage Guidelines

If media handling problems are a common occurrence, review the following storage guidelines

with the customer.

• Store paper in dark, cool, relatively dry locations. Most paper items are susceptible to

damage from ultraviolet (UV) and visible light. UV radiation, which is emitted by the sun

and fluorescent bulbs, is particularly damaging to paper items. The intensity and length of

exposure to visible light on paper items should be reduced as much as possible.

• Maintain constant temperatures and relative humidity

• Avoid light, heat, and dampness.

• Avoid attics, kitchens, garages, and basements for storing paper. Inside walls are drier

than outside walls where moisture can collect.

• Store paper flat. Paper should be stored on pallets, cartons, shelves, or in cabinets.

• Avoid having food or drinks in the area where paper is stored or handled.

• Do not open sealed packages of paper until needed. Leave paper in the original packaging. For most commercial grades, the wrapper’s inner lining protects the paper.

• Some specialty media is packaged inside sealed plastic bags. Leave the media inside the

bag until needed; return unused media to the bag.

DADF Media Guidelines

The DADF accommodates sizes from 114 x 140 mm (4.5 x 5.5 in.) to 216 x 356 mm (8.5 x 14.0

in.), with weights within the following range: 60–120 g/m2 (16–32 lb. Bond) (22–45 lb. Cover).

Follow these guidelines when loading originals into the document feeder:

• Load originals face-up, so the top of the document enters first.

• Place only loose sheets of paper in the document feeder.

• Adjust the paper guides so they fit against the originals.

• Insert paper in the document feeder only when the ink on the paper is completely dry.

Use the glass rather than the document feeder to copy or scan the following types of originals:

• Paper with paper clips or staples attached

• Paper with wrinkles, curls, folds, tears, or notches

• Coated or carbonless paper, transparencies, or items other such as cloth or metal

• Envelopes

Supported Media

The following sections provide information about paper sizes and weights that can be used in

the system trays. For more detailed information about supported paper and other media, print

the Paper Tips page:

1. On the Control Panel, press the System button.

2. Select Information, and then press the OK button.

3. Select Information Pages, and then press the OK button.

4. Select Paper Tips, and then press the OK button to print.

See also: Recommended Media List at www.xerox.com/paper

Introduction

Specifications

10/2006

xx

Initial Issue

Phaser 8510/8560MFP Multifunction Product

Page 20

Service Call Procedures.................................................................................................. 1-3

Initial Actions................................................................................................................... 1-4

Routine Maintenance Activities ....................................................................................... 1-5

Cleaning Procedures....................................................................................................... 1-5

Final Actions.................................................................................................................... 1-6

1 Service Call Procedures

Initial Issue

Phaser 8510/8560MFP Multifunction Product

10/2006

1-1

Service Call Procedures

Page 21

Service Call Procedures

This section describes an overview of the steps a service technician should take, using this

manual, to service the system and attached options. The system’s diagnostic routines report

problems using error messages and fault codes displayed on the Control Panel, logged in the

Service Usage Profile, or by flashing LEDs. These error indications serve as the entry point

into the troubleshooting process. System problems not directly indicated by or associated with

an error message or fault code are covered in Section 6, General Procedures. Print-quality

problems are covered in Section 3, Image Quality.

The steps listed here are a guide for performing any service on this system. If you choose not

to use these steps, it is recommended that you start at the appropriate troubleshooting procedure and proceed from there. When servicing the system, follow the safety measures detailed

in Service Safety Summary.

1. Identify the problem.

• Verify the reported problem does exist.

• Check for any error codes and write them down.

• Print normal customer prints and service test prints.

• Make note of any print-quality problems in the test prints.

• Make note of any mechanical or electrical abnormalities present.

• Make note of any unusual noise or smell coming from the printer.

• Print a Service Usage Profile, if the printer is able to print.

• View the Engine Error and Jam Histories under the Service Tools menu.

• Verify the AC input from the wall outlet is within specifications.

2. Inspect and clean the system.

• Follow the cleaning instructions given in Section 6.

• Verify that the power cord is in serviceable condition.

• Restart the system to check if the error reoccurs.

3. Find the cause of the problem.

• Use the troubleshooting procedures to find the root cause of the problem.

• Use Service Diagnostics to check the system and optional components.

• Use the Wiring Diagrams and Plug/Jack Locator to locate test points.

• Take voltage readings as instructed in the troubleshooting procedure.

4. Correct the problem.

• Use the Parts List to locate a part number.

• Use the Repair procedures to replace the part.

5. Final checkout

• Test the printer to verify the problem is corrected and no new problems arose.

Accessing Engine Fault History

Listed below are three ways in which you can access fault history records.

1. Print (if possible) the Status page from the Troubleshooting menu --> Service Tools. The

Engine Error History and Jam History are listed on the second page of the report.

2. View the system’s fault history on the Control Panel. Go to Troubleshooting->Service

Tools --> Engine Error History.

NOTE: Definitions of the codes that appear in the Fault and Jam History appear in Section 2.

3. If the system is connected to a network and has a TCP/IP address, view the system’s web

page using a web browser.

a. Open a web browser.

b. Enter the system’s IP address as the URL.

c. Select the Support --> Troubleshooting --> Diagnostics Logs and the fault history dis-

plays.

Technician’s Tool Kit

Table 1 lists required, recommended, and optional tools used to service this and other similar

products.

Table 1 Service Tools

Description Detail

Required Tools

Torx Driver Bits T5, T8, T10, T15, T20

Phillips Drivers Phillips # 2 and # 1 5.0 x 75 mm, 3.0 x 75 mm, 6.0 x 100 mm

Flathead Drivers 5.0 x 75 mm, 3.0 x 75 mm

Torque Screw Driver Required for this system P/N 003082700

Hex Bit 2.5mm Hex Bit, T-20 P/N 003086600

Driver Extension

Small Channel lock Pliers

Needle Nose Pliers

Wire Cutters

Flashlight

Assorted Nut Drivers

Lint-Free Cloths

Lubricant/Grease Reolube P/N 070E00890

Cleaners Multipurpose surface cleaner and Alcohol

ESD Strap

Highly Recommended Tools

Nut Driver 5.5mm (magnetic) P/N 600T2123

Network Cross-over cable Tech

Scanner Calibration page P/N 109K01910

Toner Vac Toner and general cleaning

Multimeter Volts, Ohms, Current

Initial Issue

Phaser 8510/8560MFP Multifunction Product

10/2006

1-3

Service Call Procedures

Service Call Procedures

Page 22

Table 1 Service Tools

Description Detail

Optional Tools

Canned Air

3 -Prong Claw Part-Retriever

Pointer with Magnetized Head

Tweezers

Utility Knife

Dental Mirror

Screw Box

Soldering Iron

Heat Shrink tubing

Electrical Tape

Jeweler's Screwdriver Kit

Precision/Hobby tool set phillips, flathead, pliers, small torx drivers

Serial & Parallel Loop Back

Plugs

Bootable CDs and Floppy

Disks

IC Chip Puller

Initial Actions

Purpose

Use the following procedure to determine the reason for the service call and to identify and

organize the actions which must be performed.

Procedure

1. Gather the information about the service call and the condition of the copier/printer.

a. Question the operator(s). Ask about the location of most recent paper jams. Ask

about the image quality and the copier/printer performance in general, including any

unusual sounds or other indications.

b. After informing the customer that the machine will not be available for copying and

printing, disconnect the machine from the customer’s network.

c. If a new installation, be sure all packing material is removed.

d. Check that the power cords are in good condition, directly plugged in to the power

source, and free from defects. Repair or replace the power cords as required. Check

that the circuit breaker, if present, is not tripped.

e. If the system appears is inoperative, go to Electrical Troubleshooting and repair the

problem. Then continue below.

f. Inspect any rejected copies. Inquire as to, or otherwise determine, the paper quality

and weight. Print the Paper Tips page for specific media specifications. Look for any

damage to the copies, oil marks, image quality defects, or other indications of an

unreported problem.

NOTE: If a fault code is displayed while performing a diagnostics procedure, go to

that fault code RAP and repair the fault. Return to Diagnostics and continue with the

procedure that you were performing.

g. Display and review the information in the Fault History, Jam History, Service Usage

Profile. Classify this information into categories:

Information that is related to the problem that caused the service call.

Information that is related to secondary problems.

Information that does not require action, such as a single occurrence of a prob-

lem.

2. Perform any required routine maintenance activities. Refer to the Routine Maintenance

Activities section.

3. If any DADF feed jams are reported, or fault codes are logged, replace the Feed Roll Kit.

4. Try to duplicate the problem by running the same jobs that the customer ran once repairs

are complete to verify repairs are effective.

5. Go to General Procedures to further investigate the problem.

Service Call Procedures

Service Call Procedures, Initial Actions

10/2006

1-4

Initial Issue

Phaser 8510/8560MFP Multifunction Product

Page 23

Routine Maintenance Activities

Procedure

1. Clean the Pick Rollers on every call.

2. Use the Control Panel to check maintenance item counters.

3. Compare the counter values to those listed in Table 1.

4. Advise the customer of any routine maintenance items that are approaching or over the

service limit.

Table 1 Routine Maintenance Item Life Expectancy

Routine Maintenance Items

Extended-Capacity Maintenance Kit 30,000 cycles (0-20% coverage)

20,000 cycles (20-100%) coverage.

Standard-Capacity Maintenance Kit 10,000 cycles

Waste Tray Empty every 7 Purges

DADF Pick Rollers and Separator Pad 50,000 scans

Cleaning Procedures

Purpose

The purpose is to provide cleaning procedures to be performed at every call.

Procedure

CAUTION

Do not use any solvents unless directed to do so in this manual.

General Cleaning

Use a dry lint free cloth or a lint free cloth moistened with water for all cleaning unless directed

otherwise in this manual. Wipe with a dry, lint free cloth if a moistened cloth is used.

1. Feed Components (Rolls and Pads)

Follow the General Cleaning procedure above.

2. Jam Sensors

Clean the sensors with a dry cotton swab.

3. Scanner

a. Using the optical Cleaning Cloth, clean the Document Glass.

b. Clean the Document Cover.

4. DADF

Check the paper path for debris or damage. Clean the rolls with a clean cloth and Film

Remover as required.

Initial Issue

Phaser 8510/8560MFP Multifunction Product

10/2006

1-5

Service Call Procedures

Routine Maintenance Activities, Cleaning Proce-

Page 24

Final Actions

Purpose

The intent of this procedure is to be used as a guide to follow at the end of every service call.

Procedure

1. Check that the exterior of the system and the adjacent area is clean. Use a dry cloth or a

cloth moistened with water to clean the exterior of the system. Do not use solvents.

2. Check the supply of consumables. Ensure that an adequate supply of consumables is

available according to local operating procedures.

3. Conduct any operator training that is needed. Ensure the operator understands the periodic maintenance procedures in the User Guide.

4. Reconnect the system to the customer network. Verify function by printing one or more

test prints. Present these to the customer as examples of system performance.

5. Issue copy credits as needed.

6. Discuss the service call with the customer to ensure that the customer understands what

has been done and is satisfied with the results of the service call.

Service Call Procedures

Final Actions

10/2006

1-6

Initial Issue

Phaser 8510/8560MFP Multifunction Product

Page 25

Power On Self Tests ....................................................................................................... 2-3

NVRAM Reset................................................................................................................. 2-5

Error Message Troubleshooting...................................................................................... 2-7

1,00X.4x 525-Sheet Feeder Faults ................................................................................. 2-8

1,000.6x 525-Sheet Feeder Program Faults................................................................... 2-9

2,00X.xx I/O Board Errors............................................................................................... 2-9

2,006.xx I/O Board Program Faults................................................................................. 2-10

2,0XX.6x Configuration Card Faults................................................................................ 2-10

3,0XX.6x IPC Program Faults......................................................................................... 2-11

4,0xx.4x Process Control Errors ..................................................................................... 2-11

4,024.42 Wiper Alignment Fault...................................................................................... 2-12

4,025.46 Drum Transfix Fault.......................................................................................... 2-12

4,0xx.6x Process Control Program Faults....................................................................... 2-13

5,0xx.4x Y-Axis Sub-System Faults................................................................................ 2-13

5,0xx.6x Y-Axis Sub-System Program Faults ................................................................. 2-14

6,0xx.4x X-Axis Fault ...................................................................................................... 2-15

6,0xx.6x X-Axis Program Faults...................................................................................... 2-15

7,002.44 Process Drive Fault.......................................................................................... 2-16

7,006.4x Head Tilt Solenoid Fault................................................................................... 2-16

7,007.49 Process Drive Fault.......................................................................................... 2-17

7,008.41 Printhead Tilt Fault........................................................................................... 2-17

7,009.42 Printhead Restraint Fault ................................................................................. 2-18

7,01X.4x Process Faults ................................................................................................. 2-19

7,0xx.6x Program Faults ................................................................................................. 2-20

8,0XX.4x Wiper or Media Drive Faults............................................................................ 2-21

8,0xx.6x Media Drive Program Faults............................................................................. 2-22

9,0XX.4x Ink Loader Faults............................................................................................. 2-22

9,009.44 and 9,00X.6x Ink Loader Program Faults ........................................................ 2-23

11,0XX.xx Electronics Module Interface Faults............................................................... 2-24

11,100.60 Electronics Module Temperature Fault .......................................................... 2-25

12,000.60 Program Faults............................................................................................... 2-25

13,000.48 Printhead Thermal Fault................................................................................. 2-26

13,003.42 and 13,007.46 Thermal Faults ....................................................................... 2-26

13,008.47 and 13,010.49 Drum Thermal Faults ............................................................. 2-27

13,067.43, 13,069.45, 13,071.47 Drum Temp Sensor Faults ......................................... 2-28

13,XXX.4x Preheater Thermal Faults ............................................................................. 2-28

13,1XX.4x Left Jetstack Thermal Faults ......................................................................... 2-29

13,2XX.4x Right Jetstack Thermal Faults....................................................................... 2-29

13,XXX.xx Printhead Reservoir Thermal Faults.............................................................. 2-30

13,XXX.xx Ink Loader Thermal Faults ............................................................................ 2-30

13,00x.6x Thermal Program Faults................................................................................. 2-31

19,0XX.4x Printhead Calibration Faults .......................................................................... 2-32

19,0XX.6x Waveform Program Faults............................................................................. 2-32

21,000.69 Diagnostic Firmware Version Mismatch......................................................... 2-33

22,0XX.6x Jam Fault....................................................................................................... 2-33

23,0XX.6x NVRAM Faults............................................................................................... 2-34

26,0XX.6x Printing Faults................................................................................................ 2-34

27,0XX.6x Profile Library ................................................................................................ 2-35

2 Error Messages and Codes

29,0XX.6x Jam Manager Faults ...................................................................................... 2-35

31,001.40 Mechanical Initialization Jam.......................................................................... 2-36

31,0XX.6x Program Faults.............................................................................................. 2-36

33,00X.4x Tray 1 Width Sensor Faults............................................................................ 2-37

34,00X.4x Printhead NVRAM Faults ............................................................................... 2-37

36,000.40 Drum Maintenance Faults .............................................................................. 2-38

36,001.67 Drum Maintenance Drive Faults..................................................................... 2-38

36,002.44 Drum Maintenance Kit Fault........................................................................... 2-39

37,0XX.xx PEST Heater Faults....................................................................................... 2-39

37,01X.41 PEST Fan Faults............................................................................................ 2-40

37,016.43 PEST 50 Volt Supply Fault............................................................................. 2-40

37,0XX.4x PEST Clutch/Solenoid Faults ........................................................................ 2-41

37,024.48 PEST Tray 2 Lift Motor Fault.......................................................................... 2-42

37,026.44 PEST Purge Pump Fault................................................................................ 2-42

37,02X.4x PEST Relay Board Faults .............................................................................. 2-43

37,03X.4x PEST X-Axis Motor Faults ............................................................................. 2-43

37,035.44 and 37,036.45 PEST Y-Axis Motor Faults...................................................... 2-44

37,037.46 and 37,038.47 PEST Media Drive Faults....................................................... 2-44

37,039.48 and 37,040.40 PEST Process Drive Faults.................................................... 2-45

37,0XX.4x PEST Power Supply Faults ........................................................................... 2-45

39,002.40 and 39,003.41 Scanner Subsystem Test Faults ............................................ 2-46

39,004.42 Scanhead Locked or Shipping Restraint Faults ............................................. 2-47

39,005.43 Scanner Missing Fault.................................................................................... 2-47

39,010.8 Document Feeder Disconnected or Missing .................................................... 2-48

39,011.40 and 39,012.40 DADF Subsystem Test Faults................................................ 2-49

39,013.42 Document Feeder Jam................................................................................... 2-49

39,014.43 Document Feeder Calibration Fault ............................................................... 2-50

Jam Codes ...................................................................................................................... 2-50

Initial Issue

Phaser 8510/8560MFP Multifunction Product

10/2006

2-1

Error Messages and Codes

Page 26

Power On Self Tests

This section covers the start-up, Power On Self Test (POST), Service Diagnostics, and power

supply operations of the system to aid in troubleshooting problems not associated with a

reported error. For problems associated with an error message or code, see Error Message

Troubleshooting. Troubleshooting tips are available at: www.xerox.com/support.

Check the main menu for current data and historical error data.

• Status Page

• Usage Profile

• Fault History

• Diagnostic History

Power-Up Error Messages and LED Codes

The system has three sets of tests that are run when first powered on:

• Built-In Self Tests (BIST)

• Power On Self Tests (POST)

• Print Engine Self Tests (PEST)

NOTE: BIST and POST errors are not stored in the fault history logs.

In addition to the numeric error codes appearing on the Control Panel display, the system uses

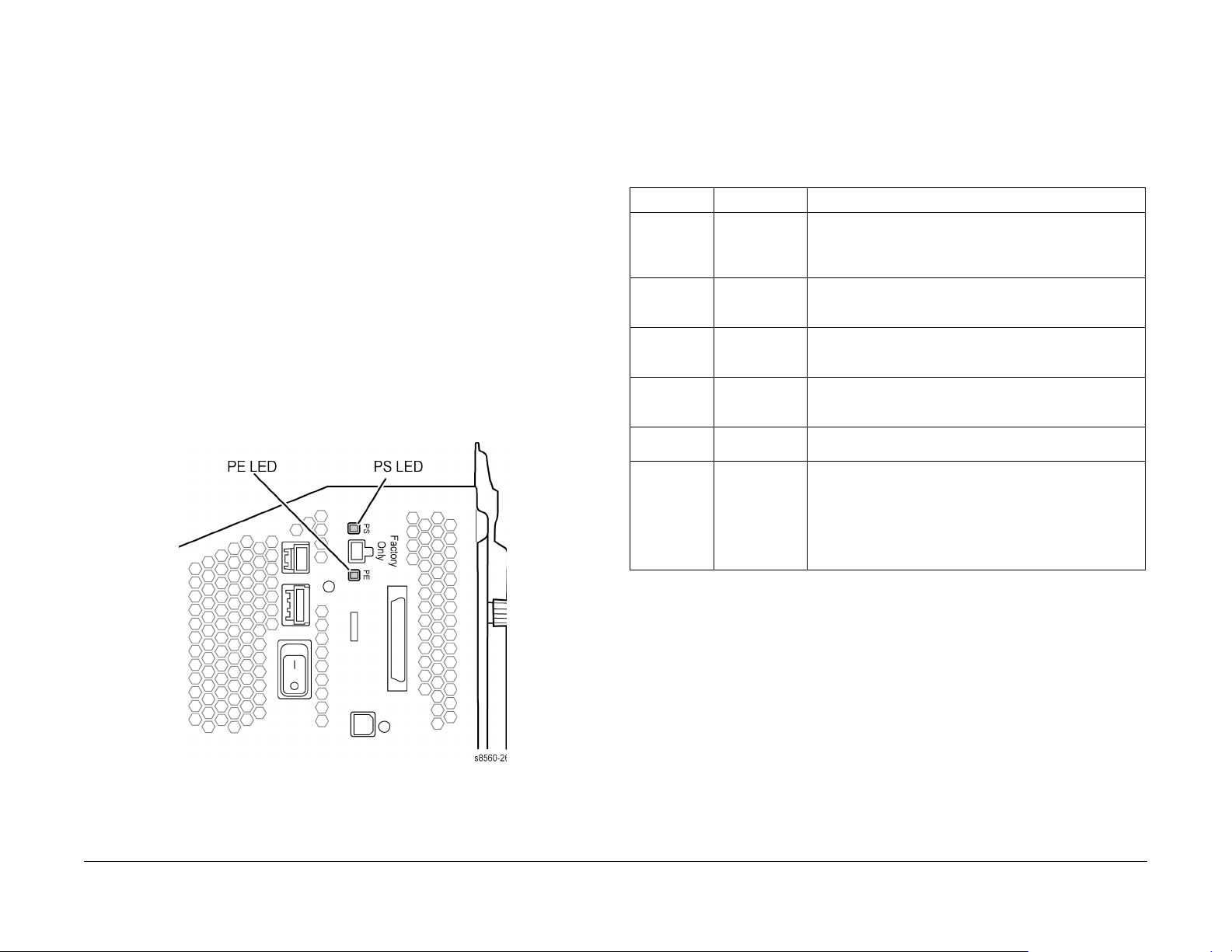

the Control Panel, PS, and PE LEDs to communicate errors. Figure 1 shows location of the PS

and PE LEDs on the Electronics Module.

BIST Error Reporting

BIST verifies basic Electronics Module CPU operation and reports failures using PS and PE

LEDs. These LEDs are located on the Electronics Module directly above the Scanner Assembly connection. BIST tests occur immediately at power-up, before POST tests are run or the

Control Panel is initialized.

The following table defines the blink patterns associated with a failure:

Table 1 BIST Blink Pattern Error Reporting

PE LED PS LED Description

Off or 1 blink,

then Off

On solid (dim) On solid (dim) Initialization failure. The system is held in reset mode. This

Off PS and Control

1 Rapid Blinking The CPU and/or PCI bus is not communicating. Reboot the

2 Rapid Blinking ROM not responding. Reboot the system, if the error still

3 Rapid Blinking System hangs during initialization

Off or 1 blink,

then Off

Panel blink at 1/

2 sec. intervals

The power supply could not remain regulated when DC

power was applied so it shut down. Follow the troubleshooting procedures for electrical shorts (see Electrical Troubleshooting) and check the power supply fuses.

can be caused by an Electronics Module fault or a +3.3 V

power supply failure. See Electrical Troubleshooting.

Boot loader memory test failure. Ensure the systems RAM is

properly seated and that the correct RAM type is installed.

system. If the error persists, replace the Electronics Module

(REP 5.0.5).

occurs, replace the Electronics Module (REP 5.0.5).

1. Unplug all connections to the Electronics Module.

2. Plug in the Power Cable.

3. Power on the system.

4. If the problem persists, reseat the RAM Modules.

5. Replace the Electronic Module (REP 5.0.5).

Figure 1 PS and PE LED Locations

Initial Issue

Phaser 8510/8560MFP Multifunction Product

POST Error Reporting