Page 1

Xerox Document Services

Platform

Color Management Guide

701P40210

Version 3.7

May, 2003

Page 2

Xerox Corporation

Global Knowledge and Language Services

800 Phillips Road

Building 845-17S

Webster, New York 14580

USA

Copyright 2003

Copyright protection claimed includes all forms and matters of copyrighted material and information now

allowed by statutory or judicial law hereinafter granted including without limitation, material generated from

the software programs that are displayed on the screen such as styles, templates, icons, screen displays,

looks, and so on.

Printed in the U.S.A., U.K., and France.

Copywright by Xerox Corporation. All rights reserved.

XEROX®, XEROX Europe®, and XEROX Canada Limited®, The Document Company, the stylized X, and

all names identifying numbers used in connection with Xerox products mentioned in this publication are

trademarks of XEROX CORPORATION. All non-Xerox brands and product names are trademarks or

registered trademarks of their respective companies. Other company trademarks are also acknowledged.

This product includes software developed by the Apache Software Foundation (http://www.apache.org/).”

SWOP® is a registered trademark of SWOP, Inc.

While the information in this Guide is correct at the time of this publication, Xerox reserves the right at any

time to change the information without notice. Changes are made periodically to this document. Changes

and technical updates will be added in subsequent editions.

Page 3

Table of contents

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Assumptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Multiple print engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

About this guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Related documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2. DocuSP color management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Queue overrides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Color workflows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Color path charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

ICC standard path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Xerox enhanced path . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

CMYK Native path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Fast Reprint path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

PANTONE® path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Color Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Associations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

New Stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Assign profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

New color group (stock group) . . . . . . . . . . . . . . . . . . . . . 2-6

Color profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

User TRCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Color tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Print engine specific mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Xerox consistent color mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Custom color mode (default) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Color adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Image quality tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Expert color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Print as grayscale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Spot color editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

OPI (Open PrePress Interface) . . . . . . . . . . . . . . . . . . . . . . . . 2-13

DRIs (Display Resolution Images) . . . . . . . . . . . . . . . . . . . . . . 2-13

3. Stock Management and Calibration. . . . . . . . . . . . . . . . . . . . . . . .3-1

Color Manage me nt Gui de i

Page 4

Table of contents

Characterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Tips for use of Xerox Qualified Stocks . . . . . . . . . . . . . . . . . . . . 3-3

Calibration process overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Calibrating the DocuColor 2045/2060/6060 family . . . . . . . . . . . 3-4

Calibrating the DocuColor iGen3 . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Calibration target tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Stock Management hints and tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

General Stock Workflow Setups . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Unspecified Stock Name Model Setup . . . . . . . . . . . . . . 3-7

Three Stock Model Setup . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Custom and Colored Stock hints . . . . . . . . . . . . . . . . . . . . . . . 3-11

4. Using color t oo ls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Using Custom color mode (default) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Basic color tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Image quality tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

User Tonal Reproduction Curves (TRCs) . . . . . . . . . . . . . . . . . . 4-4

Expert color tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Spot Color Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Understanding the Spot Color Editor window . . . . . . . . 4-10

Open PrePress Interface (OPI) . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Using Print Engine Specific mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Using XCC (Xerox Consistent Color) mode . . . . . . . . . . . . . . . . . . . . 4-13

5. Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Image paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Things to remember . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

A. System Specified defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

B. Glossary Of Color Management Terms . . . . . . . . . . . . . . . . . . . . .B-1

ii Color Management Guide

Page 5

Assumptions

1. Introduction

This guide is a reference to the DocuSP controller color

management features. The DocuSP controller serves as the

digital front end for preparing and processing jobs to print on

Xerox color print engines.

The DocuSP operator uses the information in this guide to

enhance the use of the color management tools to achieve

quality color output.

This guide assumes that the DocuSP operator is familiar with the

DocuSP controller and the attached print engine, and is also

familiar with color printing.

Refer to the DocuSP on-line help system for procedures on how

to use the DocuSP color tools.

Multiple print engines

The DocuSP controller includes colo r management tools for the

DocuColor 2045/2060/6060 and iGen3 Digital Production

Presses.

This guide provides general color management information for

the DocuSP controller; also, printer-specific information is noted

where necessary.

About this guide

Before you read in this guide, become familiar with its contents

and conventions.

Color Manage me nt Gui de 1-1

Page 6

Introduction

Conventions

This guide includes the following conventions:

• Angle brackets: Variable information that is displayed on your

window or that can be entered as part of a command line is

enclosed within angle brackets. Examples include "Unable to

copy <filename>;" “set –p <printer>.”

• Square brackets: Square brackets are used fo r the following:

– Names of menu options that you select; for example,

[Printer Default]

– Names of buttons that you select; for examp le , [OK] and

[Cancel]

– Names of text boxes, list boxes, and fields; for example,

"the [From] text box," "the [Directories] list box," “the

[Color Source] field”

• Bold: Boldface type is used for the following:

– Directory paths; for example, “Browse to the Color

– Text that you enter; for example, "Enter purple or Xerox."

– Calling attention to text that is particularly important; for

– Introductory wor ds or phrases t hat begin items in a list; for

• Note: Notes are hints that help you perform a task or

understand the text. Notes are presented in italics, in

separate paragraphs. Example:

NOTE: You cannot submit a job unless the printer is

connected to your workstation.

Related documentation

profiles directory.”

example, “Select [Stop] on the user interface window. Do

not press the red stop button on the controller.”

example,

[Hold job]: The document is held at the printer...

[Cancel job]: The document is not printed...

Further information on the specific Xerox print engines or the

DocuSP controller may be obtained by referring to the

documentation that was delivered with the elements of the

system.

1-2 Color Management Guide

Page 7

Customer Support

Introduction

For service and software support, dial 1-800-821-2797. This

number is enabled for TTY bridges. To reach Xerox

Documentation and Software Services, dial 1-800-327-9753.

Color Manage me nt Gui de 1-3

Page 8

Introduction

1-4 Color Management Guide

Page 9

2. DocuSP color management

Color management is a process of attempting to match colors

across input (scanners, digital cameras), display (computer

monitors), and output devices (color printers).

Hardware devices such as Spectrophotometers for calibration

and software tools such as color profiles, tone reproduction

curves (TRCs) and color tools are used to match or adjust color

to achieve a quality color image.

Spectrophotometers are used to calibrate data for the print

engine. Calibration da t a i s use d to ad j ust co lor ba la nce for st ock

by halftone.

Color manageme nt softw a re conv erts RGB and CMYK input

color profiles to the color gamut of a specific output device.

DocuSP supports the traditional CMYK workflow as well as the

ICC Profile workflow.

Queue overrides

TRCs and other color tools allow you to make custom color

adjustments, fine tuning the color image.

DocuSP provides the software color management tools you can

use to produce quality color output.

Refer to the DocuSP on-line help system for detailed informat ion

and step-by-step usage procedures for all tools and processes

presented in th is guide.

An override can be set for ma ny of the queue properties in

Queue Manager. A selected override property is applied to all

jobs submitted to that queue, regardless of job or job ticket

settings.

Color Manage me nt Gui de 2-1

Page 10

DocuSP color management

Color workflows

A color image follows a path as it is converted from an input color

profile to the output CMYK of the print engine. Factors that

determine the path are:

• the characteristics and type of the input profile

• conversions needed for the output profile of the print engine

• enhancements made by you, the user

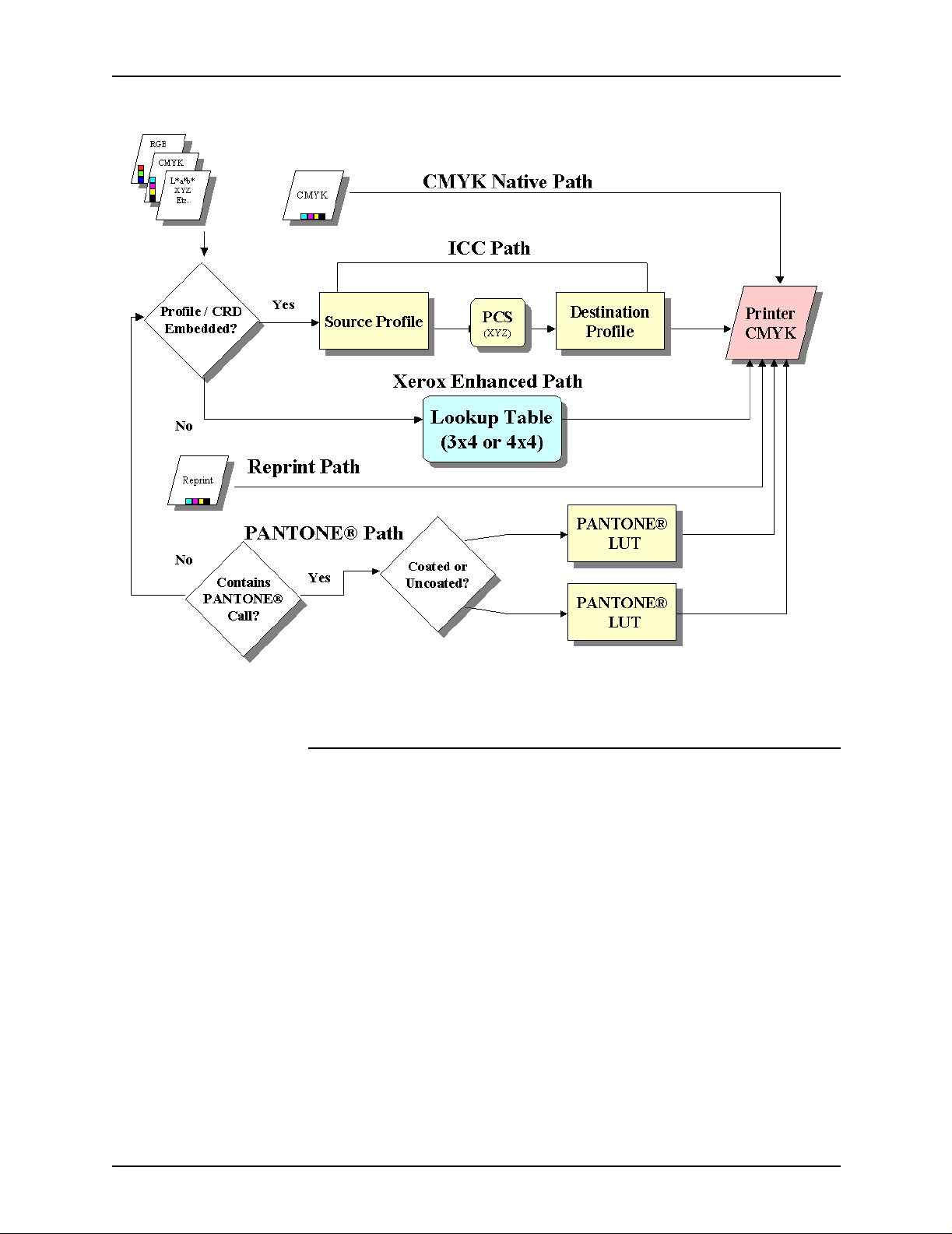

Color path charts

Jobs take one of five paths through the DocuSP controller.

Whenever possible, you should use the Xerox Enhanced Path

which provides the highest quality color for incoming SWOP™

CMYK color and faster RIP speed.

The color path chart (see Figure 2-1. Simplified DocuSP Color

Workflow) displays the paths different documents take as they

move through the DocuSP color management system and are

processed for print.

The paths are:

• ICC Standard Path

• Xerox Enhanced Path

• CMYK Native Path

• Fast Reprint Path

• PANTONE® Path

2-2 Color Management Guide

Page 11

DocuSP color management

Figure 2-1. Simplified DocuSP Color Workflow

ICC standard path

Jobs undergo a color transformation to an independent color

space before color transformation to the DocuSP print engine

CMYK color space. This path requires more RIP time as the

color is transformed from Input (such as RGB or input CMYK) to

Profile Connection Space (PCS) to output CMYK or SWOP™

CMYK. The K channel will not be preserved for incoming CMYK

data.

The chief benefit of using this path is its ease of use.

The following conditions guarantee a job follows the ICC

standard path:

• A user output profile has been assigned to the job.

• A color adjustment (lightness, co ntrast, satu ration, color cast,

trapping, black o verprint, or anti-aliasing ) has been set for t he

job.

Color Manage me nt Gui de 2-3

Page 12

DocuSP color management

• The incoming job contains embedded profiles that result in

Xerox enhanced path

Incoming RGB or CMYK data uses the DocuSP Xerox Enhance d

Path Look Up Table (LUT) or Emulation LUT when performing

the SWOP™ CMYK to DocuSP print engine CMYK

transformation.

Benefits of using this p ath include:

• Faster RIP time via use of the LUTs as contrasted with the

• This path preser ves the Black (K) channel and Black

Look Up Tables provide a quick, effective translation from the

source space to the specific printer’s CMYK space. These tables

are faster because the CMYK values are translated directly to

output space, instead of fi rst bein g tra nsla ted to deviceindependent space and then to the print-engine-specific space.

the printer driver creating a Color Space Array (CSA) for the

color data. These PDL instructions are honored by the

system.

ICC Path.

darkness.

RGB data is converted using 3 x 4 LUTs.

4 x 4 LUTs provide direct CMYK to CMYK mapping, preserving

black. When pure black is passed thr ough a source profile (ICC

profile path), it is converted to XYZ. Once in XYZ, ther e is no way

for the color management system to know that the color was

originally pure black. Thus, pure K is converted to a CMYK

combination (Gray Component Removal, or GCR, is involved in

this process). In contrast, the 4 x 4 tables recognize pure K and

output the appropriate K for the source-to-destination mapping.

The following conditions guarantee a job follows the Xerox

enhanced path:

• The incoming job is untagged and using a pre-installed

output profile.

• A Xerox stock is programmed for the job

• A non-Xerox stock that is a member of an unaltered Xerox

color group is programmed for the job

• A Xerox output color profile, included with the system, has

been assign ed to the job

2-4 Color Management Guide

Page 13

DocuSP color management

CMYK Native path

Color management is performed within the application using

DocuSP output color ICC profiles to create jobs composed with

the DocuSP print engine CMYK color profile. These jobs are sent

directly to the RIP with no color transformations, assuming you

have not programmed any color adjustments.

Documents destined for this path MUST be designed using the

appropriate CM YK color space for the DocuSP destination print

engine. This is u sually achieved by using the CMYK destination

profile for the destination media/engine combination.

Benefits of using this p a t h in clude:

• Fastest RIP performance of any of the paths

• Color will be consistent throughout, since the job is created

and submitted expressly for the specific print engin e

Fast Reprint path

Fast Reprint jobs, accessed thr ough Reprin t Manager, are saved

using “Print and Save” or “Save” commands when processing

the job. Fast Reprint jobs do not require re-RIPping. Color

management properties are se t prior to saving t he job.

The only color change that can be applied to a job on the Fast

Reprint path is a User TRC.

Benefits of using this p a t h in clude:

• No need to re-submit jobs

• Fast print times (achieving engine-rated speed) since the RIP

is bypassed on reprint

• No need to reset Color Management properties

NOTE: Calibration TRCs and User TRCs may be applied to

the reprint job, since TRC processing is done in the

hardware.

PANTONE® path

An incoming job is scanned by the controller and, if the job

contains PANTONE® calls , the P ANT ONE® pat h is invoked. The

job’s color information is processed using a pair of Look Up

Tables (one for Coated and one for Uncoated) and then passes

directly to the pr inter output, b yp assing all other co lor pro cessing

except for User TRCs.

Color Manage me nt Gui de 2-5

Page 14

DocuSP color management

Color Manager

Color Manager provides access to color management tools for

calibration, characterizat i on, assigning color profiles, managing

color groups, creatin g and applying TRCs, and importing or

exporting ICC profiles.

Associations

The Associations tab provides a list of stocks, their properties,

date last calibrated, and the assigned profile.

Calibration

Calibration is used to return the print engine to a standard

condition insuring color consistency for each stock or color

group. For more in-d epth information regarding calibratio n, see

chapter 3.

New Stock

Destination colo r profiles are required for each stock or color

group.

Stocks added from the catalog (Xerox Qualified Stocks) will

automatically be placed in the proper color group.

New custom stocks will automatically be placed in the default

color group.

Assign profile

Each stock is automatically assign ed to a profile based on its

color group.

Color profiles can be assigned to any stock or color group,

including pre-defined stocks.

New color group (stock group)

Stocks are assigned groups based upon their whitepoint. Any

stock in the group can be calib rated, and the resulting TRCs are

assigned to all stocks in the color group.

2-6 Color Management Guide

Page 15

Color profiles

DocuSP color management

NOTE: You should calibrate a stock that best represents the

other stock in the group; therefore, you should calibrate using a

stock that has a whitepoint at about the median of the stocks in

the group.

It is recommended that most users confine their use of color

groups to the 3 pre-installed groups. This method provides

excellent color results with relatively little user intervention.

For a more in-depth discussion of color groups, see chapter 3:

Calibration.

The Color Profiles tab provides a list of color profiles (both

source and destination) with their descriptions.

User TRCs

Color tools

Print engine specific mode

User Tone Reproduction Curves (TRCs) provide the skilled user

with a tool for adj usti ng the indivi dual CMYK co lor sep a rati ons i n

an image and saving those adjustments for use on other images.

The User TRCs tab provides a list of user-created TRCs and

allows you to cr eate new TRCs.

Color tools allow you to make adjustments that impact the color

characteristics of a print job. Color tools can affect jobs or

queues, if assigned at the controller, or can be assigned by an

application at the client workstation.

Selected at the queue level, the print engine or product specific

mode is unique to each Xerox color print engine and optimizes

performance fo r that print engine. Print engi ne specific mode

provides the best possible default color interpretation and

rendering values for the widest range of images.

Color Manage me nt Gui de 2-7

Page 16

DocuSP color management

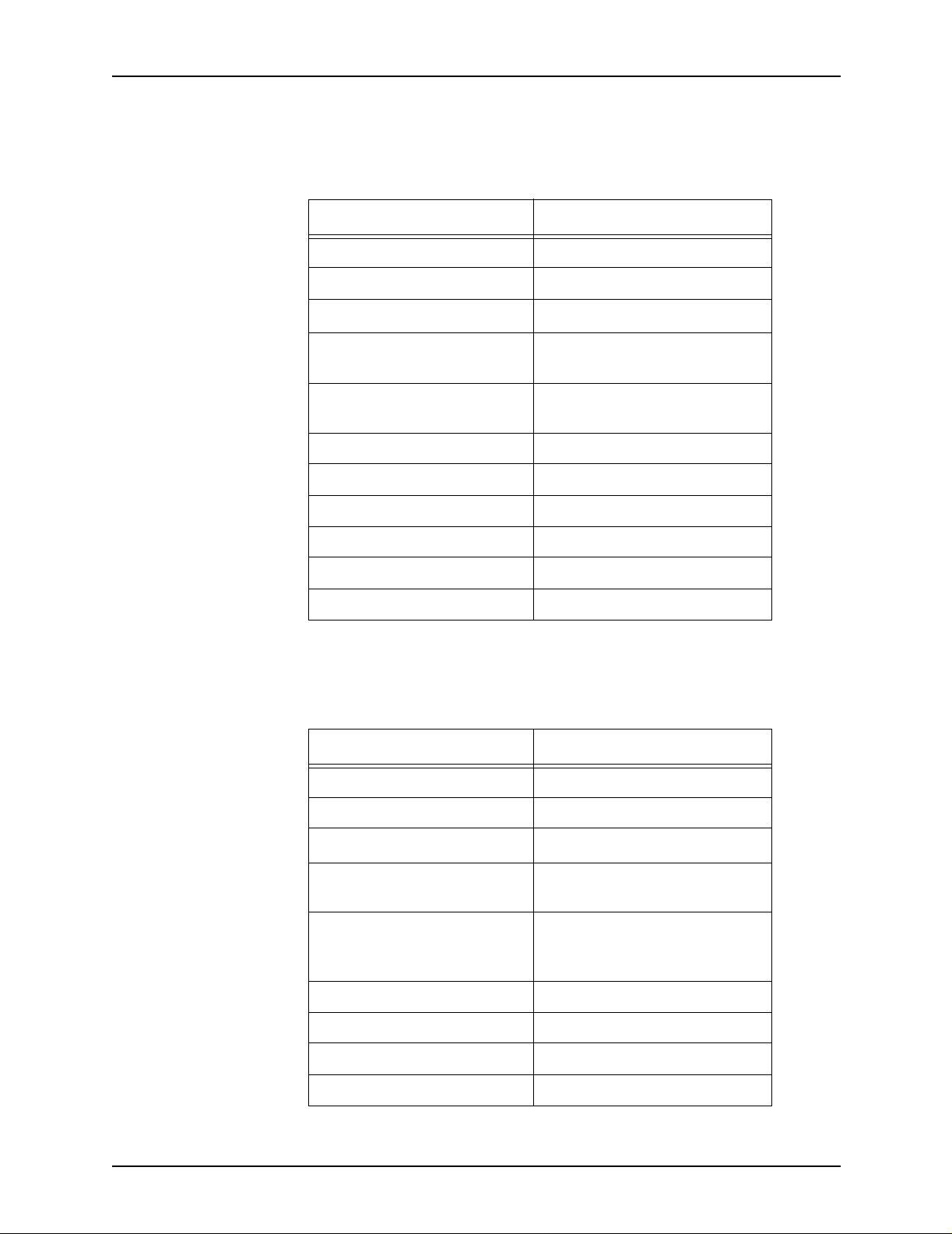

T able 2-1. DocuColor iGen3 Digital Production Press

Queue Property Queue Setting

Rendering Intent Relative Colorimetric

RGB Source sRGB

mode default property settings

CMYK Source

CMY Source

Gray Source

Destination ICC Profile Front/

Back

Lightness 0

Contrast 0

Saturation 0

Color Cast (all) 0

TRCs None

Press Color Emulation None

SWOP

System Specified

System Specified (pre-installed

and optimized for the iGen3)

™

Tabl e 2-2. DocuColor 2045/2060/6060 mode defa ult

property settings

Queue Property Queue Setting

Rendering Intent Relative Colorimetric

RGB Source sRGB

CMYK Source

CMY Source

Gray Source

Destination ICC Profile Front/

Back

Lightness 0

Contrast 0

Saturation 0

Color Cast (all) 0

SWOP

System Specified

System Specified (pre-installed

and optimized for theDC20xx/

60xx)

™

2-8 Color Management Guide

Page 17

Tabl e 2-2. DocuColor 2045/2060/6060 mode defa ult

Queue Property Queue Setting

TRCs None

Press Color Emulation None

Xerox consistent color mode

Selected at the queue level, Xerox consistent color mode

standardizes the print engine response to undefined color

spaces by assigning them default source files. De fault Source

files provide output that looks similar when submitted from the

DocuSP to a compatible Xerox color print engine, currently the

DocuColor 2045/2060/6060 and the DocuColor iGen3.

DocuSP color management

property settings

Table 2-3. XCC mode default and override settings

Queue Property Queue Setting Applicability

Rendering Intent Images

Rendering Intent Text

Rendering Intent Graphics

RGB Source XCC Mode RGB Default

CMYK Source

CMY Source

Gray Source

Destination ICC

Profile Front/Back

Lightness 0 Override

Contrast 0 Override

Saturation 0 Override

Relative Colorimetric Default

Pure Default

Saturation Default

SWOP

System Specified Default

System Specified Override

™ Coated

Default

Color cast (all) 0 Override

TRCs None Override

Color Manage me nt Gui de 2-9

Page 18

DocuSP color management

Table 2-3. XCC mode default and override settings

Queue Property Queue Setting Applicability

Press Color

Emulation

Custom color mode (default)

Selected at the queue level, Custom Color mode allows users

with a high level of color management skills to make specific

color adjustments using industry standard color tools.

Skilled users create queues with specific color properties,

defaults and overrides. Jobs sent to these queues are assigned

the queue properties automatically, improving the flow of jobs

through the DocuSP controller and reducing the adjustments

required on a standard set of color jobs.

Color adjustments

Color tools provide a m eans for you to make adju stments in colo r

images.

None Override

• Lightness controls the relative brigh tness or darkn ess of the

color image.

• Contrast is the ratio between the light tones and dark tones

in an image.

• Saturation controls the strength or purity of the color imag e.

• Color Cast adjustments provide you with the ability to

increase or decrease the amount of a single color in an

image.

• User TRCs are created to provide a consistent color

rendering based upon a given set of properties. TRCs are

saved and appl ied to jobs.

Image quality tools

Image quality tools provide you a means to improve image

quality.

• Trapping compensates for misregistration that creates white

gaps and shifted hues.

2-10 Color Management Guide

Page 19

DocuSP color management

• Black Overprint compensates for the band of white t hat may

appear when black text is printed directly on top of a color.

NOTE: Black Over print produces sometimes-unex pected

results using iGen3, due to its unique technology. Therefore,

you should avoid using this feature on the iGen3.

• Anti-aliasing reduces the jagged appearance of lines and

curves in text and line art.

Expert color

Expert color contains a set of tools for the skilled user to optimize

color quality.

•The Source color tab provides access to a list of source color

profiles. This selection is used to translate undefined data in

the incoming job. DocuSP honors embedded source profiles.

•The Output color tab provides access to a set of tools that

are applied as part of the color transformation from the device

independent s pace to the print eng ine CMYK space.

– Halftones are screen patterns achieved by printing dots

or lines in a specific pattern. The distance between the

dots is fixed. Dot size varies in acco rdance to the stren gth

of the color. The darker the color the larger the dot.

Halftones supported on the iGen3 include 150 dot, 175

dot, 200 dot and stochastic screens. The DC 20xx/60xx

series supports 150 dot, 200 dot, 200 line, 300 line, and

600 line screens.

Stochastic halftones randomly apply screens when the

difference in tone varies by different concentrations of

dots and by dot sizes.

– Image Resample

Interpolation is a method to achieve maximum image

quality. Interpolation estimates a value of function

between two known values and attempts to produce a

smooth trans ition between adjacent samples rather than

replicating pixels which would result in “blocky” images.

The supported interpolation methods include:

Nearest neighbor

Bi-linear

Smart

Color Manage me nt Gui de 2-11

Page 20

DocuSP color management

NOTE: These image resample methods are detailed in

Chapter 4: Using Color Tools.

– Output

Destination Profiles convert PCS to CMYK.

There are pre-defined destination profiles for GCR

(Gray Component Replacement). GCR replaces

equivalent percentages of the gray component for

colors (CMY), replacing the gray with black. This

conserves dry ink and prevents dry ink buildup.

Emulation can be selected in place of destination

profiles allowing you to select a color profile that

emulates a specific type of output profile for media or a

printing device.

Rendering intent provides color mapping options.

The available rendering intents are covered in detail in

Chapter 4: Using Color Tools and are as follows:

Print as grayscale

Print as grayscale converts color conte nt to gray. Refer to on-line

help for the details, as well as for information on billing.

Spot color editor

DocuSP has a built-in color lookup table to map incoming spot

color (PANTONE® Coated or Uncoated) to the matching

P ANT ONE® color created in DocuS P CMYK. If the PostScript o r

PDF file contains Uncoate d, Process or Pro Sim color, the CMYK

color represen tation is created using the color valu es in the

PostScript f ile.

Saturation

Perceptual

Relative Colorimetric

Absolute Colorimetric

Pure

The Spot Color Editor is provided allowing you to change the

standard DocuSP output for each PANTONE® color.

2-12 Color Management Guide

Page 21

The Spot Color Editor tab is covered in more detail in Chapter 4:

Using Color Tools.

OPI (Open PrePress Interface)

OPI is a process to replace low-resolution images with highresolution images at RIP time. This speeds up job submission

time because you can submit a job with the low-resolution

images much faster than with high-resolution images.

OPI is covered in more detail in Chapter 4:Using Color Tools.

DRIs (Display Resolution Images)

The option exists in the Job: Proper ties tab to save the DRIs

embedded in a job. This must be enable d to allow viewing and

editing within a job at the DocuSP.

DocuSP color management

Color Manage me nt Gui de 2-13

Page 22

DocuSP color management

2-14 Color Management Guide

Page 23

3. Stock Management and Calibrati on

Color DocuSP systems achieve high-quality color results due to

an efficient and flexible stock management model. Stock

associations, calibrat ion, an d characterization are important

processes used for stock management.

Calibration is a process that is used to return the print engine to

a known standard to achieve and maintain consistent color

quality for each stock or color group and ha lftone.

DocuSP calibration uses the X-Rite DTP41 Spectrophotometer

to measure and adjust the gray balance of the CMYK color

output. You should ca lib rate the X- Rite DTP 41 da ily. Refer to the

DocuSP on-line help for complete calibration instructions.

Calibration is generally performed once for each color group/

halftone combination. If you do not use a specific halftone for

printing, you need not calibrate it.

Characterization

Once a stock is calibrated, DocuSP saves that calibration and

automatically selects the latest calibration f or the stock wh en the

stock is required by a job. DocuSP can save up to five

calibrations per stock. These saved calibrations are assigned to

the color group in which the sto ck resides, f or use with an y stock

within that color group.

Characterization is the process of creating a destination color

profile for stocks. Stocks have different characteristics such as

coated and uncoated, color, and weight which impact how color

appears on the sheet. For most users, characterization is not

recommended for a new stock; instead, you should place the

new stock in an existing color group.

DocuSP comes with 3 pre-installed color groups, containing

Xerox Qualified S tocks. Xerox Qualified Stocks are automatically

part of one of the pre-installed color groups and have a

destination profile pre-assigned to th em; therefore, they do not

require characterization.

Color Manage me nt Gui de 3-1

Page 24

Stock Management and Calibration

New or custom stocks may require characterization if you

choose to place them in a new color group. If the new or custom

stock is placed within one of the pre-installed color grou ps, the

stock picks up the profile assigned to the color group. Each new

or custom stock needs to be characterized only once. This

characterization is assigned to the color group and is invoked

each time the stock is selected for use in a job.

Once created, a color profile is assigned to any stock within the

color group.

The three pre-instal l ed color gr ou p s ar e:

• Bright White (L* > 95)

• White (93.7 < L*< 95)

• Other (L* < 93.7)

NOTE: The L* values are white point values and can be

obtained by looking at the ream wrapper and/or from the

manufacturer.

The three pre-installed color groups cannot be deleted; Xerox

Qualified Stocks may be removed from your Stock Library, but

not from the Stock Catalog. However, you may add new, nonXerox stocks to the existing stock groups. It is advantageous to

do so, as long as the new stocks share the same white point

value.

Additionally, it is suggested that you place any colored stocks

you wish to use in the Othe r group, although pe rfectly fine result s

can be achieved by placing all stocks in the white group. While

these suggestions may not seem to make sense, they work well

in practice. Most user s who print on beige stock, or light blue

stock, for instance, are generally willing to trade off maximum

color consistency for the ability to produce good-looking prints on

non-standard media.

An advantage to maintaining the “3-stock” model is that it limits

calibration to only three representative stocks. The “ 3-stock”

model is recommended for mo st workflows, requiring a little

more setup than the “unspecified” workflow but achieving better

color outcomes.

3-2 Color Management Guide

Page 25

Tips for use of Xerox Qualified S t ock s

Here are some general tips for using Xerox Qualified Stocks:

• You are able to modify certain attributes of Xerox Qualified

Stocks. Some fundamental attributes cannot be modified, as

they affect color processing.

The fundamental attributes are:

–Name

–Color

– Weight

– Coating

– Type (Type, Opac it y, Drilled, Modu l us)

– Finish (iGen3 only)

– Color group

Stock Management and Calibration

• Xerox Qualified Stocks cannot be moved from color group to

color group. Only User Defined Stocks can be moved and

fully edited at will.

Calibration process overview

Refer to the on-li ne help for a detailed calibration proc edure.

Prior to initiating the calibration process, the stock you plan to

use for calibration needs to be in a paper tray and that tray

programmed for that stock.

Begin by calibrating the DTP41 X-Rite Spectrophotometer.

NOTE: Calibrating the Spectrophotometer needs only be done

once a day.

You need the reflective strip card that has the same serial

number as the spectrophotometer. Follow the X-Rite

instructions.

In the DocuSP Color Manager: Associations window select a

stock or color group rep resenta tive. Ope n the Calib ration Wizar d

and follow the on-screen in str uctions.

When calibration is complete, accep t the calibration data. The

calibration is now assigned to the stock or color group used for

calibration.

Color Manage me nt Gui de 3-3

Page 26

Stock Management and Calibration

Calibrating the DocuColor 2045/2060/6060 family

For the DC 2045/2060 and 6060, you should calibrate at least

once or twice a day or more often when printing jobs that are

“color-critical.”

The default number of prints of the calibration targets is 5 for the

DC 2045/2060/60 60 family. However , you ma y choose to print as

many as 200 calibration targets at one t i me; we recommend

printing 5 prints (of the 2-page target) and then choosing the 5th

print to use for calibration.

Calibrating the DocuColor iGen3

Calibration should be performed at least once per color group,

per halftone per eight hour shift for the DocuColor iGen3.

For example, if jobs to be printed during the night shift require

Stock A using 175 dot halftone for job #1 and a 200 dot halftone

for job #2, a calibration is needed for Stock A at 175 dot and at

200 dot.

These calibrations are assigned to Stock A with a 175 dot

halftone and Stock A with a 200 dot halftone.

When calibrating 8.5 x 11 - A4 stock print 40 single sided copies

of the (2-pag e) t arget. For l arger sized stock pr int 20 single sid ed

copies of the target; we recommend using the final print for

calibration.

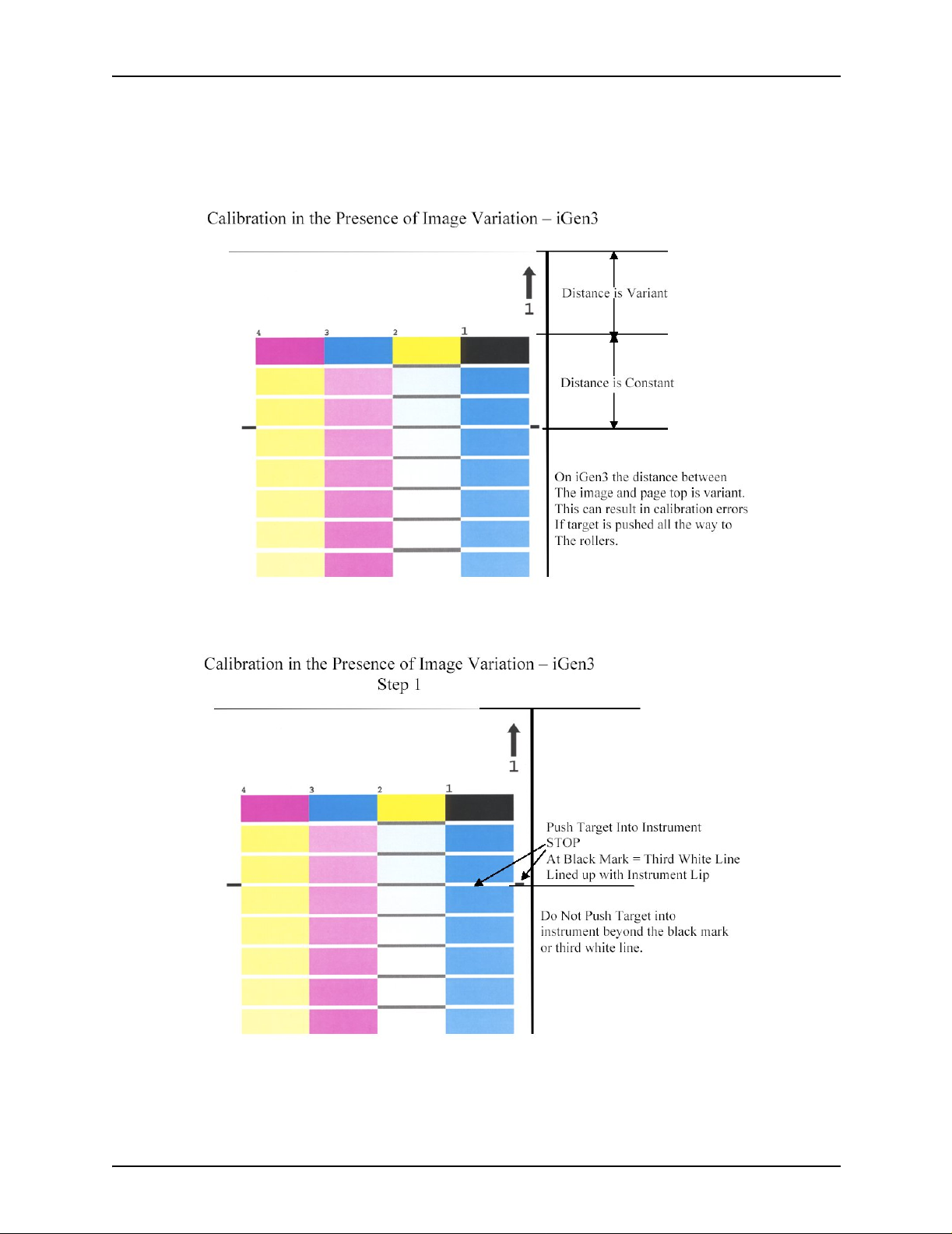

Calibration target tips

DocuSP calibration software checks the first color at the top of

each calibration stri p as a me thod o f insuri ng th at strip s 1-13 ar e

read in the correct order. If the top color is not detected, or is

detected improper ly, calibration fails. Due to image-to-page t op

variation associated mainly with the iGen3 engine, calibration

errors can occur if you pushes the target too far into the

Spectrophotometer.

Primarily, this can occur using the 11”x17” calibration targets,

which must be cut down manually to 8.5”x17” in order to feed

correctly into the X-Rite. This introduces the image-to-page top

variation previousl y men tioned.

This section provides pictorial instructions for successful

calibration in s pite of target image location fluctuation on the

calibration target.

3-4 Color Management Guide

Page 27

Stock Management and Calibration

This procedure is more likely to be necessary for iGen3 due to

image-to-pag e reg istra tion erro rs, bu t may also b e ap plicab le for

DC20xx/60xx printers.

Figure 3-1. Calibration t a rget and whitespace

Figure 3-2. Calibration step 1

Color Manage me nt Gui de 3-5

Page 28

Stock Management and Calibration

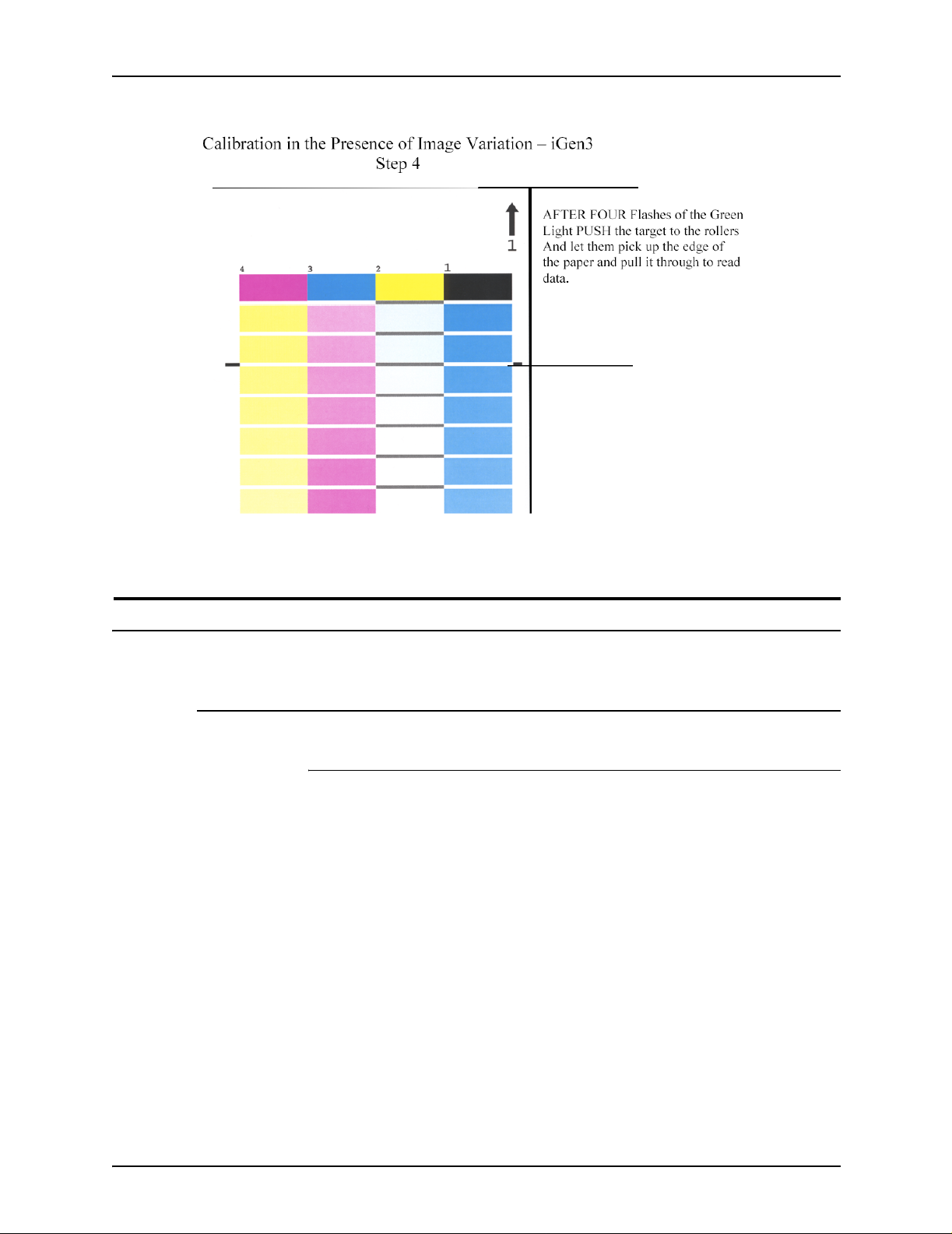

Figure 3-3. Calibration step 2

Figure 3-4. Calibration step 3

3-6 Color Management Guide

Page 29

Stock Management and Calibration

Figure 3-5. Calibration step 4

Stock Management hints and tips

General Stock Workflow Setups

Unspecified Stock Name Model Setup

The settings outlined in this section use the “Unspecified Stock

Name” model. This workflow is best for customers that have a

limited number of stocks and want very consistent color

outcomes with very easy system operation.

Key Points to this approach:

• One calibration event covers all of the stocks at a site.

• You accept the default characteristics for all stocks.

Therefore, stocks with slightly different whiteness (Bright

White, White and Non-White) will be treated the same by the

system.

Color Manage me nt Gui de 3-7

Page 30

Stock Management and Calibration

Recommendations:

• Use this workflow when you are not concerned about small

amounts of whiteness differences on stocks.

• This workflow provides simple and very quick setup.

• It is simple to maintain consistent color using this workflow

because only one calibration applies to all stocks all the time.

• You, the customer, never need to go into Color Manager;

using this workflow, you need only to use the Printer

Manager.

• Use this workflow if you want to avoid ineligible jobs fo und in

the named model.

Setup Steps (after software installation):

1. Open Printer Manager/Paper Trays and select a tray (e.g,

tray 1).

2. Select the desired stock size, type, coating etc. and close.

Leave the name Unspecified.

3. The same should be done for the other trays with physical

stock attributes selected and name remaining Unspecified.

Calibrate ANY stock named Unspecified

• In Printer Manager: Paper Trays, right click on any tray/stock

and select [calibration]. Perform the calibration process.

• You have now calibrated and loaded all stocks and trays on

the system. Any incomi ng job that matc hes an att ribute of the

stock, such as the size, pulls from the appr opriate tray.

Workflow Notes:

• Any Unspecified stocks are always placed in the default

group and use the default group’s calibration and destination

profiles.

• The default group can be cha nged a nd be use d therea fter by

any and all Unspecified stocks on the system.

Three Stock Model Setup

This set-up utilizes three stock groups to represent all the stock

you use. Three Xerox created groups represent Bright White,

White, and Other substrates.

The purpose of t his set-up, as compared to the Unspecified

workflow, is to account for common wh iteness differences in

stocks by using only three groups.

3-8 Color Management Guide

Page 31

Stock Management and Calibration

In this set-up, you add any Non-Xerox stocks you wish to print on

to one of the three groups.

• Bright White (Greater than 95)

• White (93.7 > L* <= 95)

• Other (L* <= 93.7)

NOTE: White point values can be found on the ream wrapper

and/or from the manufacturer.

Key Points to this approach:

• Accounts for the various wh i ten ess in a stock mix.

• Limits calibration to only three stock types.

• Recommended for most workflows.

• Requires three sto ck calibra tions i nstead of one ( Unspecifi ed

Model).

Adding a Xerox Qualified Stock:

1. Select [Printer Manager: Stock Library: Stock Catalog].

2. Select a Xerox stock and add the stock from the Stock

Catalog to the Stock Library.

3. Select your stock in Printe r Mana ger an d calibr ate if requi red .

NOTE: The pre-installed stocks have 1 of 3 stock profiles: Bright

White, White, or Other, based on their color group.

Adding New Stock: Non-Xerox:

1. Select Printer Mana ger : Ne w Stock.

2. Add your custom name.

3. Select the color group, i f a group othe r than the def ault group

is desired.

4. Y our new stock will automatically pick up the calibration of the

group.

NOTE: Keep in mind, if any other stock with the same whiteness

group has been calibrated, then this new stock will automatically

acquire the group’s calibratio n.

NOTE: On iGen3, custom stock will be created at the Press

Interface and will always be automatically part of the default

group. You can move the stock to another group at the DocuSP

controller.

Color Manage me nt Gui de 3-9

Page 32

Stock Management and Calibration

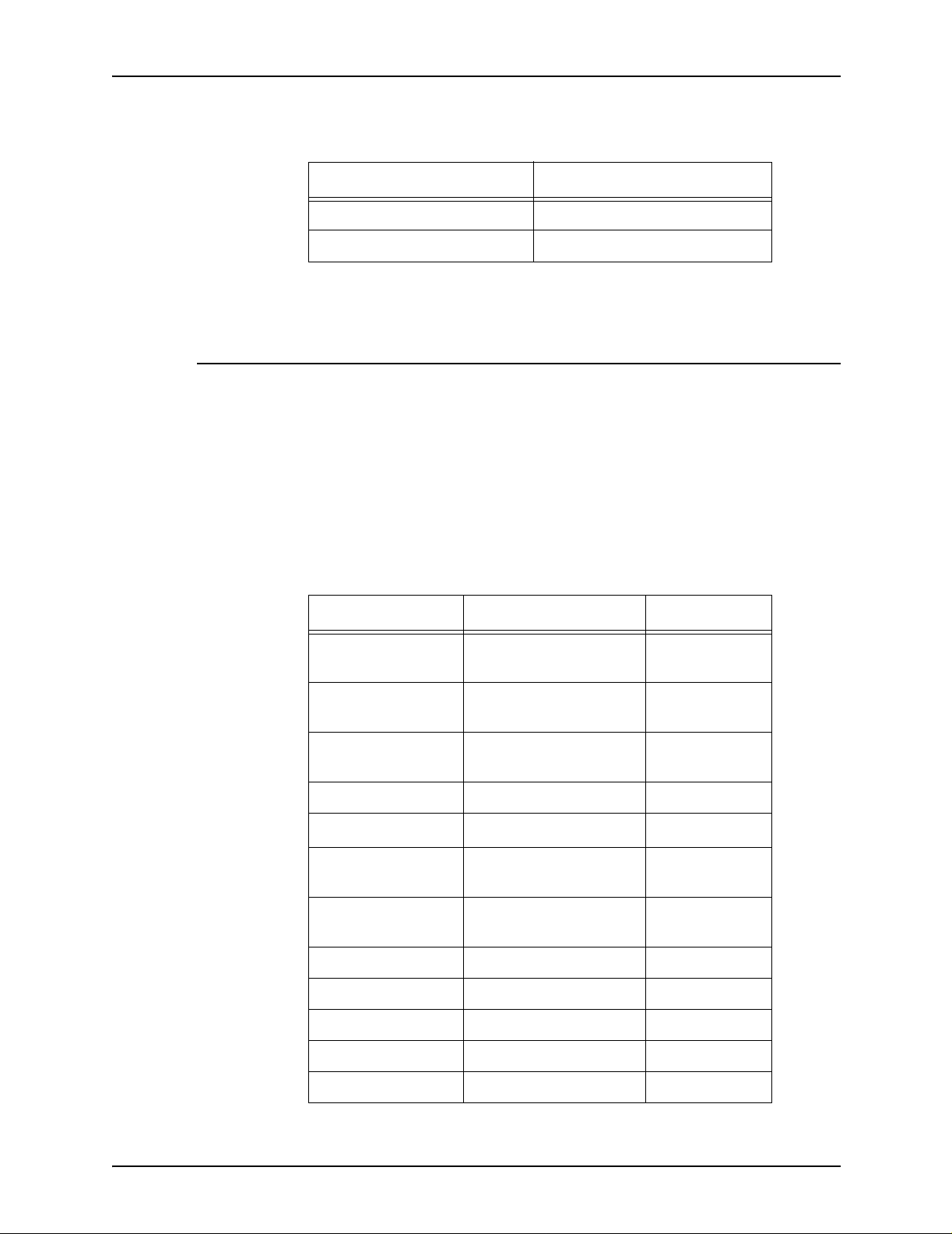

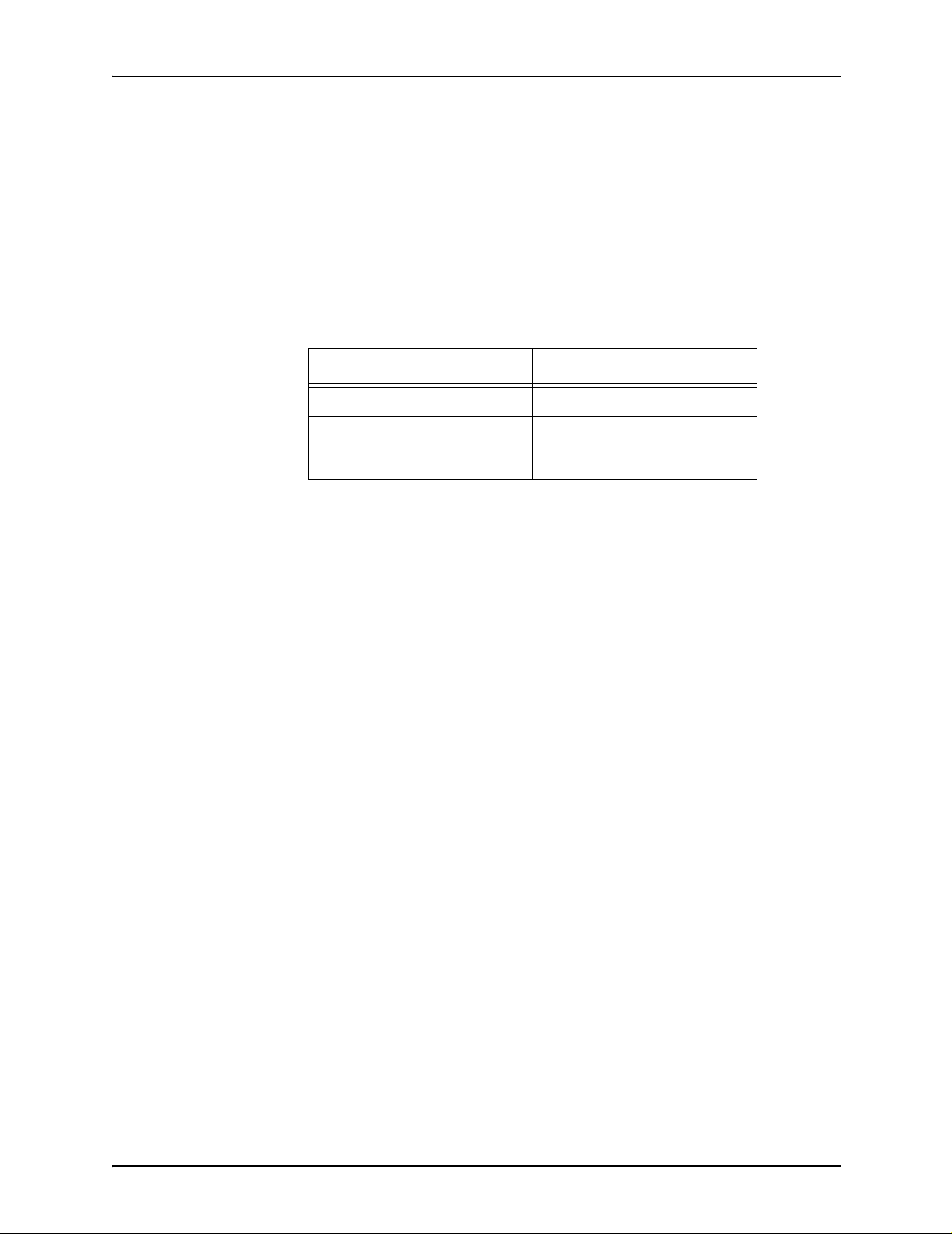

Table 3-1. DocuSP Sample Stock Grouping

Group

Name

Bright

White

White Digital Color Colotech+ SuperGloss 3r95451 135 95.0 (93.7 < L* <=

Paper Name Rnumber gsm L* Grouping

Criteria by L*

Color Expressions 98 Bright White Cover 3r11160 270 97.8 (L* > 95)

Color Expressions 98 Bright White Cover 3r5533 176 97.7

Color Expressions 98 Bright White Cover 3r6386 163 97.6

Digital Color Colotech Natural White 3r97102 100 97.5

Color Expressions+ 96 3r11390 163 97.1

Color Expressions+ 96 3r11385 105 97.0

Color Expressions+ 96 3r11387 120 97.0

Color Expressions+ 96 3r11380 90 96.8

Digital Color Super Gloss 3r6290 8pt 94.8

Digital Color Super Gloss 3r6294 10pt 94.7

Digital Color Super Gloss 3r6350 12pt 94.4

Digital Color Colotech+ Silk Coated 3r97166 120 94.3

95)

Digital Color Gloss Cover 3r11339 280 94.2

Digital Color Colotech+ 3r94641 90 94.1

Digital Color Silk 3r11360 140 93.9

Digital Color Silk Cover 3r11363 280 93.8

Digital Color Silk Cover 3r11357 210 93.8

Digital Color Colotech+ 3r94672 250 93.8

3-10 Color Management Guide

Page 33

Stock Management and Calibration

Table 3-1. DocuSP Sample Stock Grouping

Other Digital Color Gloss Cover 3r11333 210 93.7 (L* <= 93.7)

Digital Color Colotech+ Gloss Coated 3r95224 120 93.7

Digital Color Colotech+ 3r97098 280 93.7

Digital Color Colotech+ Gloss Coated 3r97163 280 93.6

Digital Color Colotech+ 3r94668 220 93.5

Digital Color Gloss Text 3r11336 140 93.4

Digital Color Graphics White Fiber 3r11166 105 93.4

Digital Color Colotech+ 3r94661 200 93.3

Digital Color Colotech+ 3r94646 100 93.3

Digital Color Colotech+ 3r94656 160 93.3

Digital Color Gloss Text 3r11330 120 93.2

Custom and Colored Stock hints

It is recommended that you place all your stocks, including new

or custom stocks, in one of the three pre-existing color groups.

This limits the need for calibration to three groups of halftones.

It may be useful to place all colored stocks into a single group.

Since all colored stock by definition will have a lower white point

than L* 93.7, the non-white stocks are expected to be placed in

the Other colo r group. However, you may prefer the results you

achieve using white or bright white profiles on the non-white

stock.

A simple way to determine which color group would be best for

your specific colored stock is:

1. Add your stock to a tray.

2. If desired, within [P rinter Manage r: Tr ays], select the option to

force feed from the tray. Alternat ively, you can just pro gram a

specific stock for your job.

NOTE: The option to force feed from a tray is not available

on the iGen3.

3. Submit a job to a hold queue on the controll er . The job should

contain a variety of image types, i.e. photos, halftones, and

graphics, as well as text. Y ou should be familiar with how this

job prints on white coa ted or uncoated stock.

4. Open properties for the job within Job Manager.

Color Manage me nt Gui de 3-11

Page 34

Stock Management and Calibration

5. Select [Expert Color: Output Color].

6. On the Output Color tab, select the radio button for

Destination Profile and open the pull-down menu.

7. Select the profil e for one of the three pre-inst alled colo r group

profiles.

8. Select [OK] to close the Expert Color dialog, and [OK] again

to save your Job Property changes.

9. Right-click on the job in Job Manager and select [Proof] from

the context menu. The job is released to RIP.

10. Retrieve your print from the output tray of your printer.

11.Repeat steps 4 through 10 twice, selecting a different

Destination profile each time.

NOTE: After the job proofs, it will appear in the inactive jobs

list of the Job Manager, and will be designated as

“successfully proofed.” This is where you will find it the

second and third time you proof it.

12.Compare the three prints. By determining which of the

destination prof iles produces the most pleasing prints on your

colored media , y ou can decide to which color group you

should add your colored stock.

If none of the three print s are satisfacto ry to meet your needs,

then you may choose t o cre ate a n ew color g roup in which to

place your new, colored stock. In addition, you may need to

use a specific user TRC to match specific colors.

NOTE: Most users will find that the White group meets most

of their color needs regardless of the color, coating, white

point, or weight of their stocks.

3-12 Color Management Guide

Page 35

4. Using color tools

The DocuSP controller pr ovi d es a nu m ber of color management

tools. Determine which color management tools to use based

upon your job requirements and your own skills and knowledge.

To address the diverse levels of job requ irements and user skill

and knowledge, the DocuSP controller provides three levels of

color management, all capable of producing high-quality col or

output.

• Automatic Color Management provides high-quality

consistent color with routine calibration and by applying

Xerox Consistent Color Mode or Print Engine Specific Mode

at the queue level.

• Simple Color Management provides hig h- qual ity con s is ten t

color with routine calibration and easy to use color tools to

adjust color cast using simple slider bars for lightness,

contrast and saturation. Trapping, Black Overprint and antialiasing can also be appli ed.

• Expert Color Management provides high-quality consistent

color with routine calibration and provides you with a full

compliment of industry-standard color management tools for

making color adjustments.

Using Custom color mode (default)

Custom Color mode is the default for new queues and will

produce great results for most jobs. Custom color mod e can be

used by skilled color users to make adjustmen ts in color

properties, renderings, image resampling, emulations, and User

TRCs. Custom color adjustments can be made at the job or

queue level.

Skilled users can create queues with specific color property

settings so that jobs sent to these queues are automatically

assigned the queue properties.

Color Manage me nt Gui de 4-1

Page 36

Using color tools

Basic color tools

Queues of this type pr ovid e opera tors a pa th to p rint hi gh-qu ality

color output without requiring a detailed knowledge of color

profiles. The profiles are pre-set prior to operator intervention.

Basic color tools can be applied at the queue, job or page level.

The adjustments a re ma de on al l of t he colo rs and are addi tive if

more than one adjustment is made on an image.

The adjustments are made during the RIP creating the DocuSP

CMYK output profile.

Basic color tools are used when an image requires a global

adjustment that can be made by one of the tools.

• Use Lightness to lighten or dar ken an image.

• Increase Contrast to lighten highlights and darken shadows.

Decrease Contrast to darken highlights and lighten

shadows.

• Increase Saturation when you want to print stronger colors.

Decrease Saturation to weaken colors.

Figure 4-1. Lightness, Contrast, and Saturation color

controls

• Adding or subt racting col ors using Color Cast impacts all the

colors in the image.

4-2 Color Management Guide

Page 37

Using color tools

Figure 4-2. Color Cast controls

– Cyan vs. Red - moving the slider bar towards cyan adds

cyan by reducing the amoun t of red. Mo ving the slid er bar

towards red adds red by reducing the amount of cyan.

– Magenta vs. Green - moving the slider bar towards

– Yellow vs. Blue - moving the slider bar towards yellow

Image quality tools

Image quality tools can be applied at the queue, job or page

level.

Magenta adds magenta by reducing green. Moving the

slider bar towards green adds green by reducing

magenta.

adds yellow by reducing blue. Moving the slider bar

towards blue adds blue by reducing yellow.

Figure 4-3. Image Quality Tools

• Trapping compensates for white gaps between colors and

regions of shifted hues caused by misregistration.

Color Manage me nt Gui de 4-3

Page 38

Using color tools

Figure 4-4. Trapping Setup dialog

Trapping should be done on the DocuSP controller but can

be done at the client application lev el as well, depending on

the application If tr app i ng i s applied at the application, do no t

trap at the controller.

• Black overprint

– DocuColor 2045/2060/6060 black overprint prevents the

background of a black object from being removed,

causing the black image to be printed on top of the

underneath color and eliminating bands of white around

the black object. To view the dialog in which to find and

set this feature, see Figure 4-3.

– DocuColor iGen3 lays the colors onto the image in a

unique manner with black being laid down first. Using

black overprint causes muddy looking blacks.

The default setting fo r Bl ack O v erpr i nt on the i Gen 3 i s off

and it is recommended that you only use this feature

when you must.

• Anti-aliasing reduces the jagged appearance of curves and

lines in text and line art. To view the dialog in which to find

and set this feature, see Figure 4-3.

User Tonal Reproduction Curves (TRCs)

User TRCs provide th e skilled user a tool for adjusting color

output on all or individual color separations of an image.

4-4 Color Management Guide

Page 39

Using color tools

Create User TRCs to make and save color adjustments that can

be applied to jobs. The creation of User TRCs should be

performed by users with a high level of color knowledge.

For example, create a TR C that compensate s for j obs submi tted

from a specific device that generates a consistent magenta tint.

A TRC adjusting for that tint could be created and applied to

every job submitted from that device. This saves job preparation

time and assures that the same adjustment is made to all jobs

submitted from that device.

Expert color tools

Skilled users employ expert color tools for high level color

adjustments. Users select source and destination color profiles

to be used in conversion to engine CMYK.

Usage of the expert color tools is dependent upon your color

requirements. You can use these tools to improve color quality.

• Source color allows you to sele ct RGB, CMYK and Gray

input color profile for the image, on an object-type basis.

Figure 4-5. User TRC setup window

Color Manage me nt Gui de 4-5

Page 40

Using color tools

Selecting a source color profile places the image on that

source profile’s color processing path when there is no

embedded profile for the image.

Figure 4-6. Expert Color: Source Color dialog

• Output color allows you to select profiles that maximize the

color potential of the output print engine.

– Halftones are created by breaking an image into a

pattern of color do ts. The larger the dots the darker the

color.

For iGen3, we suggest you use the default 175 dot for

most jobs and 200 for coated stock jobs.

For DC 20xx/60xx, we suggest you use the def ault profile .

– Image Resample: The DocuSP controller provides you

with the ability to select an interp olation, or image

resample, method to scale images for output in order to

achieve maximum Image Quality at the desired RIP

performance. Interpolation is defined as the process of

estimating a value of a function between two known

values. In the Image Interpolation context, the function of

known values is the input image, and the estimated

values are the values calculated for the output image.

Image interpolation attempts to produce a smooth

transition between adjacent samples rather than simply

replicating pixels (which would result in “blocky” images).

4-6 Color Management Guide

Page 41

Using color tools

Figure 4-7. Interpolation methods

The interpolation methods that may be selected include:

Nearest Neighbor Interpolation: A method used to

scale image data (pixels) from one resolution to

another. The output pixel value is simply the value of

the input pixel closest to the output location. Nearest

neighbor interpolation is the highest speed

interpolation on the DocuSP controller.

Bi-Linear Interpolation: A method used to scale

image data (pixels) from one resolution to another.

The replacement pixel in the scaled image is

calculated using a weighted sum of the four nearest

pixel values in the source image. This metho d offers

higher quality than Nearest Neighbor Interpolation.

Smart Interpolation: A method used to scale image

data (pixels) from one resolution to another. This

interpolation method automatically chooses between

bi-linear interpolation and filtered interpolation based

on the input ima ge charact eris tics. Sm art inte rp olat ion

is the highest quality interpolation available on

DocuSP.

Color Manage me nt Gui de 4-7

Page 42

Using color tools

Filtered Interpolation is a method used to scale image

data (pixels) from one resolution to another. The

output pixel is calculate d by passing the neighborho od

of the input pixel through the filter to determine the

output pixel. The DocuSP controller uses a filter

dynamically deter mined by the frequ ency of the output

halftone and the input image characteristics. Filtered

Interpolation is used as part of the Smart Interpolation

option in the DocuSP controller.

– Output allows you to select the output profiles.

Destination Profile provides a list of color profiles that

can be assigned to the job. An y profile can be selected

and will take precedence over the profile assigned by

the color group.

The listing includes profiles for assigning Gray

Component Remova l (GCR). GCR is a process for

replacing an equal percentage of gray with black

reducing the amount of dry ink u sed.

You can select a GCR profile for most stocks.

However, it is often best to use the System

Specified setting, which is optimized for your

system.

Use destination profiles to override the color profile

assigned by a stock’s color group.

Emulation

Use an emulation to render an RGB or native CMYK

image to simulate the look of a specific press. An

example would be selecting SW OP™ Co ate d to

simulate a SWOP™ press.

Rendering

Rendering can applied automatically to all of the data

objects in an image or individual ren dering can be

applied to a specific data image, text or graphic

objects in an image.

Image objects are defined as photographs and graphic

objects are defined as line art and business graphics.

For RGB images, using System Specified (default)

rendering is perfectly acceptable.

4-8 Color Management Guide

Page 43

For CMYK images, using System Specified (default)

rendering is perfectly acceptable. The Saturation

intent for CMYK 4x4 LUT is derived from the Relative

Colorimetric intent.

In general, use Rel ative Col orime tri c to mat ch a proo f.

Use the other rendering intents based upon

preference.

Table 4-1. System Specified Defaults

Object Type Rendering

Images Relative Colorimetric

Graphics Saturation

Text Pure

Use Saturation for rendering business graphics

such as Microsoft Power Point documents, charts,

graphs, etc.

Using color tools

Use Perceptual for rendering photographic

images to achieve a more press-like appearance.

Use Relative Colorimetric when attempting to

apply the closest color values in the print engine

color profile to the input profile, taking into

consideration the white point of the media. Used

for color matching such as matching a SWOP™

proof.

Use Absolute Colorimetric when attempting to

apply the closest color values in the print engine

color profile to the input profile using a standard

white point. Absolute Colorimetric is used for

comparing to an absolute value. Highlights tend to

be washed out and colors appear light using

Absolute Colorimetric rendering.

Use Pure for rendering text and line art, as it

subdues halftone textures to increase the visibility

of text on colored backgrounds. Pure works best

with RGB text.

Color Manage me nt Gui de 4-9

Page 44

Using color tools

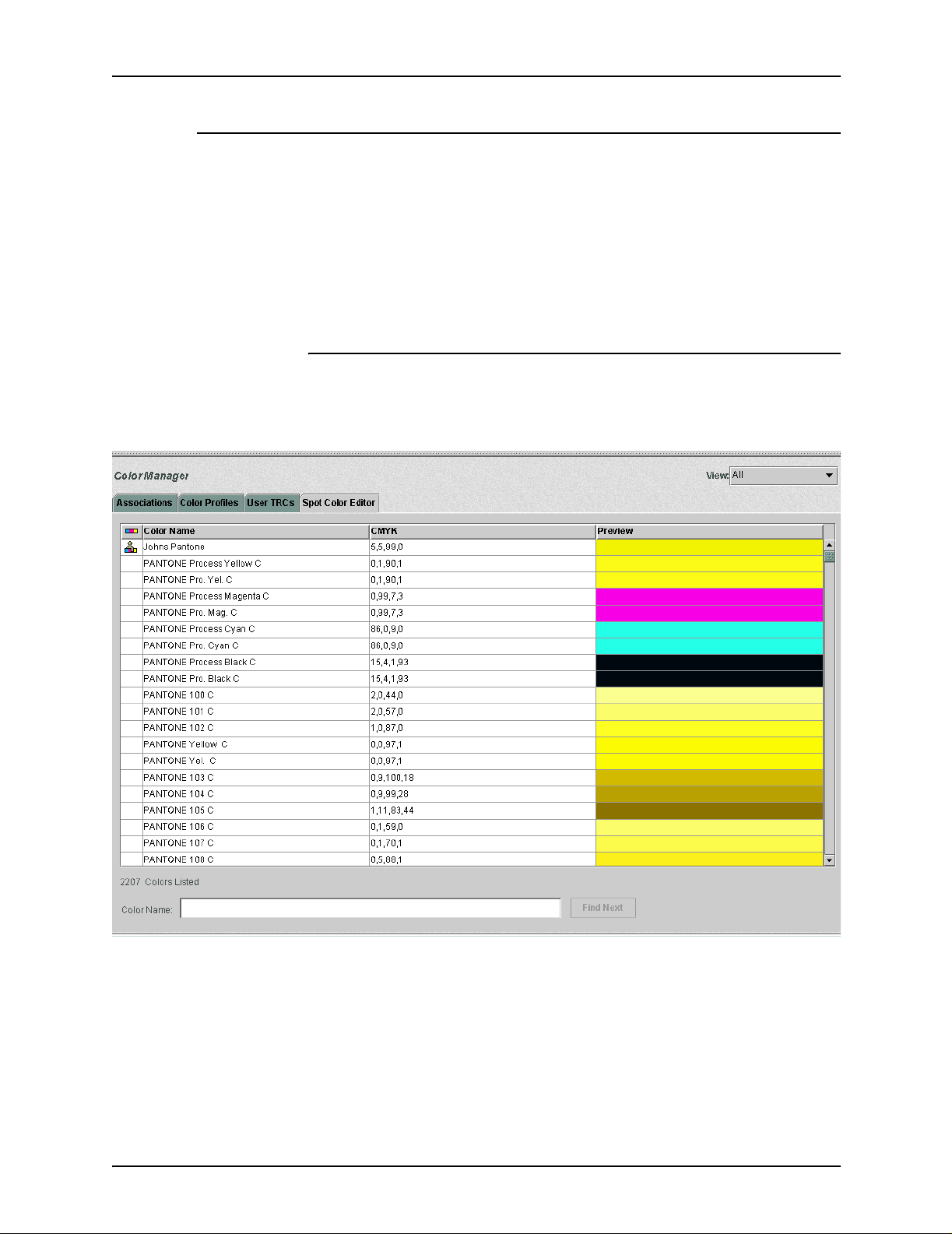

Spot Color Editor

The Spot Color Editor window displays a list of spot colors

recognized by the system. The list can display PANTONE®

Colors, Edited P ANTONE® Colors and Custom User Colors. The

operator can view the properties of all colors, edit all colors and

delete custom colors. You can print a swatch book of

PANTONE® Uncoated or PANTONE® Coated colors, or print a

proof of a color being edited.

Understanding the Spot Color Editor window

The Spot Color Editor contains several menus as well as lists

that enable you to view spo t color prop erties and ed it spot colors .

Figure 4-8. The Spot Color Editor tab

•The View menu: The View menu is a drop-box that enables

you to set the Table to show one of the following choices:

–All

– PANTONE® Coated

– PANTONE® Uncoated

4-10 Color Management Guide

Page 45

Using color tools

–Custom

• Color Type (icon): A column that displays a tool tip (if

present) when you pass the mouse pointer over the graphic

icon.

• CMYK: A column that co ntains numerical values

corresponding to the respective values of Cyan, Magenta,

Yellow, and Black that are present in each spot color.

• Preview: A column that contains representations of each

spot color in the Table.

NOTE: These representations are not necessarily coloraccurate and are intended for use only as a guide.

• Right-Click or Context menu: A menu that is available

when you right-click the mouse within a row in the Table.

The options available in the Right - Click menu are:

– Edit...: Opens the Edit dialog

– New...: Opens the New dialog

– Print Swatch Book...: Enables you to print out a full book

of PANTONE® color swatches.

– Revert: Available when an edited PANTONE® color is

selected, this control reverts an edited color back to its

original settings.

– Delete: Available when a custom color is selected, this

control displays the Delete Confirmation Alert box.

– Redisplay: refreshes the view in the Spot Color Ed itor.

• Color Name: A text field that can be used to find a specific

color name. When there is text present in the field, the [Find

Next] button becomes available. The [Find Next] button

locates the next instance of the text string in the list of color

names. If the end of the list is reached without finding a

match, an alert box will appear, stating “No Matching Name

Found.”

Open PrePress Interface (OPI)

The DocuSP controller enables you to employ Open PrePress

Interface (OPI). This feature allows for full-resolution image

substitution at RIP t ime, speeding up job subm ission time as well

as diminishing job creation/processing time.

Color Manage me nt Gui de 4-11

Page 46

Using color tools

Figure 4-9. OPI setup dialog

This process works as follows:

1. An image reposito r y is created on the DocuSP controller tha t

contains all of the full-resolution images that will be employed

by the document creators.

2. An OPI Search path is cre ated in the Setup menu so that the

DocuSP controller knows where to find a local copy of the

full-resolution tiff image.

3. A queue is set u p with OPI Sub stitu tion enable d. Th is fe ature

is found in the Queue Properties: PostScript/PDF tab.

4. A low-resolution im age is cre ated as an a nalogue to each ful lresolution image; these are distributed to the document

creators.

5. The document creators position the im ages in their

documents, and i nclude placem ent, sizing and cropping

information as well as OPI comments (these are generally

done by the application).

NOTE: Supported applications include (but are not limited

to) Pagemaker™, InDesign™, Quark™, and Freehand™)

6. The job is submitted to the DocuSP controller’s OPI-enabled

queue.

4-12 Color Management Guide

Page 47

7. At RIP time, the controller will substitute the full-resolution

images for the low-resolution images that were submitted

with the job.

Using Print Engine Specific mode

Use the Print Engine Specific mode if the job is to be printed on

multiple print e ngines of the sam e model, or if you use the TIFF

save option.

Using color tools

Figure 4-10. Example of Print Engine Specific Mode (iGen3

Print Engine Specific mode provides pre-defined settings that

optimize the performance of specific DocuSP based print

engines. This mode provides a consistent profile conversion path

for undefined profiles providing the best default color

interpretation and rendering values for the print engine. The print

engine default settings are ap plied if there is no c orresponding

property set within the job.

The Print Engine Specific mode is selected at the queue and

applied to all jobs submitted to that queue.

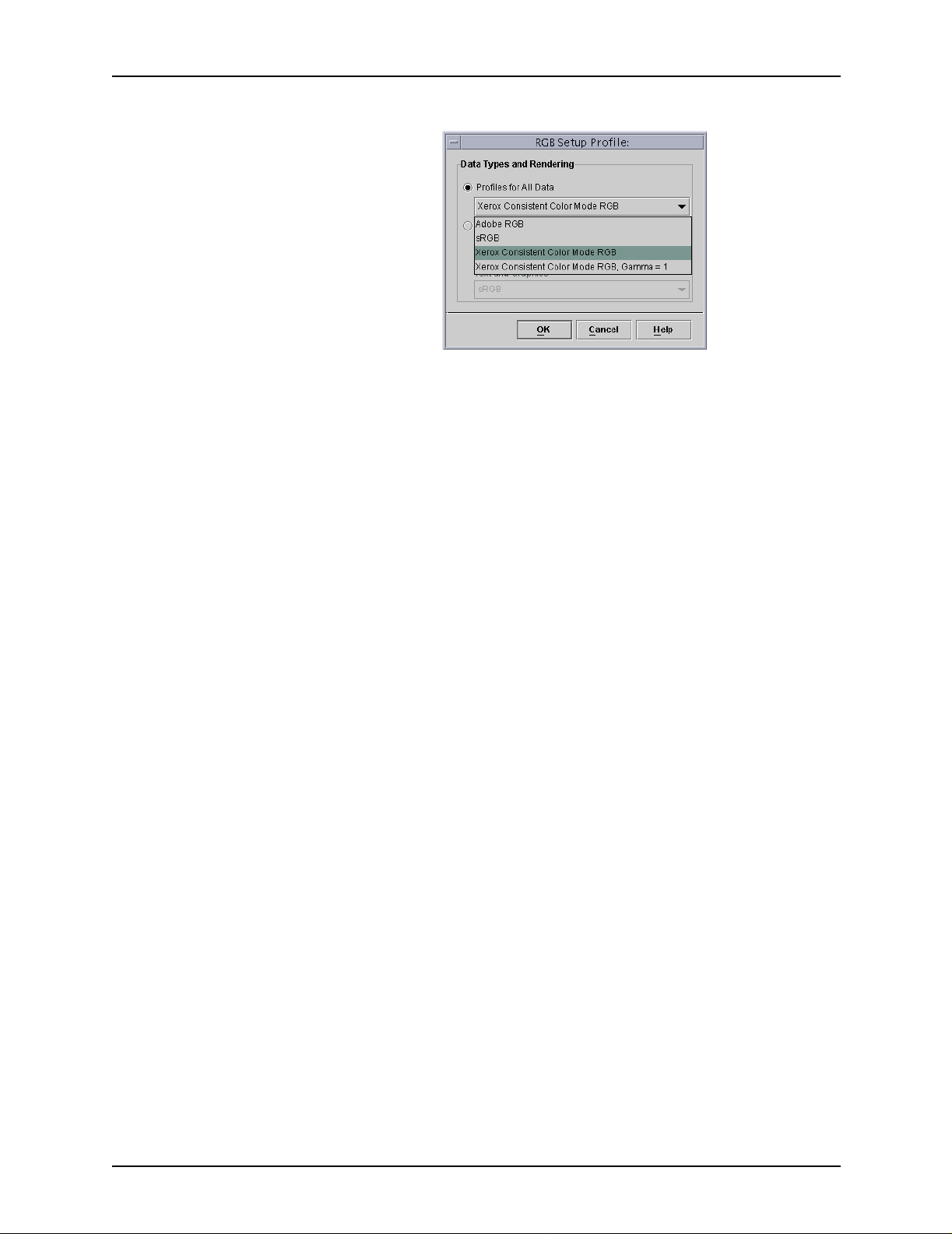

Using XCC (Xerox Consistent Color) mode

Use XCC mode for those jobs that have no unique color

requirements and may be printed on other Xerox print engines.

CMYK)

Color Manage me nt Gui de 4-13

Page 48

Using color tools

Figure 4-11. Se lecting XCC mode

XCC is selected at the queue an d applie d to all jo bs submi tted to

that queue.

Using XCC produces an image of the same document that is

similar when it is submitted to any Xerox color print engine

running in XCC mode. XCC standardizes the way the DocuSP

controller interprets unknown input color profiles and

standardizes the conversion through a Xerox standard output

profile.

When XCC is selected, you cannot make any other color

adjustments. The color properties are grayed out and not

selectable.

Many of the jobs that use XCC are saved in Fast Reprint format

for reprinting.

4-14 Color Management Guide

Page 49

5. Troubleshooting

What do you do if you experience color or image quality

problems with printed images? Determining where the problem

occurs is primary in the troubleshooting process.

Determining and defining exactly what the problem is helps

identify where the problem resi des.

Questions to ask at this stage are:

• Is the problem with the image itself?

• Is there an application setup problem?

• Are there inco rrect property settings at the DocuSP?

• Are there problems w ith the print engine?

• Can the problem be solved at the DocuSP or does it need to

escalated?

Image paths

This troubleshooting module assumes that actions can be taken

at the DocuSP to solve the problem.

A good place to st art trou bleshooting is to ident ify the image path

the job took through the system. Determine whethe r the job took

the Xerox Enhanced, Standard, Fast Reprint or Native path and

submit the job using another path. If the job successfully prints

with satisfactory color results, the problem is isolated to a

particular path.

If the imaging p ath is no t the caus e of the pr obl em, the next step

is to isolate the rendering intents used. It is possible that the

rendering intent chosen on the job is being overridden by the

rendering intent chosen for the queue.

Color Manage me nt Gui de 5-1

Page 50

Troubleshooting

A third possibility should be tested if the first two are not the

cause of the imaging problem: a source color mismatch may

exist between the queue and the job’s input color space. For

example, if the intent of the job is to render a CMYK document

which was originally designed for a SWOP™ press, you need to

select “SWOP™ Coated CMYK” as the source CMYK color

space. If FOGRA Gloss is selected in Job Properties and

SWOP™ CMYK is selected in Queue Properties a mismatch

exists.

Things to remember

In closing out this chap ter, we wanted to provide you w ith a short

list of things to remember:

• Color Adjustments ar e performed in PCS (XYZ), thus always

invoking the ICC path.

• Calibration an d Us e r TRC s ar e a pp li e d i n ha r dwar e. They do

not affect RIP performance or color pathway.

• The Xerox Enhanced Path always provides improved RIP

performance and better image quality.

• Using pre-installed profiles and Look Up Tables is sufficient

for most customer jobs and most stock.

• Building and utilizing profiles will always invoke the ICC path.

• When using untagged files, make sure the appropriate

source RGB or CMYK space is selected on the queue or job.

• If there is a mismatch between the Source CMYK and the

Destination Emulation, the resu lts will be unpredictable.

• Most PDF files have the Relative Colorimetric intent specified

in the file. If you want to change the renderi ng, a qu eue or job

override must be selected.

5-2 Color Management Guide

Page 51

A. System Specified defaults

This section details the various Color Management tools and

their system-specified, default states.

Table A-1.

Color

Management

tool DC 2045/2060/6 060 DC iGen3

Color Mode 0 +/- 100 0 +/- 100

Lightness 0 +/- 100 0 +/- 100

Contrast 0 +/- 100 0 +/- 100

Color Cast:

• Cyan vs.

Red

• Magenta

vs. Green

•Yellow vs.

Blue

• 0 +/- 100 (all Cyan

vs. all Red)

• 0 +/- 100 (all

Magenta vs. all

Green)

• 0 +/- 100 (all Yellow

vs. all Blue)

• 0 +/- 100 (all Cyan

vs. all Red)

• 0 +/- 100 (all

Magenta vs. all

Green)

• 0 +/- 100 (all Yellow

vs. all Blue)

Trapping Off

When enabled:

• height = 1

• width = 1

Image/Graphic

Trapping

Black Overprint Off Off

Anti-Aliasing Off Off

Source Color • RGB - sRGB

Output Colorhalftone

Off Off

•CMYK - SWOP

Coated CMYK

• GRAY - DC2000

GRAY

200 dot 175 dot

™

Off

When enabled:

•height = 1

• width = 1

• RGB - sRGB

• CMYK - SWOP

• GRAY - iGen3 GRAY

™

Coated CMYK

Color Manage me nt Gui de A-1

Page 52

System Specified defaults

Table A-1.

Color

Management

tool DC 2045/2060/6 060 DC iGen3

Output Color:

Image

Resample:

Destination

Profile

Emulation Off Off

Rendering

Intent:

• Saturation

• Perceptual

• Relative

Colorimetric

• Absolute

Colorimetric

•Pure

OPI Off Off

• Bi-linear

•Filtered

• Nearest Neighbor

•Smart

System Specified System Specified

• Images - Relative

Colorimetric

• Text - Pure

• Graphics - Saturation

• Bi-linear

•Filtered

• Nearest Neighbor

•Smart

• Images - Relative

•Text - Pure

• Graphics - Saturation

Colorimetric

A-2 Color Management Guide

Page 53

B. Glossary Of Color Management

Terms

Absolute

Colorimetric

Associations The DocuSP controller uses stock associations to create color

Calibration Calibration is a process that enables the user to measure the

CIELAB A standard color space model defined by the Committee

CMYK A color space model that defines the relative amounts of Cyan,

A rendering intent that maps colors to the nearest hue based

upon a perfect illuminant. When printing usin g this intent,

highlights tend to be washed out and colors ap pear lighter.

groups of similar stocks that can u se a single calibration. Once a

stock is associated with a color group, it ‘inherits’ attributes from

the group.

printer’s output against a known standard, by using a

Spectrophotometer to scan test patterns. The process enables

the user to adjust for “drift” in the color response of the printer

and achieve consistent results.

Internationale de l’Eclairage, an international standards

committee. L*A*B* is a color space that describes color in terms

of human eye response.

Magenta, Y ellow , and Black toner or ink that will be applied to the

print. CMYK can be found in both in put and output profiles.

Coated Coated refers to whether the stoc k in use has been coated or

was left uncoated. Generally, prints on coated stock will appear

glossier than do prints on uncoated or matte stocks. This visual

color difference may not be measurable, but it exists.

Color Cast The technical term for an overall color imbalance affecting an

entire image. The DocuSP contro ll e r enabl es you to adju st the

color cast in order to balance the image.

Colorimetric Refers to mapping an output color directly to the input color.

Contrast In display systems, the relation between the intensity of color,

brightness, or shading of an ar ea. High-contrast images have

darker shadows and brighter highlights, while low-contrast

images have light er shadows and dulle r highlights.

Color Manage me nt Gui de B-1

Page 54

Glossary Of Color Management Terms

Destination Profile The color profile that converts PC S to the output device’s color

space. In other w ords, a destination profile can be sent to the

printer.

Gamut The complete range of colors a device can produce. Most

printers have unique gamuts compared to other printers. Often,

however, the printer can emulate the output of a different printer

through use of a Color Space Transformation.

GCR Gray Component Replacement: the process of removing the

graying componen t, or dirtying co lor , from a colo r and replacing it

with black. For example, a red containing 100% magenta, 80%

yellow and 20% cyan withou t GCR mi g ht con tain 90% magenta,

70% yellow, 10% cyan, and 10% black after GCR has been

applied.

Halftone A pattern of dots of varying sizes applied to an image of varying

tones, or same-sized dots applied to a tint of color. Used to

reduce moire and other artifacts of the printing process.

ICC International Color Consortium

JPEG An image file format which is in RGB color space. The .jpg files

in a print job will need to be converted to CMYK prior to printing.

Lightness The perceived reflectance of a surface.

Matte Matte refers to an attribute of a stock which is a fla t color with no

glossiness. Matte stocks tend to appear halfway between

uncoated stock and coated stock.

OPI Open PrePress Interface: the process of substituting full-

resolution images residing in a reposi tory for low-resolution

images at RIP time.

PCS Profile Conn ection Space. DocuSP employs XYZ as its Profile

Connection Spa ce. XYZ i s a co lor sp ace model t hat m ap s color s

according to human eye response.

Perceptual A rendering intent that maps colors to the nearest hue relative to

the white point of the media and compresses the printer’s gamut.

The intent maps colors relative to each other, allowing more

distinction between colors and increased shadow detail.

Press Emulation The DocuSP controller can emulate outputs from other types of

printers. Examples include SWOP Fogra Matte, Fogra

Uncoated, Fogra Coated, Commercial Coated, as well as either

iGen3 CMYK or DC 2000/6000 CMYK (depending upon your

printer).

Pure A rendering intent that warps colors close to a pure colorant (C,

M, Y, K, R, G, and B) to the pure colorant.

B-2 Color Management Guide

Page 55

Glossary Of Color Management Terms

Relative

Colorimetric

Rendering Intent As part of the Profile Color Conversion in the Profile Connection

RGB A color space model that defines the relative amounts of Red,

Saturation A rendering intent that maps RGB CMYK to CMYK. The G is the

A rendering intent that maps colors to the nearest hue relative to

the white point of the media. The ga mut mapping strategy will

clip out-of-gamut colors to the gamut boundary.

Space, rendering intents can be applied to the job to achieve

specific results. The DocuSP controller provides 5 rendering

intents:

• Absolute Colorimetric

• Relative Colorimetric

• Perceptual

• Saturation

•Pure

Green, and Blue light in the image. The RGB color space is

generally seen as an input profile; the printer will need to convert

RGB to CMYK in order to print the job.

printer’s G, the B is the printer’s B, and the R is a saturated Red.

Source Profile The color profile with which the job was created at the client

workstation prior to submission. It is often embedded as part of

the PDL, but if not embedded, a source profile can be assigned

by the DocuSP controller at the job or queue level.

Spectro-

photometer

Spot Color Spot colors are selected from books or charts that contain

sRGB Standard (device-independent) RGB.