Page 1

Installation Preparation Document (for physical installation of the product only)

Xerox DocuTech 180 HighLight Color

The main DocuTech 180 HLC components are:

• Digital Front End Controller

• CD/DVD combo drive

• color flat panel monitor

• keyboard and mouse

• Ethernet interface (10/100/1000 BaseT)

• Two printer interface cards

• Controller Stand

• Options

• Solaris 10 and DocuSP print services software

• Printer

* Additional dry inks, not listed on this document, will be customer

options as they become available, and will be offered under standard

Xerox terms and conditions.

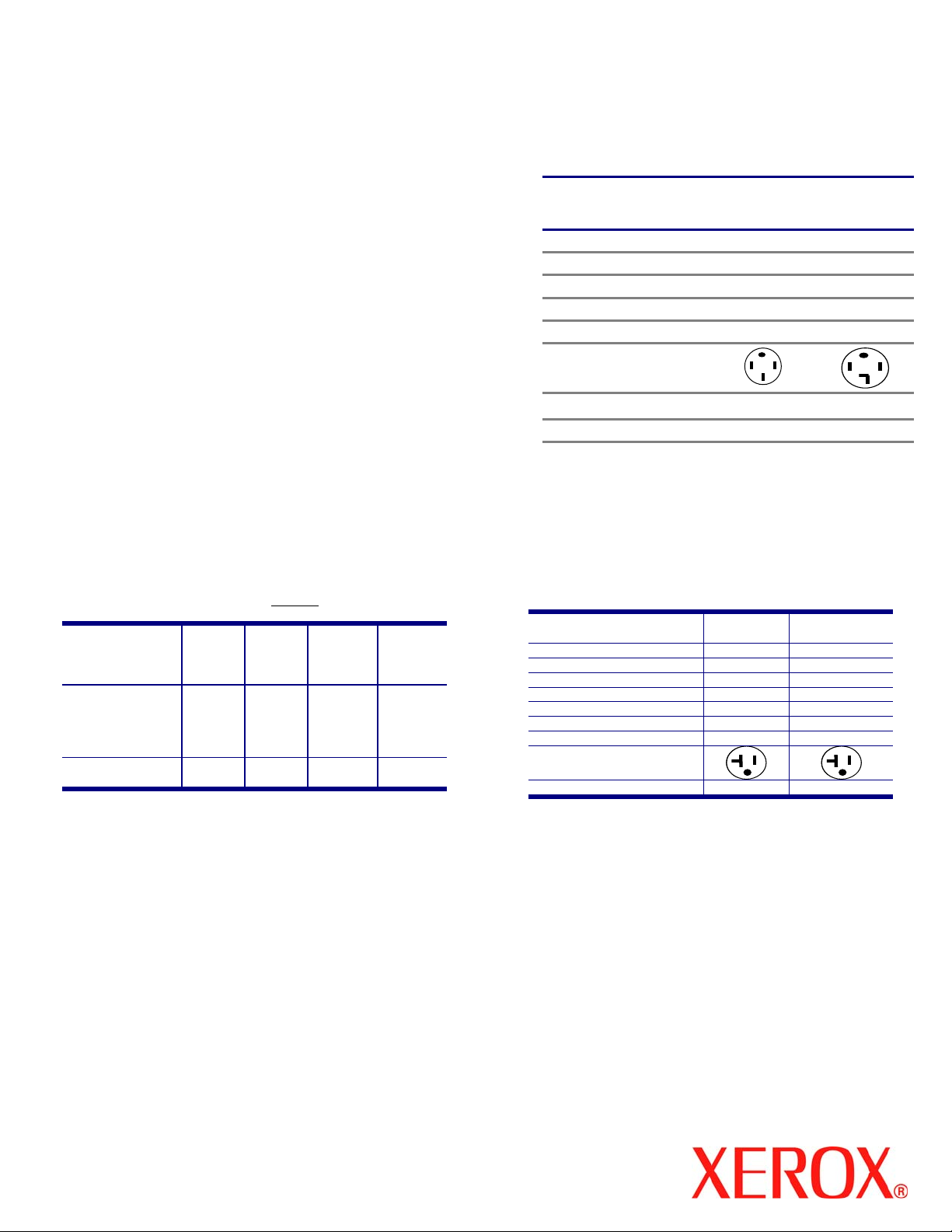

Space Requirements / Service Space Envelope

The dimensions shown below are absolute minimums.

Configuration Width Depth Min total

With two tray

Interposer and

Binder/Stitcher

Controller stand 36 (in)

• The minimum total space required includes the required space

• A minimum of 78 inches/198 cm clearance from the floor to the

• No obstructions, such as power poles, are allowed such that

• The printing system must be installed in a fixed location.

• Space requirements for the controller stand are 36 x 36

• For proper operation, the printer must be perfectly level. On

• For detailed space requirements and diagrams, refer to the

• USB floppy disk drive

• Black plus one highlight color*

• Xerographic engine with laser raster imaging system for

black and Light Emitting Diode for color

• Permanent housing for black dry ink; customer changeable

unit (CCU) for color dry ink

• Prints simplex or duplex

• Two-tray interposer

• In-line finishing module which includes a binder, stitcher,

and stacker

• Optional Bypass Transport to provide connection to

additional finishers

req’d

Width x

78 (in)

198

(cm)

91 (cm)

necessary for the Xerox service personnel to service the printer.

nearest overhead obstruction must be maintained.

they interfere with the Xerox Service Representative’s ability to

access the rear of the printer for service.

inches/91 x 91 cm.

floors less than two degrees out of level, a leveling kit must be

used to level the equipment. The printer will not function

properly on floors more than two degrees out of level.

DocuTech 128/155/180 HighLight Color Installation Planning

Guide.

42 (in)

106.6

(cm)

36 (in)

91 (cm)

depth

293.1 x

142.0 (in)

744.5 x

360.6

(cm)

Weight

3724

(lbs)

1689

(kgs)

Electrical Requirements (printer)

The printer requires for 60 HZ service (2 cords required):

Voltage 208/240(4 wire) 208/240 (4 wire)

Amperage (dedicated) 50 30

Cycles 60 Hz 60 Hz

Receptacle Xerox Part No.

Receptacle NEMA Part No. 14-50R 14-30R

Receptacle Diagram

Power Cord Kit Number

Power Cord Length 15 feet 15 feet

For 50 Hz service:

• 30 amp dedicated service (WYE): 220/380 VAC or 230/400

VAC or 240/415 VAC (3 phase)

Agency certifications: UL, cUL, CE Mark, FCC

MultiSource

2-phase, dual power cord

configuration

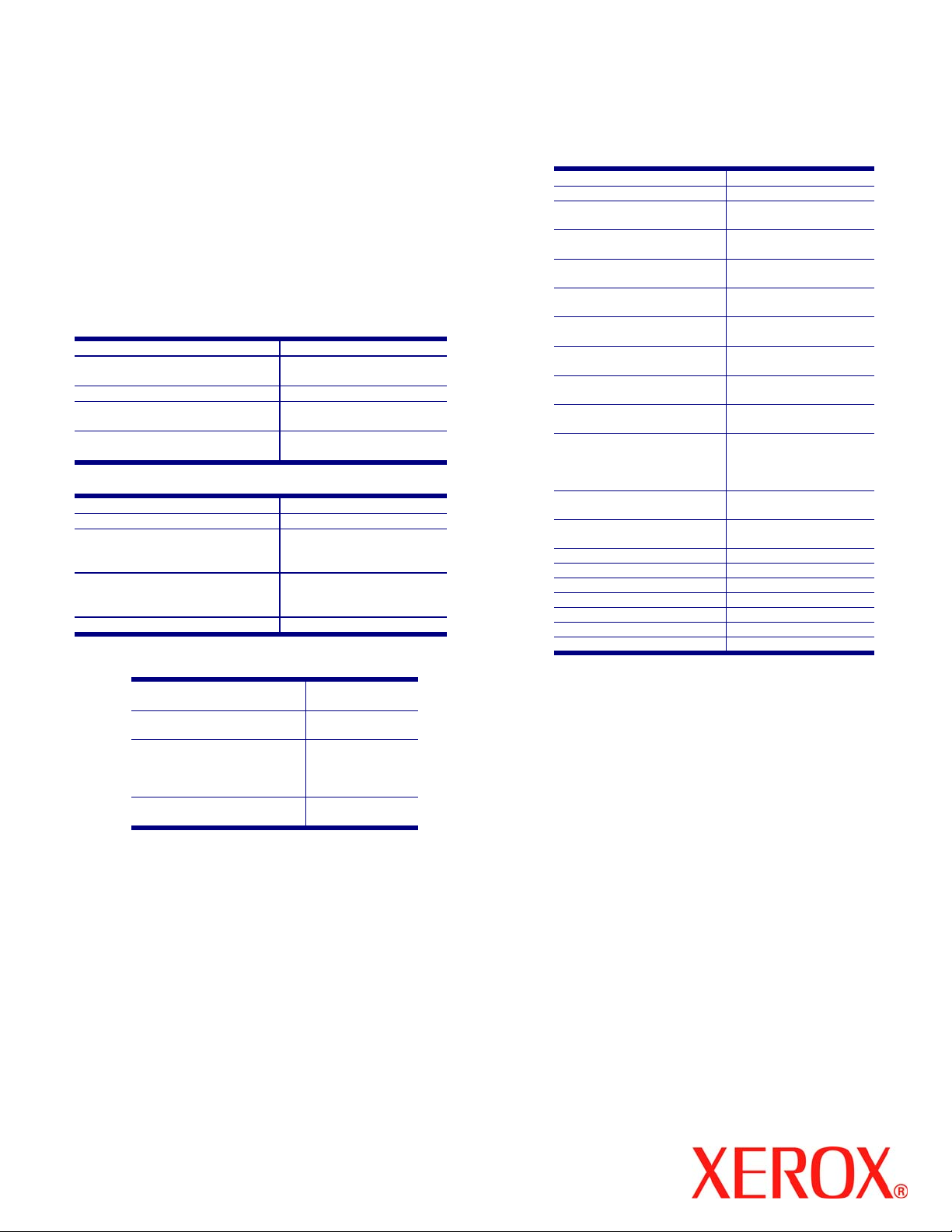

Electrical Requirements (Controller)

The Controller requires 20 AMP dedicated service. The information

for the 20 Amp electrical service is identified below.

Line Options Dedicated Dedicated

Voltage 115vac 115vac

Amperage 20 20

Cycles 60 Hz 60 Hz

Xerox Receptacle Part No. 600S3703 600S3703

Receptacle NEMA Part No. 5-20R 5-20R

Power Cord Xerox Part No. 98K19950 98K19950

Receptacle Diagram

97S02370 97S02370

Controller 36 Track Tape

(Optional)

Installation Considerations

1. Dedicated electrical service is required for each component.

2. The controller can be connected to a 15 amp or 20 amp outlet.

3. The length of the cable from the controller to the printer is 16

feet (4.8 metres).

4. Do not use an adapter to connect the controller to an electrical

outlet that lacks a ground connection terminal.

5. The customer is responsible for providing the network and the

client workstation(s). The Ethernet interface on the DocuSP

controller is a auto-sensing 10/100/1000 - MB/sec twisted pair

standard (BaseT).

6. The Ethernet connection to the DocuSP controller must be

compatible with the Institute of Electrical and Electronics

Engineers (IEEE) 802.3 standard.

701P46151

October 2006

Page 2

Installation Preparation Document (for physical installation of the product only)

Xerox DocuTech 180 HighLight Color

Paper Handling

• 16 to 110 lb. (60 to 200 gsm) cut sheet paper weights

8 by 10 in. to 14.33 x 17 in. (203 by 254 mm to 364 by 432 mm)

•

including A4, A3, and B4 paper sizes (destination dependent)

7 by 10 in. (178 by 254 mm) optional enablement kit

•

Transparencies, label stock, tab stock, carbonless paper, pre-

•

perforated stock

• Paper stock weights less than 16 lb. are not recommended.

• Textured stocks are not recommended.

• Some 65 lb. stocks may not fully fuse.

Input

Tray Capacity

Main tray (tray 1) 1,100 sheets 20 lb (75

Auxiliary tray (tray 2) 600 sheets 20 lb (75 gsm)

High capacity trays (trays 3 and

5)

Fuser bypass tray (tray 4) 550 sheets each 20 lb (75

Output

Tray Capacity

Stacker 3000 sheets 20 lb (75 gsm)

Stitcher 2 - 70 sheets 20 lb (75

Binder 15-125 sheets 20 lb (75

Top tray 500 sheets 20 lb (75 gsm)

Environmental Requirements

Temperature 50 to 85 o F

Humidity

Non-condensation

Heat Emission - printer 4454 BTU/Hr

Altitude (above sea level) Up to 6,000 ft

gsm)

2,600 sheets each 20 lb

(75 gsm)

gsm)

~35,000 stitches per spool

~425 11 in binds per spool

gsm)

gsm)

o

to 29 o C)

(10

30 to 65% RH

(Standby)

32,770 BTU/Hr

(Operating)

(1830 m)

Operating Supplies

Reorder No.

Dry Ink - Black 6R206 (US/CA)

Dry Ink – Blue 6R1191 (US/CA)

Dry Ink – Red 6R1192 (US/CA)

Dry Ink – Green 6R1193 (US/CA)

Dry Ink – Royal Blue

Dry Ink – Cardinal Red

Dry Ink – Cyan

Dry Ink – Magenta 6R1296 (US/CA)

Dry Ink – Yellow* 6R1299 (US/CA)

Developer (Black, Red,

Blue, Green, Royal Blue,

Cardinal Red, Cyan,

Magenta, Yellow)

Fuser Blend 8R12938 (1 bottle)

Fuser Shield 8R4077 (1 bottle)

Dry ink waste container NA

HLC developer waste bottle 604K24870 (4 bottles)

Binder tape – Black 8R7186

Binder tape – White 8R7187

Binder tape – Gray 8R7188

Binder tape – Blue 8R7189

Stitcher Wire 8R1174

* Will be available in the near future.

NOTE: The formula for the DocuTech HLC fuser lubricant was

changed in 2006 to provide better image quality and to prevent image

transfer. The new fuser formula is called Fuser Shield. The Fuser

Blend and the Fuser Shield CANNOT be intermixed in a DocuTech

HLC. To change from one fuser lubricant to another requires a

service call and cleaning or replacing components. The two fuser

formulas are identified with different color bottles and caps.

If a machine is running with in-line finishing equipment, the new Fuser

Shield may contribute to poor binding at the binder glue seam.

Customers experiencing this problem can have their equipment

returned to using Fuser Blend by placing a service call to clean

and/or replace components. Do NOT place Fuser Blend in a

machine that has been using Fuser Shield.

• Monthly duty cycle is up to 6 million (DT 180 HLC).

• The Xerox Supplies Marketing Center, 1-800-822-2200, is

available for ordering Xerox supplies, including paper and other

throughput material.

• The supply of developer for each of the color toners is ordered

and maintained at the customer site by the Xerox Service

Representative and is not orderable by the customer.

• The Dry ink waste container supply is maintained at the

customer site by the Xerox Service Representative and is not

orderable by the customer.

6R90343 (XE)

6R90344 (EU)

6R90345 (EU)

6R1255 (US/CA)

6R90356 (XE)

6R1277(US/CA)

6R90358(XE)

6R1284(US/CA)

6R90359(XE)

6R90360 (XE)

6R90361 (XE)

NA

8R12939 (6 bottles)

8R7618 (6 bottles)

701P46151

October 2006

Page 3

Installation Preparation Document (for physical installation of the product only)

Xerox DocuTech 180 HighLight Color

Network Connectivity

The DT 1xx HLC supports the following connectivity:

Network Operating

System

Novell 3.x / 4.x

(NDS or Bindery

mode)

Windows NT 4.0 /

Win2000 / WinXP

AppleTalk EtherTalk Ethernet

LPD Server

(Unix Systems)

Online Channel IBM

NOTE: Token Ring is not available for AppleTalk or Novell

environments.

The system supports Port Printing, and HTTP and IPP Printing

modes. Additionally, SNMP Services and DocuSP Remote Workflow

can be enabled on the customer’s network.

Print Drivers - Environments

The DT 1xx HLC supports the following print drivers:

• Windows 95/98/ME/2000/XP

• Windows NT 4.0

• MAC OS 8.6 & higher

• Solaris 2.8

PDL Compatibility

The system interprets the following data streams:

• PostScript Level 3

• HP PCL5c / HP PCL6

• ASCII

• PDF

• TIFF

• VIPP

• PPML

Additional data streams will be available post-launch.

Printing Considerations

Not all features and capabilities are available with every print driver

and OS/Protocol combination. Custom software applications may

produce unexpected results.

Other Considerations

• The Xerox Welcome Center at 1-800-821-2797 is available to

provide customer support.

Protocol Topology

IPX / SPX Ethernet

TCP / IP LPR Ethernet / Token Ring

TCP / IP Ethernet / Token Ring

3211/4245

Ethernet / Token Ring

Bus and Tag

701P46151

October 2006

Loading...

Loading...