Xerox DOCUPRINT 4850, DOCUPRINT 180, DOCUPRINT 4890, DOCUPRINT 96, DOCUPRINT 4635 User Manual

...Page 1

Xerox DocuPrint IPS

Messages Guide

Version 7.1

August 2000

721P88950

Page 2

Xerox Corporation

Printing Systems Documentation and Education

701 South Aviation Boulevard, ESM1-058

El Segundo, CA 90245

©1997, 1998, 1999, 2000 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of

copyrightable material and information now allowed by statutory or

judicial law or hereinafter granted, including without limitation,

material generated from the software programs which are displayed

on the screen, such as icons, screen displays, looks, etc.

Printed in the United States of America.

Publication number: 721P88950

Xerox® and all Xerox products mentioned in this publication are

trademarks of Xerox Corporation. Products and trademarks of other

companies are also acknowledged.

Changes are periodically made to this document. Changes, technical

inaccuracies, and typographic errors will be corrected in subsequent

editions.

Page 3

Laser safety

Warning: Adjustments, use of controls, or performance of

!

procedures other than those specified herein may result in

hazardous light exposure.

The Xerox DocuPrint printers are certified to comply with the

performance standards of the U.S. Department of Health, Education,

and Welfare for Class 1 laser products. Class 1 laser products do not

emit hazardous radiation. The DocuPrint printers do not emit

hazardous radiation because the laser beam is completely enclosed

during all modes of customer operation.

The laser danger labels on the system are for Xerox service

representatives and are on or near panels or shields that must be

removed with a tool. DO NOT REMOVE LABELED PANELS OR

PANELS NEAR LABELS. ONLY XEROX SERVICE

REPRESENTATIVES HAVE ACCESS TO THESE PANELS.

!

Ozone information

This product produces ozone during normal operation. The amount

of ozone produced depends on copy volume. Ozone is heavier than

air. The environmental parameters specified in the Xerox installation

instructions ensure that concentration levels are within safe limits. If

you need additional information concerning ozone, call 1-800-8286571 to request the Xerox publication 600P83222, OZONE.

XEROX DOCUPRINT IPS MESSAGES GUIDE iii

Page 4

Operation safety

Your Xerox equipment and supplies have been designed and tested

to meet strict safety requirements. They have been approved by

safety agencies, and they comply with environmental standards.

Please observe the following precautions to ensure your continued

safety.

• Always connect equipment to a properly grounded electrical

outlet. If in doubt, have the outlet checked by a qualified

electrician.

Warning: Improper connection of the equipment grounding

!

conductor may result in risk of electrical shock.

!

• Never use a ground adapter plug to connect equipment to an

electrical outlet that lacks a ground connection terminal.

• Always place equipment on a solid support surface with

adequate strength for its weight.

• Always use materials and supplies specifically designed for

your Xerox equipment. Use of unsuitable materials may result in

poor performance and may create a hazardous situation.

• Never move either the printer or the Printer Controller without

first contacting Xerox for approval.

• Never attempt any maintenance that is not specifically

described in this documentation.

• Never remove any covers or guards that are fastened with

screws. There are no operator-serviceable areas within these

covers.

• Never override electrical or mechanical interlocks.

• Never use supplies or cleaning materials for other than their

intended purposes. Keep all materials out of the reach of

children.

• Never operate the equipment if you notice unusual noises or

odors. Disconnect the power cord from the electrical outlet and

call service to correct the problem.

If you need any additional safety information concerning the

equipment or materials Xerox supplies, call Xerox Product Safety at

the following toll-free number in the United States:

1-800-828-6571

For customers outside the United States, contact your local Xerox

representative or operating company.

iv XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 5

Table of Contents

Laser safety iii

Ozone information iii

Operation safety iv

Introduction vii

About this guide vii

Contents vii

Conventions viii

Related publications ix

1. HCU messages 1-1

2. DocuPrint 96/4635/180 IPS messages 2-1

Printer control console messages 2-1

Message list 2-4

3. DocuPrint 4050, 4090, 4850, 4890, and 92C IPS messages 3-1

XEROX DOCUPRINT IPS MESSAGES GUIDE v

Page 6

TABLE OF CONTENTS

vi XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 7

About this guide

Introduction

The Xerox DocuPrint IPS Messages Guide contains the messages

you may encounter while using your Xerox DocuPrint IPS.

This guide is intended to assist you in dealing with the software,

hardware and system errors that may occur while using your Xerox

DocuPrint IPS. This guide assumes that you already have a general

understanding of the Xerox laser print engine and how it operates in

your PSF environment. You should also be familiar with general

printing operations using a system controller that is separate from the

print engine assembly.

Contents

This guide contains the following chapters:

• An “Introduction” provides information on how to use this guide.

• Chapter 1, “HCU messages,” contains a listing of the parser

and the channel codes that may display on the front of the host

channel unit, and what each of the codes mean.

• Chapter 2, “DocuPrint 96/4635/180 IPS messages,” contains a

description of the printer control console screen where various

kinds of messages are displayed, a listing (in numerical order

by code) of the messages that may display on a 96, 4635, or

180 IPS screen, an indication of what may have occurred to

cause the error, and the action you can take to eliminate the

problem.

• Chapter 3, “DocuPrint 4050, 4090, 4850, 4890, and 92C IPS

messages,” contains a listing (in alphabetical order by code) of

the messages that may display on these four models, an

indication of what may have occurred to cause the error, and

the action you can take to eliminate the problem.

XEROX DOCUPRINT IPS MESSAGES GUIDE vii

Page 8

INTRODUCTION

Conventions

The following conventions are used in this guide:

“Overview” References to chapters, sections, and appendices appear in

quotations marks.

Messages Guide Names of documents and documentation libraries appear in italics.

“setup” Information you enter using the keyboard appears in lowercase bold

type.

[Clear] Names of touchbuttons on the 96/4635/180 IPS printer control

console screen appear in square brackets.

<Enter> Key names appear in bold and in angle brackets.

Note: Notes are hints that help you perform a task or understand

the text.

Caution: Cautions alert you to an action that could damage

hardware or software.

Warning: Warnings alert you to conditions that could affect the

!

safety of people.

!

viii XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 9

Related publications

Xerox documents Following is a list of all Xerox DocuPrint IPS documents. For a

INTRODUCTION

This document is part of the Xerox DocuPrint IPS publication set.

complete list and description of available Xerox documentation, refer

to the Xerox Customer Documentation Catalog (publication number

610P17517), or call your service representative.

Application Programmer/System Administrator Quick Reference

Card

Customer Information Quick Reference Card

Generic MICR Fundamentals Guide

Glossary

Guide to Configuring and Managing the System

Guide to Performing Routine Maintenance

Helpful Facts About Paper

Installation Planning Guide

Master Index

Messages Guide

Solutions Guide

System Overview Guide

Troubleshooting Guide

Xerox Standard Font Library Font User Guide

The documentation set also includes an electronic version, the

DocuPrint IPS Interactive Customer Documentation CD.

IBM documents Following are related IBM documents. Contact your local IBM

representative for ordering instructions for IBM AFP/PSF manuals

that might be useful for your specific installation.

IBM 3825 Page Printer Product Description

IBM Intelligent Printer Data Stream Reference

IBM Advanced Function Presentation Printer Summary

IBM ITSC Distributing AFP Printing from a Host System

IBM Advanced Function Printing Data Stream Reference

IBM Data Stream and Object Architectures: Mixed Object Document

Content Architecture Reference

Guide to Advanced Function Presentation

XEROX DOCUPRINT IPS MESSAGES GUIDE ix

Page 10

INTRODUCTION

x XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 11

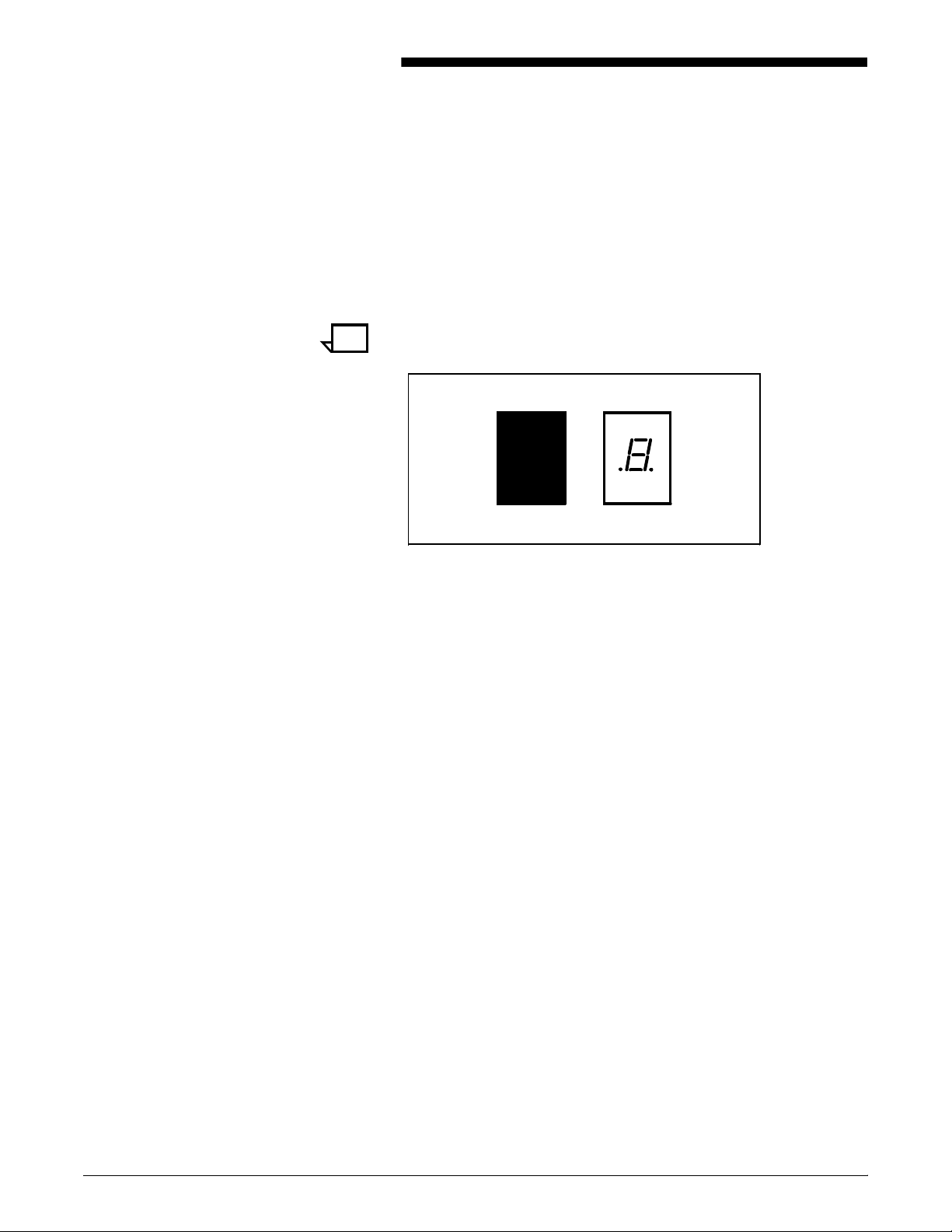

1. 1HCU messages

The messages discussed in this chapter are represented by code

numbers displayed in the LED panel on the front of the host channel

unit (HCU).

Note: The information in this chapter applies only to IPS with a

channel attachment, which requires the Host Channel Unit.

LED code number The LED code number on the HCU indicate various software states,

system faults, and microcode faults, depending on whether:

• The number is illuminated.

• The decimal point is on.

• The decimal point is on with the LED flashing.

Boot codes When the Sun workstation is first booted, the number 2 appears on

the HCU display, meaning the IPS is offline. After a few seconds, this

number changes to a 0, meaning the system is online and ready to

print.

If the code 2, 6, or another number listed on the following table

appears and remains on the HCU; if the decimal point is displayed;

and/or if the display is blinking, notify your service representative. Be

sure to provide the following information:

• Digit displayed

• Position of decimal point

• Whether the display is flashing.

XEROX DOCUPRINT IPS MESSAGES GUIDE 1-1

Page 12

HCU MESSAGES

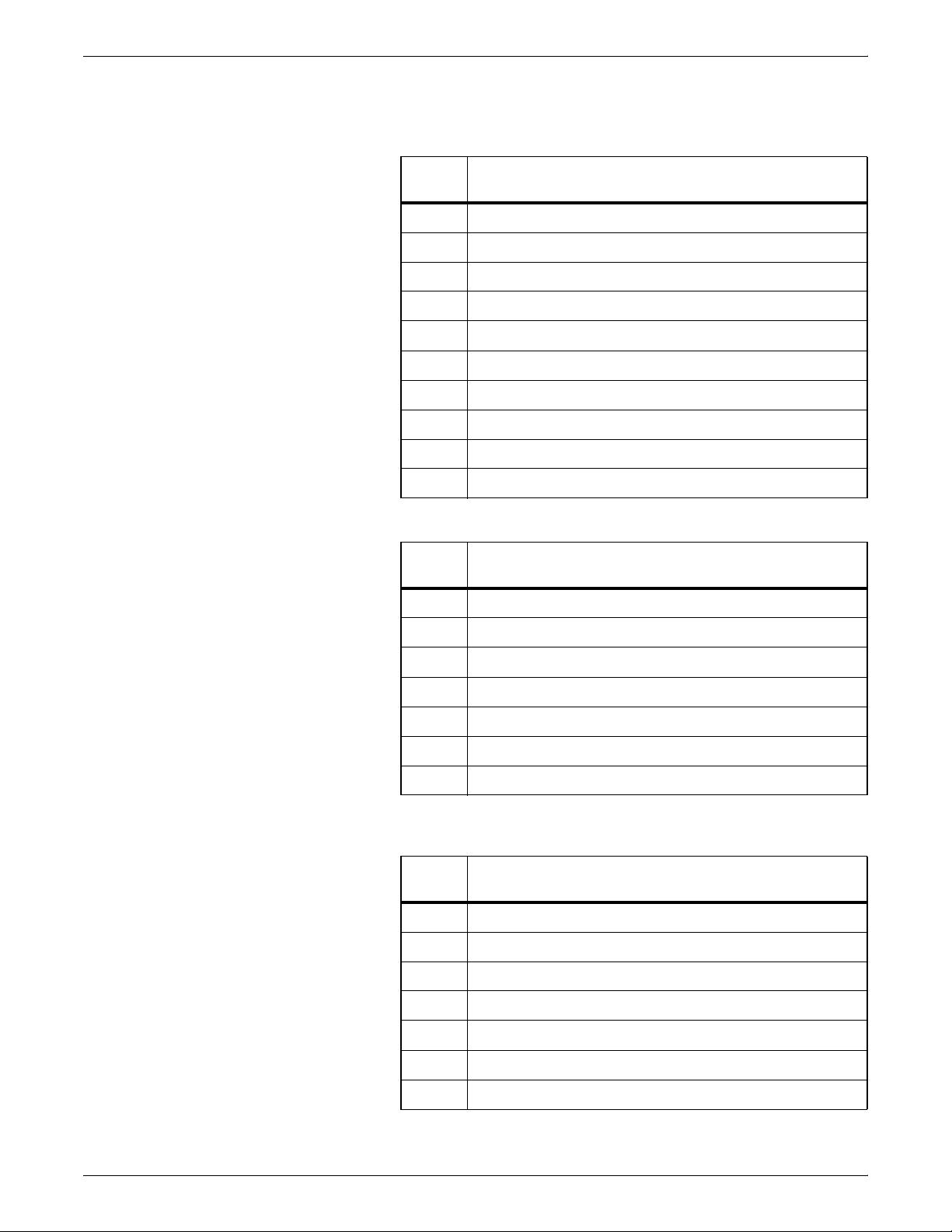

Code definitions The following tables give the meaning of the LED codes that may

appear on the HCU.

Table 1-1. Software states (no decimal point)

Code Meaning

9 Checking SRAM

8 Loading microcode and startup

7 Checking Channel interface

6 Waiting for SCSI connection/parser

5 Waiting for tailgate board

4 Waiting for end of reset from Parser

3 Block-up on OFFLINE

2 OFFLINE (parser has started)

1 Waiting for End of Process from Parser (Device End)

0 ONLINE (ready to print)

Table 1-2. System faults (decimal point on)

Code Meaning

1 SCSI initialization error

2 Not-enough-memory error

3 No communication with parser

6 Fault in SRAM

7 Fault in data streaming memory

8 Fault on channel BUS lines

9 Fault on channel TAG lines

Table 1-3. Microcode faults (decimal point on with LED

flashing)

Code Meaning

1 Parallel faults

2 Trace mode detected (CPU trace bit)

3 Invalid opcode

4 Arithmetic fault

5 Range fault/Privilege fault

6 Protection fault

7 Type mismatch

1-2 XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 13

2. 2DocuPrint 96/4635/180 IPS

This chapter contains a list, in numerical order by code, of the

messages that you may encounter while using your Xerox DocuPrint

96, 4635, or 180 IPS. It also discusses the different kinds of

messages and other information provided by the printer control

console.

Printer control console messages

The 96/4635/180 printer control console gives you status and error

information regarding the printer, in the form of messages and icons

you can open. The kinds of information the control console provides

include:

• Local controls and displays for jam clearance, paper loading/

messages

unloading, and diagnostics/service (used by the service

representative). Two types of messages are displayed on the

printer control console: fault messages, which relate to printer

malfunctions, and information messages, which relate to printer

conditions such as low dry ink.

• Touch-sensitive areas that allow you to select options by

touching the printer control console screen. A tone sounds

when you touch one of these areas.

• Printer alarm consisting of three beeps, repeated for ten

seconds. The alarm is generated by any event that stops the

printer.

The alarm stops after three cycles or as soon as you start to

clear the fault condition (for example, when you open doors or

covers specified in the clearance instructions). You can stop the

alarm by pressing one of the printer control console buttons or

by selecting a function through the touch screen.

XEROX DOCUPRINT IPS MESSAGES GUIDE 2-1

Page 14

DOCUPRINT 96/4635/180 IPS MESSAGES

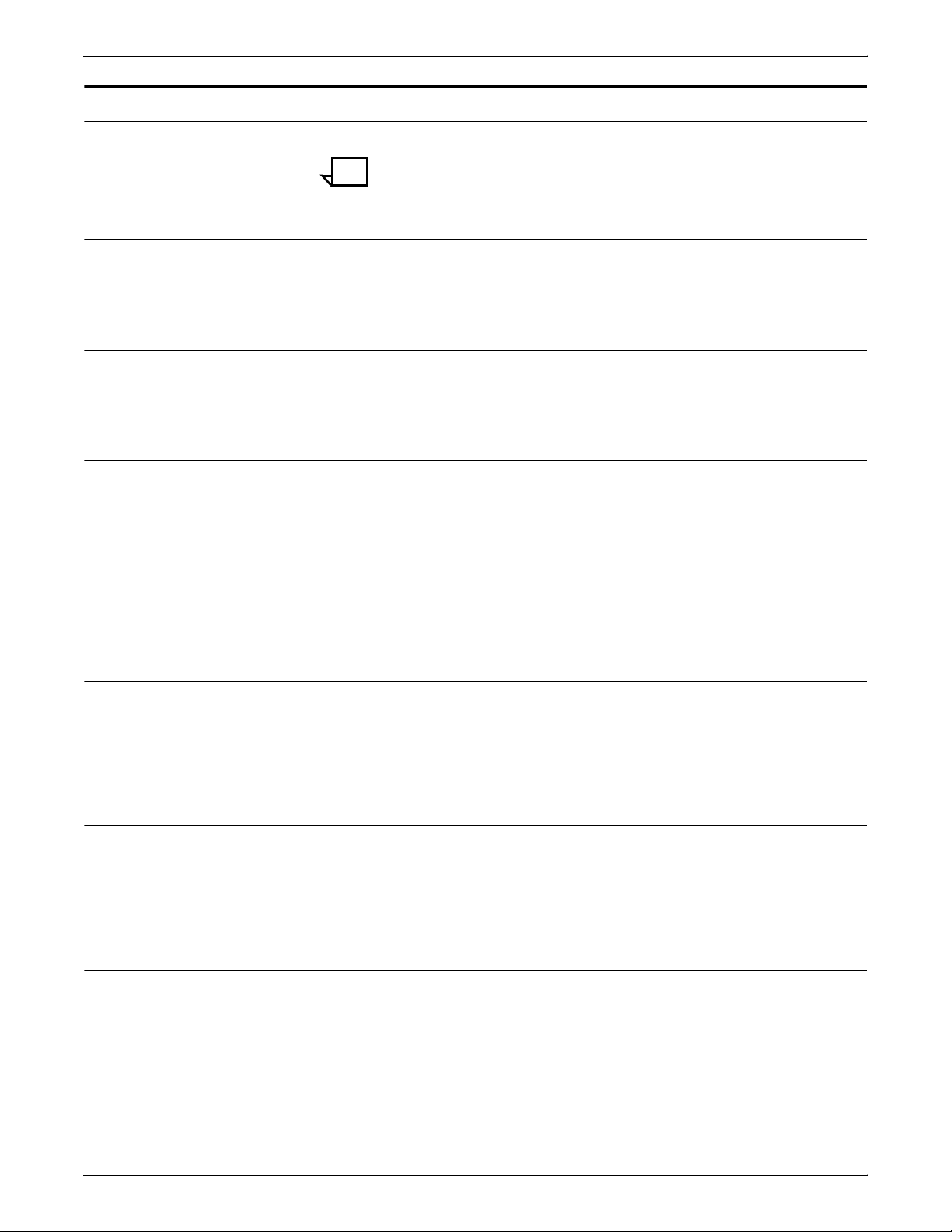

Figure 2-1. Printer control console

1

2345

12

11

Ready

Printer Options

10

1 Language icon

2 Printer icon

3 Fault List icon

4 Tools icon

5 Guarded Tools icon

6 Clear button

7 Continue button

8 Stop button

9 Sample button

10 Brightness control thumbwheel

11 Icon area

12 Message area

Clear

6

7

8

9

1. Language icon

If two languages are available for your printer control console,

select this icon to choose the language for the printer control

console messages.

2. Printer icon

Select this icon to display the printer mimic. This is the default

display on the printer control console.

3. Fault List icon

Select this icon to display the Fault List screen.

2-2 XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 15

DOCUPRINT 96/4635/180 IPS MESSAGES

4. Tools icon

Select this icon to display call for service information and to

adjust display features of the printer control console (for

example, alarm volume).

5. Guarded Tools icon

This icon is reserved for the service representative and for

operators who have completed Advanced Customer Training

(ACT).

6. Clear button

Select this button to clear fault messages.

7. Continue button

Press this button to resume printing.

8. Stop button

Press this button to stop printing.

9. Sample button

Press this button to print a sample to the sample tray.

Note: The sample button is disabled during MICR print jobs.

10. Brightness control thumbwheel

Use this thumbwheel to adjust the brightness of the printer

control console display.

11. Icons

Area where the following icons appear:

Fault icon — Appears when a fault exists in the system that

stops the printer or prevents it from printing. If you click this

button, the Clear button is displayed on the screen.

Hint icon — Appears when a masked fault or condition exists

in the printer. See the chapter “Fault masking” in the Xerox

DocuPrint 96/4635/180 IPS Troubleshooting Guide.

ACT icon — Appears when a maintenance task requiring an

ACT trained operator must be done. If you have successfully

completed ACT, either check the Printer Controller for

messages concerning the maintenance task or touch the

Guarded Tools icon to display the Guarded Tools screen. If you

are not an ACT trained operator, notify your lead operator or an

ACT trained operator at your site.

12. Message area

The message area is used as follows:

• Lines 1 and 2: Display the current status of the printer; for

example, READY.

• Line 3: Displays messages concerning masked conditions,

such as low dry ink. These messages are preceded by an

asterisk.

• Line 4: Displays messages that originate at the System

Controller.

XEROX DOCUPRINT IPS MESSAGES GUIDE 2-3

Page 16

DOCUPRINT 96/4635/180 IPS MESSAGES

Message list

Note: Throughout the messages in this section, ‘%s’ denotes a file

name that is supplied by the system when the message is

displayed.

01-210 Printer left door open in print.

The left printer door is open while the printer is attempting to print.

Action Close the left printer door and press the [Continue] button.

01-211 Printer right door open in print.

The right printer door is open while the system is attempting to print.

Action Close the right printer door and press the [Continue] button.

01-212 Printer top transport cover open.

The top transport cover is open.

Action Close the top transport cover and press the [Continue] button.

01-214 Fuser interlock open in print.

The fuser drawer is open while the printer is attempting to print.

Action Pull out the fuser drawer, then push it in firmly. Press Continue.

01-220 PHN interlocked 24V missing.

A failure occurred in the printer interlocking system.

Action Clear any jams in areas 4, 5, 6, and 7 and press the [Continue]

button. (Refer to the Xerox DocuPrint 96/4635/180 IPS

Troubleshooting Guide for the procedure.)

01-221 PHN interlock open 24V present.

A failure occurred in the printer interlocking system.

Action Clear any jams in areas 4, 5, 6, and 7 and press the [Continue]

button. (Refer to the Xerox DocuPrint 96/4635/180 IPS

Troubleshooting Guide for the procedure.)

03-201 EDN system bus comm failure.

The bus communication to the EDN system is not responding. This

error is logged by the system.

Action No action required.

2-4 XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 17

DOCUPRINT 96/4635/180 IPS MESSAGES

03-202 EDN comm problem with the UIM

The EDN cannot communicate with the UIM.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

check the shared lines. If the error still persists, contact your service

representative.

03-203 System comm problem with MIN.

The system is unable to communicate with the MIN.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

check the shared lines. If the error still persists, contact your service

representative.

03-204 System comm problem with PHN.

The system is unable to communicate with the PHN.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

check the shared lines. If the error still persists, contact your service

representative.

03-205 System comm problem with FSN1.

The system is unable to communicate with the FSN1.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

check the shared lines. If the error still persists, contact your service

representative.

03-208 System comm problem with ESS.

One of two communication errors occurred. The System Controller

did not acknowledge receipt of either a data layer or client layer

operation message from the EDN core board. The system failed to

establish data or client layer communications within four minutes of

system startup or within one second after receiving the printer

request for client layer initialization.

Action Contact your service representative.

03-221 UIM comm problem with CP-IOP.

The UIM cannot communicate with the CP-IOP board.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

XEROX DOCUPRINT IPS MESSAGES GUIDE 2-5

Page 18

DOCUPRINT 96/4635/180 IPS MESSAGES

03-223 CP-IOP unable to com with touch screen.

The CP-IOP PSB cannot communicate with the Touch Screen board.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-224 Video engine comm problem with UIM.

The video engine cannot communicate with the UIM Core board.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-225 UIM comm problem with video engine.

The UIM Core cannot communicate with the video engine board.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-232 MIN ADA 1 is offline.

The MIN Core cannot communicate with the MIN ADA board 1.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-234 MIN SLB/RDA is offline.

The Min Core cannot communicate with the MIN SLB/RDA board.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-241 PHN DIO 1 is offline.

The PHN Core cannot communicate with the PHN DIO board 1.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-242 PHN DIO 2 is offline.

The PHN Core cannot communicate with PHN DIO board 2.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

2-6 XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 19

DOCUPRINT 96/4635/180 IPS MESSAGES

03-245 PHN DIO 5 is offline.

The PHN Core cannot communicate with PHN DIO board 5.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-246 PHN DIO 6 is offline.

The PHN Core cannot communicate with PHN DIO board 6.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-247 OHN registration servo is offline.

The PHN Core cannot communicate with PHN Registration Servo

board.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-251 FSN1 DIO 1A is offline.

The FSN Core cannot communicate with FSN DIO board 1A.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-252 FSN1 DIO 2A is offline.

The FSN Core cannot communicate with FSN DIO board 2A.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-253 FSN1 DIO 3A is offline.

The FSN Core cannot communicate with FSN DIO board 3A.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-254 FSN1 stepper A is offline.

The FSN Core cannot communicate with FSN Stepper board A.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

XEROX DOCUPRINT IPS MESSAGES GUIDE 2-7

Page 20

DOCUPRINT 96/4635/180 IPS MESSAGES

03-255 FSN1 DIO 1B is offline.

The FSN Core cannot communicate with FSN DIO DIO board 1B.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-256 FSN1 DIO 2B is offline.

The FSN Core cannot communicate with FSN DIO board 2B.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-257 FSN1 DIO 3B is offline.

The FSN Core cannot communicate with FSN DIO board 3B.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-258 FSN1 stepper B is offline.

The FSN Core cannot communicate with FSN Stepper board B.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-272 TMN DIO 1 is offline.

The FSN Core cannot communicate with TMN DIO board 1.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-340 MIN ADA 1 turnaround failure.

The MIN ADA board 1 turnaround test failed. This error is logged by

the system.

Action No action is required.

03-342 SLB/RDA pixel PW8 turnaround failure.

The MIN SLB/RDA board to Pixel board turnaround test failed.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

check the shared lines. If the error still persists, contact your service

representative.

2-8 XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 21

DOCUPRINT 96/4635/180 IPS MESSAGES

03-343 ROS EXPOS$REF turnaround failure.

The MIN SLB/RDR board to raster output scanner (ROS) turnaround

test failed.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-344 SLBRDA-EPMD turnaround failure.

The MIN SLBRDA board to EPMD board turnaround test failed.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-345 FSN1 stepper A turnaround failure.

The FSN Stepper board A turnaround test failed. This error is logged

by the system.

Action No action required.

03-346 FSN1 stepper B turnaround failure.

The FSN Stepper board B turnaround test failed. This error is logged

by the system.

Action No action required.

03-361 EDN NVM battery failed.

The EDN Core board battery failed.

Action No action required.

03-362 EDN NVM not initialized.

The NVM values on the EDN Core board are not valid.

Action Contact your service representative.

03-370 SLB/RDR requiring software reset.

An internal failure occurred in SLB/RDR board.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-371 EDN needs softwreset hardwcaused.

EDN Core board detected a potential hardware problem that required

a software reset.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

XEROX DOCUPRINT IPS MESSAGES GUIDE 2-9

Page 22

DOCUPRINT 96/4635/180 IPS MESSAGES

03-372 UIM needs softwreset hardwcaused.

UIM Core board detected a potential hardware problem that required

a software reset.

Action Press the [Clear] or [Reset] button located behind the printer control

console front pull-down cover.

03-373 MIN needs softwreset hardwcaused.

MIN Core board detected a potential hardware problem that required

a software reset.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-374 PHN needs softwreset hardwcaused.

PHN Core board detected a potential hardware problem that required

a software reset.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-375 FSN1 needs softwreset hardwcaused.

FSN Core board 1 detected a potential hardware problem that

required a software reset.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-377 Video engine prob requires softwreset.

A failure occurred in the internal video engine board that required a

software reset.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-378 ESS problem requiring software reset.

The System Controller detected a problem that required a software

reset. The System Controller transmitted a meta Reset signal to the

printer.

Action Wait until the system restarts and the Main window appears, then

retry the operation or restart the job.

03-379 TMN needs softwreset hardwcaused.

TMN Core board detected a potential hardware problem that

required a software reset.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

2-10 XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 23

DOCUPRINT 96/4635/180 IPS MESSAGES

03-380 UIM boot ROM download failure.

The UIM Core Boot ROM download failed.

Action No action required.

03-381 EDN download failure.

The EDN Core board download failed.

Action No action required.

03-382 UIM download failure.

The UIM Core board download failed.

Action No action required.

03-383 MIN download failure.

The MIN Core board download failed.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-384 PHN download failure.

The PHN Core board download failed.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-385 FSN1 download failure.

The FSN Core board 1 download failed.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

03-387 Video engine download failure.

The video engine download failed.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-389 TMN download failure.

The TMN Core board download failed.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

contact your service representative.

XEROX DOCUPRINT IPS MESSAGES GUIDE 2-11

Page 24

DOCUPRINT 96/4635/180 IPS MESSAGES

03-390 UIM rigid disk fault.

A rigid disk failure was detected by the UIM Core board.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-391 UIM rigid disk access fault.

A rigid disk access failure was detected by the UIM Core board.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-392 Video engine rigid disk fault.

A rigid disk access failure was detected by the video engine board.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-393 Video engine rigid access fault.

A rigid disk access failure was detected by the video engine board.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-401 EDN system bus comm failure.

The bus communication to the EDN system is not responding. This

error is logged by the system.

Action No action required.

03-402 EDM comm problem with the UIM.

The EDM cannot communicate with the UIM.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

check the shared lines. If the error still persists, contact your service

representative.

03-403 System comm problem with the MIN.

The system is temporarily unable to communicate with the MIN. This

error is logged by the system.

Action No action is required.

2-12 XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 25

DOCUPRINT 96/4635/180 IPS MESSAGES

03-404 System comm problem with PHN.

The system is unable to communicate with the PHN.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes. If the error persists,

check the shared lines. If the error still persists, contact your service

representative.

03-405 System comm problem with FSN1.

The system is unable to communicate with the FSN1.

Action Press the [Clear] or [Reset] button located behind the printer control

console front pull-down cover. If the error persists, check the shared

lines. If the error still persists, contact your service representative.

03-407 System comm problem with TMN.

The system is temporarily unable to communicate with the TMN. This

error is logged by the system.

Action No action is required.

03-408 Transient EDN HDLC comm failure.

The System Controller did not acknowledge receipt of the data layer

or client layer operational message from the EDN Core board.

Action Contact your service representative.

03-412 UIM can’t talk to any node on bus.

The UIM Core board cannot communicate with any board on the

local bus.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-413 MIN can’t talk to any node on bus.

The MIN Core board cannot communicate with any board on the

local bus.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-414 PHN can’t talk to any node on bus.

The PHN Core board cannot communicate with any board on the

local bus.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

XEROX DOCUPRINT IPS MESSAGES GUIDE 2-13

Page 26

DOCUPRINT 96/4635/180 IPS MESSAGES

03-416 FSN2 can’t talk to any node on bus.

The FSN Core board 2 cannot communicate with any board on the

local bus.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-461 EDN problem needs software reset.

A potential hardware or software problem detected on the EDN Core

board required a software reset.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-462 UIM problem needs software reset.

A potential noise problem detected on the UIM Core board required

a software reset.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-463 MIN problem needs software reset.

A potential hardware or software problem detected on the MIN Core

board required a software reset.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-464 PHN problem needs software reset.

The PHN Core board cannot communicate with any board on the

local bus.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-465 FSN1 problem needs software reset.

The FSN Core board 1 cannot communicate with any board on the

local bus.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-467 TMN problem needs software reset.

The TMN Core board cannot communicate with any board on the

local bus.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

2-14 XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 27

DOCUPRINT 96/4635/180 IPS MESSAGES

03-471 EDN problem needs software reset.

A potential hardware or software problem detected on the EDN Core

board required a software reset.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-472 UIM needs software reset.

A potential noise problem detected on the UIM Core board required

a software reset.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-473 MIN needs software reset.

A potential hardware or software problem detected on the MIN Core

board required a software reset.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-474 PHN problem needs software reset.

The PHN Core board cannot communicate with any board on the

local bus.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-475 FSN1 problem needs software reset.

The FSN Core board 1 cannot communicate with any board on the

local bus.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-477 TMN problem needs software reset.

The TMN Core board cannot communicate with any board on the

local bus.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-480 Too many segments in the queue.

The job manager detected too many scheduling segments in the job

manager queue and initiated a cycle down of the printer.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

XEROX DOCUPRINT IPS MESSAGES GUIDE 2-15

Page 28

DOCUPRINT 96/4635/180 IPS MESSAGES

03-482 EDN unexpected stacker signal.

The job manager received an unexpected delivery signal and

initiated a cycle down of the printer.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-483 Stacker delivery route.

The job manager detected a request for an output delivery schedule

segment initiated by PHN or FSN 1, and initiated a cycle down of the

printer.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-485 JG print response late or printer late.

The job manager detected a PSP print response that was late or

never received and initiated a cycle down of the printer.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

03-492 MIN main drive enable time-out.

The MIN Core board did not receive a main drive enable from the

PHN Core board within 30 seconds after start was initiated.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

04-201 Machine clock missing at cycle up.

The machine clock could not be detected at cycle up. The control

logic senses a main drive acceleration error.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

04-202 MIN declared too many machine clocks.

Too many machine clocks were detected. The control logic senses a

main drive acceleration error.

Action Clear areas 4, 5, 6, and 7. (Refer to the Xerox DocuPrint 96/4635/180

IPS Troubleshooting Guide for the procedure.)

04-203 MIN declared too few machine clocks.

Too few machine clocks were detected. The control logic senses a

main drive acceleration error.

Action Clear areas 4, 5, 6, and 7. (Refer to the Xerox DocuPrint 96/4635/180

IPS Troubleshooting Guide for the procedure.)

2-16 XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 29

DOCUPRINT 96/4635/180 IPS MESSAGES

04-210 PHN missing machine clocks.

The machine clock sensor Q401 signal is missing at the PHN Core

board.

Action Clear areas 4, 5, 6, and 7. (Refer to the Xerox DocuPrint 96/4635/180

IPS Troubleshooting Guide for the procedure.)

04-211 Missing reg sync (sheet scheduled).

The registration sync signal is missing at the PHN Core board.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

04-212 Unexpected reg sync (no sheet).

An unexpected registration sync signal arrived at the PHN Core

PWM.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

04-213 Reg sync late.

The registration sync signal is missing at the PHN core board.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

04-220 50HZ phase wiring error.

The configuration of the three phases of the AC power entering the

printer is incorrect.

Action Contact your service representative.

06-250 SOS missing.

A Start of Scan signal was not detected by the SOS board.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

06-251 EOS missing.

An End of Scan signal was not detected by the EOS board.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

06-252 Extra start of scan signal.

The SOS board detected more than one Start of Scan signal.

Action Press the [Clear] (or [Reset]) button located behind the printer control

console front pull-down cover.

XEROX DOCUPRINT IPS MESSAGES GUIDE 2-17

Page 30

DOCUPRINT 96/4635/180 IPS MESSAGES

06-253 Extra end of scan signal.

The EOS board detected more than one End of Scan signal.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

06-350 No voltage to modulator drive.

The beam 1 and beam 2 Intensity signals sent from the EPMD board

to the Modulation board are less than +10 VDC, or the Laser Write

signal was missing during printing.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

06-351 Pixel clock input signal fault.

The voltage controlled oscillator that generates the 66 MHz Pixel

Clock signal is out of the acceptable range.

Action Press the [Clear] button located behind the printer control console

front pull-down menu.

06-352 Pixel clock output signal fault.

The 66 MHz Pixel Clock signal was not detected for at least 30

microseconds.

Action Press the [Clear] (or [Reset]) button located behind the printer control

console front pull-down menu.

06-353 ROS LVPS fault.

One or more voltages from the ROS LVPS are more than 30 percent

out of the acceptable range.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

06-354 Polygon motor drive AC fault.

The polygon motor is not receiving the Phase 1 voltage, Phase 2

voltage, or both, from the EPMD board.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

06-355 SOS PWB connector fault.

The SOS board is disconnected, or the +5 VDC was not detected on

the SOS board.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

2-18 XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 31

DOCUPRINT 96/4635/180 IPS MESSAGES

06-356 EOS PWB connector fault.

The +5 VDC was not detected at the EOS board.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

06-357 ROS module fault.

The Start of Scan Beam Intensity signal and the End of Scan beam

intensity signal from the SOS and EOS boards to the SLB/RDR

board are at least 50 percent out of the acceptable range.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

06-358 No pixel clock voltage.

The +15 VDC or -15 VDC from the printer LVPS board is over 30

percent out of the acceptable range.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

06-359 No light leveler output.

The ROS shutter cannot maintain the laser beam intensity required

by the Exposure Control signal.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

06-363 SOS PWB fault.

The Start of Scan Beam Intensity signal from the SOS board to the

SLB/RDR board is less than 50 percent of the value calculated during

the most recent xerographic setup.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

06-364 EOS PWBA fault.

The End of Scan Beam Intensity signal from the EOB board to the

SLB/RDR is less than 50 percent of the value calculated during the

most recent xerographic setup.

Action Press the [Clear] button located behind the printer control console

front pull-down cover.

06-365 Laser HVPS fault.

The Laser HIgh Voltage Power Signal cannot provide enough

voltage to operate the laser tube assembly.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

XEROX DOCUPRINT IPS MESSAGES GUIDE 2-19

Page 32

DOCUPRINT 96/4635/180 IPS MESSAGES

06-366 Polygon motor fault.

A polygon motor error occurred.

Action Select the Fault List icon on the printer control console touch screen.

Then touch the [Clear] button to clear the codes.

06-367 Card cage overtemp.

The airflow in the printer card cage will not prevent the electronic

hardware from overheating.

Action Contact your service representative.

07-211 Tray 1 not up in feed position.

The tray 1 elevator did not arrive at the stack height sensor in time,

or the elevator indexed on more than two consecutive feeds.

Action Check the paper position in tray 1, lower then raise the tray, and retry

the operation.

07-212 Tray 1 failed to move down.

The tray 1 elevator did not arrive at the tray 1 down or the low paper

sensor in time, or the elevator indexed on more than two consecutive

feeds.

Action Press the Tray Unlock button and make sure that the tray is pushed

in.

07-214 Tray 1 open in print.

Input tray 1 is open while the system is attempting to print.

Action Close input tray 1 and press Continue.

07-221 Tray 2 not up in feed position.

The tray 2 elevator did not arrive at the stack height sensor in time,

or the elevator indexed on more than two consecutive feeds.

Action Check the paper position in tray 2, lower, then raise the tray and retry

the operation.

07-222 Tray 2 failed to move down

The tray 2 elevator did not arrive at the tray 2 down or the low paper

sensor in time, or the elevator indexed on more than two consecutive

feed.

Action Press the Tray Unlock button and make sure that the tray is pushed

in.

2-20 XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 33

DOCUPRINT 96/4635/180 IPS MESSAGES

07-224 Tray 2 open in print.

Input tray 2 is open while the system is attempting to print.

Action Close input tray 2 and press Continue.

07-241-1 Tray 3 slow to feed position.

The tray 3 elevator did not arrive at the stack height or the low paper

sensor in time, or the elevator indexed on more than three

consecutive feeds.

Action Check the paper position in tray 3 and retry the operation.

07-241-2 Tray 4 slow to feed position.

The tray 4 elevator did not arrive at the stack height or the low paper

sensor in time, or the elevator indexed on more than three

consecutive feeds.

Action Check the paper position in tray 4 and retry the operation.

07-244-1 Tray 3 failed to move down in time.

The tray 3 elevator did not arrive at the tray down sensor in time.

Action Check the paper position in tray 3 and retry the operation.

07-244-2 Tray 4 failed to move down in time.

The tray 4 elevator did not arrive at the tray down sensor in time.

Action Check the paper position in tray 4 and retry the operation.

07-248-1 Tray 3 unlatched in print.

Tray 3 became unlatched during printing.

Action Make sure tray 3 is attached, close it firmly, and retry the operation.

07-248-2 Tray 4 unlatched in print.

Tray 4 became unlatched during printing.

Action Make sure tray 4 is attached, close it firmly, and retry the operation.

07-250-1 Tray 3 vert trans door open in print.

The feeder/stacker Vertical Transport Door Interlock switch opened

during printing.

Action Close the tray 3 Vertical Transport Door and retry the operation.

XEROX DOCUPRINT IPS MESSAGES GUIDE 2-21

Page 34

DOCUPRINT 96/4635/180 IPS MESSAGES

07-250-2 Tray 4 vert trans door open in print.

07-251-1 Tray 3 horz trans door open in print.

07-251-2 Tray 4 horz trans door open in print.

The Feeder/Stacker Vertical Transport Door Interlock switch opened

during printing.

Action Close the tray 4 Vertical Transport Door and retry the operation.

The feeder/stacker Horizontal Transport Door Interlock switch

opened during printing.

Action Close the tray 3 Horizontal Transport Door and retry the operation.

The feeder/stacker Horizontal Transport Door Interlock switch

opened during printing.

Action Close the tray 4 Horizontal Transport Door and retry the operation.

08-100 L E jam tray 3 at pre reg Q850.

The leading edge of the sheet of paper did not arrive at the

preregistration sensor in time, causing a jam.

Action Open the inverter door and clear area 14. Open the printer right front

door and clear area 2. Retry the operation. (Refer to the Xerox

DocuPrint 96/4635/180 IPS Troubleshooting Guide for the

procedure.)

08-101 L E jam tray 3 at pre reg Q850.

The leading edge of the sheet of paper did not arrive at the

preregistration sensor in time, causing a jam.

Action Open the inverter door and clear area 14. Open the printer right front

door and clear area 2. Retry the operation. (Refer to the Xerox

DocuPrint 96/4635/180 IPS Troubleshooting Guide for the

procedure.)

08-102 T E jam tray 3 at pre reg Q850.

The trailing edge of the sheet of paper did not arrive at the

preregistration sensor in time, causing a jam.

Action Open the inverter door and clear area 14. Open the printer right front

door and clear areas 2 and 4. Retry the operation. (Refer to the Xerox

DocuPrint 96/4635/180 IPS Troubleshooting Guide for the

procedure.)

2-22 XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 35

DOCUPRINT 96/4635/180 IPS MESSAGES

08-103 T E jam tray 3 at pre reg Q850.

The trailing edge of the sheet of paper did not arrive at the

preregistration sensor in time, causing a jam.

Action Open the inverter door and clear area 14. Open the printer right front

door and clear areas 2 and 4. Retry the operation. (Refer to the Xerox

DocuPrint 96/4635/180 IPS Troubleshooting Guide for the

procedure.)

08-104 L E jam at REGIST sensor Q861.

The leading edge of the sheet of paper did not arrive at the

registration transport sensor in time, causing a jam.

Action Open the inverter door and clear area 14. Open the printer right front

door and clear areas 2, 3, and 4. Retry the operation. (Refer to the

Xerox DocuPrint 96/4635/180 IPS Troubleshooting Guide for the

procedure.)

08-105 L E jam at REGIST sensor Q861.

The leading edge of the sheet of paper did not arrive at the

registration transport sensor in time, causing a jam.

Action Open the inverter door and clear area 14. Open the printer right front

door and clear areas 2, 3, and 4. Retry the operation. (Refer to the

Xerox DocuPrint 96/4635/180 IPS Troubleshooting Guide for the

procedure.)

08-111 L E jam at tray 1 stack force Q812.

The leading edge of the sheet of paper did not arrive at the stack

relief sensor in time, causing a jam.

Action Open tray 1, clear any damaged sheets, close the tray, and retry the

operation.

08-112 L E jam at tray 1 takeaway RQL Q811.

The leading edge of the sheet of paper did not arrive at the takeaway

roll sensor in time, causing a jam.

Action Open tray 1, clear any damaged sheets, close the tray, and retry the

operation.

08-113 T E jam at tray 1 takeaway RQL Q811.

The trailing edge of the sheet of paper did not leave the takeaway roll

sensor in time, or the leading edge of a transparency did not arrive at

the vertical transport sensor in time, causing a jam.

Action Open tray 1, clear area 3, close the tray, and retry the operation.

(Refer to the Xerox DocuPrint 96/4635/180 IPS Troubleshooting

Guide for the procedure.)

XEROX DOCUPRINT IPS MESSAGES GUIDE 2-23

Page 36

DOCUPRINT 96/4635/180 IPS MESSAGES

08-121 L E jam at tray 2 stack force Q822.

The leading edge of the sheet of paper did not arrive at the stack

relief sensor in time, causing a jam.

Action Open tray 2, clear any damaged sheets, close the tray, and retry the

operation.

08-122 L E jam at tray 2 takeaway RQL Q821.

The leading edge of the sheet of paper did not arrive at the tray 2

takeaway roll sensor in time, causing a jam.

Action Open tray 2, clear area 3, close the tray, and retry the operation.

(Refer to the Xerox DocuPrint 96/4635/180 IPS Troubleshooting

Guide for the procedure.)

08-123 T E jam at tray 2 takeaway RQL Q821.

The trailing edge of the sheet of paper did not leave the tray 2

takeaway roll sensor in time, or the leading edge of a transparency

did not arrive at the vertical transport sensor in time, causing a jam.

Action Open tray 2, clear area 3, close the tray, and retry the operation.

(Refer to the Xerox DocuPrint 96/4635/180 IPS Troubleshooting

Guide for the procedure.)

08-144 L E jam at dup vert XPORT Q851.

The leading edge of the sheet of paper did not arrive at the vertical

transport sensor in time, causing a jam.

Action Open the right front door of the printer, clear area 3, close the door,

and retry the operation. (Refer to the Xerox DocuPrint 96/4635/180

IPS Troubleshooting Guide for the procedure.)

08-145 L E jam at dup takeaway roll Q842.

The leading edge of the sheet of paper did not arrive at the duplex

takeaway roll sensor in time, causing a jam.

Action Open the top cover of the printer and clear area 8. Open the printer

right front door and clear area 9. Retry the operation. (Refer to the

Xerox DocuPrint 96/4635/180 IPS Troubleshooting Guide for the

procedure.)

08-146 T E jam at dup takeaway roll Q842.

The trailing edge of the sheet of paper did not leave the duplex

takeaway roll sensor in time, causing a jam.

Action Open the right front door of the printer, clear areas 9 and 10, close

the printer door and retry the operation. (Refer to the Xerox

DocuPrint 96/4635/180 IPS Troubleshooting Guide for the

procedure.)

2-24 XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 37

DOCUPRINT 96/4635/180 IPS MESSAGES

08-147 L E jam at dup takeaway roll Q842.

The leading edge of the sheet of paper did not arrive at the duplex

takeaway roll sensor in time, causing a jam.

Action Open the top cover of the printer and clear area 8. Open the printer

right front door and clear area 9. Retry the operation. (Refer to the

Xerox DocuPrint 96/4635/180 IPS Troubleshooting Guide for the

procedure.)

08-149 L E jam at dup vert XPORT Q851.

The leading edge of the sheet of paper did not arrive at the vertical

transport sensor in time, causing a jam.

Action Open the right front door of the printer, clear area 3, close the door,

and retry the operation. (Refer to the Xerox DocuPrint 96/4635/180

IPS Troubleshooting Guide for the procedure.)

08-151 T E jam at dup vert XPORT Q851.

The trailing edge of the sheet of paper did not leave the vertical

transport sensor in time, causing a jam.

Action Open the right front door of the printer, clear areas 3 and 4, close the

printer door and retry the operation. (Refer to the Xerox DocuPrint

96/4635/180 IPS Troubleshooting Guide for the procedure.)

08-152 L E jam at REGIST sensor Q861.

The leading edge of the sheet of paper did not arrive at the

registration transport sensor in time, causing a jam.

Action Open the inverter door and clear area 14. Open the printer right front

door and clear areas 2, 3, and 4. Retry the operation. (Refer to the

Xerox DocuPrint 96/4635/180 IPS Troubleshooting Guide for the

procedure.)

08-155 T E jam at regist sensor Q861.

The trailing edge of the sheet of paper did not leave the registration

transport sensor in time, causing a jam.

Action Open the right front door of the printer, clear areas 2 and 4, close the

printer door and retry the operation. (Refer to the Xerox DocuPrint

96/4635/180 IPS Troubleshooting Guide for the procedure.)

08-156 L E jam at REGIST sensor Q861.

The leading edge of the sheet of paper did not arrive at the

registration transport sensor in time, causing a jam.

Action Open the inverter door and clear area 14. Open the printer right front

door and clear areas 2, 3, and 4. Retry the operation. (Refer to the

Xerox DocuPrint 96/4635/180 IPS Troubleshooting Guide for the

procedure.)

XEROX DOCUPRINT IPS MESSAGES GUIDE 2-25

Page 38

DOCUPRINT 96/4635/180 IPS MESSAGES

08-164-1 L E jam at tray 3 turn baff Q853.

08-164-2 L E jam at tray 4 turn baff Q853.

08-165-1 L E jam at tray 3 turn baff Q853.

The leading edge of the sheet of paper did not arrive at the turn baffle

sensor in time, causing a jam.

Action Open the vertical transport door of tray 3 and clear areas 11 and 12.

Open the horizontal transport door of tray 4 and clear area 13. Close

the doors and retry the operation. (Refer to the Xerox DocuPrint 96/

4635/180 IPS Troubleshooting Guide for the procedure.)

The leading edge of the sheet of paper did not arrive at the turn baffle

sensor in time, causing a jam.

Action Open the vertical transport door of tray 3 and clear areas 11 and 12.

Open the horizontal transport door of tray 4 and clear areas 11, 12,

and 13. Close the doors and retry the operation. (Refer to the Xerox

DocuPrint 96/4635/180 IPS Troubleshooting Guide for the

procedure.)

The leading edge of the sheet of paper did not arrive at the turn baffle

sensor in time, causing a jam.

Action Open the vertical transport door of tray 3 and clear areas 11 and 12.

Open the horizontal transport door of tray 4 and clear area 13. Close

the doors and retry the operation. (Refer to the Xerox DocuPrint 96/

4635/180 IPS Troubleshooting Guide for the procedure.)

08-165-2 L E jam at tray 4 turn baff Q853.

The leading edge of the sheet of paper did not arrive at the turn baffle

sensor in time, causing a jam.

Action Open the vertical transport door of tray 3 and clear areas 11 and 12.

Open the horizontal transport door of tray 4 and clear areas 11, 12,

and 13. Close the doors and retry the operation. (Refer to the Xerox

DocuPrint 96/4635/180 IPS Troubleshooting Guide for the

procedure.)

08-166-1 T E jam at tray 3 turn baff Q853.

The trailing edge of the sheet of paper did not arrive at the turn baffle

sensor in time, causing a jam.

Action Open the horizontal transport door of tray 3 and clear area 13. Open

the vertical transport door of tray 3 and clear area 12. Open the

horizontal transport door of tray 4 and clear area 13. Open the

vertical transport door of tray 4 and clear area 12. Close the doors

and retry the operation. (Refer to the Xerox DocuPrint 96/4635/180

IPS Troubleshooting Guide for the procedure.)

2-26 XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 39

DOCUPRINT 96/4635/180 IPS MESSAGES

08-166-2 T E jam at tray 4 turn baff Q853.

The trailing edge of the sheet of paper did not arrive at the turn baffle

sensor in time, causing a jam.

Action Open the horizontal transport door of tray 4 and clear area 13. Open

the vertical transport door of tray 4 and clear area 12. Open the

horizontal transport door of tray 4 and clear area 13. Close the doors

and retry the operation. (Refer to the Xerox DocuPrint 96/4635/180

IPS Troubleshooting Guide for the procedure.)

08-167-1 T E jam at tray 3 turn baff Q853.

The trailing edge of the sheet of paper did not arrive at the turn baffle

sensor in time, causing a jam.

Action Open the horizontal transport door of tray 3 and clear area 13. Open

the vertical transport door of tray 3 and clear area 12. Open the

horizontal transport door of tray 4 and clear area 13. Open the

vertical transport door of tray 4 and clear area 12. Close the doors

and retry the operation. (Refer to the Xerox DocuPrint 96/4635/180

IPS Troubleshooting Guide for the procedure.)

08-167-2 T E jam at tray 4 turn baff Q853.

The trailing edge of the sheet of paper did not arrive at the turn baffle

sensor in time, causing a jam.

Action Open the horizontal transport door of tray 4 and clear area 13. Open

the vertical transport door of tray 4 and clear area 12. Open the

horizontal transport door of tray 4 and clear area 13. Close the doors

and retry the operation. (Refer to the Xerox DocuPrint 96/4635/180

IPS Troubleshooting Guide for the procedure.)

08-168-1 L E jam at tray 3 horz XPORT Q854.

The leading edge of the sheet of paper did not arrive at the horizontal

transport sensor in time, causing a jam.

Action Open the horizontal transport door of tray 3, clear area 13, close the

doors and retry the operation. (Refer to the Xerox DocuPrint 96/4635/

180 IPS Troubleshooting Guide for the procedure.)

08-168-2 L E jam at tray 4 horz XPORT Q854.

The leading edge of the sheet of paper did not arrive at the horizontal

transport sensor in time, causing a jam.

Action Open the horizontal transport door of tray 4, clear area 13, close the

doors and retry the operation. (Refer to the Xerox DocuPrint 96/4635/

180 IPS Troubleshooting Guide for the procedure.)

XEROX DOCUPRINT IPS MESSAGES GUIDE 2-27

Page 40

DOCUPRINT 96/4635/180 IPS MESSAGES

08-169-1 L E jam at tray 3 horz XPORT Q854.

08-169-2 L E jam at tray 4 horz XPORT Q854.

The leading edge of the sheet of paper did not arrive at the horizontal

transport sensor in time, causing a jam.

Action Open the horizontal transport door of tray 3, clear area 13, close the

doors and retry the operation. (Refer to the Xerox DocuPrint 96/4635/

180 IPS Troubleshooting Guide for the procedure.)

The leading edge of the sheet of paper did not arrive at the horizontal

transport sensor in time, causing a jam.

Action Open the horizontal transport door of tray 4, clear area 13, close the

doors and retry the operation. (Refer to the Xerox DocuPrint 96/4635/

180 IPS Troubleshooting Guide for the procedure.)

08-170 L E jam at dup sheet sensor Q841.

The sheet of paper did not arrive at the duplex sheet sensor in time,

causing a jam.

Action Open the top cover of the printer, clear area 8, and close the cover.

Open the printer right door, clear area 9, and close the door. (Refer

to the Xerox DocuPrint 96/4635/180 IPS Troubleshooting Guide for

the procedure.)

08-171 T E jam at dup sheet sensor Q841.

The sheet of paper did not leave the duplex sheet sensor in time,

causing a jam.

Action Open the top cover of the printer, clear area 8, and close the cover.

(Refer to the 96/4635/180 IPS Troubleshooting Guide for the

procedure.)

08-172 L E jam at dup sheet sensor Q841.

The sheet of paper did not arrive at the duplex sheet sensor in time,

causing a jam.

Action Open the top cover of the printer, clear area 8, and close the cover.

Open the printer right door, clear area 9, and close the door. (Refer

to the Xerox DocuPrint 96/4635/180 IPS Troubleshooting Guide for

the procedure.)

08-173 L E jam at dup sheet sensor Q841.

The sheet of paper did not arrive at the duplex sheet sensor in time,

causing a jam.

Action Open the top cover of the printer, clear area 8, and close the cover.

Open the printer right door, clear area 9, and close the door. (Refer

to the Xerox DocuPrint 96/4635/180 IPS Troubleshooting Guide for

the procedure.)

2-28 XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 41

DOCUPRINT 96/4635/180 IPS MESSAGES

08-179 L E jam at third party cross module.

There is a paper jam in the indicated area.

Action Clear the jam from the area using the steps provided by the system

and continue the job. (Refer to the Xerox DocuPrint 96/4635/180 IPS

Troubleshooting Guide for the procedure.)

08-180-1 L E jam at tray 3 takeaway rol Q857.

The leading edge of the sheet of paper did not arrive at the tray 3 feed

sensor in time, causing a jam.

Action Open tray 3, clear the feeder, clear area 11, and retry the operation.

(Refer to the Xerox DocuPrint 96/4635/180 IPS Troubleshooting

Guide for the procedure.)

08-180-2 L E jam at tray 4 takeaway rol Q857.

The leading edge of the sheet of paper did not arrive at the tray 4 feed

sensor in time, causing a jam.

Action Open tray 4, clear the feeder, clear area 11, and retry the operation.

(Refer to the Xerox DocuPrint 96/4635/180 IPS Troubleshooting

Guide for the procedure.)

08-181-1 L E jam at tray 3 takeaway rol Q857.

The leading edge of the sheet of paper did not arrive at the tray 3 feed

sensor in time, causing a jam.

Action Open tray 3, clear the feeder, clear area 11, and retry the operation.

(Refer to the Xerox DocuPrint 96/4635/180 IPS Troubleshooting

Guide for the procedure.)

08-181-2 L E jam at tray 4 takeaway rol Q857.

The leading edge of the sheet of paper did not arrive at the tray 4 feed

sensor in time, causing a jam.

Action Open tray 4, clear the feeder, clear area 11, and retry the operation.

(Refer to the Xerox DocuPrint 96/4635/180 IPS Troubleshooting

Guide for the procedure.)

08-182-1 T E jam at tray 3 takeaway rol Q857.

The trailing edge of the sheet of paper did not leave the tray 3 feed

sensor in time, causing a jam.

Action Open the vertical transport door or tray 3, clear area 11, and close

the door. Open tray 4, clear the feeder, close the tray, and retry the

operation. (Refer to the Xerox DocuPrint 96/4635/180 IPS

Troubleshooting Guide for the procedure.)

XEROX DOCUPRINT IPS MESSAGES GUIDE 2-29

Page 42

DOCUPRINT 96/4635/180 IPS MESSAGES

08-182-2 T E jam at tray 4 takeaway rol Q857.

08-183-1 T E jam at tray 3 takeaway rol Q857.

08-183-2 T E jam at tray 4 takeaway rol Q857.

The trailing edge of the sheet of paper did not leave the tray 4 feed

sensor in time, causing a jam.

Action Open the vertical door of the transport and clear area 11. Open tray

4, clear the feeder, close the tray, and retry the operation. (Refer to

the Xerox DocuPrint 96/4635/180 IPS Troubleshooting Guide for the

procedure.)

The trailing edge of the sheet of paper did not leave the tray 3 feed

sensor in time, causing a jam.

Action Open the vertical transport door or tray 3, clear area 11, and close

the door. Open tray 4, clear the feeder, close the tray, and retry the

operation. (Refer to the Xerox DocuPrint 96/4635/180 IPS

Troubleshooting Guide for the procedure.)

The trailing edge of the sheet of paper did not leave the tray 4 feed

sensor in time, causing a jam.

Action Open the vertical door of the transport and clear area 11. Open tray

4, clear the feeder, close the tray, and retry the operation. (Refer to

the Xerox DocuPrint 96/4635/180 IPS Troubleshooting Guide for the

procedure.)

08-184-1 L E jam at tray 3 vert XPORT Q852.

The leading edge of the sheet of paper did not arrive at the vertical

transport sensor in time, causing a jam.

Action Open the vertical door of tray 3, clear areas 11 and 12, close the

door, and retry the operation. (Refer to the Xerox DocuPrint 96/4635/

180 IPS Troubleshooting Guide for the procedure.)

08-184-2 L E jam at tray 4 vert XPORT Q852.

The leading edge of the sheet of paper did not arrive at the vertical

transport sensor in time, causing a jam.

Action Open the vertical door of tray 4, clear areas 11 and 12, close the

door, and retry the operation. (Refer to the Xerox DocuPrint 96/4635/

180 IPS Troubleshooting Guide for the procedure.)

08-185-1 L E jam at tray 3 vert XPORT Q852.

The leading edge of the sheet of paper did not arrive at the vertical

transport sensor in time, causing a jam.

Action Open the vertical door of tray 3, clear areas 11 and 12, close the

door, and retry the operation. (Refer to the Xerox DocuPrint 96/4635/

180 IPS Troubleshooting Guide for the procedure.)

2-30 XEROX DOCUPRINT IPS MESSAGES GUIDE

Page 43

DOCUPRINT 96/4635/180 IPS MESSAGES

08-185-2 L E jam at tray 4 vert XPORT Q852.

The leading edge of the sheet of paper did not arrive at the vertical

transport sensor in time, causing a jam.

Action Open the vertical door of tray 4, clear areas 11 and 12, close the

door, and retry the operation. (Refer to the Xerox DocuPrint 96/4635/

180 IPS Troubleshooting Guide for the procedure.)

08-186-1 T E jam at tray 3 vert XPORT Q852.

The trailing edge of the sheet of paper did not leave the vertical

transport sensor in time, causing a jam.

Action Open the vertical door of tray 3, clear areas 11, 12, and 13, close the

door, and retry the operation. (Refer to the Xerox DocuPrint 96/4635/

180 IPS Troubleshooting Guide for the procedure.)

08-186-2 T E jam at tray 4 vert XPORT Q852.

The trailing edge of the sheet of paper did not leave the vertical

transport sensor in time, causing a jam.

Action Open the vertical door of tray 4, clear areas 11 and 12, close the

door, and retry the operation. (Refer to the Xerox DocuPrint 96/4635/

180 IPS Troubleshooting Guide for the procedure.)

08-187-1 T E jam at tray 3 vert XPORT Q852.

The trailing edge of the sheet of paper did not leave the vertical

transport sensor in time, causing a jam.

Action Open the vertical door of tray 3, clear areas 11, 12, and 13, close the

door, and retry the operation. (Refer to the Xerox DocuPrint 96/4635/

180 IPS Troubleshooting Guide for the procedure.)

08-187-2 T E jam at tray 4 vert XPORT Q852.

The trailing edge of the sheet of paper did not leave the vertical

transport sensor in time, causing a jam.

Action Open the vertical door of tray 4, clear areas 11 and 12, close the

door, and retry the operation. (Refer to the Xerox DocuPrint 96/4635/

180 IPS Troubleshooting Guide for the procedure.)

08-188-1 L E jam at tray 3 turn baff Q853.

The leading edge of the sheet of paper did not arrive at the turn baffle

sensor in time, causing a jam.

Action Open the vertical transport door of tray 3 and clear areas 11 and 12.

Open the horizontal transport door of tray 4 and clear area 13. Close

the doors and retry the operation. (Refer to the Xerox DocuPrint 96/

4635/180 IPS Troubleshooting Guide for the procedure.)

XEROX DOCUPRINT IPS MESSAGES GUIDE 2-31

Page 44

DOCUPRINT 96/4635/180 IPS MESSAGES

08-188-2 L E jam at tray 4 turn baffle Q853.

08-189-1 L E jam at tray 3 turn baffle Q853.

08-189-2 L E jam at tray 4 turn baffle Q853.

The leading edge of the sheet of paper did not arrive at the turn baffle

sensor in time, causing a jam.

Action Open the vertical transport door of tray 3 and clear areas 11 and 12.

Open the horizontal transport door of tray 4 and clear areas 11, 12,

and 13. Close the doors and retry the operation. (Refer to the Xerox

DocuPrint 96/4635/180 IPS Troubleshooting Guide for the

procedure.)

The leading edge of the sheet of paper did not arrive at the turn baffle

sensor in time, causing a jam.

Action Open the vertical transport door of tray 3 and clear areas 11 and 12.

Open the horizontal transport door of tray 4 and clear area 13. Close

the doors and retry the operation. (Refer to the Xerox DocuPrint 96/

4635/180 IPS Troubleshooting Guide for the procedure.)

The leading edge of the sheet of paper did not arrive at the turn baffle

sensor in time, causing a jam.

Action Open the vertical transport door of tray 3 and clear areas 11 and 12.

Open the horizontal transport door of tray 4 and clear areas 11, 12,

and 13. Close the doors and retry the operation. (Refer to the Xerox