Version 1.0

February 2015

Xerox® Color 800i/1000i Presses

Xerox® Color 800/1000 Presses

System Administration Guide

©2014 Xerox Corporation. All rights reserved. Xerox®, and Xerox and Design® are

trademarks of Xerox Corporation in the United States and/or other countries.

BR678

Table of Contents

1 Administrator overview...........................................................................1-1

Logging on as Administrator...........................................................................................1-1

Remote services....................................................................................................................1-2

Automatic Meter Reading (AMR)/Automatic Supplies

Replenishment (ASR)......................................................................................1-2

Technical Key Operator (TKO).........................................................................................1-3

Backing up/transferring the stock library...................................................................1-3

2 Maintenance on UI..................................................................................2-1

Maintenance tab..................................................................................................................2-2

Dry ink/toner cleaning..........................................................................................2-2

Charge corotron cleaning....................................................................................2-3

3 Test Print option.........................................................................................3-1

Using the Test Print option...............................................................................................3-2

Test Print option for 2nd Bias Transfer Roll................................................................3-4

Running the first set of test prints...................................................................3-4

Evaluating the first set of test prints..............................................................3-5

Adjusting the test prints......................................................................................3-5

Selecting the 2nd Bias Transfer Roll settings...............................................3-5

4 Paper curl correction................................................................................4-1

Paper curl overview..............................................................................................................4-1

Paper Curl Correction options.........................................................................................4-2

1 Sided-Face Up option........................................................................................4-3

1 Sided-Face Down option..................................................................................4-3

2 Sided option..........................................................................................................4-4

Correcting the paper curl.....................................................................................4-4

5 System Settings..........................................................................................5-1

User Interface........................................................................................................................5-1

Fault Details window.............................................................................................5-3

Setting the default value for Fault Details Window....................5-3

Default Language...................................................................................................5-4

Change administrator password......................................................................5-4

Resetting the Technical Key Operator password........................................5-5

Manage Stock Library Window.........................................................................5-5

Setting the date and time................................................................................................5-6

System......................................................................................................................................5-6

System Administration Guide

iXerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

Table of Contents

Tray Options........................................................................................................................5-14

Output Devices...................................................................................................................5-16

Image Quality tab.............................................................................................................5-18

Full Width Array Overview..............................................................................................5-19

Productivity Mode..................................................................................................5-7

Single Paper Weight chart.....................................................................5-7

Mixed Paper Weight chart.....................................................................5-9

Selecting the productivity mode options........................................5-9

NVM Read/Write.....................................................................................................5-9

Using the NVM Read/Write feature................................................5-10

Power Saver............................................................................................................5-10

System PC & Print Engine....................................................................5-11

Print Engine Only....................................................................................5-11

Print Engine Only If No PC Communication For.........................5-11

Exit Power Saver......................................................................................5-12

Setting the power saver options.......................................................5-12

Auto resume after pause..................................................................................5-12

Auto logoff.............................................................................................................5-13

Attention Sounds.................................................................................................5-13

Selecting the Tray Options settings..............................................................5-15

High Capacity Stacker Settings......................................................................5-16

Perfect Binder Settings.......................................................................................5-17

Selecting the Output Device options...........................................................5-17

Fuser Refresh Mode.............................................................................................5-18

Adjusting Automatic Tone Reproduction Curve......................................5-20

Adjusting Automatic Density Uniformity...................................................5-21

6 Profiles...........................................................................................................6-1

Enter/exit the Profiles.........................................................................................................6-1

Alignment................................................................................................................................6-2

Alignment information.........................................................................................6-3

Automatic alignment information.....................................................6-3

Things to consider when creating/using an alignment

profile.......................................................................................................6-3

Adjustments to the position of the output image.......................6-4

Automatic Alignment (Full Width Array)......................................................6-5

Alignment options..................................................................................................6-8

Before creating/using an alignment profile.................................................6-8

Create/edit an Alignment profile.....................................................................6-9

Fold Adjustment.................................................................................................................6-11

Fold Adjustment information..........................................................................6-12

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Pressesii

System Administration Guide

Table of Contents

New/edit bi-fold single/multiple sheets adjustment

procedure..........................................................................................................6-13

New/edit bi-fold multiple sheets stapled adjustment

procedure..........................................................................................................6-15

New/edit c-fold adjustment procedure.......................................................6-17

New/edit z-fold adjustment procedure.......................................................6-19

New/edit z-fold half-sheet adjustment procedure.................................6-20

Finishing Devices...............................................................................................................6-23

System Administration Guide

iiiXerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

Table of Contents

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Pressesiv

System Administration Guide

1

Administrator overview

The Administrator mode allows you to set the default settings for your machine in order

to fit your individual requirements. You can change the settings for a variety of features,

such as the language to display on the UI, timers, changing the Administrator password,

creating custom paper and alignment profiles, and more.

Logging on as Administrator

Use the following procedure to enter and exit the Administrator mode:

1. Select the Logon button from the main UI window.

The Logon screen appears.

2. From the Logon screen select Administrator.

3. Use the keyboard to enter the Administrator password.

The default password is five ones (11111).

Note

For security reasons, only asterisks are displayed on the screen.

4. Select the OK button.

Note

It is recommended that you change the Administrator password as soon as possible

after installing the machine in order to prevent unauthorized access to the

Administrator mode.

5. To exit the Administrator mode, select the Logoff button.

System Administration Guide

1-1Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

Administrator overview

Remote services

The remote services program is offered for your machine. Remote services provides Xerox

with up-to-the-minute information about your machine’s current state, including:

• A secure internet connection between the machine and Xerox using Secure Socket

Layer (SSL) protocols and 256-bit encryption; only machine performance information

is sent to Xerox through this connection

• Quick identification of potential problems

• Quick and accurate diagnoses of problems

• Faster resolution of issues, often occurring in less time than sending a service person

• Automatically generating and sending current meter reads directly to Xerox as well

as Automatic Supplies Replenishment

• Scheduling maintenance calls that are convenient to your schedule and allow you to

maximize your production time

Note

Remote services may not be available in your area or some customers may wish to

decline program. For more information on this program, contact the Xerox Customer

Support Center or go to www.xerox.com.

Remote services includes Automatic Meter Reading (AMR) and Automatic Supplies

Replenishment (ASR).

Automatic Meter Reading (AMR)/Automatic Supplies Replenishment (ASR)

Automatic Meter Reading (AMR) and Automatic Supplies Replenishment (ASR) are

available with your machine through the following:

• RemoteAssistant™ is a feature within certain Xerox engines that allows customers to

authorize a Xerox specialist to remotely access the User Interface (UI) on the print

server in order to help guide the customer through corrective actions.

For more information, go to www.xerox.com/printeract.

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses1-2

System Administration Guide

Administrator overview

Technical Key Operator (TKO)

The Technical Key Operator (TKO) is a person who is certified by Xerox to carry out and

perform certain maintenance activities that are normally performed by a customer

service engineer (CSE). In order to become a TKO for your machine, you must complete

the mandatory Xerox Productivity Plus (XPP) program.

As stated previously, Xerox Productivity Plus (XPP) is a mandatory, customer

self-maintenance program that is available with your machine. Through the XPP program,

Xerox provides qualified customers with the supplies, documentation, support, and the

Technical Key Operator (TKO) training required to perform simple diagnostics, routine

maintenance tasks, and some repairs which formerly were completed by a Xerox customer

service person.

Upon successful completion of the XPP training, your trained person (TKO), receives a

mini-service manual and tool kit and is certified by a Xerox Service Trainer that he or

she can complete the specific program/machine tasks.

Using XPP, you can maintain better control of resources and job scheduling by planning

and scheduling basic maintenance at convenient times, rather than waiting for a Xerox

customer service person. XPP is a productivity initiative for which the training can be at

your location or an agreed upon Xerox location.

Xerox Productivity Plus enhances your Xerox full-service maintenance agreement by

providing better information to your Xerox Service Representative before making a

service call. Xerox continues to monitor the progress of the TKO to ensure that the

machine is performing at optimum levels.

Note

For more information on this program and/or for training information, contact the Xerox

Customer Support Center or go to www.xerox.com.

Backing up/transferring the stock library

Any stock that you have created/copied and stored in the Stock Library can be backed

up and/or transferred to another machine’s PC User Interface (UI) by using an external

USB flash drive.

Note

A USB flash drive is required to copy (backup) and/or transfer files from one machine’s

PC UI to another machine’s PC UI.

1. Insert the USB flash drive into a USB port on the machine’s PC.

2. On the machine’s PC UI, open My Computer.

System Administration Guide

1-3Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

Administrator overview

3. Browse to the directory C:\users\XRX\Xerox\ColorPress\UI\public\stock directory.

Stocks that were created/copied and stored in the library are distinguished by the

.stock extension.

4. Select all the files in the stock directory with the .stock extension.

5. Select Edit > Copy (or Ctrl > C).

6. Open the directory of the USB flash drive.

7. Select Edit > Paste (or Ctrl > V).

The files are copied onto the USB flash drive.

8. Close both directories.

9. Remove the USB flash drive from the machine’s PC.

The .stock files can remain on the USB flash drive as a backup copy. Store the USB

flash drive in a safe, secure location.

10. If desired, copy the files onto a different machine’s PC by completing all the previous

steps in this procedure.

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses1-4

System Administration Guide

2

Maintenance on UI

Selecting Maintenance on the UI opens a window which displays a status of each

consumable.

Note

When a Customer Replaceable Unit (CRU) consumable item is depleted, the machine

automatically interrupts the current job and does not restart until the consumable is

replaced.

System Administration Guide

2-1Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

Maintenance on UI

Note

The machine does not interrupt a job or stop running if a Technical Key Operator

Replaceable Unit (TKORU) status indicates a low or depleted level. Your TKORU may

continue to perform as expected far beyond the average life indicator. The Technical

Key Operator (TKO) uses this status indicator information each time service is performed

on your machine.

Important

The charge corotrons and drum cartridges can be replaced ONLY by a trained, qualified

Technical Key Operator (TKO)

Maintenance tab

Selecting the Maintenance tab opens a window which displays options for cleaning

particular components inside your machine. The Maintenance screen is divided into two

sections; Charge Corotron Cleaning, and Dry Ink Cleaning.

The Maintenance cleaning options are listed below:

• Charge Corotron Cleaning: Allows you to clean one or all of the charge corotrons.

You may want to run this cleaning procedure if you are having certain image quality

issues, such as banding or mottling. Refer to the User Guide, the Problem

solving/Image quality section for more information.

• Dry Ink Cleaning: Allows you to clean one or all of the dry ink/toner cartridge systems.

You may want to run this cleaning procedure if you are having certain image quality

issues, such as white or dark spots or blotches on the prints. These spots or blotches

are caused by dry ink/toner adhering to the drum. Refer to the User Guide, the Problem

solving/Image quality section for more information.

Related Topics:

Dry ink/toner cleaning

Charge corotron cleaning

Dry ink/toner cleaning

The following cleaning procedure purges the system of any residual dry ink/toner clumps

that possibly collected in the devleoper module.

Perform the following steps to clean one or all of the dry ink/toner cartridge dispensers.

Note

It is recommended that you run a few test prints before performing the cleaning

procedure. After the Start Cleaning button is selected, the system automatically generates

a test print. This allows you to compare the before and after prints for image quality.

1. Logon as Administrator.

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses2-2

System Administration Guide

Maintenance on UI

2. Select Maintenance from the main UI.

The Maintenance window opens.

3. Select the Maintenance tab.

4. Select the desired dry ink/toner(s) to be cleaned.

5. Select the Start Cleaning button to begin the cleaning process.

6. Select the desired paper tray and feed orientation (Long Edge Feed, or Short Edge

Feed).

7. Select the Start button to begin.

When the process is complete, a “Cleaning is complete” message will appear on the

screen.

8. Select the Close button to exit and return to the main UI.

Related Topics:

Logging on as Administrator

Charge corotron cleaning

Perform the following steps to clean one or all of the charge corotrons.

1. Logon as Administrator.

2. Select Maintenance from the main UI.

The Maintenance window opens.

3. Select the Maintenance tab.

4. Select the desired corotron(s) to clean.

5. Select the Start Cleaning button to begin the cleaning process.

When the process is complete, a “Cleaning is complete” message will appear on the

screen.

6. Select the Close button to exit and return to the main UI.

Related Topics:

Logging on as Administrator

System Administration Guide

2-3Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

Maintenance on UI

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses2-4

System Administration Guide

3

Test Print option

The Test Print option is available only when you are logged on as Administrator. The

Test Print option is available with all Advanced Stock Setup options. Please read the

following information before using the Test Print option.

• It is recommended that you choose only one option at a time, and then run a set of

test prints to evaluate the output. This helps you determine whether or not that

option is providing the desired printed output.

• If you determine that the output is unacceptable after running test prints, either

further adjust the value for a particular option (if applicable) and run more test prints

or return the option to its default value and continue to the next option.

• If you want multiple Advanced Stock Setup options selected, individually select each

option, run Test Prints, and evaluate the output. After you determine that the output

for the selected option is acceptable, then you can select another option to adjust.

• It is important to remember that any settings for a particular option that is used

today for a specific print job may not achieve the same desired outcome/output

when used on different day for that same print job. This is especially relevant if the

room in which the machine is located experiences changes in temperature and

humidity.

• You may need to continually repeat procedures and test prints for any Advanced

Stock Setup option until you achieve acceptable output prints.

• If you determine that your output still is unacceptable after repeating procedures

and test prints multiple times, call your Customer Support Center for help/assistance.

Related Topics:

Test Print option for 2nd Bias Transfer Roll

Using the Test Print option

System Administration Guide

3-1Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

Test Print option

Using the Test Print option

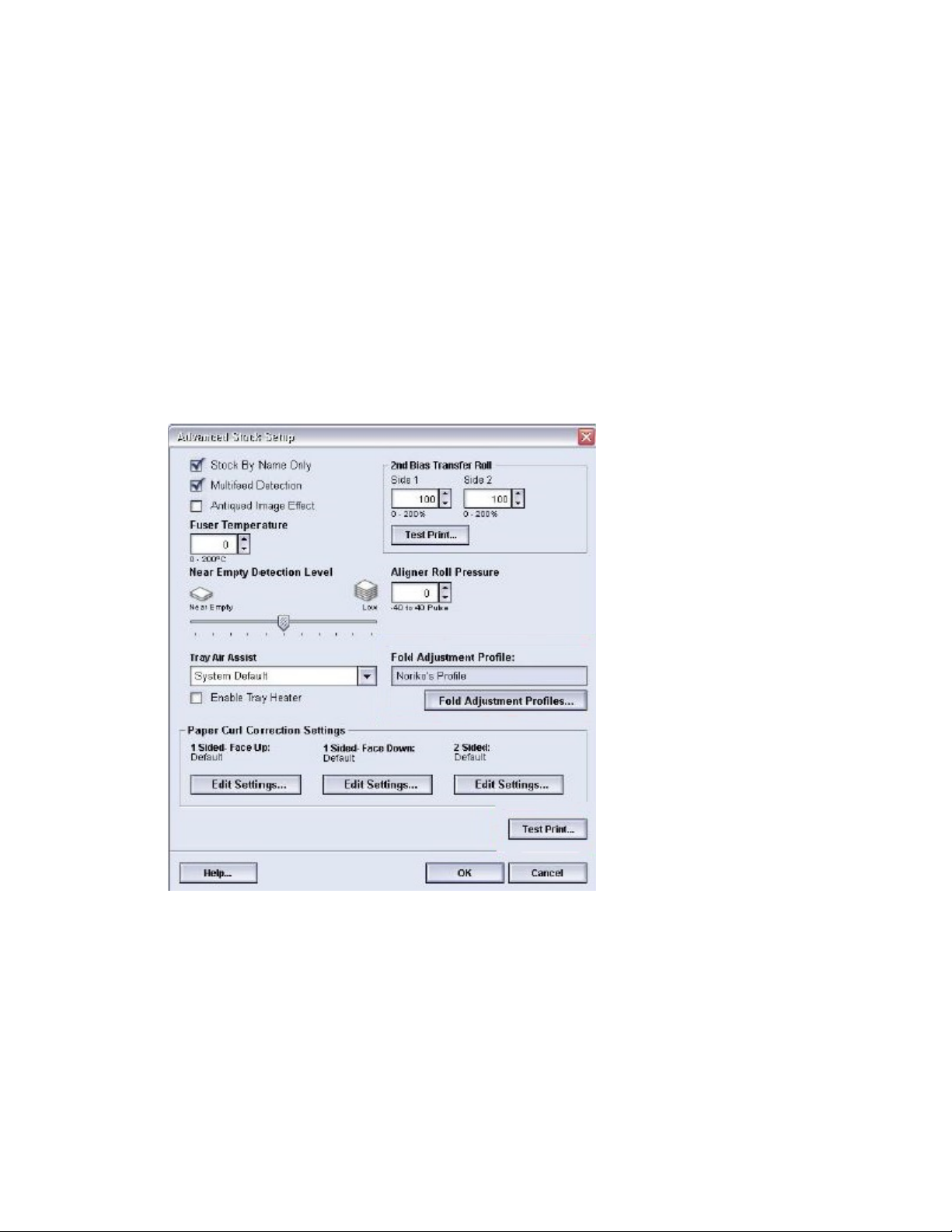

Use the following procedure to select the various Advanced Stock Setup options for a

new stock entry from the Manage Stock Library window.

The Test Print option for a new or existing stock can be accessed from the Advanced

Stock Setup window. Use to view a print of your output having advanced settings applied

such as a different fuser temperature or roll pressure for better adherence, or to correct

paper curl.

Note

The 2nd Bias Transfer Roll setting includes its own Test Print option. Refer to that section

for more information.

1. Logon as Administrator.

2. Perform one of the following:

a) Create a new stock entry (either from the Manage Stock Library window or from

the Tray Properties window), or

b) Copy an existing stock entry (either from the Manage Stock Library window or

from the Tray Properties window), or

c) Modify an existing stock entry (from the Manage Stock Library window) by

selecting the Properties button.

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses3-2

System Administration Guide

Test Print option

3. From either the New Stock Setup or Stock Properties window, select/modify the

attributes as required, including entering a new stock name.

4. Select the Advanced Setup button.

The Advanced Stock Setup window opens.

5. After selecting the advanced settings you need, select the Test Print button at the

bottom of the window.

The test print window for that specific stock opens.

6. Select the desired test print settings, including output quantity, and select Start.

Obtain your printed output from the output area of the machine.

7. Evaluate the printed output.

It may take multiple adjustments to the Advanced Stock Setup options and running

test prints before the printed output meets customer satisfaction.

8. Select OK to close the Advanced Stock Setup window.

9. Select OK to save and close either the New Stock Setup window or the Stock Properties

window.

10. Select Close to exit Manage Stock Library.

11. Select Logoff to exit the Administrator mode.

Related Topics:

Logging on as Administrator

System Administration Guide

3-3Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

Test Print option

Test Print option for 2nd Bias Transfer Roll

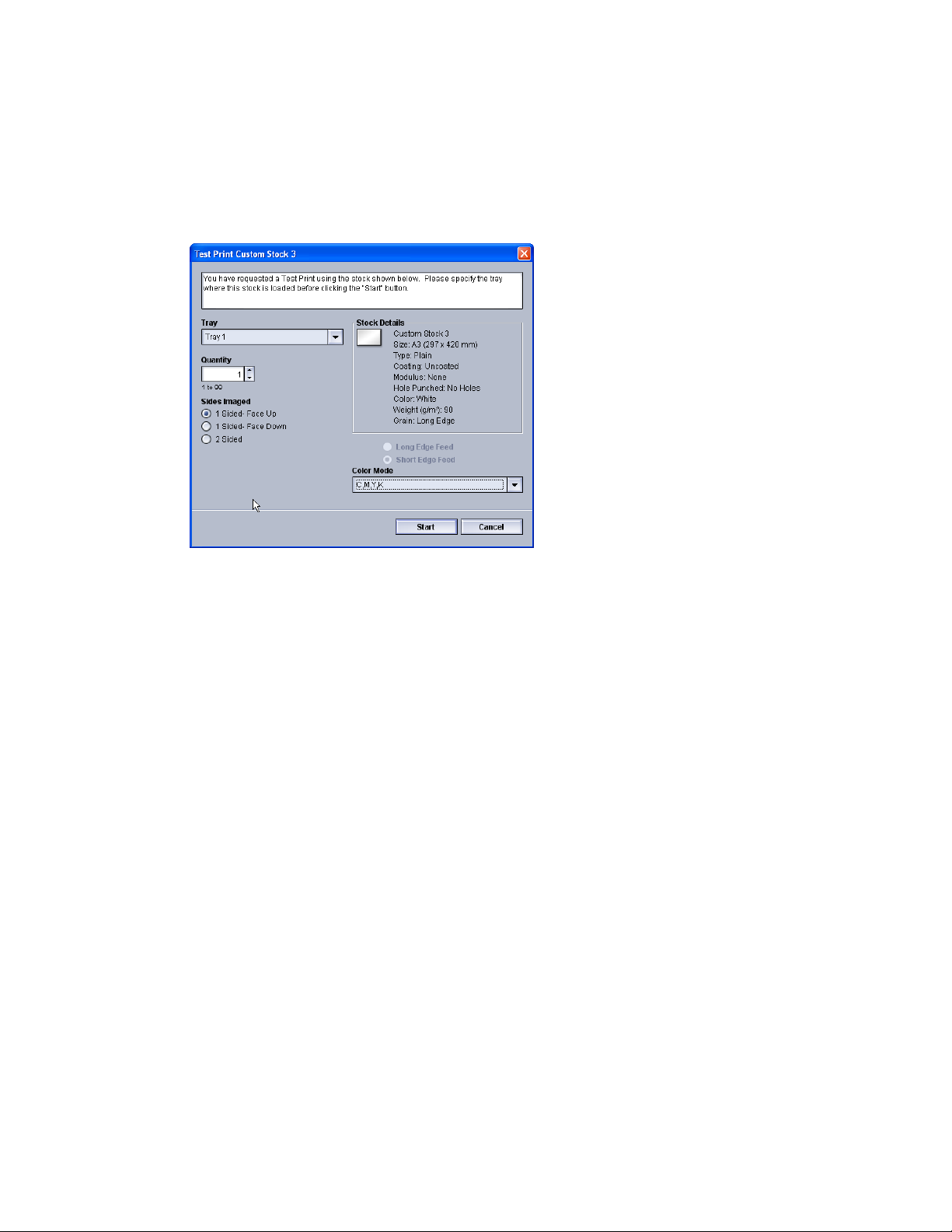

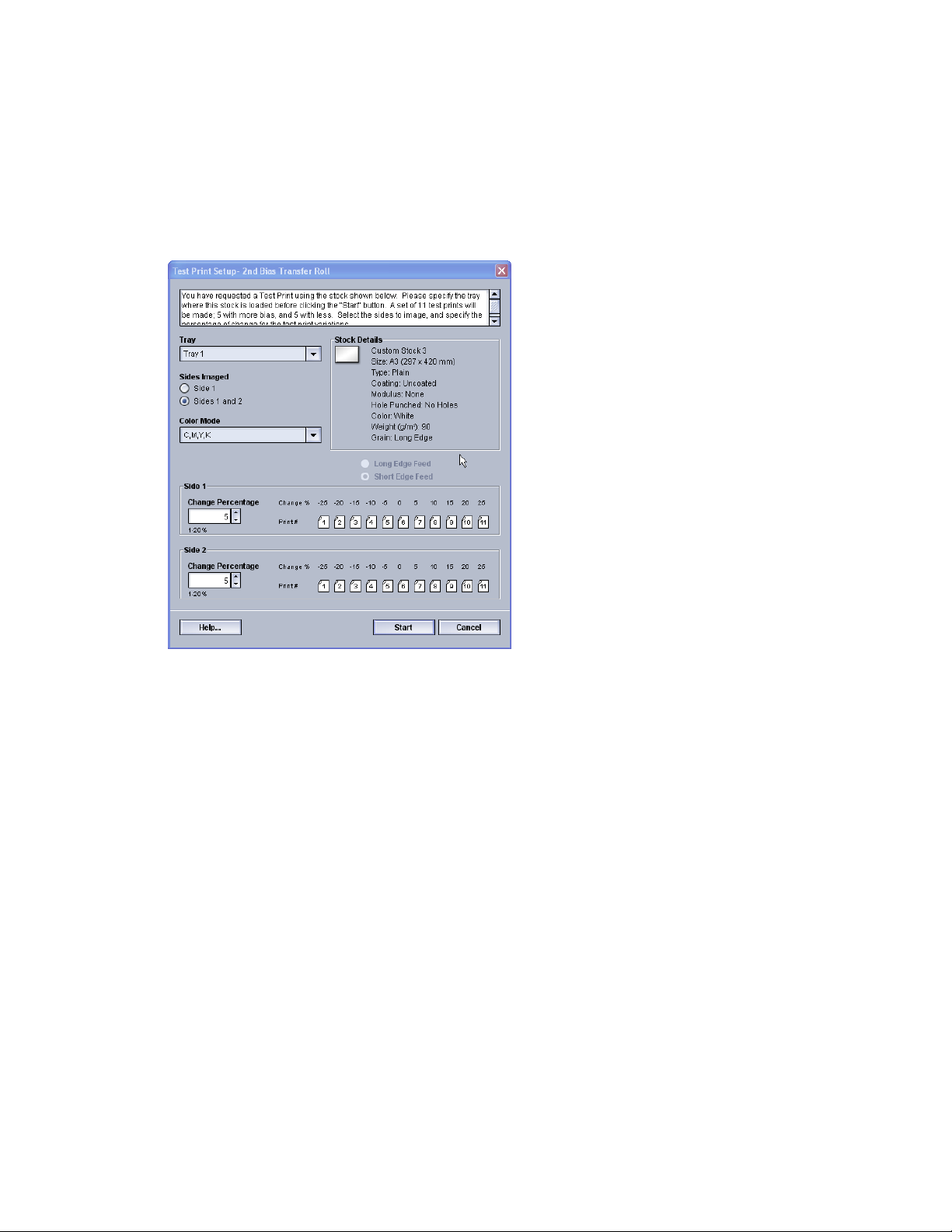

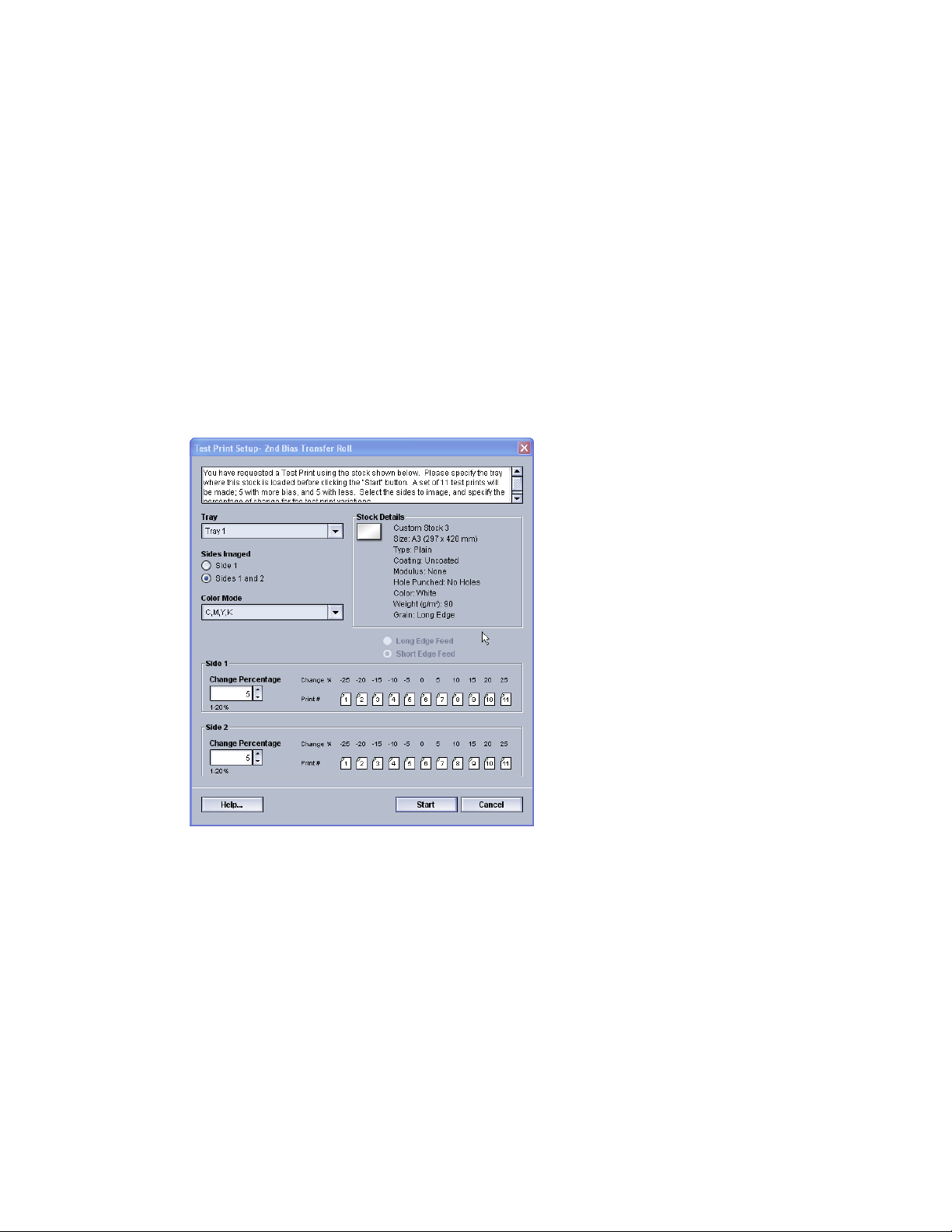

When using the 2nd Bias Transfer Roll option, always run test prints and evaluate the

output before continuing. When the Test Print button is selected, the Test Print Setup:

2nd Bias Transfer Roll window is displayed:

When the Start button is selected, there are always eleven (11) test prints generated:

• 5 test prints will have more bias applied to them (more transfer voltage)

• 5 test prints will have less bias applied to them (less transfer voltage)

• 1 test print will be the median range (this is test print number 6)

The 11 test prints are sent to the output area in the N-1 order (with test print 11 being

the last one printed and the top one on the stack of prints).

Related Topics:

Running the first set of test prints

Evaluating the first set of test prints

Adjusting the test prints

Selecting the 2nd Bias Transfer Roll settings

Running the first set of test prints

When running test prints for the first time, simply select the desired tray, sides images

(Side 1 or Sides 1 and 2), and the Color Mode, and then select Start.

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses3-4

System Administration Guide

Test Print option

Note

You do not need to select any other items, such as Change Percentage, for this first set

of test prints.

The 11 test prints are generated and sent to the output area of the machine.

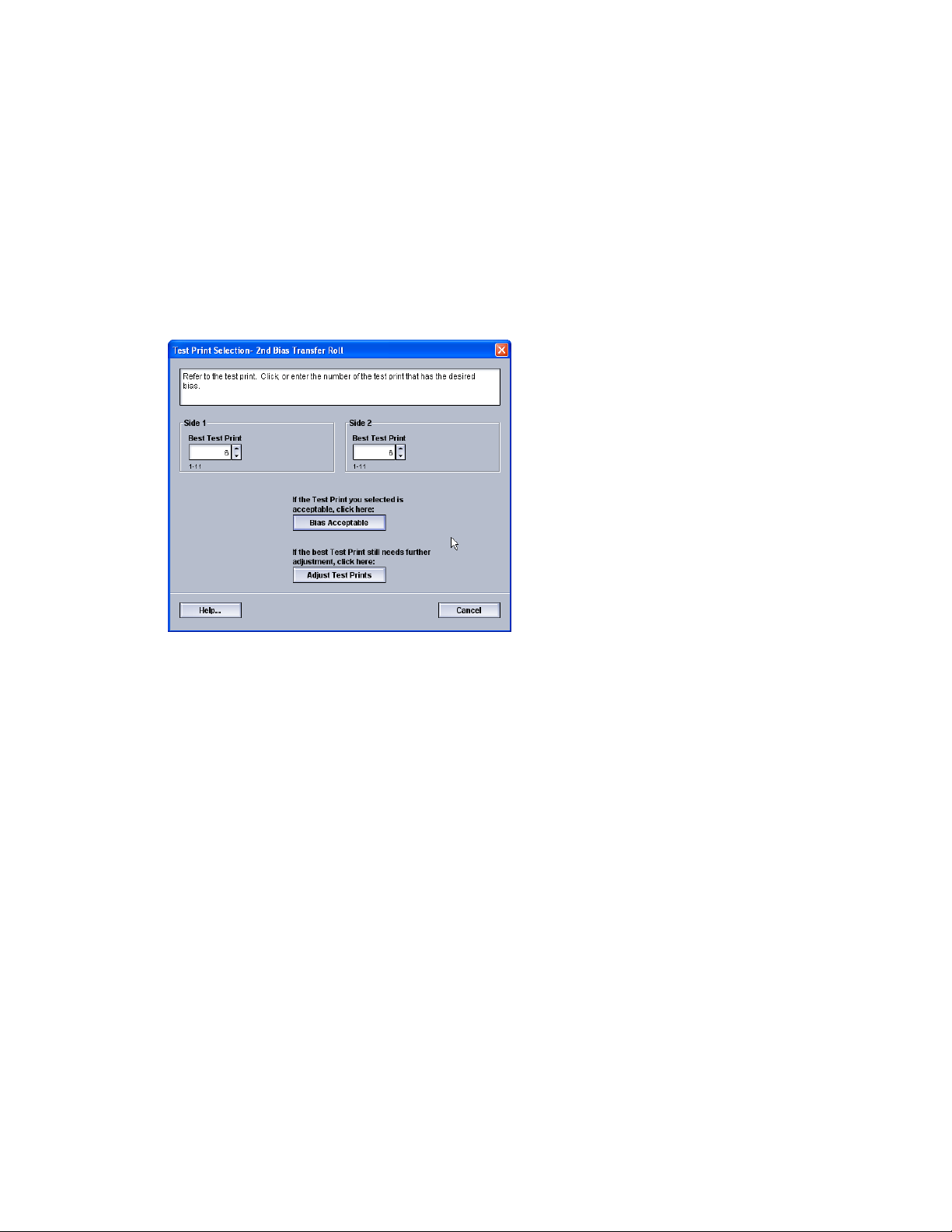

Evaluating the first set of test prints

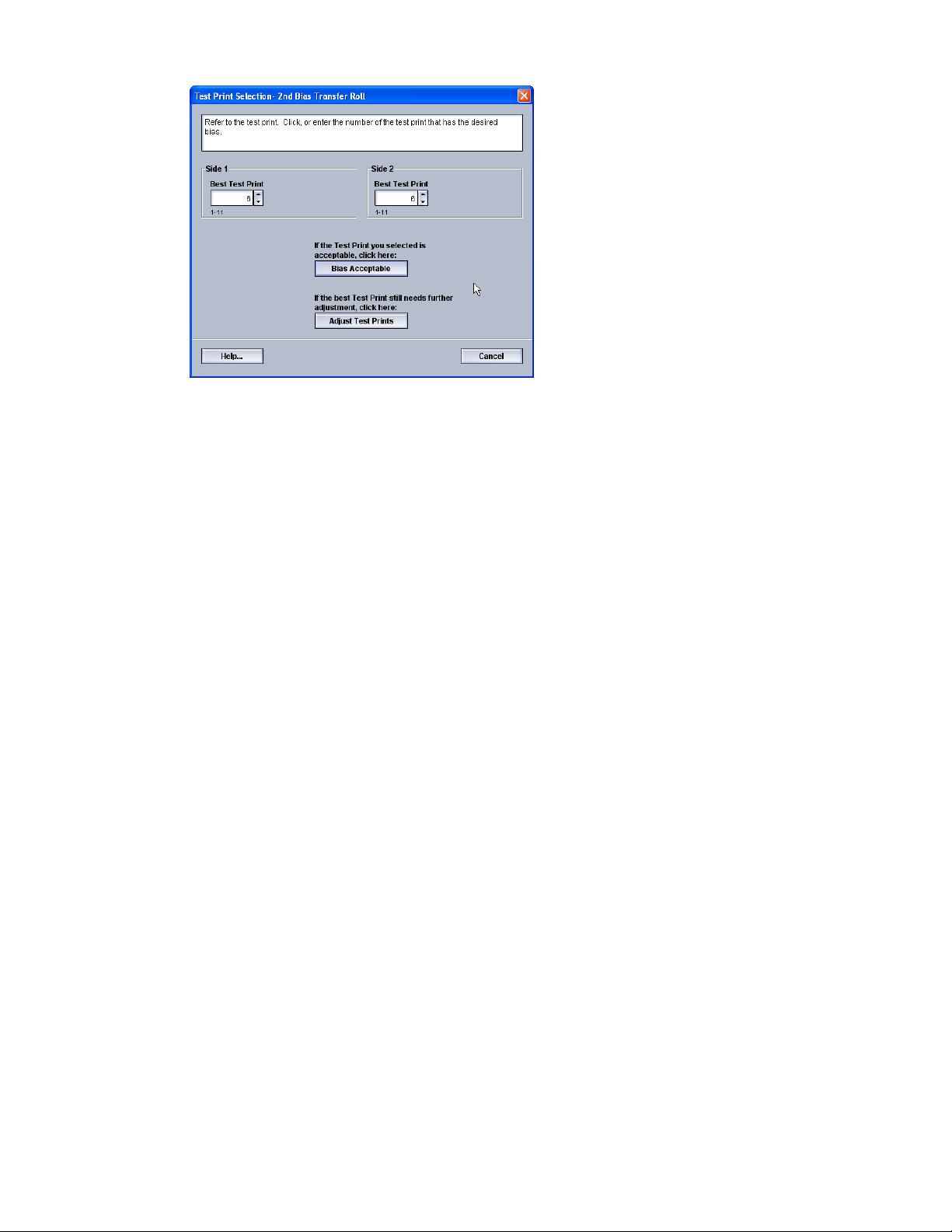

After the 11 test prints are generated, retrieve and review the test prints to find the one

with the best image quality. For example, if the best image quality is on test print 5, this

is the number you enter for the Best Test Print value on Test Print Selection: 2nd Bias

Transfer Roll window:

Note

The default value is 6.

Adjusting the test prints

Selecting the Adjust Test Prints button returns you to the Test Print Setup: 2nd Bias

Transfer Roll window. Notice that the number 5 is already entered as the Change

Percentage value. (You entered this number for the Best Test Print value on Test Print

Selection: 2nd Bias Transfer Roll window.)

Simply select Start again to generate another 11 test prints. Retrieve and evaluate the

next set of test prints for best image quality. Select the desired button depending on

whether or not the image quality is acceptable.

Selecting the 2nd Bias Transfer Roll settings

Use the following procedure to select the settings for the 2nd Bias Transfer Roll (on the

Advanced Stock Setup window).

1. Logon as Administrator.

2. Select Stock Library.

System Administration Guide

3-5Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

Test Print option

The Manage Stock Library window opens.

3. Perform one of the following:

a) Select the Create New button or

b) Select the desired stock from either the RML or the Stock Library list, and then

select the Copy button or

c) Select the desired stock from either the RML or the Stock Library list, and then

select the Properties button.

Either the New Stock Setup window or the Stock Properties window opens.

4. Modify the attributes as required.

5. Select the Advanced Setup button.

The Advanced Stock Setup window opens.

6. Select the desired 2nd Bias Transfer Roll settings for Side 1 and/or Side 2 as required

by using the up/down arrow buttons.

7. Select the 2nd Bias Transfer Roll Test Print button.

The Test Print Setup - 2nd Bias Transfer Roll window opens.

8. Select the desired test print settings and select Start.

Once the test prints are completed, the machine displays the following message:

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses3-6

System Administration Guide

Test Print option

9. Select either:

a) Bias Acceptable: Select this if the output meets customer satisfaction.

This closes the current window and returns you to the Advanced Stock Setup

window.

b) Adjust Test Prints: Select this if the output does not meet customer satisfaction

and requires further adjusting.

This returns you to the The Test Print Setup - 2nd Bias Transfer Roll window where

you can make further adjustments and run additional test prints. Repeat this step

as required until the desired output is achieved.

10. Select OK to close the Advanced Stock Setup window.

11. Select OK to save and close either the New Stock Setup window or the Stock Properties

window.

12. Select Close to exit Manage Stock Library.

13. Select Logoff to exit the Administrator mode.

Related Topics:

Logging on as Administrator

System Administration Guide

3-7Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

Test Print option

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses3-8

System Administration Guide

4

Paper curl correction

Paper curl overview

This option allows you to select the desired paper curl setting in order to prevent your

output from curling. This section provides an overview of paper curl, what causes it and

why adjustments may be required in order to obtain optimum print output.

When paper is exposed to heat, the paper loses moisture and curls toward the heat

source. High dry ink/toner coverage jobs tend to curl more due to the dryink/toner

plastification effect on the paper surface. The system tries to reduce this by using

mechanical devices within the paper path called decurlers.

Paper curl is caused by many variables, including:

• The weight of the paper and whether it is coated or uncoated.

• The amount of dry ink/toner and the area being covered on a sheet; the heavier the

coverage, the greater the tendency to curl.

• How the paper is loaded in the tray. Make sure you load the paper as instructed on

the ream wrapper.

• The atmospheric conditions of the room where the paper is stored, especially those

related to humidity and temperature.

• The heat generated during the fusing processes.

Your system is designed with an automated setting to control curl. When using the

system Default, the machine automatically sends paper through the proper decurler.

The system Default automatically determines the amount of pressure needed at the

different decurlers in order to reduce the output curl of the paper.

With some print jobs, the output prints still may be curled more than you desire even

after using the system default. In those cases, use the Paper Curl Correction option to

compensate for paper curl in your prints. Paper Curl Correction settings are based on

the job type and image density ratio. These settings are manually entered through the

Advanced Stock Setup feature, and you must be logged in as the Administrator.

System Administration Guide

4-1Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

Paper curl correction

Note

It is important to remember that a successful paper curl correction setting used today

may not be the same setting that you would use on another day. This is especially

relevant if the room in which machine is located experiences changes in temperature

and humidity.

Paper Curl Correction options

The Paper Curl Correction options from the Advanced Stock Setup window include:

• 1 Sided-Face Up: This option allows you to set specific paper curl information for

one-sided only printed output which exits the machine in the face up position.

• 1 Sided-Face Down: This option allows you to set specific paper curl information for

one-sided only printed output which exits the machine in the face down position.

• 2 Sided: This option allows you to set specific paper curl information for two-sided

printed output.

Tip

Changing the default setting should be considered a temporary solution because

environmental conditions vary from day to day. It is recommended that upon completion

of the print job, you return the option to its default setting.

Related Topics:

1 Sided-Face Up option

1 Sided-Face Down option

2 Sided option

Correcting the paper curl

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses4-2

System Administration Guide

Paper curl correction

1 Sided-Face Up option

Select the Edit Settings button and then the desired settings for one-sided only print

jobs that will exit the machine in the face-up position.

• 1 Sided Face Up Curl Correction: Select either Default or from the Custom pull-down

menu, select the setting that best describes the curl issues on your output.

• Front Print Density: Enter the desired print (dry ink/toner) density amount as required;

amounts range from zero to seventy percent. If your output is a high dry ink/toner

coverage area on the output, you may want to enter a higher print density amount.

The system default value is 10%.

Tip

You may need to run several test prints, evaluate the output, and readjust the values

before achieving your desired output.

1 Sided-Face Down option

Select the Edit Settings button and the desired settings for one-sided only print jobs that

will exit the machine in the face-down position.

• 1 Sided Face Down Curl Correction: Select either Default or from Custom the

pull-down menu, select the setting that best describes the curl issues on your output.

• Front Print Density: Enter the desired print (dry ink/toner) density amount as required;

amounts range from zero to seventy percent. If your output is a high dry ink/toner

coverage area on the output, you may want to enter a higher print density amount.

The system default value is 10%.

Tip

You may need to run several test prints, evaluate the output, and readjust the values

before achieving your desired output.

System Administration Guide

4-3Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

Paper curl correction

2 Sided option

Select the Edit Settings button and the desired settings for two-sided only print jobs.

• 2 Sided Curl Correction: Select either Default or from the Custom pull-down menu,

select the setting that best describes the curl issues on your 2-sided output.

• Front Print Density: Enter the desired print (dry ink/toner) density amount as required;

amounts range from zero to seventy percent. If your output is a high dry ink/toner

coverage area on the output, you may want to enter a higher print density amount.

The system default value is 10%.

• Black Print Density: Enter the desired print (dry ink/toner) density amount as required;

amounts range from zero to seventy percent. If your output is a high dry ink/toner

coverage area on the output, you may want to enter a higher print density amount.

The system default value is 10%.

Tip

You may need to run several test prints, evaluate the output, and readjust the values

before achieving your desired output.

Correcting the paper curl

Use this procedure when selecting/setting paper curl correction options for a stock entry

(either a new permanent stock or a modification to an existing stock).

1. Logon as Administrator.

2. Select Stock Library.

The Manage Stock Library window opens.

3. Perform one of the following:

a) Select the Create New button or

b) Select the desired stock from either the RML or the Stock Library list, and then

select the Copy button or

c) Select the desired stock from the Stock Library list, and then select the Properties

button.

Either the New Stock Setup window or the Stock Properties window opens.

4. Modify the attributes as required.

5. Select the Advanced Setup button.

The Advanced Stock Setup window opens.

6. Select the Edit Settings for the desired Paper Curl Correction option (1 Sided-Face

Up, 1 Sided-Face Down, and/or 2 Sided) as required.

The Paper Curl Correction Setup window opens for the selected 1-sided/2-sided option.

7. Select the desired curl correction option (Default or an option from the Curl Correction

pull-down menu).

8. Select the Test Print button.

The Paper Curl Correction Test Print window opens.

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses4-4

System Administration Guide

Paper curl correction

9. Select the desired print density setting.

10. Select the tray where the stock is loaded and the desired output quantity to print.

11. Select the Start button.

Once the test prints are completed, the machine displays the following message:

12. Select either:

a) Done Adjusting: Select this if the output is properly adjusted.

This closes the current window and returns you to the Advanced Stock Setup

window.

b) Continue Adjusting: Select this if the output still contains too much paper curl,

print density, and needs further adjusting.

This allows you to make further adjustments to the paper curl correction and print

density options and run additional test prints. Repeat this step as required until

the desired output is achieved.

13. Select OK to close the Advanced Stock Setup window.

14. Select OK to save the changes to the stock and close the Stock Properties window.

15. Select Close to exit Manage Stock Library.

16. Select Logoff to exit the Administrator mode.

Related Topics:

1 Sided-Face Up option

1 Sided-Face Down option

2 Sided option

Logging on as Administrator

System Administration Guide

4-5Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

Paper curl correction

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses4-6

System Administration Guide

5

System Settings

The System Settings window allows you to make changes to the following features:

• User Interface

• Date and Time

• System

• Tray Options

• Output Devices

• Image Quality

• Full Width Array

Related Topics:

User Interface

System

Tray Options

Output Devices

Image Quality tab

Full Width Array Overview

Setting the date and time

User Interface

The User Interface feature allows you to make changes to the following:

• Fault Details Window

• Default Language

• Changing the Administrator password

• Resetting the Technical Key Operator Password

System Administration Guide

5-1Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

System Settings

• Managing how the Stock Library Window is displayed on the UI

Related Topics:

Fault Details window

Setting the default value for Fault Details Window

Default Language

Change administrator password

Resetting the Technical Key Operator password

Manage Stock Library Window

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses5-2

System Administration Guide

System Settings

Fault Details window

By default, the UI automatically opens a Details window which provides additional

information about the alert, warning, or fault (as shown in the following illustration).

However, you can select whether or not you want this window to open automatically or

to open only when the user clicks on the alert, warning, or fault message in the machine

mimic and message area of the UI.

Setting the default value for Fault Details Window

Use the following procedure to choose the default setting for this feature.

1. Select the Logon button from the UI and logon as the Administrator.

2. Select the System Settings button.

3. Select whether or not you want any machine faults to automatically display on the

UI when they occur.

• Do Not Display Automatically: Select this option if you do not want the fault

Details window to open automatically when an alert, warning, or fault occurs.

• Display Automatically: Select this option if you do want the fault Details window

to open automatically when an alert, warning, or fault occurs.

4. Select OK to save the change and close the System Settings window.

Related Topics:

Logging on as Administrator

System Administration Guide

5-3Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

System Settings

Default Language

Use the Default Language feature to set the default to your desired language selection.

Language settings range depending on the Language File installed on the PC UI.

Note

Languages that are not installed on the PC UI cannot be selected through the Default

Language settings feature.

The language files loaded on your PC UI will vary from marketplace to marketplace. Use

the following procedure to change/set the default language for your machine:

1. Logon as Administrator.

2. Select the System Settings button.

3. From the User Interface tab, select the default language from the Default Language

pull-down menu.

4. Select OK to save your changes and close the System Settings window.

5. To exit the Administrator mode, select the Logoff button.

Related Topics:

Logging on as Administrator

Change administrator password

1. From the Logon window, enter the Administrator password and select OK.

For security reasons, only asterisks are displayed on the screen.

Note

The machine arrives from the factory with a default Administrator password of five

ones (11111). Use this default password to logon.

Tip

For security reasons, you should change the Administrator password from its default

password to a new one.

2. From the System Settings window, select the Change Password button from the

User Interface tab.

The Change Password window opens.

Tip

Use numbers only for creating your new password. Alpha characters (letters and other

characters, such as!*& are not allowed). A maximum of twelve numbers can be entered

for your password.

3. From the Change Password window, enter:

a) The old (current) password

b) The new password

c) Reenter the new password in the Confirm New Password area

d) Select OK

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses5-4

System Administration Guide

System Settings

Note

For security reasons, only asterisks are displayed on the screen.

4. Select OK from the System Settings window to return to the main UI window.

5. Select Logoff to exit the Administrator mode.

Related Topics:

Logging on as Administrator

Resetting the Technical Key Operator password

If the Technical Key Operator (TKO) password is lost or forgotten, it may be reset to its

manufacturing default by the system administrator.

1. Logon as Administrator.

2. Select the System Settings button.

3. From the User Interface tab, select the Reset to Default button for the TKO password.

A screen displays asking you to confirm whether or not you want to reset the TKO

password.

4. Select Yes to reset the TKO password; select No to keep the current TKO password

and return to the previous screen.

5. Select OK to save your changes and close the System Settings window.

6. To exit the Administrator mode, select the Logoff button.

Related Topics:

Logging on as Administrator

Manage Stock Library Window

The administrator may manage whether or not the Stock Library feature is displayed

on the main UI screen for the Operator user mode. By default, the Stock Library feature

is always displayed on the main UI. This is independent of the logged-on user mode.

This means that both the Operator and the Administrator user modes have access to

the Stock Library.

If the administrator chooses to restrict the Stock Library feature, it can be set from

System Settings > User Interface.

1. Logon as Administrator.

2. Select the System Settings button.

3. From the User Interface tab, select the desired setting for the Manage Stock Library

Window feature.

• Allow Casual User Access: This is the default setting. With this selection, all user

modes (operator and administrator) have access to the Stock Library and the

Stock Library feature is always displayed on the main UI.

• Restrict Casual User Access: With this selection, the Stock Library feature is no

longer displayed on the main UI when the Operator is logged on. Access to the

System Administration Guide

5-5Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

System Settings

Stock Library feature is available only to the administrator and is displayed on the

main UI only when the Administrator is logged on.

4. Select OK to save your changes and close the System Settings window.

5. To exit the Administrator mode, select the Logoff button.

Related Topics:

Logging on as Administrator

Setting the date and time

Use this feature to set the date and time for the system. The date and time is displayed

on the Machine Details screen on both the Installed Software and Error Log screens.

1. Logon as Administrator.

2. Select the System Settings button.

3. From the System Settings window, select the Date/Time tab.

4. Select the Date Format you wish to use.

5. Use the up or down arrow buttons to enter the correct year, month, and day.

6. Select the Time Format you wish to use.

7. Use the up or down arrow buttons to set the correct hour and minutes.

Note

If you selected the 12 Hour Clock, select the AM or PM button.

8. Select OK to save your changes and close the System Settings window.

9. To exit the Administrator mode, select the Logoff button.

Related Topics:

Logging on as Administrator

System

Use this feature to change the factory default settings for Productivity Mode, Power

Save Mode, Auto Resume, Auto Logoff, Attention Sounds and to enter NVM Read/Write

values when using specialized media.

Related Topics:

Productivity Mode

NVM Read/Write

Power Saver

Auto resume after pause

Auto logoff

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses5-6

System Administration Guide

System Settings

Attention Sounds

Productivity Mode

The productivity of the machine relates to the continuous speed of the media output

as measured in prints per minute (ppm). The continuous speed is dependent on paper

size, paper weight, and fuser temperature.

Use the productivity setting to optimize the throughput speed for the type of paper you

run most frequently. Productivity Setting options include:

• Single Paper Weight: This setting allows all print jobs to run at the same, or rated,

throughput speed, regardless of weight.

• Mixed Paper Weight: This setting optimizes the throughput speed of print jobs that

contain mixed media weights from different paper trays.

- Optimize for Speed: This setting prints jobs at the rated speed of the machine

(80/100 prints ppm)

- Balance Speed & Image Quality: This setting provides the best image quality on

print jobs but at a slower print speed.

• Transparency Productivity / Embossed Paper Productivity: Use this setting to

optimize the throughput speed for the paper type you run most frequently. Options

include:

- Priority on Image Quality: This selection provides the best image quality possible

on the transparency or embossed output but the machine runs at a slower print

speed in order to achieve this high image quality on the output.

- Priority on Productivity: This selection allows the machine to run at the rated

press speed (100 ppm) but the output may not provide the best image quality.

Related Topics:

Single Paper Weight chart

Mixed Paper Weight chart

Selecting the productivity mode options

Single Paper Weight chart

The following productivity chart list the various paper weights and sizes and their related

print speeds for 1 Sided and 2 Sided output.

System Administration Guide

5-7Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

System Settings

Paper Weight

in./101.64 x 152.4

mm)

Paper Size (Feed direction length)

[mm]

Print Speed (prints per minute ppm)

2 Sided1 SidedMaxMin.

50100216.018255-350 gsm

4080280.0216.1

2550482.6280.1

2040488.0482.7

--100152.4148.0Post card (4 x 6

--50216.0210.0Transparency

Note

• Two-Sided printing is not available for transparency and paper that is 350 gsm or

greater.

• There is no decrease in productivity (ppm) from the main paper trays to any additional,

optional trays.

• Transparency is only available for 1 Sided, A4 or 8.5 x 11 in. LEF.

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses5-8

System Administration Guide

System Settings

Mixed Paper Weight chart

The following productivity chart list the various paper weights and sizes and their related

print speeds for 1 Sided and 2 Sided output.

Paper Weight

Paper Size (Feed direction length)

[mm]

Print Speed (prints per minute ppm)

2 Sided1 SidedMaxMin.

50100216.018255-157 gsm

4080280.1216.1

2550482.6280.1

2040488.0482.7

4080216.0182.0158-220 gsm

2550354.0216.1

2040488.0354.1

2550280.0182.0221-350 gsm

2040431.8280.1

16.633.3488.0431.9

--50216.0210.0Transparency

Note

Print speeds may decrease due to machine setup operations, which are based on

environmental conditions and specific interval volume of continuous printing.

Selecting the productivity mode options

1. Logon as Administrator.

2. Select the System Settings button.

3. Select the System tab.

4. Select the desired Productivity Mode settings including Single or Mixed Paper Weight,

Transparency Productivity, and Embossed Paper Productivity.

5. Select OK to save your changes and close the System Settings window.

6. To exit the Administrator mode, select the Logoff button.

Related Topics:

Logging on as Administrator

NVM Read/Write

Under most conditions, this feature is not used by system administrators. Your Xerox

Service Representative may use it to change certain system settings.

5-9Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

System Administration Guide

System Settings

It is recommended that you do not enter any numbers on this screen before consulting

with your Xerox Service Representative. Entering numbers on this screen may change

system settings which may result in a service call to restore the system to the correct

settings.

Related Topics:

Using the NVM Read/Write feature

Using the NVM Read/Write feature

1. Logon as Administrator.

2. Select the System Settings button.

3. Select the System tab.

4. Select the NVM Read/Write button.

The NVM Read/Write window opens.

5. Enter the desired, six-digit Chain Link Number.

a) Using the numbers on the keyboard, enter the Chain Number.

b) Press the Tab button on the keyboard to advance to the Link field.

c) Enter the Link number.

d) Select the Next button.

The Enter the New Value window displays.

6. Using the keyboard, enter the New Value to switch on a feature.

7. Select the Apply button.

The NVM Read/Write window displays the entered value as the Current Value.

8. Select Close to save and close your new setting.

9. Select OK to close the System Settings window.

10. Select Logoff to exit the Administrator mode.

11. Run your print job.

Important

After running your print job, switch off the NVM feature; this will ensure that the

machine runs at maximum efficiency and will prevent paper jams.

Related Topics:

Logging on as Administrator

Power Saver

Use this feature to set the time that lapses until the machine and system PC UI enter a

reduced power consumption mode. The timers are activated when all print jobs have

been completed and there are no jobs in the job queue.

The Power Saver feature consists of the following options:

• Enter Power Saver

- System PC & Print Engine

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses5-10

System Administration Guide

System Settings

- Print Engine Only

- Print Engine Only If No Communication For

• Exit Power Saver

- Automatically

- Manually

The machine and/or system PC exits the power saver mode when a job is sent from the

print server to the machine or when the system PC UI is activated.

Note

The System PC & Print Engine and Print Engine Only features must be enabled

by your Xerox Representative before you can use them. If these features are not enabled,

call your Xerox Representative for more information.

Related Topics:

System PC & Print Engine

Print Engine Only

Print Engine Only If No PC Communication For

Exit Power Saver

Setting the power saver options

System PC & Print Engine

In this mode, the power to the UI and fuser unit is lowered to save power. The PC UI

display goes black, and the print engine enters power saver mode. To exit the power

saver mode, either send a job from the print server to the machine or press the print

engine power switch to the on position.

Print Engine Only

In this mode, the power to the UI and fuser unit is lowered to save power. The PC UI

display remains on, and the Power Saver button on the UI lights. To use the machine

press the Power Saver button on the UI. The Power Saver button goes out to indicate

that the power saver feature is canceled.

Print Engine Only If No PC Communication For

Use this feature when there is no communication between the PC UI and the print engine

for a specific amount of time. This will cause the print engine to enter the sleep mode.

The PC UI display remains on, and the Power Saver button on the UI lights up.

System Administration Guide

5-11Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

System Settings

Exit Power Saver

Select one of two options:

• Automatically: Select this option if you want the system to automatically exit from

power saver mode whenever the mouse, keyboard, PC power switch, or print engine

power switch is activated.

• Manually: Select this option if you want to manually exit the system from power

saver mode when the power saver button on the main UI screen is selected.

Note

To manually exit the power saver mode, press and release the power button on the

system PC.

Setting the power saver options

1. Logon as Administrator.

2. Select the System Settings button.

3. Select the System tab.

4. Uncheck the power saver options that you do not want enabled for your machine.

The system default is enabled (checked) for the Print Engine Only and Print Engine

Only If No PC Communication For options.

5. Use the up or down arrow buttons to change the time for each of the power saver

features:

• System PC & Print Engine

• Print Engine Only

• Print Engine Power Only If No PC Communication For

The range available is 1-240 minutes.

Note

The system default time is 60 minutes for System PC & Print Engine and Print Engine

Only. The system default time for Print Engine Only If No PC Communication For is

ten minutes.

6. Select the desired Exit Power Saver option.

7. Select OK to save your changes and close the System Settings window.

8. Select Logoff to exit the Administrator mode.

Related Topics:

Logging on as Administrator

Auto resume after pause

Use the Auto Resume After Pause feature to restart a job automatically after the Pause

button is selected on the UI and the job is waiting for user instruction.

1. Logon as Administrator.

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses5-12

System Administration Guide

System Settings

2. Select the System Settings button.

3. Select the System tab.

4. For the Auto Resume After Pause option, use the up or down arrow buttons to change

the time (minutes and seconds). The range for minutes is 0-60, and the range for

seconds is 0-59.

The system default time is two minutes.

5. Select OK to save your changes and close the System Settings window.

6. To exit the Administrator mode, select the Logoff button.

Related Topics:

Logging on as Administrator

Auto logoff

Use the Auto Logoff feature to have the machine automatically return to the printing

mode when no action is taken from any of the administrator functions after the set

amount of time.

1. Logon as Administrator.

2. Select the System Settings button.

3. Select the System tab.

4. To enable Auto Logoff, select the checkbox to the left of it.

5. Use the up or down arrow buttons to change the time. The range available is 1-60

minutes.

6. Select OK to save your changes and close the System Settings window.

7. To exit the Administrator mode, select the Logoff button.

Related Topics:

Logging on as Administrator

Attention Sounds

The Attention Sounds option allows you to select whether or not to sound an alarm

when a fault occurs on the machine.

1. Logon as Administrator.

2. Select the System Settings button.

3. Select the System tab.

4. To enable Attention Sounds, select the check box to the left of Enable Sounds.

5. From the Volume pull-down menu, select the desired option (High, Medium, Low).

6. From the Number of Beeps pull-down menu, select either 5 Beeps or Until User

Intervenes.

7. Select OK to save your changes and close the System Settings window.

8. To exit the Administrator mode, select the Logoff button.

Related Topics:

Logging on as Administrator

System Administration Guide

5-13Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

System Settings

Tray Options

Use this feature to change the factory default settings for the following:

• Auto Tray Switch Method: Instructs the machine to automatically switch trays in a

specific order. Options include:

- Always check from priority 1: When a tray runs out of paper, this option tells the

machine to always check the tray listed as Priority 1 before checking other

available trays.

- Check in a fixed order: This option tells the machine to check the next higher

priority tray; for example, if the paper being fed is from tray 2 and runs out of

paper, the machine then checks the tray listed in sequential order after tray 2 in

the priority list. The machine continues to check the trays in the priority list in

sequential order until a tray is found with the same stock requirements.

Note

If a tray with the same stock requirements is not found, the machine displays a message

to load the required paper.

• Manual Tray Switching: This option requires more user interaction. The options include:

- Enable: This option allows the user to choose a specific tray instead of having

the system automatically check the various available trays to find a tray with

the matching paper parameters (size, weight, etc). When the current tray runs

out of paper (or nears the empty condition), the UI displays a window informing

the user and asking from which next available tray to feed paper or to cancel

the job.

- Disable: This option does not prompt the user to select a different tray when the

current one is near empty or is empty. The machine operates in the default tray

switching method, as per the selections made for Auto Tray Switching and Auto

Tray Switch Method.

• Do not Include for Temporary Stock: Selecting a tray here (check marked) means

that the system will not automatically select and feed paper from that tray after

other trays are empty.

Note

This feature works only if there are more than two trays available for selection. If

Trays 1 and 2 are the only trays available, this feature is ignored.

• Tray Properties Window Timeout: Sets whether or not the tray properties window

automatically closes if no changes were made to it. Choices include:

- Never: The window always remains open, unless you manually close it.

- Timeout period between 1-240 minutes: If this is set, you do not need to manually

close the window. It will close automatically once the preset time is reached.

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses5-14

System Administration Guide

System Settings

• Tray Priority: Sets the priority order for automatic tray selection. If the Auto Tray

Switch Timing feature is enabled and each paper tray contains the same paper size

and weight, the machine feeds paper from the tray set at Priority 1. If there is no

paper in the Priority 1 tray, the Priority 2 tray is automatically selected and so on

Related Topics:

Selecting the Tray Options settings

Selecting the Tray Options settings

Choose the default settings for the following options:

1. Logon as Administrator.

2. Select the System Settings button.

3. Select the Tray Options tab.

4. Select the default setting for:

• Auto Tray Switch Method

• Manual Tray Switching

• Do Not Include for Temporary Stock

5. Select the desired Tray Properties Timeout Window option.

6. Set the default tray priority levels for all attached trays:

a) Click once on the desired tray in the Tray Priority list.

b) Click the up/down arrow button to move the tray up or down in the priority list.

c) Repeat the above two steps for each tray attached to your machine.

Note

You cannot set the same paper tray for more than one priority level at a time.

7. Select OK to save your changes and close the System Settings window.

8. Select Logoff to exit the Administrator mode.

Related Topics:

Logging on as Administrator

System Administration Guide

5-15Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

System Settings

Output Devices

This tab is available only when specific finishing devices are attached, such as the High

Capacity Stacker or the Perfect Binder.

Related Topics:

High Capacity Stacker Settings

Perfect Binder Settings

Selecting the Output Device options

High Capacity Stacker Settings

Use the Output Devices feature to set specific HCS output settings, including:

• Auto Output Switching: This option sets whether or not to allow the automatic

switching of the output destination from a full HCS to second HCS while jobs are

printing or when the Unload button on the HCS is pressed.

- Enable: Select this setting to allow the job output to automatically switch from

one HCS to another HCS.

- Disable: This is the default setting. Select this option if you do not want automatic

switching from one HCS to another HCS during print jobs.

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses5-16

System Administration Guide

System Settings

Note

The Auto Output Switching and Auto Output Switching Priority options are available

ONLY when there is more than one HCS attached to the machine.

• Auto Output Switching Priority: Set the priority order each attached HCS.

• Unload Timing: This option sets how the HCS Unload button functions.

- Unload at set boundary: Selecting this option causes the HCS to stop after

delivering output at the end of the set when the Unload button is pressed.

- Unload immediately: Selecting this option causes the HCS to stop after delivering

the scheduled paper immediately when the Unload button is pressed. This may

occur in the middle of a job set, and the last set delivered may not be a complete

set.

Note

If more than one HCS is attached to the machine, the option selected here applies

to all of them.

Perfect Binder Settings

Select the desired settings for the Perfect Binder power saver mode:

• Glue Heater Timeout: Select a time interval for when the adhesive unit shuts off and

the binder enters power saver mode after the last job in the queue was completed.The

time interval represents a period of system inactivity without any jobs printing or

any jobs in the queue waiting to be printed. Choose between 1-240 minutes. The

default setting is 10 minutes.

• Manual Feed Timeout: Select a time interval for when the adhesive unit shuts off

and the binder enters power saver mode after the last manual feed job was

completed.The time interval represents a period of system inactivity without any

jobs printing or any jobs in the queue waiting to be printed. Choose between 1-240

minutes. The default setting is 10 minutes.

Selecting the Output Device options

1. Logon as Administrator.

2. Select the System Settings button.

3. Select the Output Devices tab.

4. Select the desired High Capacity Stacker Settings.

Note

The Auto Output Switching and Auto Output Switching Priority options are available

ONLY when there is more than one HCS attached to the machine.

5. Select the desired Perfect Binder Settings.

6. Select OK to save your changes and close the System Settings window.

7. Select Logoff to exit the Administrator mode.

System Administration Guide

5-17Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

System Settings

Related Topics:

Logging on as Administrator

Image Quality tab

This feature allows administrators to select the default setting in order to achieve

maximum image quality on the printed output.

The Image Quality feature consists of:

• Priority When Switching Paper Types: Choose from one of two options

- Image Quality: This selection provides the best image quality possible on the

transparency output but the machine runs at a slower print speed in order to

achieve this high image quality on the output.

- Productivity: This selection allows the machine to run at the rated press speed

(100 ppm) but the output may not provide the best image quality possible.

• Silver/Gold Printing Higher Fuser Temperature: Select this checkbox to increase the

fusing temperature when printing either of these two colors thereby resulting in more

gloss and better ink adherence.

• Registration Control Setup: Run this option when image quality issues such as

color-to-color, lead edge, and side edge registration problems occur on printed output.

Running this option may fix the registration issues without placing a service call.

• Fuser Belt Refresh: Refer to Fuser Refresh Mode section for more information on this

option.

• Process Control Setup Color Mode: Select the color mode to identify the combination

of toners to use when processing and printing the job.

Related Topics:

Fuser Refresh Mode

Fuser Refresh Mode

Use the Fuser Belt Refresh option to run a fuser belt refresh when the system is

experiencing image quality defects on the printed output. These defects include scratches,

spots, streaks, or bands. The refresh option engages the fuser refresh roll against the

fuser belt and buffs out any scratches that may be occurring on the lead edge or side

edge of the output.

When enabled, the refresh mode occurs every 10,000 prints and takes approximately

60 minutes. This refresh mode occurs while the machine is idle (not printing).

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses5-18

System Administration Guide

System Settings

Note

If a job is submitted while the refresh mode is running, the refresh mode stops and the

submitted job prints. The refresh mode does not reconvene after the print job is

completed. Another refresh mode will occur after the next 10,000 prints are reached.

Set the system to run automatic fuser belt refreshes at specific intervals:

• Enabling automatic refresh tells the system to run a fuser belt refresh during a

“Waiting for printer” process.

• Refresh Duration can be set between 1-999 minutes.

• Manual Refresh: This option allows you to set up a manual fuser refresh at the point

of need instead of at a scheduled time. You may have both a scheduled refresh time

programmed and also perform a manual refresh at any time.

The duration default time is 60 minutes. If lead edge or side edge defects still occur

upon completion of a 60-minute refresh mode, the refresh time can be changed to a

longer duration to elminate these defects.

Full Width Array Overview

The Full Width Array feature uses xerographic parameters and diagnostics to scan the

finished image and correct errors in registration, density and color. This is the process

of calibrating the Print Server with the digital press.

Note

If the Full Width Array feature is not available on your press, contact your Xerox

representative.

With the Full Width Array, thare are internal color calibration strips (or tiles) used as

reference for known colors of a test pattern. These color values are automatically adjusted

to produce accurate and consistent reproductions, and this means that no longer is

customer intervention required.

Note

Refer to your Print Server user documentation when performing the calibration workflow

of the Print Server in conjunction with the digital press.

System Administration Guide

5-19Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

System Settings

The Full Width Array provides these features:

• Automatic Tone Reproduction Curve Adjustment: Run this adjustment on a daily

basis in order to ensure that your machine maintains the best image quality with less

or no down-time for color-critical jobs. This in turn enhances the machine’s overall

productivity.

• Automatic Density Uniformity Adjustment: Run this image quality adjustment

when the printed output density is inconsistent (non-uniform) within the printed

page; non-uniform, inconsistent density may appear as faded colors on portions of

the printed page. Running this adjustment to correct this non-uniformity density may

avoid a service call and possible machine down-time

• Automatic Alignment: Use this feature to adjust the image-to-paper placement on

your printed output. This includes adjusting 1-sided and/or 2-sided image registration,

perpendicularity, skew and magnification. For more information, refer to Automatic

Alignment (Full Width Array)

Related Topics:

Adjusting Automatic Tone Reproduction Curve

Adjusting Automatic Density Uniformity

Adjusting Automatic Tone Reproduction Curve

1. Logon as Administrator.

2. Select the System Settings button.

3. Select the Full Width Array tab.

4. Select the Auto Adjust button for Automatic Tone Reproduction Curve Adjustment.

5. Select the appropriate halftone and then select the Next button.

6. Select the required options:

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses5-20

System Administration Guide

System Settings

• TRC Adjustment Mode: either Simplified TRC (Faster) or High Accuracy TRC (Better

Quality)

• Tray

• Target Value (coated or uncoated)

• Color Mode

7. Select Start.

The press will now run “Target” test prints and update the system appropriately.

8. Select one of the following:

• If the output prints are acceptable, select Accept Changes.

• If the output prints are NOT acceptable, select Start again to make the adjustment

prints.

Note

If acceptable output cannot be reached after numerous attempts, contact the

Customer Support Center.

9. Select Close.

10. Select OK from the System Settings window to return to the main UI window.

11. To exit the Administrator mode, select the Logoff button.

Related Topics:

Logging on as Administrator

Adjusting Automatic Density Uniformity

1. Logon as Administrator.

2. Select the System Settings button.

3. Select the Full Width Array tab.

4. Select the Auto Adjust button for Automatic Density Uniformity Adjustment.

5. Select the tray containing 11 x 17 in. (A3) or 12 x 18 in. (SRA3) paper.

6. Select Start.

The press will print the Density test patterns and automatically update the system

controls appropriately.

7. Select one of the following:

• If the output prints are acceptable, select Accept Changes.

• If the output prints are NOT acceptable, select Start again to make the adjustment

prints.

Note

If acceptable output cannot be reached after numerous attempts, contact the

Customer Support Center.

8. Select OK from the System Settings window to return to the main UI window.

System Administration Guide

5-21Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

System Settings

9. To exit the Administrator mode, select the Logoff button.

Related Topics:

Logging on as Administrator

Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses5-22

System Administration Guide

6

Profiles

This feature allows you to create and customize profiles/procedures for Alignment. The

Alignment feature allows you to position the output image in order to accommodate

for misalignment or skew. These profiles are used at the point of need for specialized

print jobs.

If optional accessories are attached to the machine, additional profiles are available,

such as Fold Adjustment and/or Finishing Devices. These are discussed in more detail

later in this section.

Note

The Profiles features can only be accessed from the Administrator mode.

Related Topics:

Alignment

Fold Adjustment

Enter/exit the Profiles

Enter/exit the Profiles

1. Logon as Administrator.

2. Select the Profiles button.

The Profiles window opens.

The Finishing tab displays only if your machine has a third-party DFA device attached.

3. To create an Alignment profile, select the Alignment tab.

4. To create a Fold Adjustment profile, select the Fold Adjustment tab.

5. Select Close to exit Profiles and return to the main UI.

Related Topics:

Logging on as Administrator

System Administration Guide

6-1Xerox® Color 800i/1000i Presses Xerox® Color 800/1000 Presses

Profiles

Alignment

Note

The list of profiles can be sorted by name, date of change, and comment. If necessary,

use the horizontal scroll bar to view the entire text of long profile names.

The Alignment feature allows you to create and store specific alignment adjustment

profiles. These profiles allow you to accommodate different media types and how the

image is registered, aligned, or magnified for side 1 and side 2 output. These profiles

may be used at point of need in order to ensure optimum output quality of your prints.

Alignment adjustments can be made when the position of the output image is misaligned

or skewed. This may be a result of paper expansion or contraction, cutting inaccuracy,

or paper storage conditions.

Note

It is recommended that you read through the entire Alignment section before

creating/editing or performing any actual alignment adjustments.

Related Topics:

Alignment information