Page 1

Version 3.0

March 2012

Xerox® Color 800/1000 Press

User Guide

Page 2

© 2012 Xerox Corporation. All rights reserved. Xerox®, and Xerox and Design® are

trademarks of Xerox Corporation in the United States and/or other countries.

FreeFlow®, SquareFold®, Xerox prInteract™, MeterAssistant™, SuppliesAssistant™, and

RemoteAssistant™ are trademarks of Xerox Corporation in the United States and/or other

countries. Product status, build status, and/or specifications are subject to change without

notice.

Microsoft, Windows, Windows 2000, Windows XP, Windows Vista, and Windows 7 are

registered trademarks of Microsoft Corporation.

PANTONE® is a registered trademark of Pantone, Inc.

Macintosh is a registered trademark of Apple Computer, Inc., registered in the US and

other countries. Elements of Apple's Technical User Documentation used by permission

from Apple Computer, Inc.

Adobe, the Adobe logo, Acrobat, the Acrobat logo, Acrobat Reader, Distiller, Adobe PDF

logo, Adobe PDF JobReady, Illustrator, InDesign, and Photoshop are registered trademarks

of Adobe Systems, Inc. PostScript is an Adobe registered trademark used with the Adobe

PostScript Interpreter, the Adobe page description language, and other Adobe products.

This product is not endorsed or sponsored by Adobe Systems, publisher of Adobe

Photoshop.

Fiery®, is a registered trademark of Electronics For Imaging, Inc. Creo® is a registered

trademark of Creo, Inc. Plockmatic™ is a trademark of CFS Products Inc. GBC® and

AdvancedPunch™ are trademarks or registered trademarks of General Binding Corporation.

GBC®, and e/Binder 200™ are trademarks or registered trademarks of General Binding

Corporation. HP, HPGL, HPGL/2, and HP-UX are registered trademarks of Hewlett-Packard

Corporation. Netscape® is registered trademark of Netscape Communications. UNIX®

is a registered trademark of the Open Group. Mozilla FireFox™ is a trademark of Mozilla

Foundation.

Page 3

Table of Contents

1 Product overview........................................................................................1-1

Quick start/links....................................................................................................................1-2

User Interface........................................................................................................................1-2

Logon...........................................................................................................................1-3

Language...................................................................................................................1-3

Change language......................................................................................1-4

Power saver................................................................................................................1-4

Print server overview...........................................................................................................1-4

Full Width Array....................................................................................................................1-5

Clear dry ink...........................................................................................................................1-5

Productivity...............................................................................................................1-6

Full flood.....................................................................................................................1-6

Spot..............................................................................................................................1-6

Power on/off the machine................................................................................................1-7

Feeding and finishing devices.........................................................................................1-7

Oversized High Capacity Feeder (OHCF).......................................................1-8

Interface Module....................................................................................................1-8

GBC AdvancedPunch.............................................................................................1-9

High Capacity Stacker (HCS)..............................................................................1-9

Perfect Binder........................................................................................................1-10

Standard Finisher.................................................................................................1-11

Booklet Maker Finisher......................................................................................1-11

SquareFold Trimmer Module...........................................................................1-12

Standard Finisher Plus........................................................................................1-12

Third-party finishing devices...........................................................................1-13

2 Where to find help....................................................................................2-1

User Interface help..............................................................................................................2-1

Help on the World Wide Web..........................................................................................2-2

Print server customer documentation.........................................................................2-2

3 Machine/job status...................................................................................3-1

Machine status......................................................................................................................3-1

System menu............................................................................................................3-1

Dry ink/toner status area.....................................................................................3-2

Billing and Counters...............................................................................................3-2

Viewing/reseting Billing Meters/Usage Counters.........................3-2

Billing and counters information........................................................3-3

Xerox® Color 800/1000 Press

User Guide

i

Page 4

Table of Contents

Impressions information........................................................................3-3

Maintenance (on the UI).....................................................................................3-4

Job status................................................................................................................................3-5

Job/machine status area.....................................................................................3-5

Job summary............................................................................................................3-6

Pause............................................................................................................................3-6

4 Submitting a print job.............................................................................4-1

Printing from your computer...........................................................................................4-1

Printing from the Xerox FreeFlow Print Server..........................................................4-1

Printing from the Xerox EX Print Server, Powered by EFI.....................................4-2

Printing from the Xerox CX Print Server, Powered by Creo..................................4-2

5 System Administrator overview...........................................................5-1

Logging on as Administrator...........................................................................................5-1

System administrator options.........................................................................................5-1

6 Paper information.....................................................................................6-1

Loading media in Trays 1 and 2.....................................................................................6-1

Loading paper..........................................................................................................6-1

Loading tab stock...................................................................................................6-1

Loading transparencies........................................................................................6-2

Loading pre-drilled stock for 1-sided print jobs..........................................6-3

Loading pre-drilled stock for 2-sided print jobs..........................................6-3

Skew adjustment levers.....................................................................................................6-4

Tray Properties.......................................................................................................................6-7

Tray stock mismatch...........................................................................................................6-8

7 Manage Stock Library..............................................................................7-1

Recommended Media List (RML)..................................................................................7-2

Stock management.............................................................................................................7-3

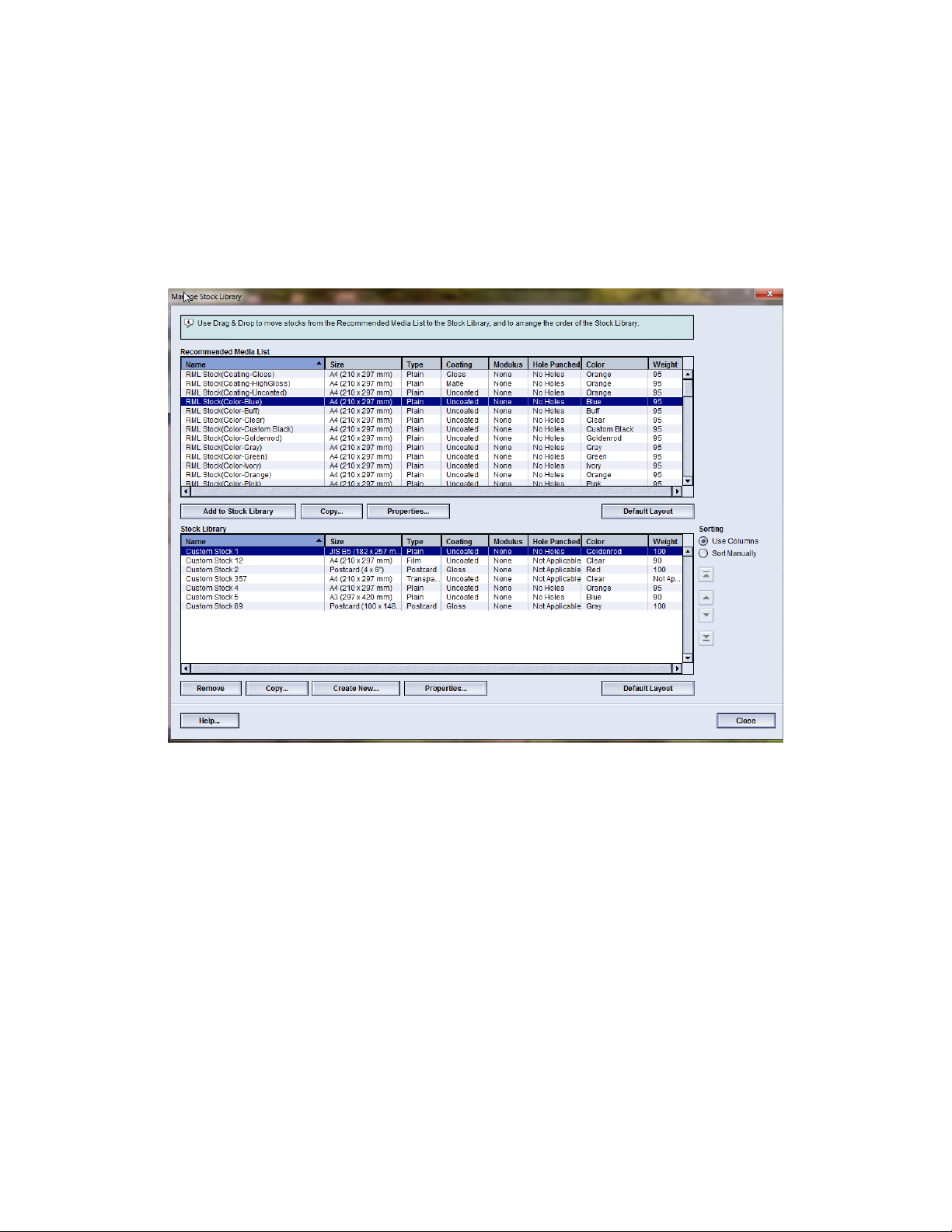

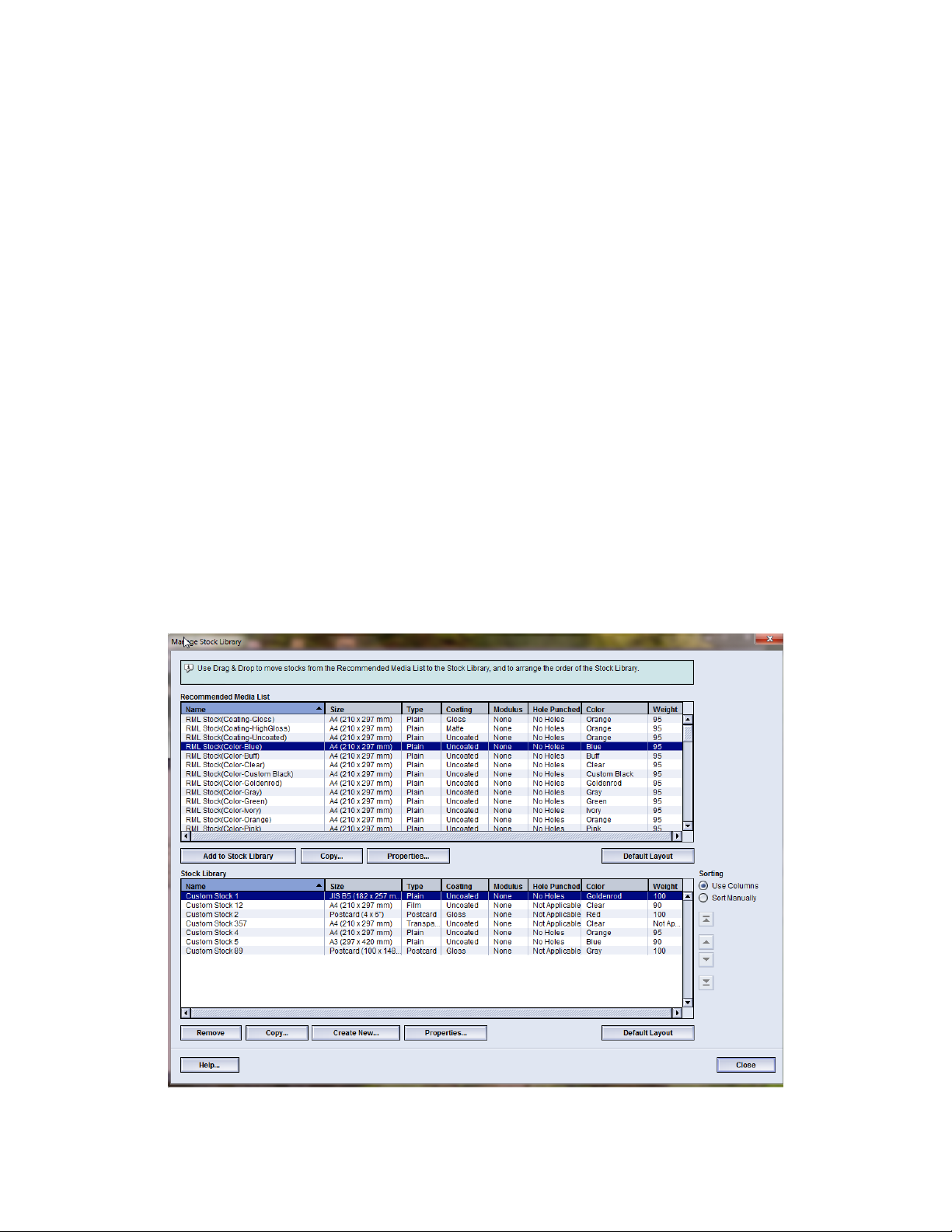

Manage Stock Library window.......................................................................................7-4

Adding a stock entry.............................................................................................7-5

Copying a stock entry...........................................................................................7-6

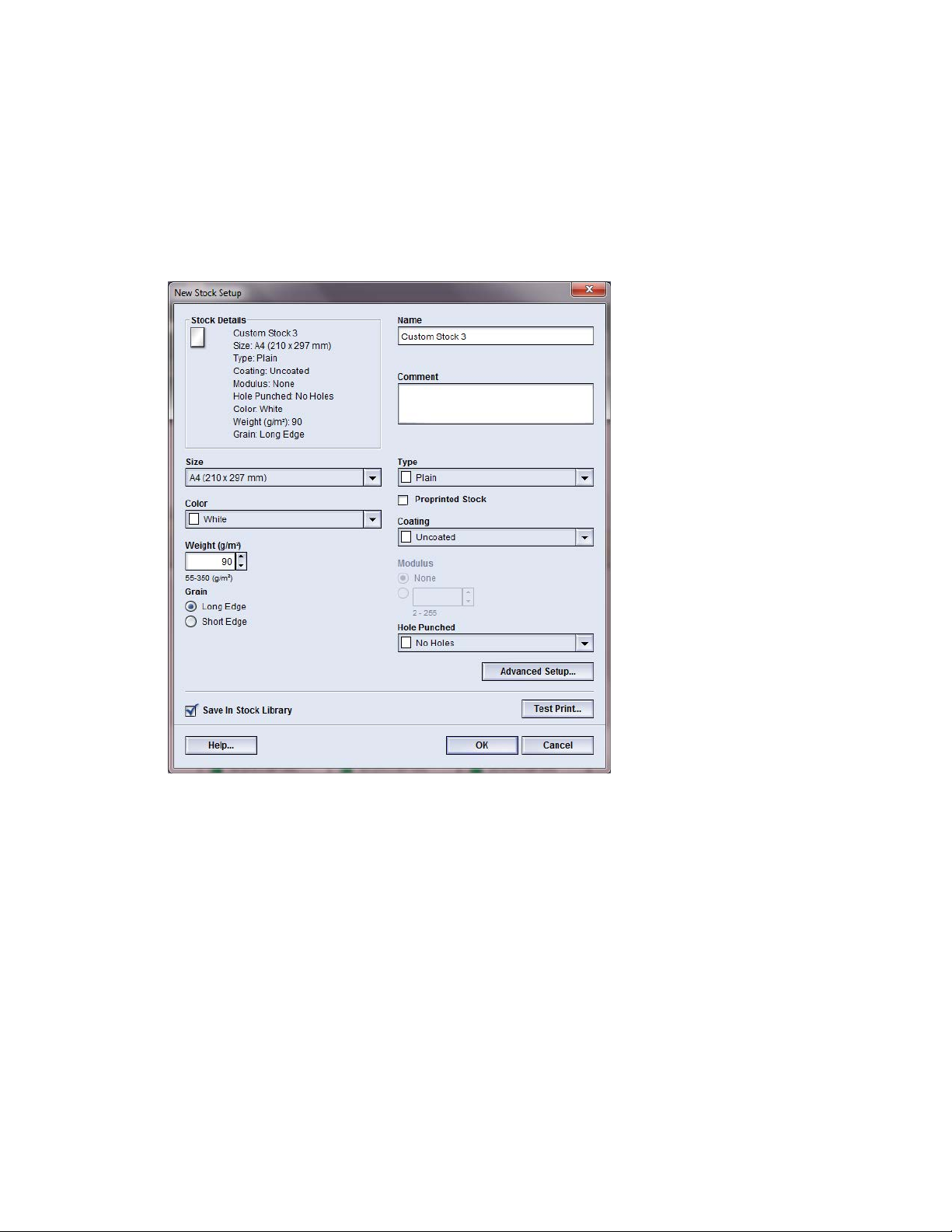

Creating a new stock (from Manage Stock Library).................................7-7

Creating a new stock (from Tray Properties)...............................................7-8

Editing an existing stock in the Stock Library..............................................7-9

Removing a stock from the Stock Library...................................................7-10

8 Advanced Stock Setup.............................................................................8-1

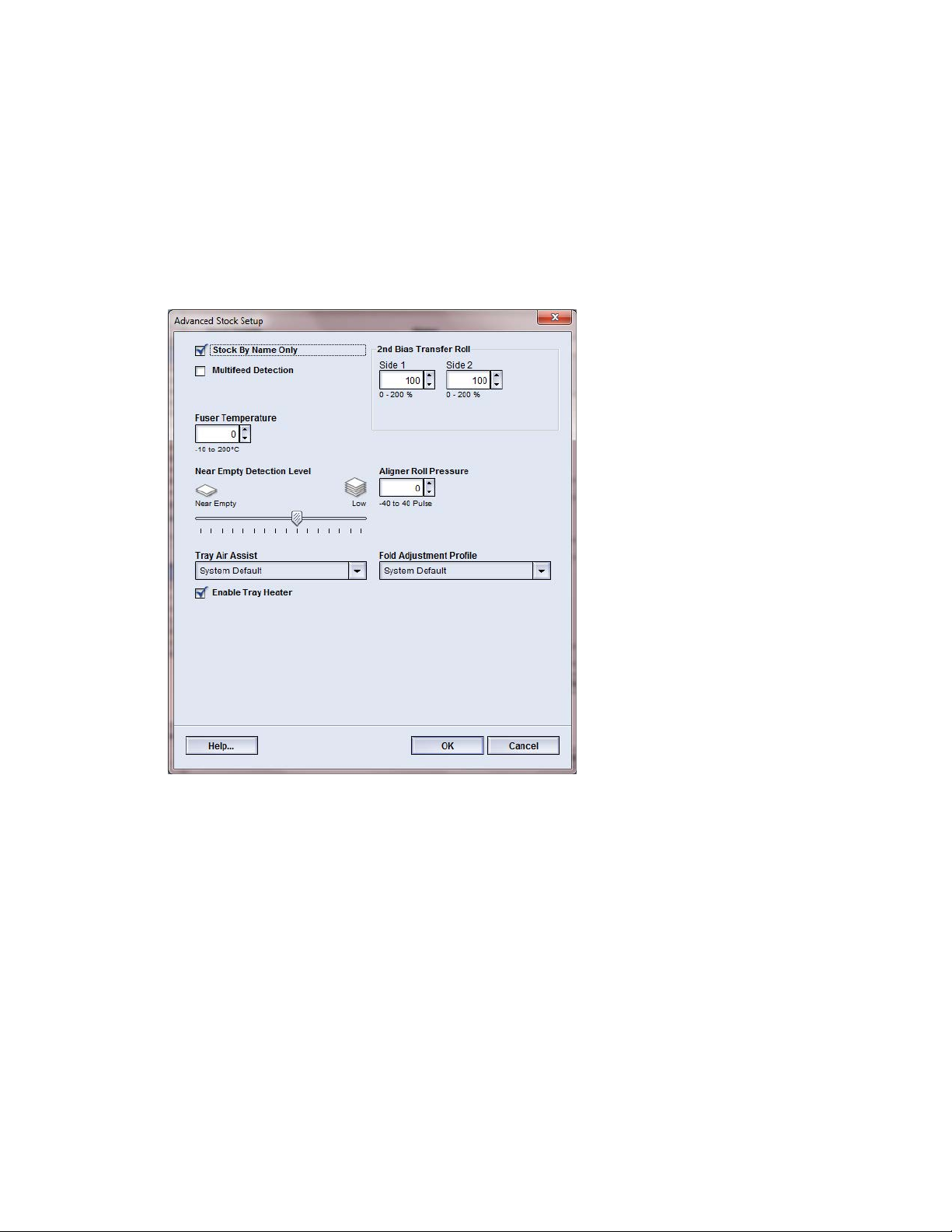

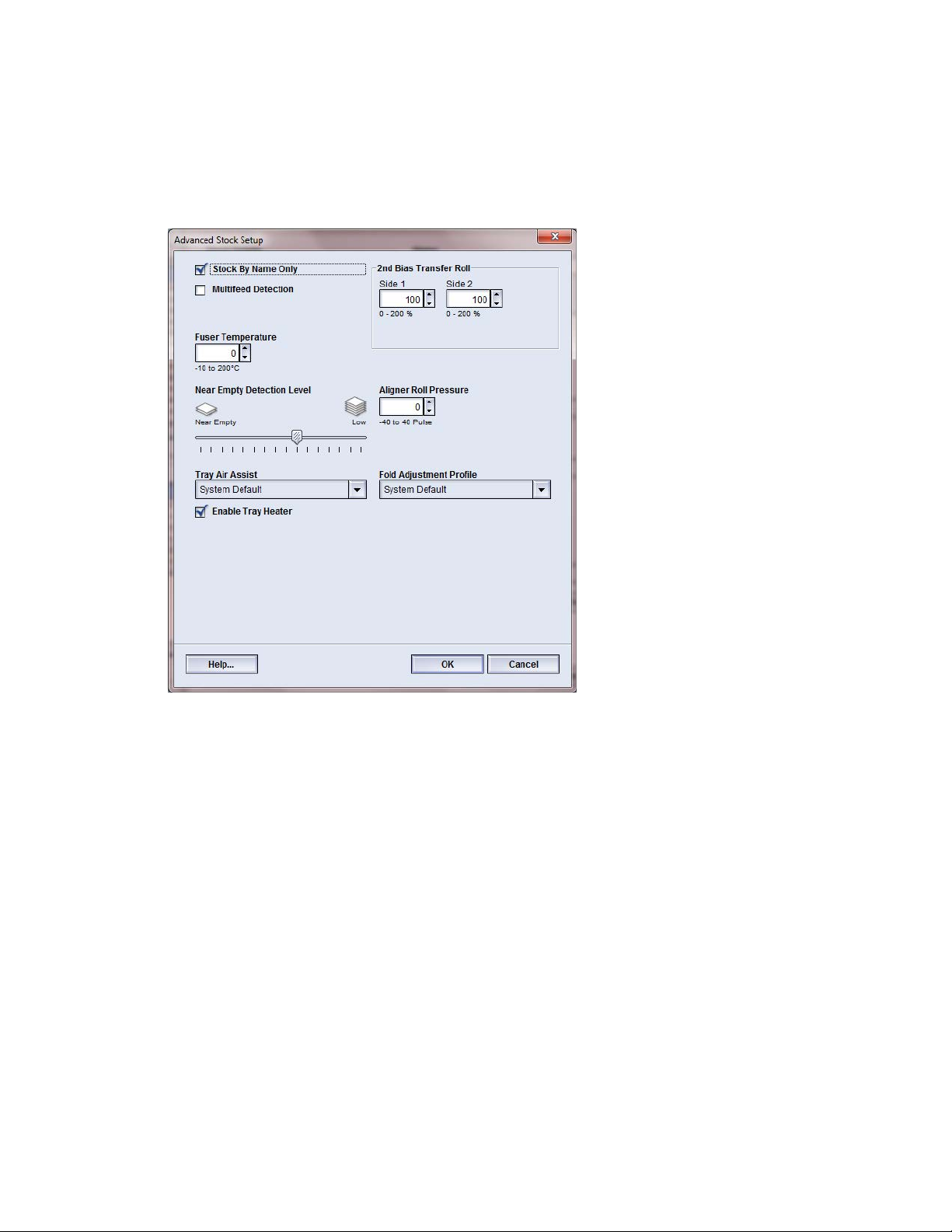

Advanced Stock Setup options.......................................................................................8-2

Tips for using Advanced Stock Setup options.............................................8-3

Create/modify Advanced Stock Setup options...........................................8-4

ii

Xerox® Color 800/1000 Press

User Guide

Page 5

Table of Contents

Paper tray/paper feed options........................................................................................8-5

Stock By Name Only..............................................................................................8-5

Multifeed Detection...............................................................................................8-6

Near Empty Detection Level..............................................................................8-6

Tray Air Assist...........................................................................................................8-7

Enable Tray Heater.................................................................................................8-8

Paper path/paper transportation options..................................................................8-8

Aligner Roll Pressure...............................................................................................8-8

Second (2nd) bias transfer roll..........................................................................8-9

Mottle..........................................................................................................8-11

Color shift...................................................................................................8-12

Selecting the 2nd Bias Transfer Roll settings...............................8-13

Fuser Temperature...............................................................................................8-14

Fold Adjustment Profile..................................................................................................8-15

9 Maintenance...............................................................................................9-1

Cleaning procedures...........................................................................................................9-1

Cleaning the UI screen.........................................................................................9-1

Cleaning the paper path......................................................................................9-1

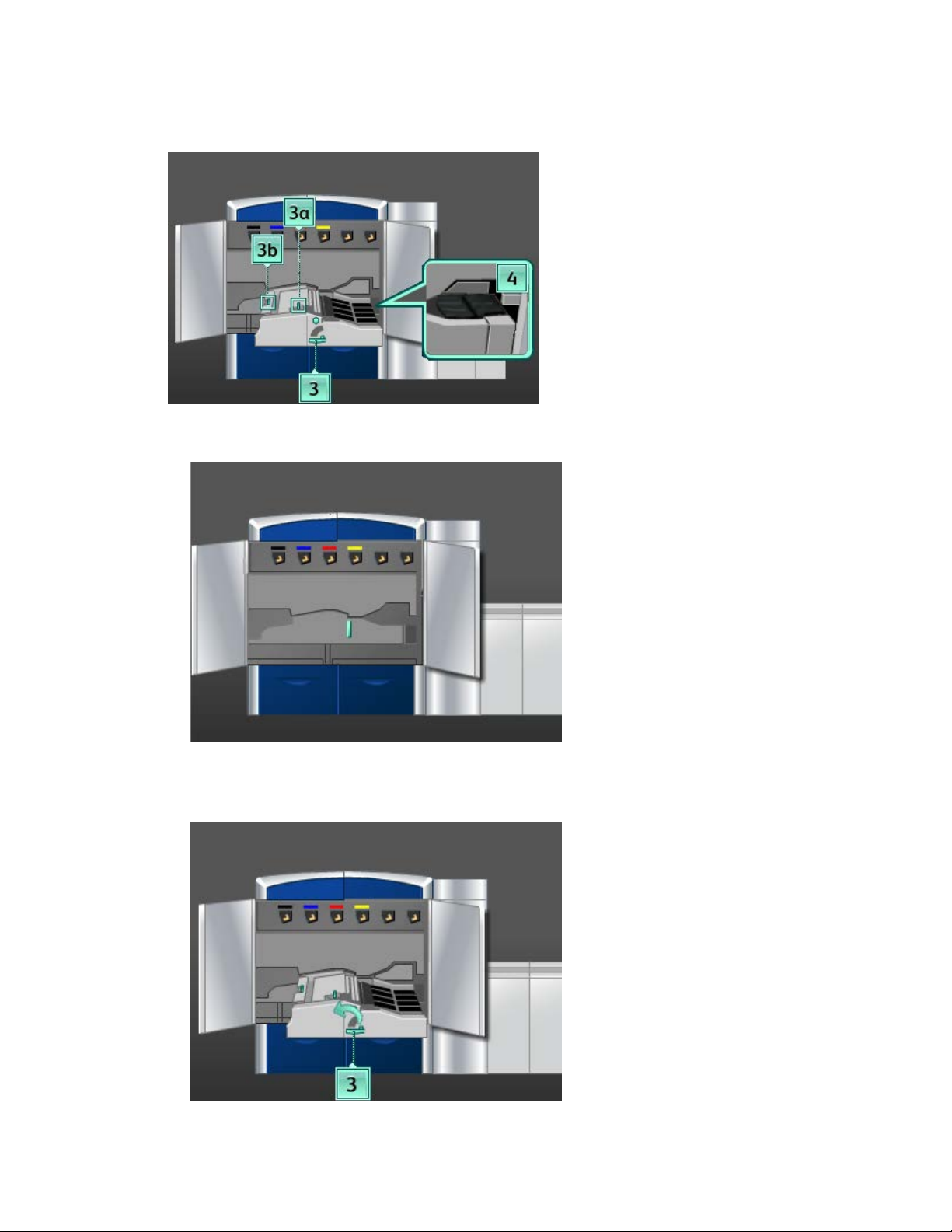

Cleaning the paper path area 2..........................................................9-2

Cleaning the paper path areas 3 and 4...........................................9-4

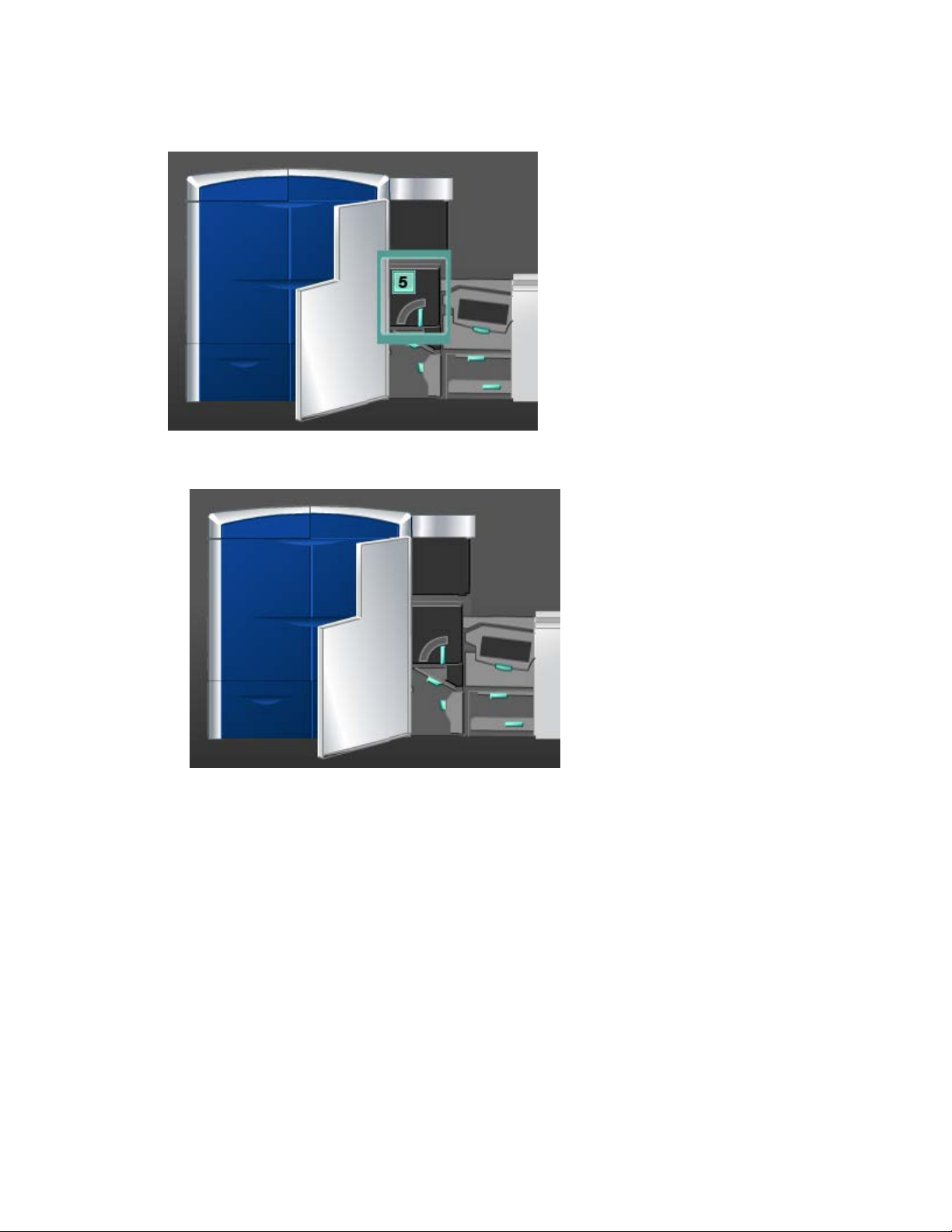

Cleaning the paper path area 5..........................................................9-7

Cleaning the paper path area 6.......................................................9-10

Cleaning the paper path area 7.......................................................9-13

Replacing consumable supplies...................................................................................9-17

Consumable supplies..........................................................................................9-17

Replacing a dry ink/toner cartridge..............................................................9-18

Dry ink/toner waste bottle...............................................................................9-20

Replacing a dry ink/toner waste bottle..........................................9-21

Replacing the fuser web assembly................................................................9-23

10 Problem solving.....................................................................................10-1

Locating the machine serial number.........................................................................10-1

Machine serial number on the UI.................................................................10-1

Serial number on the machine.......................................................................10-1

Calling for service..............................................................................................................10-2

General problems..............................................................................................................10-3

Jam clearance.....................................................................................................................10-7

Paper jams in Trays 1 and 2.............................................................................10-7

Paper jams in area 2...........................................................................................10-8

Paper jams in areas 3 and 4.........................................................................10-11

Xerox® Color 800/1000 Press

User Guide

iii

Page 6

Table of Contents

Paper jams in area 5........................................................................................10-14

Paper jams in area 6........................................................................................10-17

Paper jams in area 7........................................................................................10-20

Fault codes........................................................................................................................10-24

Image quality...................................................................................................................10-46

Charge corotrons...............................................................................................10-48

When to replace a charge corotron assembly..........................10-49

Which charge corotron assembly to replace............................10-49

Banding samples..................................................................................10-49

11 Technical data.......................................................................................11-1

Machine specifications...................................................................................................11-1

Tray capacity..........................................................................................................11-1

Throughput information for all paper trays..............................................11-1

Machine warmup time.......................................................................................11-2

First print-out time..............................................................................................11-2

Paper specifications..........................................................................................................11-3

Environmental specifications.......................................................................................11-4

12 Offset Catch Tray (OCT)....................................................................12-1

Enabling the Offset Mode on the EX Print Server................................................12-1

13 Oversized High Capacity Feeder (OHCF)....................................13-1

Overview................................................................................................................................13-1

Postcard bracket...................................................................................................13-1

Using the Postcard bracket.................................................................13-2

Loading media in the OHCF..........................................................................................13-4

Loading paper in the OHCF.............................................................................13-4

Loading tabs in the OHCF................................................................................13-4

Loading transparencies in the OHCF...........................................................13-5

Loading pre-drilled stock into the OHCF for 1-sided print

jobs......................................................................................................................13-5

Loading pre-drilled stock into the OHCF for 2-sided print

jobs......................................................................................................................13-6

Skew adjustment levers..................................................................................................13-7

Tray Properties....................................................................................................................13-9

Tray stock mismatch......................................................................................................13-10

OHCF problem solving..................................................................................................13-11

Clearing OHCF jams.........................................................................................13-11

Paper jams inside the OHCF trays.................................................13-12

OHCF paper jams at lever 1a and knob 1c................................13-13

OHCF paper jams at lever 1b and knob 1c................................13-14

iv

Xerox® Color 800/1000 Press

User Guide

Page 7

Table of Contents

OHCF paper jams at lever 1d and knob 1c................................13-15

OHCF fault codes...............................................................................................13-17

OHCF specifications.......................................................................................................13-18

14 Interface Module..................................................................................14-1

Overview................................................................................................................................14-1

Control panel.........................................................................................................14-2

Paper path..............................................................................................................14-3

Paper curl settings on the Interface Module..........................................................14-3

Preset decurler settings.....................................................................................14-3

Manual decurler buttons...................................................................................14-3

Problem solving..................................................................................................................14-4

Clearing jams.........................................................................................................14-4

Paper jams at lever 1a..........................................................................14-4

Paper jams at lever 2a..........................................................................14-5

Paper jams at lever 2b..........................................................................14-7

Fault codes..............................................................................................................14-8

15 High Capacity Stacker (HCS)...........................................................15-1

Overview................................................................................................................................15-1

Identifying the components...........................................................................15-2

Control panel.........................................................................................................15-3

HCS top tray...........................................................................................................15-3

Unloading the Stacker Tray...........................................................................................15-4

Problem solving..................................................................................................................15-5

General problems.................................................................................................15-5

Jam clearance........................................................................................................15-5

HCS entrance jams (E1, E2, and E3)...............................................15-5

HCS transport jams (E4, E5, and E6)...............................................15-6

HCS top tray jam (E7)...........................................................................15-8

HCS exit jam (E8)....................................................................................15-9

Hints and tips for using the HCS.................................................................15-10

Loss of power......................................................................................................15-11

Fault codes...........................................................................................................15-11

Specifications...................................................................................................................15-15

16 Perfect Binder........................................................................................16-1

Binder components..........................................................................................................16-1

External components..........................................................................................16-1

Cover inserter.........................................................................................................16-3

Internal components..........................................................................................16-4

Binder control panel............................................................................................16-5

Xerox® Color 800/1000 Press

User Guide

v

Page 8

Table of Contents

Book binding path.............................................................................................................16-7

Power on/off.....................................................................................................................16-10

Loading media in the cover inserter tray..............................................................16-11

Removing books from the binder.............................................................................16-12

Submitting a job to the binder..................................................................................16-12

Maintenance....................................................................................................................16-25

Binder problem solving.................................................................................................16-27

Binder circuit breaker..........................................................................................16-6

Bypass path............................................................................................................16-7

Standard path.......................................................................................................16-8

Cover inserter path..............................................................................................16-9

Power Saver mode.............................................................................................16-10

Printing from your computer to the binder.............................................16-12

Printing from the Xerox FreeFlow Print Server to the Perfect

Binder..............................................................................................................16-13

Binder manual mode with the FreeFlow Print Server............16-13

Printing/binding with preprinted covers to the FreeFlow

Print Server.......................................................................................16-14

Printing/binding from a single file to the FreeFlow Print

Server..................................................................................................16-16

Printing from the Xerox CX Print Server, Powered by Creo to the

Perfect Binder...............................................................................................16-17

Binder manual mode with the CX Print Server.........................16-17

Printing/binding from a single file to the CX Print

Server..................................................................................................16-18

Printing/binding from two files to the CX Print Server..........16-19

Printing from the Xerox EX Print Server, Powered by EFI to the

Perfect Binder...............................................................................................16-21

Binder manual mode with the EX Print Server.........................16-21

Printing/binding with preprinted covers to the EX Print

Server..................................................................................................16-21

Printing/binding from a single file to the EX Print

Server..................................................................................................16-23

Cleaning the binder..........................................................................................16-25

Empty the trimmer waste tray.....................................................................16-25

Adhesive filling tray..........................................................................................16-26

Replenishing the adhesive filling tray..........................................16-27

Paper jams in areas E1 and E2....................................................................16-28

Paper jams in area E3......................................................................................16-28

Paper jams in area E4......................................................................................16-30

Paper jams in areas E5 and E6....................................................................16-31

General problems..............................................................................................16-34

Power interruption during operation............................................16-34

vi

Xerox® Color 800/1000 Press

User Guide

Page 9

Table of Contents

Adjusting the printed image and trim.........................................16-34

Fault codes...........................................................................................................16-34

Binder specifications.....................................................................................................16-71

17 Standard/Booklet Maker Finisher..................................................17-1

Manual decurling feature on the finisher................................................................17-3

Folding feature...................................................................................................................17-4

Fold types................................................................................................................17-4

Loading paper/tabs in Tray 8/T1 (Post-Process Inserter)..................................17-6

Maintenance.......................................................................................................................17-7

Standard/Booklet Maker consumable supplies........................................17-7

Replace the standard staple cartridge........................................................17-8

Replace the booklet staple cartridge............................................................17-9

Replacing the Staple Waste Container on the finisher......................17-11

Empty the Punch Waste Container............................................................17-13

Finisher problem solving..............................................................................................17-14

Paper jams in Tray 8/T1 (Post-Process Inserter)...................................17-15

Paper jams at lever 1a and knob 1c..........................................................17-16

Paper jams at lever 1d.....................................................................................17-17

Paper jams at lever 1b.....................................................................................17-18

Paper jams at lever 3b and 3d.....................................................................17-19

Paper jams at lever 3e and knob 3c...........................................................17-21

Paper jams at lever 3g and knob 3f...........................................................17-22

Paper jams at lever 4b and knob 3a..........................................................17-23

Paper jams at lever 2a and knob 3a..........................................................17-24

Paper jams at lever 2b and knob 2c..........................................................17-25

Paper jams at 2c, 2e, 2f, and 2d..................................................................17-27

Paper jams at 2d and lever 2g.....................................................................17-28

Paper jams at unit 4 and knob 4a..............................................................17-29

Paper jams at finisher top tray....................................................................17-31

Paper jams at finisher stacker tray.............................................................17-32

Paper jams at the optional booklet maker tray....................................17-33

Stapler faults.......................................................................................................17-34

Staple jams in the standard staple cartridge...........................17-35

Staple jams in the booklet maker cartridge..............................17-36

Reinserting the standard staple cartridge...............................................17-38

Fault codes...........................................................................................................17-40

Specifications...................................................................................................................17-43

Standard/Booklet Maker Finisher...............................................................17-43

Optional C/Z Folder..........................................................................................17-46

Xerox® Color 800/1000 Press

User Guide

vii

Page 10

Table of Contents

18 SquareFold Trimmer Module...........................................................18-1

Overview................................................................................................................................18-1

Identifying the components.........................................................................................18-2

Main components................................................................................................18-2

Paper path..............................................................................................................18-3

Control panel.........................................................................................................18-4

Square Fold feature..........................................................................................................18-4

Square fold options.............................................................................................18-5

Accessing the Square Fold options...............................................................18-6

Trimmer feature.................................................................................................................18-7

Trimmer options...................................................................................................18-7

Trim guidelines......................................................................................................18-8

Accessing the Trimmer options...................................................................18-10

Hints and tips...................................................................................................................18-10

Printing full-page images on booklets......................................................18-10

Follow these tips................................................................................................18-11

Problem solving...............................................................................................................18-12

Jam clearance.....................................................................................................18-12

Clearing jams.........................................................................................18-12

Clearing E1/E2 jams............................................................................18-13

Clearing E3 jams..................................................................................18-15

Fault codes...........................................................................................................18-16

Technical data..................................................................................................................18-18

Specifications......................................................................................................18-18

19 Standard Finisher Plus........................................................................19-1

Overview................................................................................................................................19-1

Finisher Module..................................................................................................................19-2

Finisher Module main components..............................................................19-2

Folding feature......................................................................................................19-3

Fold types...................................................................................................19-3

Loading paper/tabs in Tray 8/T1 (Post-Process Inserter).....................19-5

Finishing Transport...........................................................................................................19-6

Finishing Transport main components........................................................19-6

Finishing Transport status indicators...........................................................19-7

Standard Finisher Plus maintenance.........................................................................19-8

Standard Finisher Plus consumable supplies............................................19-8

Replace the standard staple cartridge........................................................19-8

Replacing the Staple Waste Container on the finisher......................19-10

Empty the Punch Waste Container............................................................19-12

viii

Xerox® Color 800/1000 Press

User Guide

Page 11

Table of Contents

Problem solving...............................................................................................................19-14

Paper jams in the Finisher Module.............................................................19-14

Paper jams in Tray 8/T1 (Post-Process Inserter)......................19-14

Paper jams inside the finisher left cover.....................................19-15

Paper jams at lever 1a and knob 1c................................19-15

Paper jams at lever 1d..........................................................19-16

Paper jams at lever 1b..........................................................19-17

Paper jams inside the finisher right cover..................................19-19

Paper jams at lever 3b and 3d..........................................19-19

Paper jams at lever 3e and knob 3c................................19-20

Paper jams at lever 3g and knob 3f................................19-21

Paper jams at lever 4b and knob 3a...............................19-23

Paper jams at the optional C/Z Folder.........................................19-24

Paper jams at lever 2a and knob 3a...............................19-24

Paper jams at lever 2b and knob 2c................................19-25

Paper jams at 2c, 2e, 2f, and 2d.......................................19-27

Paper jams at 2d and lever 2g..........................................19-28

Paper jams in areas 4b and 4c..........................................19-30

Paper jams at the finisher output area.......................................19-31

Paper jams at finisher top tray..........................................19-31

Paper jams at finisher stacker tray..................................19-32

Paper jams in the Finishing Transport......................................................19-33

Paper jams in area 1...........................................................................19-33

Paper jams in area 2...........................................................................19-34

Paper jams in area 3...........................................................................19-35

Paper jams in area 4...........................................................................19-36

Stapler faults.......................................................................................................19-37

Staple jams in the standard staple cartridge...........................19-37

Standard Finisher Plus fault codes.............................................................19-39

Finisher Module fault codes.............................................................19-39

Finishing Transport fault codes......................................................19-40

Third-party DFA fault codes.............................................................19-40

Specifications...................................................................................................................19-41

Finisher Module specifications....................................................................19-41

Optional C/Z Folder.............................................................................19-45

Finishing Transport specifications..............................................................19-45

Xerox® Color 800/1000 Press

User Guide

ix

Page 12

Table of Contents

x

Xerox® Color 800/1000 Press

User Guide

Page 13

1

Product overview

The Xerox 800/1000 Color Press is a full color/black and white network printer that

operates at a speed of 80/100 prints per minute.

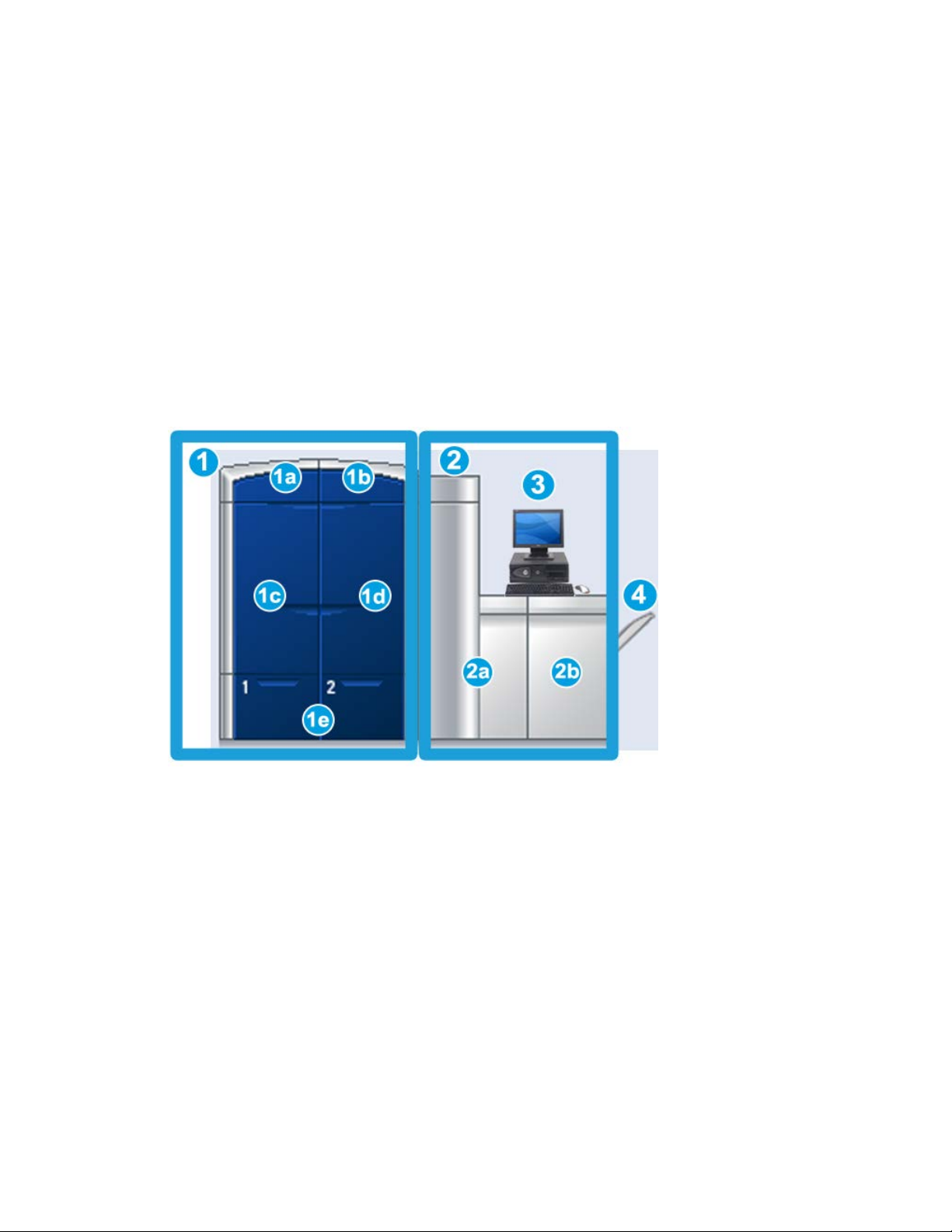

The following illustration shows a basic configuration of the digital press:

1. Print engine - left side

a. Upper left door: containing dry ink/toner cartridges

b. Upper right door: containing dry ink/toner cartridges

c. Left front door

d. Right front door

e. Trays 1 and 2; additional feeding accessories available

2. Print engine - right side

a. Left front door

b. Right front door

3. User Interface (UI)

4. Optional Offset Catch Tray (OCT); additional optional finishing accessories available

Xerox® Color 800/1000 Press

User Guide

1-1

Page 14

Product overview

Quick start/links

The following quick links will help you start using your machine quickly and easily:

• Power on/off the machine

• Where to find help

• Loading paper

• Submitting a print job

• Jam clearance

• Replacing a dry ink/toner cartridge

• Replacing a dry ink/toner waste bottle

• Logging on as Administrator

User Interface

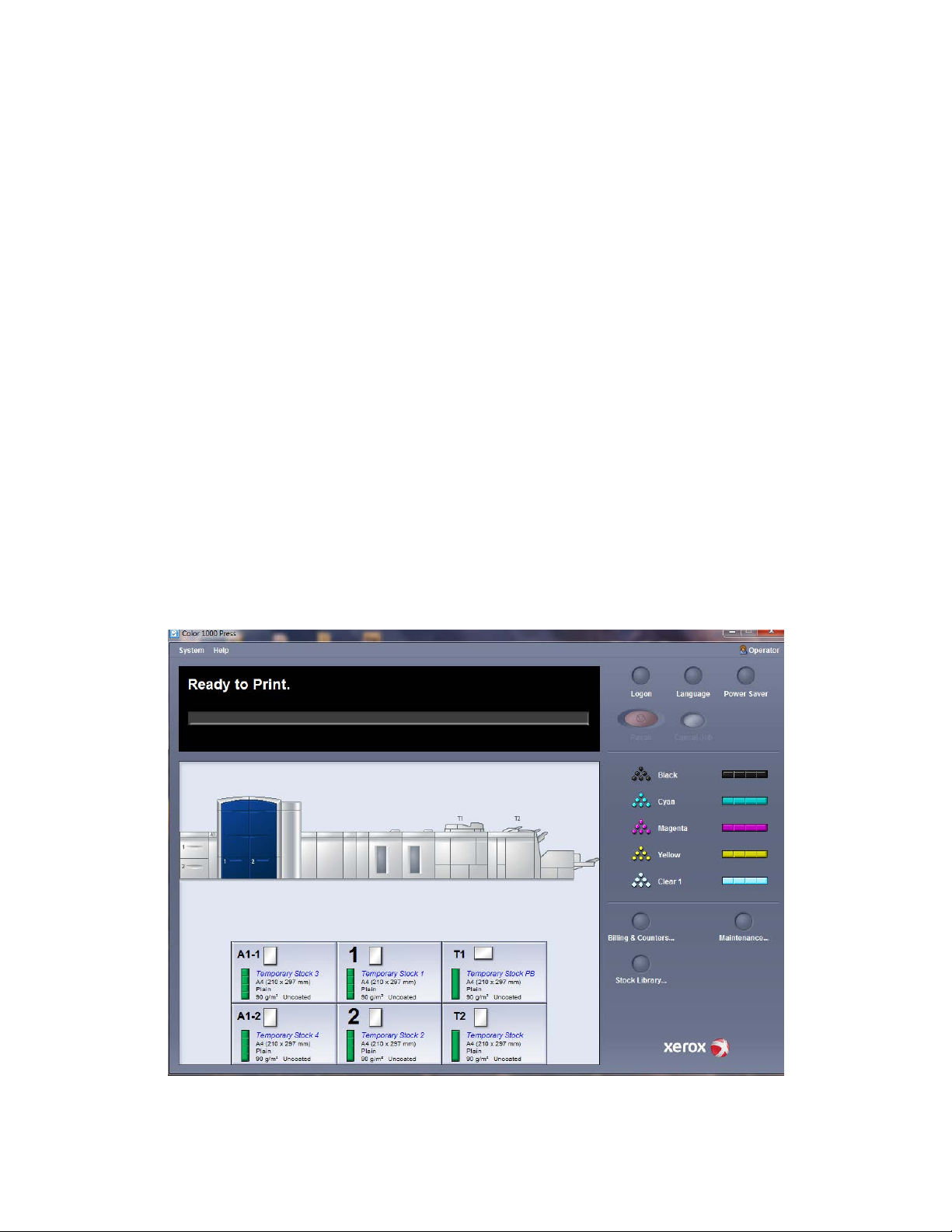

The User Interface (UI) displays messages that indicate the status of the machine during

idle, run, or fault conditions.

1-2

Xerox® Color 800/1000 Press

User Guide

Page 15

Related Topics:

User Interface help

System menu

Job status

Logon

Language

Power saver

Pause

Dry ink/toner status area

Maintenance (on the UI)

Manage Stock Library

Paper information

Machine status

Logon

Product overview

There are three logon levels:

• Operator: This is the default logon level.

• Administrator: This level allows you to customize the system defaults for your machine

and to customize particular print jobs by creating, setting, or changing parameters

for certain features.

• Technical Key Operator: This level is reserved for users who are certified by Xerox

to perform certain maintenance activities that are normally done by a customer

service engineer (CSE).

Note

Refer to the System Administration Guide for more information on the Administrator

and Technical Key Operator features.

Related Topics:

Logging on as Administrator

Language

Note

The number of languages available on your system depends on what was installed during

the initial installation process.

Selecting a particular Language button immediately changes the language. No

confirmation is required.

Xerox® Color 800/1000 Press

User Guide

1-3

Page 16

Product overview

Change language

To change the language, use the following procedure.

1. Select the Language button on the UI.

2. Select the desired language button; the language on the UI changes to the new

language and closes the Language window.

3. Select the Cancel button to return to the main UI screen.

Power saver

The machine automatically enters the power saver mode after fifteen minutes of

inactivity. This time may be changed to reflect a value of 1-240 minutes; you must enter

the Administrator mode to change it.

There are two Power Saver modes:

• System PC & Print Engine: Selecting this option places both the machine and the

System PC in power saver mode.

• Print Engine Only: Selecting this option places only the machine in power saver

mode.

The system exits the Power Saver mode when a job is sent to be printed or the UI on

the System PC is activated.

Note

To manually exit Power Saver mode, press the Power Saver button on the System PC.

Refer to the System Administration Guide for more information on this feature.

Print server overview

One of three print servers may be used with your digital press:

• Xerox® FreeFlow Print Server, for the Xerox® Color 800/1000 Press

• Xerox® CX Print Server, Powered by Creo

• Xerox® EX Print Server, Powered by Fiery

Note

For detailed information on your specific print server, refer to the customer

documentation that was delivered with it.

®

®

1-4

Xerox® Color 800/1000 Press

User Guide

Page 17

Product overview

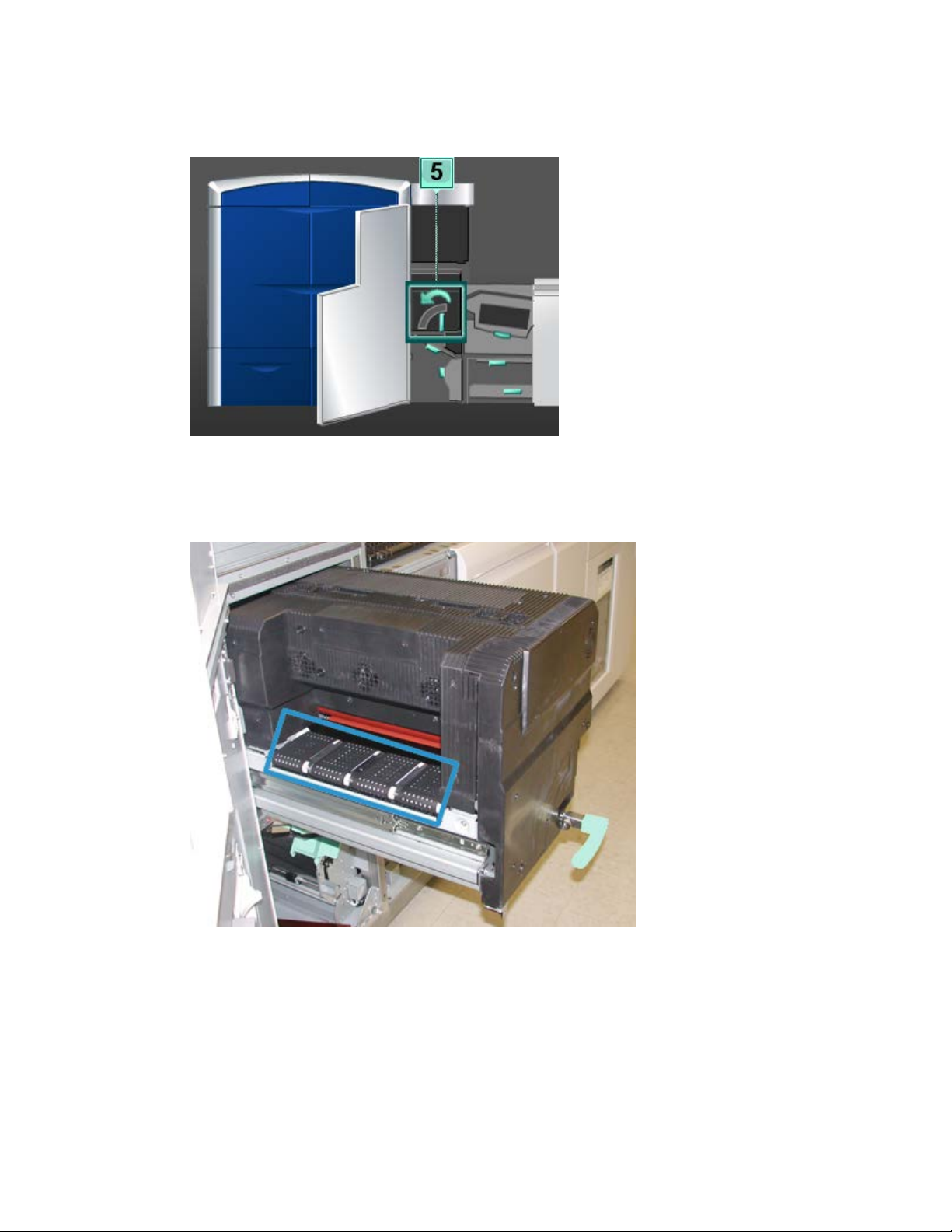

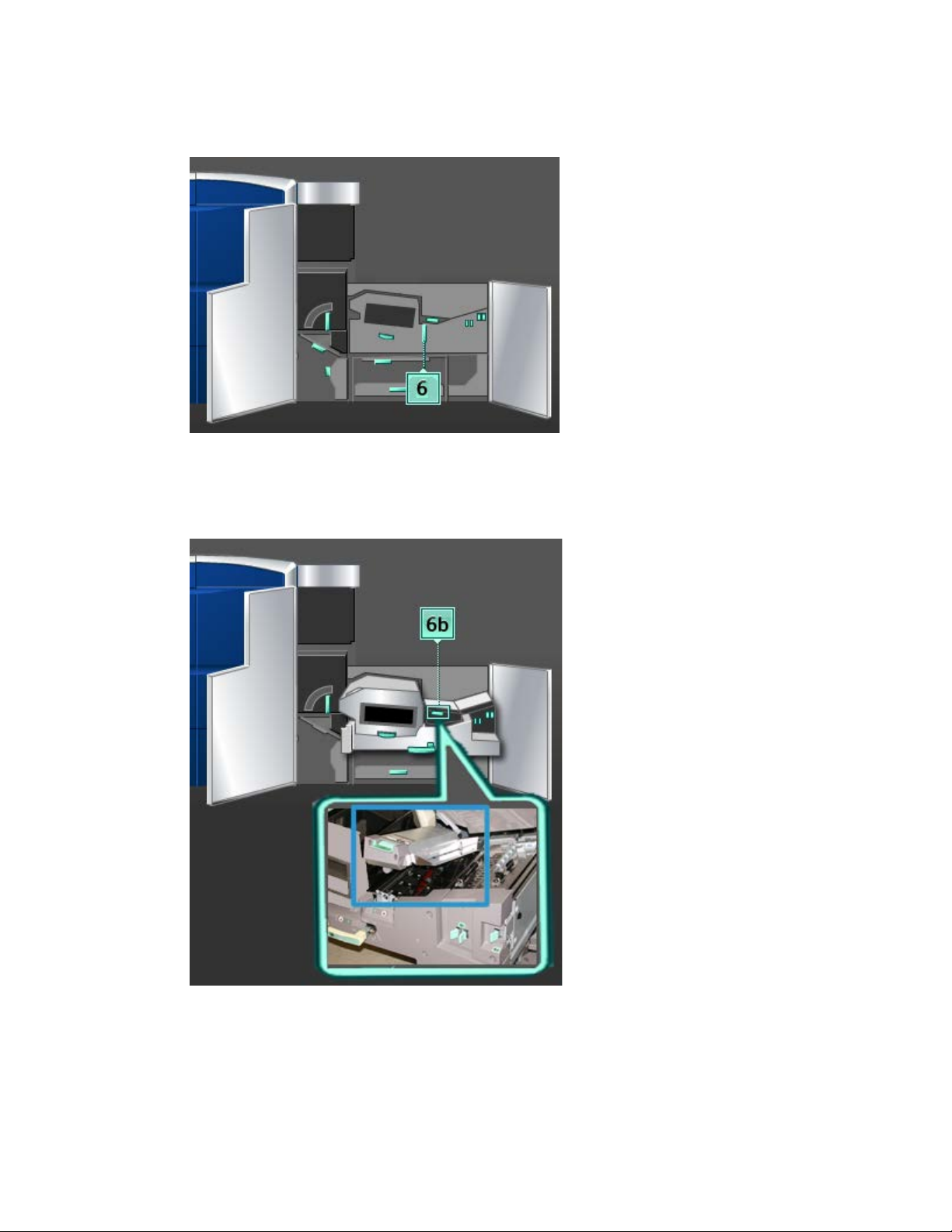

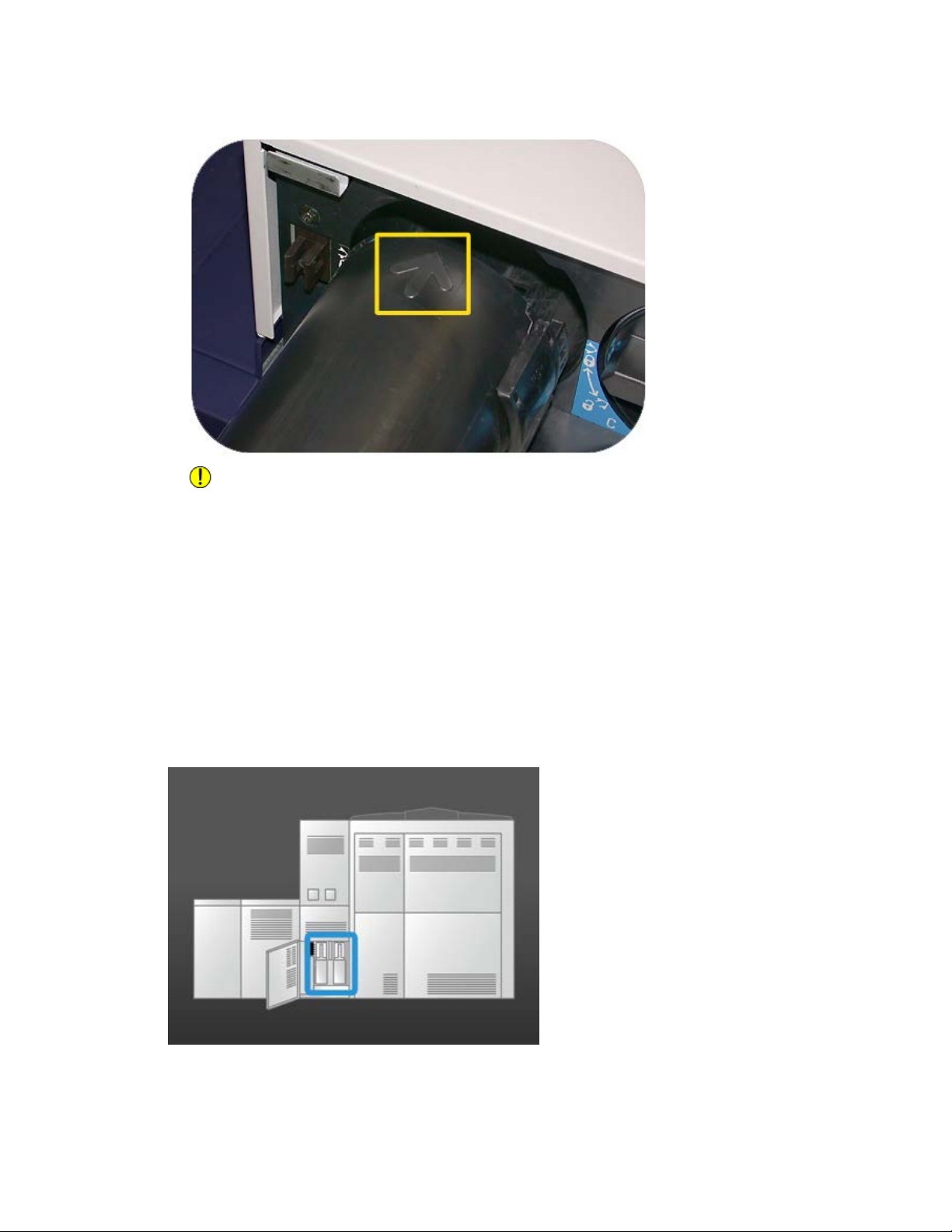

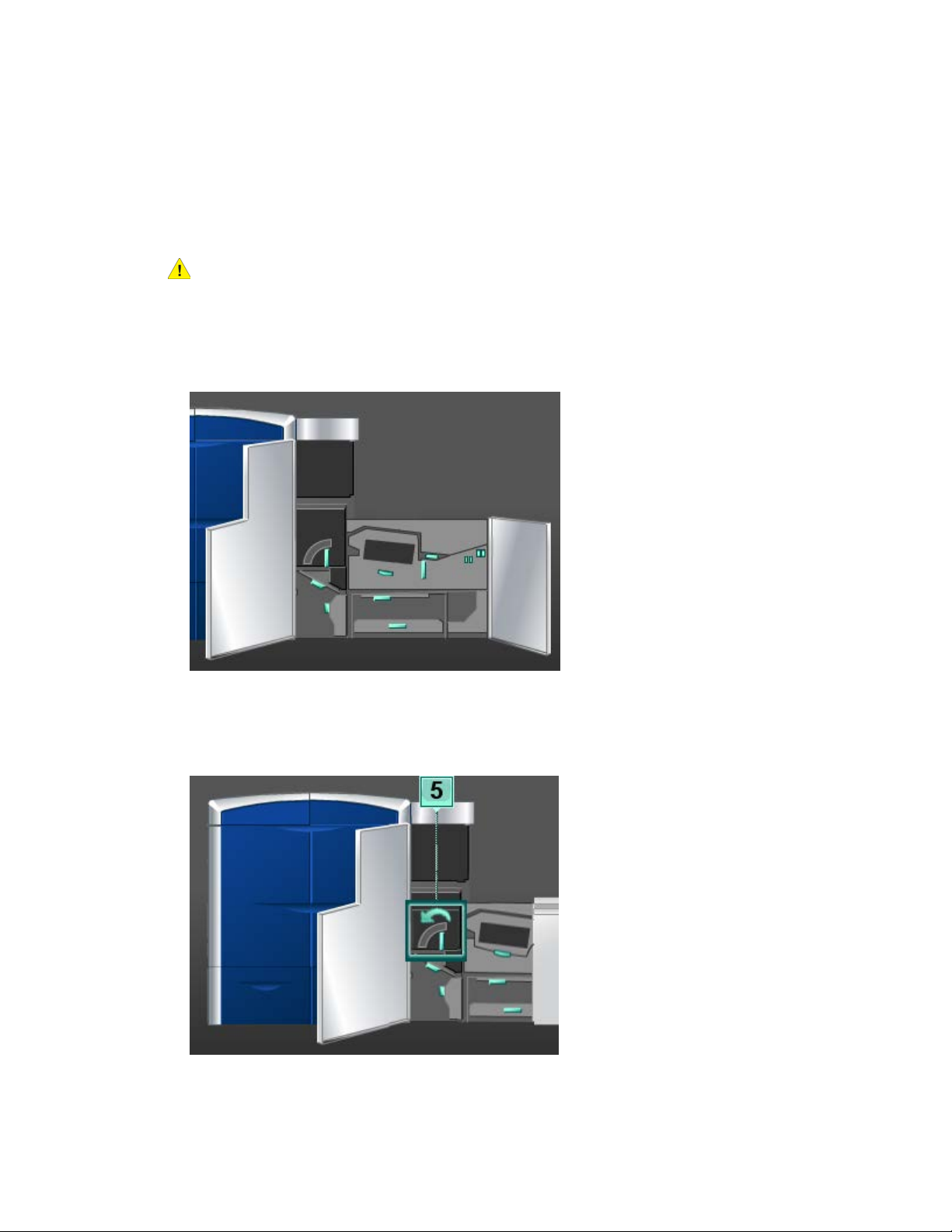

Full Width Array

Your digital press may include an internal color calibration function referred to as Full

Width Array. This is located in Area 6 of the print engine right side.

Note

The Full Width Array is an OPTIONAL feature that can be purchased for your system.

For more information, contact your Xerox representative.

The Full Width Array feature uses xerographic parameters and diagnostics to scan the

finished image and correct errors in registration, density and color. This is the process

of calibrating the Print Server with the digital press. There are now internal color

calibration strips (or tiles) used as reference for known colors of a test pattern. These

color values are automatically adjusted to produce accurate and consistent reproductions,

and this means that no longer is customer intervention required. It also allows the

customer to maintain tighter image quality control over the output of their system.

Note

Refer to your Print Server user documentation when performing the calibration workflow

of the Print Server in conjunction with the digital press. Also refer to the System

Administration Guide for detailed information on the Full Width Array feature.

Clear dry ink

The clear dry ink is an optional fifth module that provides full and spot page coverage

enhancement to print jobs.

The clear dry ink capability utilizes two methods to enhance the coverage area of printed

output. These two methods are full flood and spot (applied to specific areas only). Both

workflow methods use a “varnish” or clear coat to achieve desired effects, while also

maintaining machine productivity. The clear dry ink module is supported by all print

servers.

Xerox® Color 800/1000 Press

User Guide

1-5

Page 18

Product overview

Productivity

With the usage of the clear dry ink module, machine productivity is maintained across

all supported media, expanding the realm of endless capabilities including:

• Maintains full rated speed of 80/100 prints per minute (ppm) in five-color mode

• Supports both text and images

Full flood

Full flood varnish provides a uniform, glossy finish on the printed output when it is used

with high-end applications. The full flood option provides full page coverage as a clear,

glossy finish (varnish) which enhances the overall appearance within an application or

on a single sheet.

Spot

Using the spot option within a supported application allows the user to indicate a specific

area, or multiple areas where a clear dry ink will be applied to the printed output. This

is done in order to accent or highlight the desired area. Spot varnish can be used to:

• “Varnish” (apply a glossy finish to) specific areas of a print job

• Create artistic effects and highlights on a print job

• Enhance the appearance of metallic items with key colors such as silver, gold, or

copper

• Enhance pastel colors with a pearly luster affect

• Highlight images for visual variety to make them lift off the page (a three-dimensional

affect)

• Draw attention to headline text

• Highlight photos, logos, or other image areas

• Highlight watermarks

1-6

Xerox® Color 800/1000 Press

User Guide

Page 19

Product overview

Power on/off the machine

Use the power switch to power ON or power OFF the machine.

• Power on: Press the power switch to the ON position to power on the machine.

A screen message advises of a short wait while the fuser warms up and the machine

runs a system check. You can program the machine for a job during this time and

the printing process will start automatically when the machine is ready.

• Power off: Press the power switch to the OFF position to power off the machine.

Note

Allow the machine to remain off for a minimum of 10 seconds before switching the

power on again.

The Power on/off switch is found on the Print Engine Right Side as shown in the following

illustration. The circled area indicates the location of the power switch.

Feeding and finishing devices

Available with your machine is a variety of optional feeding and finishing devices. These

devices are briefly discussed on the following pages along with where to find specific

information on each device.

Xerox® Color 800/1000 Press

User Guide

1-7

Page 20

Product overview

Oversized High Capacity Feeder (OHCF)

2-tray Oversized High Capacity Feeder (OHCF)

Related Topics:

Oversized High Capacity Feeder (OHCF)

Interface Module

Important

The Interface Module is required with ALL finishing devices.

The Interface Module provides communication and a paper path between the print

engine and any attached finishing device or devices.

Related Topics:

Interface Module

1-8

Xerox® Color 800/1000 Press

User Guide

Page 21

Product overview

GBC AdvancedPunch

The GBC AdvancedPunch provides another level of finishing options to your output by

allowing you to punch holes in 8.5 x 11 in./A4 documents which support a variety of

binding styles. Punch types include 19-hole to a maximum of 32-Hole for 8.5 x 11 in.

media. A4 media supports punch types 21-hole to a maximum of 47-hole.

Note

The GBC AdvancedPunch is shown here with the required Interface Module and with

the optional Booklet Maker Finisher. The GBC AdvancedPunch can be attached to a

variety of optional finishing accessories.

Information on this accessory can be downloaded from www.xerox.com to download

the latest version of the desired user guide by entering the product name in the Search

field and then selecting the User Documentation link.

High Capacity Stacker (HCS)

The High Capacity Stacker (HCS) is an optional finishing device that provides stacking

and offsetting capabilities for output to a Stacker Tray.

Related Topics:

High Capacity Stacker (HCS)

Xerox® Color 800/1000 Press

User Guide

1-9

Page 22

Product overview

Perfect Binder

The Perfect Binder is an optional finishing device that takes the printed output and binds

it into a finished book; an optional front and back cover may be included with the bound

output.

Perfect binding is a process in which the leaves (pages) are bound by using an adhesive

and trimming off the excess edges. The adhesive holds the interior sheets of the book

together. Front and back covers may be included if desired. The final output is a finished,

perfect bound book with a wrap-around cover.

Note

The Perfect Binder requires the Interface Module.

Related Topics:

Perfect Binder

1-10

Xerox® Color 800/1000 Press

User Guide

Page 23

Product overview

Standard Finisher

This finisher provides a wide range of finishing/folding options.

Note

The Standard Finisher is shown here with the required Interface Module and with the

optional C/Z Folder.

Related Topics:

Standard/Booklet Maker Finisher

Booklet Maker Finisher

This finisher provides a wide range of finishing/folding options.

Note

The Booklet Maker Finisher is shown here with the required Interface Module and with

the optional C/Z Folder.

Related Topics:

Standard/Booklet Maker Finisher

Xerox® Color 800/1000 Press

User Guide

1-11

Page 24

Product overview

SquareFold Trimmer Module

The SquareFold Trimmer Module is an optional finishing device that is used in conjunction

with a finishing device that contains a booklet maker.

Note

The SquareFold Trimmer Module is shown here with the required Interface Module and

the required Booklet Maker Finisher.

Related Topics:

SquareFold Trimmer Module

Standard Finisher Plus

The Standard Finisher Plus serves as an interface to transfer paper between the print

engine and any third-party, Document Finishing Architecture (DFA) device attached to

the machine.

Note

The Standard Finisher Plus requires the Interface Module.

Related Topics:

Standard Finisher Plus

1-12

Xerox® Color 800/1000 Press

User Guide

Page 25

Product overview

Third-party finishing devices

Additional third-party, Document Finishing Architecture (DFA) devices are also available.

Always refer to the Finishing Solutions Guide and/or contact the Xerox sales

representataive for more information.

Note

All third-party, DFA devices require BOTH the Inteface Module and the Standard Finisher

Plus.

Xerox® Color 800/1000 Press

User Guide

1-13

Page 26

Product overview

1-14

Xerox® Color 800/1000 Press

User Guide

Page 27

2

Where to find help

User Interface help

Your machine’s User Interface (UI) comes with online Help.

This online Help provides information on:

• How to use and maintain your machine and optional accessories

• How to set up and change passwords and default settings

Selecting Color 800/1000 Help from the Help pull-down menu opens a new window

which displays the same type of information as provided in both this guide and the

System Administration Guide.

Once the main Help window opens, various help topics and information are available:

• On the left side of the help window two tabs are available:

- Content: Select this tab to have access to the various machine help information,

such as Product Overview or Paper Information.

- Index: Select this tab to access a full index and the selection of specific topics/areas

of interest or point of need.

• In the Content area main topics are displayed to the right of the book icons. Selecting

a book icon expands the view and provides selections to subtopics.

Xerox® Color 800/1000 Press

User Guide

2-1

Page 28

Where to find help

• The right and left arrow buttons advance forward or backward one topic at a time

using the same order as displayed on the Content tab.

Help on the World Wide Web

Xerox on the World Wide Web: For system support, user help, customer documentation,

and service support, go to www.xerox.com and click on the Contact Us link for specific

contact information/telephone numbers in your area.

It may be helpful to know your machine serial number before calling for support. The

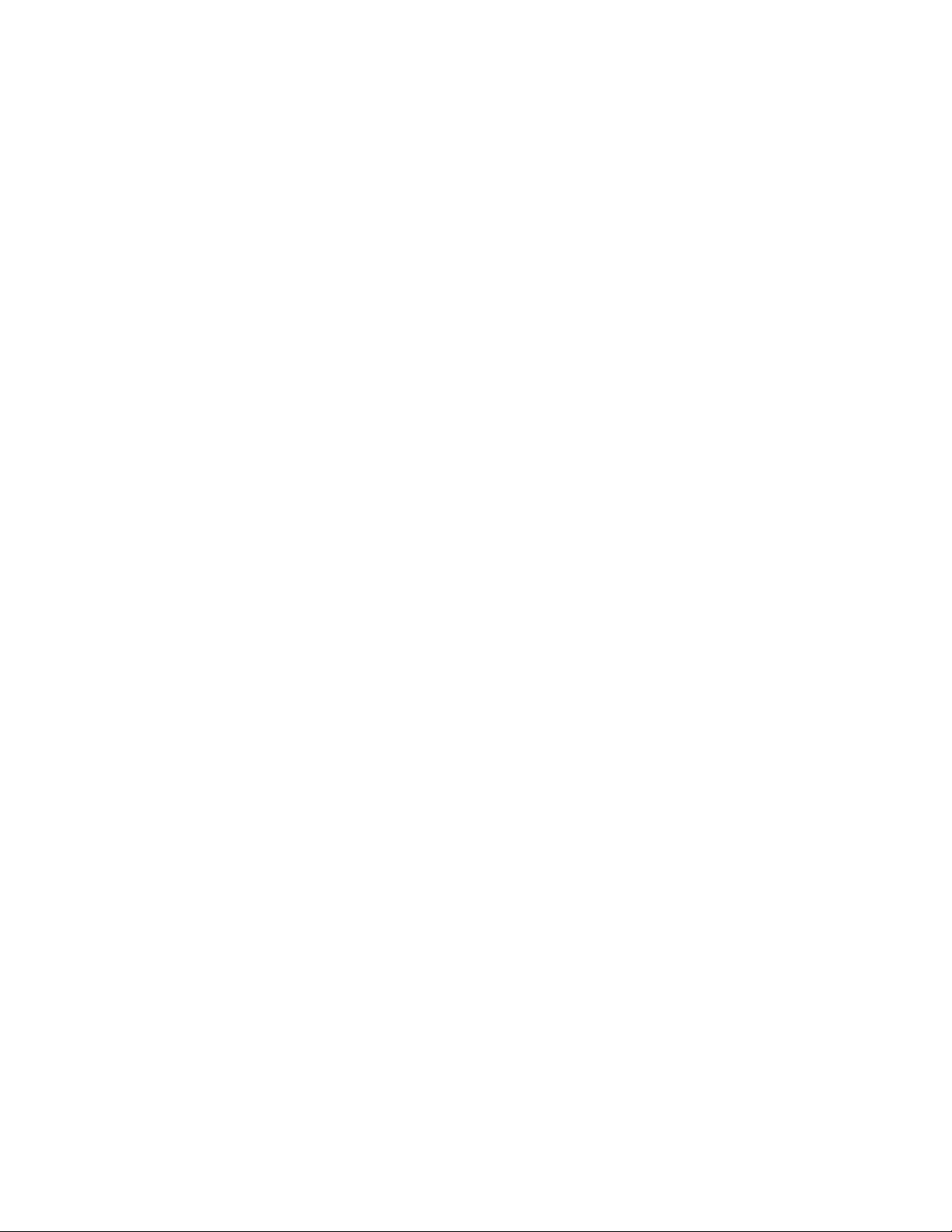

machine serial number is shown on the Machine Details tab ( System > Machine Details).

Related Topics:

System menu

Print server customer documentation

Supporting customer documentation for your print server is on a CD/DVD and is shipped

with the print server. You or your System Administrator should print these documents,

after the installation is complete.

2-2

Xerox® Color 800/1000 Press

User Guide

Page 29

3

Machine/job status

Related Topics:

Locating the machine serial number

Calling for service

Machine status

System menu

The System menu allows you to select the following options:

• Machine Details: This option provides information about the installed system

software, any attached optional feeding/finishing accessories, error log details,

customer support telephone number, and the machine serial number.

• Shutdown System PC: This option shuts down the User Interface and the system

PC.

Xerox® Color 800/1000 Press

User Guide

3-1

Page 30

Machine/job status

• Restart User Interface: This option stops and exits the User Interface and then

restarts it.

• Exit User Interface: This option exits the User Interface but leaves the System PC

running.

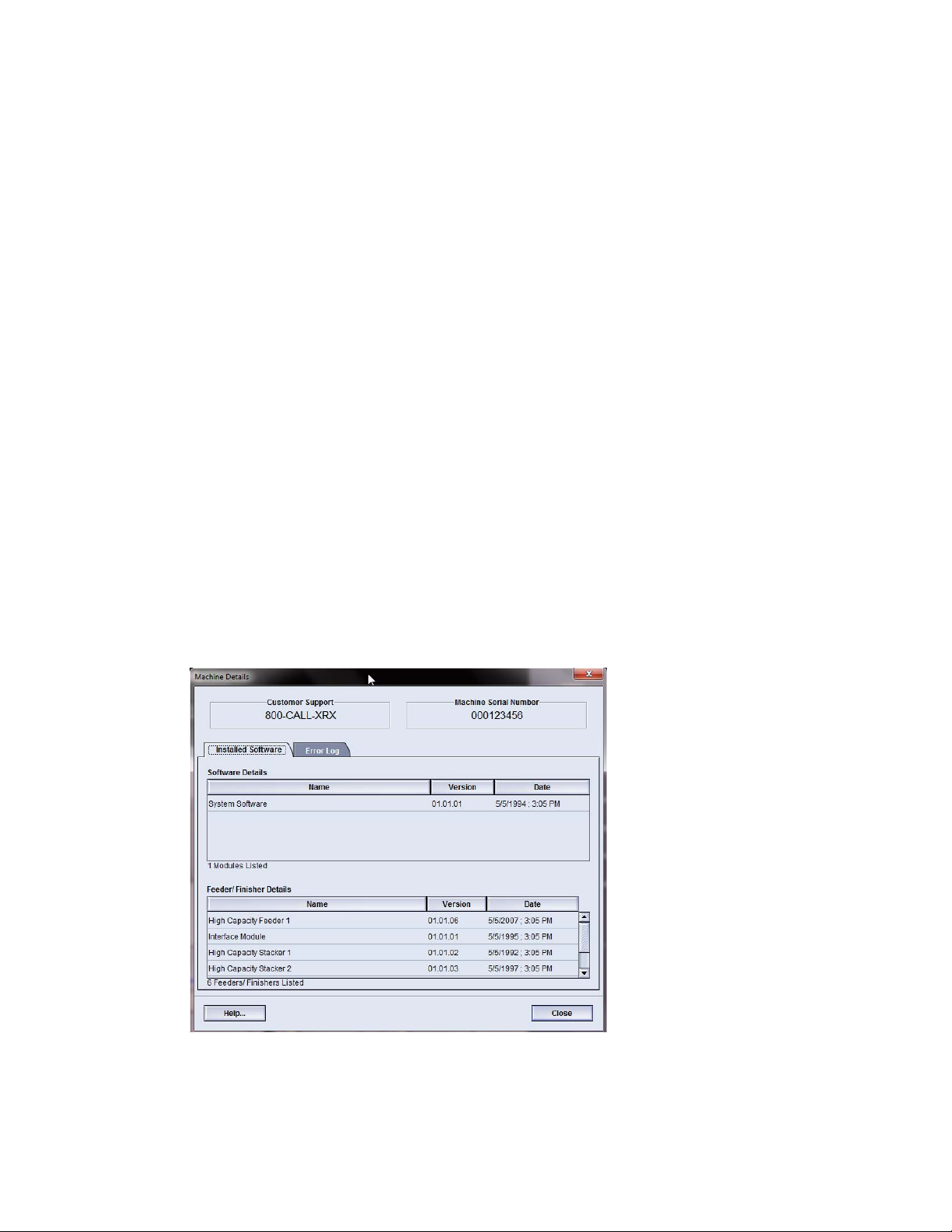

Dry ink/toner status area

This area of the UI displays the status of the dry ink/toner cartridges with a gauge

indicating the level/amount of dry ink/toner for each cartridge.

Note

Your machine may have an optional fifth dry ink/toner cartridge installed. All

characteristics described for the dry ink/toner cartridges also applies to the optional fifth

dry ink/toner cartridge as well.

Related Topics:

Replacing a dry ink/toner cartridge

Billing and Counters

The meters/counters vary depending on your machine configuration and setup.

Related Topics:

Billing and counters information

Impressions information

Viewing/reseting Billing Meters/Usage Counters

Viewing/reseting Billing Meters/Usage Counters

Note

The Billing Meters CANNOT be reset.

1. From the machine’s UI, select the Billing and Counters feature.

2. The Billing Meters and Usage Counters screen is displayed.

3. To reset the counters, perform the following:

3-2

Xerox® Color 800/1000 Press

User Guide

Page 31

Machine/job status

Select the Usage Counters tab.a)

b) Select Reset All.

A screen displays the following message: Are you sure you want to reset all the

usage counters to zero?

c) Select Yes to reset the counters; select No to exit and return to the meters/counters.

4. Select Close to exit the meters/counters and return to the main UI.

Billing and counters information

• The Billing Meters tab displays the total number of prints for both black and white

and color output. The information displayed may vary from market place to market

place.

Note

These meters CANNOT be reset.

• The Usage Counter tab works the same way as a trip odometer in a car. It can be

reset to zero. Once it is reset to zero, it keeps track of the print count from that point

forward until you select the Reset All button.

Note

If the optional clear dry ink/toner is present, the Usage Counters tab displays two

additional print counters: Clear Impressions and Clear Large Impressions.

Note

The information displayed on this screen may vary from market place to market place.

Impressions information

The meter and counters display the total impression amount. An impression is the image

on one side of one sheet of media. The meters and counters display the total impression

amount for all printed jobs. The impression information is separated into the following

categories:

• Color Impressions: This value (number) represents the total number of color

impressions regardless of the media size.

- For each color, one-sided printed output, the meter increases by one.

- For each color, two-sided printed output, the meter increases by two.

• Black Impressions: This value (number) represents the total number of black-only

impressions regardless of the media size.

- For each black-only, one-sided printed output, the meter increases by one.

- For each black-only, two-sided printed output, the meter increases by two.

• Total Impressions: This value (number) represents the total number of ALL impressions

regardless of size or color. It is the sum of the Color Impressions and the Black

Impressions combined.

Xerox® Color 800/1000 Press

User Guide

3-3

Page 32

Machine/job status

• Color Large Impressions: This value (number) represents the total number of large

color impressions. These impressions are one side of one sheet of large media (for

example 11 x17 in./A3). Large Impressions are any prints that are larger than 8.5 x

14 in./B4 size.

- For each large, color, one-sided printed output, the meter increases by one.

- For each large, color, two-sided printed output, the meter increases by two.

Note

This meter/counter is NOT added to the Total Impressions meter/counter since it is

already added to the Color Impressions meter/counter.

• Black Large Impressions: This value (number) represents the total number of large,

black-only impressions. These impressions are one side of one sheet of large media

(for example 11 x17 in./A3). Large Impressions are any prints that are larger than

8.5 x 14 in./B4 size.

- For each large, black-only, one-sided printed output, the meter increases by one.

- For each large, black-only, two-sided printed output, the meter increases by two.

Note

This meter/counter is NOT added to the Total Impressions meter/counter since it is

already added to the Black Impressions meter/counter.

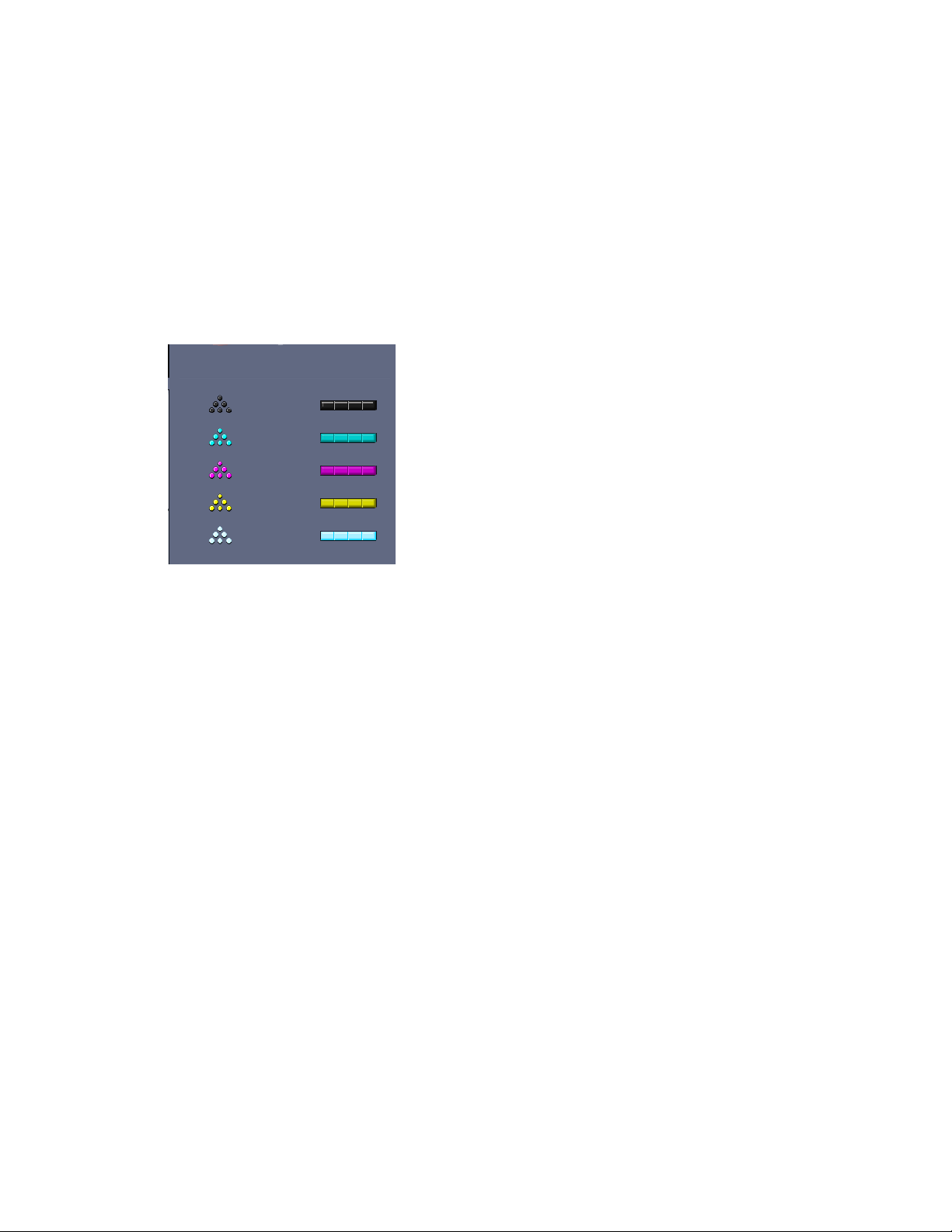

Maintenance (on the UI)

Selecting Maintenance on the UI opens a window which displays a status of each

consumable.

If logged on as Administrator, the additional Maintenance tab is available. Refer to

the System Administration Guide for more information

3-4

Xerox® Color 800/1000 Press

User Guide

Page 33

Machine/job status

Note

When a Customer Replaceable Unit (CRU) consumable item is depleted, the machine

automatically interrupts the current job and does not restart until the consumable is

replaced.

Tip

The machine does not interrupt a job or stop running if a Service Representative

Replaceable Unit status indicates a low or depleted level. Your Service Representative

Replaceable Unit may continue to perform as expected far beyond the average life

indicator. Your Service Representative uses this status indicator information each time

service is performed on your machine.

Related Topics:

Replacing consumable supplies

Consumable supplies

Job status

Job/machine status area

This area of the screen displays the status of the machine as well as displaying the status

of any currently printing job (Summary button).

1. Job status area

2. Machine status area

Xerox® Color 800/1000 Press

User Guide

3-5

Page 34

Machine/job status

Tip

Some print servers do not update the print engine with the status of the job that is

currently printing. This means that the progress bar on the print engine’s UI may continue

to display zero percentage (0%) for the printing status. If this occurs, always check the

print server’s UI for the status of the currently printing job.

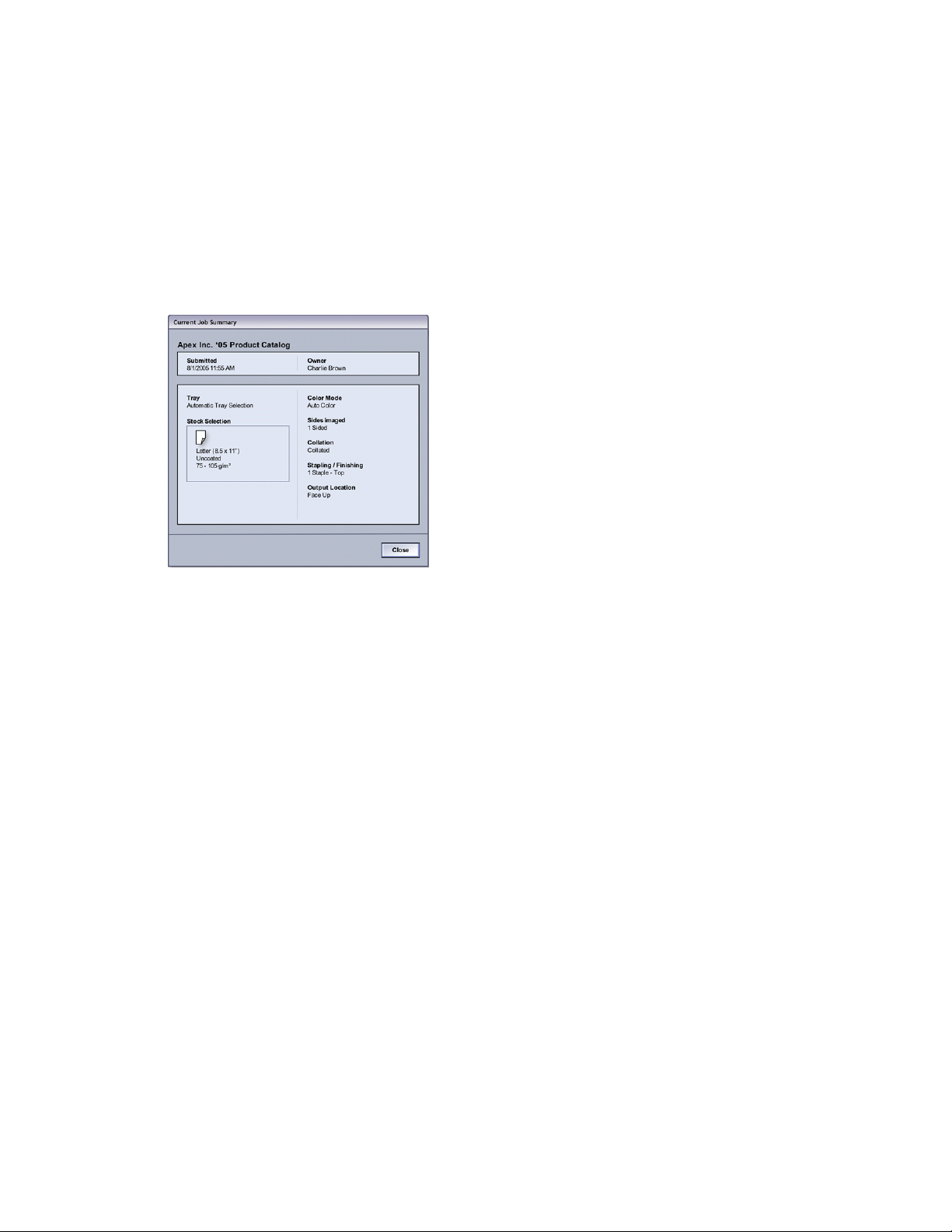

Job summary

Selecting the Summary button opens the Current Job Summary window. The Summary

button is selectable only when jobs are currently printing.

Pause

Selecting the Pause button during a print job stops or pauses the printing process.

Once a print job is paused, you may resume printing or cancel the job.

Note

Depending on the Administrator setting, your machine may automatically resume

printing after a preset period of time without selecting the Resume button. Ask your

Administrator about this, or refer to the System Administration Guide for more

information.

3-6

Xerox® Color 800/1000 Press

User Guide

Page 35

4

Submitting a print job

These exercises require the PDF files for the User Guide and System Administration

Guide. If you do not have an electronic copy of these PDFs, download them from

www.xerox.com.

The exercises instruct you on how to print one of the customer documentation guides

(User Guide or System Administration Guide).

Printing from your computer

1. From your computer open one of the PDFs files in Adobe Acrobat Reader.

2. Select File > Print.

3. Select the desired printer and print queue.

4. Select the Properties button (for that machine).

5. Select the desired output options (such as quantity, 1- or 2-sided printing).

6. Select OK to close the Properties window.

7. Select OK to send the job to the printer.

Printing from the Xerox FreeFlow Print Server

1. Copy the customer documentation PDF files onto a storage device (such as a flash

drive or CD/DVD).

2. Connect your storage device to the print server.

3. From the FreeFlow Printer Server, select Services > Print from File.

4. Select Browse.

5. Browse to your storage device containing the PDF files.

6. Select and highlight one of the PDF files (User Guide, System Administration Guide).

7. Select OK.

8. Select the desired print queue.

9. Select the desired output options (such as quantity, 1- or 2-sided printing).

Xerox® Color 800/1000 Press

User Guide

4-1

Page 36

Submitting a print job

10. Select Print.

The job is sent to the desired queue and either held or immediately printed.

11. Select Close; this closes the Print From File window.

Printing from the Xerox EX Print Server, Powered by EFI

1. Copy the customer documentation PDF files onto a storage device (such as a flash

drive or CD/DVD).

2. Connect your storage device to the print server.

3. From the Xerox EX Printer Server, select File > Import Job.

4. Select the desired queue (such as Print or Hold).

5. Select Add.

6. Browse to your storage device containing the PDF files.

7. Select and highlight one of the PDF files (User Guide, System Administration Guide).

8. Select Open.

9. Select Import.

The job is sent to the selected queue or to the printer for immediate printing.

Printing from the Xerox CX Print Server, Powered by Creo

1. Copy the customer documentation PDF files onto a storage device (such as a flash

drive or CD/DVD).

2. Connect your storage device to the print server.

3. From the Xerox CX Printer Server, select File > Import.

4. Select the desired queue (such as ProcessStore or ProcessPrint).

5. Browse to your storage device containing the PDF files.

6. Select and highlight one of the PDF files (User Guide, System Administration Guide).

7. Select Add.

8. Select Import.

The job is sent to the selected queue or to the printer for immediate printing.

4-2

Xerox® Color 800/1000 Press

User Guide

Page 37

System Administrator overview

Logging on as Administrator

1. Select the Logon button from the main UI window.

The Logon screen appears.

2. From the Logon screen select Administrator.

3. Use the keyboard to enter the Administrator password.

Note

For security reasons, only asterisks are displayed on the screen.

5

4. Select the OK button.

Note

It is recommended that you change the Administrator password as soon as possible

after installing the machine in order to prevent unauthorized access to the

Administrator mode.

5. To exit the Administrator mode, select the Logoff button.

System administrator options

The system Administrator mode includes setting, changing, and testing the following

features:

• Paper Curl Settings (Advanced Stock Setup)

• Running test prints (for changes made to Advanced Stock Setup options)

• System Setting functions, including:

- Language

- Changing the Administrator password

- Resetting the Technical Key Operator password

- Automatic display of fault windows

Xerox® Color 800/1000 Press

User Guide

5-1

Page 38

System Administrator overview

- Date and time

- Productivity settings

- Power saver settings

- Attention sounds

- Tray options, such as automatic tray switching (ATS)

- Output Devices

- Image quality options

- Full Width Array

• Profiles functions, including:

- Alignment

- Fold Adjustment; this feature is displayed if the optional finisher is attached

- Finishing Devices: This option is available only if an optional, third-party, Document

Finishing Architecture (DFA) device is attached to your system. This feature allows

you to choose specific settings for that attached DFA device.

For detailed information and instructions on the various Administrator functions, refer

to the System Administration Guide.

5-2

Xerox® Color 800/1000 Press

User Guide

Page 39

6

Paper information

Loading media in Trays 1 and 2

Loading paper

1. Select the appropriate paper stock for your print job.

2. Pull out the tray slowly until it stops.

3. Open the ream of paper with the seam side facing up.

4. Fan the sheets before loading them into the tray.

5. Load and register the paper against the right side of the tray.

6. Adjust the paper guides by pressing in the guide release and carefully moving the

Edge Guide until it lightly touches the edge of the material in the tray.

Do not load materials above the MAX line located on the rear Edge Guide.

7. If necessary, set the skew adjustment levers to the desired position for your print job.

8. Gently push in the tray until it comes to a stop.

If enabled by your System Administrator, the Paper Tray Properties screen may be

displayed on the UI.

9. From the Tray Properties window, enter the correct paper information, including size,

type, weight, and if necessary, paper curl and/or alignment option.

10. Select OK to save the information and close the Tray Properties window.

Loading tab stock

1. Select the appropriate paper stock for your print job.

2. Pull out the tray slowly until it stops.

3. Fan the tab paper before loading into the tray.

4. Load and align the edge of the tab paper against the right edge of the tray in the

LEF direction as shown in following illustration:

Xerox® Color 800/1000 Press

User Guide

6-1

Page 40

Paper information

5. Adjust the paper guides by pressing in the guide release and carefully moving the

Edge Guide until it lightly touches the edge of the material in the tray.

Do not load materials above the MAX line located on the rear Edge Guide.

6. If necessary, set the skew adjustment levers to the desired position for your print job.

7. Gently push in the tray until it comes to a stop.

If enabled by your System Administrator, the Paper Tray Properties screen may be

displayed on the UI.

8. From the Tray Properties window, enter the correct paper information, including size,

type, weight, and if necessary, paper curl and/or alignment option.

9. Select OK to save the information and close the Tray Properties window.

Loading transparencies

1. Select the appropriate paper stock for your print job.

2. Pull out the tray slowly until it stops.

3. Fan the transparencies to stop them from sticking together before loading into the

tray.

4. Load transparencies on top of a small stack of same-size paper and align the edge

of the transparency against the right edge of the as shown in following illustration:

5. Adjust the paper guides by pressing in the guide release and carefully moving the

Edge Guide until it lightly touches the edge of the material in the tray.

Do not load materials above the MAX line located on the rear Edge Guide.

6. If necessary, set the skew adjustment levers to the desired position for your print job.

7. Gently push in the tray until it comes to a stop.

If enabled by your System Administrator, the Paper Tray Properties screen may be

displayed on the UI.

6-2

Xerox® Color 800/1000 Press

User Guide

Page 41

Paper information

8. From the Tray Properties window, enter the correct paper information, including size,

type, weight, and if necessary, paper curl and/or alignment option.

9. Select OK to save the information and close the Tray Properties window.

Loading pre-drilled stock for 1-sided print jobs

1. Select the appropriate paper stock for your print job.

2. Pull out the tray slowly until it stops.

3. Open the ream of paper with the seam side facing up.

4. Fan the sheets before loading them into the tray.

5. Load and register the paper against the right side of the tray as depicted below for

LEF direction:

6. Adjust the paper guides by pressing in the guide release and carefully moving the

Edge Guide until it lightly touches the edge of the material in the tray.

Do not load materials above the MAX line located on the rear Edge Guide.

7. If necessary, set the skew adjustment levers to the desired position for your print job.

8. Gently push in the tray until it comes to a stop.

If enabled by your System Administrator, the Paper Tray Properties screen may be

displayed on the UI.

9. From the Tray Properties window, enter the correct paper information, including size,

type, weight, and if necessary, paper curl and/or alignment option.

10. Select OK to save the information and close the Tray Properties window.

Loading pre-drilled stock for 2-sided print jobs

Load drilled paper into any tray in either Long Edge Feed (LEF) or Short Edge Feed (SEF)

direction.

1. Select the appropriate paper stock for your print job.

2. Pull out the tray slowly until it stops.

3. Open the ream of paper with the seam side facing up.

4. Fan the sheets before loading them into the tray.

Xerox® Color 800/1000 Press

User Guide

6-3

Page 42

Paper information

5. Load and register the paper against the right side of the tray as depicted below for

LEF direction:

6. Load and register the paper against the right side of the tray as depicted below for

SEF direction:

7. Adjust the paper guides by pressing in the guide release and carefully moving the

Edge Guide until it lightly touches the edge of the material in the tray.

Do not load materials above the MAX line located on the rear Edge Guide.

8. If necessary, set the skew adjustment levers to the desired position for your print job.

9. Gently push in the tray until it comes to a stop.

If enabled by your System Administrator, the Paper Tray Properties screen may be

displayed on the UI.

10. From the Tray Properties window, enter the correct paper information, including size,

type, weight, and if necessary, paper curl and/or alignment option.

11. Select OK to save the information and close the Tray Properties window.

Skew adjustment levers

The skew adjustment levers are found in all paper trays. These levers are used to improve

paper feed accuracy and to reduce paper skew problems.

6-4

Xerox® Color 800/1000 Press

User Guide

Page 43

Paper information

1. Rear skew adjustment lever

2. Right-side skew adjustment lever

• These levers should remain in their default position. The position of these levers

should be changed only when there is a skew problem when running a specific print

job and/or specific media type.

• Changing the skew adjustment levers from their default position may cause more

skew problems when running certain media types, such as coated, label, transparency,

and film.

Use the following procedure to set the skew adjustment levers.

1. Pull out the tray slowly until it stops.

2. Slide the rear skew adjustment lever to the right (as shown in the above picture).

3. Gently push in the tray until it comes to a stop.

4. From the Tray Properties window, enter the correct paper information, including size,

type, weight, and if necessary, paper curl and/or alignment option.

5. Select OK to save the information and close the Tray Properties window.

6. Run your print job.

• The paper is fed accurately without skew and the printed output is satisfactory;

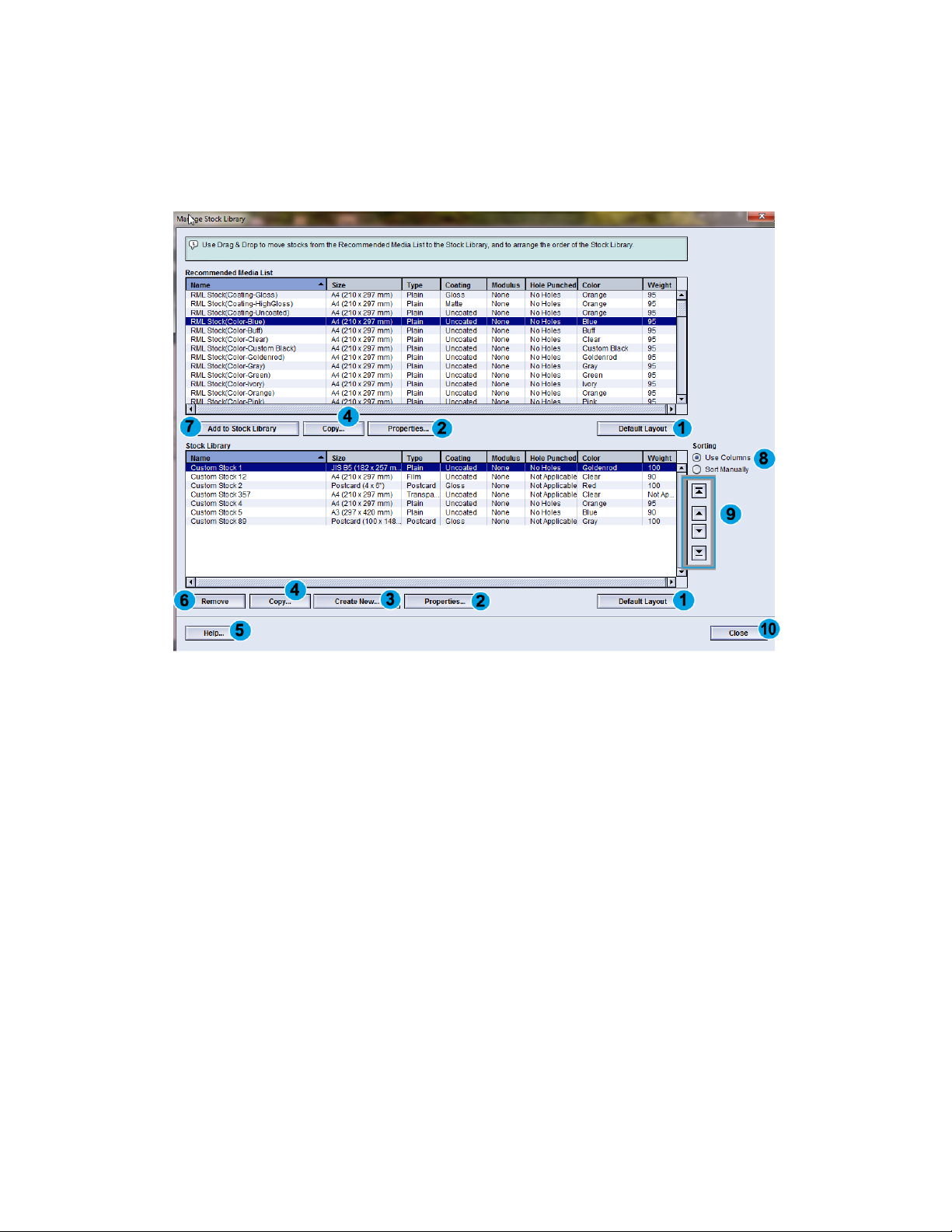

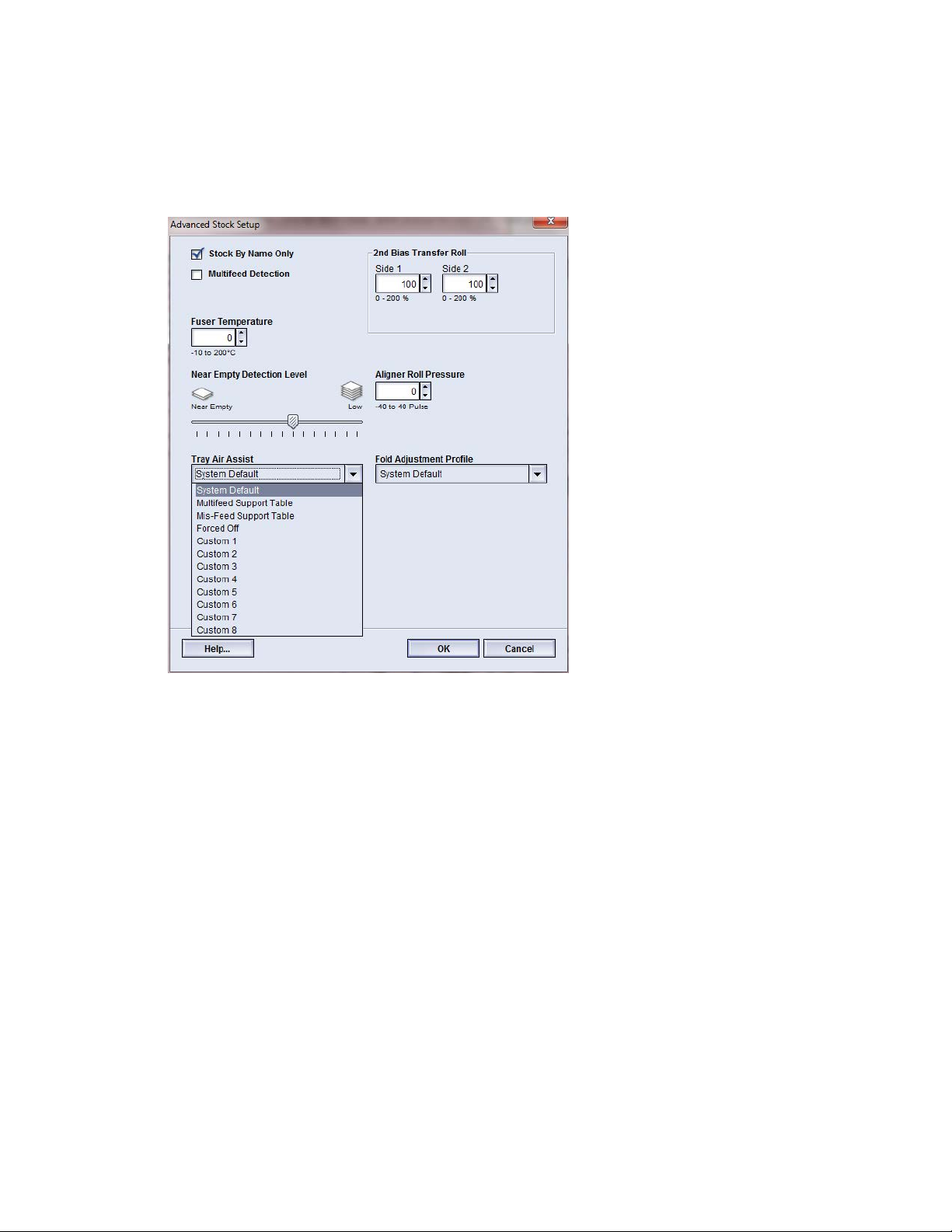

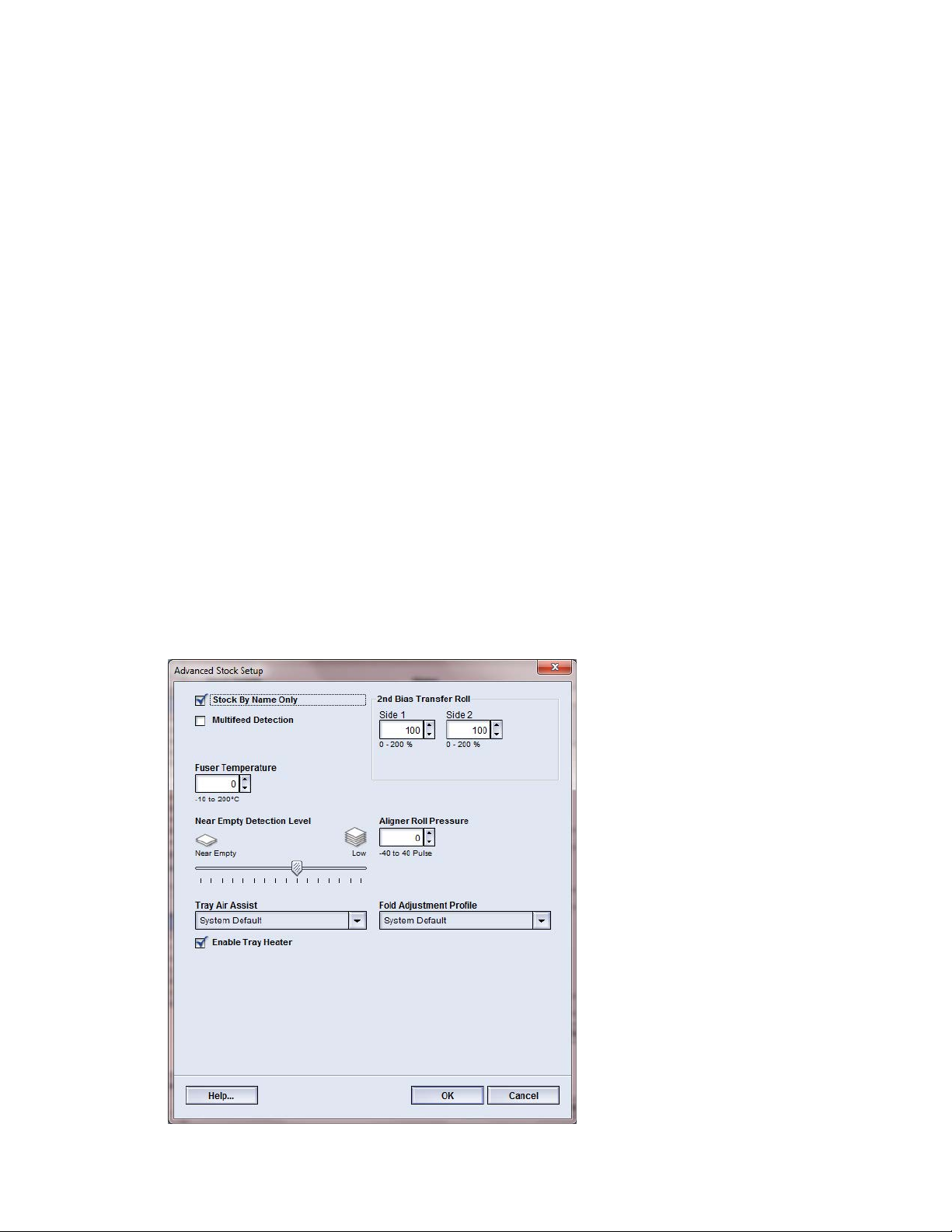

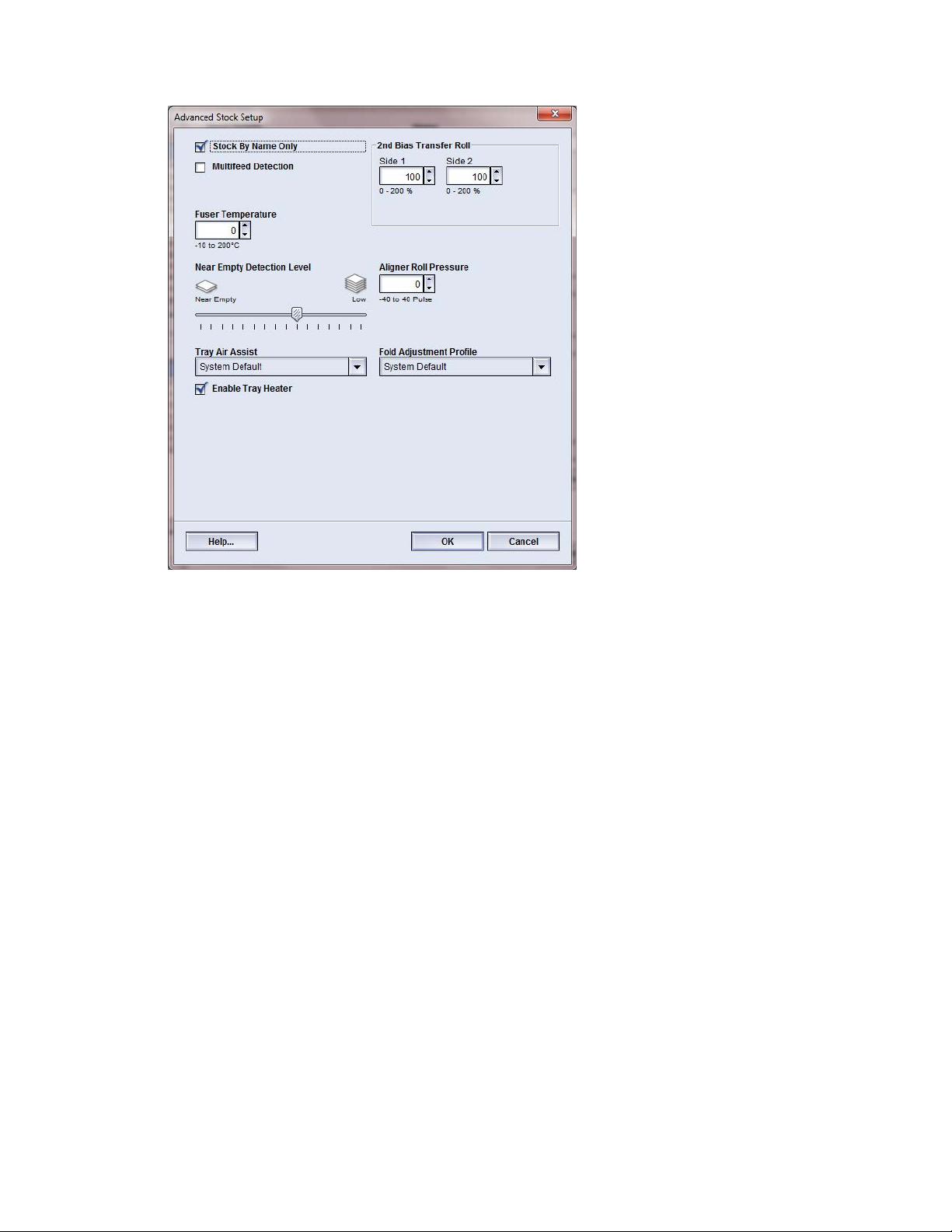

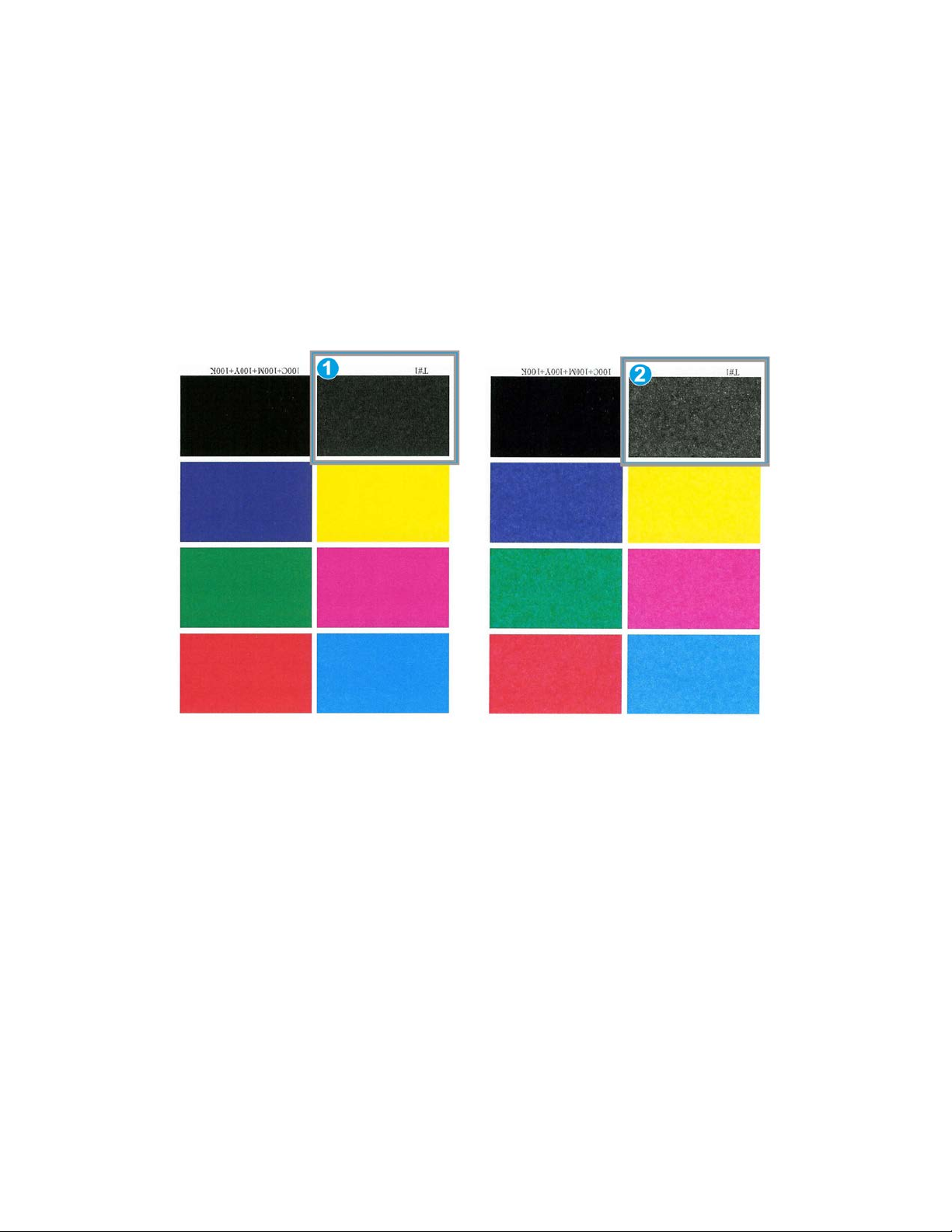

you are finished.