Page 1

Recommended

Xerox Materials for Xerox Color 550/560

For use in the US and Canada

occur when Output Format is Auto or Face Down.

Use Face Up output format if this occurs. OHCF is strongly recommended when feed

ing

occur when Output Format is Auto or Face Down.

Use Face Up output format if this occurs. OHCF is strongly recommended when feed

ing

Revision 1.1 - Issued May 2012

Important Notes:

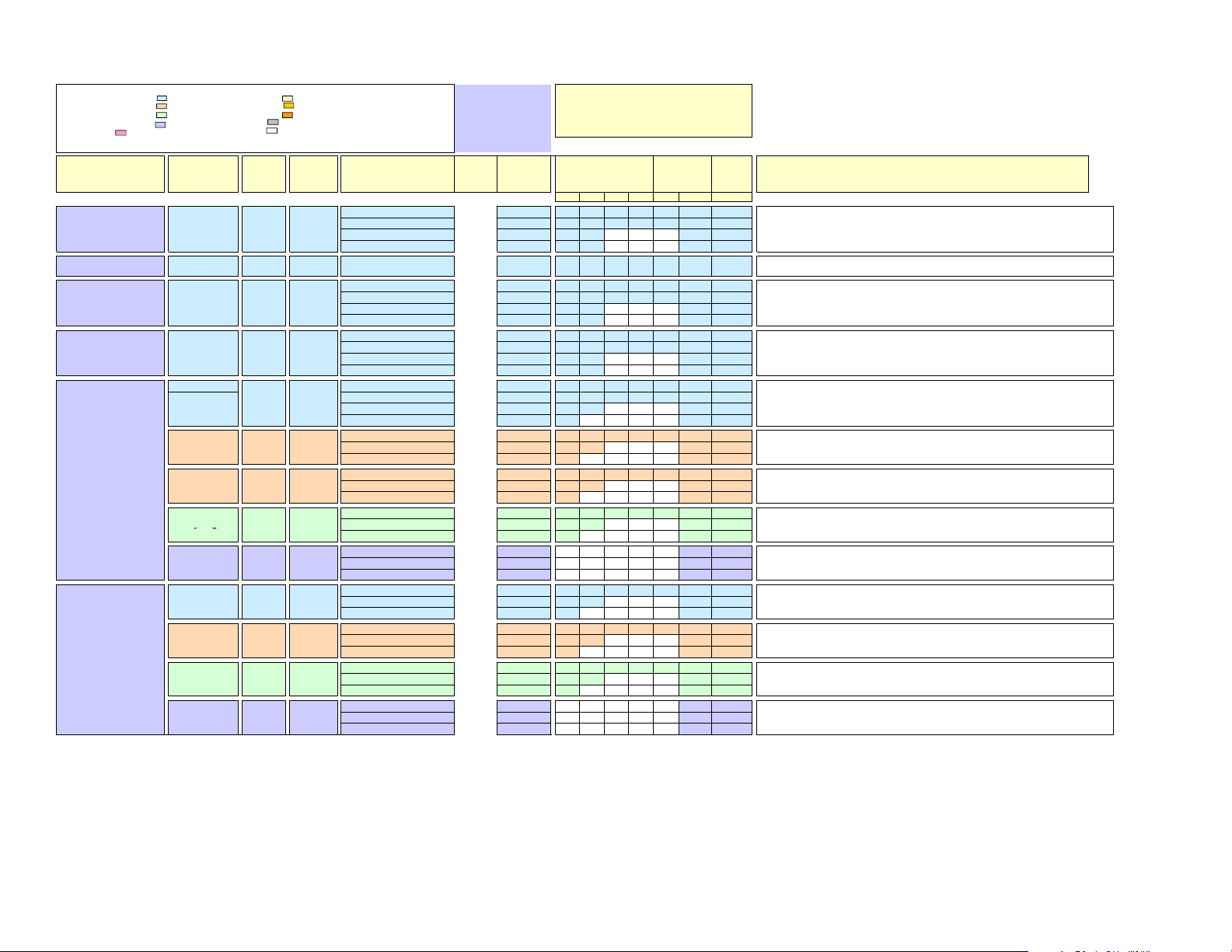

All media is listed by product, machine run mode, Image Quality System Setting, weight (standard gsm), re-order number, size, and tray

runability. The additional information column is for hints and tips on how to run certain media applications.

Media recommendations made in this publication are based on qualification tests* conducted using standard test images with moderate to

heavy image area coverage. Test duration for each product/media type is based on the suggested machine monthly copy/print volume. Test

machines are maintained within specifications defined by user documentation.

* Testing Environment temperature range of 60-75 deg. F, Relative Humidity range 20-40%.

*Machine reliability specifications may be affected by increased usage of the Heavyweight 1, Heavyweight 2, Heavyweight 3,Heavyweigt 4,

Coated 1, Coated 2 and Coated 3 modes. In addition, variances in machine reliability may occur due to extended use of some media types.

Your Xerox service representative can advise you on using Heavyweight 1, Heavyweight 2, Heavyweight 3, Heavyweight 4, Coated 1, Coated 2

and Coated 3 modes or special application media types for long duration copy/print runs.

Auto-duplexing of Coated and Heavyweight 2 media may cause increased jams. When this occurs, use manual Duplexing. Increased jams may

Heavyweight 2 and Coated 2 media.

Environmental conditions may require that coated paper be fed one at a time through Tray 5 (Bypass). Relative Humidity greater than 40%

could cause multifeeds. Oversize High Capacity Feeder Option (OHCF) prevents multifeeds for Coated 1, Coated 2 and Coated 3 modes when

Relative Humidity is greater than 40%. Output may require removal at 25 sheets in the tray when not using a finisher.

Oversize High Capacity Feeder Option is recommended for optimal feeding performance of Coated 2 Side (C2S) media. Coated 1, Coated 2 and

Coated 3 modes on the OHCF prevent multifeeds, especially in high humidity environments. Coated 1 Side (C1S) media has best feeding

performance in high humidity when using Coated 2 or Coated 3 mode. In low humidity environment, Heavyweight 2 or Heavyweight 3 mode

may yield better image quality.

For Manual Duplex, it may help to manually remove curl after printing side 1 before placing sheets into feeder for side 2.

© 2012 Xerox Corporation. All rights reserved.

Xerox® and all Xerox product names and product names and product numbers mentioned in this publication are trademarks of Xerox

Corporation. Other company trademarks are also acknowledged.

For the latest line of Xerox supplies contact your local Xerox representative or a recommended distributor. For the most recent version of this

list visit our website at www.xerox.com, select "Country", then "Supplies".

Page 2

550-560 RML North American V 1.0

1234HCF

OHCF

5

3R11771

17 x 11

SSA

A

Heavyweight 2

Image

3R11771

17 x 11

SSA

A

80lb

Heavyweight 2

When feeding HW2 and/or coated stock it is highly recommended to feed from tray 5 (Bypass) or trays 6/7 (OHCF) due to

Plain/Recycled (64-105gsm) Coated 1 (106-150gsm)

Heavyweight 1(106-176gsm) Coated 2 (151-220gsm)

Heavyweight 2 (176-220gsm) Coated 3 (221-300gsm)

Heavyweight 3/4 (221-300gsm) Label

Transparency Transfer Paper

Paper types are selected within System Settings

Media

Xerox Business 4200

Xerox Business 4200 Ring

Tuff

Mode

Plain

Hole Punched

Plain A

Xerox Business Plus Plain Plain A

Xerox Color Xpressions

Select

Plain

Plain B

Hole Punched

Plain

Plain C

Heavyweight 1

Xerox Color Xpressions

Elite

Heavyweight 1

Heavyweight 4

Plain

Plain C

Heavyweight 1

Xerox Color Xpressions

Planet 20

Heavyweight 2

Heavyweight 4

Quality

System

Setting

HW1A

HW1C

HW1C

Weight

75 gsm/

20lb

75gsm/20lb

75 gsm/

20lb

90 gsm/

24lb

105gsm/

28lb

120gsm/

32lb

163gsm/

60lb

215gsm/

270gsm/

100lb

105gsm/

28lb

175gsm/

65lb

215gsm/

80lb

270gsm/

100lb

RML

550/560

North America

V 1.1

Type

3R2047 8.5 x 11

3R2641 (3-Hole) 8.5 x 11

3R2051 8.5 x 14

3R3761 11 x 17

SizeRe-Order #

3R4429 (3-hole) 8.5 x 11

3R11600 8.5 x 11

3R11601 (3-Hole) 8.5 x 11

3R11602 8.5 x 14

3R11603 11 x 17

3R11540 8.5 x 11

3R11541 (3-hole) 8.5 x 11

3R11542 8.5 x 14

3R11543 17 x 11

3R11761 (3-hole) 8.5 x 11

3R11760 8.5 x 11

3R11762 17 x 11

3R11763

3R11764 8.5 x 11

3R11765 17 x 11

3R11766 18 x 12

3R11767 8.5 x 11

3R11768 17 x 11

3R11769 18 x 12

18 x 12

3R11770 8.5 x 11

3R11772 18 x 12

3R11774 8.5 x 11

3R11775 17 x 11

3R11776 18 x 12

3R11800 8.5 x 11

3R11801 17 x 11

3R11802 18 x 12

3R11803 8.5 x 11

3R11804 17 x 11

3R11805 18 x 12

3R11806 8.5 x 11

3R11807 17 x 11

3R11808 18 x 12

3R11809 8.5 x 11

3R11810 17 x 11

3R11811 18 x 12

A=Auto Duplex

S=Simplex Only

M=Manual Duplex

PCW=Post Consumer Waste

ECF=Elemental Chlorine Free

Trays 1 - 4

A A A A A A A

A A A A A A A

A A A A

A A A A

A A A A A A A

A A A A A A A

A A A A A A A

A A A A

A A A A

A A A A A A A

A A A A A A A

A A A A

A A A A

A A A A A A A

A A A A A A A

A A A A

A

A A A A A A A

A A A A

A A A

A A A A A A A

A A A A

A A A

S S S S S A A

S M M

A A A A A A A

A A A A

A

A A A A A A A

A A A A

A A A

S S S S S A

S S

S

Tray 6-7 Additional Information

A A

S

S

S

A A

A A

M M

S

S

S

Tray 5

(Bypass)

For 3 Hole Paper, select Hole Punched PaperType to avoid false jams.

For 3 Hole Paper, select Hole Punched PaperType to avoid false jams.

For 3 Hole Paper, select Hole Punched PaperType to avoid false jams.

On Light Production Finisher, do not staple more than 70 sheets per set.

For 3 Hole Paper, select Hole Punched PaperType to avoid false jams.

On Light Production Finisher, do not staple more than 70 sheets per set.

For 3 Hole Paper, select Hole Punched PaperType to avoid false jams.

Increased jams may occur when auto-duplexing. Increased jams may occur when Output Format is Auto or Face Down.

Use Face Up output format if this occurs.

degraded feeding performance of trays 1-4.

M

M

M

On Light Production Finisher, do not staple more than 70 sheets per set.

Increased jams may occur when auto-duplexing. Increased jams may occur when Output Format is Auto or Face Down.

A

Use Face Up output format if this occurs.

When feeding HW2 and/or coated stock it is highly recommended to feed from tray 5 (Bypass) or trays 6/7 (OHCF) due to

degraded feeding performance of trays 1-4.

M

M

M

For the latest in Xerox Supplies, contact your local Xerox Distri butor, or call Xerox at 1-800-822-2200 in the USA, or call 1-800-668-0199 in Canada.

.

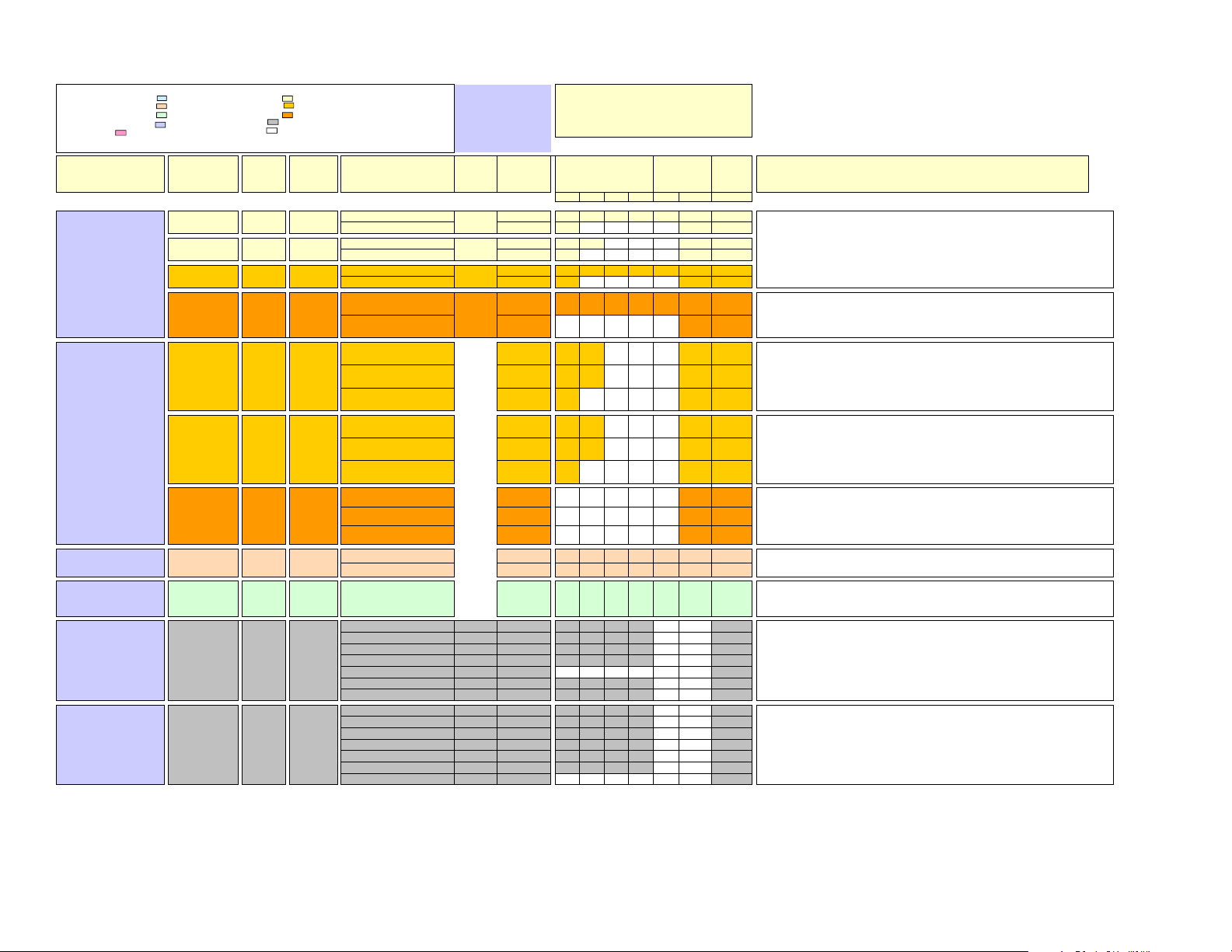

Page 3

550-560 RML North American V 1.0

1234HCF

OHCF

5

Image

3R11474

8.5 x 11

A

M

When this occurs, use Manual Duplexing. Increased jams may occur when Output Format is Auto or Face Down. Use Face

3R11474

8.5 x 11

A

M

Coated

140gsm/

Plain/Recycled (64-105gsm) Coated 1 (106-150gsm)

Heavyweight 1(106-176gsm) Coated 2 (151-220gsm)

Heavyweight 2 (176-220gsm) Coated 3 (221-300gsm)

Heavyweight 3/4 (221-300gsm) Label

Transparency Transfer Paper

Paper types are selected within System Settings

Media

Xerox Color Xpressions

Planet 100

Xerox Digital Publishing

Paper

Xerox Digital Color Elite

Gloss Coated Text and

Covers (C2S)

Mode

Recycled

Plain

Coated 1

Coated 1

Coated 2

Coated 3

Coated 3

Coated 1

Recycled B90gsm /

Plain B

Coated

Coated

Coated

Coated

Coated

Coated

Coated 1

Xerox Digital Color Elite

Silk Coated Text and

Covers (C2S)

Coated 2

Coated 3

Coated 3

Coated

Coated

Coated

Quality

System

Setting

1A

1B

2B

3B

3B

1A

1B

2B

3B

3B

Weight

24lb

90gsm/ 24lb

120gsm/

80lb

140gsm/

100lb

210gsm/

80lb

280gsm/

100lb

300gsm/

110lb

120gsm/

80lb

100lb

210gsm/

80lb

280gsm/

100lb

300gsm/

110lb

RML

550/560

North America

V 1.1

Type

A=Auto Duplex

S=Simplex Only

M=Manual Duplex

PCW=Post Consumer Waste

ECF=Elemental Chlorine Free

SizeRe-Order #

Trays 1 - 4

Tray 6-7 Additional Information

Tray 5

(Bypass)

3R11815 8.5 x 11 A A A A A A A

3R11755 8.5 x 11

3R5669 17 x 11

3R11450 8.5 x 11

3R11451 17 x 11

3R11452 18 x 12

3R11454 8.5 x 11

3R11455 17x11

3R11456 18x12

Gloss Text

Gloss Text

3R11458 8.5 x 11

3R11459 17 x 11

Gloss Cover

3R11460 18 x 12

3R11462 8.5 x 11

3R11463 17 x 11

3R11464 18 x 12

3R11466 8.5 x 11

3R11467 17 x 11

3R11468 18 x 12

3R11470 8.5 x 11

3R11471 17x11

3R11472 18x12

3R11475 17x11

3R11476 18x12

Gloss Cover

Gloss Cover

Silk Text

Silk Text

3R11478 8.5 x 11

3R11479 17 x 11

Silk Cover

3R11480 18 x 12

3R11482 8.5 x 11

3R11483 17 x 11

3R11484 18 x 12

3R11486 8.5 x 11

3R11487 17 x 11

3R11488 18 x 12

Silk Cover

Silk Cover

A A A A A A A

A A A A

A A A A A A

A A

A

A A A A A A

A A

A

A M

A M

A M

A M

S S S S S A M

S S S M

S S M

S

S

S

S

S

S

A

A M

A M

A M

A M

A M

S M

S M

S

S

S

S

S

S

On Light Production Finisher, do not staple more than 70 sheets per set.

M

Environmental conditions may require that coated paper be fed one at a time through Tray 5 (Bypass). Relative Humidity

greater than 40% could cause multifeeds. Output may require removal at 25 sheets in the tray when not using a finisher.

100lb text generally performs better than 80lb text. Increased jams may occur whwn auto-duplexing. When this occurs,

M

use Manual Duplexing. Increased jams may occur when Output Format is Auto or Face Down. Use Face Up output format

Environmental conditions may require that coated paper be fed one at a time through Tray 5 (Bypass). Relative Humidity

greater than 40% could cause multifeeds. OHCF is recommended for high humidity (>40%) environments. Gloss variation

can occur from machine rolls, especially on high area coverage prints. Increased jams may occur when auto-duplexing.

M

M

Environmental conditions may require that coated paper be fed one at a time through Tray 5 (Bypass). Relative Humidity

M

greater than 40% could cause multifeeds. OHCF is recommended for high humidity (>40%) environments. Output may

M

M

M

M

Environmental conditions may require that coated paper be fed one at a time through Tray 5 (Bypass). Relative Humidity

greater than 40% could cause multifeeds. Output may require removal at 25 sheets in the tray when not using a finisher.

100lb text generally performs better than 80lb text. Increased jams may occur when auto-duplexing. When this occurs,

use Manual Duplexing. Increased jams may occur when Output Format is Auto or Face Down. Use Face Up output format

Environmental conditions may require that coated paper be fed one at a time through Tray 5 (Bypass). Relative Humidity

greater than 40% could cause multifeeds. OHCF is recommended for high humidity (>40%) environments. Gloss variation

can occur from machine rolls, especially on high area coverage prints. Increased jams may occur when auto-duplexing.

Whenthis occurs, use Manual Duplexing. Increased jams may occur when Output Format is Auto or Face Down. Use Face

M

M

Environmental conditions may require that coated paper be fed one at a time through Tray 5 (Bypass). Relative Humidity

M

greater than 40% could cause multifeeds. OHCF is recommended for high humidity (>40%) environments. Output may

M

M

M

Gloss variation can occur from machine rolls, especially on high area coverage prints.

OHCF is recommended for high humidity (>40%) environments.

if this occurs.

Up output format if this occurs. 8.5x11 auotduplex may perform better LEF.

require removal at 25 sheets in the tray when not using a finisher. Gloss variation can occur from machine rolls,

Gloss variation can occur from machine rolls, especially on high area coverage prints.

Up output format if this occurs. 8.5x11 auotduplex may perform better LEF.

require removal at 25 sheets in the tray when not using a finisher. Gloss variation can occur from machine rolls,

especially on high area coverage prints.

OHCF is recommended for high humidity (>40%) environments.

if this occurs.

especially on high area coverage prints.

For the latest in Xerox Supplies, contact your local Xerox Distri butor, or call Xerox at 1-800-822-2200 in the USA, or call 1-800-668-0199 in Canada.

.

Page 4

550-560 RML North American V 1.0

1234HCF

OHCF

5

Image

Heavyweight 2 may occur. OHCF prevents multifeeds better using Coated 2 when Relative Humidity is greater than 40%.

Xerox Digital Color Select

Plain/Recycled (64-105gsm) Coated 1 (106-150gsm)

Heavyweight 1(106-176gsm) Coated 2 (151-220gsm)

Heavyweight 2 (176-220gsm) Coated 3 (221-300gsm)

Heavyweight 3/4 (221-300gsm) Label

Transparency Transfer Paper

Paper types are selected within System Settings

Media

Gloss Coated Text and

Covers (C2S)

Xerox Digital Color

SuperGloss Coated

Cover (C1S)

Mode

Coated 1

Coated 1

Coated 2

Coated 3

Coated 2 or

Heavyweight 2

Coated 2 or

Heavyweight 2

Coated 3 or

Heavyweight 3

Coated

Coated

Coated

Coated

Coated

Coated

Coated

Xerox Index Stock Heavyweight 1

Xerox 110# Index Stock

Xerox Digital Color

Glossy Labels

Xerox Digital Color Matte

Labels

Heavyweight 2

Label Mode

Label Mode

Quality

System

Setting

1A

1B

2B

3B

2B

2B

3A

HW1C

Weight

120gsm/

80lb

140gsm/

100lb

210gsm/

80lb

280gsm/

100lb

8pt / 176

gsm

10pt /

210gsm

12pt /

250gsm

163gsm/

90lb

199 gsm

RML

550/560

North America

V 1.1

Type

3R11503 17 x 11

3R11504 18 x 12

3R11510 17 x 11

3R11511 18 x 12

3R11506 17 x 11

3R11507 18 x 12

3R11513 17 x 11

Gloss Text

Gloss Text

Gloss Cover

Gloss Cover

SizeRe-Order #

3R11514 18 x 12

3R11680 8.5 x 11

3R11681 17 x 11

3R11682 18 x 12

3R11683 8.5 x 11

3R11684 17 x 11

3R11685 18 x 12

3R11686 8.5 x 11

3R11687 17 x 11

3R11688 18 x 12

3R11747 8.5 x 11

3R11748 17x11

3R11749 8.5 x 11

3R12735

3R12736

3R12737

3R12738

3R12739

3R12740

3R12741

3R5772

3R12371

3R5773

3R6332

3R6333

3R6330

3R12373

1 - up

1 - up

4-up

2 UP CD

6 UP CD

10 - up

30 - up

1 - up

1 - up

4-up

10-up

30-up

2 UP CD

6 UP CD

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

11 X 17

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

11 X 17

A=Auto Duplex

S=Simplex Only

M=Manual Duplex

PCW=Post Consumer Waste

ECF=Elemental Chlorine Free

Trays 1 - 4

A A A

A

A A A

A

S S S S S S M

S S M

Tray 6-7 Additional Information

A M

A M

S S S S S S M

S M

S S

S S

S

S M

S M

S M

S S S M

S S S

S

S M

S

S

S

A A A A A A A

A A A A A A A

S S S S S A A

S S S S S

S S S S S

S S S S S

S S S S S

S S S S S

S S S S S

S S S S S

S S S S S

S S S S S

S S S S S

S S S S S

S S S S S

Tray 5

(Bypass)

M

Environmental conditions may require that coated paper be fed one at a time through Tray 5 (Bypass). Relative Humidity

greater than 40% could cause multifeeds. Output may require removal at 25 sheets in the tray when not using a finisher.

M

100lb text generally performs better than 80lb text. Increased jams may occur when auto-duplexing. When this occurs,

use Manual Duplexing. Increased jams may occur when Output Format is Auto or Face Down. Use Face Up output format

Environmental conditions may require that coated paper be fed one at a time through Tray 5 (Bypass). Relative Humidity

greater than 40% could cause multifeeds. OHCF is recommended for high humidity (>40%) environments. Output may

Environmental conditions may require that coated paper be fed one at a time through Tray 5 (Bypass). Relative Humidity

greater than 40% could cause multifeeds. Output may require removal at 25 sheets in the tray when not using a finisher.

Gloss variation can occur from machine rolls, especially on high area coverage prints. Preference for Coated 1, Coated 2

or Heavyweight 2 may occur. OHCF prevents multifeeds better using Coated 2 when Relative Humidity is greater than

40%. Increased jams may occur when auto-duplexing. When this occurs, use Manual Duplexing. Increased jams may

occur when Output Format is Auto or Face Down. Use Face Up output format if this occurs. C1S media should not be

Environmental conditions may require that coated paper be fed one at a time through Tray 5 (Bypass). Relative Humidity

greater than 40% could cause multifeeds. Output may require removal at 25 sheets in the tray when not using a finisher.

M

Increased jams may occur when auto-duplexing. When this occurs, use Manual Duplexing. Increased jams may occur

Environmental conditions may require that coated paper be fed one at a time through Tray 5 (Bypass). Relative Humidity

M

greater than 40% could cause multifeeds. Output may require removal at 25 sheets in the tray when not using a finisher.

M

Heavyweight 3 may occur. OHCF prevents multifeeds better using Coated 2 when Relative Humidity is greater than 40%.

M

Increased jams may occur when auto-duplexing. Increased jams may occur when Output Format is Auto or Face Down.

Use Face Up output format if this occurs.

When feeding HW2 and/or coated stock it is highly recommended to feed from tray 5 (Bypass) or trays 6/7 (OHCF) due to

degraded feeding performance of trays 1-4.

S

Gloss variation can occur from machine rolls, especially on high area coverage prints.

OHCF is recommended for high humidity (>40%) environments.

if this occurs.

require removal at 25 sheets in the tray when not using a finisher. Gloss variation can occur from machine rolls,

Gloss variation can occur from machine rolls, especially on high area coverage prints. Preference for Coated 2 or

when Output Format is Auto or Face Down. Use Face Up output format if this occurs. C1S media should not be

Gloss variation can occur from machine rolls, especially on high area coverage prints. Preference for Coated 3 or

Labels are not intended as sole application of machine. Do not stack large amounts in Output Tray.

Labels are not intended as sole application of machine. Do not stack large amounts in Output Tray.

especially on high area coverage prints.

autoduplexed.

autoduplexed.

C1S media should not be autoduplexed.

S

For the latest in Xerox Supplies, contact your local Xerox Distri butor, or call Xerox at 1-800-822-2200 in the USA, or call 1-800-668-0199 in Canada.

.

Page 5

550-560 RML North American V 1.0

1234HCF

OHCF

5

Image

SSSSS

CF White

S

an Offset Catch Tray rather than finishing devices if possible to minimize the risk of paper jams.

S

SSSSS

Plain

Plain A

CF White

3R12440

8.5 x 11

S

Carbonless Paper

Plain/Recycled (64-105gsm) Coated 1 (106-150gsm)

Heavyweight 1(106-176gsm) Coated 2 (151-220gsm)

Heavyweight 2 (176-220gsm) Coated 3 (221-300gsm)

Heavyweight 3/4 (221-300gsm) Label

Transparency Transfer Paper

Paper types are selected within System Settings

Media

Xerox Transparency

Mode

Transparency Mode

Xerox Tabs Tab Stock1

Xerox Digital EA Transfer

Paper

Transfer Paper

Plain Plain A

Xerox Premium Digital

Carbonless Paper

(Precollated)

Plain Plain A

Plain

Plain A

Plain Plain A

Plain Plain A

Plain Plain A

Plain Plain A

RML

550/560

North America

V 1.1

Quality

System

Setting

Tab1C 3R4417 8.5/9 x 11

Weight

163gsm/

90lb index

3R3117

3R12505

3R3108

3R4418 (3-hole) 8.5/9 x 11

Type

8.5 x 11

3R12398 8.5 x 11

3R12397 17x11

2-Part (W/C)

3-Part

Straight

3-Part

Reverse

4-Part

Straight

4-Part

Reverse

CB White

CFB White

3R12420 8.5 x 11

3R12422 8.5 x 14

3R12423 11 x 17

3R12425 8.5 x 11

3R12427 8.5 x 14

3R12424 8.5 x 11

3R12430 8.5 x 11

3R12429 8.5 x 11

3R12434 8.5 x 11

3R12435 8.5 x 11

A=Auto Duplex

S=Simplex Only

M=Manual Duplex

PCW=Post Consumer Waste

ECF=Elemental Chlorine Free

SizeRe-Order #

S S

S S S S S S S

S S S S

S S S S

S

S S S S

S S S S S S

S S S

Trays 1 - 4

S S

Tray 6-7 Additional Information

S S S

S SS

S S S

S S SSS

(Bypass)

SS

S S

Tray 5

Xerox Premium Digital

(Singles)

Plain Plain A

Plain Plain A

WARRANTY DISCLAIMER

Xerox makes no guarantees or warranties, either express or implied, concerning the performance, use or replacement of non-Xerox branded media or throughput products. Customers should inquire

directly of their paper distributor or manufacturer for any guarantees they may offer. When purchasing a particular media product for the first time, customers are advised to purchase small quantities to

insure that their expectations are met.

The quality of Xerox supplies is consistent from ream to ream, carton to carton, and it is backed by a Xerox 100% guarantee. The quality of non-Xerox branded paper may vary from ream to ream or

carton to carton, so for optimum performance on Xerox color equipment, use only the best--Xerox Supplies. To learn more about the benefits of using Xerox Supplies. please contact your Supply

Account Manager or call, in the US 1-800-822-2200 and in Canada 1-800-668-0199 (English) or 1-800-668-0133 (Francais).

CFB Canary

CF Pink

3R12437 8.5 x 11

3R12439 8.5 x 11

S S S

S S S S S S

S S

S S

It is not recommended that you output more than 20 transparencies at a time.

If your job is larger than 20 pages, use Transparency Separators feature.

For copy jobs, 8.5x11 size should be selected. For print jobs, 9x11 size should be selected. Tab stock functionality and

S

work flow will vary for different Digital Front End Print/Network Controllers. Please consult the Network controller

S

Transfer Paper is not intended as sole application of machine. Limit Monthly usage. Use a machine with Offset Catch

S

Tray rather than finishing devices if possible to minimize the risk of paper jams. · While the job is printing, remove each

S

Carbonless Paper is not intended for extensive or exclusive usage. Limit monthly volumes. Use a machine equipped with

sheet as it exits the machine to avoid stacking problems in the exit tray.

an Offset Catch Tray rather than finishing devices if possible to minimize the risk of paper jams.

documentation when running tabs.

S

Carbonless Paper is not intended for extensive or exclusive usage. Limit monthly volumes. Use a machine equipped with

S

© 2012 Xerox Corporation. All rights reserved.

Xerox® and all Xerox product names and product names and product numbers mentioned in this publication are trademarks of Xerox Corporation. Other company trademarks are also acknowledged.

For the latest in Xerox Supplies, contact your local Xerox Distri butor, or call Xerox at 1-800-822-2200 in the USA, or call 1-800-668-0199 in Canada.

.

Loading...

Loading...