Page 1

Xerox® CiPress® 500

®

Xerox

Production Inkjet Systems

Brochure

CiPress® 325

Xerox® CiPress® 500

Xerox® CiPress® 325

Production Inkjet Systems

Innovative waterless inkjet technology delivers predictable

high-quality color on low-cost plain papers.

Page 2

Delight your customers with

unsurpassed color output on

low-cost, untreated plain paper.

This waterless inkjet system enables you to produce more jobs with consistency,

predictability and reliability, grow your business with high-quality color applications

with dependable productivity and reduce your costs using inexpensive plain papers.

The Xerox

®

CiPress® 500 and the Xerox® CiPress® 325 Production Inkjet Systems offer

you a distinctive combination of flexible low-cost plain paper options, unique patented

waterless inks, rugged piezo print head technology and an innovative print process.

2

Page 3

Raise your performance level.

Reduce your costs.

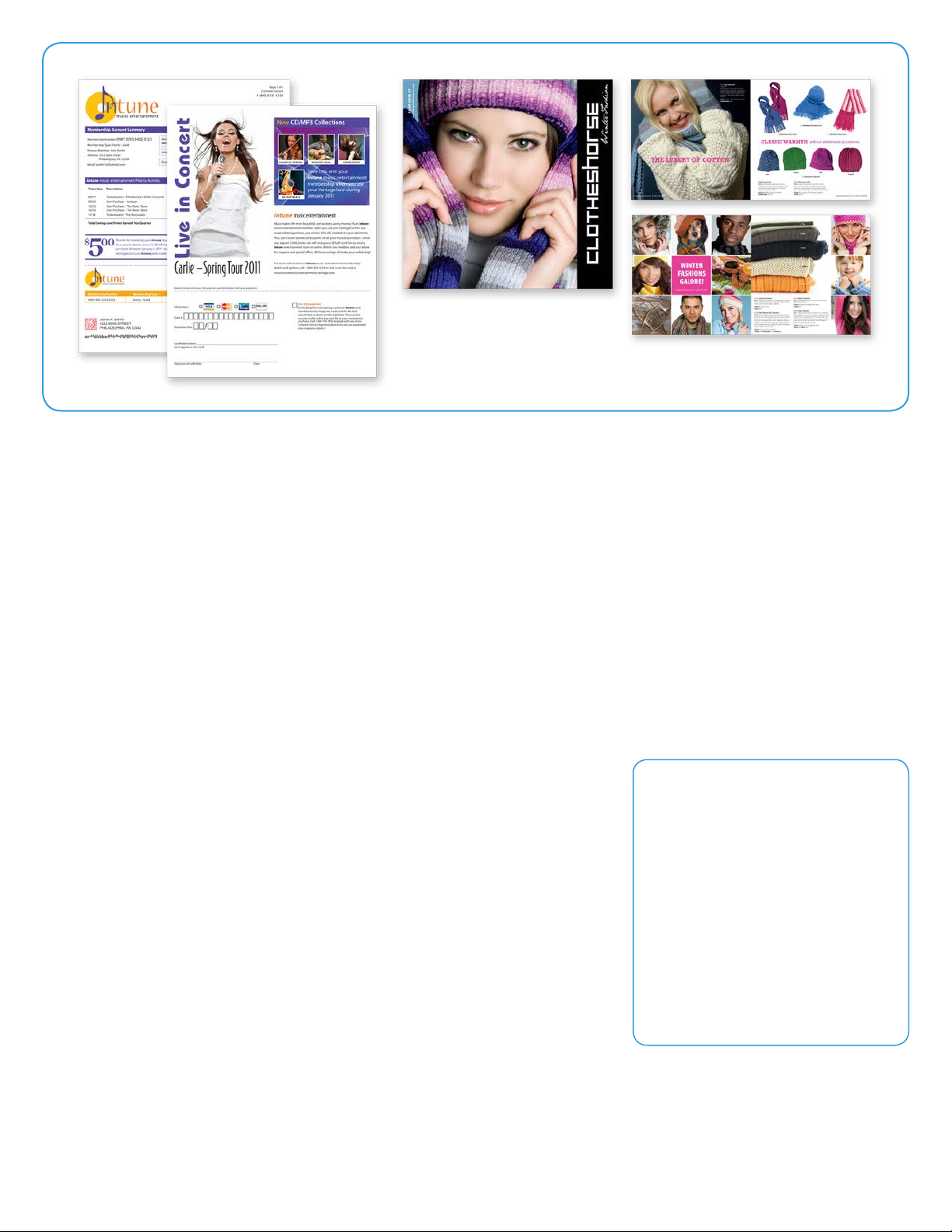

With the Xerox® CiPress® Production Inkjet

Systems, you can achieve outstanding color

results on plain paper that is uncoated and

untreated, including economical offset papers.

Our advanced waterless inks and direct-topaper print process deliver exceptional output

on stocks ranging from lightweight 29 gsm

to 160 gsm. It is ideal for your Transactional,

TransPromo and Direct Mail, Catalogs and

Manuals applications that use untreated plain

paper stocks.

The benefits of plain paper include:

• Use of lower-cost offset stocks

• Easier management of inventory

• Use of lightweight stocks with

higher yields per roll

• No long lead time for special inkjet

treated papers

• Avoid high cost of inkjet treated papers

• No disruption to existing supply chain

With Xerox

continue to use your existing paper stocks—

even your offset litho stocks—to optimize

productivity, improve lead time and obtain

greater cost benefits.

®

CiPress® printers, you can

• Cut application and paper costs. You can

take advantage of lower-cost, lightweight

paper alternatives, such as offset, for many

of your applications and still see great

results with optimum productivity. Our

inks sit on top of the paper much like toner

and litho inks rather than soaking into the

paper’s fibers like current water-based inkjet

technologies. With our patented waterless

inks, we enable high saturation and area

coverage on stocks as light as 29 gsm, with

no show-through or strike-through. As a

result, you can manage your postal rates

more effectively or include more sheets per

envelope for enhanced, more personalized

marketing messaging.

• Eliminate preprinted shells. Lower your

cost of manufacturing by eliminating the

associated supply chain costs of preprinted

shells, such as storage, transportation,

labor, obsolescence and materials

handling. You can print both static and

full color variable data on plain uncoated

paper like bills, statements, invoices and

personalized direct mail.

• Produce more jobs with greater

reliability. Designed for the print and mail

industry as well as publishing markets,

the Xerox

®

CiPress® system delivers more

reliable flat sheet output, improving

post-processing equipment performance,

enabling more efficiency, productivity and

uptime with your finishing, inserting and

mailing equipment. Even with high area

coverage, cockle and curl are significantly

reduced or eliminated because we use

no water in our printing process or inks.

Because we do not soak the paper with

water, we eliminate the problems with water

and paper saturation that can cause severe

cockle and curl in your output.

The Xerox

®

CiPress® Production

Inkjet System builds on our history of

innovation as well as our commitment

to the continuous feed market. As a

multi-technology company, we have

over 5,000 world-class scientists and

engineers working constantly to expand

the technologies and solutions we

offer to our customers. Over the past

decade, we have developed a portfolio

of continuous feed solutions that range

from 350 to 2,180 images per minute and

high speed variable data Production

Print Controllers since 1977.

3

Page 4

Expect vibrant color images with the

®

Xerox

CiPress

Our patented waterless inks deliver bright, vivid color and excellent image quality—

all on low-cost plain papers. No need for extra bonding agents or expensive specially

treated inkjet papers.

CiPress® 500 and the Xerox®

®

325 Production Inkjet Systems.

Our waterless inkjet technology offers

you significant advantages, especially in

contrast to other aqueous inks and their

printing processes that require adding high

amounts of water into the paper.

The benefits of Xerox

• High image quality is assured. The

®

Xerox

CiPress® 500 and 325 Production

Inkjet Systems deliver resolutions in

either 600 x 400 or 600 x 600 dpi with a

®

waterless inks include:

wide color gamut for the most demanding

applications. Precise, well-controlled,

predictable dots hold their shape to produce

sharp edges and excellent bar code readability

with crisp fonts, images and graphics. Our

patented closed loop image processing

ensures you get consistent, predictable results

for every job, roll to roll and month to month,

enhancing your efficiency and ability to meet

your Service Level Agreements (SLAs).

• Ongoing system reliability. Our unique

waterless inks are part of the key to the

®

Xerox

CiPress® printer’s high reliability and

uptime. Our print heads and inks are not

affected by evaporation, the most common

cause for print head clogging and failure.

With our innovative technology, our ink can

remain unused in our print heads for weeks

and the print heads will still fire on demand,

meaning there is no requirement to cap the

print heads or worry about open time. This

also means quick startup, more uptime and

reliability, fewer stoppages and cleaning

cycles and, ultimately, greater production,

less waste and more output per shift.

4

Page 5

• Easy to handle, manage and store.

Our waterless inks are dry granules that

feed easily, melt quickly and are easy to

store and refill. You don’t have to move or

recycle our ink dispensing drums because

they are permanent fixtures. You can refill

them on the fly, while the system is running,

from smaller, lighter, easy-to-handle 10 kilo

containers. This saves your operators from

handling large, heavy drums with awkward

hoses and messy liquids, increasing your

productivity and uptime. Storage is worryfree because these waterless inks have no

shelf-life restrictions.

• Waste less ink. Setup, registration,

alignment patches and cleaning procedures

are automated, saving you time and money

and minimizing waste for both ink and

paper. No clean and purge procedures are

required during standby modes to keep

the ink from evaporating and clogging the

heads that, in turn, may require additional

cleaning or head replacement.

• Ink optimization. Twelve new choices are

now available for ink management from the

highest quality for high value applications

down to a 54% ink savings for less

demanding applications. Instant flexibility

on a job by job basis helps manage ink cost

to leverage margins while still enabling

choices for maximum image quality for

those direct mail or catalog applications.

In addition, the powerful Pantone editing

feature can protect any identified objects

on each page for optimal color. This is ideal

for maintaining maximum print quality for

client logos and branding while still allowing

ink reduction on the rest of the page.

• New enhanced smoothing. This is

beneficial for certain applications that

require an extra level of smoothness,

such as photos with facial tones, tints or

gradients.

• Ink estimation and monitoring. Ink

estimation tools based on area coverage

can be highly inaccurate. With the Xerox

Ink Measurement Press Tool, we can

accurately estimate the actual amount of

ink used by measuring the post-RIP file after

all color management has been applied for

precise ink usage, which will enable more

accurate job estimation. Productivity is

increased with the electronic soft proofing

capability taking the proofing off the press.

• Vector Halftoning—patented ink drop

management and positioning. Process

all four color channels simultaneously

to optimize drop placement. Reduce

occurrences of drop-on-drop to efficiently

fill the white spaces before adding more

ink drops on top of each other. The result

is less ink usage while maintaining vibrant

image quality with a wide gamut equivalent

to offset on uncoated papers.

Consistently Excellent Inks

We’ve been developing inkjet technology

for two decades and have manufactured

thousands of tons of waterless, resintype inks. Leveraging that experience,

®

we understand the economies of scale

and precise quality controls needed

to ensure that our product delivers

excellent performance the first time

and every time you use it. Our stringent

ink manufacturing guarantees you will

find our ink colors to be consistent and

uniform from one batch to the next,

month after month.

The images below are 10X enlargement s

of 75 gsm offset paper.

Xerox® Production Waterless Ink

Aqueous Ink

5

Page 6

Innovative New Print Process

The Xerox® CiPress® 500 and Xerox® CiPress® 325 Production Inkjet Systems’ print

process is robust yet simple. Built on a heavy-duty web press transport, it offers precise

motion controls with closed loop monitoring for automated missing jet detection,

correction and registration. The print process uses precise web motion and thermal

controls with a patented “reflex” process for web management, monitoring and

correction of paper stretch and movement. This ensures very accurate pixel-to-pixel,

color-to-color registration and drop placement, job to job, roll to roll, month after month.

Xerox® CiPress® Single Engine

Duplex (SED)

Printing duplex in one frame.

A

Ink granules are fed from drums

B

Blank web enters printer

C

Web cleaner removes dust and chads

D

Web is warmed

E

Side one printing

A

G

H

M

L

F

G

H

I

J

K

J

Ink granules are melted to a liquid

Molten ink is jetted directly onto the

web and hardens instantly

Side two printing

Web is cooled

Blank side one face down returning

for side two imaging

I

F

E

C

D

K

Intelligent Scan Bar sensor scans web

for image quality consistency and

uniformity and to detect missing jets

L

Web is warmed with low temperature

ceramic heater

M

Ink is pressure fixed onto the web

B

6

Page 7

Flexible Configurations

from Entry Level to

Maximum Production

Multiple configurations of the Xerox®

®

CiPress

Production Inkjet Systems enable you to

adopt inkjet technology, and configure a

system to match your production needs

and the layout of your facility to maximize

flow of people and materials. Our newest

Single Engine Duplex (SED) system enables

A

economical duplex printing in one frame

minimizing footprint and capital investment

while still producing 1,090 1-up letter size

(1,026 A4) prints per minute. The multiple

layout choices for a twin engine duplex

system include inline, 90 degree or next to

each other in parallel, either face to face or

front to back. The Twin Engine Duplex (TED)

configurations enable 2-up letter throughput

up to 2,180 prints per minute (2,052 A4). The

flexibility doesn’t end there. You start out

with a single engine for simplex or duplex

B

printing and add a second system at any

time— as your business grows. You can also

enable duplex backup with the Single Engine

Duplex Kit installed in both printers of a twin

configuration enabling you to switch to SED

on either of the printers if needed.

C

500 or Xerox® CiPress® 325

A

B

®

CiPress® Front to Back

Xerox

®

CiPress® Inline

Xerox

Configuration with MICR Module

C

®

CiPress® 90 Degree

Xerox

New MICR Optional Print Module

for Check Printing

Combine the efficiency of printing a high

density MICR line with the benefit of full color

content in a single pass. A unique inline MICR

inkjet module can be added at the factory or

upgraded on site expanding your capabilities

and protecting your investment. The module is

available with 4-head and 8-head configurations

for 8.5" or 17" print areas for 2-up business and

12-up personal check printing.

New Inline Anilox Coating System

The Megtec inline aqueous coating system

enables multiple flood coat fluids to be applied

automatically inline at full machine speed.

Whether for the extra value of high gloss look

and feel or the added durability and protection

for the mail stream, the Megtec inline coater

enables more applications with full automation

and less labor than traditional offline

post-process coating methods.

7

Page 8

Intelligent print heads deliver on

the productivity promise.

Piezo mechanical drop-on-demand technology gives you reliability, durability,

consistent density and uniformity of color output for every roll, every week. With over

one million made and installed to date, these modular print heads are long lasting

with less maintenance, delivering more real print time every shift.

At 39,000 drops per second, ink is dispensed at very high speeds with web throughput

at either 500 feet (152 meters) or 325 feet (100 meters) per minute. The four color

CMYK system has 56 print heads, and all 50,000 jets are managed individually and

controlled for accurate pixel placement on the page. Our jets are tunable, which means

software and process controls can manage the waveform, behavior and performance

of each piezo crystal that drives each jet. Every jet is tuned and calibrated to be uniform

and consistent for accurate drop size and placement. This unique tuning also extends

print head life by adjusting weak or excessive jetting to the right normalized level.

Taken together, these factors deliver highly predictable image quality and very reliable,

consistent output roll to roll, site to site, across all substrates, month to month.

8

Page 9

More uptime = more productivity.

You’ll find productivity is engineered into every

area of the Xerox

System. We have automated many processes

to minimize operator intervention, saving time

and money. The result is a system that offers

you more uptime and more opportunity to

generate more output each shift.

Productivity features include:

• Speeds at 500 feet (152 meters) or

325 feet (100 meters) per minute

• Wide web width, 9" (229 mm) to

20.5" (520 mm)

• Closed loop monitoring

• Intelligent Scan Bar

• Automated print head maintenance,

including robotically controlled print

head cleaning

• Quick setup

• Automatic head registration and alignment

• Missing jet detection and auto

correction on the fly

• Modular manufacturing for installation

and easier, more efficient servicing

• Ink optimization to manage quality and

cost at the printer saves time and money

• No profiling of papers required

®

CiPress® Production Inkjet

Increase your uptime and

reduce your costs with

intelligent automation.

Print head maintenance is automated to

save your operators time and labor. It also

extends print head life and increases your

productivity and uptime.

• Automated print head cleaning. The

cleaning process is robotically controlled

and completed in minutes; there is no

need for operator intervention. The system

monitors and automatically detects

which print heads require cleaning and

determines when cleaning is needed.

The amount of waterless ink purged in

cleaning is minimal, reducing the amount

of wasted ink and paper you discard.

And because the ink is safe and non-toxic,

it does not require licensed waste removal.*

• Automated missing jet detection and

correction. The Xerox

Inkjet Systems’ Intelligent Scan Bar

detects missing jets and automatically

compensates with adjacent jets—on the

fly, in real time and at full machine speed—

to ensure that your print quality remains

consistent. The scan bar (which is also used

in our Xerox

®

iGen4® Press technology)

is so sensitive it can detect and correct a

single malfunctioning jet in many cases

before the human eye can see it. With

the Xerox

®

CiPress® printer you can rely

on our automated closed loop detection

and correction system for print head

performance and reliability. Your operator

can monitor all of this activity on the

Graphical User Interface.

®

CiPress® Production

• Easy print head replacement. While our

intelligent piezo print heads are a durable

long-life component of the system, when

they eventually do require replacement,

an operator can pause the production run

and replace the print head quickly and

easily. Print heads are a consumable item

so you always have spares on hand.

Key Attributes of Our

Patented Print Heads

• Modular 3" patented design

• Onboard intelligence with

values stored in non-volatile

memory (NVM)

• Multiple overlapping arrays up to

20.5" (520 mm) web width

• Fourteen print heads per color

• Precise thermal control

• Individual management of all jets

• Acoustic and fluidic process controls

• Auto registration adjusts the print

head positioning for color-to-color

and front-to-back registration

automatically, on the fly in real time

* Please consult your state and local requirements for

proper disposal.

9

Page 10

Xerox® FreeFlow® Print Server—

An Open Solutions Platform

The power behind the Xerox® CiPress® 500 and Xerox® CiPress® 325 Production

Inkjet Systems is the Xerox

scalable RIPs and servers with the power to handle even your most complex jobs and

confidence to meet your most challenging SLAs. With over 40,000 installations, the

Xerox

®

FreeFlow Print Server has the heritage and experience you expect.

®

FreeFlow Print Server. The FreeFlow Print Server offers

• Scalable RIP to match the complexity

of your jobs and maximum speed of the

printe r. Architected for scalable, parallel

RIPing across multiple computers, the

®

Xerox

FreeFlow Print Server also uses

integrated caching technologies. You take

full advantage of these technologies by

choosing the number of RIP servers. This

enables you to scale RIPs to match the

complexity of your applications so you

can maximize the print engine’s speed

without clutching.

• Native data stream support gives you

flexibility. The Xerox

supports native data streams, including

IPDS™, PDF, PostScript

without transforms or interim data formats.

It offers both native data stream support

and parallel RIP to give you more control,

enabling you to streamline your workflow

and leverage maximum performance with

no impact to rated speed.

• Xerox

®

FreeFlow VI Compose: Variable

data printing that keeps pace. The Xerox

FreeFlow

can substantially improve your productivity

for printing personalized communications.

VI Compose uses a “Dynamic Document

Construction” (DDC) method of document

composition, meaning you send the

document and the associated data and

variables directly to the printer without any

precomposition. This saves valuable network

®

VI Suite, featuring VI Compose,

®

FreeFlow Print Server

®

and Xerox® VIPP®,

resources, eliminates bottlenecks and

significantly reduces the time needed

to print the job. Maximize the power of

®

Xerox

CiPress® printers with the Xerox

FreeFlow Print Server and produce variable

jobs with unsurpassed speed and efficiency.

• A reliable predictable environment.

The Xerox

a 20-year heritage of proven performance

processing variable data and static

application content. Native support for

industry standards, like JDF and JMF,

ensures our solution will integrate

seamlessly with your current workflow.

• Consistent color means confident color.

The Xerox

advanced color management features

built-in to ensure reliable, predictable color

output across all data streams. Xerox

ConfidentColor is delivered via source and

destination profiles, object-based color

management, rendering intents with

intelligent closed loop color control.

®

All of this automation delivers consistent

worry-free color out of the box, roll to roll,

engine to engine, anywhere around

the world.

• Achieve your business goals faster.

Choose the workflows you want. Choose the

power you want. The Xerox

Server will deliver the productivity you need

to meet demanding customer requirements.

®

FreeFlow Print Server has almost

®

FreeFlow Print Server has

®

FreeFlow Print

®

®

10

Page 11

Green is this printer’s favorite color.

Environmentally responsible features and components focus on environmental

sustainability and are apparent in the Xerox

Production Inkjet Systems.

• Safe, non-toxic ink. Xerox® CiPress® printers

use waterless inks that are safe and nontoxic with no special disposal required. We

recommend that you consult with your state

and local waste disposal authorities for

additional information.

®

CiPress® 500 and Xerox® CiPress® 325

• NAPIM certified ink (in the U.S.). Xerox

solid ink has been certified to have 30%

bio-derived renewable material content

by the National Association of Printing Ink

Manufacturers (NAPIM).

• INGEDE certified output. Our output is

INGEDE (International Association of

the Deinking Industry) certified “Good

De-inkable.” This is the highest possible

rating based on ERPC (European Recovered

Paper Council) Deinkability Scores. The

®

Xerox

CiPress® Production Inkjet Systems

are the only high speed inkjet devices in the

market that have received this certification.

This means that output from Xerox

printers can be recycled from white paper

back into white office paper.

• Dryer-free design. Because no water is

used in our ink and printing process, this

system does not need costly, energyconsuming dryers.

• The CiPress

consumption does not increase

with higher area coverage.

®

system’s power

®

CiPress

®

• Reduced sensitivity to shop floor

environmental control. Our print

®

process is less sensitive to fluctuations in

temperature and humidity. Little or no paper

acclimatization is required, which means

you’ll enjoy easier paper handling and more

flexible use of “on hand” stocks.

• Print head recyclability. Manufac tured

to our highest standards using patented

techniques and durable stainless steel

components, our print heads are tough

and durable and then returned to Xerox

for recycling.

• Efficient paper and ink use. Paper and ink

waste is minimized due to efficient setup,

registration, alignment patches and cleaning

and maintenance procedures.

11

Page 12

Specifications for the Xerox® CiPress® 500 and Xerox® CiPress® 325

Production Inkjet Systems

Printer

• Print Engine: Continuous Feed, Digital Web

• Configurations: Single engine simplex (SES), single

engine duplex (SED), twin engine duplex (TED)

• Imaging Technology:

Inkjet Drop On Demand (DOD)

• Inks: Dye for CMY, Pigment for K waterless

– Capacity: 80 kilo permanent drum with

10 kilo refill containers

• Output: 600 x 400 or 600 x 600

• Print Speed: 500 fpm (152 m) and

325 fpm (100 m)

Paper Handling

Web Width

• Pinless or Pinfed:

– Single Engine Simplex and Twin Engine Duplex

9" (229 mm) to 20.5" (520 mm)

– Single Engine Duplex

7" (178 mm) to 9.5" (241 mm)

Image Area

• Pinless/Pinfed: single page image

– Single Engine Simplex and Twin Engine Duplex

Width: 1 pixel to 20.1" (495 mm)

Length: 6.5" to 22" (165 mm to 559 mm)

– Single Engine Duplex

Width: 1 pixel to 9.18" (233 mm) side one,

8.5" (216 mm) for side two

Length remains the same at 6.5" to 22"

(165 mm to 559 mm)

• Paper Types: Pinfed, pinless, uncoated, offset,

recycled, bond, newsprint

• Paper Weight: 29 gsm – 160 gsm*

(19 lb – 108 lb offset)

• Pre- and Post-Processing: The printing system

does not include web input or output devices.

These must be purchased separately from

authorized Xerox Partners.

• Pre/Post device configurations supported:

Roll to roll, roll to fold, roll to cut sheet

Xerox® FreeFlow® Print Server

Data Streams

• Adobe® PostScript® (must be DSC-compliant)

• Adobe Acrobat® 9.0, PDF 1.7, PDF/X 1a, 3, 4

• Native IPDS™ rendering

• Xerox® VIPP

– Line Mode, Database Mode and Native

®

®

Speed in Images

per Minute

Simplex: U.S. Letter (8.5" x 11")

Portrait one-up

Portrait two-up

Duplex: U.S. Letter (8.5" x 11")

Portrait one-up

Portrait two-up

Simplex: A4 (210 mm x 297 mm)

Portrait one-up

Portrait two-up

Duplex: A4 (210 mm x 297 mm)

Portrait one-up

Portrait two-up

Maximum Duty Cycle 60M 42M 34M 24M

Xerox® CiPress®

500 Twin

Engine

545

1,090

1,090

2,180

513

1,026

1,026

2,052

Xerox® CiPress® MICR Specifications

• MICR line delivered via fifth color channel

in the Xerox® FreeFlow Print Server DFE

• Data Streams: IPDS, Postscript, PDF

• 325 and 500 fpm print speeds

• Imageable area for MICR line : Up to 17",

supporting 2-up business checks and 12-up

personal checks

• Signal strength >80 (Canada) per

CPA Standard 006 at 325 fpm

• Signal strength >50 (U.S.) per ANS X9.100-20 at

325 and 500 fpm

• E13-B and CMC7 fonts

• MICR to CMYK registration +/-0.5 mm

• MICR character alignment to check

edge +/- 1/16 inch (1.6 mm)

• 20 – 24 lb uncoated (plain and preprinted)

media and check safety stock

• Pinless and pinfed media

• MICR printing enabled on upstream engine of

twin engine system

• Security Features Supported:

– Xerox® Mi cr oText

– Copy Void Pantograph

– Original Document Watermark

• Consumables:

– 2L bottle MICR ink

– 2L bottle Jetfix flush fluid

– MICR print head

Xerox

CiPress®

325 Twin

Engine

354

708

708

1,417

333

667

667

1,334

Installation Environment

• Dimensions per Engine:

– H x W x D: 78.7" (199.8 cm) x 23.6"

(60 cm) x 47.2" (120 cm)

– MICR Module adds 37.3" (94.8 cm) in width

• Weight:

– Print engine (including Thermal Controller

and four ink drums)—12,641 lb (6,697 kg)

– MICR Module adds an additional 1,450 lb

(658 kg)

• Room Temperature:

– 60°F to 85°F (15.6°C to 29.4°C)

• Relative Humidity:

– 20% to 8 0%

• Heat Output: 91,800 BTU/hr

• Electrical Requirements:

– North America

(1) 480V 75A 3-phase

(1) 208V 100A 3-phase

– Europe

(1) 380V – 415V 75A 3-phase

(1) 380V – 415V 100A 3-phase

– Electrical Consumption

Standby: 14.5 kWh

Printing: 27 kWh

* Hea vier paper weights and matte coat ings are possible base d

on succe ssful testing by Xerox.

®

Xerox

CiPress®

500 Single

Engine Duplex

545

1,090

513

1,026

®

Xerox

CiPress®

325 Single

Engine Duplex

354

708

325

667

To learn more about the Xerox® CiPress® 500 and Xerox® CiPress® 325 Production

Inkjet Systems, contact your Xerox representative or visit www.xerox.com

©2014 Xerox Corporation. All rights re served . Xerox®, Xerox and Des ign®, CiPress®, Free Flow®, iGen4® and VIPP® are trademar ks of

Xerox Cor poration in the United States a nd/or other cou ntries. 11/14 BR11809

610P730301D

WAGSC214 XPIBR-01UD

Loading...

Loading...