Page 1

TM

TM

Power

Generator On

Network

Fault

Xanbus Automatic Generator Start (AGS)

TM

FGA: 809-0915

Xanbus™ Automatic Generator Start (AGS)

Owner’s Guide

PN: 809-0915

Page 2

Page 3

Trademarks

Xantrex, Xanbus, and Smart choice for power are trademarks of Schneider

Electric Services International sprl, registered in the U.S. and other countries. Other

trademarks, registered trademarks, and product names are the property of their

respective owners and are used herein for identification purposes only.

Notice of Copyright

Xanbus Automatic Generator Start Owner’s Guide © March 2011 Xantrex

Technology USA Inc. All rights reserved. No part of this document may be

reproduced in any form or disclosed to third parties without the express written

consent of: Xantrex Technology USA Inc., 541 Roske Drive, Suite A, Elkhart,

Indiana USA 46516. Xantrex Technology USA Inc. reserves the right to revise this

document and to periodically make changes to the content hereof without obligation

or organization of such revisions or changes unless required to do so by prior

arrangement.

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY USA INC. (“XANTREX”)

A) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

(

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION;

B) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR EXPENSES,

(

WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE

OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY

AT THE USER’S RISK; AND

(C) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH,

ALTHOUGH STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF THE TRANSLATION, THE

ACCURACY CANNOT BE GUARANTEED. APPROVED XANTREX CONTENT IS CONTAINED WITH THE

ENGLISH LANGUAGE VERSION WHICH IS POSTED AT WWW.XANTREX.COM.

Date and Revision

March 2011 Rev D

Document Part Number

975-0082-01-01

Product Number

809-0915

Contact Information

Telephone: 1 800 670 0707

Fax: 1 800 994 7828

Web: www.xantrex.com

975-0082-01-01 i

Page 4

About This Guide

Purpose

The purpose of this Owner’s Guide is to provide explanations and

procedures for installing, troubleshooting, operating and maintaining the

Xanbus Automatic Generator Start (AGS).

Scope

The Guide provides safety and operating guidelines, procedures for

installing the AGS, as well as information on configuring the AGS. It also

provides information about troubleshooting the unit. It does not provide

details about configuring every Xanbus-enabled device to which the SCP

connects to within the Xanbus network. You need to consult these other

Xanbus-enabled devices’ owner’s and installation guides.

Audience

The Guide is intended for users and operators of the Xanbus Automatic

Generator Start (AGS). The Installation section is primarily intended for

qualified installers who need to install and configure an AGS. The installer

should have knowledge and experience in installing electrical equipment,

knowledge of the applicable installation codes, and awareness of the

hazards involved in performing electrical work and how to reduce those

hazards. A qualified technician or electrician has this knowledge and

experience.

Conventions Used

The following conventions are used in this guide.

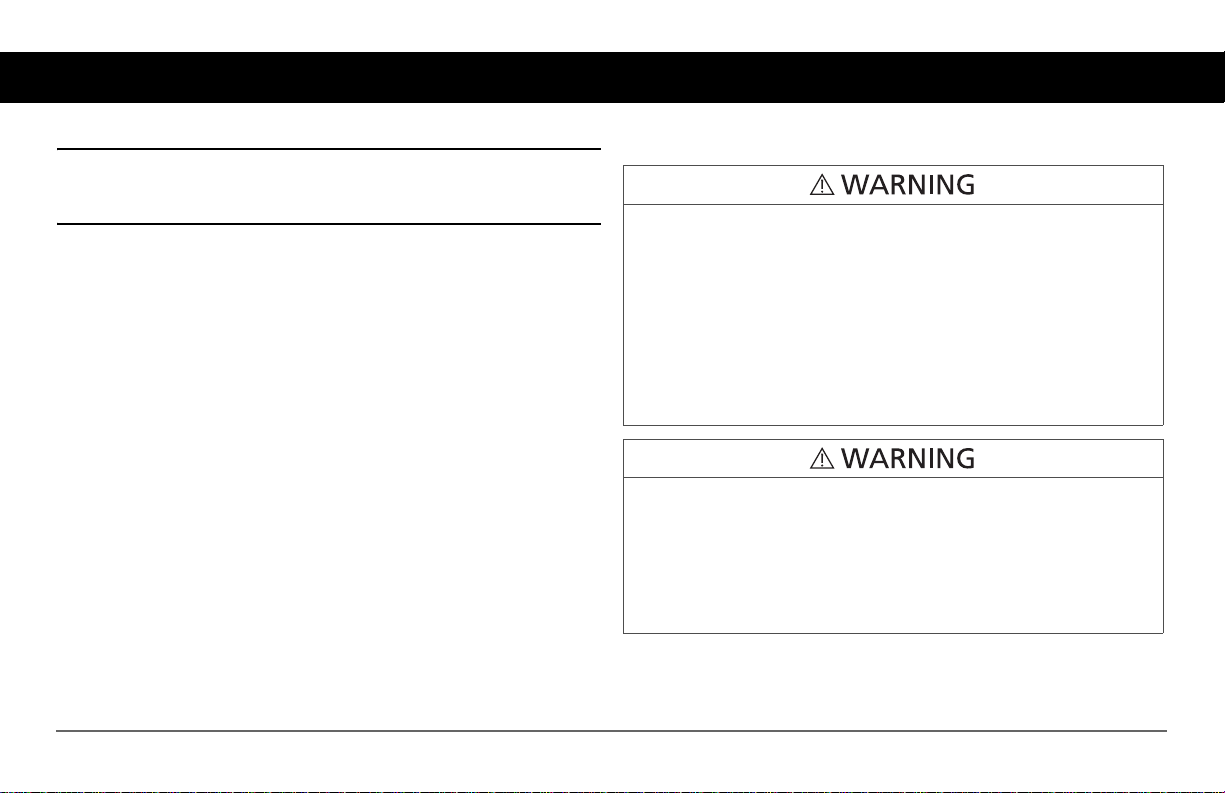

STATEMENT OF HAZARD

Contains statements of avoidance or strict compliance.

Failure to follow these instructions will result in death or serious

injury.

STATEMENT OF HAZARD

Contains statements of avoidance or strict compliance.

Failure to follow these instructions can result in death or serious

injury.

STATEMENT OF HAZARD

Contains statements of avoidance or strict compliance.

Failure to follow these instructions can result in minor or moderate

injury.

ii Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 5

STATEMENT OF HAZARD

Contains statements of avoidance or strict compliance.

Failure to follow these instructions can damage the unit and/or

damage other equipment.

IMPORTANT:

know, however, they are not as serious as a danger, warning, or caution.

These notes describe things which are important for you to

Related Information

Y ou can find more information about Xantrex Technology USA Inc. as well

as its products and services at www.xantrex.com.

The product marking on the left when found imprinted on

electrical and electronic units and appliances means that you

are to refer to this guide for cautions and warnings.

975-0082-01-01 iii

Page 6

Important Safety Instructions

IMPORTANT: READ AND SAVE THIS OWNER’S GUIDE FOR FUTURE

REFERENCE.

This chapter contains important safety, operation, and installation

instructions for the Xanbus Automatic Generator Start (AGS). Each time,

before using the AGS, READ ALL instructions and cautionary markings on

or provided with the AGS and all appropriate sections of this guide.

IMPORTANT:

1. If the Xanbus Automatic Generator Start (AGS) is inoperative, see

“W arranty and Return Information” on page 38 for guidance.

2. The Xanbus Automatic Generator Start (AGS) contains no userserviceable parts. For obtaining service, see “Warranty and Return

Information” on page 38 for guidance.

3. Protect the Freedom SW Automatic Generator Start from rain, snow,

spray, and water.

4. Disable the generator’s starting circuit by disconnecting the starter

battery, spark plug, et cetera, before wiring this device.

5. To reduce the risk of electrical shock, put the Xantrex Xanbus system

into Standby before working on any circuits connected to it.

See “Putting the AGS in Standby Mode” on page 67.

6. Disable the automatic starting circuit and/or disconnect the generator

from its starting battery to prevent accidental starting while

performing maintenance.

EXPLOSION HAZARD

This equipment is not ignition protected. To prevent fire or explosion, do

not install the unit in compartments containing flamma ble ma terial s or in

locations that require ignition-protected equipment. This includes any

space containing gasoline-powered machinery, fuel tanks, as well as

joints, fittings, or other connections between components of the fuel

system.

Failure to follow these instructions can result in death or serious

injury.

SAFETY HAZARD

Disable the Xanbus Automatic Generator Start (AGS) if the generator or

vehicle equipped with the generator is in an enclosed building or area

where the generator exhaust is not vented to the outside.

Failure to follow these instructions can result in death or serious

injury.

iv Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 7

FCC Information to the User

RESTRICTIONS ON USE

The Xanbus Automatic Generator Start (AGS) shall not be used in

connection with life support systems or other medical equipment or

devices.

Failure to follow these instructions can result in death or serious

injury.

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. Thes e limits

are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Unauthorized changes or modifications to the equipment could void the

user’s authority to operate the equipment.

975-0082-01-01 v

Page 8

Page 9

Contents

Important Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Xanbus Automatic Generator Start Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Configuration of the Xanbus AGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Operation of the Xanbus AGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Warranty and Return Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Appendix A: Generator Auto Start Requirements and Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Appendix B: Relay Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Page 10

Page 11

Introduction

IMPORTANT:

The Xanbus Automatic Generator Start (AGS) is designed

for use in a Xanbus-enabled Freedom SW Power System only.

The Xanbus AGS requires the additional use of a Xanbus System Control

Panel (SCP) for configuration and monitoring. For details see "System

Requirements".

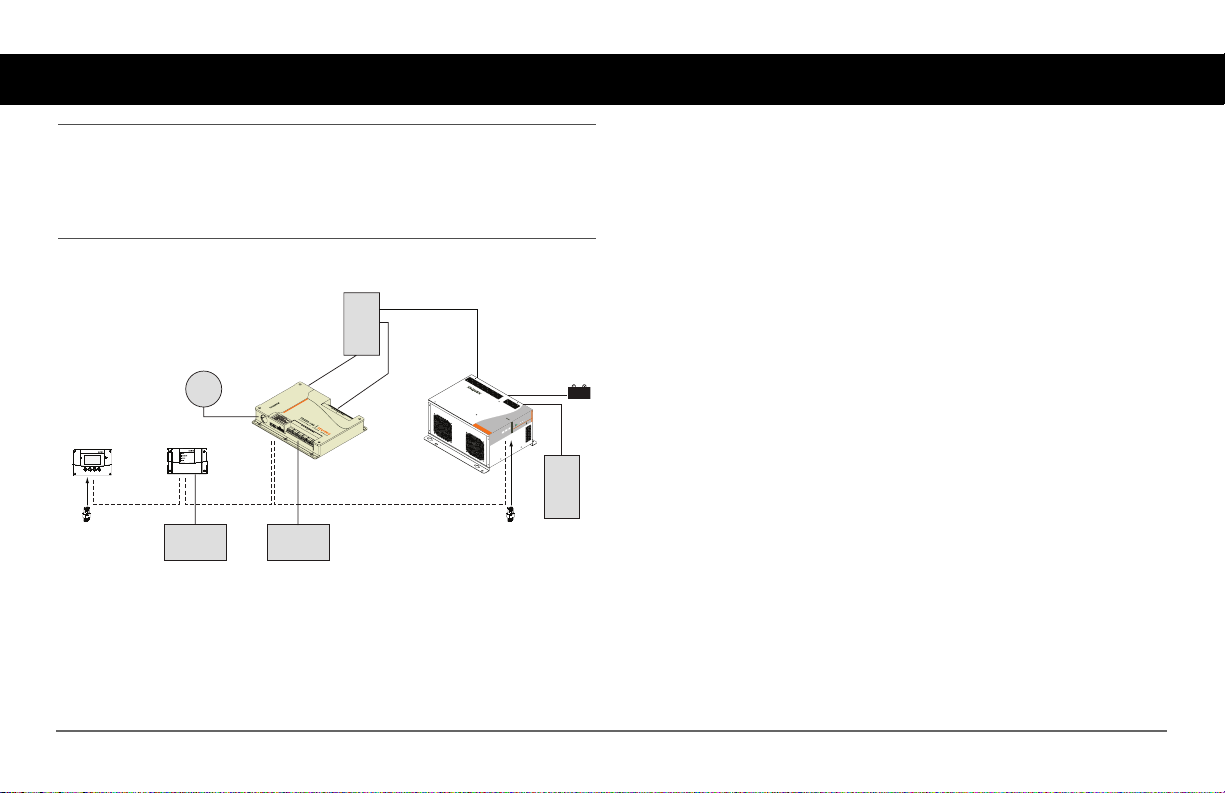

AC Panel

Shore

Power

System Control Panel

Xanbus System Control Panel

network terminator network terminator

Figure 1

Automatic Generator Start

Xanbus Automatic Generator Start

Generator

Xanbus Automatic Generator Start (AGS) Basic Function

Freedom Sequence

AC Loads

Freedom SW Inverter/Charger

FREEDOMSW 3012

BATTERY

C/

ge Fault

r

ter A

ha

r

C

nve

I

On

er

t

r

e

nv

I

Reset Enable

FREEDOM SW 3012

Inverter

Load Panel

Function The Xanbus AGS continuously monitors battery voltage and

starts, or stops, the generator when battery voltage drops below or exceeds

the preset limits. It also starts the generator to assist the system’s inverter/

charger when output power demands are high.

Start and Stop Triggers The Xanbus AGS requires a source of start and

stop triggers for automatic operation. The Xanbus AGS monitors the

Xanbus network and starts or stops the generator based on the preset limits

programmed into it.

975-0082-01-01 1

Page 12

Introduction

System Requirements

Minimum basic system components include the following:

❐ Freedom SW Series Inverter/Charger

❐ AC Generator or DC Generator

❐ Xanbus System Control Panel (SCP)

❐ Xanbus Automatic Generator Start (AGS)

Network Communication Protocol The AGS uses Xanbus, a network

communications protocol developed by Xantrex, to communicate its

settings and activity to other Xanbus-enabled devices. All network

components used in the system must be Xanbus-enabled.

Network Power Supply The Xanbus AGS requires three watts of power

(maximum) to operate. This power supply is provided by the Freedom SW

Series Inverter/Charger through the Xanbus network.

Generator The generator should be a 2-wire or 3-wire generator with

Auto Start capability.

The generator should also supply a Generator Run signal. The Generator

Run signal is connected to the Xanbus AGS and used by the Xanbus AGS

to detect whether the generator is running. Some generator manufacturers

refer to this signal as the Hour Meter Signal or Switched B+.

Connecting the Generator Run signal is optional and only used for

redundancy. The Xanbus AGS requests generator voltage from the Xanbus

in addition to checking the Generator Run signal to detect if the generator is

running.

Generator Compatibility The Xanbus AGS supports most two and

three-wire generator starters. Some manufacturers include, but are not

limited to, Onan (Quiet Diesel, gasoline, and LP), Power Tech, Generac,

Northern Lights, Fisher Panda, Westerbeke, Kohler, Honda, and Yamaha.

Check with the generator manufacturer to ensure the generator in question

includes automatic starting capabilities.

Xanbus System Control Panel (SCP) A Xanbus System Control Panel

(SCP) is required to configure the AGS and monitor generator starting and

stopping activity.

The Xanbus System Control Panel (SCP) also provides real-time clock

information for the AGS Quiet Time and Exercise Time features.

2 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 13

Functions

Introduction

Generator Starting Triggers

The AGS can automatically start a generator in response to:

• a low battery voltage,

• large AC loads when inverter is operating,

• a thermostat signal, or

• a pre-programmed exercise period at a specified time of day.

Generator Stopping Triggers

The AGS can automatically stop a generator in response to:

• the introduction of qualified grid power (grid power within acceptable

parameters),

• high battery voltage,

• battery charge stage (float or absorb stage),

• reduction in AC loads when inverter is operating,

• a thermostat signal, or

• a pre-programmed quiet time period.

The AGS can also be used to manually start and stop the generator at any

time.

Programmable Features

Quiet Time The AGS features a quiet time setting, wh ich prevents the

generator starting at night or during other inconvenient periods.

Exercise Period During times of prolonged generator inactivity, the

AGS can be programmed to run (or “exercise”) the generator for a predefined period. This ensures the generator remains operational and that the

starting battery stays charged.

Status Reporting

The AGS reports its operating mode, its settings, generator activity, and the

reason for generator starts to the Xanbus system. This information can be

viewed on the Xanbus System Control Panel (SCP).

Installation Options

The AGS can be installed with an external shutdown input, a manual

generator ON/OFF switch, and an external ON/OFF indicator light.

975-0082-01-01 3

Page 14

Introduction

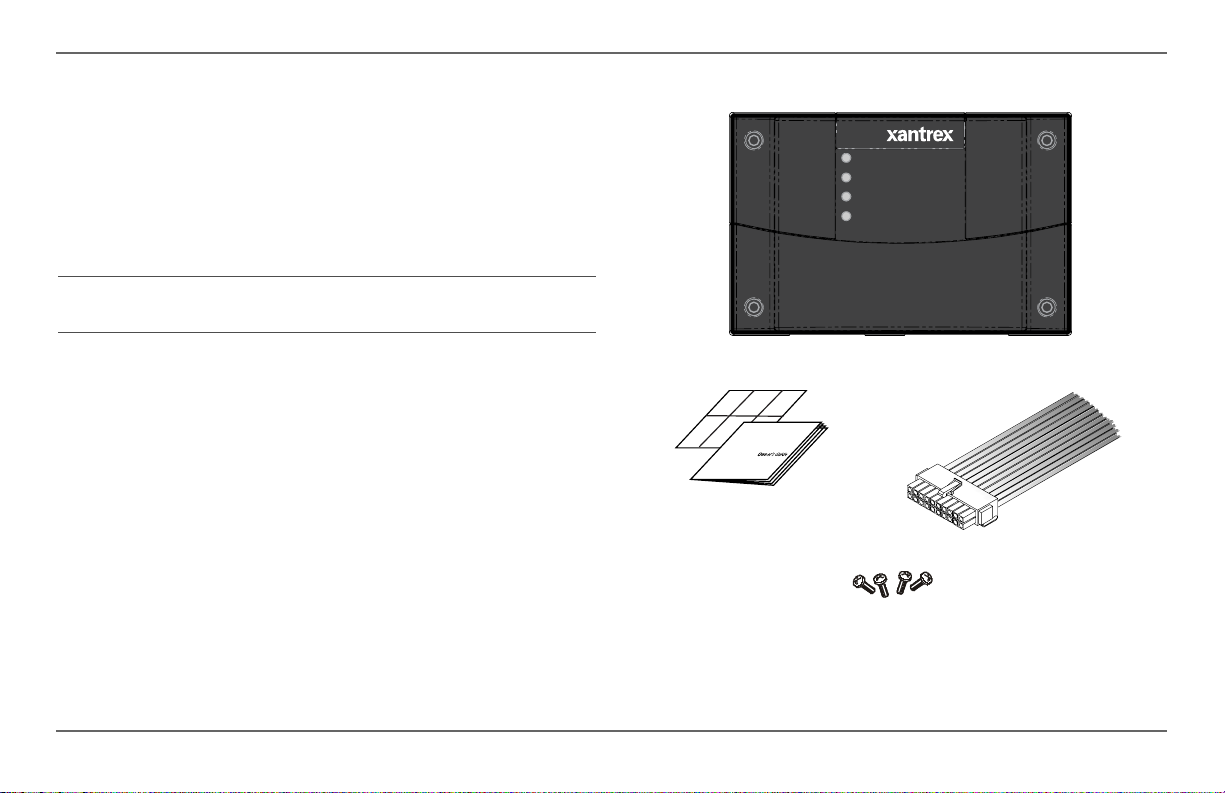

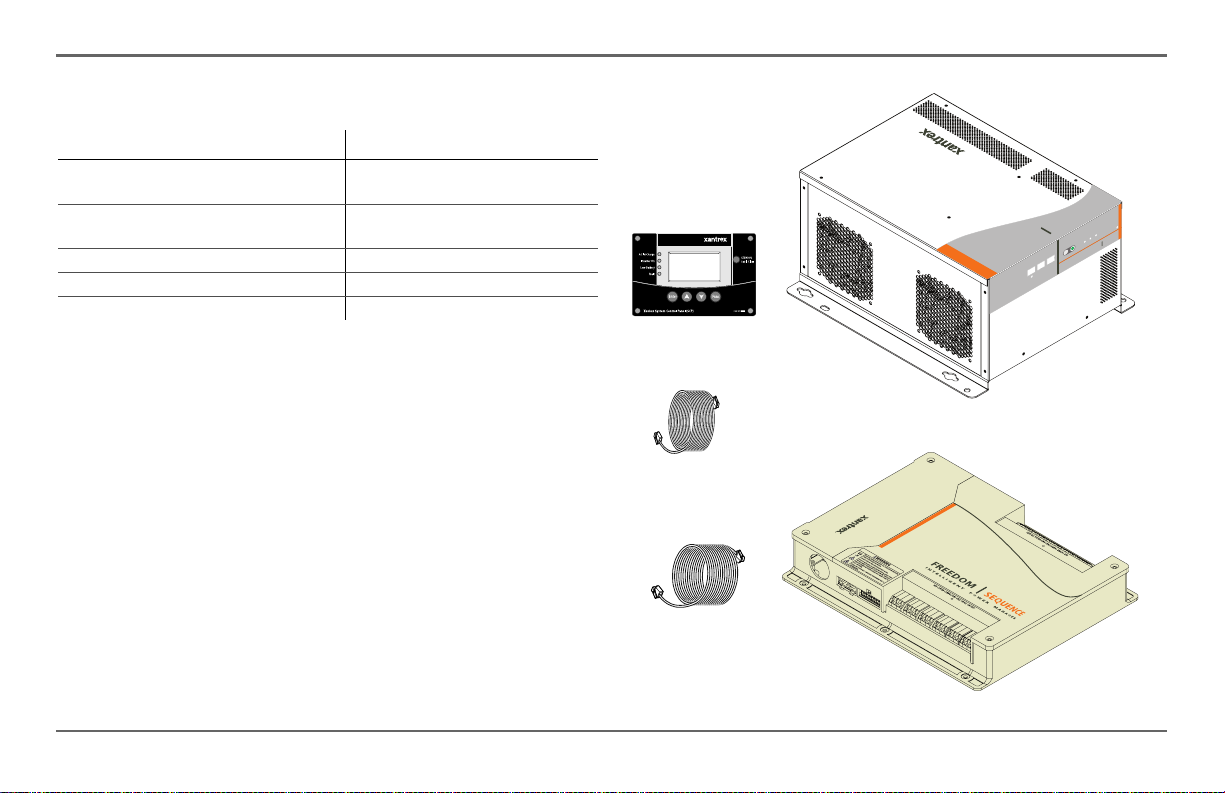

Material List

The AGS ships with the following items:

• one Xanbus Automatic Generator Start (AGS) unit,

• owner’s guide,

• wiring harness (20-pin connector),

• mounting template, and

• mounting screws (4).

NOTE: Keep the carton and packing material in case you need to return

the AGS for servicing.

AGS

unit

Xanbus Automatic Generator Start (AGS)

owner’s guide and

mounting template

Power

TM

Generator On

Network

Fault

FGA: 809-0915

wiring harness

mounting screws

4 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 15

Xanbus-Enabled Products and Accessories

Product/Accessory Product Number

Freedom SW Series Inverter/Charger 815-2012 (2kW power rating),

Freedom Sequence Intelligent Power

Manager

Xanbus System Control Panel (SCP) 809-0921

25-ft network cable for SCP 809-0940

75-ft network cable for SCP 809-0942

The Freedom SW Inverter/Charger is a true sine wave inverter/charger that

can be used for mobile, marine and commercial applications. The Freedom

SW Inverter/Chargers are designed to operate with a wide variety of

generators and are capable of operating in parallel with a generator for short

durations to assist with starting large loads. The Freedom SW is a

convenient combination of an inverter, multistage battery charger, and

transfer switch in one electronic device.

The Xanbus SCP provides configuration and monitoring capability for a

Xanbus system. It monitors activity throughout your power system,

displays the settings and status, as well as, adjusting the settings for each

Xanbus-enabled device.

The Freedom Sequence Intelligent Power Manager is a fully integrated

power management system that provides automatic power and load

management for use in recreational vehicles (RV) while receiving power

from a generator or shore power.

815-3012 (3kW power rating)

809-0913 (four-circuit model),

809-0912 (six-circuit model)

SCP

25-ft cable

75-ft cable

Freedom SW

Inverter/Charger

TM

Introduction

ter

r

e

v

n

I

Reset Enable

FREEDOM SW 3012

Freedom Sequence

power manager

nverter AC/

I

On

FREEDOM SW

Charge Fault

3012

975-0082-01-01 5

Page 16

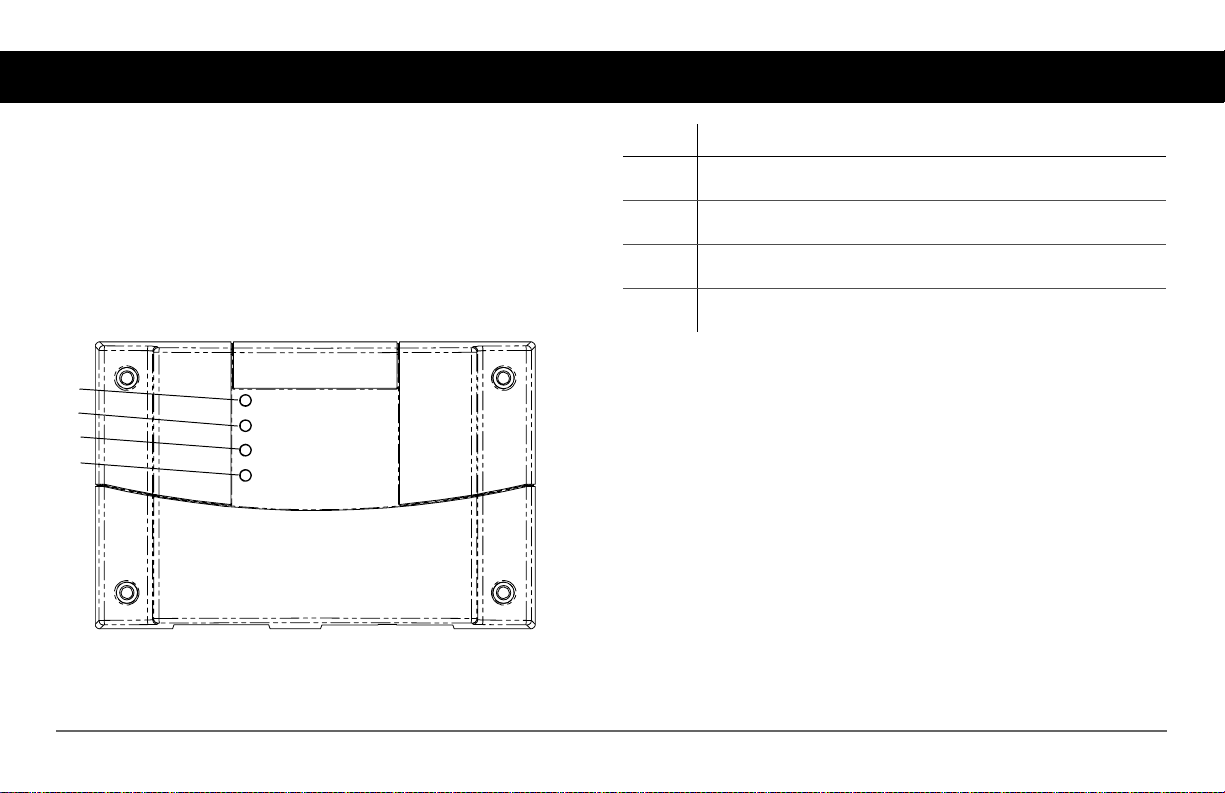

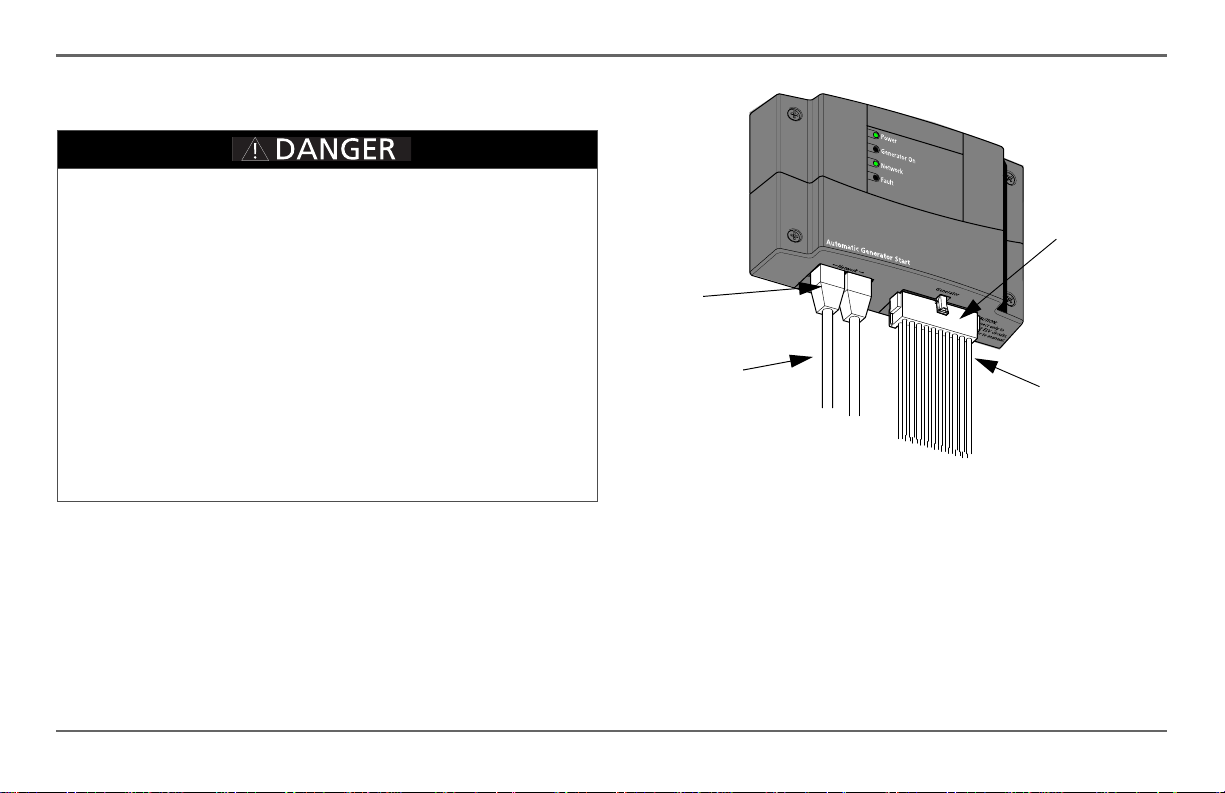

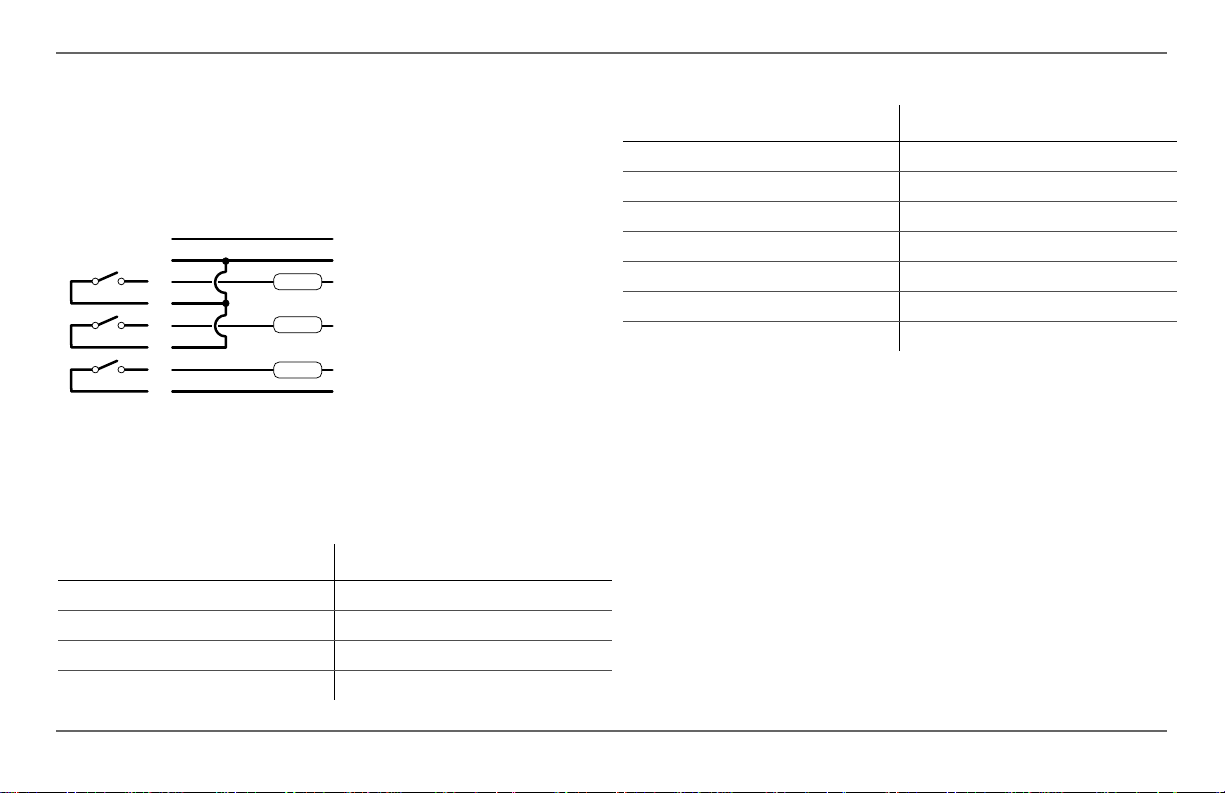

Features

The AGS has important features on the front and back of the unit. Features

on the front of the AGS are the indicator lights for reporting statuses on

power, generator, network, and faults (see Figure 2). The back of the unit

features the inputs where the AGS connects to the Xanbus system and the

20-contact wiring harness connector port (see Figure 3).

Front panel features

1

2

3

4

Xanbus Automatic Generator Start (AGS)

Power

Generator On

Network

Fault

FGA: 809-0915

Item Description

1Power light (green) indicates that the AGS is receiving power from the

Xanbus network.

2 Generator On light (green) indicates that the generator is up and

running.

3Network light (green) indicates that the Xanbus network is

maintaining a good connection with all Xanbus-enabled components.

4Fault light (red) indicates the generator is experiencing a fault and

requires user attention and intervention.

Figure 2

AGS Front Panel

6 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 17

Bottom panel features

Features

Gener at or

20-contact generator

connector port

!

WARNING

Explosion hazar d.

Do n ot ins tall in A

loc ation requiring

ignition pr otected

equipmen t. see

man ual .

!

CAUTION

CONNECT ONLY TO

CLASS 2 ELV CIRCUITS.

SEE MANUAL.

Figure 3

XANBUS

Two 8-pin RJ-45 Xanbus

network ports

AGS Bottom Panel

C

CSA 107.1

UL 458

LR 86581

MARINE

RR

US

EQUIPMENT DAMAGE

Only connect the Xanbus Automatic Generator Start (AGS) to other

Xanbus-enabled devices.

Although the cabling and connectors used in this network system are the

same as those used for Ethernet, this network is not an Ethernet system.

Equipment damage may result from attempting to connect these two

different systems.

Failure to follow these instructions can result in minor or moderate

injury.

Network Ports Each network port can accept an eight-pin RJ45 plug

attached to a Category 5 (CAT 5) Xanbus network cable. Depending on the

installation, both ports may be required.

20-contact wiring harness

connector

Figure 4

Wiring Harness Connector

Wiring Harness Connector The 20-contact connector supports a wiring

harness (supplied) that connects the AGS to a generator and thermostats.

The wiring harness also provides lines for connecting external generator

shutdown sensors or switches and external generator ON/OFF controls.

975-0082-01-01 7

Page 18

Xanbus Automatic Generator Start Installation

Before installing the A GS, consider how and where the unit will be mounted.

Pre-plan the connection routes between the AGS, the generator, thermostats,

and the Xanbus System Control Panel (SCP).

Materials and Tools Required

The following materials and tools are required to complete the installation:

❐ Mounting template (supplied)

❐ Wiring harness (manufacturer part number 809-0917, supplied)

❐ Four mounting screws (supplied)

❐ #16 or #18 AWG wire (see “Wire Size and Length” on page 12)

❐ Xanbus network cables or equivalent (CAT 5 or CAT 5e cable with RJ-

45 connectors wired to T568A standard.

❐ Two network terminators

(supplied with the Freedom SW Inverter/Charger)

❐ Phillips head screwdriver

❐ Wire cutters and wire strippers

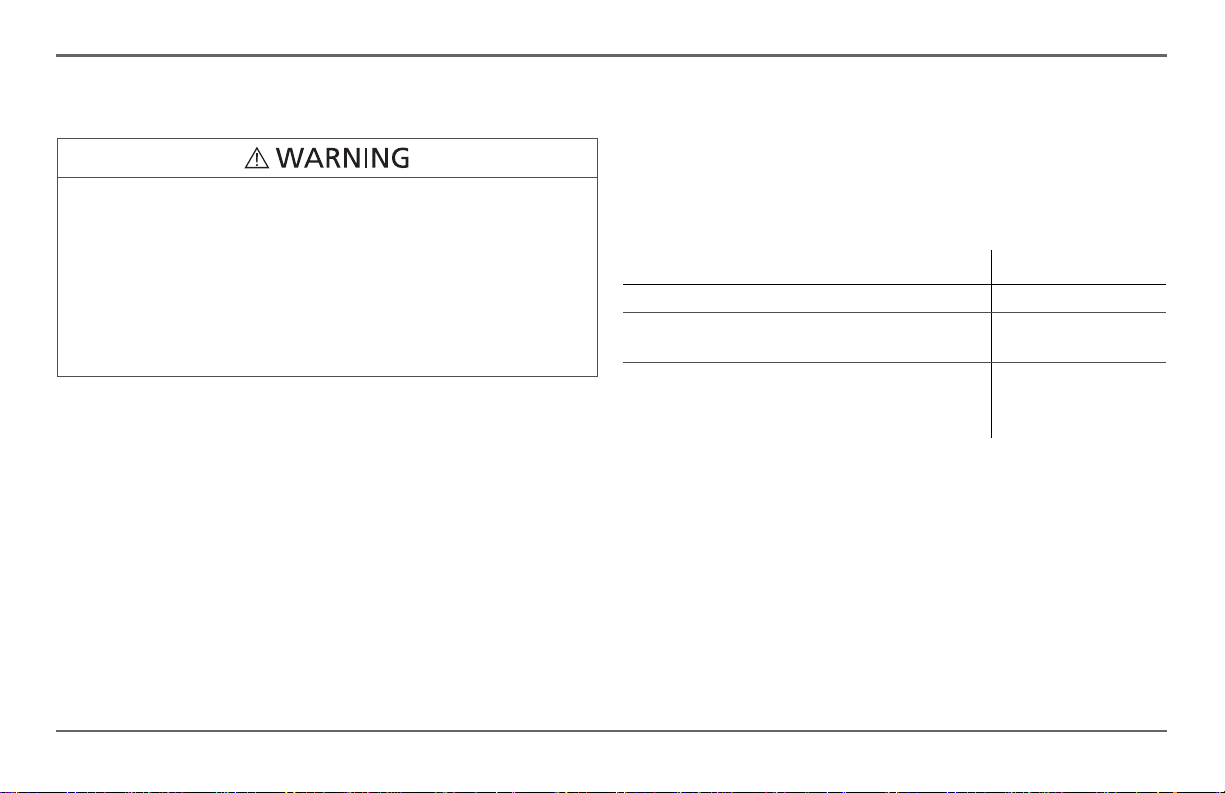

Choosing a Location

The AGS should be installed in a location that meets the following

requirements:

Dry

Cool

Safe

Close to

generator

The unit is intended for use in a dry location. The AGS

complies with UL458 Marine Supplement drip-test

requirements, but the location should be as dry as

possible.

The AGS operation is guaranteed between

-4 and 122 °F (-20 and 50 °C).

The AGS is not ignition protected. Do not install it in

areas requiring ignition-protected equipment, such as

compartments housing gasoline engines.

Avoid excessive wire lengths and use the

recommended wire lengths and sizes (see “Wire Size

and Length” on page 12). It is more important for the

AGS

to be close to the generator than close to the

inverter, although for safety reasons, the AGS should

not be installed in the same compartment as a gasolinepowered generator.

8 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 19

Routing Connections

EXPLOSION HAZARD

This equipment is not ignition protected. To prevent fire or explosion, do

not install the AGS in locations that require ignition-protected equipment.

This includes any space containing gasoline-powered machinery, fuel

tanks, as well as joints, fittings, or other connections between

components of a fuel system.

Follow all relevant instructions exactly before installing or using your

AGS.

SHOCK AND ENERGY HAZARDS

Before making any connections to the generator, ensure that the

generator’s starter is disabled and the generator’s start battery is

disconnected.

Failure to follow these instructions will result in death or serious

injury.

Connection Types Because the AGS will be part of a Xanbus system, it

is necessary to consider how to route two types of connections:

• connections to the generator, thermostats, and other external devices

and switches, using the included 20-contact connector and wiring

harness.

• connections to other Xanbus-enabled devices, using network cables.

Network ports

Network cables

to other Xanbusenabled devices

Figure 5

Xanbus Automatic Generator Start Installation

AGS External Connections

20-contact

connector

Wiring harness

(connection to

generator,

thermostats, and

external switches)

975-0082-01-01 9

Page 20

Xanbus Automatic Generator Start Installation

Installation Overview

Installing the AGS involves the following steps:

1. Mounting the unit.

2. Connecting the wiring harness to:

• the generator (page 14)

• thermostats (optional) (page 29)

• external shutdown switch (optional) (page 30)

• external ON/OFF switch and LED (optional) (page 30)

ELECTRICAL SHOCK HAZARD

Before installing the AGS as part of a pre-existing Xanbus system, put

the system in Standby in order to disable the electrical operation of

networked devices. See “Putting the AGS in Standby Mode” on page 67.

Failure to follow these instructions can result in death or serious

injury.

3. Connecting the wiring harness to the 20-contact connector on the

AGS.

4. Connecting the AGS to the Xanbus System Control Panel (SCP) and

other network-enabled devices (page 33).

IMPORTANT:

the type of generator, and the overall complexity of the Xanbus system,

these instructions can offer only general guidelines for the many

installation options available.

Because each installation varies according to the location,

Mounting the Unit

The AGS is to be mounted vertically on a wall with the connectors facing

downwards.

To mount the AGS:

1. Hold the unit flush and square against the wall, panel, or horizontal

surface.

• If the mounting surface requires pre-drill holes for the screws, use

the supplied mounting template to mark, then drill, four holes.

2. With a Phillips screwdriver and the supplied mounting screws, secure

each corner of the AGS to the mounting surface.

10 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 21

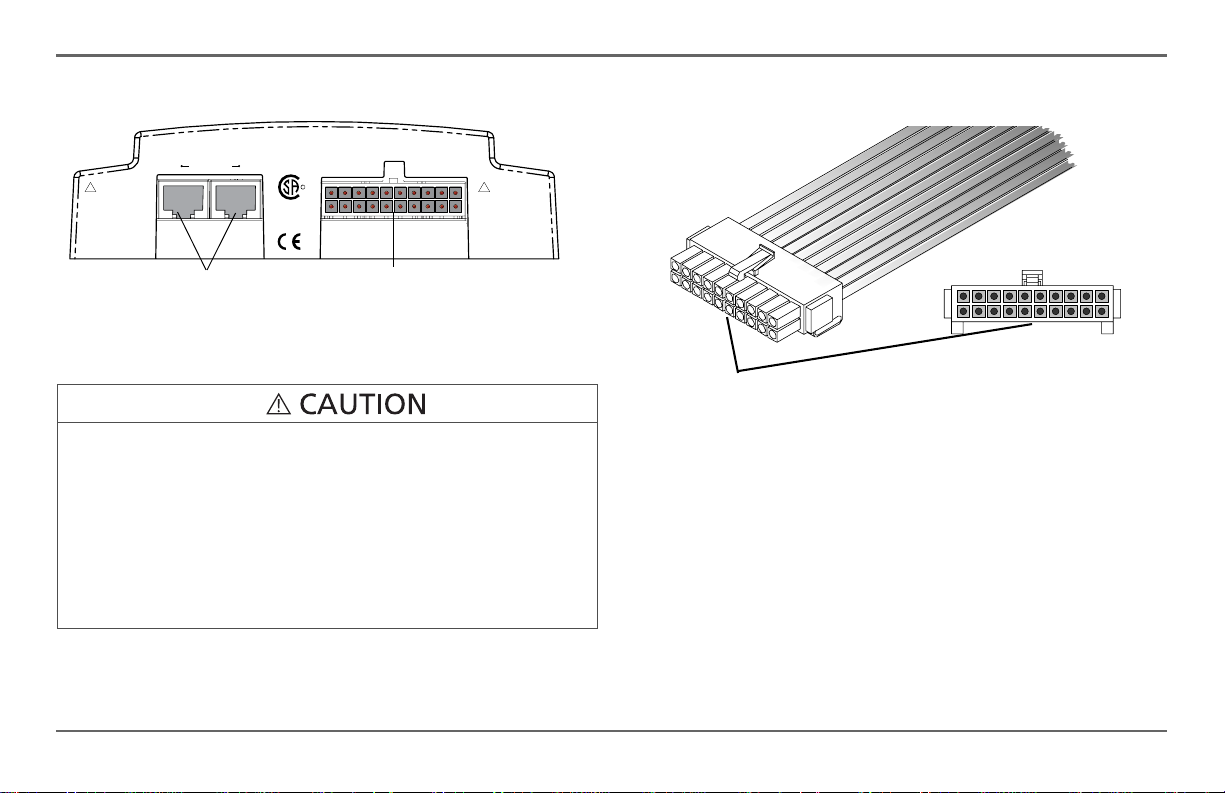

Wiring to the 20-contact Connector

ELECTRICAL SHOCK HAZARD

All installation wiring should be performed by a qualified installer or

electrician.

The 20-contact connector is intended for connection to Class 2 ELV

(Extra Low Voltage) circuits only. Do not exceed the circu it limitations

specified in the following section.

Failure to follow these instructions can result in death or serious

injury.

ELV Circuits ELV (Extra-Low Voltage) circuits have an open-circuit

voltage of not more than 30 V

not a shock hazard.

Class 2 Circuits As per the US National Electrical Code (NEC) and the

Canadian Electrical Code (CEC), available power in Class 2 circuits is

limited to 100 VA, usually by current limiting by means of overcurrent

protection or series resistance. The current is limited to 5 A for circuits with

open-circuit voltage of 20 V, and to I=100/V

voltage between 20 V and 30 V.

or 42.2 VDC or peak, and are therefore

rms

for circuits with open circuit

oc

Xanbus Automatic Generator Start Installation

Circuit Limitations The relay contacts in the AGS are rated at 5 A

maximum and all circuits on the 20-contact connector are rated at 30 V

maximum.

Ensure that all circuits connected to the 20-contact connec tor comply with

the following limits:

Circuit Parameter Circuit Maximum

Open circuit voltage (Voc) 30 V maximum

Overcurrent protection

(fuse size for open circuit voltage up to 20 V)

Overcurrent protection

(fuse size for open circuit voltage from 20 V to

30 V)

Wiring Harness Connections to the generator, thermostats, and external

ON/OFF switches are made using a wiring harness that plugs into the 20contact connector (see Figure 5).

The wires on the wiring harness can be extended to meet installation

requirements. When extending the wire harness, ensure that the extension

wires are the same color as the wires on the harness.

5 A maximum

5 A to 3.33 A

(100/V

maximum)

amps

oc

975-0082-01-01 11

Page 22

Xanbus Automatic Generator Start Installation

To install the AGS using the wiring harness:

1. Connect each wire on the harness to its intended wire or contact on the

generator, thermostats, or external sw itches. Tape, or otherwise secure,

the unused wires to ensure they do not make unintended connections.

2. Plug the harness into the connector on the bottom panel of the AGS.

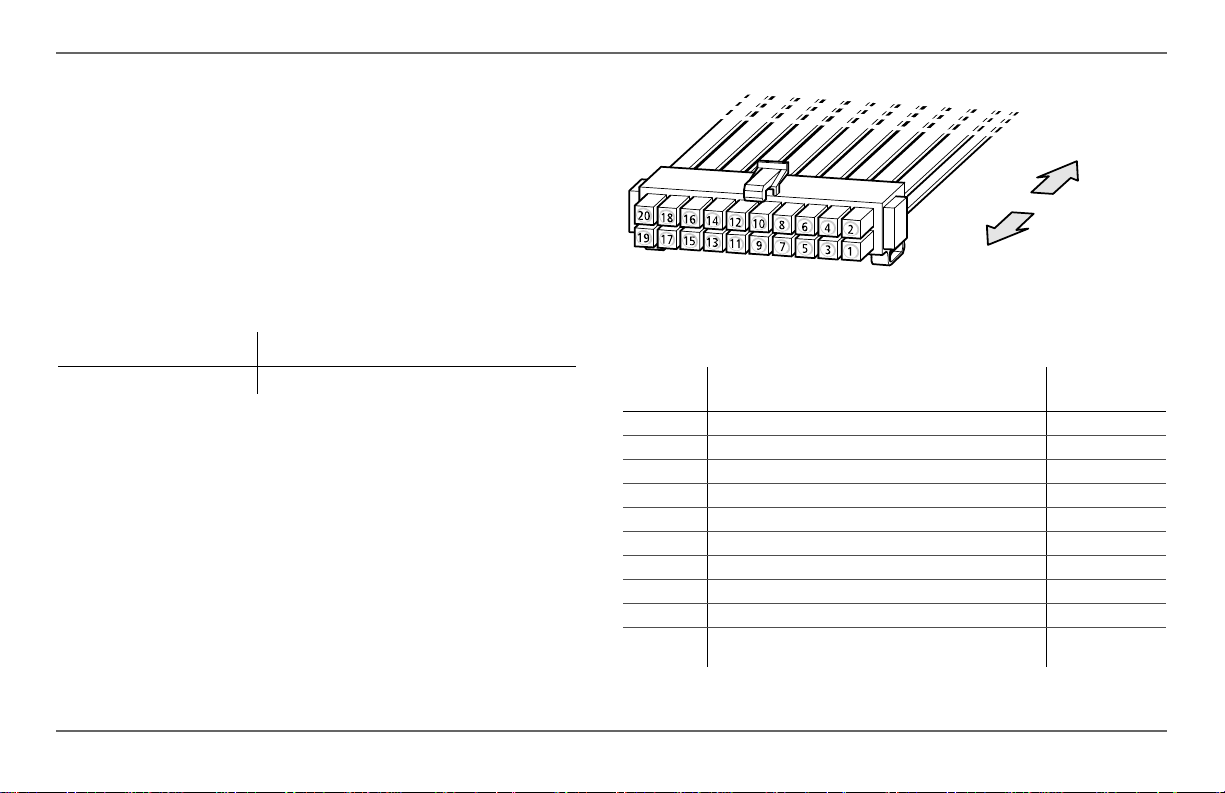

Wire Identification Each wire on the harness is identified by a number

and a color. The wire numbers are shown in Figure 6 and their colors and

functions are described in the next table.

Wire Size and Length Required wire sizes for the external connections

to the wiring harness are:

0–30 ft. (9 m) Over 30 ft. (9 m)

18 AWG 16 AWG

When planning the routing for external connections, ensure that wire

lengths are sufficient to plug the wiring harness into the AGS once all the

external connections are complete.

To generator,

thermostats, and

external switches

To 20-contact

connector on AGS

Figure 6

Wire

Number Function

1 Thermostat 1 input Yellow

2 Thermostat 1 return Gray

3 Thermostat 2 input Orange

4 Thermostat 2 return Gray

5 External shutdown input White/Black

6 External shutdown return Gray

7 External manual on input White/Green

8 External manual off input White/Red

9 External ON/OFF LED Indicator output White/Blue

10 Constant 12/24 V B+ (battery positive) for External ON/

AGS Wiring Harness

OFF/LED Indicator

Wiring Harness

Wire Color

Red

12 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 23

Wire

Number Function

11 External ON/OFF/LED Indicator return (connected

12

13

14

15

16

17

18

19

20

internally to wire number 13)

Generator run signal (switched B+) sense input

Generator run signal (switched B+) sense return

Relay 1 (Generator run/stop) Normally open contact

Relay 1 (Generator run/stop) Normally closed contact

Relay 1 (Generator run/stop ) C om m o n co nt act

Relay 2 (Generator start) Normally open contact

Relay 2 (Generator start) Common contact

Relay 3 (Preheat/cool-down) Normally open contact

Relay 3 (Preheat/cool-down) Common contact

Wiring Harness

Wire Color

Black

Violet

Black

Blue

White/Violet

Gray

White

Gray

Brown

Gray

Xanbus Automatic Generator Start Installation

975-0082-01-01 13

Page 24

Xanbus Automatic Generator Start Installation

Connecting the Generator

EQUIPMENT DAMAGE

Before connecting the AGS to your generator, read the Generator Type

descriptions in this section and consult your generator manufacturer to

ensure that Gen Type settings and connections are compatible with your

generator. Damage to the generator can result from selecting an inc o rre ct

Gen Type and following the connection diagram for an incorrect Gen

Type when connecting the AGS to the generator. Xantrex assumes no

responsibility or liability for loss or damage that might arise out of the use

of this information.

Failure to follow these instructions can damage the unit and/or

damage other equipment.

To connect the AGS to a generator , identify the start wiring configuration of

the generator to be used. Generators must be auto-start capable, and

generators equipped with remote operation connections are ideal.

If the generator is equipped for remote operation, examine the wiring of the

remote cable and connector (or read the generator’s documentation, if

available) and identify the following wires:

• Ground

•Start

•Stop

• Generator run signal, also known as the Hour Meter or Switched B+

(battery positive)

Wiring Requirements Either #16 or #18 AWG wire is required to

connect to the wiring harness. How many of these wires you connect and in

which combination depends on your generator type.

Generator Types The AGS has 14 preset generator configurations, or

“Gen Types” (see “Gen T ype” on page 42). After installing the hardware, it

will be necessary to select one of these Gen Types from the AGS

Configuration Menu on the Xanbus System Control Panel (SCP).

IMPORTANT:

Type". See “Putting the AGS in Standby Mode” on page 67.

The following section describes the preset generator configurations and

provides diagrams for connecting the wiring harness to the generator’s start

wiring.

IMPORTANT:

following section, refer to Appendix 1, “Appendix A: Generator Auto

Start Requirements and Types”. For more information about AGS

internal relay activity and timing, see Appendix 1, “Appendix B: Relay

Timing”.

IMPORTANT:

B+ Gen Run signal is not connected, it may be necessary to adjust the

Gen Run Signal hold time parameter on the AGS. See “Gen Run Hold

Time” on page 57.

Put the system in Standby BEFORE changing the "Gen

For an explanation of the terminology used in the

Connecting the B+ Gen Run signal is optional. It the

14 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 25

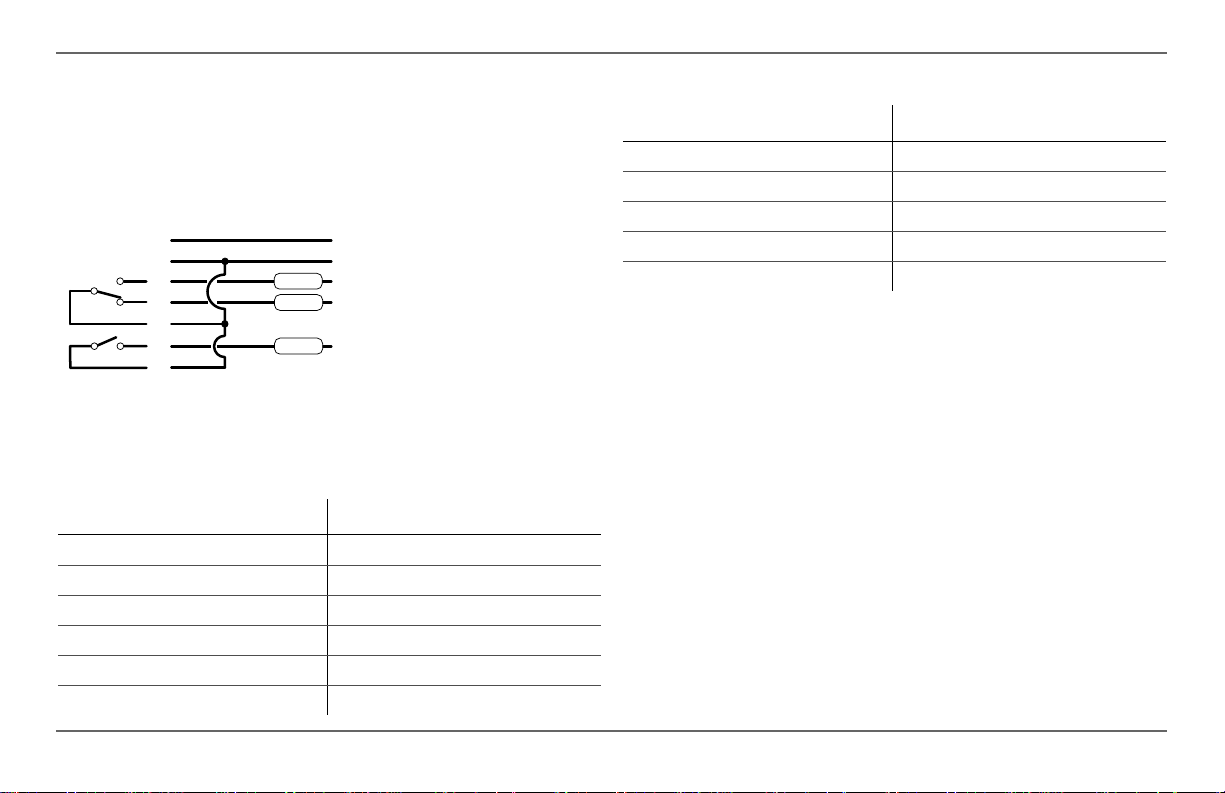

Type 1

Xanbus Automatic Generator Start Installation

Type 1 is a three-wire GlowStop configuration recommended for “threewire” generators with glow plugs that need to be operated before a start is

attempted.

AGS Har ness Wires Generator W ires

12

13

14

Relay1

16

17

Relay2

18

For additional information, see “Circuit Limitations” on page 11.

Figure 7

Type 1 Connection Diagram

GENERATOR RUN SIGNAL

GENERATOR RUN SIGNAL RETURN

5A fuse

PREHEAT/STOP

5A fuse

START

Relay Function Preset Configuration Setting

Relay 1 mode GlowStop

Relay 3 mode No function

Gen Run signal hold time 0.5 s

Preheat time 20 s

Preheat to crank delay 1 s

Crank time 15 s

Relay Function Preset Configuration Setting

Crank retry time 30 s

Gen Cool Down 30 s

Gen Spin Down 3 s

Shutdown bypass time 0 s

Start tries 3

975-0082-01-01 15

Page 26

Xanbus Automatic Generator Start Installation

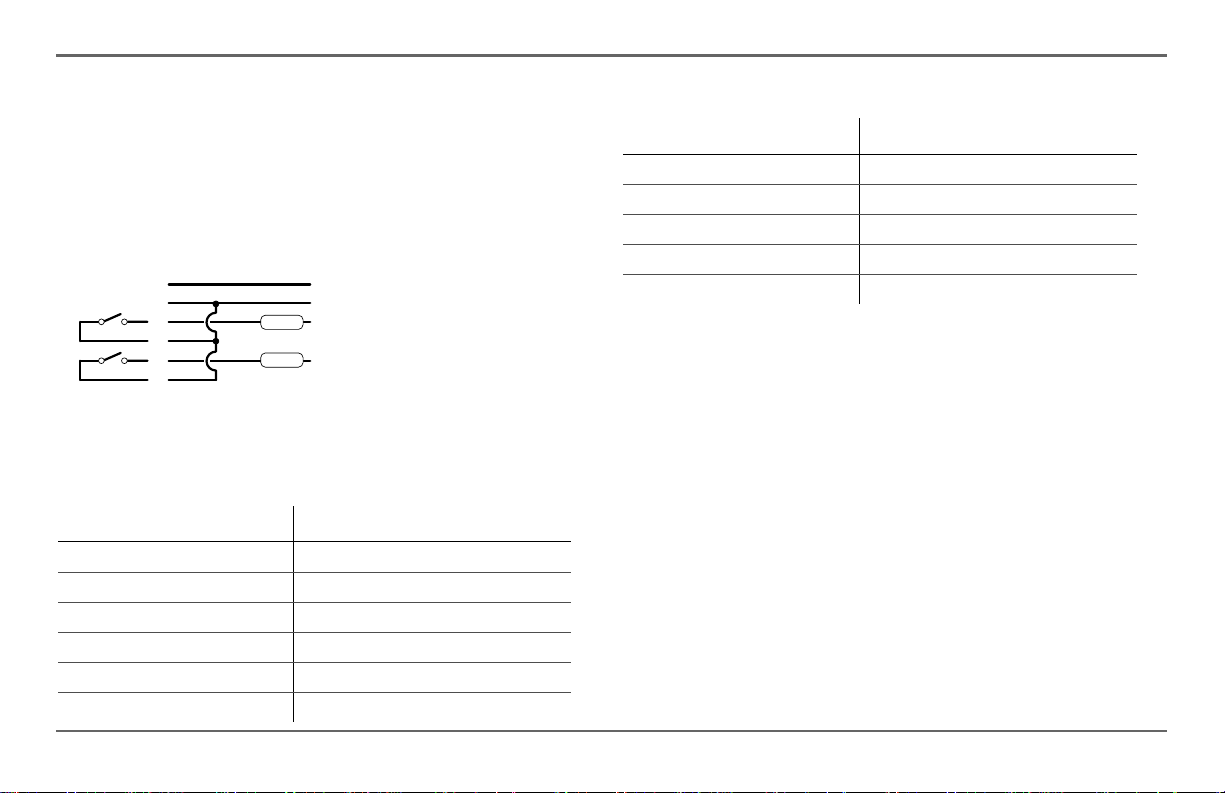

Type 2

Type 2 is a three-wire GlowStop configuration recommended for “threewire” generators that don’t require a dedicated preheat signal. In this

configuration, the start signal is applied for longer because the generator

does its own preheat and cranking while the start signal is applied.

AGSHarnessWires Generator Wires

12

13

14

Relay1

16

17

Relay2

18

For additional information, see “Circuit Limitations” on page 11.

Figure 8

Type 2 Connection Diagram

GENERATOR RUN SIGNAL

GENE RATOR RUN SIGNAL RETURN

5A fuse

STOP/PREHEAT

5A fuse

START

Relay Function Preset Configuration Setting

Relay 1 mode GlowStop

Relay 3 mode No function

Gen Run signal hold time 0.5 s

Preheat time 0 s

Preheat to crank delay 0 s

Relay Function Preset Configuration Setting

Crank time 30 s

Crank retry time 40 s

Gen Cool Down 30 s

Gen Spin Down 3 s

Shutdown bypass time 0 s

Start tries 3

16 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 27

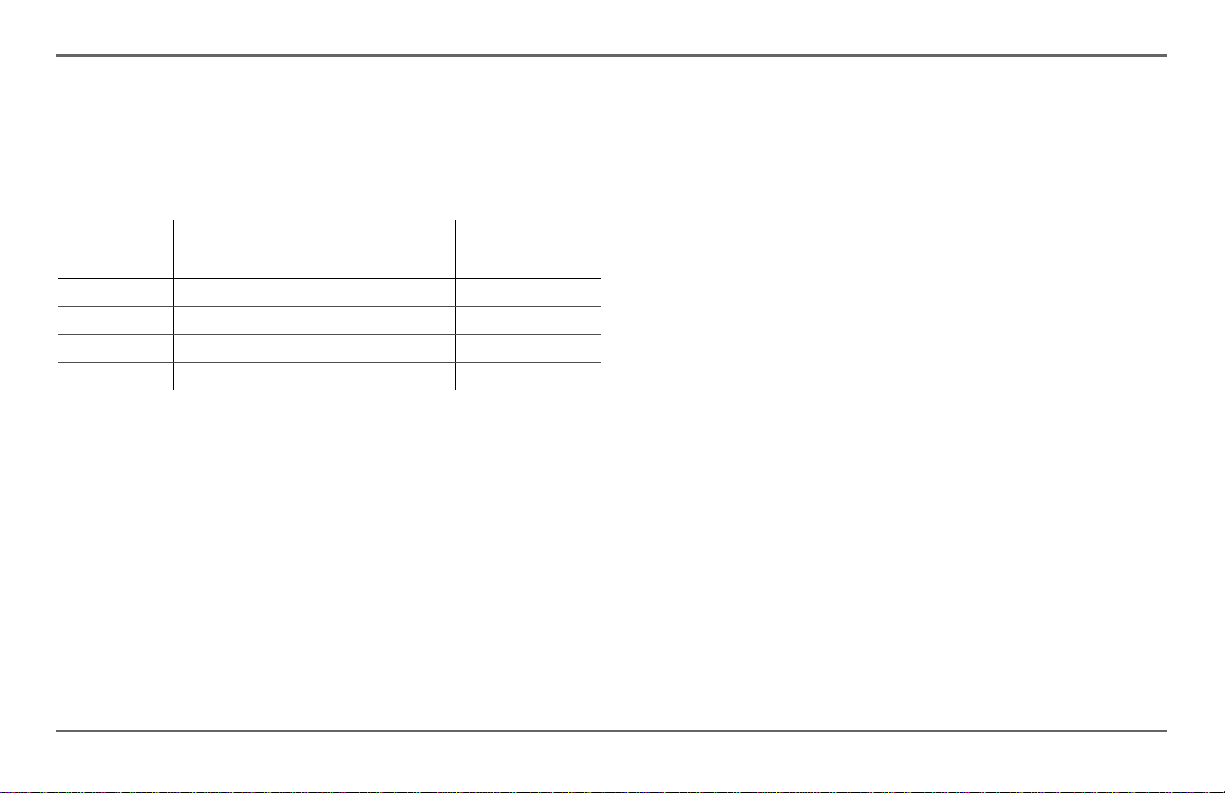

Type 3

Xanbus Automatic Generator Start Installation

Type 3 is a three-wire GlowStop with shutdown bypass configuration. The

configuration shown in Figure 9 uses a shutdown bypass output to

temporarily disable the generator’s low oil pressure shutdown functionality

during cranking. Generators with this functionality often have a manual

means of disabling it during cranking.

AGS Harness W ires Generator Wires

12

13

Relay 1

Relay 2

For additional information, see “Circuit Limitations” on page 11.

Figure 9

14

16

17

18

Type 3 Connection Diagram

5A fuse

5A fuse

GENERATOR RUN SIGNAL

GENERATOR RUN SIGNAL RETURN

PREHEAT

STOP

BYPASS SHUTDOWN

START

Relay Function Preset Configuration Setting

Relay 1 mode GlowStop/Shutdown bypass

Relay 3 mode Preheat/Shutdown bypass

Gen Run signal hold time 0.5 s

Preheat time 20 s

Relay Function Preset Configuration Setting

Preheat to crank delay 0 s

Crank time 15 s

Crank retry time 30 s

Gen Cool Down 30 s

Gen Spin Down 3 s

Shutdown bypass time 10 s

Start tries 3

975-0082-01-01 17

Page 28

Xanbus Automatic Generator Start Installation

Type 4

Type 4 is a three-wire StartStop configuration that uses relay 3 to provide a

60-second preheat signal.

AGS Harness W ires

12

13

Relay 1

Relay 2

Relay 3

For additional information, see “Circuit Limitations” on page 11.

Figure 10

14

16

17

18

19

20

Type 4 Connection Diagram

5A fuse

5A fuse

5A fuse

Generator Wires

GENERATOR RUN SIGNAL

GENERATOR RUN SIGNA L RETURN

STOP/PREHEAT

START

FUEL PRIME (PREHEAT)

12V GENERATOR BATTERY+

Relay Function Preset Configuration Setting

Relay 1 mode StartStop

Relay 3 mode Preheat

Gen Run signal hold time 10 s

Preheat time 60 s

Relay Function Preset Configuration Setting

Preheat to crank delay 5 s

Crank time 15 s

Crank retry time 15 s

Gen Cool Down 30 s

Gen Spin Down 3 s

Shutdown bypass time 0 s

Start tries 3

18 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 29

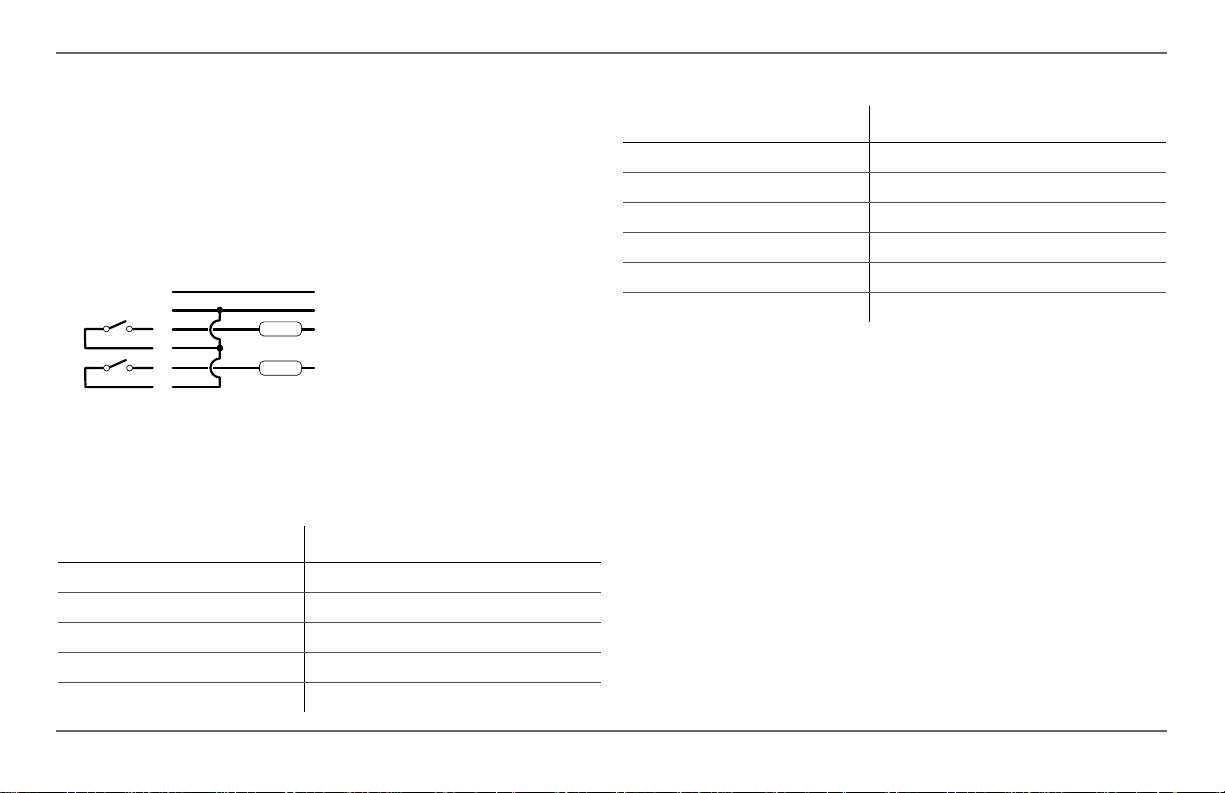

Type 5

Xanbus Automatic Generator Start Installation

Type 5 is a three-wire StartStop configuration that uses relay 3 to provide a

15-second preheat signal.

AGS Harness W ires Generator W ires

12

13

Relay 1

Relay 2

Relay 3

For additional information, see “Circuit Limitations” on page 11.

Figure 11

14

16

17

18

19

20

Type 5 Connection Diagram

5A fuse

5A fuse

5A fuse

GENERATOR RUN SIGNAL

GENERATOR RUN SIGNAL RETURN

STOP/PREHEAT

START

FUEL PRIME (PREHEAT)

12V GENERATOR BATTERY+

Relay Function Preset Configuration Setting

Relay 1 mode StartStop

Relay 3 mode Preheat

Gen Run signal hold time 2 s

Preheat time 15 s

Preheat to crank delay 2 s

Relay Function Preset Configuration Setting

Crank time 15 s

Crank retry time 15 s

Gen Cool Down 30 s

Gen Spin Down 3 s

Shutdown bypass time 0 s

Start tries 3

975-0082-01-01 19

Page 30

Xanbus Automatic Generator Start Installation

Type 6

Type 6 is a three-wire GlowStop configuration that has a normally closed

Run/Stop contact.

AGS Harness Wires Generator W ires

12

13

14

Relay1

Relay2

For additional information, see “Circuit Limitations” on page 11.

Figure 12

15

16

17

18

Type 6 Connection Diagram

5A fuse

5A fuse

5A fuse

GENERATOR RUN SIGNAL

GENERATOR RUN SIGNAL RETURN

PREHEAT

STOP

START

Relay Function Preset Configuration Setting

Relay 1 mode GlowStop

Relay 3 mode No function

Gen Run signal hold time 0.5 s

Preheat time 10 s

Preheat to crank delay 1 s

Crank time 15 s

Relay Function Preset Configuration Setting

Crank retry time 30 s

Gen Cool Down 30 s

Gen Spin Down 3 s

Shutdown bypass time 0 s

Start tries 3

20 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 31

Type 7

Xanbus Automatic Generator Start Installation

Type 7 will work with both two-wire and three-wire run mode configurations

that require a preheat signal before cranking. This Gen Type setting is suitable

for generators with an automatic engine cranking control system (two-wire)

and generators that require that the AGS control their starter separately (threewire).

AGS Harness W ires Generator W ires

12

13

Relay 1

For additional information, see “Circuit Limitations” on page 11.

Figure 13

AGS Harness W ires Generator Wires

Relay1

Relay2

For additional information, see “Circuit Limitations” on page 11.

14

16

Type 7 Connection Diagram (two-wire)

12

13

14

16

17

18

5A fuse

5A fuse

5A fuse

GENERATOR RUN SIGNAL

GENERATOR RUN SIGNAL RETURN

RUN

GENERATOR RUN SIGNAL

GENERATOR RUN SIGNAL RETURN

RUN

START

Relay Function Preset Configuration Setting

Relay 1 mode Run

Relay 3 mode No function

Gen Run signal hold time 0.5 s

Preheat time 20 s

Preheat to crank delay 1 s

Crank time 15 s

Crank retry time 30 s

Gen Cool Down 30 s

Gen Spin Down 3 s

Shutdown bypass time 0 s

Start tries 3

Figure 14

Type 7 Connection Diagram (three-wire)

975-0082-01-01 21

Page 32

Xanbus Automatic Generator Start Installation

Type 8

Type 8 will work with both two-wire and three-wire run mode

configurations. Type 8 is identical to Type 7 except that it provides no

preheat signal before cranking.

AGS Har ness Wires Generator W ires

12

13

14

Relay 1

16

For additional information, see “Circuit Limitations” on page 11.

Figure 15

AGS Harness W ires Generator W ires

For additional information, see “Circuit Limitations” on page 11.

Type 8 Connection Diagram (two-wire)

12

13

14

Relay1

16

17

Relay2

18

5A fuse

5A fuse

5A fuse

GENERATOR RUN SIGNAL

GENERATOR RUN SIGNAL RETURN

RUN

GENERATOR RUN SIGNAL

GENERATOR RUN SIGNA L RETURN

RUN

START

Relay Function Preset Configuration Setting

Relay 1 mode Run

Relay 3 mode No function

Gen Run signal hold time 0.5 s

Preheat time 0 s

Preheat to crank delay 0 s

Crank time 15 s

Crank retry time 30 s

Gen Cool Down 30 s

Gen Spin Down 3 s

Shutdown bypass time 0 s

Start tries 3

Figure 16

Type 8 Connection Diagram (three-wire)

22 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 33

Type 9

Xanbus Automatic Generator Start Installation

Type 9 is a StartStop mode configuration with shutdown bypass

functionality on relay 3.

AGS Harness Wires Generator W ires

12

13

Relay1

Relay2

Relay3

For additional information, see “Circuit Limitations” on page 11.

Figure 17

14

16

17

18

19

20

Type 9 Connection Diagram

GENERATOR RUN SIGNAL

GENERATOR RUN SIGNAL RETURN

5A fuse

STOP

5A fuse

START

5A fuse

FUEL PRIME (PREHEAT)

12V GENERATOR BATTERY+

Relay Function Preset Configuration Setting

Relay 1 mode StartStop

Relay 3 mode Shutdown Bypass

Gen Run signal hold time 0.5 s

Preheat time 0 s

Preheat to crank delay 0 s

Relay Function Preset Configuration Setting

Crank time 15 s

Crank retry time 30 s

Gen Cool Down 30 s

Gen Spin Down 3 s

Shutdown bypass time 5 s

Start tries 3

975-0082-01-01 23

Page 34

Xanbus Automatic Generator Start Installation

Type 10

Type 10 is a StartStop mode configuration with no preheat signal or

shutdown bypass functionality.

AGS Harness Wires Generator W ires

12

13

Relay 1

Relay 2

For additional information, see “Circuit Limitations” on page 11.

Figure 18

14

16

17

18

Type 10 Connection Diagram

GENERATOR RUN SIGNAL

GENERATOR RUN SIGNAL RETURN

5A fuse

STOP

5A fuse

START

Relay Function Preset Configuration Setting

Relay 1 mode StartStop

Relay 3 mode No function

Gen Run signal hold time 0.5 s

Preheat time 0 s

Preheat to crank delay 0 s

Crank time 15 s

Crank retry time 30 s

Relay Function Preset Configuration Setting

Gen Cool Down 30 s

Gen Spin Down 3 s

Shutdown bypass time 0 s

Start tries 3

24 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 35

Type 11

Xanbus Automatic Generator Start Installation

Type 11 is a two-wire run mode configuration. It requires only two wires

and one relay to control the generator. Relay 1 closes momentarily once to

start the generator, and closes momentarily again to stop the generator.

AGS Harness Wires Generator Wires

12

13

Relay 1

For additional information, see “Circuit Limitations” on page 11.

Figure 19

14

16

Type 11 Connection Diagram

5A fuse

GENERATOR RUN SIGNAL

GENERATOR RUN SIGNAL RETURN

RUN

Relay Function Preset Configuration Setting

Relay 1 mode MomentaryRun

Relay 3 mode No function

Gen Run signal hold time 0.5 s

Preheat time 0 s

Preheat to crank delay 0 s

Crank time 10 s

Crank retry time 15 s

Gen Cool Down 30 s

Relay Function Preset Configuration Setting

Gen Spin Down 3 s

Shutdown bypass time 0 s

Start tries 3

975-0082-01-01 25

Page 36

Xanbus Automatic Generator Start Installation

Type 12

Type 12 is a three-wire GlowStop configuration recommended for “threewire” generators that don’t require a dedicated preheat signal. In this

configuration, the start signal is applied for longer because the generator

does its own preheat and cranking while the start signal is applied.

AGS Harness Wires Generator W ires

12

13

Relay 1

Relay 2

For additional information, s ee “Circuit Limitations” on page 11.

Figure 20

14

16

17

18

Type 12 Connection Diagram

GENERATOR RUN SIGNAL

GENERATOR RUN SIGNAL RETURN

5A fuse

STOP

5A fuse

START

Relay Function Preset Configuration Setting

Relay 1 mode GlowStop

Relay 3 mode No function

Gen Run signal hold time 4 s

Preheat time 0 s

Preheat to crank delay 0 s

Crank time 30 s

Relay Function Preset Configuration Setting

Crank retry time 40 s

Gen Cool Down 30 s

Gen Spin Down 3 s

Shutdown bypass time 0 s

Start tries 3

26 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 37

Type 13

Xanbus Automatic Generator Start Installation

Type 13 is a three-wire PulseStop configuration that uses relay 3 to provide

the preheat signal. With this genera tor type, there will be a delay between

the generator turning off and the AGS recognizing that the generator is off.

AGS Harness W ires Generator Wires

12

13

Relay 1

Relay 2

Relay 3

For additional information, see “Circuit Limitations” on page 11.

Figure 21

14

16

17

18

19

20

Type 13 Connection Diagram

5A fuse

5A fuse

5A fuse

GENERATOR RUN SIGNAL

GENERATOR RUN SIGNAL RETURN

STOP/PREHEAT

START

FUEL PRIME (PREHEAT)

12V GENERATOR BATTERY+

Relay Function Preset Configuration Setting

Relay 1 mode PulseStop

Relay 3 mode Preheat

Gen Run signal hold time 5 s

Relay Function Preset Configuration Setting

Preheat time 15 s

Preheat to crank delay 2 s

Crank time 15 s

Crank retry time 15 s

Gen Cool Down 30 s

Gen Spin Down 3 s

Shutdown bypass time 0 s

Start tries 3

975-0082-01-01 27

Page 38

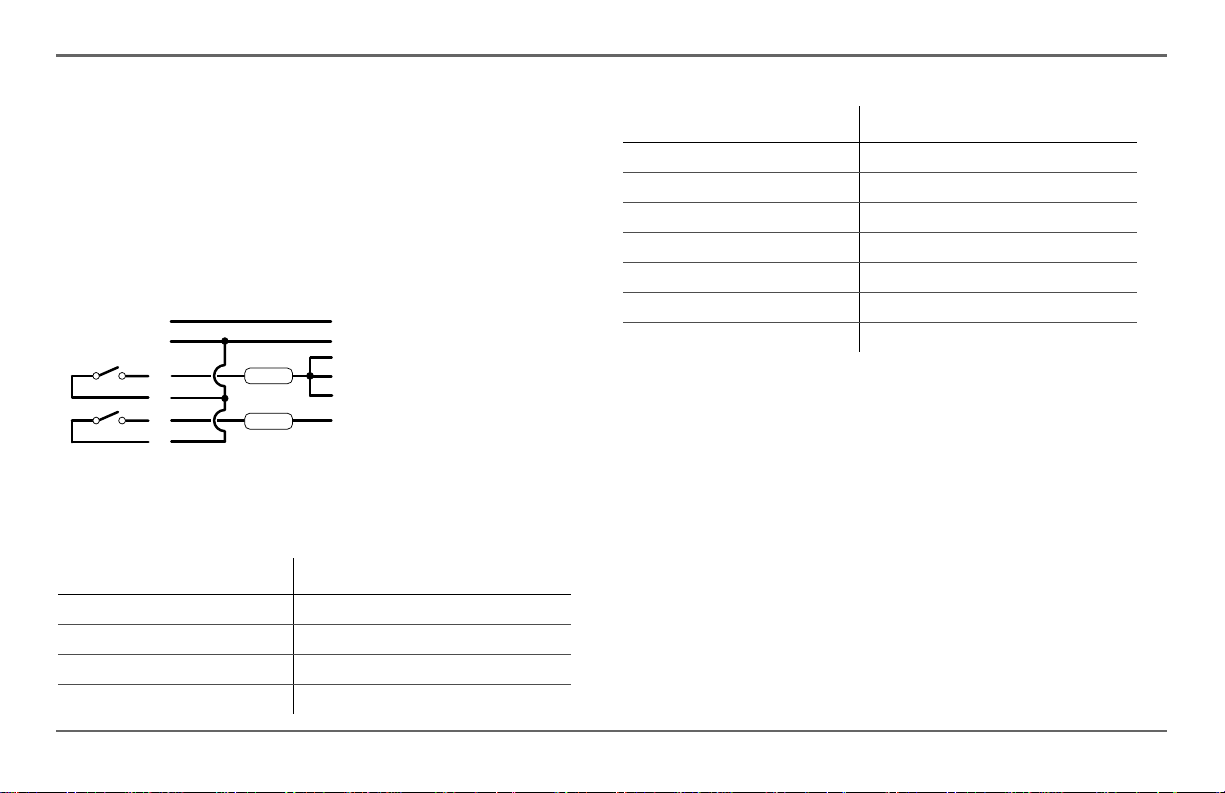

Xanbus Automatic Generator Start Installation

Type 14

Type 14 works with two-wire generators that use an integrated engine

control module to perform the necessary relay cycles to start and stop the

generator. This is similar to Type 8 but without the B+ signal requirement.

The AGS closes relay 1 to start the generator and illuminates the Generator

On light to indicate the relay is closed. To stop the generator, relay 1 is

opened and the Generator On light turned off.

AGS Harness Wires Generator Wires

Relay 1

14

16

5A fuse

RUN

RELAY1 R ETURN

IMPORTANT:

Since Type 14 does not monitor the generator run status,

illumination of the Generator On light on the AGS does not necessarily

indicate the generator is actually running. If this generator type is used,

For additional information, see “Circuit Limitations” on page 11.

Figure 22

Type 14 Connection Diagram (two-wire)

ensure the generator’s integrated controller has the ability to monitor,

control and report generator status and faults. With Type 14, no faults are

raised if the generator fails to start or stop or is externally started or

stopped.

Once the generator is stopped, there is a 10-minute delay before the

generator can be re-started using the AGS. This is to allow the generator’s

integrated engine controller to completely and safely shut down the

generator. This delay can be adjusted by changing the Gen Spin down

setting.

Relay Function Preset Configuration Setting

Relay 1 mode RunStop

Relay 3 mode Not used

Gen Run signal hold time 0 s

Preheat time 0 s

Preheat to crank delay 0 s

Crank time 0 s

Crank retry time 0 s

Gen Cool Down 30 s

Gen Spin Down 600 s

Shutdown bypass time 0 s

Start tries 1

28 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 39

Connecting the Thermostats (optional)

Wires 1, 2, 3, and 4 on the wiring harness can be connected to two

thermostats. Wires 1 (yellow) and 2 (gray) are intended for thermostat 1 and

wires 3 (orange) and 4 (gray) are intended for thermostat 2.

Xanbus Automatic Generator Start Installation

Table 1

Wire

Number Function

1 Thermostat 1 input (12/24 V) Yellow

2 Thermostat 1 return (ground) Gray

3 Thermostat 2 input (12/24 V) Orange

4 Thermostat 2 return (ground) Gray

These wires connect to 12-volt/24-volt output signals from the thermostats.

The AGS will start the generator in response to these signals. Thermostats

can not be programmed using the AGS.

For specific information about thermostat wiring and where AGS

connections should be made, please consult your thermostat documentation

or contact the thermostat manufacturer.

Wiring for Connecting Thermostats

Wiring Harness

Wire Color

975-0082-01-01 29

Page 40

Xanbus Automatic Generator Start Installation

Connecting an External Shutdown (optional)

The external shutdown input is a 12-volt/24-volt input used to assure that

the AGS keeps the generator off under conditions that may be potentially

hazardous. Wire 5 (white/black) and 6 (gray) on the wiring harness are

intended for an external switch or sensor (such as a moisture detector, or

carbon monoxide detector) that produces an active high 12-volt or 24-volt

output.

Table 2

Wire

Number Function

5 External shutdown input (12/24 V) White/Black

6 External shutdown return (ground) Gray

Wiring for Connecting an External Shutdown

Wiring Harness

Wire Color

In order for the Xanbus Automatic Generator Start (AGS) to be able to

detect these switches, connect the fused positive of the generator battery to

wire 10 on the harness (the constant 12-volt/24-volt wire). See Figure 23 on

page 32. Ensure all circuits added to the system comply with “Circuit

Limitations” on page 11.

If the generator battery does not have the required voltage, any 12-volt or

24-volt power source meeting the limits on page 11, will suit this purpose.

If an alternate power source is used, its positive terminal must be connected

to wire 10. Its negative must be connected to wire 11.

NOTE: Internally, wire 11 is connected to wire 13, so in this

configuration, the alternative power source negative may already be

connected to the negative terminal on the generator battery.

Connecting an External Manual ON/OFF

Switch (optional)

The external manual ON/OFF inputs (wires 7 and 8 on the wiring harness)

are intended for wiring to one or more remote ON/OFF switches for sta rting

and stopping the generator manually. Wire 7 (Start) and wire 8 (Stop)

should each run to their own momentary-contact switch or push-button. The

other contact on both switches (common) should be connected to wire 11 on

the harness.

NOTE: Internally, wire 11 is connected to wire 13 so it may already be

connected to the negative terminal on the generator battery.

FIRE AND ELECTRICAL SHOCK HAZARD

When making connections to a 12-volt or 24-volt power source that

exceeds the class 2 power limitation of 100 VA (e.g., a battery) always

use over-current protection as defined in Table 2. This also applies to

thermostat and external manual ON/OFF connections. Locate the

protection device at the power source in the positive wire.

Do not connect the AGS to a 48-volt battery bank. The AGS is limited to

a 30V open-circuit maximum by its regulatory approval and cannot be

connected to a 48-volt power source.

Failure to follow these instructions can result in death or serious

injury.

30 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 41

Xanbus Automatic Generator Start Installation

The External Manual On and External Manual Of f state s are not af fected by

maximum generator run time (see “Max Run Time” on page 55).

EQUIPMENT DAMAGE

Ta pping 12-volts or 24-volts from a 48-volt battery bank will unevenly

wear out the batteries and shortens the battery bank life.

Failure to follow these instructions can damage the unit and/or

damage other equipment.

Table 3

Wiring for Connecting an External Manual ON/OFF

Switch

Wire

Number Function

7 External manual on input White/Green

8 External manual off input White/Red

9 External On/Off LED Indicator

output

10 Constant 12/24 V B+ for External

On/Off/LED Indicator

11 External On/Off/LED Indicator

return

Multiple generator control panels or simple contact closures can be wired to

the external manual ON/OFF inputs. The AGS detects if any of the contacts

close and will change its operating mode to External Manual On or External

Manual Off (for more information, see “GenMode” on page 60). The AGS

turns the generator on or off according to these inputs and the resulting

operating mode change.

Wiring Harness

Wire Color

White/Blue

Red

Black

Connecting an External ON/OFF LED

Wires 9 (White/Blue) and 1 1 (Black) on the wiring harness can be

connected to an LED or other light to accompany a remote external ON/

OFF switch. This light turns on when the generator run signal is active to

visually indicate that the generator is running.

IMPORTANT:

active during the preheat stage, before the generator is actually running. In

this case, the external ON/OFF LED (and the Generator On light on the

AGS) will turn on during the preheat stage and remain on when the

generator is running.

For some generators, these lights will also remain on for a period of time

after the generator has stopped.

With some generators, the generator run signal becomes

975-0082-01-01 31

Page 42

Xanbus Automatic Generator Start Installation

2K

H11A817

2K

H11A817

5K11

H11A817

Figure 23

External ON/OFF Switch and LED Wiring Diagram

32 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 43

Connecting the Wiring Harness to the AGS

After all the external connections have been wi red to the wiring harness, th e

connector on the wiring harness must be plugged into the 20-contact

connector on the AGS.

To connect the wiring harness to the AGS:

◆ With the click-tab on the wiring harness connector on top (away from

the mounting surface), insert the wiring harness connector into the 20contact connector on the AGS until the tab clicks into place.

Xanbus Automatic Generator Start Installation

Figure 24

AGS External Connections

975-0082-01-01 33

Page 44

Xanbus Automatic Generator Start Installation

Connecting the AGS to the Xanbus Network

.

EQUIPMENT DAMAGE

Connect only to other Xanbus-enabled devices.

Although the cabling and connectors used in this network system are the

same as those used for Ethernet, this network is not an Ethernet system.

Equipment damage may result from attempting to connect a Xanbusenabled device to an Ethernet system.

Failure to follow these instructions can damage the unit and/or

damage other equipment.

To connect the AGS to the Xanbus network, plug a Xanbus network cable

Shore

Power

System Control Panel

Xanbus System Control Panel

network terminator network terminator

Automatic Generator Start

Xanbus Automatic Generator Start

Generator

Freedom Sequence

AC Loads

AC Panel

Freedom SW Inverter/Charger

FREEDOMSW 3012

BATTERY

C/

ge Fault

r

ter A

ha

r

C

nve

I

On

er

t

r

e

nv

I

set Enable

Re

FREEDOM SW 3012

Inverter

Load Panel

(standard straight-through Ethernet cable—CAT 5e) into one of the network

ports on the bottom panel of the AGS. Connect the other end of that same

cable to the next Xanbus-enabled component in the chain. See Figure 25. For

the location of the ports on the AGS, see Figure 5 on page 9

Figure 25

Xanbus Network Example

If the AGS is being installed on an existing Xanbus system, the system must

first be put into Standby. See “Putting the AGS in Standby Mode” on page

67.

Depending on the layout of the Xanbus system, the following options are

available for the other network connector on the AGS:

• A second network cable

• A network terminator (when the AGS is the last device at one end of

the network)

34 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 45

Connect one or two network

cables as required by the

installation configuration.

Xanbus Automatic Generator Start Installation

Verifying Power Is Available

When the AGS has been installed properly, the Power and Network

indicator lights illuminate.

If one or both lights are out, check the network connections. Check the

Xanbus to ensure it has battery power. Check to make sure the other devices

in the network, such as the Xanbus System Control Panel (SCP), are

responding to confirm the network is still active.

Verify Power and Network

indicator lights are illuminated.

Figure 26

Connecting the Xanbus System Control Panel (SCP)

Figure 27

Verifying Power is Available

975-0082-01-01 35

Page 46

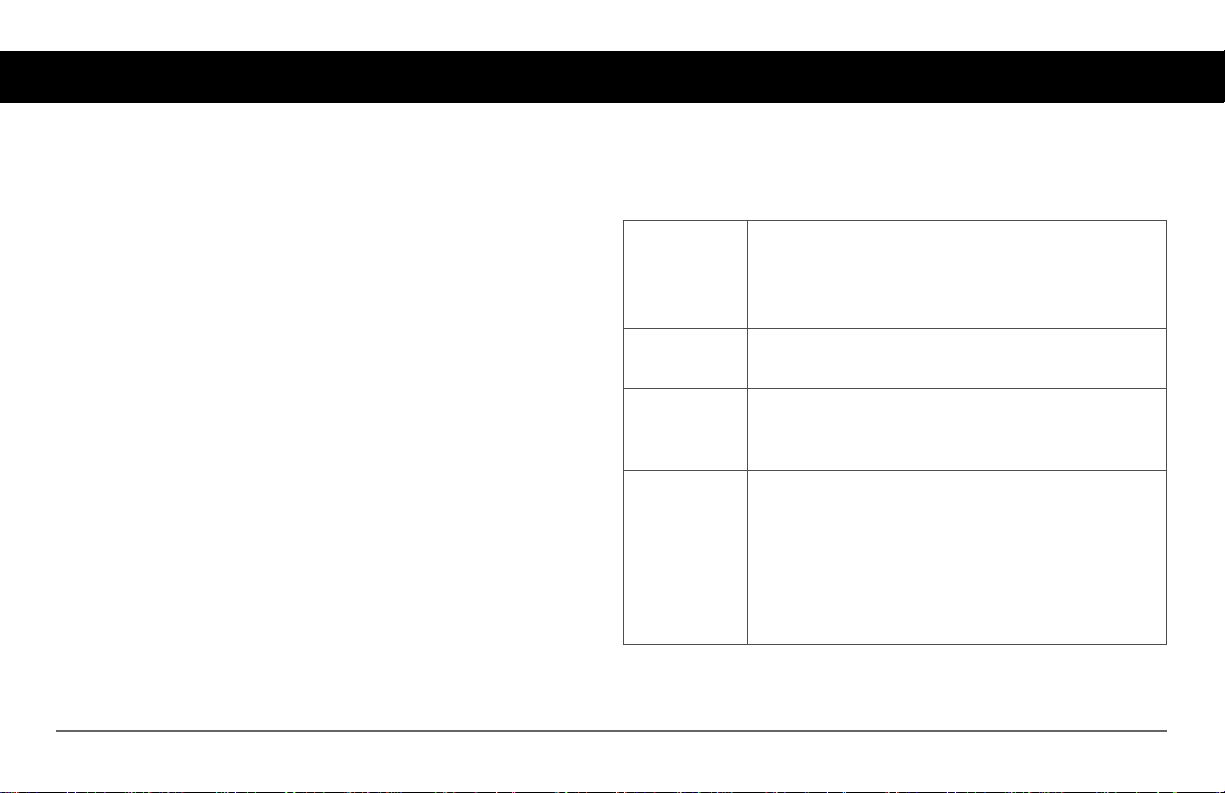

Configuration of the Xanbus AGS

Overview

The AGS has a number of settings that must be configured to ensure that

TM

the generator starts and stops under the appropriate conditions and at the

appropriate time. The AGS is configured using the Xanbus System Control

Panel (SCP).

The Freedom SW System Home Screen on the Xanbus System Control

Panel (SCP) displays basic system operational status. On the lower left

AC In/Charge

Inverter On

Low Battery

Fault

STBY/ON

Fault Clear

corner of the Freedom SW System Home Screen, there is an arrow that

points to the Enter Button below the display. Pressing the Enter Button

when the Freedom SW System Home Screen is displ ayed will take the

Enter Func

system to the Select Device Menu.

The AGS Menu is accessed from the Select Device menu screen. All

Xanbus System Control Panel (SCP)

FGA: 809-0921

configurable settings, generator mode, fault clearing, and device

information is provided in the AGS Menu.

Enter Button

Confirms

selection of a

menu item

Moves to the

next screen

Figure 28

Up arrow

Scrolls up

one line of

text

Increases a

selected

value

Down arrow

Scrolls down

one line of text

Decreases a

selected value

Xanbus System Control Panel (SCP) Navigation Buttons and

Func Button

Cancels

selection of a

menu item

Returns to the

previous screen

Freedom SW System Home Screen

36 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 47

Accessing the AGS Menu

Use the Xanbus AGS Menu to

change configuration settings, set

operating mode, clear fault

warnings, and view device

information.

To access the Xanbus AGS Menu,

start from the Xanbus System

Home Screen.

To view the Select Device Menu,

press Enter.

AC In/Charge

Inverter On

Low Battery

Fault

Enter Func

Xanbus System Control Panel (SCP)

System Status

Battery 20.4A 53.9V

BatLev

Load

AC1 1150W 3202V

Menu

1235W

Configuration of the Xanbus AGS

To change operational settings on

the AGS Menu:

1. Use the arrow buttons to select the

TM

STBY/ON

E--F

Fault Clear

FGA: 809-0921

desired operation.

2. Press Enter to highlight the current

value for that setting. Asterisks (*)

indicate the last value set.

3. Use the arrow buttons to change the

value. Holding an arrow button down

without releasing it will scroll through

the values quickly.

4. Press Enter to select the value.

5. Press Func twice to return to the

Freedom SW System Home Screen.

See Figure 31.

AC In/Charge

Inverter On

Low Battery

XAGS 00: Setup

GenMode [ManualOff]

Mode

Clear Faults Warnings

View Device Info

Fault

Enter Func

Xanbus System Control Panel (SCP)

[Operating]

Auto Gen Start Menu

TM

STBY/ON

Fault Clear

FGA: 809-0921

To select the AGS Menu, use the

arrow buttons to highlight AGS

“XAGS”. Press Enter to select the AGS

Menu.

Figure 29

Accessing the AGS Menu

AC In/Charge

Inverter On

Low Battery

Xanbus System Control Panel (SCP)

System Settings

FSW3012

EMS

XAGS

Fault

Enter Func

Select Device

TM

STBY/ON

Fault Clear

FGA: 809-0921

To access the advanced settings to

configure specific operational

parameters:

Press the Enter button and the Up and

Down Arrow Buttons at the same time.

See Figure 32.

Figure 30

Changing Settings

AC In/Charge

Inverter On

Low Battery

AGS 00: Setup

Advanced Settings

GenMode

Clear Faults Warnings

View Device Info

Fault

Setup System

Enter Func

Xanbus System Control Panel (SCP)

[ManualOff]

TM

STBY/ON

Fault Clear

FGA: 809-0921

975-0082-01-01 37

Page 48

Configuration of the Xanbus AGS

The Xanbus Automatic Generator Start

(AGS) Menu

The Xanbus Automatic Generator Start (AGS) menu provides the ability to

configure the changeable parameters, select the generator’s operating mode,

clear fault warnings and view device information.

The Xanbus Automatic Generator Start (AGS) Menu Home Screen is

divided into five sections.

• Advanced Settings (Configuration Settings)

• GenMode (Manual on/Manual off/Automatic)

• Mode of Operation (Operating/Standby)

• Clear Fault Warnings

• View Device Info

AC In/Charge

XAGS 00: Setup

Inverter On

GenMode [ManualOff]

Mode

Low Battery

Clear Faults Warnings

View Device Info

Fault

Enter F unc

Xanbus System Control Panel(SCP)

[Operating]

TM

STBY/ON

Fault C lear

FGA:809-0921

To select the Generator

Starting Mode...

To selec t the Dev ice

Operating Mode...

To clear faults and

warnings...

To view device

information...

XanbusAGS Menu To configure...

XAGS 00: Setup

GenMode [ManualOff]

Mode

[Operating]

Clear Faults Warnings

View Device Info

Press the ENTER button to

Use these buttons to

select the menu item.

move UP or DOWN.

XAGS 00: Setup

[ManualOff]

GenMode

Mode

[Operating]

Clear Faults Warnings

View Device Info

XAGS 00: Setup

GenMode [ManualOff]

[Operating]

Mode

Clear Faults Warnings

View Device Info

XAGS 00: Setup

GenMode [ManualOff]

Mode

[Operating]

Clear Faults Warnings

View Device Info

XAGS 00: Setup

GenMode [ManualOff]

Mode

[Operating]

Clear Faults Warnings

View Device Info

XAGS 00: Setup

GenMode

Mode

Clear Faults Warnings

View Device Info

XAGS 00: Setup

GenMode [ManualOff]

Mode

Clear Faults Warnings

View Device Info

Use these buttons to

change the settings.

Press the Func button to

return to the AGS Home.

Press the Func button to

return to the FSW System

Home Screen .

XAGS 00: Setup

Advanced Settings

GenMode [ManualOff]

Clear Faults Warnings

View Device Info

[ManualOff]

[Operating]

[Operating]

Press the ENTER button

accepts the new setting.

Figure 31

AGS Basic Menu Contents

38 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 49

When the AGS Home Screen is first displayed, the menu defaults to the

GenMode Menu. If configuration changes need to be made, the

Configuration Menu can be accessed by pressing the Enter, Up arrow, and

Down arrow buttons all at same time to access the Advanced Settings.

TM

ACIn /Charge

XAGS 00: Setup

InverterOn

GenMode [ManualOff]

Mode

LowBattery

Clear Faults Warnings

View Device Info

Fault

Enter Func

XanbusS ystemControl Panel (SCP)

[Operating]

STBY/ON

Fault Clear

FGA:809-0921

To access theAdvanced Settings menu,

Press Enter and Up and Down arrows together

To return to the B asic Settings menu,

Press Enter and Up and Down arrows together

XanbusAGS Menu

XAGS 00: Setup

Advanced Settings

GenMode [ManualOff]

Clear Faults Warnings

View Device Info

XAGS 00: Setup

Advanced Settings

GenMode [ManualOff]

Clear Faults Warnings

View Device Info

XAGS 00: Config

QT EN [Enabled]

[9:00PM]

QT Begin

[8:00AM]

QT End

Gen Type [2]

Cfg Trigger

Cfg Gen

Multi-Unit Config

Restore Defaults

Use these buttons to select

the desired menu.

Press ENTER to move the cursor

to the changeable settings.

Press Func to return to the

Xanbus AGS Home screen.

To change configuration parameters...

Press Enter to move forward

into the Config menu.

XAGS 00: Triggers

Start DCV 30 Sec [40.0V]

Start DCV 15 Sec

[Disabled]

Start DCV 2 hr

[Disabled]

Start DCV 24 Hr

[Disabled]

Stop Float [Disabled]

Stop Absorb

[Disabled]

StopV

[Disabled]

Temp1

[Disabled]

Temp2 [Disabled]

Load

[Disabled]

Start Load

Stop Load

XAGS 00: Gen

Starter Cool Down [60sec]

Gen Cool Down

[30sec]

Gen Spin Down

[3sec]

Max Runtime

[4hours]

Exercise per [21days]

Exercise Dur

[30min]

Exercise Time

[9:00AM]

Relay 3

[Not Used]

Gen Run Hold Time [0.5s]

Crank Delay

[1sec]

Crank Time

[30sec]

Crank Retry Time

[40sec]

Preheat Time

[0sec]

Gen Start Tries

XAGS 00: Gen

Dev Name [AGS]

Dev Number

Connections

[15A]

[10A]

[3]

[00]

Use these buttons to

change the settings.

Press ENTER to accept

the new setting.

XAGS 00: Conn

DC Conn [HouseBatt1]

AC In

AC Out

Generator [Gen1]

[Grid1]

[ACLoad]

Configuration of the Xanbus AGS

Figure 32

AGS Configuration Menu Contents

975-0082-01-01 39

Page 50

Configuration of the Xanbus AGS

The Configuration Menu

The Configuration Menu is where specific start-stop parameters are set.

This menu contains the following settings:

• "QT En"

• "QT Begin"

• "QT End"

• "Gen Type"

• "Cfg Trigger"

• "Cfg Gen"

• "Restore Defaults"

QT En

Full name Quiet Time Enable

Purpose "QT En" enables or disables the Quiet Time functionality of the

AGS. Quiet time refers to a period of time when the generator should not

run.

Dependencies "QT En" requires the AGS to be in Automatic mode.

Setting "QT En" to [Enable] requires that parameters be set for the "QT

Begin" and "QT End".

Value Descri ption

Enabled/Disabled Enables or disables the Quiet Time functionality.

When to use Set "QT En" to [Enabled] when there is a period of time

when it is not desired for the generator to run. The AGS will ignore all

automatic start triggers during the time set in "QT Begin" and "QT

Begin".

When there are no preferences or restrictions for when the generator should

run, set "QT En" to [Disabled]. When [Disabled] is selected, the AGS will

ignore the times set for "QT Begin" and "QT End".

Considerations Quiet Time prevents the automatic starting of the

generator regardless of battery condition.

40 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 51

Configuration of the Xanbus AGS

IMPORTANT:

battery drain can be significant as it may be necessary to use the inverter

and batteries to supply AC Power without the help of a generator.

Therefore, it is important to conserve battery power during this time.

Minimize the use of interior lights and set thermost at temper atu re l ower t o

prevent the furnace from coming on at night during cool weather. Set

thermostats higher to prevent air conditioning coming on at night during

warm weather.

Sometimes automatic start or automatic stop triggers may overlap with the

beginning and end of quiet time. Three different quiet time scenarios affect

when the generator stops and starts.

1. If quiet time begins after the AGS has started the generator, the

generator will stop. If the condition that started the generator is still

present when quiet time ends, the generator will restart.

2. If a condition that requires starting the generator occurs during quiet

time, the AGS will ignore it until quiet time ends. If the condition still

exists at the end of quiet time, the AGS will start the generator.

3. If the running generator stops when quiet time begins and a condition

that requires stopping the generator occurs during quiet time, the

generator will not restart when quiet time ends.

If quiet time is set for overnight, be aware that overnight

QT Begin

Full name Quiet Time Begin

Purpose "QT Begin" defines the start of quiet time.

Dependencies "QT Begin" functions only if the AGS is in Automatic

mode. This setting requires "QT En" be set to [Enabled].

Ensure the clock on the Xanbus System Control Panel (SCP) is set to the

correct local time.

Value Description

12:00AM to

11:59PM (12-hour

clock)

00:00 to 23:59

(24-hour clock)

At the time set for "QT Begin", the generator

will stop (if it is running) and not be able to start

again until the time set for "QT End". It ignores

all automatic start triggers during the time period

between "QT Begin" and "QT End".

975-0082-01-01 41

Page 52

Configuration of the Xanbus AGS

QT End

Full name Quiet Time End

Purpose "QT End" is a changeable setting that defines the end of quiet

time.

This setting also requires a setting for "QT Begin".

Dependencies "QT End" functions only if the AGS is in Automatic

mode. This setting requires "QT En" be set to [Enabled] and also requires a

setting for "QT Begin".

Ensure the clock on the Xanbus System Control Panel (SCP) is set to the

correct local time.

Value De s cription

12:00AM to

11:59PM (12-hour

clock)

00:00 to 23:59

(24-hour clock)

At the time set for "QT End" the AGS will be

able to automatically start the generator again. If

a start trigger has occurred during quiet time and

is still active, the generator will start immediately

after quiet time ends.

Gen Type

Full name Generator Type

Purpose "Gen Type" selects the starting requirements of the generator.

The starting requirements determine how the AGS must be wired to the

generator’s starting system. For more information, see “Connecting the

Generator” on page 14 or Appendix B.

IMPORTANT:

into Standby. See “Putting the AGS in Standby Mode” on page 67.

Table 4

Option

Type 1 GlowStop page 15

Type 2 GlowStop with no preheat page 16

Type 3 GlowStop with shutdown bypass page 17

Type 4 StartStop with Relay 3 prime page 18

Type 5 StartStop with Relay 3 preheat page 19

Type 6 GlowStop with normally closed RunStop contact page 20

Type 7 Run with preheat page 21

Type 8 Run with no preheat page22

Type 9 StartStop with Relay 3 preheat and shutdown

Type 10 StartStop page 24

Type 11 MomentaryRun page 25

"Gen Type" can only be changed after the system is put

Generator Type Descriptions

Description

Mode

bypass

For Technical Details, see.

page 23

a

42 Xanbus Automatic Generator Start (AGS) Owner’s Guide

Page 53

Table 4

Generator Type Descriptions

Description

Option

Type 12 GlowStop with no preheat page 26

Type 13 PulseStop with Relay 3 preheat page 27

Type 14 Run with no preheat and no switched B+

a.See “Appendix B: Relay Timing” on page 82 for additional information.

Mode

requirement

For Technical Details, see.

page 28

When to use Use this setting after installing the AGS hardware. Selecting

a suitable "Gen Type" automatically configures the AGS to work with the

ignition system and starting requirements of the generator. Consult the

generator manual or contact the generator’s manufacturer for specific

generator starting requirements.

a

Configuration of the Xanbus AGS

Outcomes Selecting a "Gen Type" from the list automatically

configures the following settings:

• Preheat time

• Preheat end to crank delay time

• Crank time

• Crank retry time

• Starter cool down time

• Generator cool down

• Generator spin down time

• Generator run signal hold time

• Start tries.