Page 1

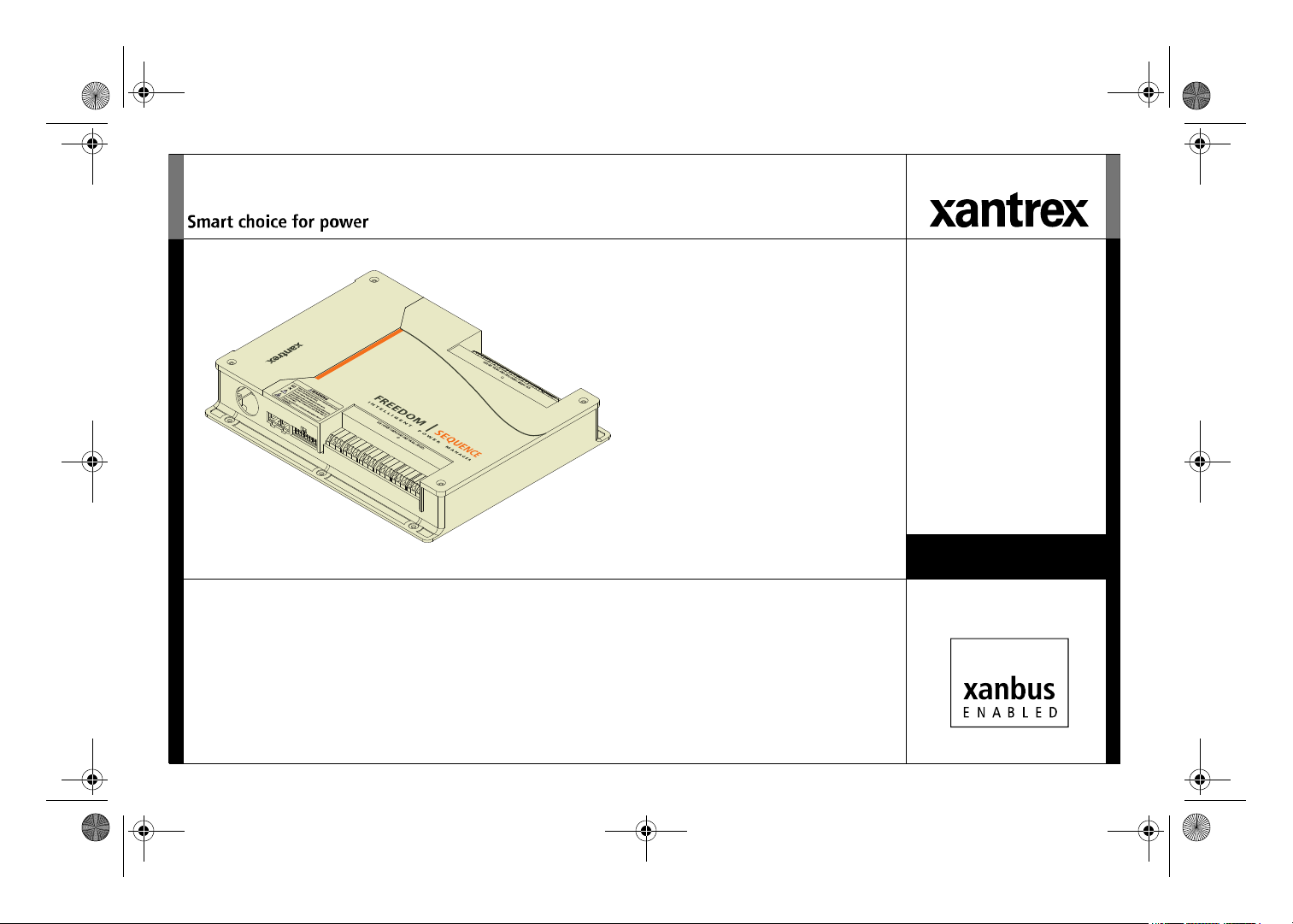

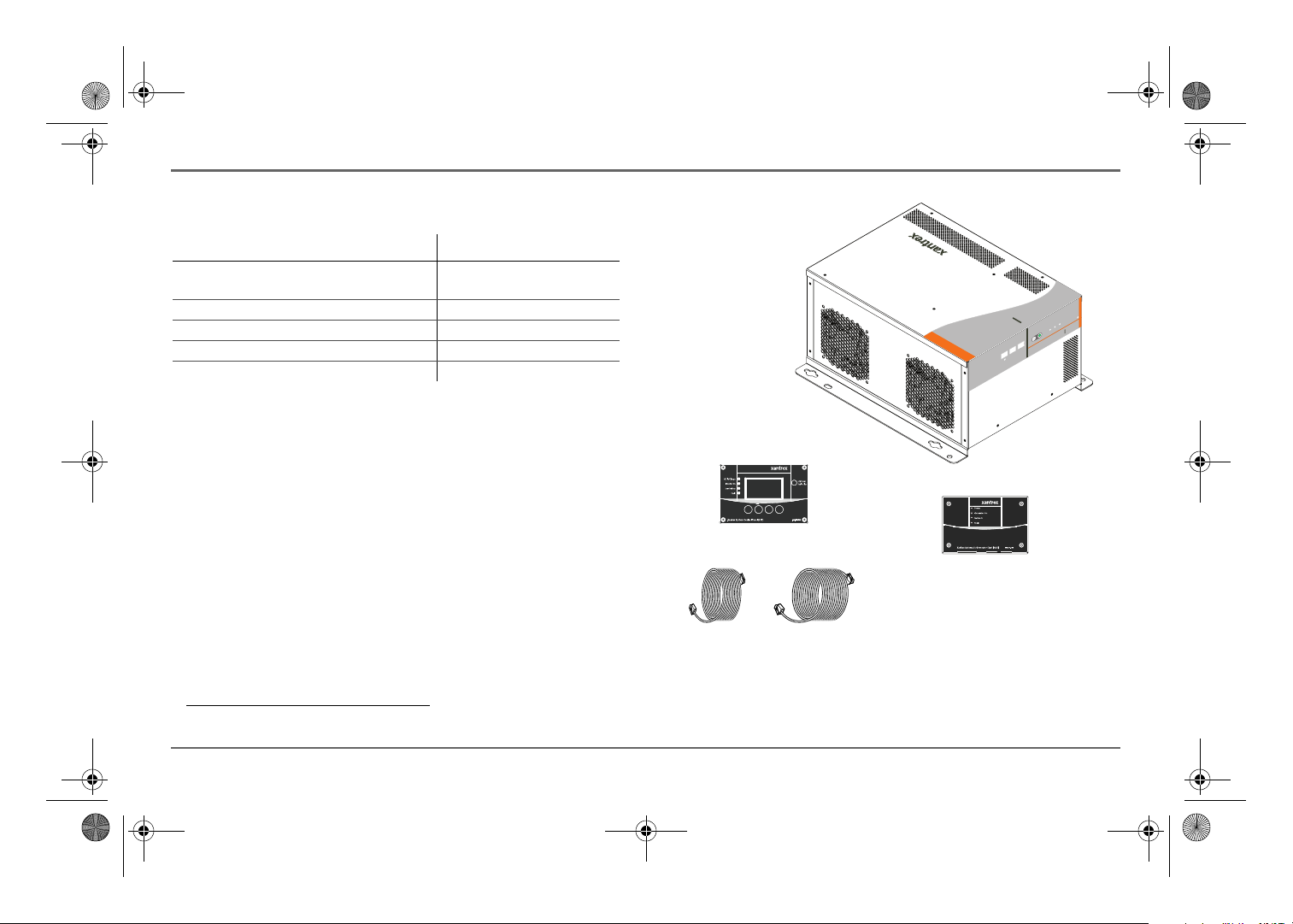

Freedom Sequence with six AC relays

PN: 809-0912 shown.

FSequence IPM Owners Guide.book Page i Thursday, October 6, 2011 3:33 PM

TM

Freedom Sequence

Owner’s Guide

809-0912

PNs:

809-0913

TM

Intelligent Power Manager

Page 2

FSequence IPM Owners Guide.book Page ii Thursday, October 6, 2011 3:33 PM

Page 3

FSequence IPM Owners Guide.book Page i Thursday, October 6, 2011 3:33 PM

Trademarks

Xantrex and Smart choice for power are trademarks of Schneider Electric Services

International sprl, registered in the United States and other countries. Other

trademarks, registered trademarks, and product names are the property of their

respective owners and are used herein for identification purposes only.

Product Numbers

809-0912 (Six AC relays)

809-0913 (Four AC relays)

Notice of Copyright

Freedom Sequence Intelligent Power Manager Owner’s Guide © August 2011

Xantrex Technology USA Inc. All rights reserved. No part of this document may be

reproduced in any form or disclosed to third parties without the express written

consent of: Xantrex Technology USA Inc., 541 Roske Drive, Suite A, Elkhart,

Indiana USA 46516. Xantrex Technology USA Inc. reserves the right to revise this

document and to periodically make changes to the content hereof without obligation

or organization of such revisions or changes unless required to do so by prior

Contact Information

Telephone: 1 800 670 0707

Fax: 1 800 994 7828

Web: www.xantrex.com

arrangement.

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY USA INC. (“XANTREX”)

A) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

(

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION;

B) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR EXPENSES,

(

WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE

OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY

AT THE USER’S RISK; AND

(C) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH,

ALTHOUGH STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF THE TRANSLATION, THE

ACCURACY CANNOT BE GUARANTEED. APPROVED XANTREX CONTENT IS CONTAINED WITH THE

ENGLISH LANGUAGE VERSION WHICH IS POSTED AT WWW.XANTREX.COM.

Date and Revision

August 2011 Rev B

To view, download, or print the latest revision, visit the website shown under Contact

Information.

Document Part Number

975-0593-01-01

975-0593-01-01 i

Page 4

Failure to follow these instructions will result in death or serious

injury.

Failure to follow these instructions can result in death or serious

injury.

Failure to follow these instructions can result in minor or moderate

injury.

FSequence IPM Owners Guide.book Page ii Thursday, October 6, 2011 3:33 PM

About This Guide

Purpose

The purpose of this Owner’s Guide is to provide explanations and

procedures for operating the Freedom Sequence Intelligent Power Manager.

Scope

The Guide provides safety and operating guidelines, as well as information

on configuring the power manager.

It does not provide details about certain components that can be attached to

the power manager. You need to consult the individual component’s

owner’s guide for this information.

Audience

The Guide is intended for users and operators of the Freedom Sequence

Intelligent Power Manager. The Installation section, if present, is intended

for qualified installers who need to install and configure any unit model of

the Freedom Sequence Intelligent Power Manager. The installer should

have knowledge and experience in installing electrical equipment,

knowledge of the applicable installation codes, and awareness of the

hazards involved in performing electrical work and how to reduce those

hazards. A qualified technician or electrician has this knowledge and

experience.

Conventions Used

The following conventions are used in this guide.

STATEMENT OF HAZARD

Contains statements of avoidance or strict compliance.

STATEMENT OF HAZARD

Contains statements of avoidance or strict compliance.

STATEMENT OF HAZARD

Contains statements of avoidance or strict compliance.

ii Freedom Sequence Intelligent Power Manager Owner’s Guide

Page 5

Failure to follow these instructions can damage the unit and/or

damage other equipment.

FSequence IPM Owners Guide.book Page iii Thursday, October 6, 2011 3:33 PM

STATEMENT OF HAZARD

Contains statements of avoidance or strict compliance.

IMPORTANT:

know, however, they are not as serious as a danger, warning, or caution.

These notes describe things which are important for you to

Related Information

You can find more information about Xantrex Technology USA Inc. as well

as its products and services at www.xantrex.com.

The product marking on the left when found imprinted on

electrical and electronic units and appliances means that you

are to refer to this guide for cautions and warnings.

975-0593-01-01 iii

Page 6

Failure to follow these instructions will result in death or serious

injury.

FSequence IPM Owners Guide.book Page iv Thursday, October 6, 2011 3:33 PM

Important Safety Instructions

IMPORTANT: READ AND SAVE THIS OWNER’S GUIDE FOR FUTURE

REFERENCE.

This chapter contains important safety instructions when operating the

Freedom Sequence Intelligent Power Manager. Each time, before using the

Freedom Sequence Intelligent Power Manager, READ ALL instructions

and cautionary markings on or provided with the power manager and all

appropriate sections of this guide.

NOTE: The Freedom Sequence Intelligent Power Manager contains no userserviceable parts. For obtaining service, see “Warranty and Return

Information” on page 41 for guidance.

NOTE: The Freedom Sequence Intelligent Power Manager must be provided

with grounding conductors connected to the AC input/output connections.

ELECTRICAL SHOCK HAZARD

• Do not expose the power manager to rain, snow, spray, or bilge water.

• Do not operate the power manager if it has received a sharp blow,

been dropped, has cracks or openings in the enclosure, or will not

close, or otherwise damaged in any other way.

• Do not disassemble the power manager.

• Disconnect both AC and DC power from the power manager before

attempting any maintenance or cleaning or working on any circuits

connected to the power manager. See note below.

• Do not operate the power manager with damaged or substandard

wiring. Make sure that all wiring is in good condition and is not

undersized. Use copper conductors only.

iv Freedom Sequence Intelligent Power Manager Owner’s Guide

NOTE: The power manager has no on/off switch. Circuits are always live

when DC and AC input are present.

Page 7

Failure to follow these instructions will result in death or serious

injury.

Failure to follow these instructions can result in death or serious

injury.

Failure to follow these instructions will result in death or serious

injury.

Failure to follow these instructions can result in death or serious

injury.

FSequence IPM Owners Guide.book Page v Thursday, October 6, 2011 3:33 PM

EXPLOSION HAZARD

Do not work in the vicinity of lead-acid batteries. Batteries generate

explosive gases during normal operation. See note below.

NOTE: Follow these instructions and those published by the battery

manufacturer and the manufacturer of any equipment you intend to use in

the vicinity of the battery. Review cautionary markings on these products

and on the engine.

Precautions When Placing the Power Manager

EXPLOSION HAZARD

Do not place the power manager in machinery space or in areas

containing gasoline tanks or fittings in which ignition-protected

equipment is required.

This equipment is intended for installation in accordance with the

National Electrical Code, NFPA 70.

PERSONAL INJURY HAZARD

This power manager is not intended for use by persons (including

children) with reduced physical, sensory, or mental capabilities or lack of

experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for

their safety. Children should be supervised to ensure that they do not play

with the power manager.

975-0593-01-01 v

ELECTRICAL SHOCK HAZARD

To reduce the risk of fire or electric shock, install in a controlled

environment relatively free of contaminants.

NOTE: A controlled environment is an environment that is relatively free of

solid airborne particulates, liquid, and/or gaseous elements. A controlled

environment may also be provided by means of a totally closed, gasketed

enclosure or the equivalent.

Page 8

Failure to follow these instructions can damage the unit and/or

damage other equipment.

FSequence IPM Owners Guide.book Page vi Thursday, October 6, 2011 3:33 PM

FCC Information to the User

RISK OF DAMAGE TO THE POWER MANAGER

• Never place the Freedom Sequence Intelligent Power Manager unit

directly above batteries; gases from a battery will corrode and

damage the power manager.

• Do not place a battery on top of the power manager.

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Unauthorized changes or modifications to the equipment could void the

user’s authority to operate the equipment.

vi Freedom Sequence Intelligent Power Manager Owner’s Guide

Page 9

FSequence IPM Owners Guide.book Page i Thursday, October 6, 2011 3:33 PM

Contents

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Mechanical Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Typical RV Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power Manager Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Circuit Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Basic Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Advanced Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Circuit Level Advanced Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Freedom Sequence Operational Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Freedom Sequence SCP Menu Map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Warranty and Return Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Page 10

FSequence IPM Owners Guide.book Page ii Thursday, October 6, 2011 3:33 PM

Page 11

FSequence IPM Owners Guide.book Page 1 Thursday, October 6, 2011 3:33 PM

Introduction

The Xantrex Freedom Sequence Intelligent Power Manager is a fully

integrated power management system (sometimes referred to as EMS or

energy management system) that provides automatic power and load

management for use in recreational vehicles (RV) while receiving power

from a generator or shore power. The Freedom Sequence power manager

optimizes the available current capacity from an AC electrical source to

power as many connected AC loads as possible. It makes decisions on

which loads get power based on a priority base set by the installer

1

.

Standard Features

• Manage power for single or split-phase AC sources up to 50 amps

including 15-, 20-, 30-, and 50-amp shore and generator power

sources.

• Fully user configurable AC and DC load management system using

the Xanbus System Control Panel (SCP).

• Monitor current draw and On/Off status for each AC load circuit,

including the current draw from the main AC source (shore or

generator power).

• Has six AC relays (PN: 809-0912) or four AC relays (PN: 809-0913)

via the AC relay terminal blocks which can control AC load circuits

rated up to 15 amps each.

• Four DC relays (via the DC auxiliary connector port) which can

control external DC circuits based on Battery Voltage.

These four DC relays can also be used to control external AC circuits

• Circuit level override from load-shed3 and priority swapping4, directly

accessible via the SCP.

• Sequential engaging of AC loads for generator soft-start that

eliminates heavy inrush demand.

• Seamless integration with Freedom SW Inverter/Chargers to provide

charger derating, automatic inverter assist, and auto-detect generator

run conditions and reset breaker rating from Shore to Generator

breaker rating.

2.External AC circuits are AC loads that are not directly controlled through the Freedom Se-

1.The installer should have knowledge and experience in installing electrical equipment, knowledge of the applicable installation codes, and awareness of the hazards involved in performing electrical work and how to reduce those hazards. A qualified technician or electrician has this

knowledge and experience.

quence’s available six (or four) AC relays.

3.Load shedding is defined as cutting power to loads that are drawing current from the system in

order to avoid an overload condition.

4.Priority swapping is defined as the automatic prioritization of loads when one load has been assigned a different priority number.

975-0593-01-01 1

2

.

Page 12

Xanbus terminator

DC auxiliary

connector wiring

harness

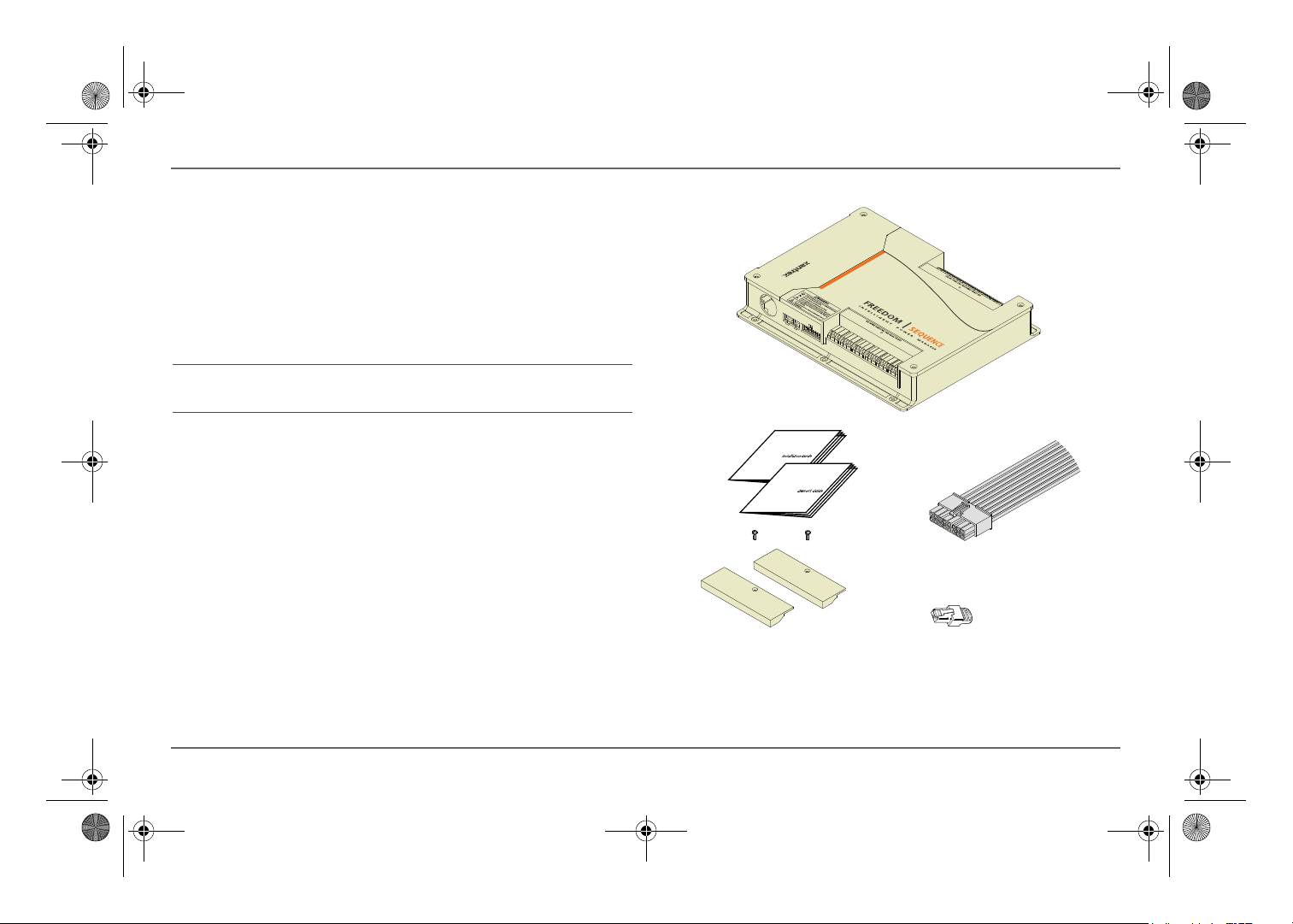

Freedom Sequence unit

AC wiring terminal

covers

Owner’s and

Installation guides

PN: 809-0912 shown

FSequence IPM Owners Guide.book Page 2 Thursday, October 6, 2011 3:33 PM

Introduction

Material List

The Freedom Sequence ships with the following items:

• one Freedom Sequence unit,

• owner’s and installation guides,

• DC auxiliary connector wiring harness,

• AC wiring terminal covers, and

• Xanbus terminator.

NOTE: Keep the carton and packing material in case you need to return

the power manager for servicing.

2 Freedom Sequence Intelligent Power Manager Owner’s Guide

Page 13

FREEDOM SW

3012

FREEDOM SW

3012

I

n

v

e

r

t

er

Reset Enable

I

n

v

e

rter A

C/

On

C

ha

r

ge Fault

Freedom

inverter/charger

SCP

AGS

25-ft cable 75-ft cable

FSequence IPM Owners Guide.book Page 3 Thursday, October 6, 2011 3:33 PM

Compatible Products and Accessories

1

Product/Accessory Product Number

Freedom SW Series Inverter/Charger

(12 and 24-volt systems)

Xanbus System Control Panel (SCP) 809-0921

Xanbus Automatic Generator Start (AGS) 809-0915

25-ft network cable for SCP 809-0940

75-ft network cable for SCP 809-0942

The Xanbus System Control Panel (SCP) enables you to monitor and

control all the power components of the Freedom Sequence power manager

from a single easy-to-use interface.

The Xanbus Automatic Generator Start (AGS) is a panel and a control

module system that provides automatic activation for your generator. If the

AGS is present in the Xanbus network, the power manager does not need

the B+ signal to be hardwired to the generator for it to receive generator-run

conditions.

Together with the Freedom SW Series Inverter/Charger, the power manager

provides advanced power optimization features of interactive charger derating and automatic inverter assist to provide additional power to support

high peak power demands.

815-2012, 815-2024 (2kW)

815-3012, 815-3024 (3kW)

Introduction

1.For an updated list, visit www.xantrex.com.

975-0593-01-01 3

Page 14

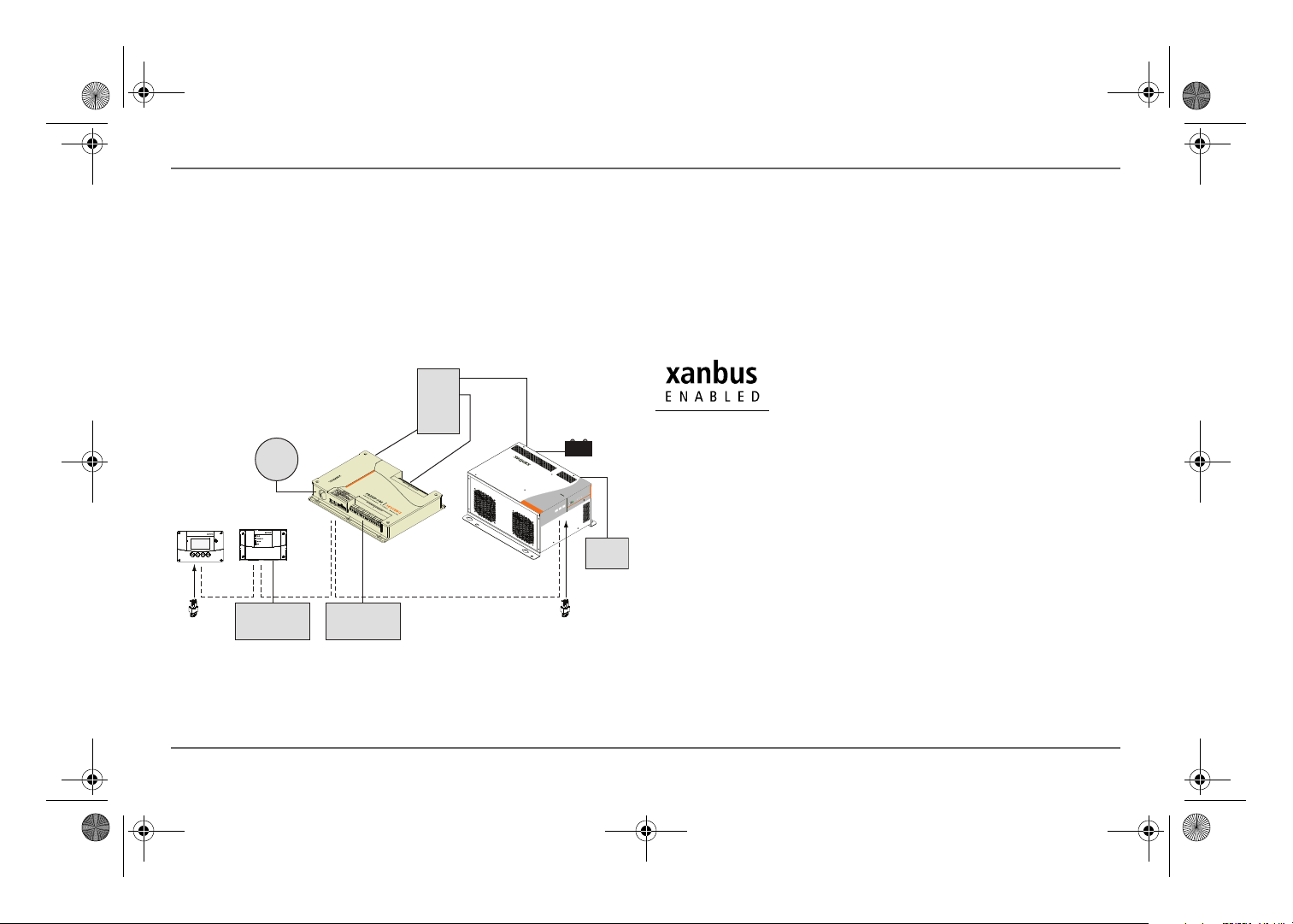

Xanbus System Control Panel

Xanbus Automatic Generator Start

System

Control

Panel

network

terminator

network

terminator

Automatic

Generator

Start

Freedom Sequence

Freedom SW Inverter/Charger

FREEDOMSW

3012

FREEDOM

SW

3012

I

n

v

e

r

ter

R

e

set Enable

I

nv

er

t

er A

C/

On

C

ha

r

ge

Fault

Generator

Shore

Power

AC Loads

AC Panel

BATTERY

Inverter

Load Panel

FSequence IPM Owners Guide.book Page 4 Thursday, October 6, 2011 3:33 PM

Introduction

Xanbus System

The Xanbus system includes the Freedom SW Series Inverter/Charger and

other Xanbus-enabled devices. The inverter/charger is the device in a

Xanbus system that typically provides network power—500 mA at 12 volts

DC. When Freedom Sequence is present in the network, it can also provide

the power for the whole Xanbus network. All of the Xanbus-enabled

devices, such as Freedom Sequence, the SCP, and the AGS are able to

communicate their settings and activity to each other. See Figure 1.

Figure 1

Typical Xanbus System Diagram

The Xanbus-enabled designation (see below) means that this product works

on a Xanbus network. Xanbus-enabled products are:

• Simple to operate and routine tasks are automated,

• Controlled by software that eliminates analog signalling errors,

• Less susceptible to interference and line loss, and

• Upgradable through new software releases.

For detailed instructions and a complete list of Xanbus-enabled devices,

visit www.xantrex.com.

4 Freedom Sequence Intelligent Power Manager Owner’s Guide

Page 15

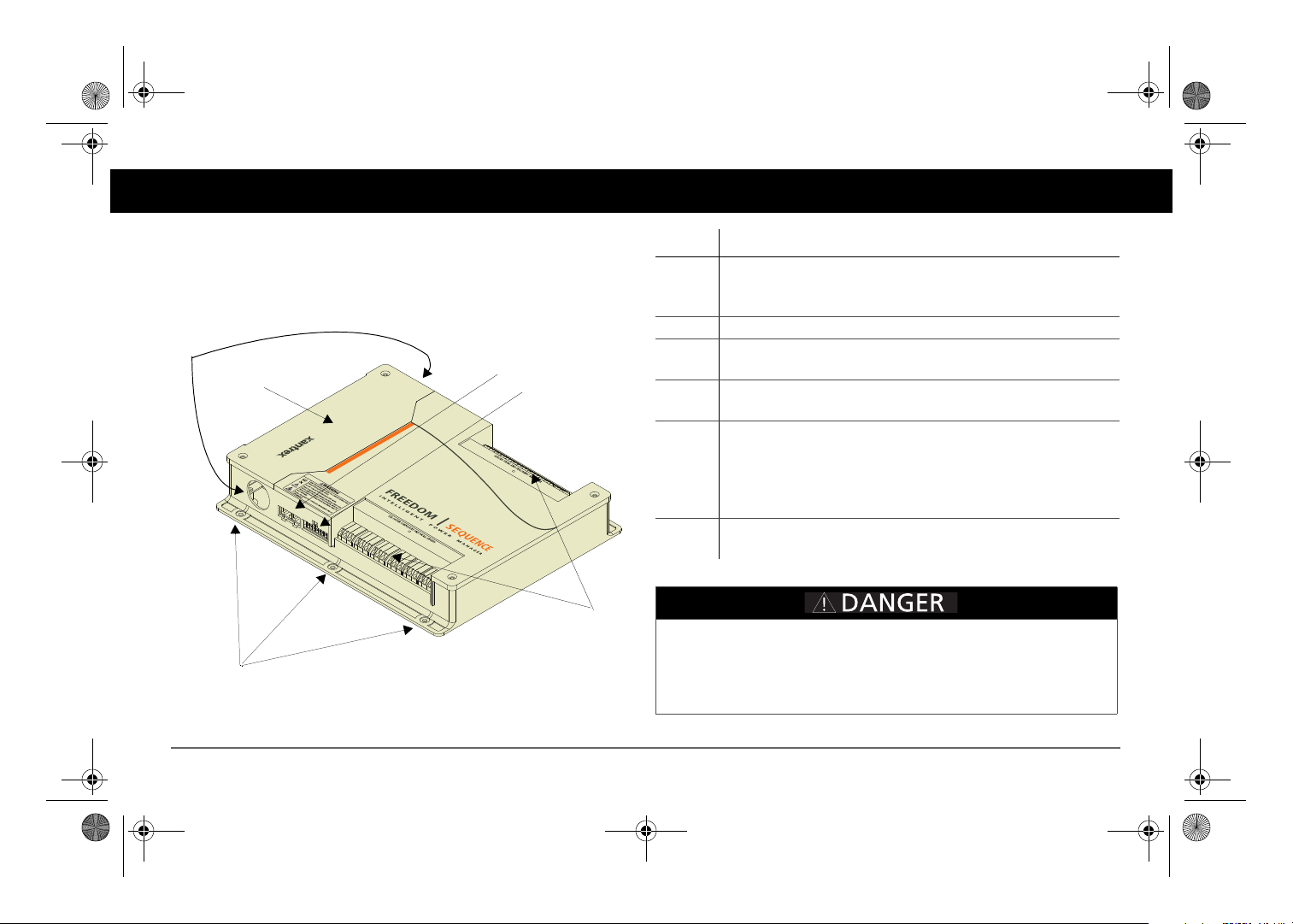

1

3

5

4

6

2

Failure to follow these instructions will result in death or serious

injury.

FSequence IPM Owners Guide.book Page 5 Thursday, October 6, 2011 3:33 PM

Mechanical Features

This section describes the different parts of the Freedom Sequence.

Item Description

Ports and Terminals

1 AC Main section contains the current and voltage sensors to

monitor the AC source and provides the pass-through wiring

from a transfer switch to the vehicle’s main distribution panel.

2 AC Main panel cover (removable for easy access)

3 Xanbus interface ports are used to connect Xanbus-enabled

devices including the SCP, AGS and Freedom SW.

4 DC auxiliary connector port contains the terminals for four

DC relays, B+ signal and DC power to the Freedom Sequence.

5 AC relay three-wire terminal blocks provide six (or four)

Cage Clamp® connectors for connecting AC load circuits. One

load circuit corresponds to one AC relay. The relays are

bidirectional meaning, there are no designated AC IN and AC

OUT terminals.

6 Mounting holes are used for mounting the Freedom Sequence

unit. There are six holes provided on the unit.

Figure 2

Freedom Sequence Ports and Terminals

ELECTRICAL SHOCK HAZARD

Disconnect all DC and AC power before opening the AC Main panel.

975-0593-01-01 5

Page 16

INVERTER

SUBPANEL

GENERATOR

30A

FREEDOMSW

3012

FREEDOM

SW

3012

I

n

v

e

r

t

er

R

e

set

Enable

I

n

ve

r

t

e

r

A

C

/

On

C

ha

r

g

e

F

a

u

lt

Inverter/Charger

TO SHORE

CONNECTION

MAIN AC

PANE L

START

HOUSE

ALTERNATOR

ISOLATOR

12V FUSE

PANE L

B+ SIGNAL

DC RELAYS

AC 6

AC 5

AC 4

AC 3

AC 2

AC 1

DC RELAY 1

DC RELAY 2

BATT

DC AUX

HARNESS

AGS

TM

SCP

TM

50A

BATTERY

DC LINE

AC LINE AC DISCONNECT

XANBUS DC DISCONNECT

50A

300A

300A

A

A

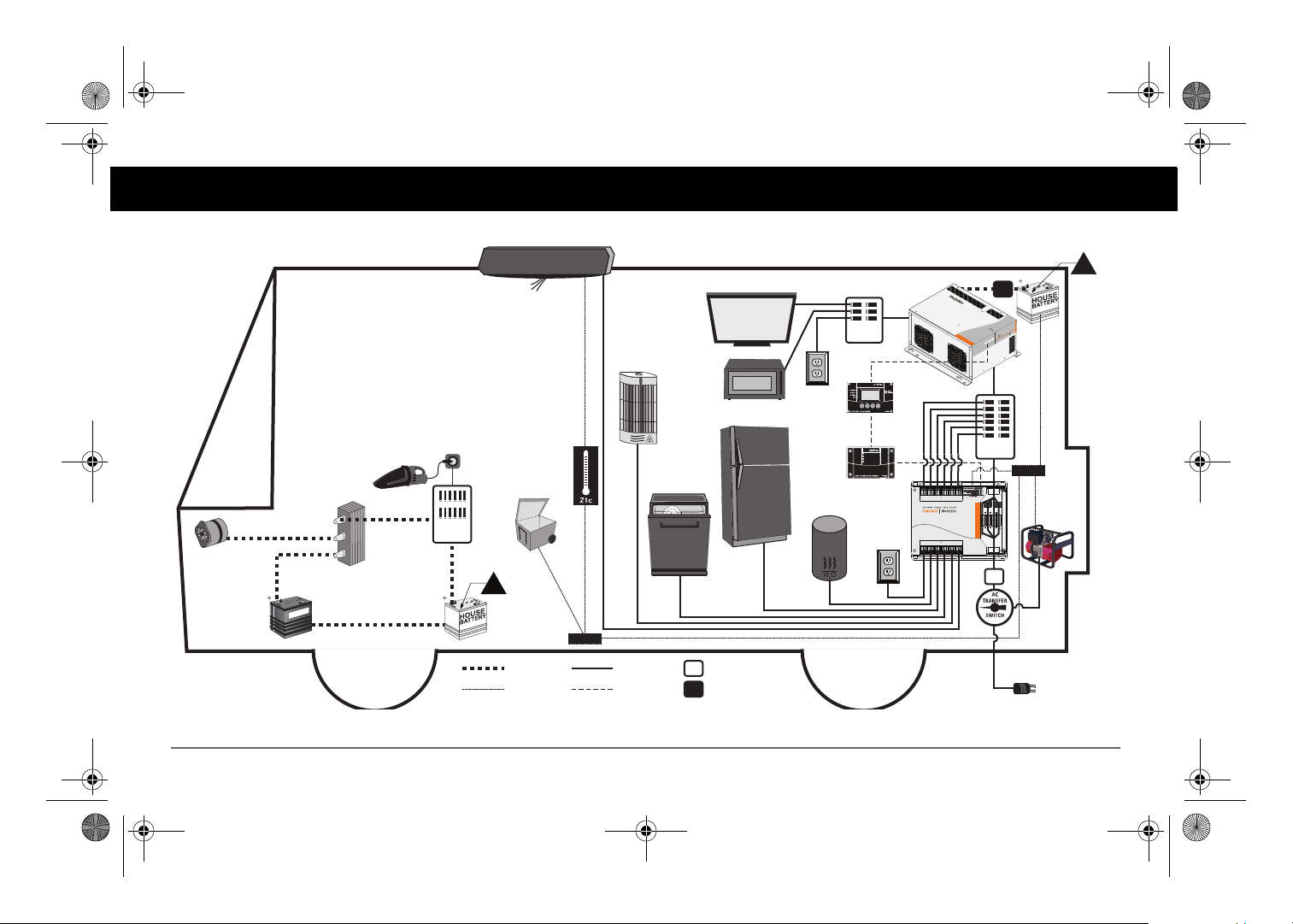

NOTE: The Freedom Sequence power manager must

be permanently installed by a qualified installer in a

controlled environment.

Figure 3 shows a simple configuration where the

power manager is installed with a power supply line

(either shore or generator), one Freedom SW inverter/

charger, a Xanbus SCP, a Xanbus AGS, and various

electrical appliances in a typical RV. Means of overcurrent protection and disconnection must be incorporated into the fixed wiring, in accordance with the

electrical code that governs each installation.

IMPORTANT: This illustration is not a detailed technical wiring schematic.

FSequence IPM Owners Guide.book Page 6 Thursday, October 6, 2011 3:33 PM

Typical RV Wiring

Figure 3

6 Freedom Sequence Intelligent Power Manager Owner’s Guide

Typical RV Wiring Diagram With Freedom Sequence

Page 17

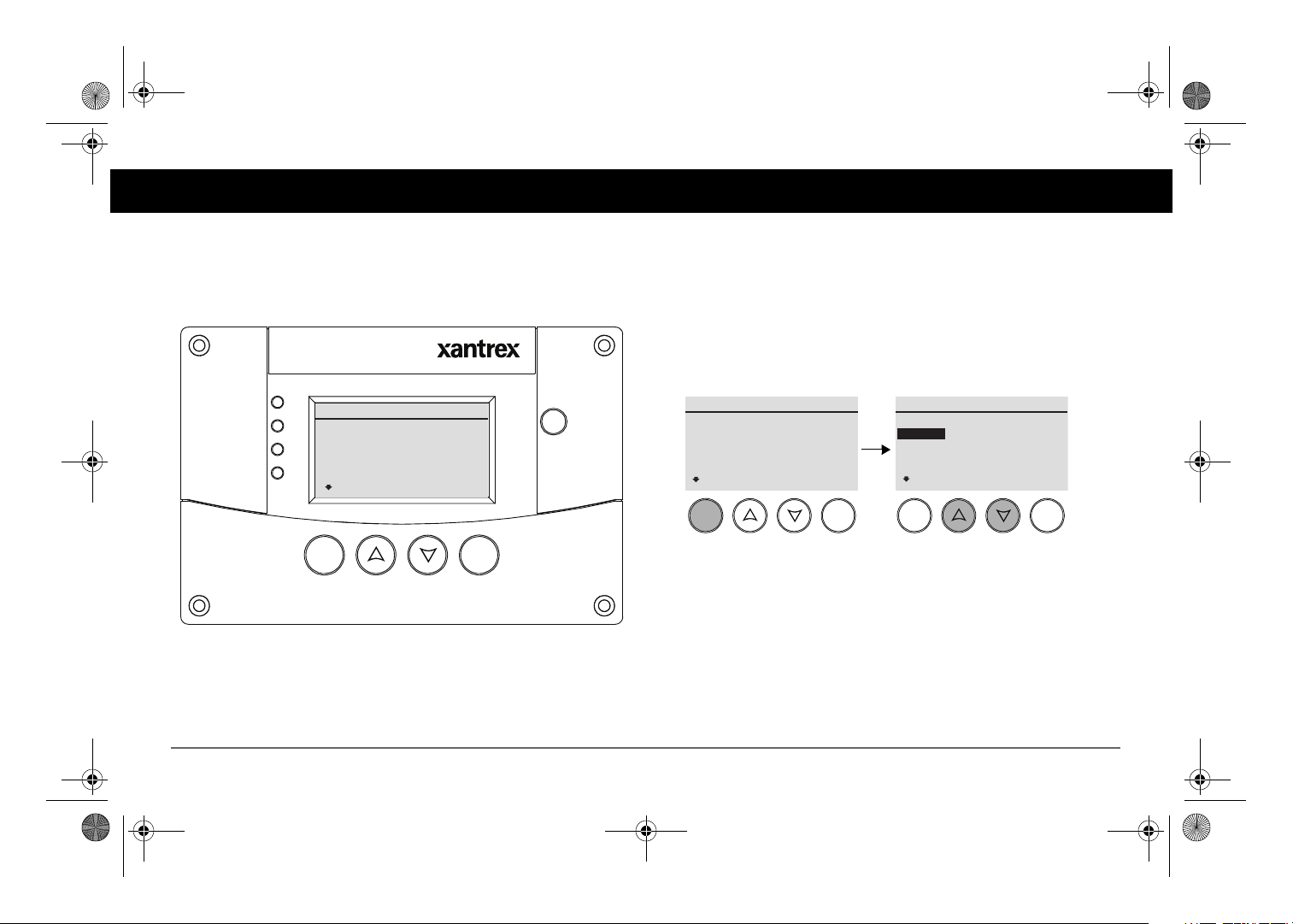

Xanbus System Control Panel (SCP)

FGA: 809-0921

AC In/Charge

Inverter On

Low Battery

Faul t

STBY/ON

Faul t Clear

TM

Enter Func

System Status

Battery

BatLev

Load

AC In

menu

System Status

Battery

BatLev

Load

AC In

menu

Enter Func Enter Func

Select Device

System Settings

FSPM 00

SCP

Clock

menu

Use the highlighted

(Enter) button to

activate the Select

Device screen.

Use the highlighted (up

and down) buttons to

choose a device.

FSequence IPM Owners Guide.book Page 7 Thursday, October 6, 2011 3:33 PM

Power Manager Configuration

The Freedom Sequence Intelligent Power Manager’s configuration settings

can only be controlled with the Xanbus System Control Panel (SCP).

Accessing the Freedom Sequence’s configuration settings start from the

SCP System Status screen shown below.

Figure 4

975-0593-01-01 7

Xanbus System Control Panel (SCP) System Status

Pressing the Enter button from the System Status screen brings up the Select

Device screen. From the Select Device screen, a user can choose a Xanbus

component device such as a power manager. In the example below, the

Freedom Sequence power manager is designated as FSPM 00.

Figure 5

Xanbus System Control Panel (SCP) Select Device

Page 18

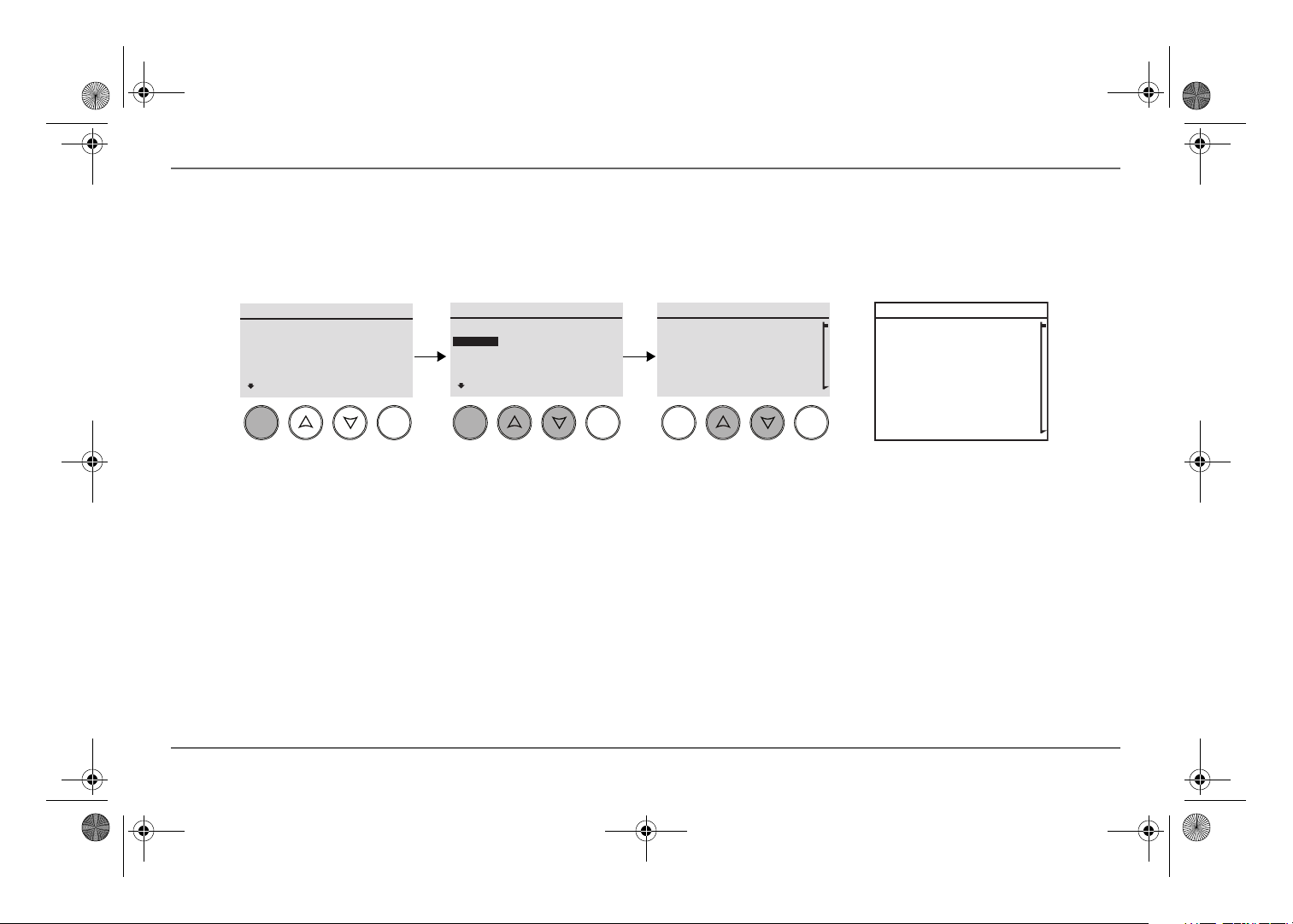

Complete list of device-specific status

information including basic

configuration and advanced settings

for the Freedom Sequence.

To view the Freedom Sequence’s

Device Status, press the Enter button

from the Select Device screen.

From this Device Status screen, use

the highlighted (up and down) buttons

to view various status information

such as the AC source type, line

current, and battery level. See the

complete list on the right.

From this Device Status screen, basic

configuration and advanced settings

can also be accessed.

The Advanced Settings are ava ilable

for installers.

FSequence IPM Owners Guide.book Page 8 Thursday, October 6, 2011 3:33 PM

Power Manager Configuration

System Status

Battery

BatLev

Load

AC In

menu

Select Device

System Settings

FSPM 00

SCP

Clock

menu

FSPM 00: Status

AC Src Type

AC Source

L1 Amps

L2 Amps

1-Ph

Auto

0.0A

0.0A

Enter Func Enter Func Enter Func

Figure 6

8 Freedom Sequence Intelligent Power Manager Owner’s Guide

Freedom Sequence Device Status Screen

FSPM 00: Status

AC Src Type

AC Source

L1 Amps

L2 Amps

Batt Voltage

Circuit Status

Config

Advanced Settings

1-Ph

Auto

0.0A

0.0A

12.0V

Page 19

FSPM 00: Circuit Status

1 ACLoad1

1 Last Shed Current

2 ACLoad2

2 Last Shed Current

On 3.0A

6.0A

On 4.5A

4.0A

Enter Func Enter Func

FSPM 00: Status

L1 Amps

L2 Amps

Batt Voltage

Circuit Status

20.0A

18.5A

12.0V

FSPM 00: Circuit Status

1 ACLoad1

1 Last Shed Current

2 ACLoad2

2 Last Shed Current

3 ACLoad3

3 Last Shed Current

4 ACLoad4

4 Last She Current

5 ACLoad5

5 Last Shed Current

Cont

On 3.0A

6.0A

On 4.5A

4.0A

On 2.5A

2.5A

On 2.3A

2.0A

On 3.7A

1.0A

FSPM 00: Circuit Status

6 ACLoad6

6 Last Shed Current

7 DCLoad1

7 Last Shed Current

8 DCLoad2

8 Last Shed Current

9 DCLoad3

9 Last She Current

10 DCLoad4

10 Last Shed Current

On 3.0A

4.0A

On N/A

N/A

On N/A

N/A

On N/A

N/A

On N/A

N/A

Enter Func

FSPM 00: Circuit Status

4 Last She Current

5 ACLoad5

5 Last Shed Current

Cont

2.0A

On 3.7A

1.0A

First five Circuit Status items.

From the device Status screen, scroll

down (1) until Circuit Status is

highlighted then, press Enter (2) to

bring up the circuit status screen.

12

3

4

Last five Circuit Status items.

NOTE: This example shows screens for a Freedom

Sequence six-circuit model PN: 809-0912.

Display each item using the Up and

Down buttons (3). The statuses of the

first five circuits are displayed.

5

To display the statuses of the next set

of circuits, scroll down (4) until Cont is

highlighted then, press Enter (5) to

bring up the second circuit status

screen.

NOTE: Use the Func button to exit out

of each screen.

FSequence IPM Owners Guide.book Page 9 Thursday, October 6, 2011 3:33 PM

Circuit Status

Figure 7

975-0593-01-01 9

Freedom Sequence Circuit Status Screen

Page 20

1

3

2

4

5

6

7

FSequence IPM Owners Guide.book Page 10 Thursday, October 6, 2011 3:33 PM

Circuit Status

In the Circuit Status screens, no item is configurable. This means that the

screens are only useful for up-to-date information on each circuit.

1 Circuit names can be up to ten characters long. Valid characters are from a

FSPM 00: Circuit Status

1 ACLoad1

1 Last Shed Current

2 ACLoad2

2 Last Shed Current

FSPM 00: Circuit Status

6 ACLoad6

6 Last Shed Current

7 DCLoad7

7 Last Shed Current

8 DCLoad8

8 Last Shed Current

9 DCLoad9

9 Last She Current

10 DCLoad10

10 Last Shed Current

On 3.0A

2.0A

On 4.5A

4.0A

On 3.0A

4.0A

On N/A

5.0A

On N/A

7.5A

On N/A

N/A

On N/A

N/A

to z, A to Z, 0 to 9, symbols '/' (forward slash) and '-'(hyphen). Spaces, an

underscore, and a period are not accepted symbols. Examples are “Main-A/

C” and “Refrigerat”.

2 Indicates whether the circuit is currently enabled (ON) or not (Off).

3 This number corresponds to the AC circuit ID label found on the product,

like AC 1 is 1, AC 2 is 2, et cetera. 7 to 10

4 Indicates the current (in amps) presently passing through the circuit. It

displays 0.0A if no AC current is passing through. It will always display

N/A for all DC relays. See #6 and #7.

a

refer to the four DC relays.

5 Last Shed Current indicates the last value of the current (in amps) for the

circuit before the circuit was shed in a load shedding event.

6 In this example, Circuits 7 and 8 are DC relays controlling AC loads. This

means that both these circuits will each display a Last Shed Current

value that is dependent on the AC load that each are controlling.

7 In this example, Circuits 9 and 10 are DC relays controlling DC loads. DC

relays that control DC loads are not monitored for amperage, thus, their

statuses are N/A and there are no Last Shed Current values.

a.5 to 8 for the Freedom Sequence four-circuit model PN: 809-0913.

10 Freedom Sequence Intelligent Power Manager Owner’s Guide

Page 21

Complete list of circuit configuration items.

To activate a specific configuration

setting, move through each item

using the Up and Down buttons (3).

When a selection is made, press the

Enter button (4) to activate the

highlighted configuration setting.

From the Device Status screen, scroll

down (1) until Config is highlighted

then, press Enter (2) to bring up the

basic Configuration screen.

12

34

NOTE: Use the Func button to exit out

of each screen.

FSequence IPM Owners Guide.book Page 11 Thursday, October 6, 2011 3:33 PM

Basic Configuration Settings

FSPM 00: Status

L2 Amps

Batt Voltage

Circuit Status

Config

Enter Func Enter Func

Figure 8

Freedom Sequence Basic Configuration Screen

On 0.0A

12.8V

FSPM 00: Config

Mode

SHR BKR Mode

SHR BKR Rating

Circuit Config

[Operating]

[Auto]

[30.0A]

FSPM 00: Config

Mode

SHR BKR Mode

SHR BKR Rating

Circuit Config

Restore Defaults

[Operating]

[Auto]

[30.0A]

List of configurable settings includes:

1. Mode – can be set to Operating or Standby.

2. SHR BKR Mode – shore breaker mode can be set to Auto or Manual.

5. Restore Defaults loads back the OEM settings for all basic

configuration and advanced settings.

3. SHR BKR Rating – shore breaker rating sets the breaker amperage.

4. Circuit Config – brings up the Circuit Config screen. See next

page.

975-0593-01-01 11

Page 22

Enter Func Enter Func

FSPM 00: Status

L2 Amps

Batt Voltage

Circuit Status

Config

On 0.0A

12.8V

FSPM 00: Config

Mode

SHR BKR Mode

SHR BKR Rating

Circuit Config

[Operating]

[Auto]

[30.0A]

Enter Func

FSPM 00: Circuit Config

1 ACLoad1

1 Priority

1 Load Shed

2 ACLoad2

[1]

[Enabled]

FSPM 00: Circuit Config

1 ACLoad1

1 Priority

1 Load Shed

2 ACLoad2

2 Priority

2 Load Shed

3 ACLoad3

3 Priority

3 Load Shed

4 ACLoad4

4 Priority

4 Load Shed

5 ACLoad5

5 Priority

5 Load Shed

Cont

[1]

[Enabled]

[2]

[Enabled]

[3]

[Enabled]

[4]

[Enabled]

[5]

[Enabled]

FSPM 00: Circuit Config

6 ACLoad6

6 Priority

6 Load Shed

7 DCLoad1

7 Priority

7 Load Shed

8 DCLoad2

8 Priority

8 Load Shed

9 DCLoad3

9 Priority

9 Load Shed

10 DCLoad4

10 Priority

10 Load Shed

[6]

[Enabled]

[7]

[Enabled]

[8]

[Enabled]

[9]

[Enabled]

[10]

[Enabled]

Enter Func

FSPM 00: Config

Mode

SHR BKR Mode

SHR BKR Rating

Circuit Config

[Operating]

[Auto]

[30.0A]

Complete list of circuit configuration items.

To activate a specific configuration

setting, move through each item

using the Up and Down buttons (3).

When a selection is made, press the

Enter button (4) to activate the

highlighted configuration setting.

To activate the circuit configuration

screen, scroll down (5) until Circuit

Config is highlighted then,

press Enter (6) to bring up the screen.

To activate a specific circuit

configuration setting, move through

each item using the Up and Down

buttons (7). When a selection is

made, press the Enter button (8) to

activate the highlighted circuit

configuration setting.

From the Device Status screen, scroll

down (1) until Config is highlighted

then, press Enter (2) to bring up the

basic Configuration screen.

12

34

56

78

To display the next set of circuit

configurations, scroll down until Cont

is highlighted then, press Enter to bring

up the second screen.

NOTE: Use the Func button to exit out

of each screen.

FSequence IPM Owners Guide.book Page 12 Thursday, October 6, 2011 3:33 PM

Basic Configuration Settings

Figure 9

List of circuit configurable settings includes:

Freedom Sequence Circuit Configuration Screen

1. Priority – a numerical circuit priority designation from 1 to 10

Each circuit will have a unique designation.

2. Load Shed – can be set to Disabled or Enabled

1.1 to 8 for the Freedom Sequence four-circuit model PN: 809-0913.

12 Freedom Sequence Intelligent Power Manager Owner’s Guide

1

.

Page 23

FSPM 00: Status

L2 Amps

Batt Voltage

Circuit Status

Config

On 0.0A

12.8V

FSPM 00: Config

Mode

SHR BKR Mode

SHR BKR Rating

Circuit Config

[Operating]

[Auto]

[30.0A]

FSPM 00: Config

Mode

SHR BKR Mode

SHR BKR Rating

Circuit Config

[Standby]

[Auto]

[30.0A]

FSPM 00: Config

Mode

SHR BKR Mode

SHR BKR Rating

Circuit Config

[*Operating]

[Auto]

[30.0A]

FSPM 00: Config

Mode

SHR BKR Mode

SHR BKR Rating

Circuit Config

[Standby]

[Auto]

[30.0A]

1 Press down until the

field is selected.

3 Press to change

the setting.

4 Press to select a

new value.

5 Press to confirm

the new value.

2 Press to select

Config.

FSequence IPM Owners Guide.book Page 13 Thursday, October 6, 2011 3:33 PM

Mode

Basic Configuration Settings

The Freedom Sequence operates in two modes: Operating or Standby.

To change the Mode from the Device Status screen:

When set to Operating mode, Freedom Sequence performs the normal

function of controlling the AC and DC loads on the system. In this mode,

all the status information of the Freedom Sequence can be accessed via the

Xanbus System Control Panel (SCP) and a limited number of configuration

settings can be changed as shown in “Freedom Sequence Basic

Configuration Screen” on page 11.

Freedom Sequence can be set to Standby mode to stop it from controlling

the AC and DC loads on the system. When this mode is selected, Freedom

Sequence allows accessibility to change all the configuration on the

Freedom Sequence, including restoring to OEM default settings

1

.

When Freedom Sequence is first powered up, it will start operation in

Operating mode.

1.OEM default settings (the “OEM Profile”) are programmed by the Original Equipment Manufacturer. The OEM profile is available and can be accessed and modified via the XDT only.

975-0593-01-01 13

Page 24

FSPM 00: Status

L2 Amps

Batt Voltage

Circuit Status

Config

On 0.0A

12.8V

FSPM 00: Config

Mode

SHR BKR Mode

SHR BKR Rating

Circuit Config

[Operating]

[Auto]

[30.0A]

FSPM 00: Config

Mode

SHR BKR Mode

SHR BKR Rating

Circuit Config

[Operating]

[Manual]

[30.0A]

FSPM 00: Config

Mode

SHR BKR Mode

SHR BKR Rating

GEN BKR Rating

[Operating]

[*Auto]

[30.0A]

FSPM 00: Config

Mode

SHR BKR Mode

SHR BKR Rating

Circuit Config

[Operating]

[Manual]

[30.0A]

1 Press down until the

field is selected.

3 Scroll down.

5 Press to select a

new value.

6 Press to confirm

the new value.

2 Press to select

Config.

4 Press to change

the setting.

FSequence IPM Owners Guide.book Page 14 Thursday, October 6, 2011 3:33 PM

Basic Configuration Settings

Shore Breaker Mode

Shore breaker setting can be set to Auto or Manual.

When set to Auto, the Freedom Sequence is capable of automatically

detecting the type of AC source (singe-phase or split-phase) and sets the

shore breaker rating (see “Breaker Ratings” on page 15). When split-phase

AC source is detected, a 50-amp breaker rating is automatically set.

Otherwise, if a single-phase AC source is detected, the breaker rating is set

to 30 amps. Because the setting is automatically determined, the shore

breaker rating cannot be modified.

When the shore breaker mode is set to Manual, the shore breaker rating can

be modified and set between 5 to 50 amps.

By default, the setting for Shore Breaker Mode is Auto.

To change the shore breaker mode from the Device Status screen:

14 Freedom Sequence Intelligent Power Manager Owner’s Guide

Page 25

FSPM 00: Status

L2 Amps

Batt Voltage

Circuit Status

Config

On 0.0A

12.8V

FSPM 00: Config

Mode

SHR BKR Mode

SHR BKR Rating

Circuit Config

[Operating]

[Manual]

[30.0A]

FSPM 00: Config

Mode

SHR BKR Mode

SHR BKR Rating

Circuit Config

[Operating]

[Manual]

[25.0A]

FSPM 00: Config

Mode

SHR BKR Mode

SHR BKR Rating

Circuit Config

[Operating]

[Manual]

[*30.0A]

FSPM 00: Config

Mode

SHR BKR Mode

SHR BKR Rating

Circuit Config

[Operating]

[Manual]

[25.0A]

1 Press down until the

field is selected.

3 Scroll down.

5 Press to select a

new value.

6 Press to confirm

the new value.

2 Press to select

Config.

4 Press to change

the setting.

FSequence IPM Owners Guide.book Page 15 Thursday, October 6, 2011 3:33 PM

Breaker Ratings

The breaker rating sets the current limit which is used by Freedom

Sequence to restrict the consumption of power within the system by all AC

load circuits. Freedom Sequence stores in its memory different settings for

the Shore Breaker and the Generator Breaker. The Freedom Sequence

applies the shore or generator breaker rating based on the source of AC

Input. See “Auto-Detection of AC Input Source (Shore/Gen)” on page 33

for more information.

Freedom Sequence can automatically detect if the AC input source passing

through it is a split-phase or single-phase. The current limits are applied on

Line1 and Line2 circuits accordingly. For example, if the AC input source is

a 30-amp split-phase AC line, Freedom Sequence will apply a current limit

of 30 amps for each circuit. Line1 will have a 30-amp limit and Line2 as

well. If it detects a single-phase AC line and the shore breaker rating is set

to 30 amps, Freedom Sequence will apply a combined 30-amp limit to

loads connected with Line1and Line2.

Shore Breaker Rating

Basic Configuration Settings

To change the shore breaker rating from the Device Status screen:

Value can only be changed when the shore breaker mode is set to Manual.

Values range from 5 to 50 amps.

975-0593-01-01 15

Page 26

FSPM 00: Status

L2 Amps

Batt Voltage

Circuit Status

Config

On 0.0A

12.8V

FSPM 00: Config

SHR BKR Mode

SHR BKR Rating

Circuit Config

Restore Defaults

[Manual]

[30.0A]

3 Press to

scroll down.

4 Press to

restore default

settings.

1 Press to

scroll down.

2 Press to select

Config.

FSequence IPM Owners Guide.book Page 16 Thursday, October 6, 2011 3:33 PM

Basic Configuration Settings

Restore Defaults

Freedom Sequence stores different profiles in its memory: Factory, OEM,

and User. Each profile can store an entirely different configuration for

Freedom Sequence and its AC/DC Relays.

By default, the OEM and User profiles have settings that are the same as the

Factory profile.

Upon start-up of Freedom Sequence, the User profile is used as the active

profile to perform the AC and DC load-shedding functions. If settings are

changed on the active profile, they automatically get copied to the User

profile. If by mistake, a wrong setting is configured, all basic and advanced

settings can be restored to their OEM settings via Restore Defaults from

the Config screen on the SCP. The OEM profile can only be accessed and

modified via the XDT tool.

To restore to OEM defaults, the Mode must be first changed to Standby.

See “Mode” on page 13.

To Restore Defaults from the Device Status screen:

16 Freedom Sequence Intelligent Power Manager Owner’s Guide

Page 27

FSPM 00: Status

L2 Amps

Batt Voltage

Circuit Status

Config

On 0.0A

12.8V

FSPM 00: Config

Mode

SHR BKR Mode

SHR BKR Rating

Circuit Config

[Operating]

[Manual]

[25.0A]

FSPM 00: Circuit Config

1 ACLoad1

1 Priority

1 Load Shed

2 ACLoad2

[1]

[Disabled]

1 Press down until the

field is selected.

3 Scroll down until

Circuit Config is

selected.

5 Scroll up and down to

view each circuit

configuration.

2 Press to activate

the screen.

4 Press to display

the circuit level

settings.

FSequence IPM Owners Guide.book Page 17 Thursday, October 6, 2011 3:33 PM

Circuit Configuration

The circuit configuration screen displays five circuits at a time (see

“Freedom Sequence Basic Configuration Screen” on page 11).

Basic Configuration Settings

Each circuit has settings that can be configured individually.

• Priority – a numerical circuit priority designation from 1 to 10

This setting will allow a circuit to be re-prioritized. 1 is highest priority

and 10 is the lowest priority.

• Load Shed – can be set to Disabled or Enabled.

This setting will allow a circuit to be subjected to load shedding or not.

1

.

IMPORTANT:

When reprogramming default circuit priority settings,

always consult a professional installer from your RV dealership.

Circuit Priority

Each AC relay of the power manager that is configured to control an AC

load circuit is assigned a priority number. The power manager uses this

priority number in a ranking order to control the load shed order or load

disconnect order in the event that an AC load demand exceeds the shore or

generator breaker capacity. See “AC Load Shedding” on page 34 for more

information. A priority of “1” is equivalent to the highest priority, therefore,

it is the last to be shed in an overload condition. Conversely, a priority of

975-0593-01-01 17

“10” is the lowest priority and the first to be shed.

1.1 to 8 for the Freedom Sequence four-circuit model PN: 809-0913.

Page 28

FSPM 00: Status

L2 Amps

Batt Voltage

Circuit Status

Config

On 0.0A

12.8V

FSPM 00: Config

Mode

SHR BKR Mode

SHR BKR Rating

Circuit Config

[Operating]

[Manual]

[25.0A]

FSPM 00: Circuit Config

1 ACLoad1

1 Priority

1 Load Shed

2 ACLoad2

[2]

[Disabled]

FSPM 00: Circuit Config

1 ACLoad1

1 Priority

1 Load Shed

2 ACLoad2

[1]

[Disabled]

FSPM 00: Circuit Config

1 ACLoad1

1 Priority

1 Load Shed

2 ACLoad2

[*1]

[Disabled]

1 Press down until the

field is selected.

3 Scroll down until Circuit

Config is selected.

5 Scroll up or down to select a

circuit priority setting.

2 Press to activate

the screen.

4 Press to display

the screen.

7 Scroll up and down to

choose a value.

6 Press to

change.

8 Press to

confirm the

selected value.

FSequence IPM Owners Guide.book Page 18 Thursday, October 6, 2011 3:33 PM

Basic Configuration Settings

AC Relays

By default, each AC load circuit is assigned a priority number in the factory

(ACLoad1 = 1 up to ACLoad6 = 61), which can be changed via SCP on the

Circuit Config screen. The priority order is then automatically swapped

as explained in “Priority Swapping Between Circuits” on page 37.

How the power manager uses the priority number to determine the loadshedding order of AC circuits is explained in “AC Load Shedding” on page

34.

DC Relays

DC Relays are not assigned a priority, but if a DC relay is associated to

either Line1 or Line2, it will assume the lowest priority ranking in the

system.

If association of a DC Relay is changed from Line1 or Line2 to Batt1, it

will lose any priority value and the power manager will re-organize the

priority numbers for the rest of the relays.

To change the priority setting from the Device Status screen:

1.For the four-circuit Freedom Sequence model, AC circuits are ACLoad1 up to ACLoad4. DC

circuits are from DCLoad1 up to DCLoad4.

18 Freedom Sequence Intelligent Power Manager Owner’s Guide

Page 29

FSPM 00: Status

L2 Amps

Batt Voltage

Circuit Status

Config

On 0.0A

12.8V

FSPM 00: Config

Mode

SHR BKR Mode

SHR BKR Rating

Circuit Config

[Operating]

[Manual]

[25.0A]

FSPM 00: Circuit Config

1 ACLoad1

1 Priority

1 Load Shed

2 ACLoad2

[2]

[Disabled]

FSPM 00: Circuit Config

1 ACLoad1

1 Priority

1 Load Shed

2 ACLoad2

[2]

[Enabled]

FSPM 00: Circuit Config

1 ACLoad1

1 Priority

1 Load Shed

2 ACLoad2

[2]

[*Enabled]

1 Press down until the

field is selected.

3 Scroll down until Circuit

Config is selected.

5 Scroll up or down to select a

load shed setting.

2 Press to activate

the screen.

4 Press to display

the screen.

7 Scroll up and down to

choose a value.

6 Press to

change.

8 Press to

confirm the

selected value.

FSequence IPM Owners Guide.book Page 19 Thursday, October 6, 2011 3:33 PM

Load Shed

Load circuits controlled by AC-only relays can be forced to remain ON and

exempt themselves from the load shedding logic of the Freedom Sequence

power manager. This exemption technique is useful when you want to keep

one or two loads running at the expense of other loads in the system that

remain subject to the load shedding logic. If the Load Shed setting is

Disabled, this can be interpreted as rendering the load circuit “invisible”

from the power system. Thus, the power manager cannot apply the load

shedding logic to this circuit but can still apply to the other loads “visible”

to the power manager. Therefore, the user should be careful to change this

setting back to Enabled since this is not done automatically.

By default, the Load Shed setting of all the AC and DC relays is set to

Enabled.

Basic Configuration Settings

To change the Load Shed from the Device Status screen:

975-0593-01-01 19

Page 30

Failure to follow these instructions can damage the unit and/or

damage other equipment.

FSequence IPM Owners Guide.book Page 20 Thursday, October 6, 2011 3:33 PM

Advanced Settings

IMPROPER CONFIGURATION DUE TO LACK OF EXPERIENCE

Always consult a certified and experienced installer from your RV

dealership when changing settings, such as the ones found in Advanced

Settings. Changes in your power manager’s settings can affect the power

management of your controlled appliances. A professional installer at

your dealership possesses the experience and training in programming

advanced settings in Freedom Sequence.

20 Freedom Sequence Intelligent Power Manager Owner’s Guide

Page 31

Enter Func

FSPM 00: Status

L2 Amps

Batt Voltage

Circuit Status

Config

0.0A

12.8V

Enter Func Enter Func

FSPM 00: Status

Batt Voltage

Circuit Status

Config

Advanced Settings

12.8V

FSPM 00: Advanced Settings

BKR Derating

GEN BKR Rating

GEN Warmup Delay

Connect Seq Delay

AC Disq Priority

Nom DC Voltage

Circuit1

Circuit2

Circuit3

Circuit4

Circuit5

Circuit6

Circuit7

Circuit8

Circuit9

Circuit10

[Enabled]

[30.0A]

[0sec]

[10sec]

[2]

[12.0V]

FSPM 00: Advanced Settings

[Enabled]

[30.0A]

[0sec]

[10sec]

BKR Derating

GEN BKR Rating

GEN Warmup Delay

Connect Seq Delay

Complete list of Advanced Settings

items.

Once the Advanced Settings item

appears from the Device Status

screen, scroll down (2) until

Advanced Settings is highlighted

then, Press Enter (3) to bring up the

Advanced Settings screen.

To activate a specific Advanced

Settings item, move through each item

using the Up and Down buttons (4).

When a selection is made, press the

Enter button to activate th e highlighted

advanced setting.

To enable the selection of Advanced

Settings, press the Enter, Up, and

Down arrow buttons (1)

simultaneously from the Device

Status screen.

1234

FSequence IPM Owners Guide.book Page 21 Thursday, October 6, 2011 3:33 PM

Advanced Settings

Figure 10

List of advanced settings include:

1. BKR Derating – sets the breaker derating to 80% or 100%.

2. GEN BKR Rating – sets the breaker rating for the generator.

3. GEN Warmup Delay – sets the generator warmup delay from 0 to 240

4. Connect Sequence Delay – sets the reconnect delay from 4 to 60

5. AC Disq Priority– sets a priority number from 1 (high) to 10 (low).

6. Nom DC Voltage – sets a DC voltage rating of 12.0 V or 24.0 V.

975-0593-01-01 21

Freedom Sequence Advanced Settings Screen

seconds.

seconds.

7. Circuit1 to Circuit10 – changes circuit level settings.

Six-circuit Freedom Sequence model (PN: 809-0912): AC circuits are

from Circuit1 to Circuit6 and the DC circuits are from Circuit7

to Circuit10.

Four-circuit Freedom Sequence model (PN: 809-0913): AC circuits

are from Circuit1 to Circuit4 and the DC circuits are from

Circuit5 to Circuit8.

Page 32

1 Press all three buttons to

enable Advanced Settings.

2 Scroll down to select

Advanced Settings.

5 Press to change

the setting.

6 Scroll up or down

to choose a value.

3 Press button.

7 Press to

confirm the

selected

value.

4 Scroll down

FSequence IPM Owners Guide.book Page 22 Thursday, October 6, 2011 3:33 PM

Advanced Settings

Breaker Derating

To change the breaker derating from the Advanced Settings screen:

According to NEC standards, the total current of all loads in a branch circuit

should be limited to 80% of its circuit breaker rating to ensure that a

combination of continuous and non-continuous loads can run without

tripping the circuit breaker. Freedom Sequence applies this conservative

standard in its load shedding logic. However, when all loads (continuous

and non-continuous) in a branch circuit including its own circuit breaker are

appropriately sized, listed, and rated to handle 100% of their rating,

derating the load capacity is not necessary and 100% capacity can be

utilized.

IMPORTANT:

Appliances and circuit breakers that are 100% rated will

have a listing on their product label similar to “Suitable For Use On SinglePhase ~AC circuits. For 100% Application.”

The option to disable breaker derating is available by changing the default

Enabled to Disabled in Advanced Settings.

For more information on how AC load shedding works, see “AC Load

Shedding” on page 34.

FSPM 00: Status

L2 Amps

Batt Voltage

Circuit Status

Config

FSPM 00: Advanced Settings

BKR Derating

GEN BKR Rating

GEN Warmup Delay

Connect Seq Delay

FSPM 00: Advanced Settings

BKR Derating

GEN BKR Rating

GEN Warmup Delay

Connect Seq Delay

0.0A

12.8V

[Enabled]

[30.0A]

[0sec]

[10sec]

[Disabled]

[30.0A]

[2sec]

[10sec]

FSPM 00: Status

Batt Voltage

Circuit Status

Config

Advanced Settings

FSPM 00: Advanced Settings

BKR Derating

GEN BKR Rating

GEN Warmup Delay

Connect Seq Delay

12.8V

[*Enabled]

[30.0A]

[*0sec]

[10sec]

22 Freedom Sequence Intelligent Power Manager Owner’s Guide

Page 33

1 Press all three buttons to

enable Advanced Settings.

2 Scroll down to select

Advanced Settings.

5 Press to change

the setting.

6 Scroll up or down

to choose a value.

3 Press button.

7 Press to

confirm the

selected

value.

4 Scroll down

FSequence IPM Owners Guide.book Page 23 Thursday, October 6, 2011 3:33 PM

Generator Breaker Rating

The generator breaker rating can be set between 5 to 50 amps. By default,

the setting is set to 30 amps.

Generator Warmup Delay

The Freedom Sequence power manager applies a generator warmup delay

timer (GEN Warmup Delay) to allow any Xanbus-controlled generator a

chance to warmup after starting. This delay is similar to warming up a car

engine before driving.

The generator warmup delay timer, which can be modified by changing the

GEN Warmup Delay setting, is set by default to zero second. The generator

warmup delay timer value can be set between 1 to 240 seconds.

NOTE: It is recommended to set the GEN Warmup Delay value to match

either the transfer switch delay timer or the generator’s warmup delay timer

specified by the manufacturer of the device. Consult the device’s user guide

under its specifications or contact the manufacturer for information on the

timer rating. Choose a delay that is highest between these two devices.

Advanced Settings

To change the generator warmup delay from the Advanced Settings

screen:

FSPM 00: Status

L2 Amps

Batt Voltage

Circuit Status

Config

FSPM 00: Advanced Settings

GEN BKR Rating

GEN Warmup Delay

Connect Seq Delay

AC Disc Priority

FSPM 00: Advanced Settings

GEN BKR Rating

GEN Warmup Delay

Connect Seq Delay

AC Disc Priority

0.0A

12.8V

[30.0A]

[0sec]

[10sec]

[30.0A]

[2sec]

[10sec]

[2]

[2]

FSPM 00: Status

Batt Voltage

Circuit Status

Config

Advanced Settings

FSPM 00: Advanced Settings

GEN BKR Rating

GEN Warmup Delay

Connect Seq Delay

AC Disc Priority

12.8V

[30.0A]

[*0sec]

[10sec]

[2]

975-0593-01-01 23

Page 34

1 Press all three buttons to

enable Advanced Settings.

2 Scroll down to select

Advanced Settings.

5 Press to change

the setting.

6 Scroll up or down

to choose a value.

3 Press button.

7 Press to

confirm the

selected

value.

4 Scroll down

FSequence IPM Owners Guide.book Page 24 Thursday, October 6, 2011 3:33 PM

Advanced Settings

Connect Sequence Delay

Reconnect-delay Timer The Freedom Sequence power manager applies

a reconnect-delay timer (Connect Seq Delay) before reconnecting an AC

circuit that was previously disconnected due to a load shedding event. In

other words, the reconnect-delay timer is applied before fully connecting to

the power source again.

The reconnect-delay timer, which can be modified by changing the

Connect Seq Delay, is set by default to ten seconds. The connect

sequence delay value applies to all AC relays and can be set between 4 to

60 seconds.

By default, the factory setting is set to 10 seconds.

Disconnect-delay Timer The disconnect-delay timer is programmed to

two seconds and cannot be modified. This means that after an overload

condition is detected, Freedom Sequence will wait for two seconds before

disconnecting the load circuit controlled through that relay.

To change the Connect Seq Delay from the Advanced Settings

screen:

FSPM 00: Status

L2 Amps

Batt Voltage

Circuit Status

Config

FSPM 00: Advanced Settings

GEN BKR Rating

GEN Warmup Delay

Connect Seq Delay

AC Disc Priority

FSPM 00: Advanced Settings

GEN BKR Rating

GEN Warmup Delay

Connect Seq Delay

AC Disc Priority

0.0A

12.8V

[30.0A]

[2sec]

[10sec]

[30.0A]

[2sec]

[5sec]

[2]

[2]

FSPM 00: Status

Batt Voltage

Circuit Status

Config

Advanced Settings

FSPM 00: Advanced Settings

GEN BKR Rating

GEN Warmup Delay

Connect Seq Delay

AC Disc Priority

12.8V

[30.0A]

[2sec]

[*10sec]

[2]

24 Freedom Sequence Intelligent Power Manager Owner’s Guide

Page 35

1 Press all three buttons to

enable Advanced Settings.

2 Scroll down to select

Advanced Settings.

5 Press to change

the setting.

6 Scroll up or down

to choose a value.

3 Press button.

7 Press to

confirm the

selected

value.

4 Scroll down

FSequence IPM Owners Guide.book Page 25 Thursday, October 6, 2011 3:33 PM

AC Disqualification Priority

Advanced Settings

The Freedom Sequence power manager is capable of detecting a compatible

inverter/charger, such as the Freedom SW 2012 or the Freedom SW 3012,

that is connected on the Xanbus network. Upon detection, it initiates

inverter/charger interactive functions. The purpose of the AC Disq

Priority is to tell the inverter/charger when a critical load circuit is

disconnected due to an overload condition. Another purpose is to request

the inverter/charger to stop drawing any current for charging or to stop

powering the connected loads through the inverter/charger’s bypass circuit

if its battery is at high battery level.

The AC Disq Priority is any number between 1 to 10. This priority

number implies that, if an AC load with a circuit Priority number that is

the same or less than the AC Disq Priority number is ever disconnected

by Freedom Sequence due to an overload condition, then an “AC disqualify

request” is sent to the inverter/charger and that request is sustained until the

same AC load circuit gets reconnected somehow. The inverter/charger can

either accept this request and disqualify its incoming AC or reject the

request and keep drawing AC current.

For more information, see “Freedom Sequence Interaction with Other

Xanbus Devices” on page 39.

By default, the factory setting is set to 2.

NOTE: This setting can only be modified when Mode is set to Standby.

To change the AC disqualification priority from the Advanced

Settings screen:

FSPM 00: Status

L2 Amps

Batt Voltage

Circuit Status

Config

FSPM 00: Advanced Settings

GEN BKR Rating

GEN Warmup Delay

Connect Seq Delay

AC Disc Priority

FSPM 00: Advanced Settings

GEN BKR Rating

GEN Warmup Delay

Connect Seq Delay

AC Disc Priority

0.0A

12.8V

[30.0A]

[2sec]

[5sec]

[30.0A]

[2sec]

[5sec]

[2]

[1]

FSPM 00: Status

Batt Voltage

Circuit Status

Config

Advanced Settings

FSPM 00: Advanced Settings

GEN BKR Rating

GEN Warmup Delay

Connect Seq Delay

AC Disc Priority

12.8V

[30.0A]

[2sec]

[5sec]

[*2]

975-0593-01-01 25

Page 36

1 Press all three buttons to

enable Advanced Settings.

2 Scroll down to select

Advanced Settings.

5 Press to change

the setting.

6 Scroll up or down

to choose a value.

3 Press button.

7 Press to

confirm the

selected

value.

4 Scroll down

FSequence IPM Owners Guide.book Page 26 Thursday, October 6, 2011 3:33 PM

Advanced Settings

DC Voltage Setting

The Freedom Sequence power manager can be used with a 12-volt or

24-volt battery system. Depending on which battery system is used, the

power manager can be set correspondingly to either 12.0V or 24.0V.

All four DC relays will have default settings for each battery trigger set/

clear values based on the selected value of the DC Voltage setting. See

“Battery Voltage Triggers” on page 32.

By default, the factory setting is set to 12.0 V.

NOTE: This setting can only be modified when Mode is set to Standby.

To change the DC voltage setting from the Advanced Settings

screen:

FSPM 00: Status

L2 Amps

Batt Voltage

Circuit Status

Config

FSPM 00: Advanced Settings

GEN Warmup Delay

Connect Seq Delay

AC Disc Priority

Nom DC Voltage

FSPM 00: Advanced Settings

GEN Warmup Delay

Connect Seq Delay

AC Disc Priority

Nom DC Voltage

0.0A

12.8V

[30.0A]

[2sec]

[5sec]

[12.0V]

[30.0A]

[2sec]

[5sec]

[24.0V]

FSPM 00: Status

Batt Voltage

Circuit Status

Config

Advanced Settings

FSPM 00: Advanced Settings

GEN Warmup Delay

Connect Seq Delay

AC Disc Priority

Nom DC Voltage

12.8V

[30.0A]

[2sec]

[5sec]

[*12.0V]

26 Freedom Sequence Intelligent Power Manager Owner’s Guide

Page 37

Complete list of circuit-level advanced

settings. Each relay will have the same

settings. However, AC relay settings

do not apply to DC relays and vice

versa.

Once the Advanced Settings item

appears from the Device Status

screen, scroll down (1) until

Advanced Settings is highlighted

then, press Enter (2) to bring up the

Advanced Settings screen.

1432

To activate a circuit-level

advanced settings item, move

through each item using the Up

and Down buttons (3).

When a circuit is selected, press the

Enter button (4) to activate the

advanced settings of that particular

circuit.

FSequence IPM Owners Guide.book Page 27 Thursday, October 6, 2011 3:33 PM

Circuit Level Advanced Settings

Figure 11

975-0593-01-01 27

FSPM 00: Status

Batt Voltage

Circuit Status

Config

Advanced Settings

12.8V

FSPM 00: Advanced Settings

GEN BKR Rating

GEN Warmup Delay

Connect Seq Delay

AC Disc Priority

[30.0A]

[0sec]

[10sec]

Enter Func Enter Func

Freedom Sequence Circuit Level Advanced Settings

[2]

FSPM 00: Advanced Settings

Connect Seq Delay

AC Disq Priority

Circuit1

Circuit2

[10sec]

Enter Func

[2]

FSPM 00: Circuit 2

Circuit Name

Load Shed

Circuit Type

AC Line

FSPM 00: Circuit 2

Circuit Name

Load Shed

Circuit Type

AC Line

Priority

Reconnect MRGN

GEN Soft Start

Batt Low Trig Set

Batt Low Trig Clr

Batt High Trig Clr

Batt High Trig Set

[ACInputOut]

[ACInputOut]

[ACLoad2]

[Enabled]

[Line1]

[ACLoad2]

[Enabled]

[Line1]

[2]

[10%]

[Disable]

[10.5V]

[11.0V]

[14.0V]

[14.5V]

Page 38

FSequence IPM Owners Guide.book Page 28 Thursday, October 6, 2011 3:33 PM

Circuit Level Advanced Settings

AC Relay Settings

The Freedom Sequence has AC relays1 that can each be used to control an

AC load up to 15 amps. Each AC relay has a unique internal identifier (for

example, Circuit1, Circuit2, etc.) Freedom Sequence allows the AC relays

to be configured with a variety of settings to best manage the AC power on

the system. The following settings can be configured for all AC relays.

• Circuit Name (page 29)

• Load Shed (page 30)

• Circuit Type (page 30)

• AC Line (page 30)

• Priority (page 31)

• Reconnect MRGN (page 32)

DC Relay Settings

The Freedom Sequence has DC relays2 which can be used to connect and

disconnect DC loads on the system based on battery voltage thresholds. The

following settings can be configured for all DC relays.

• Circuit Name (page 29)

• Load Shed (page 30)

• Circuit Type (page 30)

• Gen Soft Start (page 31)

• Batt Low Trig Set (page 32)

• Batt Low Trig Clr (page 32)

• Batt High Trig Clr (page 32)

• Batt High Trig Set (page 32)

1.Six AC relays for PN: 809-0912 and four AC relays for PN: 809-0913. 2.Four DC relays for both PNs: 809-0912 and 809-0913.

28 Freedom Sequence Intelligent Power Manager Owner’s Guide

Page 39

FSPM 00: Circuit 3

Circuit Name

Over-ride

Type

Line Association

[ACLoad3]

[Disabled]

[ACInputOut]

[Line1]

FSPM 00: Circuit 3

Circuit Name

Over-ride

Type

Line Association

[ACLoad2]

[Disabled]

[ACInputOut]

[Line1]

FSPM 00: Advanced Settings

Circuit1

Circuit2

Circuit3

Circuit4

FSPM 00: Circuit 3

Circuit Name

Over-ride

Type

Line Association

[D]

[Disabled]

[ACInputOut]

[Line1]

FSPM 00: Circuit 3

Circuit Name

Over-ride

Type

Line Association

[Dishwasher]

[Disabled]

[ACInputOut]

[Line1]

FSPM 00: Circuit 3

Circuit Name

Over-ride

Type

Line Association

[Dishwasher]

[Disabled]

[ACInputOut]

[Line1]

1

2

3

4

5

6

FSequence IPM Owners Guide.book Page 29 Thursday, October 6, 2011 3:33 PM

Circuit Level Advanced Settings

Circuit Name

All the AC and DC relays of Freedom Sequence can be assigned a

circuit name1 (a label) from the Xanbus SCP or XDT2 tool. The label for

each of these relays can be up to ten alpha-numeric characters.

The benefit of labelling the relays are for customizing and ease of use.

Relay ID Default Circuit Name Possible New Name

Circuit1 ACLoad1 Main-A/C

Circuit2 ACLoad2 Space-heat

Circuit3 ACLoad3 Dishwasher

Circuit4 ACLoad4 Refrigerat

Circuit5 ACLoad5 H2O-Heater

Circuit6 ACLoad6 WallOutlet

Circuit7 DCLoad1 Thermostat

Circuit8 DCLoad2 and so on...

Circuit9 DCLoad3

Circuit10 DCLoad4

To change the Circuit Name from the Advanced Settings screen:

1. Press the Enter button to activate the circuit setup screen for the

selected circuit.

2. Press the Enter button on the Circuit Name field.

3. Press the Func button to erase the characters one by one, except the last

character. Erasing all characters will put you back to step 2.

4. Use the arrow buttons to scroll through the character set.

5. Press the Enter button to confirm a character selection. Repeat 4 and 5

to form a new circuit name, up to ten characters.

6. Press the Enter button again on the last character to confirm the new

circuit label.

1.Circuit names can be up to ten characters long. Valid characters are from a to z, A to Z, 0 to 9,

symbols '/' (forward slash) and '-'(hyphen). Spaces, underscore and period are not accepted symbols.

2.The XDT tool is available for OEMs only.

975-0593-01-01 29

NOTE: This setting can only be modified when Desired Mode is set to

Standby.

Page 40

FSequence IPM Owners Guide.book Page 30 Thursday, October 6, 2011 3:33 PM

Circuit Level Advanced Settings

Load Shed

The Load Shed setting here is the same as the setting discussed in “Load

Shed” on page 19. The only difference here is that the change in load shed

setting happens from the circuit-level screen in Advanced Settings

instead of from the Config screen.

Circuit Type

The Freedom Sequence power manager’s circuit relays can control either

AC or DC lines. If the circuit relay controls an AC line, its type is

ACInputOut. If the circuit relay controls a DC line, its type is DCInputOut.

AC relay types cannot be modified to DCInputOut. However, a DC relay

type can be modified to ACInputOut when that DC relay is used to control

an AC appliance.

Model AC Relays Types DC Relays Types

Four-Circuit

Freedom

Sequence

Six-Circuit

Freedom

Sequence

Circuit1,

Circuit2,

Circuit3,

Circuit4

Circuit1,

Circuit2,

Circuit3,

Circuit4,

Circuit5,

Circuit6

ACInputOut

(default, cannot

be modified)

ACInputOut

(default, cannot

be modified)

Circuit5,

Circuit6,

Circuit7,

Circuit8

Circuit7,

Circuit8,

Circuit9,

Circuit10

DCInputOut

(default)

or

ACInputOut

DCInputOut

(default)

or

ACInputOut

AC Line

AC Relays All AC relays can be associated to either Line1 or Line2.

This is called Line Association. You may assign certain AC relays to

Line1 and the remaining AC relays to Line2. For example, Circuit1,

Circuit3, and Circuit5 can be assigned to Line1 and Circuit2,

Circuit4, and Circuit6 can be assigned to Line2. Default settings are

shown below.

DC Relays When the type of load circuit is changed from DC to AC, the

line association can either be Line1 or Line2. Default settings are shown

below.

NOTE: DC relays can be used to control AC loads. For example, a DC relay

can be used to signal an external AC contactor/relay to control an external

AC load circuit.

Model AC Relays Line Association

Four-Circuit

Freedom

Sequence

Six-Circuit

Freedom

Sequence

a.If the Type is changed to ACInputOut.

Circuit1,

Circuit2

Circuit3,

Circuit4

Circuit1,

Circuit2,

Circuit3

Circuit4,

Circuit5,

Circuit6

[Default]

[Line1] Circuit5,

[Line2] Circuit7,

[Line1] Circuit7,

[Line2] Circuit9,

NOTE: This setting can only be modified when Mode is set to Standby.

DC Relays DC Conn

Circuit6

Circuit8

Circuit8

Circuit10

[Default]

[Line1]

[Line1]

[Line1]

[Line1]

a

a

a

a

30 Freedom Sequence Intelligent Power Manager Owner’s Guide

Page 41

Circuit3 will get

disconnected to

avoid tripping due to

priority inversion.

Circuit2 will get

reconnected first

then Circuit3

follows, once the

generator power has

been fully ramped up

and stabilized.

FSequence IPM Owners Guide.book Page 31 Thursday, October 6, 2011 3:33 PM

Priority

The Priority setting here is the same as the priority setting discussed in

“Circuit Priority” on page 17. The only difference here is that the change in

priority setting happens from the circuit-level screen in Advanced

Settings instead of from the Config screen.

Circuit Level Advanced Settings

toggled and the power manager starts to reconnect the AC relays that have

been set to Enabled. Freedom Sequence will sequentially start to reconnect

all the load circuits in the priority order defined for AC relays.

EXCEPTION: If an AC load Circuit3 is set to a lower priority than an AC

load Circuit2 with a Generator Soft Start setting of Enabled,

Circuit3 will get disconnected to avoid a priority inversion

1

.

Generator Soft Start

The purpose of having a generator soft start (GEN Soft Start) feature is

to allow generators to be loaded gradually after the transfer switch flips

from shore power to generator or when the generator is started. Without

engaging the GEN Soft Start feature, all the load circuits controlled by

Freedom Sequence will abruptly get connected to generator power. This

may cause the generator to experience a step load which may cause its

voltage/ frequency to dip and in turn cause nuisance tripping of sensitive

loads.

Each relay of Freedom Sequence that is associated to Line1 or Line2 can be

G

AC LOAD

E

E

N

R

O

H

S

G

E

E

R

O

H

S

N

AC LOAD

GENERATOR IS OFF

PRIORITY

GEN SOFT START

Circuit1

Circuit2

Circuit3

[1]

[2]

[3]

Disabled

Enabled

Disabled

DURING GEN WARM UP DELAY

PRIORITY

GEN SOFT START

Circuit1

Circuit2

Circuit3

[1]

[2]

[3]

Disabled

Enabled

Disabled

STATUS

ON

ON