Xantrex GT100-208, GT100-480, GT100-208-NG, GT100-208-PG, GT100-480-NG Operation And Maintenance Manual

...Page 1

Xantrex™ GT100

Grid-Tied Photovoltaic

Inverter

GT100-208

GT100-480

Operation and Maintenance Manual

Page 2

Page 3

Xantrex™ GT100 Grid-Tied

Photovoltaic Inverter

Operation and Maintenance Manual

Page 4

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with products

ranging from small mobile units to utility-scale systems for wind, solar, batteries, fuel cells, microturbines, and

backup power applications in both grid-connected and stand-alone systems. Xantrex products include inverters,

battery chargers, programmable power supplies, and variable speed drives that convert, supply, control, clean, and

distribute electrical power.

Trademarks

Xantrex and Smart choice for power are trademarks of Xantrex International, registered in the United States and

other countries.

Notice of Copyright

Copyright © September 2008 Xantrex Technology Inc. No part of this document may be reproduced in any form or

disclosed to third parties without the express written consent of:

Xantrex Technology Inc.

161-G South Vasco Road

Livermore, California

USA 94551

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX™”)

(

A) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR OTHER

INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(

B) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR EXPENSES, WHETHER SPECIAL,

DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION.

T

HE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK; AND

(C) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH, ALTHOUGH STEPS HAVE BEEN

TAKEN TO MAINTAIN THE ACCURACY OF THE TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED. APPROVED

XANTREX CONTENT IS CONTAINED WITH THE ENGLISH LANGUAGE VERSION WHICH IS POSTED AT

WWW.XANTREX.COM.

Date and Revision

September 2008 Revision B

Manual Part Number

153378

Contact Information

Telephone: 1 800 670 0707 (toll free North America)

Fax: 1 800 994 7828 (toll free North America)

Email: customerservice@xantrex.com

Web: www.xantrex.com

1 408 987 6030 (direct)

Page 5

About This Manual

Purpose

The purpose of this Operation and Maintenance Manual is to provide explanations

and procedures for operating, maintaining, and troubleshooting the GT100 GridTied Photovoltaic Inverter. Installation instructions are available in the GT100

Grid-Tied Photovoltaic Inverter Planning and Installation Manual (Part

#:153379).

Scope

This Manual provides safety guidelines and information about operating and

troubleshooting the unit.

Audience

This Manual is intended for anyone who needs to operate the GT100 Grid-Tied

Photovoltaic Inverter. Operators must be familiar with all the safety regulations

pertaining to operating high-voltage equipment as dictated by local code.

Operators must also have a complete understanding of this equipment’s features

and functions. Do not to use this product unless it has been installed by a qualified

installer in accordance with the GT100 Grid-Tied Photovoltaic Inverter Planning

and Installation Manual (Part #:153379).

Organization

This Manual is organized into five chapters and two appendices.

Chapter 1, “Introduction” contains information about the features and functions of

the GT100 Grid-Tied Photovoltaic Inverter.

Chapter 2, “Operation” contains information on the basic operation of the GT100

Grid-Tied Photovoltaic Inverter.

Chapter 3, “Commissioning” contains information on safely commissioning the

GT100 Grid-Tied Photovoltaic Inverter.

Chapter 4, “Troubleshooting” contains information and procedures for

troubleshooting the GT100 Grid-Tied Photovoltaic Inverter. It provides

descriptions of common situations and errors that may occur and provides

possible solutions for resolving fault conditions. It also provides instructions for

clearing faults manually, if required.

Chapter 5, “Preventative Maintenance” contains information and procedures for

performing preventative maintenance on the GT100 Grid-Tied Photovoltaic

Inverter.

Appendix A provides the environmental and electrical specifications for the

GT100 Grid-Tied Photovoltaic Inverter.

Appendix B contains the Commissioning Test Record for the GT100 Grid-Tied

Photovoltaic Inverter.

153378 iii

Page 6

About This Manual

Conventions Used

The following conventions are used in this guide.

WARNING

Warnings identify conditions or practices that could result in personal injury or loss of life.

CAUTION

Cautions identify conditions or practices that could result in damage to the unit or

other equipment.

GT100 Models

Important:

serious as a caution or warning.

This Operation and Maintenance Manual contains information for four models of

the GT100 Grid-Tied Photovoltaic Inverter.

Two of the models are designed to operate with a 208 Vac utility input; one

configured for a negative grounded PV array (GT100-208-NG), and the other

configured for a positive grounded PV array (GT100-208-PG).

•The model GT100-208-NG Grid-Tied Photovoltaic Inverter (208 Vac input,

negative grounded) will be referred to as the GT100-208-NG when it is being

referenced individually.

•The model GT100-208-PG Grid-Tied Photovoltaic Inverter (208 Vac input,

positive grounded) will be referred to as the GT100-208-PG when it is being

referenced individually.

Additionally, two of the models are designed to operate with a 480 Vac utility

input; one configured for a negative grounded PV array (GT100-480-NG), and the

other configured for a positive grounded PV array (GT100-480-PG).

•The model GT100-480-NG Grid-Tied Photovoltaic Inverter (480 Vac input,

negative grounded) will be referred to as the GT100-480-NG when it is being

referenced individually.

•The model GT100-480-PG Grid-Tied Photovoltaic Inverter (480 Vac input,

positive grounded) will be referred to as the GT100-480-PG when it is being

referenced individually.

When all models are being referenced together, they will be referred to as

the GT100.

These notes describe things which are important for you to know, but not as

iv 153378

Page 7

Abbreviations and Acronyms

ANSI American National Standards Institute

CCU2 Converter Control Unit 2

CFM Cubic Feet per Minute

CW Clockwise

DSP Digital Signal Processor

GUI Graphical User Interface

IEEE Institute of Electrical and Electronics Engineers

IGBT Insulated Gate Bipolar Transistor

kcmil 1000 circular mils

LM Liter per Minute

NFPA National Fire Protection Association

PSL Phase-Shift Loop

About This Manual

PV Photovoltaic

UFCU Universal Frontpanel Control Unit

VFD Vacuum Fluorescent Display

Related Information

You can find more information about Xantrex Technology Inc. as well as its

products and services at www.xantrex.com.

153378 v

Page 8

vi

Page 9

Important Safety Instructions

SAVE THESE INSTRUCTIONS - DO NOT DISCARD

This manual contains important safety instructions for the GT100 Grid-Tied

Photovoltaic Inverter that must be followed during installation and maintenance

procedures.

WARNING: Shock Hazard

Read and keep this Operation and Maintenance Manual for future reference.

Before operating and maintaining the GT100, read all instructions, cautionary markings,

and all other appropriate sections of this manual. Failure to adhere to these warnings could

result in severe shock or possible death. Exercise extreme caution at all times to prevent

accidents.

WARNING: Shock Hazard

• The GT100 enclosure contains exposed high voltage conductors.

• The enclosure doors should remain closed with the latches tightened, except during

installation, maintenance or testing.

• These instructions are for use by qualified personnel who meet all local and

governmental code requirements for licensing and training for the installation of

Electrical Power Systems with AC and DC voltage to 600 volts.

• To reduce the risk of electric shock, do not perform any servicing other than that

specified in the installation instructions unless you are qualified to do so.

• Do not open the cabinet doors if extreme moisture is present (rain or heavy dew).

WARNING: Lethal Voltage

In order to remove all sources of voltage from the GT100, the incoming power must be deenergized at the source. This may be done at the main utility circuit breaker, the PV array

disconnect, and by opening the AC Disconnect and the DC Disconnect Switch on the

GT100. Review the system configuration to determine all of the possible sources of

energy. In addition, allow five minutes for the DC bus capacitors to discharge after

removing power. Follow the “Lockout and Tag (De-energize/Isolation Procedure)”

procedure on page xii to de-energize the GT100.

WARNING: Shock hazard

If a ground fault has occurred, there may be potential between TB4 and GND. The

normally grounded pole may be energized and ungrounded.

153378 vii

Page 10

Safety

Risks

WARNING: Shock Hazard

The DC bus capacitors within the GT100 can still be energized for a maximum of five

minutes after being disconnected. Open doors only after the GT100 has been disabled (S3)

and the capacitor bank discharge time has expired. Verify that the capacitors are no longer

energized (DC voltage) including terminals TB3 and TB4.

WARNING: Explosion Hazard

The IGBT module may explode in the event of a major malfunction.The GT100 enclosure

doors should remain closed with the latches tightened, except during maintenance or

testing.

WARNING: Crush Hazard

The inverters have a specific balance point that correlates to their center of gravity and can

fall over. Be very careful when moving the GT100.

WARNING: Amputation Hazard

The inverters contain integrated ventilators including rotating ventilator wheels. Do not

place fingers in ventilator.

WARNING: Burn Hazard

Inverters contain components that become hot during normal operation. Do not touch.

CAUTION

The GT100 incorporates an air supply and exhaust air area, which must remain

unobstructed. The device can overheat and be destroyed if the installation instructions are

not adhered to.

CAUTION

Sensitive electronics inside the GT100 can be destroyed when touched and when

electrostatically charged. Discharge via earth potential before touching and wear

appropriate protective gear.

CAUTION

No connections or disconnections are to be made at the terminal strips or internal

connectors during operation. Turn the unit off before performing any terminal work; wait

five minutes for the capacitors to discharge and recheck to ensure internal components are

no longer energized.

viii 153378

Page 11

General Safety Precautions

1. When installing the GT100 use only components recommended or sold by

Xantrex. Doing otherwise may result in a risk of fire, electric shock, injury to

persons, and will void the warranty.

2. Do not attempt to operate the GT100 if it has been dropped, or received more

than cosmetic damage during transport or shipping. If the GT100 is damaged,

or suspected to be damaged, see the Warranty section of this manual.

3. To reduce the risk of electrical shock, lock-out and tag the GT100 before

attempting any maintenance, service, or cleaning.

Personal Safety

Follow these instructions to ensure your safety while working with the GT100.

Qualified Personnel

Only qualified personnel should perform the transportation, installation and initial

operation and maintenance of the GT100 in accordance with National Electrical

Code ANSI/NFPA 70, as well as all state and local code requirements. Follow all

national accident prevention regulations.

Safety

Safety Equipment

Qualified personnel, within the meaning of these basic safety regulations, will be

people who are familiar with the installation, assembly, start-up and operation of

the GT100 and have the appropriate qualifications with respect to their functions.

Authorized service personnel must be equipped with standard safety equipment

including the following:

• Safety glasses

• Ear protection

• Steel-toed safety boots

• Safety hard hats

• Padlocks and tags

• Appropriate meter to verify that the circuits are de-energized

(1000 Vac and DC rated, minimum)

Check local safety regulations for other requirements.

153378 ix

Page 12

Safety

Wiring Requirements

1. All wiring methods and materials shall be in accordance with the National

Electrical Code ANSI/NFPA 70, as well as all state and local code requirements.

• Use copper conductors with an insulation rating of 90°C.

• If installed, the optional Fused Combiner (GTFC) requires the use of copper

conductors with a maximum insulation rating of 75°C.

2. The GT100 has a three-phase, four-wire output.

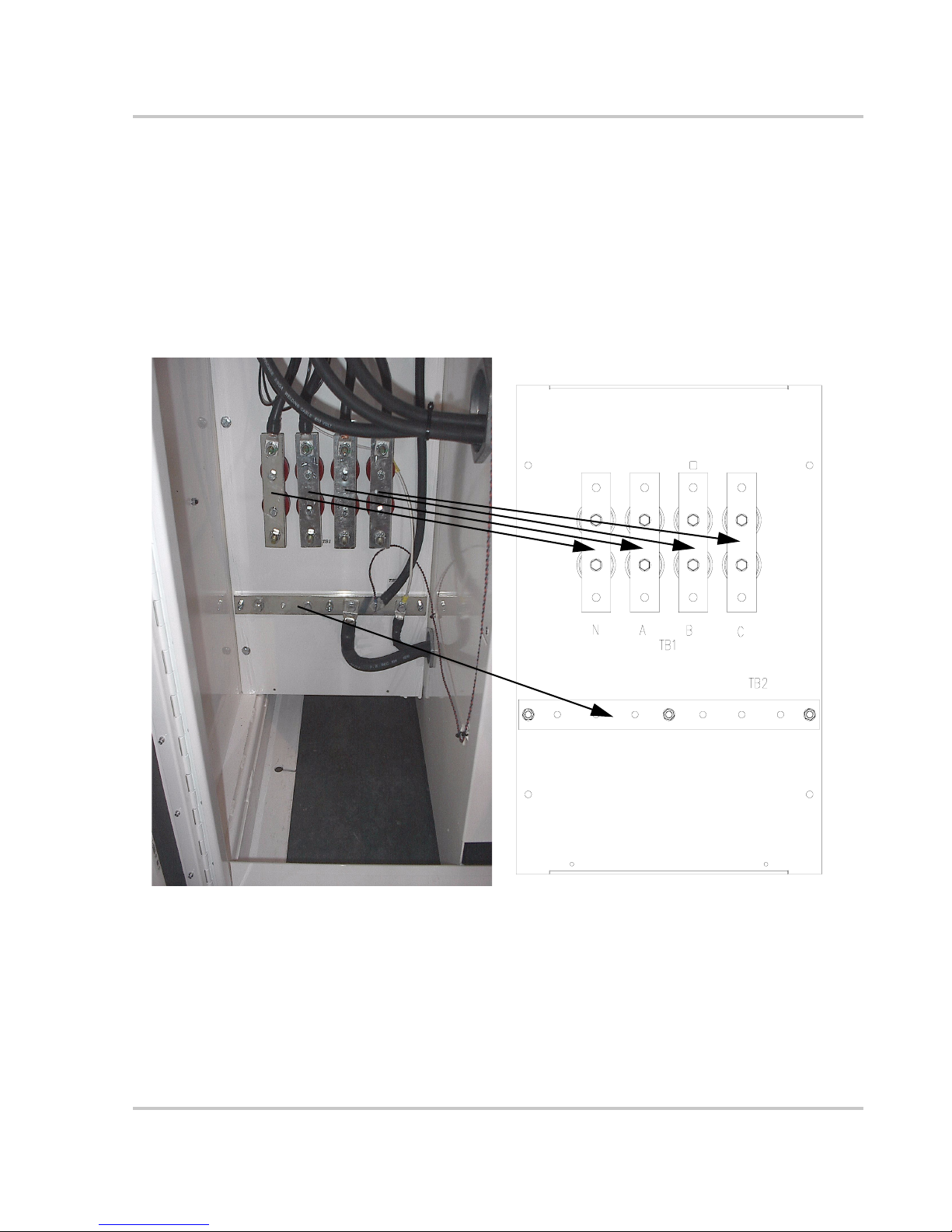

3. The GT100 is interfaced with the AC utility grid at TB1 (TB1-A, TB1-B, TB1-C

and TB1-N), located in the lower left side of the enclosure. These terminals

require the use of a UL-approved crimp-on type ring terminal or a UL-approved

compression-type lug certified for use with the chosen interface cables. Keep

these cables together as much as possible and ensure that all cables pass through

the same knockout and conduit fittings, allowing any inductive currents to

cancel. For torque values, see Table A-5 on page A–5. See Figure 1-3 on page 5

for the location of these terminals.

4. The AC neutral terminals (H0 and X0), shall be left floating (not connected) on

both the utility and inverter sides of the isolation transformer.

See page xii for details.

5. The GT100 is interfaced with the DC photovoltaic array at either the Fused

Combiner (GTFC) or TB3, as well as TB4 and TB5 (PV GND), located in the

lower right side of the enclosure. Do not connect the grounded power conductor

from the PV array directly to TB5 (PV GND); doing so will bypass the ground

fault detector and violate the NEC.

6. The TB3, TB4, and TB5 terminals require the use of a UL-approved crimp-on

type ring lug or a UL-approved compression-type lug certified for use with the

chosen interface cables. The Fused Combiner assembly includes box style

connectors for cable termination. Keep these cables together as much as possible

and ensure that all cables pass through the same knockout and conduit fittings,

allowing any inductive currents to cancel. For acceptable torque values for the

box style connectors and the TB3, TB4, and TB5 terminals, see Table A-6 and

Table A-7 on page A–5. See Figure 1-5 on page 1–8, Figure 1-6 on page 1–9,

Table 1-1 on page 1–8, and Table 1-2 on page 1–9 for the location and polarity of

these terminals.

7. This product is intended to be installed as part of a permanently grounded

electrical system as per the National Electrical Code ANSI/NFPA 70, as well as

all state and local code requirements. A copper clad earth grounding electrode

must be installed within 3 ft. (1 m) of the GT100 enclosure to ensure compliance

with FCC Part 15, Class A.. The AC ground bus bar (TB2), located in the lower

left side of the GT100 enclosure, must be used as the single point connection to

the earth grounding electrode for the inverter system.

x 153378

Page 13

8. The equipment grounds on the GT100 are marked with .

9. AC overcurrent protection for the utility interconnect (Grid-tie) must be

provided by the installers as part of the GT100 installation.

CAUTION: Fire Hazard

In accordance with the National Electrical Code, ANSI/NFPA 70, connect only to a circuit

provided with 400 amperes maximum branch circuit overcurrent protection for models

GT100-208-NG and GT100-208-PG, and only to a circuit provided with 200 amperes

maximum branch circuit overcurrent protection for models GT100-480-NG and GT100-480PG.

Inverter Isolation Transformer

The GT100 includes a custom, high-efficiency, isolation transformer. The utility

side windings of the isolation transformer are configured Wye and must match the

voltage at the utility inter-tie. The GT100 is a balanced, three-phase, currentsourcing inverter and only operates with the presence of a stable utility voltage.

The transformer is supplied with a neutral connection on both the Primary and

Secondary windings. Connection of these neutral terminals will affect the

operation of the GT100 and must be left floating or disconnected. Single-phase,

grounded loads which may be present between the transformer and utility, will

maintain their existing ground reference at the utility distribution transformer.

Safety

CAUTION: Equipment Damage

If the Isolation Transformer neutral (H0 and X0) terminals are tied to ground, they may

cause irreparable damage to the GT100. Check local regulations for their requirements

regarding the connection of these neutrals.

Operational Safety Procedures

Never work alone when servicing this equipment. A team of two is required until

the equipment is properly de-energized, locked-out and tagged, and verified deenergized with a meter.

Thoroughly inspect the equipment prior to energizing. Verify that no tools or

equipment have been inadvertently left behind.

153378 xi

Page 14

Safety

Lockout and Tag (De-energize/Isolation Procedure)

Safety requirements mandate that this equipment not be serviced while energized.

Power sources for the GT100 must be locked-out and tagged prior to servicing. A

padlock and tag should be installed on each energy source prior to servicing.

WARNING: Shock Hazard

Review the system schematic for the installation to verify that all available energy sources

are de-energized. DC bus voltage may also be present. Once all sources of input are

identified and isolated, allow five minutes for all capacitors within the main enclosure to

completely discharge before proceeding.

The GT100 can be energized from both the AC source and the DC source. To

ensure that the inverter is de-energized prior to servicing, lockout and tag the

GT100 using the following procedure.

1. Turn the GT100 main ON/OFF switch (S3) to the OFF position. This stops

the inverter from exporting power to the AC utility grid.

2. Open, lockout, and tag the incoming power at the utility main circuit breaker.

3. Open, lockout, and tag the AC Disconnect (CB1) on the left door of the

GT100. See Figure 1-8 on page 11 for the location of the AC Disconnect.

4. Open, lockout, and tag the incoming power at the PV array disconnect (if

installed.) If a PV array disconnect is not installed, see the WARNING below.

5. Open, lockout, and tag the DC Disconnect Switch (S1) on the right door of the

GT100. See Figure 1-8 on page 11 for the location of the DC

Disconnect Switch.

WARNING: Shock Hazard

Xantrex recommends the installation of PV array disconnect(s) to ensure personal safety

during GT100 maintenance. WITHOUT PV ARRAY DISCONNECT(S), ONCE THE

DC DISCONNECT SWITCH (S1) IS OPEN, THERE WILLSTILL BE DC

VOLTAGE on the DC terminals TB3, TB4 AND TB5 (PV GND). This voltage may be

as high as the open-circuit voltage of the PV Array and is limited to 600Vdc per NEC 690.

Use extreme care to avoid these terminals if no PV array disconnect is installed.

6. Using a confirmed, accurate meter, verify all power to the inverter is deenergized. A confirmed, accurate meter must be verified on a known voltage

before use. Ensure that all incoming energy sources are de-energized by

checking the following locations at all line-to-line and all line-to-ground

configurations.

• AC Utility Terminals: [TB1-A, TB1-B, TB1-C, TB1-N, and

TB2(GND BUS)]

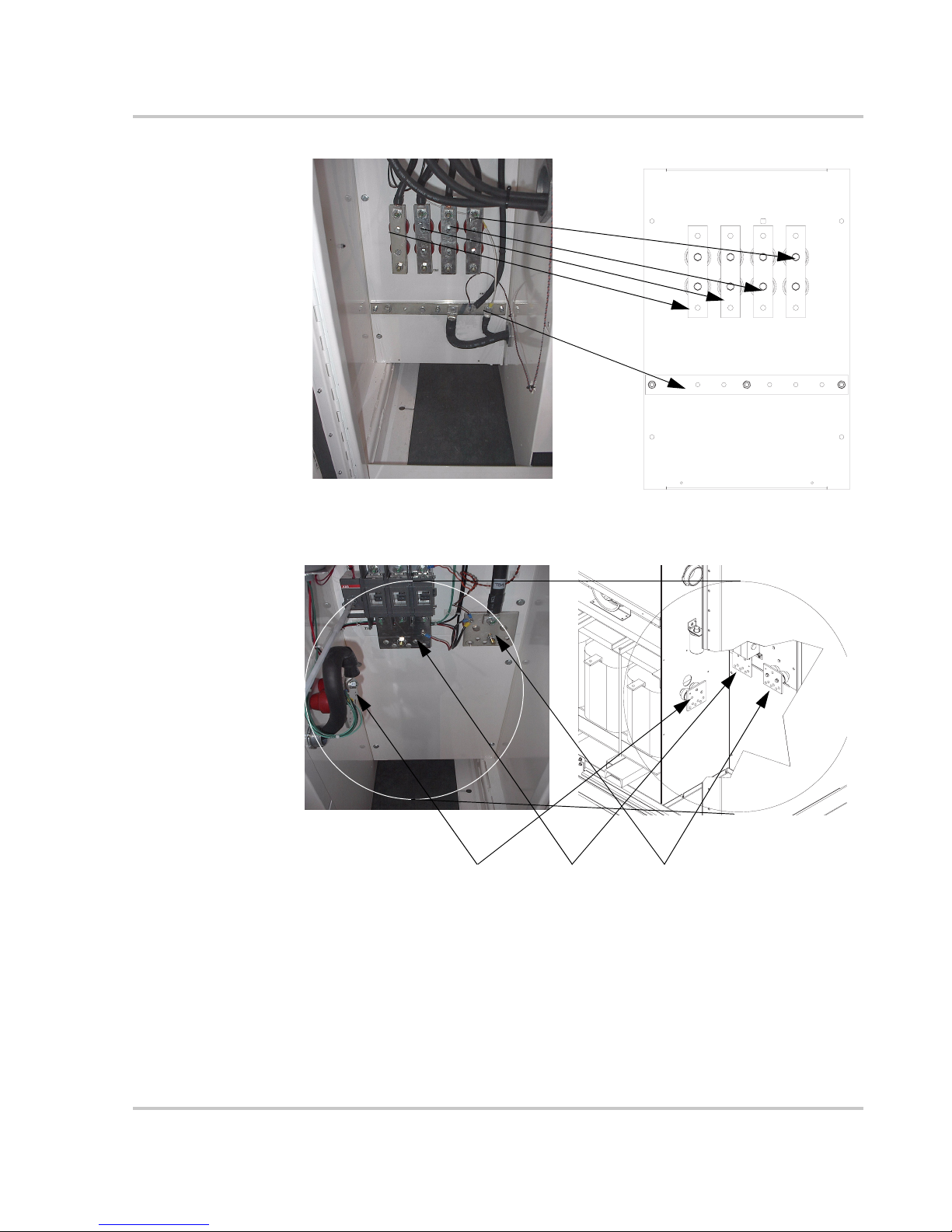

See Figure i on page xiii for the location of these terminals.

• PV Terminals: [TB3, TB4, and TB5 (PV GND)]

See Figure ii on page xiii for the location of these terminals.

xii 153378

Page 15

Safety

N

A

B

TB1

C

TB2

Figure i

Figure ii

AC Utility Terminals

TB5

(PV GND)

DC Terminals

TB3 TB4

153378 xiii

Page 16

Safety

Interconnection Standards Compliance

The GT100 complies with FCC Part 15 Class A requirements.

The GT100 is designed to meet NEC Article 690 and UL1741-2005 Static

Inverters And Charge Controllers For Use In Photovoltaic Power Systems, which

includes testing for IEEE 1547.1-2005, IEEE 929-2000 and IEEE 519-2000.

Intended Use

The GT100 may only be used in connection with PV modules. It is not suitable for

any other application areas.

xiv 153378

Page 17

Contents

Important Safety Instructions

1

Introduction

Description of the GT100 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Power Conversion System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Advanced Design Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Physical Characteristics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

AC Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

AC Utility Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

Auxiliary Control Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

Communications Circuit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

Power Electronics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

Converter Control Unit (CCU2) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

Power Electronics Matrix - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

DC Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–8

DC Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–8

Fused Combiner (Optional) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Circuit Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–10

Operator Interface Controls - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–11

On/Off Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–12

Emergency Stop (E-STOP) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–12

Auxiliary Enable/Disable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–12

AC Disconnect and DC Disconnect Switches - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–13

Operation Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–14

Fixed Unity Power Factor Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–14

Peak Power Tracking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–14

Utility Voltage/Frequency Fault Automatic Reset - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–15

Safety Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–16

Anti-Island Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–16

PV Ground Fault Detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–16

DC Over-voltage Detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–16

Communication Features and Methods - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–17

System Status and Fault Reporting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–17

Data Logging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–19

Oscillography - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–20

Optional Equipment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–21

Communication Modems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–21

PV Combiner - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–21

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -vii

153378 xv

Page 18

2

Operation

Description of System Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Faults - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Operating States - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Shutdown - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Transition - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Power Tracking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Automatic Sleep Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Manual Current - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Matrix Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–5

Fault - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–5

Operator Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–7

UFCU Keypad Operation and VFD Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–7

VFD Display - Initialization Screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

Standard Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–9

Menu Structure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–9

Read Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

WRITE Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–16

Commanding Goal State Changes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–22

Setting the Date and Time - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–23

Manual State Transitions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–24

Automatic State Transitions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–24

Auto-restart Feature - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–25

Energize Procedure (Startup) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–26

Lockout and Tag - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–26

Computer Communications with the GT100 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–28

Contents

3

Commissioning

Commissioning Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Starting the Commissioning Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Serial Number - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Inverter Enclosure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Verify AC Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Verify DC Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Apply Grid Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Front Panel Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Confirm AC Operational Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Confirm DC Operational Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Confirm Power Tracker Configuration Operational Parameters - - - - - - - - - - - - - - - - - - - - - 3–5

Apply DC Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Matrix Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Operate Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Completed Commissioning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

153378 xvi

Page 19

4

Troubleshooting

Faults and Fault Codes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

General Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Clearing Faults Manually - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Fault Code Descriptions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–5

5

Preventative Maintenance

Maintenance Safety - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–2

Operational Safety Procedures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–2

Lockout and Tag (De-energize/Isolation Procedure) - - - - - - - - - - - - - - - - - - - - - - - - - - 5–2

Maintenance Intervals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–5

Periodic Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–5

Monthly Intervals or As Required - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–5

Six Month Intervals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–5

A

Specifications

System Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–2

Environmental Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–2

Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–3

Regulatory Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–3

Over Voltage, Under Voltage and Frequency Ranges - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–4

Bolt Sizing and Torque Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–5

Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–6

Contents

B

Commissioning Test Record

Commissioning Test Record - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–3

Warranty and Return Information

Index

153378 xvii

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–1

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - WA–1

Page 20

xviii

Page 21

Figures

Figure 1-1 Main Inverter (Open Enclosure View) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Figure 1-2 GT100 Major Sections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Figure 1-3 AC Utility Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

Figure 1-4 Auxiliary Control Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

Figure 1-5 DC Terminals- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–8

Figure 1-6 GT Fused Combiner Connectors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Figure 1-7 GT100 Circuit Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–10

Figure 1-8 GT100 Operator Interface Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–11

Figure 1-9 On/Off Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–12

Figure 1-10 AC and DC Disconnect Switches- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–13

Figure 1-11 Maximum Peak Power Tracking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–15

Figure 1-12 VFD Display and UFCU Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–18

Figure 2-1 State Transition Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Figure 2-2 Operating States Flow Chart for Power Tracking - - - - - - - - - - - - - - - - - - - - - - - - - - 2–6

Figure 2-3 The Universal Front Panel Control Unit (UFCU) and VFD - - - - - - - - - - - - - - - - - - - 2–7

Figure 2-4 Initialization Screens - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

Figure 2-5 Operator Interface Menu Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Figure 2-6 Scrolling through the Read Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12

Figure 2-7 Read-by-ID Feature- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–15

Figure 2-8 State Transition Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–22

Figure 2-9 VFD showing Fault Code - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–25

Figure 2-10 AC Utility Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–27

Figure 2-11 DC Terminals- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–28

Figure 4-1 VFD showing Fault Code - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Figure 5-1 AC Terminal Connections from the Utility - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

Figure 5-2 DC Terminal Locations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–4

Figure 5-3 DC Terminal Locations (with GTFC installed) - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–4

Figure A-1 GT100 Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–6

153378 xix

Page 22

xx

Page 23

Tables

Table 1-1 DC Terminal Polarity - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–8

Table 1-2 DC Terminal Polarity (with GTFC) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Table 2-1 Scrolling through the Read Menu Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Table 2-2 Read Menu Descriptions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Table 2-3 Write Menu Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–17

Table 4-1 Fault Codes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–5

Table A-1 Environmental Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–2

Table A-2 Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–3

Table A-3 Regulatory Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–3

Table A-4 Over/Under Voltage and Over/Under Frequency Ranges - - - - - - - - - - - - - - - - - - - - - A–4

Table A-5 AC Terminal Bolt Size and Torque Values - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–5

Table A-6 DC Terminal Bolt Size and Torque Values - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–5

Table A-7 DC Terminal Conductor Range and Torque Values - - - - - - - - - - - - - - - - - - - - - - - - A–5

Table A-8 Auxiliary Control Interface Screw Size and Torque Values - - - - - - - - - - - - - - - - - - - A–6

153378 xxi

Page 24

xxii

Page 25

1

Introduction

Chapter 1, “Introduction” contains information about the features and

functions of the GT100 Grid-Tied Photovoltaic Inverter.

Page 26

Introduction

Description of the GT100

The GT100 Grid-Tied Photovoltaic Inverter is a utility interactive, three-phase

power conversion system for grid-connected photovoltaic arrays with a power

rating of 100 kW. Designed to be easy to install and operate, the GT100 automates

start-up, shutdown, and fault detection scenarios. With user-definable power

tracking that matches the inverter to the array and adjustable delay periods, users

are able to customize startup and shutdown sequences. Multiple GT100 inverters

are easily paralleled for larger power installations.

Power Conversion System

The GT100 power conversion system consists of a pulse-width modulated (PWM)

inverter, switch gear for isolation and protection of the connected AC and DC

power sources. Housed in a rugged NEMA-3R rated, corrosive resistant, powdercoated steel enclosure, the GT100 incorporates sophisticated Insulated Gate

Bipolar Transistors (IGBTs) as the main power switching devices. An advanced,

field-proven, Maximum Peak Power Tracker (MPPT) integrated within the

GT100 control firmware ensures the optimum power throughput for harvesting

energy from the photovoltaic array.

Advanced Design Features

The advanced design of the GT100 includes an EMI output filter and the main AC

contactor located electrically on the utility side of the isolation transformer to

minimize transformer tare losses when the unit is not operating.

The GT100 also includes an Inrush Limit assembly to prevent nuisance Utility

Circuit Breaker trips when the isolation transformer is energized.

A sophisticated control scheme optimizes the operation of the GT100 cooling fan

as needed for increased overall system efficiency.

Additionally, the GT100 integrated controller contains self-protection features

including over and under voltage and frequency safeguards in compliance with

UL 1741 Rev 2005.

Anti-islanding An integral anti-island protection scheme prevents the inverter from feeding

power to the grid in the event of a utility outage.

Auto-Phase

Rotation

The GT100 includes the ability to auto-sense and correct for a “mis-phased”

connection at the AC Interface terminals. In the event the power conductors from

the utility are not phased correctly at the AC Interface terminals, the GT100 will

sense the discrepancy and automatically correct for a clockwise (A-B-C)

phase rotation.

1–2 153378

Page 27

Physical Characteristics

Local Display and

Remote Graphic

User Interface

The GT100 includes a local user interface comprised of an ON/OFF switch,

keypad, and 4-line, 80 character VFD display.

A user-friendly, Xantrex GT View Graphic User Interface (GUI) provides a

remote interface for operator interrogation of GT100 system status, control,

metering/data logging and protective functions within the GT100. The status,

control, and logging features are supported by an optional modem via an RS232

connection for remote monitoring. Alternatively, a user selectable RS485/Modbus

connection is also available for remote plant monitoring.

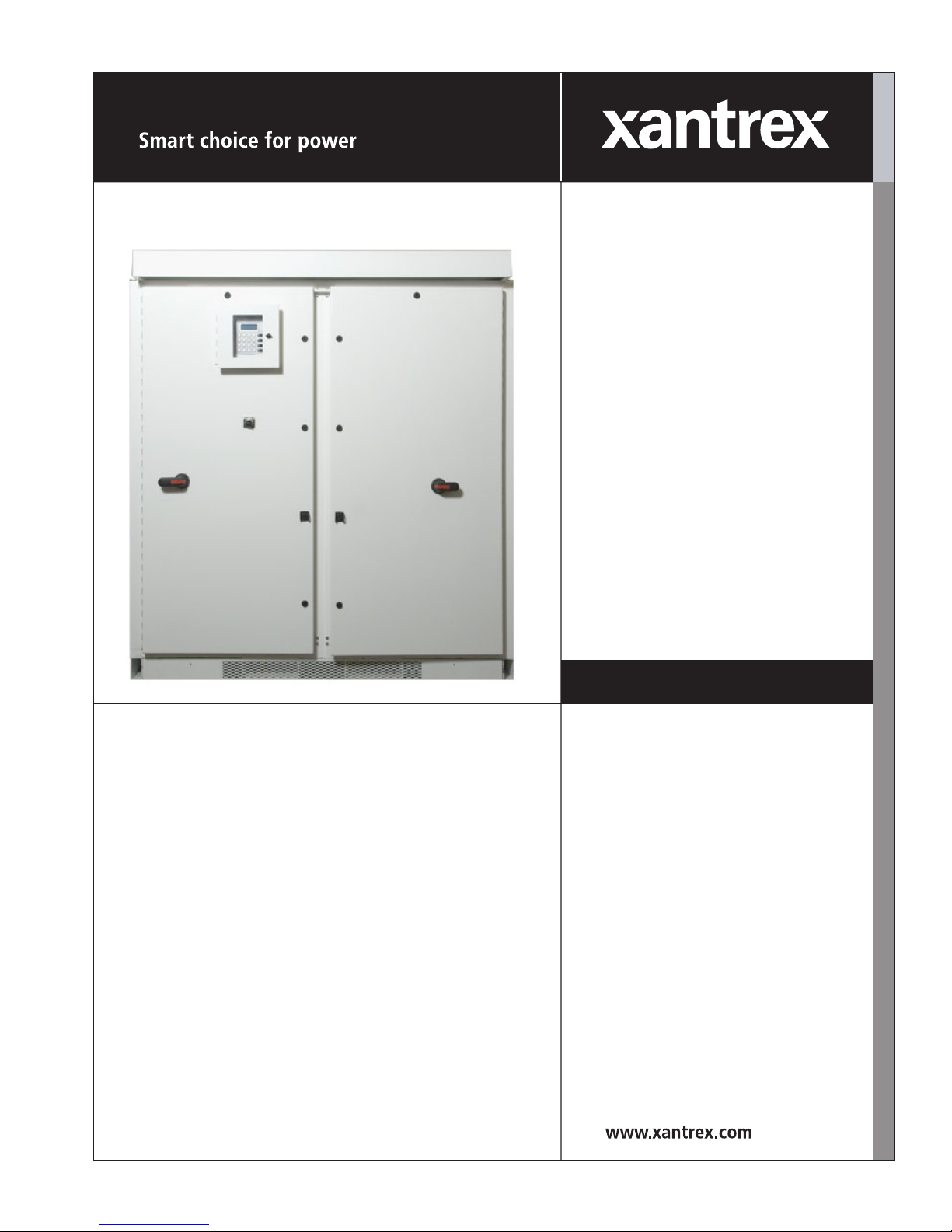

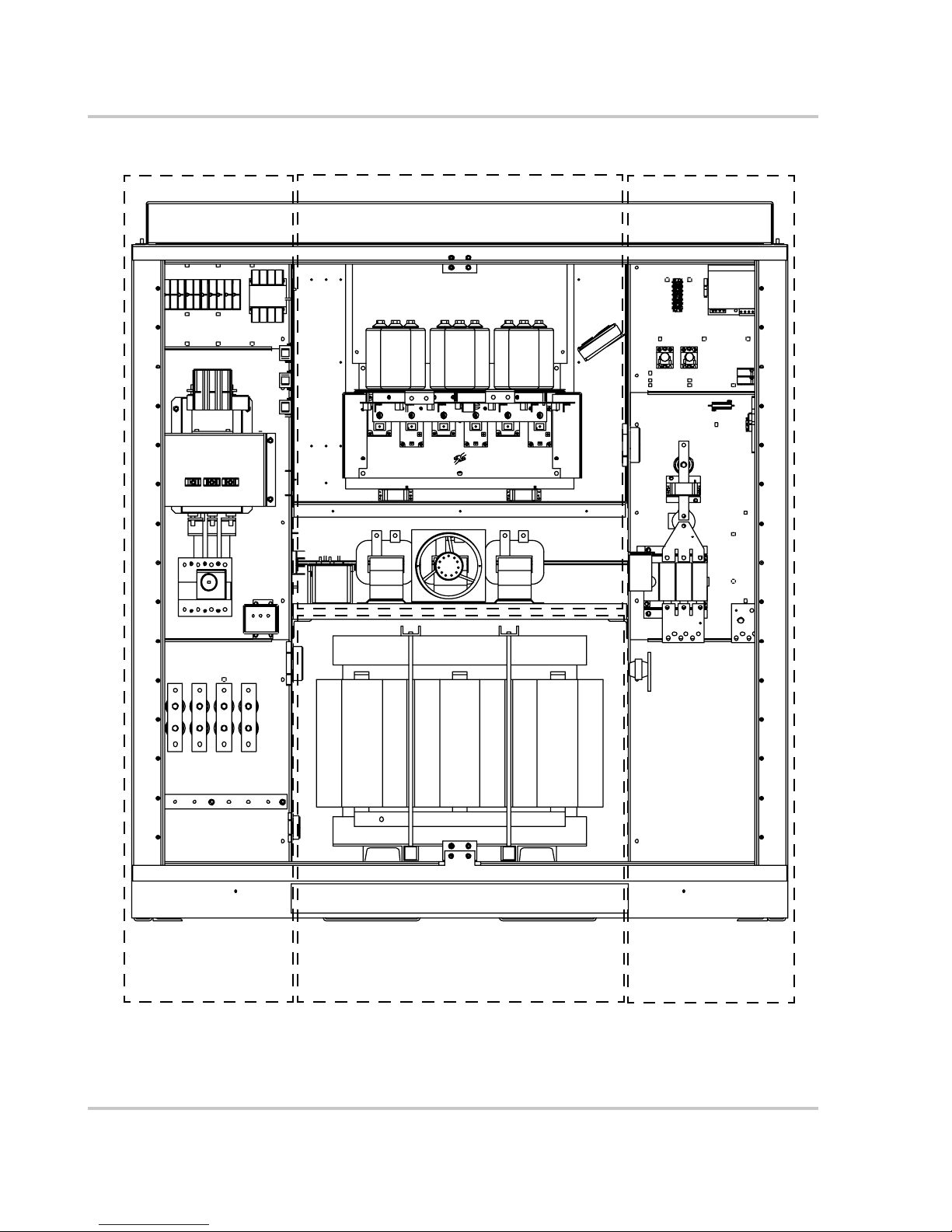

Physical Characteristics

The GT100 is assembled in a single NEMA-3R, corrosive resistant, powdercoated enclosure that includes two access doors to house the electronics described

above. Internally, the GT100 is compartmentalized to include sections for the AC

Interface (left side), the Power Electronics (upper middle), the Isolation

Transformer (lower middle), and the DC Interface (right side). The single

enclosure is constructed and delivered as one complete assembly.

These sections are identified in Figure 1-2 on page 1–4.

Figure 1-1

153378 1–3

Main Inverter (Open Enclosure View)

Page 28

Introduction

Power Electronics section

AC Interface

section

Figure 1-2

GT100 Major Sections

1–4 153378

Isolation Transformer section DC Interface

section

Page 29

AC Interface

AC Utility Terminals

Physical Characteristics

The AC Interface serves as the connection for the utility (see Figure 1-2 to locate

the AC Interface). This compartment (section) houses the AC Terminals (TB1-N,

-A, -B, and -C), AC Disconnect, AC Contactor, and EMI Filter. Additionally, the

Inrush PCB assembly, control power transformer, control fuses, and AC sensing

circuitry are also housed in this section.

Figure 1-3

AC Utility Terminals

Each terminal provides one hole with space for two cables with a M10 bore

diameter (see Table A-5 on page A–5 for torque requirements).

153378 1–5

Page 30

Introduction

Auxiliary Control Interface

The GT100 has provisions within the AC Interface for installing auxiliary control

signals that include a remote Emergency Stop and a remote Enable/Disable signal.

Auxiliary Control via the remote Enable/Disable signal is advantageous for

coordination of the GT100 at specific installations where a pre-existing back-up

emergency generator is present.

Two separate dry contact circuits at the TB7 terminal are used for control of these

input signals. Circuit termination and signal type are identified in Figure A-8 on

page A–6.

Figure 1-4

Auxiliary Control Terminals

Communications Circuit

The GT100 can be remotely accessed through an RS232 serial port or through an

RS485/Modbus connection. Xantrex offers modems that can be connected to the

RS232 port for remote monitoring. The remote user has the ability to control and

monitor the status of the inverter through this connection.

Alternatively, a user selectable RS485/Modbus connection is also available for

remote plant monitoring. The CCU2 Controller board within the GT100 may be

configured for RS485 serial communication using the Modbus protocol. This

enables users to monitor and control the inverter from a dedicated plant wide

monitoring system.

1–6 153378

Page 31

Power Electronics

The GT100 Power Electronics section contains the converter control unit (CCU2)

and the power electronics matrix. Also found within the Power Electronics section

are the Hall-effect current transducers, and an internal air circulation fan.

Converter Control Unit (CCU2)

The CCU2 is a Digital Signal Processor (DSP) based control board that performs

numerous control and diagnostic functions associated with GT100 operation. Its

most significant tasks are control of GT100 electromechanical components and

power electronics converters, communication with the Universal Front Panel

Control Unit, and system sensors. The CCU2 also contains the necessary DC

power supplies to support its operation.

Power Electronics Matrix

The power electronics converter matrix consists of switching transistors (IGBTs),

transistor gate drive electronics, laminated DC bus structure, DC capacitors and

an aluminium extrusion heatsink with a cooling fan. The fan is located behind the

matrix assembly and forces air down through the heatsink.

The PV array is tied logically to the matrix DC bus within the DC Interface

section. The embedded CCU2 control unit manages the transfer of power between

the DC bus and the utility grid.

Physical Characteristics

153378 1–7

Page 32

Introduction

DC Interface

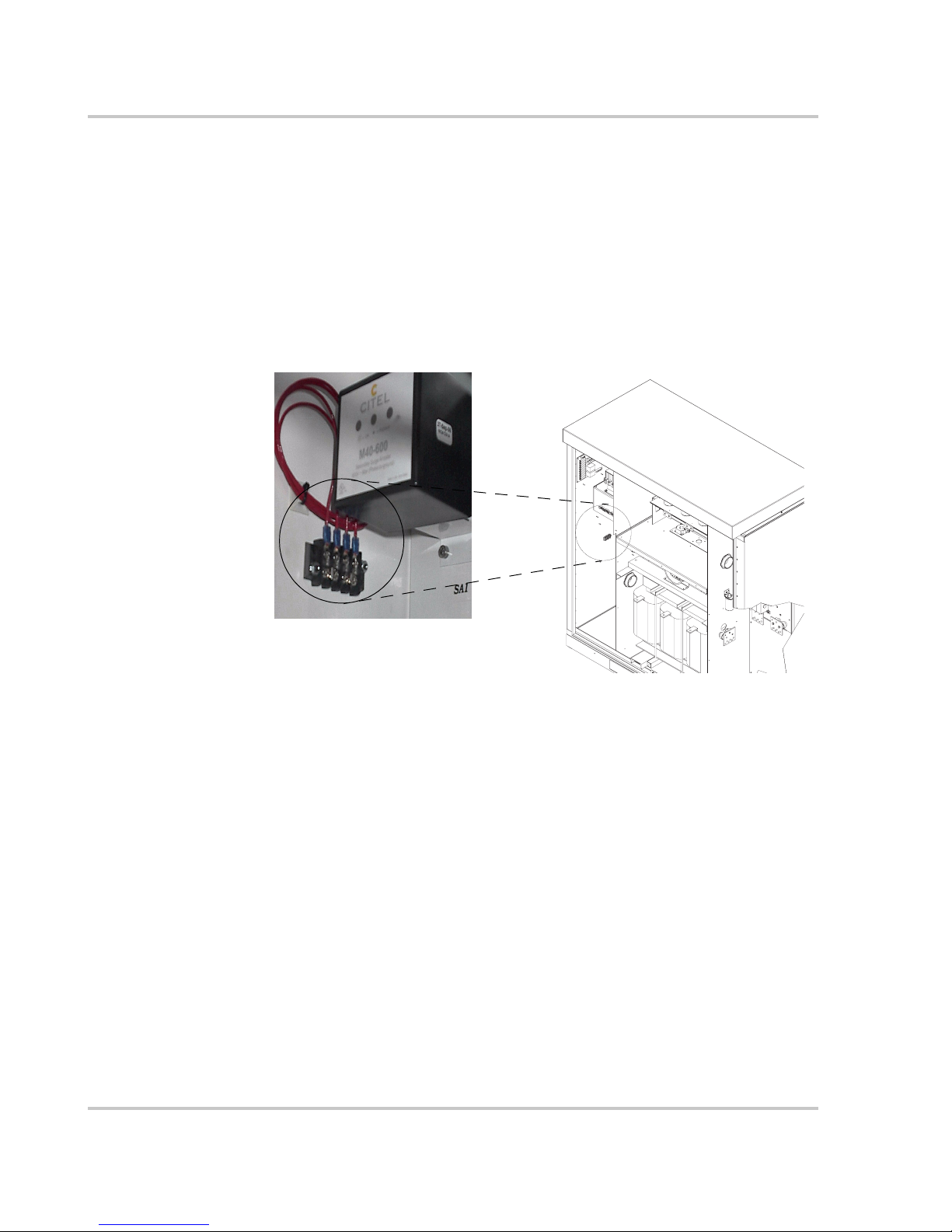

DC Terminals

The DC Interface serves as the connection interface between the PV array and the

GT100 (see Figure 1-2 on page 1–4 to locate the DC Interface). This section

houses the DC Disconnect Switch and DC contactor. Additionally, the PV Ground

Fault Detection circuitry, DC surge arrestor, Solid State Relays, and 48Vdc Power

Supply are also housed in this section.

WARNING: Shock Hazard

Xantrex recommends the installation of PV array disconnect(s) to ensure personal safety

during GT100 maintenance. WITHOUT PV ARRAY DISCONNECT(S), ONCE THE

DC DISCONNECT SWITCH (S1) IS OPEN, THERE WILLSTILL BE DC

VOLTAGE on the DC terminals TB3, TB4 AND TB5 (PV GND). This voltage may be

as high as the open-circuit voltage of the PV Array and is limited to 600Vdc per NEC 690.

Use extreme care to avoid these terminals if no PV array disconnect is installed.

TB5

(PV GND)

Figure 1-5

DC Terminals

The terminals provide six holes with space for twelve cables with a M10 bore

diameter per pole (see Table A-6 on page A–5 for torque requirements).

The table below describes the DC terminal polarity for each GT100 model.

Table 1-1

Model TB3 TB4 TB5

GT100-208-NG PV+ PV– PV GND

GT100-208-PG PV– PV+ PV GND

GT100-480-NG PV+ PV– PV GND

GT100-480-PG PV– PV+ PV GND

1–8 153378

TB3

TB4

DC Terminal Polarity

Page 33

Fused Combiner (Optional)

Physical Characteristics

Figure 1-6

TB5

(PV GND)

GT Fused Combiner Connectors

The fuse blocks of the optional Fused Combiner (GTFC) assembly provide one

box style connector per pole (see Table A-7 on page A–5 for acceptable wire

range and torque requirements.)

The table below describes the DC terminal polarity for each GT100 model with

the GTFC installed.

Table 1-2

Model GTFC TB4 TB5

GT100-208-NG PV+ PV– PV GND

GT100-208-PG PV– PV+ PV GND

GT100-480-NG PV+ PV– PV GND

GT100-480-PG PV– PV+ PV GND

DC Terminal Polarity (with GTFC)

GTFC TB4

153378 1–9

Page 34

Introduction

T1

D

Circuit Diagram

A

AC GRID

B

3 PHASE 60HZ

C

N

GND

Figure 1-7

TB1

A

B

C

N

TB2

SINGLE POINT

TO

EARTH GROUND

CB1

BOT

TOP

4

3

6

5

8

7

2

1

GT100 Circuit Diagram

FILTER

LF1

EMI

L1

L2

L3

K1

AC CONTACTOR

INRUSH LIMIT CCU2

100KVA

H1

X1

H2

X2

H3

X3

H0

SH

A

B

C

POWER

MATRIX

K2

A2

A1

F4

S1

1

536

2

4

TB3

TB4

R1

TB5

PV GN

1–10 153378

Page 35

Operator Interface Controls

Operator interface controls are located on the left front door of the main Inverter

Enclosure. These controls include an ON/OFF Switch, 4-line VFD display and

keypad called the Universal Frontpanel Control Unit (UFCU) used to manipulate

and view system operation and status. The keypad is comprised of 20 touchsensitive keys that provide a means to navigate through the menus and alter userchangeable settings. Additionally, there is an AC Disconnect switch handle and

DC Disconnect switch handle on the AC Interface door (left) and the DC Interface

door (right) respectively.

VFD

Display

Operator Interface Controls

Universal

Frontpanel

Control

(UFCU)

On/Off

Switch

AC Disconnect

(CB1)

DC Disconnect

Switch (S1)

AC Interface

Figure 1-8

153378 1–11

GT100 Operator Interface Components

DC Interface

Page 36

Introduction

On/Off Switch

The GT100 incorporates a maintained position ON/OFF switch located on the left

front door, under the UFCU. Under normal operating conditions, the

ON/OFF

switch is in the ON position. Turning the switch to the OFF position will initiate an

immediate controlled shutdown of the GT100 and open both the main AC and DC

contactors within the unit. The main AC and DC contactors cannot be closed

unless the switch is in the

restarted until the

ON/OFF switch is turned back to the ON position.

ON position. The GT100 is prevented from being

WARNING: Shock Hazard

Turning the ON/OFF switch to the OFF position does NOT remove all hazardous voltages

from inside the inverter. Before attempting to service the GT100, follow the de-energize

Lockout and Tag procedure on page xii and page 5–2.

Figure 1-9

Emergency Stop (E-STOP)

Provisions are supplied for adding a remote emergency stop. Circuit termination

and signal type are identified in Table A-8 on page A–6.

Auxiliary Enable/Disable

The GT100 also has provisions for installing an auxiliary Enable/Disable switch

in series with the local control. This is advantageous for coordination of the

GT100 at specific installations where a pre-existing back-up emergency generator

is present. Circuit termination and signal type are identified in Table A-8 on

page A–6

1–12 153378

On/Off Switch

Page 37

AC Disconnect and DC Disconnect Switches

Both enclosure doors of the GT100 are equipped with lockout hasps for personnel

safety. The enclosure doors should not be opened while the GT100 is operating.

The switch handles and shafts provide a mechanical door interlock for both the

AC and DC Interface sections. The doors cannot be opened when the switches are

in the

ON position.

Although the Main ON/OFF switch (S3) is recommended for an orderly

shutdown, the DC Disconnect switch is equipped with an auxiliary contact block

which enables the switch to be used as a load break DC disconnect. In the event

the DC Disconnect switch is opened while the GT100 is processing power from

the PV array, the early-break contact block will signal the CCU2 (Converter

Control Unit) to stop processing power prior to opening the DC Disconnect

switch.

Additionally, opening the DC Disconnect switch will cause the GT100 to execute

an immediate orderly shutdown, open both the main AC and DC contactors, and

report a PV disconnect fault on the VFD of the UFCU.

Both GT100 enclosure doors must be closed and locked during normal operation.

Operator Interface Controls

AC Disconnect

switch (CB1)

AC Interface

Figure 1-10

153378 1–13

AC and DC Disconnect Switches

DC Interface

DC Disconnect

switch (S1)

Page 38

Introduction

Operation Features

The GT100 has the following operation features.

Fixed Unity Power Factor Operation

The GT100 maintains unity power factor during operation. The control software

constantly senses utility voltage, and constructs the output current waveform to

match the utility voltage. The GT100 is not capable of operation without the

presence of normal utility voltage, nor is it capable of varying the output power

factor off unity.

Peak Power Tracking

An advanced, field-proven, Maximum Peak Power Tracker (MPPT) algorithm

integrated within the GT100 control software ensures the optimum power

throughput for harvesting energy from the photovoltaic array. The peak power

voltage point of a PV array can vary, primarily depending upon solar irradiance

and surface temperature of the PV panels. This peak power voltage point is

somewhat volatile, and can easily move along the I-V curve of the PV array every

few seconds. The MPPT algorithm allows the GT100 to constantly seek the

optimum voltage and current operating points of the PV array, and maintain the

maximum peak PV output power.

Accessible via the UFCU, there are five user-settable parameters that control the

behavior of the maximum peak power tracker within the GT100. As show in

Figure 1-11 on page 1–15, user settable parameters include:

• PPT V Ref (ID# 37),

• I PPT Max (ID#42),

• PPT Enable (ID# 44),

• PPT Rate (ID# 45), and

• PPT V Step (ID# 46).

Upon entering the Power Tracking mode, it takes approximately 20 seconds for

the GT100 to ramp the PV voltage to the “PPT V Ref” setpoint regardless of the

actual PV voltage.

With the “PPT Enable” set to “0” (power tracker disabled), the GT100 will

regulate the DC Bus at the “PPT V Ref” setpoint. Regulating the DC bus means

drawing more or less current out of the PV array to maintain this desired voltage.

With the “PPT Enable” set to “1” (power tracker enabled), followed by the

expiration of the “PPT Rate” (MPPT decision frequency), the MPPT will reduce

the reference voltage by an amount equal to the “PPT V Step” value.

At this point the MPPT will compare the amount of AC output power produced to

the previous amount of AC power produced by the GT100. If the output power

has increased, the next change made (after “PPT Rate” has again expired) to the

reference voltage, will be in the same direction.

1–14 153378

Page 39

Operation Features

Conversely, if the power comparison proves undesirable, the power tracker will

reverse the direction of the change to the “PPT_V Step”. The MPPT algorithm

within the GT100 will then continue this ongoing process of “stepping and

comparing” in order to seek the maximum power throughput from the PV array.

The changes made by the MPPT to the reference voltage are restricted to ± 40% of

“PPT V Ref” and by the maximum and minimum PV input voltage (600 and

300 V respectively). Also, the MPPT will not attempt to produce power greater

than that allowed by the “I PPT Max” setpoint. If available PV power is above the

maximum allowable power level of the GT100, the MPPT will increase voltage as

needed to maintain output power below the rated maximum.

Optimization of the GT100 MPPT will result in an increase in energy production.

The user is encouraged to study the PV array’s I-V curves and to adjust the MPPT

user settable parameters accordingly.

Figure 1-11

Maximum Peak Power Tracking

Utility Voltage/Frequency Fault Automatic Reset

In the event of a utility voltage or frequency excursion outside of preset limits, the

GT100 will stop operation and display a fault at the operator interface. Once the

utility voltage has stabilized within acceptable limits for a period of at least

5 minutes, the GT100 will automatically clear the fault and resume normal

operation. Voltage and frequency fault setpoints are detailed later in this section.

153378 1–15

Page 40

Introduction

Safety Features

Anti-Island Protection

A condition referred to as "Islanding" occurs when a distributed generation source

(such as the GT100 Grid-tied Photovoltaic Inverter) continues to energize a

portion of the utility grid after the utility experiences an interruption in service.

This type of condition may compromise personnel safety, restoration of service,

and equipment reliability.

The GT100 employs a method for detecting the islanding condition using a PhaseShift-Loop (PSL). This method is implemented in the CCU2 to prevent islanding

of the GT100. The CCU2 continuously makes minor adjustments to the power

factor phase angle above and below unity. In the event of a utility interruption or

outage, these adjustments destabilize the feedback between the inverter and the

remaining load, resulting in an over/under frequency or voltage condition.

Upon detection of such a condition, the GT100 then performs an immediate

orderly shutdown and opens both the main AC and DC contactors. The fault

condition will remain latched until the utility voltage and frequency have returned

to normal for at least 5 minutes.

This method has been extensively tested and proven to exceed the requirements of

IEEE-929 (Recommended Practices for Utility Interface of Photovoltaic [PV]

Systems) and UL 1741 (Static Inverters and Converters for use in Independent

Power Systems).

PV Ground Fault Detection

The GT100 is equipped with a PV Ground Fault Detection and Interruption

circuit. The circuit employs a 4 A fuse between TB4 and TB5 (PV GND). If

sufficient ground current clears the fuse, and auxiliary contact will signal the

GT100 to execute an immediate orderly shutdown, open both the AC and DC

contactors and report a PV Ground on the VFD of the UFCU. The GT100 will

remain faulted until the fault is remedied, the fuse is replaced, and the advisory is

cleared at the operator interface.

DC Over-voltage Detection

In the event of DC voltage greater than 600 Vdc, the GT100 will execute an

orderly shutdown and will report a PV over-voltage fault on the VFD of the

UFCU. If the DC voltage remains greater than 600 Vdc, the GT100 may be

irreparably damaged.

See Chapter 4, “Troubleshooting” for further information on this fault condition.

1–16 153378

Page 41

Communication Features and Methods

The GT100 provides three types of information to the user:

• system status and/or fault information,

• data logging information, and

• oscillography.

System status and fault information can be accessed using the Universal Front

Panel Control Unit (UFCU), via an RS232 connection to a PC or via an RS485/

Modbus connection to a remote monitoring system. Data logging and

oscillography is available via the RS232 or the RS485/Modbus connection.

The GT100 communicates system status information to the user using the

following methods.

• The Front Panel Control Unit (UFCU) Display

• PC Connection (Remote) - GT View Graphic User Interface (GUI) Software

required (may require additional hardware)

• External Monitoring - (Optional) via a RS485/Modbus connection for remote

plant monitoring.

Communication Features and Methods

System Status and Fault Reporting

Basic system status and all fault conditions rising from within the GT100 are

reported to the UFCU. The 4-line VFD will display a hexadecimal value and a

brief text description of the fault. Additionally, the CCU2 stores the time and

details of all faults in non-volatile memory for later retrieval.

The fault value is also made available to the GT View Graphic User Interface

(GUI) via the RS485/Modbus protocol and will include a more extensive

description of the fault.

Types of status information include:

• Current Operating State or Goal State

• Fault Code (if applicable)

• Inverter State

• Line Voltage and Current

• Inverter Matrix Temperature

•Inverter Power

•PV State

• PV Voltage and Current

• PV Power

• Grid Frequency

• Peak Power Tracker Enabled

153378 1–17

Page 42

Introduction

Universal Front

Panel Control Unit

(UFCU)

Figure 1-12

VFD Display and UFCU Location

1–18 153378

VFD Display

Page 43

Data Logging

Communication Features and Methods

The GT100 inverter stores data values and software metrics for debugging. The

firmware maintains a data log located in the CCU2 non-volatile memory with a

capacity of 25840 32-bit words. The GT100 records the 17 parameters listed

below, and logs them into a circular buffer, such that the earliest records shall be

overwritten once the capacity of the buffer is exceeded. The log capacity is

25840 / 20 = 1292 records (each record has 2 words for timestamp and 18 words

for parameters). Data logging requires the use of a PC connection using the GT

View Graphic User Interface (GUI) software or via the RS485/Modbus

connection.

The following is the list of parameters which values shall be stored in the data

logging records:

•Inverter Vab

•Inverter Vbc

•Inverter Vca

• I Phase A

• I Phase B

• I Phase C

•Grid Freq

•Real Power

• PV Voltage

• PV Current

• PV Power

•System State

•Fault Code

• Intake air Temp.

•Matrix Temp.

• Analog input

• Fan speed control

153378 1–19

Page 44

Introduction

Oscillography

The GT100 includes a graphic data analysis tool known as Oscillography. The

inverter firmware continuously records, in the CCU2 non-volatile memory, 500

samples of data at 1 millisecond intervals. Of these, 250 samples are taken right

before a fault occurs and 250 samples are taken after the fault. Once a fault occurs

and the 250 samples are logged, the log stops and goes into DONE status. The log

will start recording again as soon as the fault is cleared. Oscillography requires the

use of a PC connection using the GT View Graphic User Interface (GUI) software

or via the RS485/Modbus connection.

The following is the list of parameters which instant values shall be stored in the

oscillography records:

• Vab - Grid voltage phase A to phase B

• Vbc - Grid voltage phase B to phase C

• Vca - Grid voltage phase C to phase A

• Ia - Grid current phase A

• Ib - Grid current phase B

• Ic - Grid current phase C

• Grid Hz - Grid frequency

• DC_V - PV array voltage

• DC_I - PV array current

• Fault - hexadecimal code of the fault

1–20 153378

Page 45

Optional Equipment

The following options are available for purchase for use with the GT100 to

enhance its capability. Contact a Xantrex distributor for further information on

installation options.

Communication Modems

Xantrex offers modems that can be connected to the RS232 serial port for remote

monitoring of the inverter. Please check with Xantrex on available modem types.

The remote user has the ability to control and monitor the status of the inverter

through this connection.

PV Combiner

The GT100 is available with an optional fused sub-array combiner (GTFC).

The GTFC-fused combiner is integrated in the inverter enclosure and allows for

multiple runs from the PV Arrays to the inverter directly into a fuse for

circuit protection.

The GTFC Fused Combiner assemblies are available for the GT100 Grid-Tied

Photovoltaic Inverter in the following configurations.

• GTFC 100A (Xantrex p/n 1-153509-01),

six individual Class RK5 fuses rated at 100A

• GTFC 150A (Xantrex p/n 1-153510-01),

four individual Class RK5 fuses rated at 150A

• GTFC 200A (Xantrex p/n 1-153511-01),

three individual Class RK5 fuses rated at 200A

See Figure 1-6 on page 1–9 and Table 1-2 on page 1–9 for the location and

polarity of these assemblies.

Optional Equipment

153378 1–21

Page 46

1–22

Page 47

2

Operation

Chapter 2, “Operation” contains information on the basic operation of

the GT100 Grid-Tied Photovoltaic Inverter.

Page 48

Operation

Description of System Operation

Overview

The GT100 is a fully automated grid-interactive photovoltaic power inverter.

System startup, system shutdown, PV power tracking, and fault detection

scenarios are all governed and monitored by the CCU2 controller within the

GT100. Manual interaction or control of the inverter is necessary only in the

event of a system fault. Additionally, the following conditions govern operation

of the GT100.

• Stable utility AC voltage and frequency as specified in Table A-4 must be

present for all states of operation.

• PV voltage as specified in Table A-2 must be present.

• With the exception of the Matrix Test state, the

the front door of the GT100 Inverter Enclosure, must be switched to the

position for all operating states.

• Both the AC and DC Disconnect switches must be in the ON or

closed position.

• Fault conditions must not be present.

ON/OFF switch (S3), located on

ON

Faults

Fault states are automatic from any state of operation. In the event of a fault

condition, the GT100 will immediately stop processing power and execute an

immediate orderly shutdown, open both the main AC and DC contactors, and

remain in a faulted state until the fault is remedied and cleared (manually or

automatically).

Most faults are latching, and only those faults associated with grid disturbances

and Air Duct Intake temperature are auto-clearing and thus enable the GT100 to

restart after a delay period. All fault conditions arising from within the GT100 are

reported to the UFCU (Universal Frontpanel Control Unit). The 4-line VFD on

the UFCU will display a hexadecimal value (fault code) and a brief text

description of the fault.

Once the cause of the fault has been identified and corrected, and it is determined

to be safe to proceed, GT100 faults may be cleared from the UFCU keypad or via

the remote GUI.

See “Clearing Faults Manually” on page 4–4 for instructions on this procedure.

2–2 153378

Page 49

Operating States

A state machine implemented within the CCU2 control software governs the

operation of the GT100 with clearly defined transitions between its operating

states. There are five steady-state operating states and numerous intermediate

transition states.

•Shutdown

• Transition

• Power Tracking

• Automatic Sleep Test

• Manual Current

•Matrix Test

•Fault

The user should be aware of the following conditions governing GT100

state transitions:

• Qualified utility voltage must be present for all states of operation.

• Fault states are automatic from any state of operation. A fault will cause the

• Most GT100 faults are latching and must be cleared at the operator interface

•The

Operating States

GT100 to immediately stop processing all power. The fault condition will be

reported to the operator interface VFD.

keypad before transitioning to another operating state.

ON/OFF switch, located on the front door of the GT100, must be in the ON

position for all operating states except Matrix Test, in which case it must be in

OFF position.

the

SHUTDOWN

Inverter =

Disabled

Automatic

POWER

TRACKING

Inverter =

PV Power

Figure 2-1

153378 2–3

State Transition Diagram

Manual

FAULT

Manual

MATRIX

TEST

Inverter =

Idle

MANUAL

CURRENT

Inverter = PV

Current

Page 50

Operation

Shutdown

Trans ition

Power Tracking

The line interface controller is idle. The CCU2 monitors the status of the PV array

and utility grid, waiting in standby until the PV array is available to produce

power to the grid.

The intermediate transition states provide an orderly progression from one

operating state to the next. The user has the ability to manually transition the

GT100 between operating states via the operator interface keypad or remotely

using the GUI software. Manual transitions are initiated by entering a “Goal

State”, where the goal state is the desired operating state. Given all applicable

system parameters are within acceptable limits, and the request is valid within the

state machine, the GT100 will initiate the proper sequence of operations necessary

to progress to the requested goal state. Refer to Figure 2-1 on page 2–3 for an

illustration of valid state transitions.

This is the standard operating state of the GT100. The GT100 maximum power

tracker will demand maximum power from the PV array, given sufficient PV

irradiance. Refer to Figure 2-2 on page 2–6 for an illustration of valid operating

states for Power Tracking.

Automatic Sleep Test

Toward the end of every solar day, the GT100 automatically determines when to

stop producing power dependent upon the output power of the inverter. As the net

output power of the GT100 nears zero, a timer is started to allow the inverter to

ride through any brief irradiance reductions.

Manual Current

This operating state is provided to evaluate the existing PV array V-I

characteristics. The PV controller regulates a constant amount of PV current as

commanded by the user from the operator interface keypad, up to the PV current

limit of the GT100. If the user commands more PV current than is available, the

DC bus voltage will drop below the minimum bus voltage level and the GT100

will enter Shutdown mode.

2–4 153378

Page 51

Matrix Test

Fault

Operating States

This operating state is provided to verify proper operation of the matrix and

associated control electronics. In this state, the CCU2 will send digitized gating

signals (On/Off) to the IGBTs at a 2 Hz rate. There is no power transfer between

the PV and utility in this mode. The

ON/OFF switch must be in the OFF position for

the GT100 to enter this state.

The GT100 has encountered a fault condition. When this happens, regardless of

the GT100 state of operation, the GT100 will stop processing all power and

execute an orderly system shutdown. A description of the fault and fault code will

appear on the operator interface VFD. The Fault state may be cleared from the

keypad once the cause of the fault has been corrected. See Chapter 4,

“Troubleshooting” for a complete description of all fault codes.

See next page for the Operating States Flow Chart for Power Tracking.

153378 2–5

Page 52

Operation

System State: Switched Off

System State: Key Disable

Inverter State: Standby

Inverter State: Standby

PV State: Sleep

PV State: Sleep

POWER UP

INITIALIZING

INITIALIZING

PV contactor opened.

PV contactor opened.

Inverter matrix off.

Inverter matrix off.

Grid contactor open.

Grid contact or open.

CCU2 Green LED on.

Green LED on. Red off.

Red Off.

SWITCHED

KEY

OFF

DISABLE

PV contactor open.

Inverter matrix off.

Grid contact or open.

Enable Key

Inverter matrix off. Line contactor open

System State: Shutdown

Inverter State: Standby

PV State: Sleep

PV Voltage > 440V

(PV V START)

System State: Shutdown

Inverter State: Standby

PV State: Wake Up

Grid Contactor K1 Close

System State: Shutdown

Inverter State: Main Settling

PV State: Wake Up

Inverter Matrix On

System State: Power Tracking

Inverter State: On Line

PV State: On Line

SLEEP

for at least 10

seconds

WAKE UP

for 5.0 min.

(PV T START)

K1 Settle

for .5 seconds

ON LINE

PV Voltage >

PV Voltage <

PV Voltage < 440V (PV V Start)

PV Voltage <

PV Power < 1.0kW (PV P STOP)

PV Power > 1.0kW (PV P STOP)

300V

Close K2

50V (300V - 250V

300V (Min. Oper.)

margin)

TEST

for 5.0 min.

(PV T STOP)

PV Contactor Closed

PV Contactor Open

PV Voltage <

5 minutes elapsed

300V (Min. Oper.)

Retrun to Sleep State

Return to Sleep State

FAULT

Fault from any State Fault Cleared

Figure 2-2

Operating States Flow Chart for Power Tracking

PV contactor opened.

Inverter matrix off.

Grid contact or open.

Red LED on. Green off.

2–6 153378

System State: Power Tracking

Inverter State: On Line

PV State: Sleep Test

Bold

- constant value

Italic - User settable.

Underline

- Default value.

Page 53

Operator Interface

The purpose of the operator interface is to provide a means of communicating

critical operational information to and from the unit. This communication occurs

between the operator and the UFCU Keypad and VFD display or between the

operator and a personal computer running the GT View GUI software. The

RS485/Modbus connection is also available for remote monitoring and

control systems.

UFCU Keypad Operation and VFD Display

The UFCU keypad is located on the left front door of the inverter enclosure to

manipulate and view system operation and status.

The keypad is comprised of 20 touch-sensitive, membrane switch keys that

provide a means to navigate through the menus and alter user-changeable settings.

System: PWR Tracking

Inverter: Online

PV: Online

<Read Menu Item>

Operator Interface

Standard Display

VFD Display

UFCU Keypad

Figure 2-3

The Universal Front Panel Control Unit (UFCU) and VFD

1. Four function keys are available.

• F1 - While in the R

Volts

”. If the GT100 is faulted while in the Read Menu, this key is used

to send the “

Menu, this key is used to set “

• F2 - While in the R

While in the W

• F3 - While in the R

While in the W

EAD Menu, this key jumps to display “INV A

Clear Fault” message to the CCU2. While in the Write

Goal:”.

EAD Menu, this key jumps to display “INV kW”.

RITE Menu, this key jumps to display “PPT V Ref:”.

EAD Menu, this key jumps to display “PV kW:”.

RITE Menu, this key jumps to display “PPT Enable:”.

• F4 - While in the Read Menu, this key jumps to display “

While in the Write Menu, this key is used to both confirm and display

parameters.

– When confirming a Goal State change, this key sends the “

Goal State