World Dryer B-974 Installation Manual

AirStyle Model B Hair Dryer

Surface and Recess Mounted Heavy Duty Hair Dryers

secadora de pelo Empotrado Resistente AirStyle Modelo B

Sèche-cheveux robuste à montage encastré, AirStyle modèle B

All B, RBSeries

Todos los Modelos de las Series B y RB

Toutes les modèles de série B et RB

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or service

the product described. Protect yourself and others by observing all safety information. Failure to comply with

instructions could result in personal injury and/or property damage. Retain instructions for future reference.

Por favor lea y guarde estas instrucciones. Léalas cuidadosamente antes de tratar de montar, instalar, operar o dar mantenimiento al producto aquí

descrito. Protéjase usted mismo y a los demás observando toda la información de seguridad. No seguir las instrucciones puede ocasionar daños,

tanto personales como materiales. Guarde estas instrucciones para referencia en el futuro.

Lire et conserver ces instructions. Les lire attentivement avant de commencer à assembler, installer, faire fonctionner, réparer ou entretenir l’appareil

décrit. Pour se protéger et protéger autrui, observer toutes les consignes de sécurité. Le fait de négliger d’appliquer ces instructions peut entraîner

des blessures et/ou des dommages matériels. Conserver ces instructions pour consultation ultérieure.

World Dryer Corporation

5700 McDermott Drive

Berkeley, IL 60163 U.S.A.

800-323-0701

www.worlddryer.com

1

Description

World Dryer AirStyle surface mounted and recessed mounted warm air hair dryer, powered by a high speed universal motor,

delivering 2300 Watts of drying power. This hair dryer runs on 115 Volts AC, 208/220-240 Volts AC, or 277 volts AC electrical supply,

depending on model. Push-button models are represented in this product group. This appliance is intended for hair drying. This hair

dryer may be used in schools, clubs and public facility environments.

Basic Models Nozzle Drying Cycle Dimensions (WxDxH) Weight Cover Material

RB Rotating Nozzle 80 Seconds 13.1” x 13.8” x 4”

B Rotating Nozzle 80 Seconds 11.3” x 9.6” x 8.1”

DB Rotating Nozzle 80 Seconds 11.3” x 9.6” x 8.1”

333 mm x 351 mm x 102 mm 28.6 lbs / 12.9 kgs Cast Iron

287 mm x 244 mm x 206 mm 27.3 lbs / 12.4 kgs Cast Iron

287 mm x 244 mm x 206 mm 15.6 lbs / 7.1 kgs Steel

Models Type Electrical Input Amperage Watts

B, RB, DB Push-button 110-120 V, 60 Hz 20 2300

B1, RB1, DB1 Push-button 110-120 V, 60 Hz 15 1725

B3, RB3, DB3 Push-button 208-240 V, 60 Hz 10 2300

B7, RB7, DB7 Push-button 277 V, 60 Hz 8.5 2300

B38, RB38, DB38 Push-button 220-240 V, 50 Hz 10 2300

(cULus Listed, E19860, CE TUV-GS)

General Safety Information

• Always disconnect the power source before servicing or installing the hair dryer.

DANGER

DANGER

dryer’s wall base.

• We recommend GFCI protection in wet or damp locations or as required by local code.

WARNING

• Connect the hand dryer to the nearest suitable distribution panel.

• Do not connect to a branch circuit with CB or fuse protection over 20 Amps. This is in compliance with The National Electrical Code.

Failure to disconnect the power source before installation or servicing can

result in serious injury or death from electric shock.

Failure to properly ground this unit could result in severe electrical shock

and/or death.

NEC codes or safety recommendations are not followed.

.

CAUTION Improper mounting could result in personal injury or property damage.

Unpacking

1. Remove all packing material. Recycling is recommended.

2. Carefully remove the hair dryer from the shipping carton, using care not to drop the appliance.

3. Inspect carefully for any damage that may have occurred during transit. Check for any loose, missing or damaged parts. If the hair

dryer is damaged, promptly inform the shipper or dealer where you purchased it.

2

3"

1 1/4"

3"

1 1/4"

3"

3"

3"

3"

1 1/4"

1 1/4"

3"

3"

SEE TABLE

DIMENSION "A"

SECTION "A"

8 HOLES FOR #10

WOOD SCREWS

8 KNOCKOUTS

7/8" + 1 1/8"

11 3/4"

OPENING

12 1/2"

OPENING

A

A

STEEL BOX

#16 GA.

EDGE FLUSH

TO RECESS

1/8" MAX.

3 1/2"

1 1/4"

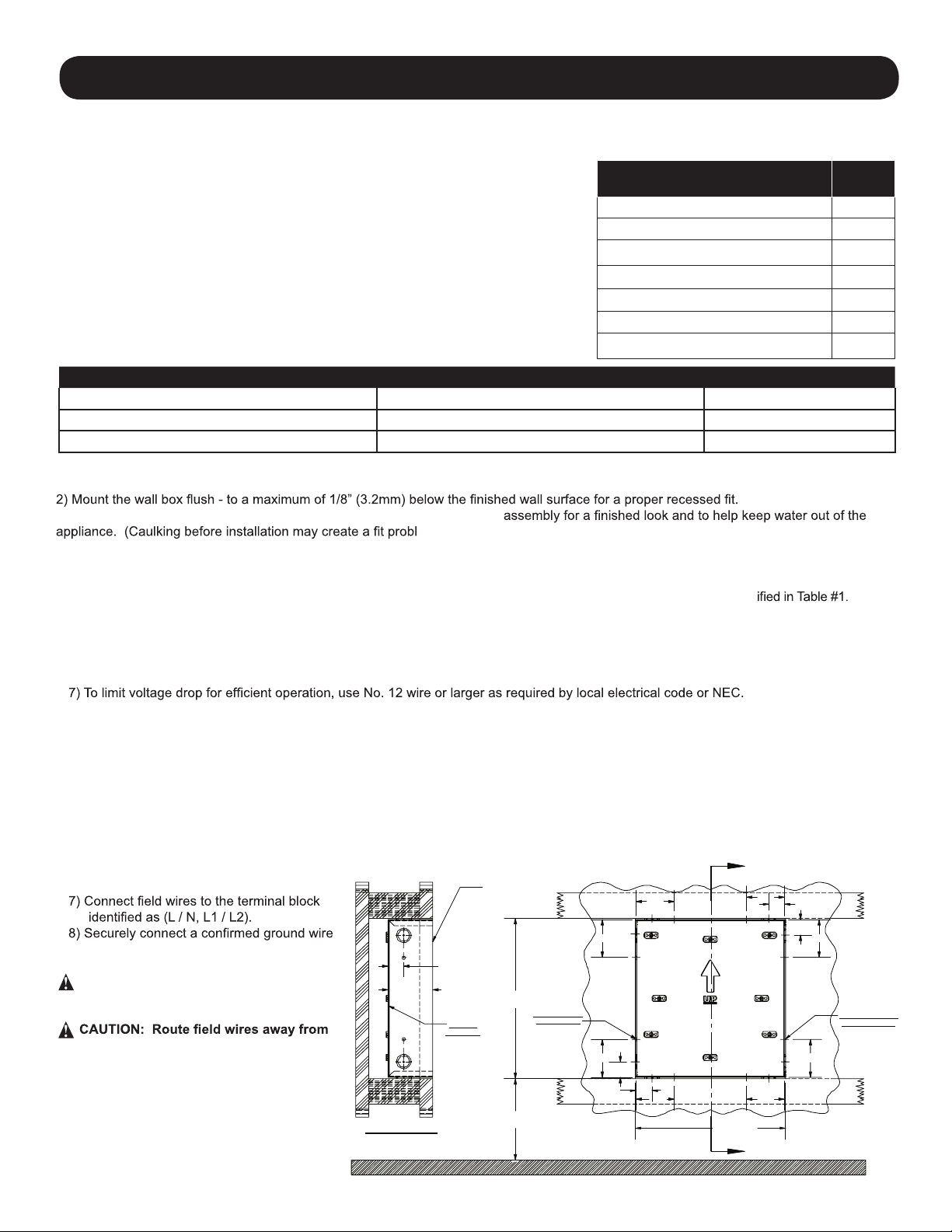

Installation

IMPORTANT: Consult local and general regulations before performing dryer installation. Make certain that the electrical

network is not overloaded. Do not connect to a branch circuit with a circuit breaker or fuse rated over 20 Amps. This is a UL

recommendation and complies with NEC.

A) DISCONNECT THE POWER SOURCE.

B) Surface Mounted Models

1) Use the security Allen wrench supplied to remove the (2) cover mounting screws. Remove

the cover from the dryer.

2) Place the hand dryer base on the wall at the desired location using Table 1 to determine

the recommended mounting height. With the base so located, use it as a template to mark

locations of the 4 mounting bolt holes on the wall. When two or more dryers are installed,

they should be spaced 24” (61 cm) minimum from center to center.

3) Fasten the base to the wall, using the type of bolts suggested in Table 2.

4) Connect the dryer to the nearest suitable distribution panel.

5) Replace cover, making certain not to over-tighten cover bolts.

Type of Wall Type of Bolt Minimum Bolt Length

Hollow Tile, Lath, Wall Board or Metal 1/4” (M6) Screw Type or Wing Type Toggle Bolts Dependent on wall thickness

Cement, Brick, or Tile Covered Cement or Brick 1/4” (M6) Stud Type Expansion Bolts 3” (76 mm)

Stud Wall with Wood Backing No.16 (M8) Wood Screws 23/4” (70 mm)

C) Recessed Mounted Models

1) Mount the hand dryer wall box at the recommended height per Table #1.

3) Caulking is recommended AFTER installation of the aluminum base

em.)

Table 1

Table 2

Recommended Mounting Heights from

Floor to Dryer Bottom Edge

in. (cm.)

Men’s washrooms 68 (173)

Women’s washrooms 59 (150)

Children’s washrooms, ages 4-7 41 (104)

Children’s washrooms, ages 7-10 48 (122)

Children’s washrooms, ages 10-13 54 (137)

Children’s washrooms, ages 13-17 59 (150)

Handicap Mounting Height 55 (140)

D) Mounting the Steel Wall Box;

CAUTION: Proper installation requires that the base be installed into the steel wall box supplied.

1) Locate the steel wall box in the wall at the desired position, having the lower edge of the box at the selected height spec

2) When two or more dryers are installed, they should be spaced 24” (61cm) minimum from center to center.

3) To mount the wall box, frame the opening in the wall per Figure #1.

4) Allow an opening in the framing to correspond with the preferred wall box knock-out for easy access of electrical conduit.

5) Mount the wall box in the opening. Fasten with No.10 (M5) wood screws or appropriate fasteners as required.

6) Using the nearest suitable distribution panel, run conduit.

8) Provide a minimum length of 24” (61cm) of wire in the wall box to allow easy connection to the dryer terminals.

E) Mounting the Dryer in the Wall Box;

1) Remove all shipping / packing material including the protective rubber corner squares if present on the dryer cover.

2) Use the security allen wrench supplied, to remove the (2) cover mounting screws. Remove the cover from the dryer base assembly.

CAUTION: should be exercised when handling porcelain enameled cast iron covers. Do not drop or hit against hard surfaces to

avoid damaging the porcelain enamel.

3) Insert the base assembly in the pre-mounted wall box.

4) Facing the dryer, the blower housing will be on the left side as installed.

Figure 1

5) Fasten the base to the wall box with (4) 1/4-20 screws supplied.

6) Route the wires through the openings in

the base assembly.

3

to the ground screw point.

DANGER: This hand dryer must be

properly earth connected (grounded).

any moving parts or sharp edges.

9) Install the Hand Dryer Cover with the (2)

mounting screws. To avoid chipping the

porcelain enamel, do not over-tighten.

INSTALLATION MUST BE PERFORMED

BY QUALIFIED ELECTRICIAN.

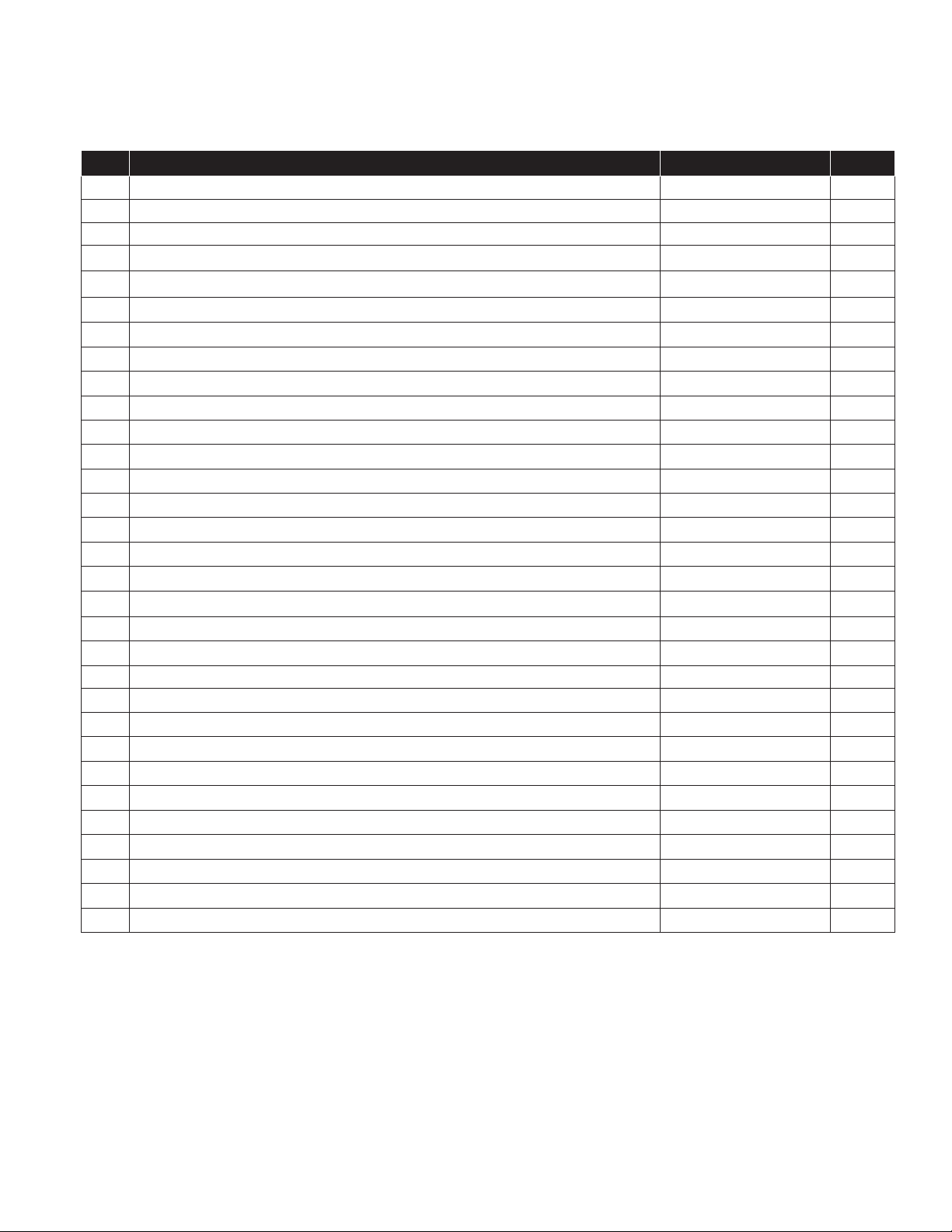

Parts List

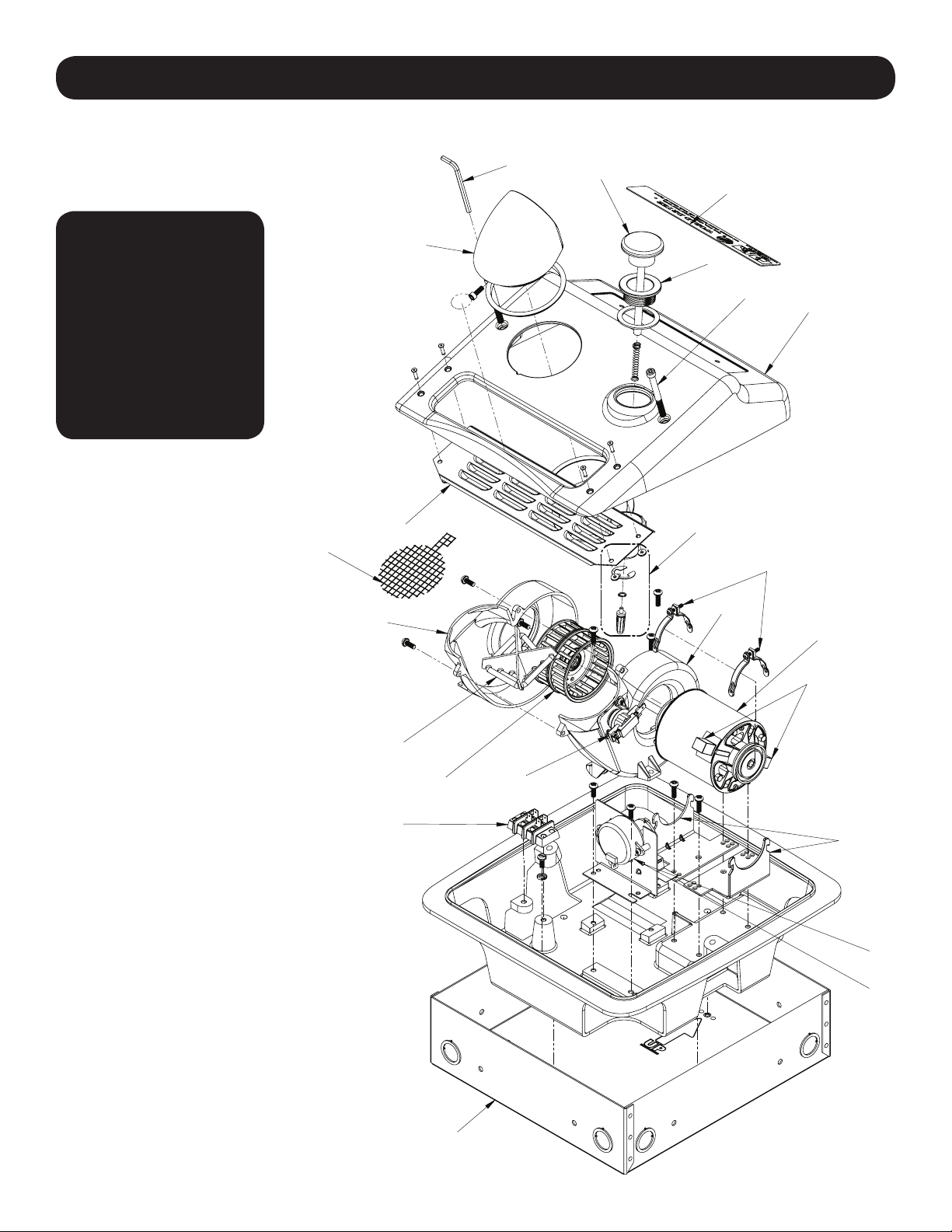

Figure 2.1 - Repair Parts List For (D)B, B1, B3, B38, B7

For Repair Parts, visit

www.WorldDryer.com.

Please provide following

information:

Model number

Serial number

Part description and

number shown in parts list

31

8

41

11

9

21

01

5

7

6

2

02

51

81

3

1

61

4

71

91

4

Description Part Number Qty.

#

1 Motor - 115 V (D)B, (D)B1 210K 1

Motor - 208/220-240 V (D)B3, (D)B38, (D)B7

†

210ACEK 1

2 Motor Brush 206NL 2 Req’d

3 Motor Mounting Strap 110-4A 2 sets

4 Motor Mounting Brackets 110-4 2

5 Micro Switch Only (All) 143F 1

6 Switch Timer Unit - 115 V, 80 seconds (D)B, (D)B1 125H-K 1

Switch Timer Unit - 208-230 V, 80 Seconds (D)B3 125K-K 1

Switch Timer Unit - 220-240 V, 50 Hz, 80 Seconds (D)B38 125P-K 1

Switch Timer Unit - 277 V, 80 Seconds (D)B7 225K7 1

7 Cover Complete, Cast Iron, Pushbutton, White (All)* 70B5-974CUK 1

Cover Complete, Steel, Pushbutton, White (All)* 72DB5-974CUK 1

8 Pushbutton Retaining Ring, Insulated Push Rod Tip, and Spring Kit (All) 193K 1

9 Security Allen Wrench 204TP 1

10 Inlet Grill, Cast Iron, Pushbutton, with Mtg. Hardware (All) 194-1K 1

11 Tamper Proof Cover Screw, Cast Iron Covers 100B2 2

Tamper Proof Cover Screw, Steel Covers 46-330 2

Lock Washer, Steel Covers 59-005028 2

12 Nozzle Assembly Kit 34-172K 1

13 Pushbutton Adapter, Gasket and Bushing Unit (All) 190K 1

14 Pushbutton Assembly Kit (Knob, Rod, Ring, Spring and Tip) (All) 185K 1

15 Blower Scroll Half with Base Mount and Thermostat 211PK 1

16 Blower Plastic 101P 1

17 Blower Scroll Half with Terminal Block - Left Side 112P 1

18 Heating Element - 115 V, 20 AMP (D)B 213 1

Heating Element - 115 V, 15 AMP (D)B1 213B 1

Heating Element - 230 V (D)B3 (D)B38 213A4 1

Heating Element - 277 V, 8.5 AMP (D)B7 213A7-2 1

19 Grid, Ground Assy (All) 12-001 1

20 Thermostat Only 3/4” 1111-03 1

Resistor, 277V, 50Ω, 90W, (D)B7 43-10152 1

* Specify model when ordering.

(†) 277 Volt Models Use 210ACEK Motor (230 V Power Tap).

Not shown.

5

Parts List

Figure 2.2 - Repair Parts List For RB, RB1, RB3, RB38, RB7

For Repair Parts, visit

www.WorldDryer.com.

Please provide following

information:

Model number

Serial number

Part description and

number shown in parts list

23

20

13

15

12

16

22

10

14

9

11

5

18

3

21

4

19

17

2

6

7

8

1

6

Description Part Number Qty.

#

1 Wall Box (All) 17-034 1

2 Terminal Block (All) 156-3 1

3 Motor 115V, RB, RB1 210K 1

3 Motor 208/220-240V, RB3, RB38, RB7

†

210ACEK 1

4 Motor Brush 206NL 2

5 Motor Mounting Strap 110-4A 2 sets

6 Motor Mounting Brackets 110-4 2

7 Micro Switch (All) 143F 1

8 Switch Timer Unit -115V, 80SEC RB, RB1 125H-K 1

8 Switch Timer Unit - 208-230V, 80Sec, RB8 125K-K 1

8 Switch Timer Unit - 220-240V, 50Hz, RB38 125P-K 1

8 Switch Timer Unit - 277V, 80Sec, RB7 225K7 1

9 Cover Complete, Cast Iron, Push-button, White (All)* 703B-974CK 1

10 Push-button Adapter, Gasket and Bushing Unit (All) 190K 1

11 Push-button Retaining Ring, Insulated Push Rod Tip, and Spring Kit (All) 193K 1

12 Security Allen Wrench, Cast Iron Cover 204TP 1

13 Inlet Grill, Cast Iron, Push-button, with Mtg. Hardware (All) 194-3K 1

14 Tamper Proof Cover Screw, Cast Iron Covers (All) 100B3 1

15 Nozzle Assembly Kit 34-172K 1

16 Push-button Assembly Kit (Knob, Rod, Ring, Spring and Tip) RA (All) 185K 1

17 Thermostat Only 3/4” 1111-03 1

18 Blower Scroll Half with Base Mount and Thermostat 211PA 1

19 Fan Metal 101i 1

20 Blower Scroll Half - Left Side 112P 1

21 Heating Element 115V, 20A, RB 213 1

21 Heating Element 115V, 15A, RB1 213B 1

21 Heating Element 230V, RB3, RB38 213A4 1

21 Heating Element 277V, 8.5A, RB7 213A7-2 1

22 Nameplate, Push-button RA (All) * 38-223 1

23 Grid, Ground Assy (All) 12-001 1

Resistor, 277V, 50Ω, 90W, RB7 43-10152 1

* Specify model when ordering.

(†) 277 Volt Models Use 210ACEK Motor (230 V Power Tap).

Not shown.

7

Maintenance

NOTE: Disconnect The Power Before Performing Any Of The Following

CLEANING INSTRUCTIONS:

Read complete Instructions before proceeding. Under normal use, cleaning the Dryer once a year will keep it in good operating

dryer can result in damage to motor and heating element as well as hot emissions that could injure the user.

1. Remove two cover mounting screws from dryer cover using security Allen wrench provided. Support cover while removing screws.

2. Remove three (3) side screws holding blower housing together. Note position of heating element and protective screen. The lead

wires are directed through the clearance hole in the blower housing halves. Carefully remove the heating element however, do not

disconnect the wires.

3. Clean blower wheel halves using a 1/2“ diameter radial bristle brush. Insert brush through space between individual blades and

dislodge dirt. Do not bend or damage blades.

4. Vacuum out dirt from blower and housing, reposition heating element, protective screen and housing half and replace three (3) side

screws. Tighten gently making sure that mica heating element pieces are positioned in housing slots with connecting wires passing

through blower housing hole.

5. Use soft-medium bristle 1/2“ paint brush to clean dust and dirt from motor and switch timer. Do not bend switch blade when

cleaning.

of cover before replacing if water is used.

7. Inspect motor brushes. To inspect brushes insert tooth pick in hole in end of brush assembly. If tooth pick is inserted more than one

inch, replace brushes. (See replacement instructions.)

not over-tighten.

REPLACEMENT OF MOTOR BRUSHES

1. Remove locking spring clip securing brush holder.

2. Draw brush cap out of motor slowly until wire connector appears.

3. Detach wire connector and remove brush and holder assembly.

NOTE: When unpacking brush assembly from carton it is important to hold carbon brush in brush holder securely. P/N

206NL

4. Insert new assembly to point where wire quick connect connection can be made.

5. Push brush quick-connects on motor and brush sleeve together.

6. Push brush assembly back in place and insert locking spring clip.

REPLACEMENT OF HEATING ELEMENT

1. Remove three screws holding blower housing (#211P and #112P) together, and remove #112P side of housing.

2. Disconnect the white wires of the heating element at the terminal block and switch terminal. Replace with the new heating element

of proper voltage and wattage, being careful to connect it identically to the old one.

grooves in blower housing and both wires run through notch at top of air outlet. Reinstall the protective screen and replace three

screws fastening blower housing together.

4. Reconnect wires to terminal block and switch. Make certain all wires are properly reconnected and match the wiring diagram.

REPLACEMENT OF SWITCH TIMER MODELS All

1. Remove screws from each of the two terminals on switch timer, marking wires for correct reconnection to switch terminals.

2. Replace defective timer with new one. (Specify Dryer Model when ordering Timer.)

3. Reconnect wires to terminals.

screws. Do not over-tighten the mounting screws.

5. Turn on power to dryer.

8

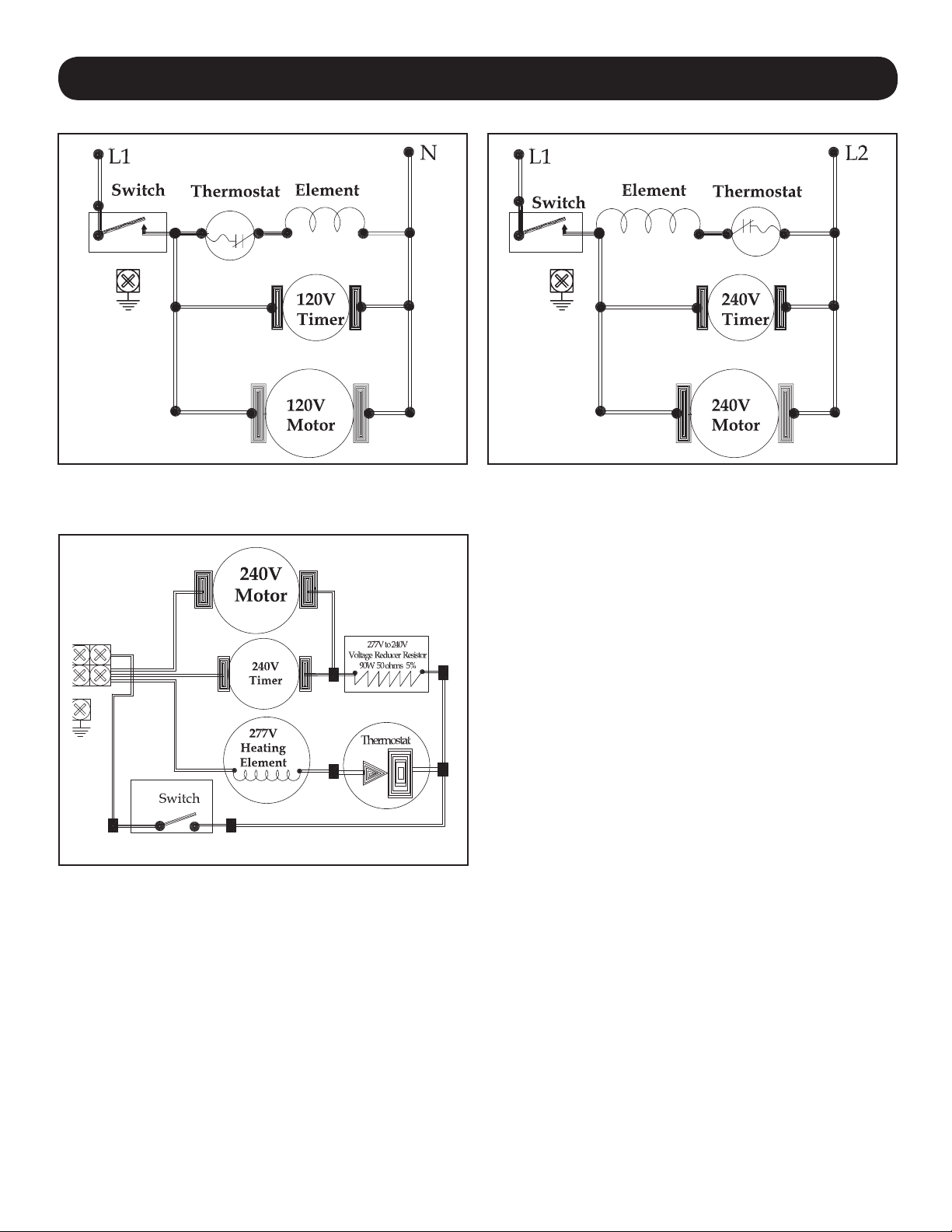

Wiring Diagram

Wiring Diagram - Model B, B1, RB, RB1 Wiring Diagram - Model B3, RB3, B38, RB38

Wiring Diagram - Model B7, RB7

9

Loading...

Loading...