Page 1

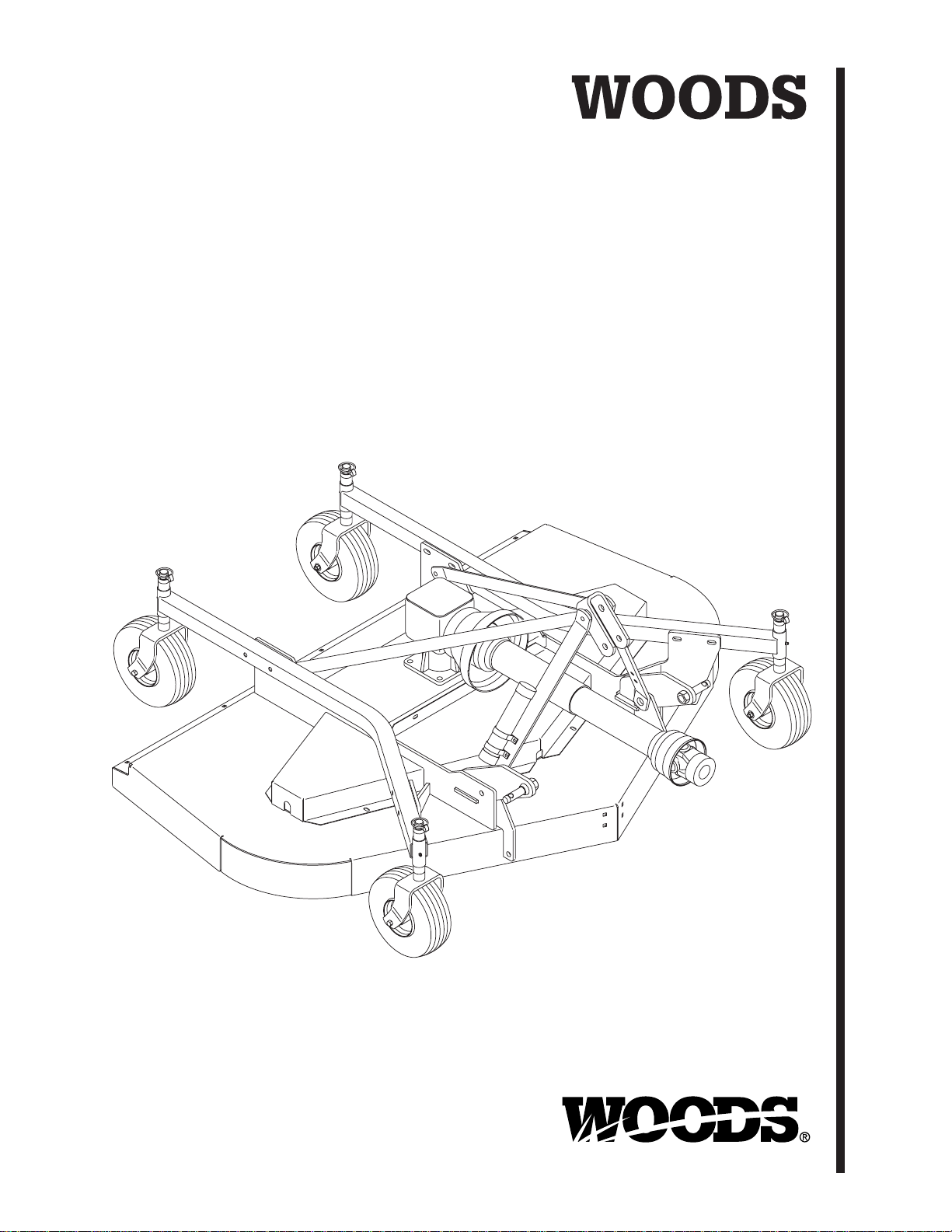

HERITAGE

REAR DISCHARGE

MOWER

RDC54

RD60

RD72

MAN0260

Rev. 1/12/2007

Tested. Proven. Unbeatable.

Page 2

TO THE DEALER:

CAUTION

IMPORTANT

WARNING

DANGER

NOTE

®

Assembly and proper ins tallation of this product is the r esponsibility of the Woods

and safety rules. Make su re all item s on the Dealer ’s Pr e-Delivery and Delivery Check L ists in the O perator ’s Ma nual

are completed before releasing equipment to the owner.

The dealer must complete the Produc t Registrati on included with the Oper ator ’s Manual. The cust omer must si gn the

registration which cer tifies that all Dealer Check List items have been completed. The de aler is to return the prepaid

postage portion to Woods, give one co py to th e custo mer, and retain one co py. Failure to complete and return this

card does not diminish customer’s warranty rights.

TO THE OWNER:

Read this manual before operating your W oods equipm ent. The informa tion presented will prepare you to do a better and

safer job. Keep this manual handy for ready reference. Require all operators to read this manual carefully and become

acquainted with all adjustment and operating procedures before attempting to operate. Replacement manuals can be

obtained from your dealer. To locate your nearest dealer, check the Dealer Locator at www.WoodsEquipment.com, or in

the United States and Canada call 1-800-319-6637.

The equipment you have purchased has been carefully engineered and manufactured to provide dependable and

satisfactory use. Like all mechanical products, it will require cleaning and upkeep. Lubricate the unit as specified.

Observe all safety information in this manual and safety decals on the equipment.

For service, your author ized Woods dealer has trained me chanics, genuine Woods serv ice parts, and the necessary

tools and equipment to handle all your needs.

Use only genuine Woods service parts. Substitute parts will void the warranty and may not meet standards required for

safe and satisfactory operation. Record the model number and serial number of your equipment in the spaces

provided:

dealer. Read manual instructions

Model:_______________________________ Date of Purchase: _____________________

Serial Number: (see Safety Decal section for location) ____________________________________

Provide this information to your dealer to obtain correct repair parts.

Throughout this manual, the term IMPORTANT is used to indicate that failure to observe can cause damage to

equipment. The ter ms CAUTION, WARNING, and DANGER are used in co njunction with the Sa fety-Alert Symbol (a

triangle with an exclamation mark) to indicate the degree of hazard for items of personal safety.

This Safety-Alert Symbol indicates a hazard and means ATTENTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED!

Indicates an imminently hazardous situation that, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, could

result in death or serious injury, and includes hazards that are exposed

when guards are removed.

Indicates a potentially hazardous situation that, if not avoided, may

result in minor or moderate injury.

Indicates that failure to observe can cause damage to equipment.

IMPORTANT

DANGER

WARNING

CAUTION

NOTE

2 Introduction

Indicates helpful information.

Gen’l (Rev. 6/6/2005)

Page 3

TABLE OF CONTENTS

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SAFETY DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

OWNER SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

DEALER SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

DEALER CHECK LISTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

PARTS LISTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

BOLT TORQUE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

BOLT SIZE CHART & ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 44

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

REPLACEMENT PARTS WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

PRODUCT WARRANTY . . . . . . . . . . . . . . . . . . . . . . . INSIDE BACK COVER

!

LEA EL INSTRUCTIVO!

Si no lee Ingles, pida ayuda a

alguien que si lo lea para que le

traduzca las medidas de seguridad.

MAN0260 (Rev. 1/12/2007)

Introduction 3

Page 4

SPECIFICATIONS

MODEL RDC54 RD60 RD72

3-Point Hitch Limited Cat. 1 Cat. 1 Cat. 1

Cutting Width 54" 60" 72"

Cutting Height Range 1" - 4-1/2" 1" - 4-1/2" 1" - 4-1/2"

Operating Weight with

Chain Shielding 417 lbs. 521 lbs. 624 lbs.

Blade Speed (feet per minute) 16,200 18,000 18,100

Blade Spindles 3 3 3

Number of Blades 3 3 3

Universal Drive Series ASAE Cat. 3 ASAE Cat. 3 ASAE Cat. 3

Caster Wheels 3.5 x 4 x 10 3.5 x 4 x 10 3.5 x 4 x 10

Tractor PTO Speed RPM 540 540 540

Recommended Maximum

Tractor Horsepower 15-25 25-35 25-35

Mower Frame Thickness 10 GA 8 GA 8 GA

GENERAL INFORMATION

The purpose of this manual is to assist you in operating

and maintaining your mower. Read it carefully. It furnishes information and instructions that will help you

achieve years of dependable performance. These

instructions have been compiled from extensive field

experience and engineering data. Some information

may be general in nature , due to u nknown and v aryin g

operating conditions. However, through experience

and these instruction s, you should be able to deve lop

procedures suitable to your particular situation.

WARNING

■ Some illustrations in this manual show the

mower with safety shields removed to provide a

better view. The mower should never be operated

with any safety shielding removed.

The illustrations and data used in this manual were current at the time of printing. However, due to possible

inline production changes, your machine may vary

slightly in detail. We reserve the right to redesign and

change the machines as may be necessary without

notification.

Throughout this m anual, references are made to right

and left directions. Th ese are determined by standing

behind the tractor facing the direction of forward travel.

4 Introduction

MAN0260 (Rev. 1/12/2007)

Page 5

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped

out by an operator’s single careless act.

In addition to the design and configuration of

equipment, hazard control and accident prevention are dependent upon the awareness, concern,

judgement, and proper training of personnel

involved in t he operation, transport, maintenanc e

and storage of equipment.

It has been said “The best safety device is an

informed, careful operator.” We ask you to be that

kind of operator.

TRAINING

Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information. (Replacement manuals and safe ty decals are a vailabl e from

your dealer. To locate your nearest dealer, check

the Dealer Locator at www.WoodsEquipment.com,

or in the United States and Canada call 1-800-319-

6637.) Failure to follow inst ructions or safe ty rules

can result in serious injury or death.

Know your controls and how to stop engine and

attachment quickly in an emergency.

If you do not understand any part of this manual

and need assistance, see your dealer.

Operators must be instructed in and be capable

of the safe operation of the equipment, its attachments, and all controls. Do not allow anyone to

operate this equipment without proper instructions.

Never allow children or untrained persons to

operate equipment.

PREPARATION

Check that all hardware is properly installed.

Always tighten to torque chart specification s

unless instructed otherwise in this manual.

Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Make sure spring-activat ed locking p in or collar

slides freely and is seated f irmly in tractor PTO

spline groove.

Make sure driveline shield tether chains are

attached to the tra ctor and equ ipme nt as sho wn in

this manual. Replace if damage d or broken. Chec k

that drivel ine guards ro tate freely on drivel ine

before putting equipment into service.

Before starting power unit, check a ll equipment

driveline guards for damage. Replace any da maged

guards. Make sure all guards rotate freely on all

drivelines. If guards do not rotate freely on drivelines, repair and replace bearin gs before putting

equipment into service.

Power unit must be equipped with ROPS or

ROPS cab and seat bel t. Keep seat belt se curely

fastened. Falling off power unit can result in death

from being run over or crushed. Keep foldable

ROPS systems in “locked up” position at all times.

Power unit must be equipped with ROPS or

ROPS cab and seat bel t. Keep seat belt se curely

fastened. Falling off power unit can result in death

from being run over or crushed. Keep foldable

ROPS systems in “locked up” position at all times.

Remove accumulated debris from this equipment, power unit, and engine to avoid fire hazard.

Make sure all safety decals are installed.

Replace if damaged. (See S afet y Deca ls se ctio n f or

location.)

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

A minimum 25% of tractor and equipment

weight must be on the tractor front wheels when

attachments are in transport position. Without this

weight, tractor could tip over, causing personal

injury or death. The weight may be attained with a

loader. Weigh the tract or and equ ipment. D o not

estimate.

OPERATION

Full chain shielding, designed to reduce the

possibility of thrown objects, must be installed

when operating in populated areas or other areas

where thrown objects could injure people or damage property. If this machine is not equipped with

full chain shielding, operation must be stopped

when anyone comes within several hundred feet.

RD 54/60/72 (Rev. 1/12/2007)

Safety 5

Page 6

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Inspect and clear area of stones, branches, or

other hard objects that might be thrown, causing

injury or damage.

Never direct discharge toward people, animals,

or property.

Keep bystanders away from equipment.

Never go underneath equipment (lowered to the

ground or raised) unless it is properly blocked and

secured. Never place any part of the body underneath equipment or between moveable parts even

when the engine has been turned off. Hydraulic

system leak down, hydraulic system failures,

mechanical failures, or mov ement of co ntrol le vers

can cause equipment to drop or rotate unexpectedly and cause severe injury or death. Follow Operator's Manual instructions for working underneath

and blocking requirements or have work done by a

qualified dealer.

Do not operate or transport equipment while

under the influence of alcohol or drugs.

Operate only in daylight or good artificial light.

Keep hands, feet, hair, and clothing away from

equipment while engine is running. Stay clear of all

moving parts.

Always comply with all state and local lighting

and marking requirements.

Never allow riders on power unit or attachment.

Always sit in power unit seat when operating

controls or startin g engine. Se curely faste n seat

belt, place transmission i n neutral, engage brake,

and ensure all other controls are disengaged

before starting power unit engine.

Operate tractor PTO at 540 RPM. Do not exceed.

Look down and to the rear and make sure area

is clear before operating in reverse.

Do not operate or transport on steep slopes.

Do not stop, start, or change directions sud-

denly on slopes.

Use extreme care and reduce ground speed on

slopes and rough terrain.

Watch for hidden hazards on the terrain during

operation.

Stop power unit and implement immediately

upon striking an obstruction. Dismount power unit,

using proper procedure. Inspect and repair any

damage before resuming operation.

TRANSPORTATION

Use additional caution and reduce speed when

under adverse surface conditions, turning, or on

inclines.

Do not operate PTO during transport.

A minimum 25% of tractor and equipment

weight must be on the tractor front wheels when

attachments are in transport position. Without this

weight, tractor could tip over, causing personal

injury or death. The weight may be attained with a

loader. Weigh the tract or and equ ipment. D o not

estimate.

Do not operate or transport on steep slopes.

Do not operate or transport equipment while

under the influence of alcohol or drugs.

Always comply with all state and local lighting

and marking requirements.

Never allow riders on power unit or attachment.

MAINTENANCE

Before working underneath, carefully read Op erator’s Manual instructions, disconnect driveline,

raise mower, securely block up all corners with

jackstands, and check stability. Secure blocking

prevents equipment from dropping due to hydraulic leak down, hydraulic system failures, or

mechanical component failures.

Do not modify or alter or permit anyone else to

modify or alter the equipment or any of i ts components in any way.

Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Make certain all movement of equipmen t components has stopped before app roaching fo r service.

Never go underneath equipment (lowered to the

ground or raised) unless it is properly blocked and

secured. Never place any part of the body underneath equipment or between moveable parts even

6 Safety RD 54/60/72 (Rev. 1/12/2007)

Page 7

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

when the engine has been turned off. Hydraulic

system leak down, hydraulic system failures,

mechanical failures, or mov ement of co ntrol le vers

can cause equipment to drop or rotate unexpectedly and cause severe injury or death. Follow Operator's Manual instructions for working underneath

and blocking requirements or have work done by a

qualified dealer.

Frequently check blades. They should be sharp,

free of nicks and cracks, and securely fastened.

Do not handle blades with bare hands. Careless

or improper handling may result in serious injury.

Your dealer can supply genuine replacement

blades. Substitute blades may not meet original

equipment specifications and may be dangerous.

Tighten all bolts, nuts, and screws to torque

chart specifications. Check that all cotter pins ar e

installed securely to ensure equipment is in a safe

condition before putting unit into service.

Make sure all safety decals are installed.

Replace if damaged. (See S afet y Deca ls se ctio n f or

location.)

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

Wear gloves when installing belt. Be careful to

prevent fingers from being caught between belt

and pulley.

Use care when installing or removing belt from

spring-loaded idler. Springs store energy when

extended and, if released suddenly, can cause personal injury.

STORAGE

Follow manual instructions for storage.

Keep children and bystanders away from stor-

age area.

RD 54/60/72 (Rev. 1/12/2007)

Safety 7

Page 8

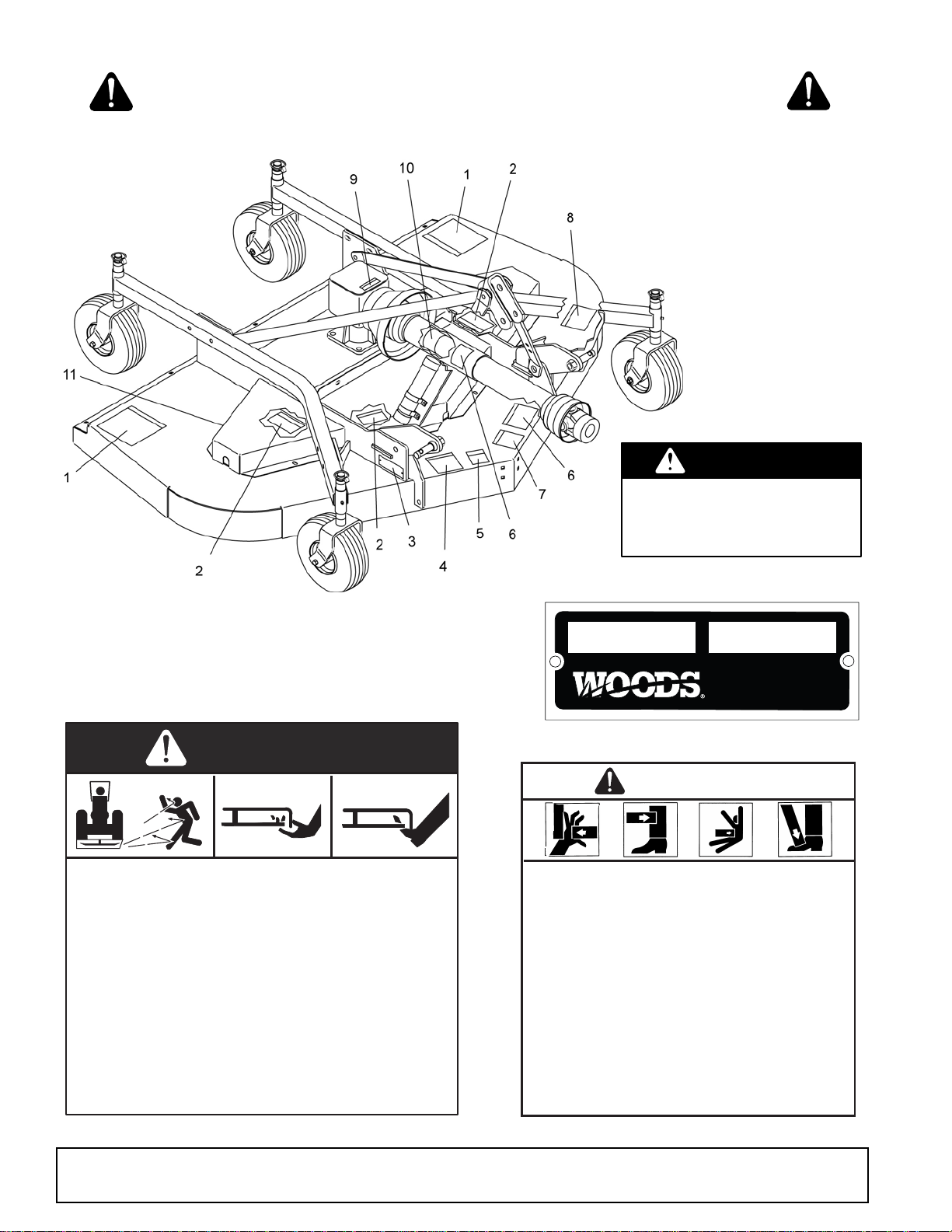

SAFETY & INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged!

DANGER

SHIELD MISSING

DO NOT OPERATE

PUT SHIELD ON

2 - 18867

18867--B

11 - 20106 - Rear Reflector (RD60 & RD72 Only)

1 - 15503

DANGER

ROTATING BLADES AND

THROWN OBJECTS

Do not put hands or feet under or into mower when

engine is running.

Before mowing, clear area of objects that may be

thrown by blade.

Keep bystanders away.

Keep guards in place and in good condition.

BLADE CONTACT OR THROWN OBJECTS CAN

CAUSE SERIOUS INJURY OR DEATH.

15503-C

3 - Serial Number Plate

MODEL NO. SER IAL NO.

Woods Equipment Company

Oregon, Illinois, U.S.A.

4 - 1003751

WARNING

CRUSHING AND PINCHING HAZARD

Be extremely careful handling various parts of

the machine. They are heavy and hands, fingers,

feet, and other body parts could be crushed or

pinched between tractor and implement.

Operate tractor controls from tractor seat only.

Do not stand between tractor and implement

when tractor is in gear.

Make sure parking brake is engaged before

going between tractor and implement.

Stand clear of machine while in operation or

when it is being raised or lowered.

FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD RESULT IN

SERIOUS INJURY OR DEATH.

1003751-A

8 Safety MAN0260 (Rev. 1/12/2007)

Page 9

SAFETY & INSTRU CTIONAL DECALS

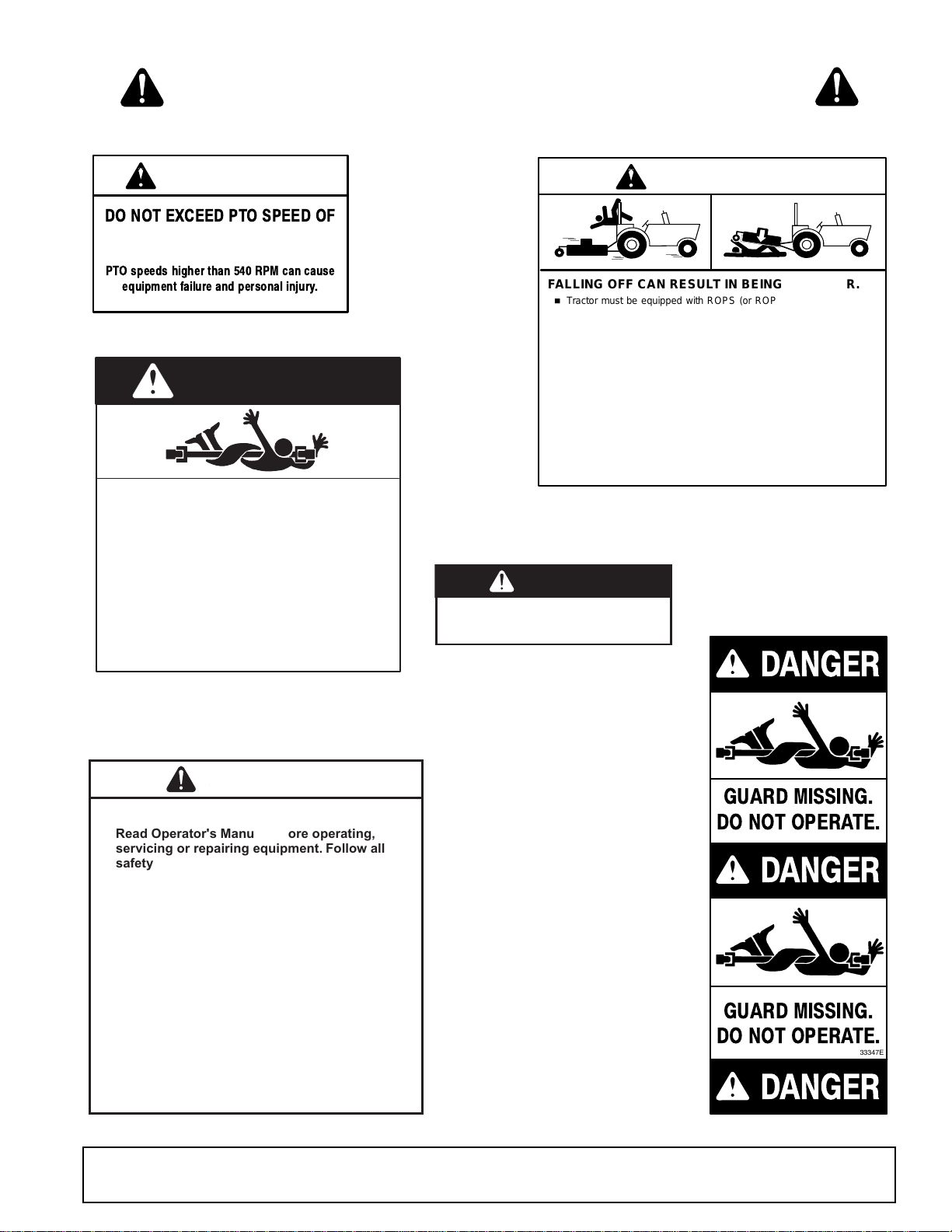

5 - 18866

DA

NG

ER

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged!

WARNING

DO NOT EXCEED PTO SPEED OF

540 RPM

PTO speeds higher than 540 RPM can cause

equipment failure and personal injury.

18866-D

DANGER

ROTATING DRIVELINE

CONTACT CAN CAUSE DEATH

KEEP AWAY!

DO NOT OPERATE WITHOUT -

All driveline guards, tractor and

equipment shields in place

Drivelines securely attached at both ends

Driveline guards that turn freely on

driveline

18864-C

8 - 18865

FALLING OFF CAN RESULT IN BEING RUN OVER.

Tractor must be equipped with ROPS (or ROPS CAB) and seat

belt. Keep foldable ROPS systems in “locked up” position at all

times.

Buckle Up! Keep seat belt securely fastened.

6 - 18864

9 - 1004114

If shaft connection is visible, shield

is missing. Replace shield before

operating equipment.

Allow no riders.

RAISED EQUIPMENT CAN DROP AND CRUSH.

Before working underneath, follow all instructions and safety rules in

operator’s manual and securely block up all corners of equipment

with jack stands.

Securely blocking prevents equipment dropping from hydraulic leakdown, hydraulic system failures or mechanical component failures.

FALLING OFF OR FAILING TO BLOCK SECURELY CAN

RESULT IN SERIOUS INJURY OR DEA TH.

NG

ER

WARNING

1004114

10 - 33347

18865--C

DANGER

7 - 1002423

WARNING

TO AVOID SERIOUS INJURY OR DEATH:

Read Operator's Manual before operating,

servicing or repairing equipment. Follow all

safety rules and instructions. (Manuals are

available from your selling dealer.)

Never allow riders.

Keep bystanders away from equipment during

operation.

Operate from tractor seat only.

Keep all shields in place and in good condition.

Lower equipment to ground, stop engine,

remove key and set brake before dismounting

tractor.

Never allow children or untrained persons to

operate equipment.

Do not transport towed or semi-mounted units

over 20 MPH.

FAILURE TO FOLLOW THESE INSTRUCTIONS

CAN RESULT IN INJURY OR DEATH.

1002423-B

BE CAREFUL!

Use a clean, damp cloth to

clean safety decals. Avoid

spraying too close to decals

when using a pressure

washer; high-pressure water

can enter through very small

scratches or under edges of

decals causing them to peel

or come off.

Replacement safety decals

can be ordered free from your

Woods dealer. To locate your

nearest dealer, check the

Dealer Locator at

www.WoodsEquipment.com,

or in the United States and

Canada call 1-800-319-6637.

GUARD MISSING.

DO NOT OPERATE.

DANGER

GUARD MISSING.

DO NOT OPERATE.

33347E

DANGER

MAN0260 (Rev. 1/12/2007)

Safety 9

Page 10

OPERATION

CAUTION

The operator is responsible for the safe operation of

the mower. The operator must be properly trained.

Operators should be familiar with the mower, the tractor, and all safety practices before starting operation.

Read the safety rules and safety decals on page 5

through page 9.

This mower is design ed for lawn and grass m owing. It

is not designed for rough conditions or heavy weed

mowing. It is equipped with suction type blades for best

results in lawn mowing.

Recommended mowing speed for most conditions is

from 2 to 5 mph.

DANGER

Full chain shielding, designed to reduce the

possibility of thrown objects, must be installed

when operating in populated areas or other areas

where thrown objects could injure people or damage property. If this machine is not equipped with

full chain shielding, operation must be stopped

when anyone comes within several hundred feet.

using proper procedure. Inspect and repair any

damage before resuming operation.

Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

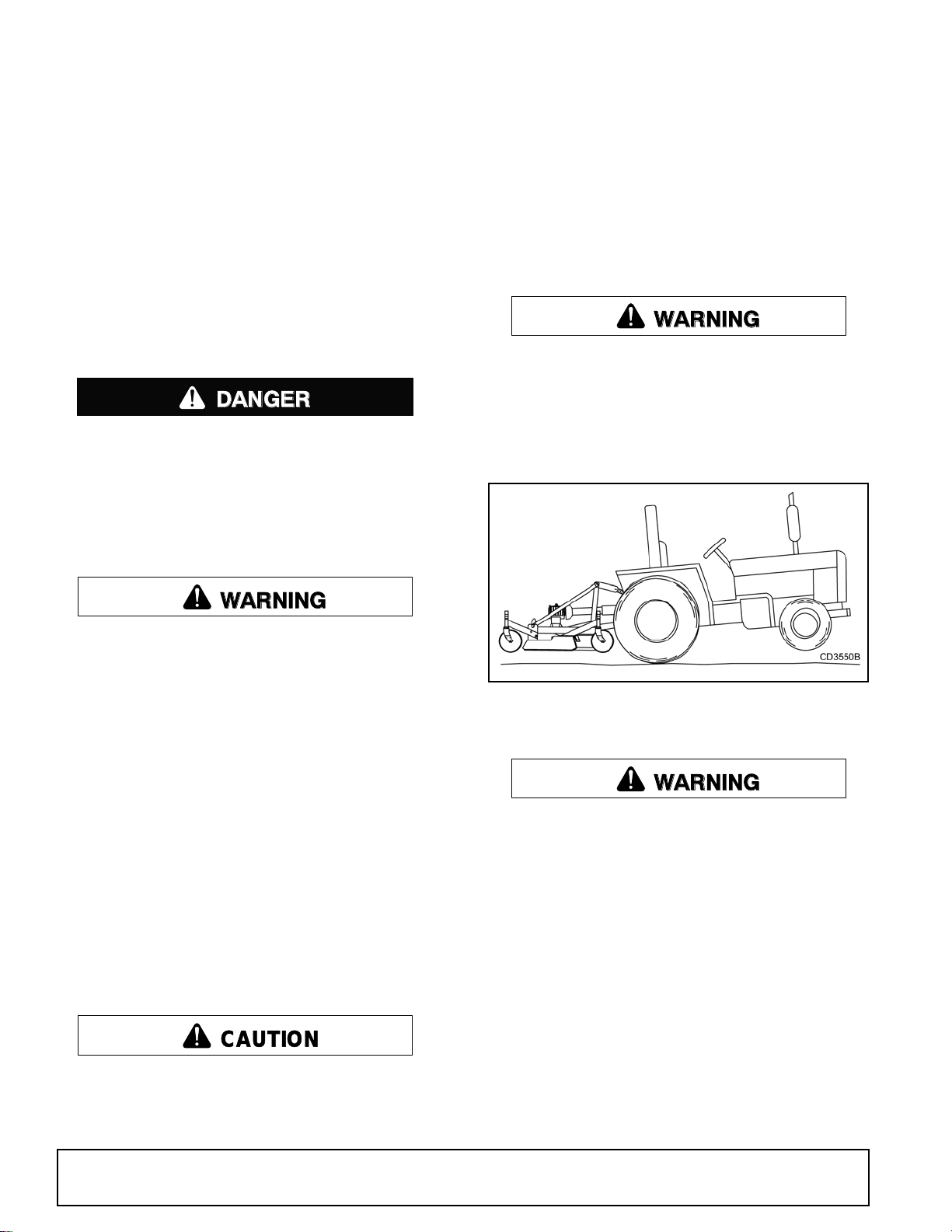

T r ac tor Stability

WARNING

A minimum 25% of tractor and equipment

weight must be on the tractor front wheels when

attachments are i n transp or t positi on. Witho ut thi s

weight, tractor could tip over, causing personal

injury or death. The weight may be attained with a

loader. Weigh the tractor and equipment. Do not

estimate.

WARNING

Never allow children or untrained persons to

operate equipment.

Keep bystanders away from equipment.

Make sure spring-acti vated locking pin or collar

slides freely and is seated firmly in tractor PTO

spline groove.

Operate tractor PTO at 540 RPM. Do not exceed.

Before working underneath, carefully read Oper-

ator’s Manual instructions, disconnect driveline,

raise mower, securely block up all cor ners with

jackstands, and check stability. Secure blocking

prevents equipment from dropping due to hydraulic leak down, hydraulic system failures, or

mechanical component failures.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Figure 1. Tractor Stability

Attach Mower to Tractor

WARNING

Make sure spring-activat ed locking p in or collar

slides freely and is seated f irmly in tractor PTO

spline groove.

The standard 1-3/8" 6B-spline dri veli ne with a QD yoke

is used to connect the mower to the tractor.

1. Attach the mower hitch pins to the lower tractor lift

arms and secure.

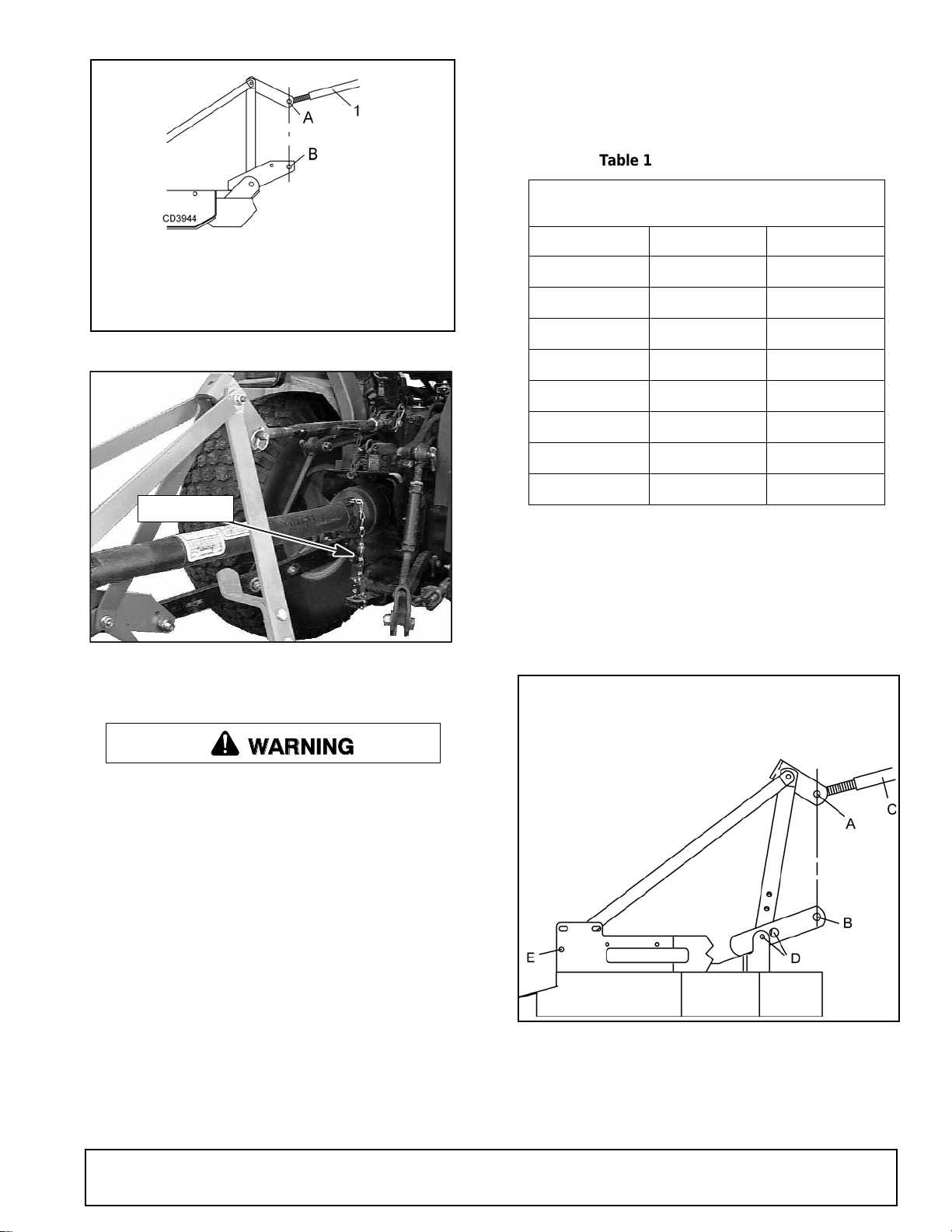

2. Attach tractor top link (1), Figure 2, to mower top

link bracket attachment point (A). Connect the

driveline to the tractor PTO shaft.

3. Attach tether chain to tractor drawbar (Figure 3).

Stop power unit and implement immediately

upon striking an obstruction. Dismount power unit,

10 Operation

4. Adjust the tractor lower 3-point arm anti-sway

devices to prevent mower from swinging side to

side during transport.

MAN0260 (Rev. 1/12/2007)

Page 11

4. To raise rear of mower, move caster adjustment

spacers under rear caster arms.

5. To raise front of mower, move spacers under front

caster wheel arms.

Table 1: Cutting Height Chart

Spacers Required Under

Caster Arm Pivot Tube

1. Tractor Top Link

A. Mower Top Link Attachment Point

B. Mower Hitch Pin

Figure 2. Attachment Points

Tether Chain

CM906

Figure 3. Attach Mower to T ractor

Adjust Cutting Height

WARNING

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Cut Height 1/2" Spacer 1" Spacer

1" 00

1-1/2" 10

2" 01

2-1/2" 11

3" 02

3-1/2" 12

4" 03

4-1/2" 13

T ractor Top Link Adjustment

When the cutting height is set, adjust tractor top link

until mower top link a ttachment point (A), Figure 4, is

aligned vertically with mower hitch pin (B). The front

tires of the mower will lift off the ground before the rear

tires when the unit is raised. This will allow the mower

to follow the ground contour.

A. Mower top link attachment point

B. Mower hitch pin

C. Tractor top link

D. Mower hitch plate attach-

ment point

IMPORTANT

■ Avoid low cutting heights. Striking the ground

with blades produces one of the most damaging

shock loads a mower can encounter. Allowing

blades to contact ground repeatedly will cause

damage to mower and drive.

1. Level mower from side to side. Check by

measuring distance from mower frame to the

ground at each deck rail.

2. Verify that the same am ount of spacers are under

all caster arms.

3. Control cutting height by adjusting front and rear

caster wheels.

MAN0260 (Rev. 1/12/2007)

Figure 4. Top Link Adjustment

RDC54 Only

The RDC54 has two mower hitch plate attachment

points (D). It may be ne cessary to change the mo wer

Operation 11

Page 12

hitch plate attachment poi nt to obtain prop er tire clear -

CAUTION

ance and/or lift height.

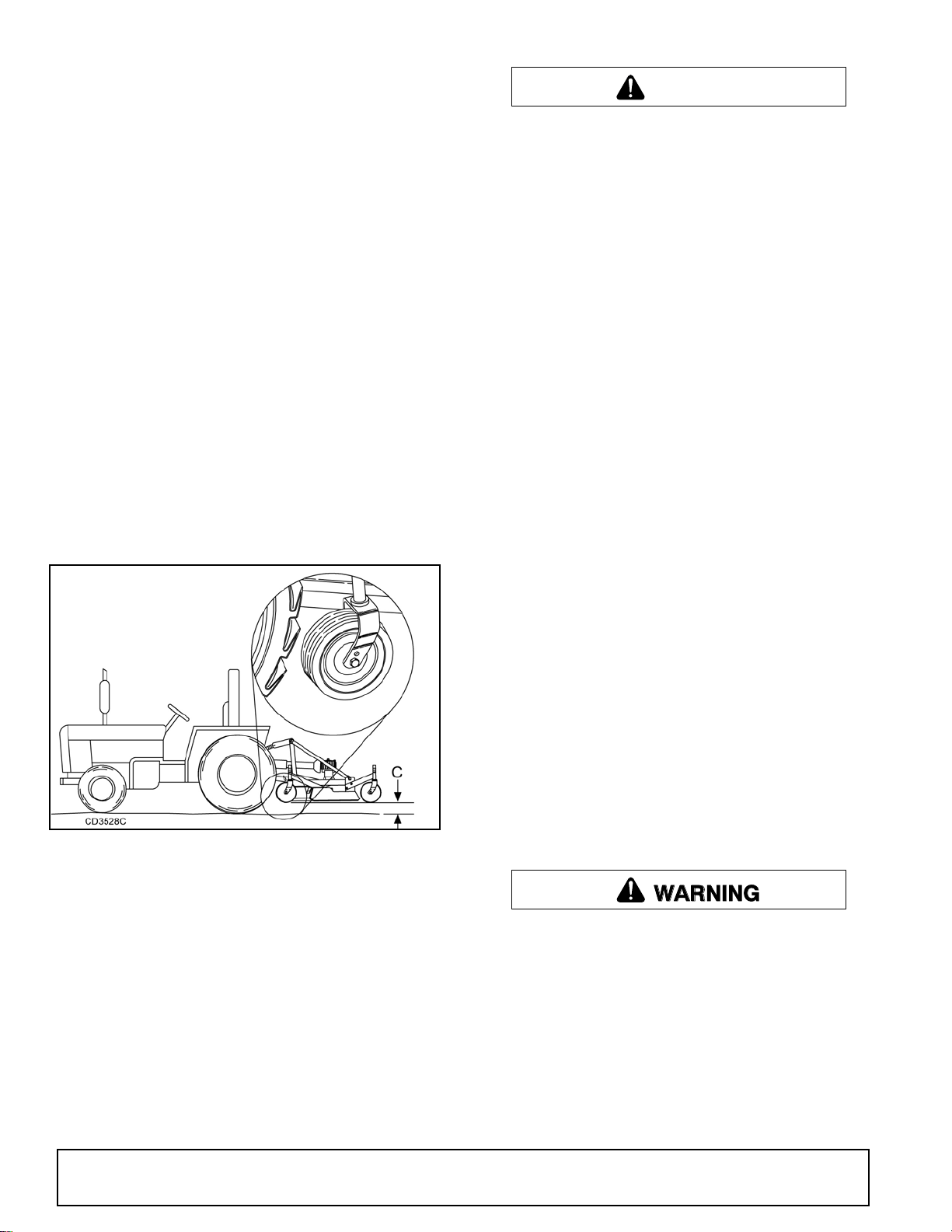

Front Caster Wheel Interference Check

IMPORTANT

■ Do not operate tractor and mower until this

interference check has been performed. If you

change tractors, you must perform the check for

that mounting.

Perform this check with all of th e spacers and springs

above the caster wheel arm. This will place the caster

wheels in their hi ghest positi on and provid e the lowes t

cutting height for the mower.

1. Raise mower with tractor hydraulics to 16" at

dimension C, Figure 5, or maximum height of

tractor lift, whichever is less.

2. Pi vot both front caster wheels forw ard and check

that there is clear ance betw een caster wheels an d

tractor tires.

3. If there is interference on RDC54 model, adjust

mower hitch plate point a s shown in Figure 4. On

model RD60 and RD72, the hitch plate is not

adjustable; see tractor operator’s manual and

adjust tractor wheels accordingly.

Stop power unit and implement immediately

upon striking an obstruction. Dismount power unit,

using proper procedure. Inspect and repair any

damage before resuming operation.

Power for operating the mower is supp lied by the tractor PTO. Operate PTO at 540 rpm. Know how to stop

tractor and mower quickly in an emergency.

If mower becomes p lugged c aus in g b el t to s lip fo r over

two seconds, follow these steps:

1. Maneuver equipment into a previously cut area

and allow mower to clear accumulated material.

2. Continue running at least two minutes, allowing

pulleys to cool. Stopping the mower when in

contact with a very hot pulley will bake and ruin

belt.

Proper ground spee d will depe nd upon the terrain, the

height, and type and density of material to be cut.

Normally, ground speed will range from 2 to 5 mph. Tall

dense material should be cut at a low speed; thin

medium-height mater ial can be cut at a faster ground

speed. Always operate tractor PTO at 540 rpm to maintain proper blade speed and produce a clean cut.

Figure 5. Front Caster Wheel Interference Check

Front Roller (Optional)

The caster wheels effectively reduce scalping in most

cases. However, you may encoun ter areas where the

caster wheels an d/or side skids drop into dep ressions

and allow center of the mower to co ntact ground and

scalp. An optional front roller may be installed to minimize scalping. See page 40.

Operating Technique

Under certain conditions, tractor tires may roll some

grass down and prevent it from being cut at the same

height as the surrounding area. When this occurs,

reduce your ground speed, but maintain PTO at 540

rpm. The lower groun d speed will permit gr ass to partially rebound.

In general, lower cutting heights give a more even cu t

and leave less tire tracks. Howe ver, it is better to cut

grass frequently rather than too short. Short grass

deteriorates rapidly in hot weather and invites weed

growth during growing seasons. Follow local recommendations for the suitable cutting height in your area.

Operating Tips

WARNING

Inspect and clear area of stones, branches, or

other hard objects that might be thrown, causing

injury or damage.

Extremely tall material should be cu t twice. Set mower

at a higher cutting he ight for the first pass. Then cut a t

desired height, 90 degre es to the first pass. Remember, sharp blades produce cleaner cuts and require

less power.

12 Operation

Analyze area to be cut to determine the best procedure. Consider height and type of grass and terrain

MAN0260 (Rev. 1/12/2007)

Page 13

type: hilly, level, or rough. Plan your mowing patter n to

travel straight forward whenever possible. Mow with

uncut grass to the right. This will distribute the clippings

over the cut area.

Uneven Terrain

WARNING

Do not operate or transport on steep slopes.

Do not stop, start, or change directions sud-

denly on slopes.

Use extreme care and reduce ground speed on

slopes and rough terrain.

Watch for hidden hazards on the terrain during

operation.

Pass diagonally through sharp dips and avoid sharp

drops to prevent hanging up trac tor and mower. Practice will improve your skills in maneuver ing rough terrain.

Removing Mower from Tractor - Storage

Follow cleaning procedure, page 17.

1. Dis engage tractor PTO and raise mower with the

3-point hitch.

2. Disconnect mower driveshaft from tractor PTO.

3. Col lapse driveshaft as far as possibl e and store it

in PTO hanger bracket to prevent ground contact.

4. Place blocks under mower side skids. Lower

mower onto blocks, disconn ect mower from trac tor

3-point hitch, and carefully drive tractor away from

mower.

WARNING

Keep children and bystanders away from storage area.

OWNER PRE-OPERATION CHECK LIST

(OWNER'S RESPONSIBILITY)

___ Review and follow all safety rules and safety

decal instructions on page 5 through page 9.

___ Check th at all safety decals are installe d and in

good condition. Replace if damaged.

___ Check that all shields and guards are properly

installed and in good condi tion. Replace if damaged.

___ Check that chain shielding is in good condition

and replace any damaged chain links.

___ Check that all har dware and cotte r pins are prop-

erly installed and secured.

___ Check to ensure blades are sharp, in good condi-

tion, and installed correctly. Replace if damaged.

___ Check that equipment is properly and securely

attached to tractor.

___ Make sure driveline spring-activated locking pin

or collar slid es freely and is seated firmly i n tractor PTO spline groove.

___ Make su re the drivel ine gu ards and te ther chai ns

are in good conditi on. Guards must rotate freely

on driveline. Fasten tether chains to the tractor

and the equipment as instructed.

___ Inspect area and remove stones, branches or

other hard objects that might be thro wn, causing

injury or damage.

___ Do not allow riders.

___ Check all lubrication points and grease as

instructed in “Lubric at ion Infor mat ion ” on page 14

& page 15. Make sure the PTO slip joint is lu bri-

cated and that the gearbox fluid levels are cor-

rect.

___ Set tractor PTO at correct rpm for your equip-

ment.

___ Make sure tr actor ROPS or ROPS cab and seat

belt are in good condition. Keep seat belt

securely fastened during operation.

___ Before starti ng engine, operator must be in t rac-

tor seat with seat belt fastened. Pl ace transmis-

sion in neutral or park, engage brake, and

disengage tractor PTO.

Figure 6. Mower Storage Position

MAN0260 (Rev. 1/12/2007)

Operation 13

Page 14

OWNER SERVICE

CAUTION

The information in this section is written for operators

who possess basic mechanical skills. If you need help,

your dealer has trained service technicians available.

For your protection, read and follow the sa fety info rmation in this manual.

Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

WARNING

Never allow children or untrained persons to

operate equipment.

Keep bystanders away from equipment.

Before working underneath, carefully read Oper-

ator’s Manual instructions, disconnect driveline,

raise mower, securely block up all cor ners with

jackstands, and check stability. Secure blocking

prevents equipment from dropping due to hydraulic leak down, hydraulic system failures, or

mechanical component failures.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Make sure spring-acti vated locking pin or collar

slides freely and is seated firmly in tractor PTO

spline groove.

Operate tractor PTO at 540 RPM. Do not exceed.

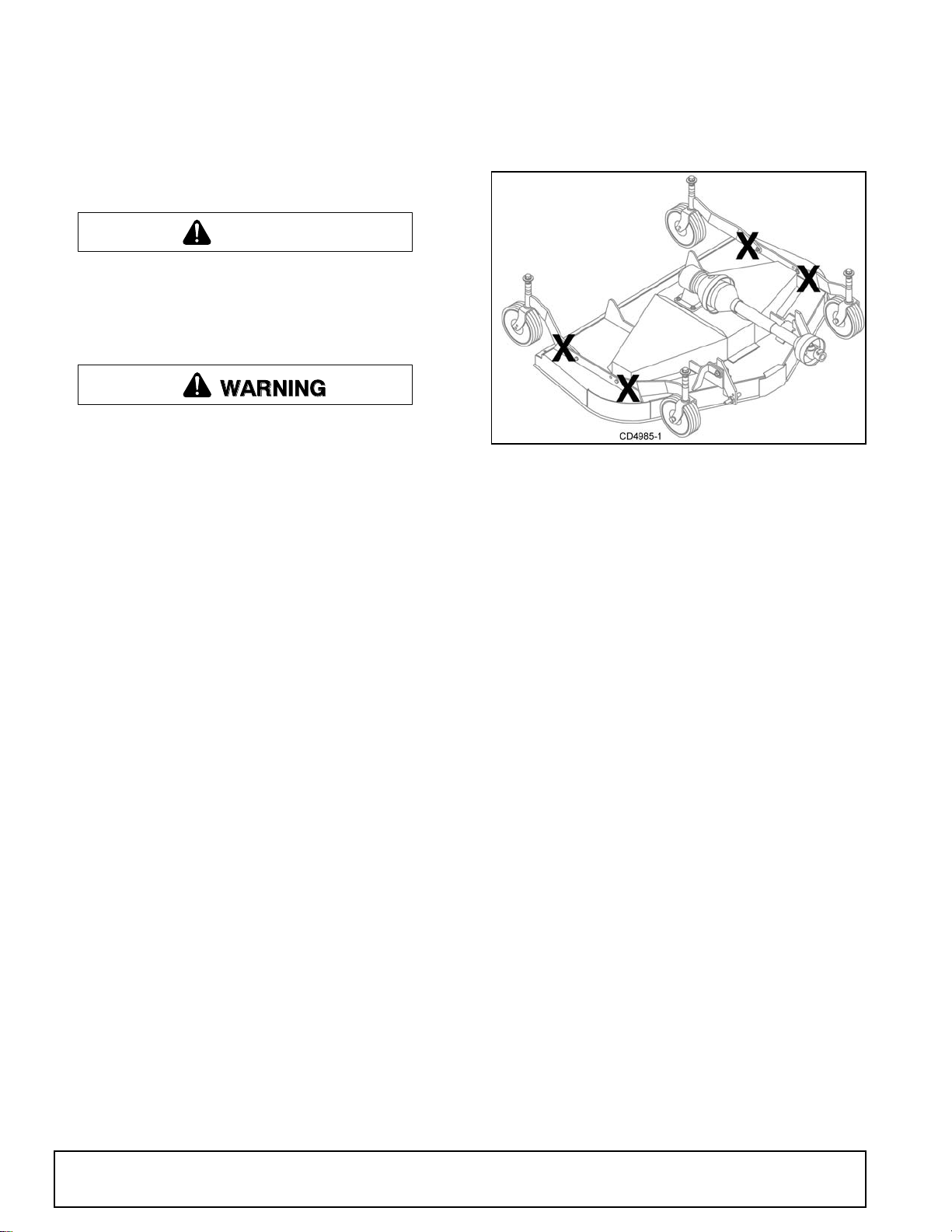

BLOCKING METHOD

Do not work underneath mower unless it is properly

attached to the tractor and blocked securely. When

properly attached, the unit will be anchored to minimize

front to rear movement.

Raise mower completely, set tractor brakes, turn

engine off, remove key, block tractor wheels fron t and

rear, and disconnect mower driveline from tractor.

The only approved blocking devic es for this mo wer are

jackstands with a load rating of 1000 poun ds or more.

One jackstand under each corner of the mower (four

total) must be installed befo re working und erneath this

unit.

When blocking, you must consider overall stability of

the unit. Just blocking under the unit will not ensure

your safety. The working surface must be level and

solid to support the loaded weight of the jackstands.

Test ja ckstand stability before worki ng under any portion of the mower.

Figure 7. Jackstand Placement

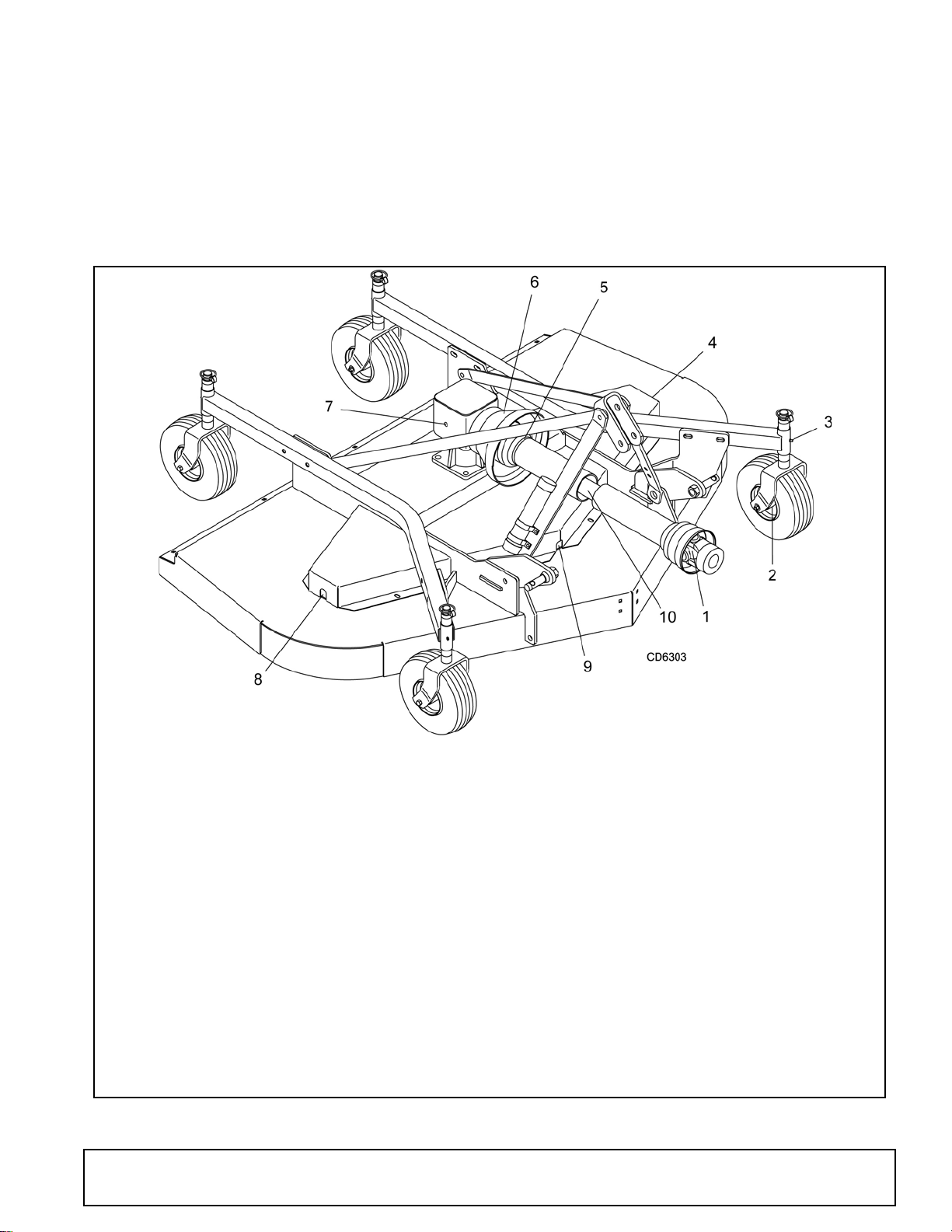

Lubrication Information

Do not let excess grease collect on or around parts,

particularly when operating in sandy areas.

Figure 8 shows the lubric ation points. Th e accom panying chart gives the fr eq uen cy of l ubri ca tio n in ope ra tin g

hours, based on normal operating conditions.

Severe or unusual conditions may require more frequent lubrication. So me refer ence num bers have mor e

than one location; be sure you lubricate all locations.

Use a lithium grease of #2 consistency with a MOLY

(molybdenum disulfide) additive for all locations. Be

sure to clean fittings thoroughly before attaching

grease gun. When a pplied accordin g to the lubricat ion

chart, one good pump of most guns is sufficient.

Use SAE 90W gear lube i n the gearb ox. Fill to pl ug on

side of gearbox.

Check gearbox daily for evidence of leakage at both

seals and the gasket between the housing and cover. If

leakage is noted, repair imm ediately. There may be a

small amount of lube em itted from the vent plug; thi s is

not considered leakage.

Overfilling the ge arbox wi ll caus e the e xces s gear lube

to blow out vent plug and ruin the belt.

Driveshaft Lubrication

Lubricate the driveshaft slip joint every 40 operating

hours. Failure to maintain proper lubrication could

result in damage to U-joints, gearbox, and driveshaft.

1. Lower mower to ground.

14 Owner Service

MAN0260 (Rev. 1/12/2007)

Page 15

2. Remove front half of driveshaft.

3. Apply grease all around and along inner shaft.

4. Reassemble driveshaft halves.

5. Rai se and lower mower several times to distribute

grease.

SERVICE BELT

Replace Belt

One of the major causes of belt failure is improper

installation. Before installi ng a new belt, check the following:

1. Check pulley shafts and bearings for wear.

2. Check pulley grooves for cleanliness.

3. Make sure spindles turn freely and without wobble.

Ref

No.

1 Front U-Joint 8 Hours

2 Caster Wheel (Four wheels) 8 Hours

3 Caster Pivot (Four wheels) 8 Hours

4 Left Spindle (Access through hole) 40 Hours

5 Shield Bearings 8 Hours

6 Rear U-Joint 8 Hours

7 Gearbox (Fill to center of horizontal shaft with

SAE 80W or 90W gear lube)

8 Right Spindle (Access through hole) 40 Hours

9 Center Spindle (Access through hole) 40 Hours

10 Slip Joint 40 Hours

MAN0260 (Rev. 1/12/2007)

Description Frequency

Check Daily

For Leakage

Figure 8. Lubrication Points & Chart

Owner Service 15

Page 16

If grooves require cle ani ng, moi ste n a clo th wi th a no n-

CAUTION

flammable, non-toxic deg reasing agent or commercial

detergent and water.

Avoid excessive force during installation. Do not use

tools to pry belt into pulley groov e. Do not roll be lt over

pulleys to install . This can cause hidden dam age and

premature belt failure.

Install Belt

Refer to Figure 9.

1. Sl ide belt under d rive pulley A an d over idler arm .

Position belt around drive pulley A.

2. It ma y be necessary to r emove front bolts (1) and

swing gearbox stand up to g a in acce ss to pul le y A .

Route belt around pulley B, idler C, and pulley D as

shown.

3. Make sure belt is on drive pulley A and route

around idler F.

4. Grasp belt between spindle pulley E, spring-loaded

idler F and spindle pulley D. Pull spring-loaded

idler with belt to obtain enoug h belt length to r oute

it over pulley E. Make sure spring-loaded idler

pivots freely with belt installed.

IMPORTANT

■ Use care when installing or removing belt from

spring-loaded idler. Springs store energy when

extended and, if released suddenly, can cause personal injury.

SERVICE BLADE

WARNING

Before dismounting power unit or performing

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3-point

hitch and all raised components to the ground,

operate valve levers to release any hydraulic pressure, set parking brake, stop engine, remove key,

and unfasten seat belt.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Frequently check blades. They should be sharp,

free of nicks and cracks, and securely fastened.

1. Inspect blades before ea ch use to determine that

they are mounted securely and are in good condition.

2. Replace any blade that is bent, excessively nicked,

worn, or has any other damage.

3. Small nicks can be ground out when sharpening.

Remove Blades

WARNING

Figure 9. Belt Routing

Do not handle blades with bare hands. Careless

or improper handling may result in serious injury.

1. Remove bolt (1), Figu re 11, which has right hand

threads.

2. Remove washer and blade.

Sharpen Blades

IMPORTANT

■ When sharpening blades, be sure to balance

them. Unbalanced blades will cause excessive

vibration that can damage blade spindle bearings.

Vibration may also cause structural cracks in

mower housings.

16 Owner Service

MAN0260 (Rev. 1/12/2007)

Page 17

Figure 10. Blade Balancing

CAUTION

1. Follow original sharpening pattern.

2. Do not sharpen blade to a razor edge, but leave

approximately 1/64" blunt edge.

3. Do not sharpen back side of blade.

4. Sharpen both cutting edges equally to keep blad e

balanced. Balance blade using the me thod shown

in Figure 10.

Install Blades

Chain Shielding

DANGER

Full chain shielding, designed to reduce the

possibility of thrown objects, must be installed

when operating in populated areas or other areas

where thrown objects could injure people or damage property. If this machine is not equipped with

full chain shielding, operation must be stopped

when anyone comes within several hundred feet.

Check that chain shielding is in good condition and

replace any damaged chain links.

CLEANING

After Each Use

● Remove large debris such as clumps of dirt, grass,

crop residue, etc. from machine.

● Inspect machine and replace worn or damaged

parts.

● Replace any safety decals that are missing or not

readable (supplied free by your Woods dealer).

Your dealer can supply genuine replacement

blades. Substitute blades may not meet original

equipment specifications and may be dangerous.

IMPORTANT

■ When installing blade, the lift of the blade must

be toward the spindle blade housing as shown in

Figure 11. Torque bolt (1) into shaft assembly to

100 lbs-ft.

1. Place blade over bla de pilot on the bottom of the

shaft assembly.

2. Place bell washer (2) over blade and insert blade

bolt (1). Torque blade bolt to 100 lbs-ft.

Periodically or Before Extended Storage

● Clean large debris such as clumps of dirt, grass,

crop residue, etc. from machine.

● Remove the remainder using a low-pressure water

spray.

1. Be careful when spraying near scratched or torn

safety decals or near edges of decals as wa ter

spray can peel decal off surface.

2. Be careful when spraying near chipped or

scratched paint as water spray can lift paint.

3. If a pressure washer is used, follow the advi ce

of the pressure washer manufacturer.

● Inspect machine and replace worn or damaged

parts.

● Sand down scratches and the edges of areas of

missing paint and coat with Woods spray paint of

matching color (purchase from your Woods

dealer).

● Replace any safety decals that are missing or not

readable (supplied free by your Woods dealer).

See Safety Decals section for location drawing.

1. 5/8 NF x 2 Cap screw GR5

2. Bell washer, 5/8 x 1-3/4 x .075

Figure 11. Blade and Spindle Assembly

MAN0260 (Rev. 1/12/2007)

Owner Service 17

Page 18

TROUBLESHOOTING

MOWING CONDITIONS

PROBLEM POSSIBLE CAUSE SOLUTION

Grass cut higher in center of

swath than at edge

Grass cut lower in center of

swath than at edge

Streaking conditions in swath Conditions too wet for mowing Allow grass to dry before mowing.

Height of mower higher at front

than at rear

Loose blade Check blade hardware.

Height of mower lower at front

than at rear

Loose blade Check blade hardware.

Blades unable to cut that part of

grass pressed down by path of

tractor tires

Dull blades Sharpen or replace blades.

Adjust mower height and attitude so

that mower rear and front are within

1/2 inch of same height. See instructions on page 11.

Adjust mower height and attitude so

that mower rear and front are within

1/2 inch of same height. See instructions on page 11.

Slow ground speed of tractor but keep

engine running at fu ll PTO rpm. Cutting lower will help. Adj ust tractor tire

spacing if possible.

Material discharges from mower

unevenly; bunches of material

along swath

Loose blade Check blade hardware.

Material too high and too much

material

Grass is wet Allow grass to dry before mowing.

Reduce ground speed but maintain

540 rpm at tractor PTO, or make two

passes over material. Raise mower

for the first pass and lower for the second and cut 90-degrees to firs t pass.

Raise rear of mower high enough to

permit material discha rge, but not so

high that conditions listed above

occur.

Slow ground speed of tractor but keep

engine running at full PTO rpm.

18 Owner Service

MAN0260 (Rev. 1/12/2007)

Page 19

TROUBLE SHOOTING

BELT COND I T IONS

PROBLEM POSSIBLE CAUSE SOLUTION

Belt slippage Mower overloading; material too

tall or heavy

Oil on belt from over lubricating Be careful not to over lubricate. Clean

Belt hung up or rubbing Check belt position in pulleys and

Frayed edges on belt cover Belt is misaligned Re-align belt. Be sure belt does not

Pulley is misaligned Inspect to ensure belt is running in

Reduce tractor ground speed but

maintain full PTO rpm. Cut material

twice, one high pass and then mow at

desired height. Cut 90-degrees to first

pass.

lubricant from belt and pulleys with

clean rag. Replace oil-soaked belt.

idlers. Check belt for free travel in pulleys. Check under mo wer and ar ound

blade spindle shaft for wire, rags, or

other foreign material. Clean all material from under mower.

rub any other part while running.

center of backside idler. Shim idler as

necessary to a l ign.

Belt rollover Pulley is misaligned Re-align.

Damaged belt Replace belt. *

Foreign object in pulley groove Inspect all pulley grooves for rust,

paint, or weld spots and remove.

Worn pulley groove Replace pulley.

Damaged belt Rollover, high shock loads or

installation damaged

Belt breakage High shock loads Avoid abusive mowing. Avoid hitting

Belt came off drive Check pulleys for foreign material in

* Check belt for damage by laying it flat on the floor. A belt that does not lie flat (has humps or twists, indicating broken

or stretched cords) must be replaced.

Replace belt. *

the ground or large obstructions.

grooves. Avoid hit ting solid objects or

ground.

MAN0260 (Rev. 1/12/2007)

Owner Service 19

Page 20

DEALER SERVICE

CAUTION

The information in this section is written for de aler service personnel. The repair described here requires

special skills and tools. If your shop is not properly

equipped or your mec han ic s a r e not pr ope rly trained in

this type of repair, you may be time and money ahead

to replace complete assemblies.

WARNING

Before working underneath, read manual

instructions, securely block up, and check stability .

Secure blocking prevents equipment from dropping due to hydraulic leak down, hydraul ic system

failure, or mechanical component failure.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Figure 12. Jackstand Placement

BLADE SPINDLE REPAIR

Spindle repair requires special sk ills and tools. If your

shop is not properly equipp ed or your mechanics are

not trained in this type of repair, you may be time and

money ahead to use a new spindle assembly.

Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

BLOCKING METHOD

Do not work underneath mower unless it is properly

attached to the tractor and blocked securely. When

properly attached, the unit will be anchored to minimize

front to rear movement.

Raise mower completely, set tractor brakes, turn

engine off, remove key, block tractor wheels fron t and

rear, and disconnect mower driveline from tractor.

The only approved blocking devic es for this mo wer are

jackstands with a load rating of 1000 poun ds or more.

One jackstand under each corner of the mower (four

total) must be installed befo re working und erneath this

unit.

When blocking, you must consider overall stability of

the unit. Just blocking under the unit will not ensure

your safety. The working surface must be level and

solid to support the loaded weight of the jackstands.

Test ja ckstand stability before worki ng under any portion of the mower.

For reference, the grease fitting is in the top of the spindle shaft.

Permatex

recommended as a sealant.

®

3D Aviation Form-A-Gasket or equivalent is

Remove Spindle

1. Remove belt shields from deck.

2. Remove belt.

3. Remove blade from spindle assembly.

4. Remove nuts (6) and bolts (9) that sec ure spindle

to mower. (See Figure 13.)

Disassemble Spindle

1. Remove bolt (1) and washer (2) from the top of the

spindle.

2. Remove sheave (3) and spacer (4).

NOTE: A wheel puller may be needed if sheave

can not be removed by hand. Retain key (11).

3. Slide shaft assembly (12), lower bearing (5), and

long spacer (10) out the bottom of s pindle h ousing

(8).

4. Remove upper bearin g (5) and spacer (4 ) from to p

of spindle housing.

5. Inspect parts and replace as needed.

20 Dealer Service

MAN0260 (8/6/2004)

Page 21

4. Install upper bearing (5) over shaft with the seal

facing up.

5. Install spacer (4) and sheave (3) over shaft.

6. Align keyways i n shaft and sheave and insert ke y

(11).

7. Install washer (2), and bolt (1). Torque bolt to 35

lbs-ft.

8. Rotate sheave and check for free movement.

9. Lubricate spindle.

GEARBOX REPAIR

Read this entire section before starting any repair.

Many steps are dependent on each other.

Fill gearbox with SAE 80W or 90W gear lube until it

runs out the side level plug.

Repair to this gearbox is limited to replacing bearings ,

seals, and gaskets. Replacing gears, shafts, and a

housing is not cost effective. It is more economical to

purchase a complete gearbox if repair to anything other

than replacement of bearings, seals or gaskets is

required.

Inspect gearbox for leakage and bad bearings.

CD6308

1. 3/8 NF x 1 HHCS GR5

2. Cup washer

3. Sheave

4. Spacer

5. Spindle bearing

6. 3/8 NC Flange lock nut

7. 1/4 Tapered grease fitting

8. Spindle housing

9. 3/8 NC x 1-1/2 HHCS

GR5

10. Spacer

11. Square key

12. Shaft assembly

13. Blade kit

14. Cup washer

15. 5/8 NF x 2 HHCS GR5

Figure 13. Blade Spindle Assembly

Assemble Spindle

1. Slide lower bearing (5) over shaft assembly (12)

with seal down.

2. Slide long spacer (10) on shaft assembly.

3. Insert shaft assembly with bearing and spacer int o

spindle housing from the bottom.

Leakage is a very serious problem and must be corrected immediately.

Bearing failure is indicated by excessive noise and side

to side or end play in gear shafts.

Seal Replacement

Recommended sealant for gearbox repair is Perma-

®

Aviation 3D Form-A-Gasket or equivalent.

tex

Leakage can occur at th e vert ical or horiz ontal gaskets

and shaft seals.

Leakage at the horizontal gasket or seal can be

repaired without removing the gearbox from the mower.

Seal Installation

NOTE: Proper seal installation is important. An improp-

erly installed seal will leak.

1. Clean area in housing wh ere seal outer diameter

(OD) seats. Apply a thin coat of Permatex.

2. Inspect area of shaft where seal seats. Remove

any burrs or nicks with an emery cloth.

3. Lubricate gear shaft and seal lips.

4. Place seal squarely on housin g, spring-loaded lip

toward housing. Select a piece of pipe or tubing

with an OD that will sit on the outside edge of the

seal but will clear th e housing. Tubing with an OD

that is too small will bow seal cage and ruin seal.

5. Carefully press seal into housing, avoiding

distortion to the metal seal cage.

(Rev . 5/27 /20 05)

MAN0260 (8/6/2004)

Dealer Service 21

Page 22

2

Incorrect

Installation

3

CD1092

1

1.Seal

2.Pipe or tube

3.Seal seat

4.Casting

Pipe or tube must

press at outer

edge of seal

Figure 14. Seal Installation Figure 15. Gearbox Stand Assembly

1. Seal

2. Snap ring

3. Shim 55.4 mm x 61.7 mm

4. Ball bearing

5. Input shaft

6. Key 8 mm x 10 mm x 30

mm

7. Input gear

8. Ball bearing

9. Shim 60.3 mm x 71.7 mm

10. Snap ring

11. Oil cap

12. Output shaft & gear

13. Ball bearing

14. Shim kit

15. Snap ring

16. Spacer

17. Shim 60.3 mm x 71.7 mm

18. Snap ring

19. Seal

20. Washer, 1.58 x 3.13 x .04

21. Snap ring

4

CD1094

CD6306

22. Washer 25 mm x 44 mm x

4 mm

23. Castle nut M24 x 2

24. 3/16 x 2 Cotter pin

25. 3/8 Solid plug

26. M10 x 22 mm Hex head

screw

27. Vent plug

28. Cover

29. Ball bearing

30. Spacer

Figure 16. Gearbox Assembly

22 Dealer Service

(Rev . 1/1 2/20 07)

MAN0260 (8/6/2004)

Page 23

Vertical Shaft Seal Replacement

Disassemble Gearbox

Refer to Figure 15.

1. Disconnect and remove the driveline from the

gearbox.

2. Rem ove vent plug (15) and sipho n gear lube from

housing through this opening.

3. Remove gearbox stand from mower deck.

4. Remove gearbox and pulley from stand (2).

5. Rem ove vertical s haft seal. Replace with new seal

(see Seal Replacement, page 21).

Vertical seal should be re cessed in housin g. Hori-

zontal seal should be pr essed flu sh with ou tside of

housing.

NOTE: Distortion to seal c age or damage to seal

lip will cause seal to leak.

6. Fill gearbox with SAE 80W or 90W gear lube until it

runs out the level plug.

7. Assemble gearbox and pulley to gearbox stand.

Attach gearbox stand to mower deck.

Horizontal Shaft Seal Replacement

1. Disconnect and remove the driveline from the

gearbox.

2. Remove vent plug (27), Figure 16, and siphon gear

lube from housing through this opening.

3. If the leak occurred at either end of horizontal shaft,

remove oil cap (11) and/or oil seal (1). Replace

with new one (see Seal R eplacement, page 21).

4. Fill gearbox with SAE 80W or 90W gear lube until it

runs out the level plug.

1. Remove top cover (28), Figure 16, from housing.

Turn gearbox upside down and pour out r emai ning

gear oil from gearbox.

2. Remove oil cap (11) (to be replaced).

3. Remove snap ring (10) and shim (9) from input

shaft (5).

4. Support gearbox in hand press and push on input

shaft (5) to remove bearing (8).

5. Remove gear (7) from inside housing.

6. Remove oil seal (1) from front of housing (to be

replaced).

7. Remove snap ring (2) and shim (3) from front of

housing.

8. Remove input bearing (4) by using a punch and

hammer from outside of housing.

9. Support housing in vise in a horizontal position.

10. T he castle nut (23) an d cotter pin (24) are alre ady

removed with the drive sheave. Remove the snap

ring (18), washer (20), and seal (19).

11. Remove output shaft (12) and bear ings by using a

punch and hammer and tap on top to drive down.

12. Inspect gears for broken teeth and wear. Some

wear is normal and will show on laded side. Forged

gear surfaces are rough when new. Check that

wear pattern is smooth.

13. Inspect vertical and horizontal shafts for grooves,

nicks, or bumps in the areas where the seal s seat.

Resurface any damage with emery cloth.

14. Inspect housing and caps for cracks or other

damage.

Remove Gearbox from Mower

1. Dis connect and r emove the r ear driveline fro m the

gearbox.

2. Remove vent plug (15), Figure 15, and siphon gear

lube from housing through this opening.

3. Remove gearbox stand (2) from mower deck by

removing four hex screws (8).

4. Remove four cap screws (14) and washers (13)

and remove shield (12) from gearbox.

5. Rem ove castle nut (6) and hardware from output

shaft of gearbox.

6. Remove sheave (3) from gearbox.

7. Remove four bolts (10) that attach gearbox to

gearbox stand and remove gearbox.

MAN0260 (8/6/2004)

Reassemble Gearbox (RD60, RD74 shown,

RDC54 similiar)

Refer to Figure 16.

NOTE: Repair to this gearbox is limited to replacing

bearings, seals, and ga skets. Replacing gears, shafts,

and a housing is not cost effective. Purcha sing a complete gearbox is more economical.

1. Clean housing, paying special attention to areas

where seals will be installed.

2. Wash housing and component thoroughly. Select a

clean area for gearbox assembly. Replace all seals

and bearings. All parts must be clean and lightly

oiled before reassembling.

Dealer Service 23

Page 24

RD60 & RD72

3. Ins tall upper output bearing (13), shims (14), and

snap ring (15) on output shaft (12). Use new shims

equal to the thickness of the original shims.

4. Pr ess output shaft assembly into housin g from the

bottom opening.

5. Install spacer (16), lower output bearing (13),

shims (17), and snap ring (18) in bottom of

housing.

RDC54

3. Ins tall shim s (14 ), uppe r outpu t bearing ( 8), spacer

(16), lower output bearing (8), shims (17), and

snap ring (15) on output shaft. Use new shims

equal to the thickness of the original shims.

4. Pr ess output shaft assembly into housin g from the

bottom opening.

5. Install snap ring (18) in bottom of housing.

All Models

6. Apply grease to lower seal lips (19), and press seal

over output shaft (5), using a round tube of the

correct diameter. Be sure not to damage the seal

lip. Press in housing so that the seal is recessed.

7. Ins ert protective washer (20) (R D60 & RD72 only)

by hand.

8. Ins tall snap ring (21) and position it together with

seal (19) by pressing it into positi on. Verify that the

snap ring is seated properly.

9. Pr ess bearing (8) into the h ousing, using a round

tube of the correct diameter and a hand press.

Secure with shims (9) and snap ring (10).

10. Install key (6) on input shaft (5).

11. Place gear (7) through top of housing and align the

two gears so they match.

12. While holding gear (7) in place, slide input shaft (5)

through the gear and bearing (8).

13. Slide spacer (29) (RDC54 only) and bearing (4)

over input shaft (5) and press in to ho us ing , us ing a

round tube of the correct diameter and a hand

press.

17. Pr ess in input seal (1), using a round tube of the

correct diameter. Be careful not to damage the seal

lip.

18. Pr ess oil cap (11) on to the rear cover of housing ,

using a round tube of the correct diameter.

19. Che ck the gearbox housing for leaks by plugging

all holes except one. Apply 4 psi compressed air

and immerse the gearbox in water to verify that

there are no leaks.

20. Rem ove the gearbox from water and dry off with

compressed air. Add SAE 80W or 90W EP oi l until

it runs out of the side level hole. Tighten all plugs.

Install Gearbox

NOTE: Gearbox is heavy: do not attempt to move with-

out mechanical assistance.

1. Set gearbox on gearbox stand and fasten with

bolts and nuts. Torque bolts to 175 lbs-ft.

2. Attach drive sheave to output s haft. Secure using

castle nut and hardware previo usly remo ve d.

3. Attach gearbox stand to mower using four hex

screws.

Install Drive Sheave

1. When gear stand is installed on mower, dimension

A (from the top of the mower deck to the center line

of the drive pulley) must be 2-1/16" (±1/32"). This is

a critical dimens ion a nd mus t be ca reful ly ad juste d

for proper belt life. Add or sub tract shim washers

under idler pulley to align with drive pulley.

2. Tighten gear stand hardware.

3. Fill gearbox half full with SAE 90W gear lube.

4. Check level after waiting five minutes to permit

lube to work through bearings. Add lube, if

necessary, until gearbox is half full.

5. Replace driveline shield. Attach driveline to

gearbox.

14. Slide shim (3) over input shaft and secure with

snap ring (2).

15. Check input shaft end float by moving the input

shaft by hand. If the end float is more than .012",

insert shim (9) between the rear bearing (8) and

snap ring (10).

16. Check that gear backlash is between .006" and

.016". You should not have to adjust the backlash.

24 Dealer Service

MAN0260 (8/6/2004)

Page 25

UNIVERSAL JOINT REPAIR

1. Yok e

2. Cup and bearings

3. Snap ring

4. Journal cross

Figure 17. U-Joint Exploded View

U-Joint Disassembly

1. Remove external snap rings from yokes in four

locations as shown in Figu re 18.

CD1386

Figure 19

CD1385A

Figure 18

2. With snap rings removed, support drive in vise,

hold yoke in hand and tap on yoke to drive cup u p

out of yoke. See Figure 19.

3. Cla mp cup in vise as sho wn in Figure 20 and tap

on yoke to completely remove cup from yoke.

Repeat Step 2 & Step 3 for opposite cup.

4. Place universal cross in vise as shown in Figure 21

and tap on yoke to remove cup. Repeat Step 3 for

final removal. D rive remaining cup ou t with a drift

and hammer.

CD1387

Figure 20

CD1388

MAN0260 (8/6/2004)

Figure 21

Dealer Service 25

Page 26

U-Joint Assembly

1. Place seals securely on bearing cups. Insert cup

into yoke from outside and press in with hand

pressure as far as possible. Insert journal cross

into bearing cup with grease fitting away from

shaft. Be careful not to disturb needle bearings.

Insert another bearing cup directly across from first

cup and press in as far as possible with hand

pressure.

2. Trap cups in vise and apply pressure. Be sure

journal cross is started into bearings and continue

pressure with vise, squeezing in as far as possible.

Tapping the yok e will help .

3. Seat cups by placing a drift or socket (slightly

smaller than the cup) on cup and rap with a

hammer. See Figure 22. Install snap ring and

repeat on opposite cup.

4. Repeat Step 1 & Step 2 to install remaining cups in

remaining yoke.

5. Move both yokes in all directions to check for free

movement. If movement is restricted, rap on yokes

sharply with a hammer to relieve any tension.

Repeat until both yokes move in all directions

without restriction.

Figure 22

26 Dealer Service

MAN0260 (8/6/2004)

Page 27

ASSEMBLY INSTRUCTIONS

CAUTION

DEALER SET-UP INSTRUCTIONS

Assembly of this mower is the responsibility of the

Woods dealer. It should be delivered to the owner completely assembled, lubric ated, and adjusted for normal

cutting conditions.

Complete Dealer Check Lists on page 31 when you

have completed the assembly.

The mower is ship ped partially assembled. Assembly

will be easier if components are aligned and loosely

assembled before tightening hardware. Recommended

torque values for hardware are located on page 43.

Select a suitable worki ng area. Open parts boxes and

lay out parts and hardware to make location easy.

Refer to illustrations, accompanying text, parts lists and

exploded view drawings.

WARNING

Before working underneath, carefully read Operator’s Manual instructions, disconnect driveline,

raise mower, securely block up all cor ners with

jackstands, and check stability. Secure blocking

prevents equipment from dropping due to hydraulic leak down, hydraulic system failures, or

mechanical component failures.

Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

Uncrate Mower

1. Remove sides and top of mower shipping crate.

Install A-Frame Arms

1. Loosen lock nuts (52) at lower hitch point and

install A-frame arms (13) as shown.

2. Tighten nut securely.

3. Repeat for opposite side.

CD6497

13. A-frame arms

14. Rear offset link arms

15. Top link U-bracket

16. Sleeve 1-1/4 x 1-3/4 x 2-3/4

25. Sleeve 5/8 x 1 x 7/16

51. 1/2 NC Flanged lock nut

52. 5/8 NC Flanged lock nut

54. 5/8 Standard flat washer

55. 1/2 NC x 1-1/4 HHCS GR5

56. 5/8 NC x 2-1/2 HHCS GR5

Figure 23. A-Frame Arms Installed

2. Remove lag screws and brackets that secure

mower to crate base.

3. Remove driveshaft wired to mower deck.

(Rev. 1/13/2006)

MAN0260 (8/6/2004)

Assembly 27

Page 28

Install Rear Offset Link Arms

Install Driveshaft

1. Loosen nut (51) and bolt (55) at rear frame lug and

attach rear offset link arm (14) as shown in Figur e

24. (Do not use wheel tube bolt.)

2. Repeat for opposite side.

3. Do not tighten at this time.

CD6497A-1

14. Rear offset link arm

51. Nut, flanged lock 1/2 NC

55. 1/2 NC x 1-1/4 HHCS GR5

Figure 24. Right Rear Offset Link Installed

1. Slide QD yoke of driveshaft assembly onto

gearbox shaft. Make sure QD yoke pin is seated

securely in groove of gearbox shaft.

2. Attach shield anti-rotation chai n to drive shield.

Fill Gearbox

1. Make sure vent plug hole is clear. Fill gearbox half-

full with high quality gear oil that has a viscosity

index of 80W or 90W and an API service rating o f

GL-4 or GL-5.

2. Fill gearbox until oil runs out the side plug on

gearbox.

3. Pour in one pint of gear lube, wait five minute s and

add additional ge ar lube until it just comes o ut of

side hole.

4. Allow an additional fiv e m in utes for the lube to flow

through bearings, then check to make sure oil level

is at bottom of side hole. Re place side pl ug. Install

vent plug.

IMPORTANT

■ Gearbox is not filled at the factory. Prior to

delivery, make sure each gearbox is filled half-full

with 80W or 90W API GL-4 or GL-5 gear lube.

Install Top Link

1. Ins ert cap screw (54) through A-frame a rms (13),

U-bracket (15), sleeve (16) and rear offset link

arms (14) and tighten securely with nut (51).

2. Tighten hardware on rear frame lug and offset link.

CD6497-2

13. A-frame arms

14. Rear offset link arms

15. Link, U-bracket

16. Sleeve, .62 x .84 x 2.75

51. Nut,flanged lock 1/2 NC

54. Screw, HHCS 1/2 NC x 4-3/4 GR5

Figure 25. Top Link Assembled

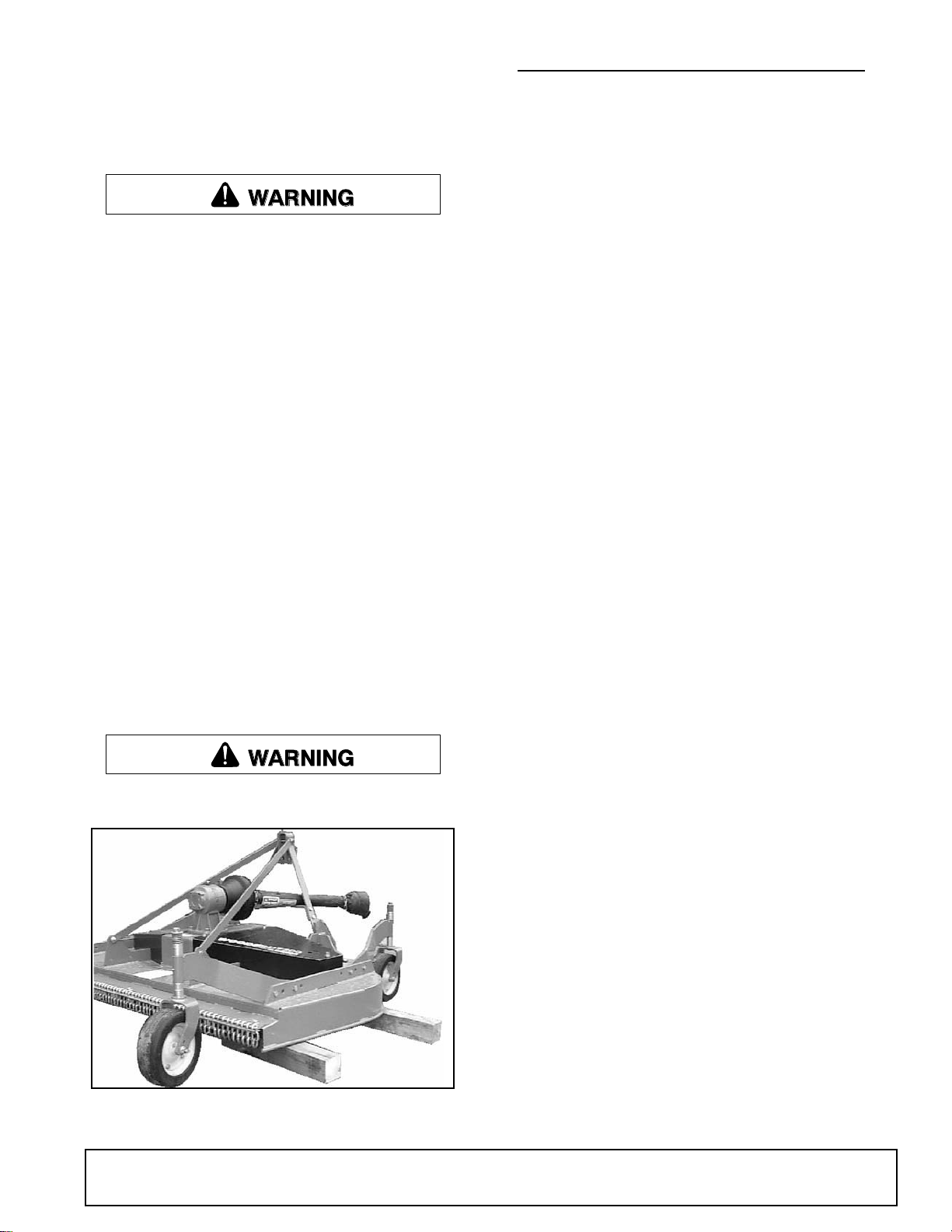

Install Chain Shielding (Optional)

3. Shield, chain plate

14. Bolt, carriage 3/8 NC x 1

15. Nut, flanged lock 3/8 NC

15

14

3

CM768

Figure 26. Chain Shielding Installed

(RD60 & RD72 Only)

28 Assembly

(Rev. 1/13/2006)

MAN0260 (8/6/2004)

Page 29

1. 1/4 Pin

2. 3-Link 1/4 proof chain

3. Shield, chain plate

4. Sleeve 1/2 x 3/4 x 1/2

5. 3/8 NC x 1-1/4 Carriage bolt

6. 3/8 NC Flanged lock nut

Figure 27. Chain Shield Instal led (RDC54 Only)

DANGER

Full chain shielding, designed to reduce the

possibility of thrown objects, must be installed

when operating in populated areas or other areas

where thrown objects could injure people or damage property. If this machine is not equipped with

full chain shielding, operation must be stopped

when anyone comes within several hundred feet.

1. Install chain shielding plate (3) to rear mower frame

as shown.

2. Secure with carriage bolts (14) and flanged lock

nuts (15).

3. Insert carriage bolts from bottom upward as

shown.

Install Quick Hitch Kit (Optional)

(RD60 & RD72 Only)

NOTE: Figure 28 shows RD60. Other models use th e

same assembly instru ct io ns .

NOTE: This kit allows mower to fit only Cat. 1 standard

ASAE quick hitch.

1. Offset link, .38 x 2 x 25.88 (A-frame bars)

2. 38" Long chain

3. Sleeve, .91 x 1.44 x 1.25

4. 1/2 NC x 6 Cap screw

5. 1/2 Flat washer

6. Sleeve, .5 x .75 x 3.38

7. 1/2 NC Flange lock nut

8. Sleeve, .875 x 1.125 x .593 HT

9. 7/8 Flat washer

10. Sleeve, .81 x 1.25 x 1.81

Figure 28. Quick Hitch Kit Installation

1. Attach offset link (1) to mounting pins, using 7/8"

sleeve (8) and flat washer (9). Do not tighten

hardware.

2. Attach upper end of offset link to p ivot link, using

flat washer (5), sleeves (6 & 10), flange lock nut

(7), and 1/2" x 4-3/4" cap screw.

3. Remove rear offset links and replace with chains

(2).

4. Attach chain to top of A-frame as shown, using cap

screw (4), flat washer (5) , and nu t. Attach oppos ite

end of chain (2) to rear mower frame as shown.

5. Cut chain to length (RD60 - 40", RD72 45"). Vary

length slightly as desired. Twist chain to make finite

adjustments in length until unit lifts level.

NOTE: Do not bottom out the drive on front of

deck.

6. Install sleeve (3) on mountin g pins and retain wit h

klik pin.

(Rev. 1/13/2006)

MAN0260 (8/6/2004)

Assembly 29

Page 30

Install Front Roller (Optional)

1. Insert four carriage bolts (8) through the front

mower frame from inside out.

2. Place roller bracket (2) over bolts; then install

flange lock nuts (9) on bolts and tighten.

3. Pl ace front roller (1), sle eve (3), bearings (4), an d

washers (5) in roller bracket as shown in Figure 29.

4. Insert cap screw (3) through bracket and roller.

5. Secure with flanged lock nut (2). Do not

overtighten, roller must spin freely.

NOTES

1. Roller

2. Roller bracket

3. Spacer

4. Bearing

5. 1/2 Flat washer SAE

6. 1/2 NC x 9 HHCS GR5

7. 1/2 NC Flanged locknut

8. 3/8 NC x 1-1/4 Carriage bolt

9. 3/8 NC Flanged locknut

Figure 29. Front Roller Installation

CD6310

30 Assembly

MAN0260 (8/6/2004)

Page 31

DEALER CHECK LISTS

DEALER PRE-DELIVERY CHECK LIST

(DEALER’S RESPONSIBILITY)

Inspect the equipment thoroughly after assembly to

ensure it is se t up properly befo re delivering it to the

customer.

The following check lists are a reminde r of points to

inspect. Check off each item as it is found satisfactory

or after proper adjustment is made.

___ Check tha t all safety de cals are insta lled and in

good condition. Replace if damaged.

___ Check that shields and guards are properly

installed and in g ood c ondition. Rep lace if da maged.

DEALER DELIVERY CHECK LIST

(DEALER’S RESPONSIBILITY)

___ Show cu stomer how to make adjus tments and

select proper PTO speed.

___ Instruct cu stomer how to lubricate and explain

importance of lubrication.

___ Point out the s afety decals. Ex plain their mean-

ing and the need to k eep them in place and in

good condition. Emphasize the increased safety

hazards when instructions are not followed.

___ Present Operator's Manual and request that

customer and all o perators read it before o perating equipment. Point out the manual safety

rules, explain their meanings and emphasize

the increased safety hazards that exist when

safety rules are not followed.

___ Show customer how to make sure driveline is

properly installed and that spring-activated locking pin or collar slides freely and is seated in

groove on tractor PTO shaft.

___ Show custome r the safe, proper procedures to

be used when mounting, dismo unting, and storing equipment.

___ Check all bolts to be sure they are properly

torqued.

___ Check that all cotter pins and safety pins are

properly installed. Replace if damaged.

___ Check and greas e all lubric ation points as iden-

tified in “lubrication information” on page 14.

___ Gearboxe s are not filled at the factory. Prior to

delivery, fill as specified in the "S ervice , lubrication information" o n page 14 and chec k to see

that there are no leaking seals.

___ Check that blades have been properly installed.

___ Explain to c ustomer the potential crus hing haz-

ards of going underneath raised equipment.

Instruct that before go ing u nderneath to d isc onnect the driveline, securely bl ock up all c orners

with jackstands and to follow all instructions i n

the "Service, blocking methods" section of the

Operator’s Manual. Explain that blocking up

prevents equipment dropping from hydraulic

leak down, hydraulic system failures, or

mechanical component failures.

___ For mounted units, add wheel weights, ballast in

front tires, and/or front tractor weight to enhance

front end stability. A minimum 25% of tractor

and equipment gross weight must be on front

tractor wheels. When adding weight to attain