Woods Equipment SG100 User Manual

STUMP GRINDER

SG100

MAN0155 |

(Rev. 2/16/2007) |

|

Tested. Proven. Unbeatable. |

OPERATOR'S MANUAL

OPERATOR'S MANUAL

TO THE DEALER:

Assembly and proper installation of this product is the responsibility of the Woods® dealer. Read manual instructions and safety rules. Make sure all items on the Dealer’s Pre-Delivery and Delivery Check Lists in the Operator’s Manual are completed before releasing equipment to the owner.

The dealer must complete the Product Registration included with the Operator’s Manual. The customer must sign the registration which certifies that all Dealer Check List items have been completed. The dealer is to return the prepaid postage portion to Woods, give one copy to the customer, and retain one copy. Failure to complete and return this card does not diminish customer’s warranty rights.

TO THE OWNER:

Read this manual before operating your Woods equipment. The information presented will prepare you to do a better and safer job. Keep this manual handy for ready reference. Require all operators to read this manual carefully and become acquainted with all adjustment and operating procedures before attempting to operate. Replacement manuals can be obtained from your dealer. To locate your nearest dealer, check the Dealer Locator at www.WoodsEquipment.com, or in the United States and Canada call 1-800-319-6637.

The equipment you have purchased has been carefully engineered and manufactured to provide dependable and satisfactory use. Like all mechanical products, it will require cleaning and upkeep. Lubricate the unit as specified. Observe all safety information in this manual and safety decals on the equipment.

For service, your authorized Woods dealer has trained mechanics, genuine Woods service parts, and the necessary tools and equipment to handle all your needs.

Use only genuine Woods service parts. Substitute parts will void the warranty and may not meet standards required for safe and satisfactory operation. Record the model number and serial number of your equipment in the spaces provided:

Model: _______________________________ |

Date of Purchase: _____________________ |

Serial Number: (see Safety Decal section for location) ____________________________________

Provide this information to your dealer to obtain correct repair parts.

Throughout this manual, the term IMPORTANT is used to indicate that failure to observe can cause damage to equipment. The terms CAUTION, WARNING, and DANGER are used in conjunction with the Safety-Alert Symbol (a triangle with an exclamation mark) to indicate the degree of hazard for items of personal safety.

DANGER

DANGER

WARNING

WARNING

CAUTION

CAUTION

IMPORTANT or NOTICE

NOTE

This Safety-Alert Symbol indicates a hazard and means ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury, and includes hazards that are exposed when guards are removed.

Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury.

Indicates that failure to observe can cause damage to equipment.

Indicates helpful information.

|

|

|

|

2 Introduction |

Gen’l (Rev. 2/5/2007) |

||

|

|

|

|

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 7 SAFETY DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 9 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 OWNER SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 DEALER SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 DEALER CHECK LISTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 PARTS

STUMP GRINDER ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 STUMP GRINDER PARTS LIST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 GEARBOX ASSEMBLY AND PARTS LIST . . . . . . . . . . . . . . . . . . . . . 26 DRIVELINE ASSEMBLY AND PARTS LIST. . . . . . . . . . . . . . . . . . . . . 27

BOLT TORQUE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 BOLT SIZE CHART & ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 29 PARTS WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 PRODUCT WARRANTY . . . . . . . . . . . . . . . . . . . . . . . INSIDE BACK COVER

MAN0155 (Rev.2/16/2007) |

Introduction 3 |

|

|

SG100 SPECIFICATIONS

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1012 lbs. Cutting wheel diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 inches Cutting wheel speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 895 rpm Cutting arc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55 degrees Hub torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 450 lbs-ft. Required horsepower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 to 100 HP Cutting teeth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25 carbide steel teeth Maximum stump height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 inches Maximum cutting depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 inches

GENERAL INFORMATION

The purpose of this manual is to assist you in operating and maintaining your stump grinder. Read it carefully. It furnishes information and instructions that will help you achieve years of dependable performance. These instructions have been compiled from extensive field experience and engineering data. Some information may be general in nature due to unknown and varying operating conditions. However, through experience and these instructions, you should be able to develop procedures suitable to your particular situation.

The illustrations and data used in this manual were current at the time of printing but, due to possible inline production changes, your machine may vary slightly in detail. We reserve the right to redesign and change the machines as may be necessary without notification.

Throughout this manual, references are made to right and left directions. These are determined from the operator’s position in the tractor seat.

4 Introduction |

MAN0155 (Rev. 2/16/2007) |

|

|

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Safety is a primary concern in the design and manufacture of our products. Unfortunately, our efforts to provide safe equipment can be wiped out by an operator’s single careless act.

In addition to the design and configuration of equipment, hazard control and accident prevention are dependent upon the awareness, concern, judgement, and proper training of personnel involved in the operation, transport, maintenance, and storage of equipment.

It has been said, “The best safety device is an informed, careful operator.” We ask you to be that kind of operator.

TRAINING

Safety instructions are important! Read all attachment and power unit manuals; follow all safety rules and safety decal information. (Replacement manuals and safety decals are available from your dealer. To locate your nearest dealer, check the Dealer Locator at www.WoodsEquipment.com, or in the United States and Canada call 1-800-319- 6637.) Failure to follow instructions or safety rules can result in serious injury or death.

If you do not understand any part of this manual and need assistance, see your dealer.

Know your controls and how to stop engine and attachment quickly in an emergency.

Operators must be instructed in and be capable of the safe operation of the equipment, its attachments, and all controls. Do not allow anyone to operate this equipment without proper instructions.

Keep hands and body away from pressurized lines. Use paper or cardboard, not hands or other body parts to check for leaks. Wear safety goggles. Hydraulic fluid under pressure can easily penetrate skin and will cause serious injury or death.

Make sure that all operating and service personnel know that if hydraulic fluid penetrates skin, it must be surgically removed as soon as possible by a doctor familiar with this form of injury or gangrene, serious injury, or death will result. CONTACT A PHYSICIAN IMMEDIATELY IF FLUID ENTERS SKIN OR EYES. DO NOT DELAY.

PREPARATION

Check that all hardware is properly installed. Always tighten to torque chart specifications unless instructed otherwise in this manual.

Always wear relatively tight and belted clothing to avoid getting caught in moving parts. Wear sturdy, rough-soled work shoes and protective equipment for eyes, hair, hands, hearing, and head; and respirator or filter mask where appropriate.

Make sure attachment is properly secured, adjusted, and in good operating condition.

Power unit must be equipped with ROPS or ROPS cab and seat belt. Keep seat belt securely fastened. Falling off power unit can result in death from being run over or crushed. Keep foldable ROPS system in “locked up” position at all times.

Make sure all safety decals are installed. Replace if damaged. (See Safety Decals section for location.)

Make sure shields and guards are properly installed and in good condition. Replace if damaged.

OPERATION

Do not allow bystanders in the area when operating, attaching, removing, assembling, or servicing equipment.

Consult local utilities before working. Know location of all underground cables, pipelines, overhead wires, and other hazards in working area and avoid contact.

Do not put stump grinder into service unless all shields and guards are in place and in good condition. Replace if damaged.

Keep bystanders away from equipment.

Do not operate or transport equipment while under the influence of alcohol or drugs.

Operate only in daylight or good artificial light.

(Safety Rules continued on next page)

SG100 Safety Rules (Rev. 6/16/2006)

Safety 5

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

(Safety Rules continued from previous page)

Avoid contact with electrical wires.

Keep hands, feet, hair, and clothing away from equipment while engine is running. Stay clear of all moving parts.

Always comply with all state and local lighting and marking requirements.

Never allow riders on power unit or attachment.

Power unit must be equipped with ROPS or ROPS cab and seat belt. Keep seat belt securely fastened. Falling off power unit can result in death from being run over or crushed. Keep foldable ROPS system in “locked up” position at all times.

Always sit in power unit seat when operating controls or starting engine. Securely fasten seat belt, place transmission in neutral, engage brake, and ensure all other controls are disengaged before starting power unit engine.

Shift tractor transmission into park or neutral and set brakes before engaging PTO and grinding.

Do not operate PTO during transport.

Do not operate auxiliary hydraulics during transport.

Look down and to the rear and make sure area is clear before operating in reverse.

Use extreme care when working close to fences, ditches, other obstructions, or on hillsides.

Do not operate or transport on steep slopes.

Do not stop, start, or change directions suddenly on slopes.

Use extreme care and reduce ground speed on slopes and rough terrain.

Before performing any service or maintenance, lower equipment to ground or block securely, turn off engine, remove key, and disconnect driveline from tractor PTO.

NEVER GO UNDERNEATH EQUIPMENT. Never place any part of the body underneath equipment or between moveable parts even when the engine has been turned off. Hydraulic system leak-down, hydraulic system failures, mechanical failures, or movement of control levers can cause equipment to drop or rotate unexpectedly and cause severe injury or death.

•Service work does not require going underneath.

•Read Operator's Manual for service instruc-

tions or have service performed by a qualified dealer.

TRANSPORTATION

A minimum 20% of tractor and equipment weight must be on the tractor front wheels when attachments are in transport position. Without this weight, tractor could tip over, causing personal injury or death. The weight may be attained with a loader, front wheel weights, ballast in tires or front tractor weights. Weigh the tractor and equipment. Do not estimate.

Reduce transport speed to avoid bouncing and brief loss of steering control.

Always comply with all state and local lighting and marking requirements.

Never allow riders on power unit or attachment.

Turn off power to unit before transporting.

Do not operate or transport on steep slopes.

Do not operate or transport equipment while under the influence of alcohol or drugs.

MAINTENANCE

Service and maintenance work not covered in OWNER SERVICE must be done by a qualified dealership. Special skills, tools, and safety procedures may be required. Failure to follow these instructions can result in serious injury or death.

Before performing any service or maintenance, lower equipment to ground or block securely, turn off engine, remove key, and disconnect driveline from tractor PTO.

Do not modify or alter or permit anyone else to modify or alter the equipment or any of its components in any way.

Always wear relatively tight and belted clothing to avoid getting caught in moving parts. Wear sturdy, rough-soled work shoes and protective equipment for eyes, hair, hands, hearing, and head; and respirator or filter mask where appropriate.

Do not allow bystanders in the area when operating, attaching, removing, assembling, or servicing equipment.

Make sure attachment is properly secured, adjusted, and in good operating condition.

Never perform service or maintenance with engine running.

6 Safety

SG100 Safety Rules (Rev. 6/16/2006)

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Keep all persons away from operator control area while performing adjustments, service, or maintenance.

Tighten all bolts, nuts, and screws to torque chart specifications. Check that all cotter pins are installed securely to ensure equipment is in a safe condition before putting unit into service.

Make sure shields and guards are properly installed and in good condition. Replace if damaged.

When lubricating telescoping PTO drives, keep fingers out of shield access slots to prevent injury.

STORAGE

Block equipment securely for storage.

Do not climb or lean on equipment stored on stand.

Keep children and bystanders away from storage area.

SG100 Safety Rules (Rev. 6/16/2006)

Safety 7

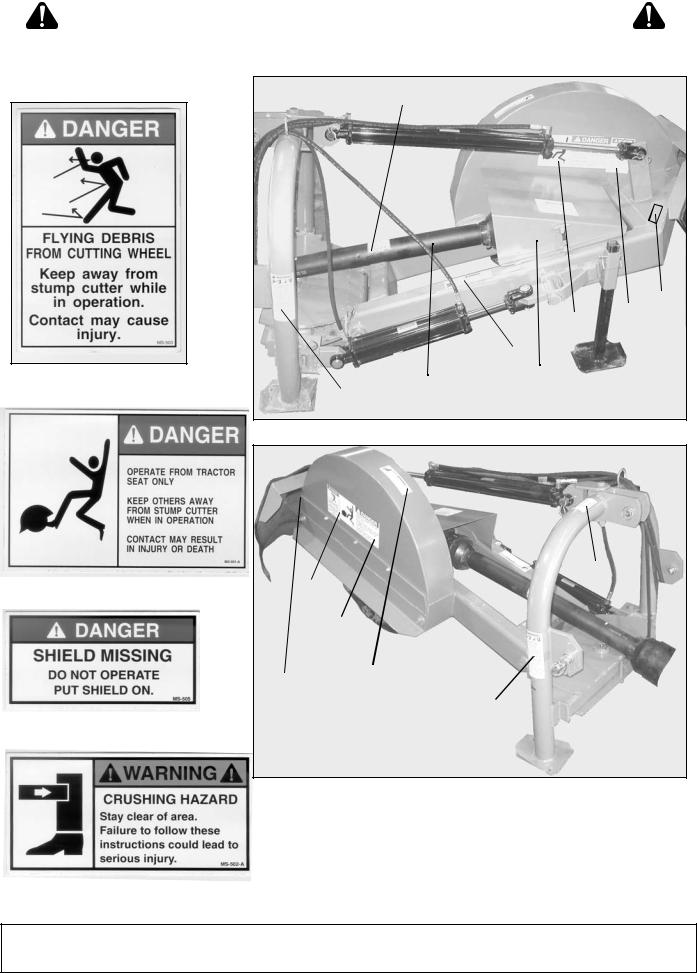

SAFETY & INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged!

1 - PN MS-503

2 - PN MS501-A

3 - PN MS-505

4 - PN MS-502-A

Early Production Only

10

11

|

|

2 |

1 |

|

|

|

|

|

|

5 |

|

|

9 |

3 |

|

7 |

Under Shield |

|

|

Under Shield |

|

||

|

|

|

6

1 |

|

|

2 |

3 |

5 |

|

|

Under Shield |

7 |

8 Safety

SG100 Safety Rules (Rev.2/16/2007)

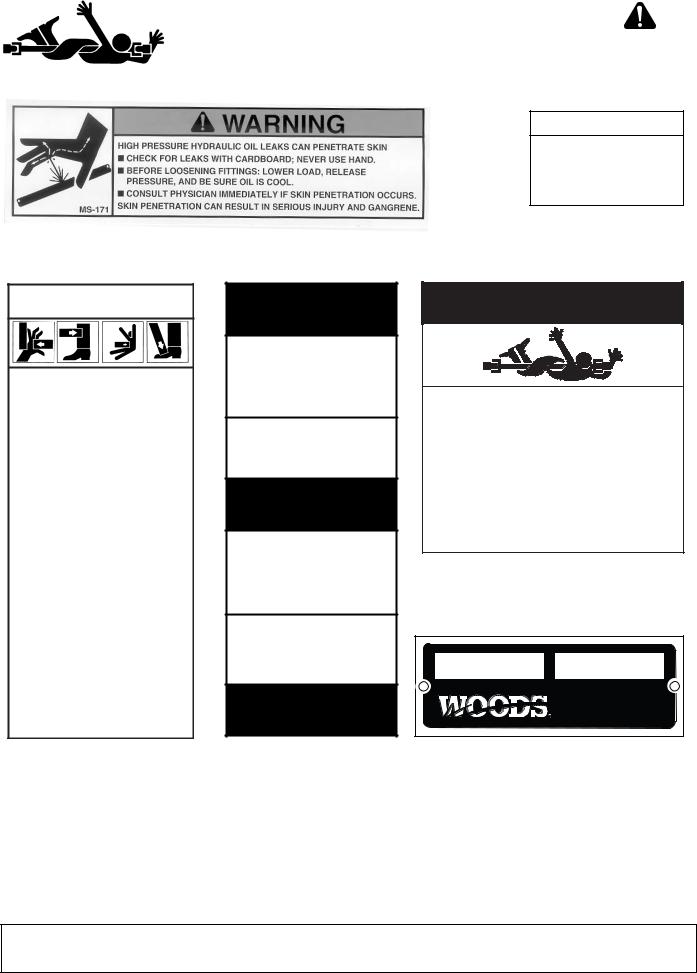

SAFETY & INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged!

5 - PN - MS-171

7 - PN 102941 |

9 - PN33347 |

WARNING

WARNING

CRUSHING AND PINCHING HAZARD

Be extremely careful handling various parts of the machine. They are heavy and hands, fingers, feet, and other body parts could be crushed or pinched between tractor and implement.

Operate tractor controls from tractor seat only.

Do not stand between tractor and implement when tractor is in gear.

Make sure parking brake is engaged before going between tractor and implement.

Stand clear of machine while in operation or when it is being raised or lowered.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN SERIOUS INJURY

OR DEATH.

1002941-A

33347E

BE CAREFUL!

Use a clean, damp cloth to clean safety decals.

6 - 18866

WARNING

WARNING

540 RPM

! " #$

18866-D

10 - PN 18864

DANGER

DANGER

ROTATING DRIVELINE

CONTACT CAN CAUSE DEATH

KEEP AWAY!

DO NOT OPERATE WITHOUT -

All driveline guards, tractor and equipment shields in place

Drivelines securely attached at both ends

Driveline guards that turn freely on

driveline |

18864-C |

|

11 - Serial Number Plate

MODEL NO. |

SERIAL NO. |

Woods Equipment Company

Oregon, Illinois, U.S.A.

Avoid spraying too close to decals when using a pressure washer; high-pressure water can enter through very small scratches or under edges of decals causing them to peel or come off.

Replacement safety decals can be ordered free from your Woods dealer. To locate your nearest dealer, check the Dealer Locator at www.WoodsEquipment.com, or in the United States and Canada call 1-800-319-6637.

SG100 Safety Rules (Rev. 2/16/2007)

Safety 9

OPERATION

The operator is responsible for the safe operation of this stump grinder. The operator must be properly trained. Operators should be familiar with the tractor, stump grinder, and all safety practices before starting operation. Read the safety rules and safety decals on page 5 through page 9.

Do not allow bystanders in the area when operating, attaching, removing, assembling, or servicing equipment.

Make sure attachment is properly secured, adjusted, and in good operating condition.

Do not put digger into service unless all shields and guards are in place and in good condition. Replace if damaged.

CAUTION

CAUTION

Always wear relatively tight and belted clothing to avoid getting caught in moving parts. Wear sturdy, rough-soled work shoes and protective equipment for eyes, hair, hands, hearing, and head; and respirator or filter mask where appropriate.

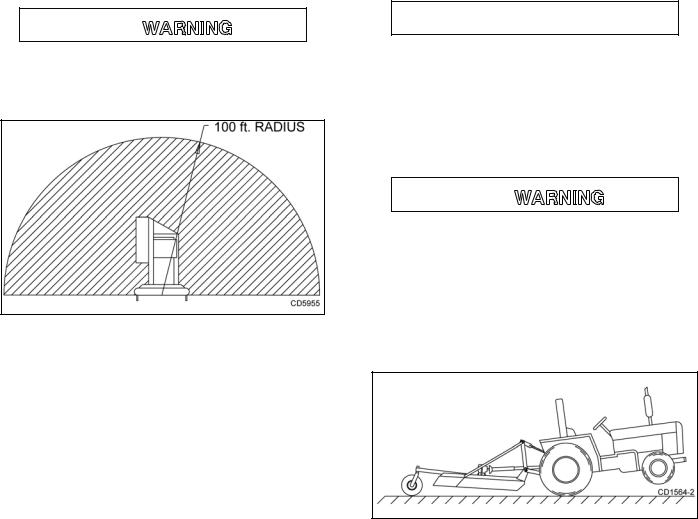

Figure 1. 100 ft. Hazard Zone

Keep bystanders away from equipment.

Keep hands and body away from pressurized lines. Use paper or cardboard, not hands or other body parts to check for leaks. Wear safety goggles. Hydraulic fluid under pressure can easily penetrate skin and will cause serious injury or death.

Make sure that all operating and service personnel know that if hydraulic fluid penetrates skin, it must be surgically removed as soon as possible by a doctor familiar with this form of injury or gangrene, serious injury, or death will result. CONTACT A PHYSICIAN IMMEDIATELY IF FLUID ENTERS SKIN OR EYES. DO NOT DELAY.

Make sure spring-activated locking pin or collar slides freely and is seated firmly in tractor PTO spline groove.

Know your controls and how to stop engine and attachment quickly in an emergency.

Operators must be instructed in and be capable of the safe operation of the equipment, its attachments, and all controls. Do not allow anyone to operate this equipment without proper instructions.

Never allow children or untrained persons to operate equipment.

TRACTOR STABILITY

A minimum 20% of tractor and equipment weight must be on the tractor front wheels when attachments are in transport position. Without this weight, tractor could tip over, causing personal injury or death. The weight may be attained with a loader, front wheel weights, ballast in tires or front tractor weights. Weigh the tractor and equipment. Do not estimate.

Figure 2. Tractor Stability

STUMP GRINDER PRE-OPERATION

NOTE: For operation of this stump grinder, references to right, left, forward, and rearward directions are determined from the operator’s position in the tractor seat.

NOTICE

■ Gearbox does not contain oil. Fill before operating.

1.Fill gearbox with 6 pints of SAE 90 oil.

2.Grease both fittings on the swivel assembly as shown in Figure 4.

3.Grease U-joints on end of driveline as shown.

10 Operation |

MAN0155 (Rev. 2/16/2007) |

|

|

Loading...

Loading...