Page 1

Save this manual

for future reference.

Gardez ce manuel pour

référence ultérieure.

Conserve este manual

para referencia futura.

wolfcraft

630-773-4777

www.wolfcraft.com

OWNER'S

MANUAL

MANUEL

D'UTILISATION

®

MANUAL DEL

PROPIETARIO

MODEL NO. 3408

MODÈLE No. 3408

MODELO NO. 3408

Pages 12-21

Français/Español

CAUTION:

Before using this product,

read this manual entirely

and follow all safety rules

and operating instructions.

MISE EN GARDE:

Avant d'utiliser ce produit,

lire ce manuel entièrement

et respecter toutes les

consignes de sécurité et le

mode d'emploi.

PRECAUCIÓN:

Antes de utilizar este producto,

lea este manual en su totalidad

y siga todas las reglas de

seguridad e instrucciones de

operación.

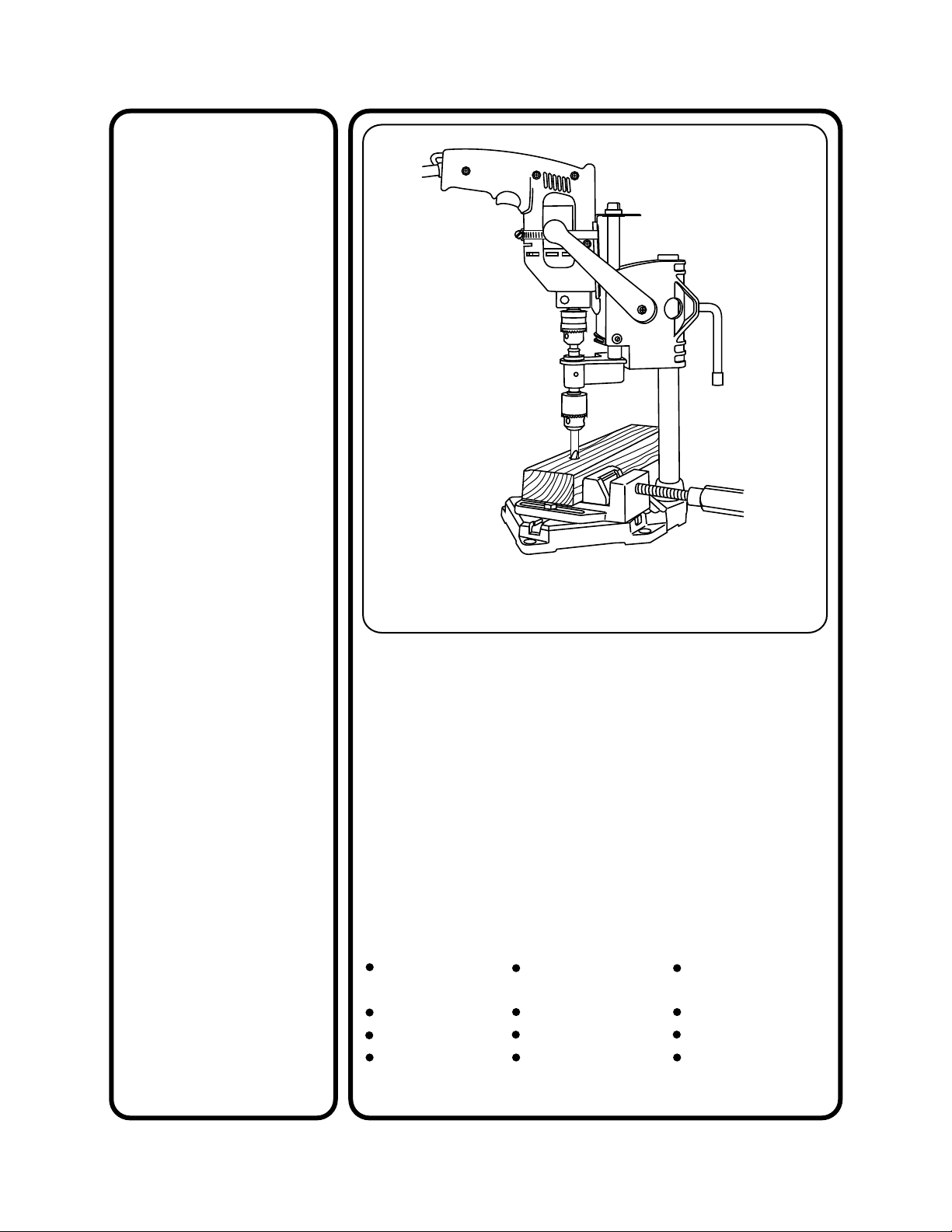

3408

Power tools and some accessories NOT included.

Les outils motorisés et certains accessoires NE sont PAS inclus.

NO se incluyen las herramientas eléctricas y ciertos accesorios.

®

wolfcraft

UNIVERSAL DRILL PRESS STAND

SUPPORT UNIVERSEL DE

PERCEUSE À COLONNE

TALADRADORA UNIVERSAL DE

COLUMNA CON PEDESTAL

Safety

instructions

Assembly

Operation

Repair parts

Consignes de

sécurité

Assemblage

Utilisation

Pièces de

rechange

Instrucciones

de seguridad

Armado

Operación

Piezas de

reparación

Page 2

TABLE OF CONTENTS

WARRANTY.................................................................

SAFETY INSTRUCTIONS ...........................................

UNPACKING AND CHECKING CONTENTS ..............

INTRODUCTION .........................................................

FEATURES AND SPECIFICATIONS...........................

PACKAGE CONTENTS & HARDWARE LEGEND.......

WARRANTY

LIMITED LIFETIME WARRANTY

WARRANTY

This wolfcraft® Drill Press Stand is

warranted against defects in material and

workmanship for the life of the product. The

obligation of the manufacturer under this

warranty is limited to replacement or repair, at

its option, of the product or of any defective

portions thereof. This warranty extends to the

first purchaser only and does not apply to

conditions resulting from abuse, misuse,

alteration, negligence, improper maintenance,

or normal wear and tear. Unauthorized

repairs or tampering with the product will void

this warranty in its entirety.

If you find a defect in material or

workmanship, contact the wolfcraft®

Customer Service Department by e-mail at

customer.service@woa.wolfcraft.com, by

telephone at 630.773.4777, by fax at

630.773.4805, or through the mail at 1222 W.

Ardmore Avenue, Itasca, Illinois 60143. You

will be given instructions on how to resolve the

problem or, if the problem cannot be resolved,

on how to return the product to the

manufacturer for repair or replacement.

LIMITATION ON LIABILITY

Manufacturer shall not be liable for loss or

damage of any kind including incidental or

consequential damages, resulting either

directly or indirectly from the use of this

product.

2

3

4

4

4

5

ASSEMBLY ...............................................................

DRILL MOUNTING.....................................................

OPERATING INSTRUCTIONS.................................

REPAIR PARTS.......................................................

FRANÇAIS/ESPAÑOL ............................................

PRODUCT REGISTRATION CARD........................

7

9

10

11

12

23

Some states do not allow the exclusion or

limitation of incidental or consequential

damages so the above limitation or exclusion

may not apply to you. User assumes all risk or

liability in connection with installation or use of

this product.

This warranty gives you specific legal rights and

you may also have other rights which vary from

state to state.

THE EXPRESS WARRANTY HEREIN IS IN

LIEU OF ANY AND ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED.

NO IMPLIED WARRANTY OF

MERCHANTABILITY IS MADE AND THERE

ARE NO WARRANTIES WHICH EXTEND

BEYOND THE DESCRIPTION ON THE FACE

HEREOF.

WARRANTY CARD

Please complete the information on the

attached warranty card and mail it to

wolfcraft® within 30 days of purchase, or

complete the card on-line at

www.wolfcraft.com. Failure to submit this card

will not adversely affect your warranty rights if

you can otherwise show in a reasonable way

that you were the original purchaser of the

product. Nevertheless, sending this card is a

convenient way to establish in our files the date

of your purchase and help us better meet your

needs in the future.

2

Page 3

SAFETY INSTRUCTIONS

GENERAL SAFETY INSTRUCTIONS FOR POWER TOOLS

READ ALL SAFETY INSTRUCTIONS BEFORE USING

Read the owner's manual carefully. Learn its applications

and limitations as well as the specific potential hazards.

GROUND ALL TOOLS (UNLESS DOUBLE INSULATED)

If tool is equipped with an approved 3-conductor cord and a

3-prong grounding type plug to fit the proper grounding type

receptacle. The green conductor in the cord is the

grounding wire. NEVER connect the green wire to a live

terminal.

KEEP AWAY FROM HAZARDOUS MATERIALS

Normal sparking of the motor could ignite fumes, flammable

liquids, or combustibles.

PROTECT YOURSELF AGAINST PERSONAL INJURY

DO NOT operate any tool while under the influence of

drugs, alcohol, or any medication.

DRESS FOR SAFETY

Do not wear loose clothing, gloves, neckties, or jewelry, as

these items can get caught and draw you into moving parts.

ALWAYS wear non-slip footwear. Tie back long hair. Roll

long sleeves above the elbow.

WEAR SAFETY GOGGLES

Wear safety goggles (must comply with ANSI Z87.1) at ALL

times. Also, use face or dust mask if cutting operation is

dusty, and use ear protectors (plugs or muffs) during

extended periods of operation.

NEVER LEAVE TOOL RUNNING UNATTENDED

Turn power off. Do not leave tool until it comes to a

complete stop.

KEEP HANDS AWAY FROM CUTTING AREA

DISCONNECT TOOLS BEFORE SERVICING

When changing bits, make sure tool is unplugged.

KEEP GUARDS IN PLACE

Be sure guards are in working order, properly adjusted,

and aligned.

KEEP WORK AREA CLEAN

ALWAYS keep your work area clean, uncluttered, and well

lit. DO NOT work on or place router table legs on floor

surfaces that are slippery from sawdust, oil, water, or wax.

DO NOT FORCE THE TOOL

Do not force tool or attachment to do a job for which it was

not designed. It will do the job better and more safely at

the rate for which it was designed.

USE CLAMPS OR A VISE TO HOLD WORK WHEN

PRACTICAL

Using clamps or a vise to hold work is safer than using

your hand. It also frees both hands to operate the tool.

DO NOT OVERREACH

Keep proper footing and balance at all times.

AVOID ACCIDENTAL STARTING

Make sure all switches are in "OFF" position before

plugging in.

NEVER STAND ON TOOL

Serious injury could occur if the tool is tipped or if the

cutting tool is accidentally contacted. DO NOT store

materials above or near the tool making it necessary to

stand on the tool to reach them.

PROTECT AND USE SUITABLE CORDS

NEVER carry tool by cord or yank it to disconnect from

receptacle. Protect cord from heat, oil, and sharp edges.

For outdoor operation, use extension cords intended for

outdoor use.

AVOID A DANGEROUS ENVIRONMENT

DO NOT use power tools in damp or wet locations or

expose them to rain. Keep work area well lit and provide an

adequate surrounding work space.

CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part that is

damaged should be carefully checked to ensure that it will

operate properly and perform its intended function. Check

for alignment of moving parts, binding of moving parts,

breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is

damaged should be properly repaired or replaced.

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and

changing accessories.

USE RECOMMENDED ACCESSORIES

Consult this manual for recommended accessories.

Follow the instructions that accompany the accessories.

The use of improper accessories may cause hazards.

REMOVE ADJUSTING KEYS AND WRENCHES

Form the habit of checking to see that keys and adjusting

wrenches are removed from the tool before turning it on.

ENSURE SAFETY OF OTHERS

Keep visitors and children a safe distance away from the

work area, especially when operating a power tool.

Visitors should wear the same safety equipment as the

operator.

SAVE THESE INSTRUCTIONS

3

Page 4

ADDITIONAL SAFETY INSTRUCTIONS FOR YOUR UNIVERSAL DRILL PRESS STAND

Safety items throughout this manual are labeled with WARNING and CAUTION.

WARNING

Means that failure to follow this safety statement may result in

extensive product damage, serious personal injury, or death.

CAUTION

WARNING

ALWAYS USE EYE PROTECTION

The operation of any power tool can result

in foreign objects being thrown into the

eyes, which can result in severe eye

damage. Always wear safety goggles

complying with ANSI Z87.1 during power

tool operation.

SECURE STAND TO WORKBENCH

Do not attempt to use your Universal Drill

Press Stand unless it is fastened firmly to

your workbench.

Means that failure to follow this safety statement may result in minor or

moderate personal injury, or property or equipment damage.

CAUTION

MOUNT DRILL TO STAND CORRECTLY

Ensure quick-release clamp does not block

ventilation slots on the drill when mounted in

place.

DO NOT USE AS DRILL PRESS WHEN

DRILL IS MOUNTED HORIZONTALLY IN

STAND

SAVE THESE INSTRUCTIONS

UNPACKING AND CHECKING CONTENTS

Separate all parts from packaging materials and

check each item against the package contents

listed in this manual, found on page 5.

Your wolfcraft® Universal Drill Press Stand is

shipped complete in one carton. Make sure all

items are accounted for before discarding any of

the packaging materials.

INTRODUCTION

The wolfcraft® Universal Drill Press Stand

provides an economical and accurate method

for drilling holes in wood, plastic, and metal.

The unique horizontal mounting capability

provides added flexibility to grind, buff, and

sand.

The wolfcraft® Universal Drill Press Stand

can be used with most popular drills.

We are certain you will find the wolfcraft®

Universal Drill Press Stand a valuable addition

to your workshop.

FEATURES AND SPECIFICATIONS

The wolfcraft® Universal Drill Press Stand

features include:

2-1/2" travel adjustable in increments of 1/8"

4-1/2" throat depth

drill bit holding grooves

V-groove in the base to guide round stock

4

a cord mount to keep the drill cord away from

the work area

a cast base that provides stability and

strength

a built-in chuck that ensures accuracy and

repeatability in drilling

a chuck key holder that keeps the chuck key

conveniently available when not in use

Page 5

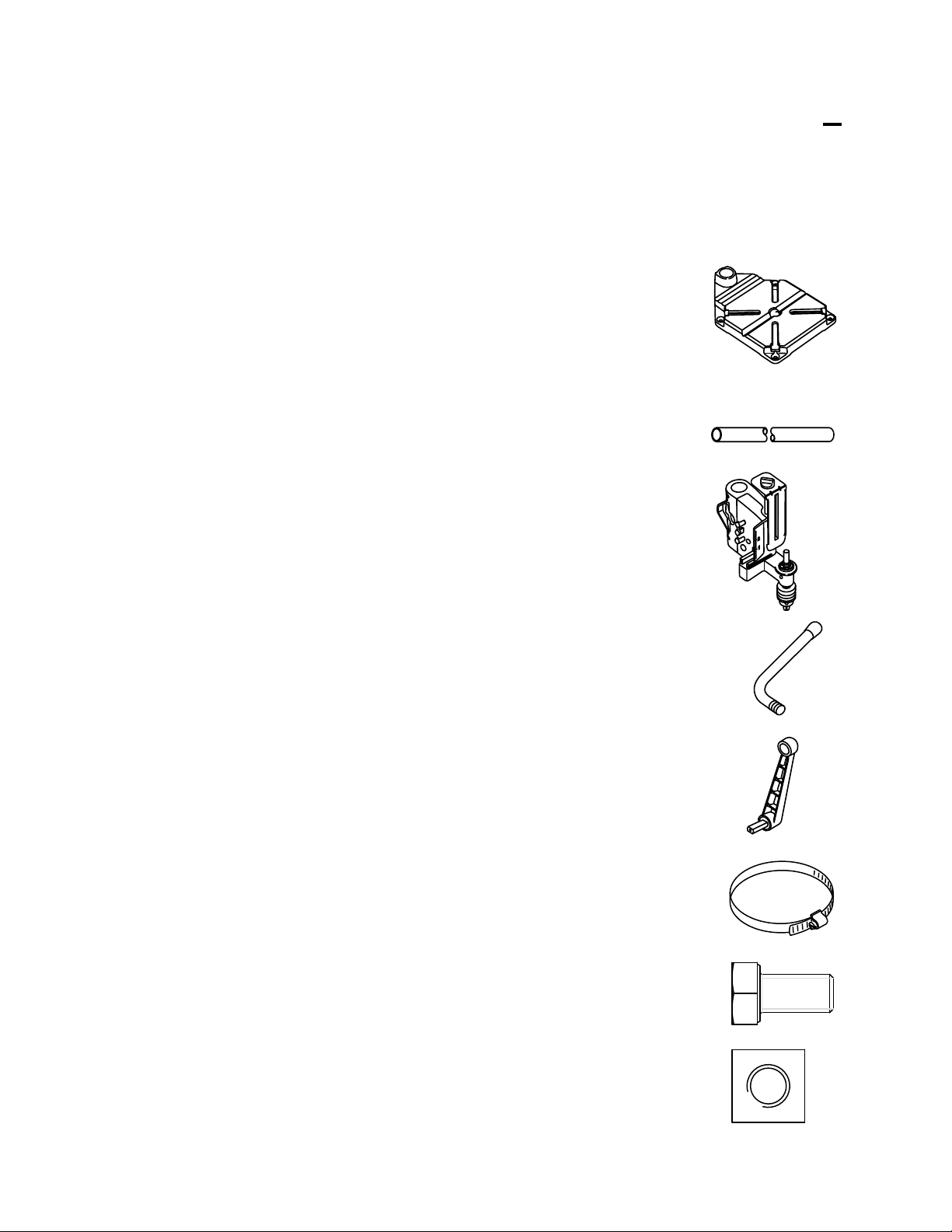

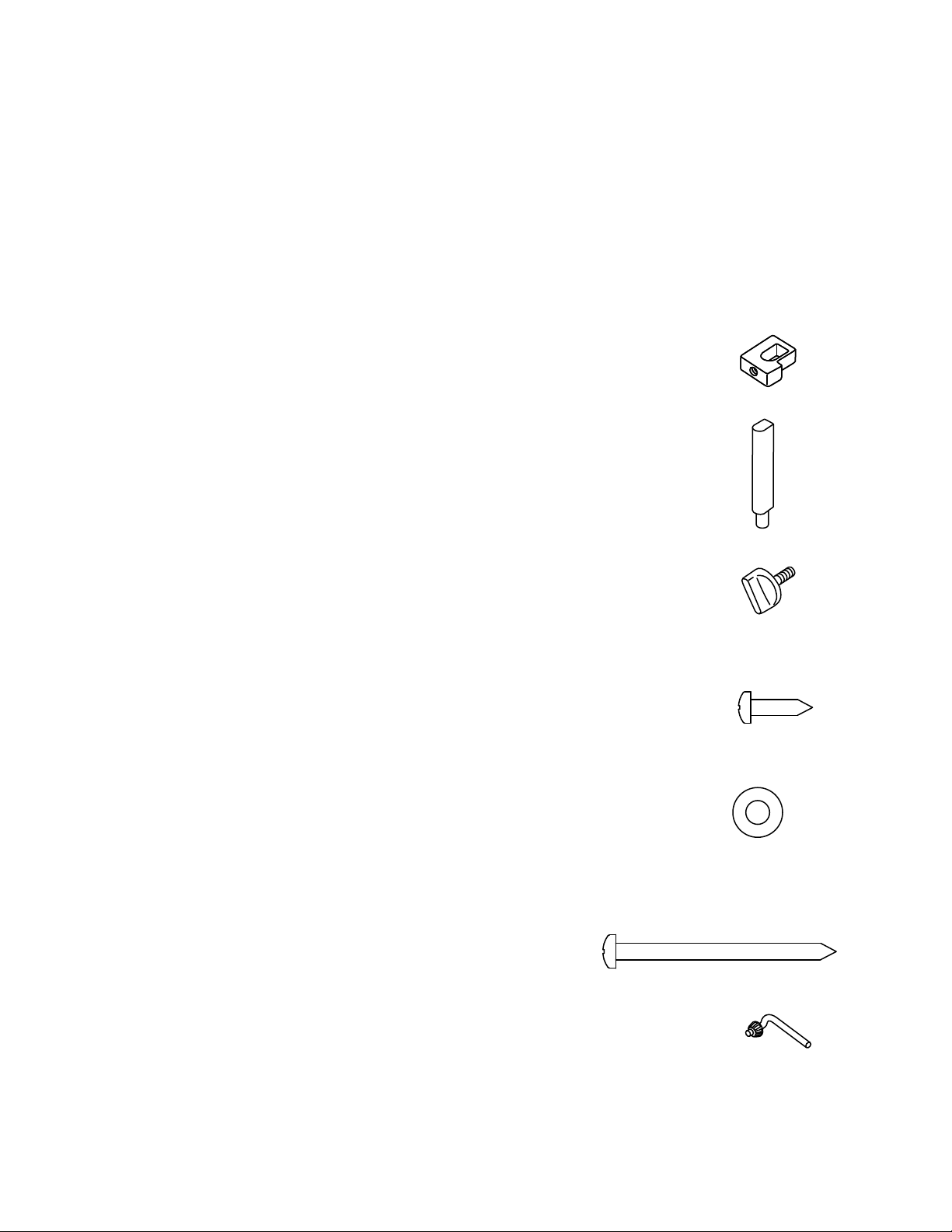

PACKAGE CONTENTS & HARDWARE LEGEND

NOTE: Hardware parts shown (screws, washers, nuts) are actual size

DESCRIPTION QTY.ITEM

B

C

D

E

Base 1A

Post 1

Head assembly 1

Adjustment handle 1

Handle 1

A

B

C

D

E

F

G

Quick-release clamp 1

Base bolt (M8x16) 1

Square nut (M10) 1H

F

G

H

5

Page 6

PACKAGE CONTENTS & HARDWARE LEGEND (cont.)

NOTE: Hardware parts shown (screws, washers, nuts) are actual size

ITEM

J

K

L

DESCRIPTION QTY.

Depth stop collar 1

Depth stop carriage

Depth stop adjustment knob 1

1

J

K

L

M

N

P

Q

Depth adjustment screw

(M4x13)

Depth adjustment washer (M4) 1

Handle screw (M4x50) 1

Chuck key 1

1

M

N

P

Q

6

Page 7

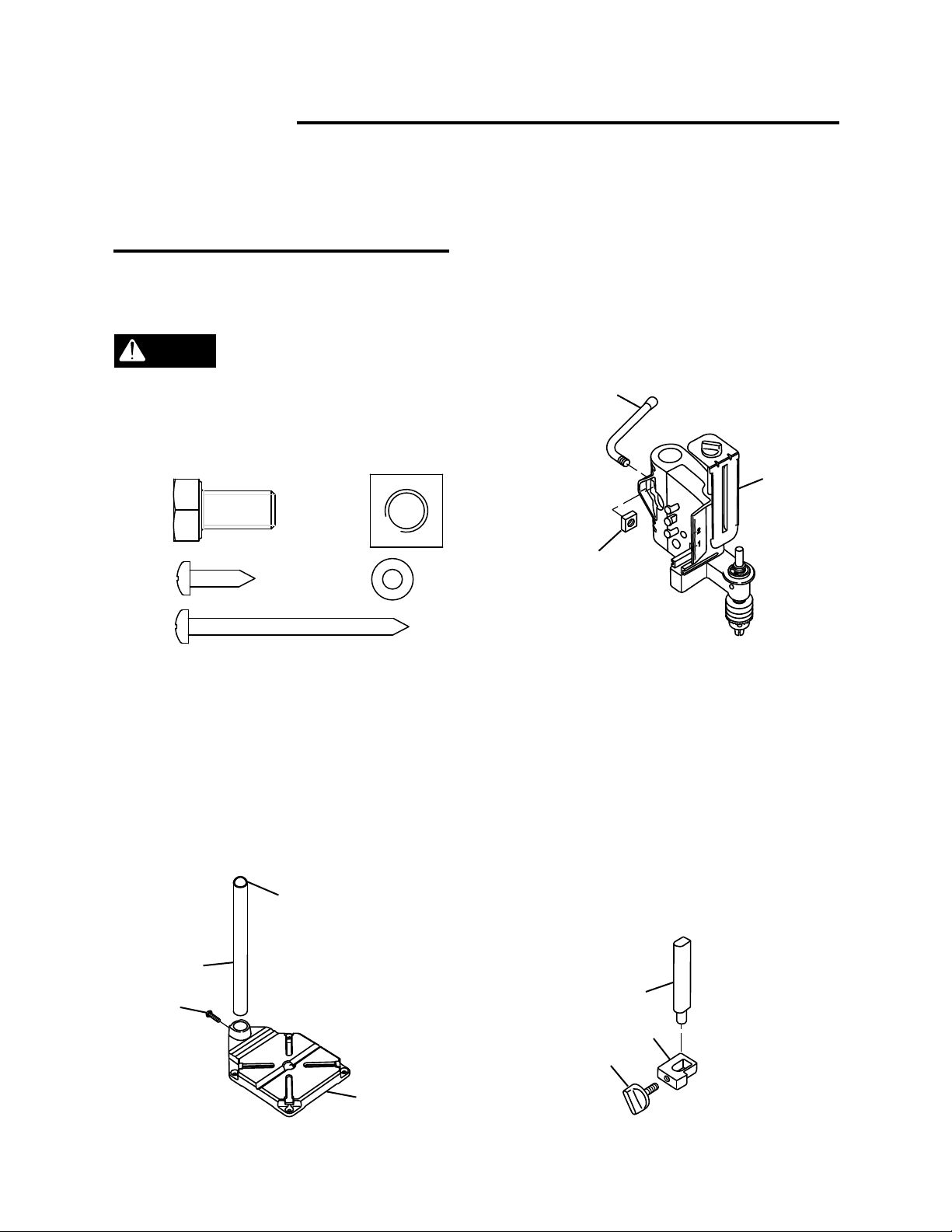

ASSEMBLY

Tools Required

• Adjustable Wrench

• #2 Phillips Screwdriver

Assemble Drill Press Stand

Do not attempt to use

WARNING

your Universal Drill Press

Stand unless it is fastened firmly to your

workbench or floor. Failure to do so

may result in serious injury.

G (1) H (1)

M (1) N (1)

3. Assemble adjustment handle (D) to

head assembly (C) with square nut

(H). Place square nut in recess in

back of head assembly. Insert

adjustment handle through head

assembly and thread it into square

nut three full turns. See Figure 2.

D

C

H

P (1)

1. Secure base (A) to a solid object

such as a workbench or a clampeddown board. Four holes are provided

in the base for mounting (hardware

not included).

2. Insert post (B) into base. Make sure

plastic cap is on top. Install and

tighten base bolt (G) securely. See

Figure 1.

Plastic Cap

B

G

Figure 2

4. Assemble depth stop by sliding depth

stop collar (J) onto the depth stop

carriage (K) from the bottom with the

round side of the collar matching the

round side of the carriage. Secure

the collar by screwing the depth stop

adjustment knob (L) in the threaded

hole. See Figure 3.

K

J

L

A

Figure 1

Figure 3

7

Page 8

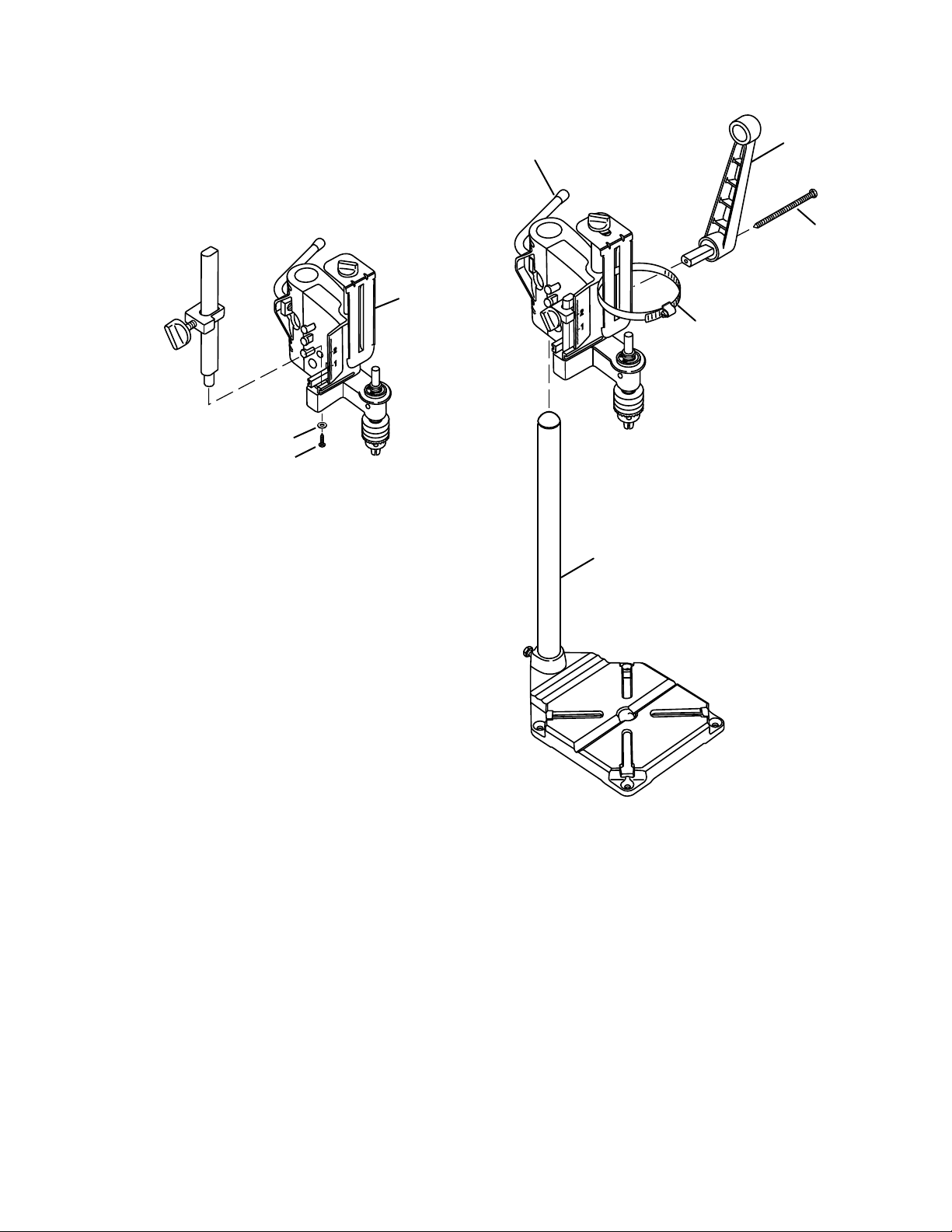

5. Slide depth stop assembly into head

assembly (C) and secure with screw

(M) and washer (N). See Figure 4.

C

N

M

Figure 4

D

E

P

F

6. Insert quick-release clamp (F) through

adjustment bracket. Position clamp

behind outer two ribs and in front of

middle rib of bracket. See Figure 5.

7. Align shaft on handle (E) with slot in

head assembly. Install handle facing

up. Secure handle with handle screw

(P). See Figure 5.

8. Slide head assembly onto post (B).

Secure head assembly to post by

tightening adjustment handle (D).

B

Figure 5

8

Page 9

DRILL MOUNTING

Tools Required

• Flat blade Screwdriver

Standard Mounting

See Figure 6 for reference.

1. Adjust the quick-release clamp so

that it is in the wide open position.

2. Open the chuck on the drill to its

widest position.

3. Insert the drill through the quickrelease clamp and onto the shaft.

Tighten the drill chuck.

4. Loosen the knob at the top of the

adjustment bracket.

Detail of Cord Mount

Chuck Key

Storage Hole

Adjustment

Handle

Depth

Adjustment

Assembly

Post

Chuck

Handle

Adjustment

Knob

Adjustment

Bracket

Handle Screw

Quick-Release

Clamp

Drill Chuck "L"

Adapter Bracket

5. Move the adjustment bracket so that

it is in contact with the drill. Tighten

the knob on the adjustment bracket

securely.

6. Secure the drill to the adjustment

bracket by tightening the quickrelease clamp. Make sure the drill

vent slots remain uncovered to

provide proper cooling for the drill

motor.

7. Route cord through the mount

located on the head assembly. See

Figure 6 inset.

Base

Bolt

Base

Mounting

Holes

Figure 6

9

Page 10

HORIZONTAL MOUNTING

The horizontal

WARNING

mounting option is to be

used for grinding, buffing, sanding,

and flex-shaft operations only. Do

not attempt to use your Universal Drill

Press Stand as a horizontal drill

press. Failure to comply may result

in serious injury.

See Figure 7 for reference.

1. Install your drill while the head

assembly is mounted vertically (see

"Standard Mounting" instructions).

2. Loosen adjustment handle and

remove head assembly from post.

3. Rotate head assembly 90°.

Adjustment

Handle

Figure 7

4. Replace head assembly onto post

and tighten adjustment handle

securely.

OPERATING INSTRUCTIONS

Rotating machinery can

WARNING

cause serious injury.

Keep hands, body parts, and clothing

away from rotating heads. Please

read, understand, and follow all

safety instructions included with your

drill or hobby tool.

Operation of the Universal Drill Press

Stand is simple and straightforward.

1. With the drill turned on, use the

handle to feed the bit into the

material. Let the bit cut at its own

speed.

2. Adjust the depth the material is

being drilled into with the depth

adjustment knob. The depth is

adjustable in 1/8" increments.

3. When operating in the horizontal

mode, do not use as a drill press.

4. With the drill turned on, use

attachments for grinding, wire

brushing, sanding, and buffing.

5. Make sure to follow all power tool

safety instructions and keep

hands, body parts, and clothing

away from the rotating heads.

10

Page 11

REPAIR PARTS 3408 Universal Drill Press Stand

5

16

15

14

12

4

13

2

7

9

18

17

8

19

6

3

11

20

10

KEY

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

ITEM

A

B

C

D

E

F

G

H

J

K

L

M

N

P

Q

PART NO.

118 220 009

117 920 109

119 800 515

119 800 514

116 620 191

117 010 267

117 010 260

116 620 277

116 700 027

116 710 100

119 800 028

119 900 891

116 720 037

116 720 041

116 620 204

116 620 203

116 620 225

116 710 029

116 710 102

116 710 041

015 100 039

1

DESCRIPTION

Base

Post

Head assembly

Adjustment handle

Handle

Quick-release clamp

Adjustment bracket

Bracket adjustment knob

Washer (M8)

Bracket screw (M8x16)

Drill chuck L-bracket assembly

HARDWARE AND LOOSE PARTS BAG

Base bolt (M8x16)

Square nut (M10)

Depth stop collar

Depth stop adjustment carriage

Depth stop adjustment knob

Depth adjustment screw (M4x13)

Depth adjustment washer (M4)

Handle screw (M4x50)

Chuck key

QTY.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

11

Page 12

TABLE DES MATIERES / ÍNDICE

......

12

13

GARANTIE/GARANTÍA................................................

CONSIGNES DE SECURITE/INSTRUCCIONES DE SEGURIDAD

DEBALLAGE ET VERIFICATION DU CONTENU/

DESEMPAQUE Y REVISIÓN DEL CONTENIDO.........

INTRODUCTION/INTRODUCCIÓN ............................

14

14

CARACTÉRISTIQUES ET FICHE TECHNIQUE/

CARACTERÍSTICAS SOBRESALIENTES Y ESPECIFICACIONES...

14

GARANTIE / GARANTÍA

GARANTIE ILLIMITÉE

Ce support universel de perceuse à colonne wolfcraft® est garanti

contre tout défaut de matériel et de main-d'œuvre et ce pendant toute

la durée de vie du produit. Pendant la durée de la garantie, les

obligations du fabricant se limitent au remplacement ou à la

réparation, à son choix, du produit ou de toute pièce défectueuse.

Cette garantie couvre seulement l'acheteur initial et ne s'applique pas

aux conditions survenant suite à : un usage abusif, un usage à

mauvais escient, une altération, une négligence, un entretien

inadéquat ou une usure normale. Des réparations ou une altération

non autorisées du produit annuleront cette garantie dans son

intégralité.

Si vous remarquez un défaut dans le matériel ou la main d'œuvre,

veuillez contacter le service à la clientèle wolfcraft® par courrier

électronique à customer.service@woa.wolfcraft.com, par téléphone

au 630.773.4777, par télécopie au 630.773.4805, ou par courrier à

1222 W. Ardmore Avenue, Itasca, Illinois 60143. Des directives vous

seront données pour résoudre le problème ou, si le problème ne peut

être solutionné, on vous indiquera comment retourner le produit au

fabricant pour réparation ou remplacement.

LIMITATION DE RESPONSABILITÉ

Le fabricant ne pourra être tenu responsable de la perte ou de

dommages quels qu'ils soient y compris accidentels ou

indirects, résultant directement ou indirectement de l'usage de

ce produit.

CONTENU DE L'EMBALLAGE ET LÉGENDE DU MATÉRIEL/

CONTENIDO DE LA CAJA Y EXPLICACIÓN DE LOS COMPONENTES

...

ASSEMBLAGE/ARMADO........................................

MONTAGE DE LA PERCEUSE/MONTAJE DEL TALADRO

...

UTILISATION/OPERACIÓN ....................................

PIECES DE RECHANGE/PIEZAS DE REPARACIÓN...

CARTE D'ENREGISTREMENT DU PRODUIT/

TARJETA DE REGISTRO DEL PRODUCTO ..........

Certains états n'autorisent pas l'exclusion ou la limitation des

dommages accidentels ou indirects, par conséquent la limitation ou

l'exclusion stipulée ci-dessus ne s'applique pas à vous. L'utilisateur

assume tous les risques ou responsabilités relatifs à l'installation ou

l'utilisation de ce produit.

Cette garantie vous donne des droits spécifiques reconnus par la loi

et vous pouvez également profiter d'autres droits qui varient

d'un état à l'autre.

LA GARANTIE EXPRÈSSE CONTENUE DANS LES PRÉSENTES

REMPLACE TOUT AUTRE GARANTIE QUELLE QU'ELLE SOIT

EXPRESSE OU IMPLICITE. AUCUNE GARANTIE IMPLICITE DE

QUALITÉ MARCHANDE N'EST PROPOSÉE ET IL N'EXISTE

AUCUNE GARANTIE QUI COUVRIRAIT PLUS QUE CE QUI EST

DÉCRIT CI-CONTRE.

CARTE DE GARANTIE

Veuillez remplir la carte de garantie ci-jointe et l'envoyer par courrier

à wolfcraft® dans les 30 jours suivant la date d'achat; vous

pouvez également remplir la carte en ligne à www.wolfcraft.com.

Négliger d'envoyer cette carte n'affectera pas vos droits à la garantie,

si vous pouvez justifier que vous étiez l'acheteur initial du produit. Il

n'en reste pas moins qu'envoyer cette carte est un moyen pratique

d'inscrire la date de votre achat dans nos dossiers et nous aideront

à répondre à vos besoins à l'avenir.

15

17

19

20

21

23

GARANTÍA DE POR VIDA LIMITADA

Este wolfcraft® taladradora universal de columna con pedestal

está garantizado contra defectos en materiales y mano de obra

durante la vida del producto La obligación del fabricante bajo esta

garantía se limita a reemplazar o reparar, a su opción, el producto o

cualquier parte defectuosa del mismo. Esta garantía se extiende al

primer comprador solamente y no procede para condiciones

resultantes de abuso, mal uso. alteración, negligencia,

mantenimiento inadecuado o desgaste normal y deterioro cau sado

por el uso. Las reparaciones no autorizadas o manejo indebido del

producto anulará esta garantía en su totalidad.

Si encuentra un defecto en materiales o mano de obra, contacte al

departamento de Servicio al Cliente de wolfcraft® por e-mail a:

customer.service@woa.wolfcraft.com, por teléfono al 630.773.4777,

por fax al 630.773.4805, o por correo a: 1222 W. Ardmore Avenue,

Itasca, Illinois 60143. Se le darán instrucciones sobre cómo resolver

el problema o, si el problema no se puede resolver, cómo devolver el

producto al fabricante para su reparación o reemplazo.

LIMITACIÓN DE LA RESPONSABILIDAD

El fabricante no será responsable por pérdida o daño de

cualquier clase incluyendo daños incidentales o consecuentes

que resulten ya sea directa o indirectamente del uso de este

producto.

Algunos estados no permiten la exclusión o limitación de daños

incidentales o consecuentes por lo que la limitación o exclusión

anterior puede no ser aplicable para usted. El usuario asume todos

los riesgos y responsabilidad respecto a la instalación o uso de este

producto.

Esta garantía le da derechos legales específicos y es posible que

usted también tenga otros derechos que varían de estado a estado.

LA EXPLÍCITA GARANTÍA EN EL PRESENTE ES EN LUGAR DE

CUALQUIER OTRA GARANTÍA, EXPRESA O IMPLÍCITA. NO SE

HACE NINGUNA GARANTÍA IMPLÍCITA DE COMERCIALIZACIÓN

Y NO HAY GARANTÍAS QUE SE EXTIENDAN MÁS ALLÁ DE LA

DESCRIPCIÓN EN LA CARÁTULA DEL PRESENTE.

TARJETA DE GARANTÍA

Sírvase llenar la información en la tarjeta de garantía adjunta y

envíela por correo a wolfcraft® dentro de los 30 días después de la

compra, o llene la tarjeta en línea en www.wolfcraft.com. La

omisión en entregar esta tarjeta no afectará adversamente sus

derechos de garantía si de alguna otra manera razonable puede

demostrar que usted fue el comprador original del producto. Sin

embargo, enviar esta tarjeta es una manera conveniente de

establecer en nuestros archivos la fecha de su compra y nos puede

ayudar a satisfacer mejor sus necesidades en el futuro.

12

Page 13

CONSIGNES DE SECURITE/INSTRUCCIONES DE SEGURIDAD

MODE D'UTILISATION GÉNÉRALE POUR LES OUTILS ÉLECTRIQUE

CONNAISSEZ VOTRE OUTIL ÉLECTRIQUE

Lisez bien le manuel du propriétaire. Apprenez les applications et les restrictions de

l’instrument, ainsi que les dangers possibles, particuliers à cet outil.

METTEZ TOUS LES OUTILS À LA TERRE (À MOINS QU’ILS NE SOIENT DOUBLEMENT

ISOLÉS)

Si l’outil est équipé d’un fil approuvé à 3 conducteurs et d’une fiche du type à 3 ergots avec

mise à la terre, branchez le au bon type de prise avec mise à la terre. Le conducteur vert du fil

est le fil de mise à la terre. Ne raccordez jamais le fil vert à une borne sous tension.

GARDEZ LA ZONE DE TRAVAIL BIEN PROPRE

Les zones de travail et les établis mal rangés invitent les accidents. Le plancher ne devrait pas

être rendu glissant par de la cire ou du brin de scie.

ÉVITEZ LES ENVIRONNEMENTS DANGEREUX

N’utilisez pas d’outils électriques dans les endroits humides ou mouillés et ne les exposez pas

à la pluie. Gardez la zone de travail bien éclairée. L’espace de travail doit être convenable.

ÉLOIGNEZ LES ENFANTS

Tous les visiteurs devraient rester à une distance respectueuse de la zone de travail.

NE FORCEZ PAS L’OUTIL

Votre outil fonctionnera mieux et d’une façon plus sécuritaire à la vitesse pour laquelle il a été

conçu.

UTILISEZ LE BON OUTIL

Ne forcez pas un outil ou un accessoire de façon à lui faire faire un travail pour lequel il n’a pas

été conçu.

PORTEZ LES BONS VÊTEMENTS

Ne portez pas de vêtements lâches, de gants, de cravate ou d’articles de bijouterie (bagues,

bracelet de montre) qui pourraient se coincer dans des pièces mobiles. Il est préférable

d’utiliser des chaussures antidérapantes. Portez une coiffure protectrice pour retenir les

cheveux longs. Roulez les manches longues audessus du coude.

UTILISEZ DES LUNETTES DE SÉCURITÉ (protection de la tête)

Portez des lunettes de sécurité (elles doivent se conformer à ANSI Z87.1) en tout temps.

Utilisez aussi un masque pour le visage ou masque antipoussière si l’opération de coupe

risque de créer de la poussière. Portez des protecteurs pour l’ouïe (protecteurs auriculaires) ou

un serre-tête antibruit durant les périodes d’utilisation prolongées.

FIXEZ LA PIÈCE

Utilisez des serre-joints ou un étau pour retenir la pièce, dans la mesure du possible. Ceci est

plus sécuritaire que de se servir des mains et, de cette façon, vous pouvez utiliser les deux

mains pour actionner l’outil.

NE VOUS ÉTENDEZ PAS TROP

Gardez toujours un bon équilibre et les pieds appuyés sur le sol en tout temps.

ENTRETENEZ AVEC SOIN LES OUTILS

Gardez les outils bien affûtés et propres pour plus de sécurité et une meilleure performance.

Conformez-vous aux instructions concernant la lubrification et le changement des accessoires.

DÉBRANCHEZ LES OUTILS

Avant l’entretien et lorsque vous changez les accessoires tels que lames, mèches, couteaux, etc.

ÉVITEZ UNE MISE EN MARCHE ACCIDENTIELLE

Assurez-vous que l’interrupteur est bien sur la position d’ARRÊT (OFF) avant de brancher

l’appareil.

UTILISEZ LES ACCESSOIRES

Consultez le manuel du propriétaire concernant les accessoires recommandés. Suivez les

instructions qui accompagnent les accessoires. L’utilisation d’accessoires inadéquats peut causer

des dangers.

NE VOUS TENEZ JAMAIS DEBOUT SUR L’OUTIL

Des blessures graves peuvent se produire si l’outil bascule ou si l’outil coupant est mis en

marche accidentellement. N’entreposez pas de matériaux au-dessus ou à proximité de l’outil, au

point où il serait nécessaire de se tenir debout sur l’outil pour les atteindre.

VÉRIFIEZ LES PIÈCES ENDOMMAGÉES

Avant de continuer à utiliser un outil, tout protecteur ou autre pièce qui serait endommagé doit

être soigneusement vérifié pour s’assurer de son bon fonctionnement et pour être certain qu’il

remplit toujours la fonction pour laquelle il est prévu. Vérifiez l’alignement des pièces mobiles, le

grippage des pièces mobiles, le bris des pièces, le montage et toutes autres conditions qui

pourraient affecter le fonctionnement de l’outil. Un protecteur ou autre pièce qui serait

endommagé devrait être convenablement réparé ou remplacé.

DIRECTION D’ALIMENTATION

Alimentez la pièce dans la lame ou le couteau, seulement contre la direction de rotation de la

lame ou du couteau.

NE LAISSEZ JAMAIS UN OUTIL EN FONCTIONNEMENT SANS SURVEILLANCE

Fermez le courant. Ne laissez pas l’outil sans qu’il ne soit pas entièrement arrêté.

INSTRUCCIONES GENERALES DE SEGURIDAD EN EL USO DE HERRAMIENTAS ELÉCTRICAS

CONOZCA SU HERRAMIENTA ELÉCTRICA

Lea cuidadosamente el manual del usuario. Aprenda el uso y limitaciones de la herramienta así

como los peligros potenciales y específicos peculiares a esta herramienta.

PONGA A TIERRA TODAS LAS HERRAMIENTAS (A MENOS QUE ESTÉN DOBLEMENTE

AISLADAS)

Si la herramienta está equipada con un cable aprobado de 3 conductores y un enchufe con 3

espigas para puesta a tierra que empalme debidamente en el receptáculo apropiado para la

conexión a tierra. El conductor color verde es el cable para conectarse a tierra. Nunca

conecte el cable verde a un terminal vivo.

MANTENGA LIMPIA EL ÁREA DE TRABAJO

Las áreas y mesas de trabajo desordenadas son una invitación para los accidentes. El piso no

debe estar resbaloso debido a la cera o al aserrín.

EVITE EL AMBIENTE PELIGROSO

No use herramientas eléctricas en lugares húmedos, mojados o expuestos a la lluvia.

Mantenga las áreas de trabajo bien iluminadas. Disponga de un adecuado espacio para poder

trabajar.

MANTENGA LOS NIÑOS ALEJADOS DEL ÁREA DE TRABAJO

Los visitantes deben situarse a una distancia prudencial y segura del área de trabajo.

NO EXCEDA EL ESFUERZO SOBRE LAS HERRAMIENTAS

Las herramientas trabajarán mejor y con mayor seguridad dentro del régimen de esfuerzo para

el cual fueron diseñadas.

USE LA HERRAMIENTA ADECUADA

No obligue una herramienta o accesorio a realizar una labor para la cual no fue diseñada.

USE LA VESTIMENTA ADECUADA

No use ropas sueltas, guantes, corbatas o prendas (anillos o relojes de muñeca) que puedan

quedar atrapados por las piezas en movimiento. Se recomienda el uso de calzado

antiresbalable. Si tiene cabello largo, use una cobertura protectora adecuada. Enróllese las

mangas largas hasta encima del codo.

USE GAFAS DE SEGURIDAD (Protectores de Cabeza)

todo momento, use gafas de seguridad (deben cumplir los requisitos ANSI Z87.1). Igualmente,

use caretas protectoras para la cara, o contra el polvo, si las operaciones de corte son

polvorientas así como protectores para los oídos (tapones u orejeras) durante prolongados

períodos de operación.

ASEGURE EL TRABAJO

Siempre que resulte práctico, use abrazaderas o tornillos de banco para sujetar el trabajo; es

más seguro que usar sus manos. Deje ambas manos en libertad para operar la herramienta.

NO PRETENDA AGARRAR LO QUE NO ESTA A SU ALCANCE

En todo momento, mantenga sus pies firmemente asentados y en equilibrio.

MANTENGA LAS HERRAMIENTAS DEBIDAMENTE ATENDIDAS

Conserve las herramientas afiladas y limpias para obtener el mejor y más seguro rendimiento.

Siga las instrucciones apropiadas para su lubricación y cambio de accesorios.

DESCONECTE LAS HERRAMIENTAS

Antes de dar servicio a una herramienta, antes de cambiar accesorios como cuchillas, barrenas,

cortadoras, etc., desconecte la herramienta.

EVITE LOS ARRANQUES ACCIDENTALES

Antes de enchufar el cable de una herramienta en un receptáculo eléctrico, esté seguro que el

interruptor está en “OFF” (apagada, desactivada).

USE LOS ACCESORIOS RECOMENDADOS

Consulte el manual del usuario sobre los accesorios recomendados. Siga las instrucciones que

se adjuntan con los accesorios. El uso de accesorios inadecuados puede provocar riesgos.

NUNCA SE PARE SOBRE UNA HERRAMIENTA

Se pueden producir lesiones graves si se vuelca la herramienta o si accidentalmente se hace

contacto con la herramienta de corte. No almacene materiales encima o cerca de la herramienta

en forma tal, que sea necesario pararse sobre la herramienta para alcanzar dichos

materiales.

REVISE LAS PIEZAS DAÑADAS

Antes de usar una herramienta, si está dañado un protector o pieza, se deberá revisar

cuidadosamente para asegurar que trabajará debidamente y que realizará la función adecuada.

Compruebe el alineamiento de las piezas en movimiento, la sujeción de las piezas en

movimiento, la roturas de piezas, el montaje y cualquier otra condición que pueda afectar la

operación de una pieza. Un protector u otra pieza dañada deberá ser debidamente reparada o

sustituida.

SENTIDO DE DIRECCIÓN DE LA ALIMENTACIÓN

Alimente el trabajo hacia una cuchilla o cortadora únicamente en sentido contrario a la rotación

de la hoja o de la cortadora.

NUNCA DEJE DESATENDIDA UNA HERRAMIENTA EN FUNCIONAMIENTO

Desactive el suministro eléctrico a la herramienta. No abandone la herramienta hasta que su

movimiento no se haya detenido completamente.

13

Page 14

INSTRUCTIONS SUPPLÉMENTAIRES DE SÉCURITÉ POUR SUPPORT UNIVERSEL DE PERCEUSE À COLONNE

INSTRUCCIONES DE SEGURIDAD ADICIONALES PARA U.D.P.S.

Les articles portant sur la sécurité dans ce manuel sont étiquetés avec les mentions AVERTISSEMENT et MISE EN GARDE.

AVERTISSEMENT

MISE EN GARDE

1. N’essayez pas d’utiliser votre support universel de perceuse à colonne à moins qu’il ne soit fixé fermement sur l’établi.

2. Assurez-vous que la brise de serrage ne bloque pas les fentes d’aération sur l’outil électrique lorsque l’outil est monté.

3. Lorsque le montage est horizontal, n’utilisez pas l’outil comme perceuse à colonne.

ADVERTENCIA

PRECAUCIÓN

1. No intente usar su taladradora universal de columna con pedestal a menos que esté firmemente sujeta a su mesa de trabajo.

2. Cerciórese de que las bandas de sujeción del montaje no obstruyan las ranuras de ventilación de la herramienta eléctrica,

cuando ésta se encuentre instalada en su lugar.

3. Al montar horizontalmente esta herramienta, no la use como taladradora de columna.

signifie que négliger de respecter les instructions de sécurité risque de provoquer des détériorations importantes, des blessures graves, voire

même la mort.

signifie que négliger de respecter les instructions de sécurité risque de provoquer des détériorations minimes ou moyennes, ou des détériorations

des biens ou de l'équipement.

En todo este manual, los aspectos de seguridad están etiquetados con las palabras ADVERTENCIA y PRECAUCIÓN.

significa que la omisión en apegarse a esta manifestación de seguridad puede resultar en daño extenso al producto, lesiones personales graves,

o la muerte.

significa que la omisión en apegarse a esta manifestación de seguridad puede resultar en lesiones personales menores o moderadas, o daño al

equipo o propiedades.

DÉBALLAGE ET VÉRIFICATION DU CONTENU / DESEMPAQUE Y REVISIÓN DEL CONTENIDO

Séparez toutes les pièces du matériel d’emballage et vérifiez-les par

rapport à l’illustration et au “tableau des pièces détachées”. Assurezvous que toutes les pièces sont bien là avant de jeter une partie

quelconque du matériel d’emballage.

Retire todas las piezas del material de embalaje y compruébelas

contra la ilustración y la “Tabla de piezas sueltas”. Cerciórese de que

todas las piezas se han recibido antes de desechar cualquier

material de embalaje.

INTRODUCTION / INTRODUCCIÓN

Le support universel de perceuse à colonne wolfcraft®

fournit une méthode économique et précise pour percer des trous

dans le bois et le métal. Les possibilités de montage horizontal

uniques offrent une flexibilité accrue pour le meulage, le polissage et

le sablage.

Le support universel de perceuse à colonne peut être utilisé avec la

plupart des perceuses et outils de bricolage populaires.

El wolfcraft® Taladradora universal de columna con

pedestal, proporciona un método económico y preciso para

taladrar agujeros tanto en madera como en metal. La singular

capacidad para montaje horizontal proporciona flexibili-dad

adicional para desbastar, pulir y esmerilar.

La taladradora universal de columna con pedestal se puede

usar con la mayoría de los taladros populares.

CARACTÉRISTIQUES ET FICHE TECHNIQUE / CARACTERÍSTICAS SOBRESALIENTES Y ESPECIFICACIONES

Les caractéristiques comprennent:

• un réglage de déplacement de 2-1/2 po par multi-ples de 1/8 po

• une profondeur de gorge de 4-1/2 po

• des rainures de retenue de mèche

• une rainure en V dans la base pour guider les pièces rondes

• une monture de fil pour garder le fil de la perceuse éloigné de la

zone de travail

• la base en fonte fournit à la fois stabilité et robustesse.

• le mandrin incorporé assure à la fois précision et fidélité dans le

perçage.

• un porte-clavette de mandrin garde la clavette de mandrin à portée

de la main lorsqu’elle n’est pas utilisée.

Sus características incluyen:

• una corredera de 2-1/2" ajustable en incrementos de 1/8"

• profundidad de garganta de 4-1/2"

• ranuras para la sujeción de brocas

• ranura en-V en la base para guiar materiales redondos

• un montaje del cable eléc-trico del taladro que lo mantiene alejado

del área de trabajo.

• la base fundida proporciona estabilidad y robustez.

• el porta-herramientas incorporado asegura precisión en la

repetición de las operaciones de taladrado.

• un sujetador para la llave del portaherramientas conserva la llave

convenientemente situada cuando no está en uso.

14

Page 15

CONTENU DE L'EMBALLAGE ET LÉGENDE DU MATÉRIEL

CONTENIDO DE LA CAJA Y EXPLICACIÓN DE LOS COMPONENTES

REMARQUE : Les pièces (vis, écrous, rondelles) sont illustrées en dimension réelle

NOTA: Accesorios de montaje (tornillos, tuercas, rondanas) se muestran en su tamaño real

ARTICLE

ARTÍCULO

B

C

D

DESCRIPTION

DESCRIPCIÓN

QTÉ

CANT.

Base 1A

Colonne/Columna 1

Tête de perceuse à colonne

Cabezal de la taladradora de

columna

Poignée de réglage

Manija de ajuste

A

B

1

1

C

D

E

F

G

Poignée/Palanca 1

Collier métallique

Abrazadera metálica

Vis de support

Tornillo para el soporte (M8x16)

Écrou carr

Tuerca cuadrada (M10)

15

E

1

1

1H

F

G

H

Page 16

CONTENU DE L'EMBALLAGE ET LÉGENDE DU MATÉRIEL (suite)

CONTENIDO DE LA CAJA Y EXPLICACIÓN DE LOS COMPONENTES (cont.)

REMARQUE : Les pièces (vis, écrous, rondelles) sont illustrées en dimension réelle

NOTA: Accesorios de montaje (tornillos, tuercas, rondanas) se muestran en su tamaño real

ARTICLE

ARTÍCULO

J

K

L

M

DESCRIPTION

DESCRIPCIÓN

Collier de réglage de profondeur

Collarín para el ajuste de profundidad

Chariot de réglage de profondeur

Carrilera para el ajuste de profundidad

Bouton de réglage de profondeur

Pomo de ajuste de profundidad

Vis de support

Tornillo para el soport (M4x13)

QTÉ

CANT.

1

1

1

1

J

K

L

M

N

P

Q

Rondelle/Arandela (M4) 1

Vis de la poignée

Tornillo de palanca (M4x50)

Clavette de mandrin

Llave para el portabrocas

16

N

1

1

P

Q

Page 17

ASSEMBLAGE / ARMADO

Outils requis/Herramientas necesarias

• Clé réglable / Llave ajustable

• Tournevis Phillips n° 3 / Destornillador Phillips Nº 3

Montage de votre support universel

de perceuse à colonne

Ensamblaje de su taladradora

universal de columna con pedestal

N’essayez pas d’utiliser votre support

AVERTISSEMENT

universel de perceuse à colonne à moins qu’il

ne soit fermement fixé sur votre établi, sinon des blessures graves

risqueraient de se produire.

No intente usar su taladradora universal

ADVERTENCIA

de columna con pedestal, a menos que esté

firmemente sujeta a su mesa de trabajo; no tenerla sujeta puede

producir lesiones graves.

G (1) H (1)

1. Sujete la base (A) a un objeto sólido, tal como su banco de

trabajo, o un tablero bien sujeto. Se proveen cuatro agujeros en la

base para el montaje (no se incluyen los fijaciones).

2. Insert el montante (B) en la base. Coloque y apriete bien el perno

de la base (G). Consulte la Figura 1.

3. Sujete la manija de ajuste (D) al conjunto de cabezal (C) con la

tuerca cuadrada (H). Coloque la tuerca cuadrada en el rebajo

practicado en la parte posterior del conjunto de cabezal. Inserte

la manija de ajuste en el conjunto de cabezal y enrósquela en la

tuerca cuadrada tres vueltas completas. Consulte la Figura 2.

4. Sujete el tope de profundidad. Use collarín para el ajuste de

profundidad (J), carrilera para el ajuste de profundidad (K), y

pomo de ajuste de profundidad (L). Consulte la Figura 3.

B

G

M (1) N (1)

P (1)

1. Fixez la base (A) à un objet solide, tel qu'un établi ou une planche

fixée par des serre-joints. Quatre trous sont pratiqués dans la base

pour le montage (matériel non inclus).

2. Introduisez la colonne (B) dans la base. Installez et serrez à fond

le boulon de base(G). situé dans la base. Voir la figure 1.

3. Montez la poignée de réglage (D) sur l’ensemble de tête (C), avec

un écrou carré (H). Placez l'écrou carré dans la renfoncement

situé sur l'arrière de l’ensemble de tête. Introduisez la poignée de

réglage dans l’ensemble de tête et vissez-la dans l'écrou carré en

faisant trois tours complets. Voir la figure 2.

4. Assemblez la poignée de reglage. Utilisez collier de réglage de

profondeur (J), chariot de réglage de profondeur (K), et bouton de

réglage de profondeur(L). Voir la figure 3.

A

Figure 1

Figura 1

D

C

H

Figure 2

Figura 2

K

J

L

Figure 3

Figura 3

17

Page 18

5. Faites coulisser l'ensemble de butée de profondeur dans

l'ensemble de tête (C) avec la poignée de réglage orientée vers

l'extérieur. Fixez l'ensemble de butée de profondeur avec une vis

(M) et une rondelle (N). Voir la figure 4.

6. Introduisez le collier métallique (F) dans le support de réglage.

Placez le collier derrière les deux nervures extérieures et en face

de la nervure médiane du support. Voir la figure 5.

7. Alignez la fente dans la poignée (E) avec l'axe de l'ensemble de

tête. Montez la poignée en la dirigeant vers le haut. Fixez la

poignée avec la vis de la poignée (P). Voir la figure 5.

8. Faites coulisser l'ensemble de tête sur la colonne (B). Fixez

l'ensemble de tête a la colonne en serrant la poignée de réglage

(D).

C

N

M

Figure 4

Figura 4

D

E

P

F

B

5.Deslice el tope deprofundidad en el conjunto de cabeza (C), con el

pomo de ajuste mirando hacia fuera. Sejute el tope de profundidad

con el tornillo (M) y la arandela (N). Consulte la Figura 4.

6. Inserte la abrezadera metálica (F) en el soporte de ajuste.

Posicione la abrezadera detrás de las dos estrías externas y

delante de la estría central del soporte. Consulte la Figura 5.

7. Alinee la ranura en la palanca (E) con el eje del conjunto de

cabezal. Instale la palanca mirando hacia arriba. Sujete la palanca

con el tornillo de la misma (P). Consulte la Figura 5.

8. Deslice el conjunto de cabezal sobre el montante. Sujete el

conjunto de cabezal al montante apretando la palance de ajuste

(D).

Figure 5

Figura 5

18

Page 19

MONTAGE DE LA PERCEUSE / MONTAJE DEL TALADRO

Outils requis/Herramientas necesarias

• Tournevis à lame plate

Destornillador de hoja plana

Voir la figure 6. / Consulte la Figura 6.

1. Réglez le collier métallique de façon à ce qu'il soit dans la position

grande ouverte.

2. Ouvrez le mandrin de la perceuse dans sa position la plus large.

3. Insérez la perceuse dans le collier métallique et sur l'axe. Serrez

le mandrin de la perceuse.

4. Desserrez le bouton situé au sommet du support de réglage.

5. Déplacez le support de réglage de façon à ce qu'il se trouve en

contact avec la perceuse. Serrez à fond le bouton sur le support

de réglage.

6. Fixez la perceuse au support de réglage en serrant le collier

métallique. Assurez-vous que les évents de refroidissement de la

perceuse ne sont pas couverts de sorte à garantir un bon

refroidissement du moteur de la perceuse.

7. Acheminez le fil à travers la monture située sur l’ensemble de tête.

Voir détail de la figure 6.

1. Ajuste la abrazadera metálica para dejarla en la posición

totalmente abierta.

2. Ponga el portaherramientas del taladro en la posición totalmente

abierta.

3. Inserte el taladro en la abrazadera metálica y sobre el eje. Apriete

el portaherramientas del taladro.

4. Afloje el pomo en la parte superior del soporte de ajuste.

5. Mueva el soporte de ajuste hasta dejarlo en contacto con el

taladro. Apriete bien el pomo en el soporte de ajuste.

6. Sujete el taladro al soporte de ajuste apretando la abrazadera

metálica. Cerciórese de que están descubiertas las ranuras de

ventilación del taladro para proporcionar el enfriamiento adecuado

para el motor del taladro.

7. Encauce el cable a través del dispositivo de montaje ubicado en el

conjunto del cabezal. Consulte detalle de la Figura 6.

Détail de la monture du fil

Detalle del montaje del cable

Trou de rangement

de la clavette de mandrin

Orificio para guardar la llave

del portaherramientas

Poignée de réglage

Manija de ajuste

Ensemble de réglage

de profondeur

Conjunto para ajuste

de profundidad

Colonne

Colomna

Boulon de base

Perno de base

Trous de montage

de base

Agujeros para le

montaje de la base

Mandrin

Portaherramienta

Poignée

Palanca

Bouton de réglage

Pomo de ajuste

Bride de serrage

Banda de sujeción

Vis de la poignée

Tornillo de palanca

Collier métallique

Abrazadera metálica

Support d'adaptateur en L

de mandrin de perceuse

Soporte adaptador L

para el portaherramientas

del taladro

Figure 6

Figura 6

19

Page 20

Montage Horizontal

Montaje Horizontal

L’option de montage horizontal doit être

AVERTISSEMENT

utilisée pour le meulage, le frottage, le

sablage et les utilisations avec axe flexible seulement. N’ utilisez pas

le support universel de perceuse à colonne en tant que perceuse

horizontale à colonne, sinon des blessures graves risqueraient de se

pro-duire.

1. Installez votre perceuse ou votre outil de bricolage pendant que

l’ensemble de tête est monté verticalement selon les instructions

précédentes.

2. Desserrez la poignée de réglage et retirez l’ensemble de tête de la

colonne.

3. Tournez l’ensemble de tête sur 90°.

4. Remettez en place l’ensemble de tête sur la colonne et serrez à

fond la poignée de réglage.

La opción para montaje horizontal es para

ADVERTENCIA

usarla solamente en labores de desbastado,

pulido, esmerilado y opera-ciones con el eje flexible. No use la

taladradora universal de columna con pedestal como una taladradora

horizontal ya que se pueden producir graves lesiones.

1. Instale su taladro o herramienta para aficionado mientras el

conjunto del cabezal se encuentre en posición vertical y según las

instrucciones ofrecidas anterior-mente.

Poignée de réglage

Manija de ajuste

Figure 7

Figura 7

2. Afloje la manija de ajuste y desmonte de la columna el conjunto del

cabezal.

3. Imparta al cabezal una rotación de 90°.

4. Vuelva a colocar el conjunto del cabezal sobre la columna y apriete

firmemente la manija de ajuste.

UTILISATION / OPERACIÓN

La machinerie rotative peut causer des

AVERTISSEMENT

blessures graves. Gardez les mains, les

parties du corps et les vêtements éloignés des têtes rotatives.

Veuillez lire, comprendre et suivre toutes les instructions de sécurité

comprises avec votre perceuse ou votre outil de bricolage.

Le fonctionnement du support universel de perceuse à colonne est

simple et sans complication.

1. Lorsque la perceuse ou l’outil de bricolage est en marche, utilisez

la poignée pour alimenter la mèche dans la pièce à percer. Ne

forcez pas la mèche sur la pièce. Laissez la mèche mordre à sa

propre vitesse.

2. Ajustez la profondeur de perçage de la pièce en utilisant la

molette de réglage de profondeur. La profondeur est réglable par

multiples de 1/8 po.

3. Lors du fonctionnement dans le mode horizontal, n’utilisez pas

l’outil comme une perceuse à colonne.

4. Lorsque la perceuse ou l’outil de bricolage est en marche, utilisez

vos accessoires pour le broyage, le brossage à la brosse

métallique, le sablage et le frottage.

5. Assurez-vous que vous avez bien suivi toutes les instructions de

sécurité pour les outils électriques et gardez les mains, les parties

du corps et les vêtements éloignés des pièces rotatives.

Una maquinaria rotativa puede provocar

lesiones graves. Mantenga las manos,

partes del cuerpo y ropas alejadas del cabezal giratorio. Por favor,

lea, comprenda y observe todas las instrucciones de seguridad con

su taladro o herramienta para aficionado.

La operación de la taladradora universal de columna con pedestal es

sencilla y sin problemas.

1. Teniendo activado el taladro, use la manija para introducir la broca

2. Ajuste la profundidad del material que se barrena, mediante el

3. Al trabajar en la modalidad horizontal, no la use como un taladro

4. Con el taladro activado, utilice los accesorios para desbastar, usar

5. Cerciórese de que sigue todas las instrucciones de seguri-dad de

ADVERTENCIA

en el material que se vaya a barrenar. No fuerce la broca al

introducirla en el material. Deje que la broca corte a su propia

velocidad.

botón de ajuste de profundidad. La profundidad es ajustable en

incrementos de 1/8".

de banco.

el cepillo de alambre, lijar y pulir.

las herramientas eléctricas y mantenga las manos, las partes del

cuerpo y la ropa bien apartadas de las piezas rotativas.

20

Page 21

PIÈCES DE RÉPARATION / PIEZAS DE REPARACIÓN

3408 - Support universel de perceuse à colonne / Taladradora universal de columna con pedestal

5

16

15

14

12

4

13

2

7

9

18

17

8

19

6

3

11

20

10

o

CLÉ N

CLAVE NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

ARTICLE

ARTÍCULO

A

B

C

D

E

F

G

H

J

K

L

M

N

P

Q

PIECE N

PIEZA No.

118 220 009

117 920 109

119 800 515

119 800 514

116 620 191

117 010 267

117 010 260

116 620 277

116 700 027

116 710 100

119 800 028

119 900 891

116 720 037

116 720 041

116 620 204

116 620 203

116 620 225

116 710 029

116 710 102

116 710 041

015 100 039

1

o

DESCRIPTION

DESCRIPCIÓN

Base

Colonne/Columna

Tête de perceuse à colonne/Cabezal de la taladradora de columna

Poignée de réglage/Manija de ajuste

Poignée/Palanca

Collier métallique/Abrazadera metálica

Support de réglage/Soporte de ajuste

Support de réglage bouton/Pomo de ajuste el soporte

Rondelle/Arandela (M8)

Vis de support/Tornillo para el soporte (M8x16)

Support en L de mandrin de perceuse/Soporte en L para el portabrocas del taladro

SAC DE MATÉRIEL/BOLSA PARA ACCESORIOS

Boulon de base/Perno para la base (M8x16)

Écrou carr/Tuerca cuadrada (M10)

Collier de réglage de profondeur/Collarín para el ajuste de profundidad

Chariot de réglage de profondeur/Carrilera para el ajuste de profundidad

Bouton de réglage de profondeur/Pomo de ajuste de profundidad

Vis de support/Tornillo para el soport (M4x13)

Rondelle/Arandela (M4)

Vis de la poignée/Tornillo de palanca (M4x50)

Clavette de mandrin/Llave para el portabrocas

QTÉ

CANT.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

21

Page 22

®

wolfcraft

116 305 003, 10/02 wolfcraft, Inc., Itasca, IL 60143 USA

OWNER'S

MANUAL

MODEL NO.

3408

22

MANUEL

D'UTILISATION

MODÈLE No.

3408

MANUAL DEL

PROPIETARIO

MODELO NO.

3408

Page 23

To register your product, please visit our website at: www.wolfcraft.com

or complete the form below and mail or fax to: wolfcraft, Inc.

1222 W Ardmore Ave.

Itasca, IL 60143 USA

630-773-4805 (fax)

630-773-4777 (phone)

PRODUCT REGISTRATION CARD

Please complete the information and return within 30 days of purchase. Information marked * is required for warranty registration.

Veuillez remplir la carte de garantie ci-jointe et la retourner dans les 30 jours suivant la date d'achat. Il est nécessaire de donner les renseignements indiqués * pour l'enregistrement de la garantie.

Sírvase completar la información y devolver dentro de los 30 días a partir de la compra. La información marcada * se requiere para el registro de la garantía.

CONFIDENTIALITY GUARANTEE / GARANTIE DE CONFIDENTIALITÉ/ GARANTÍA DE CONFIDENCIALIDAD

Vos renseignements personnels resteront confidentiels et ne seront pas diffusés ou vendus à d'autres compagnies.

NAME * Sex M F

NOM/NOMBRE Sex/Sexo

STREET ADDRESS *

ADRESSE/DIRECCIÓN

CITY * STATE * ZIP *

VILLE/CIUDAD ÉTAT/ESTADO ZIP/ZONA POSTAL

PHONE * EMAIL

TÉLÉPHONE/TELÉFONO COURRIEL/EMAIL

I want to receive information on wolfcraft products via email.

Je souhaite recevoir de l'information sur les produits Wolfcraft par courrier électronique.

Deseo recibir información sobre los productos wolfcraft por email.

What is your preferred language? English Françias Español Other

Dans quelle langue préférez-vous communiquer?/¿Cuál es su idioma preferido?

MODEL NUMBER (from package) *

MODÈLE NUMÉRO (du packet) / MODELO NÚMERO (del paquete)

AGE ANNUAL INCOME SKILL LEVEL

ÂGE / EDAD REVENUS ANNUELS / INGRESO ANUAL NIVEAU DE QUALIFICATION / NIVEL DE DESTREZA

CARTE DE GARANTIE DU PRODUIT/TARJETA DE PRODUCTO DE LA GARANTÍA

Your information will be kept confidential and will not be shared with or sold to any other company.

Su información de mantendrá confidencial y no se compartirá con o vender a otra compañia.

Yes

Oui/Si

No

Non/No

3408 Drill Press Stand

< 21 46-55 < $30,000

21-35 56-65 $30-$75,000

Beginner/Débutant/Principiante

Intermediate

/

Intermédiaire/Intermedio

36-45 > 65 > $75,000 Expert/Spécialiste/Experto

Date Purchased: * Day * Month * Year *

Date d'achat/Fecha de compra Jour/Día Mois/Mes Année/Año

Store Name * Store Location *

Nom de magasin/Nombre de la tienda Emplacement du magasin/Ubicación de la tiends

Retail Price Paid $

Prix de détail pavé/Precio al público pagado

Why was this product purchased?

Pour quelles raisons le produit a-t-il été acheté?

¿Por qué se compró el producto?

Other:

Autre/Otro

Why did you select this product?

Pour quelles raisons avez-vous choisi ce produit?

¿Por qué seleccionó este producto?

Appearance Brand Name Store Recommendation Own Other wolfcraft Products Price

Aspect Nome de la marque Recommendation du magasin Possédez-vous d'autres produits wolfcraft Prix

Apariencia Marca Recomendación de la tienda Tengo otros productos wolfcraft Precio

Special Features (which ones?):

Caractéristiques spéciales (lesquelles?)

Características especiales (¿Cuales?)

Other:

Autre/Otro

For what specific projects do you intend to use this product?

Pour quel projet spécifique avez-vous l'intention d'utiliser ce produit?

¿Para qué proyectos específicos intenta usar este producto?

How would you rate our assembly instructions?

Comment évaluez-vous nos instructions d'assemblage?

¿Cómo calificaría nuestras instrucciones de montaje?

(Puede marcar más de una razón.)

(Vous pouvez indiquer plusieurs raisons.)

Professional Use Personal Use Gift

Usage professionnel/Uso profesional Usage personnel/Uso personal Cadeau/Regalo

(You may mark more than one reason.)

Excellent Good Fair Poor

Excellentes Bonnes Passables Médiocres

Excelentes Buenas Aceptables Insuficientes

23

Page 24

®

wolfcraft

116 305 003, 10/02 wolfcraft, Inc., Itasca, IL 60143 USA

OWNER'S

MANUAL

MODEL NO.

3408

24

MANUEL

D'UTILISATION

MODÈLE No.

3408

MANUAL DEL

PROPIETARIO

MODELO NO.

3408

Loading...

Loading...