Page 1

PRO ISLAND HOOD

INSTALLATION GUIDE

SPECIFICATIONS, INSTALLATION, AND MORE

Page 2

PRO ISLAND HOOD

Contents

3 Pro Island Hood

4 Specications

6 Installation

10 Blower Specications

11 Troubleshooting

Features and specications are subject to change at any

time without notice. Visit wolfappliance.com/specs for the

most up-to-date information.

Important Note

To ensure this product is installed and operated as safely

and efciently as possible, take note of the following types

of highlighted information throughout this guide:

IMPORTANT NOTE highlights information that is especially

important.

CAUTION indicates a situation where minor injury or product

damage may occur if instructions are not followed.

WARNING states a hazard that may cause serious injury or

death if precautions are not followed.

IMPORTANT NOTE: Throughout this guide, dimensions in

parentheses are millimeters unless otherwise specied.

IMPORTANT NOTE: Save these instructions for the local

electrical inspector.

2 | Wolf Customer Care 800.222.7820

Page 3

PRO ISLAND HOOD

Product Information

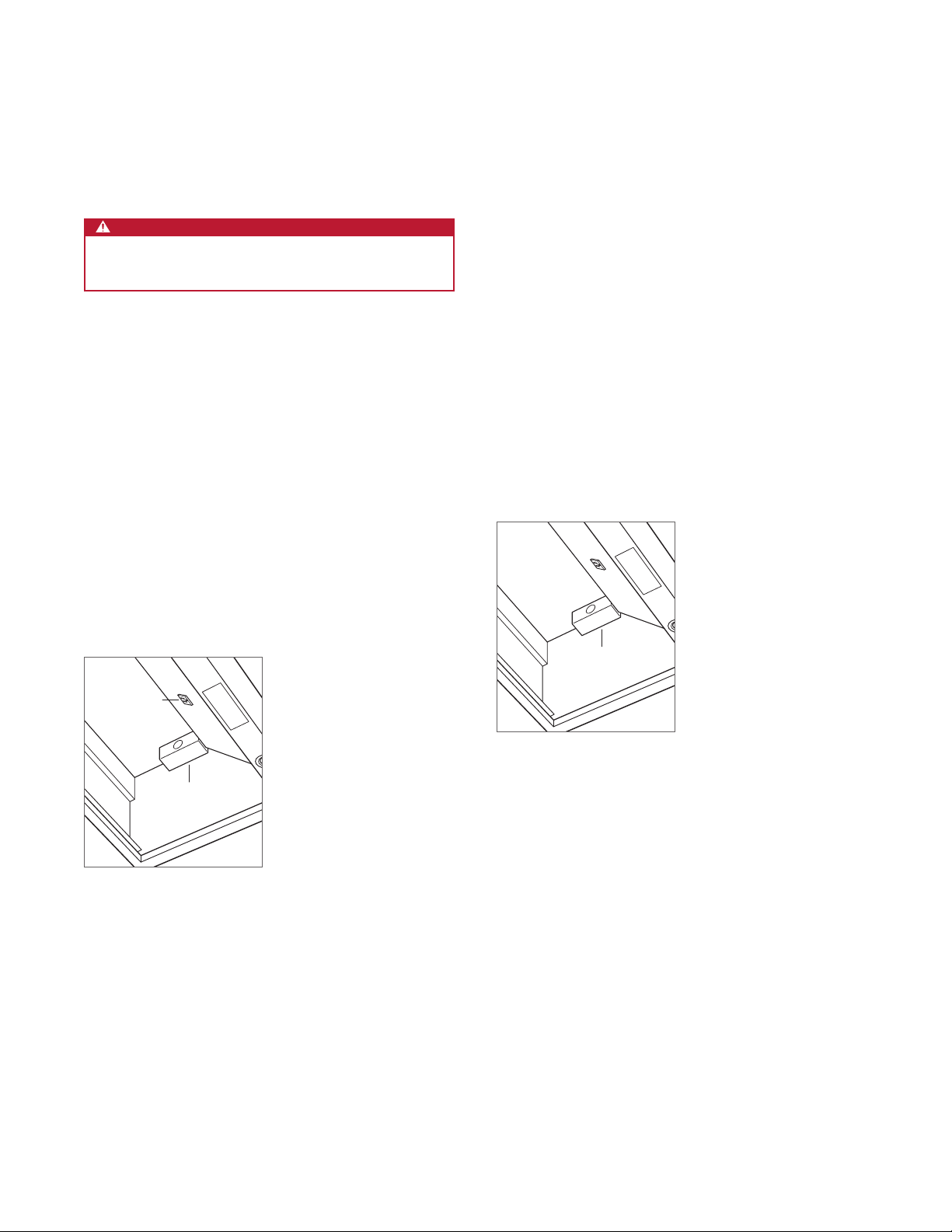

Important product information, including the model and

serial number, are listed on the product rating plate. The

rating plate is located on an inside wall of the hood shell

(lters need to be removed). Refer to the illustration below.

If service is necessary, contact Wolf Factory Certied

Service with the model and serial number. For the name of

the nearest Wolf Factory Certied Service or for questions

regarding the installation, visit the contact and support

section of our website, wolfappliance.com, or call Wolf

Customer Care at 800-222-7820.

RATING PLATE

Rating plate location

IMPORTANT INSTRUCTIONS

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY, OBSERVE THE FOLLOWING:

• Installation work and electrical wiring must be

done by qualied person(s) in accordance with all

applicable codes and standards, including rerated construction.

• Two installers are recommended due to the size

and weight of the pro hood.

• Install the pro hood only with a blower manufac-

tured by Wolf.

• When cutting or drilling into the wall or ceiling,

do not damage electrical wiring and other hidden

utilities.

• Ducted fans must always be vented to the

outdoors.

CAUTION

To reduce the risk of re and properly exhaust air,

be certain to duct air outside. Do not vent exhaust

air into spaces within walls or ceilings or into

attics, crawl spaces, or garages.

wolfappliance.com | 3

Page 4

SPECIFICATIONS

Installation Requirements

Install the hood 30" (762) to 36" (914) from the bottom of the

hood to the countertop.

BLOWER ASSEMBLIES

Pro Island Hoods require an internal, in-line, or remote

blower assembly, avail able through an authorized Wolf

dealer. For local dealer information, visit the nd a showroom section of our website, wolfappliance.com. Refer to

specic installation instructions provided with each blower

assembly.

DUCT COVER

Optional stainless steel duct covers, in multiple heights, are

available through your authorized Wolf dealer. For local

dealer information, visit the find a showroom section of our

website, wolfappliance.com.

Ducting

WARNING

To reduce the risk of re, use only metal ducting.

IMPORTANT NOTE: Consult a qualied HVAC professional

for specic installation and ducting applications.

Pro Island Hoods accommodate a 10"

only rigid metal ducting.

A straight, short duct run allows the hood to perform most

efciently. If the duct run exceeds 50'

blower may be required to maintain proper air ow.

Internal and in-line blowers require a roof or wall cap.

Connect ducting to the cap or to the remote blower and

work back towards the hood. Use sheet metal screws and

high-temperature duct tape to seal joints between ducting

sections.

Pro Island Hoods include a backdraft damper. Local codes

may require the use of an additional backdraft and/or makeup air damper. Contact your local HVAC professional for

specic requirements.

(254) round duct. Use

(15 m), a higher CFM

A make-up air damper is available through an authorized

Wolf dealer. For local dealer information, visit the nd a

showroom section of our website, wolfappliance.com.

4 | Wolf Customer Care 800.222.7820

Page 5

SPECIFICATIONS

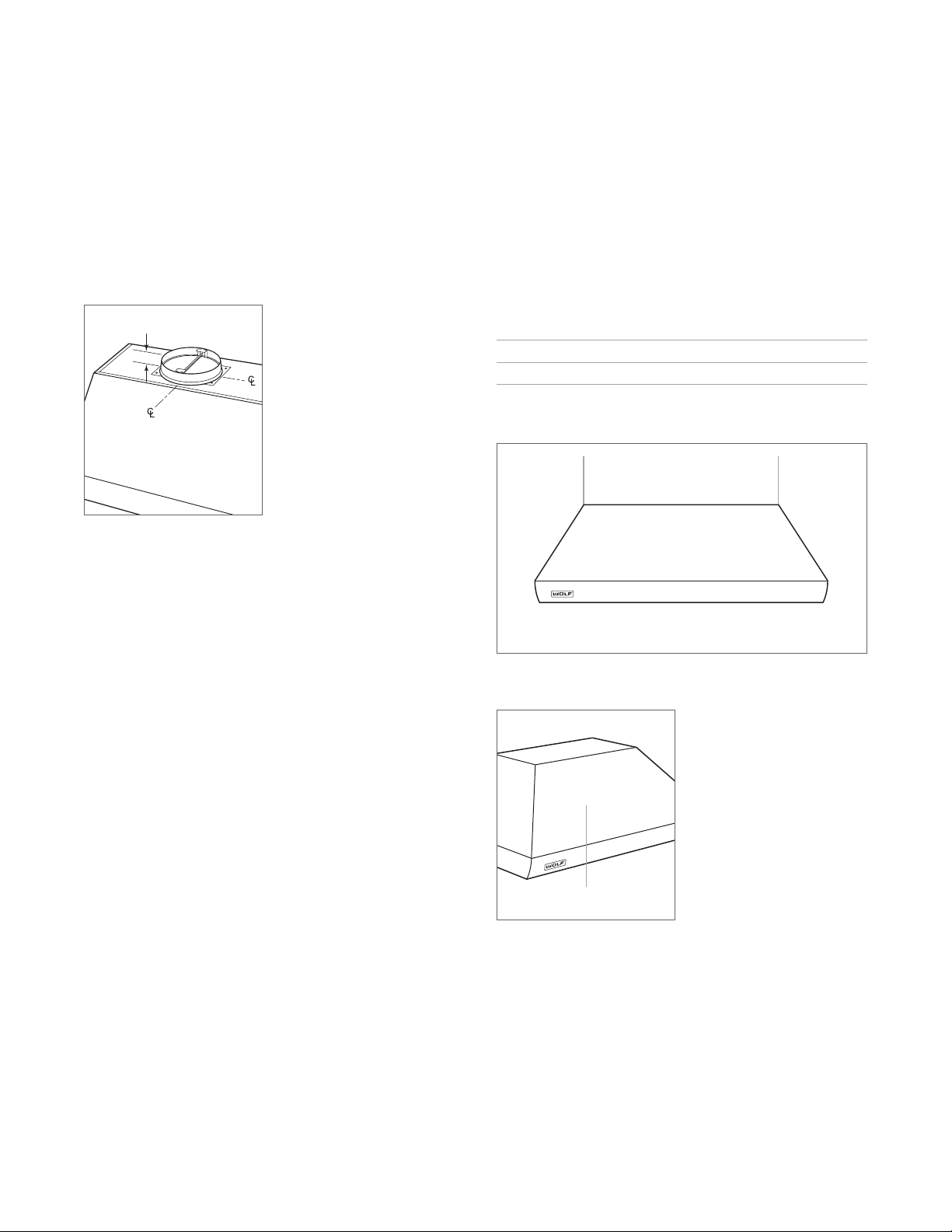

Discharge

Pro Island Hoods have a vertical discharge. Refer to the

illustration below.

2" (51)

Vertical discharge

Electrical Requirements

Installation must comply with all applicable electrical codes.

Locate the electrical supply as shown in the illustration

below. A separate circuit servicing only this appliance is

required.

ELECTRICAL REQUIREMENTS

Electrical Supply grounded, 120 VAC, 60 Hz

Service 15 amp dedicated circuit

ELECTRICAL LOCATION

THROUGH TOP OF HOOD

30" (762) TO 36" (914) BOTTOM EDGE TO COUNTERTOP

Electrical location

RATING PLATE

Rating plate location

wolfappliance.com | 5

Page 6

INSTALLATION

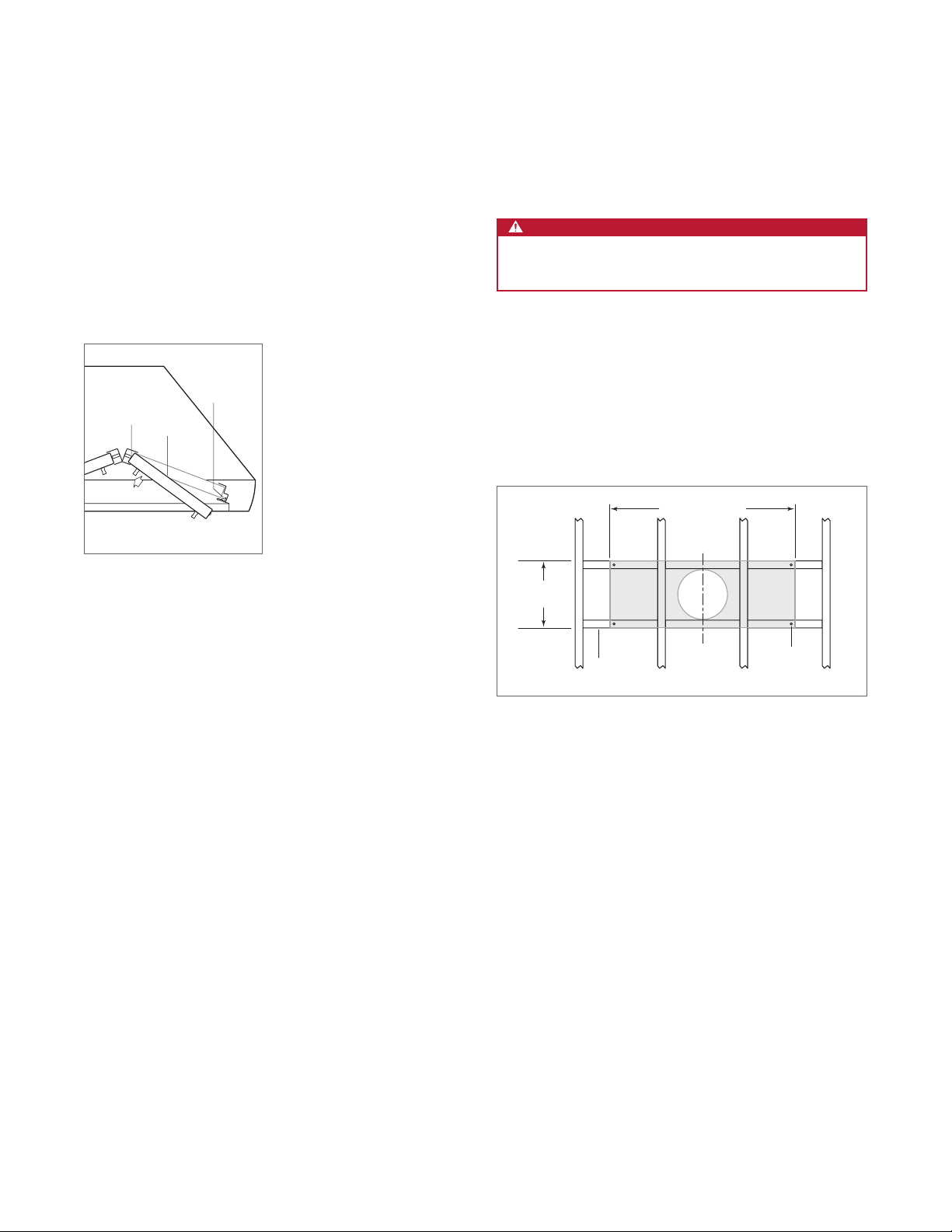

Hood Preparation

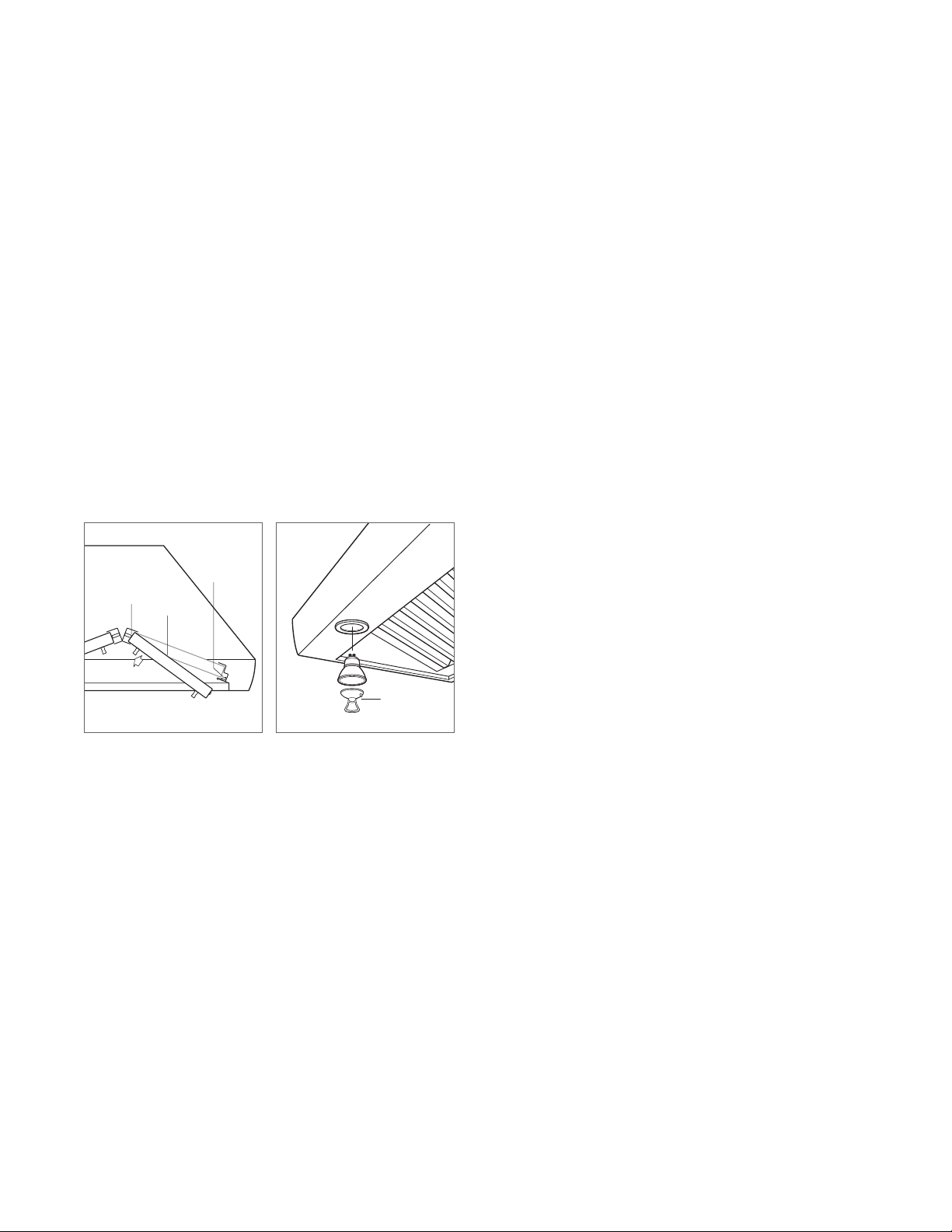

Remove the lters prior to installation. To remove, press

the lter upward and rotate the bottom. Remove the grease

cups from the bottom edge of the hood. Refer to the illustration below.

GREASE

CUP

SPRING

FILTER

SIDE VIEW

Filters

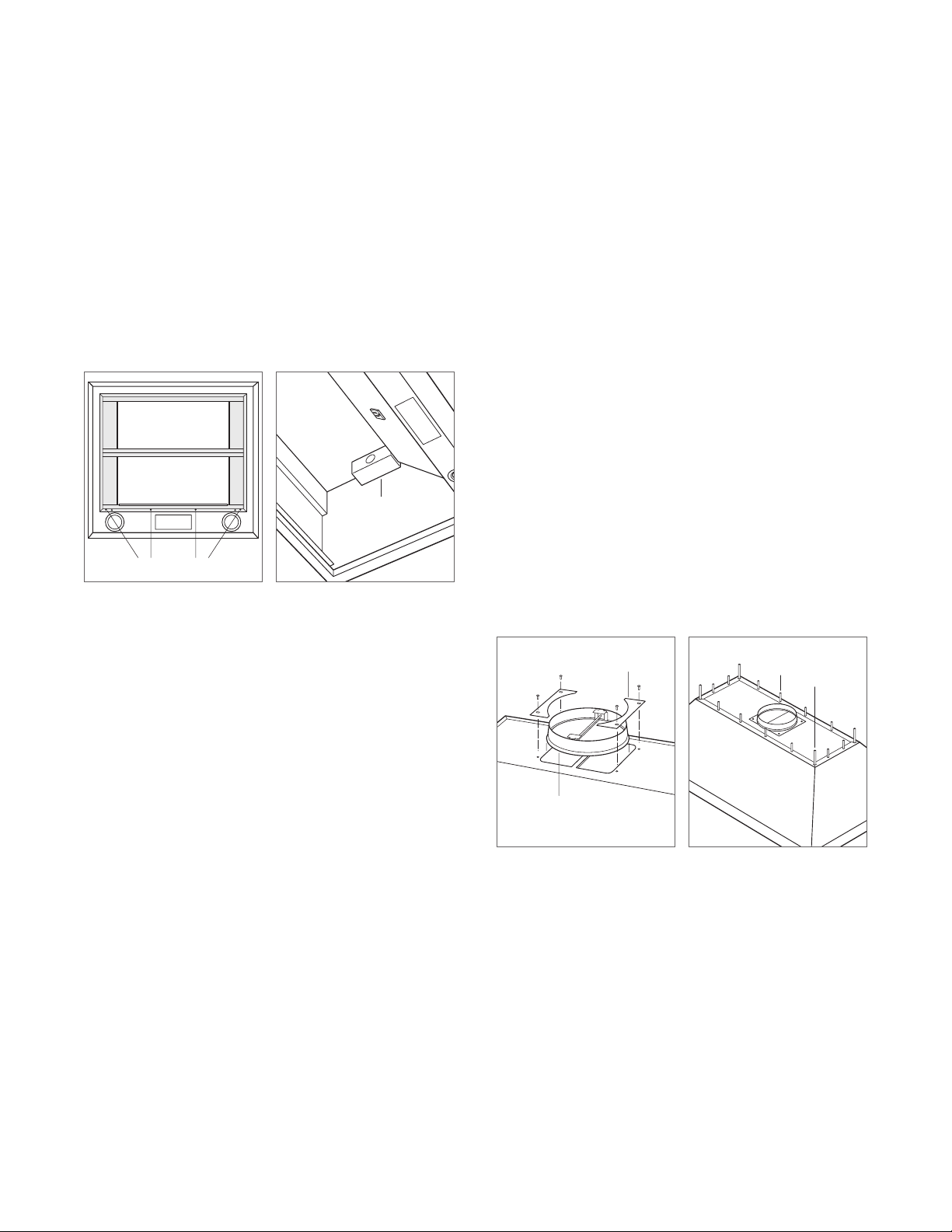

Installation

WARNING

Ceiling framing must be able to support the weight of

the hood and internal blower, if applicable.

1 Refer to the illustration below for typical ceiling framing.

Additional framing or blocking is required in the

mounting location of the hood.

13"

(330)

5

/32" (4) diameter holes in the ceiling framing to

TOP PLATE WIDTH

2 Drill four

match the mounting holes in the corners of the hood’s

top plate.

BLOCKING

Ceiling framing (typical)

C

L

MOUNTING

HOLE

6 | Wolf Customer Care 800.222.7820

Page 7

INSTALLATION

Installation

3 Remove the hood’s internal frame indicated by the

shaded area. Remove only the four screws indicated in

the illustration below.

4 Remove the electrical box from the inside the hood.

Refer to the illustration below.

ELECTRICAL

BOX

REMOVE SCREWS

Internal frame Electrical box

5 Remove the transition, hold-down brackets, and screws

from the packaging and use the hold-down brackets and

screws to secure the transition to the top of the hood.

Refer to the illustration below.

6 Lift the hood into position aligning the hood mounting

holes with the pre-drilled holes in the ceiling framing.

Install the four provided lag screws with washers through

each corner of the top plate and into the ceiling framing.

Refer to the illustration below.

7 Install the provided hex head screws through the

remaining holes in the hood’s top plate and into the

ceiling framing.

8 Insert Romex

®

wire(s) into the electrical knockout and

secure with the provided connector.

9 Connect the ducting to the transition and secure with

duct sealing tape.

10 Reinstall the internal frame.

HOLD-DOWN

BRACKET

HEX HEAD

SCREW LAG

SCREW

TRANSITION

Transition mounting Hood installation

wolfappliance.com | 7

Page 8

INSTALLATION

Electrical Connections

WARNING

Before making electrical connections, verify the power

is turned off at the service panel.

IMPORTANT NOTE: Refer to installation instructions pro-

vided with the blower assembly.

INTERNAL BLOWER

1 Connect black to black and white to white with the

provided connectors, and connect the green/bare wire

to the ground screw.

2 Verify all wires are secure and not pinched, and reinstall

the box.

3 Plug the blower power cord into the receptacle inside

the hood. Refer to the illustration below.

4 Turn on the power to the hood and verify light and

blower operation.

IN-LINE/REMOTE BLOWER

1 Remove the connector from the end of the orange wire.

2 Connect the home supply. Connect black to black and

connect the green/bare wire to the ground screw.

3 Connect the blower supply. Connect black to orange,

all three white wires, and connect the green/bare wire to

the ground screw.

4 Verify all wires are secure and not pinched, and reinstall

the box.

5 Turn on the power to the hood and verify light and

blower operation.

ELECTRICAL

BOX

RECEPTACLE

ELECTRICAL

BOX

Electrical connections

Electrical connections

8 | Wolf Customer Care 800.222.7820

Page 9

INSTALLATION

Complete the Installation

FILTERS

Install the grease cups at the bottom edges of the hood.

Orient the lters with the lines running vertically. To install,

place the top edge of the lter against the spring, press

upward and rotate the bottom. Refer to the illustration

below.

LIGHT BULBS

A suction-cup-style light bulb changer is provided with

the hood. To install, use the changer to push the bulb into

the receptacle and rotate counterclockwise one-quarter

turn. Refer to the illustration below.

GREASE

CUP

SPRING

FILTER

WOLF LOGO

To attach the Wolf logo, clean the mounting area with

rubbing alcohol. Remove the paper backing, position the

logo parallel with the bottom of the hood, and press into

place.

LIGHT BULB

SIDE VIEW

Filters Light bulb installation

CHANGER

wolfappliance.com | 9

Page 10

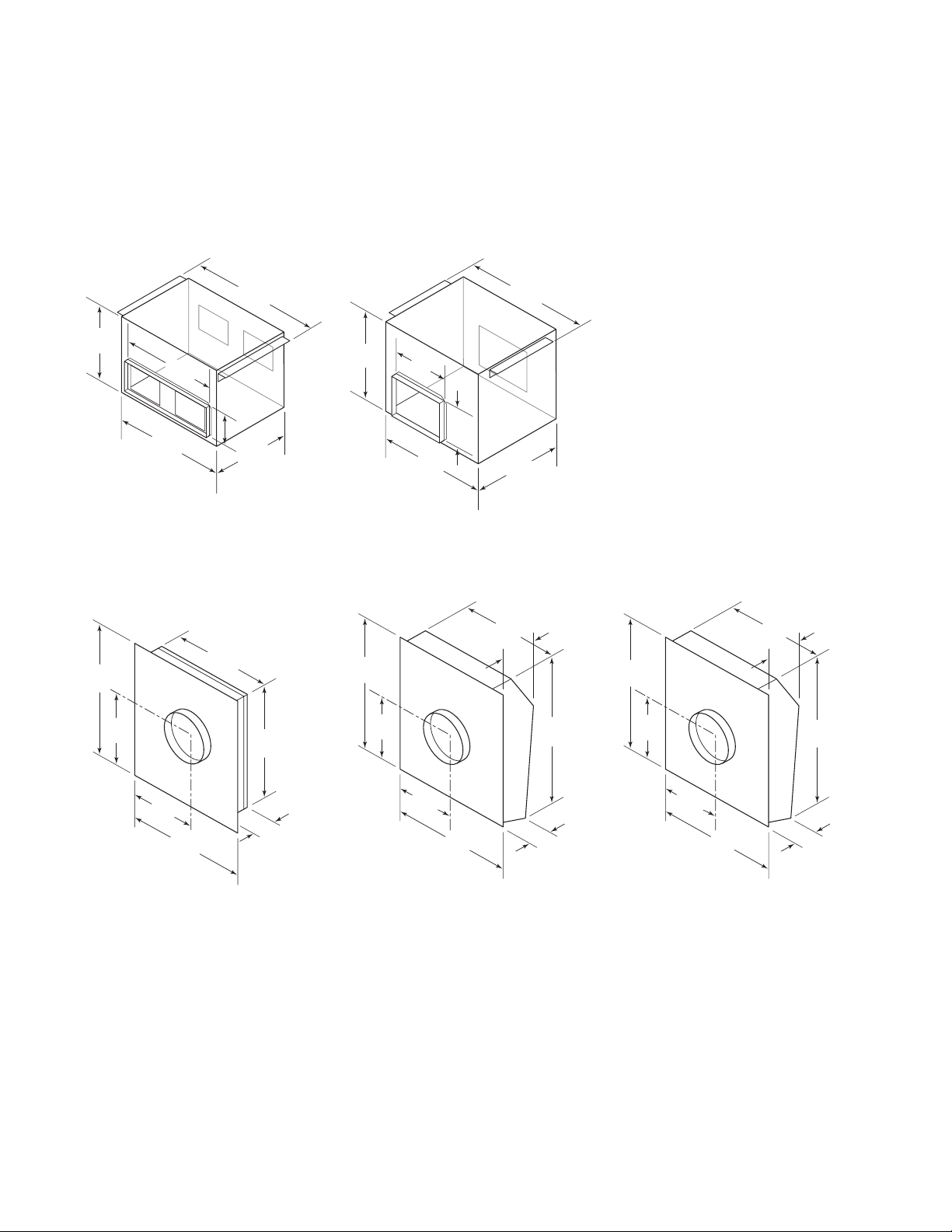

BLOWER SPECIFICATIONS

28

29

29

11

Blower Dimensions

IN-LINE BLOWERS

243/8"

(619)

3

/4"

(298)

181/2"

(470)

41/2"

(114)

211/2"

(546)

121/4"

(311)

18"

(457)

12"

(305)

22"

(559)

8"

(203)

24

(632)

18"

(457)

7

/8

"

600 CFM in-line blower

1100 CFM in-line blower

REMOTE BLOWERS

18" (457)

10"

(254)

29

(749)

7

(184)

1

/2

"

(749)

1

/2

"

1

/4

"

14

(375)

10" (254)

DIAMETER

3

/4

"

3

/8

10

"

(264)

25"

(635)

1

(718)

/4

15

(394)

3

/4

20

"

24

(629)

(527)

1

/2

24

"

(622)

3

/4

4

3

/4

"

(121)

"

"

10" (254)

DIAMETER

1

/2

"

14"

(356)

1

(749)

/2

14

(375)

"

10" (254)

DIAMETER

3

/4

"

1

/8

10

"

(257)

22"

(559)

600/900 CFM remote blower 1200 CFM remote blower 1500 CFM remote blower

21" (533)

10"

(254)

29

(749)

7

(184)

1

/2

"

1

/4

"

10 | Wolf Customer Care 800.222.7820

Page 11

TROUBLESHOOTING

Troubleshooting

IMPORTANT NOTE: If the hood does not operate properly,

follow these troubleshooting steps:

• Verify electrical power is supplied to the hood.

• Verify proper wiring connections.

• If the hood does not operate properly, contact Wolf

Factory Certied Service. Do not attempt to repair the

hood. Wolf is not responsible for service required to

correct a faulty installation.

Sub-Zero, Sub-Zero & Design, Sub-Zero & Snowake Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, Wolf, Wolf &

Design, Wolf Gourmet, W & Design, red colored knobs, Cove, and Cove & Design are registered trademarks and service marks of Sub-Zero Group, Inc. and its subsidiaries.

All other trademarks are property of their respective owners in the United States and other countries.

wolfappliance.com | 11

Page 12

CAMPANA PARA ISLAS PROFESIONAL

Contenido

3 Campana para islas profesional

4 Especicaciones

6 Instalación

10 Especicaciones del extractor

11 Solución de problemas

Las características y especicaciones están sujetas a

cambios sin previo aviso. Visite wolfappliance.com/specs

para obtener la información más actualizada.

Aviso importante

Para garantizar que este producto se instale y opere de

la forma más segura y eciente posible, tome nota de los

siguientes tipos de información resaltada en este manual:

AVISO IMPORTANTE señala la información que es

especialmente importante.

PRECAUCIÓN indica una situación en la que se pueden

sufrir heridas leves o provocar daños al producto si no se

siguen las instrucciones.

ADVERTENCIA indica peligro de que se produzcan heridas

graves o incluso la muerte si no se siguen las precauciones.

AVISO IMPORTANTE: En toda esta guía, las dimensiones

entre paréntesis son milímetros, a menos que se especique

lo contrario.

AVISO IMPORTANTE: guarde estas instrucciones para el

inspector eléctrico local.

2 | Atención al cliente de Wolf 800.222.7820

Page 13

CAMPANA PARA ISLAS PROFESIONAL

Información del producto

La información importante del producto, incluidos el modelo

y el número de serie de la unidad, se encuentra en la placa

de datos del producto. La placa de datos se encuentra en

una pared interior de la carcasa de la campana (se deben

quitar los ltros). Consulte la siguiente ilustración.

Si es necesario realizar algún servicio, póngase en contacto

con el servicio certicado de fábrica de Wolf y tenga a mano

el modelo y el número de serie. Para obtener los datos del

Centro de Servicio Certicado de la fábrica de Wolf más

cercano o si tiene preguntas acerca de la instalación, visite

la sección de contacto y soporte técnico en nuestra página

de Internet wolfappliance.com; o bien, llame a la línea de

atención al cliente de Wolf al 800-222-7820.

PLACA DE DATOS

Ubicación de la placa de datos

INSTRUCCIONES

IMPORTANTES

PARA REDUCIR EL RIESGO DE INCENDIO,

DESCARGA ELÉCTRICA O LESIONES,

TOME LAS SIGUIENTES PRECAUCIONES:

• Una persona calicada debe realizar el trabajo de

instalación y cableado eléctrico de conformidad

con todos los códigos y normas aplicables,

incluyendo los de construcción a prueba de fuego.

• Se recomiendan dos instaladores debido al

tamaño y peso de la campana profesional.

• Solo instale la campana profesional con un

extractor fabricado por Wolf.

• Al cortar o perforar la pared o el techo, no dañe el

cableado eléctrico ni otros servicios ocultos.

• Los ventiladores con conductos siempre deben

descargarse hacia el exterior.

PRECAUCIÓN

Para reducir el riesgo de incendio y extraer el aire

de manera apropiada, asegúrese de dirigir el aire

hacia el exterior. No ventile el aire del escape en

espacios cerrados por paredes o techos, áticos,

espacios angostos o garajes.

wolfappliance.com | 3

Page 14

ESPECIFICACIONES

Requisitos de instalación

Instale la cubierta 30" (762) a 36" (914) desde la parte inferior

de la campana a la encimera.

CONJUNTOS DE EXTRACTOR

Las campanas para islas profesionales requieren que

se instale un extractor interno, en línea o remoto, que

se puede obtener a través de un distribuidor autorizado

de Wolf. Para obtener más información acerca de los

distribuidores locales, visite la sección para encontrar una

sala de exposición de nuestro sitio web, wolfappliance.

com. Consulte las instrucciones de instalación especícas

provistas con cada conjunto de extractor.

TAPA DE CONDUCTO

Hay disponibles tapas de conducto de acero inoxidables

opcionales de diversas alturas a través de un distribuidor

autorizado de Wolf. Para obtener más información acerca

de los distribuidores locales, visite la sección para

encontrar una sala de exposición de nuestro sitio web,

wolfappliance.com.

Conductos

ADVERTENCIA

Para reducir el riesgo de incendio, utilice solamente

conductos metálicos.

AVISO IMPORTANTE: Consulte a un profesional de

climatización calicado para la instalación especíca y las

aplicaciones de conductos.

Las campanas para islas profesionales admiten un

conducto redondo de 10"

metálicos rígidos.

Un tramo de conductos recto y corto permite que la

campana tenga un mejor funcionamiento. Si el tramo de

conducto supera las 50'

extractor CFM más alto para mantener un ujo de aire

adecuado.

Los extractores internos y en línea necesitan una rejilla de

techo o de pared. Conecte los conductos a la rejilla o al

extractor remoto y trabaje hacia la campana. Utilice tornillos

de metal y cinta para conductos de alta temperatura para

sellar las uniones entre las secciones de los conductos.

(254). Utilice solamente conductos

(15 m), se puede necesitar un

Las campanas para islas profesionales incluyen una

compuerta de contraujo de aire. Es posible que los

códigos locales exijan que se utilice una compuerta

adicional de contraujo o aire renovable. Comuníquese

con un profesional local de climatización para conocer los

requisitos especícos.

Una compuerta de aire renovable está disponible a través

de un distribuidor autorizado de Wolf. Para obtener más

información acerca de los distribuidores locales, visite la

sección para encontrar una sala de exposición de nuestro

sitio web, wolfappliance.com.

4 | Atención al cliente de Wolf 800.222.7820

Page 15

ESPECIFICACIONES

Descarga

Las campanas para islas profesionales tienen una descarga

vertical. Consulte la siguiente ilustración.

2" (51)

Descarga vertical

Requisitos eléctricos

La instalación debe cumplir con todos los códigos

eléctricos vigentes.

Coloque el suministro eléctrico como se muestra en la

siguiente ilustración. Se necesita un circuito independiente

que le suministre electricidad únicamente a este

electrodoméstico.

REQUISITOS ELÉCTRICOS

Suministro eléctrico Con conexión a tierra, 120 V CA, 60 Hz

Servicio Circuito dedicado de 15 amperes

UBICACIÓN ELÉCTRICA A TRAVÉS DE

LA PARTE SUPERIOR DE LA CAMPANA

30" (762) A 36" (914) DESDE EL BORDE INFERIOR A LA ENCIMERA

Ubicación eléctrica

PLACA DE DATOS

Ubicación de la placa de datos

wolfappliance.com | 5

Page 16

INSTALACIÓN

Preparación de la campana

Quite los ltros antes de la instalación. Para quitarlos,

presione el ltro hacia arriba y gire la parte inferior. Retire los

engrasadores del borde inferior de la campana. Consulte la

siguiente ilustración.

ENGRASADOR

RESORTE

FILTRO

VISTA LATERAL

Filtros

Instalación

ADVERTENCIA

La estructura del techo debe ser capaz de soportar

el peso de la campana y del extractor interno,

si corresponde.

1 Consulte la ilustración a continuación para ver el

marco de techo típico. Se requiere encuadre o bloqueo

adicional en el lugar de montaje de la capucha.

2 Taladre cuatro oricios de

marco del techo para coinciden con los oricios de

montaje en las esquinas de la campana la placa superior.

13"

(330)

5/32" (4)

ANCHO DE LA PLACA SUPERIOR

de diámetro en el

ENTRAMADO

Estructura de techo (típica).

C

L

ORIFICIO DE

MONTAJE

6 | Atención al cliente de Wolf 800.222.7820

Page 17

INSTALACIÓN

Instalación

3 Retire el marco interno del capó indicado por el area

sombreada. Quite solo los cuatro tornillos indicados en la

siguiente ilustración.

4 Retire la caja eléctrica del interior de la campana.

Consulte la siguiente ilustración.

CAJA

ELÉCTRICA

QUITAR TORNILLOS

Marco interno Caja electrica

5 Retire la transición, los soportes de sujeción y los

tornillos. del embalaje y utilizar los soportes de sujeción

y tornillos para asegurar la transición a la parte superior

de la campana. Consulte la siguiente ilustración.

6 Levante la cubierta hasta su posición, alineando el

montaje de la cubierta. Oricios con los oricios preperforados en la estructura del techo. Instale los cuatro

tornillos provistos con arandelas a través cada esquina

de la placa superior y en el marco del techo. Consulte la

siguiente ilustración.

7 Instale los tornillos de cabeza hexagonal provistos a

través del agujeros restantes en la placa superior de la

campana y en el estructura de techo.

8 Inserte el (los) cable(s) Romex

®

en el oricio eléctrico y

asegure con el conector provisto.

9 Conecte los conductos a la transición y asegúrelos con

cinta de sellado de conductos.

10 Vuelva a instalar el marco interno.

SOPORTE

SUJECIÓN

TORNILLO

DE CABEZA

HEXAGONAL

TORNILLO DE

COMPRESIÓN

TRANSICIÓN

Montaje de la transición Instalación de la campana

wolfappliance.com | 7

Page 18

INSTALACIÓN

Conexiones eléctricas

ADVERTENCIA

Antes de realizar las conexiones eléctricas, verique

que la corriente eléctrica esté apagada en el panel

de servicio.

AVISO IMPORTANTE: Consulte las instrucciones de

instalación provistas con el conjunto de extractor.

EXTRACTOR INTERNO

1 Conecte de negro a blanco y de blanco a blanco con el

conectores provistos, y conecte el cable verde/desnudo

al tornillo de tierra.

2 Verique que todos los cables estén seguros y no estén

pellizcados, y reinstálelos la caja.

3 Enchufe el cable de alimentación del soplador en el

receptáculo interior la capucha. Consulte la siguiente

ilustración.

4 Encienda la campana y verique la luz y funcionamiento

del soplador.

EXTRACTOR EN LÍNEA / REMOTO

1 Retire el conector del extremo del cable naranja.

2 Conecte la fuente de la casa. Conecte negro con negro y

conecte el cable verde/pelado al tornillo de tierra.

3 Conecte el suministro de soplador. Conecte negro con

naranja, los tres cables blancos, y conecte el cable

verde/desnudo a el tornillo de tierra.

4 Verique que todos los cables estén seguros y no

pellizcados, y vuelva a instalarlos la caja.

5 Encienda la campana y verique la luz y funcionamiento

del soplador.

CAJA

ELÉCTRICA

RECEPTÁCULO

CAJA

ELÉCTRICA

Conexiones eléctricas

8 | Atención al cliente de Wolf 800.222.7820

Conexiones eléctricas

Page 19

INSTALACIÓN

Complete la instalación

FILTROS

Instale los engrasadores en los bordes inferiores de la

campana. Oriente los ltros con las tuberías instaladas de

forma vertical. Para instalar, coloque el borde superior del

ltro contra el resorte, presione hacia arriba y gire la parte

inferior. Consulte la siguiente ilustración.

FOCOS

Se suministra un cambiador de foco tipo ventosa. Para

instalar, use el cambiador para empujar el foco en el

receptáculo y gire en sentido contrario a las agujas del reloj

un cuarto de vuelta. Consulte la siguiente ilustración.

ENGRASADOR

RESORTE

FILTRO

LOGOTIPO DE WOLF

Para jar el logotipo de Wolf, limpie el lugar de montaje

con alcohol. Retire el papel protector, coloque el logotipo

de forma paralela a la parte inferior de la campana, luego

presione para jarlo.

Filtros

VISTA LATERAL

Instalación de focos

CAMBIADOR

DE FOCO

wolfappliance.com | 9

Page 20

ESPECIFICACIONES DEL EXTRACTOR

28

29

29

11

Dimensiones del extractor

EXTRACTORES EN LÍNEA

243/8"

(619)

3

/4"

(298)

181/2"

(470)

41/2"

(114)

211/2"

(546)

121/4"

(311)

18"

(457)

12"

(305)

22"

(559)

8"

(203)

24

(632)

18"

(457)

7

/8

"

Extractor en línea 600 CFM

Extractor en línea 1100 CFM

EXTRACTORES REMOTOS

(718)

1

/4

15

(394)

"

1

/2

"

10" (254)

DE DIÁMETRO

14"

(356)

3

/4

24

"

(629)

20

(527)

18" (457)

3

/4

"

1

/2

24

"

(622)

3

/4

4

"

(121)

(749)

1

/2

14

(375)

"

3

/4

DE DIÁMETRO

"

10

(257)

10" (254)

1

/8

"

22"

(559)

10"

(254)

29

(749)

7

(184)

1

/2

"

(749)

1

/2

"

1

/4

"

14

(375)

3

/4

"

10" (254)

DE DIÁMETRO

3

/8

10

"

(264)

25"

(635)

21" (533)

Extractor remoto 600/ 900 CFM Extractor remoto 1200 CFM Extractor remoto 1500 CFM

10"

(254)

29

(749)

7

(184)

1

/2

"

1

/4

"

10 | Atención al cliente de Wolf 800.222.7820

Page 21

SOLUCIÓN DE PROBLEMAS

Solución de problemas

AVISO IMPORTANTE: Si la campana no funciona

correctamente, siga estos pasos para resolver problemas:

• Compruebe que la campana tiene corriente eléctrica.

• Compruebe que las conexiones de cableado estén

correctas.

• Si la campana no funciona correctamente, póngase

en contacto con el centro de Servicio certicado de

fábrica de Wolf. No intente reparar la campana. Wolf no

es responsable del servicio necesario para corregir una

instalación defectuosa.

Sub-Zero, Sub-Zero & Design, Sub-Zero & Snowake Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, Wolf, Wolf

& Design, Wolf Gourmet, W & Design, red colored knobs, Cove, and Cove & Design son marcas registradas y marcas de servicio de Sub-Zero Group, Inc. y sus liales.

Todas las demás marcas registradas son propiedad de sus dueños respectivos en Estados Unidos y otros países.

wolfappliance.com | 11

Page 22

HOTTE POUR ÎLOT DE STYLE PROFESSIONNEL

Table des matières

3 Hotte pour îlot de style professionnel

4 Spécications

6 Installation

10 Spécications du ventilateur

11 Dépannage

Les caractéristiques et les spécications peuvent être

modiées en tout temps sans préavis. Visitez wolfappliance.

com/specs pour obtenir les renseignements les plus récents.

Remarque importante

Pour s'assurer que ce produit est installé et utilisé en toute

sécurité et aussi efcacement que possible, prenez note des

types de renseignement mis en évidence tout au long de ce

guide :

REMARQUE IMPORTANTE met en évidence des

renseignements qui sont particulièrement importants.

MISE EN GARDE indique une situation où une blessure

mineure ou des dommages au produit peuvent se produire

si les directives ne sont pas respectées.

AVERTISSEMENT décrit un danger qui peut causer une

blessure grave ou la mort si les précautions ne sont pas

respectées.

REMARQUE IMPORTANTE : Tout au long de ce guide, les

dimensions entre parenthèses sont en millimètres à moins

d'indication contraire.

REMARQUE IMPORTANTE : Conservez ces directives pour

l'inspecteur en électricité local.

2 | Service à la clientèle de Wolf 800.222.7820

Page 23

HOTTE POUR ÎLOT DE STYLE PROFESSIONNEL

Renseignements sur le produit

Des renseignements importants sur le produit, y compris

les numéros de modèle et de série, se trouvent sur la

plaque signalétique du produit. La plaque signalétique est

située sur une paroi intérieure de la coquille de la hotte (les

ltres doivent être retirés). Reportez-vous à l'illustration

ci-dessous.

Si vous avez besoin de service, communiquez avec le

service Wolf certié par l'usine avec les numéros de modèle

et de série. Pour obtenir le nom du centre de service

Wolf certié par l'usine le plus près de chez vous ou si

vous avez des questions concernant l'installation,

consultez la section Contact et assistance de notre site

Web, www.wolfappliance.com ou appelez le service à la

clientèle de Wolf au 800-222-7820.

DIRECTIVES IMPORTANTES

EN VUE DE RÉDUIRE LE RISQUE D'INCENDIE,

DE CHOC ÉLECTRIQUE OU DE BLESSURES,

RESPECTEZ LES DIRECTIVES SUIVANTES :

• Le travail d'installation et le câblage électrique

doivent être effectués par une (des) personne(s)

qualiée(s) conformément à tous les codes et

normes applicables, y compris ceux concernant la

construction résistante au feu.

• Il est recommandé d’avoir deux installateurs en

raison de la taille et du poids de la hotte de style

professionnel.

• Installez la hotte de style professionnelle

uniquement avec un ventilateur fabriqué par Wolf.

• Lorsque vous coupez ou percez dans un mur ou

un plafond, n'endommagez pas les ls électriques

ou les autres services publics cachés.

• Les ventilateurs à enveloppe doivent toujours être

ventilés vers l'extérieur.

PLAQUE

SIGNALÉTIQUE

Emplacement de la plaque

signalétique

MISE EN GARDE

En vue de réduire le risque d'incendie et

correctement évacuer l'air, assurez-vous

d'acheminer l'air vers l'extérieur. Ne ventilez

pas l’évacuation dans des espaces entre des

murs ou des plafonds, ou dans des greniers,

des galeries, ou des garages.

wolfappliance.com | 3

Page 24

SPÉCIFICATIONS

Exigences d'installation

Installez la hotte à une distance de 30po (762) à 36po (914)

du bas de la hotte au comptoir.

ASSEMBLAGES DE VENTILATEUR

Les hottes d'îlot de style professionnel nécessitent un

assemblage de ventilateur interne en ligne ou à distance,

offert par les dépositaires Wolf autorisés. Pour obtenir des

renseignements sur le dépositaire local, visitez la section

salle d'exposition de notre site Web, wolfappliance.com.

Reportez-vous aux directives d'installation précises fournies

avec chaque assemblage de ventilateur.

COUVERCLE DE CONDUIT

Des couvercles de conduit en acier inoxydable de plusieurs

hauteurs sont offerts en option par votre dépositaire

Wolf autorisé. Pour obtenir des renseignements sur le

dépositaire local, visitez la section salle d'exposition de

notre site Web, wolfappliance.com.

Conduits

AVERTISSEMENT

En vue de réduire le risque d'incendie, utilisez seulement des gaines en acier.

REMARQUE IMPORTANTE : Consultez un professionnel en

CVC qualié pour des installations et des applications de

conduits précises.

Les hottes pour îlot de style professionnel acceptent un

conduit rond de 10po

des conduits métalliques rigides.

Un tracé de conduit court et rectiligne permet à la hotte de

fonctionner le plus efcacement possible. Si le tracé des

conduits dépasse 50pi

élevé pourra être requis pour obtenir le débit d'air approprié.

Les ventilateurs internes et en ligne nécessitent un

capuchon de toit ou de mur. Reliez les conduits au

capuchon ou au ventilateur à distance, et remontez vers la

hotte. Utilisez des vis autotaraudeuses et du ruban adhésif

en toile pour haute température pour sceller les joints entre

les sections de conduit.

(254) de diamètre. Utilisez uniquement

(15m), un ventilateur à débit plus

La hotte pour îlot de style professionnel comprend une

persienne antiretour. Les codes locaux peuvent exiger

l'utilisation d'une persienne antiretour/ou d'air d'appoint

supplémentaire. Communiquez avec votre professionnel en

CVC local pour connaître les exigences précises.

Une persienne d'air d'appoint est offerte par les dépositaires

Wolf autorisés. Pour obtenir des renseignements sur le

dépositaire local, visitez la section salle d'exposition de

notre site Web, wolfappliance.com.

4 | Service à la clientèle de Wolf 800.222.7820

Page 25

SPÉCIFICATIONS

Évacuation

Les hottes pour îlot de style professionnel comprennent

une évacuation verticale. Reportez-vous à l'illustration

ci-dessous.

2 PO (51)

Évacuation verticale

Exigences électriques

L'installation doit se conformer à tous les codes électriques

applicables.

Repérez l'alimentation électrique, comme il est montré

dans l'illustration ci-dessous. Un circuit séparé servant

uniquement cet appareil est requis.

EXIGENCES ÉLECTRIQUES

Alimentation électrique mise à la terre, 120 volts CA, 60 Hz

Service circuit dédié de 15 ampères

EMPLACEMENT DE L'ÉLECTRICITÉ DANS

LA PARTIE SUPÉRIEURE DE LA HOTTE

30 PO (762) À 36 PO (914) DU REBORD INFÉRIEUR JUSQU'AU COMPTOIR

Emplacement de l'électricité

PLAQUE

SIGNALÉTIQUE

Emplacement de la plaque

signalétique

wolfappliance.com | 5

Page 26

INSTALLATION

Préparation de la hotte

Retirez les ltres avant de procéder à l’installation. Pour

retirer, poussez le ltre vers le haut et tournez la partie

inférieure. Retirez les godets de graisse du rebord inférieur

de la hotte. Reportez-vous à l'illustration ci-dessous.

GODET DE

GRAISSE

RESSORT

FILTRE

VUE DE PROFIL

Filtres

Installation

AVERTISSEMENT

Le cadrage au plafond doit pouvoir soutenir le poids de

la hotte et du ventilateur interne, le cas échéant.

1 Reportez-vous à l'illustration ci-dessous pour la

structure de plafond typique. Un encadrement ou un

blocage supplémentaire est requis dans le emplacement

de montage de la hotte.

2 Percez quatre trous de

charpente du plafond pour correspondre aux trous de

xation dans les coins de la hotte la plaque supérieure.

13 PO

(330)

5

/32 po (4) de diamètre dans la

LARGEUR DE LA

PLAQUE SUPÉRIEURE

BLOCAGE

Cadrage au plafond (typique)

C

L

TROU DE

MONTAGE

6 | Service à la clientèle de Wolf 800.222.7820

Page 27

INSTALLATION

Installation

3 Retirez le cadre interne de la hotte indiqué par le zone

ombragée. Ne retirez que les quatre vis indiquées dans

l'illustration ci-dessous.

4 Retirez le boîtier électrique de l'intérieur de la hotte.

Reportez-vous à l'illustration ci-dessous.

COFFRET

ÉLECTRIQUE

RETIREZ LES VIS

Cadre interne

Boîte électrique

5 Retirez la transition, les supports de xation et les vis de

l'emballage et utilisez les supports de xation et vis pour

sécuriser la transition vers le haut de la hotte. Reportezvous à l'illustration ci-dessous.

6 Soulevez le capot en alignant le support de capot

trous avec les trous pré-percés dans la charpente du

plafond. Installez les quatre tirefonds fournis avec les

rondelles chaque coin de la plaque supérieure et dans

la charpente du plafond. Reportez-vous à l'illustration

ci-dessous.

7 Installez les vis à tête hexagonale fournies à travers le

trous restants dans la plaque supérieure de la hotte et

dans le plafond encadrant.

8 Insérez le ou les ls Romex

®

dans l’embouchure

électrique sécuriser avec le connecteur fourni.

9 Connectez le conduit à la transition et xez-le avec

ruban d'étanchéité de conduit.

10 Réinstallez le cadre interne.

SUPPORT DE

RETENUE

VIS À TÊTE

HEXAGONALE

TIRE-FOND

VIS

TRANSITION

Montage de la transition

Installation de la hotte

wolfappliance.com | 7

Page 28

INSTALLATION

Raccordements électriques

AVERTISSEMENT

Avant d’effectuer des raccordements électriques,

assurez-vous que l’alimentation est coupée au niveau

du panneau de service.

REMARQUE IMPORTANTE : Reportez-vous aux directives

d'installation fournies avec l’assemblage de ventilateur.

VENTILATEUR INTERNE

1 Connectez le noir au noir et le blanc au blanc avec le

connecteurs fournis et connectez le l vert/nu à la vis de

terre.

2 Vériez que tous les ls sont bien xés et non pincés,

puis réinstallez la boîte.

3 Branchez le cordon d'alimentation du ventilateur dans la

prise à l'intérieur la hotte. Reportez-vous à l'illustration

ci-dessous.

4 Mettez la hotte sous tension et vériez le voyant et

fonctionnement du ventilateur.

VENTILATEUR EN LI GN E / À DISTANCE

1 Retirez le connecteur de l'extrémité du l orange.

2 Connectez l'alimentation à domicile. Connectez le noir

au noir et connectez le l vert/nu à la vis de terre.

3 Connectez l'alimentation du ventilateur. Connectez le

noir à l'orange, les trois ls blancs et connectez le l

vert/nu à la vis de terre.

4 Vériez que tous les ls sont bien xés et non pincés,

puis réinstallez la boîte.

5 Allumez la hotte et vériez le voyant et fonctionnement

du ventilateur.

COFFRET

ÉLECTRIQUE

PRISE

COFFRET

ÉLECTRIQUE

Connections electriques

8 | Service à la clientèle de Wolf 800.222.7820

Connections electriques

Page 29

INSTALLATION

Terminer l'installation

FILTRES

Installez les godets de graisse sur les rebords inférieurs de

la hotte. Orientez les ltres en gardant les lignes orientées

verticalement. Pour installer, placez le rebord supérieur du

ltre contre le ressort, poussez vers le haut et pivotez la

partie inférieure. Reportez-vous à l'illustration ci-dessous.

AMPOULES

Un changeur d’ampoule de style à ventouse est fourni avec

la hotte. Pour installer, utilisez le changeur pour pousser

l’ampoule dans le socle et tournez dans le sens horaire d’un

quart de tour. Reportez-vous à l'illustration ci-dessous.

GODET DE

GRAISSE

RESSORT

FILTRE

LOGO DE WOLF

Pour xer le logo de Wolf, nettoyez la zone de montage

avec de l’alcool à friction. Retirez l’endos en papier, placez

le logo parallèle à la partie inférieure de la hotte, puis

appuyez en place.

Filtres

VUE DE PROFIL

CHANGEUR

D’AMPOULE

Installation de l’ampoule

wolfappliance.com | 9

Page 30

SPÉCIFICATIONS DES VENTILATEURS

28

29

29

18 PO

11

Dimensions des ventilateurs

VENTILATEURS EN LIGNE

243/8 PO

(619)

3

/4 PO

(298)

181/2 PO

(470)

41/2 PO

(114)

211/2 PO

(546)

121/4 PO

(311)

(457)

12 PO

(305)

22 PO

(559)

8 PO

(203)

7

24

(632)

18 PO

(457)

/8

PO

Ventilateur en ligne de 600 pi³/min

Ventilateur en ligne de 1100 pi³/min

VENTILATEURS À DISTANCE

1

/4

(718)

15

PO

1

(394)

/2

PO

10 PO (254)

DE DIAMÈTRE

14 PO

(356)

3

/4

24

PO

(629)

20

3

/4

(527)

PO

24

1

/2

(622)

3

4

(121)

PO

/4

PO

1

/2

(749)

14

PO

3

(375)

/4

PO

10 PO (254)

DE DIAMÈTRE

1

/8

10

PO

(257)

22 PO

(559)

18 PO (457)

10 PO

(254)

29

7

1

(749)

1

/4

(184)

/2

PO

PO

1

/2

(749)

14

PO

3

(375)

/4

PO

10 PO (254)

DE DIAMÈTRE

3

/8

10

(264)

PO

25 PO

(635)

21 PO (533)

10 PO

(254)

29

7

1

(749)

1

/4

(184)

/2

PO

Ventilateur à distance de 600/ 900 pi³/min Ventilateur à distance de 1200 pi³/min Ventilateur à distance de 1500 pi³/min

PO

10 | Service à la clientèle de Wolf 800.222.7820

Page 31

DÉPANNAGE

Dépannage

REMARQUE IMPORTANTE : Si la hotte ne fonctionne pas

correctement, suivez les étapes de dépannage suivantes:

• Vériez l'alimentation électrique de la hotte.

• Vériez les raccordements.

• Si la hotte ne fonctionne toujours pas correctement,

communiquez avec un centre de service Wolf certié

par l’usine. Ne tentez pas de réparer la hotte. Wolf n'est

pas responsable du service requis pour corriger une

installation défectueuse.

Sub-Zero, Sub-Zero & Design, Sub-Zero & Snowake Design, Dual Refrigeration, The Living Kitchen, Great American Kitchens The Fine Art of Kitchen Design, Wolf, Wolf &

Design, Wolf Gourmet, W & Design, les boutons de couleur rouge, Cove et Cove & Design sont des marques déposées et de service de Sub-Zero Group, Inc. et ses liales.

Toutes les autres marques de commerce appartiennent à leurs propriétaires respectifs aux États-Unis et dans d'autres pays.

wolfappliance.com | 11

Page 32

WOLF APPLIANCE, INC. P.O. BOX 44848 MADISON, WI 53744 WOLFAPPLIANCE.COM 800.222.7820

0

2/2019

Loading...

Loading...