Wolf OG30LP, OG36 Installation manual

Outdoor Gas Grills Installation Guide

OUTDOOR GAS GRILLS

Contents

3 Outdoor Gas Grills

4 Safety Precautions

5 Specications

9 Installation

18 Troubleshooting

Features and specications are subject to change at any

time without notice. Visit wolfappliance.com/specs for the

most up-to-date information.

Important Note

To ensure this product is installed and operated as safely

and efciently as possible, take note of the following types

of highlighted information throughout this guide:

IMPORTANT NOTE highlights information that is especially

important.

CAUTION indicates a situation where minor injury or product

damage may occur if instructions are not followed.

WARNING states a hazard that may cause serious injury or

death if precautions are not followed.

IMPORTANT NOTE: Throughout this guide, dimensions in

parentheses are millimeters unless otherwise specied.

IMPORTANT NOTE: Save these instructions for the local

electrical inspector.

2 | Wolf Customer Care 800.222.7820

OUTDOOR GAS GRILLS

Product Information

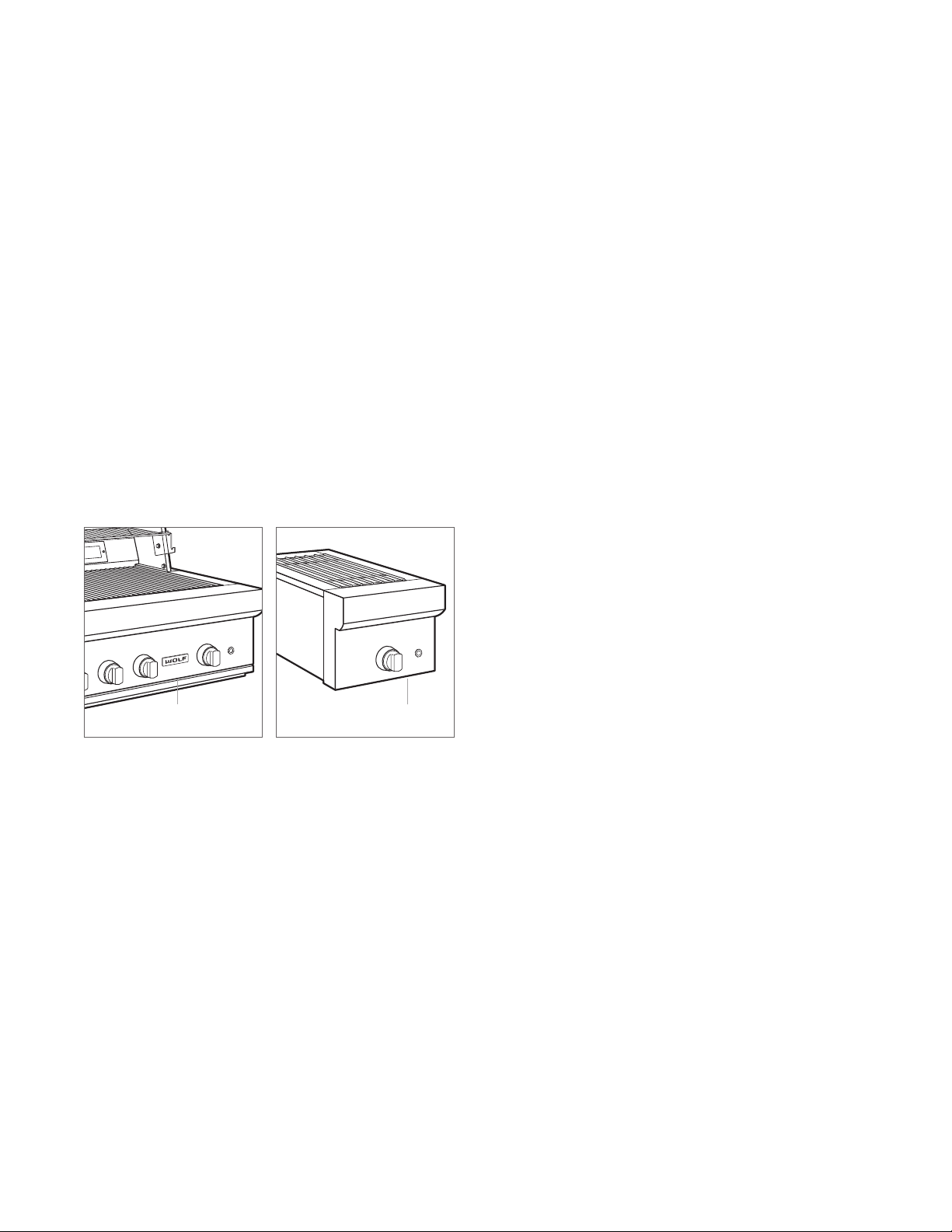

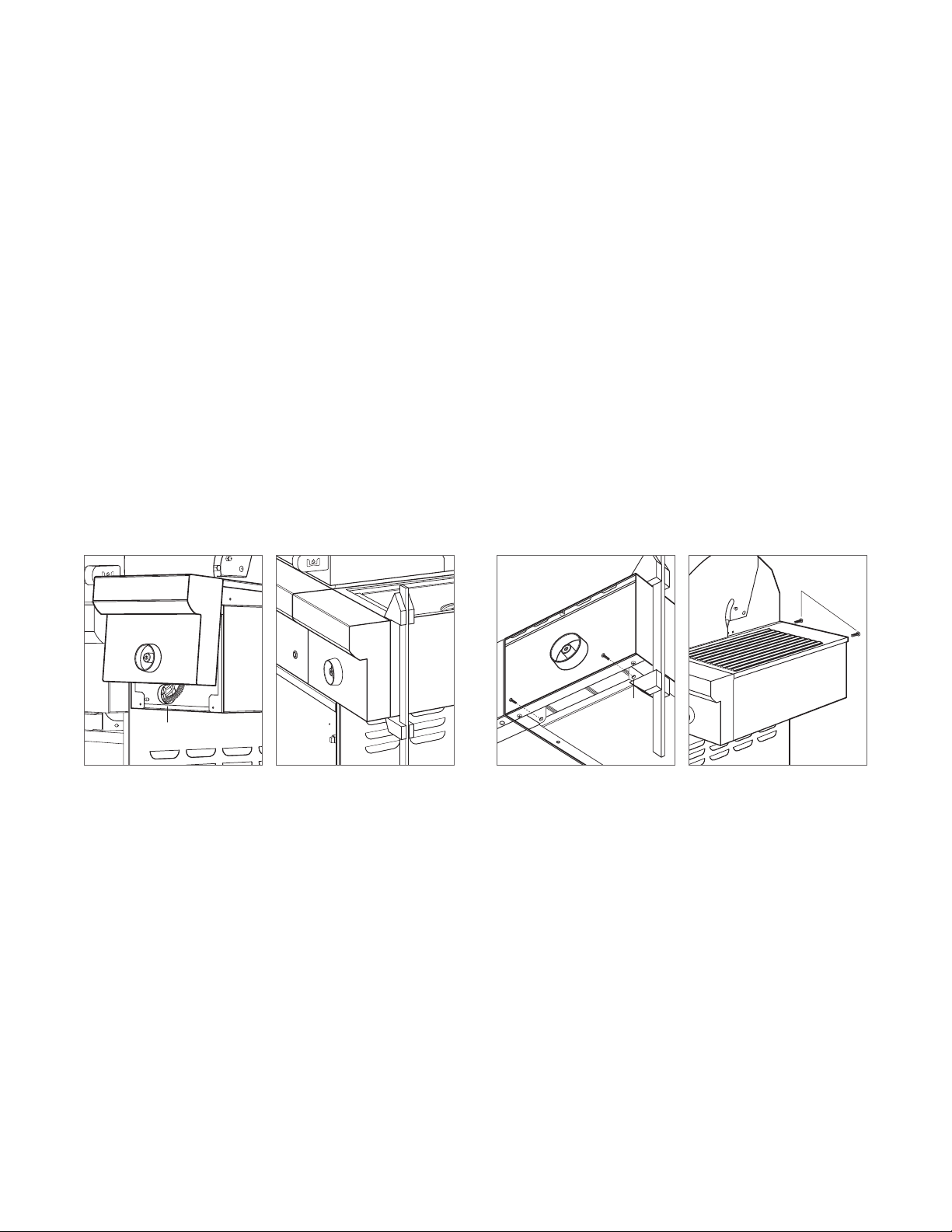

Important product information including the model and

serial number are listed on the product rating plate. For

outdoor grills, the rating plate is located above the drip tray,

behind the logo. The drip tray must be removed to view the

rating plate. For outdoor modules, the rating plate is located

on the bottom of the control panel, on the right side. Refer

to the illustration below.

If service is necessary, contact Wolf factory certied service

with the model and serial number. For the name of the

nearest Wolf factory certied service or for questions

regarding the installation, visit the contact & support section

of our website, wolfappliance.com or call Wolf customer

care at 800-222-7820.

RATING PLATE

Outdoor gas grill.

RATING PLATE

Outdoor module.

wolfappliance.com | 3

SAFETY PRECAUTIONS

IMPORTANT INSTRUCTIONS

• Wolf outdoor gas grills and modules are for out-

door use only. Do not install or operate in an

enclosed area.

• Installation must be performed by a qualied

installer, service agency or the gas supplier.

• Warranty service must be performed by Wolf

factory certied service.

• Do not store or use gasoline or other ammable

liquids or vapors in the vicinity of this or any other

appliance. An LP gas cylinder not connected for

use shall not be stored in the vicinity of this or any

other appliance.

• In Massachusetts: All gas products must be

installed using a “Massachusetts” licensed

plumber or gastter. A “T” handle type manual gas

valve must be installed in the gas supply line to this

appliance. This applies to permanently installed

natural gas and propane installations. This does

not apply to propane portable installations using a

20-lb tank.

BEFORE LIGHTING:

• Read instructions before lighting.

• Open hood or remove cover before lighting.

• If ignition does not occur in 5 seconds, turn the

burner control(s) off, wait 5 minutes, and repeat

the lighting procedure.

WHAT TO DO IF YOU SMELL GAS:

• Shut off gas to the appliance.

• Extinguish any open ames.

• Open hood or remove cover.

• If odor continues, keep away from the appli-

ance and immediately call your gas supplier or

re department.

• A built-in appliance for use with a remote self-con-

tained LP gas supply system must use rigid pipe,

semi-rigid tubing, or a connector complying with

the Standard for Connectors for Gas Appliances,

ANSI Z21.24/CSA 6.10, or the Standard for Connectors for Outdoor Gas Appliances and Manufactured Homes, ANSI Z21.75/CSA 6.27, to connect

the appliance to the remote self-contained gas

supply system. When using semi-rigid tubing, aluminum or aluminum alloy tubing is not permitted.

4 | Wolf Customer Care 800.222.7820

SPECIFICATIONS

Installation Requirements

For portable applications, Wolf grill carts are designed

specically to t grill models OG30, OG36 and OG42 and

the side burner. Model OG54 is designed for built-in applications only.

For built-in applications, Wolf outdoor grills and the burner

module are designed for easy placement into a built-in

enclosure. For outdoor grills, installation in a combustible

enclosure requires an insulating liner. For the burner module,

an insulating liner is not required. The enclosure should be

built according to specications for your specic installation on the following pages. If the burner module is installed

next to an outdoor grill, a minimum of 12"

between units on the rotisserie motor side and 2"

opposite side. A rotisserie side conversion kit is available

from an authorized Wolf dealer.

Grill carts, insulating liners and stainless steel doors and

drawers are avail able through an authorized Wolf dealer. For

local dealer information, visit the nd a showroom section of

our website, wolfappliance.com.

(305) is required

(51) on the

Electrical

Installation must comply with all applicable electrical codes.

The electrical outlet must be located within reach of the

power cord. A separate circuit, servicing only this appliance

is required.

IMPORTANT NOTE: A ground fault circuit interrupter (GFCI)

is required to reduce the risk of electrical shock.

ELECTRICAL REQUIREMENTS

Electrical Supply grounded, 120 VAC, 60 Hz

Service 15 amp dedicated circuit

Receptacle 3-prong grounding-type, GFCI

Power Cord 6'

(1.8 m), 9' (2.7 m) rotisserie

wolfappliance.com | 5

SPECIFICATIONS

Gas Supply

Installation must comply with local codes or, in the absence

of local codes, with the National Fuel Gas Code.

Locate the gas supply within the shaded area shown in the

illustrations on pages 7–8.

The outdoor grill is equipped for use with natural or liquid

propane (LP) gas. It is design certied by the Canadian

Standards Association (CSA) for natural or LP gases. The

product rating plate has information on the type of gas that

should be used. For rating plate location, refer to the illustration below. If this information does not agree with the type

of gas available, check with the local gas supplier.

GAS REQUIREMENTS

NATURAL GAS WC

Supply Pressure 5" (12.5 mb)

Min Line Pressure 7" (17.5 mb)

Max Regulator Pressure 14" (34.9 mb), .5 psi (3.5 kPa)

LP GAS WC

Supply Pressure 10" (25 mb)

Min Line Pressure 11" (27.4 mb)

Max Regulator Pressure 14" (34.9 mb), .5 psi (3.5 kPa)

The outdoor grill must be connected to a regulated gas

supply. The supply line must be equipped with an approved

external gas shut-off valve located near the grill in an accessible location. Do not block access to the shut-off valve.

Refer to the illustration below.

3

A gas supply line of

/4" (19) rigid pipe must be provided to

the outdoor grill or module. If local codes permit, a certied,

(.9 m) long,

3'

connector is recommended to connect the units

1

/2" (13) or 3/4" (19) ID exible metal appliance

1

/2" NPT

female inlet to the gas supply line. Pipe joint compounds,

suitable for use with natural or LP gas should be used.

The appliance and its shut-off valve must be disconnected

from the gas supply piping system during any pressure

testing of the system at test pressures in excess of .5 psi

(3.5 kPa)

. The appliance must be isolated from the gas

supply piping system by closing its individual manual shutoff valve during any pressure testing of the system at test

pressures equal to or less than .5 psi

SHUT-OFF VALVE

OPEN POSITION

(3.5 kPa).

RATING PLATE

Outdoor gas grill.

6 | Wolf Customer Care 800.222.7820

Outdoor module.

RATING PLATE

Gas shut-off valve.

GAS SUPPLYTO APPLIANCE

SPECIFICATIONS

NO

combus

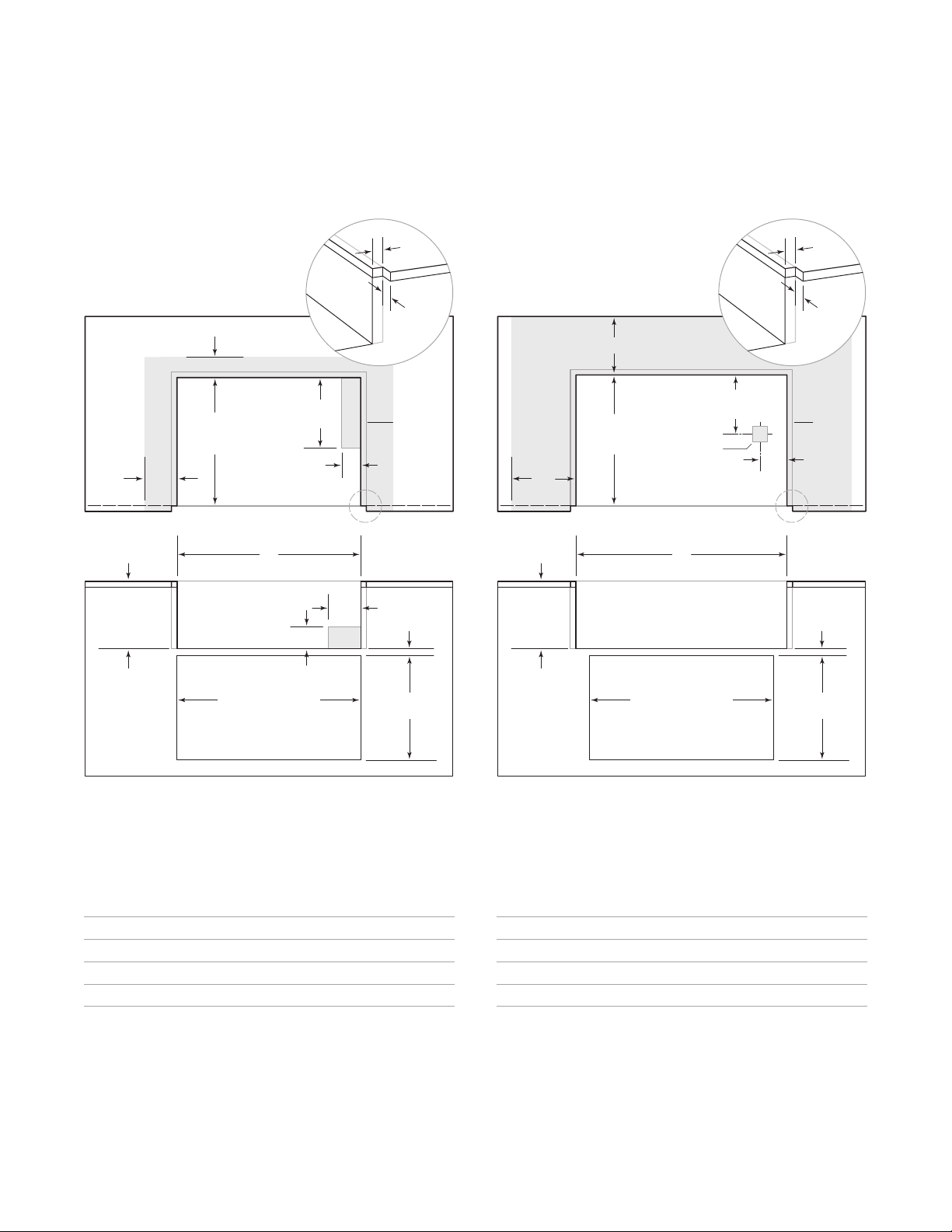

Outdoor Grills

NON-COMBUSTIBLE INSTALLATION COMBUSTIBLE INSTALLATION

13

/16"

(21)

GRILL

OPENING

COUNTERTOP

OVERHANG

(305)

12"

21/2" (64)

13"

G

(330)

31/2"

(89)

W

6"

(152)

(102)

4"

G

GRILL

OVERLAP

1" (25) min

12"

(305)

125/8"

(321)

OPENING

HEIGHT

26" (660)

OPENING

DEPTH

23/4" (70)

KNOCKOUT

TOP VIEW

W

OPENING WIDTH

113/4"

(298)

OPENING

HEIGHT

6"

(152)

241/4" (616)

OPENING

DEPTH

OPENING WIDTH

TOP VIEW

LINER

OPENING

103/4"

(273)

C

G

L

(127)

5"

COUNTERTOP

OVERHANG

C

OVERLAP

L

1" (25) min

13

/16"

(21)

LINER

DOORS / DRAWERS

OPENING WIDTH

FRONT VIEW

TE: Shaded area above countertop indicates minimum clearance to

tible surfaces, combustible materials cannot be located within this area.

NON-COMBUSTIBLE ENCLOSURE

OPENING

HEIGHT

WIDTH (W)

OG30 281/2" (724)

OG36 341/2" (876)

OG42 401/2" (1029)

OG54 521/2" (1334)

DOORS / DRAWERS

OPENING WIDTH

FRONT VIEW

NOTE: Shaded area above countertop indicates minimum clearance to

combustible surfaces, combustible materials cannot be located within this area.

COMBUSTIBLE ENCLOSURE

OPENING

HEIGHT

WIDTH (W)

OG30 331/2" (851)

OG36 391/2" (1003)

OG42 451/2" (1156)

OG54 571/2" (1461)

wolfappliance.com | 7

SPECIFICATIONS

Outdoor Grills

ACCESSORY DOORS | DRAWERS

OPENING

DOORS W H

18" Single 161/4" (413) 19" (483)

30" Double 281/4" (718) 19" (483)

36" Double 341/4" (870) 19" (483)

42" Double 401/4" (1022) 19" (483)

54" Double 521/4" (1327) 19" (483)

DRAWERS W H

Single Drawer 271/4" (692) 93/4" (248)

2- or 3-Drawer Unit 121/8" (308) 19" (483)

Drawer | Door Unit 291/4" (743) 19" (483)

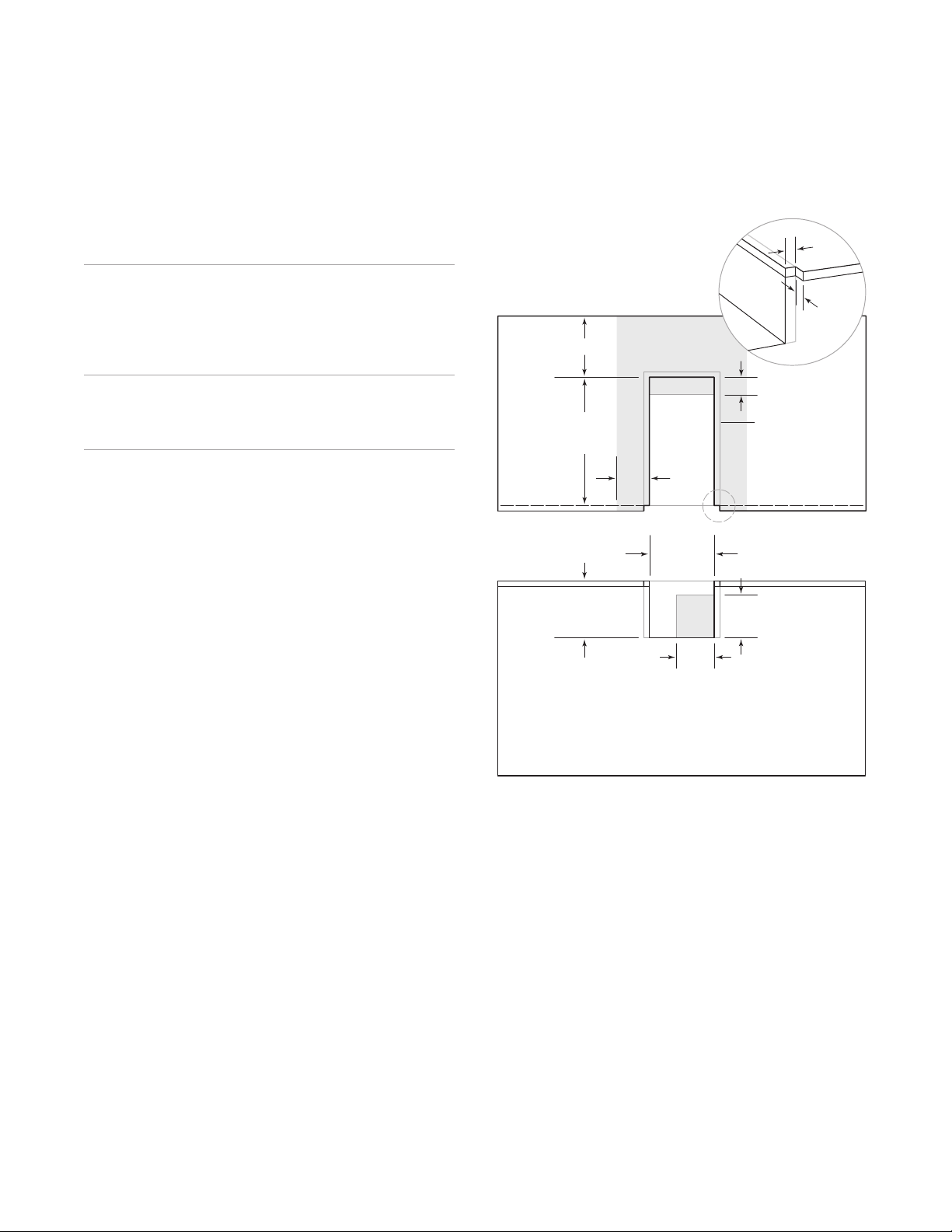

Burner Module

INSTALLATION

12" (305)

241/4" (616)

OPENING

DEPTH

10" (254)

OPENING

HEIGHT

6"

(152)

G

TOP VIEW

(305)

12"

OPENING

G

7"

(178)

MODULE

OPENING

3"

(76)

8"

(203)

MODULE

OVERLAP

9

/16"

(14)

COUNTERTOP

OVERHANG

8 | Wolf Customer Care 800.222.7820

FRONT VIEW

NOTE: Shaded area above countertop indicates minimum clearance to

combustible surfaces, combustible materials cannot be located within this area.

An insulating liner is not required.

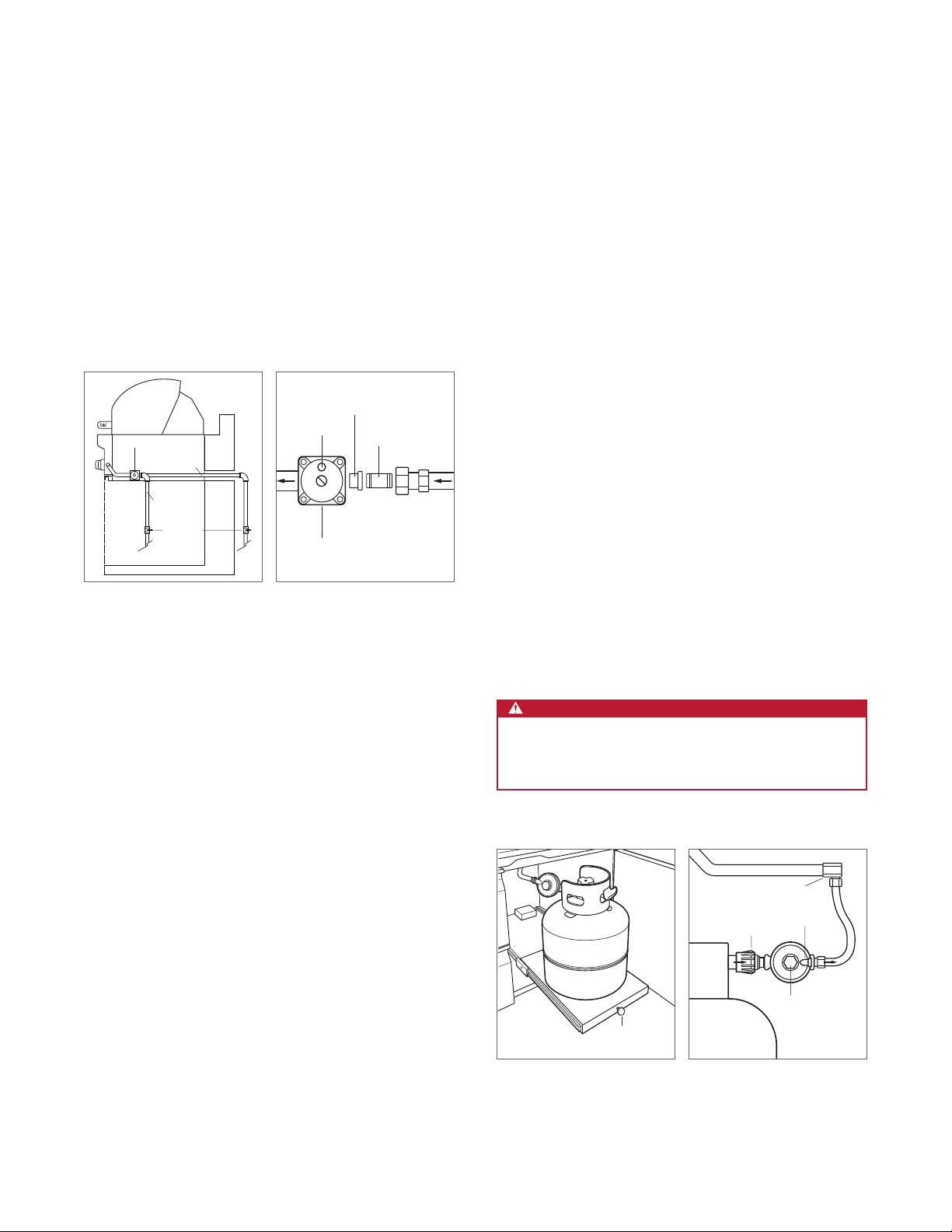

INSTALLATION

FROM GAS

SUPPLY

REGULATOR

TO GRILL

ADAPTER

CLOSE

NIPPLE

VENT

Gas Supply Line

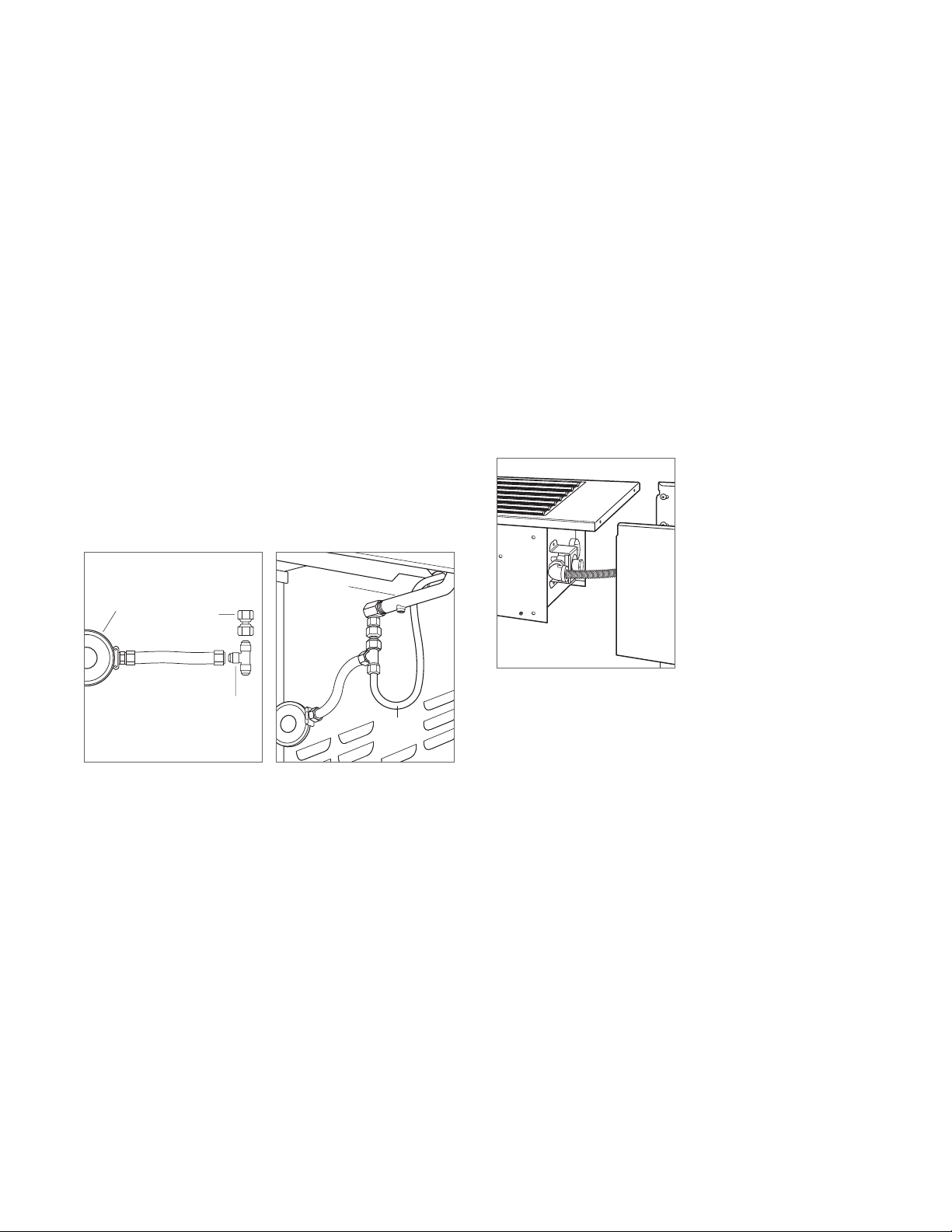

NATURAL GAS CONNECTION

Install the natural gas pressure regulator supplied with the

outdoor product with the arrow on the regulator pointing

towards the unit. Refer to the illustrations below for a typical

natural gas installation.

REGULATOR

REAR GAS

CONNECTION

BOTTOM GAS

CONNECTION

SHUT-OFF

VALV E

Natural gas connection.

Natural gas regulator.

LP GAS CONNECTION

For whole house LP gas connection, the LP gas pressure

regulator is not provided. It can be purchased from an

authorized Wolf dealer. For local dealer information, visit the

nd a showroom section of our website, wolfappliance.com.

For connection to LP gas cylinder, use only the LP gas pressure regulator and hose supplied with the outdoor product.

Use only a 20-lb LP gas cylinder with an approved overlling

preventive device (OPD) and shut-off valve terminating in

the cylinder valve outlet.

1 Connect the

3

/8" are end of the hose to the unit cou-

pling. Do not apply pipe sealant to the are connection.

2 Install the LP gas cylinder, pull out the shelf and place

the cylinder on it. Refer to the illustration below.

3 Ensure the gas valve on top of the cylinder is closed.

4 Connect the LP gas regulator to the cylinder and hand-

tighten only. Open the cylinder valve. Check for gas

leaks. Refer to the illustration below.

5 Tighten the LP tank retention screw to secure the cyl-

inder to the shelf.

WARNING

Perform a gas leak test each time the LP gas cylinder is

changed. Do not place more than one LP gas cylinder

in an enclosure at a time.

GRILL

COUPLING

LP tank shelf.

LP TANK

RETENTION SCREW

COUPLING

NUT

LP gas cylinder connection.

wolfappliance.com | 9

VENT

TO GRILL

REGULATOR

INSTALLATION

Gas Supply Line

LP GAS SAFETY REQUIREMENT

This gas appliance and its individual shut-off valve must

be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures greater

than .5 psi (3.5 kPa).

This gas appliance must be isolated from the gas supply

piping system by closing its individual manual shut-off valve

during pressure testing of the gas supply piping sys-tem at

test pressures equal to or less than .5 psi (3.5 kPa).

GAS LEAK TESTING

Perform a gas leak test at least once a year, each time the

LP gas cylinder is connected to the regulator and any time

part of the gas line is disconnected or replaced. This applies

to natural gas as well as LP gas.

1 Prepare a leak testing solution of half liquid soap and

half water in a spray bottle.

2 Verify all control knobs are in the OFF position.

3 Turn the cylinder valve knob counterclockwise one turn

to open.

4 Spray the leak testing solution on pipe joints, ttings and

hose. Bubbles in the solution indicate a gas leak.

5 Tighten any loose joint or replace any faulty part with a

Wolf replacement part to stop the leak. Do not attempt to

repair the cylinder valve. If damaged, the cylinder must

be replaced.

6 If the leak persists, shut off the gas supply at the cylinder

valve and remove the LP gas cylinder. Call Wolf factory

certied service. Do not use the outdoor product until

the leak has been xed.

7 Push in and turn any control knob to the ON position to

release pressure, then turn the control knob back to OFF.

WARNING

To prevent re or explosion hazard, do not smoke or

permit sources of ignition in the area while performing

a gas leak test. Perform the gas leak test outdoors in a

well ventilated area. Never use an open ame to check

for gas leaks.

10 | Wolf Customer Care 800.222.7820

INSTALLATION

Installation

PREPARATION

Remove and recycle packing materials. Remove labels and

protective plastic lm from the grill.

Place briquette trays in the grill above the burners with ash

tubes positioned at the front. Refer to the illustration below.

Place burner grates directly above the briquette trays with

square openings in the grates at the front.

POWER TRANSFORMER

For built-in installation, secure the transformer box in a dry

location, away from the grill rebox and excessive heat area,

but within 2'

(.6 m) of the right rear opening. Do not install

the transformer box inside the insulating liner.

For cart installation, mount the transformer box by the two

screws located at the bottom right rear corner of the grill

cart, behind the pull-out shelf. Utilize the same transformer

for the side burner if installed.

CART INSTALLATION

1 Two mounting screws are provided at the bottom right

rear corner of the cart for the power transformer. Install

the transformer box.

2 Remove front mounting screws from the cart. Place grill

onto the cart, allowing enough space at the back to

make connection to the transformer.

3 Make connections from the wiring harness located at the

right rear of the grill to the transformer, then slide the grill

back until it is fully engaged with the cart.

4 Secure grill to cart with four screws provided. Mounting

holes in the upper back corners of the grill will align with

holes in the cart. Secure with two screws. Remove the

drip tray. Install two screws through side mounting holes

below the grill front panel and into the cart.

FLASH TUBE

Flash tube position.

wolfappliance.com | 11

UPPER

SCREW

SIDE SHELF

FRONT

BRACKET

INSTALLATION

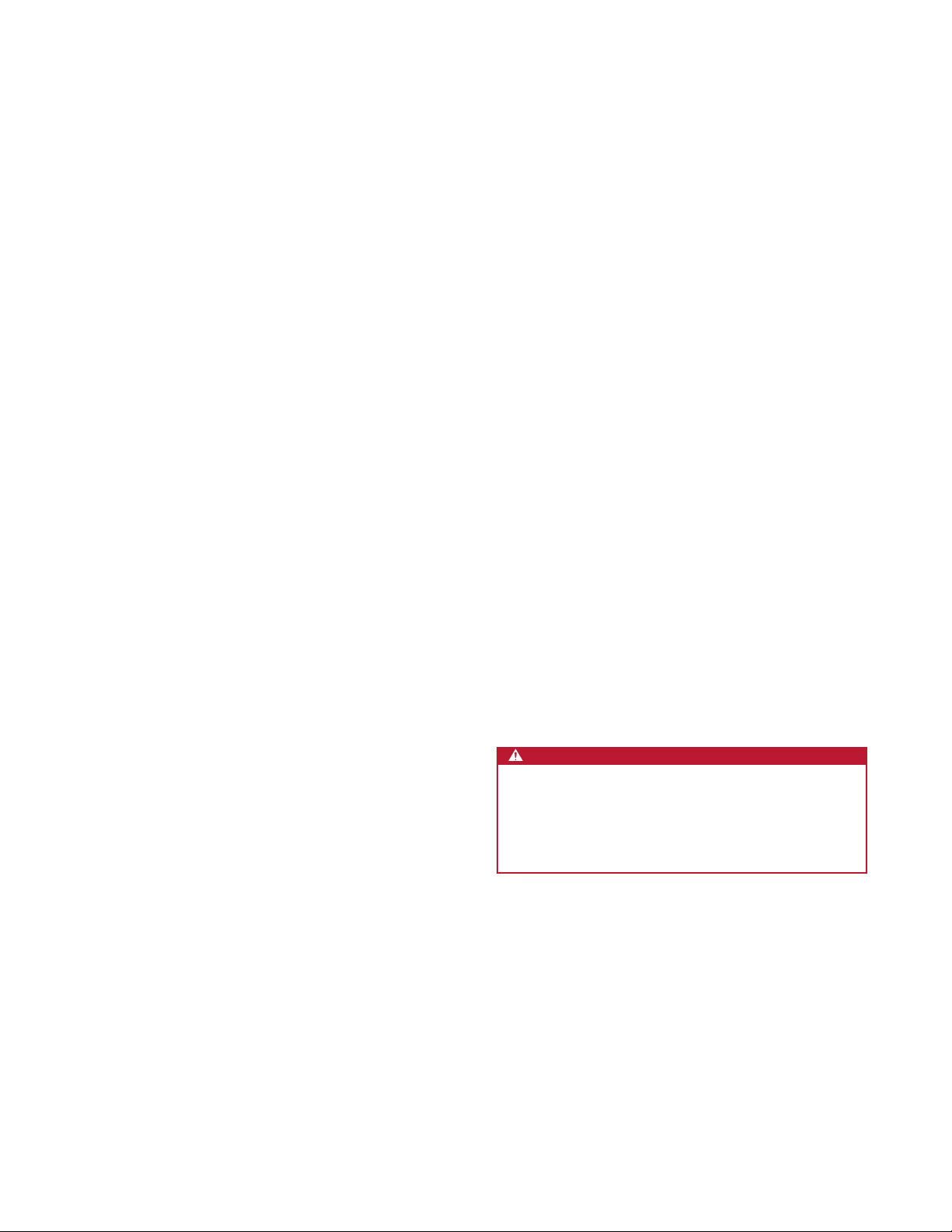

Side Burner Installation

The Wolf side burner can be installed on the right side of

any Wolf grill cart.

PREPARE GRILL CART

1 If installed, the right side shelf must be removed. To

remove, lift shelf up so the lower front screw is exposed,

then remove screw. Refer to the illustration below.

2 Fold side shelf down and remove the upper front screw,

then remove the side shelf and front bracket. Refer to the

illustration below.

LOWER SCREW

3 Remove the rear screws and bracket, then remove the

cart plug from the access hole by pushing out from

inside the cart. Refer to the illustration below.

4 For easier access, the upper rear panel and right side

door of the cart can be removed. Remove the rear panel

by removing four screws.

5 To remove the right side door, depress the rear lever on

each hinge, then remove door. Refer to the illustration

below.

6 For easier access, the drip tray of the grill can be

removed. To remove, slide forward and lift out.

7 Insert the plastic bushing provided through access

hole from inside the grill cart, where the cart plug was

removed previously.

DRIP TRAY

REAR

BRACKET

Side shelf lower screw.

Side shelf upper screw.

CART PLUG

REAR LEVER

Remove rear bracket and plug. Remove cart door.

12 | Wolf Customer Care 800.222.7820

INSTALLATION

Side Burner Installation

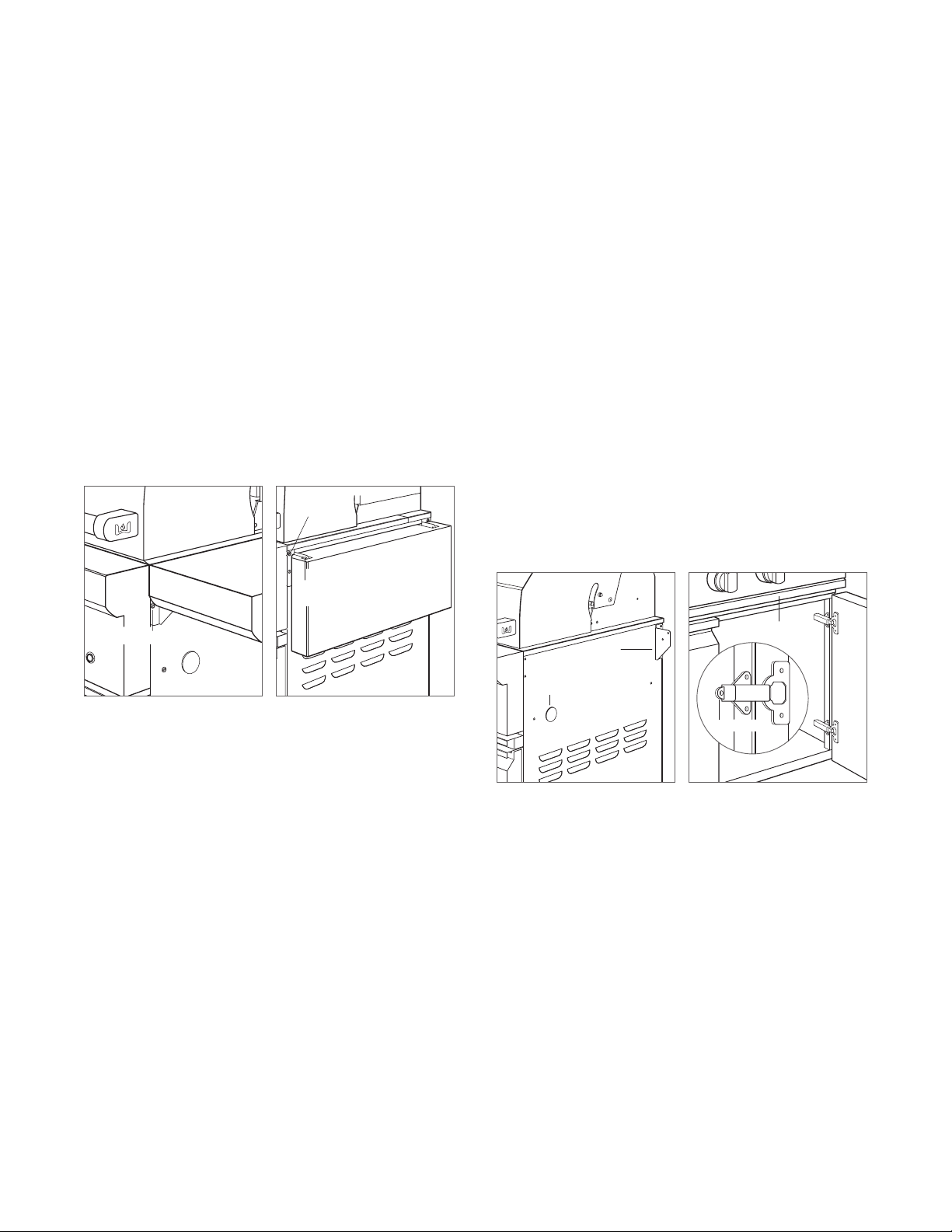

INSTALL SIDE BURNER SHROUD

1 Side burner is placed inside shroud for shipping. Lift out

to remove side burner from shroud.

2 Hang shroud by hand-starting four 10-32 machine

screws provided through upper slots of shroud, into

upper holes of cart. Do not fully tighten screws until

shroud is properly aligned. Refer to the illustration below.

3 Place alignment tool provided with lip placed in the gap

between the grill and shroud as shown in the illustration

below.

4 To align front of shroud, push alignment tool back until

center block of tool is ush against front vertical ange

of shroud.

5 Align front of shroud (up and down) with alignment tool

until top of tool is ush with top surface of grill bullnose.

Align shroud (front to back) with tool until front of tool is

ush with front of bullnose. Tighten upper screw. Refer

to the illustration below.

6 To align back of shroud, place alignment tool at rear of

shroud. Align rear of shroud (up and down) with tool until

top of tool is ush with top surface of grill. Tighten upper

screw. Refer to the illustration below. Verify with alignment tool that front of shroud did not move, realign if

necessary.

7 Remove alignment tool and tighten two remaining

screws to slots just below the upper screws.

8 Install two

5

/16 x 3/8 hex drive shoulder screws provided

into lower holes of shroud and through cart. Place two

1

/4–20 hex nuts from inside of cart and tighten. Refer to

the illustration below.

SURFACES

FLUSH

SHOULDER

SCREWS

UPPER

SCREW

ALIGNMENT

TOOL

SCREWS

Hang shroud.

SCREWS

ALIGNMENT

SURFACES

FLUSH

Align front of shroud.

TOOL

UPPER

SCREW

Align back of shroud.

Secure shroud.

HEX NUT

(INSIDE CART)

wolfappliance.com | 13

INSTALLATION

HOLES

ALIGN

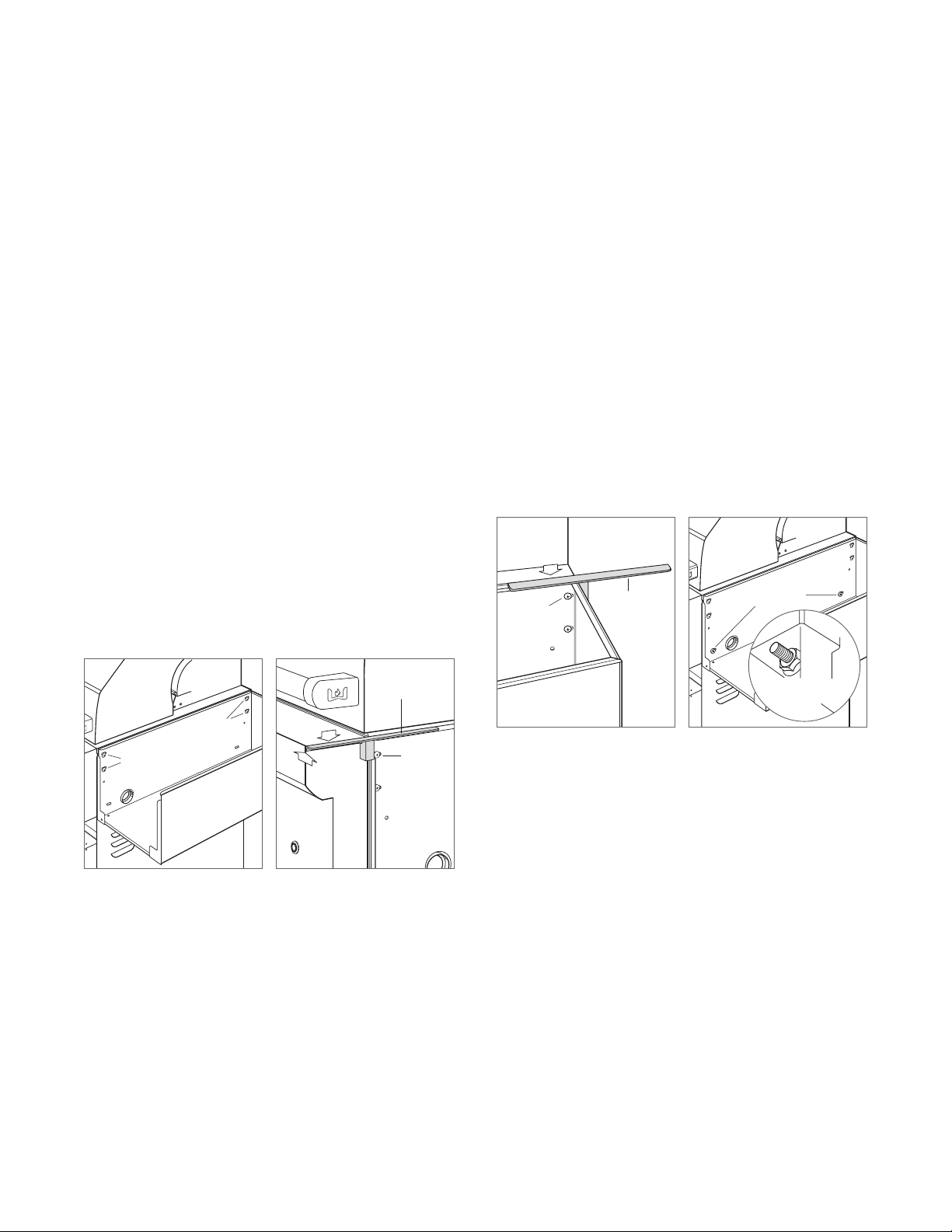

Side Burner Installation

For natural gas installations, the gas line connection must

be made before installing the side burner.

INSTALL SIDE BURNER

1 Place side burner into shroud as shown in the illustration

below. Guide exible gas line and wire harness into cart

access hole. Verify alignment of unit prior to securing

side burner to shroud. If side burner does not align properly, remove, loosen screws and check shroud alignment

with tool. Reposition side burner until properly aligned.

2 Place a bar clamp with protected ends behind bullnose

on re box and under shroud. Do not include any part

of bullnose within bar clamp. Refer to the illustration

below.

3 Compress bar clamp until hole in bullnose aligns with

threaded hole in shroud. Alignment and placement of

this screw is very important to side burner alignment.

Refer to the illustration below.

4 Attach side burner to shroud by rst placing 8-32 hex

cap screw provided into right side of front underside of

bullnose and into shroud. Then, place left side hex cap

screw. Tighten screws and remove bar clamp.

5 At rear of unit, push side burner toward grill to establish

proper gap at rear. Loosen rear cart screws and shift

grill if necessary to achieve proper gap. Install two 8-18

pan head screws provided through shroud and into rear

of side burner as shown in the illustration below. Verify

proper alignment.

REAR

SCREWS

ACCESS HOLE

Position side burner.

14 | Wolf Customer Care 800.222.7820

Position bar clamp.

Hole alignment.

Secure side burner.

INSTALLATION

AUXILLARY

Side Burner Installation

ELECTRICAL CONNECTION

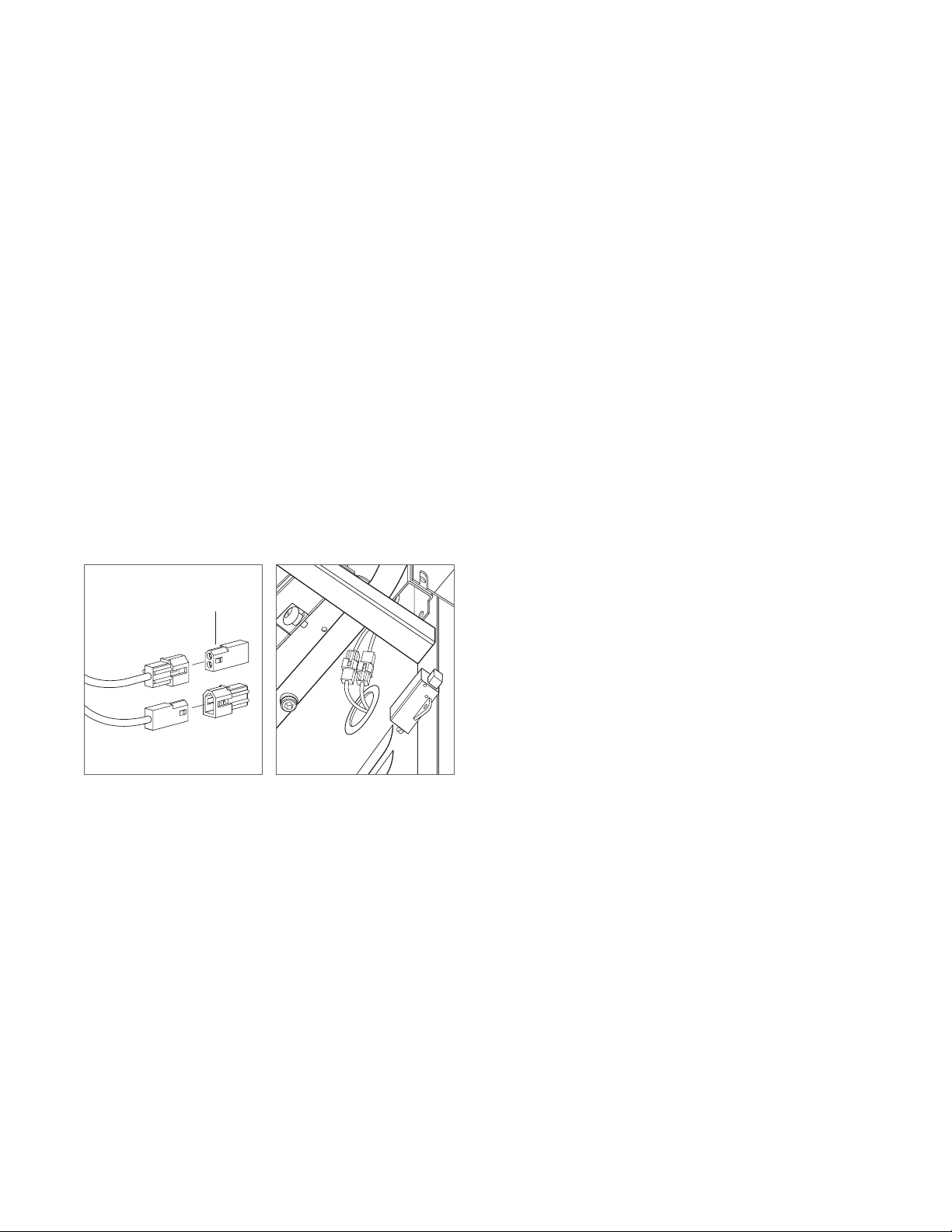

1 Depending on the serial number of the grill, there may

be one or two connectors near the front of the grill just

above the manifold. Refer to auxiliary harness section

for serial numbers. Locate the connector(s) by looking

above the manifold near the front of the grill.

2 Remove the unpopulated connector housing(s) from the

wire harness(es) coming from the grill as shown in the

illustration below.

3 Attach the appropriate connector housing(s) from the

side burner to the grill. Refer to the illustration below.

If only one connector is found on the grill, refer to the

auxiliary harness section for assembly of the second

connector housing.

Connectors.

UNPOPULATED

CONNECTORS

Connector housing.

wolfappliance.com | 15

INSTALLATION

Side Burner Installation

LP GAS CONNECTION

1 Connect 2-stage LP gas regulator to are tee at location

shown. Connect are swivel connector to one end of

are tee. Refer to the illustration below.

2 Connect regulator assembly to exible gas line coming

into grill cart from side burner as shown in the illustration

below.

3 Connect regulator assembly assembly to grill manifold at

are swivel connector as shown in the illustration below.

4 Reinstall rear panel and door of grill cart. Reposition grill

drip tray. Place burner cap on burner head, place grate

on burner pan and afx knob to bezel with bezel nylon

liner.

LP GAS

REGULATOR

FLARE

SWIVEL

FLARE

TEE

GRILL

MANIFOLD

FLEXIBLE

GAS LINE

NATURAL GAS CONNECTION

1 Split high pressure natural gas line into two lines, one to

attach to grill natural gas regulator and one to attach to

1

side burner via exible line and

/2" NPT adapter. Place

exible gas line through cart access hole.

2 Place exible gas line through cart access hole and

attach to side burner regulator at pipe elbow. Elbow may

be rotated to face downward for larger adapters. Do not

rotate elbow upward. Refer to the illustration below.

Natural gas connection.

LP gas regulator assembly.

LP gas connection.

16 | Wolf Customer Care 800.222.7820

INSTALLATION

AUXILLARY

Side Burner Installation

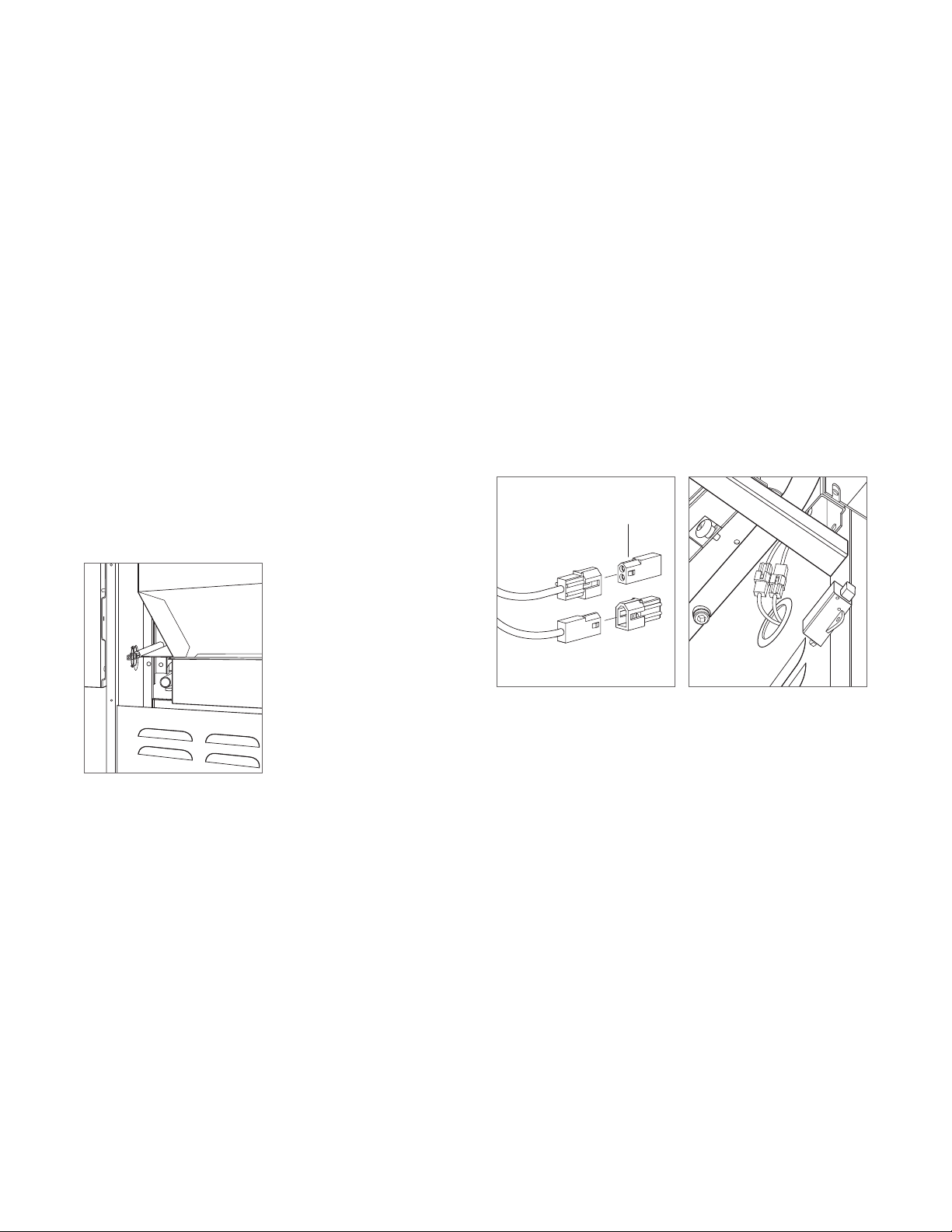

AUXILIARY HARNESS (IF APPLICABLE)

If the Wolf outdoor grill has a serial number prior to the

numbers listed (OG30: 11364339, OG36: 11363946,

OG42: 11363911) an auxiliary harness will be provided

with the side burner. If not, contact Wolf customer care

800-222-7820.

1 Upper rear panel of grill cart must be removed to install

auxiliary harness. Remove rear panel by removing four

screws.

2 With wire ties provided, attach auxiliary harness to re

box n or existing wire harness. 4-pin connector cluster

should be placed facing rear of grill and 2-pin connector

facing front. Harness must be tied down tightly and must

not touch grill re box. Refer to the illustration below.

3 If connected, disconnect transformer 4-pin connector at

rear of grill. Attach one of 4-pin connectors to 4-pin connector attached to grill. Attach other 4-pin connector to

4-pin connector from transformer.

4 Remove unpopulated connector housing from wire har-

ness coming from grill. Insert each connector housing

from side burner harness to corresponding housing on

grill harness and on auxiliary harness. There are two connections to be made. Refer to the illustrations below.

5 Reinstall upper rear panel of cart.

UNPOPULATED

CONNECTORS

Auxiliary harness.

Connectors.

Connector housing.

wolfappliance.com | 17

Loading...

Loading...