Page 1

INDUCTION CO O K TOPS

INSTAL LATION IN ST RUCTIONS

INS T RU CCI ONE S D E INS TALACIÓ N

INS T RU CTI ONS D’ I NSTA LLATIO N

IST RUZ ION I PER L’IN S TALL AZI O NE

INS TA LLATI O NSA NWE ISU N GEN

Page 2

2

Page 3

E N G L I S H 4

S P Ã N O L 2 1

E

F R A N Ç A I S 3 8

I T A L I A N O 5 5

D E U T S C H 7 2

3

Page 4

C O N TA C T

I N F O R M A T I O N

Website:

wolfappliance.com

As you follow these instruc tions, you will

notice WARNING and CAUTION symbols.

This blocked information is impor tant for the

safe and efficient installation of Wolf equipment. There are two types of potential

hazards that may occur during installation.

WOLF®is a registered trademark of Wolf Appliance, Inc.

signals a situation where minor injury or

product damage may occur if you do not

follow instructions.

states a hazard that may cause serious

injury or death if precautions are not

followed.

Another footnote we would like to identify is

IMPORTANT NOTE: This highlights information that is especially relevant to a problemfree installation.

Page 5

W O L F IN D U C T I O N C O O K TO P S

I N S TA L L AT I O N R E Q U I R E M E N T S

IMPORTANT NOTE:

Save these Installation

Instructions for the local inspector’s use.

Please read the entire Installation Instructions prior to installation.

This installation must be completed by a

qualified technician.

Installer:

please retain these instructions

for local inspector’s reference, then leave

them with the homeowner.

Homeowner:

please read and keep these

instructions for future reference and be sure

to read the entire Use & Care Information

prior to use.

IMPORTANT NOTE:

This appliance must be

installed in accordance with local codes. The

correct voltage, frequency and amperage must

be supplied to the appliance from a dedicated,

grounded circuit which is protected by a

properly sized circuit breaker or time delay

fuse. The proper voltage, frequency, and

amperage ratings are listed on the product

rating plate.

B E F O R E YO U S TA R T

Proper installation is your responsibility.

Have a qualified technician install this

cooktop. You must also assure that electrical installation is adequate and in compliance with all local codes and ordinances.

Installations and repairs must be performed

by a qualified or licensed contractor or

electrician qualified or licensed by the state,

province, or region where this appliance is

being installed.

Make sure you have everything necessary

for correct installation. It is the responsibility of the installer to comply with the installation clearances specified on the product

rating plate. The rating plate is located on

the underside of the cooktop.

Electrical ground is required; see Electrical

Requirements on pages 16–17.

This cooktop is intended for indoor use.

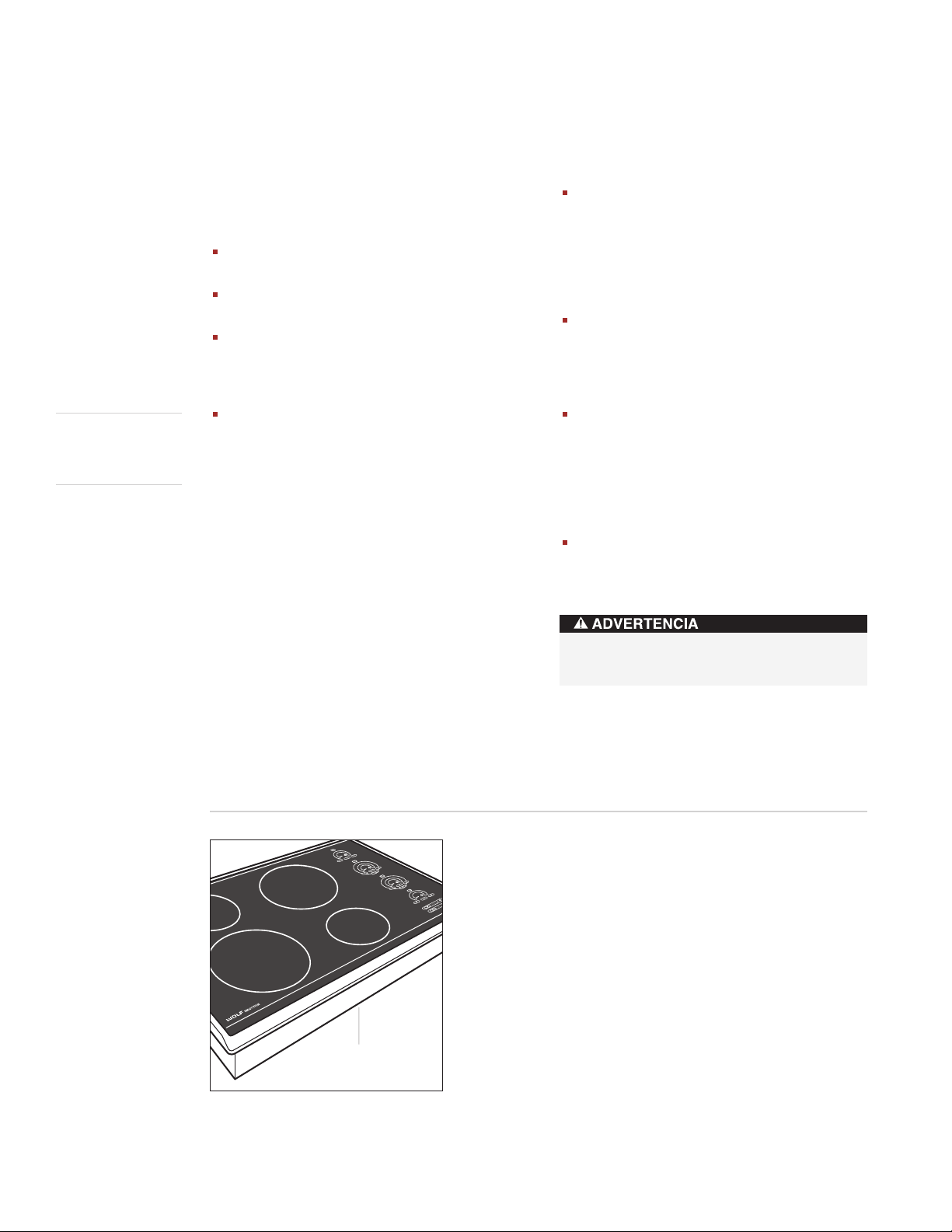

R AT I N G PL AT E

I N F O R M AT I O N

Model Number

Serial Number

Record the model and serial numbers before

installing the cooktop. Both numbers are on

the rating plate, located on the underside of

the cooktop. Refer to the illustration below.

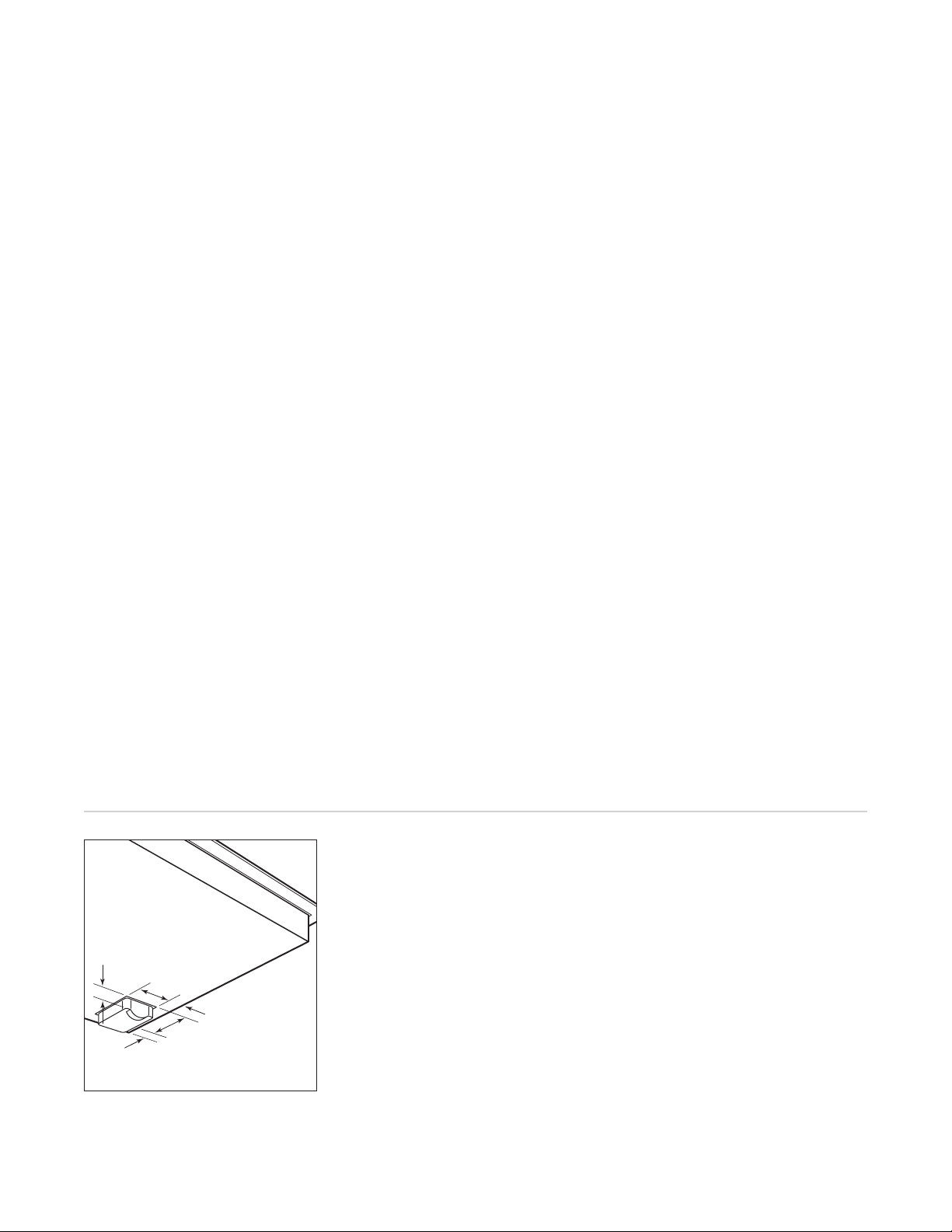

Location of rating

plate under cooktop

Rating plate location

5

Page 6

W O L F IN D U C T I O N C O O K TO P S

C

G

D

A

B

B

E

F

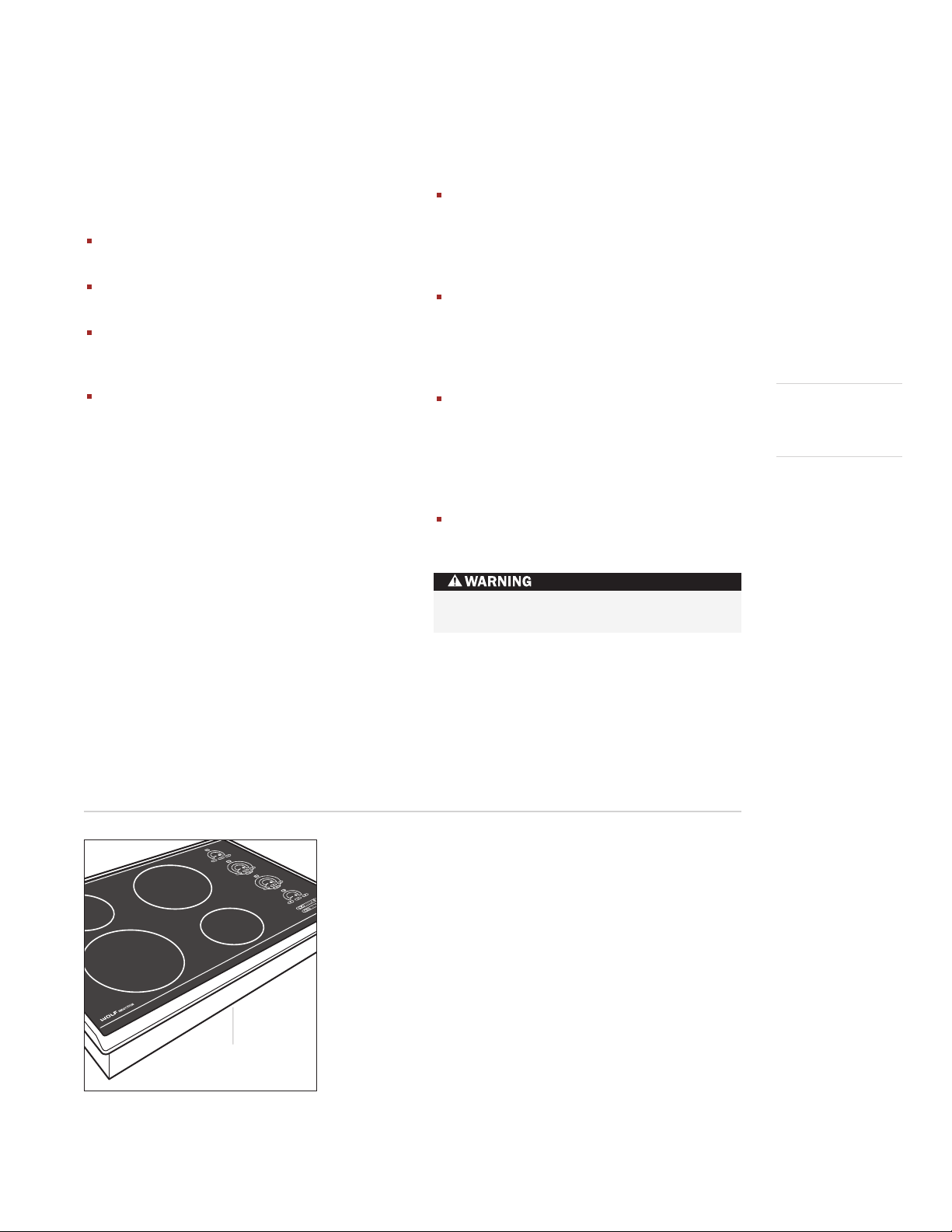

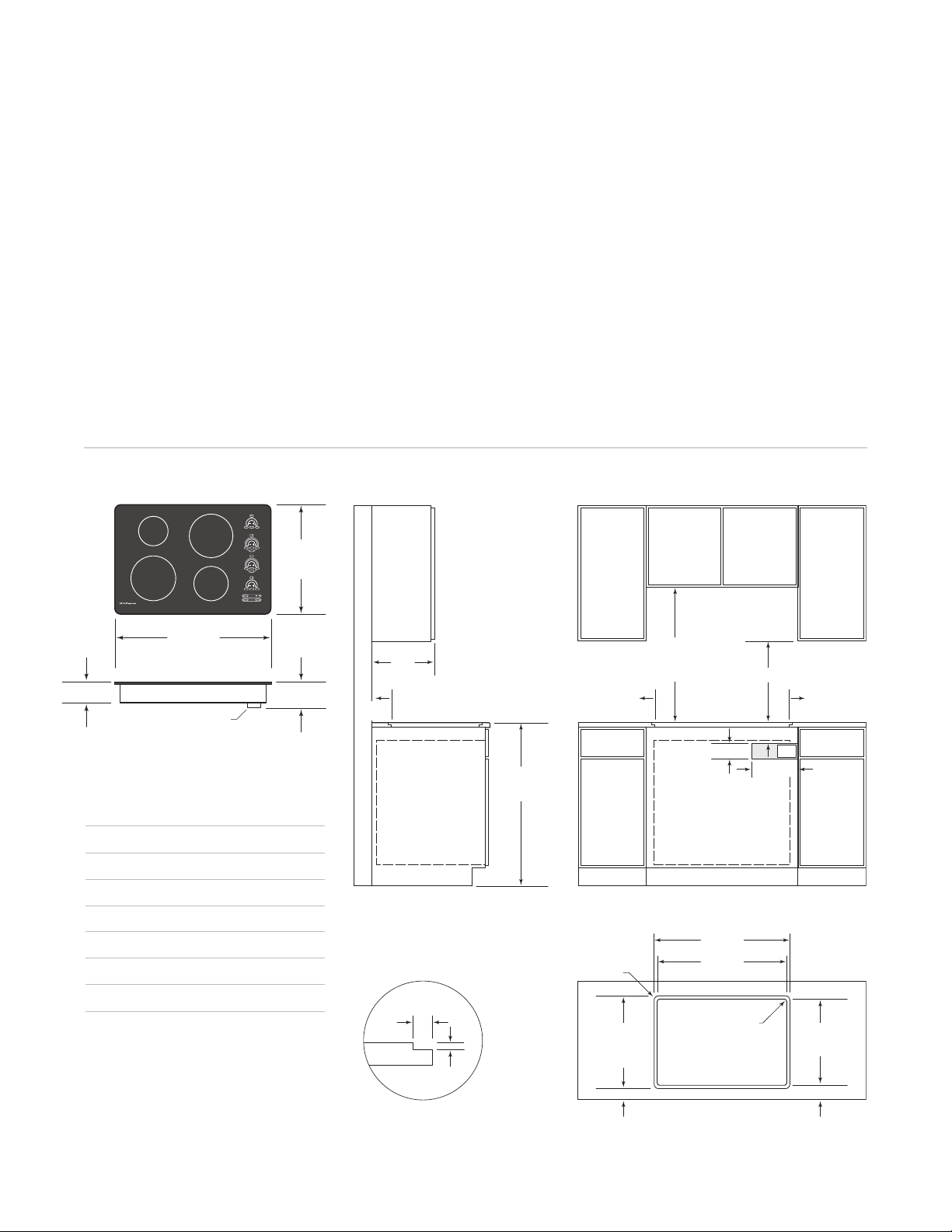

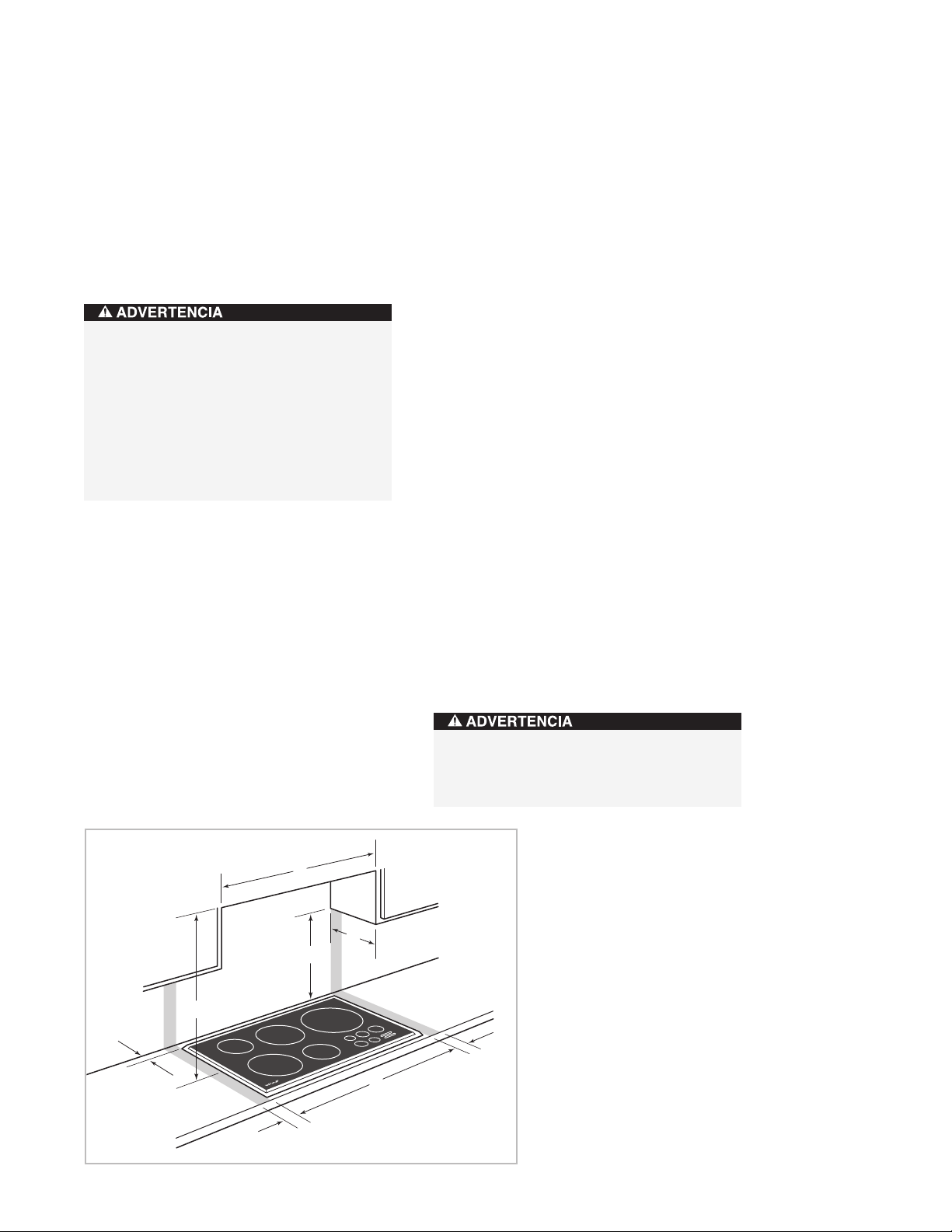

S I T E P R E PA R A T IO N

IMPORTANT NOTE:

Installation of the Wolf

induction cooktop must meet the following

location requirements. All dimensions listed

are minimum requirements for safe operation.

Refer to the illustration below.

To eliminate the risk of burns or fire by

reaching over heated surface units,

cabinet storage space located above the

surface units should be avoided. If

cabinet storage is to be provided, the risk

can be reduced by installing a ventilation

hood that projects horizontally a

minimum of 127 mm beyond the bottom

cabinets.

L O C AT I O N I N C O U N T E R T O P

A)

Minimum flat countertop surface. Must be

equal to or greater than cooktop width.

B)

Minimum 25 mm wide clearance from the

cooktop side edge to any combustible

urface up to 457 mm above the cooktop

s

(noted by shaded area).

O V E R H E A D C A BI N E T D I M E N S I O N S

C)

Minimum spacing between overhead side

cabinets must be greater than or equal to

the nominal width of the cooktop unit(s).

D)

Minimum 457 mm vertical distance from

the countertop to the bottom of side

cabinets within minimum side clearance.

E)

Minimum vertical distance between the

countertop and combustible materials

above the cooktop must be 762 mm.

F)

Minimum 25 mm from rear wall.

G)

Maximum 330 mm depth of overhead and

side cabinets directly above and within side

clearance.

Minimum installation clearances

6

Failure to locate the cooktop without the

proper clearances will result in a fire

hazard.

Page 7

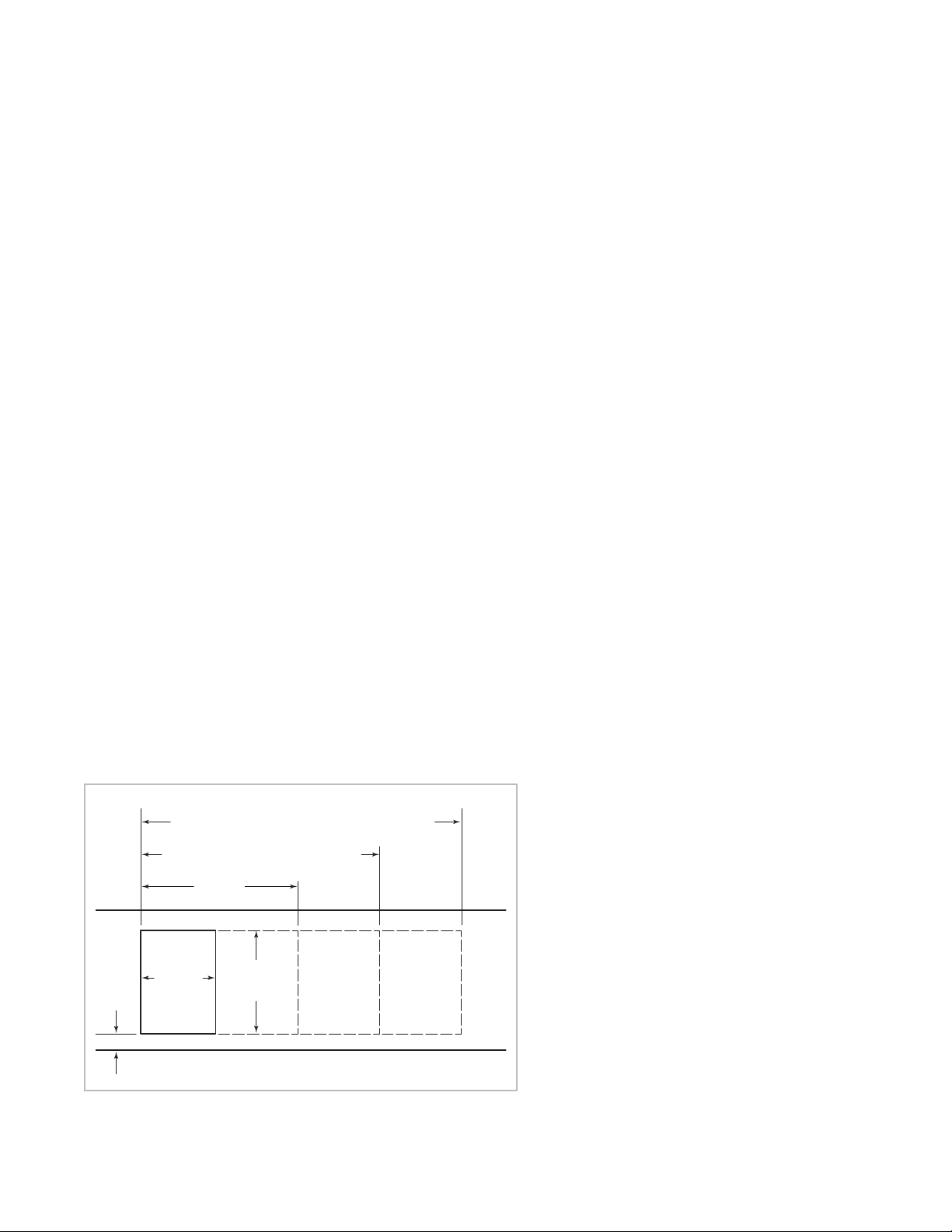

I N S TA L L AT I O N I N S T R U C T I O N S

84

mm

56

mm

24

mm

22 mm

32 mm

I N S TA L L AT I O N S P E C I F I C AT I O N S

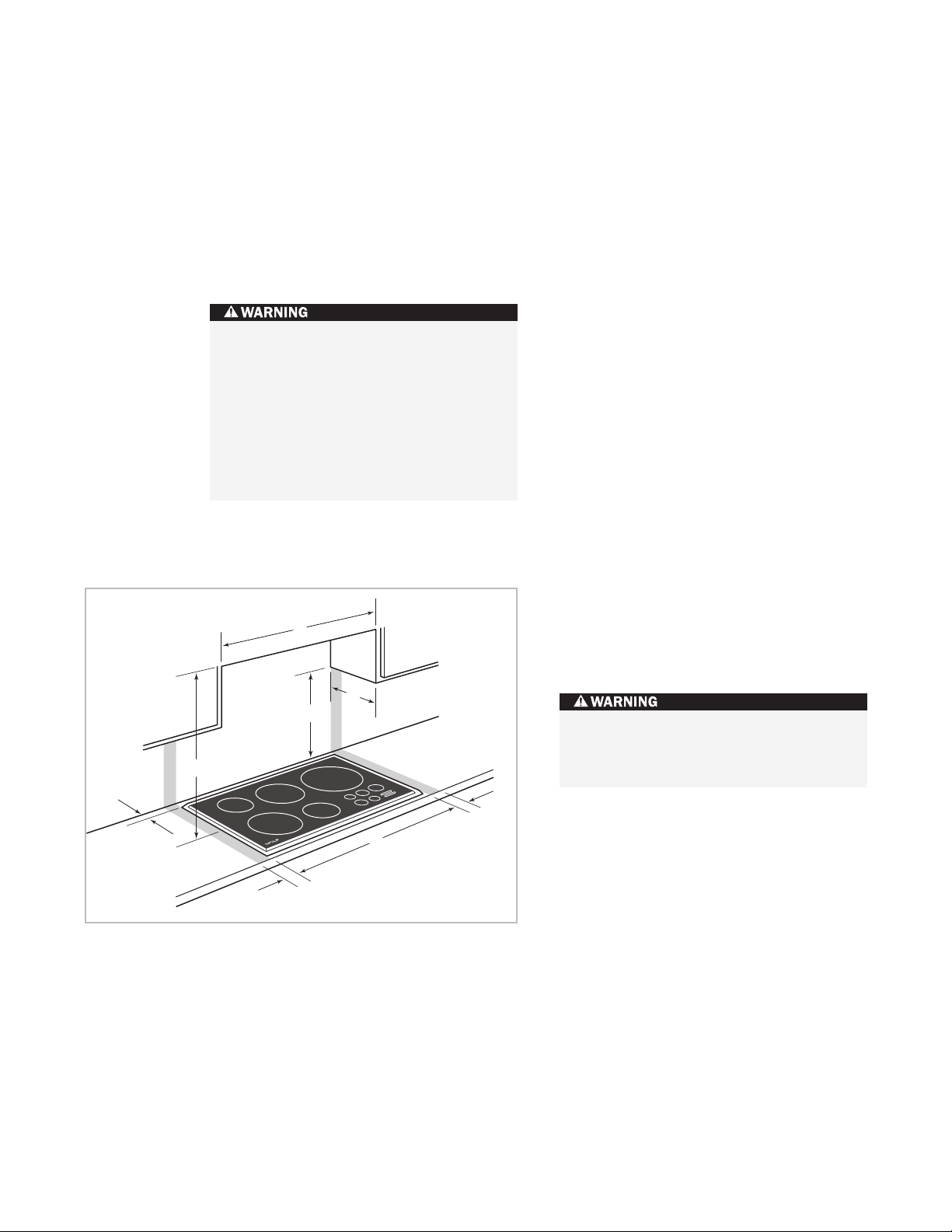

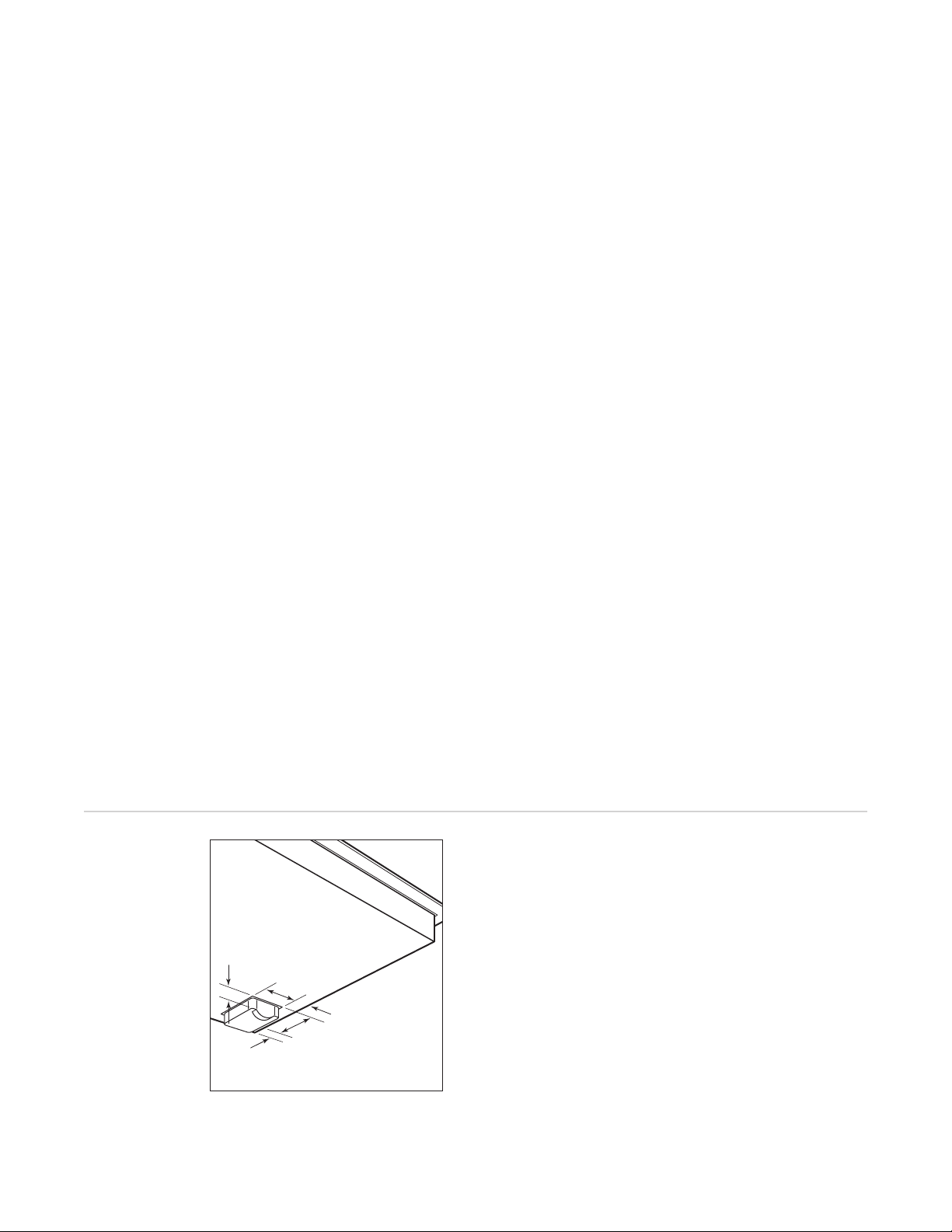

The illustrations on pages 8–13 provide the

overall dimensions, installation specifications

and countertop cut-out for each of the Wolf

induction cooktop models.

These cooktops are designed to fit a standard

610 mm deep base cabinet with a 635 mm

deep countertop. Before making the countertop cut-out, verify that the cooktop will clear

the side walls of the base cabinet below.

Clearance is required for the terminal block

located at the right rear of the cooktop. Refer

to the illustration below for dimensions.

F R A M E D I N D U C T I O N C OO K T O P S

IMPORTANT NOTE:

A minimum height clearance of 152 mm is required between the countertop and any combustible surface directly

below the cooktop. This includes upper edges

of drawers located directly below unit. If a

shelf is installed below the unit, a 25 mm gap

at the rear of the cabinet shelf is necessary to

allow for proper ventilation. Failure to do so

could result in decreased performance or

product damage.

Wolf induction cooktops are designed to be

installed in combination with other cooktop

units.

IMPORTANT NOTE:

When multiple cooktops

and/or modules are installed side by side, refer

to countertop cut-out dimensions on page 11.

Wolf induction cooktops can accommodate a

Wolf downdraft ventilation system. Refer to

installation instructions provided with the

downdraft for additional specifications.

U N F R A M E D I N D U C T I O N C O OK TO P S

IMPORTANT NOTE:

A minimum height clearance of 165 mm is required between the countertop and any combustible surface directly

below the cooktop. This includes upper edges

of drawers located directly below unit. If a

shelf is installed below the unit, a 25 mm gap

at the rear of the cabinet shelf is necessary to

allow for proper ventilation. Failure to do so

could result in decreased performance or

product damage.

IMPORTANT NOTE:

Unframed induction

cooktops are not designed to be installed in

combination with other cooktops.

IMPORTANT NOTE:

Unframed induction

cooktops cannot be installed with a downdraft

ventilation system.

For installation options of the unframed induction cooktops, refer to Unframed Installation

on pages 14–15.

Terminal block dimensions

7

Page 8

914 mm

FLOOR TO

COUNTERTOP

762 mm

min

COUNTERTOP

TO COMBUSTIBLE

M

ATERIALS

S

EE COUNTERTOP

CUT-OUT BELOW

340 mm

CUT-OUT

WIDTH

COUNTERTOP CUT-OUT

FRONT

489 mm

CUT-OUT

DEPTH

64 mm min

51 mm T

O

COMBUSTIBLE

*

51 mm T

O

COMBUSTIBLE

*

51

mm*

SIDE

CABINET

330 mm

m

ax

*Minimum clearance from cooktop cut-out to com bustible materials up to 457 mm above countertop.

NOTE: Application shown a llows for installation of t wo 381 mm modules side by s ide.

E

381 mm

381

mm

114 mm

457 mm min

533 mm

OVERALL

DEPTH

381 mm

OVERALL WIDTH

64 mm

TERMINAL BOX

96 mm

W O L F IN D U C T I O N C O O K TO P S

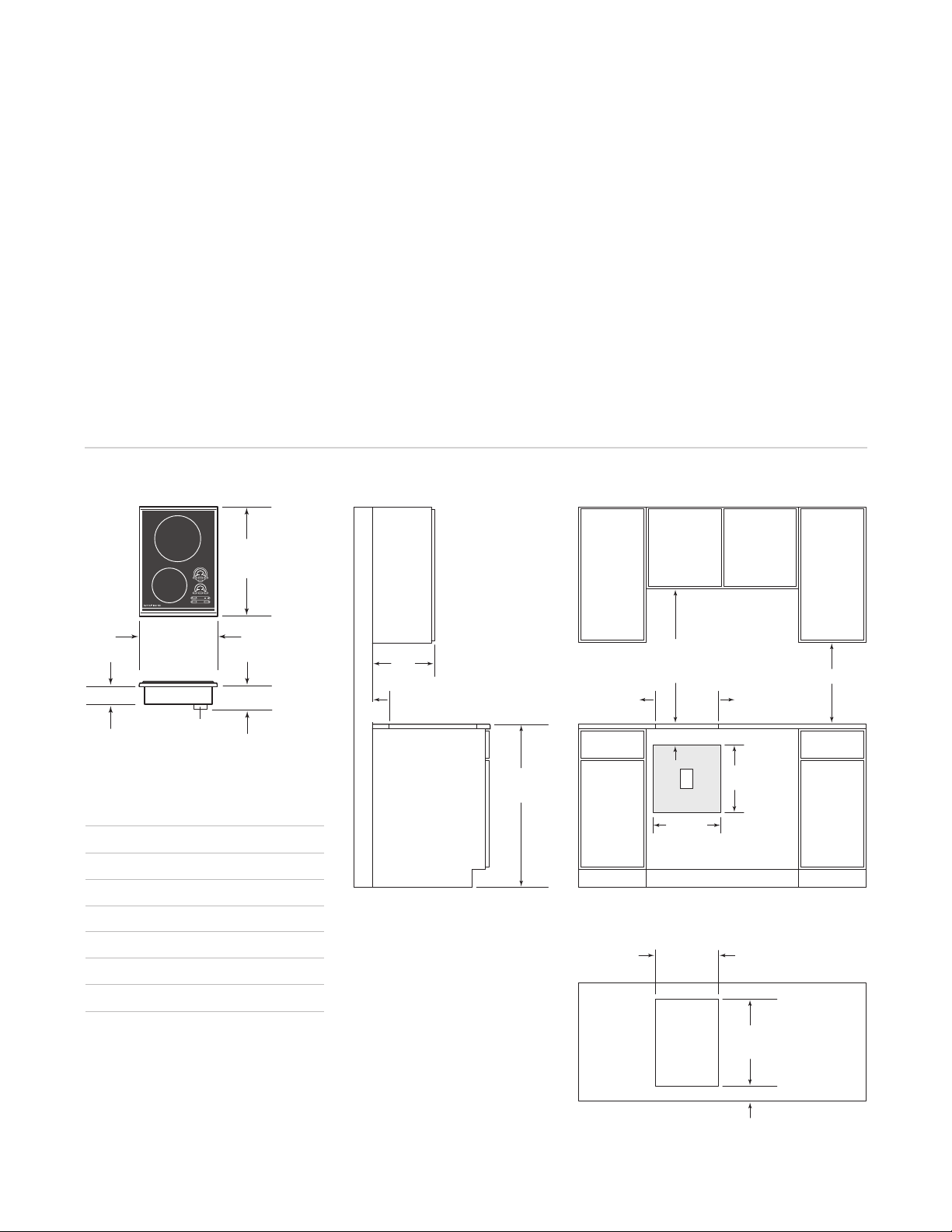

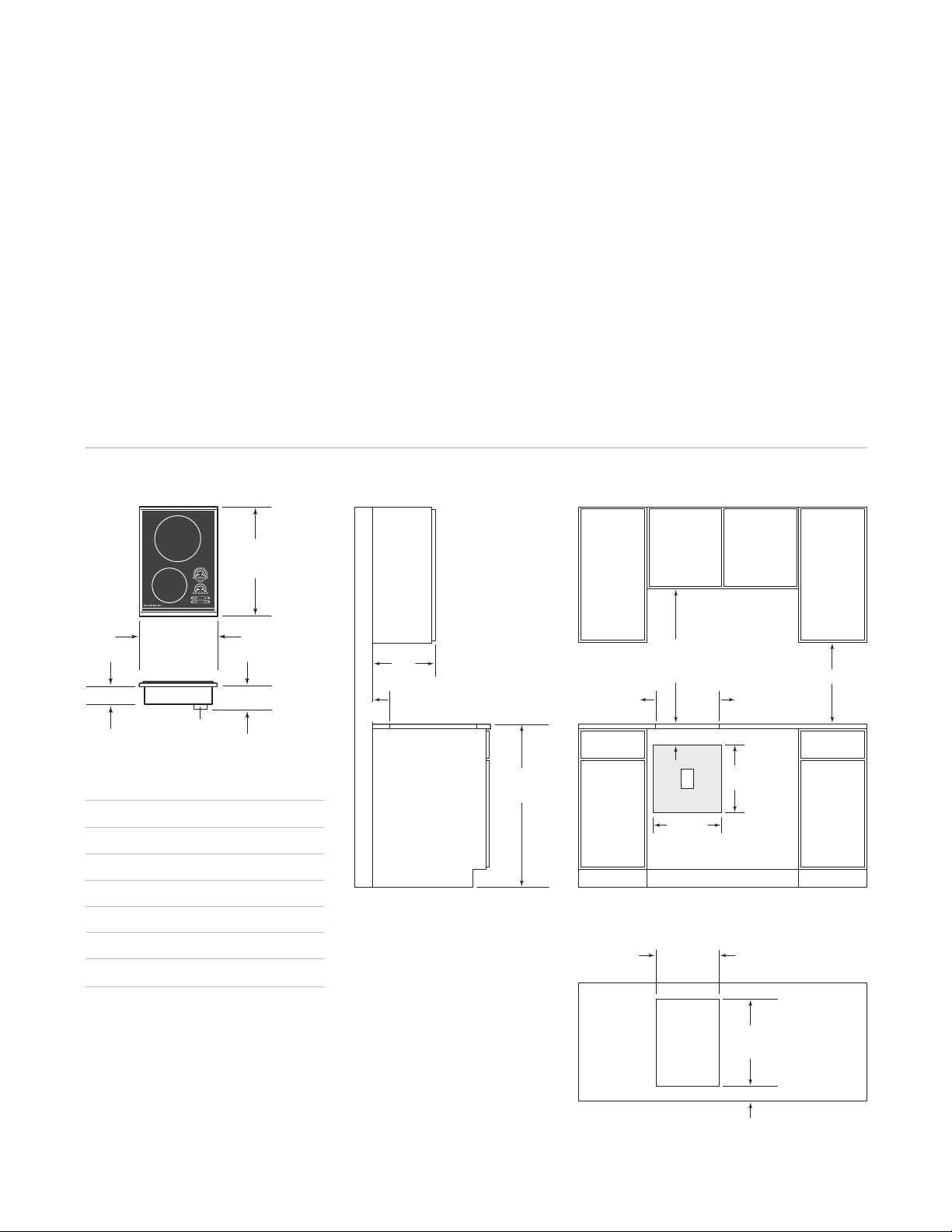

F R A M E D M O D E L I C B C T 1 5 I / S

The illustrations below provide installation

specifications for Model ICBCT15I/S.

I N S TA L L AT I O N S P E C I F I C AT I O N S – M O D E L I C B C T 1 5 I / S

If Model ICBCT15I/S is installed above

cabinets, the electrical placement is not critical.

The appliance shall be installed in such a way

to allow disconnection of the appliance from

the supply mains after installation.

Overall Dimensions

M O D E L I C B C T 1 5 I / S

Overall Width 381 mm

Overall Height 64 mm

Overall Depth 533 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance* 96 mm

Cut-Out Width 340 mm

Cut-Out Depth 489 mm

*Minimum 152 mm clearance is required

between countertop and any combustible

surface directly below the cooktop.

For detailed terminal block dimensions,

refer to the illustration on page 7.

Dimensions may vary to ±3 mm.

8

Page 9

457 mm min

914 mm

FLOOR TO

COUNTERTOP

762 mm min

COUNTERTOP

T

O COMBUSTIBLE

MATERIALS

762 mm OVEN OPENING

114 mm

254 mm

89 mm

E

SEE COUNTERTOP

CUT-OUT BELOW

51 mm TO

C

OMBUSTIBLE

*

51 mm TO

C

OMBUSTIBLE

*

51

mm*

SIDE

CABINET

330 mm

max

721 mm

CUT-OUT WIDTH

COUNTERTOP CUT-OUT

FRONT

489 mm

CUT-OUT

DEPTH

64 mm min

*Minimum clearance from cooktop cut-out to com bustible materials up to 457 mm above countertop.

NOTE: Electrical location applies only to installati on with built-in oven.

533 mm

OVERALL

DEPTH

762 mm

OVERALL WIDTH

TERMINAL BOX

64 mm

96 mm

I N S TA L L AT I O N I N S T R U C T I O N S

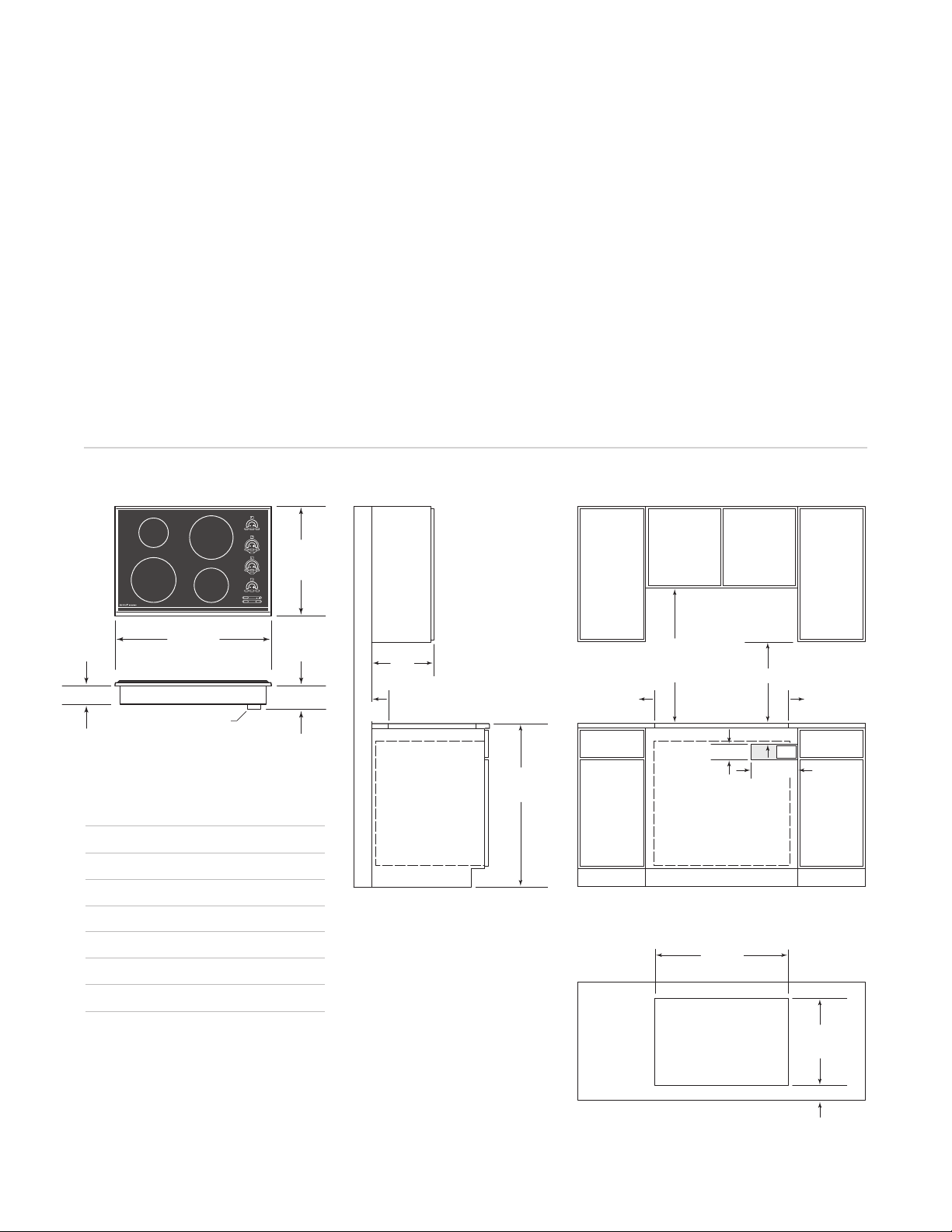

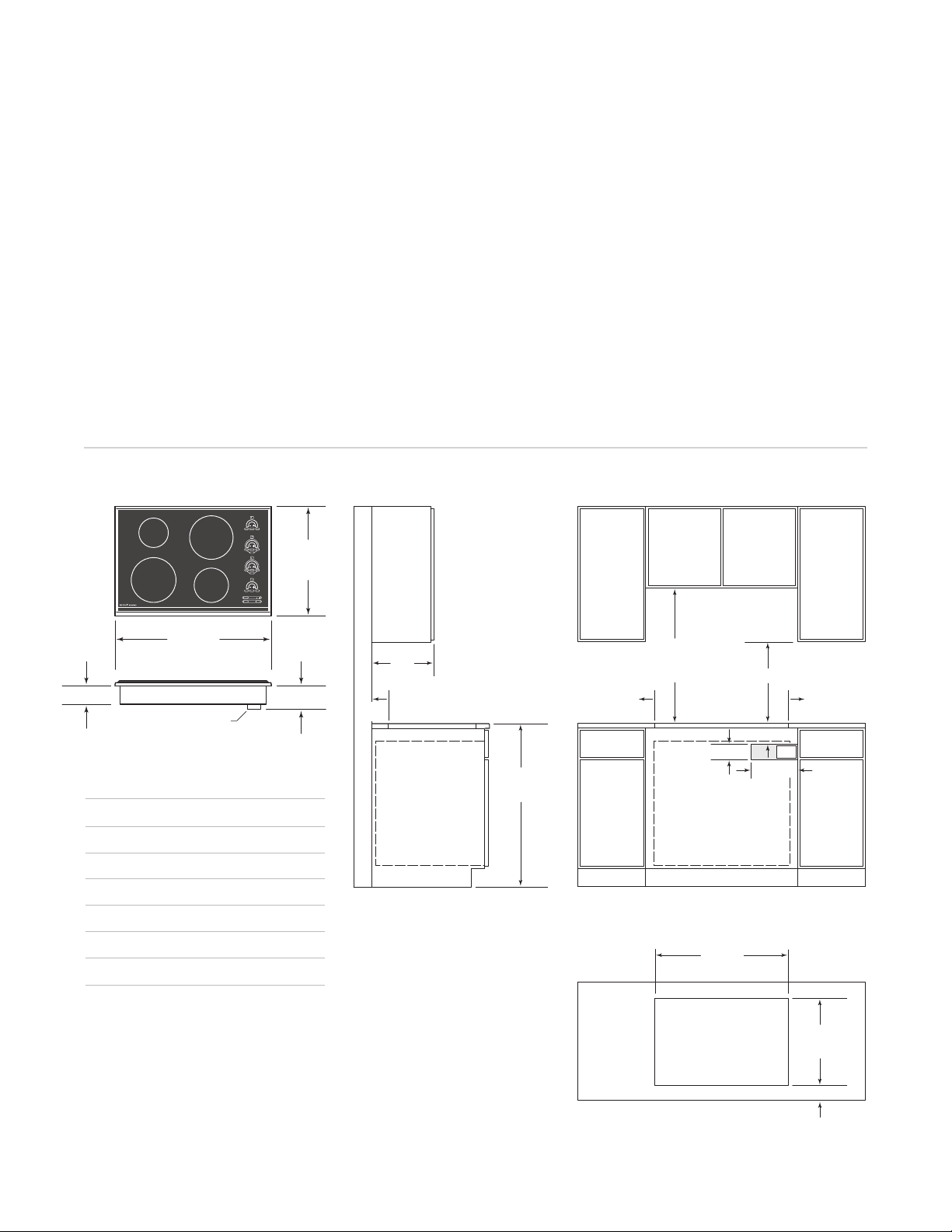

F R A M E D M O D E L I C B C T 3 0 I / S

The illustrations below provide installation

specifications for Model ICBCT30I/S.

For ease of installation, 838 mm cabinets are

recommended for installation of Model

ICBCT30I/S.

A Wolf 762 mm or 914 mm built-in single oven

may be installed below Model ICBCT30I/S. For

Refer to installation instructions provided with

the built-in oven for additional specifications.

If Model ICBCT30I/S is installed above

cabinets, the electrical placement is not critical.

The appliance shall be installed in such a way

to allow disconnection of the appliance from

the supply mains after installation.

this installation, unless you are using cabinets

deeper than 610 mm, it is recommended that

the electrical supply be placed in the base

cabinet to the right of the oven.

I N S TA L L AT I O N S P E C I F I C AT I O N S – M O D E L I C B C T 3 0 I / S

Overall Dimensions

M O D E L I C B C T 3 0 I / S

Overall Width 762 mm

Overall Height 64 mm

Overall Depth 533 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance* 96 mm

Cut-Out Width 721 mm

Cut-Out Depth 489 mm

*Minimum 152 mm clearance is required

between countertop and any combustible

surface directly below the cooktop.

For detailed terminal block dimensions,

refer to the illustration on page 7.

Dimensions may vary to ±3 mm.

9

Page 10

W O L F IN D U C T I O N C O O K TO P S

457 mm

min

914 mm

FLOOR TO

COUNTERTOP

762 mm min

COUNTERTOP

T

O COMBUSTIBLE

MATERIALS

914 mm OVEN OPENING

114 mm

254 mm

89 mm

E

SEE COUNTERTOP

CUT-OUT BELOW

873 mm

CUT-OUT WIDTH

COUNTERTOP CUT-OUT

FRONT

489 mm

CUT-OUT

DEPTH

64 mm min

51 mm TO

COMBUSTIBLE*

51 mm TO

COMBUSTIBLE*

51

mm*

SIDE

CABINET

330 mm

max

*Minimum clearance from cooktop cut-out to com bustible materials up to 457 mm above countertop.

NOTE: Electrical location applies only to installati on with built-in oven.

533 mm

OVERALL

DEPTH

914 mm

OVERALL WIDTH

TERMINAL BOX

64 mm

96 mm

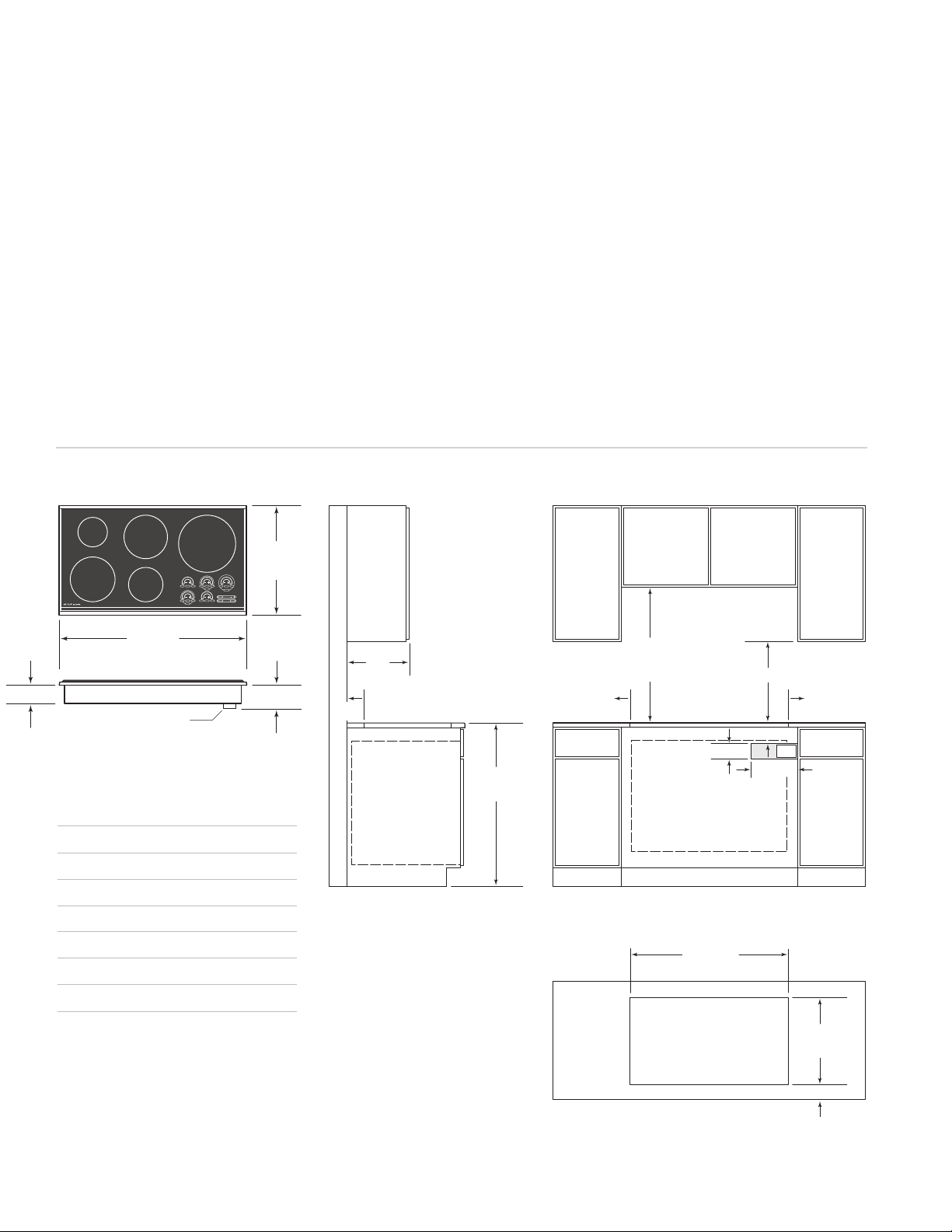

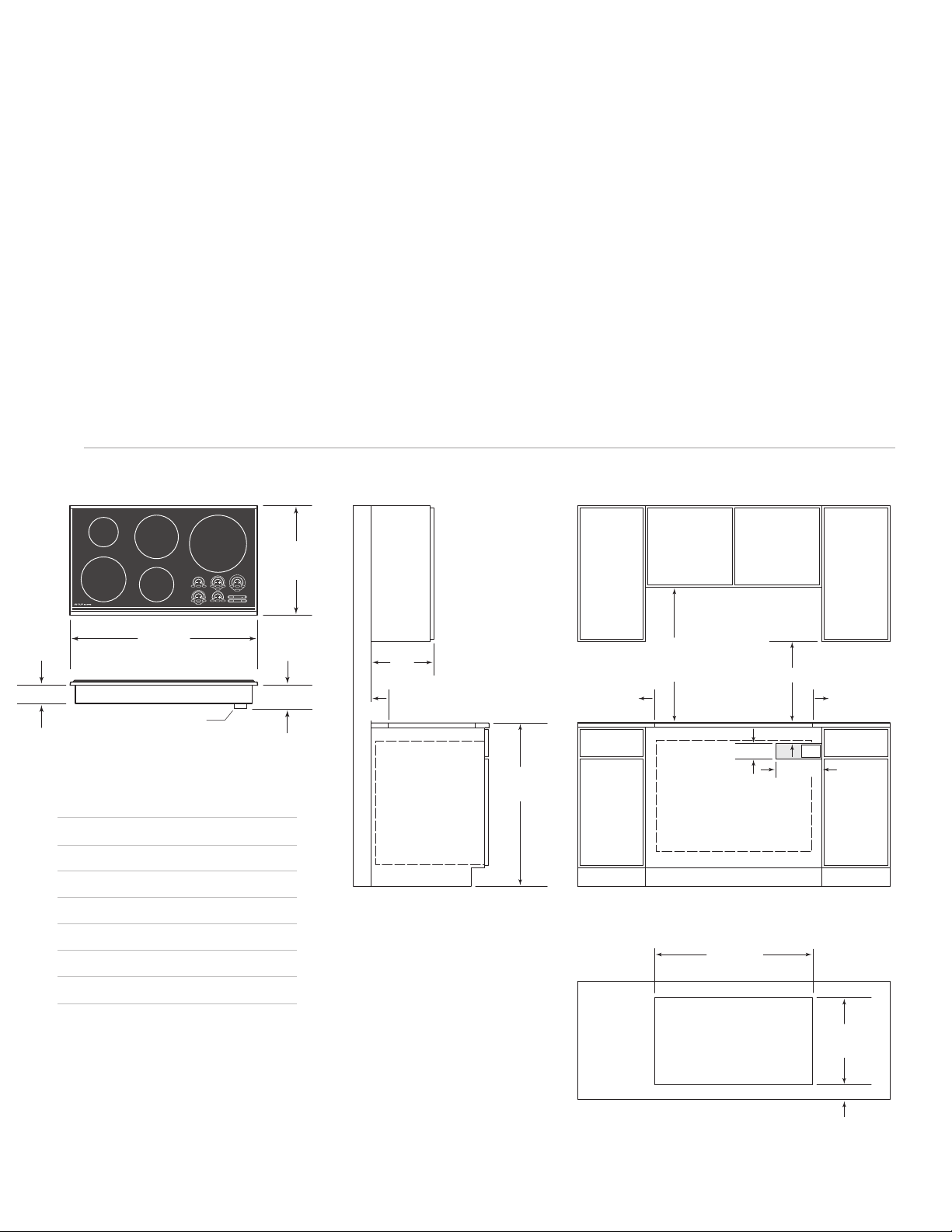

F R A M E D M O D E L I C B C T 3 6 I / S

The illustrations below provide installation

specifications for Model ICBCT36I/S.

For ease of installation, 991 mm cabinets are

recommended for installation of Model

ICBCT36I/S.

A Wolf 762 mm or 914 mm built-in single oven

may be installed below Model ICBCT36I/S. For

this installation, unless you are using cabinets

deeper than 610 mm, it is recommended that

the electrical supply be placed in the base

cabinet to the right of the oven.

I N S TA L L AT I O N S P E C I F I C AT I O N S – M O D E L I C B C T 3 6 I / S

Refer to installation instructions provided with

the built-in oven for additional specifications.

If Model ICBCT36I/S is installed above

cabinets, the electrical placement is not critical.

The appliance shall be installed in such a way

to allow disconnection of the appliance from

the supply mains after installation.

Overall Dimensions

M O D E L I C B C T 3 6 I / S

Overall Width 914 mm

Overall Height 64 mm

Overall Depth 533 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance* 96 mm

Cut-Out Width 873 mm

Cut-Out Depth 489 mm

*Minimum 152 mm clearance is required

between countertop and any combustible

surface directly below the cooktop.

For detailed terminal block dimensions,

refer to the illustration on page 7.

Dimensions may vary to ±3 mm.

10

Page 11

I N S TA L L AT I O N I N S T R U C T I O N S

64 mm

min

FRONT OF COUNTERTOP

489 mm

CUT-OUT

DEPTH

743 mm

TWO MODULES WIDTH

1130 mm – THREE MODULES WIDTH OR

1124 mm – 762 mm COOKTOP AND ONE MODULE

1518 mm – FOUR MODULES WIDTH OR

1511 mm – 762 mm COOKTOP AND TWO MODULES OR

1276 mm – 914 mm COOKTOP AND ONE MODULE

356 mm

CUT-OUT

WIDTH

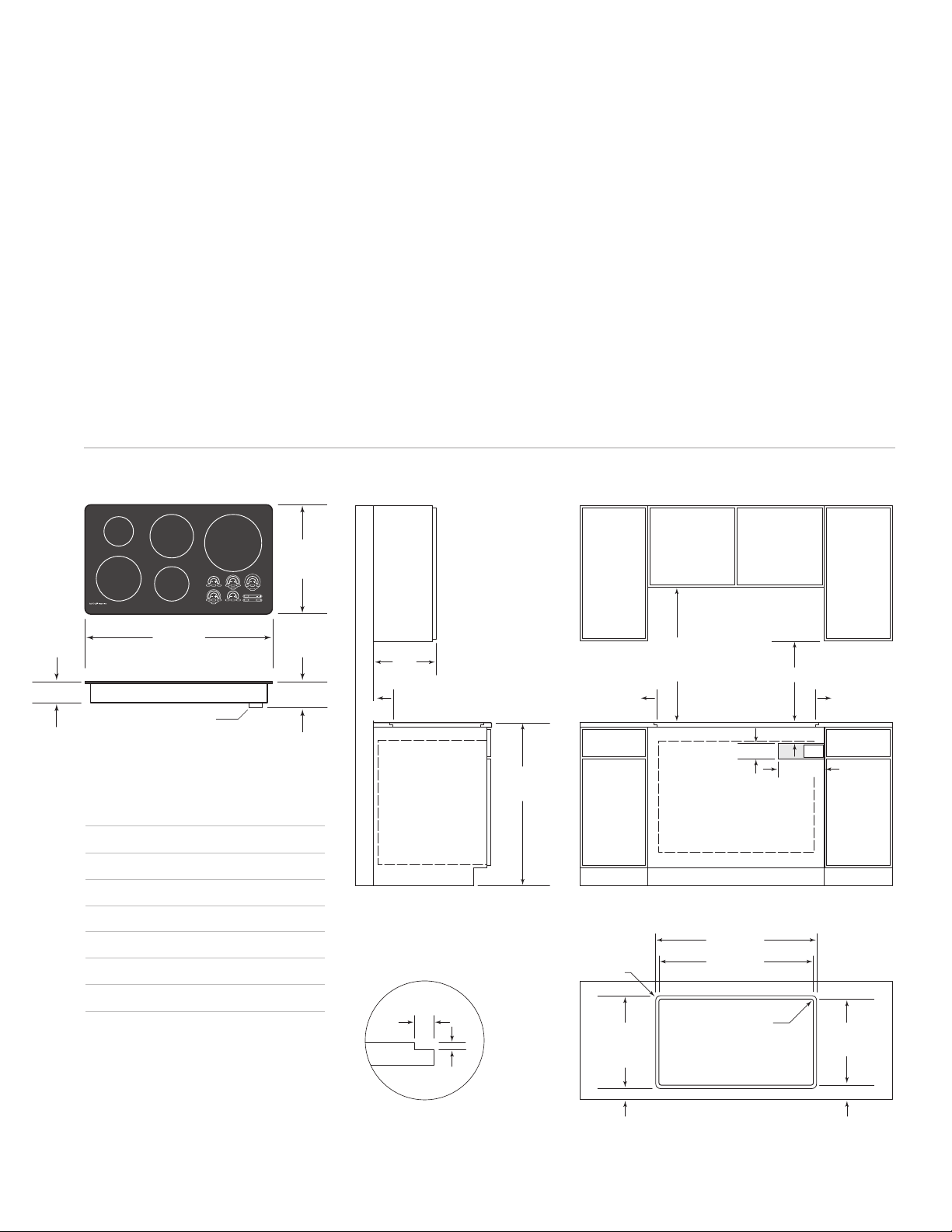

M U LT I P L E CO O K T O P I N S TA LL AT I O N

If the framed induction cooktop is to be used

with any combination of additional cooktop

units or modules with a filler strip, the cut-out

width is calculated by adding the corresponding units’ cut-out dimensions plus 32 mm for

each additional unit. Refer to the illustration

below.

IMPORTANT NOTE:

For Model ICBCT15I/S,

the cut-out width should be increased from

340 mm to 356 mm when installed with

multiple units.

IMPORTANT NOTE:

Unframed induction

cooktops are not designed to be installed in

combination with other cooktops.

IMPORTANT NOTE:

When multiple units are

installed side by side, each unit must have its

own separate recommended electrical circuit.

When two or more modules are installed

together, an integrated module filler strip

(IFILLER/S) is recommended. If a 762 mm

downdraft ventilation system is also installed,

an integrated module support for downdraft

ventilation (ISUPPORT) is also required.

Contact your Wolf dealer for information on

these accessory components.

A C C E S S O R I E S

Optional accessories are available

through your

Wolf dealer. To

obtain local dealer

information, visit

our website,

wolfappliance.com.

Countertop cut-out dimensions for installation of multiple cooktops

11

Page 12

457 mm min

914 mm

FLOOR TO

COUNTERTOP

762 mm

min

COUNTERTOP

TO COMBUSTIBLE

M

ATERIALS

762 mm OVEN OPENING

114 mm

254 mm

89 mm

E

S

EE COUNTERTOP

CUT-OUT BELOW

721 mm

CUT-OUT WIDTH

COUNTERTOP CUT-OUTRECESS FOR FLUSH INSTALLATION

FRONT

492 mm

CUT-OUT

DEPTH

62 mm mi n

537 mm

RECESS

FOR FLUSH

INSTALLATION

40 mm

51 mm T

O

COMBUSTIBLE

*

51 mm T

O

COMBUSTIBLE

*

51

mm*

SIDE

CABINET

330 mm

m

ax

*Minimum clearance from cooktop cut-out to com bustible materials up to 457 mm above countertop.

NOTE: Electrical location applies only to installati on with built-in oven.

8 mm

22

mm max

COUNTERTOP

PROFILE

33 mm

RADIUS

11 mm RADIUS

765 mm

RECESS FOR FLUSH INSTALLATION

533 mm

OVERALL

DEPTH

762 mm

OVERALL WIDTH

98 mm

76 mm

TERMINAL BOX

W O L F IN D U C T I O N C O O K TO P S

U N F R A M E D MO D E L I C B C T 3 0 I U

he illustrations below provide installation

T

specifications for Model ICBCT30IU.

For ease of installation, 838 mm cabinets are

recommended for installation of Model ICBCT30IU.

A Wolf 762 mm built-in single oven may be

installed below Model ICBCT30IU. For this

installation, unless you are using cabinets

deeper than 610 mm, it is recommended that

the electrical supply be placed in the base

cabinet to the right of the oven. Refer to installation instructions provided with the built-in

oven for additional specifications.

I N S TA L L AT I O N S P E C I F I C AT I O N S – M O D E L I C B C T 3 0 I U

f Model ICBCT30IU is installed above cabinets,

I

electrical placement is not critical. The appliance shall be installed in such a way to allow

isconnection of the appliance from the supply

d

mains after installation.

For Model ICBCT30IU installation options, refer

to Unframed Installations on pages 14–15.

IMPORTANT NOTE:

For flush mount applications, it is recommended to measure the

cooktop glass before cutting the countertop to

ensure a proper fit. Small variances may exist

between the template and the cooktop.

Overall Dimensions

M O D E L I C B C T 3 0 I U

Overall Width 762 mm

Overall Height 76 mm

Overall Depth 533 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance*

98 mm

Cut-Out Width 721 mm

Cut-Out Depth 492 mm

*Minimum 165 mm clearance is required

between countertop and any combustible

surface directly below the cooktop.

For detailed terminal block dimensions,

refer to the illustration on page 7.

Dimensions may vary to ±3 mm.

12

Page 13

457 mm min

914 mm

FLOOR TO

COUNTERTOP

762 mm

min

COUNTERTOP

TO COMBUSTIBLE

MATERIALS

914 mm OVEN OPENING

114 mm

254 mm

89 mm

E

SEE COUNTERTOP

C

UT-OUT BELOW

873 mm

CUT-OUT WIDTH

COUNTERTOP CUT-OUTRECESS FOR FLUSH INSTALLATION

FRONT

492 mm

CUT-OUT

DEPTH

62 mm mi n

537 mm

RECESS

FOR FLUSH

INSTALLATION

40 mm

51 mm T

O

COMBUSTIBLE

*

51 mm T

O

COMBUSTIBLE

*

51

mm*

SIDE

CABINET

330 mm

max

*Minimum clearance from cooktop cut-out to com bustible materials up to 457 mm above countertop.

NOTE: Electrical location applies only to installati on with built-in oven.

8 mm

22

mm max

COUNTERTOP

PROFILE

33 mm

RADIUS

11 mm RADIUS

918 mm

RECESS FOR FLUSH INSTALLATION

533 mm

OVERALL

DEPTH

914 mm

OVERALL WIDTH

98 mm

76 mm

TERMINAL BOX

I N S TA L L AT I O N I N S T R U C T I O N S

U N F R A M E D

he illustrations below provide installation

T

specifications for Model ICBCT36IU.

For ease of installation, 991 mm cabinets are

recommended for installation of Model ICBCT36IU.

A Wolf 914 mm built-in single oven may be

installed below Model ICBCT36IU. For this

installation, unless you are using cabinets

deeper than 610 mm, it is recommended that

the electrical supply be placed in the base

cabinet to the right of the oven. Refer to installation instructions provided with the built-in

oven for additional specifications.

M O D E L I C B C T 3 6 I U

f Model ICBCT36IU is installed above cabinets,

I

electrical placement is not critical. The appliance shall be installed in such a way to allow

isconnection of the appliance from the supply

d

mains after installation.

For Model ICBCT36IU installation options, refer

to Unframed Installations on pages 14–15.

IMPORTANT NOTE:

tions, it is recommended to measure the

cooktop glass before cutting the countertop to

ensure a proper fit. Small variances may exist

between the template and the cooktop.

I N S TA L L AT I O N S P E C I F I C AT I O N S – M O D E L I C B C T 3 6 I U

For flush mount applica-

Overall Dimensions

M O D E L I C B C T 3 6 I U

Overall Width 914 mm

Overall Height 76 mm

Overall Depth 533 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance*

98 mm

Cut-Out Width 873 mm

Cut-Out Depth 492 mm

*Minimum 165 mm clearance is required

between countertop and any combustible

surface directly below the cooktop.

For detailed terminal block dimensions,

refer to the illustration on page 7.

Dimensions may vary to ±3 mm.

13

Page 14

W O L F IN D U C T I O N C O O K TO P S

U N F R A M E D

Flush mount installations are intended

for granite, solid surface or stone countertop surfaces only. Failure to use high

heat resistant surface will result in countertop damage if hot cooking utensils are

accidentally moved off the cooking

surface.

I N S TA L L AT I O N S

M O D E L S I C B C T 3 0 I U A N D I C B C T 3 6 I U

Unframed induction cooktop Models

ICBCT30IU and ICBCT36IU can be mounted

flush with the top of the countertop or as a

frameless installation with the glass mounted

on top of the countertop surface.

IMPORTANT NOTE:

The materials required

for a flush mount installation are provided with

the unframed Models ICBCT30IU and

ICBCT36IU. Refer to the instructions provided

with the unframed cooktop installation kit for

additional specifications. The template

provided with the unframed cooktops is for

reference only. Use the actual cooktop for

marking the cut-out.

L U S H M O U N T I N ST A L L AT I O N

F

There are two options for a flush mount

installation of the unframed induction cooktop;

Option 1 and Option 2.

OPTION 1:

For this flush mount installation, a

recessed area surrounding the standard countertop cut-out is required. Fabrication of the

recessed area must take place before the final

countertop installation. A template of the countertop cut-out is provided with the unframed

cooktop for fabrication purposes.

IMPORTANT NOTE:

This fabrication method is

not recommended for molded backsplash style

countertops (triple cove).

For countertop cut-out dimensions, refer to

the Installation Specifications illustration on

page 12 for Model ICBCT30IU and page 13 for

Model ICBCT36IU.

In order to rout the required recessed area for

this flush mount installation, a second

template must be made from 13 mm plywood.

The template will be used as a guide for a top

bearing router bit.

Make the wood template wide enough so that

clamps used to hold this template to the countertop do not interfere with the router base.

The cut-out dimension of the wood template

should match the outer perimeter of the

template supplied with the cooktop.

14

Center the wood template over the existing

cut-out in the countertop and clamp. It may be

helpful to use medium-strength double-sided

tape to adhere the template to the countertop;

this will keep the template from shifting during

the routing operation. Make sure that the

adhesive can be easily removed by testing it

on a scrap piece of the countertop. Using a top

bearing router bit with the wood template as a

guide, rout out a 8 mm deep recessed area in

the countertop cut-out.

Page 15

I N S TA L L AT I O N I N S T R U C T I O N S

22 mm

8 mm

L-Shaped

Brackets

U N F R A M E D I N S TA LL AT I O N S

L U S H M O U N T I N ST A L L AT I O N

F

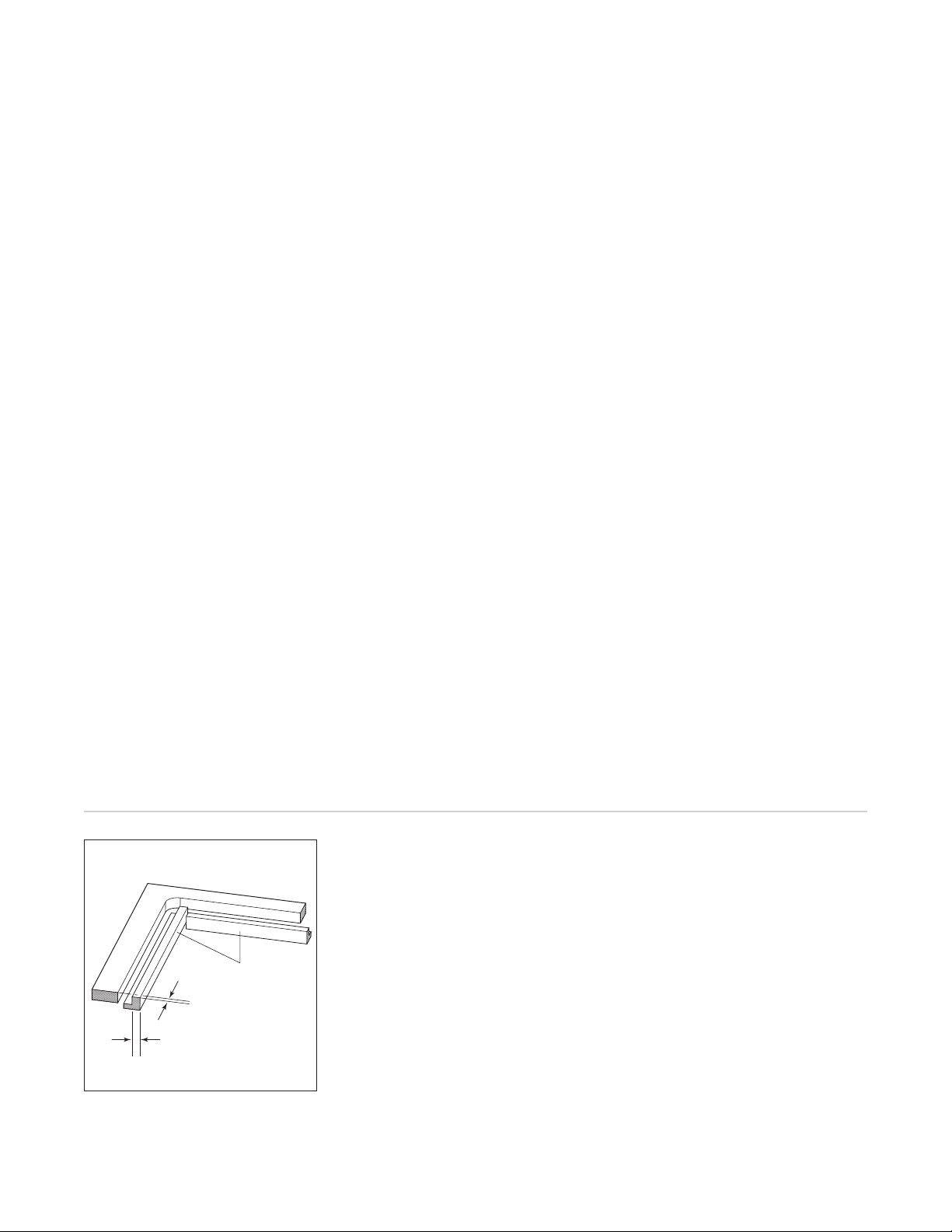

OPTION 2:

For this flush mount installation,

the countertop cut-out will be the same size as

the outer edge of the glass top. It is recommended that cooktop itself be used as the

template for the cut-out. Turn the cooktop over

and mark the opening using the glass top as a

template.

It will be necessary to attach L-shaped brackets

or cleats to the inner perimeter of the cut-out

to support the cooktop. The top edge of the

bracket can be no wider than 22 mm and will

be attached 8 mm below the surface of the

countertop. Refer to the illustration below.

Attachment of the brackets is up to the

installer's discretion, wherever enough countertop material is present.

For additional support in the cut-out area,

adhere scrap countertop material to the

bottom side of the countertop. Consult your

countertop supplier for the proper methods of

attachment.

R A M E L E S S I N S T A L L AT I O N

F

Unframed induction cooktop Models

ICBCT30IU and ICBCT36IU can be installed as a

frameless application, with the glass mounted

on top of the countertop surface. For countertop cut-out dimensions, refer to the Installation

Specifications illustration on page 12 for Model

ICBCT30IU and page 13 for Model ICBCT36IU.

Flush mount installation brackets

15

Page 16

I M P O R T A N T

N

L1

N

L1

L2

L3

N O T E

Be aware of local

codes and ordinances when

installing your

service.

W O L F IN D U C T I O N C O O K TO P S

E L E C T R I C A L R E Q U I R E M E N T S

Verify that power is disconnected from

the electrical box before proceeding.

3 8 1 m m I N D U C T I O N C O O K T O PS

Required power supply:

Single phase: 220-240V AC; 50 Hz

3phase: 380-410V AC; 50 Hz

Maximum connected load:

Single phase: 3.6 kW

3phase: 3.6 kW

Total amps:

Single phase: 16 amps

3phase: 16 amps

9 1 4 m m I N D U C T I O N C O O K T O PS

Required power supply:

ingle phase: 220-240V AC; 50 Hz

S

3phase: 380-410V AC; 50 Hz

Maximum connected load:

Single phase: 11.2 kW

3phase: 4 kW

Total amps:

Single phase: 49 amps

3phase: 18 amps

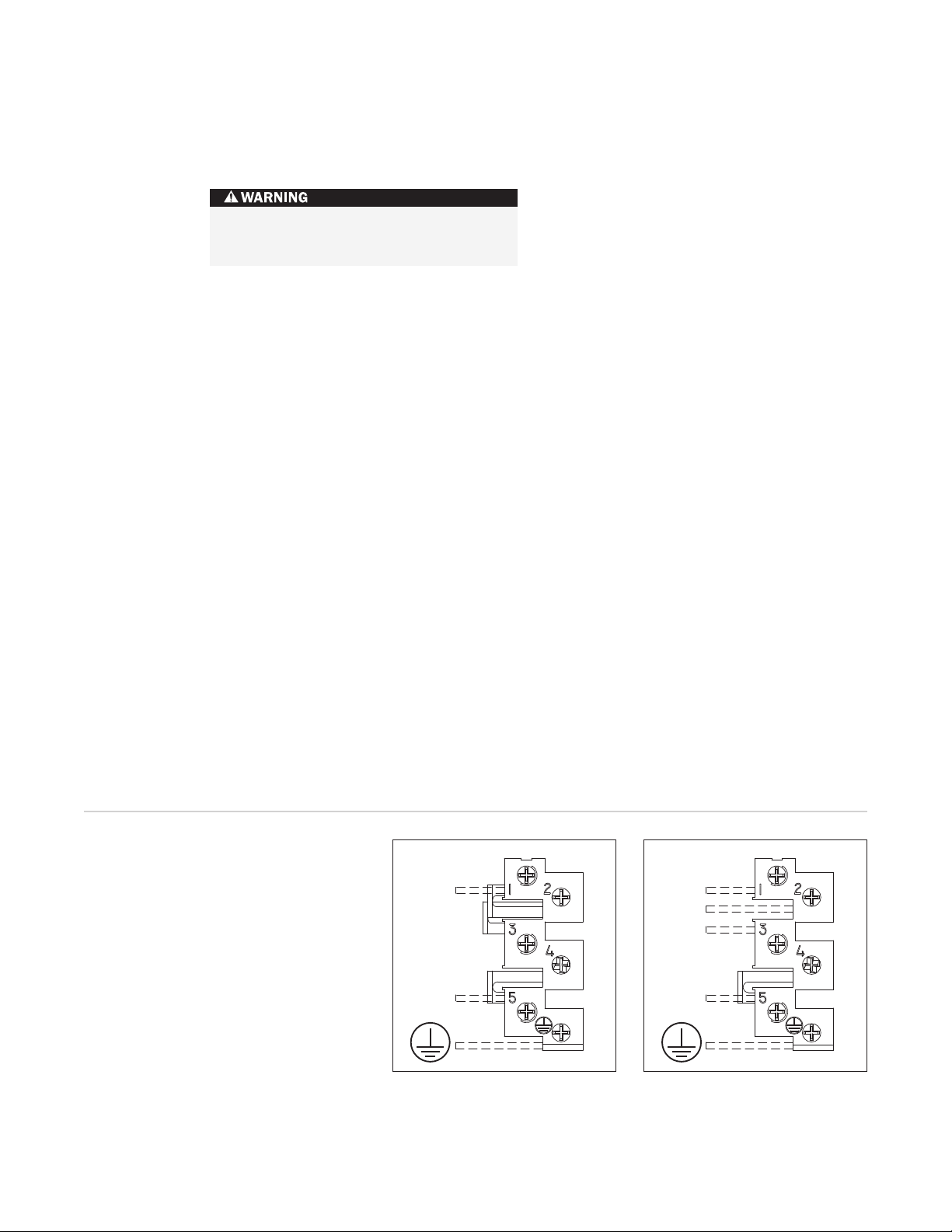

Refer to the wiring diagram showing the

connections for each lead to the terminal box

on the unit.

7 6 2 m m I N D U C T I O N C O O K T O PS

Required power supply:

Single phase: 220-240V AC; 50 Hz

3phase: 380-410V AC; 50 Hz

Maximum connected load:

Single phase: 7.2 kW

3phase: 3.6 kW

Total amps:

Single phase: 32 amps

3phase: 16 amps

˜

3N

˜

Single phase wiring diagram

16

3phase wiring diagram

Page 17

I N S TA L L AT I O N I N S T R U C T I O N S

E L E C T R I C A L R E Q U I R E M E N T S

The complete appliance must be properly

grounded at all times when electrical

ower is applied.

p

NOTE: Improper connection can result in

a fire hazard.

Before obtaining access to terminals, all

supply circuits must be disconnected.

Open the terminal box to expose the screws

with corresponding numbers. Run the cord

through the strain relief hole and into the

terminal box.

For Single Phase Install (Line, Neutral,

Ground):

Loosen the 1, 5, and ground screws.

Attach the Neutral wire to the number 5

position. Line should be attached to the 1

postion and attach the ground to the corresponding ground screw.

For 3phase Install (L1, L2, L3, Neutral,

Ground):

Loosen the 1, 2, 3 and remove the

copper bars. Loosen 5 and ground screws.

Attach L1 to position 1. L2 to position 2. L3 to

position 3. Neutral wire to position 5 and attach

the ground to the corresponding ground screw.

IMPORTANT NOTE:

Connection of this appliance should be through a fused connection

unit or a suitable isolator, which complies with

national and local safety regulations. The

on/off switch should be easily accessible after

the appliance has been installed. If the switch

is not accessible after installation (depending

on country) an additional means of disconnection must be provided for all poles of the

power supply. When switched off there must

be an all pole contact gap of 3 mm in the

isolator switch. This 3 mm contact disconnect

gap must apply to any isolator switch, fuses

and/or relays according to EN60335.

Copper bars must be removed from positions 1, 2, and 3 when connecting to

3phase power.

After tightening the screws, tighten down the

cord strain relief and close the cover to the

terminal box without pinching any of the wires.

17

Page 18

COOKTOP

FOAM

STRIP

COOKTOP

COUNTERTOP

BRACKET

SCREWS

BRACKET

89 mm

CLAMPING

SCREW

W O L F IN D U C T I O N C O O K TO P S

A C C E S S O R I E S

Optional accessories are available

through your

Wolf dealer. To

obtain local dealer

information, visit

our website,

wolfappliance.com.

C O O K T O P

I N S TA L L AT I O N

Attach the foam strip to the underside of the

cooktop frame. Refer to the illustration below.

IMPORTANT NOTE:

For unframed installation,

adhere foam strip to the outer edge of the

glass, not the support frame.

Gently lower the cooktop into the cut-out area

in the countertop and center. Check that the

front edge of the cooktop is parallel to the

front edge of the countertop. Check that all

required clearances are met.

Attach the brackets to the bottom of the unit,

as shown in the illustration below. Install the

clamping screws into the bracket and tighten

until the screws contact the underside of the

countertop.

IMPORTANT NOTE:

Do not overtighten the screws.

Do not seal the cooktop

to the countertop. It must be removed if

service is necessary.

If the ceramic glass top of the cooktop is

broken, turn off power to the unit. Do

not operate until glass has been replaced

by a Wolf authorized service center.

B E F O R E O P E R AT I N G

Clean the ceramic glass surface carefully using

the Cooktop Cleaning Crème provided with the

cooktop. Remove all cleaning residue.

Read the entire Wolf Induction Cooktops

Use & Care Information included with the

cooktop. Important safety and service information is contained within the book.

C O O K T O P

IMPORTANT NOTE:

R E M O VA L

This procedure should

only be performed by a Wolf authorized

service center.

If it is necessary to remove the cooktop for

cleaning or service, disconnect the electrical

supply. Remove the mounting brackets on the

right and left side of the unit and remove the

cooktop. Reinstall in the reverse order.

IMPORTANT NOTE:

For flush mount installations, use a razor blade to cut around the RTV

seal. A new RTV installation kit (811358) will be

required to reinstall the cooktop. This kit is

available through your Wolf dealer. To obtain

local dealer information, visit our website,

wolfappliance.com.

18

Foam strip Installation brackets

Page 19

I N S TA L L AT I O N I N S T R U C T I O N S

T R O U B L E S H O OT I N G

I F C O O K T O P D OE S N OT O P E R AT E

IMPORTANT NOTE:

If the induction cooktop

does not operate properly, follow these

troubleshooting steps:

Verify that power is being supplied to the

ooktop.

c

Check electrical connections to ensure that

the installation has been completed

correctly.

Follow troubleshooting procedures as

described in the Wolf Induction Cooktops

Use & Care Information.

If the power bar indicator lights operate but

the unit shows that it is in Lock mode, the

unit is in Showroom mode. Contact your

local Wolf dealer.

If the cooktop still does not work, contact

a Wolf authorized service center. Do not

attempt to repair the cooktop yourself.

Wolf is not responsible for service required

to correct a faulty installation.

The unit must be disconnected from

power prior to service.

19

Page 20

C O N TA C T

I N F O R M A T I O N

Website:

wolfappliance.com

W O L F IN D U C T I O N C O O K TO P S

I F Y O U N E E D SE R V I C E

If service is necessary, maintain the quality

built into your induction cooktop by calling

a Wolf authorized service center.

To obtain the name and number of a

Wolf authorized service center, visit our

website,

wolfappliance.com

.

When calling for service, you will need the

cooktop model and serial numbers. Both

numbers are listed on the rating plate,

located on the underside of the cooktop.

Refer to the illustration on page 5 for

location of the rating plate.

20

The information and images in this book are the

copyright property of Wolf Appliance, Inc., an

affiliate of Sub-Zero, Inc. Neither this book nor any

information or images contained herein may be

copied or used in whole or in part without the

express written permission of Wolf Appliance, Inc.,

an affiliate of Sub-Zero, Inc.

©Wolf Appliance, Inc. all rights reserved.

Page 21

I NF O R M A C IÓ N

D E C O N T A C T O

ágina web:

P

wolfappliances.com

Cuando consulte las instrucciones que aparecen

en esta guía, encontrará símbolos de ADVERTENCIA y PRECAUCIÓN. Esta información en

recuadros es importante para instalar el equipo

de Wolf de forma segura y eficaz. Existen dos

tipos de posibles riesgos que pueden producirse

durante una instalación.

WOLF®es una marca comercial registrada de Wolf Appliance, Inc.

indica una situación en la que se pueden

sufrir heridas leves o provocar daños

secundarios al producto si no se siguen

las instrucciones.

indica peligro de que se produzcan heridas

personales graves o incluso puede provocar

la muerte si no se siguen las precauciones

especificadas.

Otro tipo de anotación que es importante

resaltar es la que se incluye en NOTA

IMPORTANTE: En esta nota se resalta la

información que resulta especialmente

importante para que la instalación se

realice sin problemas.

Page 22

P L A C A S D E I N DU CC I Ó N D E W O L F

I N FO R M AC IÓ N

D E L A P L A C A

D E D AT O S

eferencia del

R

odelo

m

úmero de serie

N

R EQ U I S I TO S D E I N S TA L AC I Ó N

NOTA IMPORTANTE:

Guarde estas instrucciones

de instalación para que el inspector local pueda

utilizarlas.

Lea las instrucciones de instalación antes de

llevar a cabo la instalación.

sta instalación debe ser realizada por un

E

técnico cualificado.

Instalador:

guarde estas instrucciones para

que el inspector local pueda utilizarlas como

eferencia y, a continuación, entréguelas al

r

propietario del aparato.

Propietario:

lea y guarde estas instrucciones

para que pueda utilizarlas como referencia en

el futuro y asegúrese de leer la guía de uso y

mantenimiento antes de utilizar el aparato.

NOTA IMPORTANTE:

Este aparato debe instalarse siguiendo las normativas nacionales correspondientes. Se debe aplicar al aparato el voltaje,

la frecuencia y el amperaje adecuados desde una

instalación eléctrica resistente con toma de tierra

protegida por un fusible de retardo. El voltaje, la

frecuencia y el amperaje se muestran en la placa

de datos del producto.

Apunte la referencia del modelo y el número

de serie antes de instalar el aparato. Esta información se muestra en la placa de datos del

producto situada en la parte inferior de la

placa. Observe la siguiente ilustración.

A N T E S D E C O M E N Z A R

Es responsabilidad del propietario asegurarse

de que la instalación se realiza de manera

correcta. Esta placa debe ser instalada por un

técnico cualificado. Debe asegurarse de que la

instalación eléctrica es la correcta y que

cumple todos los códigos y normativas

nacionales.

Las instalaciones y reparaciones deben ser

realizadas por un contratista cualificado o

autorizado o por un electricista cualificado o

autorizado por el estado, provincia o región

en la que se va a instalar este aparato.

Compruebe que tiene todo lo necesario para

que la instalación se lleve a cabo de la manera

correcta. Es responsabilidad del instalador

dejar los espacios necesarios para la instalación que se especifican en la placa de datos

del producto. La placa de datos está ubicada

en la parte inferior del aparato.

Este aparato necesita una conexión a tierra;

consulte la sección Requisitos eléctricos en las

páginas 33 y 34.

Esta placa está diseñada para que se utilice

en espacios interiores.

22

Ubicación de la

placa de datos debajo

de la placa

Ubicación de la placa de datos

Page 23

P L A C A S D E I N DU CC I Ó N D E W O L F

C

G

D

A

B

B

E

F

P RE PA R A C I Ó N D E L

NOTA IMPORTANTE:

S I T I O

La instalación de la placa

de inducción de Wolf debe cumplir los siguientes

requisitos de colocación. Las medidas que se

especifican son las mínimas para que el funcionamiento de la placa sea seguro. Observe la siguiente ilustración.

Para eliminar el riesgo de sufrir quemaduras

o de que se produzca un incendio al

alcanzar las superficies calientes, debe

evitar colocar armarios por encima de los

módulos de superficie. Si va a colocar

armarios, el riesgo se puede reducir al

instalar una campana de extracción que

sobresalga horizontalmente un mínimo de

127 mm de la parte inferior de los armarios.

C OL O C A C IÓ N E N L A E N C I M E R A

A)

Superficie mínima de encimera plana. Debe

ser igual o superior al ancho de la placa.

B)

Espacio mínimo de 25 mm desde el borde

lateral de la placa a cualquier superficie

combustible situada a 457 mm por encima de

la placa (área sombreada de la ilustración).

E DI DA S D E L O S A RM A R I O S

M

S UP E R I O R E S

C)

El espacio mínimo entre los armarios laterales

superiores debe ser igual o superior al ancho

nominal de la placa o placas.

D)

Debe existir una distancia vertical mínima de

457 mm desde la encimera hasta la parte

inferior de los armarios laterales con una

distancia lateral mínima.

E)

La distancia vertical mínima entre la encimera

y los materiales combustibles situados por

encima de la placa debe ser de 762 mm.

F)

Distancia mínima de 25 mm a la pared trasera.

G)

El fondo máximo de los armarios superiores

laterales situados por encima de la placa

debe ser de 330 mm con una distancia

lateral mínima.

Distancias mínimas de instalación

Si no coloca la placa siguiendo las

distancias de separación correctas, es

posible que se produzca un incendio.

23

Page 24

I NS T R U C C I ON E S DE I N S TA L A C I ÓN

84

mm

56

mm

24

mm

22 mm

32 mm

ES P EC IF I CA C I O N E S D E

L A

I N S TA L A C I Ó N

Las ilustraciones de las páginas 25–30 proporcionan las medidas totales, las especificaciones de la

instalación y las medidas del corte de la encimera

para cada uno de los modelos de placas de

nducción de Wolf.

i

Esta placa está diseñada para que se adapte a un

armario de base estándar de 610 mm de fondo

con una encimera de 635 mm de fondo. Antes de

cortar la encimera, compruebe que la placa va a

quedar separada de las paredes laterales del

armario inferior.

Se necesita dejar un espacio para el bloque de

terminales en la parte trasera derecha de la placa.

Observe la siguiente ilustración para ver las

medidas.

P LA C A S D E I N D U C C I ÓN C O N M A R C O

NOTA IMPORTANTE:

Es necesario dejar un

espacio mínimo de altura de 152 mm entre la

placa y cualquier superficie combustible que se

encuentre justo debajo de la placa. Esto incluye

los bordes superiores de los cajones situados

directamente debajo de la unidad. Si instala un

estante debajo del aparato, debe dejar un espacio

de 25 mm en la parte trasera del armario para

que la ventilación sea correcta. Si no deja este

espacio, es posible que se reduzca el rendimiento

del aparato o que se produzcan daños en el

mismo.

Las placas de inducción de Wolf están diseñadas

para que se puedan instalar junto con otras

placas.

NOTA IMPORTANTE:

Cuando instale varias

placas juntas y/o módulos, consulte las dimensiones de corte de la encimera en la página 28.

Las placas de inducción de Wolf pueden

instalarse con un sistema de ventilación de tiro

ascendente de Wolf. Consulte las instrucciones de

instalación que se proporcionan con el sistema

de ventilación de tiro ascendente para obtener

más información.

P LA C A S D E I N D U C C I ÓN S I N M A R C O

NOTA IMPORTANTE:

Es necesario dejar un

espacio mínimo de altura de 165 mm entre la

placa y cualquier superficie combustible que se

encuentre justo debajo de la placa. Esto incluye

los bordes superiores de los cajones situados

directamente debajo de la unidad. Si instala un

estante debajo del aparato, debe dejar un espacio

de 25 mm en la parte trasera del armario para

que la ventilación sea correcta. Si no deja este

espacio, es posible que se reduzca el rendimiento

del aparato o que se produzcan daños en el

mismo.

NOTA IMPORTANTE:

Las placas de inducción

sin marco de Wolf están diseñadas para que se

puedan instalar junto con otras placas.

NOTA IMPORTANTE:

Las placas de inducción

sin marco no se pueden instalar con un sistema

de ventilación de tiro ascendente.

Si desea consultar las opciones de instalación

de las placas de inducción sin marco, consulte

la sección Instalación sin marco en las

páginas 31–32.

24

Medidas del bloque de terminales

Page 25

914 mm

DEL SUELO A

LA ENCIMERA

762 mm

mín.

ENCIMERA HASTA

LOS MATERIALES

I

NFLAMABLES

C

ONSULTAR CORTE DE

LA ENCIMERA A CONT.

340 mm

ANCHO

DE CORTE

CORTE DE LA ENCIMERA

PARTE DELANTERA

489 mm

FONDO

DE CORTE

64 mm mín.

51 mm HASTA

LOS MATERIALES

INFLAMABLES*

51 mm HASTA

LOS MATERIALES

INFLAMABLES*

51

mm*

ARMARIO

LATERAL

330 mm

m

áx.

*Espacio de separación mí nimo desde el corte de la s uperficie de cocción hasta los materiales inflamables hasta un máximo de 457 mm

sobre la encimera.

NOTA: la instalación deta llada permite montar dos mó dulos de 381 mm contiguos.

E

381 mm

381

mm

114 mm

457 mm mín.

533 mm

PROFUNDIDAD

TOTAL

381 mm

ANCHURA TOTAL

64 mm

CAJA PARA TERMINAL

96 mm

P L A C A S D E I N DU CC I Ó N D E W O L F

M O D E L O IC B C T 1 5 I / S

Las siguientes ilustraciones proporcionan las

especificaciones de instalación del modelo

ICBCT15I/S.

C ON M A R C O

Si instala el modelo ICBCT15I/S encima de los

armarios, la colocación de la toma eléctrica no es

importante. El aparato se instalará de tal forma

que se pueda desconectar de la red después de

su instalación.

E SP E C I F I C A C I O N E S D E L A I N S TA LA CI Ó N – M O D E L O I C B C T 1 5 I / S

Medidas totales

M OD E L O I C B C T 1 5 I / S

Anchura total 381 mm

Altura total 64 mm

Profundidad total 533 mm

Fondo mínimo del armario 578 mm

Espacio de altura mínimo* 96 mm

Ancho del corte 340 mm

Profundidad del corte 489 mm

*Es necesario dejar un espacio mínimo de

altura de 15 2 mm entre la encimera y

cualquier superficie combustible que se

encuentre justo encima de la placa.

Si desea obtener las medidas detalladas

del bloque de terminales, consulte la

ilustración en la página 24.

Las medidas pueden variar ±3 mm.

25

Page 26

457 mm mín.

914 mm

DEL SUELO A

LA ENCIMERA

762 mm mín.

ENCIMERA HASTA

L

OS MATERIALES

INFLAMABLES

762 mm APERTURA DEL HORNO

114 mm

254 mm

89 mm

E

CONSULTAR CORTE DE

LA ENCIMERA A CONT.

51 mm HASTA

L

OS MATERIALES

INFLAMABLES

*

51 mm HASTA

LOS MATERIALES

INFLAMABLES*

51

mm*

ARMARIO

LATERAL

330 mm

máx.

721 mm

ANCHO DE CORTE

CORTE DE LA ENCIMERA

PARTE DELANTERA

489 mm

FONDO

DE CORTE

64 mm mín.

*Espacio de separación mí nimo desde el corte de la s uperficie de cocción hasta los materiales inflamables hasta un máximo de 457 mm

sobre la encimera.

NOTA: la ubicación de la toma eléctrica solo se apli ca a una instalación con ho rno empotrable.

533 mm

PROFUNDIDAD

TOTAL

762 mm

ANCHURA TOTAL

CAJA PARA TERMINAL

64 mm

96 mm

I NS T R U C C I ON E S DE I N S TA L A C I ÓN

M O D E L O IC B C T 3 0 I / S C ON M A R C O

Las siguientes ilustraciones proporcionan las

especificaciones de instalación del modelo

ICBCT30I/S.

Para que la instalación le resulte más sencilla,

cuando instale el modelo ICBCT30I/S le

recomendamos que utilice armarios de 838 mm.

Debajo del modelo ICBCT30I/S se puede instalar

un horno sencillo de Wolf integrado de 762 mm

Consulte las instrucciones de instalación que

se proporcionan con el horno integrable para

obtener más información.

Si instala el modelo ICBCT30I/S encima de los

armarios, la colocación de la toma eléctrica no

es importante. El aparato se instalará de tal

forma que se pueda desconectar de la red

después de su instalación.

o 914 mm. Para realizar esta instalación, a menos

que utilice armarios con una profundidad mayor

a 610 mm, se recomienda colocar la alimentación

eléctrica en el armario de la base a la derecha

del horno.

E SP E C I F I C A C I O N E S D E L A I N S TA LA CI Ó N – M O D E L O I C B C T 3 0 I / S

Medidas totales

M OD E L O I C B C T 3 0 I / S

Anchura total 762 mm

Altura total 64 mm

Profundidad total 533 mm

Fondo mínimo del armario 578 mm

Espacio de altura mínimo* 96 mm

Ancho del corte 721 mm

Profundidad del corte 489 mm

*Es necesario dejar un espacio mínimo de

altura de 15 2 mm entre la encimera y

cualquier superficie combustible que se

encuentre justo encima de la placa.

Si desea obtener las medidas detalladas

del bloque de terminales, consulte la

ilustración en la página 24.

Las medidas pueden variar ±3 mm.

26

Page 27

P L A C A S D E I N DU CC I Ó N D E W O L F

457 mm mín.

914 mm

DEL SUELO A

LA ENCIMERA

762 mm mín.

ENCIMERA HASTA

L

OS MATERIALES

INFLAMABLES

914 mm APERTURA DEL HORNO

114 mm

254 mm

89 mm

E

CONSULTAR CORTE DE

L

A ENCIMERA A CONT.

873 mm

ANCHO DE CORTE

CORTE DE LA ENCIMERA

PARTE DELANTERA

489 mm

FONDO DE

CORTE

64 mm mín.

51 mm H

ASTA

LOS MATERIALES

INFLAMABLES

*

51 mm H

ASTA

LOS MATERIALES

INFLAMABLES

*

51

mm*

ARMARIO

LATERAL

330 mm

máx.

*Espacio de separación mí nimo desde el corte de la s uperficie de cocción hasta los materiales inflamables hasta un máximo de 457 mm

sobre la encimera.

NOTA: la ubicación de la toma eléctrica solo se apli ca a una instalación con ho rno empotrable.

533 mm

PROFUNDIDAD

TOTAL

914 mm

ANCHURA TOTAL

CAJA PARA TERMINAL

64 mm

96 mm

M O D E L O IC B C T 3 6 I / S C ON M A R C O

Las siguientes ilustraciones proporcionan las

especificaciones de instalación del modelo

ICBCT36I/S.

Para que la instalación le resulte más sencilla,

cuando instale el modelo ICBCT36I/S le

recomendamos que utilice armarios de 991 mm.

Debajo del modelo ICBCT36I/S se puede instalar

un horno sencillo de Wolf integrado de 762 mm

Consulte las instrucciones de instalación que

se proporcionan con el horno integrable para

obtener más información.

Si instala el modelo ICBCT36I/S encima de los

armarios, la colocación de la toma eléctrica no

es importante. El aparato se instalará de tal

forma que se pueda desconectar de la red

después de su instalación.

o 914 mm. Para realizar esta instalación, a menos

que utilice armarios con una profundidad mayor

a 610 mm, se recomienda colocar la alimentación

eléctrica en el armario de la base a la derecha

del horno.

E SP E C I F I C A C I O N E S D E L A I N S TA LA CI Ó N – M O D E L O I C B C T 3 6 I / S

Medidas totales

M OD E L O I C B C T 3 6 I / S

Anchura total 914 mm

Altura total 64 mm

Profundidad total 533 mm

Fondo mínimo del armario 578 mm

Espacio de altura mínimo* 96 mm

Ancho del corte 873 mm

Profundidad del corte 489 mm

*Es necesario dejar un espacio mínimo de

altura de 15 2 mm entre la encimera y

cualquier superficie combustible que se

encuentre justo encima de la placa.

Si desea obtener las medidas detalladas

del bloque de terminales, consulte la

ilustración en la página 24.

Las medidas pueden variar ±3 mm.

27

Page 28

I NS T R U C C I ON E S DE I N S TA L A C I ÓN

64 mm

mín

PARTE DELANTERA DE LA ENCIMERA

489 mm

FONDO

DE CORTE

743 mm

ANCHURA DE DOS MÓDULOS

1.130 mm – ANCHURA DE TRES MÓDULOS !

1.124 mm – 762 mm SUPERFICIE DE COCCIÓN Y

UN MÓDULO

1.518 mm – ANCHURA DE CUATRO MÓDULOS O

1.511 mm – 762 mm SUPERFICIE DE COCCIÓN Y DOS MÓDULOS !

1.276 mm – 914 mm SUPERFICIE DE COCCIÓN Y UN MÓDULO

356 mm

ANCHURA

DE CORTE

I NS TA L A C I Ó N DE OT R A S

S U P E R FI C I E S D E C O C C I Ó N

A C C E S O R I OS

odrá disponer de

P

accesorios opcion-

les a través

a

e su distribuidor de

d

Wolf. Para obtener

la información del

istribuidor más

d

cercano, visite

nuestra página

eb:

w

wolfappliance.com.

Si la placa de inducción con marco se va a utilizar

on otras combinaciones de módulos o unidades

c

de cocción adicionales con un embellecedor, el

ancho del corte se calcula al sumar las medidas

de corte de las unidades correspondientes más

32 mm por cada unidad adicional. Observe la

siguiente ilustración.

NOTA IMPORTANTE:

Para el modelo ICBCT15I/S,

el ancho del corte debe aumentarse de 340 mm a

356 mm cuando se instale con varias unidades.

NOTA IMPORTANTE:

Las placas de inducción

sin marco de Wolf están diseñadas para que se

puedan instalar junto con otras placas.

NOTA IMPORTANTE:

Cuando se instalen varias

unidades juntas, cada unidad debe tener su

propio circuito eléctrico recomendado.

Cuando se instalen dos o más módulos juntos,

e recomienda utilizar un embellecedor de

s

módulo integrado (IFILLER/S). Si además se

instala un extractor de tiro ascendente de 762

mm, es necesario disponer de un soporte del

módulo integrado para el extractor de tiro

ascendente (ISUPPORT). Póngase en contacto

con su distribuidor de Wolf para obtener

información sobre estos accesorios.

28

Dimensiones de corte de la encimera para la instalación de otras

superficies de cocción

Page 29

457 mm mín.

914 mm

DEL SUELO A

LA ENCIMERA

762 mm mín.

E

NCIMERA HASTA

LOS MATERIALES

INFLAMABLES

762 mm APERTURA DEL HORNO

114 mm

254 mm

89 mm

E

CONSULTAR CORTE DE

LA ENCIMERA A CONT.

721 mm

ANCHO DE CORTE

CORTE DE LA ENCIMERAENTRANTE DE PARED PARA

INSTALACIÓN EMPOTRABLE

PARTE DELANTERA

492 mm

FONDO DE

CORTE

62 mm mín.

537 mm

ENTRANTE

DE PARED PARA

INSTALACIÓN

EMPOTRABLE

40 mm

51 mm H

ASTA

LOS MATERIALES

INFLAMABLES

*

51 mm H

ASTA

LOS MATERIALES

INFLAMABLES

*

51

mm*

ARMARIO

LATERAL

330 mm

máx.

*Espacio de separación mí nimo desde el corte de la s uperficie de cocción hasta los materiales inflamables hasta un máximo de 457 mm

sobre la encimera.

NOTA: la ubicación de la toma eléctrica solo se apli ca a una instalación con ho rno empotrable.

8 mm

22

mm máx.

PERFIL

DE ENCIMERA

33 mm

RADIO

11 mm RADIO

765 mm

ENTRANTE DE PARED PARA

INSTALACIÓN EMPOTRABLE

533 mm

PROFUNDIDAD

TOTAL

762 mm

ANCHURA TOTAL

98 mm

76 mm

CAJA PARA TERMINAL

P L A C A S D E I N DU CC I Ó N D E W O L F

O D E LO I C B C T 3 0 I U SIN MA RC O

M

Las siguientes ilustraciones proporcionan las

especificaciones de instalación del modelo

ICBCT30IU.

Para que la instalación le resulte más sencilla,

cuando instale el modelo ICBCT30IU le recomendamos que utilice armarios de 838 mm.

Se puede instalar un horno integrable sencillo de

762 mm debajo del modelo ICBCT30IU. Para esta

instalación, a menos que vaya a utilizar armarios

con un fondo superior a 610 mm, se recomienda

que la toma eléctrica se coloque en un armario

ase situado a la derecha del horno. Consulte las

b

instrucciones de instalación que se proporcionan

Si instala el modelo ICBCT30IU encima de los

armarios, la colocación de la toma eléctrica no

es importante. El aparato se instalará de tal

forma que se pueda desconectar de la red

después de su instalación.

Si desea consultar las opciones de instalación

del modelo ICBCT30IU, vaya a la sección

nstalaciones sin marco en las páginas 31–32.

I

NOTA IMPORTANTE:

En el caso de instalaciones

empotradas, se recomienda medir el cristal de la

placa antes de cortar la encimera para asegurarse

e que encaja de manera correcta. Puede haber

d

pequeñas variaciones entre la plantilla y la placa.

con el horno integrable para obtener más información.

E SP E C I F I C A C I O N E S D E L A I N S TA LA CI Ó N – M O D E L O I C B C T 3 0 I U

98 mm

Medidas totales

M OD E L O I C B C T 3 0 I U

Anchura total 762 mm

Altura total 76 mm

Profundidad total 533 mm

Fondo mínimo del armario 578 mm

Espacio mínimo de altura*

Ancho del corte 721 mm

Profundidad del corte 492 mm

*Se necesita dejar un espacio mínimo de

altura de 165 mm entre la encimera y

cualquier superficie combustible que se

encuentre justo encima de la placa.

Si desea obtener las medidas detalladas

del bloque de terminales, consulte la

ilustración en la página 24.

Las medidas pueden variar ±3 mm.

29

Page 30

457 mm mín.

914 mm

DEL SUELO A

LA ENCIMERA

762 mm

mín.

ENCIMERA HASTA

LOS MATERIALES

INFLAMABLES

914 mm APERTURA DEL HORNO

114 mm

254 mm

89 mm

E

C

ONSULTAR CORTE DE

LA ENCIMERA A CONT.

873 mm

ANCHO DE CORTE

CORTE DE LA ENCIMERAENTRANTE DE PARED PARA

INSTALACIÓN EMPOTRABLE

PARTE DELANTERA

492 mm

FONDO DE

CORTE

62 mm mí n.

537 mm

ENTRANTE

DE PARED PARA

INSTALACIÓN

EMPOTRABLE

40 mm

51 mm HASTA

LOS MATERIALES

INFLAMABLES

*

51 mm HASTA

LOS MATERIALES

INFLAMABLES

*

51

mm*

ARMARIO

LATERAL

330 mm

máx.

*Espacio de separación mí nimo desde el corte de la s uperficie de cocción hasta los materiales inflamables hasta un máximo de 457 mm

sobre la encimera.

NOTA: la ubicación de la toma eléctrica solo se apli ca a una instalación con ho rno empotrable.

8 mm

22

mm máx.

PERFIL DE

ENCIMERA

33 mm

RADIO

11 mm RADIO

918 mm

ENTRANTE DE PARED PARA

INSTALACIÓN EMPOTRABLE

533 mm

PROFUNDIDAD

TOTAL

914 mm

ANCHURA TOTAL

98 mm

76 mm

CAJA PARA TERMINAL

I NS T R U C C I ON E S DE I N S TA L A C I ÓN

M O D E L O I C B C T 3 6 I U SI N MA RC O

as siguientes ilustraciones proporcionan las

L

especificaciones de instalación del modelo

ICBCT36IU.

Para que la instalación le resulte más sencilla,

cuando instale el modelo ICBCT36IU se

recomienda utilizar armarios de 991 mm.

Se puede instalar un horno integrable sencillo de

914 mm debajo del modelo ICBCT36IU. Para esta

instalación, a menos que vaya a utilizar armarios

con un fondo superior a 610 mm, se recomienda

que la toma eléctrica se coloque en un armario

base situado a la derecha del horno. Consulte las

instrucciones de instalación que se proporcionan

con el horno integrable para obtener más

información.

E SP E C I F I C A C I O N E S D E L A I N S TA LA CI Ó N – M O D E L O I C B C T 3 6 I U

Si instala el modelo ICBCT36IU encima de los

armarios, la colocación de la toma eléctrica no es

importante. El aparato se instalará de tal forma

ue se pueda desconectar de la red después de

q

su instalación.

Si desea consultar las opciones de instalación del

modelo ICBCT36IU, vaya a la sección Instalaciones sin marco en las páginas 31–32.

NOTA IMPORTANTE:

En el caso de instalaciones

empotradas, se recomienda medir el cristal de la

placa antes de cortar la encimera para asegurarse

de que encaja de manera correcta. Puede haber

pequeñas variaciones entre la plantilla y la placa.

Medidas totales

M OD E L O I C B C T 3 6 I U

Anchura total 914 mm

Altura total 76 mm

Profundidad total 533 mm

Fondo mínimo del armario 578 mm

Espacio mínimo de altura*

98 mm

Ancho del corte 873 mm

Profundidad del corte 492 mm

*Se necesita dejar un espacio mínimo de

altura de 165 mm entre la encimera y

cualquier superficie combustible que se

encuentre justo encima de la placa.

Si desea obtener las medidas detalladas

del bloque de terminales, consulte la

ilustración en la página 24.

Las medidas pueden variar ±3 mm.

30

Page 31

P L A C A S D E I N DU CC I Ó N D E W O L F

I NS TA L A C I O N E S S I N M A R C O

I NS TA L A C I Ó N EN C A S T R A DA

Las instalaciones empotradas están

diseñadas para que se coloquen sólo

en superficies sólidas de granito o en

encimeras de piedra. Si no utiliza

superficies resistentes a altas temperaturas,

la encimera podría resultar dañada en el

caso de que algún utensilio de cocina

caliente se salga por descuido de la

superficie de cocción.

M OD E L O S I C B C T 3 0 I U E I CB C T 3 6 I U

Las placas de inducción sin marco modelo

ICBCT30IU e ICBCT36IU se pueden colocar

empotradas y niveladas con la parte superior

de la encimera o se pueden instalar sin marco

con el cristal montado sobre la superficie de la

encimera.

NOTA IMPORTANTE:

Con los modelos

ICBCT30IU e ICBCT36IU se proporcionan los

materiales necesarios para llevar a cabo una

instalación encastrada. Consulte las instrucciones

que se incluyen con el kit de instalación de la

placa sin marco para obtener especificaciones

adicionales. La plantilla proporcionada con las

placas sin marco es solo de referencia. Utilice la

placa real para marcar el corte.

Existen dos opciones disponibles para instalar

una placa de inducción sin marco encastrada y

nivelada; la opción 1 y la opción 2.

OPCIÓN 1:

Para esta instalación encastrada y

nivelada se necesita una área acoplada que rodee

el corte de la encimera estándar. La fabricación

de esta área debe realizarse antes de que se lleve

a cabo la instalación final de la placa. Se propor-

iona una plantilla del corte de la placa junto con

c

la placa sin marco para que pueda construir el

área usted mismo.

NOTA IMPORTANTE:

No se recomienda utilizar

este método de fabricación en el caso de las

encimeras con protector contra salpicaduras

(triple moldura cóncava).

Para obtener las medidas del corte de la

encimera, consulte la ilustración Especificaciones

de la instalación en la página 29 para el modelo

ICBCT30IU y la página 30 para el modelo

ICBCT36IU.

Para fresar el área acoplada necesaria para

realizar está instalación, debe crear una segunda

plantilla de madera laminada de 13 mm. La

plantilla se va a utilizar como guía para una

broca de fresadora para el cojinete superior.

La plantilla de madera debe ser lo suficientemente ancha para que las pinzas utilizadas para

sujetar esta plantilla a la encimera no interfieran

con la base de la fresadora. Las medidas del corte

de la plantilla de madera deben coincidir con el

perímetro exterior de la plantilla que se proporciona con la placa.

Centre la plantilla de madera sobre el corte existente en la encimera y sujétela. Puede utilizar

cinta adhesiva de doble cara de densidad media

para pegar la plantilla a la encimera; esto evitará

que la plantilla se mueva o despegue durante el

trazado. Asegúrese de que el adhesivo se pueda

quitar con facilidad al pegarlo antes en un trozo

sobrante de encimera. Con una broca de

fresadora para el cojinete con la plantilla de

madera como guía, frese un área acoplada

de 8 mm de fondo en el corte de la encimera.

31

Page 32

I NS T R U C C I ON E S DE I N S TA L A C I ÓN

22 mm

8 mm

Soporte en

forma de L

I NS TA L A C I O N E S

S I N M A R C O

I NS TA L A C I Ó N EN C A S T R A DA

OPCIÓN 2:

Para esta instalación encastrada, el

corte de la encimera tendrá la misma medida que

el borde exterior de la superficie de cristal. Se

recomienda que la placa se utilice como plantilla

para el corte. Gire la placa y marque la abertura

utilizando la superficie de cristal como plantilla.

Es necesario unir los soportes en forma de L o

listones al perímetro interior del corte para

sujetar la placa. El borde superior del soporte

no puede tener una anchura superior a 22 mm

y debe estar sujeto 8 mm por debajo de la

superficie de la encimera. Observe la siguiente

ilustración. La manera de sujetar los soportes

depende del instalador pero siempre debe

haber suficiente material en la encimera.

Si desea colocar soportes adicionales en el área

del corte, pegue material sobrante de la encimera

en el lateral inferior de la encimera. Póngase en

contacto con el proveedor de la encimera para

que le indique los métodos adecuados para

sujetar la placa.

I NS TA L A C I Ó N SI N M A R C O

Las placas de inducción sin marco modelo

ICBCT30IU e ICBCT36IU se pueden instalar como

una aplicación sin marco, con el cristal montado

sobre la superficie de la encimera. Para obtener

las medidas del corte de la encimera, consulte la

ilustración Especificaciones de la instalación en la

página 29 para el modelo ICBCT30IU y la página

30 para el modelo ICBCT36IU.

32

Soportes para instalación encastrada

Page 33

P L A C A S D E I N DU CC I Ó N D E W O L F

N

L1

N

L1

L2

L3

R E Q U I S I TO S EL É C T R I C O S

P L AC A S D E I N D U C C I Ó N D E 9 14 m m

Compruebe que la unidad está

desconectada de la caja de

conexiones antes de continuar.

P L AC A S D E I N D U C C I Ó N D E 3 81 m m

limentación eléctrica requerida:

A

Monofásica: 220-240 VCA; 50 Hz

Trifásica: 380-410 VCA; 50 Hz

Carga máxima conectada:

Monofásica: 3,6 kW

Trifásica: 3,6 kW

Amperaje total:

Monofásica:

Trifásica:

P L AC A S D E I N D U C C I Ó N D E 7 62 m m

Alimentación eléctrica requerida:

Monofásica: 220-240 VCA; 50 Hz

Trifásica: 380-410 VCA; 50 Hz

Carga máxima conectada:

Monofásica: 7,2 kW

Trifásica: 3,6 kW

Amperaje total:

Monofásica:

Trifásica:

16 amperios

16 amperios

32 amperios

16 amperios

Alimentación eléctrica requerida:

Monofásica: 220-240 VCA; 50 Hz

Trifásica: 380-410 VCA; 50 Hz

Carga máxima conectada:

Monofásica: 11,2 kW

Trifásica: 4 kW

Amperaje total:

Monofásica:

Trifásica:

Vea el cuadro de conexiones que muestra las

conexiones de cada cable a la caja de cables

en la unidad.

49 amperios

18 amperios

N O TA

I M P O R T A N T E

Deberá cumplir la

normativa eléctrica

nacional al instalar

el aparato.

3N

˜

Diagrama de cableado monofásico

˜

Diagrama de cableado trifásico

33

Page 34

I NS T R U C C I ON E S DE I N S TA L A C I ÓN

R EQ U I S I TO S EL É C TR I C O S

El aparato debe estar conectado a tierra

de manera correcta siempre que esté

onectado a la red eléctrica.

c

NOTA: Si la conexión no se realiza de

manera correcta, existe riesgo de que se

produzca un incendio.

Antes de tener acceso a los terminales,

se deben desconectar todos los circuitos

de suministro.

Abra la caja de terminales para ver los tornillos

con los números correspondientes. Pase el cable

por el agujero aliviador de tensión e introdúzcalo

en la caja de cables.

Para la instalación monofásica (línea, neutro,

tierra): Afloje los tornillos 1, 5 y el tornillo de

conexión a tierra. Conecte el cable neutro en la

posición número 5. El cable de línea debe conectarse en la posición número 1 y el cable de

conexión a tierra en el tornillo de conexión a

tierra correspondiente.

Para la instalación trifásica (L1, L2, L3, neutro,

tierra): Afloje 1, 2 y 3 y quite las barras de cobre.

Afloje 5 y los tornillos de conexión a tierra. Conecte

L1 a la posición 1. L2 a la posición 2. L3 a la posición

3. El cable neutro a la posición 5 y conecte la tierra al

tornillo de conexión a tierra correspondiente.

Una vez que haya apretado los tornillos, apriete

el aliviador de tensión del cable y cierre la tapa

de la caja de cables asegurándose de que los

cables no quedan enganchados.

NOTA IMPORTANTE:

la conexión de este aparato

debe realizarse a una unidad de conexión con

fusibles o a un aislador adecuado, que cumple con

las normativas de seguridad nacionales y locales.

El interruptor de encendido/apagado debe encontrarse en un lugar accesible después de haber

instalado el aparato. Si no es posible acceder al

interruptor después de la instalación (según el

país), se deberá brindar un medio de desconexión

adicional para todos los polos de la alimentación

eléctrica. Al estar desconectado, deberá existir una

separación de contacto entre todos los polos de 3

mm en el interruptor del aislador. Esta separación

de 3 mm de desconexión de los contactos deberá

aplicarse a cualquier interruptor, fusibles o relés

del aislador según la norma EN60335.

Las barras de cobre deben quitarse de las

posiciones 1, 2 y 3 al conectar a la corriente trifásica.

34

Page 35

PLACA

EMBELLE-

CEDOR

PLACA

ENCIMERA

TORNILLOS

DE SOPORTE

SOPORTE

89 mm TORNILLO

DE SUJECIÓN

P L A C A S D E I N DU CC I Ó N D E W O L F

I N S TA LA C I Ó N D E L A P L AC A

oloque el embellecedor en la parte inferior

C

del marco de la placa. Observe la siguiente

ilustración.

NOTA IMPORTANTE:

Para instalaciones sin

marco, pegue el embellecedor al borde exterior

del cristal, no al marco de soporte.

Coloque con cuidado la placa en el área cortada

de la encimera y céntrela. Compruebe que el

borde delantero de la placa se coloque en

paralelo al borde delantero de la encimera.

Compruebe que se han dejado los espacios

mínimos necesarios.

Coloque los soportes en la parte inferior de la

unidad tal y como se muestra en la siguiente

ilustración. Instale los tornillos de sujeción en

el soporte y apriételos hasta que los tornillos

toquen la parte inferior de la encimera.

No apriete los tornillos demasiado.

NOTA IMPORTANTE:

No selle la placa a

la encimera. Es posible que necesite quitarla

para realizar alguna tarea de mantenimiento.

Si la parte superior de cristal cerámico de la

placa se rompe, desconecte el aparato de la

red eléctrica. No ponga en funcionamiento

el aparato hasta que un centro de asistencia

técnica autorizado de Wolf cambie el cristal.

A NT E S D E UT IL I Z A R L A UN I D A D

Limpie con cuidado la superficie de cristal

cerámico con el producto para limpiar

vitrocerámicas que se proporciona con la placa.

Quite todos los restos de la limpieza.

Lea la guía de uso y mantenimiento de

las placas de inducción de Wolf que se incluye

con la placa. Esta guía contiene información

importante sobre la seguridad y el

mantenimiento del módulo.

E X T R A C C I Ó N D E L A PL AC A

NOTA IMPORTANTE:

Este procedimiento

debe ser realizado únicamente por un centro

de asistencia técnica autorizado de Wolf.

Si necesita extraer la placa para limpiarla o

para realizar alguna tarea de mantenimiento,

desconecte el suministro eléctrico. Quite los

soportes de montaje situados en los laterales

derecho e izquierdo de la unidad y extraiga

la placa. Vuelva a instalar la placa en el

orden inverso.

NOTA IMPORTANTE:

Para instalaciones

encastradas, utilice una cuchilla para cortar

el sellado con RTV. Para volver a colocar la

placa necesitará un nuevo kit de instalación

RTV (811358). Este kit está disponible en su

distribuidor de Wolf. Para obtener la información

del distribuidor más cercano, visite nuestra

página web wolfappliance.com.

A C C E S O R I OS

odrá disponer de

P

accesorios

opcionales a través

e su distribuidor de

d

Wolf. Para obtener

la información del

istribuidor más

d

cercano, visite

nuestra página

eb:

w

wolfappliance.com.

Embellecedor Soportes de instalación

35

Page 36

I NS T R U C C I ON E S DE I N S TA L A C I ÓN

S OL U C I Ó N D E P R O B L E M A S

S I L A P L A C A N O F U N C I O N A

NOTA IMPORTANTE:

Si la placa de inducción

no funciona correctamente, siga estos pasos de

localización y solución de problemas:

Compruebe que la placa esté conectada a la

red eléctrica.

Compruebe las conexiones eléctricas para

asegurarse de que la instalación se ha llevado

a cabo de manera correcta.

Realice los procedimientos de solución de

problemas tal y como se describe en la guía

de uso y mantenimiento de la placa de

inducción de Wolf.

Si las luces indicadoras de la barra de

potencia funcionan pero la unidad indica

que está en modo de bloqueo, la unidad se

encuentra en modo de exposición. Póngase

en contacto con su distribuidor local de Wolf.

Si la placa sigue sin funcionar, póngase en

contacto con un centro de asistencia técnica

autorizado de Wolf. No intente realizar usted

mismo ninguna reparación en la placa.

Wolf no se hace responsable de las tareas

de mantenimiento que deban realizarse para

corregir una instalación defectuosa.

La unidad no debe estar conectada a la red

eléctrica para extraerla y realizar las tareas

de mantenimiento.

36

Page 37

P L A C A S D E I N DU CC I Ó N D E WO L F

S I N E C E S I TA A S IS T E N C I A TÉ C NI C A

Cuando necesite solicitar asistencia técnica,

mantenga la calidad de su placa de inducción

al llamar a un centro de mantenimiento

autorizado de Wolf.

Para obtener el nombre y el número de

un centro de mantenimiento autorizado

de Wolf, visite nuestra página web

wolfappliance.com

Cuando solicite asistencia técnica, deberá

tener localizado el número de serie y el

modelo de la placa. Esta información se

muestra en la placa de datos del producto

situada en la parte inferior de la placa.

Consulte la ilustración de la página 22

para ubicar la placa de datos.

I NF O R M A C IÓ N

D E C O N T A C T O

ágina web:

P

olfappliance.com

w

La información y las imágenes que se incluyen en

esta guía son propiedad de Wolf Appliance, Inc., una

filial de Sub-Zero, Inc. Este documento junto con la

información y las imágenes que en él se incluyen no

pueden copiarse ni utilizarse, total ni parcialmente, sin

el consentimiento por escrito de Wolf Appliance, Inc.,

una filial de Sub-Zero, Inc.

©Wolf Appliance, Inc. se reserva todos los derechos.

37

Page 38

C ON TA C T

ite Internet :

S

wolfappliance.com

Vous remarquerez tout au long de ce manuel

d’instructions les mentions AVERTISSEMENT

et MISE EN GARDE destinées à fournir des