Page 1

GAS COOKTOPS

INSTALLATION INSTRUCTIONS

INSTRUCCIONES DE INSTALACIÓN

INSTRUCTIONS D’INSTALLATION

ISTRUZIONI PER L’INSTALLAZIONE

Page 2

As you follow these instructions, you will

notice WARNING and CAUTION symbols.

This blocked information is important for the

safe and efficient installation of Wolf equipment. There are two types of potential

hazards that may occur during installation.

Another footnote we would like to identify is

IMPORTANT NOTE: This highlights information that is especially relevant to a problemfree installation.

signals a situation where minor injury or

product damage may occur if you do not

follow instructions.

states a hazard that may cause serious

injury or death if precautions are not

followed.

WOLF®is a registered trademark of Wolf Appliance, Inc.

CONTACT

INFORMATION

Website:

wolfappliance.com

Page 3

3

INSTALLATION REQUIREMENTS

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electrical switch.

Do not use any phone in your

building.

Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

If you cannot reach your gas

supplier, call the fire department.

WOLF GAS COOKTOPS

IMPORTANT NOTE:

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

Do not store or use gasoline or

other flammable vapors and liquids

in the vicinity of this or any other

appliance.

The use of a gas cooking appliance

results in the production of heat and

moisture in the room in which it is

installed. Ensure that the kitchen is

well ventilated; keep natural ventilation holes open or install a mechanical ventilation device (mechanical

extractor hood)

Prolonged intensive use of the appliance may for additional ventilation,

for example opening of a window, or

more effective ventilation, for

example increasing the level of

mechanical ventilation where

present.

This appliance shall be installed

in accordance with the regulations in force and only used in a

well ventilated space. Read the

instructions before installing or

using this appliance.

Page 4

INSTALLATION REQUIREMENTS

IMPORTANT NOTE: This installation must

be completed by a qualified installer,

service agency or gas supplier.

IMPORTANT NOTE:

Save these Installation

Instructions for the local inspector’s use.

Please read the entire Installation Instructions prior to installation.

Installer:

please retain these instructions

for local inspector’s reference, then leave

them with the homeowner.

Homeowner:

please read and keep these

instructions for future reference and be sure

to read the entire Use & Care Information

prior to use.

IMPORTANT NOTE:

This appliance must be

installed in accordance with local codes. The

correct voltage, frequency and amperage must

be supplied to the appliance from a dedicated,

grounded circuit which is protected by a

properly sized circuit breaker or time delay

fuse. The proper voltage, frequency, and

amperage ratings are listed on the product

rating plate.

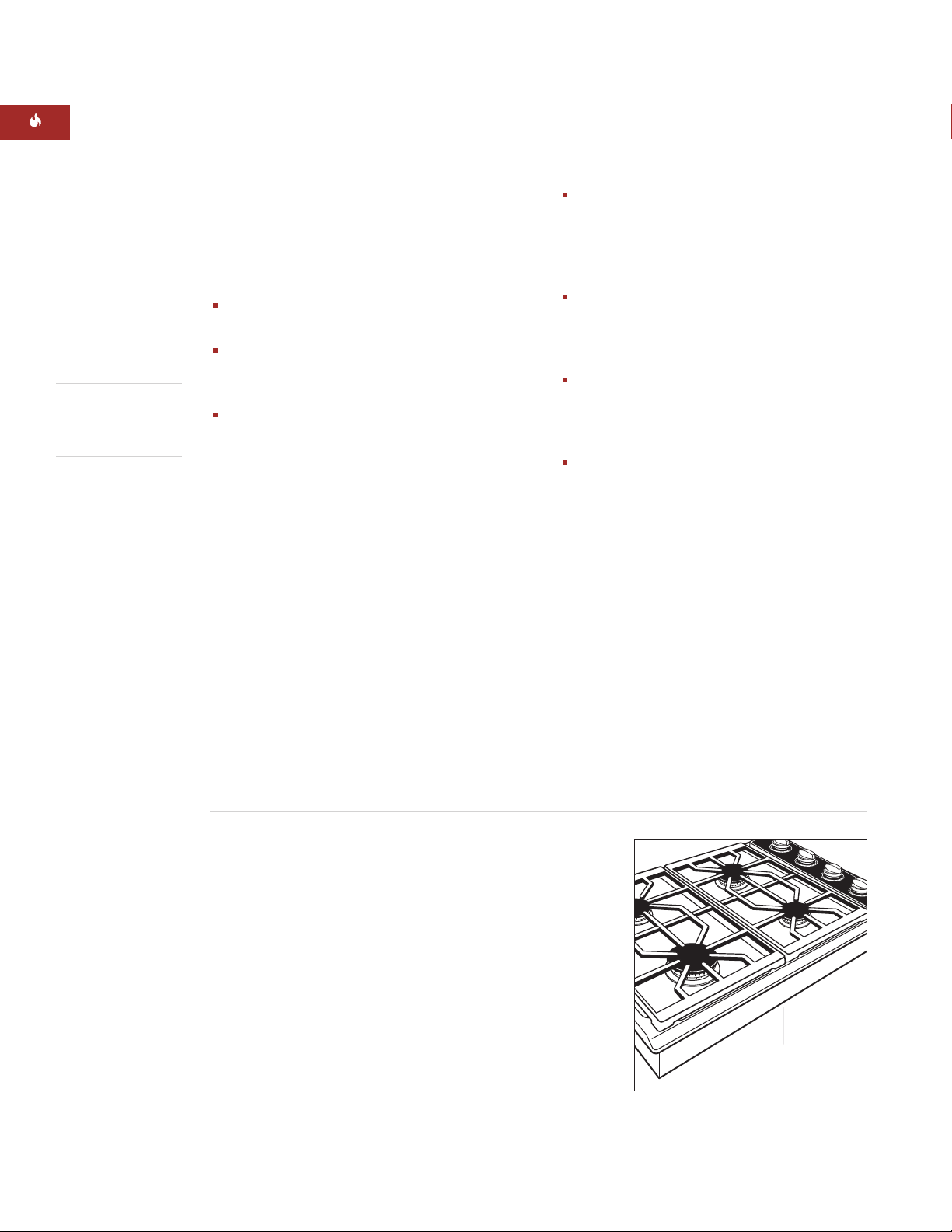

Record the model and serial numbers before

installing the cooktop. Both numbers are listed

on the rating plate, located on the underside of

the cooktop. Refer to the illustration below.

4

BEFORE YOU STA RT

Proper installation is your responsibility.

Have a qualified technician install this

cooktop. You must also assure that electrical installation is adequate and in compliance with all local codes and ordinances.

Prior to installation, ensure that the local

distribution conditions (nature of the gas

and gas pressure) and the adjustment of

the appliance are compatible.

Proper gas supply connection must be

available; refer to Gas Supply Requirements

on page 10. Electrical ground is required;

see Electrical Requirements on page 11.

The adjustment conditions for this appliance are stated on the label (or rating

plate). The data plate can be found on the

underside of the cooktop.

WOLF GAS COOKTOPS

Rating plate location

Location of rating

plate under cooktop

RATING PLATE

INFORMATION

Model Number

Serial Number

Page 5

5

INSTALLATION INSTRUCTIONS

LOCATION REQUIREMENTS

Illustrations on the following pages provide the

overall dimensions, countertop cut-out and

installation specifications for Wolf gas

cooktops. Maintain the following minimum

installation dimensions:

Minimum horizontal clearance from the

sides and back of the cooktop cut-out to

adjacent vertical combustible construction,

extending a minimum of 457 mm above the

countertop, is as follows: 178 mm from side

edges of cut-out for the 381 mm cooktop;

229 mm from side edges of cut-out for the

762 mm and 914 mm cooktops; 64 mm

from rear edge of cut-out.

Minimum vertical distance between the

countertop and combustible materials

above the cooktop must be 762 mm.

Maximum 330 mm depth of overhead side

cabinets directly above and within side

clearance.

IMPORTANT NOTE:

When installing a ventilation hood, refer to the specific requirements

of the hood for the minimum dimension to

countertop.

BEFORE YOU STA RT

Check the location where the cooktop will

be installed. The location should be away

from strong draft areas, such as windows,

doors and strong heating vents or fans. Do

not obstruct flow of combustion and

ventilation air.

This appliance is not connected to a

combustion products evacuation device. It

shall be installed and connected in accordance with current installation regulations.

Particular attention shall be given to the

relevant requirements regarding ventilation.

SITE PREPARATION

COUNTERTOP CUT-OUT DIMENSIONS

IMPORTANT NOTE:

Countertop opening

dimensions shown on the following pages

must be used. The dimensions shown provide

for required clearances.

These cooktops are designed to fit a standard

610 mm deep base cabinet with a 635 mm

deep countertop. Before making the countertop cut-out, verify that the cooktop will clear

the side walls of the base cabinet below. There

should be at least 140 mm clearance between

the countertop and any combustible surface

directly below the unit.

IMPORTANT NOTE:

Do not seal the cooktop

to the countertop. It must be removed if

service is necessary.

Failure to locate the cooktop without the

proper clearances will result in a fire

hazard.

This cooktop is intended for indoor use.

Page 6

6

INSTALLATION SPECIFICATIONS

The illustrations below provide the overall

dimensions, countertop cut-out and installation

specifications for Model ICBCT15G.

For Model ICBCT15G, the gas service may be

supplied through the floor if the cooktop is not

installed above an oven. Refer to the illustration

for specifics on placement of gas and electrical.

WOLF GAS COOKTOPS

Overall Dimensions

Countertop Cut-Out

MODEL ICBCT15G

DIMENSIONS

Overall Width 381 mm

Overall Height 102 mm

Overall Depth 533 mm

Recommended

Cabinet Width 838 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance 102 mm

Cut-Out Width 356 mm

Cut-Out Depth 489 mm

Unit dimensions may vary to ±3 mm.

INSTALLATION SPECIFICATIONS – MODEL ICBCT15G

IMPORTANT NOTE:

When multiple cooktop

units are installed side by side, refer to the

countertop cut-out dimensions on page 9.

533 mm

OVERALL

DEPTH

381 mm

OVERALL WIDTH

102 mm

838 mm

330 mm

max

64**

NOTE: Application shown allows for installation of two 381 mm modules side-by-side with 838 mm recommended cabinet width. 457 mm

recommended cabinet width for installation of single 381 mm cooktop or module. *Minimum clearance from both side edges of cooktop cut-out

to combustible materials up to 457 mm above countertop. **Minimum clearance from rear edge of cooktop cut-out to combustible materials up

to 457 mm above countertop.

489 mm

mm

COOKTOP CUT-OUT

DEPTH

LOCATION OF GAS

SUPPLY MAY ALSO

EXTEND 127 mm ON

FLOOR FROM BACK WALL

127

mm

457 mm

64 mm

min

914 mm

STANDARD

FLOOR TO

COUNTERTOP

HEIGHT

178 mm*min

CUT-OUT TO

COMBUSTIBLE

MATERIALS

(BOTH SIDES)

COOKTOP CUT-OUT

LOCATION OF GAS SUPPLY

MAY ALSO EXTEND 127 mm ON

FLOOR FROM BACK WALL

COOKTOP CUT-OUT

CABINET WIDTH

356 mm

WIDTH

E

381 mm

381 mm

356 mm

WIDTH

RECOMMENDED

102 mm

G

381

mm

762 mm

COUNTERTOP TO

COMBUSTIBLE

MATERIALS

ABOVE COOKTOP

489 mm

64 mm

min

FRONT OF COUNTERTOP

COOKTOP

CUT-OUT DEPTH

Page 7

7

INSTALLATION INSTRUCTIONS

Overall Dimensions

Countertop Cut-Out

INSTALLATION SPECIFICATIONS

The illustrations below provide the overall

dimensions, countertop cut-out and installation

specifications for Model ICBCT30G.

IMPORTANT NOTE:

838 mm wide cabinets are

recommended for installation of Model

ICBCT30G.

A Wolf 762 mm single built-in oven may be

installed below Model ICBCT30G. For this

installation, unless you are using cabinets

deeper than 610 mm, it is recommended that

the electrical and gas supply be placed in the

base cabinet to the right of the oven. Refer to

installation instructions provided with the builtin oven for additional specifications.

If the Model ICBCT30G is installed above

cabinets, the gas and electrical placement is not

critical. A grounded outlet needs to be placed

within 1.2 m of the right rear of the cooktop.

IMPORTANT NOTE:

When multiple cooktop

units are installed side by side, refer to the

countertop cut-out dimensions on page 9.

MODEL ICBCT30G

DIMENSIONS

Overall Width 762 mm

Overall Height 102 mm

Overall Depth 533 mm

Recommended

Cabinet Width 838 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance 102 mm

Cut-Out Width 737 mm

Cut-Out Depth 489 mm

Unit dimensions may vary to ±3 mm.

INSTALLATION SPECIFICATIONS – MODEL ICBCT30G

533 mm

OVERALL

DEPTH

762 mm

OVERALL WIDTH

102 mm

838 mm

330 mm

max

64**

*Minimum clearance from both side edges of cooktop cut-out to combustible materials up to 457 mm above countertop.

**Minimum clearance from rear edge of cooktop cut-out to combustible materials up to 457 mm above countertop.

489 mm

mm

COOKTOP CUT-OUT

DEPTH

610 mm min

457 mm

64 mm

min

914 mm

STANDARD

FLOOR TO

COUNTERTOP

HEIGHT

229 mm*min

CUT-OUT TO

COMBUSTIBLE

MATERIALS

(BOTH SIDES)

95 mm

RECOMMENDED

CABINET WIDTH

762 mm min

737 mm COOKTOP

CUT-OUT WIDTH

102 mm

89 mm

min

762 mm OVEN OPENING

737 mm

COOKTOP CUT-OUT WIDTH

E

254

mm

64 mm

min

FRONT OF COUNTERTOP

762 mm

COUNTERTOP TO

COMBUSTIBLE

MATERIALS

ABOVE COOKTOP

G

489 mm

COOKTOP

CUT-OUT DEPTH

Page 8

8

WOLF GAS COOKTOPS

INSTALLATION SPECIFICATIONS

The illustrations below provide the overall

dimensions, countertop cut-out and installation

specifications for Model ICBCT36G.

IMPORTANT NOTE:

991 mm wide cabinets are

recommended for installation of Model

ICBCT36G.

A Wolf 914 mm built-in oven may be installed

below Model ICBCT36G. For this installation,

unless you are using cabinets deeper than 610

mm, it is recommended that the electrical and

gas supply be placed in the base cabinet to the

right of the oven. Refer to installation instructions provided with the built-in oven for additional specifications.

If the Model ICBCT36G is installed above

cabinets, the gas and electrical placement is not

critical. A grounded outlet needs to be placed

within 1.2 m of the right rear of the cooktop.

When a 914 mm built-in oven is installed below

Model ICBCT36G, it is recommended that the

rough opening for the oven be 197 mm from

the floor to ease the use of the oven door.

IMPORTANT NOTE:

When multiple cooktop

units are installed side by side, refer to the

countertop cut-out dimensions on page 9.

Overall Dimensions

Countertop Cut-Out

MODEL ICBCT36G

DIMENSIONS

Overall Width 914 mm

Overall Height 102 mm

Overall Depth 533 mm

Recommended

Cabinet Width 991 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance 102 mm

Cut-Out Width 889 mm

Cut-Out Depth 489 mm

Unit dimensions may vary to ±3 mm.

INSTALLATION SPECIFICATIONS – MODEL ICBCT36G

533 mm

OVERALL

DEPTH

914 mm

OVERALL WIDTH

102 mm

330 mm

max

64**

*Minimum clearance from both side edges of cooktop cut-out to combustible materials up to 457 mm above countertop.

**Minimum clearance from rear edge of cooktop cut-out to combustible materials up to 457 mm above countertop.

489 mm

mm

COOKTOP CUT-OUT

DEPTH

610 mm min

457 mm

64 mm

min

914 mm

STANDARD

FLOOR TO

COUNTERTOP

HEIGHT

229 mm*min

CUT-OUT TO

COMBUSTIBLE

MATERIALS

(BOTH SIDES)

991 mm

RECOMMENDED CABINET WIDTH

914 mm min

889 mm

COOKTOP CUT-OUT WIDTH

102 mm

95 mm

min

914 mm OVEN OPENING

COOKTOP CUT-OUT WIDTH

89 mm

889 mm

64 mm

min

FRONT OF COUNTERTOP

E

254

mm

G

762 mm

COUNTERTOP TO

COMBUSTIBLE

MATERIALS

ABOVE COOKTOP

489 mm

COOKTOP

CUT-OUT DEPTH

Page 9

9

INSTALLATION INSTRUCTIONS

INSTALLATION OPTIONS

MULTIPLE COOKTOP INSTALLATION

If the gas cooktop is to be used with any

combination of additional cooktop units or

modules with a filler strip, the cut-out width is

calculated by adding the corresponding units'

cut-out dimensions plus 32 mm for each additional unit. Refer to the illustration below.

IMPORTANT NOTE:

When multiple units are

installed side by side, each unit must have its

own separate recommended electrical circuit.

When two or more modules are installed

together, an integrated module filler strip

(IFILLER/S) is recommended. Contact your

Wolf dealer for information on these accessory

components.

Countertop cut-out dimensions for installation of multiple cooktops

OPTIONAL

INSTALLATIONS

Dimensions will

vary according to

the specific

installation.

1518 mm – FOUR MODULES WIDTH OR

1511 mm – 762 mm COOKTOP AND TWO MODULES OR

1276 mm – 914 mm COOKTOP AND ONE MODULE

1130 mm – THREE MODULES WIDTH OR

1124 mm – 762 mm COOKTOP AND ONE MODULE

743 mm

TWO MODULES WIDTH

356 mm

CUT-OUT

64 mm

min

WIDTH

FRONT OF COUNTERTOP

489 mm

CUT-OUT

DEPTH

Page 10

10

WOLF GAS COOKTOPS

IMPORTANT NOTE:

The gas cooktop must be

connected to a regulated gas supply.

IMPORTANT NOTE:

This installation must

conform with local codes and ordinances.

IMPORTANT NOTE:

The natural gas cooktop

is rated for elevations up to 2438 m without

adjustment. Install a high altitude kit for elevations from 2438 to 3084 m. The LP gas cooktop

is rated for 3084 m.

The rating plate, located on the underside of

the burner box, has information on the type of

gas that should be used. If this information

does not agree with the type of gas available,

check with the local gas supplier.

EXPLOSION HAZARD—

Securely tighten all external gas

connections.

Failure to do so can result in explosion,

fire or death.

GAS SUPPLY REQUIREMENTS

Provide a gas supply line of 19 mm rigid pipe

to the cooktop location. A smaller size pipe on

long runs may result in insufficient gas supply.

Pipe joint compounds, suitable for use with LP

gas should be used. For LP gas, piping or

tubing size can be 13 mm minimum. LP gas

suppliers usually determine the size and materials used on the system.

If local codes permit, a flexible metal appliance

connector is recommended for connecting this

cooktop to the gas supply line. Do not kink or

damage the flexible connector when moving

the cooktop. You will need to determine the

fittings required, depending on the size of your

gas supply line, flexible metal connector and

shut-off valve.

If rigid pipe is used as a gas supply line, a

combination of pipe fittings must be used to

obtain an in-line connection to the cooktop. All

strains must be removed from the supply and

gas lines so the cooktop will be level and in

line.

IMPORTANT

NOTE

This installation

must conform with

local codes and

ordinances.

GAS RATING

Total Heat Electrical Types and

Output Gas Rating Appliance Pressures

Model # (Gas) Units (Watts) Category (mbar) Country of Destination

I2H G20 at 20

AT, DK, EE, FI, GR, IE, IT, LT,

ICBCT15G/S 6.8 kW 230

NO, PT, ES, SE, SI, SK, GB, CH

I2E G20 at 20 DE, PL

I2E+ G20 at 20/25 BE, FR

ICBCT15G/S-LP 494 g/h 230 I3P G31 at 37

BE, CZ, FR, GR, IE, NL, NO, PT,

ES, GB, CH

I2H G20 at 20

AT, DK, EE, FI, GR, IE, IT, LT,

ICBCT30G/S 14.7 kW 230

NO, PT, ES, SE, SI, SK, GB, CH

I2E G20 at 20 DE, PL

I2E+ G20 at 20/25 BE, FR

ICBCT30G/S-LP 1069 g/h 230 I3P G31 at 37

BE, CZ, FR, GR, IE, NL, NO, PT,

ES, GB, CH

I2H G20 at 20

AT, DK, EE, FI, GR, IE, IT, LT,

ICBCT36G/S 17.7 kW 230

NO, PT, ES, SE, SI, SK, GB, CH

I2E G20 at 20 DE, PL

I2E+ G20 at 20/25 BE, FR

ICBCT36G/S-LP 1287 g/h 230 I3P G31 at 37

BE, CZ, FR, GR, IE, NL, NO, PT,

ES, GB, CH

Page 11

11

INSTALLATION INSTRUCTIONS

ELECTRICAL REQUIREMENTS

ELECTRICAL SHOCK HAZARD—

Plug into a grounded 3-prong adapter.

Do not remove ground prong.

Do not use an adapter.

Failure to follow these instructions can

result in electric shock, fire or death.

RECOMMENDED GROUND METHOD

IMPORTANT NOTE:

For your personal safety,

this cooktop must be grounded. This cooktop

is equipped with a 3-prong ground plug. To

minimize possible shock hazard, the cord must

be plugged into a mating 3-prong ground-type

outlet, grounded in conformance with all local

codes and ordinances. If a mating outlet is not

available, it is the obligation of the customer to

have a properly grounded, 3-prong outlet

installed by a qualified electrician.

IMPORTANT NOTE:

If product is connected to

a GFCI protected outlet, nuisance tripping of

power supply may occur, resulting in loss of

product operation.

WIRING DIAGRAM

A wiring diagram covering the control circuit

for each Wolf gas cooktop model can be found

on page 15.

IMPORTANT NOTE:

If codes permit and a

separate ground wire is used, it is recommended that a qualified electrician determine

that the ground path is adequate.

IMPORTANT NOTE:

Check with a qualified

electrician if you are not sure whether the

cooktop is properly grounded.

IMPORTANT NOTE:

Do not ground to a gas

pipe.

A 220-240 VAC, 50/60 Hz, fused electrical

supply is required. A time-delay fuse or circuit

breaker is recommended. It is recommended

that a separate circuit serving only this appliance be provided.

Electronic ignition systems operate within

wide voltage limits, but proper ground and

polarity are necessary. In addition to checking

that the outlet provides 220-240 VAC power

and is correctly grounded, the outlet must be

checked by a qualified electrician to see if it is

wired with correct polarity. A wiring diagram is

provided in the literature package.

This appliance, when installed, must be electrically grounded in accordance with local codes.

Page 12

COOKTOP INSTALLATION

Remove the cooktop, burner grates and burner

caps from the shipping package.

Lower the cooktop into the countertop cut-out

opening. Center the cooktop in the opening

and check that the front edge of cooktop is

parallel to the front edge of the countertop.

Check that all required clearances are met. Use

a pencil to outline the rear edge of the cooktop

on the countertop. Remove the cooktop from

the countertop opening.

IMPORTANT NOTE:

When repositioning the

cooktop in the countertop cut-out opening, lift

the entire cooktop up from the opening to

prevent scratching the countertop.

Remove the foam strip from the hardware

package. Apply the foam strip around the

bottom of the burner box flush with the edge

as shown in the illustration below.

Reinsert the cooktop into the countertop

opening. Check that the cooktop is parallel to

the front edge of the countertop. Lift the entire

cooktop to make adjustments and align the

rear edge with the pencil line.

Attach the brackets to the burner box. Insert

the 89 mm clamping screws into the brackets.

Use a screwdriver to tighten the clamping

screws against the underside of the countertop. Refer to the illustration below. Do not

overtighten screws.

12

GAS LEAK TESTING

Use a brush and liquid detergent to test all gas

connections for leaks. Bubbles around connections will indicate a leak. If a leak appears, shut

off gas valve controls and adjust connections.

Then check connections again. Clean all the

detergent solution from the cooktop.

Cooktop

Burner Box

Foam

Strip

Foam strip application

WOLF GAS COOKTOPS

89 mm

Clamping

Screw

Burner Box

Countertop

Bracket

Screws

Bracket

Bracket installation

Never test for a gas leak with a match or

other flame.

Page 13

13

INSTALLATION INSTRUCTIONS

SURFACE BURNERS

INITIAL LIGHTING

The surface burners use electronic igniters in

place of standing pilots. When the cooktop

control knob is pushed in and turned to the

position, the system creates a spark to

light the burner. This sparking continues until

the electronic ignition senses a flame. If the

burner fails to ignite after 10 seconds, return

the knob to the position and attempt to

ignite by turning the knob back to the

position.

Be sure to place the burner heads and caps on

each burner base and position the burner

grates over the burner bases and heads before

lighting.

To check operation of the surface burners,

push in and turn each control knob to the

position. The flame should light within four

seconds.

If the burners do not light properly, turn

control knob to the position. Check that

the burner heads and caps are in the proper

position. Check that the power supply cord is

plugged in and that the circuit breaker or

house fuse has not blown. Check operation

again, if the burners do not light properly at

this point, contact a Wolf authorized service

center.

IMPORTANT NOTE:

Initial lighting of the

surface burners may take slightly longer, as air

in the system must be purged before gas can

be supplied to the burner.

COOKTOP REMOVAL

If it is necessary to remove the cooktop for

cleaning or service, shut off the gas supply.

Disconnect the gas and electric supply.

Remove the mounting brackets on the right

and left side of the burner box and remove the

cooktop. Reinstall in the reverse order and

check the gas connection for leaks.

TROUBLESHOOTING

IMPORTANT NOTE:

If the cooktop does not

operate properly, follow these troubleshooting

steps:

Verify that power is being supplied to the

cooktop.

Check that gas valves are turned to the ON

position.

Check the gas supply and electrical

connections to ensure that the installation

has been completed correctly.

Follow troubleshooting procedures as

described in the Wolf Gas Cooktops

Use & Care Information.

If the cooktop still does not work, contact

a Wolf authorized service center. Do not

attempt to repair the cooktop yourself. Wolf

is not responsible for service required to

correct a faulty installation.

Page 14

14

CONTACT

INFORMATION

Website:

wolfappliance.com

WOLF GAS COOKTOPS

IF YOU NEED SERVICE

For service in your area, contact either your

Wolf dealer or visit the Showroom Locator

section of our website, wolfappliance.com

to find the regional distributor by country.

When calling for service, you will need the

cooktop model and serial numbers. Both

numbers are listed on the rating plate,

located on the underside of the cooktop.

Refer to the illustration on page 4 for

location of the rating plate.

The information and images in this book are the

copyright property of Wolf Appliance, Inc., an

affiliate of Sub-Zero, Inc. Neither this book nor any

information or images contained herein may be

copied or used in whole or in part without the

express written permission of Wolf Appliance, Inc.,

an affiliate of Sub-Zero, Inc.

©Wolf Appliance, Inc. all rights reserved.

Page 15

15

INSTALLATION INSTRUCTIONS

POWER CORD

FRONT

RIV

GAS VALVE

RED

RED

BLACK

WHITE

GRN/YEL

BLACK

REAR

BLACK

BLACK

WHITE

WHITE

Model ICBCT15G

POWER CORD

WHITE

RIGHT

FRONT

BLACK

RIV

GAS VALVE

RED

RED

RED

RED

WHITE

GRN/YEL

BLACK

RIGHT

REAR

LEFT

REAR

LEFT FRONT

BLACK

WHITE

WHITE

BLACK

LEFT FRONT

POWER CORD

RED

RIV

GAS VALVE

WHITE

BLACK

RIGHT

REAR

LEFT REAR

RIGHT

FRONT

CTR REAR

GRN/YEL

BLACK

RED

RED

RED

BLACK

WHITE

WIRING DIAGRAMS

Model ICBCT30G

Model ICBCT36G

Page 16

WOLF APPLIANCE, INC.

PO BOX 44848

MADISON, WI 53744 USA

WOLFAPPLIANCE.COM

810127 11/2007

Loading...

Loading...